Patents

Literature

1288 results about "Lanthanum compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum oxide is La2O3, an inorganic compound containing the rare earth element lanthanum and oxygen. It is used to develop ferroelectric materials, as a component of optical materials, and is a feedstock for certain catalysts.

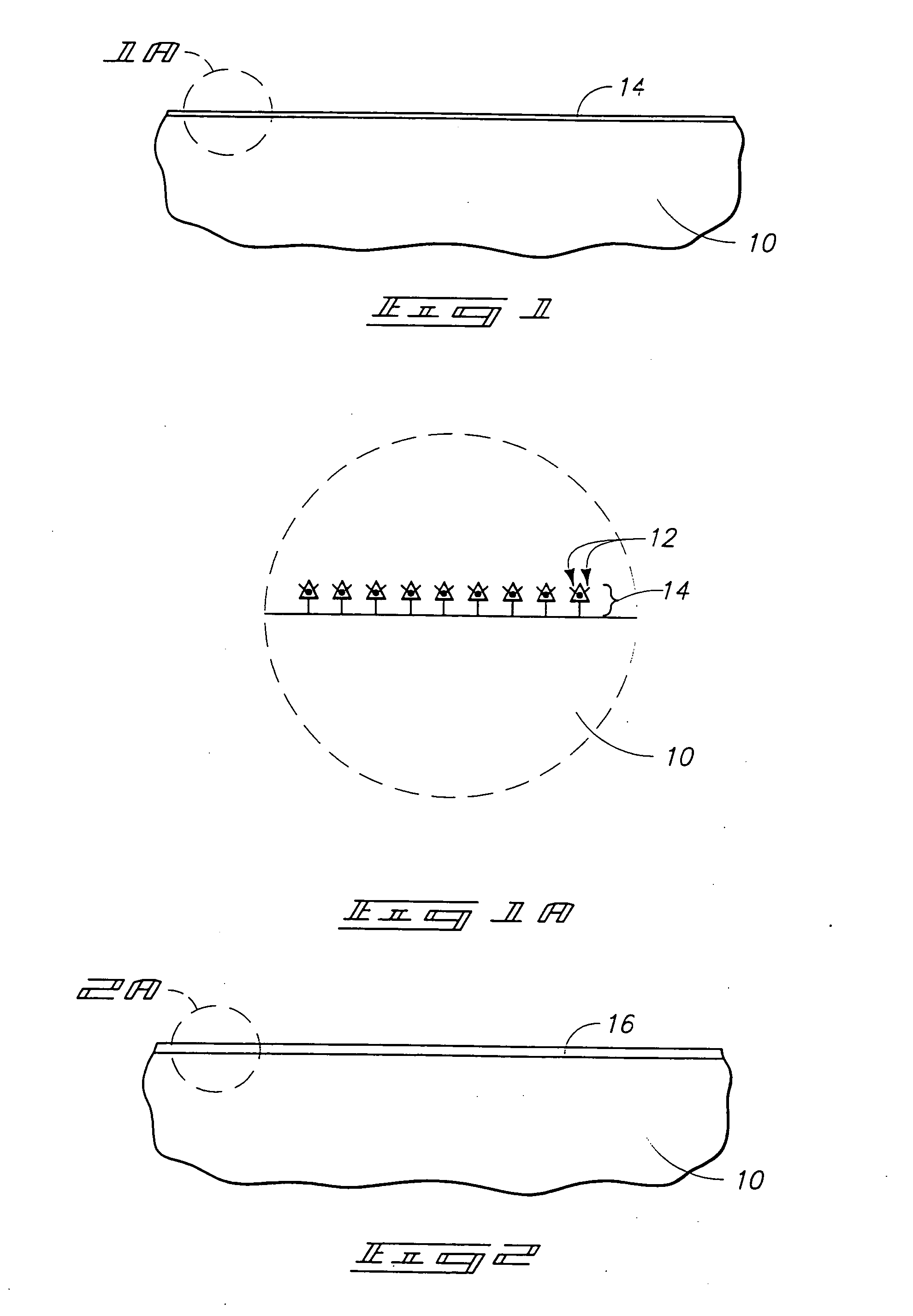

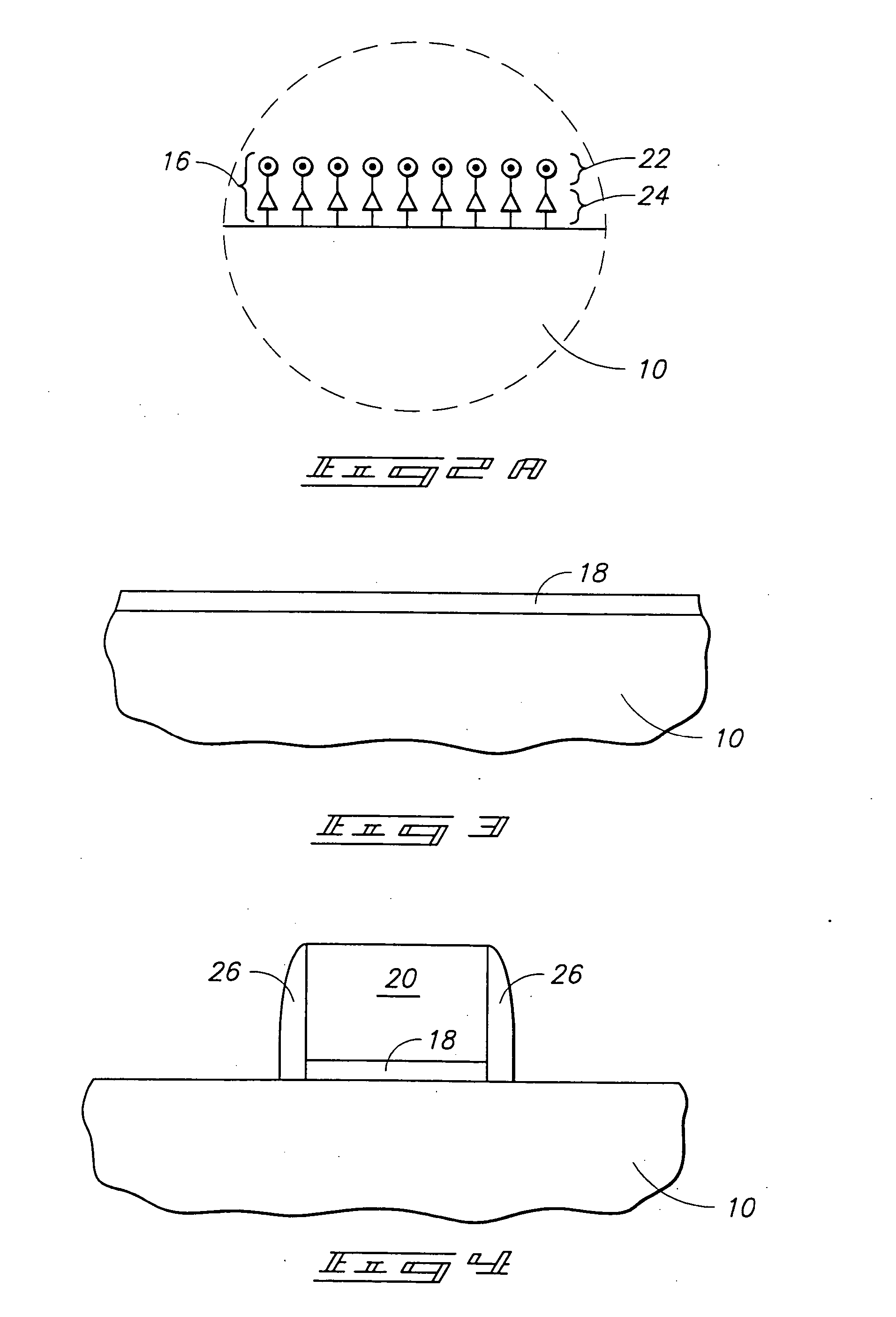

Composite dielectric forming methods and composite dielectrics

InactiveUS20050009370A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricCapacitor

A composite dielectric forming method includes atomic layer depositing alternate layers of hafnium oxide and lanthanum oxide over a substrate. The hafnium oxide can be thermally stable, crystalline hafnium oxide and the lanthanum oxide can be thermally stable, crystalline lanthanum oxide. A transistor may comprise the composite dielectric as a gate dielectric. A capacitor may comprise the composite dielectric as a capacitor dielectric.

