Patents

Literature

202results about How to "Timely supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pregnant sow feeding mode

ActiveCN103960548AIncrease exercisePromote absorptionFood processingAnimal feeding stuffPregnancy second trimesterMortality rate

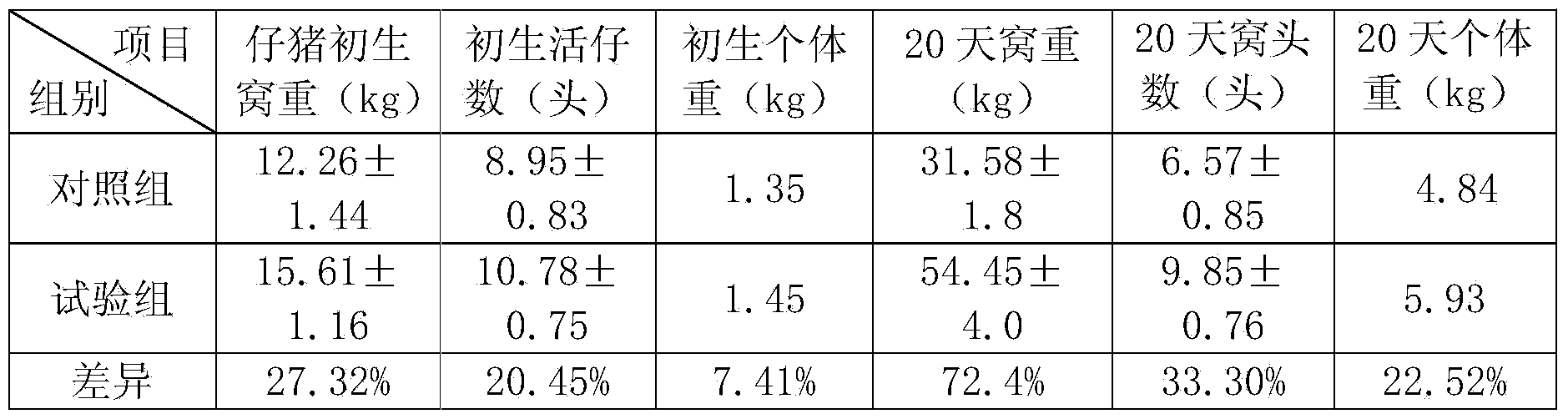

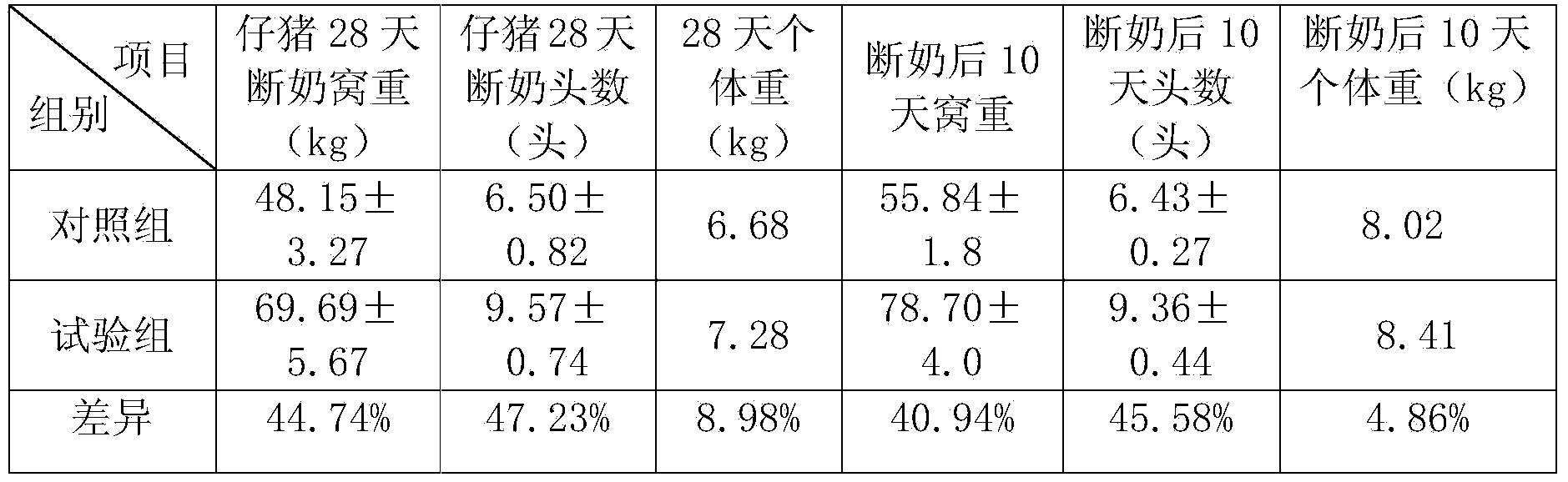

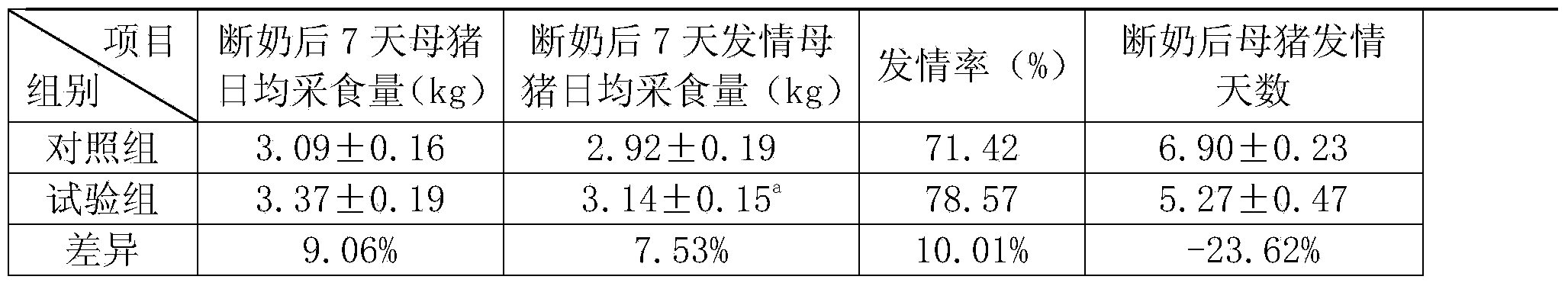

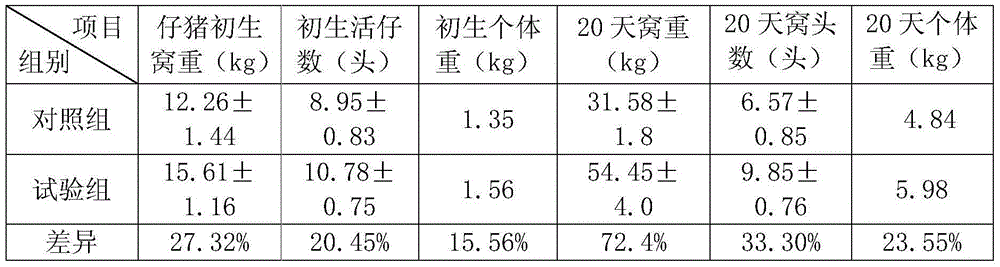

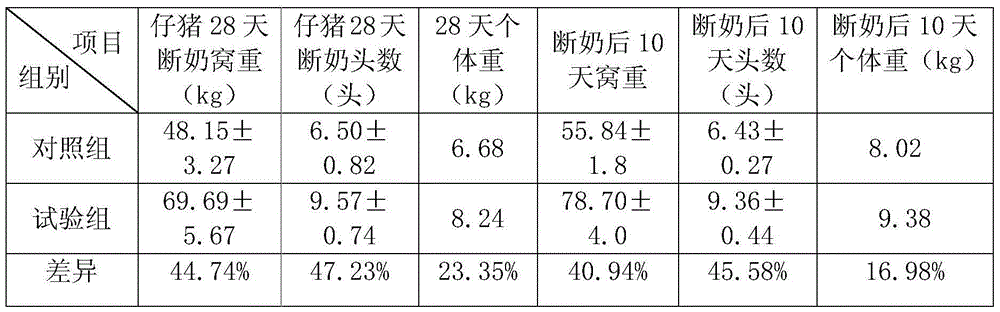

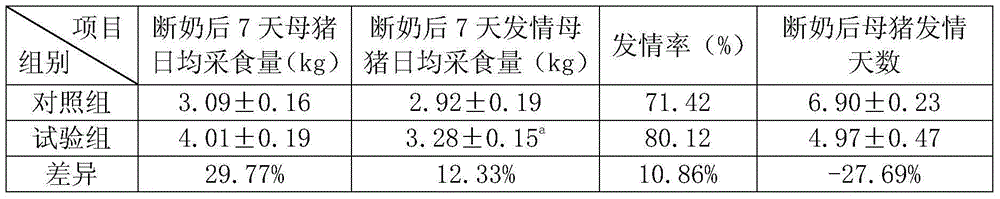

The invention discloses a pregnant sow feeding mode and belongs to the technical field of sow breeding. Aiming at physiological characteristics and nutritional requirements of sows during gestation period, the physiological stage of pregnant sows is further subdivided, the nutritional requirements of the pregnant sows at each stage per day are specified, and the body conditions, feeding environments and the like of different pregnant sows are combined. Meanwhile, aiming at the physiological characteristics and feeding modes of the pregnant sows at each stage, pregnancy beginning feed, pregnancy first-half-period feed, pregnancy second trimester feed, pregnancy latter half feed and perinatal feed are scientifically compounded. A reasonable, detailed and scientific feeding mode is formulated, the motion quantity of the pregnant sows can be effectively improved, the nutrient substances are accurately and timely supplied, the functions of the digestion and absorption system and immune system of the pregnant sows are promoted and improved, the number of living piglets is obviously increased, the embryo mortality is reduced, and the birth weight and uniformity of piglets are improved.

Owner:LIAONING WELLHOPE AGRI TECH

Pig feed and application thereof

ActiveCN103976190AIncrease exerciseEnhance immune system functionFood processingAnimal feeding stuffMortality rateEmbryo

The invention discloses a pig feed and application thereof, belonging to the technical field of sow feeding. Physiological stages of a pregnant sow are further subdivided and detailed according to physiological characteristics and nutritional requirements of the sow during a pregnancy period, the feed suitable for each stage is provided according to the nutritional requirements of the pregnant sow at each stage each day, and a reasonable and detailed feeding method is designed by combination with body conditions, feeding environments and the like of different pregnant sows, so that the exercise of the pregnant sow can be effectively increased, nutritional substances can be accurately and timely fed, the functions of a digestive absorption system and an immunity system of the pregnant sow can be promoted and improved, the number of living piglets is remarkably increased, the embryo mortality is reduced, the birth weight of the piglets is increased, and the uniformity of the piglets is improved.

Owner:山西南山百世食安农牧业有限公司

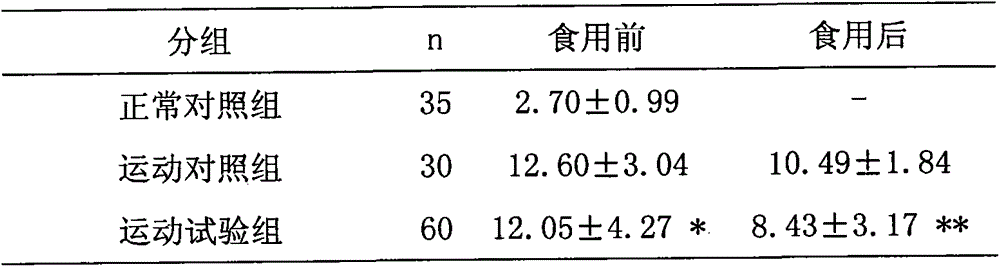

Ugine sport nutrition milk tea powder and preparation method thereof

The invention discloses ugine sport nutrition milk tea powder and a preparation method thereof and belongs to the technical fields of solid drinks, modified milk powder and nutritious foods. The milk tea powder is characterized by comprising whole milk powder, skim milk powder, whey protein powder, collagen powder, soy peptides powder, maize oligopeptide, inulin, maltodextrin, soluble soybean polysaccharide, instant tea powder, phospholipid, L-carnitine, a vitamin premix and a mineral premix. The milk tea powder disclosed by the invention has the advantages of giving a full play to the effects of nutrition complementation and cooperative gain, filling a market vacancy and integrating the functions of supplementing calcium, strengthening bones, losing the weight, relieving fatigues, keeping fit and the like; the milk tea powder is good in taste, convenient to eat, good in safety, strong in acceptability, free of toxic or side effects, simple in production process and easy to product and has a great market development potential.

Owner:BEIJING SANLIYUAN FOOD TRADING

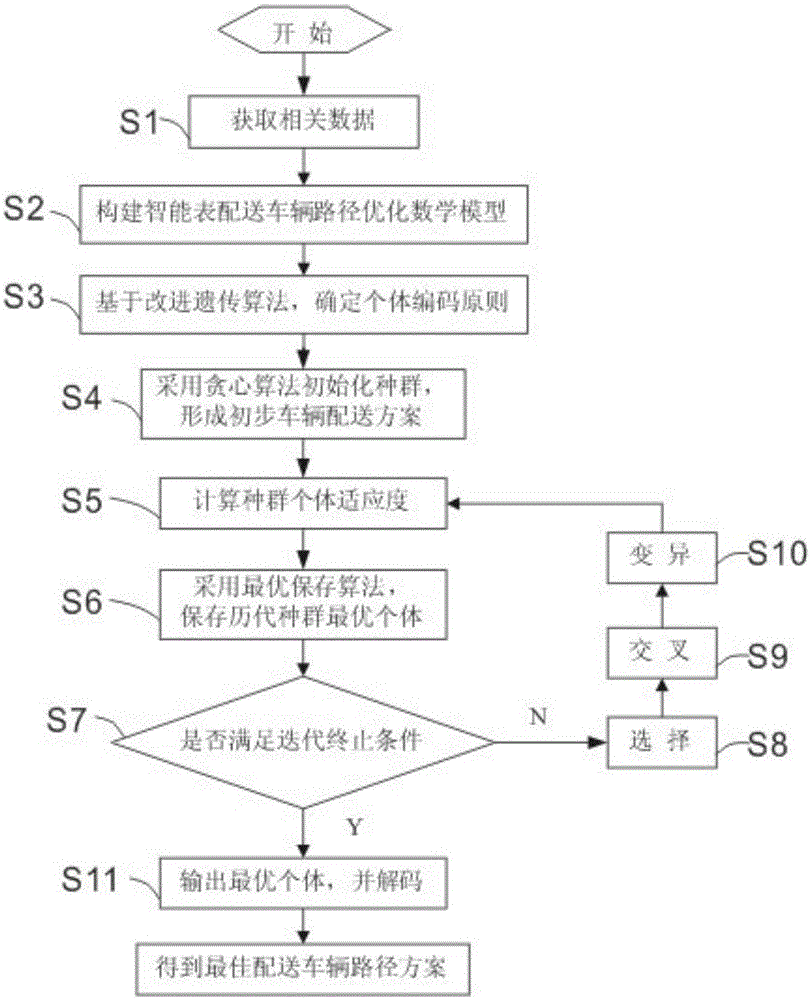

Method for optimizing a routing of an intelligent ammeter distributing vehicle

InactiveCN105096006ATimely supplyEconomic supplyForecastingLogisticsOptimal schedulingGenetic algorithm

The present invention relates to a method for optimizing a routing of an intelligent ammeter distributing vehicle. The optimization method mainly considers an intelligent ammeter distributing plan from a perspective of time and space, converts a problem of routing planning of the intelligent ammeter distributing vehicle into a problem of vehicle routing optimal scheduling with a distribution center, many vehicles, and a restriction of capacity and time by combining with a real situation of a provincial level measuring center, establishes a corresponding mathematical model, and solves and analyze the mathematical model by adopting an improved genetric algorithm so as to obtain a reasonable routing plan of the intelligent ammeter distribution vehicle. The method avoids many defects of a traditional intelligent meter distributing plan which is manually made, and provides a powerful support for the timely, economic, efficient and accurate intelligent ammeter distribution.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

LCD instilling device and method thereof

The invention relates to a LCD instillation arrangement and its instillation method. The arrangement comprises a LCD container for holding LCD, a LCD dropping tube for dropping LCD from LCD container to LCD panel, a first induction apparatus for monitoring residual amount in LCD container, a LCD replenishment container for supplying the LCD container with LCD, and a LCD carrier pipe for connecting the bottom of the LCD replenishment container and the LCD container. The LCD instillation arrangement and instillation method incorporating the invention has improved productivity which can be used to drop for a plurality of LCD panels and saved the cost.

