Patents

Literature

1549 results about "Potassium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium silicate is the name for a family of inorganic compounds. The most common potassium silicate has the formula K₂SiO₃, samples of which contain varying amounts of water. These are white solids or colorless solutions.

Water-soluble inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationPowder mixture

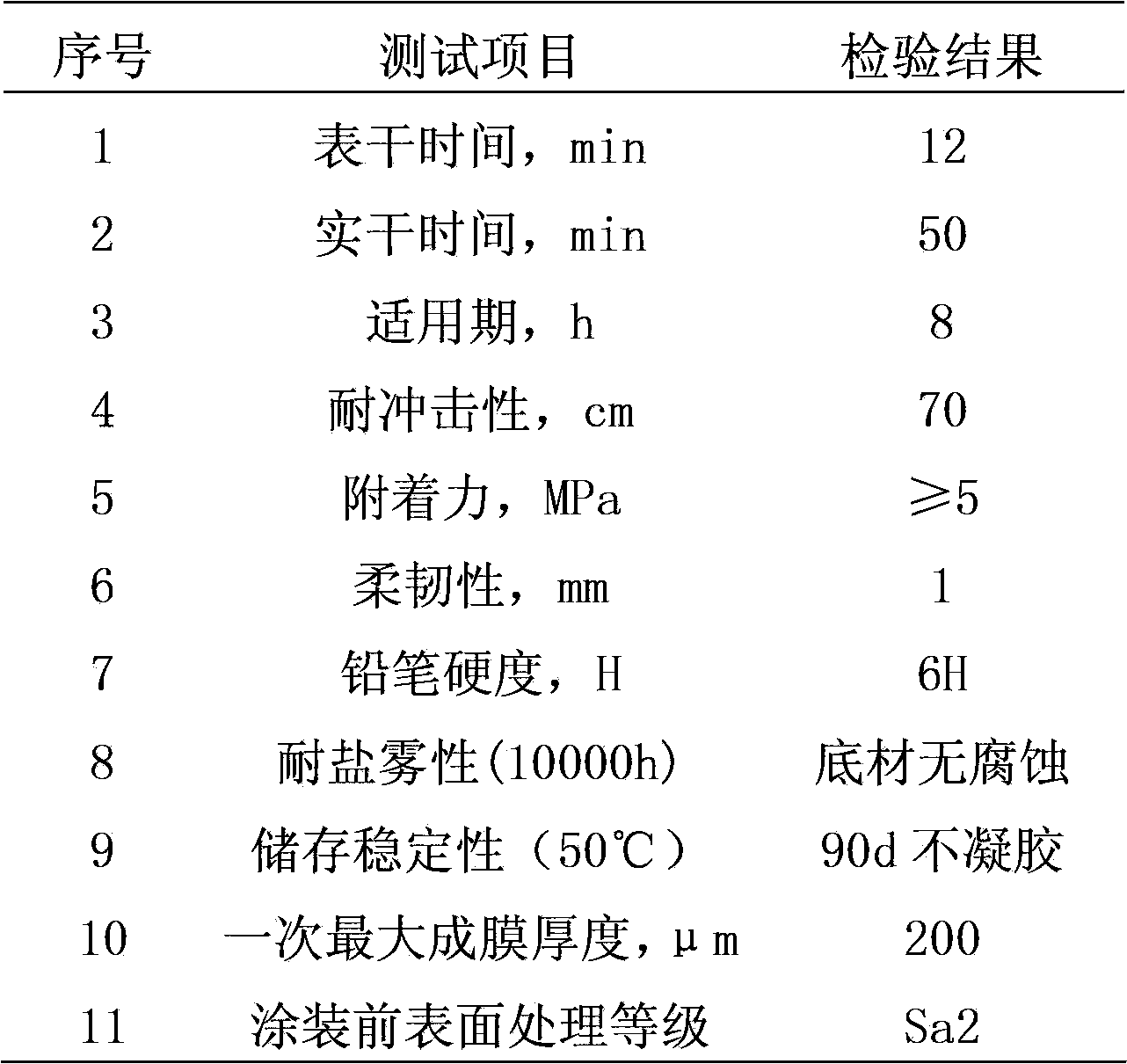

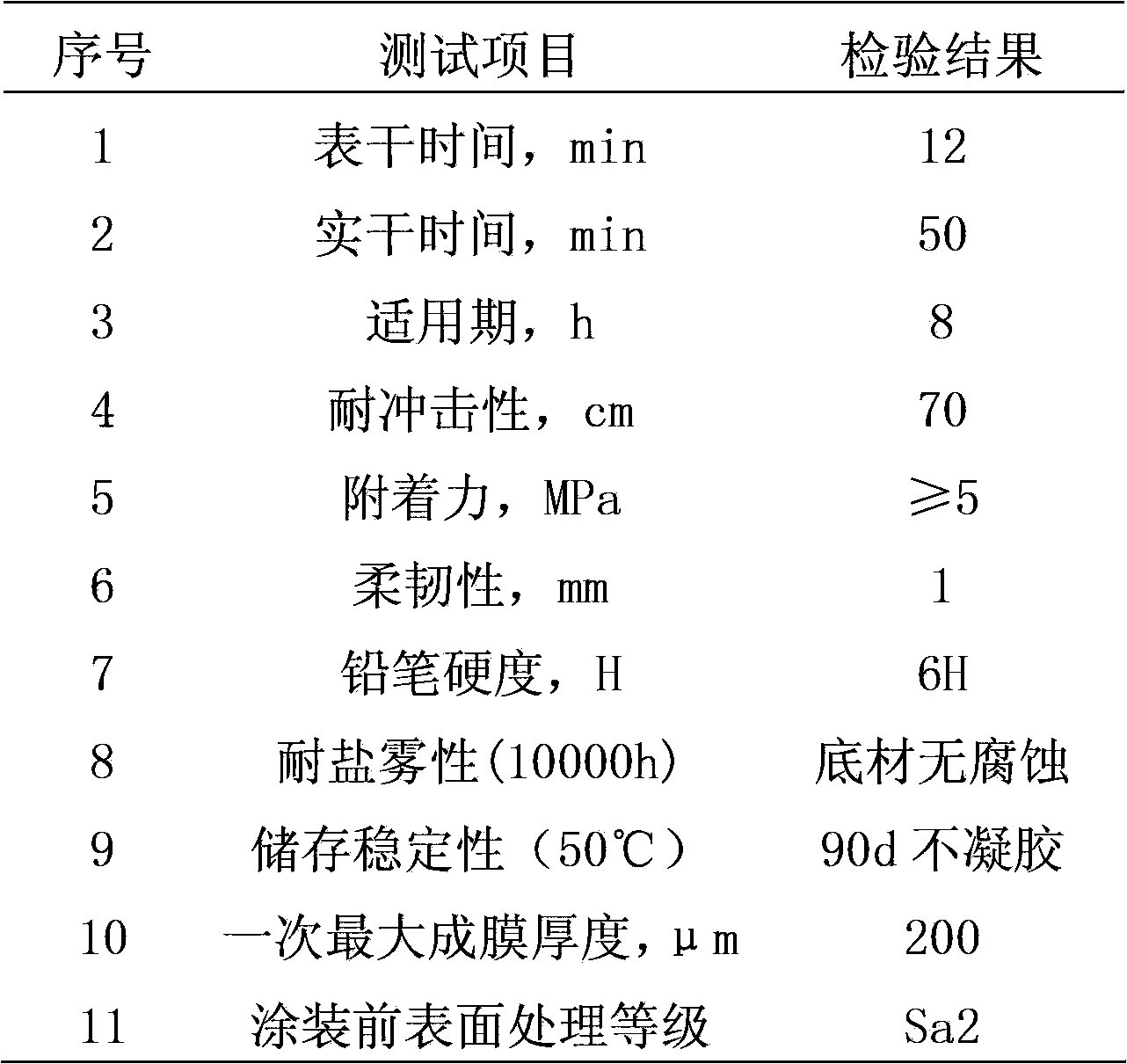

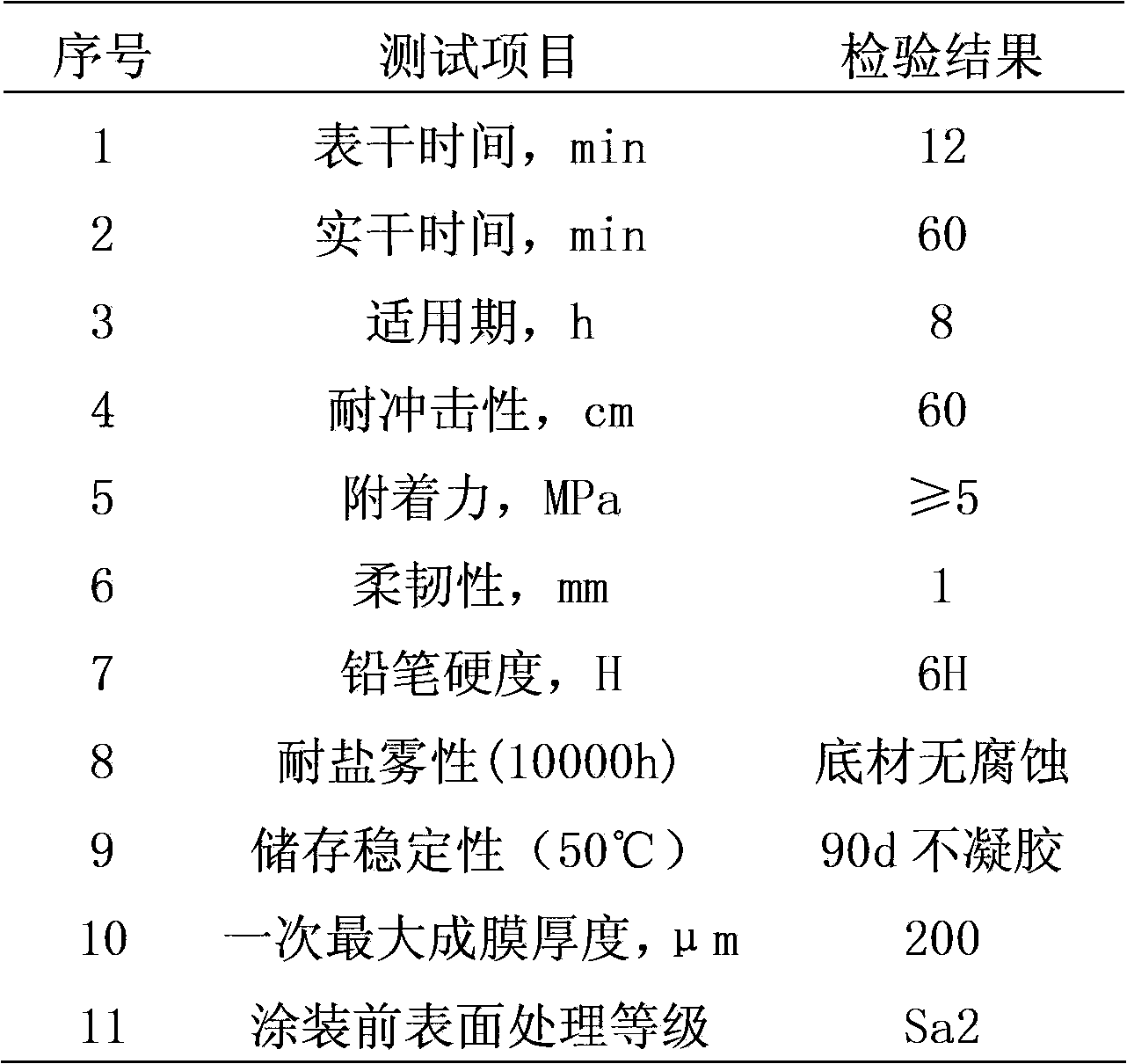

The invention provides a water-soluble inorganic zinc-rich paint and a preparation method thereof. The preparation method comprises the following steps: dropwise adding aluminum-modified silica sol into potassium silicate solution with low modulus, so as to obtain a high-modulus potassium silicate solution as a binder; and adding a catalyst, a siloxane oligomer and a modifier to ensure that the high-modulus potassium silicate solution are uniform in size distribution, and does not have gelatinization reaction for a long time, wherein after the high-modulus potassium silicate solution and a zinc powder mixture are stirred uniformly, the zinc-rich paint has the advantages that reaction rates of all parts of a coating are uniform, and no stress concentration phenomenon exist. Proved by experiments, the zinc-rich paint provided by the invention has no gel after being stored for 90 days at 50 DEG C, the thickness of a film formed once can reach 200 mu m, no cracking or bubbling phenomenon exists, construction can be carried out after the treatment level of the steel surface reaches Sa2, and the salt fog resistance of the coating can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Liquid silicon fertilizer and technique for producing the same

InactiveCN101440001APromote growthIncrease resistanceOrganic fertilisersUrea compound fertilisersMetasilicateSilicic acid

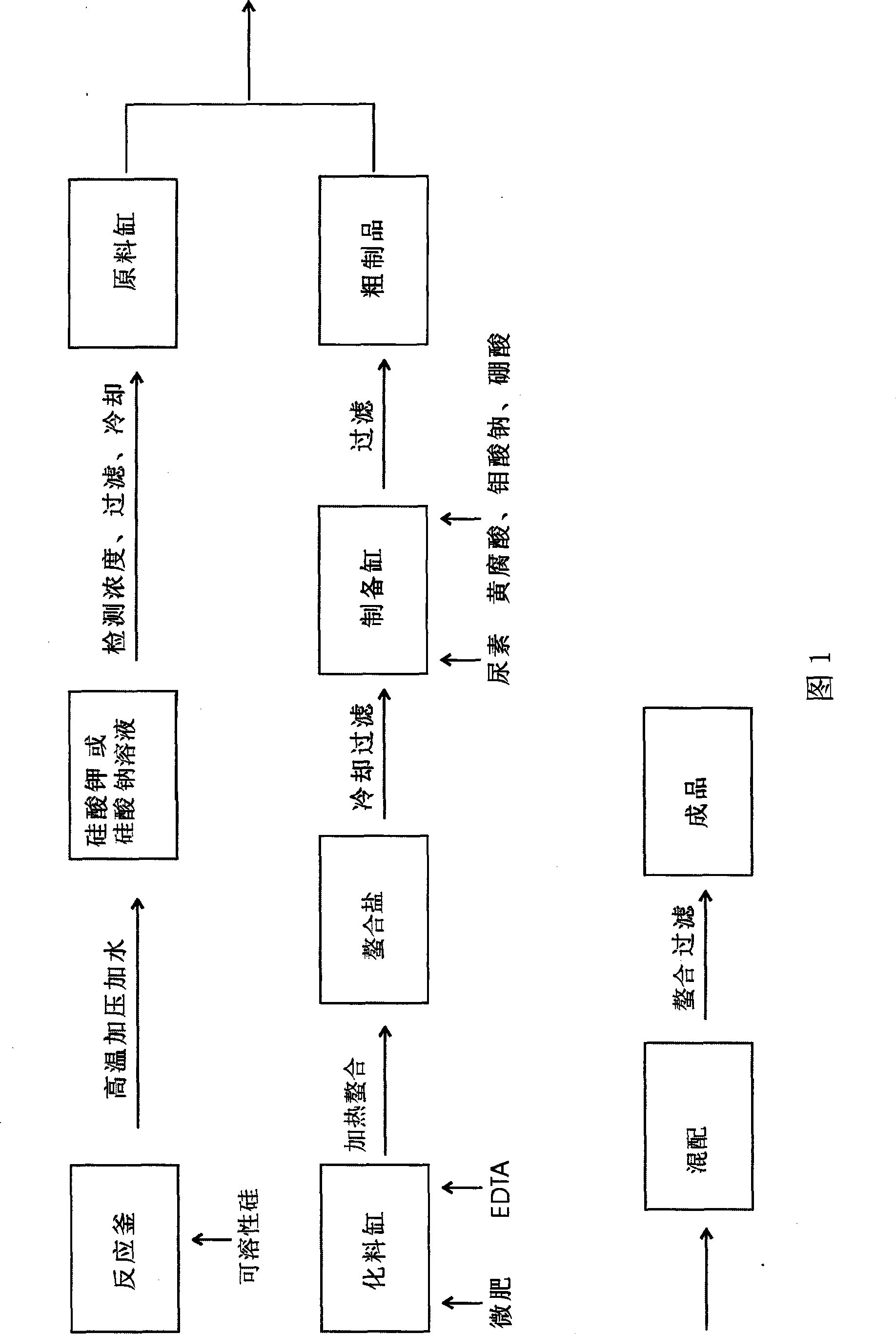

The invention relates to a liquid silicon fertilizer and a production technique thereof, and belongs to the technical field of fertilizer. The liquid silicon fertilizer is characterized in that raw materials comprise soluble silicon, urea, trace elements, chelate and fulvic acid, which are prepared into the balanced compound fertilizer. The production