Fusion-deposition 3D printer and printing method thereof

A 3D printer and fusion deposition technology, applied in the field of 3D printing, can solve the problems of inability to meet the requirements of engineering applications, rough surface of printed products, large limitations of printing materials, etc., to reduce limitations, improve strength and surface smoothness, Overcome the effects of rough surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

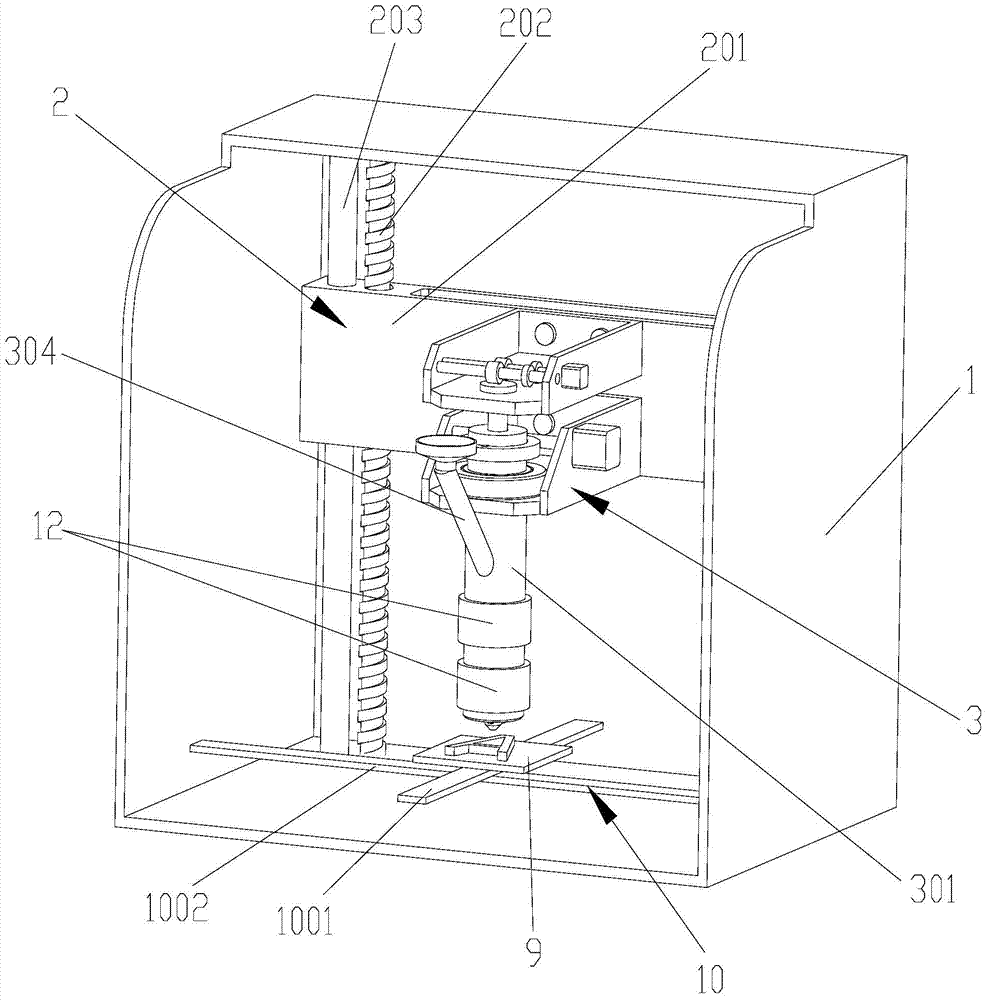

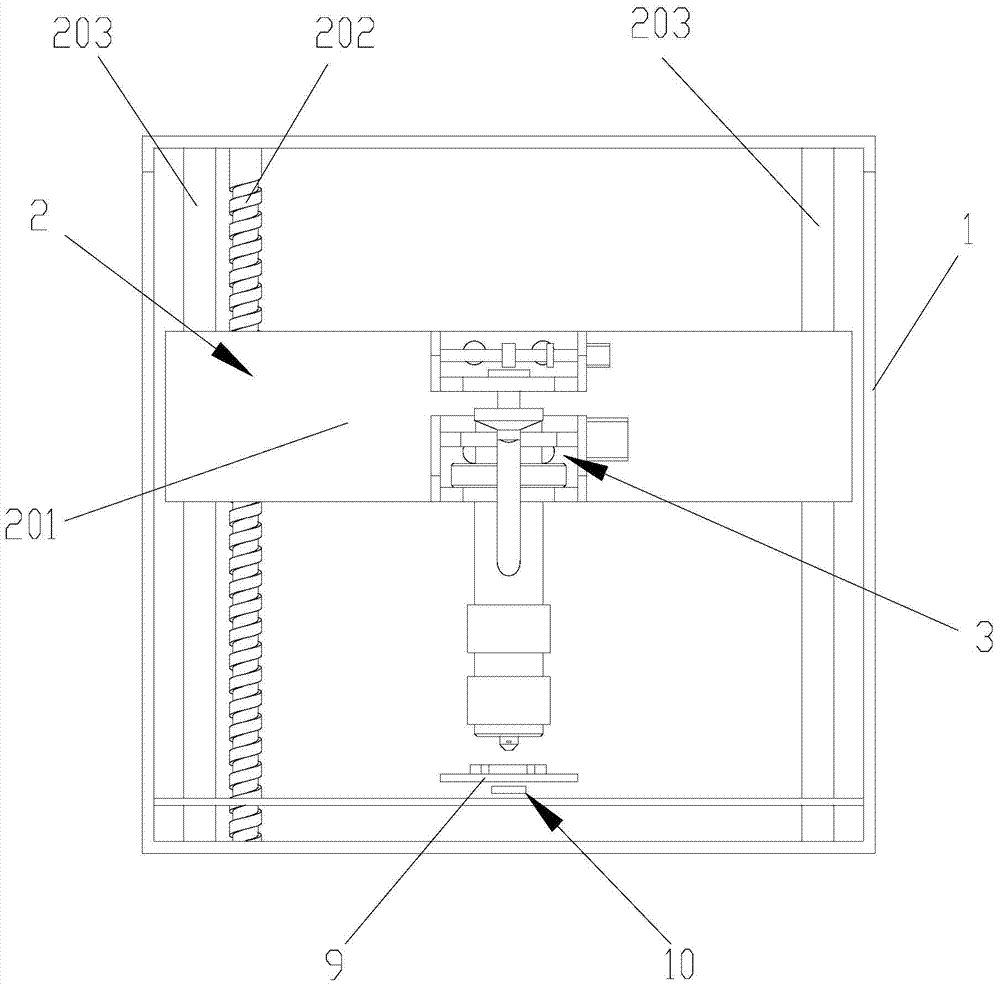

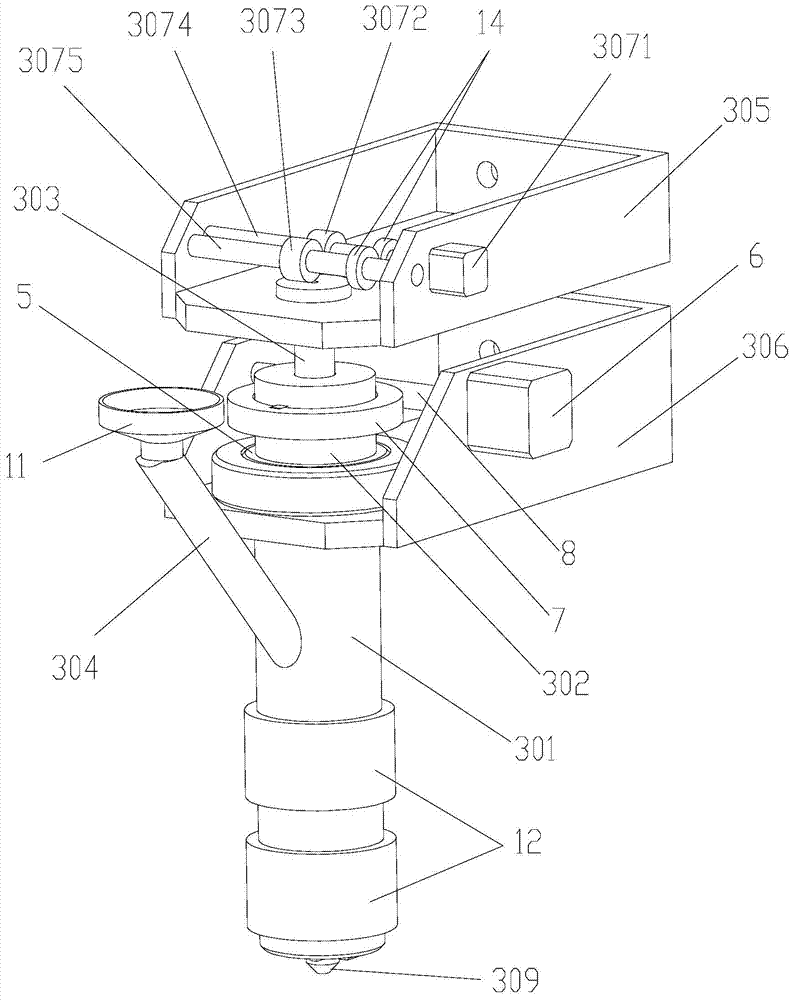

[0035] Such as Figure 1 to Figure 9 The fused deposition 3D printer shown includes a housing 1 and a lifting mechanism 2, the lifting mechanism 2 is installed in the housing 1, and also includes a composite extrusion mechanism 3, and the composite extrusion mechanism 3 includes a barrel 301, a screw 302 and long fiber conveying pipe 303, the side wall of described machine barrel 301 is provided with the feeding pipe 304 that communicates with the material chamber 3011 of machine barrel 301, and described screw rod 302 is rotatably installed in the material chamber 3011, and described screw rod 302 is provided with installation channel 3021, and described installation channel 3021 communicates the upper end and the lower end of screw rod 302; The delivery channel 3031; the delivery channel 3031, the installation channel 3021 and the material cavity 3011 are connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com