Owner:KUSN INFOVISION OPTOELECTRONICS

Multifunctional fertilizer dedicated for nursery stock and preparation method thereof

InactiveCN101265137AEasy to useImprove seedling rateFertilizer mixturesMicroorganismSoil organic matter

The invention relates to a multifunctional seedling special fertilizer and a preparation method thereof, and belongs to the technology field of fertilizer. The multifunctional seedling special fertilizer comprises the following components: A components comprising plant ashes, rooting powders and malathion, B components comprising nitrogenous fertilizer, phosphate fertilizer and potash fertilizer, and C components comprising acidity regulator. The fertilizer is prepared by the following method: the material in the B components is crushed, appropriate acidity regulator is added in the plant ashes, the rooting powders and the malathion are added after the pH value of the plant ashes is adjusted to 6 to 8 to form the A components; the A components and the B components are evenly mixed, and pelleting adhesive is added for pelleting and drying. The multifunctional seedling special fertilizer has obvious improving effect to soil, increases the content of organic matters in the soil, and effectively keeps soil from packing together; the organic matters in the soil can be increased by 15 percent to 30 percent after using the fertilizer for 3 to 4 years. The soil microbiota is improved obviously.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Special fertilizer for seedling culture

InactiveCN105565999AIncrease the number of rootsWeight increaseSuperphosphatesAlkali orthophosphate fertiliserDiseasePhosphate

The invention discloses a special fertilizer for seedling culture. The invention is characterized in that the fertilizer is composed of the following components in parts by weight: 10-20 parts of ammonium sulfate, 8-15 parts of monoammonium phosphate, 15-20 parts of calcium superphosphate, 10-18 parts of potassium sulfate, 4-9 parts of sulfur, 2-4 parts of ferrous sulfate, 0.02-0.04 part of malathion, 10-15 parts of livestock / poultry manure, 10-12 parts of rape seed cake, 0.8-1.5 parts of ferment, 15-25 parts of plant ash, 0.8-1.5 parts of ferment, 10-12 parts of Chinese herbal medicine residue, 15-25 parts of vinasse, 20-30 parts of weed, 5-10 parts of cottonseed meal, 15-20 parts of rice bran and 20-25 parts of medical stone. The special fertilizer for seedling culture can enhance the stocking percent, reduce the disease and pest damage and improve the soil. The special fertilizer for seedlings ensures the timely and sufficient supply of nutrients, and shortens the seedling recovery time. The plant ash and other raw materials in the special fertilizer enhance the inhibiting action on soil insects and harmful bacteria in soil, and reduce the disease and pest damage, thereby enhancing the soil organic matter content and effectively controlling soil hardening.

Owner:江苏艺轩园林景观工程有限公司

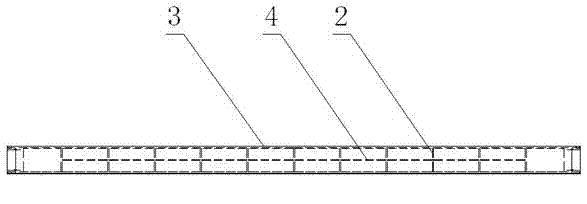

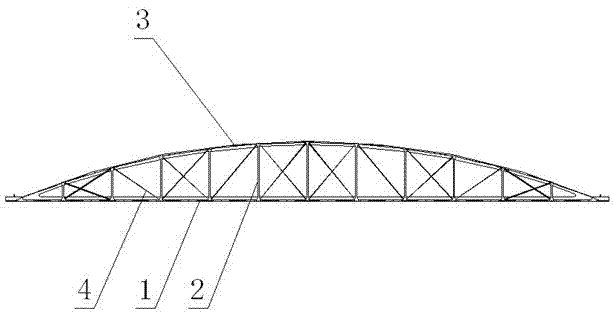

Construction method for reinforced concrete arched roof of grain store

InactiveCN102251667AReduce investmentReduce temporary land useBuilding material handlingFalseworkReinforced concrete

The invention discloses a construction method for a reinforced concrete arched roof of a grain store. The method comprises the following steps of: erecting a scaffold at the middle longitudinal part of a ring beam, and making a pedestal; paving lower chord prestressed steel bars, and performing prestressed tensioning; erecting a lower chord bottom die and a side die, installing a partition plate,and installing an upper chord arched bottom die and an upper chord arched side die at the top of the partition plate; paving upper chord steel bars; pouring concrete; stretching the prestressed steelbars when the strength of the concrete reaches over 85 percent, welding diagonal braces, and obtaining an arched plate after the diagonal braces are welded; and translating the arched plate, and welding and fixing the arched plate with an embedded steel plate. Because the construction mode of overhead prefabrication and integral translation is adopted, a large machine for hoisting is avoided, theconstruction progress is quickened, the safety risk is reduced, the cost is saved, the temporary site is reduced, and the construction efficiency is improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