technique comprises the following steps: 1, dissolving solid potassium metasilicate; 2, dissolving sulfate of the trace elements in water, and adding EDTA into the mixture to obtain the chelate of the EDTA trace elements; and adding boric acid, ammonium molybdate, the urea and the fulvic acid into the mixture after cooling and filtration; and 3, blending the chelate into the mixture to obtain the liquid silicon fertilizer. The production technique is characterized in that (1) the production technique uses water glass and the fulvic acid chelate, has better buffer action for alkali, and can effectively improve stability of SiO3; and (2) the trace elements are chelated twice by using the EDTA and the fulvic acid to form chelated metal ions, so as to prevent silicic acid radicals and the metal ions reacting to form silicate difficult to be dissolved in water, and influence utilization rate of silicon element. The production technique uses the liquid potassium metasilicate and large amount of elements, trace elements and organic substances to establish a balanced compound system, and can effectively improve utilization rate of the silicon element and various nutrient elements for the crops.

Owner:于春开

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and preparation method thereof

The invention discloses a polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and a preparation method of the liquid chelated fertilizer. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer comprises the components by weight percent: 5-25% of urea, 5-15% of ammonium polyphosphate, 5-25% of potassium nitrate, 0.2-3% of potassium silicate, 0.8-5% of potassium chloride, 0.008-0.1% of polyaspartic acid, 0.8-5% of ammonium sulfate, 0.8-5% of ethylene diamine tetraacetic acid (EDTA) calcium, 0.2-3% of EDTA magnesium, 0.02-1.5% of EDTA boron, 0.005-0.1% of EDTA zinc, 0.005-0.1% of EDTA iron, 0.005-0.05% of EDTA copper, 0.005-0.05% of EDTA manganese, 0.001-0.01% of nickel sulfate, 0.001-0.01% of ammonium molybdate, 0.0008-0.01% of cobaltous sulfate, 0.008-0.1% of polyacrylamide and the balance of water. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer disclosed by the invention is simple in technology, scientific in proportion, balanced in fertilization, low in cost and good in effect.

