Patents

Literature

62results about How to "Brush evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component thread locking epoxy precoated adhesive and preparation method thereof

InactiveCN101665674AStable storageNo chemical reactionNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

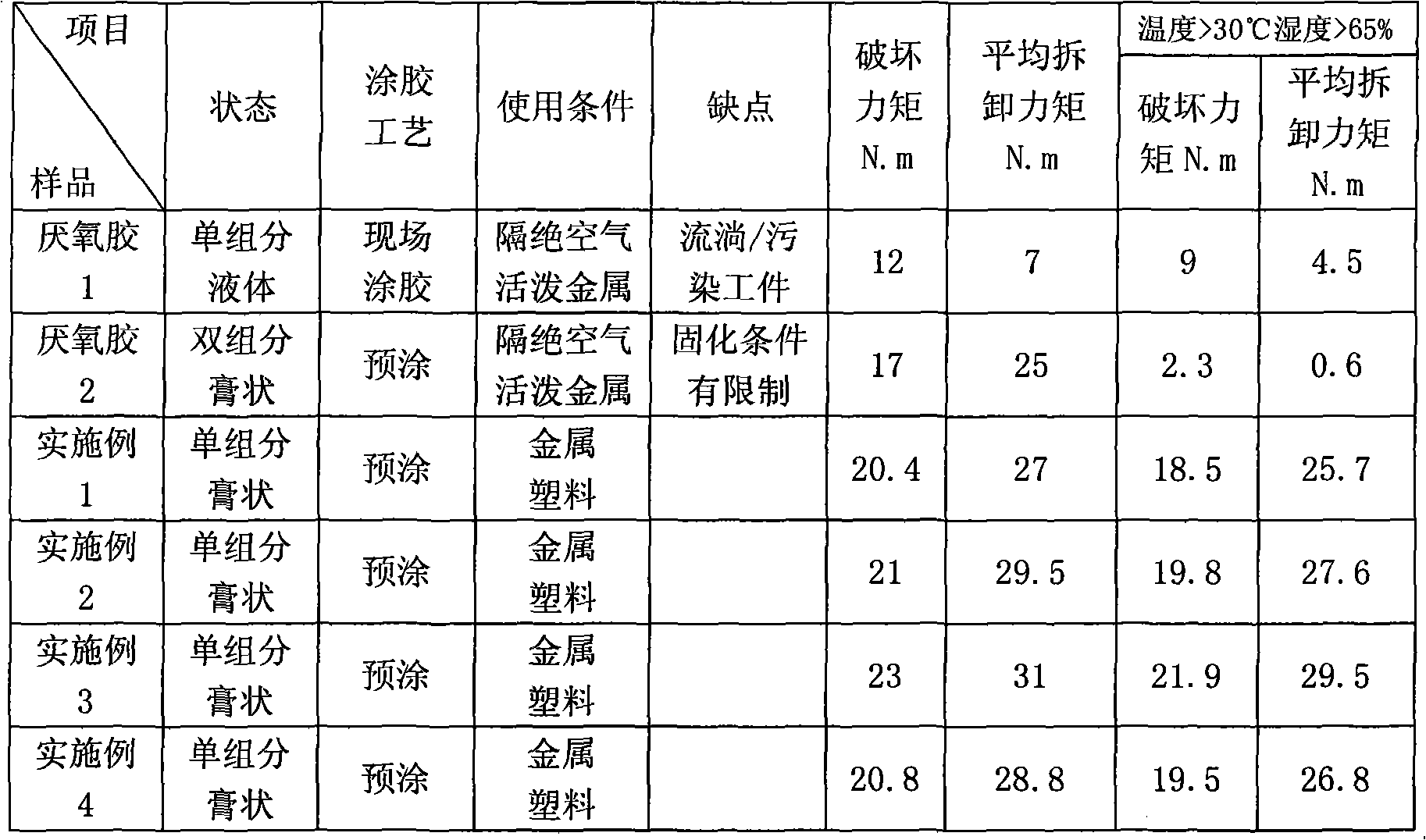

The invention discloses a single-component thread locking epoxy precoated adhesive which is characterized by being prepared from the following components in proportion by weight: 40-70 parts of epoxyresin, 10-80 parts of activated thinner, 20-60 parts of epoxy hardener, 8-20 parts of urea, 30-60 parts of formaldehyde solution, 10-30 parts of hydroxyphenol, 0.5-5 parts of stuffing, 5-15 parts of surfactant, 80-200 parts of distilled water, 0.5-2 parts of membrane material, 0.1-1 part of hydrolysis inhibitor and 5-10 parts of solvent; and a preparation method comprises the steps: firstly, respectively microencapsulating the epoxy resin and the epoxy hardener are and then uniformly mixing with other components in proportion. The single-component thread locking epoxy precoated adhesive has the characteristics of convenient construction, applicable workpiece material diversification, less curing condition restriction, good moisture resistance and high destabilizing moment and average disassembly moment, ensures the locking performance and better guarantees the safe reliability of products.

Owner:YANTAI DARBOND TECH

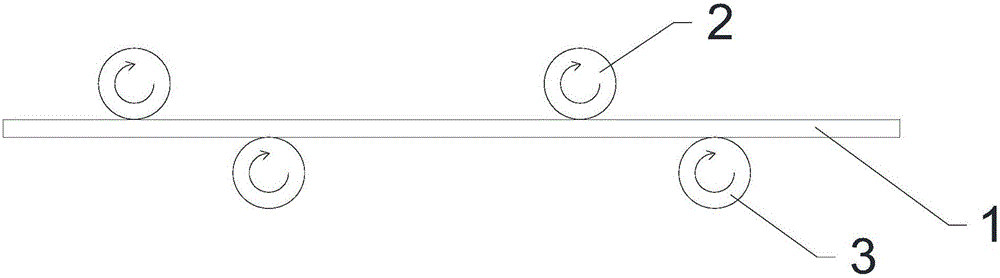

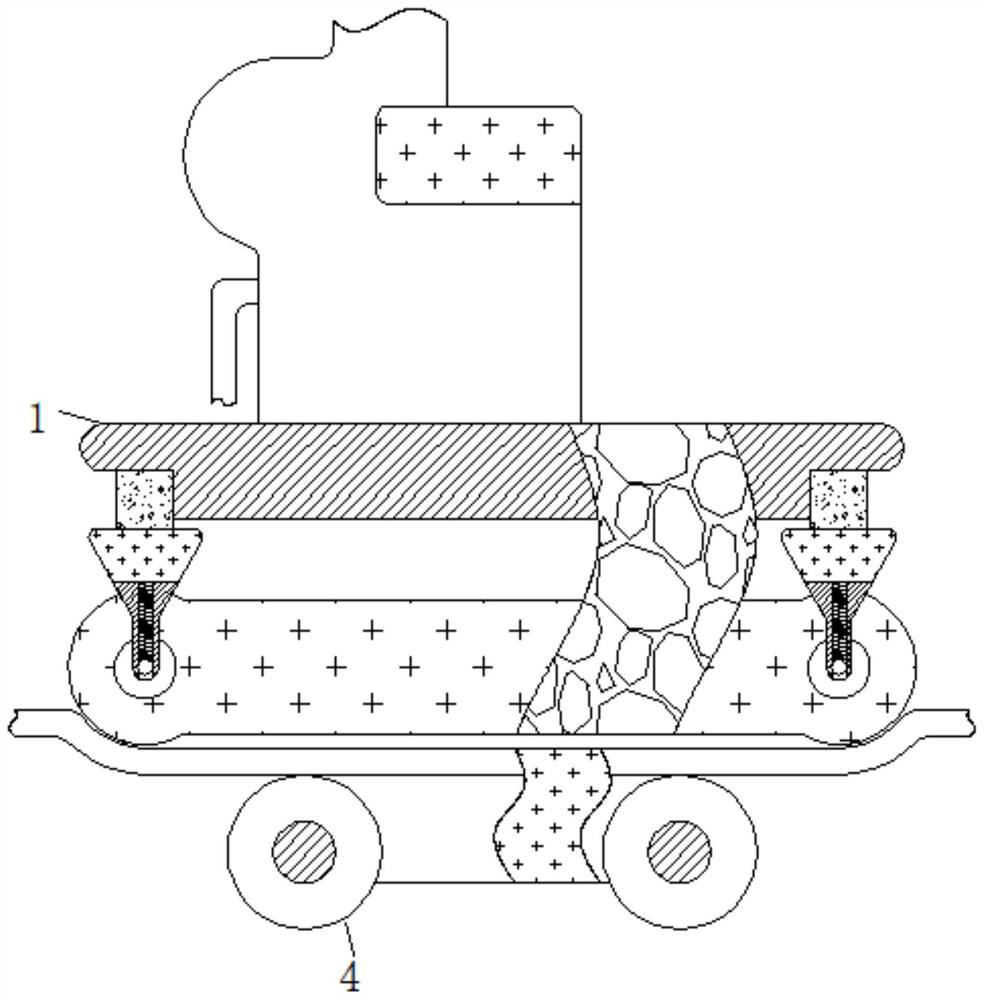

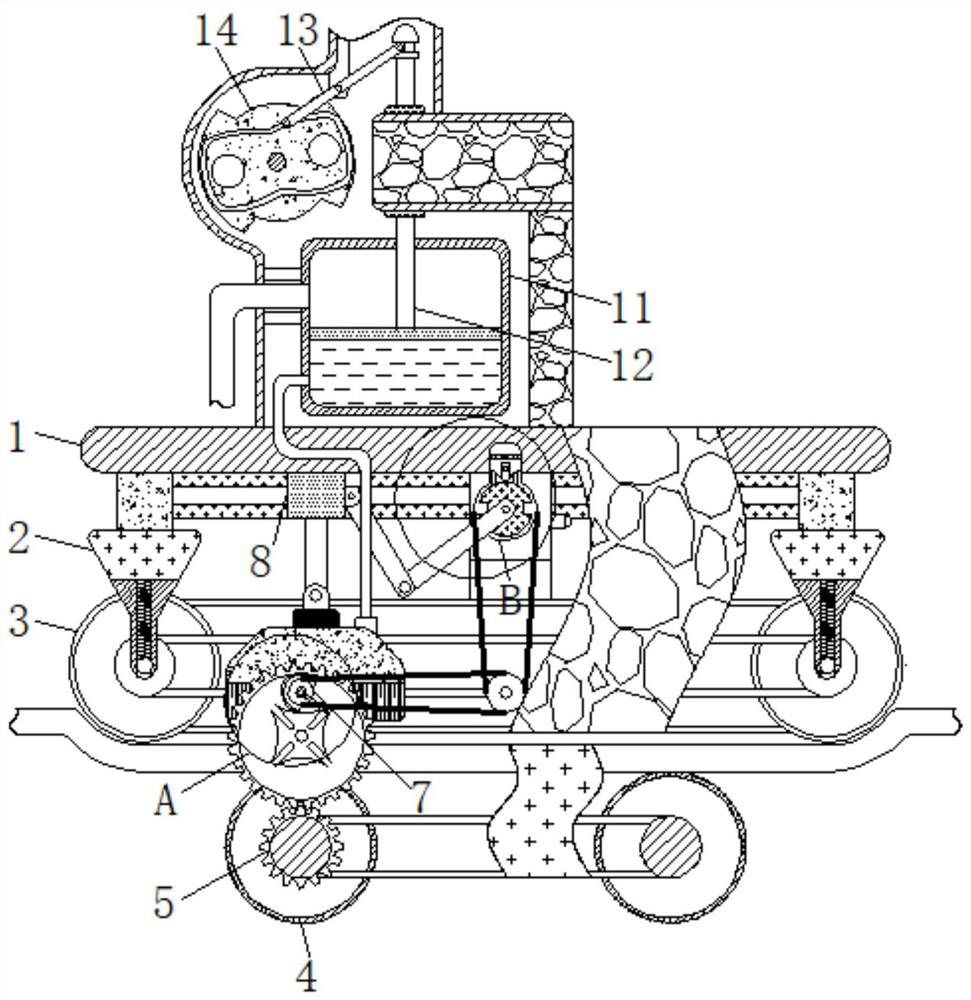

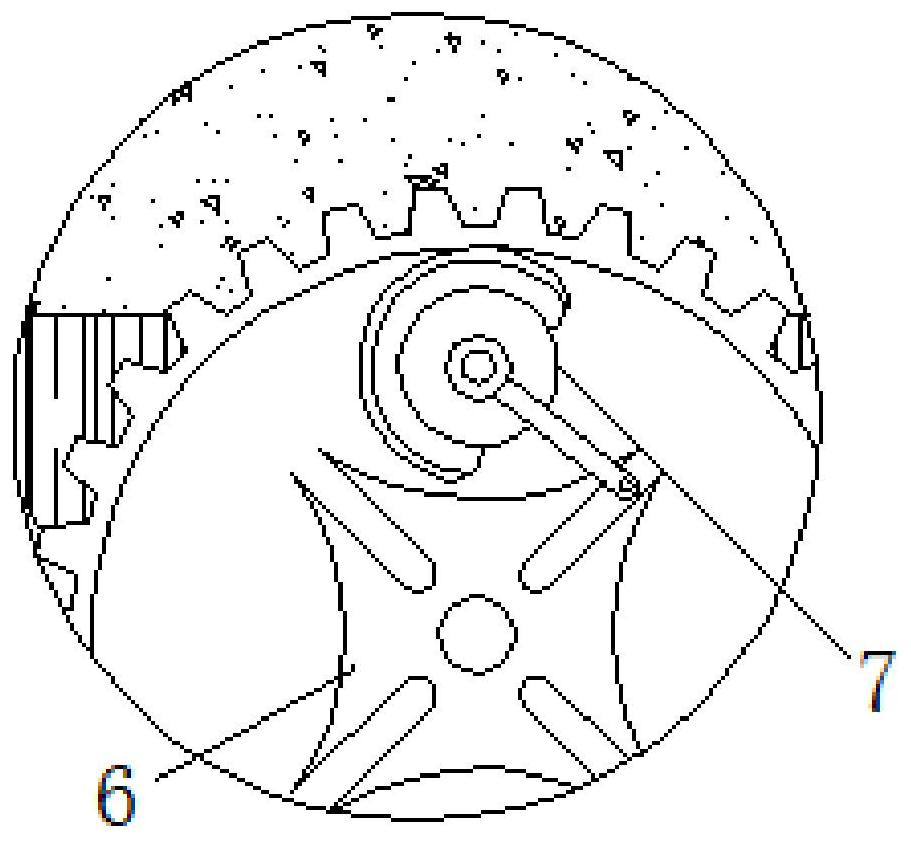

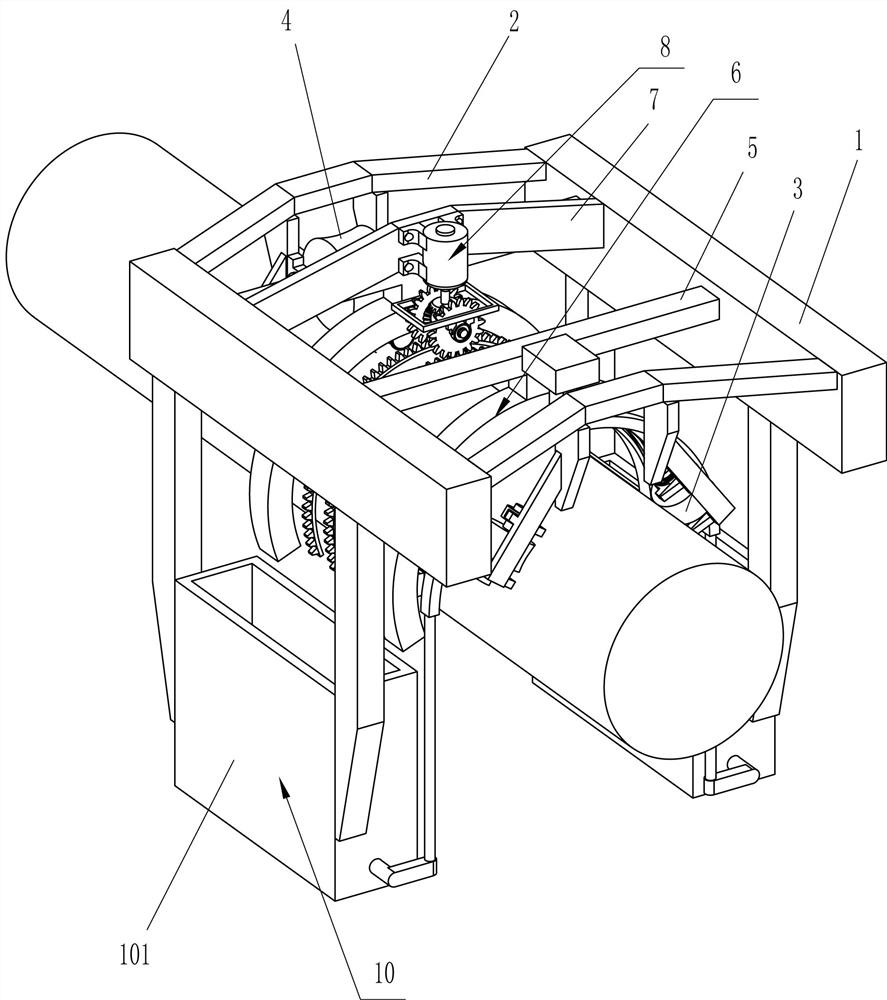

Automatic painting equipment for surface of outdoor pipeline

ActiveCN111558496AAvoid dangerHigh degree of automationLiquid surface applicatorsCoatingsStructural engineeringCounter rotation

Owner:台州伟兴科技有限公司

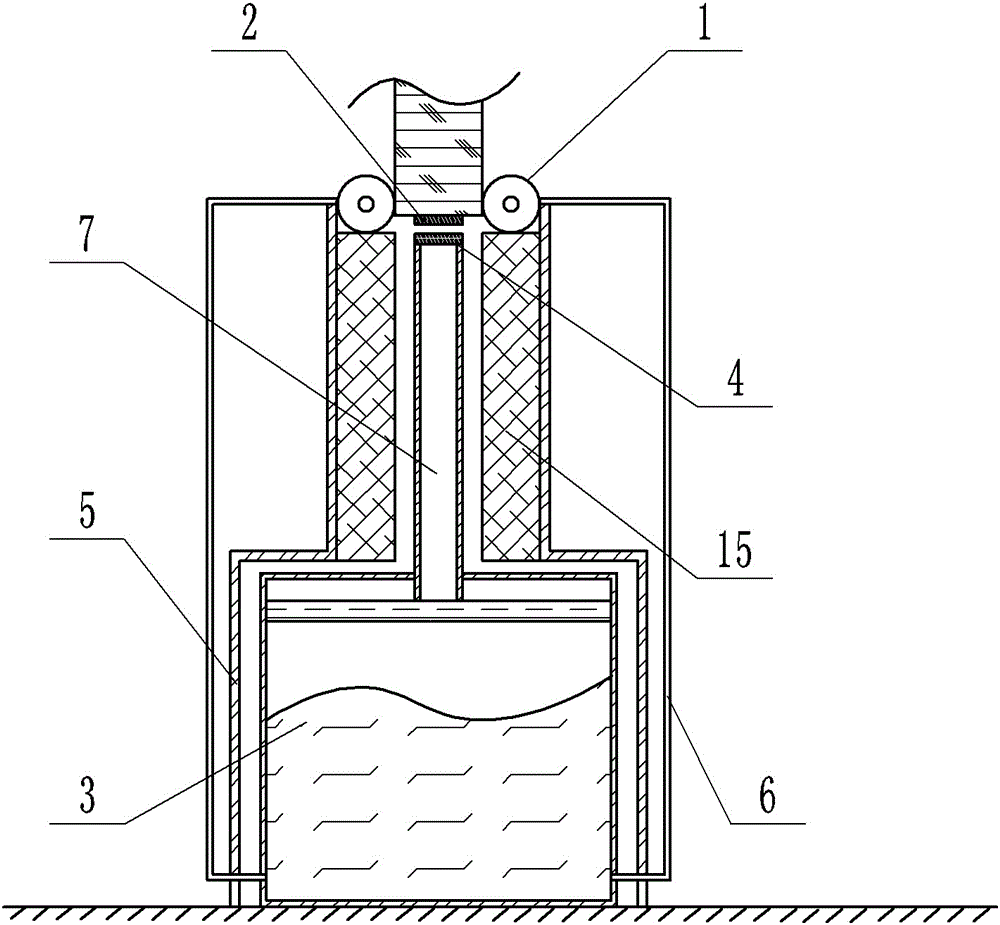

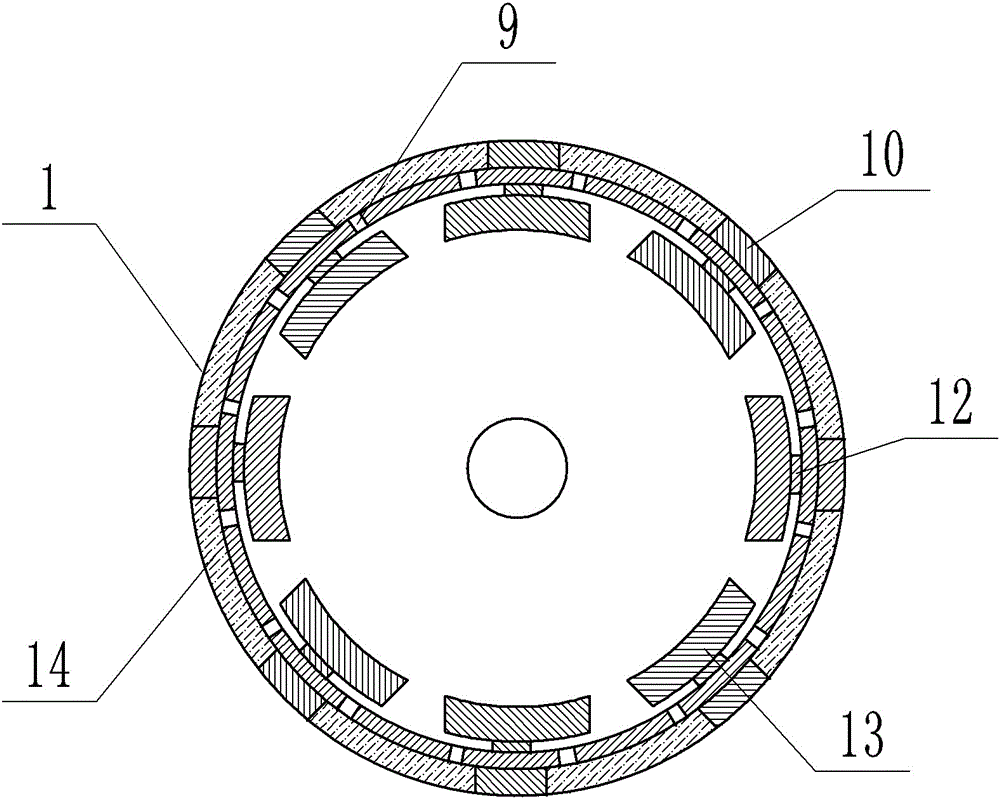

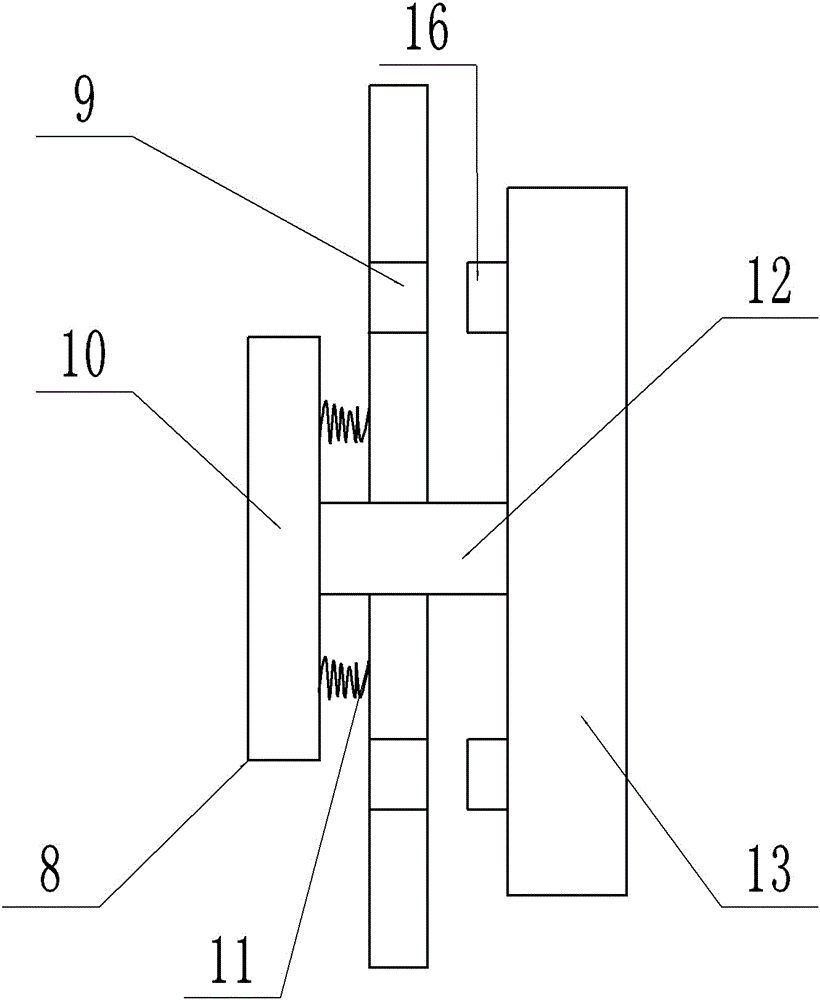

Wooden door painting device

ActiveCN106733484AReduce falling speedAchieve transferLiquid surface applicatorsCoatingsLacquerEngineering

The invention belongs to the field of automatic spraying equipment, and particularly discloses a wooden door painting device. The wooden door painting device comprises a rack, and further comprises a roller couple, a first magnet arranged at the bottom of a wooden door, and a paint cylinder, wherein the roller couple is arranged at the upper end of the rack, the paint cylinder is arranged in the middle of the bottom of the rack, a paint pipe communicating with the roller couple is arranged on the paint cylinder, a cavity for a wooden door to pass through is formed between the rollers in the roller couple, a plurality of press type paint outlet mechanisms are evenly distributed on the surface of each roller in the roller couple circumferentially, and paint outlets are formed in the outer wall of each roller in the roller couple. Each press type paint outlet mechanism comprises a spring seat, a connecting rod, a spring, a through hole for the connecting rod to penetrate through, and a sealing plate which can block off the corresponding paint outlet from the inner side of one roller in the roller couple, wherein the spring seat is movably connected with one end of the corresponding connecting rod, the other end of each connecting rod penetrates through the corresponding through hole to be connected to the corresponding sealing plate, and the spring is connected between the corresponding spring seat and the outer wall of the corresponding roller in the roller couple. With the wooden door painting device, the two surfaces of one wooden door can be painted synchronously, painting is more uniform, and the painting efficiency is high.

