Patents

Literature

419results about How to "Meet the intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser sintering sand, preparation method thereof, sand core and preparation method thereof

ActiveCN101837427AHigh sintered initial strengthMeet the intensityFoundry mouldsFoundry coresGenerating capacityMetal

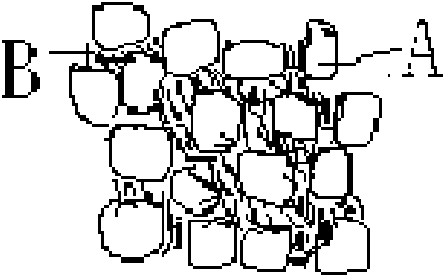

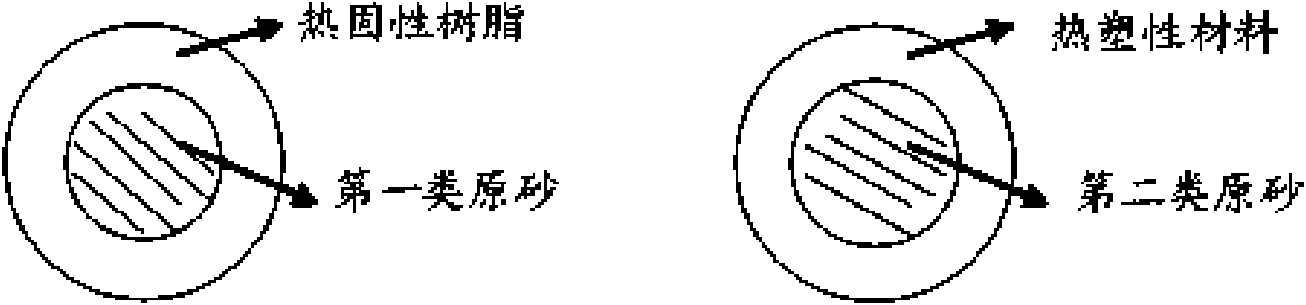

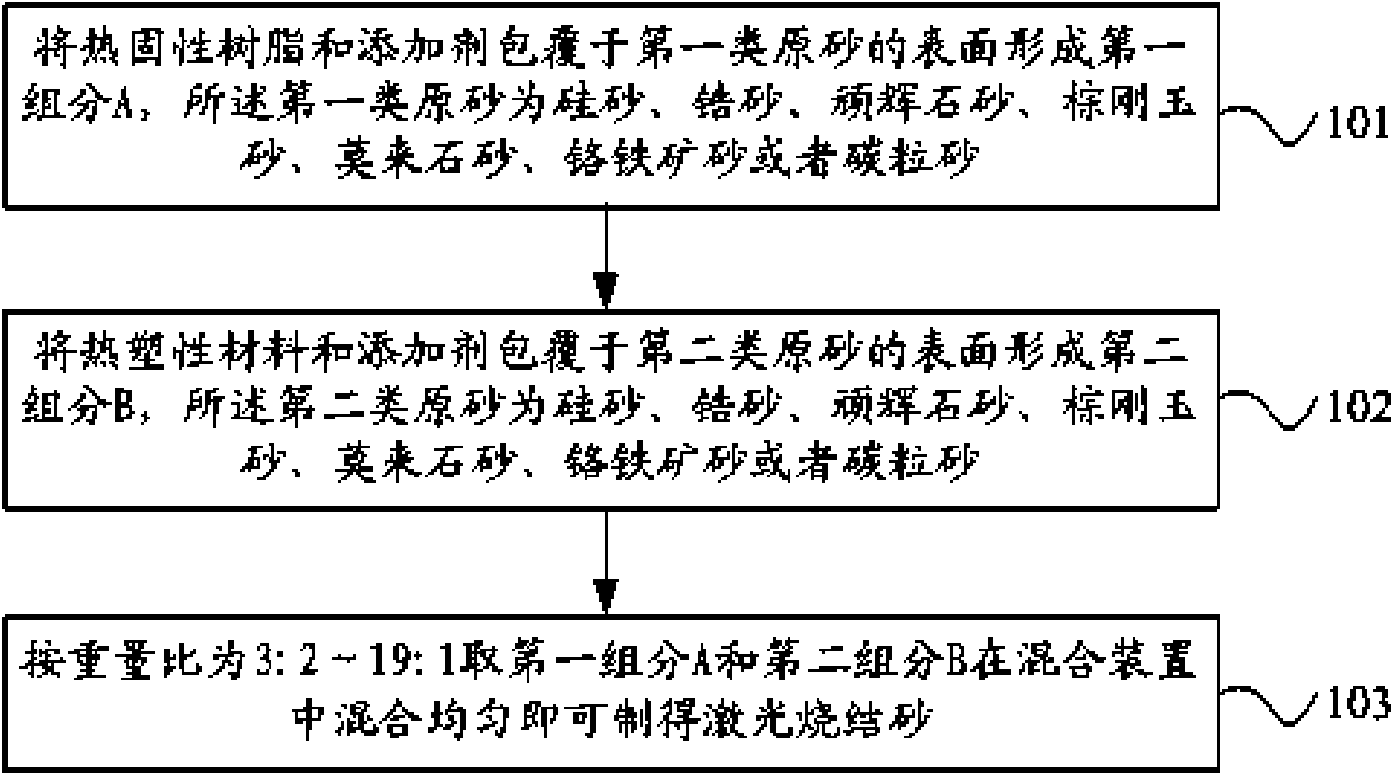

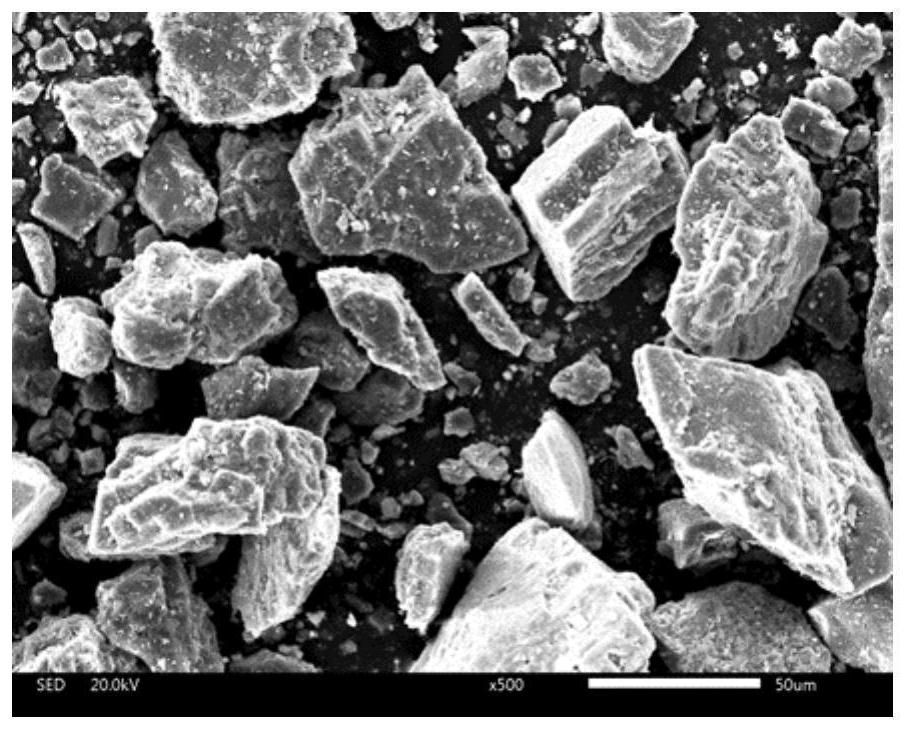

The invention relates to a laser sintering sand, a preparation method thereof, a sand core and the preparation method thereof. The laser sintering sand consists of a first component and a second component which are evenly mixed, the first component consists of a first type of raw sand with the coefficient of angularity of less than 1.3, thermosetting resin and additives, wherein the thermosetting resin and the additives are coated on the surface of the first type of the raw sand; and the second component consists of a second type of raw sand with the coefficient of angularity of less than 1.1, a thermoplastic material and the additives, wherein the thermoplastic material and the additives are coated on the surface of the second type of the raw sand. The adoption of the laser sintering sand does not need to add an auxiliary support structure during the laser sintering process, thereby improving the molding efficiency and reducing the manual intervention; and the any complex sand core can be manufactured without using a mold, and the sand core simultaneously has high sintering initial strength and can meet the requirements on the thermal strength and the gas-generating capacity of the sand core during the metal casting process.

