Patents

Literature

4672 results about "Feces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feces (or faeces) are the solid or semisolid remains of food that could not be digested in the small intestine. Bacteria in the large intestine further break down the material. Feces contain a relatively small amount of metabolic waste products such as bacterially altered bilirubin, and the dead epithelial cells from the lining of the gut.

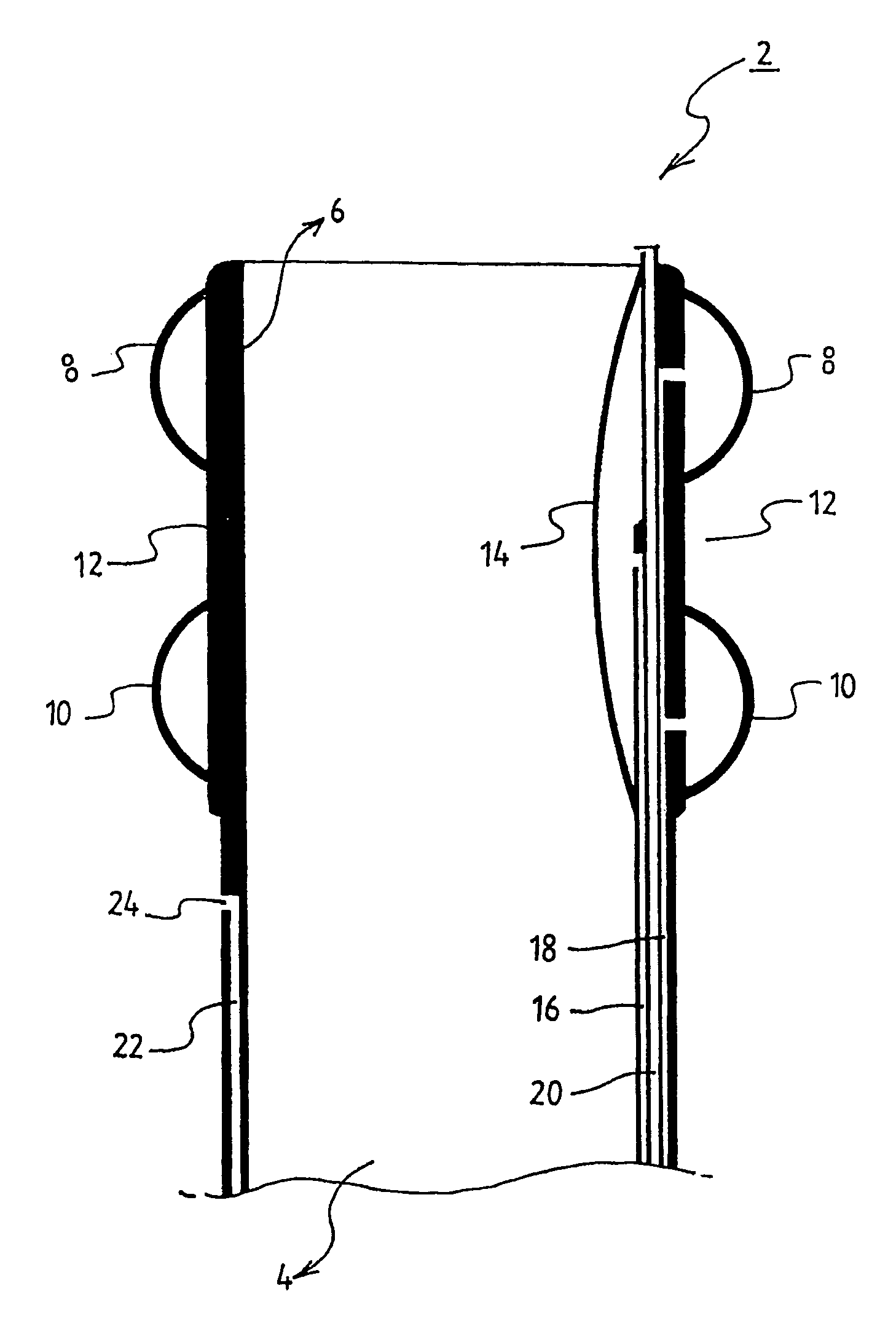

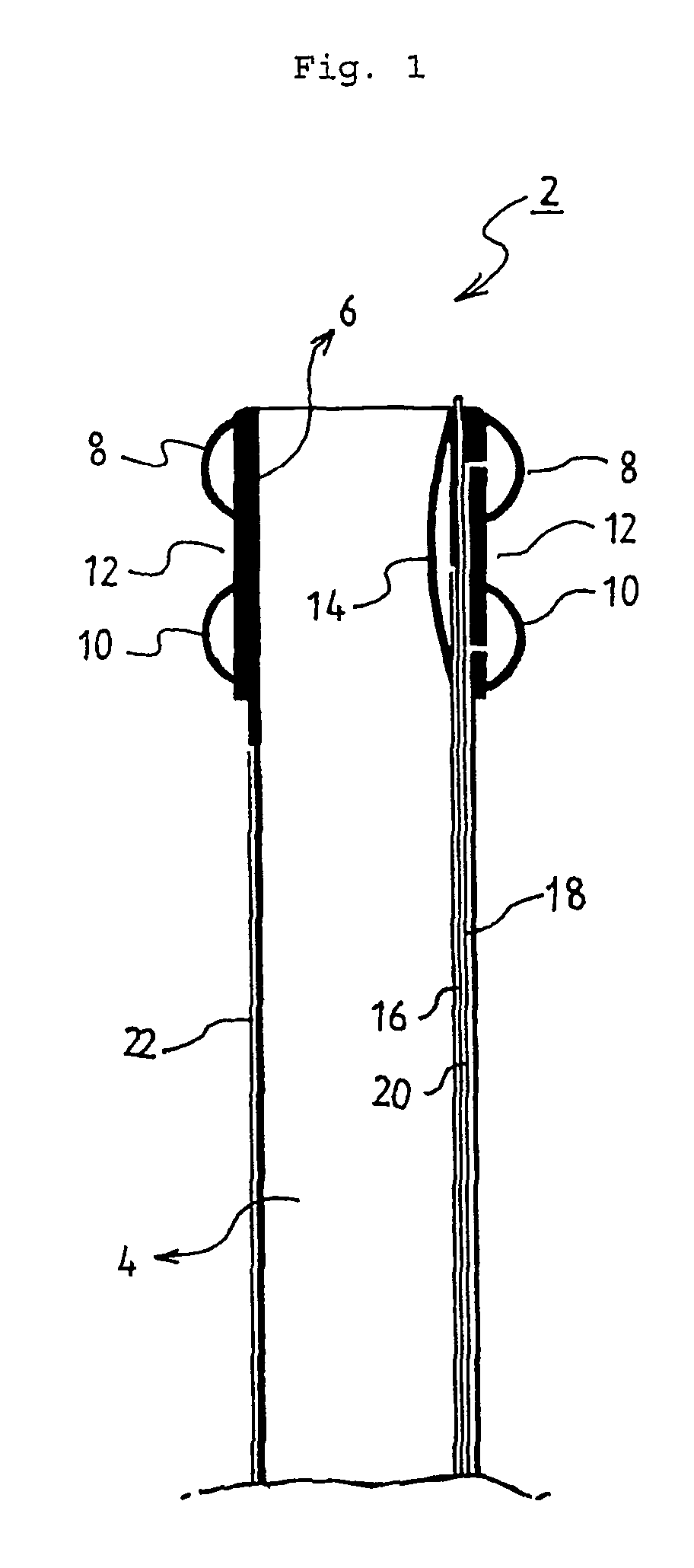

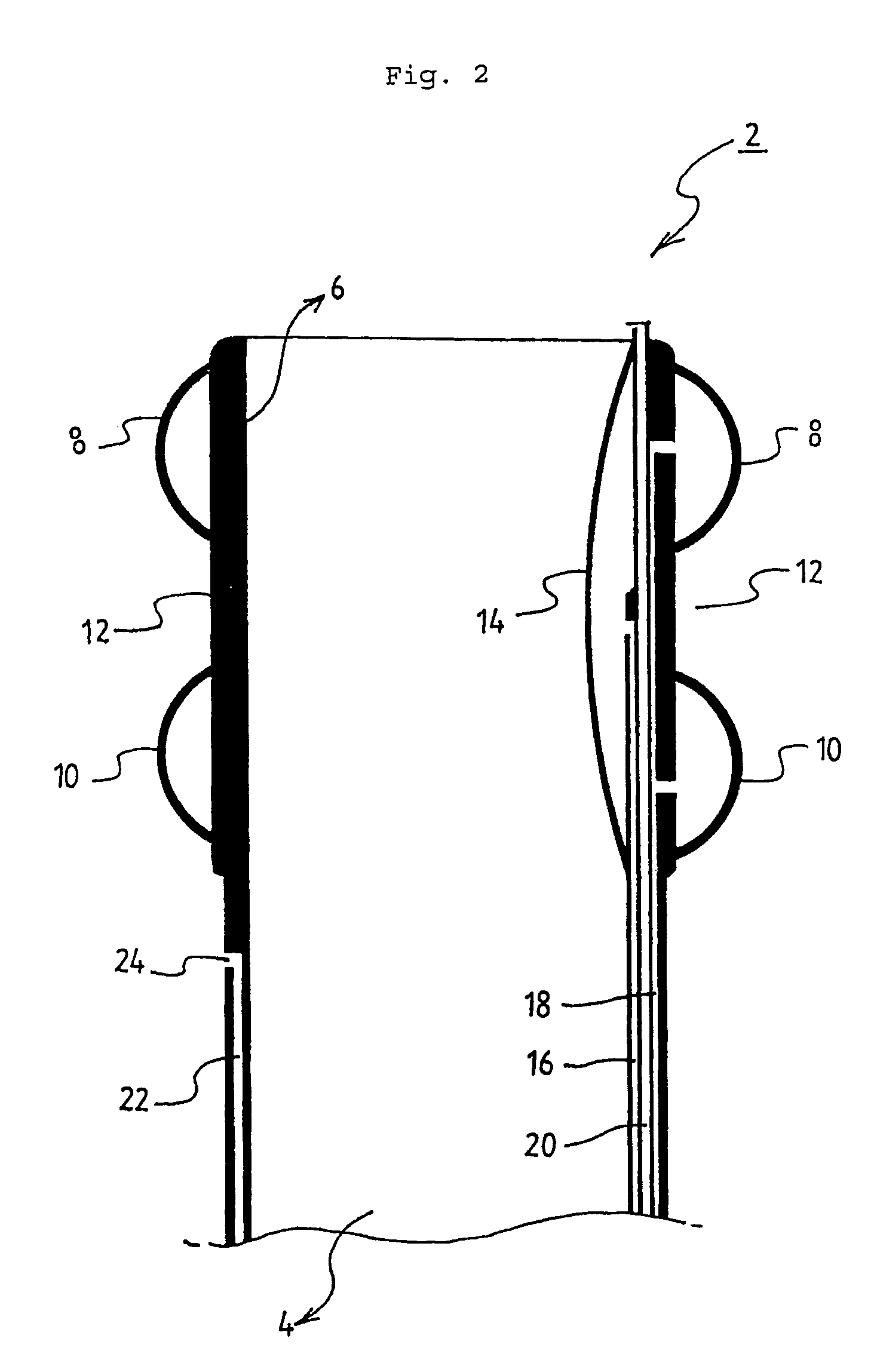

Indwelling fecal diverting device

ActiveUS8398669B2Improve securityEasy to installBalloon catheterAnti-incontinence devicesFecesSurgery

Disclosed is an indwelling fecal diverting device. The device comprises an elongate tube formed, at an upper end thereof, with a tubular body part; a pair of fixing balloons attached up and down to an outer surface of the tubular body part such that a clamping portion is defined between the fixing balloons; and a tube opening and closing balloon attached to an inner surface of the tubular body part. An injection passage is defined in the tube so that a remedial liquid can be injected through the injection passage to the outside of the tube to medically treat an anastomosed portion of an intestinal tract of a patient. The indwelling fecal diverting device is fitted into the intestinal tract of the patient, air is supplied into the fixing balloons to inflate them, and the intestinal tract is clamped around the clamping portion using a clamping band.

Owner:YUSHIN MEDICAL +1

Treatment of gastro-intestinal disorders

InactiveUS6645530B1Dampen bacterial inactivationAcid secretion in the stomach could also be pharmacologically suppressedBiocideMilk preparationEscherichia coliDisease

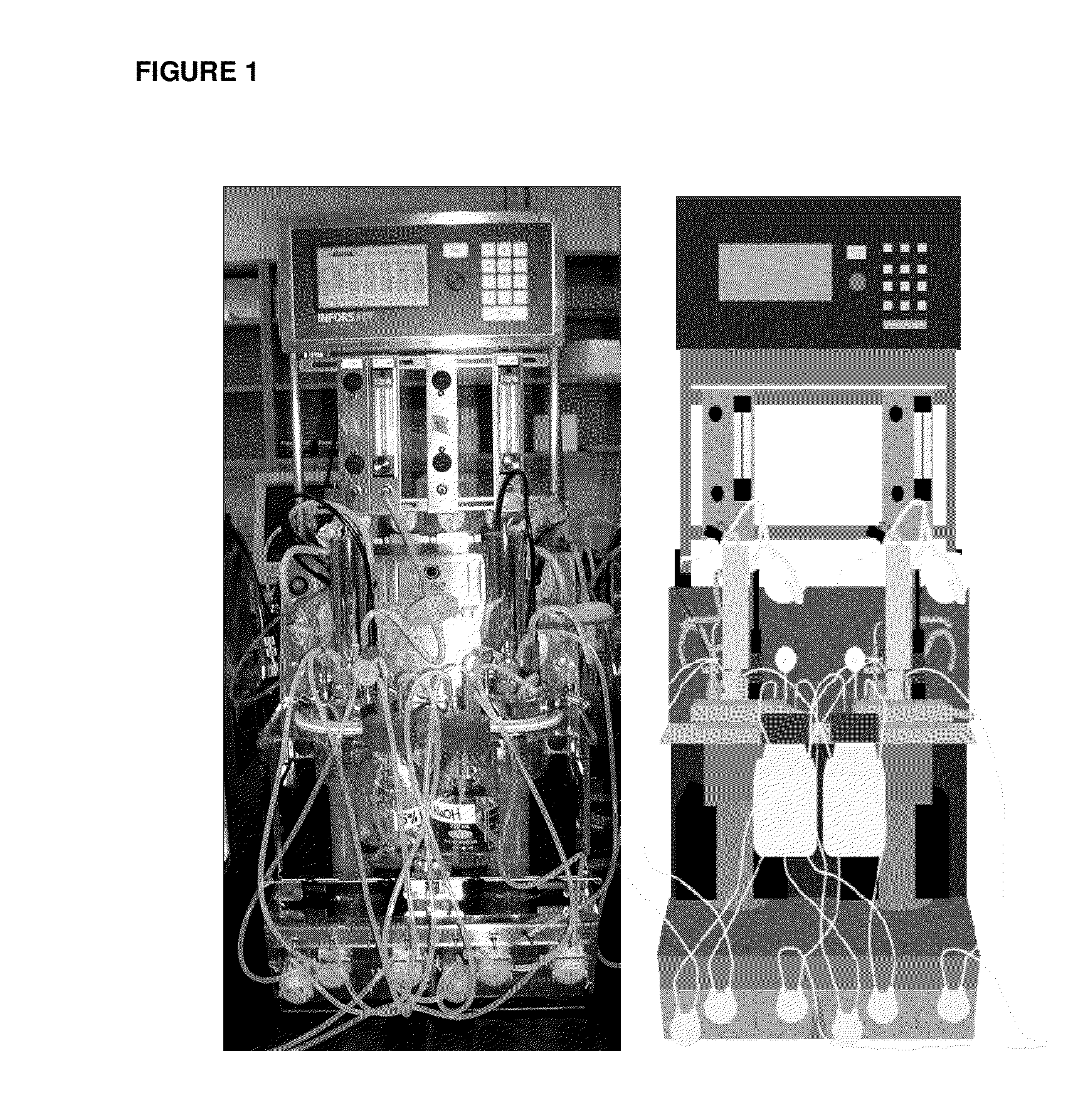

A method of treating chronic disorders associated with the presence of abnormal microflora or an abnormal distribution of microflora in the gastrointestinal tract involves removing the host's existing enteric microflora and substitution of feces from a disease screener donor or composition comprising microorganism selected from the group consisting of Bacteroides and E. coli.

Owner:CRESTOVO LLC

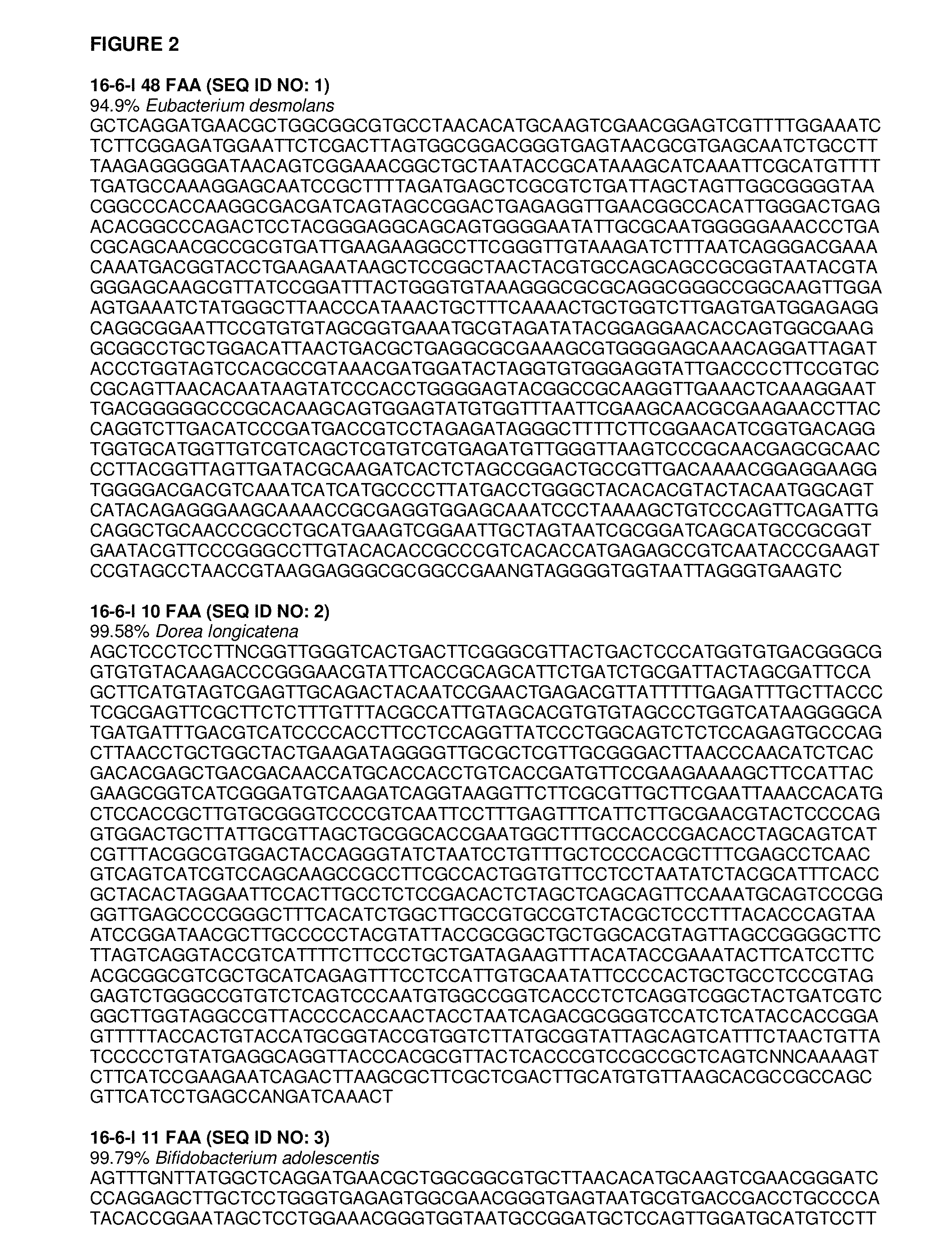

Method for treatment of disorders of the gastrointestinal system

There are provided novel synthetic stool preparations comprising bacteria isolated from a fecal sample from a healthy donor. The synthetic stool preparations are used for treating disorders of the gastrointestinal tract, including dysbiosis, Clostridium difficile infection and recurrent Clostridium difficile infection, prevention of recurrence of Clostridium difficile infection, treatment of Crohn's disease, ulcerative colitis, irritable bowel syndrome, inflammatory bowel disease, and diverticular disease, and treatment of food poisoning such as salmonella. Methods of preparation and methods of use of the synthetic stool preparations are also provided.

