Patents

Literature

1200 results about "Wire wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire wheels, wire-spoked wheels, tension-spoked wheels, or "suspension" wheels are wheels whose rims connect to their hubs by wire spokes. Although these wires are generally stiffer than a typical wire rope, they function mechanically the same as tensioned flexible wires, keeping the rim true while supporting applied loads. The term suspension wheel should not be confused with vehicle suspension.

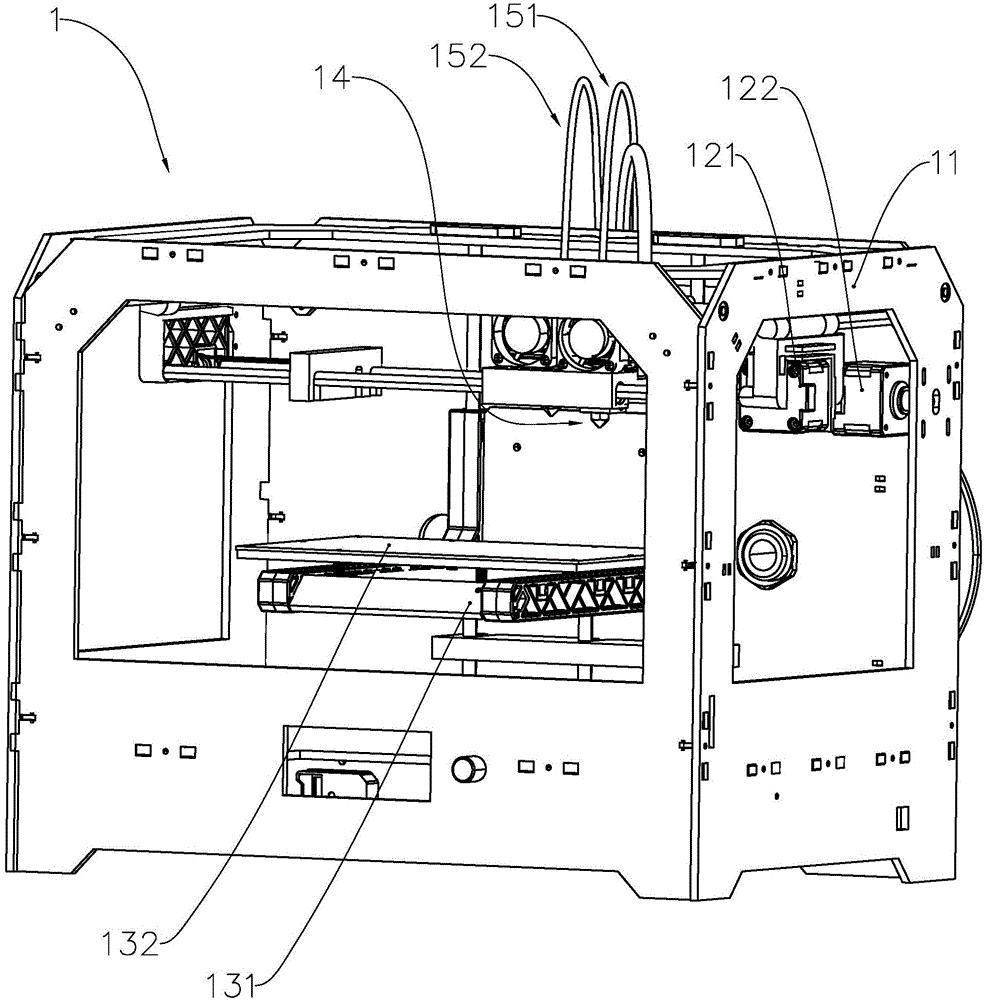

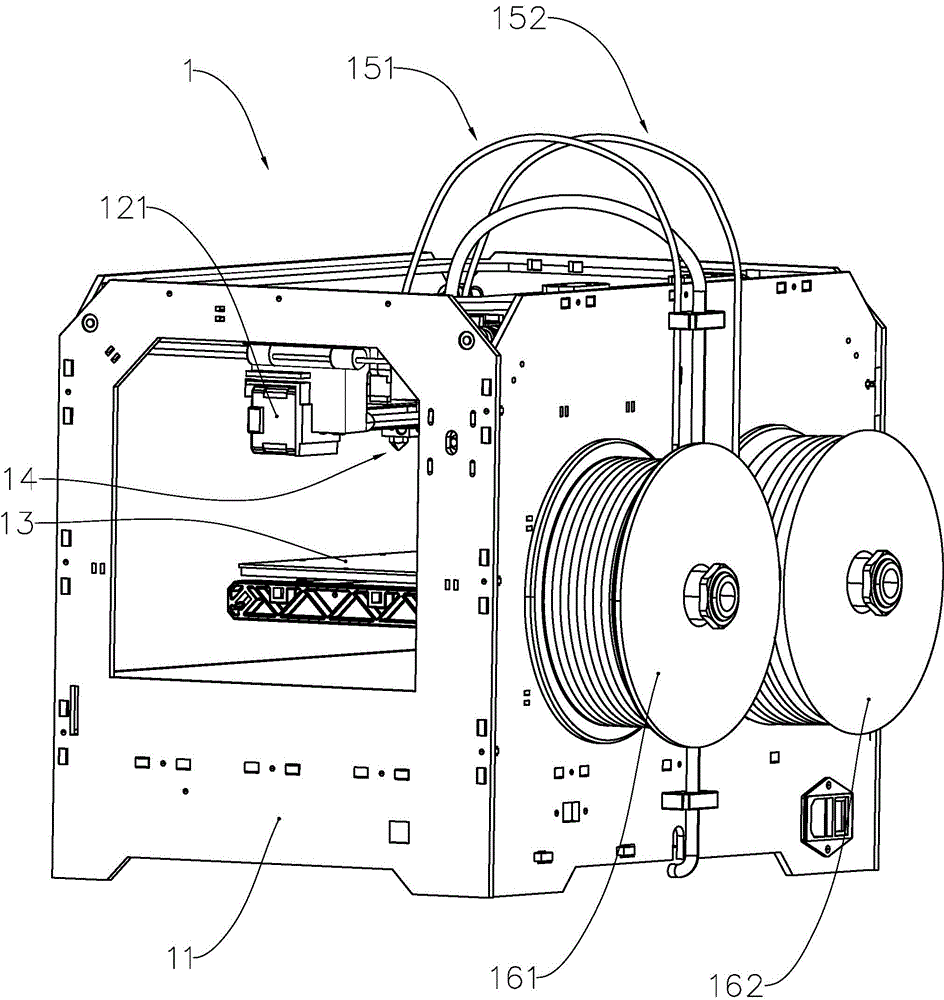

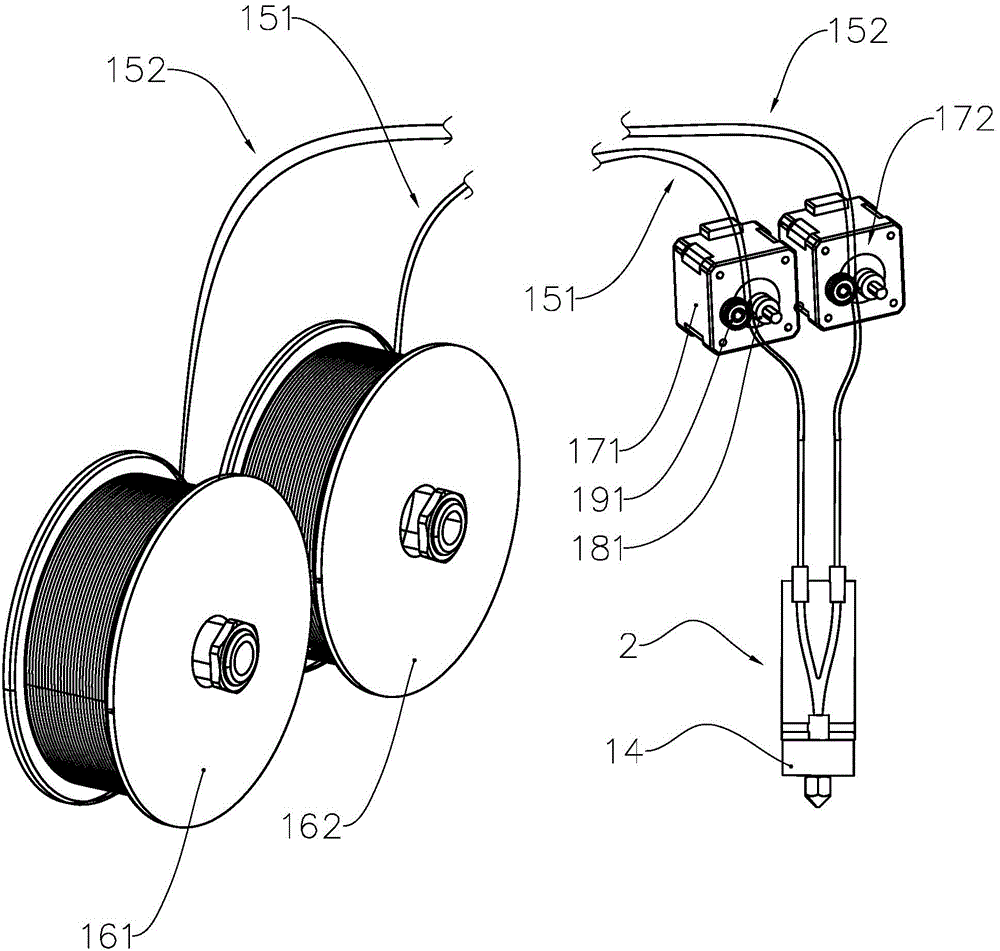

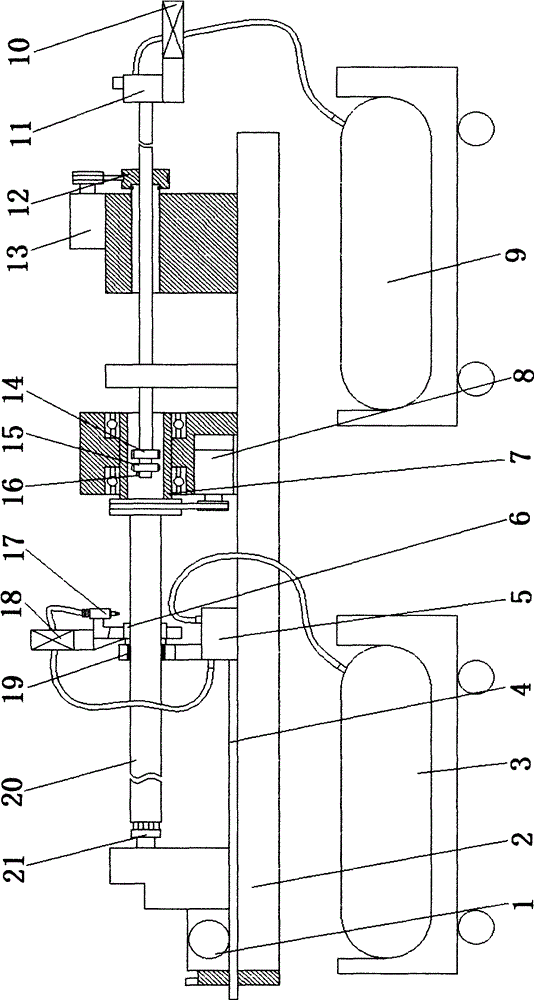

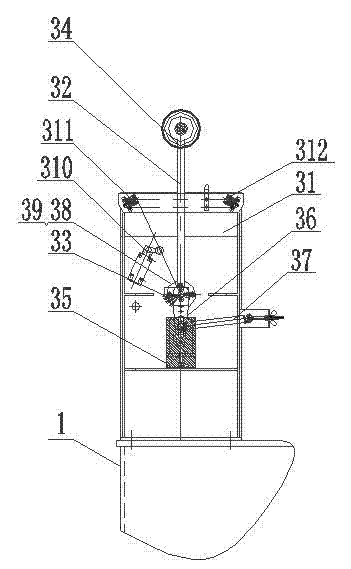

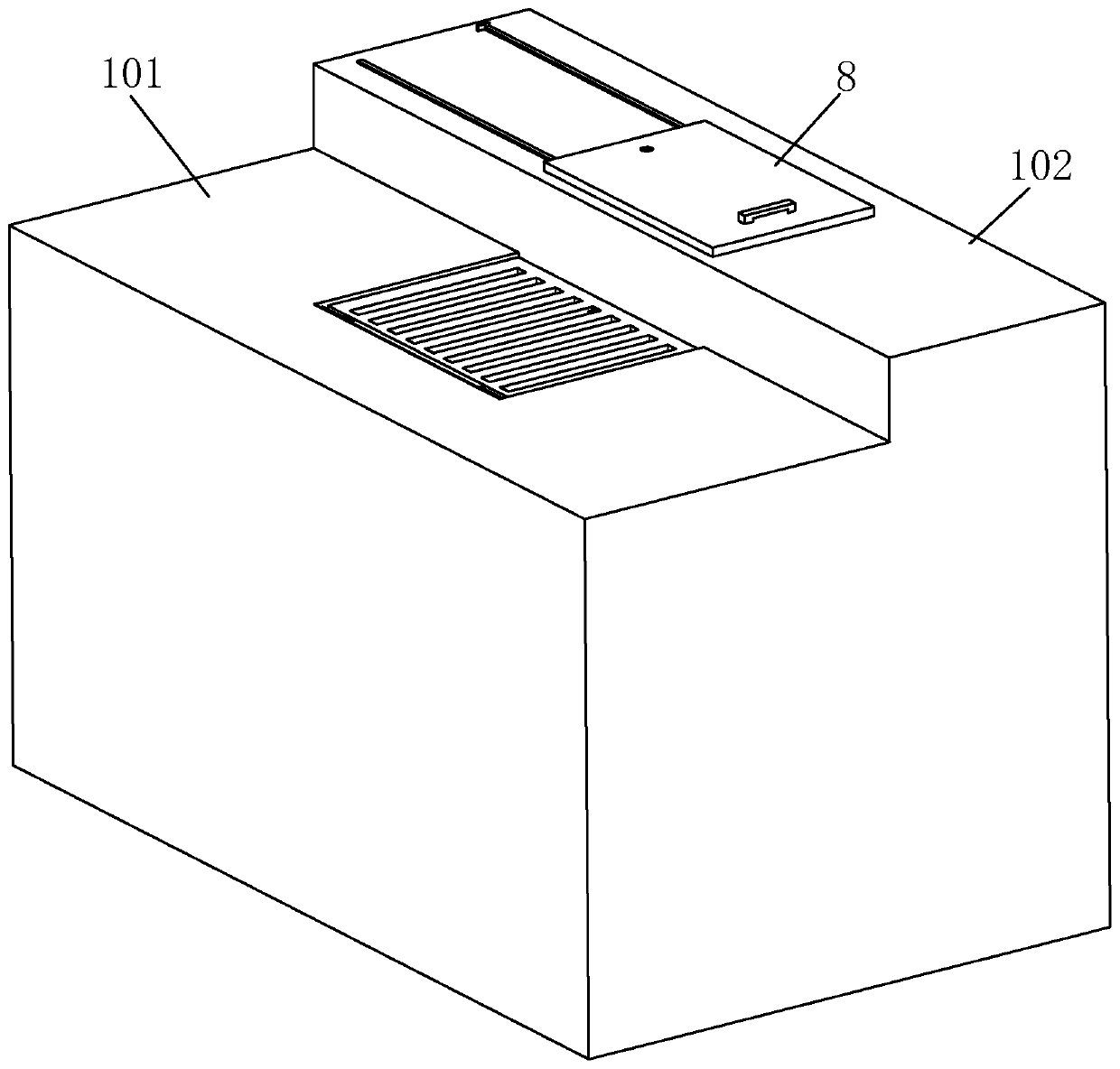

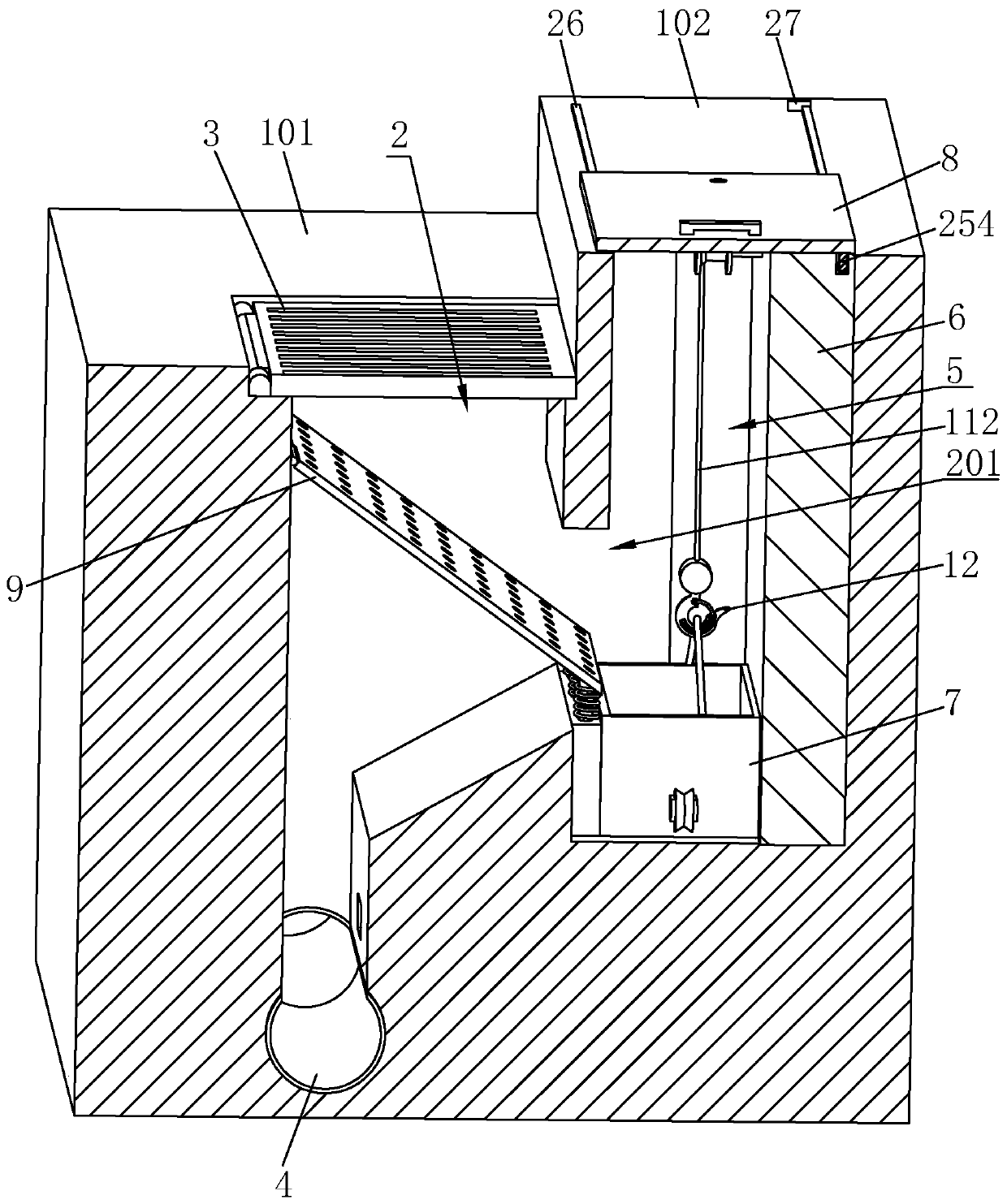

Three-dimensional printer and three-dimensional printing method

ActiveCN104690967AAvoid misalignmentAvoid pollutionAdditive manufacturing apparatus3D object support structuresFiberWire rod

The invention provides a three-dimensional printer and a three-dimensional printing method. The three-dimensional printer comprises multiple wire wheels, a printing head, a forming base, a movable motor component and a consumable supplying motor component, wherein each wire wheel is provided with a kind of imaging material, the printing head is used for extruding the imaging material, the consumable supplying motor component comprises multiple motors, each motor is used for driving the corresponding imaging material to be transferred into the printing head, wherein a wire changing device is arranged between the consumable supplying motor component and the printing head, multiple fiber material input ends and a fiber output end are arranged on the wire changing device, the fiber material output end is connected with the printing head, and the wire changing device is communicated with a guide hole between each fiber material input end and the fiber output end. The invention also provides the three-dimensional printing method applied to the three-dimensional printer. The guide holes are used for guiding fiber materials so as to improve imaging stability, the displacement of wires is avoided, and multi-color volume rendering can also be realized through the single printing head, and the three-dimensional printer is simple in structure and low in cost.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Steel tube rust removal device with automatic paint spraying function

ActiveCN104084872AGuaranteed SprayingAvoid harmPolishing machinesRevolution surface grinding machinesMotor drivePhysical health

Provided is a steel tube rust removal device with the automatic paint spraying function. When a control cabinet controls the whole device to operate, a second motor drives a steel tube to rotate while driving a rotary clamping base to rotate, rust removal and polishing are carried out on the inner wall and the outer wall of the steel tube at the same time through an inner wire wheel, an inner polishing wheel, an outer wire wheel and an outer polishing wheel, and a rack and a gear of a first motor are in transmission to control a first paint can, the outer wire wheel and the outer polishing wheel to move horizontally to carry out rust removal, polishing and paint spraying on the outer wall of the whole steel tube evenly, wherein the outer wire wheel and the outer polishing wheel are installed on the first paint can. Meanwhile, a screw rod is driven by a guide wheel and a third motor to rightwards rotate and move, and the rotation direction of the screw rod is opposite to the rotation direction of the steel tube. By means of rust removal and polishing carried out through the inner wire wheel and the inner polishing wheel, spraying on the inner wall of the steel tube through an inner spray gun is ensured. By means of the automatic rust removal and spraying device, harm to physical health of staff by rust and dust is avoided. Meanwhile, due to timely spraying, later corrosion and manpower resource waste caused when the machining time of the steel tube is too long can be prevented.

Owner:广州市南粤钢管有限公司

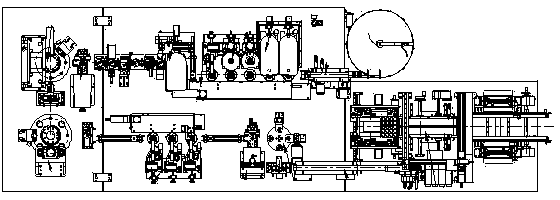

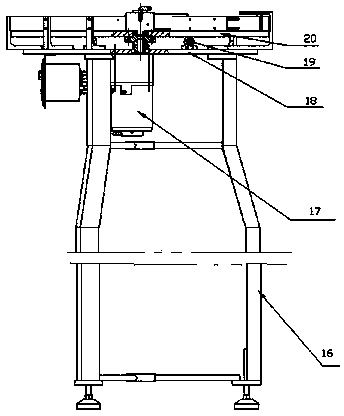

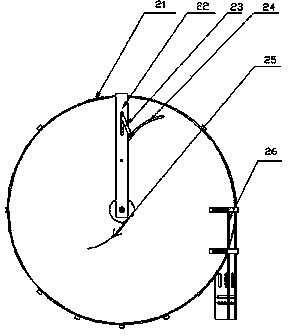

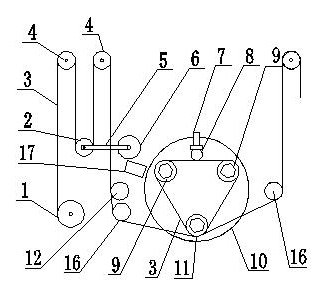

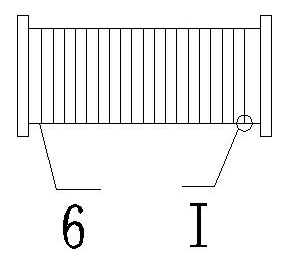

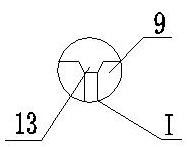

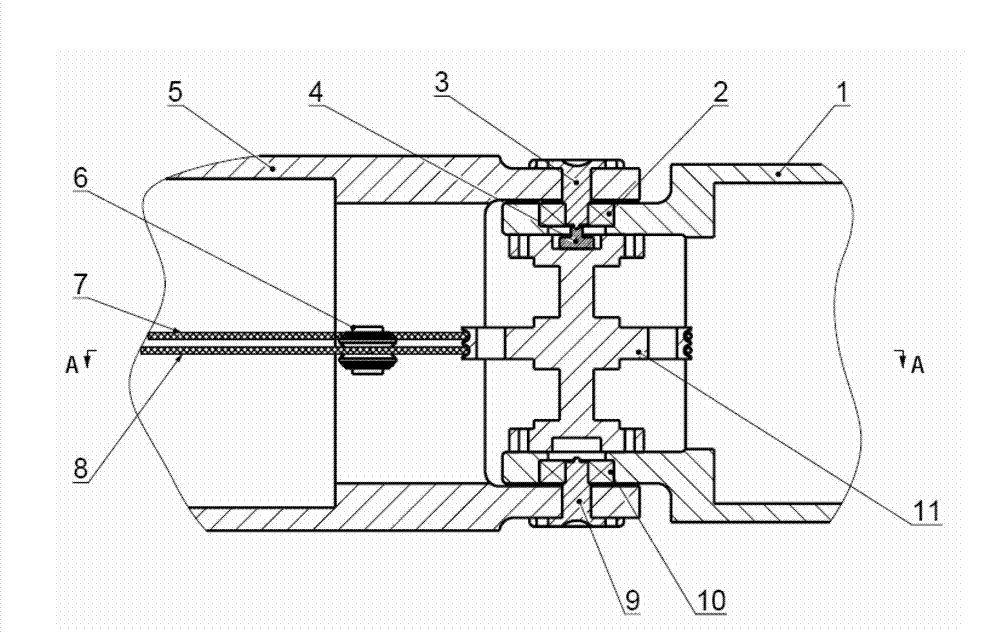

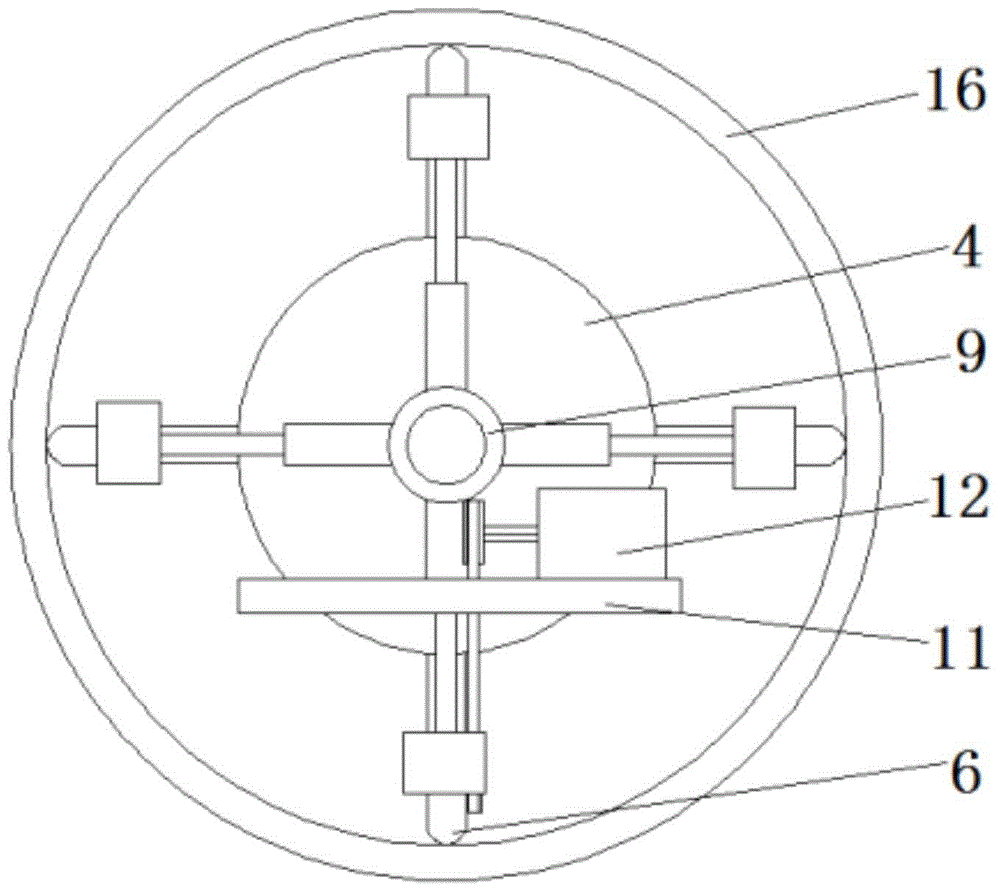

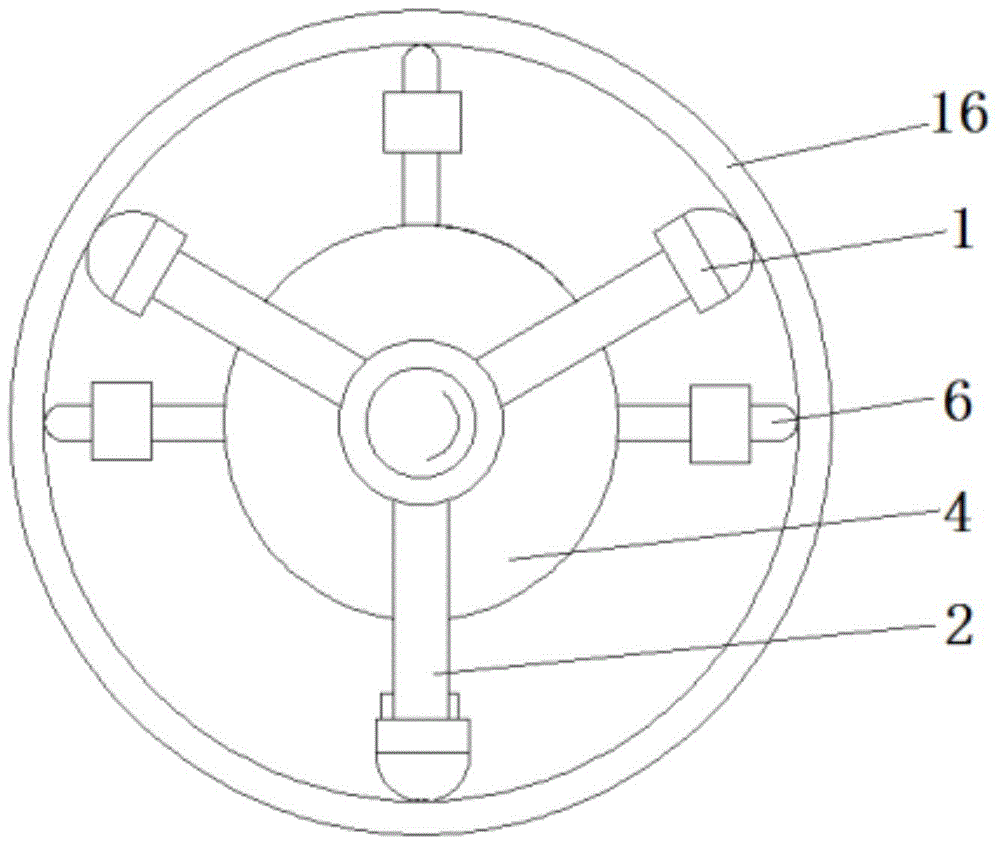

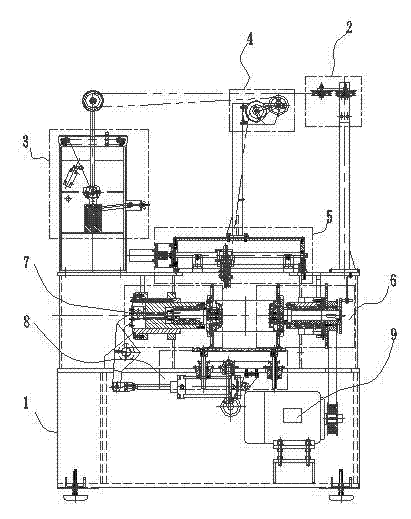

Automatic assembly line of reverser

InactiveCN103639709AEasy to operateMeasurement/indication equipmentsOther manufacturing equipments/toolsCircular discWire wheel

The invention relates to an automatic processing assembly line of a reverser. The automatic processing assembly line is characterized in that an automatic rotating disc feeding machine, a loading belt line, an abrasive band polishing mechanism, a steel wire wheel polishing mechanism, an electric cylinder lifting and translating material-taking mechanism, a reaming mechanism, an inner hole detection mechanism, a linear array camera locating mechanism, a pre-hooking mechanism, a final hooking mechanism, a secondary steel wire wheel polishing mechanism, a camera detecting and locating mechanism, a pressure resistant testing mechanism, a long belt line and an automatic tray loader are arranged on a working table; and the mechanisms are sequentially arranged on a table board in a U shape from front to back, a material is loaded from a loading rotary disc firstly, is subjected to abrasive belt polishing, primary steel wire wheel polishing, reaming, inner hole detection, hooking, secondary steel wire wheel polishing and pressure resistant testing, then is conveyed to the automatic tray loader by the long belt line for tray loading, the whole process only requires two workers, one worker performs loading in the rotating disc position, the other worker performs material receiving in the automatic tray loader position, and the operation is simple and reliable.