Owner:安徽隆源成型科技有限公司

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

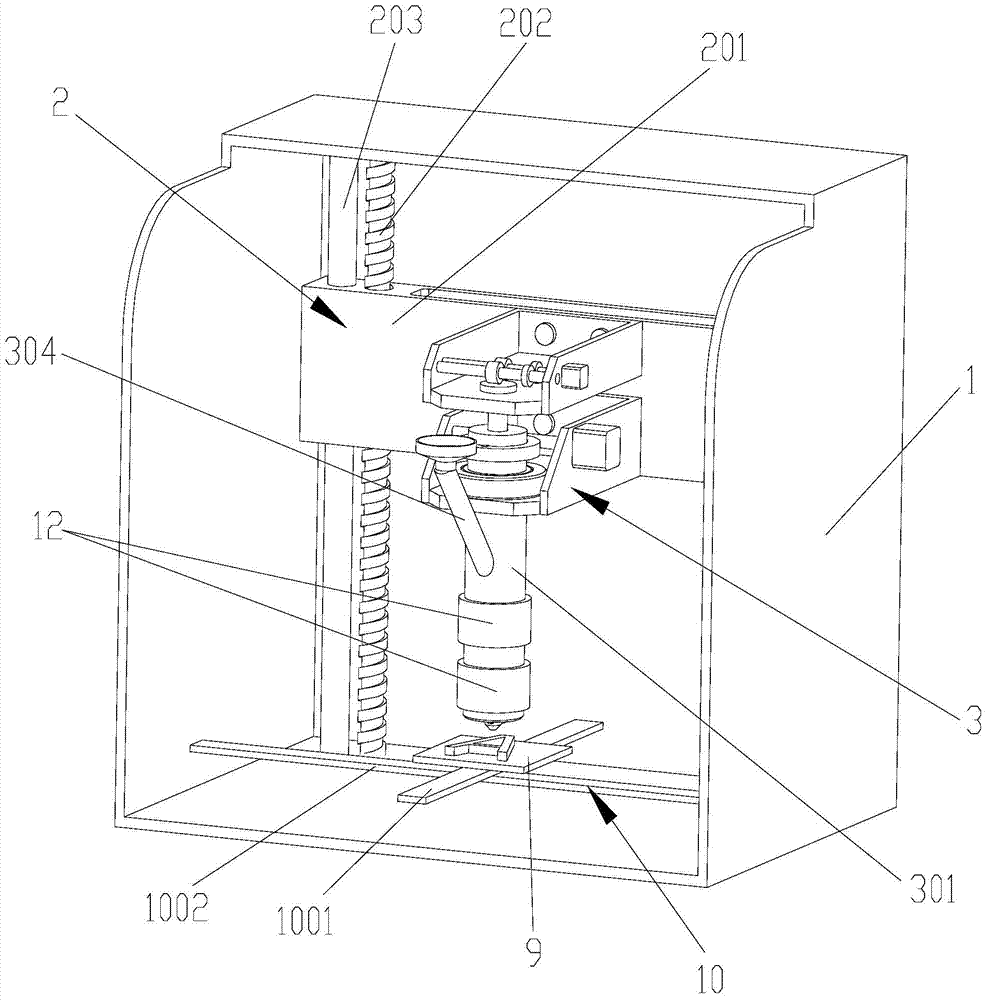

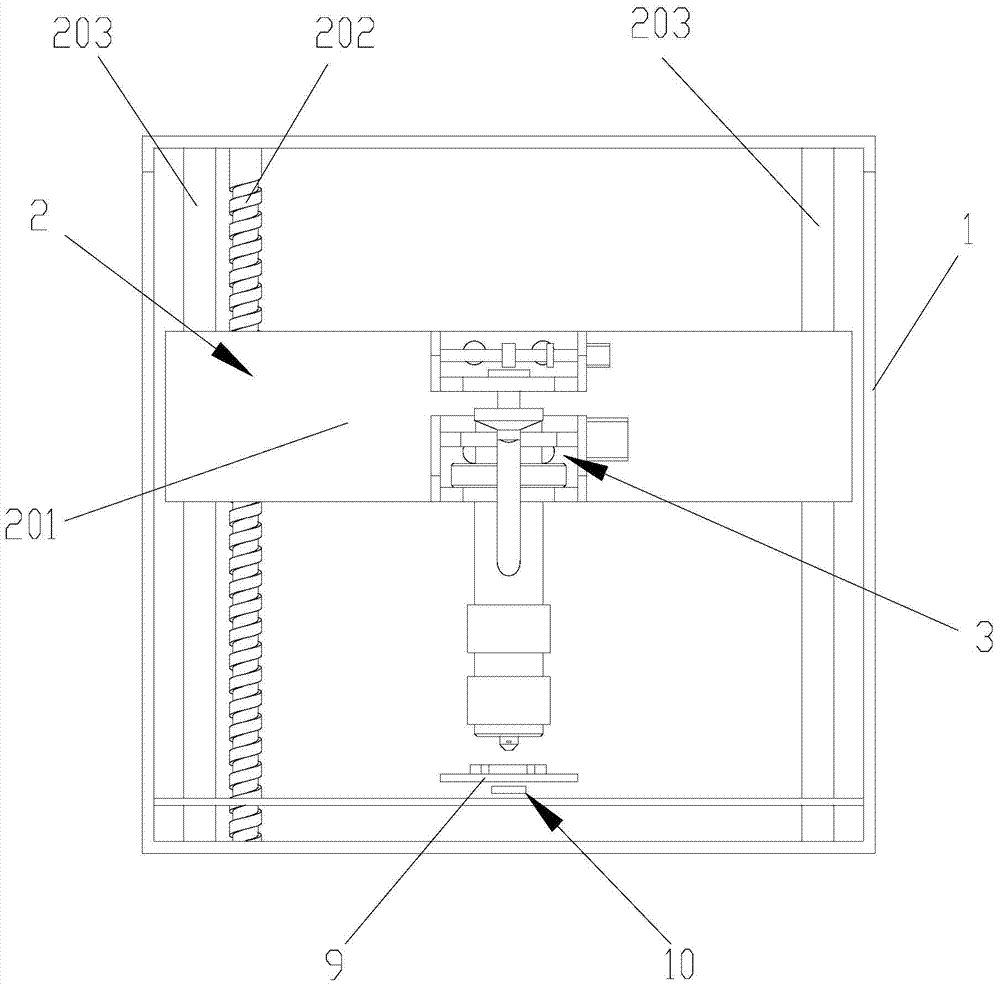

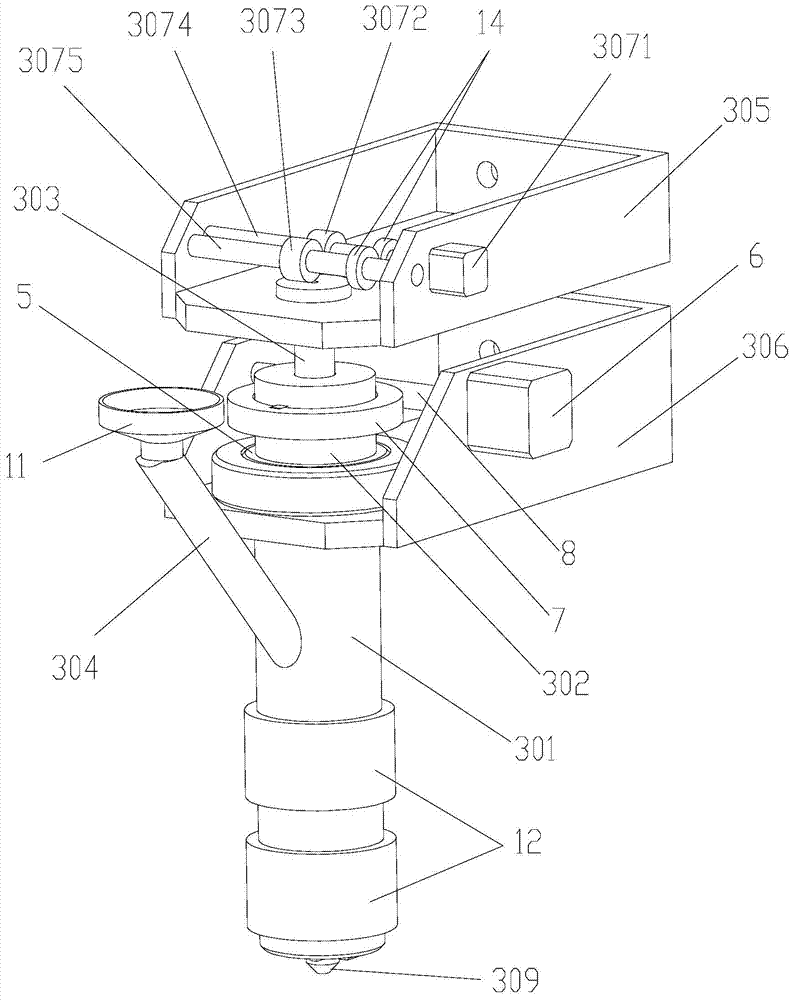

Fusion-deposition 3D printer and printing method thereof

The invention discloses a fusion-deposition 3D printer. The fusion-deposition 3D printer comprises a shell, a lifting mechanism and a composite extruding mechanism, wherein the lifting mechanism is mounted in the shell; the composite extruding mechanism comprises a machine cylinder, a screw rod and a long-fiber conveying pipe, a feeding pipe communicated with a material cavity of the machine cylinder is arranged on the side wall of the machine cylinder, the screw rod is rotatably mounted in the material cylinder and is provided with a mounting channel, and the upper and lower ends of the screw rod are communicated through the mounting channel; the long-fiber conveying pipe is inserted into the mounting channel and is provided with a conveying channel for conveying long continuous fibers; the conveying channel, the mounting channel and the material cavity are sequentially communicated. The invention further discloses a printing method of the fusion-deposition 3D printer. According to the fusion-deposition 3D printer and the printing method thereof, the long continuous fibers and printing materials packing the long continuous fibers are synchronously extruded to a working platform, so that the strength and surface flatness of a printed product are improved, and the machining efficiency is improved.

Owner:余金文 +1

Beta type titanium alloy and method for producing same

The invention discloses a beta-Ti alloy, which comprises the components by weight percentage as follows: molybdenum is 9 to 15 percent, niobium is 6 to 10 percent, tantalum is 2 to 6 percent, zirconium is 2 to 6 percent, aluminum is 1 to 3 percent, ferrum is less than or equal to 1.0 percent, carbon is less than or equal to 0.1 percent, nitrogen is less than or equal to 0.05 percent, hydrogen is less than or equal to 0.015 percent, oxygen is less than or equal to 0.02 percent, and titanium is in the balancing amount. A preparation method comprises the steps as follows: sponge titanium, pure aluminium, sponge zirconium, Ti-Mo (the Mo is 31 percent), Ti-Nb (Nb is 53 percent) and Al-Ta (Ta is 80 percent) are mixed and made into a consumable electrode; the consumable electrode is smelted through a vacuum consumable electrode arc furnace to obtain a primary cast ingot; the primary cast ingot is used as the consumable electrode and is smelted to obtain a secondary cast ingot; the secondary cast ingot is used as the consumable electrode and is processed through vacuum consumable smelting to obtain finished products that is titanium alloy ingot. The beta-Ti alloy not only has high hardness, but also has higher unit extension and plasticity, and not only satisfies the intensity of application requirement, but also is easy to manufacture and mold and reduces the energy consumption.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND +1

Blow molding type halogen-free flame-retardant polypropylene material

InactiveCN102286171AOvercome strengthOvercoming problems such as brittleness at low temperaturesBlow moldingHalogen

The invention provides a blow molding type halogen-free flame-retardant polypropylene material, which comprises the following components in part by weight: 100 parts of polypropylene, 40 to 85 parts of phosphorus-nitrogen series expanded halogen-free composite flame retardant, 3 to 20 parts of resin modifier, 0.05 to 0.5 part of pigment, 0.4 to 2.0 parts of antioxidant, 0.3 to 2.0 parts of ultraviolet absorbent, 0.3 to 2.0 parts of light stabilizer, and 1.0 to 3.0 parts of other processing aids. The material has good tensile strength, high impact strength, good low-temperature performance and excellent flame-retardant performance, and is particularly suitable for hollow blow molding type small and large components of automobiles, furniture and the like.