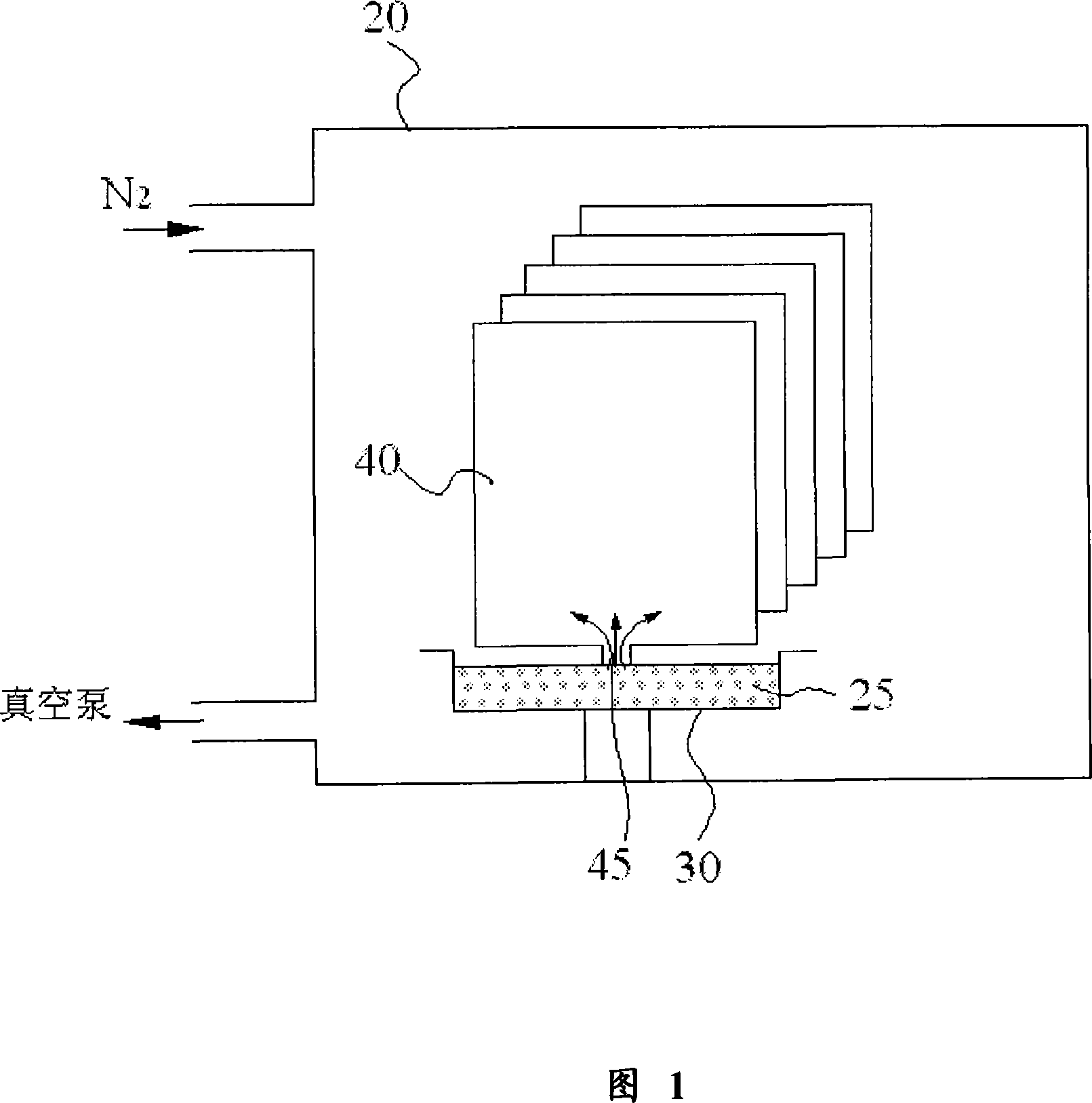

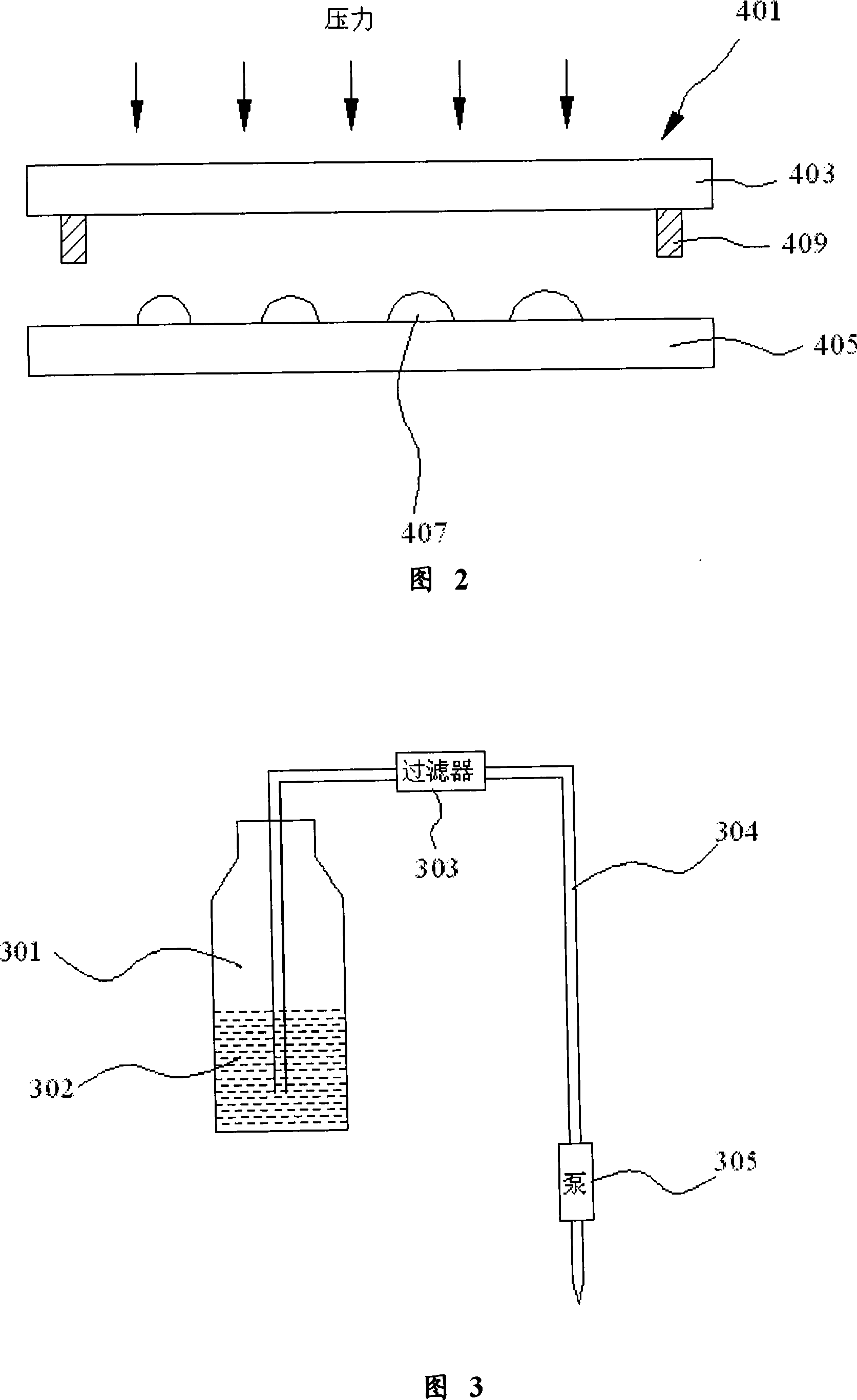

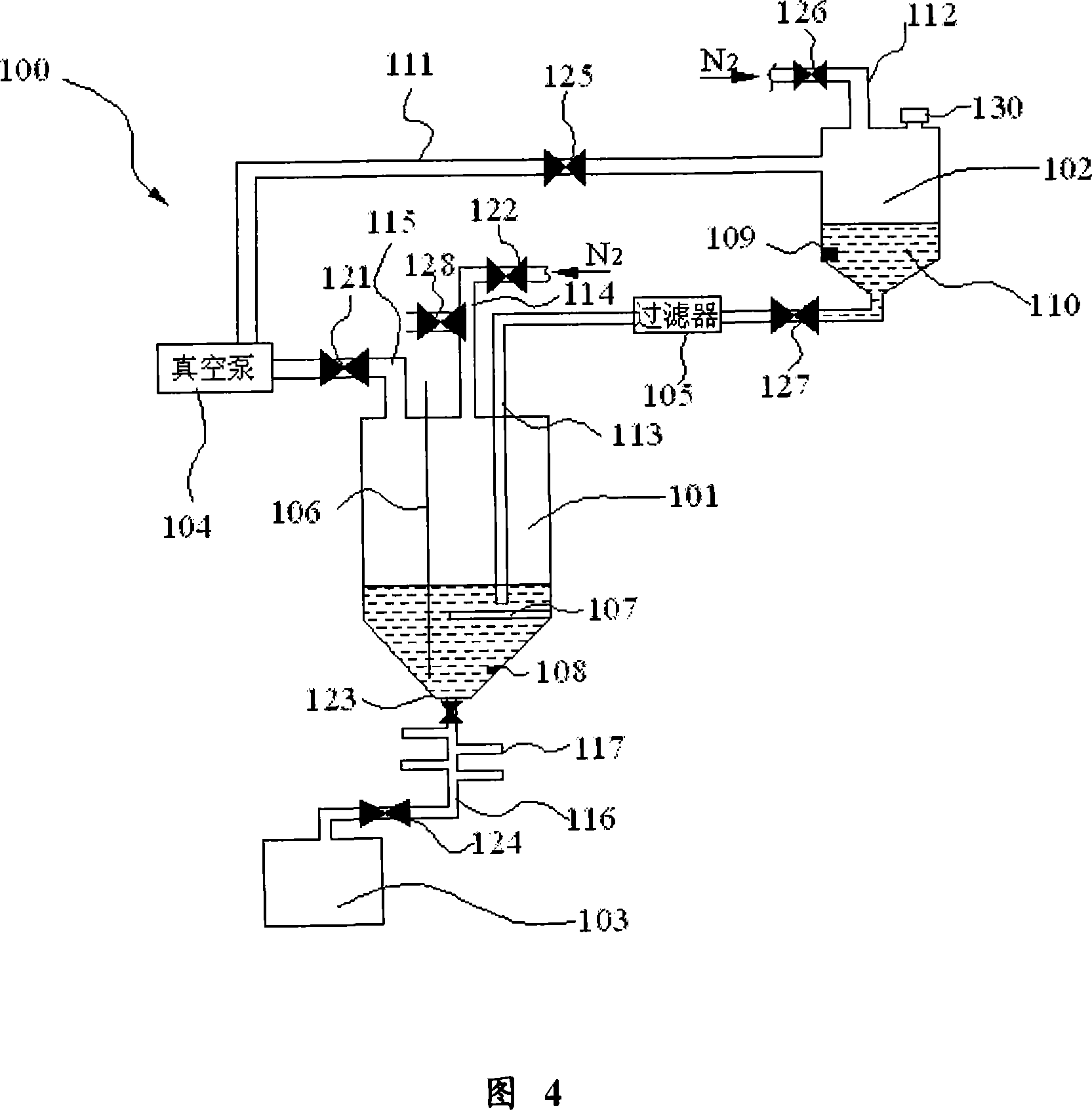

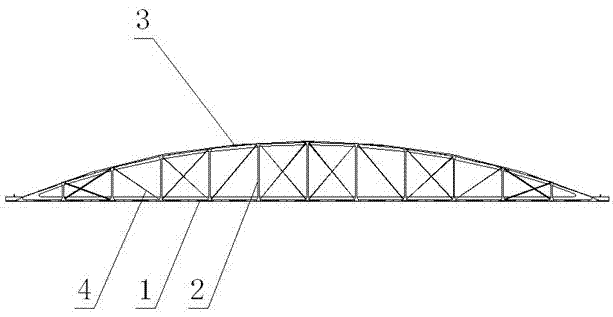

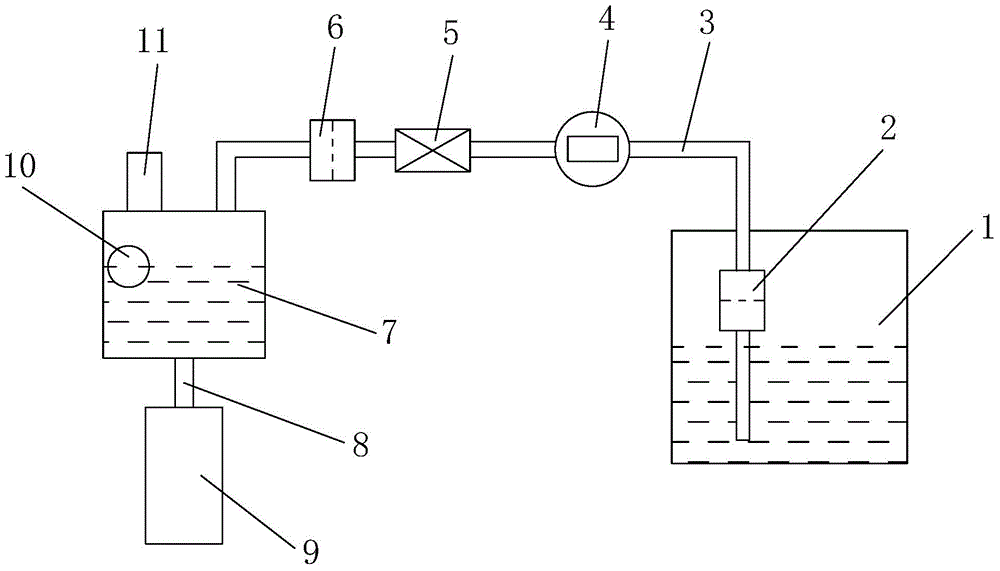

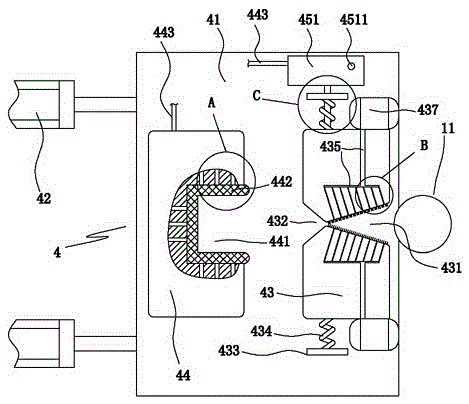

Light-cured 3D printing material supply fluid path system

InactiveCN104626403ASimple structureNovel and reasonable designPipeline systemsSolenoid valveHost material

The invention discloses a light-cured 3D printing material supply fluid path system. The system comprises a host material box, a first filter, a fluid conveying pipeline, a fluid pump, a solenoid valve, a second filter, an auxiliary material box, a flexible tube, a fluid level sensor and a negative pressure device, the host material box is arranged above the shell of a printer, the auxiliary material box is arranged on the printing head of the printer, the auxiliary material box is connected with the printing head through the flexible tube, the fluid level sensor is arranged in the auxiliary material box, the negative pressure device is arranged at the top of the auxiliary material box, one end of the fluid conveying pipeline stretches into the host material box, the other end of the fluid conveying pipeline is connected with the auxiliary material box body, the first filter, the fluid pump, the solenoid valve and the second filter are sequentially arranged on the fluid conveying pipeline, the first filter is arranged on the fluid conveying pipeline in the host material box, and the second filter is arranged on the fluid conveying pipeline close to the auxiliary material box. The light-cured 3D printing material supply fluid path system shortens a distance from a printing material to the printing head, guarantees timely supply of the printing material, reduces the load of a printing system and improves the printing efficiency.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

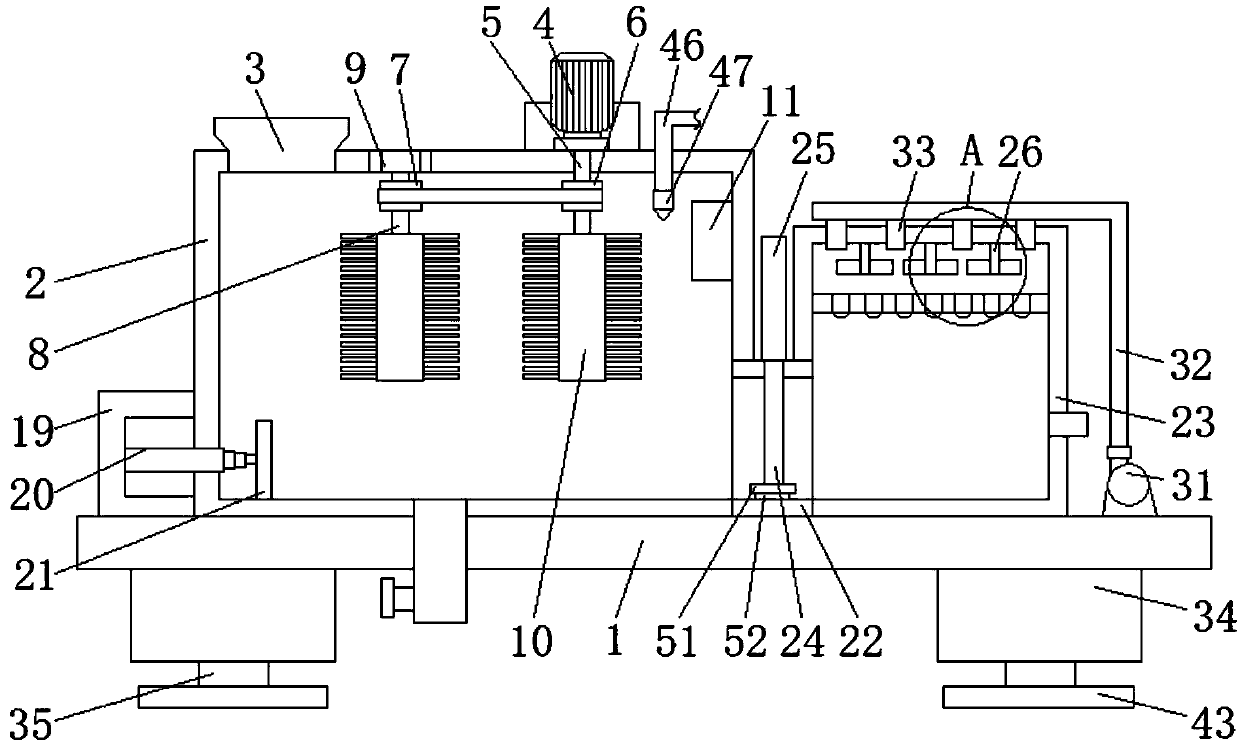

Sport equipment cleaning equipment

InactiveCN107649432AEasy to cleanEffective rotationDrying gas arrangementsCleaning using toolsDrive shaftSports equipment

The invention discloses sport equipment cleaning equipment. The sport equipment cleaning equipment comprises a base. The top of the base is fixedly connected with a cleaning tank. The top of the cleaning tank is fixedly connected with a feed port and a motor. An output shaft of the motor is fixedly connected with a transmission shaft. The end, far from the motor, of the transmission shaft penetrates through and extends into the cleaning tank. The outer surface, located in the cleaning tank, of the transmission shaft is fixedly sleeved with a first belt pulley. According to the sport equipmentcleaning equipment, the first belt pulley and a second belt pulley are arranged; under the action of a belt, two rolling brushes can be driven to rotate simultaneously to effectively clean sport equipment in the cleaning tank; through arrangement of a first button and under the action of a floating plate, a first press plate can be made to press the first button to control turn-off of the motor; through arrangement of a second button and under the action of the floating plate, a second press plate can be made to press the second button to control water inflow of a water inlet pipe. Automationof the equipment is guaranteed.