Owner:张朝晖

Long-acting water-soluble and environmentally-friendly steel structural protective coating

ActiveCN103450719AImprove adhesionHigh reactivityAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceAcrylic coating

The invention provides a long-acting water-soluble and environmentally-friendly steel structural protective coating. The long-acting water-soluble and environmentally-friendly steel structural protective coating is characterized in that a water-soluble inorganic zinc silicate coating is used as a primer of the protective coating; a water-soluble silicon-acrylic coating is used as an intermediate coating; a water-soluble fluorocarbon coating serves as a top coating; the water-soluble inorganic zinc silicate coating comprises the raw materials of high-modulus potassium silicate inorganic nanometer resin and synthesized organic polymer emulsion, wherein the high-modulus potassium silicate inorganic nanometer resin has the modulus of 5.3 to 6.2, and the particle diameter is 5 to 20nm; the synthesized organic polymer emulsion is composed of one or a plurality of water-soluble styrene-acrylic emulsion, water-soluble pure acrylic emulsion, water-soluble silicone acrylic emulsion, water-soluble fluorocarbon emulsion and water-soluble fluoro-silicon emulsion; and the water-soluble silicon-acrylic coating comprises the raw material of a silicon-acrylic matrix, wherein the silicon-acrylic matrix is one of a mixture of silicone acrylic emulsion and pure acrylic emulsion, the mixture of silicone acrylic emulsion and styrene-acrylic emulsion, and silicone acrylic emulsion. By adopting the long-acting water-soluble and environmentally-friendly steel structural protective coating, the corrosion resistance and weather resistance of the protective coating are obviously improved; the corrosion resisting effect can last for 20 years; and the weather resistance lasts for more than 20 years.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Iron-base catalyst for Fischer-Tropsch synthesis and its preparation method

ActiveCN1597105AReduce manufacturing costLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIron sulfatePotassium silicate

A Fe-based catalyst for the Fischer-Tropsch synthesis contains Re2O3, Fe3O4, La2O3, CuO, K2O and SiO2. It is prepared through using oxidant to oxidize partially the ferrous sulfate to obtain the mixed solution of iron sulfate and ferrous sulfate, mixing with the mixed solution of lanthanum nitrate and copper salt, fast depositing by alkaline compound, washing the deposited slurry, adding potassium silicate-water glass solution, and spray drying.

Owner:SYNFUELS CHINA TECH CO LTD

Iron base catalyzer through Fischer-Tropsch synthesis and preparation method

InactiveCN1562471AReduce manufacturing costReduce preparation energy consumptionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMicrosphereSlurry

A Fe-base catalyst with high antiwear performance, activity and stability for the Fischer-Tropsch synthesis contains Fe, Zn, Cu, K and SiO2. It is prepared through proportionally mixing sodium carbonate solution as precipitant with the mixed solution of iron nitrate, zinc nitrate and copper acetate, depositing to obtain deposit slurry, adding the mixed solution of potassium silicate and silicon sol, spray drying and calcining.

Owner:中科合成油淮南催化剂有限公司

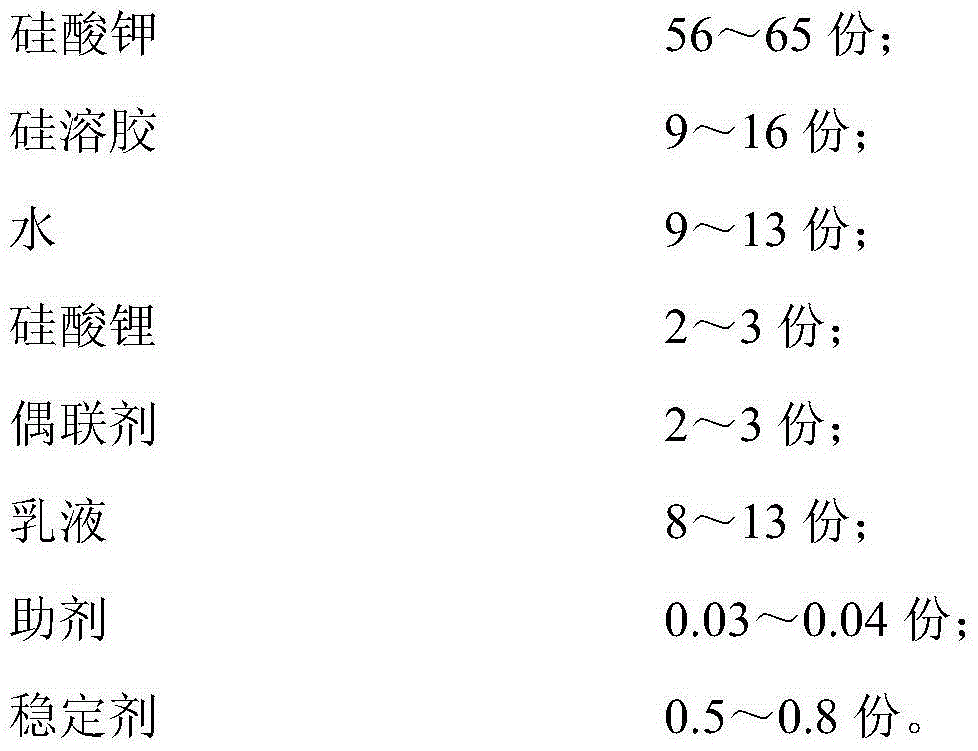

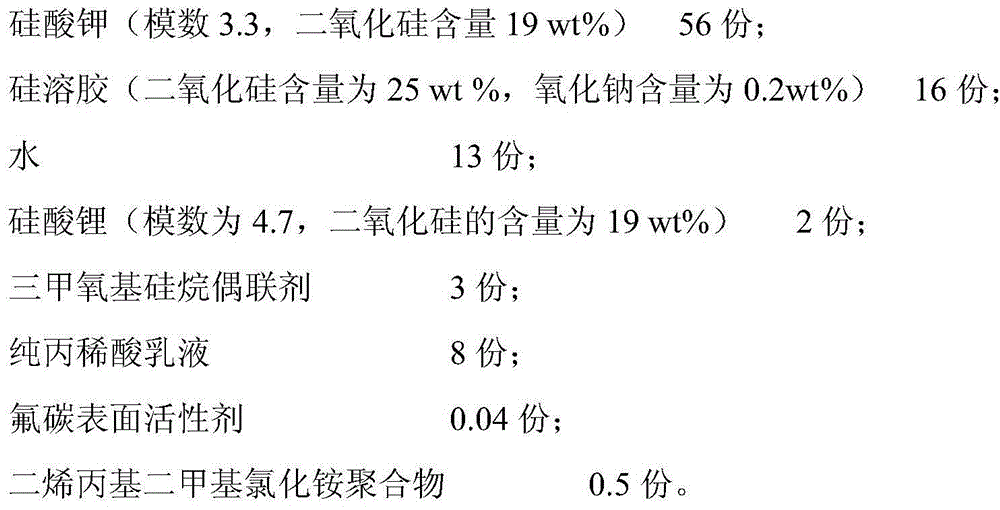

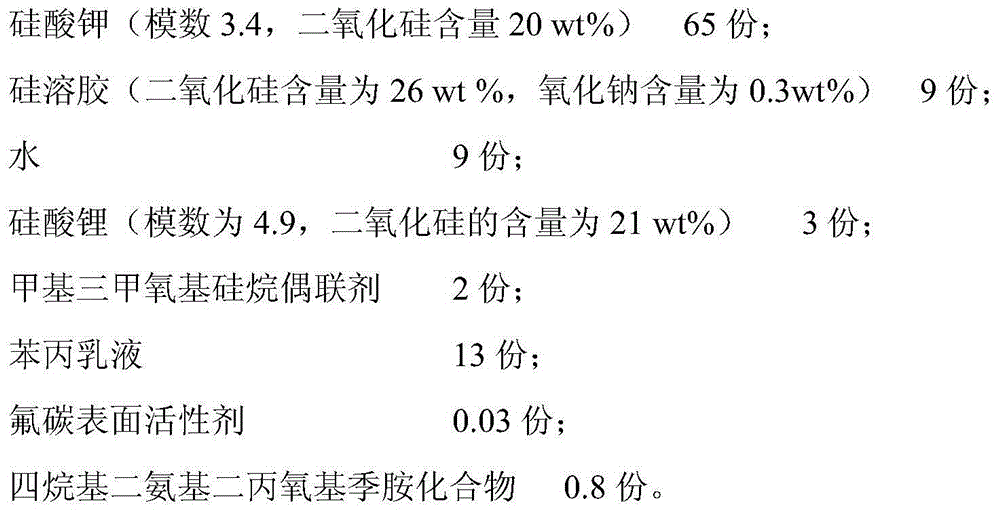

Water-based inorganic resin and preparation method thereof

InactiveCN103602107AGood resistance to salt sprayHigh hardnessAlkali metal silicate coatingsAnti-corrosive paintsWater basedLithium

The invention discloses water-based inorganic resin and a preparation method thereof. The preparation method comprises the following steps: carrying out hydrolysis reaction on a formula amount of potassium silicate, silica sol and lithium silicate under the effect of a coupling agent, and after reaction is stable, adding elastic emulsion so as to adjust the flexibility, thus obtaining the water-based inorganic resin with excellent properties. The water-based inorganic resin prepared by the method is environment-friendly, odorless, non-toxic, non-ignitable and unexplosive, and has very excellent salt fog resistance, permanent corrosion resistance, high hardness, strong adhesive force and heat and humidity resistance, and therefore, the water-based inorganic resin has wide development space in numerous heavy corrosion protection fields and atmosphere and ocean steel structure heavy corrosion protection fields.