Owner:MICRON TECH INC

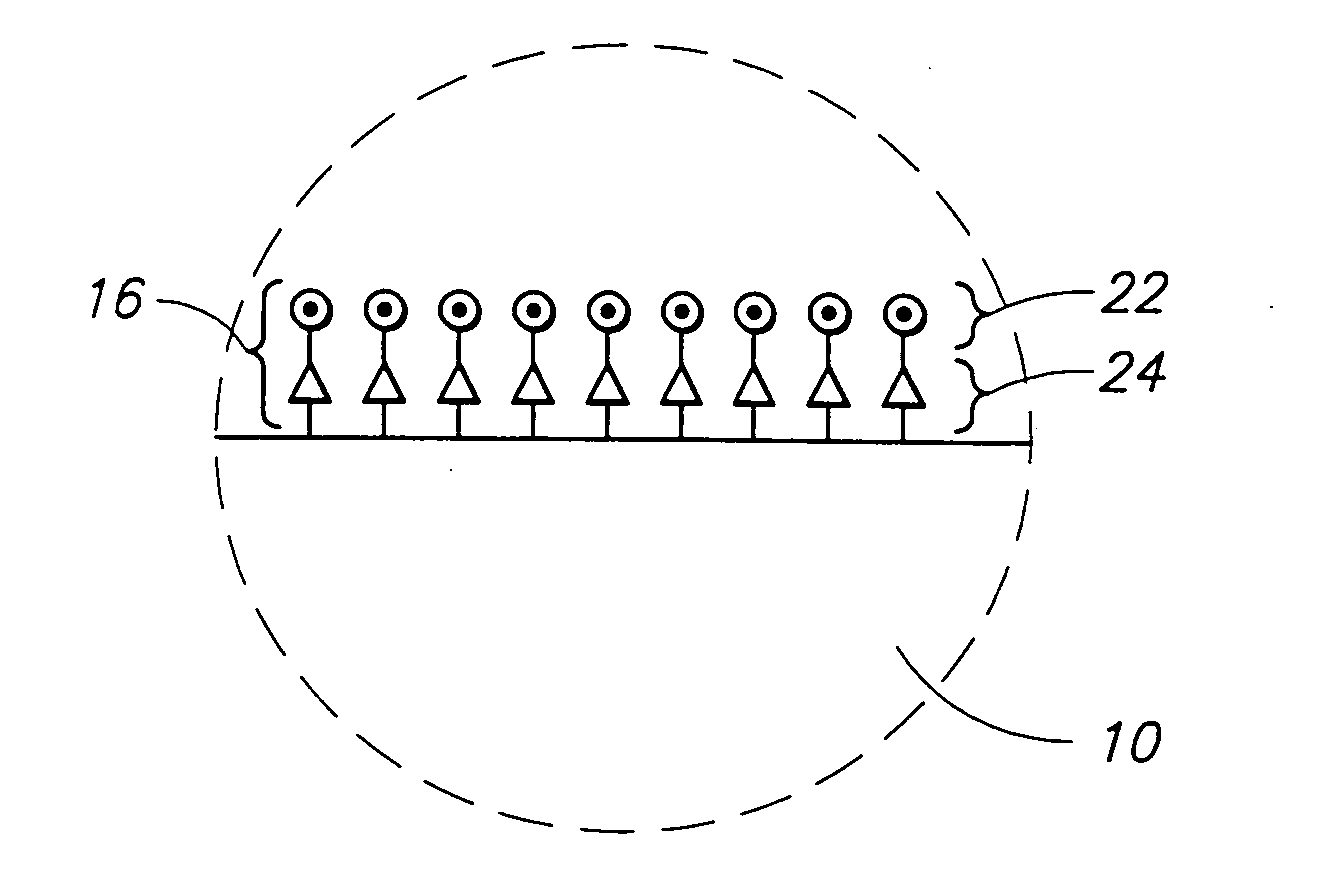

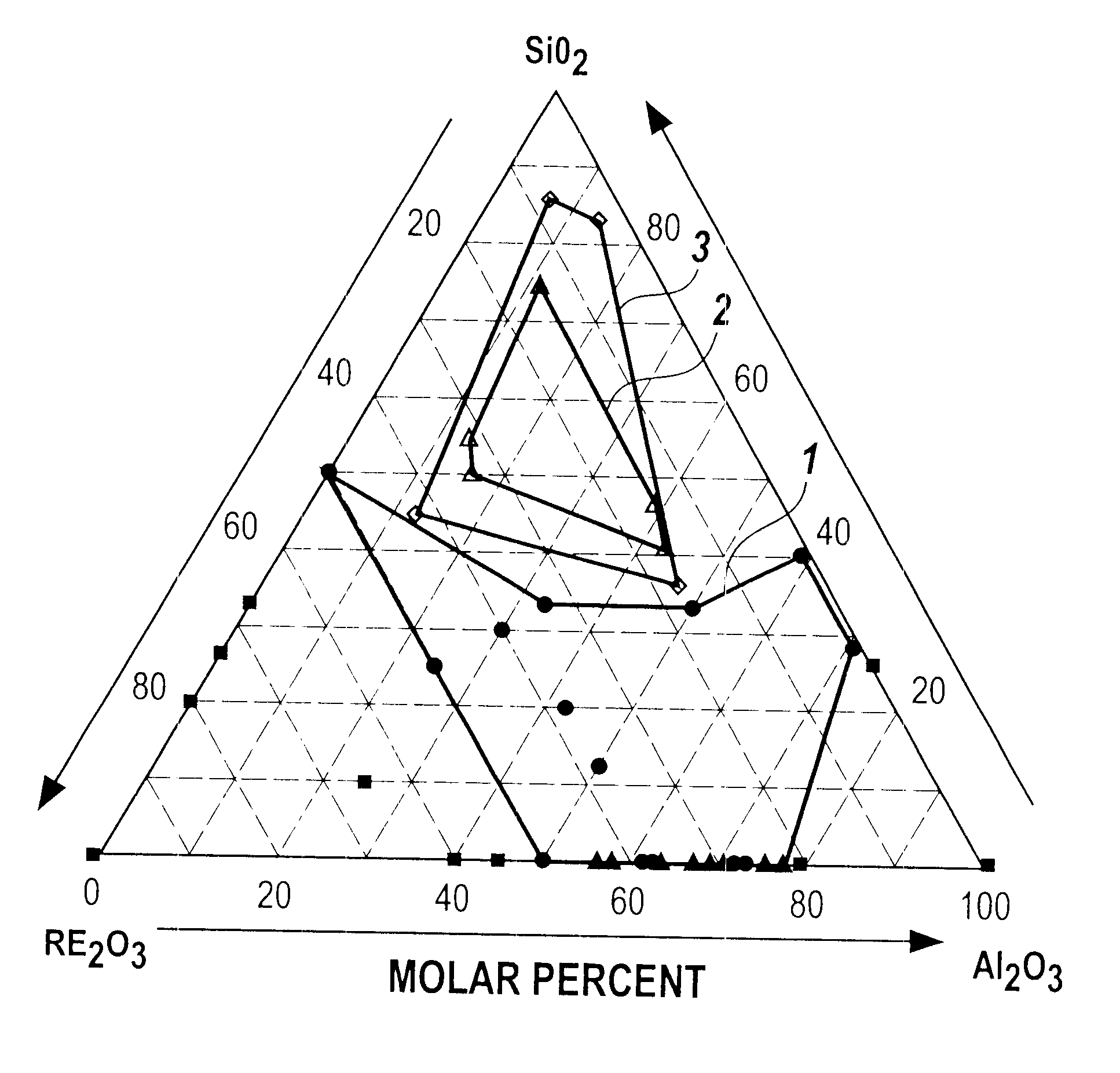

Single phase rare earth oxide-aluminum oxide glasses

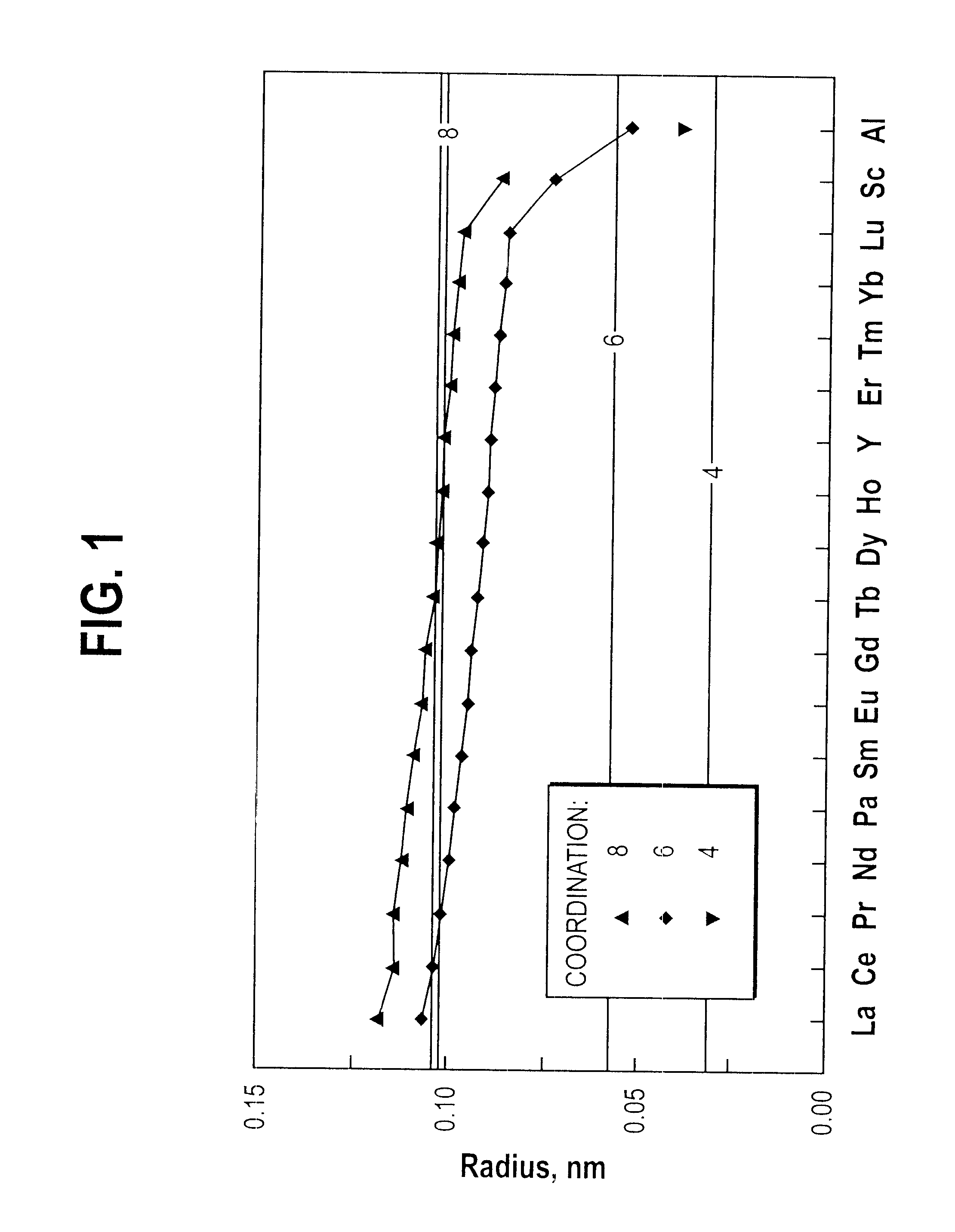

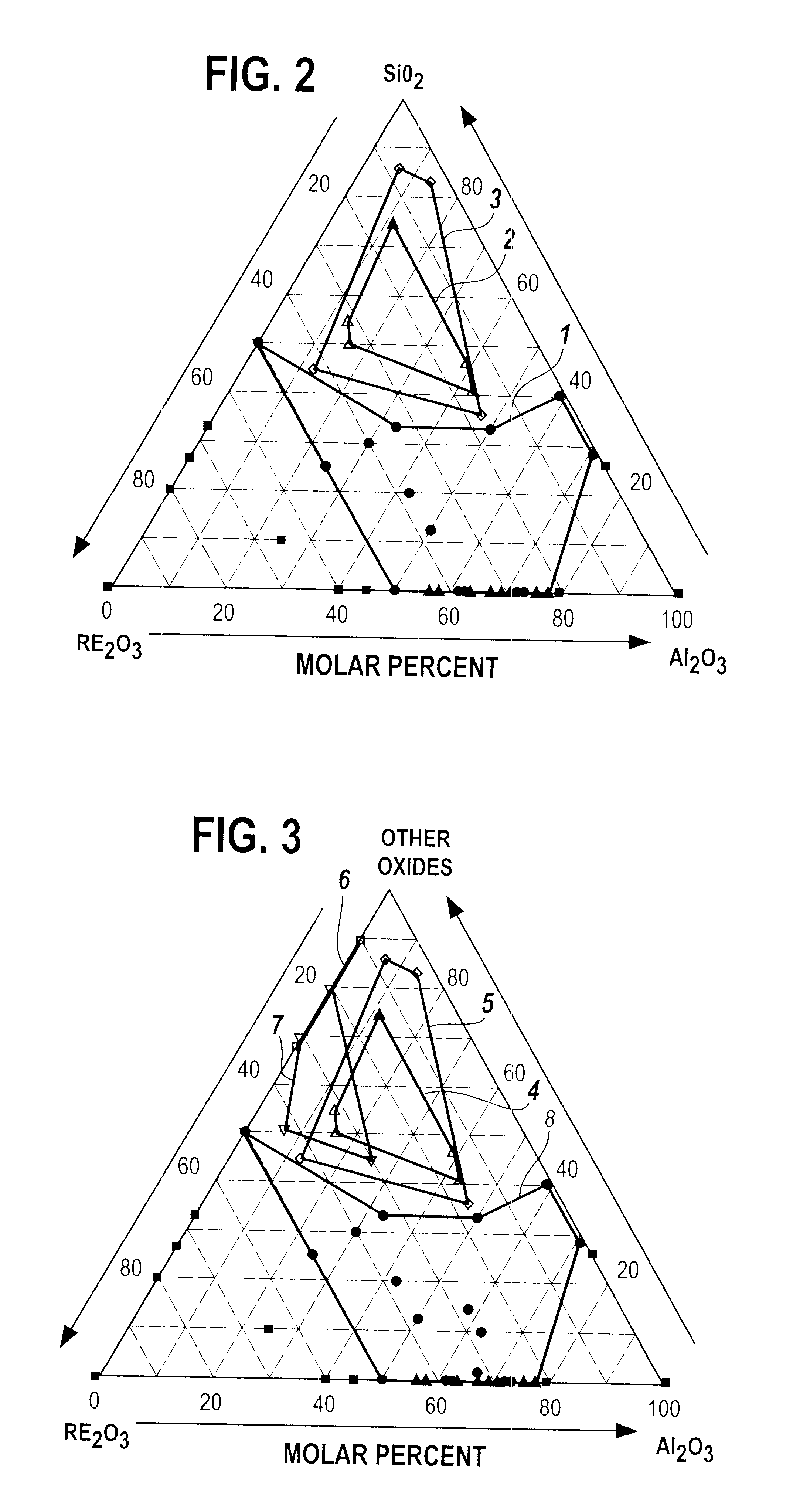

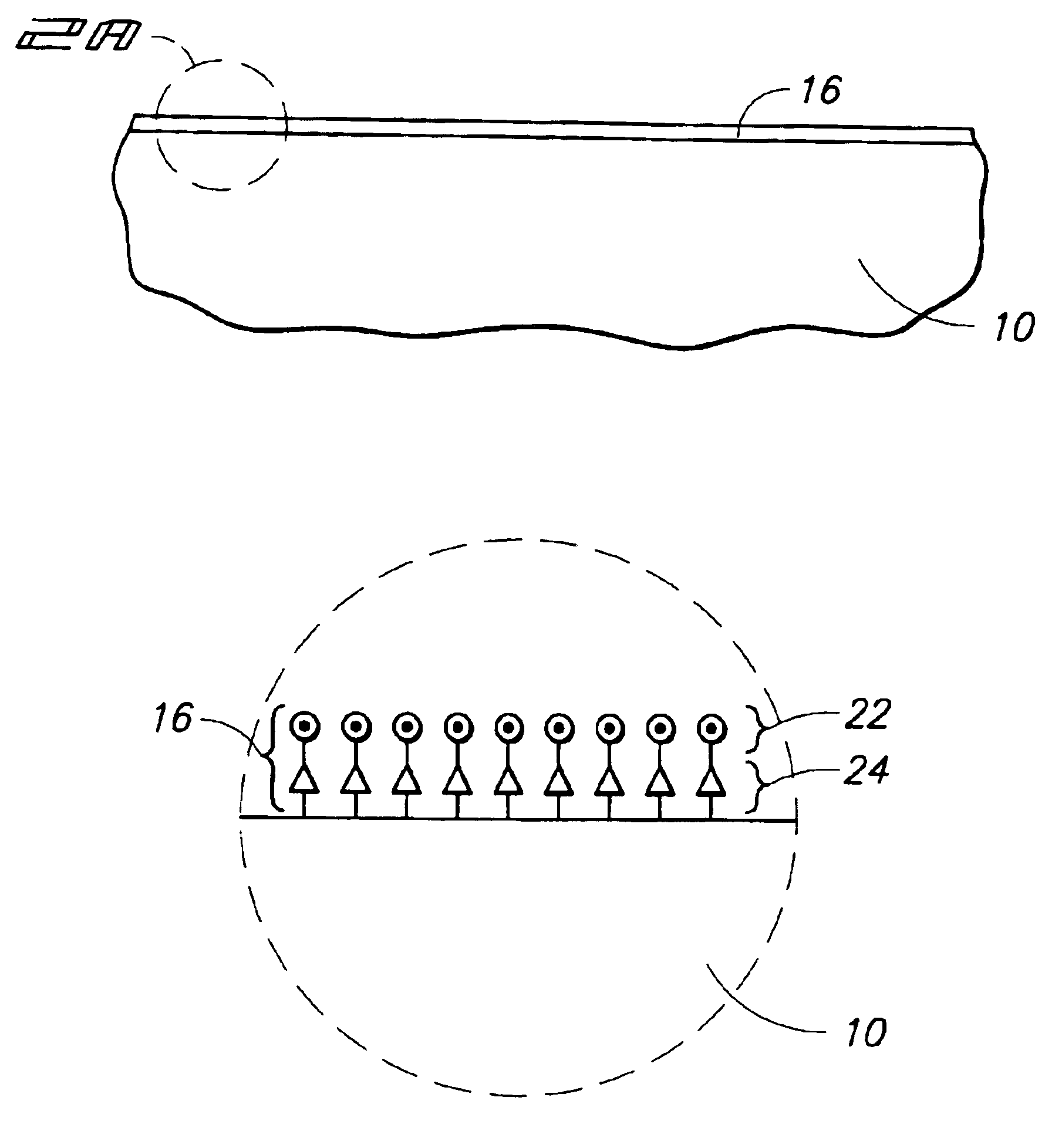

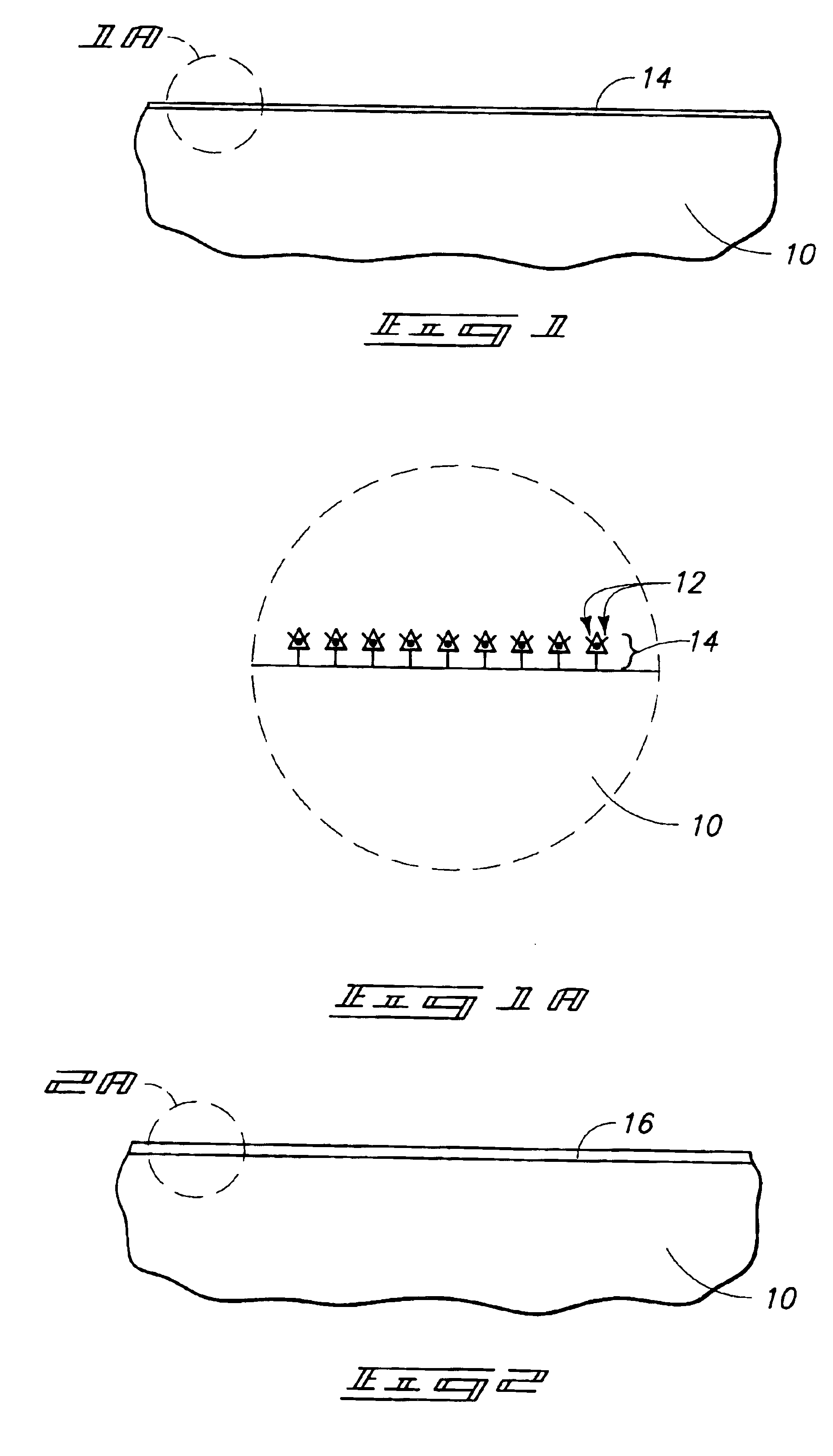

A bulk single phase glass comprising 23 molar % to 50 molar % rare earth oxides, RE203, and 50 molar % to 77 molar % aluminum oxide, A12O3 is provided. The glass contains at least 50 molar % of Al2O3+RE2O3 and smaller amounts of oxide glass forming agents and other oxides than are found in prior art glasses. The addition of small amounts of lanthanum oxide, La2O3, prevents phase separation. The single phase glass is useful for optical applications such as lasers and optical amplifiers.

Owner:CONTAINERLESS RES

Composite dielectric forming methods and composite dielectrics

InactiveUS6960538B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricCapacitor

A composite dielectric forming method includes atomic layer depositing alternate layers of hafnium oxide and lanthanum oxide over a substrate. The hafnium oxide can be thermally stable, crystalline hafnium oxide and the lanthanum oxide can be thermally stable, crystalline lanthanum oxide. A transistor may comprise the composite dielectric as a gate dielectric. A capacitor may comprise the composite dielectric as a capacitor dielectric.

