Method for producing compost

A production method and a composting technology, which are applied in the field of composting, can solve the problems of inability to effectively improve plant growth conditions, crop yield, low resistance, and reduction of humus, and achieve the effects of enhancing plant resistance to diseases and insect pests, good decomposing degree and lasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

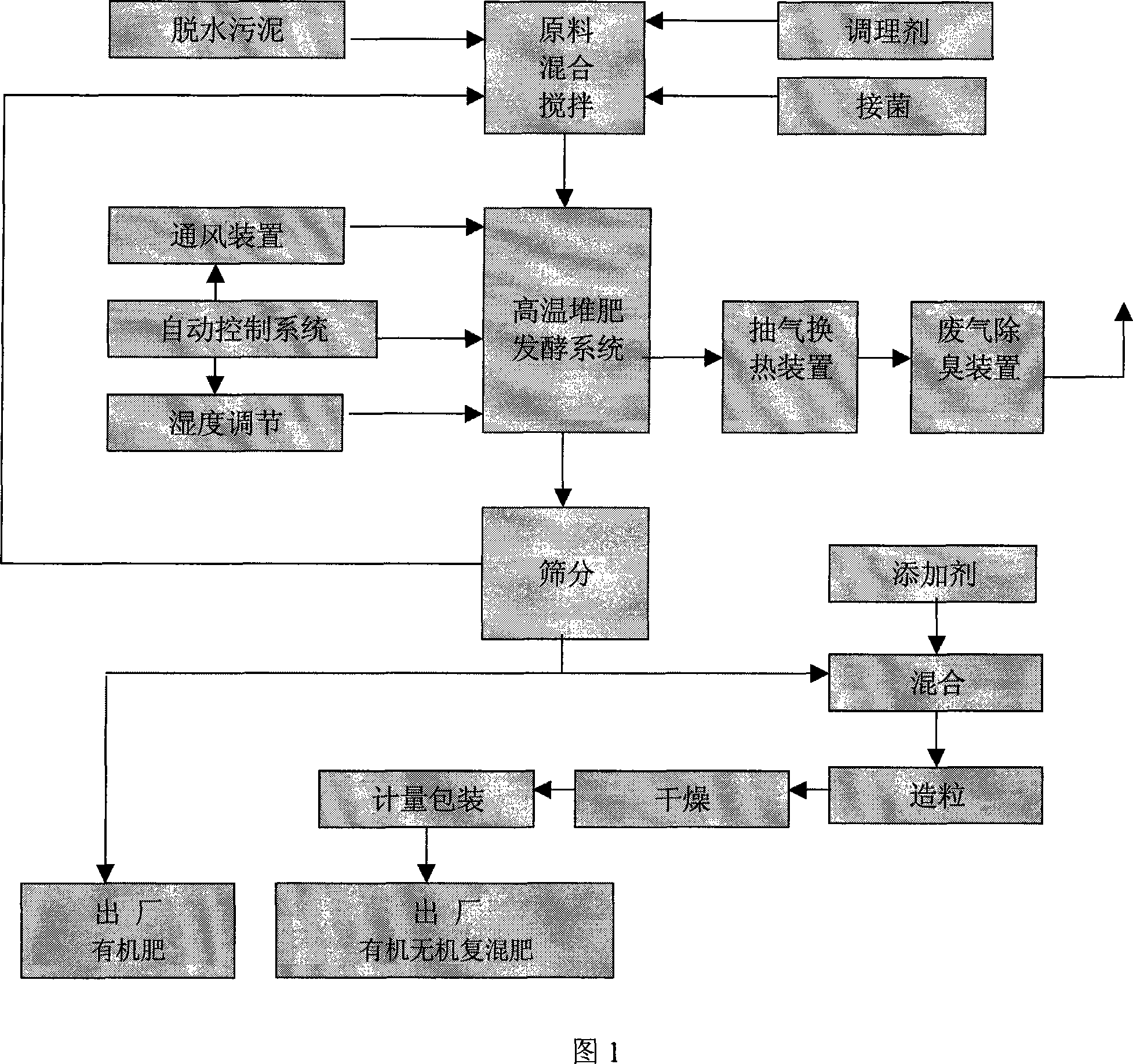

Image

Examples

Embodiment 1

[0027] Select 500 kg of sludge from a sewage treatment plant for dehydration treatment, take 300 kg of dehydrated sludge, select 350 kg of cow dung and 350 kg of wood chips as conditioners, fully mix the three raw materials, and take samples from the mixture. The C / N value is 25 (the weight of cow dung and wood chips is determined by the test of the target value of C / N of 25). In the mixture, add 350ml of VT bacteria, then stir and put it into the fermentation tank for fermentation. During the fermentation process, an automatic control system is used to ventilate, and the system parameters are set so that the oxygen content in the air in the fermentation tank is 18%, and the humidity is controlled at 18%. 60%, the temperature is at 50 degrees Celsius.

[0028] After 7 days of fermentation, a thorough turning is performed. After 15 days of fermentation, the compost fermentation is basically mature. Sampling analysis mature compost, its main component content is as follows (fi...

Embodiment 2

[0032] Select 500 kg of sludge from a sewage treatment plant for dehydration treatment, take 300 kg of dehydrated sludge, select 200 kg of slag and 400 kg of poplar leaves as conditioners, fully mix the three raw materials, and take samples of the mixture to measure Its C / N value is 28 (the weight of slag and poplar leaves is determined through experiments by the purpose value of C / N of 21). In the mixture, add 350ml of VT bacteria, then stir and put it into the fermentation tank for fermentation. During the fermentation process, an automatic control system is used to ventilate, and the system parameters are set so that the oxygen content in the air in the fermentation tank is 18%, and the humidity is controlled at 18%. 60%, the temperature is at 50 degrees Celsius.

[0033] After 7 days of fermentation, a thorough turning is performed. After 15 days of fermentation, the compost fermentation is basically mature. Sampling analysis mature compost, its main component content is...

Embodiment 3

[0037] Select 500 kg of sludge from a sewage treatment plant for dehydration treatment, take 300 kg of dehydrated sludge, select 350 kg of cow dung, and 300 kg of crushed rice straw as conditioners, fully mix the three raw materials, and sample the mixture Its C / N value was measured to be 20. In the mixture, add 350ml of VT bacteria, then stir and put it into the fermentation tank for fermentation. During the fermentation process, an automatic control system is used to ventilate, and the system parameters are set so that the oxygen content in the air in the fermentation tank is 18%, and the humidity is controlled at 18%. 60%, the temperature is at 50 degrees Celsius.

[0038] After 7 days of fermentation, a thorough turning is performed. After 15 days of fermentation, the compost fermentation is basically mature. Sampling analysis mature compost, its main component content is as follows (first 6 groups of data are percentages by weight):

[0039] water

[0040] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com