Patents

Literature

423results about "Lubricant transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

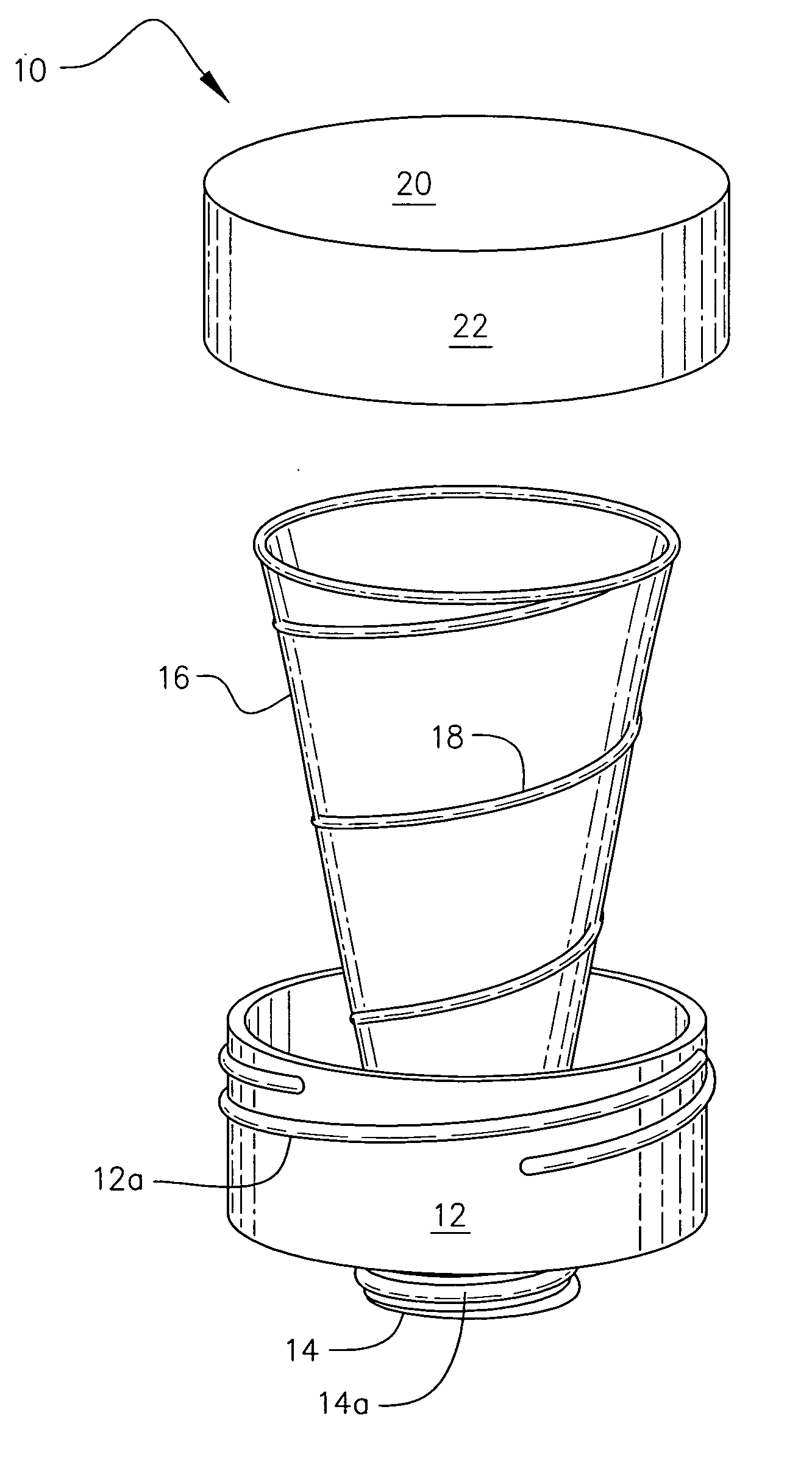

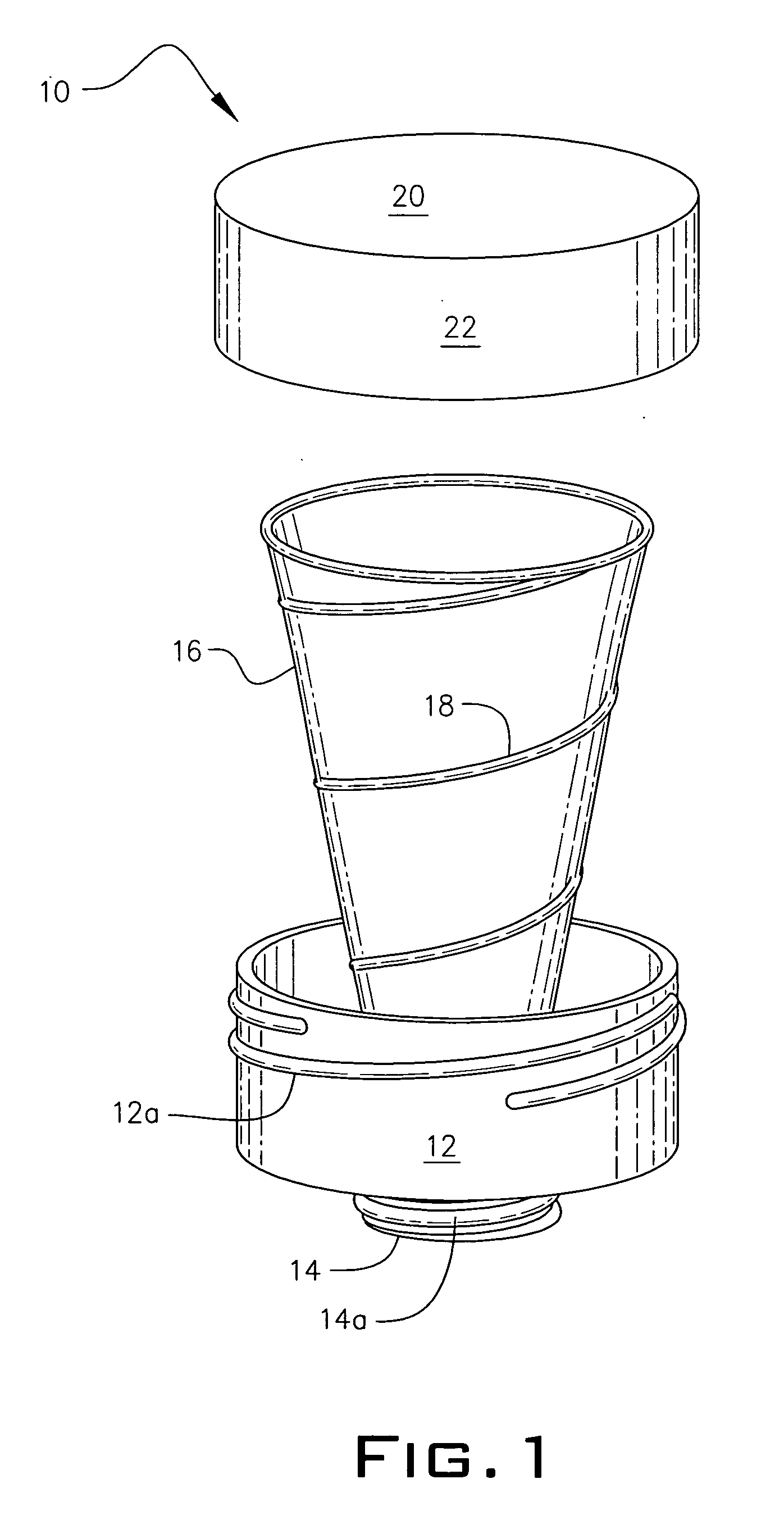

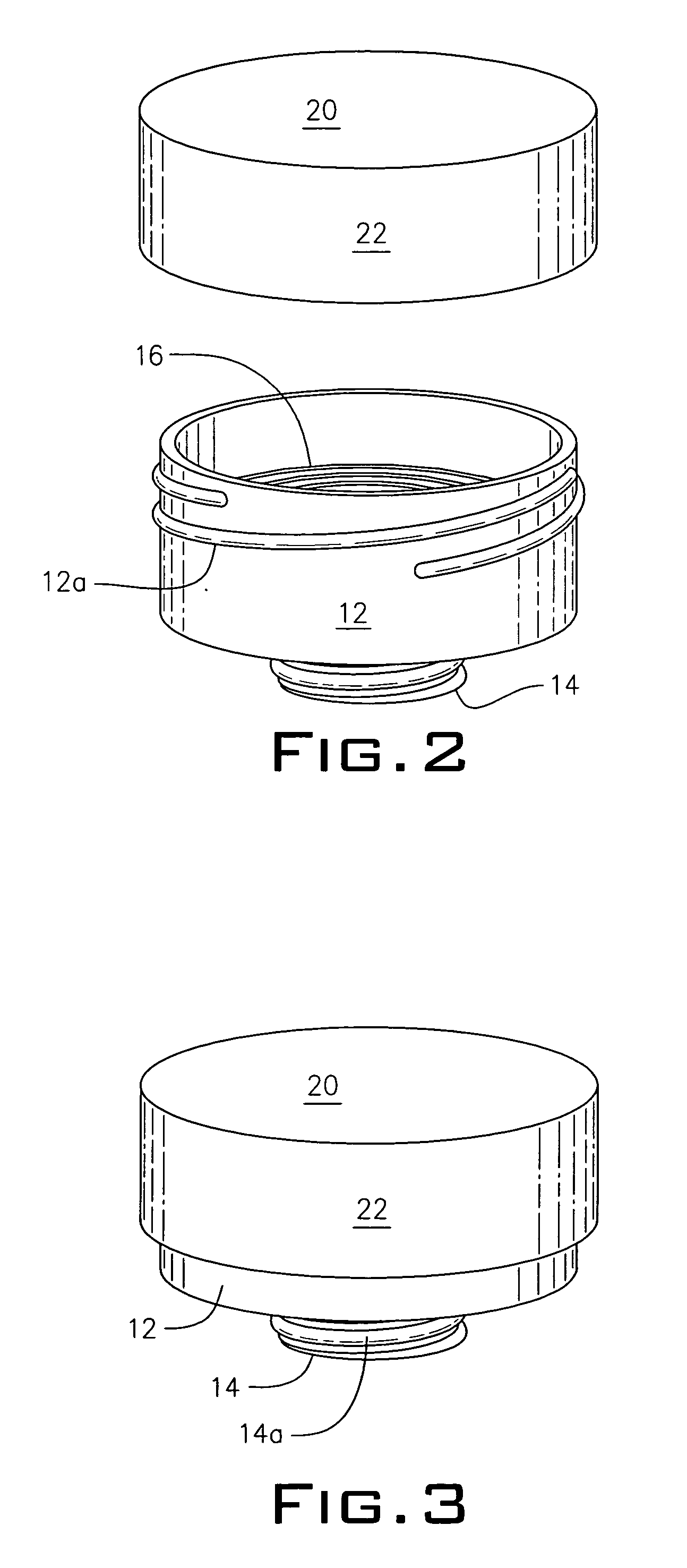

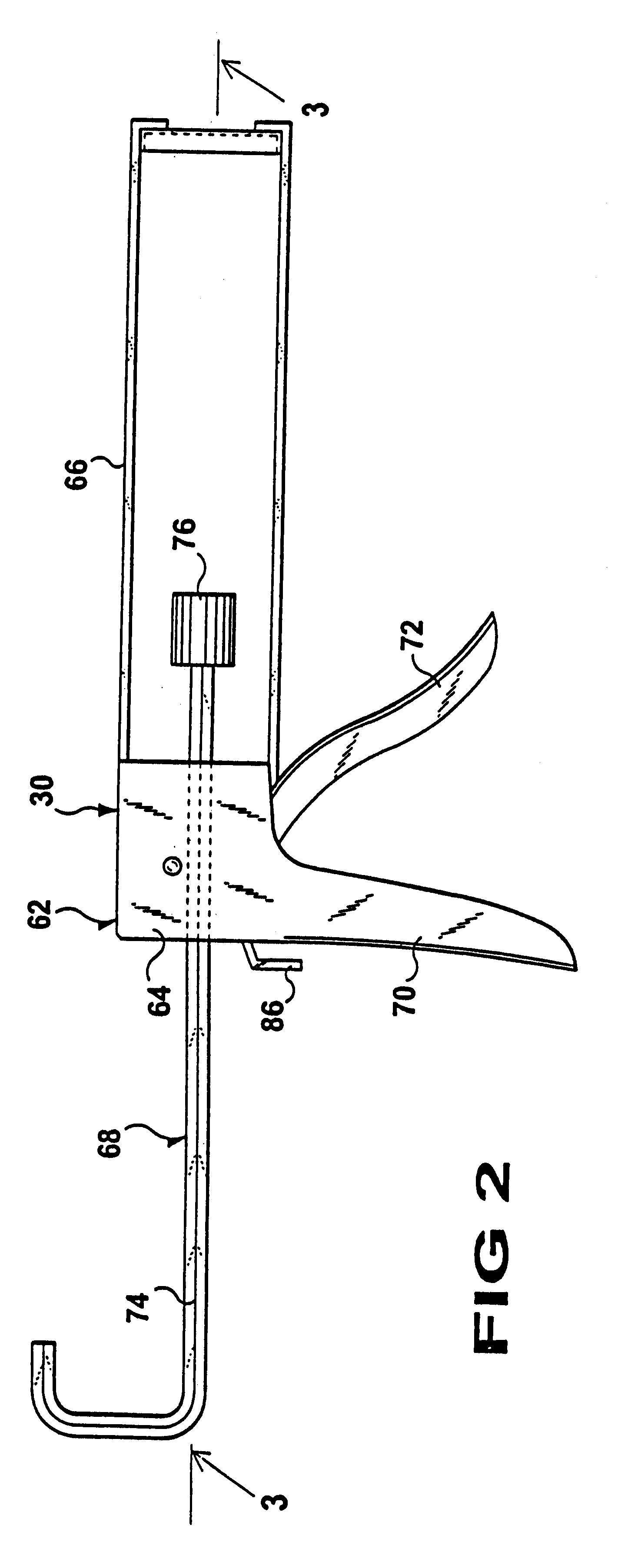

Self-deploying funnel

A funnel assembly includes a collapsible funnel mounted to a base. The funnel is formed by consecutive windings of spring steel wire. Each winding has a reduced diameter so that the windings collectively form a funnel having a conical shape and an inherent bias. The funnel is confined into a relatively small storage space and the funnel is compressed when a cap releasably engages the base. Upon disengaging the cap from the base, the bias unloads and fully deploys the funnel. A downspout depends from the base and engages the fill spout of an oil crankcase so that the funnel assembly is mounted to the fill spout. A user therefore does not hold the funnel assembly while pouring oil from a can into the deployed funnel. By holding the base in one hand and the cap in the other, a user may deploy the funnel and return it to storage without touching the funnel.

Owner:RINALDI MARK

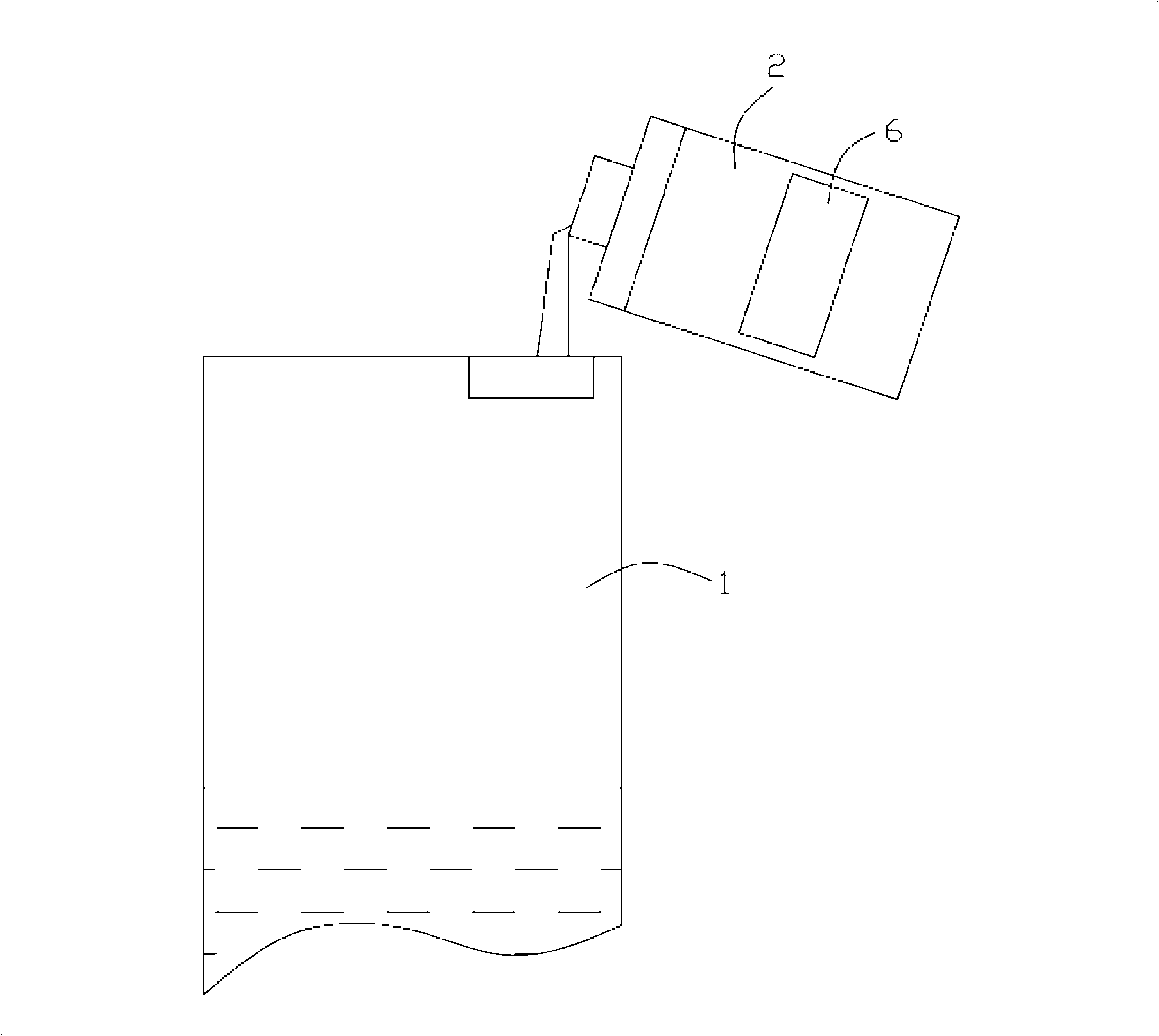

Container System

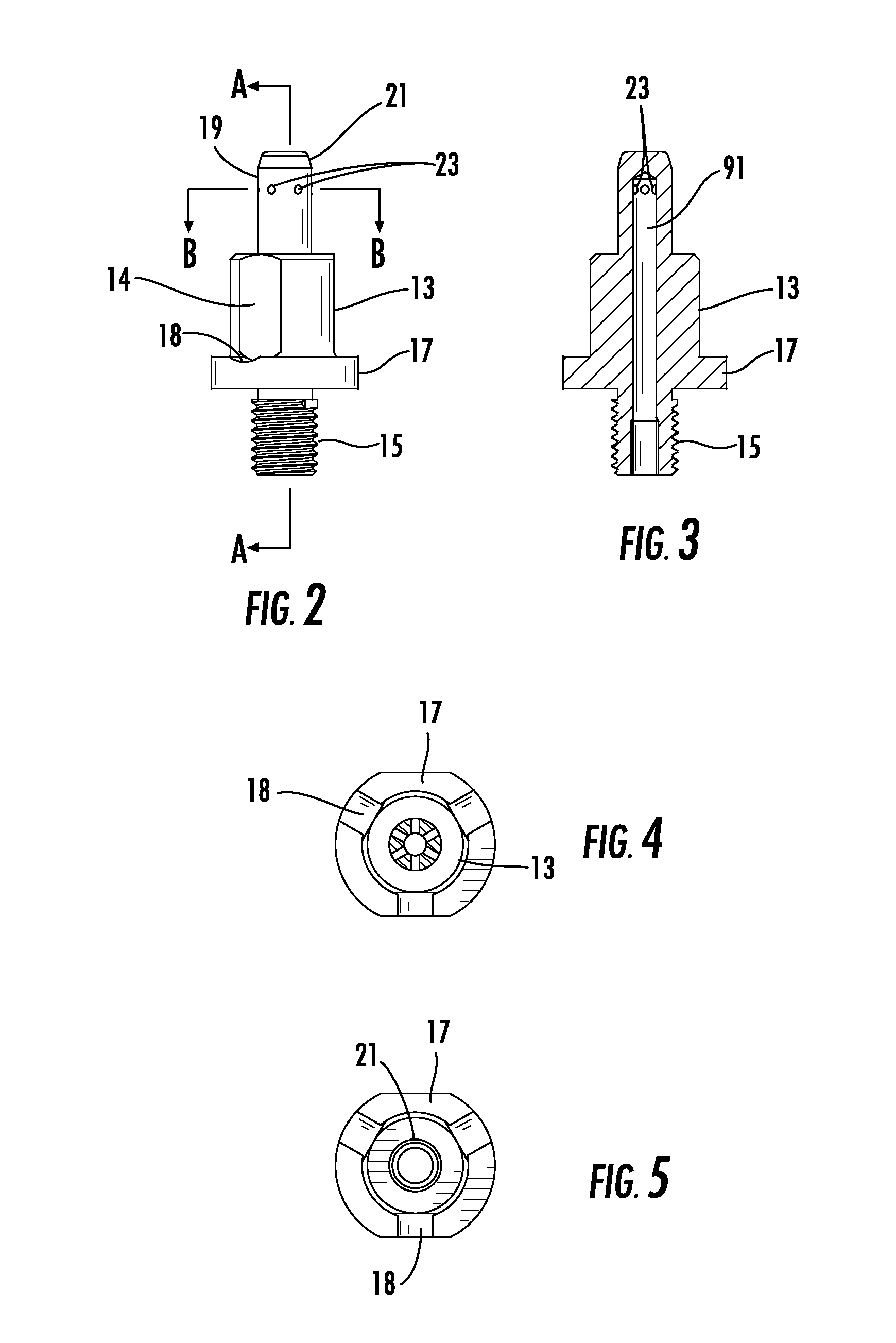

ActiveUS20070289994A1Inhibit bindingLubricant transferLiquid transferring devicesEngineeringFluid level

A container system of this invention includes a container for holding a fluid, a follower in the container which moves in the container in response to a change in a level of fluid in the container, and a sensor assembly for sensing the level of fluid in the container. The sensor assembly is especially (albeit not exclusively) suited for viscous fluids.