Owner:WUXI HUHUANG PAINT

Composition of materials for production of acid resistant cement and concrete and methods thereof

InactiveUS6749679B2High strengthImprove moisture and high-temperature curing propertySolid waste managementAlkali metal silicate coatingsSlagPortland cement

A cement composition for use in acidic environment containing liquid alkali silicate, vitreous silicate setting agent, lime containing material and inert filler and building materials made therefrom as well as the method of making such building materials. The liquid alkali silicate may include sodium silicate or potassium silicate. The vitreous silicate setting agent may include soda-lime glass powder or coal fly ash. The lime containing material refers to the materials containing more than 20% lime and may include quicklime, hydrated lime, Portland cement, blast furnace slag or steel slag. The inert fillers include ground quartz, ground ceramic, and / or clay.

Owner:ADVANCED MATERIALS TECHNOLOGIES

Thermal protective coating

ActiveUS20060156958A1Extended shelf lifeExcellent optical propertiesAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

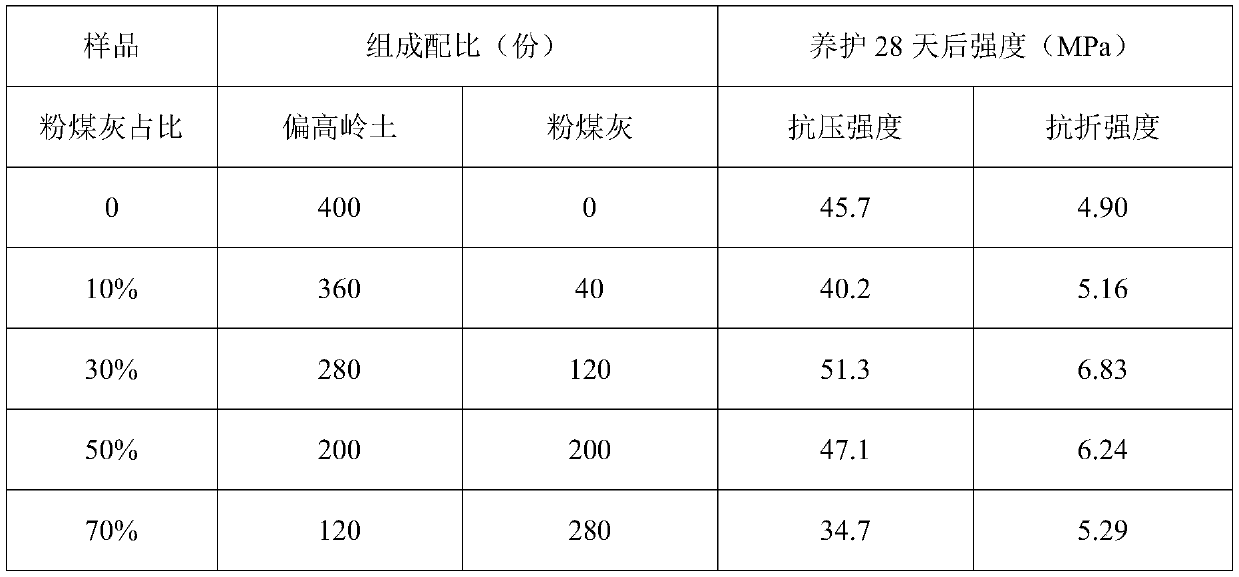

Fly ash geopolymer concrete and preparation method thereof

ActiveCN110255996AImprove mechanical propertiesIncreased durabilityCement productionFiberMicrosphere

The invention discloses fly ash geopolymer concrete. The concrete is prepared by taking fly ash and metakaolin as base materials, taking one or more than two of sodium hydroxide, potassium hydroxide, sodium silicate and potassium silicate as well as water glass as alkaline activators, and adding modified ceramic microsphere particles, polymer fibers, coarse aggregates, fine aggregates and water. The fly ash geopolymer concrete has good mechanical properties, high durability and high corrosion resistance.

Owner:神木市万盛隆能源发展有限公司

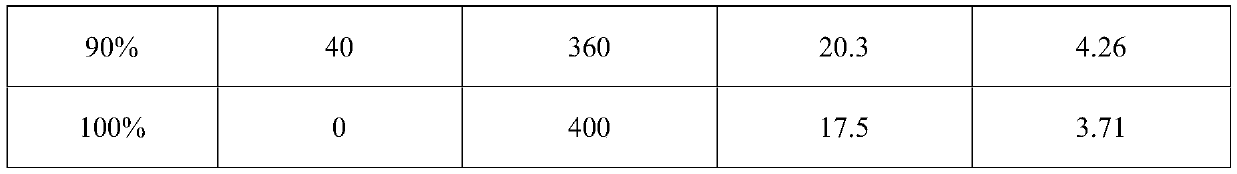

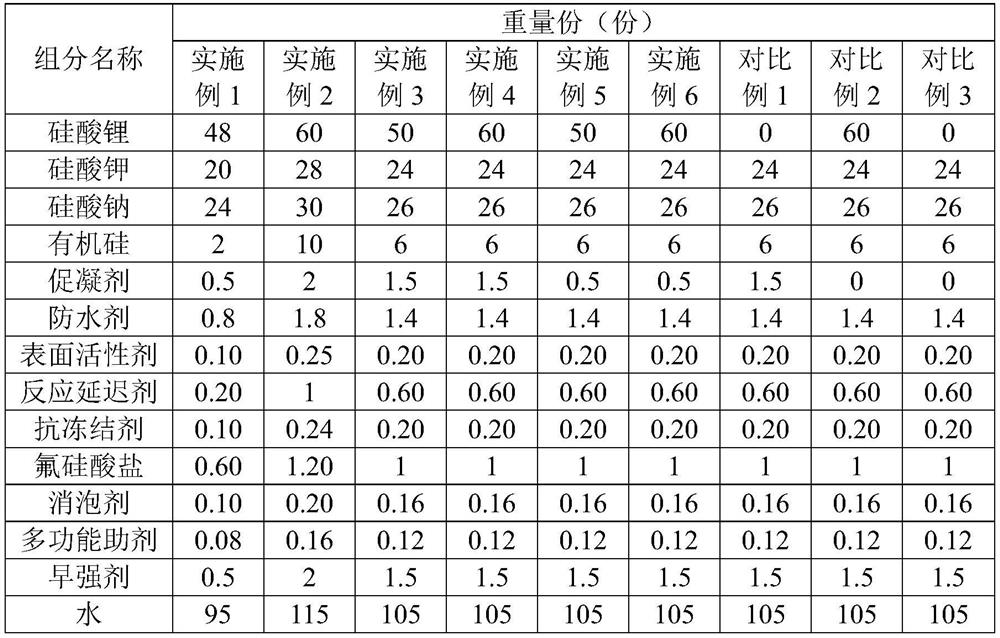

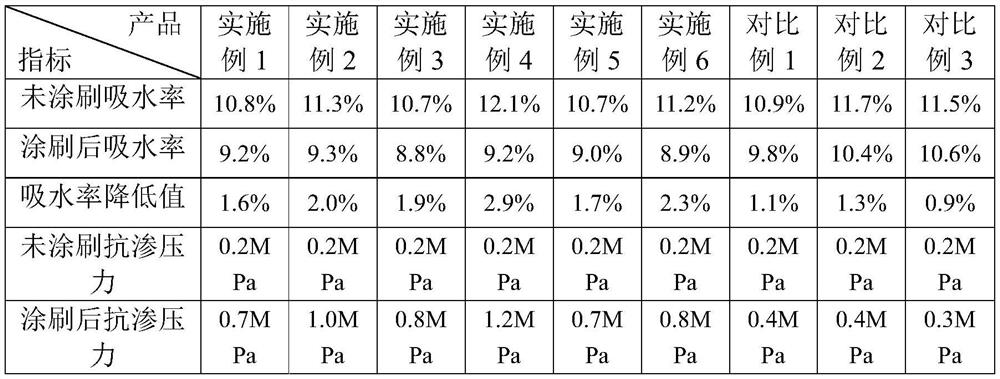

Water-based capillary crystalline concrete surface layer repairing and reinforcing material as well as preparation method and application thereof

The invention discloses a water-based capillary crystalline type concrete surface layer repairing and reinforcing material as well as a preparation method and application thereof. The material comprises 48-60 parts of lithium silicate, 20-28 parts of potassium silicate, 24-30 parts of sodium silicate, 2-10 parts of organosilicon, 0.5-2 parts of a coagulant, 0.8-1.8 parts of a waterproof agent, 0.1-0.25 parts of a surfactant, 0.2-1 part of a reaction retarder, 0.1-0.24 parts of an anti-freezing agent, 0.6-1.2 parts of fluosilicate, 0.1-0.2 parts of an antifoaming agent, 0.08-0.16 parts of a multifunctional auxiliary agent, 0.5-2 parts of an early strength agent and 95-115 parts of water. The water-based capillary crystalline type concrete surface layer repairing and reinforcing material hasthe characteristic of quick strength improvement, has an obvious repairing effect on concrete and mortar, and can repair and heal cracks and fine cracks, so that the water permeability resistance ofthe concrete can be improved. The water-based capillary crystalline type concrete surface layer repairing and reinforcing material is good in durability, long in service life, simple and convenient toprepare and convenient to construct.