Owner:赵顺豪

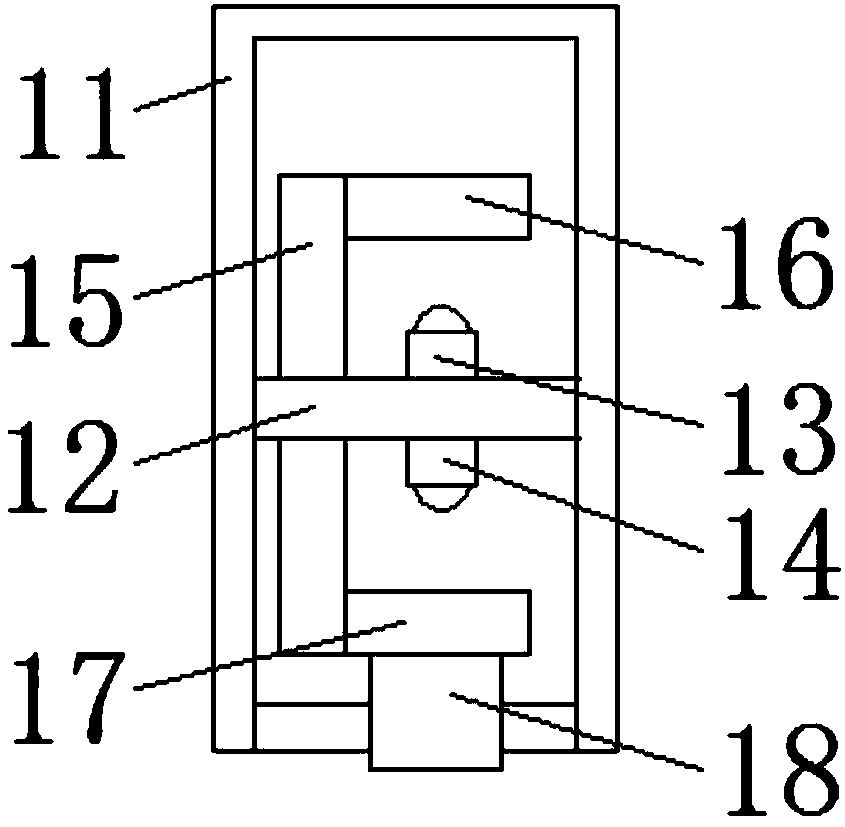

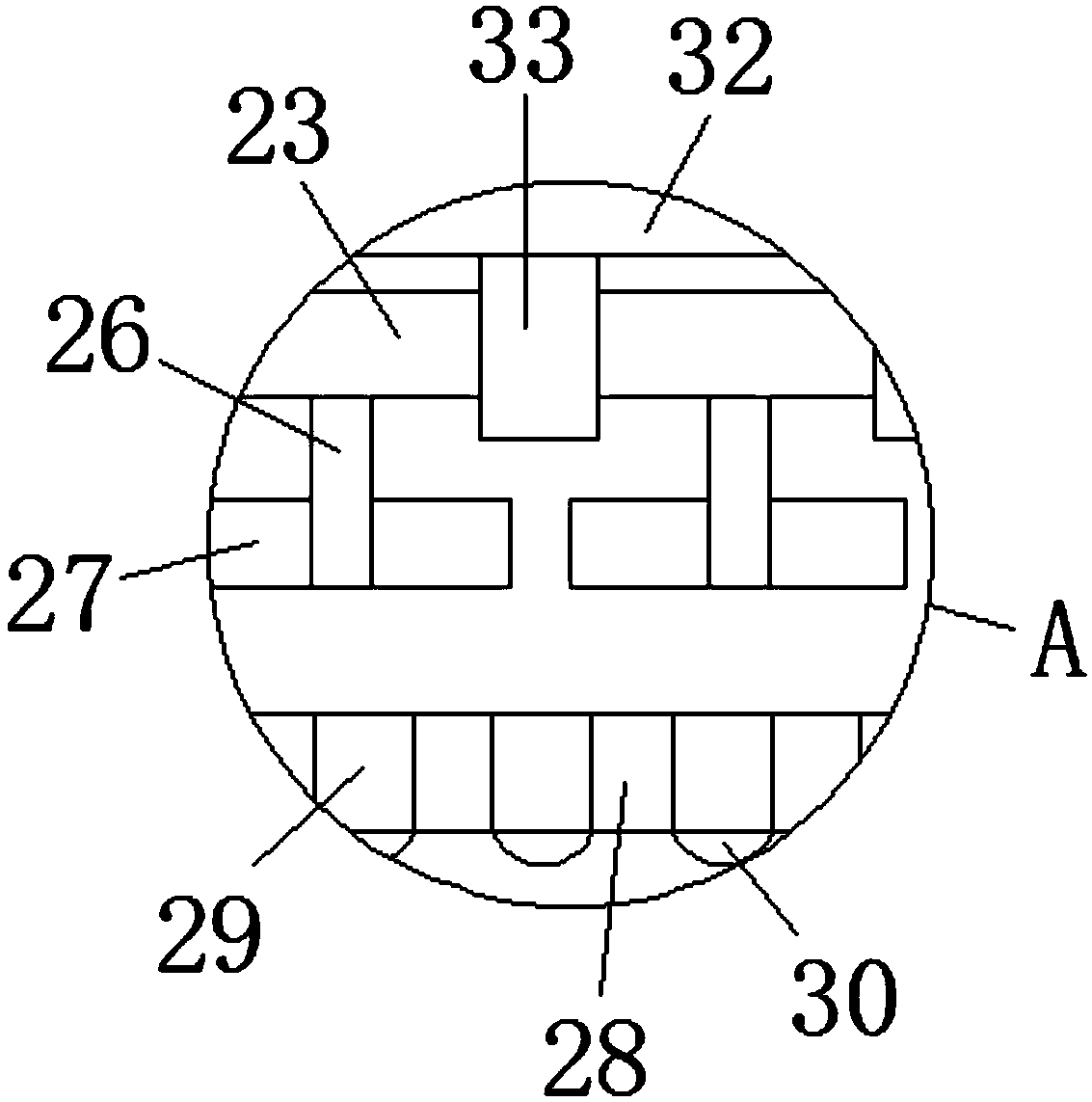

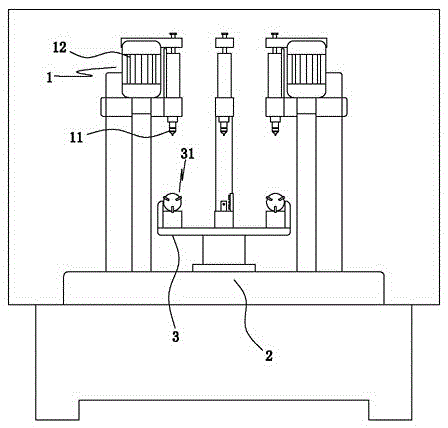

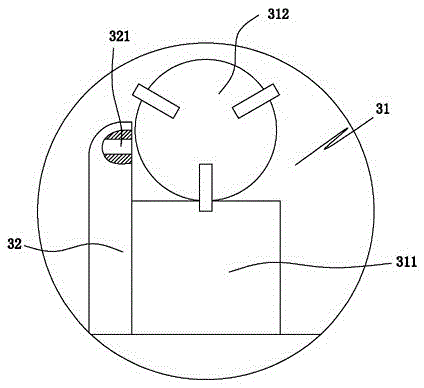

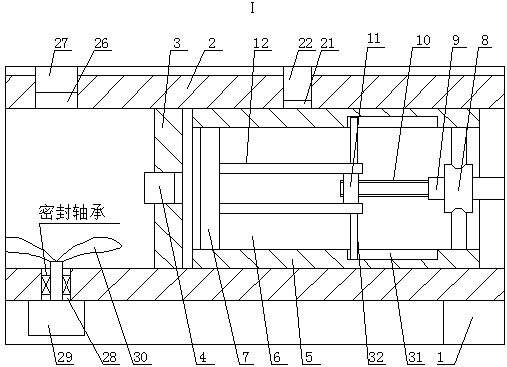

Drilling device

InactiveCN105598492AHigh degree of functional integrationExtended service lifeWork clamping meansPositioning apparatusElectric machineryEngineering

The invention discloses a drilling device. The drilling device comprises a plurality of single drilling machines and a plurality of clamping tools, wherein each single drilling machine is composed of a drill bit, a power motor for driving the drill bit to rotate and a single machine hoisting mechanism for driving the drill bit and the power motor to move up and down together; the drilling device further comprises a worktable and a cooling liquid supply general pipe; an electric rotary table is arranged on the worktable; each clamping tool is arranged on the electric rotary table; a liquid supply seat is arranged on each clamping tool; a liquid outlet channel is arranged on each liquid supply seat; an inlet of each liquid outlet channel is communicated with the cooling liquid supply general pipe; and the cooling liquid supply general pipe is connected with a cooling liquid supply source. The drilling device disclosed by the invention has the beneficial effects that a plurality of parts can be machined at the same time, the switching of stations is rapid and the machining efficiency is high; a cooling liquid is supplied in time and a cooling liquid supply device has high functional integration and excellent overall efficiency; and the drill bit which finishes working can be cleaned and protected so that the service life of the drill bit can be prolonged, and the drill bit has a good working condition in a subsequent machining process.

Owner:余姚志佳汽车部件厂(普通合伙)

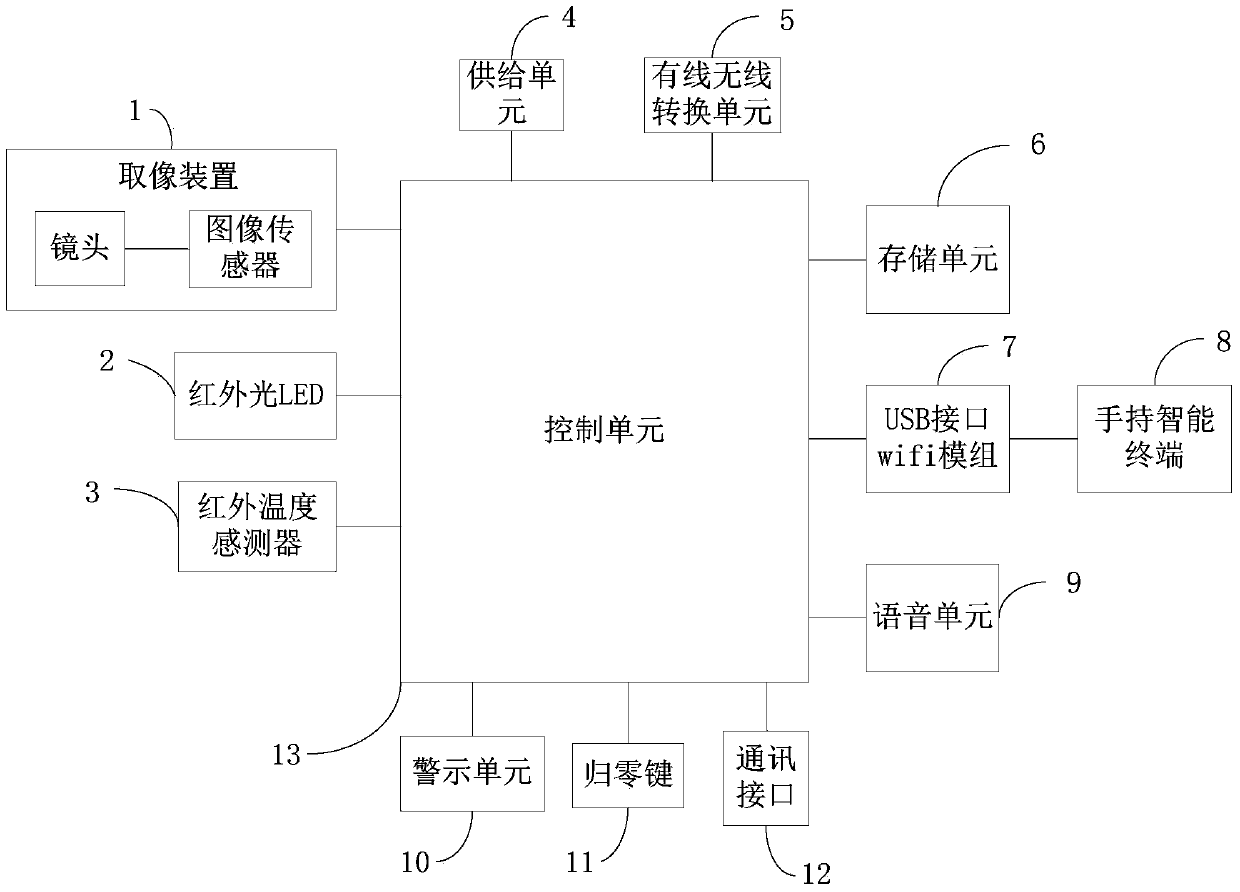

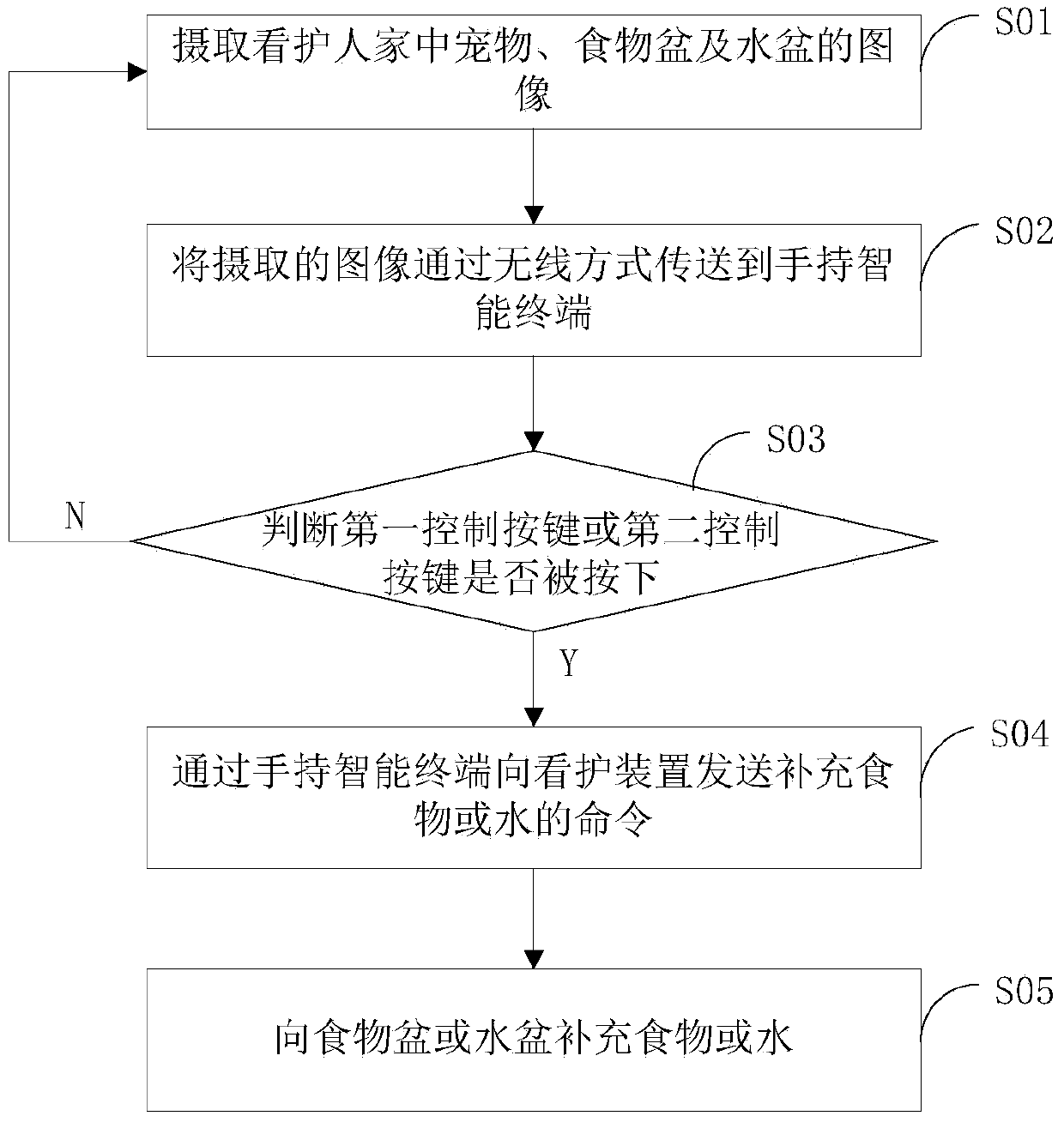

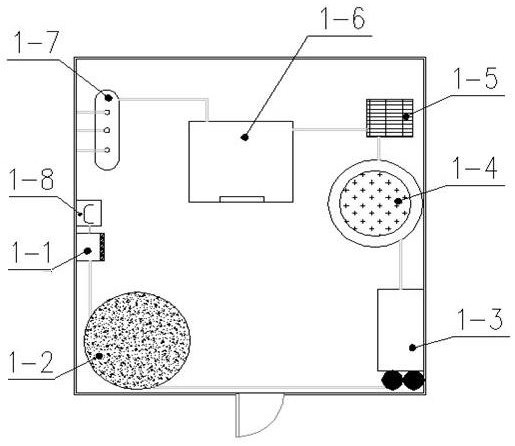

System and method for pet nursing

InactiveCN103766228AControl food intakeGood for healthAnimal watering devicesAnimal feeding devicesVoice communicationHand held

This invention provides a pet nursing system which comprises a nursing device and a hand-held intelligent terminal connected with the nursing device in a wireless communication way, wherein the nursing device comprises a control unit, an infrared temperature sensor used for measuring the pet temperature, an image-taking device used for taking the images of a pet, a food bowl and a water bowl in a nursed home, a supplying unit used for supplying food or water required by the pet and a voice unit used for bi-directional voice communication between a keeper and a pet; the infrared temperature sensor, the image-taking device, the supplying unit and the voice unit are respectively connected with the control unit; the voice unit is connected with the hand-held intelligent terminal in a wireless communication way. The invention further relates to a pet nursing method. The system and method for pet nursing, disclosed by the invention, have the benefits that food and water can be timely supplied for pets, the waste of food is avoided, and the system and method are conductive to pet health.