Owner:MICRON TECH INC

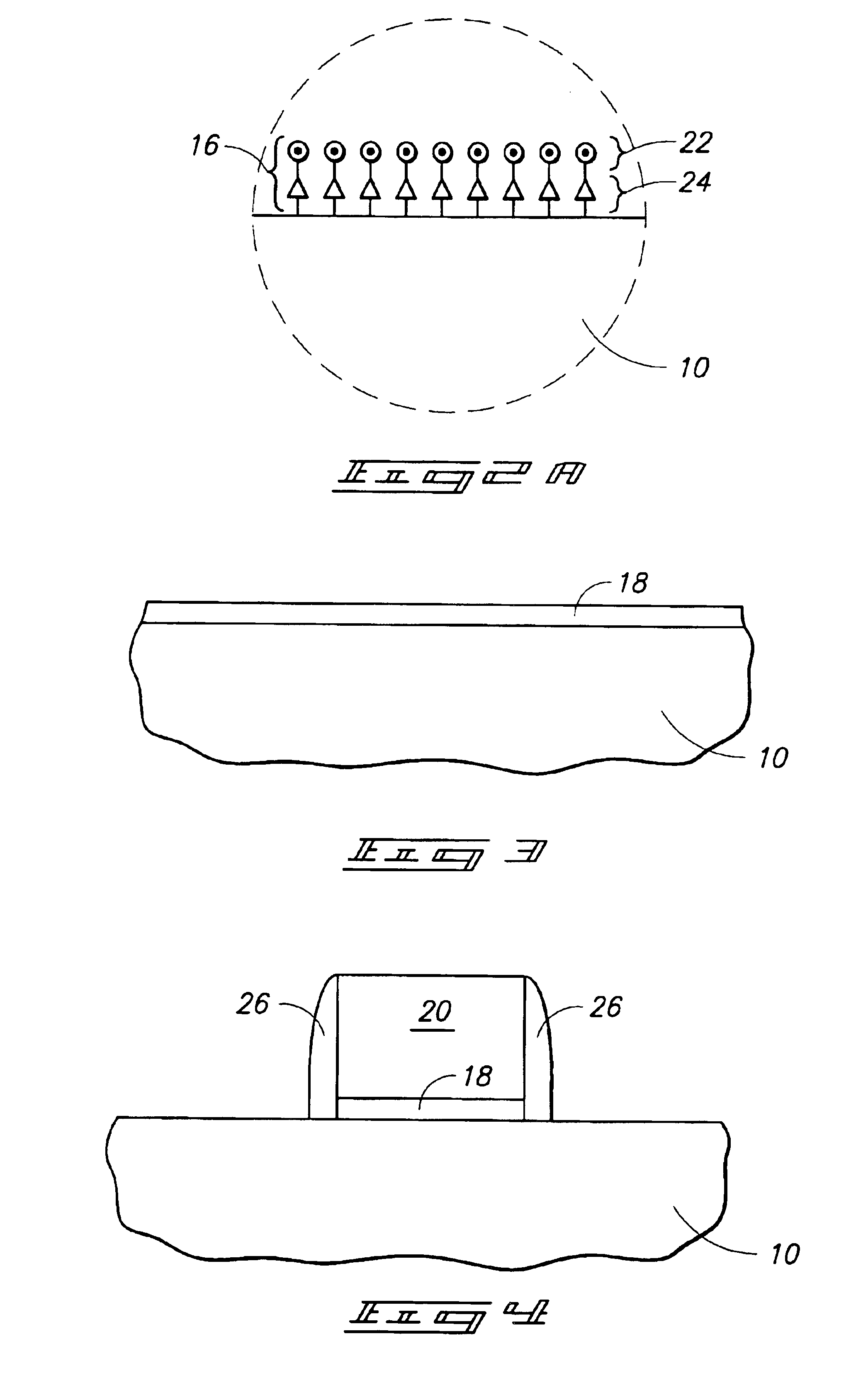

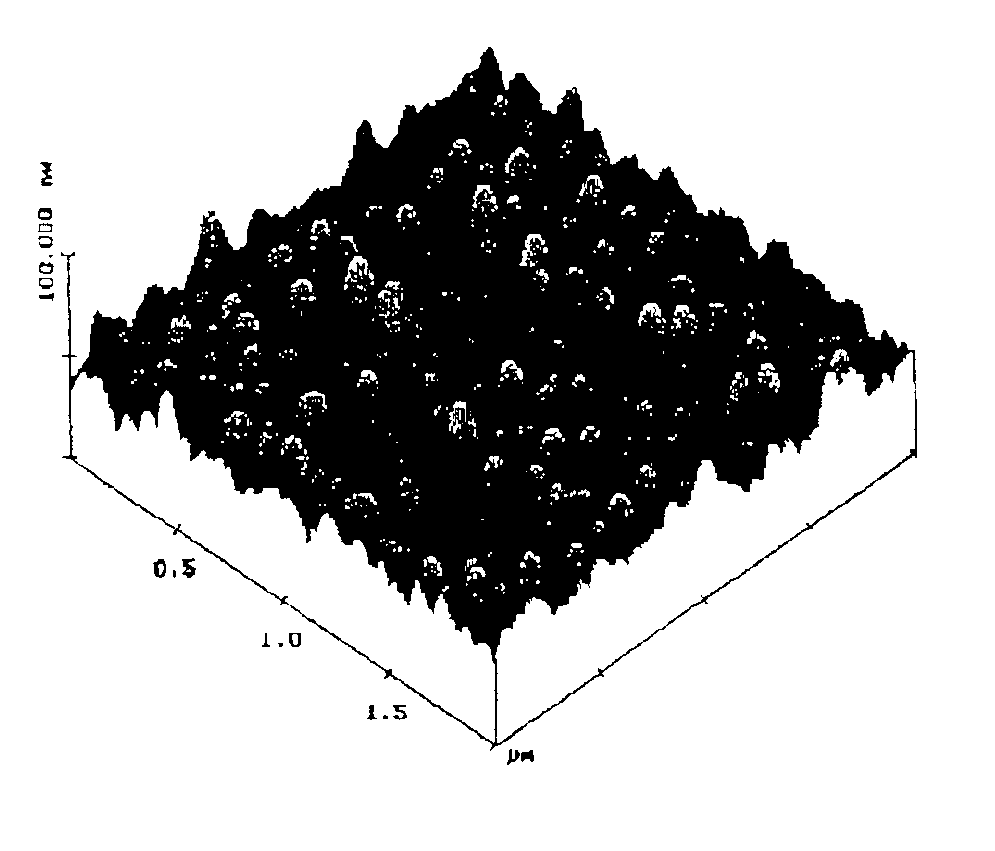

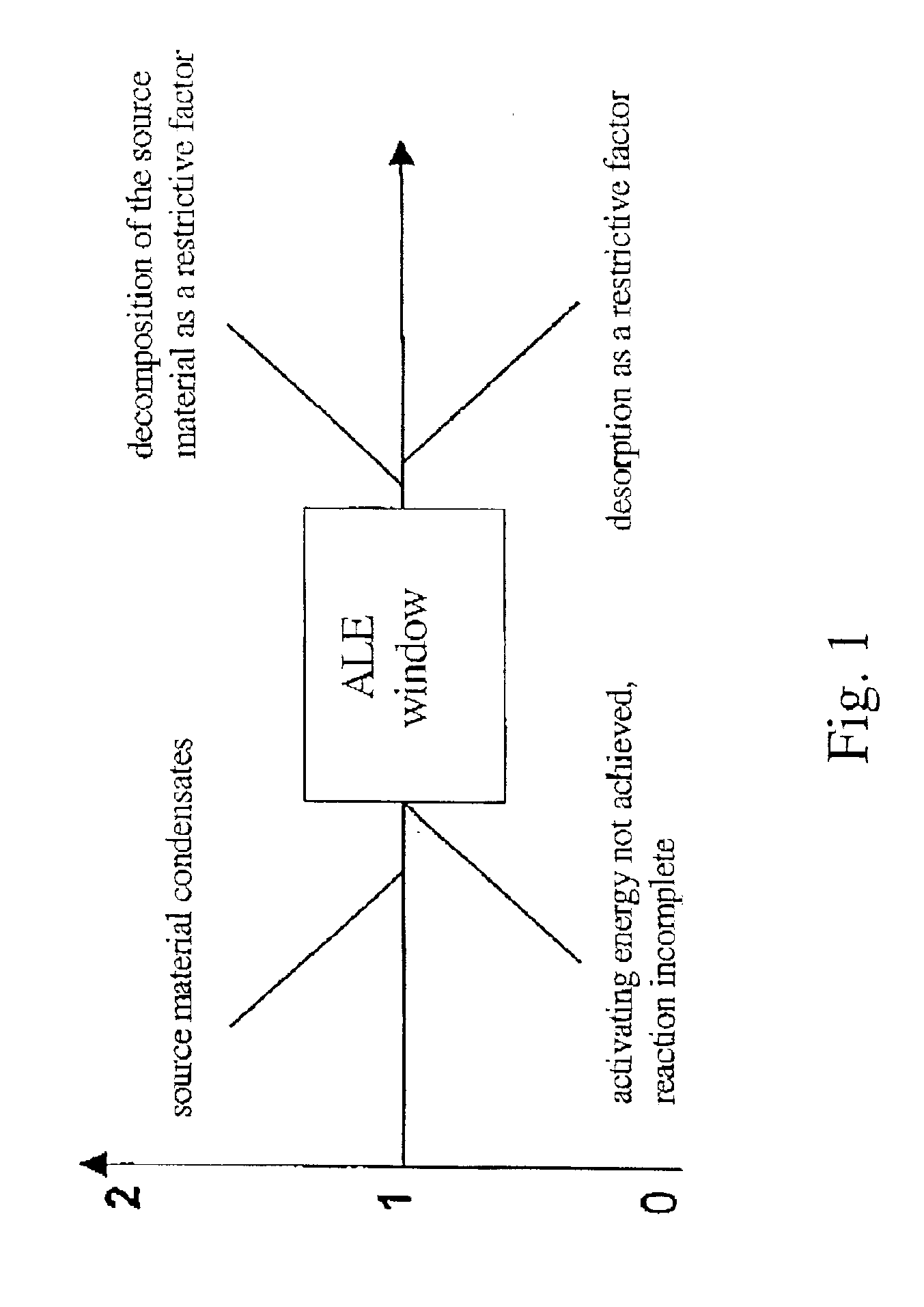

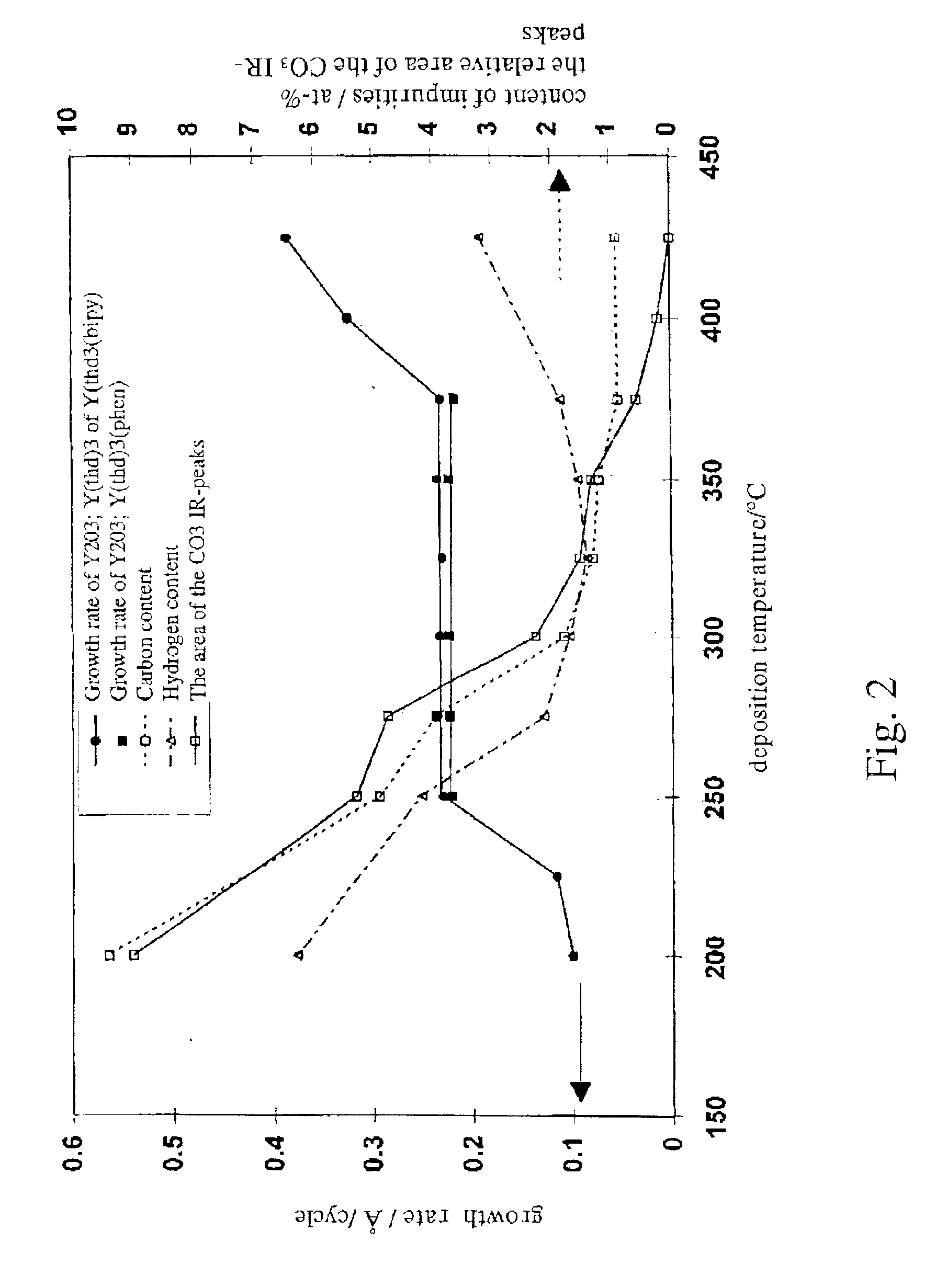

Method of depositing rare earth oxide thin films

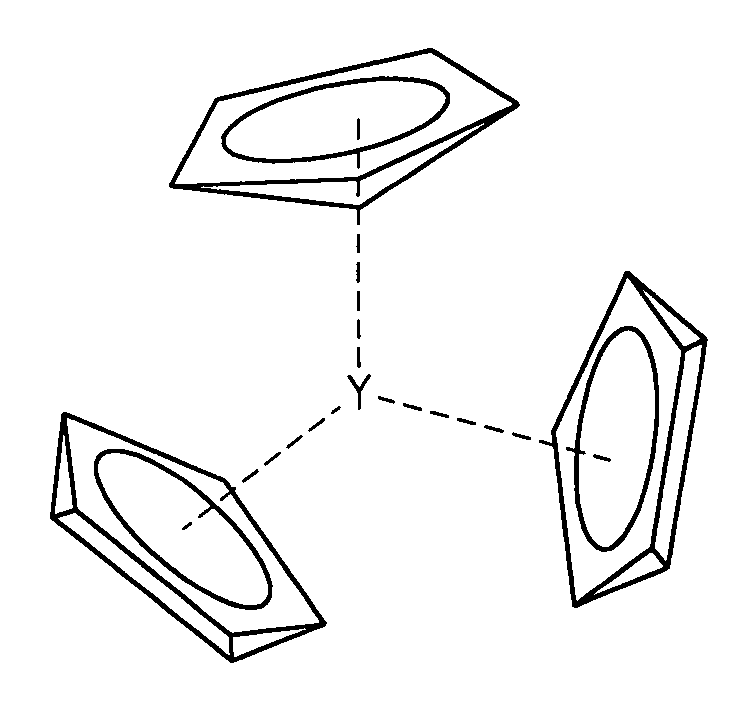

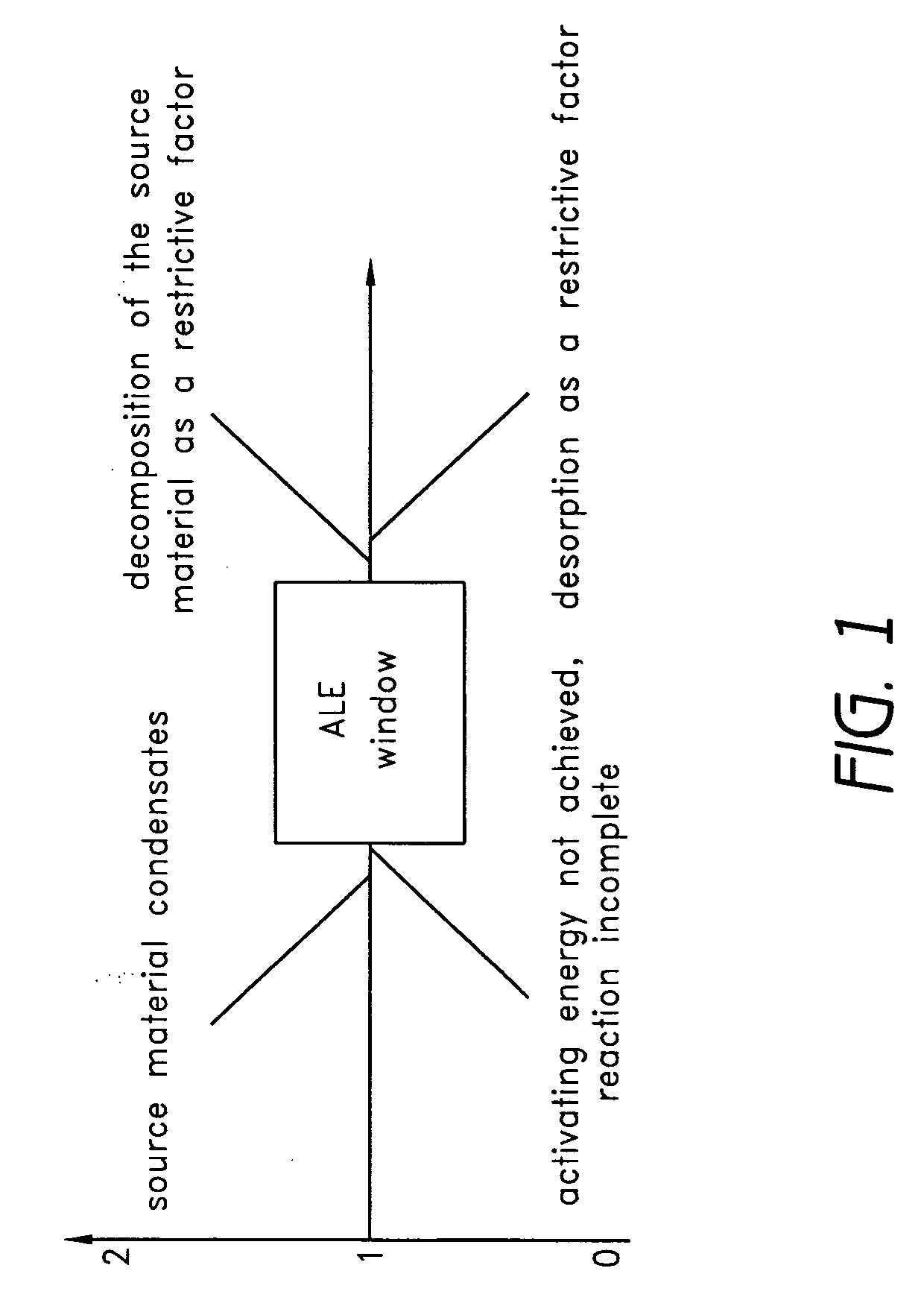

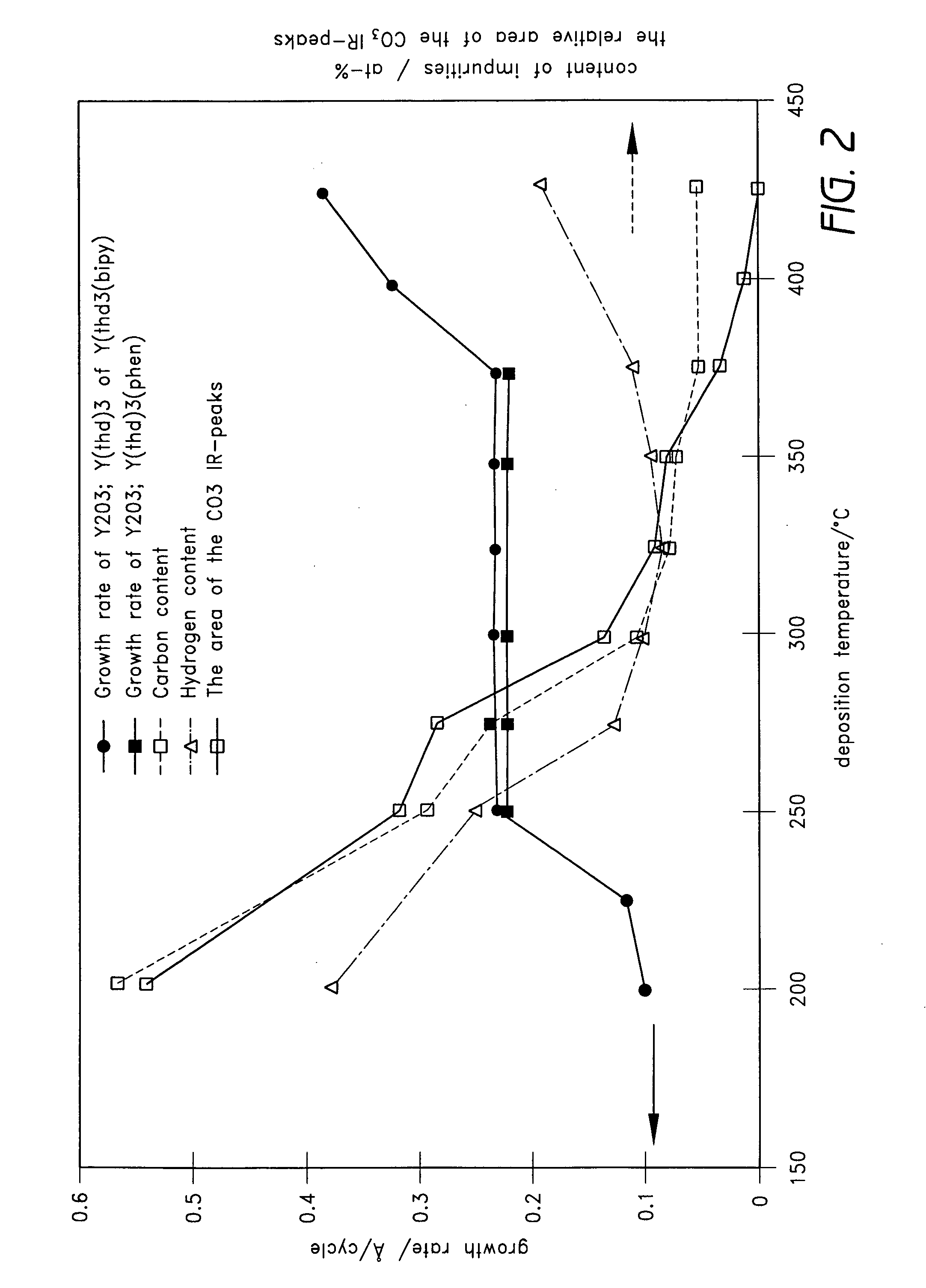

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

Novel methanation catalyst and preparation method thereof

InactiveCN101380581AImprove conversion rateGood choiceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementLanthanum compounds

The invention provides a novel methane catalyst and a preparation method thereof, which is characterized in that by adding rare earth elements of La and Ce during the process of the catalyst, the activity and selectivity of the catalyst are improved, and especially for the reaction that CO2 is carried out hydrogenation to be changed into methane, the conversion rate is higher. By adding an appropriate amount of Ca, Mg, Ba, Na and other alkali metals and alkaline earth metals, the thermal stability and the anti-carbon property of the catalyst are improved. The components of the catalyst by weight percentage are as follows: 70-86% ofAl2O3, 12-20% NiO, 0.5-5% of La2O3, 0.5-5% of MgO, 0.1-5% of CeO2, 0.1-3% of CaO, 0.1-1% of Na2O and 0.01-2% of BaO; the specific surface of the catalyst is 100-180m<2> / g, and the pore volume is 0.4- 0.8ml / g.

Owner:ENN SCI & TECH DEV

Nickel system hydrogenation catalyst, preparation method and application

ActiveCN101037613AImprove hydrogenation activityImprove stabilityHydrocarbon by hydrogenationRefining to eliminate hetero atomsResistAdjuvant

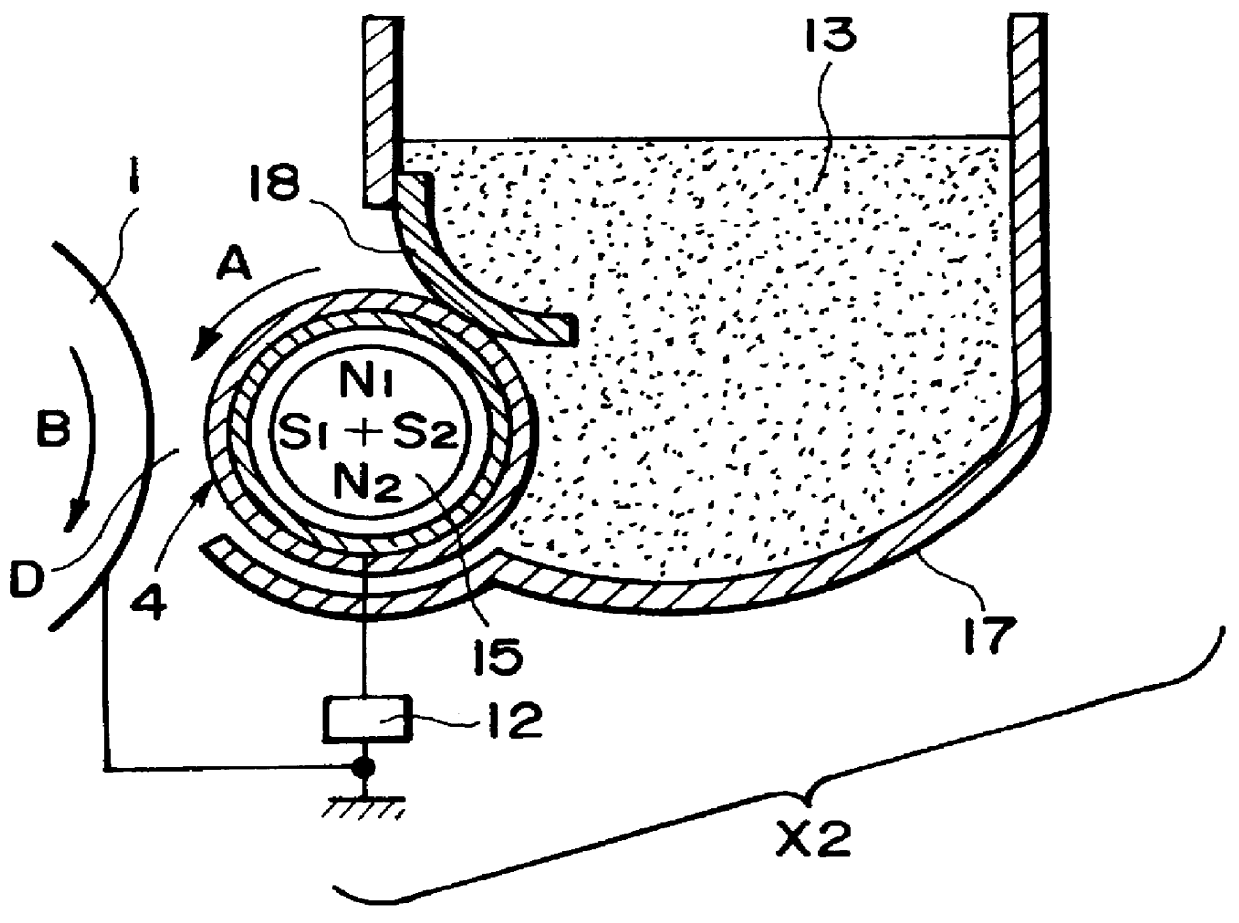

The invention realtes to a nickel based hydrogenation catalyst, preparation and application thereof. Using alumina or and monox silica as carrier, the catalyst prepared by means of coprecipitation, main containing active component Ni, is characterized in catalyst composed by active component Ni, La, adjuvant X1 and carrier X2O. Calculated by weight of component, the catalyst including: NiO 40-70%, La2O3 2-5%, X2O 20-50%, wherein X1 is selected from one or more of Cu, Mg, Zr, X2 is selected from Al or and Si; surface area to volume ratio thereof is 80-200 m<2> / g, pore volume ratio is 0.4-0.8 ml / g. The catalyst is suit for mono olefin hydrogenation, especially for hydrogenation of pyrolysis C9 distillation, which has higher hydrogenation activity, definited sulfur poison resist and carboid resist to fit for higher require of high colloid raw material hydrogenation which of catalyst has high hydrogenation activity and good stability.

Owner:PETROCHINA CO LTD

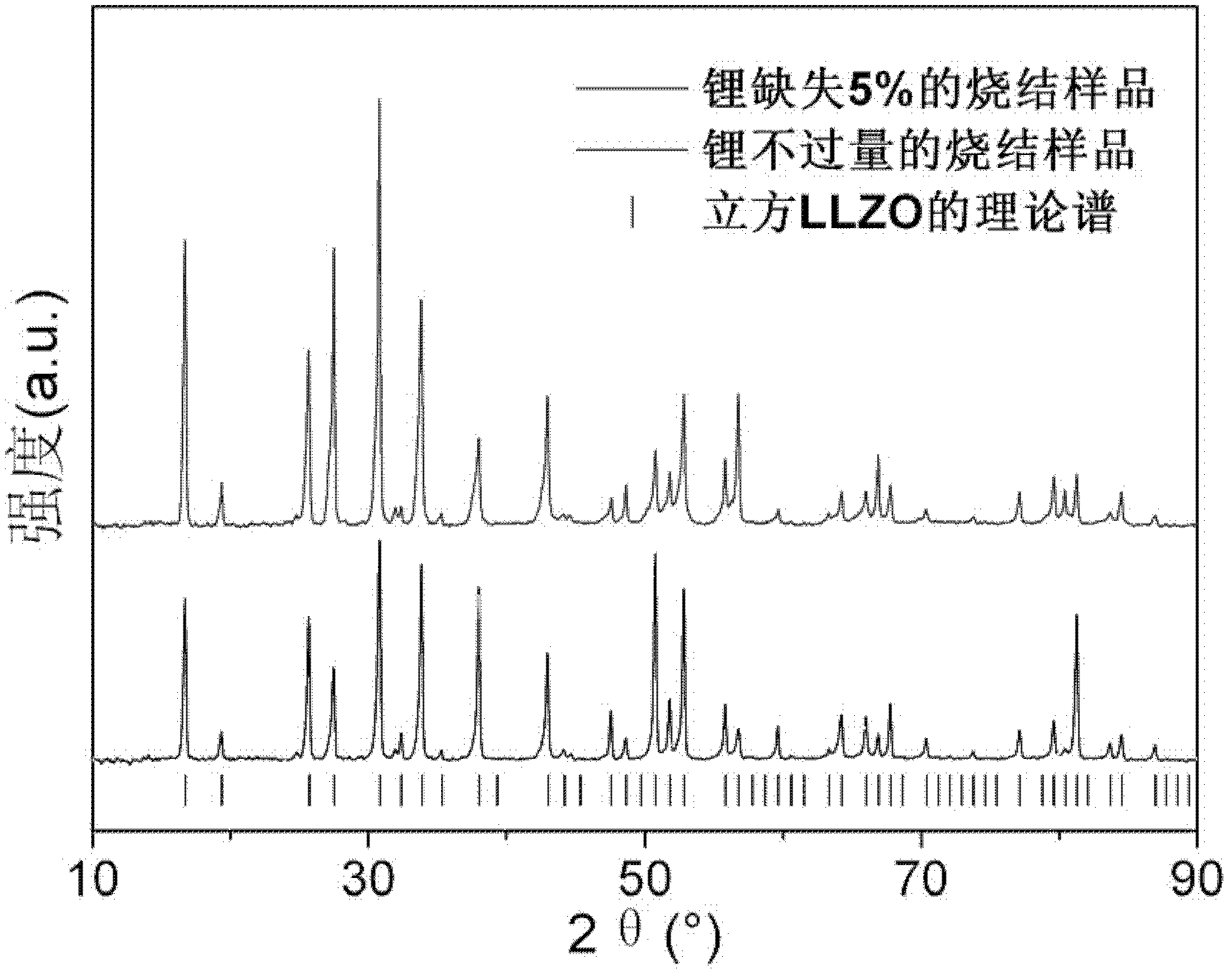

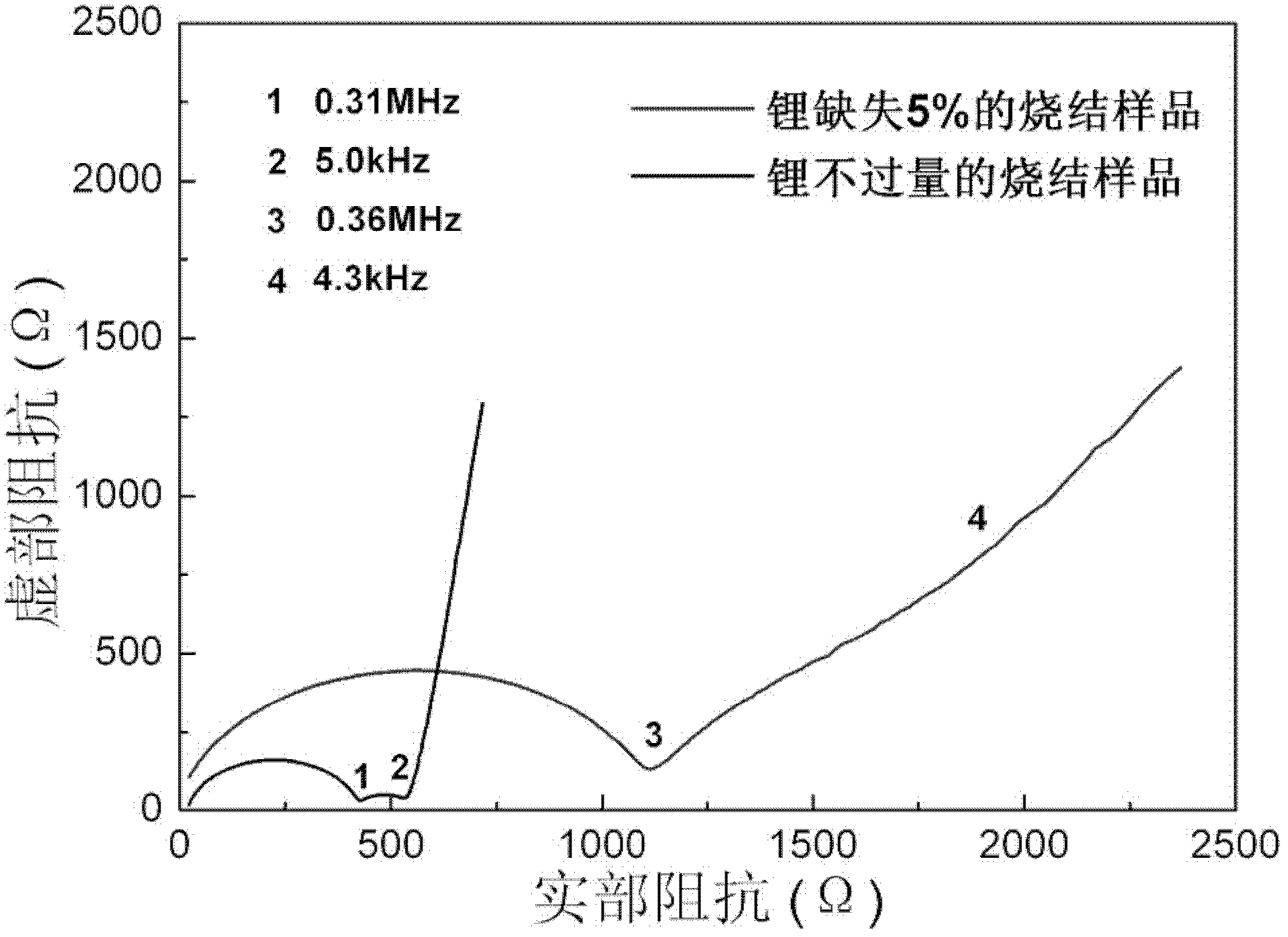

Lithium lanthanum zirconium oxide solid electrolyte material and its preparation method and application

