Patents

Literature

23778results about How to "Improve conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

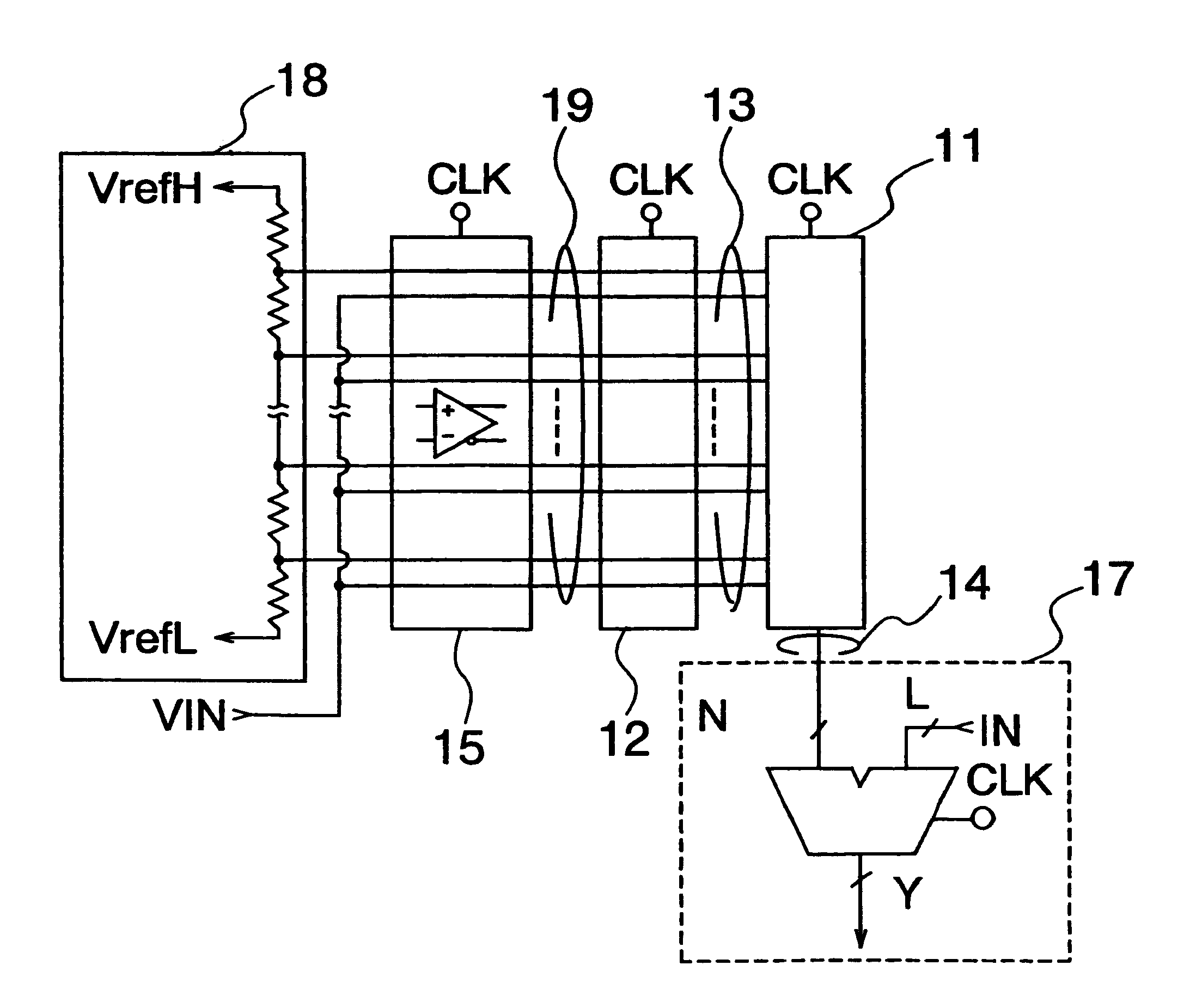

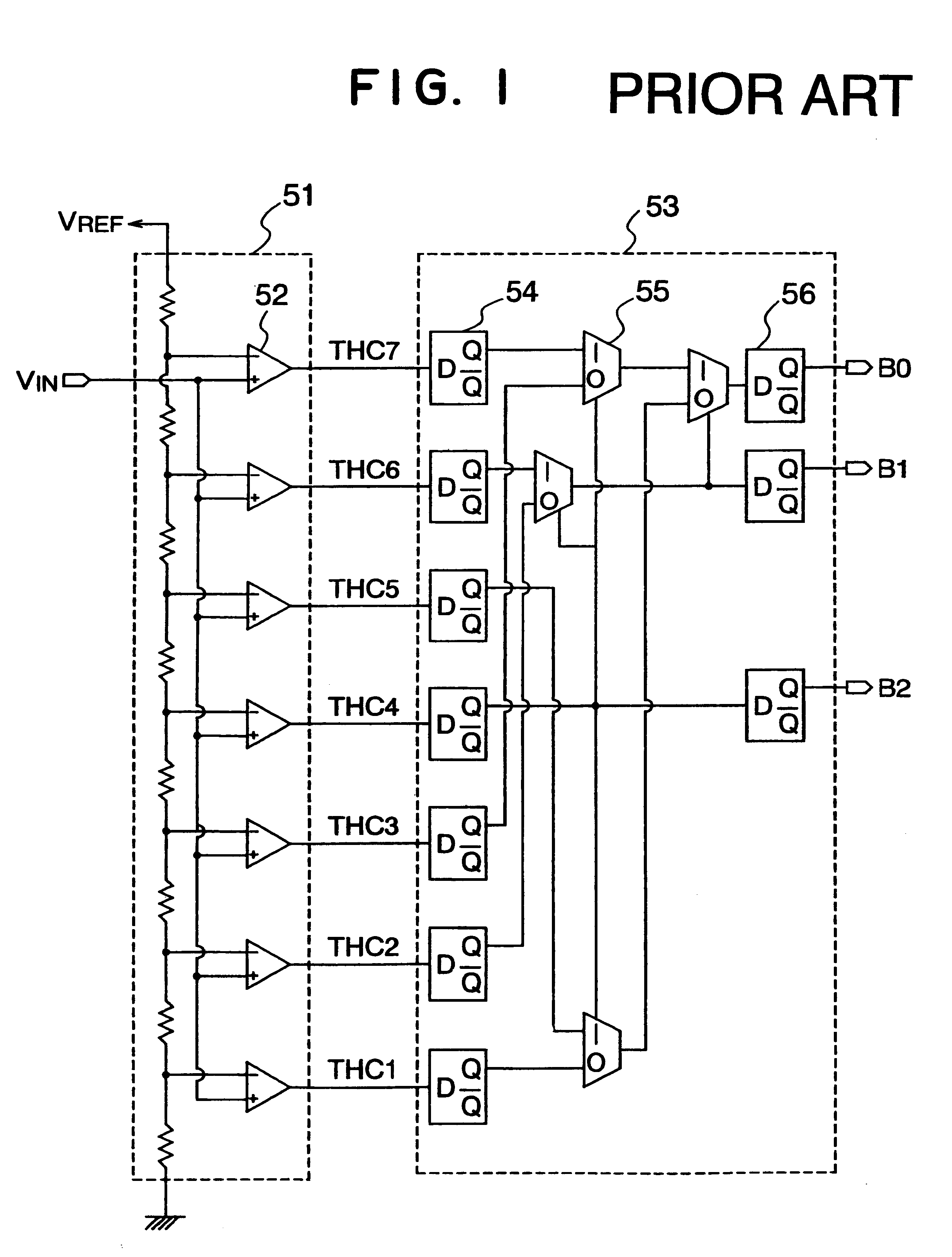

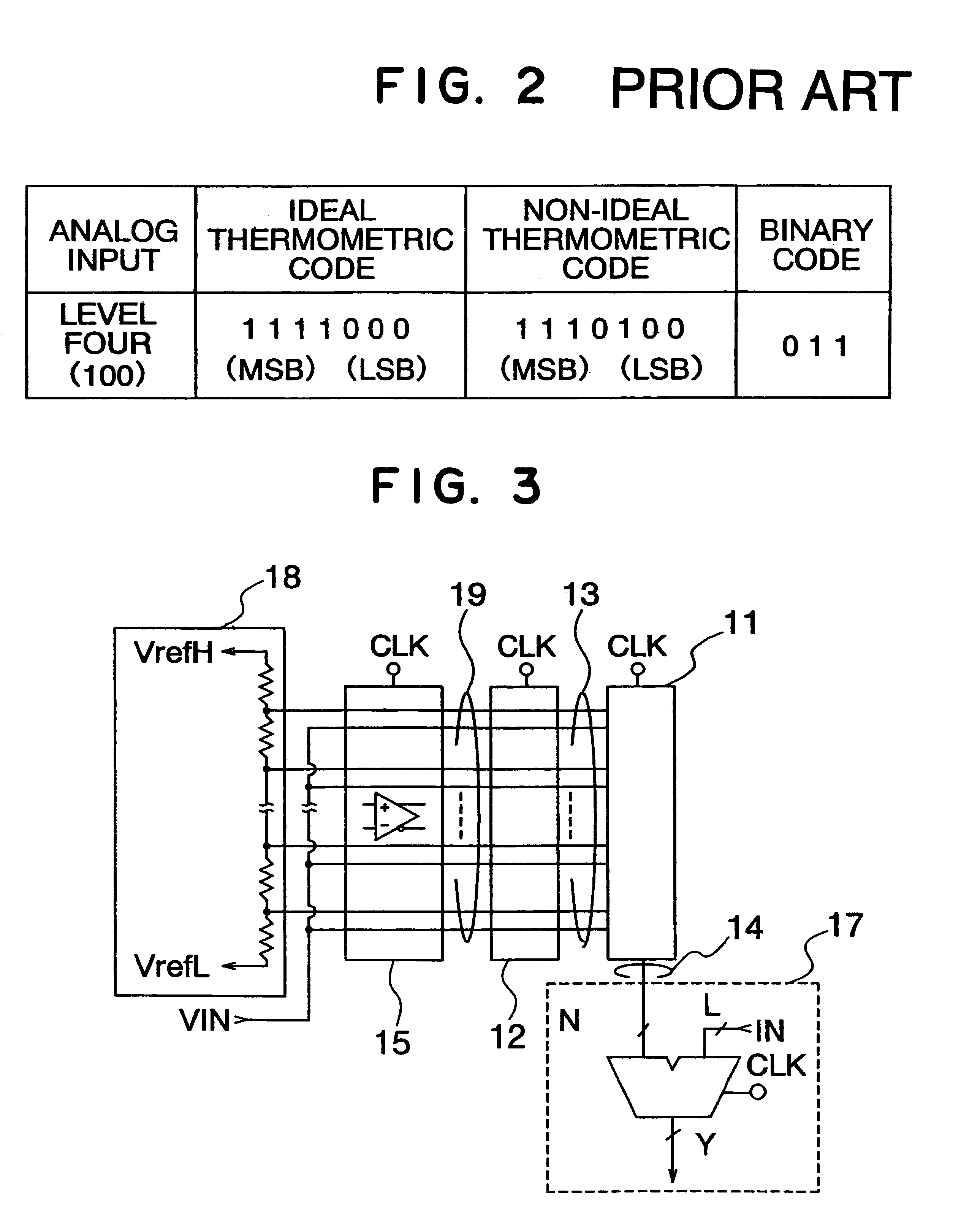

A/D converter having a dynamic encoder

InactiveUS6232908B1Increase speedReduce circuit sizeElectric signal transmission systemsAnalogue-digital convertersBuck converterA d converter

An A / D converter includes a resistor ladder for generating a plurality of reference potentials, a comparing section for comparing each of the reference potentials against an input analog signal to output a thermometric code, and a dynamic encoder composed of a combinational circuit to encode the thermometric code to a binary code by responding a clock signal. The A / D conversion is finished in a single clock cycle at a high speed, with a reduced number of elements and reduced power dissipation.