Owner:SHENZHEN WEIWEI OPTOELECTRONICS TECH CO LTD

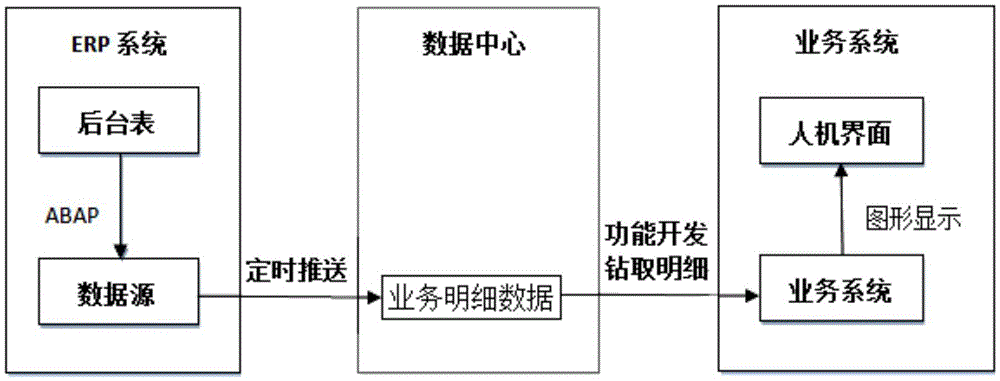

Electric power material supply whole-course early-warning supervise system and method

The invention discloses an electric power material supply whole-course early-warning supervise system and method. The system is composed of an ERP system, a data center and a business system. The ERP system connected with the data center collects information data of a whole business process, a drawing, an inventory, and contract resources of a master ERP system regularly; the data center is used for gathering and analyzing all available resources and providing a data support for whole-course early warning of the material supply; and the business system is used for setting an early-warning threshold value, displaying all monitoring early-warning and early-warning supervision information. An early-warning threshold value is set for an electric power material supply key node and corresponding treatment is carried out according to different business logics; for a business processing node close to the threshold value, the analyzed data are sent to a user for prompting; and a corresponding chart is generated at a client. According to the invention, analyses on business tracking and monitoring early warning of an information management and control node of an electric power material supply chain are realized; and thus the electric power material supply chain can be tracked and monitored conveniently.

Owner:STATE GRID SHANDONG ELECTRIC POWER

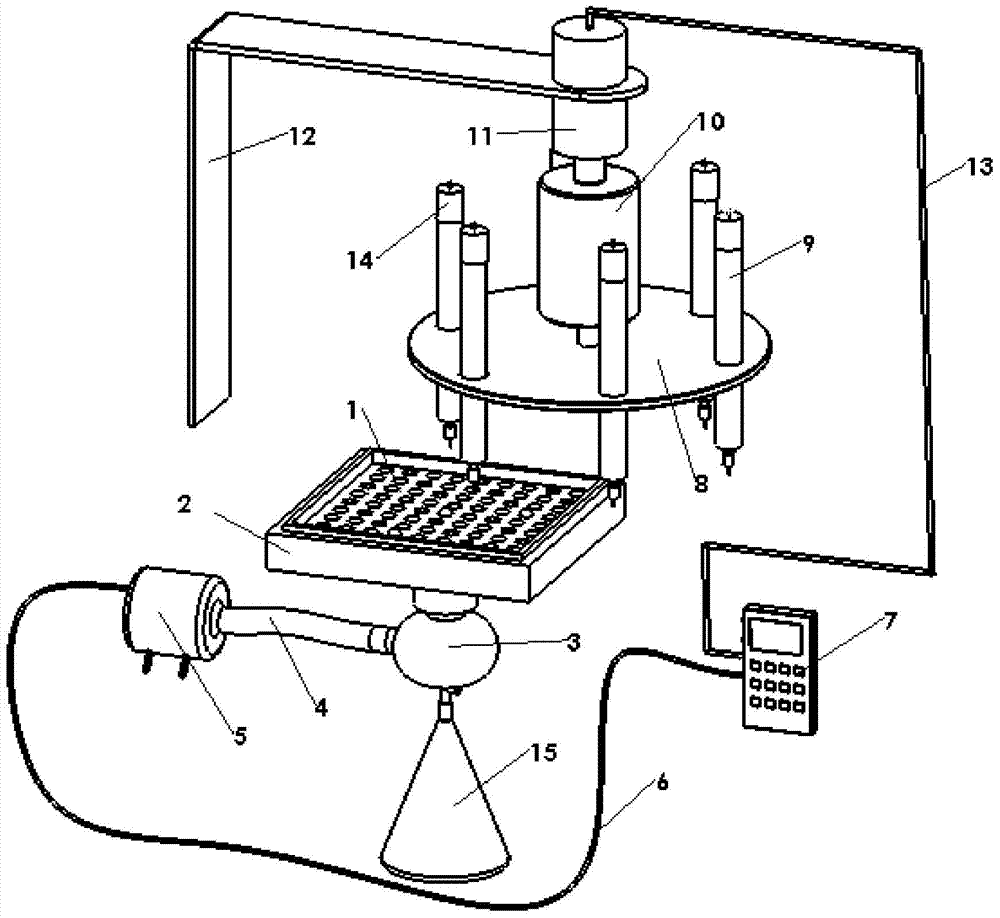

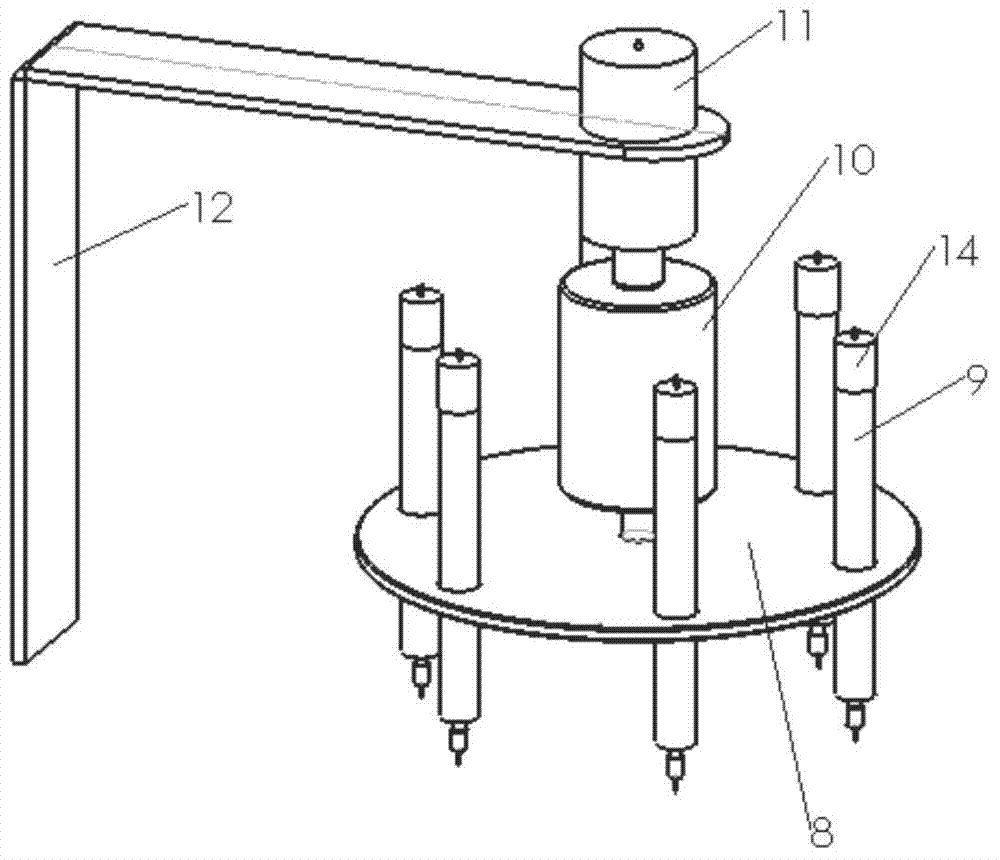

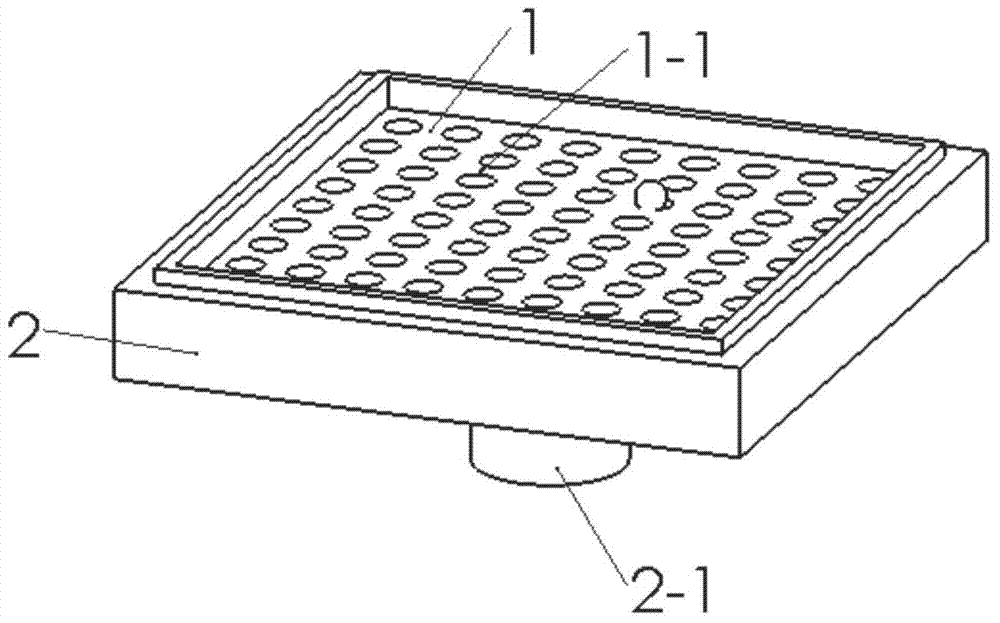

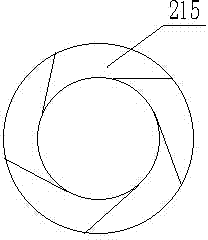

Automatic egg cell capturing and culturing device

ActiveCN103695313AObvious noveltyObvious practicalityTissue/virus culture apparatusBiological material testing proceduresEgg cellComputer science

The invention discloses an automatic egg cell capturing and culturing device. The automatic egg cell capturing and culturing device comprises a culture solution supply mechanism which is arranged on a bracket and is linked by an electric motor, wherein the culture solution supply mechanism is connected with the motor through the bracket; the electric motor is connected with a rotary wheel disc connected by a bearing; injectors which penetrate through the disc surface are annularly and uniformly distributed on the rotary wheel disc; a cell capturing mechanism is arranged below the culture solution supply mechanism and comprises a base formed by a rectangular frame; a double-layer hole film embedded on the base is arranged on an enclosure of the rectangular frame; a waste liquid removal mechanism is arranged below the cell capturing mechanism and comprises a flask connected to the lower side of a three-neck container; a control mechanism comprises a control board which is respectively connected with a micro pump, the electric motor and a motor through wires. According to the device, batch capture of egg cells and liquid transfer culture automation are realized, and a technical scheme which is low in cost and easy to operate is provided for realizing in-vitro culture of egg cells, fertilization and early culture of embryos.

Owner:XIDIAN UNIV

Tomato planting method

ActiveCN109380069AUniform sizeIncrease productionCalcareous fertilisersSeed and root treatmentTemperature controlFood flavor

The invention provides a tomato planting method. The tomato planting method mainly comprises the multiple links of seed preprocessing of 'ultraviolet radiation, flotation and seed soaking', seedling cultivation of 'germination accelerating, sowing, fertilization and field planting', scientific planting of 'sectioned control and variable-temperature management', photosynthesis promotion of 'lighting increase and temperature control and timely carbon supplementing', high-yield effect improvement of 'physical disease prevention and biological insect control' and the like. Tomatoes planed by adopting the tomato planting method have uniform fruits, are high in yield and short in growth period, also contain rich nutritional substances, have better taste and flavor, and the planting benefits aregreatly increased.

Owner:武汉楚为生物科技有限公司

Convenient and efficient construction method for piles

InactiveCN105839638ASave the degree of compactionControl the degree of crowdingBulkheads/pilesTime efficiencyBuilding construction

The invention discloses a convenient and high-efficiency pile construction method, which comprises the steps of placing in place, sinking pipes, pouring, pulling out pipes and the like. The invention has convenient construction and good effect. The invention improves the material feeding process, the immersed tube process and the bottom expansion process, and improves the timeliness and work efficiency. It can construct static pressure, hammering, internal ramming piles, bottom expansion piles; static pressure, hammering, internal ramming composite piles, expansion bottom piles and other pile types. It is a kind of static pressure that is more environmentally friendly, process controllable, and quality guaranteed. , hammering, internal ramming pile new technology.

Owner:徐明

Novel direct slag-feeding washing mixed material application method in converter tapping process

InactiveCN103233098ALighten the refining burdenReduce dosageProcess efficiency improvementSlagAluminium powder

The invention relates to a novel direct slag-feeding washing mixed material application method in a converter tapping process. A mixed material comprises the following components in parts by weight: 5-40 parts of aluminium powder, 35-60 parts of alumina, 30-50 parts of calcined lime, 1-6 parts of magnesium oxide, 0-6 parts of fluorite and 5-6 parts of silicon dioxide powder. The application method is used in a tapping process according to the following steps: firstly, adding 30% of the novel direct slag-feeding washing mixed material into the bottom of a steel ladle; adding the rest 70% of the material and the calcined lime along with molten steel flow when 1 / 4 tapping is completed; and moreover, feeding the mixed material into an argon blowing station, blowing argon to stir for 10-15 minutes, and then directly and continuously casting blanks so as to form finished products. The slag washing mixed material has high desulfurization degree in the converter tapping process, the refining time can be effectively shortened, and the cost of each ton of steel can be greatly lowered.

