Patents

Literature

2171 results about "Surface flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Substrate Pretreatment To Achieve High-Quality III-Nitride Epitaxy

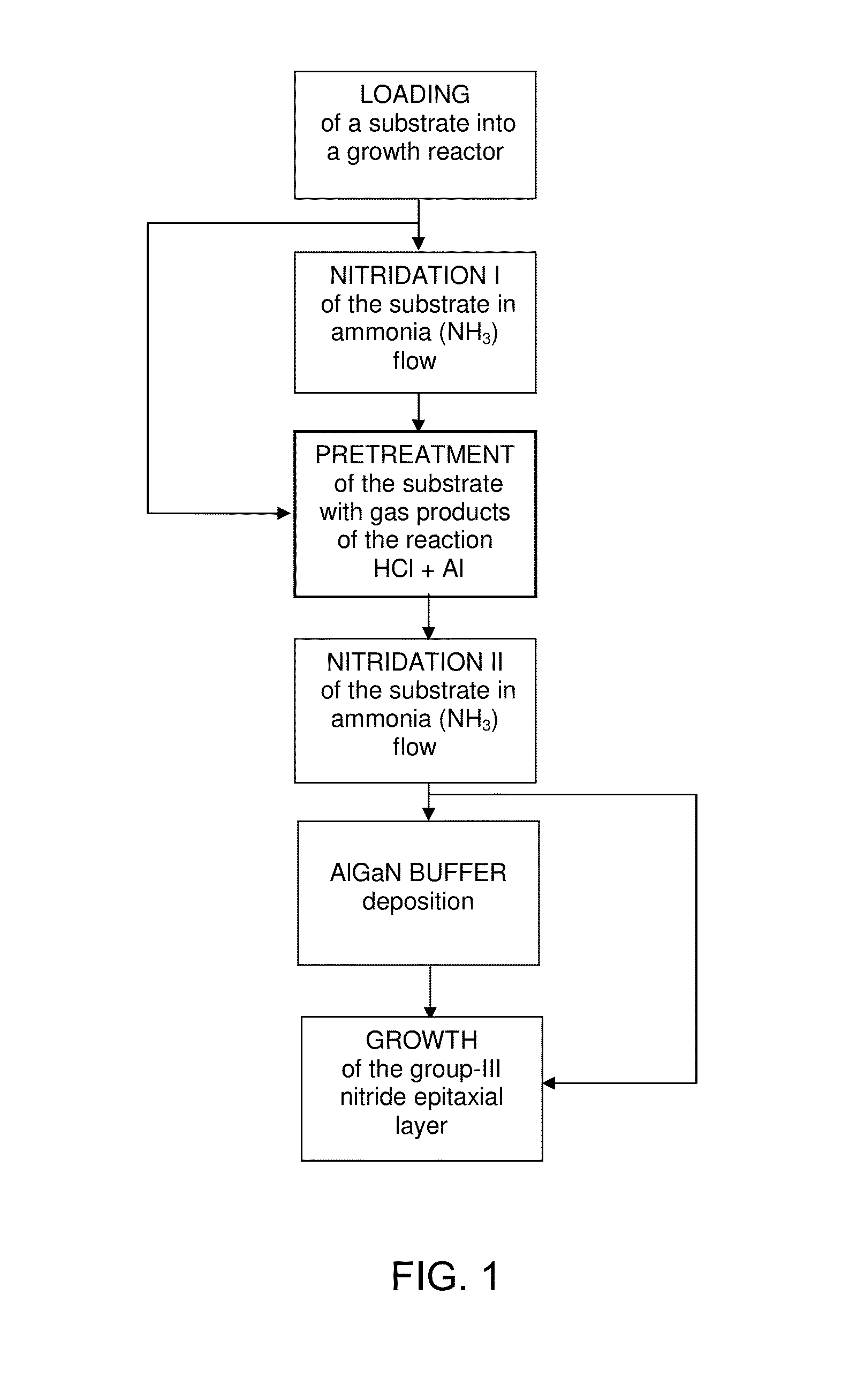

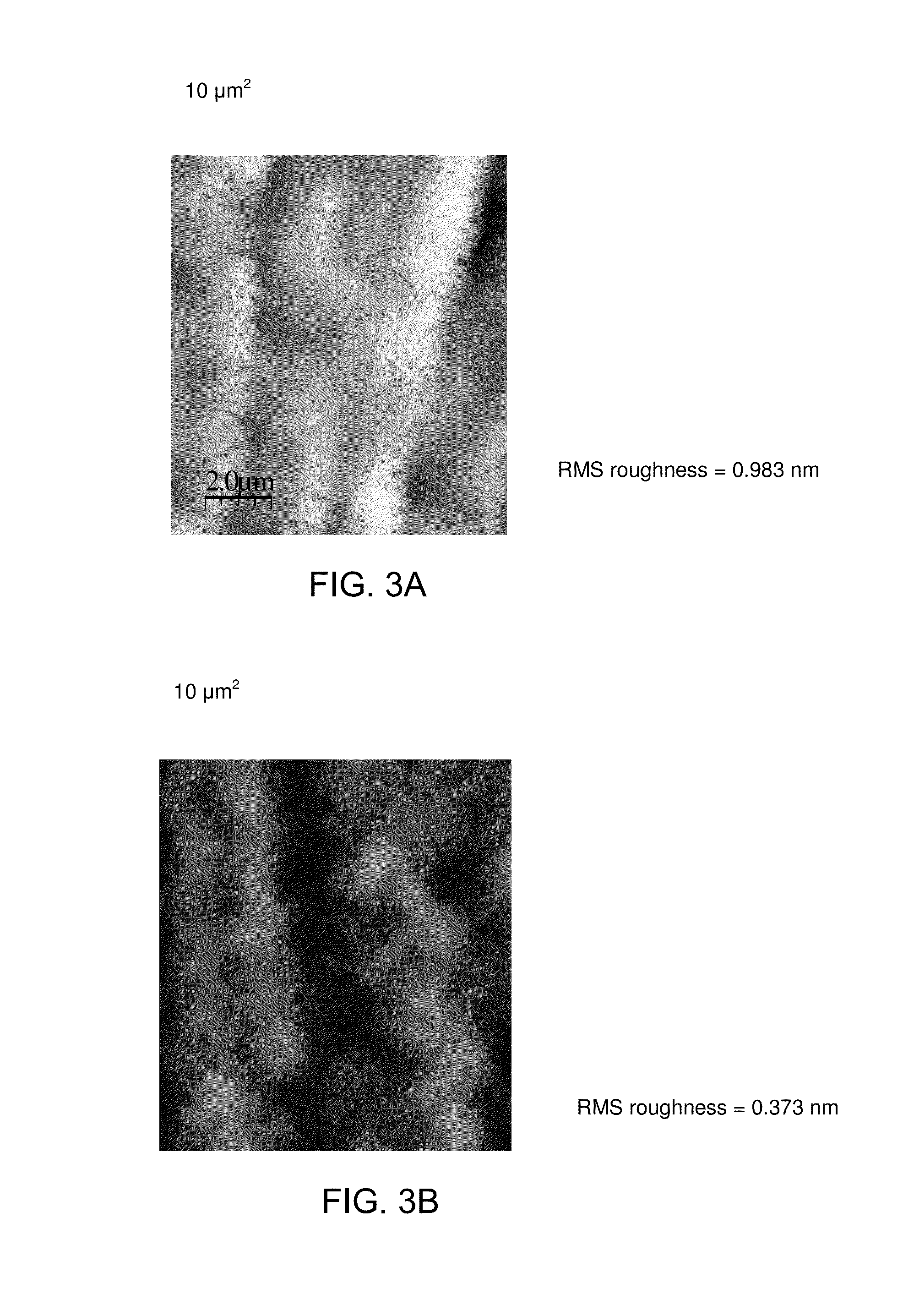

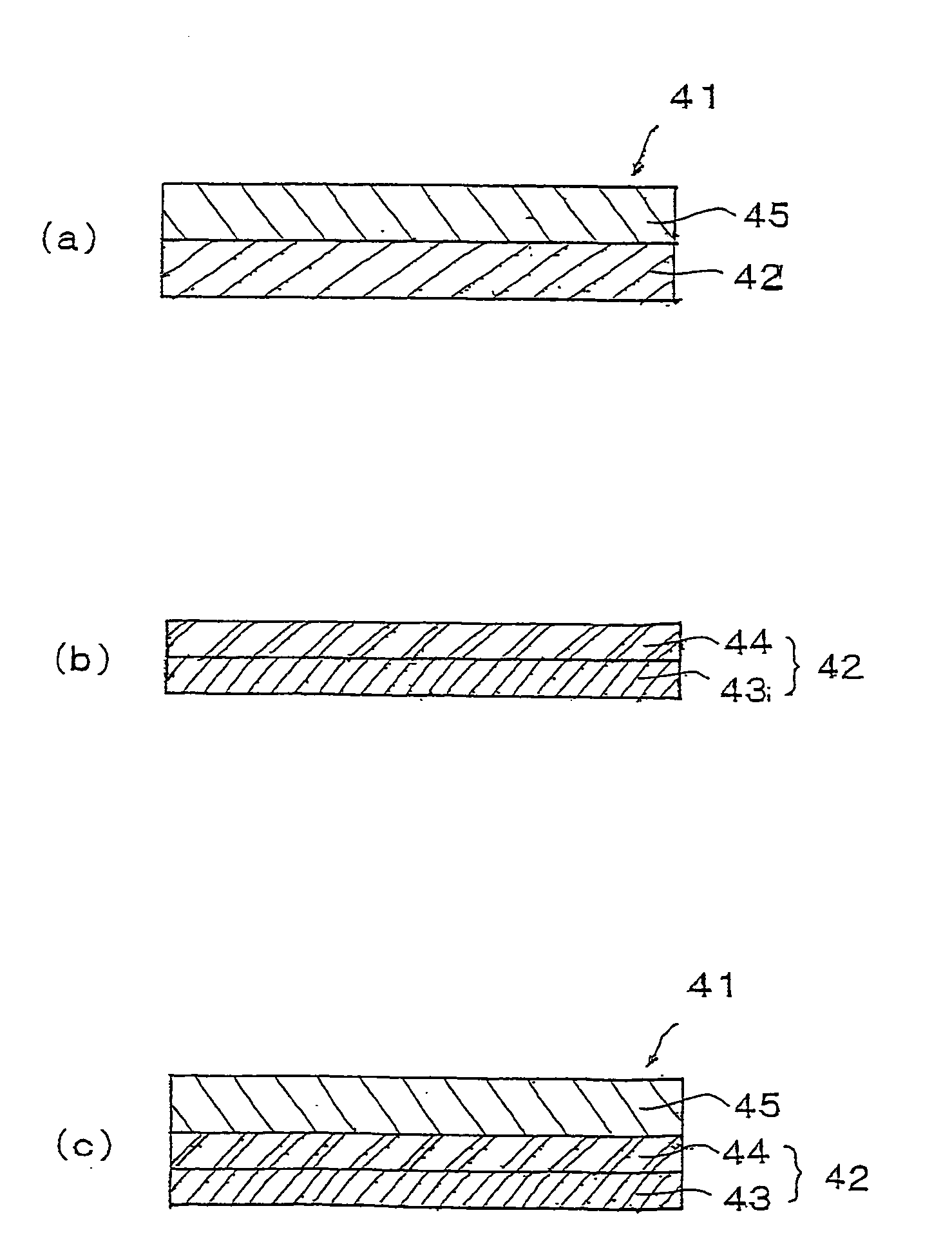

The present invention relates to a method for producing a modified surface of a substrate that stimulates the growth of epitaxial layers of group-III nitride semiconductors with substantially improved structural perfection and surface flatness. The modification is conducted outside or inside a growth reactor by exposing the substrate to a gas-product of the reaction between hydrogen chloride (HCl) and aluminum metal (Al). As a single-step or an essential part of the multi-step pretreatment procedure, the modification gains in coherent coordination between the substrate and group-III nitride epitaxial structure to be deposited. Along with epilayer, total epitaxial structure may include buffer inter-layer to accomplish precise substrate-epilayer coordination. While this modification is a powerful tool to make high-quality group-III nitride epitaxial layers attainable even on foreign substrates having polar, semipolar and nonpolar orientation, it remains gentle enough to keep the surface of the epilayer extremely smooth. Various embodiments are disclosed.

Owner:OSTENDO TECH INC

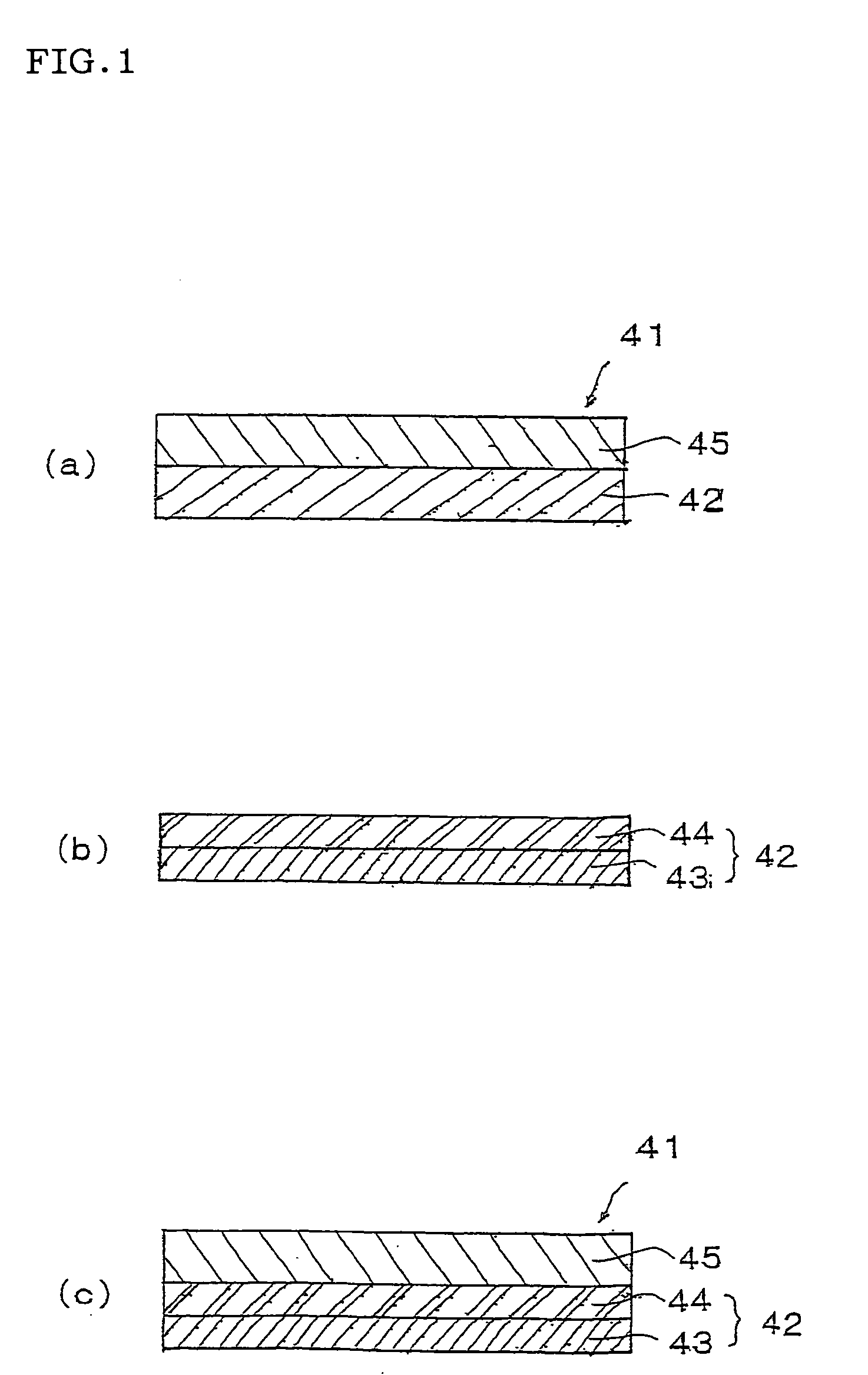

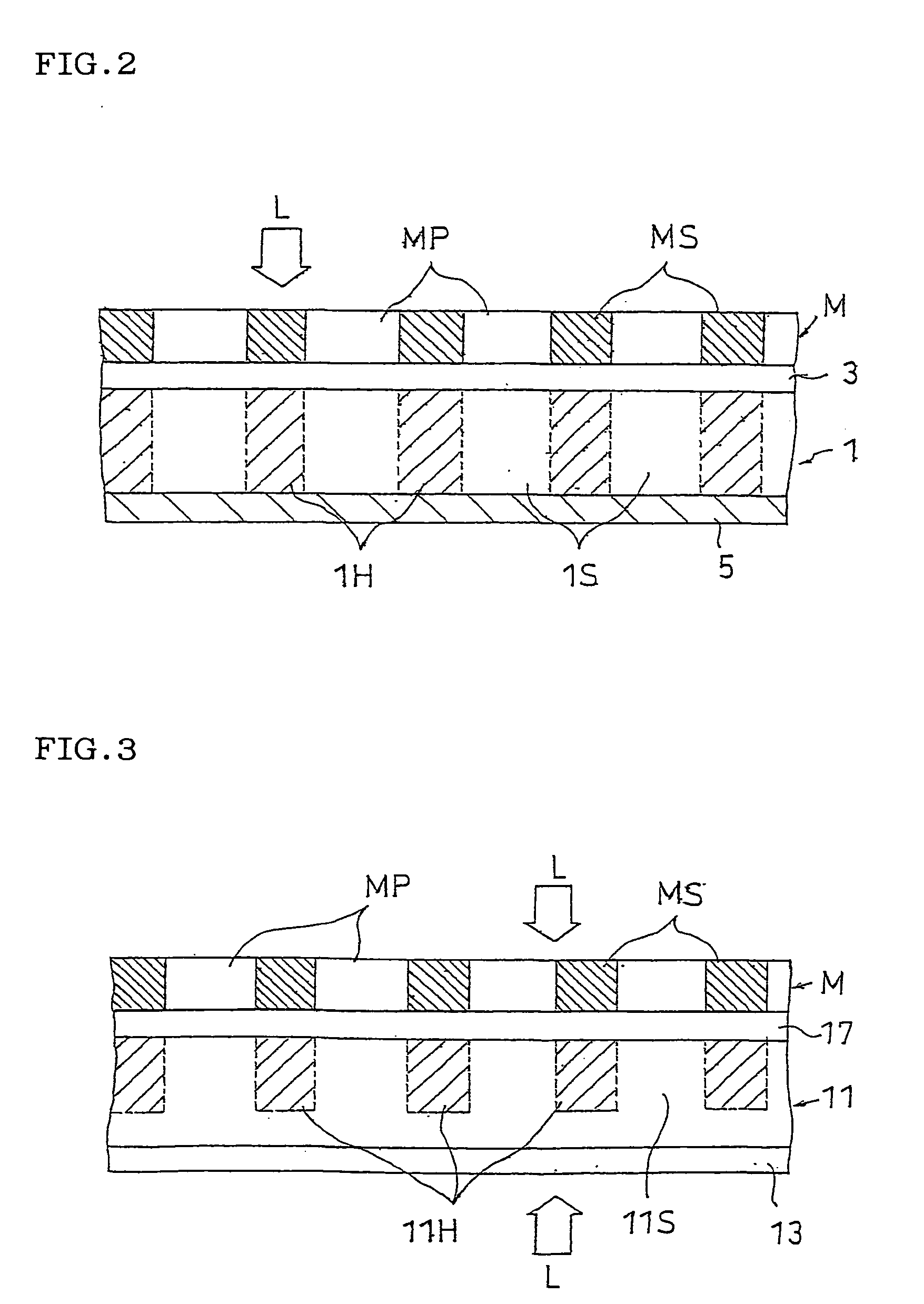

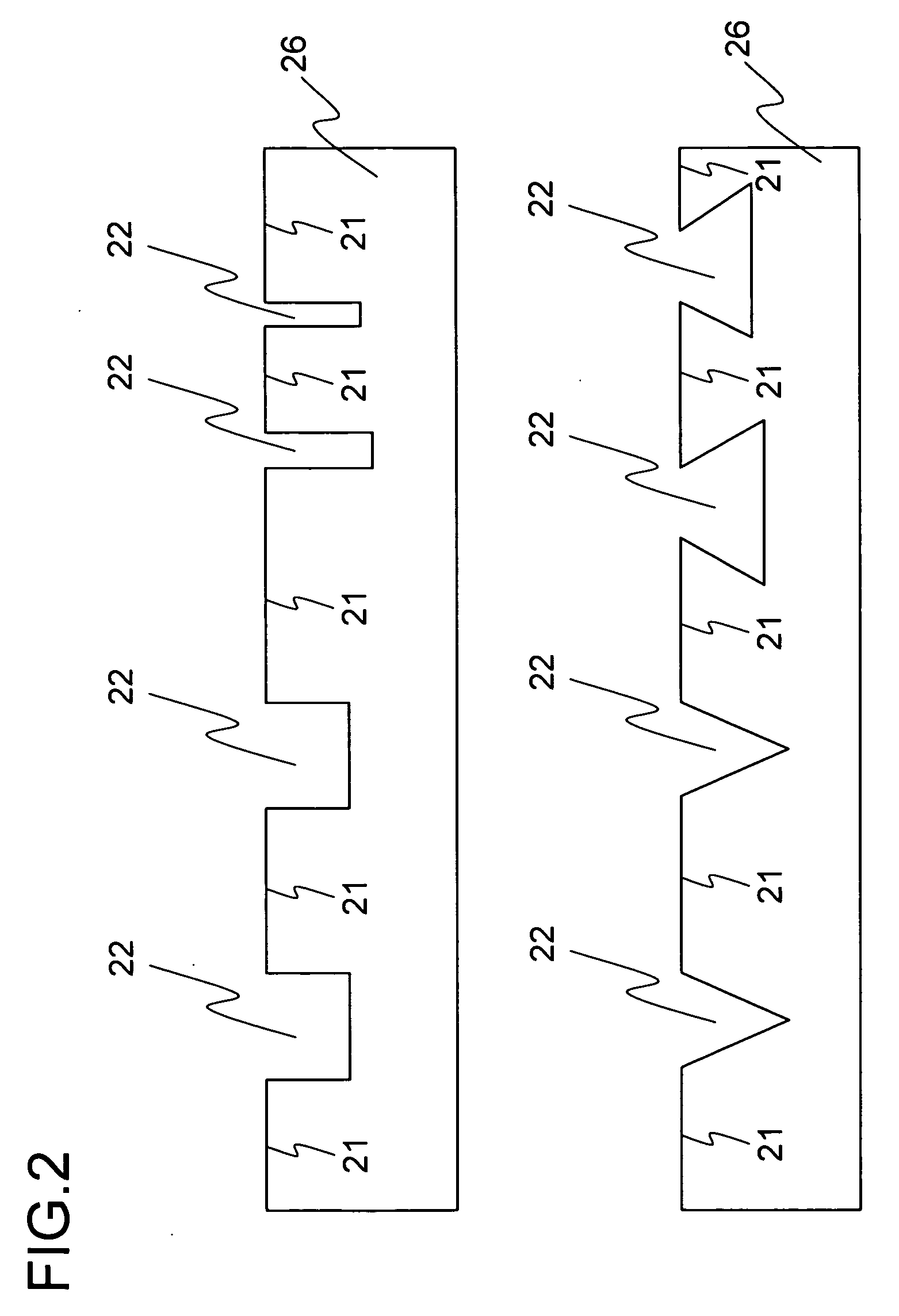

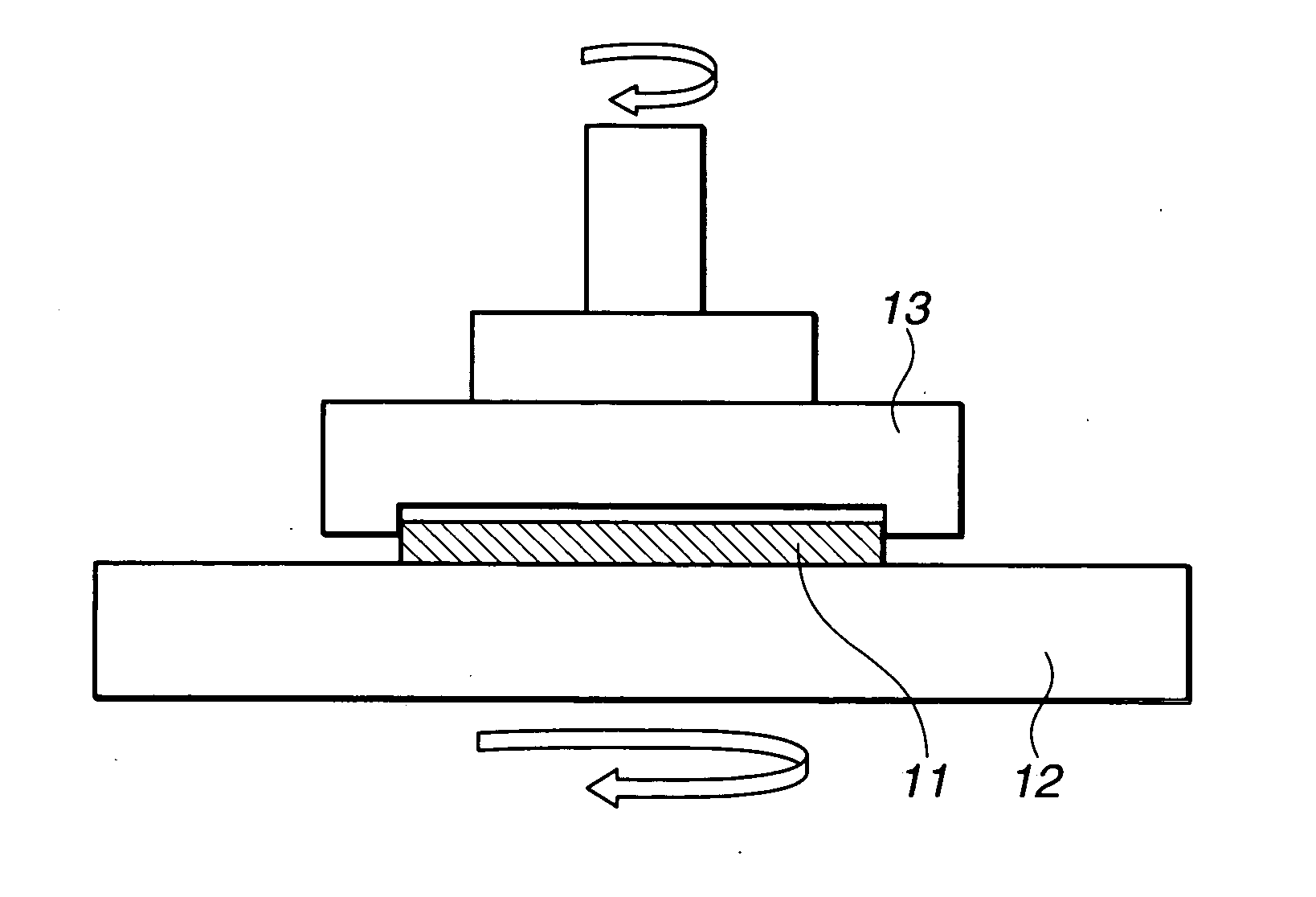

Polishing pad, method of manufacturing the polishing pad, and cushion layer for polishing pad

InactiveUS20040055223A1Easy to processHigh thickness accuracyOther chemical processesAbrasion apparatusSurface patternEngineering

The polishing pad of this invention is a polishing pad effecting stable planarizing processing, at high polishing rate, materials requiring surface flatness at high level, such as a silicon wafer for semiconductor devices, a magnetic disk, an optical lens etc. This invention provides a polishing pad which can be subjected to surface processing to form a sheet or grooves, is excellent in thickness accuracy, attains a high polishing rate, achieves a uniform polishing rate, and also provides a polishing pad which is free of quality variations resulting from an individual variation, easily enables a change the surface patterns, enables fine surface pattern, is compatible with various materials to be polished, is free of burrs upon forming the pattern. This invention provides a polishing pad which can have abrasive grains mixed at very high density without using slurry, and generates few scratches by preventing aggregation of abrasive grains dispersed therein. The polishing pad of this invention has a polishing layer formed from a curing composition to be cured with energy rays, the polishing layer being formed surface pattern thereon by photolithography. The polishing pad of this invention comprises a polishing layer resin having abrasive grains dispersed therein, the resin containing ionic groups in the range of 20 to 1500 eq / ton.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

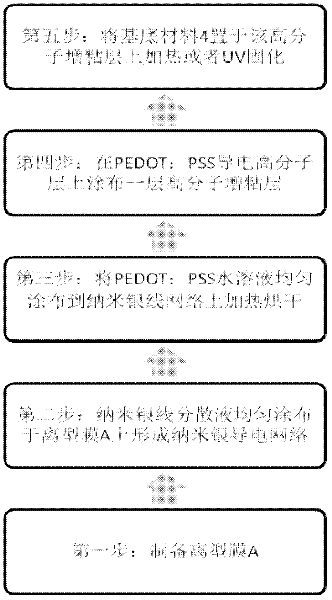

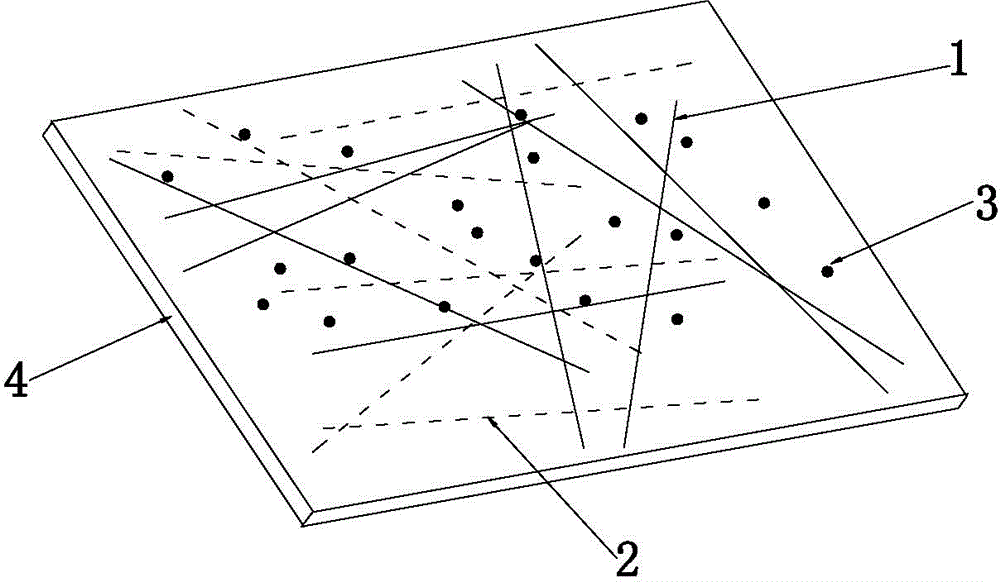

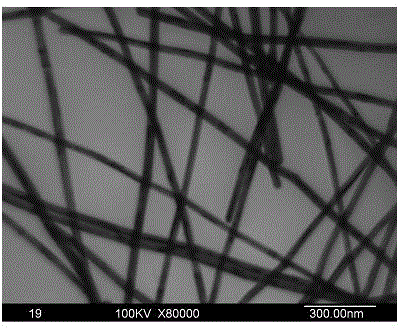

Nanometer silver transparent electrode material and preparation method thereof

ActiveCN102522145AEasy to manufactureTo prevent the phenomenon of insulationConductive layers on insulating-supportsCable/conductor manufactureElectricityHigh volume manufacturing

The invention discloses a nanometer silver transparent electrode material and a preparation method thereof. The nanometer silver transparent electrode material comprises the following four layers of structures: 1 a nanometer silver wire network, 2 poly(3,4-ethylenedioxythiophene) (PEDOT): an electricity conductive high molecular layer formed by evenly coating PSS aqueous solution, 3 a high molecular material tackifying layer and 4 a substrate. The nanometer silver wire transparent electrode is high in light transmitting rate, low in resistance, good in adhesion between the electricity conductive layer and the substrate, high in surface flatness degree, simple in preparation process and convenient for large-scale production and overcomes the shortcomings of being complex in a process for preparing the nanometer silver wire transparent electrode through a transfer method and not suitable for large-scale production.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