Owner:LINCOLN INDUSTRIES CORP

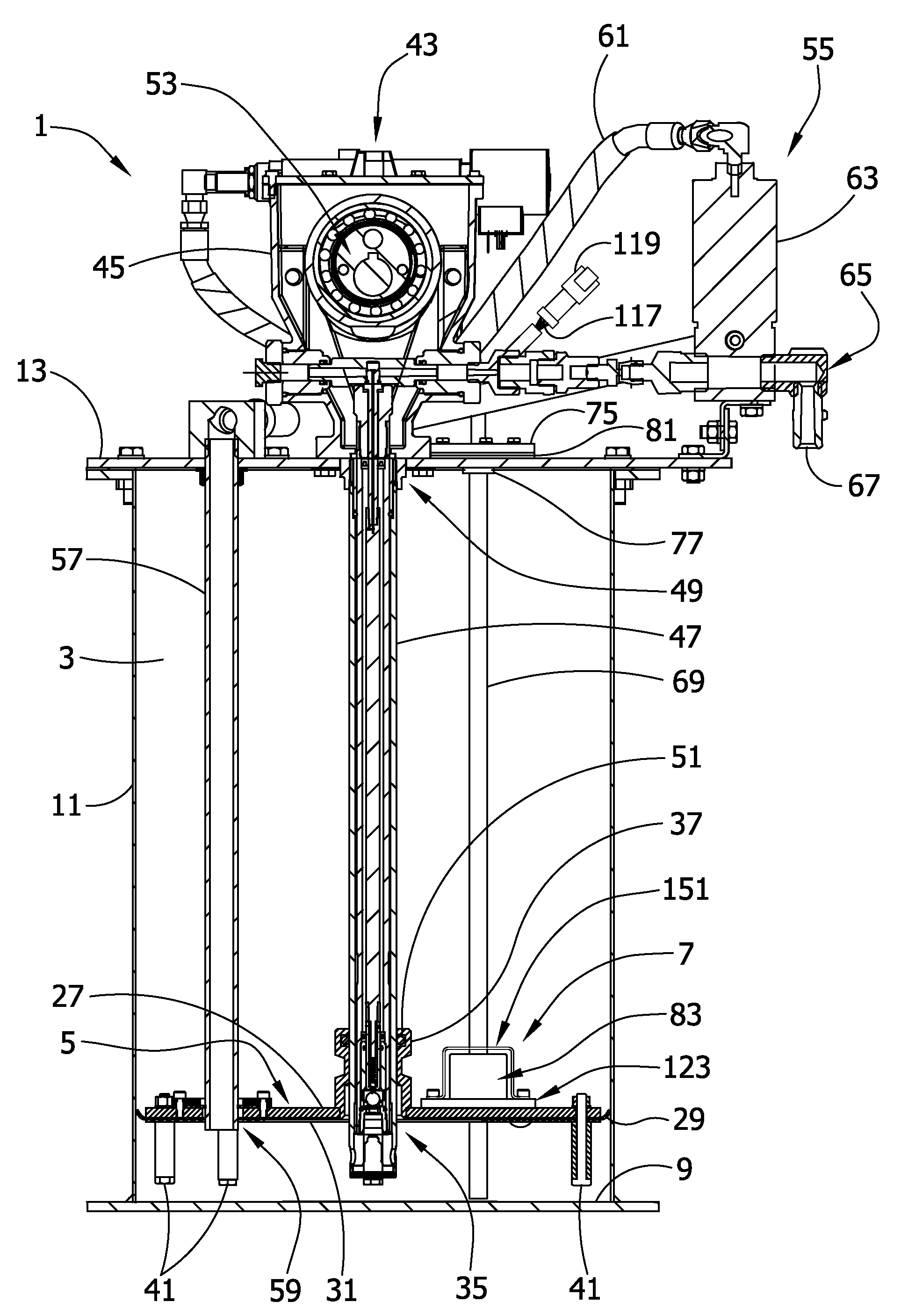

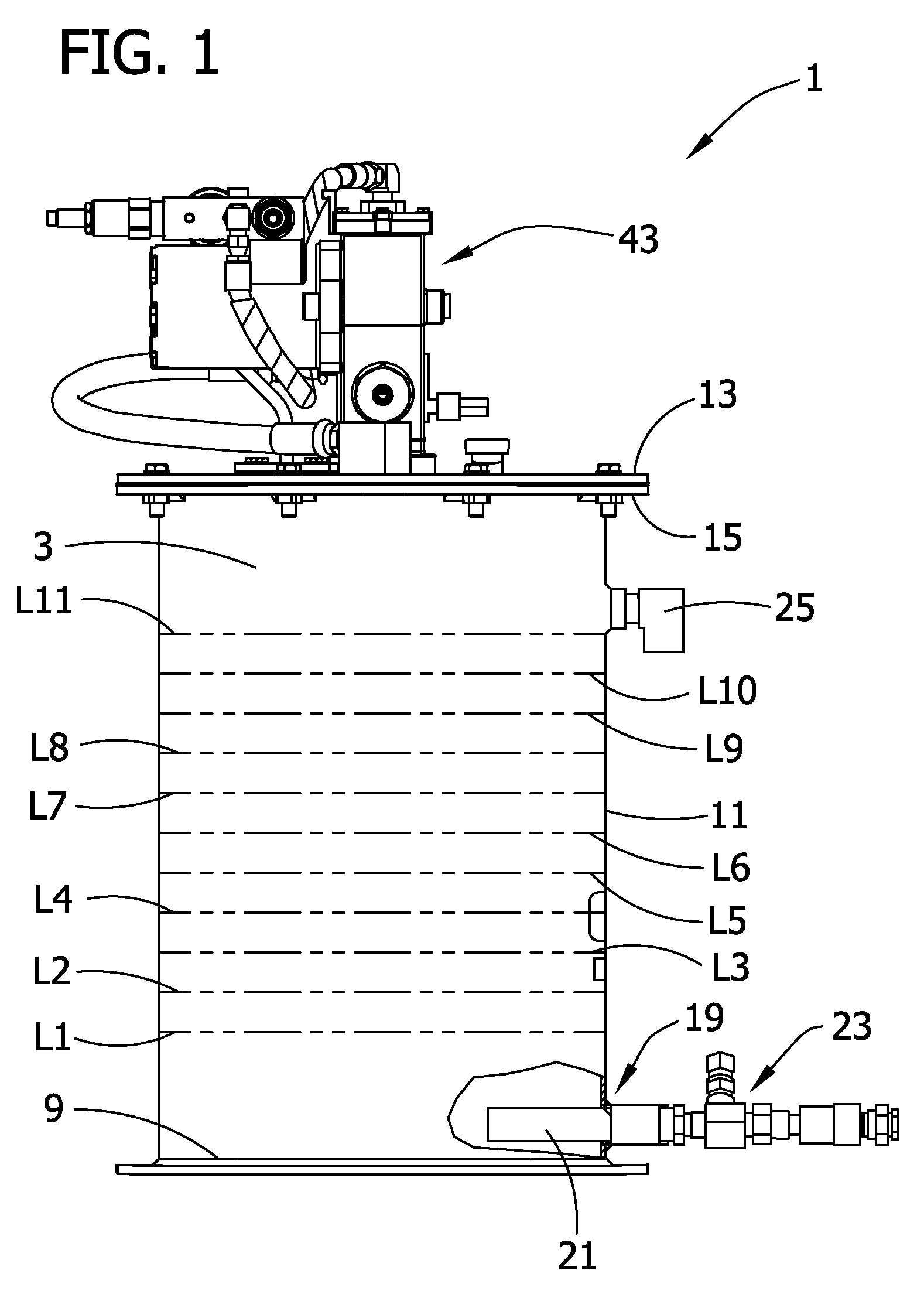

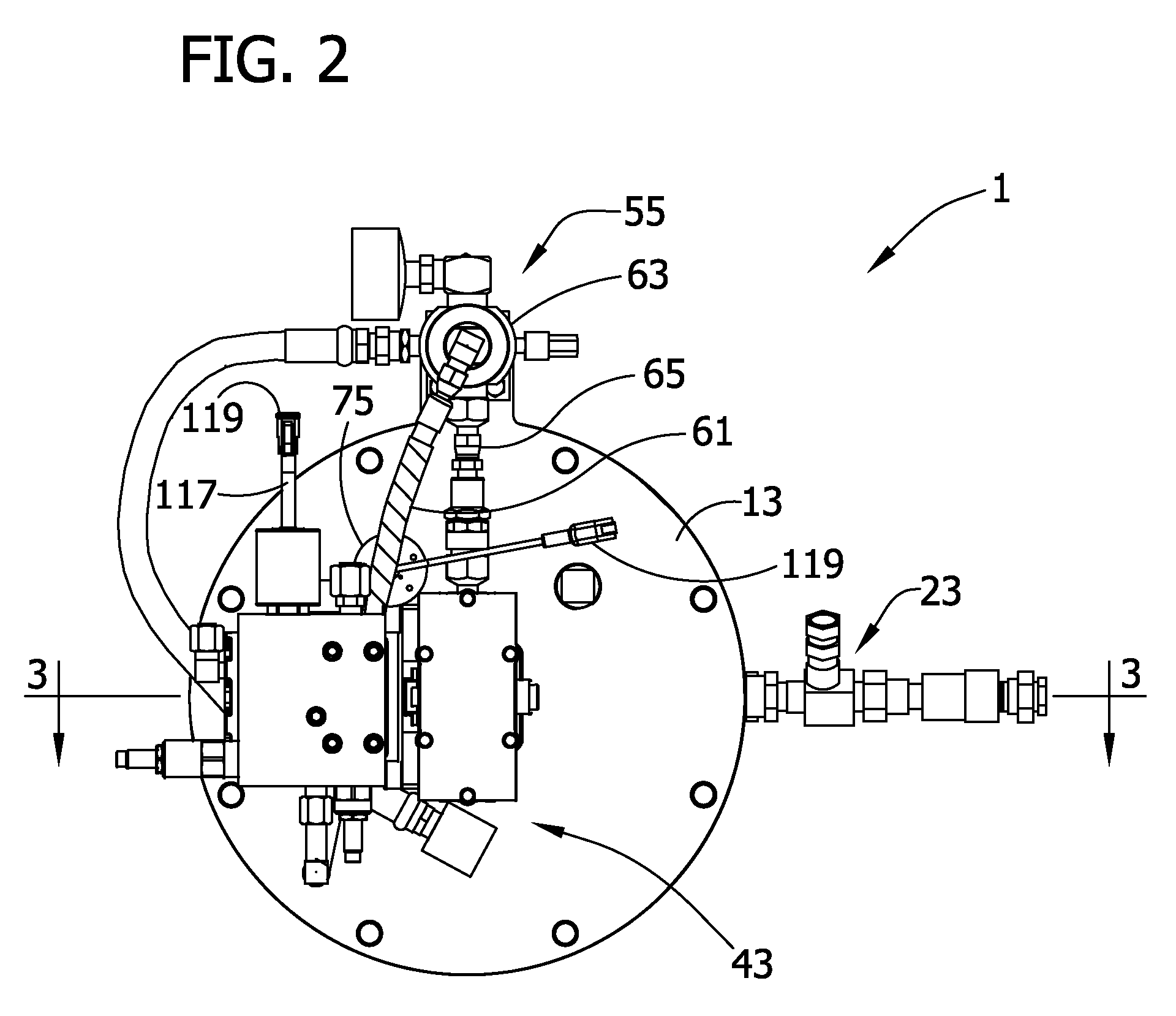

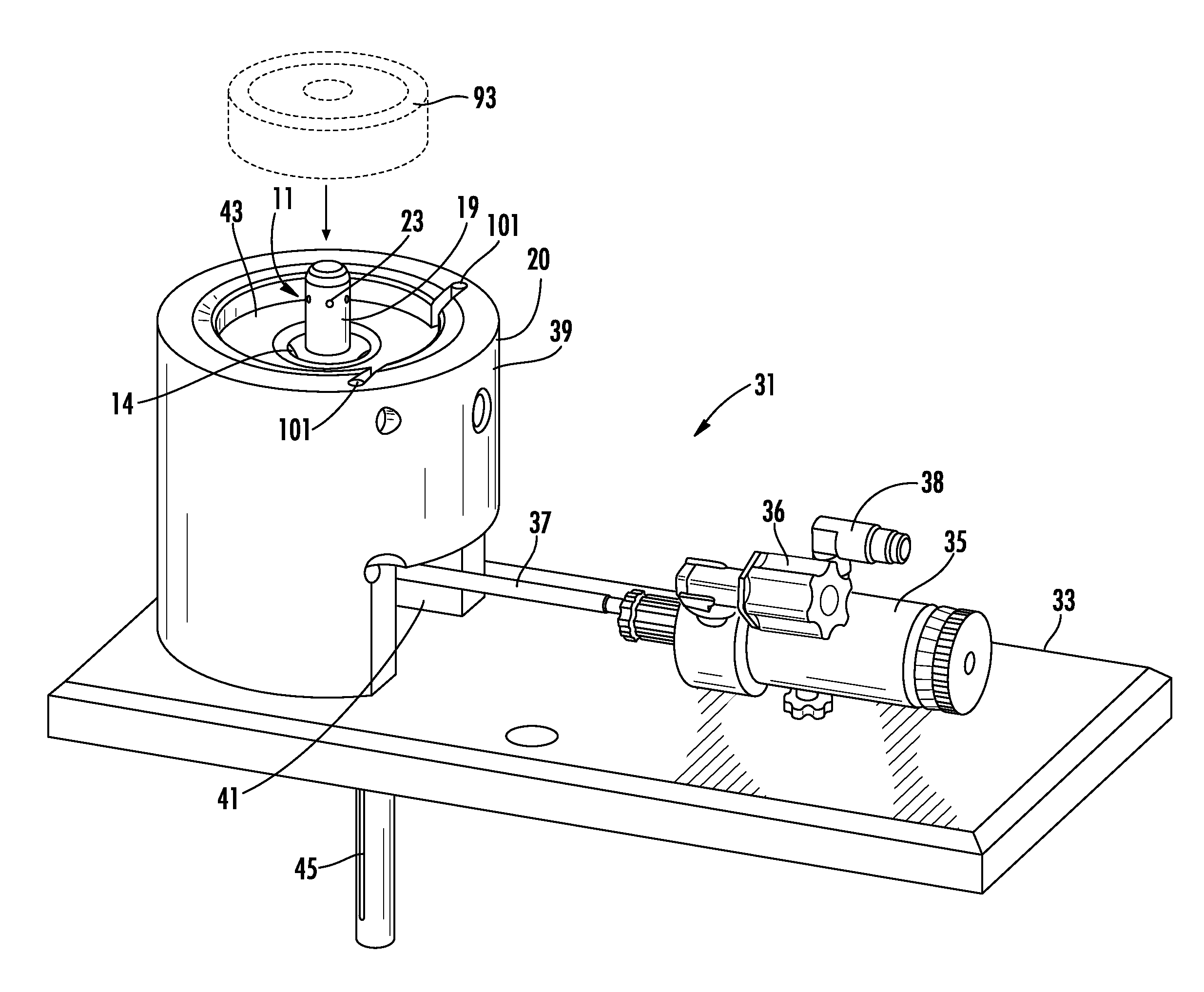

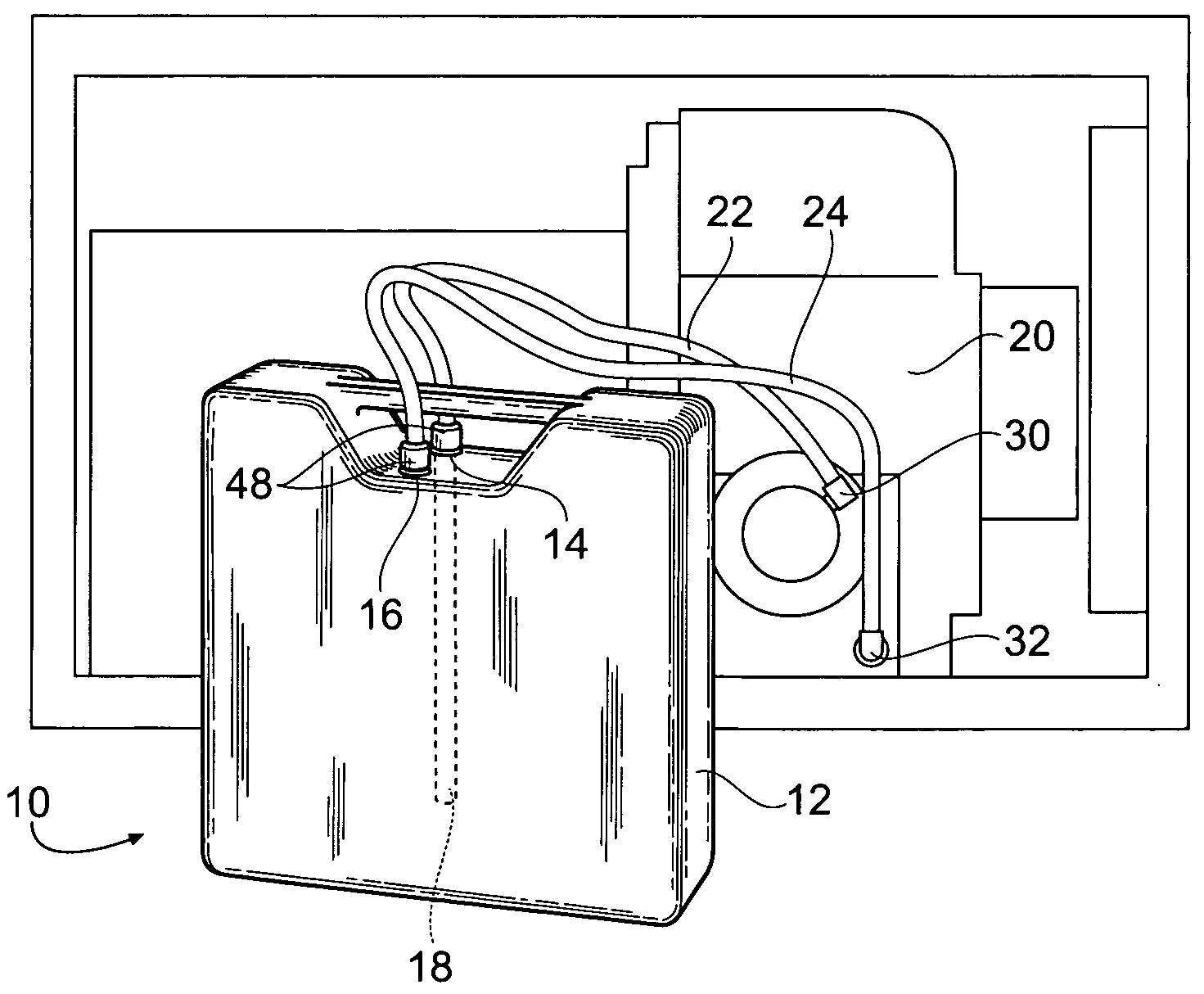

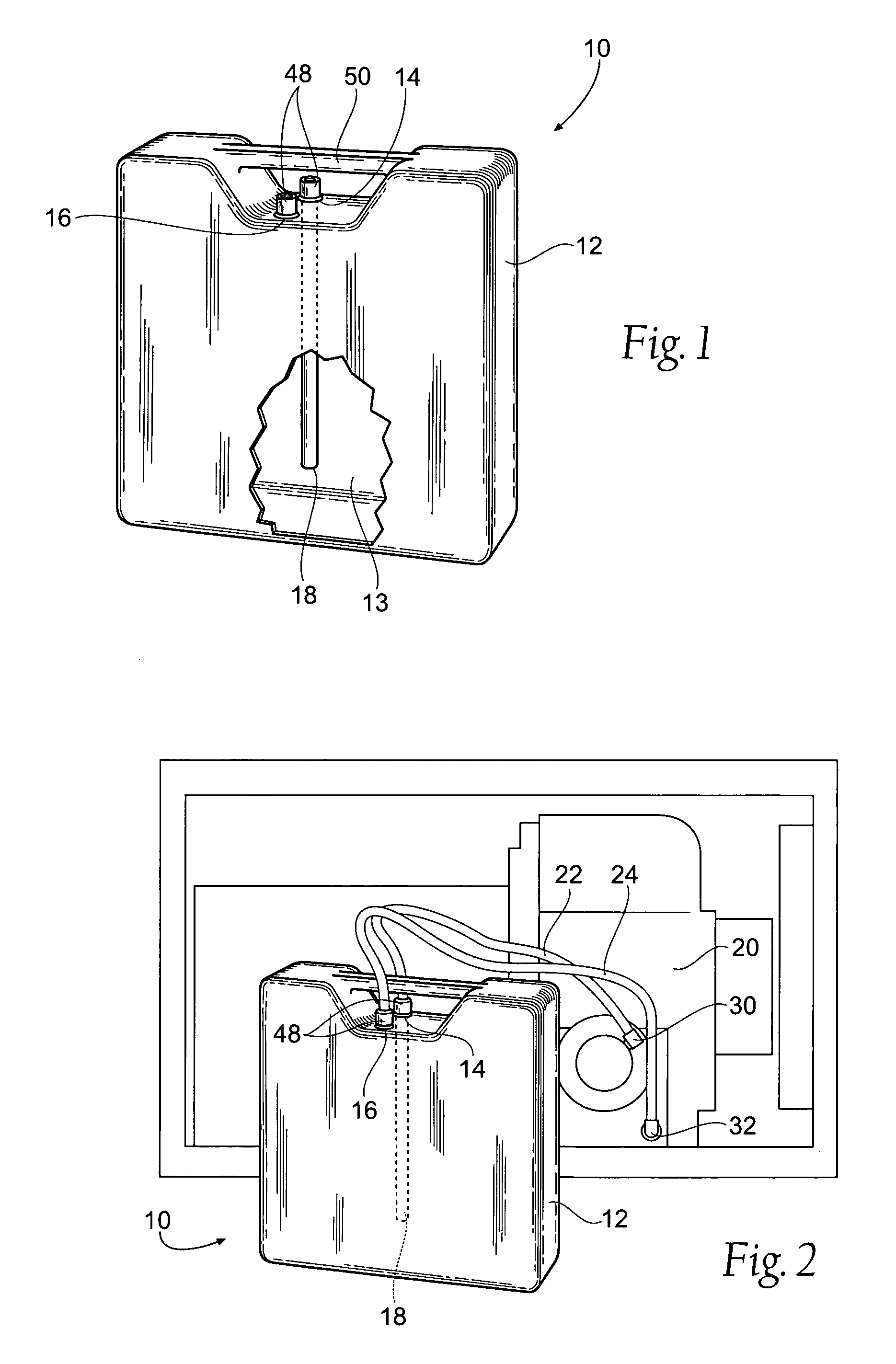

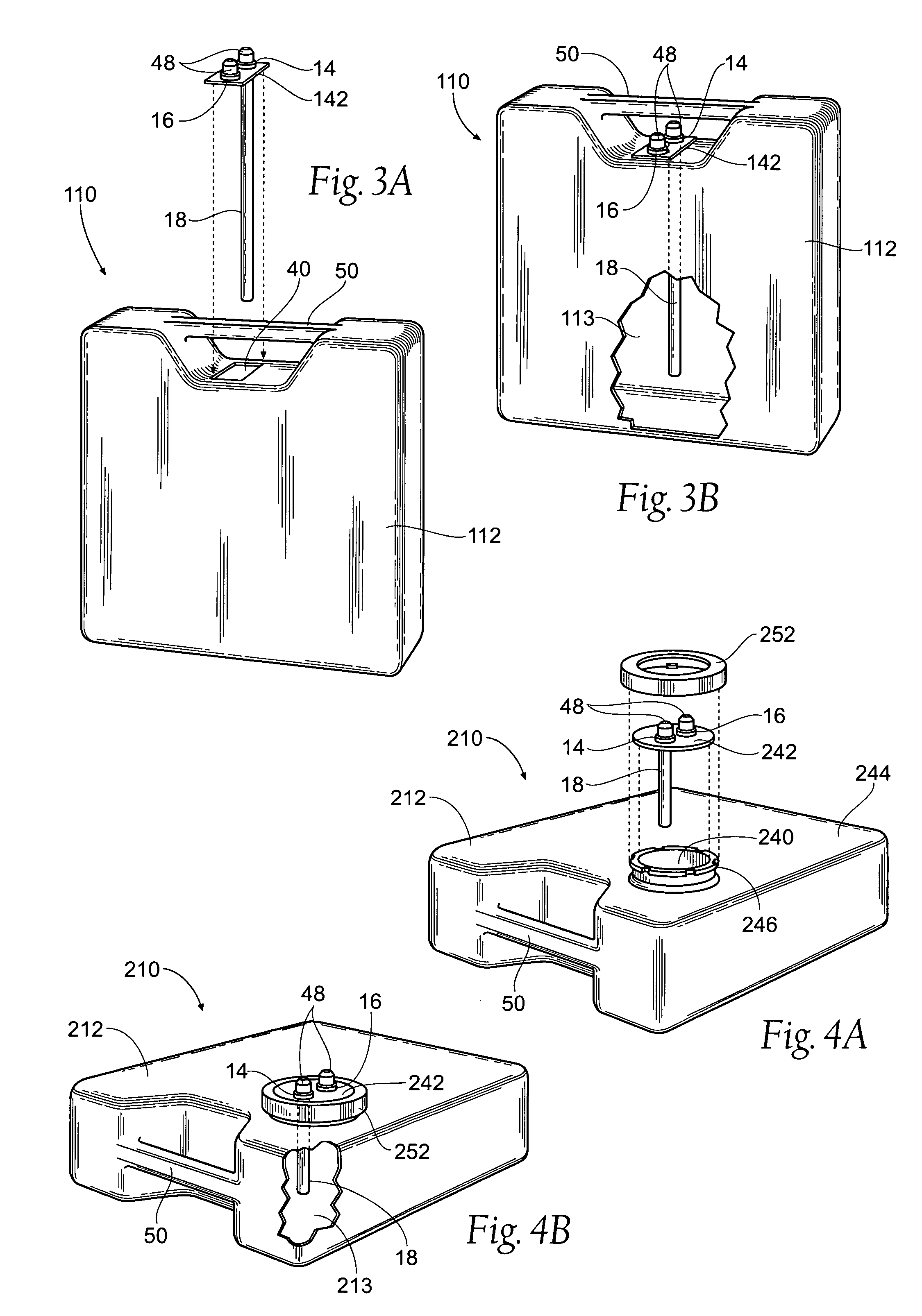

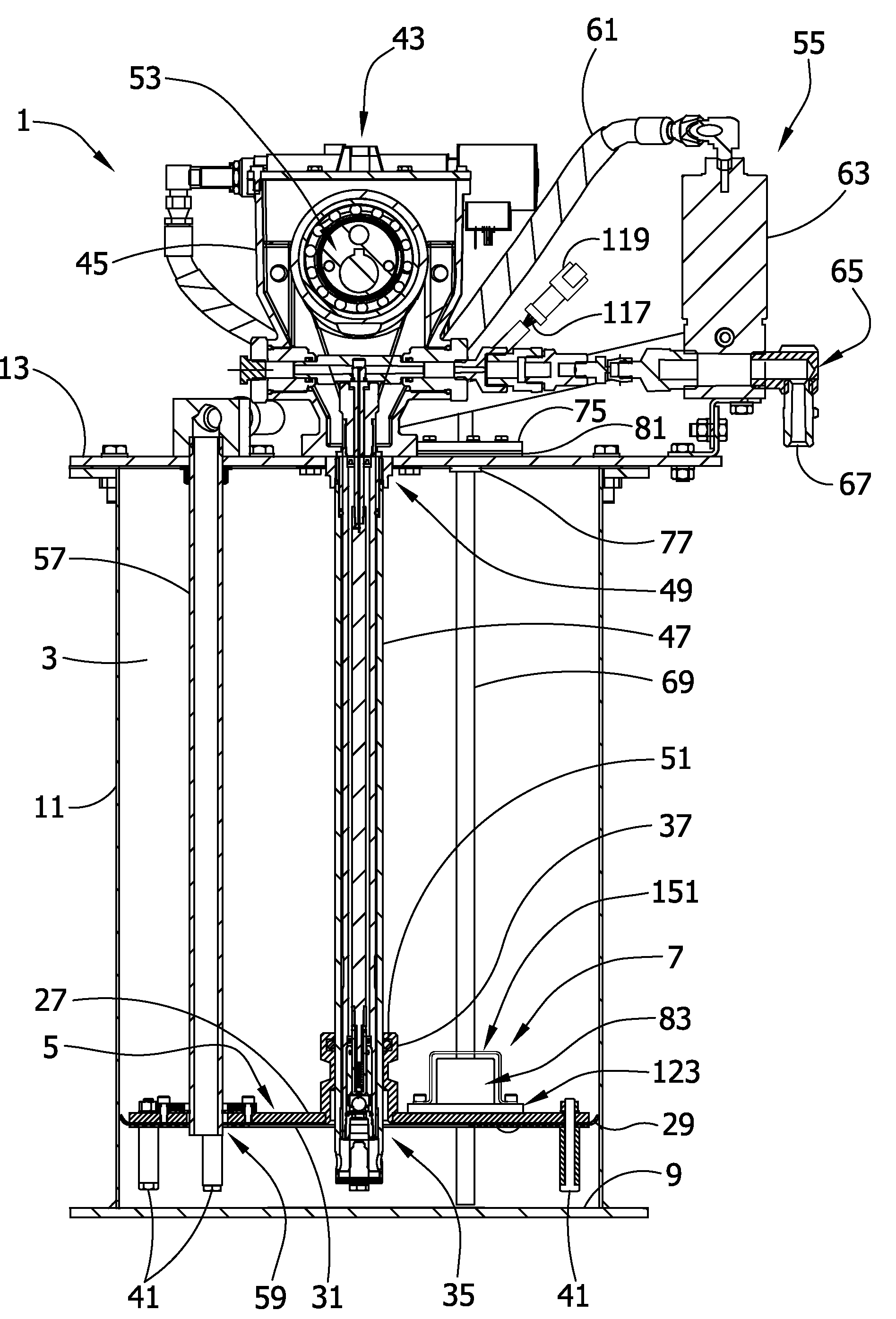

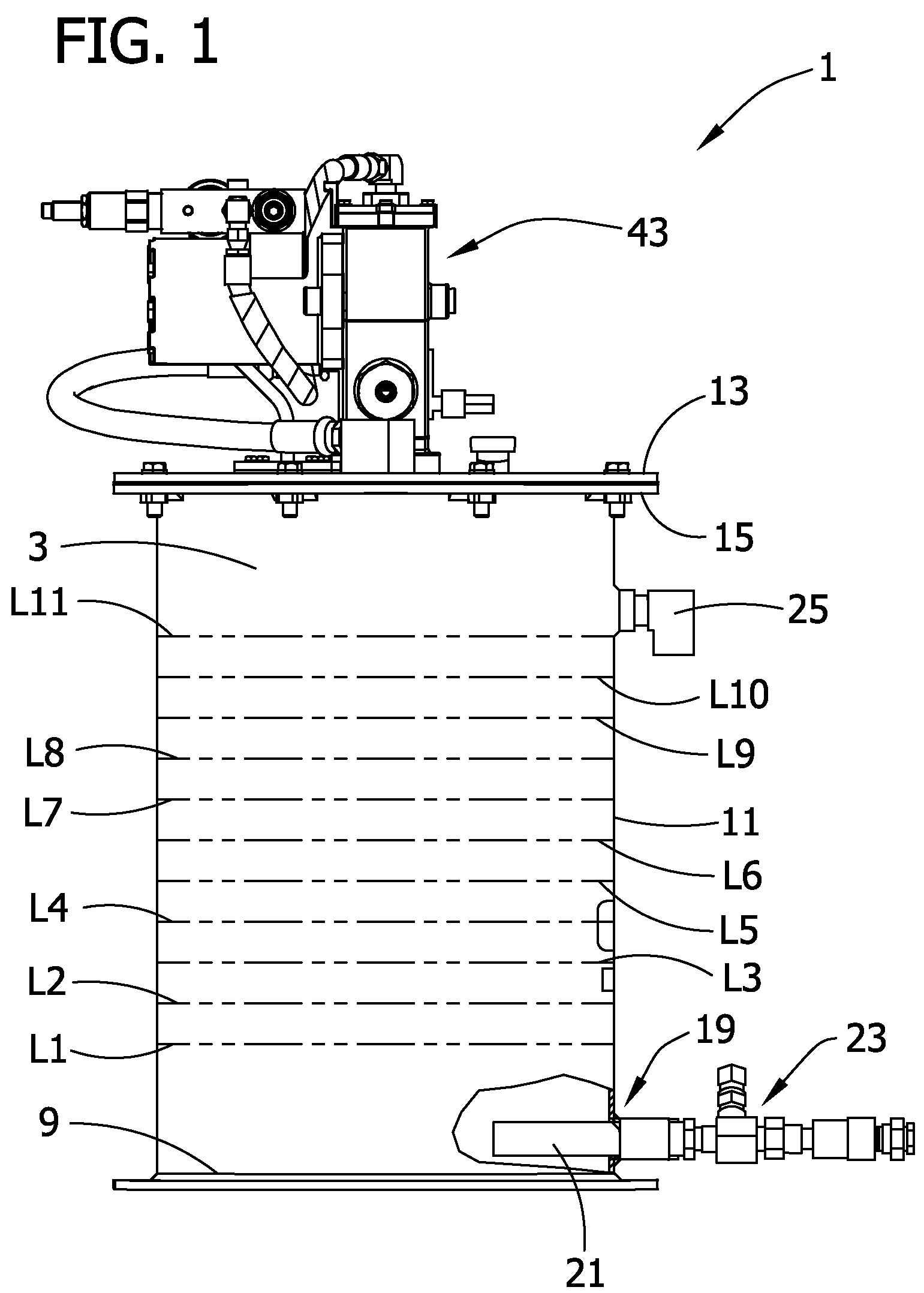

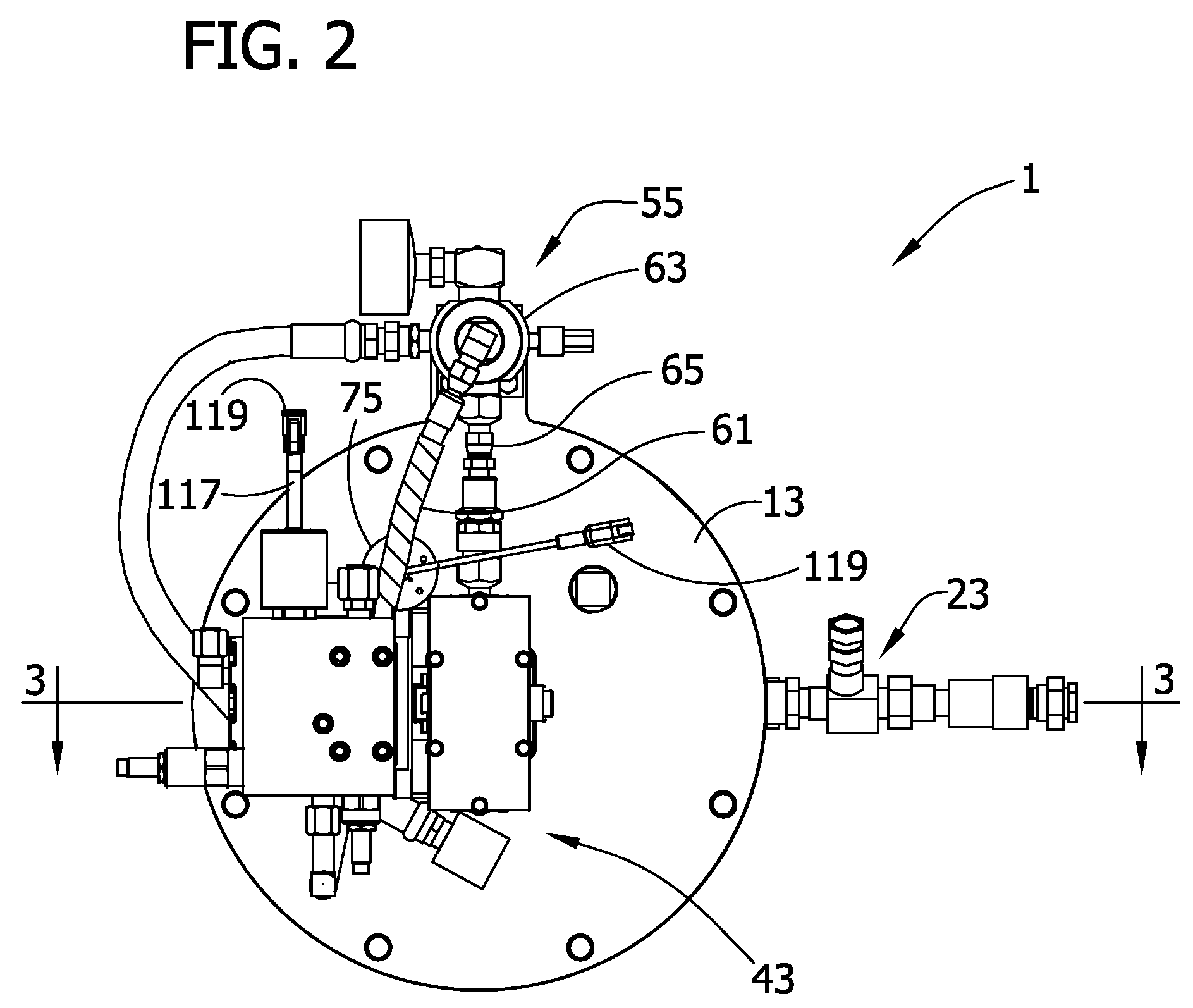

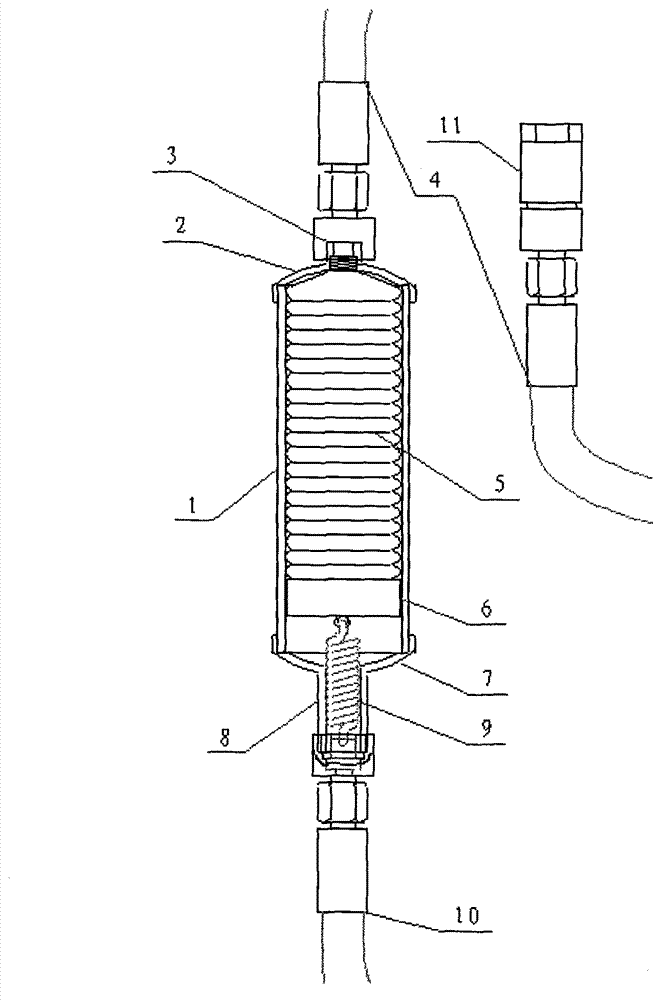

Lubricant reservoir refilling system with shut-off

InactiveUS20130256062A1Hinder lubricant from flowingAvoid flowOperating means/releasing devices for valvesLubricant transferLiquid tankEngineering

A lubricant reservoir system. The system includes a reservoir for containing lubricant. The reservoir has a top, a bottom, a peripheral wall, and an inlet for delivering lubricant to the reservoir from a supply. The system also includes a follower in the reservoir slidingly and sealingly engaging the peripheral wall of the reservoir, the follower moving up and down in the reservoir in response to a changing level of lubricant in the reservoir. The lubricant reservoir system has a shut-off valve in fluid communication with the inlet for selectively preventing lubricant flow through the inlet. The valve is operatively connected to the follower for closing the valve and preventing lubricant flow through the inlet when lubricant in the reservoir reaches a predetermined level.