Owner:SHANGHAI ZHAOCHENG COMMUTATOR TECH

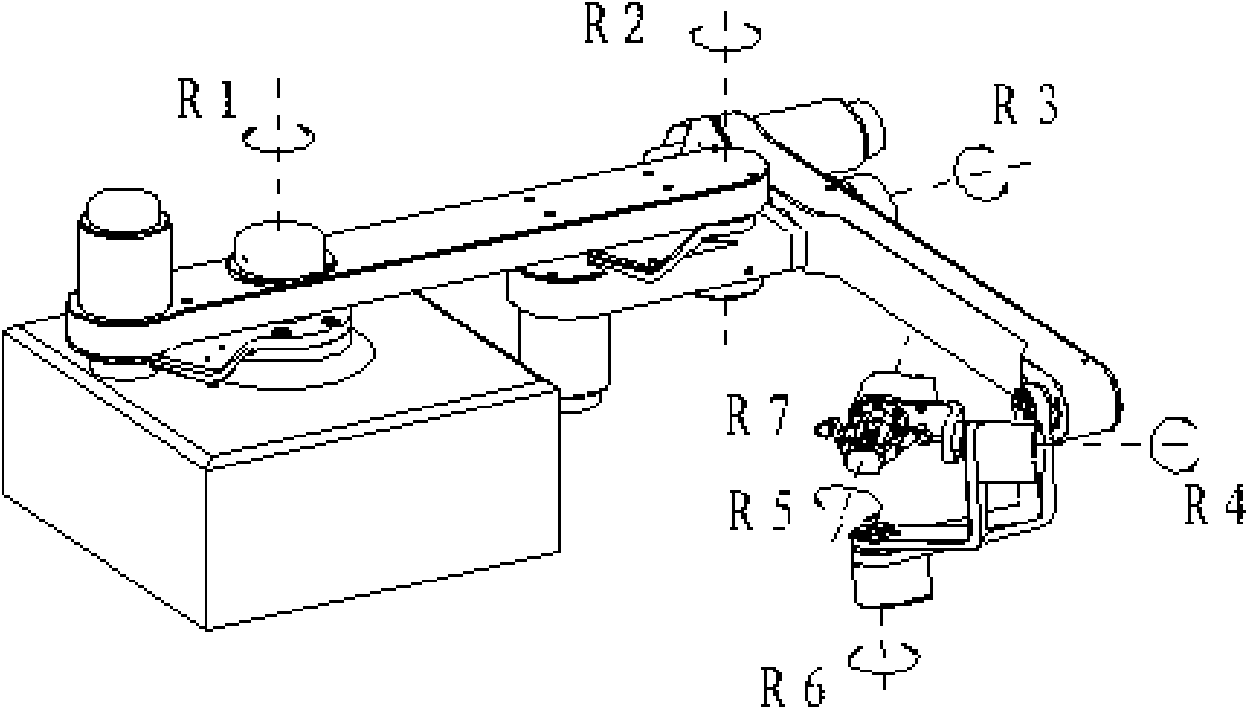

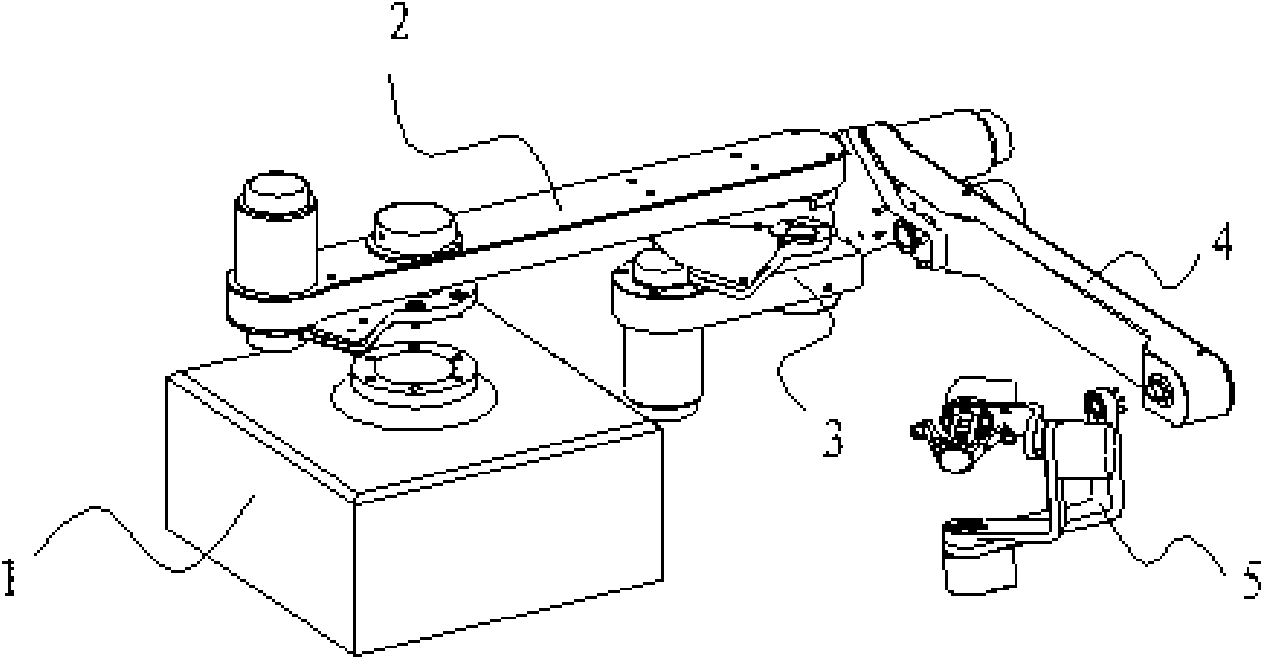

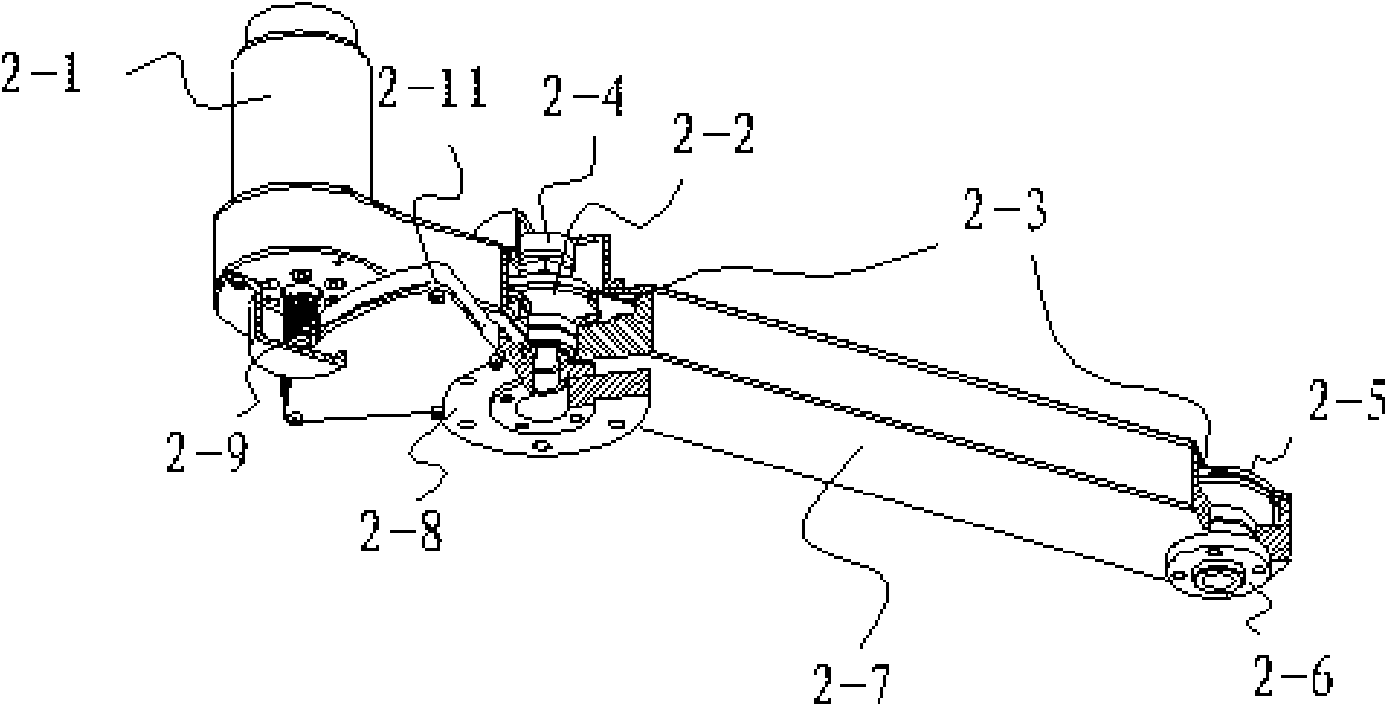

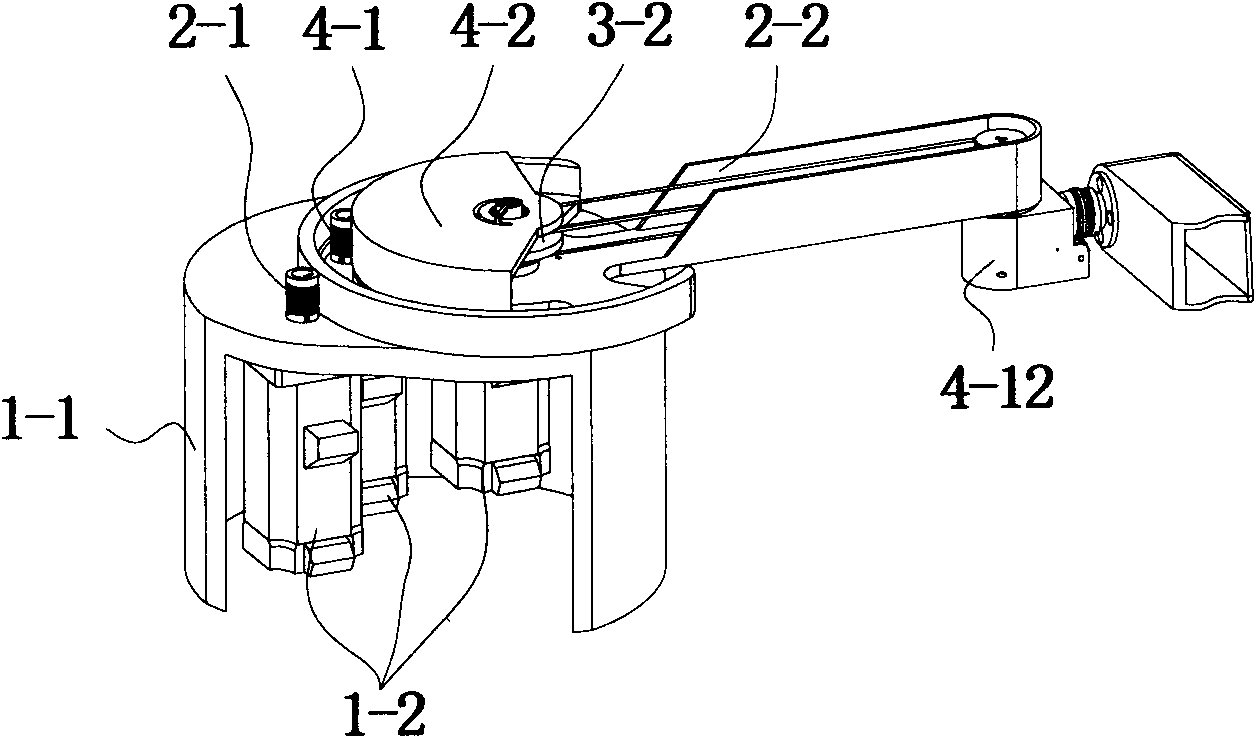

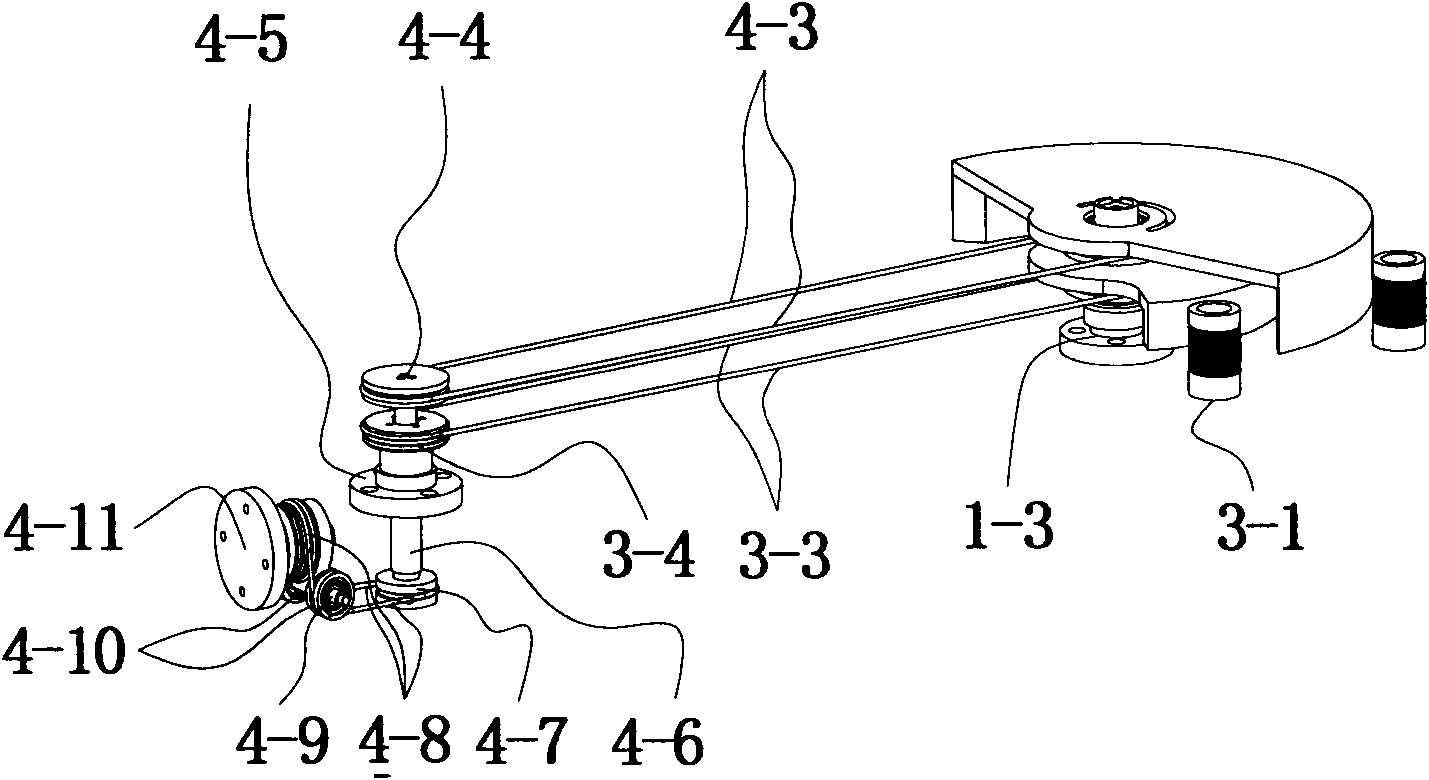

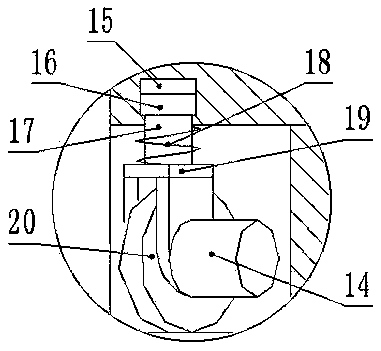

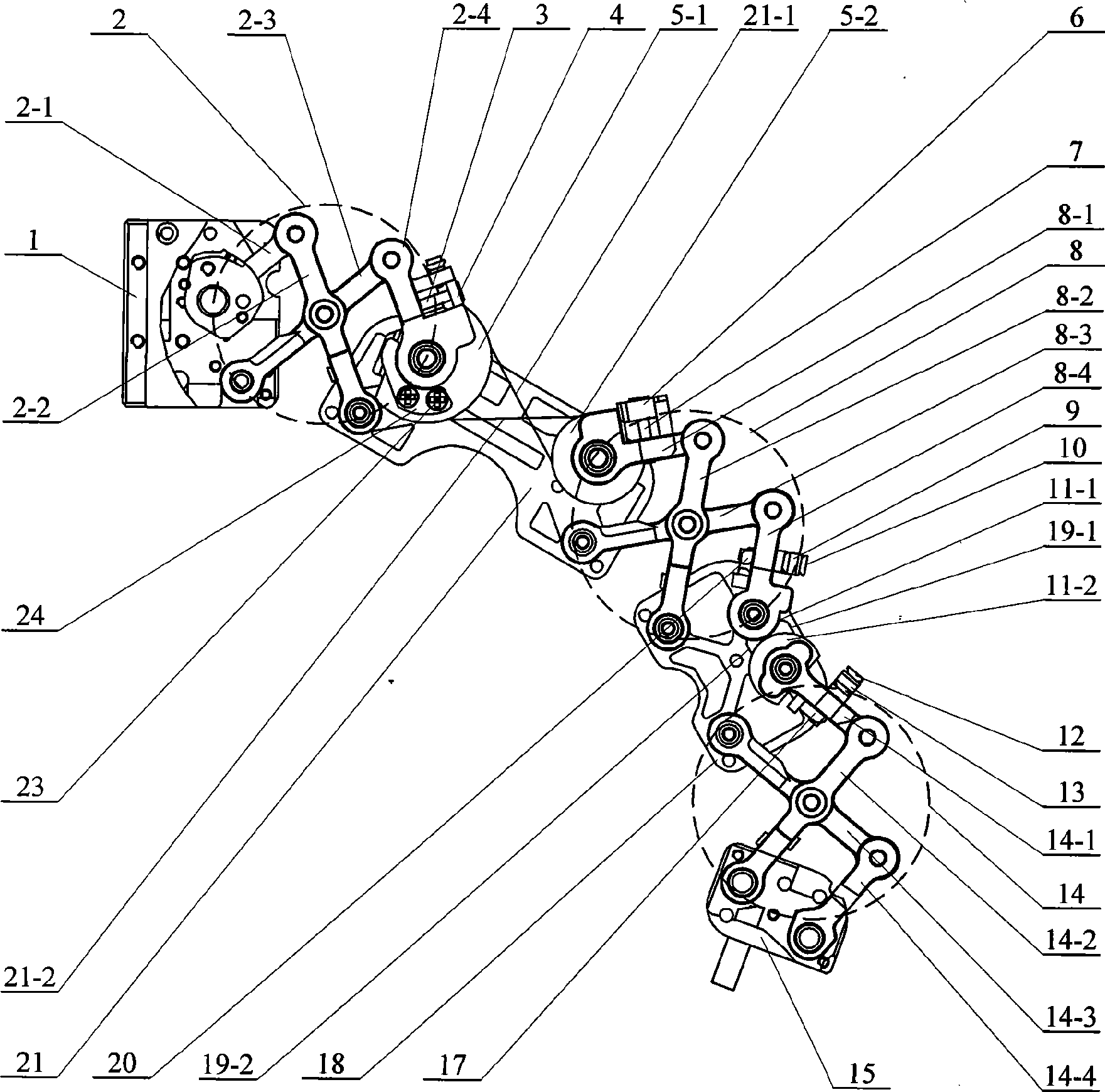

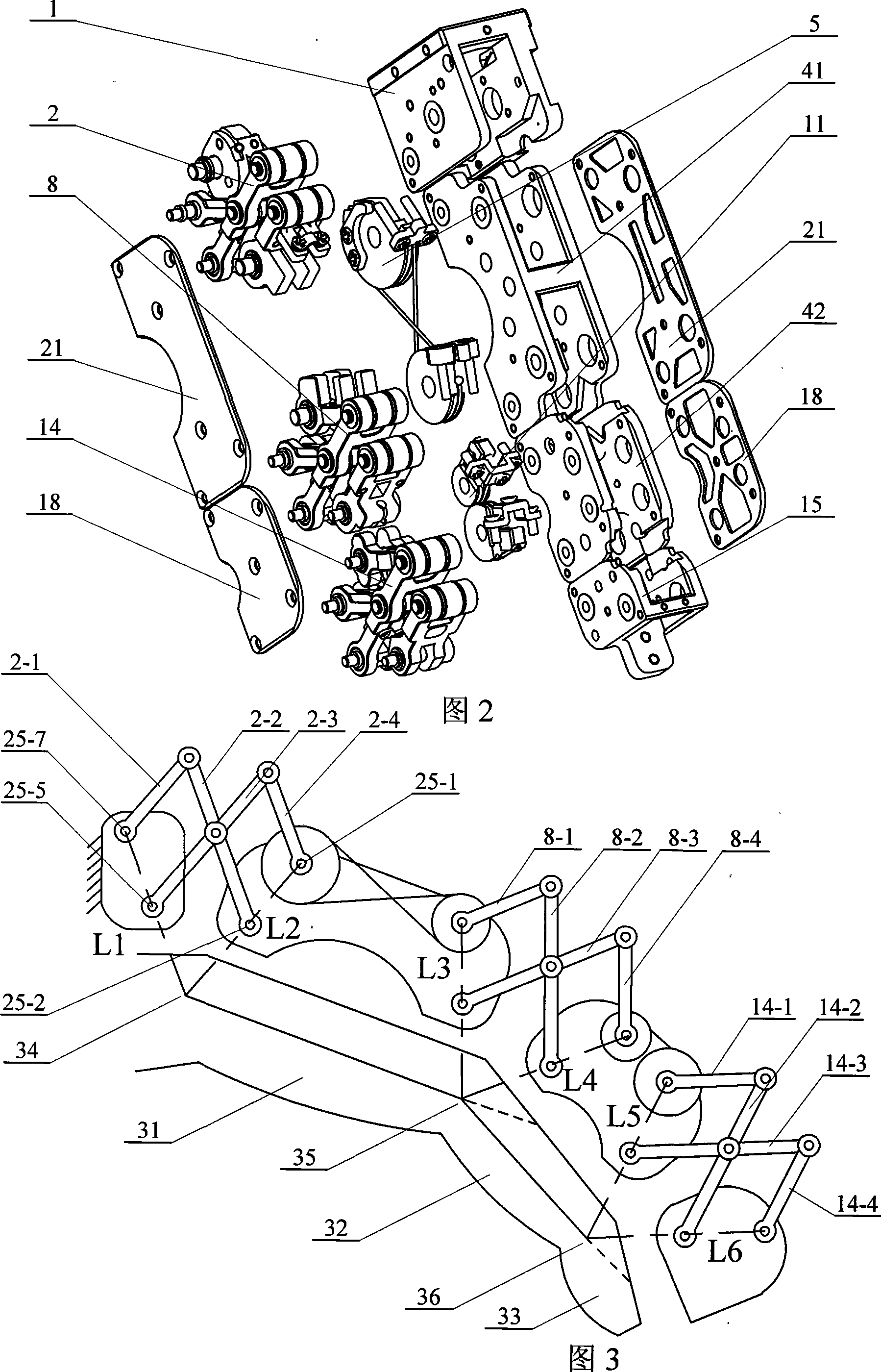

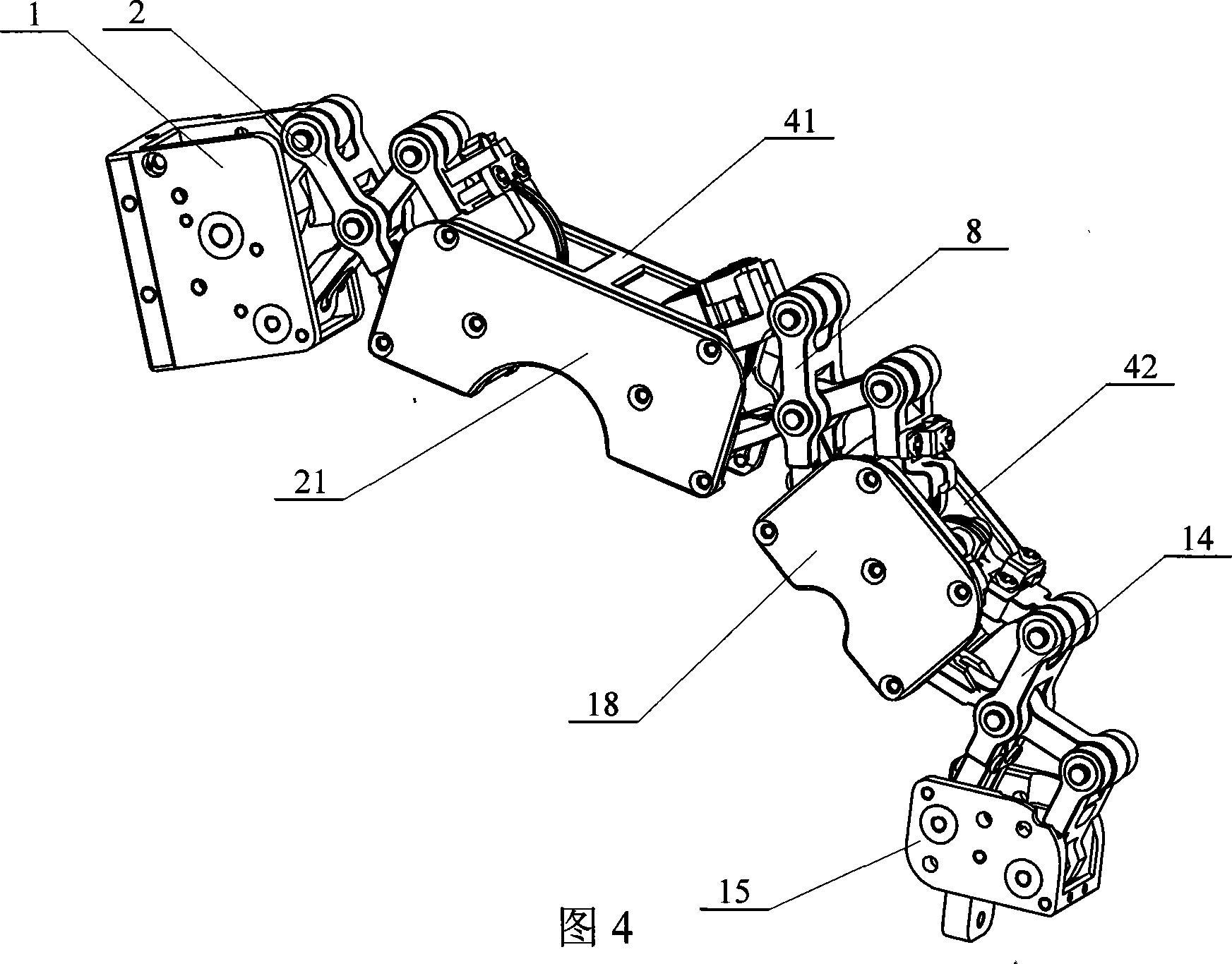

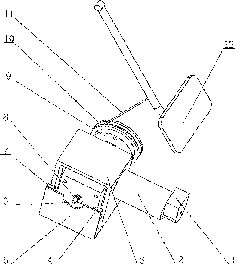

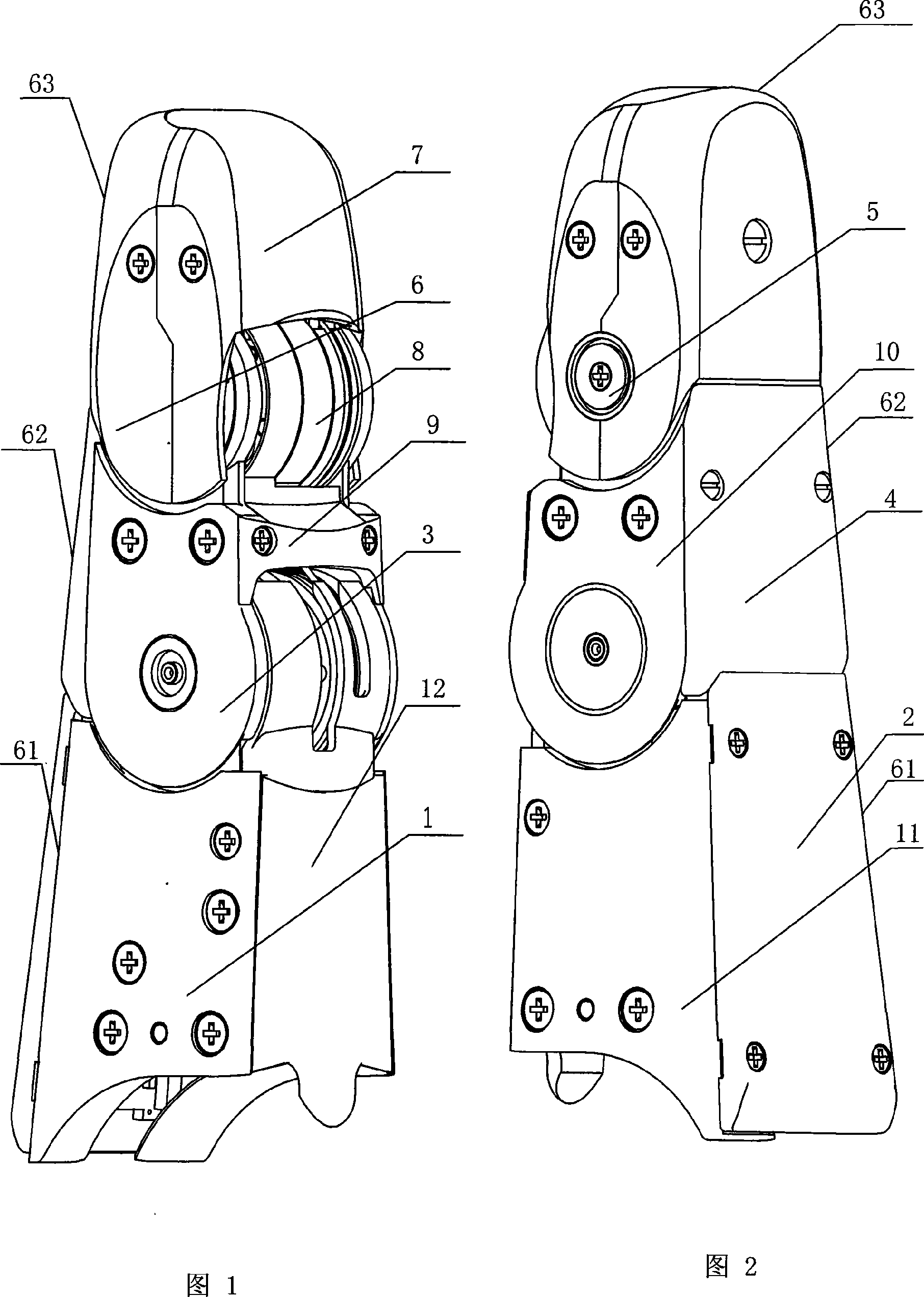

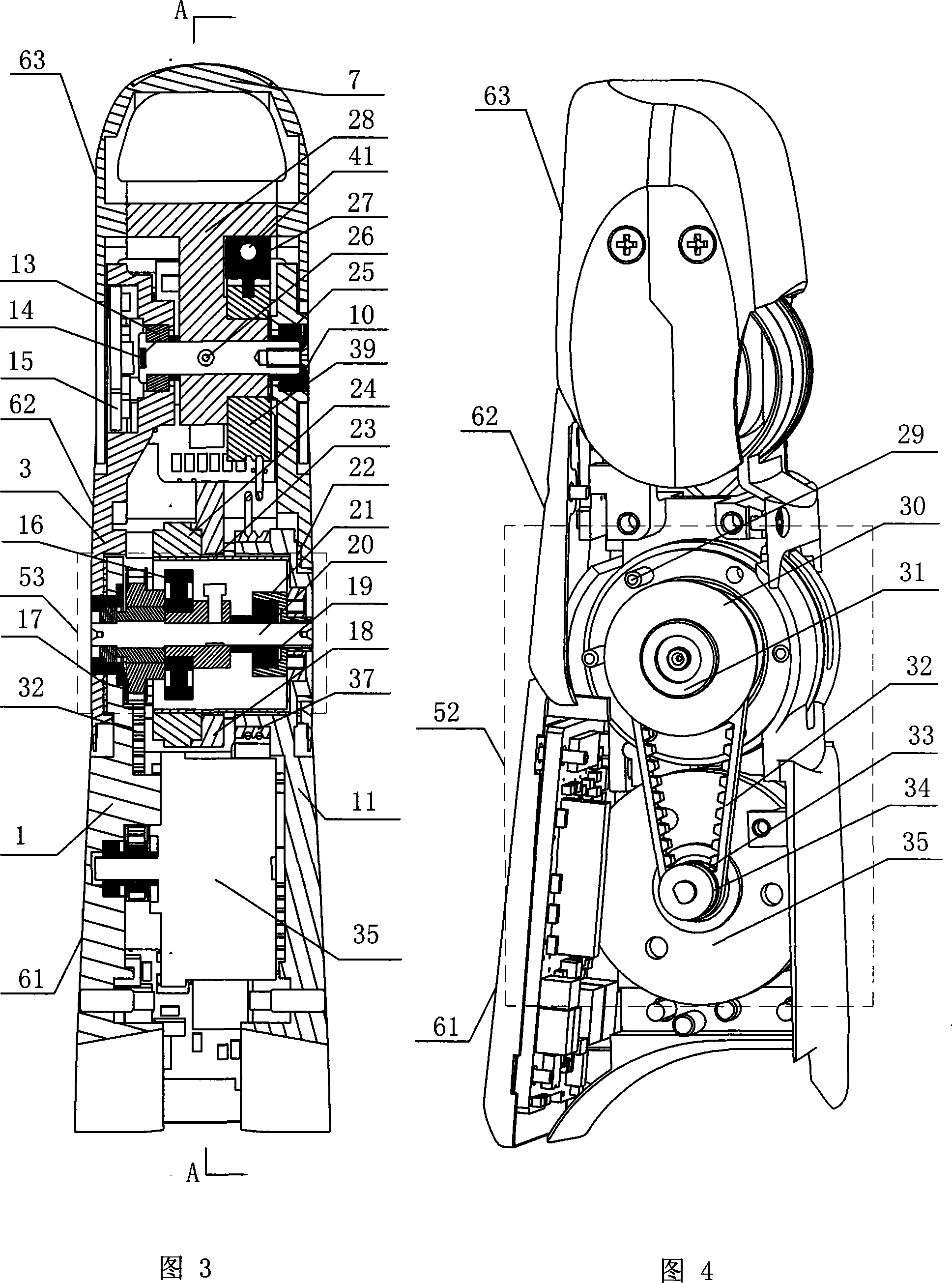

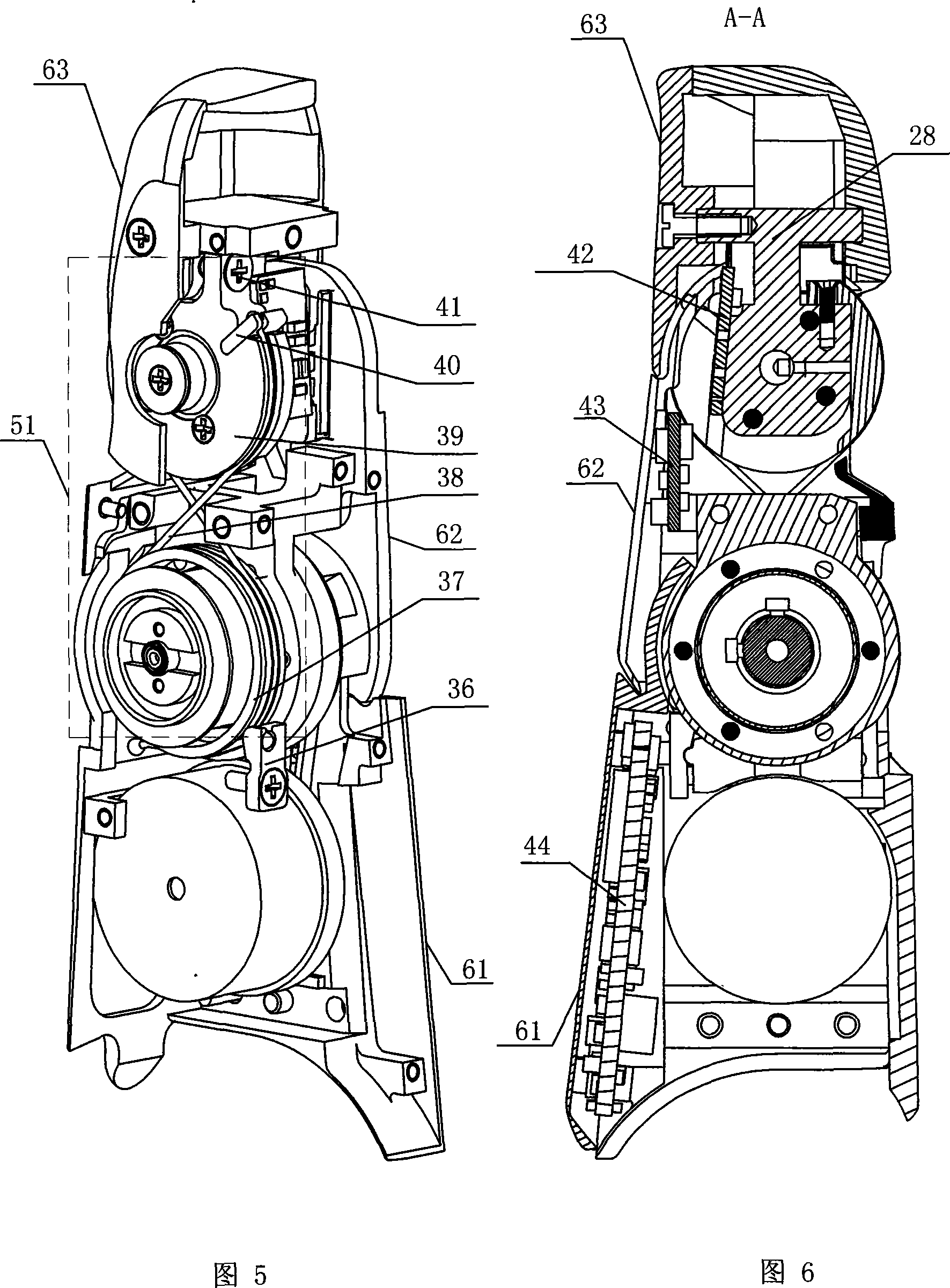

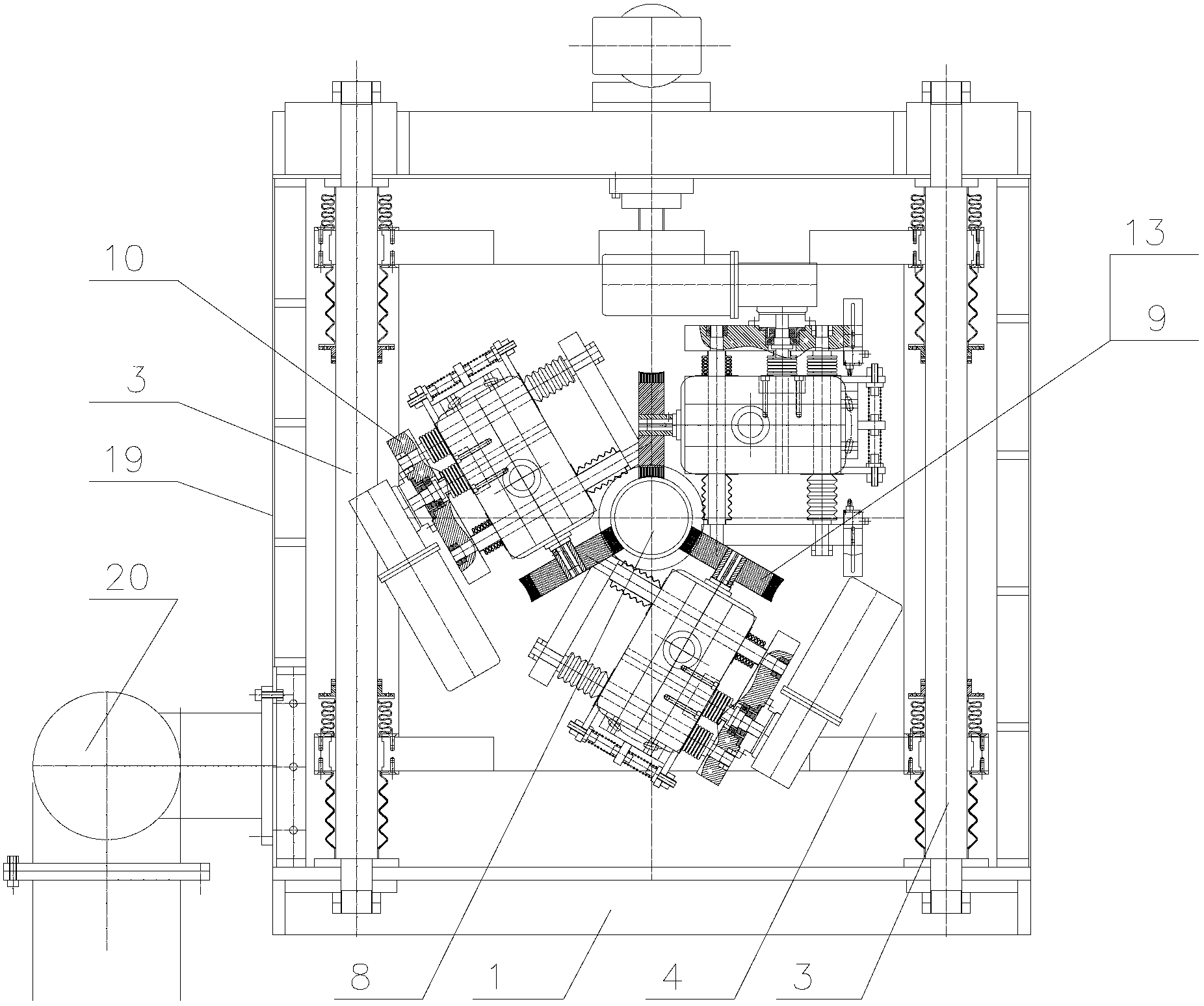

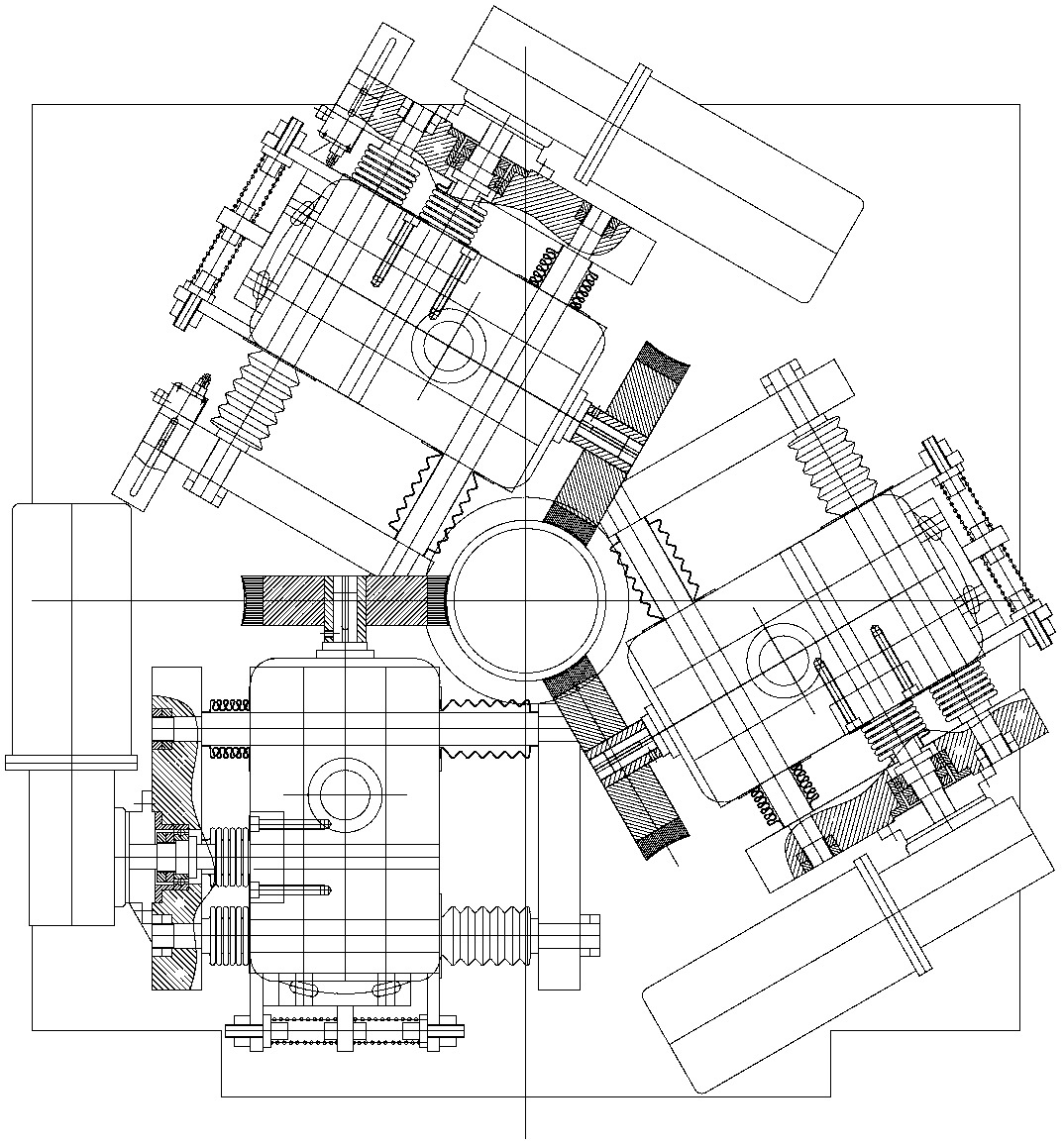

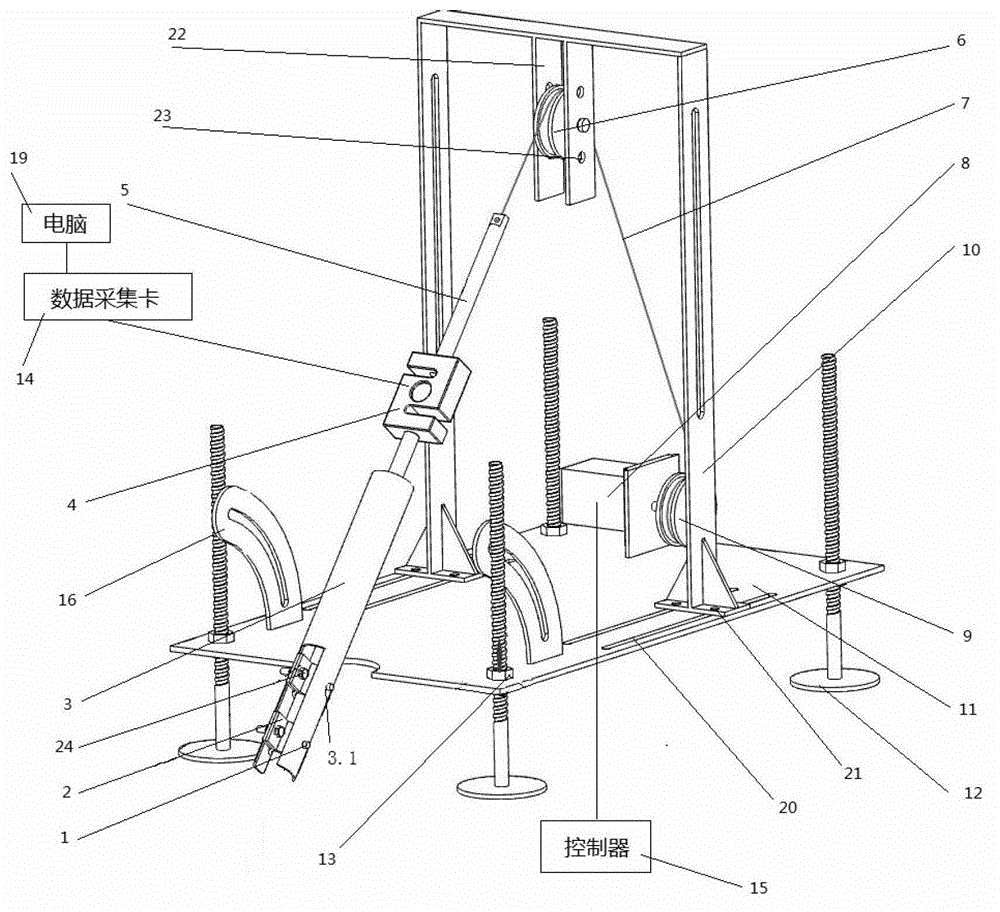

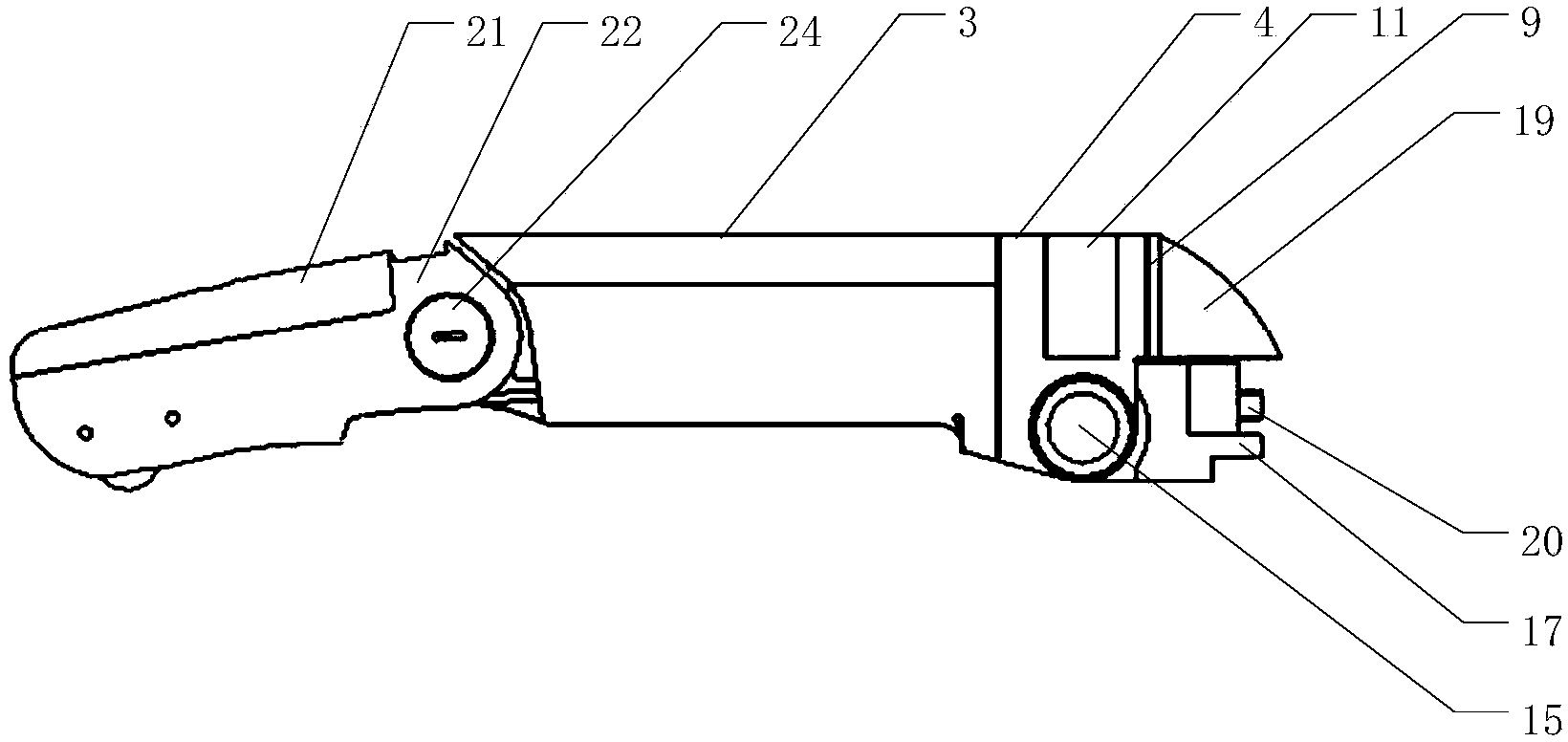

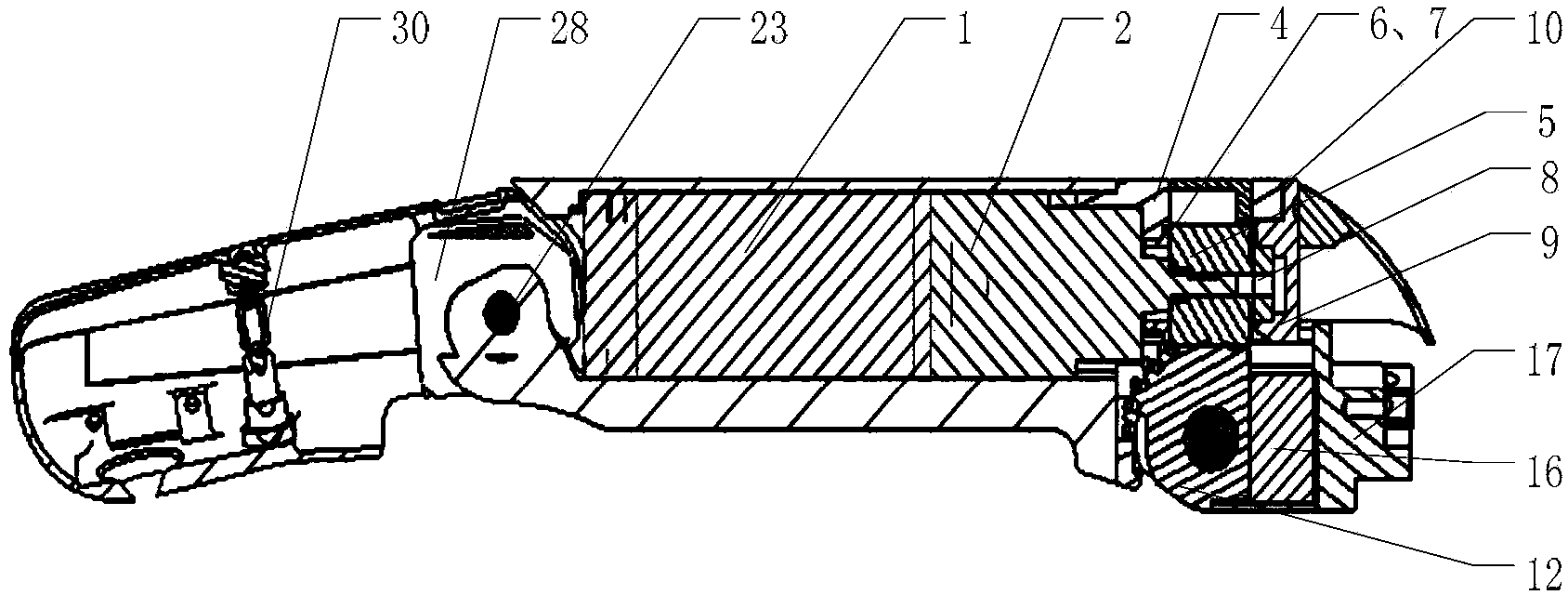

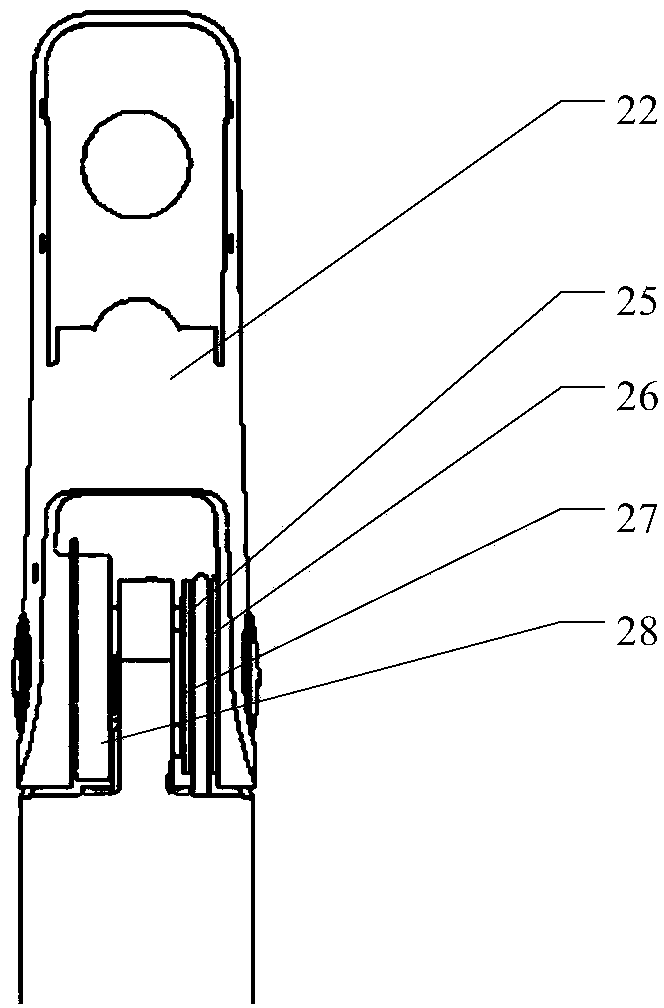

Force feedback type master manipulator with deadweight balance property

The invention discloses a force feedback type master manipulator with deadweight balance property, comprising a big arm mechanism, a small arm mechanism, an elbow joint mechanism, a wrist joint mechanism and a controller. The big arm mechanism, the small arm mechanism and the elbow joint mechanism respectively comprise connecting rods and rotating input mechanisms provided with rotating shafts; one end of the connecting rod of the big arm mechanism, one end of the connecting rod of the small arm mechanism and the rotating shafts of the connecting rods are respectively provided with wire wheels connected through transmission wires; the rotating shafts of the connecting rods of the big arm mechanism, the small arm mechanism and the elbow joint mechanism are respectively connected with potentiometers; the rotating shaft of the small arm mechanism is rotatably connected with a first flange; the first flange is connected with a side end surface of the connecting rod of the elbow mechanism; the rotating shaft of the elbow mechanism is rotatably connected with a second flange; the second flange is fixedly