Owner:UNIVERSITY OF GUELPH +2

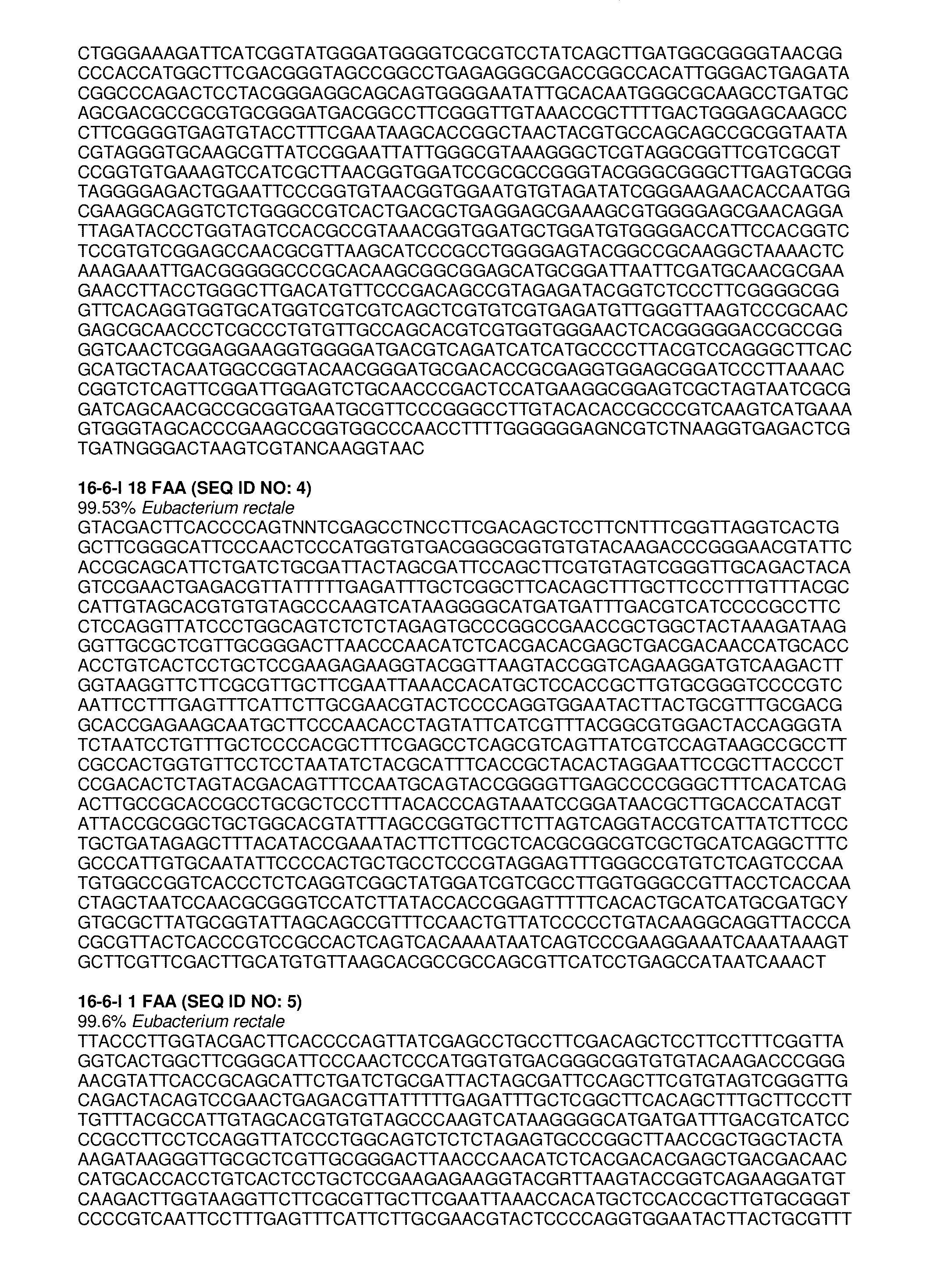

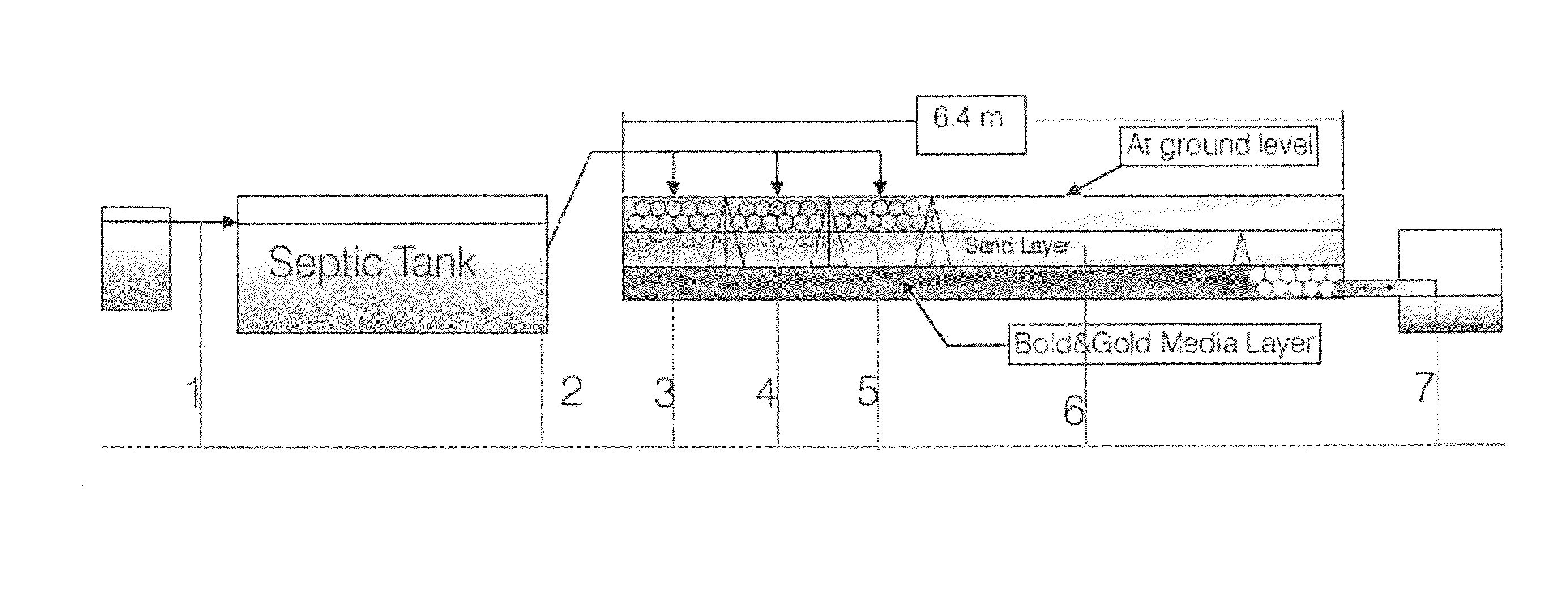

Subsurface upflow wetland system for nutrient and pathogen removal in wastewater treatment systems

ActiveUS8252182B1Low maintenance burdenHigh benefit cost ratioWater cleaningContaminated soil reclamationFecesTotal suspended solids

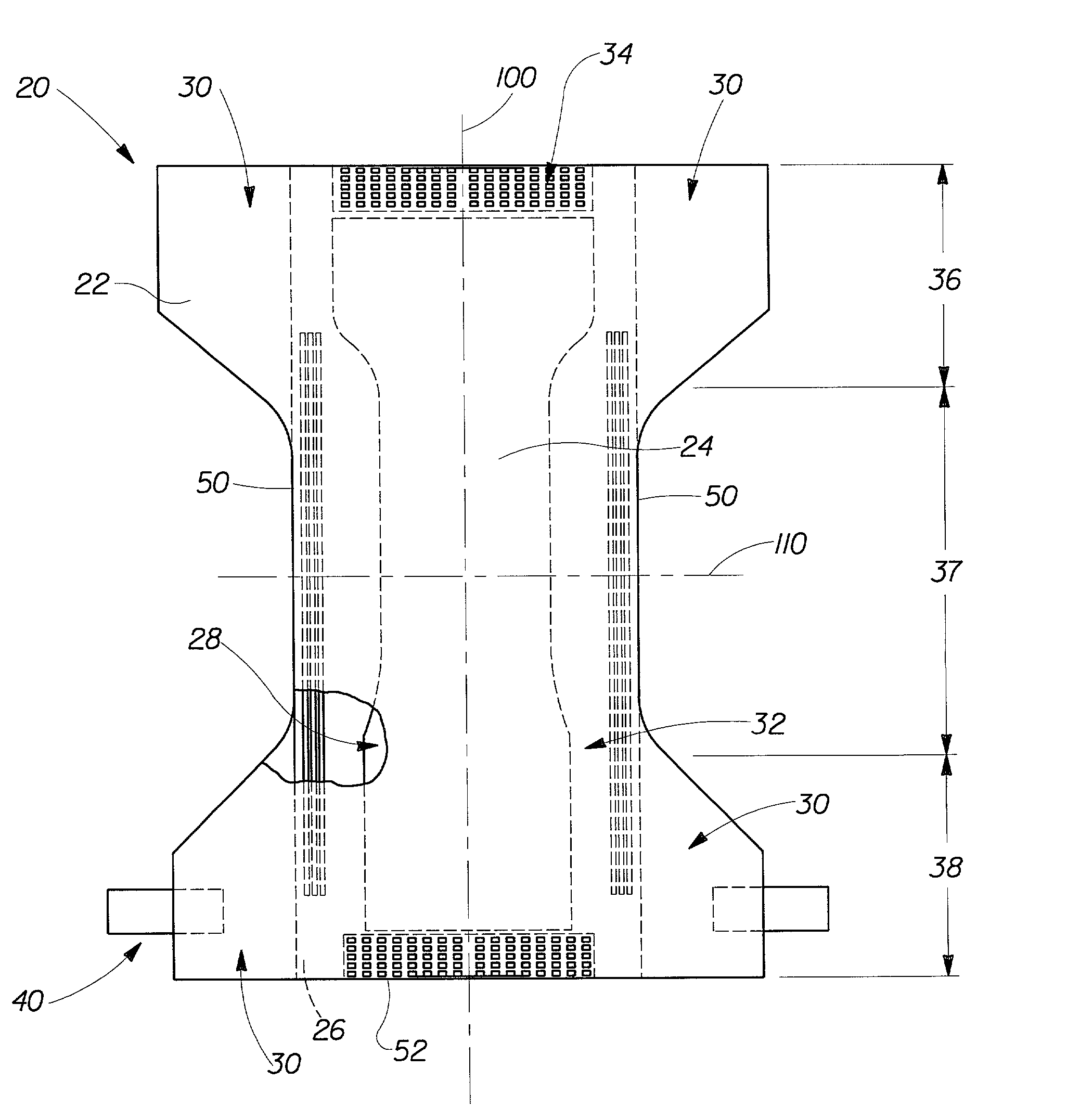

Methods and systems for a subsurface upflow wetland for wastewater treatment that includes a series of parallel treatment cells, each cell including from bottom to top, a layer of gravel, a layer of sand over the gravel to remove pathogens from a septic effluent, a pollution control medium above the sand layer to remove nutrients, total suspended solid, and biochemical oxygen demand and a growth media mixture layered on top of the pollution control media to grow plants, and a gravity distribution system to distribute effluent to the series of parallel treatment cells. The pollution control medium includes at least one recycled material and at least one naturally occurring material. In an embodiment it includes recycled tire crumb, sand and limestone or recycled tire crumb, compost, sand and limestone.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

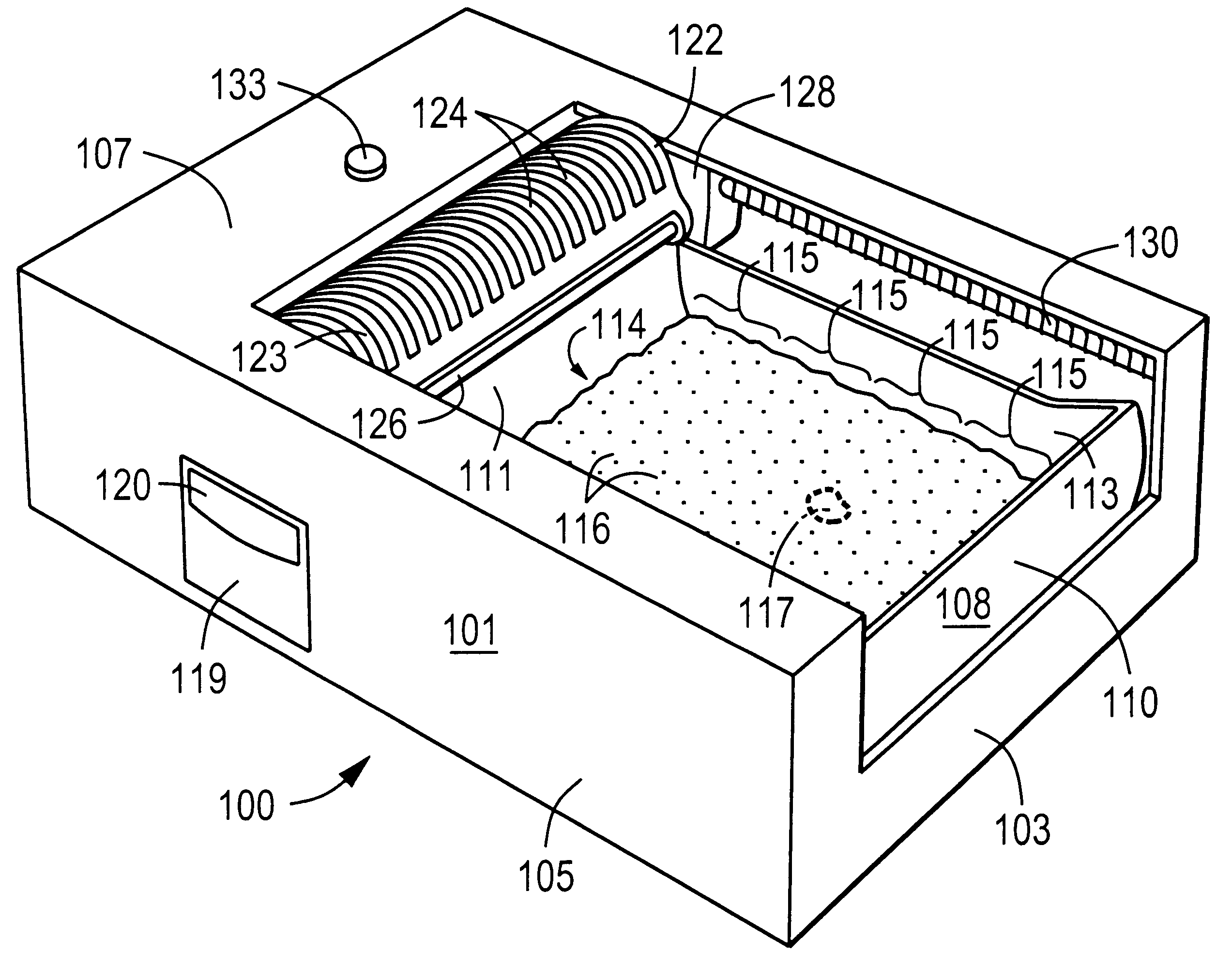

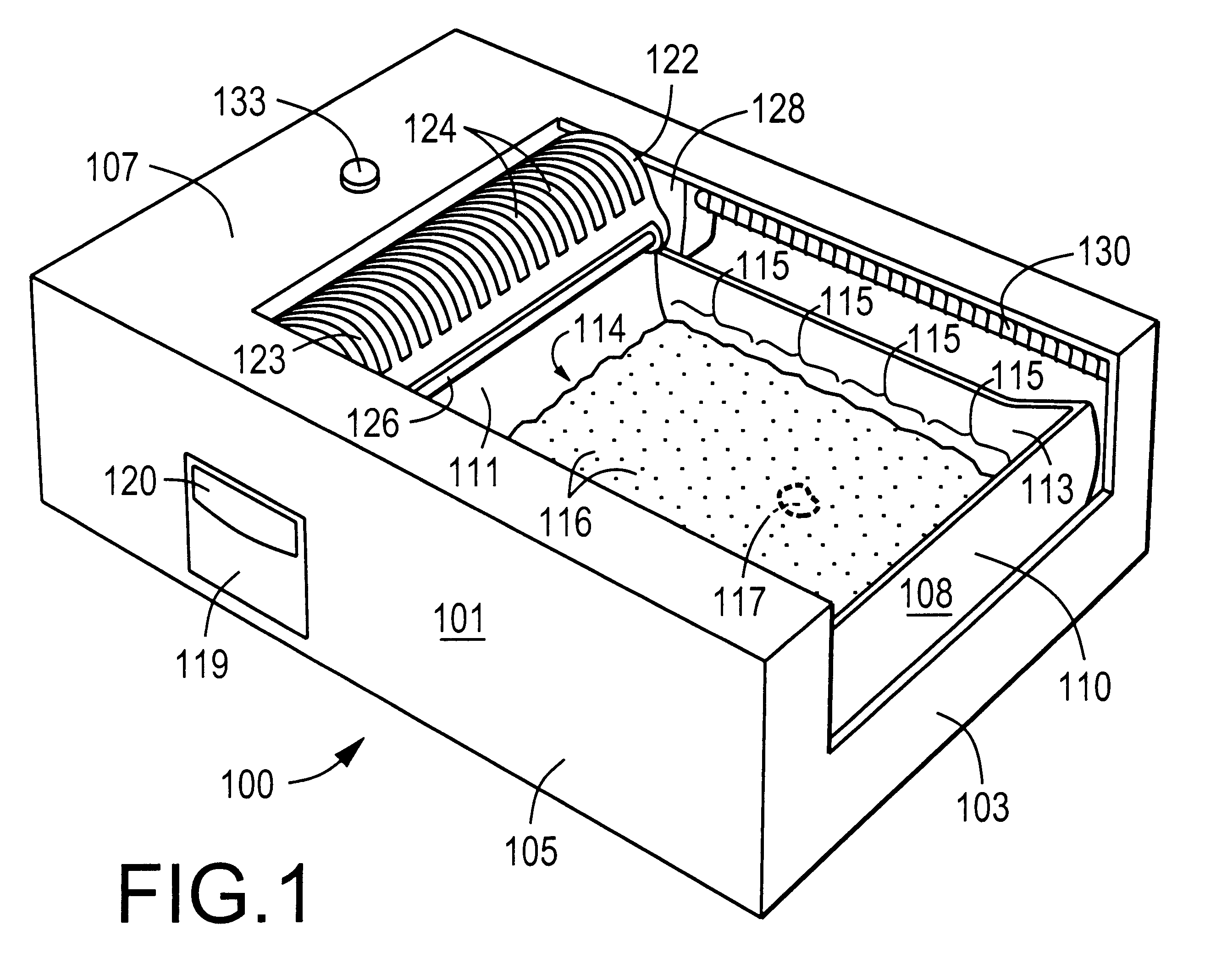

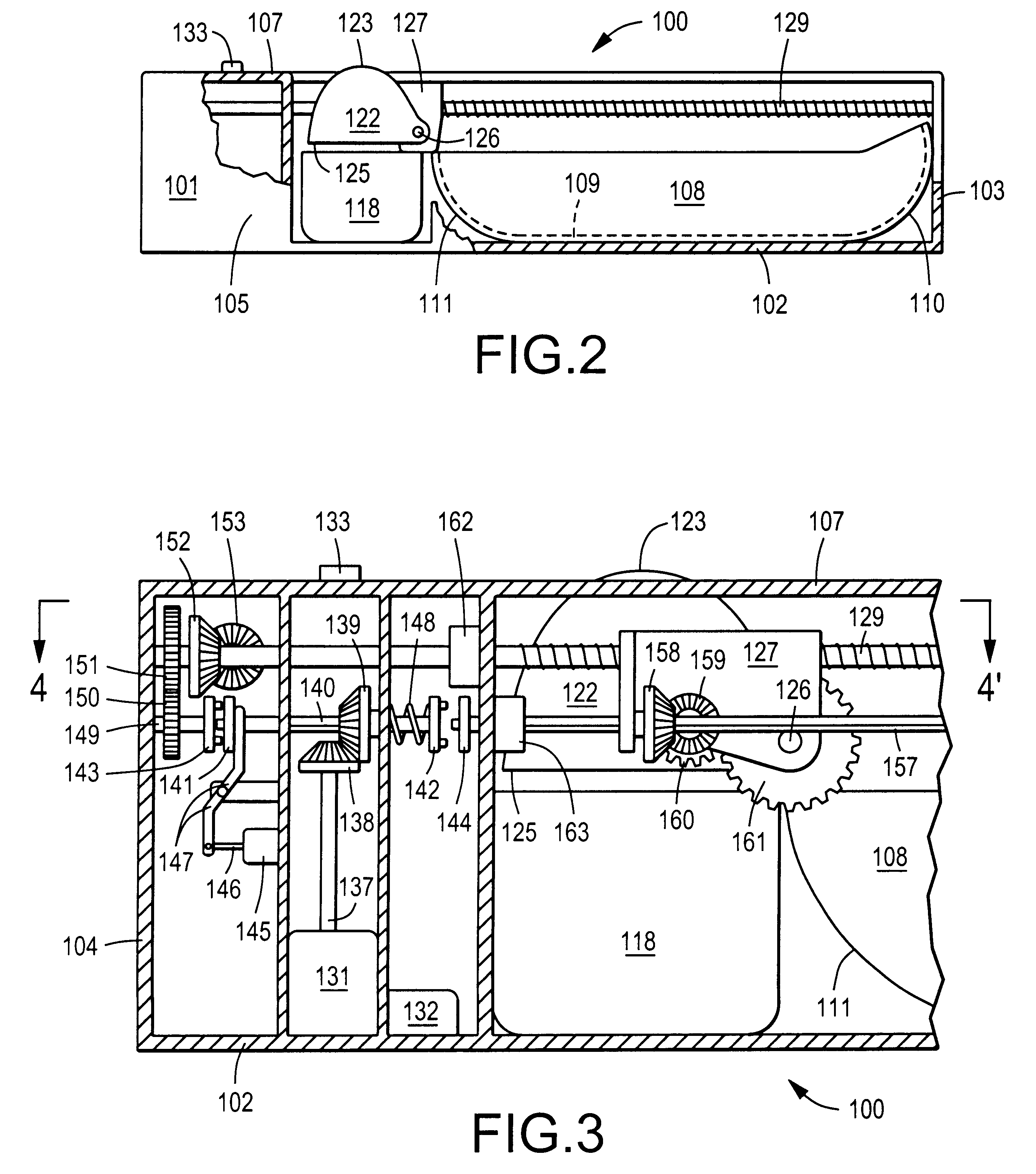

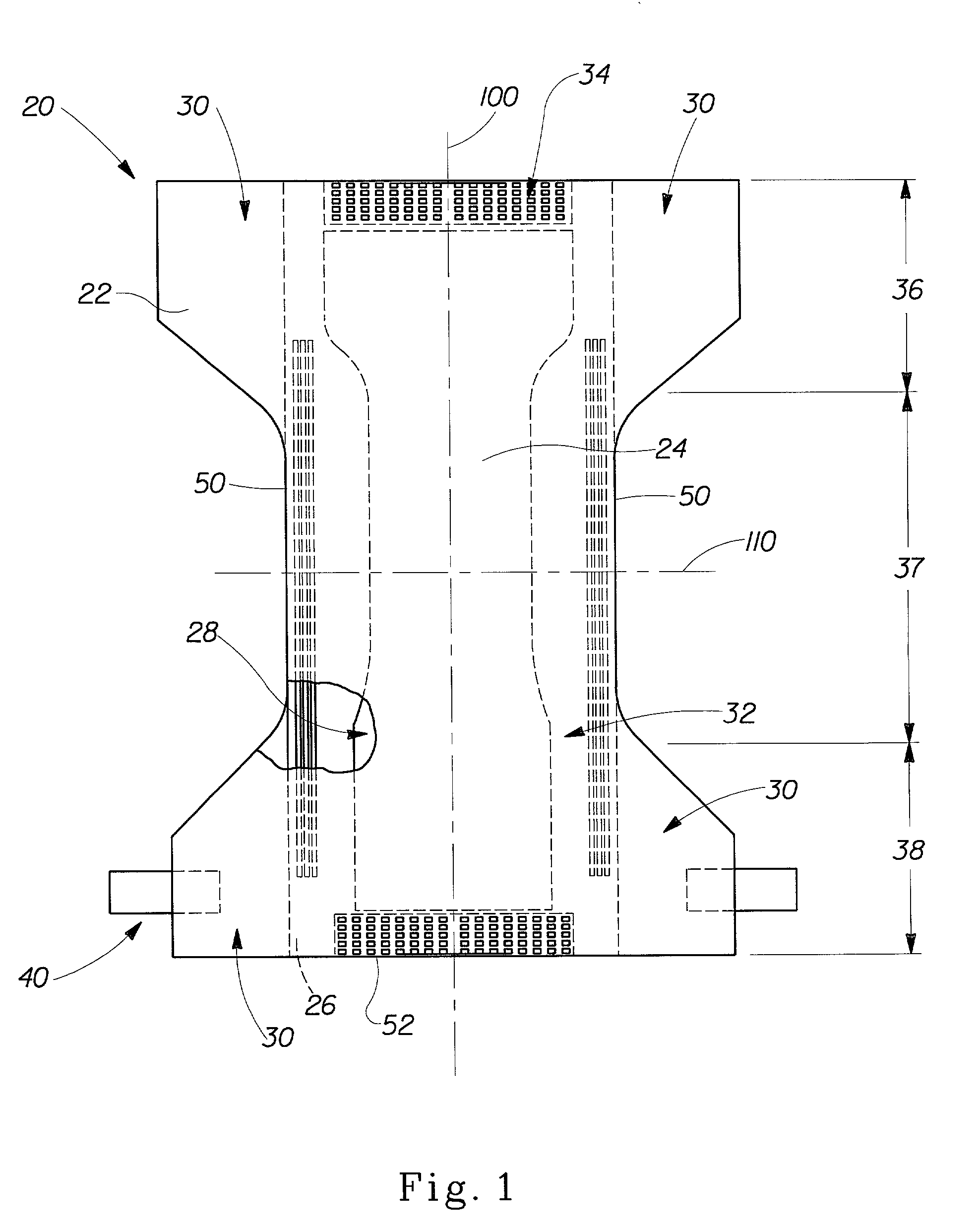

Animal waste disposal system

An animal waste disposal system including a housing with an area for holding a bed of particulate litter, a scoop with a plurality of perforations for separating animal's waste from the particulate litter, and a drive mechanism for moving the scoop to remove animal's waste from the bed of particulate litter. The waste-removing operation is carried out by collecting a mixture of animal's waste and particulate litter in the interior of the scoop and moving the scoop in a raised position over the area for holding the bed of particulate litter to allow the collected particulate litter to sift through the perforations in the scoop while retaining animal's waste for disposal into a waste container. The bed of particulate litter may be arbitrarily defined by a plurality of contiguous sections, each of which can be cleaned or processed separately and independently. Two types of retractable partitions are provided to make the waste-removing mechanism inaccessible to the animal during its automatic operation.

