Patents

Literature

73results about How to "Reduce contact frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

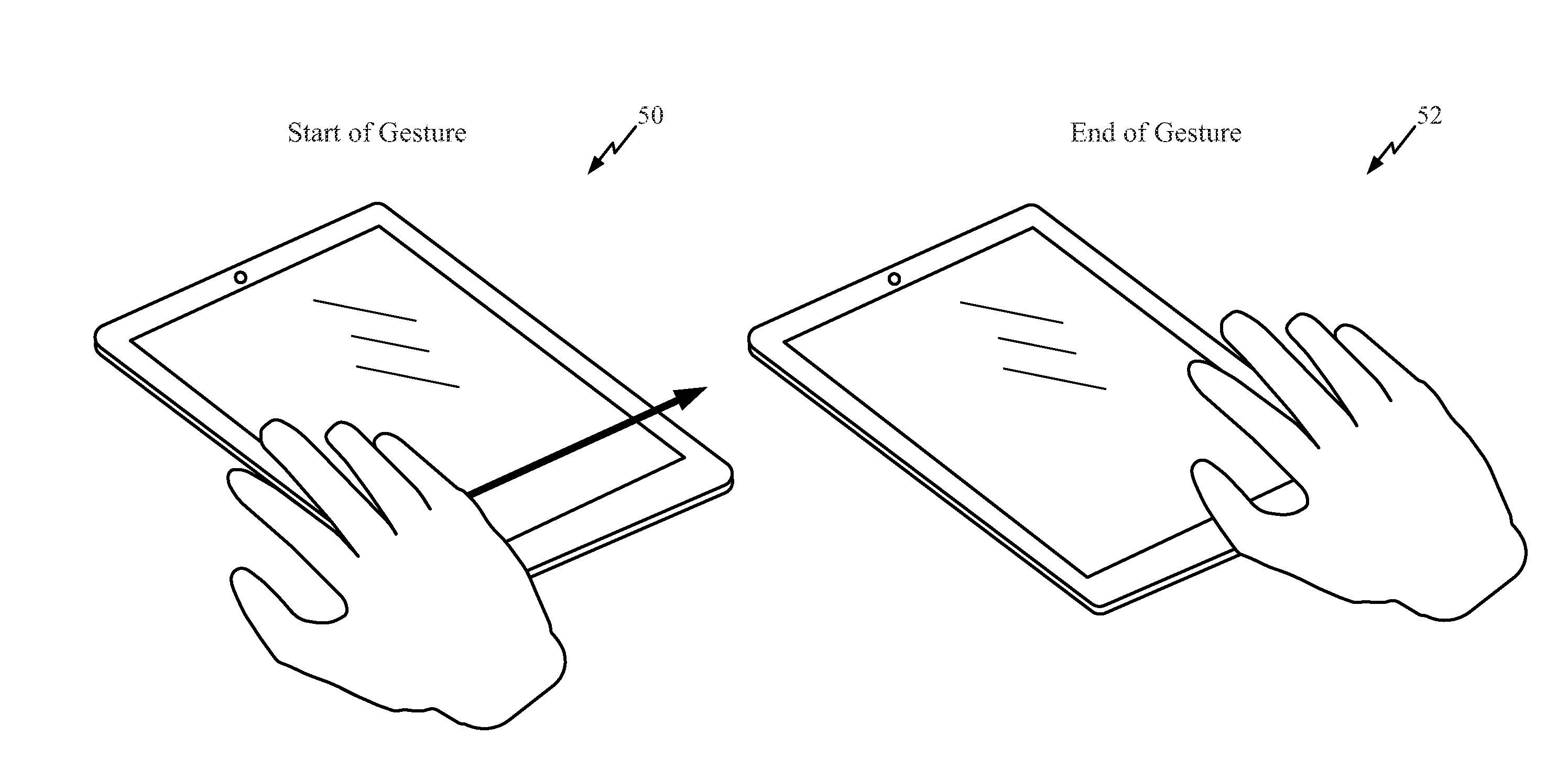

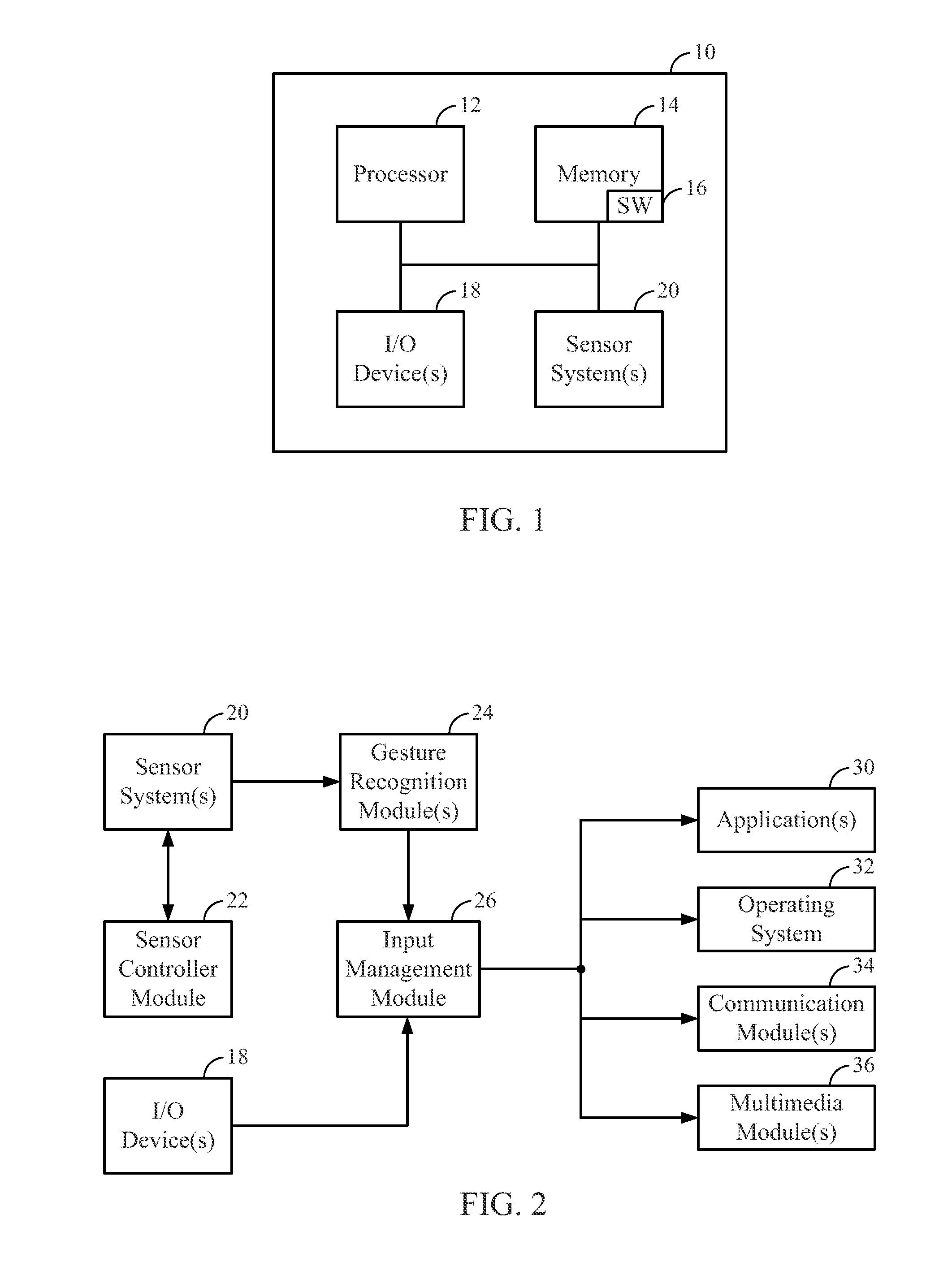

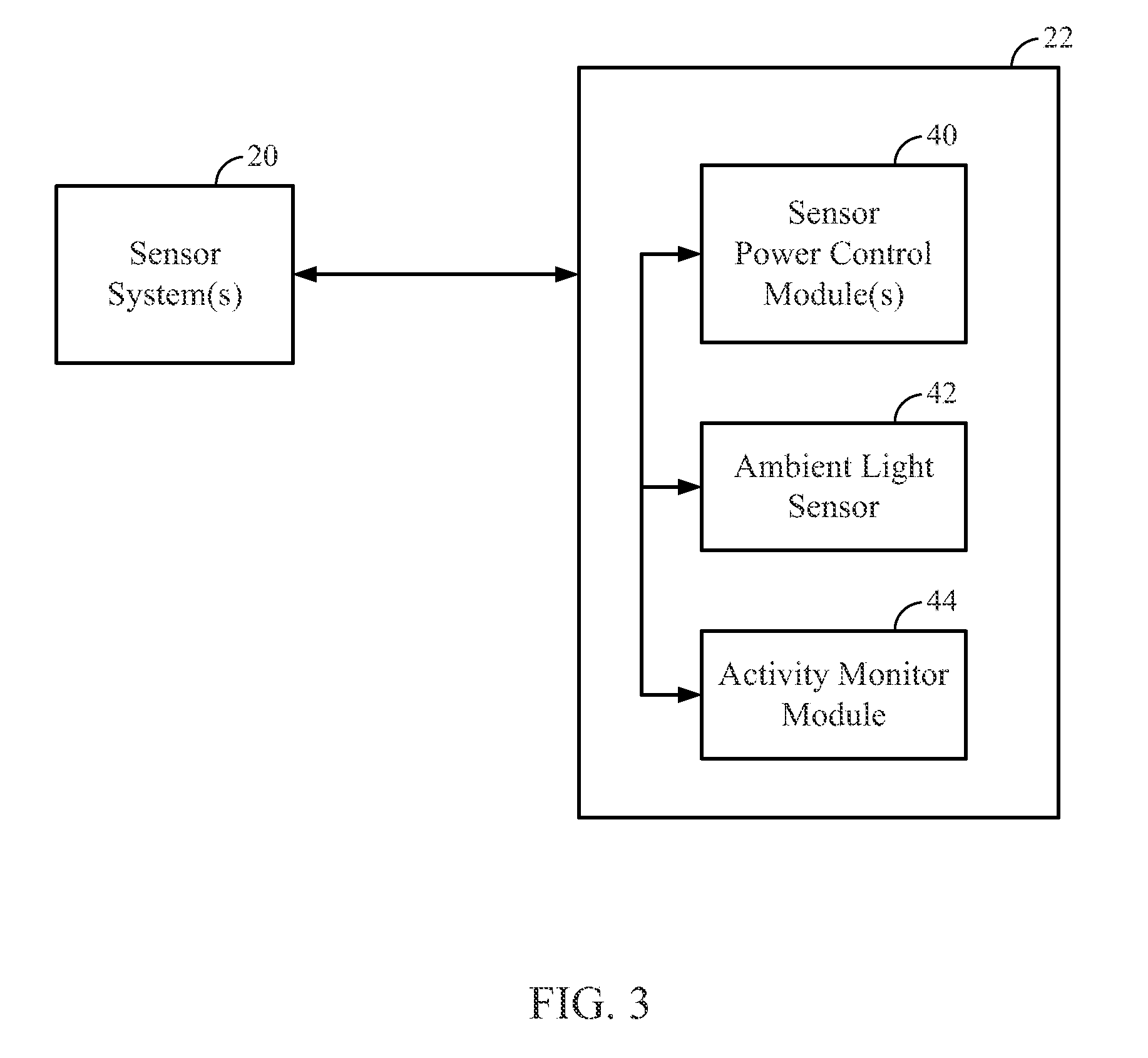

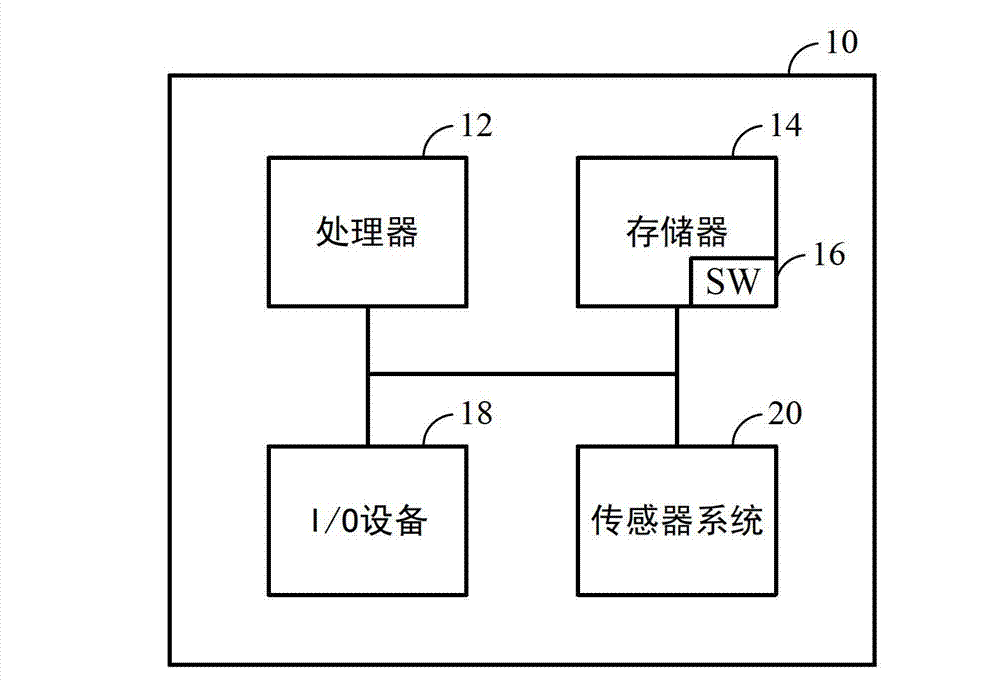

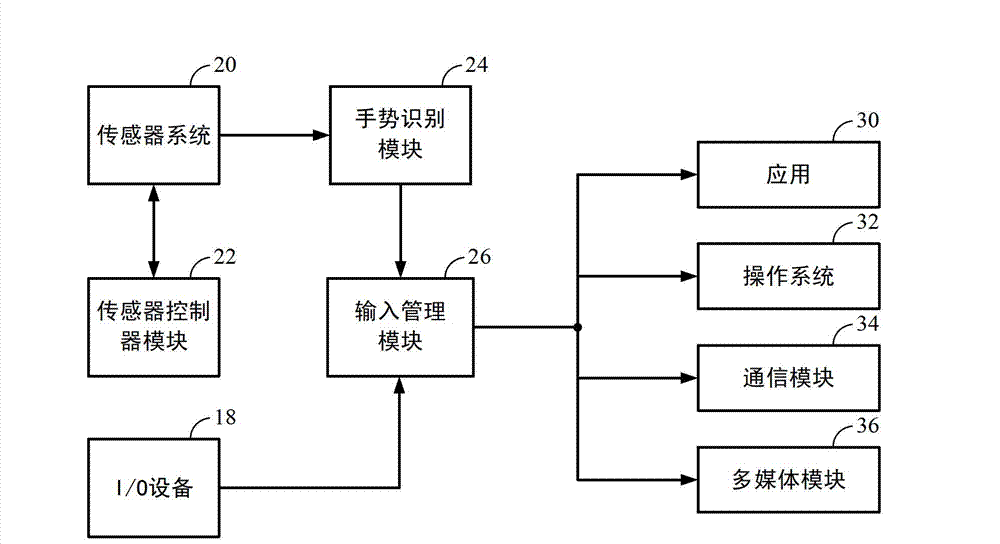

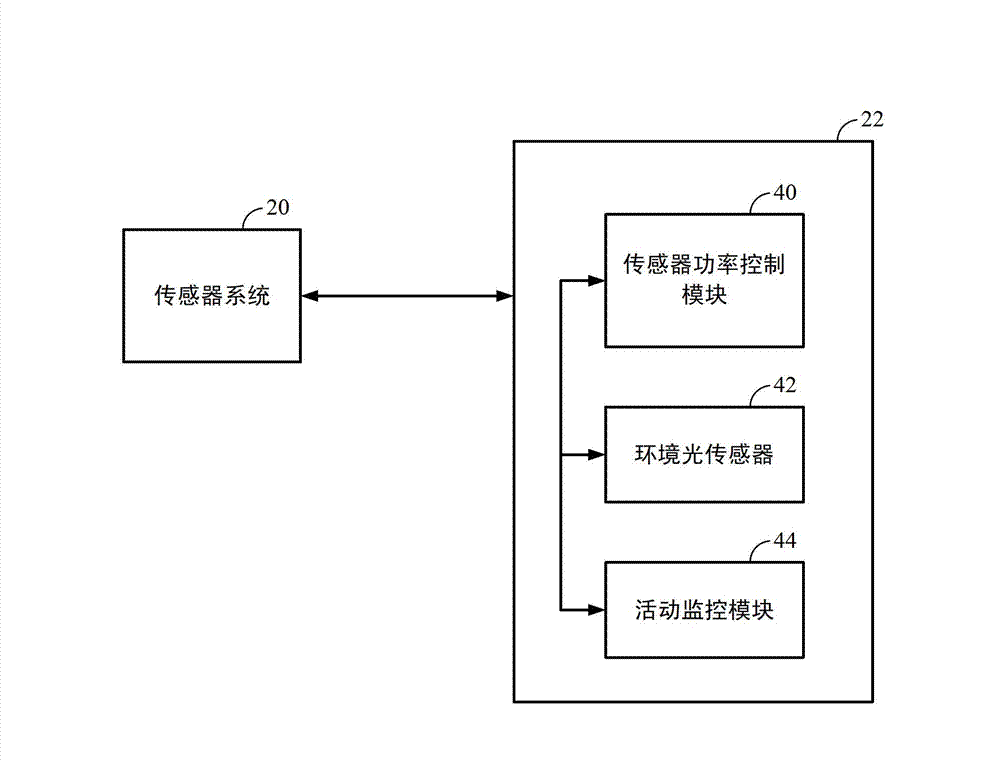

Methods and apparatus for contactless gesture recognition

InactiveUS20110310005A1Reduce wearImprove aestheticsInput/output for user-computer interactionEnergy efficient ICTProximity sensorHuman–computer interaction

Systems and methods are described for performing contactless gesture recognition for a computing device, such as a mobile computing device. An example technique for managing a gesture-based input mechanism for a computing device described herein includes identifying parameters of the computing device relating to accuracy of gesture classification performed by the gesture-based input mechanism and managing a power consumption level of at least an infrared (IR) light emitting diode (LED) or an IR proximity sensor of the gesture-based input mechanism based on the parameters of the computing device.

Owner:QUALCOMM INC

Methods and apparatus for contactless gesture recognition and power reduction

ActiveCN102971701AReduce contact frequencyReduce generationInput/output for user-computer interactionEnergy efficient ICTProximity sensorHuman–computer interaction

Owner:QUALCOMM INC

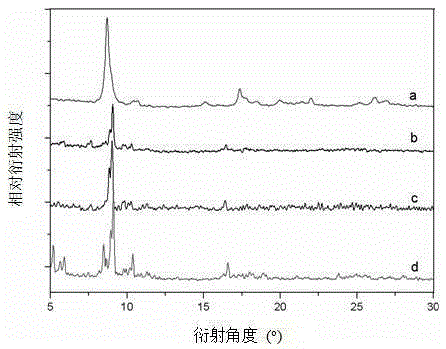

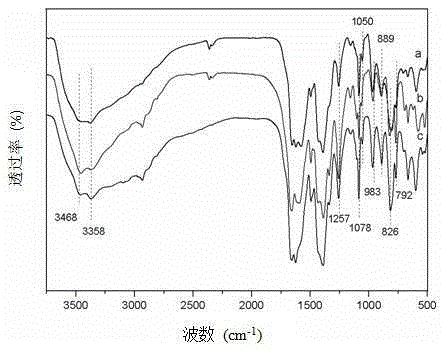

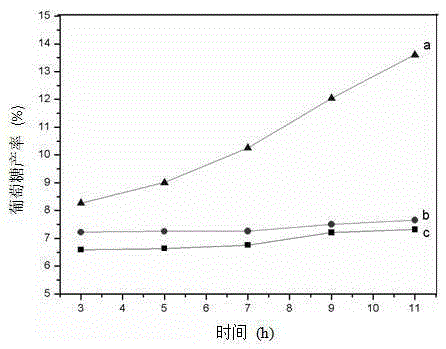

Phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and preparation method and application thereof

InactiveCN105344378AEnsure loading efficiencyEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionCellulosePolymer science

The invention discloses a phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and a preparation method and application thereof. According to the invention, organic ligand with strongly electronegative groups and basic groups is screened out and participates in coordination reaction of a metal organic skeletal material so as to realize functionalization, phospho-tungstic acid is directly added into a synthesis system, and immobilization is realized in the process of synthesis. The prepared phosphotungstic acid-metal organic skeleton reduces the frequency of contact with glucose through formation of a hydrogen bond with cellulose so as to reduce side reaction of glucose under the catalysis of acid, high glucose selectivity is obtained, and oriented conversion of cellulose to glucose can be realized; meanwhile, the effect of the hydrogen bond can weaken the effect of a hydrogen bond in cellulose, reduces the crystallization degree of cellulose, enables cellulose to be easier to hydrolyze and improves hydrolysis efficiency.

Owner:SOUTH CHINA UNIV OF TECH

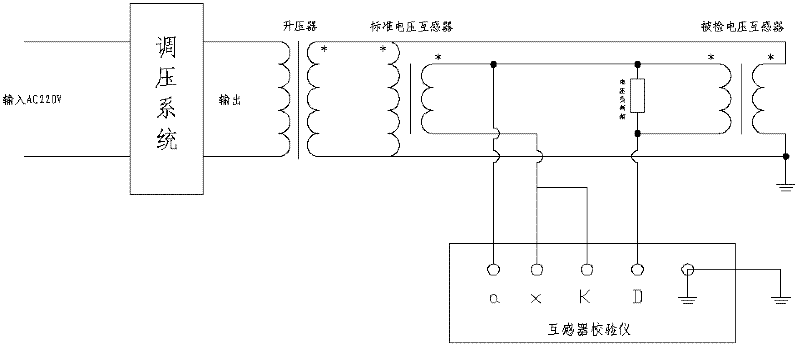

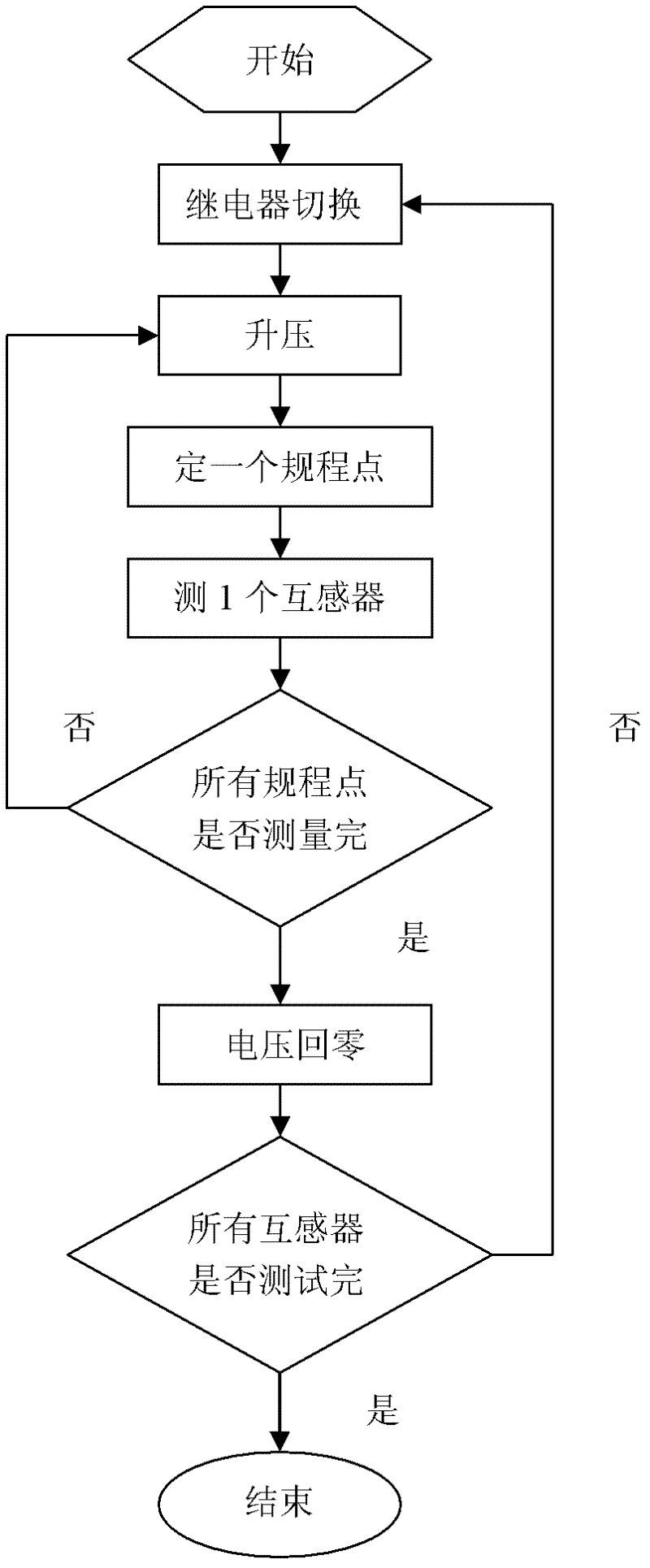

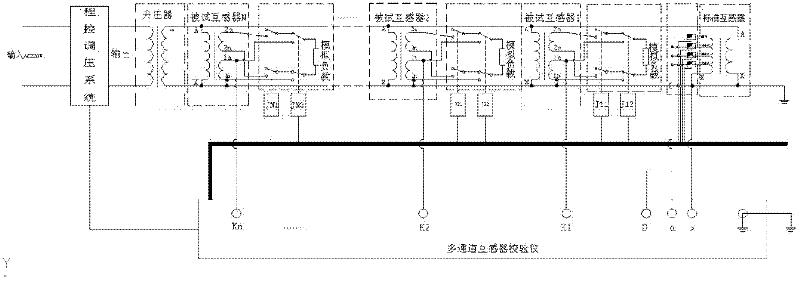

Calibration device and method capable of synchronously measuring multiple voltage transformers at one time

ActiveCN102305919AImprove work efficiencySafe and reliable workElectrical measurementsContact highHigh pressure

The invention discloses a calibration device and a calibration method capable of synchronously measuring multiple voltage transformers at one time, and belongs to the technical field of metering tests of electric power. In order to solve the problems that the efficiency of measurement is extremely low, an operator frequently contacts high voltage and the safety of production is reduced because the conventional voltage transformer can only be independently measured, a method for combining a plurality of calibrated voltage transformers with a high-standard voltage transformer to form a comparison method circuit is used in the invention; a multi-channel transformer calibrator is used for directly acquiring a differential voltage signal between the plurality of calibrated voltage transformers and the high-standard voltage transformer; and the multiple voltage transformers can be synchronously measured at one time by calculation. By the calibration device, the working efficiency of measuring the voltage transformers by the operator is improved, and the high-voltage contacting frequency of the operator is reduced, so that more safe measurement is ensured. Therefore, the calibration device and the calibration method are major breakthrough in a voltage transformer calibration technology.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

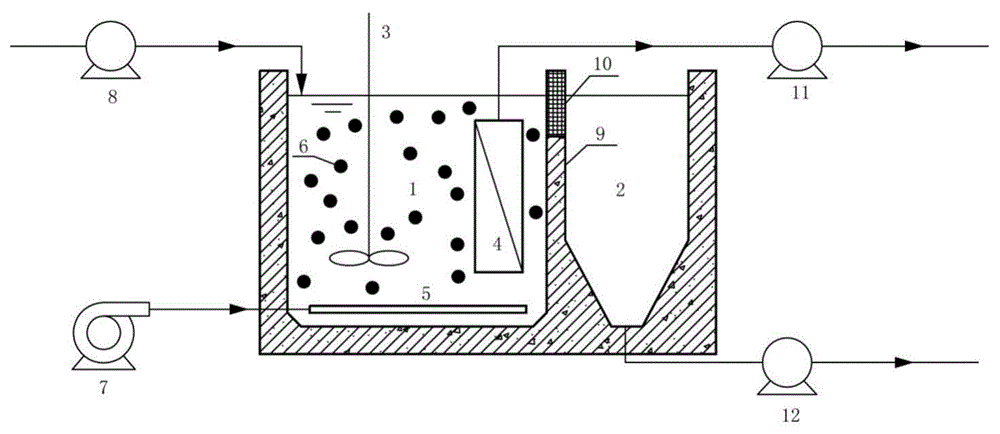

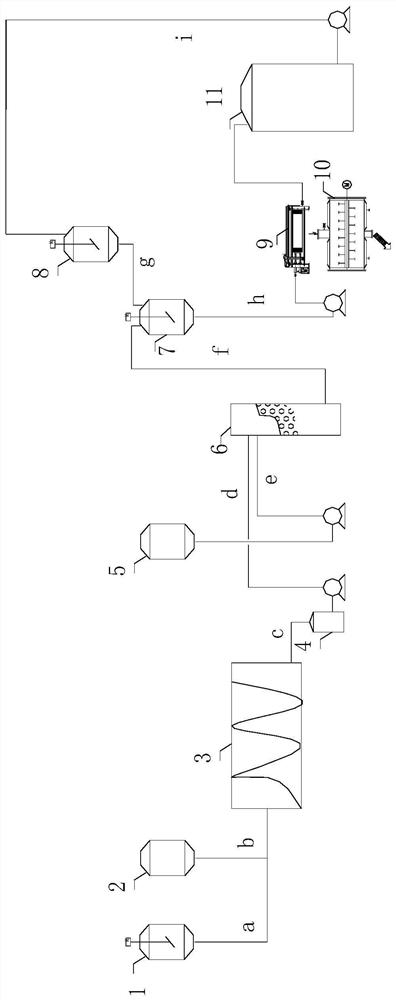

Device and method for processing coking wastewater by adopting suspended filler-anaerobic membrane bioreactor

InactiveCN104085988ARealize synchronous removalSimple processTreatment with aerobic and anaerobic processesActivated sludgeChemical oxygen demand

The invention discloses a device and a method for processing a coking wastewater by adopting a suspended filler-anaerobic membrane bioreactor, belonging to the field of coking wastewater treatment. The device comprises an anaerobic reaction pool and a sludge sedimentation pool, wherein a micropore aeration system, a suspended particle packing, a membrane module and a stirring system are arranged inside the anaerobic reaction pool; the activated sludge in the anaerobic reaction pool takes a biological membrane attached to the suspended particle packing as a main component; the suspended activated sludge is collected, separated and discharged out of the system through the sludge sedimentation pool; and synchronous nitrification and denitrification functions of the biological membrane on the suspended packing are enhanced by stirring for fluidization of the stirring system under an anaerobic condition, thereby achieving the treatment effect of synchronously removing chemical oxygen demand (COD) and total nitrogen in the coking wastewater. By adopting the device, the aeration rate is significantly reduced, and the operating cost is reduced. The activated sludge takes the biological membrane in the attached state as the primary component, so that the contact frequency of the activated sludge and the membrane module filtering surface is reduced, and the membrane pollution process is effectively retarded by the scraping effect of the suspended particle packing.