connected with a wire wheel shaft at the rod end of the connecting rod of big arm mechanism; and the wrist joint mechanism is connected with the wire wheel shaft of the wire wheel arranged at the rod end of the connecting rod of the small arm mechanism. The force feedback type master manipulator has the advantages of compact structure, high rigidity, large feedback force, small volume and low manufacture cost.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

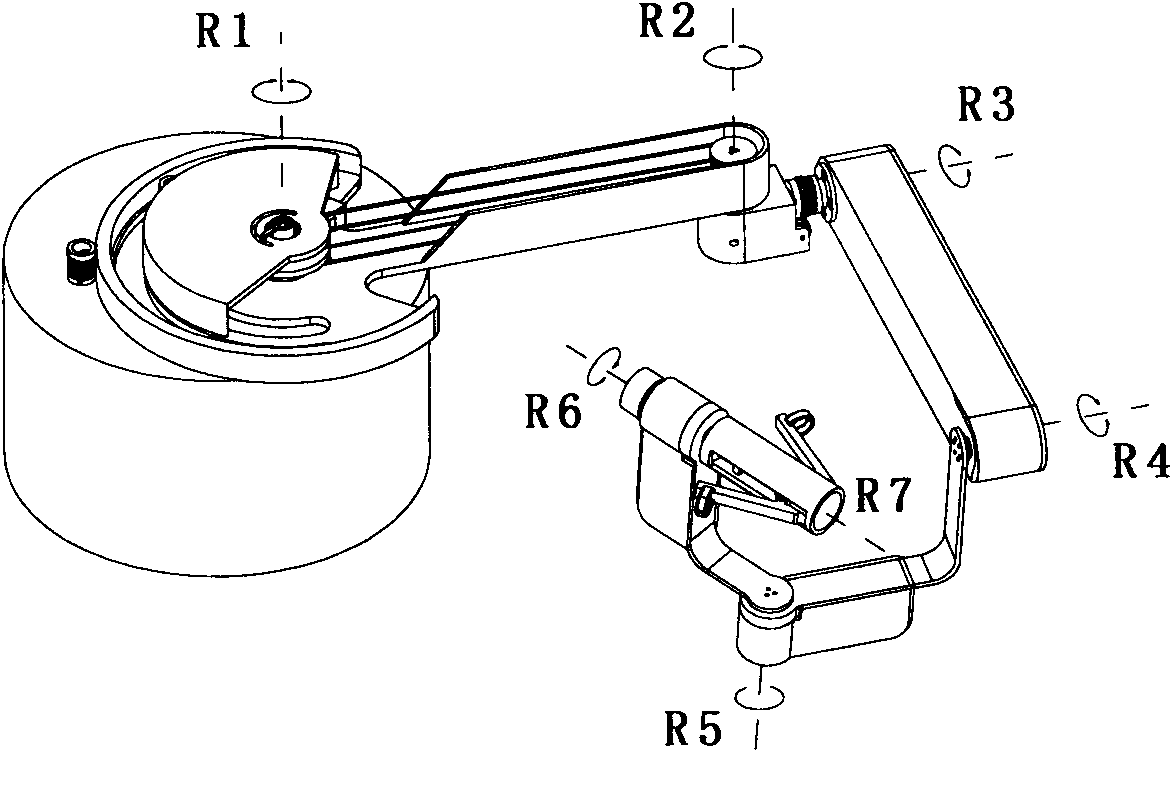

(6 plus 1)-dimension force feedback sensing device

InactiveCN102152299AHigh precisionImprove balanceProgramme-controlled manipulatorJointsWire wheelEngineering

The invention discloses a (6 plus 1)-dimension force feedback sensing device, comprising a base, a large arm mechanism, an elbow joint mechanism, a small arm mechanism, a wrist joint mechanism and a controller, wherein wire wheels are arranged respectively at the large arm mechanism, the two ends of the elbow joint mechanism, one end of the small arm mechanism and a motor output shaft for driving the mechanisms; power is transferred to the needed positions by wire transmission in a step-by-step manner; the positions of rotating shafts of the three mechanism rod parts are respectively provided with an angle displacement sensor; the elbow joint mechanism comprises a posture realizing part and a gripper; and the posture realizing part, the gripper and a motor output shaft for driving the devices are respectively provided with a bevel gear. A motor for providing power for the large arm mechanism, the elbow joint mechanism and the small arm mechanism is arranged in the base, and motors for providing power for all posture frames of the elbow joint mechanism are arranged in the small arm and the posture frames. In the (6 plus 1)-dimension force feedback sensing device, the structure is compact, the inertia influence of the motors is less, the dimensionality of force feedback is high, the volume is small and the manufacturing cost is low.