Owner:应急管理部四川消防研究所

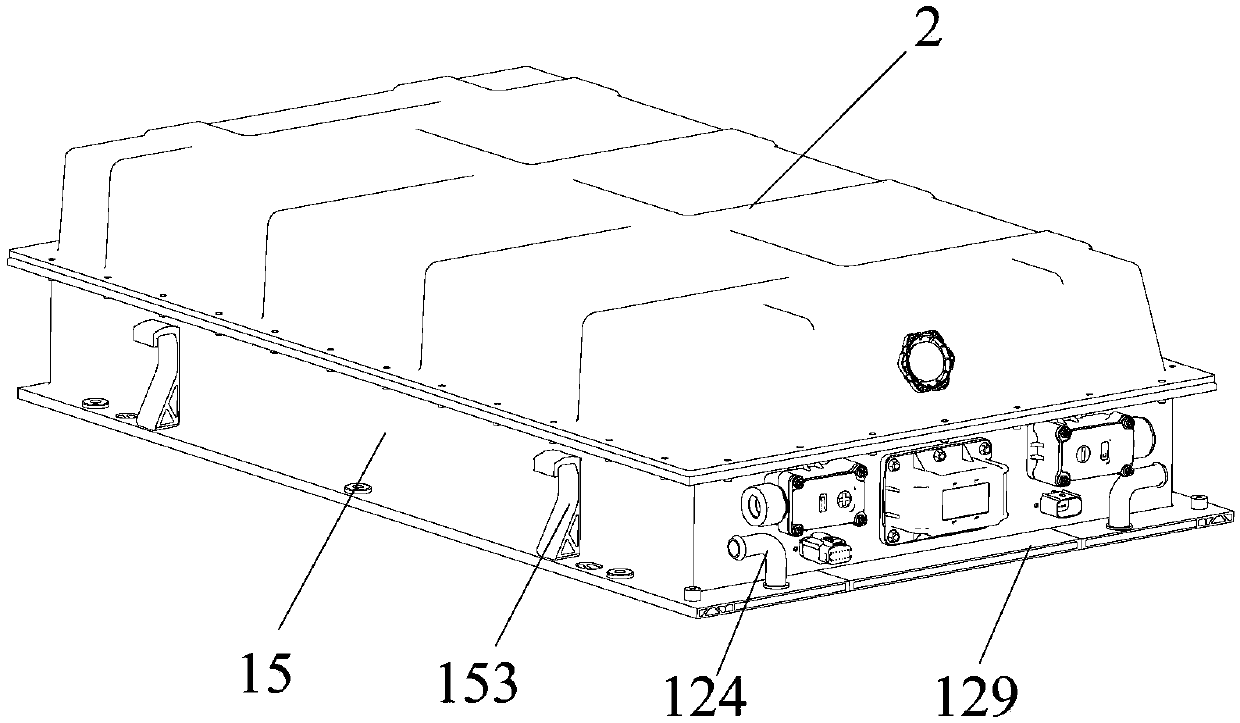

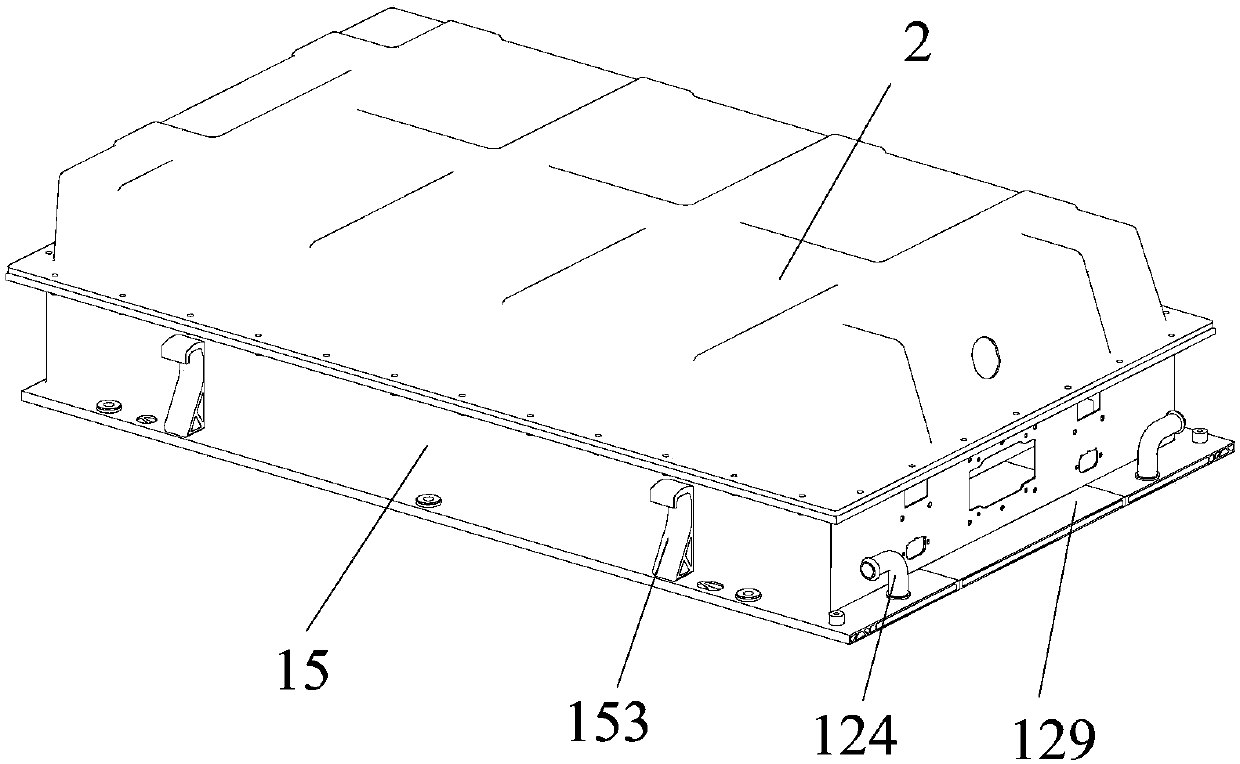

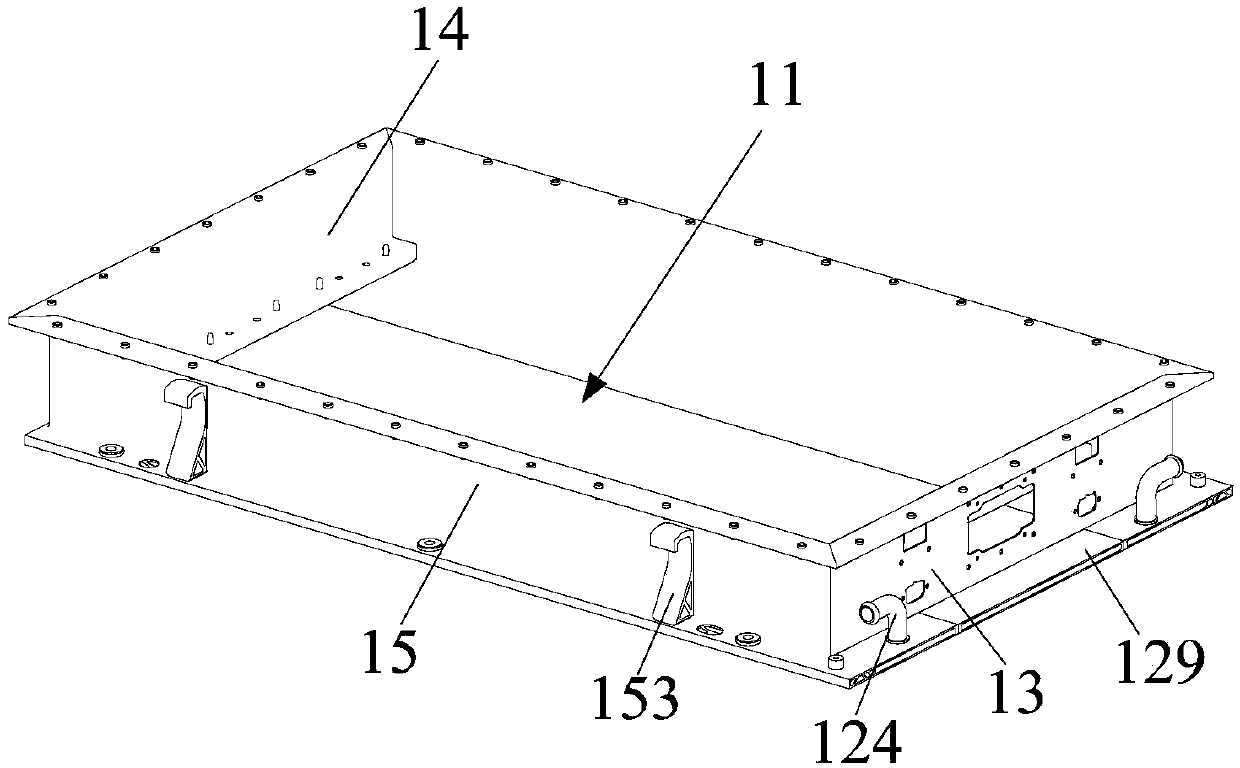

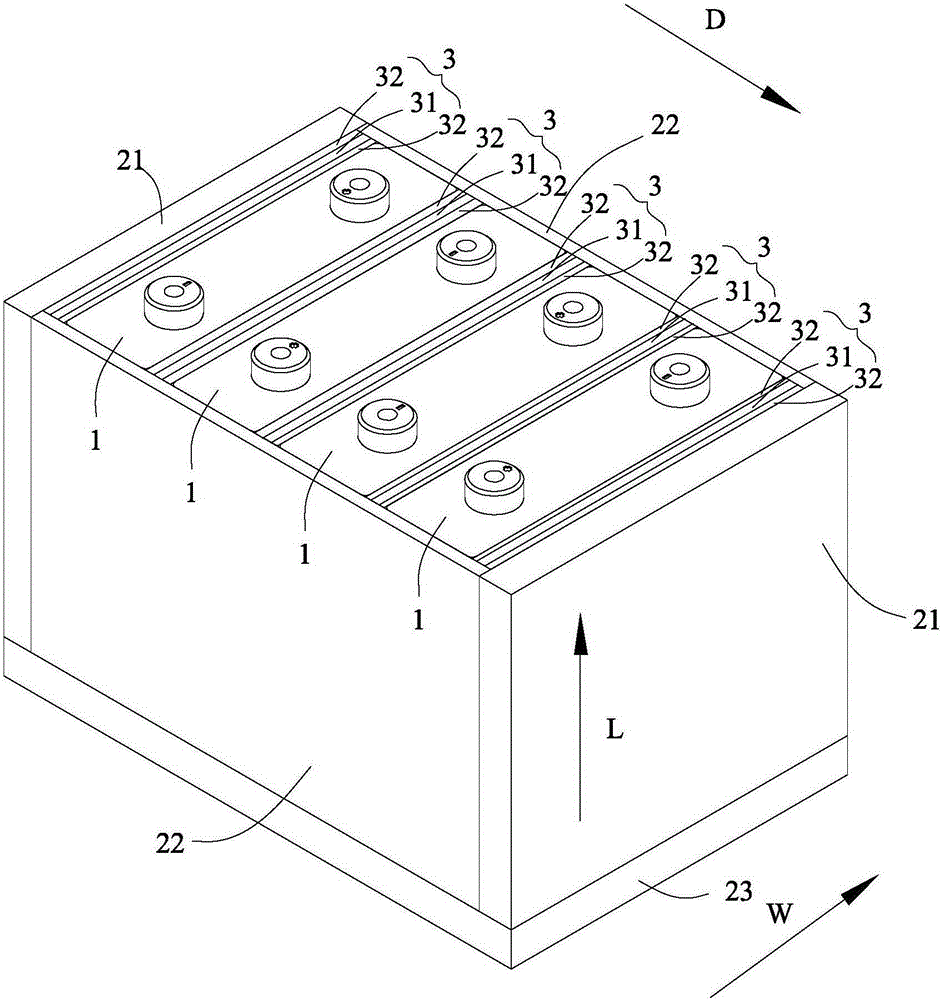

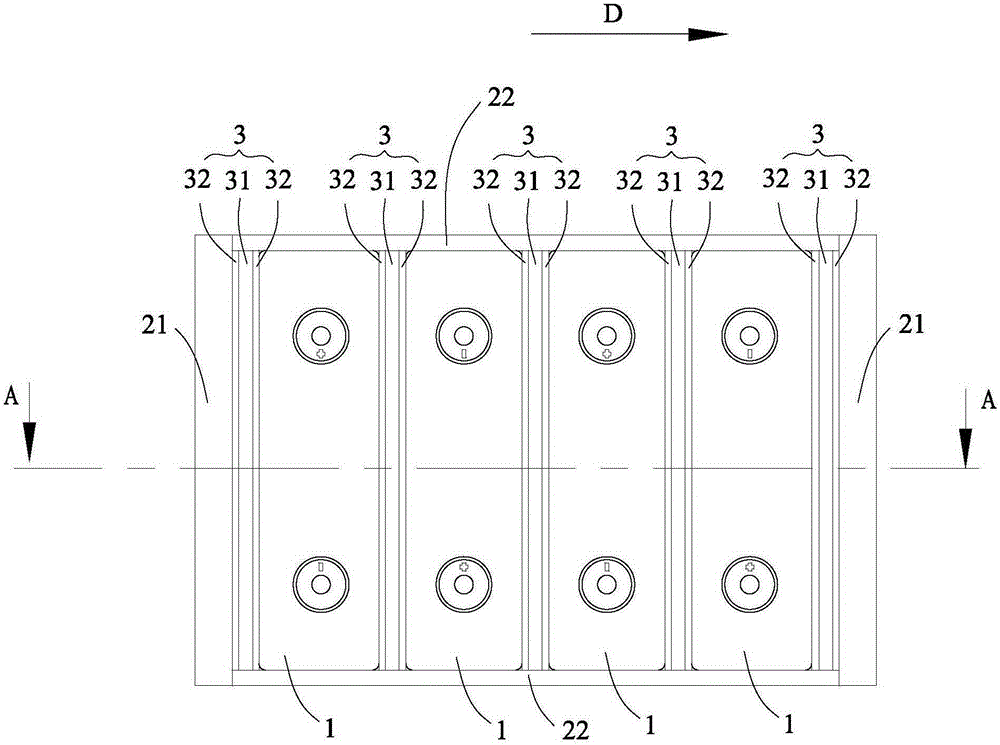

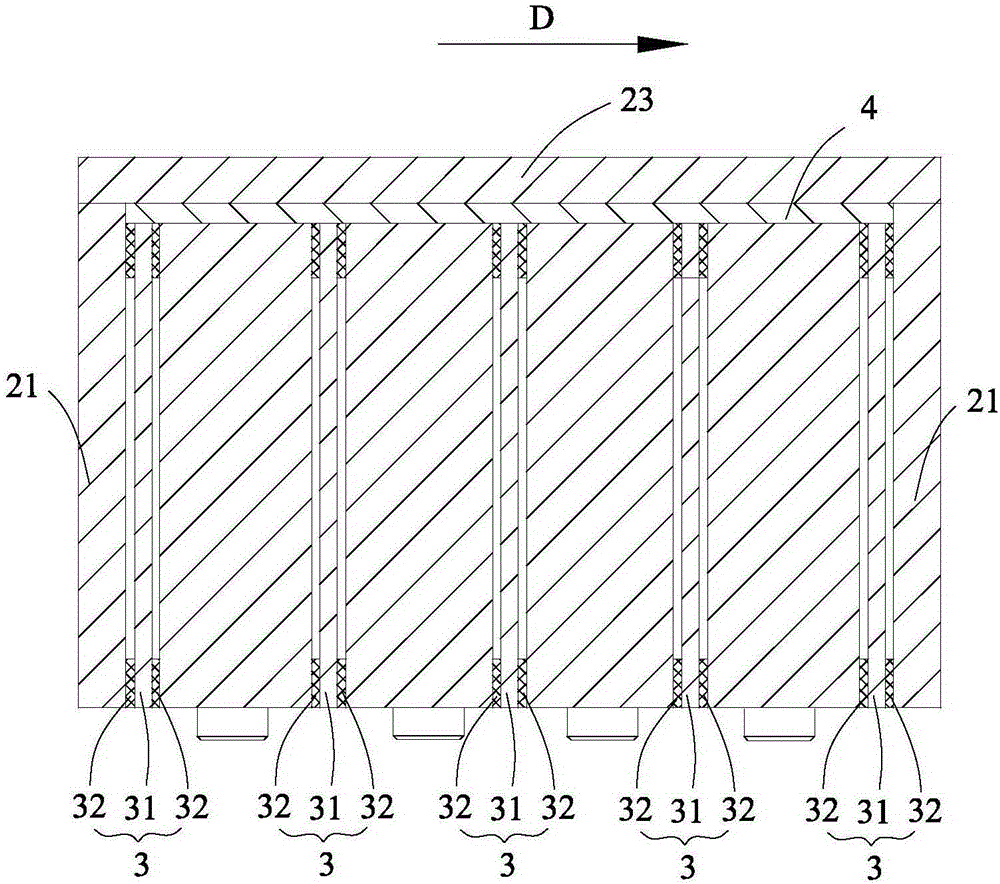

Integrated water-cooled power battery box

PendingCN108039434AMeet the intensityFulfil requirementsBattery isolationSecondary cellsPower batteryMechanical property

The invention relates to the technical field of electric cars, in particular to an integrated water-cooled power battery box. The integrated water-cooled power battery box provided by the invention comprises a box cover, a box body and a temperature regulating power system, wherein the box body is made of an aluminum alloy material and is manufactured by an extrusion moulding technology; a circulating flow passage is formed in the wall of the box body; a circulating loop for a temperature regulating medium to flow circularly is arranged inside the wall of the box body; and the temperature regulating power system can drive the temperature regulating medium to circularly flow in the circulating loop. In such a way, a water cooling board and a battery box are designed in an integrated manner,a hollow aluminum alloy section is adopted to achieve lightweight design, mechanical properties such as strength and rigidity are met, the integrated water-cooled power battery box is simpler in structure, better in technical performance and smaller in occupied space, and the comprehensive cost can be reduced; the heat-dissipating, cooling and temperature-raising and heating functions can be achieved by using one set of temperature regulating power system, the integrated water-cooled power battery box is simpler in structure, more convenient and fast to use and smaller in occupied space, themanufacturing cost and the using cost can be reduced, and the heat-dissipating efficiency and the heating efficiency can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