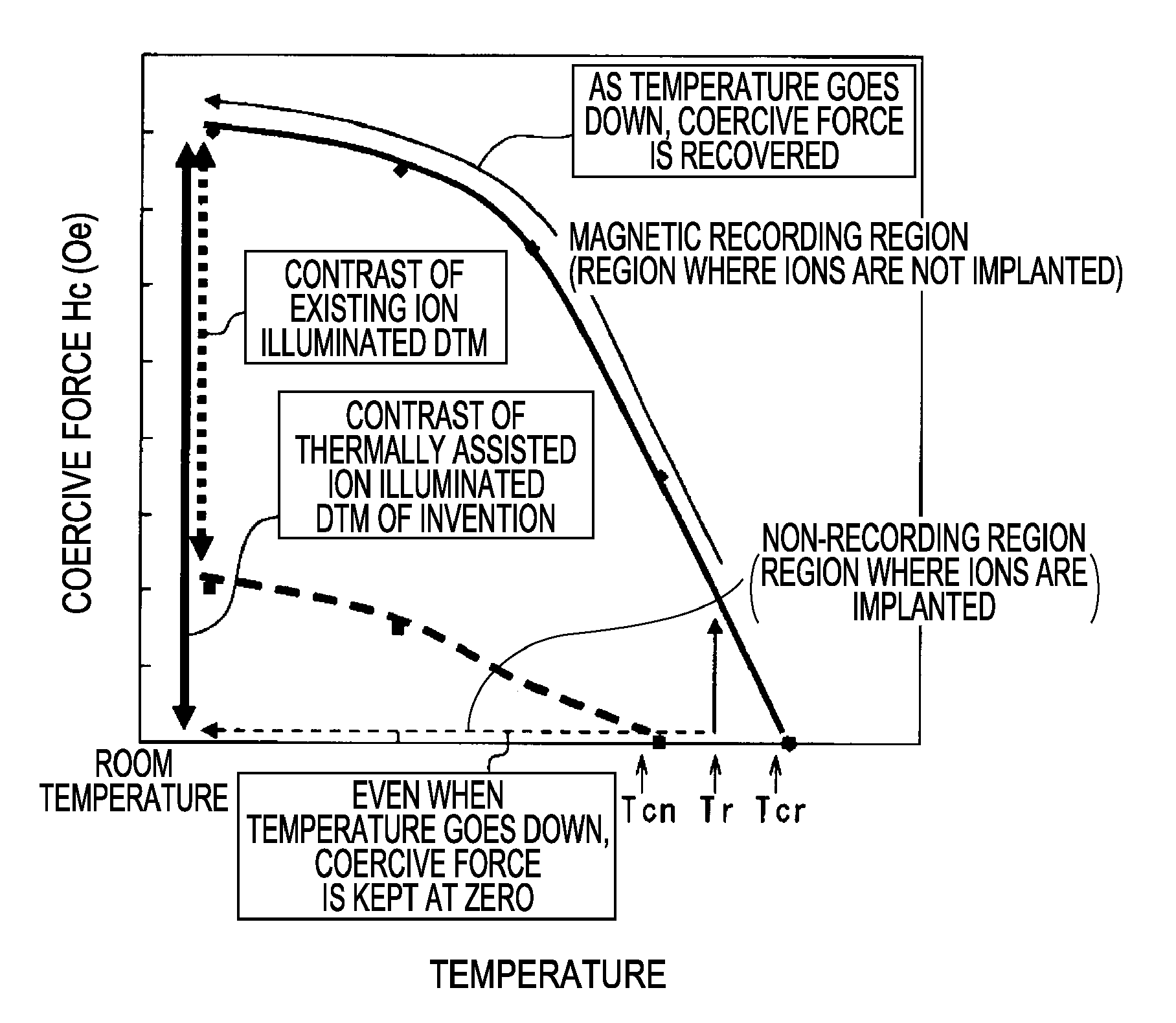

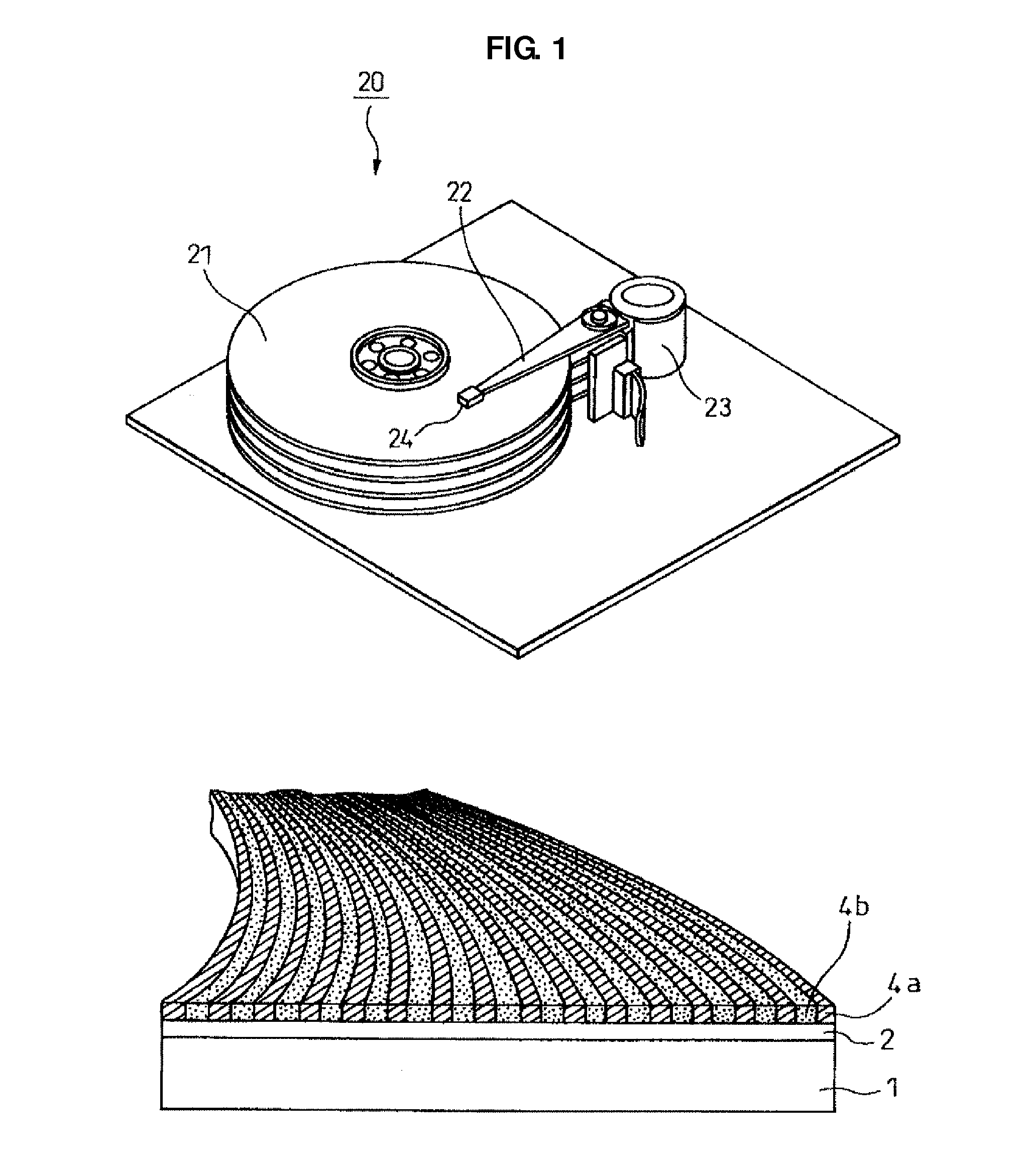

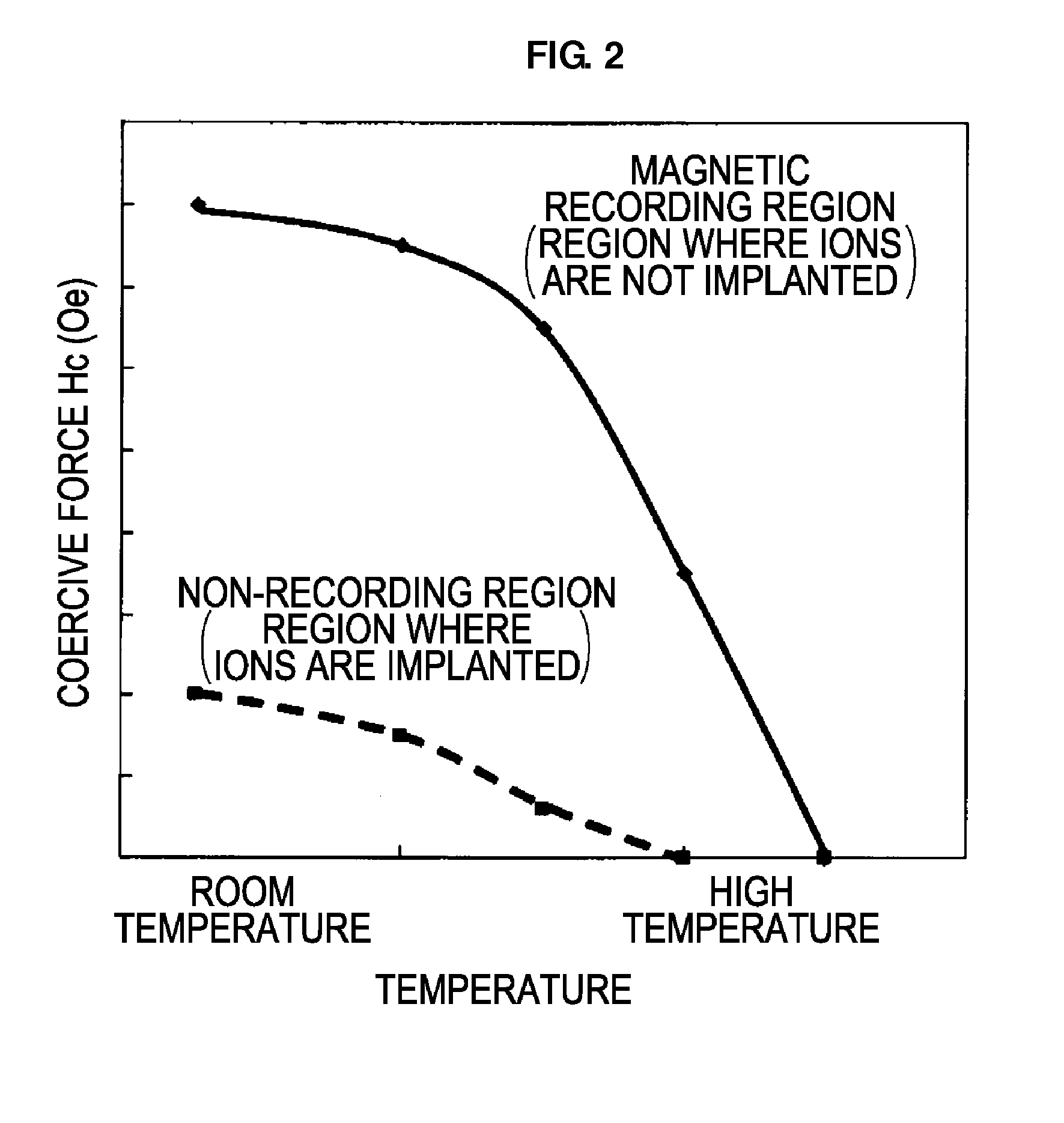

Thermally assisted magnetic recording disk with ion-implant facilitated non-magnetic regions, manufacturing method thereof, and magnetic recording method

ActiveUS8634155B2Low coercivityPatterned record carriersNanoinformaticsHeat-assisted magnetic recordingThermal expansion

The invention provides a magnetic disk that solves (1) a problem of cross-talk that cannot be solved even by an existing thermally assisted recording method or a discrete method (DTM or the like), (2) a problem of surface flatness, which an existing embedding type DTM or the like has, and (3) a problem of a difference in thermal expansion coefficient between materials when a thermally assisted method is applied to the DTM, and that (4) does not necessitate a special medium structure, and is excellent in a surface flatness and economically and functionally high in realizability. A DTM manufactured by ion implantation is excellent in the surface flatness, and can solve the cross-talk problem by conducting the thermally assisted recording at a temperature between a Curie temperature (Tcn) of a portion where ions are implanted (non-recording region) and a Curie temperature (Tcr) of a portion where ions are not implanted (recording region).

Owner:WESTERN DIGITAL TECH INC

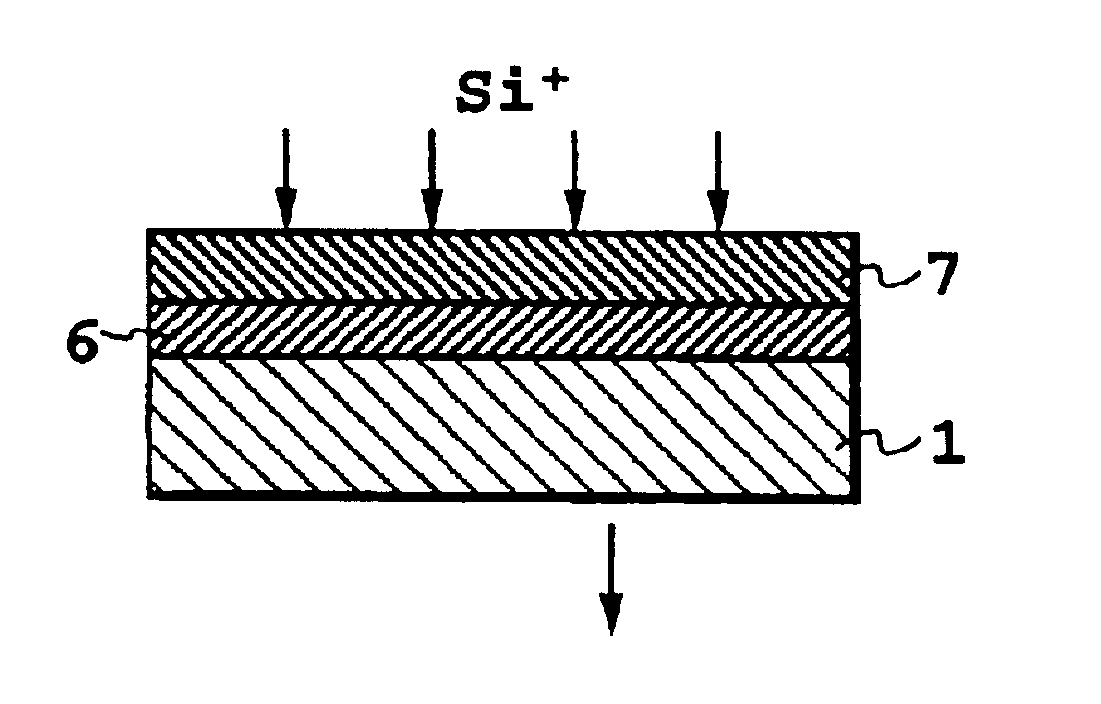

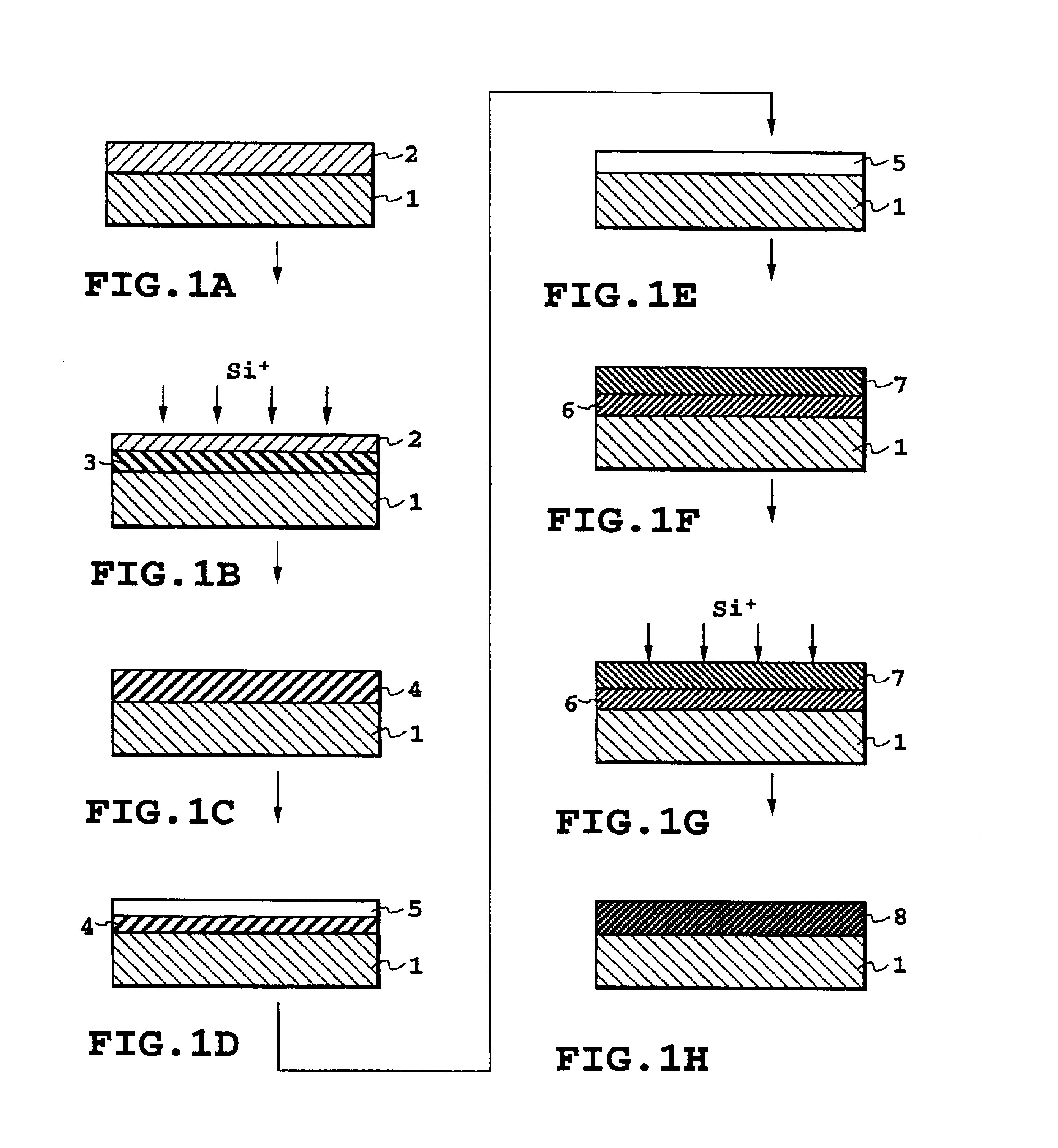

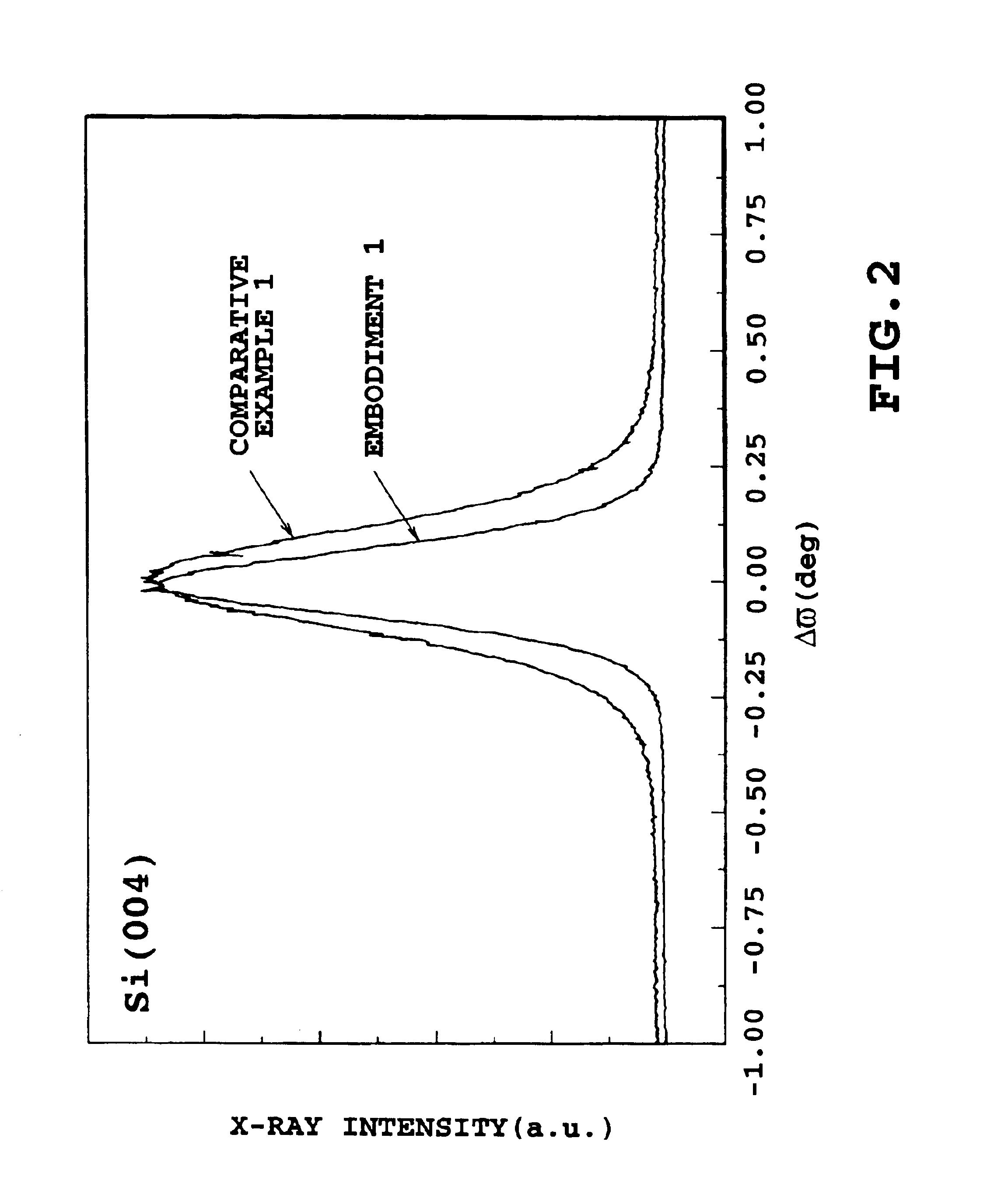

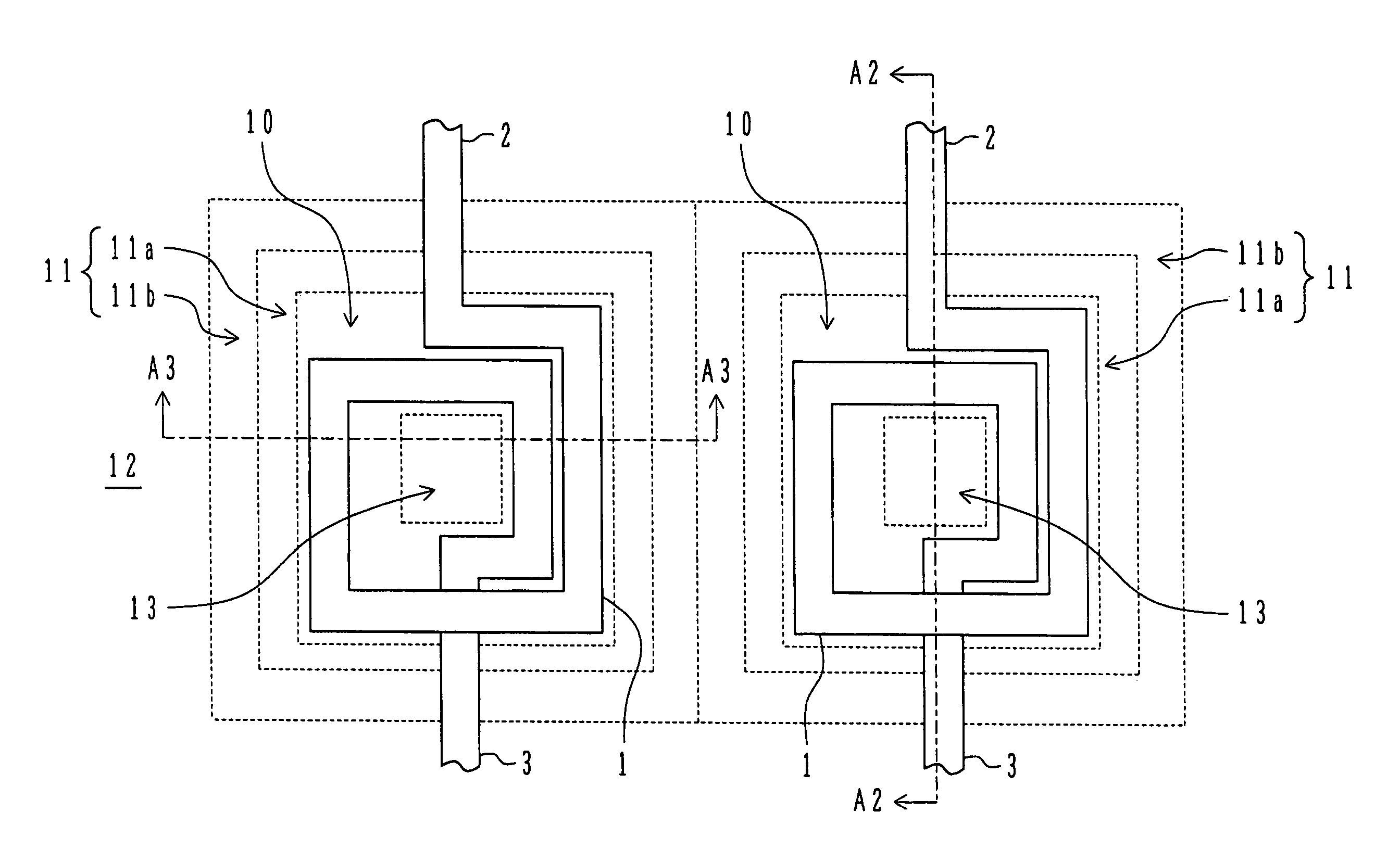

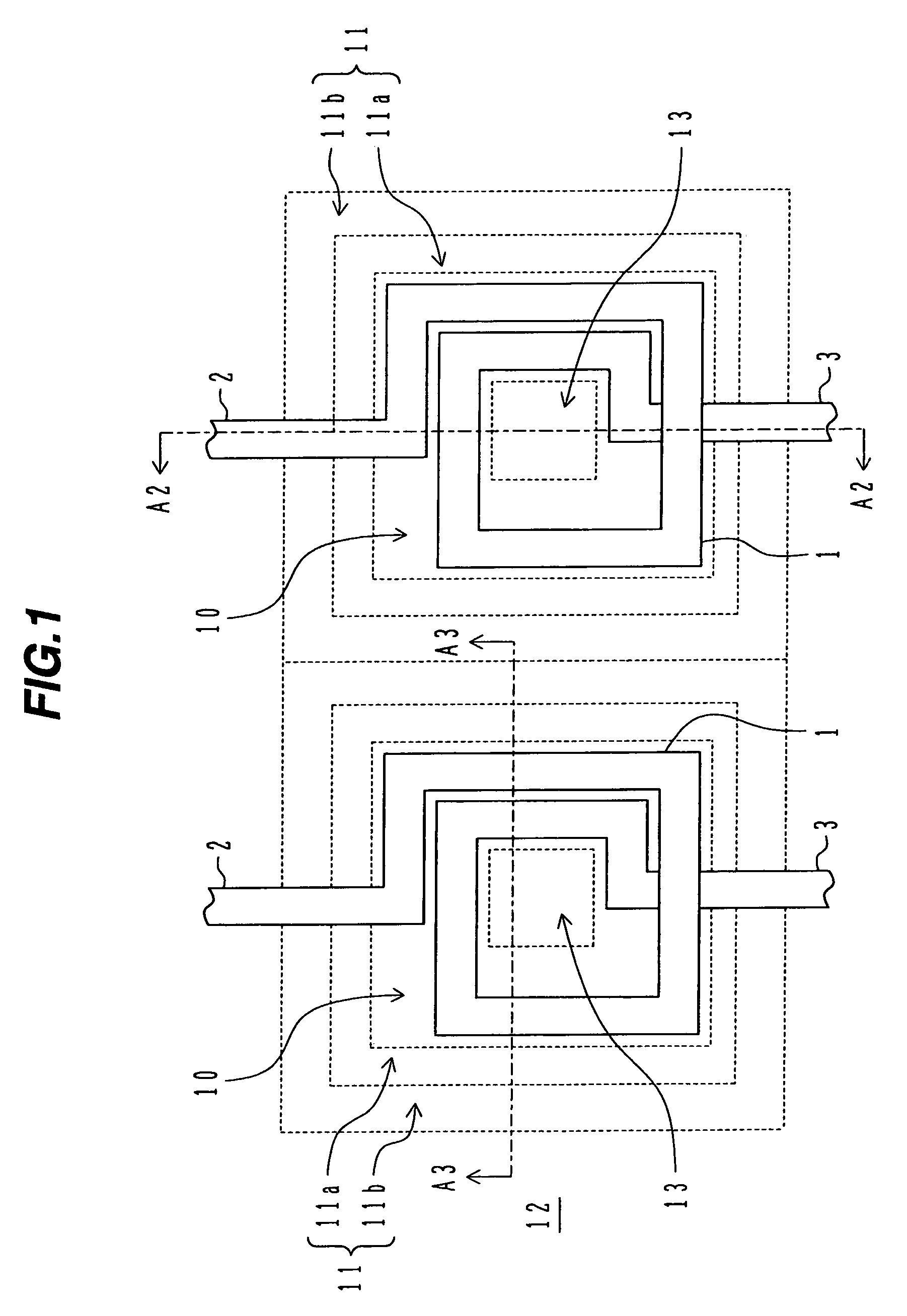

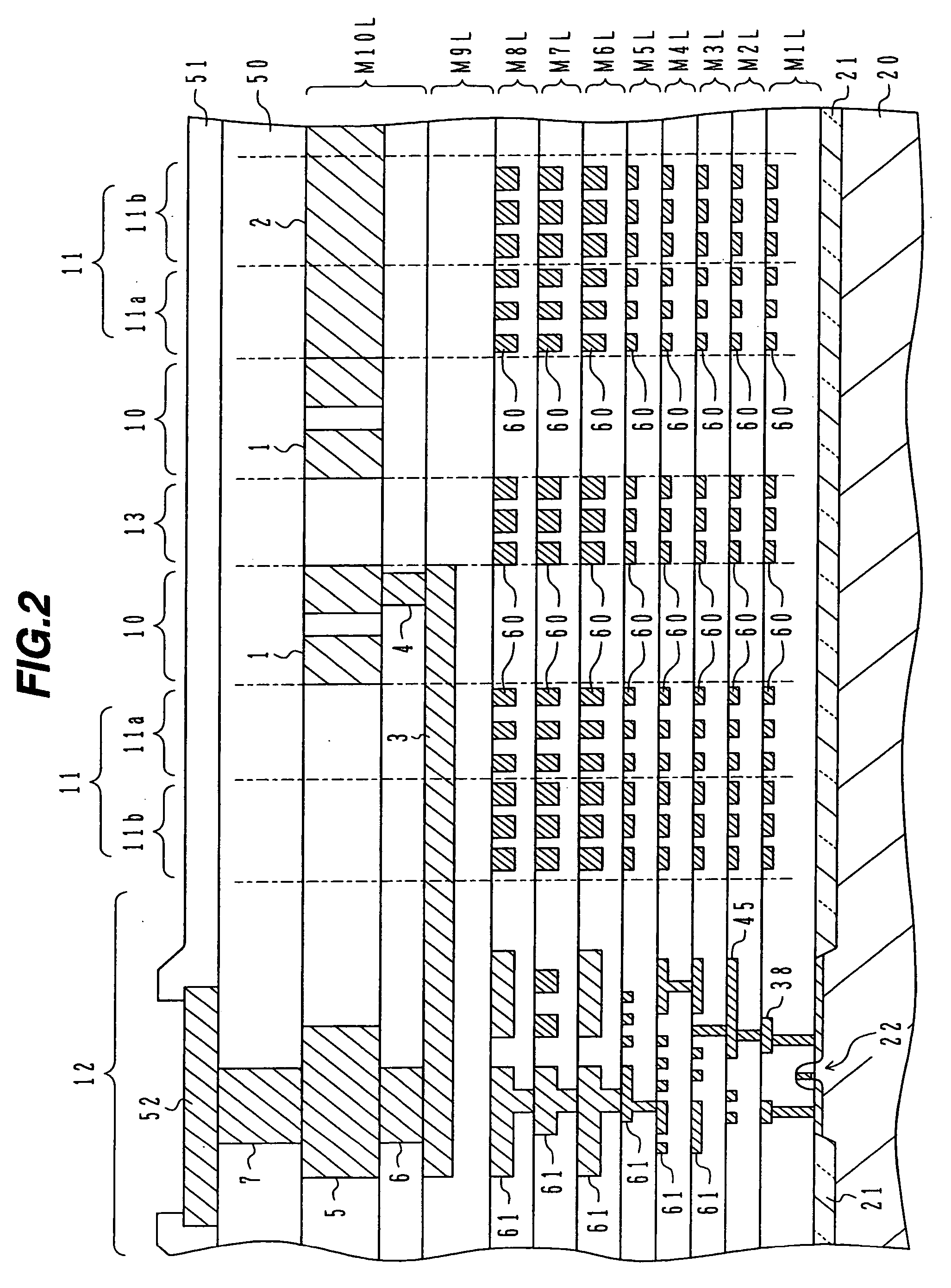

Semiconductor substrate and its production method, semiconductor device comprising the same and its production method

InactiveUS6768175B1High crystallinityFew defectSemiconductor/solid-state device testing/measurementSolid-state devicesSilicon oxideSoi substrate

When a SOI substrate is produced a first silicon layer epitaxially grown on the insulating underlay is ion implanted to make deep part of interface of the silicon layer amorphous, and then annealed to recrystallize. Next, the silicon layer is heat treated to oxidize part of the surface side, and after the silicon oxide is removed by etching, a silicon layer is epitaxially grown on the remaining first silicon layer to form a second silicon layer. Subsequently, the second silicon layer is again ion implanted to make deep part of interface amorphous, then annealing is performed to recrystallize. With this method, a SOI substrate, which is very small in crystal defect density of the silicon layer and good in surface flatness, can be produced. Therefore, on the semiconductor substrate an electronic device or optical device having high device performance and reliability can be realized.