Owner:TIANJIN POLYTECHNIC UNIV

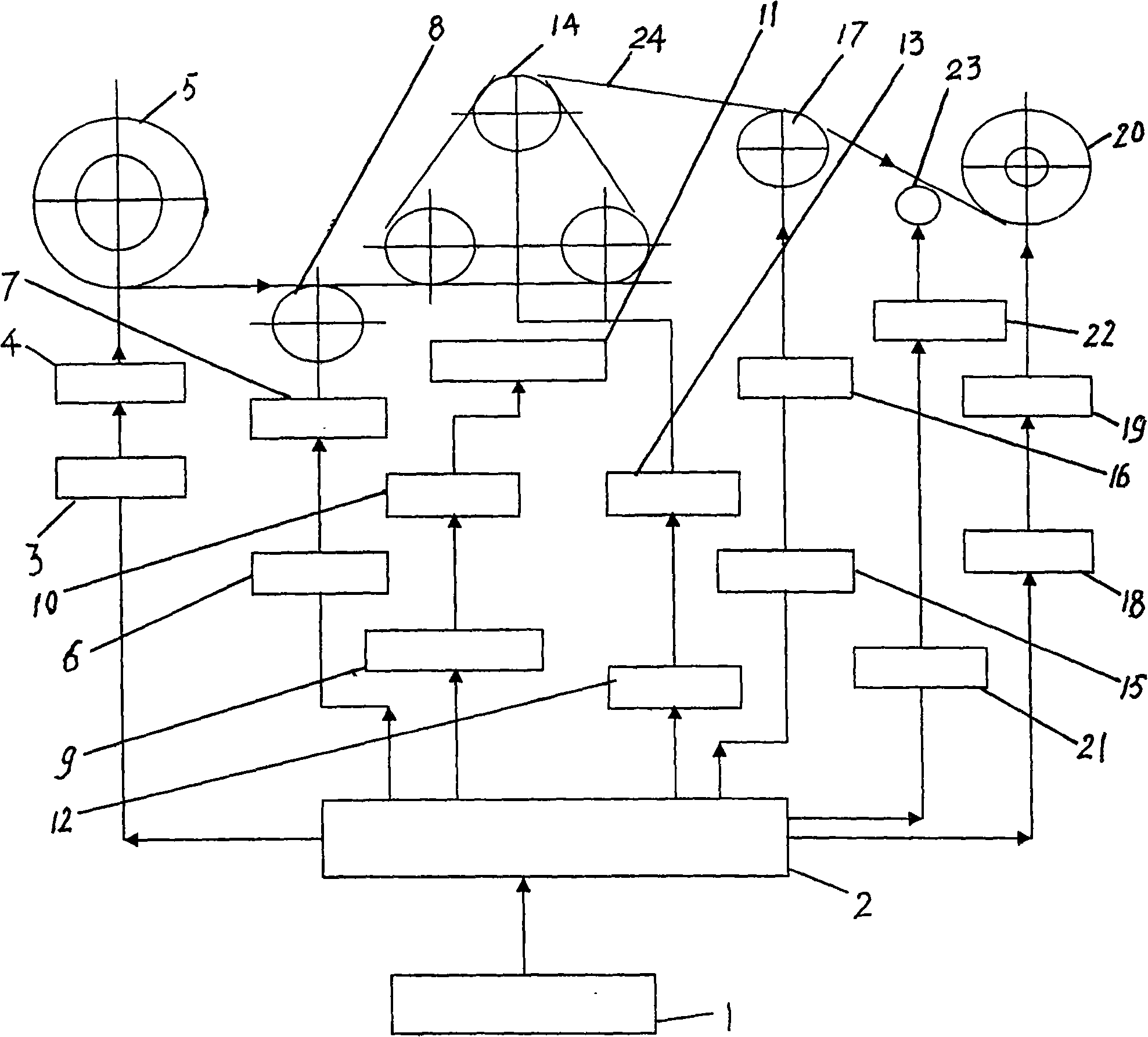

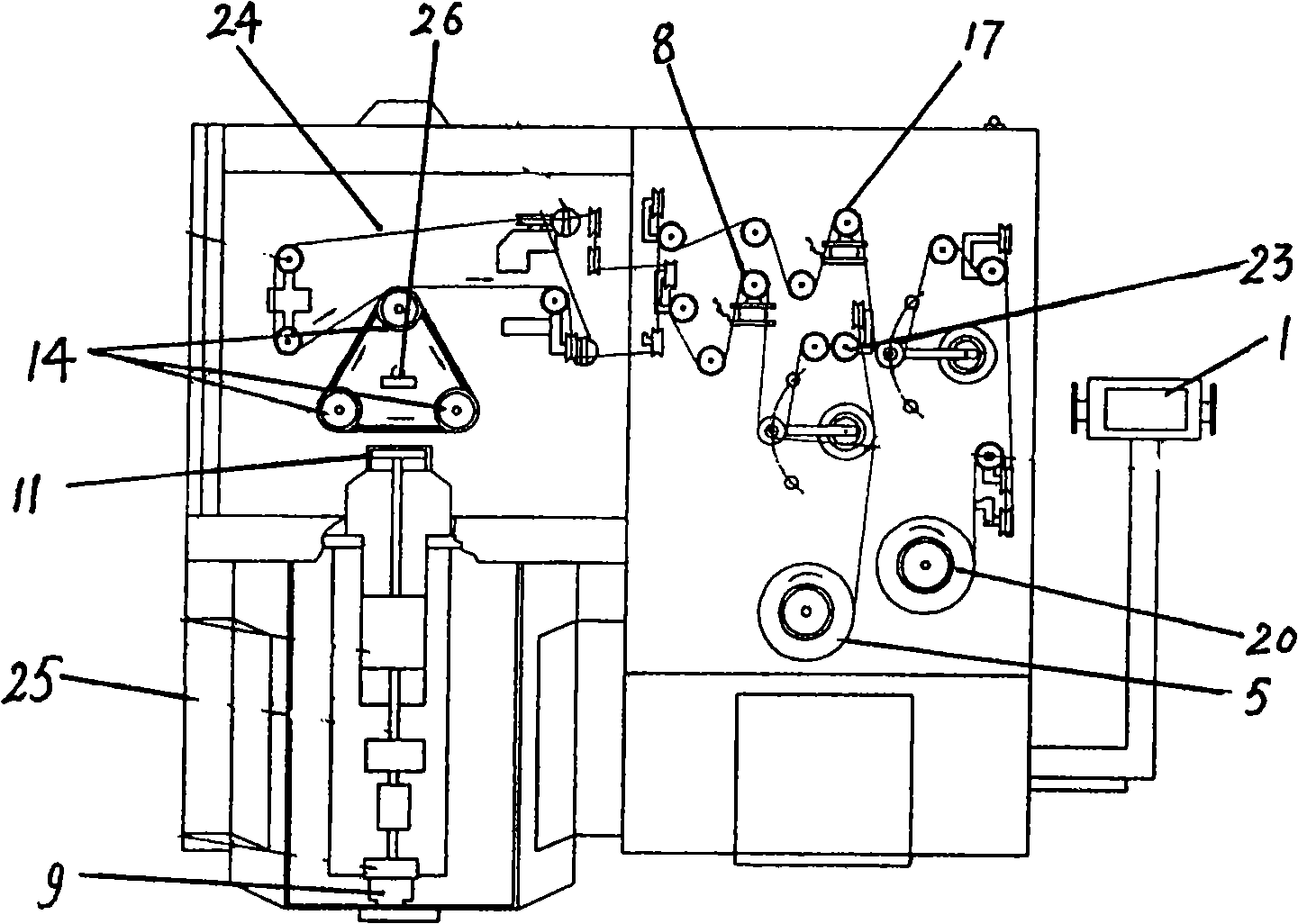

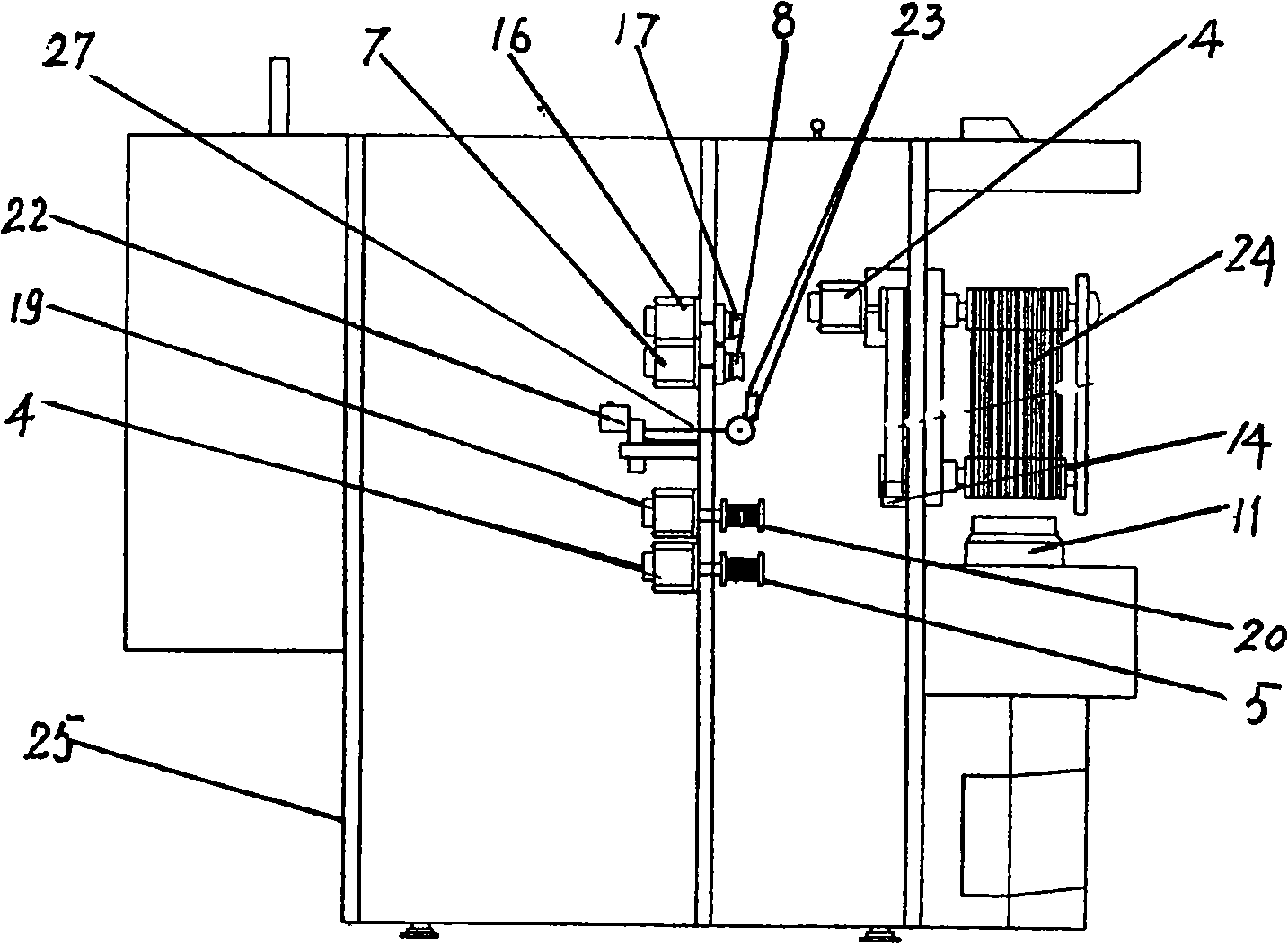

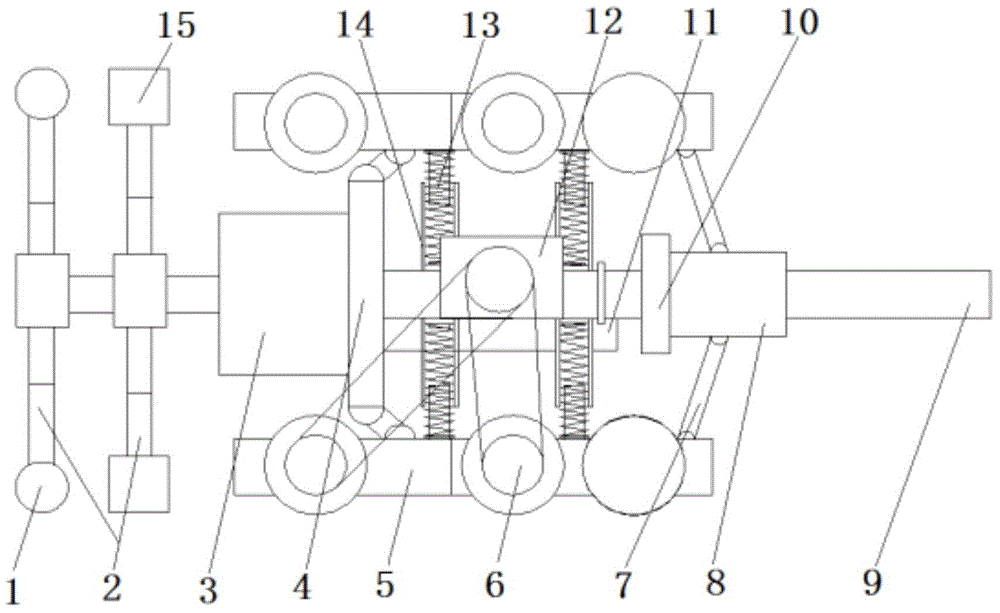

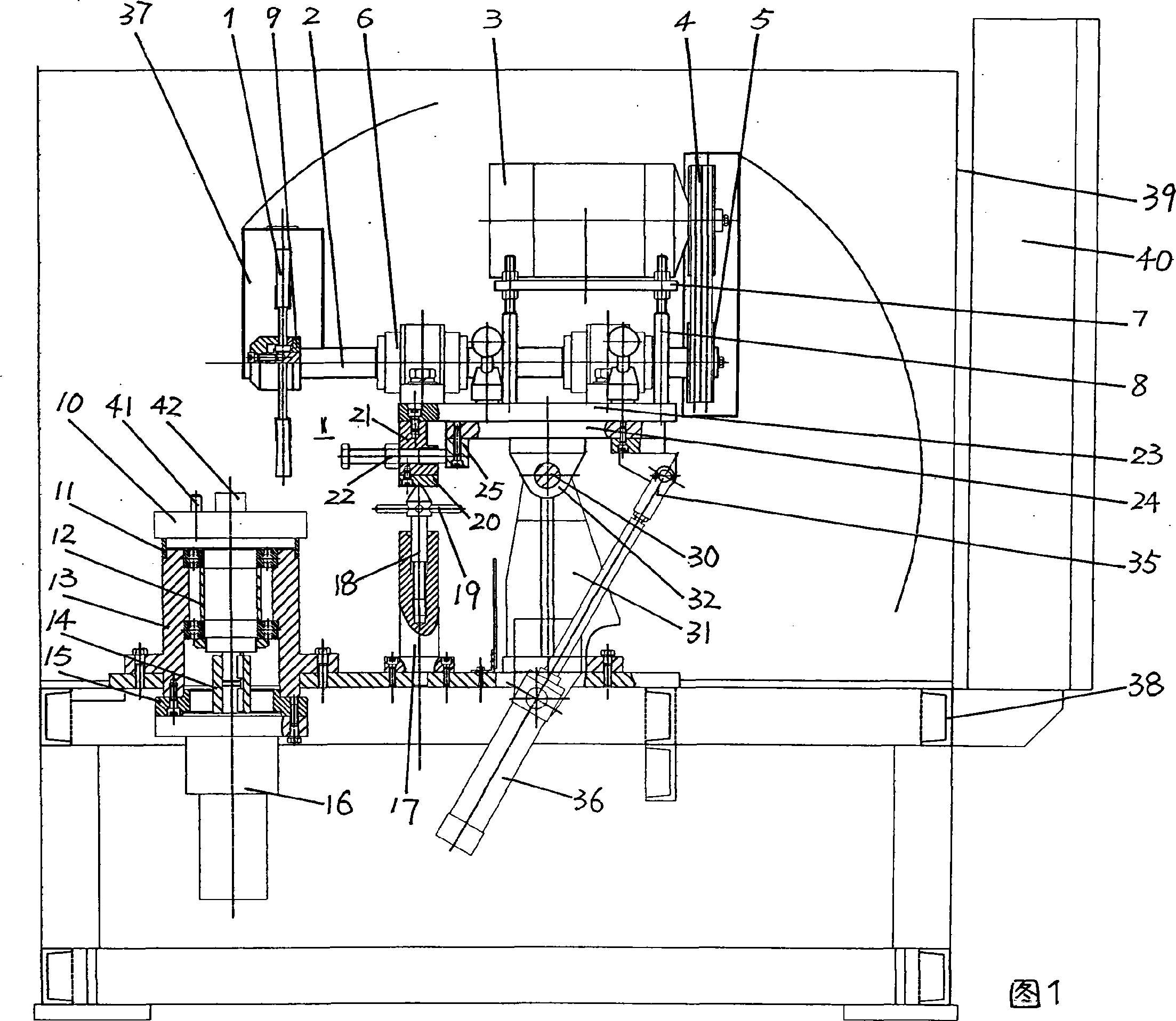

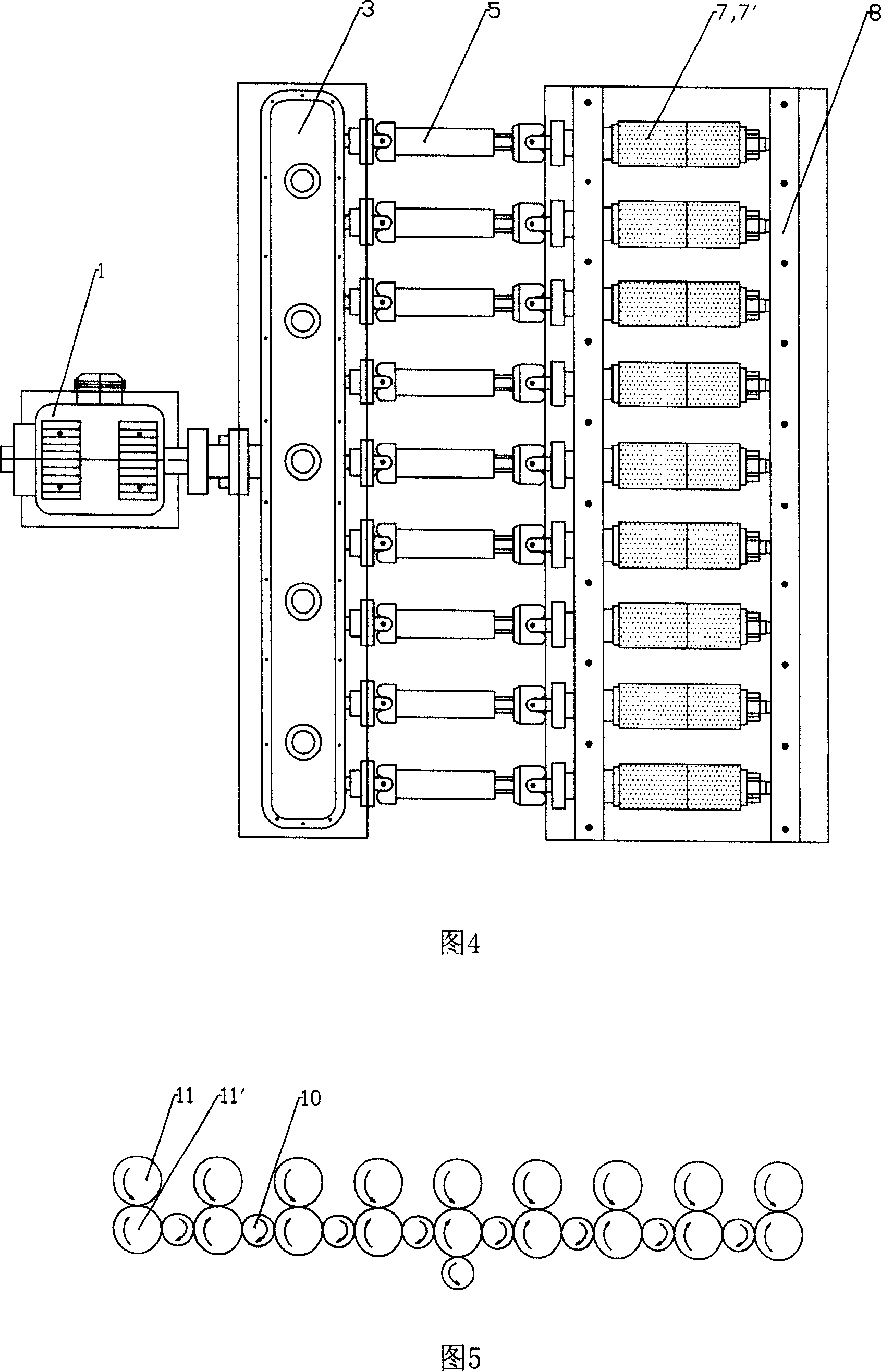

Microcomputer control multiline cutting machine

InactiveCN101301734AConstant tensionAchieve the purpose of being cutGrinding machinesFine working devicesAudio power amplifierWire wheel

The invention provides a micro-computer control multi-wire cutting machine, comprising a frame, a worktable, a metal wire, and a grinding lubricant supply mechanism; the control part of the micro-computer control multi-wire cutting machine adopts the programming of a main substrate to control a CPU module; the parameters of the CPU module are set by a touch display; furthermore, a servo amplifier is controlled by optical fibres; the servo amplifier controls a servo motor; a frame is internally provided with at least six servo amplifiers and six servo motors which respectively control the lifting of the worktable; the micro-computer control multi-wire cutting machine also comprises three rotation rollers, a wiring wheel, a wiring tensioning sensor, a stranding wheel, and a stranding tensioning sensor; the grinding lubricant supply mechanism leads out an emery liquid injection pipe; the outlet of the emery liquid injection pipe is in the middle of an isosceles triangle which is presented by three rotation rollers; the metal wire extends from wiring wheel passing through the wiring tensioning sensor and winding parallel hundreds of rounds on three rotation rollers to form a cut surface, the main substrate programming controls the CPU module so as to control the rotation / direction of the servo motors, thus leading the rotation rollers, stranding wheel and wiring wheel to reciprocate to rotate. The micro-computer multi-wire cutting machine has high cutting precision and working efficiency.

Owner:乐清市新晶电子器件有限公司 +1

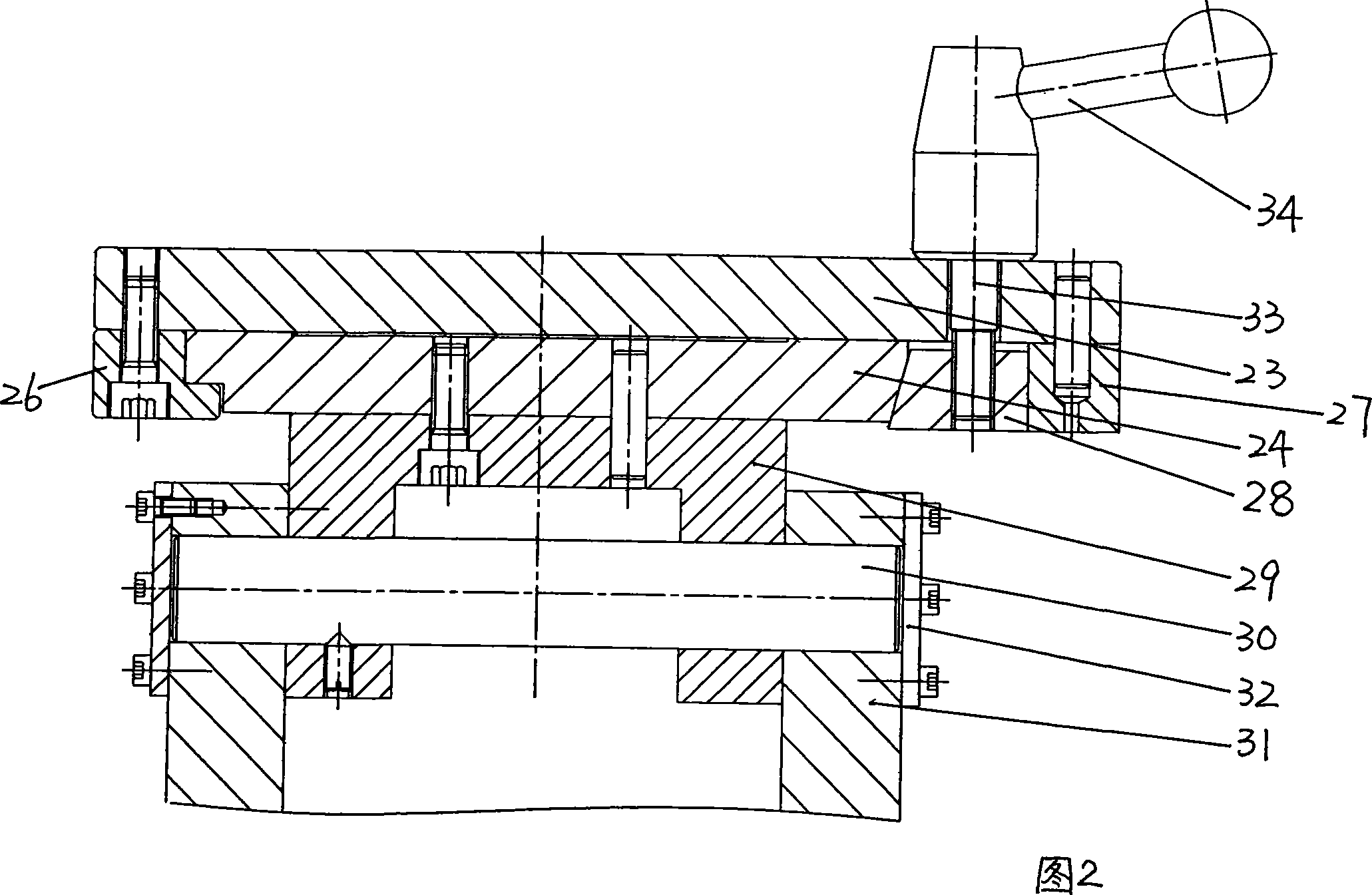

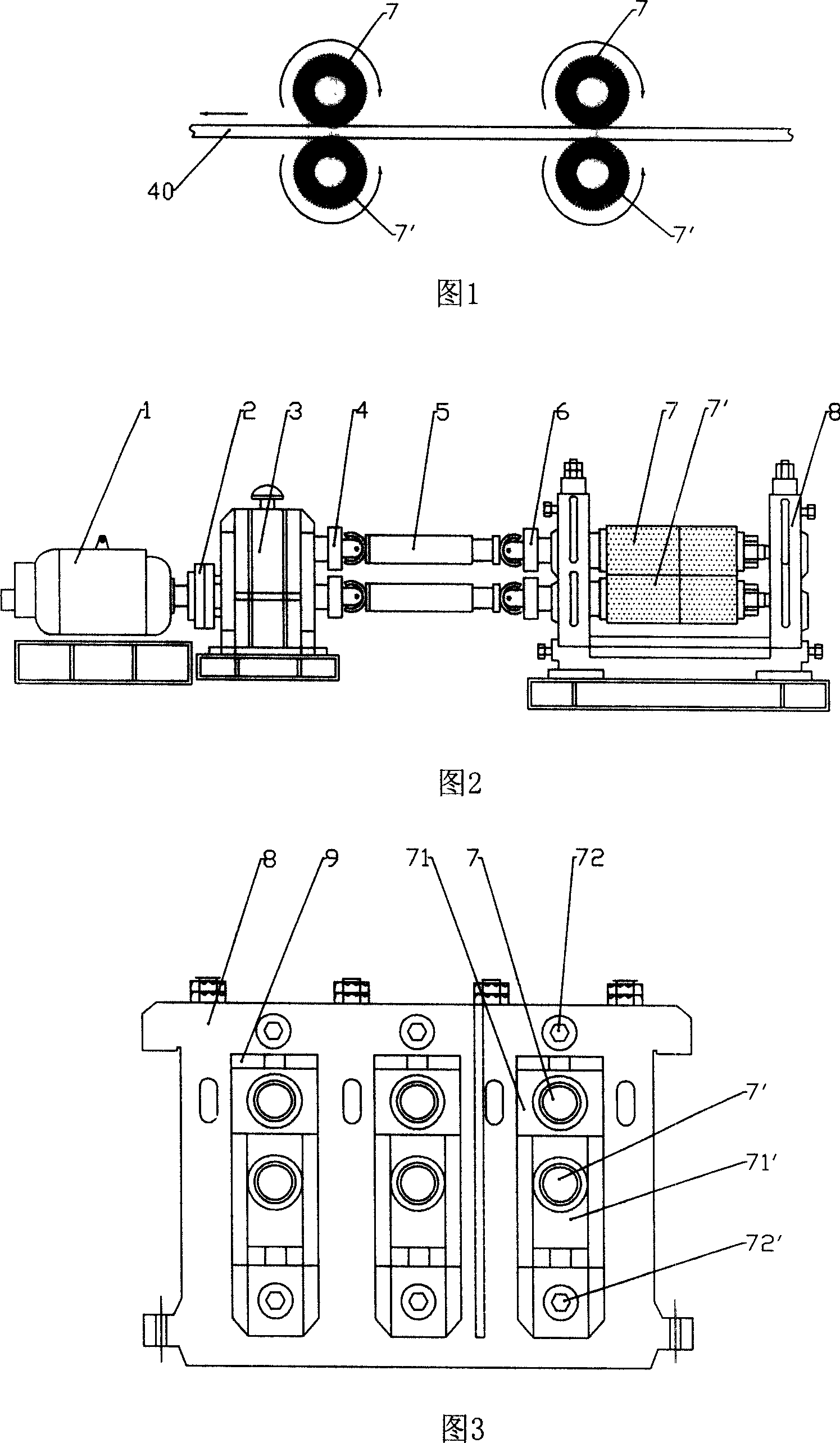

Automatic winding device with swinging mechanism for multi-wire cutting machine,

InactiveCN101973084AFast winding speedImprove efficiencyWorking accessoriesFine working devicesCircular discWire wheel

The invention relates to an automatic winding device with swinging mechanism for a multi-wire cutting machine. In the automatic winding device, a wire cutting wire is wound on a paying-off wheel, a wire guiding wheel is arranged above the paying-off wheel, a wire wheel is connected with a swinging wheel by a cutting wire, the swinging wheel is connected with another wire guiding wheel above the swinging wheel by the cutting wire, the another wire guiding wheel is connected with a wire winding wheel by the cutting wire, a weight bearing wheel is arranged below the wire winding wheel, and the cutting wire is connected with a driven working roller through the wire winding wheel and the weight bearing wheel; the driven working roller and two driving working roller are vertically arranged on a swinging disk in a triangular way, and the cylindrical surfaces of the driven working roller and the driving working roller are respectively provided with a plurality of annular wire winding grooves; the swinging wheel is connected with a swinging rod which is vertically fixed on the output shaft of a tension servo motor to form a swinging mechanism; the wire winding wheel is connected with a ball screw which is connected with a wire winding motor; and the technical scheme that an approach switch is arranged near the swinging disk overcoms the defects that a mode of manual winding is time-consuming and is easy to fault. The invention is suitable for cutting machines used for cutting sapphire and silicon carbide in the manufacture of LED chips, and other similar machines.

