Patents

Literature

327results about How to "Accurate supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Showerhead for film depositing vacuum equipment

ActiveUS9315897B2Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasMixed gas

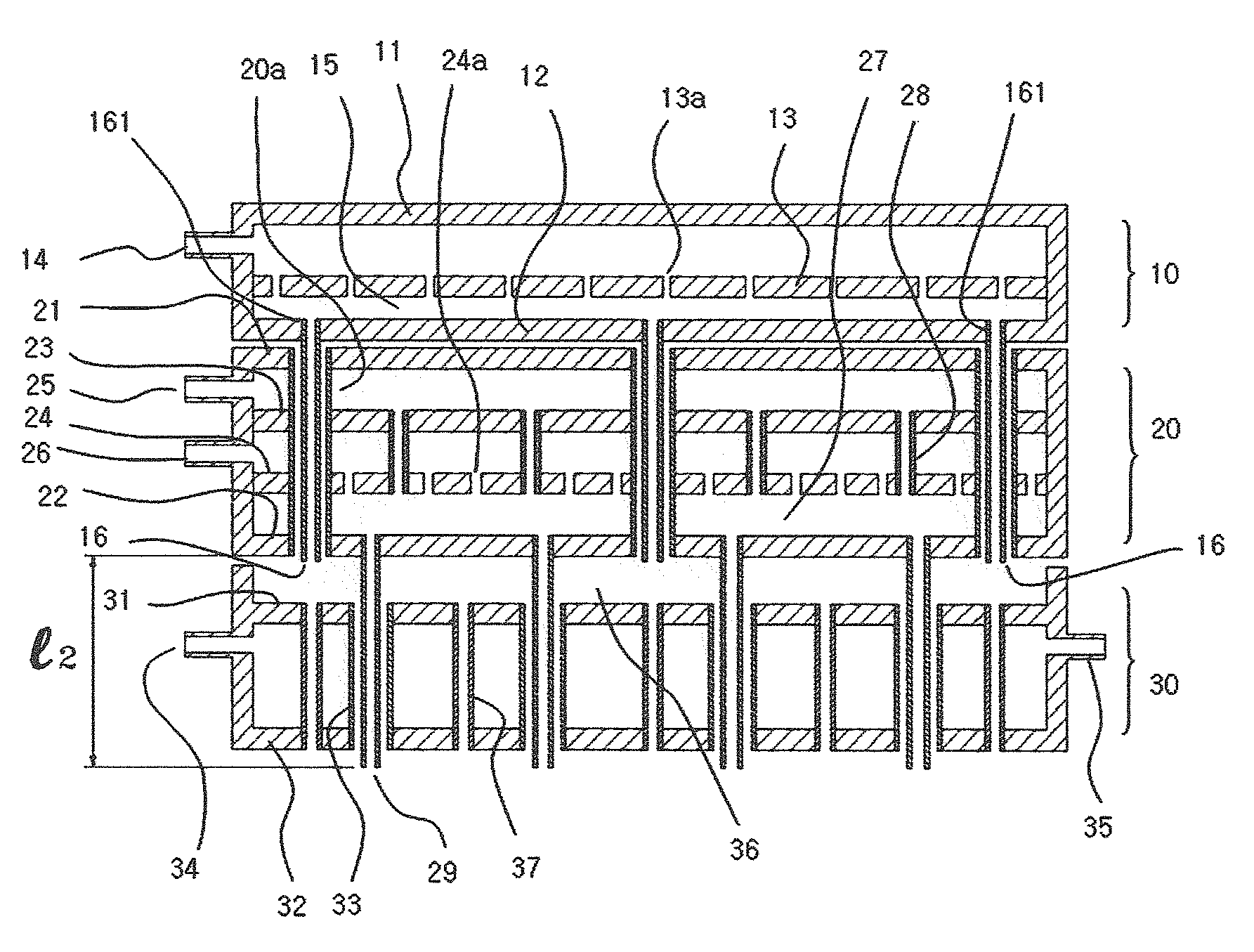

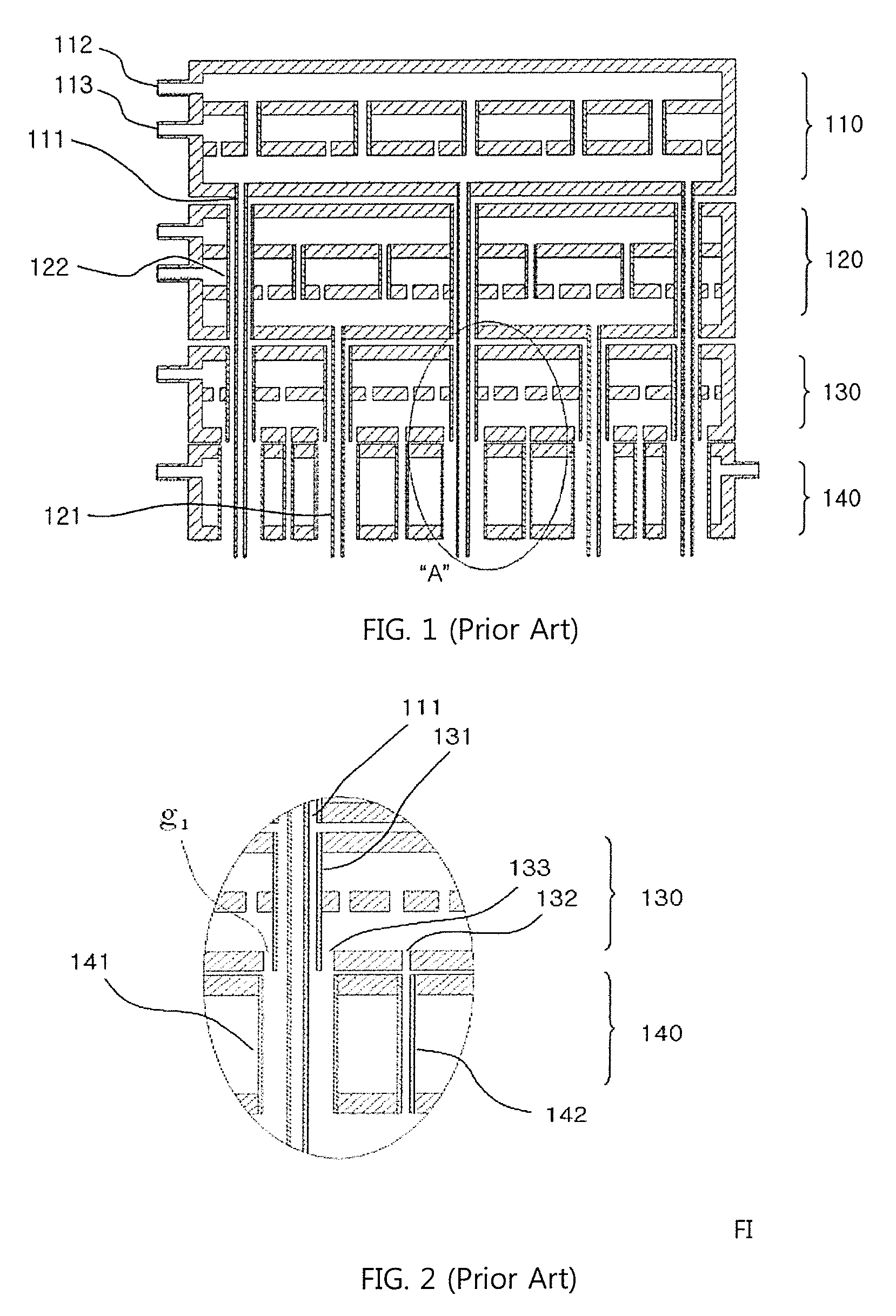

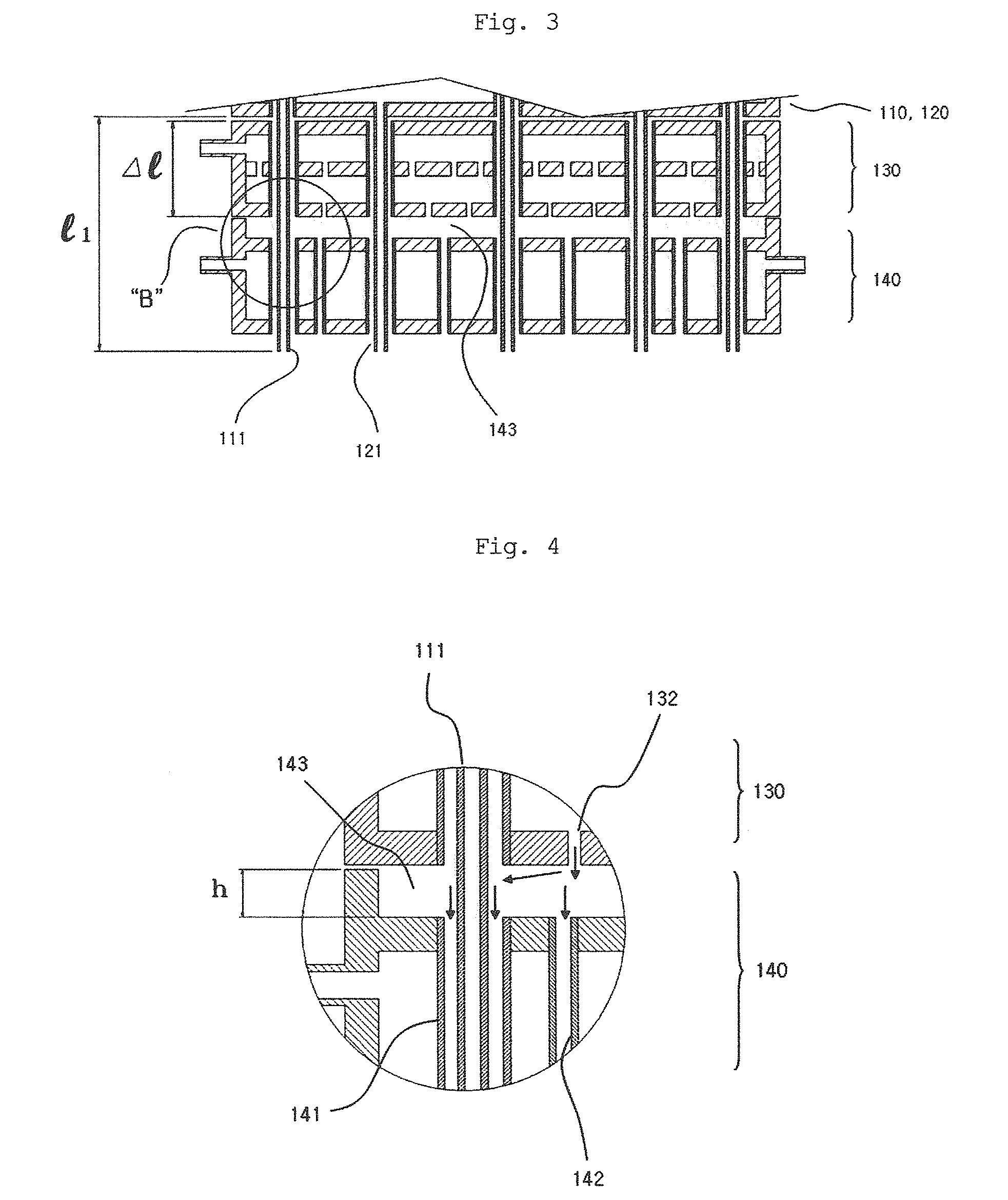

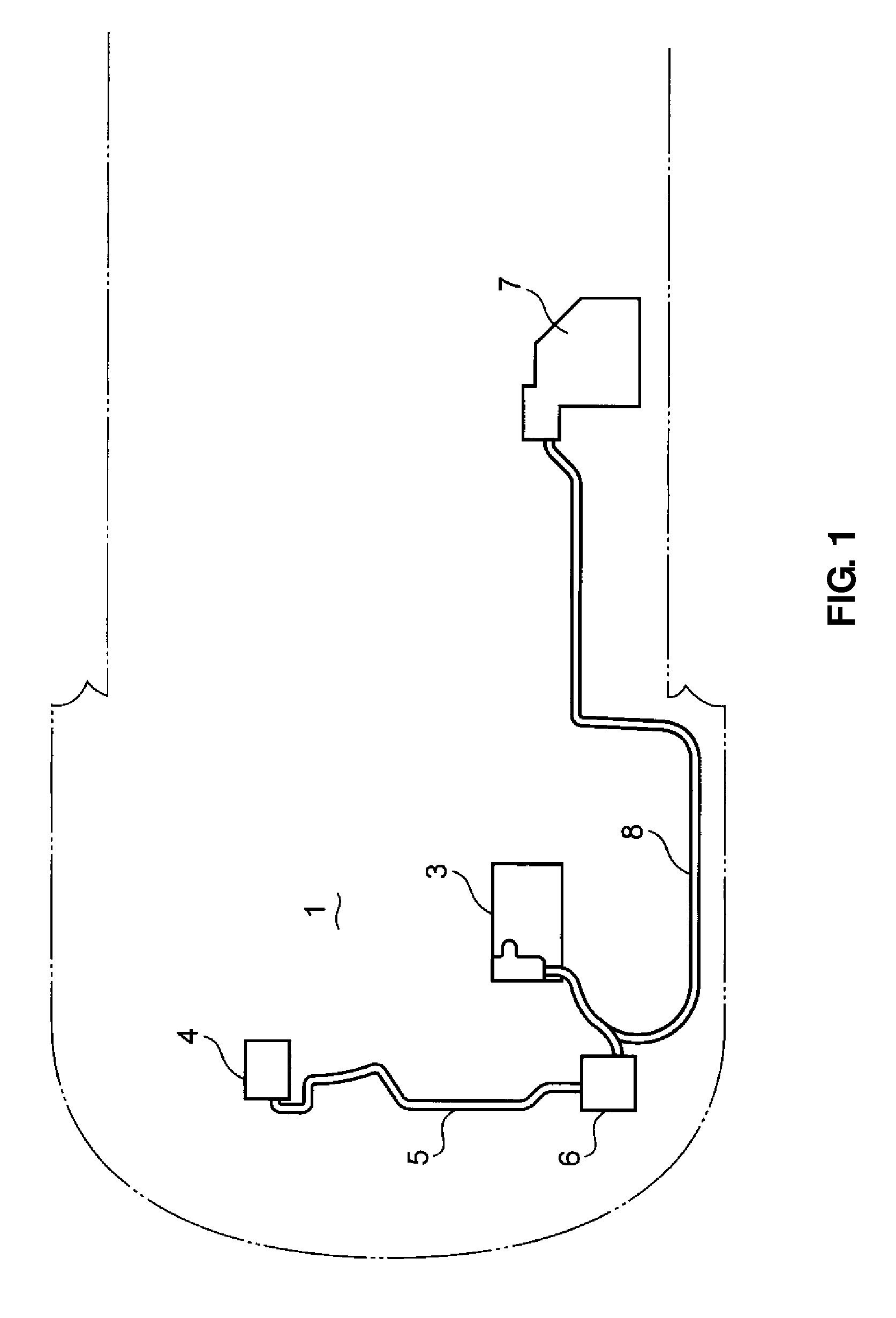

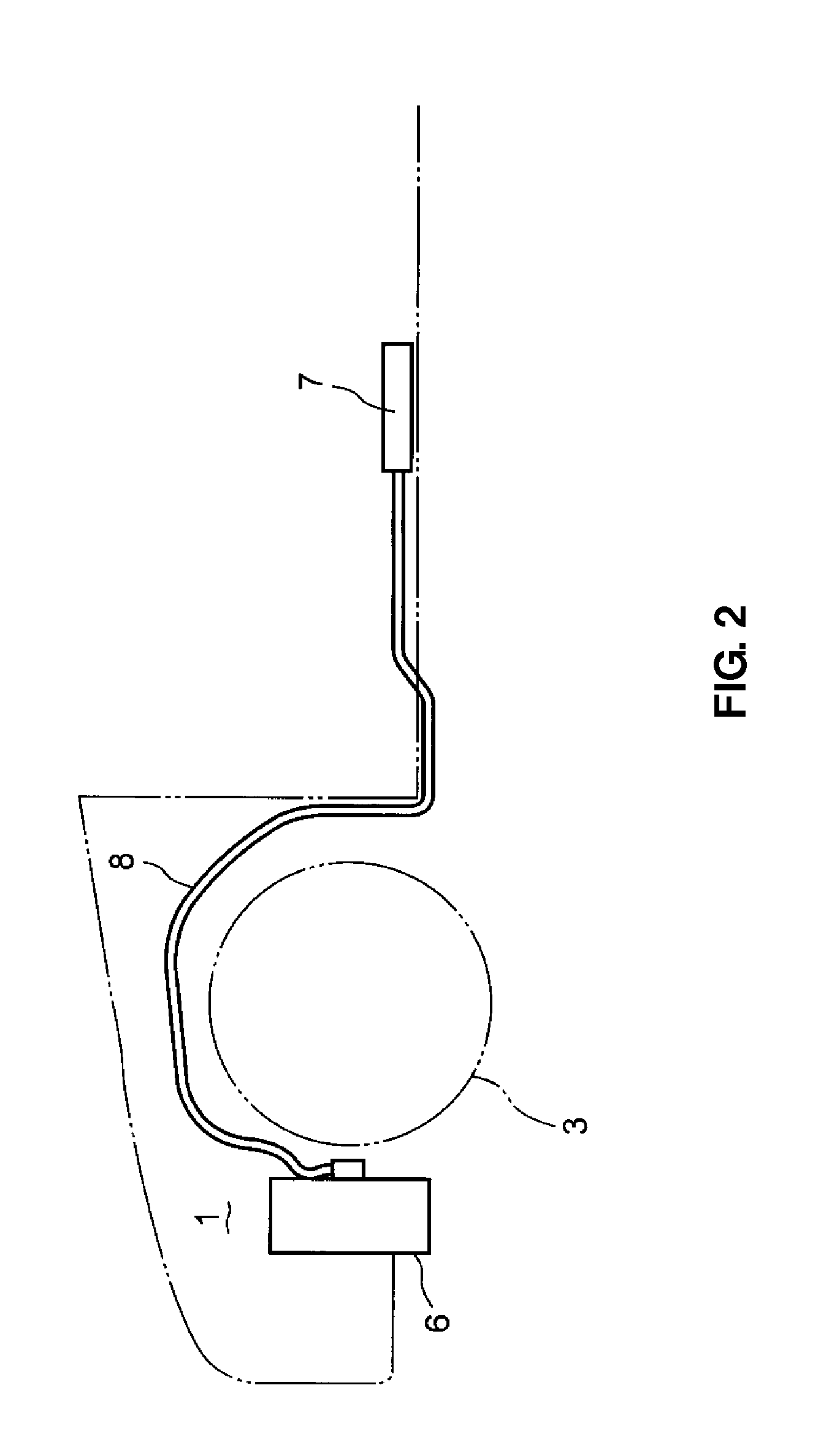

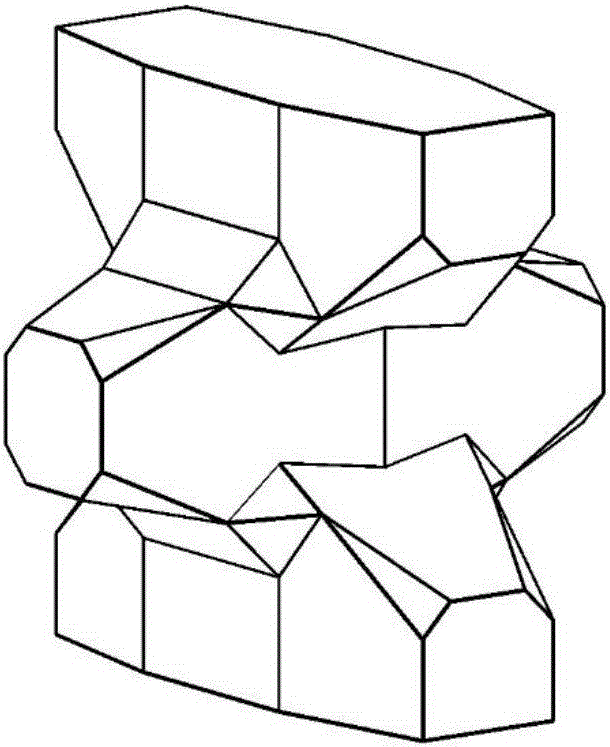

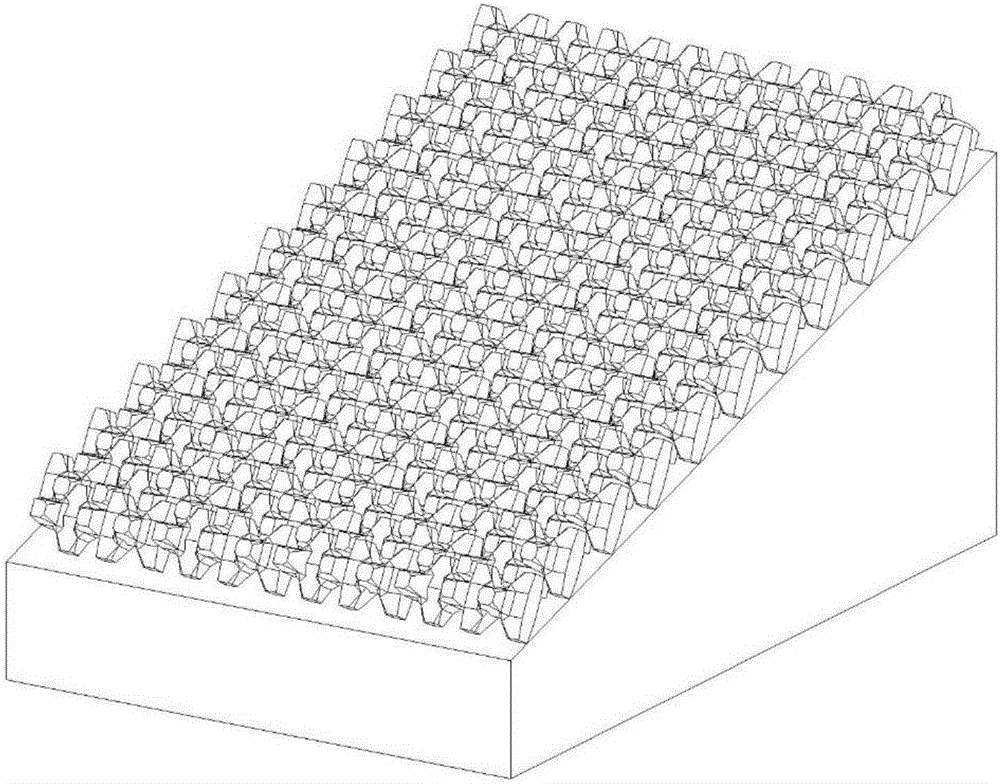

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

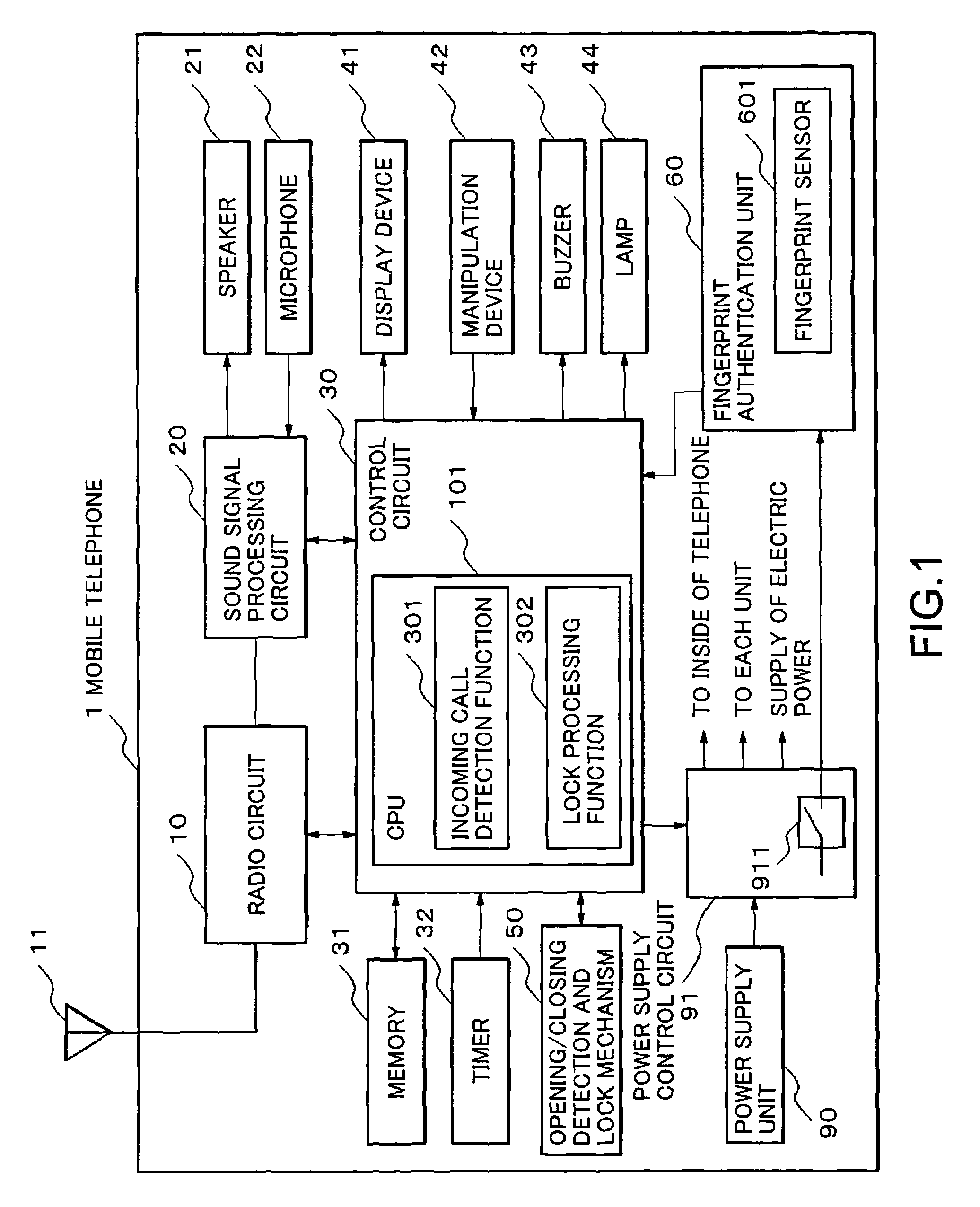

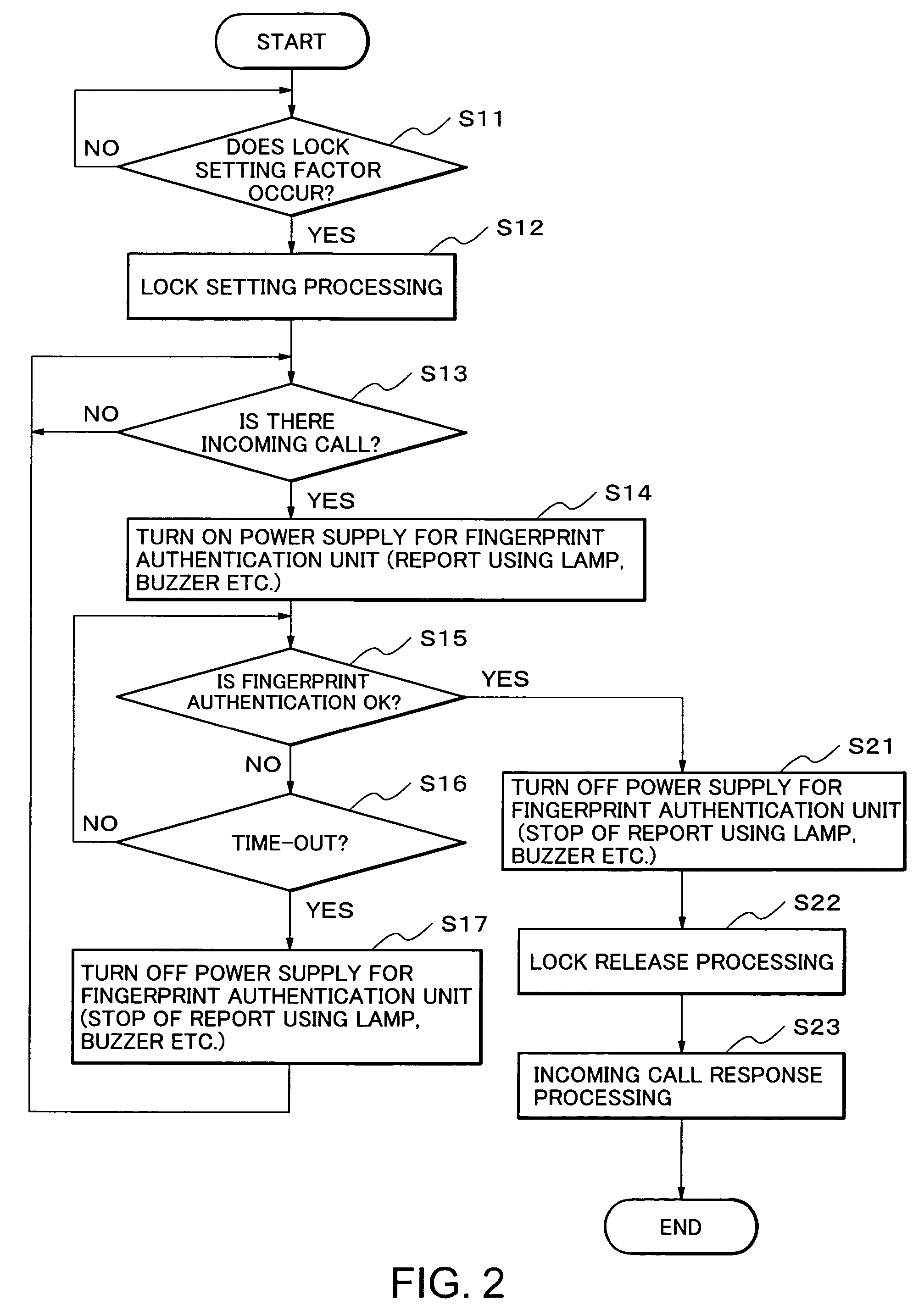

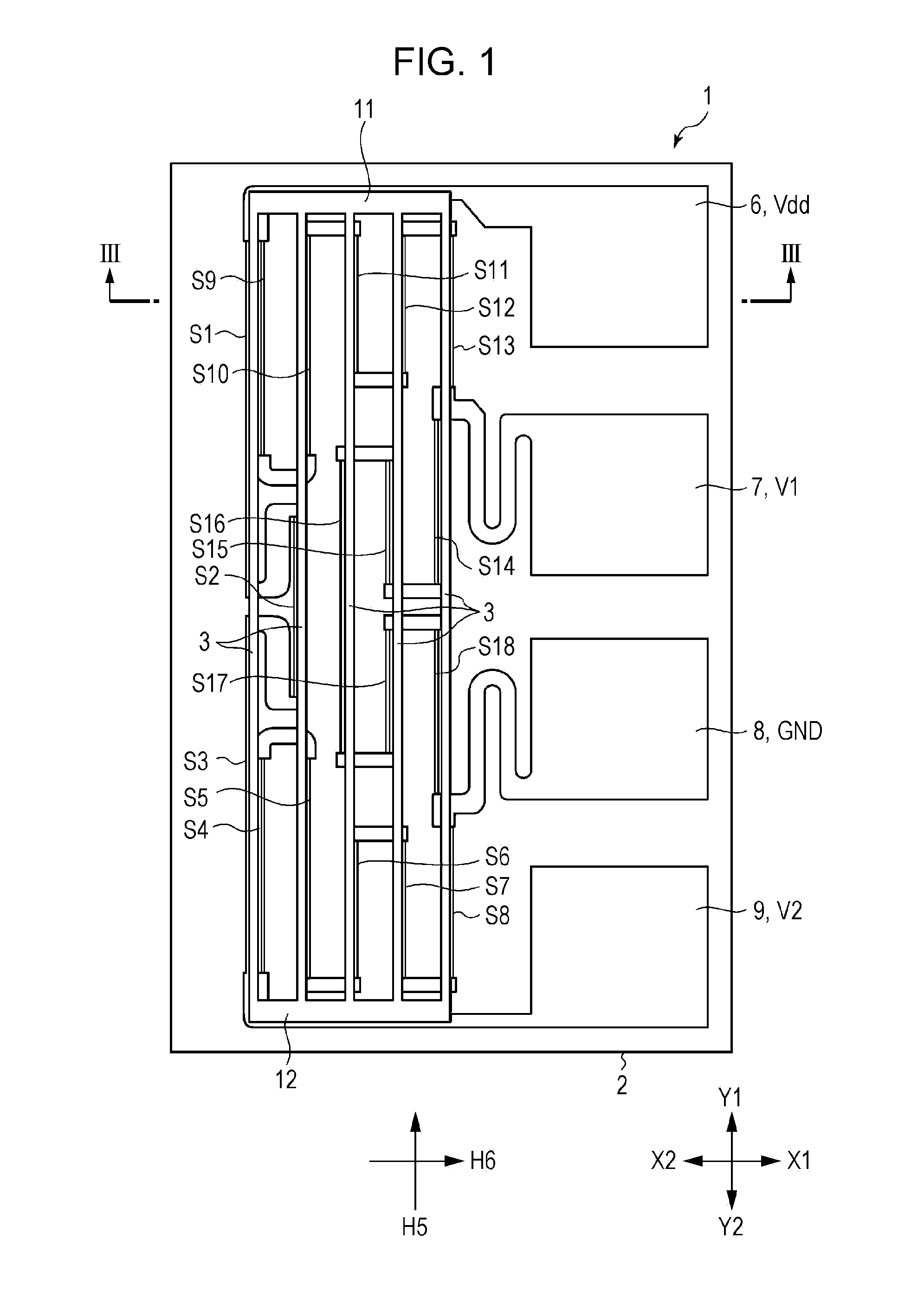

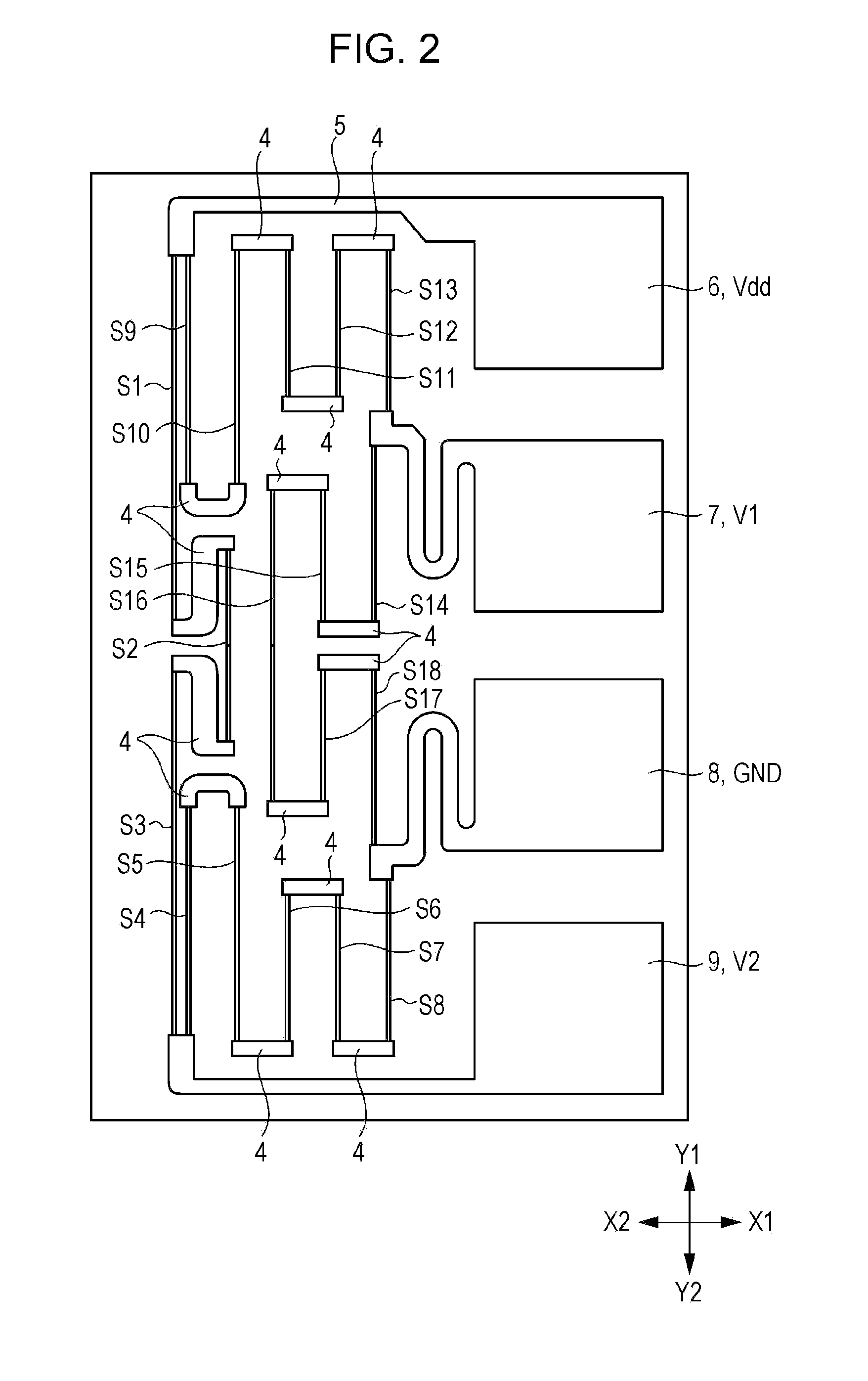

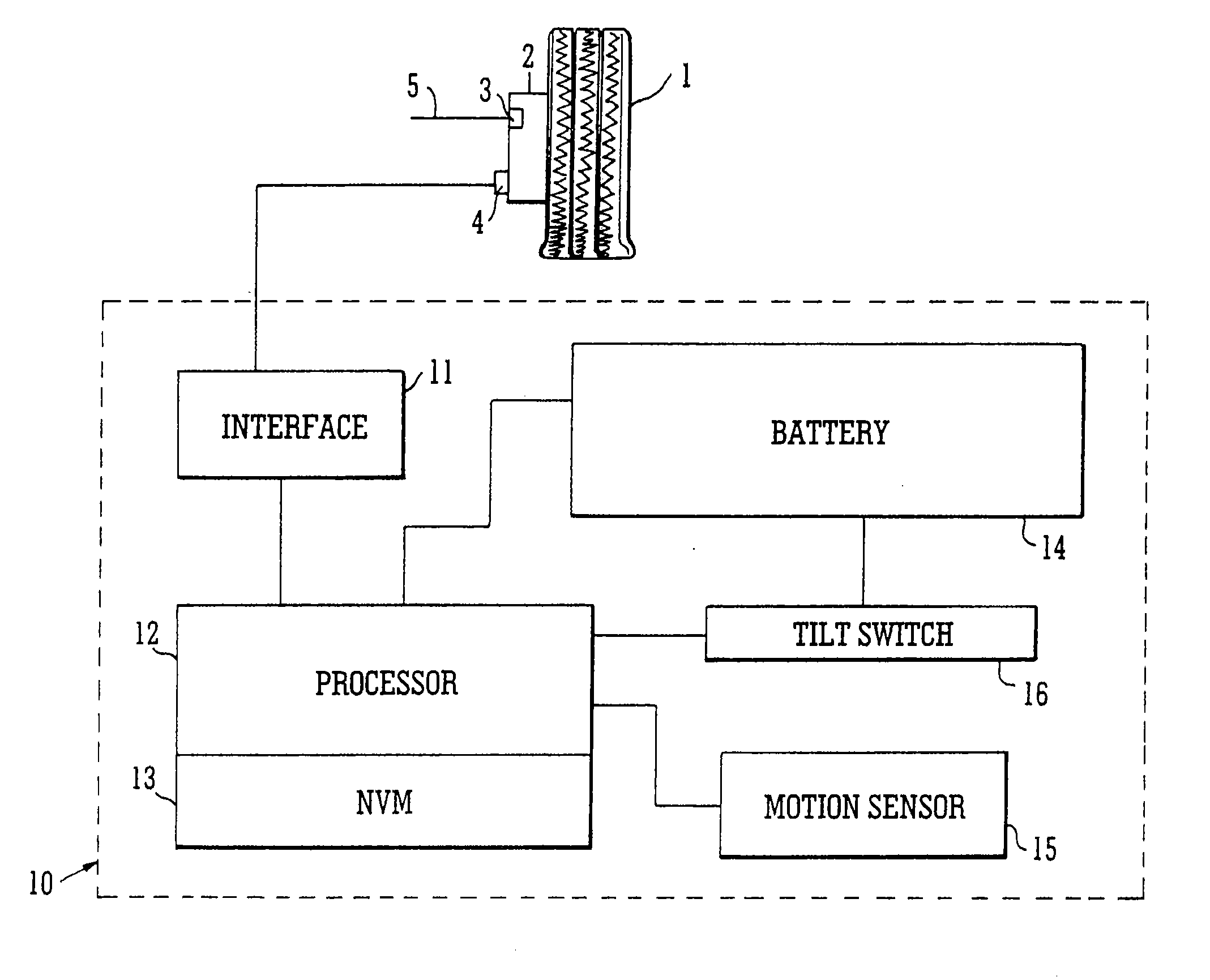

Mobile terminal, method of controlling the same, and computer program of the same

InactiveUS7366497B2Increase the burdenReduce power consumptionPower managementEnergy efficient ICTLocking mechanismComputer terminal

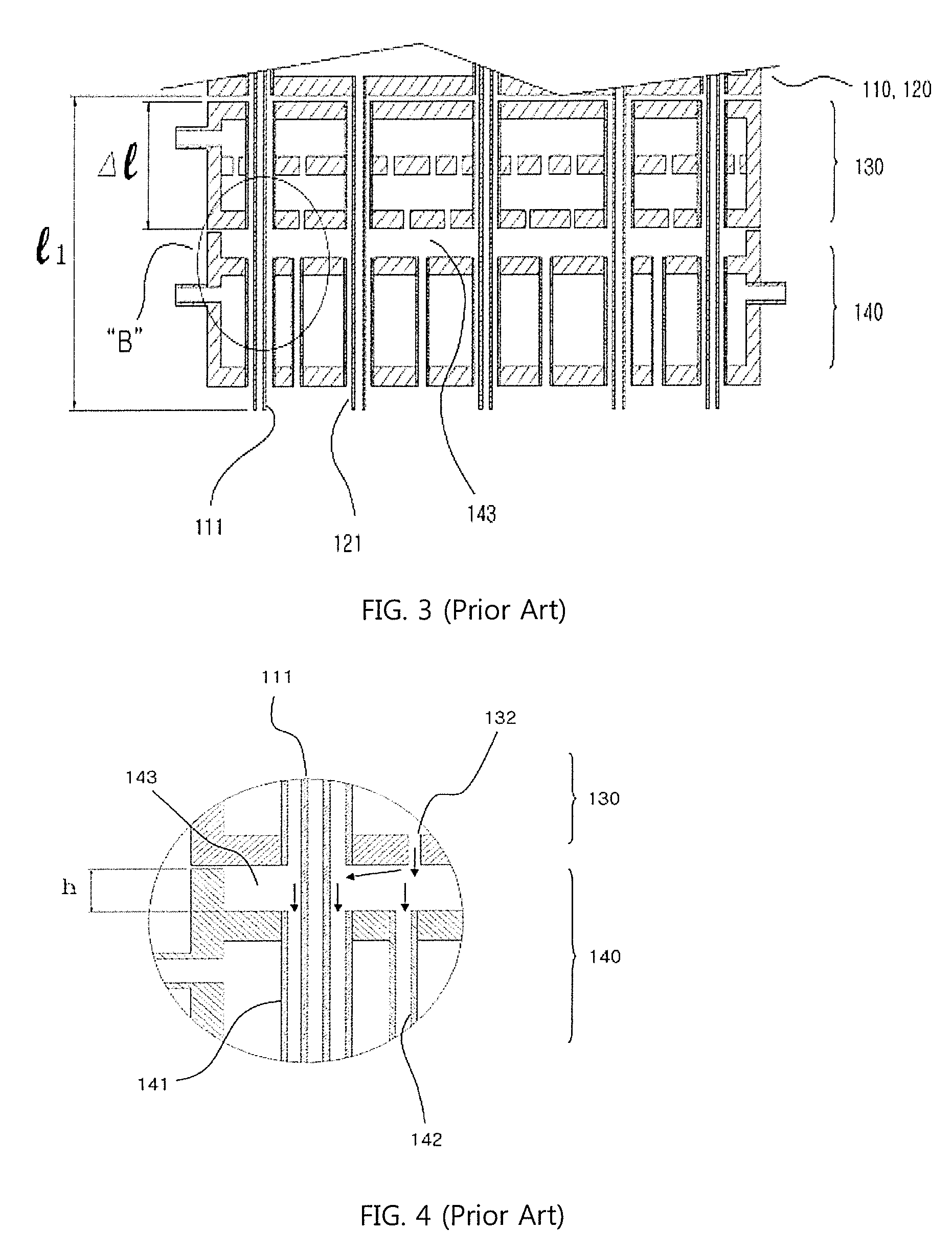

A mobile telephone (1), when being folded, is set in a lock state by an opening / closing detection and lock mechanism (50), and then a control circuit (30) stops supply of an electric power to a fingerprint authentication unit (60). In this state, upon detection of an incoming call from an external apparatus, the control circuit (30) restarts the supply of the electric power to the fingerprint authentication unit (60), and when a user is authenticated as a legitimate user by the fingerprint authentication unit (60), instructs the opening / closing detection and lock mechanism (50) to carry out an unlocking operation.