Owner:UNIV OF SCI & TECH BEIJING

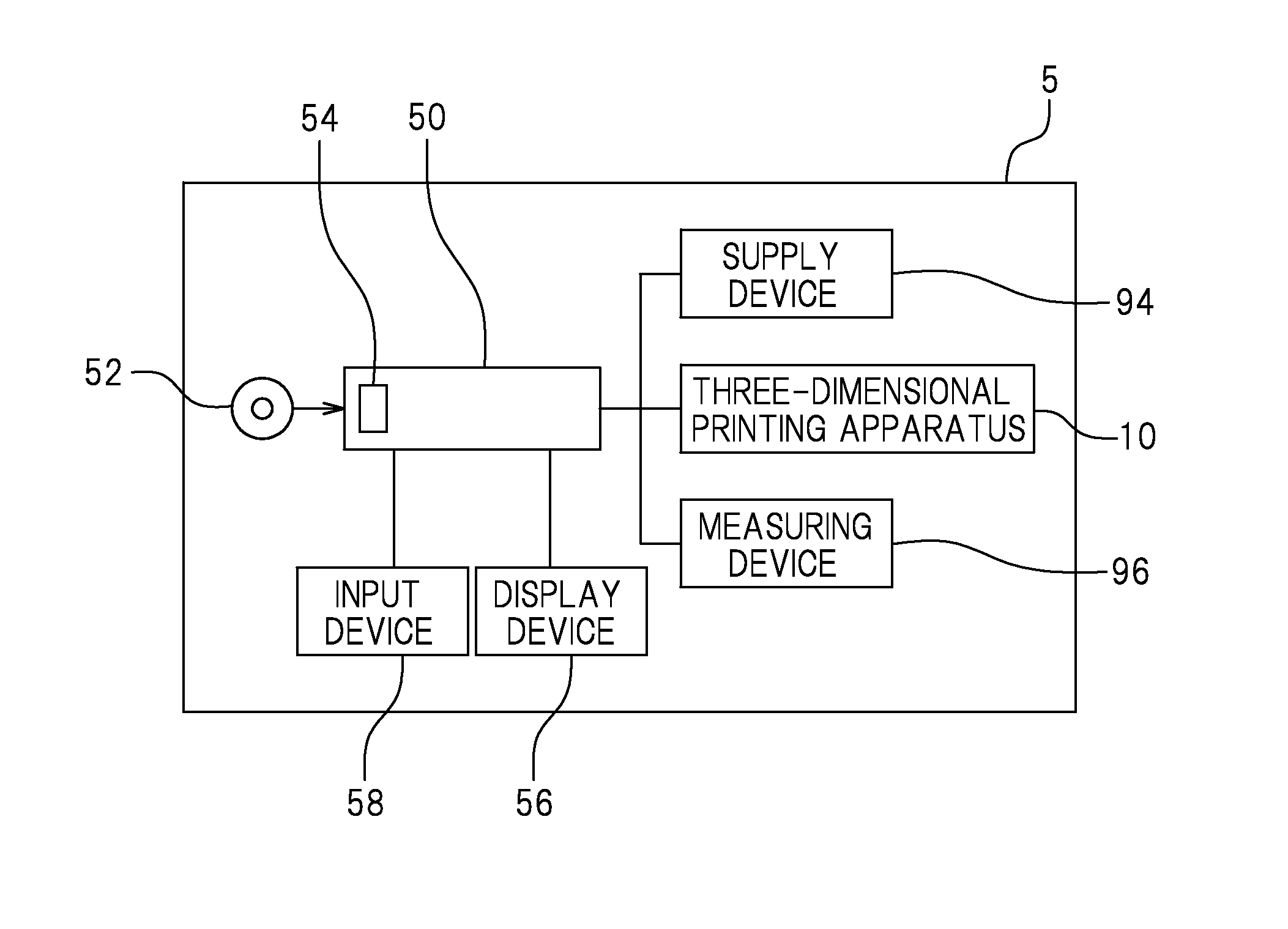

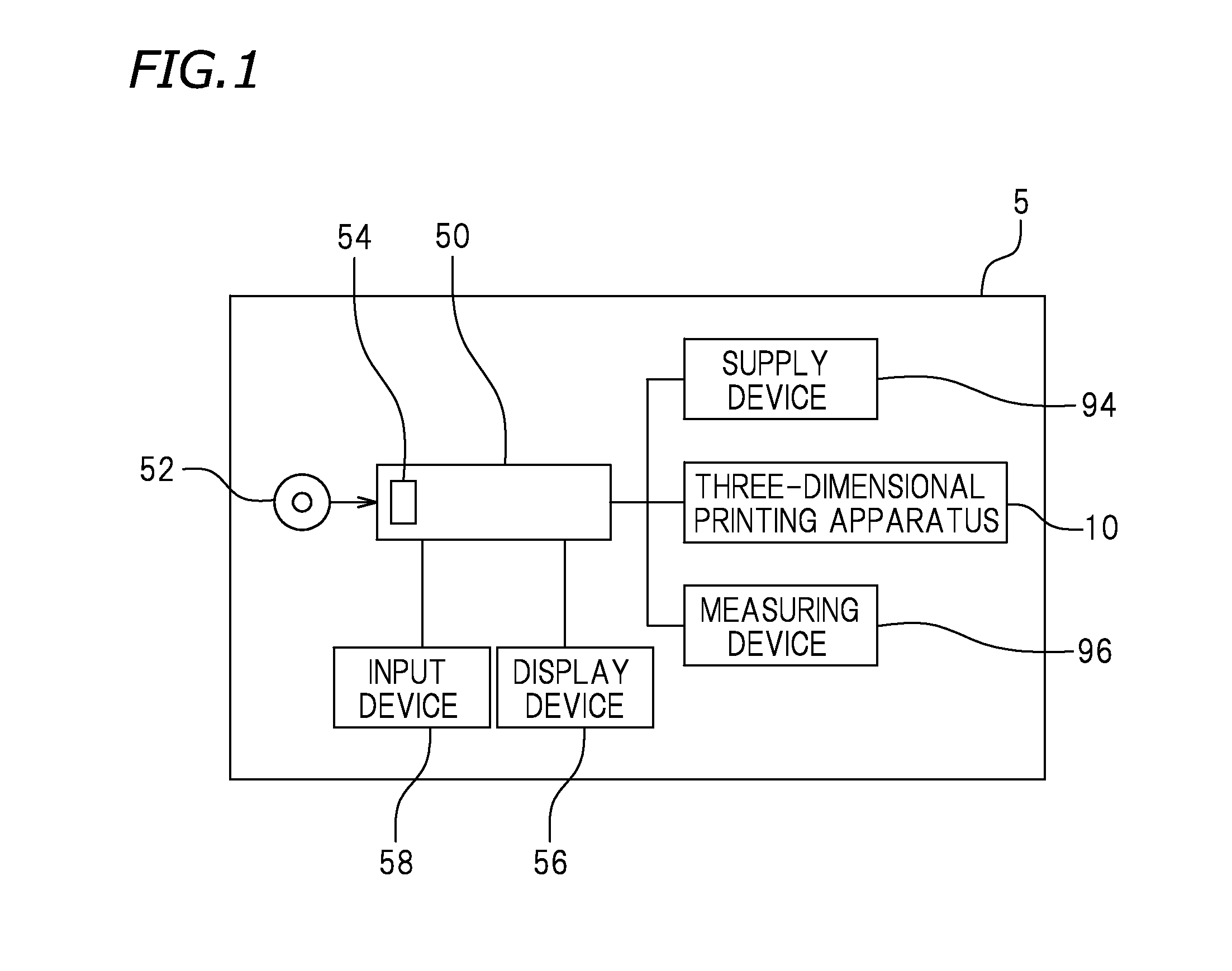

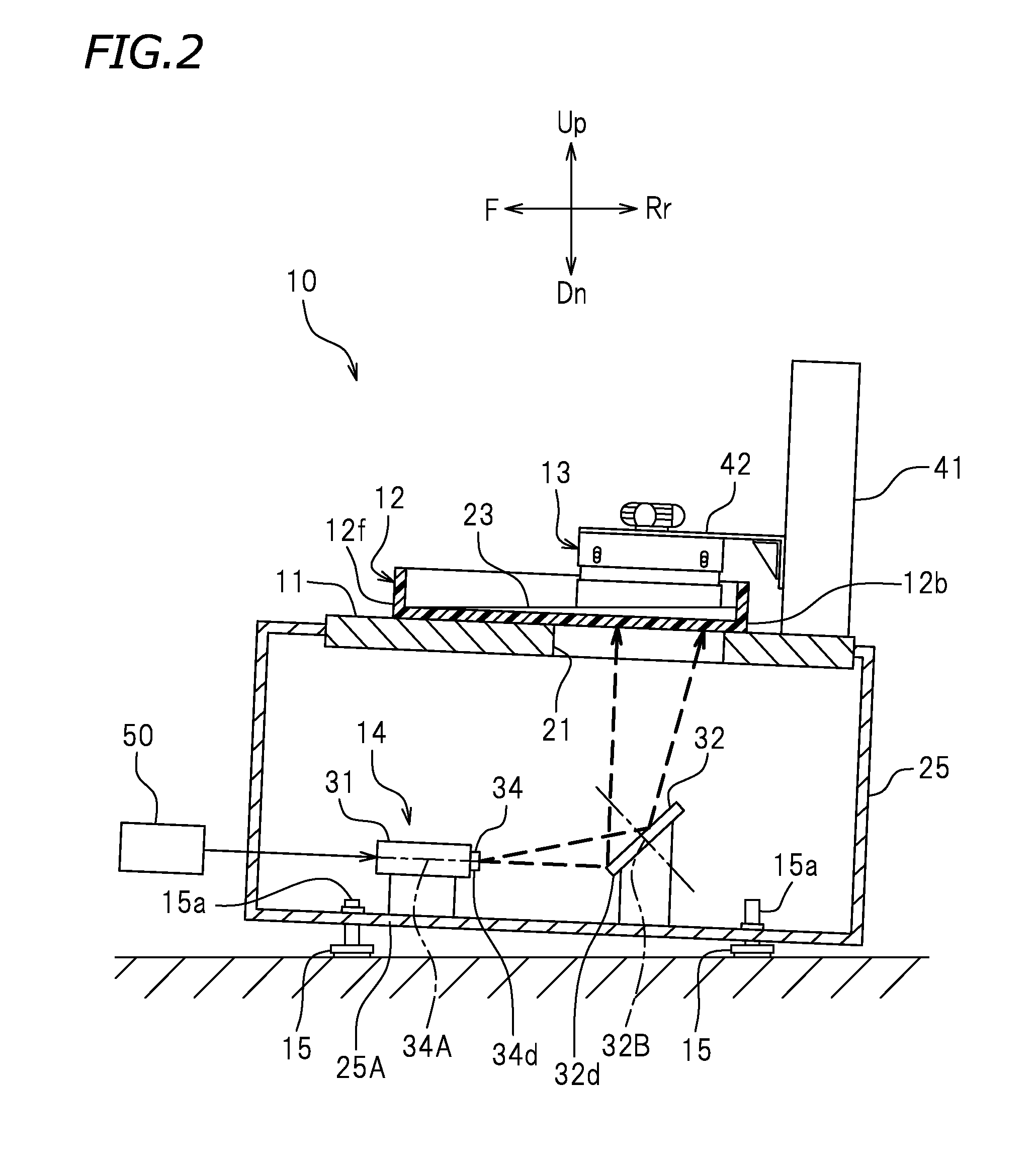

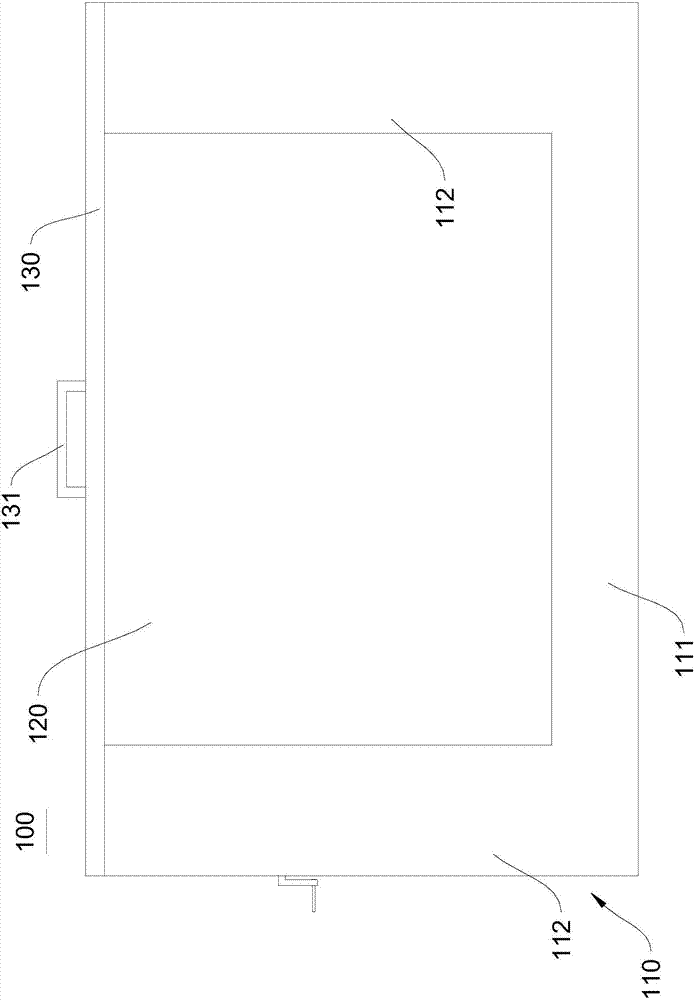

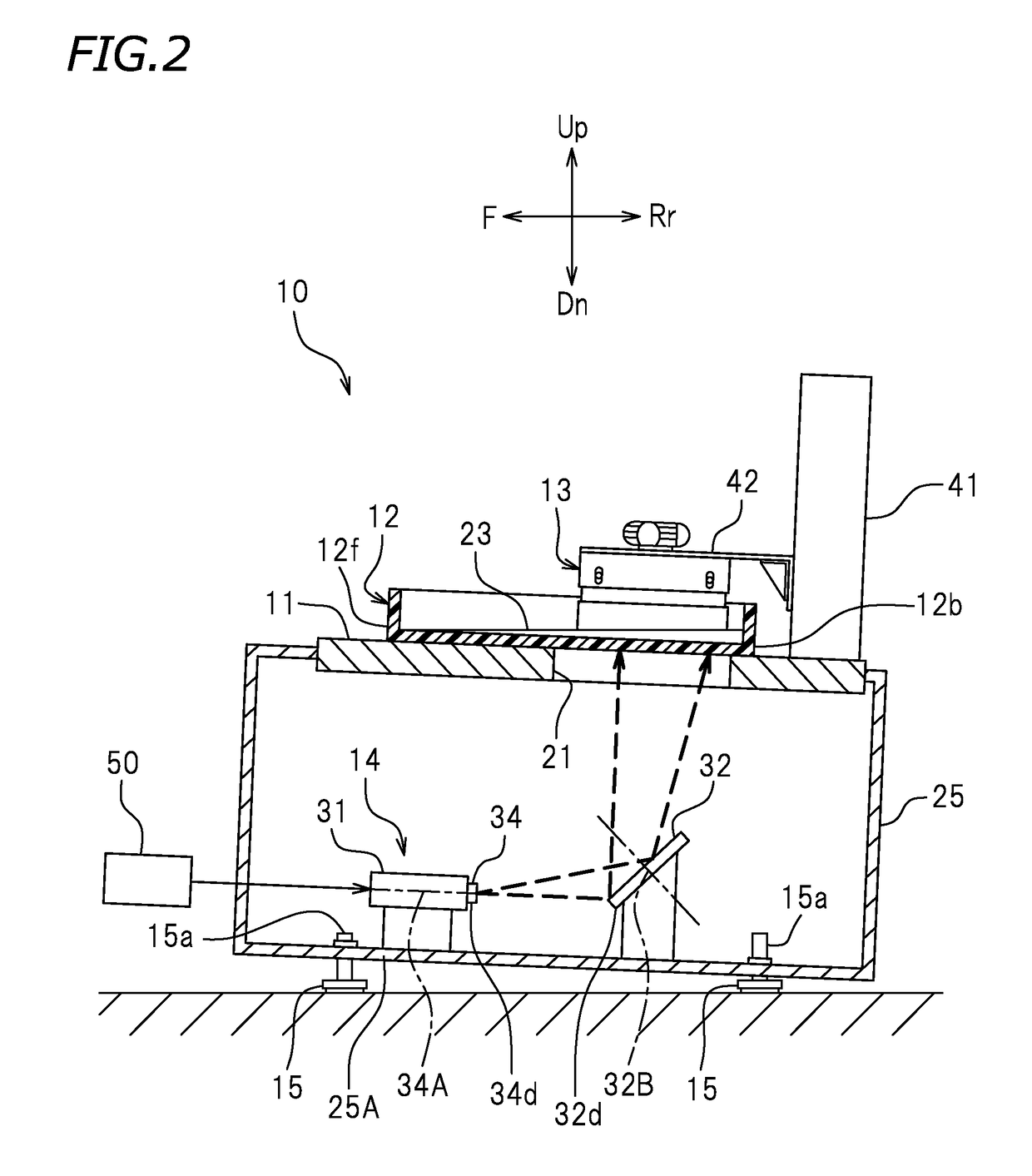

Three-dimensional printing system

InactiveUS20150231824A1Reduce amountPrevent degradationAdditive manufacturing apparatus3D object support structuresAuxiliary memory3D printing

A three-dimensional printing system calculates a resin amount required to print a three-dimensional object by curing a liquid photo-curable resin and sequentially stacking layers of the cured resin each having a predetermined cross-sectional shape. The system includes a first storage section configured to store information of a three-dimensional object, and information of an auxiliary member that supports the three-dimensional object, a first calculation section configured to calculate a resin amount necessary to print the three-dimensional object and a resin amount necessary to print the auxiliary member based on the information of the three-dimensional object and the auxiliary member stored in the first storage section, an output section configured to output a first resin amount that is the sum of the calculated resin amounts necessary to print the three-dimensional object and the auxiliary member, and a three-dimensional printing apparatus.

Owner:ROLAND DG CORP

Adhesive patch

ActiveCN101658512AAvoid stickingHelp take outPlastersAdhesive dressingsEngineeringBiomedical engineering

Owner:NITTO DENKO CORP

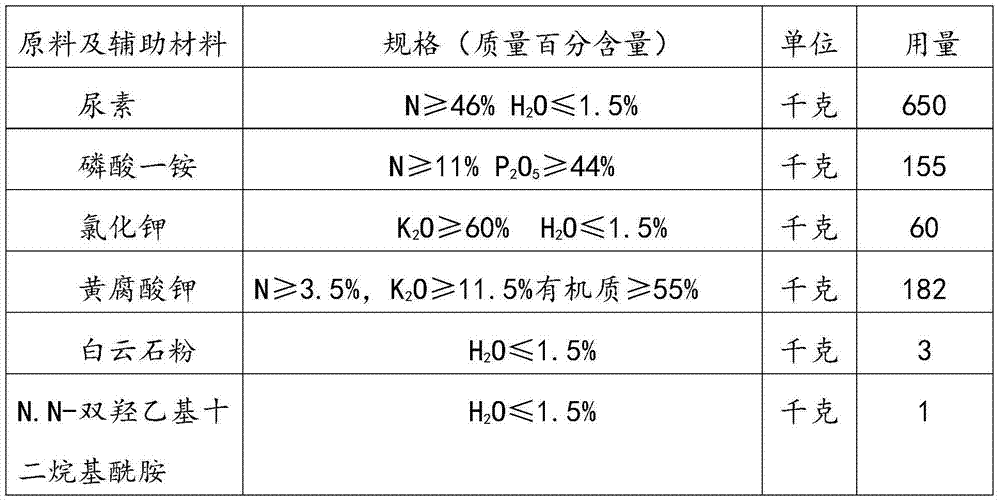

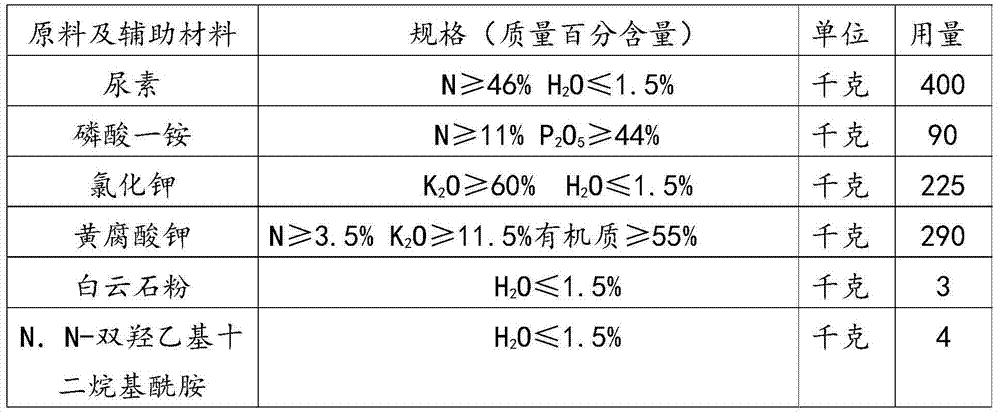

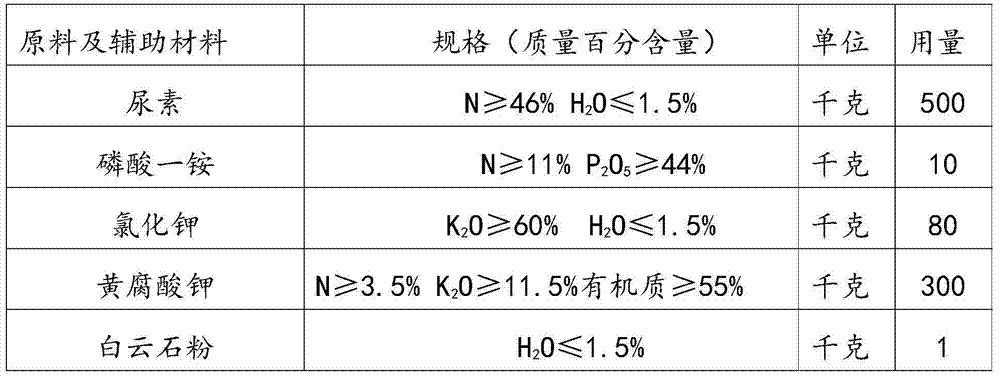

Compound fertilizer preparation method for improving utilization rate of phosphorus element

The invention relates to a compound fertilizer preparation method for improving the utilization rate of the phosphorus element. The method comprises the following steps: mixing molten urea or molten ammonium nitrate with a potash fertilizer and a filler to obtain a mixture; carrying out blending chelating on one or a mixture of more of potassium fulvate, ammonium humate and monoammonium phosphate and the mixture; defoaming the above blend-chelated product by a defoaming agent; sending the defoamed product to a high tower mixing tank, and carrying out high tower granulation; processing a composition comprising, by weight, 5 parts of guar gum, 3 parts of nonionic polyacrylamide and 2 parts of potassium polyacrylate to prepare a liquid with 10% of the composition, and uniformly sprinkling the surface of a granulated granular fertilizer with the liquid to wrap the fertilizer. The compound fertilizer adopting potassium fulvate or ammonium humate as an organic matter has the advantages of high content of nutrients, good dissolvability, low water content, reduction of the frequency of contact of phosphate radicals with metal ions, reduction of the curing probability of phosphorus, and improvement of the utilization rate of a phosphate fertilizer.