Owner:ASAHI KASEI KK

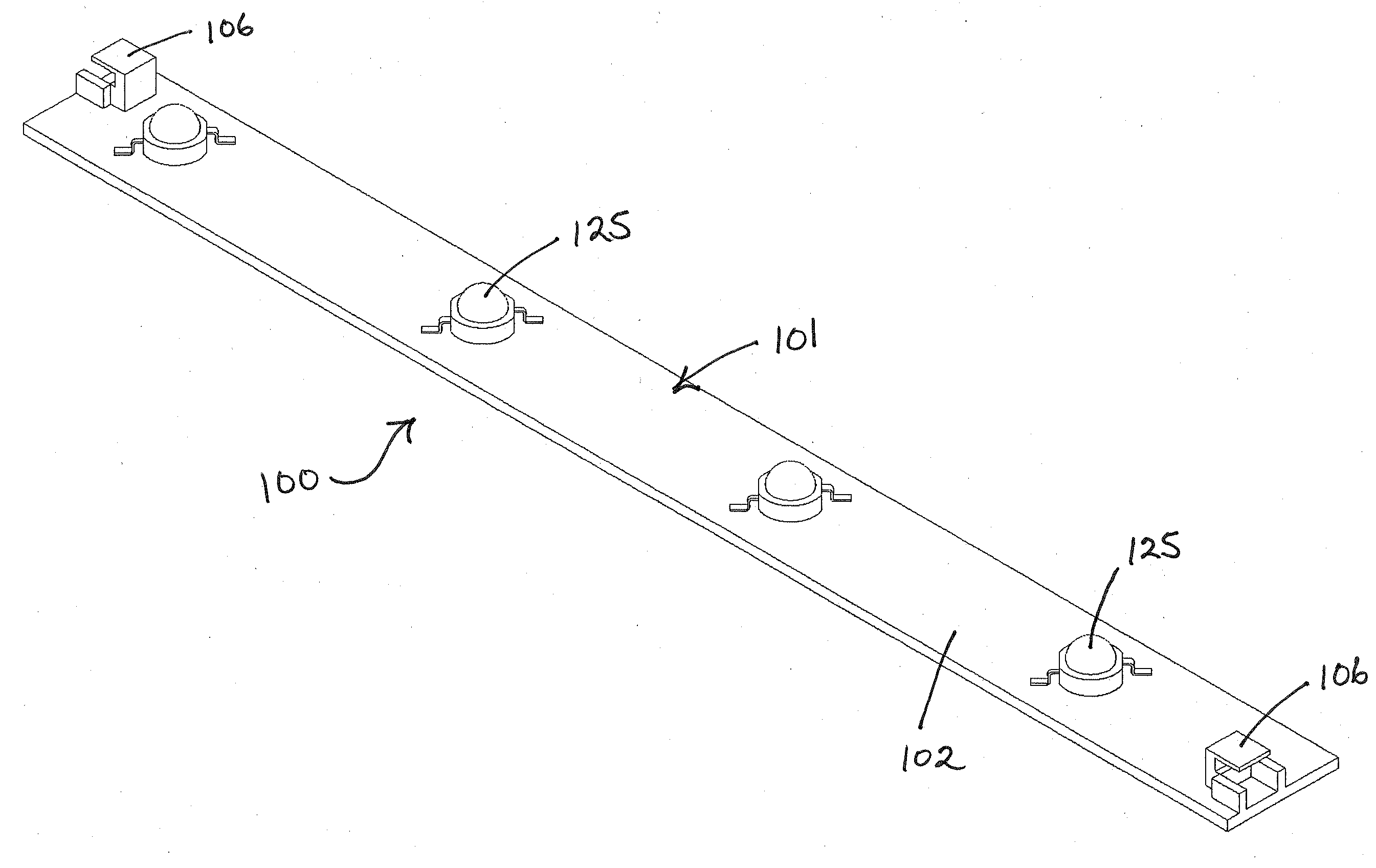

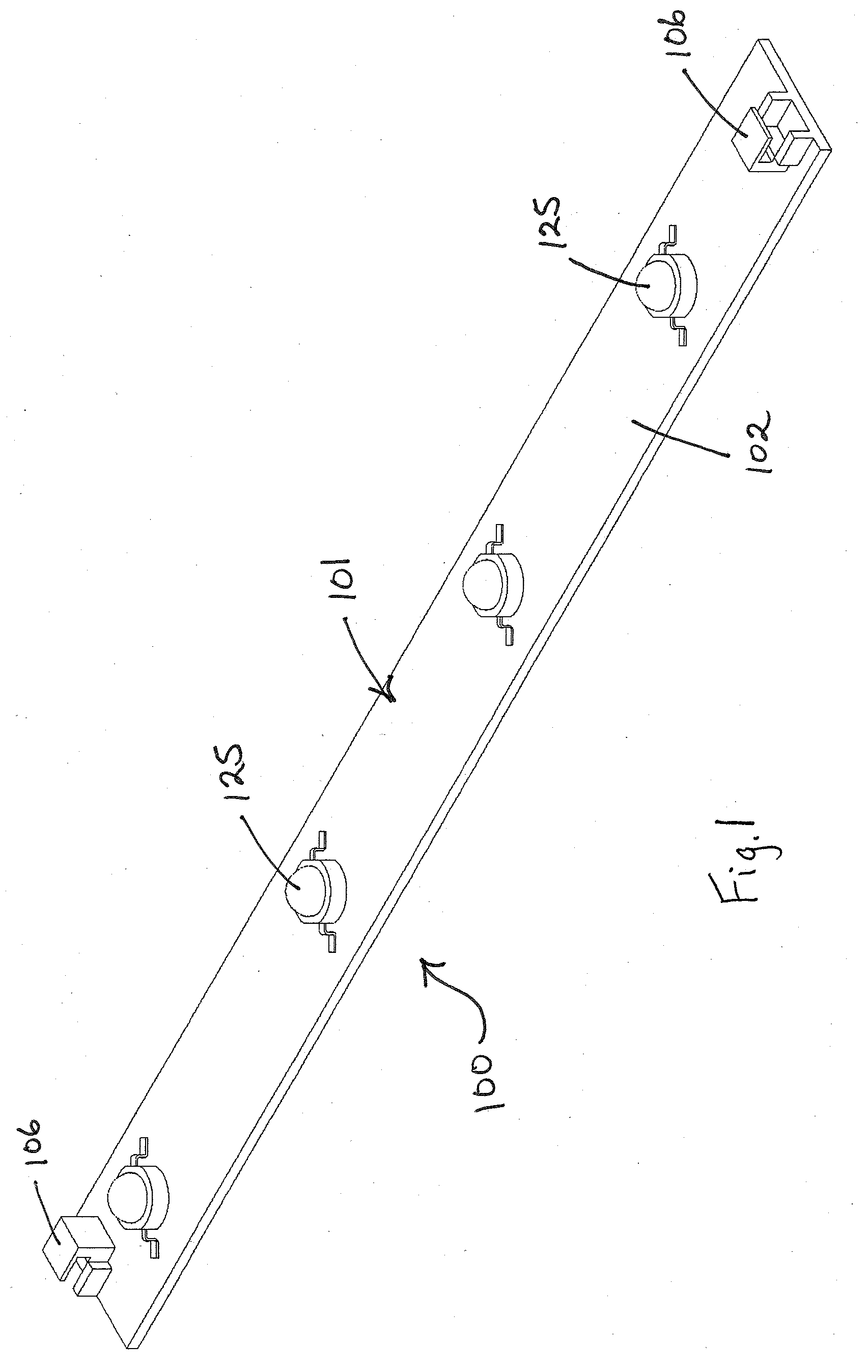

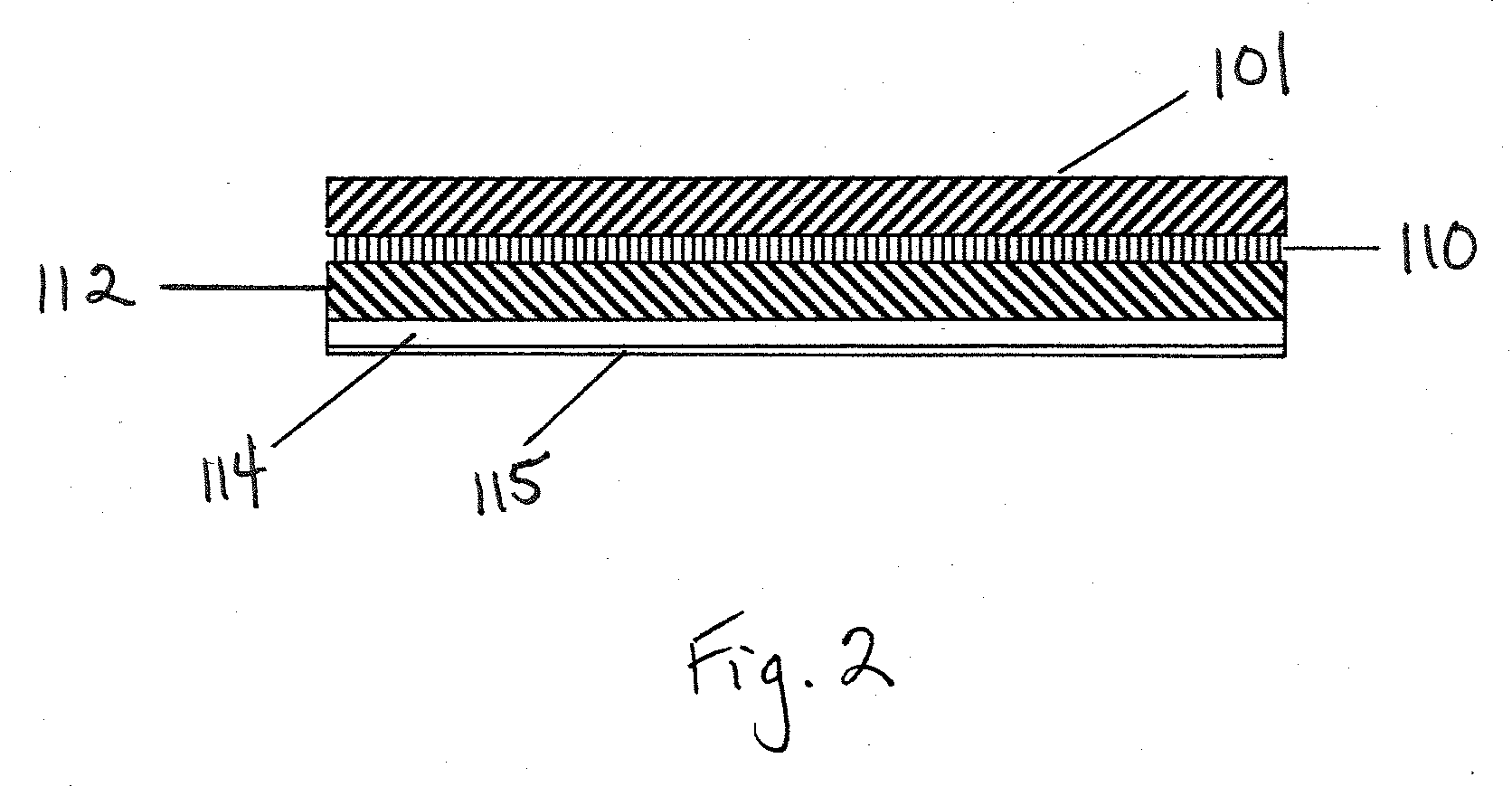

Layered structure for use with high power light emitting diode systems

A layered structure for use with a high power light emitting diode system comprises an electrically insulating intermediate layer interconnecting a top layer and a bottom layer. The top layer, the intermediate layer, and the bottom layer form an at least semi-flexible elongate member having a longitudinal axis and a plurality of positions spaced along the longitudinal axis. The at least semi-flexible elongate member is bendable laterally proximate the plurality of positions spaced along the longitudinal axis to a radius of at least 6 inches, twistable relative to its longitudinal axis up to 10 degrees per inch, and bendable to conform to localized heat sink surface flatness variations having a radius of at least 1 inch. The top layer is pre-populated with electrical components for high wattage, the electrical components including at least one high wattage light emitting diode at least 1.0 Watt per 0.8 inch squared.

Owner:METROSPEC TECH

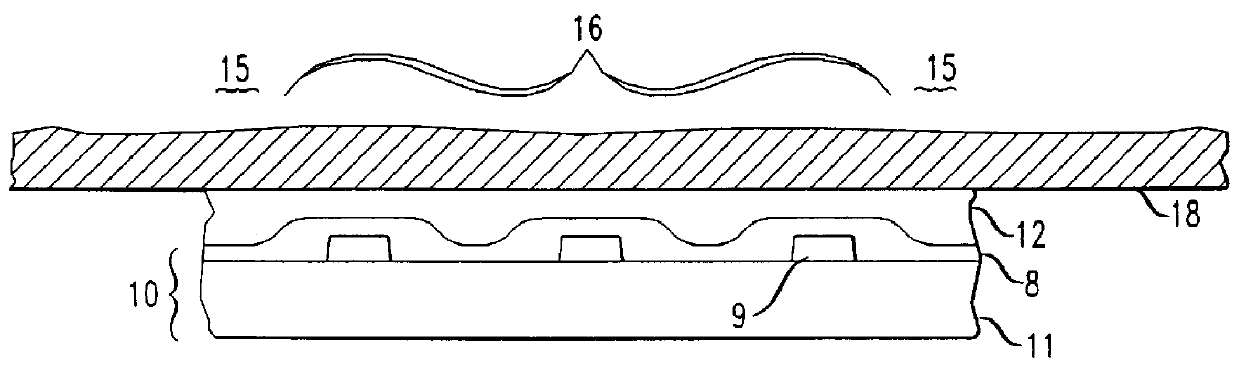

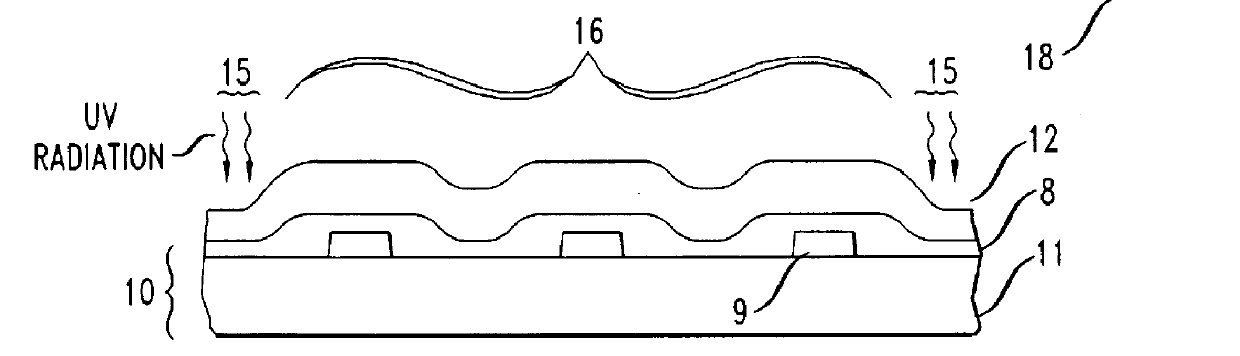

Device fabrication involving surface planarization

A method for improving the planarity of a layer of material formed on the surface of a topographic substrate, is disclosed. The layer of planarization material formed over the topographic substrate has a first area and a second area. The planarization material in the first area is proximate to the perimeter of the topographic substrate and surrounds the planarization material in the second area. The planarization material in the first area is partially solidified, so that the planarization material in the second area is substantially confined throughout the height of the planarization material in the first area and remains within the perimeter of the topographic substrate when the surface of the layer of planarization material is planarized. The planarization material is planarized by contacting such material with a flat surface of an object with sufficient force to transfer the surface flatness from the flat surface of the object to the layer of planarization material. A release material is optionally placed between the layer of planarization material and the object with the flat surface to facilitate separation of the flat surface of the object from contact with the layer of planarization material after planarization and solidification.

Owner:LUCENT TECH INC

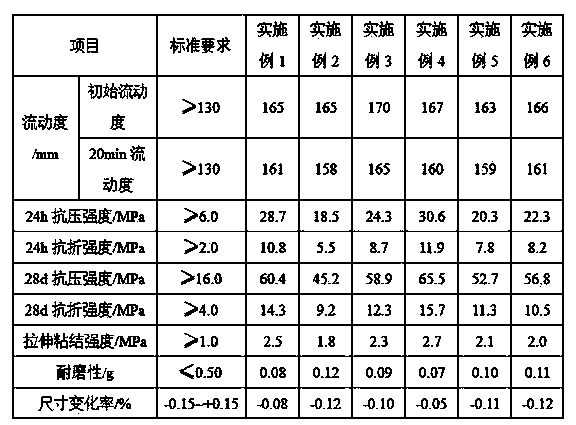

High performance cement-base self-leveling mortar

The invention discloses a high performance cement-base self-leveling mortar. The mortar is characterized by comprising cement, an auxiliary gel material, fine aggregate, a filling material, an additive, and water; wherein the cement is common silicate cement and sulphoaluminate-silicate cement, the auxiliary gel material comprises mineral slag, fly ash, silica fume, and gypsum, and the ratio of common silicate cement to sulphoaluminate-silicate cement to gypsum is equal to 1:0.2-0.6:0.1-0.4. The mortar has a self-leveling function without vibration, so the surface flatness is very high. The curing speed of the mortar is very quick, and after two hours, the strength of the mortar can meet the requirements of subsequent construction. Moreover the mortar has the advantages of low contraction rate, good volume stability, good surface wear resistance, and high compression strength.

Owner:广东省建筑工程监理有限公司

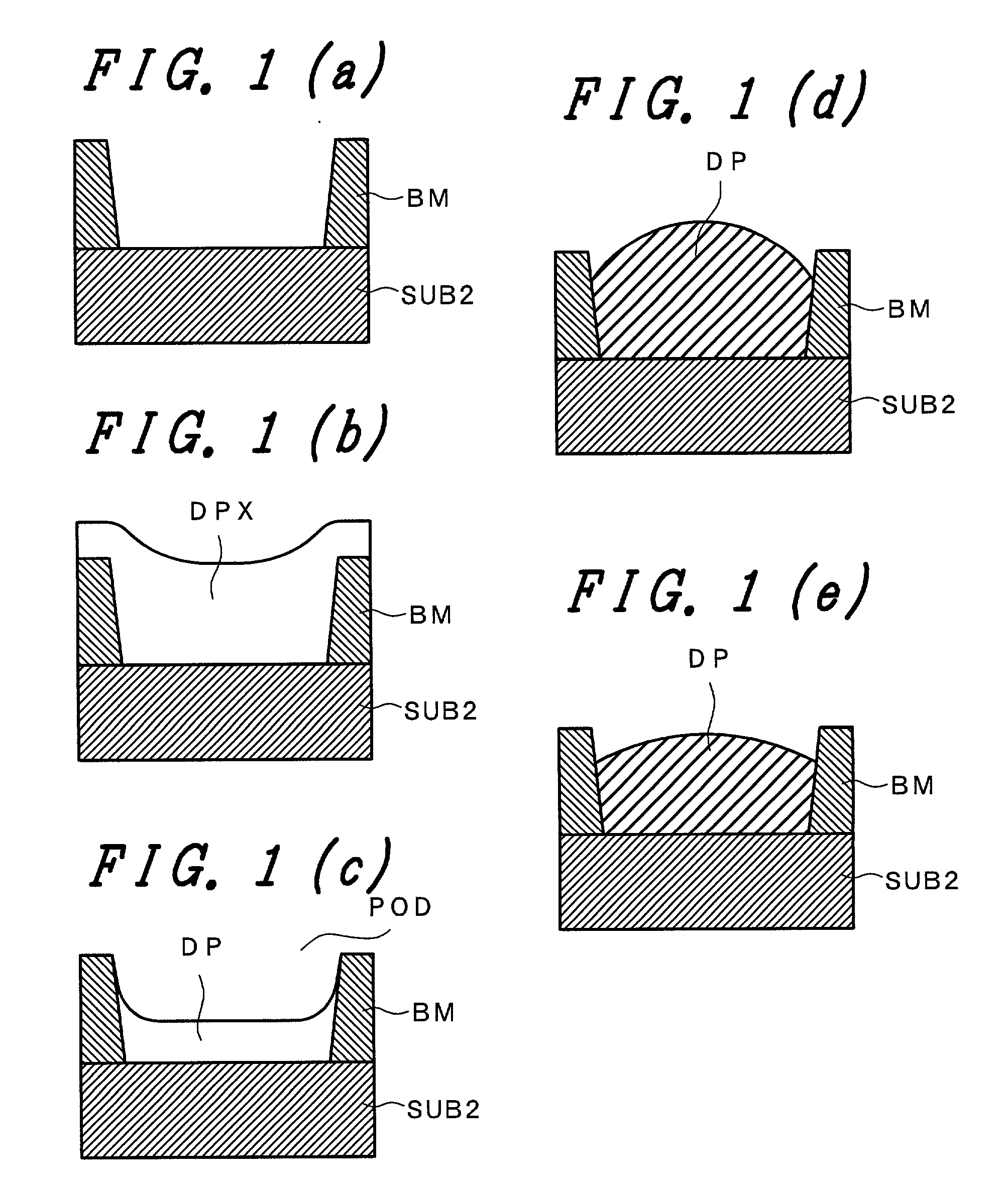

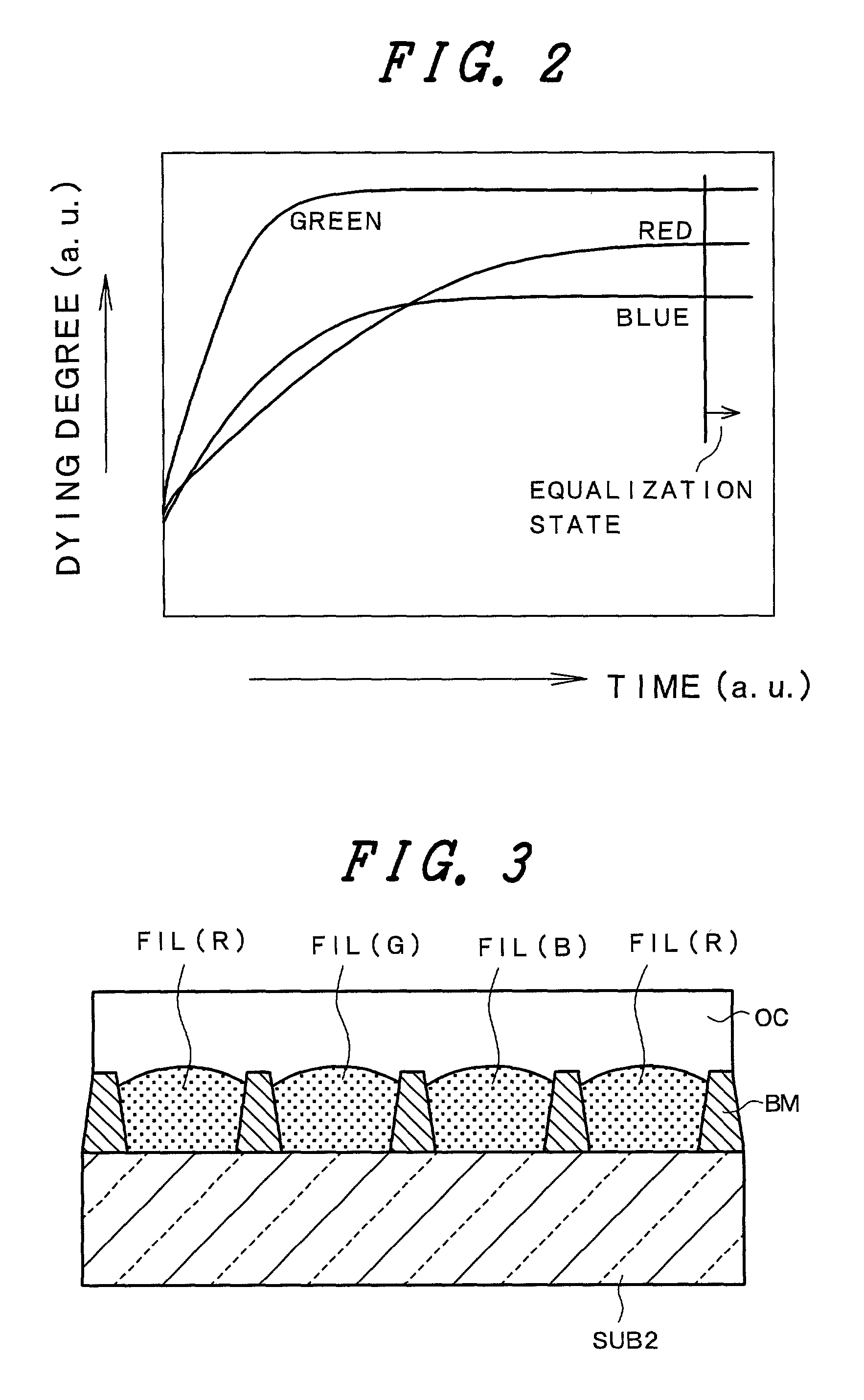

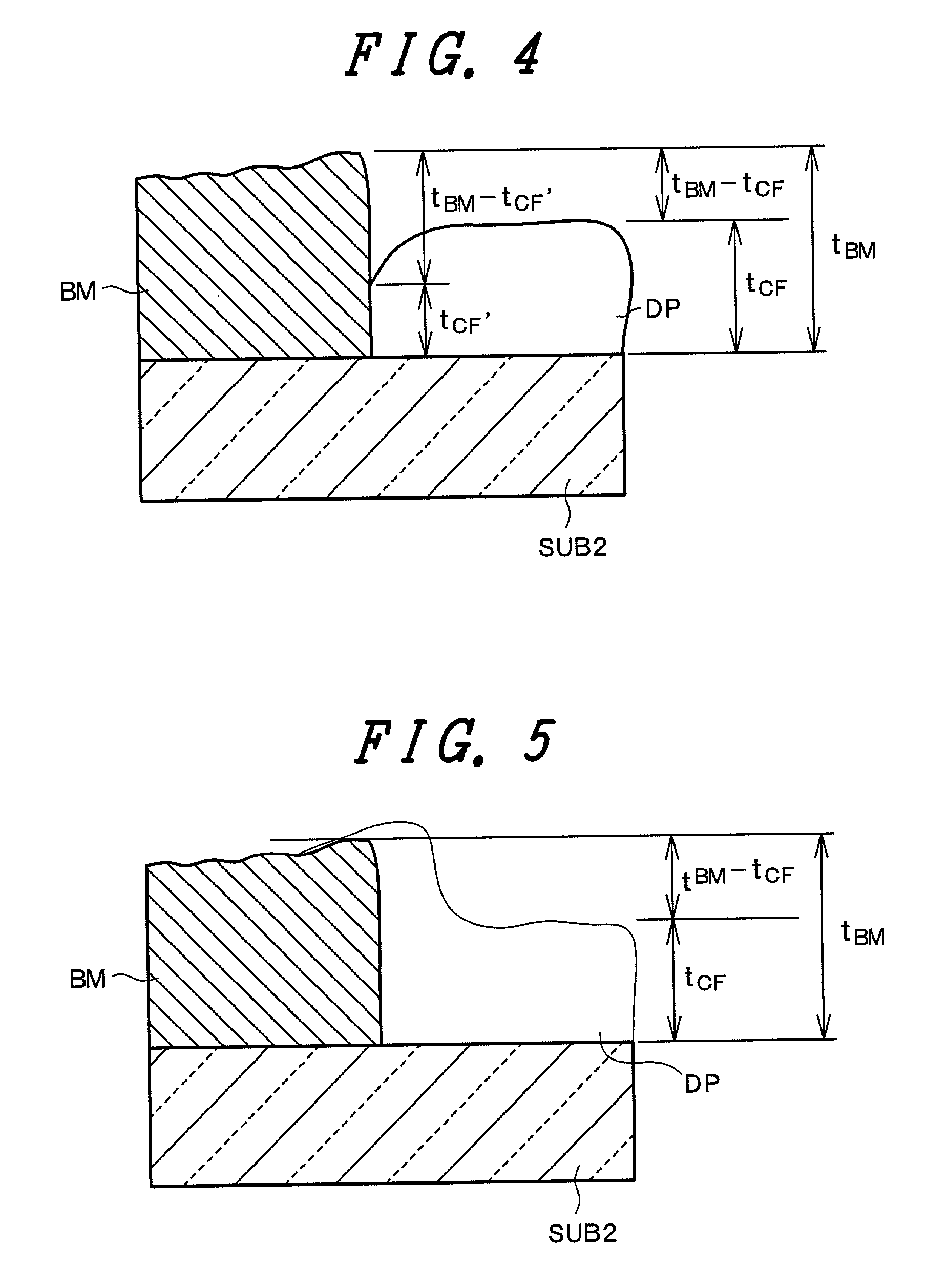

Method of manufacturing color filters and liquid crystal display device using these color filters

InactiveUS20010007733A1Improve flatnessImprove display qualityOptical filtersTypewritersUltravioletEngineering

After forming a black matrix which defines pixel regions on a substrate, dyed substrate layers of photo hardening property are formed. By irradiating ultraviolet rays to the dyed substrate layers from the back of the substrate and by developing, ink reservoirs which use the black matrix as partition walls are formed. The dyeing material such as the dye is supplied to these ink reservoirs by an ink jet system. Due to these partition walls, there is no possibility that the dyeing material scatters to the neighboring or adjacent pixel regions to cause the mixed color. Further, since the filters having a sufficient thickness can be formed in the ink reservoirs, the surface flatness of the color filters can be sufficiently ensured without coating the thick overcoat layer.