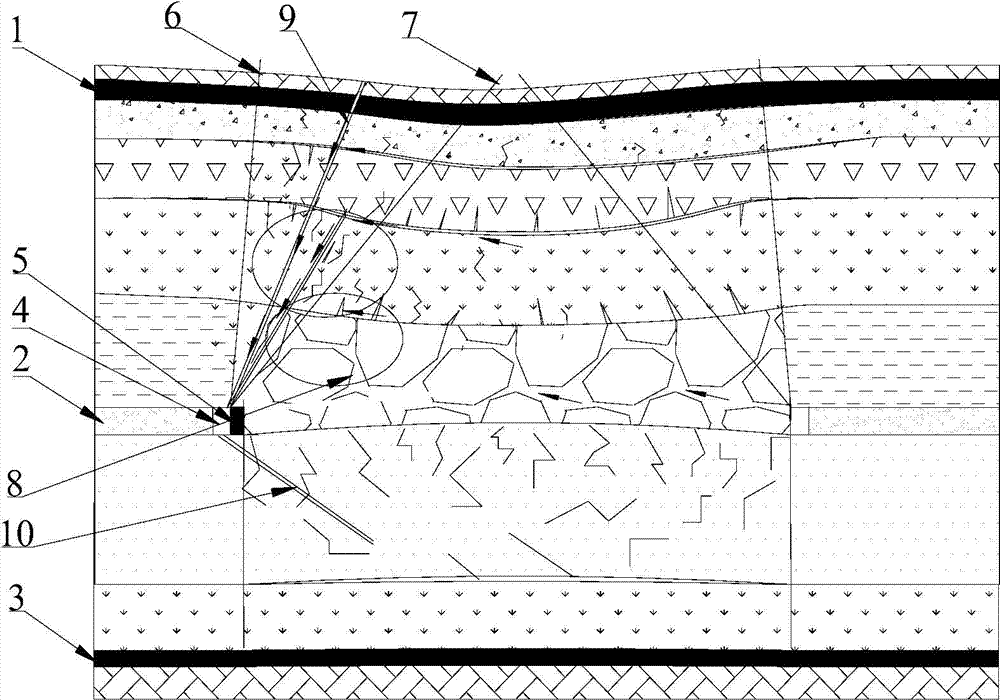

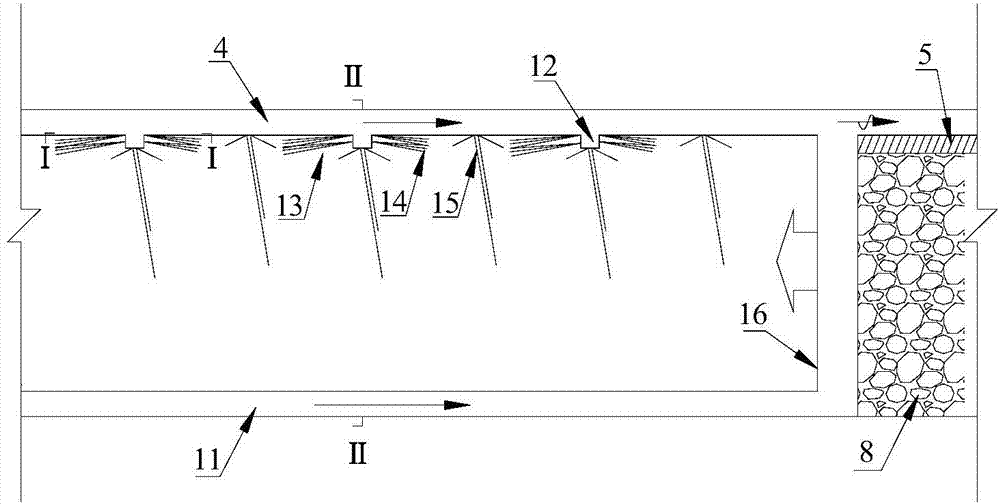

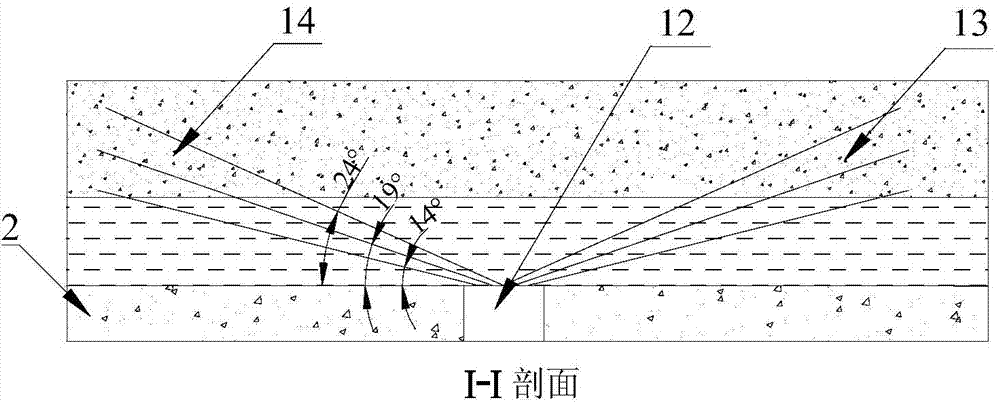

Coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of working face of first mining total rock pressure relief

InactiveCN104712358ALayer selection is flexibleSolve the outstanding problem of safe miningFluid removalGas removalLithologyPlate pressure

The invention discloses a coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of a working face of first mining total rock pressure relief. When a first mining pressure relief coal seam can not be selected, the coal and rock seams are moved and broken through the working face of first mining total rock pressure relief, an upper covered coal seam with high gas and a lower covered coal seam which high gas are subjected to pressure relief and swollen, fractures of a surrounding rock mass are developed, the gas permeability is increased, the gas is subjected to desorption and transportation, and finally a top plate pressure relief annular fracture area and a bottom plate pressure relief annular fracture area are generated. To create a favorable stress environment of retained roadway surrounding rock, retained roadway mining empty side cantilever crest truncation is conducted to first advance mining drill site toward and backward the working face in a bi-directional mode, according to the top plate lithologic characters, the first advance is subjected to top plate deep hole pre-splitting and cover caving so that it is guaranteed that the top plate is sufficiently collapsed to fill a worked out section. By means of the method, the prominent problems of exhausting and mining of coal seam group pressure relief gas and safe mining when the first mining pressure relief coal seam of the coal seam group with high gas content is difficult to select are solved.

Owner:CHINA UNIV OF MINING & TECH

Full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing LNG storage tank

ActiveCN107052618AAvoid organizationAvoid performance changesArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthToughness

The invention discloses a full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing an LNG storage tank. According to the technical scheme, the full-automatic submerged-arc welding solid-core welding wire comprises 0.25-0.45wt% of C, 23-26wt% of Mn, 6-8wt% of Ni, 3-5wt% of W, 0.02-0.04wt% of N, less than or equal to 0.02wt% of P, less than or equal to 0.001wt% of S and the balance of Fe and inevitable impurities. The full-automatic submerged-arc welding solid-core welding wire has the advantages that the price of adopted alloy elements is low, and an alloy component system is simple; and the low-temperature toughness of weld metal formed by the prepared full-automatic submerged-arc welding solid-core welding wire is excellent, the strength of the full-automatic submerged-arc welding solid-core welding wire is matched with the strength of the ultralow-temperature high-manganese steel for preparing the LNG storage tank, and the technical requirements for the strength and the ultralow-temperature toughness of the welded LNG storage tank can be met.

Owner:WUHAN UNIV OF SCI & TECH +1

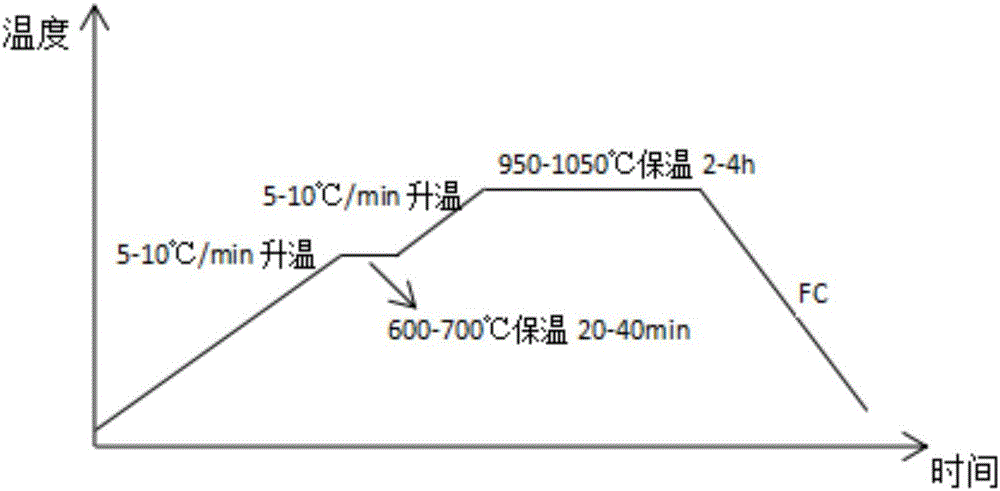

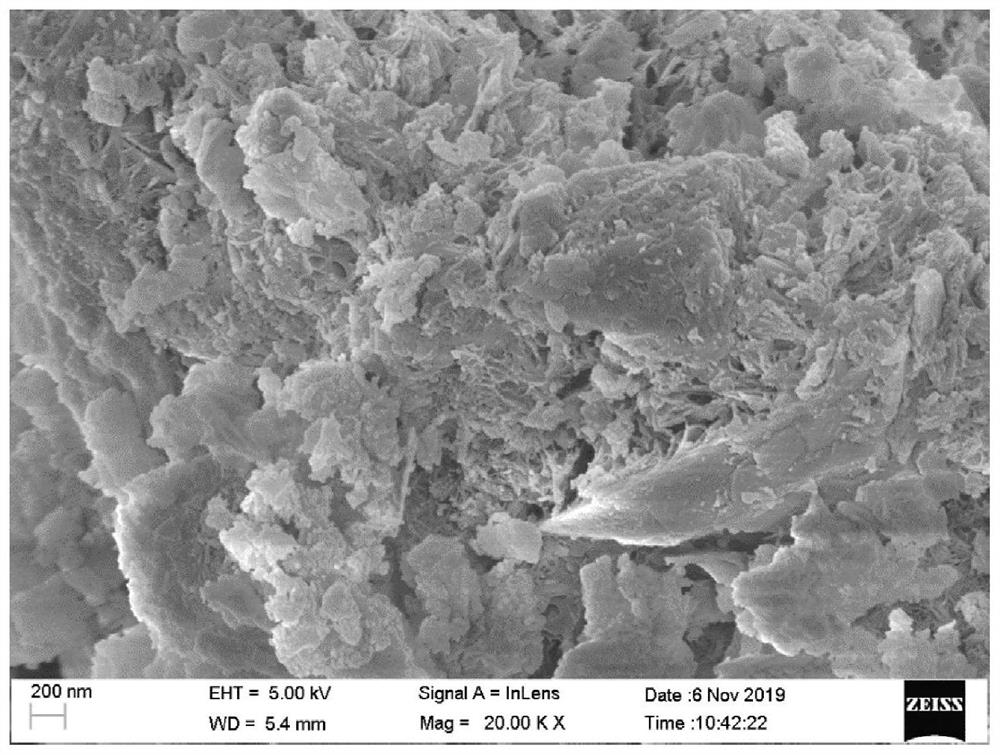

Fabrication method of soft magnetic alloy materials

ActiveCN104008844AReduce magnetic lossImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureProduction rateHigh intensity

The invention relates to a fabrication method of soft magnetic alloy materials. The fabrication method includes flattening, drying and annealing, and post-treating. The surface of soft magnetic alloy powder is provided with a metal oxide film, so that magnetic loss of the powder is reduced on the premise of not reducing magnetic conductivity of the powder and magnetic performance of the powder is improved. The fabrication method is simple, low in cost, and suitable for large-scale batch production; the soft magnetic alloy materials fabricated can meet the high requirements for high saturation flux density, high magnetic conductivity, low iron loss, high strength and high productivity.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Battery module

PendingCN106450406AExtended service lifeEnhanced shear strengthCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical batteryAdhesive