Owner:ATCRAVI ITTY

Film-forming compositions for protecting skin from body fluids and articles made therefrom

The present invention relates to a film-forming barrier composition useful for protecting the skin from body fluids, such as urine, feces, menses. The composition comprises a skin conditioning agent, a viscosity enhancing agent and an oleophilic film-forming agent. Optionally, the lotion may comprise skin care ingredients for treating or maintaining skin health. The composition may be applied to the skin by suitable delivery vehicles, such as absorbent articles or components thereof, sheet materials, pads, bandages, sponges, foam pads, pumps, sprays, depending on the viscosity of the composition.

Owner:THE PROCTER & GAMBLE COMPANY

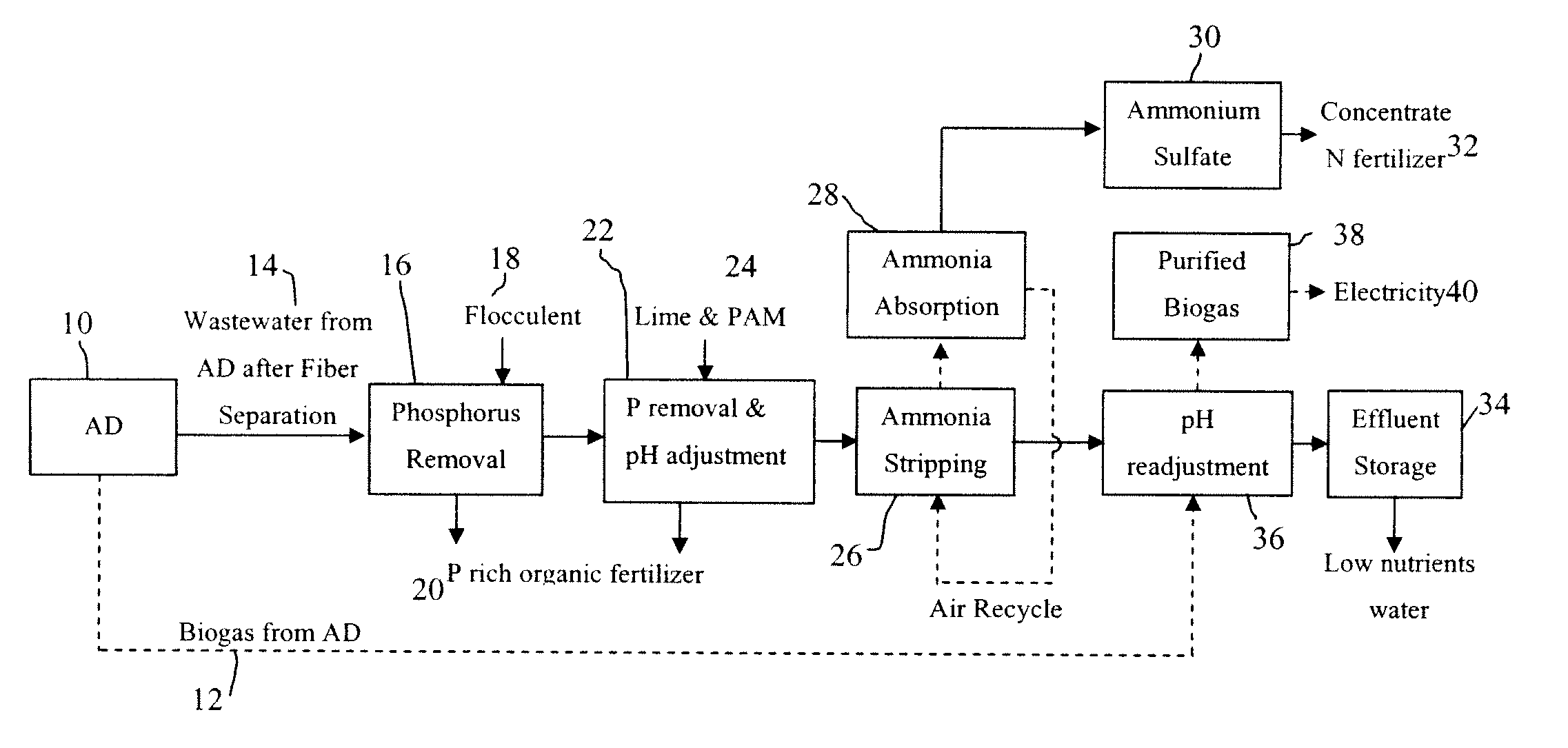

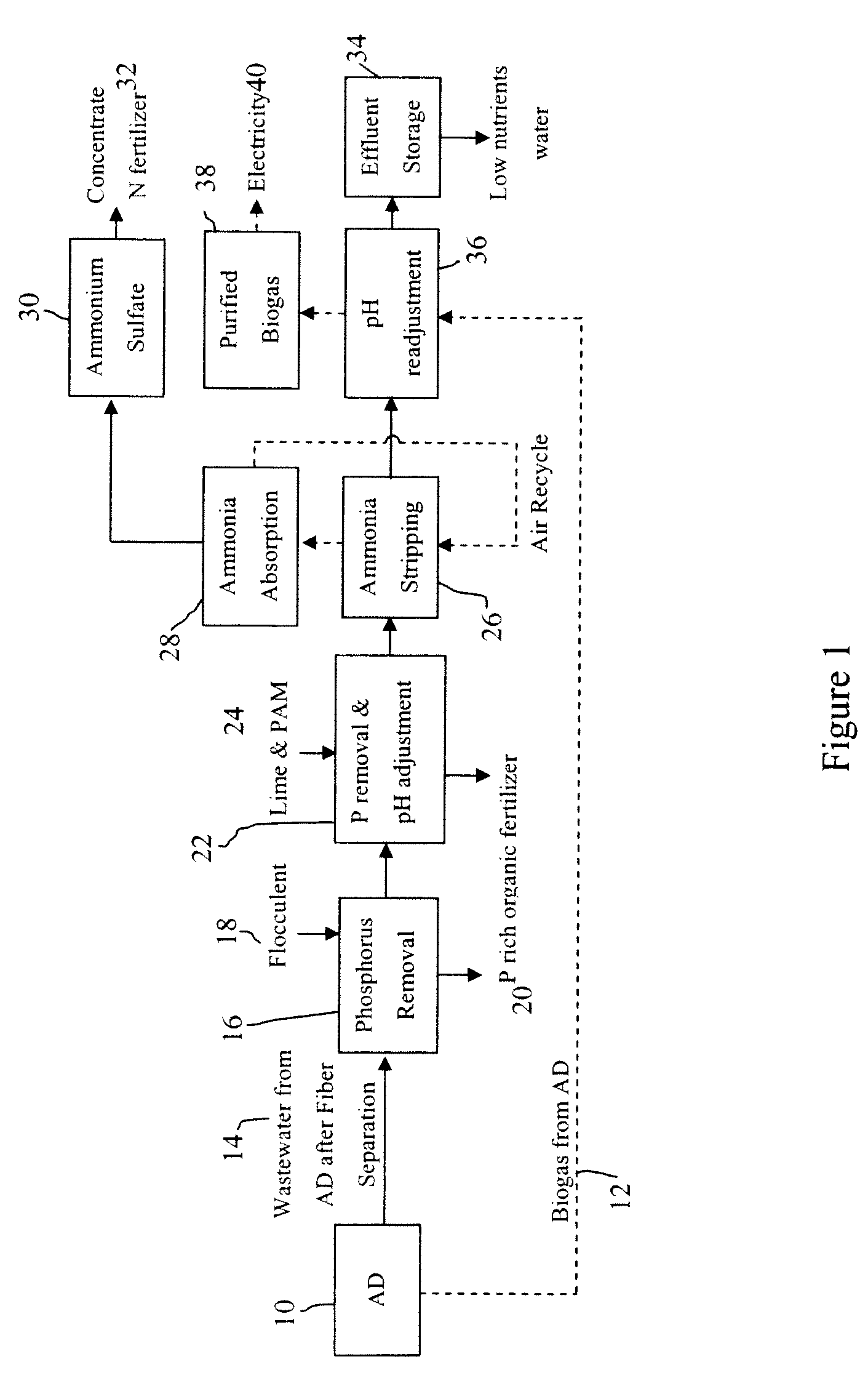

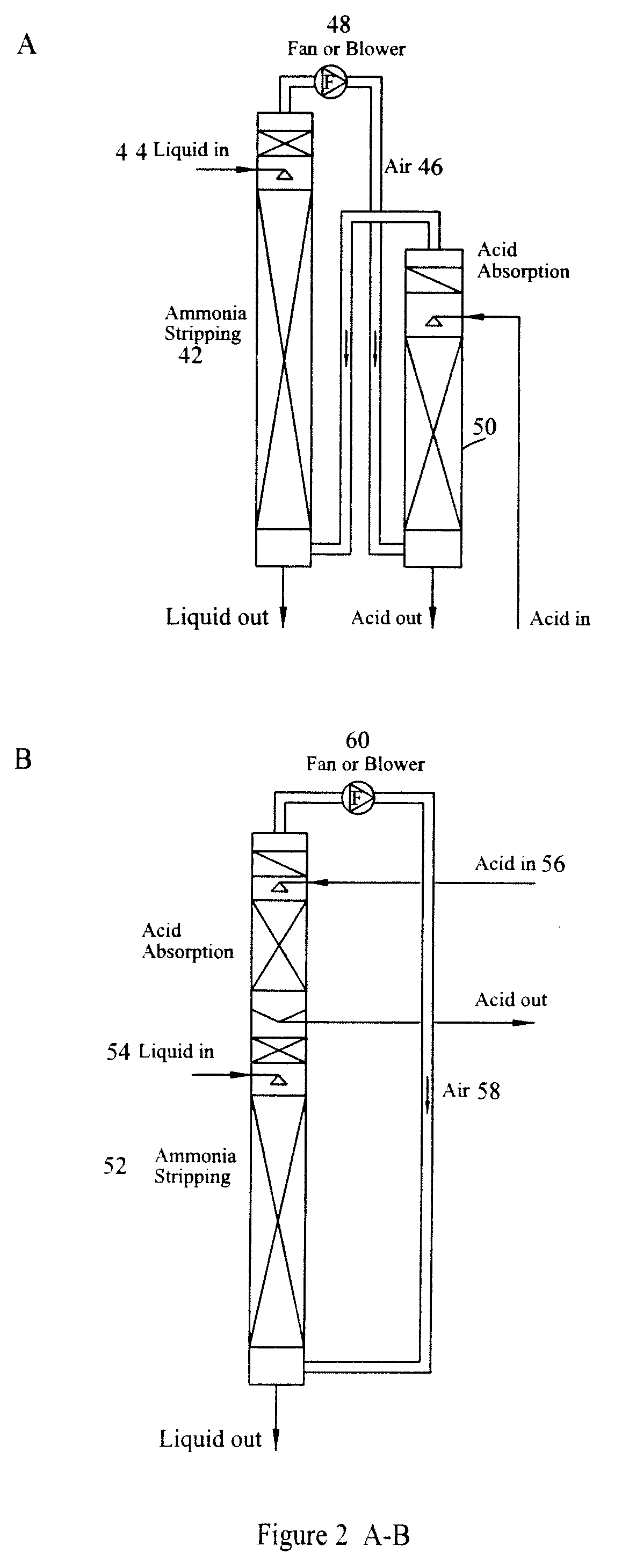

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

Fabric or garment containing fecal enzyme inhibitor

Skin irritation, such as diaper rash, appearing when the skin is allowed to remain in contact with proteolytic enzymes found in feces is prevented by inactivating the fecal proteolytic enzymes by contact with organophilic clays. The organophilic clays are applied to the skin in areas likely to come into contact with feces or to garments such as diapers. A composition suitable for practicing the method of the invention comprises an amount of an organophilic clay effective to inactivate irritating fecal proteolytic enzymes dispersed in a pharmaceutically acceptable non-toxic dermatological vehicle. A fabric incorporating organophilic clay, preferably dispersed in a matrix of a superabsorbent polymer is useful for preparing diapers for infants that can help to prevent skin irritation by fecal enzymes.