Owner:NEC CORP

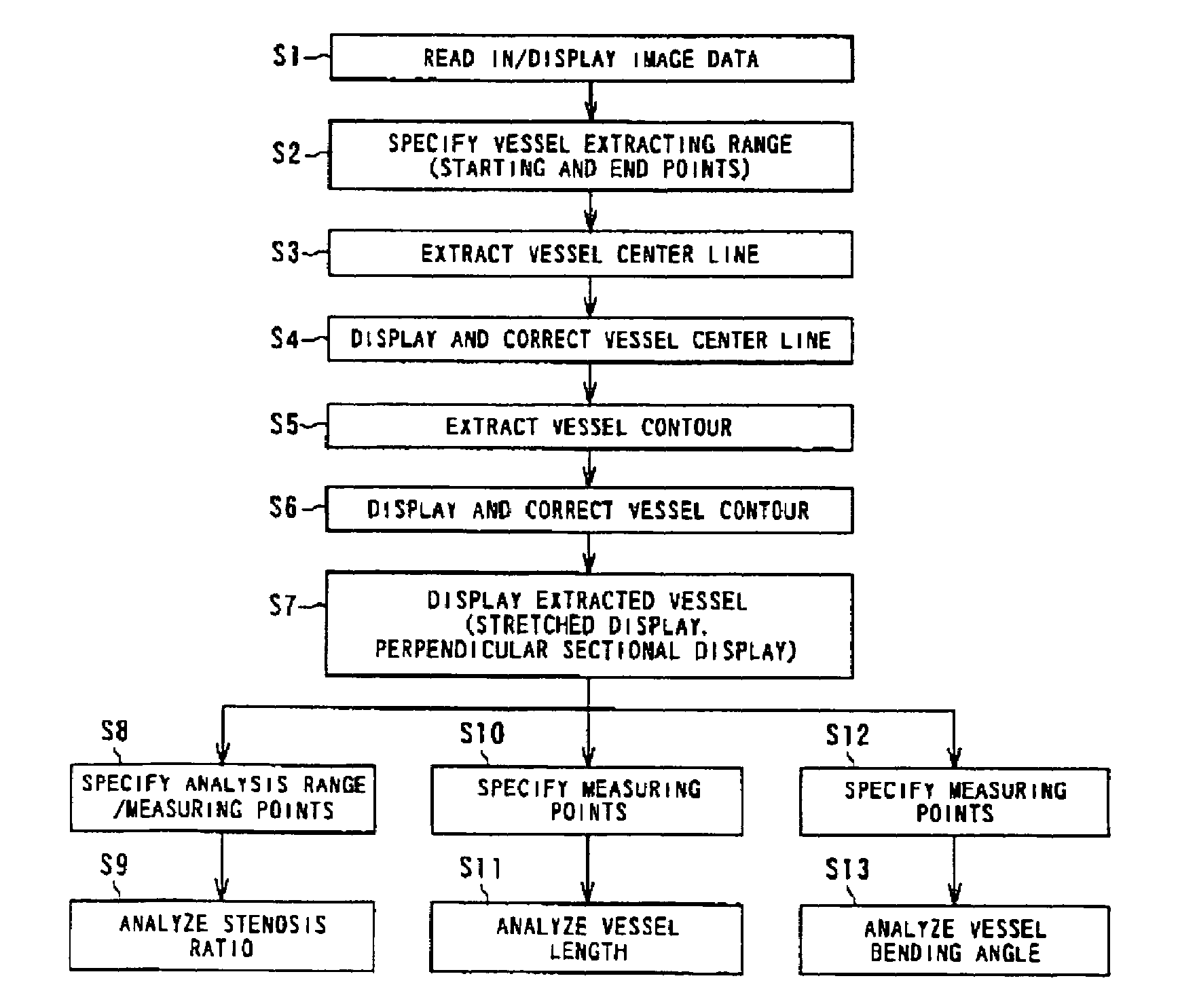

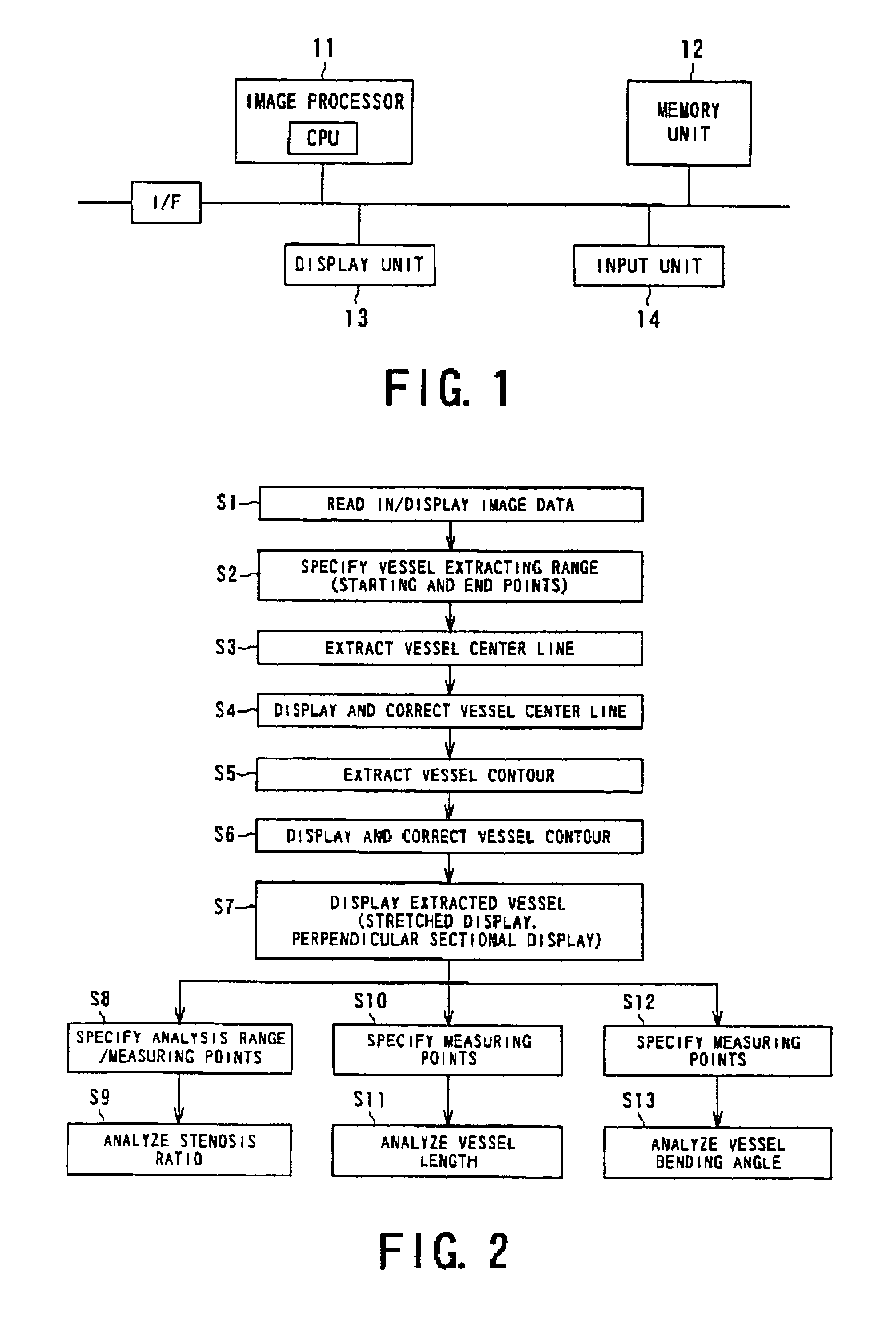

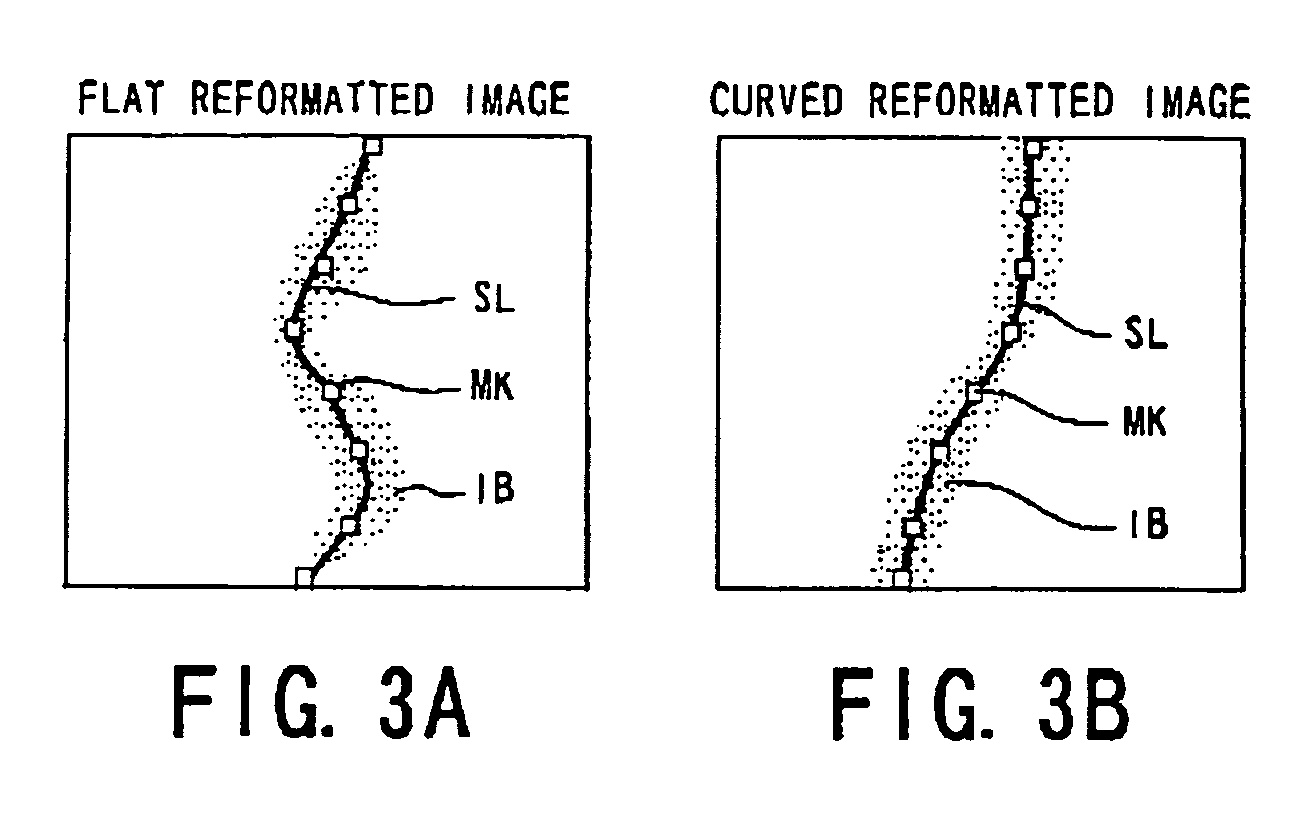

Processor for analyzing tubular structure such as blood vessels

InactiveUS7369691B2Reduce operational burdenEasy to masterUltrasonic/sonic/infrasonic diagnosticsImage enhancementReference imageImaging data

Using medical three-dimensional image data, at least one of a volume-rendering image, a flat reformatted image on an arbitrary section, a curved reformatted image, and an MIP (maximum value projection) image is prepared as a reference image. Vessel center lines are extracted from this reference image, and at least one of a vessel stretched image based on the center line and a perpendicular sectional image substantially perpendicular to the center line is prepared. The shape of vessels is analyzed on the basis of the prepared image, and the prepared stretched image and / or the perpendicular sectional image is compared with the reference image, and the result is displayed together with the images. Display of the reference image with the stretched image or the perpendicular sectional image is made conjunctive. Correction of the center line by the operator and automatic correction of the image resulting from the correction are also possible.

Owner:TOSHIBA MEDICAL SYST CORP

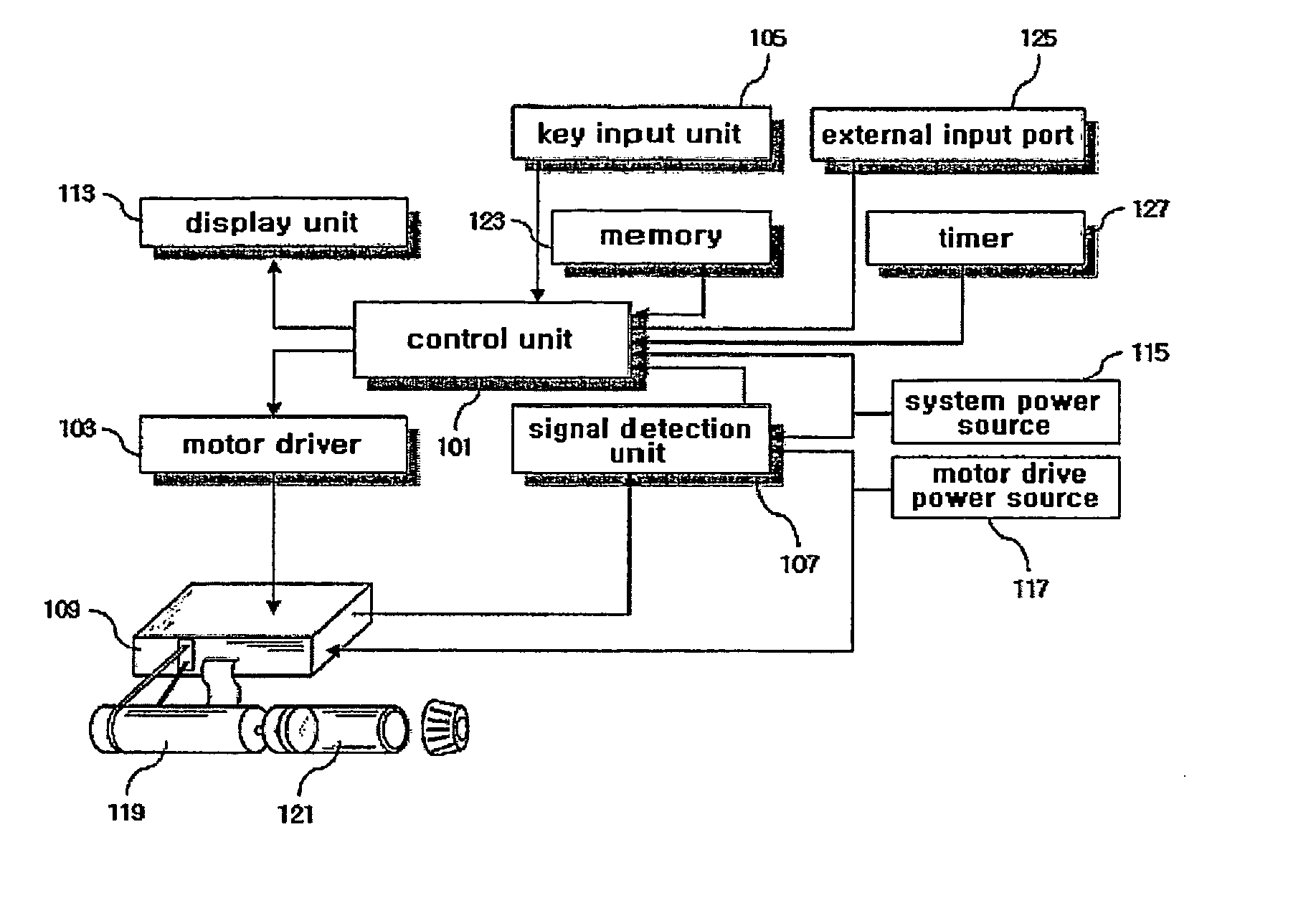

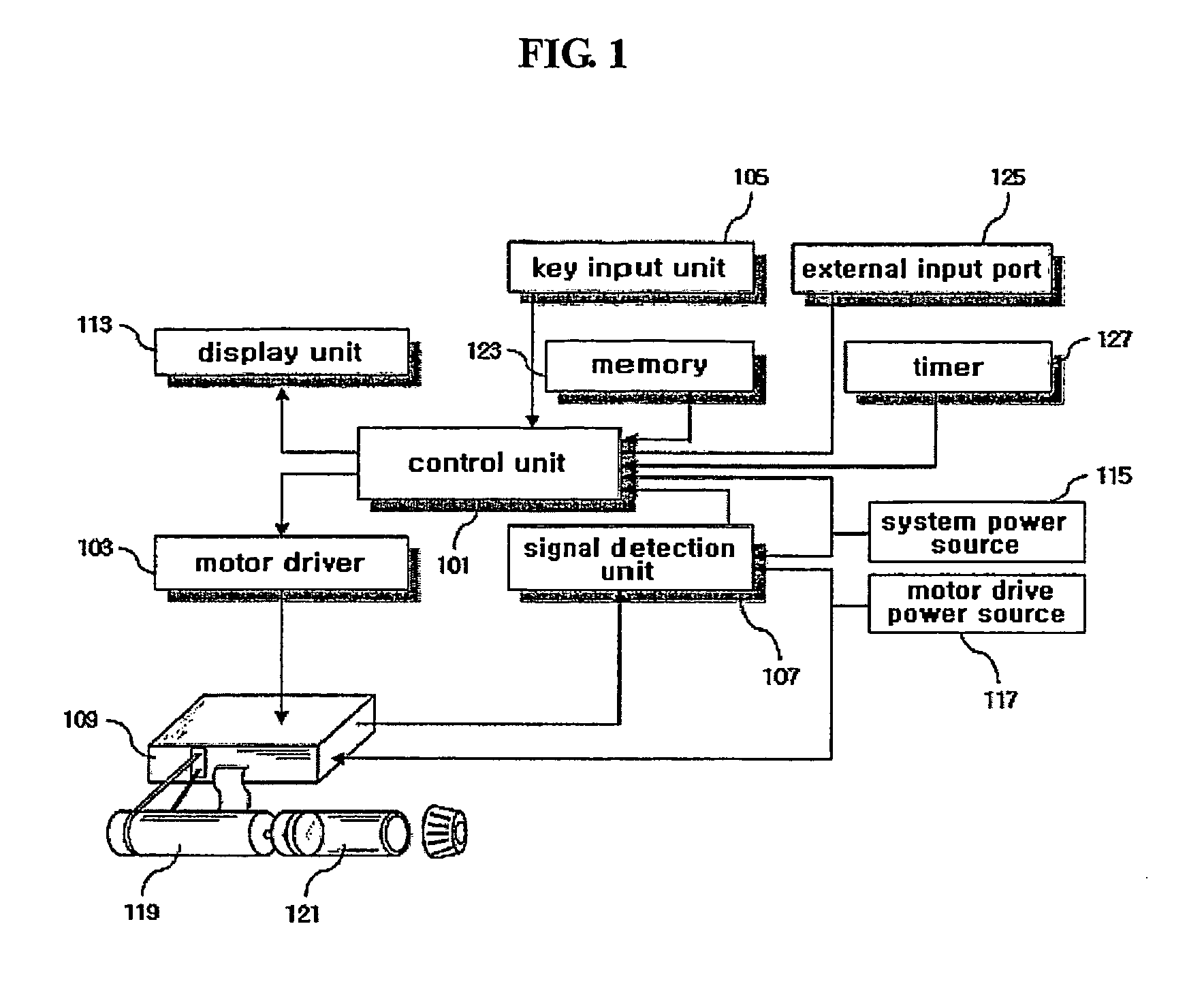

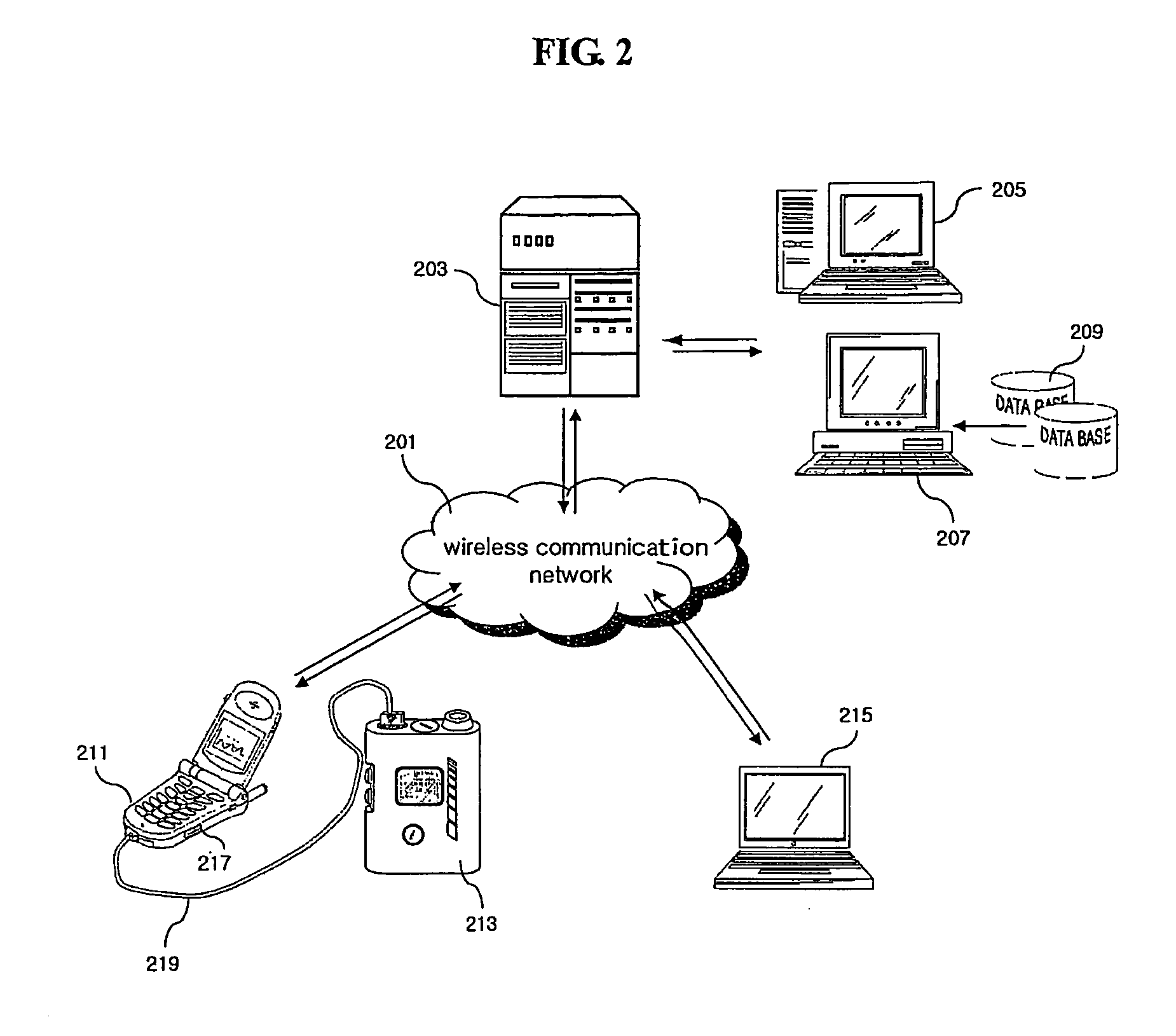

Insulin pump for use in conjunction with mobile communication terminal capable of measuring blood glucose levels and network system for transmitting control information for insulin pump

InactiveUS20070060796A1Improve ease of useAccurate supplyDrug and medicationsMedical devicesKey pressingMotor drive

An insulin pump for use in conjunction with a mobile communication terminal capable of measuring a blood glucose level, and a network for transmitting control information for the insulin pump are disclosed. The insulin pump includes an external input port, an output port, memory, a key input unit, a control unit, and a motor driver. The external input port receives information on the amounts of insulin to be injected. The output port outputs information on the amounts of insulin injected. The memory stores the information on the amounts of insulin injected. The key input unit inputs the status of a user. The control unit extracts the information on the amounts of insulin to be injected from the memory. The motor drive operates a soft motor to supply insulin.

Owner:KIM YOON NYUN

Magnetic sensor

ActiveUS20120200292A1Simple configurationLow costNanomagnetismMagnetic-field-controlled resistorsMagnetizationPerpendicular magnetic field

A magnetic sensor includes magnetoresistive elements and a soft magnetic body. The magnetoresistive elements have multi layers including a magnetic layer and a nonmagnetic layer on a substrate, and exert a magnetoresistance effect. The soft magnetic body is electrically disconnected with the magnetoresistive elements, and converts a vertical magnetic field component from the outside into a magnetic field component in a horizontal direction so as to provide the magnetoresistive elements with the horizontally converted magnetic field component. The magnetoresistive elements have a pinned magnetic layer having a fixed magnetization direction and a free magnetic layer having a variable magnetization direction. The free magnetic layer is stacked on the pinned magnetic layer with a nonmagnetic layer interposed between the free magnetic layer and the pinned magnetic layer. The magnetization directions of the pinned magnetic layers of the magnetoresistive elements are the same direction. The magnetoresistive elements form a bridge circuit.

Owner:ALPS ALPINE CO LTD

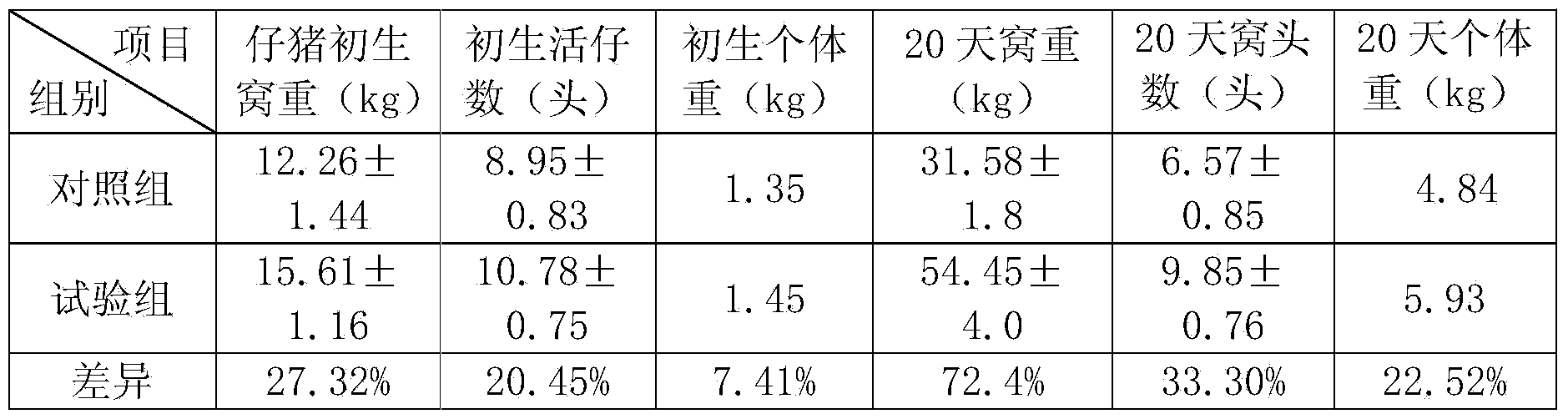

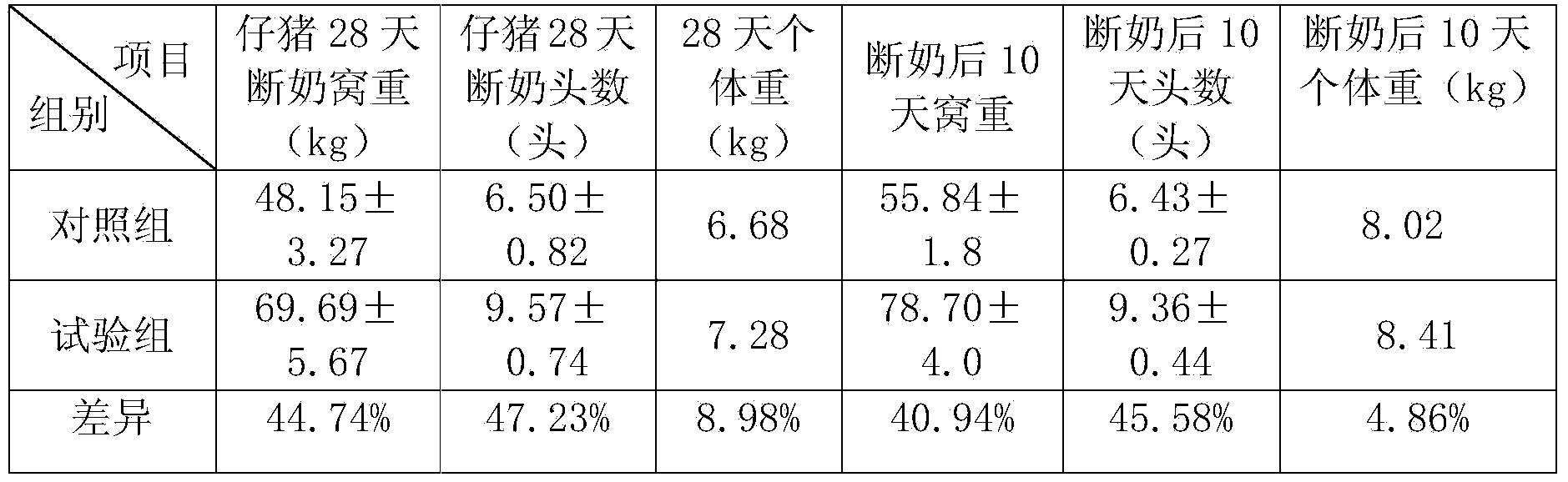

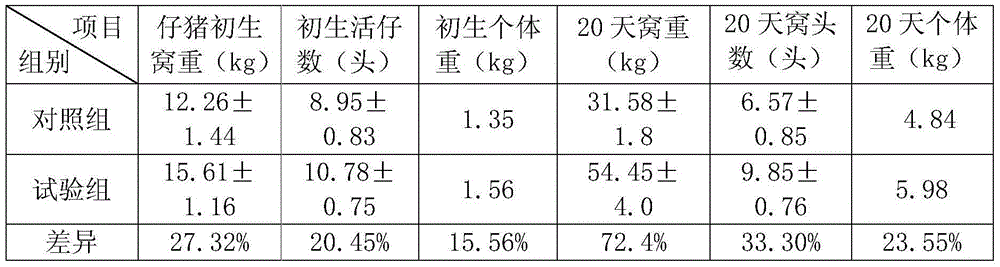

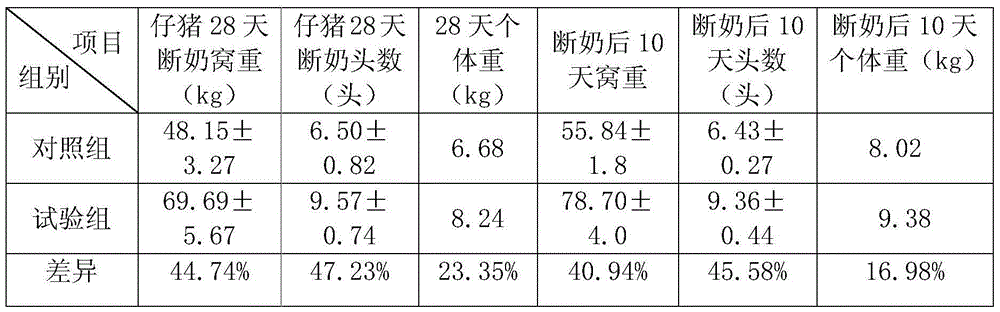

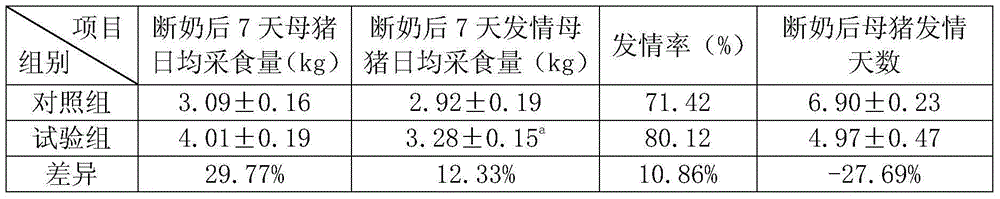

Pregnant sow feeding mode

ActiveCN103960548AIncrease exercisePromote absorptionFood processingAnimal feeding stuffPregnancy second trimesterMortality rate

The invention discloses a pregnant sow feeding mode and belongs to the technical field of sow breeding. Aiming at physiological characteristics and nutritional requirements of sows during gestation period, the physiological stage of pregnant sows is further subdivided, the nutritional requirements of the pregnant sows at each stage per day are specified, and the body conditions, feeding environments and the like of different pregnant sows are combined. Meanwhile, aiming at the physiological characteristics and feeding modes of the pregnant sows at each stage, pregnancy beginning feed, pregnancy first-half-period feed, pregnancy second trimester feed, pregnancy latter half feed and perinatal feed are scientifically compounded. A reasonable, detailed and scientific feeding mode is formulated, the motion quantity of the pregnant sows can be effectively improved, the nutrient substances are accurately and timely supplied, the functions of the digestion and absorption system and immune system of the pregnant sows are promoted and improved, the number of living piglets is obviously increased, the embryo mortality is reduced, and the birth weight and uniformity of piglets are improved.