Owner:胡红辉

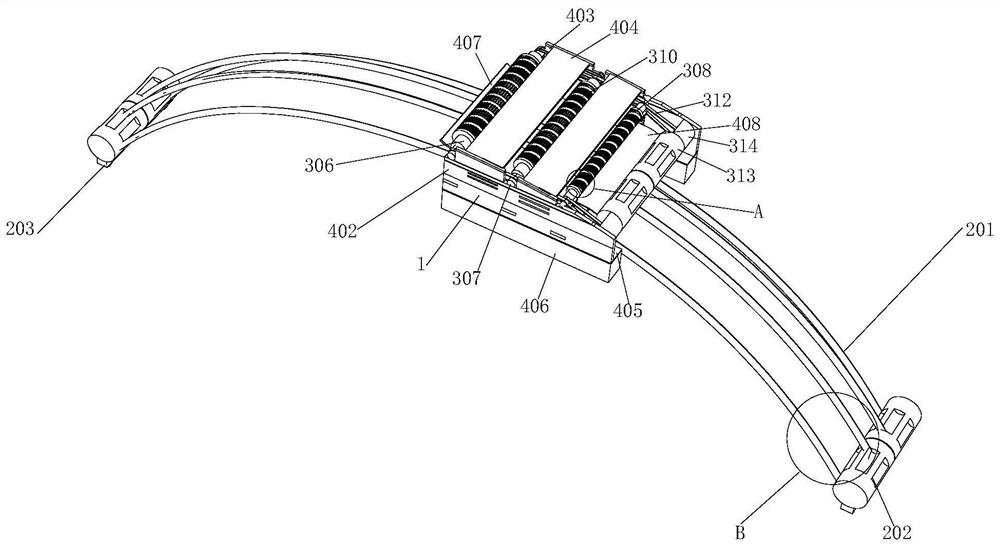

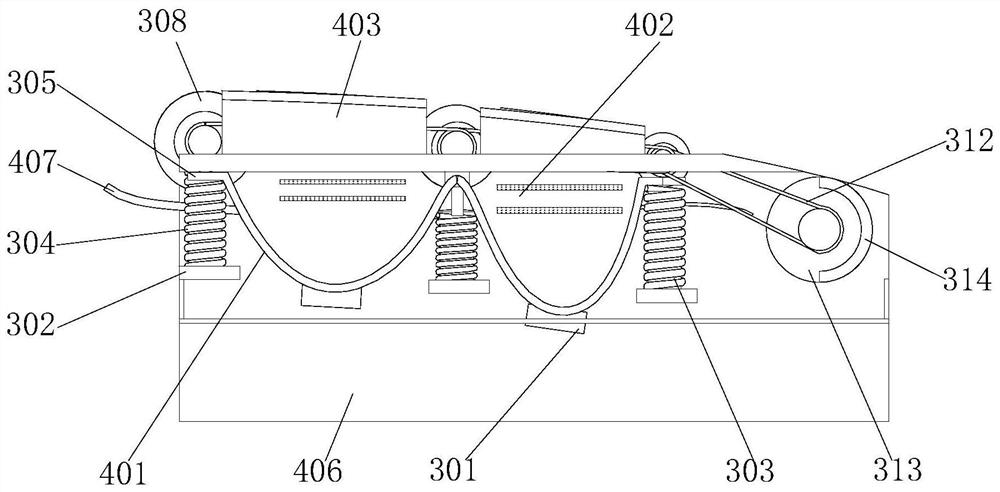

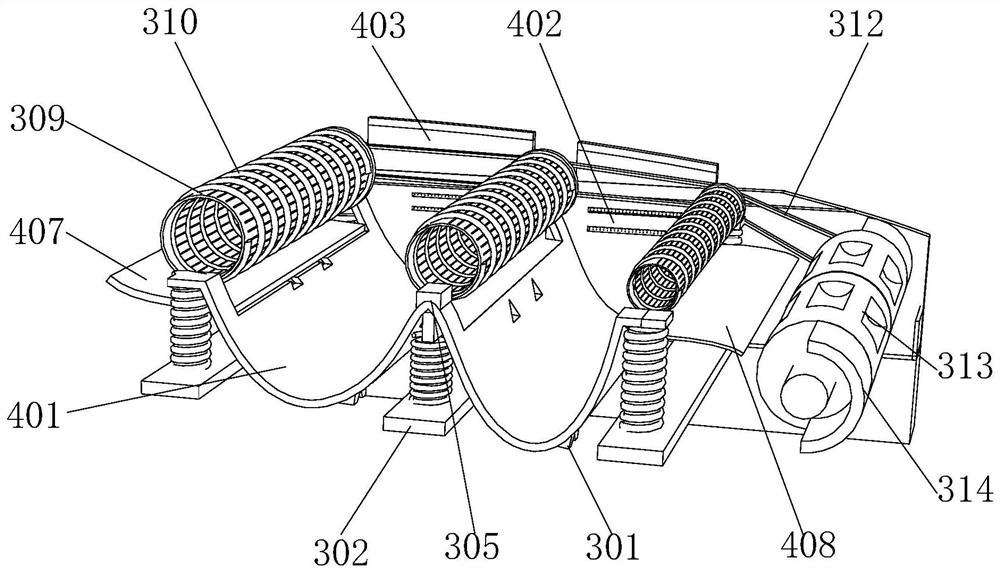

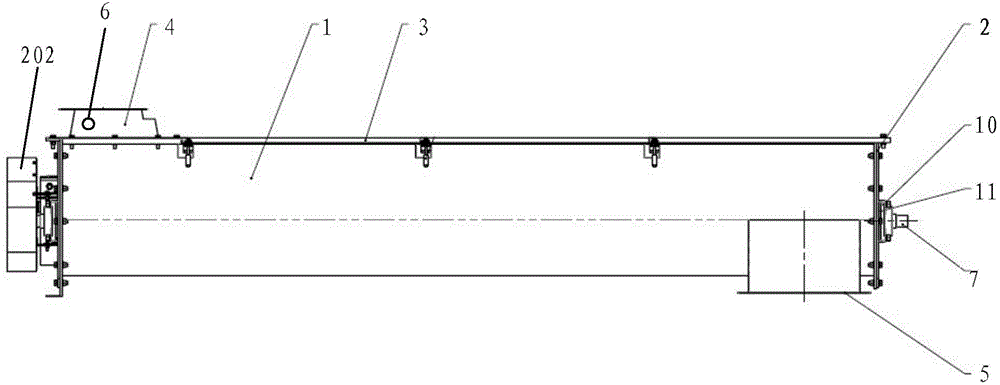

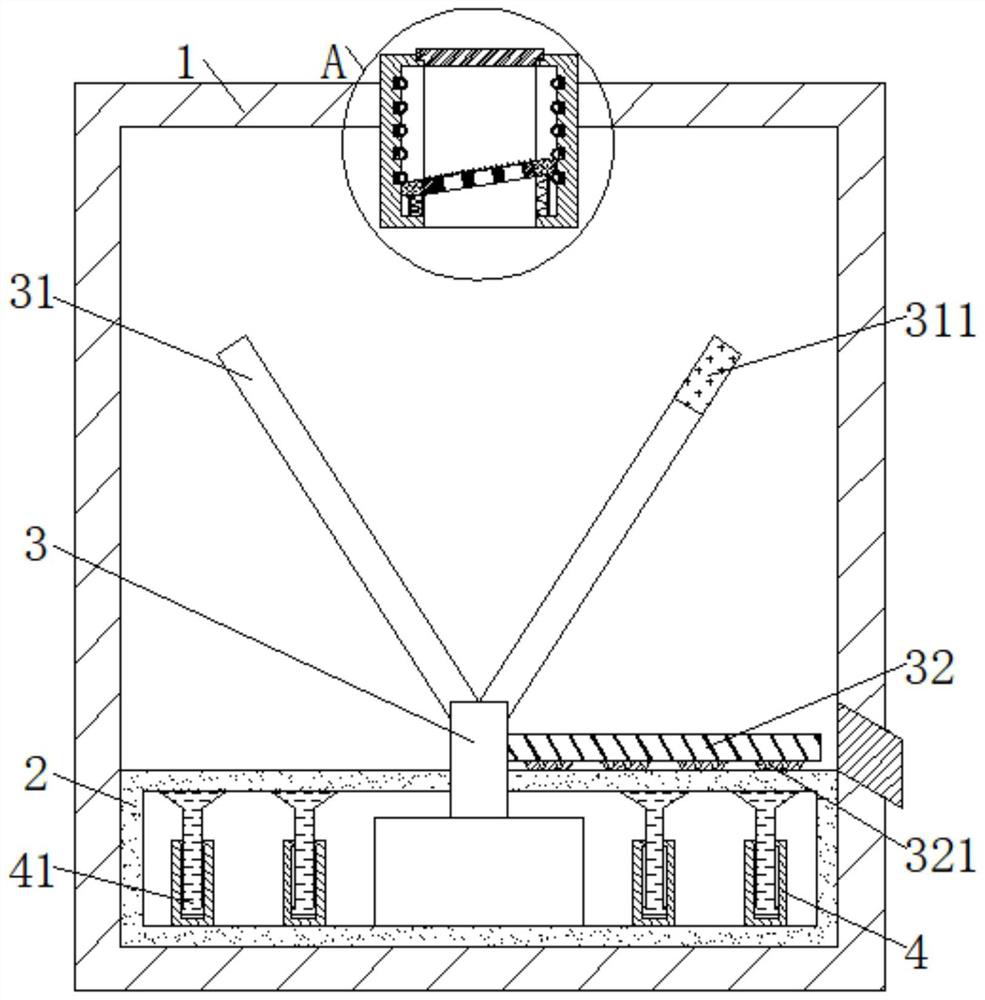

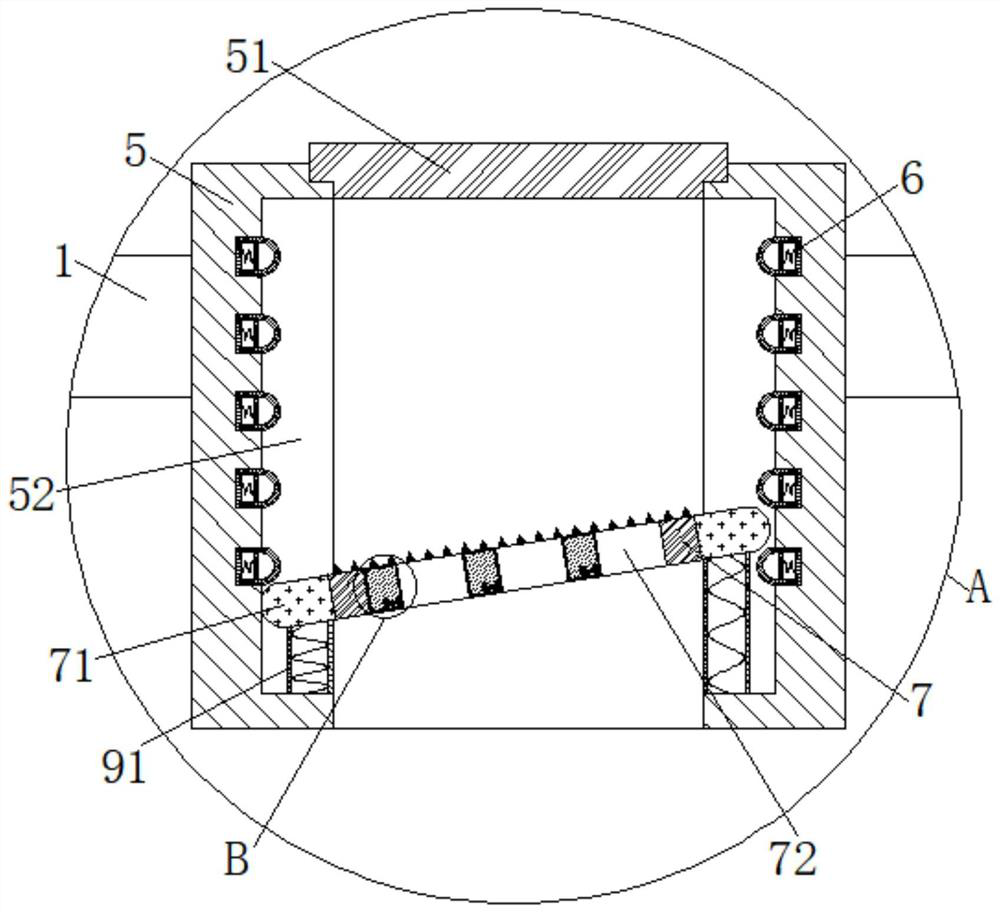

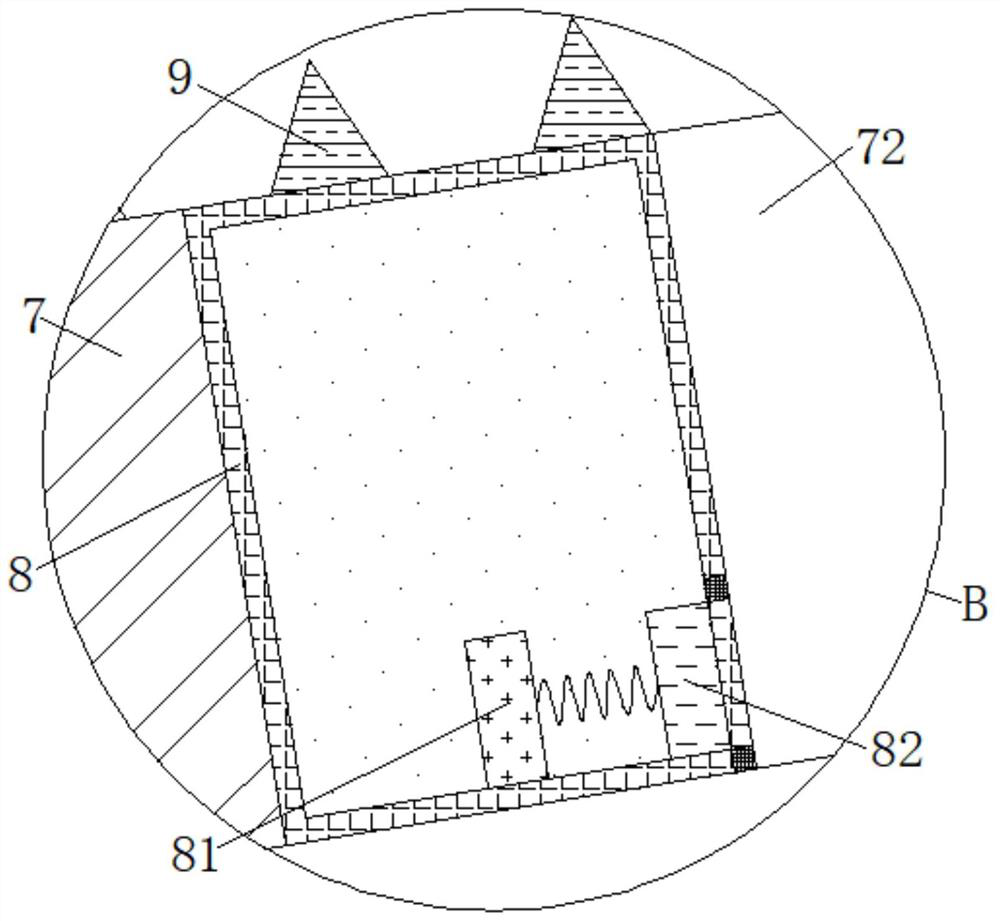

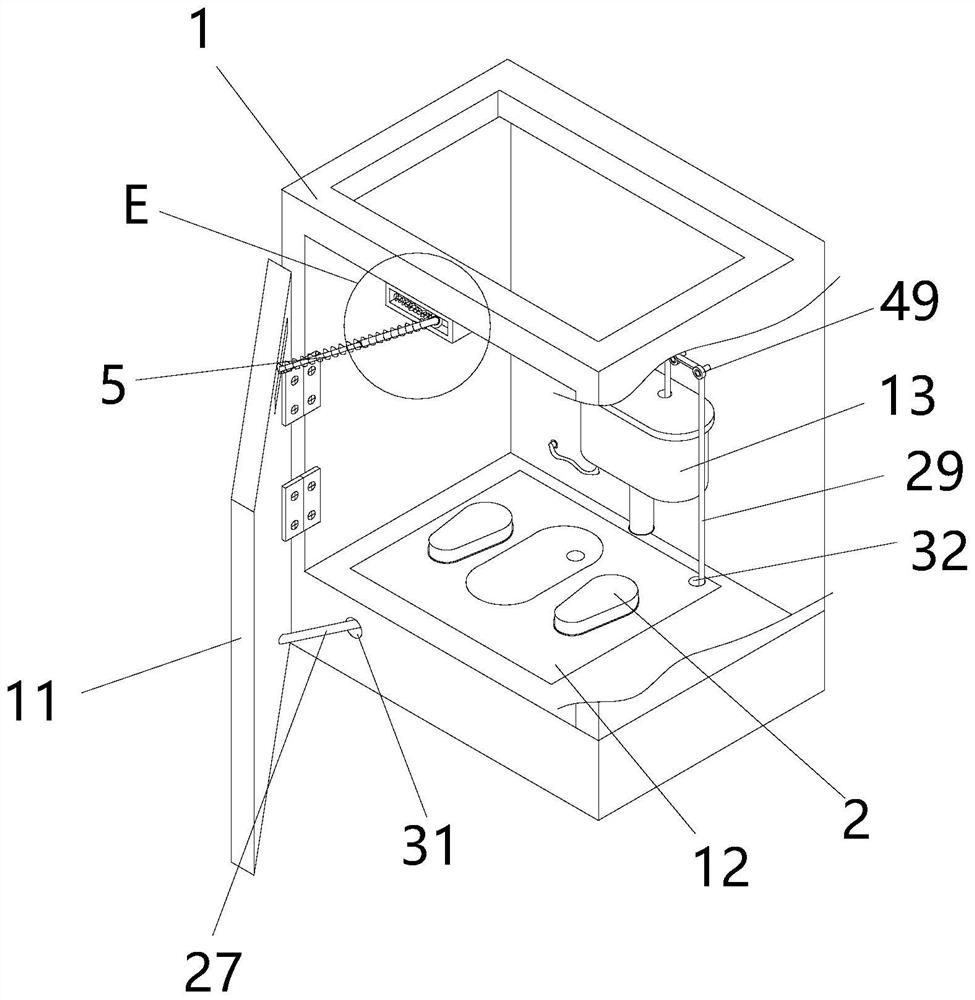

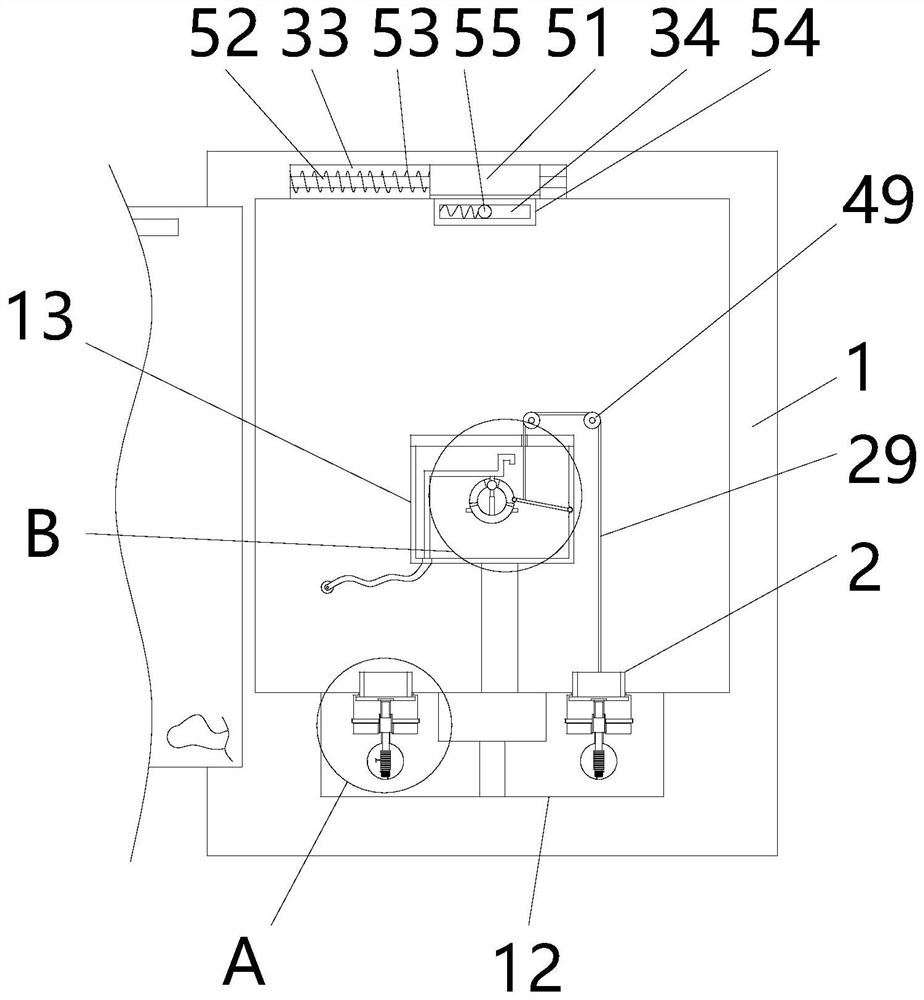

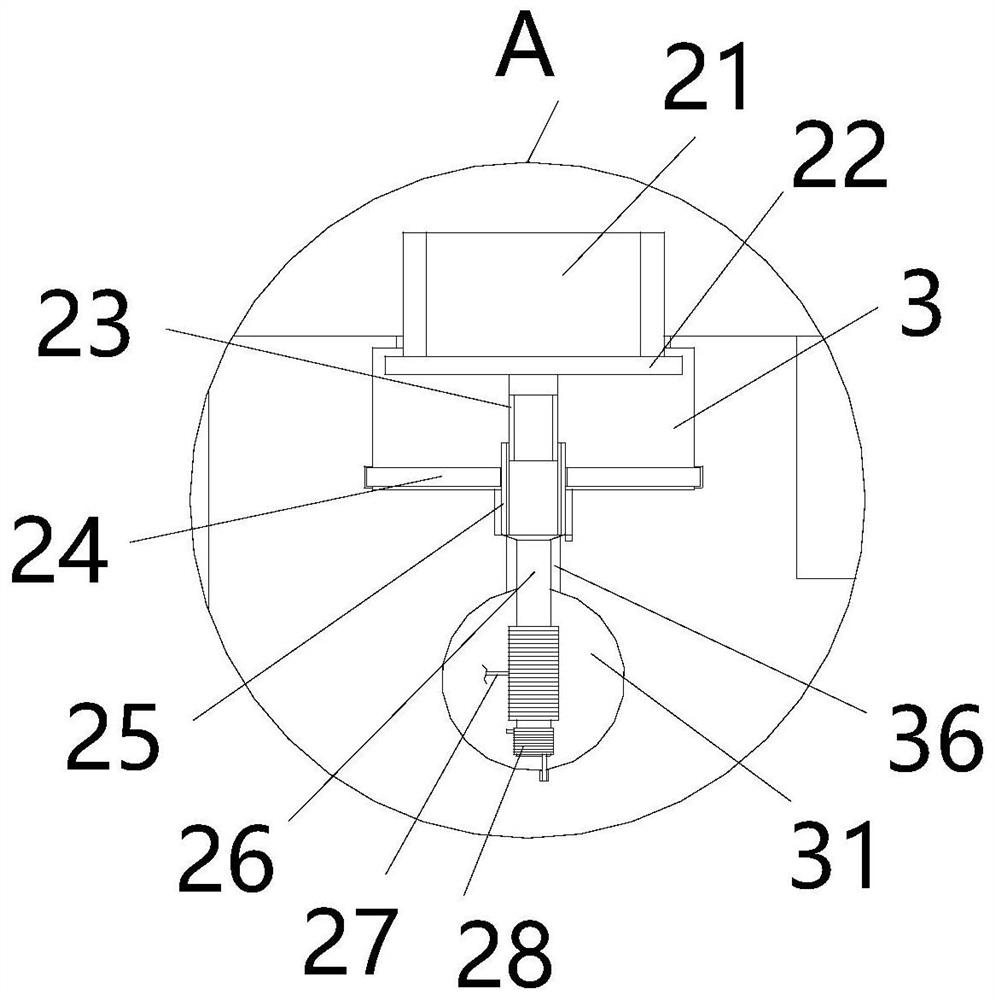

Railway tunnel vault deicing device

InactiveCN112360555AImprove cleanlinessSave manpower and material resourcesMining devicesUnderground chambersRailway tunnelStructural engineering

The invention provides a railway tunnel vault deicing device, and relates to the technical field of railway transportation. The railway tunnel vault deicing device comprises connecting parts, slidingdevices, deicing mechanisms, ice melting mechanisms and rolling wheels; the ice melting mechanisms are arranged at the top ends and the bottom ends of the connecting parts, cleaned broken ice is melted through the ice melting mechanisms, and the ice melting mechanisms are fixedly connected with the top ends and the bottom ends of the connecting parts; the deicing mechanisms are arranged between the connecting parts, and the deicing mechanisms are used for removing ice columns on a vault and ice on the surface of the vault; the left end and the right end of each deicing mechanism are fixedly connected with the corresponding connecting part; sliding devices are arranged at the bottom ends of the deicing mechanism so that the deicing mechanisms can be conveniently attached to the vault to remove ice; and the top ends of the sliding devices are in sliding connection with the top ends of the deicing mechanisms, the rolling wheels are arranged at the bottom ends of the sliding devices, and the rolling wheels penetrate through the bottom ends of the sliding devices to be rotationally connected with the bottom ends of the sliding devices. The problem that ice on the surface of the vault cannot be removed when the vault is deiced so as to cause secondary icing easily is solved.