Owner:涟源市飞达冶金炉料厂

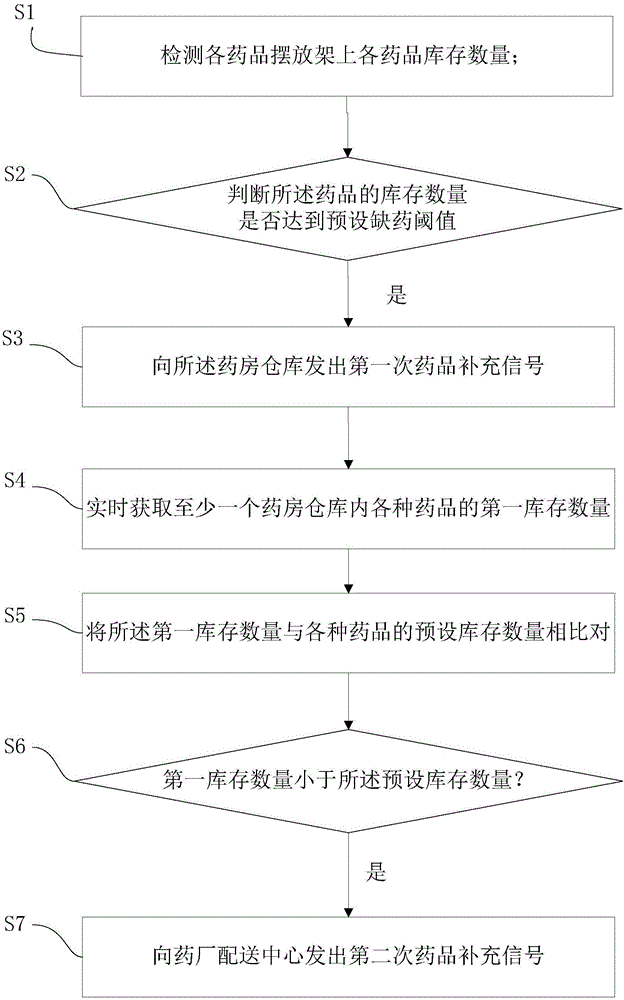

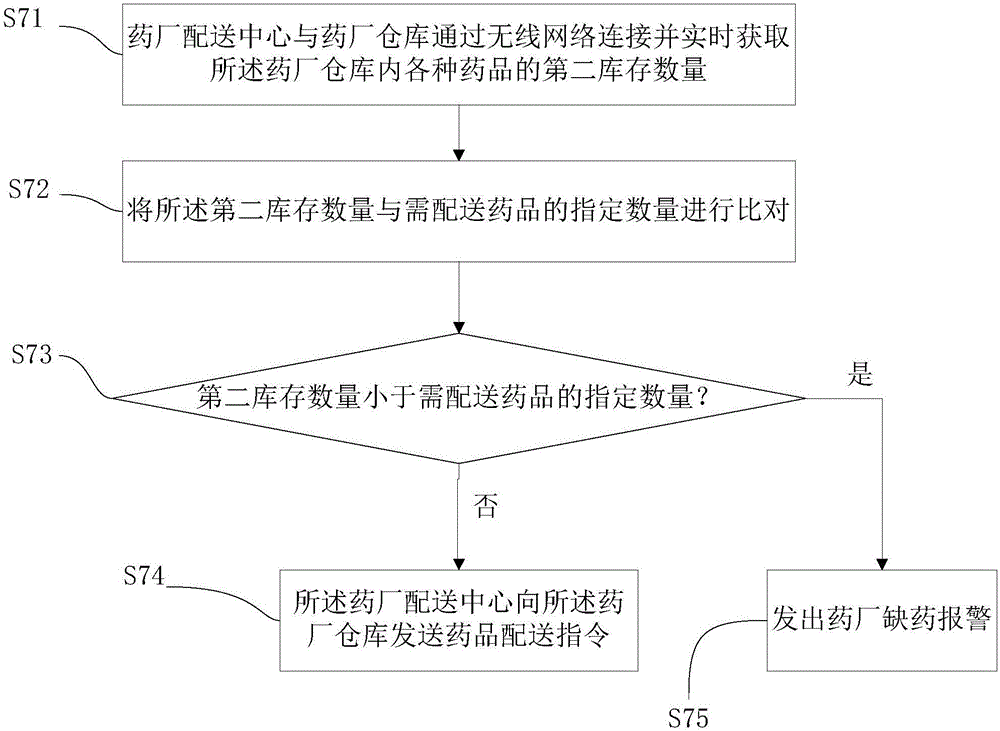

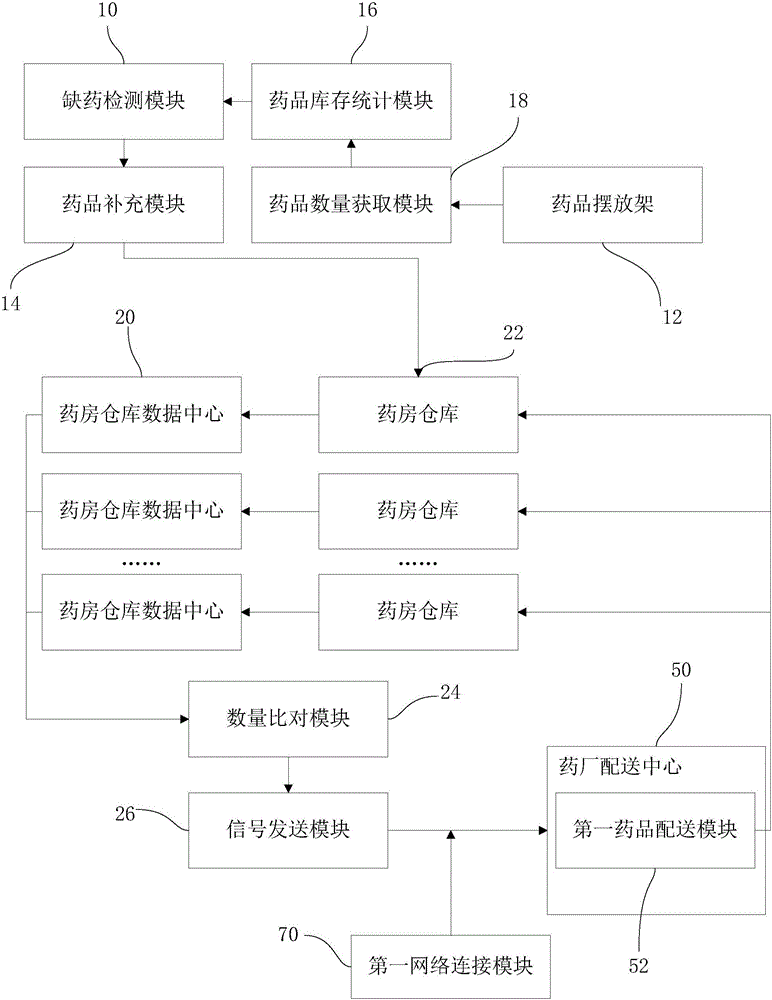

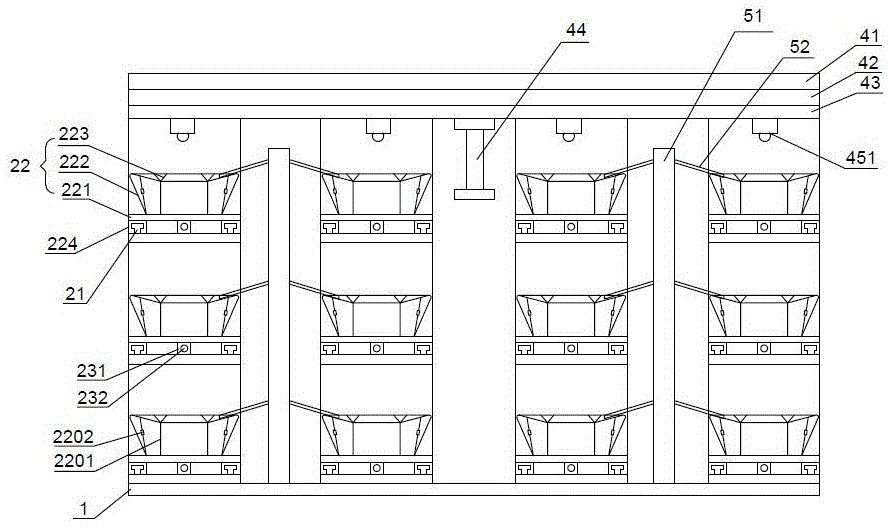

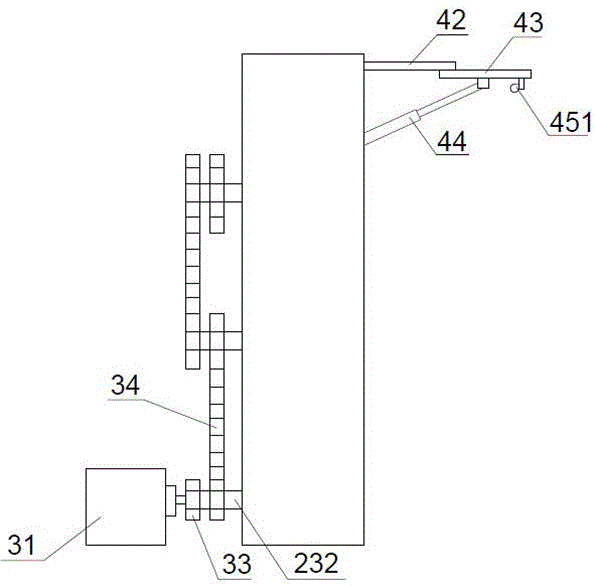

IoT (Internet of Things)-based medicine dispensing method and system for pharmacy

The invention applies to the technical field of medicine supply based on IoT (Internet of Things) and provides an IoT-based medicine dispensing method for a pharmacy. The method comprises the following steps: detecting stock numbers of medicines on medicine storage racks; judging whether the stock numbers of the medicines reach preset medicine shortage threshold values; sending first medicine supplementing signals to pharmacy warehouses when the stock numbers of the medicines on the medicine storage racks are smaller than the preset medicine shortage threshold values. According to the medicine dispensing method for the pharmacy, influence on normal supply of the medicines due to shortage of the medicines on the medicine storage racks is avoided by detecting whether the stock numbers of the medicines on the medicine storage racks reach the preset medicine shortage threshold values, namely, by detecting the stock numbers of the medicines on the medicine storage racks automatically, and comparing the detected stock numbers with the preset medicine shortage threshold values; further, whether to send the first medicine supplementing signals to the pharmacy warehouses or not is judged, so that the pharmacy warehouses can supplement corresponding medicines to the medicine storage racks timely when receiving the first medicine supplementing signals, and timely supply of the medicines is guaranteed.

Owner:SHENZHEN ALLWINS TECH

Flower and tree maintaining stand for gardening

InactiveCN106034798AImprove light absorptionSufficient lightingSelf-acting watering devicesSaving energy measuresGreeningDrive motor

The invention discloses a flower and tree maintaining stand for a garden, and belongs to the field of garden greening. The flower and tree maintaining stand comprises a support frame, wherein the support frame is provided with a plurality of flower holding parts; gap parts are arranged between adjacent flower holding parts; the flower holding parts comprise a plurality of flower holding units which are arranged vertically; each flower holding unit comprises sliding rails on two sides, a sliding rack and a sliding component; the sliding racks are connected with the sliding rails through sliding grooves formed in the bottoms of the sliding racks; the sliding components comprise screw rod nuts which are arranged at the bottoms of the sliding racks, and screw rods which are connected with the screw rod nuts; each flower holding part is provided with a set of driving mechanism; each driving mechanism comprises a driving motor, a driving gear which is arranged at the output end of the driving motor, two driven gears which are arranged at one end of the screw rod of each flower holding unit, and transmission chains which are sequentially connected with corresponding driven gears of adjacent screw rods and are connected with the driving gear and one driven gear; the radiuses of the driven gears which are arranged on the screw rods from bottom to top are gradually increased. By adopting the flower and tree maintaining stand, the adaptability of plants to different severe weather and environment conditions can be effectively improved, and healthy growth of the plants can be ensured.