Owner:SUD CHEM INC

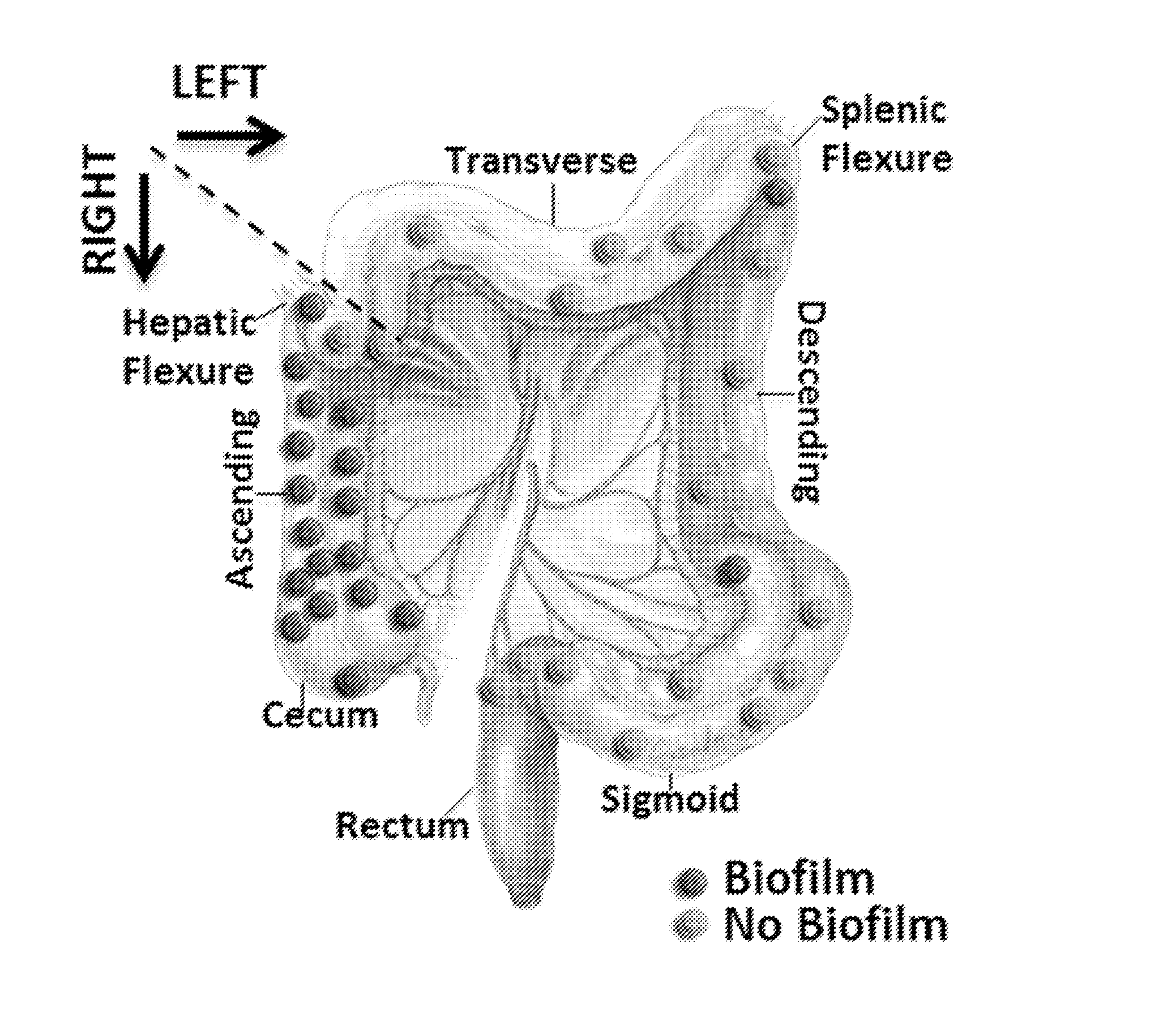

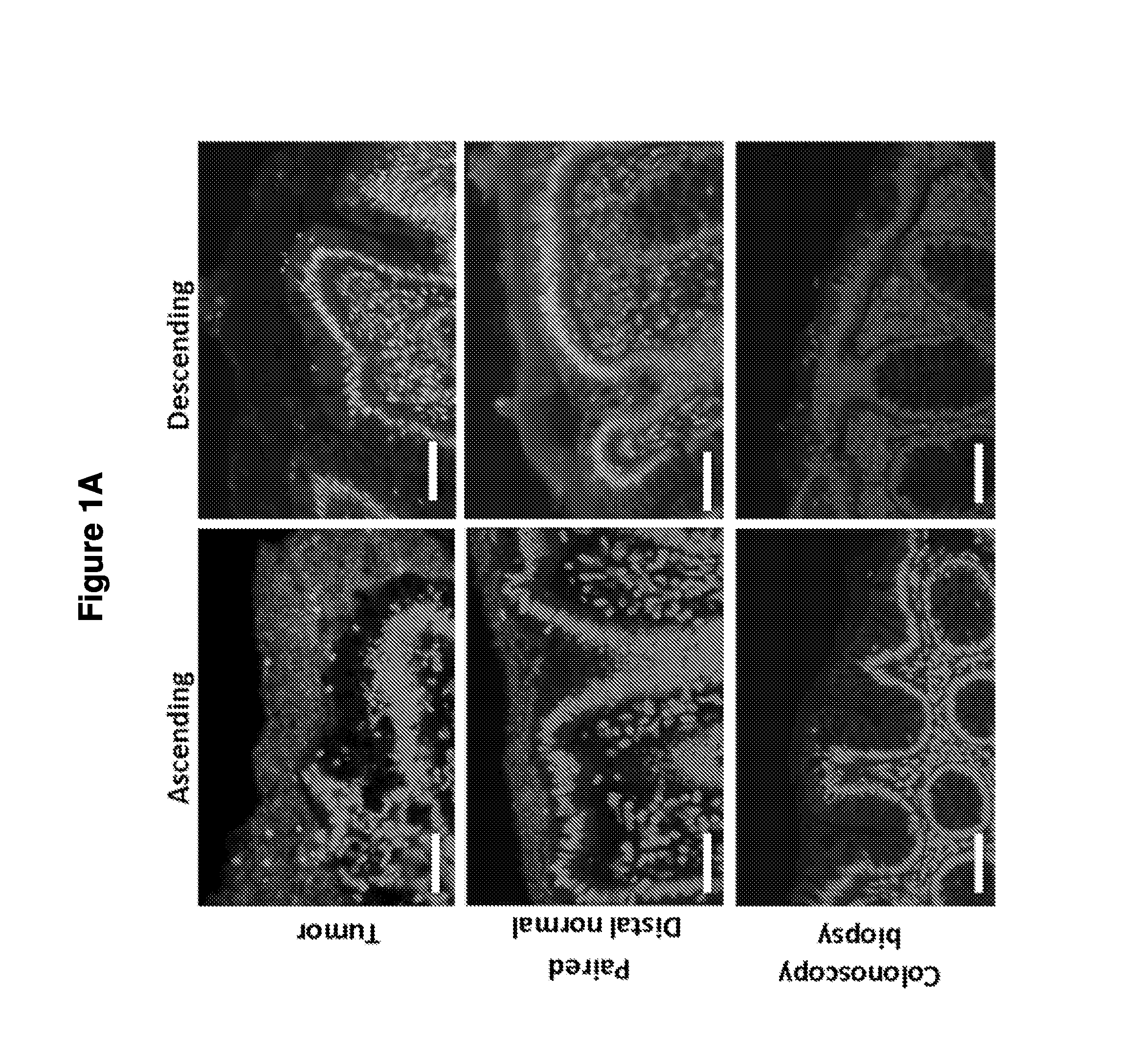

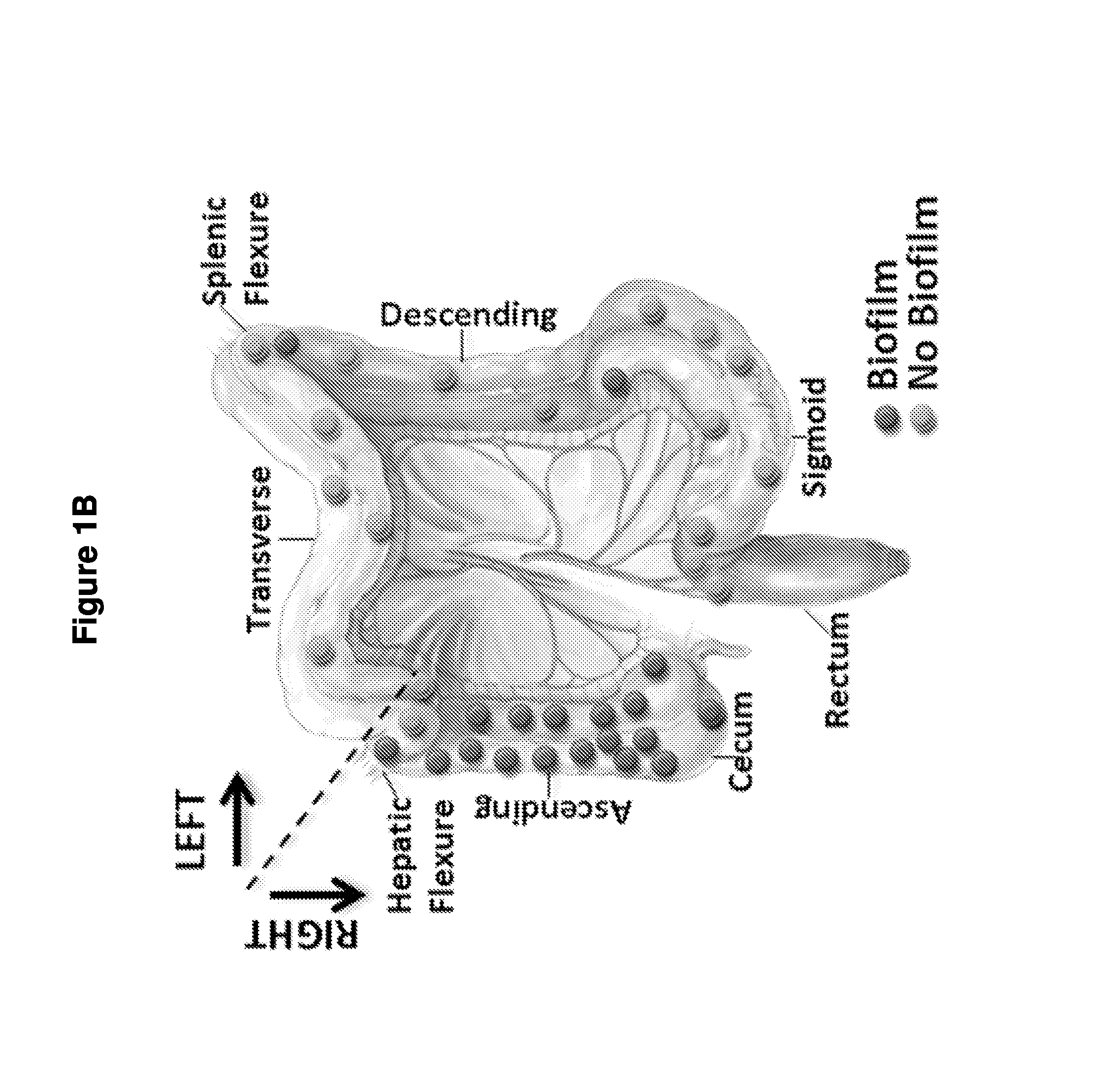

Biofilm formation to define risk for colon cancer

ActiveUS20160223553A1Preventing and diminishing developmentIncreased proliferationMicrobiological testing/measurementUnknown materialsFecesIncreased risk

Methods of identifying subjects at increased risk of cancer, based upon detection of biofilms and / or biofilm-associated microbes within a subject, are disclosed. Therapies designed to prevent formation and / or reduce the size of biofilms in a subject identified to be at increased risk of cancer based upon detection of biofilms and / or biofilm-associated microbes are disclosed. In particular embodiments, the invention provides for identification of a subject at elevated risk of developing or having colorectal cancer and / or a colorectal adenoma, based upon detection of a biofilm and / or biofilm-associated bacteria within the gastrointestinal tract of the subject (optionally, within a biopsy specimen and / or stool sample of such subject). Therapies involving administration of an antibiotic agent and / or a probiotic agent to a subject, to prevent or reduce biofilm formation within the gastrointestinal tract of the subject, optionally provided in combination with additional cancer therapy, are also disclosed.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Tea-derived feed additive and animal feed containing the same

InactiveUS6068862AReduce generationQuality improvementSolid waste disposalAnimal feeding stuffFecesAdditive ingredient

The present invention relates to a feed additive for animals comprising tea extract, to a feed additive for animals of which active ingredient is tea leaf fiber, and to an animal feed comprising the feed additive for animals. The tea extract in the present invention exerts great effects in preventing and treating noninfectious and infectious diarrhea in domestic animals, poultry, and pet animals, improving milk quality of fresh milk, increasing milk yield, and improving reproductive efficiency. Also, the tea leaf fiber of the present invention improves intestinal function in domestic animals, decreases the occurrence of diarrhea, increases milk yield, improves feed efficiency and removes malodor of feces and urine.

Owner:TAIYO KAGAKU CO LTD

In vivo use of water absorbent polymers

InactiveUS6908609B2Reduce the amount requiredReduce the numberBiocideSynthetic polymeric active ingredientsFecesRemove blood

The subject invention is a method and material for removing fluid from the intestinal tract of a host and may be useful in treating animals or human patients suffering from fluid overload states. In one embodiment, the subject method involves ingesting an enterically coated non-systemic, non-toxic, non-digestible, water absorbing polymer which absorbs fluid while passing through the intestinal tract. The polymer is excreted in the feces wherein the polymer and absorbed fluid is removed from the body. Preferred polymers include super absorbent acrylic acid polymers, preferably provided in bead form. The polymers may include functional groups for selectively removing blood borne waste products, e.g. urea, from the G.I. tract.

Owner:RELYPSA INC

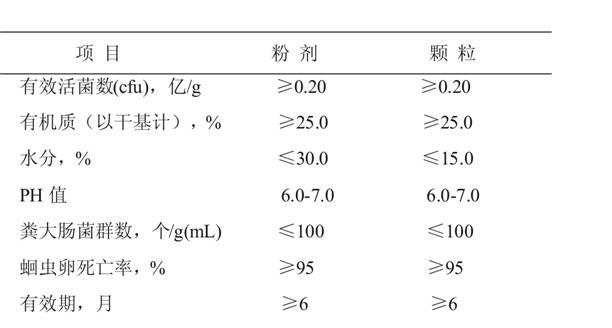

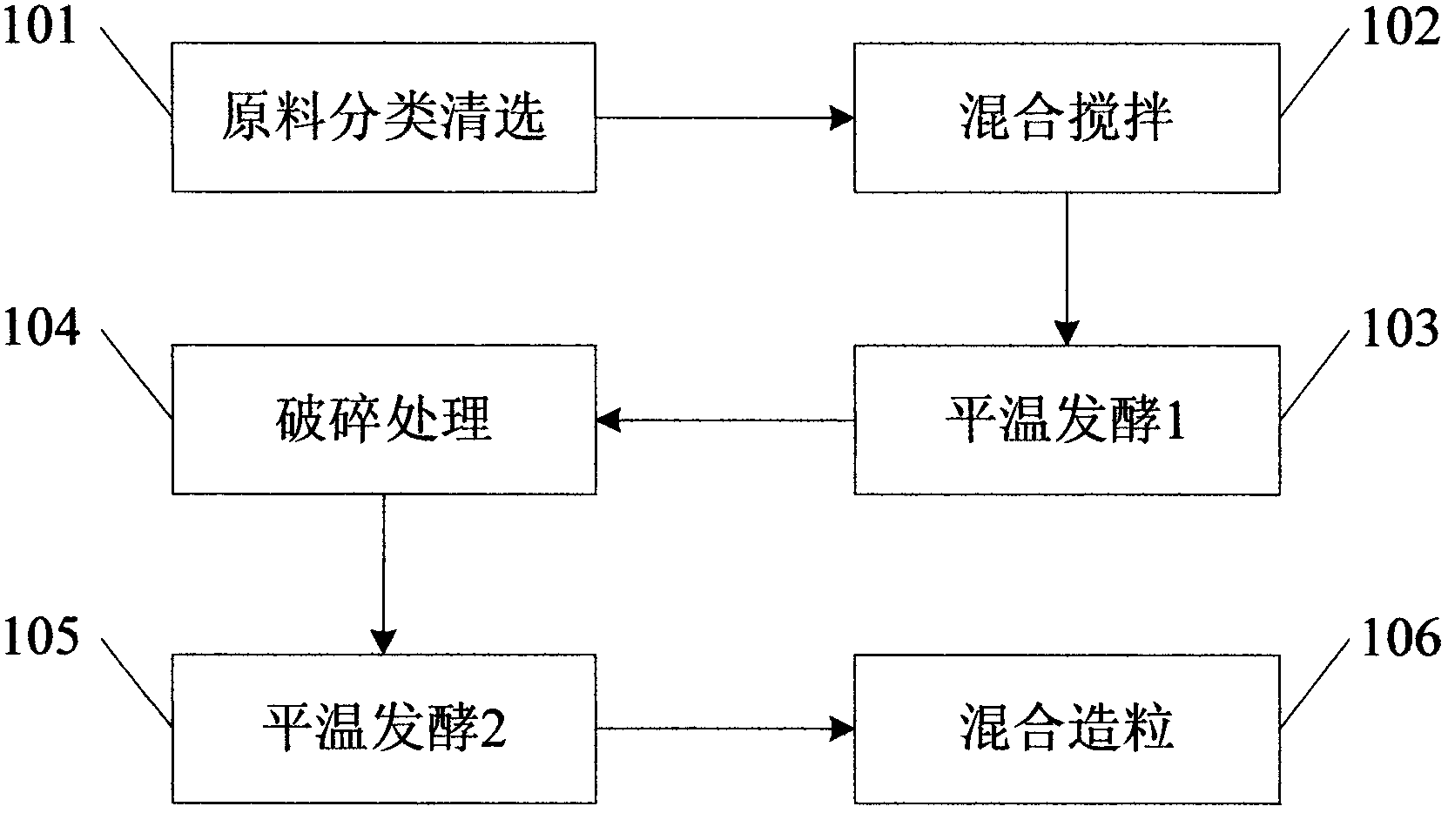

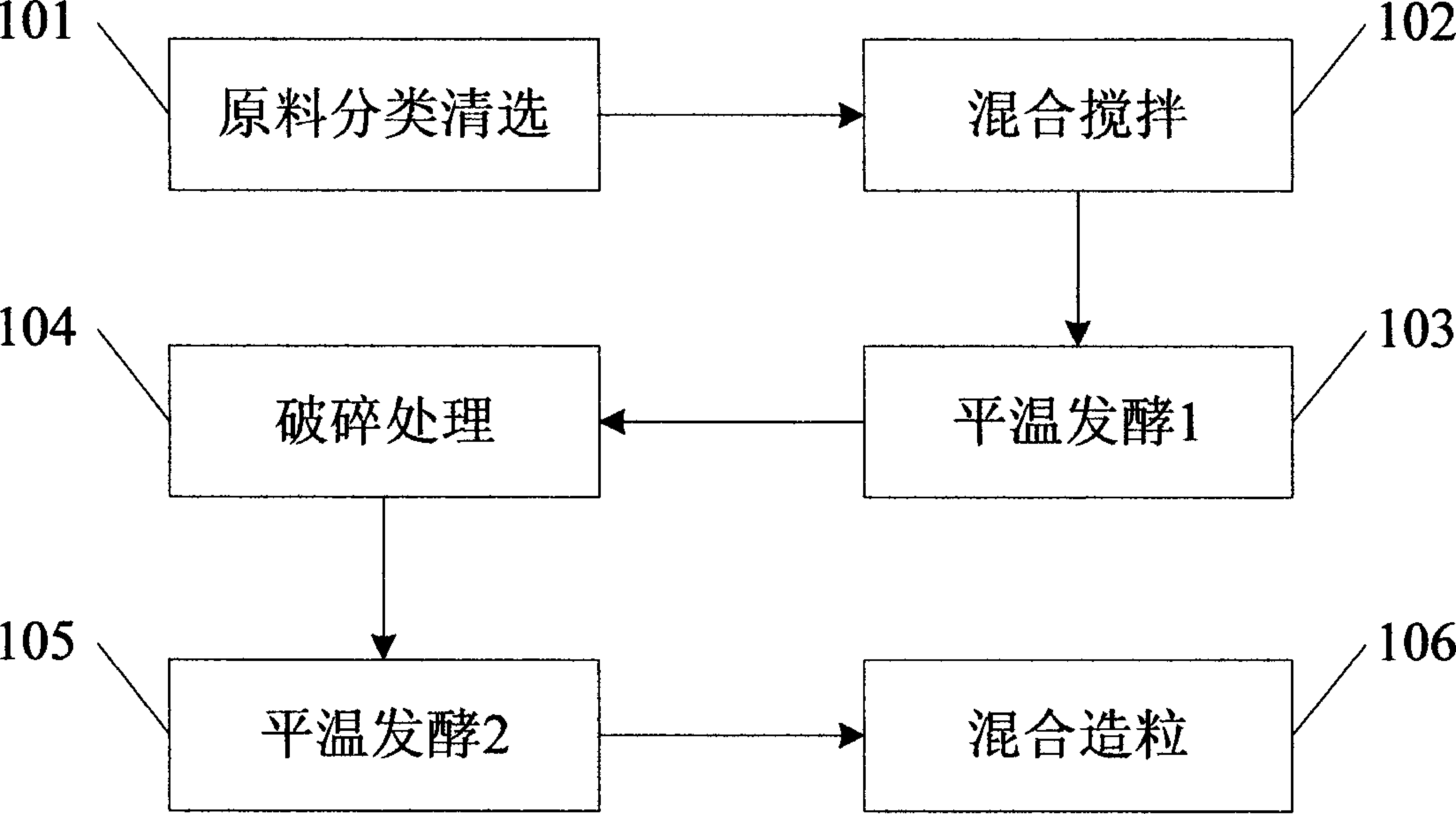

Bio-organic fertilizer produced by using livestock manure

ActiveCN102219570ASimple structureImprove conversion rateBio-organic fraction processingFungiLivestock manureAgricultural science

The invention provides an efficient active bio-organic fertilizer produced by using livestock manure and a preparation method thereof. The preparation method comprises the following steps: pre-treating the livestock manure, straw and peat; mixing the livestock manure, straw and peat at a weight ratio of (3-5):(1-2):(1-2); adding a composite ageing bactericide based on the condition that the weight ratio of the mixture to the high-concentrated organic material ageing bactericide is (5000-10000):(1-2), evenly mixing, and then carrying out composting fermentation for 7-10 days, wherein during the composting fermentation, the material needs to be stirred 1-2 times each day; and mixing the material decayed by fermentation with a functional composite bactericide which is generated by single fermentation at a weight ratio of (5000-1000):(1-2), granulating and drying at low temperature so as to obtain the high-efficiency and active bio-organic fertilizer. The process is relatively simple, is easy to operate, and can be used for lowering the product cost is low, saving energy and turning wastes into wealth, thereby being beneficial to promotion of benign ecological circulation and environment conservation; and by utilizing the fertilizer, the quality of the product is good, thereby obviously improving the yield and quality of agricultural products.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

Biological deodorization and purification agent, and its use

A biologic deodoring and cleaning agent for treating the refuse to prepare fertilizer and cleaning and activating water area contains high-safety yeast, lactobacillus, nitrogen-fixing bacteria, functional bacillus, and photosynthetic bacteria.