Owner:日照福临门业有限公司

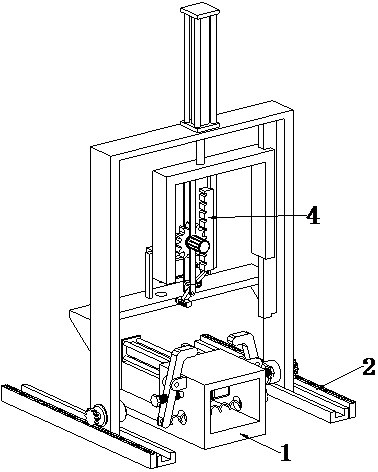

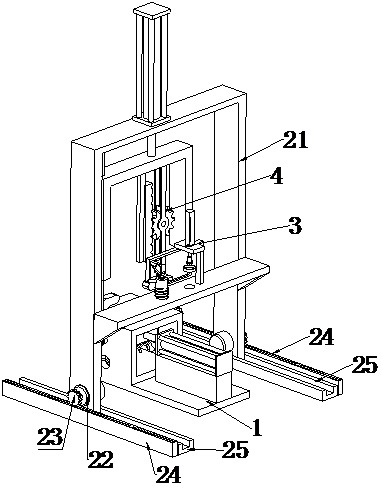

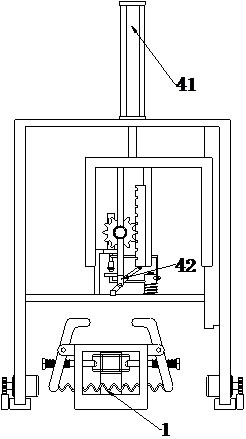

Automatic coating device

ActiveCN111515075APrecise positioningRise steadilyLiquid surface applicatorsSpraying apparatusElectric machineryEngineering

The invention discloses an automatic coating device. The automatic coating device comprises a vertical plate, a transverse plate arranged at the lower portion of the vertical plate, a material distribution box arranged on the left side of the upper portion of the transverse plate, a coating box arranged on the right side of the upper portion of the transverse plate, a coating recycling box arranged in the transverse plate, a moving box arranged on the right side of the vertical plate, a moving mechanism arranged in the moving box, a coating mechanism arranged in the coating box, and a cutting-off mechanism arranged on the material distribution box. The automatic coating device is characterized in that the moving mechanism comprises a first motor, a first screw rod arranged at the upper portion of the first motor, a first nut arranged at the outer portion of the first screw rod in a sleeving manner, and a lifting part arranged on the right side of the first nut, wherein the first nut can move vertically on the first screw rod.

Owner:吴璐纯

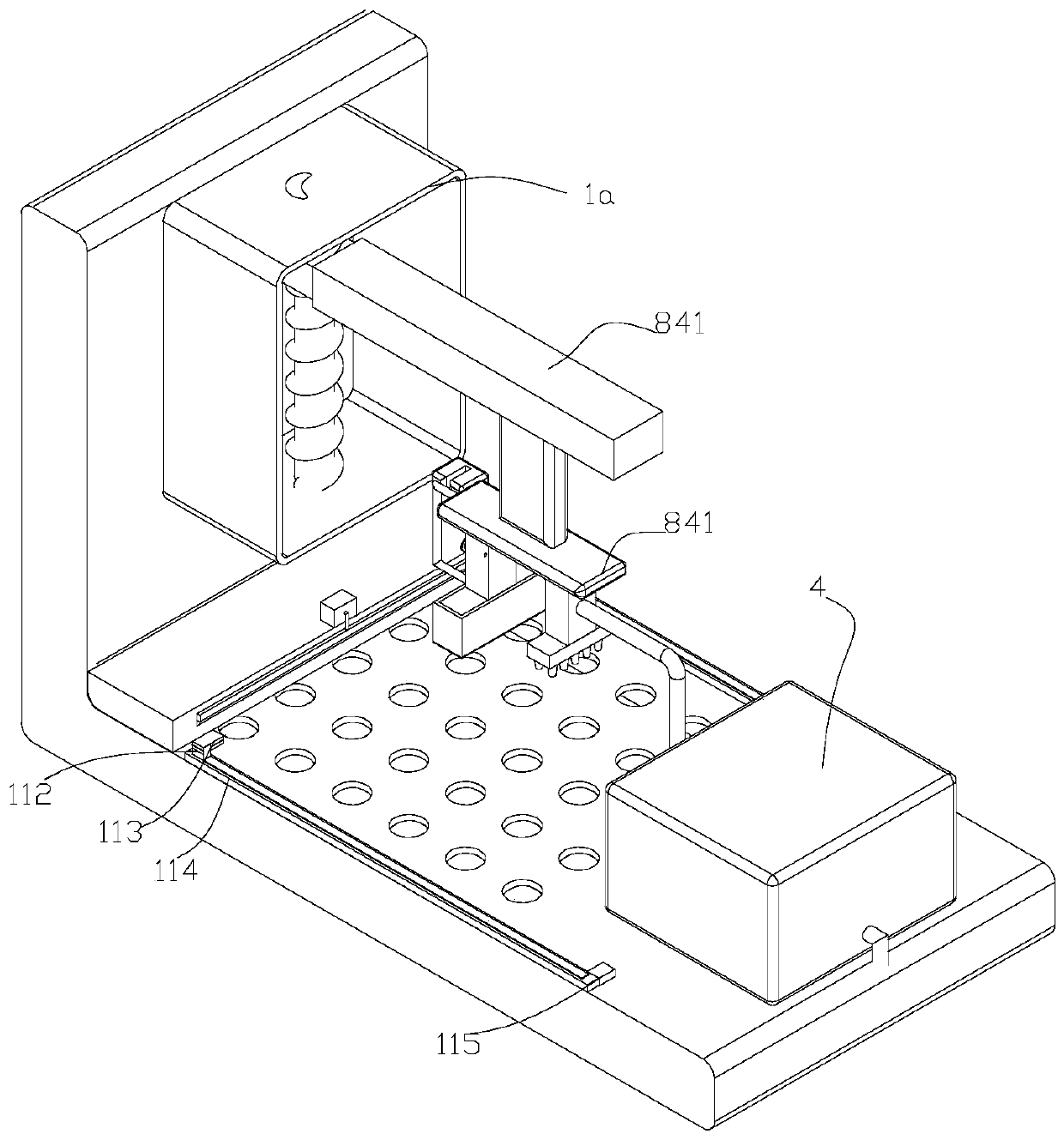

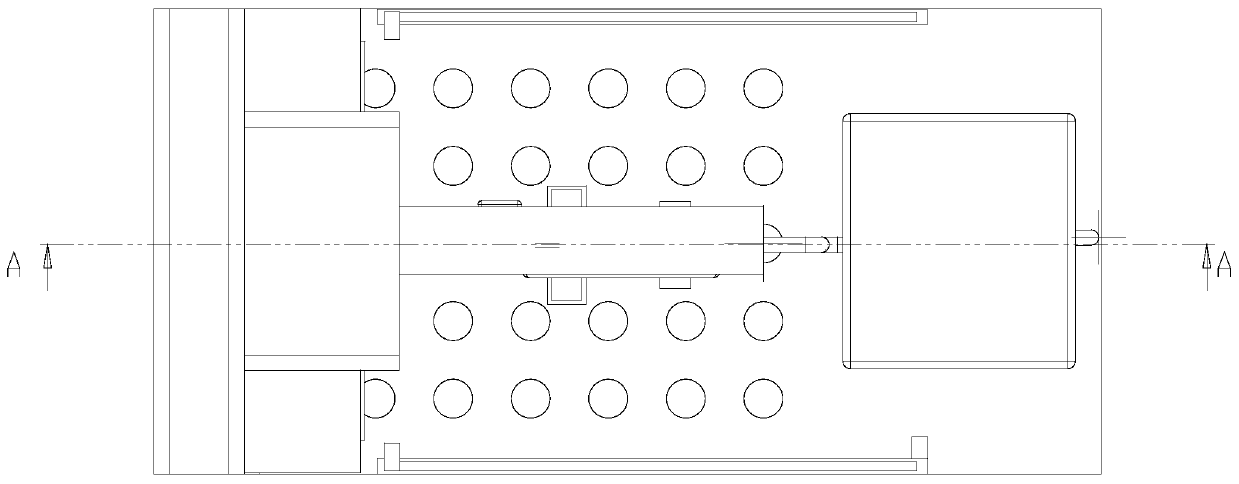

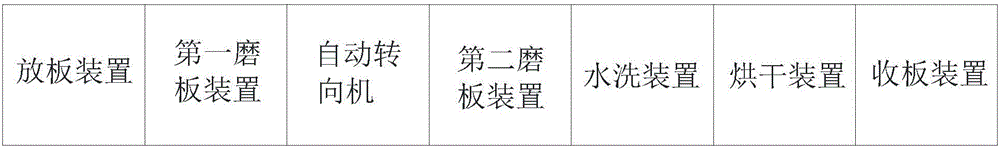

Novel method for removing porthole flashing of PCB

The invention discloses a novel method for removing porthole flashing of a PCB. The novel method comprises the following steps: first-time board grinding: putting the PCB after drilling in a first board grinding device for carrying out first-time board grinding; horizontal 90-degree steering: carrying out 90-degree horizontal rotation on the PCB after the first-time board grinding; and second-time board grinding: putting the PCB after horizontal 90-degree steering into a second board grinding device for carrying out second-time board grinding. According to the novel method, the effect of removing the porthole flashing is good, the grinding of a copper surface is uniform, the quality of the PCB is guaranteed, the process is simplified, and the whole operation process is in automatic operation, so that manual carrying actions can be reduced, and the production efficiency is improved.

Owner:江西景旺精密电路有限公司

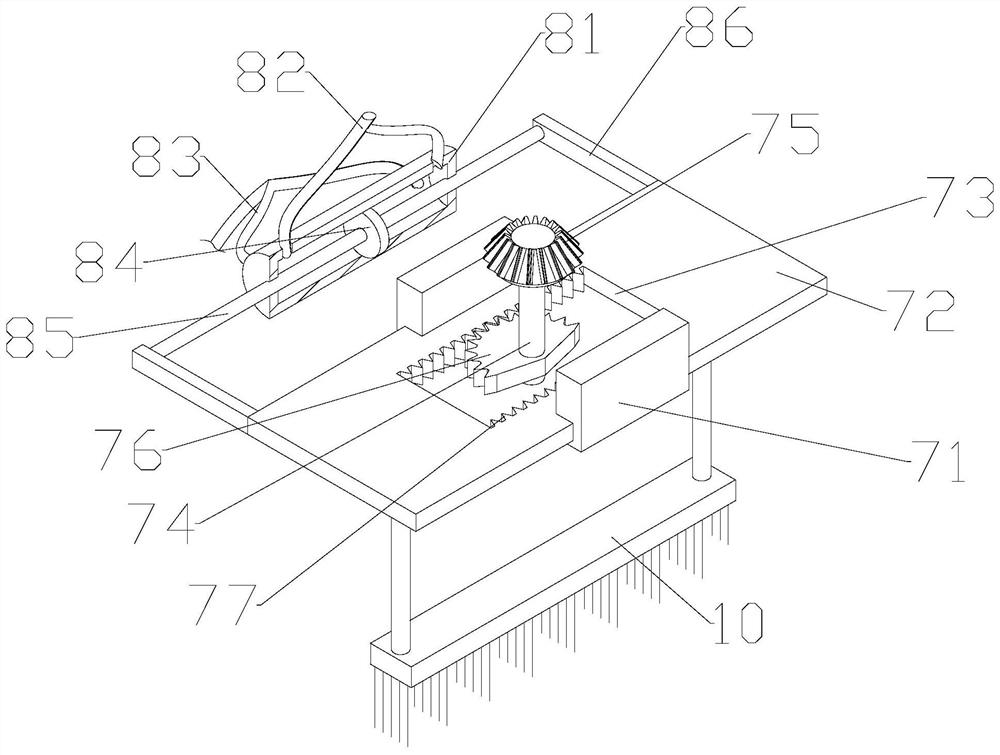

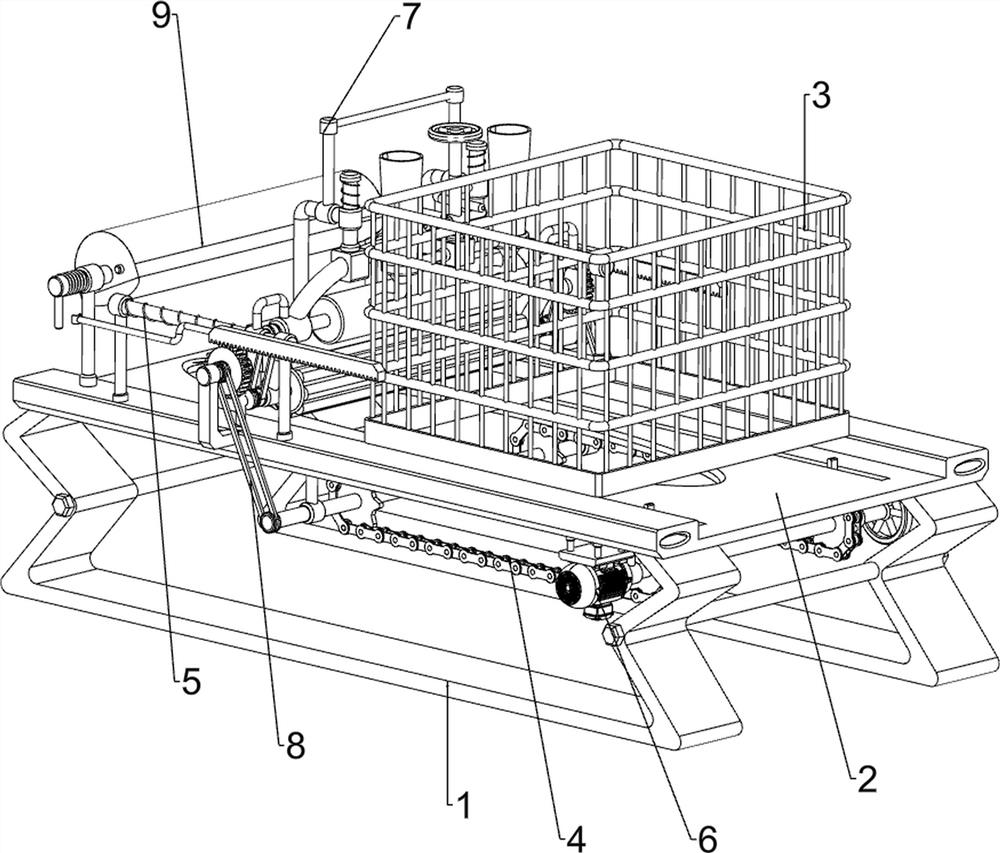

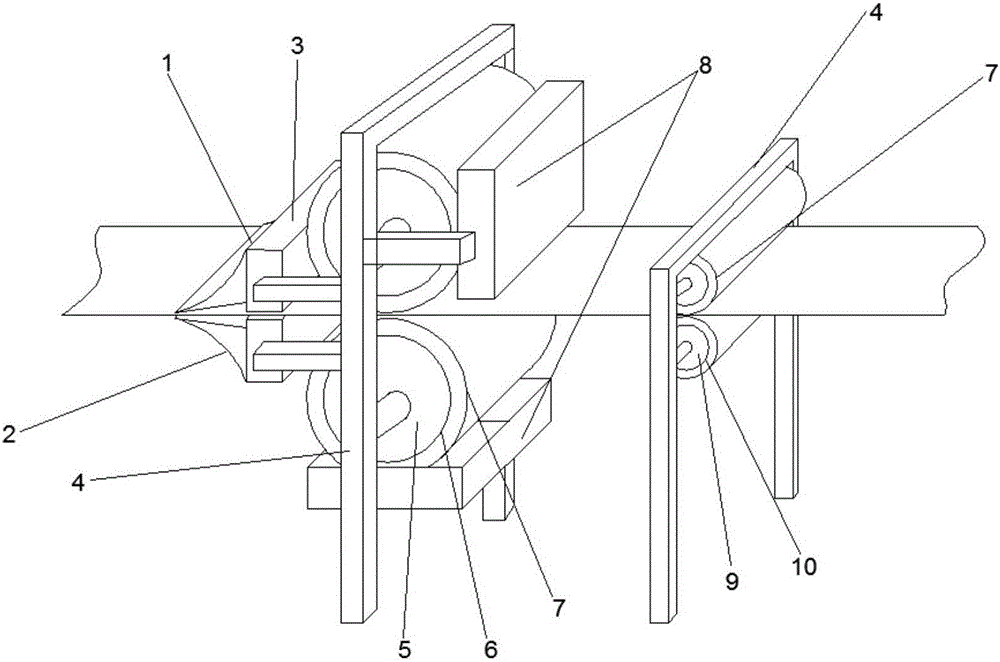

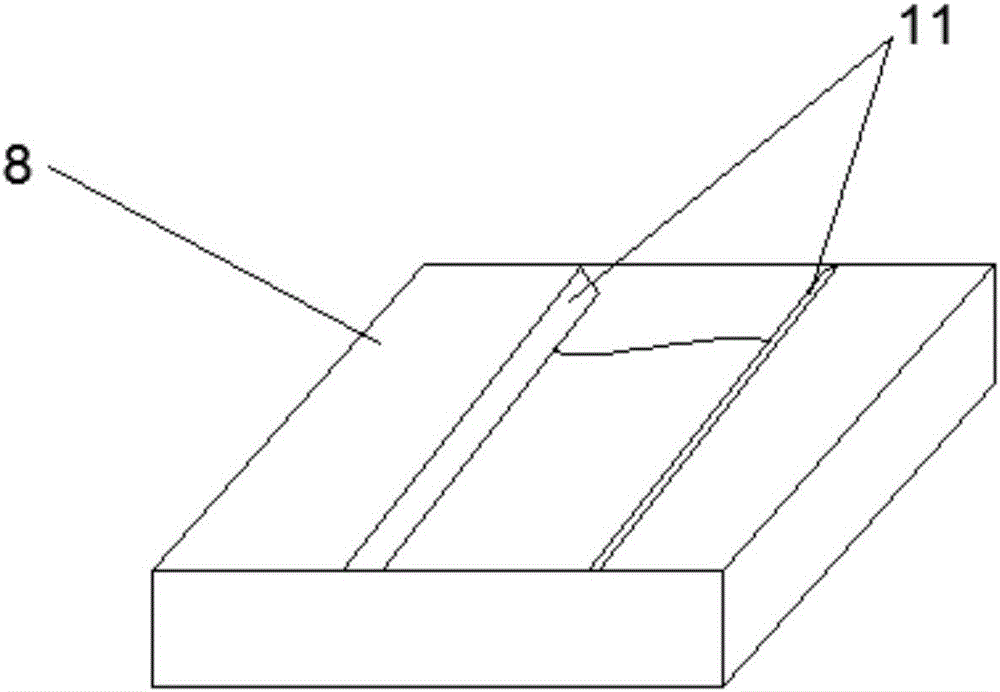

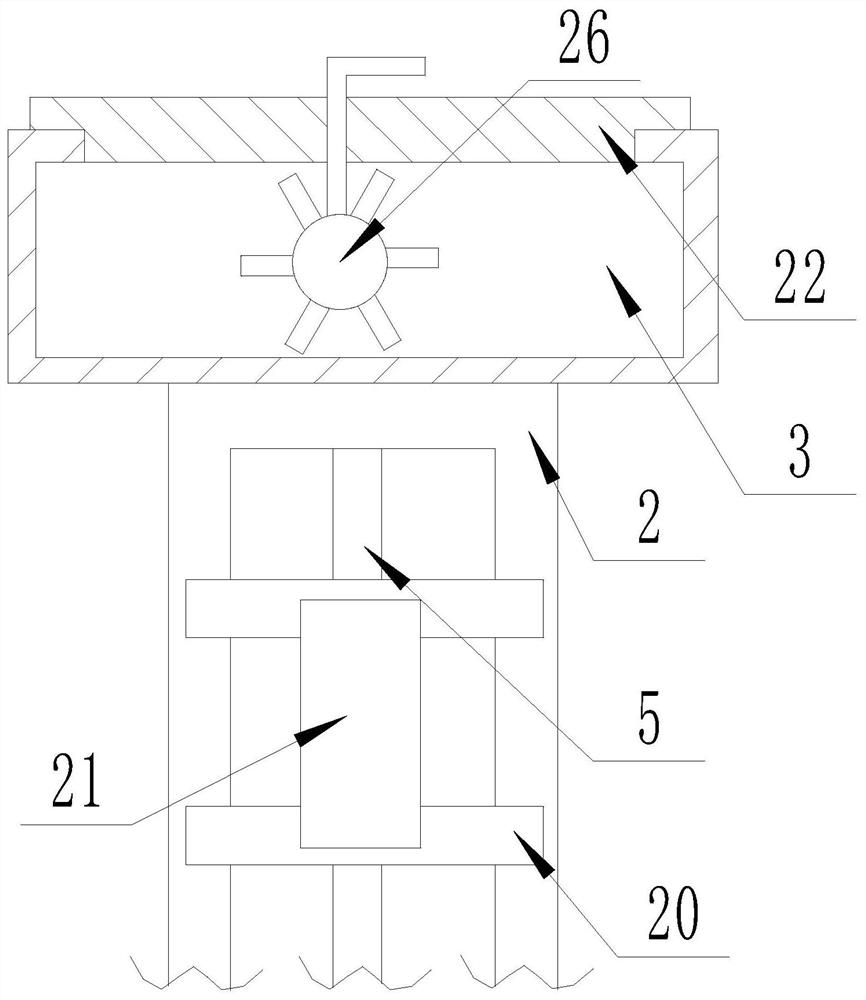

Infiltration device coated on surface of glass fabric

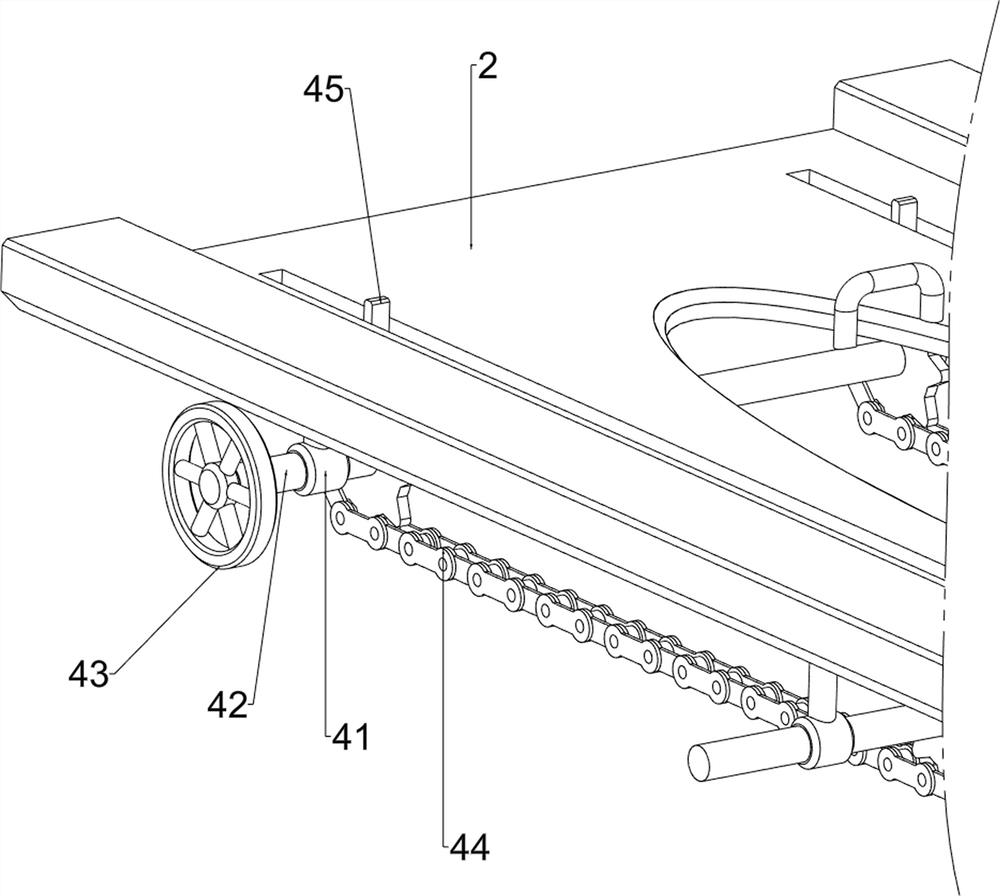

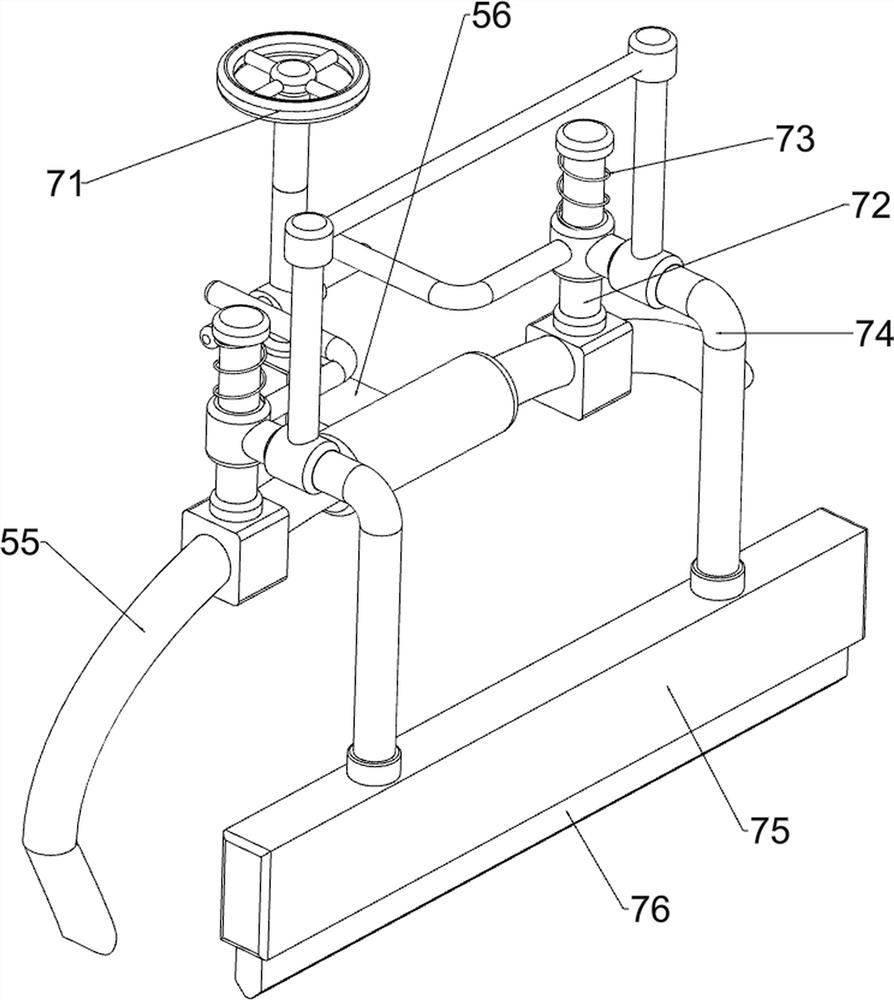

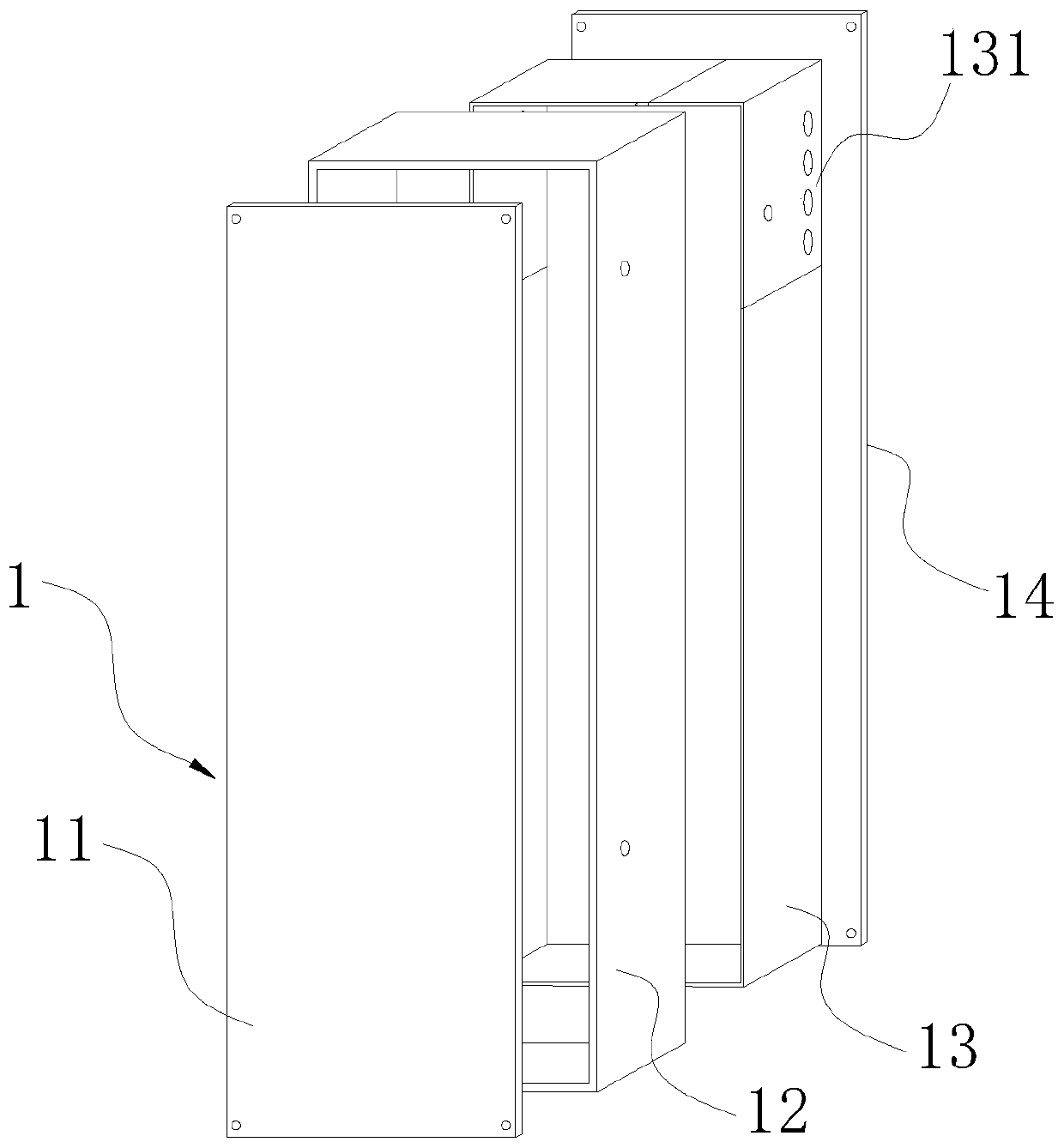

ActiveCN112791901ABrush evenlyCoating wetting is completely uniformPretreated surfacesCoatingsTransmission beltEngineering