The invention discloses a lithium lanthanum zirconium oxygen solid electrolyte material. The molecular formula of the material is shown as Li7+xLa3Zr2O12+0.5x, wherein -0.35≤x≤+0.35. The structure of the lithium lanthanum zirconium oxygen solid electrolyte material is a cubic garnet structure; the total ion conductivity of the lithium lanthanum zirconium oxygen solid electrolyte material at room temperature is greater than 1×10-4 S / cm. The method comprises the steps of: mixing the lithium source compound, the lanthanum source compound and the zirconium source compound according to the molar ratio of Li, La and Zr (7+x):3:2, and then calcining and sintering to obtain the lithium Lanthanum zirconium oxide solid electrolyte material; wherein, -0.35≤x≤+0.35. This material can prepare lithium lanthanum zirconium oxide solid electrolyte material at lower lithium content and lower sintering temperature, and the total room temperature ion conductivity can be greater than 1×10-4S / cm, which has important applications value.

Owner:TSINGHUA UNIV

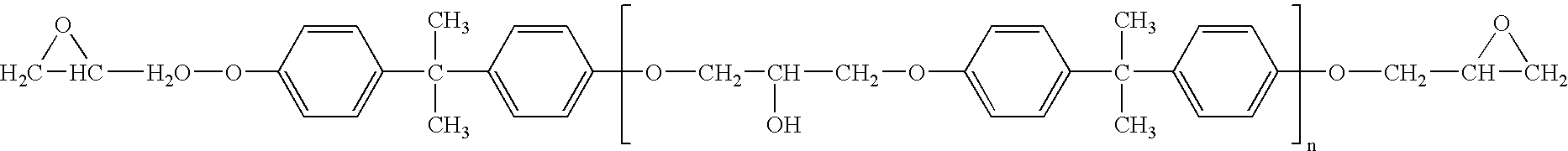

Coating composition and article coated therewith

InactiveUS20050215670A1Improve corrosion resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyTriazole antifungals

A coating composition used for coating of a steel material and / or aluminum material comprises a corrosion inhibitor, a base resin and a curing agent. The corrosion inhibitor may be selected from cerium compounds, lanthanum compounds, molybdate salt compounds, gluconic acid derivative salts, porous base materials, triazole compounds, thiazole compounds, tetracyclines, and metal phosphate salt compounds of ascorbic acid. The base resin may include a xylene-formaldehyde-resin-modified amino-containing epoxy resins obtained by reacting an epoxy resin having an epoxy equivalent of from 180 to 2500 with a xylene formaldehyde resin and an amino-containing compound. The curing agent may be a blocked polyisocyanate compound obtained by blocking an isocyanate group of a polyisocyanate compound with a blocking agent.

Owner:KANSAI PAINT CO LTD

Method of depositing rare earth oxide thin films

InactiveUS20090035949A1Eliminate the problemIncrease probabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureMischmetal

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds or rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

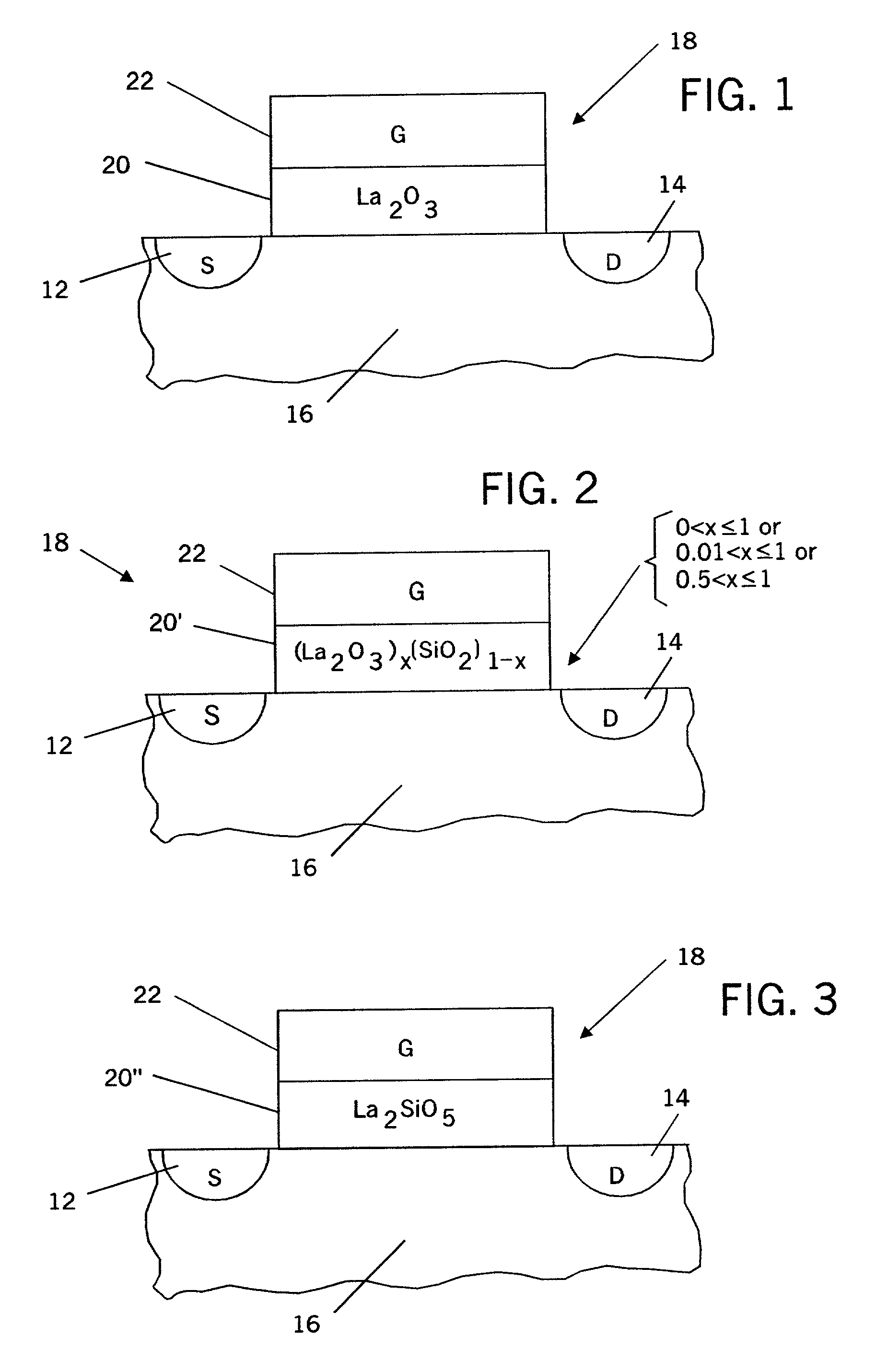

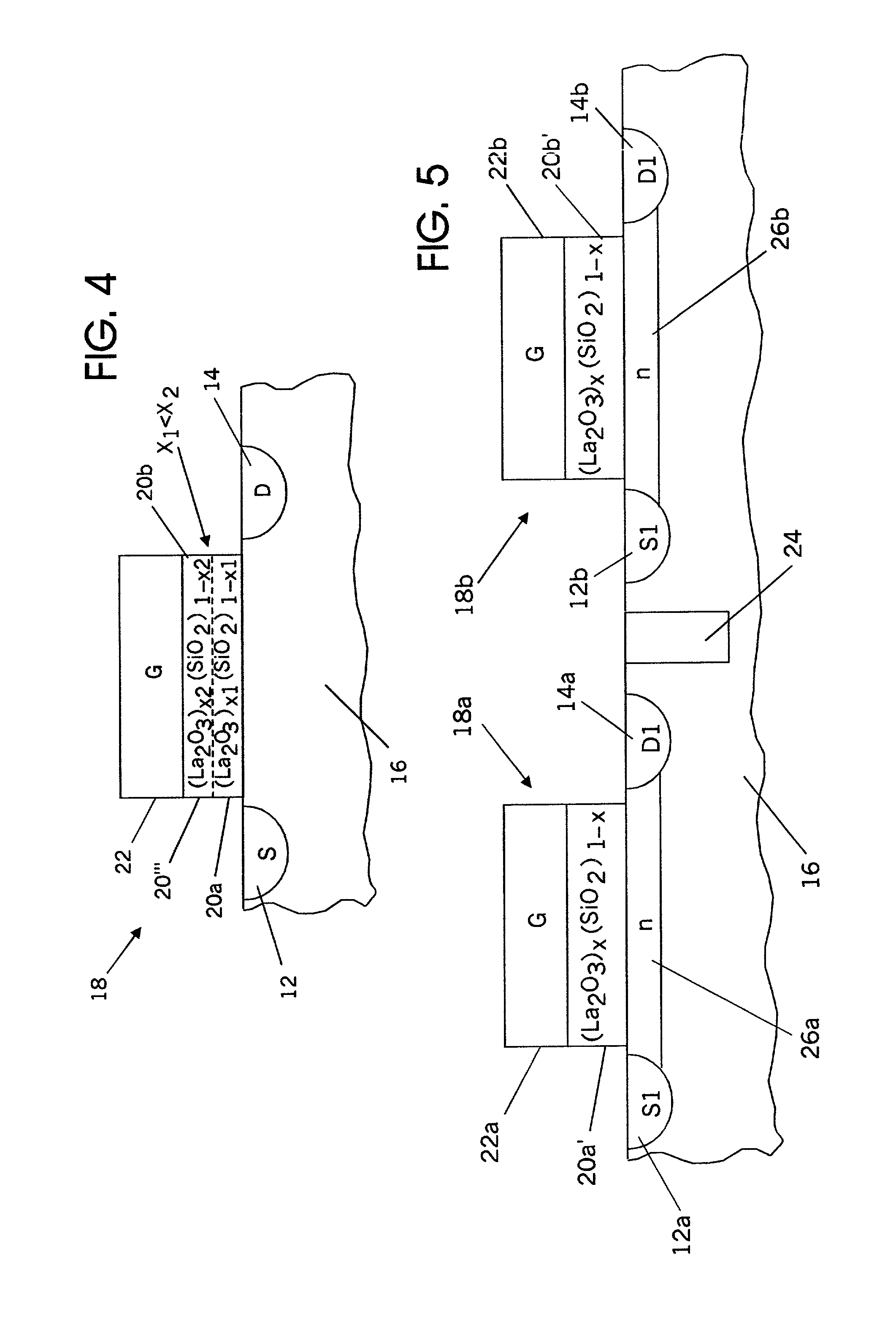

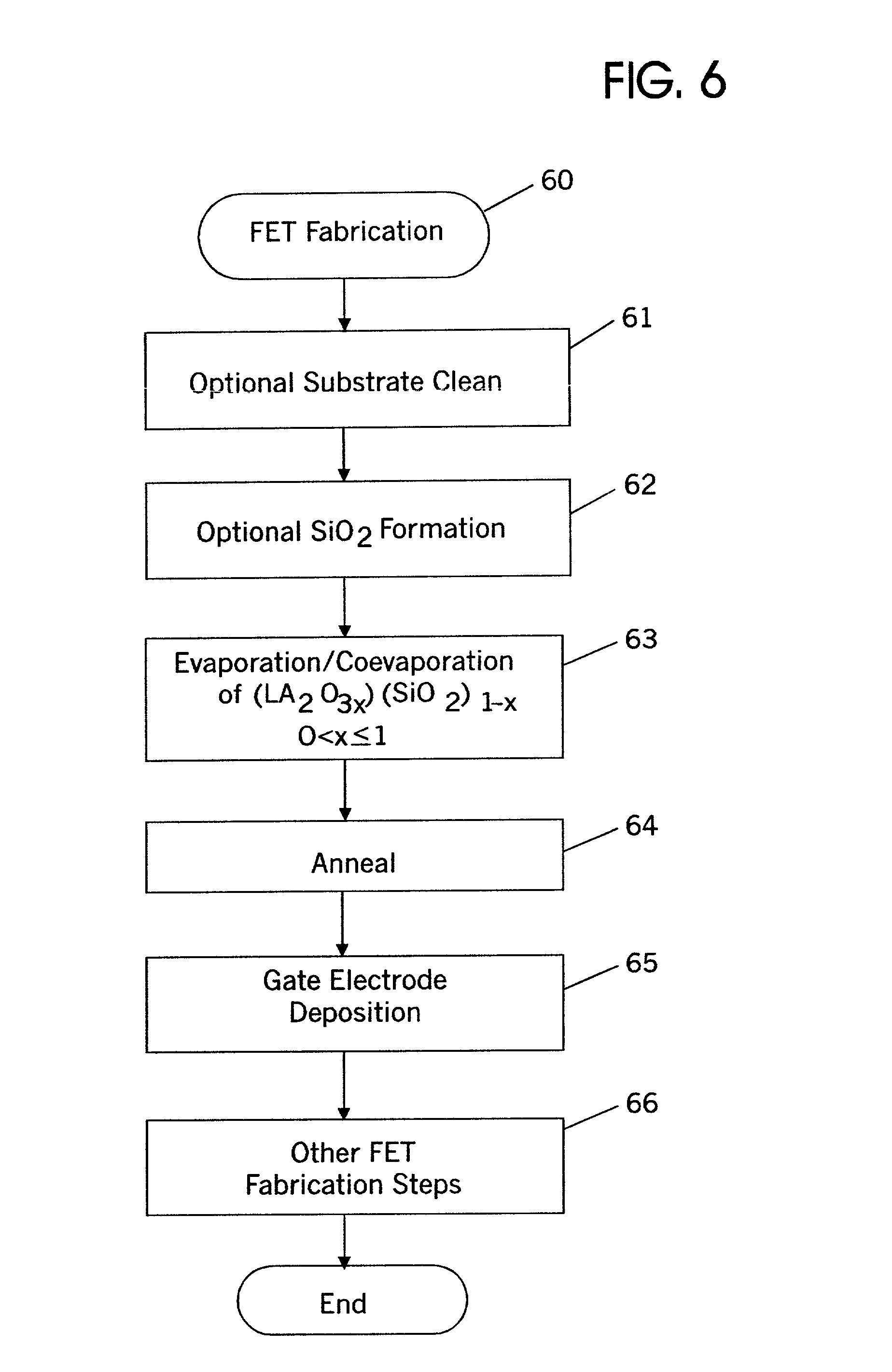

Lanthanum oxide-based gate dielectrics for integrated circuit field effect transistors and methods of fabricating same

Lanthanum oxide-based gate dielectrics are provided for integrated circuit field effect transistors. The gate dielectrics may include lanthanum oxide, preferably amorphous lanthanum oxide and / or an alloy of lanthanum oxide and silicon oxide, such as lanthanum silicate (La.sub.2SiO.sub.5). Lanthanum oxide-based gate dielectrics may be fabricated by evaporating lanthanum on a silicon surface of an integrated circuit substrate. The lanthanum may be evaporated in the presence of oxygen. Lanthanum and silicon may be co-evaporated. An anneal then may be performed. Lanthanum oxide-based dielectrics also may be used for integrated circuit capacitors.

Owner:NORTH CAROLINA STATE UNIV

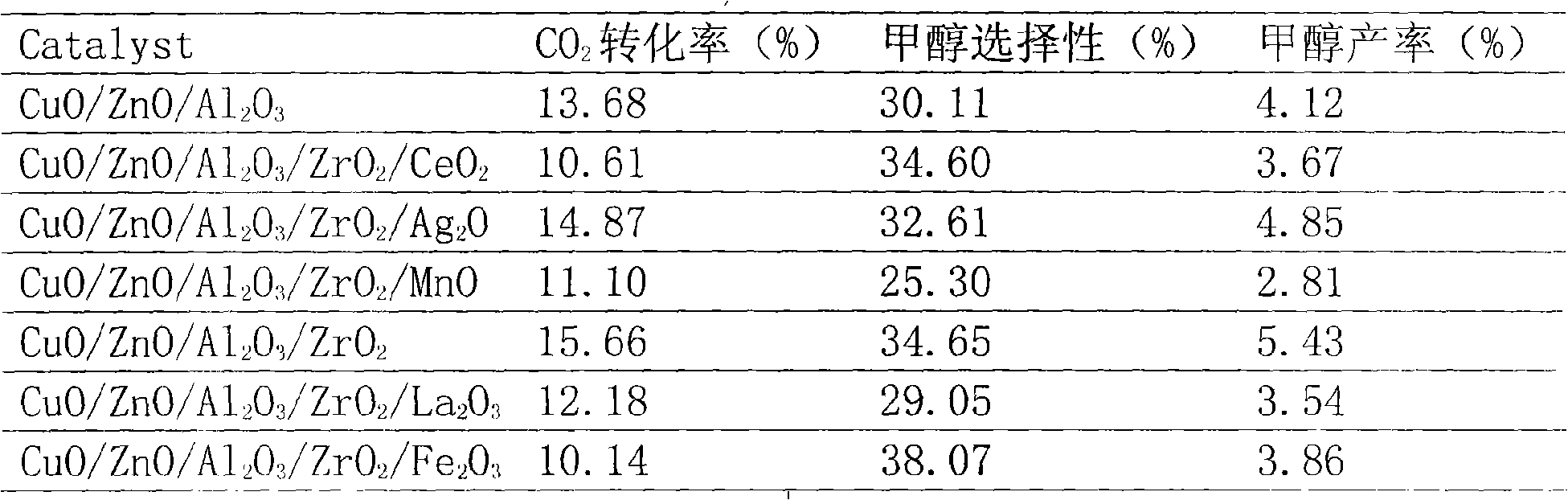

Carbon dioxide-synthesized methanol catalyst and preparation method thereof

ActiveCN101513615AImprove conversion rateHigh activityOrganic compound preparationHydroxy compound preparationCopperZinc

A carbon dioxide-synthesized methanol catalyst and a preparation method thereof are disclosed, belonging to the technical field of catalyst. The invention is characterized in that the carbon dioxide-synthesized methanol catalyst has the molar ratio of components of Ci to Zn to Al to Zr to M being 45 to 45 to 10 to 5 to 2, wherein M is MnO, CeO2, Ag2O, Fe2O3, La2O3, and is prepared by stepped co-deposition. The preparation steps are that: (1) a mixed liquid of aluminum nitrate solution and zirconium nitrate solution is in concurrent flow and co-deposition with carbonate solution to prepare a carrier precursor; (2) copper-zinc M mixed nitrate is in concurrent flow and co-deposition with the carbonate solution and added into (1), and then the synthesized methanol catalyst is prepared by aging, filtering, drying and roasting. The inventive effect and benefit are that the prepared catalyst is excellent in activity and thermal resistance and can effectively decompose carbon dioxide with high one-step conversion rate, therefore, the invention provides an effective catalyst for synthesizing methanol by hydrogenising the carbon dioxide.