Owner:CONTEMPORARY AMPEREX TECH CO

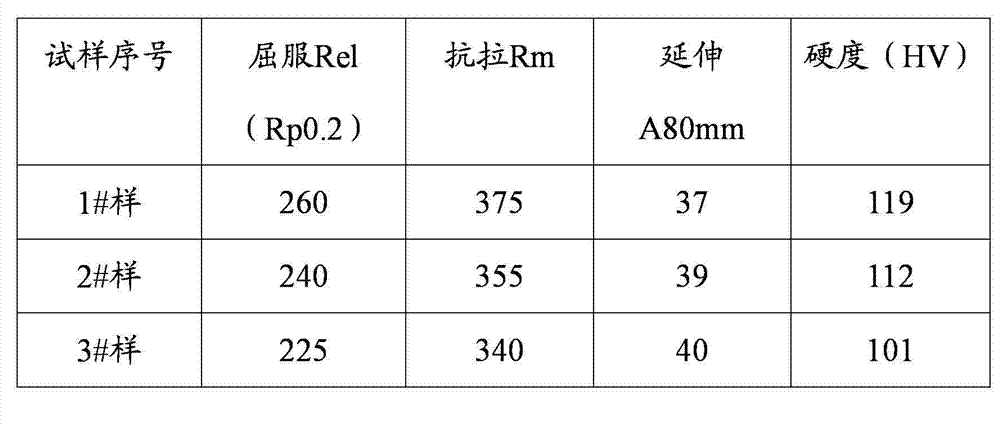

Mg alloys containing misch metal, manufacturing method of wrought mg alloys containing misch metal, and wrought mg alloys thereby

There are provided a magnesium alloy with a misch metal, a method of producing a wrought magnesium alloy with a misch metal, and a wrought magnesium alloy produced thereby, in which a great deal of misch metal is added to magnesium, and thus refractory eutectic phases or multi-phases are formed into a stable network structure or a stable dispersed phase, thereby inhibiting deformation of a magnesium matrix at a high temperature to maintain a high strength. The magnesium alloy with the misch metal has the formula of Mg100-x-y-z AxByCz , where A is zinc (Zn) or aluminum (Al); B is the misch metal; C is at least one element selected from the group consisting of manganese (Mn), nickel (Ni), copper (Cu), tin (Sn), yttrium (Y), phosphor (P), silver (Ag), and strontium (Sr); and x, y and z are the compositions of 0 at% = x =6 at%, 0.8 at% = y =7 at%, and 0 at% = z =2 at%, respectively.