Owner:CHINA AGRI UNIV

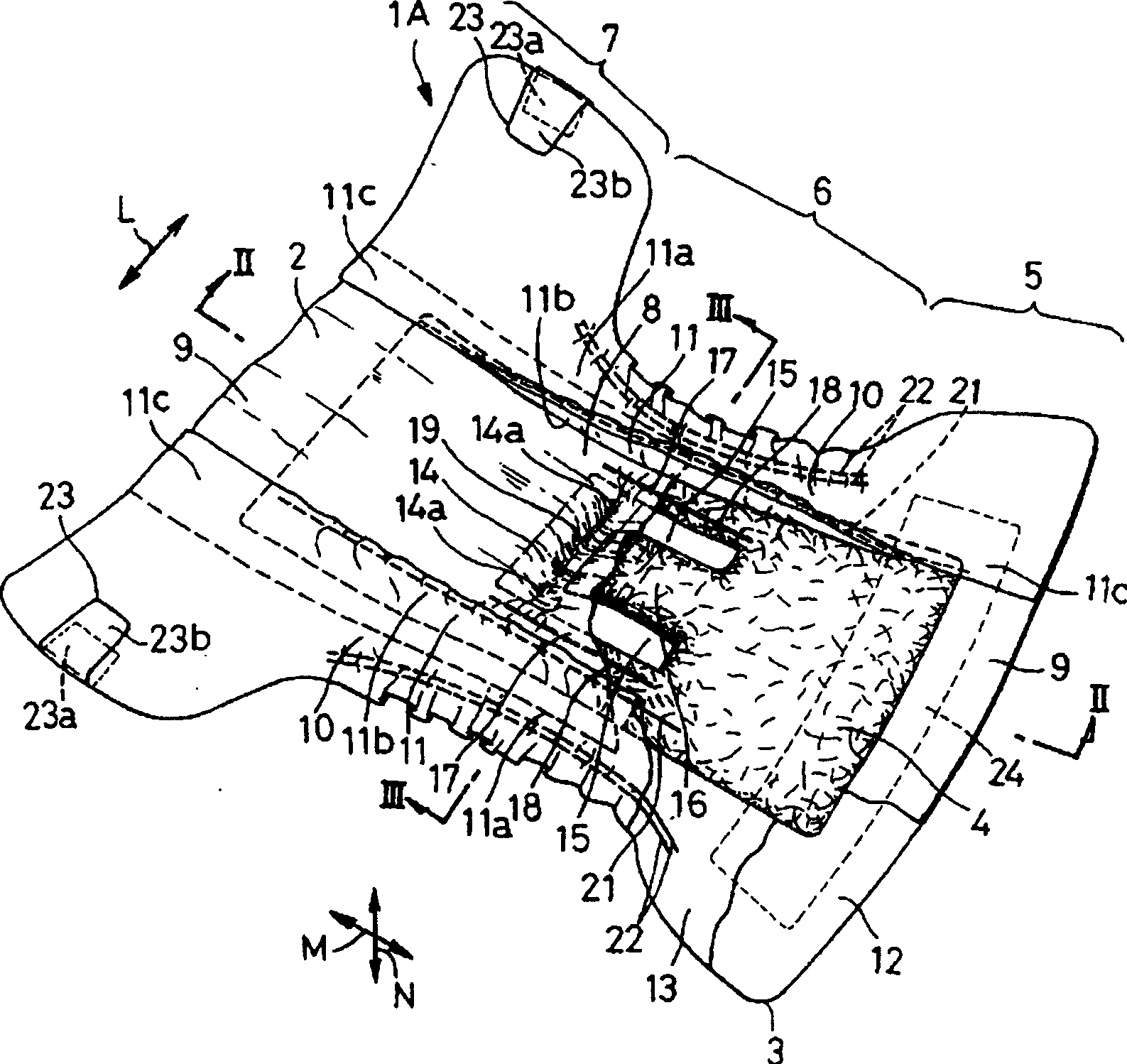

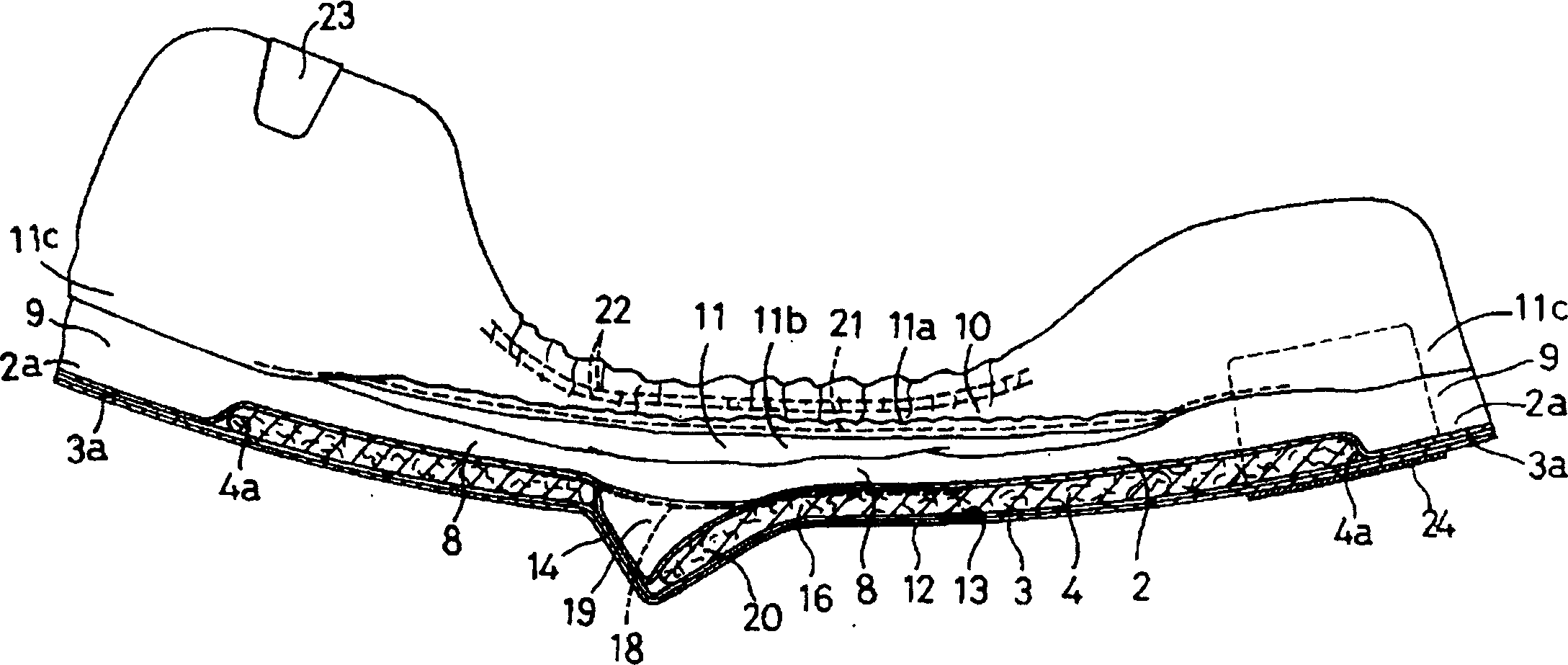

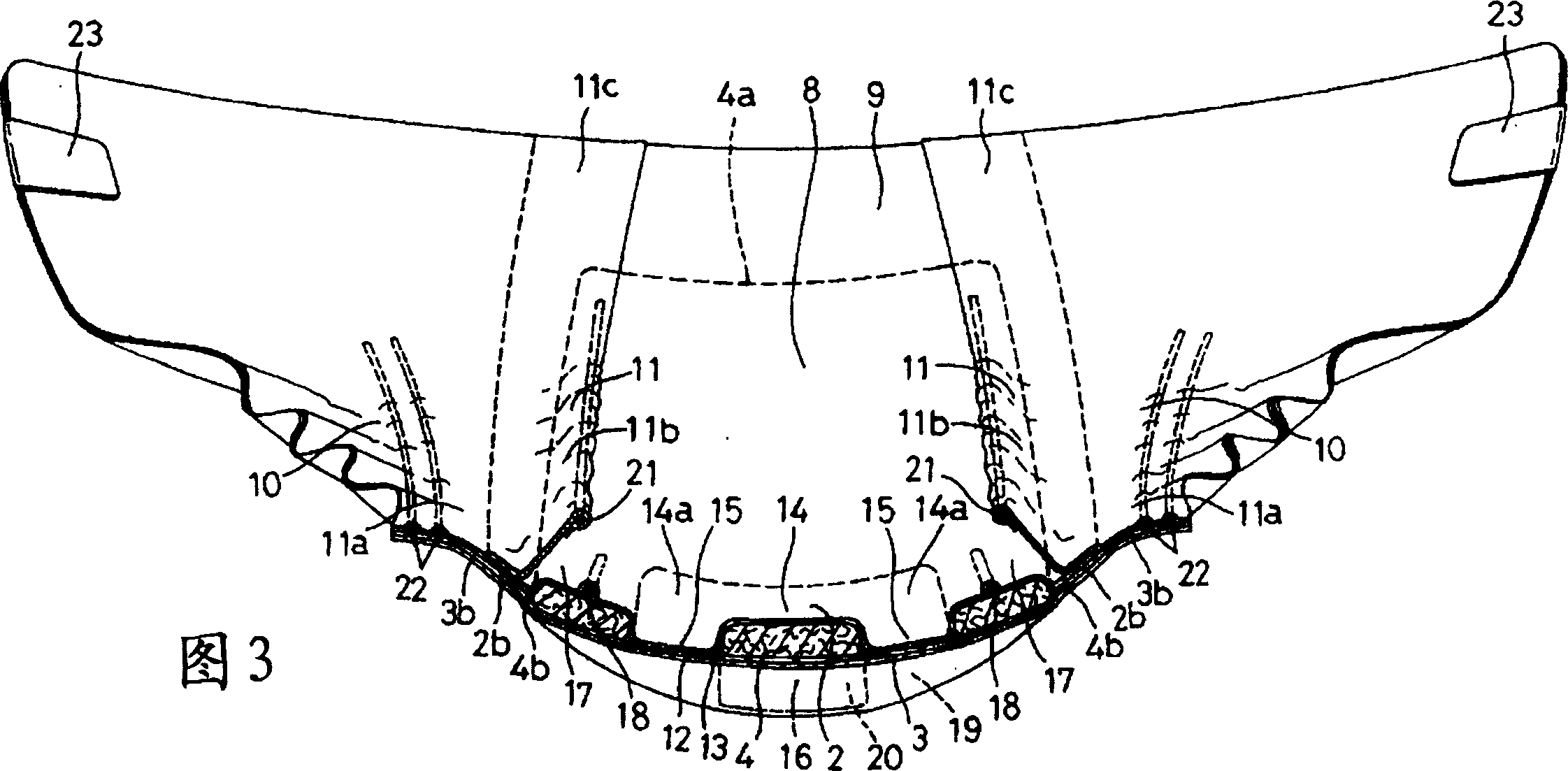

Disposable diaper

Owner:UNI CHARM CORP

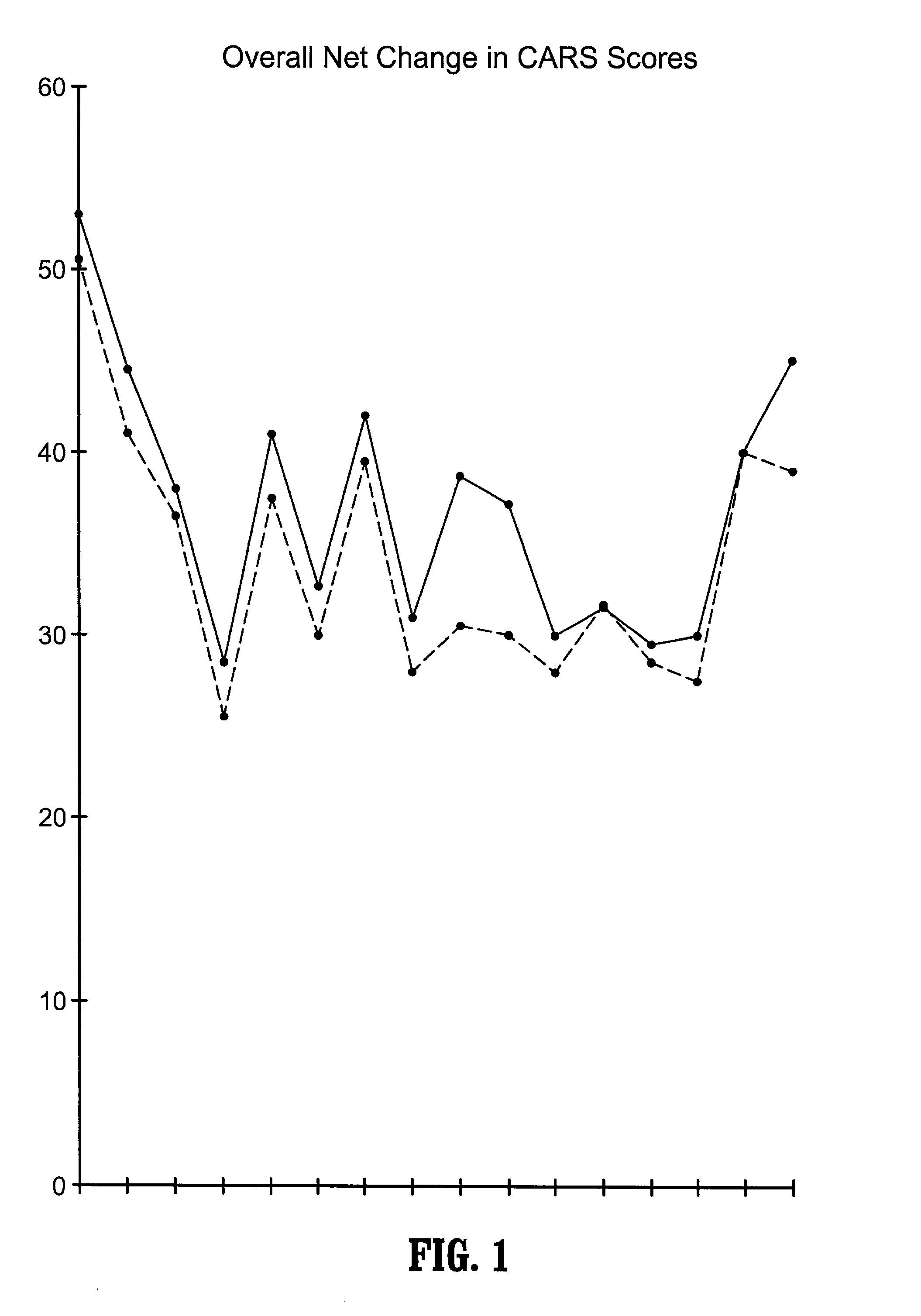

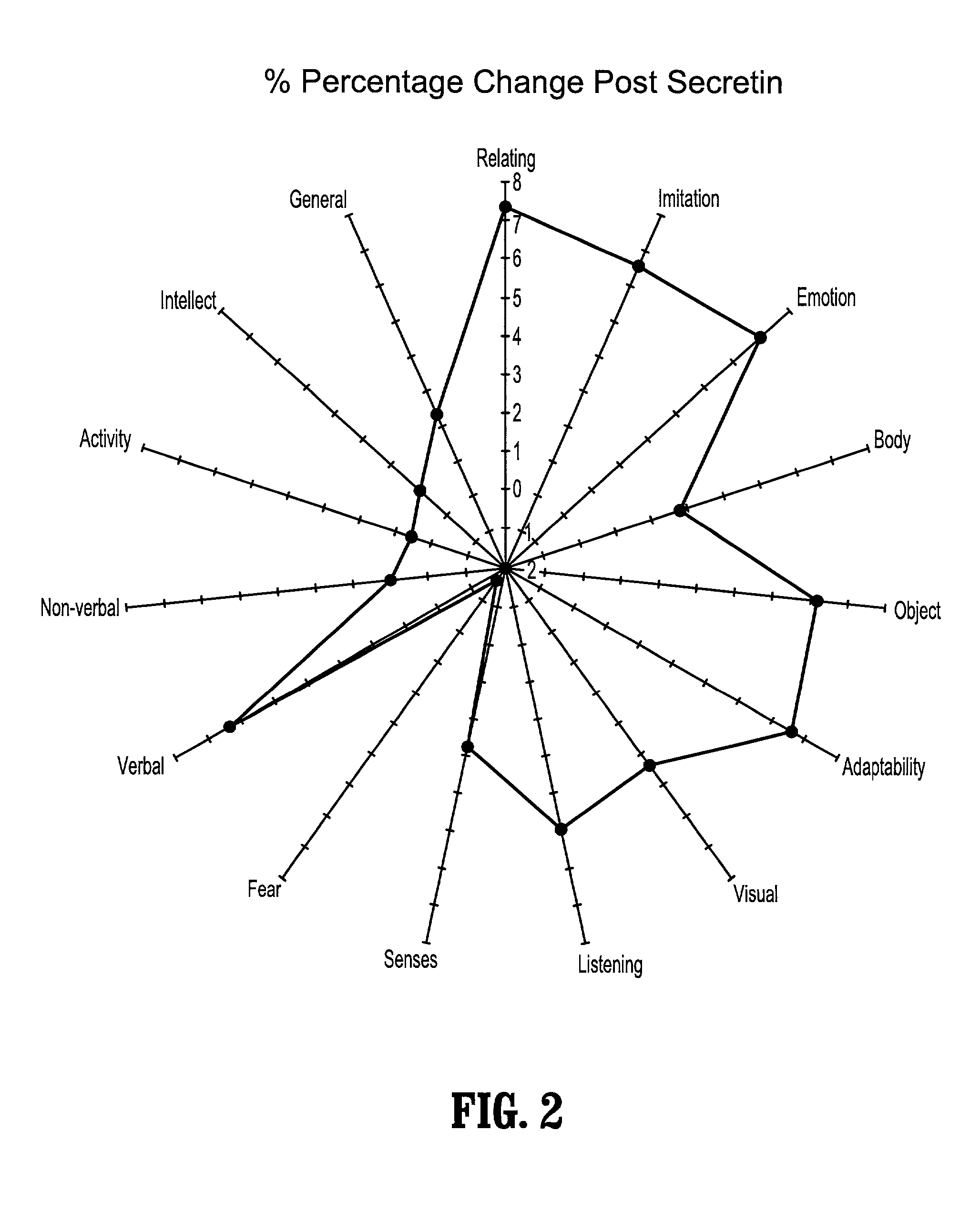

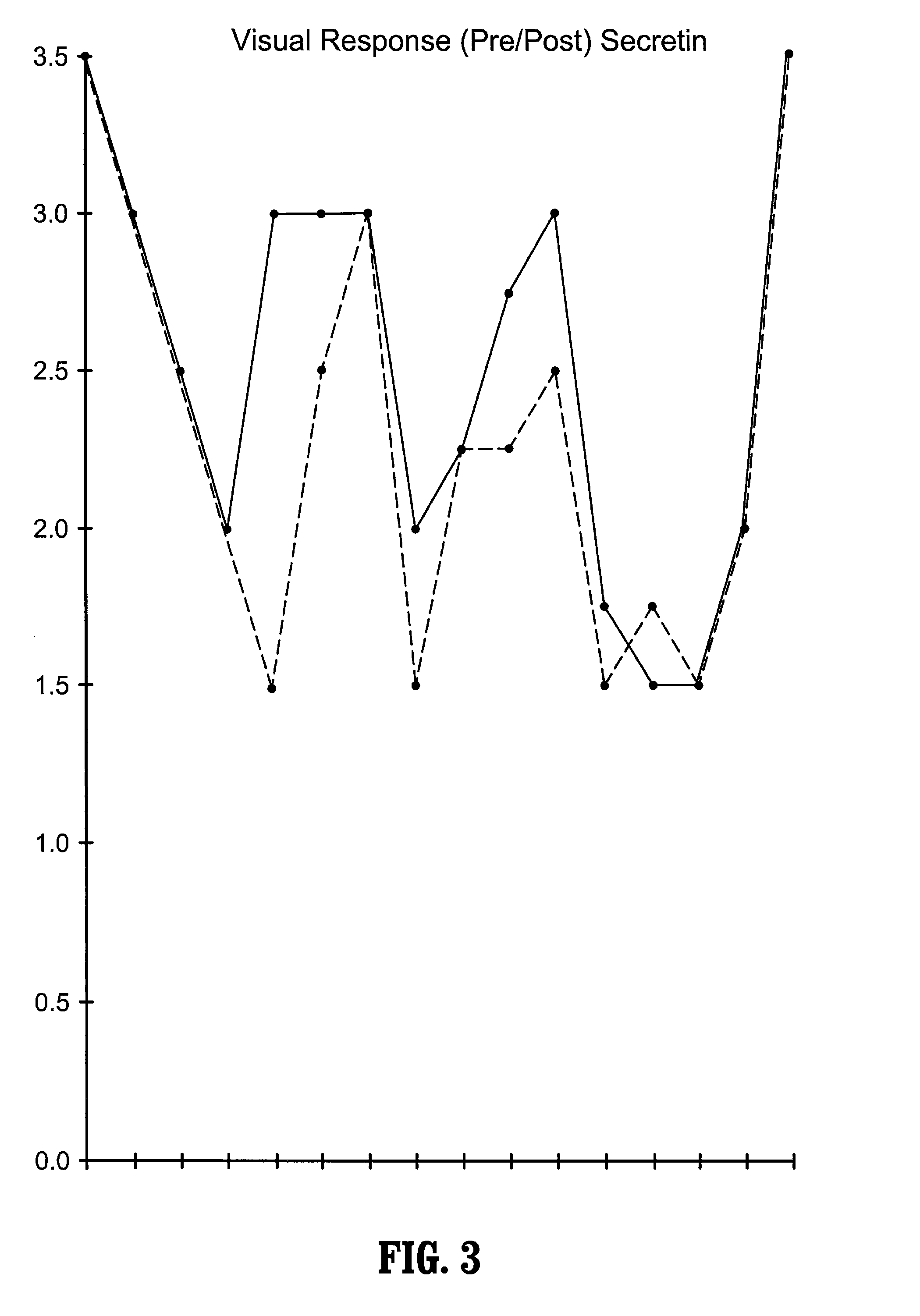

Methods of treating pervasive development disorders

InactiveUS20020090653A1Symptoms improvedPromote digestionPeptide/protein ingredientsMicrobiological testing/measurementDiseaseFeces

A method of utilizing the chymotrypsin level of an individual as a measure of the success of secretin, other neuropeptides, and peptides or digestive enzyme administration to such individuals, and in particular, as a prognosticative of potential secretin, other neuropeptides, peptides, and digestive enzyme administration for persons having ADD, ADHD, Autism and other PDD related disorders. In one aspect, a method for determining the efficacy of secretin, other neuropeptides, peptides, or digestive enzymes for the treatment of an individual diagnosed with a pervasive developmental disorder (PDD) comprises obtaining a sample of feces from an individual, determining a quantitative level of chymotrypsin present in the sample, and correlating the quantitative level of chymotrypsin determined to be present in the sample with the PDD to determine the efficacy of treating the individual with secretin, other neuropeptides, peptides, or digestive enzyme administration. In another aspect, a therapeutic method for treating an individual diagnosed with a PDD pervasive developmental disorder comprises determining the efficacy of secretin, other neuropeptides, peptides, and digestive enzyme administration for the treatment of the individual based on a measure of the individual's chymotrypsin level, and administering secretin, other neuropeptides, peptides, or digestive enzymes to the individual based on the determination of the measure of the individual's chymotrypsin level.