Owner:刘展飞

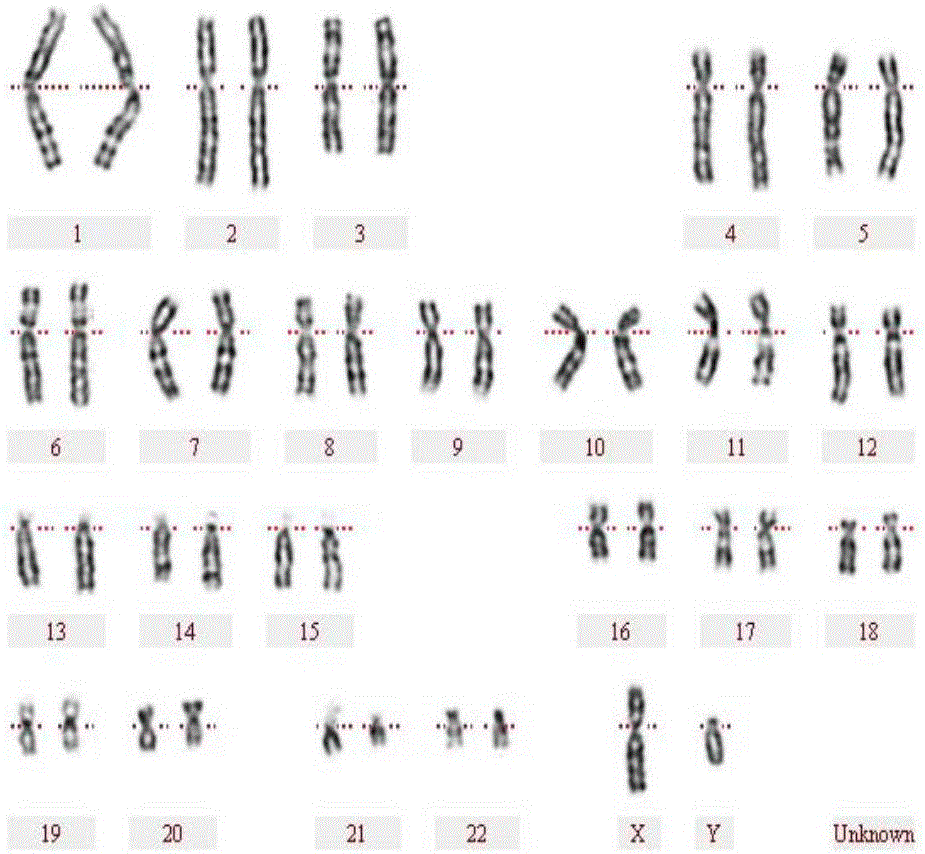

Human peripheral blood chromosome synchronization preparation kit

InactiveCN106501040AAvoid toxic effectsHighly toxicPreparing sample for investigationColchicineCulture mediums

The invention discloses a human peripheral blood chromosome synchronization preparation kit which comprises thymidine, 2'-deoxycytidine, colchicine, a 1640 culture medium and a fixing solution. According to the kit, growth cycles of peripheral blood lymphocytes are synchronized, enough 500-550 chromosome karyotypes with stripes can be obtained, so that chromosomal aberration and small abnormal structures are accurately identified. The synchronization kit adopting excessive thymidine single occlusion, deoxycytidine releasing and ethanol acetic acid harvesting is capable of increasing resolution ratio, simple in operation steps, capable of reducing the contact frequency of toxic reagents, and suitable for wide and conventional application.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV +1

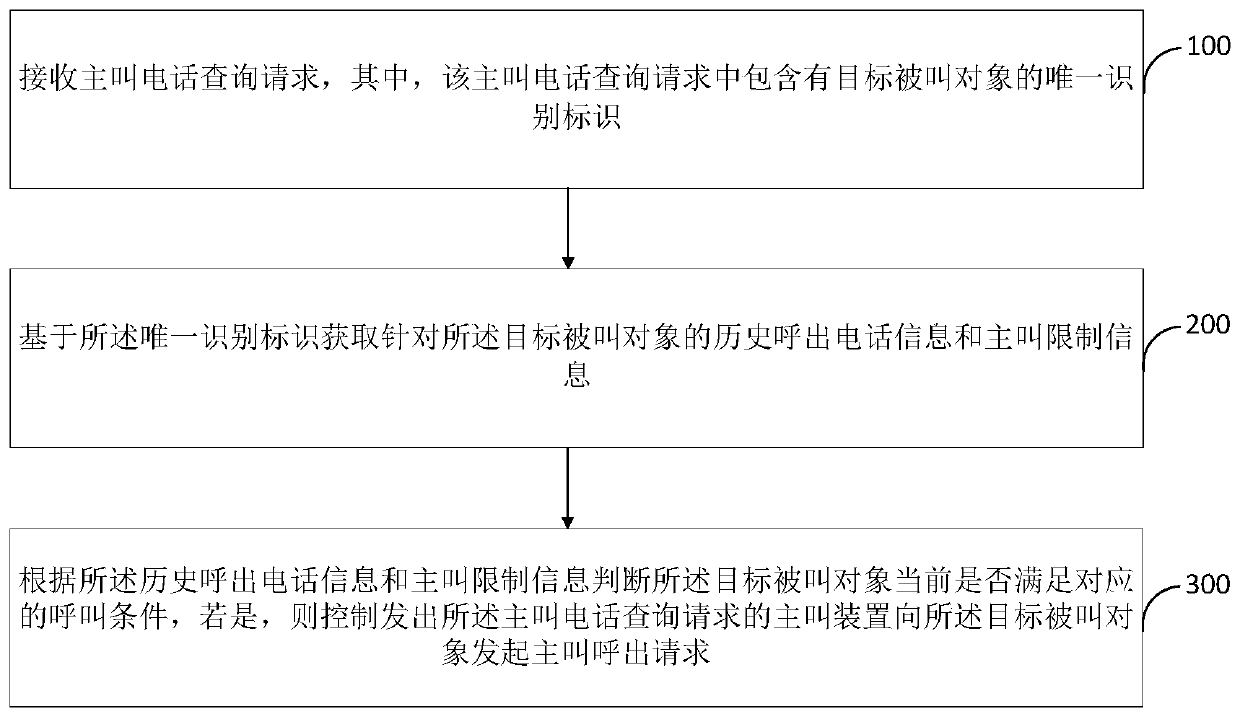

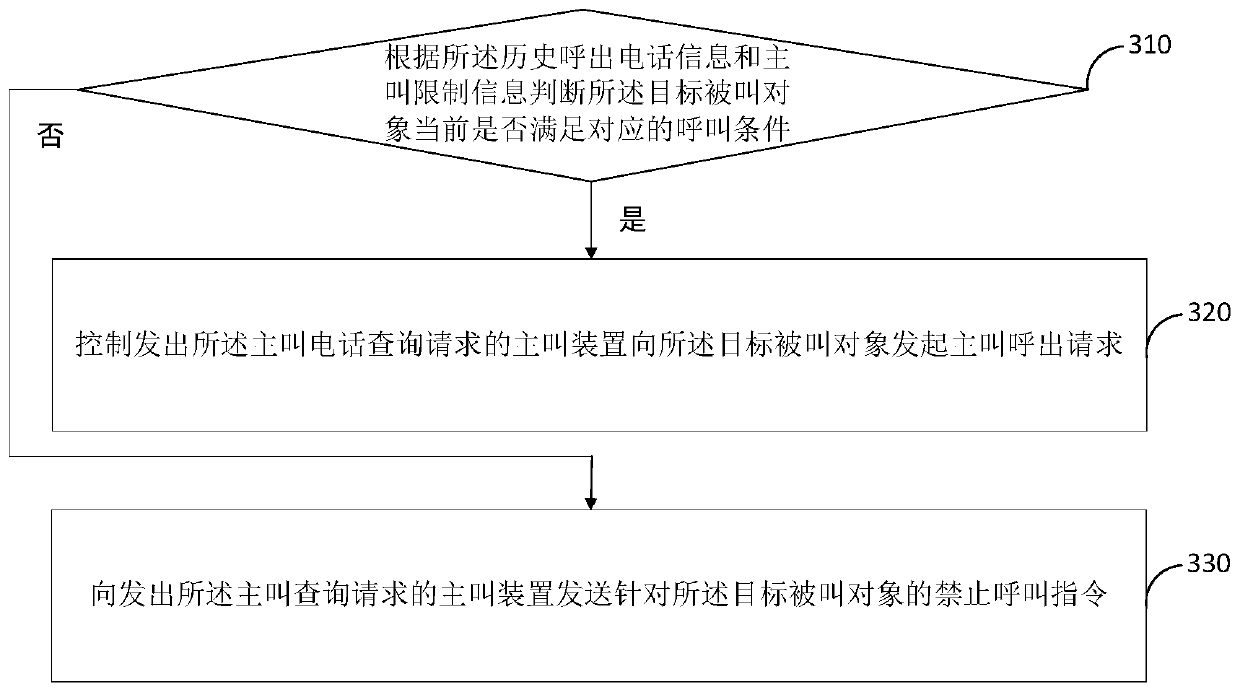

Calling call control method and device

InactiveCN110868493AImprove experienceImprove communication effectivenessSubstation equipmentEngineeringCall control

The embodiment of the invention provides a calling call control method and device, and the method comprises the steps: receiving a calling call query request which comprises a unique identification mark of a target called object; acquiring historical outgoing call information and calling restriction information for the target called object based on the unique identification identifier; and judgingwhether the target called object currently meets a corresponding calling condition or not according to the historical outgoing call information and the calling restriction information, and if so, controlling a calling device sending the calling call query request to initiate a calling outgoing request to the target called object. According to the method and the device, the frequency of making a call to the user can be actively controlled from the source, the frequency of making the user call in the dialing time interval can be effectively reduced, and meanwhile, the possibility that the useris considered as a harassment call can be effectively reduced.

Owner:CHINA CONSTRUCTION BANK +1

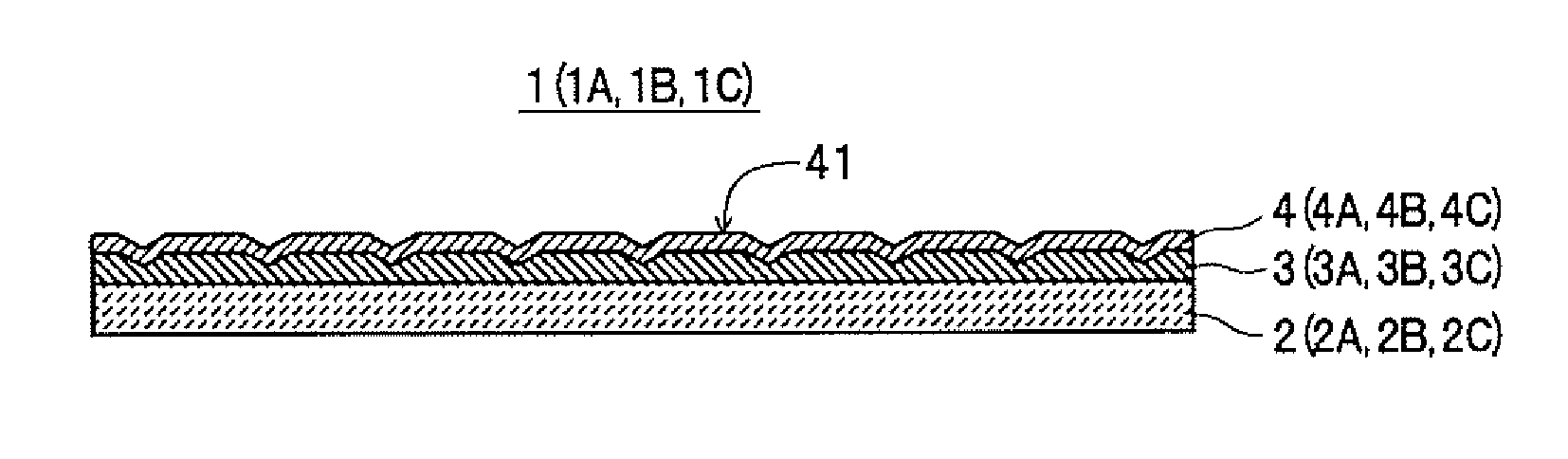

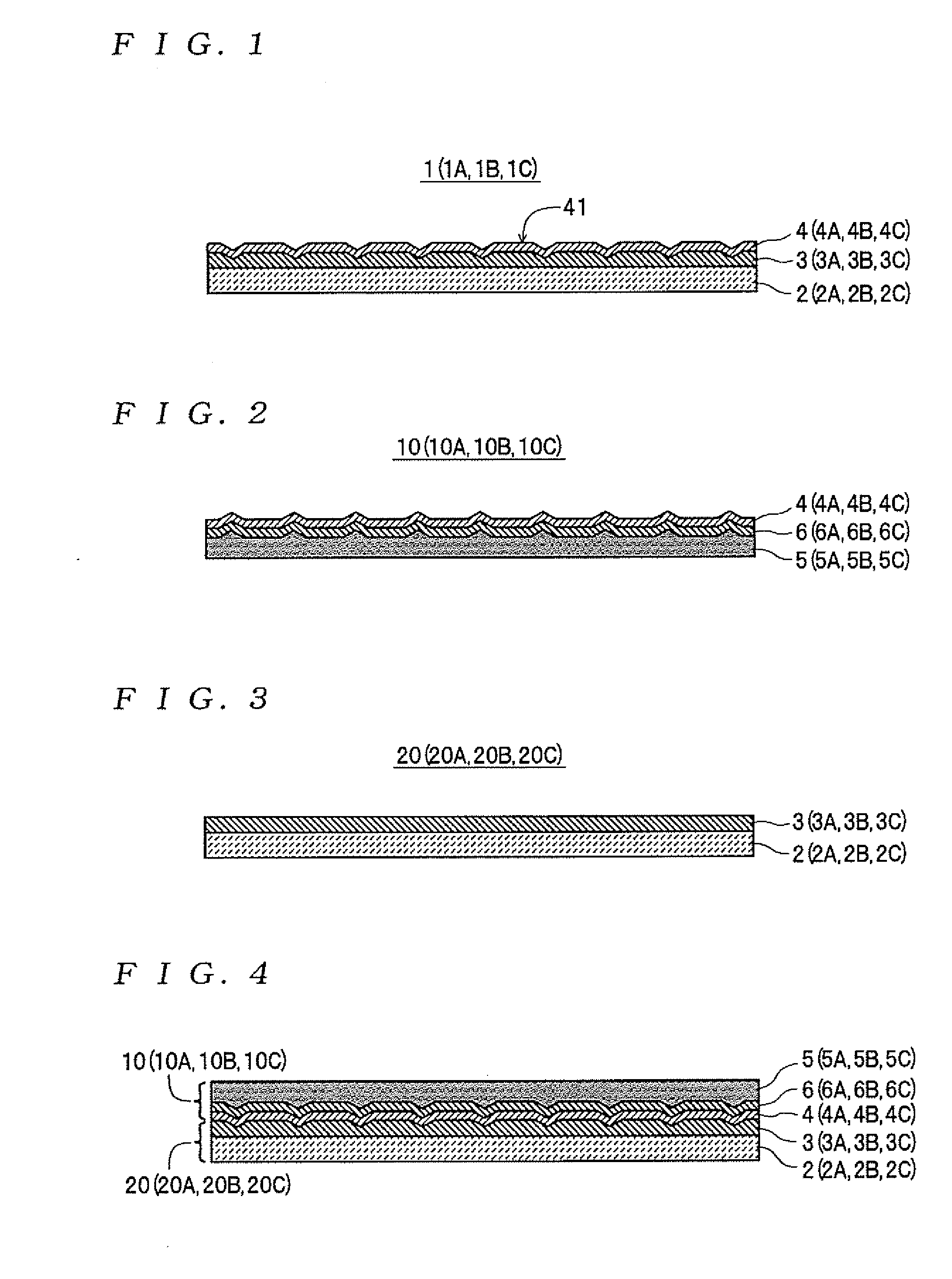

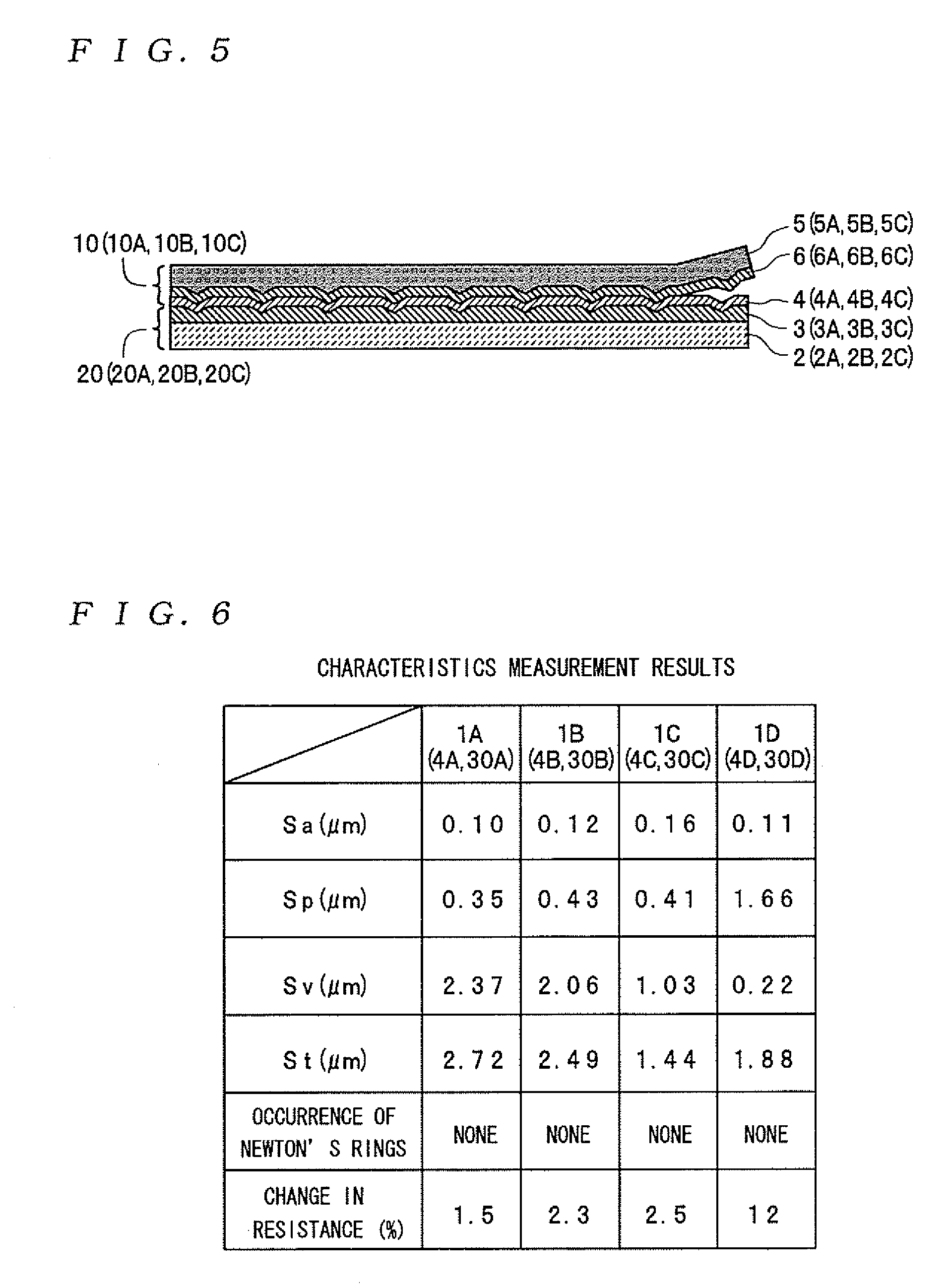

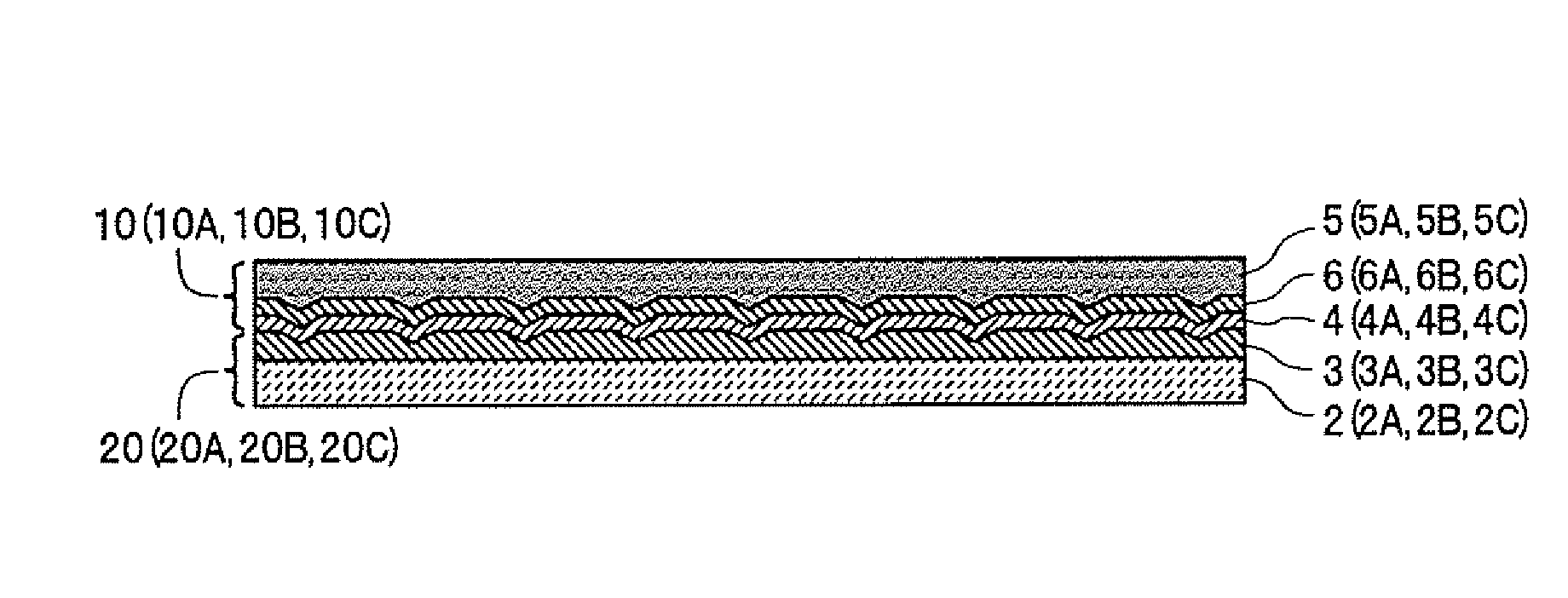

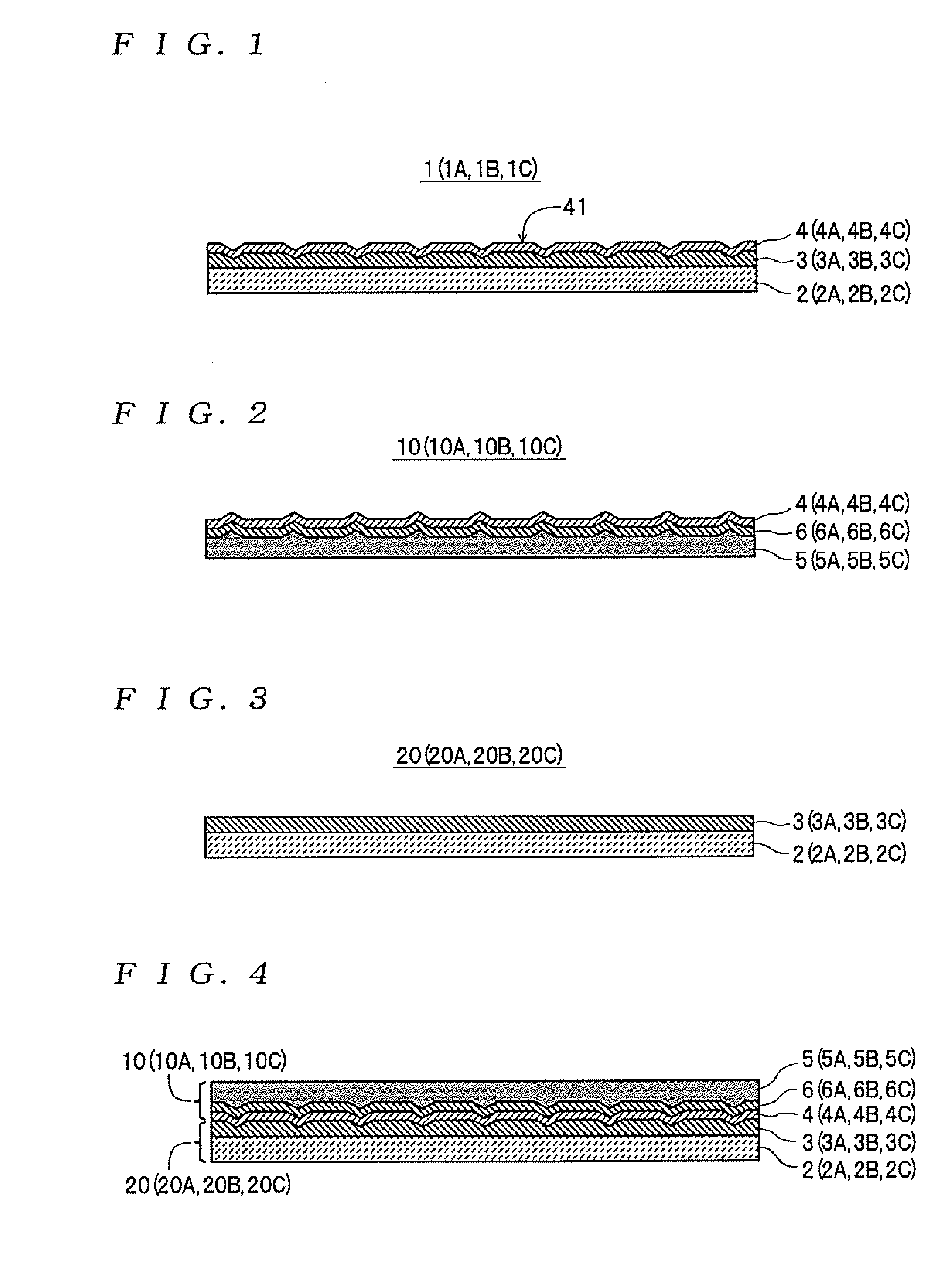

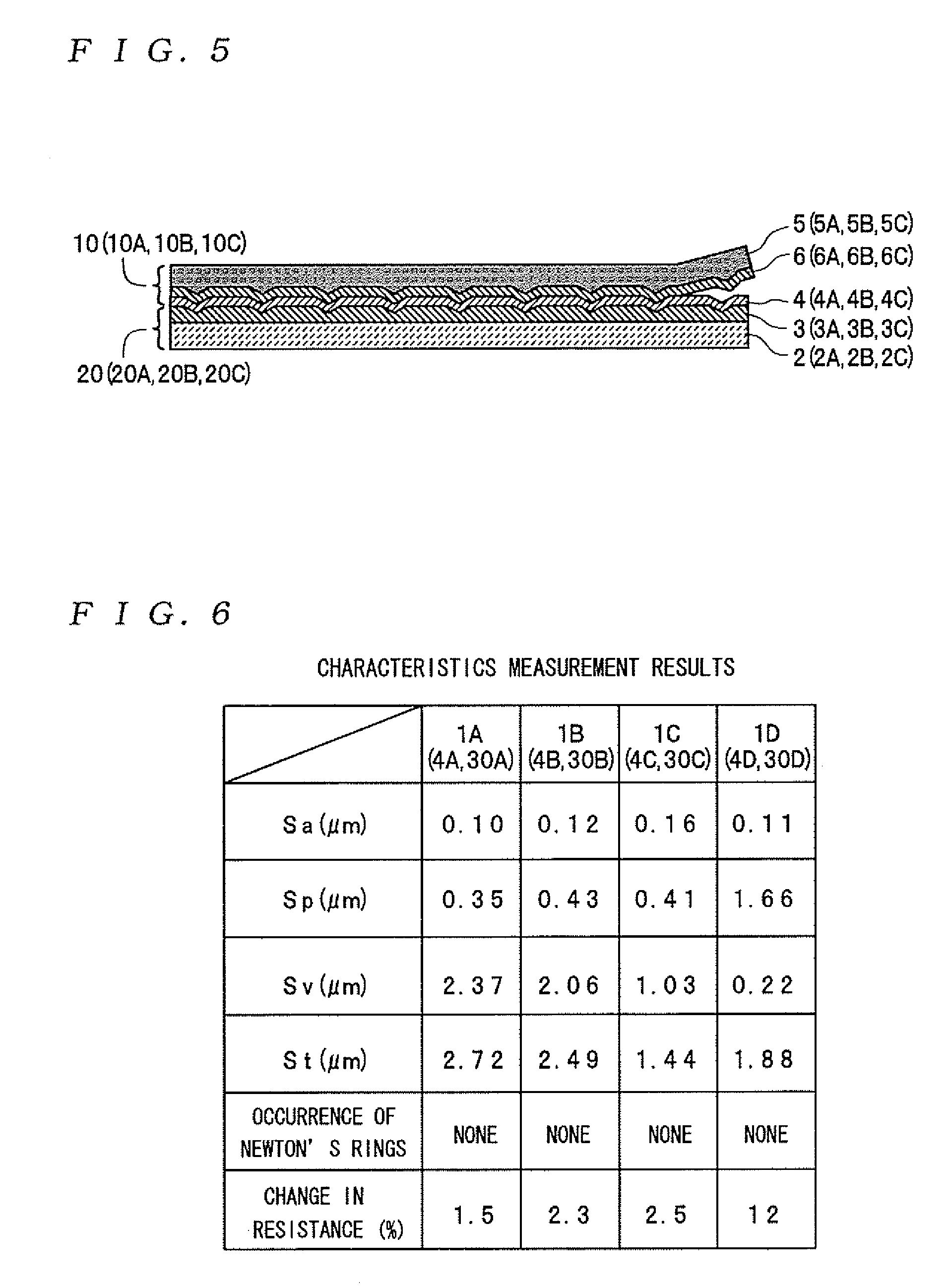

Transparent conductor

InactiveUS20070000678A1Increased durabilityDecrease damage to surfaceInsulated cablesPhotovoltaic energy generationRough surfaceElectrical conductor

A transparent conductor includes a film-shaped or plate-shaped support and a transparent conductive layer that is disposed on the support and has a surface formed as a rough surface. The surface of the transparent conductive layer is formed so that a maximum peak height that shows a surface roughness of the surface is in a range of 0.35 μm to 0.43 μm, inclusive.

Owner:TDK CORPARATION

Pipe electrode with flexible supporting function and function of promoting discharge of machined products and small deep hole electrical machining method thereof

InactiveCN109676208ADischarge in timeGuarantee processing straightness requirementsMachining electrodesElectrical-based machining electrodesEngineeringMachining process

The invention provides a pipe electrode with a flexible supporting function and a function of promoting discharge of machined products and a small deep hole electrical machining method thereof. Oblique through holes uniformly distributed in a ring-shaped array manner are machined in one or more cross section side walls, distancing from the machining end face by a certain distance, of the pipe electrode. In the machining process, working liquid with certain pressure is sprayed out from the end face of the pipe electrode to carry out electrical hole machining, meanwhile, the oblique holes in theside walls close to the end face of the pipe electrode spray out working liquid with certain pressure, the working liquid sprayed out from the oblique holes and the inner walls of machined holes affect mutually, thus the upper end face of the pipe electrode is in a fixed supporting state, and the machining end face is in a flexible supporting state. When the center of the end face of the pipe electrode is eccentric, under the effect of flexible supporting force, it can be ensured that the axis of the end face of the pipe electrode and the axis of the machined holes are restored to the coaxialstate, and the straightness of the machined small deep holes is ensured. Meanwhile, the working liquid sprayed out from the through holes oblique upwards has a negative pressure sucking function in amachining side gap, and the products in the machining gap are promoted to be discharged in time. According to the pipe electrode, by changing the structure of the pipe electrode, the straightness ofthe machined small deep holes is ensured, discharging of the machined products is promoted, and the machining stability is improved.