Owner:苏州佳固士新材料科技有限公司

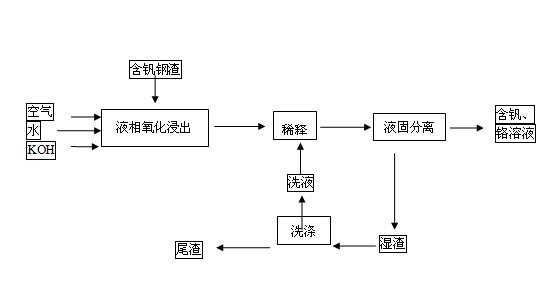

Method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide

ActiveCN102071321AHigh single recovery rateReduce productionProcess efficiency improvementSlagPotassium

The invention relates to a method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide, and belongs to the technical field of metallurgy. The invention adopts a technical scheme that: the steel slag together with water and potassium hydroxide is added into a reactor, the mixture is decomposed under normal pressure, and then the obtained reaction slurry is cooled and diluted by a diluent to obtain mixed slurry containing the potassium hydroxide, potassium vanadate, potassium silicate, potassium chromate and tailings; the alkalinity of the potassium hydroxide in the mixed slurry is controlled to be more than or equal to 100g / L, the mixed slurry is filtered and separated while the temperature is kept to be 80 to 130 DEG C to obtain the tailings and vanadium and chromium-containing water solution. The method has the advantages that: the high-temperature roasting is avoided, the reaction time is shortened, the single high-efficientextraction and simultaneous extraction of the vanadium and the chromium are realized; atmospheric pollutant as Cl2, HCl, dust, SO2 and the like caused by roasting are effectively avoided in the vanadium extraction process; and compared with the conventional roasting process, the generated amount and the discharged amount of waste water are effectively reduced, and clean production is realized.

Owner:HEBEI IRON AND STEEL

A kind of inorganic coating with geopolymer material as film-forming substance

The invention discloses an inorganic coating using geopolymer material as a film-forming substance. It is a single-component water-based inorganic coating using alkali polymerized metakaolin geopolymer material as a film-forming substance. The coating is characterized in that It consists of solid phase S and liquid phase L. The solid phase S is metakaolin, heavy calcium carbonate powder, quartz powder, and anti-cracking additives; the liquid phase L is sodium or potassium water glass and water. The solid phase S and the liquid phase L are mixed in a weight ratio of 1:1.0 to 1.5. The invention eliminates many defects caused by organic polymer film formation. It has the characteristics of high strength, high hardness, water resistance, high temperature resistance, anti-aging, low cost, non-toxic and environmentally friendly, especially with good bonding force with cement mortar layer. It can be applied directly on the surface of buildings or products to provide decorative and protective properties.

Owner:GUANGXI UNIV

Aqueous composition for rendering a substrate hydrophobic

A substrate treatment method for imparting hydrophobicity to a substrate or for rendering the substrate hydrophobic. This method includes the step of treating an agricultural soil substrate by applying an aqueous solution that preferably includes a mixture of sodium and / or potassium methylsiliconate and sodium and / or potassium silicate. The method imparts hydrophobicity to the substrate and renders it hydrophobic.

Owner:JACQUES VIONNET

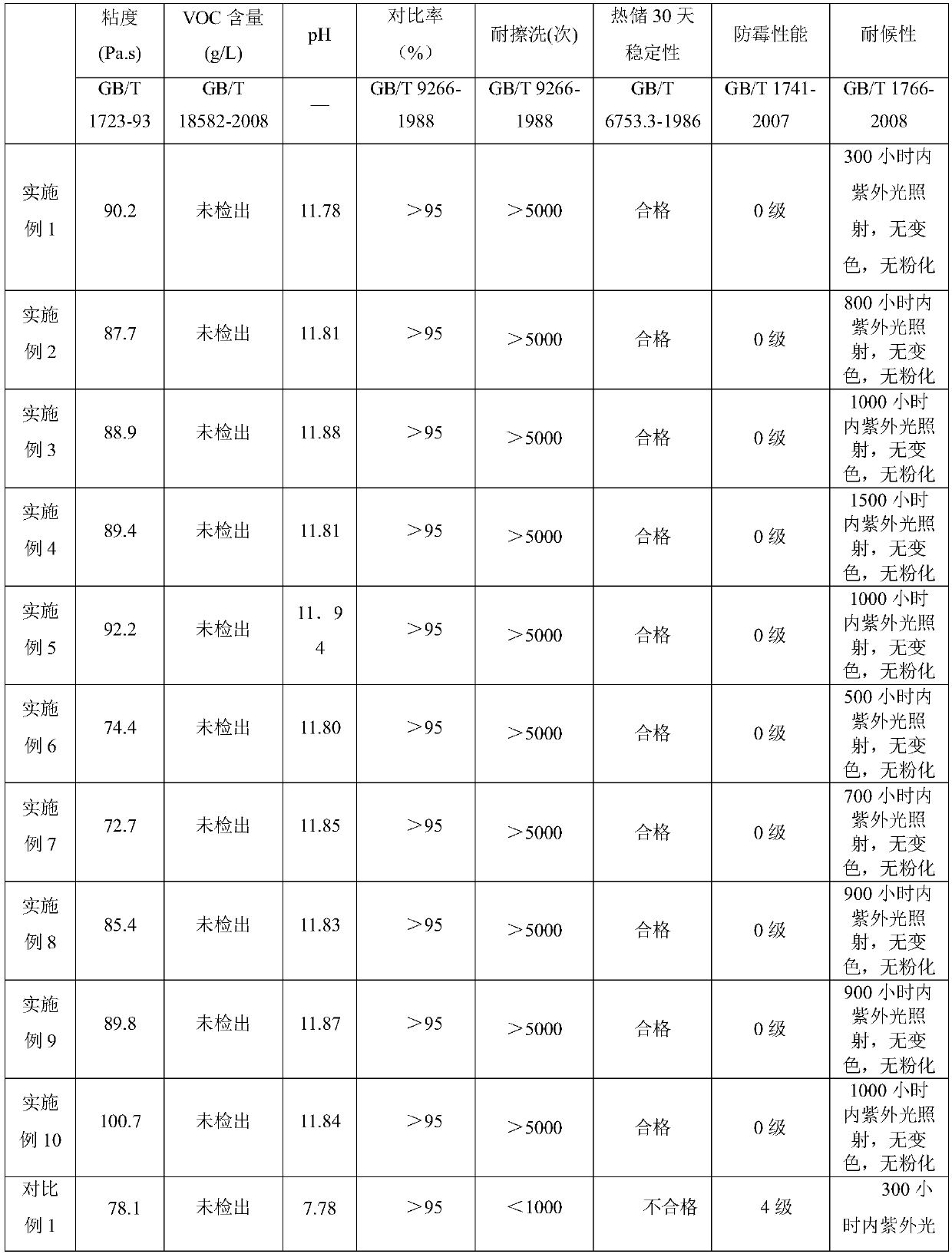

Inorganic silicate coating, preparation method thereof and application of coating

InactiveCN109575659AImprove mildew resistanceNever fall offFireproof paintsAntifouling/underwater paintsCelluloseEmulsion

The invention relates to the technical field of coatings for inner walls and outer walls of buildings, in particular to an inorganic silicate coating, a preparation method thereof and an application of the coating. The inorganic silicate coating is prepared from, by weight, 18-30 parts of deionized water, 0.1-0.8 part of cellulose, 0.5-1.5 parts of dispersing agents, 0.01-1.0 part of wetting agents, 0.01-1.0 part of defoaming agents, 10-20 parts of titanium dioxide, 10-20 parts of ground calcium carbonate, 10-20 parts of talcum powder, 5-10 parts of emulsion, 20-30 parts of modified potassiumsilicate, 0.01-5 parts of stabilizing agents and 0.01-5 parts of hydrophobic agents. The modified potassium silicate is selected from one or more of VB-2837 and INOCOT 955 or K-2837, and the emulsionis selected form one or more of styrene-acrylic ester and pure acrylic emulsion. The coating reaches the standard without a detected VOC (volatile organic compound) and good in fungus resistant and falling-off prevention performances.

Owner:北京莱恩斯新材料科技有限公司

Alkaline fertilizer

InactiveCN104761322AGood characterPrevent acidificationFertilizer mixturesPotassium hydroxideManganese

The invention discloses an alkaline fertilizer composed of the following components in percentage by weight: 31-99.4% of macroelements, 0.5-50% of medium elements, 0.1-15% of microelements and 0-50% of synergic components, wherein the macroelements include two and even more selected from urea, diammonium phosphate, ammonium polyphosphate, dipotassium phosphate, tripotassium phosphate, potassium pyrophosphate, potassium tripolyphosphate, potassium nitrate, potassium carbonate, potassium sulfate, potassium chloride, potassium formate, potassium silicate and potassium hydroxide; the medium elements are one or more selected from calcium nitrate, calcium chloride, magnesium chloride, magnesium sulfate, EDTA calcium and EDTA magnesium; the microelements are one or more selected from ferrous sulfate, zinc sulfate, manganese sulfate, copper sulfate or an EDTA chelate of iron, zinc, manganese and copper, EDDHA iron, borax, disodium octaborate tetrahydrate and sodium molybdate; and the synergic components include one or more selected from sodium humate, potassium humate, sodium fulvate, potassium fulvate, sodium alginate, potassium alginate and a plant growth regulator.