Owner:CUREMARK

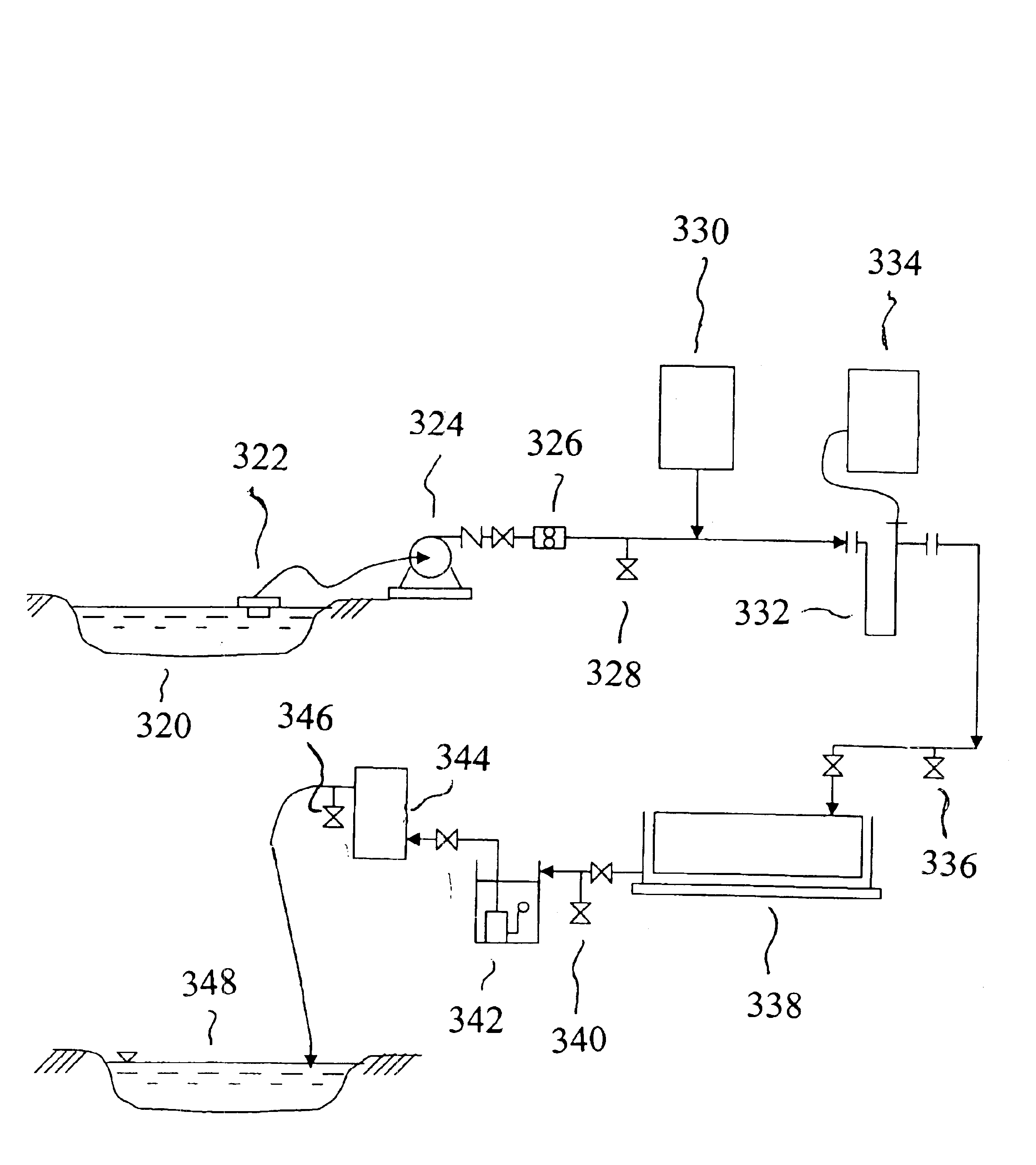

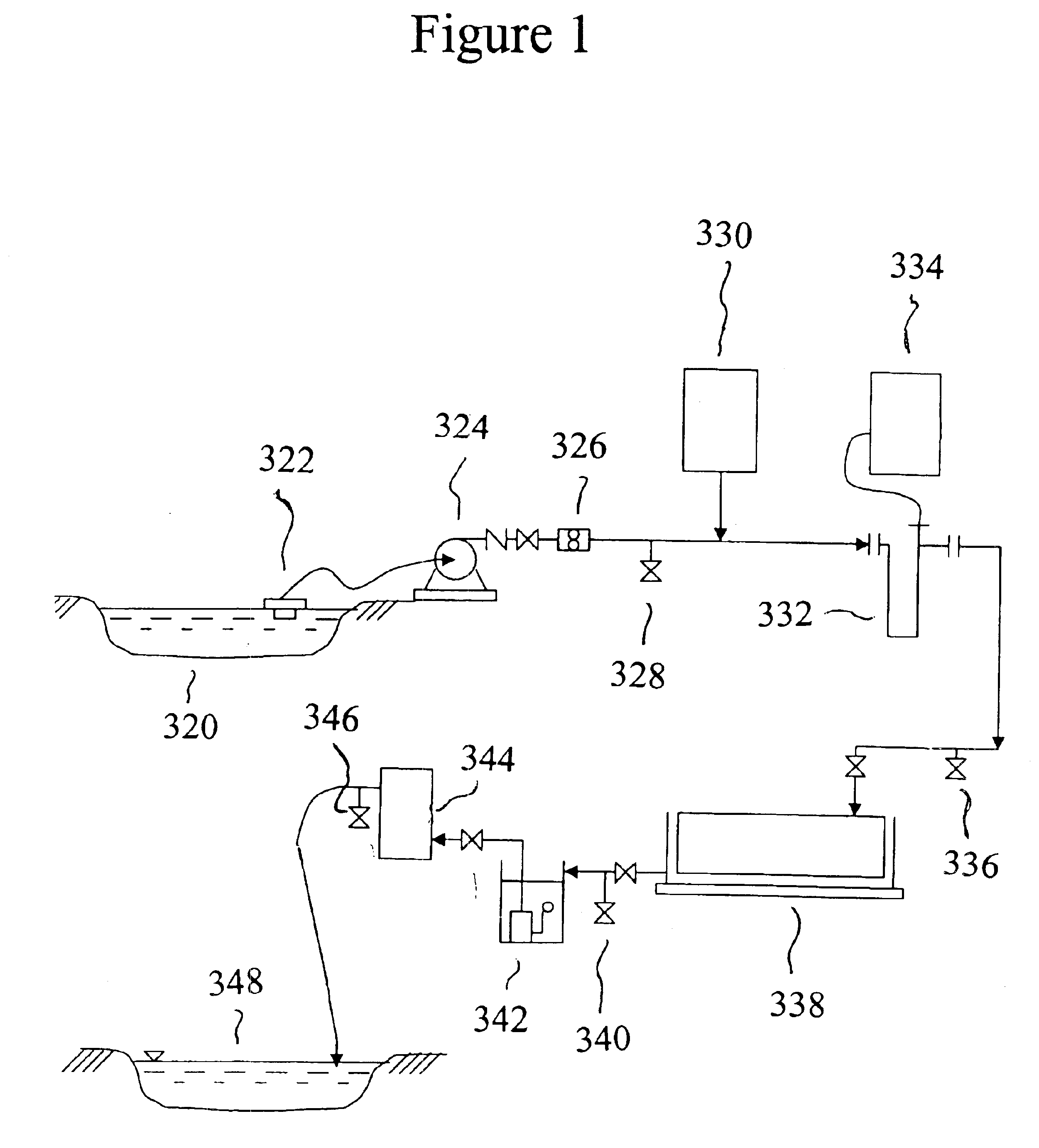

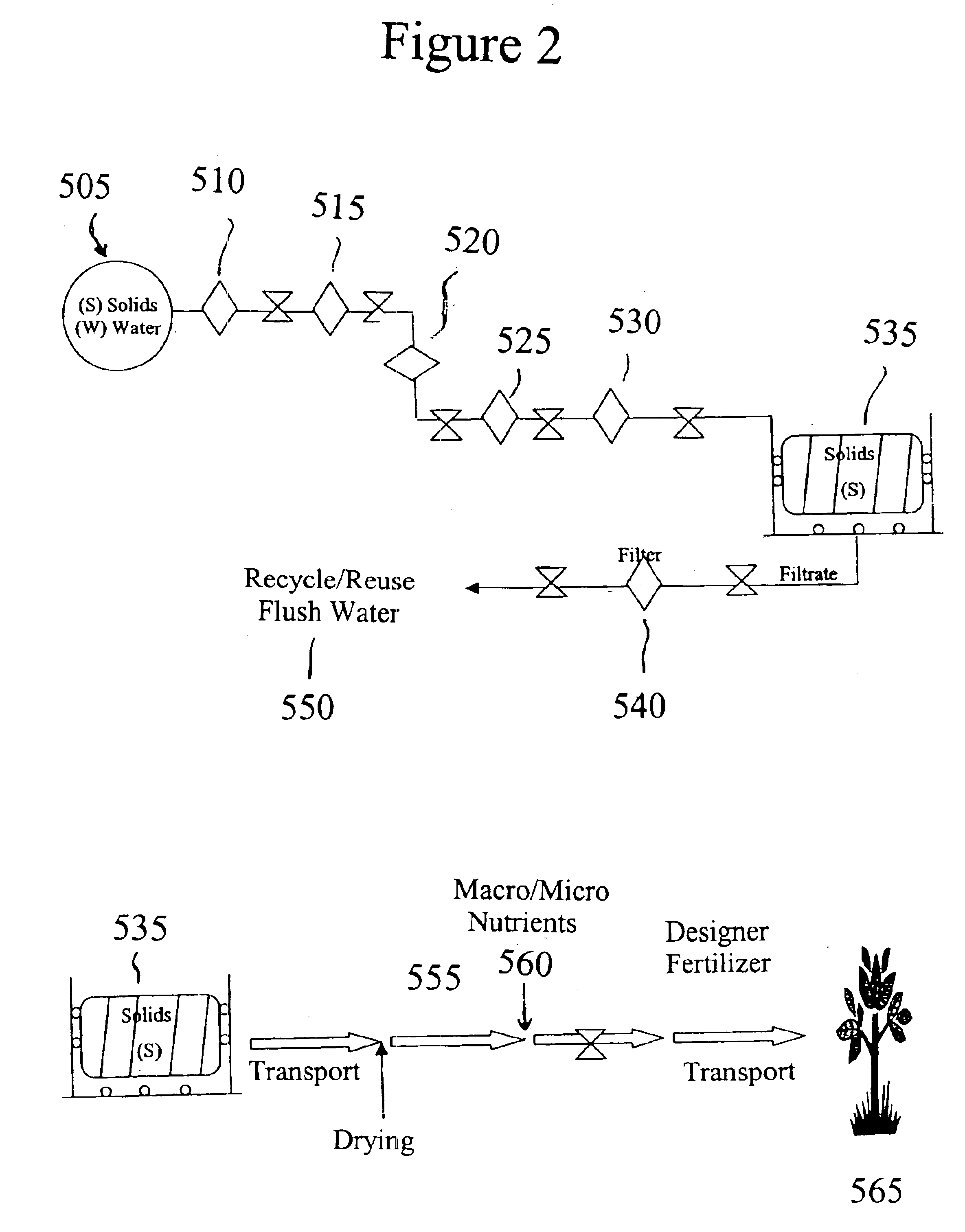

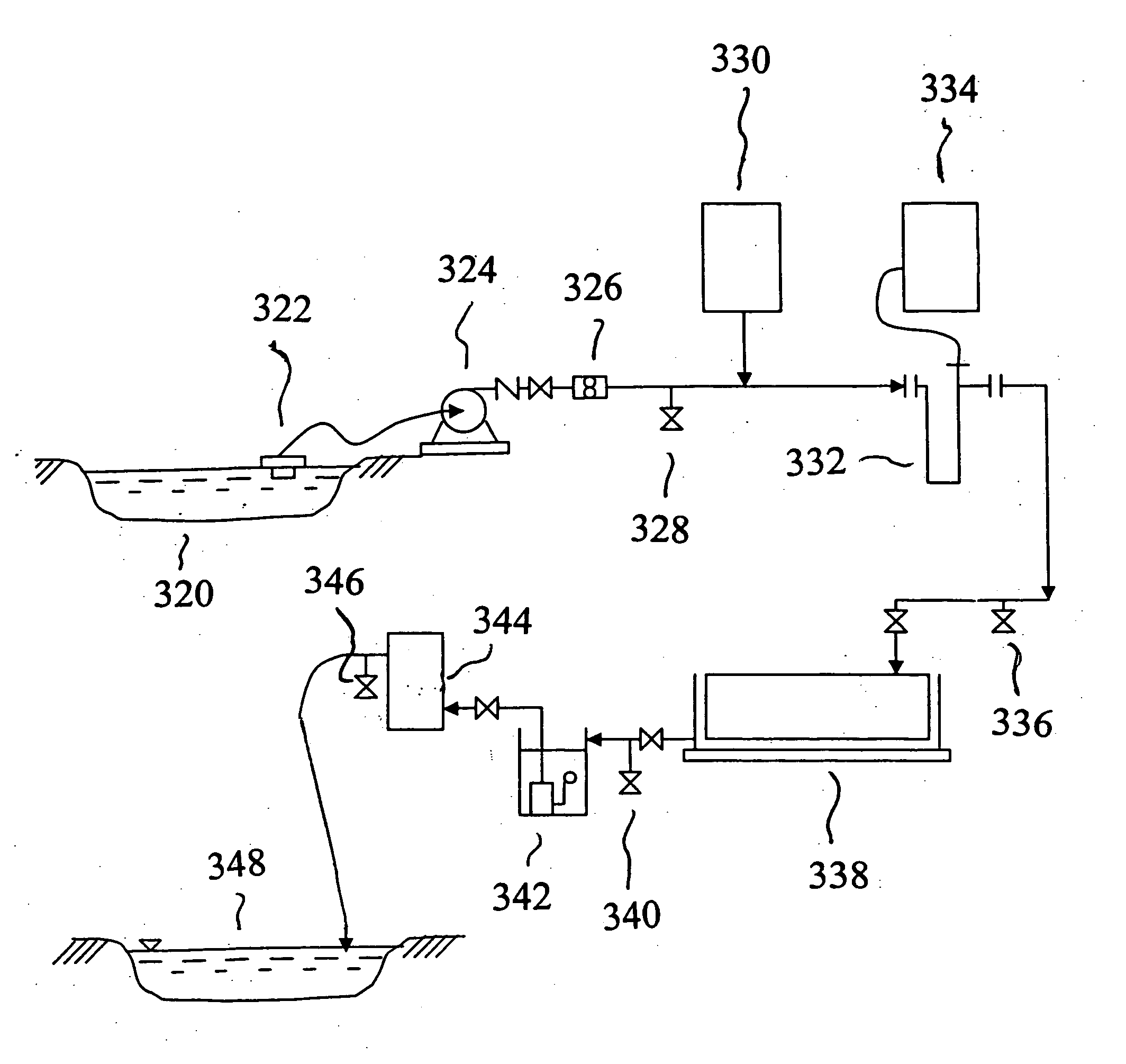

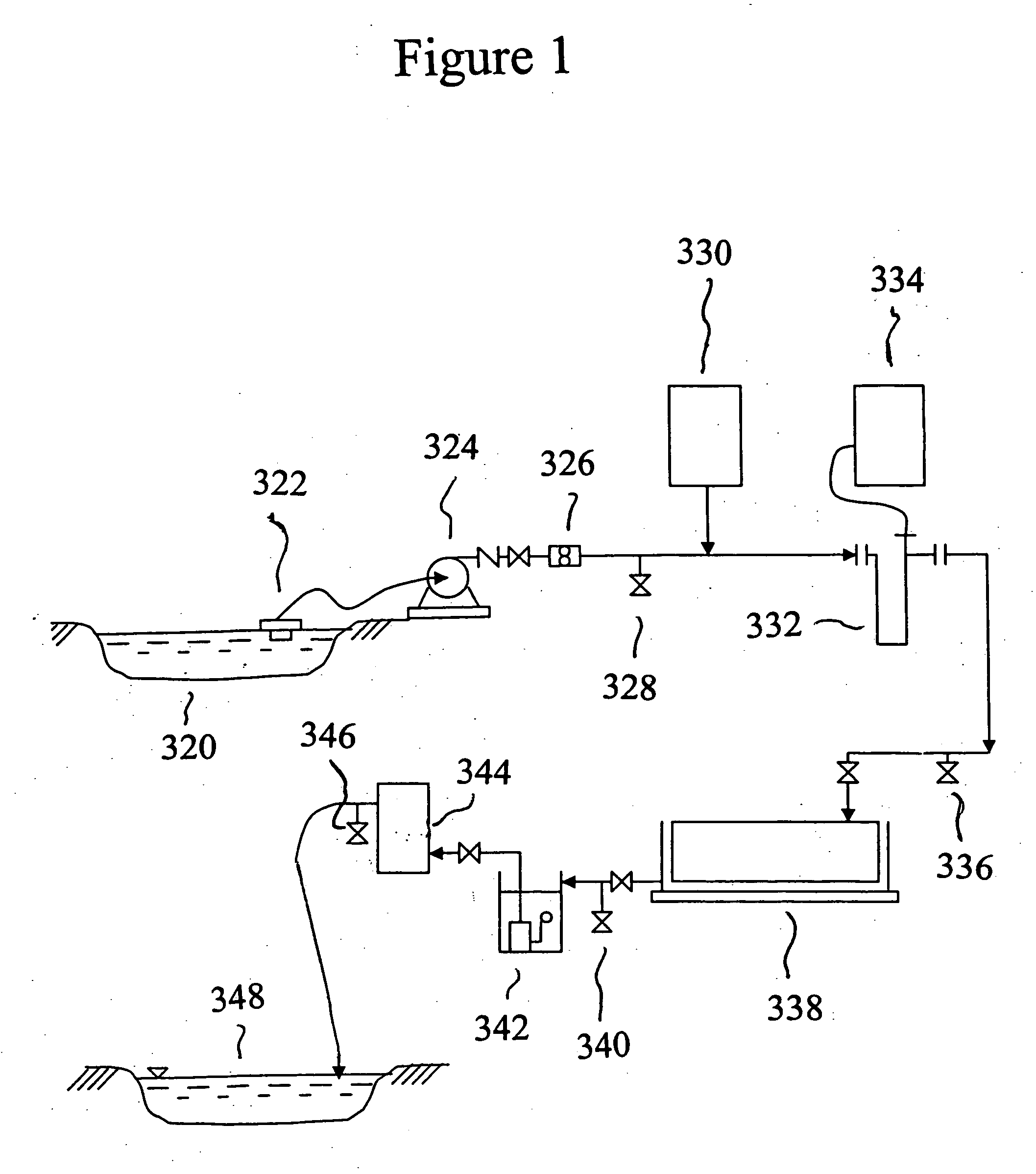

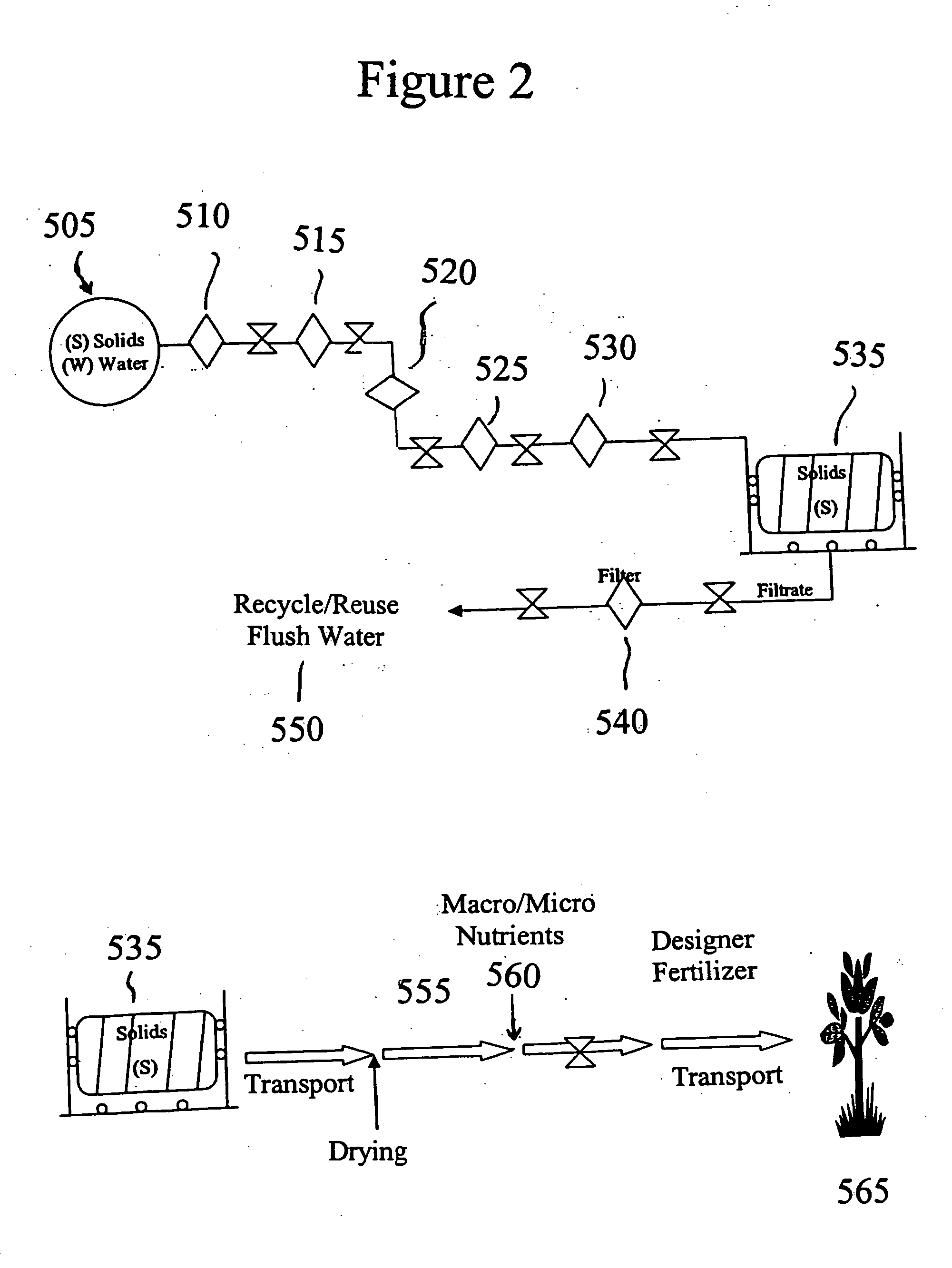

Animal waste effluent treatment

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

Feed additives for reducing odor of animal waste products

InactiveUS20030230245A1Reduce production of odorous waste productReduce odorFungiAnimal feeding stuffFood additiveYeast

The invention relates to biological compositions comprising yeast cells that can be added to animal feed which upon ingestion by an animal can reduce the odor of manure produced by the animal. The invention also relates to methods for manufacturing the biological compositions, and methods of using the biological compositions as animal feed additives.

Owner:ULTRA BIOTECH

Method for preparing insect repelling organic fertilizer

InactiveCN1872814AReduce pollutionGood qualityBio-organic fraction processingOrganic fertiliser preparationFecesNicotiana tabacum

This invention discloses a method for manufacturing an insecticidal organic fertilizer. The fertilizer is composed of human or animal excrement, straw powder, tree leaves, wine lees, drug residues, sawdust, edible fungi residues, furfural residues, lime powder, fermentation agent, phosphorus- and potassium-leaching bacteria, tobacco powder, Ricinus communis leaf powder, Zanthoxylum cake powder, Datura and Strychnos nuxvomica. The fertilizer has such advantages as wide raw material resources, low cost, convenient usage, abundant nutrition, low fertilizer application amount, high efficiency, no toxicity, no pollution and no residues.

Owner:白会新 +1

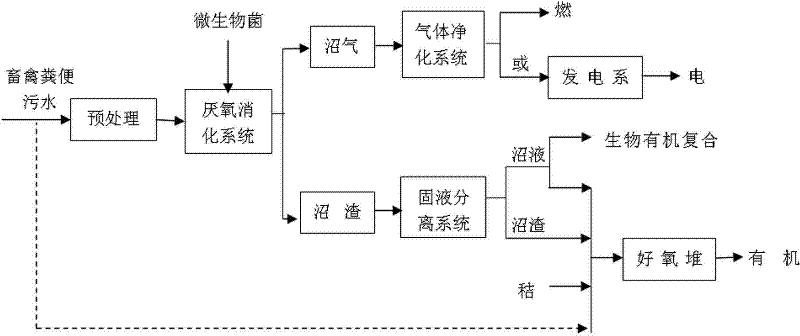

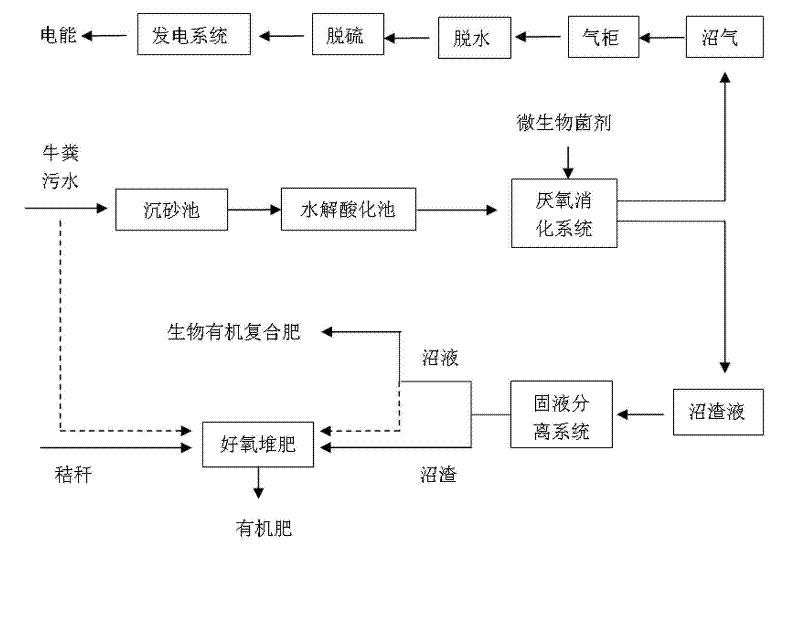

Method for comprehensively recycling fecal sewage of large-scale livestock and poultry farms and farmland crop straws

InactiveCN102173507AOvercome the problem of insufficient productionIncrease gas productionBio-organic fraction processingWaste based fuelFecesSlurry

The invention relates to a method for comprehensively recycling the fecal sewage of large-scale livestock and poultry farms and farmland crop straws, which comprises the following steps of: (1) performing anaerobic digestion, namely regulating the solid content of the fecal sewage of livestock and poultry to be between 5 and 10 percent, adding anaerobic digestion inocula, and performing the anaerobic digestion to generate methane; (2) performing energy utilization on the methane, namely purifying the methane obtained in the step (1) to be used as fuel gas or allowing the purified methane to be used for power generation to perform energy utilization; (3) performing solid-liquid separation, namely performing the solid-liquid separation on biogas residues and biogas slurry which are obtainedin the step (1) to obtain the biogas slurry and the biogas residues of which the moisture content is about 60 percent; (4) preparing a biological organic compound fertilizer from the biogas slurry, and mixing the biogas residues and part of biogas slurry with the straws and part of excrement to perform aerobic compost; and (5) mixing and performing the aerobic compost, namely mixing part of biogas slurry obtained in the step (3) and the crushed straws, regulating the moisture content of the mixture to be between 50 and 60 percent, and performing the aerobic compost. In the method, clean resources are recovered by the anaerobic digestion, and the biogas slurry is used for producing the biological organic compound fertilizer with a high additional value.