Owner:ANHUI UNIV OF SCI & TECH

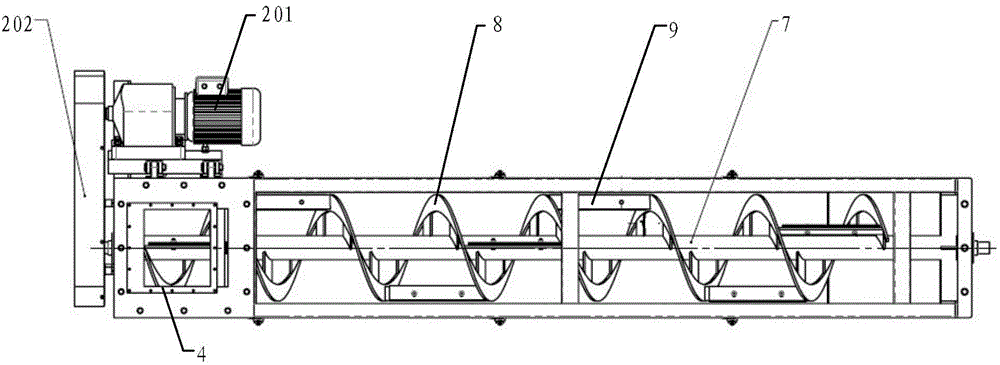

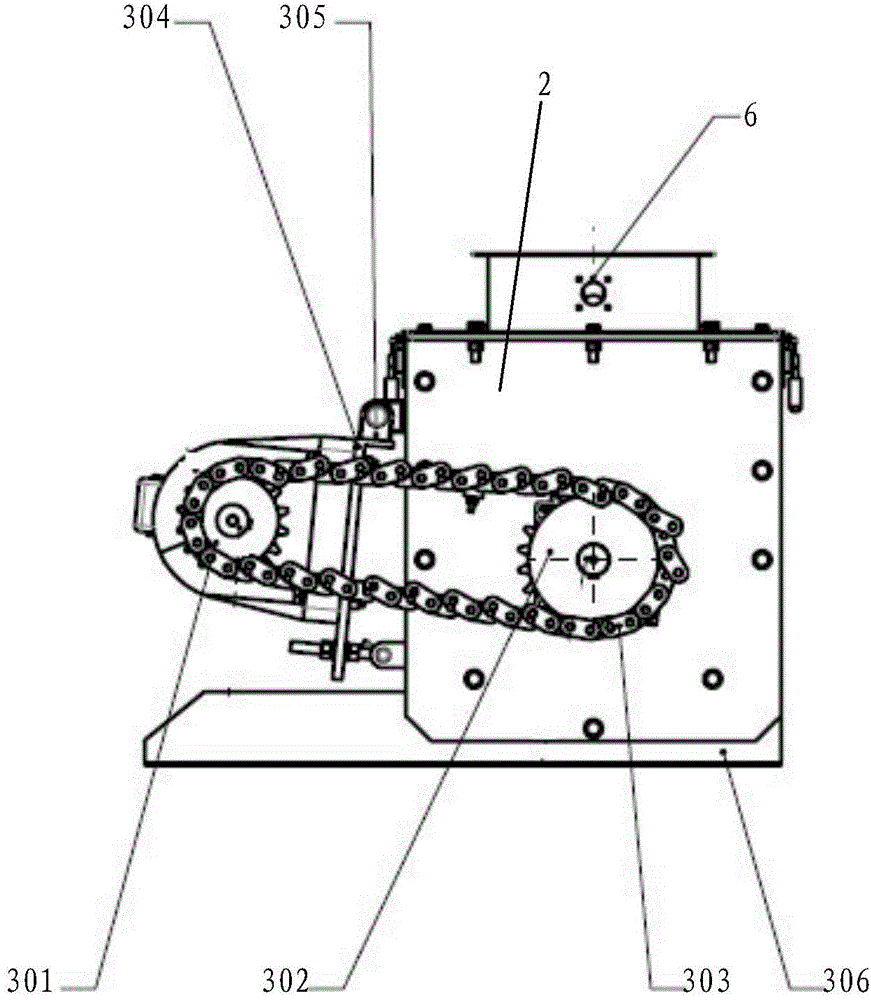

Helical tape mixing machine

The invention discloses a helical tape mixing machine which comprises a hollow shell, a feeding hole, a discharge opening and a stirring shaft, wherein the top end and two opposite side ends of the hollow shell are open; side plates are respectively fixed on the end surfaces of the side ends; a cover plate is fixed on the end surface of the top end; the feeding hole and the discharge opening are respectively fixed in the two side ends; a first material enters from the feeding hole; a nozzle is arranged on the feeding hole; a second material is ejected from the nozzle and is mixed with the first material so as to enter the hollow shell; the stirring shaft is positioned in the hollow shell; two ends of the stirring shaft are respectively rotationally fixed on the two side plates; a helical tape is fixed on the stirring shaft; a scraper is fixed on the helical tape; and when the stirring shaft rotates, the helical tape and the scraper are driven to rotate, so that the mixture of the first material and the second material is stirred and pushed to the discharge opening, and the mixture is discharged from the discharge opening. The mixing machine provided by the invention is used for solving the technical problems in the prior art that the materials are non-uniformly mixed and the powder content is high. The technical effects of improving the uniformity of the mixed materials and reducing the powder content are achieved.

Owner:武汉新科谷技术股份有限公司

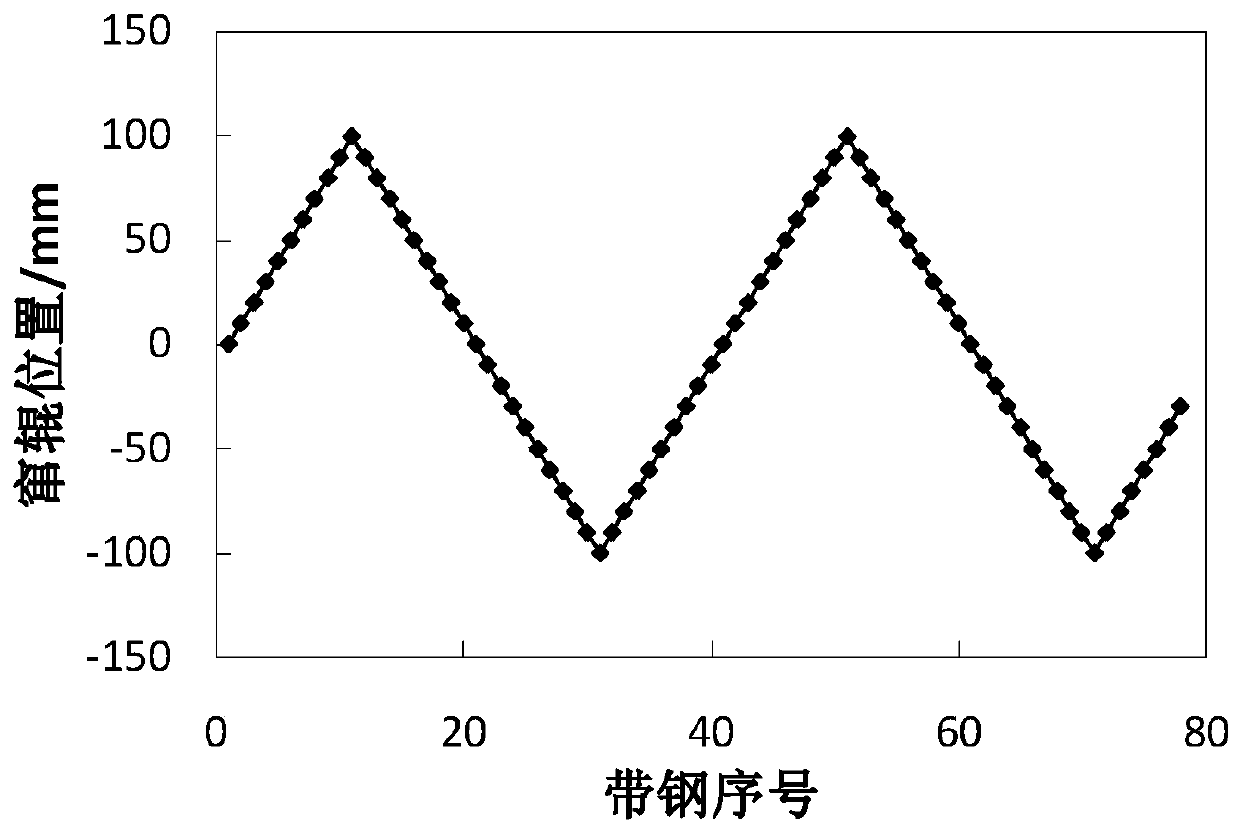

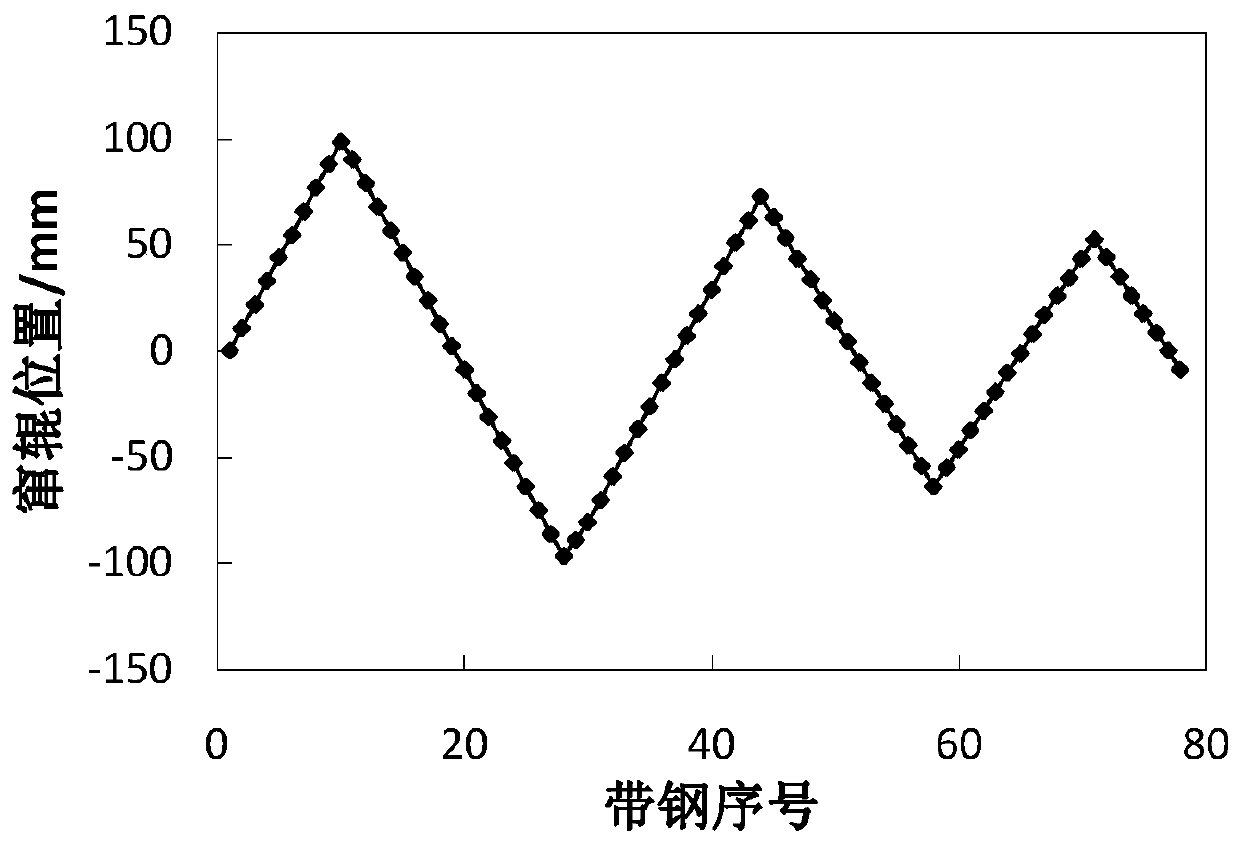

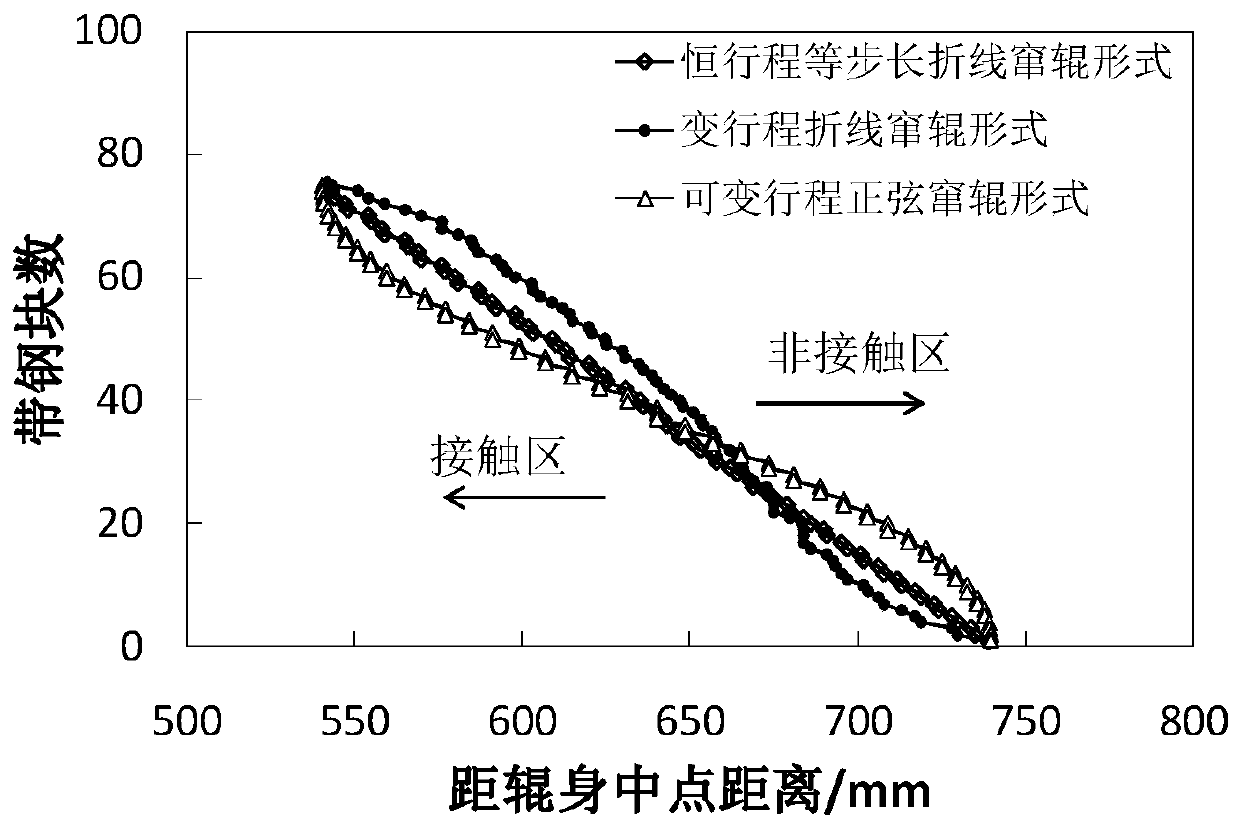

Work roll shifting method used for hot rolled strip steel same-width rolling conditions

ActiveCN110883102ASpread wearUniform wearMetal rolling arrangementsProfile control deviceEngineeringHot rolled

The invention discloses a work roll shifting method used for hot rolled strip steel same-width rolling conditions. The frequency of contact between the middle of a roll body of a work roll and strip steel is reduced, the frequency of contact between the edge portion of the work roll and the strip steel is increased, accordingly, the advantage of the length of the roll body of the work roll is fully utilized, abrasion of the middle of the work roll is scattered, abrasion of the work roll is uniform and is relieved to a larger extent, and the ability of the roll shape of the work roll to adjustthe plate shape in the service period is better maintained.