Owner:LINCOLN INDUSTRIES CORP

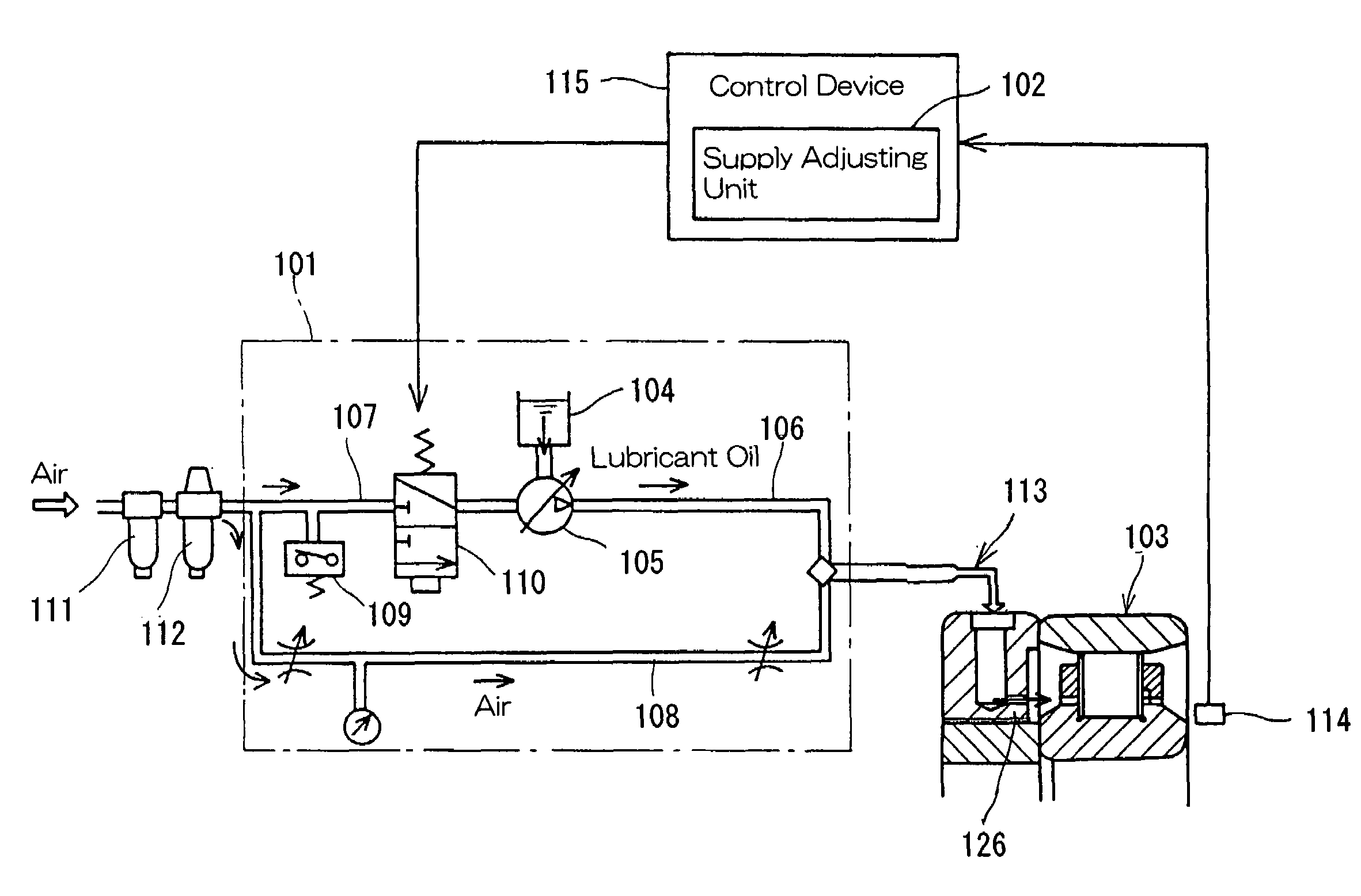

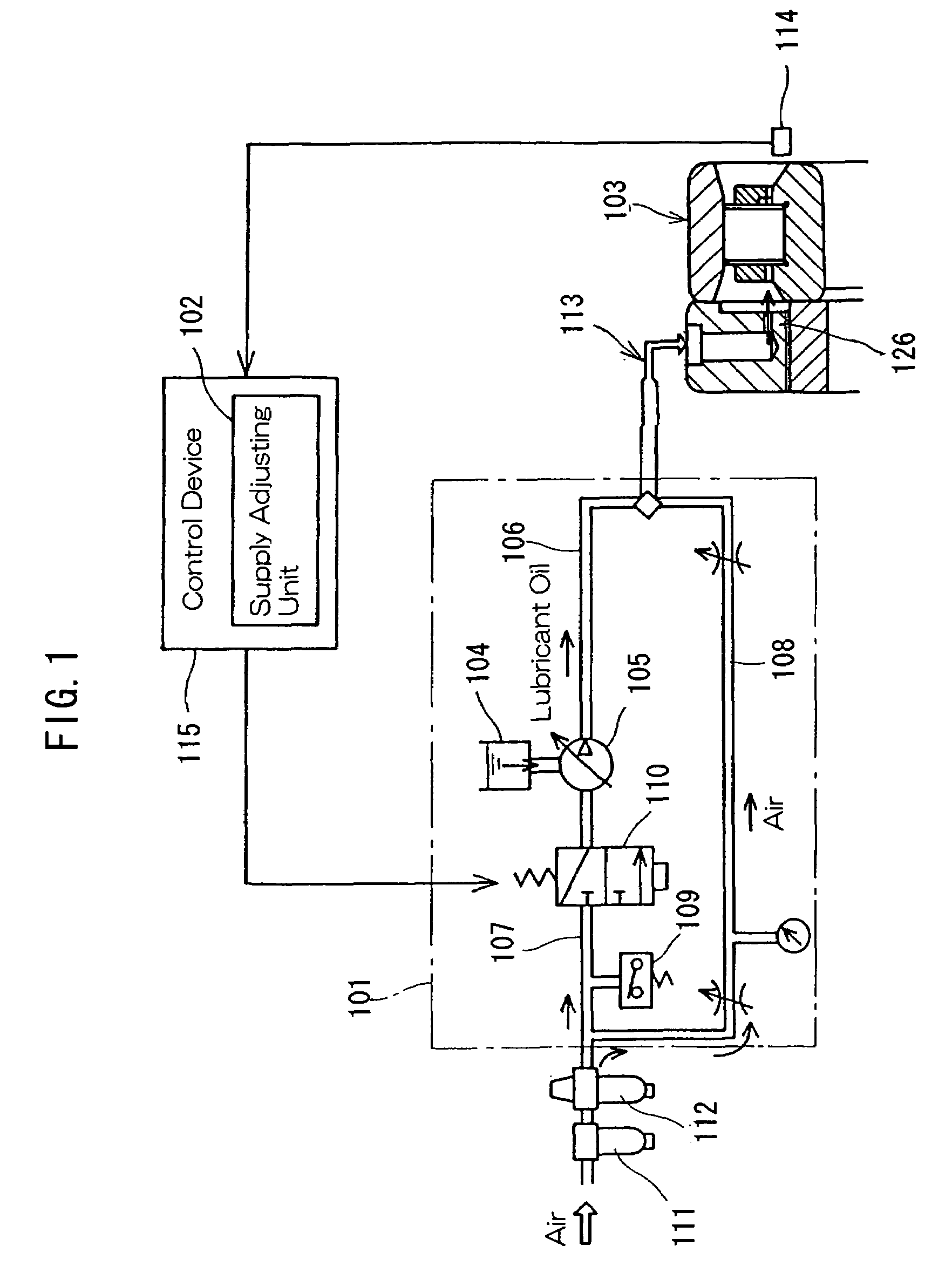

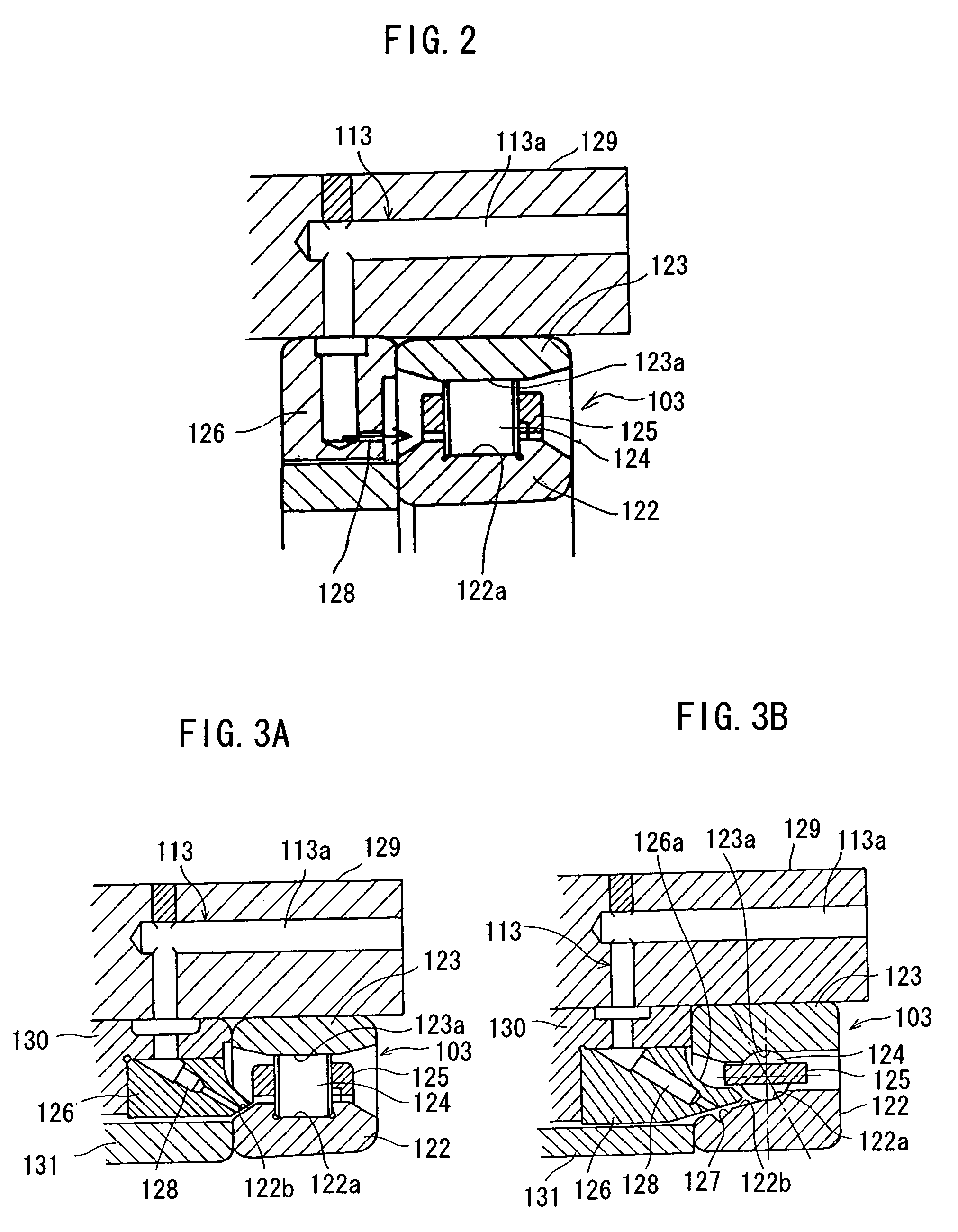

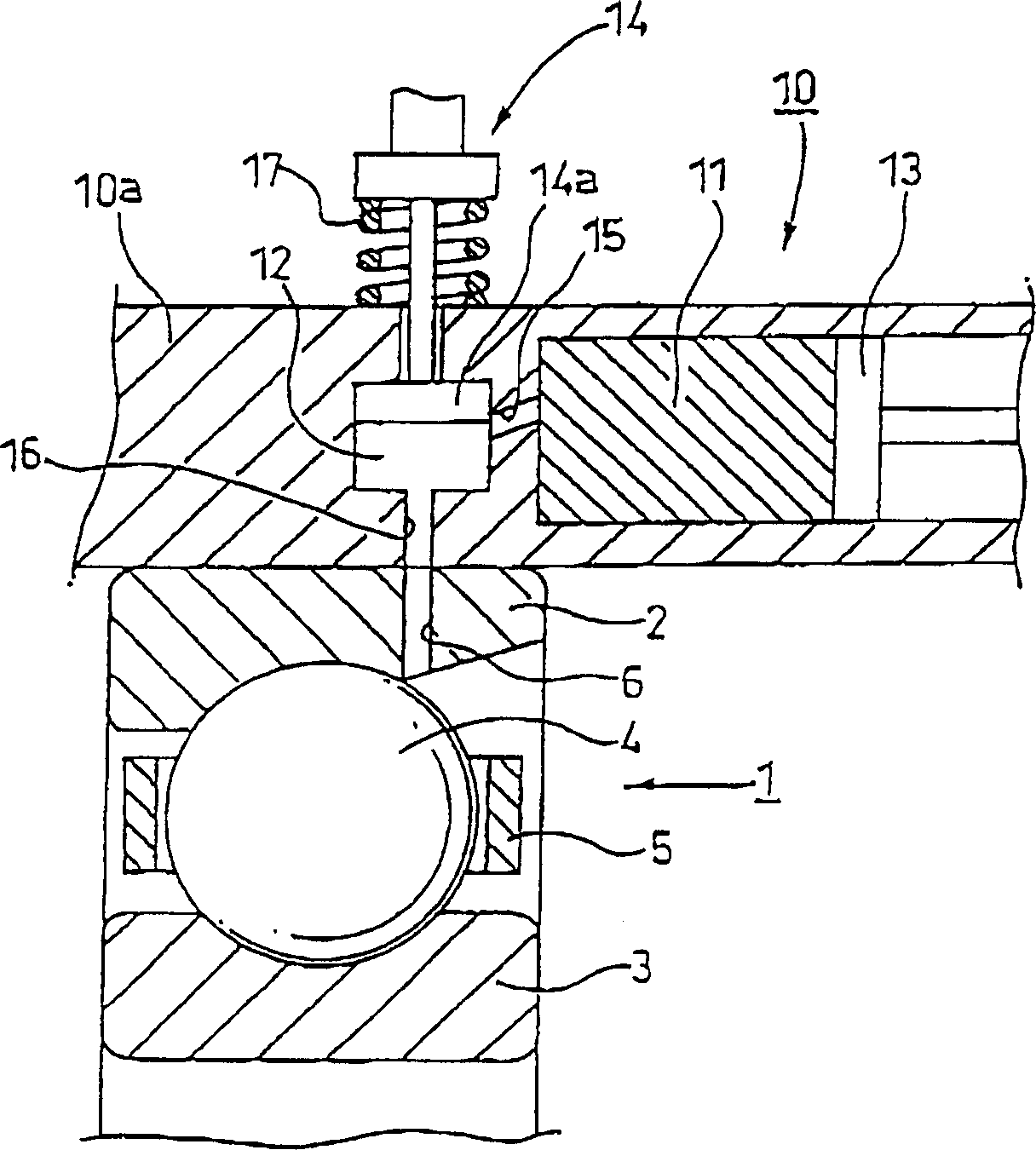

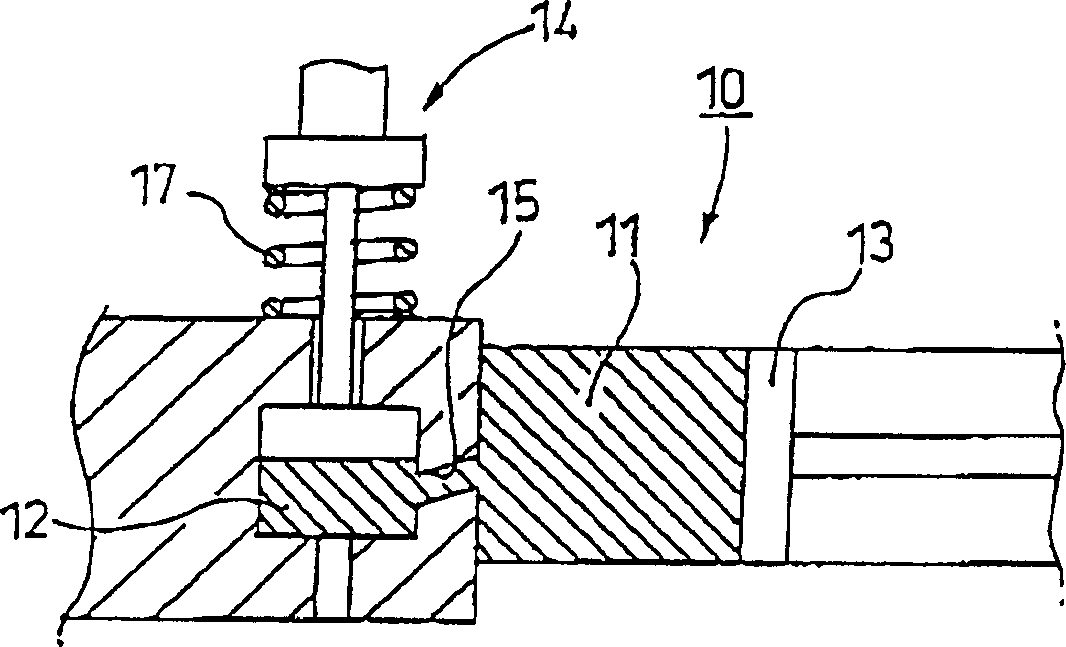

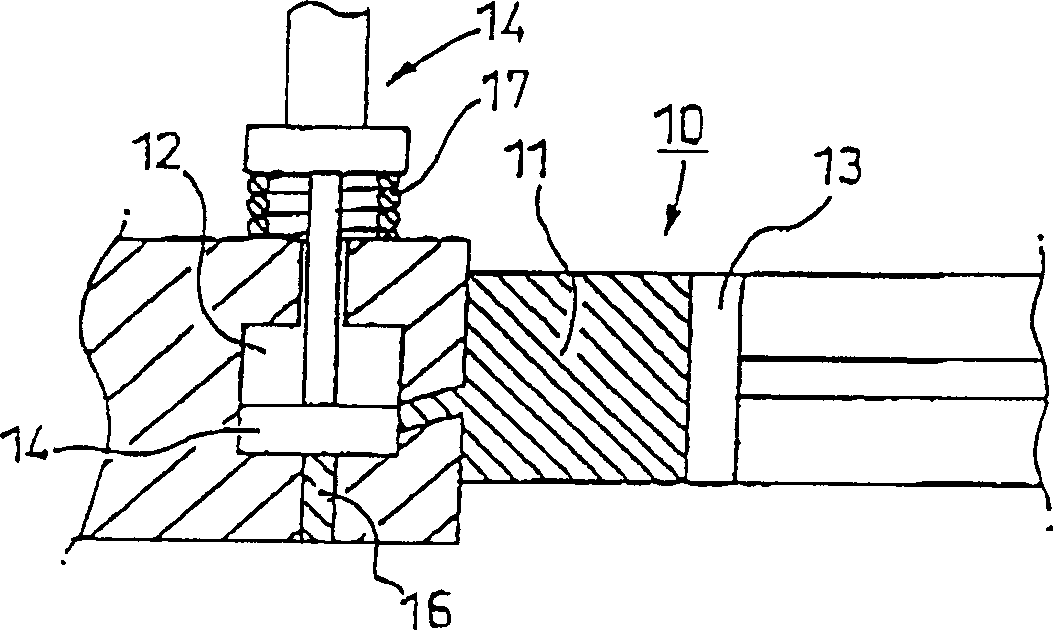

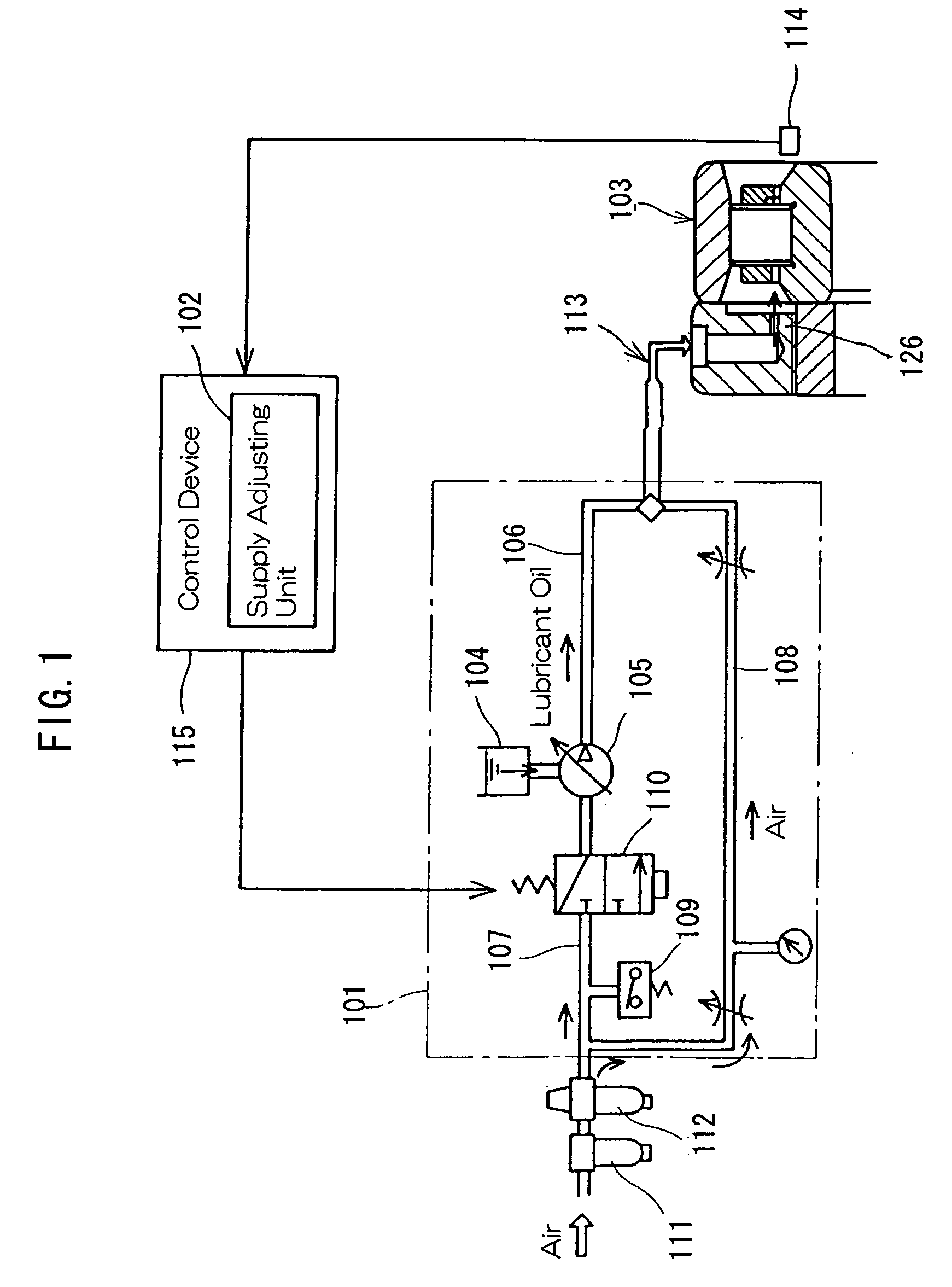

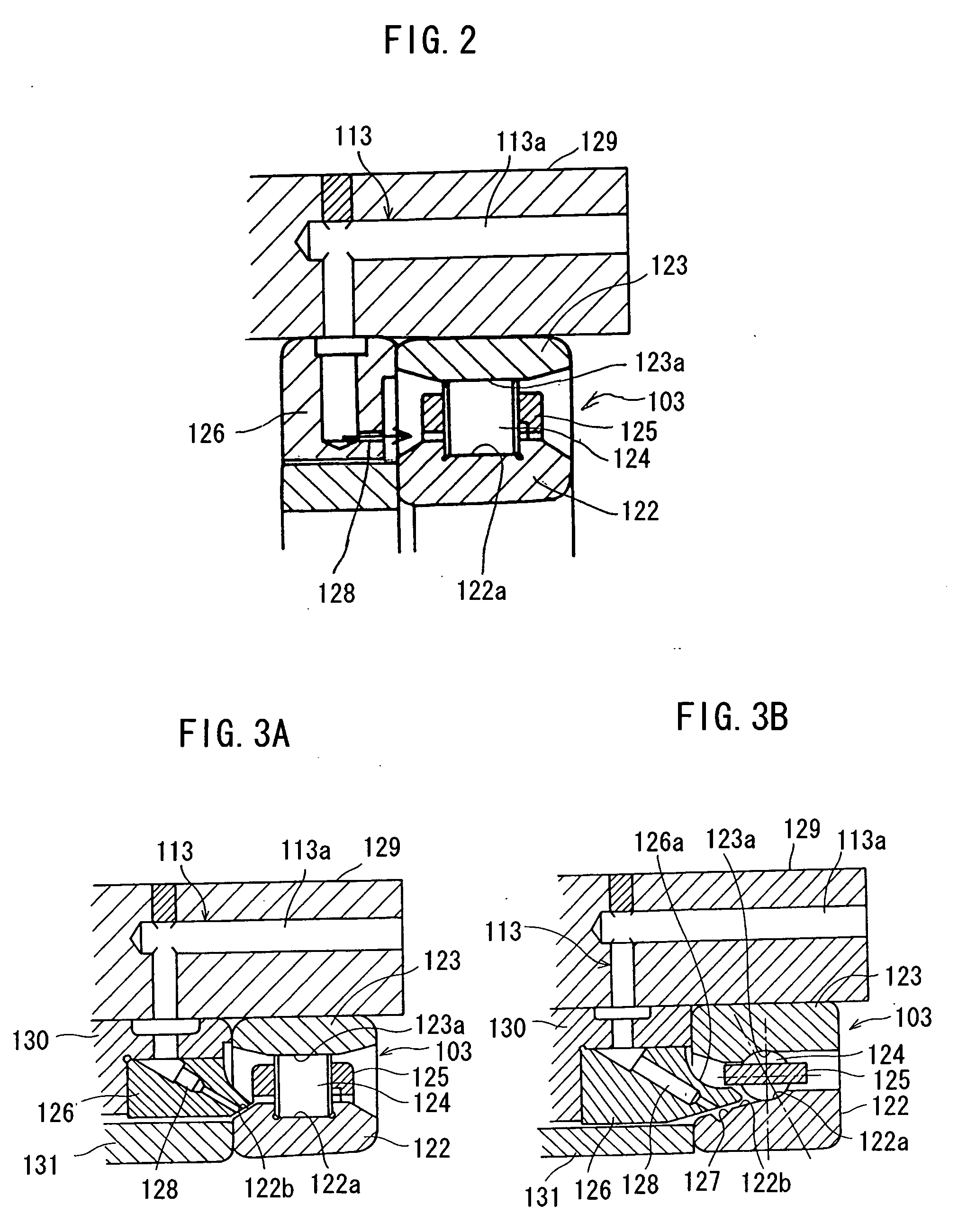

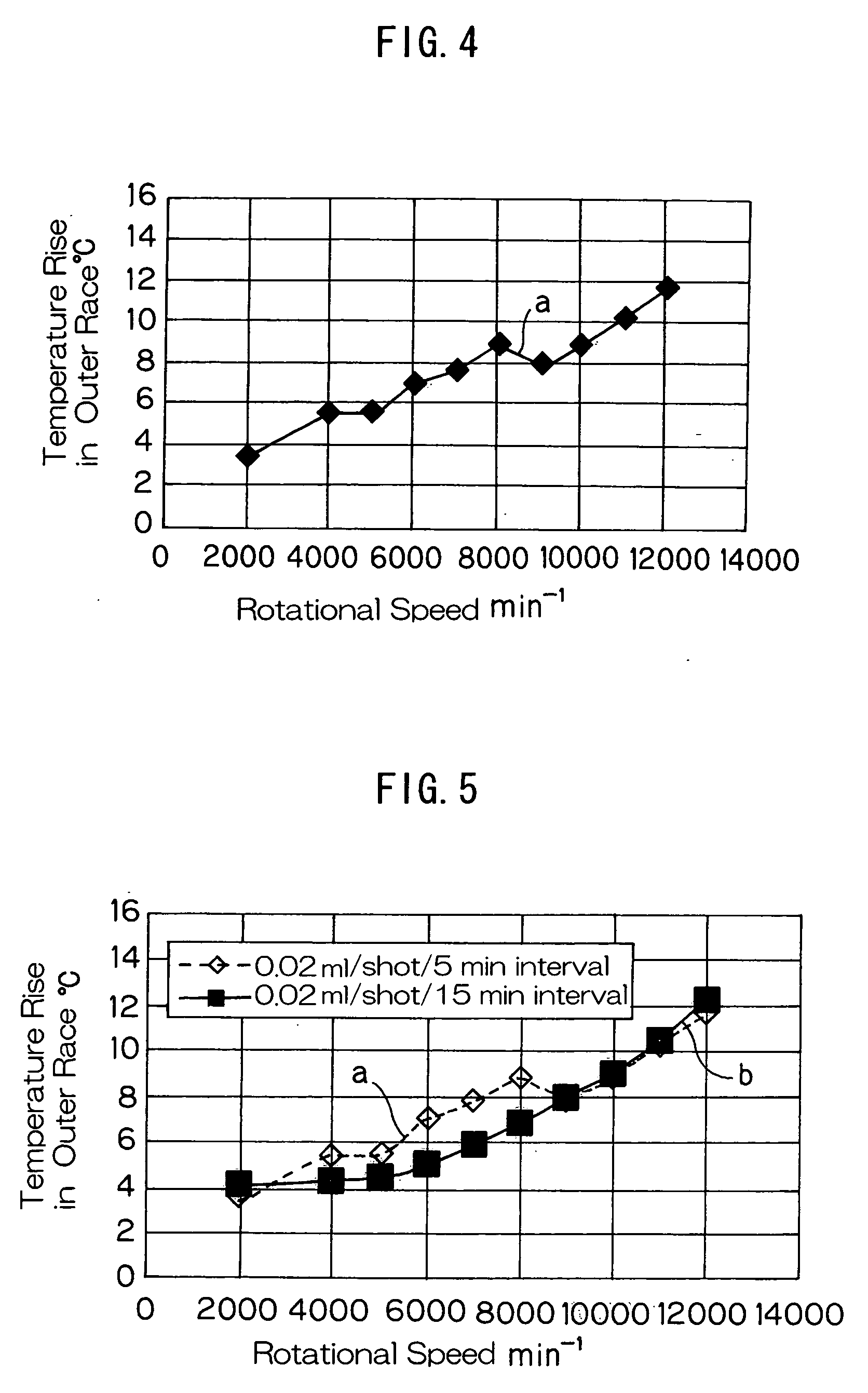

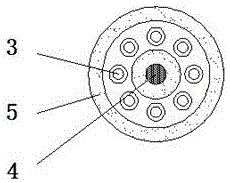

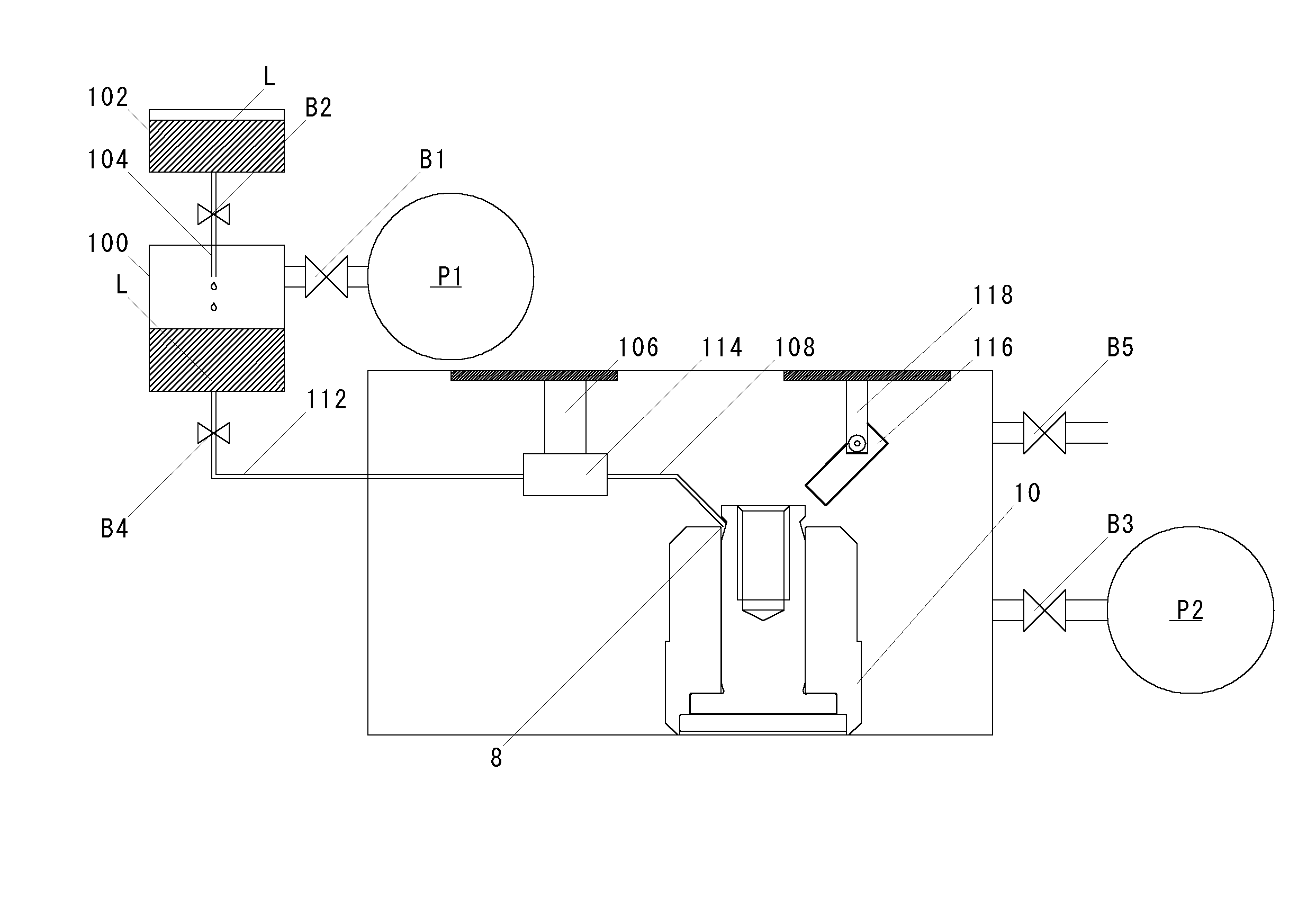

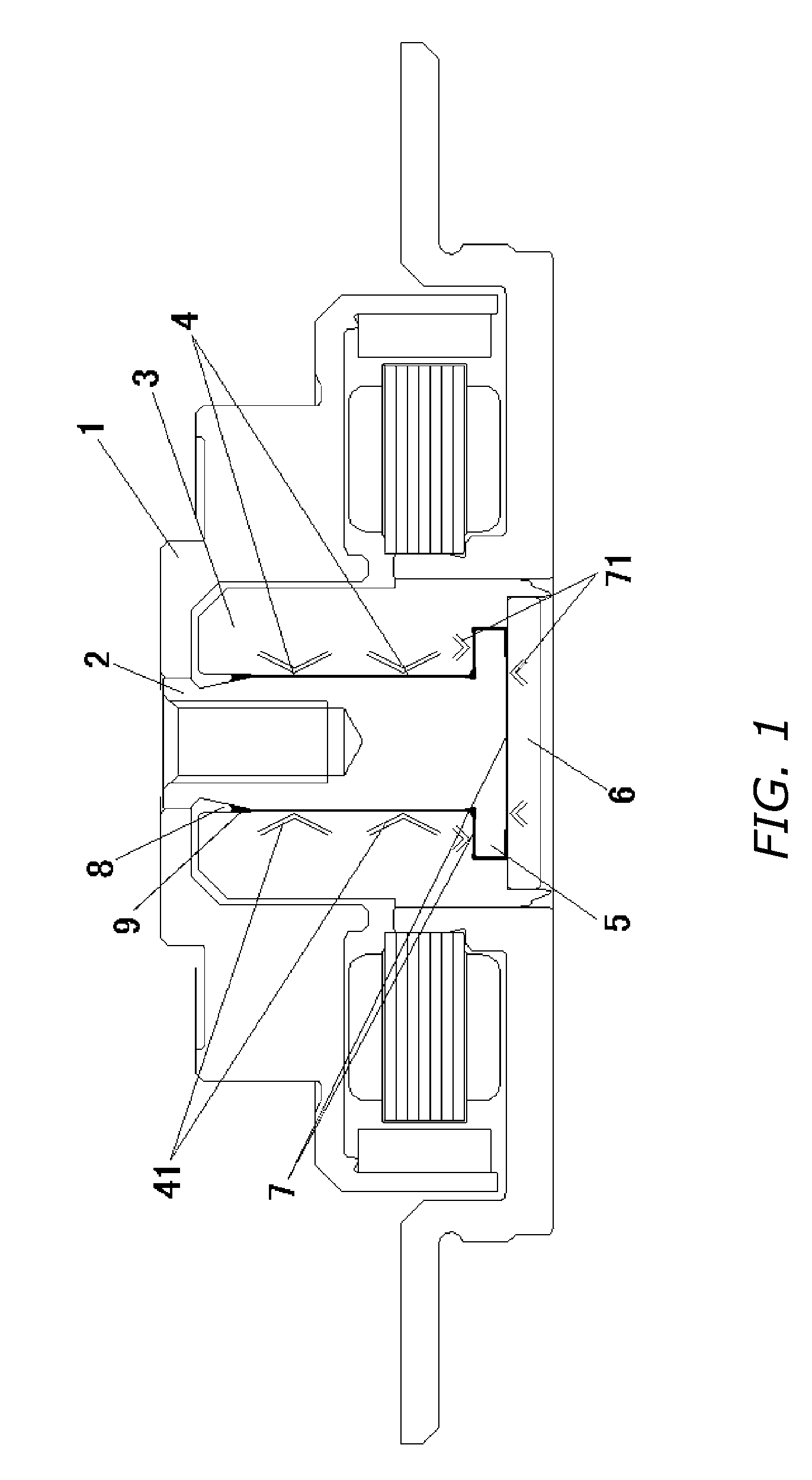

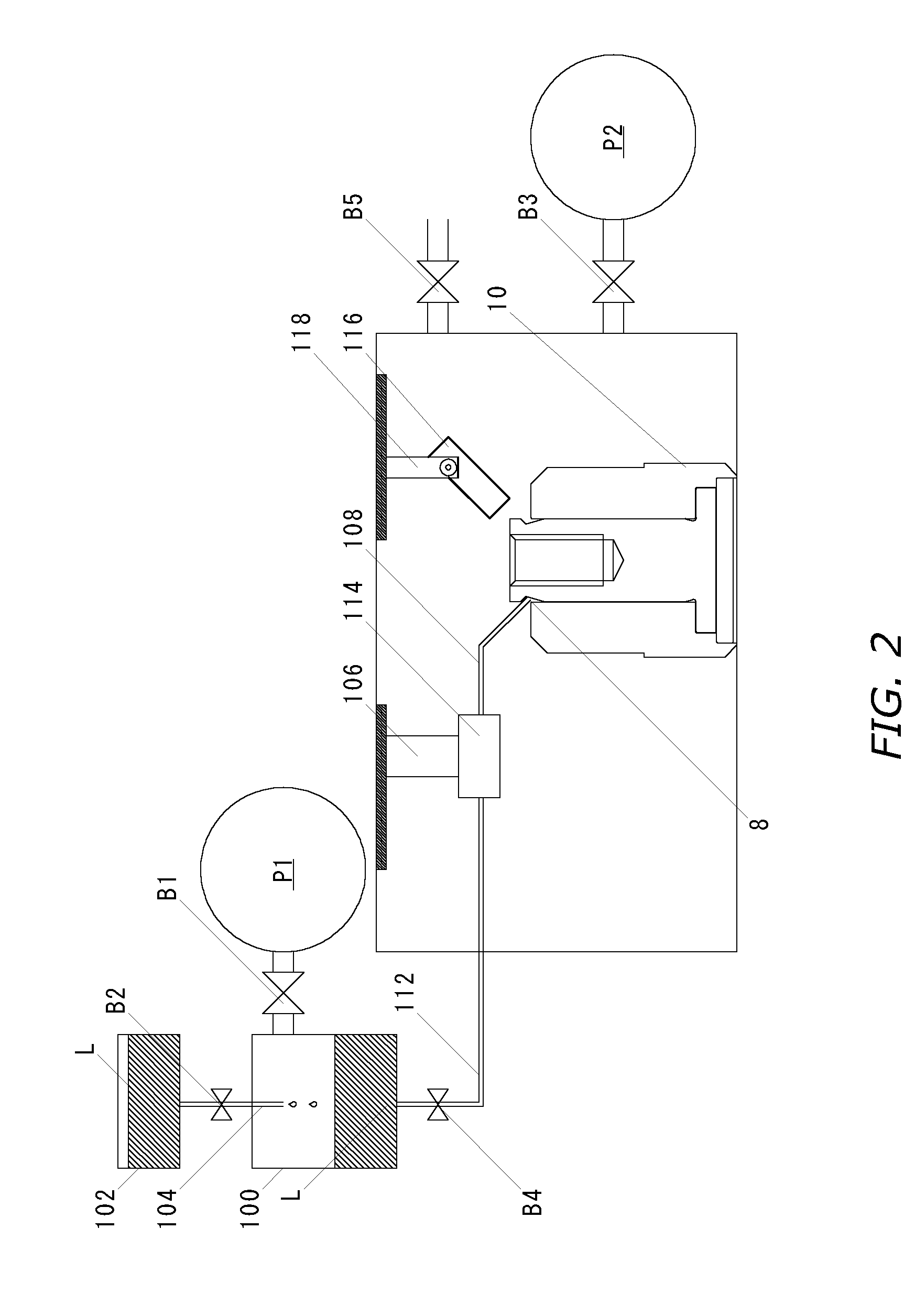

Method of and device for lubricating rolling bearings

ActiveUS7374019B2Stable temperature riseEnsure reliabilityRoller bearingsBall bearingsRolling-element bearingEngineering

There is provided a lubricating method for a rolling bearing assembly capable of achieving a reliable lubrication and exhibiting a stable temperature rise. The method is for supplying a lubricant oil to the rolling bearing assembly during the operation thereof, in which in order to keep the temperature of a rolling bearing assembly (103) within a predetermined tolerance, the amount of the lubricant oil to be supplied during the operation is automatically or manually adjusted by means of a supply adjusting unit (102). Supply of the lubricant oil is performed in the form of an air / oil mixture by the use of a lubricant supply unit (101). The amount of the lubricant oil supplied varies depending on the rotational speed of the rolling bearing assembly (103). Change of the amount of the lubricant oil supplied depending on the rotational speed of the rolling bearing assembly (103) is carried out based on a result of sampling of data showing increase in temperature of the rolling bearing assembly (103) depending on the rotational speed thereof under a plurality of different lubricating conditions in which a different amount of the lubricant oil to be supplied is employed.

Owner:NTN CORP

Vehicle Fluid Dispensing Apparatus and Method of Use

InactiveUS20100200609A1Low costShorten the timeOpening closed containersBottle/container closureBiomedical engineeringNozzle

This invention relates to a vehicle fluid dispensing apparatus and a method of use. The apparatus includes a plurality of motive force devices for fluid communication with a plurality of reservoirs. The apparatus also includes a plurality of metering devices in fluid communication with the motive force devices and a single nozzle in fluid communication with the plurality of motive force devices.