Owner:HITACHI LTD +1

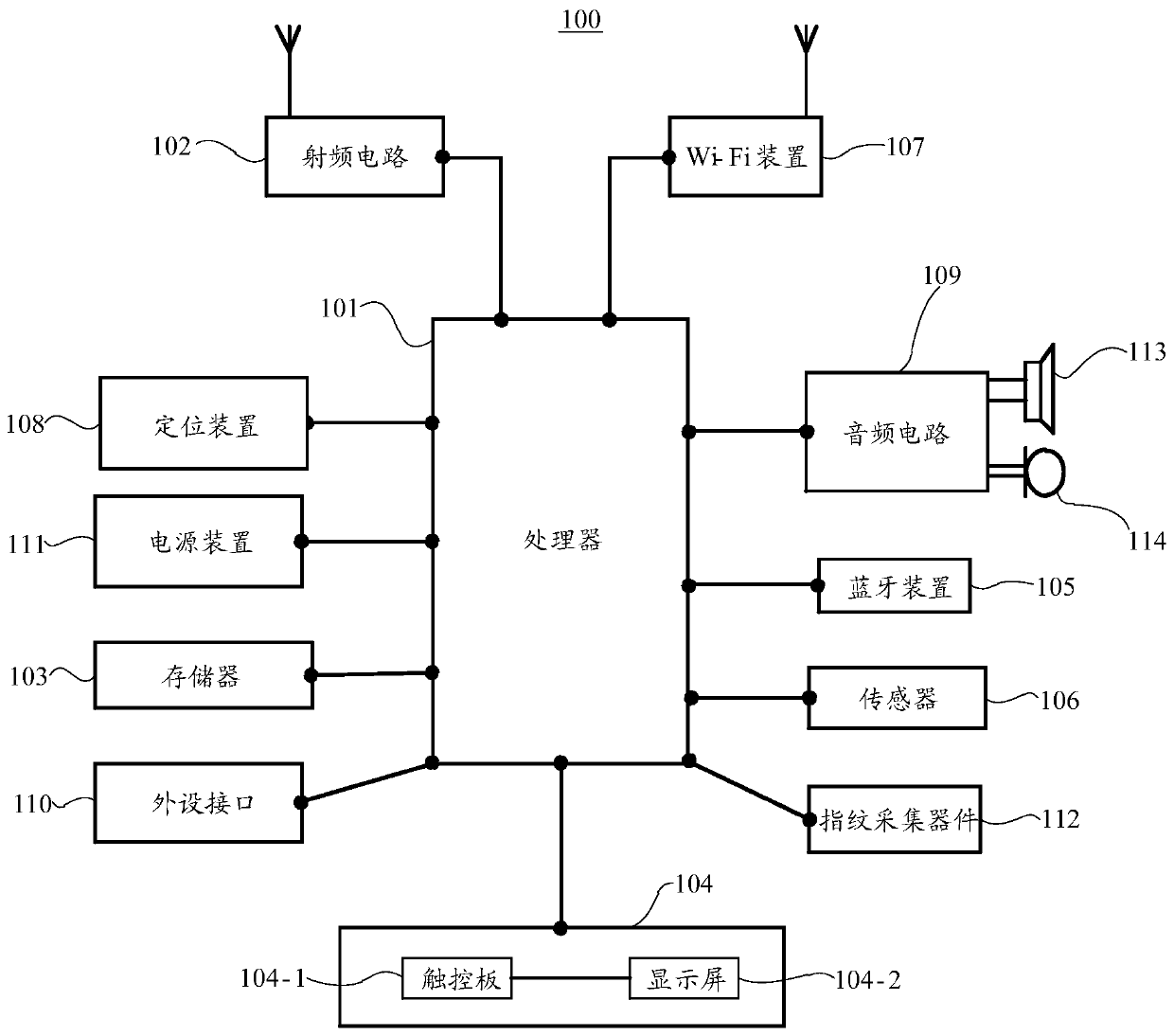

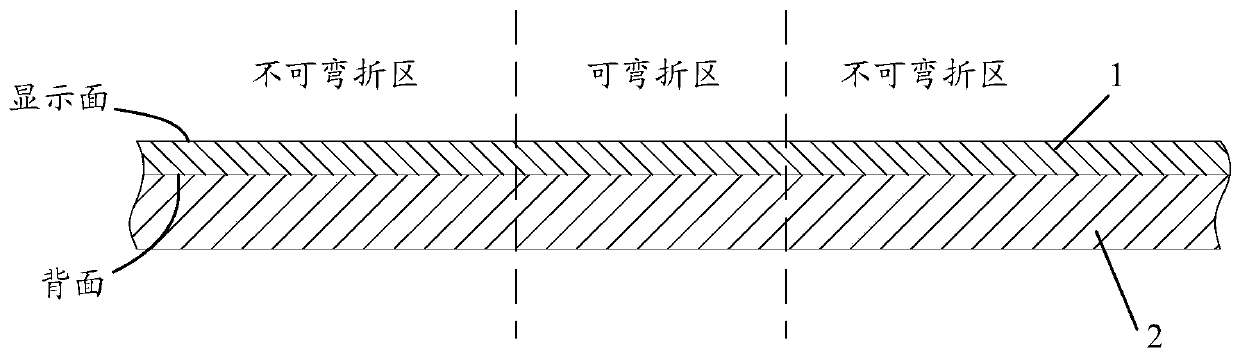

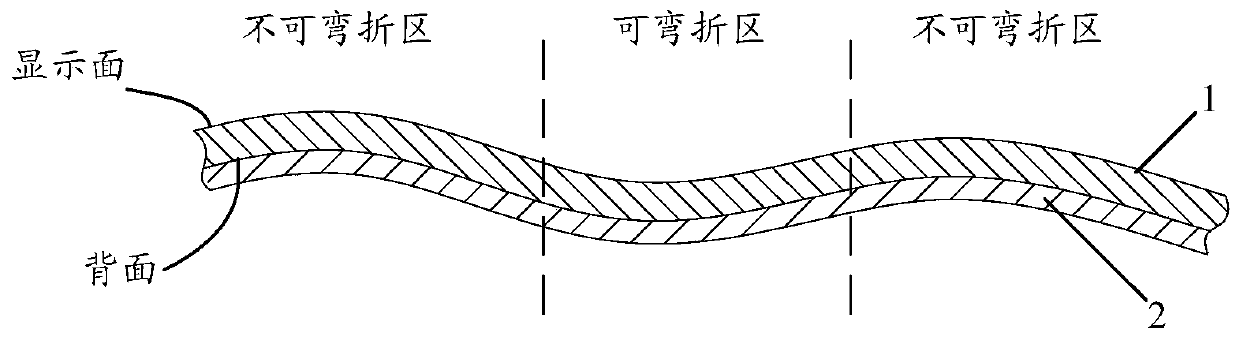

Supporting piece for foldable terminal device and foldable terminal device

InactiveCN110062077AGuaranteed mechanical strengthStable supportDigital data processing detailsTelephone set constructionsTerminal equipmentEngineering

The invention provides a supporting piece for foldable terminal device and the foldable terminal device, relates to the technical field of terminal device. The supporting piece and the device and canimprove the surface flatness of the terminal device on the premise that the bending activity of the terminal device is not limited. The terminal device comprises a flexible display screen and a supporting piece arranged on one side of the flexible display screen. The supporting piece comprises at least one bendable area, a plurality of gaps are formed in at least one bendable area. Each gap is provided with at least one opening, and the orientation of at least one opening in each gap is the same as the bending direction of the bendable area where the gap is located. When the bendable area of the supporting piece is bent, the gap can absorb stress generated in the bending process, the bending movement of the terminal device cannot be limited, the supporting piece can provide a supporting effect for the flexible display screen, and the surface flatness of the terminal device is improved. The terminal device provided by the invention can be folded, and has the functions of providing large-size display, being convenient to carry and the like.

Owner:HUAWEI DEVICE CO LTD

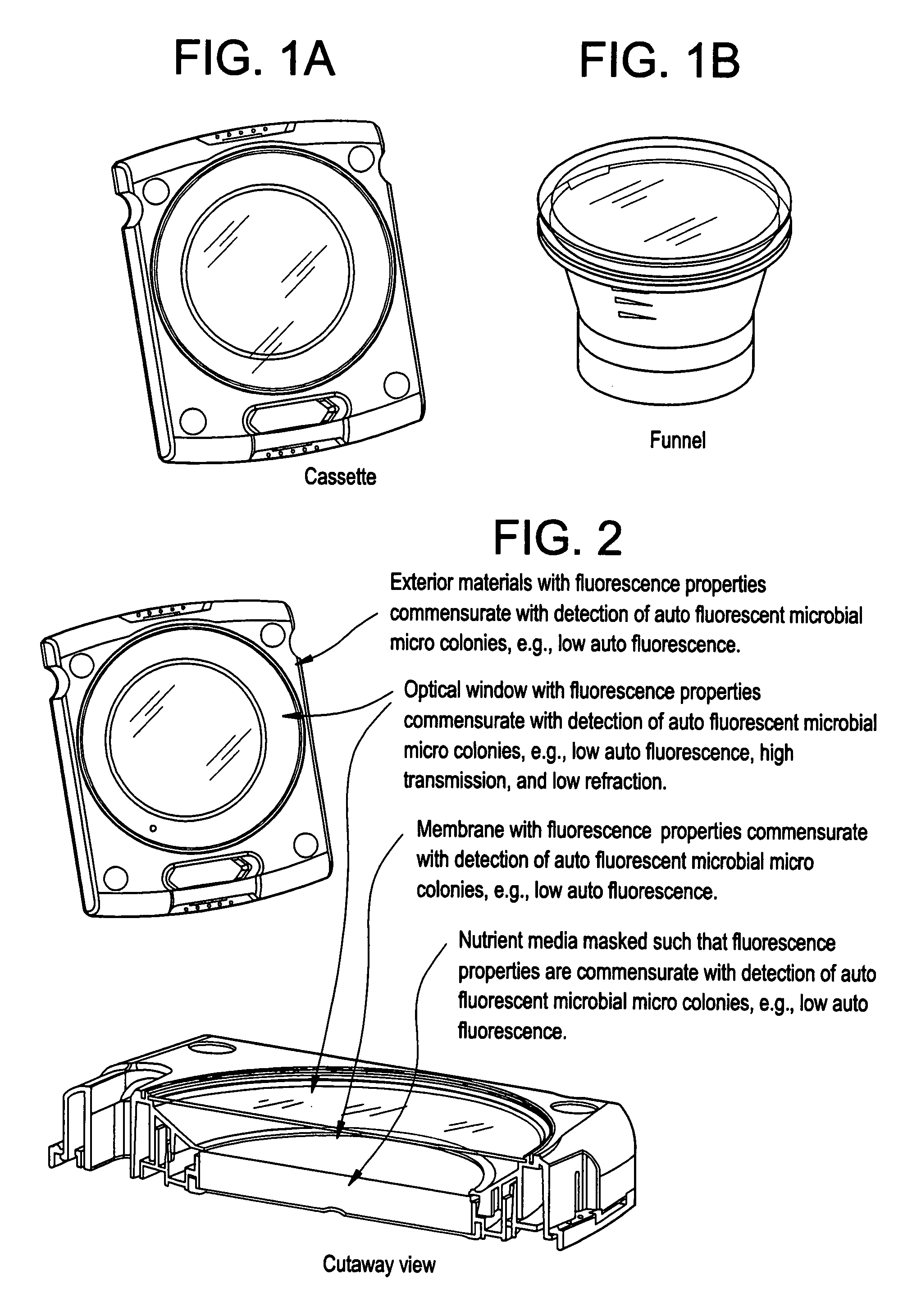

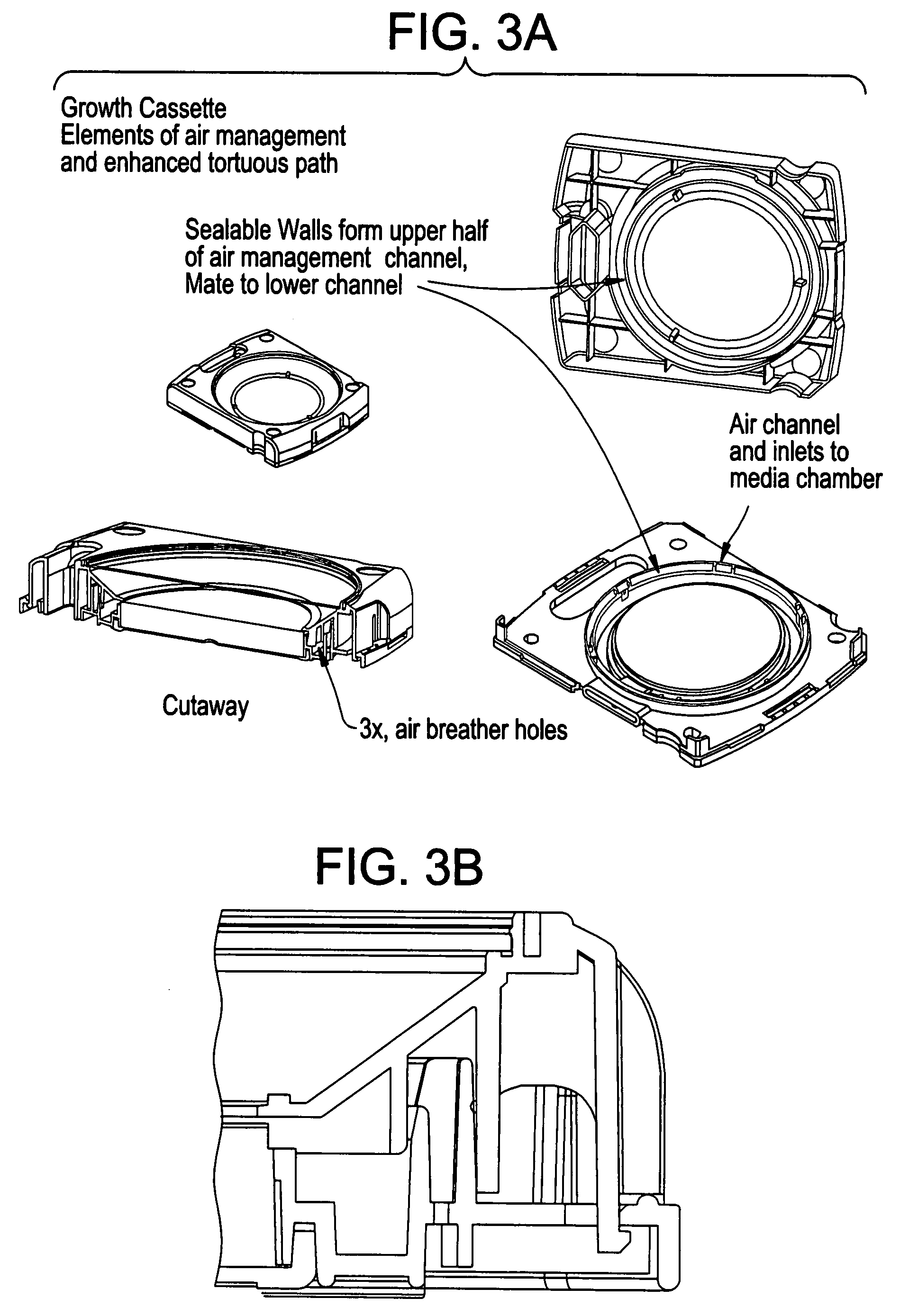

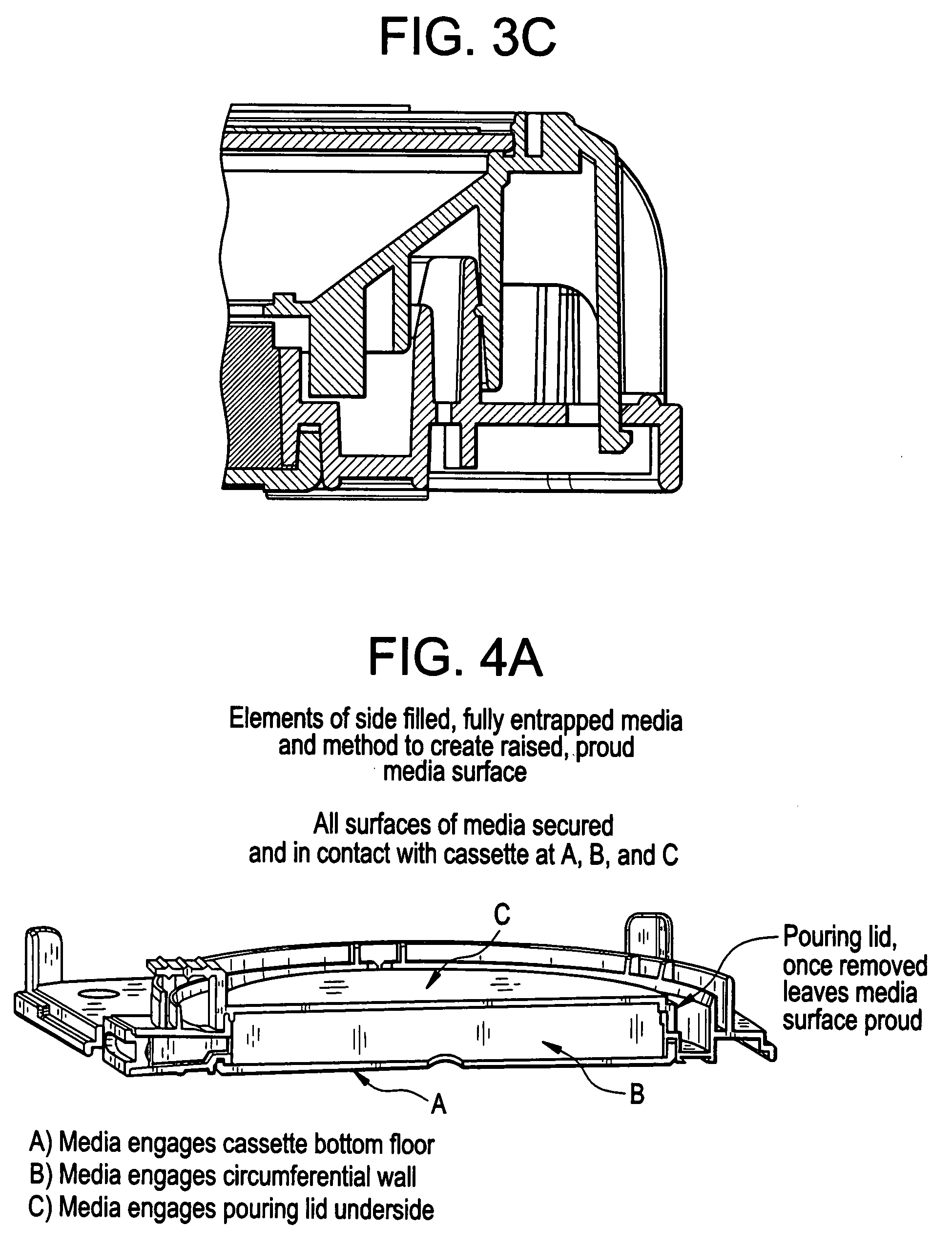

Cassette containing growth medium

ActiveUS20070212747A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationCell culture media

The invention features devices for capturing and culturing cells (e.g., microorganisms, cells containing microorganisms, or cells from eukaryotic cell cultures) and methods of using these devices. One device is a cassette containing growth media that may be employed in an automated rapid enumeration system. The cassette has, for example, been enhanced with features for controlling surface flatness, optical imaging, controlled dehydration of semi solid nutrient media, controlled air and particle exchange, and automated handling. Another device of the invention is a filtration funnel that may used to concentrate cells in a sample onto a membrane.