The invention discloses an infiltration device coated on the surface of a glass fabric. The infiltration device comprises a base, wherein a top plate is arranged on the base; installing racks are arranged on the end surface of the base; cloth dragging rollers are arranged between the installing racks; fixing plates are arranged on the top of the top plate; a rotating shaft is sleeved and connected between the fixing plates; a transmission belt is arranged between the rotating shaft and a main shaft of the cloth dragging rollers; a driving mechanism is arranged between the rotating shaft and the top plate; one end of the driving mechanism is connected with a feeding mechanism; a material storage box is arranged on the top of the top plate; one end of the feeding mechanism is connected with the material storage box, and the other end of the feeding mechanism is connected with a coating box; and a brush plate is arranged at the bottom of the driving mechanism. The cloth dragging rollers rotate to drag and convey the glass fabric, the cloth dragging rollers and the rotating shaft synchronously rotate through the transmission belt, the rotating shaft drives the driving mechanism to move, the driving mechanism synchronously drives the feeding mechanism and the brush plate to move, and the feeding amount of the feeding mechanism is in direct proportion to the moving speed of the glass fabric, so that the same coating amount of the glass fabric in unit length is guaranteed; and then, paint is uniformly coated through the back-and-forth movement of the brush plate.

Owner:徐州志正装饰材料有限公司

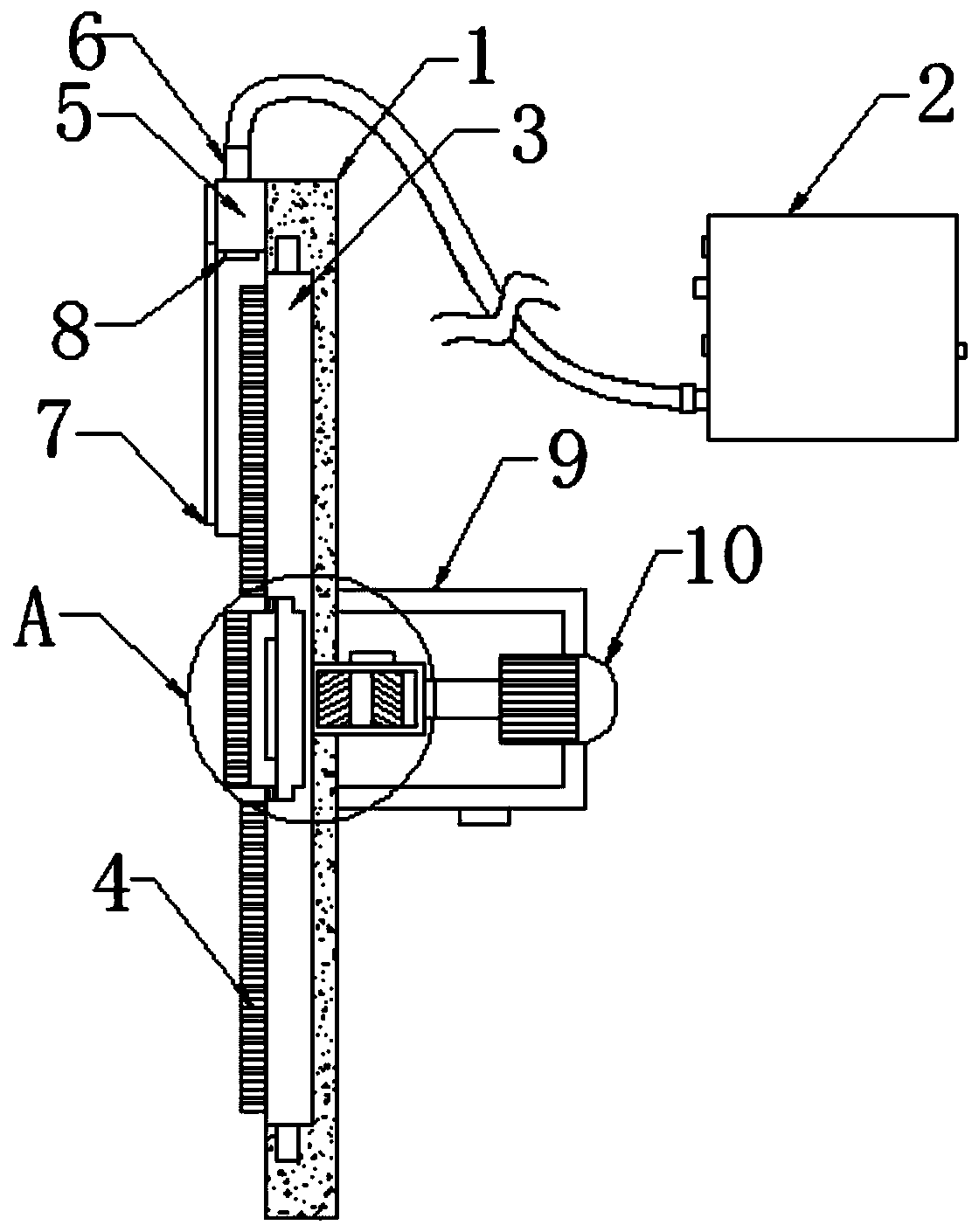

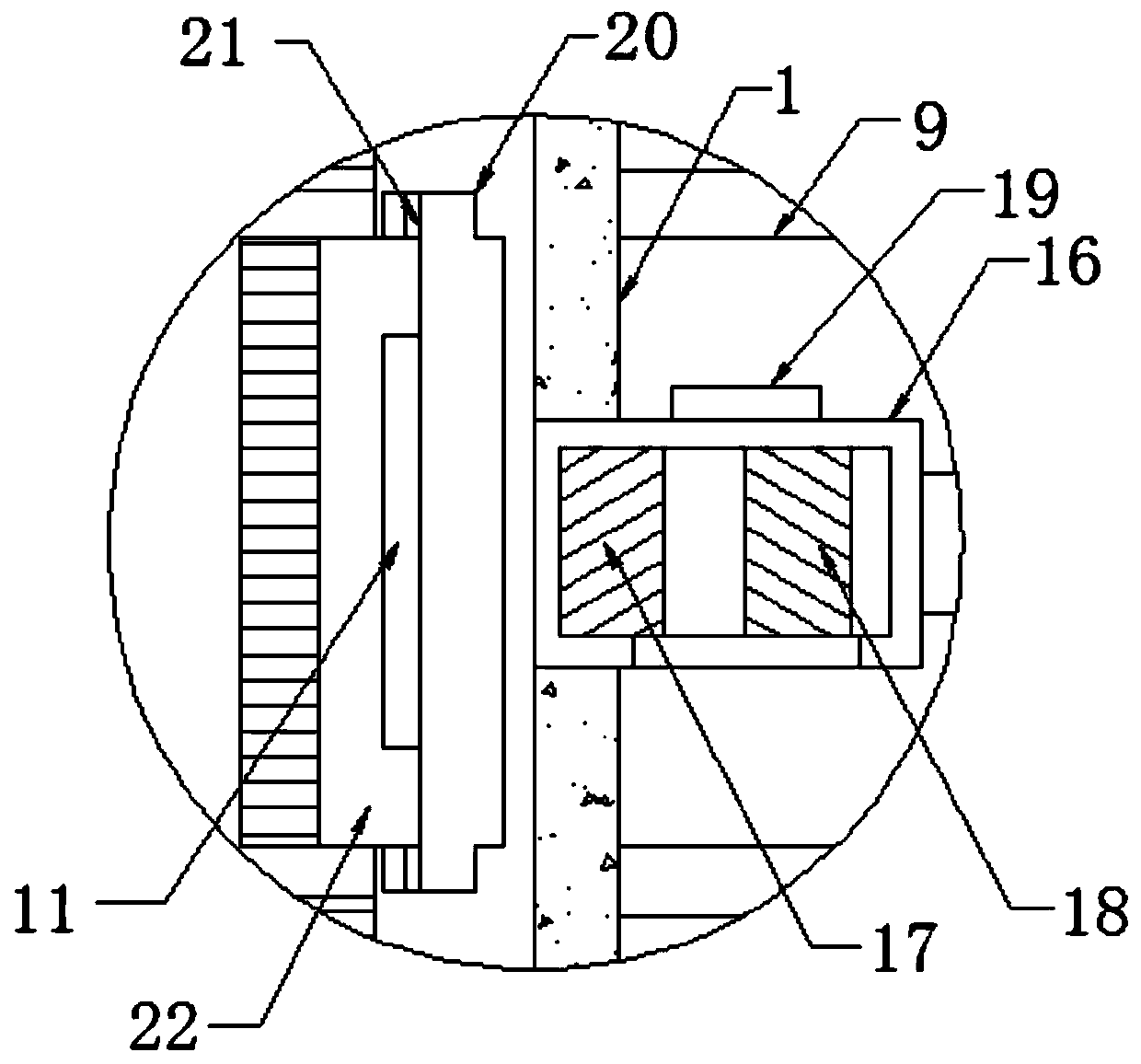

Device for coating natural gas pipeline surface with corrosion remover

InactiveCN107570368APrevent precipitationInhibit sheddingPretreated surfacesCoatingsMaterials scienceRust

The invention relates to a corrosion remover coating device, in particular to a device for coating the natural gas pipeline surface with a corrosion remover. The device for coating the natural gas pipeline surface with the corrosion remover achieves the technical aims that time and labor are saved, the labor intensity is small, corrosion remover coating is even, the corrosion remover is not proneto falling, and waste is not prone to being caused. In order to achieve the above technical aims, the device for coating the natural gas pipeline surface with the corrosion remover is provided and comprises a base plate and the like; a support plate is installed on the left side of the top of the base plate, a first through hole is formed in the middle portion of the support plate, a containing frame is installed on the left side of the top of the base plate and is located on the right side of the support plate, supporting plates are installed on the left and right sides of the top of the baseplate, the supporting plate on the left side is placed on the right side of the containing frame, and a rust removal device is arranged between the middle portions of the supporting plates on the left and right sides. According to the device, rust removal on a natural gas pipeline can be achieved through the rust removal device, and the effects that the time and labor are saved, the labor intensity is small, corrosion remover coating is even, the corrosion remover is not prone to falling, and waste is not prone to being caused are achieved.

Owner:文永林

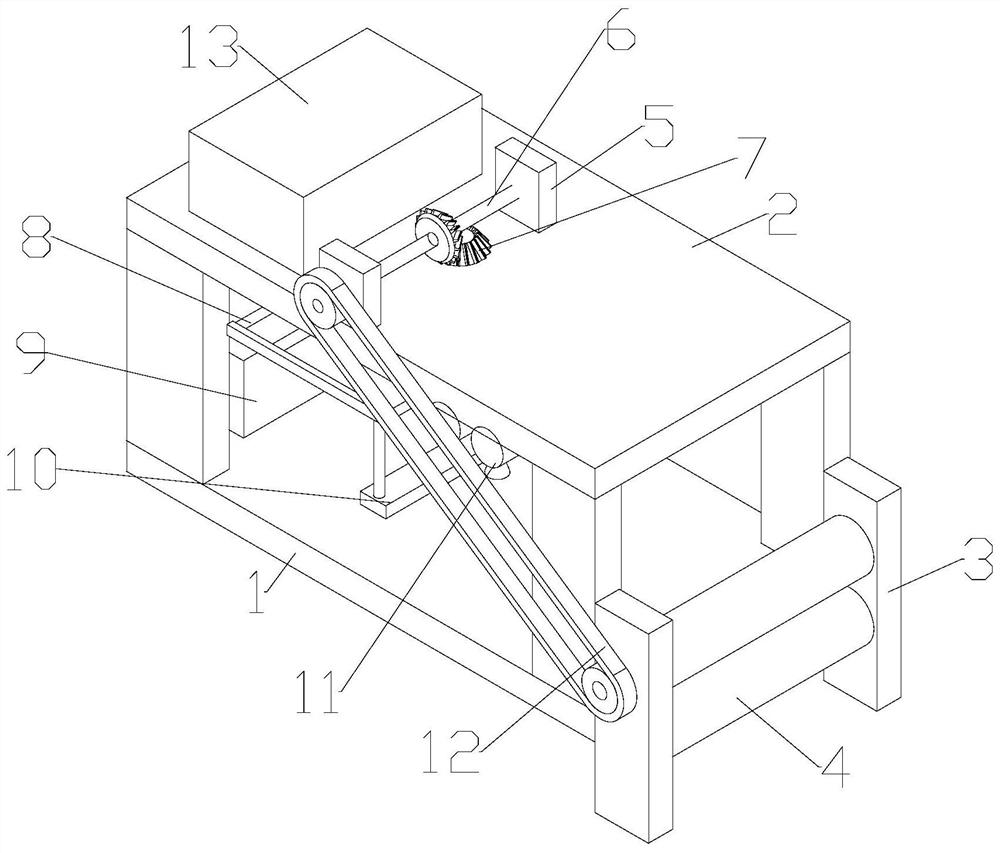

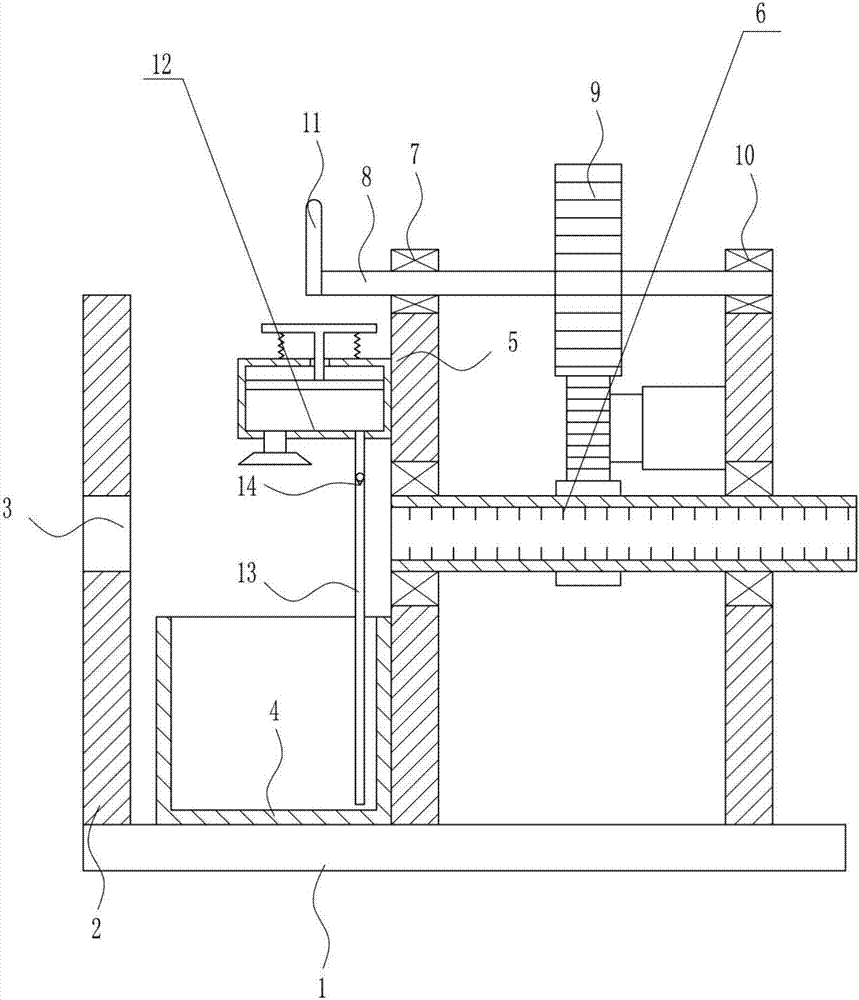

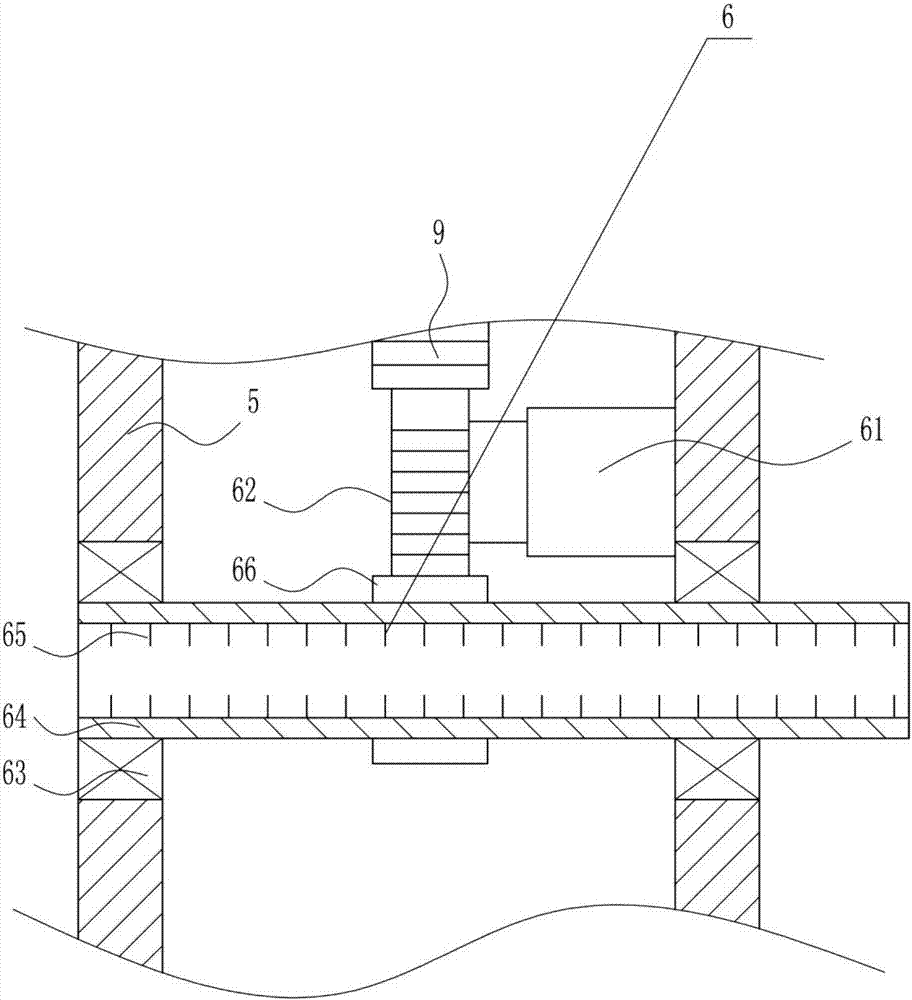

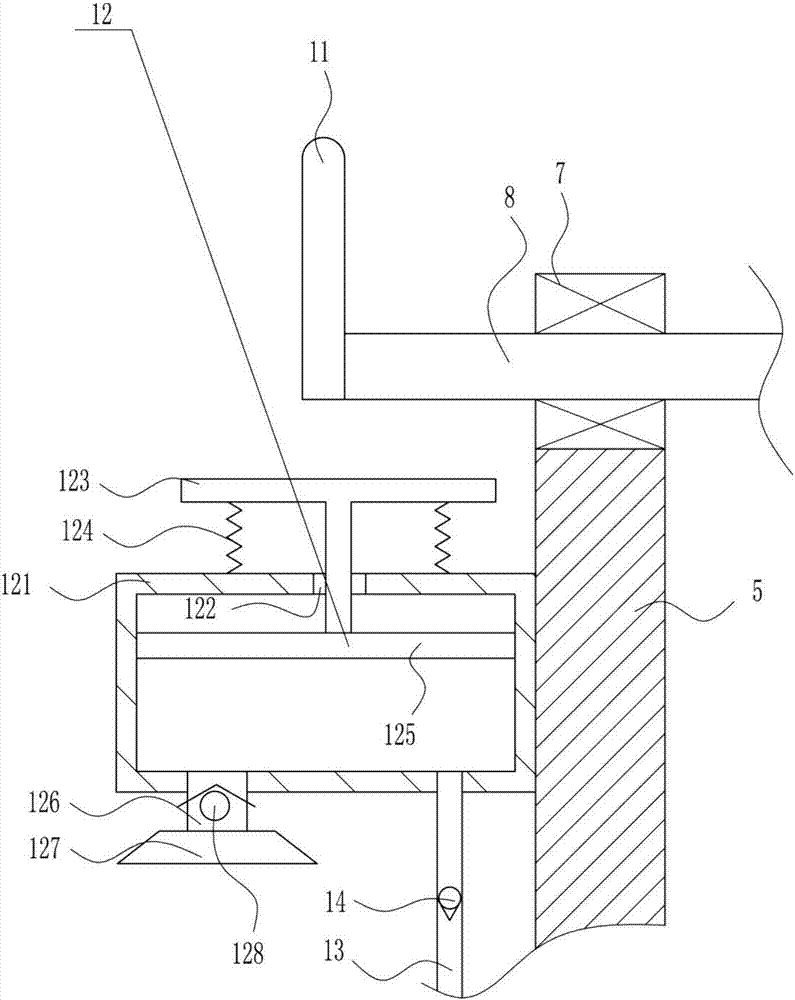

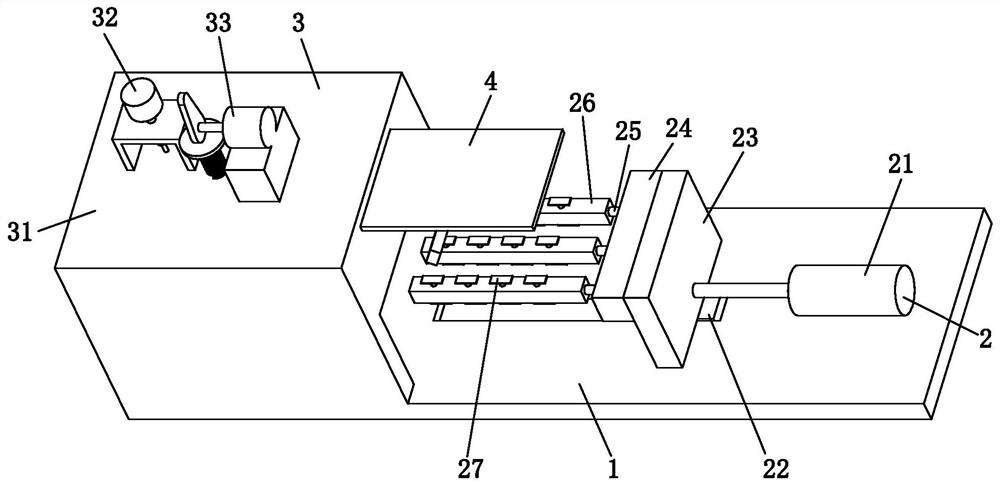

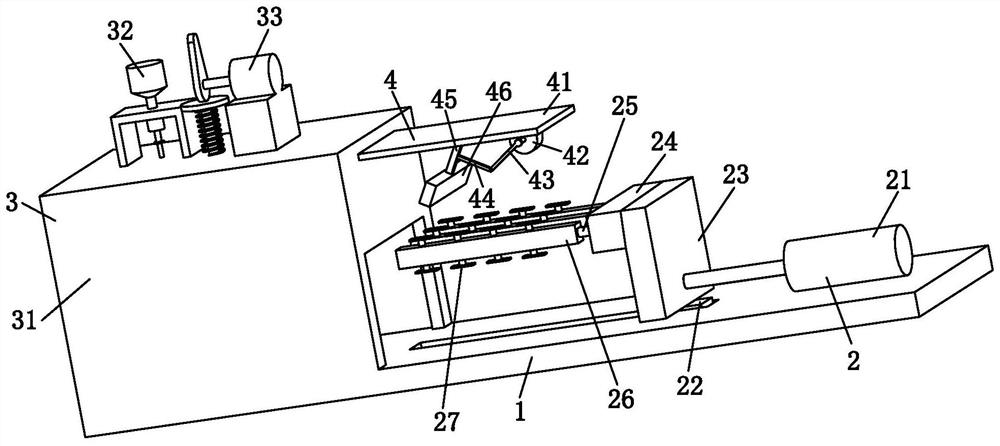

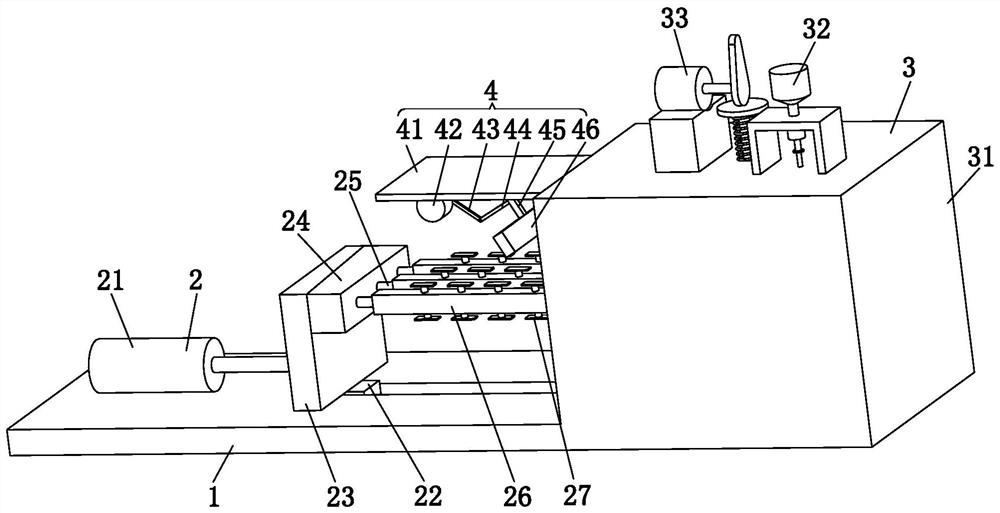

Wood board surface paint brushing device for furniture production

PendingCN113385380ABrush evenlyLiquid surface applicatorsCoatingsPulp and paper industryBrush device

The invention relates to a paint brushing device, in particular to a wood board surface paint brushing device for furniture production. According to the wood board surface paint brushing device for furniture production, time and labor are saved, repeated paint spraying and missing spraying are avoided, the machining effect is good, and the paint utilization rate can be increased. According to the technical scheme, the wood board surface paint brushing device for furniture production comprises supporting legs and a first mounting plate, and the first mounting plate is arranged between the supporting legs; a placing frame is arranged on the first mounting plate; a pushing mechanism is arranged at the bottom of the first mounting plate; and a driving mechanism is arranged on the first mounting plate. Through the arrangement of a drying box, after the surface of a wood board is uniformly painted by a brush and a scraping plate, the drying box can dry the paint on the surface of the wood board.