Owner:CASTROL LTD

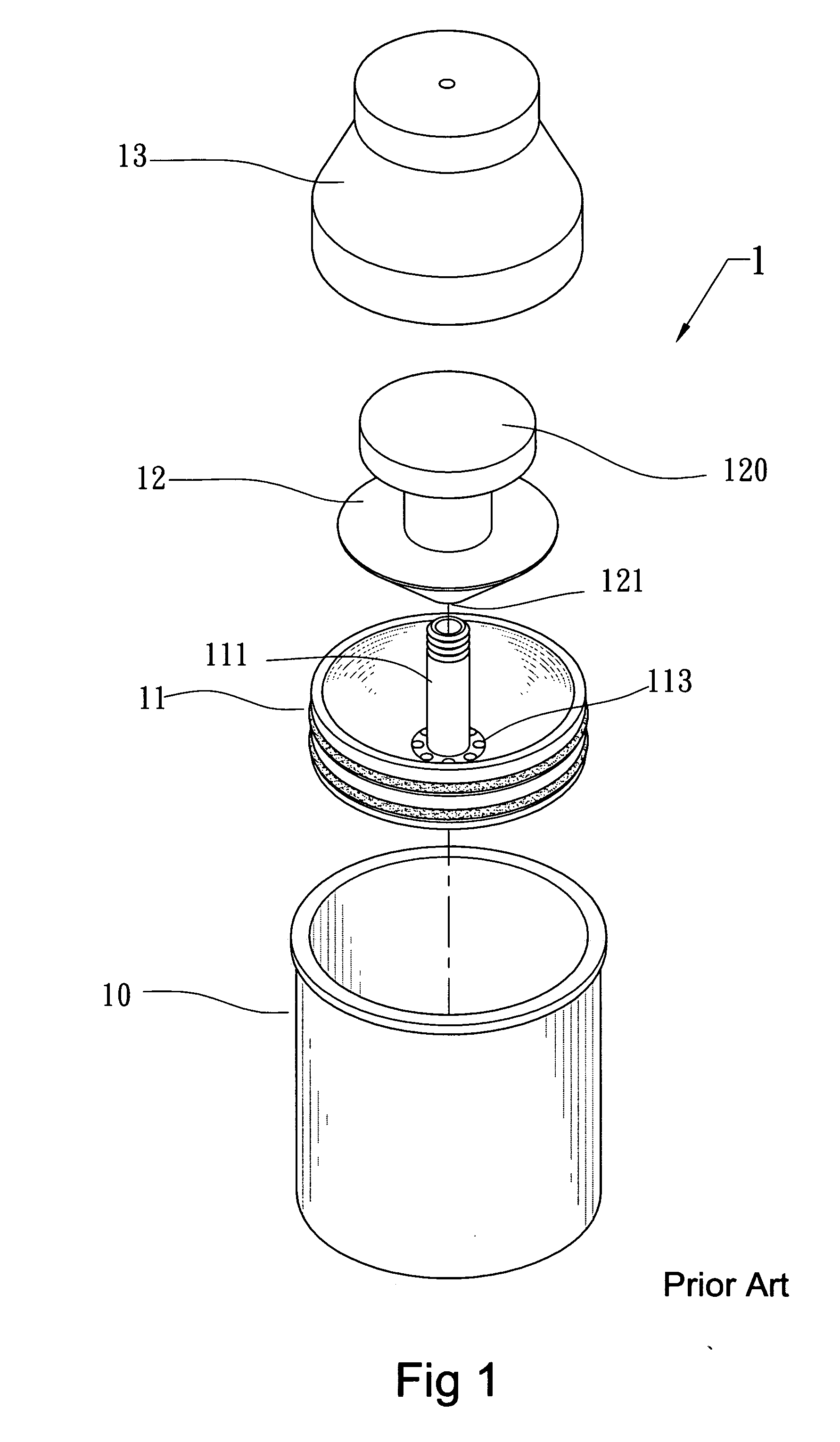

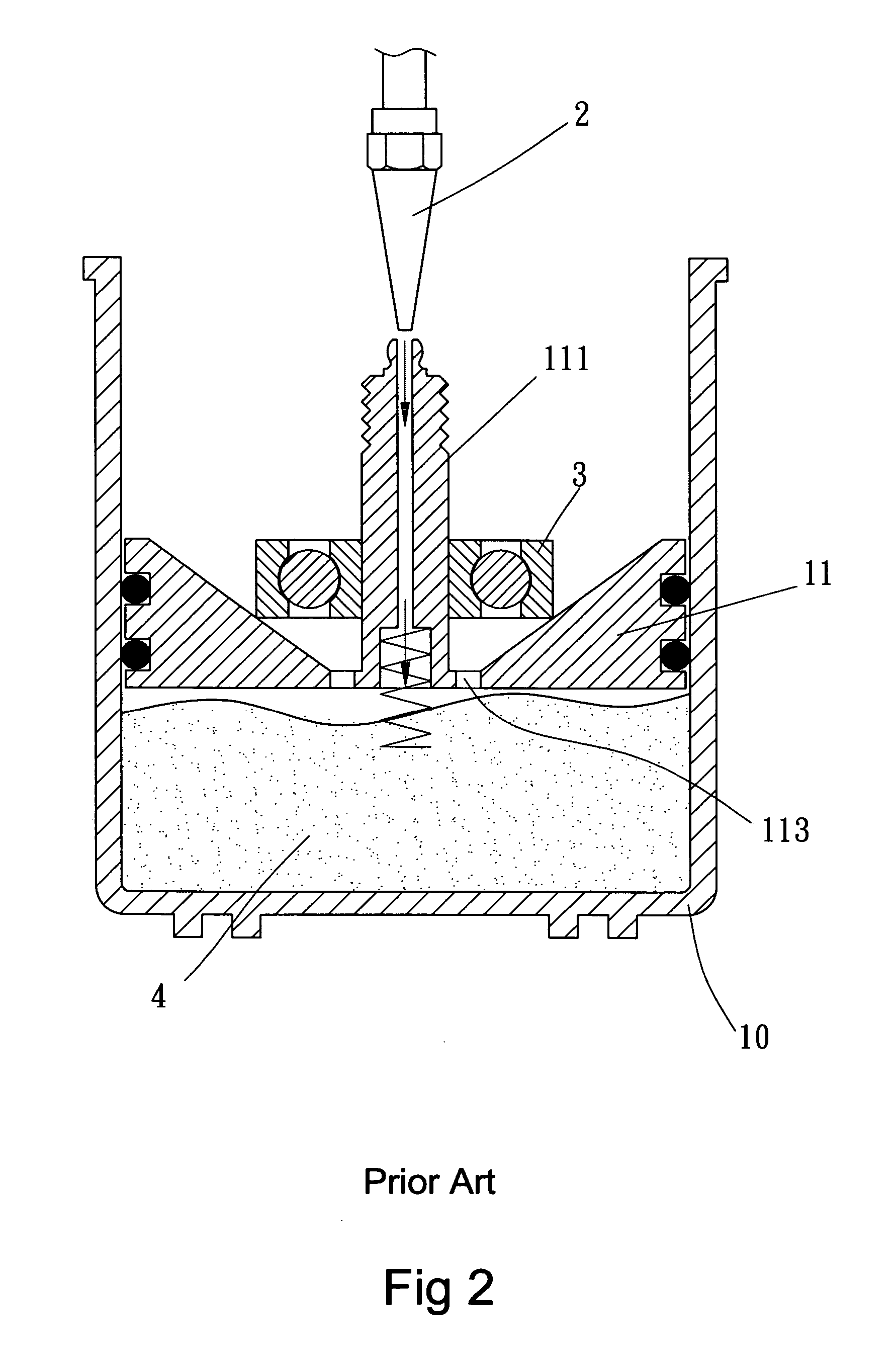

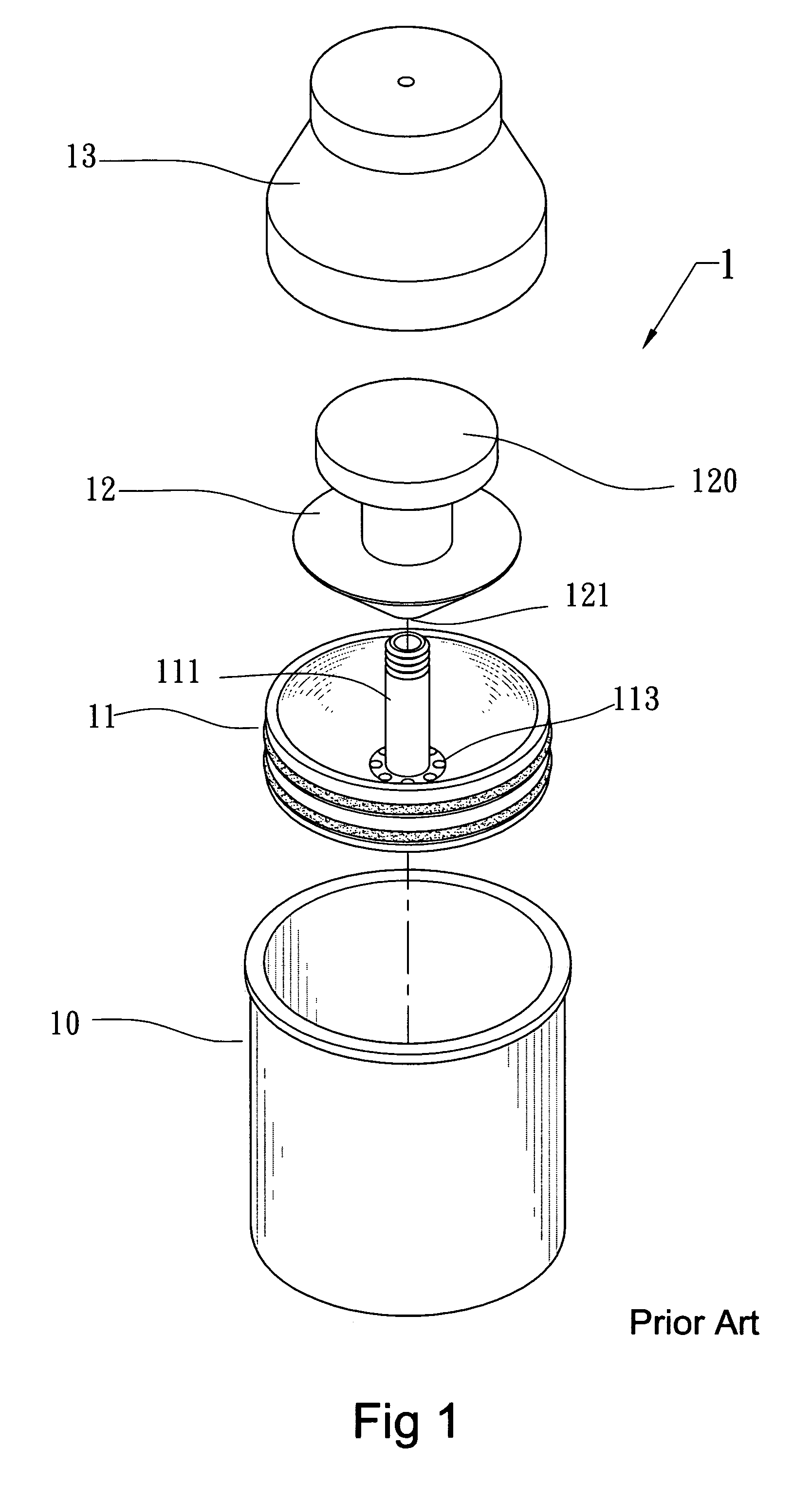

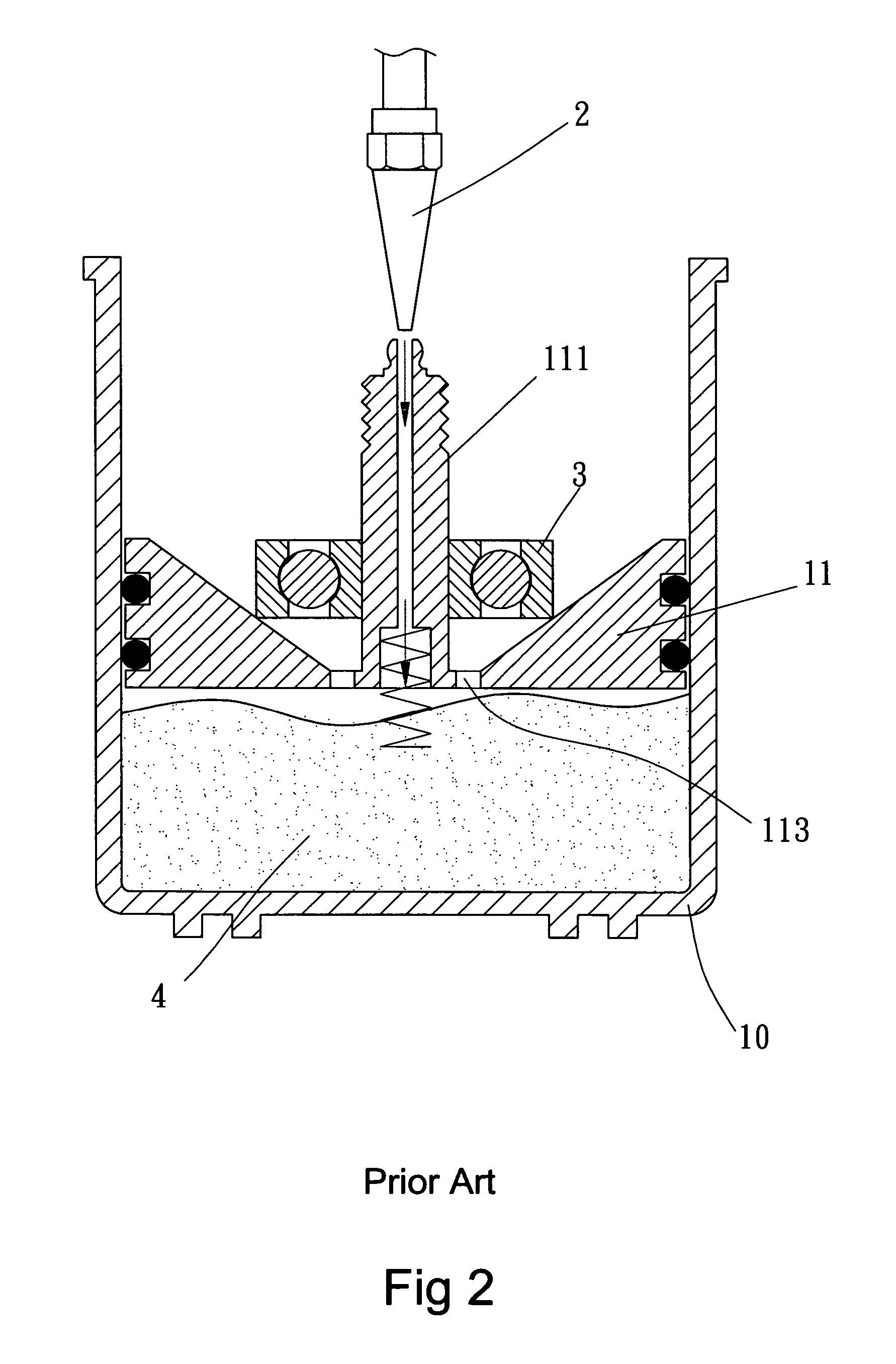

Grease supplementing apparatus

InactiveCN1405483ARolling contact bearingsLubricant transferRolling-element bearingMechanical engineering

A grease replenishing device replenishes a grease-lubricated rolling bearing with a grease. The grease replenishing device has a storage chamber portion and a pressing member. The storage chamber portion stores the grease. The pressing member pushes the grease out of the storage chamber into an interior of the rolling bearing.

Owner:NSK LTD

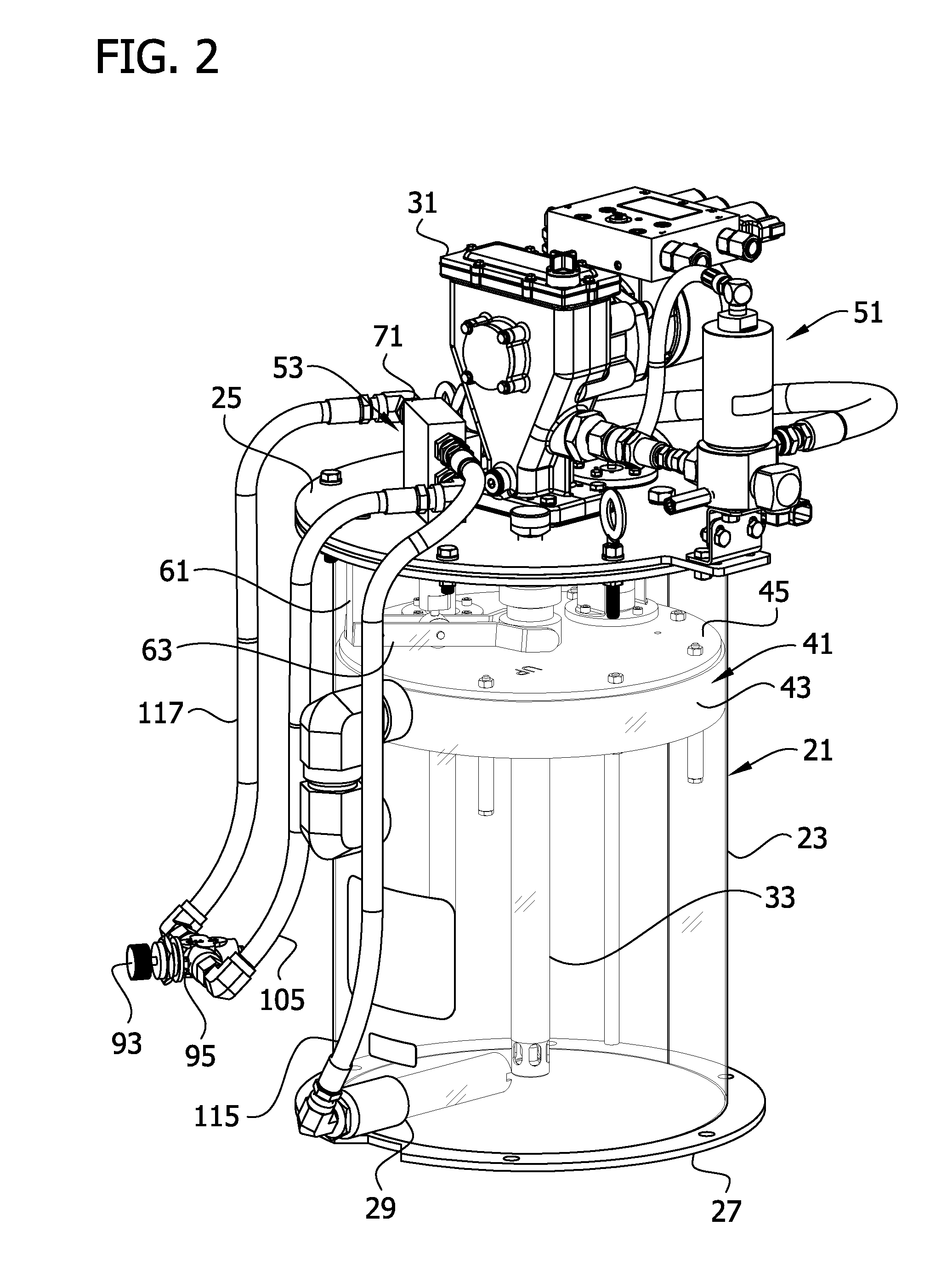

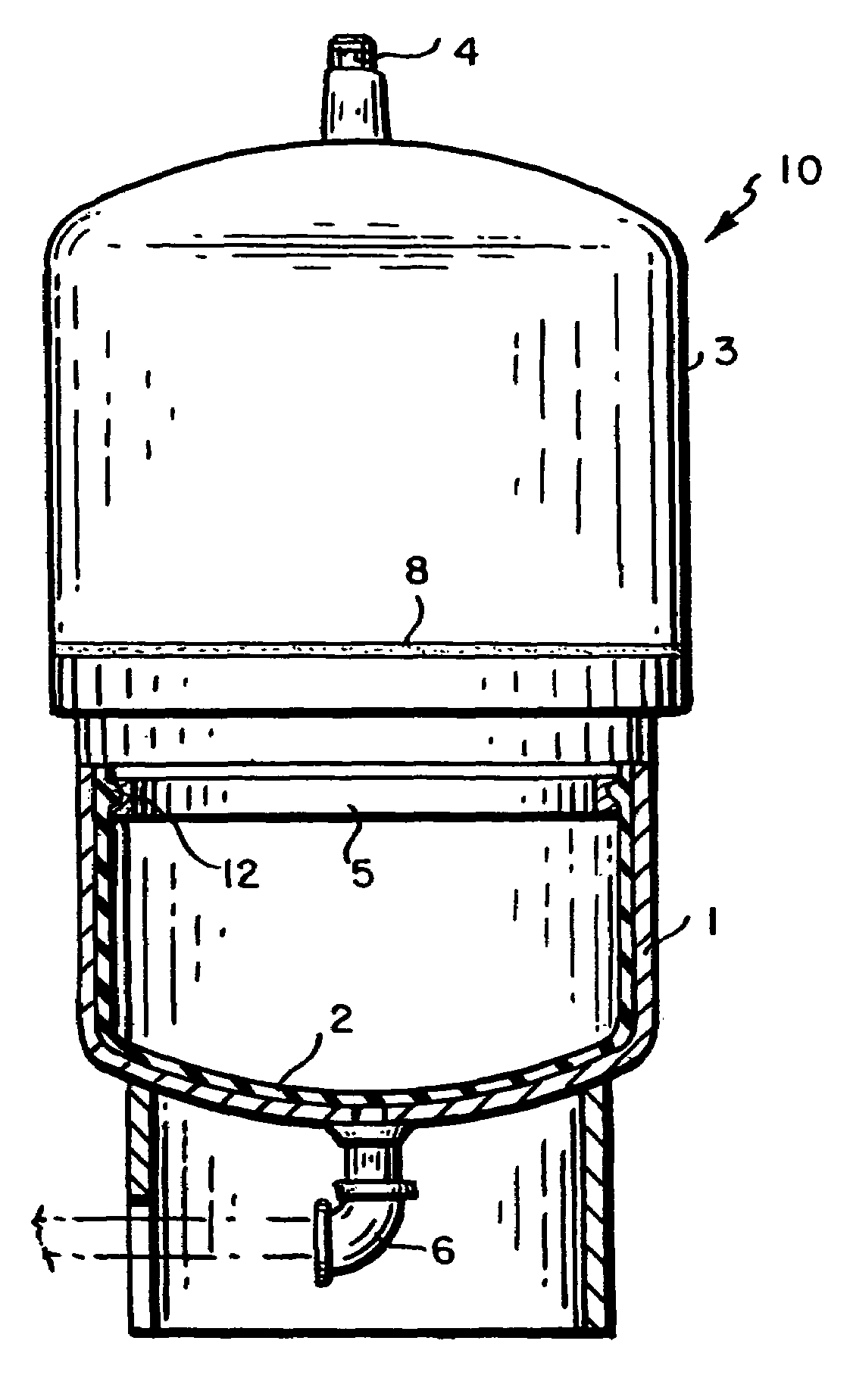

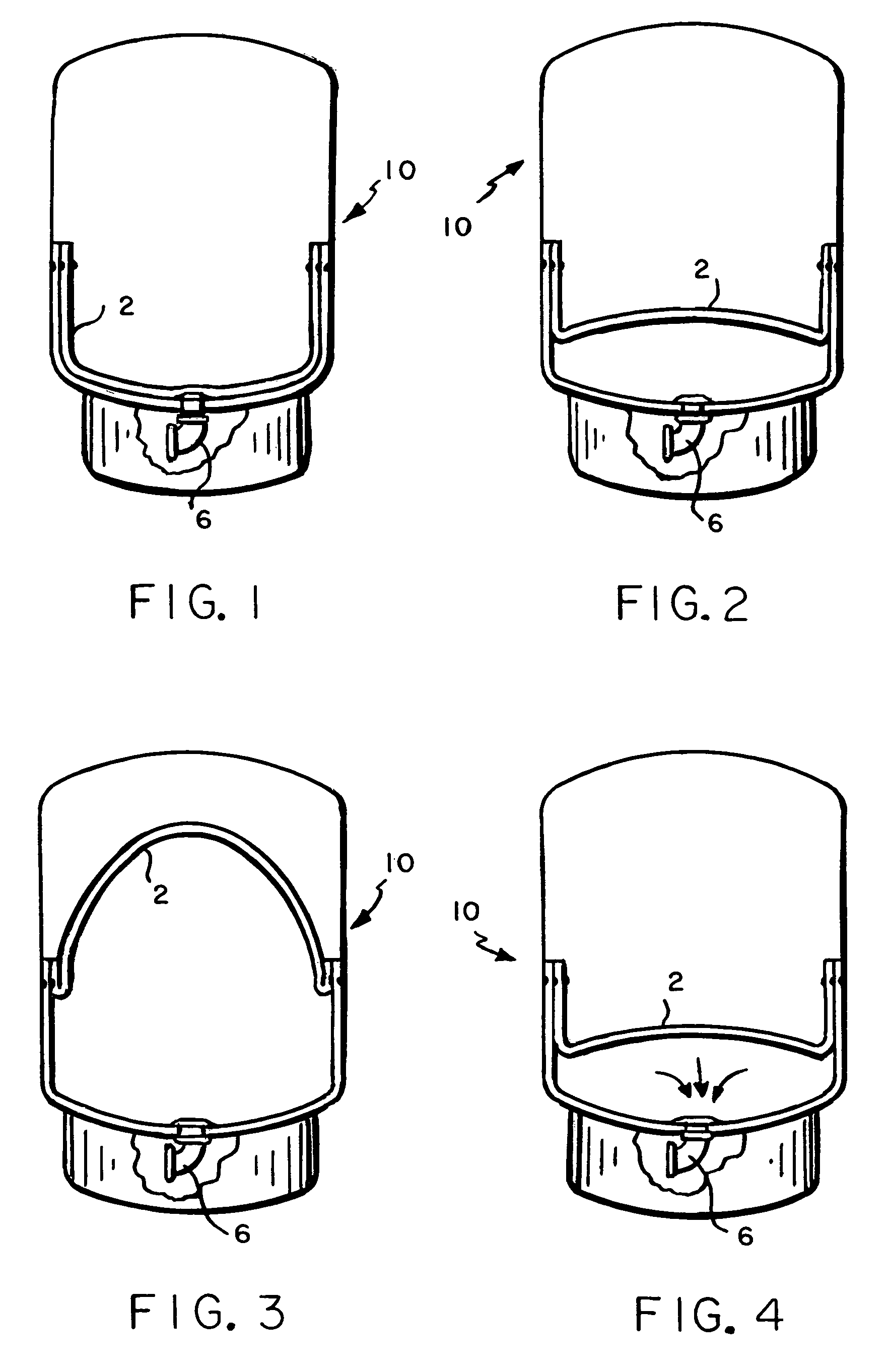

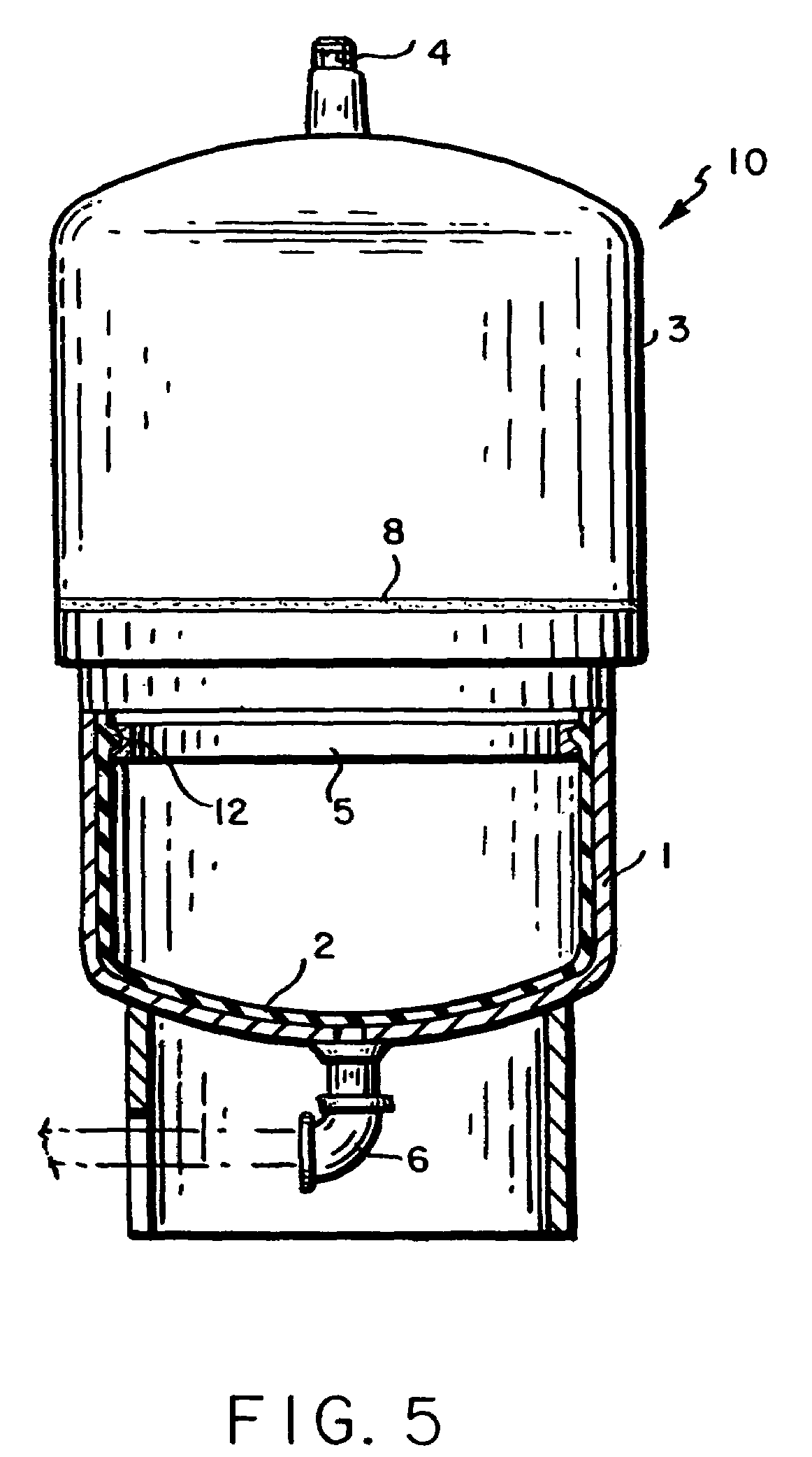

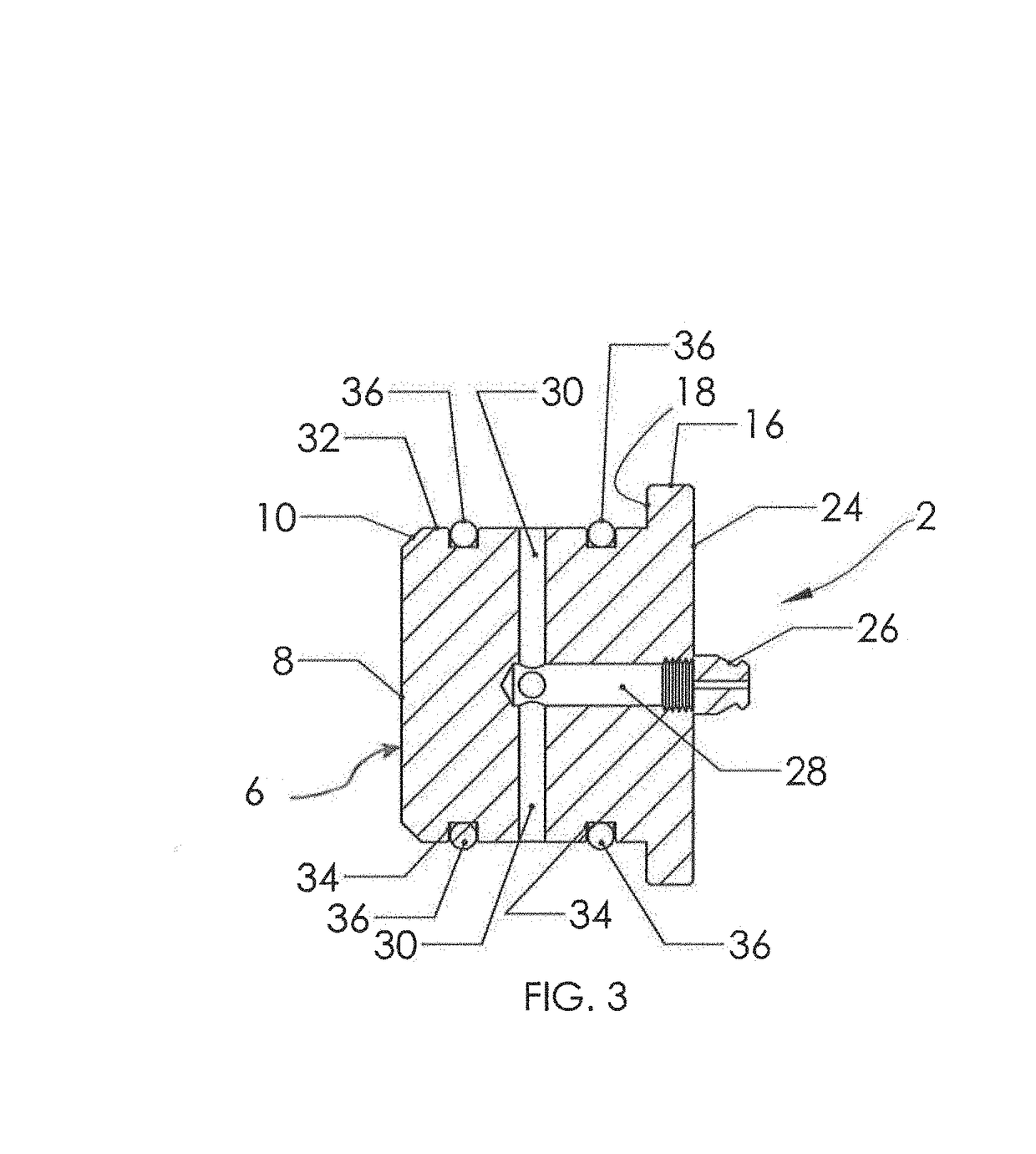

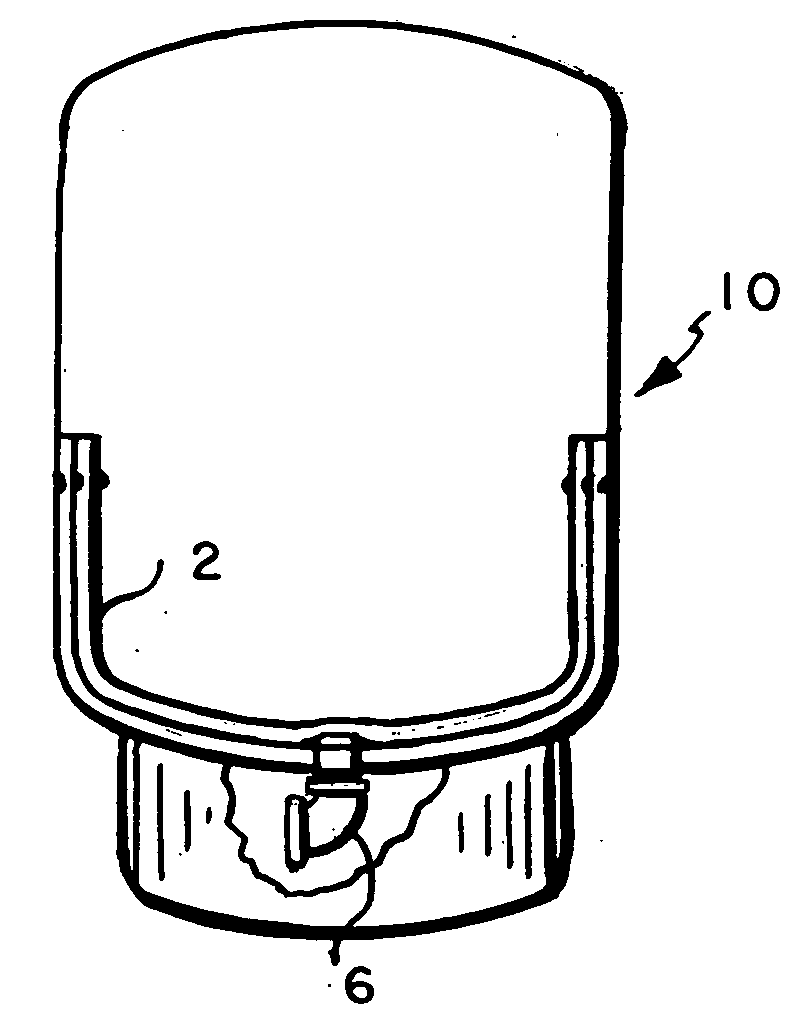

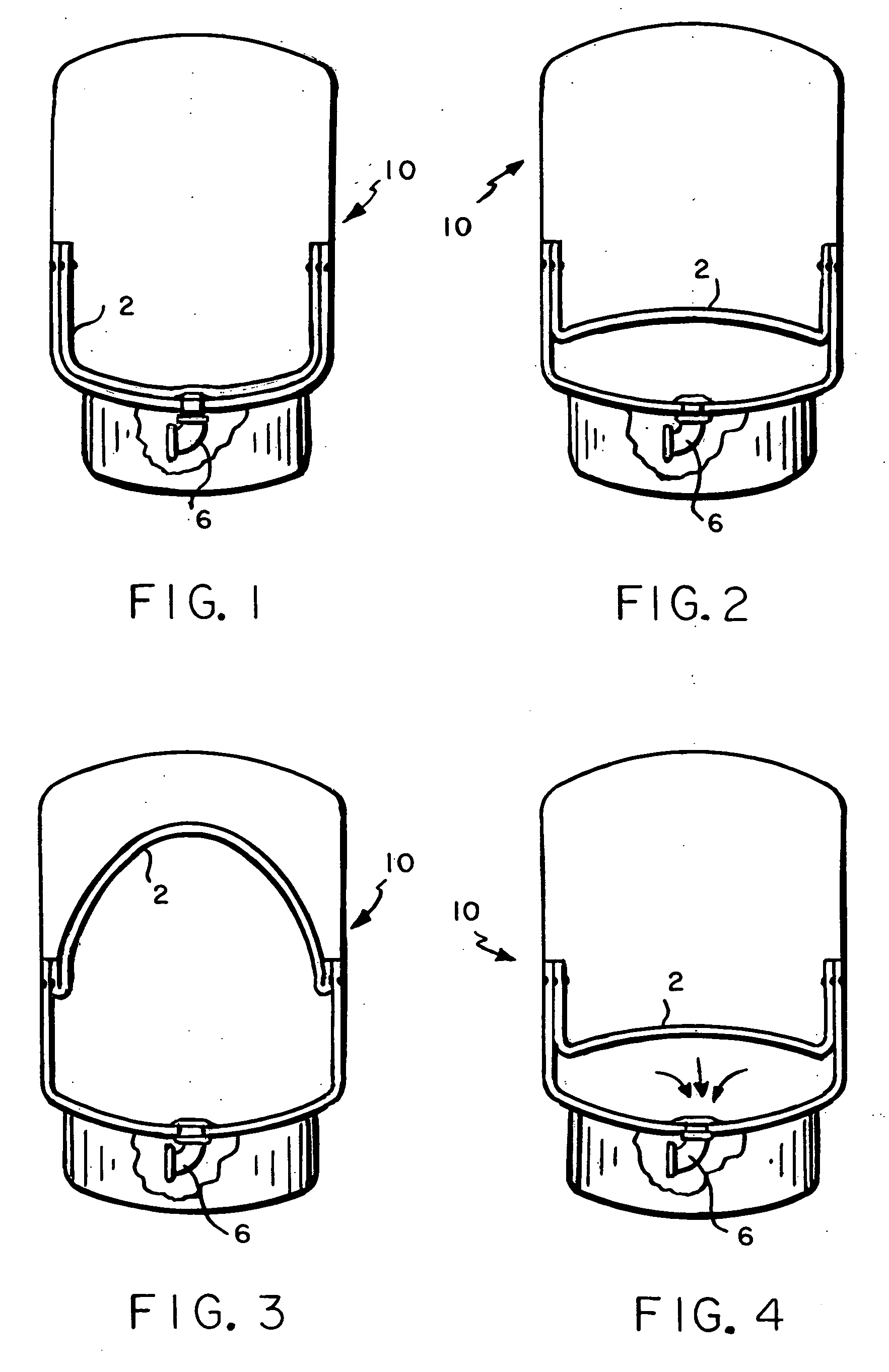

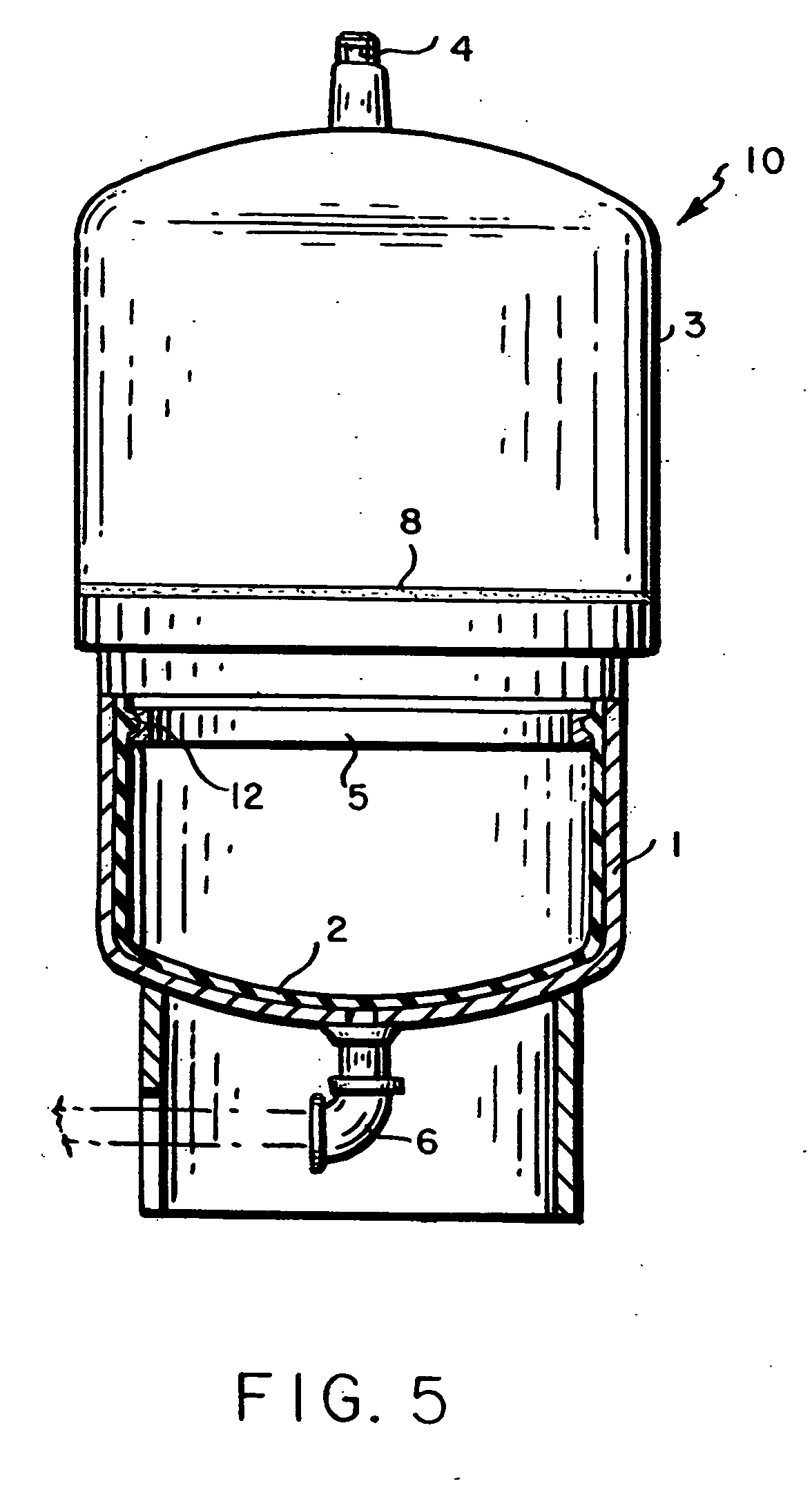

Mobile prepressurized diaphragm type fluid storage tank

A mobile prepressurized fluid storage tank is disclosed where the compressed air, completely separated from the fluid by a flexible diaphragm, dispenses the fluid under pressure, e.g., into an engine. The prepressurized diaphragm-type fluid storage tank is initially charged with a gas on one side of the diaphragm. A connector on the other end of the tank is connected to the fluid pumping system. Fluid is pumped into the tank until a predetermined pressure is reached and then the fill valve is shut off. A second connection attached to a bottom system connection has a hose. At the end of the hose there is a fluid shut off valve. Dispensing of the fluid takes place through the fluid shut off valve. The prepressurized fluid storage tank is mounted on a frame that contains wheels for mobility.