Owner:HUNAN YUJING MACHINE

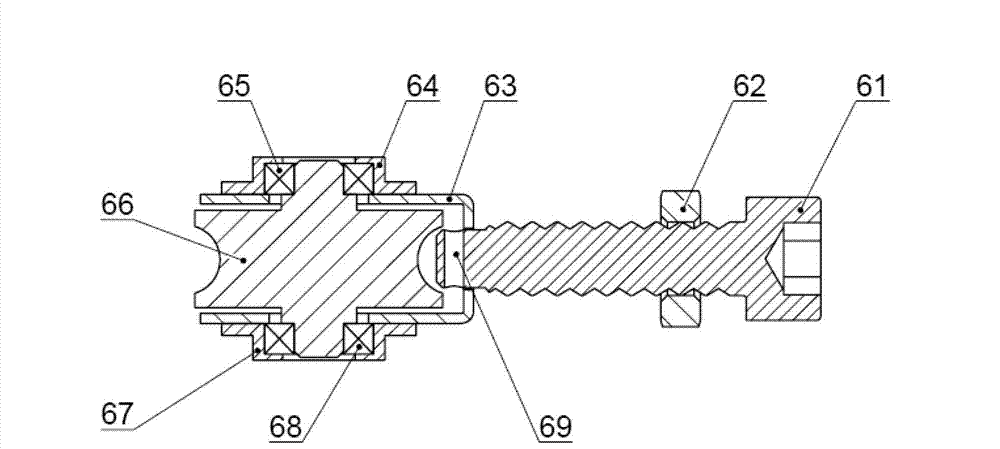

Mechanical arm high-angle controllable rotary joint device driven by two steel wire ropes

The invention discloses a mechanical arm high-angle controllable rotary joint device driven by two steel wire ropes. The mechanical arm high-angle controllable rotary joint device is characterized in that a front-stage mechanical arm and a rear-stage mechanical arm are connected through a rotation shaft and a bearing and rotate relative to each other; a steel wire wheel disc is fixed between an upper boss and a lower boss of the front-stage mechanical arm; a shaft of an angle sensing output device which is arranged in a cavity in the middle of a flange at one end of a rotation shaft of the steel wire wheel disc is coaxial with the rotation shaft and rotates synchronously with the rotation shaft; two driving steel wire ropes are clamped on groove through holes through ball heads and are wound in a U-shaped groove of the rim of the steel wire wheel disc; and a steel wire rope pre-tightening device is used for adjusting pre-tightening force of the driving steel wire ropes through adjustment screws. According to the joint device provided by the invention, the joint displacement can be obtained in real time so that the accurate control of joints is realized; and the relative sliding does not occur between each steel wire rope and the steel wire wheel disc, so that the rolling contact is realized between each steel wire rope and the steel wire rope pre-tightening device, the frictional loss is small, the steel wire rope transfer efficiency is high and the applicability is brought to the serial-connect expansion of the multi-stage mechanical arms.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Steel pipe polishing and painting robot

InactiveCN107775504AGuaranteed uniformityBrush evenlyLiquid surface applicatorsPortable grinding machinesBristleLacquer

The invention discloses a steel pipe grinding and painting robot, which includes a cylindrical shell, a dust removal device, a painting device and a driving device. The dust removal device is composed of a retaining ring, a grinding shell, a steel wire wheel, a switch A, an annular sponge layer, It is composed of dust outlet, suction fan, dust storage shell, square hole, sponge block and battery. In the present invention, a plurality of rotating wheels arranged clockwise at an angle of 30° to the axis of the paint seepage cylinder move forward in a spiral along the steel pipe. Moving, the rotating wire wheel in the front will completely remove the rust on the steel pipe through the helical movement and forward movement, and the bristles on the helically moving paint seepage tube will paint the paint evenly to ensure the uniform painting of the steel pipe In this way, during the working process, no extra work is required for the staff, saving trouble and labor, the steel pipe is polished and painted faster and the efficiency is higher, the paint is painted evenly, and the quality is high, and the dust from grinding will also be recycled. The environment is well protected.

Owner:广西环游信息技术开发有限公司

Exoskeleton mechanism based on parallelogram connection-rod and wire rope

InactiveCN101455609AGuaranteed interference-free movementHigh degree of integrationProgramme-controlled manipulatorGymnastic exercisingWire wheelEngineering

The present invention relates to an external skeleton mechanism based on parallelogram connecting rod and wire cable, and relates to an external skeleton mechanism. The aim of the invention is to settle the problems that the existing external skeleton mechanism which is used aiming at the hand part can not realize bidirectional active driving, the mechanism is overstaffed, the strong friction between the cable and the mechanism makes the control more difficult, etc. A first thread wheel and a second thread wheel of the invention are respectively installed on two sides of the upper part of second machine frame. The first thread wheel is coaxial with one end of the fourth connecting rod. The second thread wheel is coaxial with one end of Number1 connecting rod. One end of the second wire cable is connected with a clamp plate. The other end of the second wire cable is installed on a second adjusting slider. The third thread wheel and the fourth thread wheel are respectively installed on two sides of the upper part of third machine frame. The third wire wheel is coaxial with the Number4 connecting rod. The fourth thread wheel is coaxial with connecting rod 4. Each joint of the invention adopts a parallelogram link mechanism. The middle driving component adopts a wire cable for transmission. The hand can be surrounded with the external skeleton form for executing an enveloping movement.

Owner:HARBIN INST OF TECH

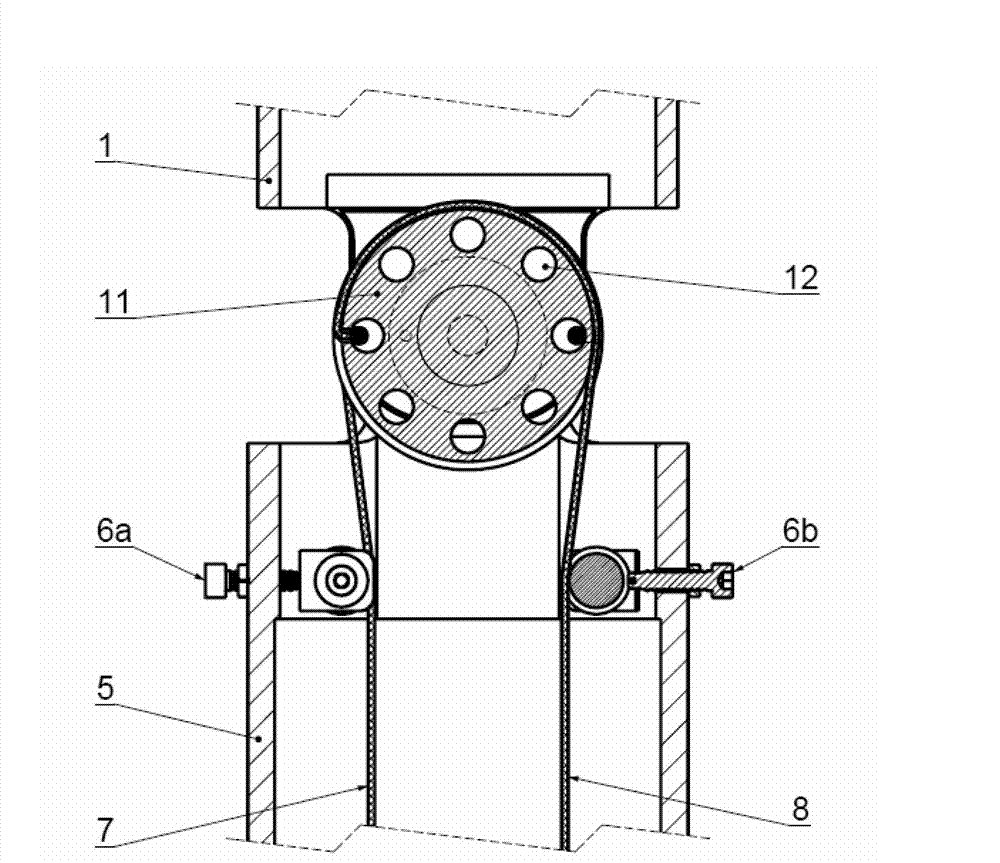

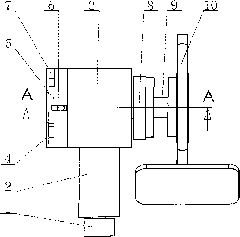

Braking device of unmanned vehicle

InactiveCN101797917AEffective protectionEnsure safetyAutomatic initiationsControl devicesReduction driveWire wheel

The invention relates to a braking device of an unmanned vehicle. The device comprises a motor, a reducer, a coder and a sensing mechanism, wherein the reducer is a worm gear reducer, the input end of the reducer is connected with the motor, and an output shaft at the back end of the motor is connected with the coder; one end of the output shaft of the reducer is connected with the contacts of sensors, the other end of the output shaft of the reducer is connected with a torque sensor, and the other end of the torque sensor is connected with a wire wheel wound with steel wires; and both sides of the upper part of a sensor fixing mount connected with the shell of the reducer are respectively provided with a zero-position sensor and a pole-position sensor, and the contacts of the two sensors are respectively positioned at the inner side of the circular motion trajectory of sensor contacts. In the invention, the worm gear mechanism can effectively keep a vehicle in the braking state; the spacing sensor and the torque limiter realize the effective braking and ensure the safety of the vehicle; and the steel wires avoid the interaction between the unmanned driving mode and the manual driving mode. The invention has the advantages of simple and compact structure, low cost and strong universality, and does not destruct the structure of the original vehicle.

Owner:中国人民解放军炮兵学院

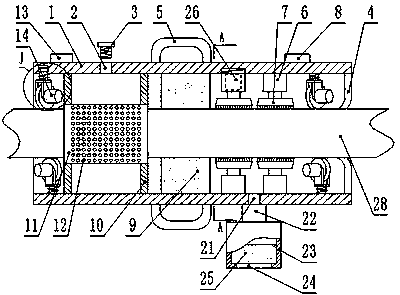

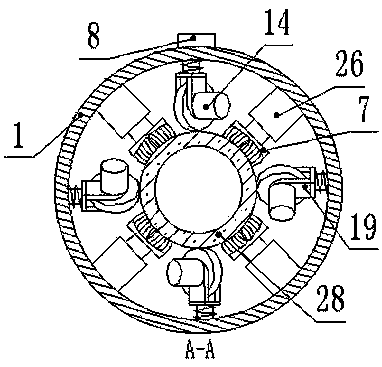

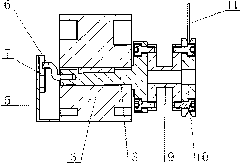

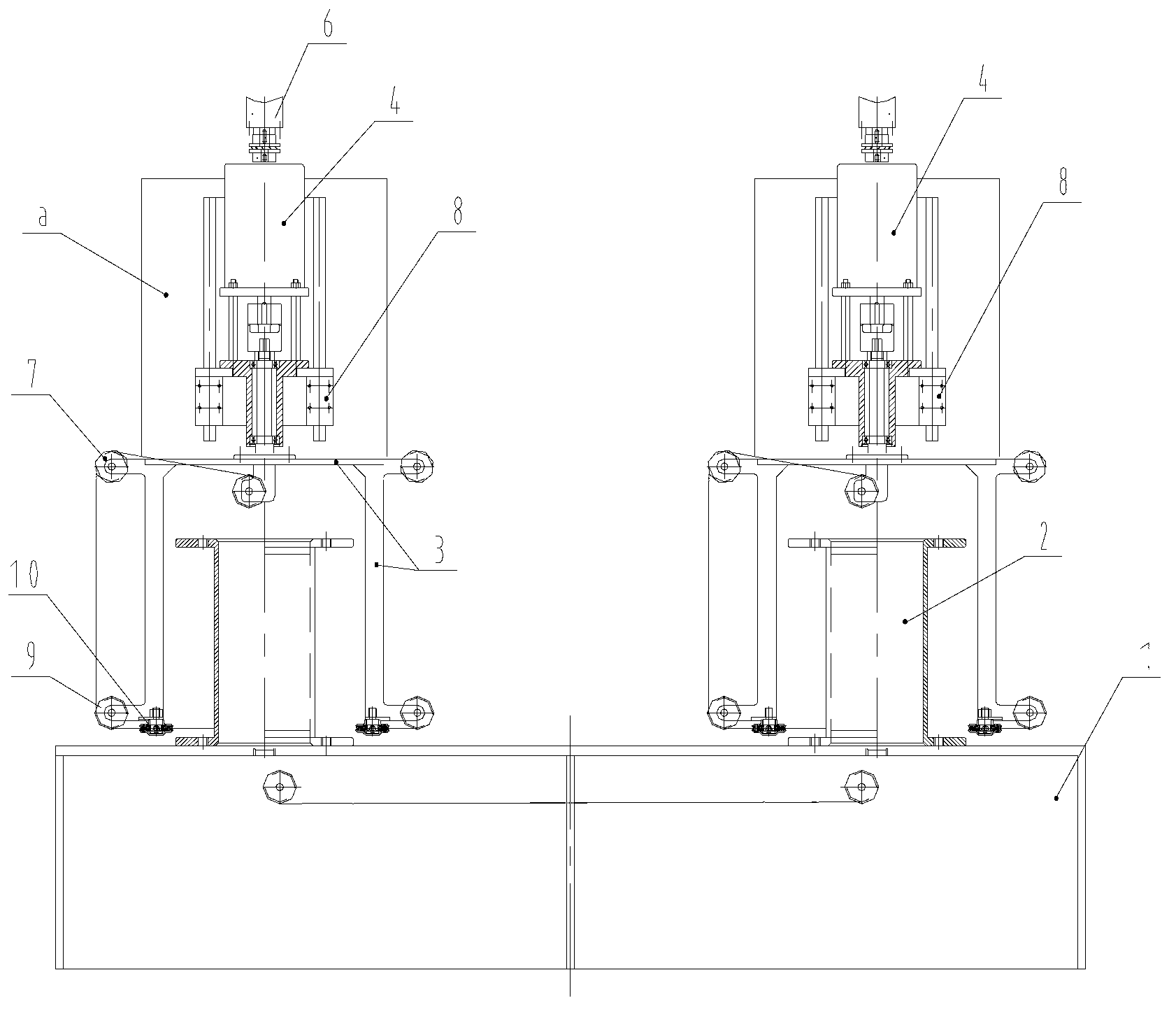

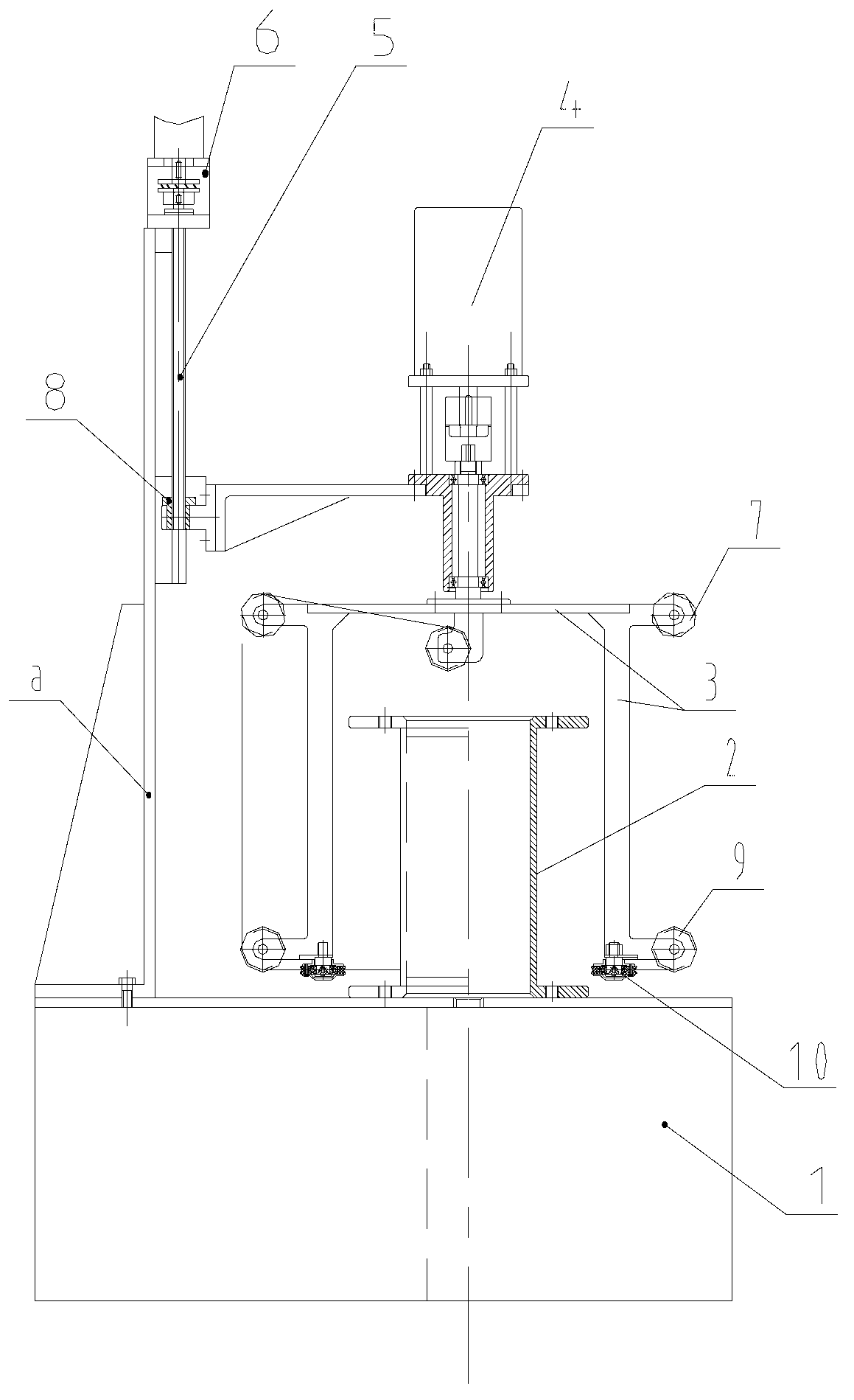

Portable steel tube inner wall de-rusting vehicle

The invention discloses a portable steel tube inner wall de-rusting vehicle. Steel wire wheels and polishing wheels are arranged on motor shaft brackets of a de-rusting motor of a vehicle body through a frame, so that the de-rusting motor can rotate to drive the steel wire wheels and the polishing wheels to de-rust and polish the interior of a steel tube; springs in limiting grooves perform tensioning on limiting supporting beams, so that wheels on the limiting supporting beams are attached to the inner wall of the steel tube; meanwhile, the limiting supporting beams are connected to the frame and a sleeve through connecting rods, and the sleeve is adjusted by an adjusting nut, so that the distance between the limiting supporting beams and a central shaft is adjusted, and the vehicle body can adapt to more steel tubes with different inner diameters. Thus, the de-dusting vehicle can effectively remove rust and dust on the inner wall of the steel tube, does not raise the dust, and is good in using effect; the inner wall of the steel tube is cleanly de-rusted, and the treated inner wall of the steel tube is brighter; meanwhile, the dust is prevented from floating in a using process, and the environmental pollution is avoided.

Owner:河北德瑞环保设备有限公司

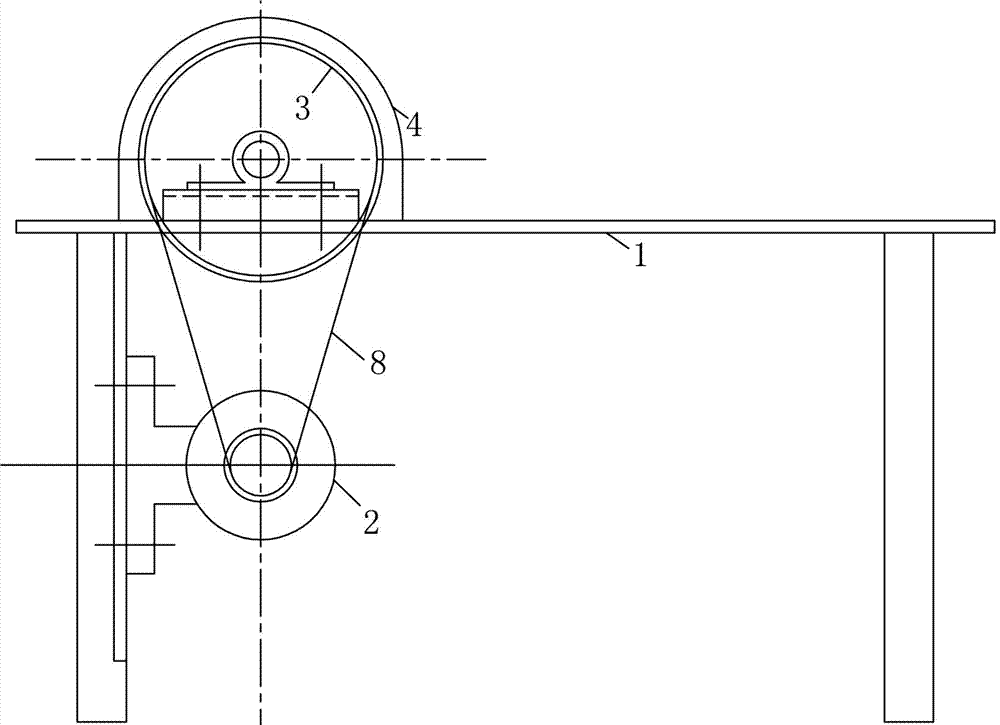

Steel bar derusting machine

InactiveCN103358214AImprove work efficiencyEasy to replaceGrinding machinesWire wheelElectric machinery

The invention discloses a steel bar derusting machine which comprises a working platform, wherein a motor is mounted on a support leg of the working platform; one end of a belt is matched with the motor; the other end of the belt is mounted on a belt pulley; the belt pulley is connected with a rotating shaft; the rotating shaft is matched with a front end bearing and a rear end bearing; the front end bearing is mounted in a front fixing bracket; the rear end bearing is mounted in a rear fixing bracket; a dismountable wire wheel is connected with the rotating shaft; a feeding port is formed in the working platform; and a protective cover is mounted on the belt pulley. According to the steel bar derusting machine, the motor is used to drive the wire wheel to rotate by the rotating shaft to accomplish steel bar derusting, and the derusting quality can reach the standard once, so that the operation efficiency of the steel bar derusting machine is far higher than that of the traditional manual derusting, and the dismountable wire wheel is adopted, so that replacement is facilitated.

Owner:CHINA NUCLEAR IND 22ND CONSTR

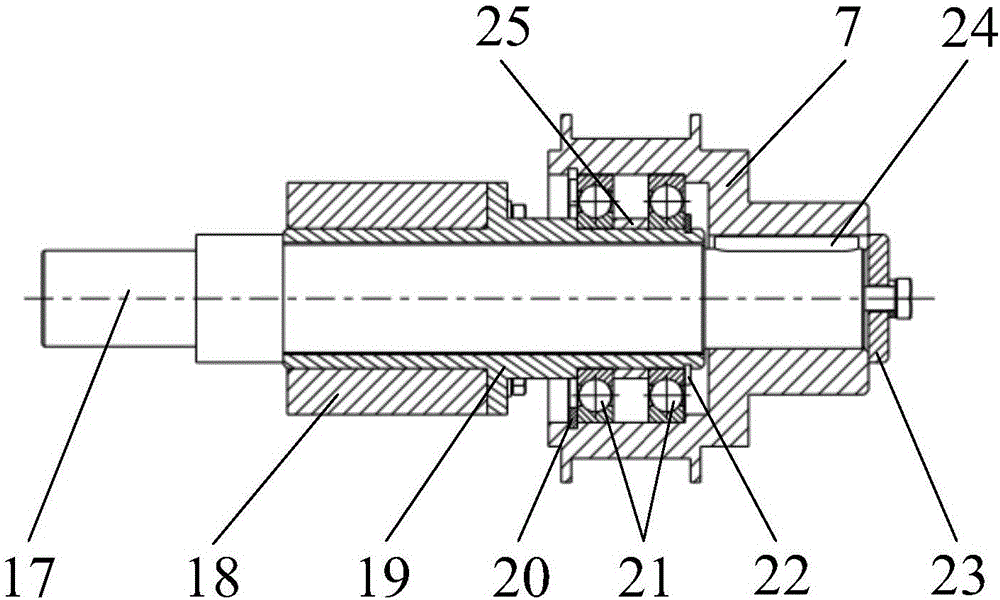

Double-centre wire rewinding machine for wire drawing machine

The invention discloses a double-centre wire rewinding machine for a wire drawing machine. The double-centre wire rewinding machine comprises a machine frame, a wire wheel subassembly, a tension mechanism, a meter wire metering subassembly, a wire arranging mechanism, a spool wire rewinding mechanism and a wire rewinding motor, wherein the wire wheel subassembly, the tension mechanism, the meter wire metering subassembly, the wire arranging mechanism, the spool wire rewinding mechanism and the wire rewinding motor are arranged on the machine frame. Compared with traditional wire rewinding machine, the double-centre wire rewinding machine disclosed by the invention has the advantages that the spool wire rewinding mechanism adopts the combination of two groups of contact ball bearings under opposite angles, therefore, a wire rewinding shaft can be stable in rotating along with low vibration and low noise; two spools which are respectively BS200 and NTC210 can perform wire rewinding without replacing the centers; the lifting mechanisms for loading and unloading a spool adopt chain type transmission in a lifting way, and the operation is convenient to carry out; ball screws can be driven through the wire arranging mechanism by utilizing a servo motor, thus, the wires can be precisely layered and flatly arranged; and the tension mechanism adjusts the tension through a balancing weight and an adjusting spring, and the tension mechanism is simple in structure and convenient to adjust. The double-centre wire rewinding machine disclosed by the invention is compact in structure, stable in running, convenient to operate, safe and reliable, and low in noise.

Owner:江苏泰隆机电科技有限公司

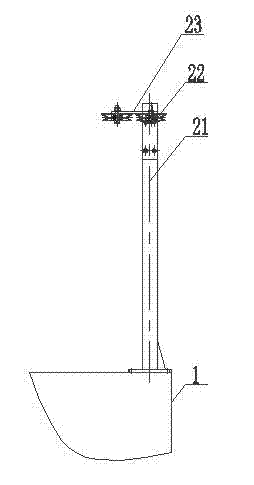

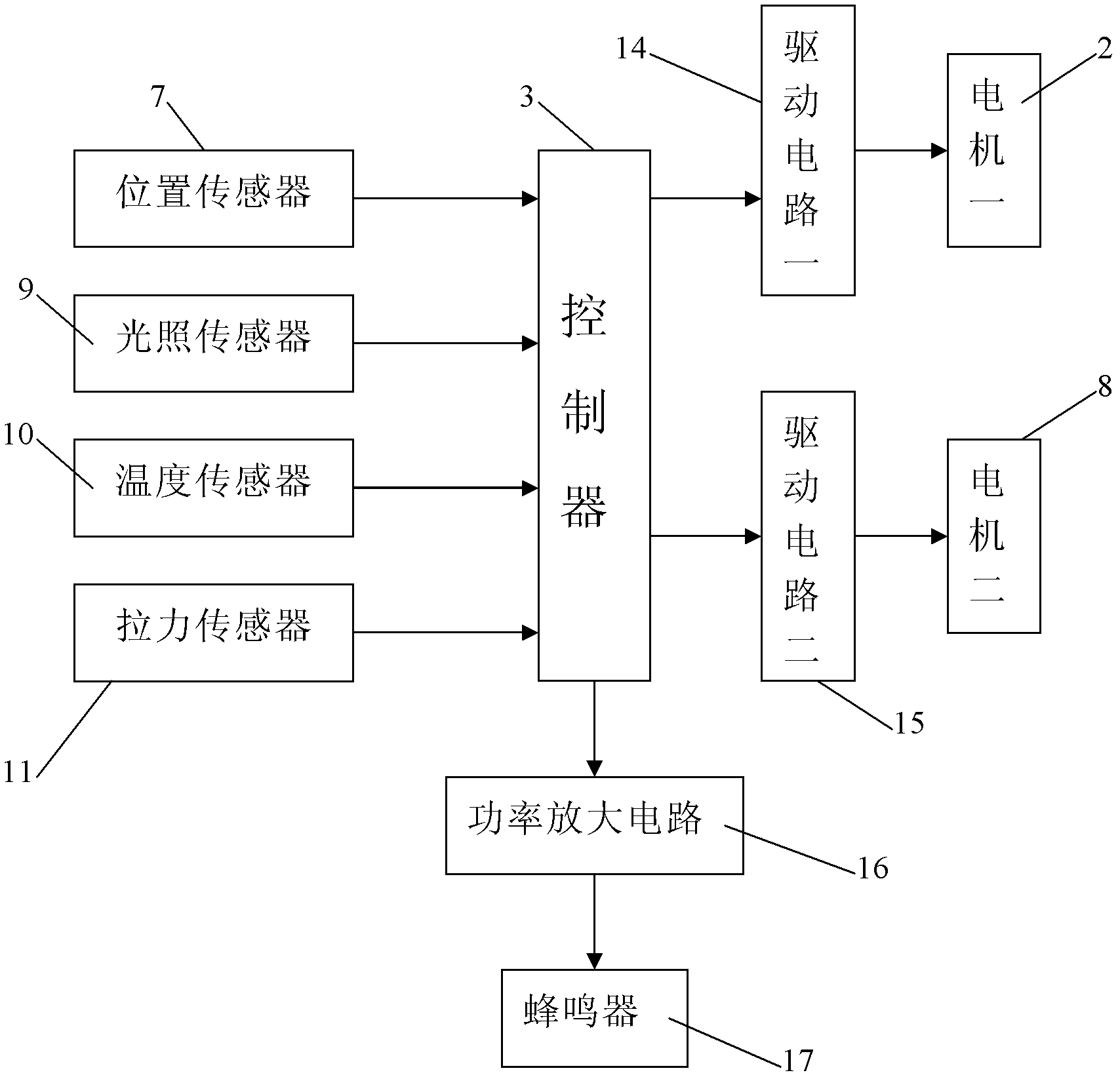

Intelligent clothes airing device

InactiveCN103173967ASimple structureReasonable designOther drying apparatusTextiles and paperWire wheelControl system

The invention discloses an intelligent clothes airing device. The intelligent clothes airing device comprises a stand column, a cross bar, a clothes airing rack and a control system. A first electrical machine is arranged on the stand column, a first pulley and a second pulley are arranged above the cross bar, and a steel wire rope is arranged between the first electrical machine and the clothes airing rack. A wire wheel is arranged at an output shaft of the first electrical machine, and one end of the steel wire rope is wound on the wire wheel. The other end of the steel wire rope winds though the first pulley, the clothes airing rack and the second pulley in sequence to be fixed on the wire wheel. The clothes airing rack comprises a cylindrical rack body and an annular clothes rack which is arranged on the cylindrical rack body, the annular clothes rack is arranged on the cylindrical rack body through a connecting shaft, and the upper end of the cylindrical rack body is connected with a second electrical machine. The control system comprises a tension sensor, a temperature sensor, a light sensor, a position sensor and a controller. The intelligent clothes airing device has a rain-proof function and a sun-proof function, the intelligent clothes airing device can further achieve automatic rotation when clothes are aired and automatic taking back after the clothes are dry, and the problem that damage of the clothes caused by the clothes not taken back for a long time is effectively avoided.