Owner:HUZHOU HAOSHANHAOSHUI LANDSCAPE ENG

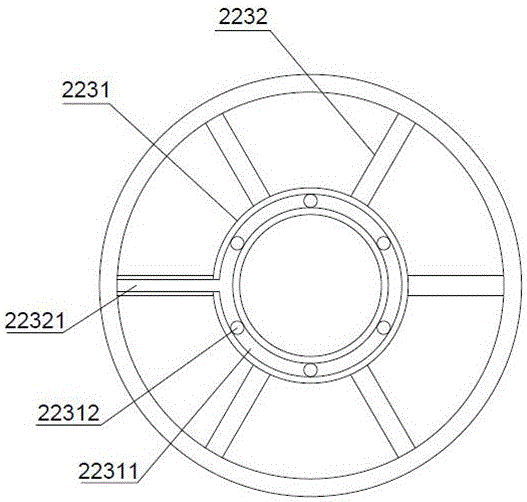

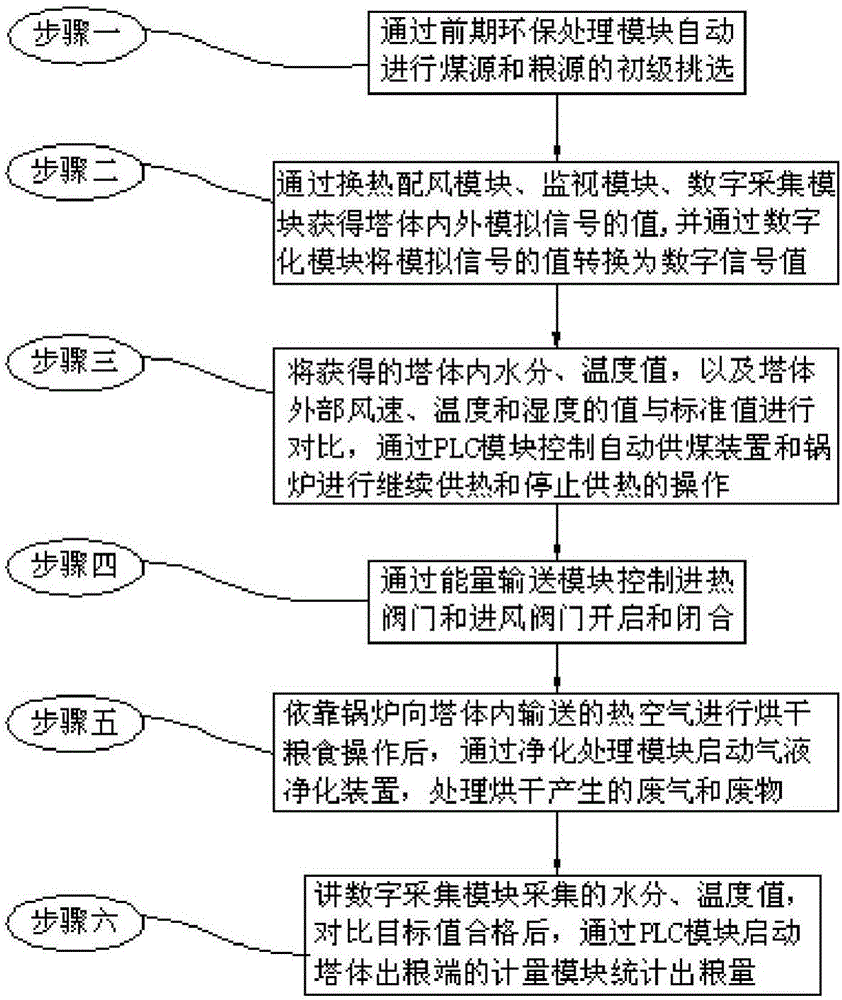

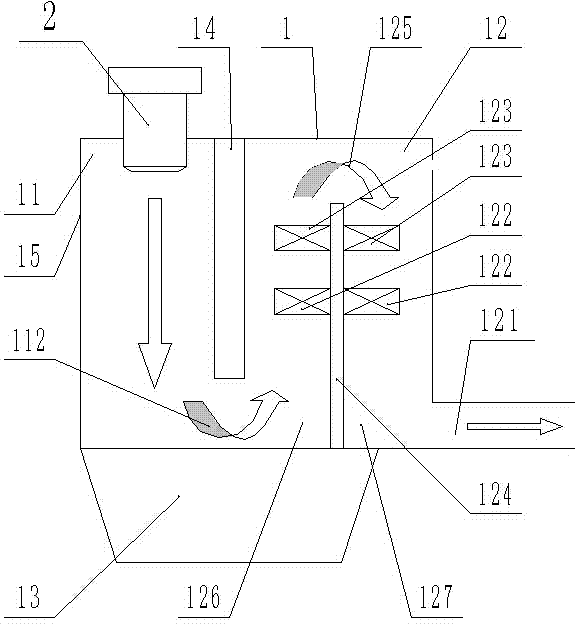

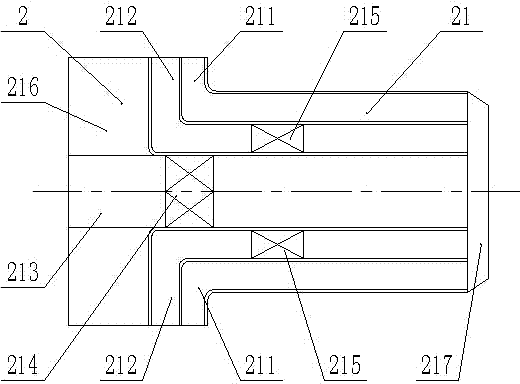

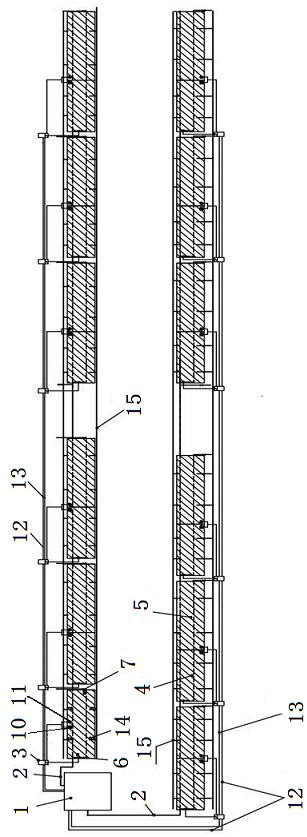

Grain drying control system and drying control method thereof

InactiveCN106125660AStrengthen online monitoringTimely supplyProgramme control in sequence/logic controllersEnvironmental resistanceAutomatic control

The invention relates to a grain drying control system and a drying control method thereof, which belong to the field of grain drying control, and aim to solve the problems that the existing grain drying equipment is low in automation degree, manual operation and control equipment operation are prone to misoperation, and the cost is high. The grain drying control system comprises a tower body, wherein an early-stage environmental protection treatment module, an energy transferring module, a heat-exchange air-distribution module, a temperature control boiler module, a coal feeding system module, a purification treatment module, a monitoring module, a digital acquisition module, a metering module and a digitization module are installed on the tower body, are connected with a PLC module outside the tower body, and are powered by means of a power supply control module; and the power supply control module is connected with the PLC module and a communication module. The grain drying control method comprises the steps of: comparing values of moisture and temperature inside the tower body as well as wind speed, temperature and humidity outside the tower body with standard values; and controlling an automatic coal feeding device and a boiler through the PLC module to perform operations of continuance and suspension of heating. The grain drying control system and the drying control method thereof have the advantages of being capable of automated control, and being high in heat exchange rate and low in cost.

Owner:黑龙江北谷创新科技发展有限公司

Boiler provided with dual-register pulverized coal burner on top

InactiveCN104121579AThorough heat exchangeReduce energy consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlueCoal

The invention discloses a boiler provided with a dual-register pulverized coal burner on the top, belonging to the technical field of boilers, and aiming at providing a U-shaped flame boiler which is provided with the dual-register pulverized coal burner on the top and is high in combustion efficiency. According to the technical scheme, the boiler provided with the dual-register pulverized coal burner on the top comprises a boiler body and an ash falling pit, wherein the ash falling pit is formed in the bottom of the boiler body, a membrane type water-cooling wall is arranged on the inner wall of the boiler body, a first partitioning wall is arranged on the top in the boiler body and is used for partitioning the boiler body into a combustion chamber and a waste gas chamber, the lower parts of the combustion chamber and the waste gas chamber are communicated with each other to form a first pair of flue channels, the dual-register pulverized coal burner is arranged at the top of the combustion chamber, a second partitioning wall is arranged at the bottom of the waste gas chamber and is used for partitioning the waste gas chamber into a left chamber and a right chamber, the upper parts of the left chamber and the right chamber are communicated with each other, and a flue discharging channel is arranged at the bottom of the side wall of the right chamber. The boiler is high in heat utilization rate and less in waste gas emission.

Owner:BEIJING DABANG SHICHUANG ENERGY SAVING TECHSERVICE

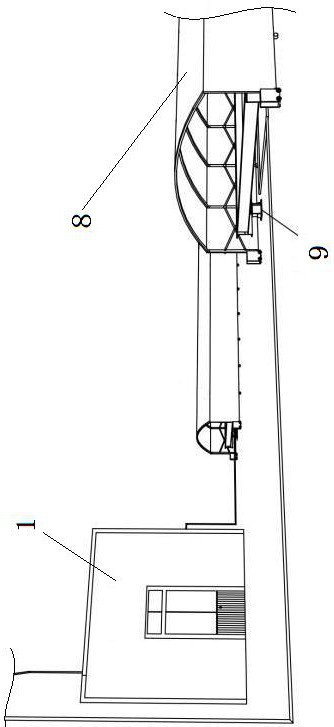

Prefabricated concrete member steam curing production line and steam curing method

PendingCN111605034AEasy to fillImprove utilization efficiencyCeramic shaping plantsAuxillary shaping apparatusTemperature controlProcess engineering

The invention discloses a prefabricated concrete member steam curing production line and a steam curing method. The production line is composed of a steam heat source machine system, a steam transmission pipeline, a mold table and a steam curing shed, wherein water is converted into dry steam through the steam heat source machine, the dry steam is distributed to all pipelines through a steam distributing cylinder and finally enters the steam curing shed of a production line, valves on the steam transmission pipeline independently control mold table sets, temperature and humidity control is conducted through the steam curing shed and a temperature and humidity sensing probe, temperature control in a curing process is divided into temperature rise and then natural cooling, the heat preservation time of each stage is strictly controlled, and finally it is ensured that the strength of a component meets the specified requirement after the natural cooling. The prefabricated concrete member steam curing production line and the steam curing method are energy-saving, consumption-reducing, emission-reducing and efficiency-improving, the construction cost is low, the occupied area is small, the site utilization rate is high, the operation flexibility is high, the curing effect is good, the mold stripping time is shortened, the mold stripping strength is improved, the production efficiencyis improved, the component surface is crack-free, and the heat energy utilization rate is high.

Owner:山东诺扬建筑科技有限公司 +1

Rock and soil moisture properties regulator

InactiveCN1702146AIncrease soil porosityImprove soil permeabilityOrganic fertilisersSoil conditioning compositionsNutrientPolyacrylamide

The invention provides a soil and rock water property amendment, the ingredient by weight ratio being: prairie peat 4-8, straw fibre 1-2.5, clay mineral 0.5-2, polyacrylamide 0.3-0.6, disperser 0.1-0.5, and PH buffer 0.02-0.05. The amendment can increase the degree of porosity of soil and rock, improve the permeability, decrease the unit weight, promote the water stability cumularsharolith, improve water retention property, and increase fertility, thus it can provide vegetation requiring water and nutrient just in time and quantity. And it can apply in improving shale soil and rock, sandstone soil and rock, chalkstone soil and rock, and so on.

Owner:SICHUAN SANHE SLOPE TECH CO LTD

Manufacturing technique of balanced-nutrition seedling cultivation fertilizer

InactiveCN105859468AIncrease profitReduce lossesSuperphosphatesBioloigcal waste fertilisersDiseaseSkunk

The invention discloses a manufacturing technique of a balanced-nutrition seedling cultivation fertilizer. The fertilizer comprises the following raw materials in parts by weight: 5-20 parts of urea, 5-25 parts of ammonium sulfate, 1-8 parts of ferrous sulfate, 10-25 parts of calcium superphosphate, 1-8 parts of zinc sulfate, 1-15 parts of sulfur, 0.5-5 parts of Dittany Bark, 0.01-0.2 part of malathion, 0.5-5 parts of radix rehmanniae, 5-20 parts of rape seed cake, 0.5-5 parts of moutan bark, 5-35 parts of plant ash, 0.5-5 parts of skunk bugbane, 0.1-5 parts of ferment, 0.5-5 parts of nutshell, 5-35 parts of vinasse, 0.5-5 parts of herba violae, 10-40 parts of weed and 5-30 parts of rice bran. The technique comprises the following steps: grinding the plant ash into a paste, adding vinasse, and grinding to obtain a mixed thick paste; adding the weed and rice bran into the mixed thick paste to obtain a mixture; and fermenting the rape seed cake and ferment to obtain a fermentation product, adding the fermentation product into the mixture, adding the rest raw materials, drying and pulverizing. The technique can enhance the stocking percent, reduce the disease and pest damage and improve the soil, thereby shortening the seedling recovering time and saving the production cost. The nutrient elements are absorbed in a balanced mode in various growth periods of the seedlings.

Owner:XINCHANG RUAO XIYANSHAN FAMILY FARM

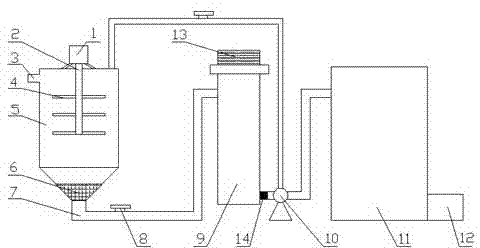

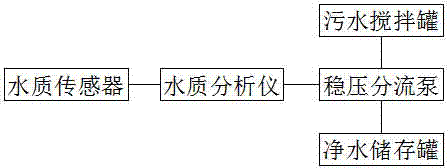

Recirculation type wastewater treatment recycling system

InactiveCN104761026AReduce the amount of purified waterQuick refillWater/sewage treatment by magnetic/electric fieldsElectric fieldWater storage tank

The invention relates to a recirculation type wastewater treatment recycling system. The recirculation type wastewater treatment recycling system comprises the following main steps: after a water quality analyzer detects that the water quality at an outlet of an electric field water treater reaches a set index, a controller starts to open an electrically operated valve on a three-way connecting pipe, which is closed previously, meanwhile, an electrically operated valve on a two-way connecting pipe, which is opened previously, is closed, and water conforming to the set index is conveyed into a purified water storage tank; and b. after the water quality analyzer detects that the water quality at an outlet of an electric field water treater does not conform to a set index, the controller firstly starts to close the electrically operated valve on the three-way connecting pipe, which is opened previously, meanwhile, the electrically operated valve on the two-way connecting pipe, which is closed previously, is opened, and water which does not conform to the set index is conveyed into a wastewater stirring tank and is recycled and treated, thus realizing the recirculation and treatment of the wastewater which does not conform to the set index, and the technical problem that wastewater which does reach the set index is taken as purified water to be stored is solved. The recirculation type wastewater treatment recycling system has the beneficial effect of being capable of reliably supplying purified water conforming to the set index.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Cultivation method for reserving seeds of globe artichoke

Disclosed is a cultivation method for reserving seeds of globe artichoke. The cultivation method includes greenhouse selection, seedling culturing, transplantation, field management, seed collection and the like. The field management specifically includes managements of transplanting time, winter management technology of seedling earlier stage, spring management technology of seedling later period, bud stage, flowering period and grain filling stage. The cultivation method for reserving seeds of globe artichoke has the advantages that the costs are reduced, each seed from foreign countries is 0.5 yuan, and each seed obtained by the scheme is 0.1 yuan; the supply is timely, the seeds from the foreign countries are ripe basically in August but sowing is required in September in China so that season connection is not timely, and the seeds obtained by the scheme can be completely ripe in July without delay of sowing of the next season; the seeds obtained by the scheme are produced in local area, advantages exist in terms of area adaptability, and the number of hybrid seeds and hybrid plants is small.