Owner:GALLOY TECH

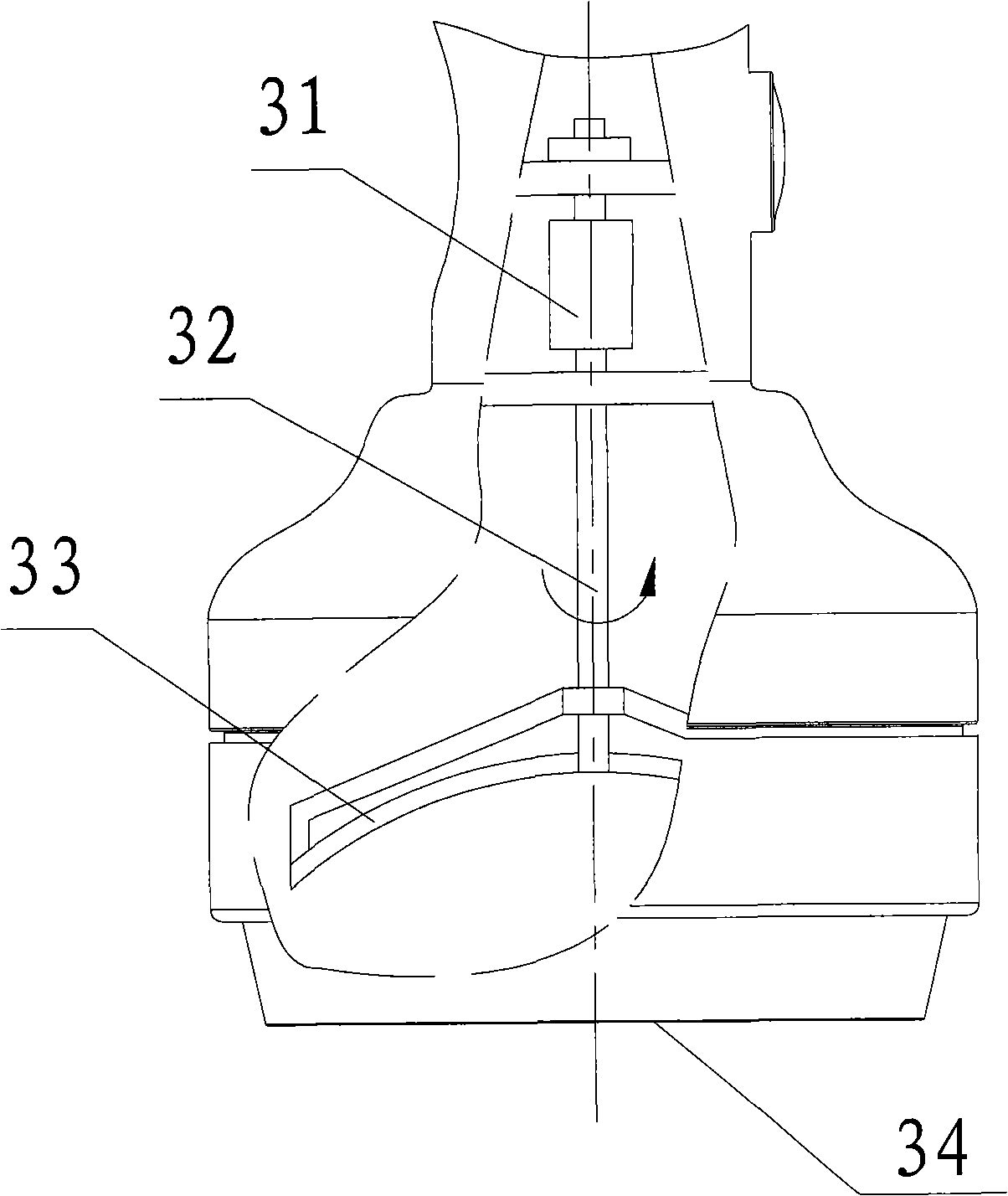

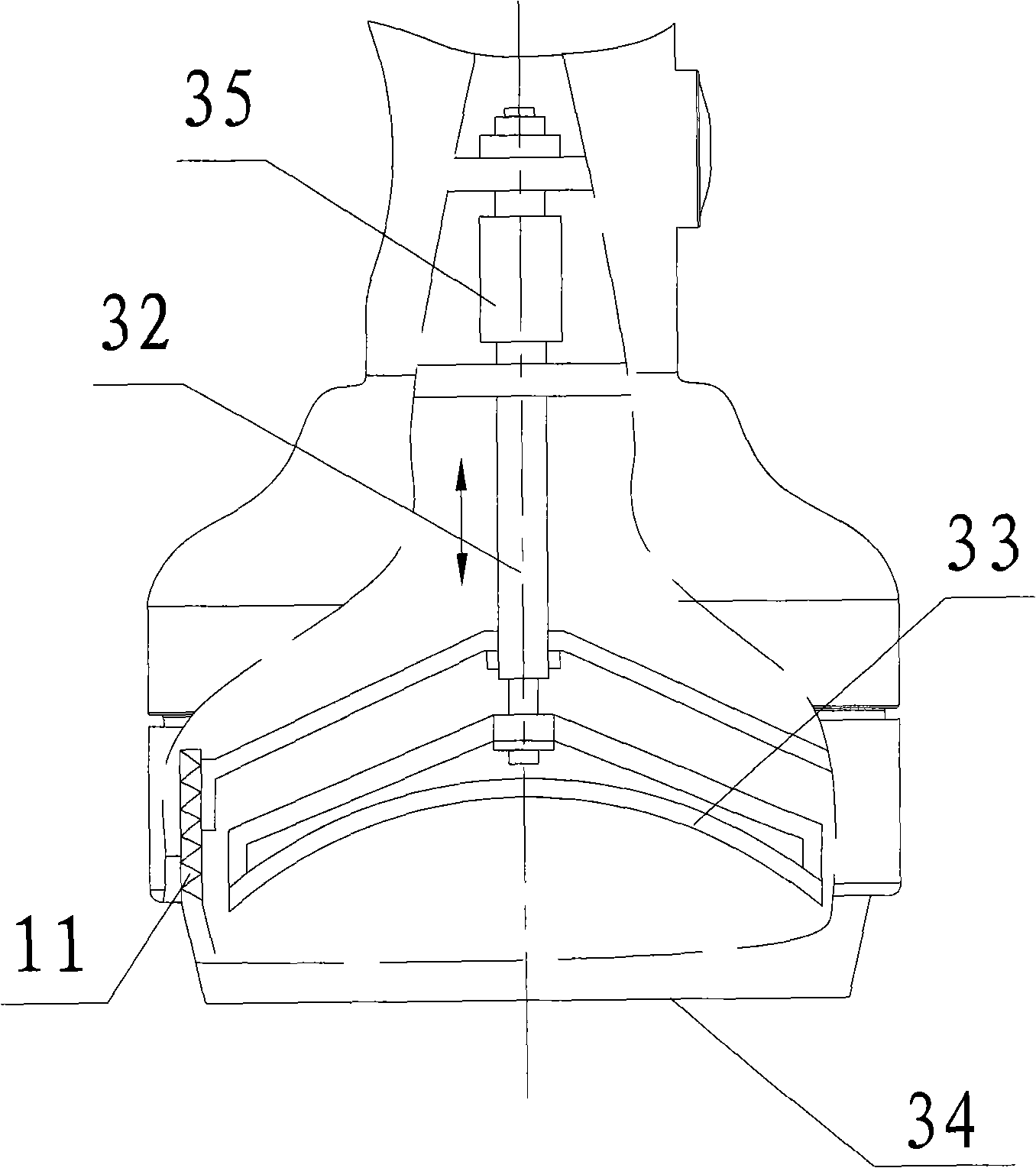

Focused ultrasonic point therapeutic equipment

InactiveCN101284163APenetratingAvoid the risk of infectionUltrasound therapyDevices for heating/cooling reflex pointsUltrasonic sensorCurative effect

The invention discloses a focused ultrasonic-wave point treatment device, comprising a host machine and a treatment gun. The treatment gun is connected with the host machine through a connecting cable; an ultrasonic transducer that can generate focused ultrasonic-waves is arranged inside the treatment gun; an acoustic-field controlling unit that leads the ultrasonic transducer to generate a non-axial symmetry acoustic field is included inside the treatment gun. The focused ultrasonic-wave point treatment device is a noninvasive treatment device, effectively increases the therapeutic safety, and achieves the same curative effect with the traditional acupuncture.

Owner:RONGHAI SUPERSONIC MEDICINE EN

Copolyester used as 3D printing material and preparation method of copolyester

ActiveCN104877118AImprove thermal stabilityGood mechanical propertiesAdditive manufacturing apparatusPolymer scienceManufactured material

The invention relates to copolyester used as a 3D printing material and a preparation method of the copolyester. The copolyester is that the raw material composition and mixing ratio design are reasonably selected; the esterification polymerizing method is adopted; the prepared copolyester is high in heat stability and outstanding in mechanical property. The copolyester material prepared by the method has the stretching strength generally exceeding 45MPa; the elongation at break is up to be about 80%; therefore, the requirements on strength and stretching of the 3D printing technology on raw materials can be effectively met; meanwhile, the direct copolymerizing reaction method is adopted to prepare the copolyester material, so that the preparation process is simple, the cost is reduced, and moreover, the problem of compatibility caused by blending can be effectively avoided.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