Owner:SHAANXI YATAI ELECTRIC APPLIANCE

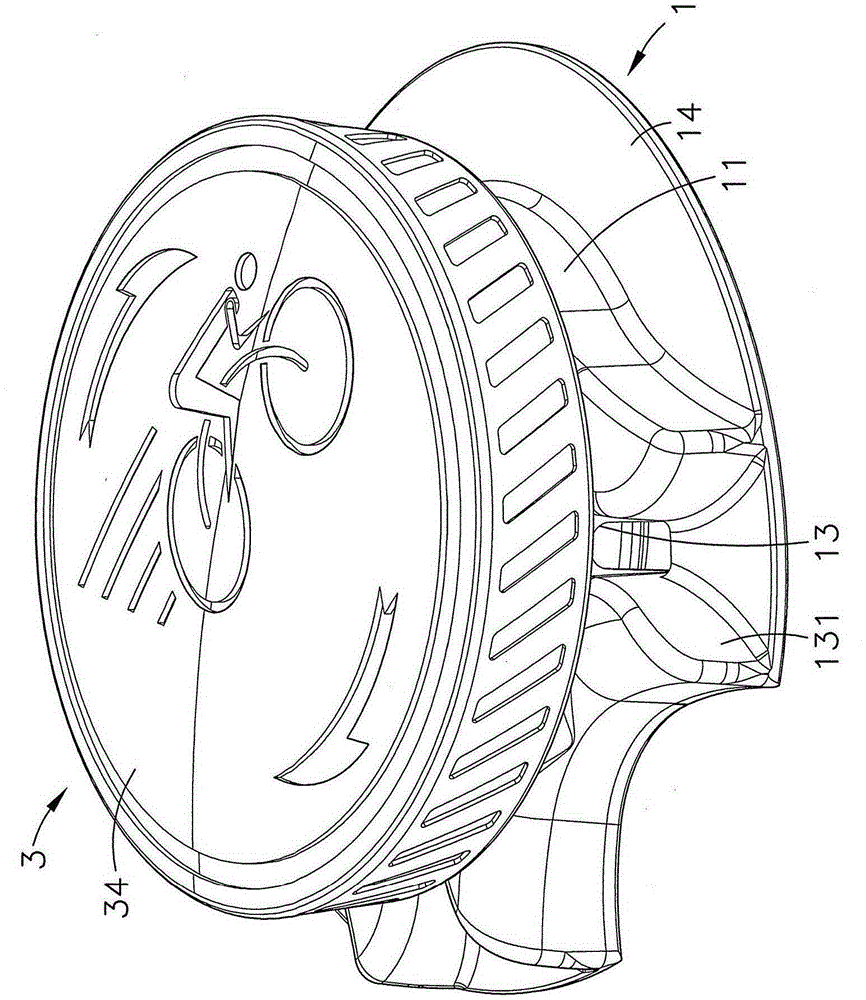

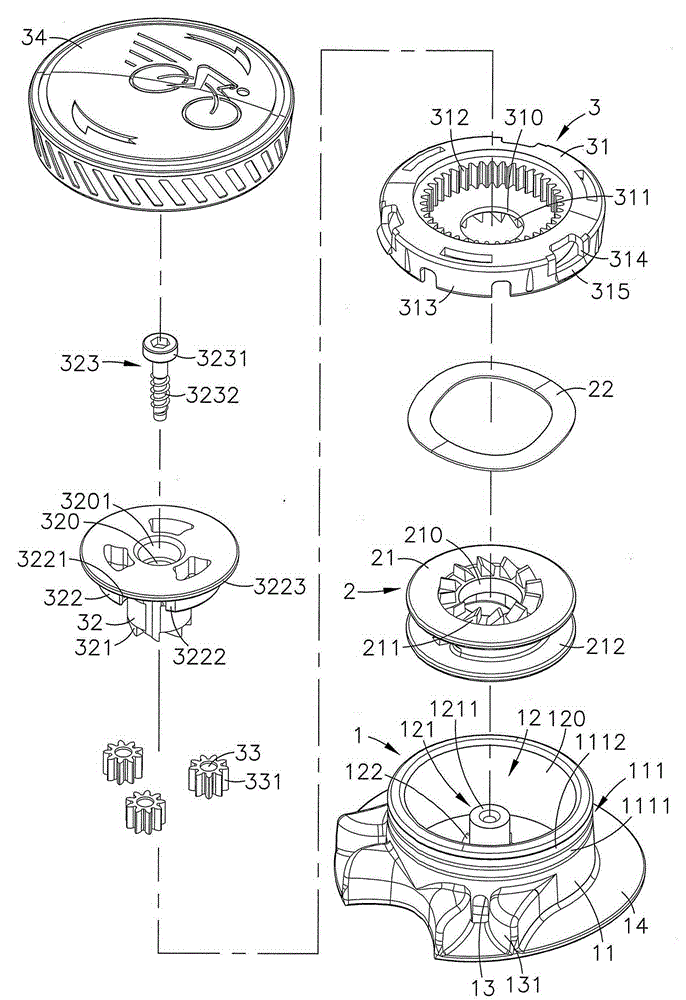

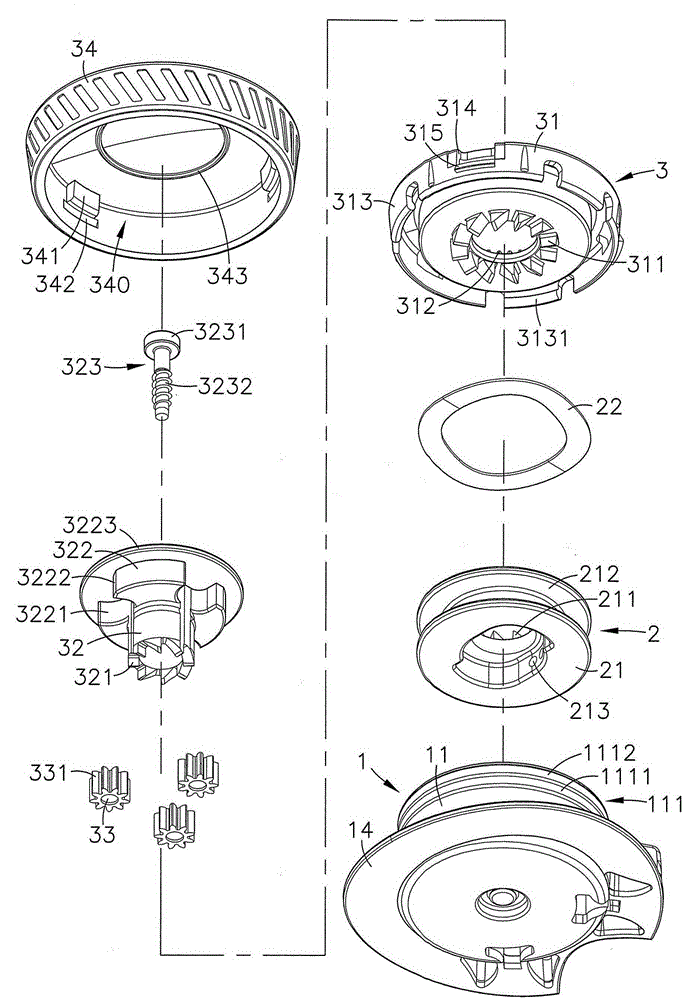

Cord adjustment buckle

The invention discloses a cord adjustment buckle. A wire wheel is contained in a containing groove in the substrate; a plurality of first clamping teeth are arranged on the circumference of a shaft portion of a bottom portion of a containing groove in an annular manner; a top of a wire wheel main body which is pivoted on the shaft portion is provided with a plurality of second clamping teeth which are arranged in an annular manner; a rope is arranged in a coiling groove on the circumference of the main body; a shaft column which is connected to the shaft portion passes through a connection seat of a one-way clutch mechanism; a plurality of third clamping teeth are meshed with the second clamping teeth on the bottom of the connection seat; a plurality of fourth clamping teeth which are meshed on the first clamping teeth are arranged on the bottom of the shaft column; a plurality of brake portions on the circumference of the shaft colum accomodate a planetary gear meshed with the top of the connection seat; a rotation plate covers the outside of the connection seat, such that the rotation plate drives the connection seat to rotate and the wire wheel is in linkage to retract and tie up a role, or the rotation plate is lifted and the connection seat is seperated from the wire sheel in order to unlock and pull out the rope /

Owner:NIFCO TAIWAN

Finger joint for robot clever hand finger

InactiveCN101100063AReduce maintenance difficultyReduce maintenance costsJointsGripping headsHysteresisRobot hand

The present invention relates to finger joint of robot, and is especially finger joint of skillful robot hand. The present invention has one motor fixed to the inner wall of the first finger knuckle casing, the first synchronous pulley fixed onto the output shaft of the motor, the second synchronous pulley fixed onto the first joint shaft, one harmonic reducer mounted onto the first joint shaft, one driving member mounted onto the harmonic reducer, one 1D finger tip torque sensor mounted onto the second joint shaft, one first joint wire wheel connected to the inner wall of the first finger knuckle casing, and one second joint wire wheel connected to the 1D finger tip torque sensor. The finger joint of skillful robot hand has the advantages of high integration level, high reliability, high position accuracy and less hysteresis.

Owner:HARBIN INST OF TECH

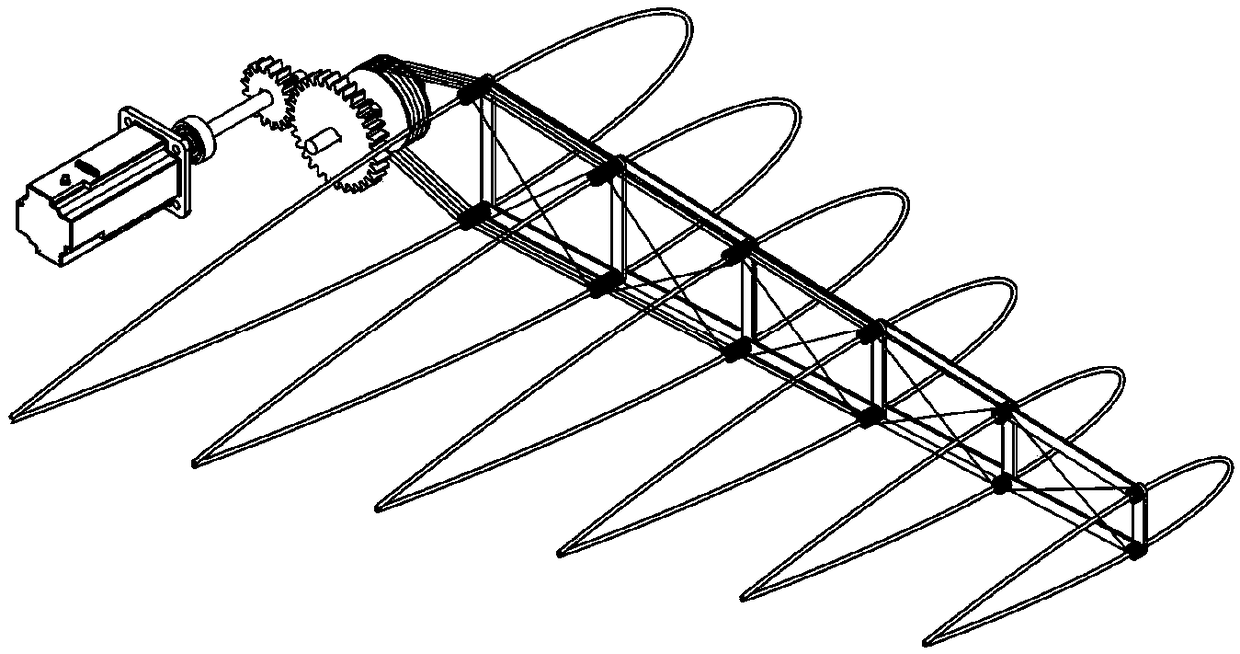

Underwater bionic flexible flapping wing propelling device

ActiveCN108622356ASimple and lightweight structureIncrease stiffnessPropulsive elements of non-rotary typeMotor driveFlapping wing

The invention discloses an underwater bionic flexible flapping wing propelling device. The device is composed of a motor, a transmission gear, a bracing wire wheel set, a fin ray mechanism, an outer framework and a skin. The outer framework is installed on pressed rods of the fin ray mechanism and covered with the skin. The fin ray mechanism is composed of the multiple pressed rods and inhaul cables to flap and is high in rigidity and capable of transmitting large power and bringing the performance of materials into full play. The structure of the flexible flapping wing propelling device is simple and light and quick and convenient to use, and the motor drives the transmission gear through a coupling to rotate. The moment is transmitted to the bracing wire wheel set through a reduction gear, the bracing wire wheel set rotates to pull the multiple inhaul cables, so that the fin ray mechanism is pulled to swing up and down, the outer framework fixed to the fin ray mechanism and the skincovering the outer framework move and deform along with the swing of fin rays, and streams are pushed to generate stable periodical thrust. The flexible flapping wing propelling device has the beneficial effects of being simple in control, large in deformation range, small in noise and high in stability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

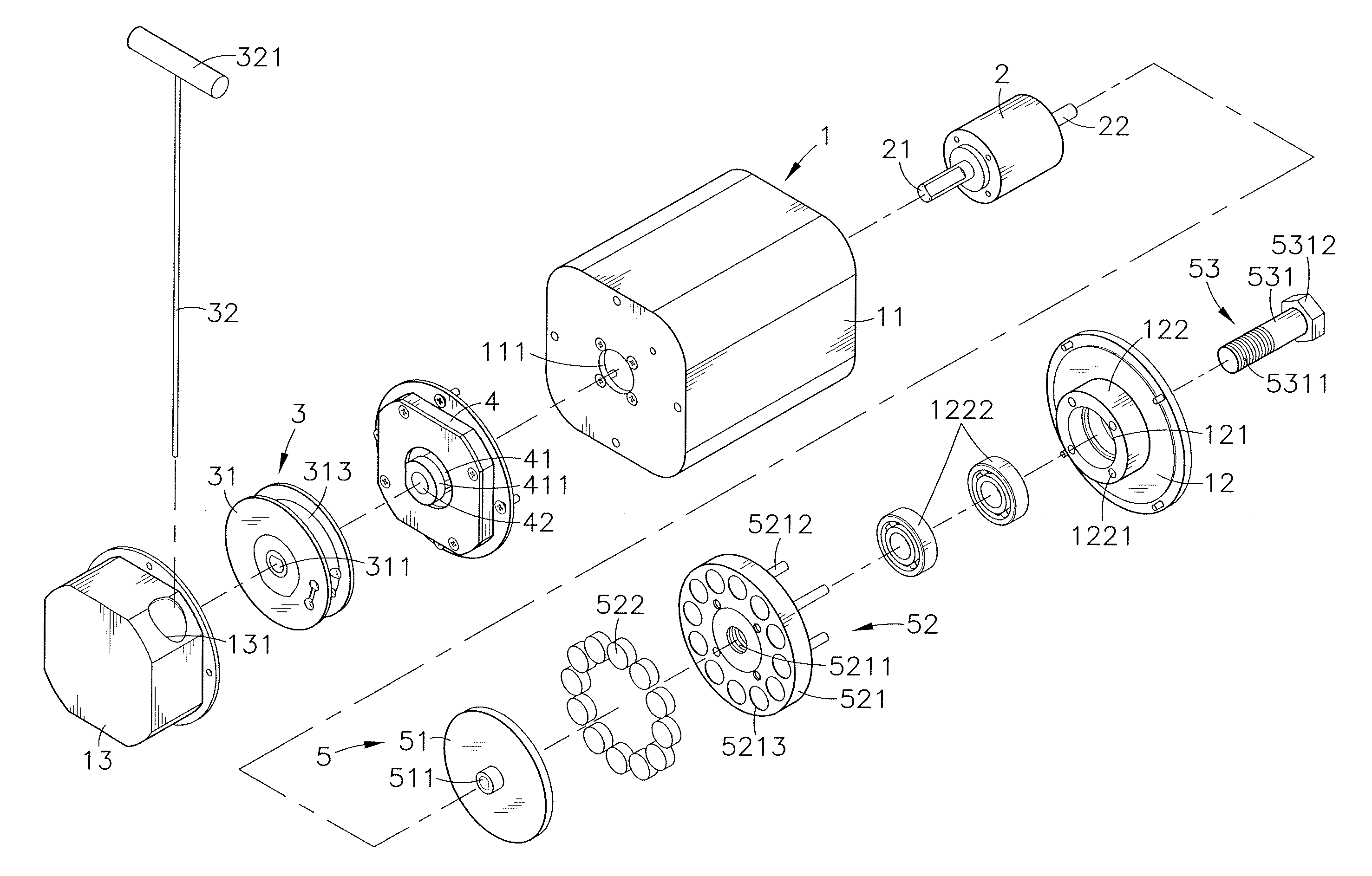

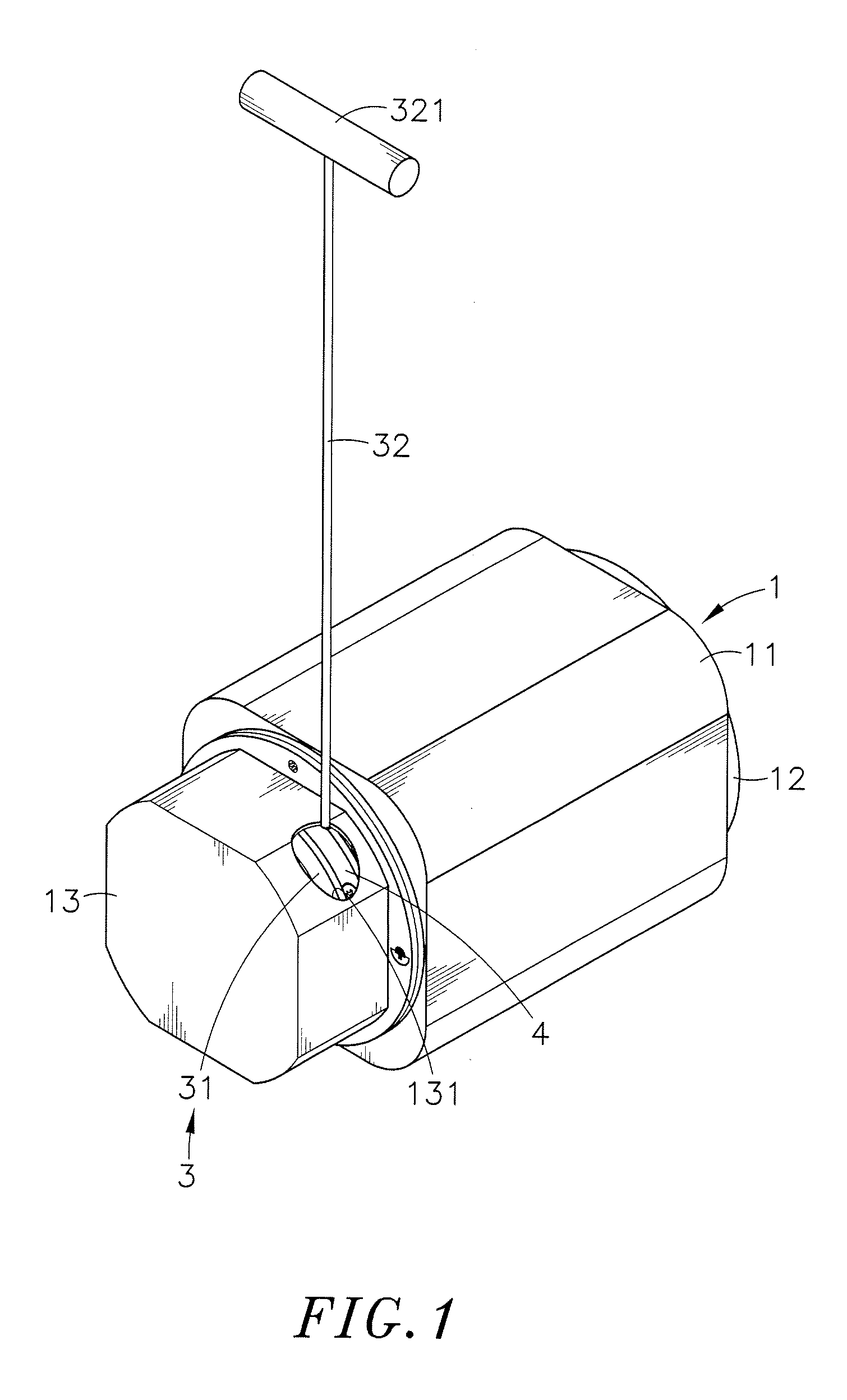

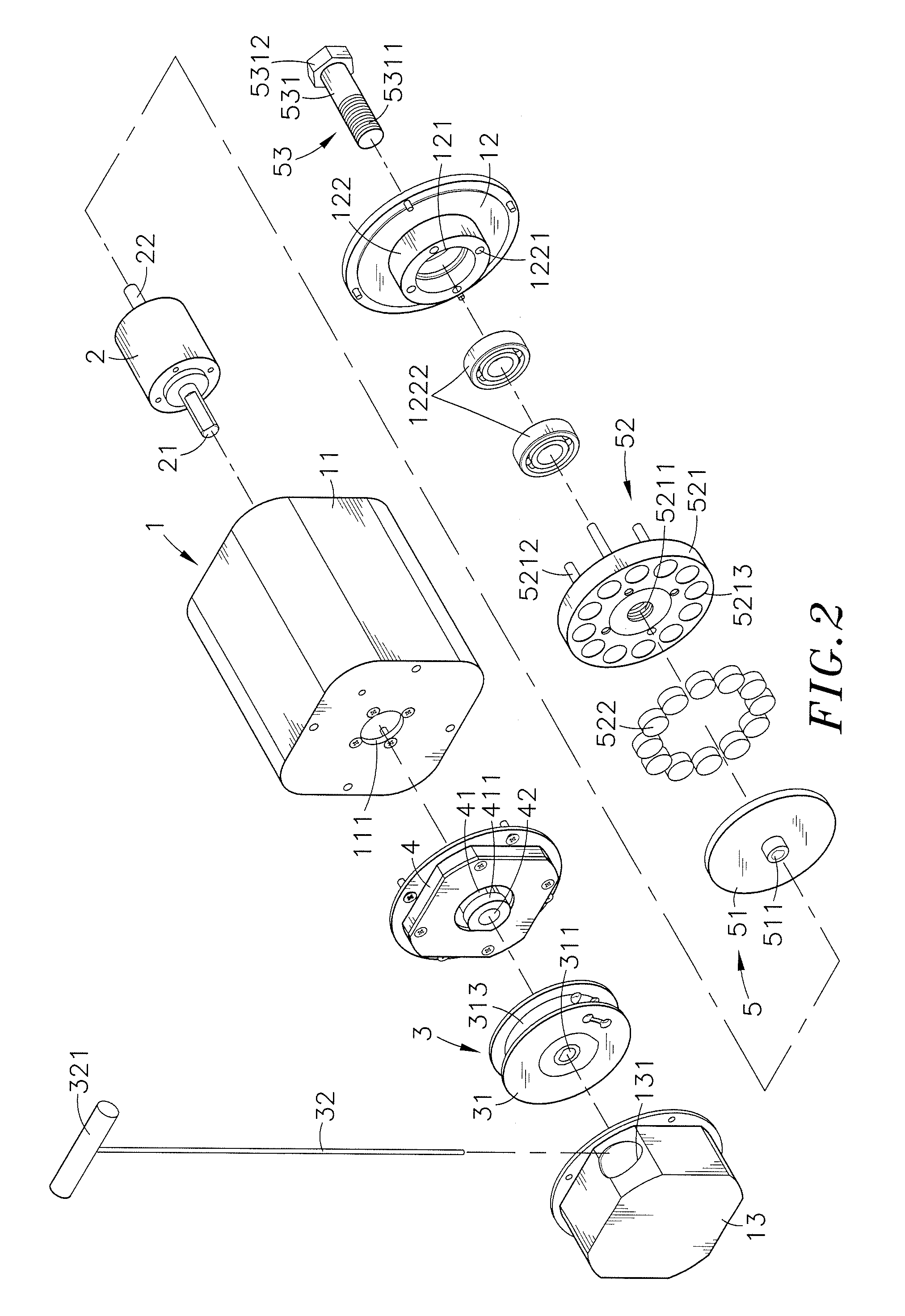

Damping device

InactiveUS20170014661A1Improve life-timeImprove portabilityFrictional force resistorsMovement coordination devicesEngineeringElectrical and Electronics engineering

A damping device includes a casing structure, a retarding mechanism, a driving mechanism, a restoring mechanism and a resistance mechanism. An accommodating space is formed in the casing structure to accommodate the retarding mechanism, and a through hole and a hollow-out hole are formed at wall surfaces of two opposite sides of the accommodating space respectively. The retarding mechanism has a main shaft passed through out of the through hole, and a retarding shaft acting simultaneously with the main shaft. The driving mechanism has a wire wheel fastened on the main shaft. The restoring mechanism has a restoring wheel fastened on the wire wheel. The resistance mechanism has a metal element fastened on the retarding shaft, and a magnetic part is disposed between the metal element and the hollow-out hole, and an interval is formed between the magnetic part and the metal element.