Owner:NEC ELECTRONICS CORP

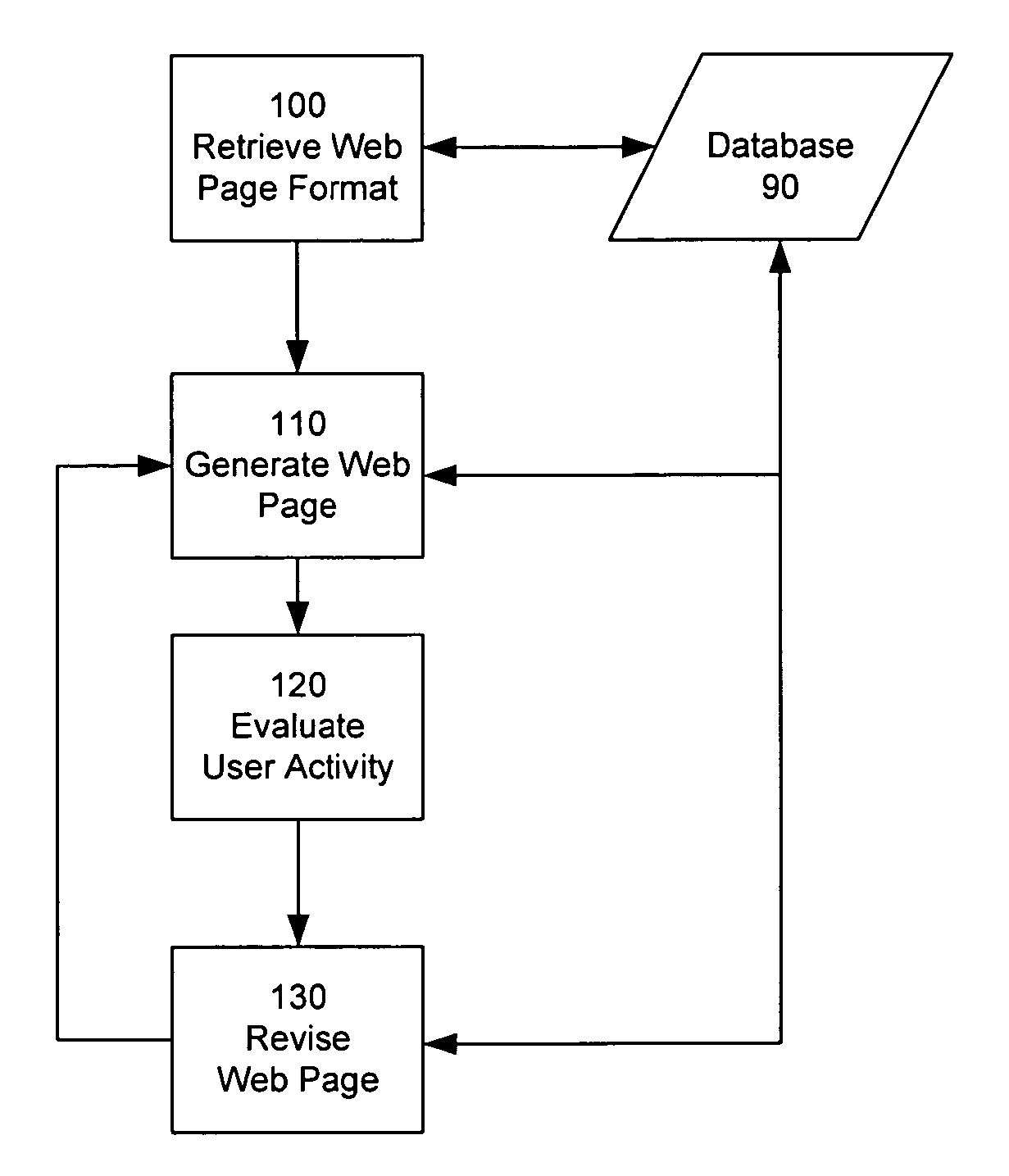

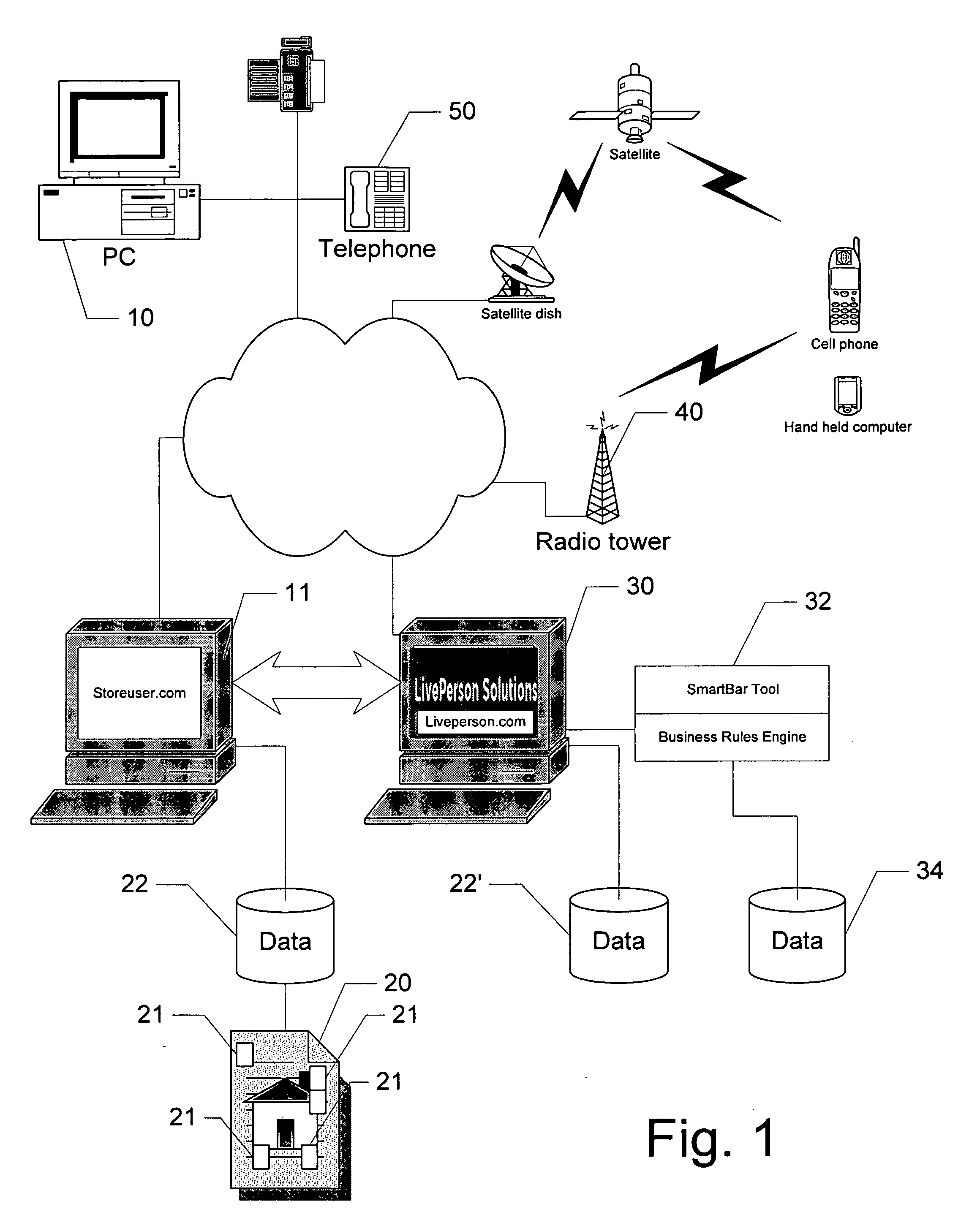

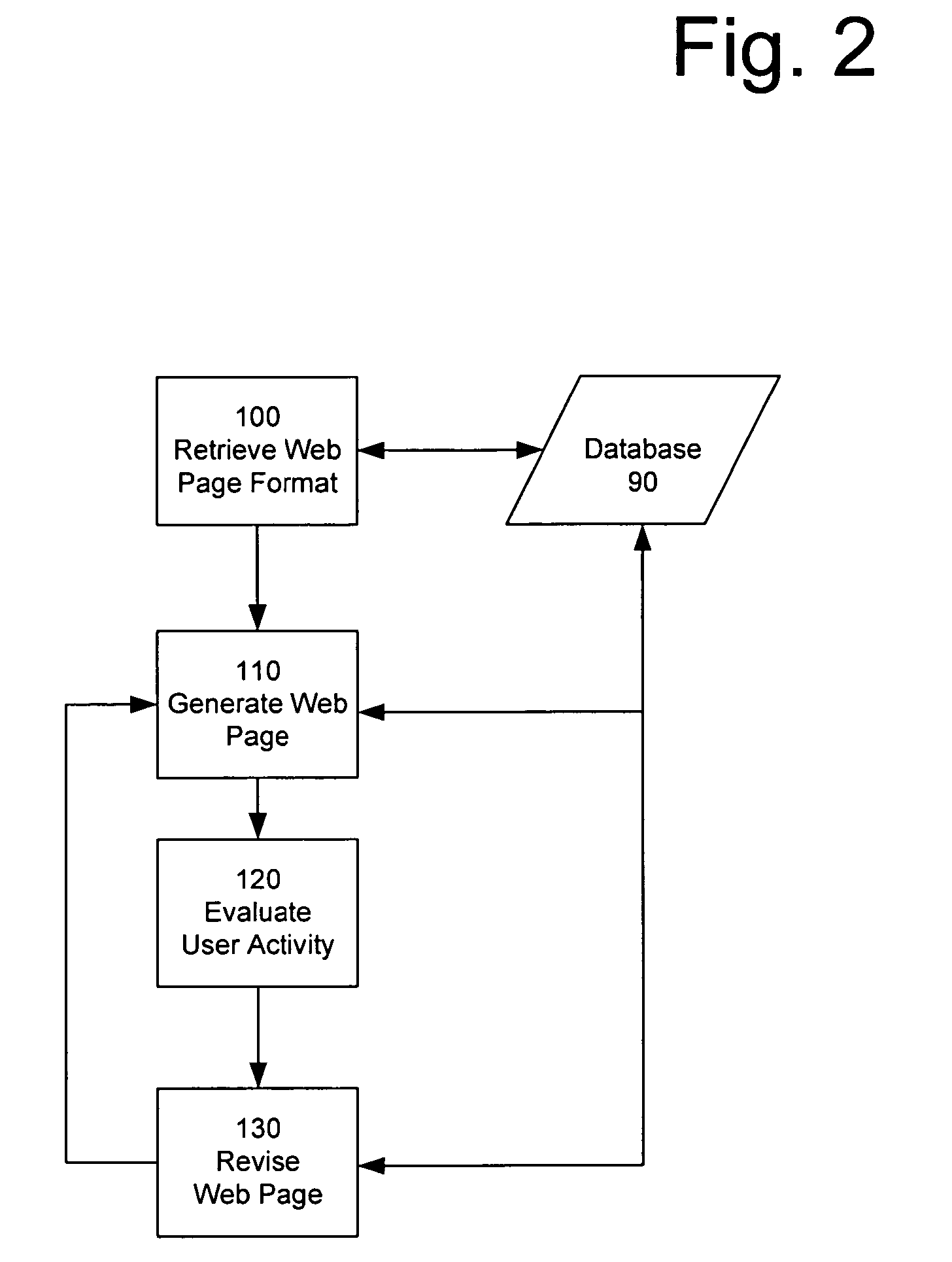

System and method for design and dynamic generation of a web page

ActiveUS20070061412A1Improve conversion rateIncrease customer satisfactionMultiple digital computer combinationsWebsite content managementInformation retrievalBusiness rule

A system and method for dynamically generating a web page is disclosed. The web page includes a frame having content cells. Content for the content cells is provided based in part on business rules. A business rules engine processes, in real-time, an online interaction and determines appropriate content for the content cells. The business rules engine outputs a pointer to the content which is used to populate the content cell.

Owner:LIVEPERSON

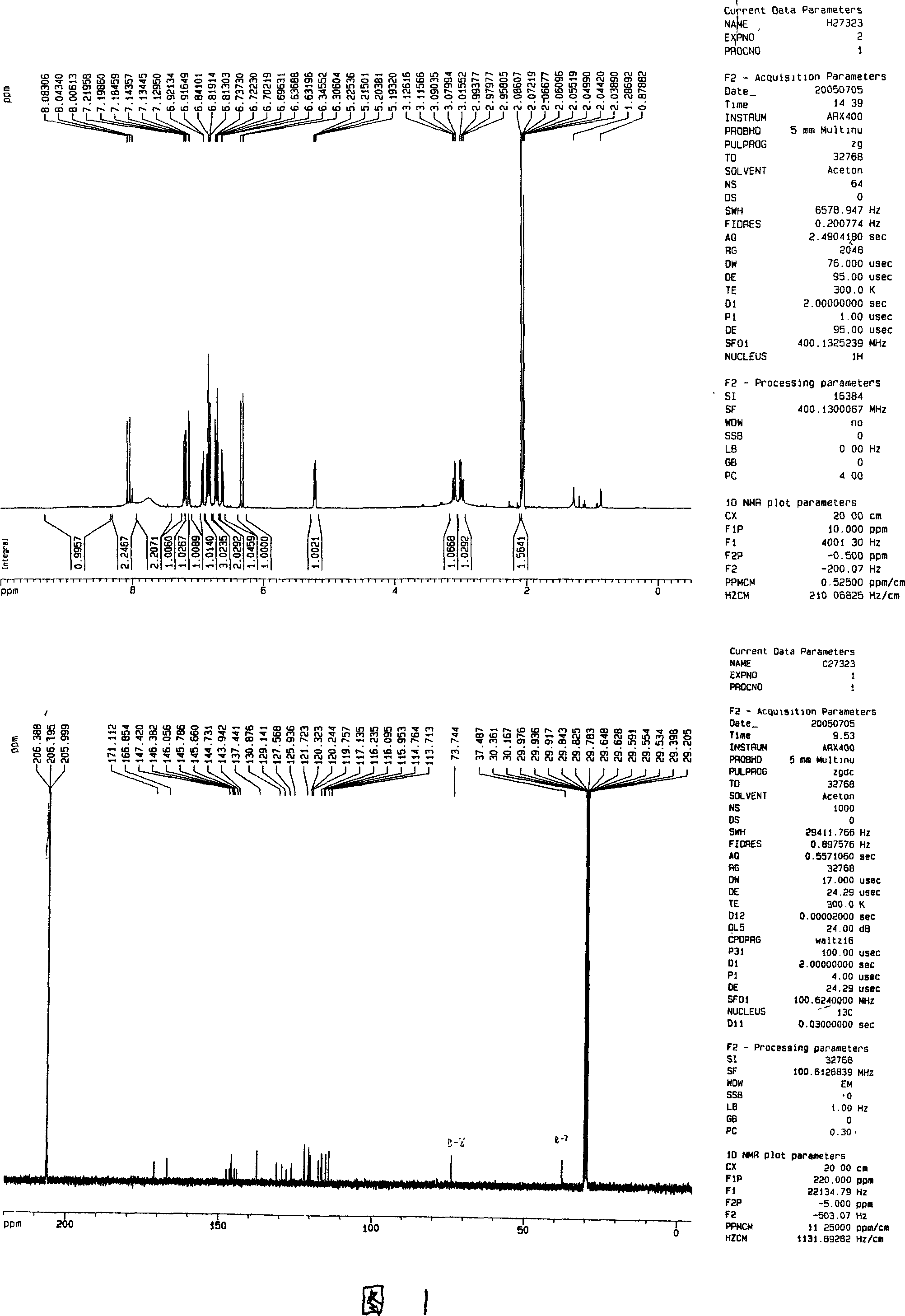

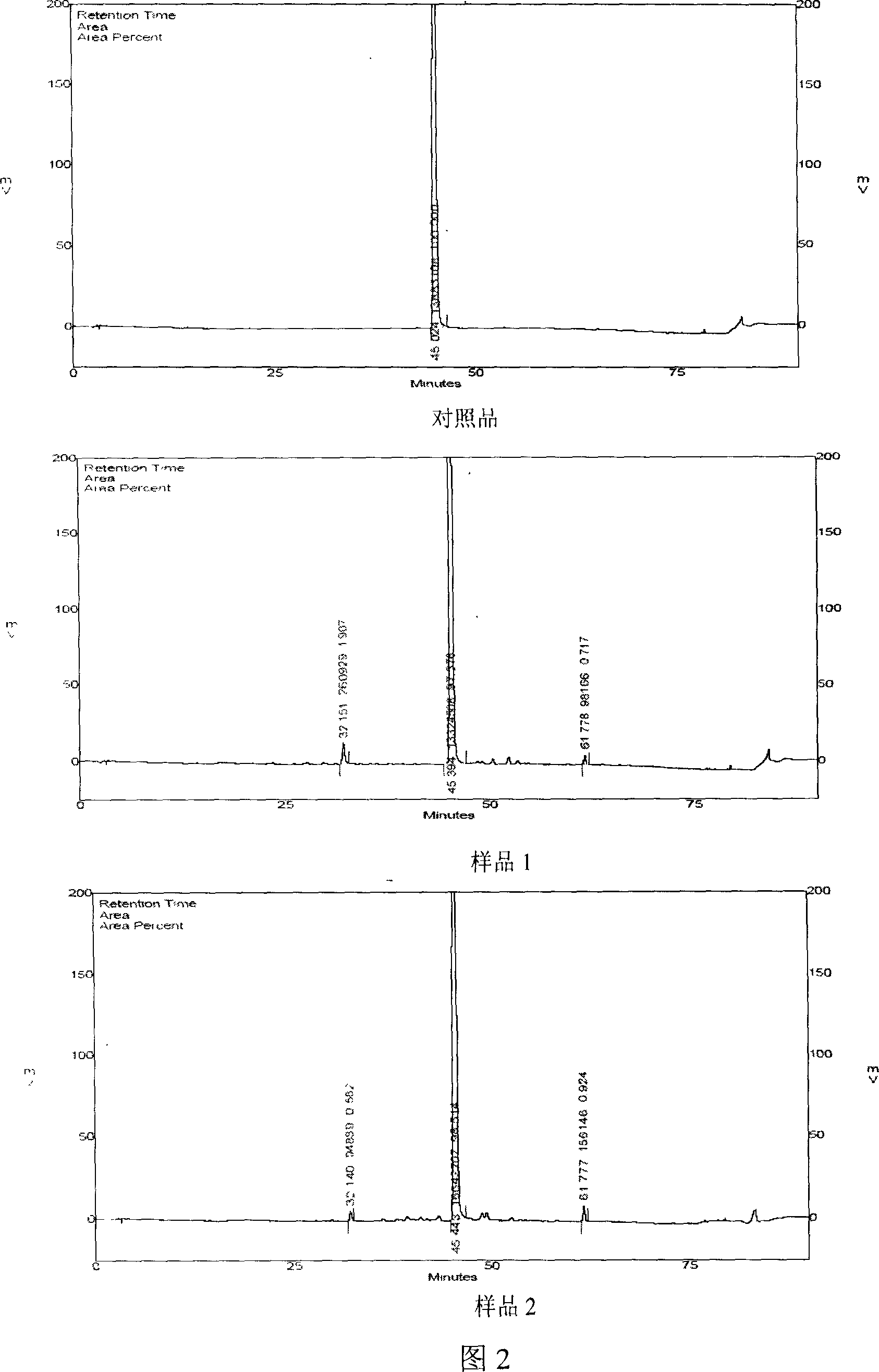

Salvia minium phenolic acid A and process of preparing preparation and use

InactiveCN100999470AImprove conversion rateGood repeatabilityOrganic active ingredientsOrganic chemistryMedicineCurative effect

This invention concerns the method of extracting salvianolic acid A from Chinese crude drug: danshen root, and the quality control methods and drug combinations, and the application of this drug. It can be used in the preparation of the prevention drugs for cardiovascular disease, liver damage, liver fibrosis, pulmonary fibrosis and other.