Owner:LIAONING WELLHOPE AGRI TECH

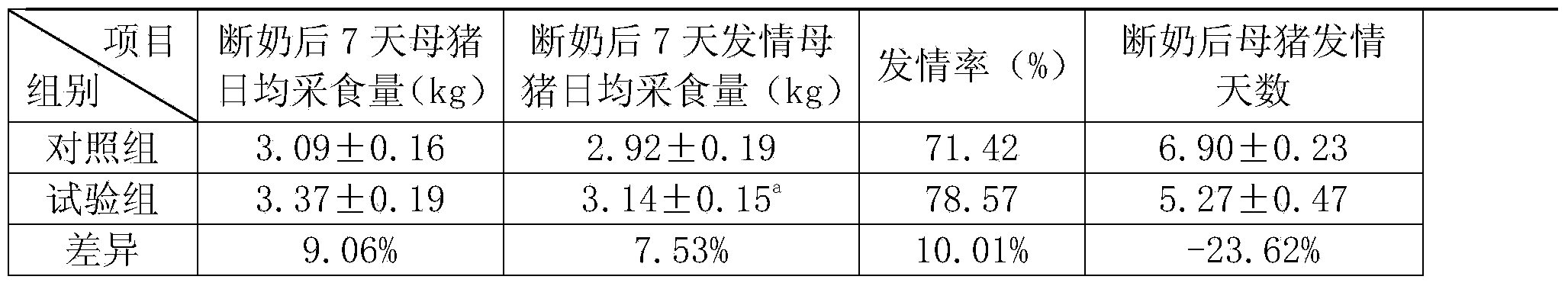

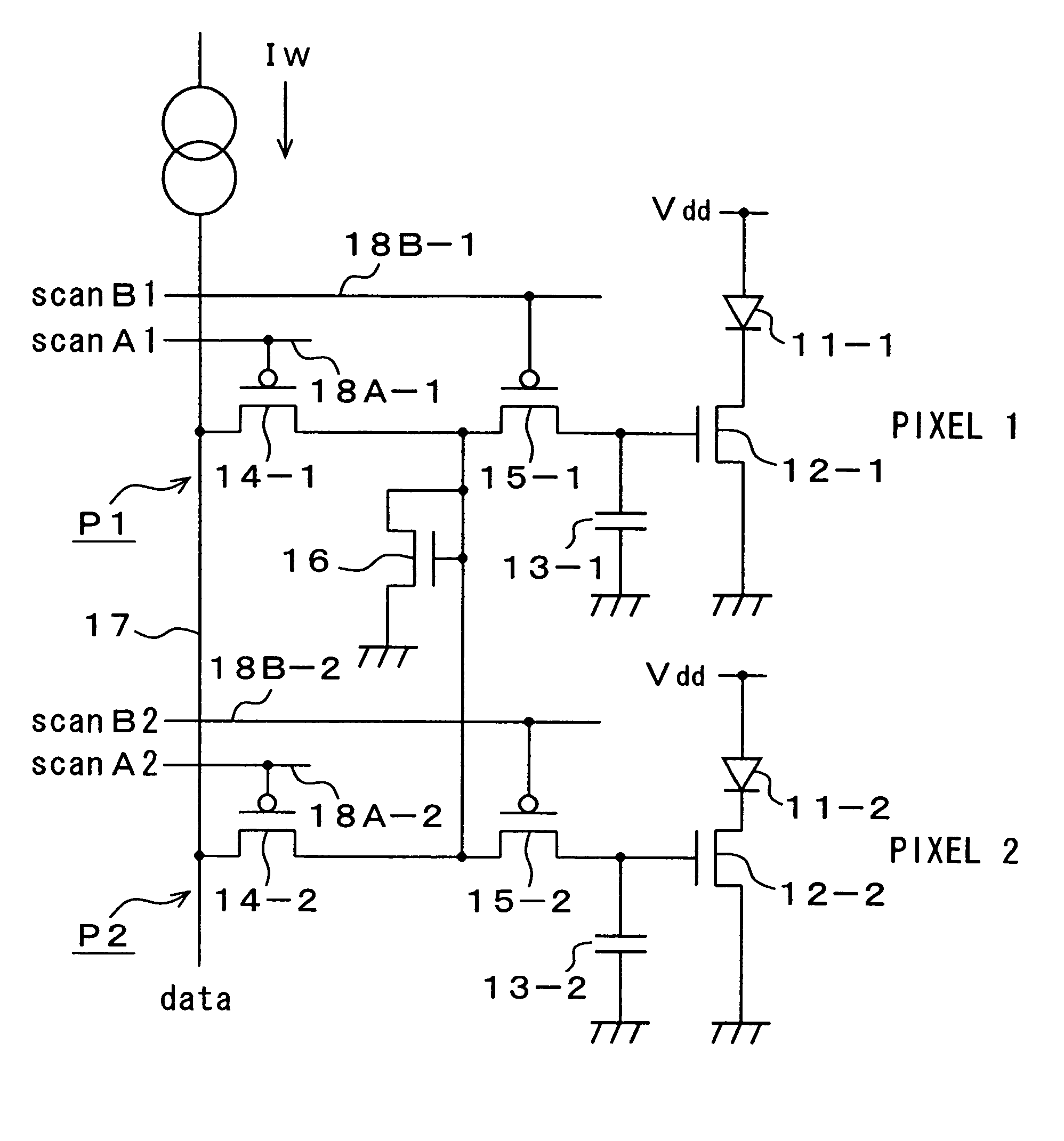

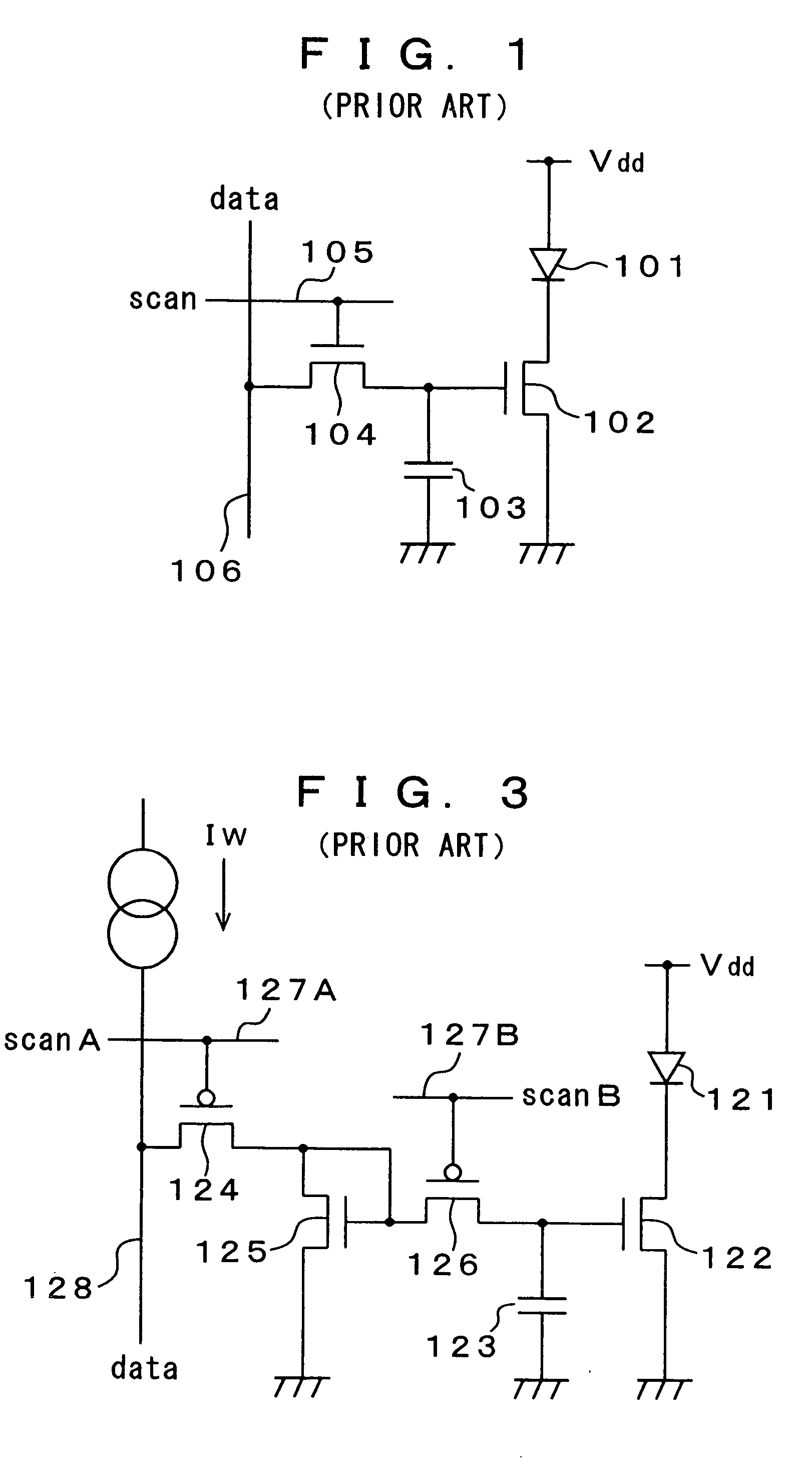

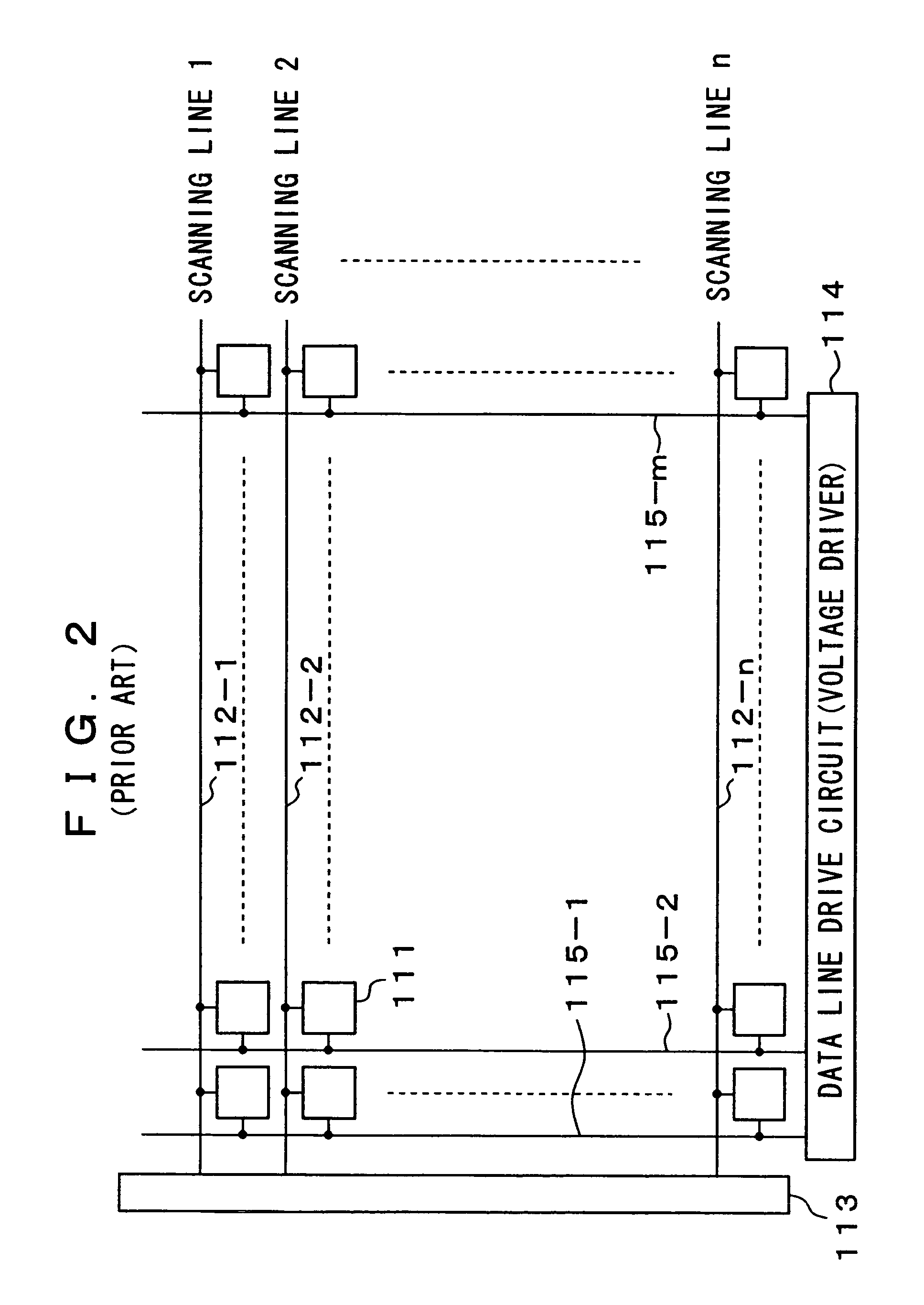

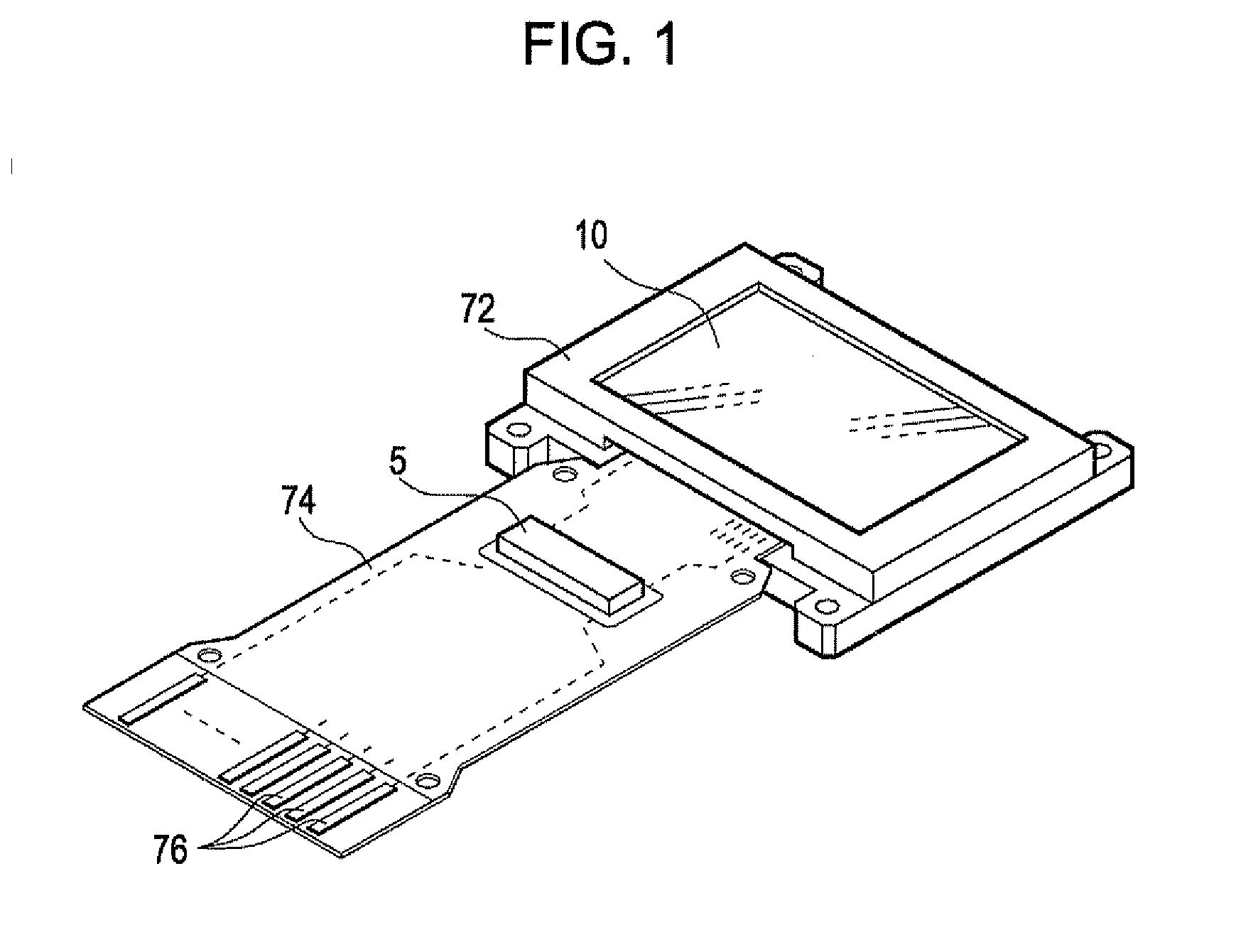

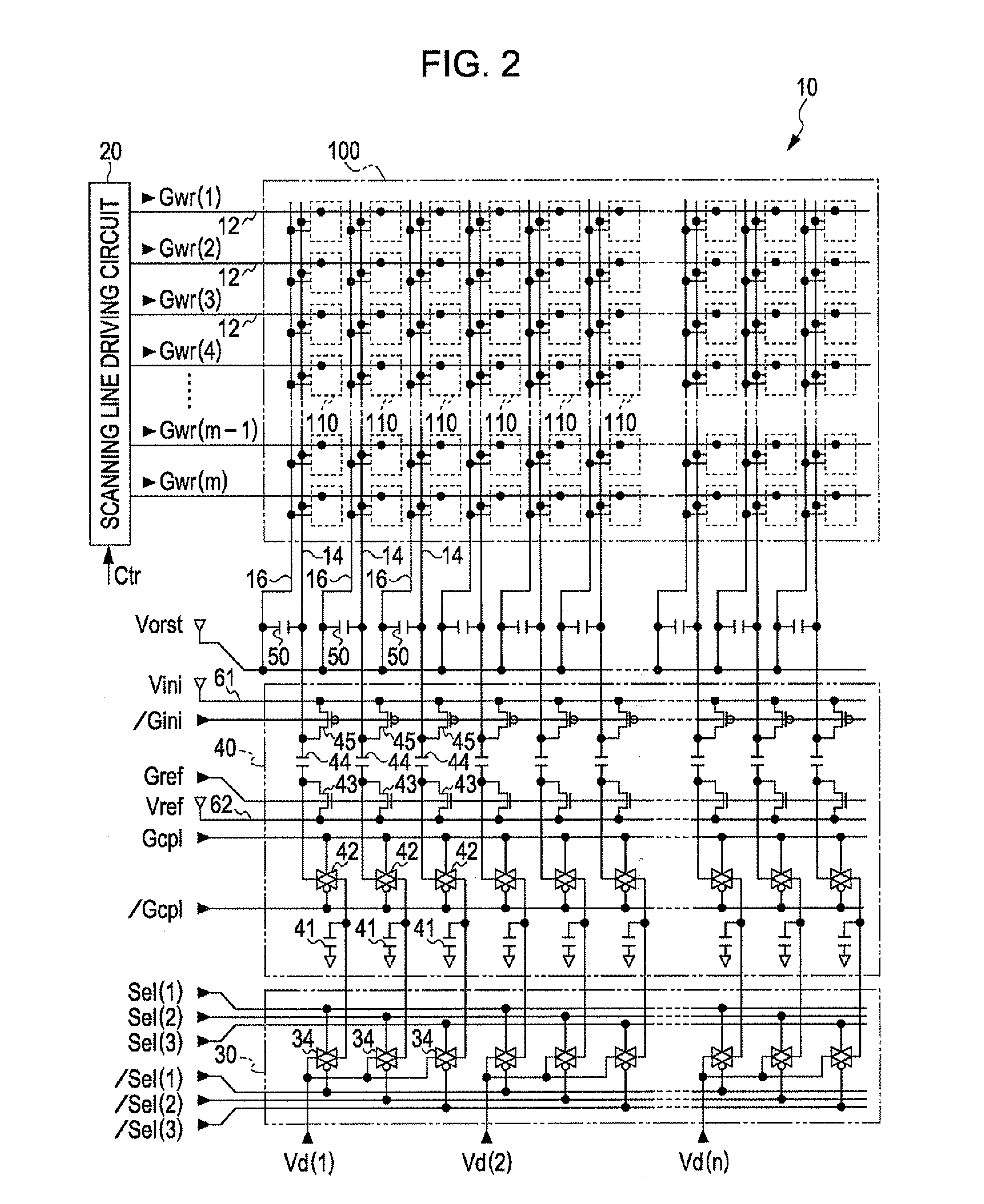

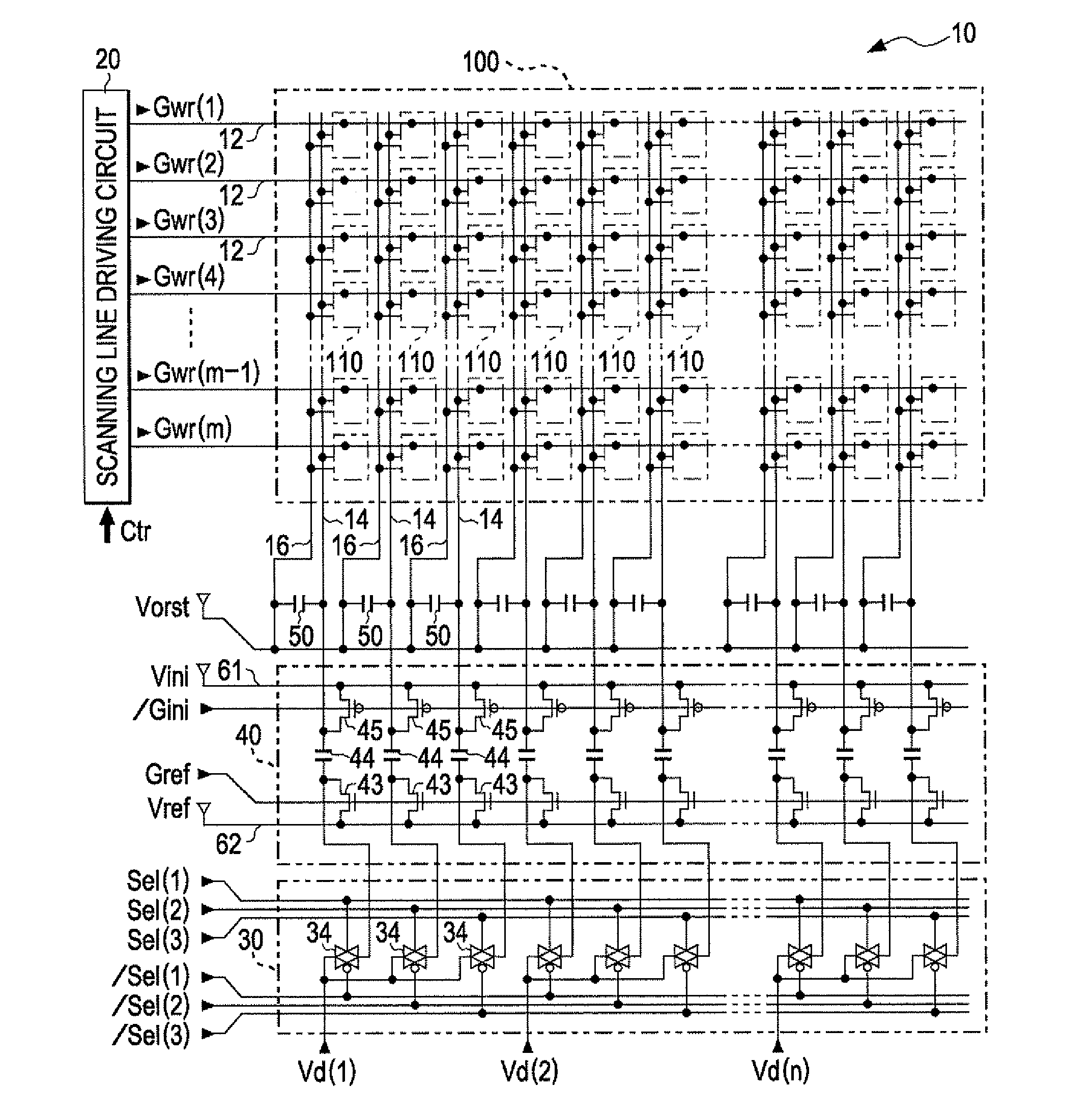

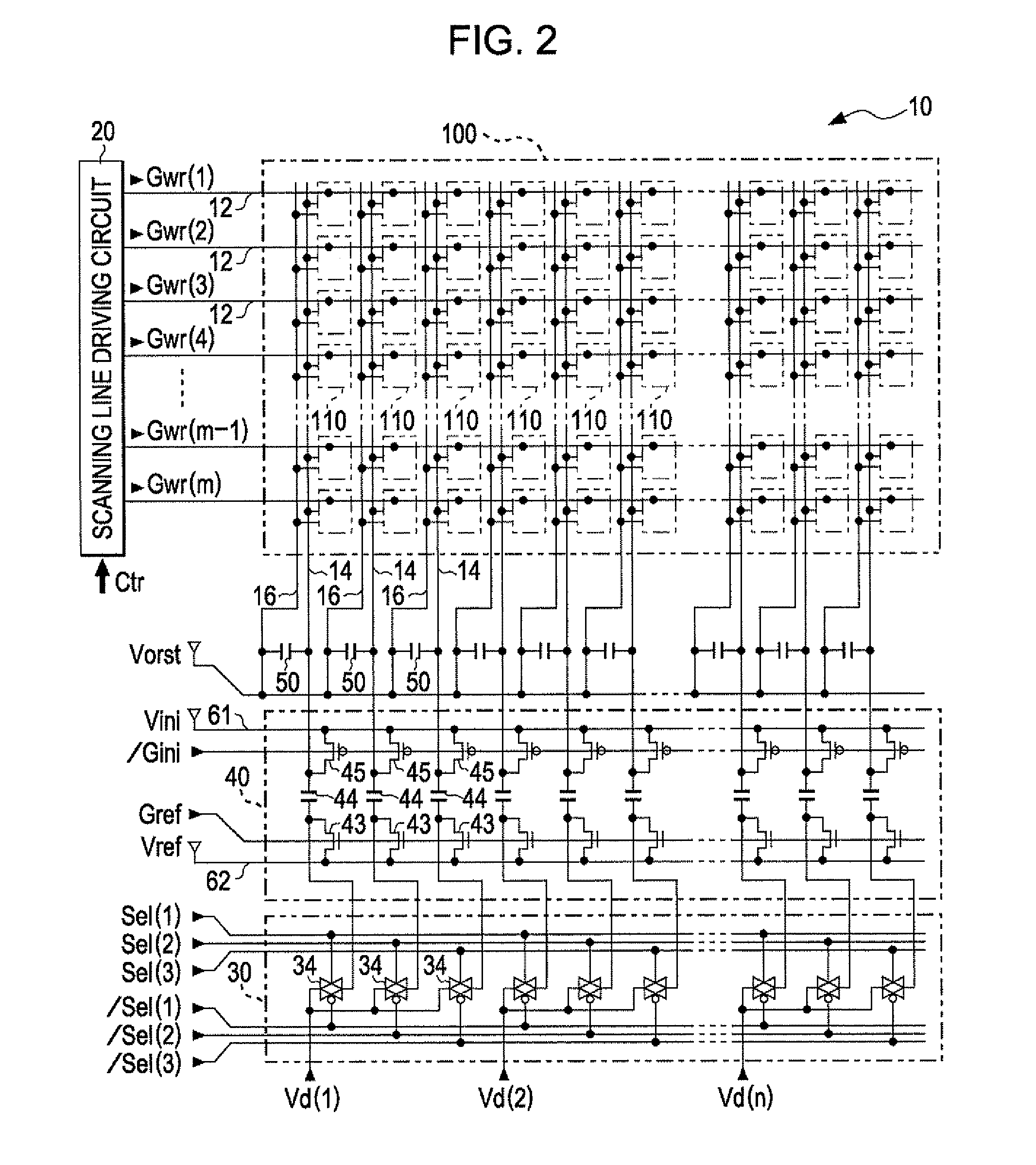

Active matrix type display device, active matrix type organic electroluminescent display device, and methods of driving such display devices

InactiveUS7612745B2Increase the areaReduce areaStatic indicating devicesElectroluminescent light sourcesActive matrixCurrent voltage

When a current-writing type pixel circuit is made, it involves a greater number of transistors and TFTs occupy much of the area of the pixel circuit. To alleviate this problem, two pixel circuits (P1, P2) have a first scanning TFT (14), a current-voltage conversion TFT (16), respective second scanning TFTs (15-1, 15-2), capacitors (13-1, 13-2), and drive TFTs (12-1, 12-2) for OLED including organic EL elements (11-2, 11-2) of two pixels, for example, in a row direction. In each of the pixel circuits, the first scanning TFT (14) handling a large amount of current (Iw) as compare with current flowing through the OLED (11-2, 11-2), and the current-voltage conversion TFT (16) are shared between two pixels.