Owner:唐珊

Shoemaking method through aerial fog glue spraying

InactiveCN106490768AIncrease productivityImprove product qualityMineral oil hydrocarbon copolymer adhesivesEpoxy resin adhesivesAdhesiveEngineering

The invention discloses a shoemaking method through aerial fog glue spraying and belongs to the technical field of shoemaking. The method comprises the steps of assembly unit placing, dedusting, adhesive spraying and bonding, wherein the step of assembly unit placing comprises the procedures of flatly laying one piece or above shoe sole or upper of a shoe on a glue spraying plate according to a suit cut method, and a 2-4 mm gap is left between the assembly units; the step of dedusting comprises the procedures of conducting overall dedusting on glue spraying assembly units through a sparger, and the speed of the overall dedusting is 6-9 s / m<2>; the glue spraying step comprises the procedures of adopting aerial fog glue spraying to conduct spraying and smearing on the glue spraying assembly units, and the interval between a glue spraying device and the glue spraying assembly units is 25-40 cm and the speed of spraying is 3-5 s / m<2>; the step of bonding comprises the procedures of bonding each of the glue-sprayed glue spraying assembly unit together in sequence and conducting drying. According to the shoemaking method through the aerial fog glue spraying, a traditional brush coating is replaced by the aerial fog glue spraying so that the amount of glue using of shoes is effectively controlled, and the brushing and smearing of the glue can be uniform, not only can production efficiency and product quality of the shoes be improved, but also comfort indexes of the shoes can be increased.

Owner:天津百世丹达科技有限公司

Original-state whole-section soil specimen collecting and manufacturing device and method

ActiveCN111380717AEasy to collectEasy to manufactureWithdrawing sample devicesPreparing sample for investigationSoil scienceAgricultural engineering

The invention belongs to the technical field of soil specimen collection and manufacturing, and particularly relates to original-state whole-section soil specimen collection and manufacturing equipment and method. The equipment comprises a soil specimen box body, a profile knife and a rubber brush device. The soil specimen box body comprises an outer box and a soil containing frame used for containing and shaping soil specimens, the soil containing frame is arranged in the outer box in a sleeved mode, and the soil containing frame is detachably connected with the outer box. By combining a plurality of pieces of soil sample collecting and manufacturing equipment, soil is more convenient to collect and manufacture, the integrity of the soil can be guaranteed, and later soil display and maintenance are better facilitated.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

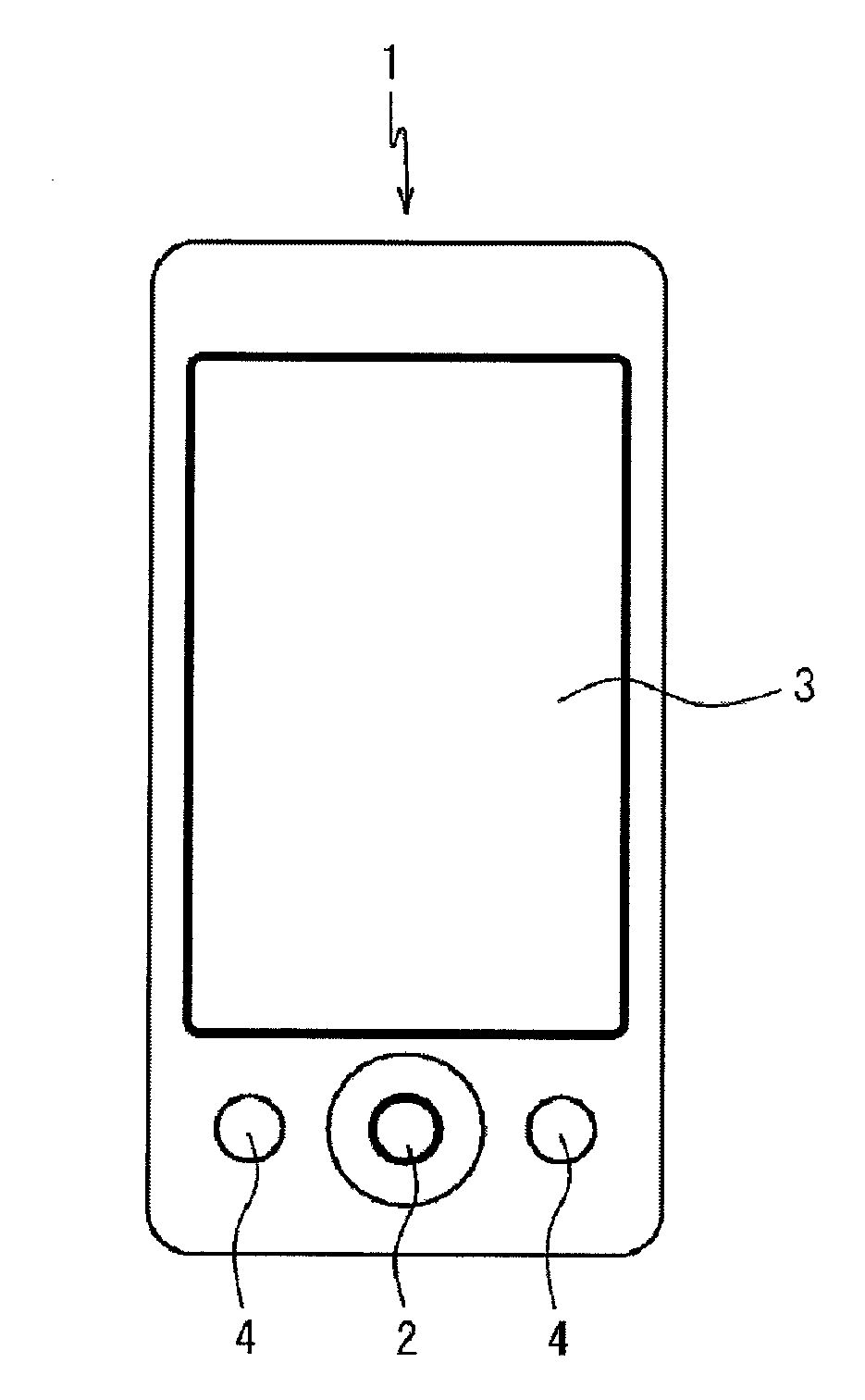

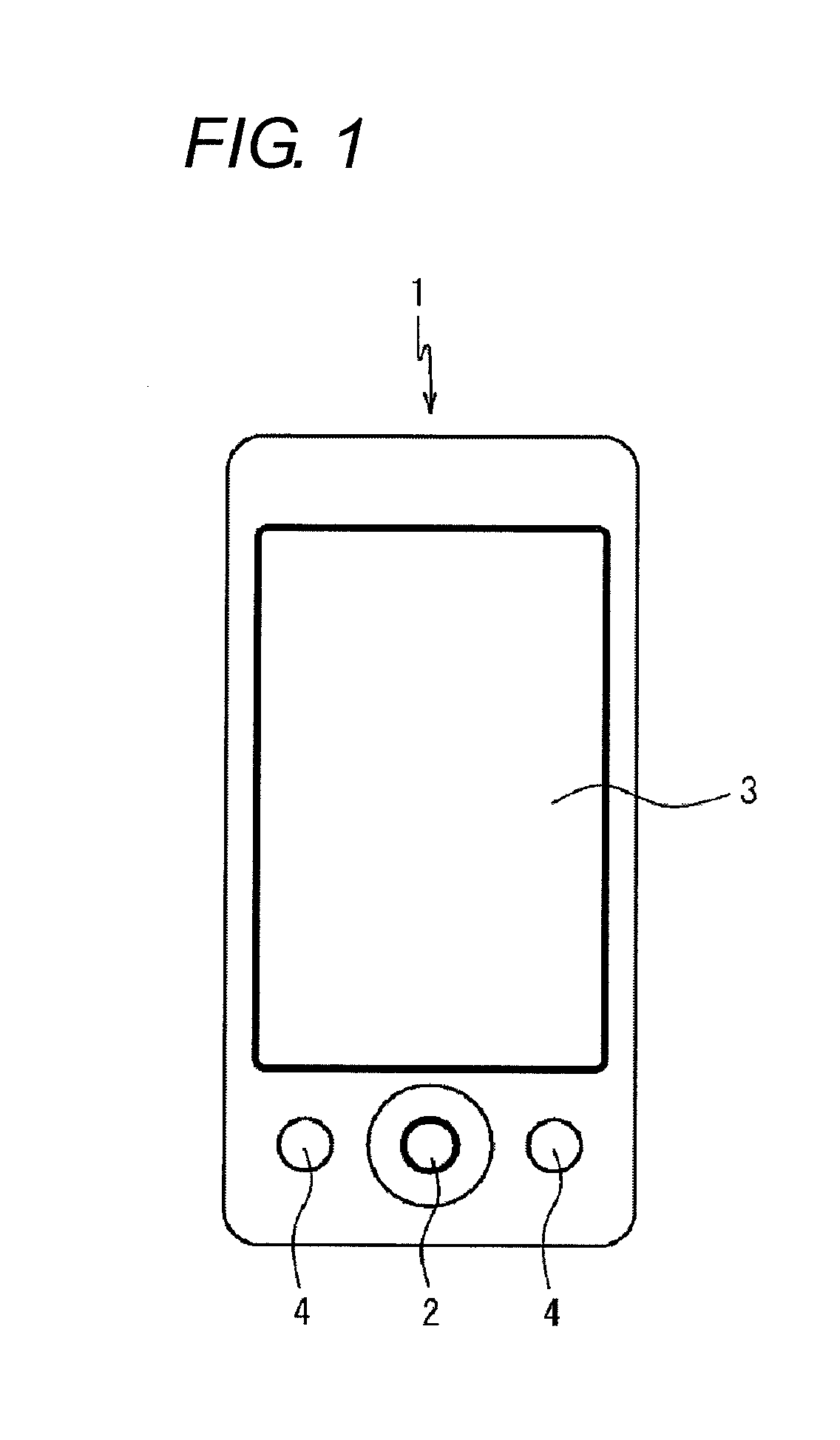

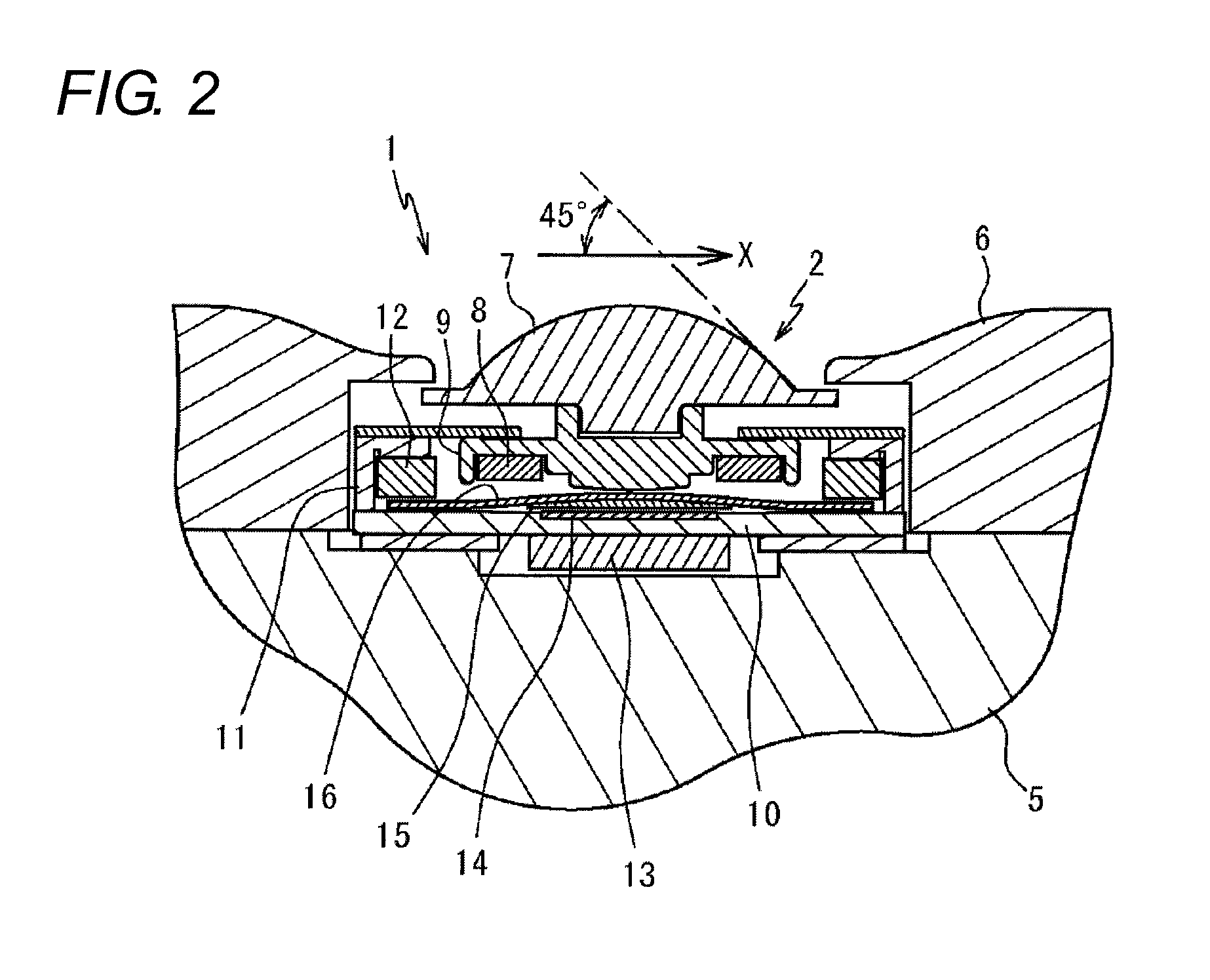

Input device and pointing device

InactiveUS20110221690A1Brush evenlySmooth slidingInput/output for user-computer interactionTransmission systemsEngineeringPointing device

An input device has an operation member, that is configured to be brushed by a finger of a user, and a detection unit for detecting a component of a force acting in a predetermined input direction with respect to the operation member when the user brushes the operation member. The input direction is two directions orthogonal to each other.

Owner:ORMON CORP

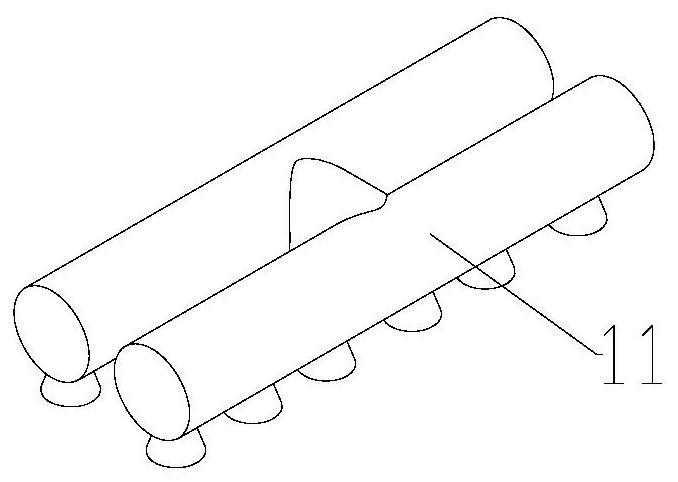

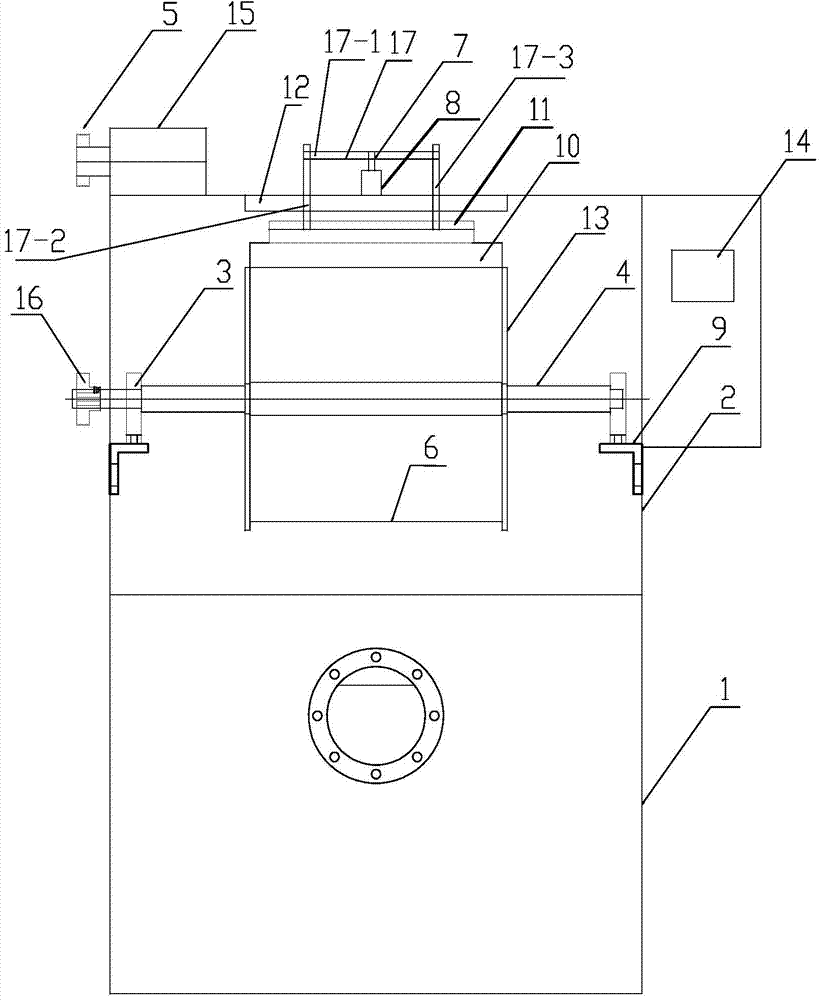

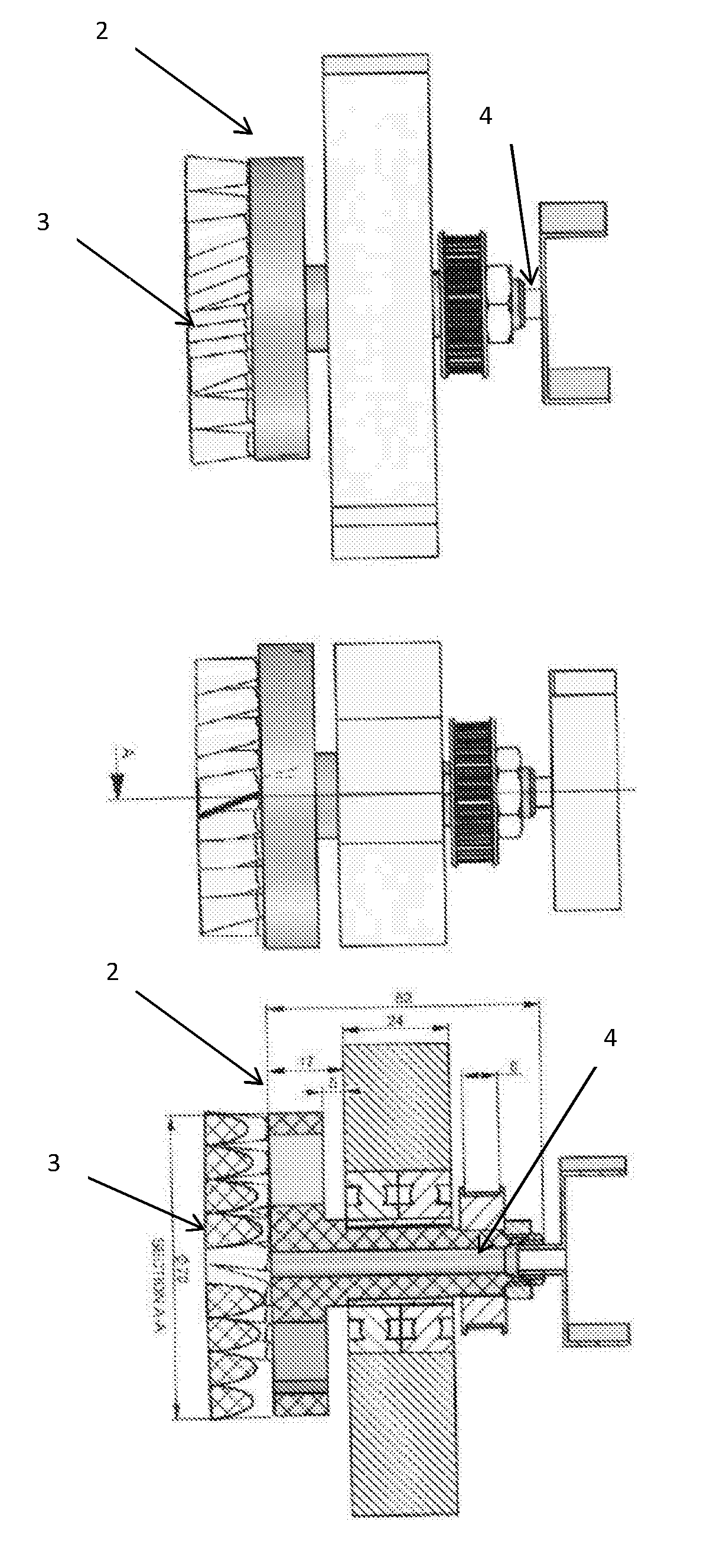

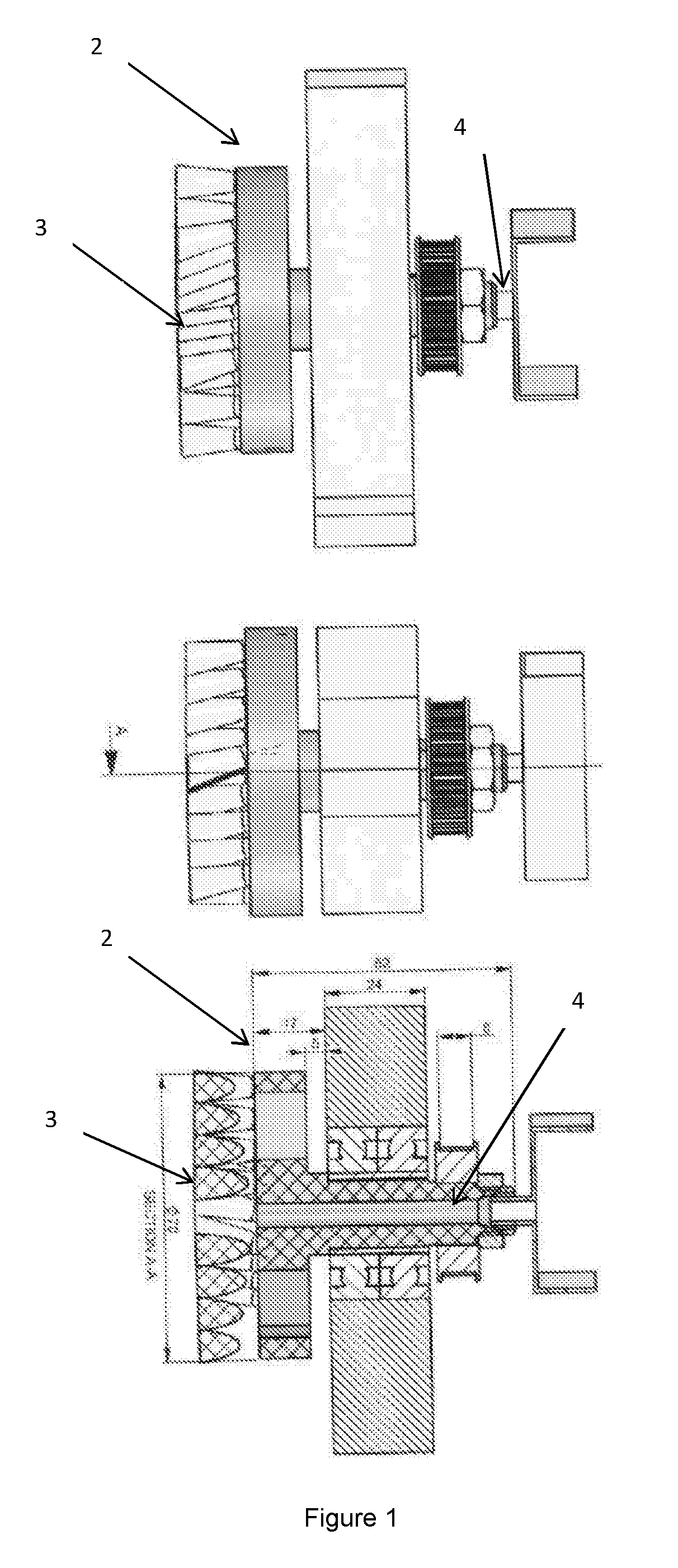

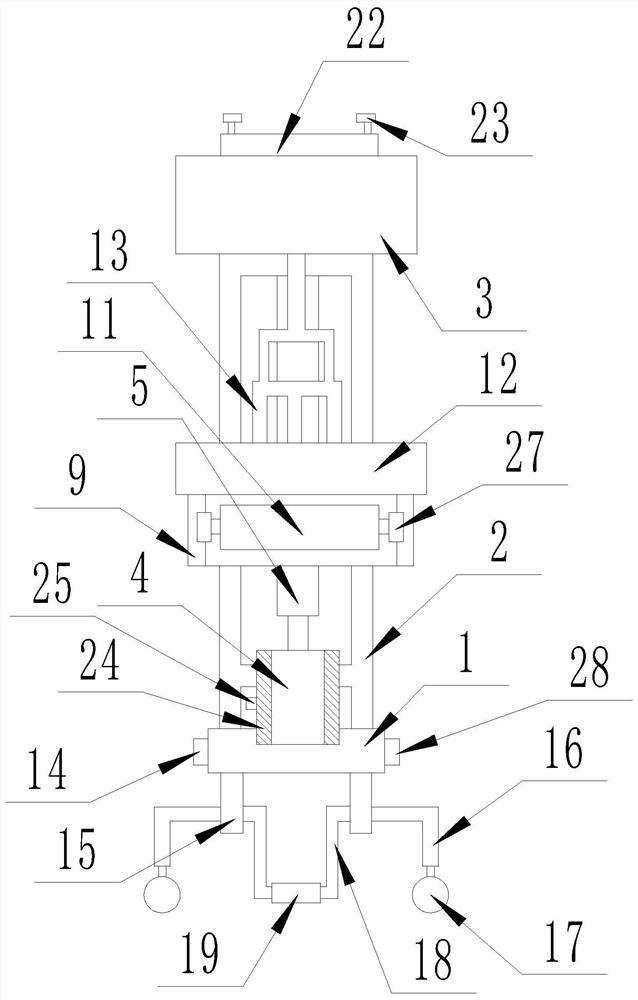

Bristle brush cleaning machine for micro bearing inner ring

ActiveCN103785632ABrush evenlyEasy to cleanCleaning using toolsCleaning using liquidsBristleFuel tank

The invention belongs to the field of cleaning machines and particularly relates to a bristle brush cleaning machine for a micro bearing inner ring. The bristle brush cleaning machine comprises a lower box body used for supporting an upper box body and serving as an oil tank. Material disc bearing pedestal supporting bases are fixed at the two ends inside the upper box body in the length direction respectively. A material disc bearing pedestal is fixed to each material disc bearing pedestal supporting base. A material disc shaft is supported on the material disc bearing pedestals in a rotating mode, material discs are installed on the material disc shafts in a sleeved mode and fixed through flat keys, and a first belt wheel is fixed to the shaft end, extending out of the outer side of the upper box body, of the material disc shaft. A material disc motor is arranged at the top of the upper box body, a second belt wheel is fixed to the output end of the material disc motor, and the second belt wheel is connected with the first belt wheel through a belt. The cleaning machine can clean channels in the bearing inner ring, and the surfaces of the channels and inner holes can also be brushed and flushed, so that a better effect is achieved, and the machine is simple in design, easy to operate and maintain and high in production efficiency and cleaning quality.