Owner:DALIAN UNIV OF TECH

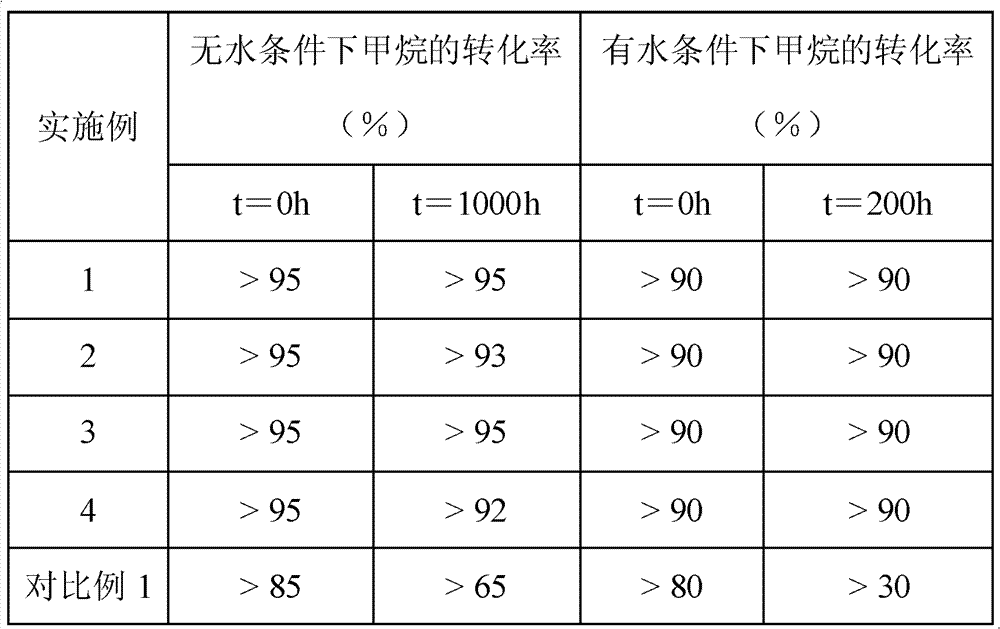

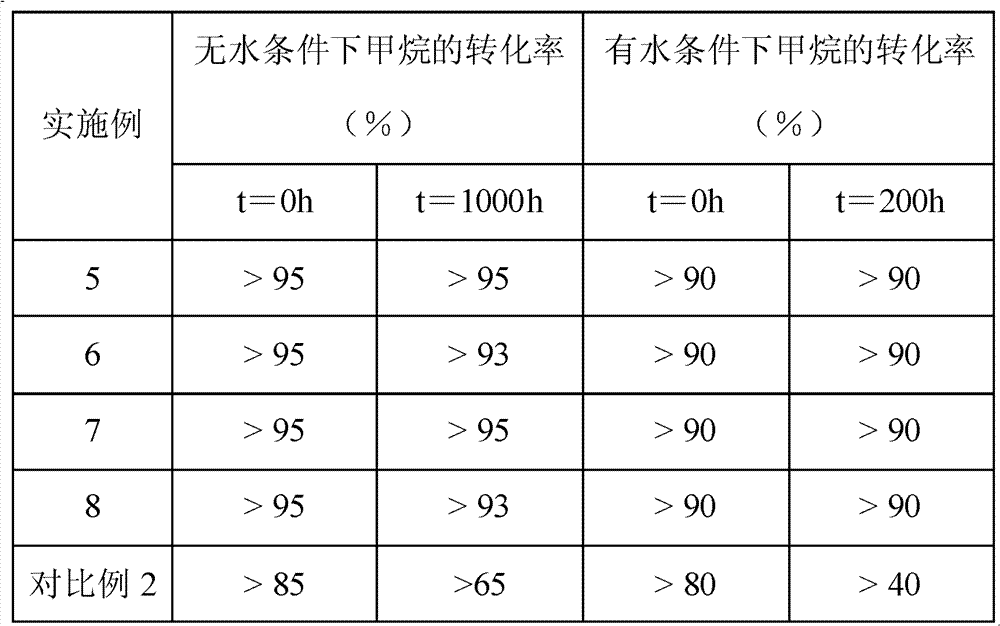

Low-concentration methane combustion catalyst and its preparation method

InactiveCN103191733APromote resultsReduced activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCoal mine methaneHigh activity

The invention provides a low-concentration methane combustion catalyst and its preparation method. The catalyst treats Al2O3 as a carrier, treats a precious metal Pd as a primary catalytic activity component, and treats one or more of precious metals comprising Pt, Rh, Ru and Ir and one or more of metal oxides comprising CeO2, ZrO2, La2O3 and TiO2 as catalytic assistants. The catalyst can be applied in particle, and Al2O3, all catalytic activity components and the assistants can be supported on honeycomb ceramic to prepare a whole catalyst. The catalyst has the advantages of high activity, high hydrothermal stability, long life and the like; and the catalyst can be used for the efficient utilization of low-concentration methane in a coal mine gas (coal mine methane), and can also be used for the efficient removal and utilization processes of other VOC gases to realize the full utilization, energy saving and environmental protection purposes of energy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

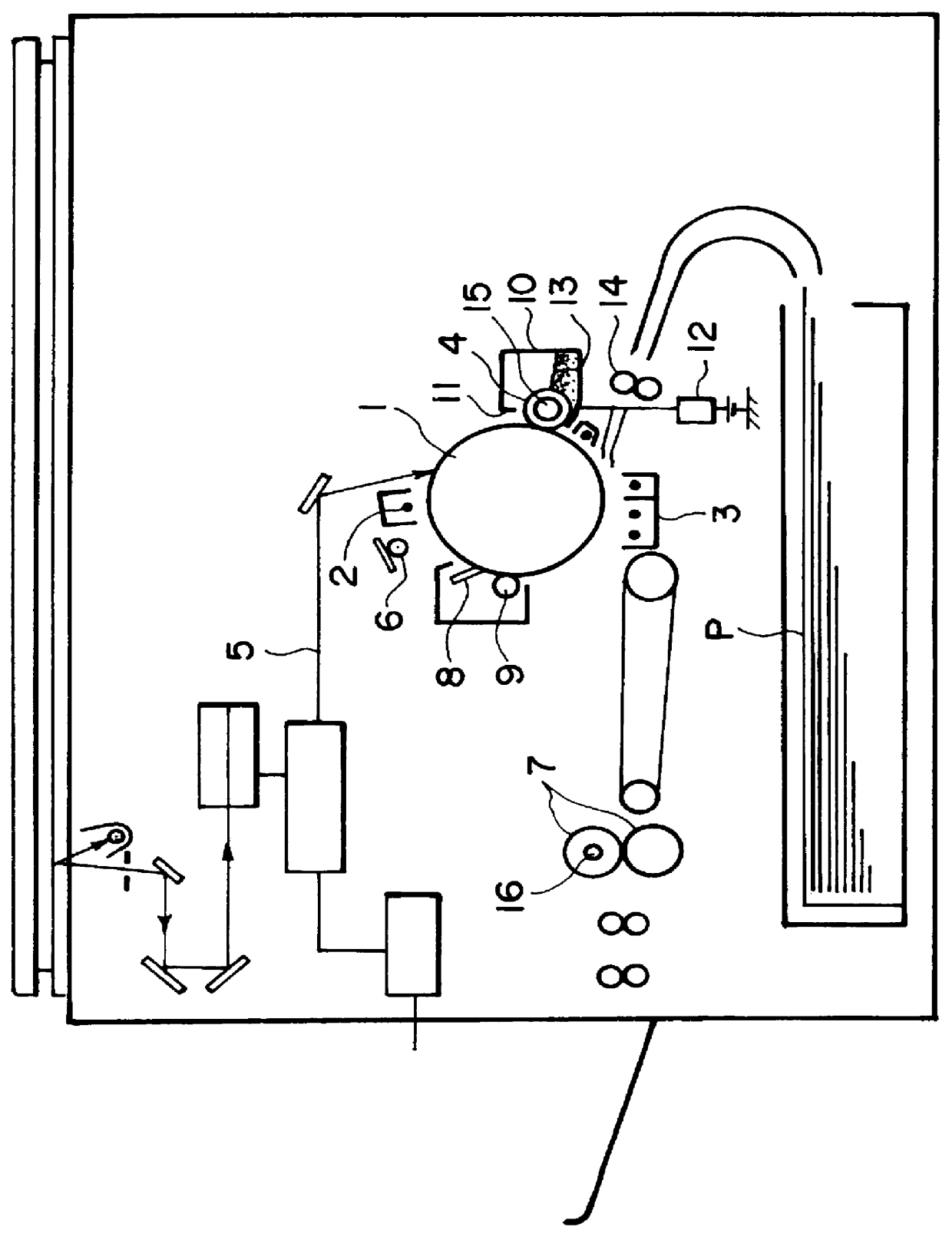

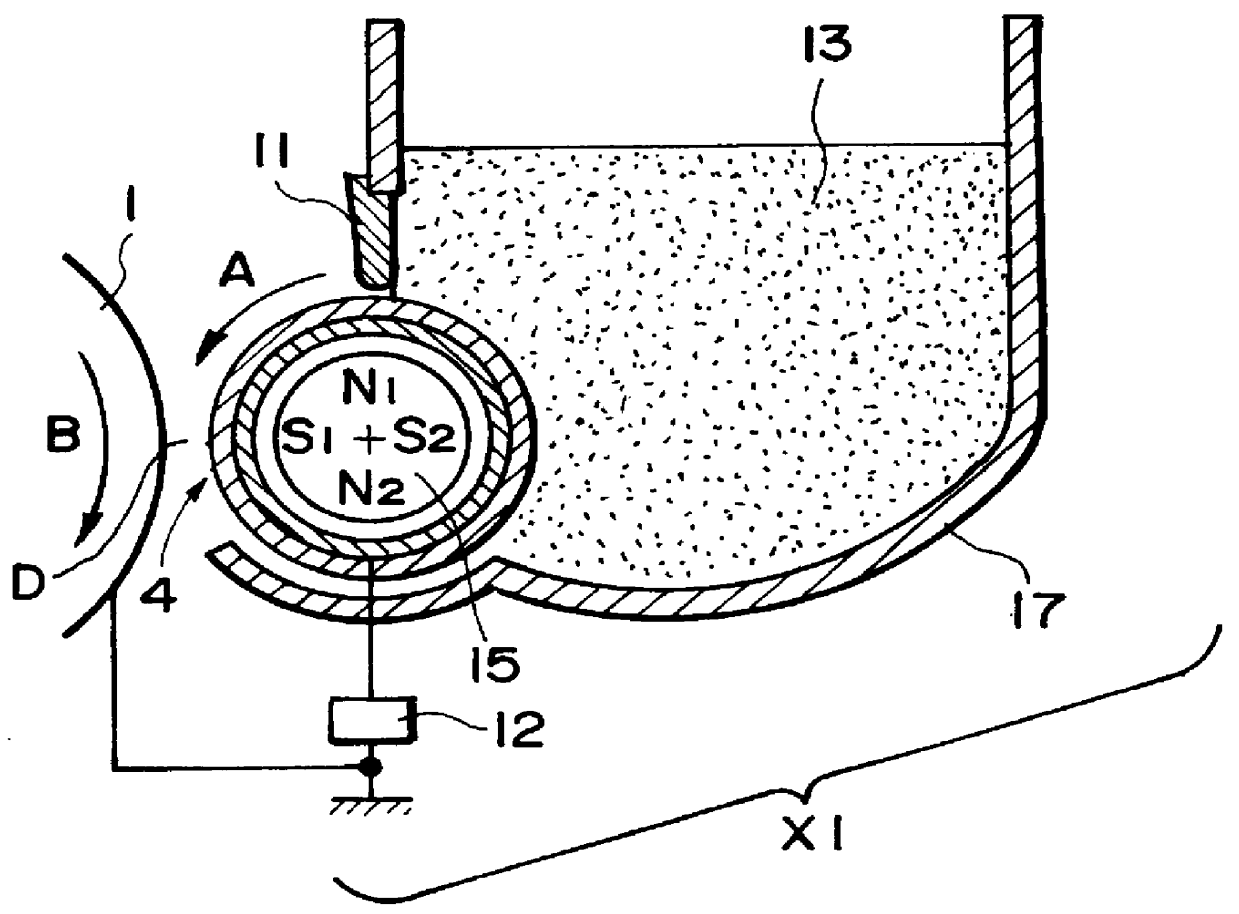

Toner and image forming method

InactiveUS6156471AImprove development performanceHigh densityDevelopersElectrographic process apparatusLatent imageAmorphous silicon

An electrophotographic toner showing good cleanability and is suitable for use in developing an electrostatic latent image formed on an amorphous-silicon photosensitive member is provided. The toner includes toner particles each comprising a binder resin and a colorant, and inorganic fine powder A. The inorganic fine powder A contains 88.0-97.0 wt. % of a rare earth compound comprising a rare earth oxide. The rare earth compound contains 40.0-65.0 wt. % of Ce (calculated as CeO2), 25.0-45.0 wt. % of La (calculated as La2O3), 1.0-10.0 wt. % of Nd (calculated as Nd2O3) and 1.0-10.0 wt. % of Pr (calculated as Pr6O11). The rare earth compound contains further a fluorinated rare earth compound in such an amount as to provide the inorganic fine powder A with a fluorine content of 2.0-11.0 wt. %.

Owner:CANON KK

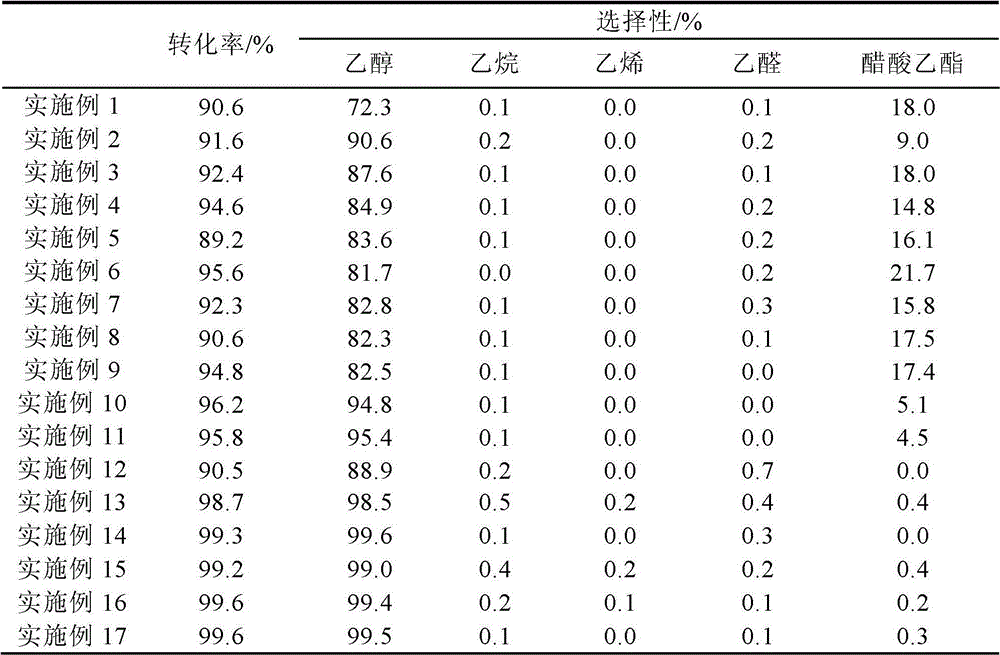

Catalyst for preparing ethanol from acetic ester hydrogenation, preparation method and application thereof

ActiveCN102872878AEasy to prepareHigh activityOrganic compound preparationHydroxy compound preparationHydrogenCopper oxide

The invention relates to a catalyst for preparing ethanol from acetic ester hydrogenation, a preparation method and an application thereof. The main catalytic components of the catalyst are copper or copper oxide with a content of 30 wt%-75 wt%; an auxiliary agent is one or more of La2O3, ZrO2, CeO2, Fe2O3, NiO, MgO, MnO, Al2O3 and K2O, with a content of 1wt%-40 wt%; a carrier is zinc oxide with a content of 20 wt%-65 wt%. In a relatively low hydrogen ester ratio and relatively large liquid hourly space velocity, the catalyst has a conversion rate of acetate larger than 99% and a selectivity of ethanol larger than 99%. Besides, the catalyst has good stability, can reduce cost greatly, and obtains higher production gains. The catalyst is simple in preparation method; the raw materials of the catalyst have wide sources and low cost; and the preparation process of the catalyst is environment-friendly, and is suitable for industrialized production.

Owner:SHANGHAI HUAYI GRP CO

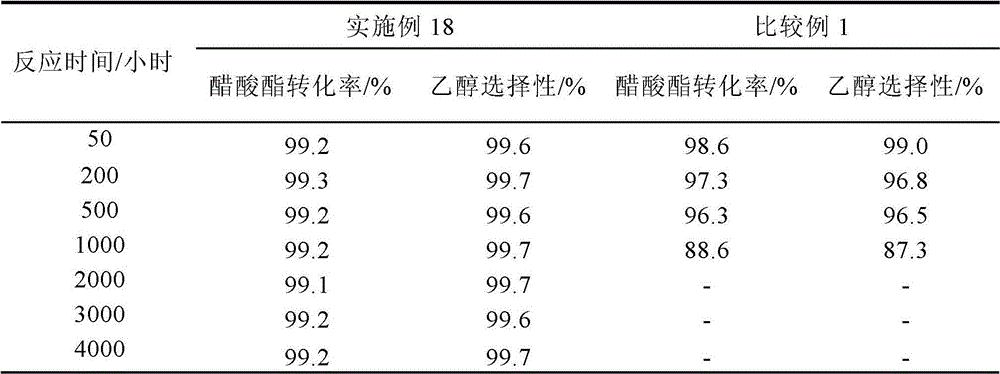

Catalyst for full methanation of carbon dioxide and preparation method thereof

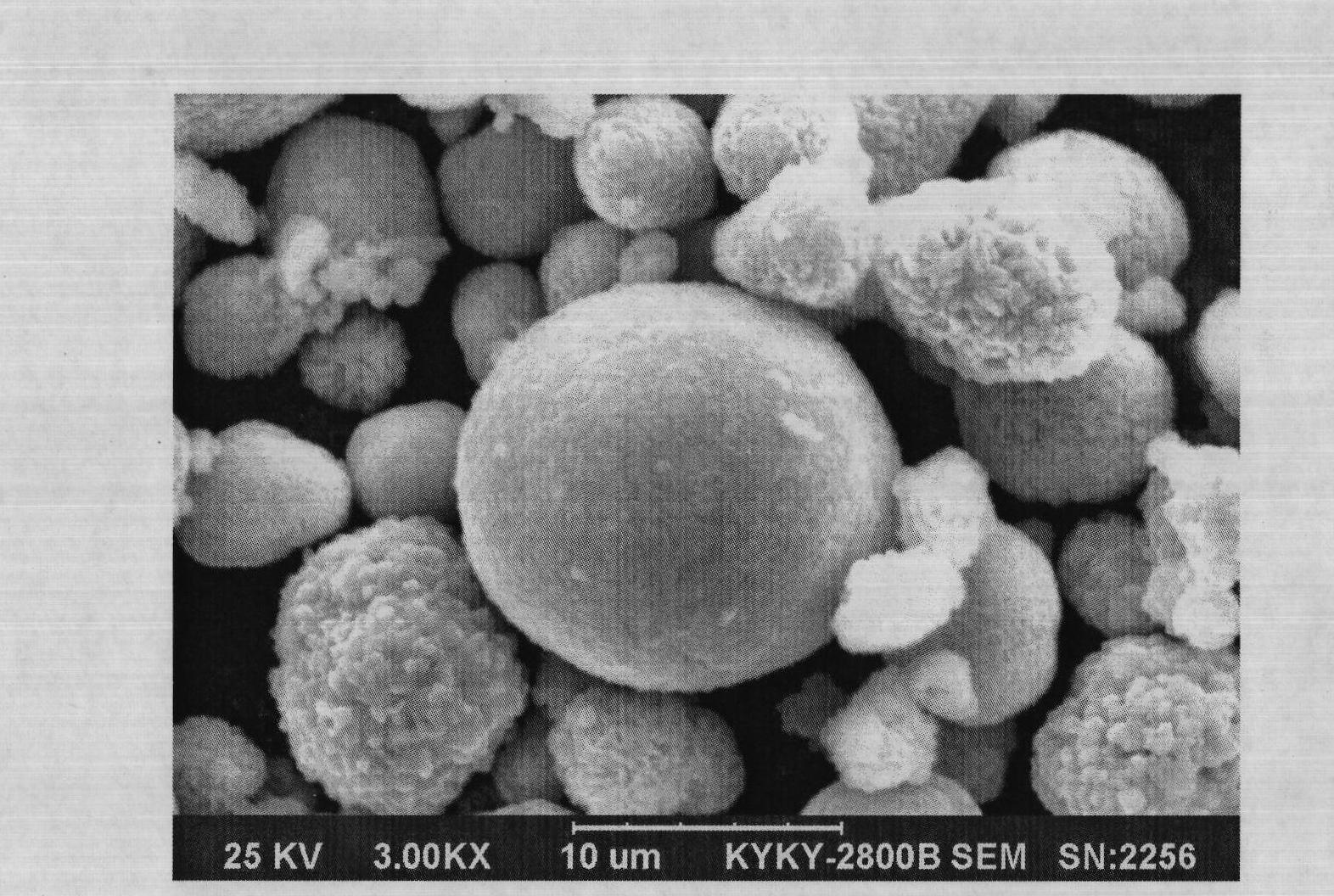

ActiveCN101884927AImprove fluidization qualityHigh strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationThermal stability

The invention discloses a catalyst for full methanation of carbon dioxide, which belongs to the technical field of methanation of carbon dioxide. In the catalyst, spherical gamma-Al2O3 is used as a carrier, Ni and Fe are used as active ingredients, and MgO, La2O3 or CeO2 is used as an auxiliary agent. The catalyst is prepared by adopting an ordered soaking method through drying, roasting and reduction. The catalyst comprises the following components in percentage by mass: 60 to 80 percent of gamma-Al2O3, 10 to 20 percent of NiO, 5 to 15 percent of Fe2O3, 1 to 10 percent of MgO, and 1 to 10 percent of La2O3 or CeO2. Under the reaction conditions that the pressure is between 3.0 and 5.0MPa, the volume airspeed of the raw material gas is 5,000 to 10,000 per hour and the ratio of H2 to CO2 is 4.1, both the CO2 conversion rate and the CH4 selectivity can be close to 100 percent. The catalyst has the characteristics of high strength, good thermal stability, carbon deposition resistance, easy fluidization and the like.