Owner:江苏加德绿色能源有限公司

Special microorganism composite bacterial agent for directly decomposing and fermenting crops straws to generate marsh gas and application method thereof

InactiveCN101775359AGood degradation activityEasy to storeFungiBacteriaBacillus licheniformisVaccination

The invention discloses a special microorganism composite bacterial agent for directly decomposing and fermenting crops straws to generate marsh gas and application method thereof. The special microorganism composite bacterial agent is liquid or solid, and is formed by fermenting, culturing, combining and compositing one or a plurality of bacillus cereus, bacillus subtilis, bacillus licheniformis, bacillus megaterium, bacillus mucilaginosus, bacillus circulans, bacillus sphaerieus, clostridium sporogenes, clostridium acetobutylicum, clostridium barati, clostridium beijerinckii, clostridium thermocellum, trichoderma viride, trichodermareesei and aspergillus niger. Simultaneously, by taking the special microorganism composite bacterial agent as a vaccination bacterial agent, the invention provides an application method for decomposing the crops straws and accelerating the ferment to generate marsh gas; and the microorganism composite bacterial agent-treated crops straws have fast ferment speed, large marsh gas generation quantity, low treating cost and no secondary pollution, can be fermented to generate the marsh gas under the condition of no faeces of poultry, and have very wide application range.

Owner:刘相梅 +1

Pigpen fermentation bed and use thereof

The present invention relates to a fermentation bed for pigsty, comprising a groove for storing bedding materials, wherein the bedding materials formed by fermenting organic materials are laid in the groove. Using the fermenting bed to raise pigs can digest and decompose excrement such as feces and urine quickly, such that no flushing and no smell for the pigsty are in result by proper management and maintenance. The influence to the environment and residents around farms are greatly eased and the economic benefit is raised obviously.

Owner:CHINA AGRI UNIV

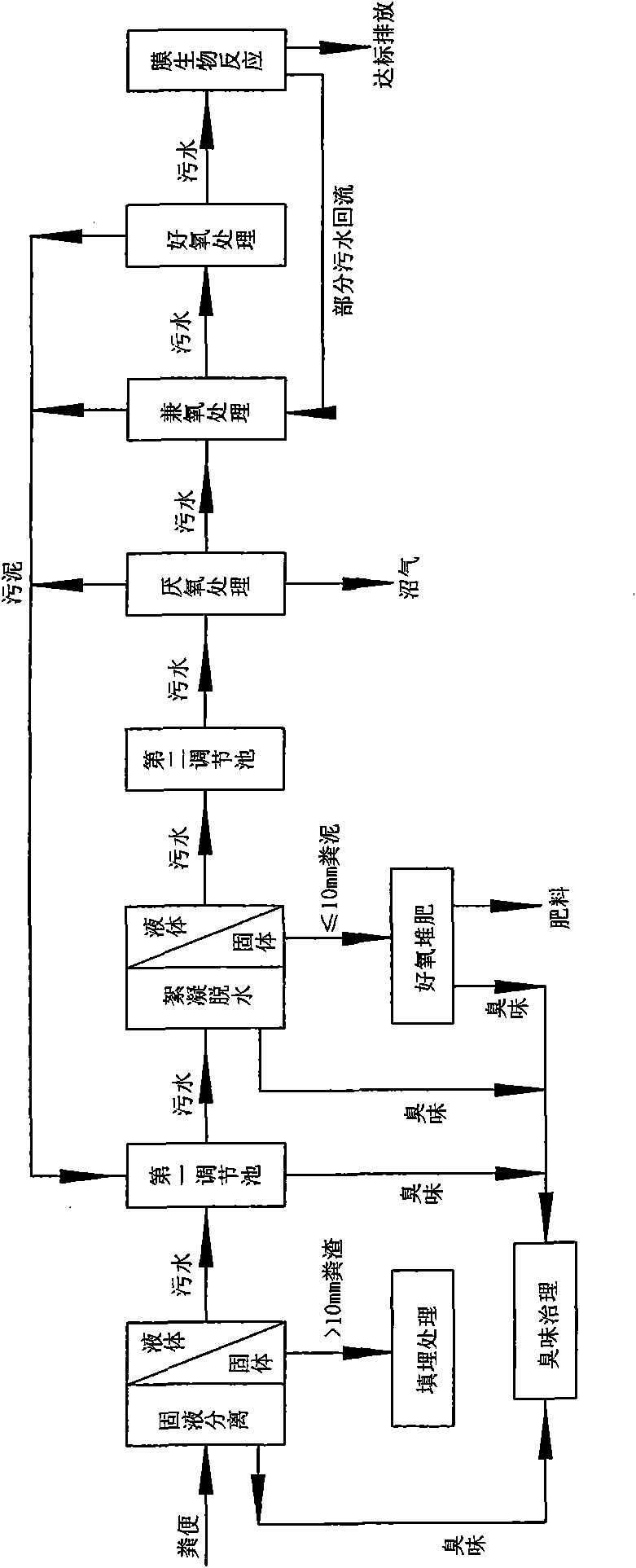

Excrement centralized processing method

ActiveCN101654318AAvoid cloggingCOD removalBio-organic fraction processingSludge treatment by de-watering/drying/thickeningFlocculationFeces

The invention relates to an excrement centralized processing method, comprising the steps of solid-liquid separation, flocculation water removing, aerobic compost treatment, anaerobic sewage treatment, facultative anaerobic sewage treatment, aerobic sewage treatment, membrane anaerobic reacting sewage treatment and odor treatment. Treated with the processing method of the invention, the urban night soil is 100% decontaminated, is 99.7% minimized and the excrement sludge is completely changed into resource.

Owner:北京昊业怡生科技有限公司

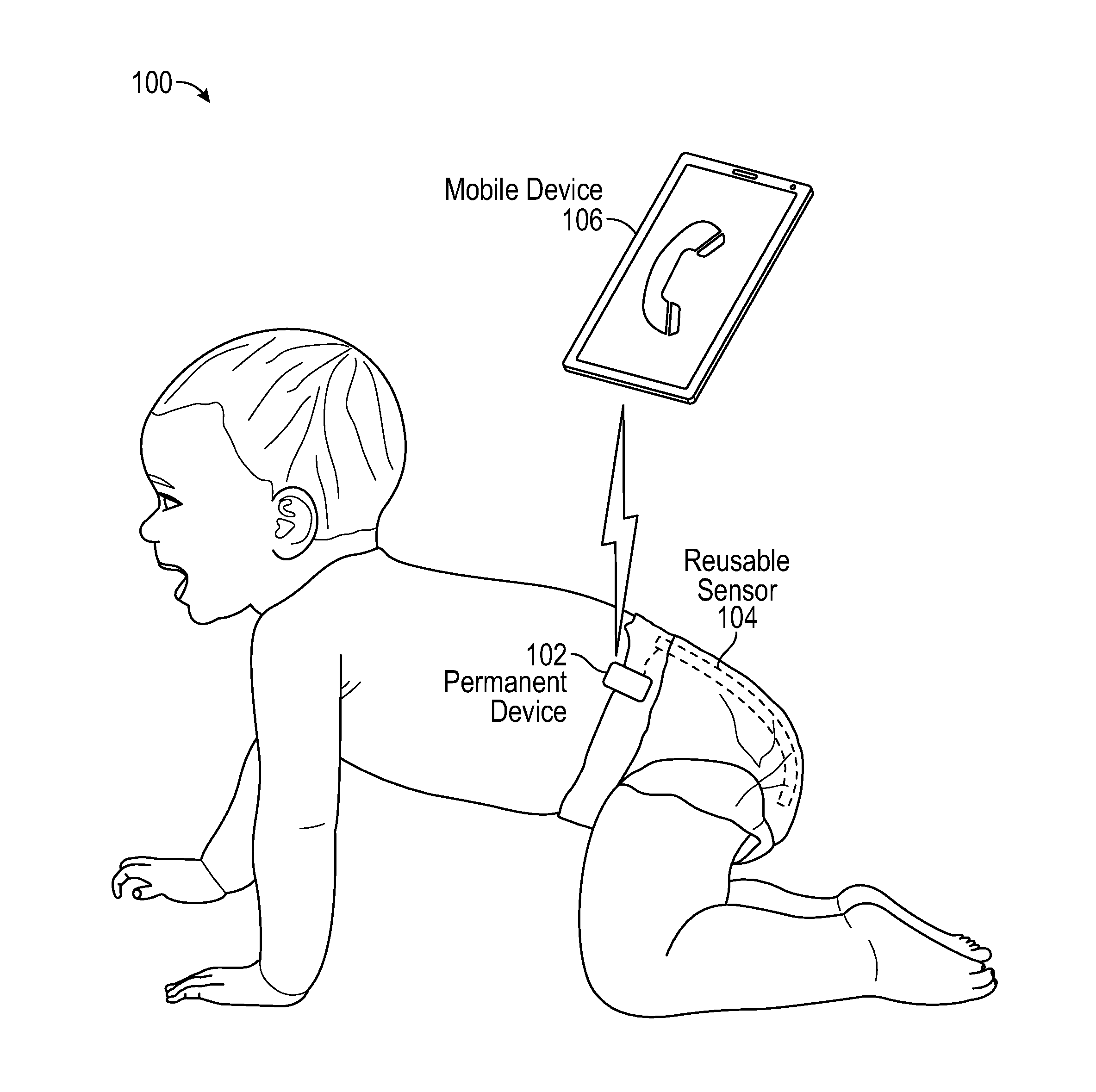

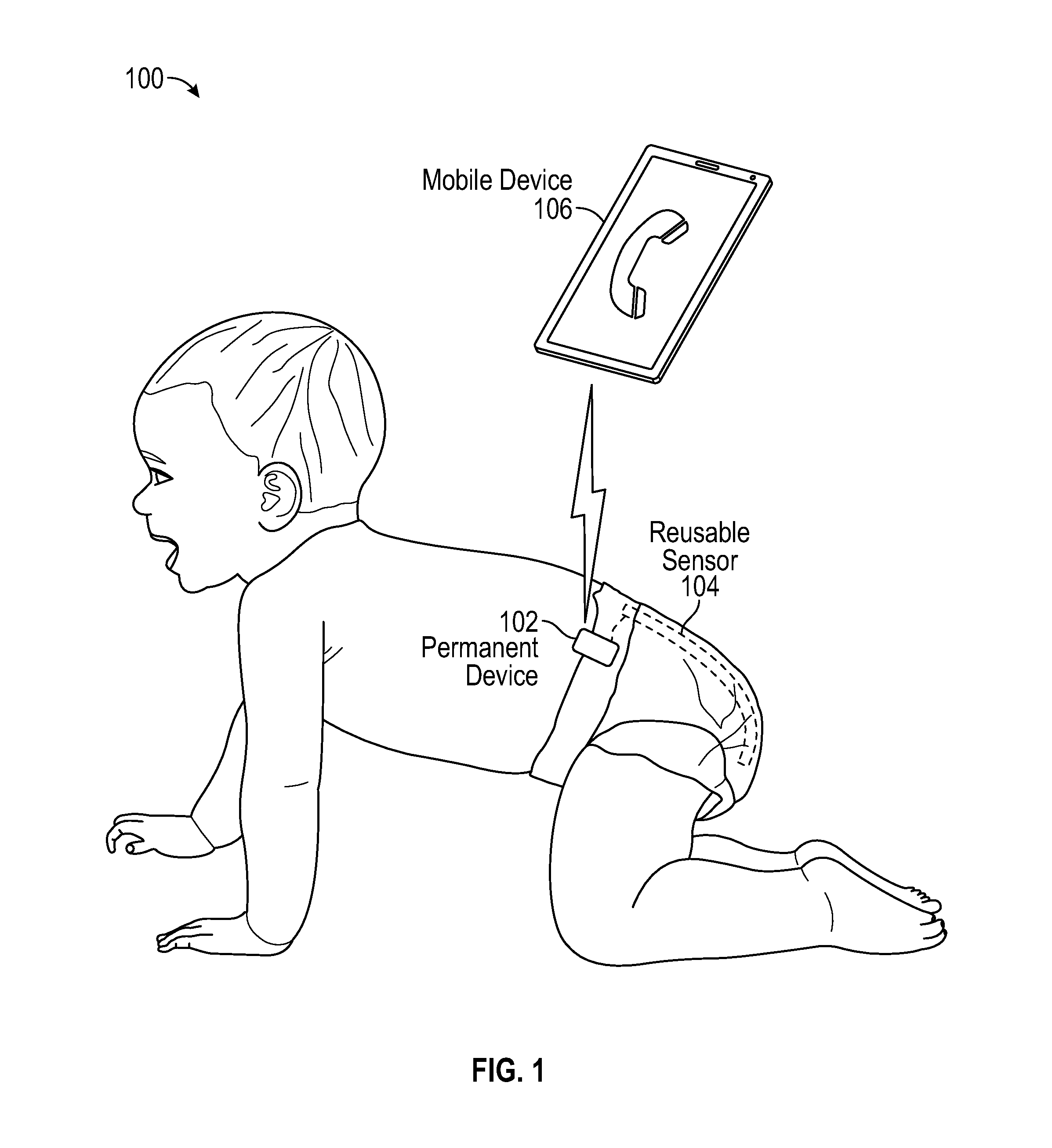

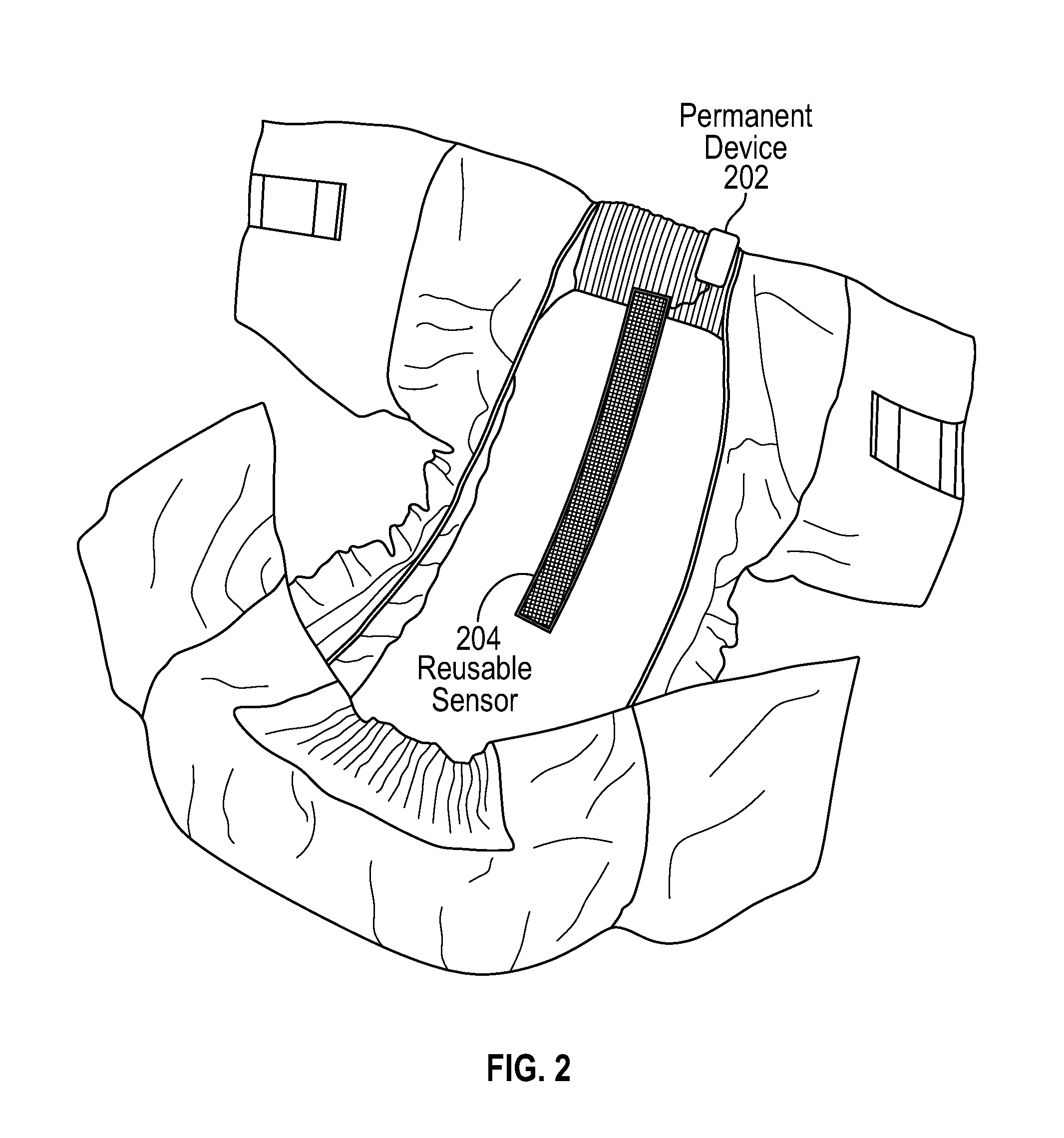

System and methods for monitoring defecation, urination, near-body temperature, body posture and body movements in young children, patients and elderlies

Remotely detecting the presence of urine or feces in a diaper of an infant or adult using a disposable sensor placed inside the diaper, in conjunction with a permanent device that is capable of wirelessly transmitting data to a mobile device or base station is disclosed. The permanent device can also be capable of measuring temperature and body movements. This additional information can be used in conjunction with the detection of urine or feces to identify patterns.

Owner:MAVIN WEAR INC

Ecological organic fertilizer containing organic, inorganic and beneficial microorganism

InactiveCN101486609ASimple structureImprove water retentionOrganic fertiliser preparationFertilizer mixturesCelluloseFeces

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

Microbial organic fertilizer and manufacture method of microbial organic fertilizer

ActiveCN102674996ASolve the problem of burning roots and seedlingsImprove survival rateBio-organic fraction processingClimate change adaptationFecesLivestock

The invention discloses an organic fertilizer, which comprises the following raw materials including livestock excrement, poultry excrement, organic matters, domestic garbage, meal cake, leaves, rice husks, straw, weeds, crop straw, fire ashes, nitrogen fertilizers, phosphoric fertilizers, potash fertilizers, trace elements, compound bactericides 1 and compound bactericides 2. The invention also discloses a manufacture method of the microbial organic fertilizer. The microbial organic fertilizer disclosed by the invention has the advantages that the technical problems are solved to realize the effect that the household garbage, the leaves, the weeds and the like are perfectly applied to the organic fertilizer, and the defects that in the existing organic fertilizer product, phenomena of root burning and seedling burning more or less exist, the fertilizer effect and the effect period are equivalent to that of chemical compound fertilizers, the soil improvement effect is poor, and the like are overcome.