Owner:PHARMA RES INST OF BENCAO TIANYUAN OF BEIJING

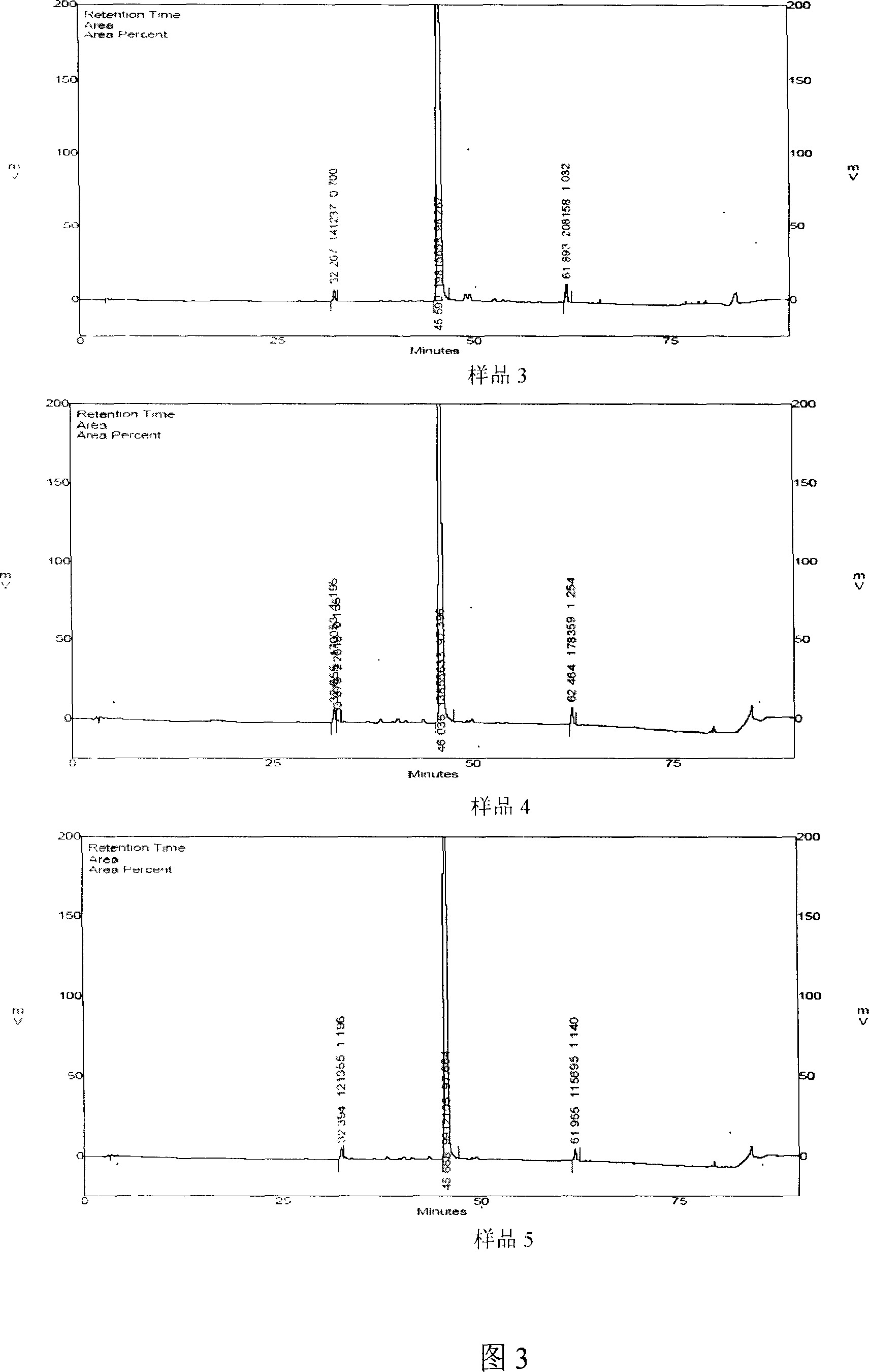

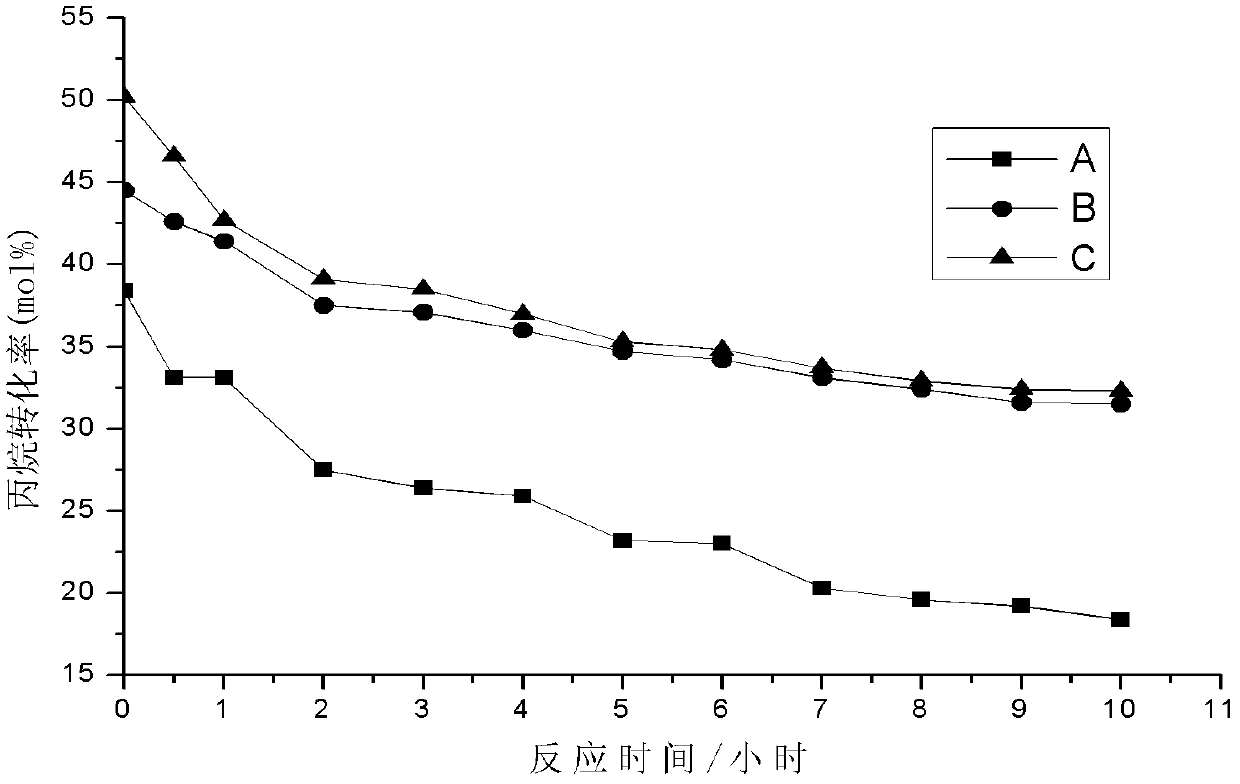

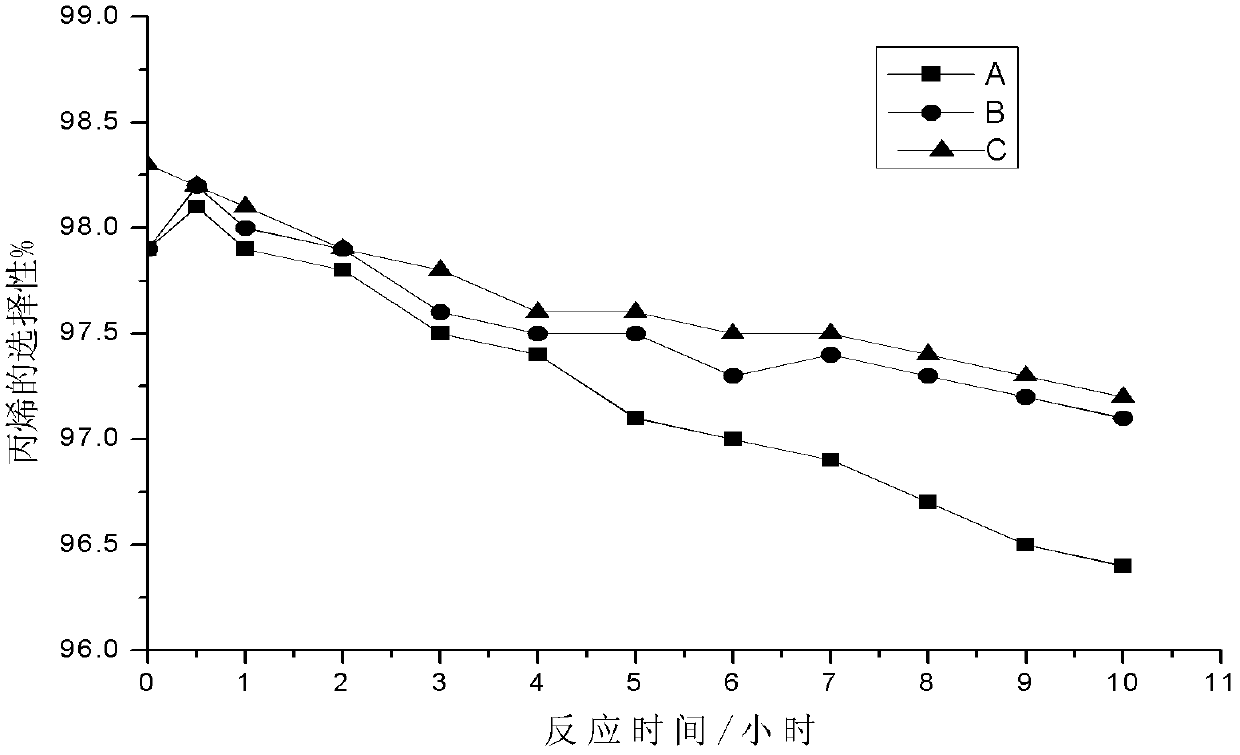

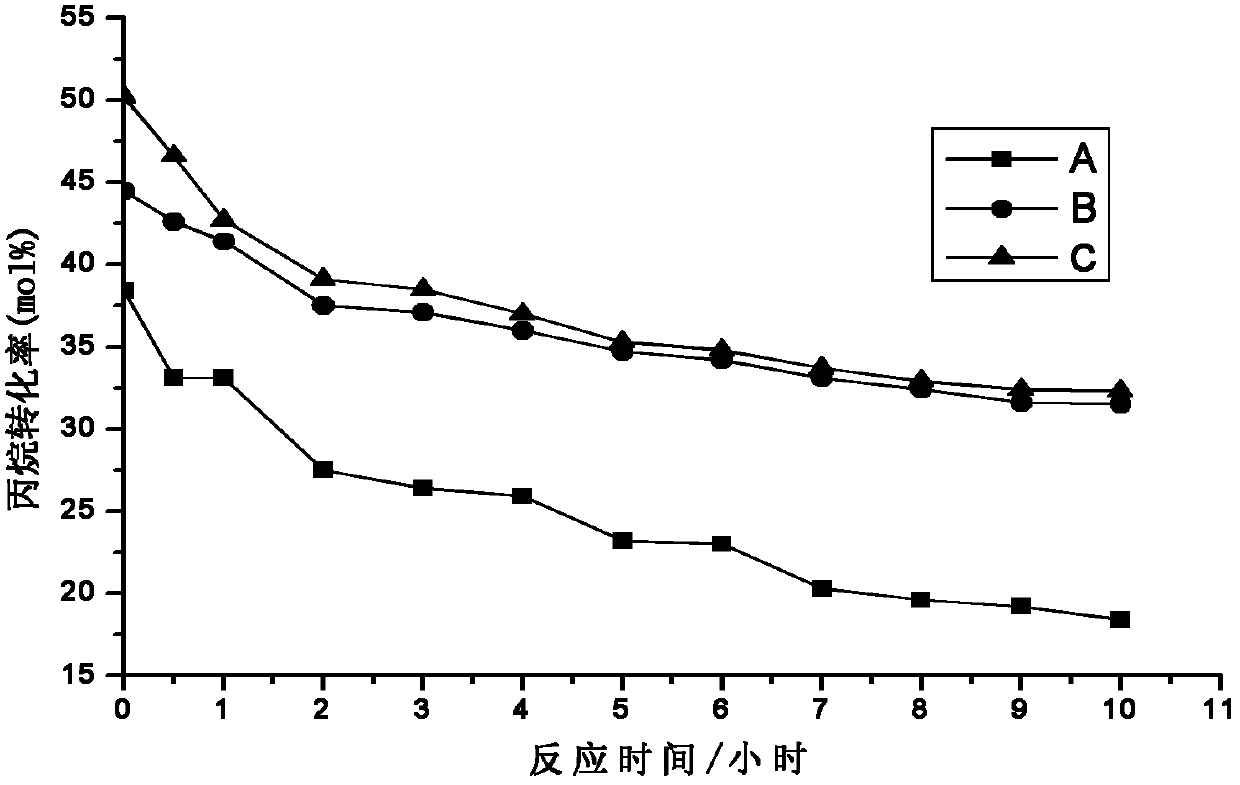

Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

InactiveCN102389831ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsHydrocarbonsDehydrogenationEconomic benefits

The invention relates to a catalyst for preparing propylene through propane catalytic dehydrogenation, which is a load type platinum-based catalyst and is characterized in that home-made mesoporous molecular sieves MCM-41 are used as carriers, metal Pt is used as an active ingredient, and metals Sn, Sn-Ce or Sn-Ce-Ca are used as auxiliary agents. In a preparation method, an isovolumetric continuous immersion method is adopted for preparation. The catalyst and the preparation method have the advantages that the isovolumetric continuous immersion method is adopted for preparing multi-component catalysts, wherein the content of any one component is easy to control, the prepared catalyst has higher specific surface area (700 to 900m<2> / g) and has high catalytic activity, the propane conversion rate is high, the propylene selectivity is good, the one-path stability is good, in addition, the service life is longer, the preparation method of the catalyst carriers is simple and feasible, the economic benefit is obvious, and good industrial development and application prospects are realized.

Owner:NANKAI UNIV

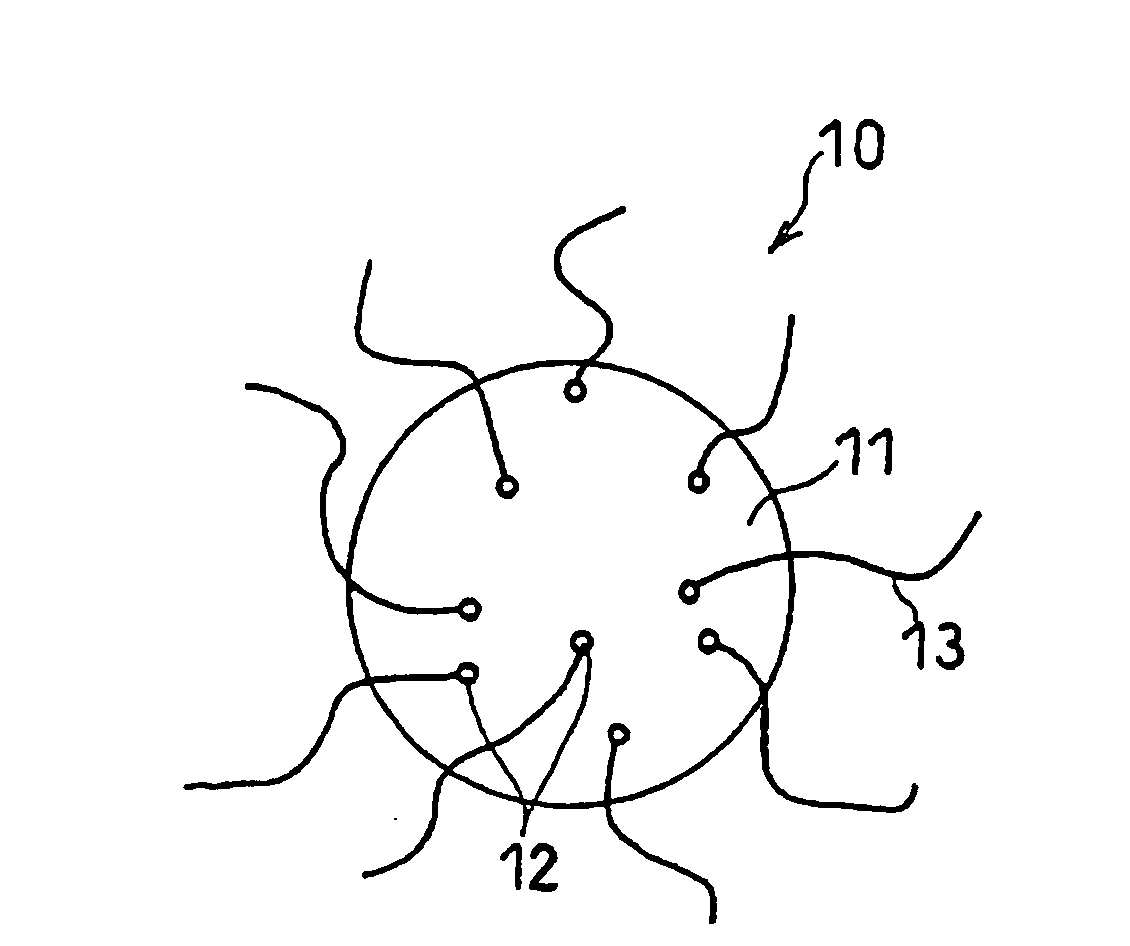

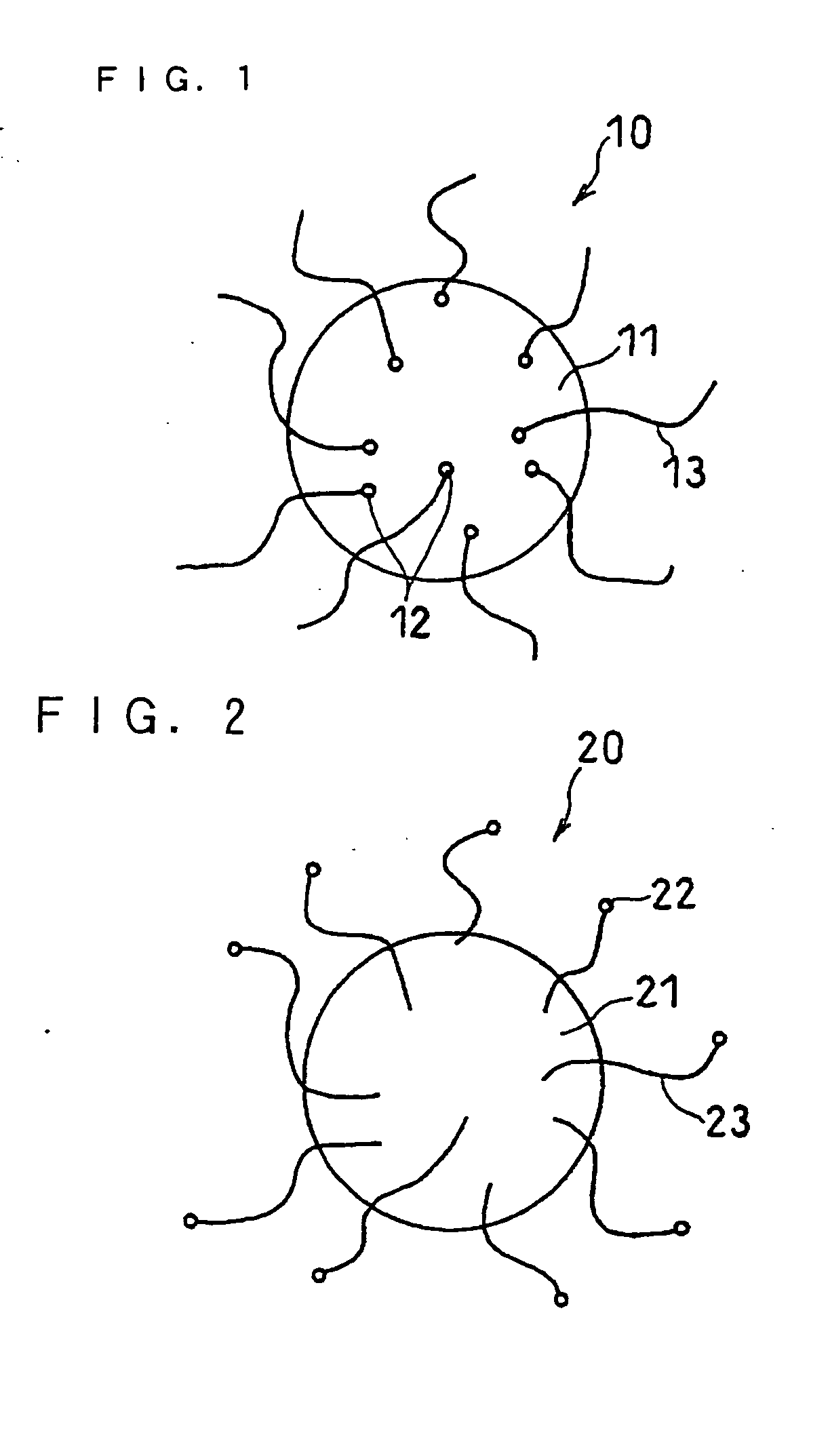

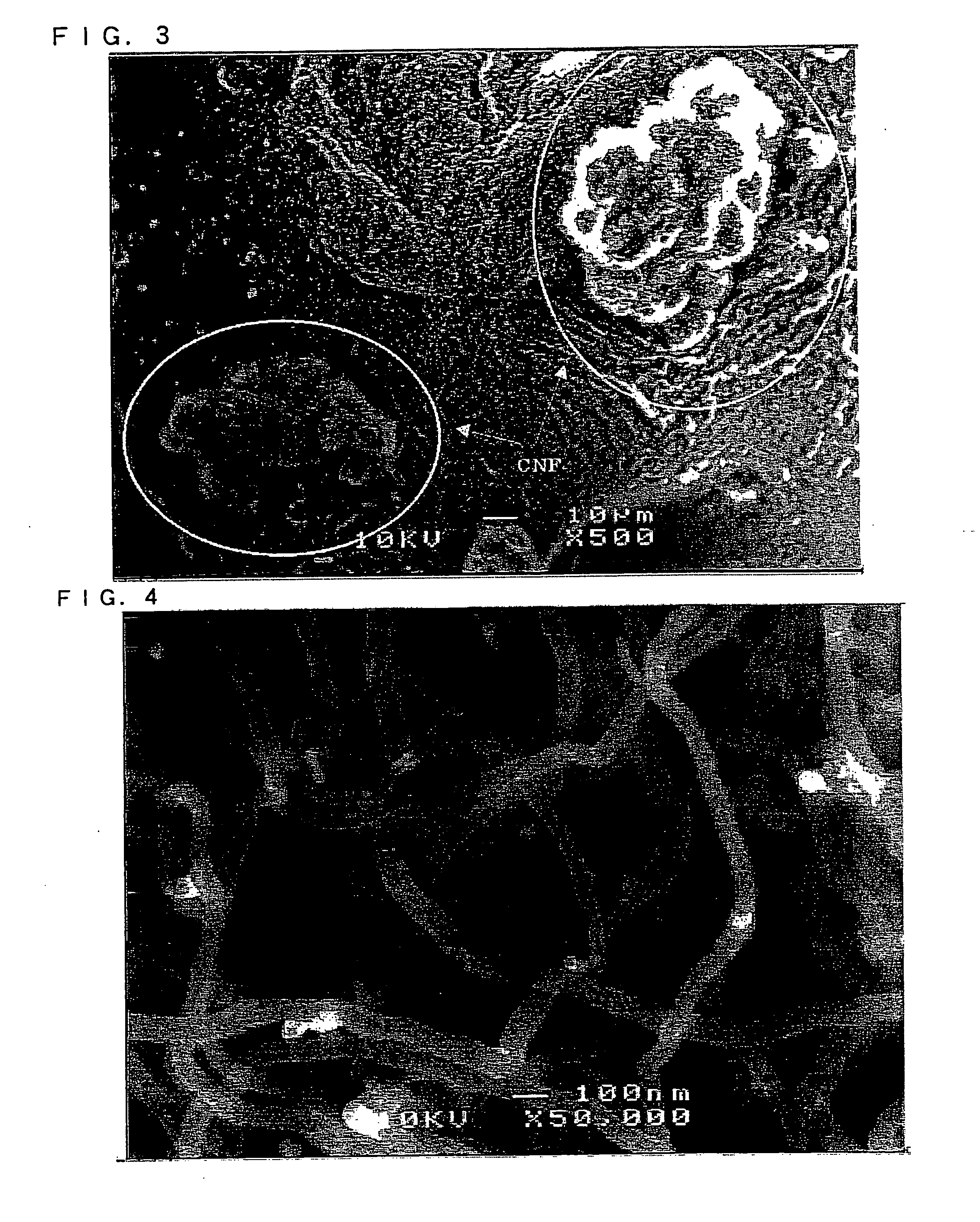

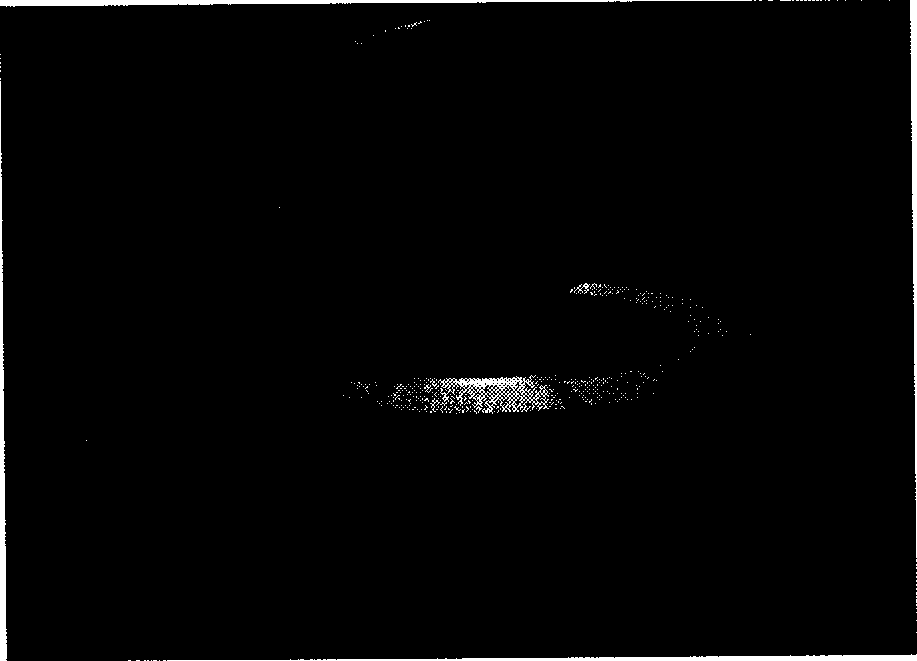

Composite Particle for Electrode, Method for Producing the Same and Secondary Battery

InactiveUS20080160409A1Improve electronic conductivityExcellent initial charge/discharge characteristicMaterial nanotechnologyElectrode manufacturing processesFiberSurface layer

A composite particle for an electrode including an active material particle, carbon nanofibers bonded to the surface of the active material particle, and a catalyst element for promoting the growth of the carbon nanofibers, wherein the active material particle includes an electrochemically active phase. As the catalyst element, for example, Au, Ag, Pt, Ru, Ir, Cu, Fe, Co, Ni, Mo, Mn and the like are used. The composite particle for an electrode may be produced, for example, by means of a method which includes: a step of preparing an active material particle including a catalyst element for promoting the growth of carbon nanofibers at least in the surface layer of the active material particle; and a step of growing carbon nanofibers on the surface of the active material particle in an atmosphere including a raw material gas.