Owner:GLOBAL WIN TECH CO LTD

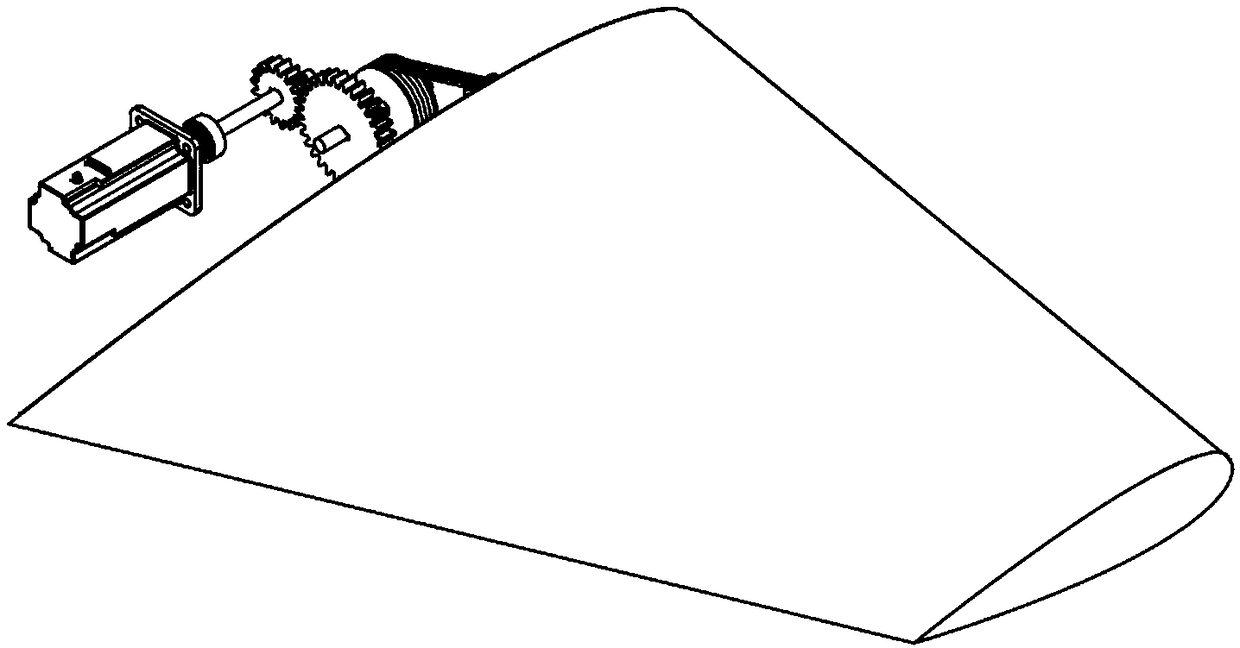

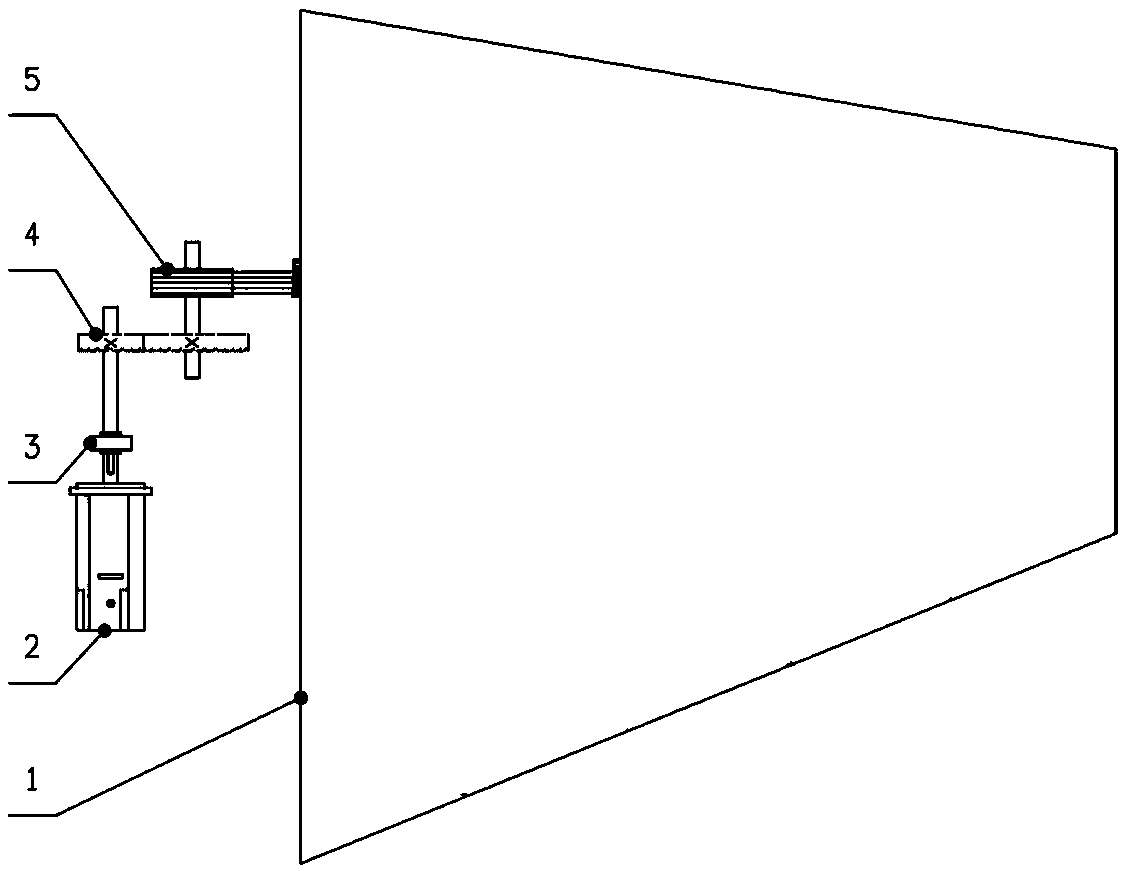

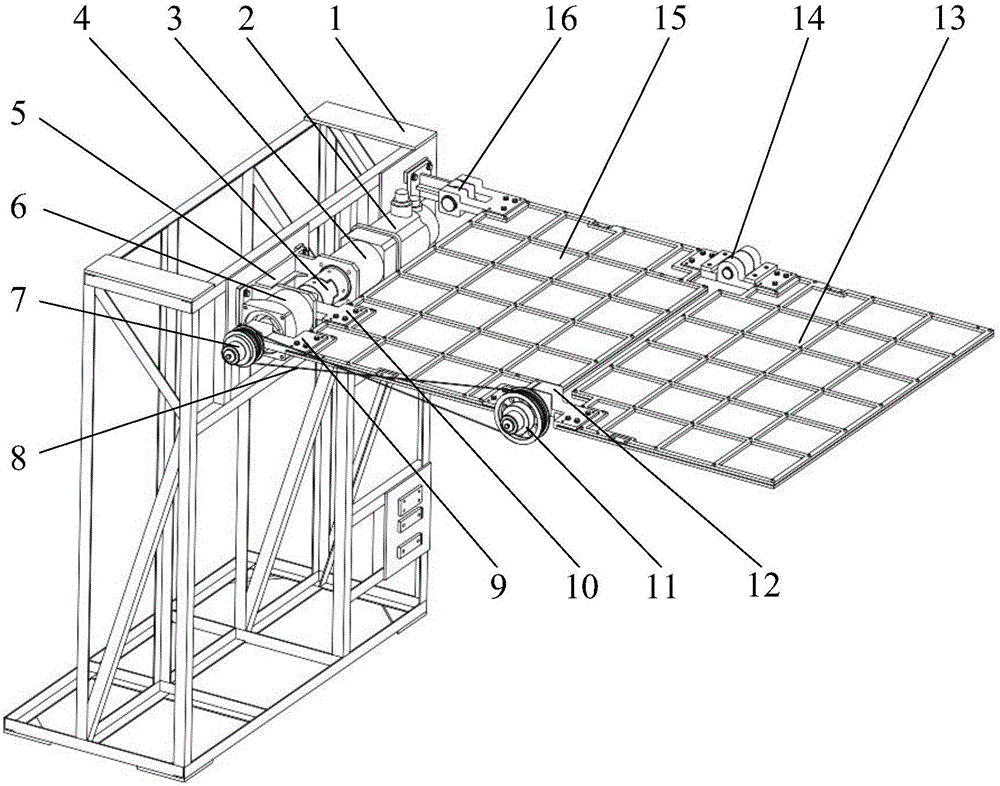

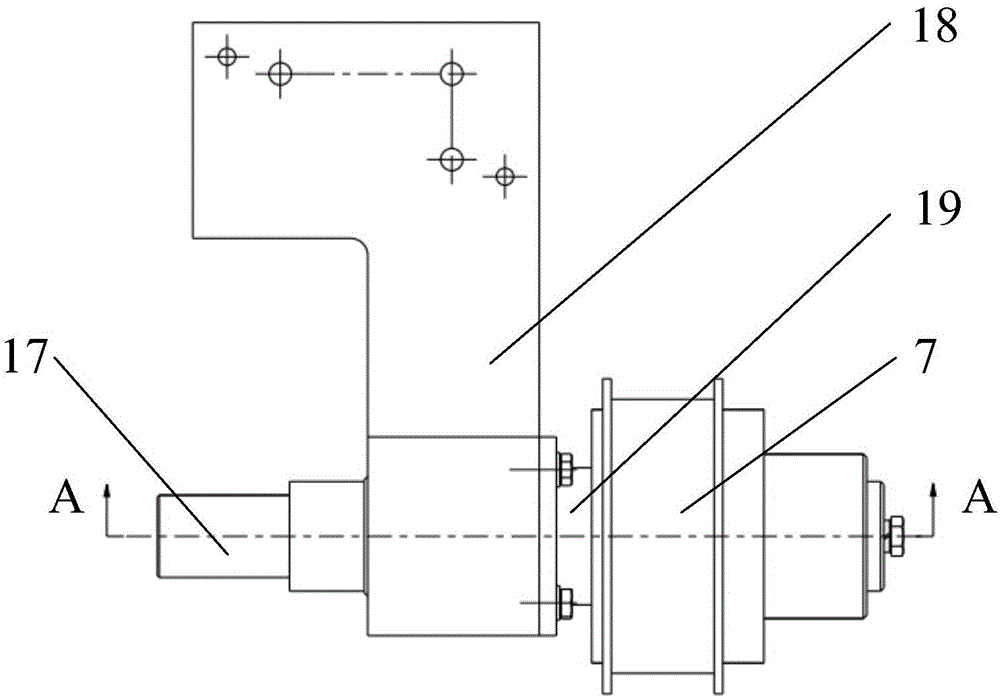

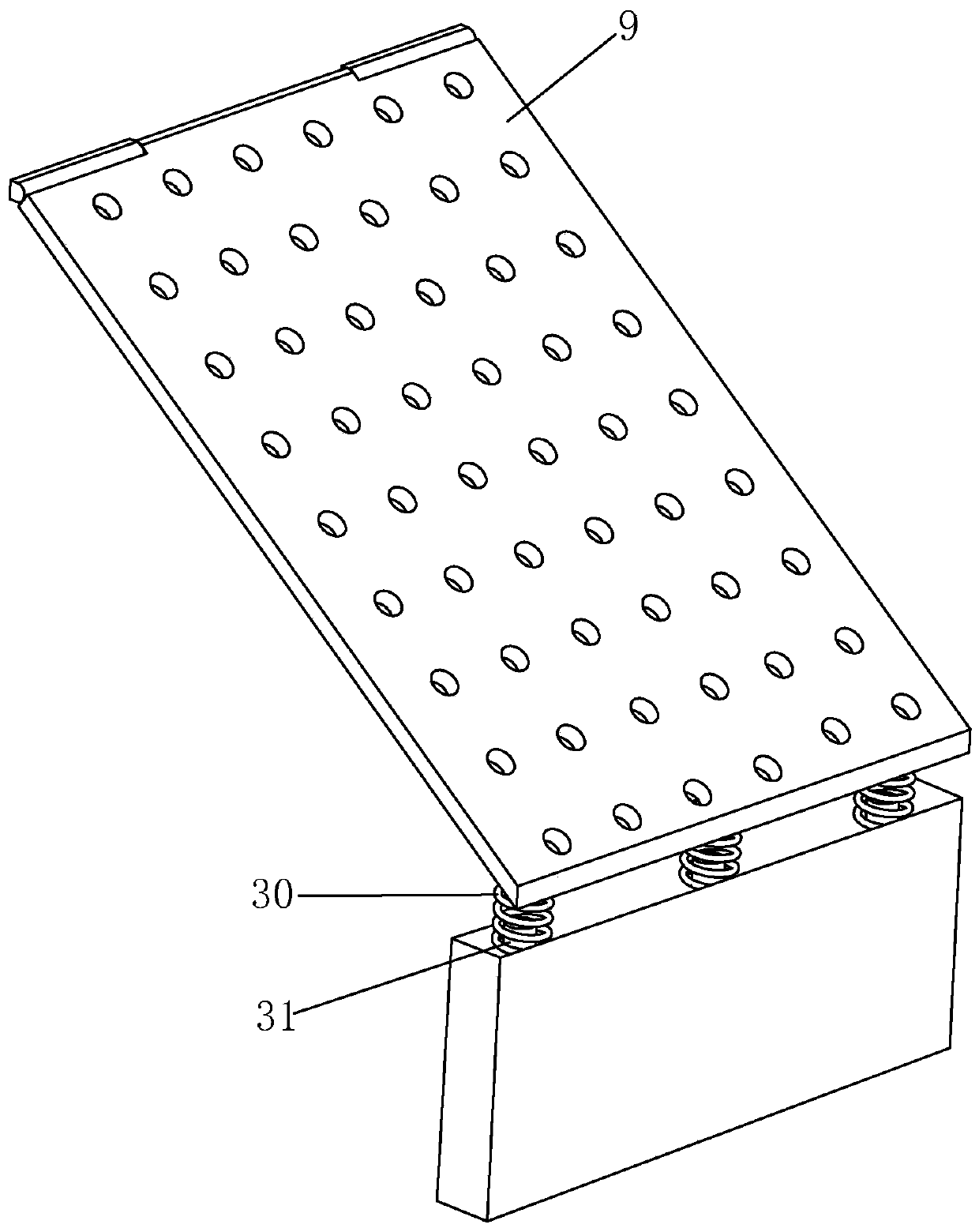

Single driving multi-stage synchronous stretch-retract repeatable solar panel unfolding mechanism

ActiveCN106428638ASimple structureLow costCosmonautic power supply systemsPhotovoltaicsFailure rateDrive shaft

Disclosed is a single driving multi-stage synchronous stretch-retract repeatable solar panel unfolding mechanism. The solar panel unfolding mechanism comprises a machine frame, a motor, a speed reducer, a speed accelerator, large and small steel wire rope wheel set components, steel wire ropes and two-stage solar panels, wherein the machine frame is fixed on the ground, the motor, the speed reducer, a coupling and the speed accelerator are in series connection, the speed reducer and the speed accelerator are fixed on the machine frame, the small steel wire rope wheel set component is fixed on one end of one side of a first stage solar panel, and the other end of the same side of the first stage solar panel is connected with the machine frame through a first hinge; two ends of the other side of the first solar panel are connected with the second solar panel through a second hinge and a third hinge respectively; the large steel wire rope wheel set component is arranged between the two-stage solar panels and the steel wire ropes are connected with the large steel wire wheel set component and the small steel wire rope wheel set component. The single driving multi-stage synchronous stretch-retract repeatable solar panel unfolding mechanism has the advantages of being simple in structure, low in cost, strong in reliability, low in failure rate and long in service life; meanwhile, the mechanism is capable of effectively unloading a radial tensile force exerted on a driving shaft during a driving process, can prevent the driving shaft from bending or deforming, thus increasing transmission precision.

Owner:YANSHAN UNIV

Electric automatic take-up device

The invention relates to an electric automatic take-up device and belongs to the field of electric installation auxiliary devices. The electric automatic take-up device comprises a base plate, wherein a motor and a speed reducer are fixed above the base plate; the motor is connected with the speed reducer; the output end of the speed reducer is connected with a rotary shaft and a wire winding device and a supporting seat are arranged at the other end of the rotary shaft; the wire winding device is mounted on the rotary shaft; the rotary shaft is mounted on the supporting seat; the supporting seat is fixed on the base plate; a cable sorting device is arranged on the other side of the wire winding device; and the cable sorting device is fixedly arranged on the base plate. The electric automatic take-up device can be used for automatically winding wires and a wound wire wheel can be taken off and is convenient to move and store; furthermore, the cable sorting device is additionally arranged and can be used for sorting cables, so that the cable skins can be prevented from damaging in a take-up process.

Owner:STATE GRID CORP OF CHINA +1

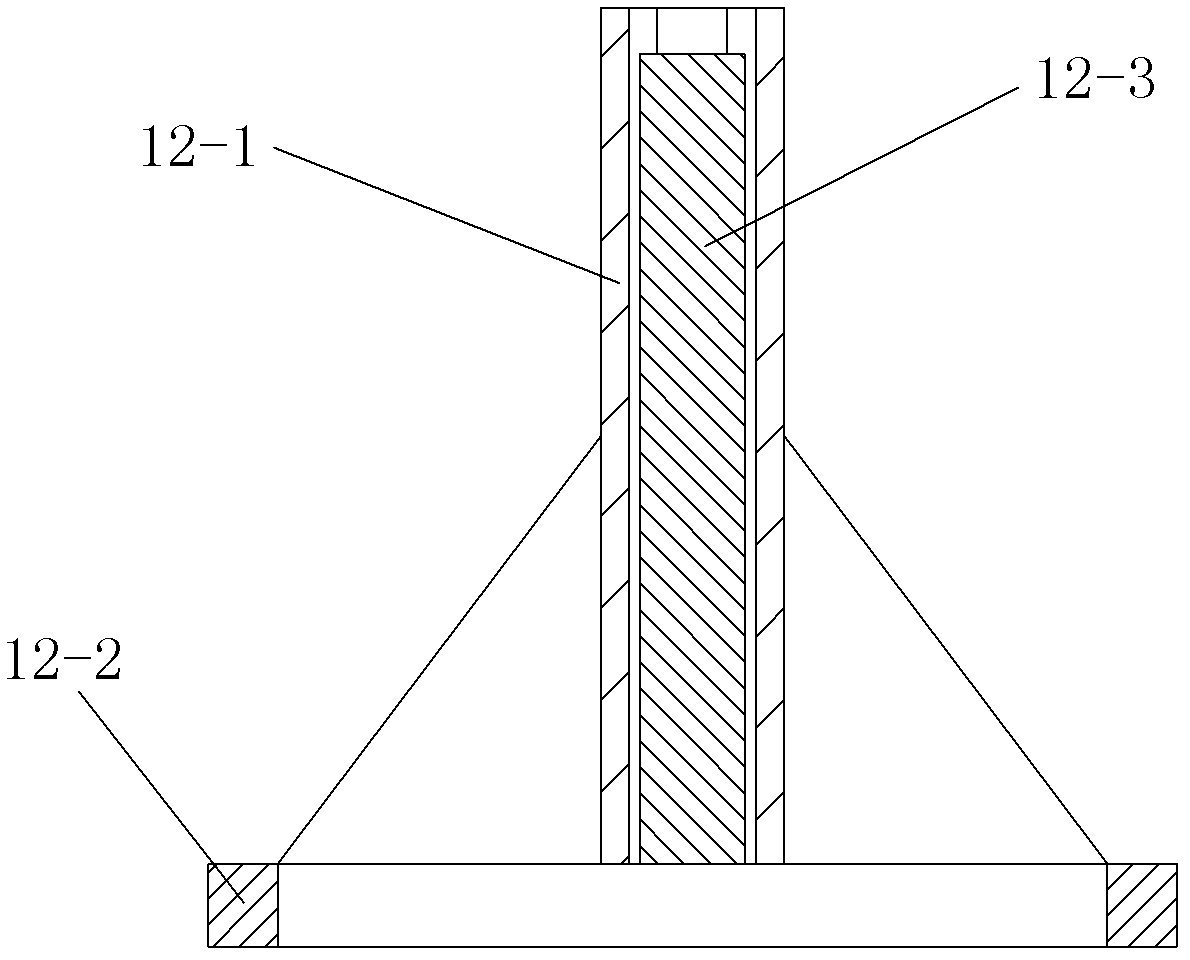

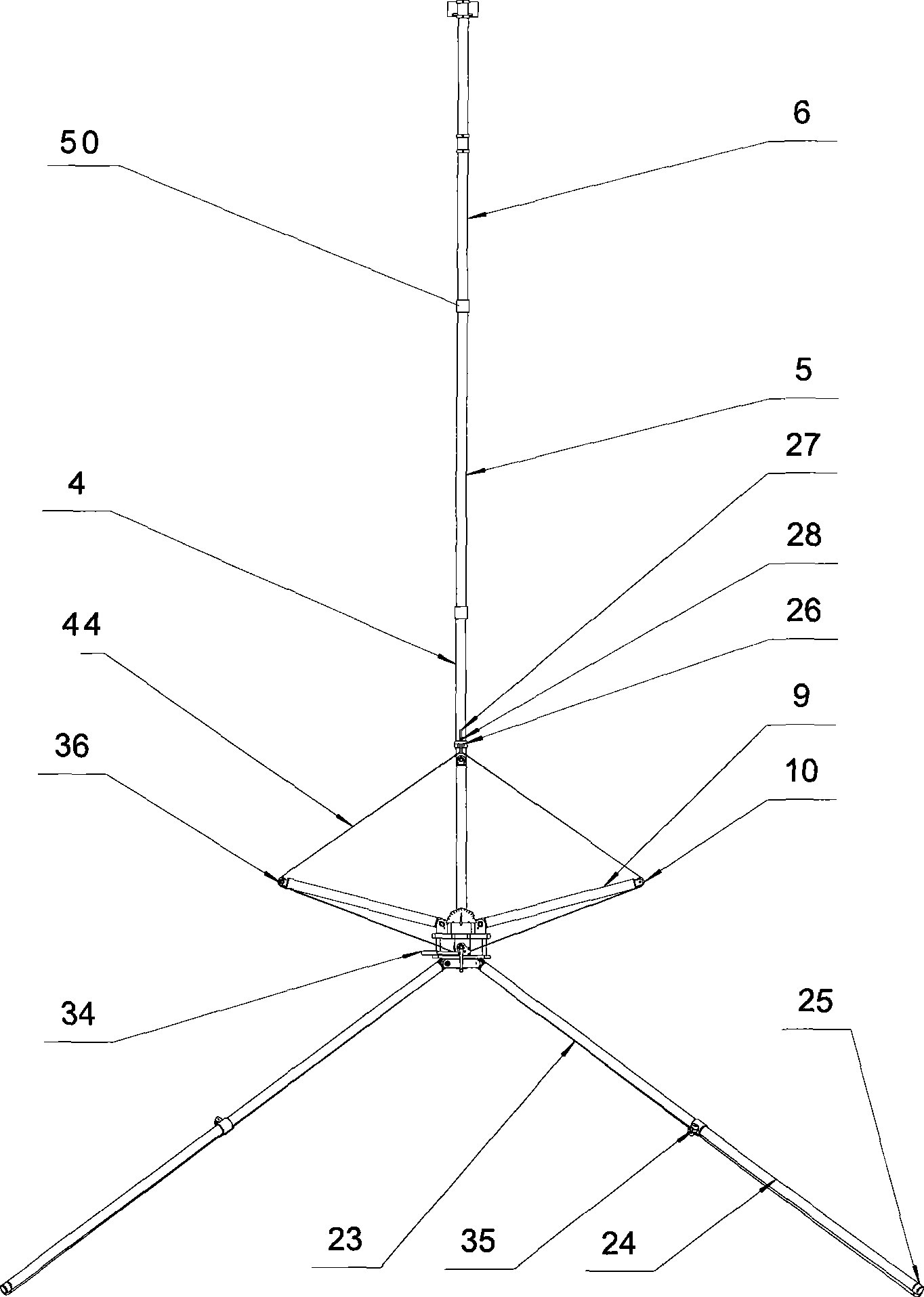

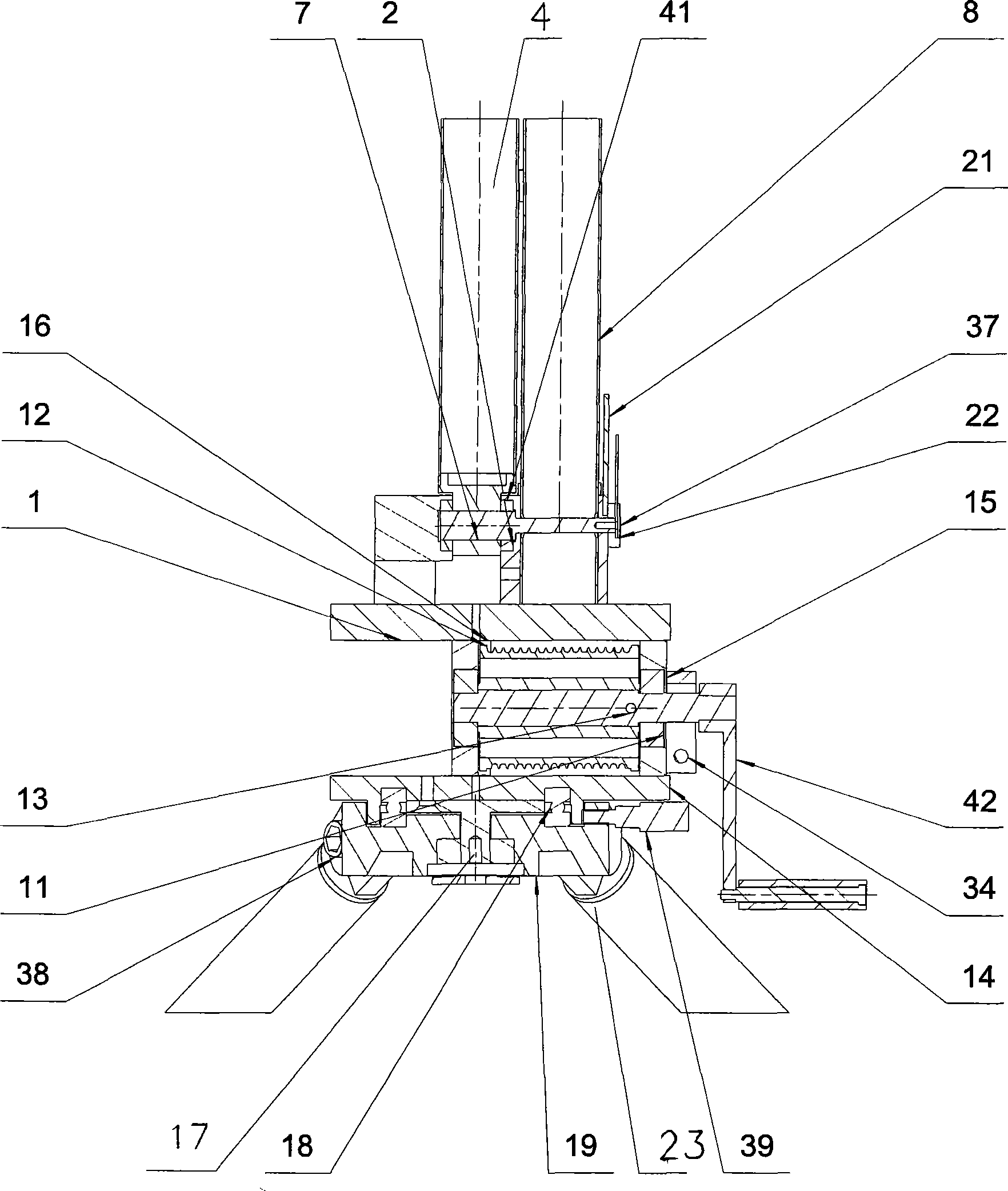

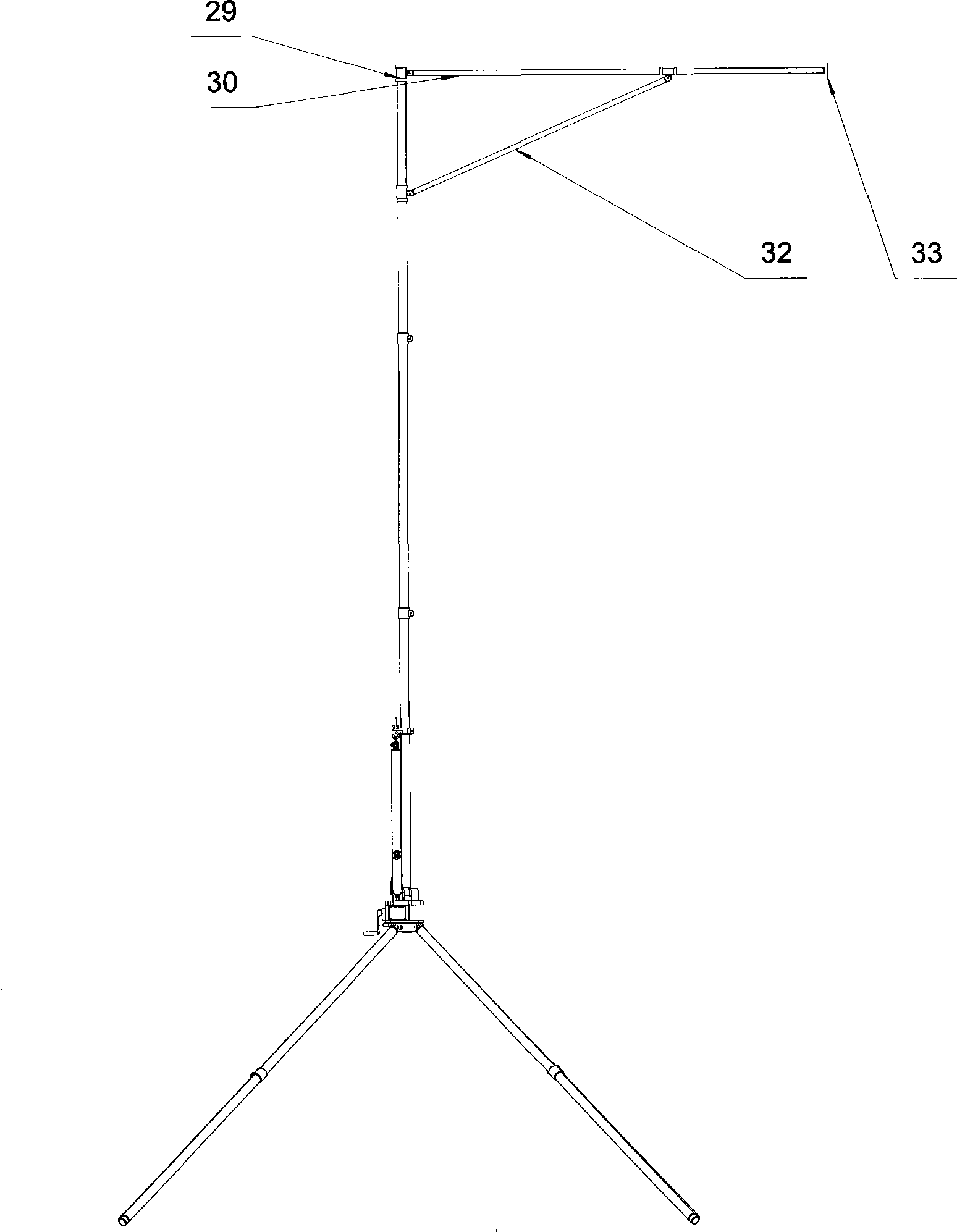

Portable manual multi-angle observation frame

The invention discloses a potable manual multi-angle observing scaffold, which mainly comprises a tripod, a rotary base, an inclination angle adjusting device, and a main rod and a cross rod, wherein the tripod is fixed at the lower end of the rotary base, the upper end of rotary base is provided and fixed with a wire wheel of which one end has a crank and provided with a center shaft, the bottom of the main rod is fixed with the center shaft, one end of each of two shorter side auxiliary tubes is fixed on the upper end of the rotary base, the other ends of the two shorter side auxiliary tubes separate at a certain angle, the end parts of the other ends of the two side auxiliary tubes are fixed with wheels respectively, two ends of a stainless steel wire rope are both fixed at a proper position a the main rod after the stainless steel wire rope goes around two wheels and the wire wheel, one end of the cross rod is fixed on the top of the main rod, and the other end of the cross rod is provided with a fixed plate for mounting a sensor probe. The observing scaffold can solve the technical problems of the major part of the prior multi-angle measurement system such as high cost, low portability, signal measured height and serious shadow interference of the apparatus in a hotspot direction.

Owner:BEIJING NORMAL UNIVERSITY

High-speed winding machine

The invention discloses a high-speed winding machine. An engine base is provided with a wire wheel, a rotary arm, a hollow shaft servo motor, a cycloid screw rod and a cycloid motor; a center shaft of the wire wheel faces to the rotary shaft center of the engine base, and is fixed on the rotary shaft center of the engine base; the wire wheel and the hollow shaft servo motor are positioned at the same axis; the rotary arm is provided with a guide wheel; a wire on the wire wheel moves along an arm body of the rotary arm though a guide wheel on the rotary arm; the rotary arm is fixed on the lower part of the hollow shaft servo motor; the hollow shaft servo motor is connected with the cycloid motor through the cycloid screw rod; the side part of the hollow shaft servo motor is provided with a linear guide rail; and the cycloid motor and the cycloid screw rod drive the rotary arm to move up and down along the linear guide rail. Wires are released and wound by adopting the rotation mode of the rotary arm, and wire releasing and winding speed is rapid; the hollow shaft servo motor is used, wires pass through the hollow shaft; and a servo motor at the wire releasing end operates in a torsion mode, so that the tension of wires in releasing process can be regulated and kept stably.

Owner:株洲岱勒新材料有限责任公司

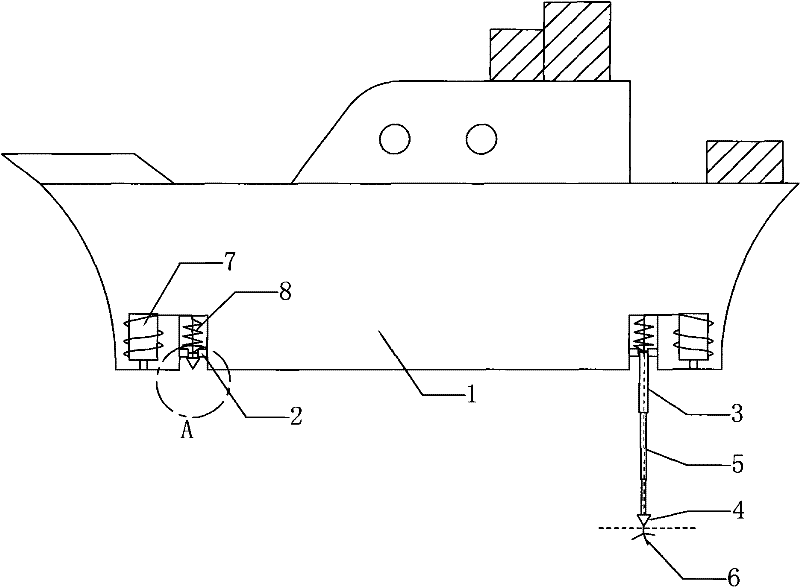

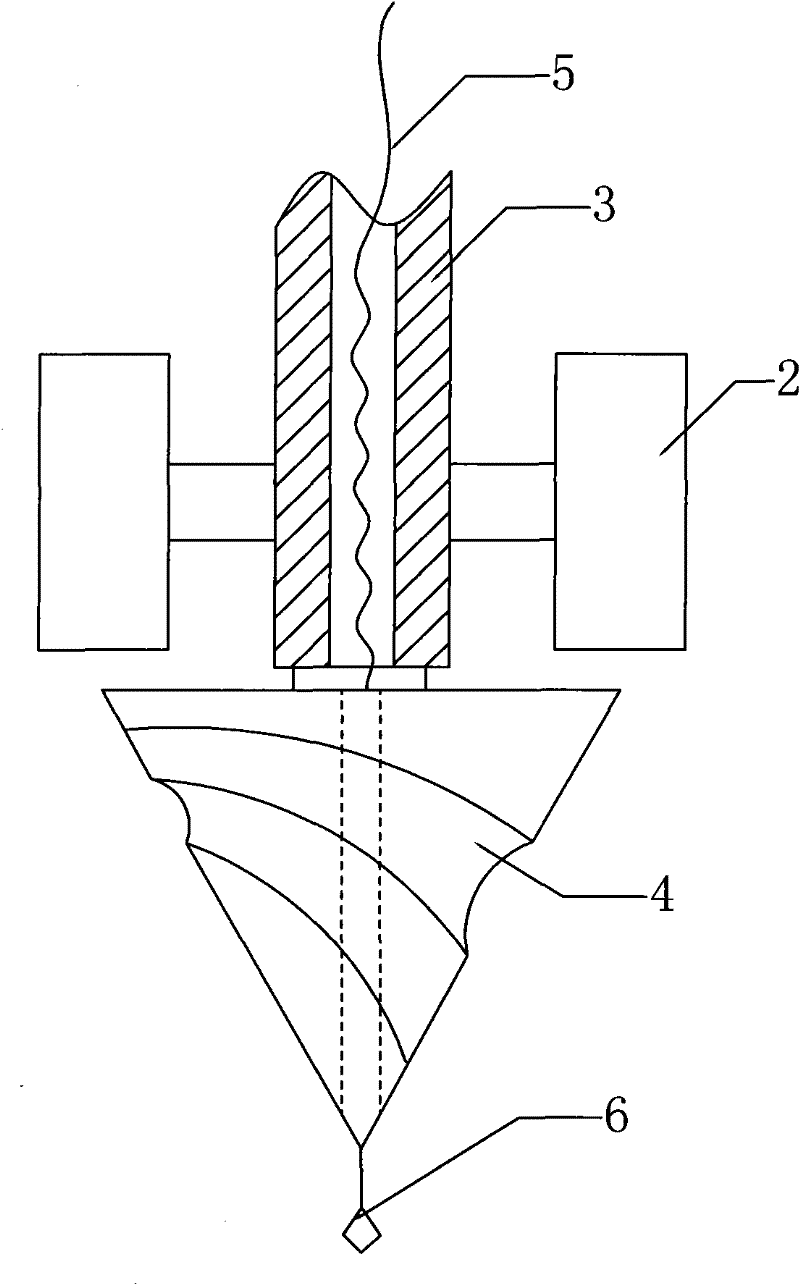

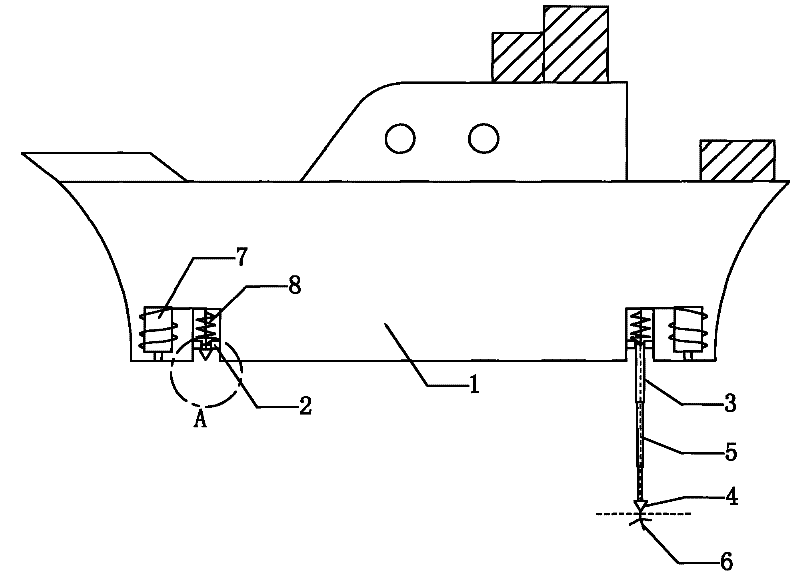

Shooting type stable wave-breaking anchor

The invention discloses an anchor, particularly a shooting type stable wave-breaking anchor. The anchor is characterized in that the bottom end of a ship body is provided with an electrically controlled launch muzzle; an electrically controlled telescopic rod is arranged in the electrically controlled launch muzzle; one end of the electrically controlled telescopic rod is fixed on the ship body; and the other end of the electrically controlled telescopic rod is movably connected with a spiral taper drilling bit; a steel wire is arranged in the electrically controlled telescopic rod; one end of the steel wire is connected with the spiral taper drilling bit; and the other end of the steel wire is wound on a steel wire wheel; and the steel wire wheel is arranged on the ship body. The shooting type stable wave-breaking anchor can be operated fast and used conveniently, makes up the defect that traditional anchor relies on barriers to apply force, so that the ship can park stably and firmly both in a deep water area and a shallow water area.