Owner:RAPID MICRO BIOSYSTEMS INC

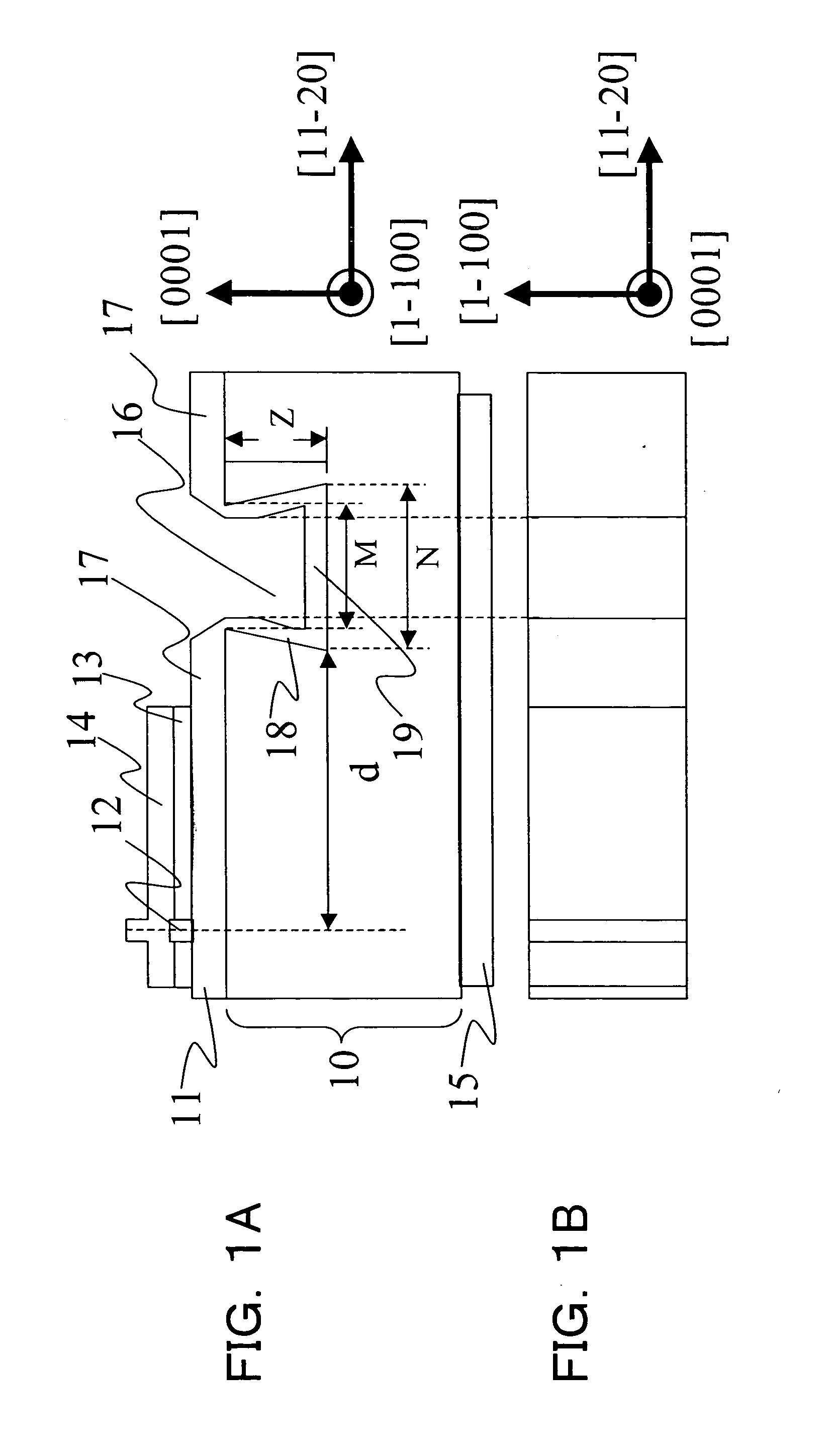

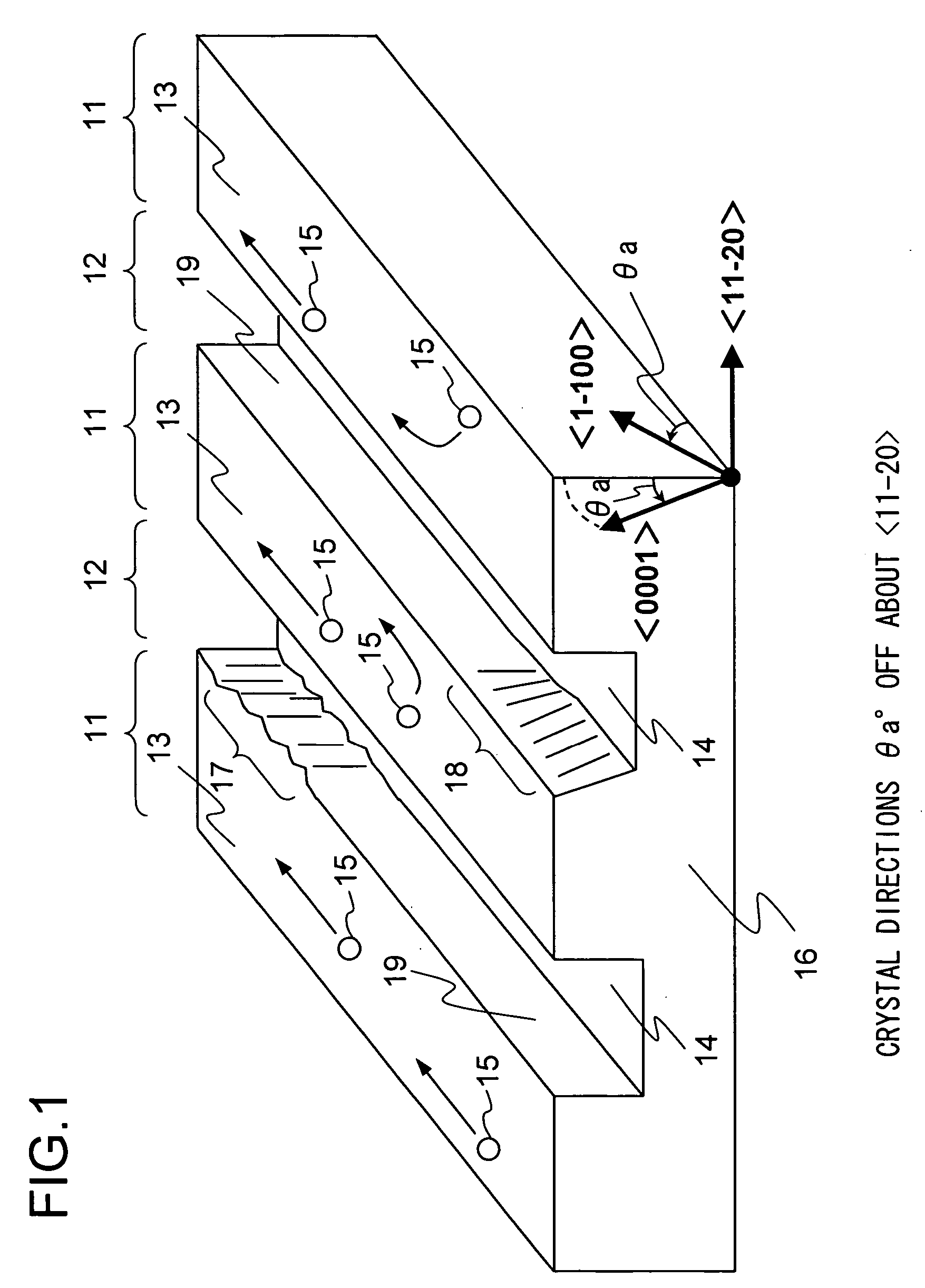

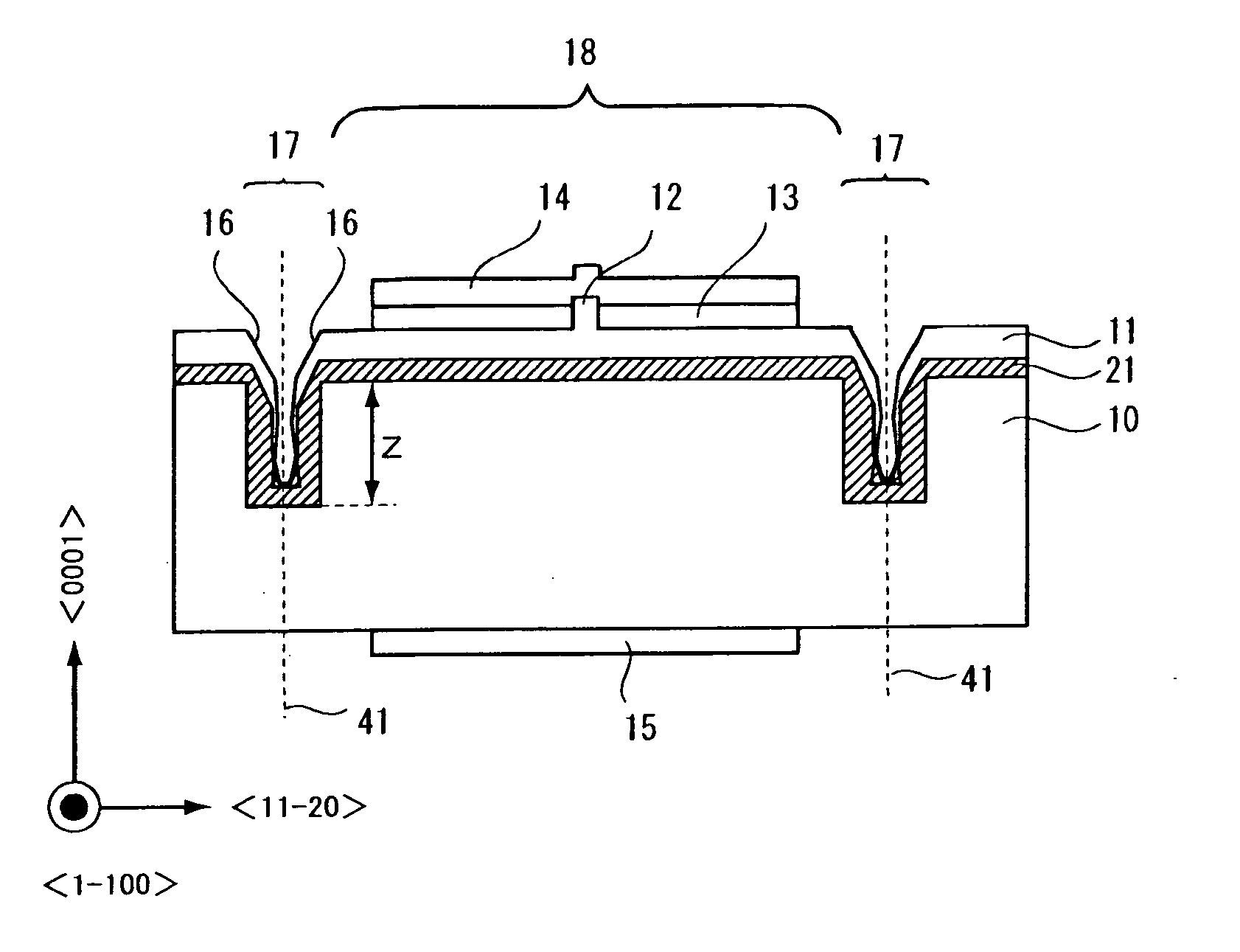

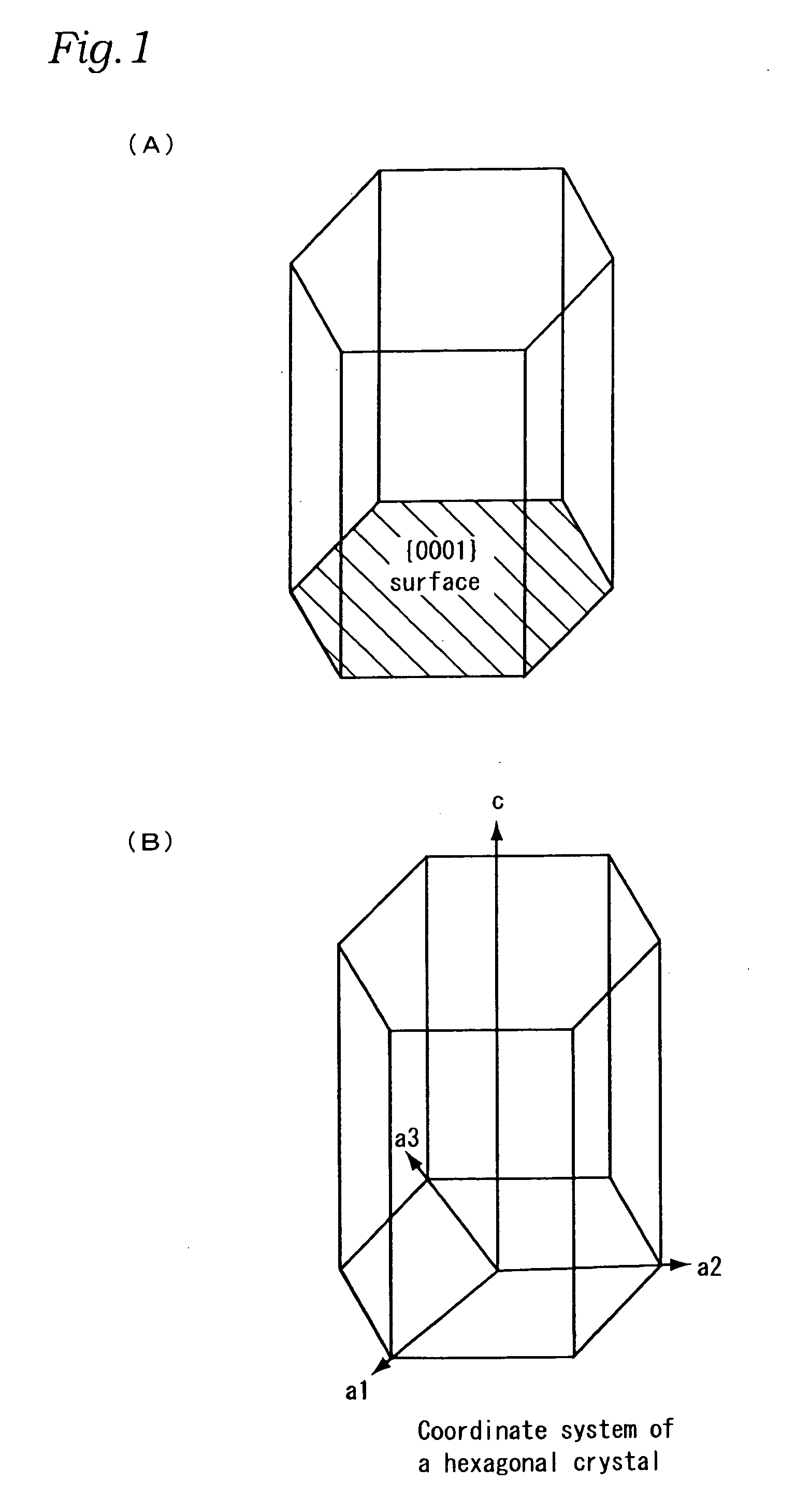

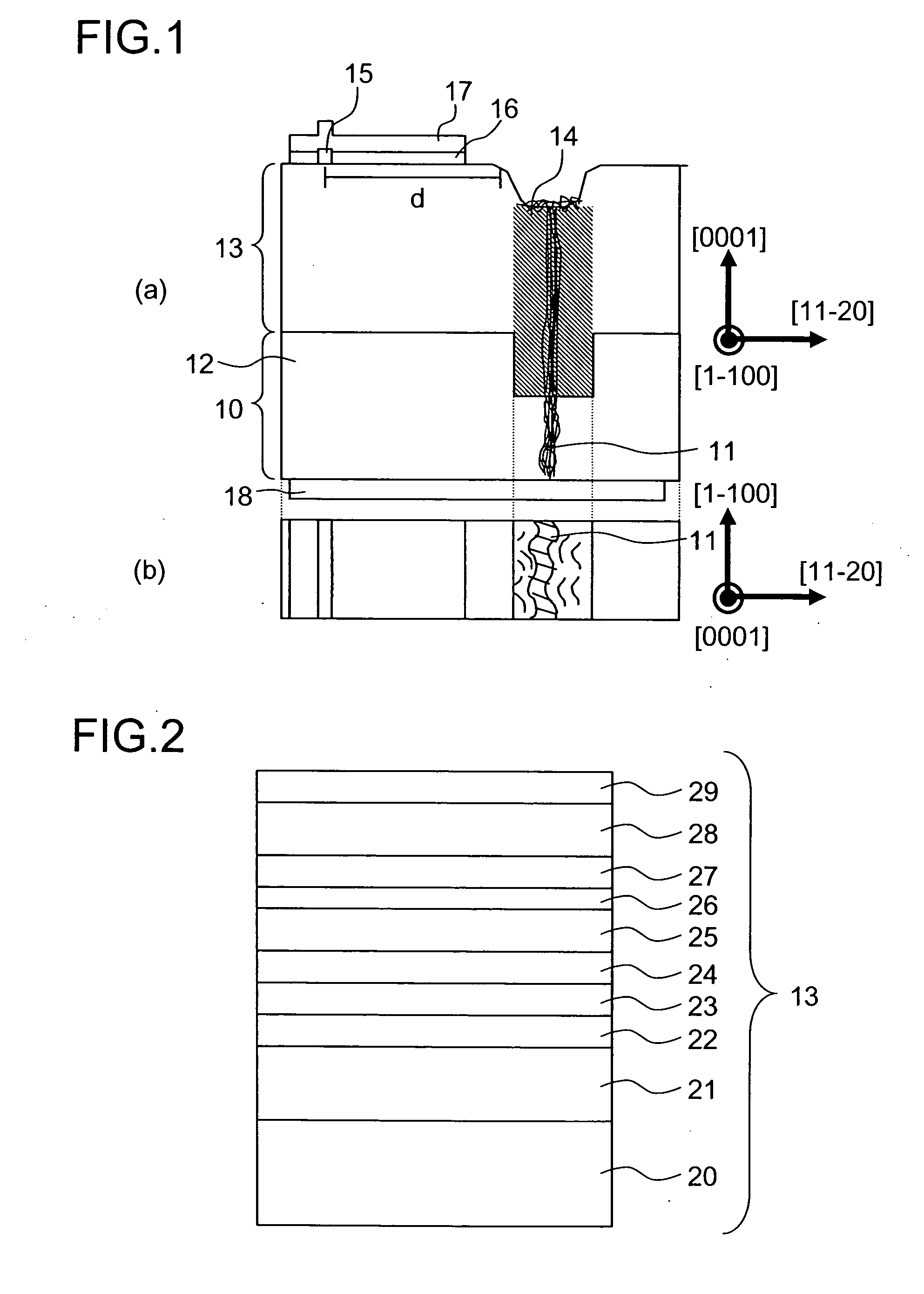

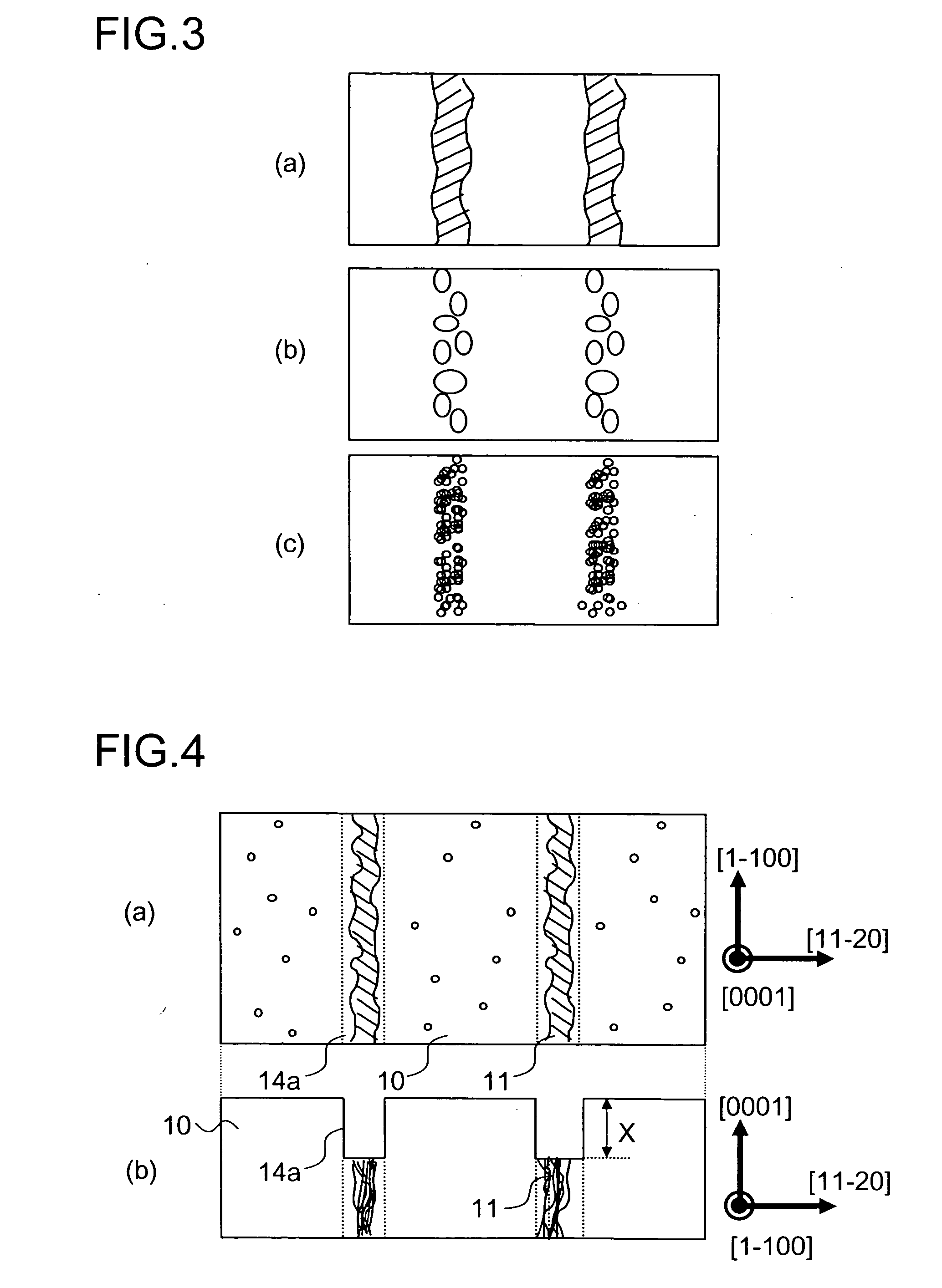

Nitride semiconductor laser device and method for fabrication thereof

InactiveUS20050151153A1Avoid crackingGood surface smoothnessLaser detailsSemiconductor laser structural detailsLight emitting deviceNitride semiconductors

In a nitride semiconductor light-emitting device, and according to a method for fabricating it, a low-defect region having a defect density of 106 cm−2 or less and a carved region in the shape of a depressed portion are formed on the surface of a nitride semiconductor substrate, and the etching angle θ, which is the angle between the side surface portion of the depressed portion and an extension line of the bottom surface portion thereof as measured with the depressed portion seen in a sectional view, is in a range of 75°≦θ≦140°. This prevents the development of cracks, and reduces the creep-up growth from the bottom growth portion of the carved region, thereby reducing the film thickness of the side growth portion. This makes it possible to produce, with a high yield, a nitride semiconductor laser device having a nitride semiconductor growth layer with good surface flatness.

Owner:SHARP KK

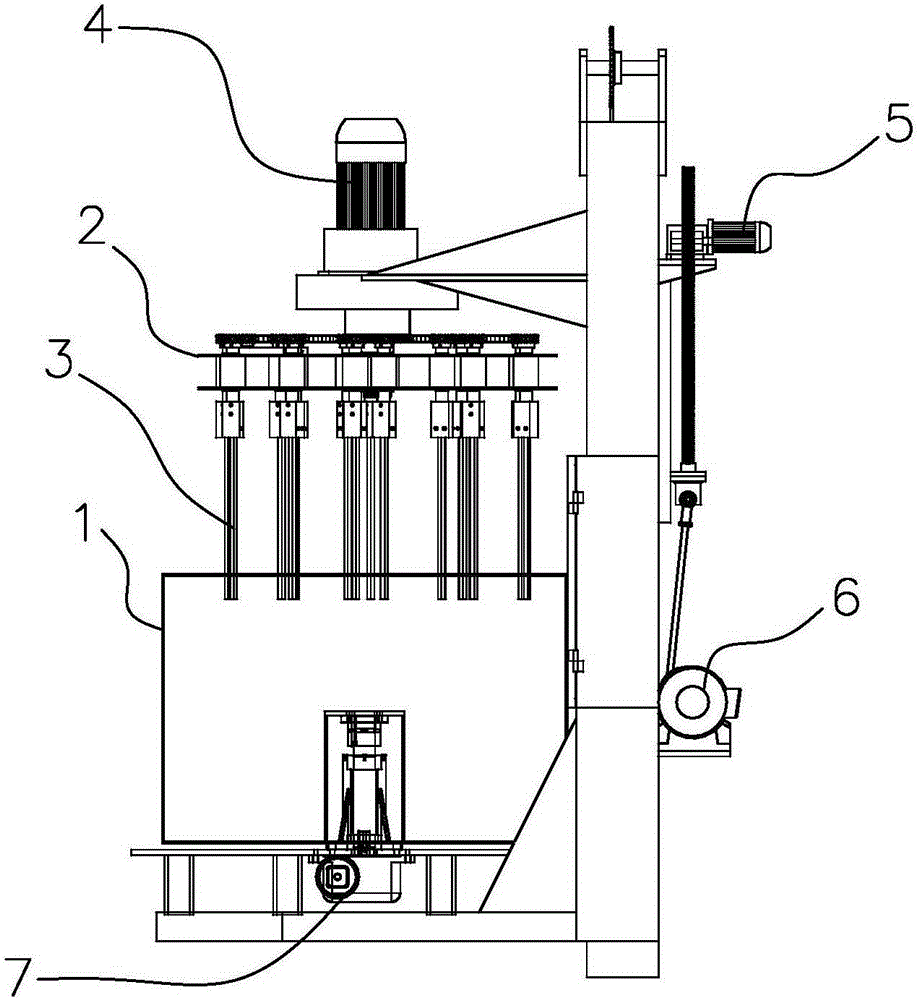

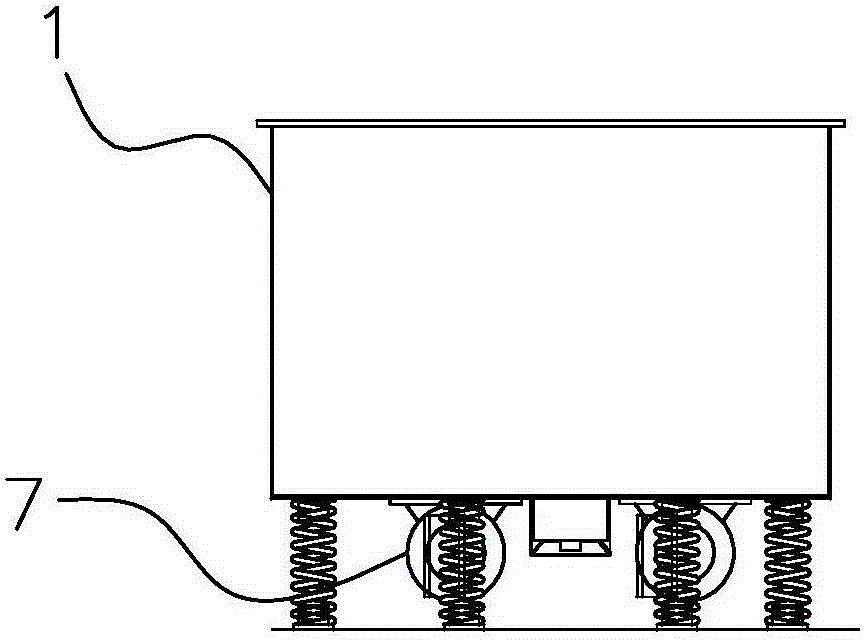

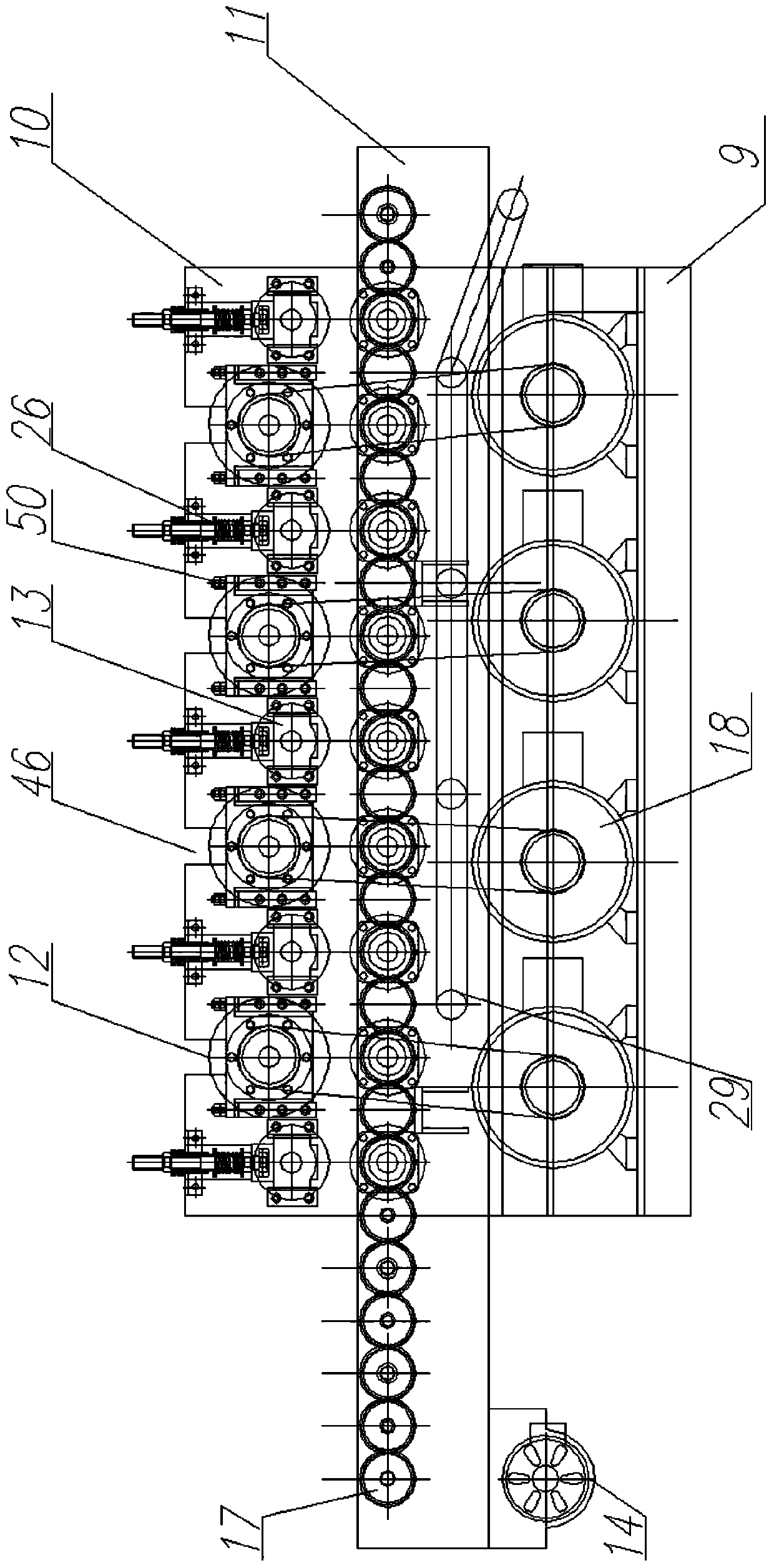

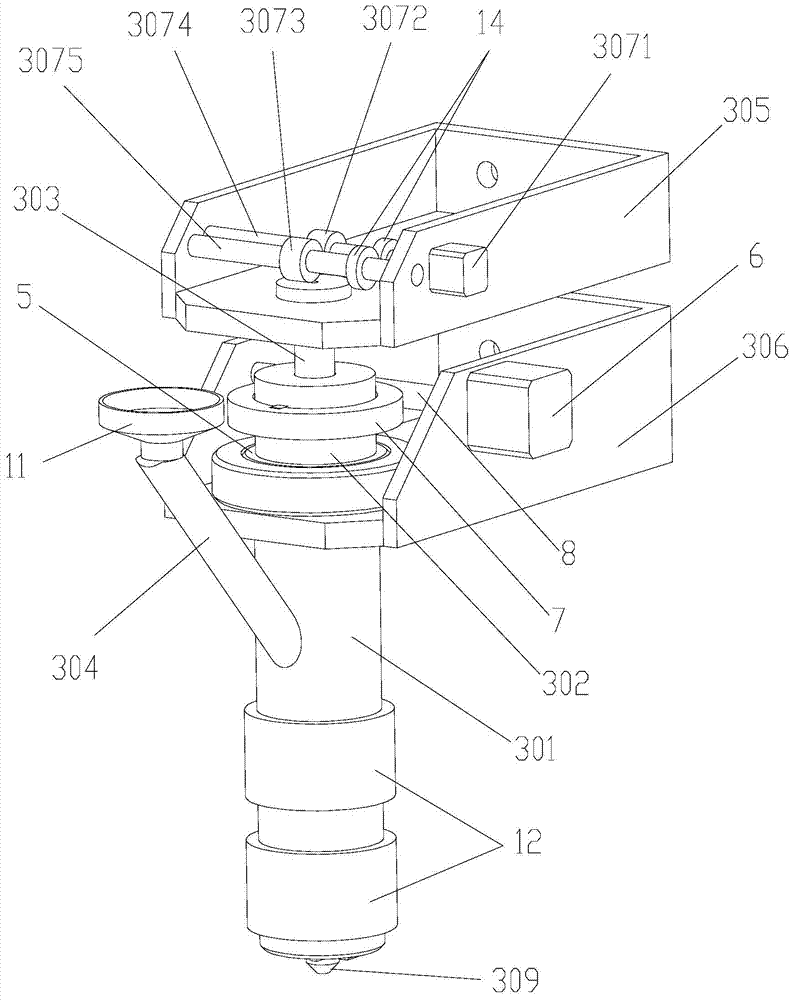

Multi-head polisher machine

The invention provides a multi-head polisher machine. The multi-head polisher machine comprises a container, a rotating plate, a rotating mechanism, a lifting mechanism and a plurality of loading sticks. An opening is formed in the upper end of the container. The rotating plate is horizontally arranged over the container. The rotating mechanism comprises a first motor, a chain, a main chain wheel, a main shaft and a plurality of auxiliary chain wheels. The main shaft is fixed to the middle of the rotating plate. An output shaft of the first motor and the main shaft are coaxially fixed. The main shaft is sleeved with the main chain wheel. The loading sticks are sleeved with the auxiliary chain wheels respectively. The main chain wheel and the auxiliary chain wheels are linked through the chain. According to the multi-head polisher machine, parts are assembled on the loading sticks, the loading sticks are driven by the rotating plate to revolve, the loading sticks unceasingly rotate, and therefore the parts can rub abrasive materials in the container, and the mirror surface effect can be generated within a certain period of time when the abrasive materials make contact with the parts at a high speed. The surface flatness can not be damaged as long as the parts do not collide.

Owner:杨一舟

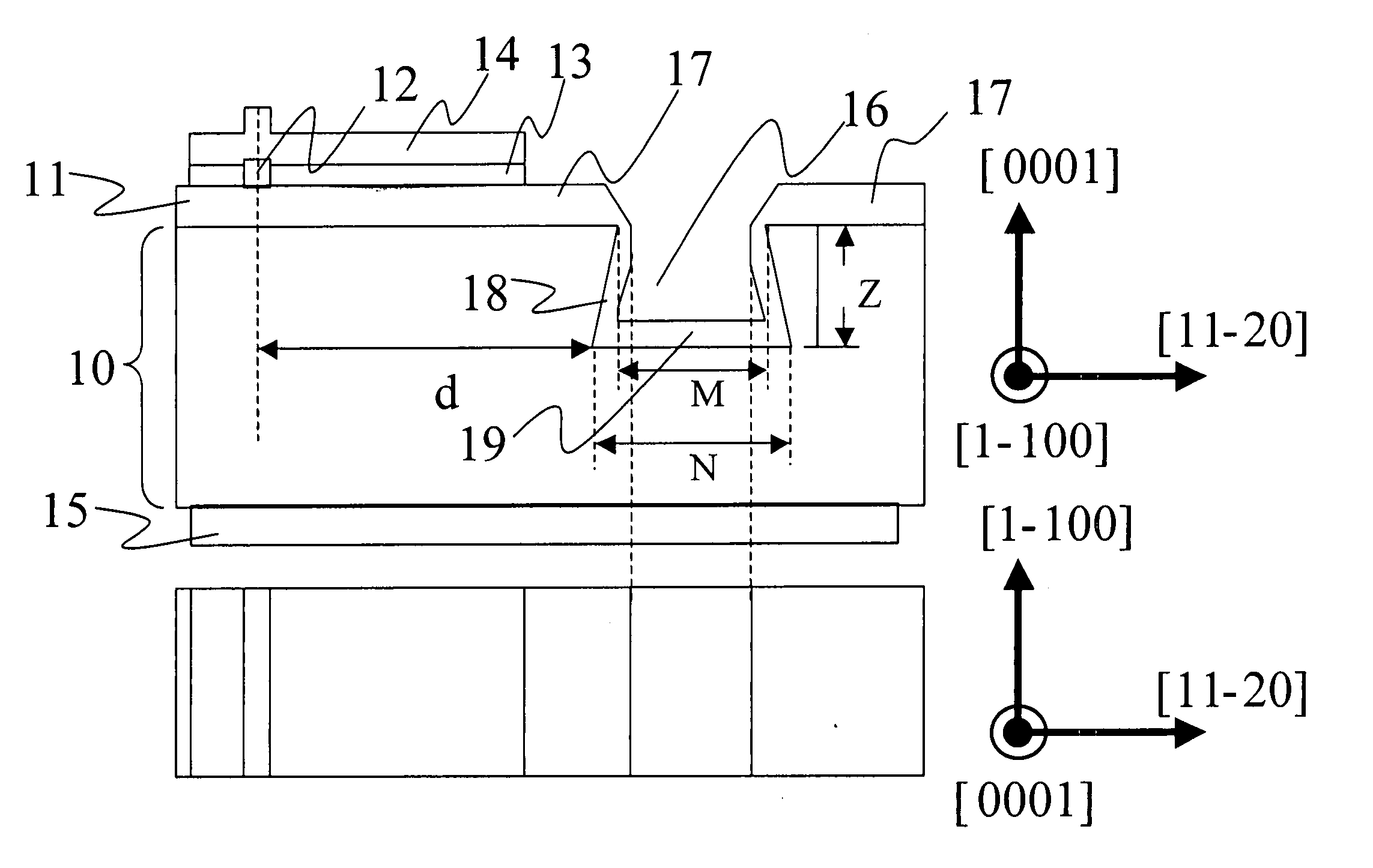

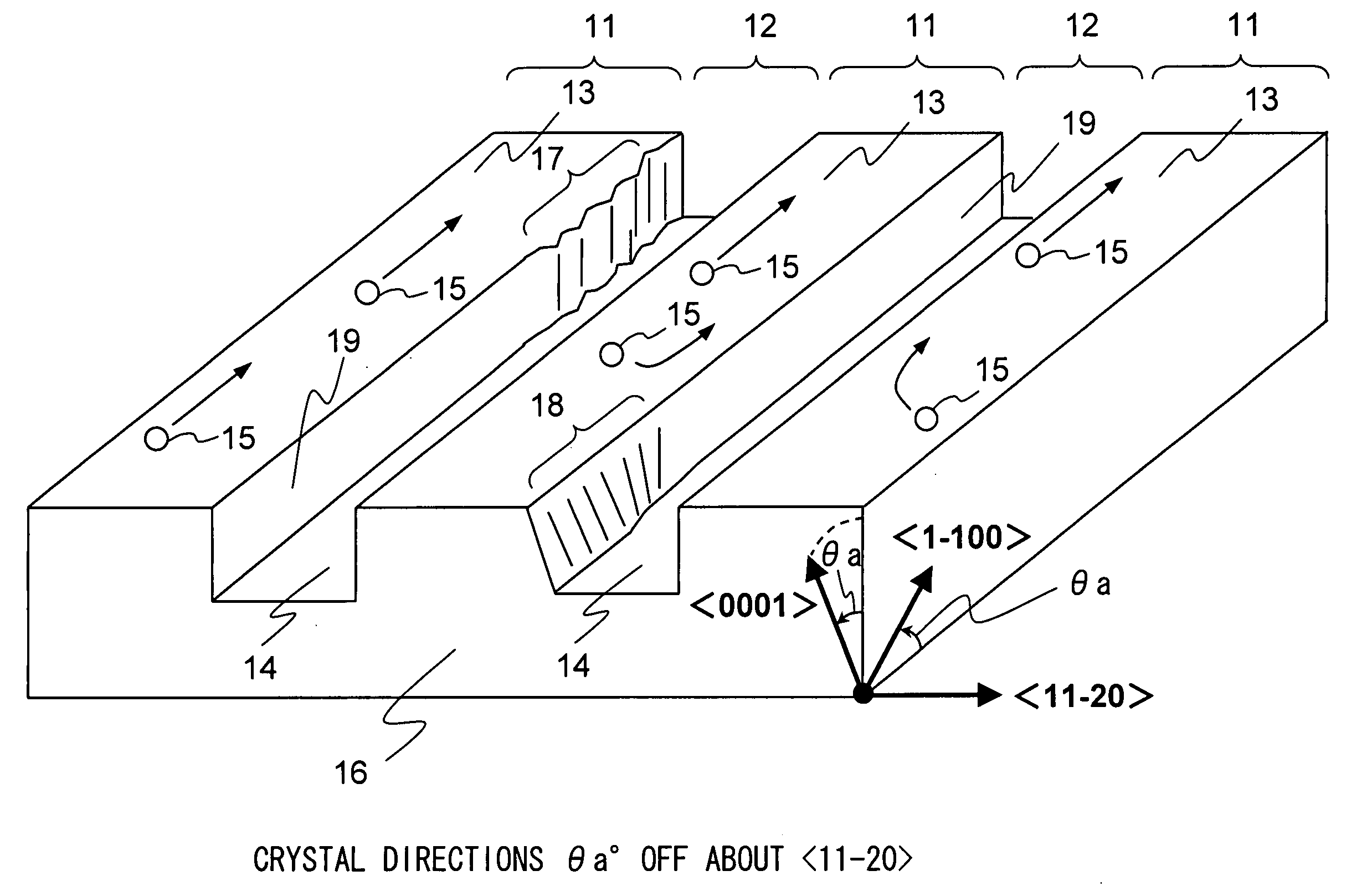

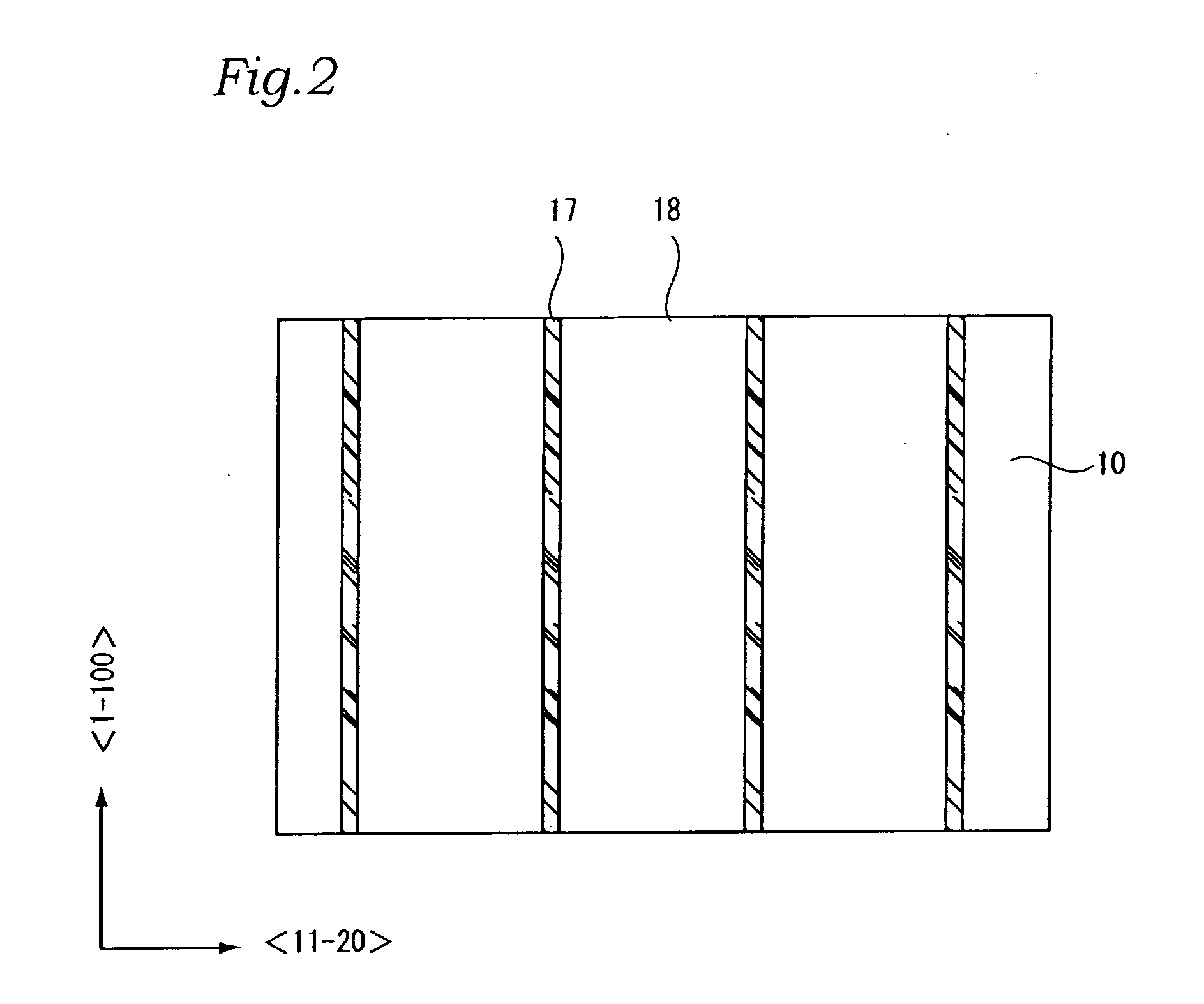

Nitride semiconductor device and fabrication method thereof

ActiveUS20060094244A1Acceptable surface roughnessLong life-timeSemiconductor/solid-state device manufacturingSemiconductor lasersCrazingSource material

A nitride semiconductor device is provided that prevents development of cracks, that has nitride semiconductor thin films with uniform thicknesses and good growth surface flatness, and is thus consistent in characteristics, and that can be fabricated at a satisfactory yield. In this nitride semiconductor device, the nitride semiconductor thin films are grown on a substrate having an off-angle between a direction normal to the surface of ridges and the crystal direction <0001>. This helps either reduce or intentionally promote diffusion or movement of the atoms or molecules of a source material of the nitride semiconductor thin films through migration thereof. As a result, a nitride semiconductor growth layer with good surface flatness can be formed, and thus a nitride semiconductor device with satisfactory characteristics can be obtained.