Owner:PANASONIC CORP

Template process of preparing hollow ball and composite hollow ball

InactiveCN1772363ARealize the intelligent switching processWide adaptabilityMicroballoon preparationMicrocapsule preparationPolymer scienceSolvent

The present invention belongs to the field of hollow material preparing technology, and is especially the preparation process of hollow ball of inorganic matter, metal, organic matter and composite structure with hollow polymer ball as template. The present invention prepares composite hollow ball through combining hollow polymer ball template with sol-gel, deposition reaction, oxidation-reduction process and through forced interface process or surface deposition process; and obtain hollow ball of inorganic matter, metal and organic matter through high temperature sintering or selective solvent extraction to eliminate template polymer. The control of hollow ball structure and size and the compounding of several kinds of matters may be realized through controlling reactant activity, material feeding mode, reactant concentration and circulating reaction process. The hollow ball has excellent dispersivity, high strength and size stability. The present invention also relates to the application of these hollow structure materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

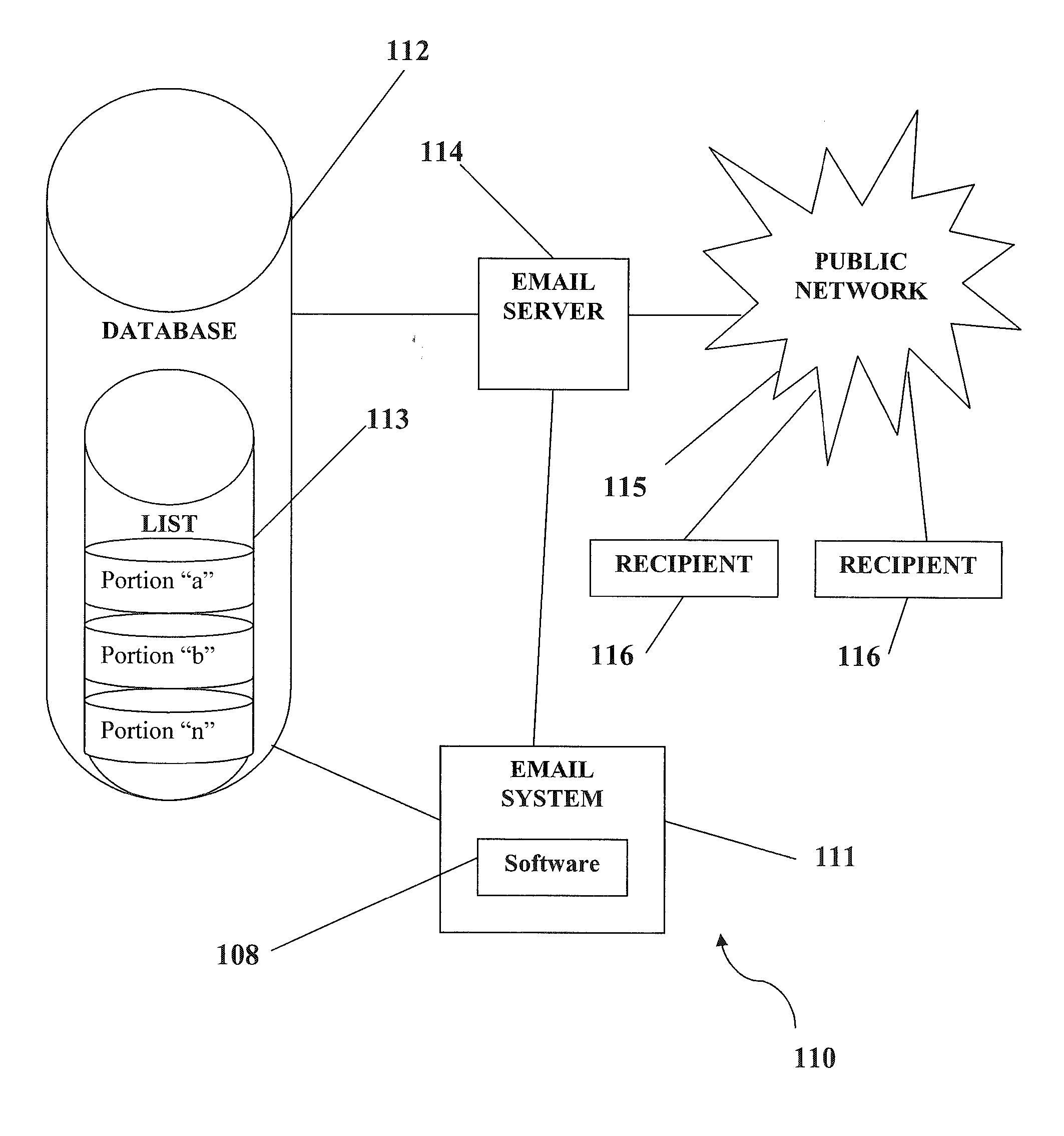

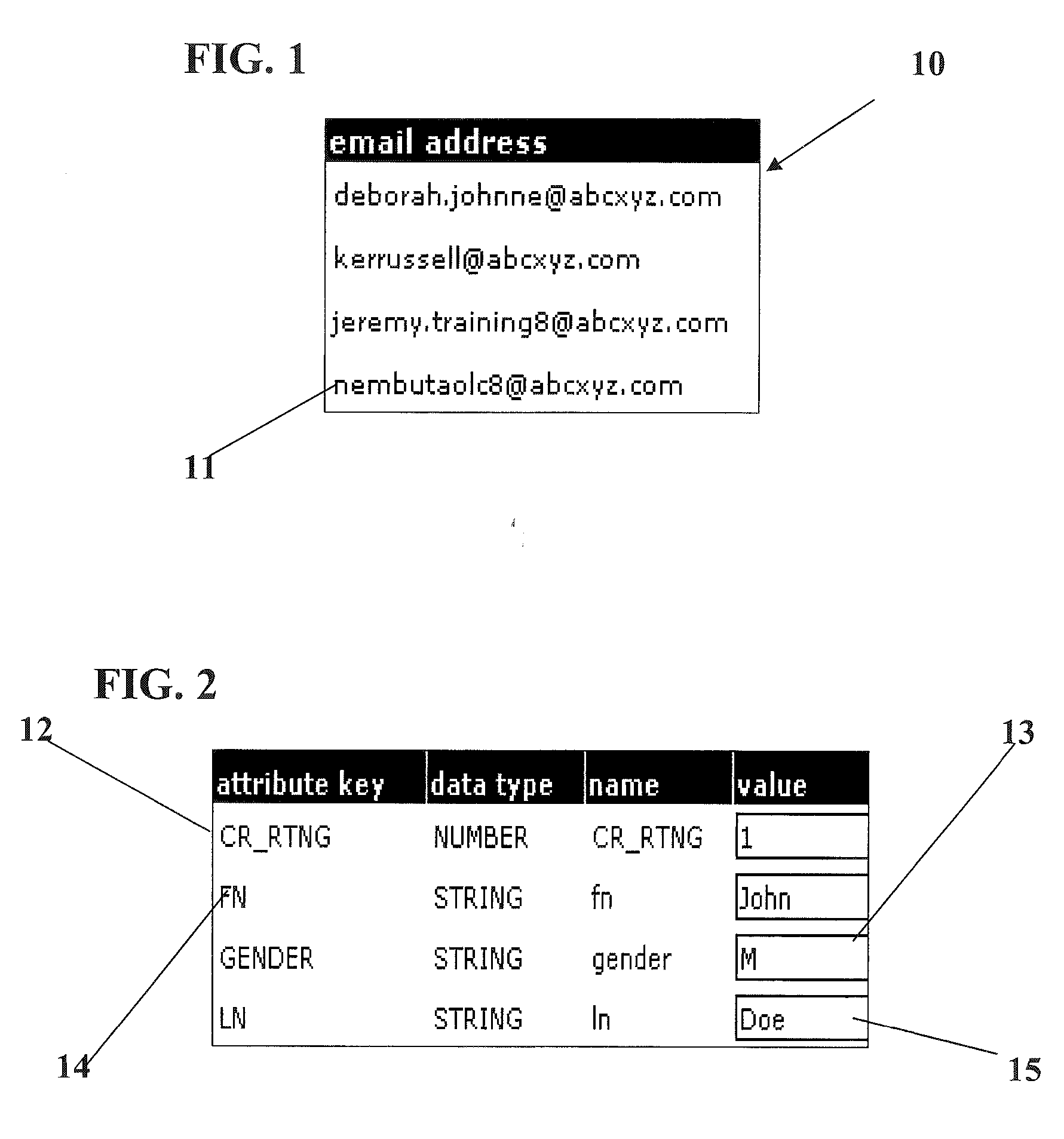

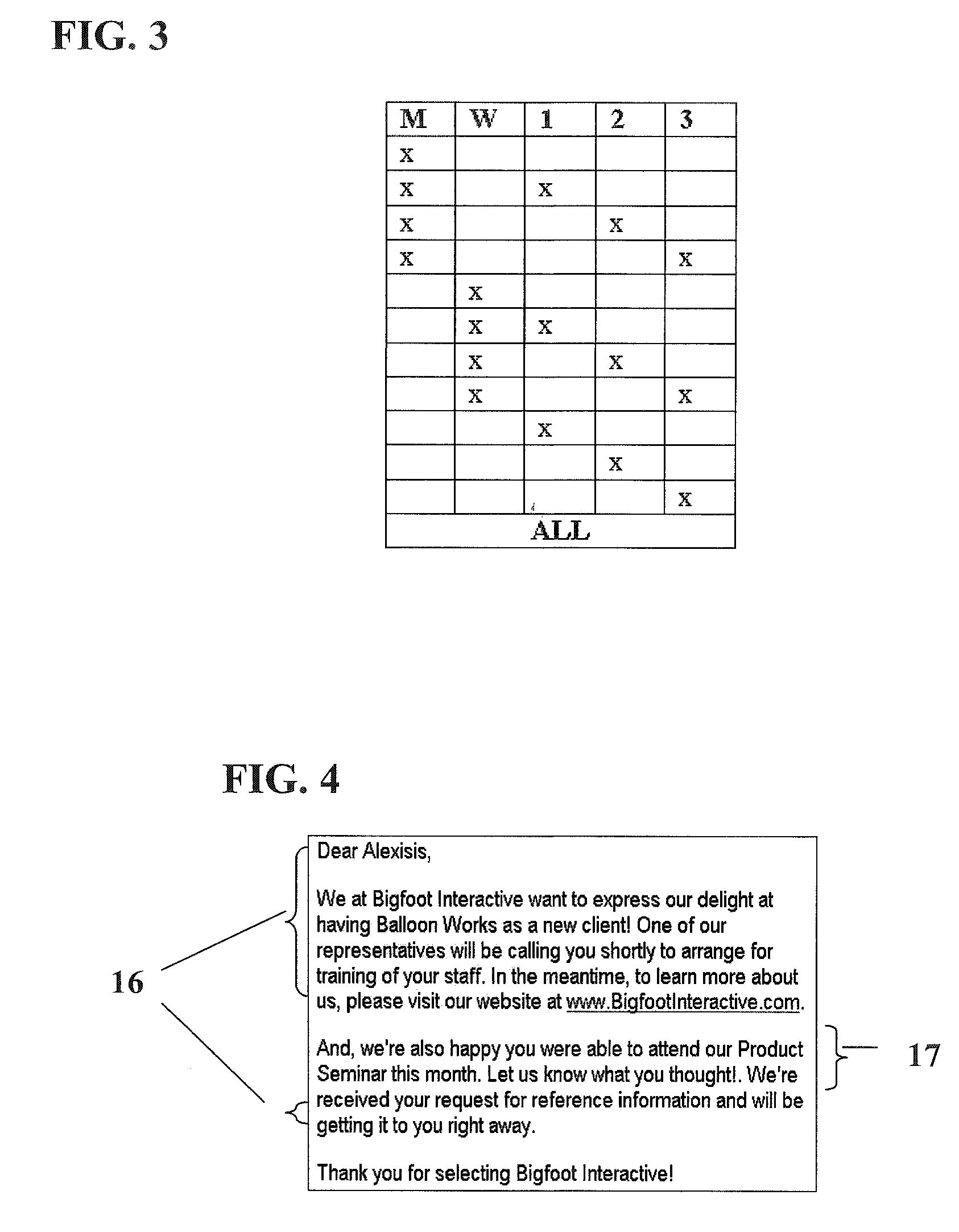

Method and system for providing automated email optimization

InactiveUS20060253537A1Different in contentIncrease the number ofMultiple digital computer combinationsData switching networksEmail marketingSubject matter

A method and system for providing rules-based or algorithms based automated response optimization in the email-marketing environment such that recipient responses during the delivery process of an email campaign influence the delivery parameters and / or message elements of the portions of the campaign yet to be mailed. Responses to an email marketing campaign determine its marketing effectiveness and include delivery statistics, undeliverable statistics, opens, link-clicks, replies, opt-outs, and conversion events. Conversion events are recipient actions that are intended results from the marketing campaign and include marketing or service transactions that are completed online (e.g. purchases, registrations, filling out surveys, etc) and / or offline (e.g. brand awareness, store visits etc.). The system monitors emails as they are being received by recipients during delivery and, based on rules established by the marketer or on default rules established by the system using algorithms, tracks designated response statistics and dynamically alters the email elements, such as subject line and / or other content, including clickable links so that messages that produce the most desirable response statistics is sent to a greater percentage of the remaining recipients. Rather than completing the entire emailing operation using the same content throughout, this invention allows for changing the content for emails remaining to be sent so that the more effective content (in terms of stimulating favorable recipient reactions and purchases) is delivered to as many of the recipients as possible. Additionally, the process may be applied between separately mailed campaigns so that the delivery parameters for subsequent campaigns in a “campaign stream” are automatically modified based on the results of the prior campaigns in the stream and on the rules being applied to the stream.