Owner:AMTROL LICENSING INC

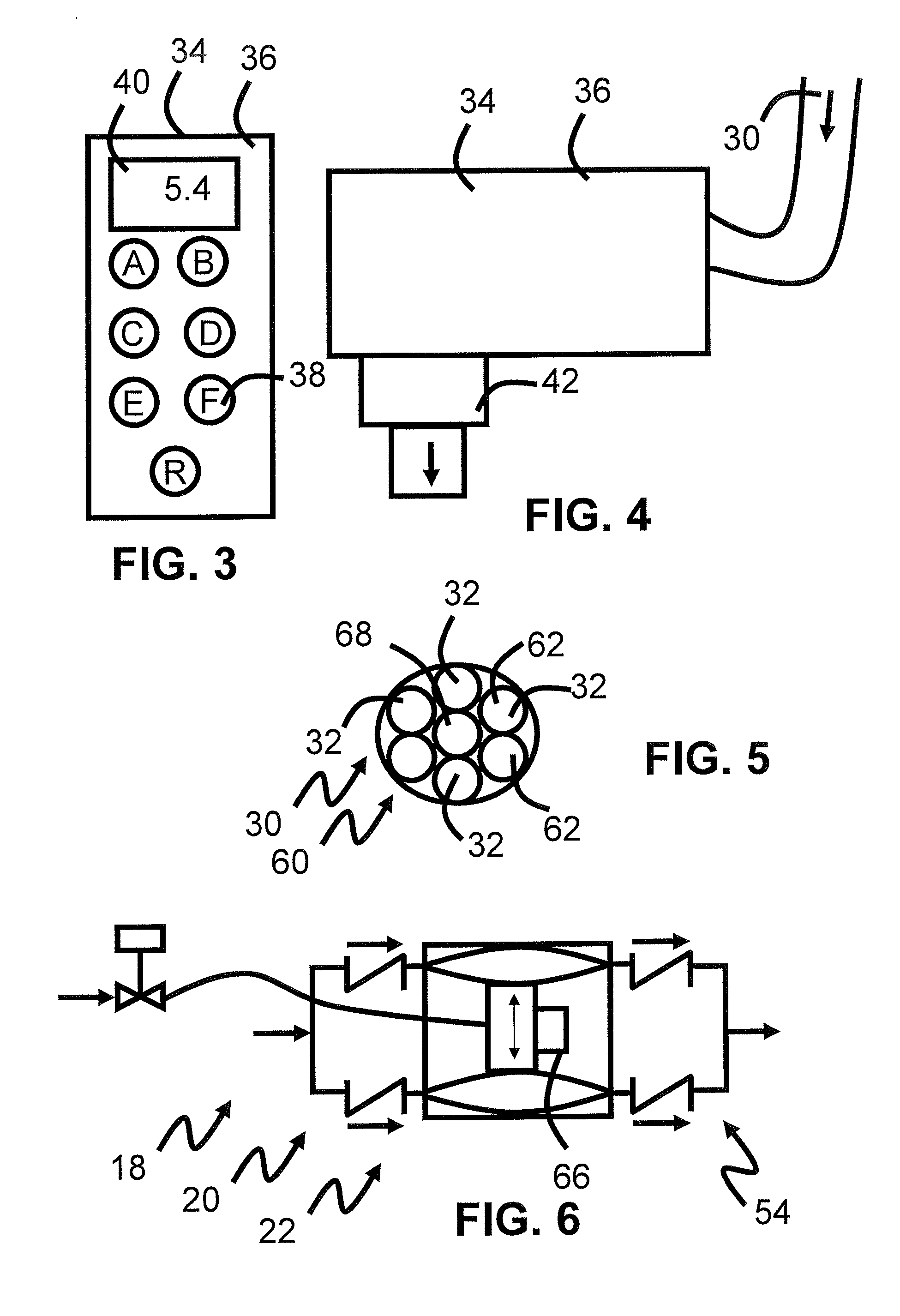

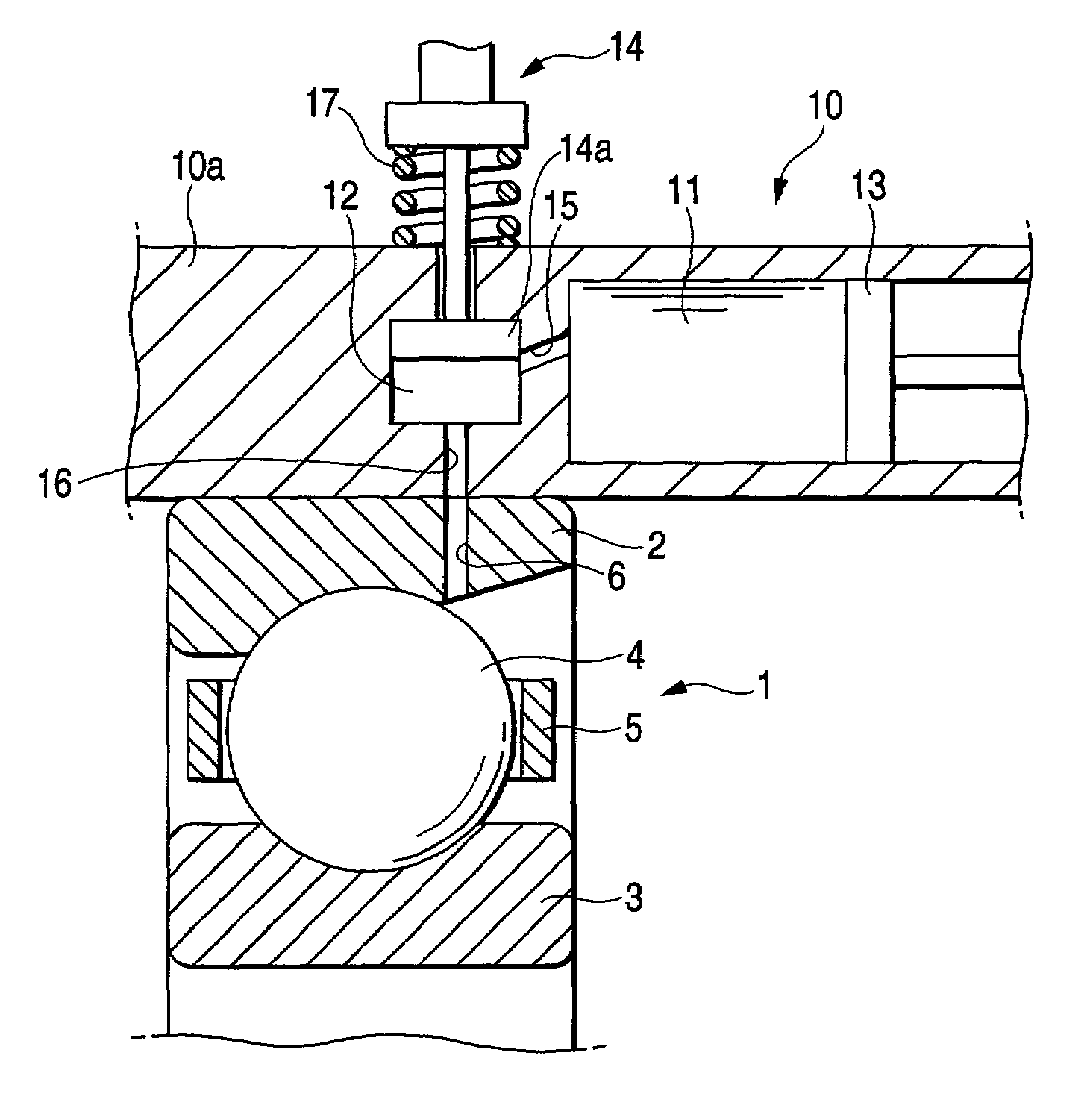

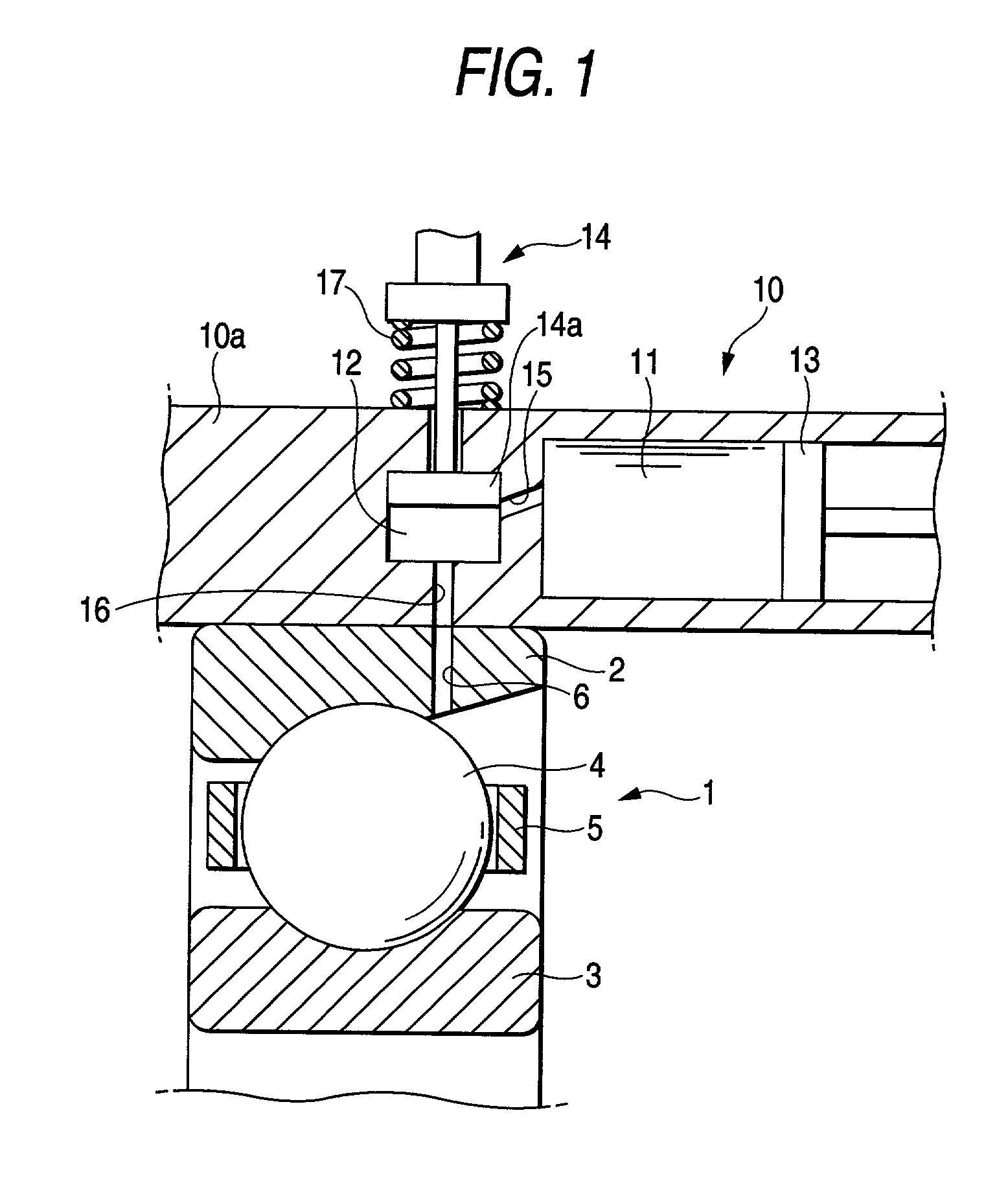

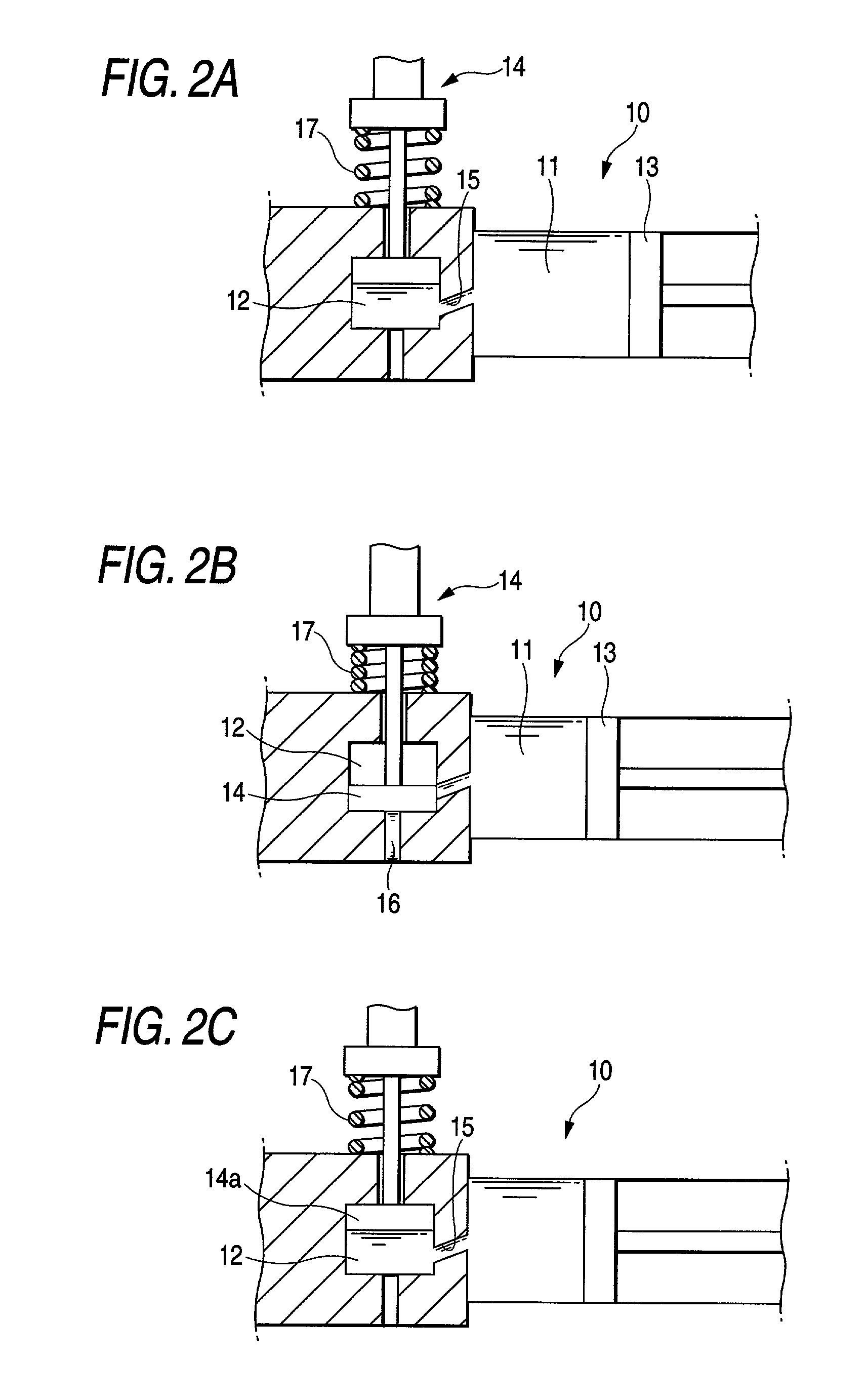

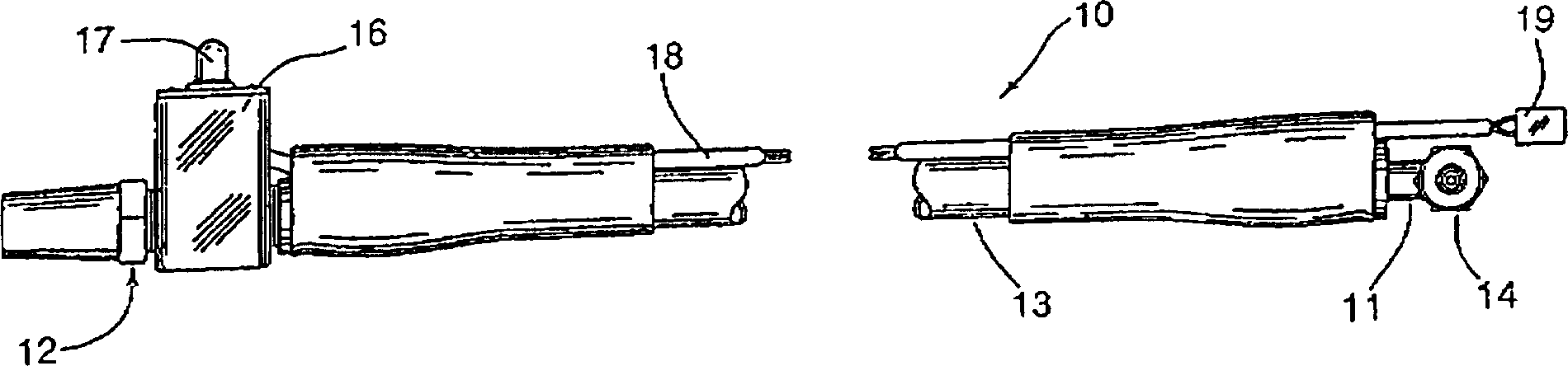

Rolling bearing lubricating method and device

ActiveUS20050252722A1Increase contact pressureEffective lubricationRoller bearingsBall bearingsRolling-element bearingEngineering

There is provided a lubricating method for a rolling bearing assembly capable of achieving a reliable lubrication and exhibiting a stable temperature rise. The method is for supplying a lubricant oil to the rolling bearing assembly during the operation thereof, in which in order to keep the temperature of a rolling bearing assembly (103) within a predetermined tolerance, the amount of the lubricant oil to be supplied during the operation is automatically or manually adjusted by means of a supply adjusting unit (102). Supply of the lubricant oil is performed in the form of an air / oil mixture by the use of a lubricant supply unit (101). The amount of the lubricant oil supplied varies depending on the rotational speed of the rolling bearing assembly (103). Change of the amount of the lubricant oil supplied depending on the rotational speed of the rolling bearing assembly (103) is carried out based on a result of sampling of data showing increase in temperature of the rolling bearing assembly (103) depending on the rotational speed thereof under a plurality of different lubricating conditions in which a different amount of the lubricant oil to be supplied is employed.

Owner:NTN CORP

Grease replenishing device

InactiveUS6994473B2Extended service lifeSlow heatingProportioning devicesRolling contact bearingsRolling-element bearingEngineering

A grease replenishing device replenishes a grease-lubricated rolling bearing with a grease. The grease replenishing device has a storage chamber portion and a pressing member. The storage chamber portion stores the grease. The pressing member pushes the grease out of the storage chamber into an interior of the rolling bearing.

Owner:NSK LTD

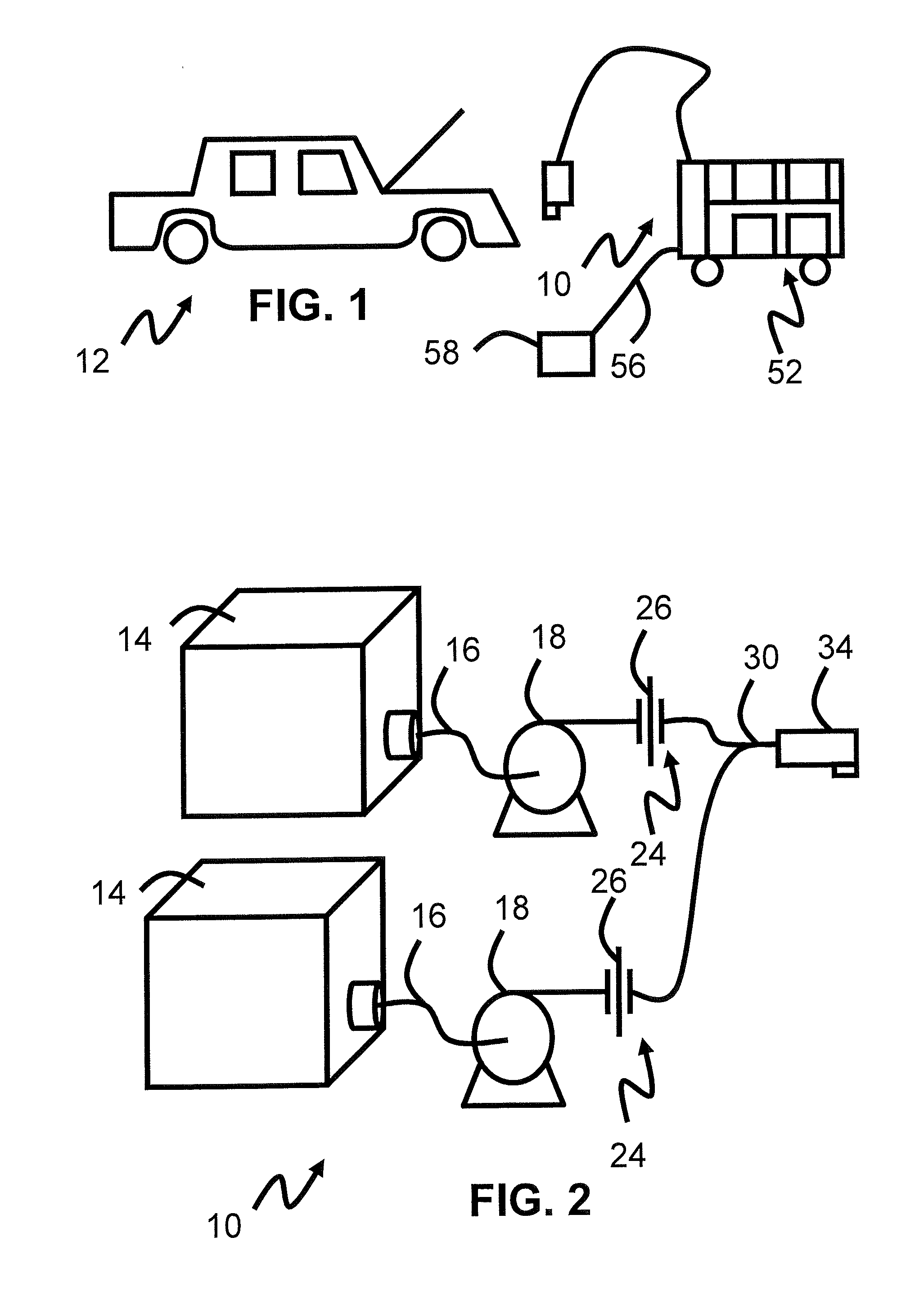

Methods and systems for performing, monitoring and analyzing multiple machine fluid processes

InactiveCN1836095AImprove performanceExtended service lifeLubricant transferMachines/enginesFluid systemBiomedical engineering

In one embodiment, a method is provided for performing a fluid process within a machine having a fluid system including at least two reservoirs of different types of fluids. The method includes the steps of identifying a first reservoir for use in performing a fluid process; (a) adjusting a configuration of a valve system operatively coupled to the fluid system to permit a fluid evacuation process to be performed for the reservoir, (b) subsequently performing the fluid evacuation process for the reservoir, (c) subsequently adjusting the configuration of the valve system to permit a fluid refill process to be performed for the reservoir, (d) subsequently performing the fluid refill process for the reservoir; and, subsequently identifying an additional reservoir and performing at least one of the steps (a), (b), (c) and (d) for the additional reservoir, wherein the first reservoir includes a fluid of a type which is different from a type of a fluid of the additional reservoir. Various system and computer-readable media embodiments are also provided.

Owner:RPM IND LLC

Bushing lubricator and system

A bushing lubricator includes an elongate body having a lubricant passage extending from an inlet opening to an outlet port. The elongate body includes a connection portion at the inlet opening for engaging with a lubricant tray of a lubricating system, a main body portion in a central region, and a bushing lubricator portion of a width to accommodate a bushing with an interior surface of the bushing surrounding the bushing lubricator portion. The outlet port on a periphery of the bushing lubricator portion discharges lubricant onto the interior surface of a bushing.

Owner:BSH HOME APPLIANCES CORP

Container for engine lubricating oil

A removable oil storage tank for lubricating an engine. The oil storage tank includes a body having a reservoir, an oil inlet and an oil outlet. A pick up tube in connected to the oil outlet. Connectors are coupled to the oil inlet and oil outlet. Oil lines are coupled to the connectors to couple to oil inlet of the tank to the outlet of the engine and the oil outlet of the tank to the inlet of the engine.

Owner:PAPAS GARY R

Container system

A container system of this invention includes a container for holding a fluid, a follower in the container which moves in the container in response to a change in a level of fluid in the container, and a sensor assembly for sensing the level of fluid in the container. The sensor assembly is especially (albeit not exclusively) suited for viscous fluids.

Owner:LINCOLN INDUSTRIES CORP

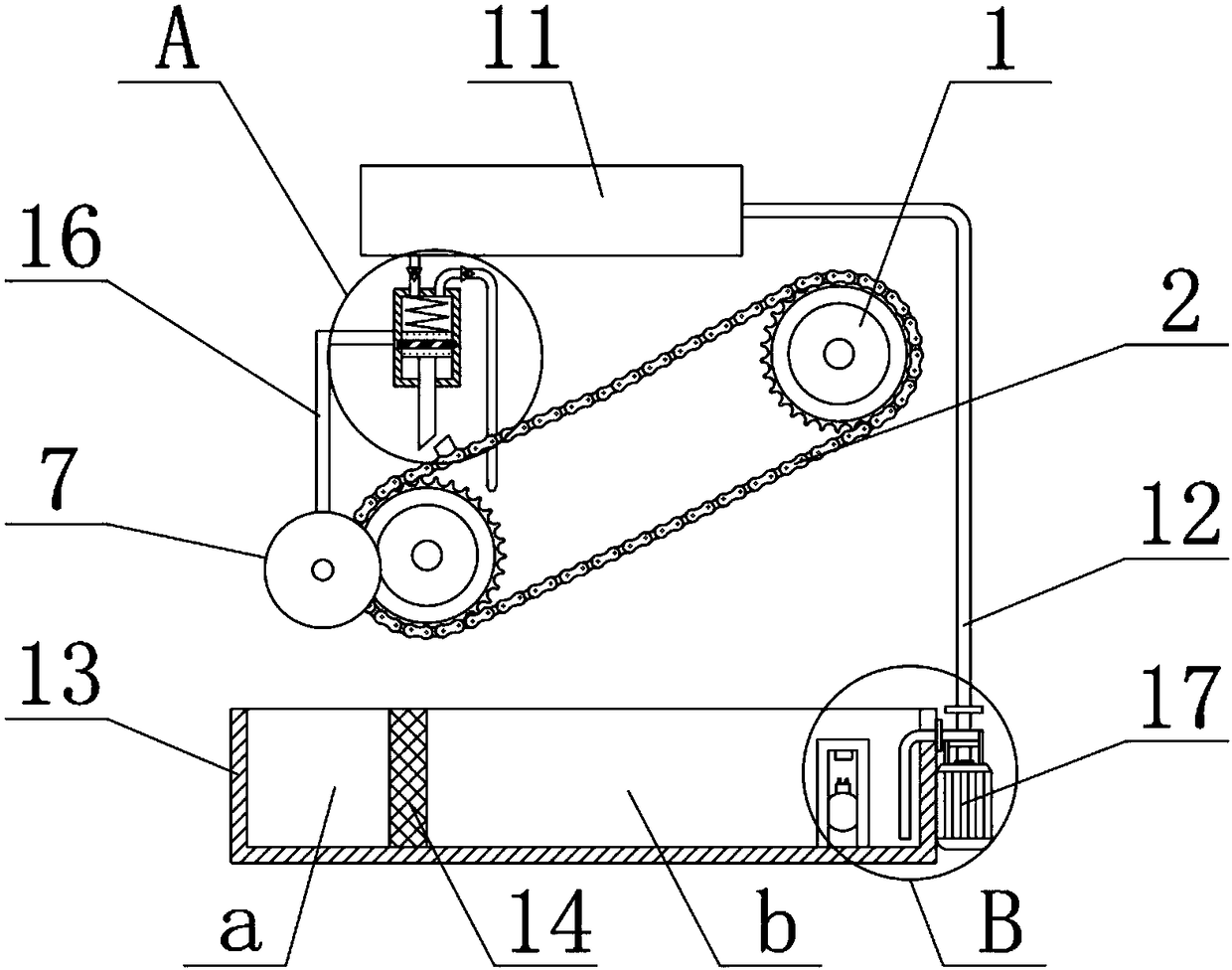

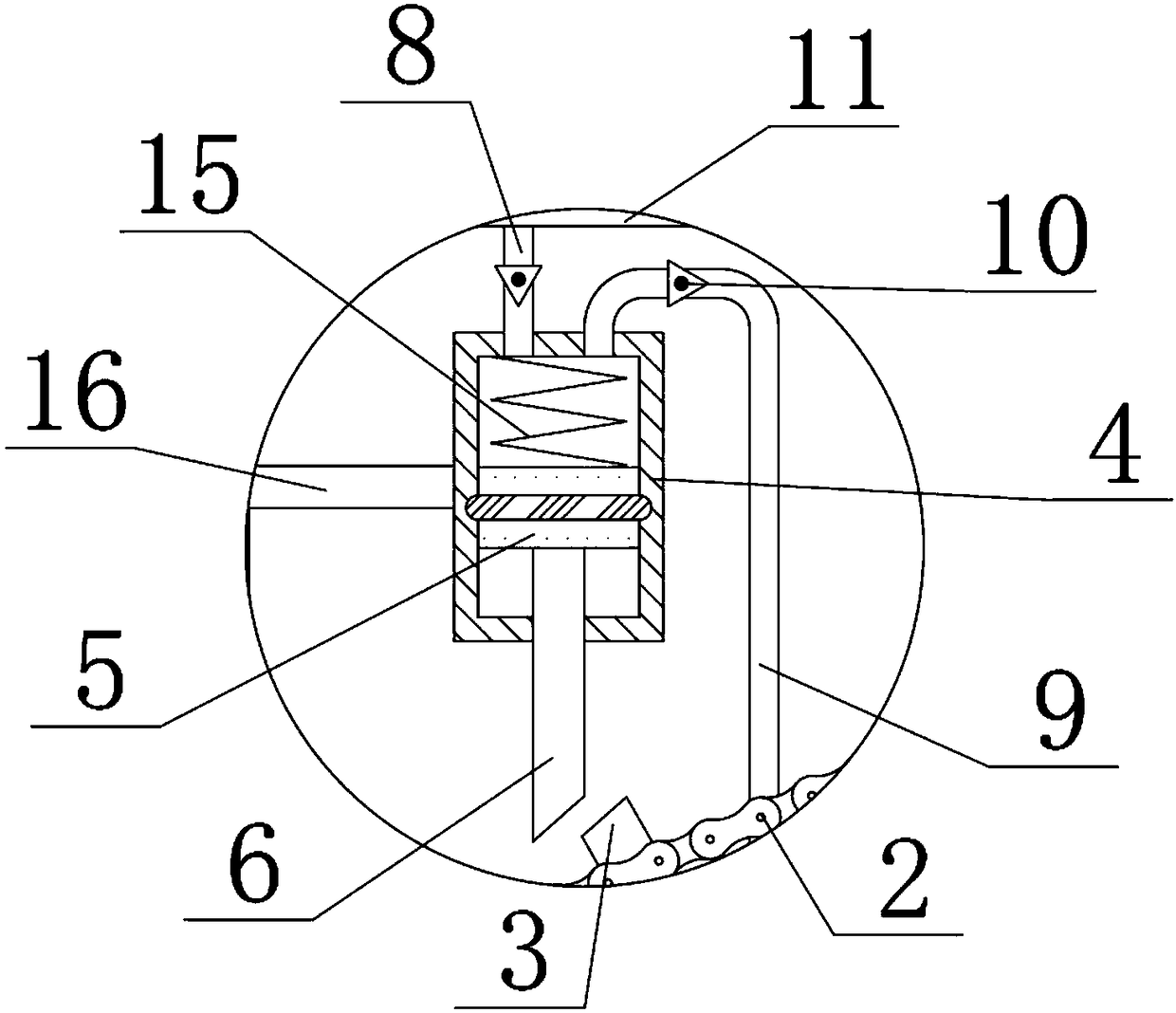

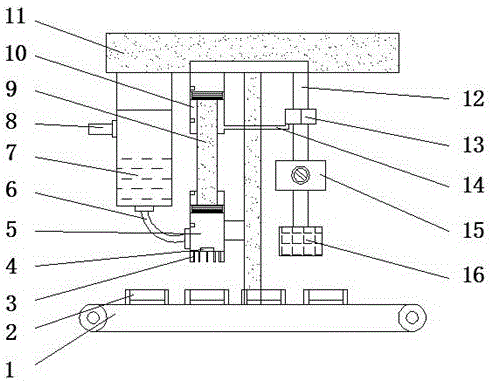

Automatic lubricating device for mechanical equipment chains

InactiveCN108591796AGuaranteed transmission efficiencyApply evenlyLubricant transferCleaning using toolsOil canFuel tank

The invention relates to the technical field of mechanical equipment, in particular to an automatic lubricating device for mechanical equipment chains. The device comprises a chain wheel and a chain;the chain is fixedly connected with a clamping block; a piston cylinder is arranged above the clamping block; a piston block is slidingly connected into the piston cylinder; a piston rod is fixedly connected to the center piston of the bottom end surface of the piston block; the top end surface of the piston cylinder communicates with a connecting pipe and an oil dripping pipe arranged left and right; the other end of the connecting pipe communicates with an oil tank; the right end surface of the oil tank communicates with an oil outlet pipe; a collecting box is arranged at the bottom end of the chain; and a filter screen is arranged in the collecting box. Through arrangement of the clamping block, the piston rod, the piston cylinder and the piston block, lubricating oil can be automatically and intermittently coated in the chain rotating process; and the device is novel in design concept, scientific in design, huge in economical benefit and broad in market prospect, and deserves popularization and application.