Owner:WUXI CHENGSHI BEARING

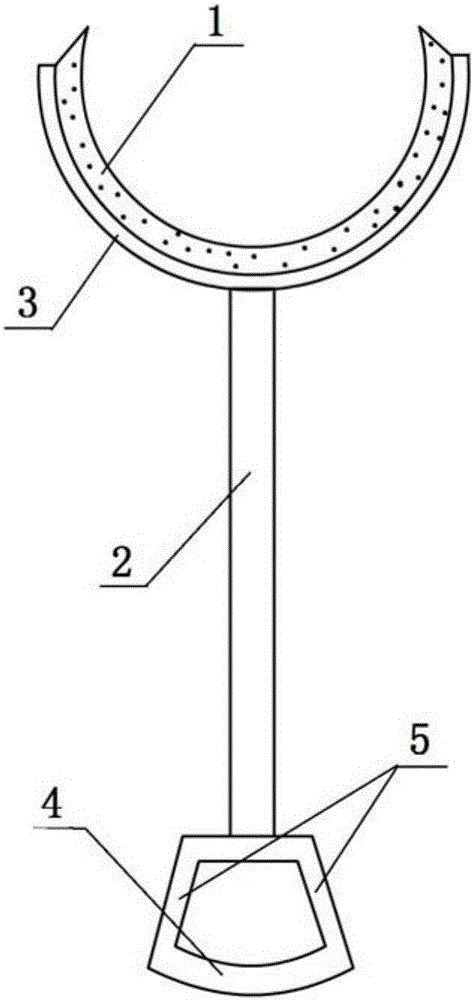

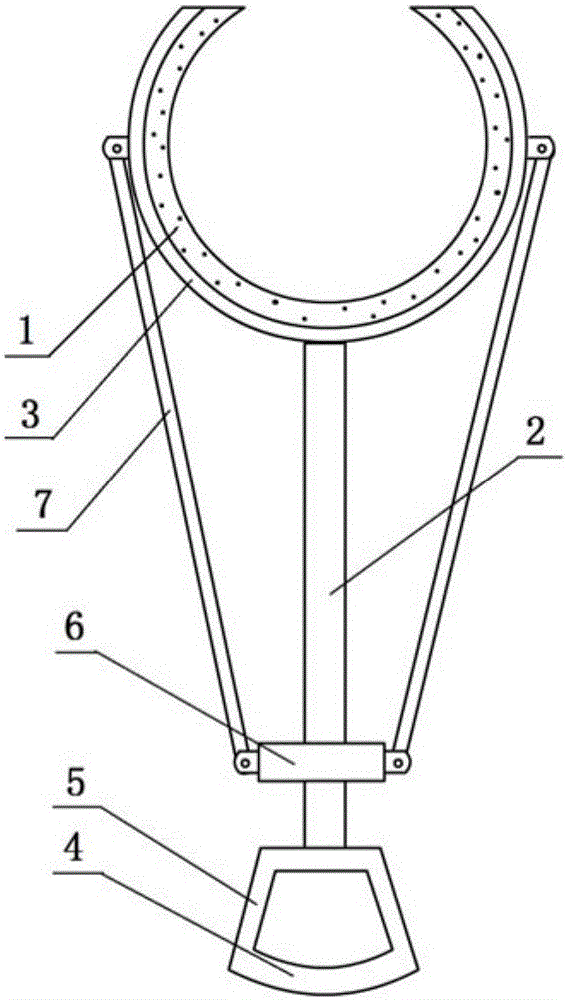

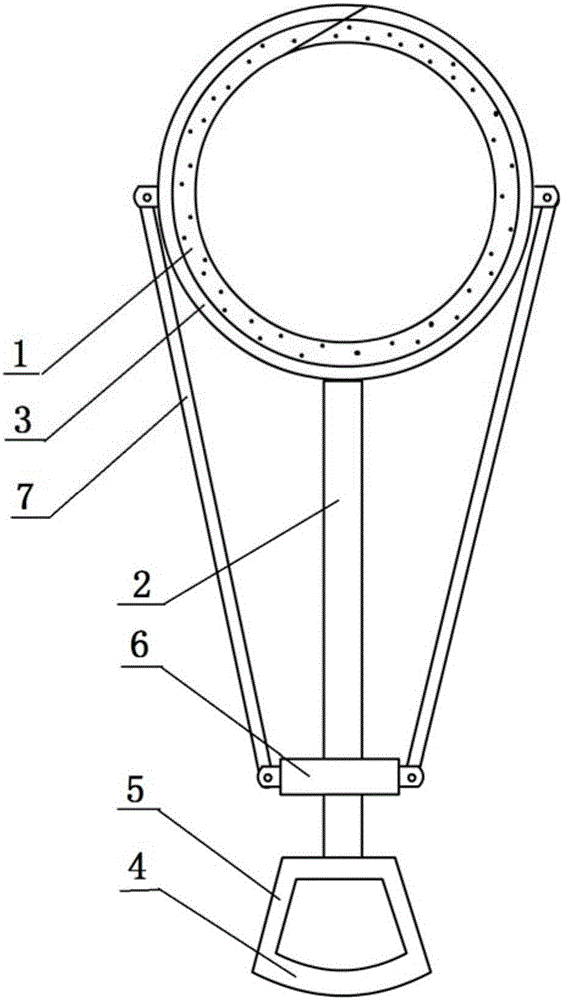

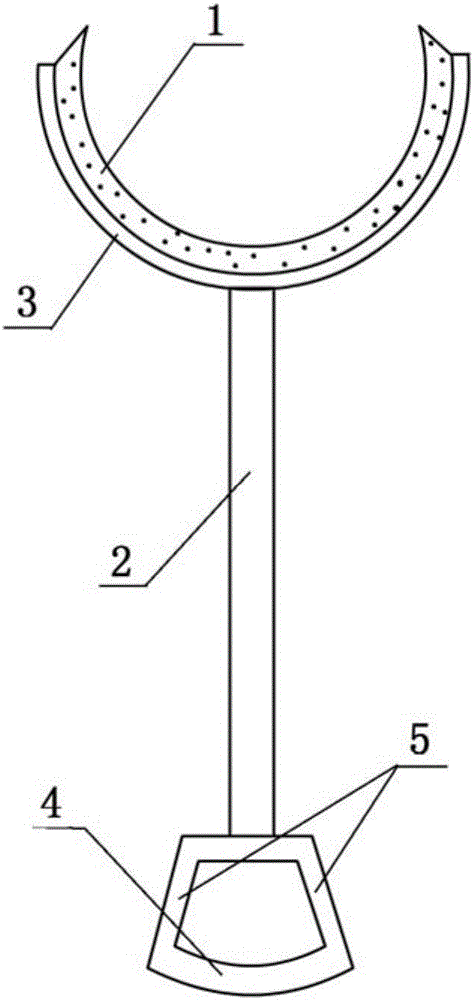

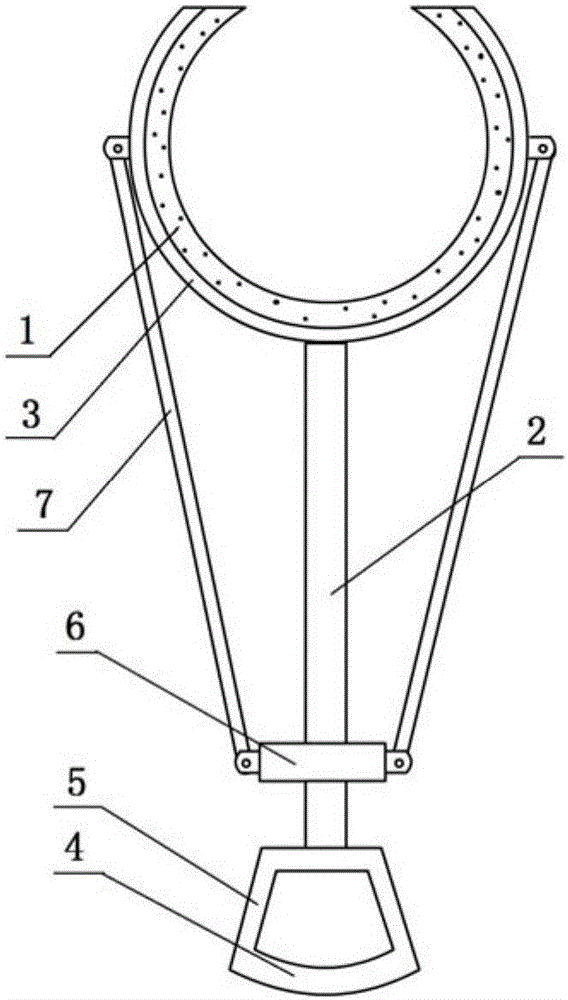

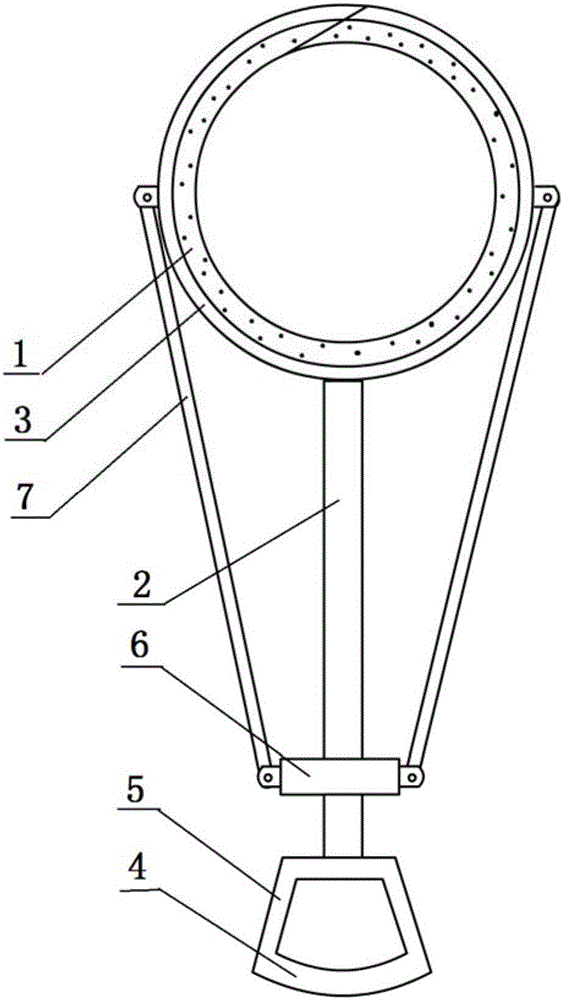

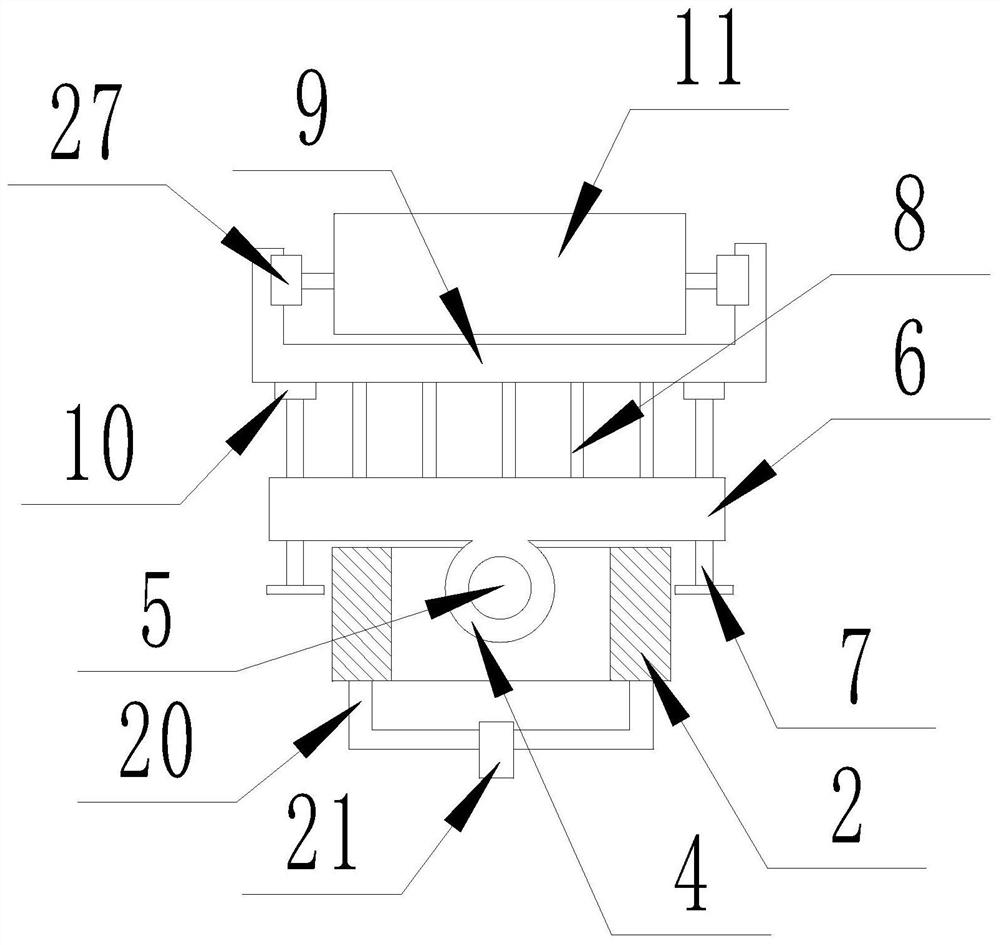

Arc-shaped multi-dimensional brush coating tool applied to building stand column

ActiveCN104989086AImprove brushing efficiencyBrush evenlyBrush bodiesBristle carriersBristleEngineering

The invention discloses an arc-shaped multi-dimensional brush coating tool applied to a building stand column. The tool comprises bristles, bristle carriers and a brush rod and is characterized in that the bristle carriers are arc-shaped elastic sheets, the bristles adhere to the inner sides of the elastic sheets, and the brush rod is connected with the middle of each elastic sheet; the central angle opposite to each elastic sheet is greater than 180 degrees, a sliding block capable of sliding on the body of the brush rod is arranged on the brush rod, pull rods are hinged to the elastic sheets on the two sides of the brush rod, and the other end of each pull rod is hinged to the sliding block. When the tool is used for brush coating, over half even the whole surface of the stand column can be covered through one-time brushing, brush coating efficiency can be improved greatly, brush coating leakage or repeating can be reduced, and brush coating can be conducted more evenly.

Owner:广州北环智能交通科技有限公司

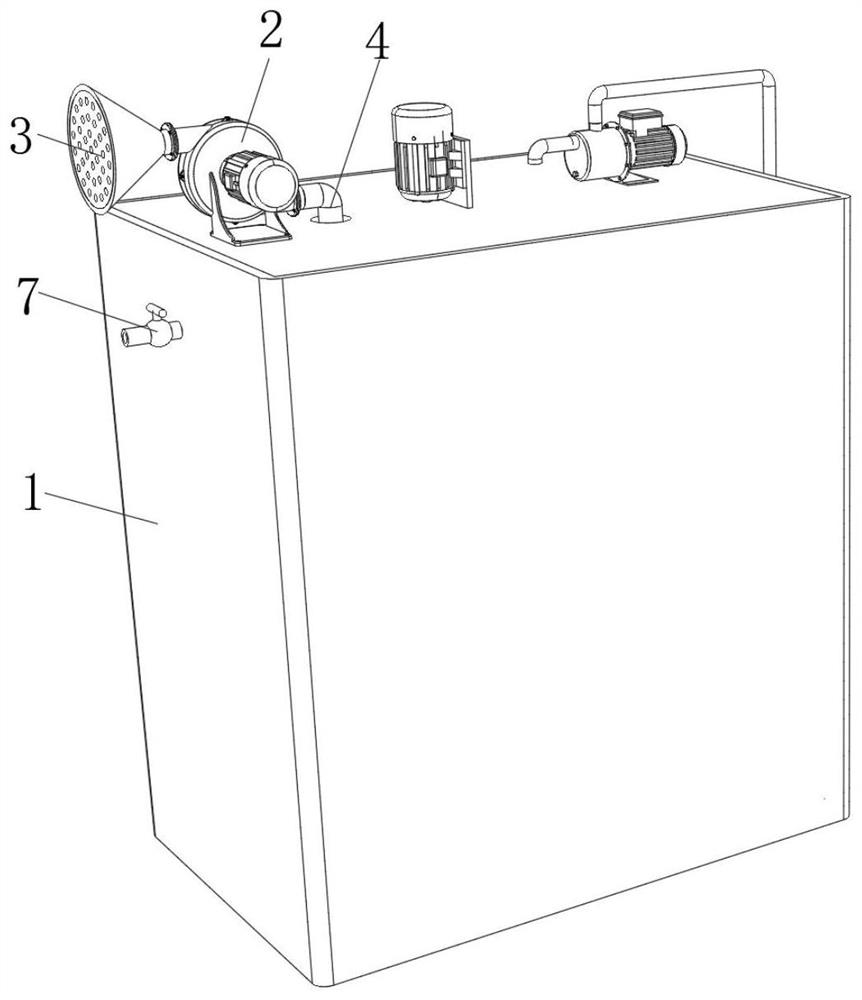

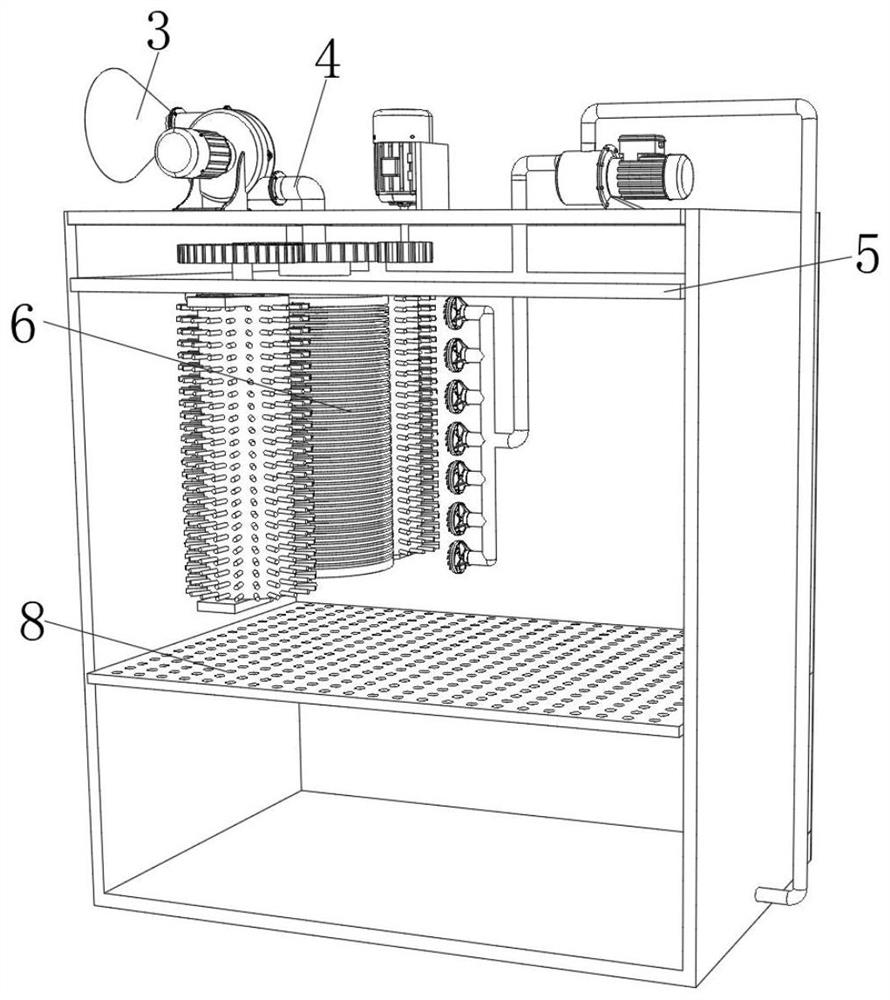

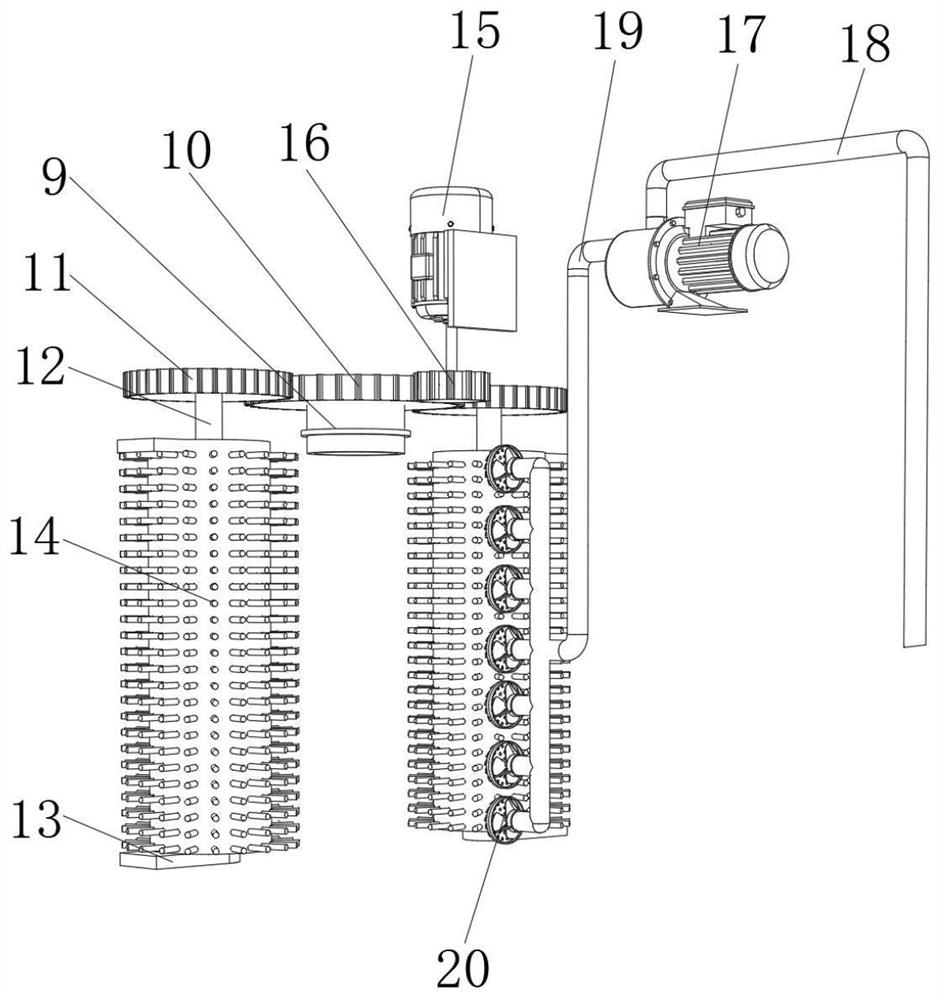

Efficient waste gas recovery device for paper production

InactiveCN112191645AEfficient adsorption treatmentImprove adsorption efficiencyDispersed particle filtrationTransportation and packagingPaper productionElectric machinery

The invention relates to the technical field of waste gas treatment, and discloses an efficient waste gas recovery device for paper production. The efficient waste gas recovery device comprises a waste gas recovery box, wherein a suction fan is fixedly connected to the left side of the upper surface of the waste gas recovery box, the input end of the suction fan communicates with an air inlet cover, a conveying pipe is in communication with the output end of the suction fan, a stable supporting plate is fixedly connected to the inner top of the waste gas recovery box, and a filtering column isarranged at the bottom of the conveying pipe. According to the efficient waste gas recovery device for paper production, water is sprayed to the surface of the filtering column through a water pump,a driving motor is matched to drive a cleaning rotating brush to rotate so as to comprehensively and uniformly brush the surface of the filtering column, stubborn dust of the filtering column can be better cleaned, a better cleaning effect on the surface of the filtering column is achieved, convenience of later use of the filtering column is better guaranteed, waste gas can be more efficiently adsorbed, and dust adsorption efficiency can be better improved.