Owner:爱可道生物科技有限公司

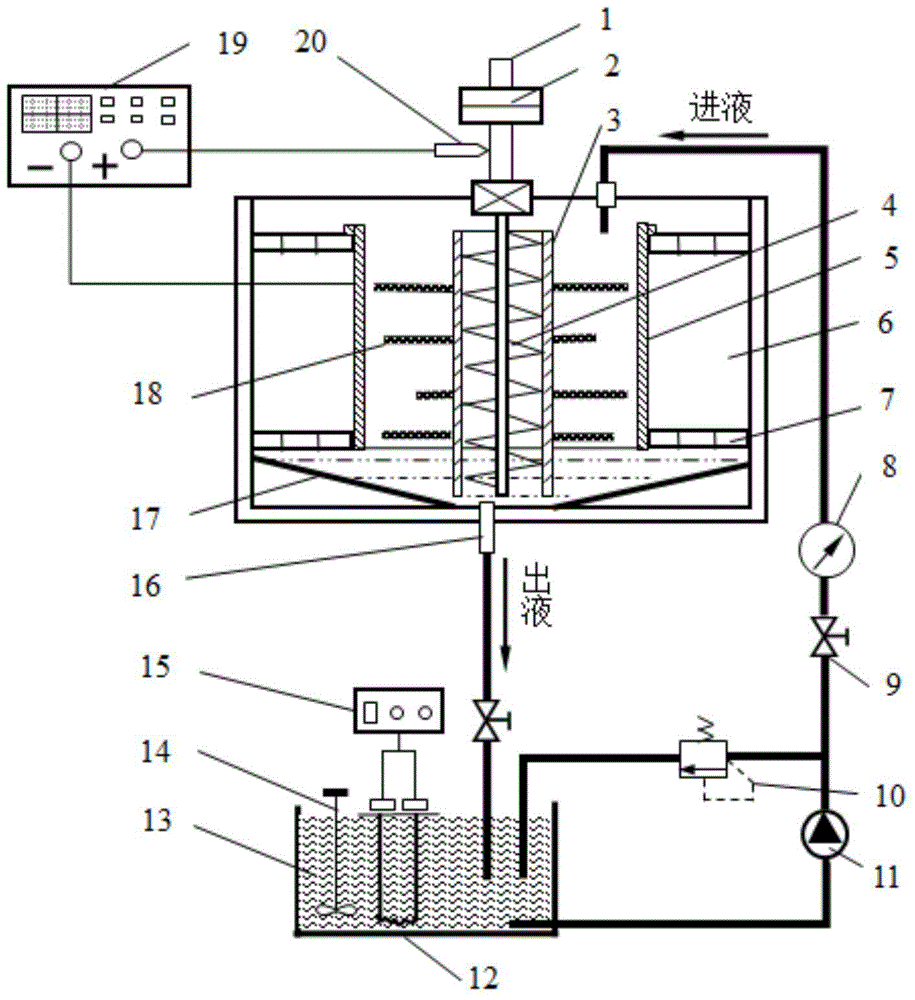

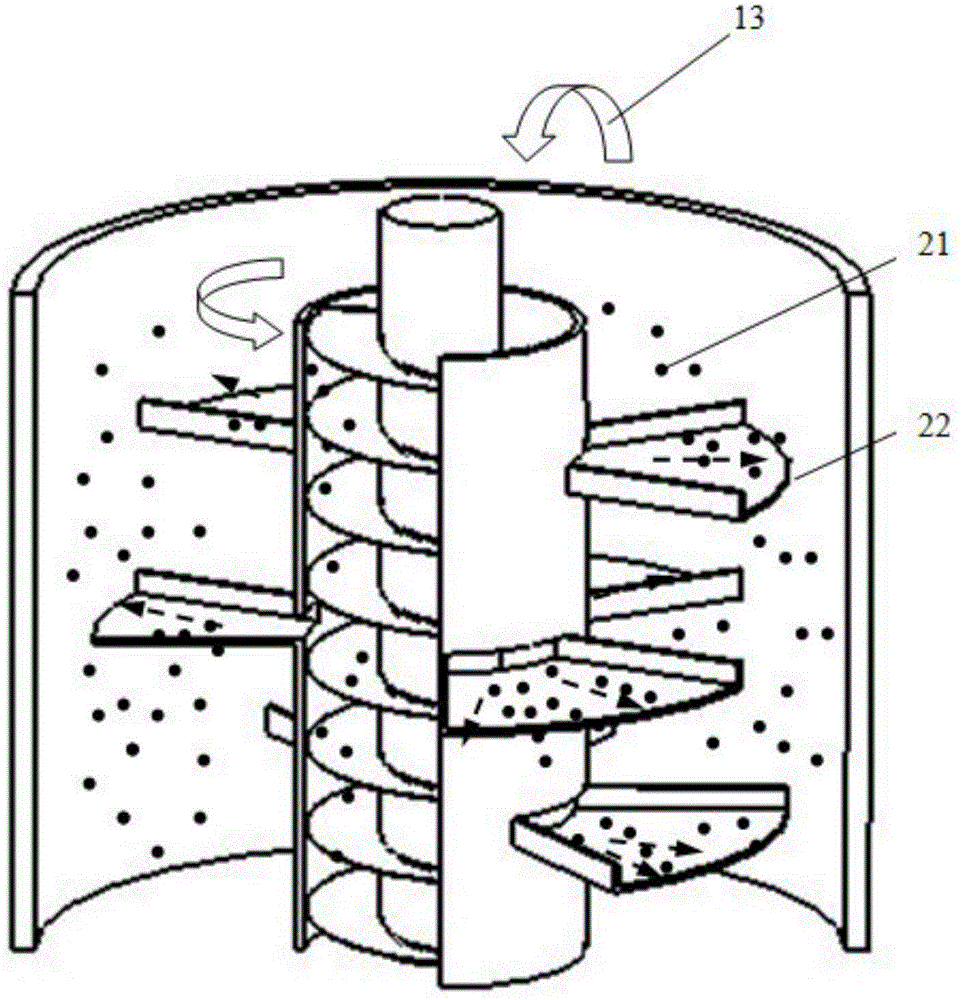

Centrifugal shot blasting electroforming manufacturing method and device

ActiveCN105177639APrevents adsorption of air bubblesInhibits buildup and pitsElectroforming processesSkin blisterElectrochemistry

The invention provides a centrifugal shot blasting electroforming manufacturing method and device. Centrifugal force generated through rotation of a leaf disc is utilized for enabling an electroforming solution and spherical hard particles to be ejected and impact the surface of an electroforming core mold, accordingly, the reduction reaction is generated on the surface of the cathode of the electroforming core mold, a component with the needed shape is prepared in a deposition forming manner, and the electrochemical machining field in non-traditional machining is involved. Under the action of centrifugal force, the hard particles are thrown out together and hit the surface of the core mold, the rapid forming manufacturing of ejecting electro-deposition in the casting process is achieved, and the effect of the surface shot blasting strengthening processing is achieved. The rapid forming manufacturing and the surface shot blasting strengthening processing are synchronously combined, and therefore skin blister adsorption of the deposition and generation of accumulated protrusions can be effectively prevented; and the surface flatness and smoothness are improved, residual compressive stress can be generated for surface stamping, and the fatigue resisting strength of a casting layer is improved. The centrifugal shot blasting electroforming manufacturing method and device can be used for inner surface defect mending and performance intensifying of components, rapid preparing of functional materials and surface coating of cavity type components.

Owner:JIANGSU UNIV

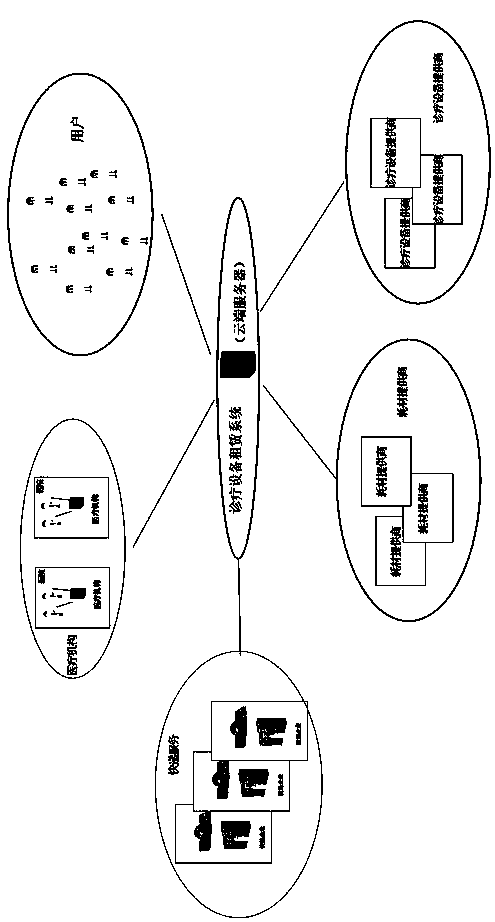

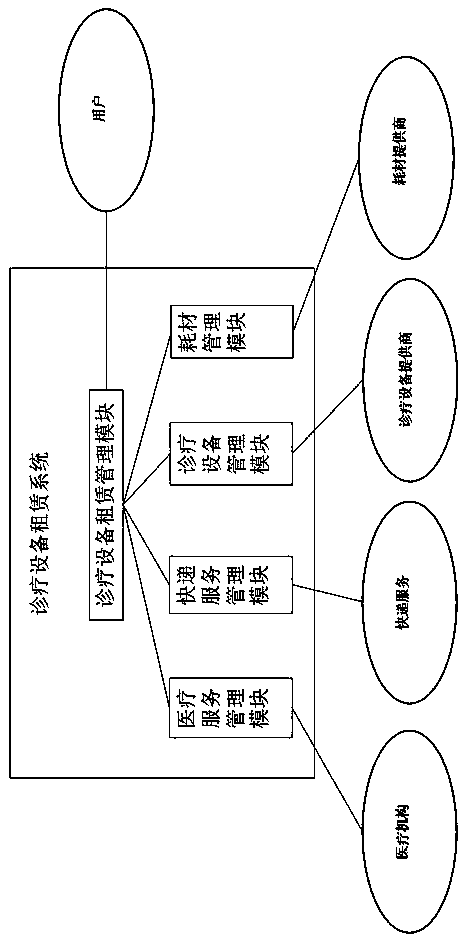

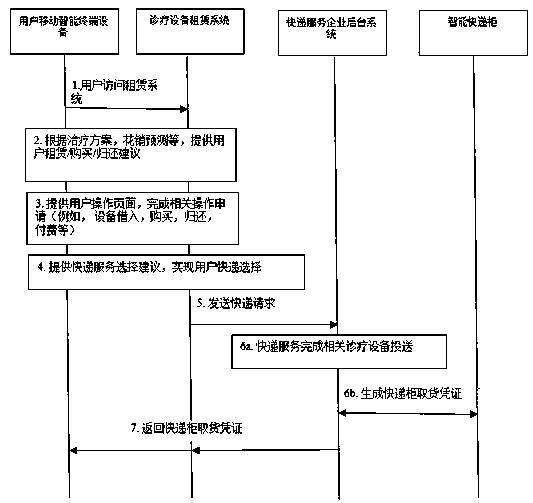

Medical equipment rental system and rental method

InactiveCN108681949AAvoid wastingIncrease profitBuying/selling/leasing transactionsMedical equipmentMedical institution

The invention provides a medical equipment rental system and rental method. The medical equipment rental system is characterized in that the system is deployed on a cloud server, by connecting a user,a medical institution, a courier enterprise, a medical treatment equipment provider and a consumable supplier, the rental of medical treatment equipment, real-time rental equipment distribution and courier services, equipment usage guidance and management and the timely delivery of related consumables are completed. The medical equipment rental system comprises a medical equipment rental management module, a medical service management module, a delivery service management module, a medical treatment equipment management module, and a consumable management module. A variety of acute and chronic disease patients can conveniently borrow or return relevant medical equipment at any time according to their needs, thus the waste of social medical resources is effectively avoided, and the socialmedical resources are fully used.

Owner:QINGDAO FUTURE MEDICAL TECH CO LTD

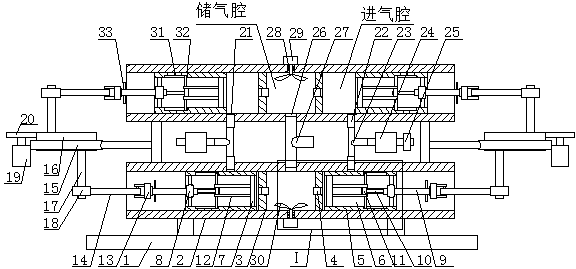

Anaesthetic-concentration-adjustable device

The invention provides an anaesthetic-concentration-adjustable device. The device comprises a base; two horizontal pipes distributed up and down are arranged above the base; the horizontal pipe on thelower side is fixedly connected with the base; the two horizontal pipes are fixedly connected; annular partition plates which are symmetrical from side to side are arranged on the middle parts of thehorizontal pipes respectively; the inner side of each annular partition plate and the inner periphery of the corresponding horizontal pipe form a gas storage cavity; the interiors of the annular partition plates are fixedly connected with the gas inlet ends of first one-way valves respectively; first pistons are respectively arranged on the left sides and right sides of the interiors of the horizontal pipes; the inner side of each first piston, the outer side of the corresponding annular partition plate, and the inner periphery of the corresponding horizontal pipe form a gas inlet cavity; thegas inlet cavities and the gas storage cavities are communicated through the first one-way valves; the outer periphery of each first piston is respectively matched with the inner wall of the corresponding horizontal pipe in a sliding contact way; first through holes are respectively formed in the middles of the outer sides of the first pistons. The anaesthetic-concentration-adjustable device is ingenious in design and convenient in use and operation, and can continuously mix anesthetic gas and loaded gas in small batches; the mixing is more uniform; waste caused by residues after mixing of alarge quantity of anesthetic gas is avoided.

Owner:肖锦亮 +2

Organic fertilizer for garden nursery stock

InactiveCN108329086AShorten seedling timeGood characterBio-organic fraction processingAnimal corpse fertilisersDiseaseSoil properties

The invention provides organic fertilizer for garden nursery stock. The organic fertilizer is prepared from the following raw materials in parts by weight: 15 to 25 parts of rape seed cake, 15 to 20 parts of corncobs, 10 to 15 parts of furfural residue, 10 to 15 parts of brewer's grain, 8 to 10 parts of edible mushroom leftovers, 8 to 10 parts of wood dust, 5 to 10 parts of waste molasses, 8 to 12parts of spoiled milk, 8 to 12 parts of bamboo shoot shell, 5 to 10 parts of cottonseed meal, 10 to 15 parts of rice bran, 5 to 8 parts of maifanite powder, 5 to 8 parts of turfy soil, 4 to 8 parts of paper ash, 3 to 6 parts of crab shell powder, 10 to 15 parts of dead leaf powder, 5 to 8 parts of bagasse, 2 to 5 parts of vinegar residue and 1 to 3 parts of leavening agent. The organic fertilizerprovided by the invention overcomes the defects of the prior art, the organic fertilizer is reasonable in component design and high in utilization rate, the requirements of landscaping plants on allkinds of nutrients can be met through one fertilization, and the fertilization cost is reduced; meanwhile, the soil properties are improved, the soil fertility is enhanced, and the function of soil-borne diseases is reduced.

Owner:安徽兴华农庄有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com