Owner:于书强

Nano ceramic coating with high emissivity

The invention discloses a nano ceramic coating with high emissivity, which is prepared from a high temperature resistant basic material, an additive with high emissivity, a binder, a stabilizing agent and a solvent. The high temperature resistant basic material and the additive with high emissivity are one or several of alumina, silicon oxide, boron nitride, silicon carbide, ferric oxide and cerium oxide. The binder is one or several of silica gel, potassium silicate solution, aluminium phosphate solution, silicon oxide hydrate, ethanol and water. By weight percentage, the high temperature resistant basic material and the additive with high emissivity account for 5-78%, the binder accounts for 5-30%, the stabilizing agent accounts for 0.5-3% and the balance of solvent is water. The coating which can be used above 1300 DEG C has the advantages of being wide in work temperature range with the maximum service temperature close to 2000 DEG C, applicable to various base materials, strong in adhesive force to the base materials, applicable to reaction atmosphere, good in long-time durability and strong in heat shock endurance, improving thermal efficiency, lowering temperature of the base materials, and being excellent in abrasion and corrosion resistance, less in impact on environment, convenient to use and the like.

Owner:赵凯

Modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as anti-settling dispersant

The invention relates to an anticorrosive coating, and particularly relates to a modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as an anti-settling dispersant. The modified silicate waterborne zinc-rich anticorrosive coating is prepared from components A and B, wherein the component A is prepared from 10-60% of flake zinc powder; the component B is prepared from 25-85% of silicone acrylic emulsion-modified potassium silicate solution, 0.1-5% of ricinate, 0.1-5% of organic montmorillonite, 0.1-5% of defoamer, and 0.01-2% of thickener, and the percent is weight percent. The modified silicate waterborne zinc-rich anticorrosive coating has the advantages that the dosage of zinc powder can be greatly reduced, and the cost of the coating is reduced. The water resistance of the coating is improved by the organic emulsion-modified potassium silicate solution; excellent painting hardness of the coating is achieved, the barrier property of the coating is improved, and meanwhile, the anticorrosive coating is almost zero in volatile organic compound (VOC) release property, and free of environmental pollution.

Owner:SHENYANG POLYTECHNIC UNIV

Synthesis of high-molar ratio potassium silicate adhesive and aqueous anticorrosive paint composition

InactiveCN1468924AGood storage stabilityReduce volatile illsInorganic adhesivesEmulsionPotassium silicate

The synthesis of high-molar ratio potassium silicate adhesive includes adding water soluble silica sol to low-molar ratio potassium silicate solution, adding small amount of silane as blocking agent and adhesion reinforcer, adding proper stabilizer, and adding organic polymer emulsion to improve the filming property of the adhesive. One kind of anticorrosive paint composition obtained through compounding the adhesive and zinc powder is also disclosed.

Owner:MARINE CHEM RES INST

Process for preparing organically modified aerogels using alcohols, wherein the resultant salts are precipitated

InactiveUS6129949AReduce contributionImprove mechanical stabilityLiquid surface applicatorsSilicaOrganic solventAlcohol

PCT No. PCT / EP96 / 04820 Sec. 371 Date Oct. 26, 1998 Sec. 102(e) Date Oct. 26, 1998 PCT Filed Nov. 5, 1996 PCT Pub. No. WO97 / 18161 PCT Pub. Date May 22, 1997The invention concerns a process for preparing organically modified aerogels, in which a) a silicic acid sol with a pH < / =4.0 is produced from an aqueous potassium silicate solution using at least one organic and / or inorganic acid; b) the resultant silicic acid sol is polycondensed by the addition of a base to form SiO2 gel; c) the gel produced in step b) is washed with an organic solvent until the water content of the gel is < / =5 wt %; d) the gel obtained in step c) is surface-modified with at least one C1-6 alcohol; and e) the surface-modified which are difficult to dissolve in the silicic acid sol. Before step b), the resultant salts, which are difficult to dissolve, are precipitated to the greates possible extent and separated from the silicic acid sol.

Owner:CABOT CORP

Feather protein fiber and method for preparing same

InactiveCN102733001AImprove wrinkle resistanceImprove toughnessConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentPotassium silicateAqueous solution

The invention discloses a feather protein fiber and a method for preparing the same. The feather protein fiber comprises the following components: 5-40 parts by weight of feather protein and 60-95 parts by weight of chemical fiber. The method for preparing the feather protein fiber comprises the following steps: A, feather protein spinning solution preparing: dissolving feather in an alkaline aqueous solution comprising sodium silicate and potassium silicate with the total mass concentration of 20-35%, and filtering to obtain the feather protein spinning solution, wherein the mass ratio of the sodium silicate to the potassium silicate is 1:(0.5-1); B, blending the feather protein spinning solution and the chemical fiber spinning solution, and spinning; and C, subjecting the feather protein fiber trickle to coagulation-bath treatment, pickling, washing and drying to obtain the feather protein fiber. The method for preparing the feather protein fiber can effectively ensure that the feather protein and the chemical fiber are fully and uniformly blended to achieve the purpose of spinning.

Owner:成都天之蚕生物科技有限公司

Water-borne permeable crystalline waterproofing material and preparation method thereof

Water-borne permeable crystalline waterproofing material and a preparation method thereof belong to the technical field of the building engineering; the waterproof material comprises components according to the mass percentage: 0.01-0.07% of alkyl benzene sulfonic acid solution, 0.05-0.3% of isopropanol, 0.005-0.075% of nonylphenol polyoxyethylene ether, 7.5-25.0% of sodium silicate, 0.75-3.5% oftartaric acid powder, 0.532-2.428% of anhydrous sodium carbonate, 1.65-7.5% of potassium methyl silicate solution and the rest of ionized water. The waterproofing material has simple production technique, low cost, outstanding waterproofing effect, is not-toxic and pollution-free, and belongs to the environmental friendly building material.

Owner:SHANGHAI JIAO TONG UNIV

Water high-temperature resistant flaming-proof anticorrosive paint

ActiveCN101165129AHigh temperature resistance hasPrevent rustFireproof paintsAnti-corrosive paintsEmulsionHeat resistance

The present invention relates to paint, and is especially one kind of water soluble high temperature fireproof antirust paint comprising silicone propylene emulsion 30-40 (in wt%, the same below), water 8-16, polysodium acrylate 0.3-0.5, sodium hexametaphosphate 0.1-0.3, moldproof fungicide 0.1-0.2, antirust agent 0.2-0.3, fire retardant 5-8, aluminum tripolyphosphate 3-5, titania powder 8-10, magnet powder 8-10, mica powder 3-5, barium metaborate 8-10, silica sol 3-5, potassium silicate 2-5, defoaming agent 0.1-0.3, and leveling agent 0.1-0.2. The water soluble high temperature fireproof antirust paint is prepared through mixing, stirring and depurating. It has heat resistance, fireproof effect and capacity of preventing metal from rusting.

Owner:青岛居芳环保技术有限公司

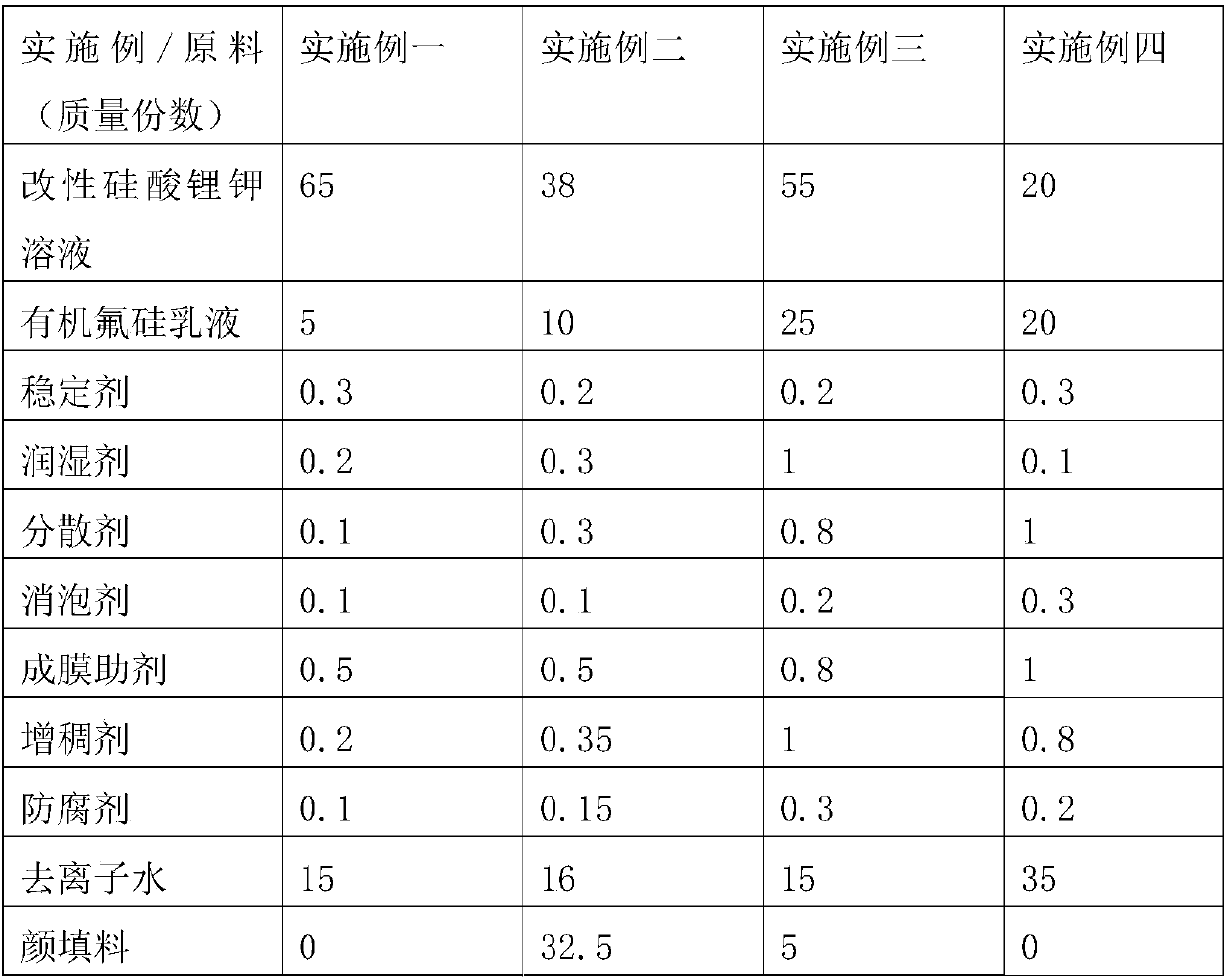

Inorganic potassium lithium silicate solution composite organic fluorosilicone coating and preparation method thereof