Owner:石光忠

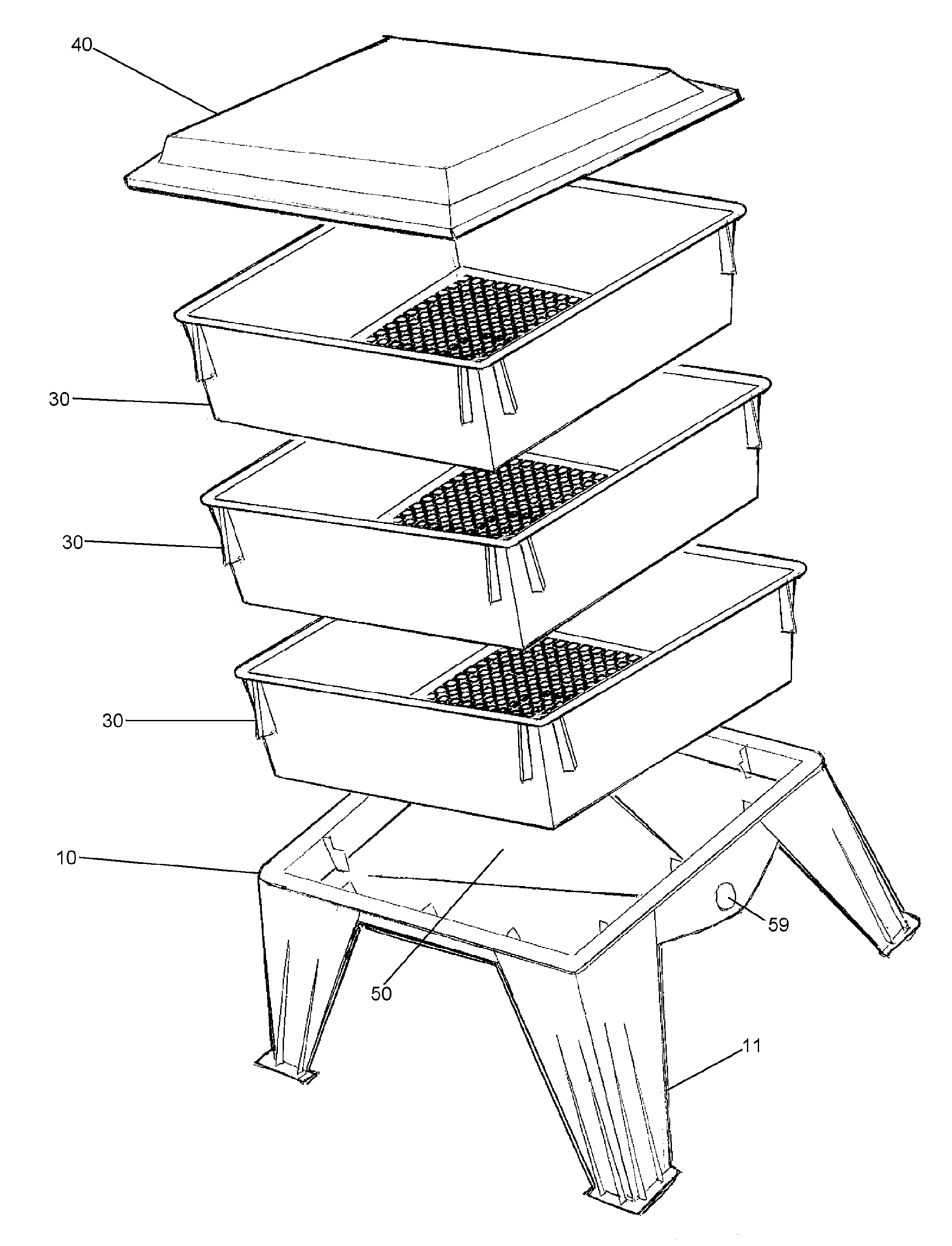

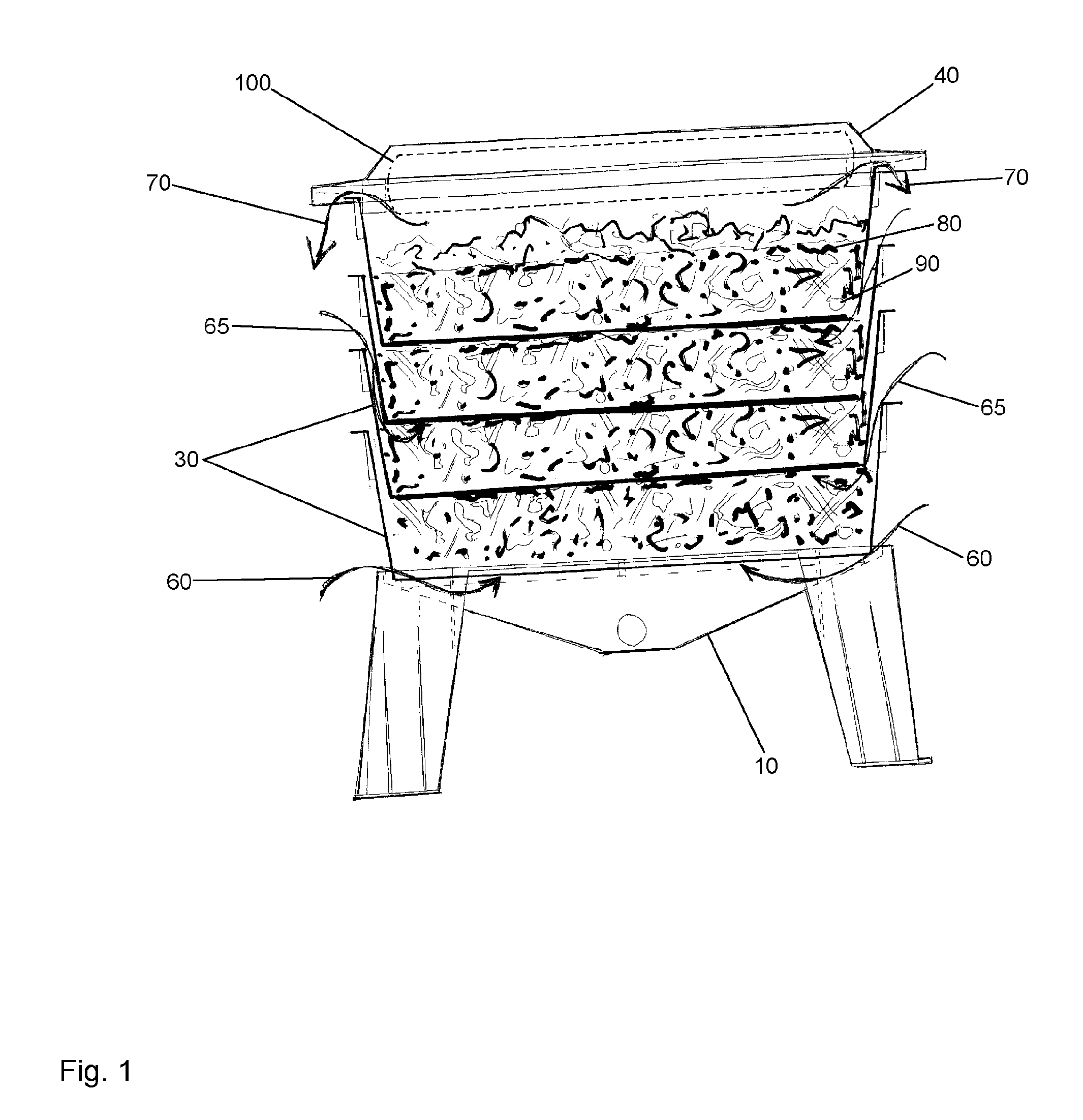

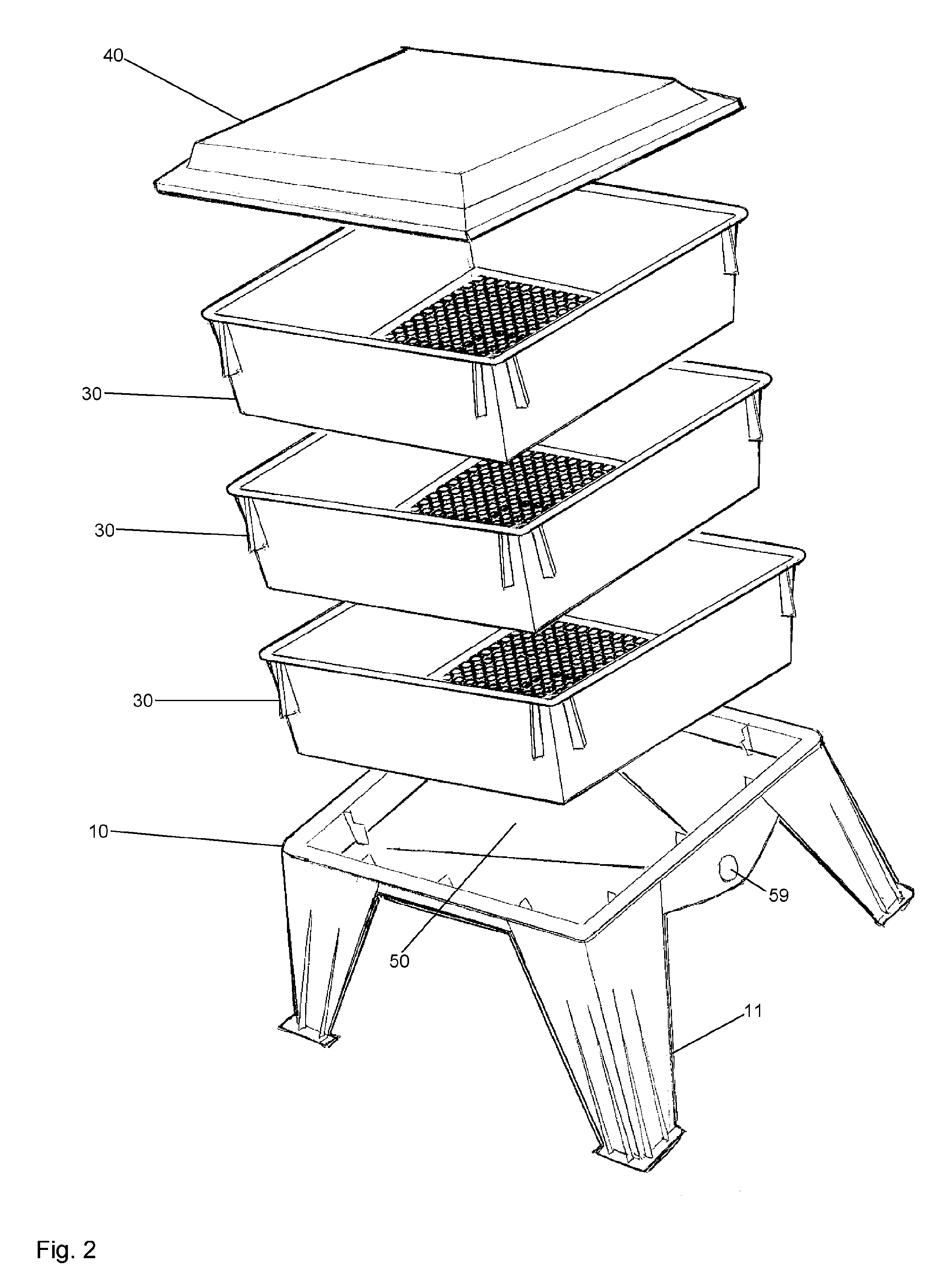

Multiple tray vermicomposter with thermal siphon airflow

InactiveUS7998728B2Maximize processingImprove balanceBioreactor/fermenter combinationsBio-organic fraction processingSiphonFeces

Multiple Tray Vermicomposter with Thermal Siphon Airflow is a vermiculture composting device that uses earthworms to create compost where worms eat and digest food to excrete compost. It is a multiple tray system with a base and a lid. New compost trays with freshly loaded food and bedding are stacked on top of older trays containing worms and compost to instigate a continuous upward migration of the worms thereby creating continuous compost production. Compost trays have permeable bottoms to allow worms to pass through. Compost production is accelerated from thermal siphon airflow to provide ample airflow to the worms without the requirement of a power source. Light-tight air-permeable connections between trays, lid, and base, also accelerate compost production by keeping the worms completely dark. If worms fall through the bottom compost tray, there exists a ramp to enable the fallen worms to climb back into the bottom compost tray.

Owner:RHOADS RALPH +1

Method for cultivating earthworm by cattle manure and corps stalks

InactiveCN101233835ASolve processing problemsAchieve recyclingFood processingAnimal feeding stuffAgricultural scienceFeces

The invention discloses a method for raising earthworm by taking advantage of dairy manure and straws and stalks of crop, which applies fresh dairy manure and straws and stalks of crop to raise earthworm. The invention adopts fresh dairy manure and straws and stalks of crop as raw materials, which can not only solve the treatment problem of dairy manure in large-scale cattle farms and reduce environment pollution, but also obtain earthworm with high economic value as well as odourless, clean and natural organic manure with high quality, thus realizing the regeneration and utilization of dairy manure, reducing treatment cost for dairy manure on cattle farms, and greatly improving economic benefits of enterprises.

Owner:GUIZHOU JILONG ECOLOGICAL TECH

Compositions and methods for enhancing mineral levels in animals with reduced environmental impact

InactiveUS20070269495A1Increase the amount of metalReduce amountBiocideAnimal feeding stuffFecesNitrate

A method of enhancing a mineral level in an animal with reduced environmental impact can comprise orally administering a metal amino acid chelate to an animal, wherein the amino acid to metal molar ratio of the metal amino acid chelate is from about 1:1 to 4:1. The metal can contribute to a mineral level within the blood and tissues of the animal that is effective for stimulating growth of the animal to a greater degree than would be realized by administering the same amount of metal in the form of an inorganic metal salt. Additionally, the amount of the metal excreted in the feces of the animal can be less than would be present when administering the same amount of metal in the form of the inorganic metal salt. The metal amino acid chelate can also serve as a source highly bioavailable amino acids, so that the excretion of nitrates by the animal may be reduced while still promoting efficient growth.

Owner:NOVUS INTERNATIONAL INC

Animal waste effluent treatment

InactiveUS20050145552A1Weaken energyBio-organic fraction processingExcrement fertilisersFecesTrapping

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

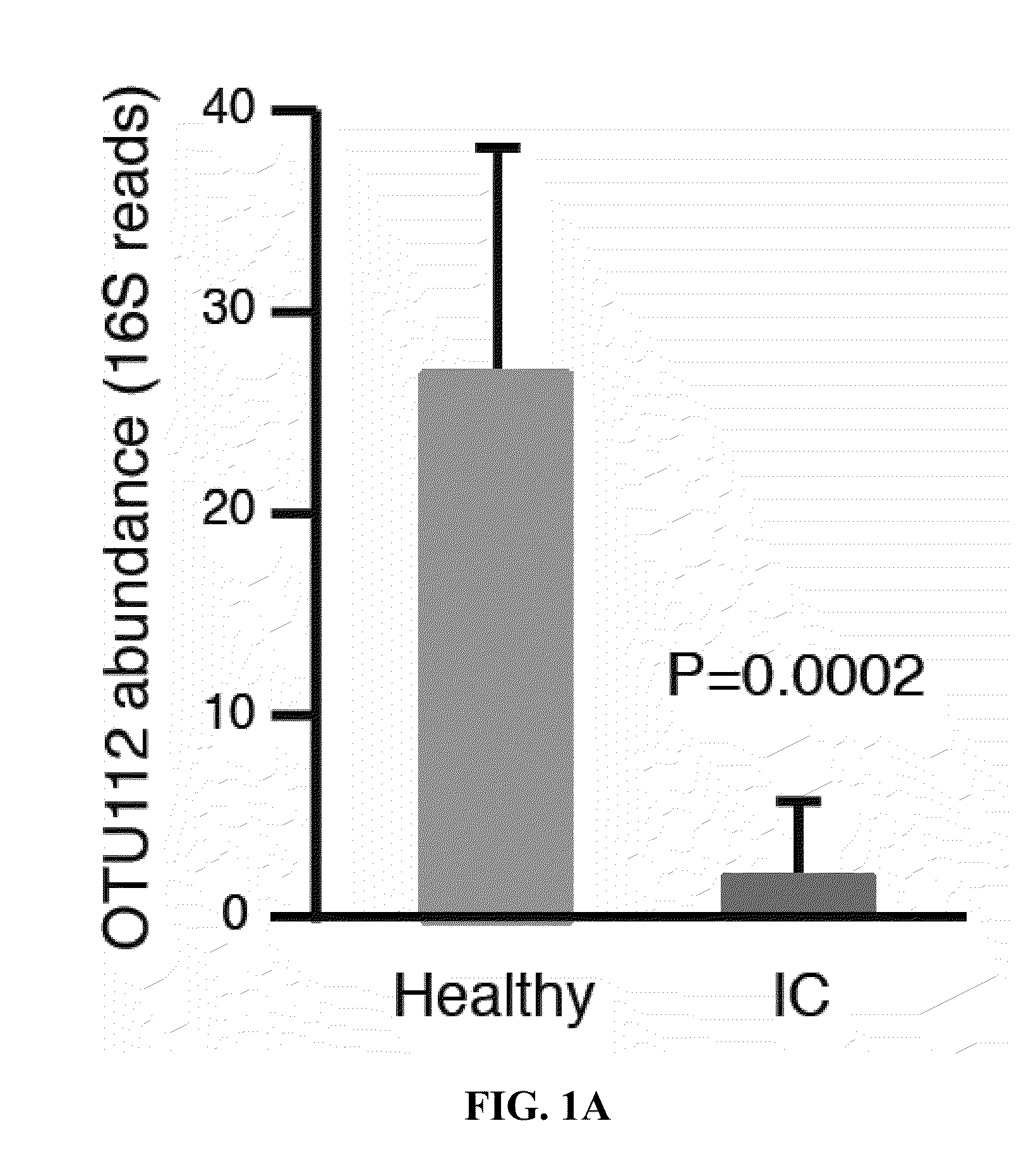

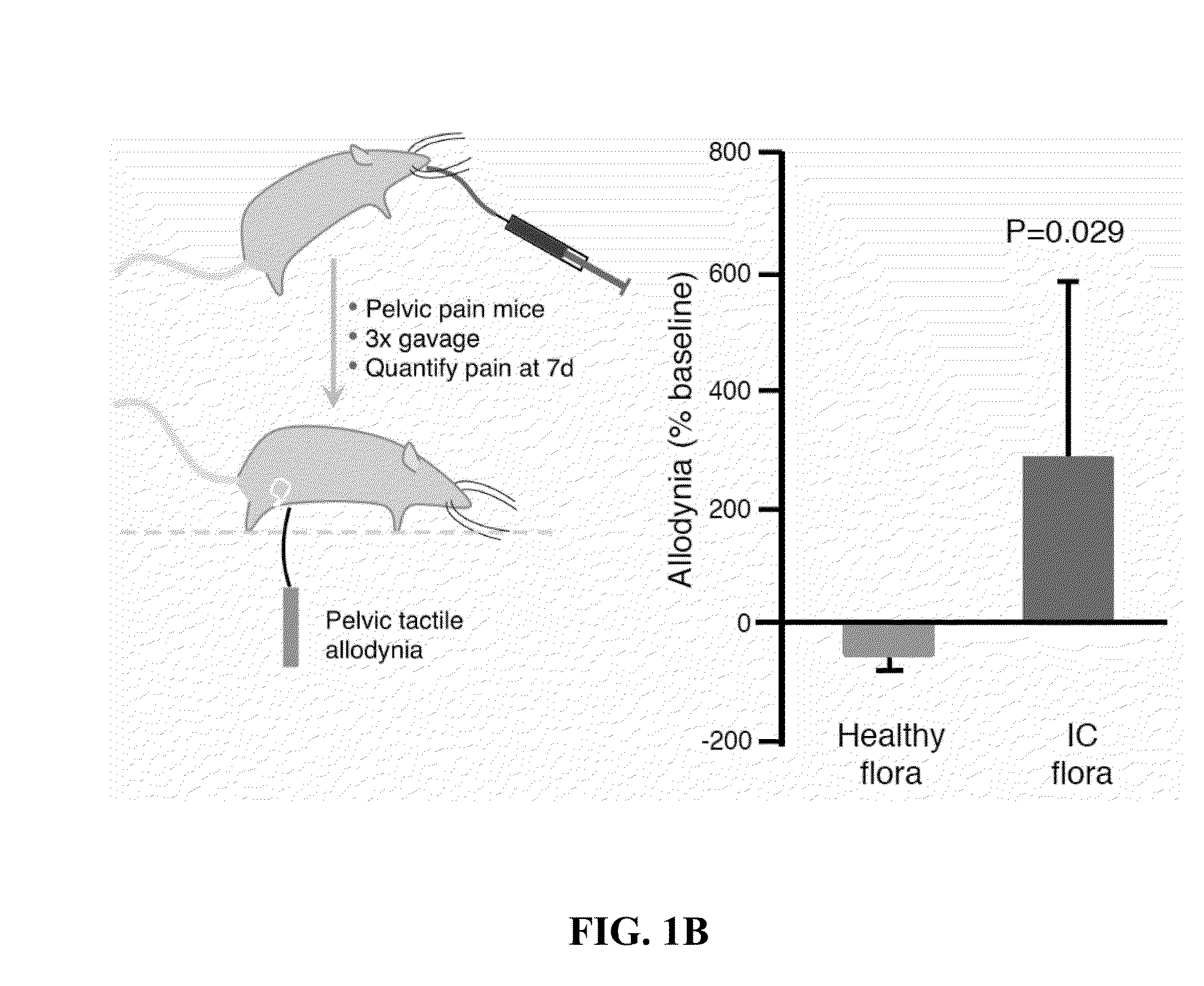

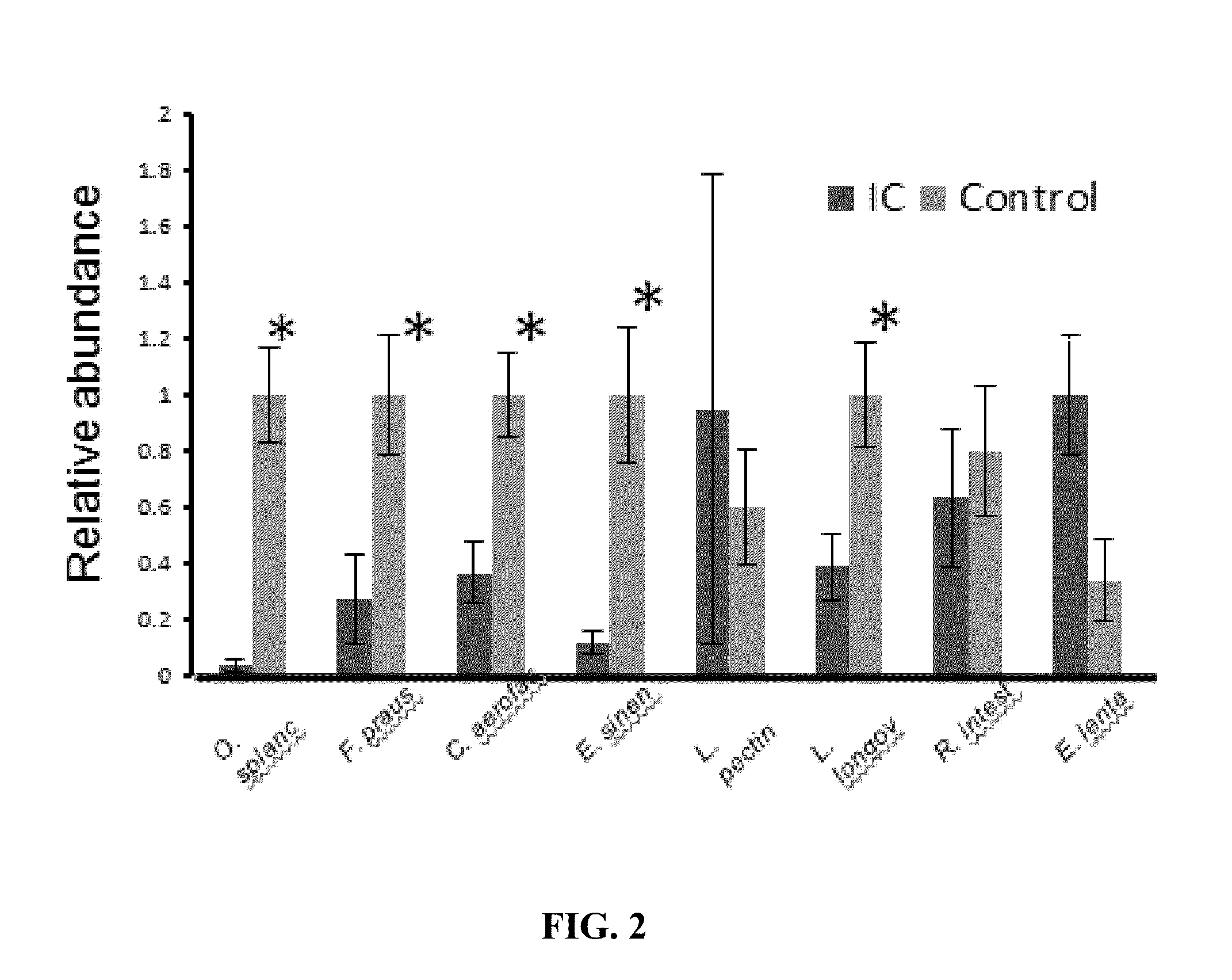

Altered microbiome of chronic pelvic pain

Provided herein are kits, compositions, and methods for diagnosing and treating interstitial cystitis (IC) and / or interstitial cystitis / bladder pain syndrome (IC / BPS) based on finding lower levels of certain bacteria in a subject's stool sample (e.g., O. splanchnicus, F. prausnitzii, C. aerofaciens, E. sinensis, L. longoviformis, and R. intestinalis). In certain embodiments, then present invention provides probiotic formulations containing live bacteria (e.g., from O. splanchnicus, F. prausnitzii, C. aerofaciens, E. sinensis, L. longoviformis, and R. intestinalis).

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com