Owner:SONY CORP

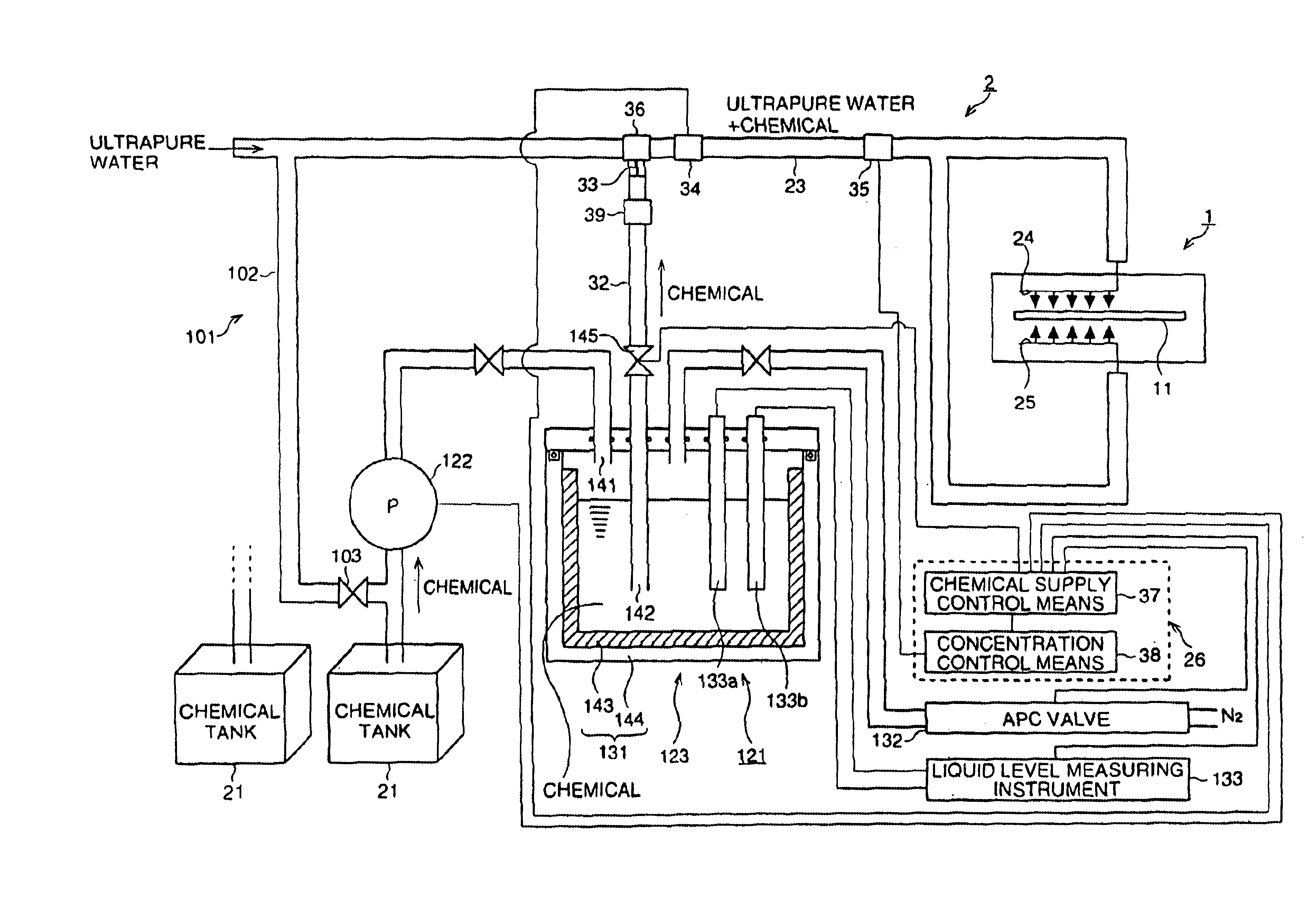

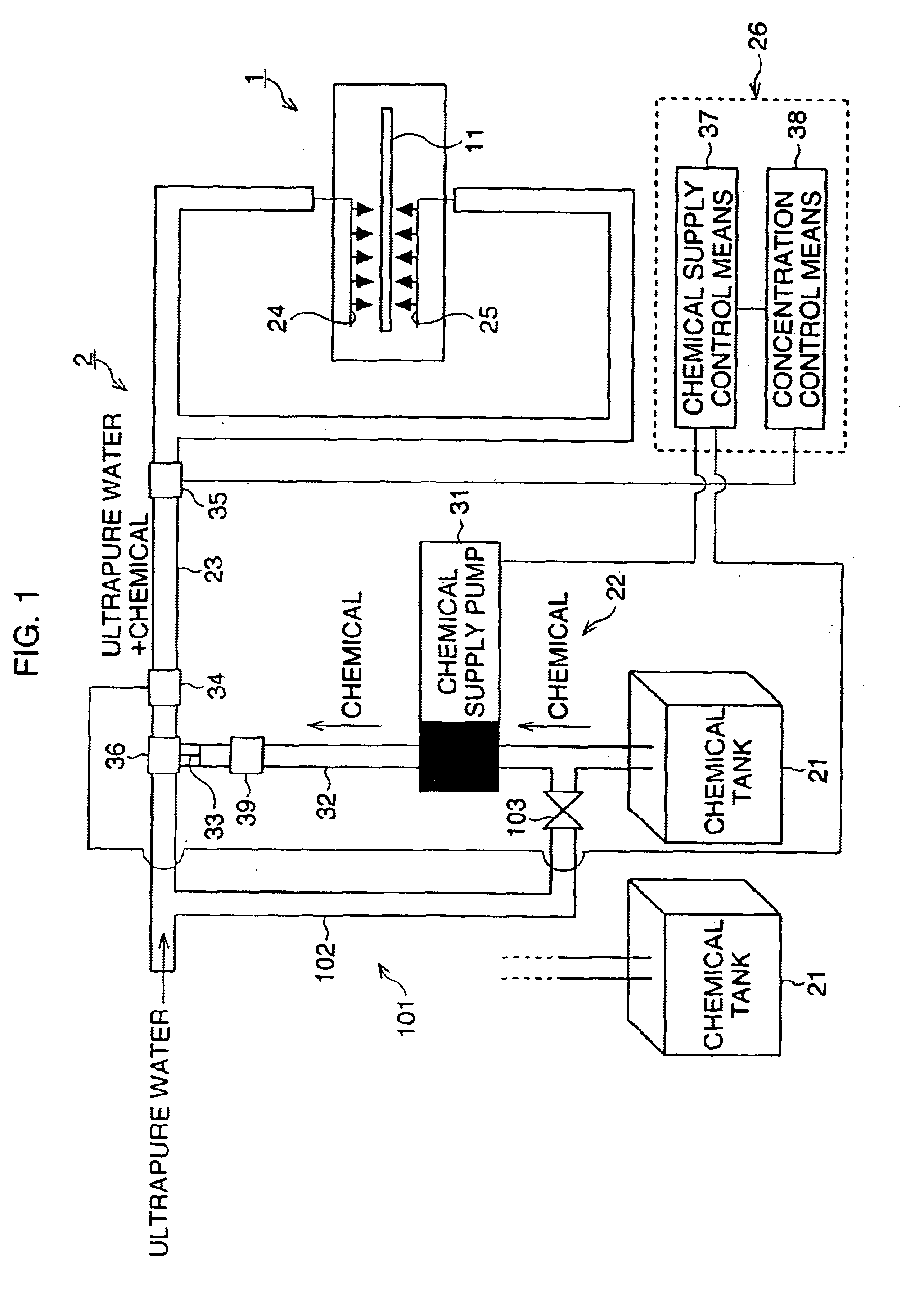

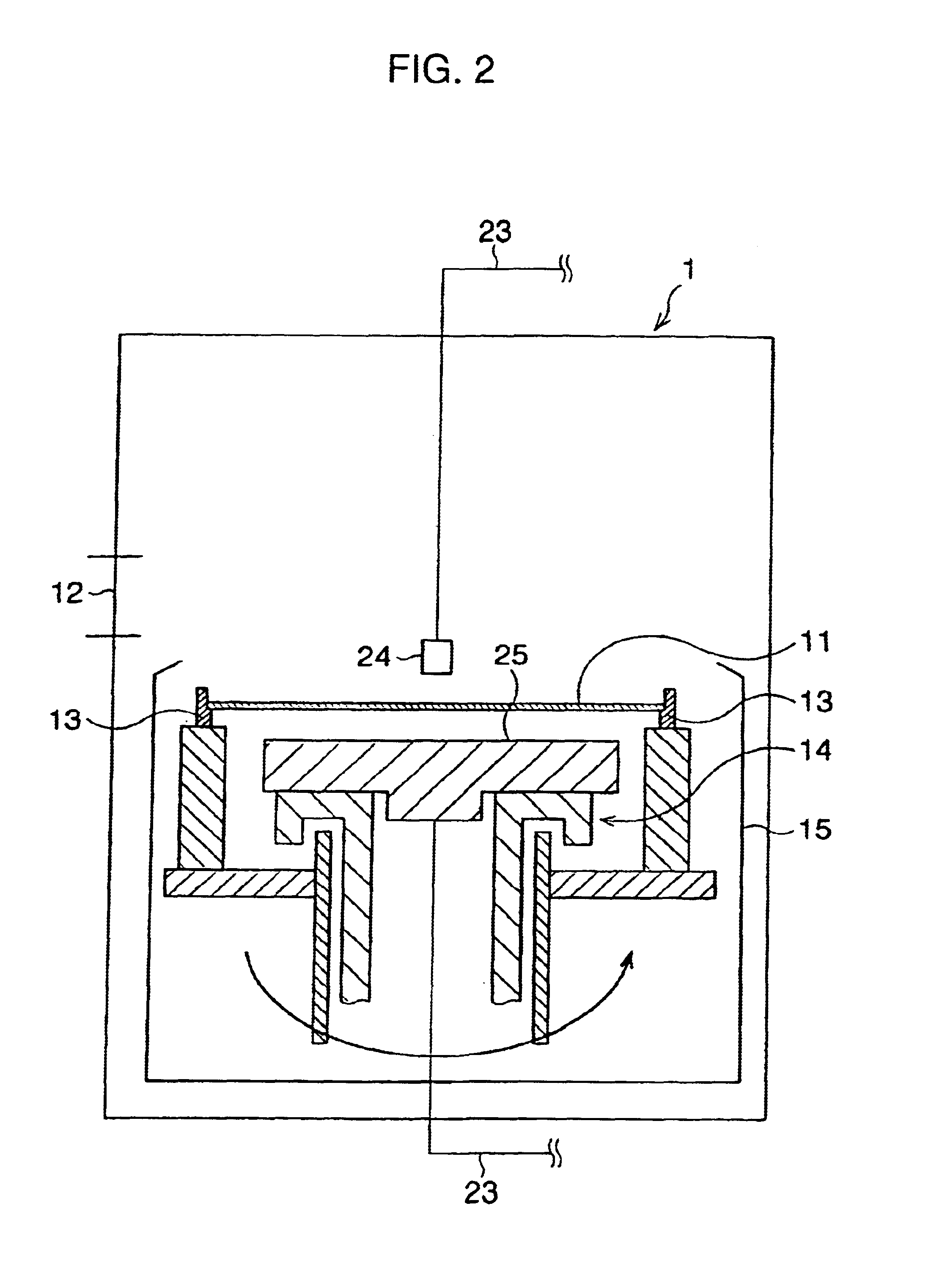

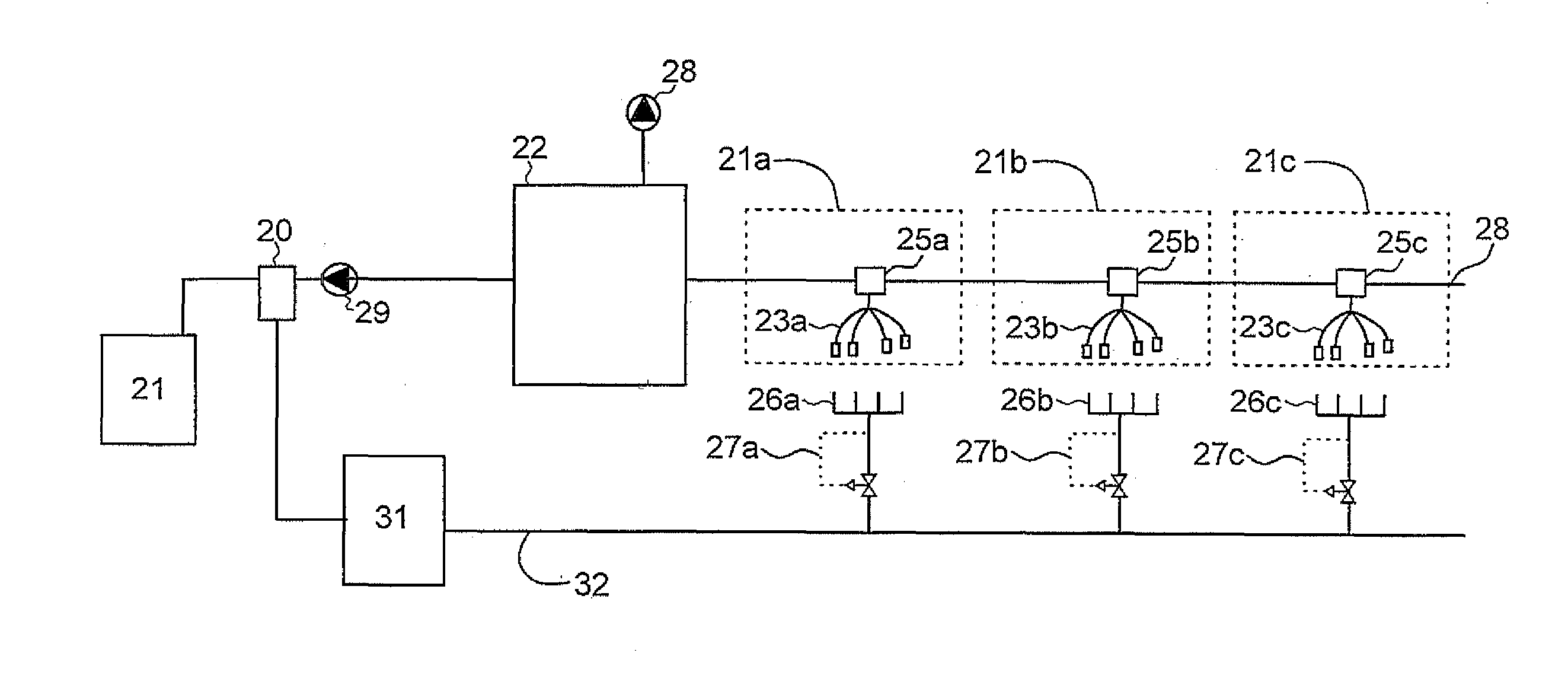

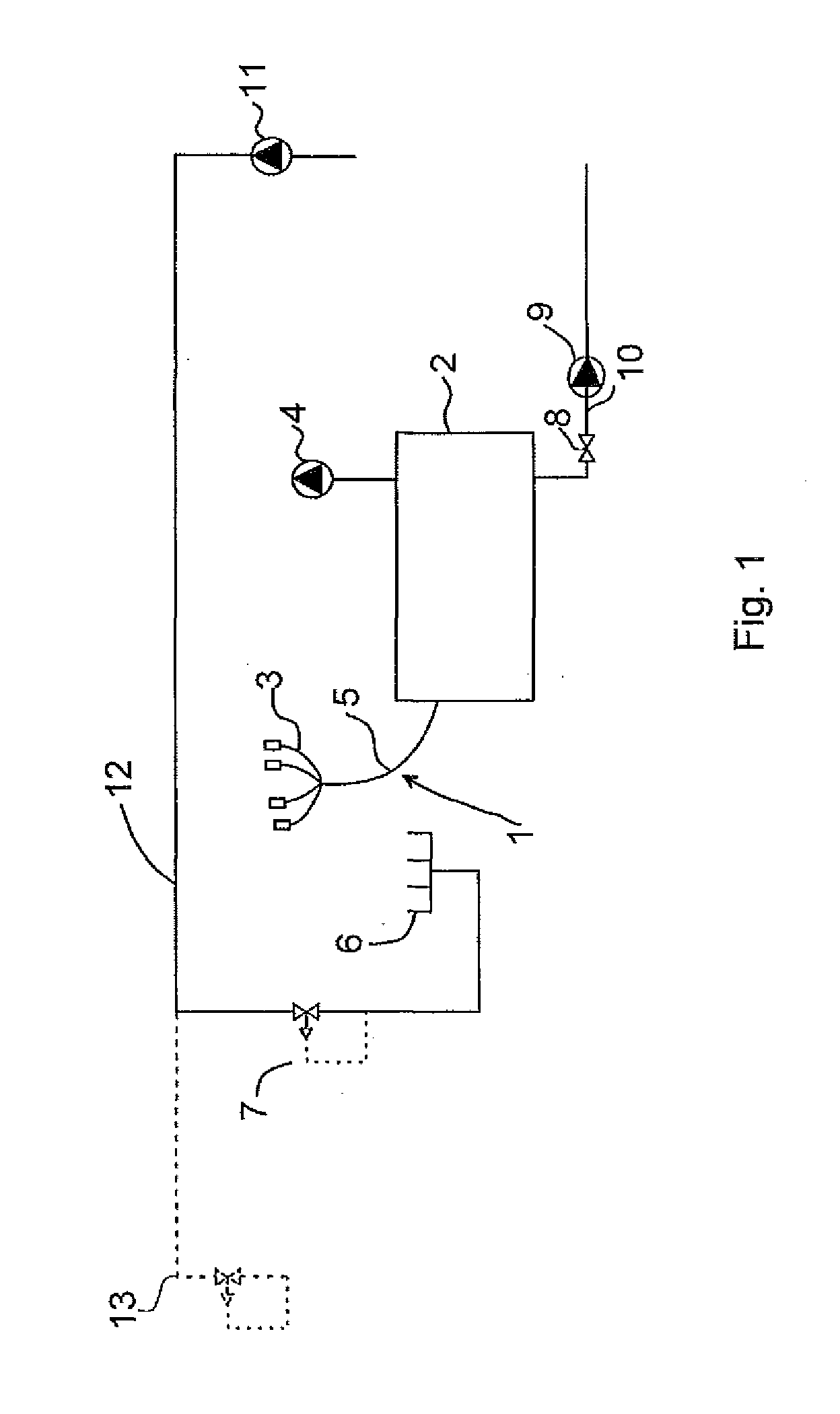

Chemical supply system

InactiveUS6764212B1Improve anti-corrosion performanceEasy to control its porosityDiaphragm valvesShaking/oscillating/vibrating mixersChemical storageMiniaturization

A chemical supply system comprises, as principal elements, a chemical storage tank in which a liquid chemical for cleaning is stored in the state of its formulated concentrate, a chemical supply apparatus connected to the chemical storage tank for positively performing chemical supply, a piping system connected to the chemical supply apparatus to form a supply flow passage that is a passage for ultrapure water which the liquid chemical is to be mixed with, a pair of discharge nozzles disposed at end portions of the piping system so as to oppose surfaces of a wafer set in a cleaning chamber to supply a cleaning liquid onto the surfaces. Thereby, remarkable miniaturization / simplification of a cleaning liquid supply system including chemical tanks is intended, it is made possible easily and rapidly to compound and supply a cleaning liquid at an accurate chemical concentration, and particles or the like being generated and mixing in a cleaning liquid, are suppressed to the extremity.

Owner:ULTRACLEAN TECH RES INST

Pig feed and application thereof

ActiveCN103976190AIncrease exerciseEnhance immune system functionFood processingAnimal feeding stuffMortality rateEmbryo

The invention discloses a pig feed and application thereof, belonging to the technical field of sow feeding. Physiological stages of a pregnant sow are further subdivided and detailed according to physiological characteristics and nutritional requirements of the sow during a pregnancy period, the feed suitable for each stage is provided according to the nutritional requirements of the pregnant sow at each stage each day, and a reasonable and detailed feeding method is designed by combination with body conditions, feeding environments and the like of different pregnant sows, so that the exercise of the pregnant sow can be effectively increased, nutritional substances can be accurately and timely fed, the functions of a digestive absorption system and an immunity system of the pregnant sow can be promoted and improved, the number of living piglets is remarkably increased, the embryo mortality is reduced, the birth weight of the piglets is increased, and the uniformity of the piglets is improved.

Owner:山西南山百世食安农牧业有限公司

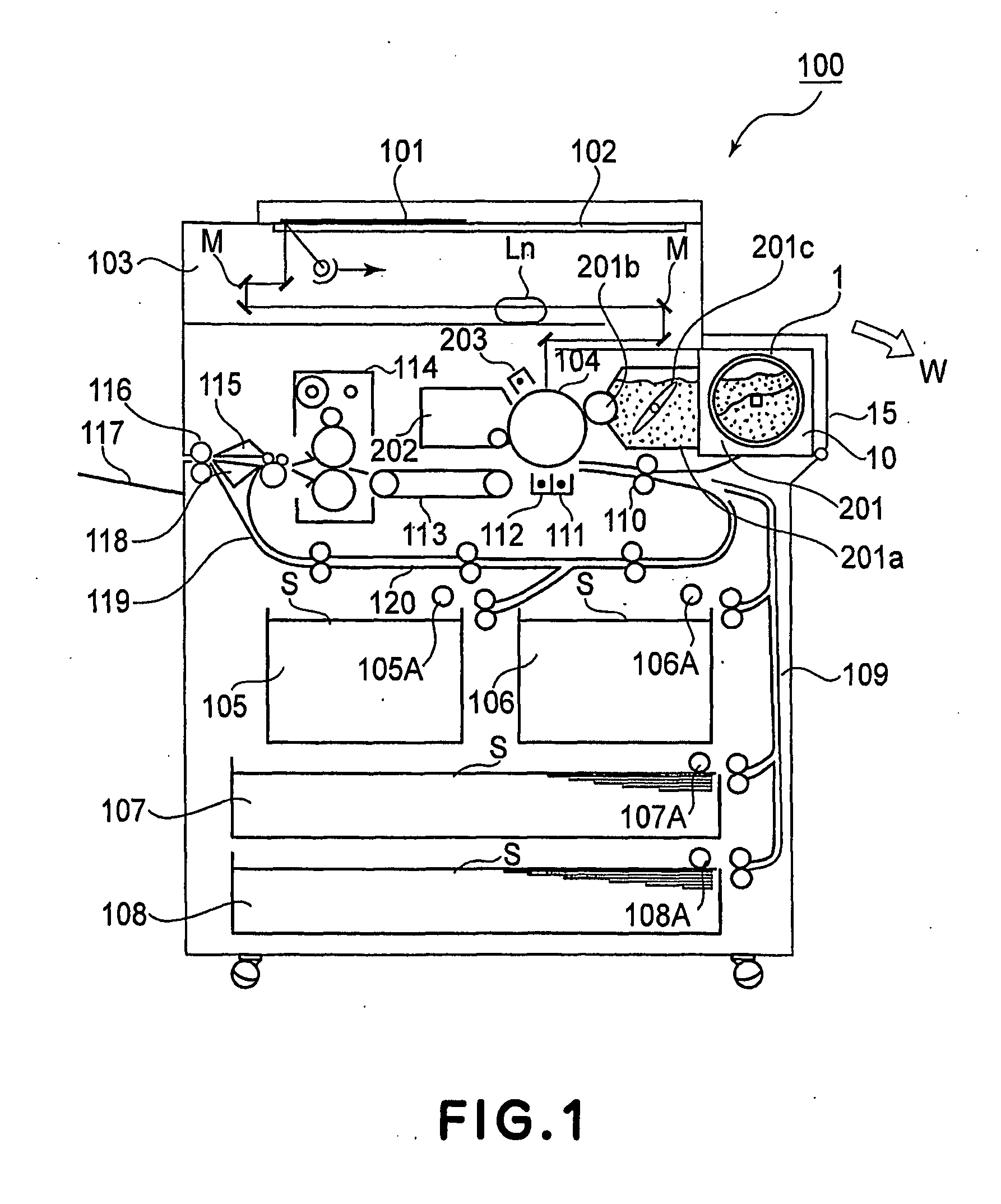

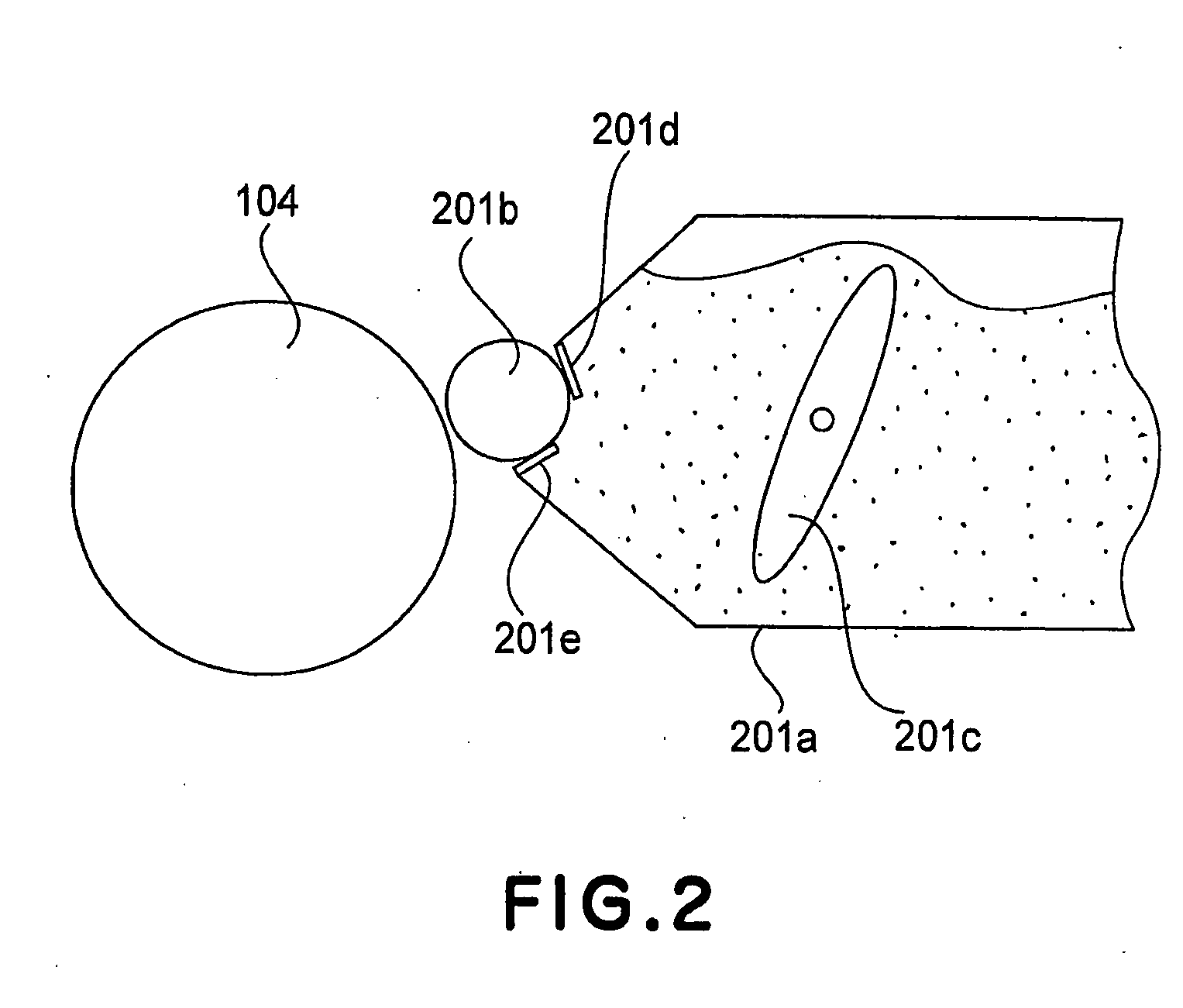

Developer supply container and developer receiving apparatus

ActiveUS20090297226A1Deterioration of a drive transmission member can be suppressedAccurate supplyElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

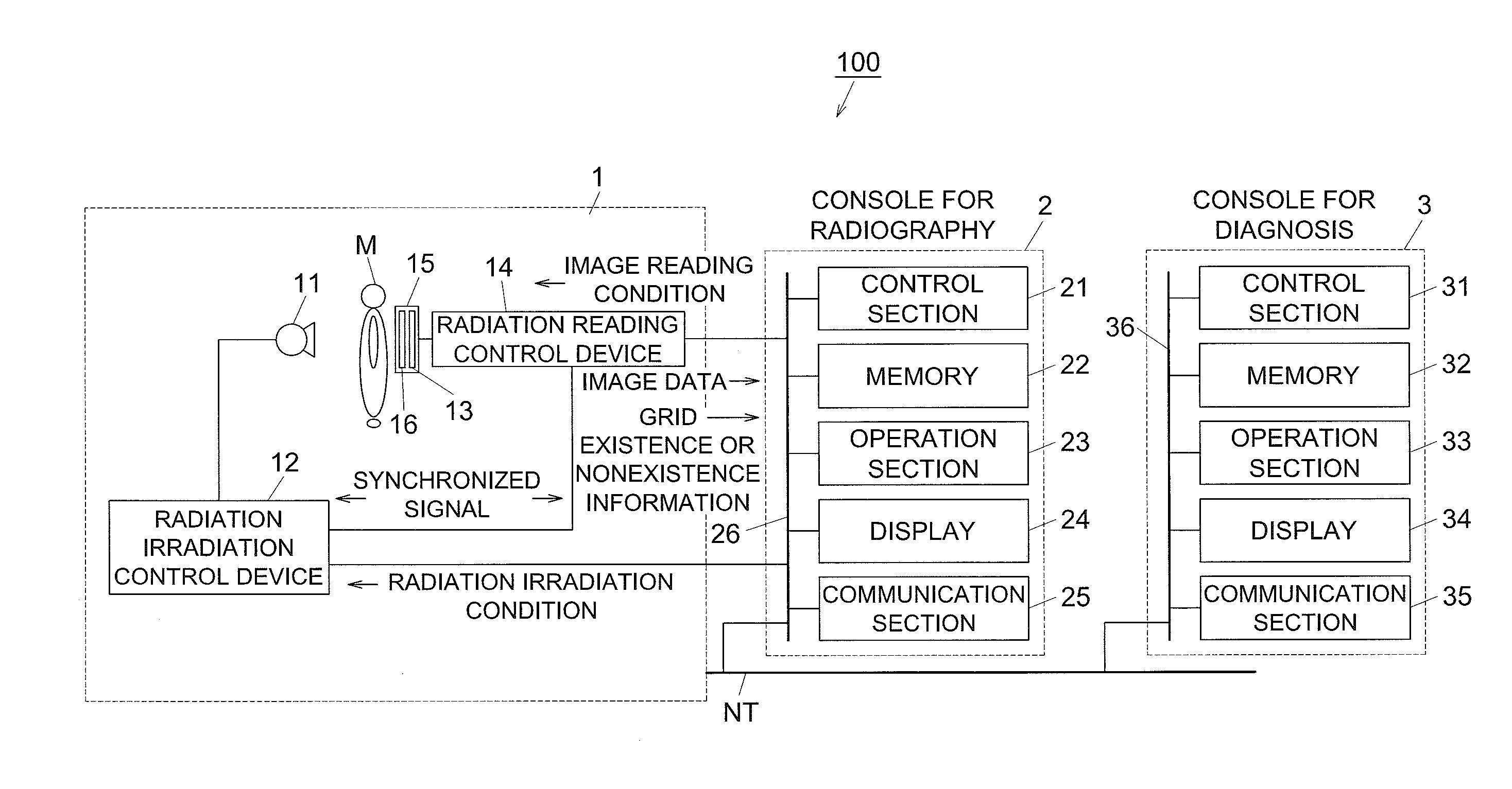

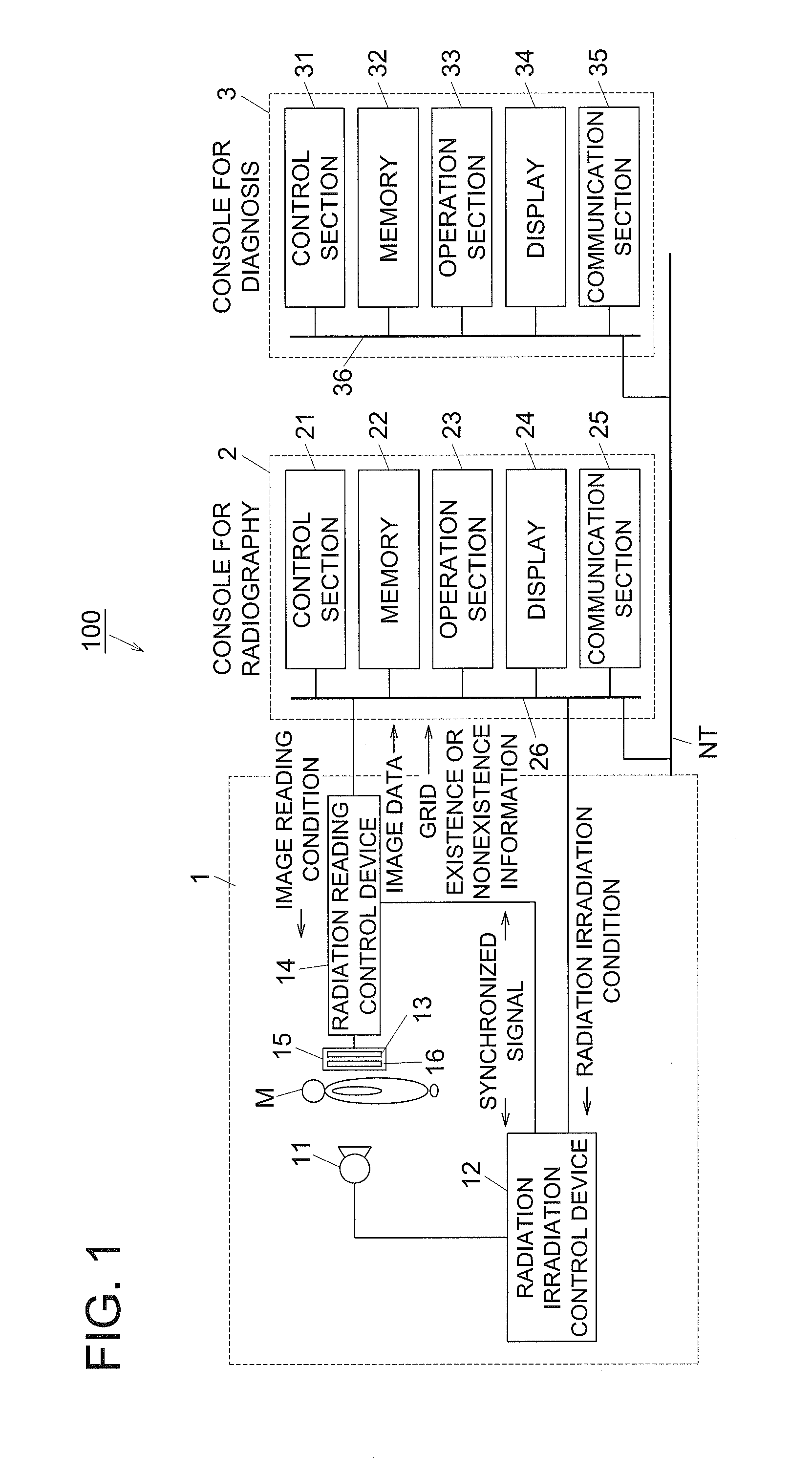

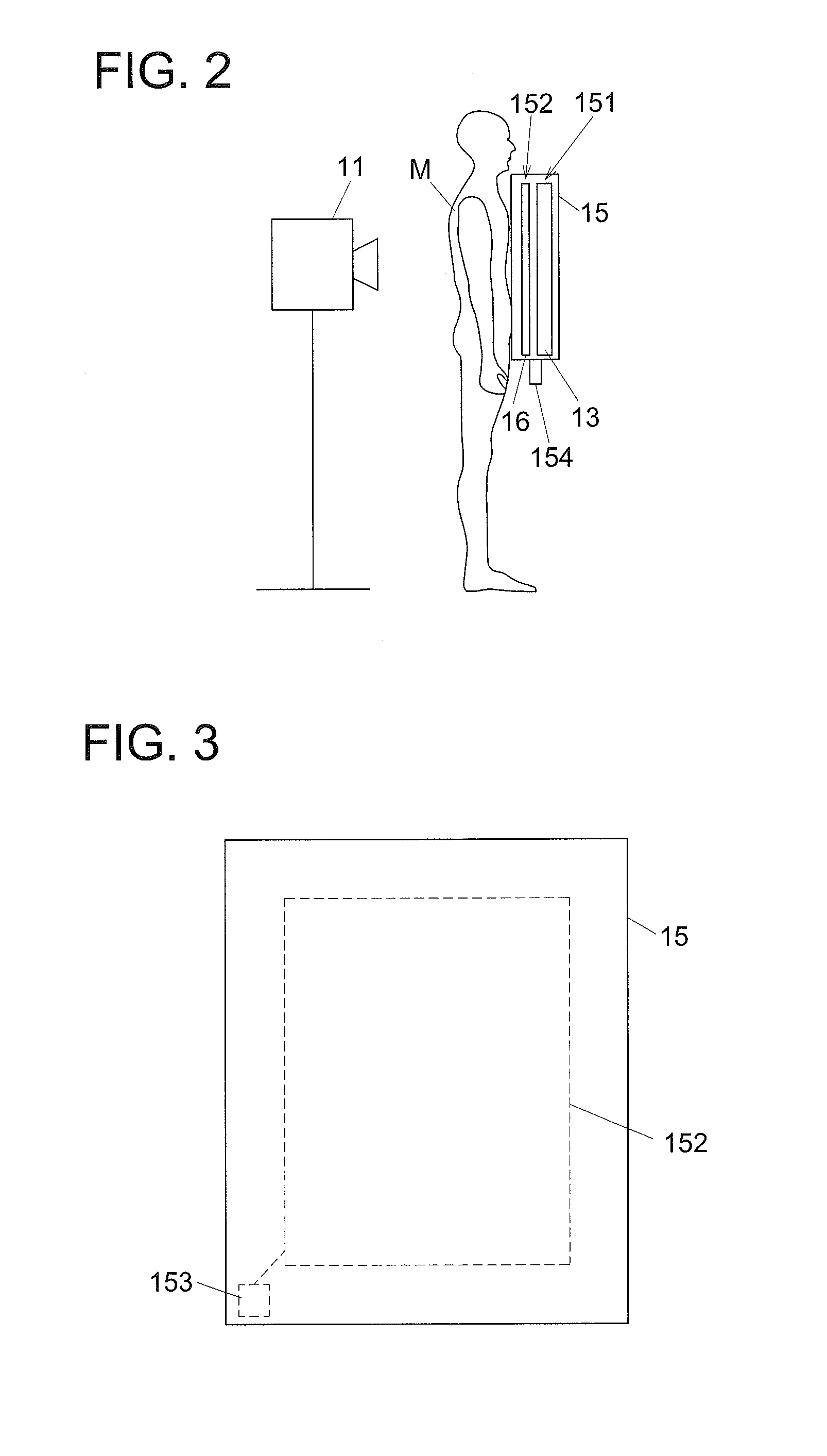

Chest diagnostic support information generation system

A chest diagnostic support information generation system includes: a radiography section which radiographs a chest portion of a subject; an image analysis section which generates a diagnostic support information based on an image data generated by the radiography section; and a display which displays the diagnostic support information, wherein the radiography section obtains a plurality of frame images which show a motion state of the chest of the subject, and the image analysis section includes: a breathing information generation section which generates the diagnostic support information relating to breathing of the subject based on a difference value of the pixel or the block corresponded with each other between image frames temporally adjacent among the plurality of frame images; and a blood flow information generation section which generates the diagnostic support information relating to blood flow of the subject based on a generated output signal wave form.