Owner:TSINGHUA UNIV

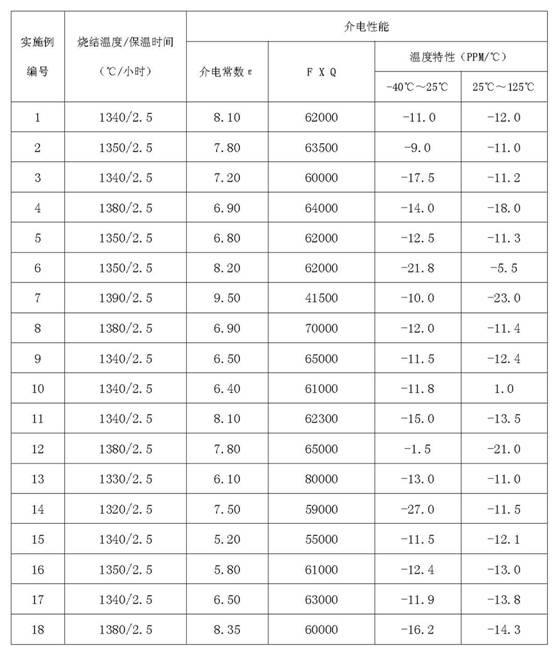

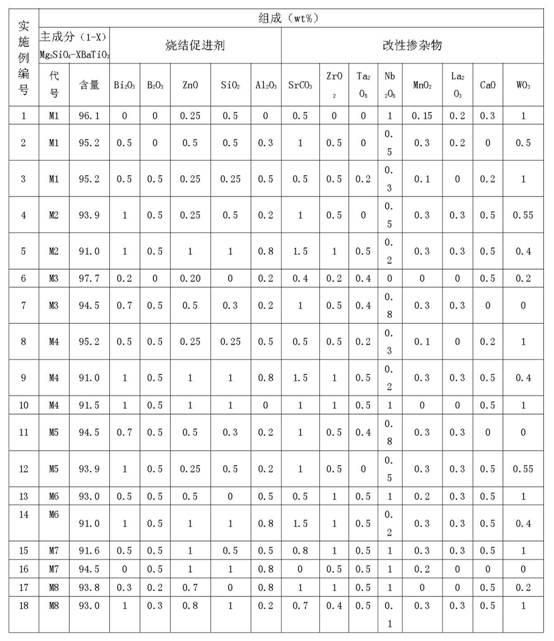

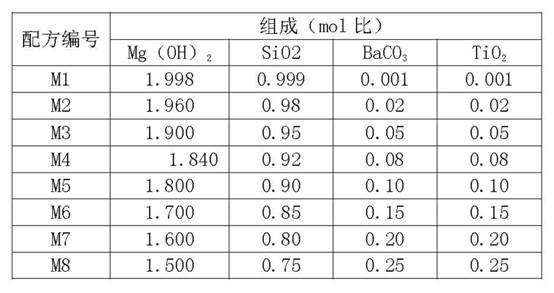

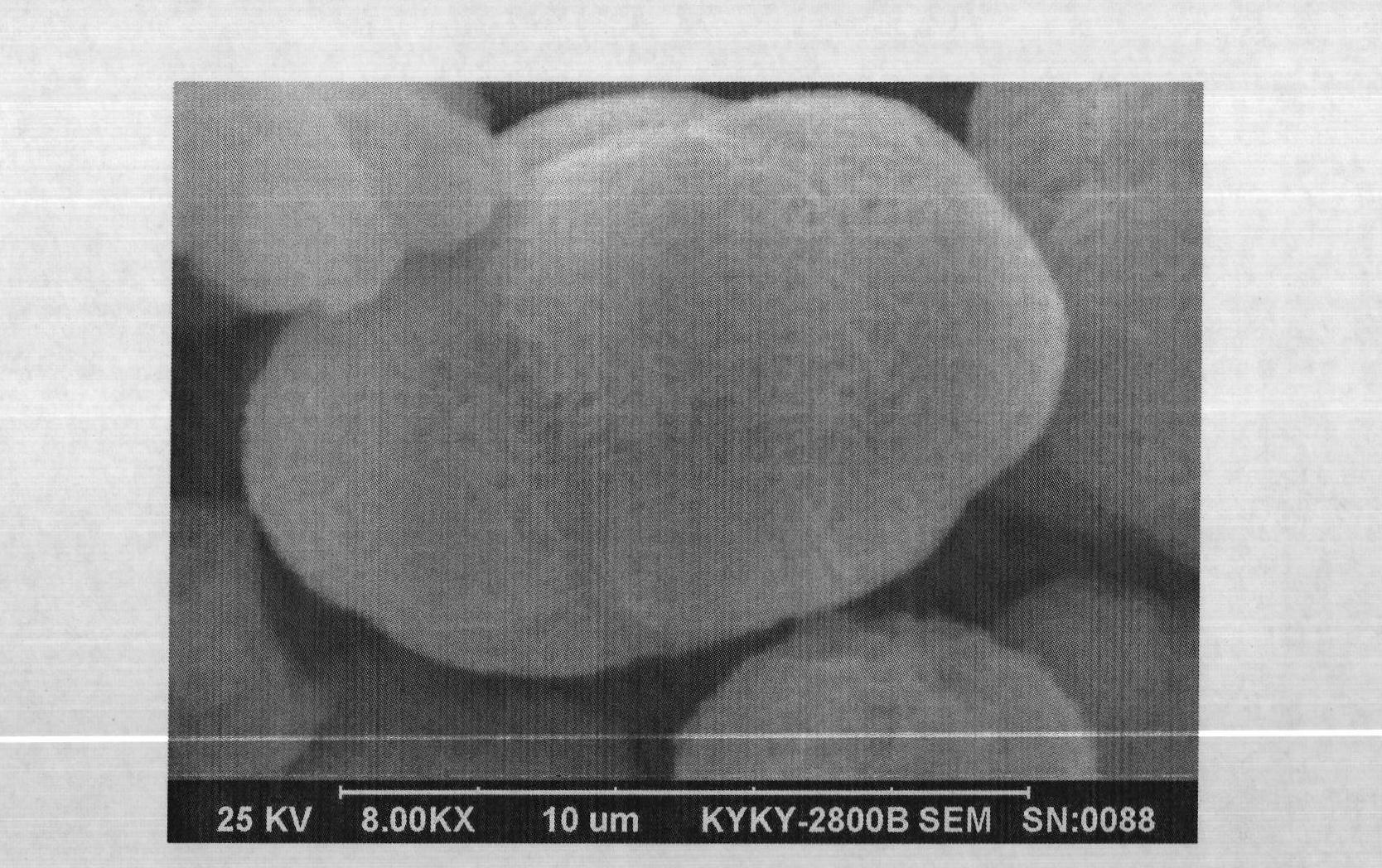

Low-dielectric constant microwave ceramic dielectric material and preparation method thereof

This invention provides a microwave ceramic dielectric material with a low dielectric constant [epsilon]r of 3-8 and a preparation method thereof, and the material is composed of (1-X)Mg2SiO4-XBaTiO3 as a main component, a modification adulterant and a sintering promoter. 1) The said major constituent is a (1-X)Mg2SiO4-XBaTiO3 solid solution, wherein the X=0.001-0.25; 2) The said modification adulterant comprises one or a mixture of more than one of SrCO3, ZrO2, Ta2O5, Nb205, MnO2, CaO, La2O3 and WO3; 3) The said sintering promoter comprises low-melting oxides such as Bi2O3, B2O3, ZnO, SiO2, Al2O3 and Nb2O5,and one or more kinds of the glass powder with a low melting point. After reasonably reasonable formulation, optimizing synthesis and ball milling, the microwave medium material prepared from the method can be sintered at a relatively low temperature of 1340 DEG C to 1380 DEG. C.A microwave capacitor made by this method has an excellent dielectric property: [epsilon]r=3-8>Qf) 60000GHZ, [epsilon] f(-40DEG C. -25DEG C. / 25 DEG C-125 DEG C)<=20PPM / DEG C.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

Integral catalyst for producing hydrogen dioxide solution as well as preparation and application thereof

InactiveCN101497040AImprove mass transfer efficiencyReduce internal mass transfer resistancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationActive componentHydrogenation reaction

The invention provides a monolithic catalyst for oxydol production and a preparation method thereof. The catalyst uses ceramic monolithic honeycomb or metal monolithic honeycomb as a substrate, one or more of Al2O3, SiO2, CaO, MgO, TiO2, ZrO2, La2O3, CeO2, Fe2O3 and Cr2O3 as a coating material, and noble metal palladium as an active component to be used in an anthraquinone hydrogenation reaction of oxydol production. The monolithic catalyst adopts a preparation method of fractional support so as to effectively control depth of impregnation of the active component. The monolithic catalyst used in the anthraquinone hydrogenation process has the advantages of high activity, good selectivity and 82.21kg (100 percent of H2O2) / mcat.h of space-time yield of the oxydol, which is over 3 times more than a commercial bead catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Low carbon alkane dehydrogenation catalyst and its preparation method and application

ActiveCN103769079AHigh activityHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The invention discloses a low carbon alkane dehydrogenation catalyst and its preparation method and application. The low carbon alkane dehydrogenation catalyst uses La-containing alumina as a carrier, and chromium as an active component, taking the weight content of oxides as a reference, the lanthanum oxide content in the final catalyst is 0.1 to 5.0%, the chromium oxide content is 5.0% to 20.0%, and La in the La-containing alumina carrier is introduced in during gelatinizing in the alumina preparation process. The preparation method of the low carbon alkane dehydrogenation catalyst comprises the following steps: preparation of the La-containing Al2O3 carrier and a process of loading active component chromium by an impregnation method. The low carbon alkane dehydrogenation catalyst can be used in production of propylene by dehydrogenation of propane. The low carbon alkane dehydrogenation catalyst prepared by the method does not contain alkaline oxides to avoid strong interaction between the alkaline oxides and the active component, and the activity, stability and propylene selectivity of the low carbon alkane dehydrogenation catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Laser cladding Co-based alloy powder for conductor roll

InactiveCN101187022ASolve repair problemsImprove performanceMetallic material coating processesChemical compositionAlloy substrate

Provided is cobalt-based alloy powder for laser cladding electricity conducting roller, the weight percentages of the chemical components of the material are that Cr is 24-30%, W is 6-10%, Mo is 3-6%, Ni takes 6-12%, Fe holds 2-10%, Mn is 0.5-2%, Si holds 0.2-2%, V is 0.1-0.6%, B takes 0.3-1.5%, C holds 0.5-2.5%, Y2O3 is 0-0.5%, Hf takes 0-0.5%, La2O3 holds 0-0.5%, Ce is 0-0.5%, and the rest is Co. The invention has the advantages that with multiple strengthened methods, the alloy substrate is strengthened and the crystal boundary quality is improved, which enables the alloy to achieve perfect combination property, thereby achieving medium rigidity and relatively high intensity of the alloy, simultaneously forming self-fluxing alloy and reducing alloy melting point, and increasing properties of oxidation resistance, abrasion resistance, corrosion resistance, and certain electricity conduction.

Owner:SHENYANG DALU LASER TECH

Iron-base catalyst for Fischer-Tropsch synthesis and its preparation method

ActiveCN1597105AReduce manufacturing costLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIron sulfatePotassium silicate

A Fe-based catalyst for the Fischer-Tropsch synthesis contains Re2O3, Fe3O4, La2O3, CuO, K2O and SiO2. It is prepared through using oxidant to oxidize partially the ferrous sulfate to obtain the mixed solution of iron sulfate and ferrous sulfate, mixing with the mixed solution of lanthanum nitrate and copper salt, fast depositing by alkaline compound, washing the deposited slurry, adding potassium silicate-water glass solution, and spray drying.

Owner:SYNFUELS CHINA TECH CO LTD

Rare earth polishing powder and production method thereof

The invention discloses rare earth polishing powder and a production method thereof. As an abrasive substance, the polishing powder comprises CeO2, La2O3 and Pr6O11. The total rare earth oxides (TREO) are above 90wt%. Meanwhile, in the TREO of the 877-3 rare earth polishing powder, CeO2 accounts for 70-80%, La2O3 19-29%, Pr6O11 0.05-2% and Nd2O3 less than 0.2%. To ensure necessary polishing speed, fluorine element which has chemical action is added to the wet synthesis process and initial shaping of product granularity is controlled, so that the obtained 877-3 rare earth polishing powder can be used for fast producing polished surface with good polishing effect.

Owner:甘肃稀土新材料股份有限公司

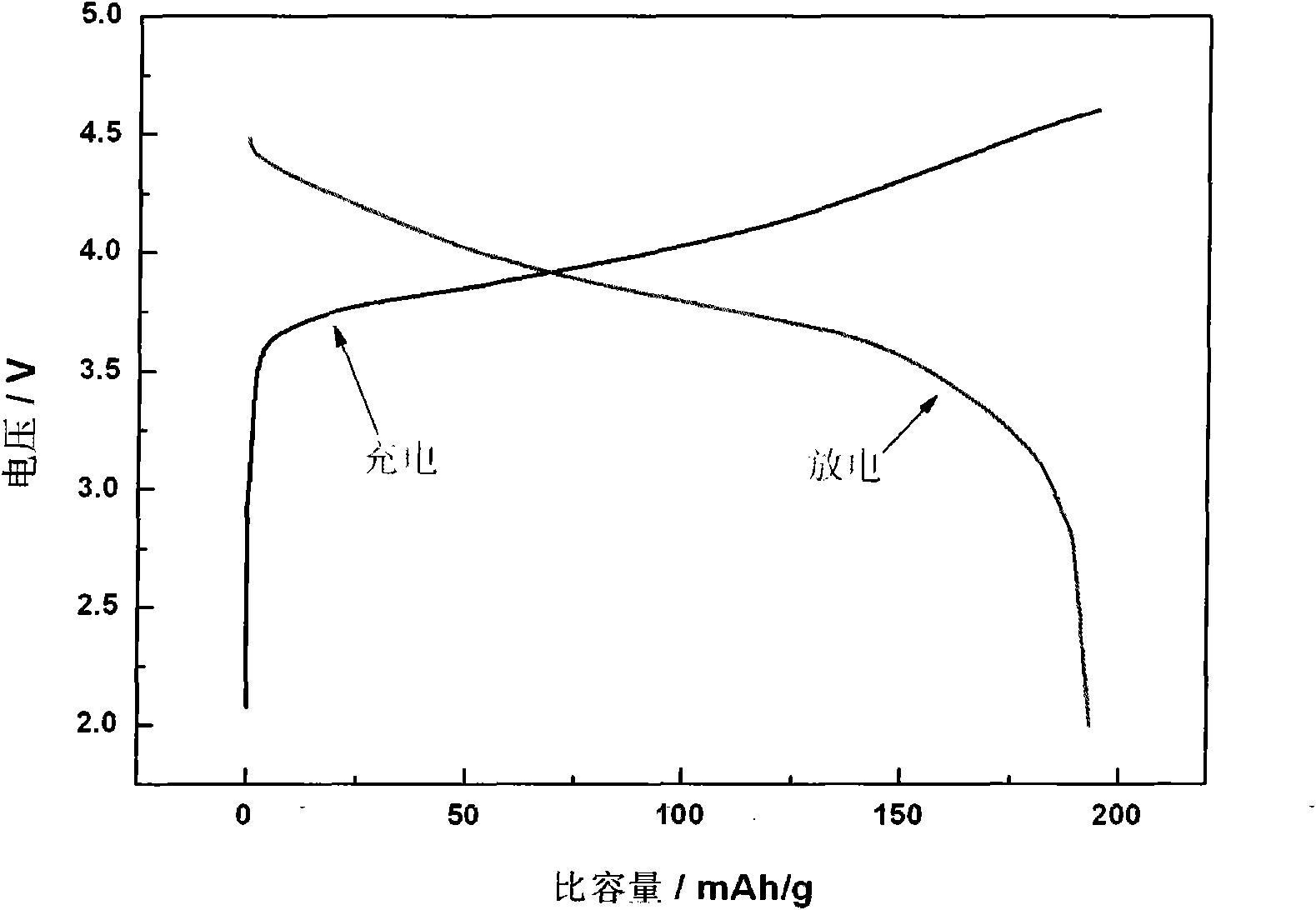

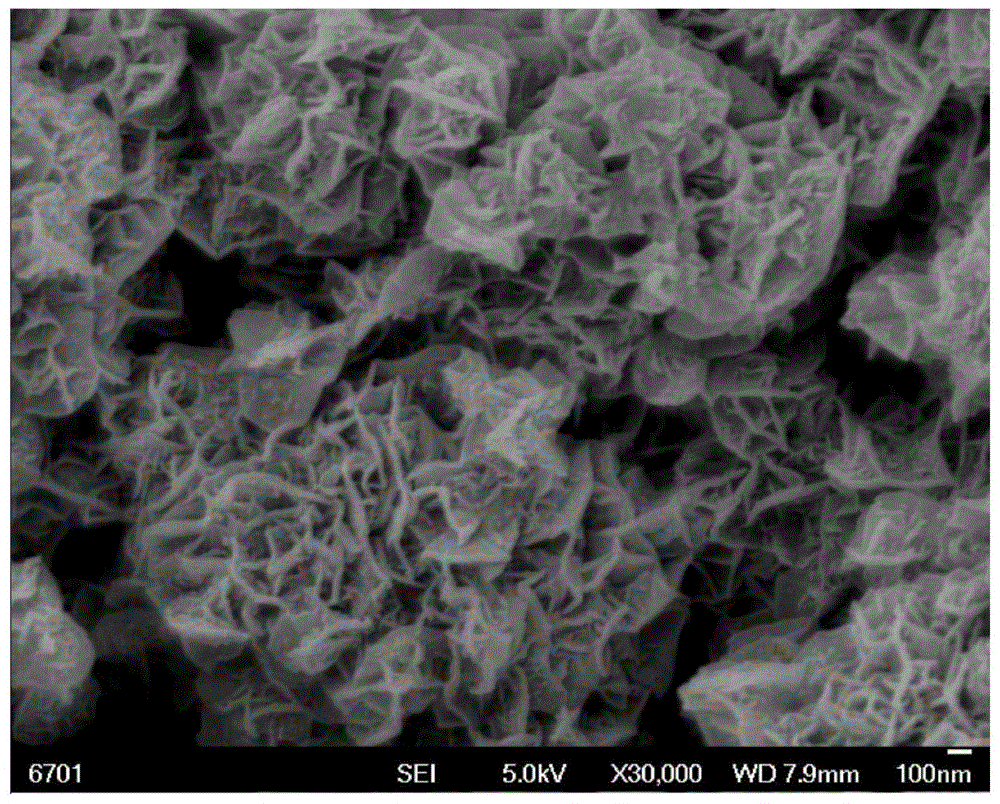

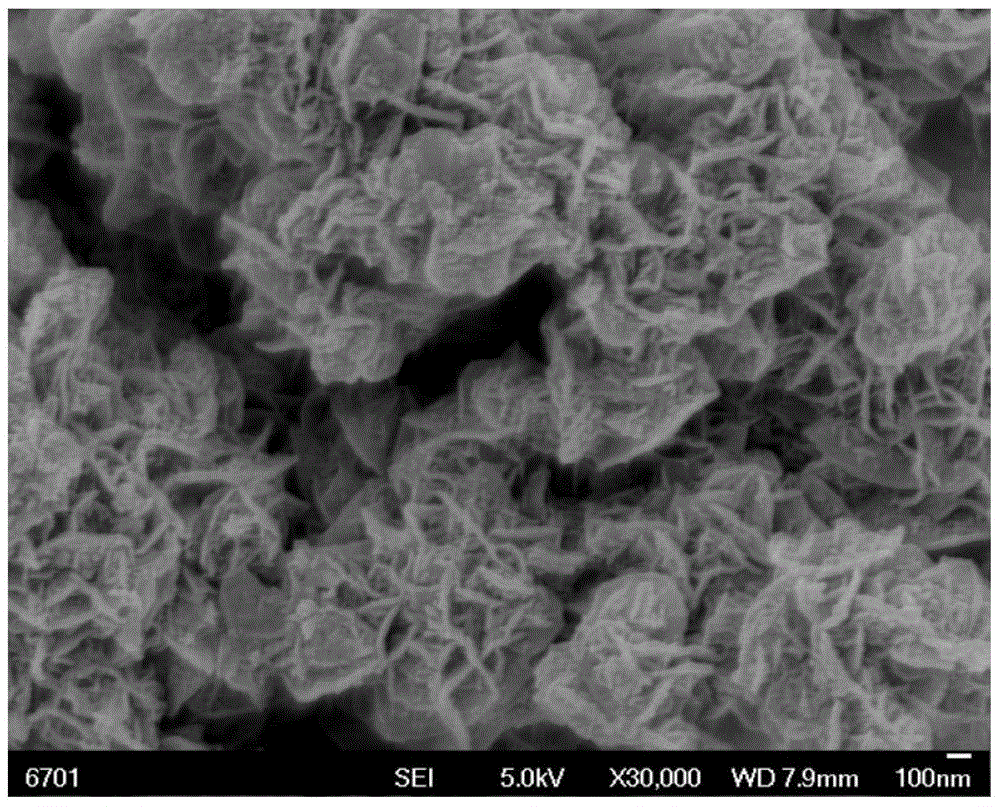

Laminated ternary positive material and preparation method thereof

The invention provides a laminated ternary positive material and a preparation method thereof. The chemical formula of the laminated ternary positive material is aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 / M, wherein a is more than 0 and less than 1; x is more than 0 and less than 1; y is more than 0 and less than 1; and M is aluminium oxide (Al2O3), titanium dioxide (TiO2), zirconium oxide (ZrO2), lanthanum oxide (La2O3), zinc oxide (ZnO) or magnesium oxide (MgO). The preparation method comprises the following steps of: preparing a precursor mixture; sintering the precursor mixture in a sintering furnace to synthesize a aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 positive material; and performing compounding to obtain the aLi2MnO3.(1-a)LiMn(1-x-y)NixCoyO2 / M material. The laminated ternary positive material has high energy density, a stable high-voltage charging and discharging structure, a simple preparation process and low production cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Low-temperature sulfur-resistant denitration catalyst and preparation method thereof

InactiveCN105727936AHigh activityImprove sulfur resistanceNitrous oxide captureHeterogenous catalyst chemical elementsCopper oxideManganese oxide

The invention discloses a preparation method of a catalyst for removing NOx in coke oven tail gas through low-temperature sulfur-resistant catalytic reduction.The catalyst is prepared by taking titanium oxide as a carrier, taking one or two of cerium oxide, zirconia oxide and lanthanum oxide as an auxiliary, taking one or more than two of manganese oxide, cobalt oxide, copper oxide and ferric oxide as an active ingredient and adopting a precipitation-deposition method, wherein two or three of TiO2, ZrO2, CeO2, La2O2, MgO, CaO and BaO can be adopted as the carrier.In the low-temperature sulfur-resistant denitration catalyst, the loading quantity of the active ingredient is 5 wt%-20 wt%, and the loading quantity of the auxiliary is 0.5%-5%.According to the preparation method, the active ingredient prepared by achieving precipitation and deposition sodium carbonate and oxidizing and loading the active ingredient manganese dioxide through potassium permanganate is mainly distributed in the surface area of the carrier, and the dosage of the active ingredient can be effectively decreased.The catalyst is high in activity and sulfur poisoning resisting capacity and particularly suitable for catalytic removal of the NOx in the coke oven tail gas, and the denitration effect of the catalyst also can be expanded to the low-temperature denitration process of other tail gases.