Owner:EPSILON INTERACTIVE

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

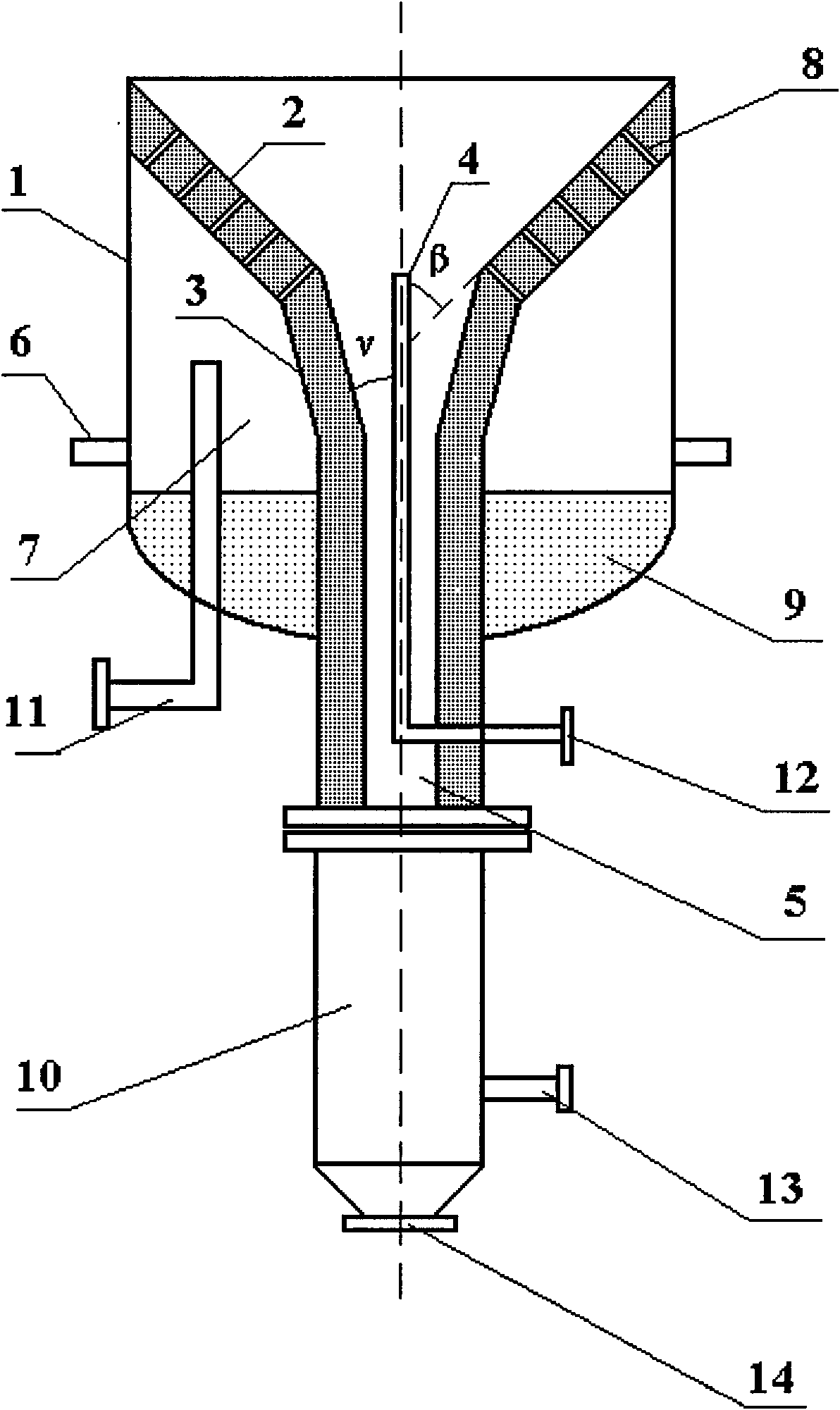

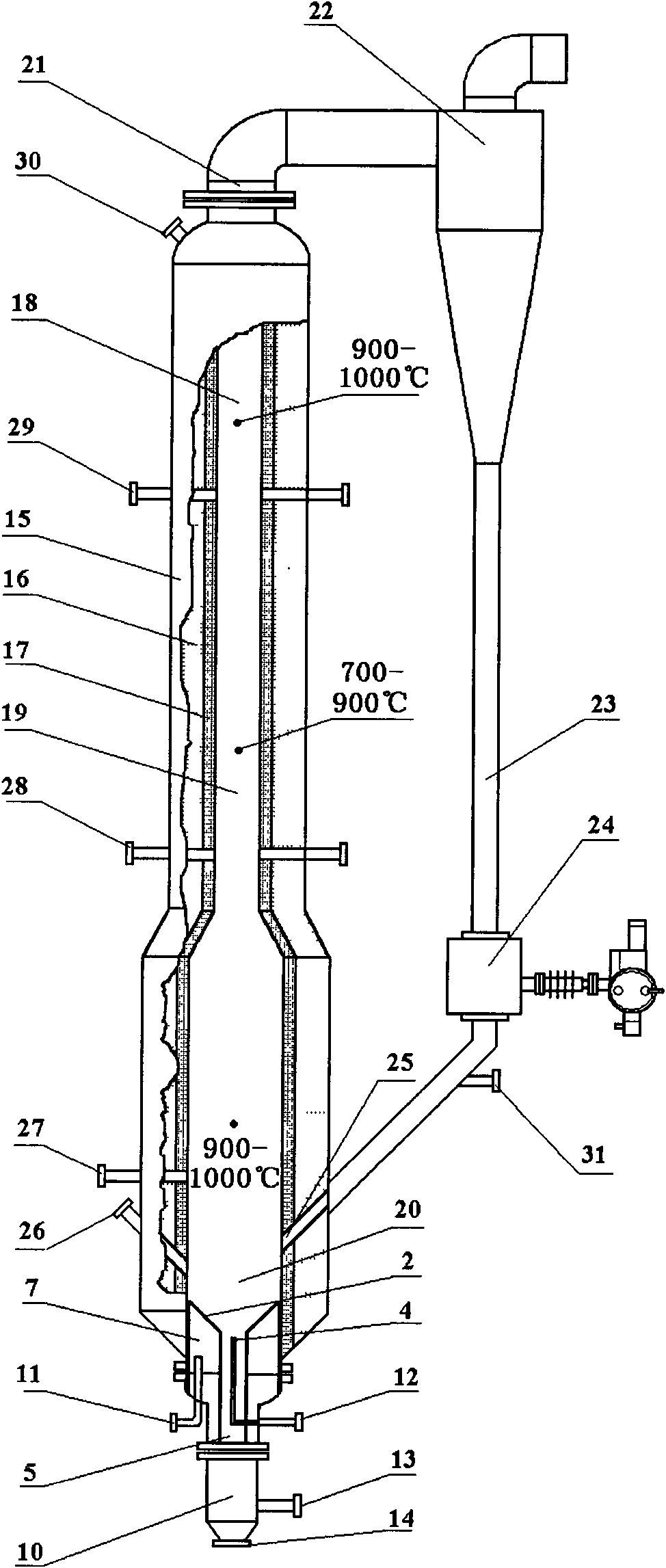

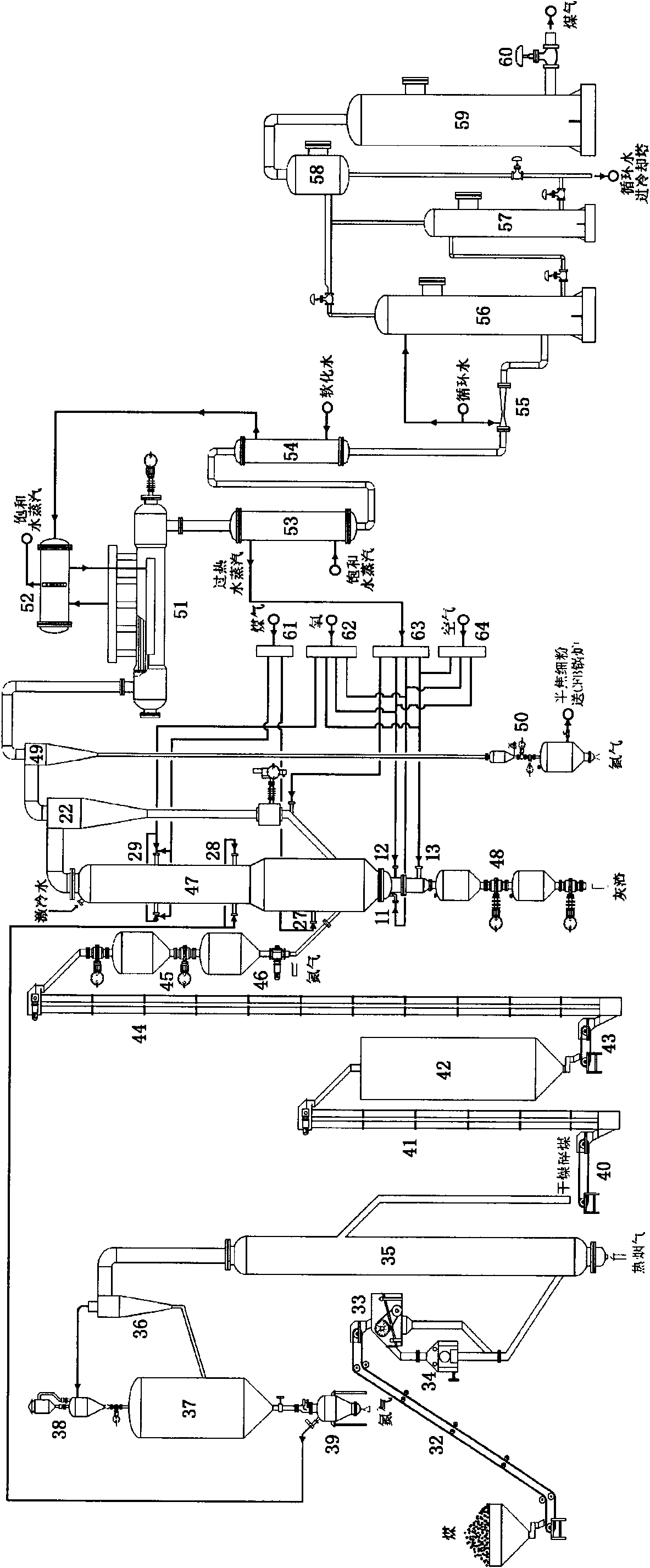

Method and device for gasifying multi-segment staged converted fluidized bed

ActiveCN101942344ALow ash carbon contentExtended stayEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

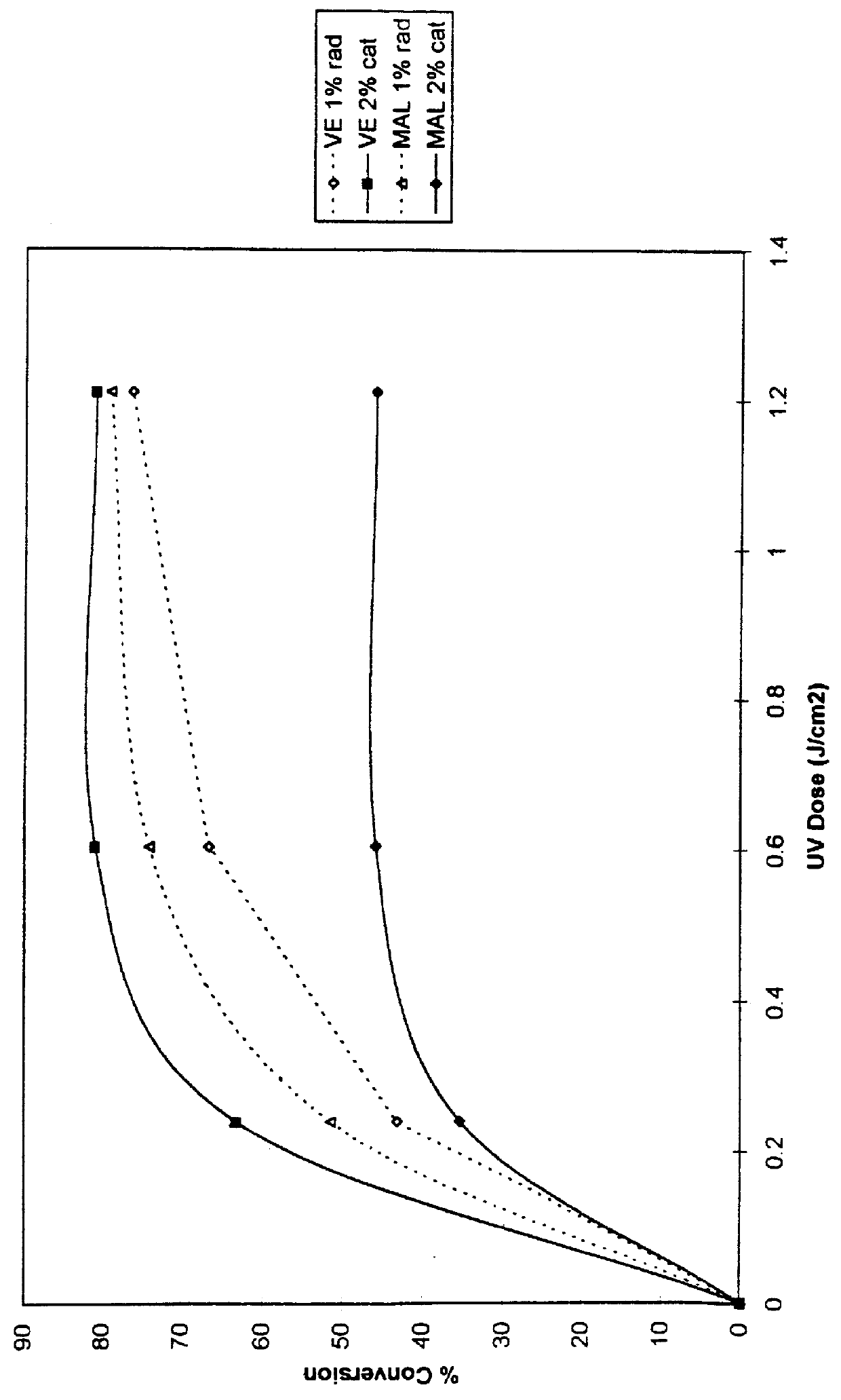

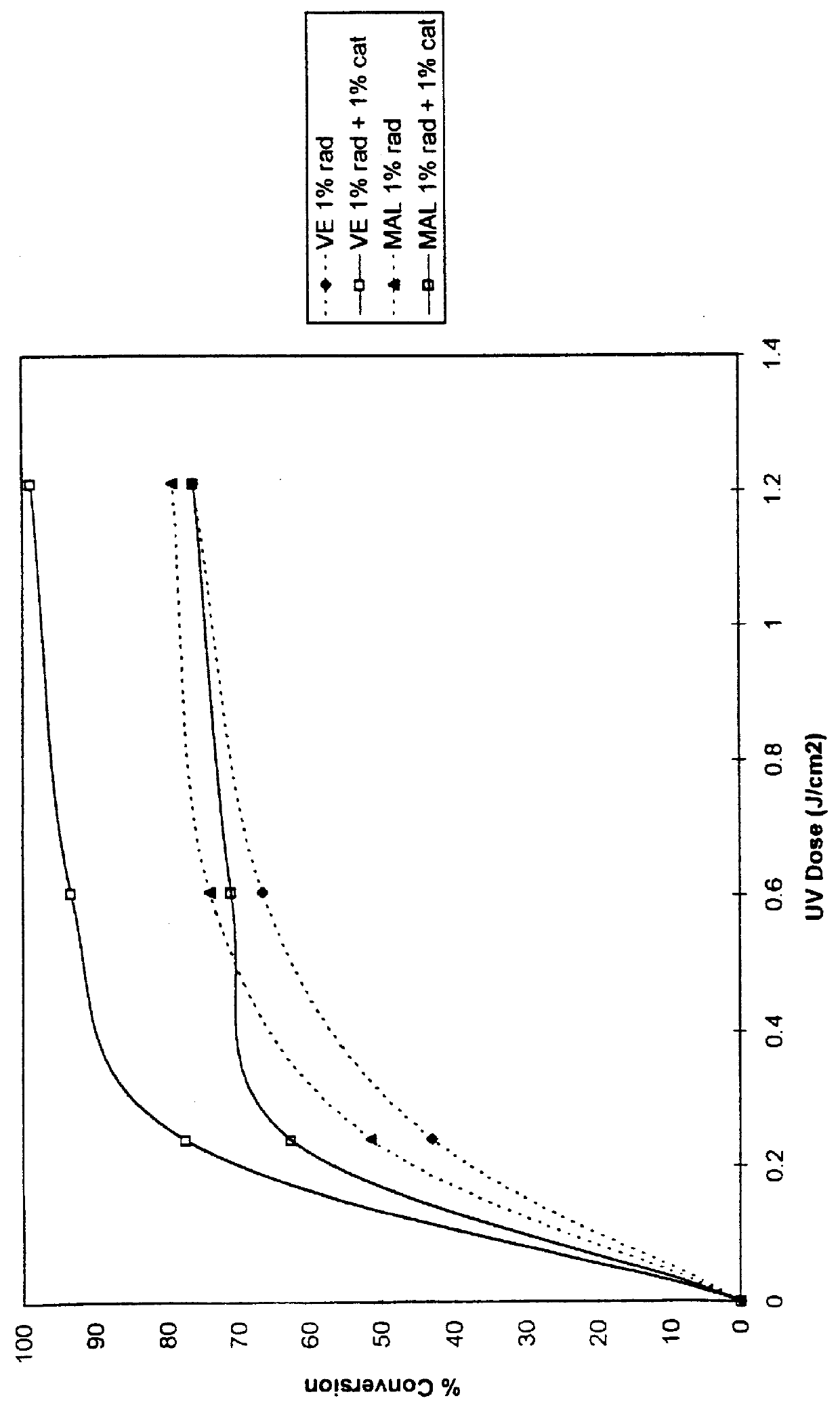

Photopolymerization process and composition employing a charge transfer complex and cationic photoinitiator

InactiveUS6127447AAccelerating polymerizationExtend curing timePhotomechanical apparatusOptical articlesVinyl etherCharge-transfer complex

A radiation curable coating composition is provided and includes an effective amount of cationic photoinitiator, in combination with a charge transfer complex, the charge transfer complex comprising at least one electron withdrawing reactant component and at least one electron donating reactant component free radically reactive therewith, the electron withdrawing reactant component comprising an unsaturated nitrogen containing compound and the electron donating reactant component comprising an unsaturated compound having at least one vinyl ether group, the electron donating reactant component may be separate from or structurally incorporated within the electron withdrawing reactant component and an effective amount of a cationic photoinitiator. A photopolymerization process employing the composition is also provided.

Owner:FUSION UV SYST

Process for preparing small crystal ZSM-5 zeolite

The preparation process of small crystal grain ZSM-5 zeolite includes the following steps: mixing alumino sillica gel grain in SiO2 / Al2O3 molar ratio of 20-600 and granularity of 20-300 mesh and water solution of organic template agent, and hydrothermal crystallization of the mixture with or without ZSM-5 zeolite crystal seed; and once filtering, drying and roasting. The said process can preparing ZSM-5 zeolite product with Si / Al molar ratio of 15-200 and initial crystal granularity of 0.1-0.5 micron. The process uses no sodium ion material, needs no ammonium exchange, filtering and roasting process, and thus has high zeolite product yield and simplified production process. The zeolite product is used in the catalyst for hydrolyzing cyclohexene to prepare cyclohexanol and has high cyclohexanol converting rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for hydrogenation of dimethyl oxalate to prepare methyl glycolate, preparation method and application thereof

ActiveCN101954288AEasy to prepareGood synthesis reproducibilityOrganic compound preparationCarboxylic acid esters preparationCoprecipitationDimethyl oxalate

The invention relates to a catalyst for hydrogenation of dimethyl oxalate to prepare methyl glycolate, a preparation method and application thereof. The catalyst is prepared by using Cu as main active component and using one or more of Ag, Mg, Au, Ru, Rh, Pd, Pt, Re, Ni, Co, Cr, Zn and Zr as additive through a urea decomposition-homogeneous coprecipitation process, wherein the mass fraction of Cuis 0 to 30 percent, the mass fraction of the additive is 0 to 20 percent, and the rest is carrier silica. The method for preparing the catalyst is simple, and good in synthesis repetitiveness, and when being applied for hydrogenation of dimethyl oxalate to prepare methyl glycolate, the catalyst is high in activity and stability, and the selectivity of methyl glycolate is high.