ActiveCN107779090AImprove permeabilityExcellent weather resistance and stain resistanceAntifouling/underwater paintsPaints with biocidesSilicic acidPotassium silicate

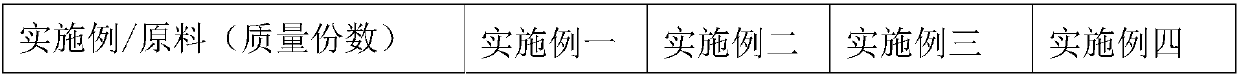

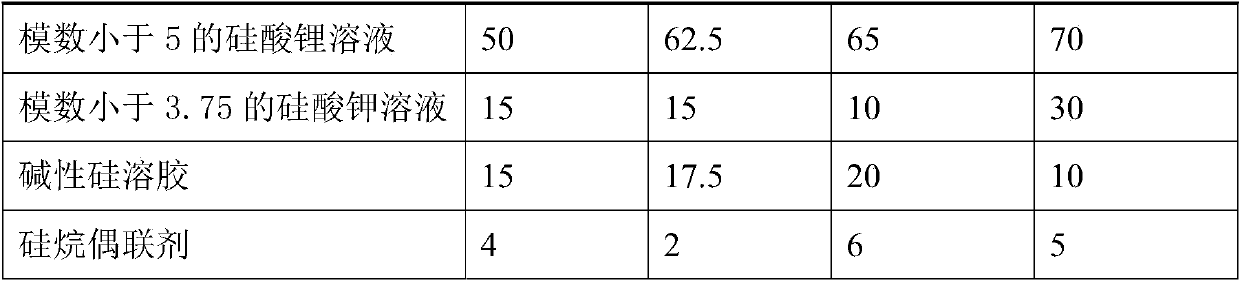

The invention discloses an inorganic potassium lithium silicate solution composite organic fluorosilicone coating which is prepared from, by weight, 20-65 parts of modified potassium lithium silicatesolution, 5-25 parts of organic fluorosilicone emulsion, 0.2-0.3 part of stabilizing agents, 0.1-1 part of wetting agents, 0.1-1 part of dispersing agents, 0.1-0.3 part of defoaming agents, 0.5-1 partof coalescing agents, 0.2-1 part of thickening agents, 0.1-0.3 part of preservative and 15-35 parts of deionized water. The invention further discloses a preparation method of the coating. Low-modulus lithium silicate and potassium silicate mixed solution and basic silica sol serve as main raw materials, organic silane coupling agents serve as modifying agents, so that stable potassium lithium silicate mixed solution is prepared, the stable potassium lithium silicate mixed solution and the organic fluorosilicone emulsion are coldly spliced and combined to serve as film-forming materials of the coating, pigments, fillers and various additives are added, and a multifunctional inorganic and organic fluorosilicone composite system coating is prepared. The coating is wide in application, and acoating film is excellent in physical and chemical performance.

Owner:固克节能科技股份有限公司

Preparation method and use for ultra-hydrophobic cotton fibrous material or ultra-hydrophobic paper fibrous material

The invention relates to super hydrophobic cotton or paper fiber material manufacturing method and their use. It is processed surface modification for the cellulose by silicon material which can be methane sodium silicate, methane potassium silicate, or chlorosilane. Thus the processed cellulose has good super hydrophobic property and air permeability, can be used in garment material, package, health aids fields etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Green nutritional compound fertilizer and method for preparing same

The invention relates to green nutritional compound fertilizer and a method for preparing same. The green nutritional compound fertilizer is prepared from plant material, urea or ammonium nitrate, superphosphate, potassium silicate, sodium borate, hydrated magnesium sulphate, zinc sulphate, chelated iron, sodium molybdenum, manganese sulfate, copper sulfate, cobalt nitrate and bio-fertilizer. 60 percent of the green nutritional compound fertilizer can be more easily absorbed by the crops, and the residue of the green nutritional compound fertilizer can be reduced. The green nutritional compound fertilizer can promote the growth of the crops, improve the quality of the crops, make the crops sprout and ripe earlier and have the developed root system and the luxuriant foliage and increase the yield of the crops by 50-80 percent. The green nutritional compound fertilizer can inhibit the breeding and the propagation of pathogens in the soil, reduce the crop diseases, enhance the disease resistance ability of the crops, improve the soil structure, activate the soil nutrient and realize the ecological planting of the crops.

