Bristle brush cleaning machine for micro bearing inner ring

A technology of miniature bearings and washing machines, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of impurity dust cleaning, bump damage, etc., and achieve simple structure and uniform brushing , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

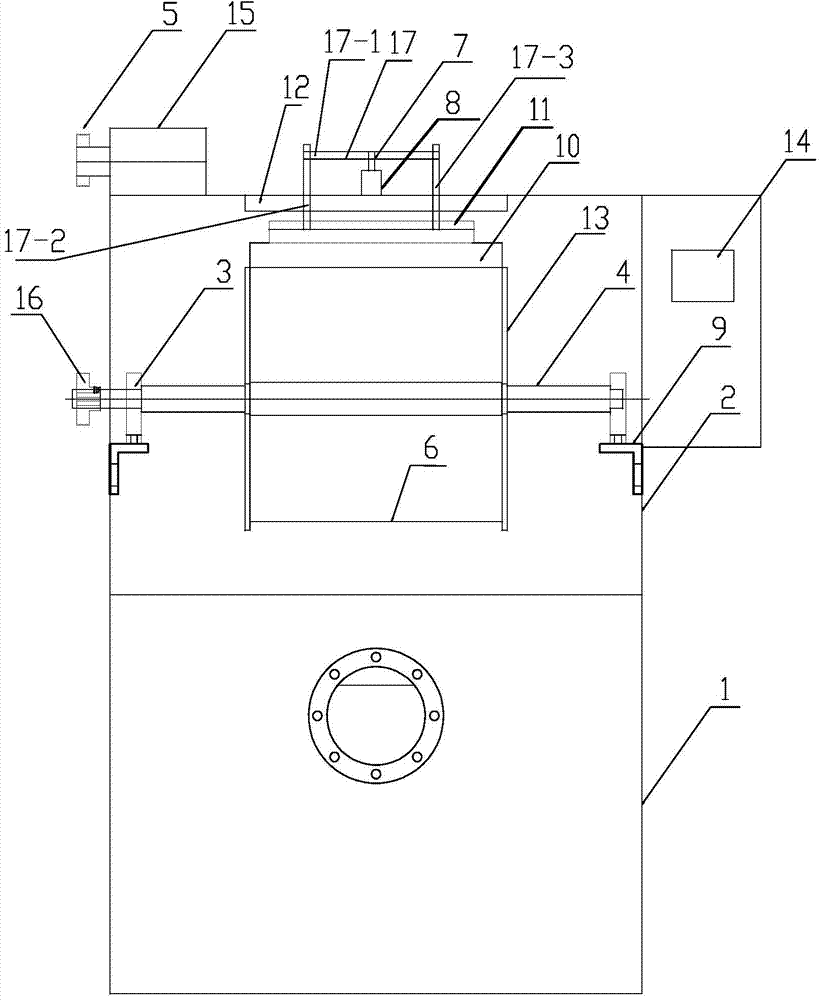

[0013] Such as figure 1 As shown, it includes the lower box body 1, the upper box body 2, the material tray bearing seat 3, the material tray shaft 4, the second pulley 5, the string rod 6, the brush lifting cylinder 7, the cylinder support 8, the material tray bearing seat support Seat 9, brush 10, brush fixing seat 11, sprinkler head 12, material tray 13, electrical cabinet 14, material tray motor 15, first pulley 16, balance bar 17, cross bar 17-1, first vertical bar 17-2, the second vertical bar 17-3 and so on.

[0014] Such as figure 1 As shown, a miniature bearing inner ring brush cleaning machine of the present invention includes a lower box 1 for supporting the upper box 2 and also serving as an oil tank, and a material is respectively fixed at both ends of the upper box 2 along the length direction. Disc bearing seat support 9, all is fixed with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com