Owner:曾彬

Burr removing machine tool

InactiveCN101108466AThe processing method is simple and practicalSave human effortEdge grinding machinesWire wheelProcess efficiency

The invention belongs to a removing furr machine tool technology field, which solves the problem in the existing technology that the removing furr machine tool is not suitable for the removing burr of refined component. The removing burr machine tool comprises a removing furr tool, a work piece table and a drive device, which is characterized by the furr removing tool steel wire wheel, the steel wire wheel is connected with a drive device by a steel wire wheel axle, the steel wire wheel axle is arranged on a motherboard, the bottom of the motherboard is connected with a hydraulic pressure oil cylinder, the work piece table is an automatic work piece table. The beneficial effects are as follows: the process method is simple and practical, which can save a great deal of work labor; the operation is simple and convenient, adopts PC control, the operation only need the upper and the lower work piece, start the switch; the process efficiency is high, the using time of proceeding one end surface is about 10 to 20 seconds; the cost is low, a steel wire wheel can process 5000 to 10000 work piece; the investment is little, the machine tool has simple structure, the investment of producing a set of machine tool is about 40 thousand Yuan.

Owner:SHANXI DATONG GEAR GROUP

Derusting and descaling machine for belt steel

The invention discloses a band steel descaling machine, comprising a frame via a bearing parallel arranged with several couples of steel wire wheels, wherein two steel wire wheels of each couple are up and down parallel with a space between to pass steel plate. The invention also comprises a power device for rotating the steel wire wheels via a transmitter, all upper steel wire wheels rotate in same direction, while all lower steel wire wheels rotate reversed to the upper wheels. The invention can save acid material and cost or the like.

Owner:翟文海 +1

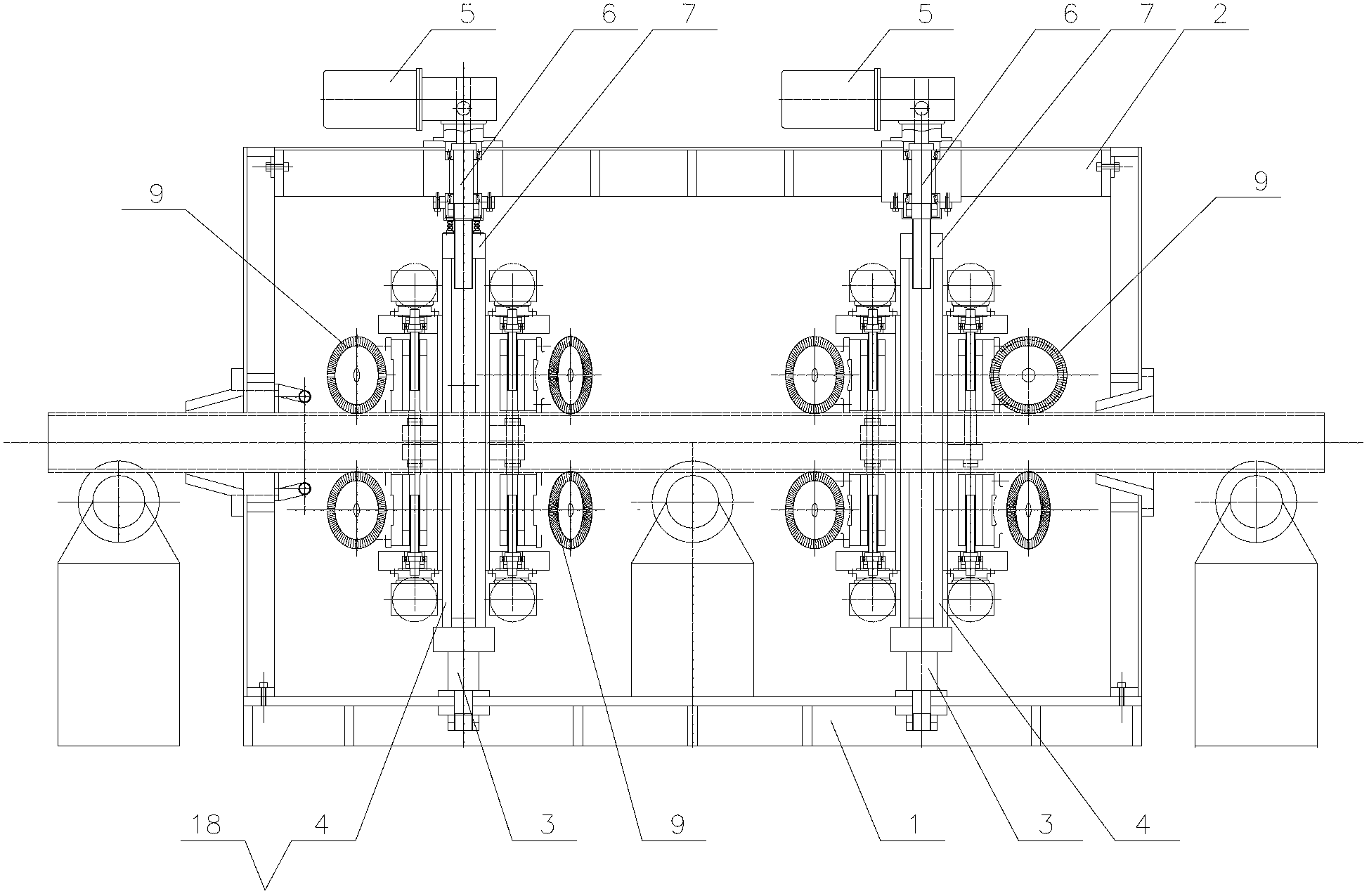

Steel pipe derusting machine

ActiveCN102699801ARealize the continuous flow operation of derustingAdapt to continuous derusting operationsGrinding machinesGrinding/polishing safety devicesWire wheelArchitectural engineering

The invention relates to a steel pipe derusting machine. The machine comprises a base, wherein a gantry bracket is fixedly arranged on the base; upright posts are arranged on the gantry bracket; wall plates are sleeved on the upright posts and can vertically slide; lifting adjustment speed reducing motors and lifting screw rods are arranged above the gantry bracket; the upper ends of the lifting screw rods are connected with power output shafts of the lifting adjustment speed reducing motors; lifting screw nuts are fixedly arranged in the centers of the upper ends of the wall plates; the lower ends of the lifting screw rods are screwed in the lifting screw nuts; through holes are formed in the centers of the wall plates; and steel wire wheel assemblies are uniformly distributed in the through holes along the circumferential direction. 3 to 12 steel wire wheels are uniformly distributed at the periphery of a steel pipe to axially coat the external surface of the steel pipe at 360 degrees, rust or the residual oxide layer on the surface of the steel pipe is removed in an axial friction mode by rotating the steel wire wheels, and the flaw detection and paint spraying quality of the steel pipe is ensured; and in addition, concentricity adjustment and radial adjustment can be performed according to the diameter of the steel pipe, and the requirements of derusting steel pipes of different specifications are met.

Owner:BAOJI XINSHAN TECH CO LTD

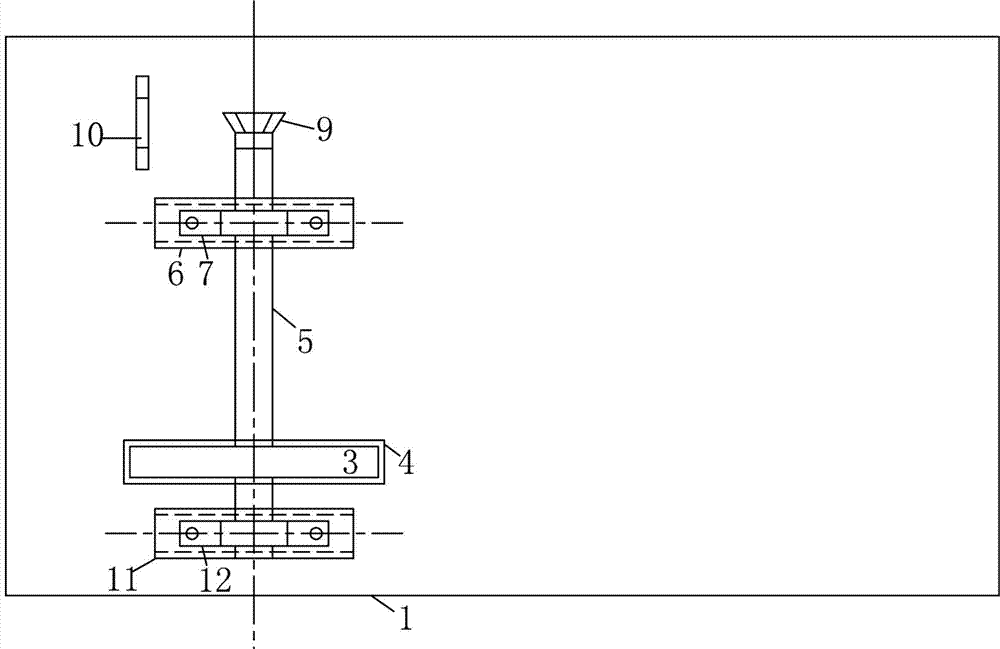

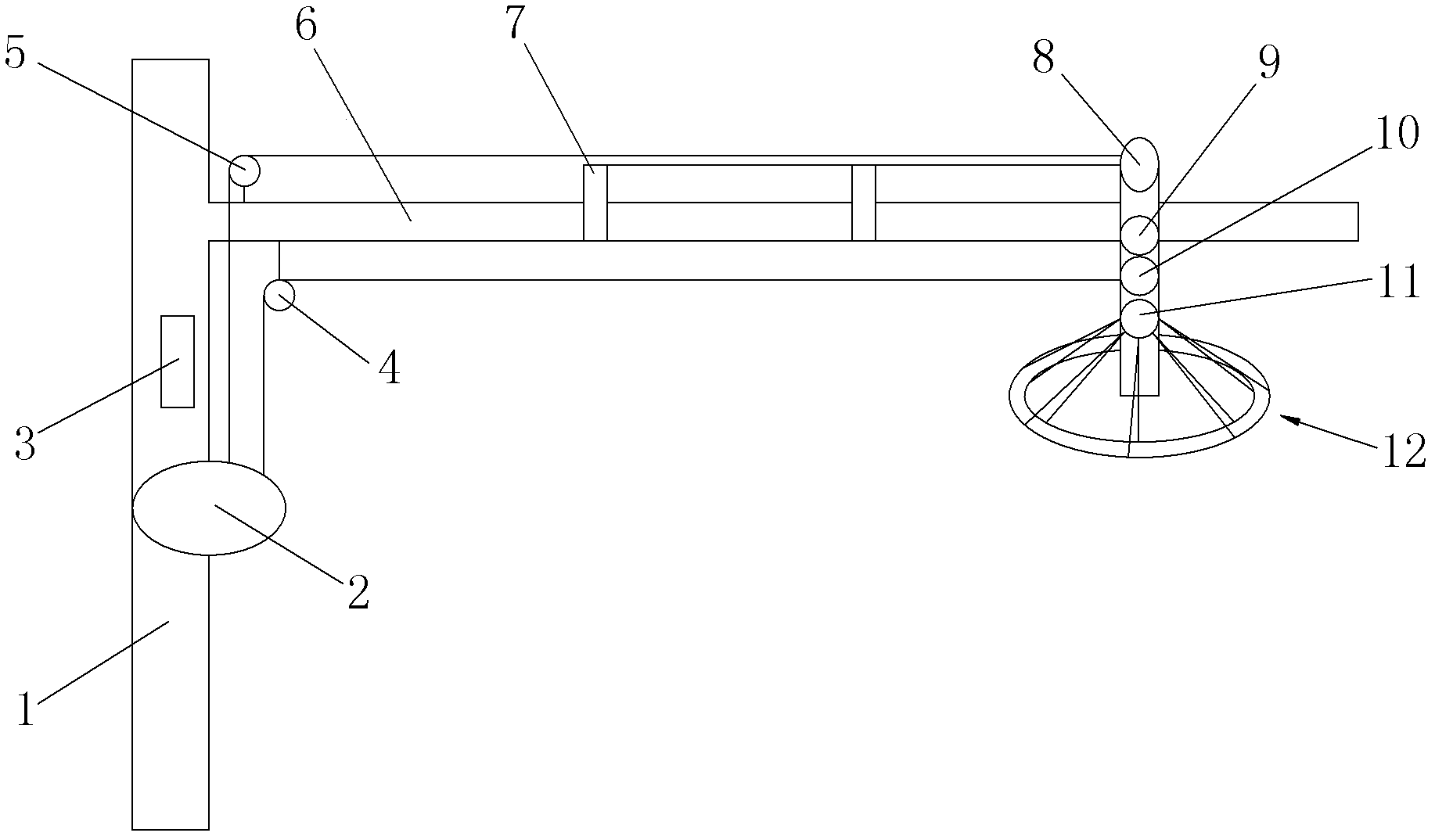

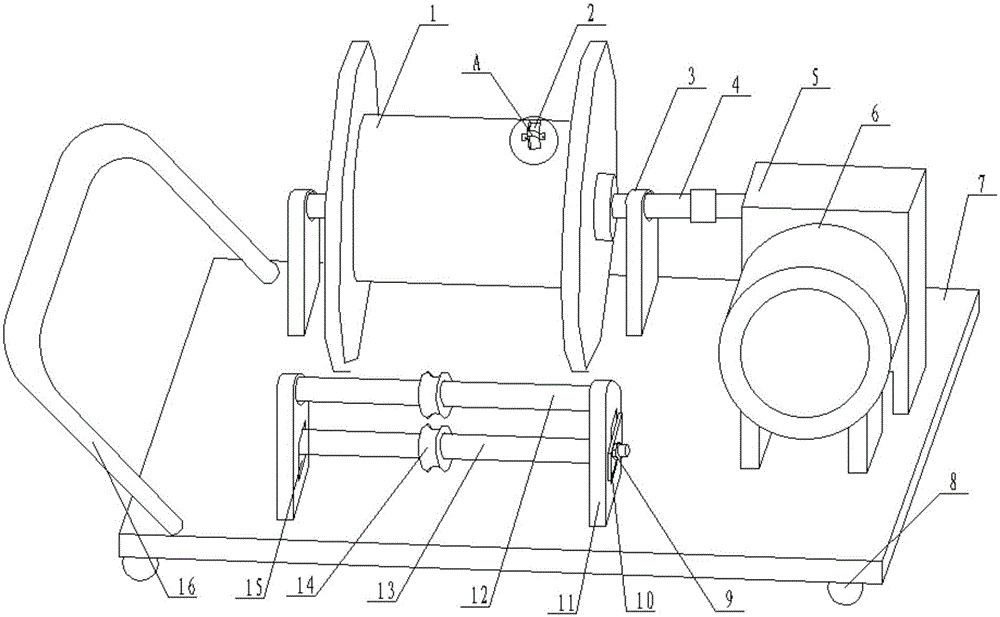

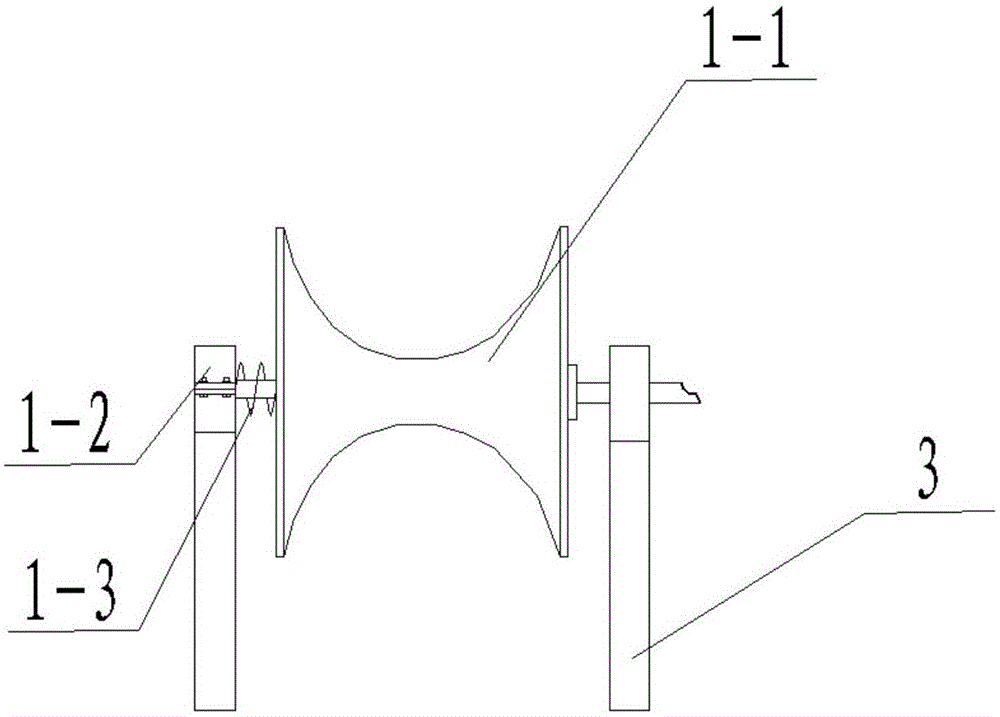

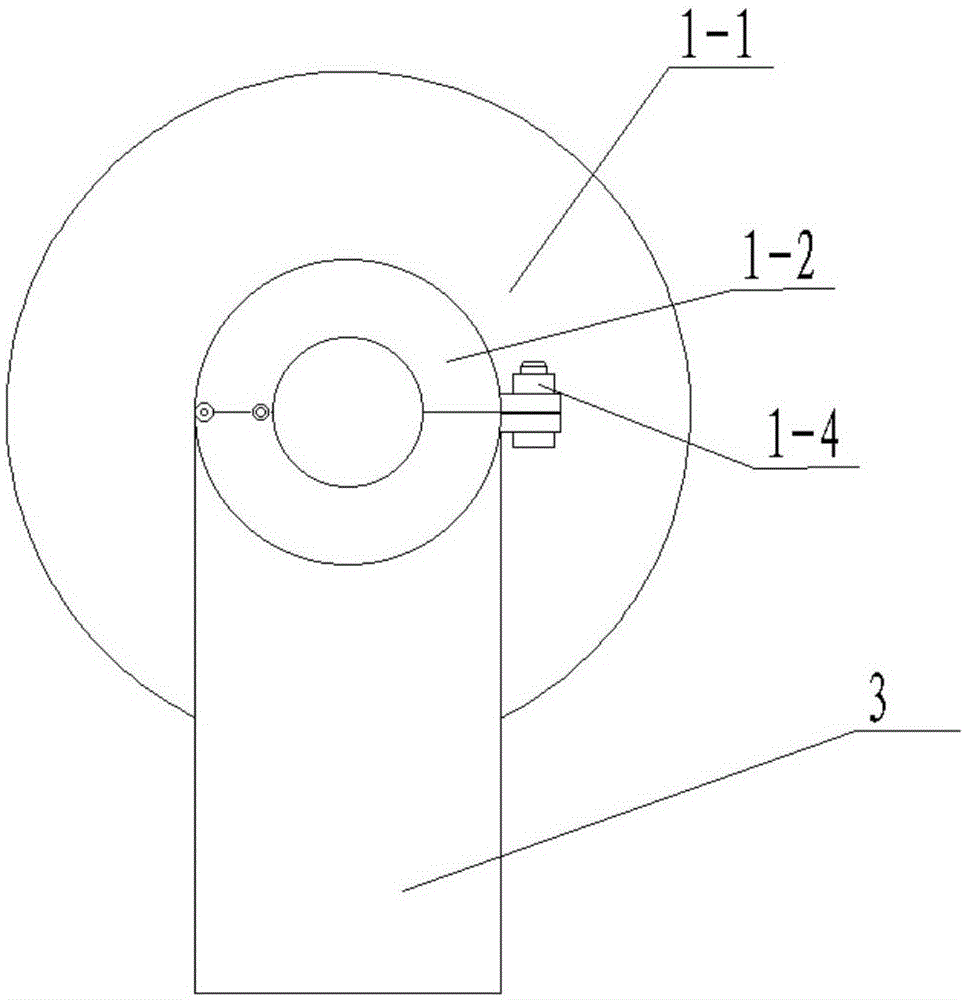

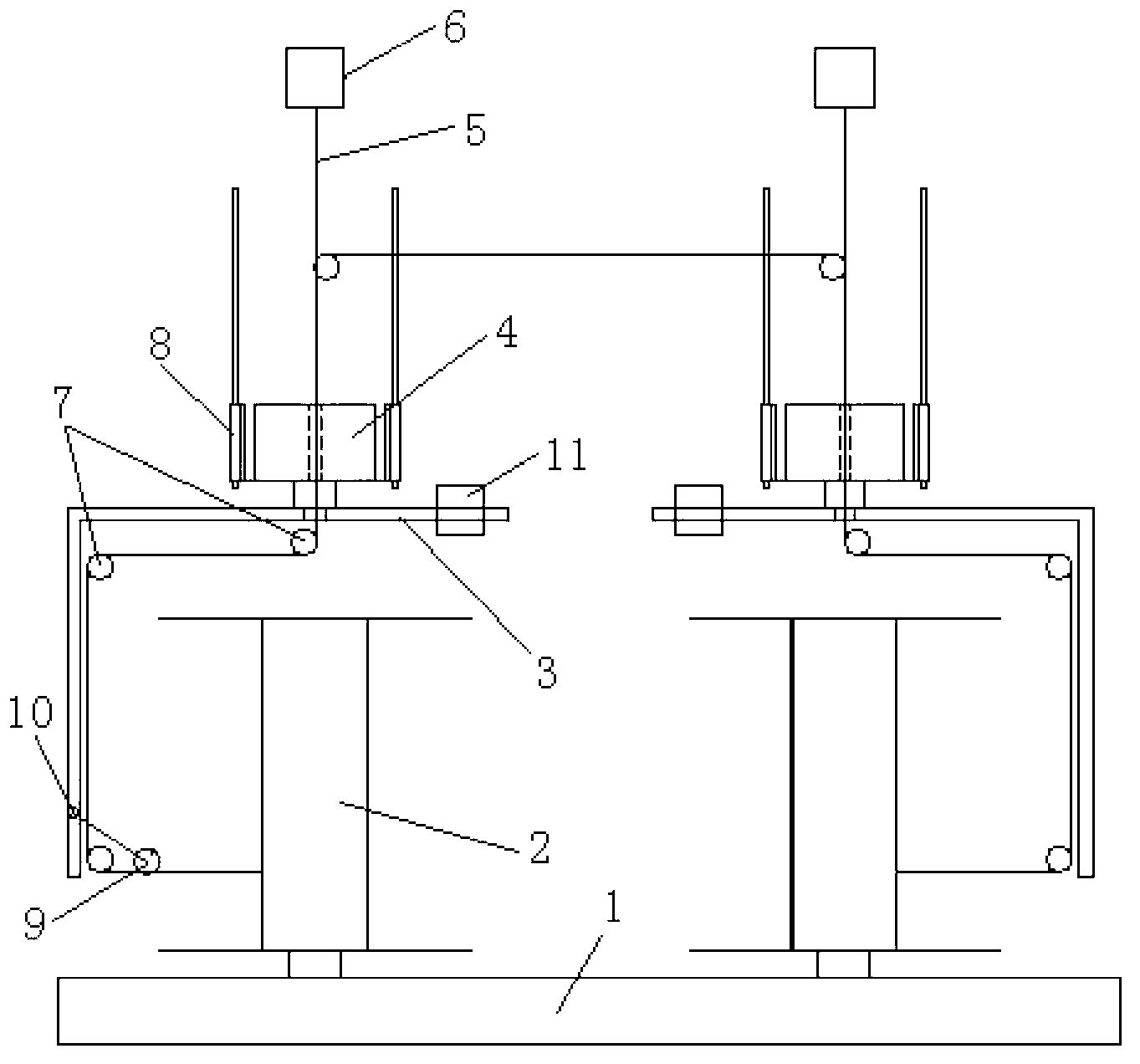

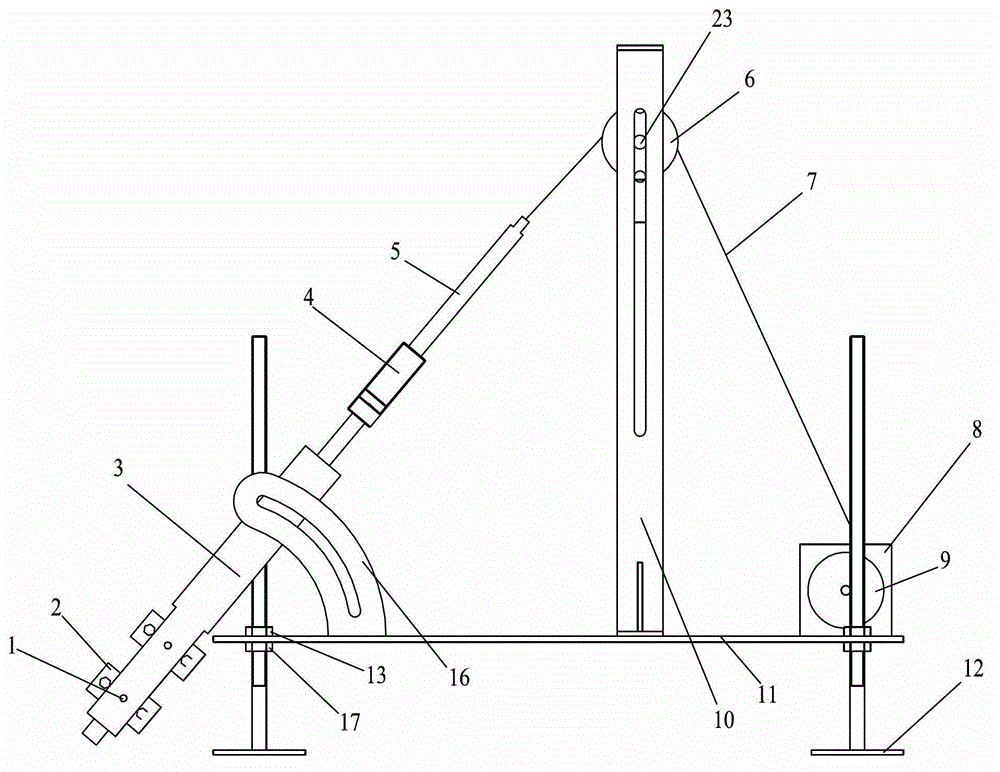

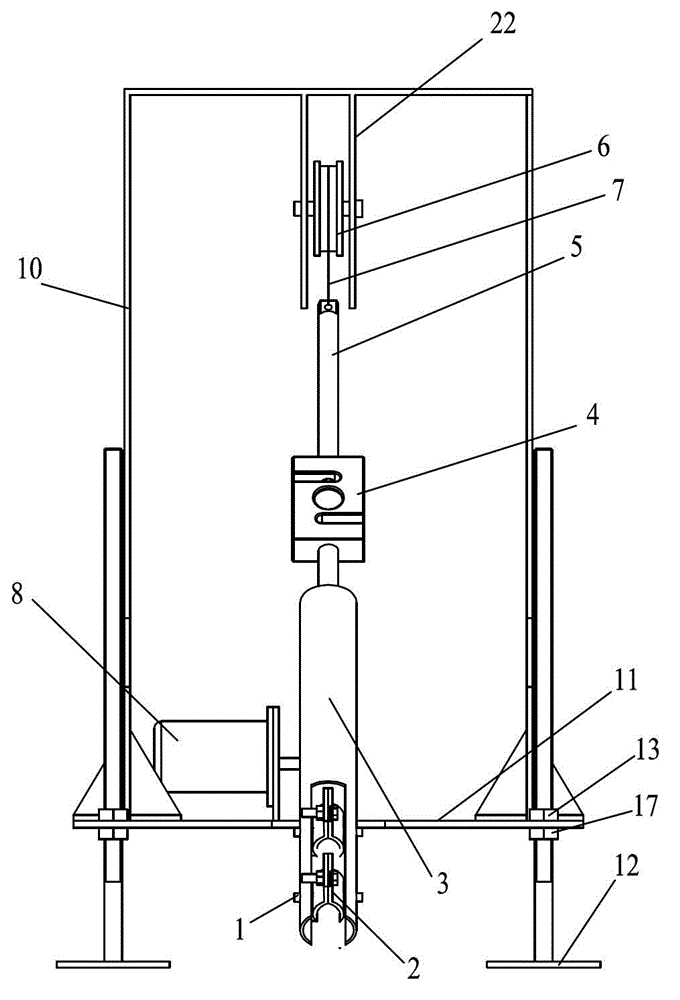

Flexible and adjustable biological straw lifting force measuring apparatus and measuring method

InactiveCN103335765AImprove measurement efficiencySimple structureApparatus for force/torque/work measurementPull forceMeasurement device

The invention discloses a flexible and adjustable biological straw lifting force measuring apparatus which comprises a frame, a supporting rack and a stepping motor which are disposed on the frame, a first wire wheel disposed on an output shaft of the stepping motor, a second wire wheel disposed on the supporting rack, a lifting sleeve cylinder, a lifting rod, a steel wire rope with one end connected with the lifting rod, a pull force sensor disposed between the lifting sleeve cylinder and the lifting rod, a data acquisition card connected with a signal output end of the pull force sensor, and a controller connected with a control end of the stepping motor, wherein the other end of the steel wire rope is fixed onto the first wire wheel after being turned by the second wire wheel; a lifting clamp group are fixedly connected in the lifting sleeve cylinder through fastening bolts, and are positioned on one side of the supporting rack; and the first wire wheel is positioned on the other side of the supporting rack. The flexible and adjustable biological straw lifting force measuring apparatus helps to effectively reduce labor intensity of measurement operators, has good adaptability to outdoor tests, and the acquired data serve as references to the design of biological straw harvesting machines.

Owner:HUAZHONG AGRI UNIV

Motor built-in type modularized prosthetic finger with self-locking function

The invention relates to a modularized prosthetic finger, in particular to a motor built-in type modularized prosthetic finger with a self-locking function. The problems that an existing prosthetic finger is complex in transmission mechanism and not high in modularization degree, a single finger body cannot be independently controlled, the self-locking function is not achieved, and the endurance time of the existing prosthetic finger is short are solved. A near knuckle shell is arranged on a rotary frame, the other end of a worm is connected with an end cover through a worm shaft, a base joint base is connected with the rotary frame through a base joint shaft, the base joint shaft is sleeved with a worm gear, the worm gear is meshed with the worm, a first joint steel wire wheel is arranged on a boss on the side face of the worm gear in a sleeved mode, a second joint steel wire wheel is arranged on a circular table on the inner side wall of a fingertip lower cover plate in a sleeved mode, a fingertip upper cover plate and a fingertip circuit board are arranged on the fingertip lower cover plate through double-screw bolts, and one end of a steel wire is fixed to the base joint base through a wire pressing plate. The motor built-in type modularized prosthetic finger belongs to the field of robots.

Owner:HARBIN INST OF TECH

Road pavement drainage structure and construction method thereof

ActiveCN111395505AReduce congestionEasy to handleSewerage structuresSewer pipelinesWire wheelArchitectural engineering

The invention relates to the technical field of road drainage, and particularly relates to a road pavement drainage structure and a construction method thereof. According to the technical scheme, theroad pavement drainage structure is characterized by comprising a road body and a drainage pipeline, wherein the road body comprises a lane and a sidewalk; a drainage well is arranged on the side, close to the sidewalk, of the lane; a drainage grating is arranged at a well opening of the drainage well; the drainage pipeline communicates with the lower end of the drainage well; a sewage collectionwell communicating with the ground is arranged on one side of the sidewalk; a cover plate is arranged at the sewage collection well in a sliding mode; a sewage discharge hole is formed in the drainagewell; a collection frame is contained at the well bottom of the sewage collection well; a mounting plate is arranged on the inner side wall of the sewage collection well; the mounting plate rotationally bears a rotating shaft; the rotating shaft is fixedly sleeved with a wire wheel; a steel wire rope is wound around the wire wheel; a lifting hook is arranged at the free end of the steel wire rope; and a hanging piece is fixedly connected to the collection frame. Sewage discharged by municipal roads can be effectively filtered, filtered garbage is collected and treated, and then the situationthat the drainage pipeline is blocked is reduced.

Owner:佛山市禅鸿建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com