Owner:GANSU TIANLANG CHEM TECH CO LTD +1

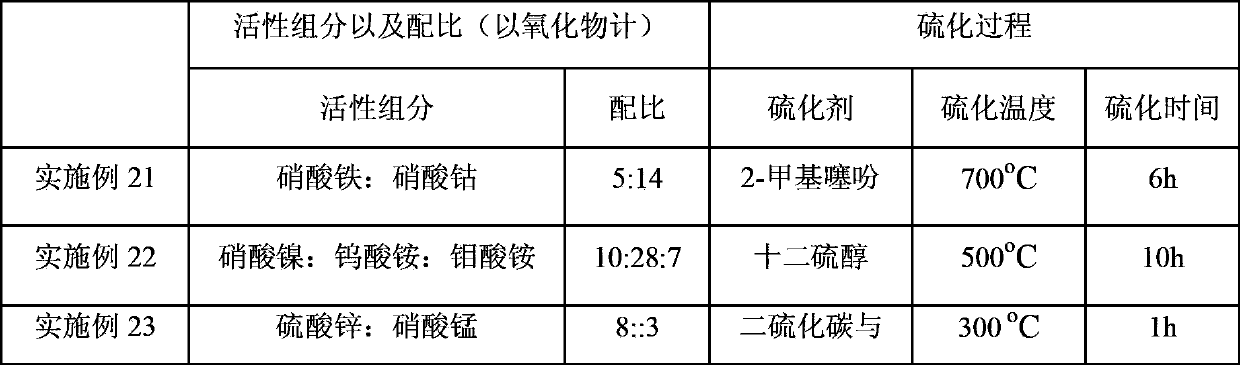

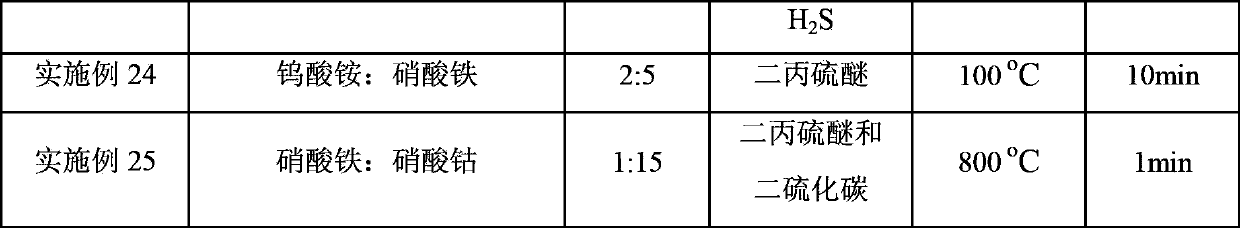

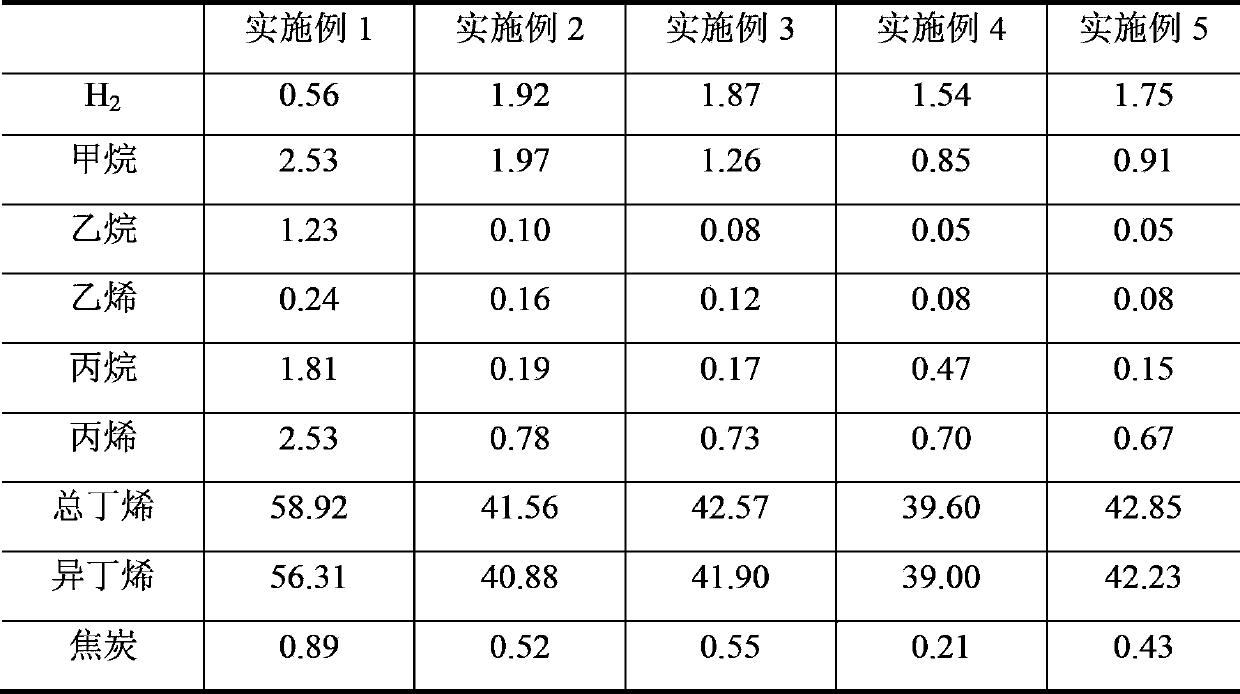

Alkane dehydrogenation sulfide catalyst and alkane dehydrogenation method

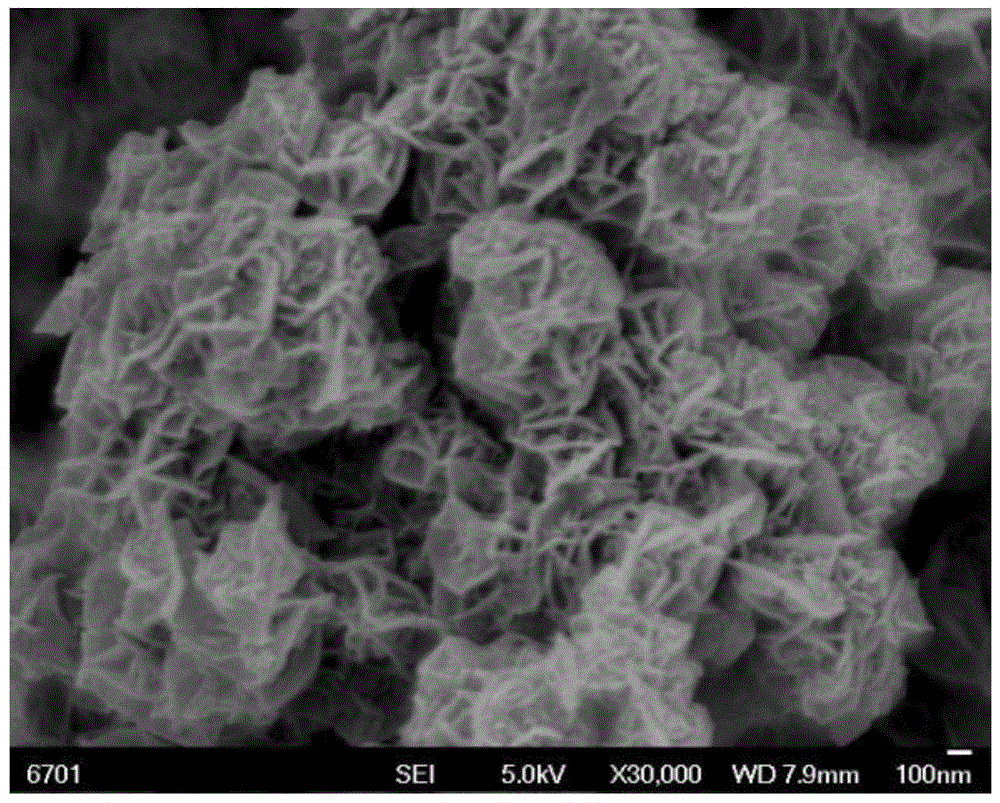

InactiveCN103861619ALow priceHigh dehydrogenation activityPhysical/chemical process catalystsHydrocarbonsAlkaneMixed oxide

The present invention provides an alkane dehydrogenation sulfide catalyst, which comprises an active ingredient and a carrier, wherein the active ingredient comprises one or a plurality of elements selected from Fe, Co, Ni, Cu, Zn, Mo, W and Mn, the active ingredient content in the catalyst (calculated as the oxide having the highest valence) is 0.5-40 wt%, the carrier is a mixed oxide or a composite oxide formed from one or a plurality of materials selected from SiO2, Al2O3, ZrO2, La2O3, CeO2, CaO, P2O5, Nb2O5 and MgO, the carrier content is 60-99.5 wt%, and the active ingredient on the surface of the alkane dehydrogenation sulfide catalyst exists in a sulfide form. When the catalyst is adopted for the alkane dehydrogenation reaction, characteristics of high activity, high selectivity, good stability, slow deactivation, low cost and no environment pollution are provided.

