Process for reclaiming city domestic sludge

A technology of urban domestic sludge and resource utilization, applied in the direction of bio-organic part treatment, organic fertilizer, organic fertilizer preparation, etc., can solve the problem of not being able to effectively reduce the toxicity of heavy metals in sludge, and not providing comprehensive treatment of organic waste, fermentation The process is not easy to go smoothly and other problems, to achieve the effect of improving crop yield and quality, reducing urban environmental pressure, and deodorizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

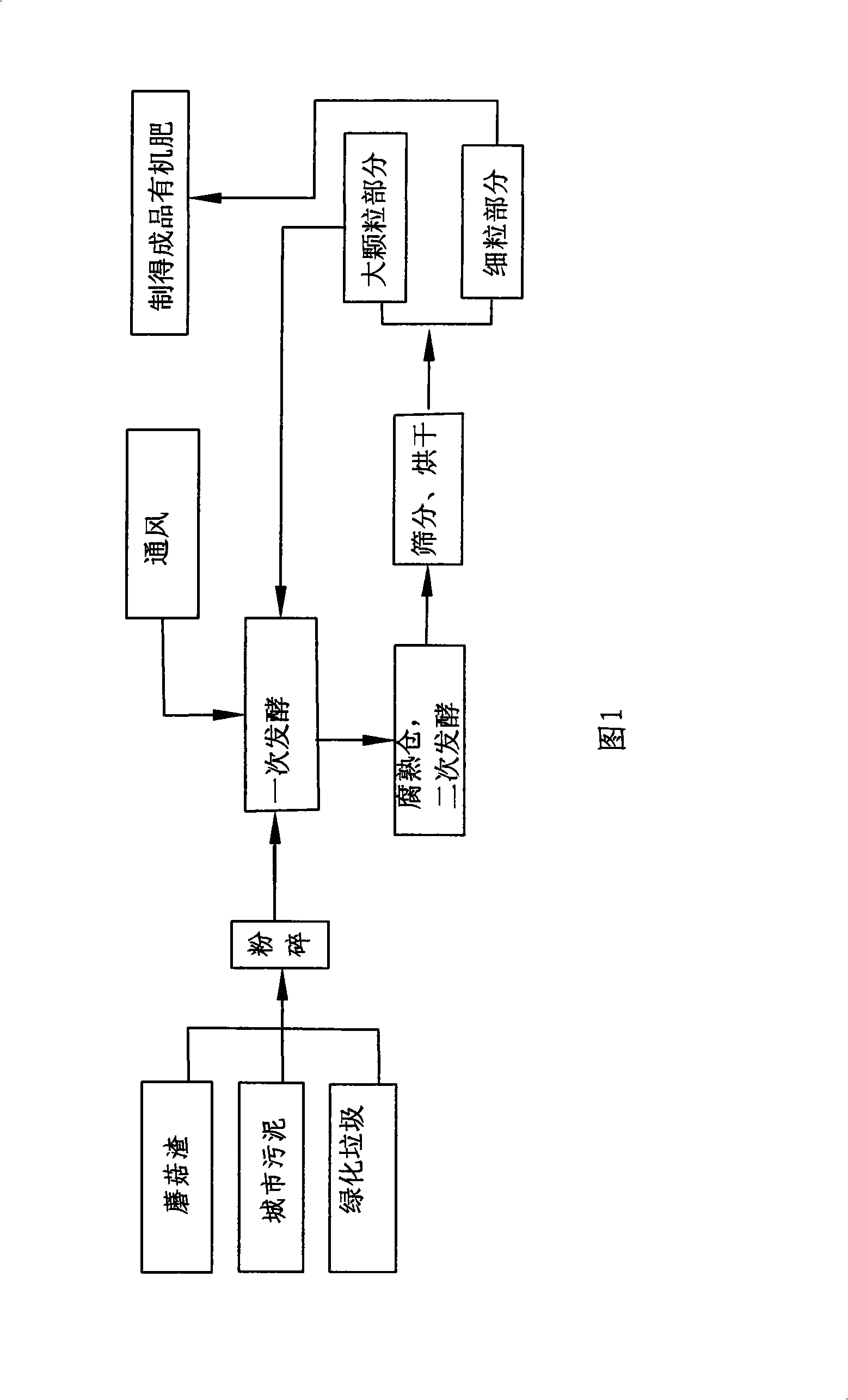

[0027] Below in conjunction with accompanying drawing, the present invention is further described, see shown in accompanying drawing 1, a kind of aerobic bio-physics-chemical combined fast fermentation technology is processed the technique of urban domestic sludge recycling, comprises the following steps:

[0028] Pretreatment: First, crush the collected green waste to make the particle size 15mm;

[0029] Fermentation treatment of municipal sludge, green waste and mushroom slag, the total amount of the three is 100m 3 , municipal sludge is used as raw material, mushroom slag is used as conditioning agent, and green waste is used as leavening agent. First, measure 60m of municipal sludge 3 , Mushroom residue 30m 3 , green garbage 10m 3 , so that the ratio of urban sludge: mushroom slag: green waste is 6:3:1; 3 , can adjust the pH value of the compost, so that the compost can quickly heat up; on the other hand, it can passivate the leaching toxicity of heavy metals in the sl...

Embodiment 2

[0038] Pretreatment: First, crush the collected green waste to make its particle size 5mm;

[0039] Fermentation treatment of municipal sludge, green waste and mushroom slag, the total amount of the three is 100m 3 , urban sludge as raw material, mushroom slag and green waste as leavening agent, firstly measure 70m of urban sludge 3 , Mushroom residue 20m 3 , green garbage 10m 3 , so that the ratio of urban sludge: mushroom slag: green waste is 7:2:1.

[0040] After the above materials are mechanically mixed, they are transferred to a fermentation tank with a width of 3 meters and a depth of 1.5 meters equipped with a PVC ventilation pipe at the bottom. Every day, a pressure air pump is used to ventilate from the bottom at regular intervals. The ventilation time is 4 times a day, 30 minutes each time. The air flow rate is 200L / min; when the fermentation lasts for 2 days, the temperature of the pile body rises to 50°C. At this high temperature stage, all pathogenic bacteria,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com