Owner:KONICA MINOLTA INC

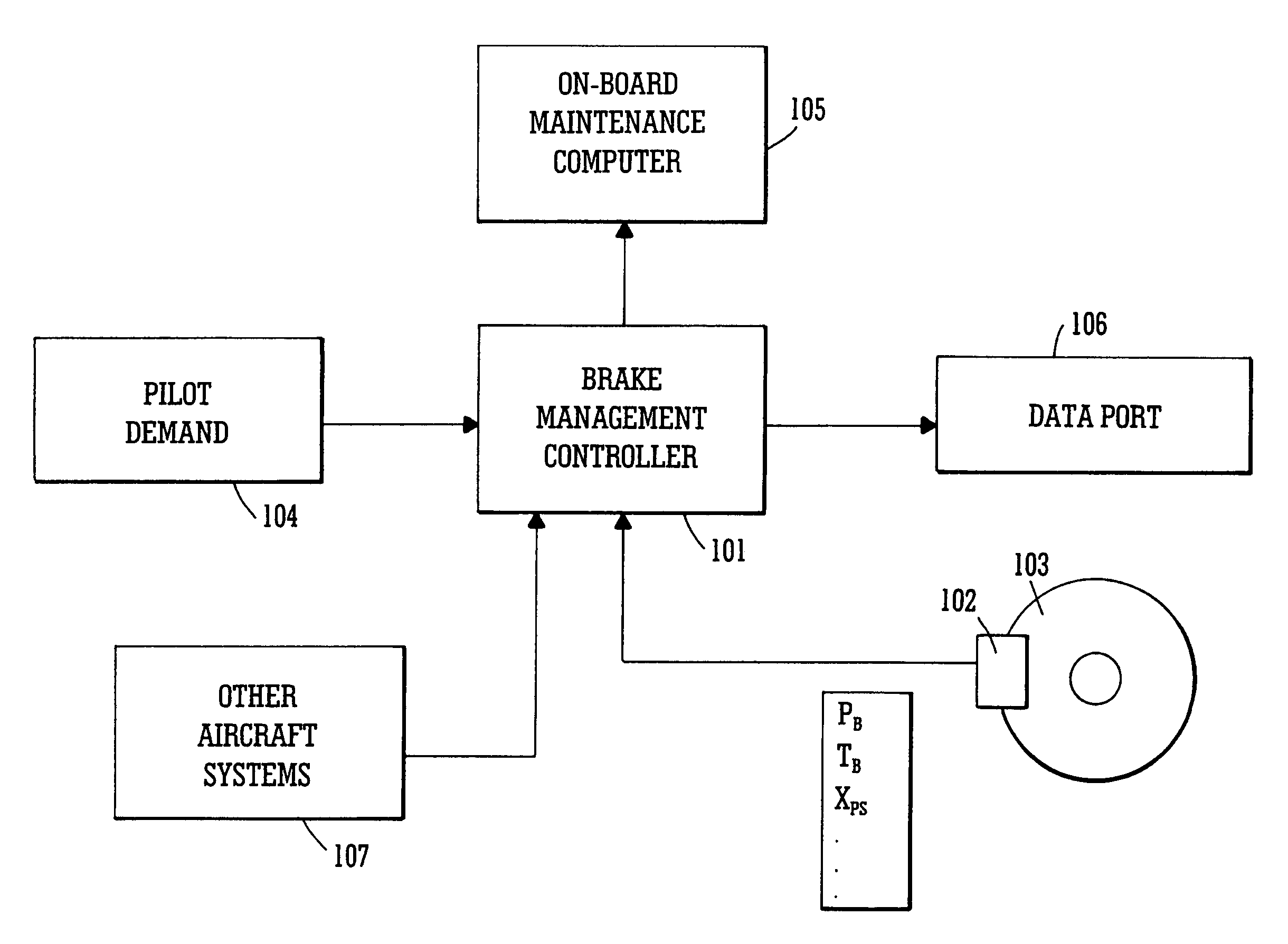

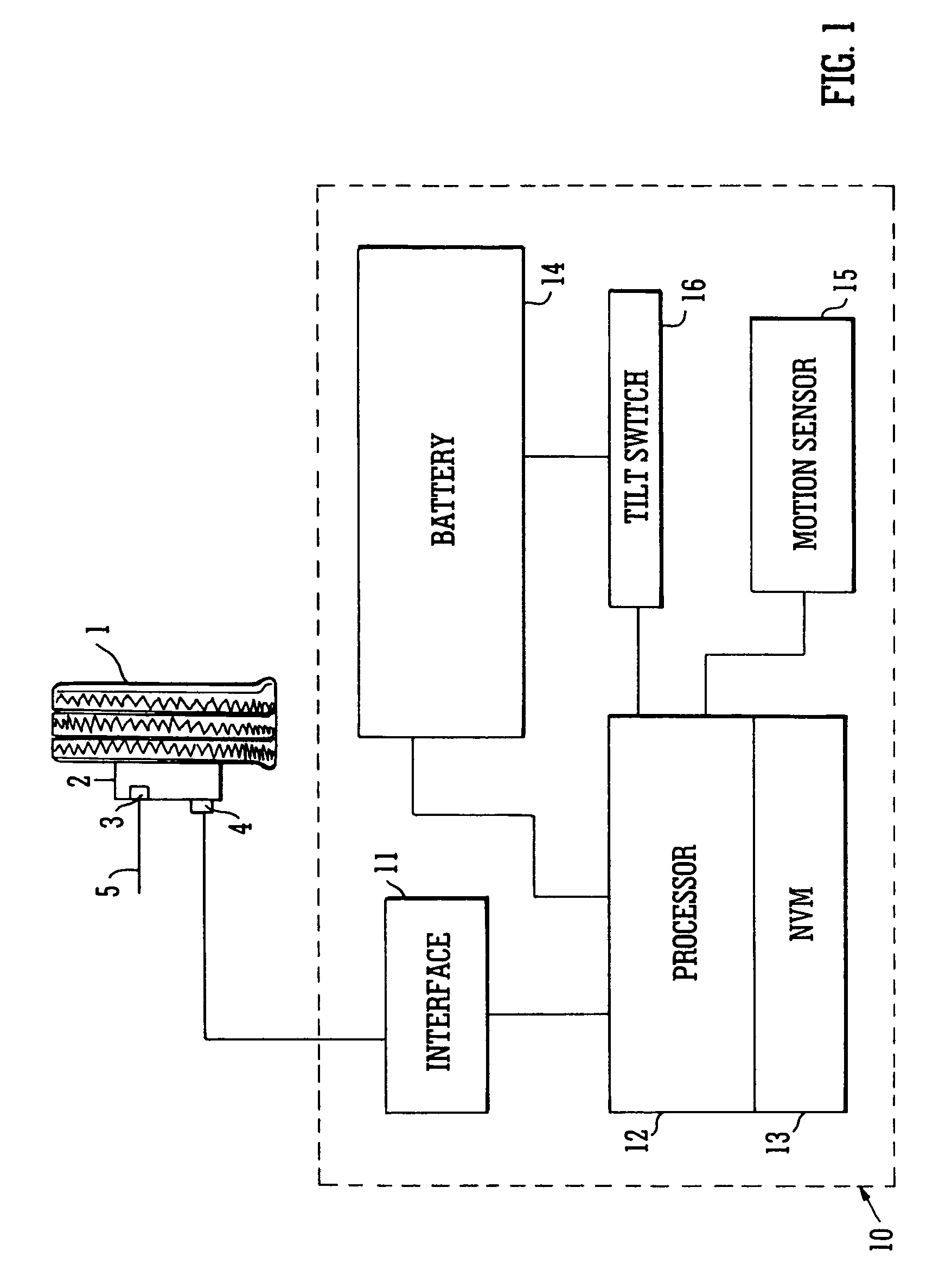

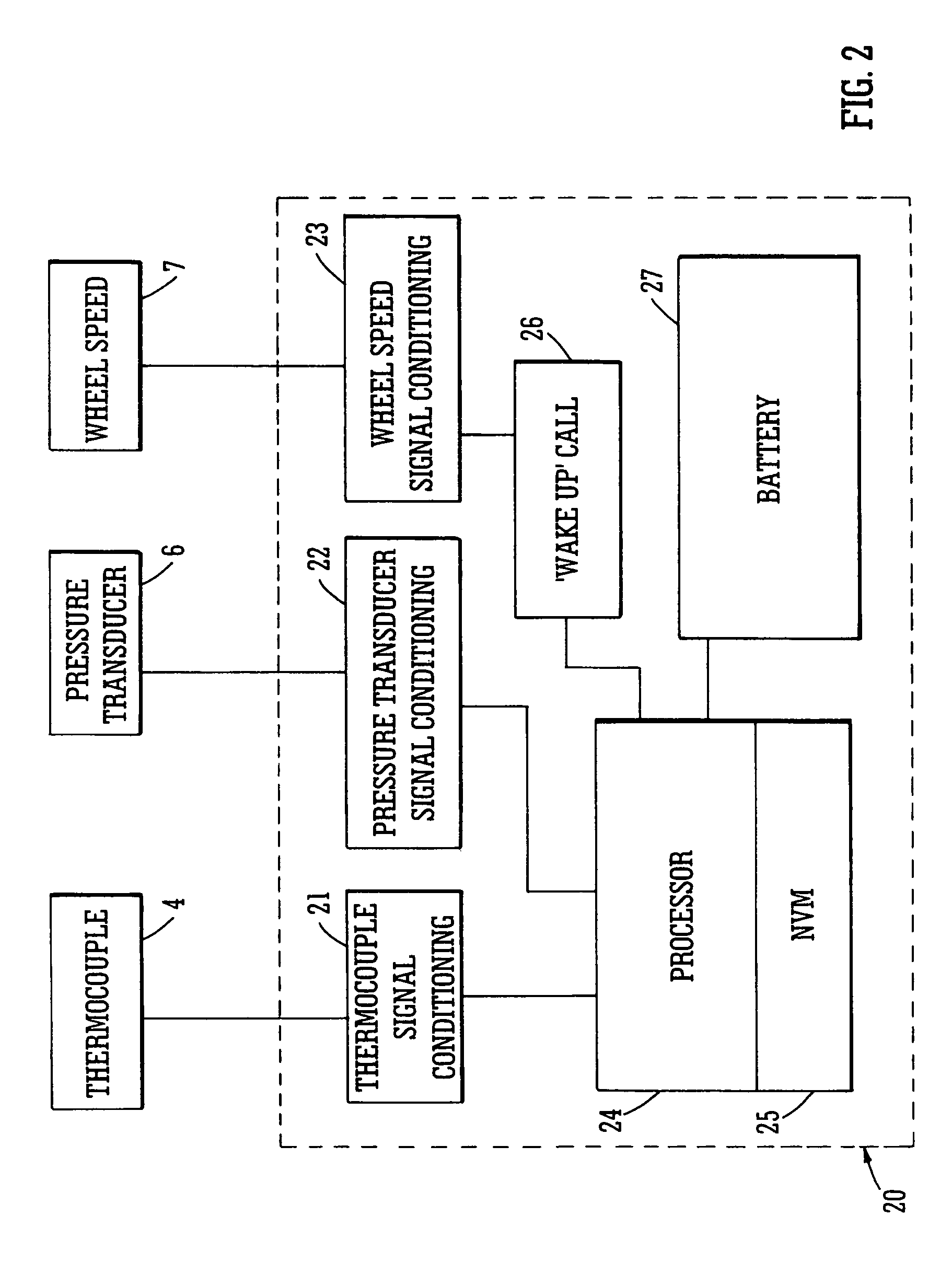

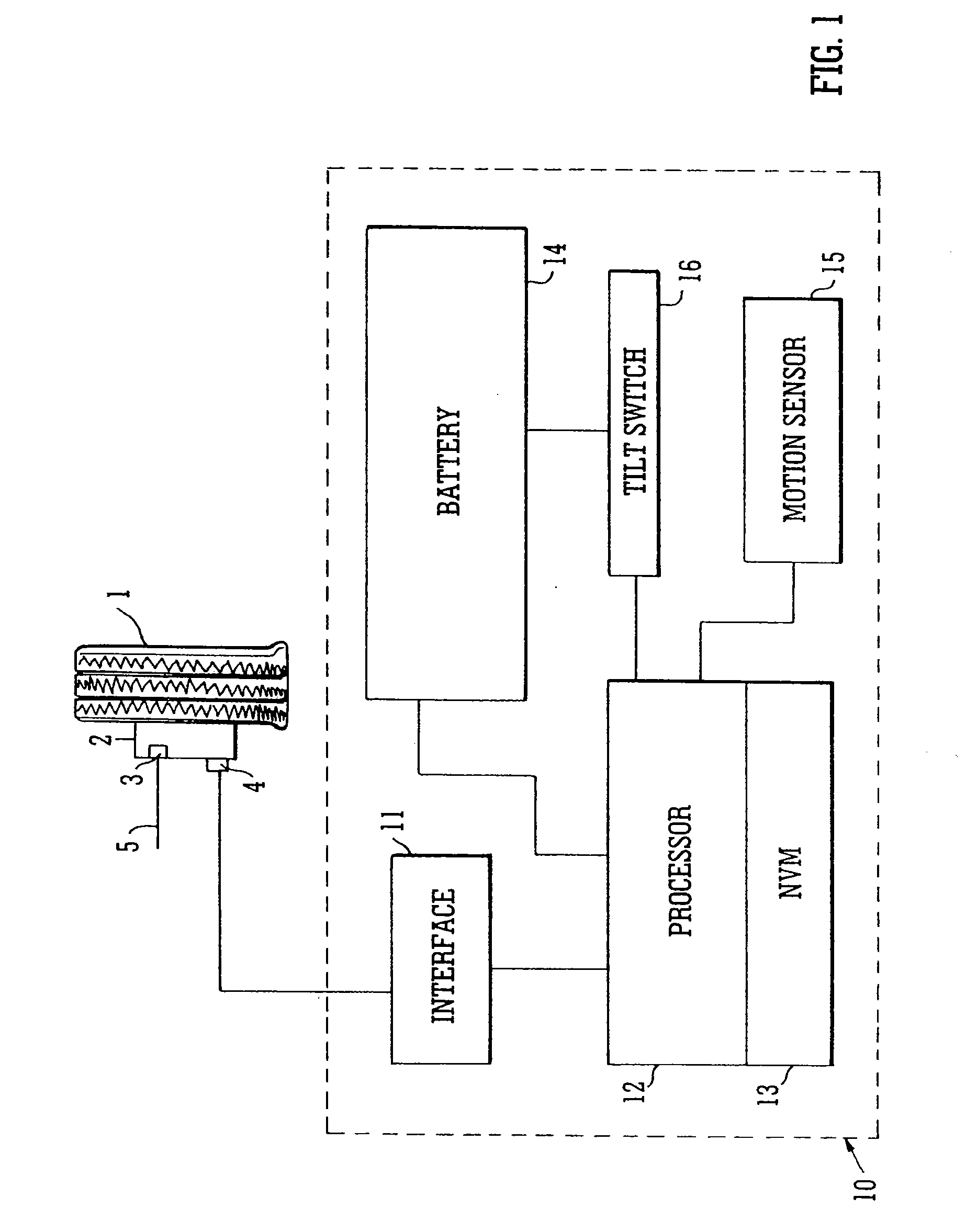

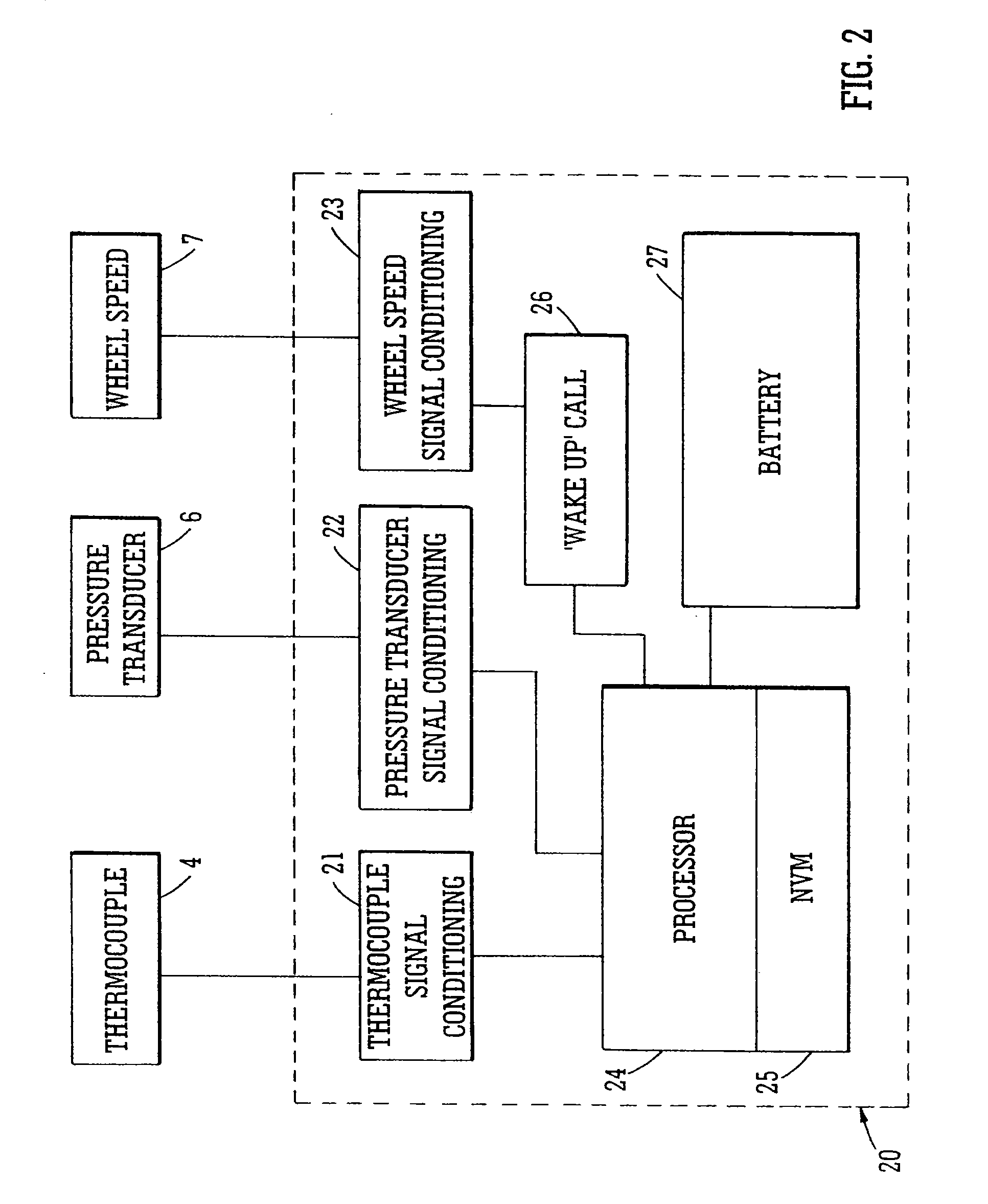

Brake condition monitoring

InactiveUS7086503B2Less-rapid decelerationBrake fluid pressure increaseFinanceAircraft braking arrangementsRelative motionBraking system

System and method for monitoring the applications of the brakes, e.g. of an aircraft to determine brake condition and operate a brake maintenance programme or charge a brake system user. It is desirable to have accurate information for determining the condition and predicting the life of carbon-carbon brake discs. This is important for safety as well as commercial reasons. The number of landings of an aircraft is often used as a determinant for such as lifetime warranties for brake discs and recommended maintenance periods. However, at least for carbon disc brakes, this may not be entirely accurate. For example such brake discs also wear during taxiing. The system and method herein includes monitoring each actuation of the brakes and making a separate record of each actuation of the brakes in which there is relative movement of the facing friction surfaces that cause wear, and from that separate record determining brake usage. The monitoring may include measuring changes and processing the signals to distinguish between those which fall below and those which are above a threshold value. Herein there is also described, a method and apparatus for monitoring a braking system comprising sensing a plurality of braking parameters having values dependent upon wear in the system and different faults of the system, and identifying and recording wear and faults based on combinations of values of said parameters.

Owner:MEGGITT AEROSPACE

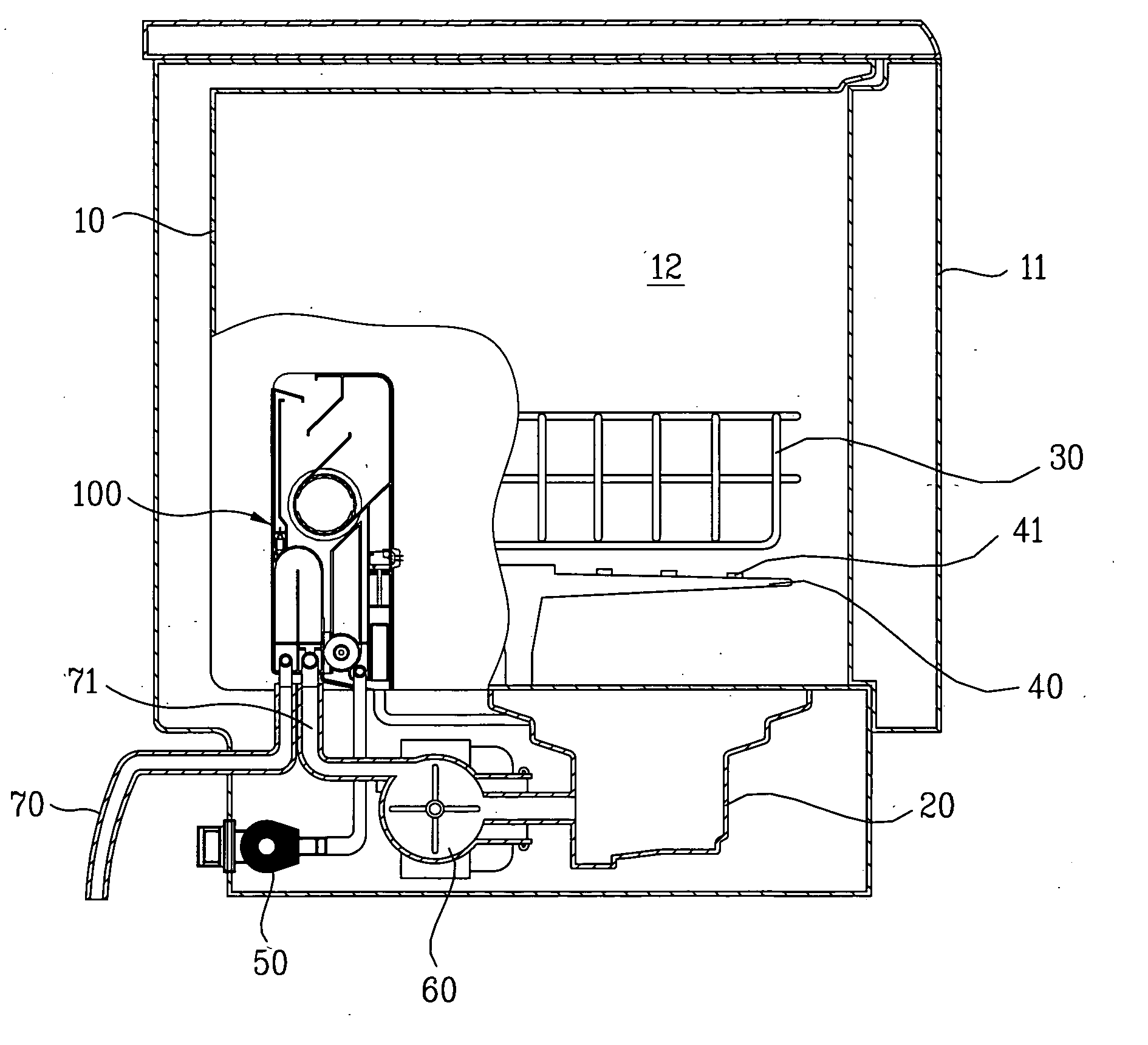

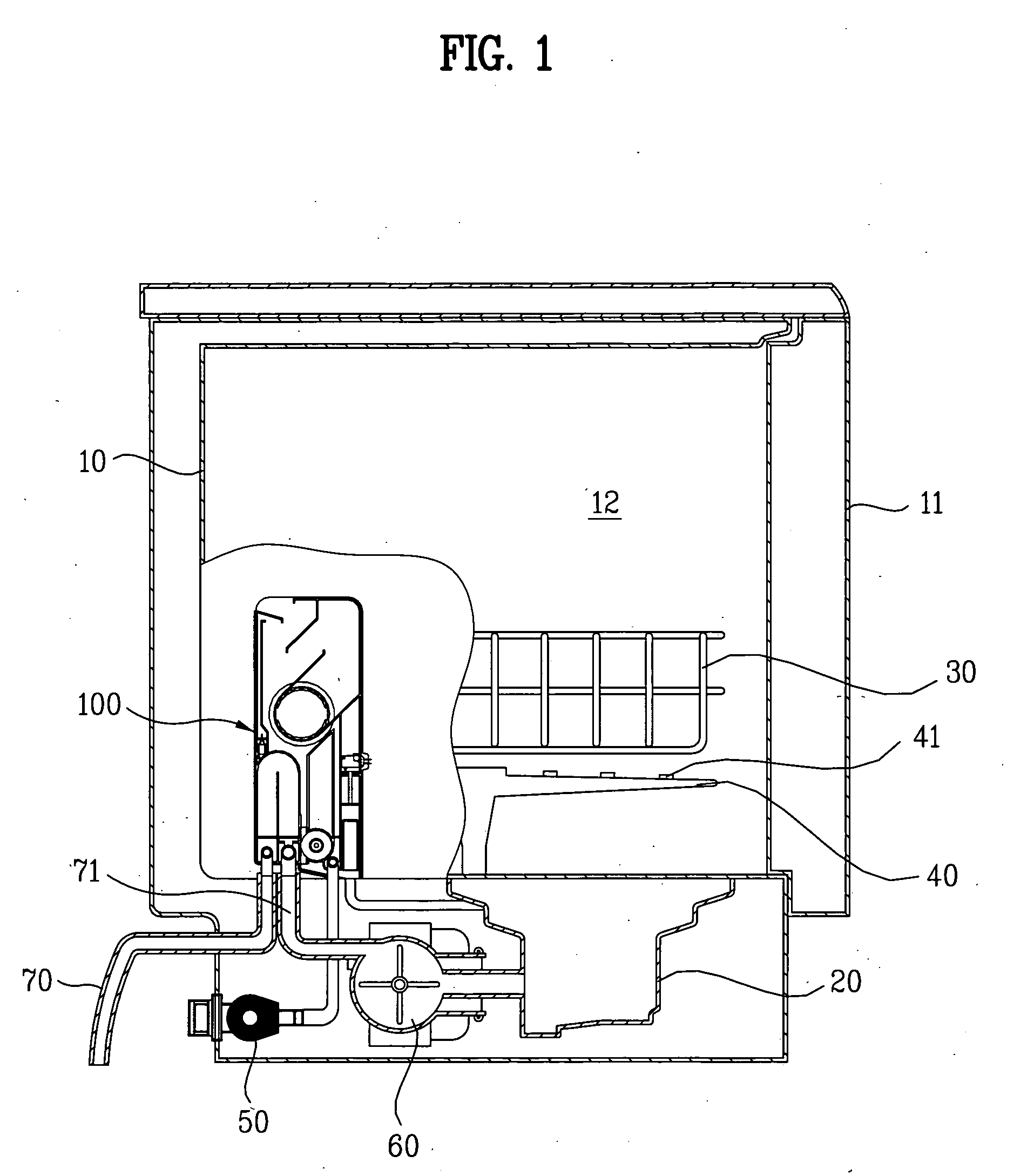

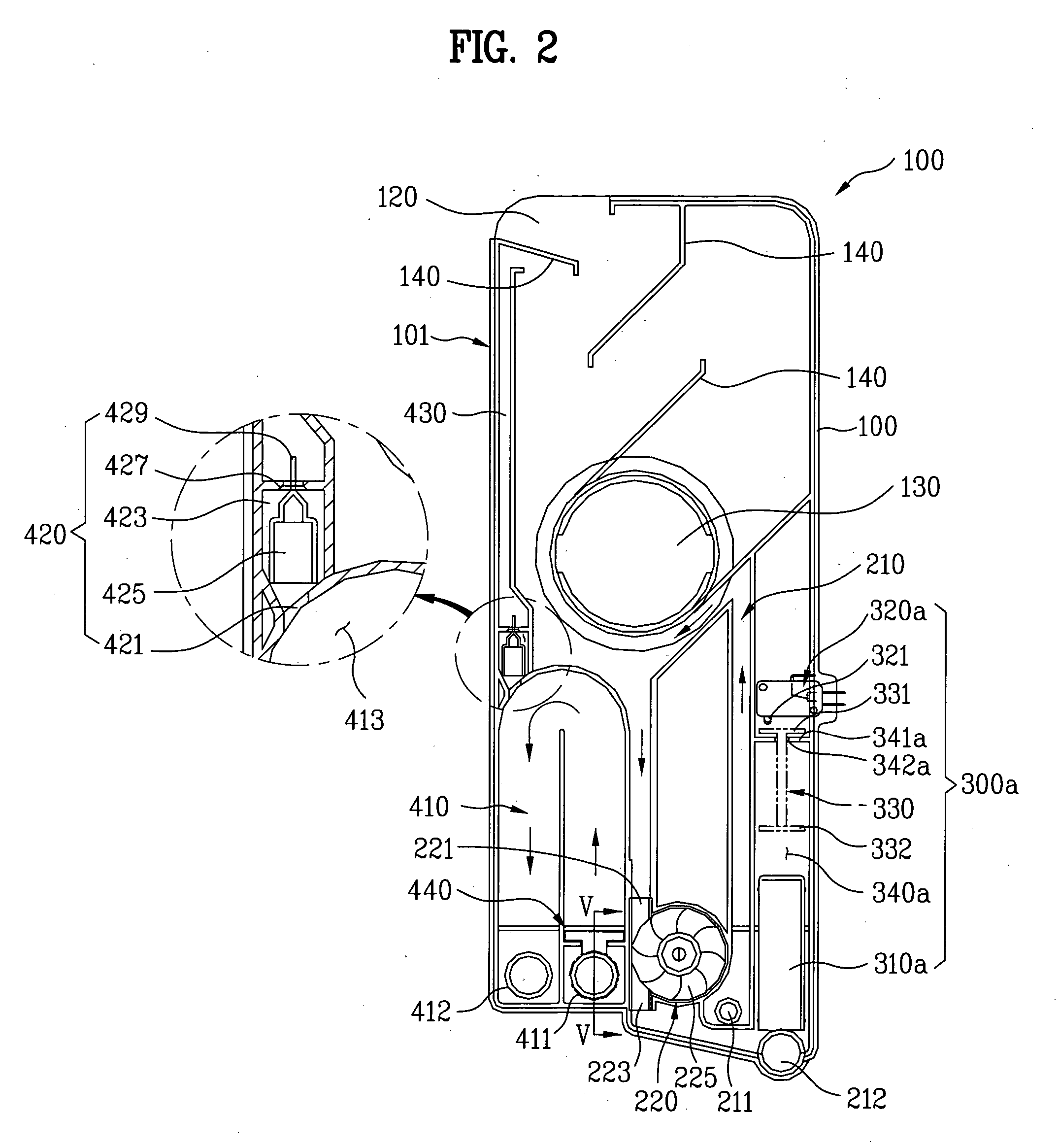

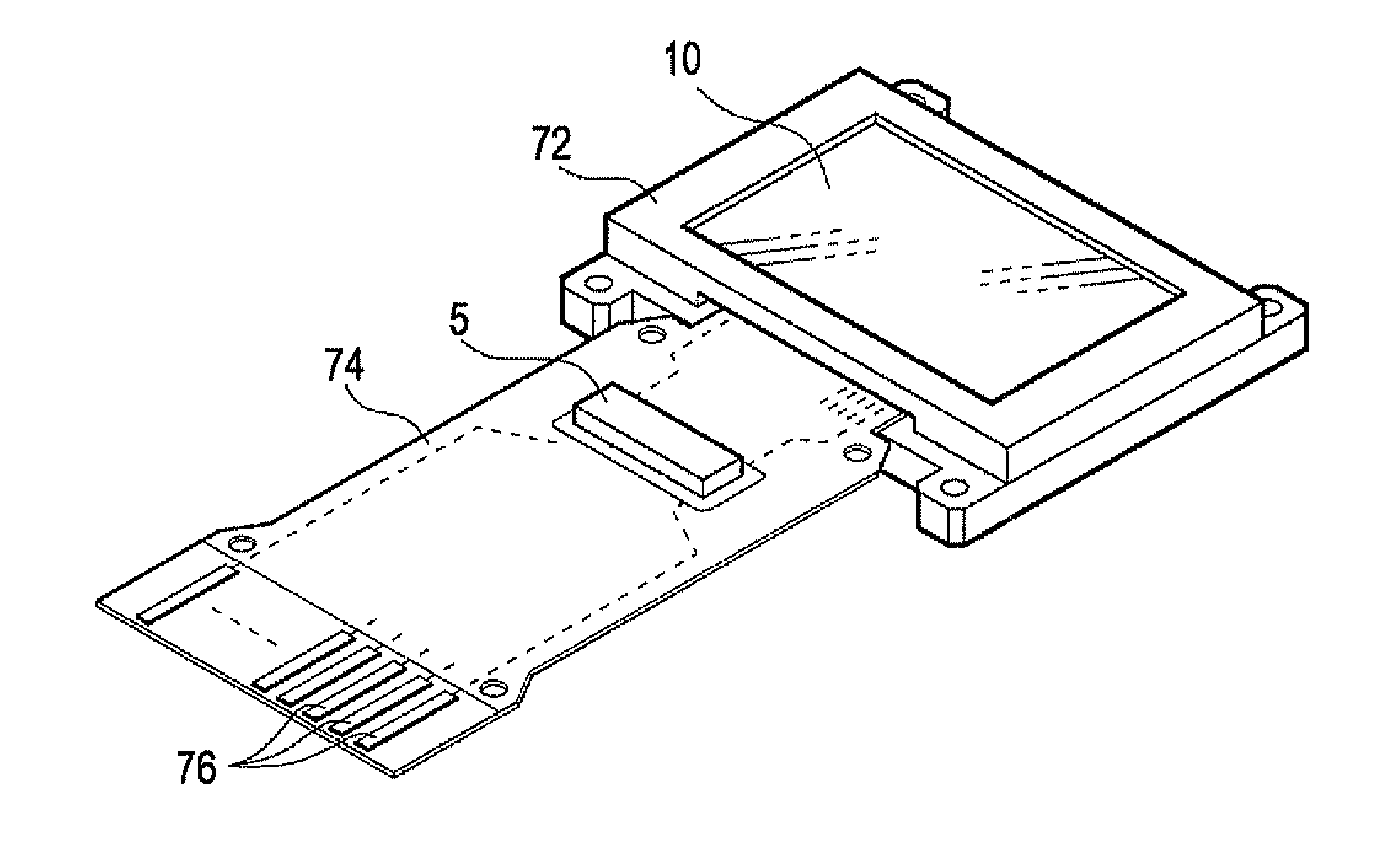

Water guide for dishwasher and dishwasher having the same

InactiveUS20050241675A1Avoid oversupplyAvoid undersupplyTableware washing/rinsing machine detailsHollow article cleaningWater flowEngineering

A water guide for guiding the flow of water in a dishwasher via a sump maintains a precise level of water in the sump by directly measures an actual water level of the sump. The water guide includes a supply channel for supplying washing water to the sump; and a sensor configuration, installed along the supply channel, for sensing a water level of washing water contained in the sump.

Owner:LG ELECTRONICS INC

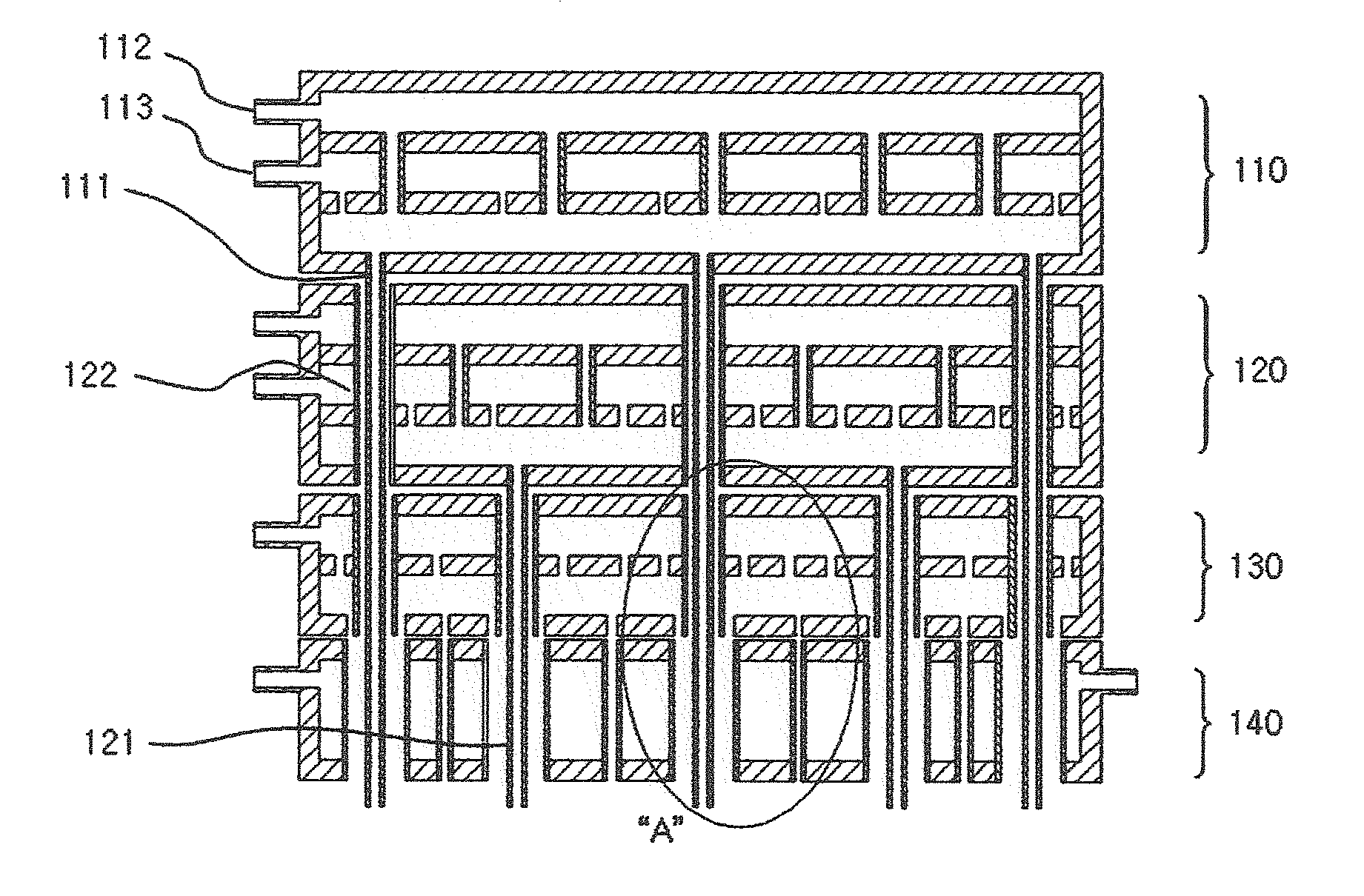

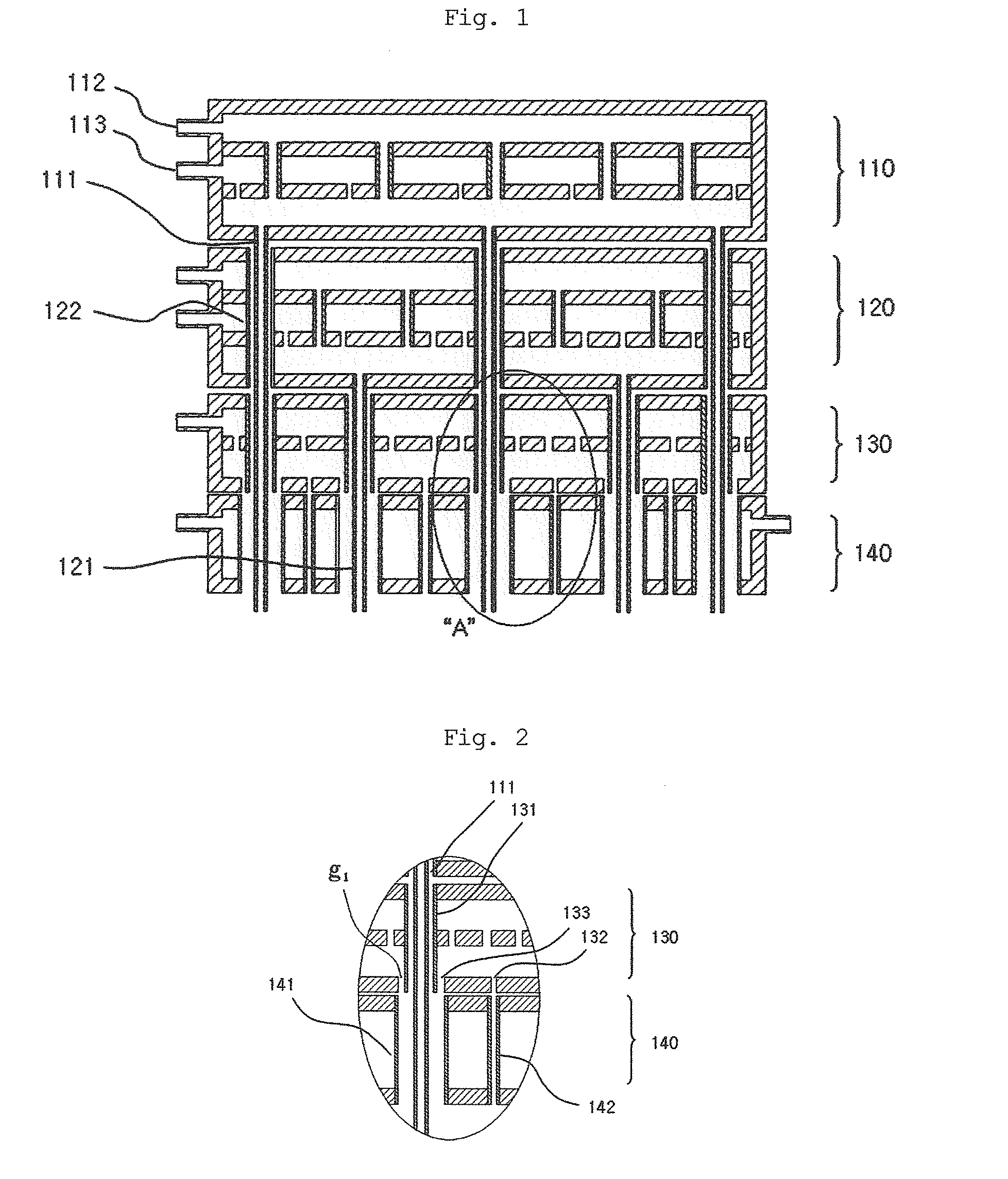

Electro-optical device and electronic apparatus

ActiveUS20130120338A1Decrease pitchRaise the ratioCathode-ray tube indicatorsInput/output processes for data processingData signalEngineering

An electro-optical device comprises a substrate, a scanning line, a data line, a pixel circuit, and a first storage capacitor holding a first voltage corresponding to a data signal. The first storage capacitor includes a first portion and a second portion connected in parallel. The first portion and the second portion overlap when viewed from a direction orthogonal with respect to the first main surface.

Owner:SEIKO EPSON CORP

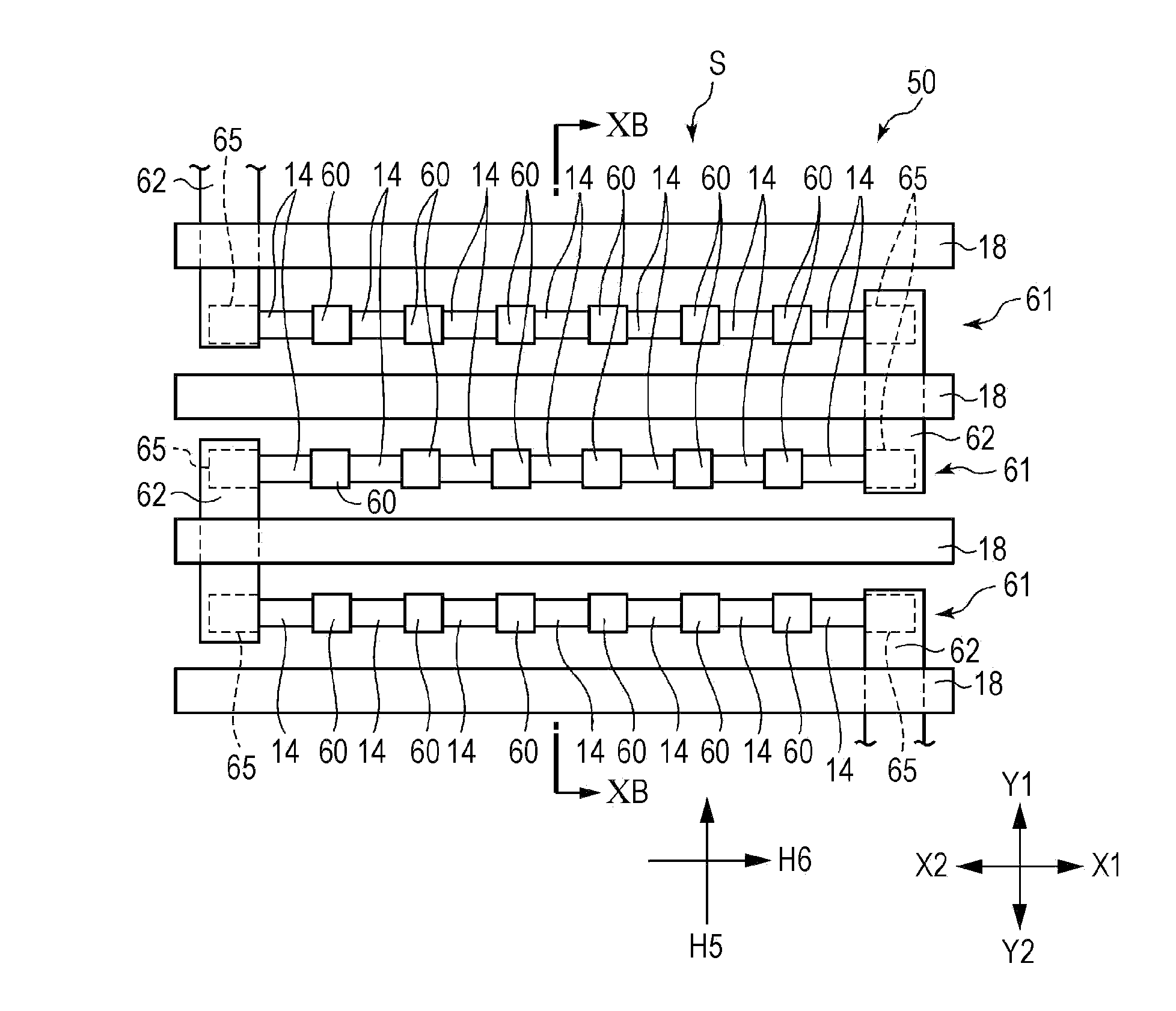

Showerhead for film depositing vacuum equipment

ActiveUS20120067971A1Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasProduct gas