Owner:繁昌县通民机械制造有限公司

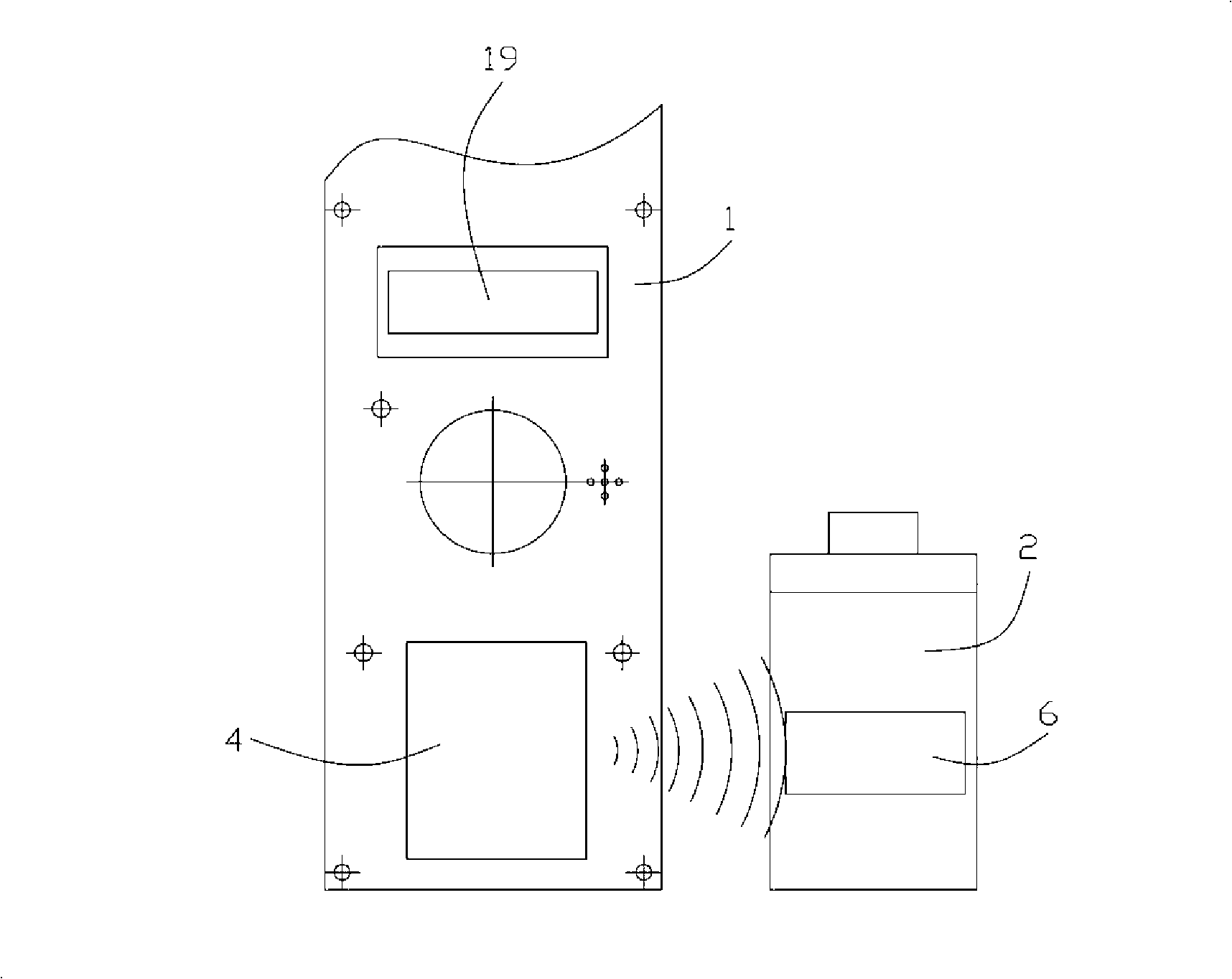

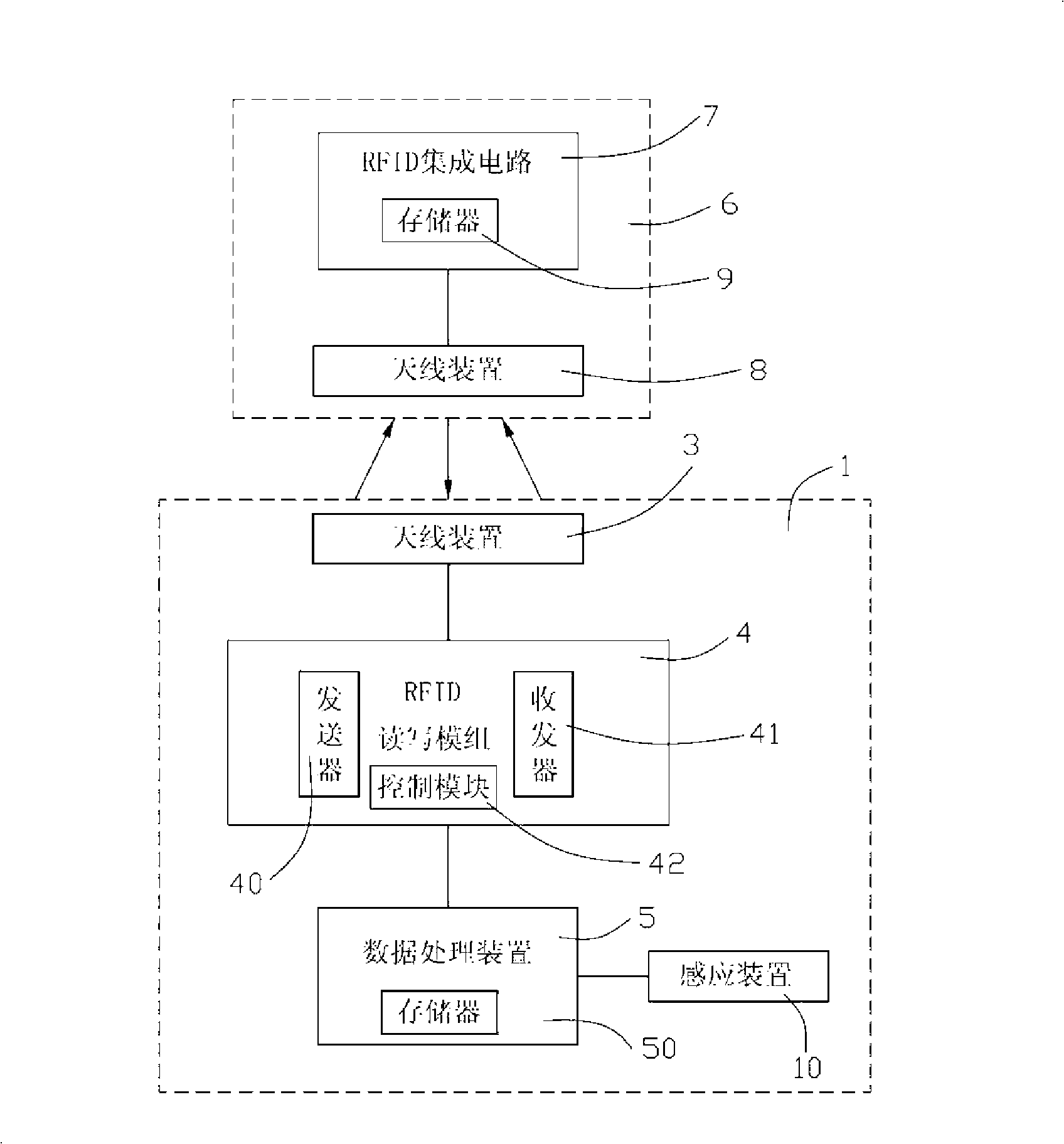

Radio frequency recognition system and application thereof

InactiveCN101256634AFacilitate confirmation of authenticityAvoid reuseLubricant transferCo-operative working arrangementsInternal memoryRelevant information

The invention relates to a radio frequency identification system and application thereof, comprising a radio frequency identification label which is provide with a memorizer for storing identifying information of products; a first antenna device connected with the memorizer, for receiving or sending the identifying information of the products stored in the memorizer; a second antenna device; a RFID read-write module connected with the second antenna device, for reading the identifying information of the products received by the second antenna device from the first antenna device; a data processing device connected with the RFID read-write module, for processing the identifying information of the products sent by the RFID read-write module, verifying the associated information stored in the internal memorizer to check the authenticity, and for feeding back the processing result to the RFID read-write module, the processing result is sent by the second and the first antenna devices to store in the memorizer of the radio frequency identification label.

Owner:HONGZHUN PRECISION MOLD KUNSHAN +1

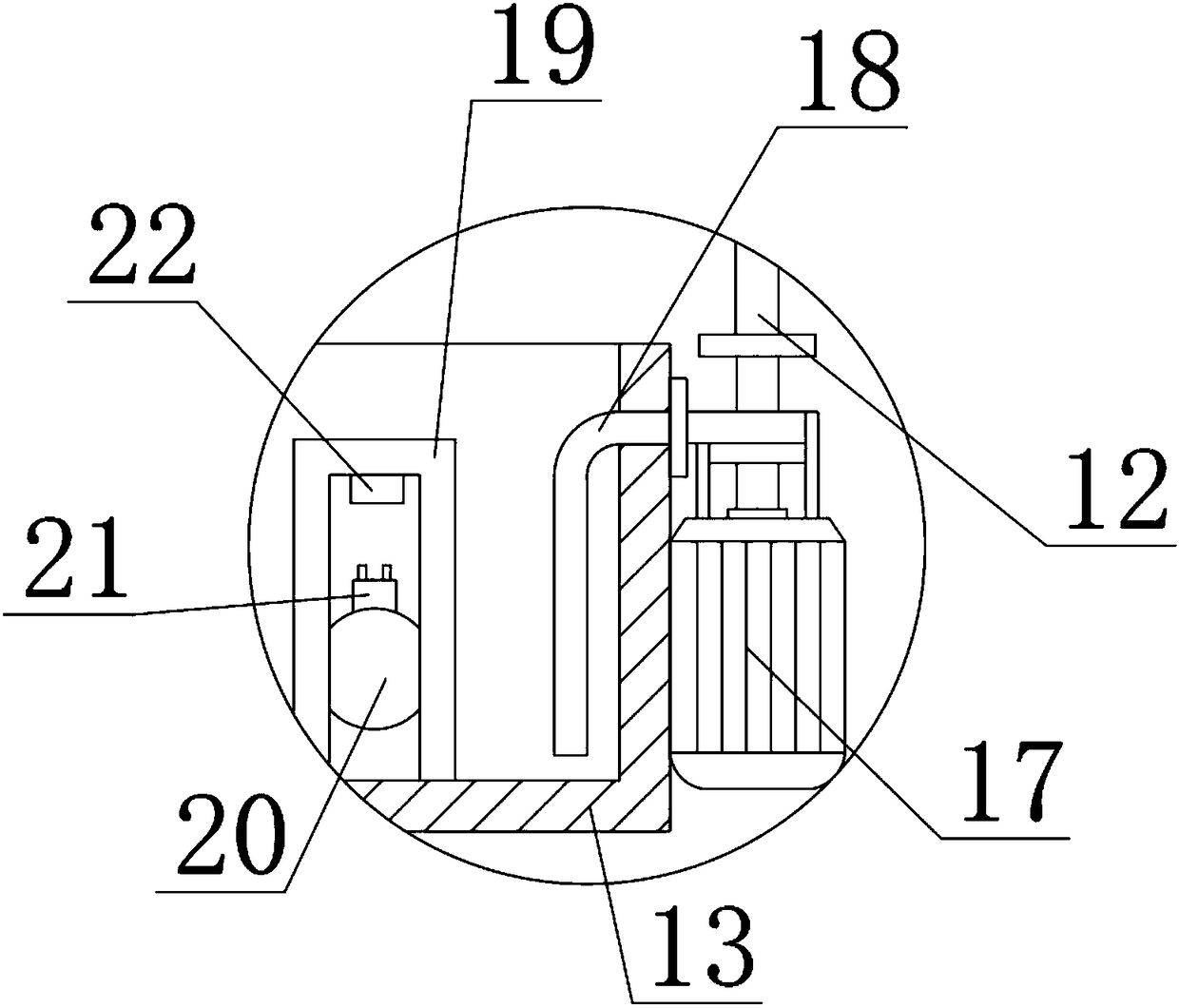

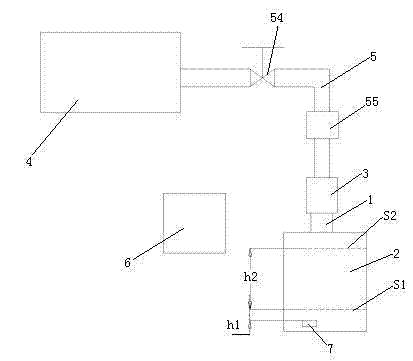

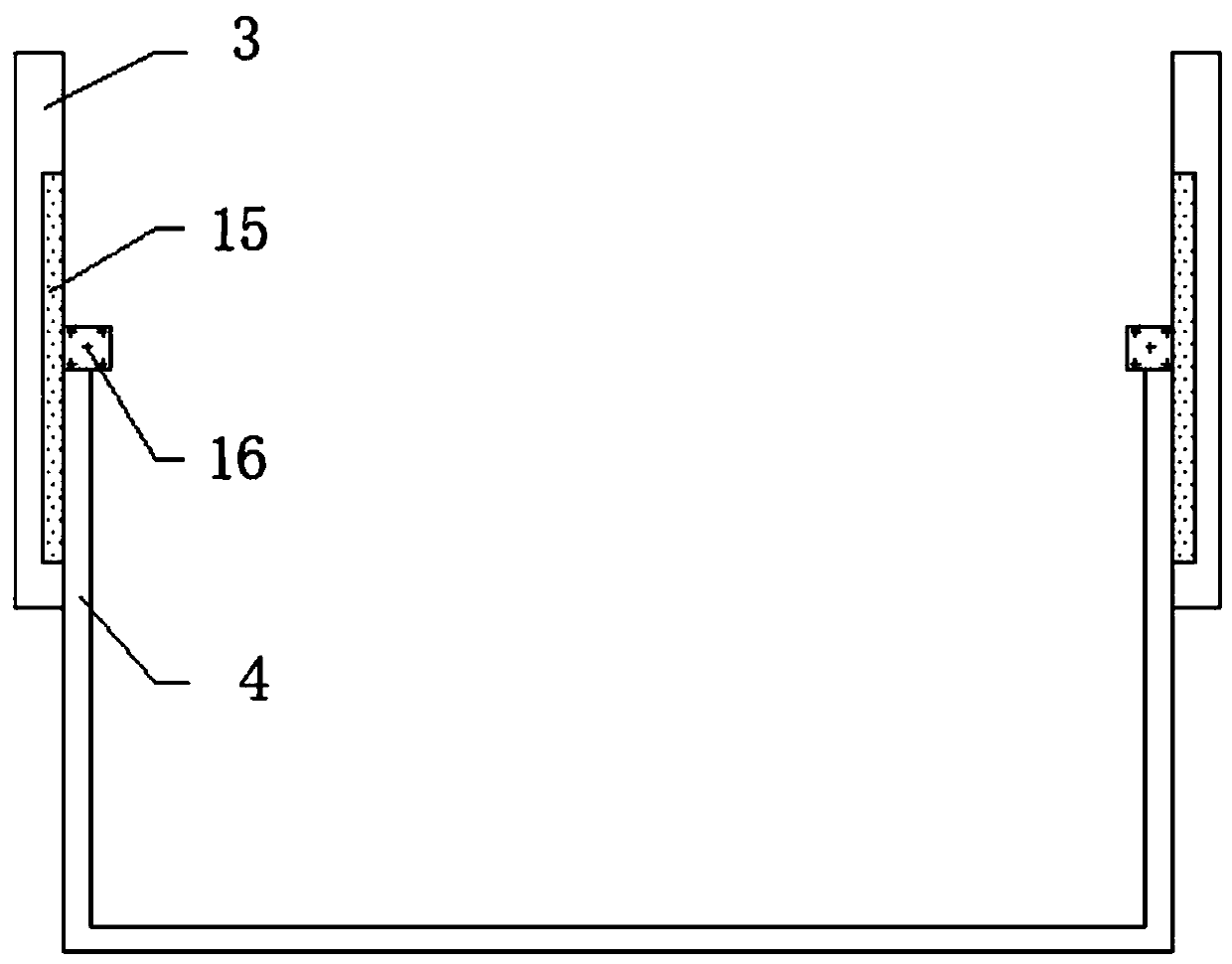

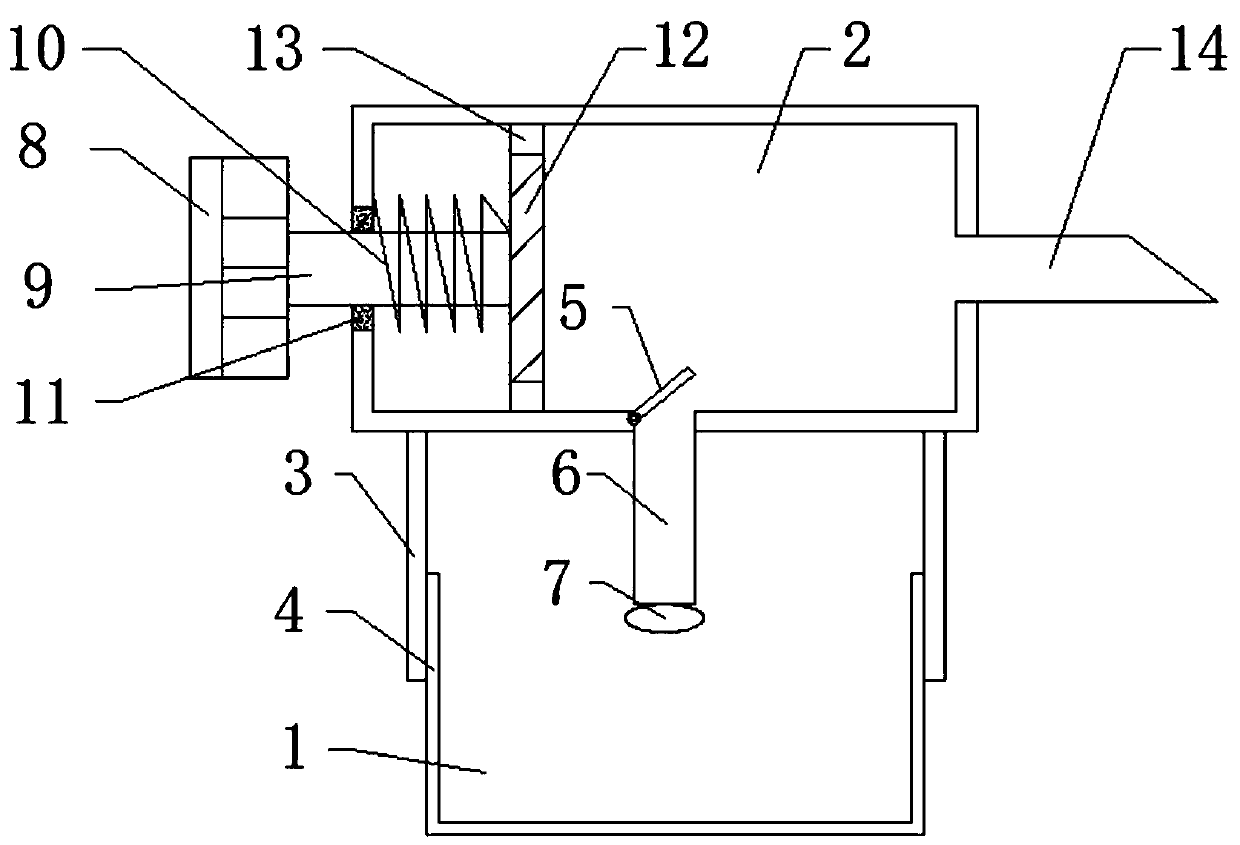

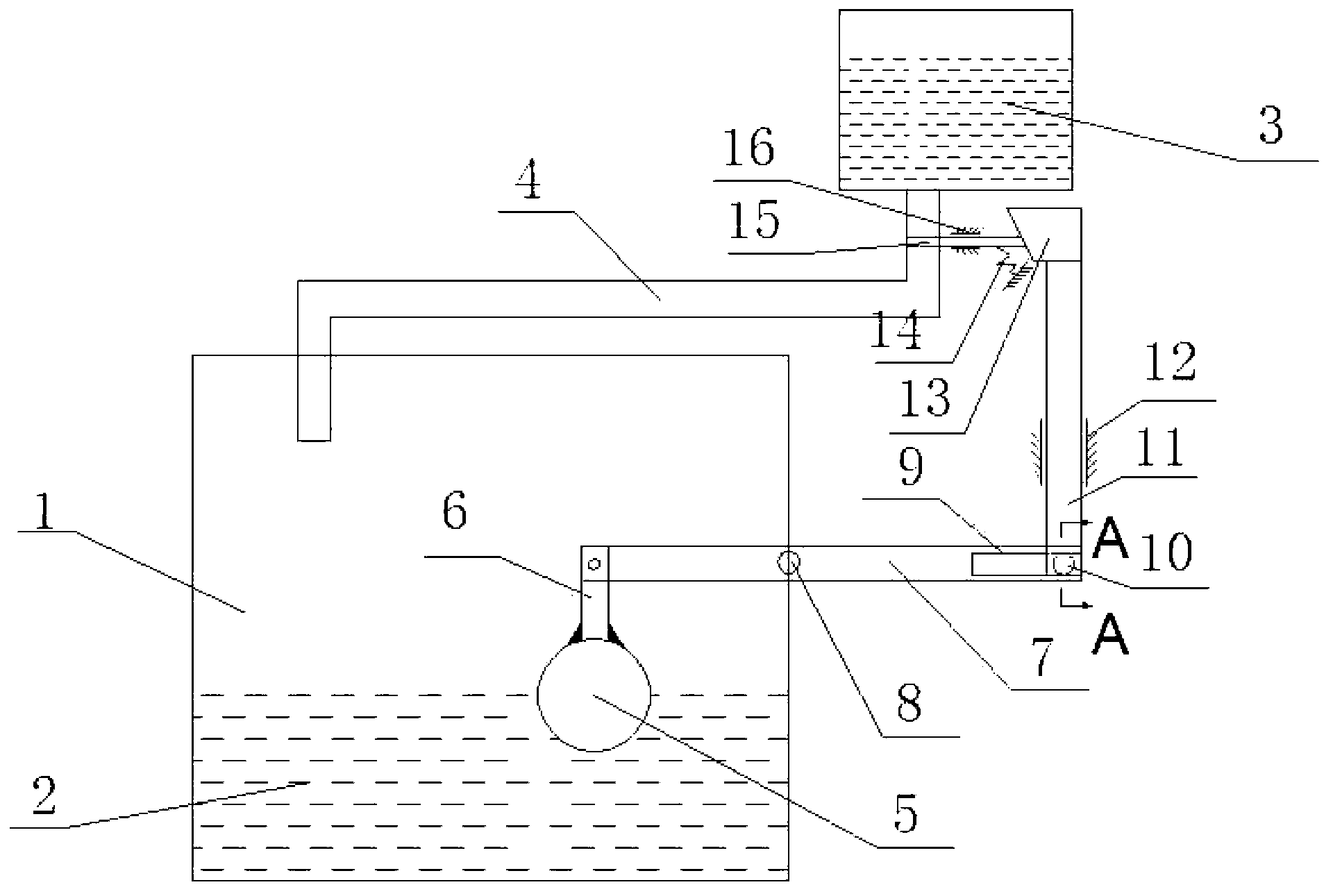

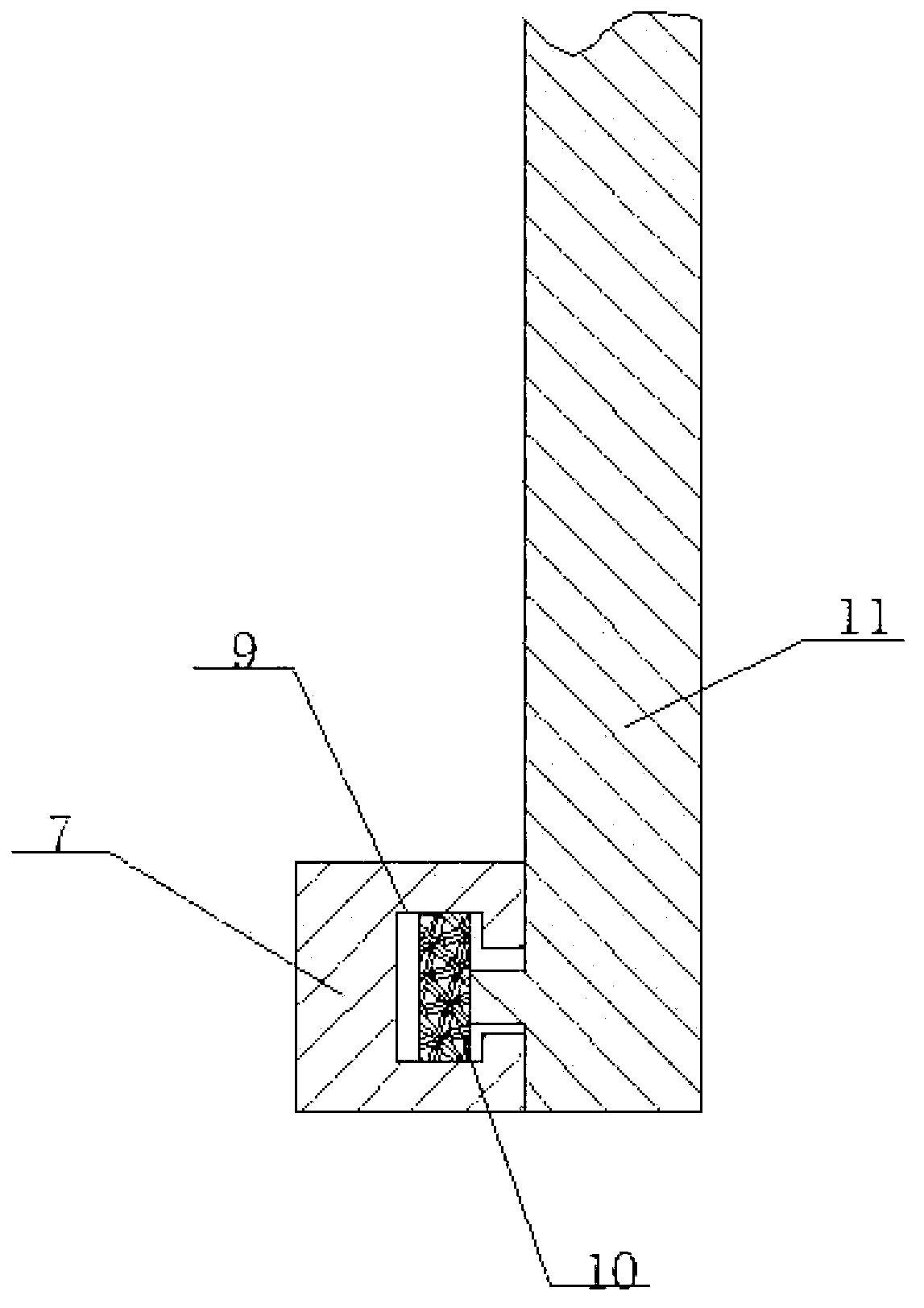

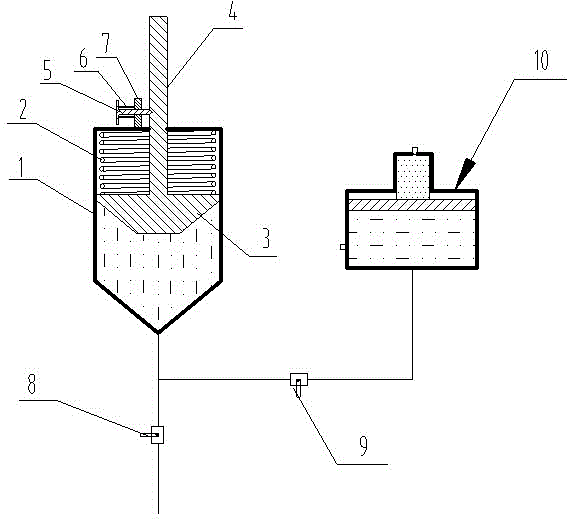

Lubrication device with automatic oil filling capacity

ActiveCN103807590ADoes not increase oil consumptionReduce in quantityLubricant transferMaintainance and safety accessoriesFuel tankLubrication

The invention relates to a lubrication device with automatic oil filling capacity. The lubrication device comprises a lubrication oil tank, a main oil tank and a control unit, wherein the main oil tank is located above the lubrication oil tank which is connected with the main oil tank through an oil pipe provided with an electrically operated valve, and the lubrication oil tank is provided with an oil sensor; and the control unit is used for switching on the electrically operated valve so as to enable lubricating oil in the main oil tank to flow into the lubrication oil tank under the action of gravity when the oil sensor detects that oil in the lubrication oil tank is less than the set minimum quantity and switching off the electrically operated valve when the oil in the lubrication oil tank reaches the set maximum quantity. The lubrication device with the automatic oil filling capacity can fill the lubrication oil tank automatically with the lubrication oil, so that the problem of time waste caused by the fact that the conventional lubrication device requires manual lubrication oil filling into the lubrication oil tank is solved.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

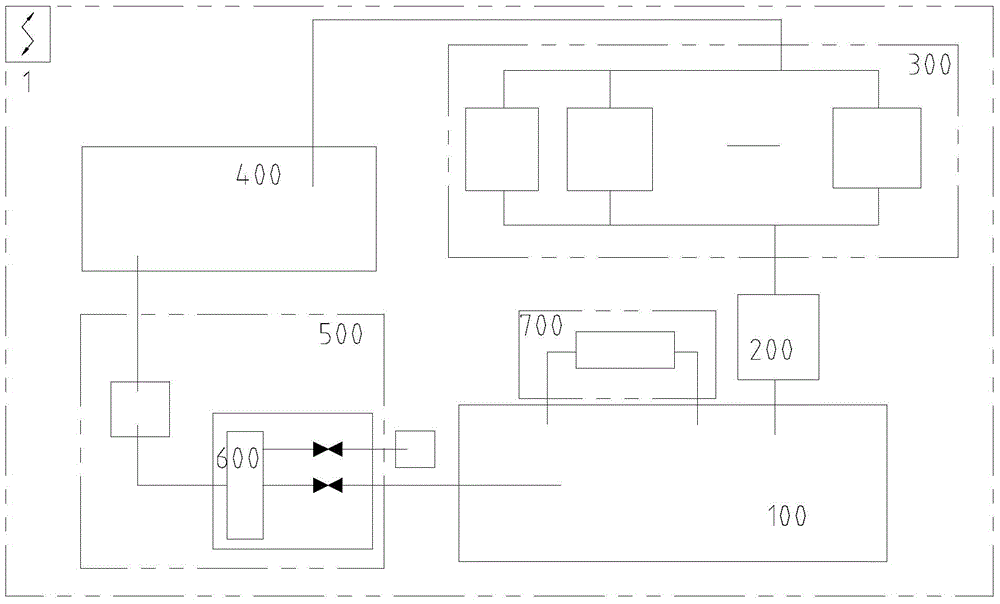

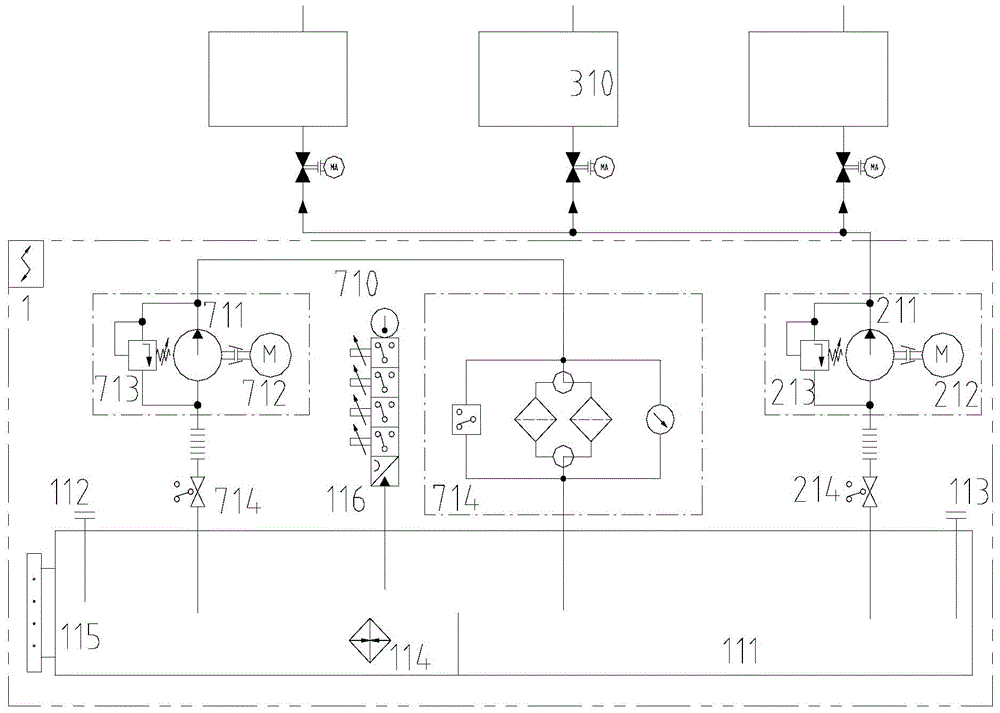

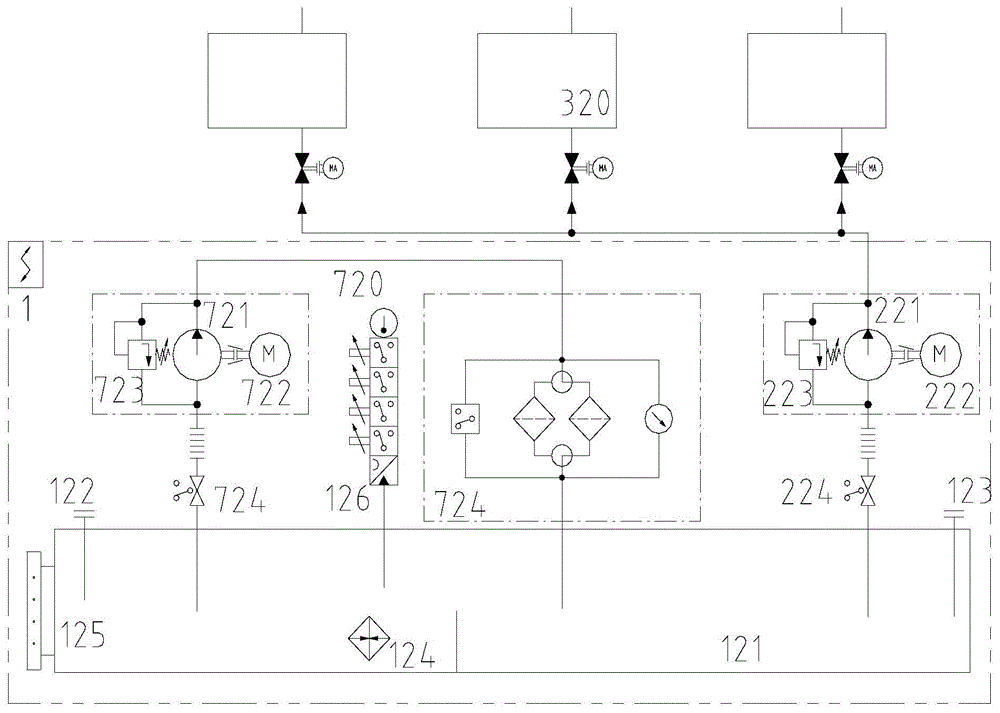

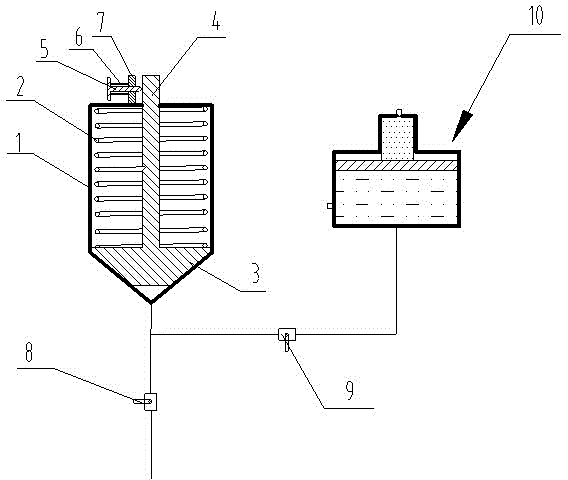

Oil supplementation system

InactiveCN104454796AAvoid pollutionReduce maintenanceLubricant transferFluid-pressure actuator componentsOil canContamination

The invention discloses an oil supplementation system. The oil supplementation system comprises an oil supplementation device and an effluent oil treatment device. The oil supplementation device comprises an oil supplementation oil tank (100) and an oil supplementation loop (200), wherein the oil supplementation oil tank (100) is connected with the oil inlet of a working oil tank (300) through the oil supplementation loop (200) and conducts oil supplementation on the working oil tank (300). The effluent oil treatment device comprises an effluent oil tank (400) and an effluent oil treatment loop (500), wherein the oil collection opening of the effluent oil tank (400) is communicated with the effluent oil opening of the working oil tank (300), the effluent oil tank (400) is used for collecting and treating effluent oil in the working oil tank (300), the oil discharge opening of the effluent oil tank (400) is connected with the effluent oil treatment loop (500), and effluent oil which is not treated or treated oil can be discharged in a classified mode through the effluent oil treatment loop (500). By means of the oil supplementation system, contamination caused by oil media is thoroughly eliminated from the source; the effluent oil in an oil system is collected in a concentrated mode, and therefore the maintenance amount of the oil system is reduced, and the oil tank cleaning time is shortened.