Owner:新邵县金龙纸业有限责任公司

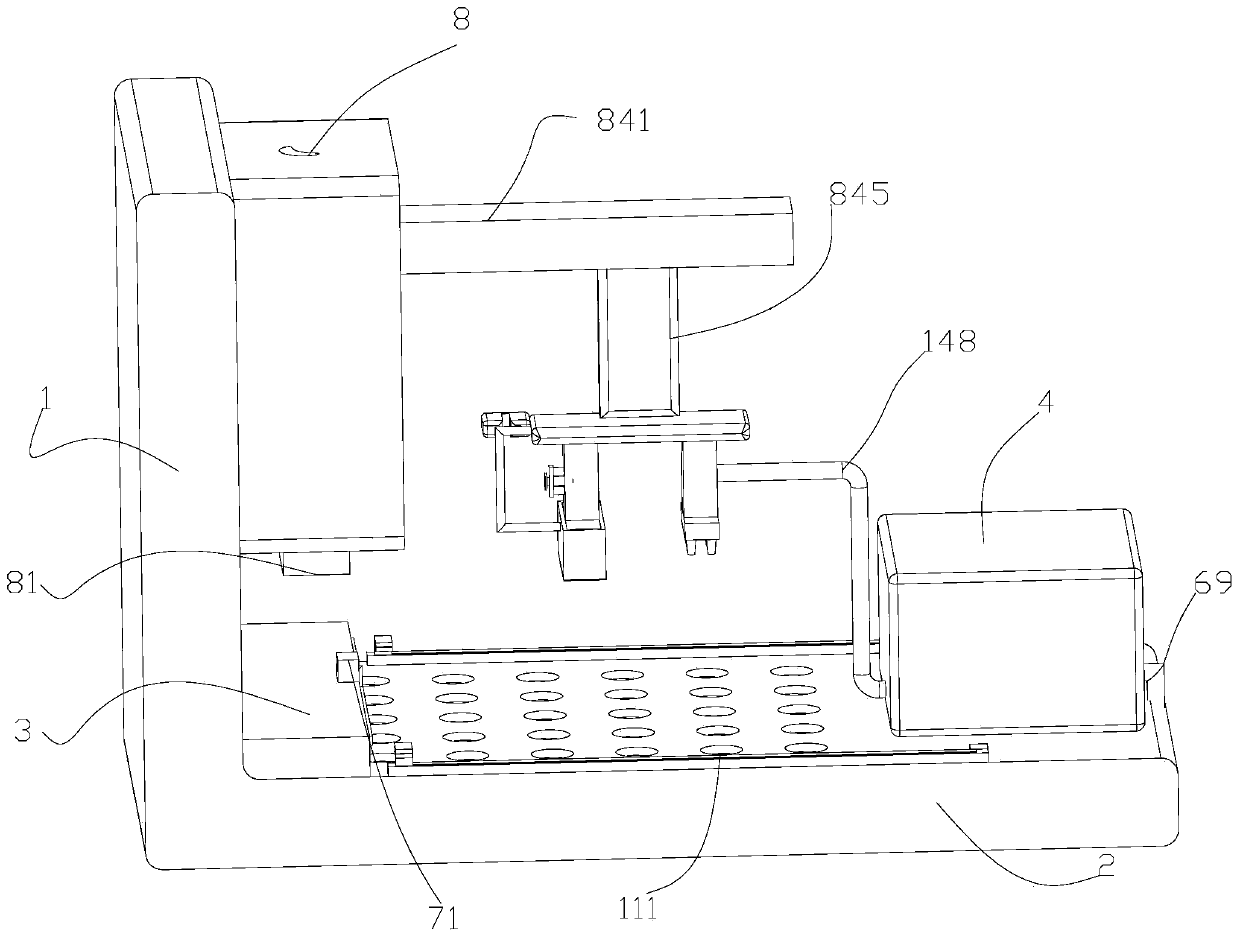

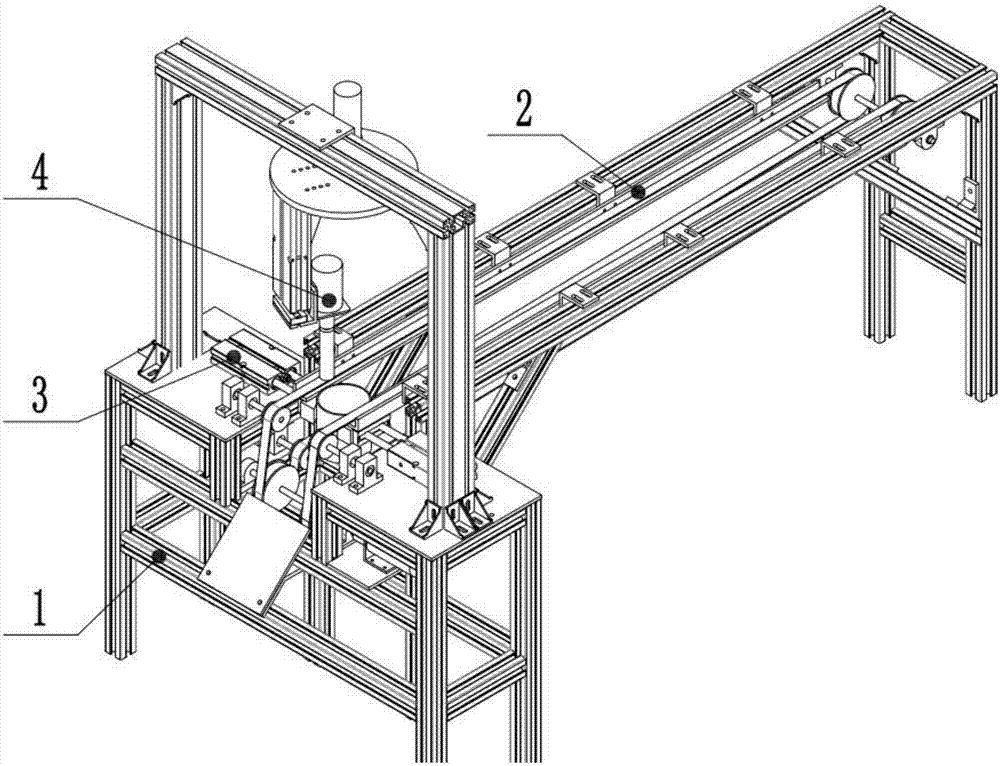

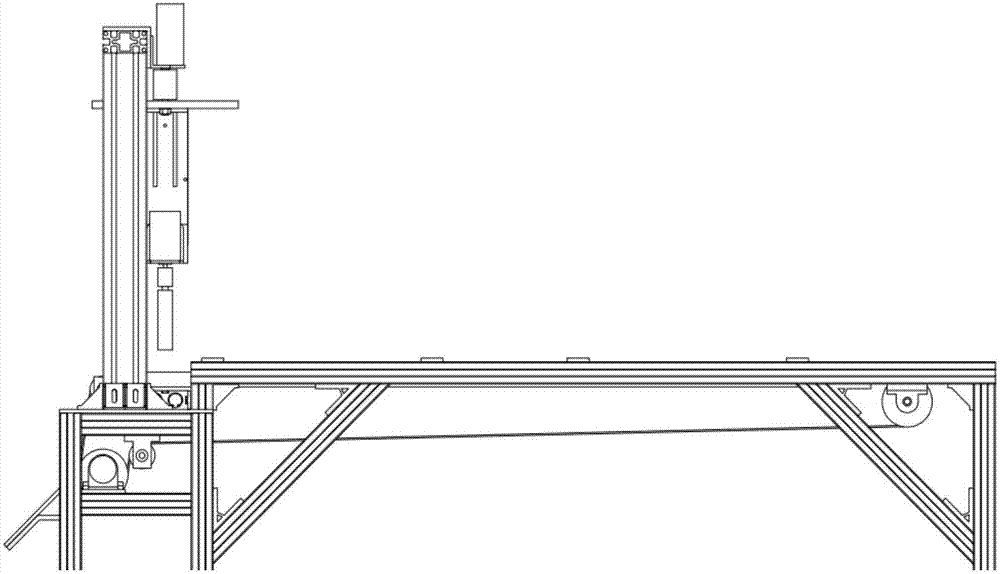

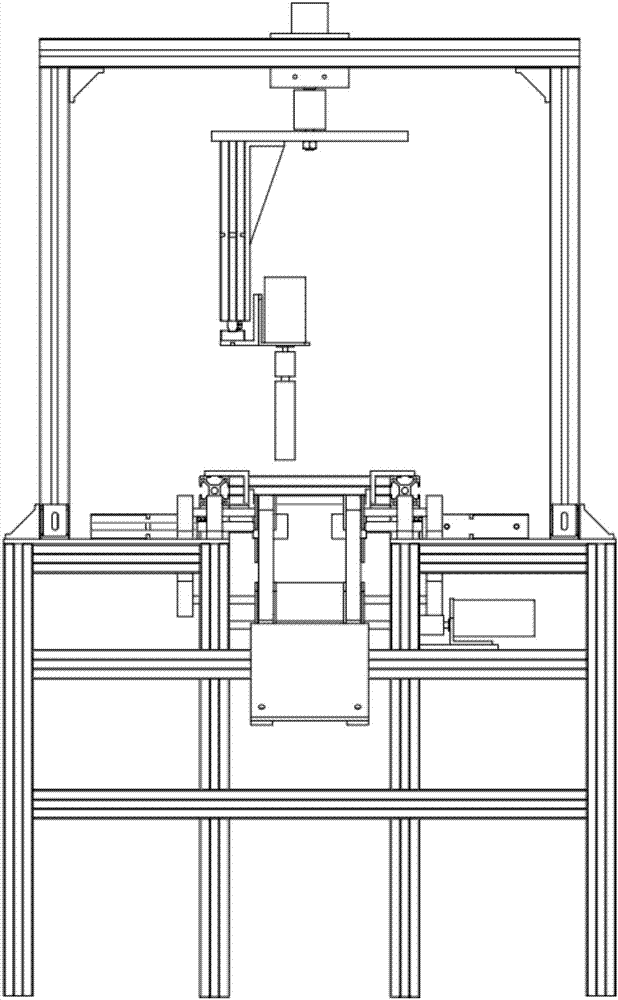

Oil cup inner wall grinding and brushing assembly line device

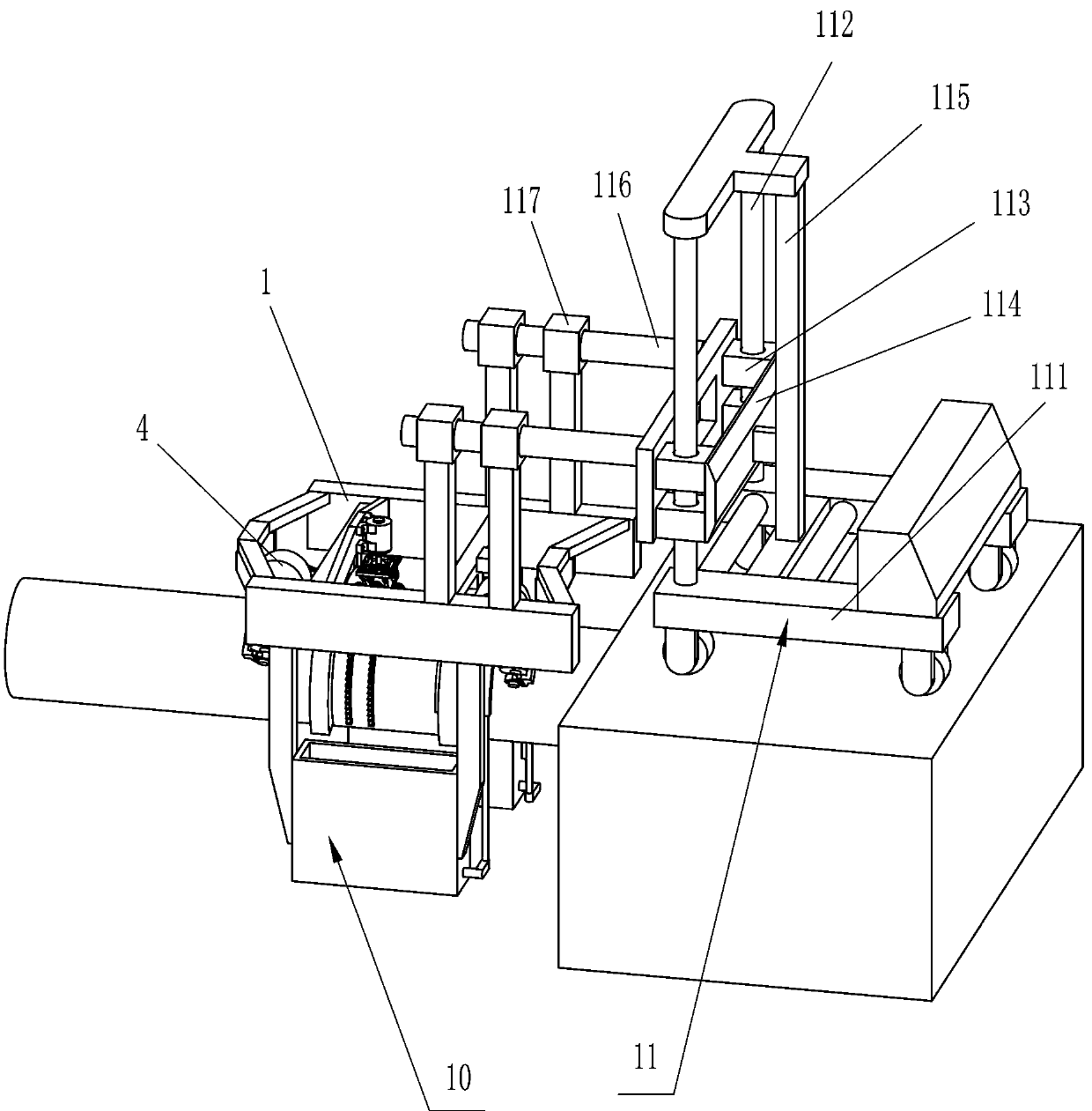

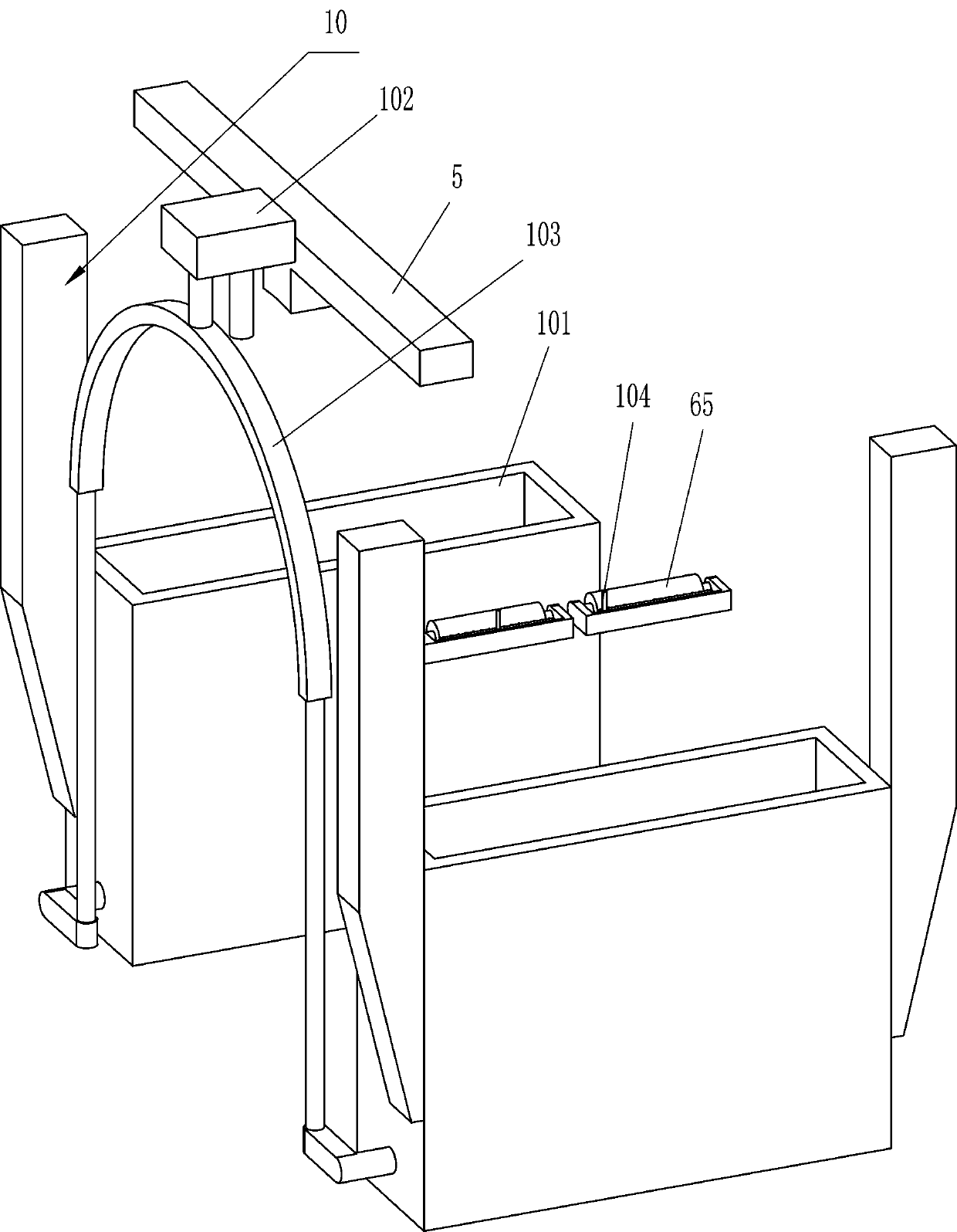

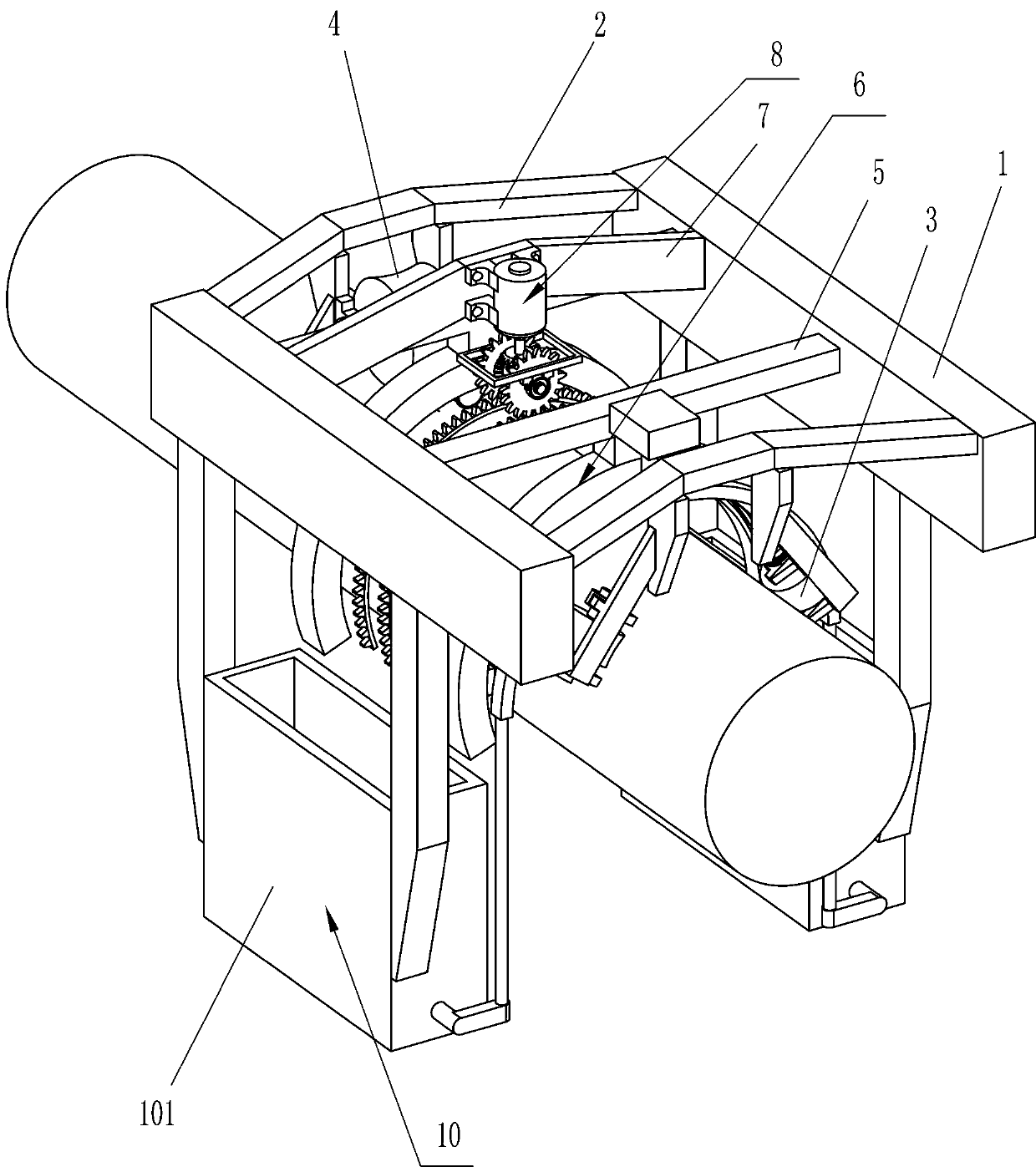

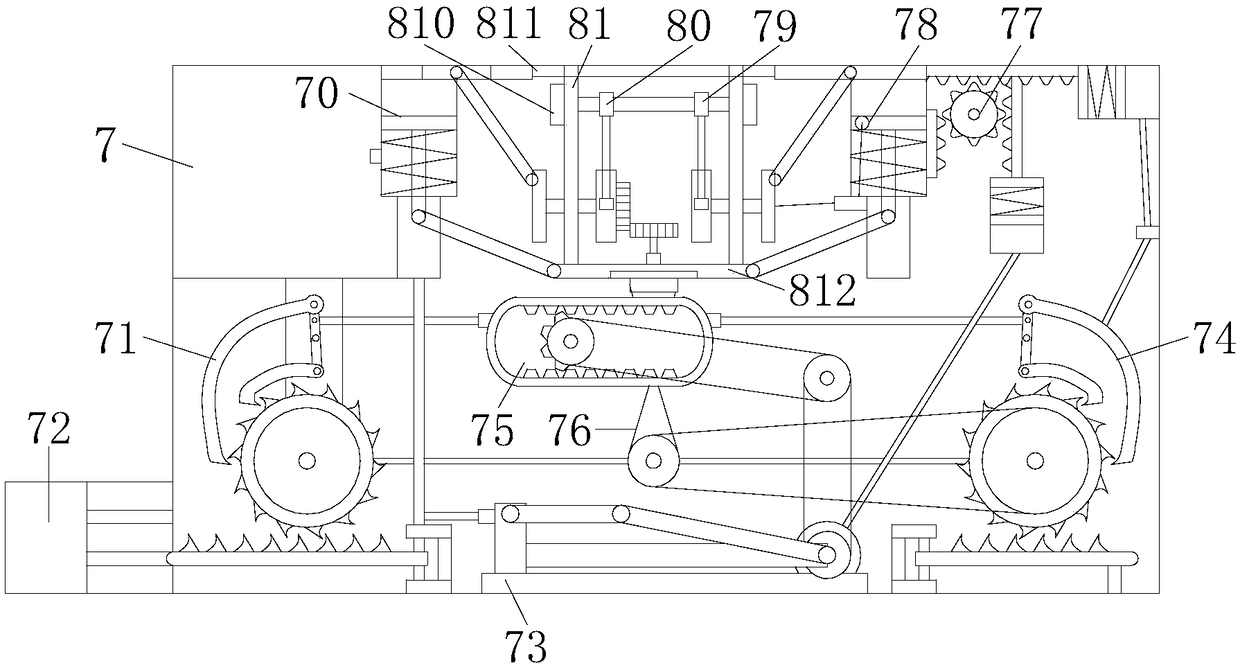

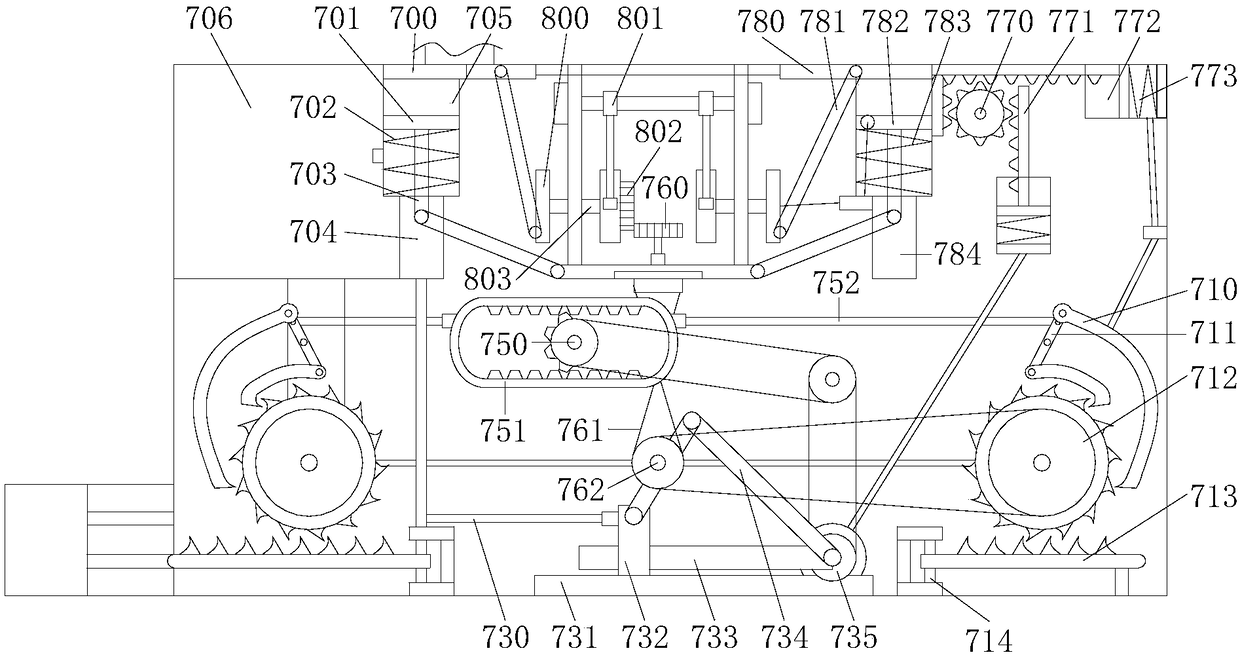

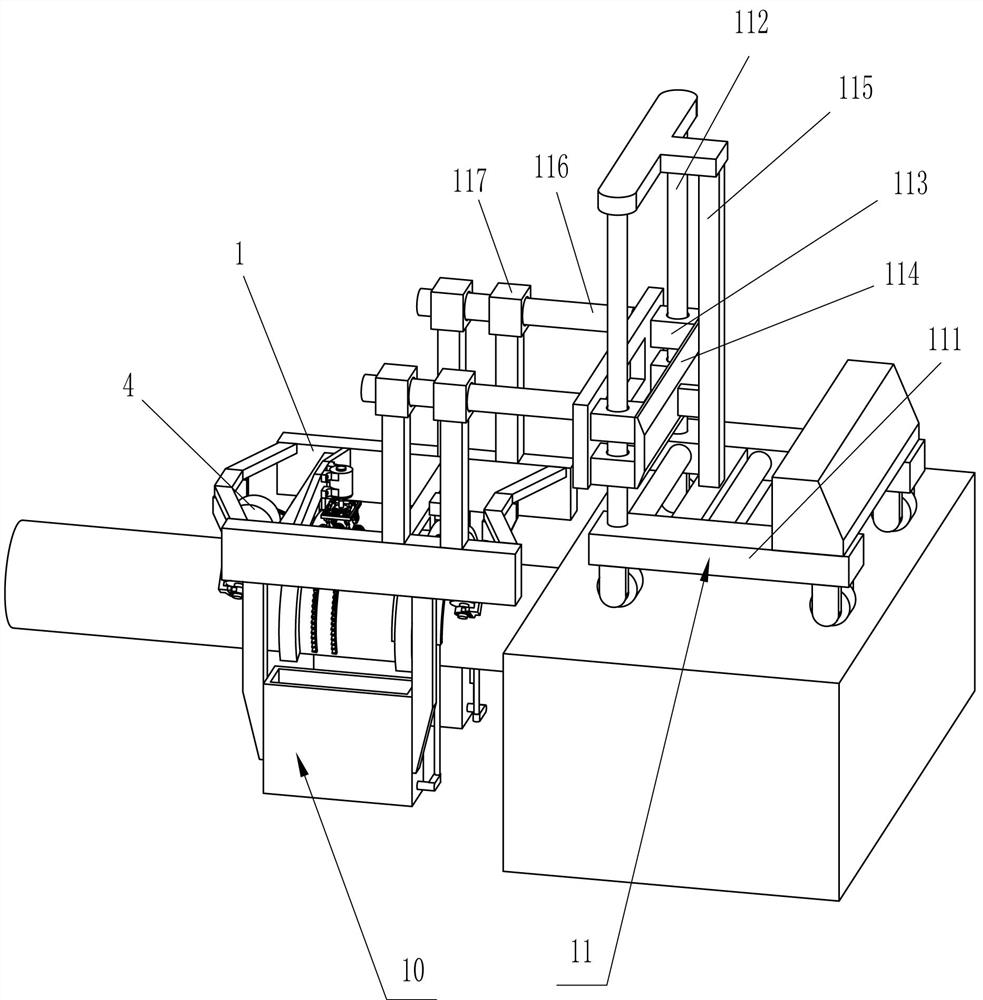

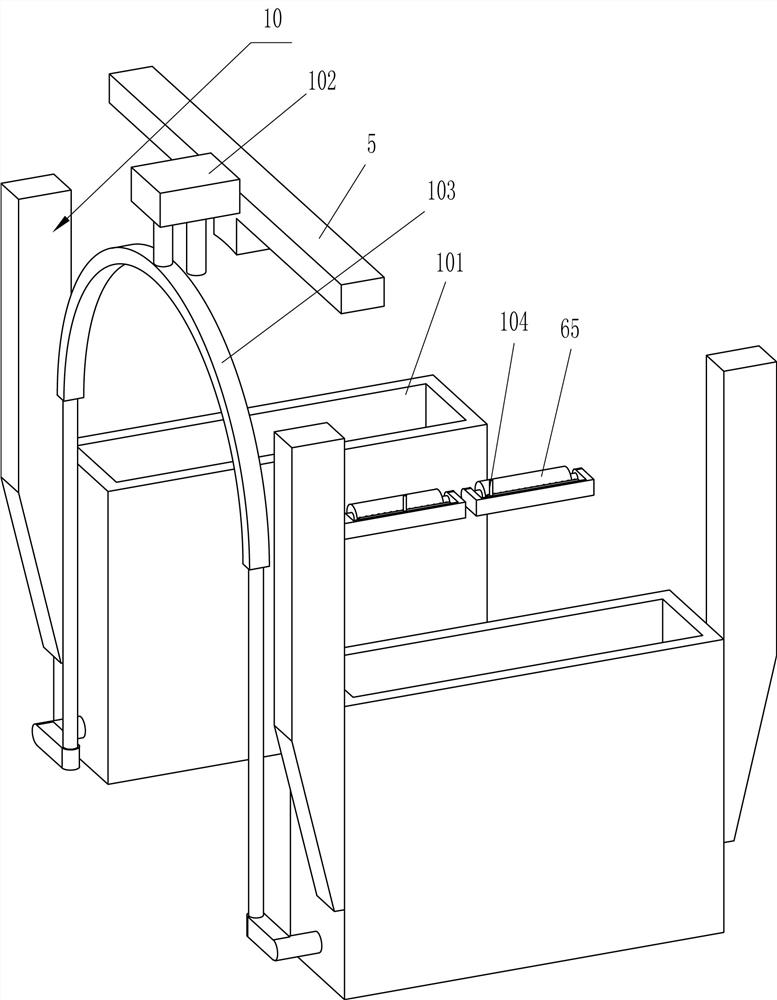

ActiveCN107414614AComplete processContinuously workingRevolution surface grinding machinesGrinding feedersDrive motorEngineering

An oil cup inner wall grinding and brushing assembly line device comprises an outer frame. The assembly line device further comprises a feeding mechanism, a clamping and centering mechanism and a grinding and brushing mechanism. An outlet of the feeding mechanism is connected with a clamping station of the clamping and centering mechanism. The grinding and brushing mechanism is located above the clamping station and comprises a dull polish bar, a drilling and grinding motor, an air cylinder, a rotary disc and a drive motor. The dull polish bar is vertically arranged and connected with an output shaft of the drilling and grinding motor. The drilling and grinding motor is arranged on the piston end portion of the air cylinder. The air cylinder is a driver capable of driving a piston to move up and down. The upper end of the air cylinder is fixed to the rotary disc. A rotation shaft of the rotary disc is connected with an output shaft of the drive motor used for driving the rotary disc to rotate. The drive motor is arranged on the outer frame. The oil cup inner wall grinding and brushing assembly line device capable of achieving machining and eliminating potential safety hazards, high in machining efficiency and good in rapidity is provided.

Owner:杭州亦侬农业科技有限公司

Leather swabbing device

InactiveCN105779671AQuick BrushBrush evenlyLeather/skins/hides/pelt chemical treatment apparatusEngineeringMechanical engineering

The invention discloses a leather swabbing device which comprises a cleaning device, a swabbing device body and a secondary treating device. The cleaning device comprises two symmetrical and same cleaning blocks, each cleaning block comprises an impurity removing block and a water absorbing block, the cleaning blocks are fixed to the water absorbing blocks, the water absorbing blocks are connected with a support, and the support is provided with the swabbing device body; the swabbing device body comprises two symmetrical and same swabbing rollers, and the swabbing rollers are provided with sponge sleeves and slurry boxes; the secondary treating device comprises two symmetrical and same rolling rollers fixed to the support, and the rolling rollers are provided with sponge sleeves. According to the leather swabbing device, the swabbing speed is high, the working intensity is low, produced swabbed leather is high in quality, the condition that the swabbing thicknesses are different cannot occur, and slurry is saved through the specially-made slurry boxes.

Owner:ANHUI RUISI ENVIRONMENT FRIENDLY ENERGY CO LTD

Paint spraying equipment for magnesium-aluminum alloy decorative line manufacturing and paint spraying method

InactiveCN113019762AImprove spraying efficiencyImprove product qualitySpray boothsMagnaliumAluminium alloy

The invention relates to paint spraying equipment for magnesium-aluminum alloy decorative line manufacturing and a paint spraying method. The paint spraying equipment comprises a bottom plate, a fixing device, a paint spraying device and an air drying device; and the fixing device is arranged at the position, close to the right end, of the upper end face of the bottom plate, the paint spraying device is installed on the left side of the fixing device, and the air drying device is connected to the right side wall of the paint spraying device. According to the paint spraying equipment and the paint spraying method, the following problems possibly occurring in the existing production and manufacturing process of a magnesium-aluminum alloy decorative line can be solved: a, the outer surface of the magnesium-aluminum alloy decorative line is manually sprayed with paint by using a spray gun, and the mode is relatively high in labor intensity and relatively low in efficiency, so that the production efficiency of the magnesium-aluminum alloy decorative line is relatively low; and b, manual spraying possibly causes incomplete or non-uniform spraying due to workers, so that the spraying effect is poor, and the appearance quality of the magnesium-aluminum alloy decorative line is influenced.

Owner:湖北民科汉业安装工程有限公司

Copper foil removing equipment for UWB positioning base station substrate production

PendingCN114423162AAvoid damageReduce adverse effectsPrinted circuit liquid treatmentInsulating layers/substrates workingMetallurgyEngineering

The invention relates to the technical field of electronics, in particular to copper foil removing equipment for UWB positioning base station substrate production. The technical problem is that a copper foil on a substrate has impurity particles during pressing, after the copper foil is etched and removed, the impurity particles fall into blind holes of the substrate, and additional processing steps need to be added for processing, so that the production cost is increased. According to the technical scheme, the copper foil removing equipment for UWB positioning base station substrate production comprises a bottom frame, a collecting box and the like; a collecting box is connected to the left portion of the bottom frame. When the device is used, residual glue residues in the blind holes of the substrate are cleaned through the air jet, the damage to the substrate is avoided, meanwhile, the adverse effect of the glue residues on etching is avoided, only the lower surface of the substrate is etched through overturning each time, the upper surface is sealed and protected, and the production efficiency is improved. Impurity particles are prevented from falling into the blind holes of the substrate after the copper foil is etched and removed when the copper foil is pressed, and additional processing steps are avoided.