Owner:SHANGHAI HUAYI GRP CO

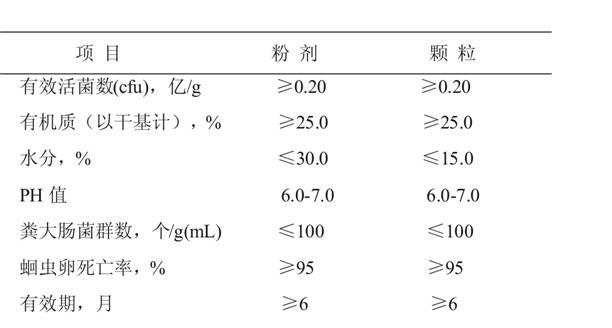

Bio-organic fertilizer produced by using livestock manure

ActiveCN102219570ASimple structureImprove conversion rateBio-organic fraction processingFungiLivestock manureAgricultural science

The invention provides an efficient active bio-organic fertilizer produced by using livestock manure and a preparation method thereof. The preparation method comprises the following steps: pre-treating the livestock manure, straw and peat; mixing the livestock manure, straw and peat at a weight ratio of (3-5):(1-2):(1-2); adding a composite ageing bactericide based on the condition that the weight ratio of the mixture to the high-concentrated organic material ageing bactericide is (5000-10000):(1-2), evenly mixing, and then carrying out composting fermentation for 7-10 days, wherein during the composting fermentation, the material needs to be stirred 1-2 times each day; and mixing the material decayed by fermentation with a functional composite bactericide which is generated by single fermentation at a weight ratio of (5000-1000):(1-2), granulating and drying at low temperature so as to obtain the high-efficiency and active bio-organic fertilizer. The process is relatively simple, is easy to operate, and can be used for lowering the product cost is low, saving energy and turning wastes into wealth, thereby being beneficial to promotion of benign ecological circulation and environment conservation; and by utilizing the fertilizer, the quality of the product is good, thereby obviously improving the yield and quality of agricultural products.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

Method for producing fuel oil by biomass hydrothermal liquefaction

InactiveCN101805629AImprove conversion ratePotential for industrial applicationsLiquid hydrocarbon mixture productionMass ratioReaction temperature

The invention discloses a method for producing fuel oil by biomass hydrothermal liquefaction. The method is characterized by comprising the following steps: fully mixing a biomass raw material and solvent water (or adding catalyst water solution) to prepare seriflux, wherein a mass ratio of a catalyst to the raw material is 1:10 to 1:50, and the mass ratio of the raw material to water is 1:2 to 1:8; performing a reaction in a slurry bed reactor under a reducing atmosphere; controlling a liquefaction reaction temperature between 300 and 450 DEG C, a reaction pressure between 5 and 30 MPa and reaction time between 5 and 40 minutes; after the reaction, separating a product to obtain the fuel oil, solid residue, water, gas and the like. The method has the advantages of achieving complete biomass conversion, high oil product productivity, obtaining an oil product with a heat value equal to that of standard oil, relieving dependence on fossil energy, contributing to environment protection, lowering production cost and achieving good social and economic benefits.

Owner:EAST CHINA UNIV OF SCI & TECH

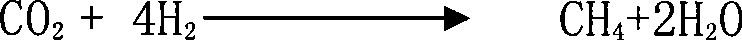

Novel methanation catalyst and preparation method thereof

InactiveCN101380581AImprove conversion rateGood choiceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementLanthanum compounds

The invention provides a novel methane catalyst and a preparation method thereof, which is characterized in that by adding rare earth elements of La and Ce during the process of the catalyst, the activity and selectivity of the catalyst are improved, and especially for the reaction that CO2 is carried out hydrogenation to be changed into methane, the conversion rate is higher. By adding an appropriate amount of Ca, Mg, Ba, Na and other alkali metals and alkaline earth metals, the thermal stability and the anti-carbon property of the catalyst are improved. The components of the catalyst by weight percentage are as follows: 70-86% ofAl2O3, 12-20% NiO, 0.5-5% of La2O3, 0.5-5% of MgO, 0.1-5% of CeO2, 0.1-3% of CaO, 0.1-1% of Na2O and 0.01-2% of BaO; the specific surface of the catalyst is 100-180m<2> / g, and the pore volume is 0.4- 0.8ml / g.

Owner:ENN SCI & TECH DEV

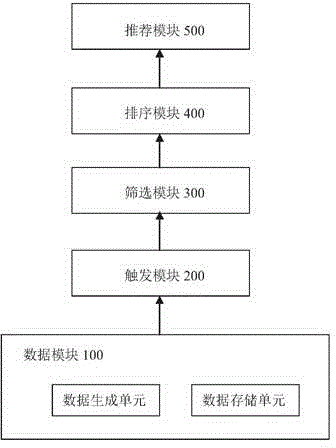

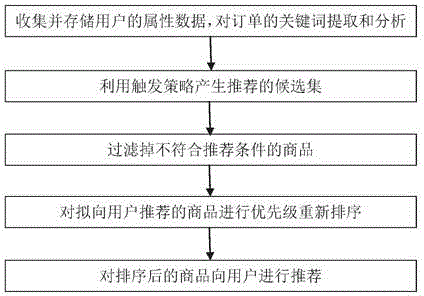

Information recommendation system and information recommendation method

InactiveCN106327227AIncrease diversityOptimize the recommendation functionMarketingRecommender systemThe Internet

The invention relates to the technical field of the internet, in particular to a recommendation system and a recommendation method for a website provision object. An information recommendation system comprises a data module used for collecting and storing attribute data of users and extracting and analyzing keywords of orders, a triggering module used for generating recommended candidate sets by utilizing a triggering policy, a screening module used for fusing the recommended candidate sets and filtering commodities which do not meet recommendation conditions, a sorting module used for performing priority re-sorting on commodities to be recommended to the users, and a recommendation module used for recommending the sorted commodities to the users. According to the system and the method, commodities related to commodities browsed or purchased by the users can be recommended to the users, so that the diversity of recommendation is greatly enhanced, the commodities purchased by the users are not repeatedly recommended, a recommendation function is optimized, the conversion from recommendation to sale is promoted, and the conversion rate of sale and the usage rate of the users are increased.

Owner:航天信息软件技术有限公司

Nanometer grade low carbon paraffin dehydrogen catalyst

InactiveCN1911502ALarge specific surface areaHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsAlkaneCarbon nanotube

The present invention relates to one kind of nanometer level low carbon alkane dehydrogenating catalyst, and features that the C3-C5 low carbon alkane dehydrogenating catalyst comprises carrier of single wall or multiple wall carbon nanotube and two active components selected from chromic oxide in 2-30 wt%, alumina in 2-25 weight and nickel oxide in 2-30 wt%. The catalyst has high catalysis activity, increased active structures, long service life, low catalytic dehydrogenation reaction temperature, high conversion rate, high selectivity and other advantages.

Owner:DAQING PETROLEUM ADMINISTRATION

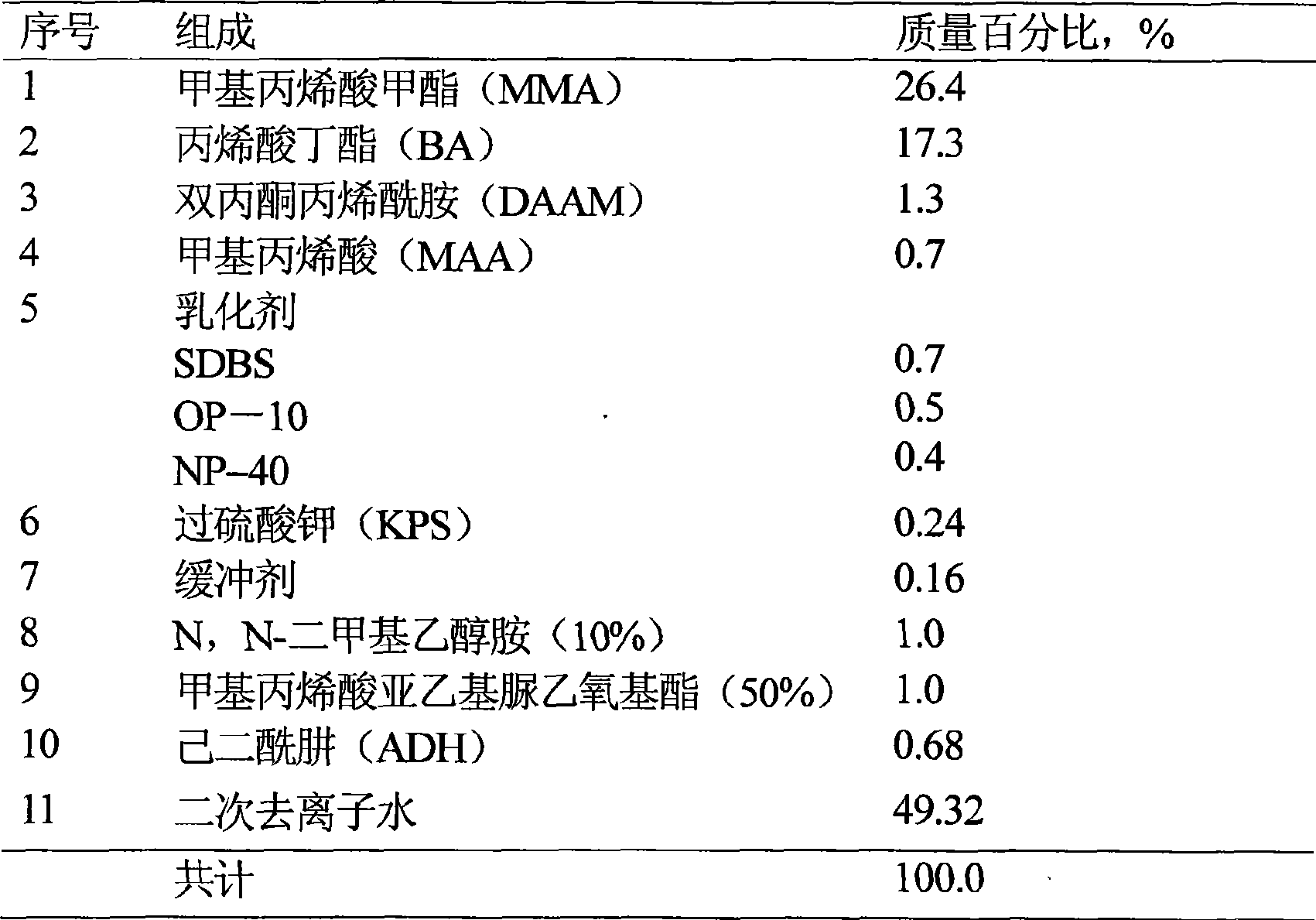

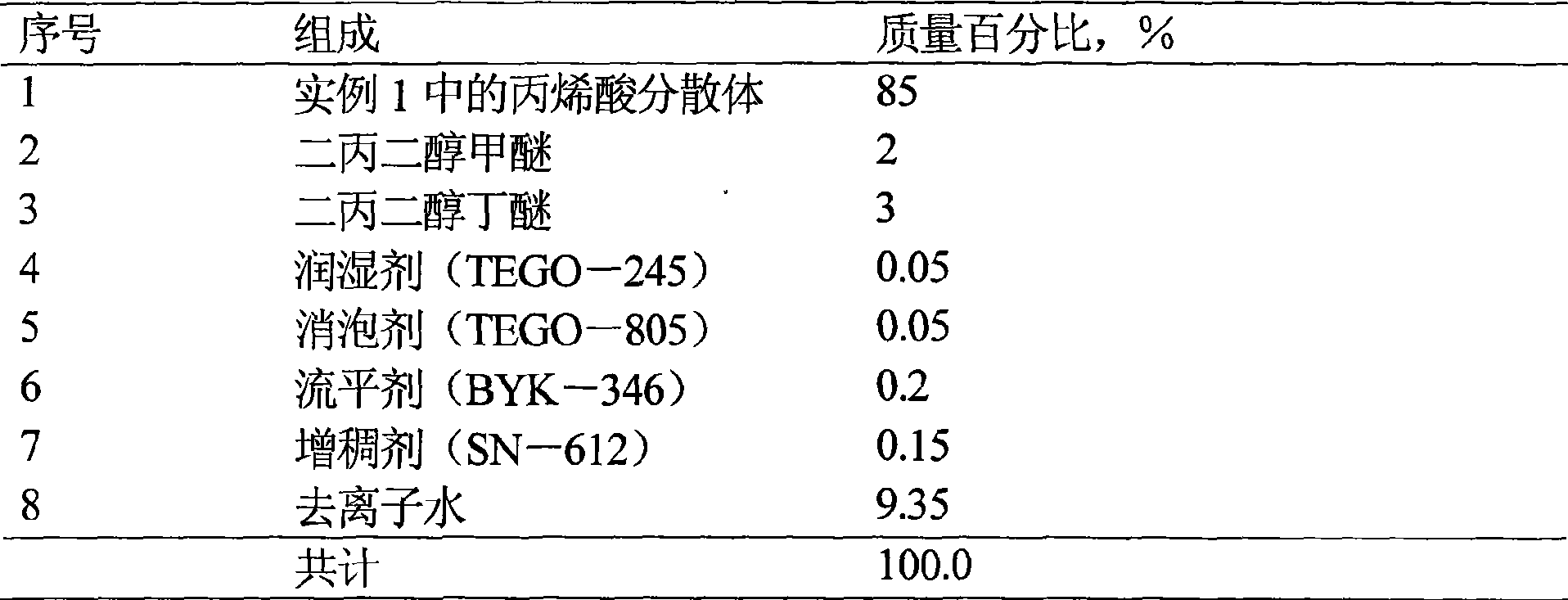

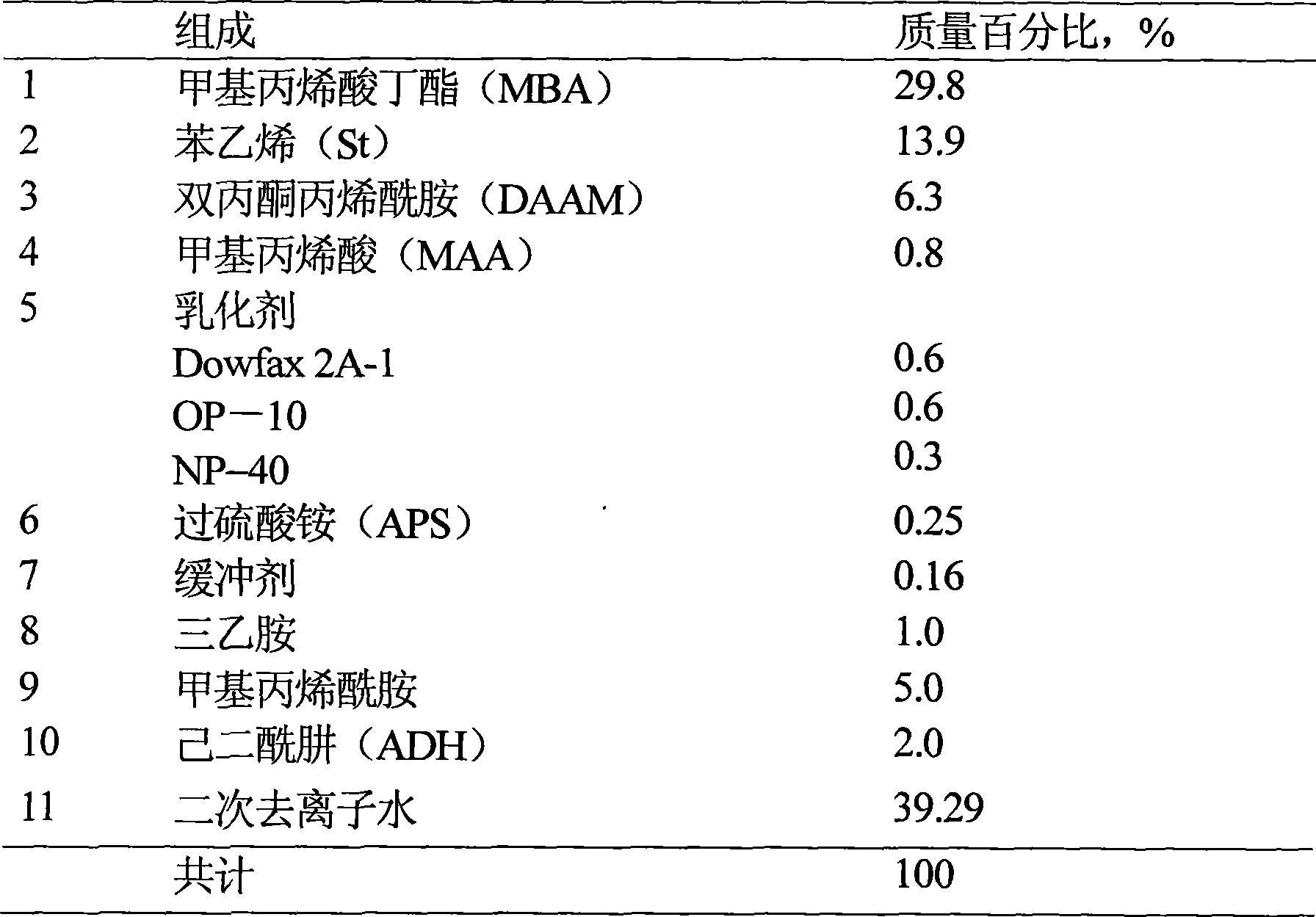

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

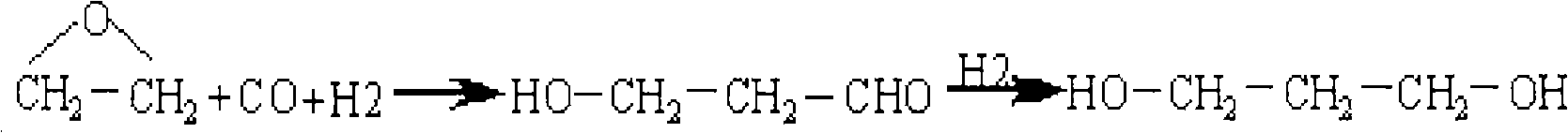

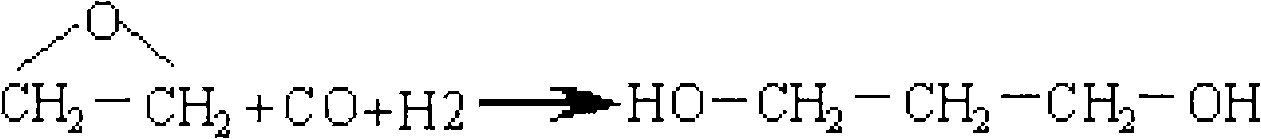

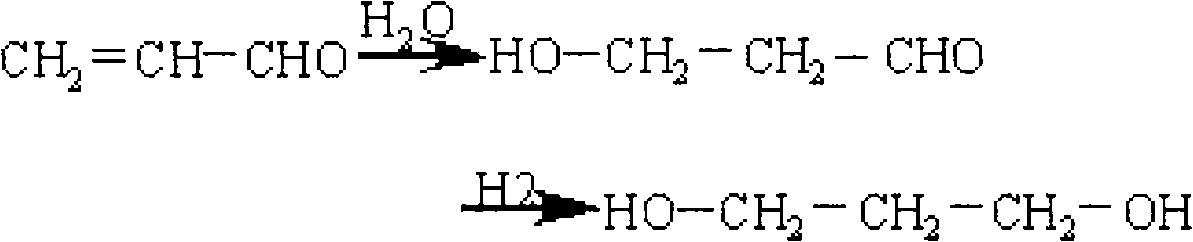

Method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol

The invention relates to a chemical material production method, in particular to a method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol. Alkyl carboxylic acid vinyl ester carries out hydroformylation with carbon monoxide and hydrogen under the action of olefin hydroformylation catalyst, so that 3-alkylacyloxy propaldehyde and 2- alkylacyloxy propaldehyde are produced, the 3-alkylacyloxy propaldehyde and the 2- alkylacyloxy propaldehyde react with hydrogen under the action of aldehyde hydrogenation catalyst, so that 3-alkylacyloxy propyl alcohol and 2-alkylacyloxy propyl alcohol are produced, and the 3-alkylacyloxy propyl alcohol and the 2-alkylacyloxy propyl alcohol are hydrolyzed under the action of esterolytic catalyst, so that the 1,3-propylene glycol and the 1,2-propylene glycol are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

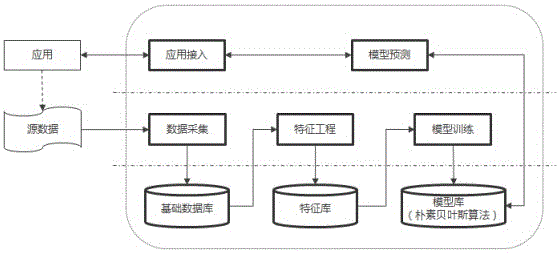

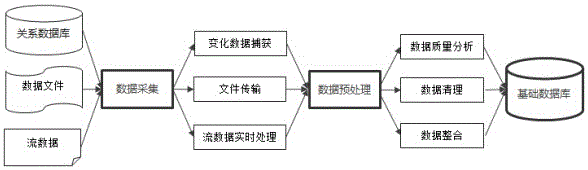

Real-time recommendation system and method of financial products of banks based on Naive Bayesian classification

InactiveCN106600369AImprove experienceIncrease stickinessMathematical modelsFinanceData setData mining

The invention discloses a real-time recommendation system and method of financial products of banks based on Naive Bayesian classification wherein the method comprises: acquiring the data of a bank business system, a peripheral system, and an internet / mobile internet; processing and storing the data in a basic database; conducting characteristic processing to the data attributes of the customers in a certain area; converting for data characteristics to develop a characteristic database; classifying the data in the characteristic database as a training data set and a verification data set which are used respectively for the training and estimating of a Naive Bayesian classification algorithm model; obtaining a model base after several times of iteration; identifying the characteristics of customers and in combination with the Naive Bayesian classification algorithm model base, matching the customers with the financial products they are mostly likely to purchase in real time; and recommending to the customers the financial products that are forecasted and matched by the models. The recommendation system and method of the invention are capable of helping customers to find out suitable products, therefore, increasing the user experience and the bonding effect of the customers to the financial products, lifting up the transferring rate of the products and making the bank more competitive.