Owner:江苏省海洋石化股份有限公司 +1

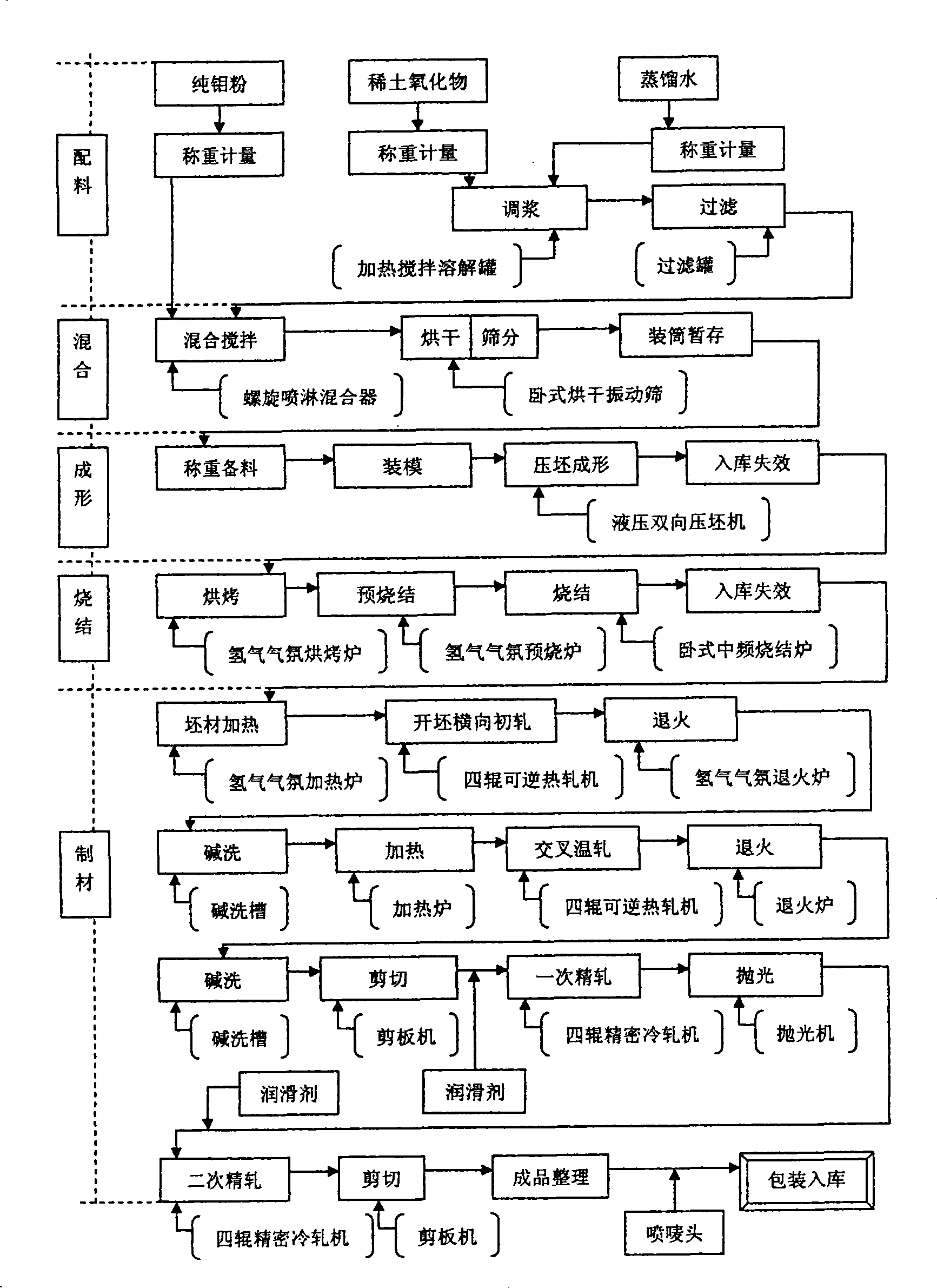

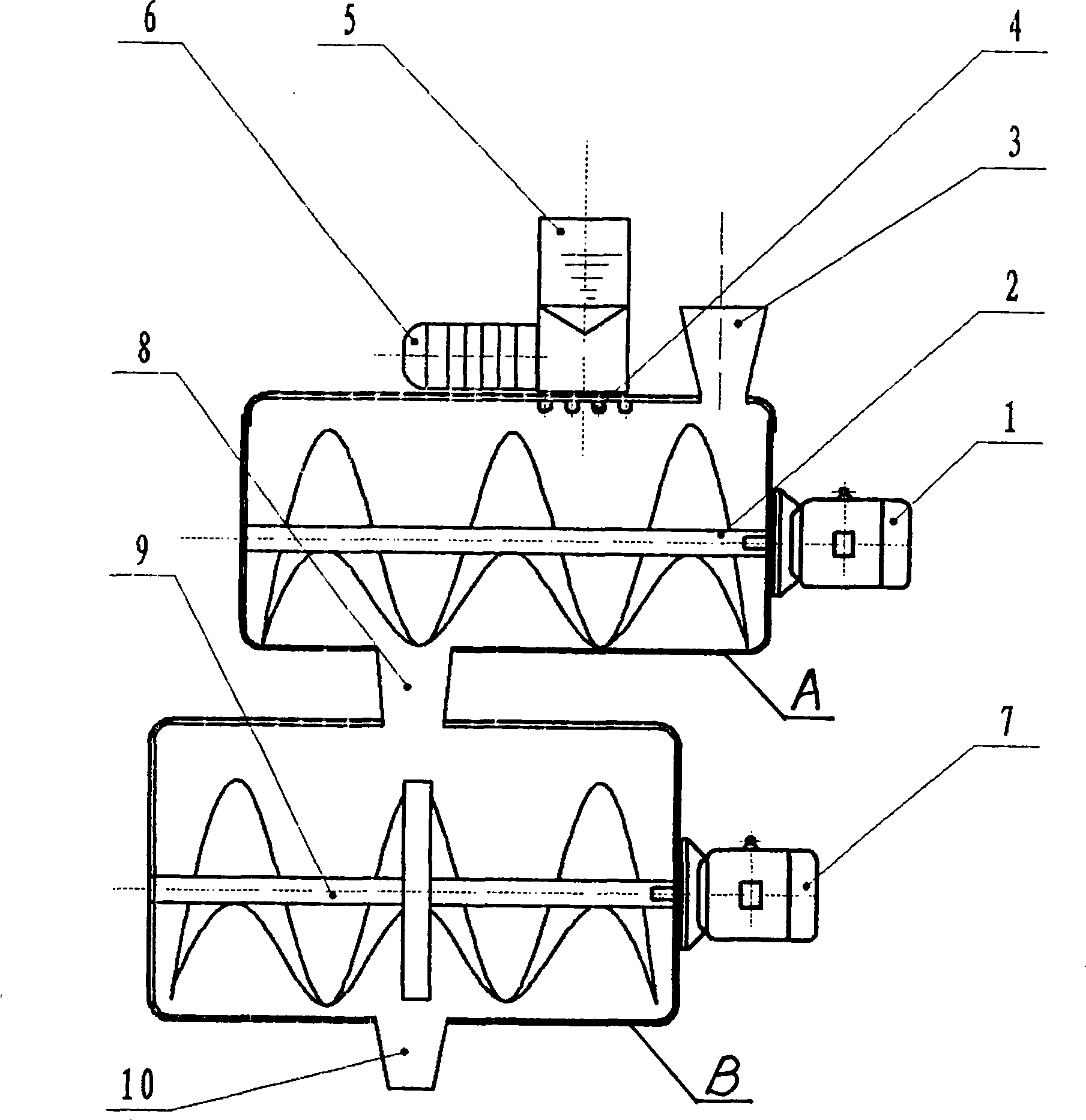

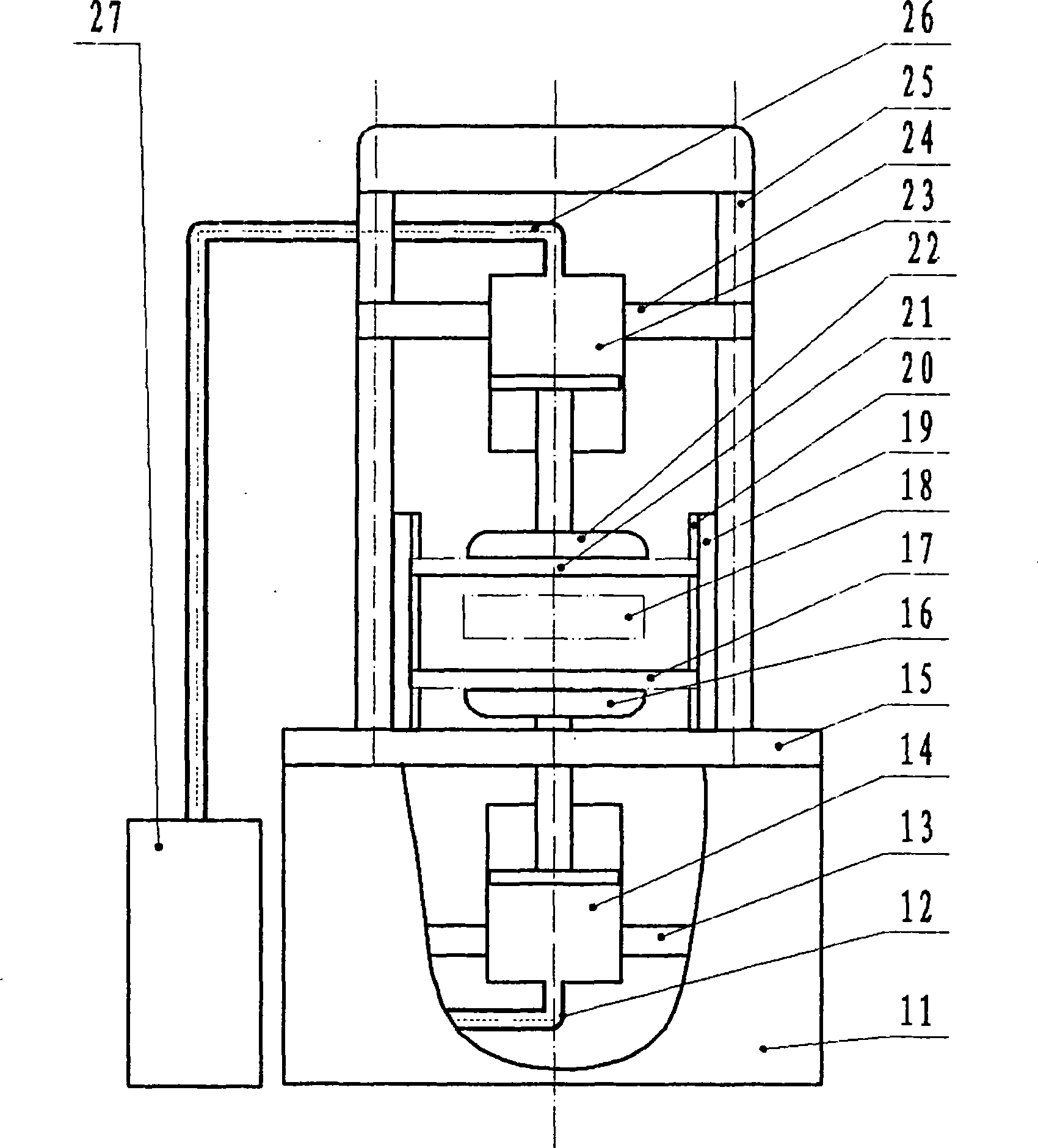

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

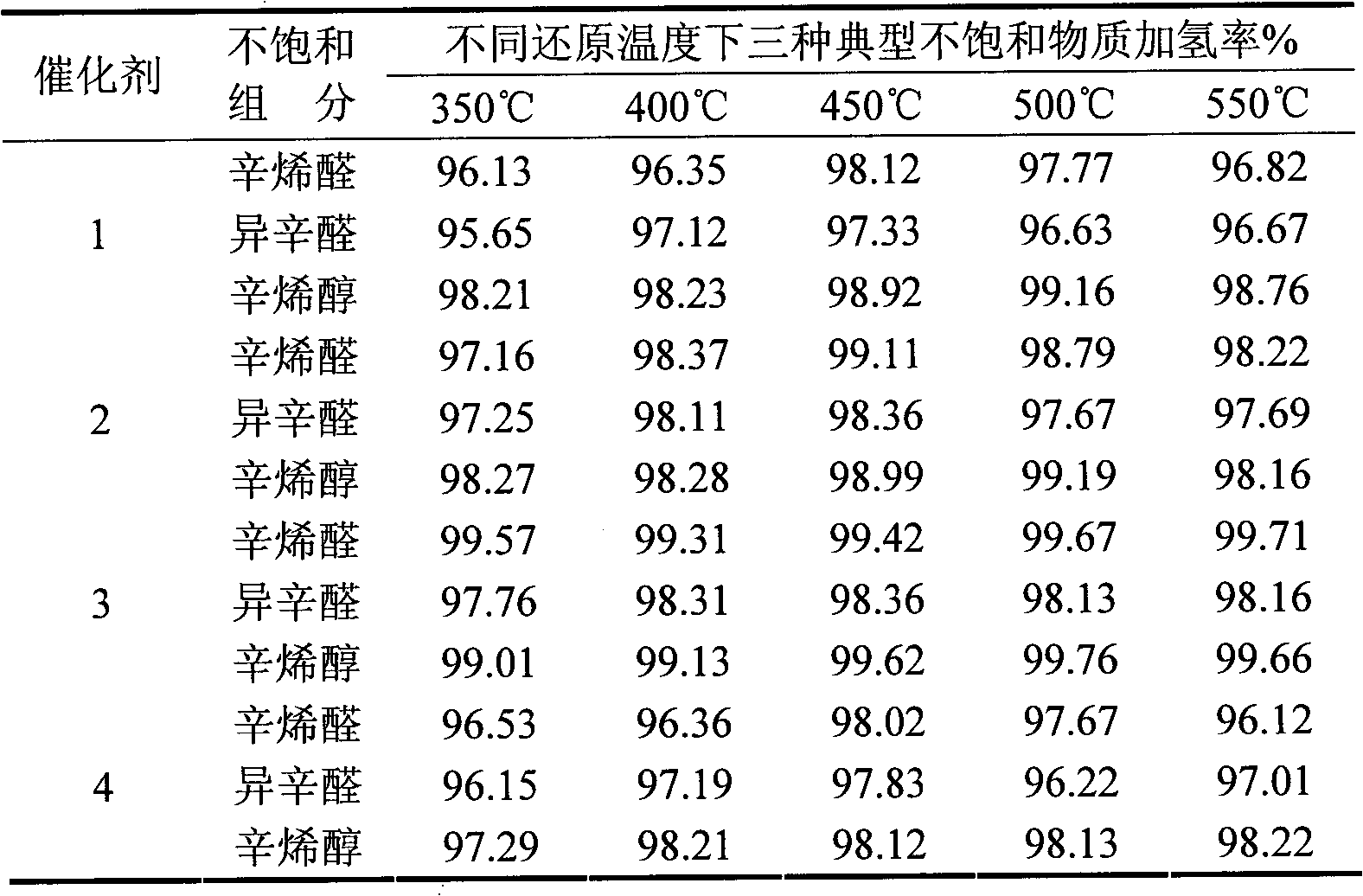

Lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof

ActiveCN102059121AReduce generationReduce coalescenceOrganic compound preparationHydroxy compound preparationReaction temperatureOctanol

The invention relates to a lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof. The catalyst is prepared by taking Gamma-Al2O3 as a carrier, taking lanthanum as an auxiliary agent, taking nickel-copper as a active component and adopting an immersion method; and the aluminum oxide accounts for 40-90%in the terms of 100% by mass, the content of nickel is 1-40% in the terms of NiO, the content of copper is 1-30% in the terms of CuO, and the lanthanum as the auxiliary agent is 0.1-10% in the terms of La2O3; and a hydrogenation evaluation result indicates that the catalyst is reduced at a temperature of 350-550 DEG C, and under the conditions that the reaction temperature is 120 DEG C, the reaction pressure is 2.5MPa, the volume ratio of hydrogen to liquid is 8:1 and the volume air speed is 3.0h<-1>, the hydrogenation rates of unsaturated substances such as octylene aldehyde, isooctyl aldehyde and octylene alcohol are all more than 95%.

Owner:PETROCHINA CO LTD +1

Silver paste for solar cells and preparation method thereof

ActiveCN102324263AImprove photoelectric conversion efficiencyStrong adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureEnvironmental resistanceSolar cell

The invention discloses a silver paste for solar cells. The silver paste consists of silver powder, lead-free glass powder and an organic carrier, the organic carrier consists of organic solvent and organic additive, the silver powder is spherical and / or flaky, and the grain sizes of the silver powder are coarse and fine; the lead-free glass powder adopts a lanthanum-boron-zinc glass system, and the components of the lead-free glass powder are La2O3, B2O3, Al2O3, ZnO, Na2O, LiO2, V2O5 and P2O5. A preparation method for the silver paste includes the following steps: after being uniformly mixed, the materials of the lead-free glass powder are put into a high-temperature muffle furnace to heat, the temperature is preserved, and the melted glass powder particles are quenched and then ball-milled; the organic solvent and the organic additive are uniformly mixed and stirred according to proportion; the silver powder, the lead-free glass powder and the organic carrier are weighed, uniformly stirred in a container, put into a three-roll mill and ball-milled, and thereby the uniform silver paste for the solar cells is prepared. Under the premise of meeting the electrical properties of the solar cells, the silver paste also can meet the requirement on lead-free environment-friendliness.

Owner:JIANGSU RUIDE NEW ENERGY TECH

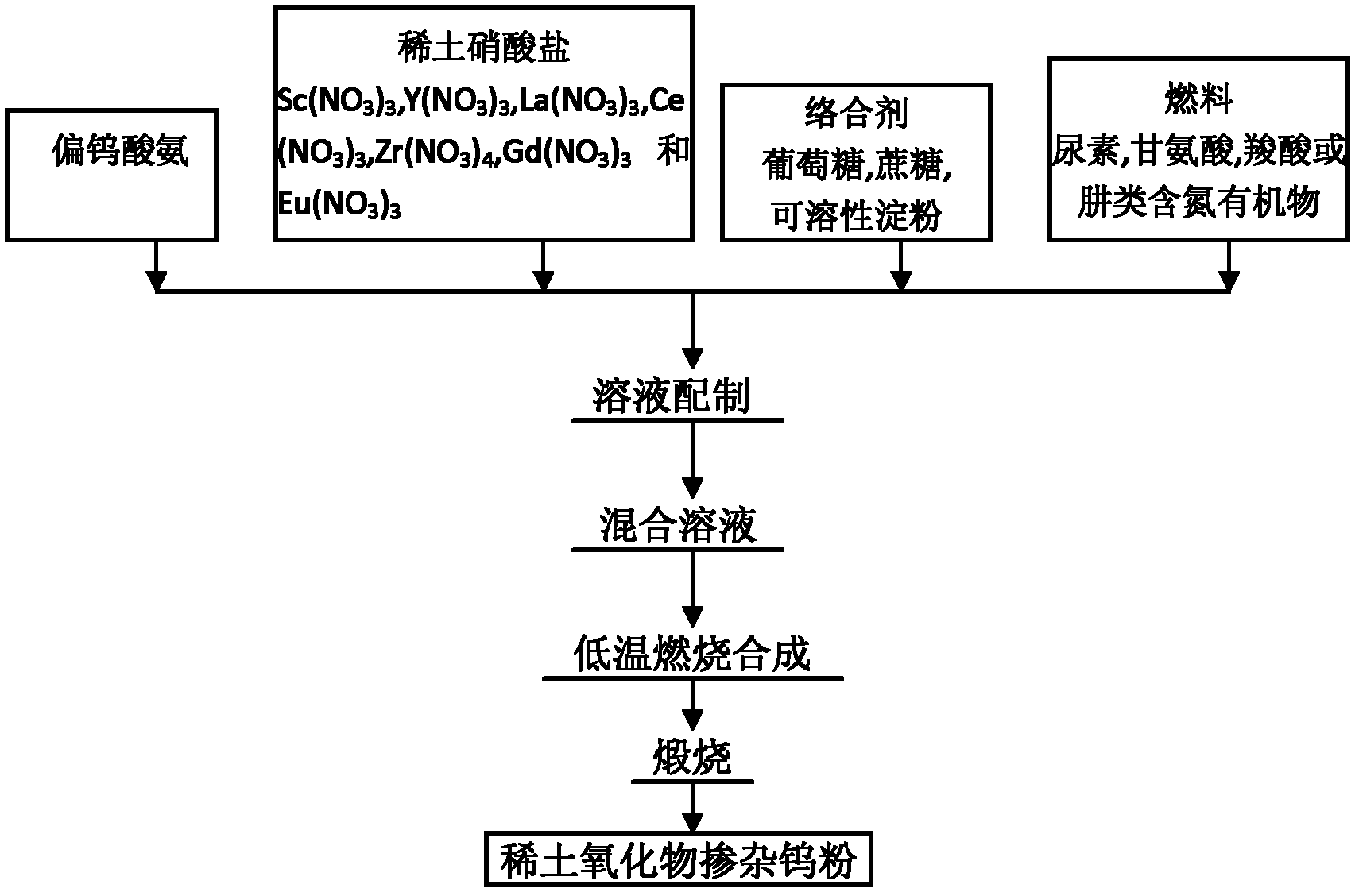

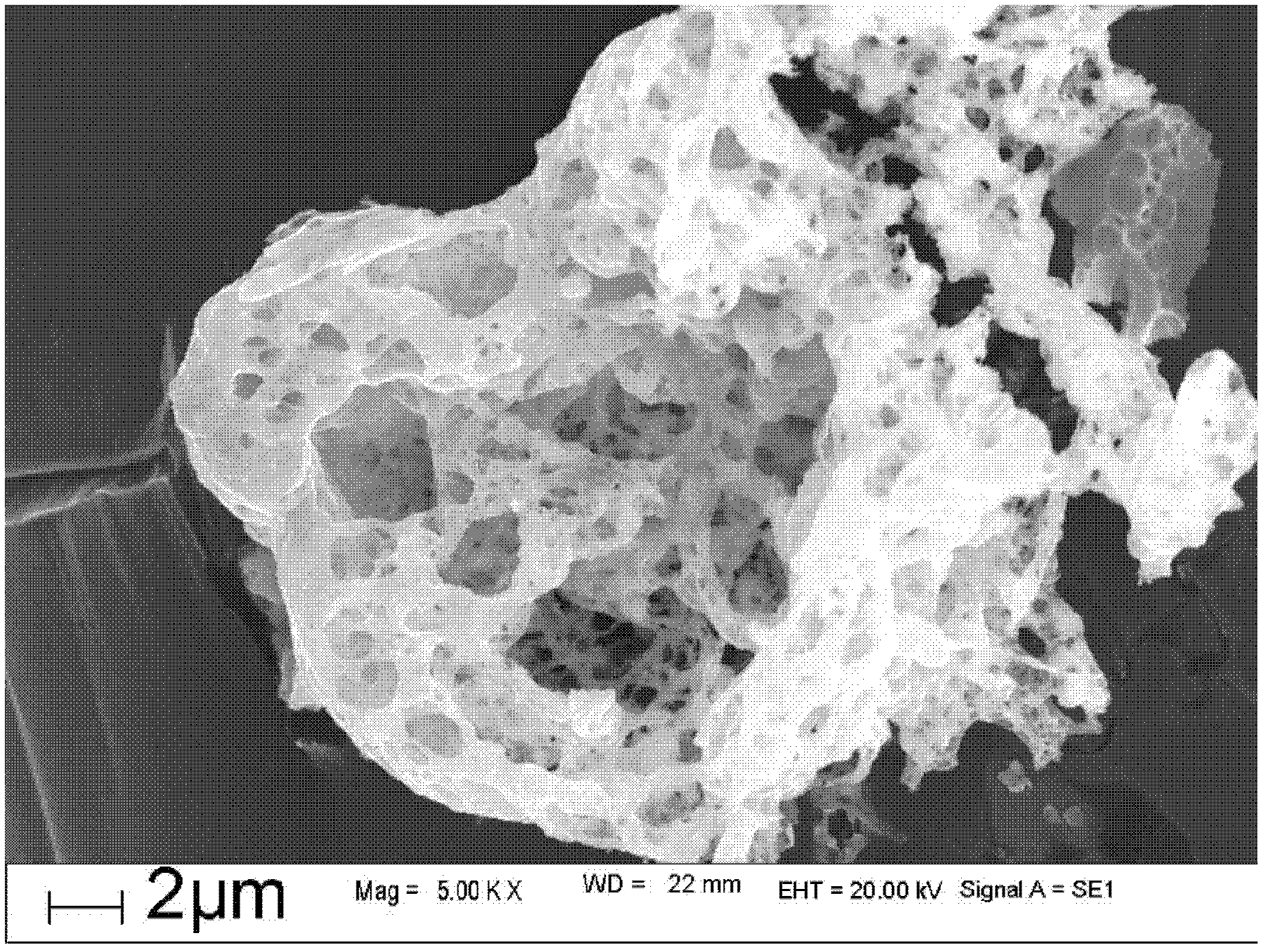

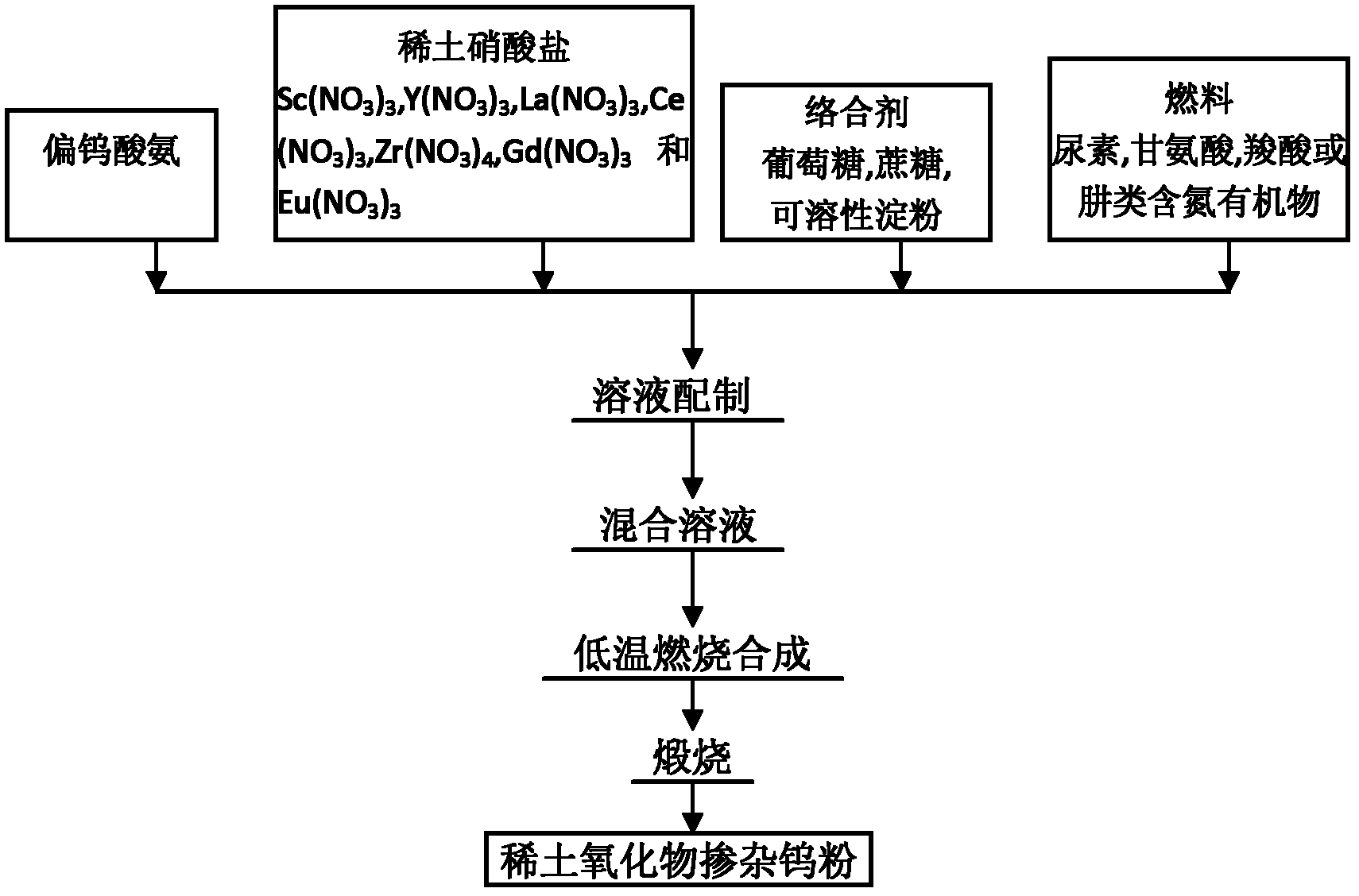

Preparation method for rare earth oxide doped tungsten powder

The invention provides a preparation method of rare earth oxide doped tungsten powder, belonging to a technical field of rare earth refractory metal material. The process flow is that: firstly, a precursor powder is obtained by adopting low-temperature combustion synthesis, wherein the precursor powder is a uniform mixture of rare earth oxide (at least one of Sc2O3, Y2O3, La2O3, CeO2, ZrO2, Gd2O3and Eu2O3) and tungsten oxide; secondly, the precursor powder undergoes calcination in a muffle furnace; lastly, two-step reduction is carried out in the atmosphere of hydrogen or dissociated ammonia. Easy-reduction tungsten oxide is reduced to tungsten matrix powder, and the rare earth oxide that can not be reduced is reserved, thereby the rare earth oxide doped tungsten powder is obtained. The content of the rare earth oxide in the rare earth oxide doped tungsten powder is 0.05-35 wt%. The advantage of the invention is that target element and organic carbon source are capable of forming a highly dispersed system, and particle sizes of the obtained oxide are uniform and fine. The method is suitable for industrialization production because of low cost of raw materials, quick reaction speed, low energy consumption and simple technology.

Owner:UNIV OF SCI & TECH BEIJING

Integral automobile exhaust purification catalyst and preparation method thereof

InactiveCN101947456AEasy to makeLow priceCatalyst carriersDispersed particle separationRare earthCordierite

The invention discloses an integral automobile exhaust purification catalyst and a preparation method thereof, and relates to preparation of aluminum oxide sol, modification of a plurality of oxides in the introduced La2O3, CeO2, BaO, SrO, CaO, ZrO2, CuO, SiO2 and the like, load of the modified aluminum oxide sol on cordierite honeycomb ceramic and loads of a plurality of catalyst active ingredients in La, Sr, Co, Cu, Mn, Fe, Pd and the like. The cordierite honeycomb ceramic is used as a carrier; the modified aluminum sol is loaded on the cordierite honeycomb ceramic carrier by adopting a vacuum impregnation method; and the catalyst active ingredients are loaded on a modified aluminum oxide coating by adopting the vacuum impregnation method. When the modified aluminum oxide coating with large specific surface area is used for loading a perovskite type rare-earth catalyst, the load is uniform, the bonding property is strong, the crystal form structure of the catalyst is not changed; and the catalyst has good catalytic activity, air-fuel ratio fluctuation resistance and sulfur dioxide poisoning resistance.

Owner:SOUTH CHINA UNIV OF TECH

Cerium zirconium aluminum based multiple oxide material and preparing method thereof

ActiveCN101745375AImprove anti-aging propertiesHigh specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCe element

The present invention provides cerium zirconium aluminum based multiple oxide material and a preparing method thereof, wherein on the basis of the total amount of the cerium zirconium aluminum based multiple oxide material, the cerium zirconium aluminum based multiple oxide material is composed of the following components by weight: 25 to 70 shares of aluminum oxide, 20 to 60 shares of cerium oxide, 5 to 25 shares of zirconium oxide, 2 to 4.9 shares of lanthanum oxide and 2 to 15 shares of stable addition agent which is one or more oxides selected from Y, Eu, Gd and Sm. The cerium zirconium aluminum based multiple oxide material has high specific surface area. After the cerium zirconium aluminum based multiple oxide material is roasted in 450 DEG C to 550 DEG C for two to four hours, the specific surface area is all larger than 100m2 / g; after the cerium zirconium aluminum based multiple oxide material is roasted in 1000 DEG C for ten hours, the specific surface area at least can reach60 m2 / g; after the cerium zirconium aluminum based multiple oxide material is roasted in 1100 DEG C for five hours, the specific surface area at least can reach 40m2 / g. thus, the cerium zirconium aluminum based multiple oxide material is superior to the anti-aging performance of multiple oxide material of the prior art, and can be used as an addition agent or carrier for vehicle tail gas purifying three-way catalyst.

Owner:苏州相城埭辰科技产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com