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

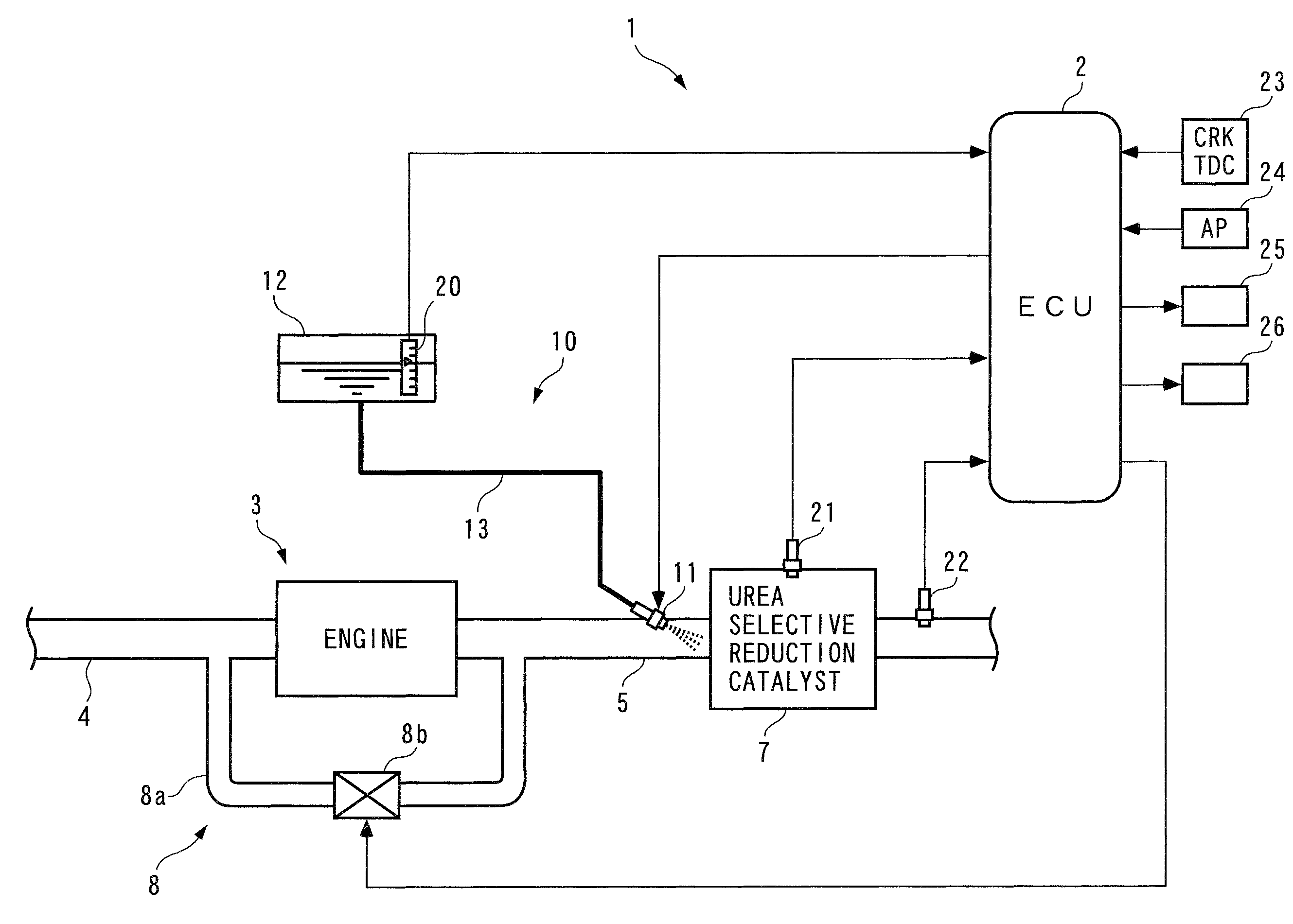

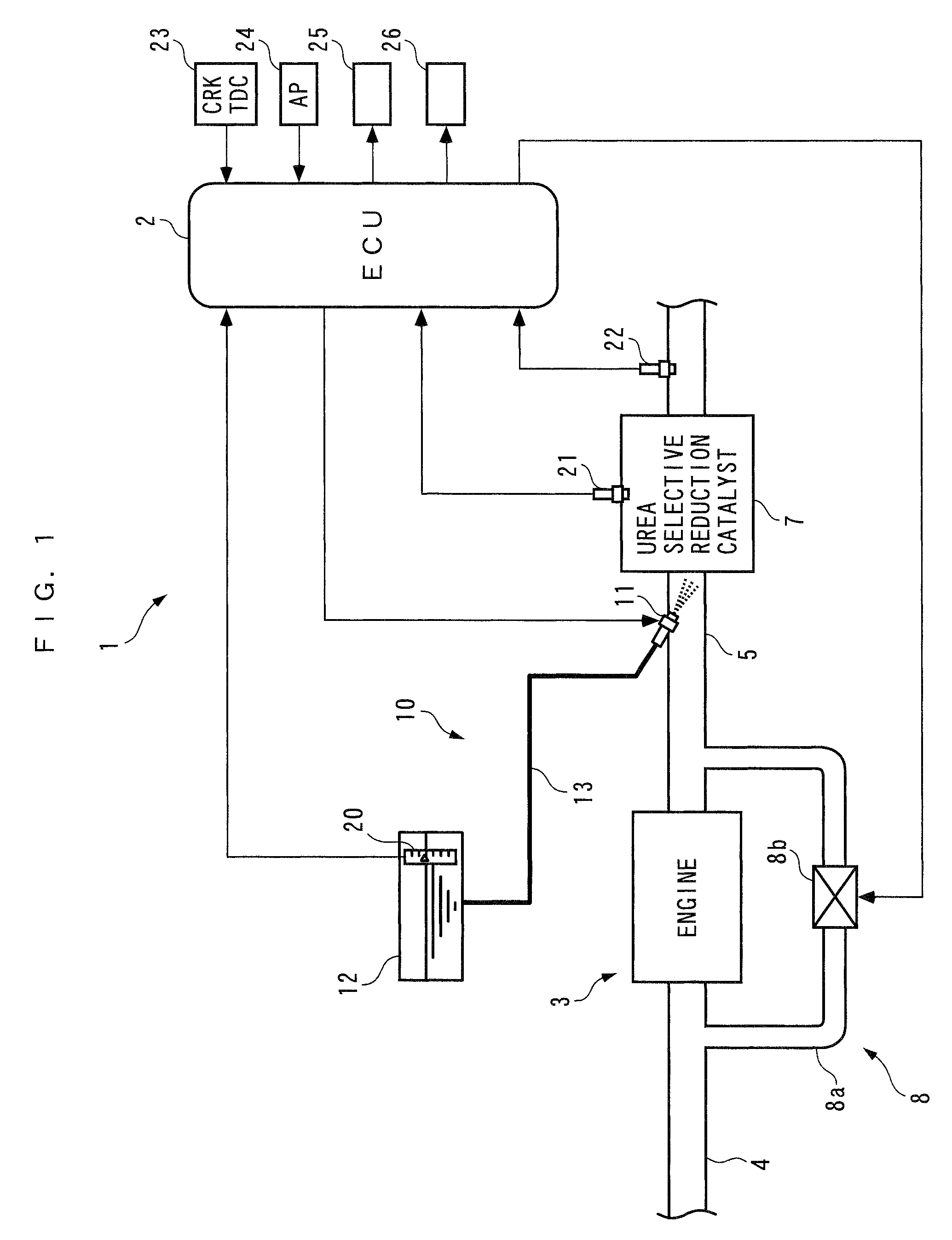

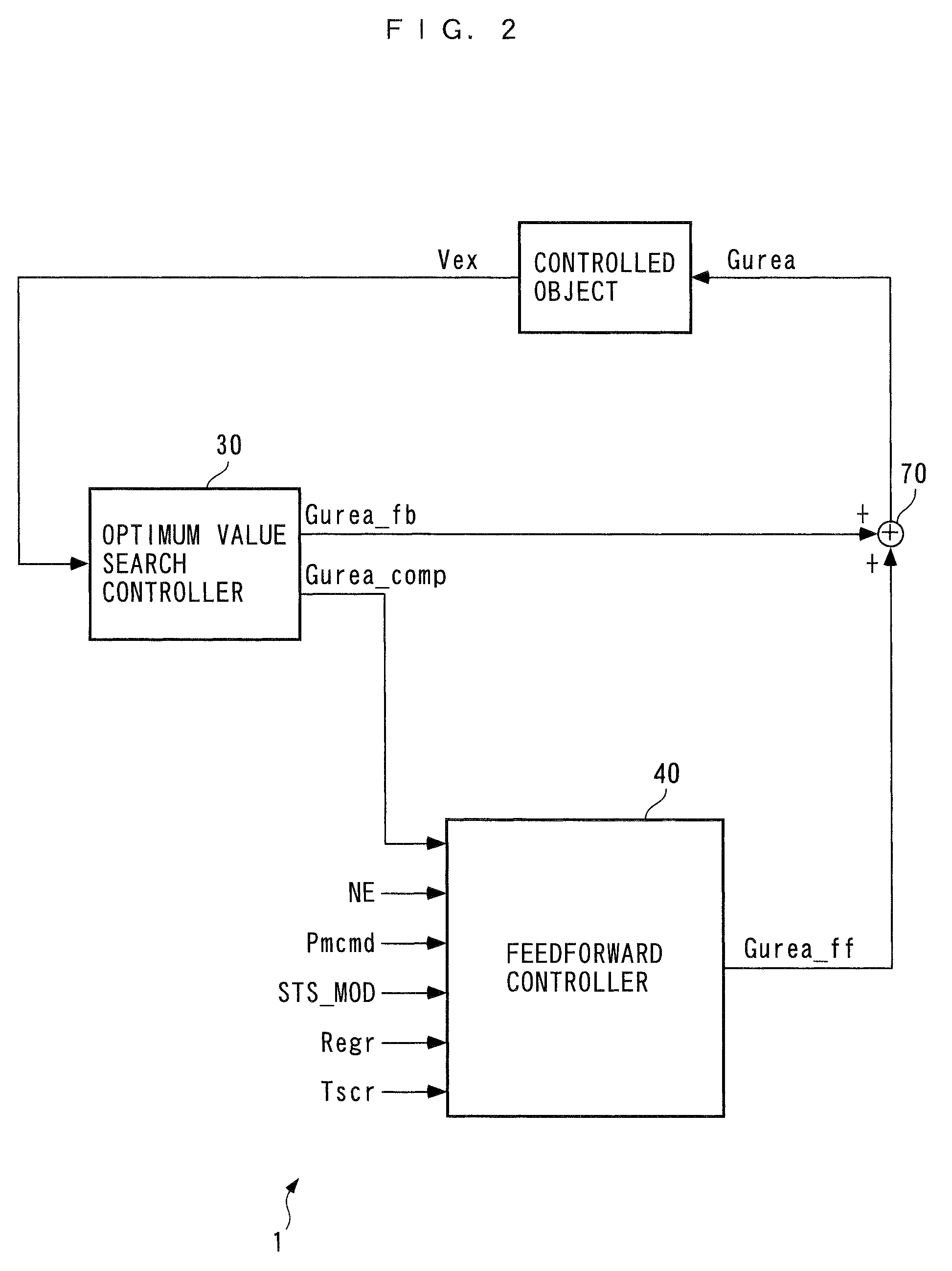

Exhaust emission control device for internal combustion engine

InactiveUS7997070B2Reduce the valueImprove concentrationAnalogue computers for vehiclesInternal combustion piston enginesMoving averageExhaust fumes

An exhaust emission control device for an internal combustion engine, capable of supplying a just enough amount of reducing agent to a selective reduction catalyst even when a NOx purification ratio of the catalyst is changed by various causes, thereby enabling a high NOx purification ratio and very low exhaust emissions to be maintained. An ECU calculates a filtered value based on a signal from an exhaust gas concentration sensor, calculates a moving average value of a product of the filtered value and a reference input, calculates a control input such that the moving average value becomes equal to 0, and adds a reference input to the control input to calculate an FB injection amount. The ECU calculates an FF injection amount with a predetermined feedforward control algorithm, and adds the FF injection amount to the FB injection amount, to thereby calculate a urea injection amount.

Owner:HONDA MOTOR CO LTD

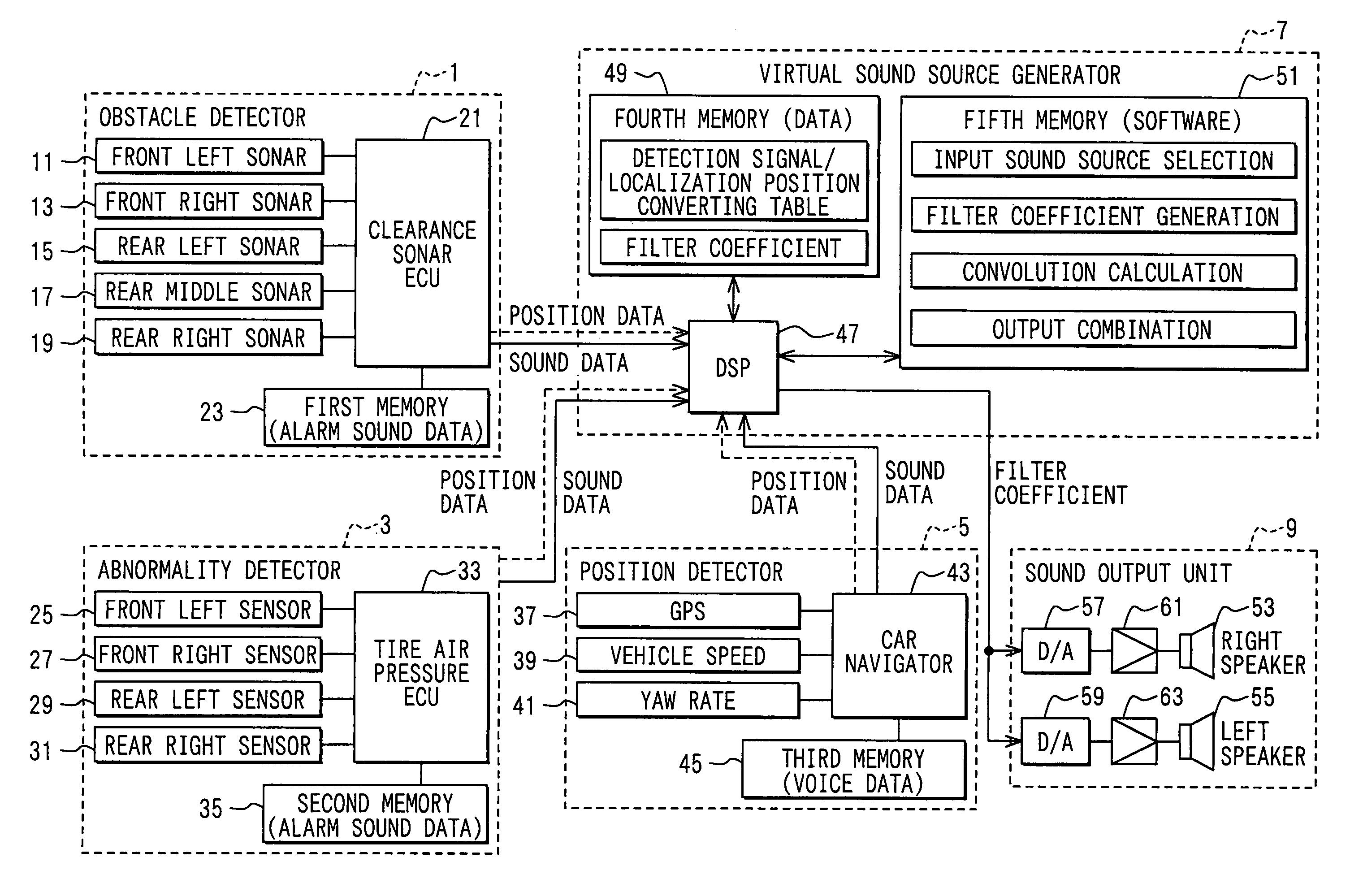

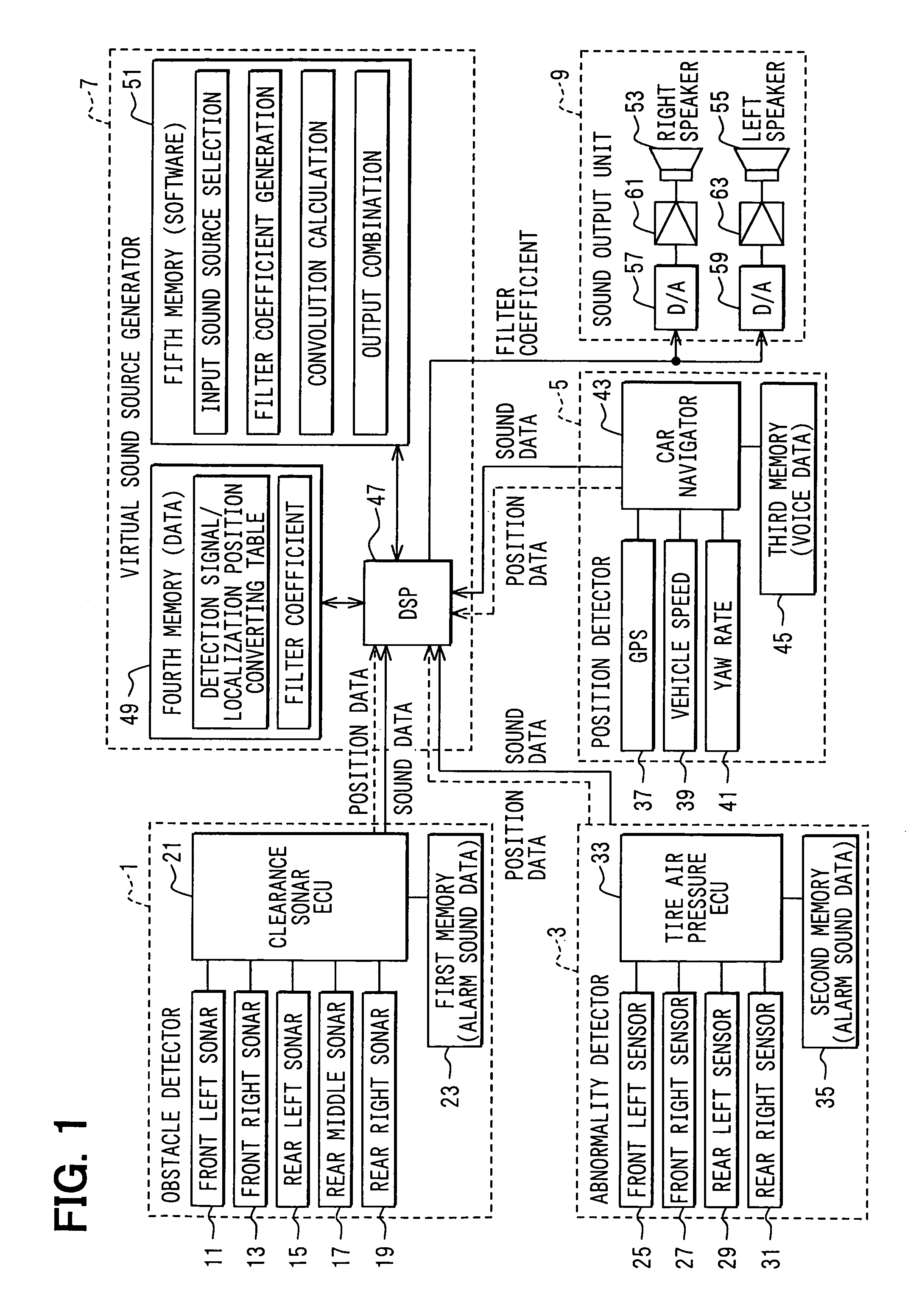

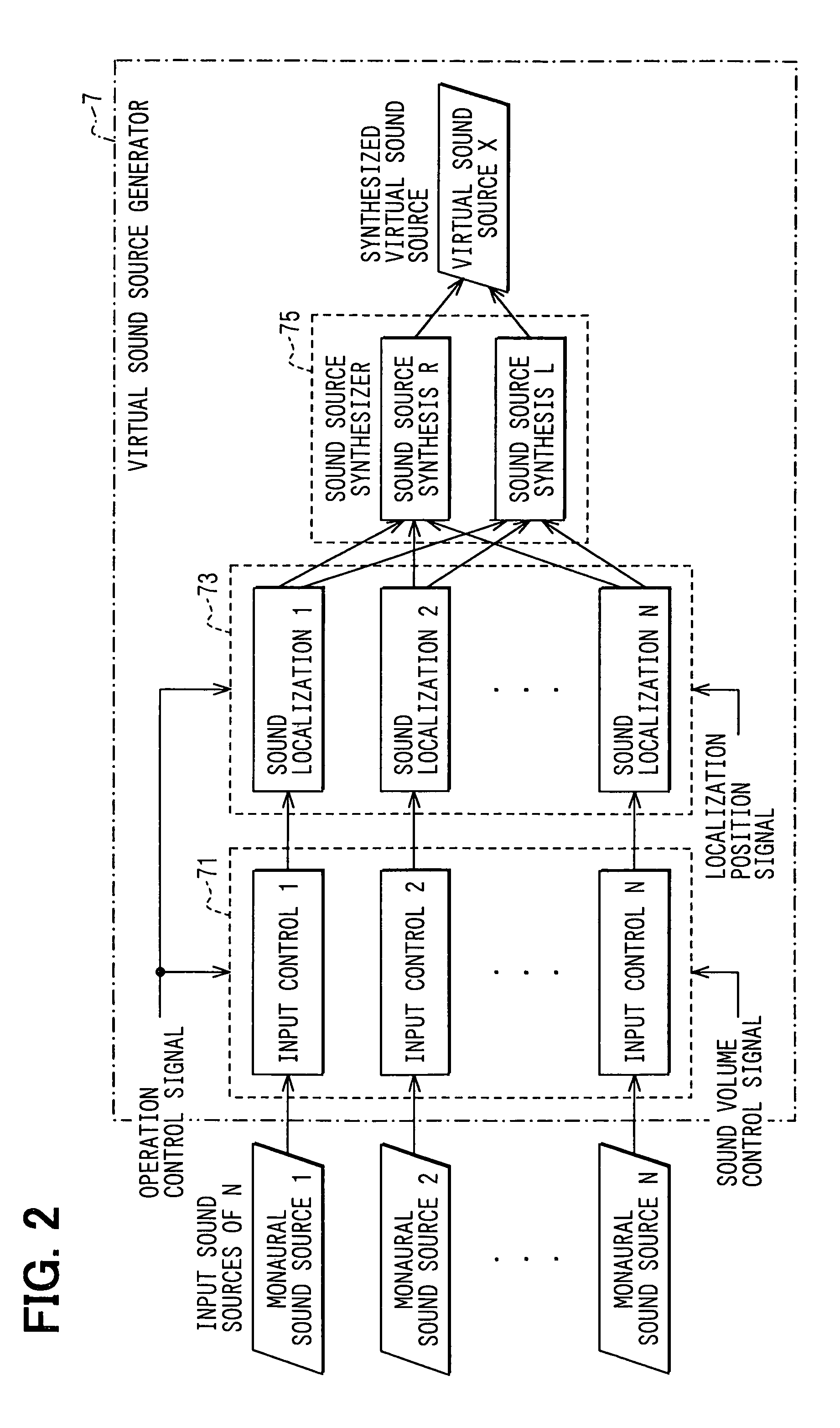

Vehicle alarm sound outputting device and program

ActiveUS7274288B2Accurate supplyStereophonic circuit arrangementsSignalling system detailsSound sourcesAnomaly detection

In a vehicle alarm sound output device and a program, position data of an obstacle(s) and sound data of an alarm sound are output from an obstacle detector to DSP of a virtual sound source generator. Position data of a tire having air pressure abnormality and sound data of an alarm sound are output from an abnormality detector to DSP. Position data of a target object of a route guidance and sound data of a voice are output from a position detector to DSP. In DSP, an audio signal with which a virtual sound source can be implemented is created by using a detection signal / localization position converting table and head related transfer functions, and the audio signal thus created is output to a sound output unit. In the sound output unit, the signal corresponding to the audio signal is output to speakers so that a passenger(s) can hear an alarm sound such as a warning sound, a voice guidance or the like from the localization position of a virtual sound source.

Owner:DENSO CORP

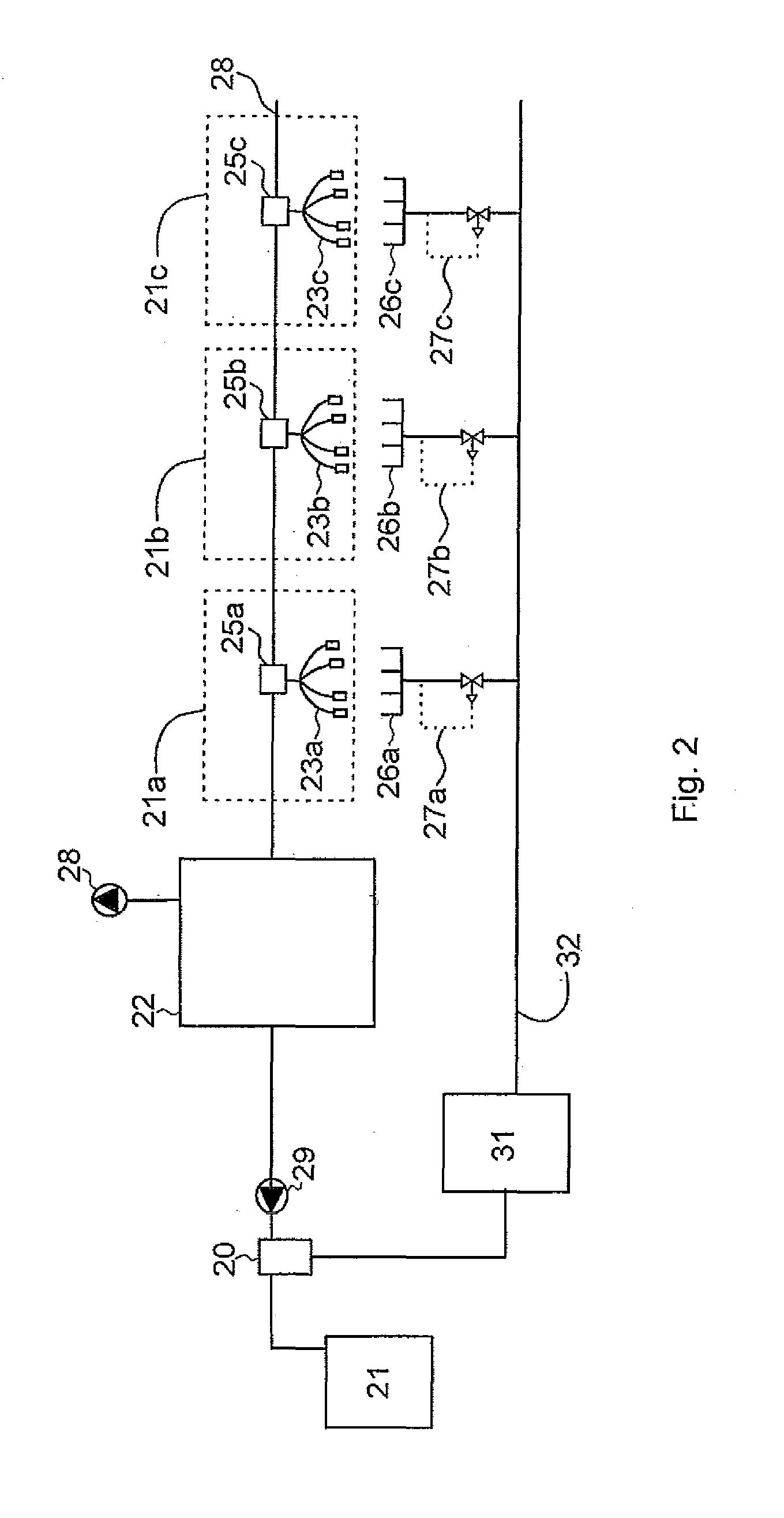

Cleaning arrangement

InactiveUS20110220160A1Prevent leakageOvercome disadvantagesCleaning using liquidsMilking devicesProcess engineeringAtmospheric pressure

An arrangement for controlling the supply of cleaning liquid into a milking system includes a pressurizing arrangement adapted to pressurize the cleaning liquid, a supply arrangement for selectively supplying cleaning liquid and a pressure sensing arrangement for sensing the pressure in the milking system. The pressure sensing device is operatively connected to the supply arrangement, and the supply arrangement is adapted to supply cleaning liquid into the milking system depending on the sensed pressure in the milking system. The arrangement can be adapted to supply cleaning liquid when the sensed pressure in the milking system is below the atmospheric pressure.

Owner:DELAVAL HLDG AB

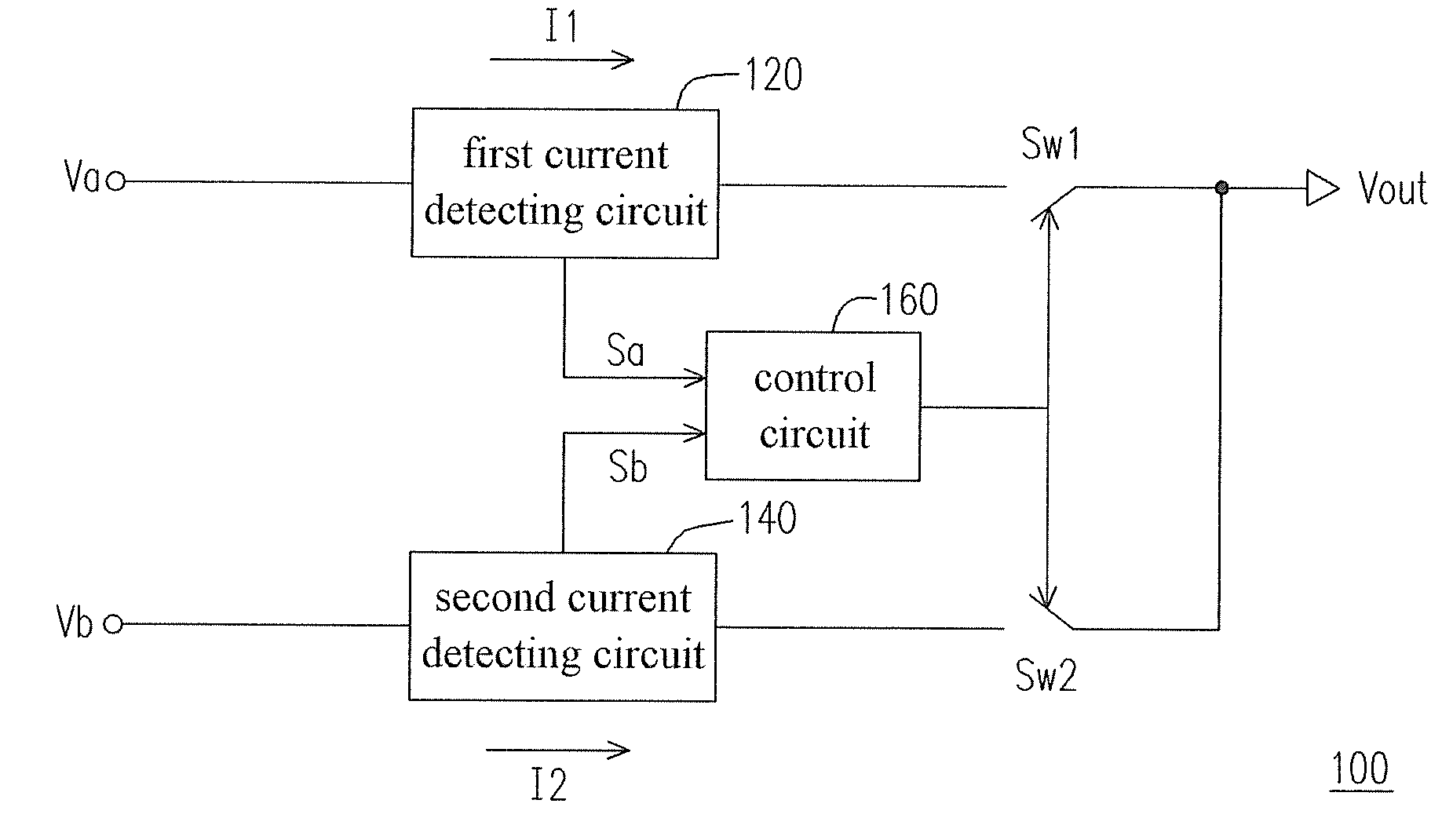

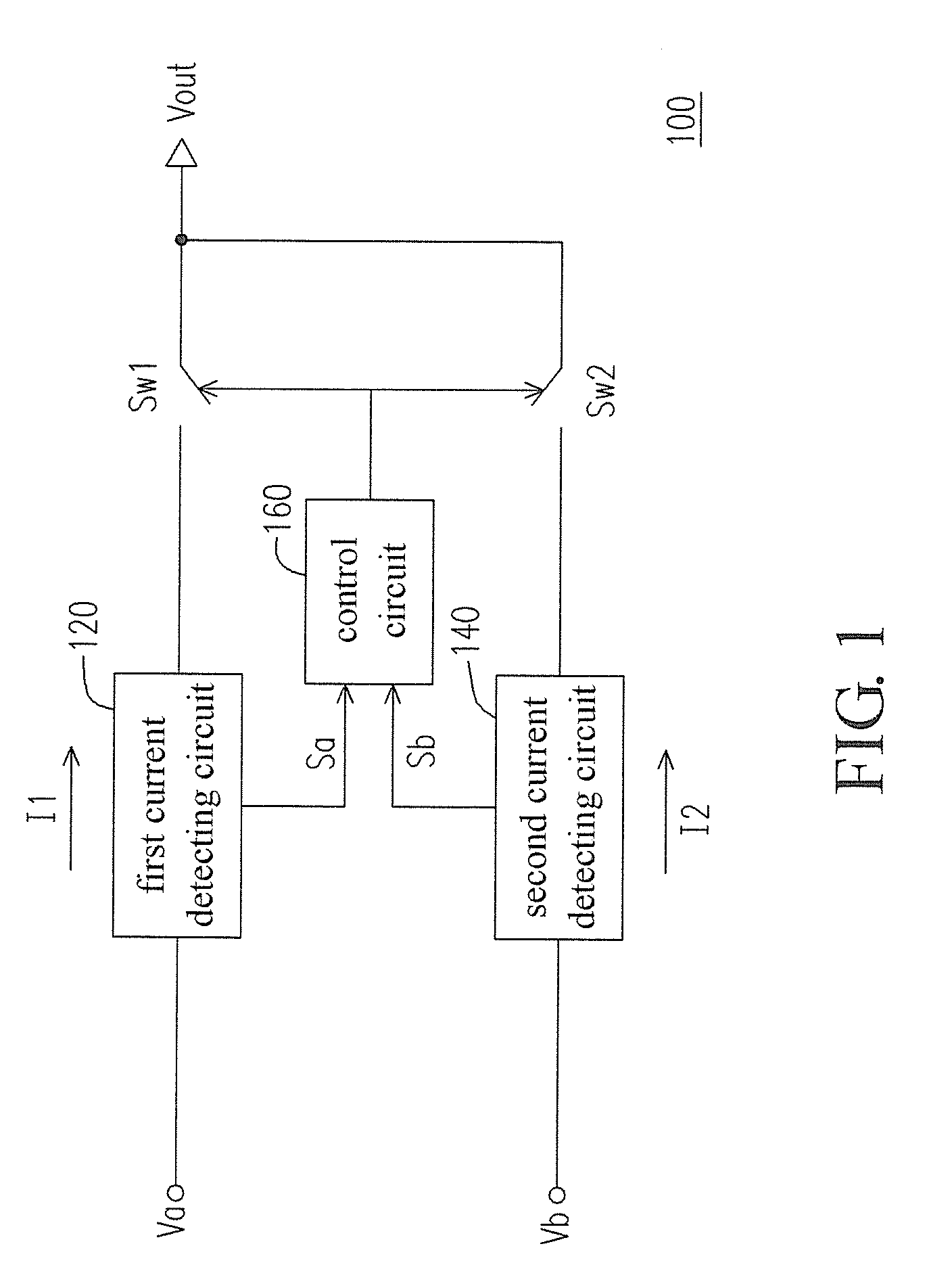

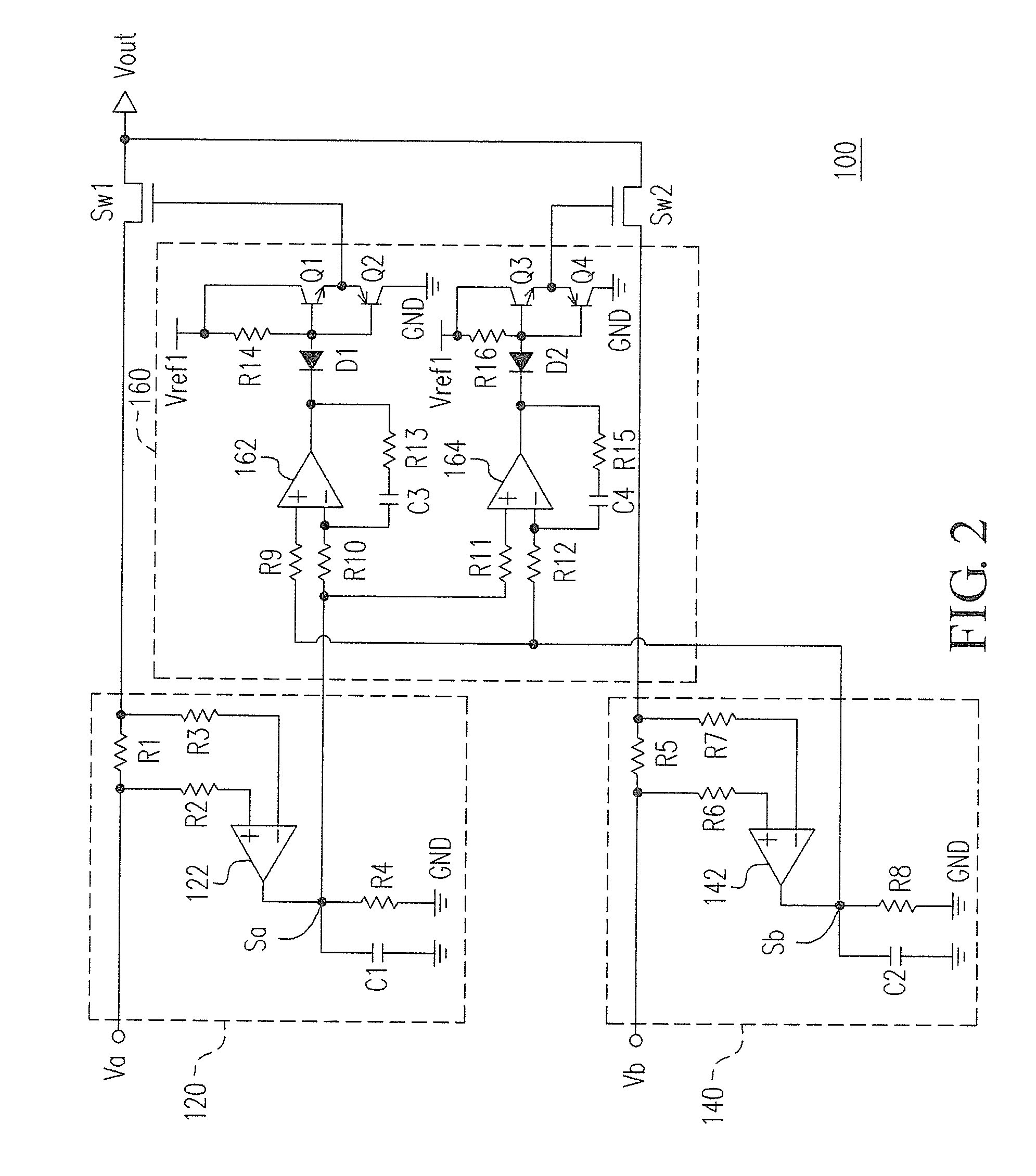

Current regulator

ActiveUS20100164452A1Improve power transmission capacityEfficient powerElectric signal transmission systemsDc source parallel operationEngineeringControl circuit

A current regulator includes a first switch, a second switch, a first current detecting circuit, a second current detecting circuit and a control circuit. Both of the first and second current detecting circuits detect the current of corresponding power route. The control circuit controls the first and the second switches on the route to be turned on or turned off according to detecting signals, and regulates to keep the wiring current in balance.