Owner:XICHUAN YUANKE BIOLOGICAL TECH

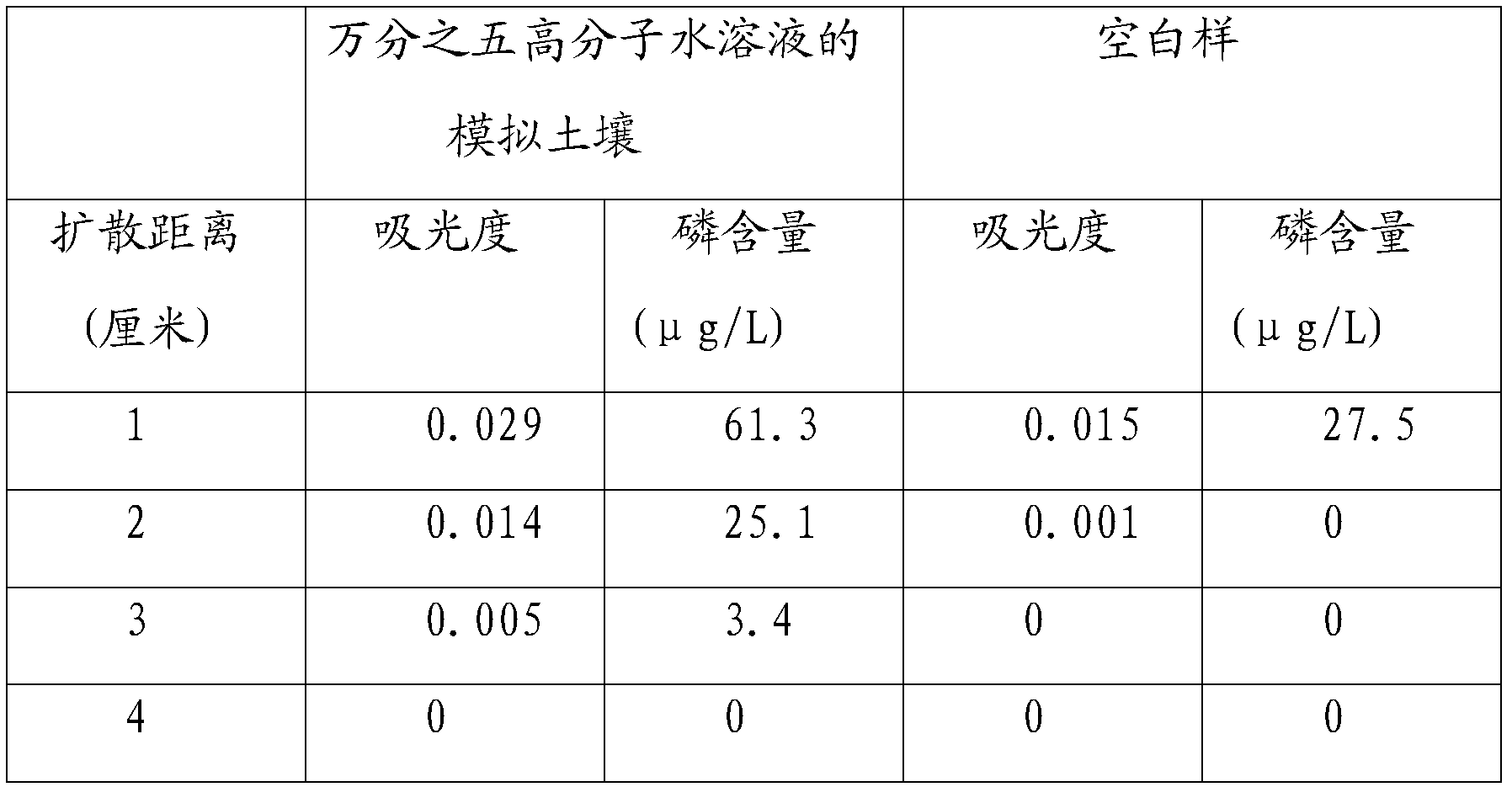

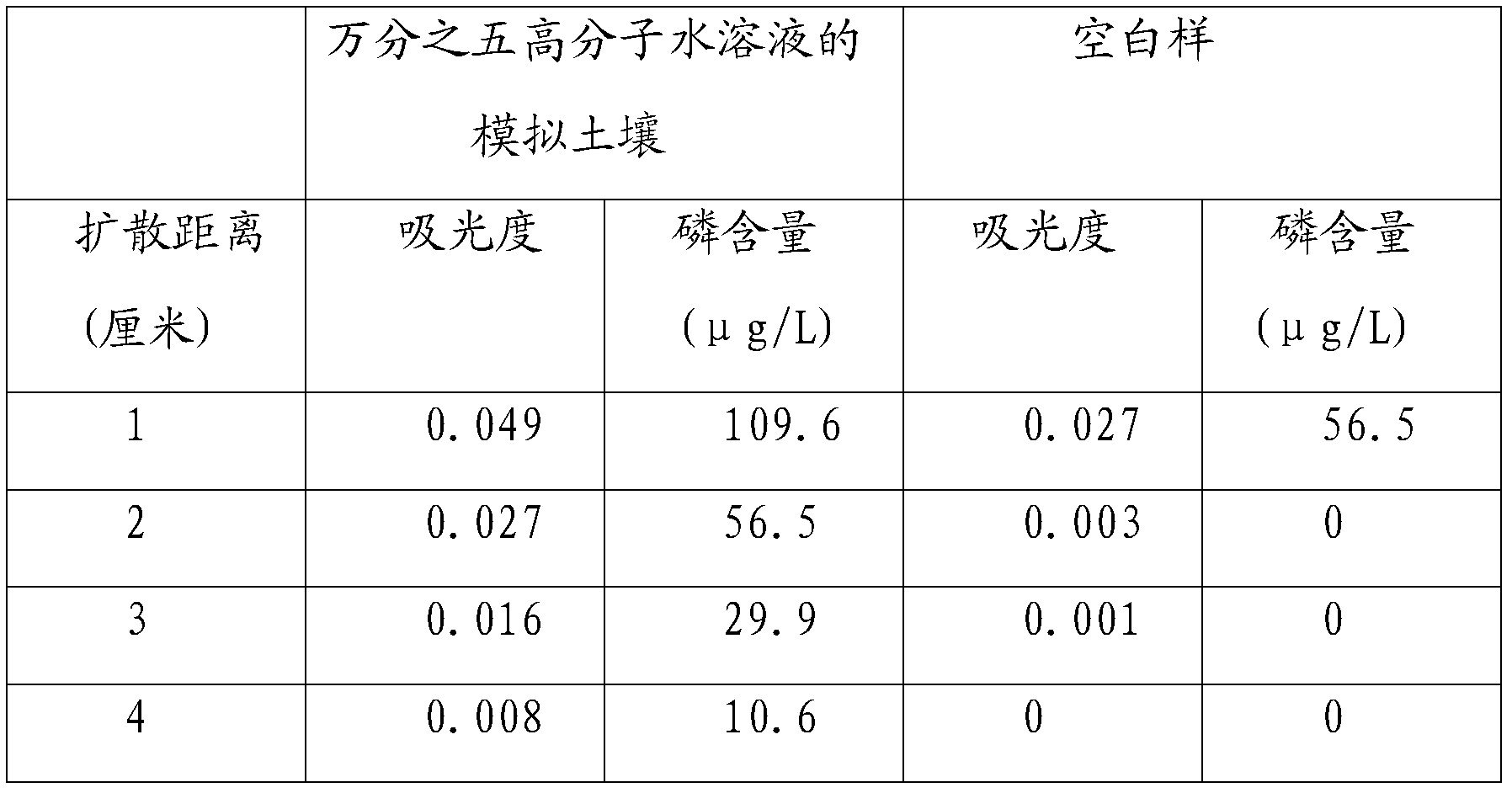

Water-soluble polymer synergist used for fertilizers, its preparation method and application

The invention relates to a water-soluble polymer synergist used for fertilizers, its preparation method and application. The fertilizer synergist consists of 10%-20% (weight percent) of guar gum, 20%-30% (weight percent) of non-ionic polyacrylamide, 20%-30% (weight percent) of potassium polyacrylate, and 20%-30% (weight percent) of polysilicate potassium. The water-soluble polymer synergist of the invention can obviously increase the transmission speed and transmission distance of phosphorus in soil, reduce the fixation probability of phosphorus, enhance the water-retention property and fertilizer preserving property of soil, substantially increase crop yield, as well as effectively improve fertilizer utilization rate and reduce fertilizer usage.

Owner:北京北方凯旋科技有限公司 +2

Drilling fluid for shale hydrocarbon reservoir exploration

InactiveCN104610941AInhibition of hydrationPrevent collapseDrilling compositionWell drillingPotassium silicate

The invention provides a drilling fluid for shale hydrocarbon reservoir exploration. The drilling fluid is based on water, and comprises 4-6wt% of bentonite, 2-5wt% of potassium silicate, 0.2-0.5wt% of a coating inhibitor, 0.2-1.5wt% of a flow pattern regulator, 4-6wt% of a fluid loss additive, 2-3wt% of a shale caving inhibitor, 2-3wt% of a plugging agent, 0.5-1wt% of a filter cake surface modifier, 2-4wt% of a lubricant and 0.4-0.6wt% of a pH value regulator. The drilling fluid has the characteristics of good plugging property, strong inhibition, good lubricity and stable high temperature performances to shale hydrocarbon reservoir stratums, and is suitable for the exploration of shale hydrocarbon reservoirs.

Owner:CHINA PETROCHEMICAL CORP +1

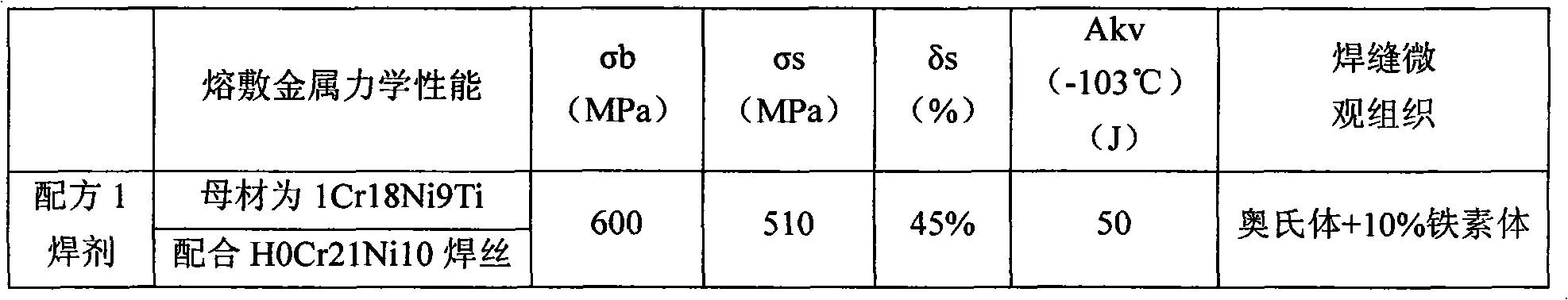

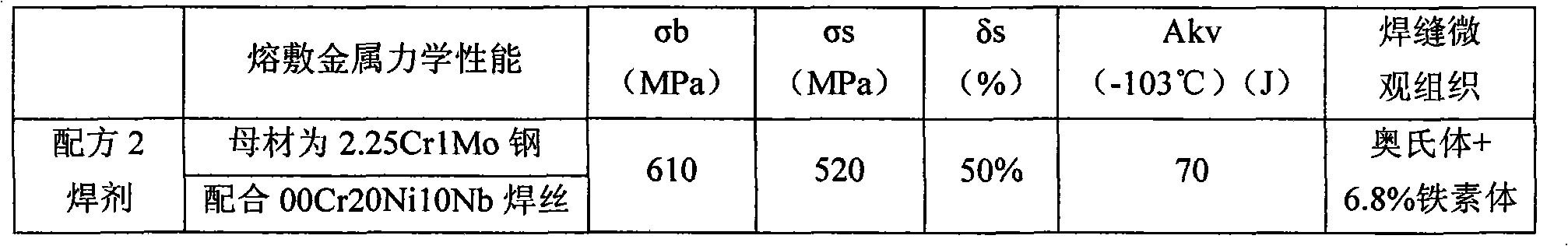

Sintered flux for stainless steel

InactiveCN101585123AEasy to remove slagArc stabilizationWelding/cutting media/materialsSoldering mediaSlagPotassium silicate

The present invention provides a sintered flux for stainless steel. The slag system of the flux is CaF2-Al2O3. The invention is characterized in that the oxidability and the sensibility of the gas hole are small. The stainless steel structure and the stainless steel overlaying welding can be welded when the sintered flux is matched with the corresponding welding stick. The invention is characterized in that the sintered flux comprises the following components: more than 40% by weight of calcium fluoride (CaF2), and furthermore the summation of the calcium fluoride and aluminum oxide (CaF2+Al2O3) is larger than or equal to 70% by weight; other components as follows: smaller than or equal to 5% by weight of CaCO3, 1-3% by weight of CrO3, smaller than 4% by weight of NaAlF6, 1-3% by weight of rare earth fluoride, 3-10% by weight of SiO2, 3-10% by weight of MnO, 1-3% by weight of TiO2, 5-10% by weight of MgO, and 1-3% of iron alloy; and bonding agent of sodium potassium silicate.

Owner:THE LINCOLN ELECTRIC HELI ZHENGZHOU WELDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com