Owner:HANGZHOU CCRFID MICROELECTRONICS

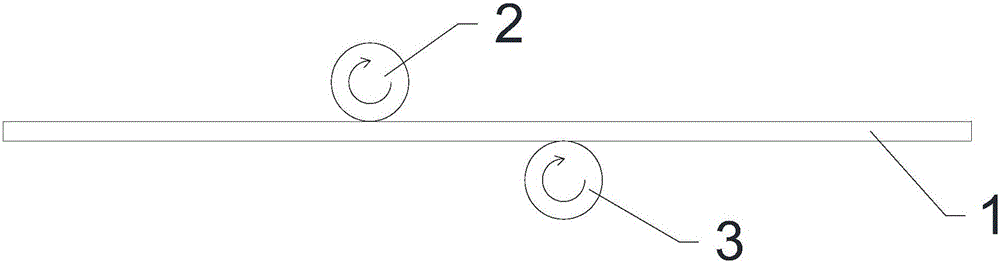

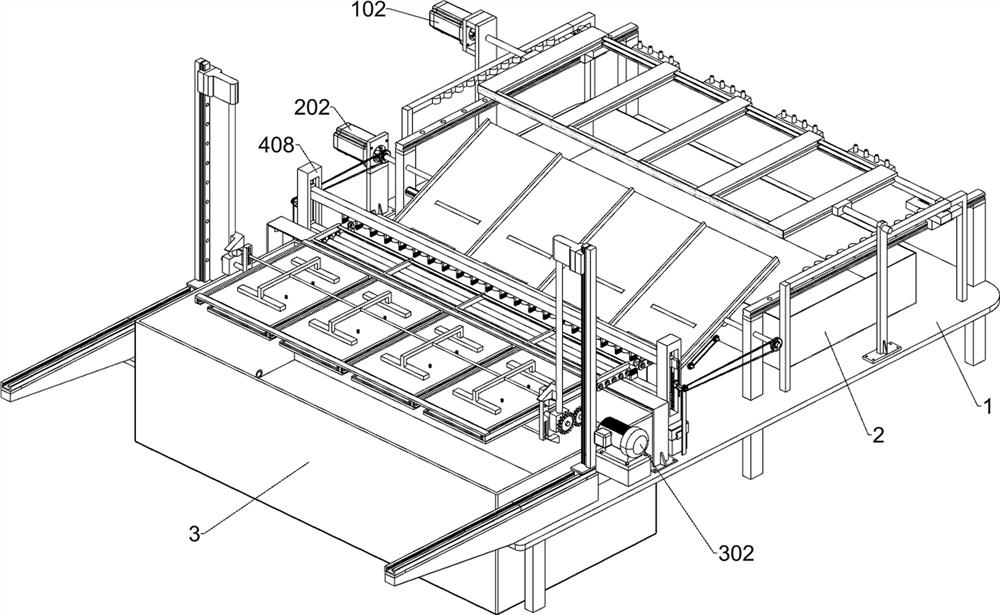

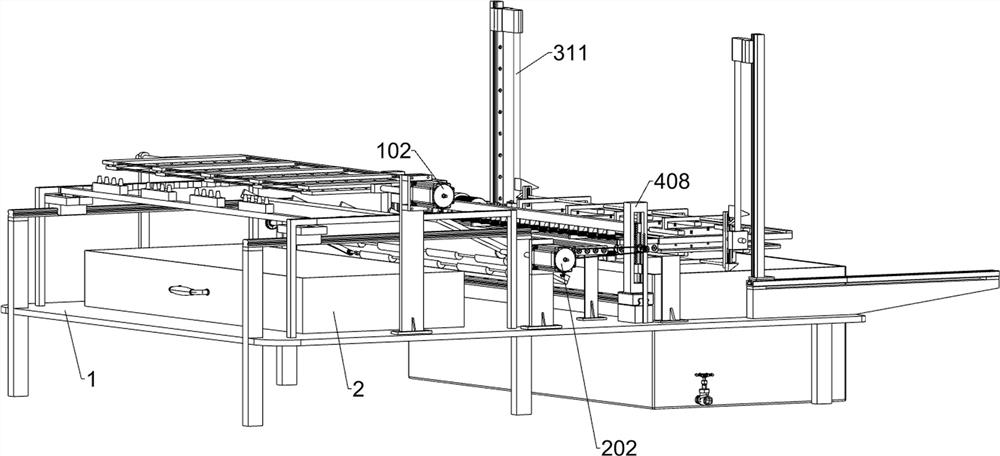

System for cleaning flexographic printing plates

InactiveUS20180281500A1Without the risk of obtaining plate areas brushed differently from other areasBrush evenlyPhotomechanical apparatusPrinting pre-treatmentEngineeringFlexography

There is provided a system or apparatus for washing out flexographic printing plates. The system is presented in two distinct embodiments or aspects. In one embodiment the system is provided with a large number of rotating brushes which are at least partly immersed in a liquid bath. The second embodiment is based on a flat brush with an eccentric suspension

Owner:GLUNZ & JENSEN

Device capable of solving problem of discontinuous ink output or unclear printing during platemaking of packaging bag

InactiveCN112428687APrint clearAvoid ghostingRotary pressesOther printing apparatusEngineeringMechanical engineering

The invention relates to the technical field of platemaking, and discloses a device capable of solving the problem of discontinuous ink output or unclear printing during platemaking of a packaging bag. The device comprises a supporting seat, a connecting column is supported by the supporting seat, and the lower part of the supporting seat is fixedly connected with the connecting column. Through the cooperation use of an ink storage box, a push rod, a swing rod and a fourth turntable, ink can be continuously output during use, printing discontinuity caused by insufficient ink output during platemaking printing is avoided, repeated ink adding is avoided, more time and labor are saved, through cooperative use of a moving block, a second rotary disc and a third rotary disc, the packaging bag is in a stable state during platemaking printing, so that ghosting caused by poor stability during printing is avoided, the stability during printing is improved, printing is clearer, and through cooperative use of the moving block, the second rotating disc and the third rotating disc, a brush head uniformly brushes the upper portion of a template during printing, so that brushing is more uniform.

Owner:程铁熔

Arc-shaped brushing tool applied to building stand column

ActiveCN106677498AImprove brushing efficiencyBrush evenlyBrush bodiesBristle carriersBristleEngineering

The invention discloses an arc-shaped brushing tool applied to a building stand column. The arc-shaped brushing tool comprises bristles, a bristle carrier and a brush rod. The arc-shaped brushing tool is characterized in that the bristle carrier is an arc-shaped elastic sheet with elasticity; the bristles adhere to the inner side of the elastic sheet; the brush rod is connected with the middle of the elastic sheet; the central angle covered by the elastic sheet is larger than 180 degrees; a sliding block capable of sliding on a rod body of the brush rod is arranged on the brush rod; pull rods are hinged to the portions, on the two sides of the brush rod, of the elastic sheet; and the other ends of the two pull rods are hinged to the sliding block. When the brushing tool is used for brushing, more than half or even all of the surface of the stand column can be covered through one-time traveling, and the brushing efficiency can be greatly improved; and in addition, brushing omission or repeated brushing can be reduced, and brushing is more uniform.

Owner:浙江巨力宝纺织科技有限公司

Floor paint composition

The invention discloses a floor paint composition. The floor paint composition is prepared from the following raw materials in parts by weight: 20-40 parts of short-oil alkyd resin, 30-40 parts of diethylene glycol, 10-18 parts of bentonite, 11-19 parts of epoxidized soybean oil, 4-8 parts of acrylic flatting agent, 6-10 parts of lavender essential oil, 12-18 parts of ferrite yellow, 9-16 parts of polyester resin and 5-10 parts of lead naphthenate. The floor paint composition does not need to be polished after being applied, and is high in adhesive force, high in drying speed and good in decoration effect; besides, the floor paint composition can be applied evenly.

Owner:QINGDAO JISHUNLONG TRADING

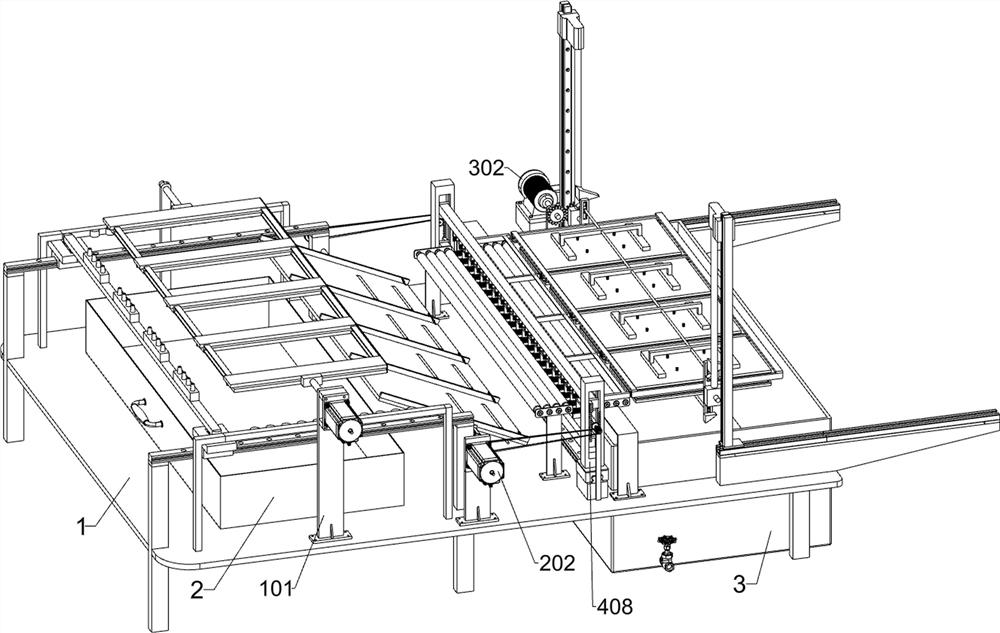

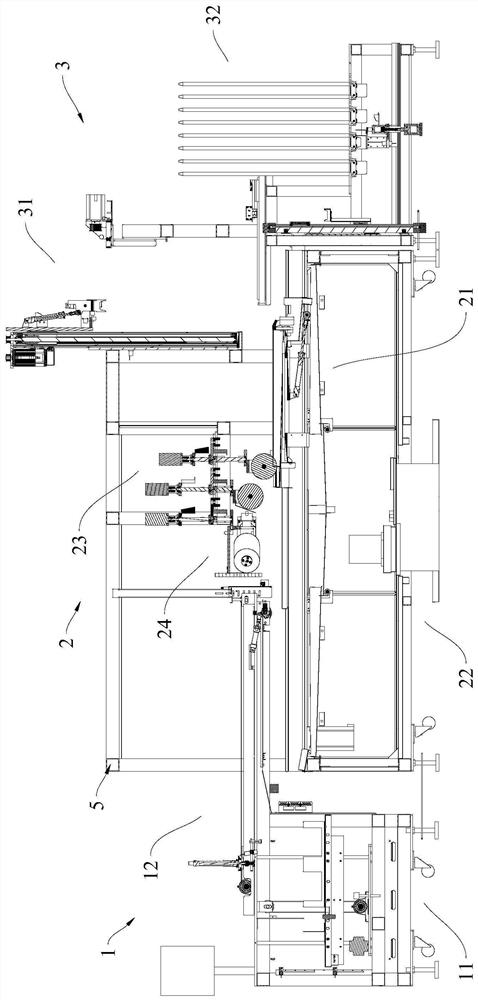

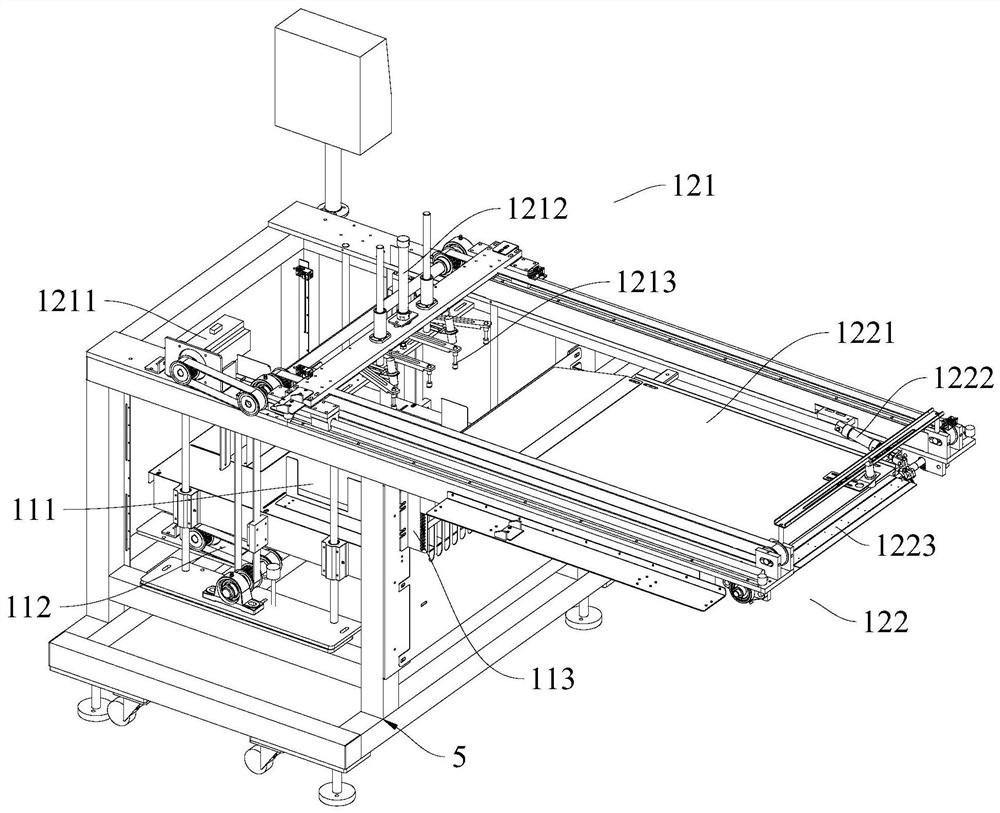

Automatic stained paper swabbing machine

PendingCN112958380ABrush evenlyImprove permeabilityLiquid surface applicatorsCoatingsProcess engineeringMechanical engineering

The invention discloses an automatic stained paper swabbing machine. A single piece of stained paper is fed to a swabbing device through a paper feeding device, the swabbing device receives the stained paper discharged from the paper feeding device and carries out swabbing on the stained paper, the swabbed stained paper is conveyed to a paper hanging device through the swabbing device, the paper hanging device receives the swabbed stained paper conveyed by the swabbing device and hangs the swabbed stained paper through a hanging clamp, the hanging clamp clamping the stained paper is conveyed to a drying device through the paper hanging device, and the drying device receives the hanging clamp clamping the stained paper and dries the stained paper. The swabbing device sprays slurry to a carrying mechanism and the stained paper on the carrying mechanism, and sufficient sizing is achieved. In addition, the swabbing mechanism is used for rolling the stained paper on the carrying mechanism, manual operation is imitated, swabbing is uniform, and the permeation effect is good.