Owner:BERIS ENG & RES CORP

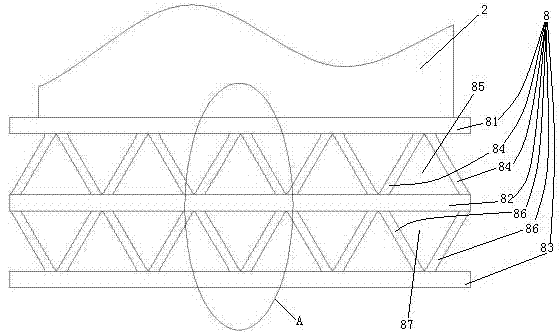

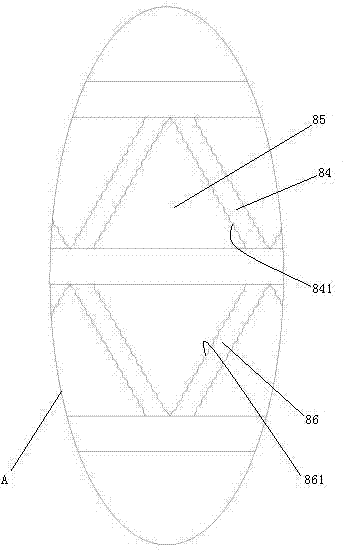

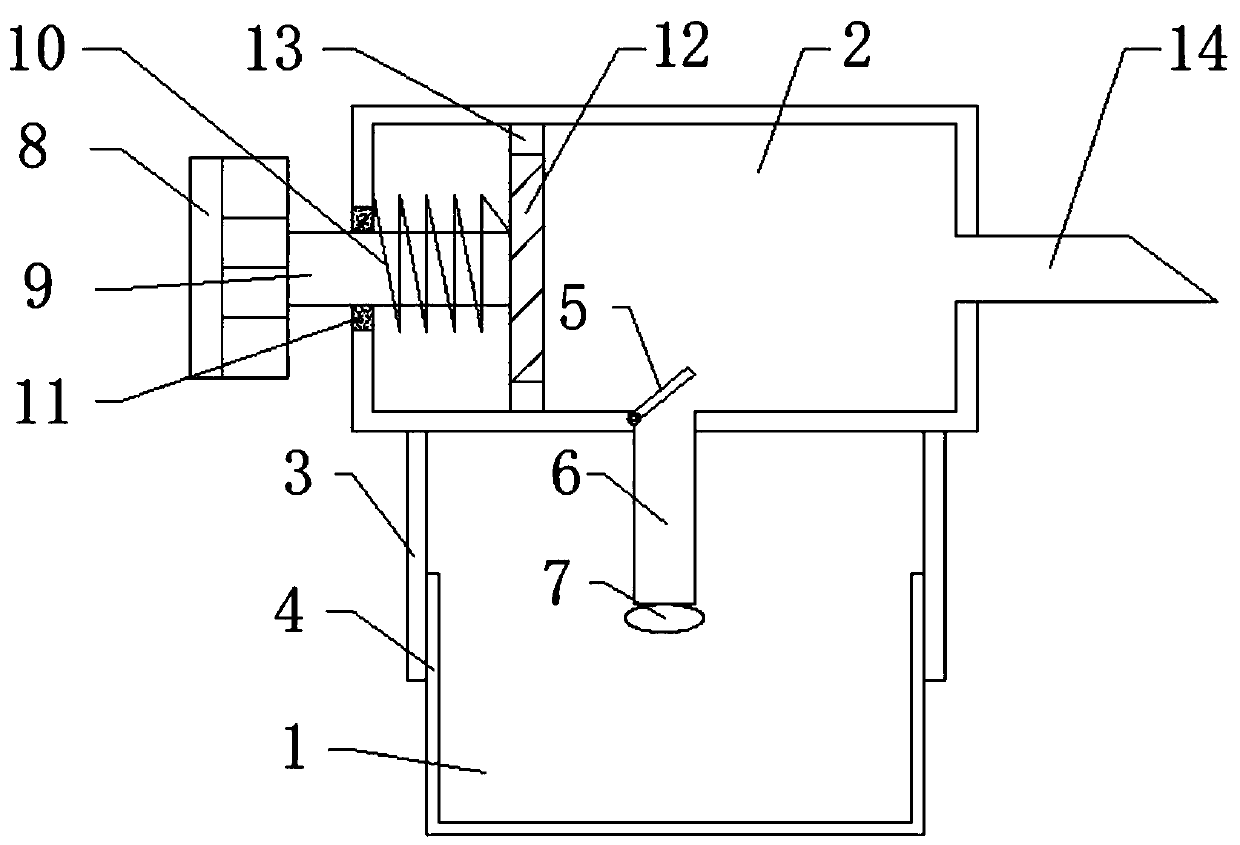

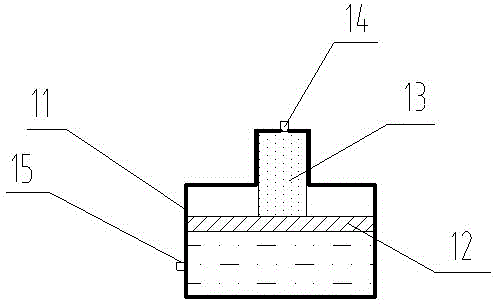

Lubricating oil filling device for bearing

InactiveCN109707984AScientific and reasonable designPrevent backflowLubricant transferViscosityWelding

The invention discloses a lubricating oil filling device for a bearing. The lubricating oil filling device comprises an oil injection cavity, wherein an oil outlet is formed in the middle of the rightside of the oil injection cavity, and the middle of the left side of the oil injection cavity is slidably connected with a telescopic rod; an air cylinder is slidably connected to the tail end of theleft side of the telescopic rod, a sealing ring is connected to the joint of the left side of the oil injection cavity and the telescopic rod through viscosity, the tail end of the right side of thetelescopic rod is fixedly connected with a baffle through welding, rubber plugs are fixedly connected to the joints of the baffle and the oil injection cavity through viscosity, and a spring is fixedly connected to the telescopic rod; an oil storage tank is fixedly arranged below the oil injection cavity, and the oil storage tank is formed by a cavity defined by fixing plates and a telescopic cup;and the lower surface of the oil injection cavity is fixedly connected with the fixing plates through welding, and a sliding rail is fixedly connected to a groove formed in each fixing plate throughviscosity. The lubricating oil filling device is scientific and reasonable in design, feasible in scheme and high in market popularization value.

Owner:梁克俭

Lever-type automatic oiling device

InactiveCN103292147AReduce workloadGuaranteed normal processingLubricant transferFuel tankWedge shape

The invention discloses a lever-type automatic oiling device. The lever-type automatic oiling device comprises a working oil tank and an external oil storage tank which are connected through an oil conveying pipe, wherein a lever is connected with the side wall of the working oil tank in a rotary mode, one end of the lever is connected with a float rod and stretches into the working oil tank, the other end of the lever is connected with a push rod in a sliding mode, the push rod is placed inside a first guide groove, the upper end of the push rod is connected with a control rod which controls the oil conveying pipe to conduct oil supplying through a wedge-shaped block, and the control rod is arranged inside a second guide groove. When oil quantity of the oil tank is not sufficient, the lever-type automatic oiling device can supplement oil timely, and workload of workers is relieved.

Owner:WUXI INST OF COMMERCE

Automatic lubricating device

The invention discloses an automatic lubricating device. The automatic lubricating device comprises a lubricating mechanism and an oil replenishing mechanism. During lubricating operation, operating personnel unlocks an oil driving piston, and lubricating operation can be automatically finished under the action of a driving spring; after the completion of lubrication, an oil replenishing cylinder is communicated with a lubricating cylinder, the oil replenishing mechanism can be used for automatically finished oil replenishment, and the oil driving piston, a connecting rod and the driving spring are driven to restore to initial positions. During lubrication and oil replenishment, the automatic lubricating device is very easy to operate; moreover, during each oil replenishment and lubrication, the motion travel of the oil driving piston is the same, so that the volume amount of lubricating oil output each time can be kept the same, and a uniform lubricating effect is ensured. Moreover, the lubricating cylinder in the lubricating device is conical, and only one oil flow port positioned in a cone bottom is formed, so that the oil driving piston can be protected from being scratched by the oil flow port in a reciprocating motion process.

Owner:WUHAN LIANCHUANG HENGYE SCI & TECH

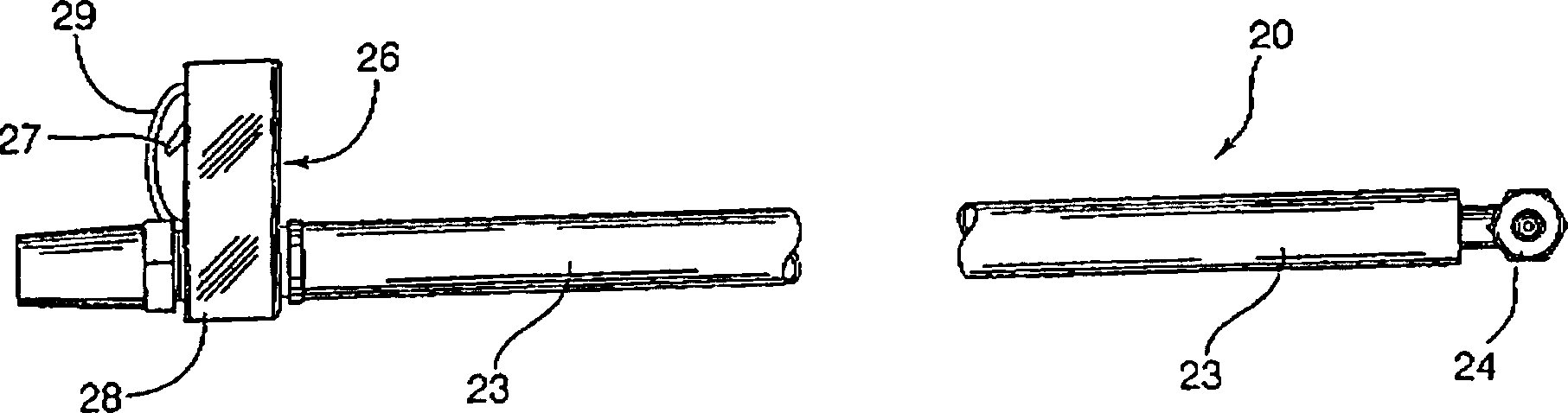

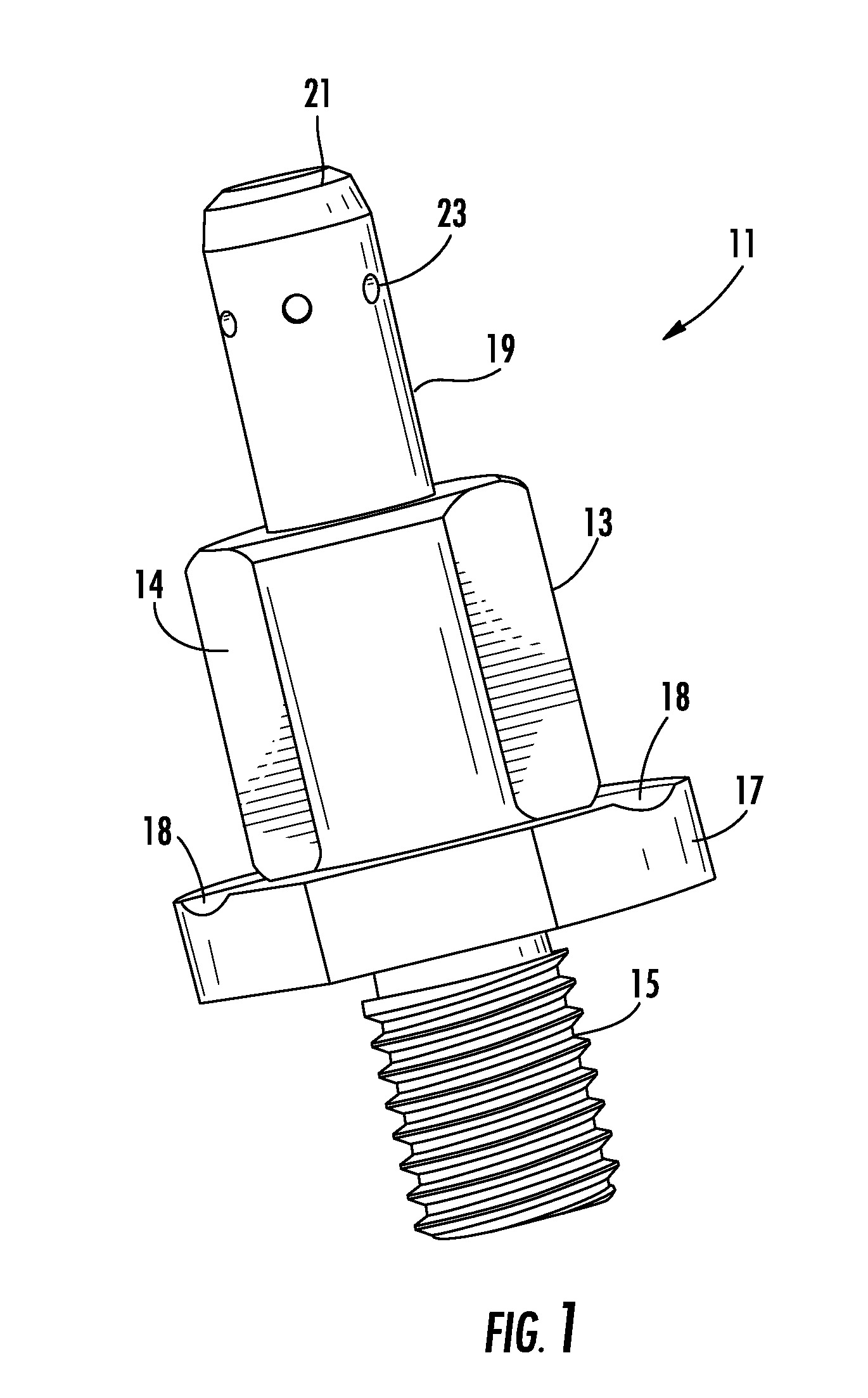

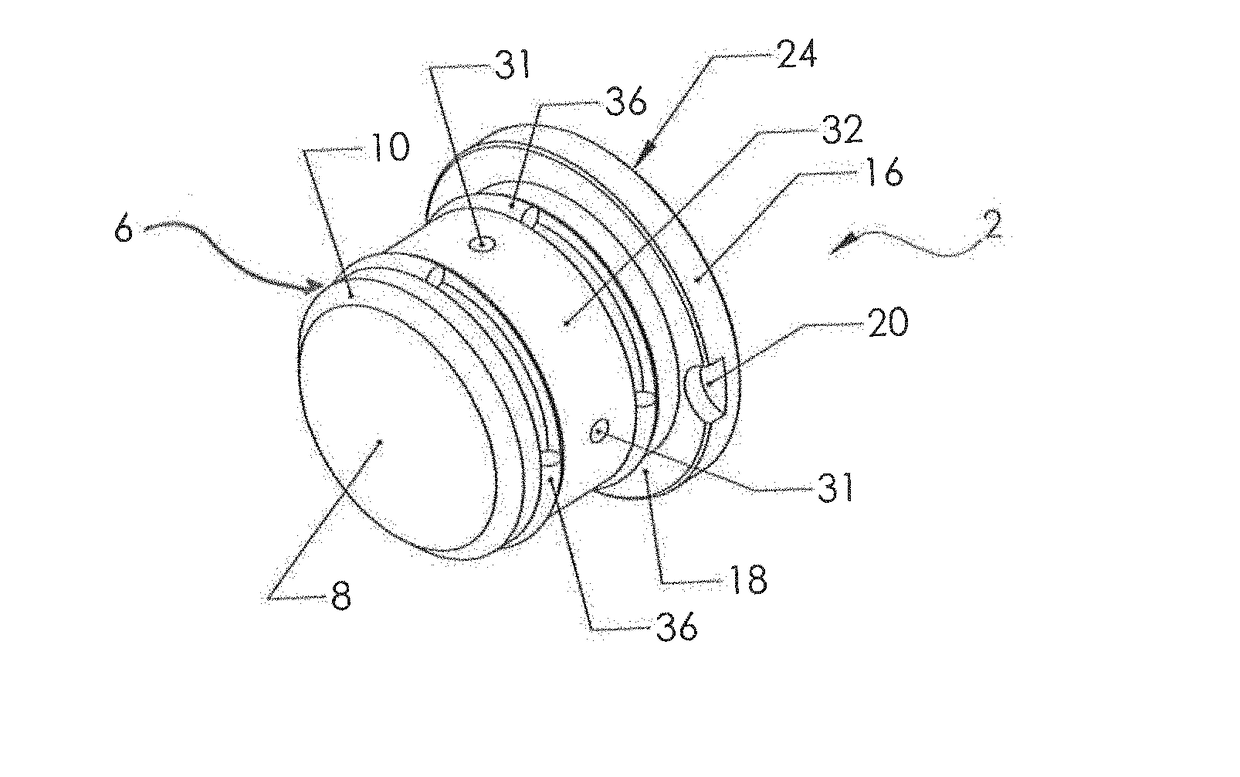

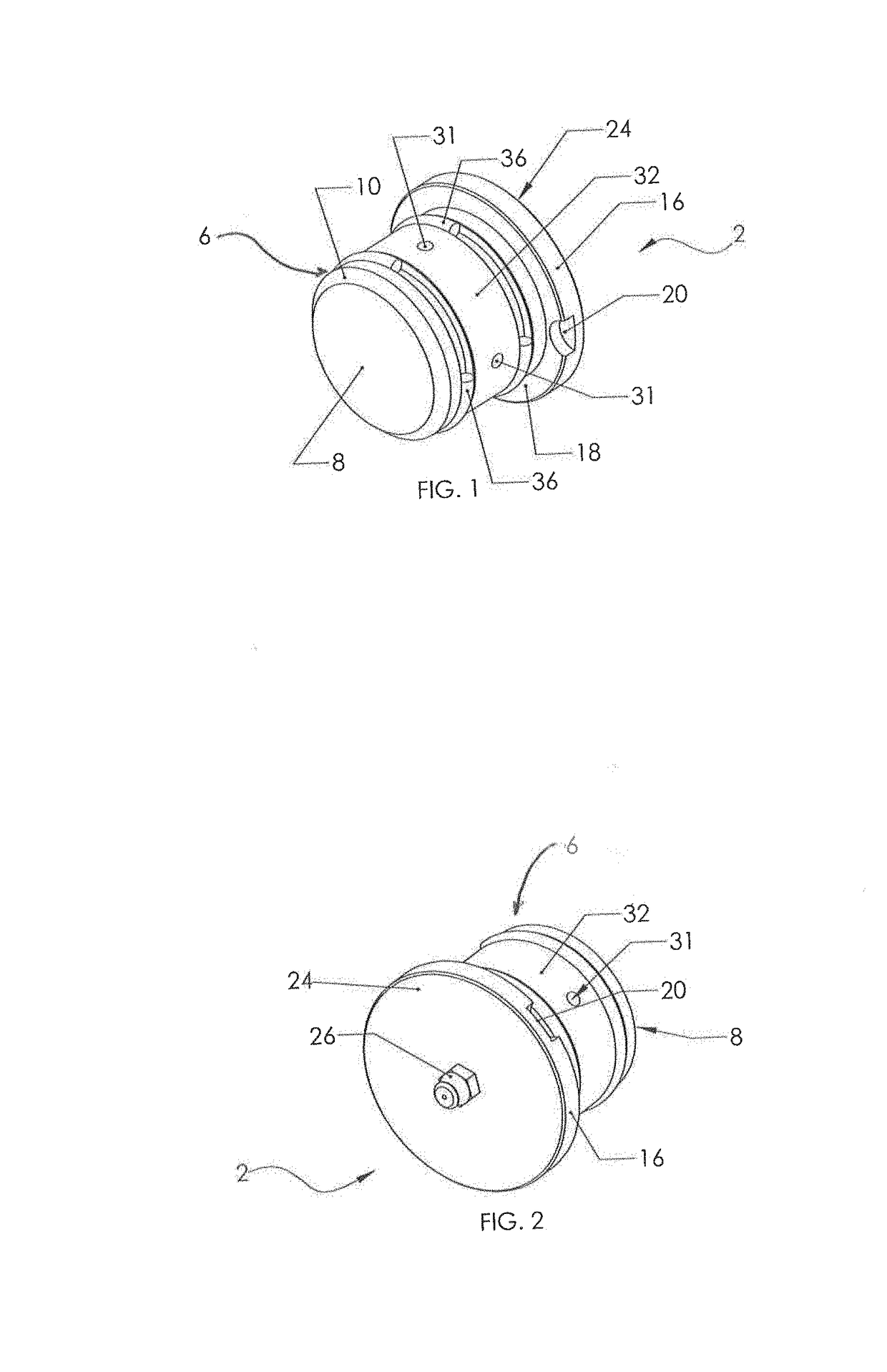

Grease tool for repacking dual angular contact bearing with grease, and method of using same

ActiveUS20170370412A1Easy to disassembleEasy to cleanBearing repair/replacementRolling contact bearingsGrease fittingFlange

A grease tool and method for greasing a dual angular contact bearing where the grease tool is fabricated from a single unitary piece of material. The grease tool comprises a cylindrical hub, a flange supported adjacent only one end of the cylindrical hub, and a grease fitting attached to the grease tool to facilitate a supply of grease thereto. During use, a pair of spaced apart O-rings, accommodated by an exterior surface of the cylindrical hub, form a pair of grease seals with an inwardly facing surface of an inner race of the dual angular contact bearing. A supply passage conveys the supplied grease from the grease fitting to a grease outlet(s) located in an exterior cylindrical surface of the grease tool, between the pair of O-rings, for conveyance of the supplied grease radially to the inner race of the dual angular contact bearing and facilitate repacking thereof.

Owner:PETIT DENIS

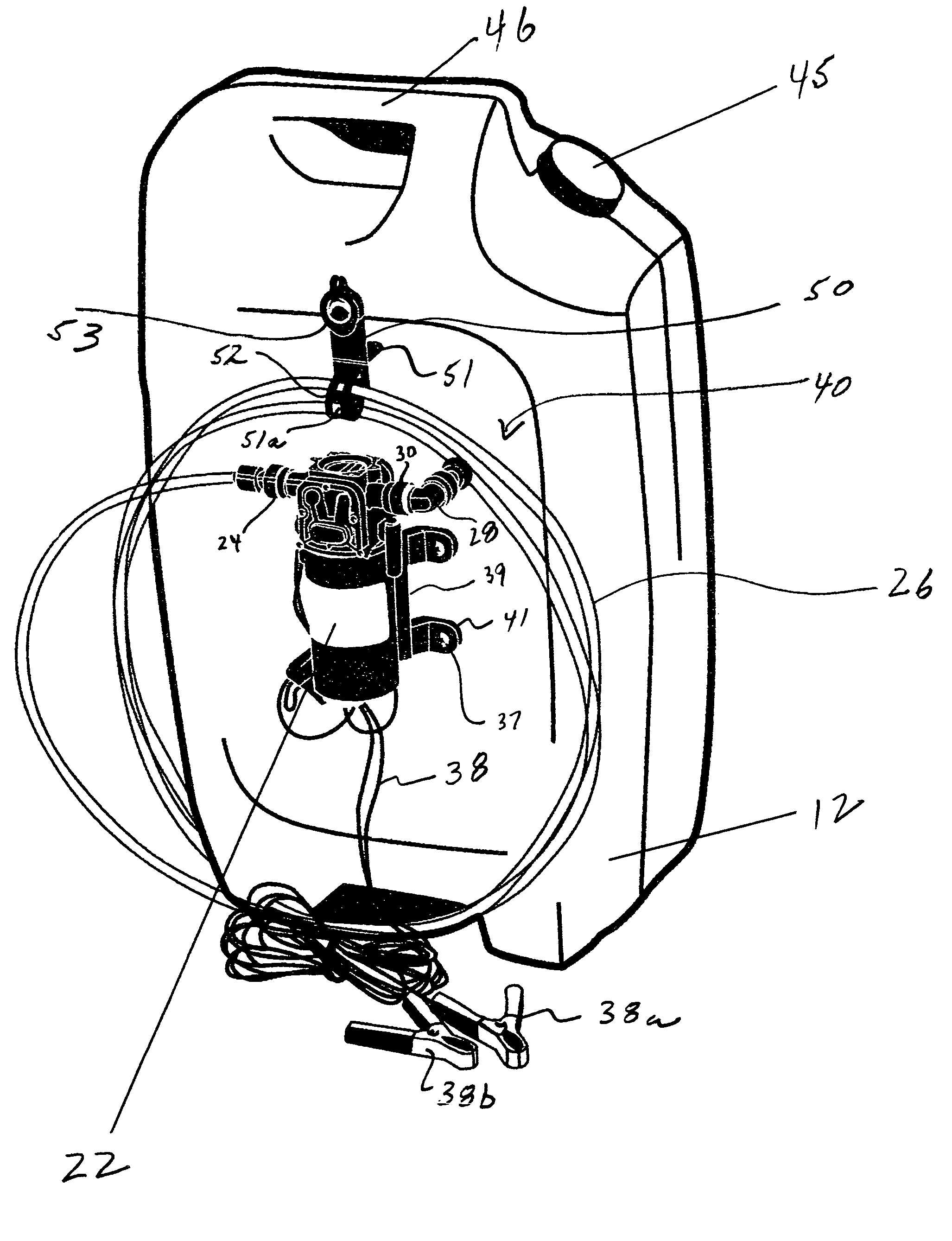

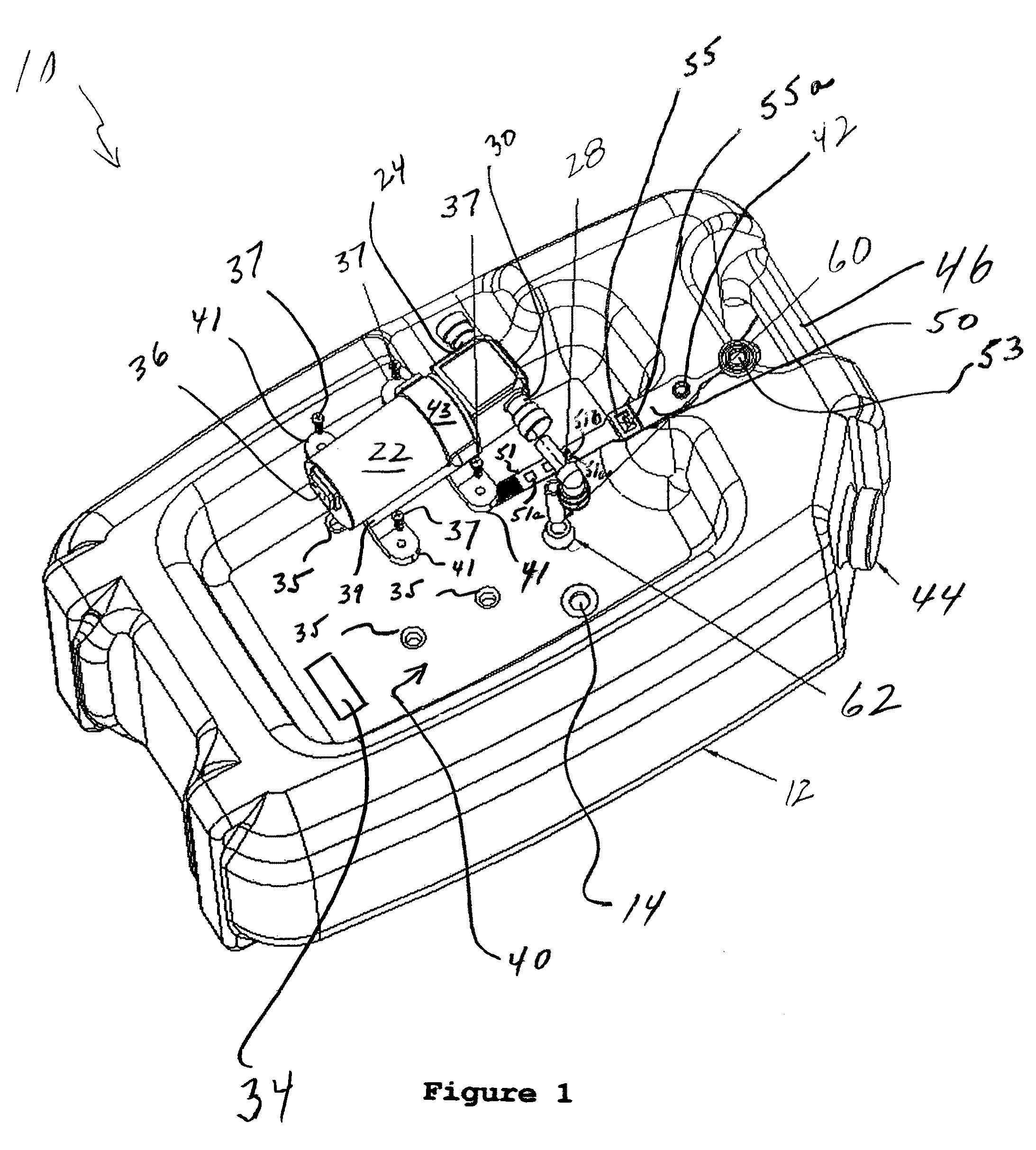

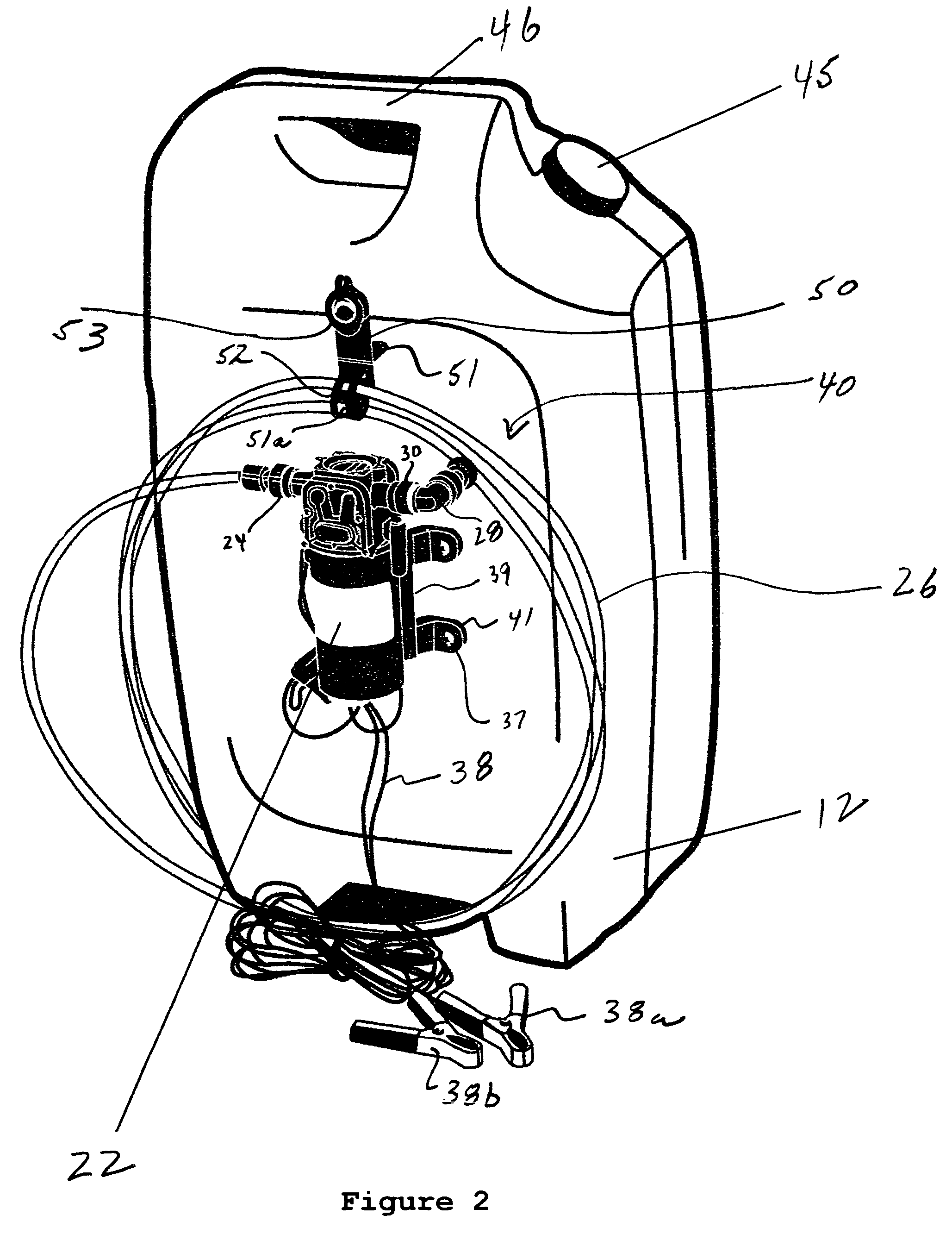

Mobile prepressurized diaphragm type fluid storage tank

A mobile prepressurized fluid storage tank is disclosed where the compressed air, completely separated from the fluid by a flexible diaphragm, dispenses the fluid under pressure, e.g., into an engine. The prepressurized diaphragm-type fluid storage tank is initially charged with a gas on one side of the diaphragm. A connector on the other end of the tank is connected to the fluid pumping system. Fluid is pumped into the tank until a predetermined pressure is reached and then the fill valve is shut off. A second connection attached to a bottom system connection has a hose. At the end of the hose there is a fluid shut off valve. Dispensing of the fluid takes place through the fluid shut off valve. The prepressurized fluid storage tank is mounted on a frame that contains wheels for mobility.

Owner:AMTROL LICENSING INC

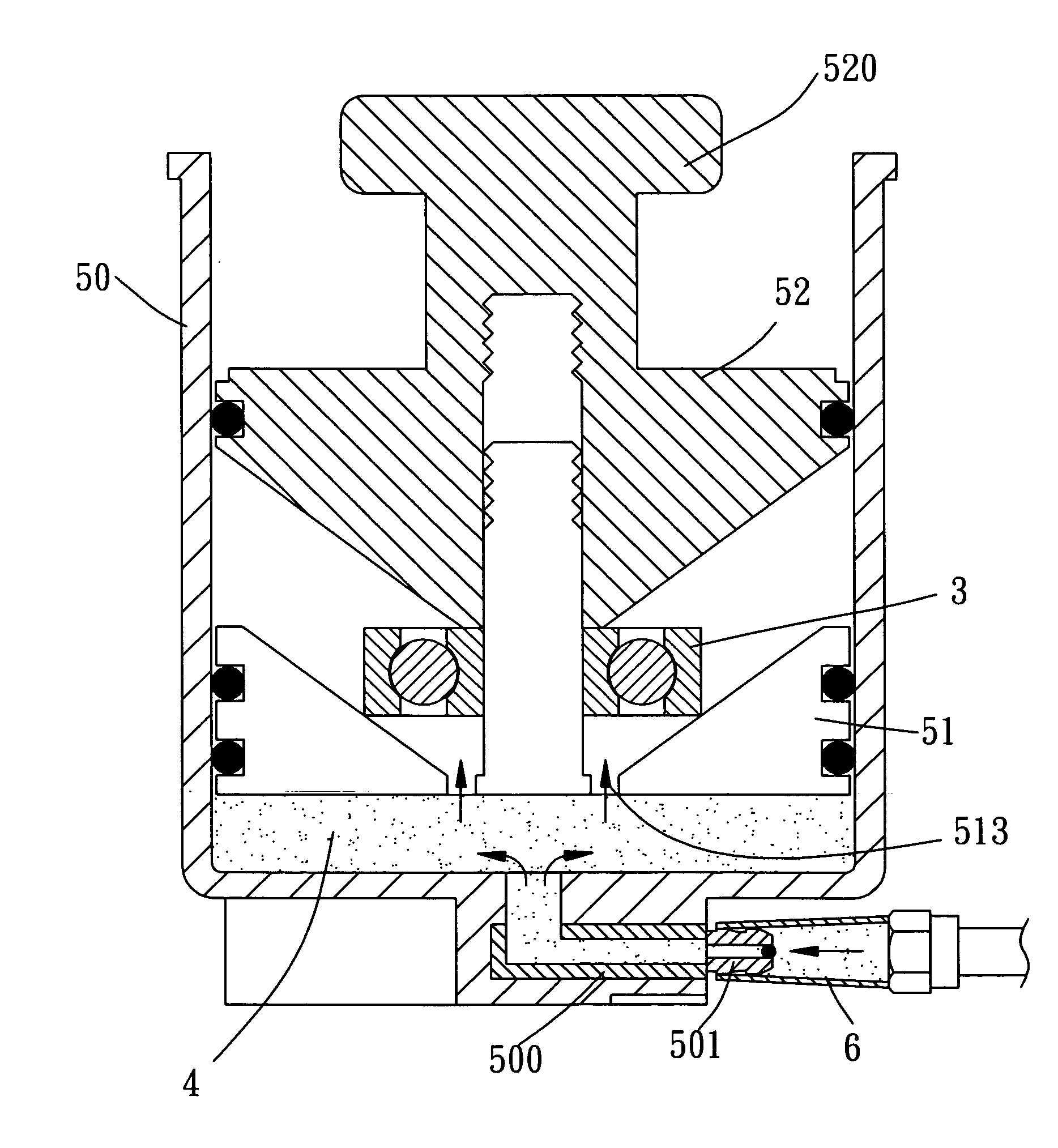

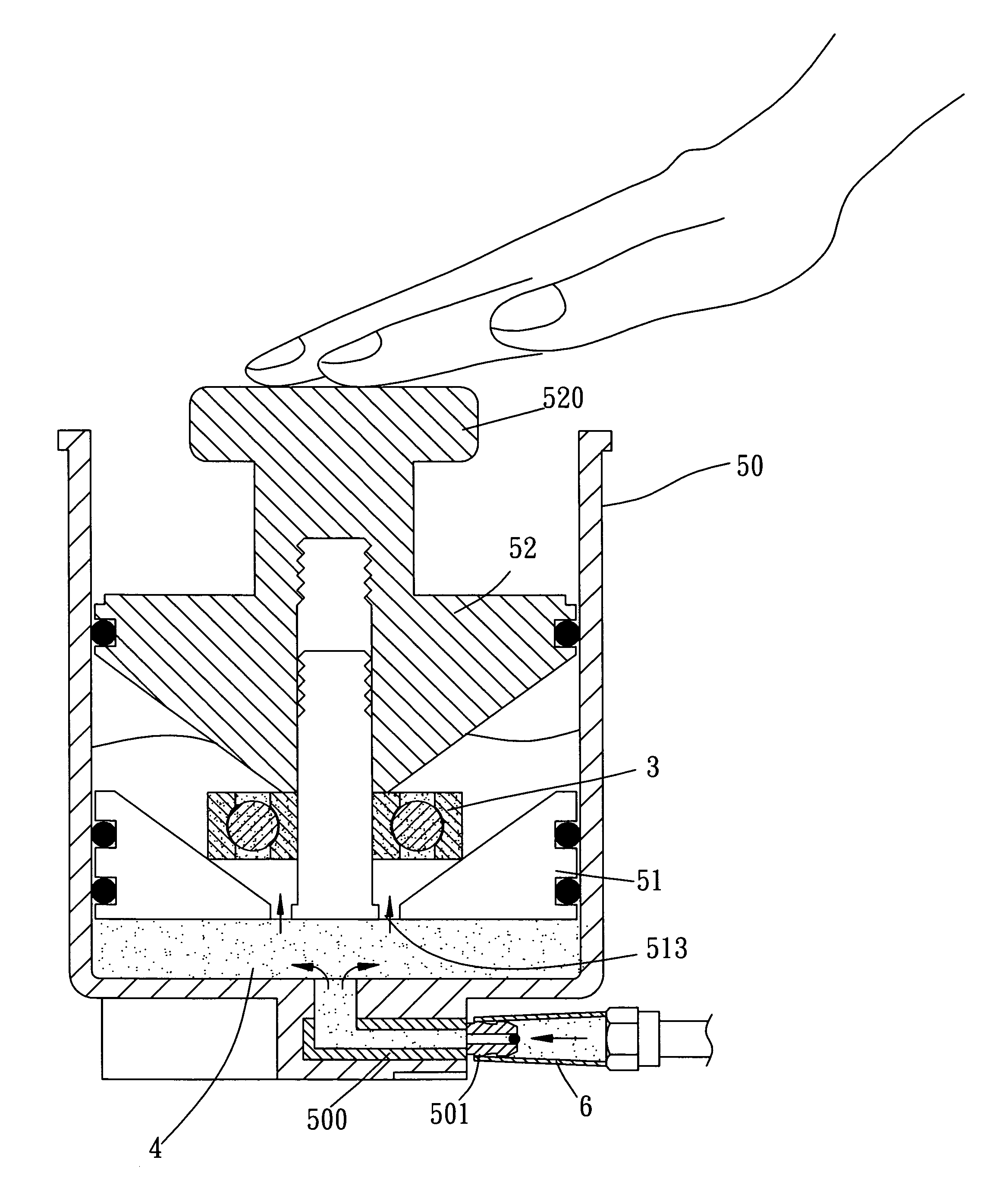

Pneumatic grease applicator

ActiveUS20070034451A1Simple structureSimple manufacturing processLubricant transferBall bearingsEngineeringExternal source

Disclosed is a pneumatic grease applicator includes a receptacle in which a retainer that retains a bearing to which grease is to be applied and a presser that securely holds the presser on the retainer are movably received. The receptacle has a bottom nozzle through which grease is continuously supplied from an external source under a pneumatically induced driving force, whereby the grease can be consecutively applied to a number of bearings without interrupts. Sealing members are provided between the retainer and the presser and side wall of the receptacle to prevent leakage of grease.