Owner:SHARP FUKUYAMA LASER CO LTD

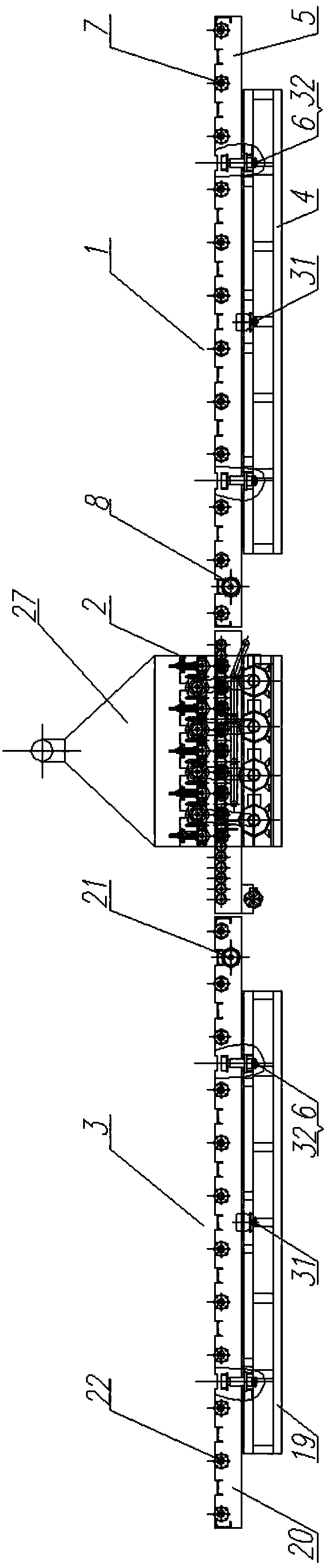

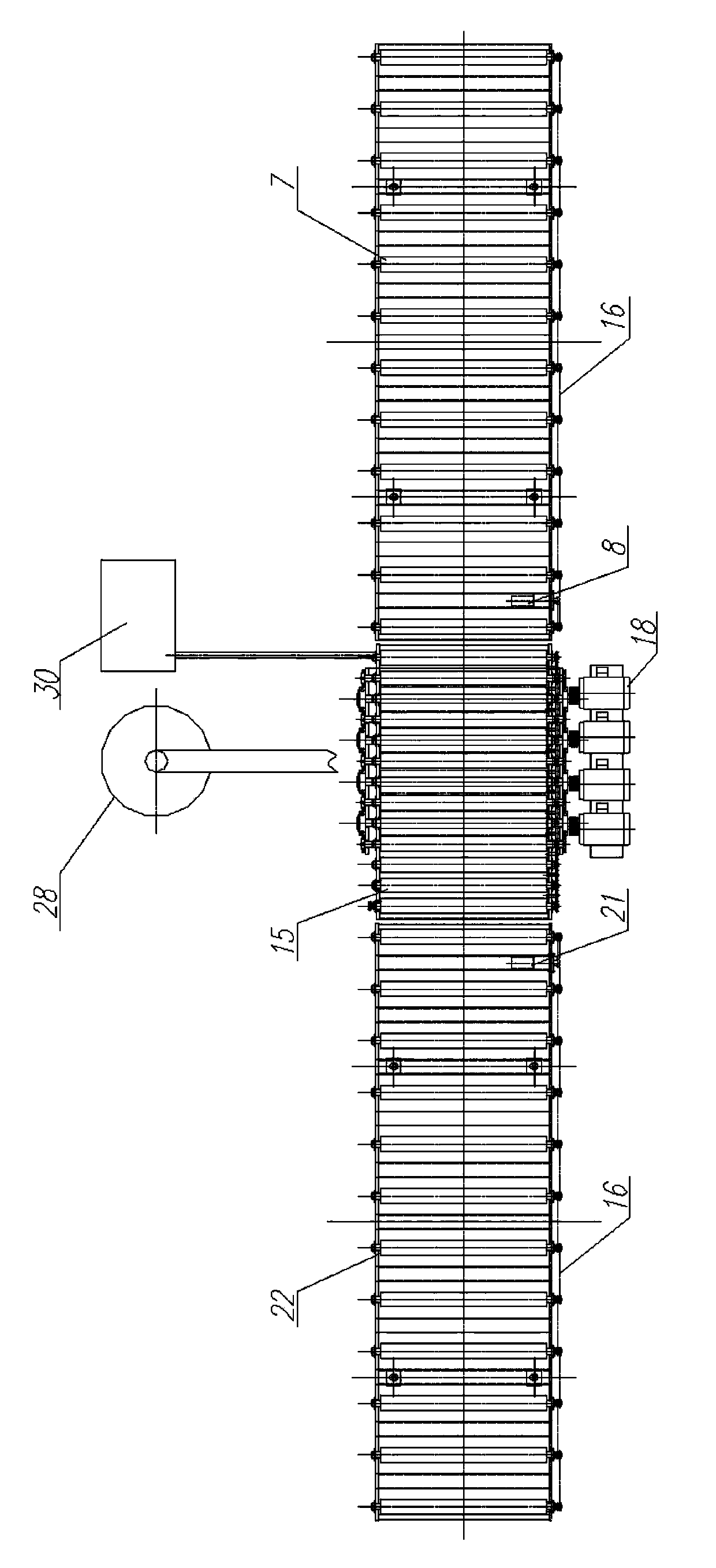

Metal sheet surface scale grinding and removing machine

InactiveCN104175197AImprove work efficiencyReduce labor intensityGrinding machinesGrinding/polishing safety devicesElectric machineryEngineering

Disclosed is a metal sheet surface scale grinding and removing machine which is formed by connection of a feed device, a grinding device and a discharge device. The feed device is provided with a feed frame, and feed rolls which are driven by a feed motor and arranged in parallel are arranged on the feed frame. The grinding device is provided with a grinding base, supporting wallboards fixed on the grinding base and a supporting frame mounted above the grinding base through a lifting device. Grinding rolls are fixedly mounted between the two supporting wallboards, upper pressure rolls are elastically mounted between the two supporting wallboards, and supporting rolls which are driven by a conveying motor and arranged in parallel are mounted on the supporting frame. The grinding rolls are driven through grinding motors fixed on the grinding base. A discharge frame is arranged on the discharge device, and discharge rolls driven through a discharge motor and arranged in parallel are arranged on the discharge frame. The grinding rolls in stepped arrangement are adopted to grind the surfaces of sheets gradually, scale removal efficiency is high, and the surfaces of the sheets with the scales removed are high in flatness and uniform in smooth finish.

Owner:张坤

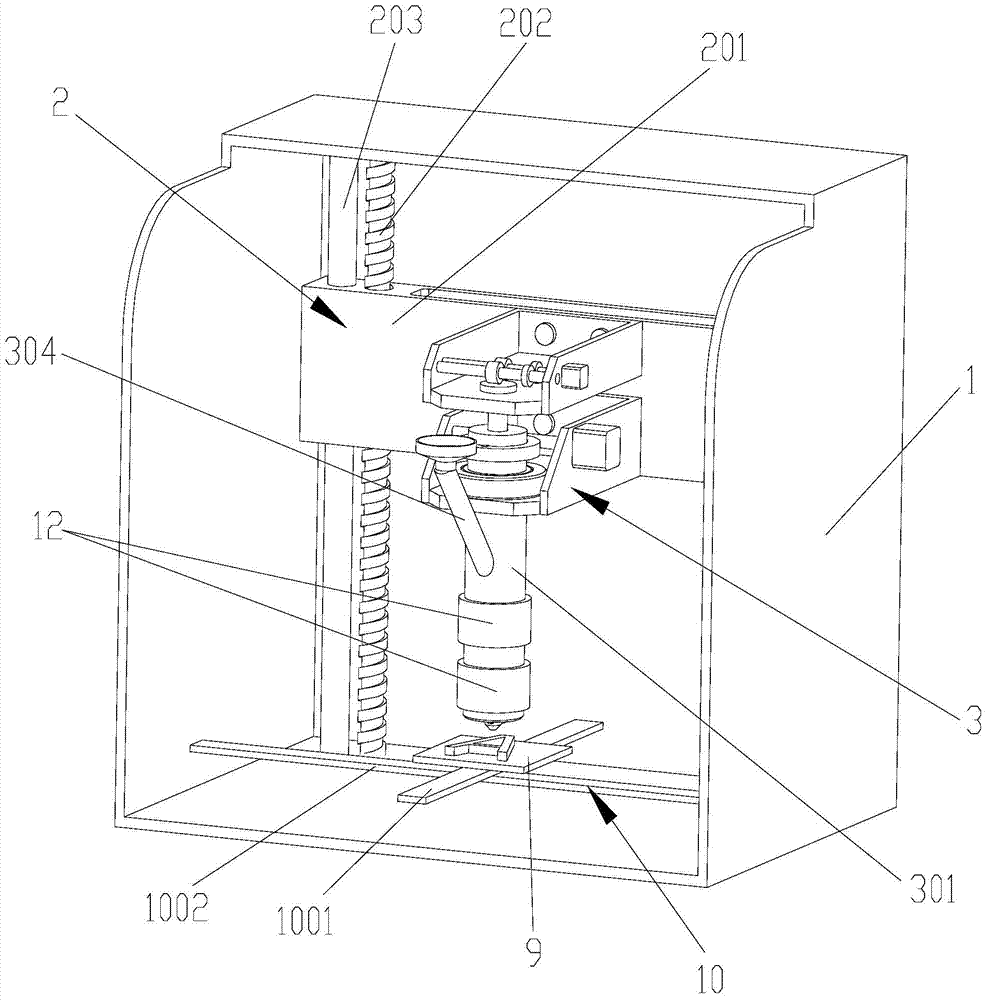

Fusion-deposition 3D printer and printing method thereof

The invention discloses a fusion-deposition 3D printer. The fusion-deposition 3D printer comprises a shell, a lifting mechanism and a composite extruding mechanism, wherein the lifting mechanism is mounted in the shell; the composite extruding mechanism comprises a machine cylinder, a screw rod and a long-fiber conveying pipe, a feeding pipe communicated with a material cavity of the machine cylinder is arranged on the side wall of the machine cylinder, the screw rod is rotatably mounted in the material cylinder and is provided with a mounting channel, and the upper and lower ends of the screw rod are communicated through the mounting channel; the long-fiber conveying pipe is inserted into the mounting channel and is provided with a conveying channel for conveying long continuous fibers; the conveying channel, the mounting channel and the material cavity are sequentially communicated. The invention further discloses a printing method of the fusion-deposition 3D printer. According to the fusion-deposition 3D printer and the printing method thereof, the long continuous fibers and printing materials packing the long continuous fibers are synchronously extruded to a working platform, so that the strength and surface flatness of a printed product are improved, and the machining efficiency is improved.

Owner:余金文 +1

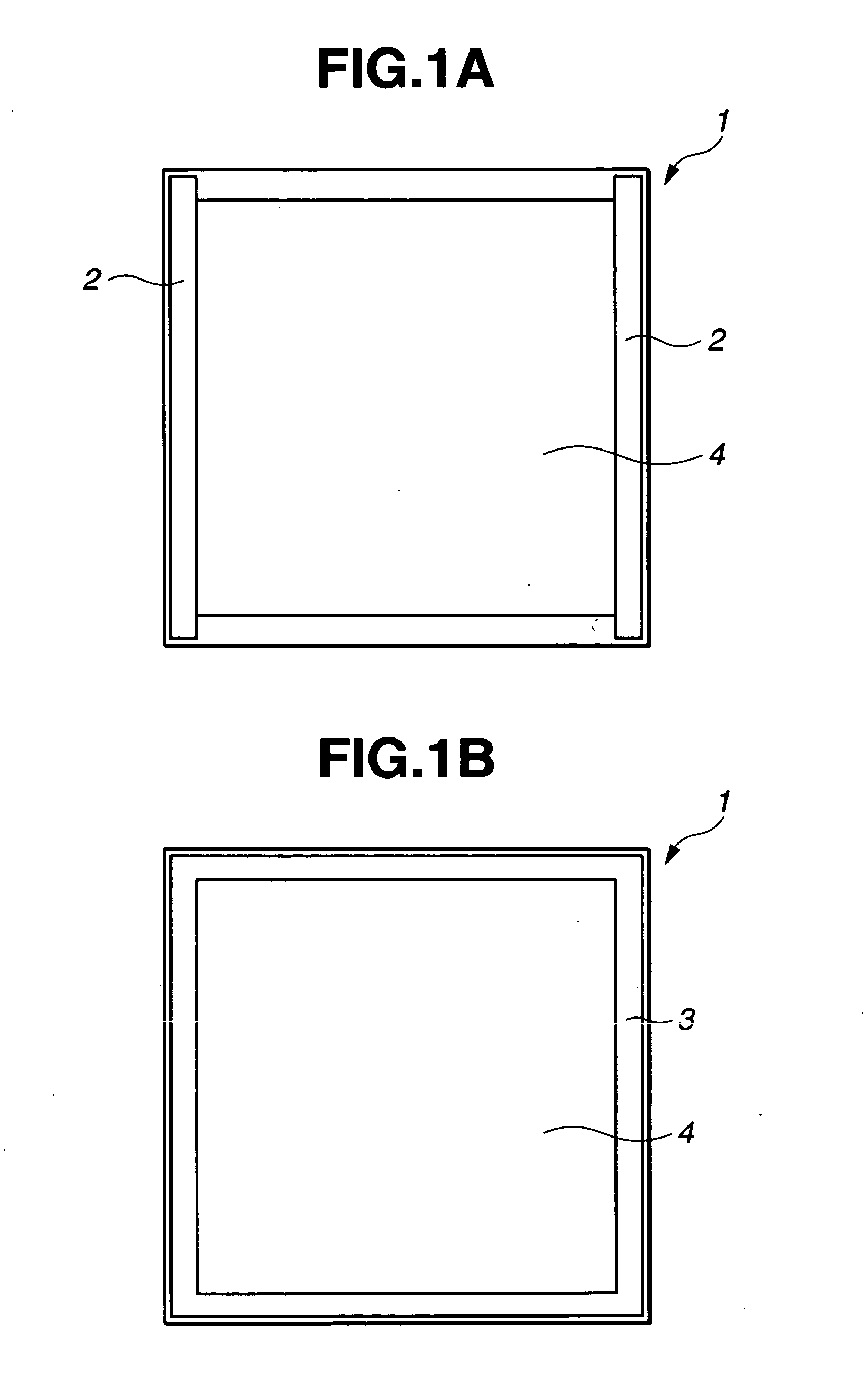

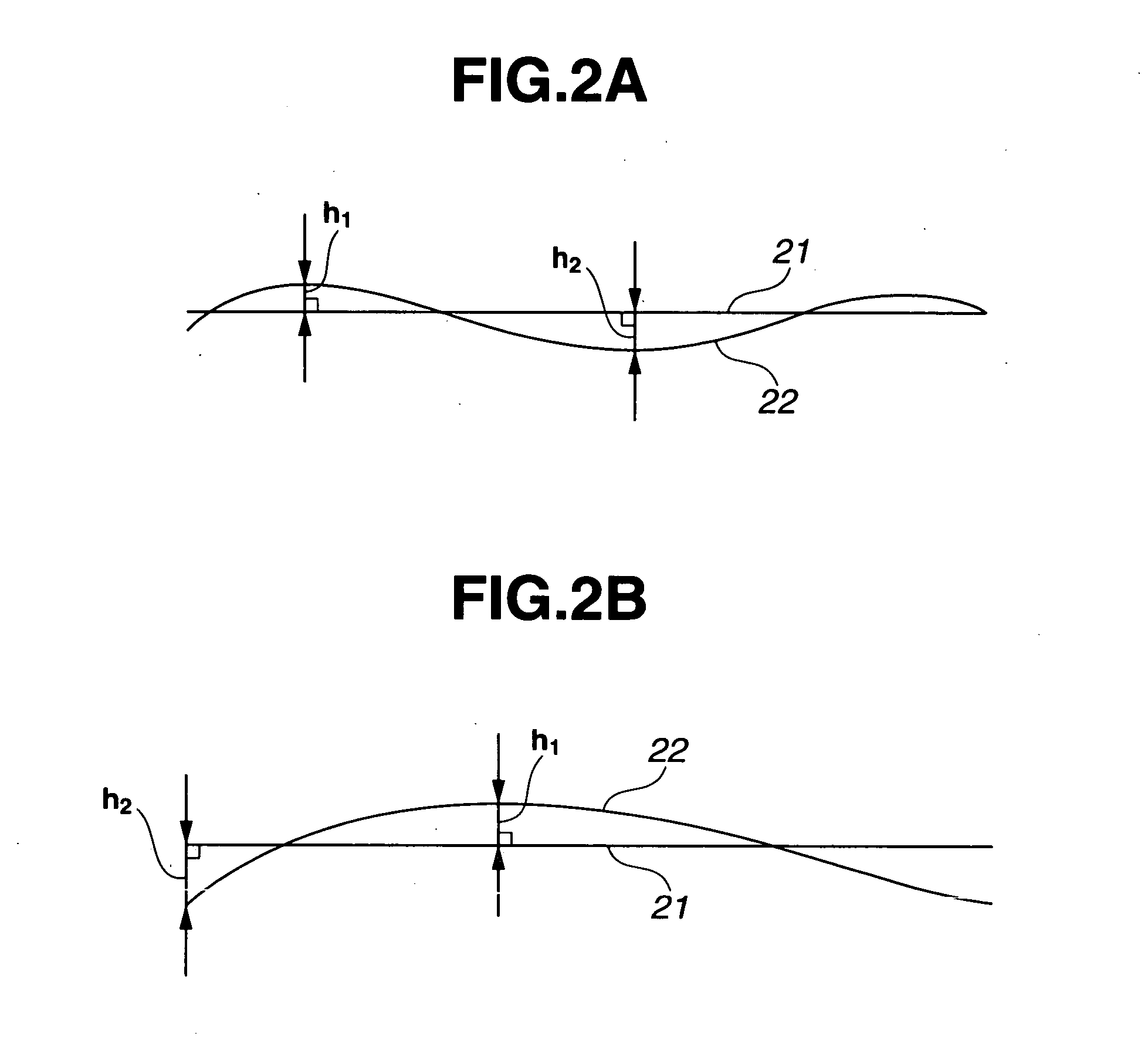

Photomask blank substrate, photomask blank and photomask

ActiveUS20050019677A1Good surface smoothnessImprove flatnessGlass/slag layered productsOriginals for photomechanical treatmentLeast squaresPhotomask

In a quadrangular photomask blank substrate with a length on each side of at least 6 inches, which has a pair of strip-like regions that extend from 2 to 10 mm inside each of a pair of opposing sides along an outer periphery of a substrate top surface, with a 2 mm edge portion excluded at each end, each strip-like region is inclined downward toward the outer periphery of the substrate, and a difference between maximum and minimum values for height from a least squares plane for the strip-like region to the strip-like region is at most 0.5 μm. The substrate exhibits a good surface flatness at the time of wafer exposure.

Owner:SHIN ETSU CHEM IND CO LTD +2

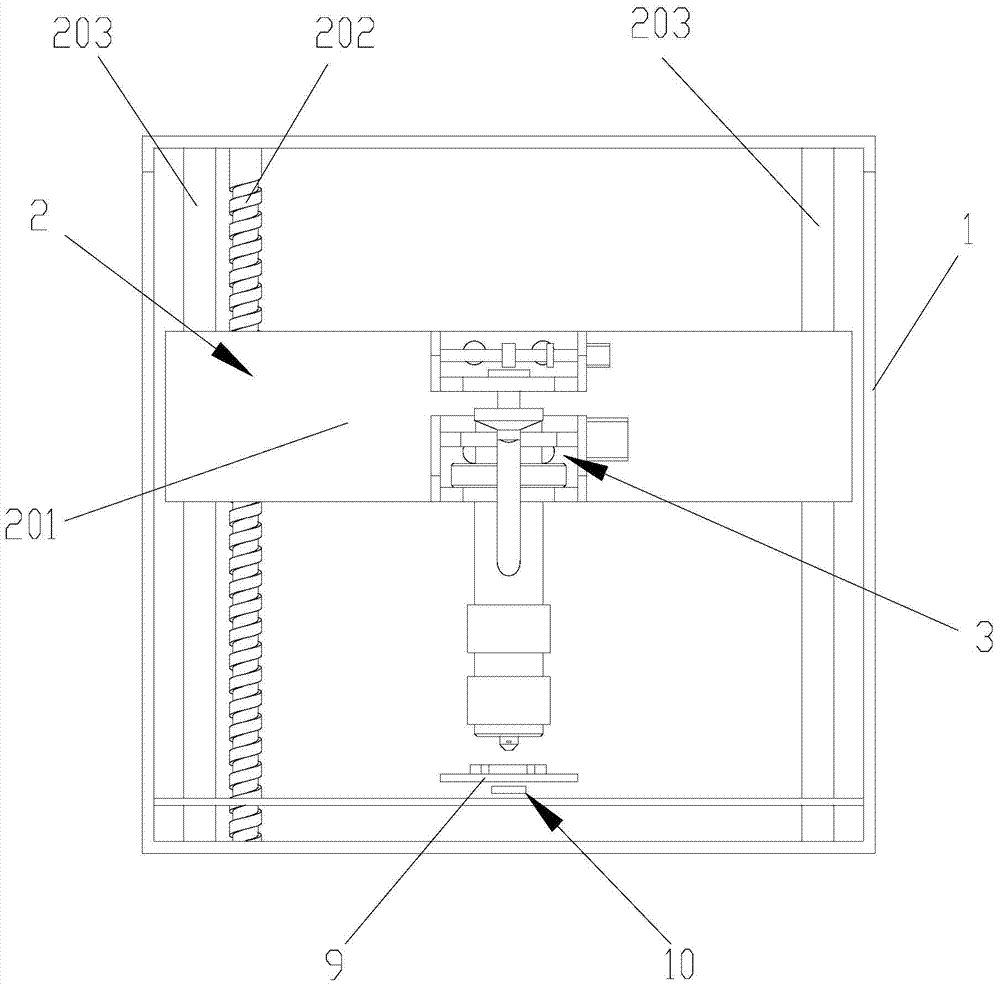

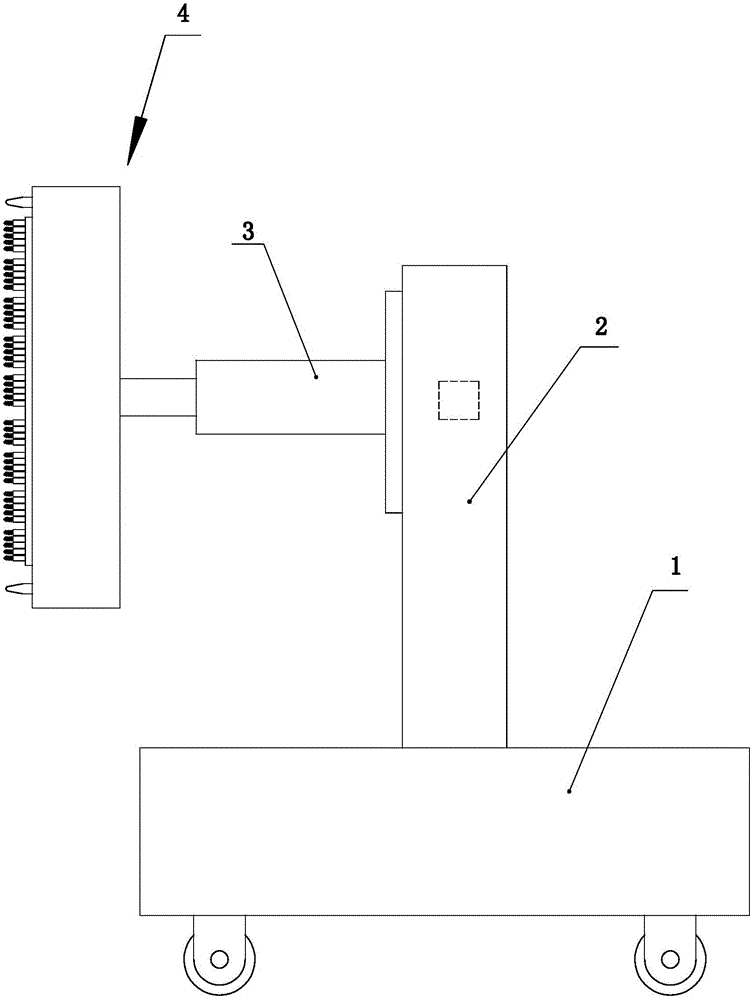

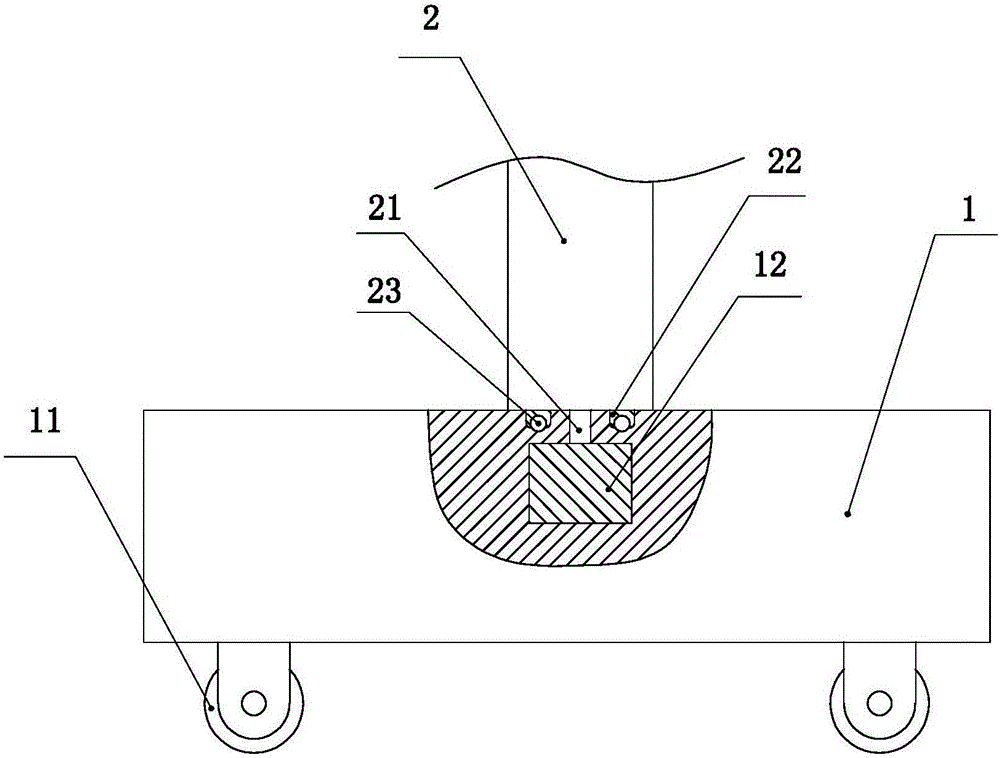

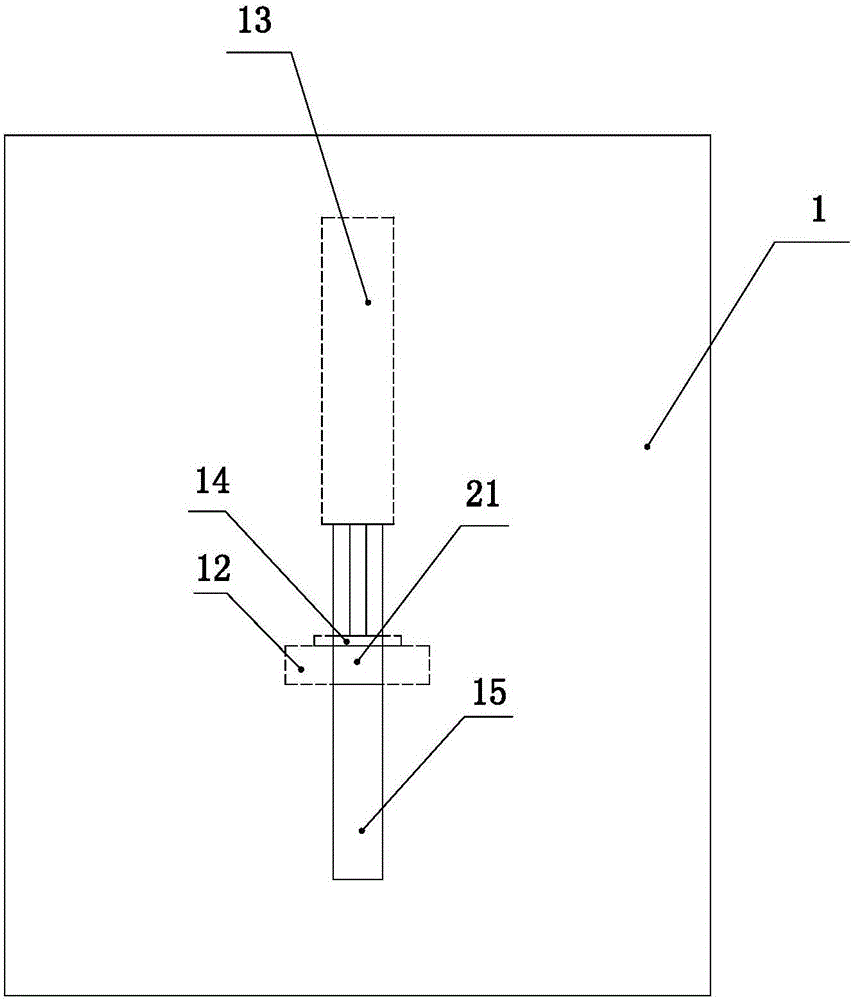

Building wall surface flatness measuring device

InactiveCN106017289AEasy to detectRealize detectionMechanical roughness/irregularity measurementsEngineeringMechanical engineering

A building wall surface flatness measuring device is used for ensuring the precision of wall surface flatness measurement. The device includes a device body, a vertical beam, a cross beam and a measurement assembly. The vertical beam is mounted on the top of the device body in a sliding manner. A feed air cylinder driving the vertical beam is arranged on the device body. A rack is mounted on the vertical beam in a sliding manner. A first gear and a second gear are mounted on the vertical beam in a rotary manner and one of the first gear and the second gear is disposed at an upper position while the other one is disposed at a lower position. A drive mechanism driving the first gear and the second gear to act synchronously is arranged on the vertical beam. The cross beam arranged horizontally is fixed on the rack. A flexible telescopic rod is arranged at the inner side of the cross beam. A telescopic air cylinder is arranged between the telescopic rod and the cross beam. The measurement assembly is fixed on the telescopic rod. The body of the measurement assembly is a support capable of swinging relative to a positioning support. A fixed board is arranged on the lower end face of the support. Multiple groups of rod sleeves are arranged on the fixed board. Press rods are mounted in the rod sleeves in a sliding manner. The press rods are provided with tips. Springs are arranged between the press rods and the rod sleeves. The device provided by the invention can ensure the precision of wall surface flatness measurement.