Owner:广东奡风科技股份有限公司

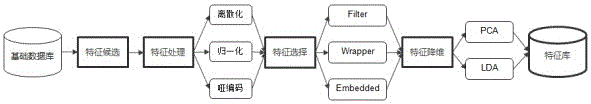

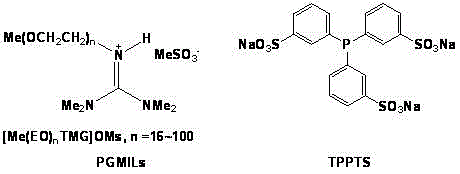

Olefin two-phase hydroformylation method

ActiveCN102617308AEffective fixed loadSeparation and easy handlingOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionTPPTSPolymer science

The invention relates to an olefin two-phase hydroformylation method, which consists of three parts: polyether guanidine mesylate ionic liquid (PGMILs) with room temperature solidifiable characteristics, complex catalysts (Rh-TPPTS) formed by RhCl3.3H2O or dicarbonylacetylacetonato rhodium and triphenylphosphine sodium trithionate (TPPTS), and reactants of C6-C14 straight chain 1-olefin, wherein the Rh-TPPTS is dissolved in the PGMILs to form a lower layer catalyst phase, the C6-C14 straight chain 1-olefin or product aldehyde forms an upper layer organic phase, the selectivity of high-carbon aldehyde is 85 to 99 percent, the mol ratio of normal aldehyde to isomerism aldehyde is 2.0 to 2.4, the PGMILs phase containing Rh-TPPTS can be cyclically used for 35 times, the activity and the selectivity are unchanged, the accumulated conversion number (TON) reaches higher than 30000, rhodium flowing to the product phase is 0.04 percent to 0.07 percent, and ultra-long-period catalysis activity and selectivity can be realized.

Owner:山东聚强绿洲生物科技有限公司

Non-mercury catalyst for acetylene hydrochlorination and method of preparing the same

InactiveCN101249451AEasy to prepareHigh selectivityPhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonHydrogen chloride

The invention discloses a non-mercury catalyst used in the acetylene hydrochlorination and preparation method thereof. The method includes the following steps: (1) dissolving noble metal chloride 0.5-3 parts by weight and base metal chloride 1-10 parts by weight into 2-4 mol / L hydrochloric acid solution to obtain a 0.01-0.05mol / L noble metal chloride solution; (2) adding the activated carbon 100 parts by weight into the solution at room temperature for 5-12 hours; (3) evaporating the immersion liquid on the activated carbon at 80-100 DEG C, drying at 70-80 DEG C for 2-4 hours and calcining at 120-140 DEG C for 4-12 hours; (4) and activating in hydrogen chloride atmosphere for 0.5-3 hours. The inventive catalyst can be used for green synthesis of vinyl chloride monomer to reach a conversion rate of acetylene up to 95-98% and selectivity of vinyl chloride greater than 99%.

Owner:SICHUAN UNIV

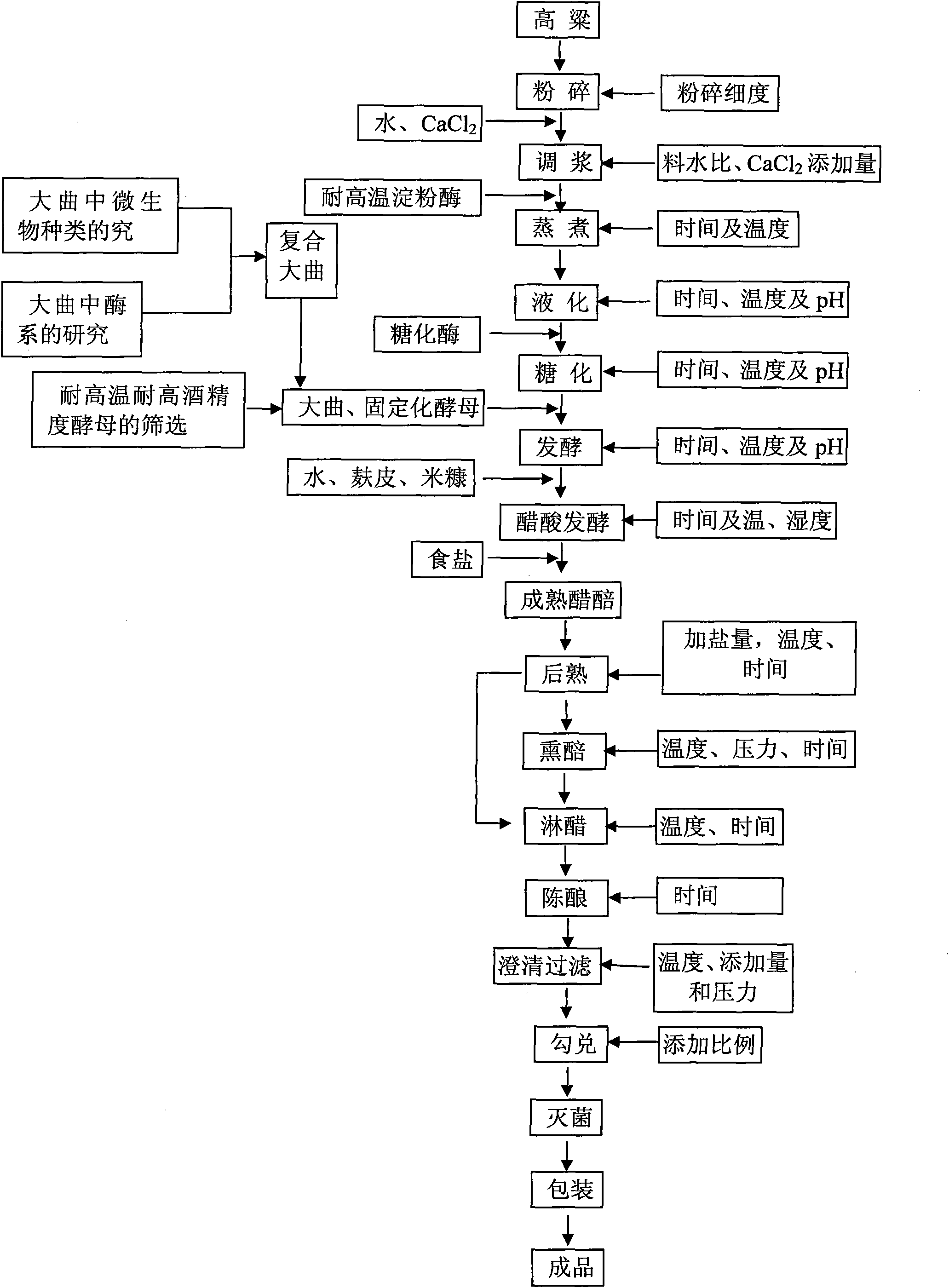

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

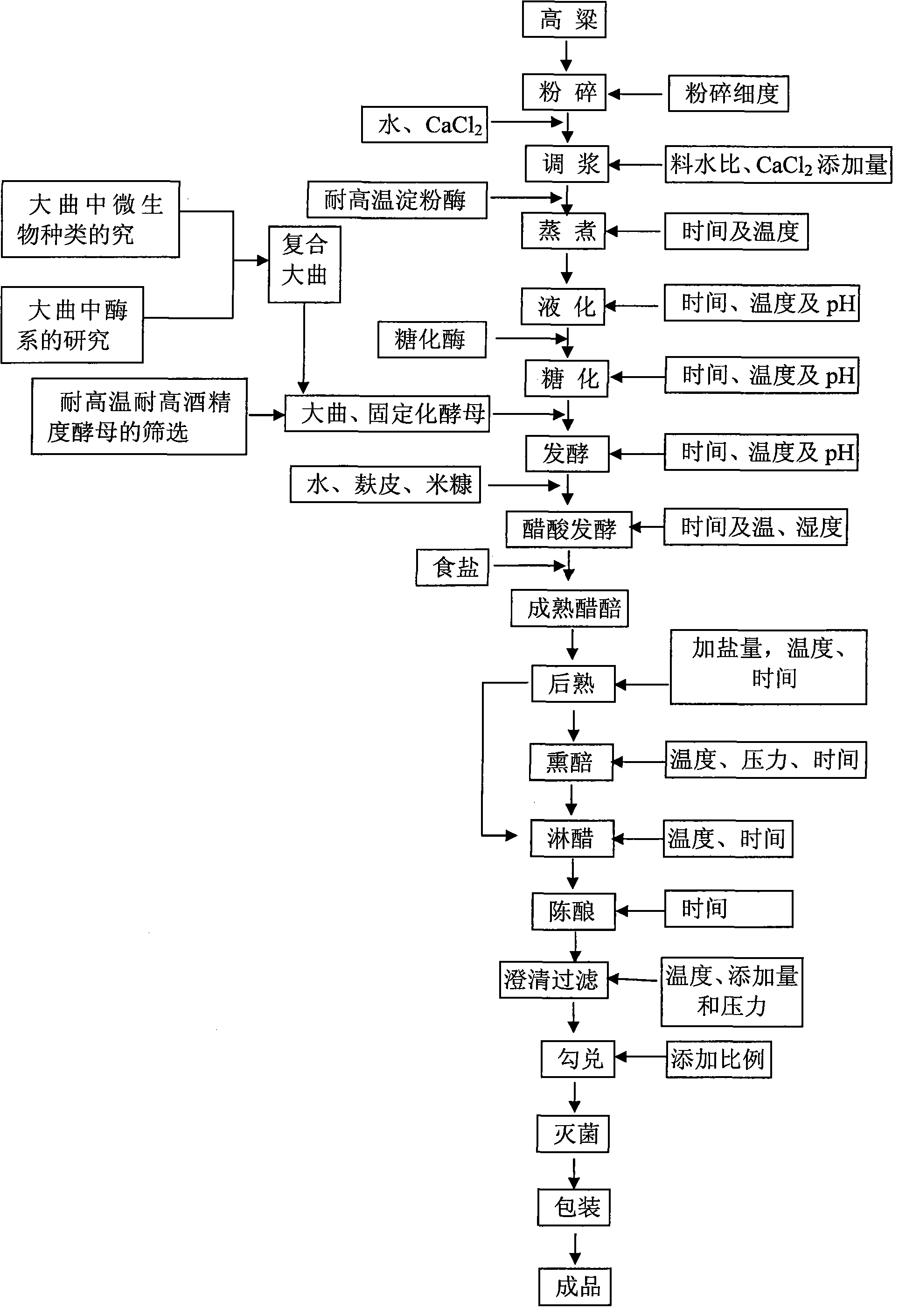

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

A kind of Chinese herbal medicine feed for laying hens and preparation method thereof

InactiveCN102273551AReasonable formulaEasy to prepare and operateFood processingAnimal feeding stuffDiseaseWheat gluten

The invention relates to a Chinese herbal medicinal forage for a laying hen and a preparation method thereof. The Chinese herbal medicinal forage for the laying hen comprises two parts of a raw material pulvis which comprises soybean meal, wheat bran, corn, wheat gluten powder, carrot powder, a feed of visceral organs of fresh fish, and the like and a Chinese herbal medicinal additive which comprises raw materials of honeysuckle flower, phellodendron, Radix Codonopsis, bitter apricot kernel, licorice, fructus forsythiae, isatis root and the like. The preparation method comprises the followingsteps: sequentially crushing above raw materials, mixing, stirring, crushing, drying, stirring, bulking, and producing the hard particulate forage. The preparation method has the advantages of reasonable formula, convenient preparation and operation, good environmental protection effect and the like. The Chinese herbal medicinal forage, which can promote the metabolism level of an individual of the laying hen, has good prevention and treating effects on diseases of cold, bird flu, new castle disease, white diarrhea, gastritis, proctoptosia, red and swollen arse and bad digestive system of thelaying hen, and can obviously improve the immunological competence of the laying hen and effectively solve an epidemic prevention problem of a large-scale laying hen culturing farm, accords with production requirements of nuisance free eggs and has a high cost performance.