Owner:ASUSTEK COMPUTER INC +1

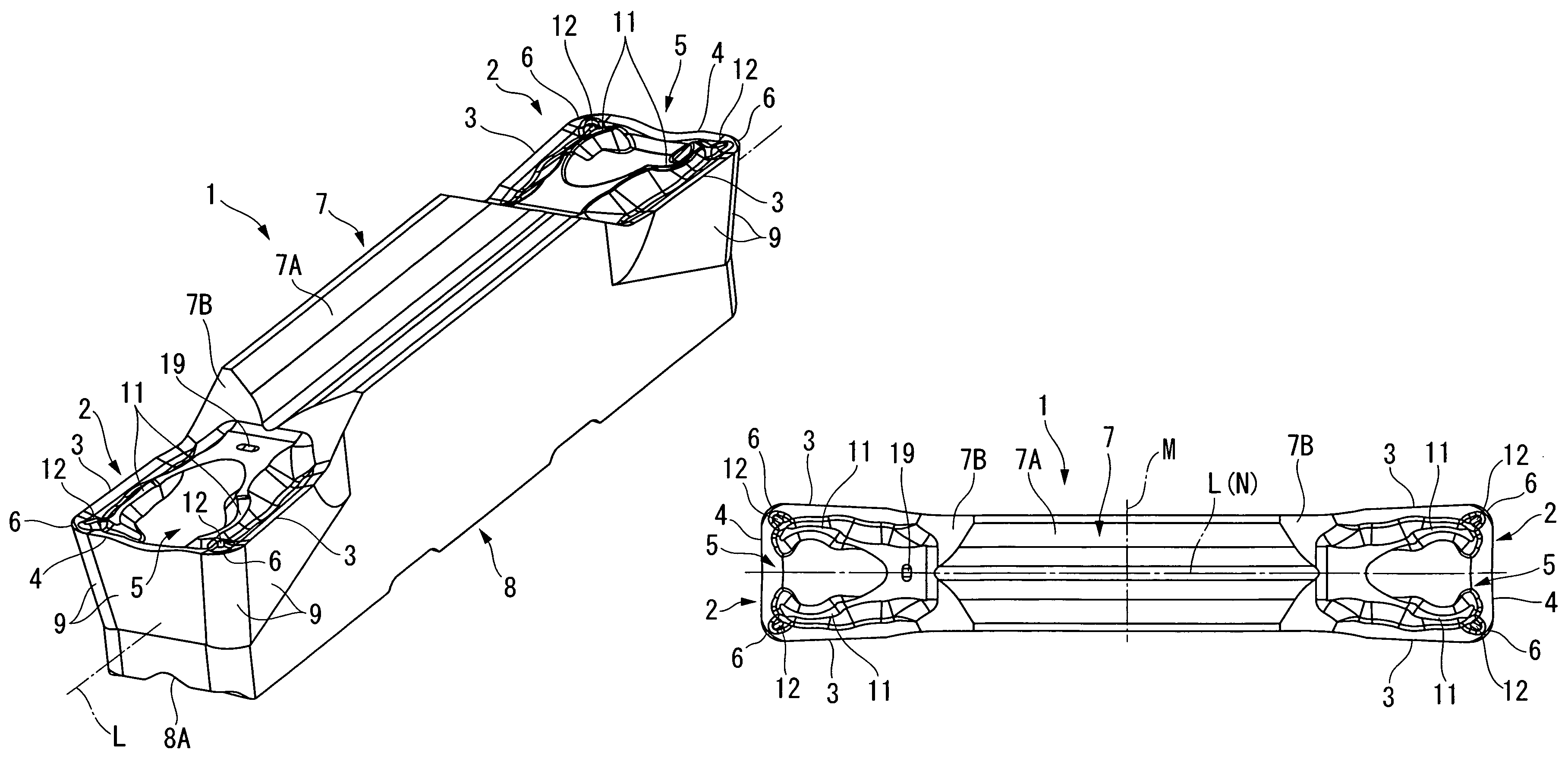

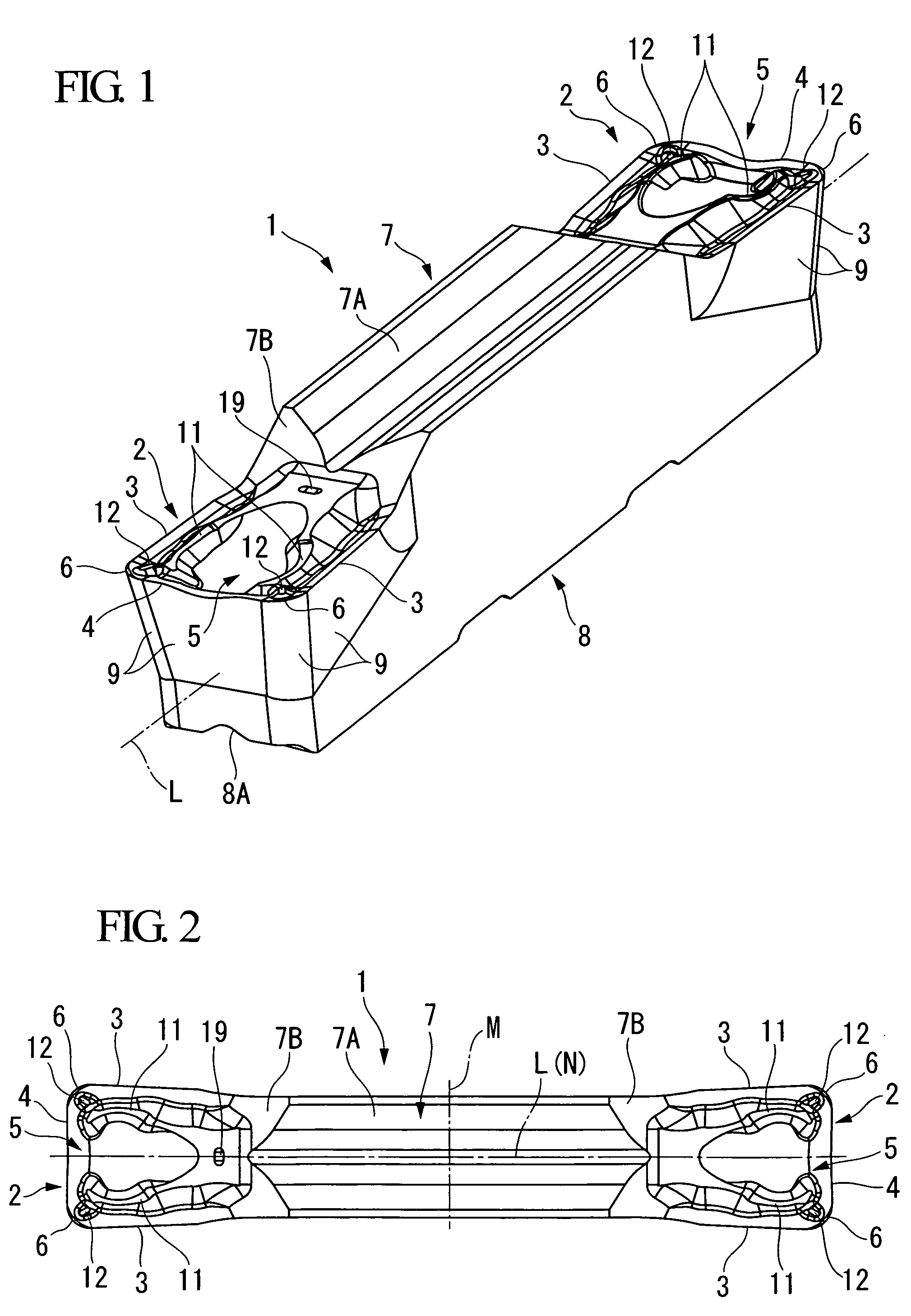

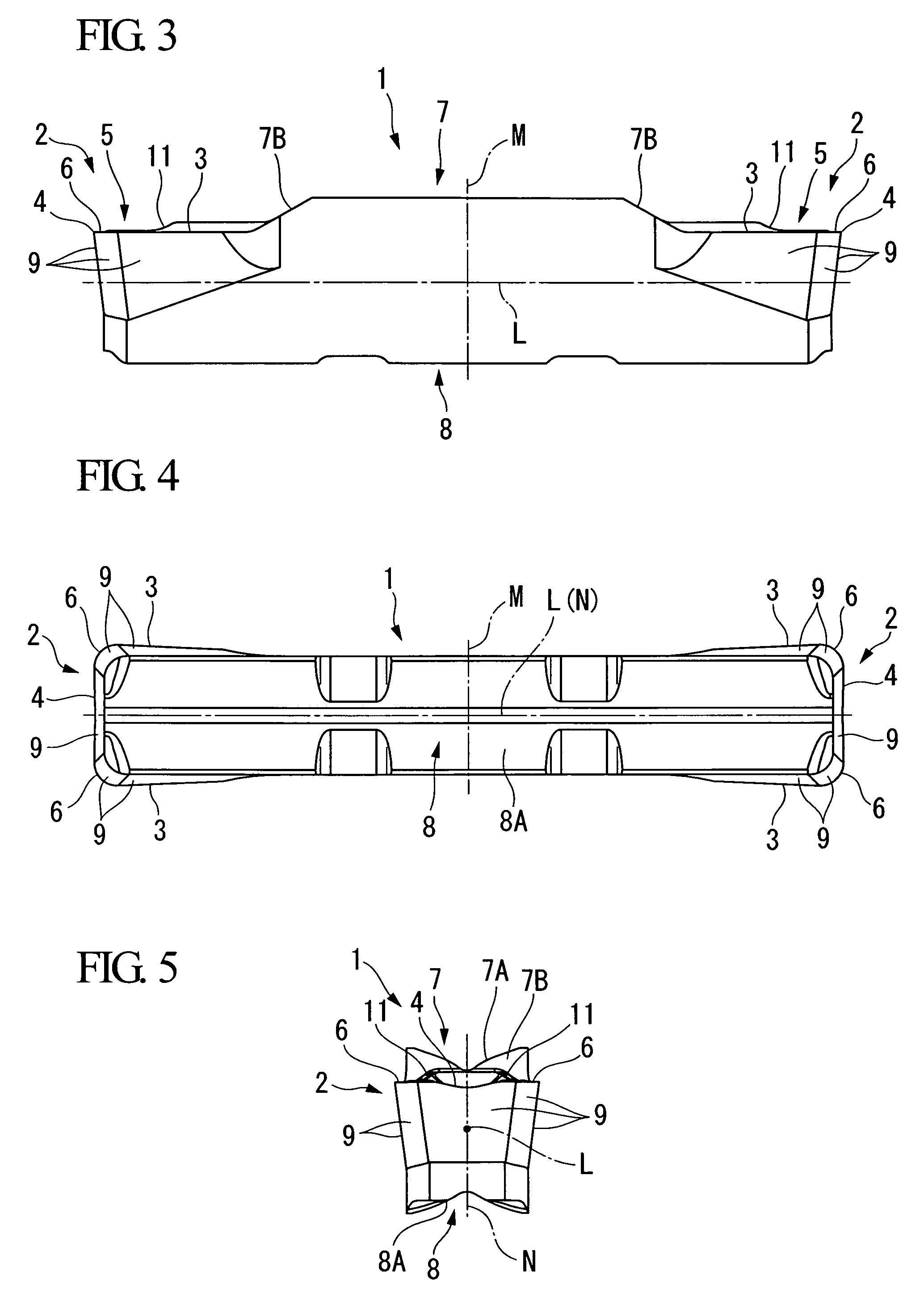

Cutting insert

ActiveUS7665933B2Preventing damage and adhesionImprove accuracyCutting insertsTurning toolsEngineeringMechanical engineering

A cutting insert having an insert body formed in a shaft-shape, wherein a cutting edge portion having a square rake face is formed on an end portion of the insert body, and wherein the rake face includes: a pair of side cutting edges extending in a longitudinal direction of the insert body; a front cutting edge extending in a transverse direction perpendicular to the longitudinal direction between each front end of the side cutting edges; a pair of protruded streaks extending toward each of corner portions at which each of the side cutting edges intersect the front cutting edge, and a projection which protrudes and is separated from the protruded streaks between front ends of the protruded streaks in the vicinity of the corner portion and the corner portion.

Owner:MITSUBISHI MATERIALS CORP

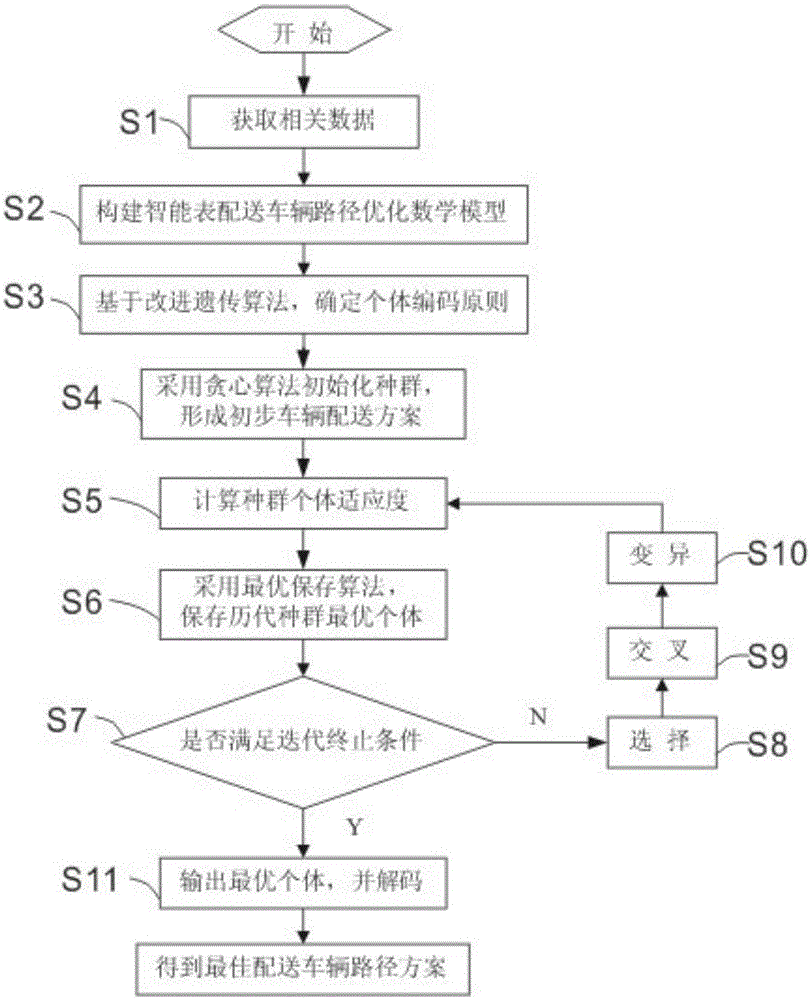

Method for optimizing a routing of an intelligent ammeter distributing vehicle

InactiveCN105096006ATimely supplyEconomic supplyForecastingLogisticsOptimal schedulingGenetic algorithm

The present invention relates to a method for optimizing a routing of an intelligent ammeter distributing vehicle. The optimization method mainly considers an intelligent ammeter distributing plan from a perspective of time and space, converts a problem of routing planning of the intelligent ammeter distributing vehicle into a problem of vehicle routing optimal scheduling with a distribution center, many vehicles, and a restriction of capacity and time by combining with a real situation of a provincial level measuring center, establishes a corresponding mathematical model, and solves and analyze the mathematical model by adopting an improved genetric algorithm so as to obtain a reasonable routing plan of the intelligent ammeter distribution vehicle. The method avoids many defects of a traditional intelligent meter distributing plan which is manually made, and provides a powerful support for the timely, economic, efficient and accurate intelligent ammeter distribution.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

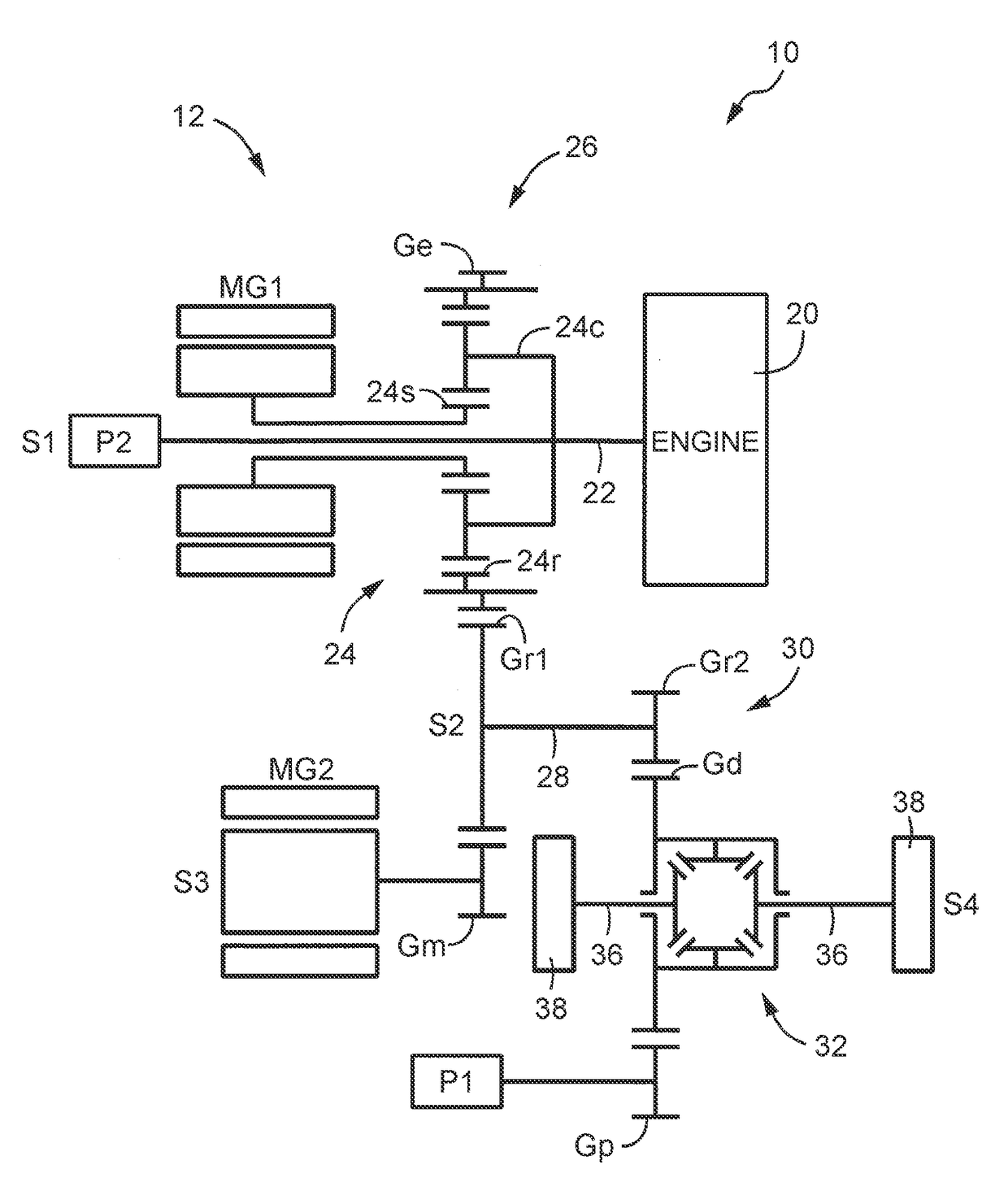

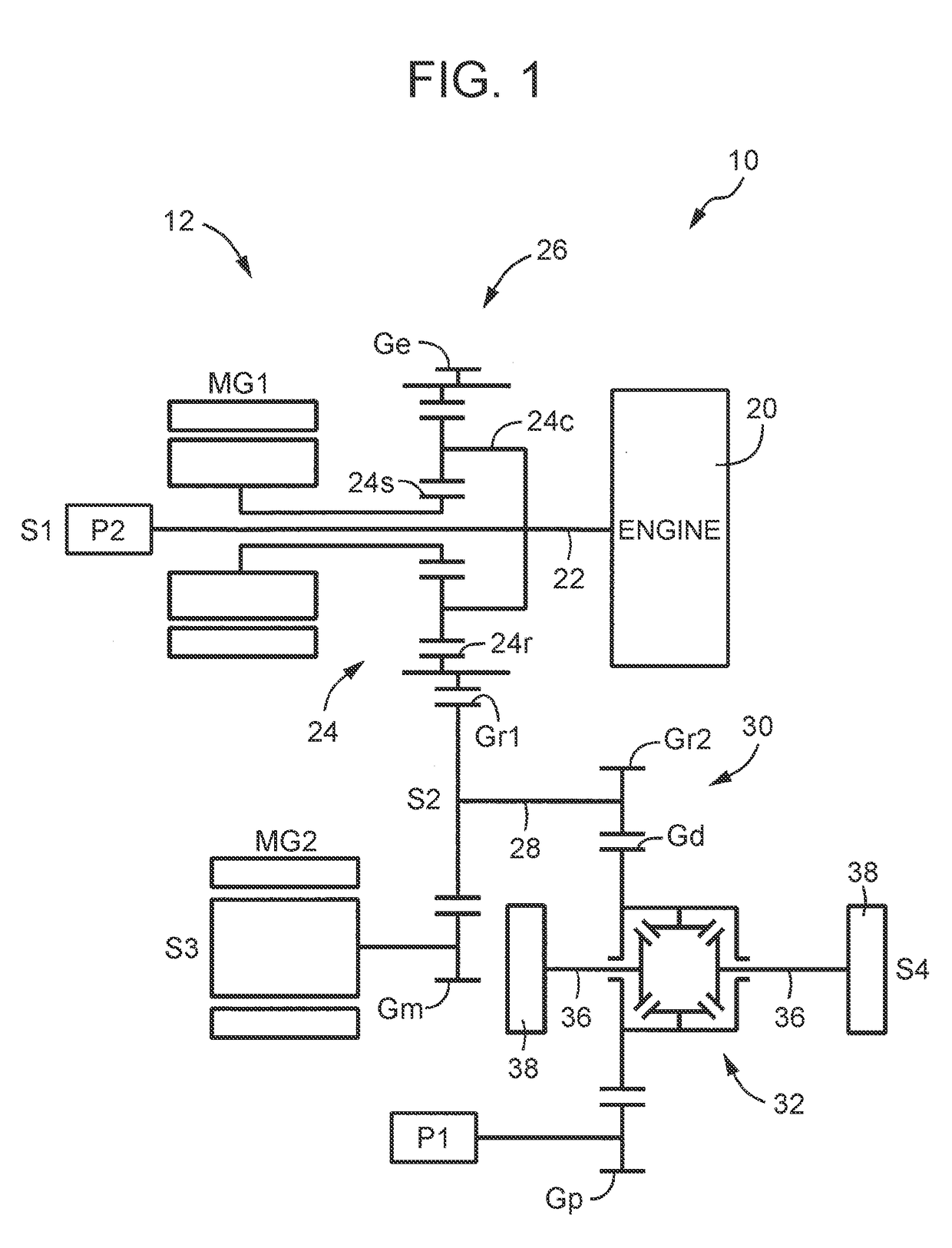

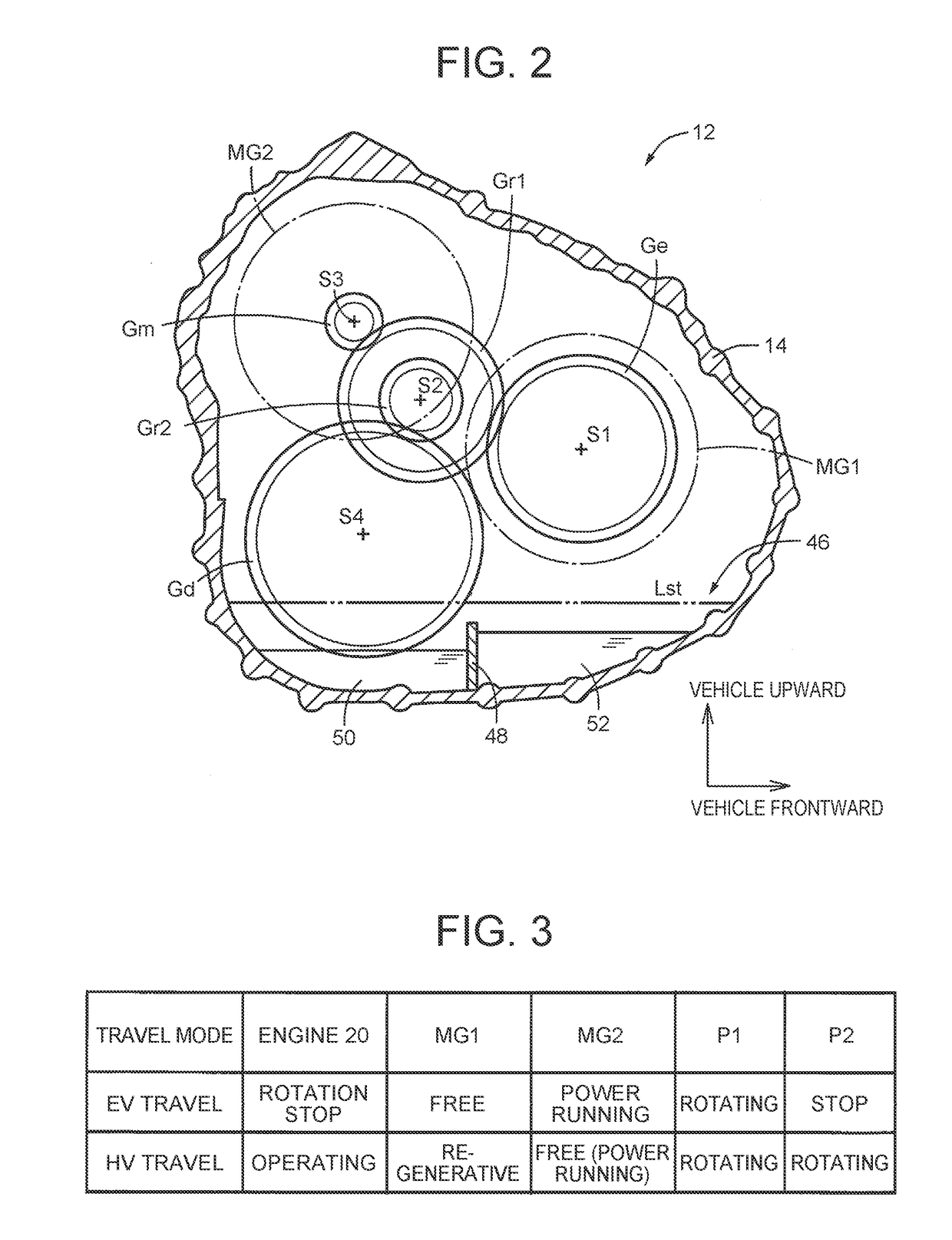

Lubricating apparatus of vehicle

ActiveUS20180045295A1Cost advantageHigh discharge pressureHybrid vehiclesGear lubrication/coolingDrivetrainWaste management

A lubricating apparatus for a vehicle, comprises a first oil pump and a second oil pump, and a first supply passage connected to a discharge side of the first oil pump on which the lubricating oil is discharged so as to supply the lubricating oil discharged from the first oil pump to lubricated parts of the power transmission system, a second supply passage that is provided independently from the first supply passage and is connected to a discharge side of the second oil pump on which the lubricating oil is discharged so as to supply the lubricating oil discharged from the second oil pump to the lubricated parts of the power transmission system.

Owner:TOYOTA JIDOSHA KK

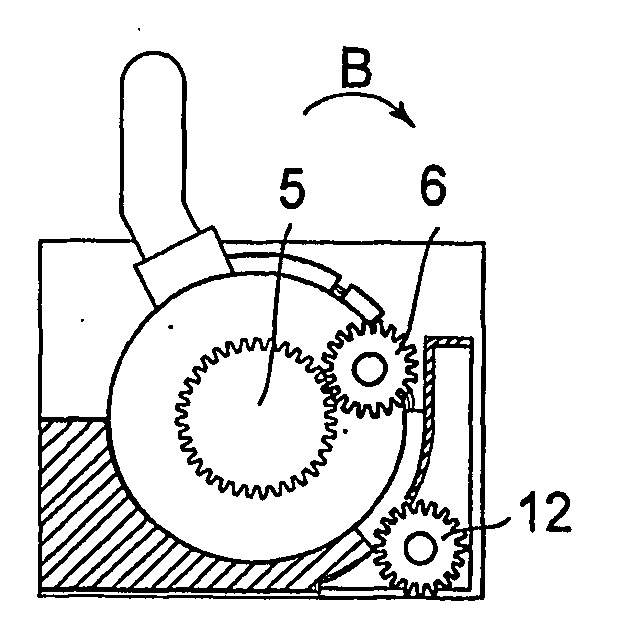

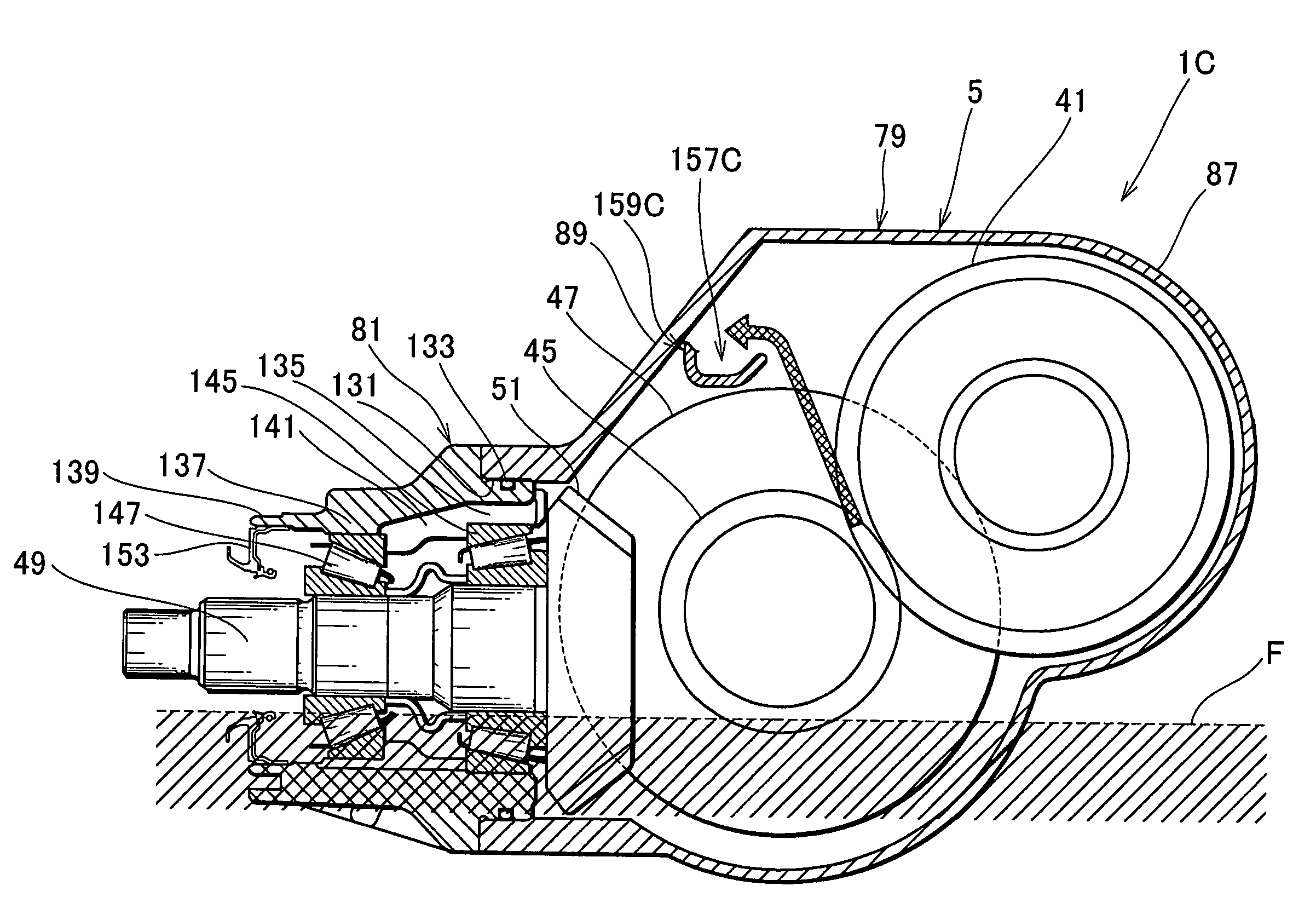

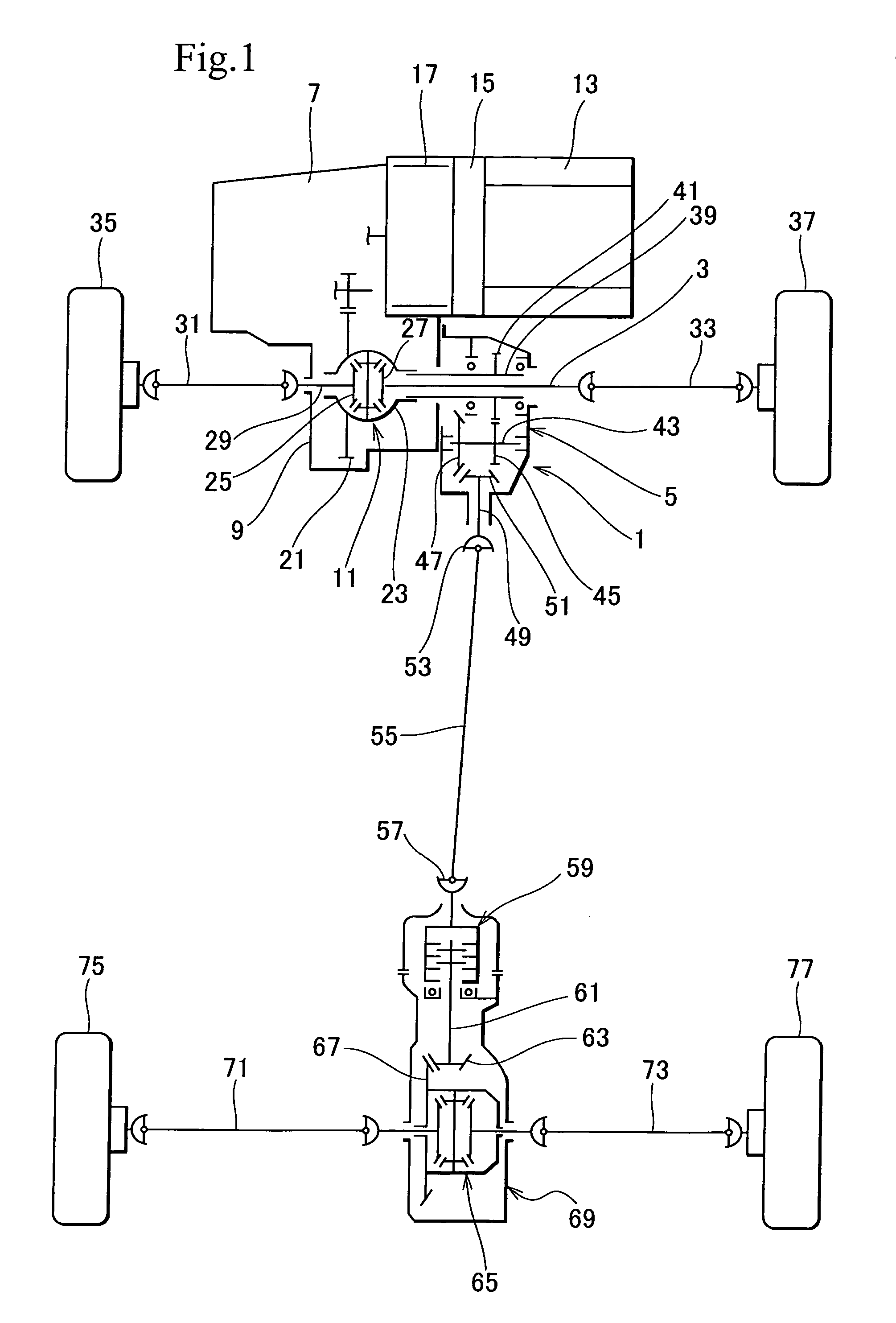

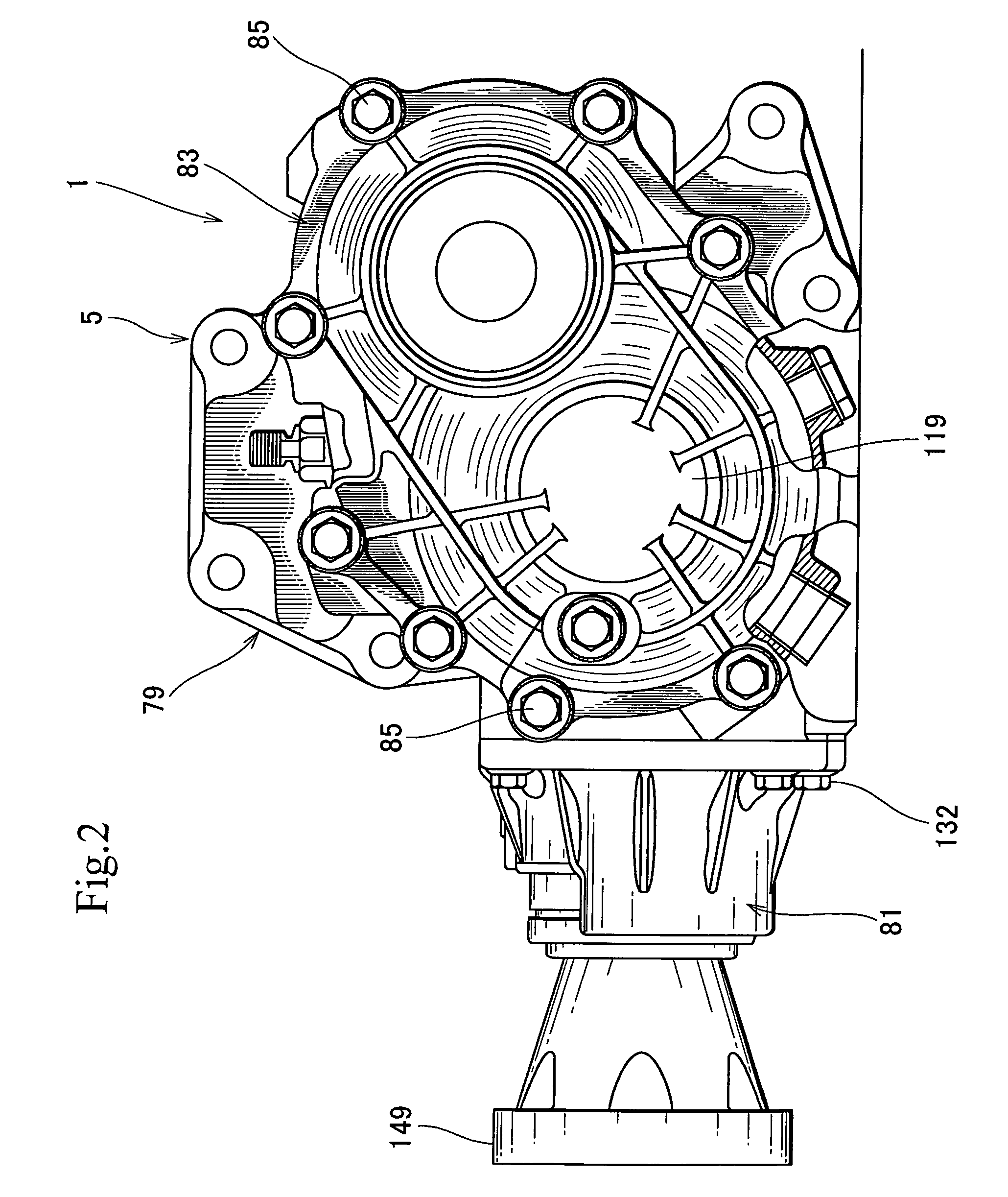

Power transmission apparatus

InactiveUS8657073B2Accurate supplyDrip or splash lubricationGear lubrication/coolingElectric power transmissionTransfer case

A power transmission apparatus is capable of easily passing lubricant toward a seal arranged between a higher shat and an opening of a case of the apparatus. The apparatus includes the higher shaft, i.e., a hollow connecting shaft that faces the outside of the transfer case through the opening of the transfer case. The oil seal is arranged between the hollow shaft and the opening of the transfer case. The hollow shaft meshes, through helical spur gears, with an intermediate transferring shaft that is positioned lower than the hollow shaft. A lubricant guide is arranged to receive lubricant splashed up by the ring gear and helical spur gear of the intermediate shaft and guide the received lubricant toward the oil seal and a ball bearing.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK

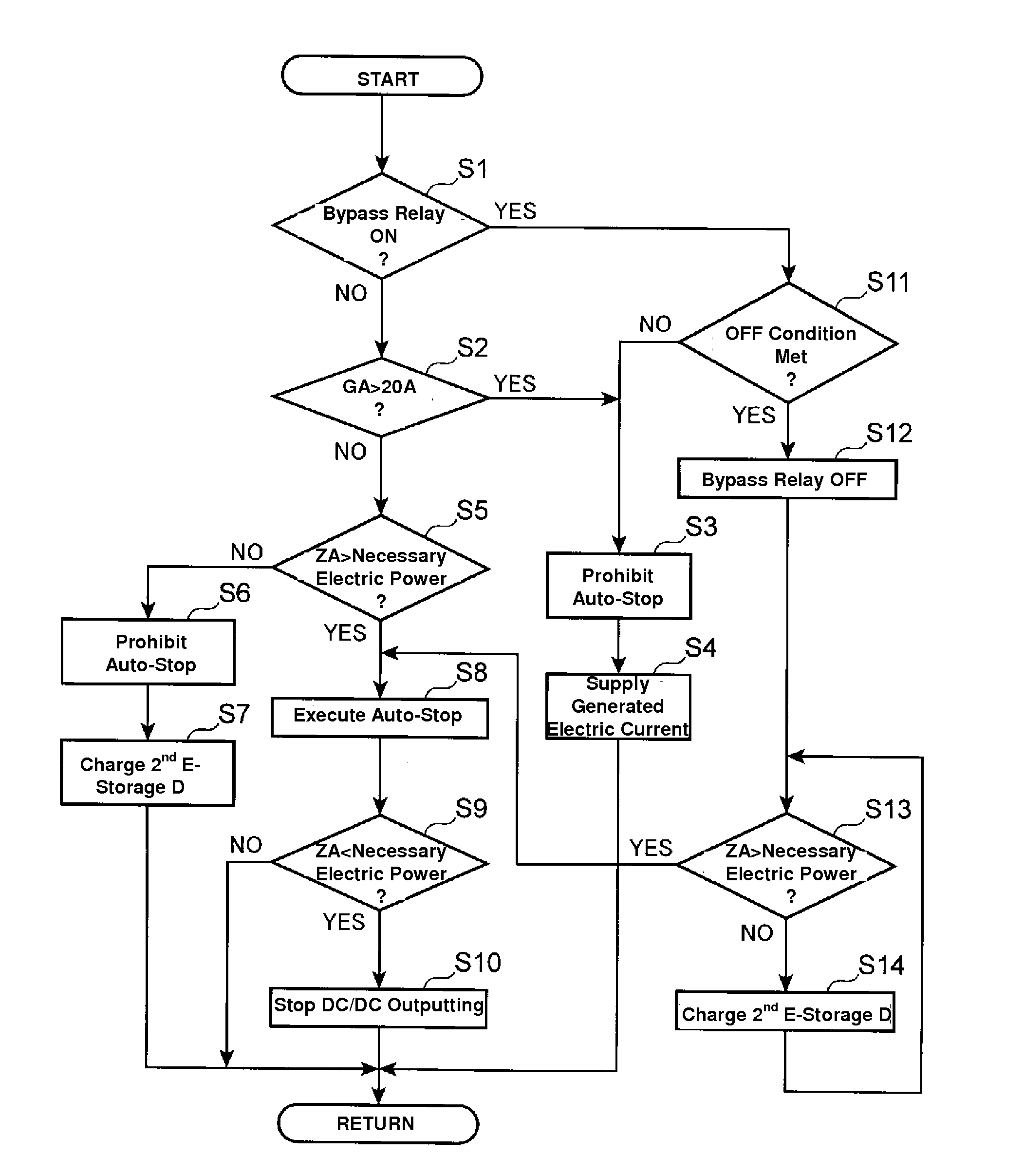

Power-supply control apparatus of vehicle

InactiveUS20120296506A1Simple constitutionAccurate supplyDc network circuit arrangementsBatteries circuit arrangementsExecution controlElectric energy

A power-supply control apparatus of a vehicle comprises a first electricity-storage device to supply electric power to a starter for starting engine, a generator to convert kinetic energy of the vehicle during a vehicle deceleration to electric energy for energy recovery, a second electricity-storage device coupled to the generator to store the electric power from the generator thereat, a feeder circuit coupling the second electricity-storage device to an electric load with a relatively-small electric-load capacity via a DC / DC convertor, a coupling line coupling the second electricity-storage device to the first electricity-storage device via a coupling relay, and a controller to control the electric power passing through the feeder circuit and the coupling line, wherein the controller executes a control to make the coupling relay on the coupling line in an OFF state when the starter operates.