Owner:麟州(巨野)孵化器有限公司

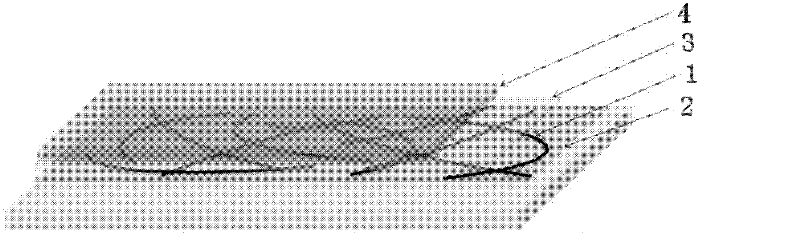

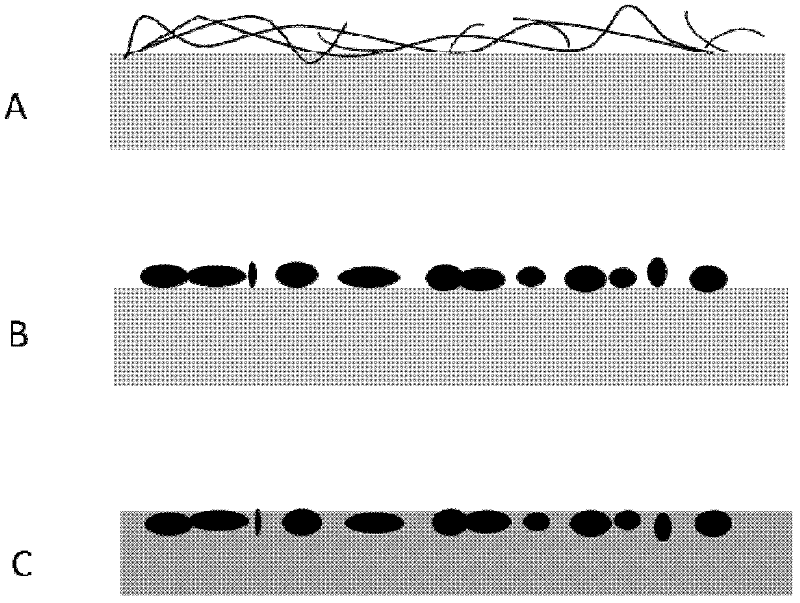

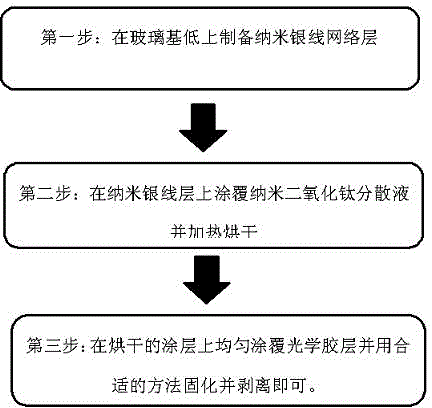

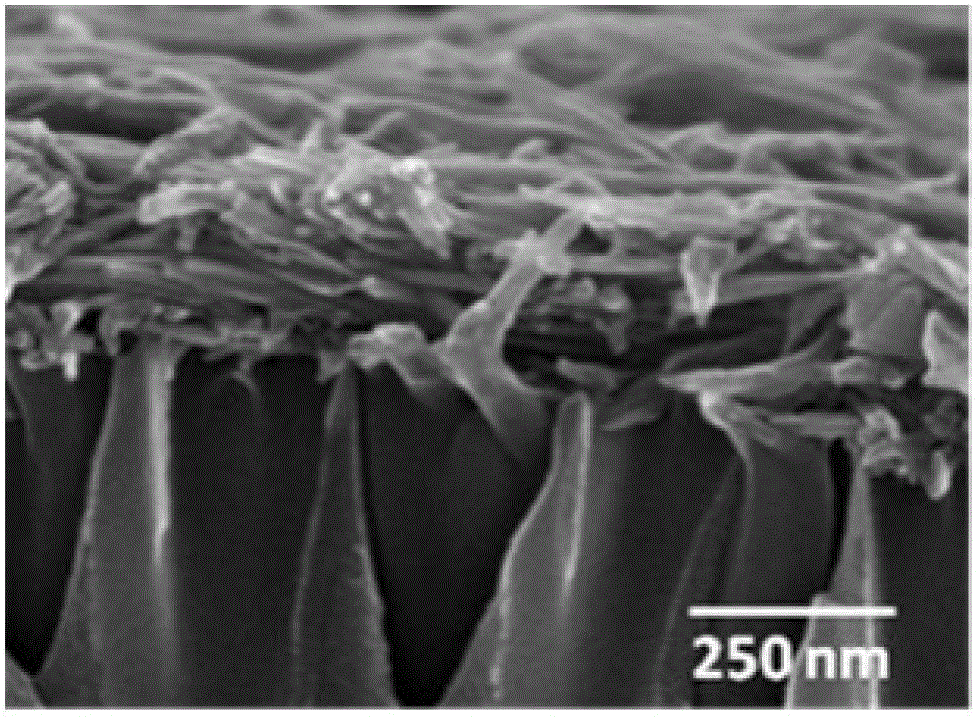

Flexible transparent conductive film based on silver nanowires and preparation method

ActiveCN104134484AImprove flexibilityImprove transmittanceConductive layers on insulating-supportsCable/conductor manufactureFilm baseAdhesive

The invention provides a flexible transparent conductive film based on silver nanowires and a preparation method. The transparent conductive film comprises a silver nanowire network layer (1), a nano particle filled layer (2) and an optical adhesive layer (3). The prepared transparent conductive film based on the silver nanowires is low in resistance, high in transmittance and surface evenness and simple in structure and preparation process, operation is simple and convenient, no high-temperature and high-pressure process is needed, safety is guaranteed, energy consumption is low, and a cumbersome process of film transferring is not needed. Meanwhile, the flexible transparent conductive film is low in cost and suitable for large-scale application.

Owner:NANJING GUOZHAO OPTOELECTRONICS TECH CO LTD

Reflective Ag alloy film for reflectors and reflector provided with the same

ActiveUS20050008883A1Improve reflectivityProductivity is deterioratedMirrorsVacuum evaporation coatingRare-earth elementSurface roughness

A reflective Ag alloy film for reflectors, which has excellent surface flatness and shows high reflectivity even under a heating environment and a reflector. The reflective Ag alloy film for reflectors has an average surface roughness of 2.0 nm or less and contains a rare earth element (such as Nd) in a content in the range of 0.1 to 3.0 at %, or further at least one selected from Au, Pd, Cu and Pt in a content in the range of 0.5 to 5.0 at %. The reflector comprises the above reflective Ag alloy film formed on a substrate.

Owner:KOBE STEEL LTD

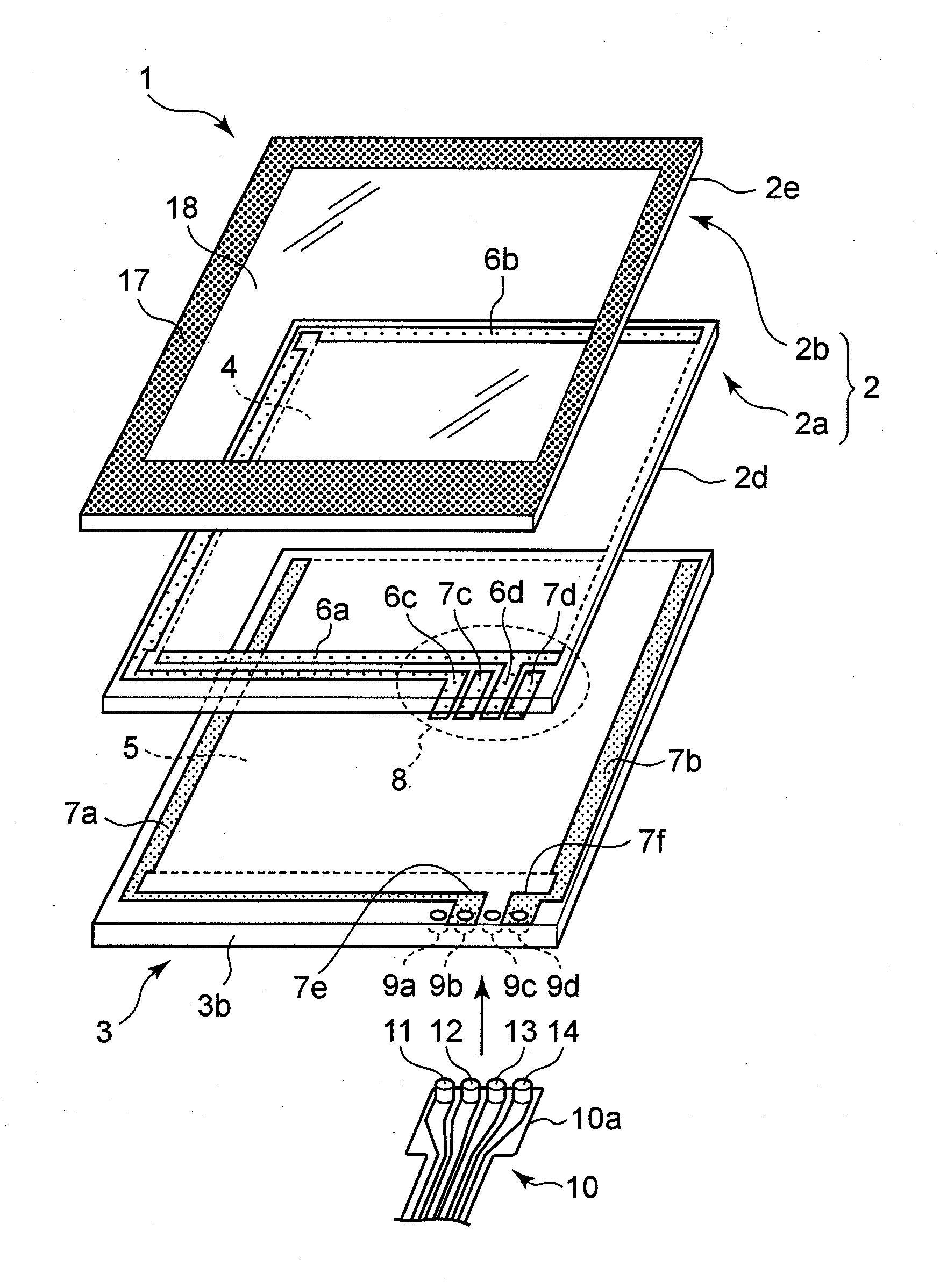

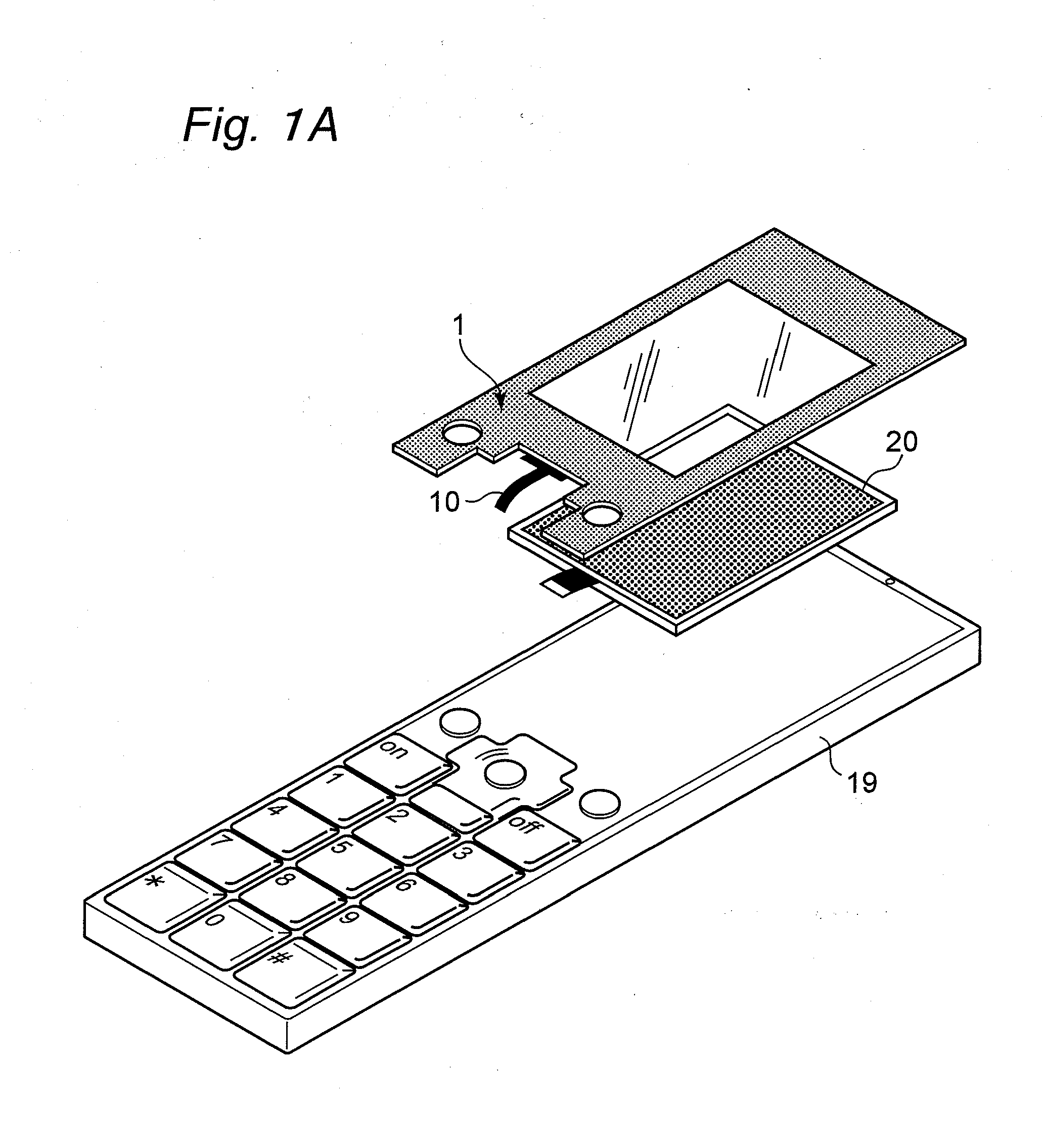

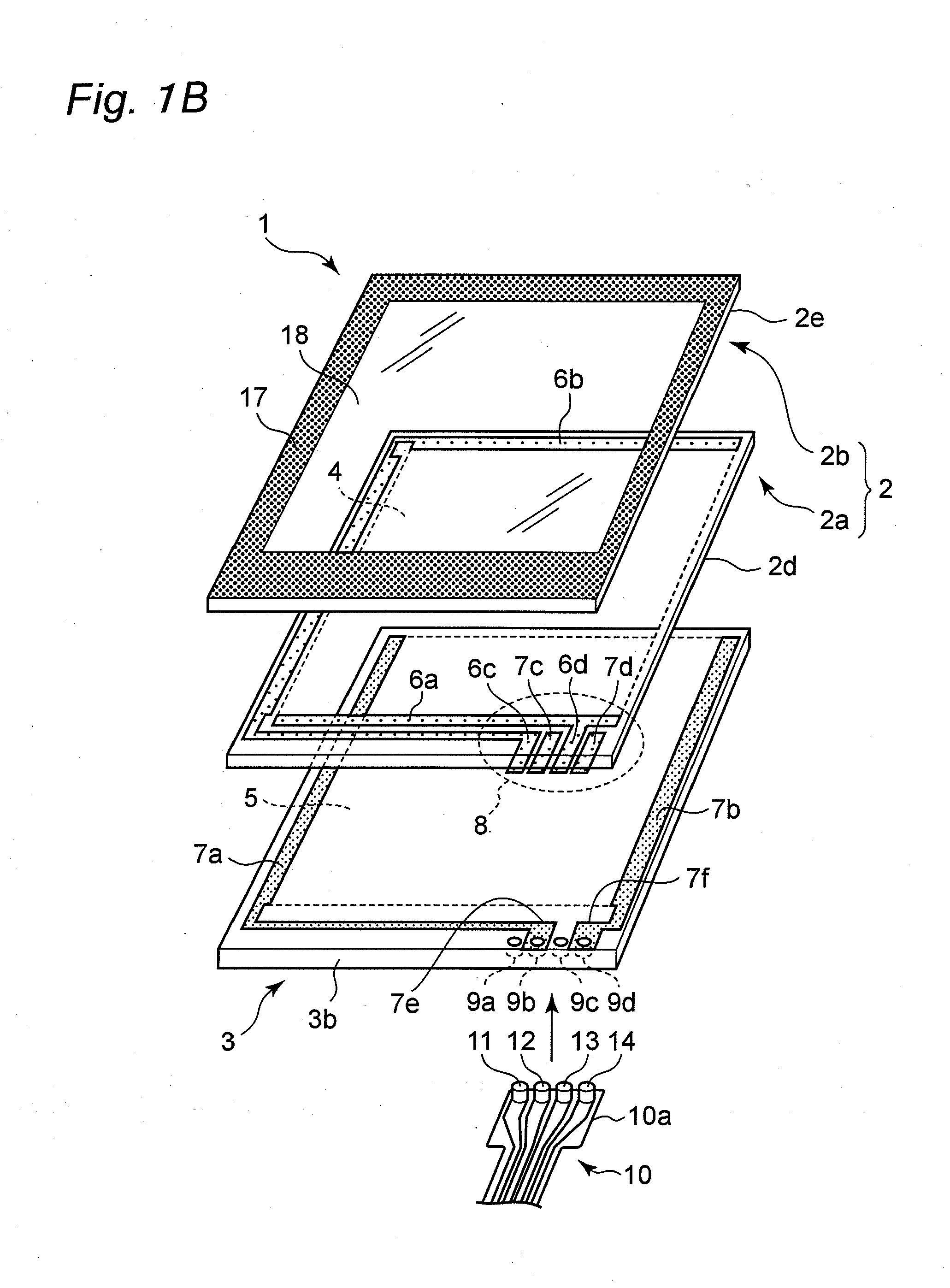

PROTECTIVE PANEL WITH TOUCH INPUT FUNCTION SUPERIOR IN SURFACE FLATNESS AND ELECTRONIC APPARATUS HAVING THE PROTECTIVE PANEL (amended

InactiveUS20110151937A1Superior outside appearance without sink markInput/output for user-computer interactionDigital data processing detailsElectrical conductorEngineering

In a protective panel with a touch input function of an electronic apparatus display window, with a built-in antenna being placed on a back side thereof, an upper electrode sheet and a lower electrode panel that constitute the protective panel with a touch input function are respectively provided with radio-wave transmitting sections with no conductor formed therein, within a frame area to be covered with a decorative layer, in association with the built-in antenna, and with respect to all the portion or most of the portion of a border relative to the conductor of the radio-wave transmitting section on the upper electrode sheet side, since a paste layer, used for bonding the upper electrode sheet to the lower electrode panel at peripheral edge portions thereof, is provided with a through hole in a manner so as to overlap with, at least, an area near the inside of the border, with air inside the through hole being allowed to flow in or flow out through an air bent.

Owner:NISSHA PRINTING COMPANY

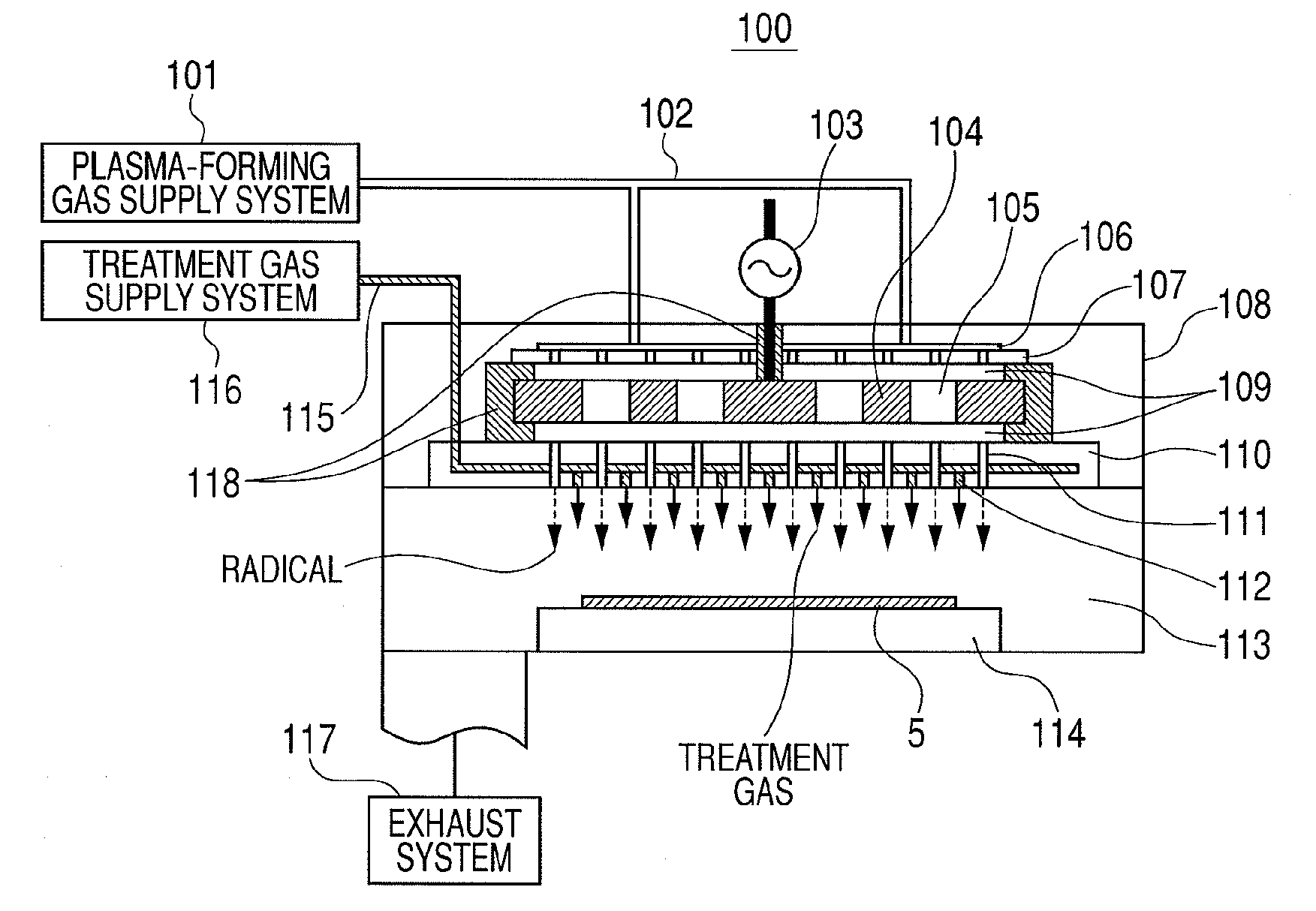

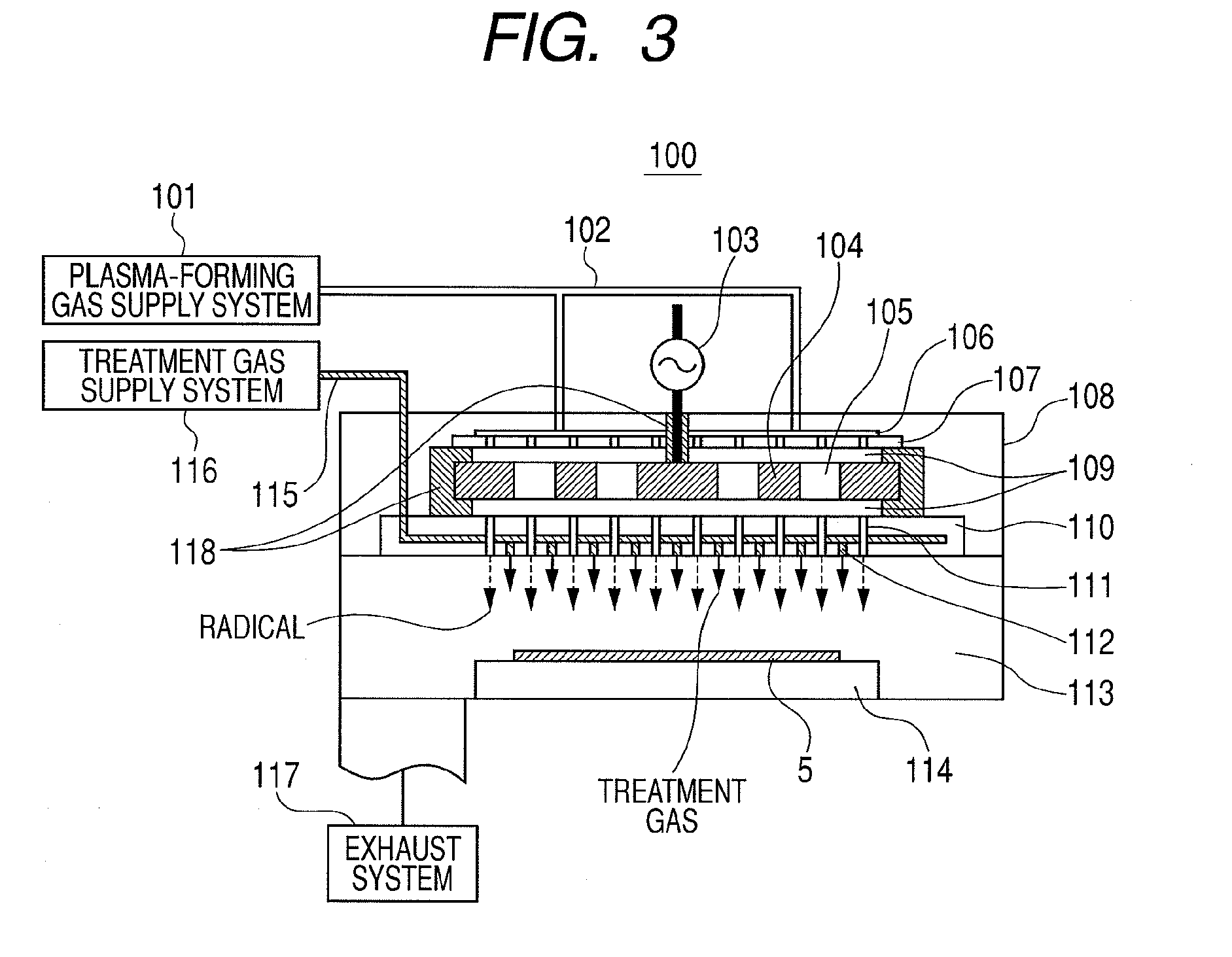

Surface treatment apparatus and surface treatment method

InactiveUS20100221895A1Decrease native oxide filmReduce organic impuritiesElectric discharge tubesSemiconductor/solid-state device manufacturingHysteresisAtmospheric air

HF-originated radicals generated in a plasma-forming chamber are fed to a treatment chamber via feed holes, while HF gas molecules as the treatment gas are supplied to the treatment chamber from near the radical feed holes to suppress the excitation energy, thereby increasing the selectivity to Si to remove a native oxide film. Even with the dry-treatment, the surface treatment provides good surface flatness equivalent to that obtained by the wet-cleaning which requires high-temperature treatment, and further attains growth of Si single crystal film on the substrate after the surface treatment. The surface of formed Si single crystal film has small quantity of impurities of oxygen, carbon, and the like. After sputtering Hf and the like onto the surface of the grown Si single crystal film, oxidation and nitrification are applied thereto to form a dielectric insulation film such as HfO thereon, thus forming a metal electrode film. All through the above steps, the substrate is not exposed to atmospheric air, thereby suppressing the adsorption of impurities onto the interface, and thus obtaining a C-V curve with small hysteresis. As a result, good device characteristics are obtained in MOS-FET.

Owner:CANON ANELVA CORP

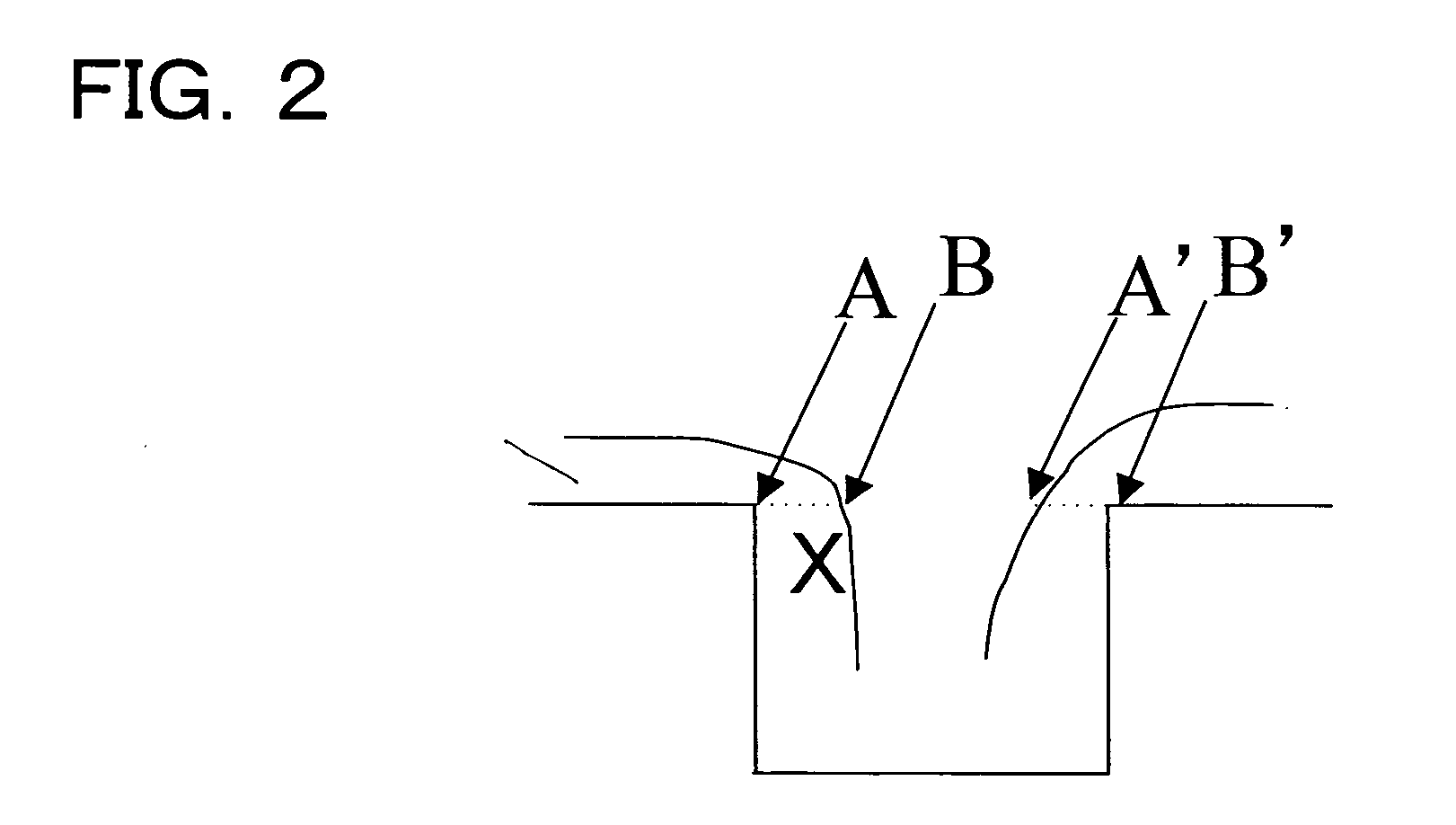

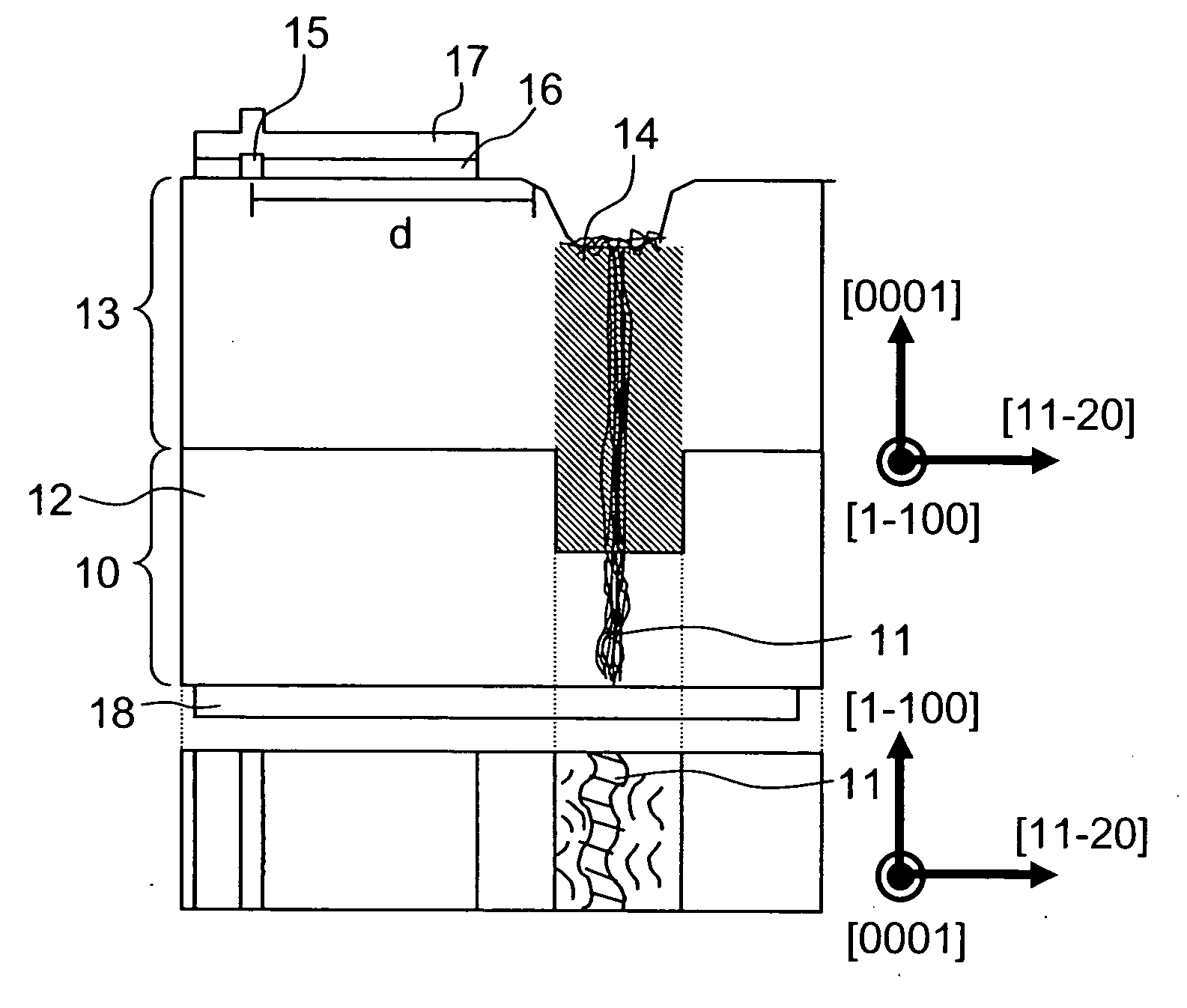

Nitride semiconductor light-emitting device and method for producing same

ActiveUS20060131590A1Good surface smoothnessAvoid crackingOptical wave guidanceLaser detailsActive layerLight emitting device

In a method for producing a nitride semiconductor light-emitting device according to the present invention, first, a nitride semiconductor substrate having groove portions formed is prepared. An underlying layer comprising nitride semiconductor is formed on the nitride semiconductor substrate including the side walls of the groove portions, in such a manner that the underlying layer has a crystal surface in each of the groove portions and the crystal surface is tilted at an angle of from 53.5° to 63.4° with respect to the surface of the substrate. Over the underlying layer, a light-emitting-device structure composed of a lower cladding layer containing Al, an active layer, and an upper cladding layer containing Al is formed. According to the present invention, thickness nonuniformity and lack of surface flatness, which occur when accumulating a layer with light-emitting-device structure of nitride semiconductor over the nitride semiconductor substrate, are alleviated while inhibiting occurrence of cracking.