Owner:君诺智能(广东)冷链科技有限公司

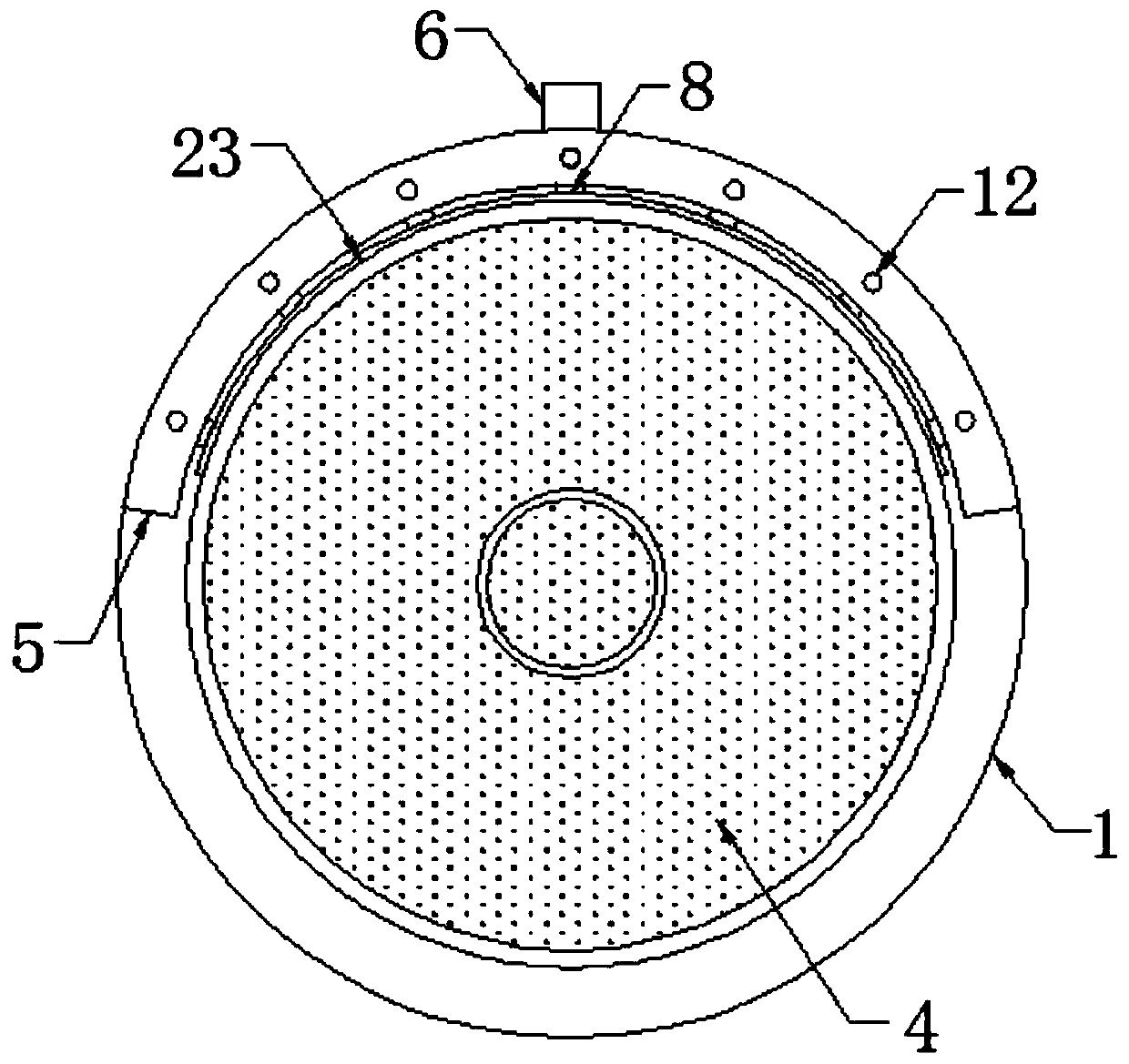

Special correction agent for exposed aggregate pervious concrete surface and smearing method of correction agent

The invention discloses a special correction agent for an exposed aggregate pervious concrete surface and a smearing method of the correction agent, belongs to the field of concrete correction agents,and discloses the special correction agent for the exposed aggregate pervious concrete surface and the smearing method of the correction agent. The correction agent comprises the following components: an acidic solution (oxalic acid, dilute sulfuric acid or dilute hydrochloric acid), a viscosity regulator (xanthan gum, honey, maltodextrin or acidity regulator), a stabilizer (an emulsion delamination inhibitor EE, a beverage special stabilizer JJKW004 or a liquid suspension stabilizer SF-1) and water. A brush can be electrically driven to be matched with the correction agent to quickly wipe and brush a concrete wall; the correction agent is uniform in wiping and brushing, high in efficiency, capable of reducing labor intensity, capable of meeting the wiping requirements of concave surfacesand planes in cooperation with flexible movement of the movable disc, capable of guaranteeing uniform wiping and brushing of the correction agent of various wall forms, easy to operate and high in flexibility; a partition plate is arranged in a storage box, clear water is sprayed to flush the wall, and the wiping and brushing effect of the correction agent is further improved.

Owner:广东龙越建筑工程有限公司

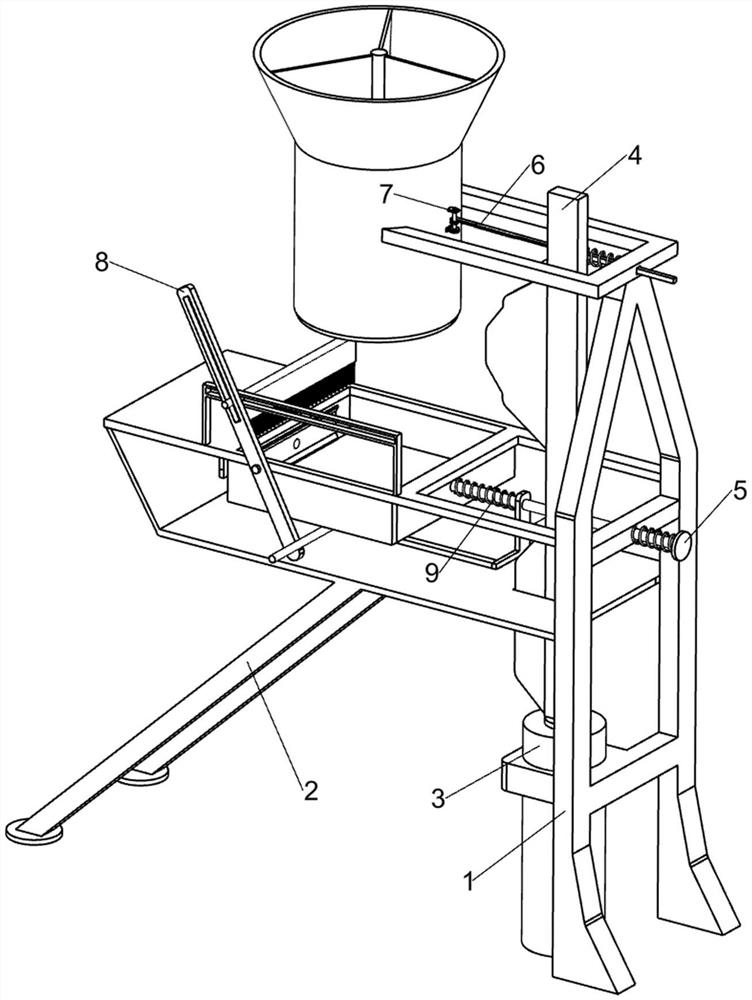

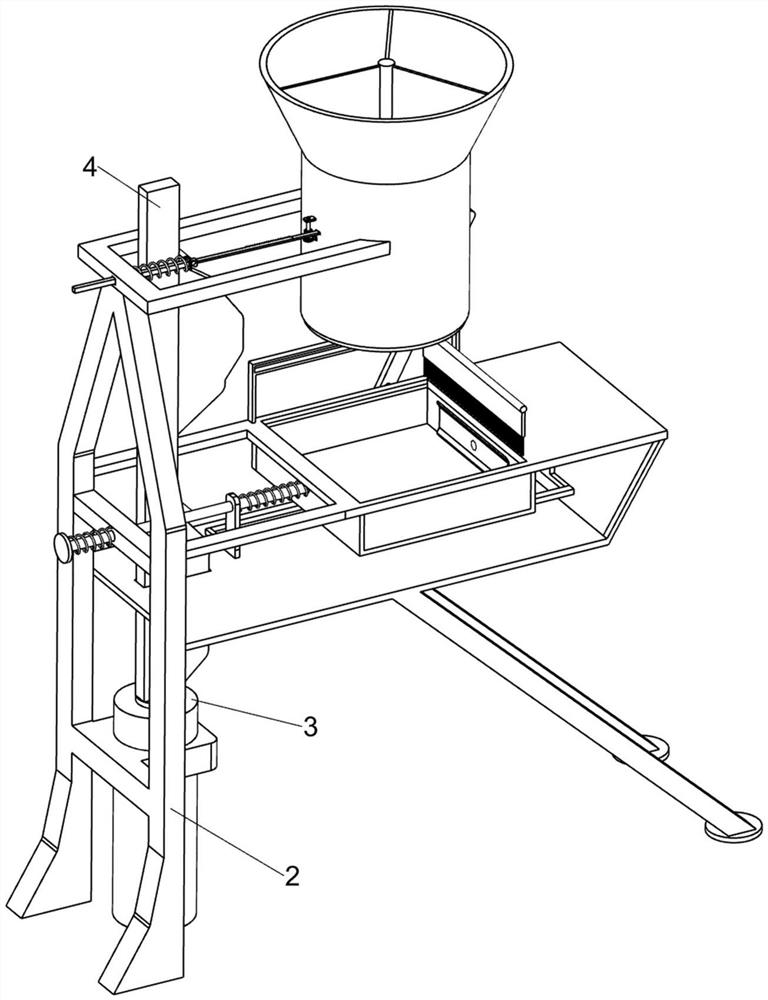

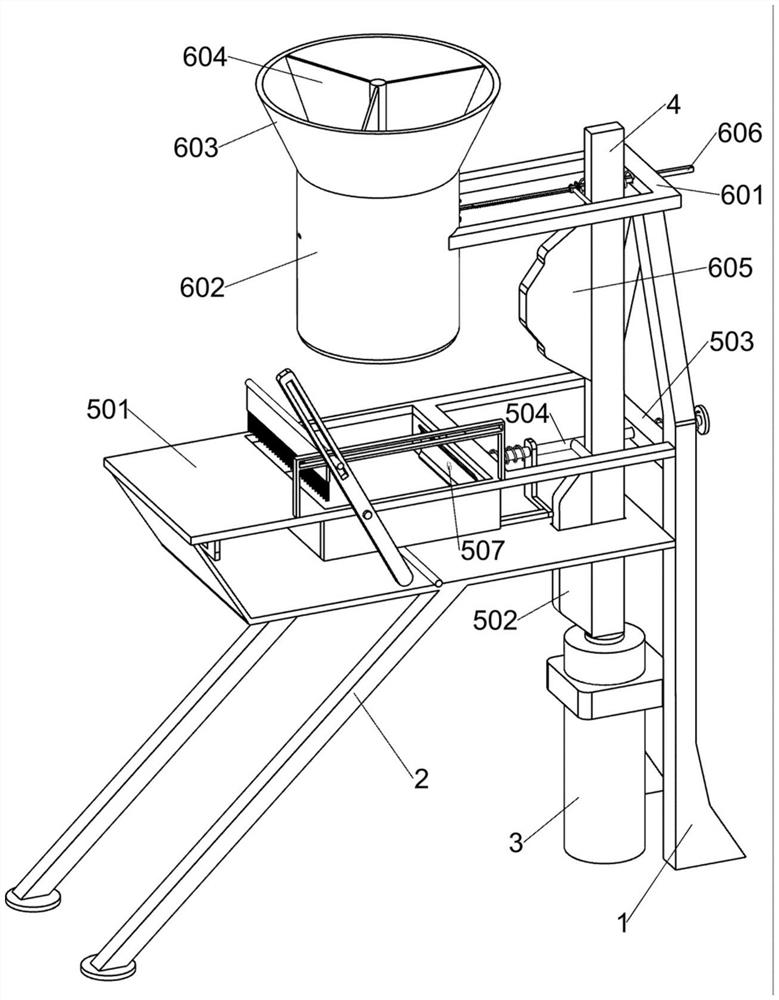

Preserved meat pickling seasoning uniform scattering device for preserved product processing

The invention relates to the field of preserved product processing, in particular to a preserved meat pickling seasoning uniform scattering device for preserved product processing. The device comprises a supporting frame, an inclined support, an electric push rod, a lifting plate, an opposite clamping assembly and the like; the inclined support is fixedly installed on the supporting frame, the electric push rod is fixedly installed on the supporting frame, one end of the electric push rod is fixedly connected with the lifting plate, and the opposite clamping assemblies are arranged on the supporting frame. The seasoning stirring assembly and the unfilled corner fan blades rotate to stir pickling seasonings at the bottom in the cylinder, so that the different pickling seasonings are uniformly mixed, the unfilled corner fan blades push the pickling seasonings into the groove holes in the bottom in the cylinder, and the groove holes in the material spreading disc are matched with the groove holes in the cylinder, so that the pickling seasonings are uniformly scattered on the meat strips.

Owner:河北大锤食品科技有限公司

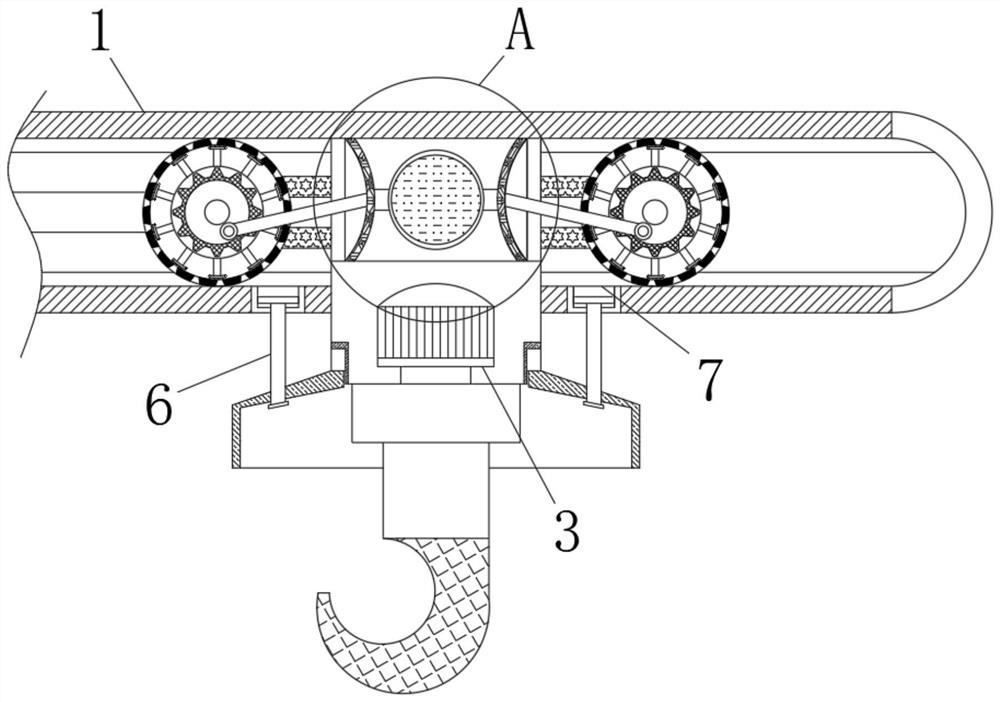

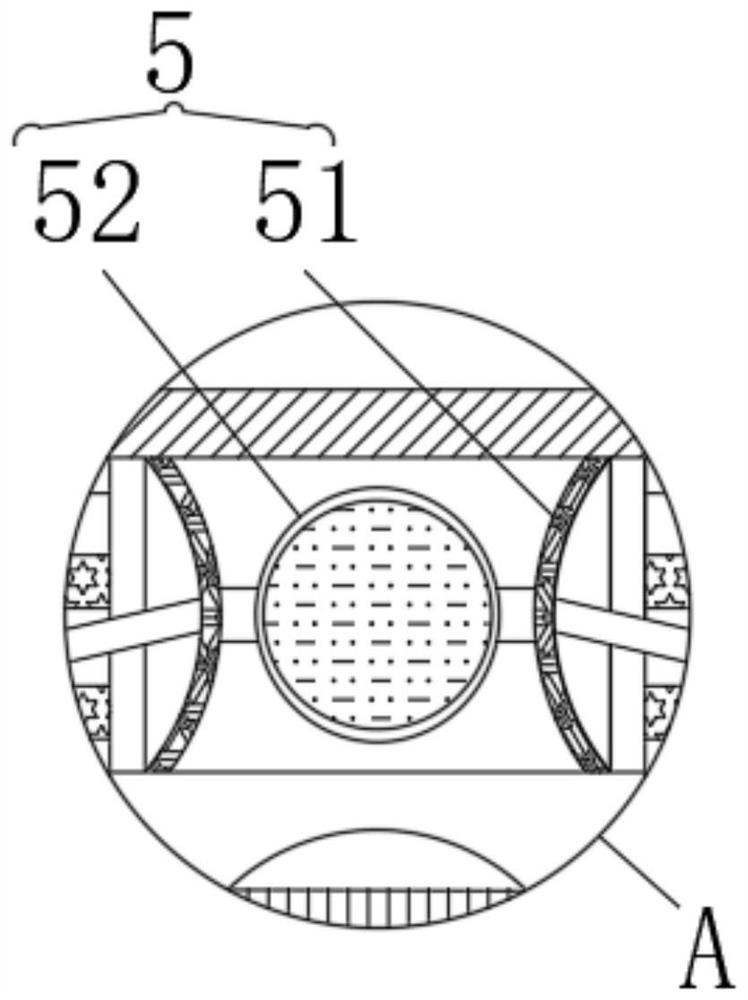

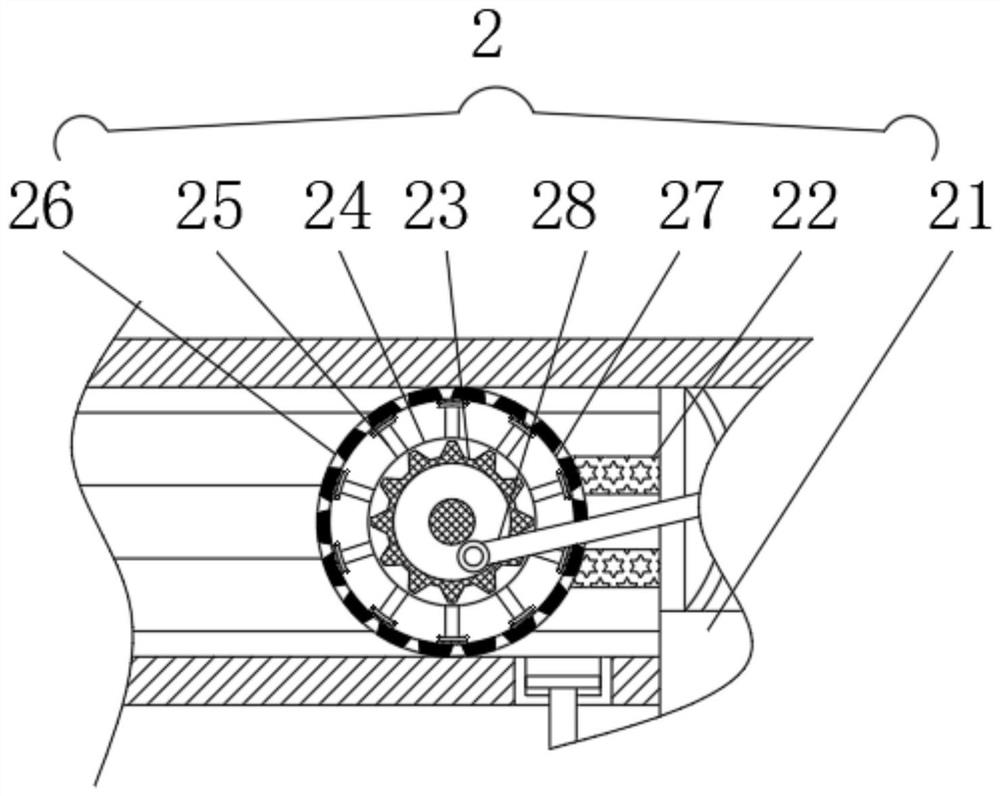

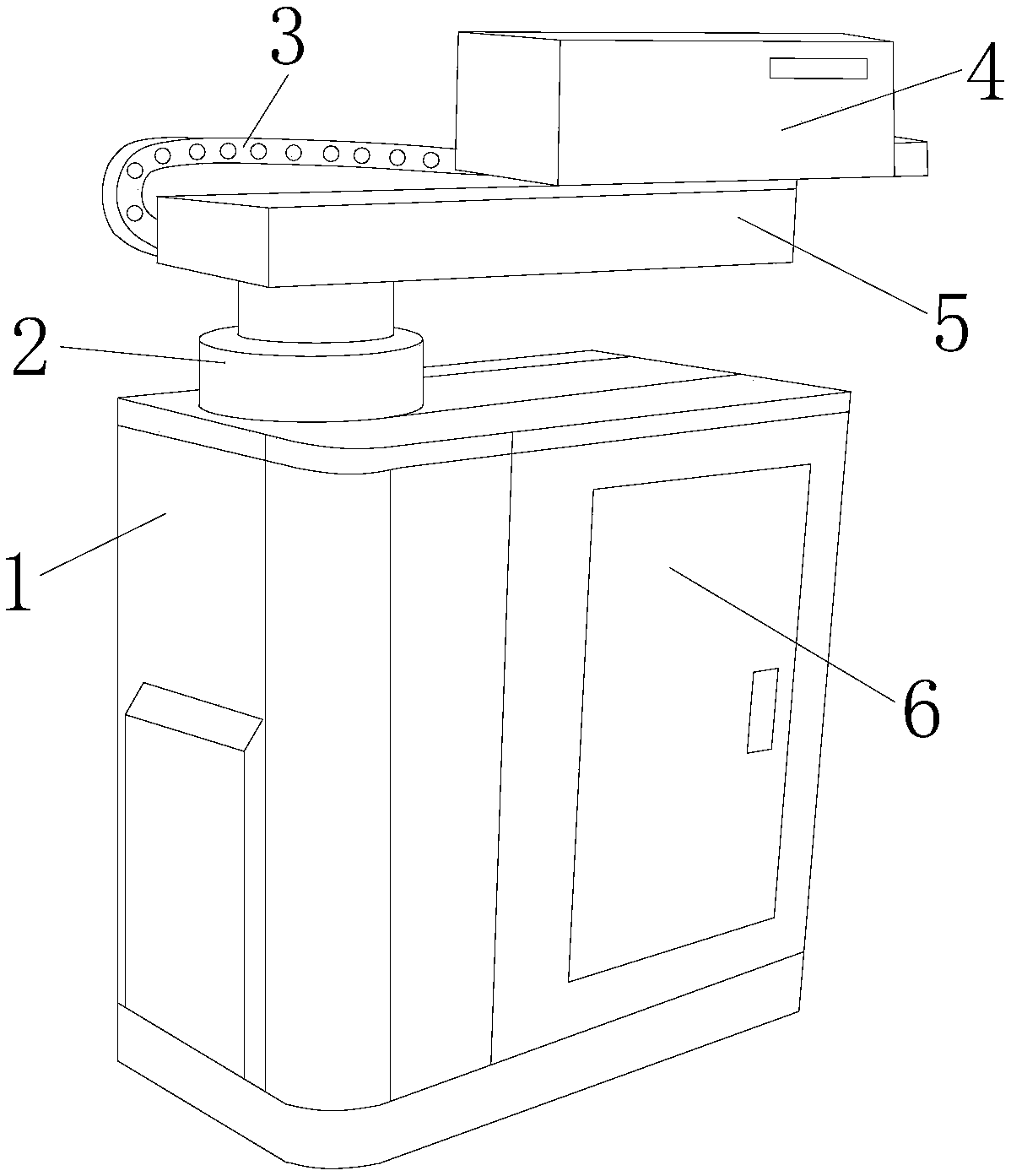

Cantilever beam crane

InactiveCN113734969ABrush evenlyTo achieve the effect of filling lubricating oilLubricant transferConduits/junctionsCantilevered beamClassical mechanics

The invention relates to the technical field of cranes, and discloses a cantilever beam crane which comprises a fixing plate. A liquid injection mechanism is fixedly mounted in the fixing plate, a driving device is fixedly mounted at the lower end of the fixing plate, and an adjusting mechanism is rotatably connected to the lower end of the driving device. According to the cantilever beam crane, in the process that a connecting plate slides in the fixing plate, a lifting hook can be driven to move left and right in the fixing plate, meanwhile, a rotating wheel is driven to rotate, then the rotating wheel can drive a fixing ring to rotate in a liquid storage ring in the rotating process, an upper brush rod acts at the same time, and therefore lubricating oil in the liquid storage ring can be evenly brushed away. Meanwhile, the rotating wheel can be matched with the action of a guide rod in the rotating process to apply pressure to an elastic plate, the elastic plate continuously extrudes the liquid storage bag, so that the lubricating oil in the liquid storage bag can be extruded into the liquid storage ring, then the actions are repeated, and the effect of filling the lubricating oil is achieved.

Owner:吴法海

Oil brushing device for bread production line

The invention belongs to the technical field of food processing, particularly relates to an oil brushing device for a bread production line, and aims to solve the problems that in the prior art, manually performing oil brushing on bread is low in speed, and waste is easy to cause. In order to solve the technical problem, the invention provides the oil brushing device for the bread production line.The oil brushing device comprises a seat box, a shaft rail, a transmission outer chain, a mechanical elbow, a manipulator, a box bin and an oil brushing transmission mechanism. The oil brushing device disclosed by the invention has the effect of being capable of quickly brushing oil on the bread in batches.

Owner:王丹丹

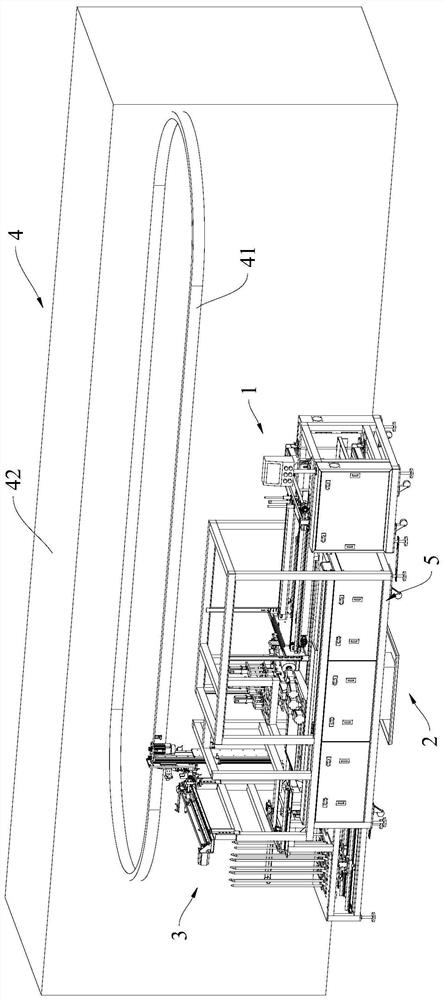

An automatic painting equipment for outdoor pipeline surface

ActiveCN111558496BAvoid dangerHigh degree of automationLiquid surface applicatorsCoatingsDrive wheelIndustrial engineering

The invention relates to outdoor pipeline maintenance, in particular to an automatic painting equipment for the surface of outdoor pipelines. Technical problem: To provide an automatic painting equipment for the surface of outdoor pipelines that can avoid manual painting and reduce danger, does not require frequent dipping of paint, and simplifies the work process. The technical solution is as follows: an automatic painting equipment for the surface of outdoor pipelines, including installation frames, the number of installation frames is at least two groups, and there are first connecting frames on both sides of the mounting frames, and the two sides of each group of first connecting frames are The uniform rotation type is provided with a guide wheel, and the rotation type is provided with a drive wheel at a position close to the guide wheel of a group of first connecting frames. The present invention adopts two groups of paint brushing cylinders that rotate in opposite directions to paint the pipeline, so that the painting process does not need to be manually performed, and the danger caused by manual painting on the pipeline is avoided.

Owner:台州伟兴科技有限公司

An automatic painting device capable of quickly painting walls

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Adhesive dispensing device for sensor processing

InactiveCN113941479AProcessing effectBrush evenlyLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention discloses an adhesive dispensing device for sensor processing, and belongs to the technical field of sensor processing. The adhesive dispensing device comprises a processing fixing mechanism, processing moving mechanisms, a processing adhesive dispensing mechanism and a processing adhesive brushing mechanism; the processing fixing mechanism is horizontally arranged on the ground, and the processing moving mechanisms are located at the two ends of the processing fixing mechanism; and the processing adhesive dispensing mechanism is located on the side wall of the processing moving mechanism, the processing adhesive brushing mechanism is located on the processing moving mechanism, the processing adhesive brushing mechanism comprises an adhesive brushing moving assembly and a uniform adhesive brushing assembly, the adhesive brushing moving assembly is slidably connected to the processing moving mechanism, and the uniform adhesive brushing assembly is located at the moving end of the adhesive brushing moving assembly. According to the adhesive dispensing device, adhesive dripping on a sensor is uniformly smeared through the processing adhesive brushing mechanism, and after the adhesive is uniformly smeared, subsequent processing and use of the sensor are facilitated.

Owner:湖南麦旭科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com