Owner:LIH YANN INDAL

Viscous-material filling method

ActiveUS20120205001A1Increase costWeight increaseLiquid surface applicatorsLubricant transferPlungerBung

A method and apparatus are disclosed for transferring and filling a viscous material from a container into a syringe while preventing the ingress of gas into the viscous material during the process of filling the syringe with the viscous material, but without requiring a housing for holding both the container and the syringe in an air-tight manner. The method includes inserting a plunger into the container that holds the viscous material and inserting a first plug, which permits gas flow in one direction, into the syringe. Then, the container is coupled to the syringe, a rod is inserted into the syringe such that the rod engages with the first plug, and the plunger is pushed within the container, thereby extruding the viscous material from the container. As a result, the extruded viscous material is transferred into the syringe and the syringe is filled with the viscous material.

Owner:KAGA WORKS

Automatic grease-injection device of bearing

InactiveCN106402632AImprove grease injection efficiencySave labor costsLubricant transferAutomatic transmissionEngineering

The invention discloses an automatic grease-injection device of a bearing. The automatic grease- injection device of the bearing comprises a driving belt, grease discharging thin pipes, a grease storing box, a T-shaped supporting frame and an air pressure adjusting valve. Bearing grooves are fixedly arranged on the driving belt, the T-shaped supporting frame is arranged on one side of the driving belt, and an upper piston bucket is arranged on one side of the bottom of a cross beam of the T-shaped supporting frame. The upper piston bucket is connected with a lower piston bucket through an inner double-end piston rod, a pneumatic pump is connected with the lower portion of an electromagnetic valve, and the air pressure adjusting valve is arranged in the middle position between the electromagnetic valve and the pneumatic pump. According to the automatic grease-injection device of the bearing, the bearing is subjected to grease injection by combination of automatic transmission and quantitative grease injection. The driving belt can enable the grease injection of the bearing to be streamlined, grease-injection efficiency is improved, and manual cost is reduced. The grease discharging thin pipes distributed in a ring shape, an infrared detector and the air pressure adjusting valve can enable fat to be injected between the inner ring and the outer ring of the bearing evenly, accurately and quantitatively, so that a reject ratio of the grease injection is reduced.

Owner:湖南天天特训教育咨询有限公司

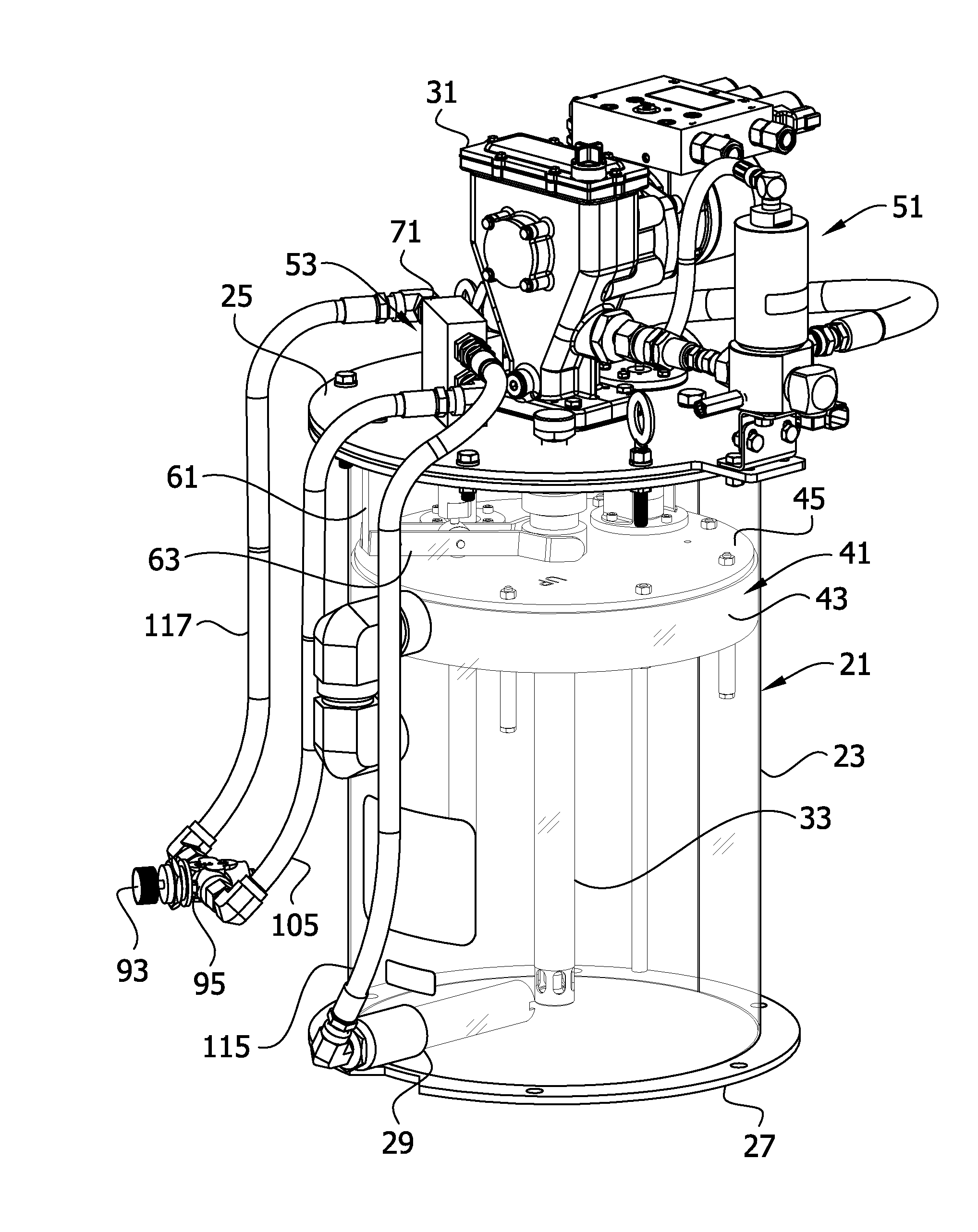

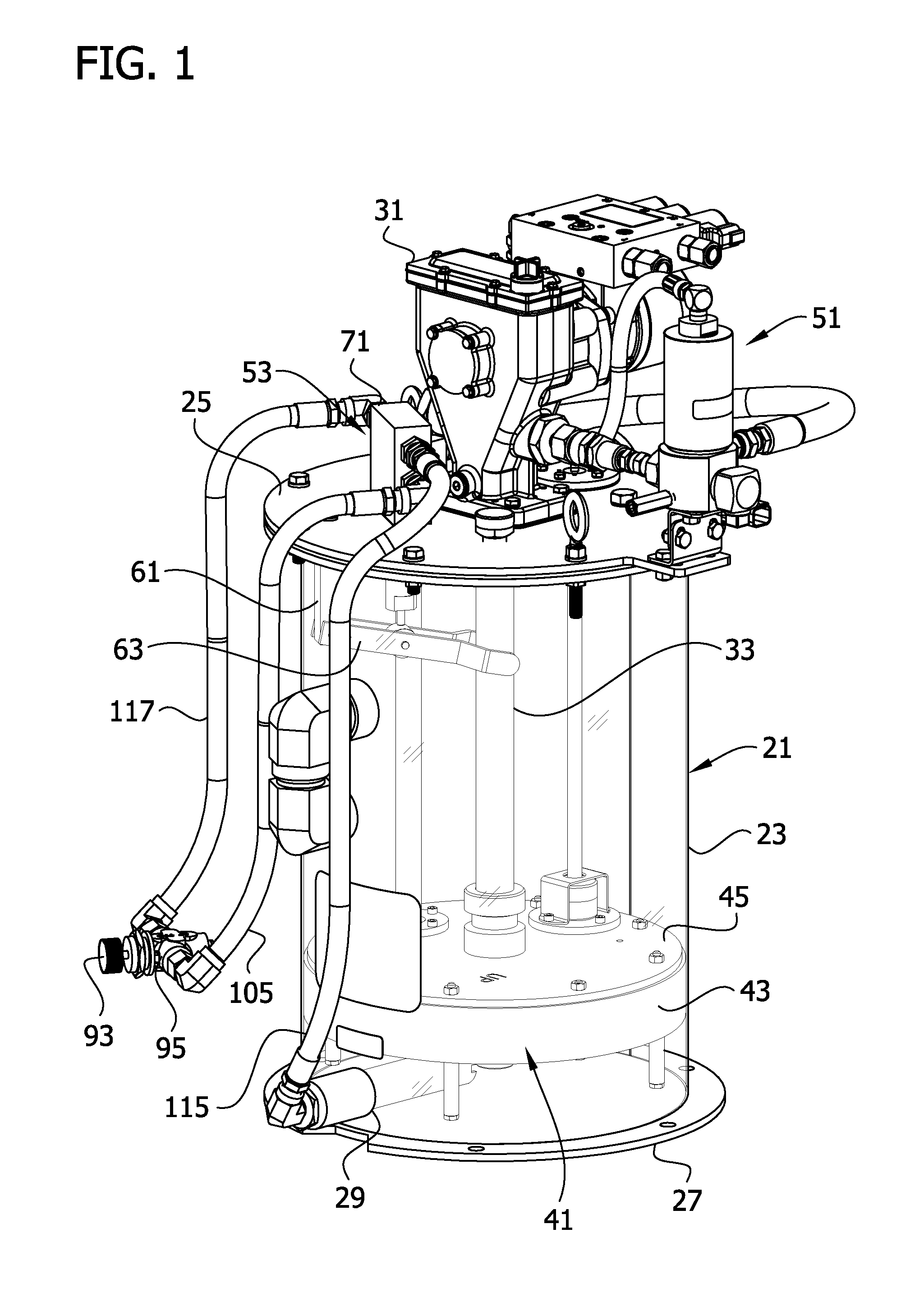

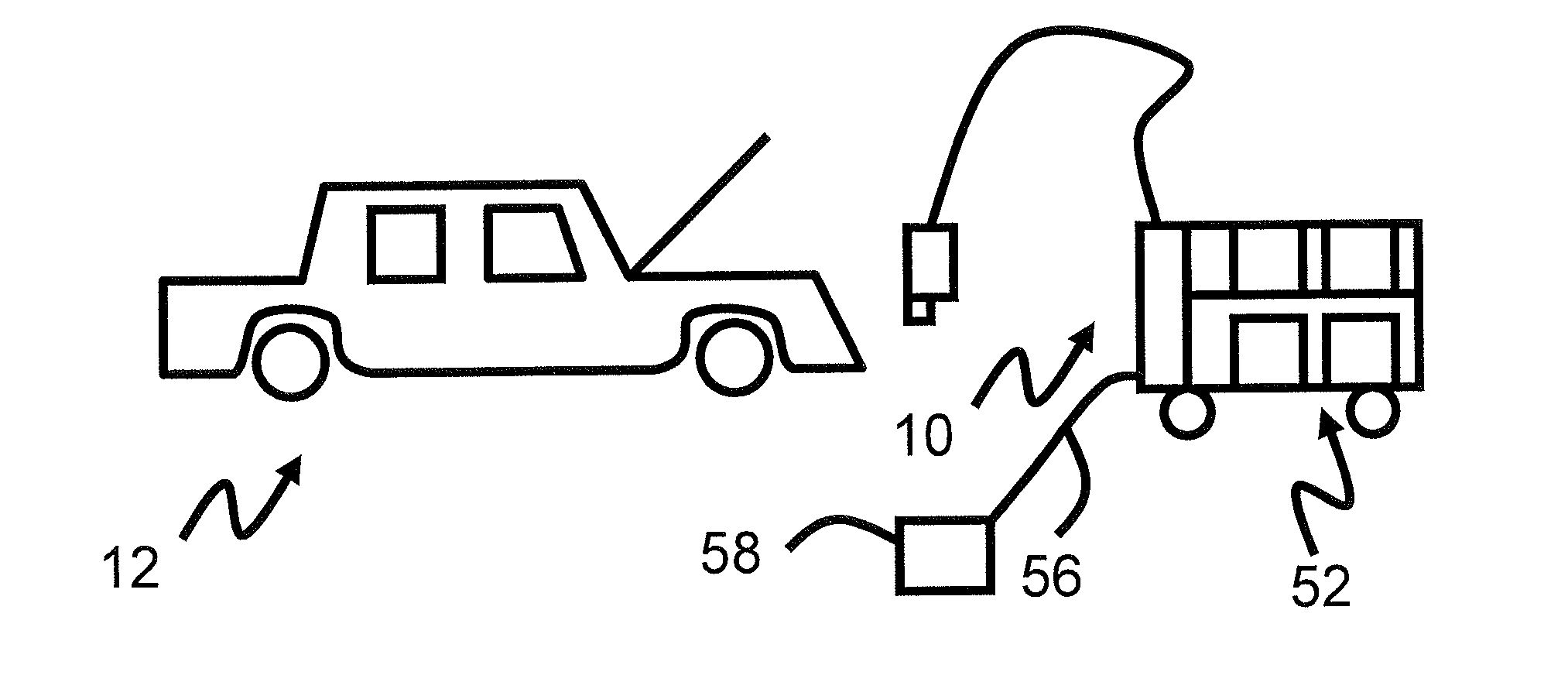

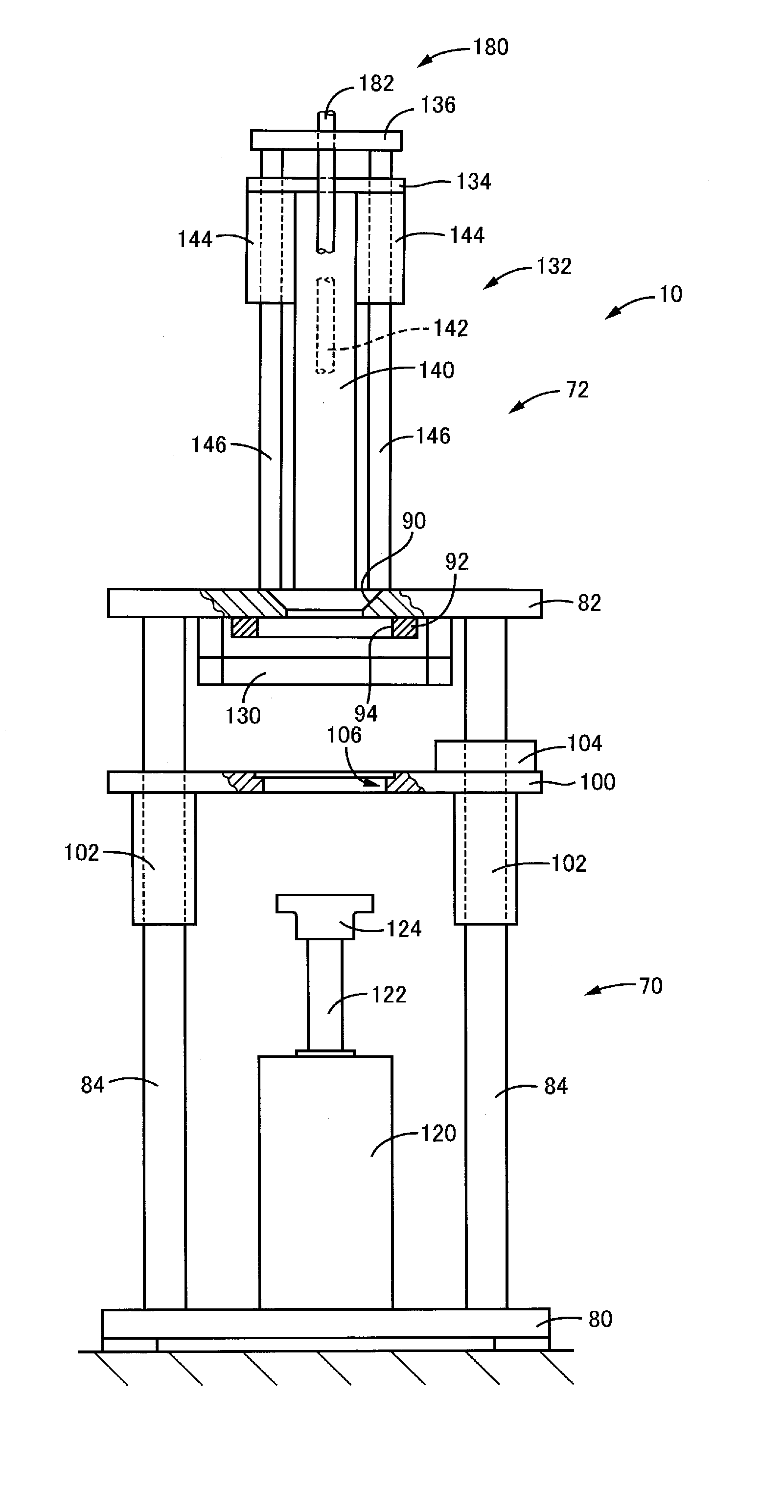

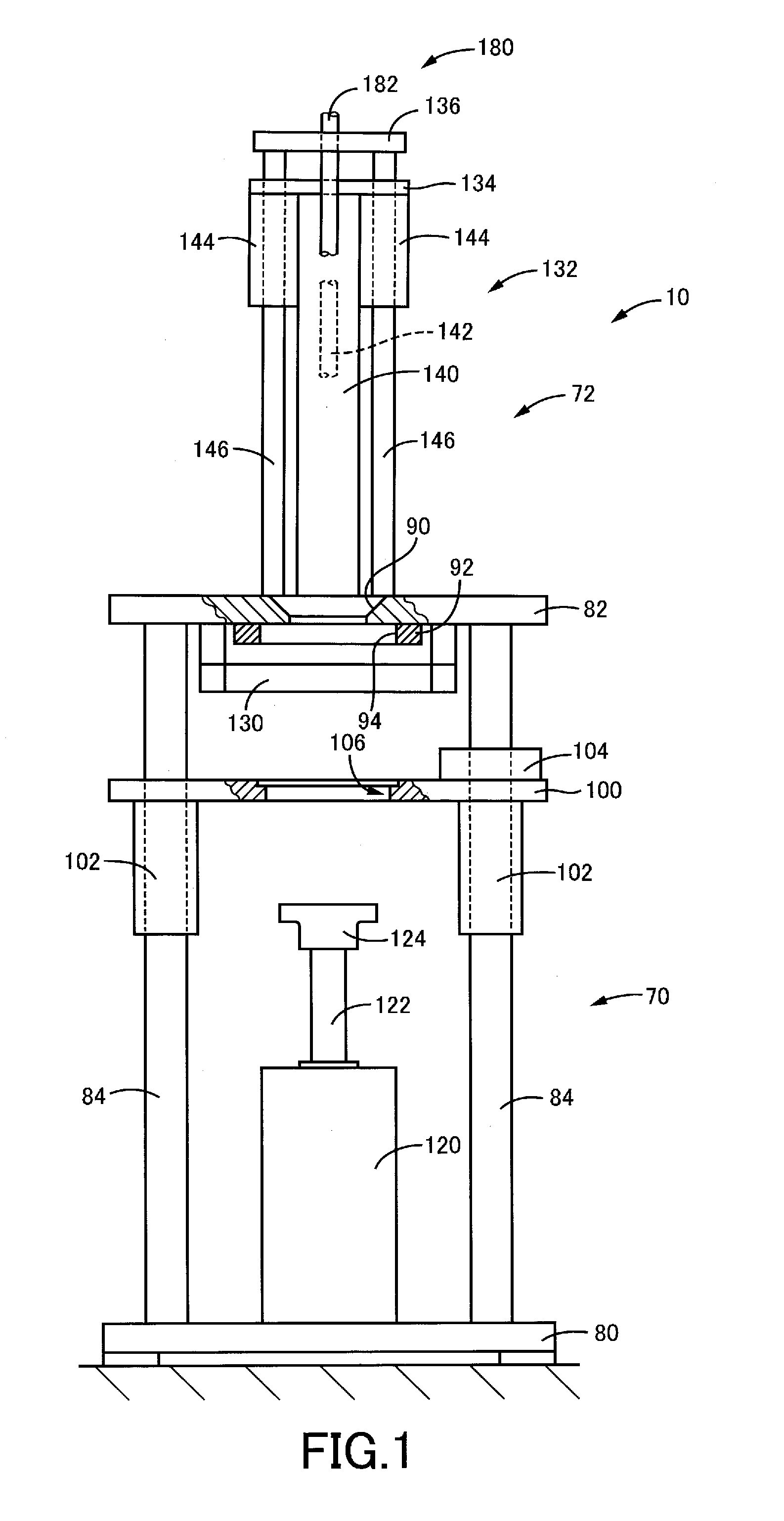

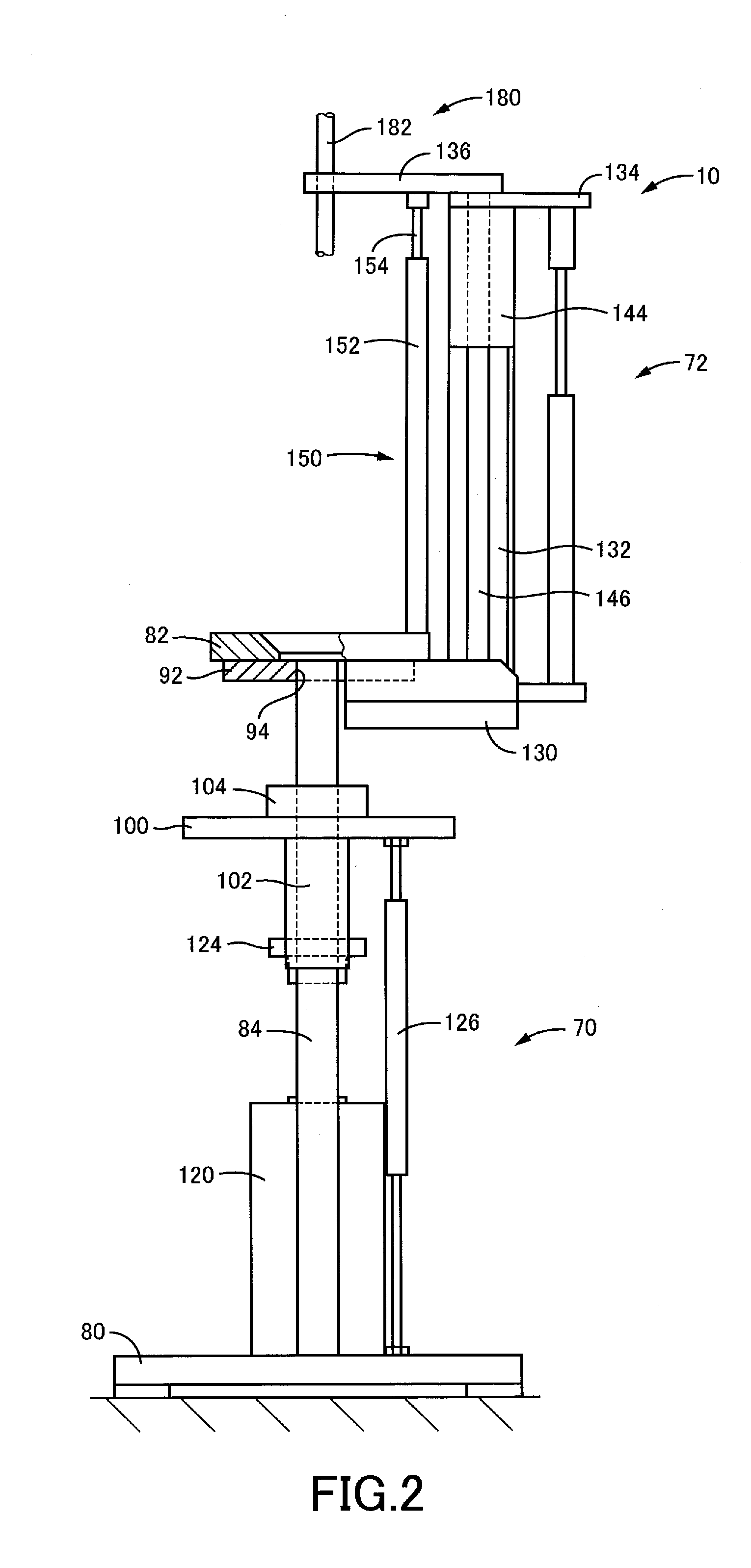

Portable self-contained fluid system

ActiveUS8109364B2Quickly and easily mountingQuickly and easily dischargingCrankshaftsLiquid fillingChange TypeFluid system

Owner:XYLEM IP HLDG

Method for use in the manufacturing of a fluid dynamic pressure bearing

ActiveUS7328511B2Reduce and prevent likelihoodAccurate supplyLubricant transferMetal-working apparatusEngineeringAtmospheric pressure

Owner:NIDEC CORP

Lubrication device for bearings and other mechanical parts

ActiveUS7467690B2Effectively and uniformlySimple structureLubricant transferBall bearingsEngineeringLubrication

Disclosed is a pneumatic grease applicator includes a receptacle in which a retainer that retains a bearing to which grease is to be applied and a presser that securely holds the presser on the retainer are movably received. The receptacle has a bottom nozzle through which grease is continuously supplied from an external source under a pneumatically induced driving force, whereby the grease can be consecutively applied to a number of bearings without interrupts. Sealing members are provided between the retainer and the presser and side wall of the receptacle to prevent leakage of grease.

Owner:LIH YANN INDAL

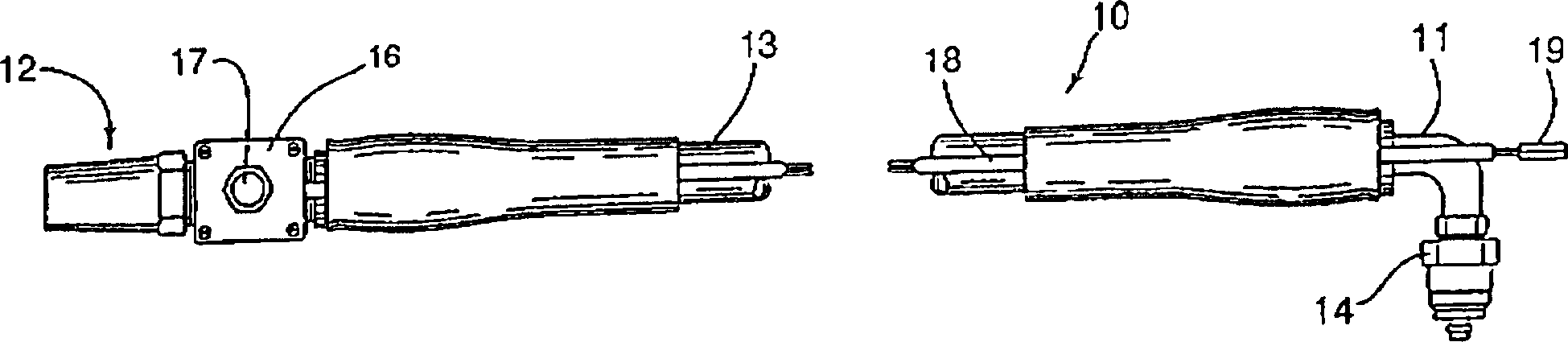

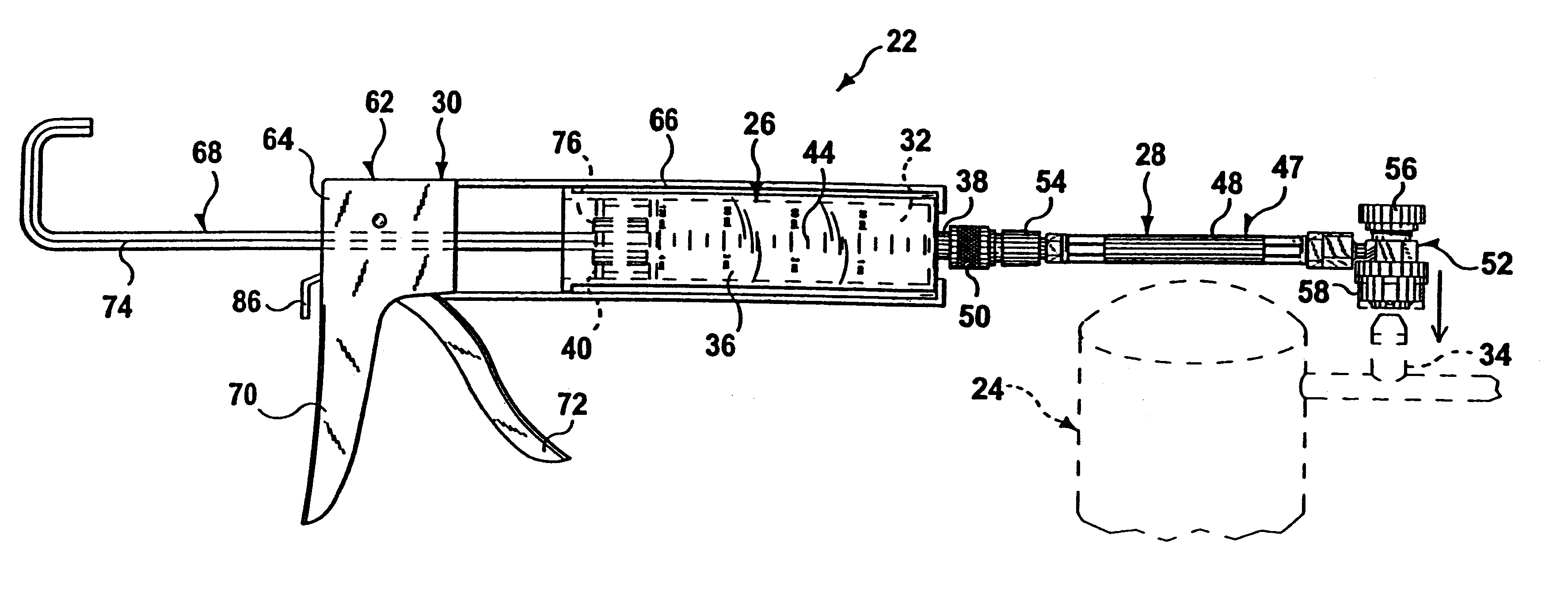

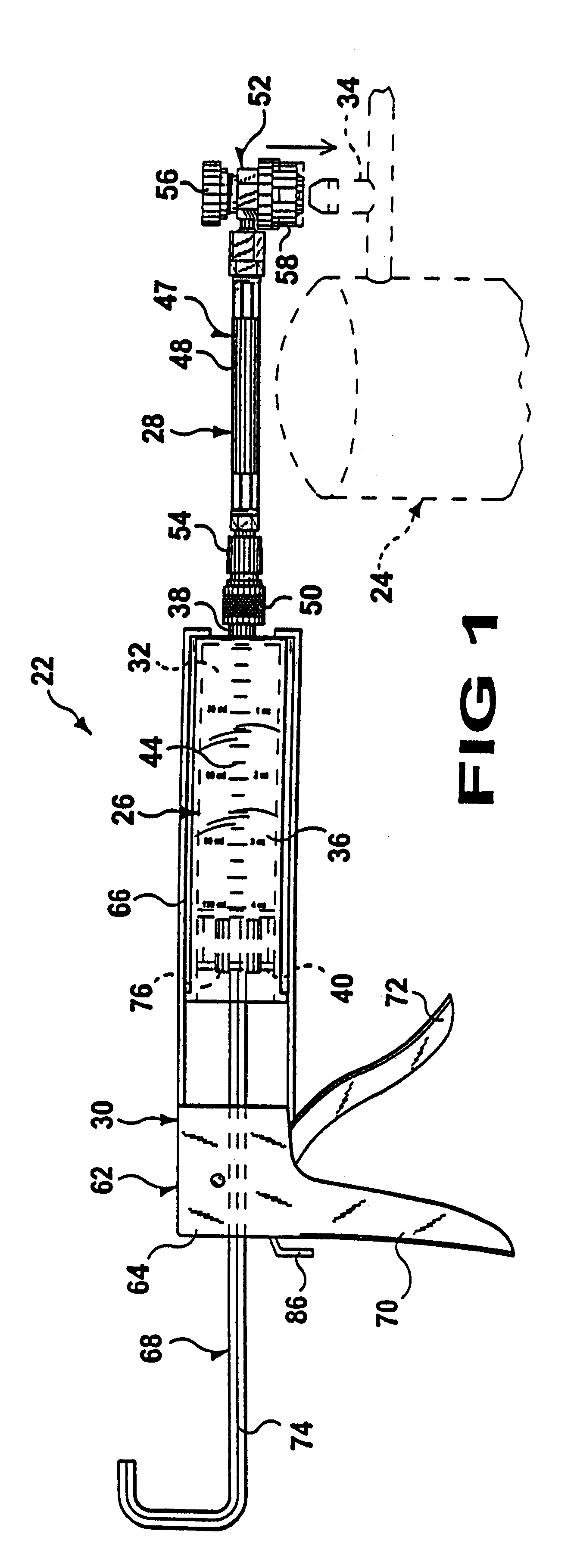

Apparatus for detecting leaks in a pressurized air conditioning or refrigeration system

InactiveUSRE38342E1Allocation is accuratePrevent leakageCompressorLubricant transferEngineeringAir conditioning

An apparatus (22) and method for detecting leaks in a pressurized air conditioning or refrigeration system (24) comprising a cartridge (26) is described. A facility (28) is for fluidly coupling the cartridge (26) to the pressurized system (24). An assemblage (30) is for forcing a secondary fluid (32) out of the cartridge (26), through the fluidly coupling facility (28) and into a service valve (34) of the pressurized system (24). The cartridge (26) has a first open end with an inner nozzle (33) which connects to the system being charged and an outer nozzle (37).

Owner:CPS PROD CANADA

Packaging bag filling type automatic grease gun

InactiveCN102788238AGuaranteed cleanlinessImprove work efficiencyManual lubricationLubricant transferHydraulic pumpEngineering

The invention relates to a packaging bag filling type automatic grease gun, wherein a lubricating grease packaging bag (5) containing the lubricating grease can be directly packaged in a storage tube (1), a piston (6) is arranged between an oil storage chamber (1) of the grease gun and a grease bag (5), and a spring sleeve (8) is arranged in the centre of a bottom cover (7). A tension spring (9) is threaded inside the spring sleeve. One end of the tension spring (9) is connected with the piston (6), while the other end of the tension spring (9) is fixedly arranged at the top end of the spring sleeve (8). The top end of the spring sleeve (8) is further connected with a high pressure hose (10) which is communicated with a hydraulic oil discharge opening of a set of hydraulic oil pump system. The set of hydraulic oil pump system provides the hydraulic power to push the piston (6) to squeeze and inject the grease in the lubricating grease packaging bag (5) into a device needing to be lubricated.

Owner:甄国卿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com