Owner:SHAANXI FUTURE GREEN AGRI ANIMAL HUSBANDRYDEV

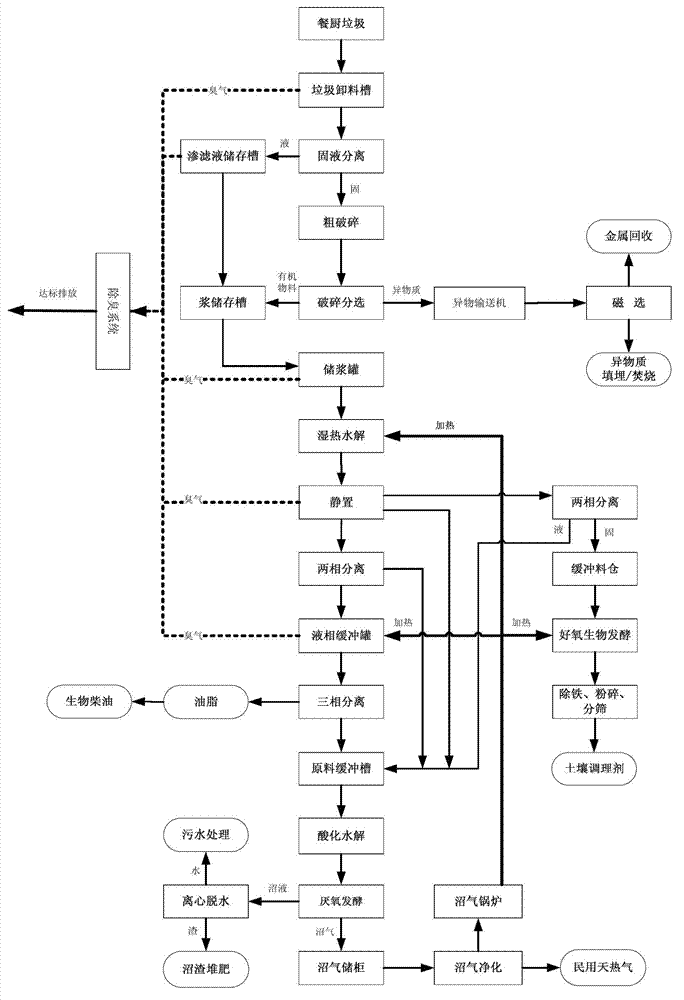

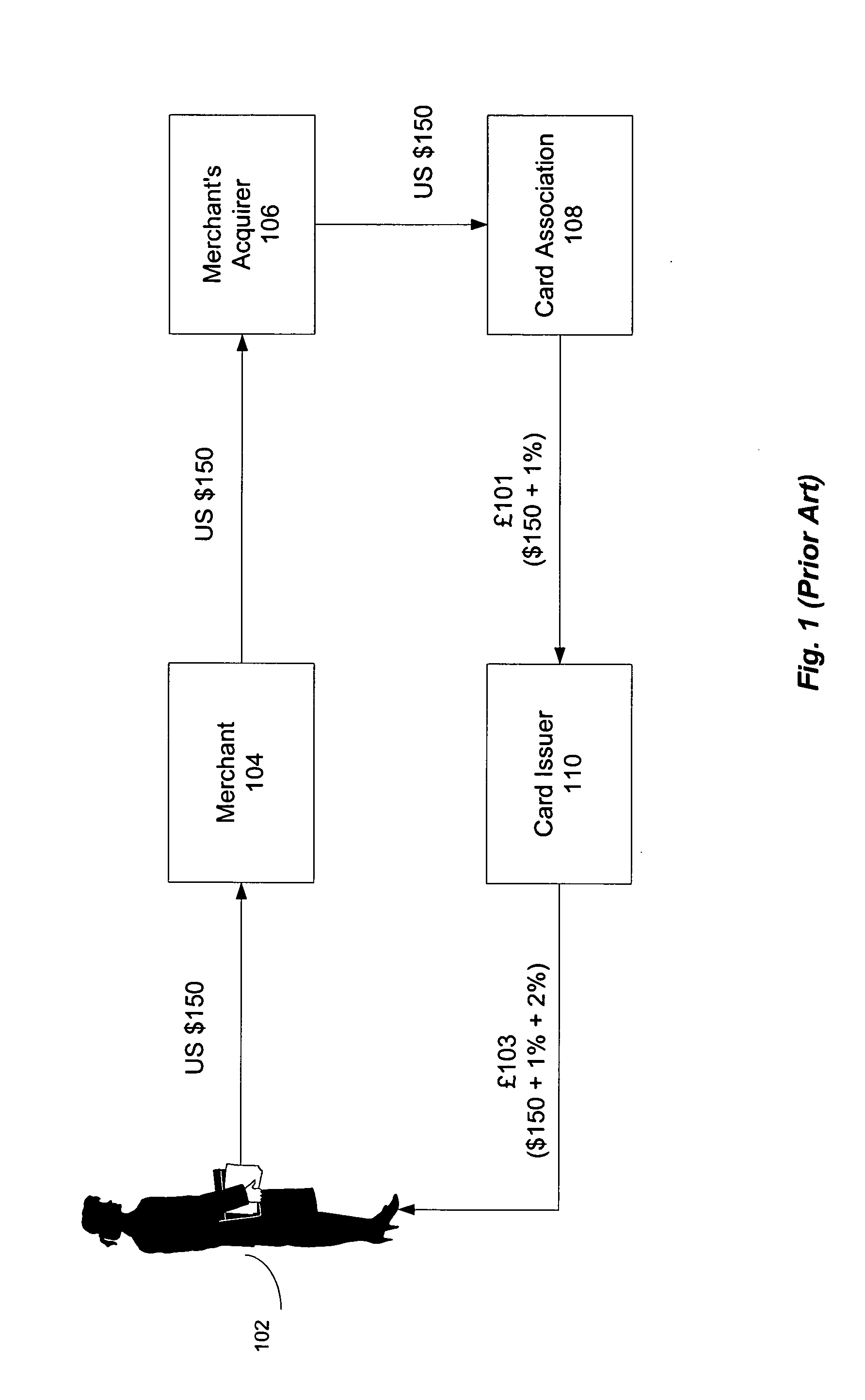

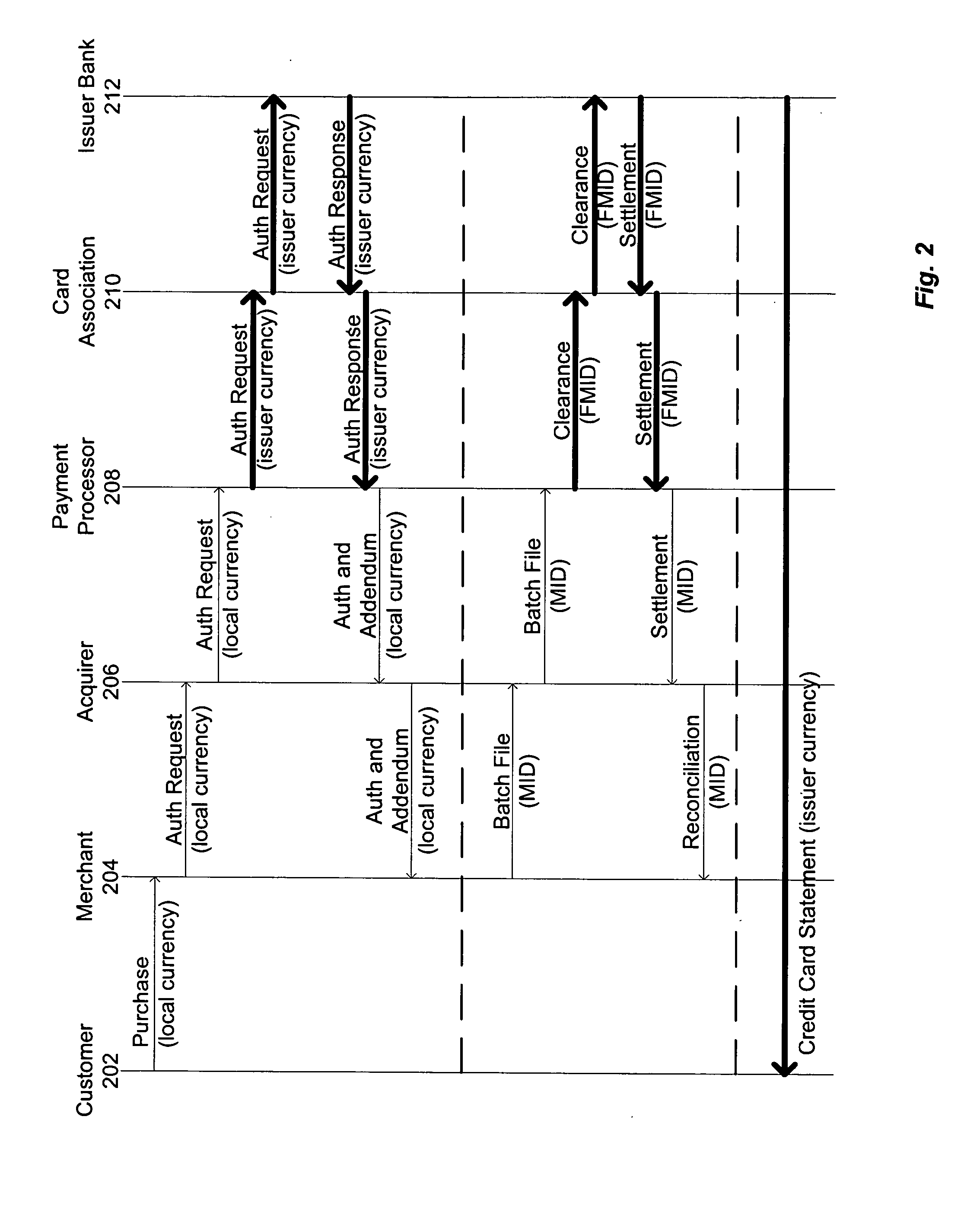

Time-Of-Transaction Foreign Currency Conversion

InactiveUS20100145744A1Improve conversion rateComplete banking machinesFinanceCredit cardIssuing bank

Owner:PLANET PAYMENT

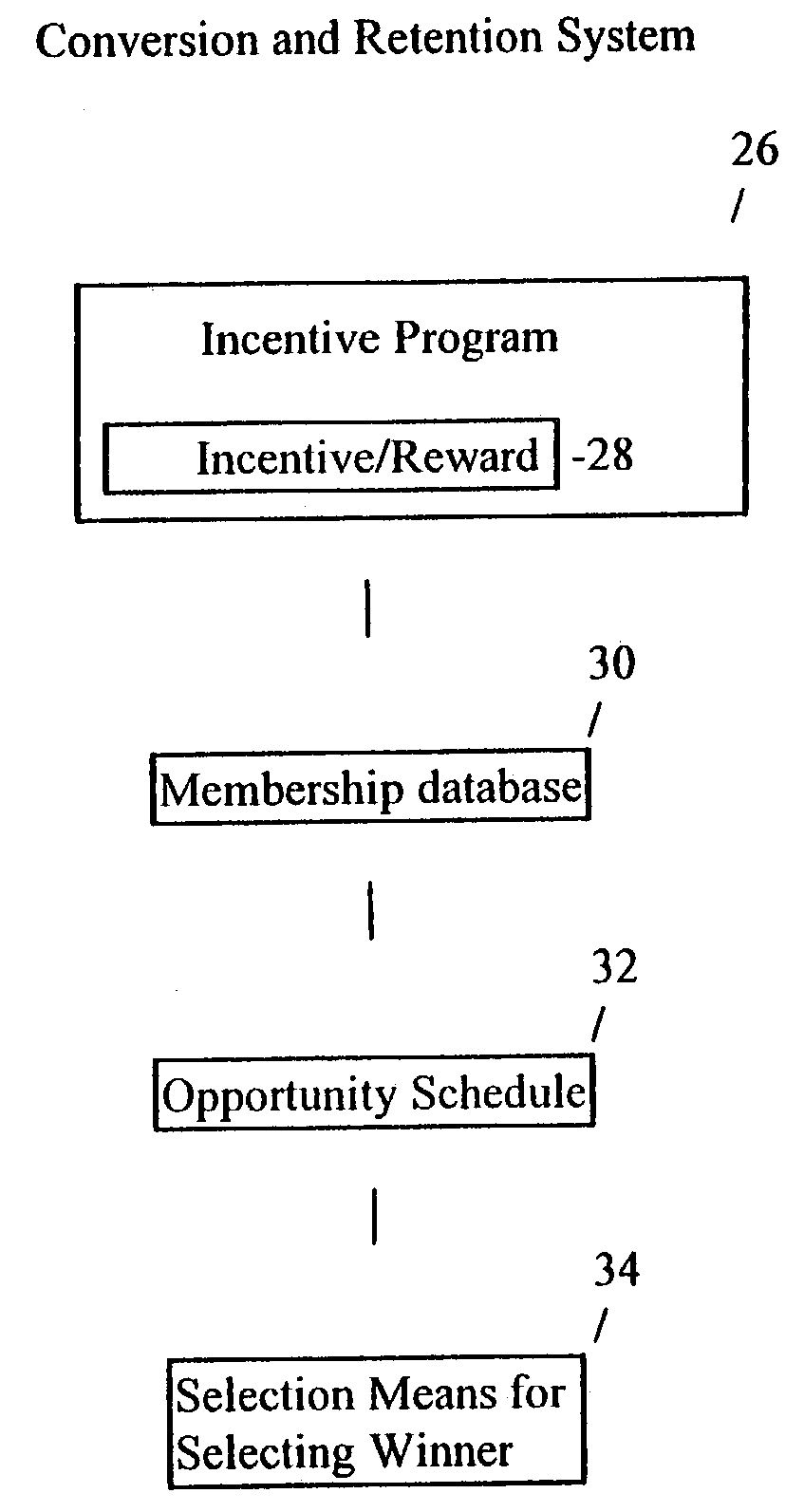

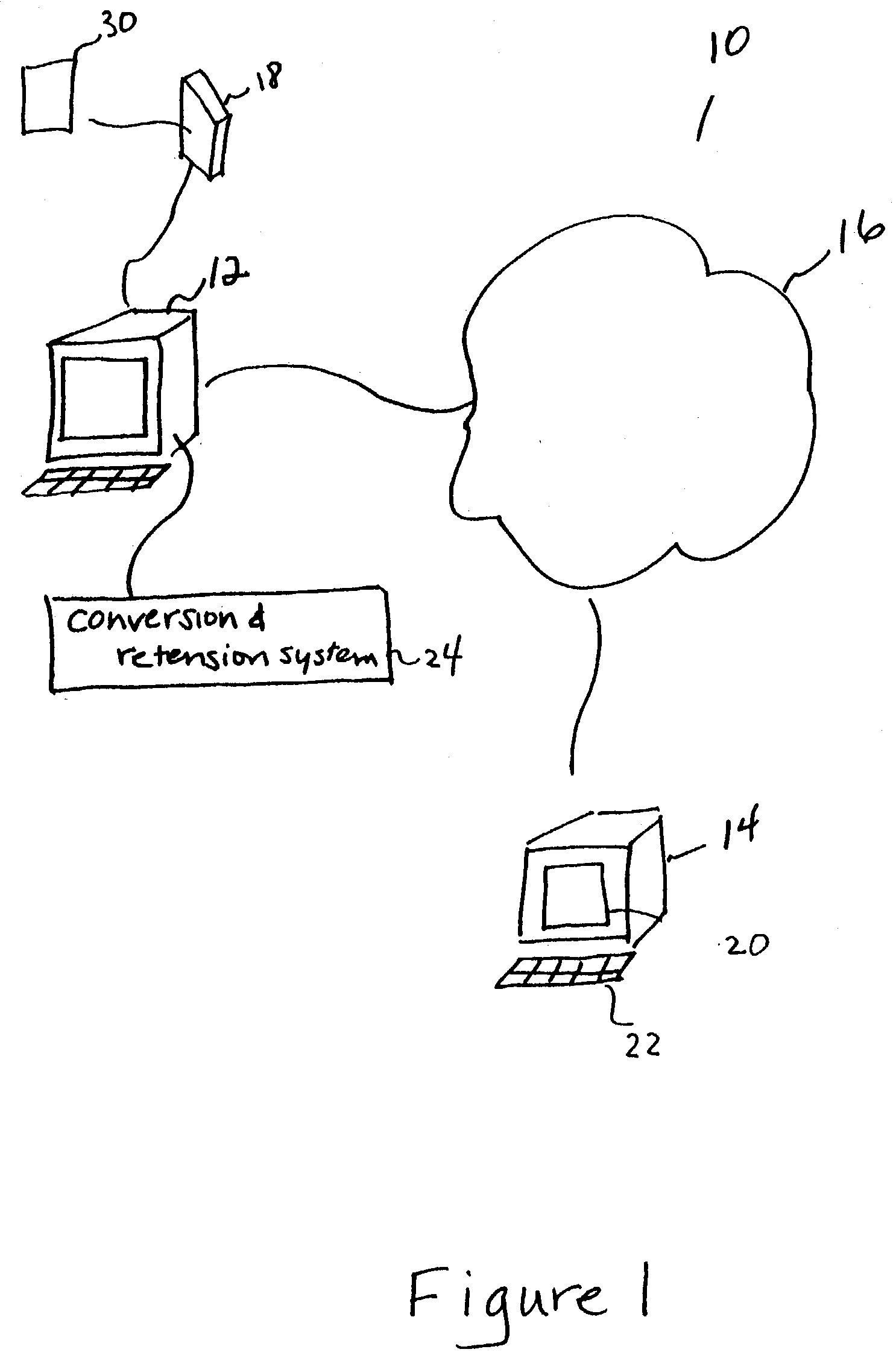

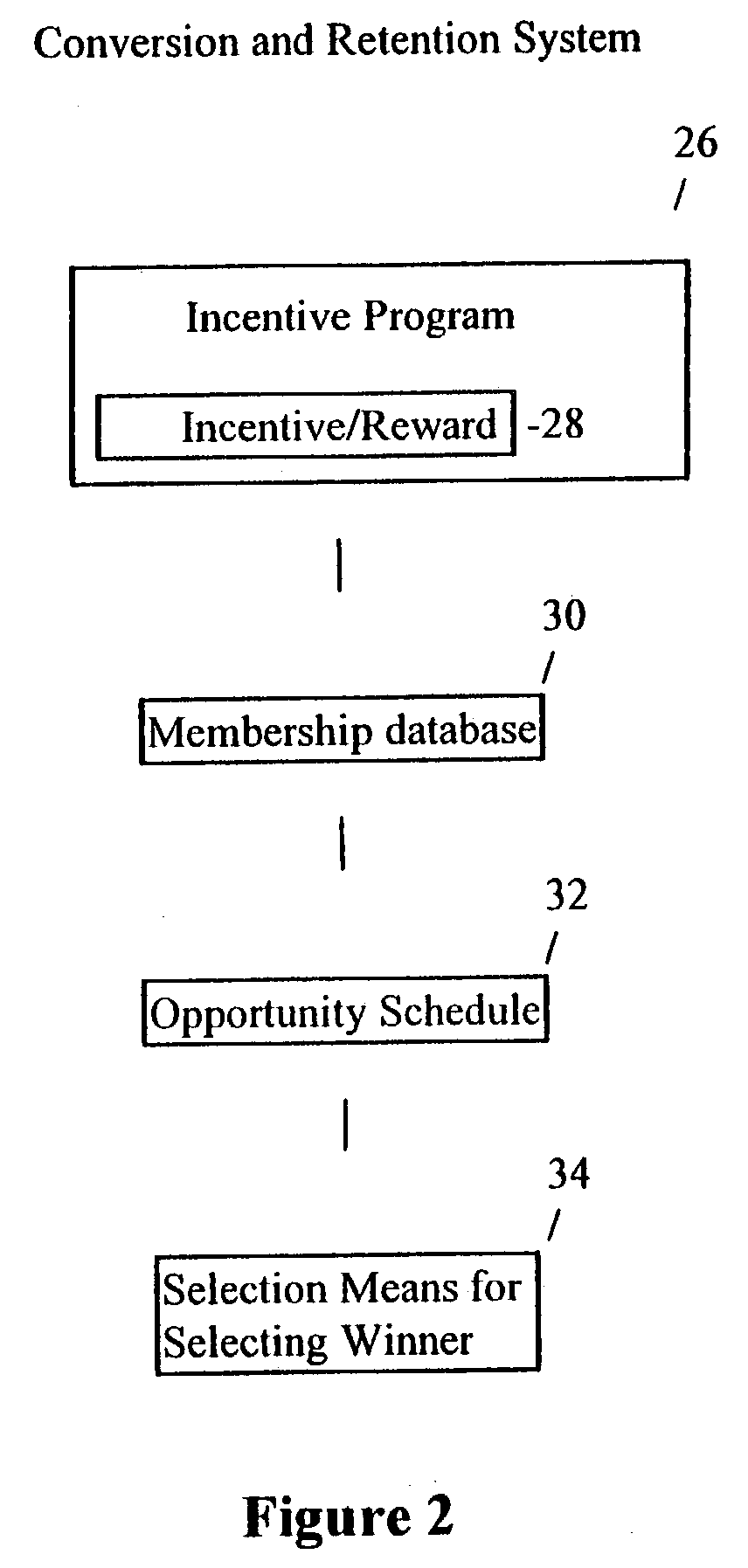

System, method and apparatus for membership retention and conversion

InactiveUS20040010447A1Increase participationStabilize membership baseApparatus for meter-controlled dispensingSpecial data processing applicationsTime scheduleProgram planning

Embodiments of the invention are directed to retention and conversion system for retaining existing members of a membership based program and encouraging new members to join the membership based program. In preferred embodiments, the system comprises an incentive program having an identifiable reward and an opportunity schedule, wherein the opportunity schedule sets forth the relationship between the membership type and extent of the opportunity to obtain the identified incentive Once a winning entry is selected, the identification of the winner is displayed in a restricted environment, wherein the winner must enter the restricted environment within a preset period of time to claim the incentive.

Owner:ASAYAMA TAKAO

High-performance polycarboxylic acid water reducing agent and preparation method thereof

The invention discloses a preparation method of a high-performance polycarboxylic acid water reducing agent. The preparation method of the high-performance polycarboxylic acid water reducing agent comprises the following steps of: adding an unsaturated polyether macromonomer A and water into a reactor, uniformly stirring and dissolving, and then adding an initiator F hydrogen peroxide; then respectively dropwise adding unsaturated carboxylic acid or an unsaturated carboxylic acid anhydride small monomer B, an unsaturated carboxylate ester small monomer C, an aqueous solution of an initiator D, an aqueous solution of an initiator E and an aqueous solution of a molecular weight regulator, and carrying out reaction for 3-5 hours at the room temperature of 10-40 DEG C, so as to obtain a copolymerization product; carrying out a neutralization reaction, namely regulating the pH value of the copolymerization production to be 6-7 by adopting sodium hydroxide, so as to obtain the high-performance polycarboxylic acid water reducing agent. The invention also discloses a high-performance polycarboxylic acid water reducing agent prepared by adopting the preparation method. By controlling a material adding manner, two initiators are compounded, initiated and synthesized to form the high-performance polycarboxylic acid water reducing agent, the synthesized high-performance polycarboxylic acid water reducing agent is environmentally-friendly, pollution-free and high in reaction conversion ratio, and concrete doped with the high-performance polycarboxylic acid water reducing agent has better water reducing property, slump loss resistant property, dispersibility and workability.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com