Owner:SHANDONG JIAOTONG UNIV

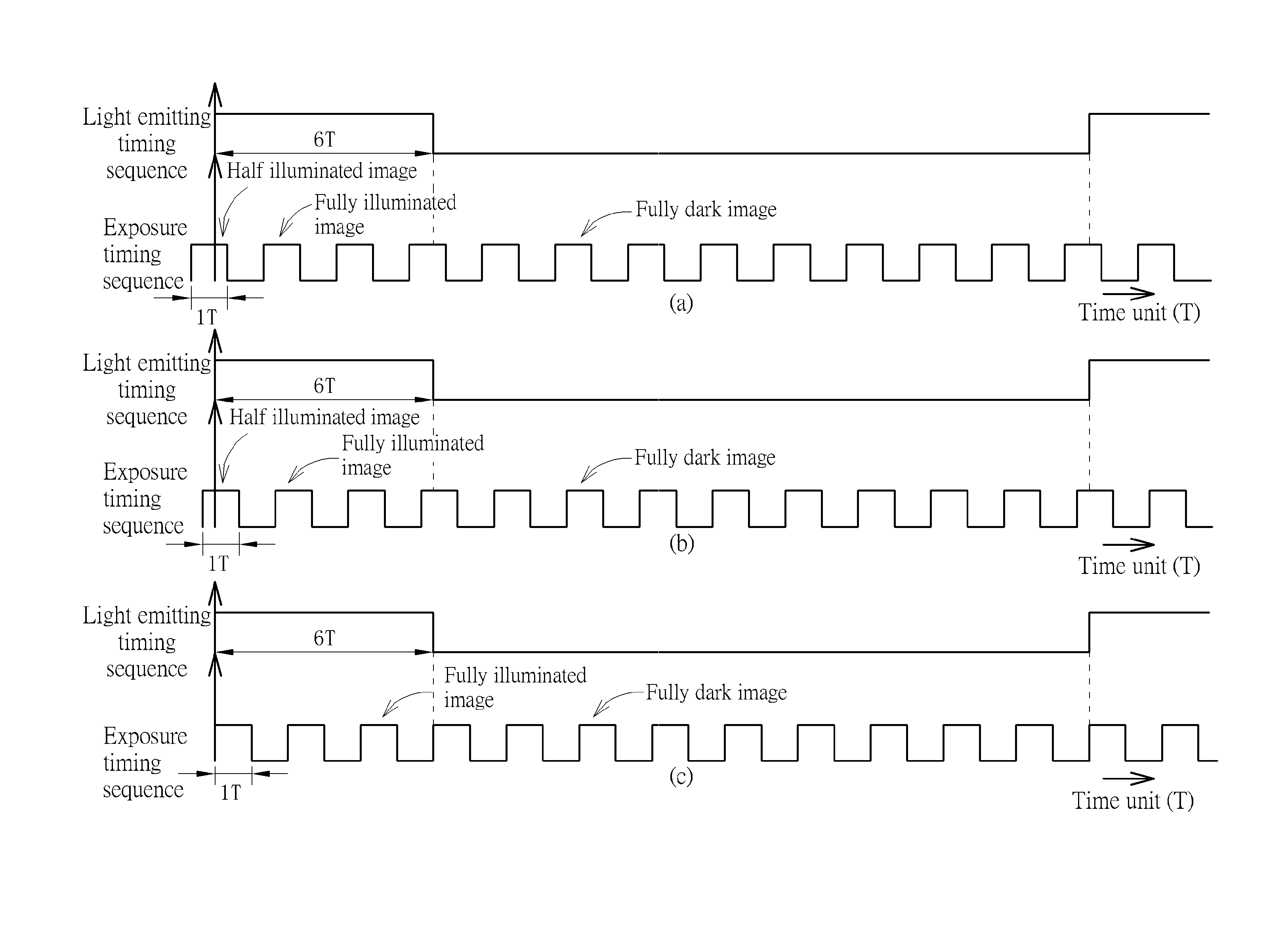

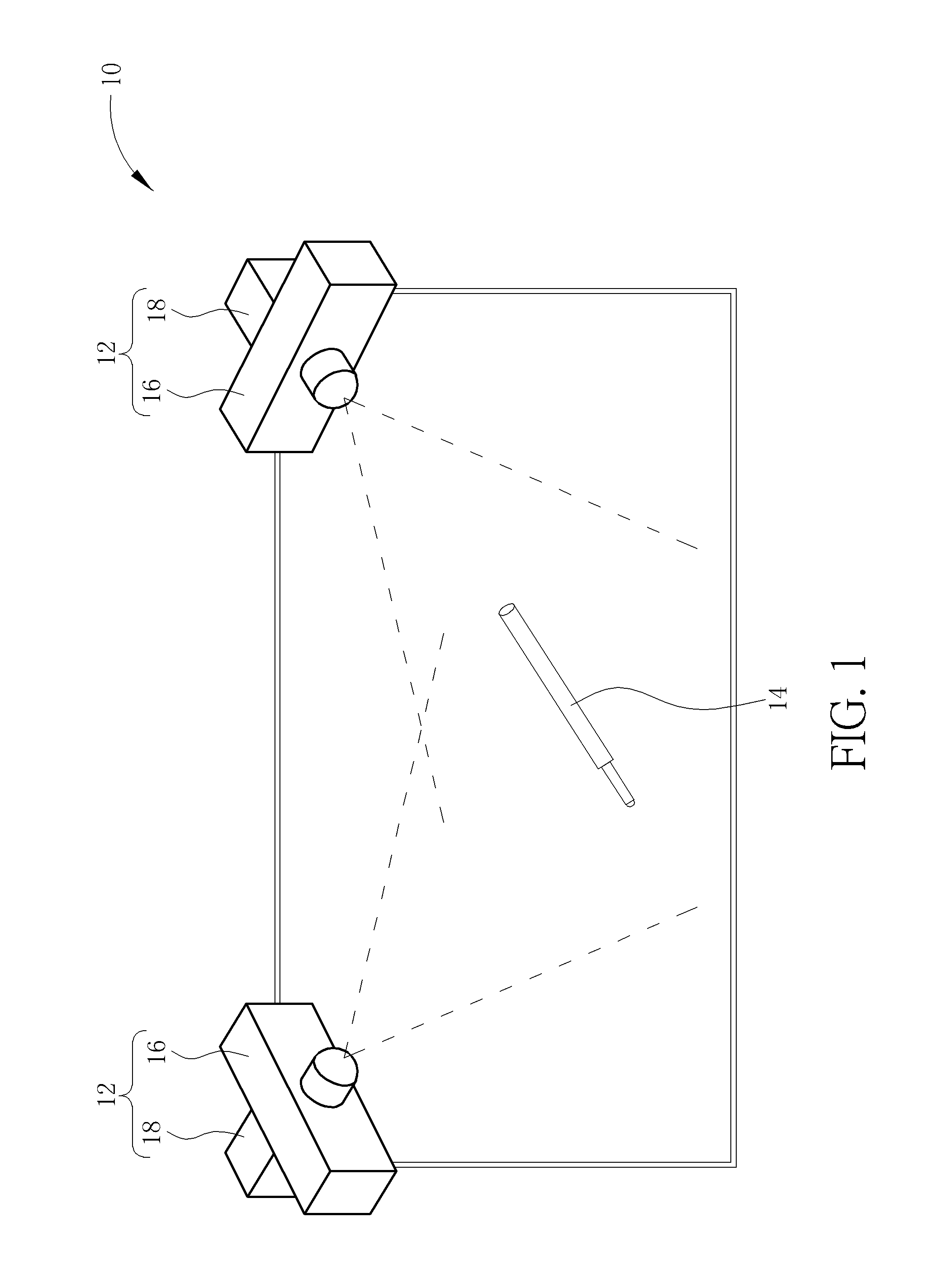

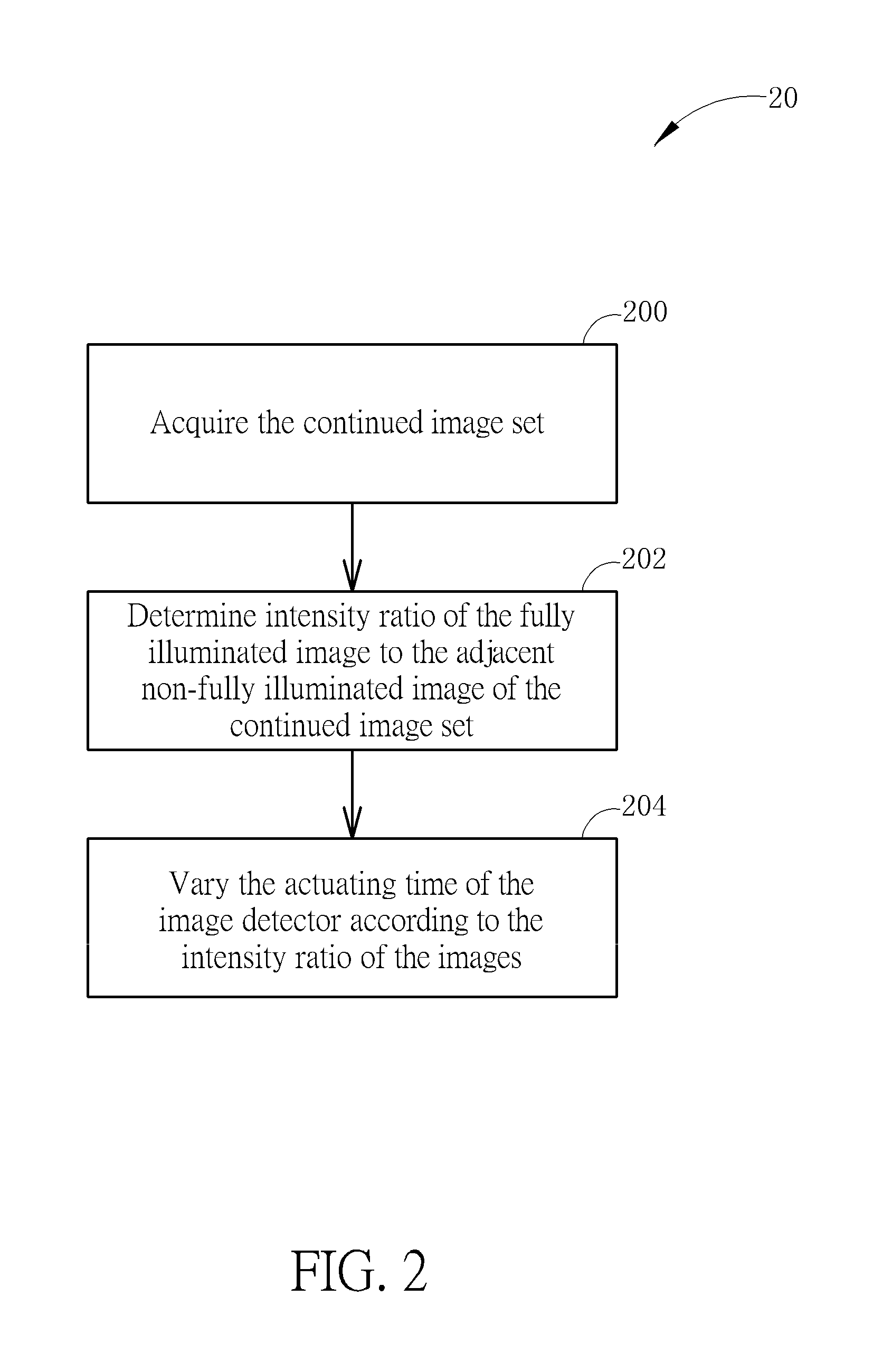

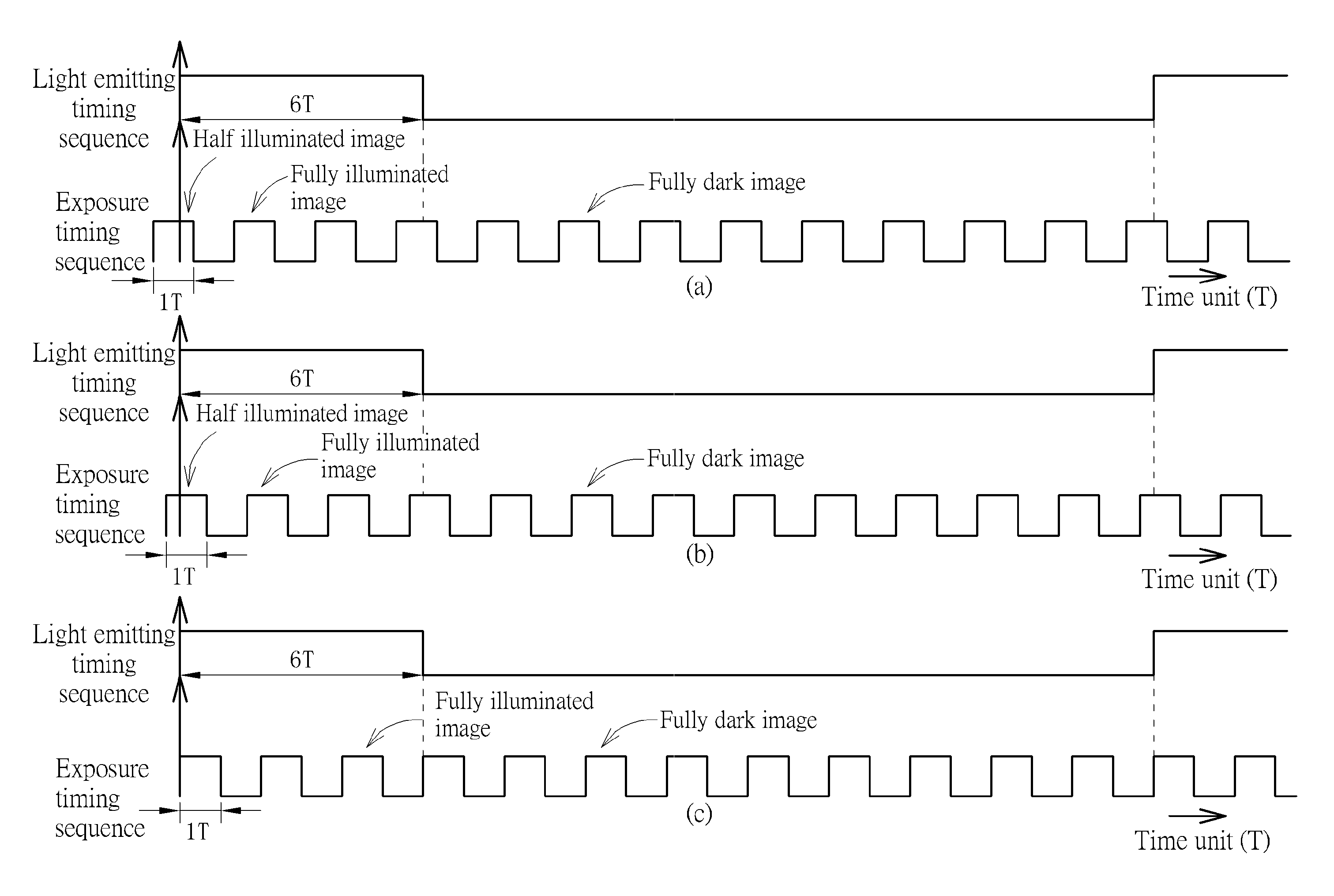

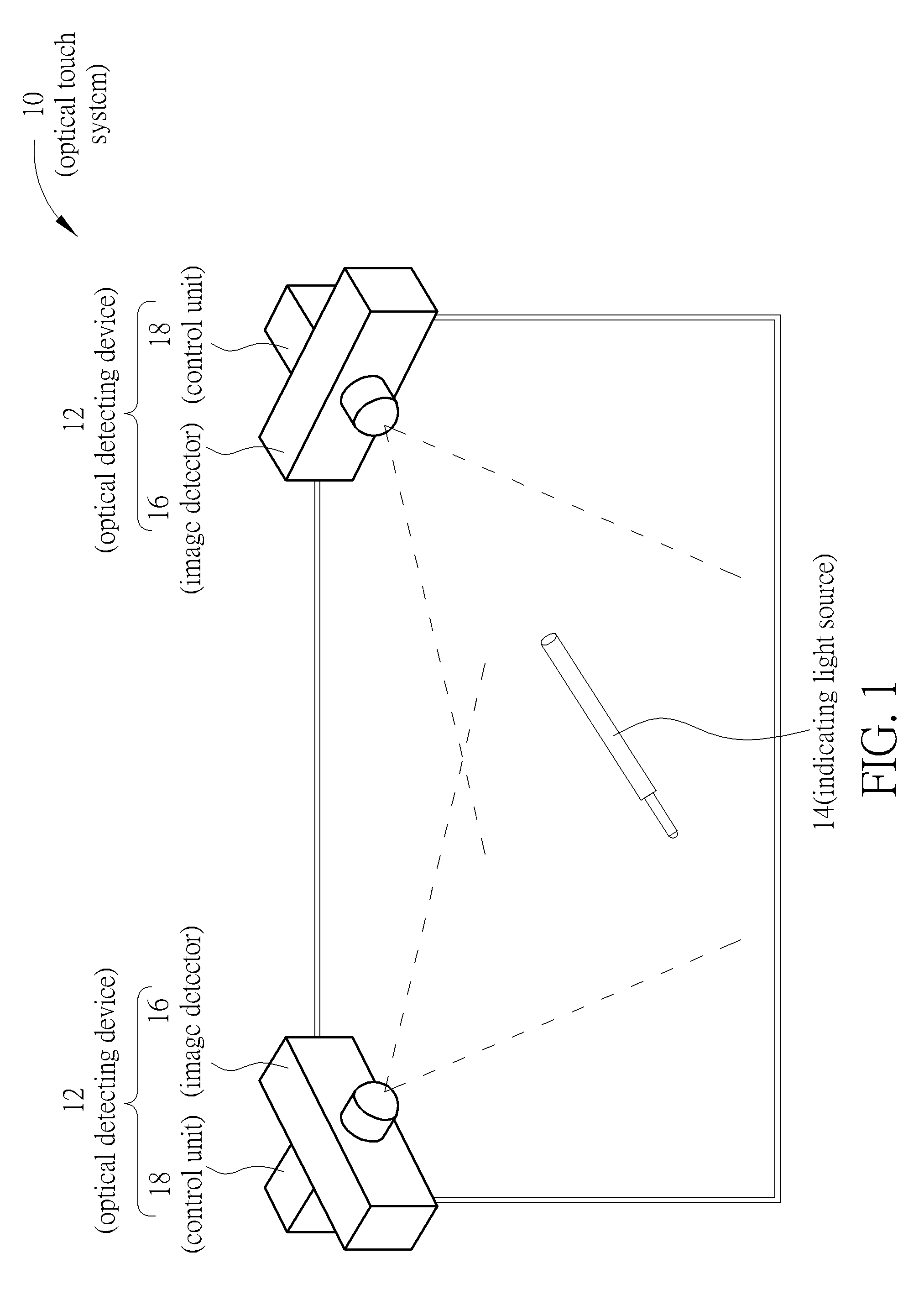

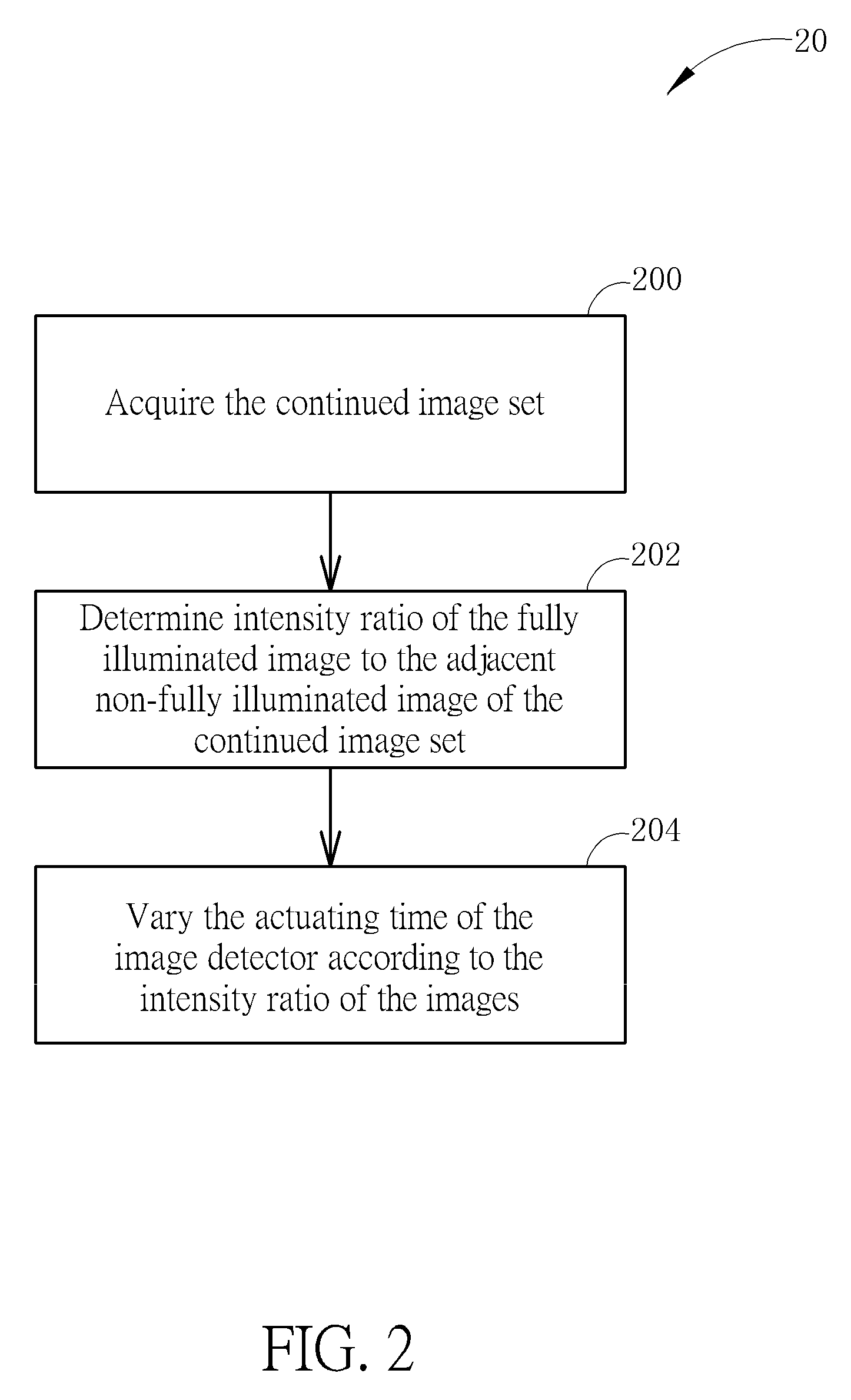

Optical detecting device and related method of synchronization adjustment

ActiveUS20140340721A1Accurately distinguishedReduce contact frequencyInput/output processes for data processingPictoral communicationImage detectorLight source

A method of synchronization adjustment is applied to an optical detecting device, so as to synchronize an exposure timing sequence of an image detector with a light emitting timing sequence of an indicating light source. The method includes acquiring a continued image set, analyzing intensity of each image of the continued image set, and adjusting the exposure timing sequence according to duty cycle of the image detector and intensity ratio of at least two images. An exposure frequency of the image detector is greater than a flickering frequency of the indicating light source.