Owner:MAZDA MOTOR CORP

Standardized construction method for hydraulic prefabricated member based on BIM (Building Information Modeling)

InactiveCN106326536APrecise layoutFast, accurate and reasonable arrangementDesign optimisation/simulationSpecial data processing applicationsEngineeringControl parameters

The invention provides a standardized construction method for a hydraulic prefabricated member based on BIM (Building Information Modeling). The standardized construction method comprises the following steps: S1, modeling a three-dimensional parameterization model by using a BIM modeling tool, and further implementing the design of three-dimension drawing according to the model; S2, dividing and classifying project units according to different members; S3, deploying corresponding members in a three-dimensional model of a specific project; S4, exporting to obtain an arrangement drawing, a detail table and control parameters of the members, and counting the project quantity of the members; S5, performing BIM on a prefabricated field, and guiding capital construction of the prefabricated field based on the BIM; S6, exporting the three-dimensional parameterization model, thereby performing specific three-dimension design and structure operation on the members; S7, simulating all stages of field operation for prefabricating the members; S8, implementing field prefabrication of the members; S9, prefabricating the members and implanting chips containing traceable prefabrication quality information of the members into the members; S10, after prefabrication of the members is finished, performing hanging safe construction on the members.

Owner:上海交通建设总承包有限公司

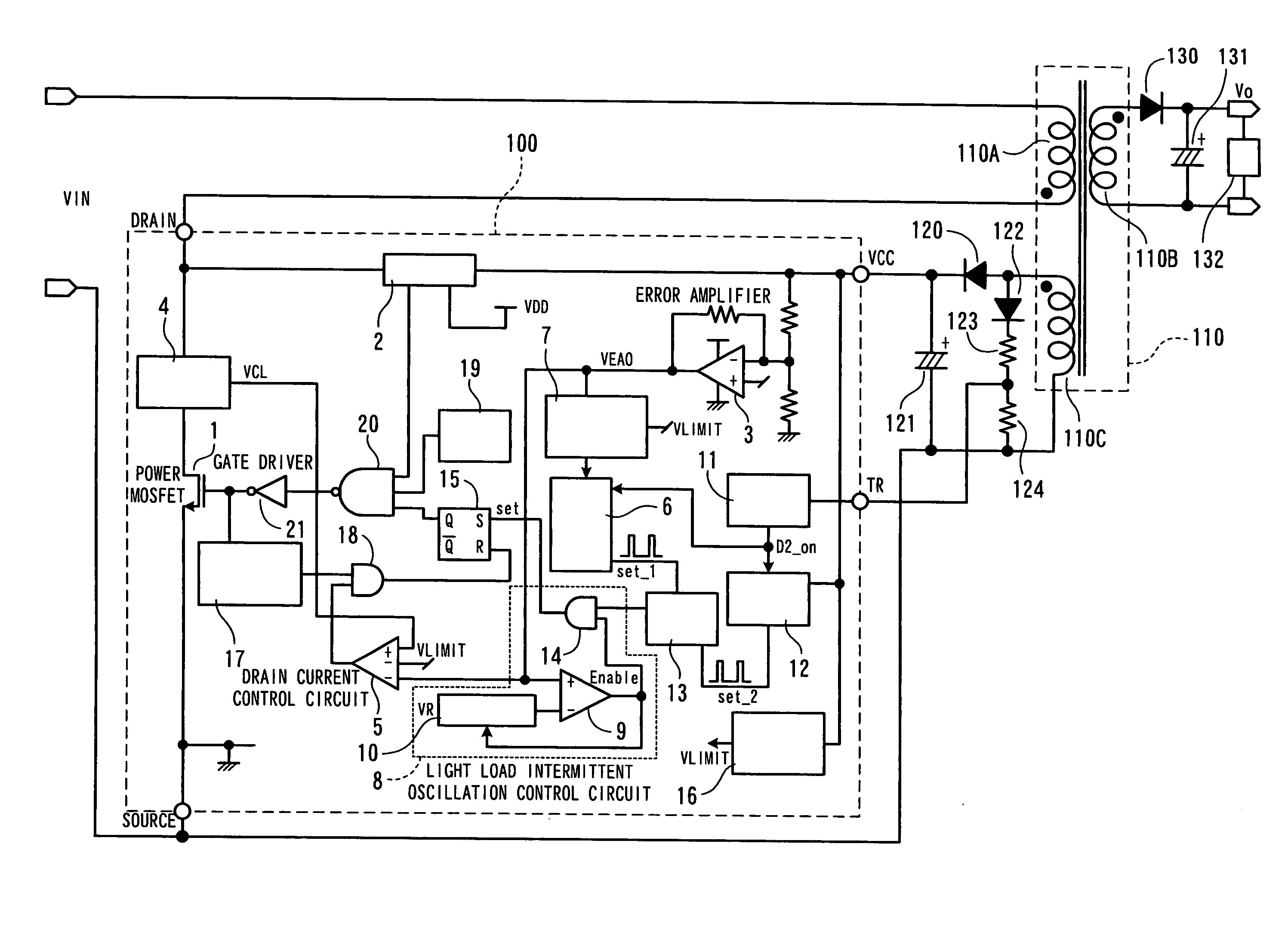

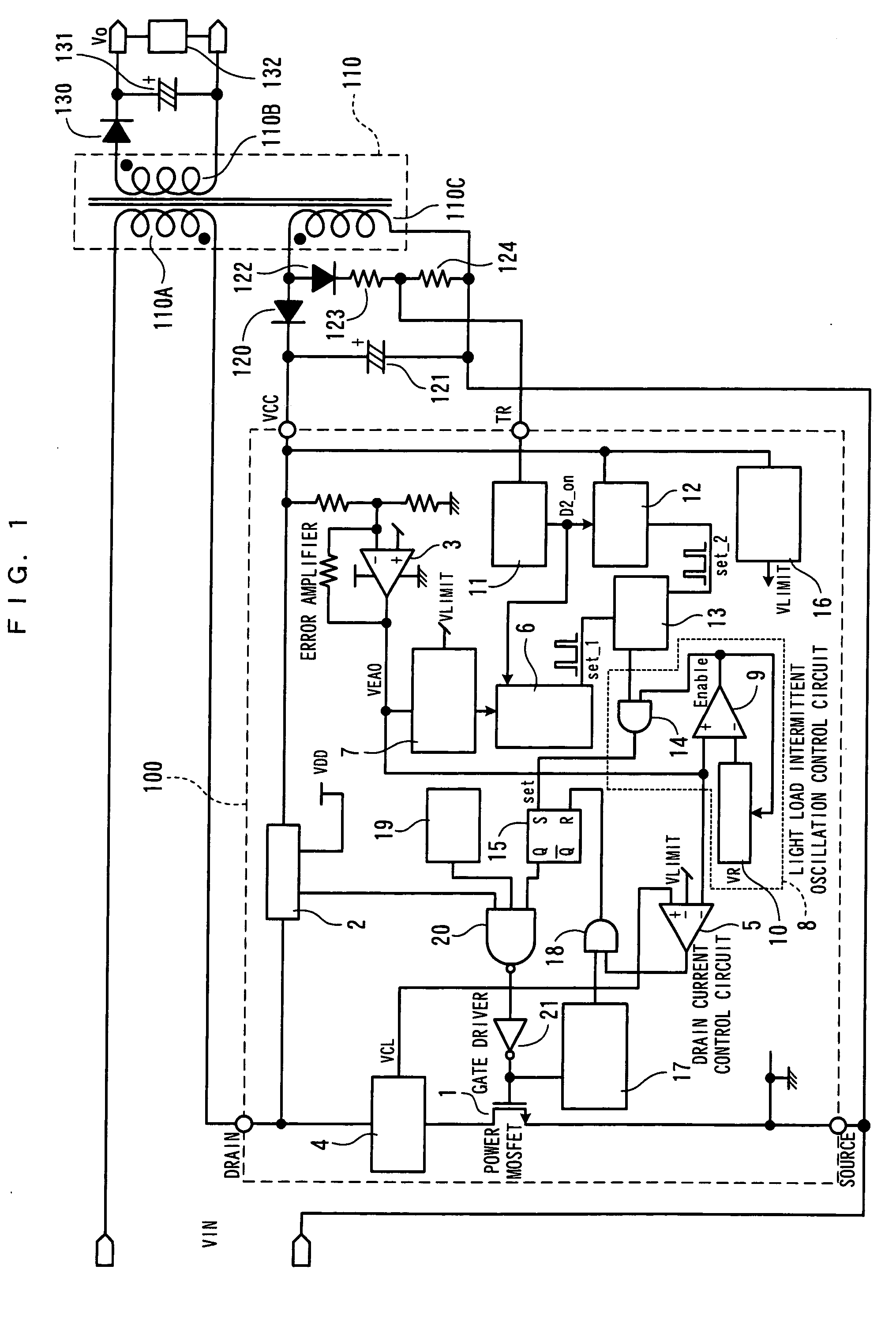

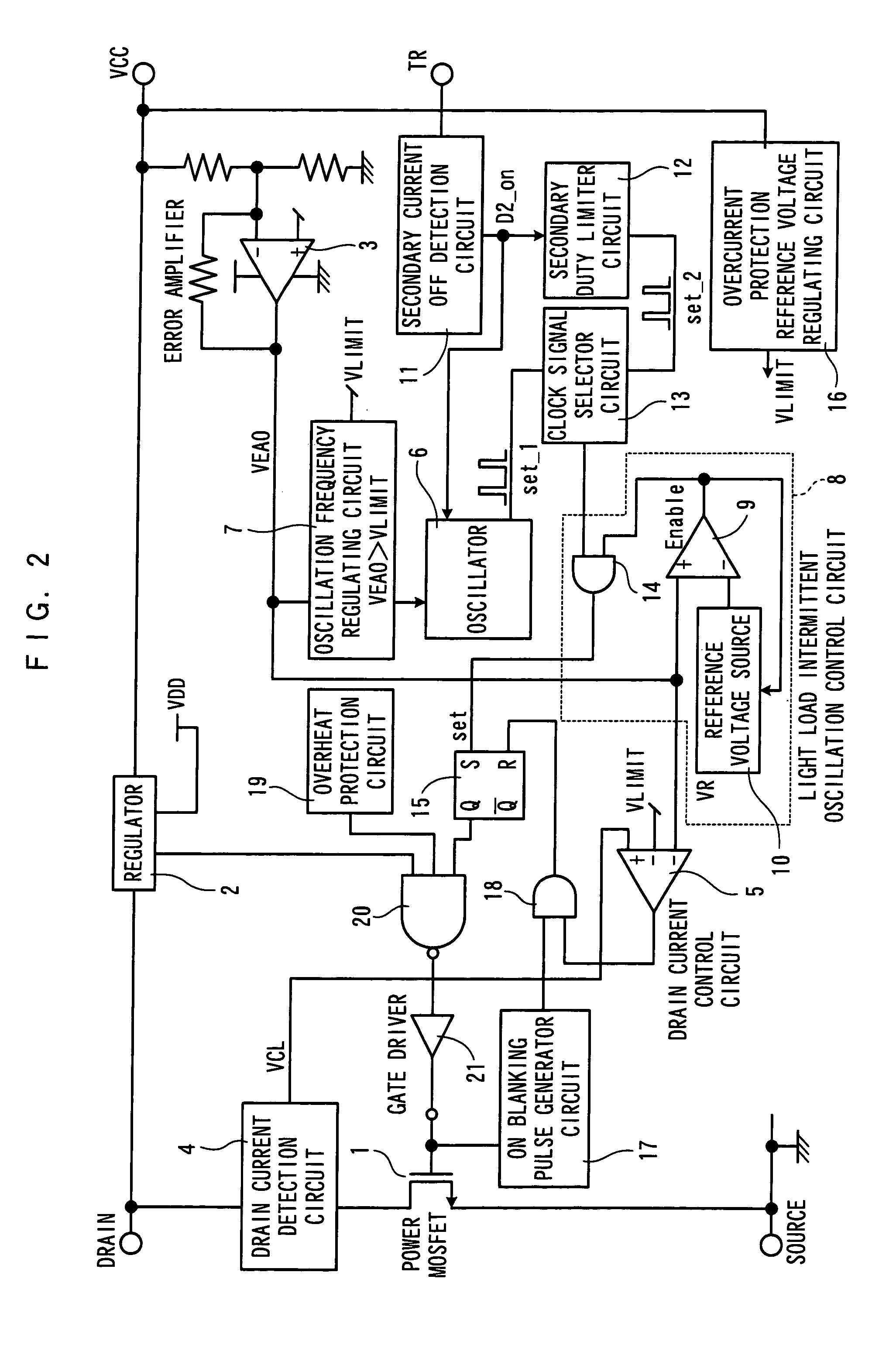

Switching power supply

InactiveUS20050259455A1Low costMinimal number of componentAc-dc conversionApparatus with intermediate ac conversionTransformerPeak value

A switching power supply for achieving a constant current drooping characteristic of sufficient accuracy with low cost and the minimum number of components. In the switching power supply, a secondary duty limiter circuit outputs a clock signal from the time a switching element is turned off until the time the on duty of secondary current, which starts flowing to a secondary winding of a transformer, is fixed at a predetermined value. A clock signal selector circuit selects and outputs the clock signal when a load increases and the on duty of the secondary current reaches the predetermined value. Consequently, when the load increases, a direct current output voltage decreases and an output characteristic becomes a constant current drooping characteristic. At this point, when the voltage of an element current detection signal reaches an overcurrent protection reference voltage, a drain current control circuit outputs a turn-off signal for determining the turn-off of the switching element, therefore the peak current of the secondary current is kept at a fixed value.

Owner:COLLABO INNOVATIONS INC

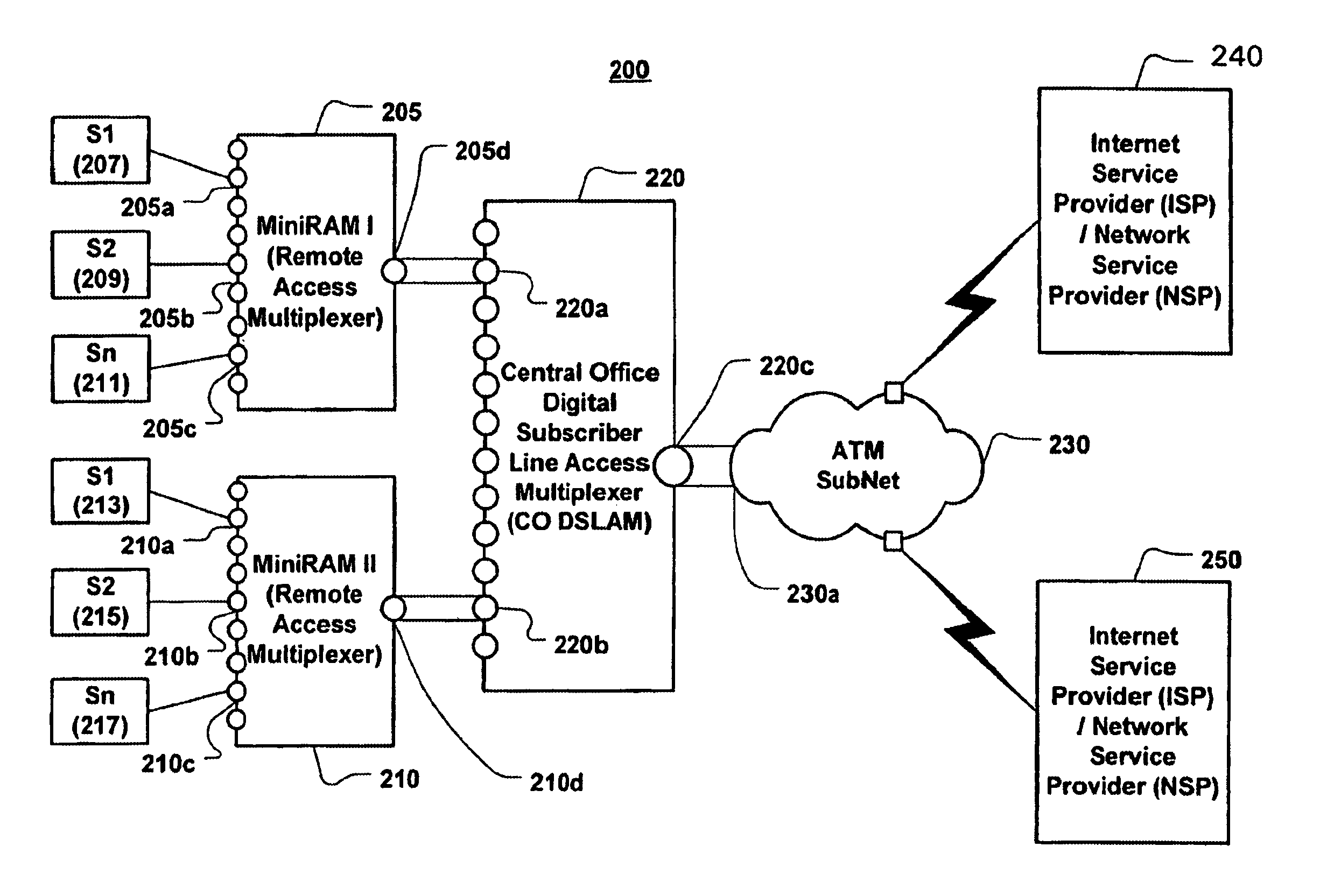

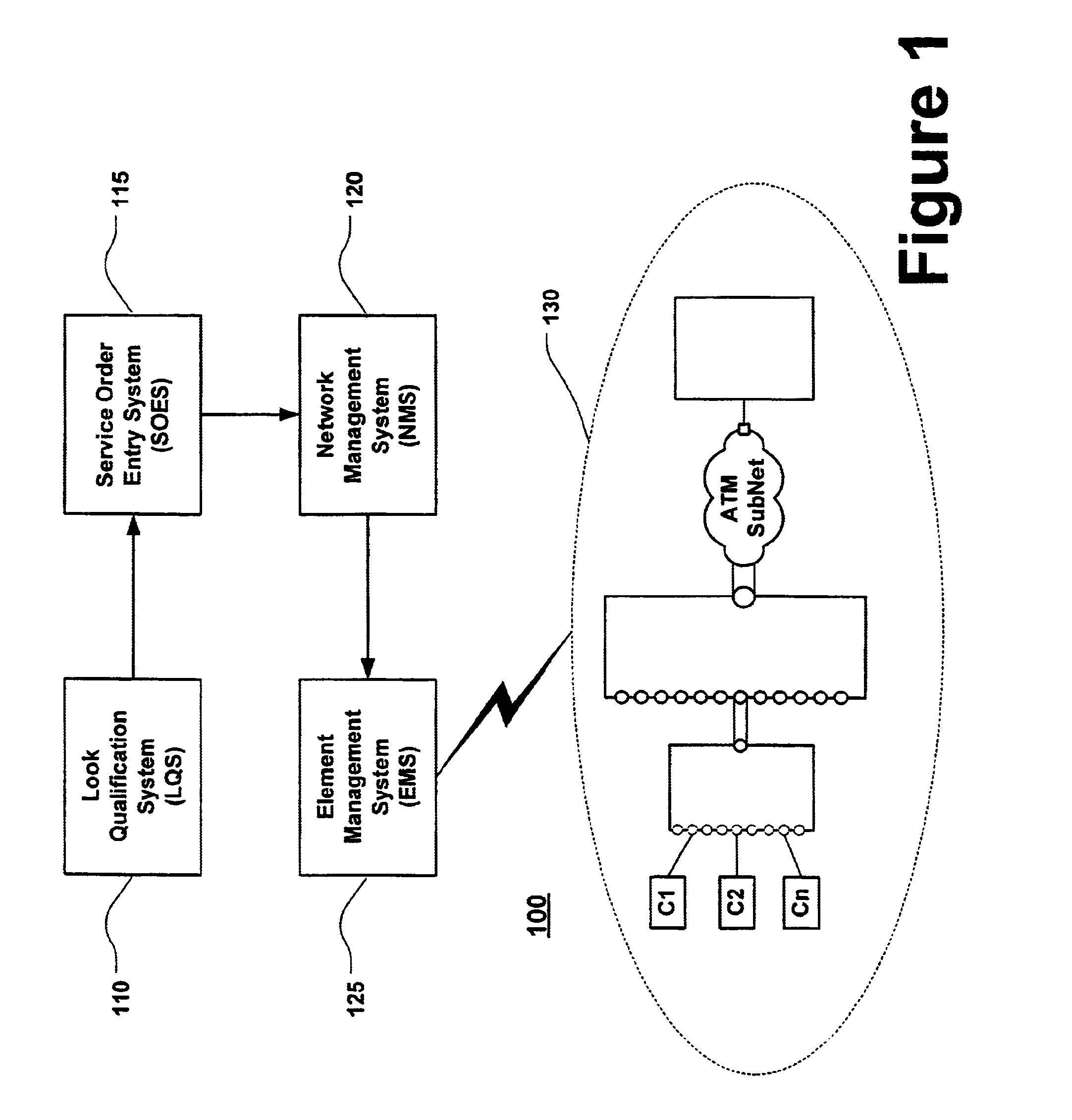

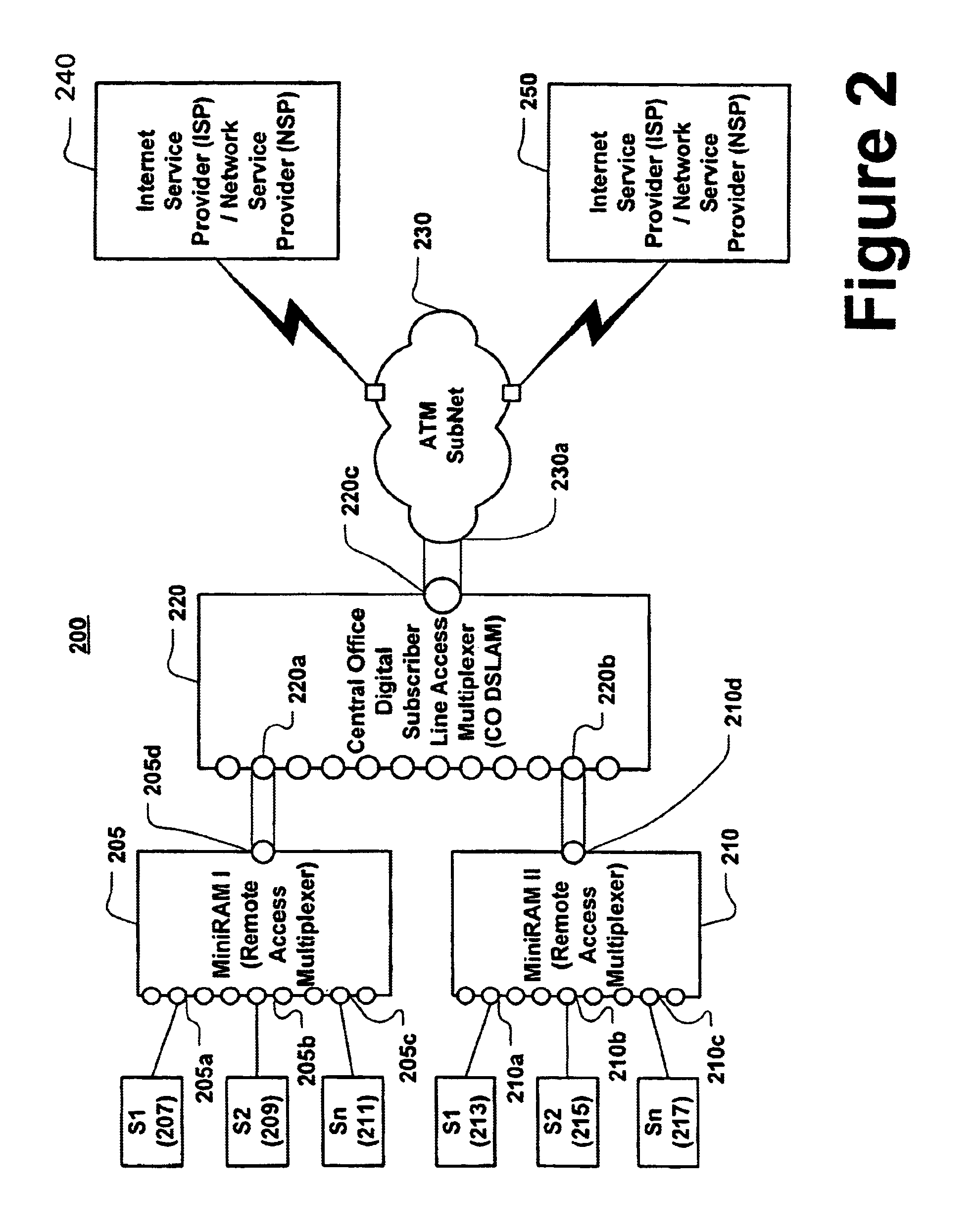

Asynchronous digital subscriber line (ADSL) resource planning

InactiveUS6873628B1Easy to optimizeEasy to calculateMultiplex system selection arrangementsFrequency-division multiplexNetwork managementAsymmetric digital subscriber line

A system and methods to optimize the resource planning of ADSL services is provided. In an illustrative implementation, a network management system (NMS) communicates with an ADSL network to provision resources for participating users. The provisioning process yields a permanent virtual circuit (PVC). Included in the provisioning process is the creation and management of configuration variables, such as, the virtual path identifier (VPI) and the virtual circuit identifier (VCI). The VPI / VCI combination uniquely identifies each PVC. If the provisioning process is aborted or fails, it may be reanimated by the NMS using the VPI / VCI combination. In this implementation, the VPI may be set to a constant value and the VCI value calculated using ADSL configuration values (e.g. the physical connection position on a first, second, third, etc. ADSL network component.) The deterministic nature of the VPI and VCI configuration variables assist the NMS to track and optimize available resources.

Owner:AT&T INTPROP I L P

Brake condition monitoring

InactiveUS20060191751A1Accurate supplyPrecise maintenanceFinanceAircraft braking arrangementsPaymentFlight vehicle

A system and method for monitoring the usage of brake members of an aircraft braking system. The system makes a separate record of each brake actuation in which there is relative movement of the brake member's facing friction surfaces which causes wear, determines the types of brake usage and operates a pricing / payment scheme to charge for brake usage.

Owner:MEGGITT AEROSPACE

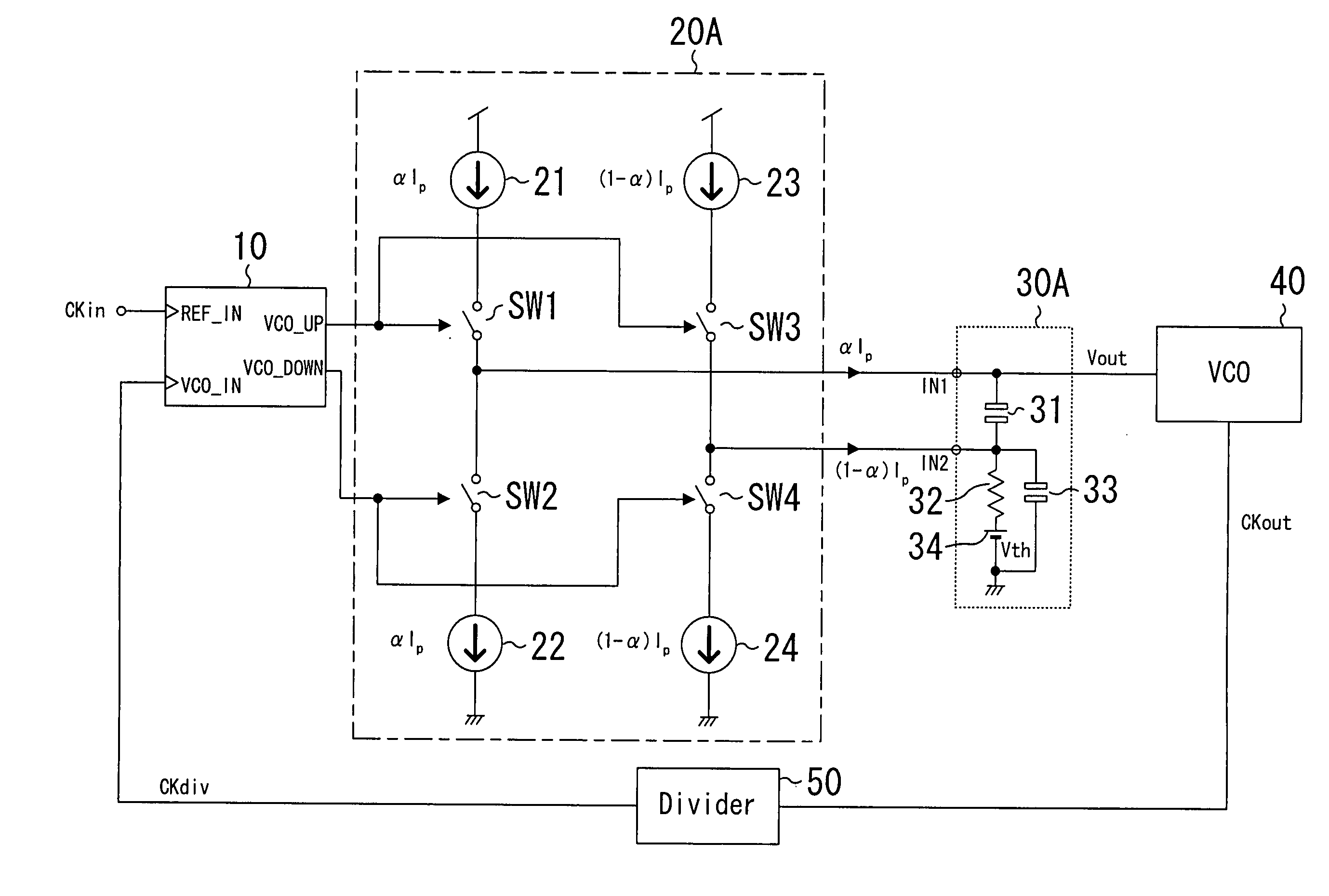

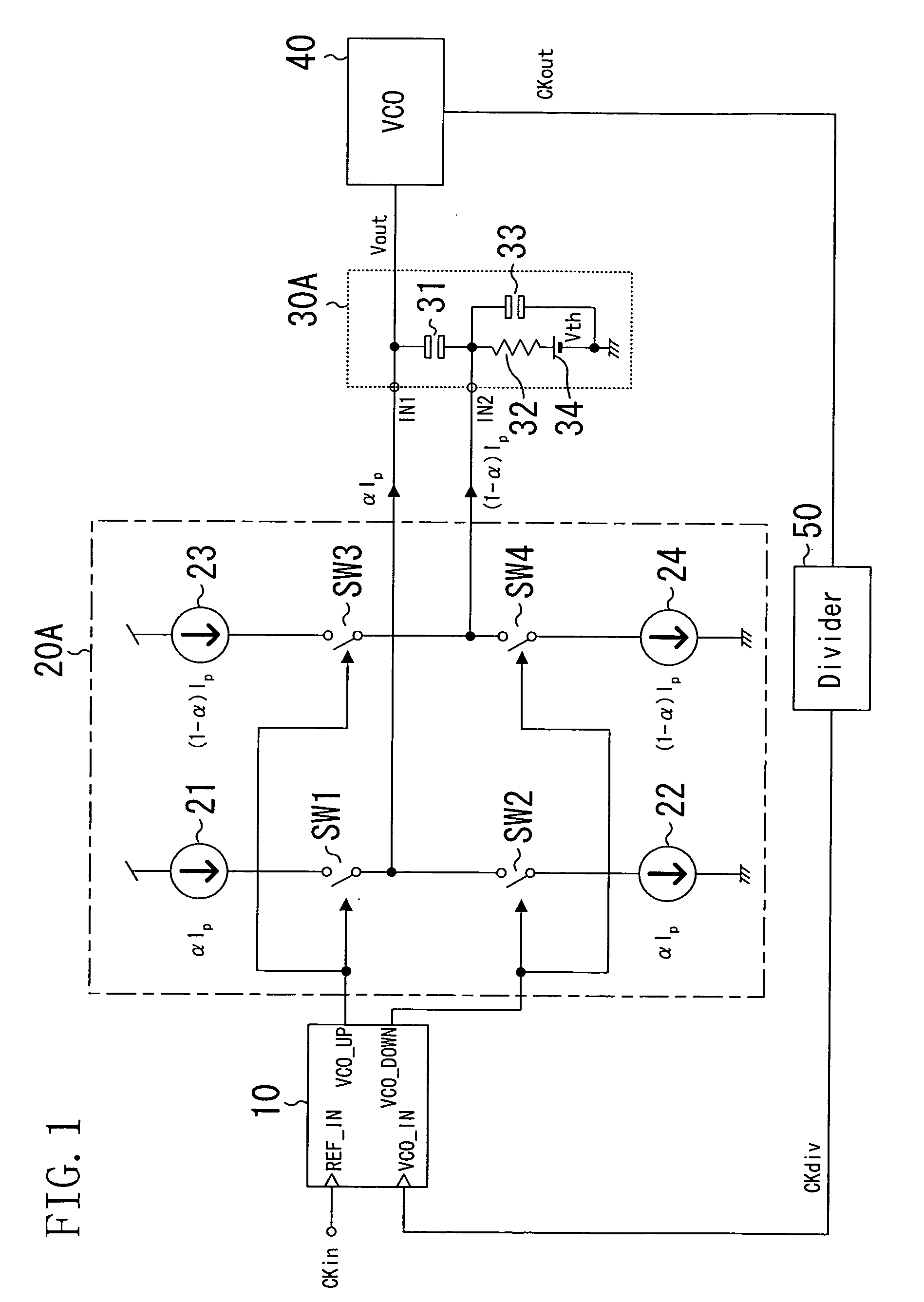

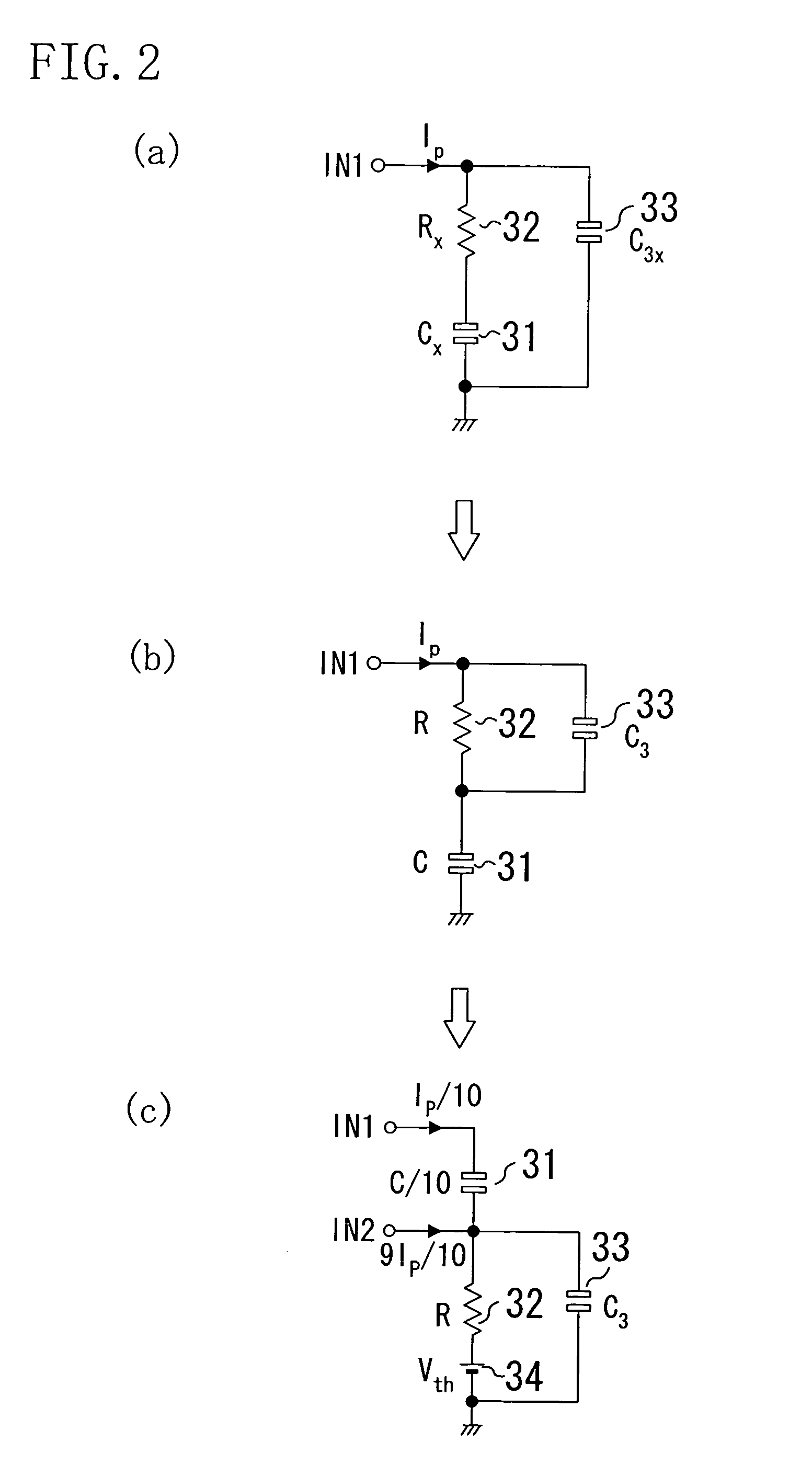

Low-pass filter and feedback system

InactiveUS6995607B2Easy to useSmall sizeMultiple-port networksPulse automatic controlCapacitanceBand-pass filter

In a low-pass filter, the filter characteristics equivalent to those of a conventional low-pass filter are maintained, the size of a capacitive element is decreased, and the low-pass filter operates stably. Further, a MOS capacitor is used as a capacitive element. For such purposes, in a low-pass filter including a first capacitive element, and a resistive element and a second capacitive element which are connected in series to the first capacitive element, a first electric current is supplied to the first input terminal connected to one end of the first capacitive element, and a second electric current is supplied to the second input terminal connected to the other end of the first capacitive element. Herein, the capacitance value of the first capacitive element is set according to the magnitude of the first electric current. Further, the resistive element is provided with a power supply that is connected in series to the resistive element, and a voltage equal to or higher than the threshold voltage of a MOS transistor is always applied between the second input terminal and the ground.

Owner:PANASONIC CORP

Electro-optical device, driving method of electro-optical device and electronic apparatus

An electro-optical device includes a first storage capacitor that has a first electrode and a second electrode, and a second storage capacitor that has a third electrode and a fourth electrode, and a first pixel circuit. The first pixel circuit includes a first transistor having a first gate, a first drain, and a first source, an electro-optical element, a second transistor through which a first data line is electrically connected to the first gate during the second transistor is in an on-state, and a third transistor through which the first gate is electrically connected to the first drain or the first source. The second electrode and the third electrode are electrically connected to the first data line.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com