Owner:SHARP FUKUYAMA LASER CO LTD

Nitride semiconductor light-emitting device

InactiveUS20070051961A1Improve yieldUniform characteristicsLaser detailsDischarge tube luminescnet screensLight emitting deviceNitride semiconductors

A nitride semiconductor light-emitting device wherein a substrate or nitride semiconductor layer has a defect concentration region and a low defect density region other than the defect concentration region. A portion including the defect concentration region of the nitride semiconductor layer or substrate has a trench region deeper than the low defect density region. Thus by digging the trench in the defect concentration region, the growth detection is uniformized, and the surface planarity is improved. The uniformity of the characteristic in the wafer surface leads to improvement of the yield.

Owner:SHARP KK +1

Laser aluminized transfer coating suitable for use in gravure and preparation method thereof

InactiveCN101760107ASimple to useLess laborCoatingsCoatings without pigmentsCellulosePolymer science

The invention relates to a laser aluminized transfer coating suitable for use in gravure and a preparation method thereof. The coating comprises the following components in part by weight: 4 to 26 parts of polyacrylate resin, 0 to 6 parts of vinylit resin, 0 to 5 parts of modified styrol resin, 0 to 12 pars of cellulose ester resin, 0 to 3.2 parts of assistant and 70 to 83 parts of solvent. The preparation method comprises the steps of: firstly, dissolving the resin in the solvent; secondly, filling the assistant in a reactor; and finally, stirring, cooling and filtering the mixture to obtain the final product. Compared with the prior art, the laser aluminized transfer coating can be directly printed and the product has the advantages of simple use process, low production cost, high surface finish, good smoothness, high wearing resistance and high-temperature resistance and wide use range.

Owner:SHANGHAI WEIKAI CHEM

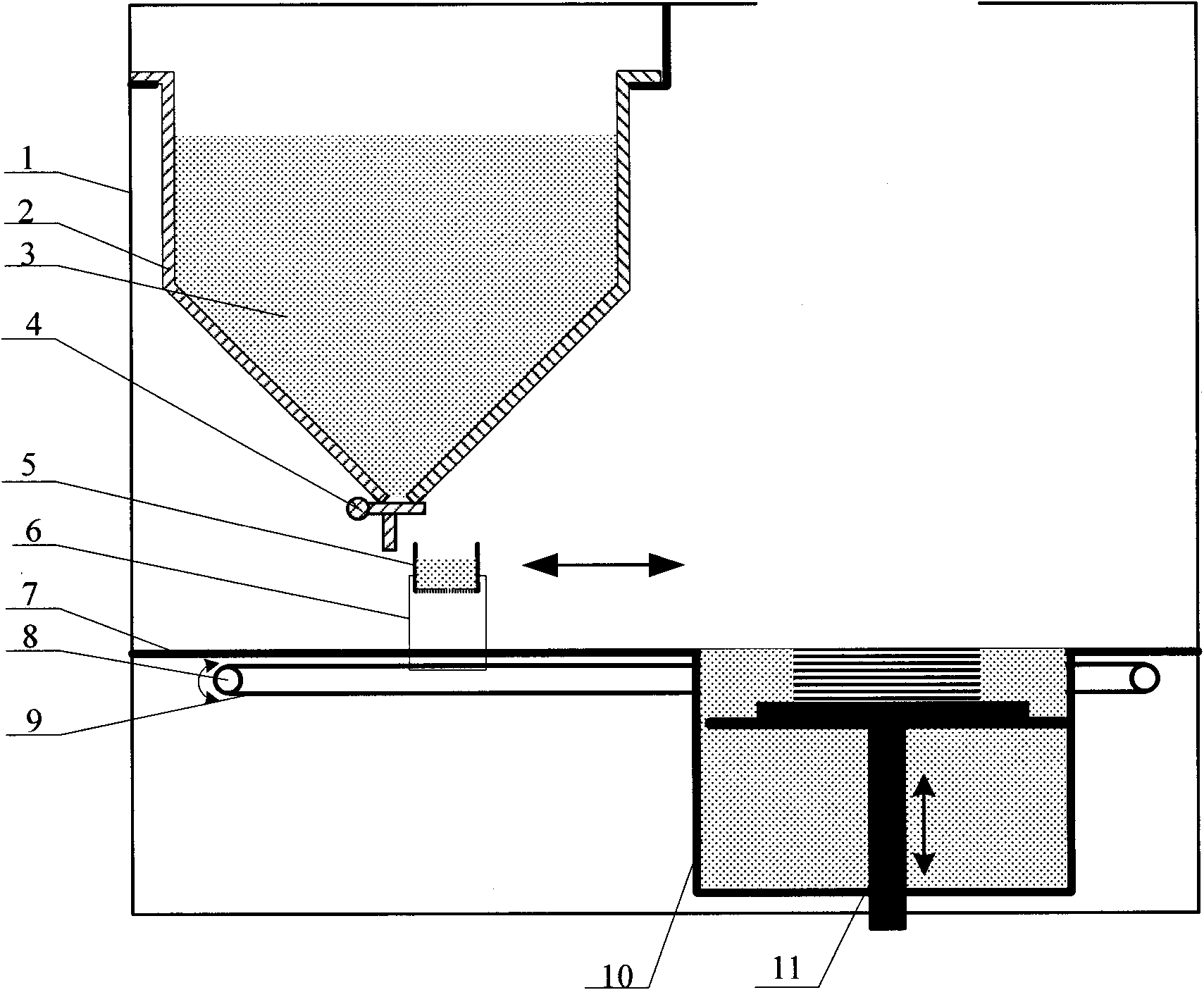

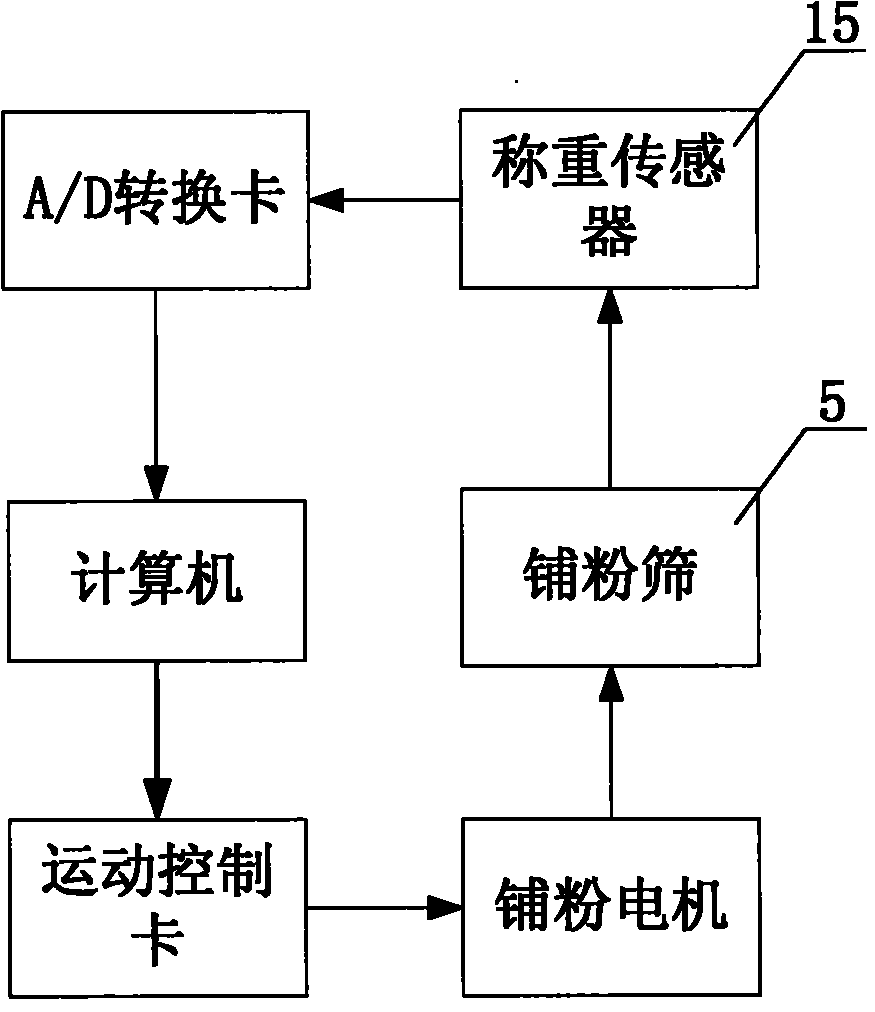

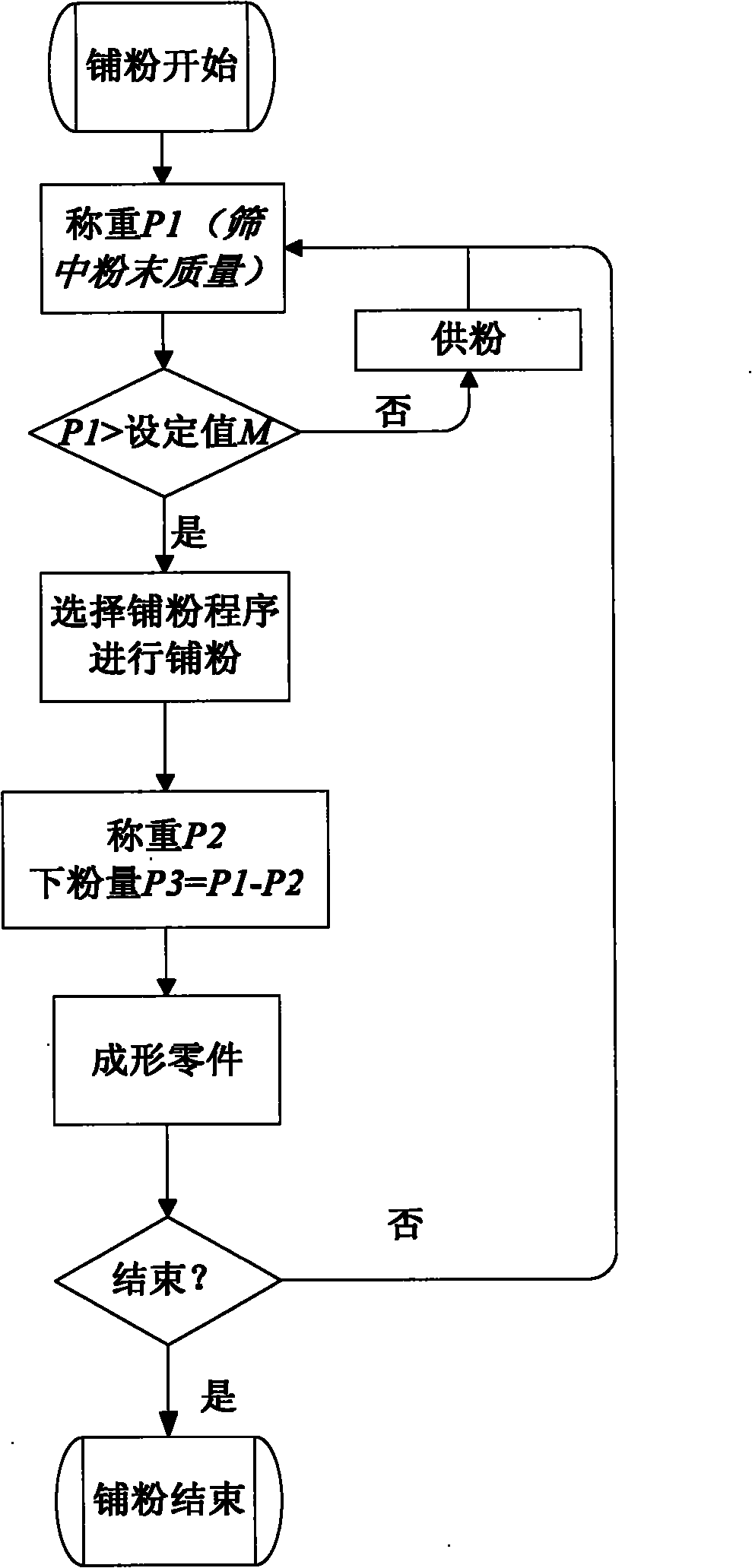

Non-contact type power automatic feeding and paving device

InactiveCN101829782AWill not be affected by powder spreading movementSpread powder evenlyMotion parameterEngineering

A non-contact type power automatic feeding and paving device belongs to the field of electron beams / laser selective area melting technology. The device mainly comprises a working cavity, a work bin, a stop block, a worktable, an automatic power paving device, a computer containing a power paving control program, an A / D conversion card and a motion control card, wherein the power paving system consists of a power paving sieve, a connecting piece, a cantilever weighting sensor and a driving device. Since the power paving sieve is not in contact with a forming area, the surface evenness of the forming area has no influence on the power paving movement and the uniform power pavement of different thicknesses can be realized by controlling the aperture size and motion parameters of the power paving sieve; and especially, the invention has remarkable effect of paving power on the non-even surface.

Owner:TSINGHUA UNIV

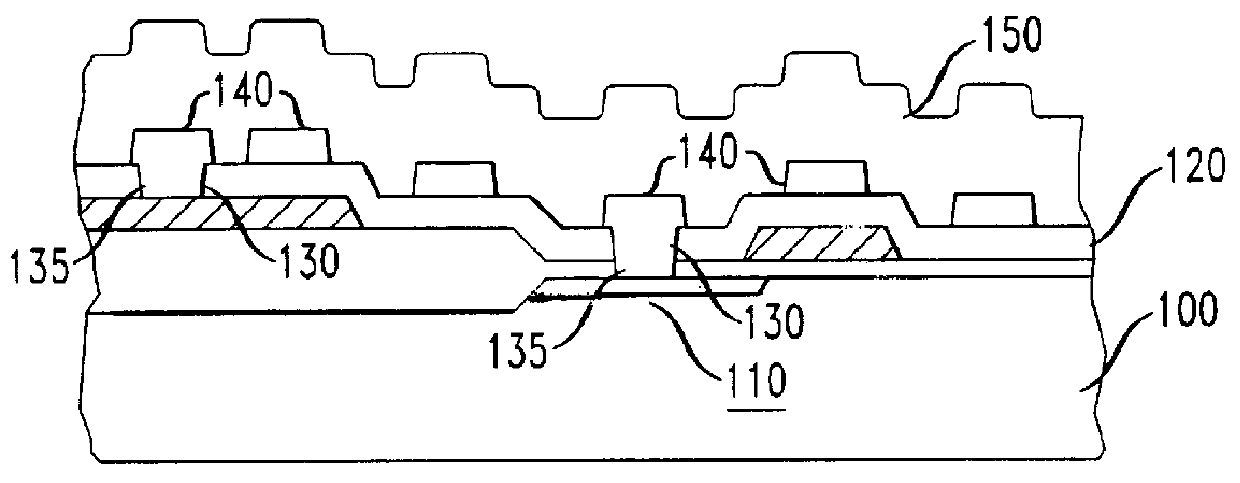

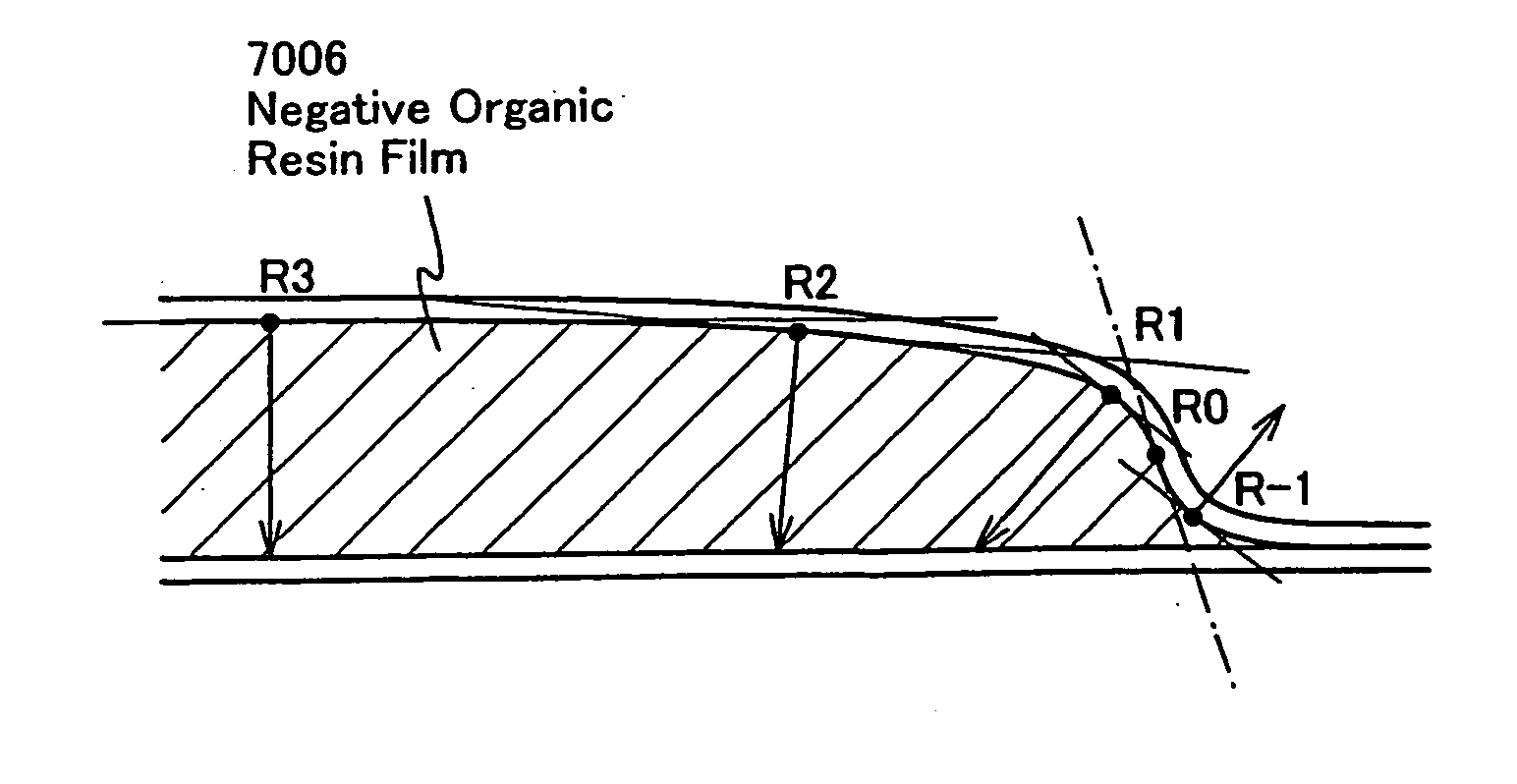

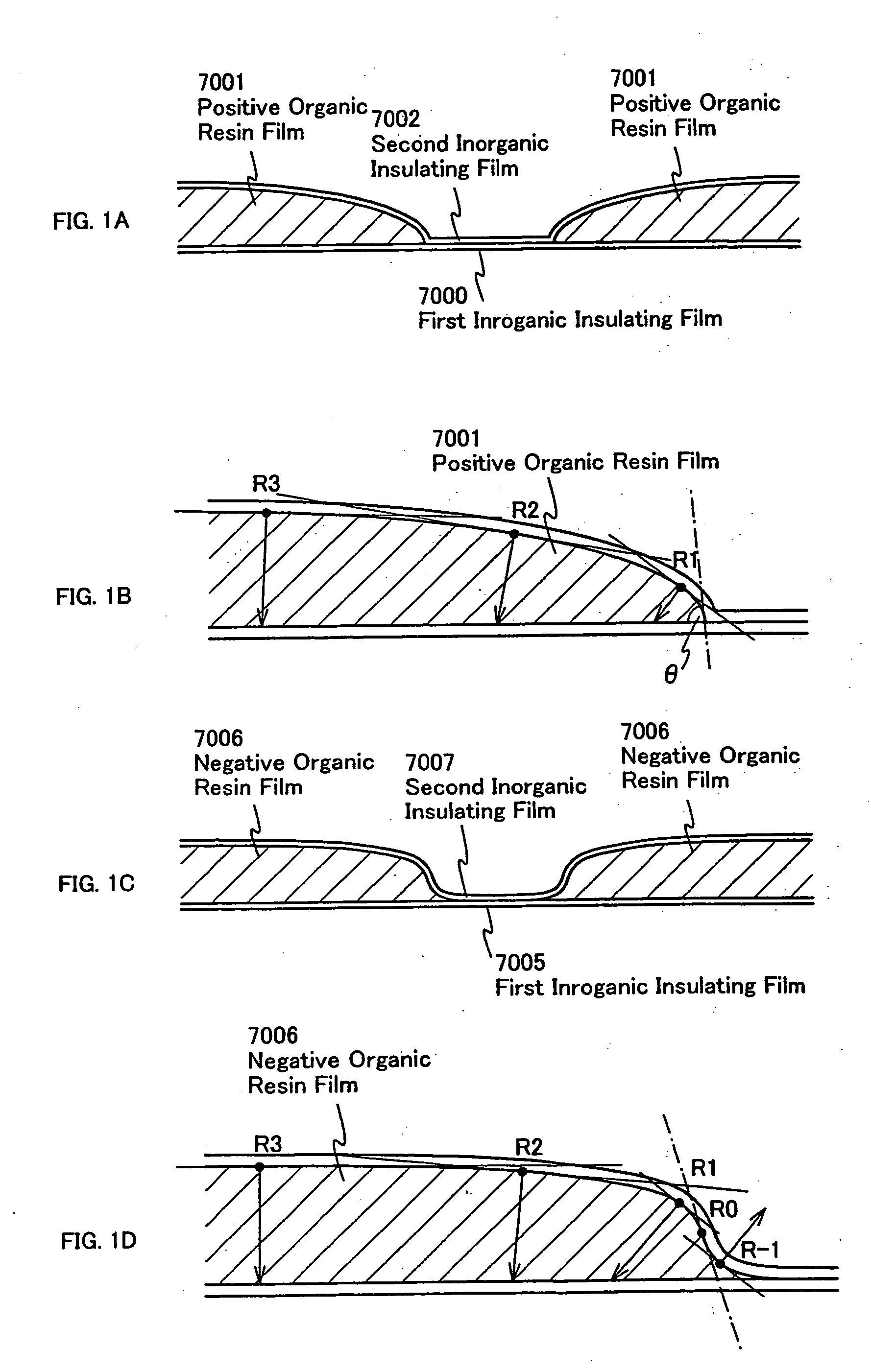

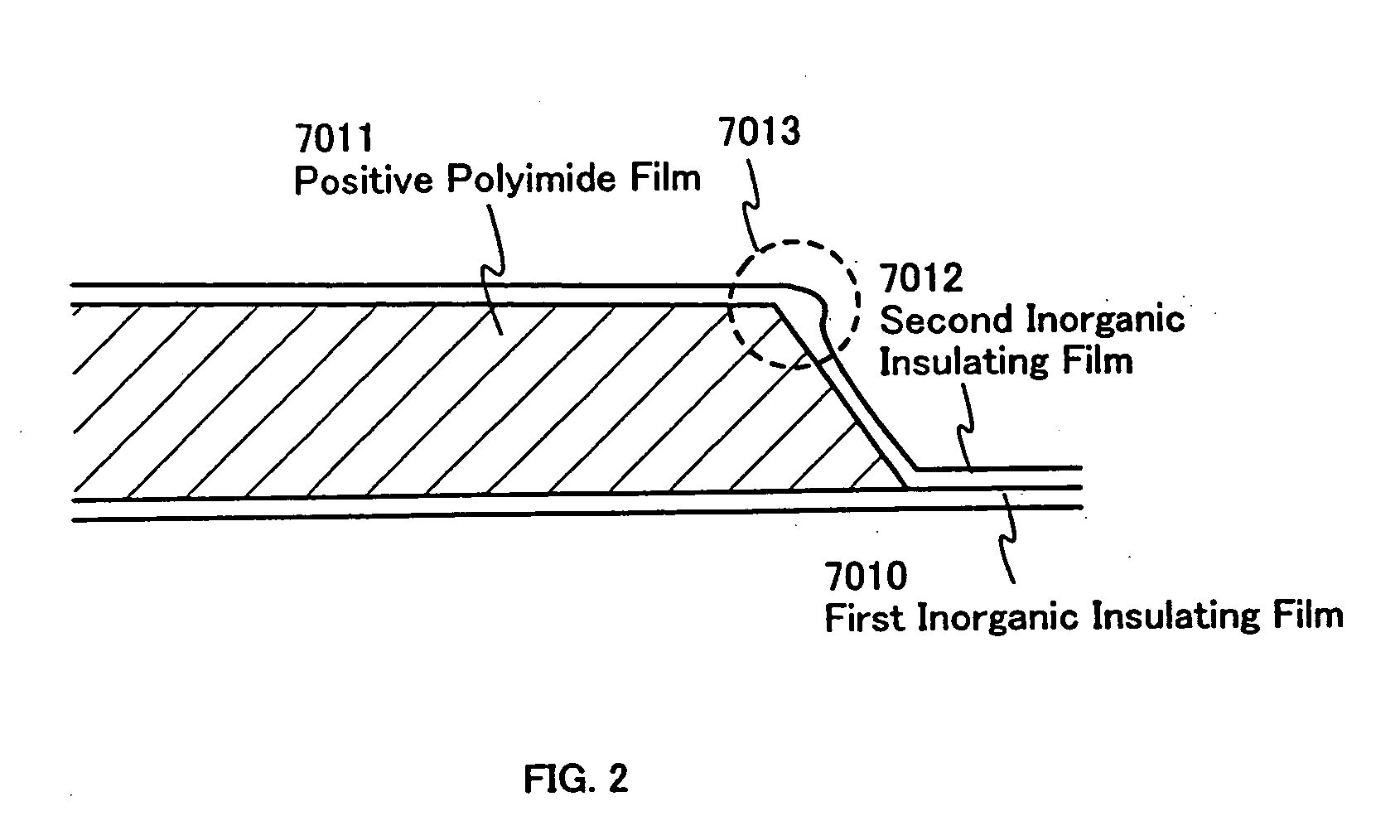

Semiconductor display device and method of manufacturing the same

InactiveUS20050233507A1Timely controlPrevent moistureTransistorSolid-state devicesAcrylic resinDisplay device

A semiconductor display device with an interlayer insulating film in which surface levelness is ensured with a limited film formation time, heat treatment for removing moisture does not take long, and moisture in the interlayer insulating film is prevented from escaping into a film or electrode adjacent to the interlayer insulating film. A TFT is formed and then a nitrogen-containing inorganic insulating film that transmits less moisture compared to organic resin film is formed so as to cover the TFT. Next, organic resin including photosensitive acrylic resin is applied and an opening is formed by partially exposing the organic resin film to light. The organic resin film where the opening is formed, is then. covered with a nitrogen-containing inorganic insulating film which transmits less moisture than organic resin film does. Thereafter, the gate insulating film and the two layers of the nitrogen-containing inorganic insulating films are partially etched away in the opening of the organic resin film to expose the active layer of the TFT.

Owner:SEMICON ENERGY LAB CO LTD

Single-coating aluminum plating transfer coating suitable for gravure and preparation method thereof

InactiveCN101724327ASimple production processIncrease productivityCoatingsCoatings without pigmentsCelluloseAcrylic resin

The invention relates to a single-coating aluminum plating transfer coating suitable for gravure and a preparation method thereof. The coating comprises the following components in percentage by weight: 0 to 6 percent of vinyl acetate chlorate resin, 8 to 25 percent of acrylic resin, 0 to 12 percent of cellulose resin, 0 to 1 percent of auxiliary agent, and 70 to 85 percent of solvent. The preparation method comprises the following steps of: preparing materials, and then adding the solvent, the resin components and the auxiliary agent into a reaction kettle; controlling the stirring speed, the reaction temperature, the solid content and the viscosity; and performing cooling and filtering to obtain a final product. Compared with the prior art, the single-coating aluminum plating transfer coating has a simple production process, a high production efficiency, less energy consumption and a low cost; an printing ink has good levelling on the surface of a coating layer, has no lifting, and is difficult to generate alligator cracks and expose colors; and a piece of aluminized paper has good surface flatness, high metallic luster, good smoothness and good abrasion resistance, and contains no industrial forbidden solvents such as a triphen type solvent and the like.

Owner:SHANGHAI WEIKAI CHEM

Preparation method and application of separation film with nano composite cortical layer

ActiveCN102908906AImprove throughputImprove interception effectSemi-permeable membranesDesalinationNanofiltration

The invention provides a preparation method and application of a separation film with a nano composite cortical layer. The separation film comprises a non-woven fabric layer, two porous support layers and a desalination layer, and is characterized in that the lower layer of the two porous support layers is a porous body layer containing polymers and / or nano particles, and the upper layer of the two porous support layers is a porous cortical containing polymers and nano particles. The preparation method includes coating the upper layer and the lower layer of the non-woven base material by means of a double-layer coating technology. An ultrafilter support layer of the composite separation film prepared by the preparation method is good in surface evenness, hight water flux is kept in the meantime of keeping higher cutoff rate, and the separation film can be directly used as an ultrafiltration film or can be used as a basic porous support layer to further prepare a composite forward osmosis, reverse osmosis and nanofiltration film. The preparation method can be applied to preparing the reverse osmosis film and the nanofiltration film which are good in performance, and a composite ultrafiltration film with low molecular weight cutoff.

Owner:VONTRON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com