Owner:PIXART IMAGING INC

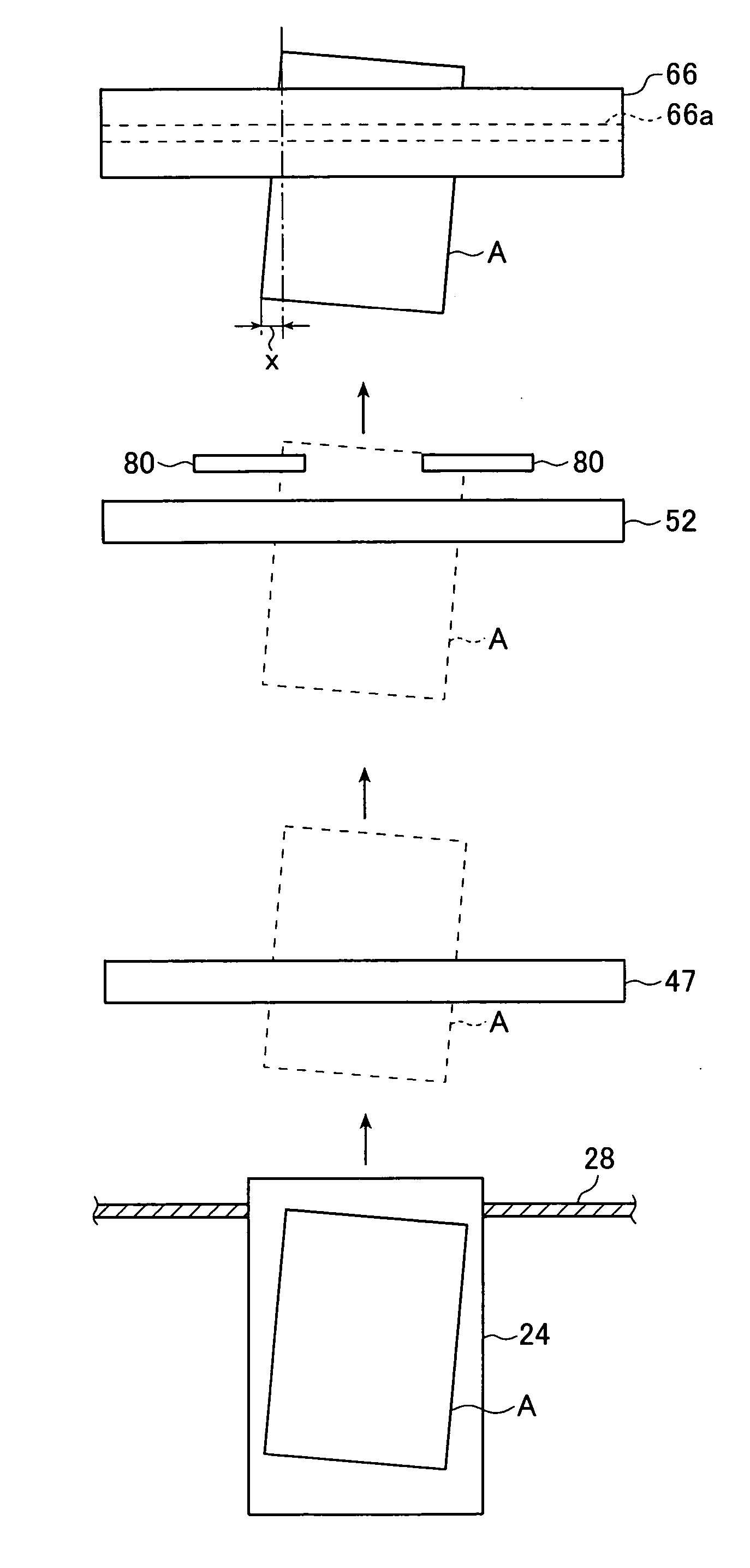

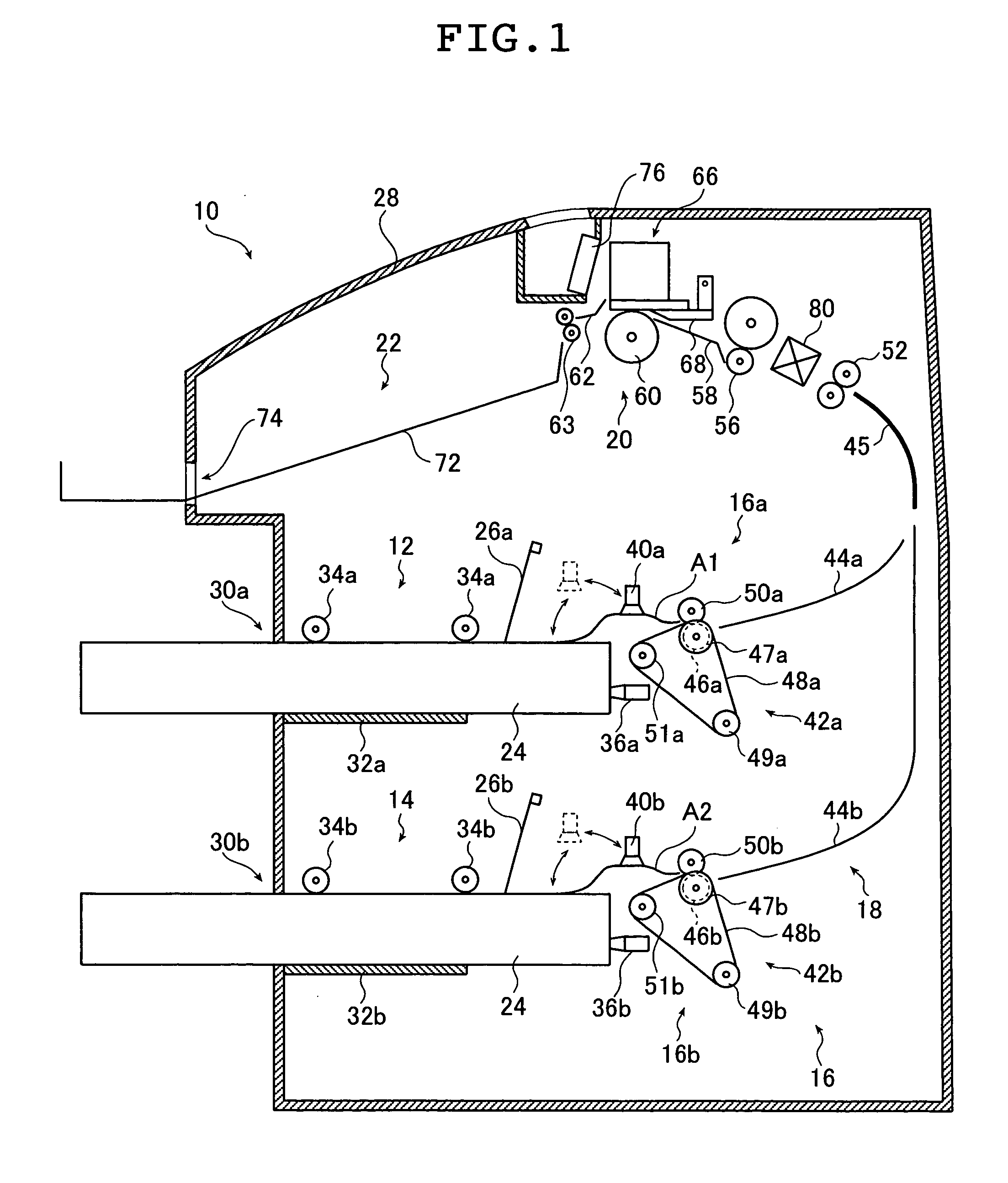

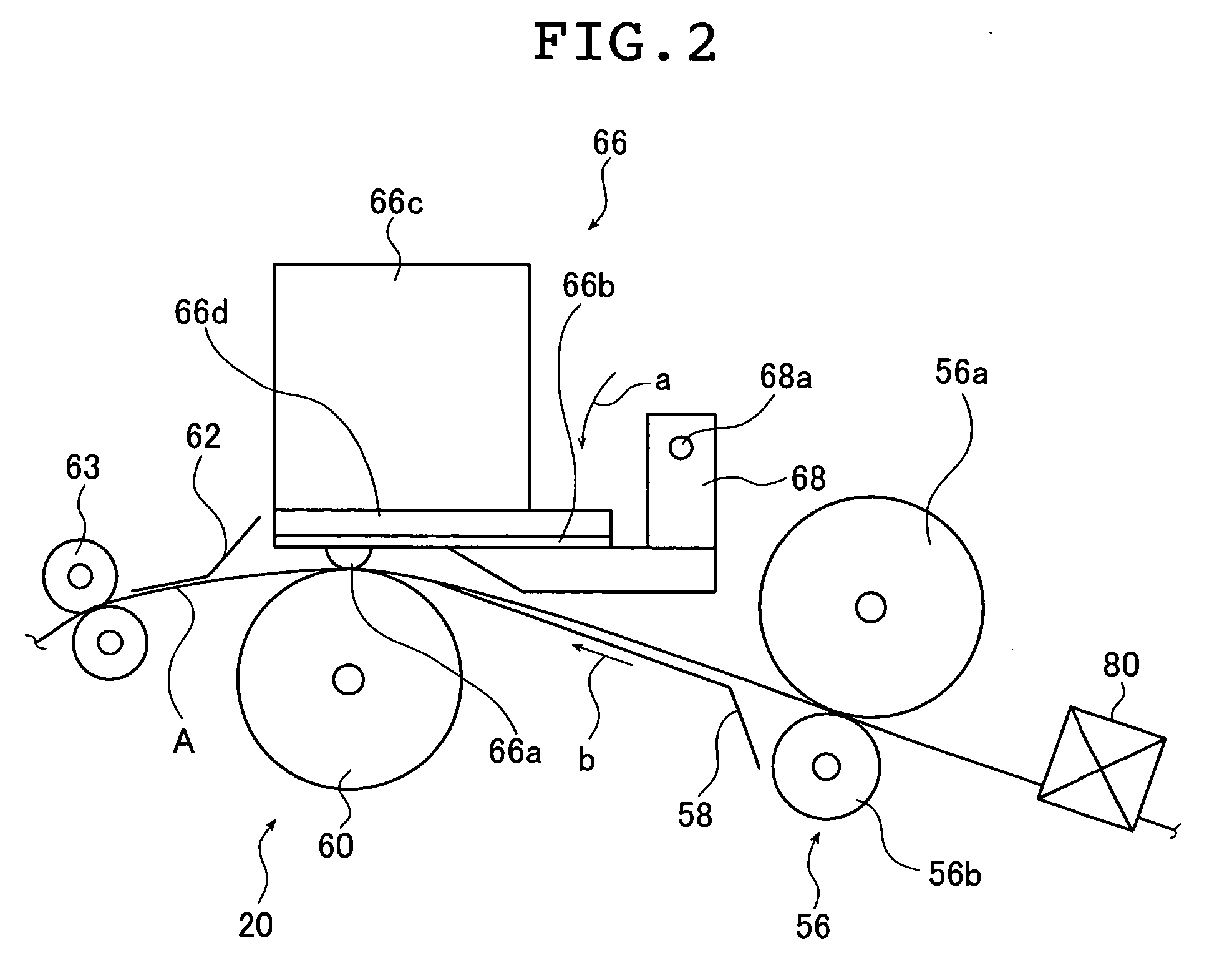

Thermal printer

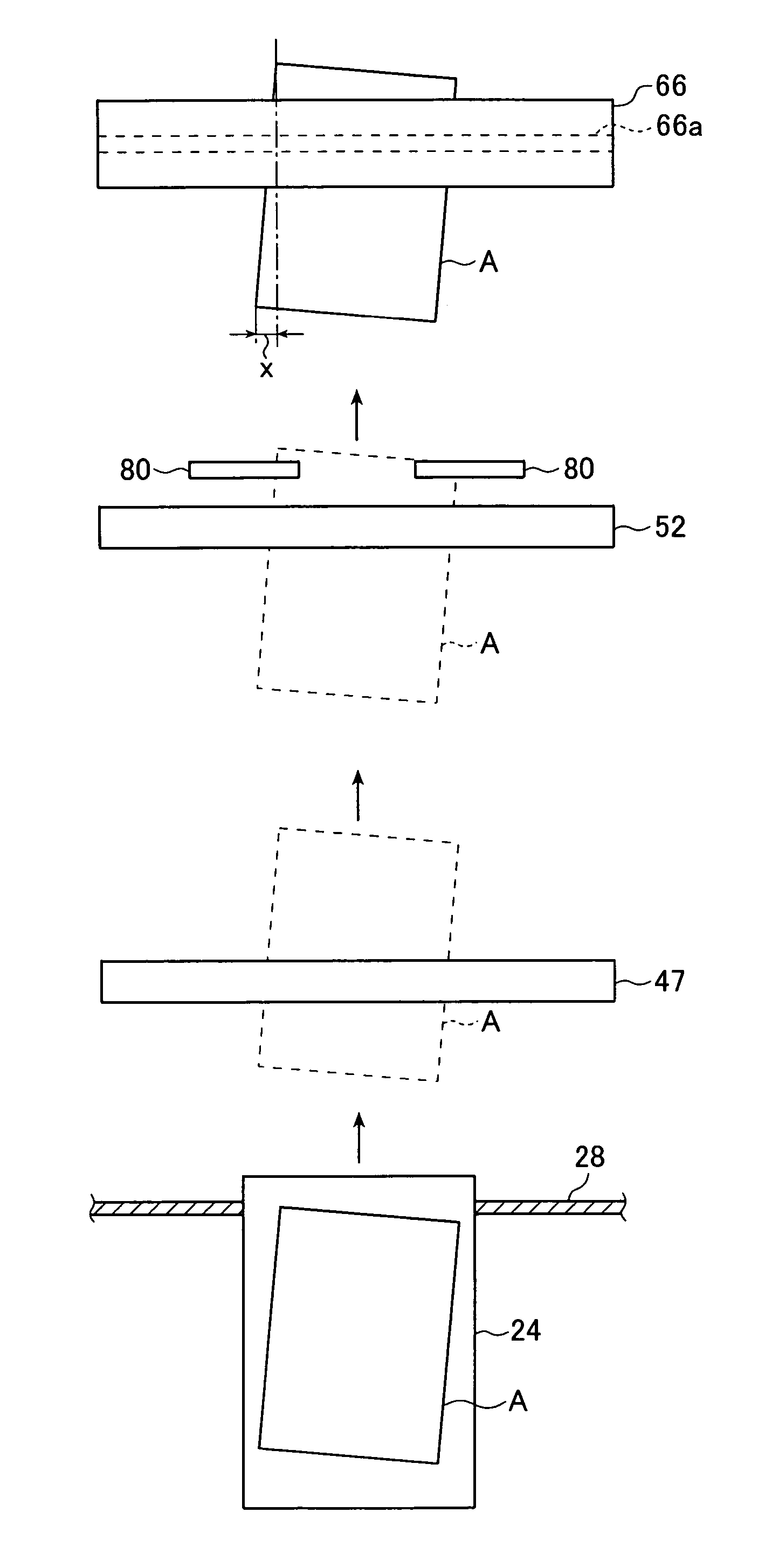

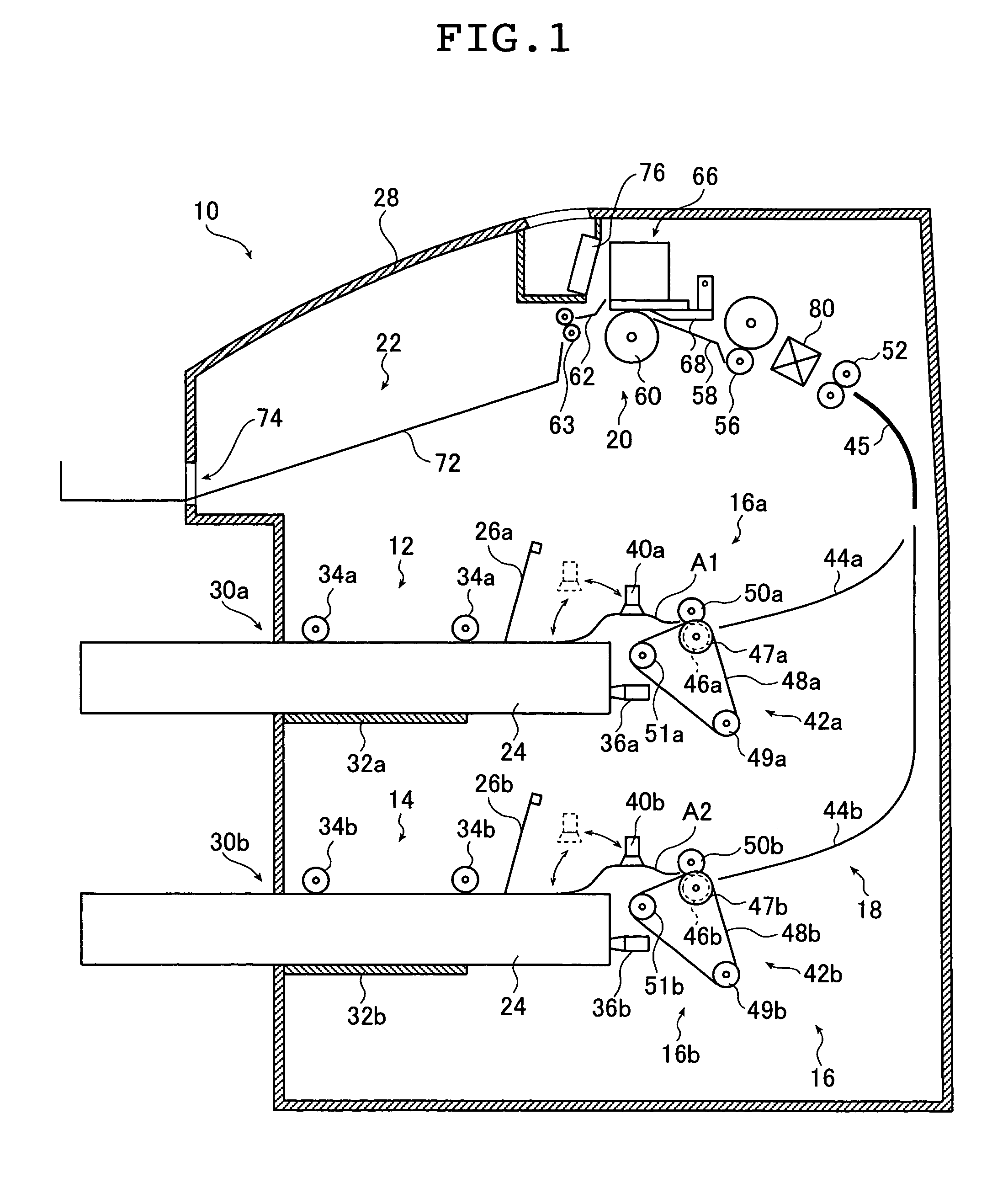

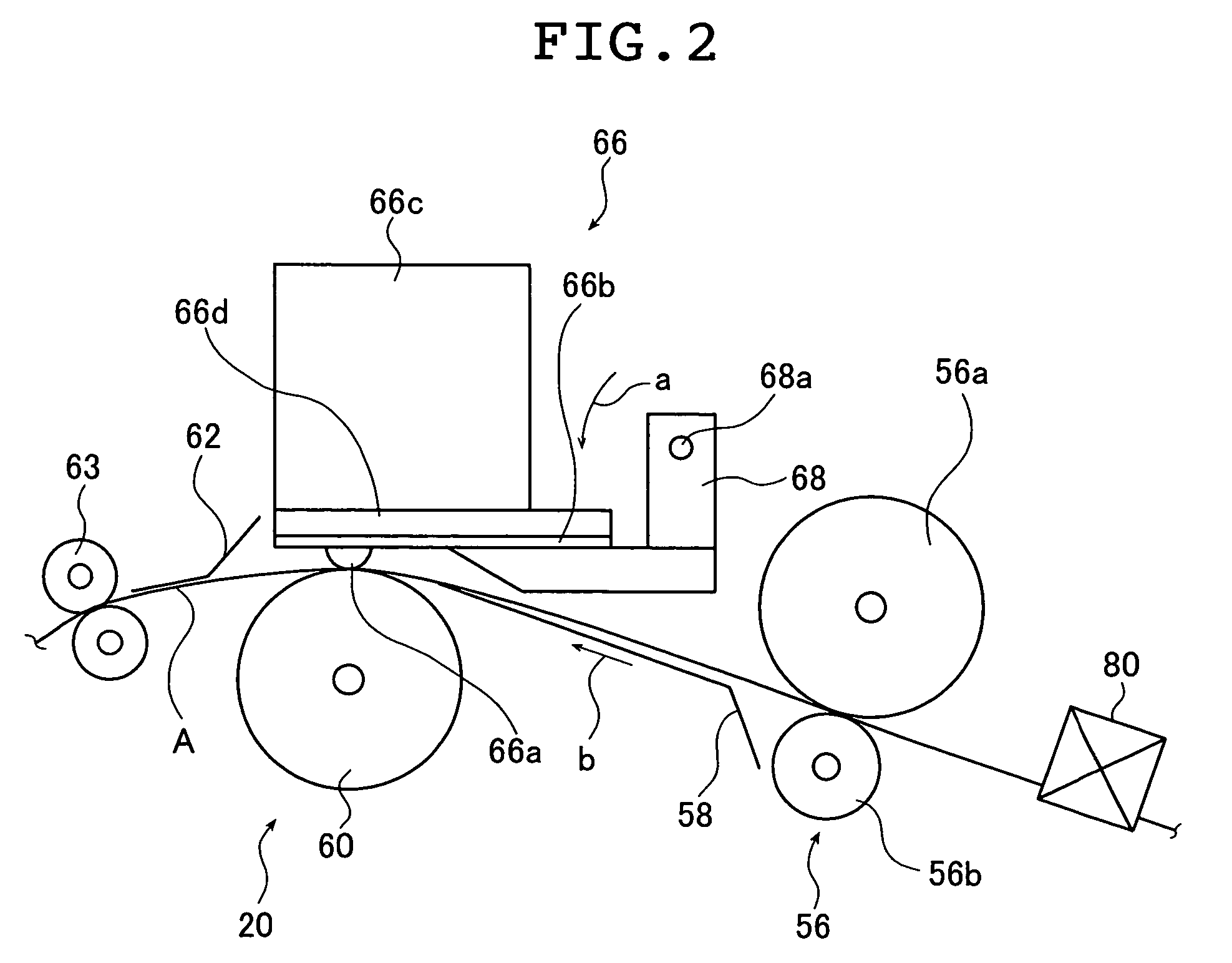

InactiveUS7352383B2Increase productionIncrease in sizeRecording apparatusDuplicating/marking methodsEngineeringHeat sensitive

A thermal printer includes a thermal head which has heating elements arranged in a main scanning direction, a transport unit for transporting a thermal recording material in a sub scanning direction perpendicular to the main scanning direction and a skewing unit for skewing the thermal recording material so that its ends in the main scanning direction form an angle with respect to the sub scanning direction at a predetermined recording position. The thermal recording material that has been skewed so that its ends form the angle is supplied to the recording position, and the thermal recording on the thermal recording material is performed with the thermal head while the thermal recording material that remains skewed is transported in the sub scanning direction.

Owner:FUJIFILM CORP +1

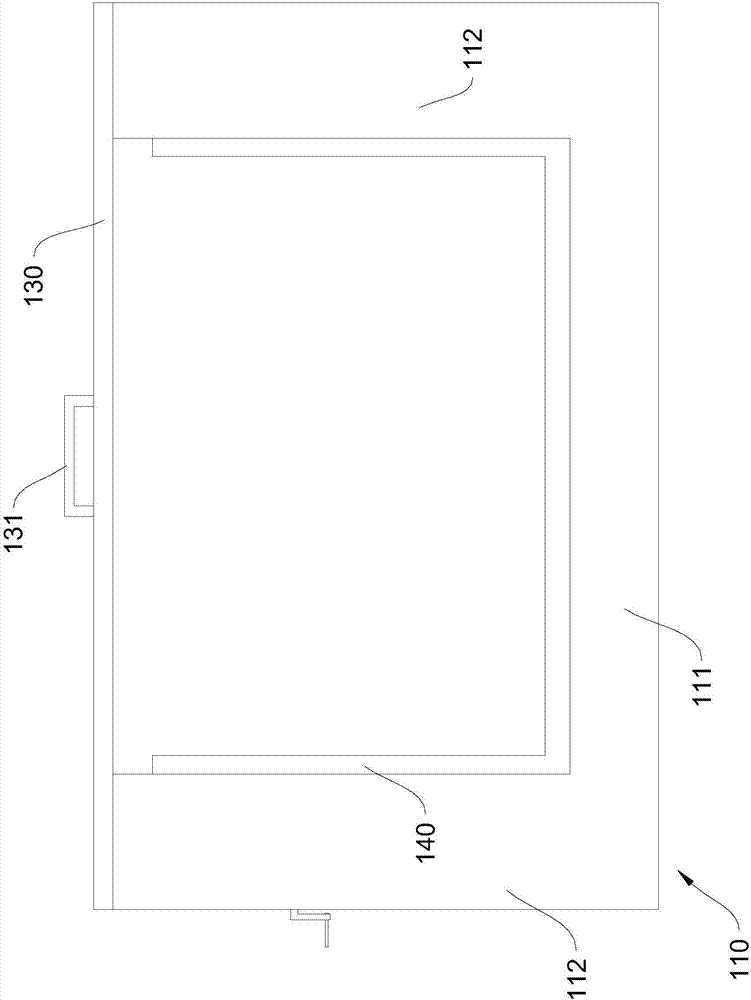

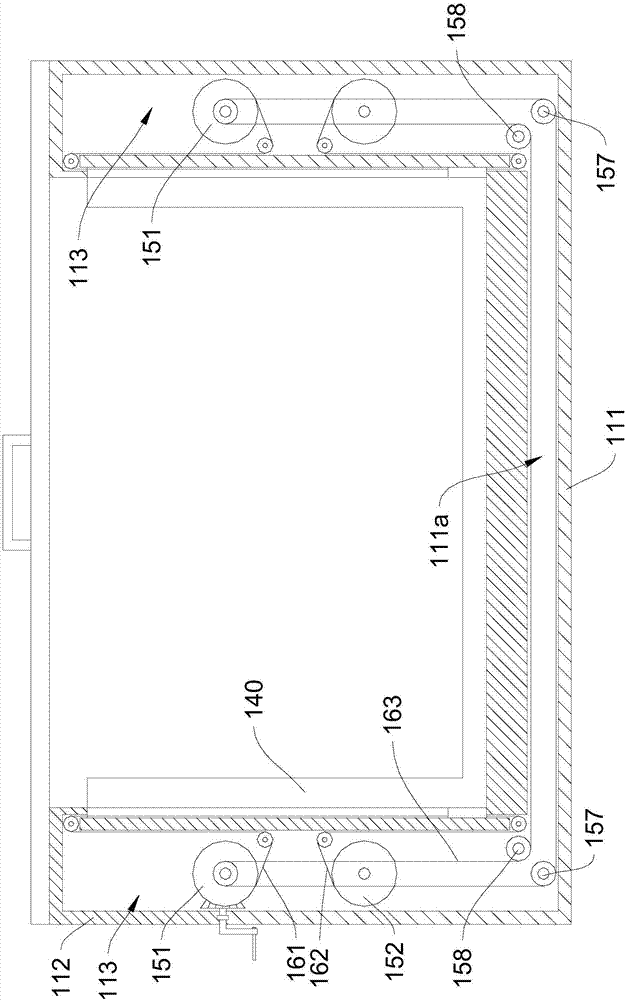

Bee observation box and bee colony research system

The invention provides a bee observation box and a bee colony research system, and relates to the technical field of biological research. The observation box comprises a box frame, a transparent board, a box cover, a honeycomb frame, a transmission assembly and a regulating part, wherein the box frame is approximately U-shaped; each convex arm of the box frame is provided with a chute and an inner cavity; two ends of each chute are respectively provided with a through hole communicating with each inner cavity; the beecomb frame is provided with slide blocks; each slide block is slidably accommodated in each chute; the transmission assembly comprises pulley units respectively arranged in each inner cavity; each pulley unit comprises a first wire wheel, a second wire wheel and pull ropes, wherein one pull rope is connected with one end of a slide block and winds around the first wire wheel through one through hole, and another pull rope is connected with the other end of the slide block and winds around the second wire wheel through the other through hole; each second wire wheel is provided with a torsional spring; the transmission assembly also comprises a transmission belt which connects two first wire wheels in constant rotation speed; and the adjusting part is used for rotating the first wire wheels. The bee colony research system comprises the above-mentioned observation box. The bee colony research system and the bee observation box can enable beecombs to be smoothly placed and removed, reduce direct contact with the beecombs and damage to bees, and have little interference to the bees.

Owner:重庆市春旭农业发展有限公司

Flocculating agent dissolving equipment for sewage treatment tank

ActiveCN113952865AAvoid clumpingPrevent excessive clumpingRotary stirring mixersTransportation and packagingProcess engineeringSewage treatment

The invention relates to the technical field of sewage treatment, and discloses flocculating agent dissolving equipment for a sewage treatment tank, the flocculating agent dissolving equipment comprises a machine body, the inner bottom end of the machine body is fixedly connected with a lower cavity, the middle part of the inner bottom end of the lower cavity is fixedly connected with a rotating assembly, and the movable shaft of the rotating assembly is movably connected with the top end of the lower cavity in a sleeving manner; the top end of the rotating assembly located outside the lower cavity is fixedly connected with two stirring rods, a stirring block is arranged at the top end of one stirring rod, and a square hole is formed in the middle of the top end of the machine body. The stirring block is arranged at the top end of one stirring rod, so that the stirring rod drives the blocking assembly on a main plate to swing to open the discharging hole in the rotating process, and a flocculating agent located in a feeding part equivalently falls into the machine body at a constant speed to be mixed with an aqueous solution; the flocculating agent is effectively prevented from being agglomerated or blocked too much due to too much or too fast one-time addition, and the dissolving efficiency of the flocculating agent is improved.

Owner:湖南高晟环保科技有限公司

Optical detecting device and related method of synchronization adjustment

InactiveUS9049333B2Reduce contact frequencyIncrease exposure frequencyInput/output processes for data processingPictoral communicationImage detectionComputer science

A method of synchronization adjustment is applied to an optical detecting device, so as to synchronize an exposure timing sequence of an image detector with a light emitting timing sequence of an indicating light source. The method includes acquiring a continued image set, analyzing intensity of each image of the continued image set, and adjusting the exposure timing sequence according to duty cycle of the image detector and intensity ratio of at least two images. An exposure frequency of the image detector is greater than a flickering frequency of the indicating light source.

Owner:PIXART IMAGING INC

Induction inner door of public washroom toilet

InactiveCN112282580AEasy to useReduce contact frequencyWing operation mechanismsFlushing devicesPublic environmentTorsion spring

The invention relates to the technical field of public facilities, and discloses an induction inner door of a public washroom toilet. The induction inner door comprises a door frame, a door body is movably installed on the left side wall face of the door frame through a hinge, a squatting pan table and a water tank are fixedly installed at the bottom of the door frame, and two gravity pressing devices which are symmetrical left and right are arranged on the squatting pan table. According to the induction inner door of the public washroom toilet, through the gravity effect of a user, when the user enters the door frame to press and tread the pressing plate, the door body can be automatically closed through the gravity pressing device by means of the gravity of the user, and meanwhile, through the gravity pressing effect of the pressing plate on the right side, the door body can be automatically opened and closed. After a user goes to the toilet and leaves the pressing plate, the door body is automatically opened under the torsion action of the supporting mechanism and the torsion spring on the left side, and the water tank automatically discharges water to wash away dirt. Accordingto the invention, the frequency of contact between a user and public equipment in a public environment is reduced.

Owner:张光荣

Transparent conductor

InactiveUS7288716B2Reduce morbidityObstruction is producedPlastic/resin/waxes insulatorsFlat/ribbon cablesRough surfaceElectrical conductor

Owner:TDK CORPARATION

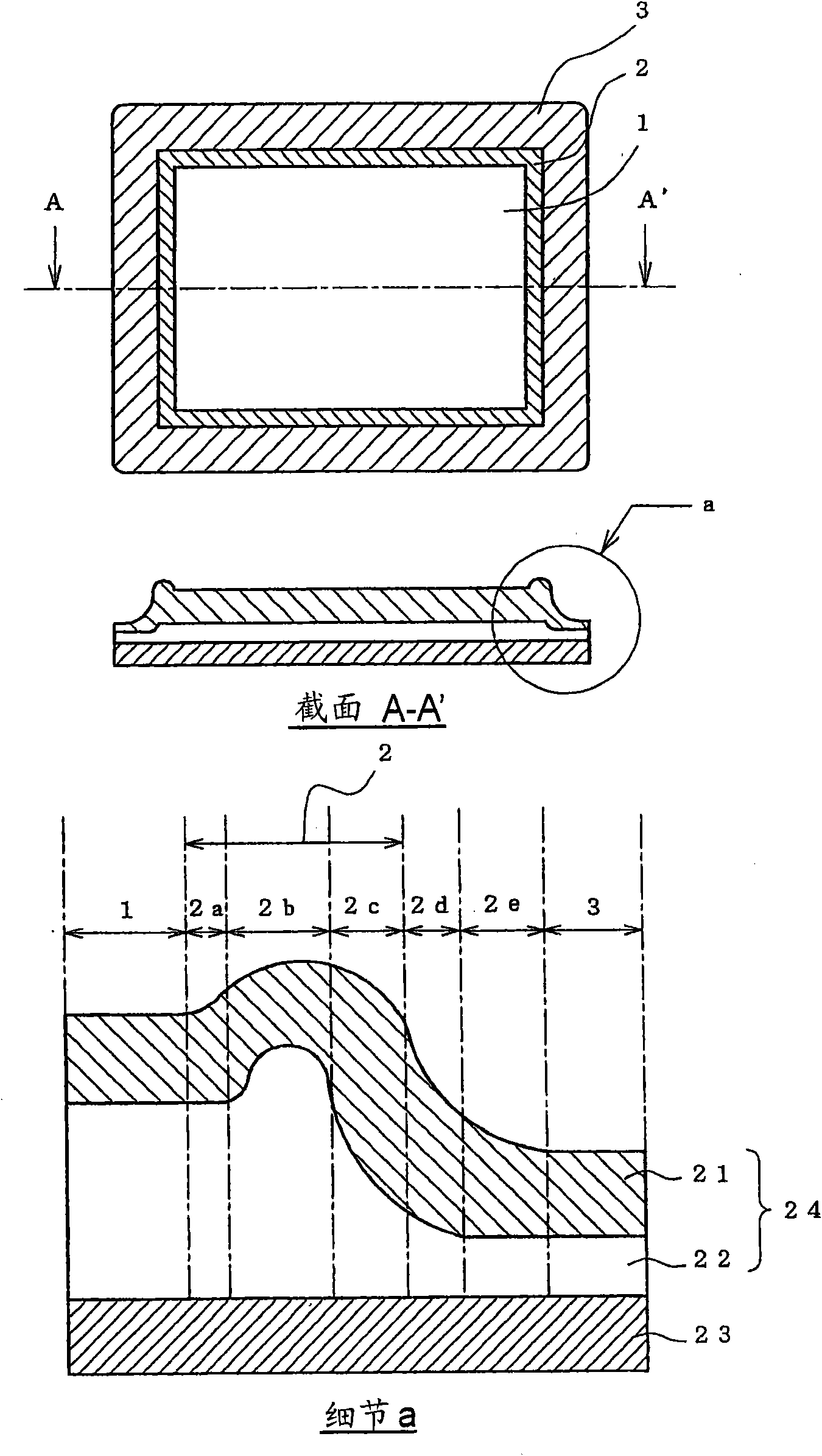

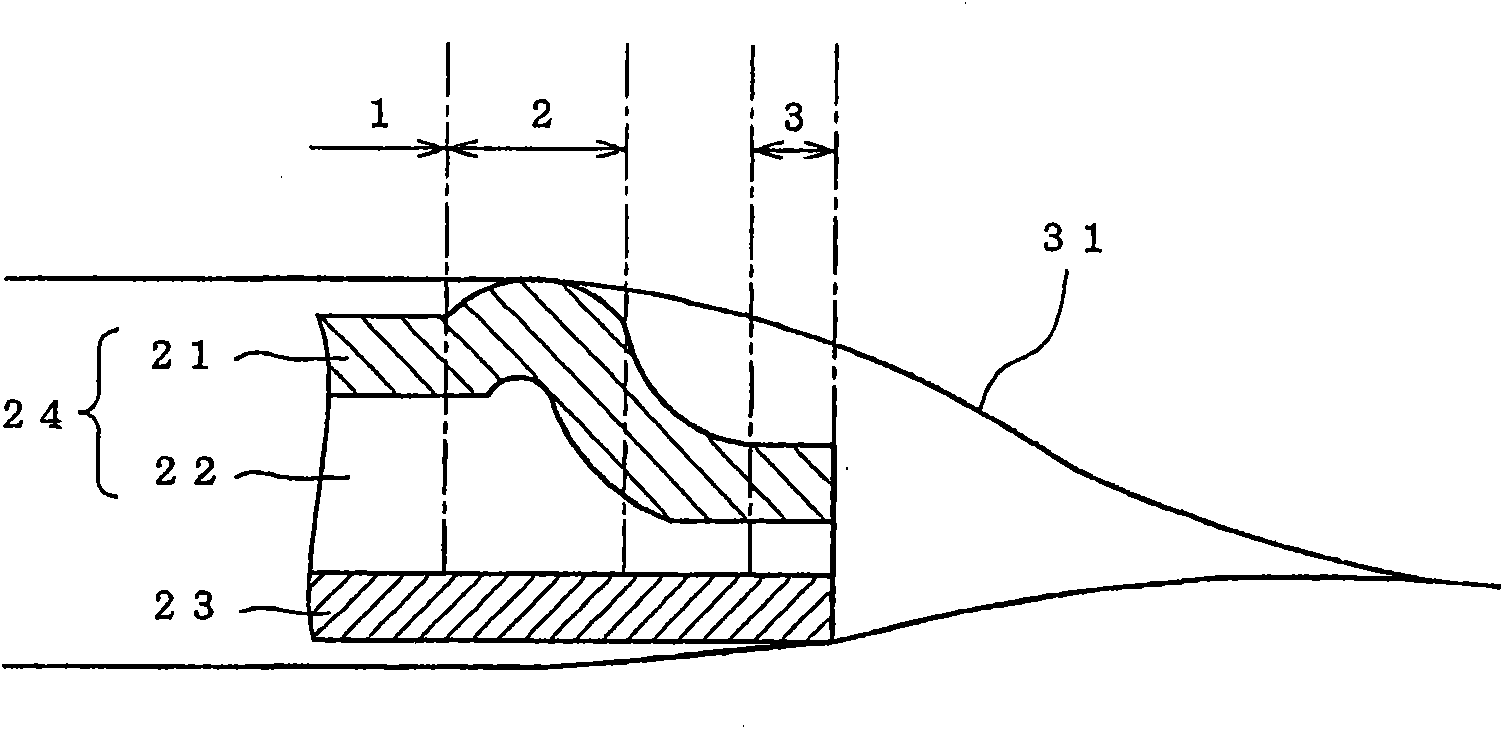

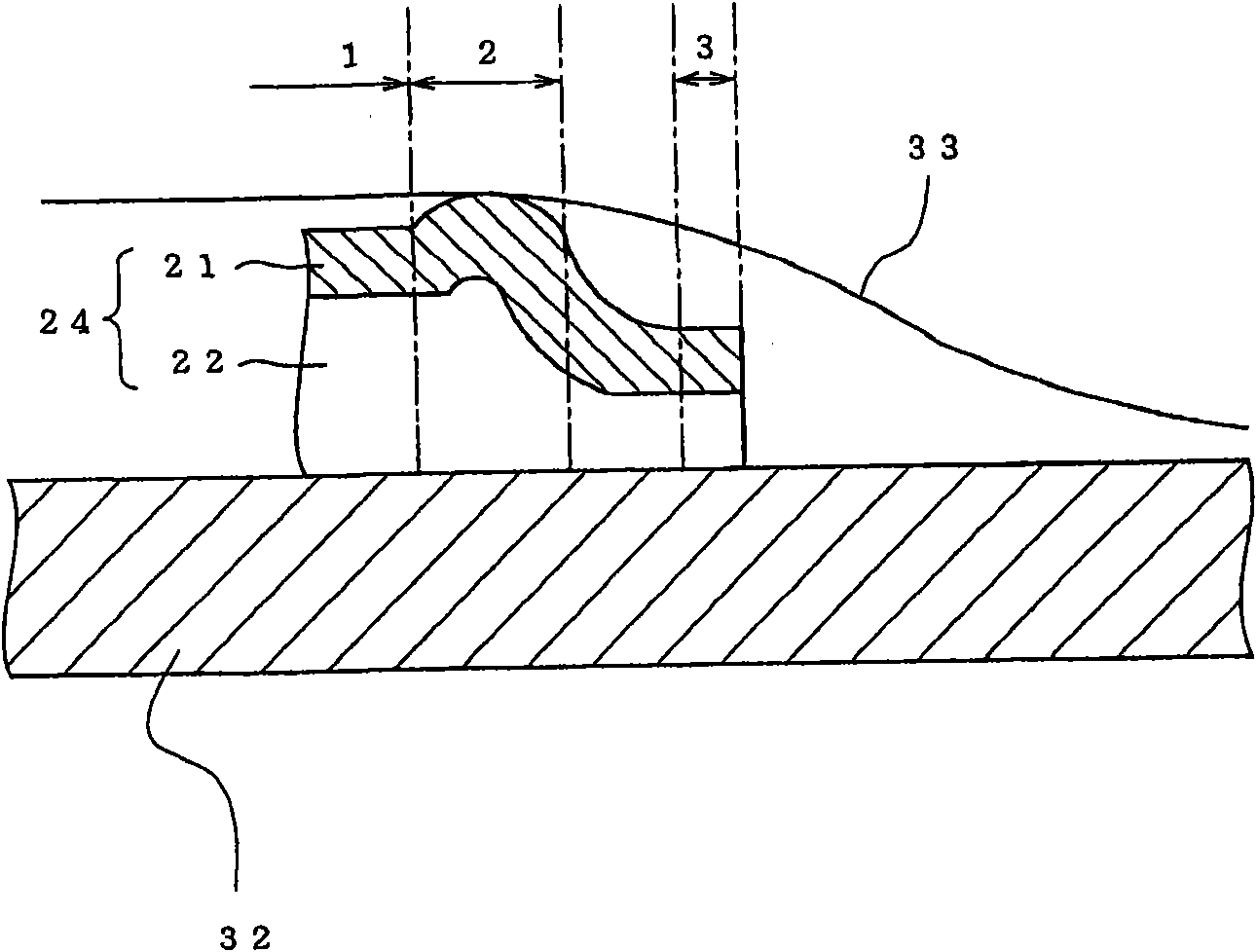

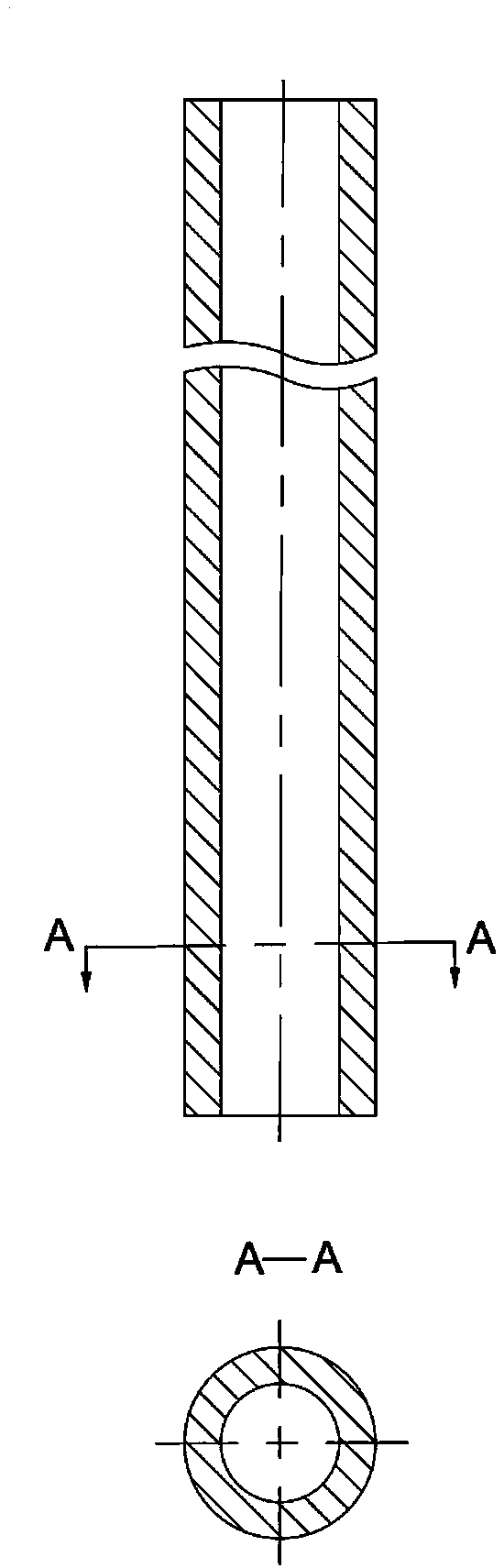

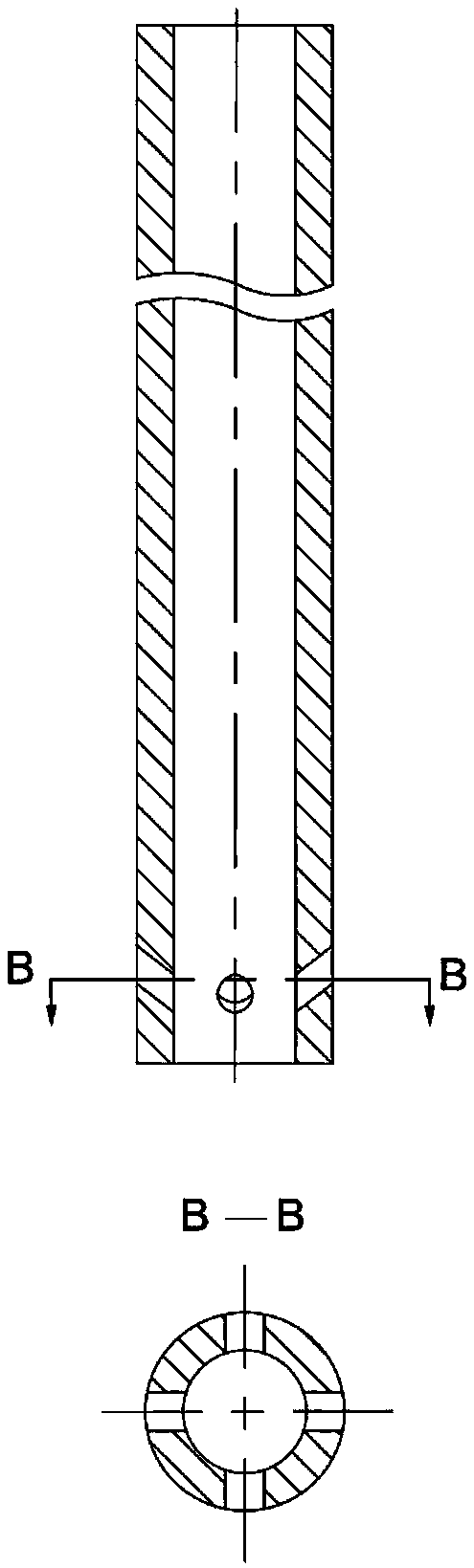

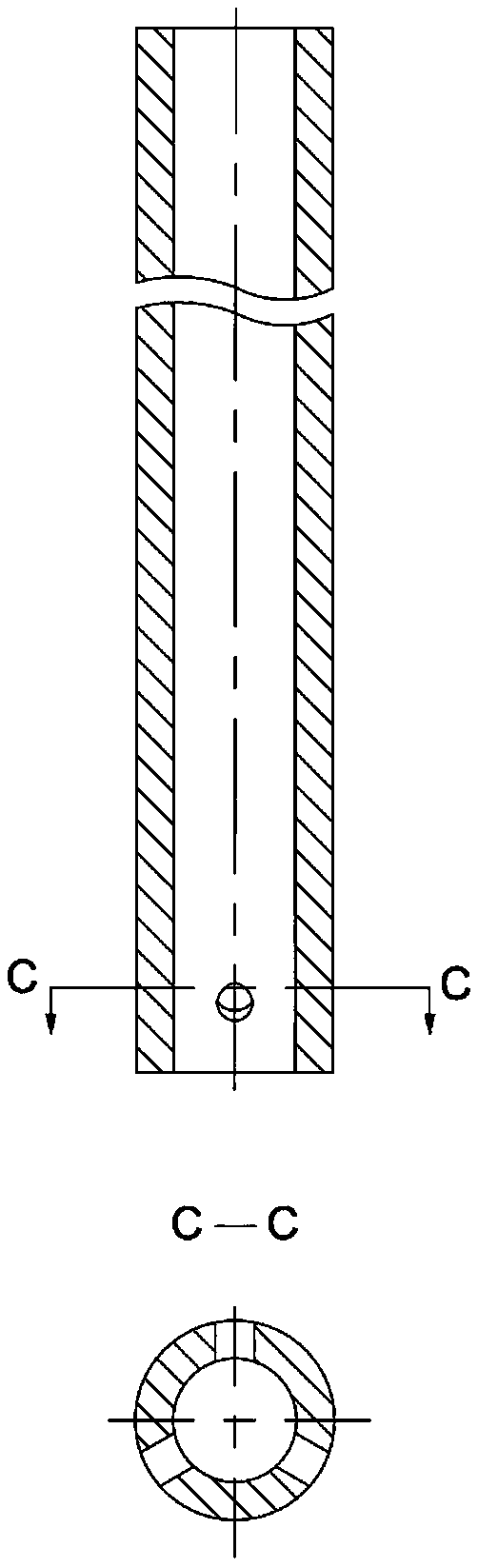

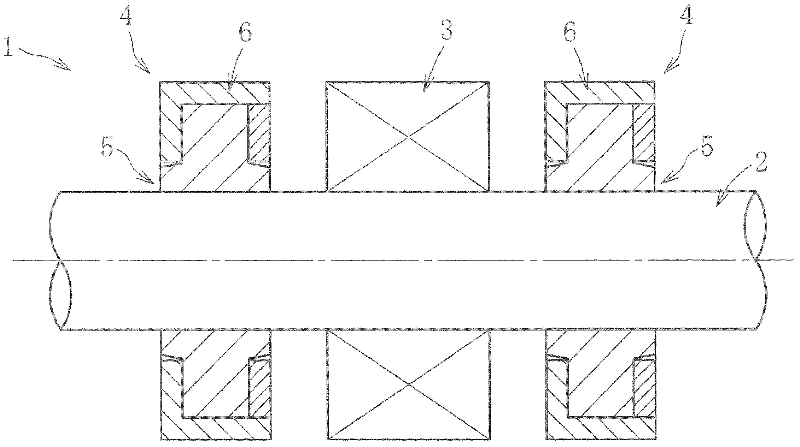

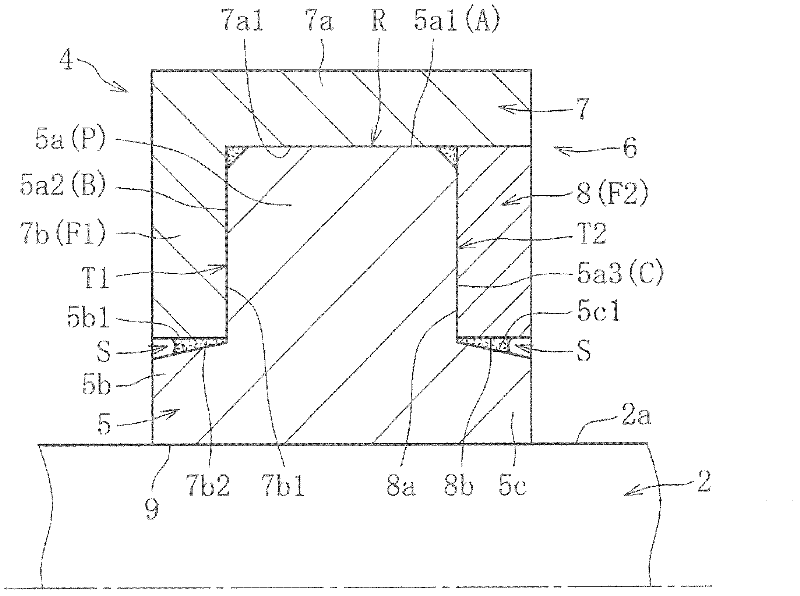

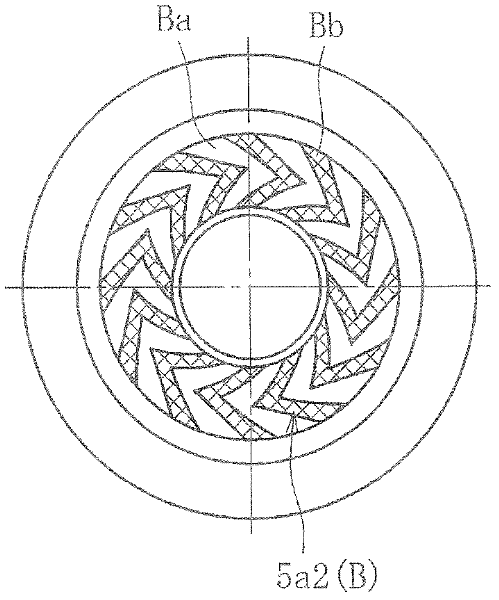

Slide bearing, slide bearing unit with same, and motor with the bearing unit

InactiveCN102483089AReduce contact frequencyGuaranteed shape accuracyBearing assemblyShaft assemblyThick wallMechanical engineering

A bearing which can satisfy the demand for a reduction in cost and for improved quietness and which can, in addition, stably maintain high supporting accuracy. A slide bearing (4) provided with an inner member (5) which has a mounting surface (9) mounted to a rotating shaft (2), and also with a mounting surface which is disposed on the inner member (5) on the outer diameter side thereof and is mounted to a stationary member. A thick-walled section (5a) which is a protrusion section (P) is provided to the inner member (5), and a radial bearing clearance in which a lubricating oil is disposed is formed between the outer peripheral surface (5a1) of the thick-walled section (5a) and the inner peripheral surface (7a1) of an outer member (6), said inner peripheral surface (7a1) facing the outer peripheral surface (5a1). Seal clearances (S, S) for retaining the oil surfaces of the lubricating oil at positions on both sides of the radial bearing clearance in the axial direction are formed between the inner member (5) and the outer member (6). At least a portion of the mounting surface (9) of the inner member (5) consists of metal.

Owner:NTN CORP

Thermal printer

InactiveUS20070002123A1Reduce frequencyIncreasing apparatus sizeRecording apparatusDuplicating/marking methodsComputer printingHeat sensitive

A thermal printer includes a thermal head which has heating elements arranged in a main scanning direction, a transport unit for transporting a thermal recording material in a sub scanning direction perpendicular to the main scanning direction and a skewing unit for skewing the thermal recording material so that its ends in the main scanning direction form an angle with respect to the sub scanning direction at a predetermined recording position. The thermal recording material that has been skewed so that its ends form the angle is supplied to the recording position, and the thermal recording on the thermal recording material is performed with the thermal head while the thermal recording material that remains skewed is transported in the sub scanning direction.

Owner:FUJIFILM CORP +1

Worn steel wire rope core conveyor belt reusing method

The invention provides a worn steel wire rope core conveyor belt reusing method and belongs to the technical field of conveyor belt transmission. By means of the worn steel wire rope core conveyor belt reusing method, the technical problem of resource waste caused by directly replacing worn conveyor belts with new conveyor belts is solved. The solution scheme comprises the following steps that a,the scratched degree of the working surface of the steel wire rope core conveyor belt is recognized; b, the worn steel wire rope core conveyor belt is cut off; c, the cut-off steel wire rope core conveyor belt is formed into a mobius ring structure; d, the steel wire rope core conveyor belt of the mobius ring structure is slowly pulled to move utilizing a loading machine to make the non-working surface of the worn steel wire rope core conveyor belt run to one side of the outer surface; e, the conveyor belt in the step d is cut off again to make the non-working surface of the worn steel wire rope core conveyor belt all run to one side of the outer surface, and overall overturning of the steel wire rope core conveyor belt is finished. By means of the worn steel wire rope core conveyor belt reusing method, the service life of the steel wire rope core conveyor belt is greatly prolonged, the production cost is lowered, spilling of materials along the route is reduced, the material cleaningtimes is reduced, the frequency of man-machine contact is lowered, and safety hazards are reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

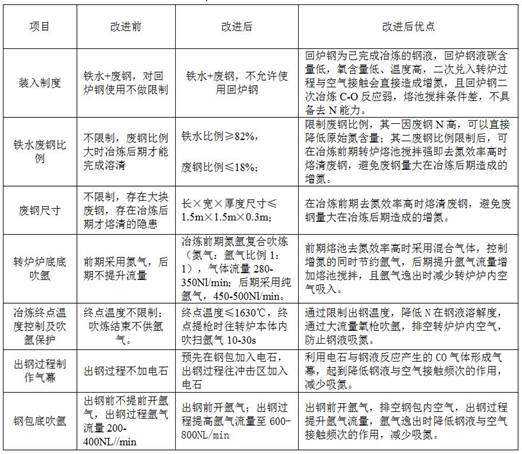

Smelting method for reducing nitrogen increase of molten steel in converter process

PendingCN114635006AReduce total nitrogenReduce contact frequencyManufacturing convertersMolten steelCalcium carbide

The invention relates to a smelting method for reducing nitrogen increase in molten steel in a converter process. The smelting method comprises the following steps: limiting the nitrogen content and size of a waste steel raw material, changing bottom argon blowing in the early stage of a converter into nitrogen-argon combined blowing, increasing the gas flow, adopting bottom pure argon blowing in the middle and later stages of smelting, and increasing the bottom blowing gas flow; the smelting final temperature is smaller than or equal to 1630 DEG C, an oxygen lance is switched into argon, and argon is blown into the converter for 10-30 s; in the tapping process, 1.0 Kg / t to 1.2 Kg / t of calcium carbide is added to the bottom of a steel ladle in advance before tapping, 0.5 Kg / t to 1.0 Kg / t of calcium carbide is thrown in a steel flow impact area in the tapping process, CO generated by calcium carbide deoxidation is used for forming an air curtain, molten steel is isolated from air, and nitrogen absorption of the molten steel is reduced; the content of [O] in the molten steel in the tapping process is controlled to be (200-400) * 10 <-4 >%; bottom argon blowing of the steel ladle is started 20 seconds before tapping, air in the steel ladle is emptied, argon is stopped immediately after tapping is finished from 20 seconds before tapping to the end of tapping, and the steel ladle is covered for heat preservation to prevent molten steel from being exposed to increase nitrogen; the method is simple and clear in technological process, high in operability and easy to control.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

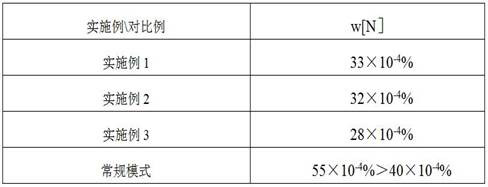

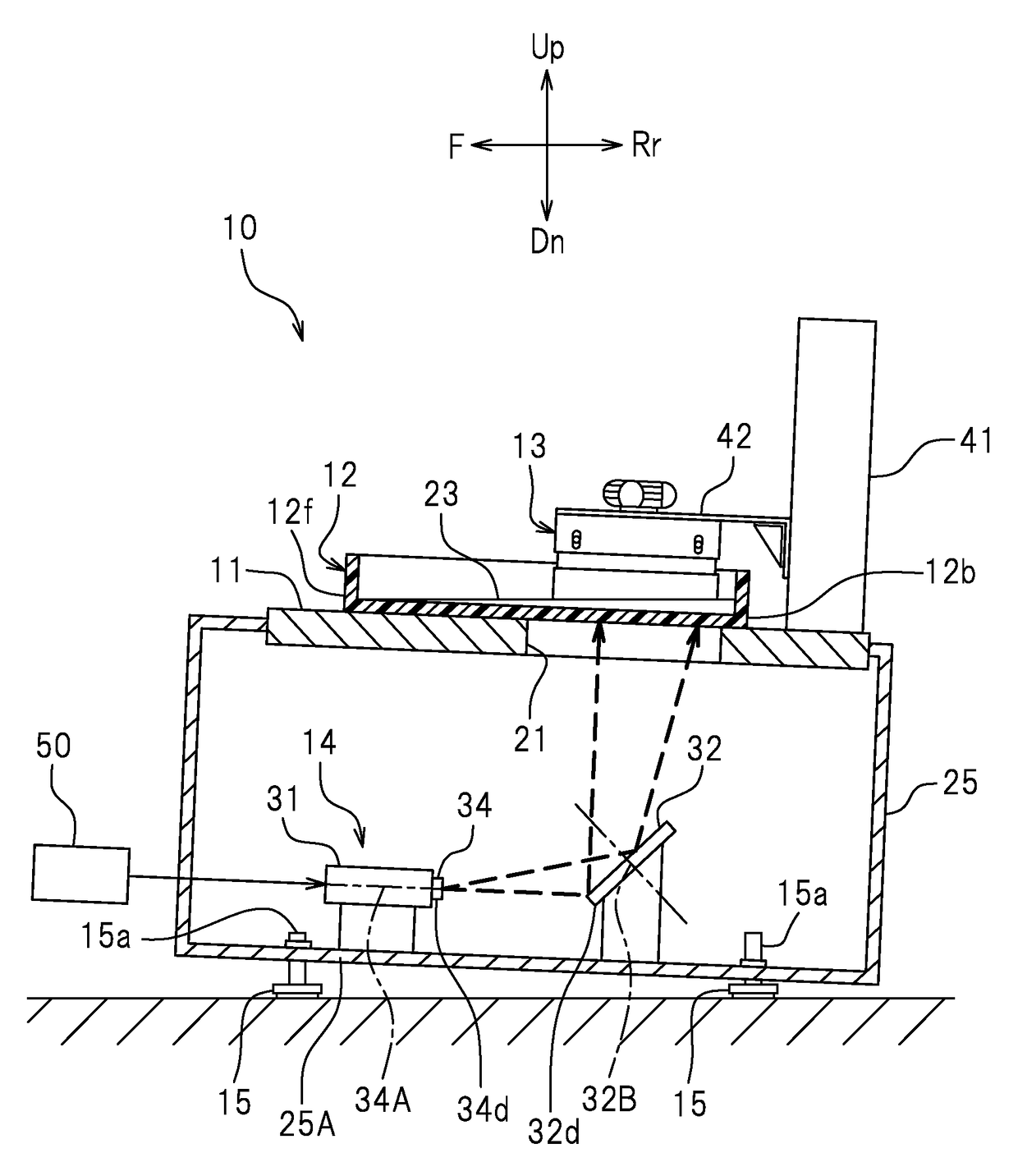

Three-dimensional printing system

InactiveUS9833985B2Reduce contact frequencyPrevent degradationAdditive manufacturing apparatus3D object support structuresAuxiliary memoryComputer science

A three-dimensional printing system calculates a resin amount required to print a three-dimensional object by curing a liquid photo-curable resin and sequentially stacking layers of the cured resin each having a predetermined cross-sectional shape. The system includes a first storage section configured to store information of a three-dimensional object, and information of an auxiliary member that supports the three-dimensional object, a first calculation section configured to calculate a resin amount necessary to print the three-dimensional object and a resin amount necessary to print the auxiliary member based on the information of the three-dimensional object and the auxiliary member stored in the first storage section, an output section configured to output a first resin amount that is the sum of the calculated resin amounts necessary to print the three-dimensional object and the auxiliary member, and a three-dimensional printing apparatus.

Owner:ROLAND DG CORP

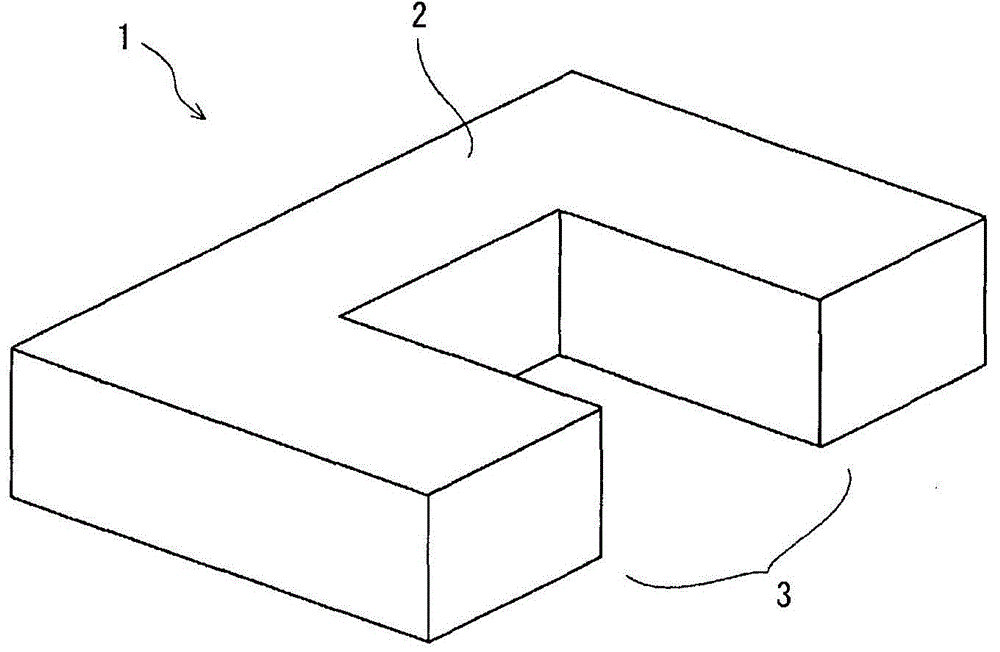

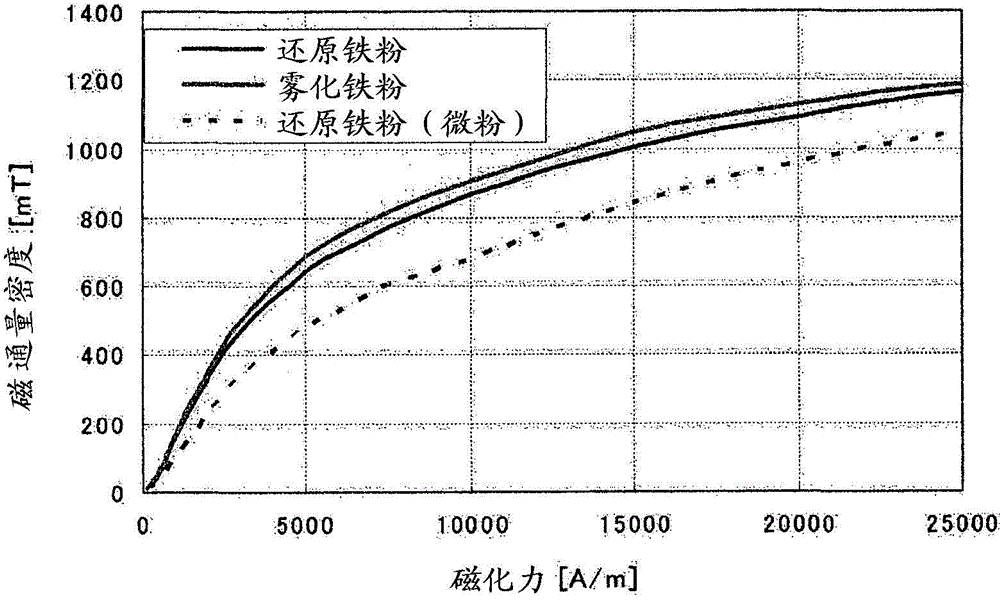

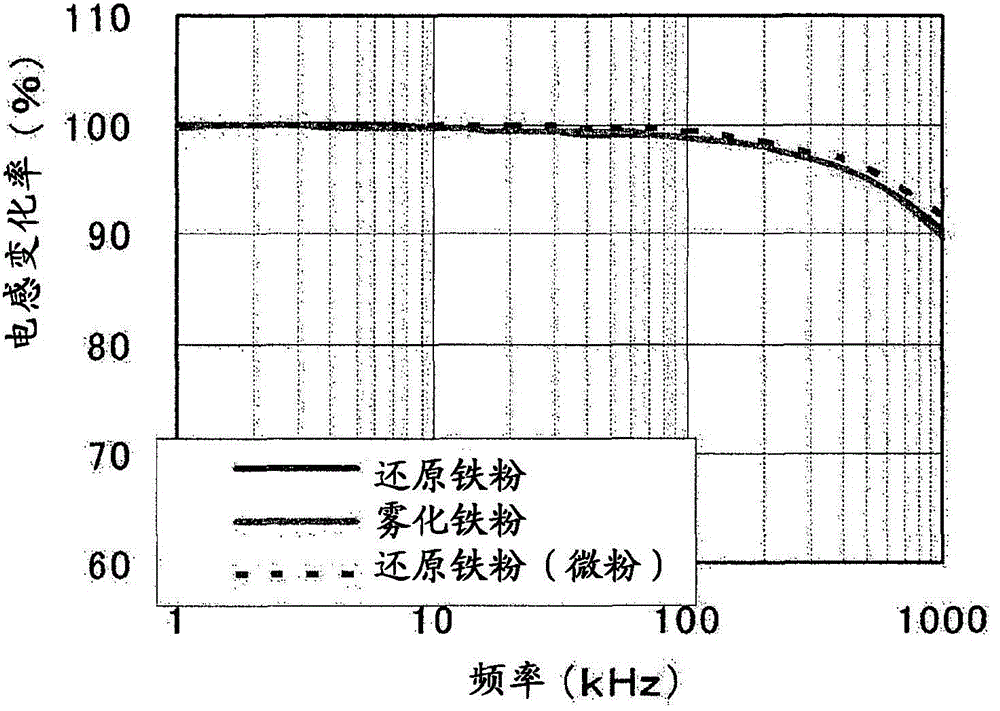

Magnetic core and process for producing same

InactiveCN104685583AHigh densityReduce segregationTransportation and packagingMetal-working apparatusEpoxyProduction rate

Provided are a magnetic core which can be produced more efficiently without increasing the raw material cost and which has required magnetic properties and mechanical properties, and a process for producing the magnetic core. The magnetic core is produced by compacting a powder of an iron-based soft-magnetic material in which the particles have a resinous coating film formed on the surface, and then thermally hardening the compact. The resinous coating film is an uncured resinous coating film formed by dry-mixing the powder with an epoxy resin containing a latent hardener at a temperature that is not lower than the softening temperature of the epoxy resin and is lower than the thermal-hardening initiation temperature thereof. The compaction is production of a compact using a mold. The thermal hardening is conducted at a temperature which is not lower than the thermal-hardening initiation temperature of the epoxy resin containing a latent hardener.

Owner:NTN CORP

Process and device for continuously producing bentazone intermediate o-aminobenzoic acid

ActiveCN112159332ASolving the Problem of Waste Organic SolventsLow costOrganic compound preparationChemical/physical/physico-chemical microreactorsBenzoic acidPropylamine

The invention discloses a process and a device for continuously producing bentazone intermediate o-aminobenzoic acid isopropyl amine by taking phthalimide as a raw material. The process comprises thefollowing steps: (1) adding phthalimide solid and pure water into a reaction kettle, stirring at a low speed, adding a 32% sodium hydroxide solution, and stirring at normal temperature for 30 minutes;(2) respectively feeding the phthalimide sodium salt solution and the sodium hypochlorite solution into a micro-channel reactor according to a certain flow rate, carrying out a Huffman rearrangementreaction at a low temperature, and feeding the mixture into a temporary storage tank; (4) mixing the reaction solution in the temporary storage tank 1 with hydrochloric acid (or sulfuric acid and thelike) through a static mixer, feeding the mixture into a reaction kettle, heating the mixture to room temperature, adding an isopropylamine aqueous solution at a certain flow rate, and continuously stirring for 2-3 hours; (4) enabling the solution to pass through a plate-and-frame filter press, returning the filtrate to the first step for repeated application, and drying the filter cake to obtainisatoic anhydride with the purity of 99% or above.

Owner:QINGDAO UNIV OF SCI & TECH

New process for boning roasted duck

The invention discloses a new process for boning a roasted duck. In the process, boning steps are set according to the physiological structure of the duck; the conventional boning sequence of the roasted duck is changed, namely the meat on shinbone is first cut open, shinbone is removed and then truck bone, bones of upper limb and thighbone are removed in turn; and thus the skeleton of the roasted duck is completely removed by the least cutting. The process comprises the following steps of: 1, selecting; 2, ripping the back; 3, ripping the breast; 4, removing the shinbone; 5, separating the brisket; 6, removing the shoulder joint; 7, removing the thighbone; 8, separating the truck bone; 9, removing the wing bone; 10, removing the thighbone; 11, trimming; 12, sterilizing; and 13, packaging under vacuum. In the process, the bone steps are set according to the physiological structure of the duck, and the skeleton of the roasted duck is completely removed by the least cutting; and thus the labor intensity of workers is reduced, the qualification rate of the finished product of the product is increased, the completeness and attractive appearance of the product are ensured, the contact frequency between a cutter and the duck meat and between an operating hand and the duck meat is reduced, the man-made pollution is prevented, and the hygiene standard is guaranteed.

Owner:ZHONGAO HLDG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com