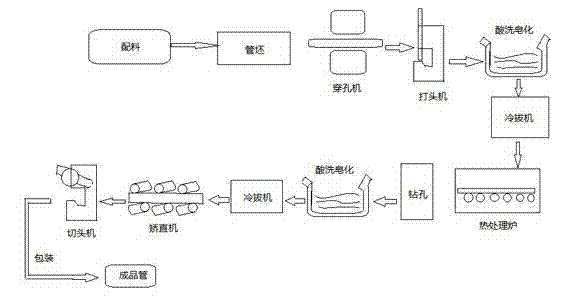

Manufacturing method of vehicle seamless steel tubes

The invention relates to a manufacturing method of vehicle seamless steel tubes. Surface quality of finished products can be improved through twice phosphorus acid saponification processing and secondary cold drawing processing; during manufacturing, external and internal quality of the products can be guaranteed through twice test, performance index of the steel tubes with the tensile strength larger than or equal to 500Mpa and extension larger then or equal to 10% and internal and external surface roughness smaller than or equal to 0.4 micrometers can be achieved by directly using saw cutting without heat treatment and mechanical machining, requirements of the steel tubes of vehicle parts on strength, toughness and surface quality are met, and meanwhile, technical requirement of processing-free steel tube parent materials of the vehicle parts can be met.

Owner:泰州双马节能科技有限公司

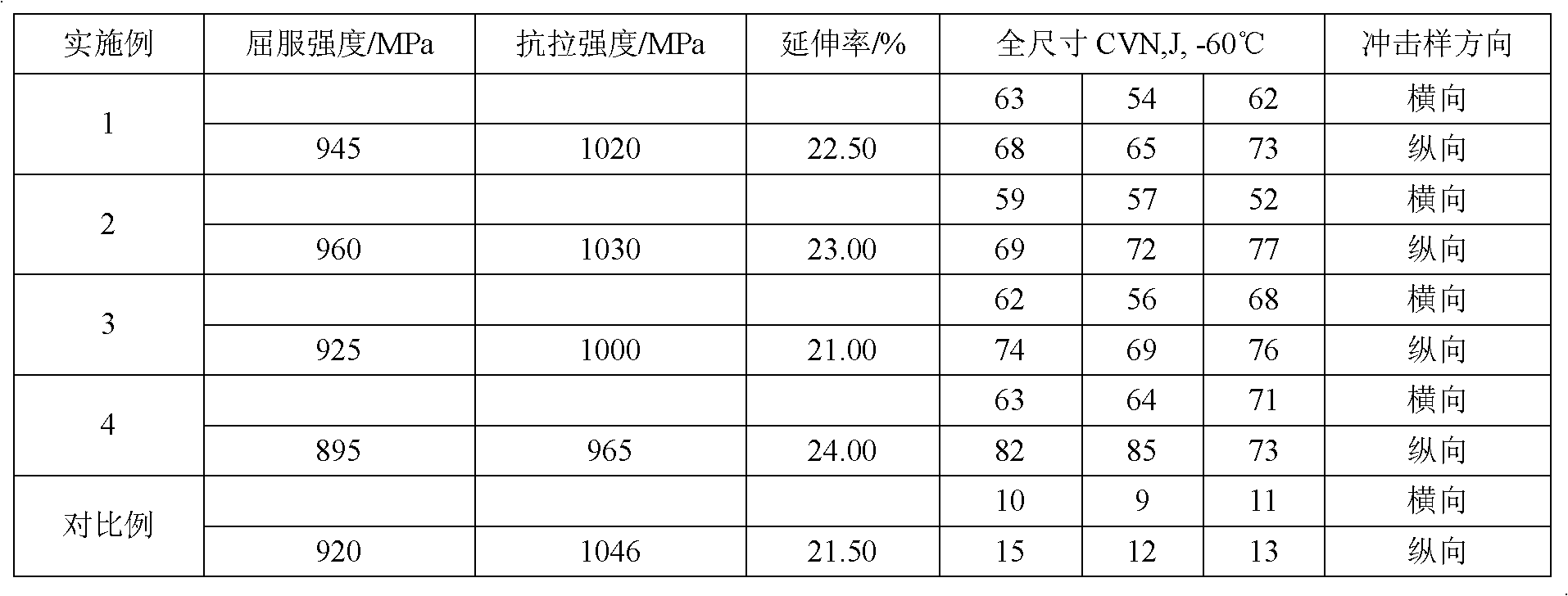

High strength seamless steel pipe with excellent low temperature toughness and manufacturing method thereof

ActiveCN103160752AImprove uniformityImprove stabilityFurnace typesHeat treatment furnacesTemperingPipe

The invention provides a high strength seamless steel pipe with excellent low temperature toughness and manufacturing method thereof. The steel pipe comprises 0.15%-0.20% of C, 0.20%-0.30% of Si, 0.2%-0.5% of Mn, no more than 0.010% of P, no more than 0.003% of S, 0.6%-0.8% of Cr, 0.4%-0.7% of Mo, 1.0%-1.4% of Ni, 0.01%-0.035% of Nb, 0.01-0.05% of Als and the balance of Fe. The method comprises steps of: (1) smelting: pretreated molten iron with sulfur no more than 0.005%; and after smelting: P<=0.010%, S<=0.003%, O<=0.002%, N<=0.006% and H<=0.0002%; (2) manufacturing of round billet: degree of superheat of continuous casting superheat of square billet less than 30 DEG C, casting speed fluctuation less than 0.05m / min, straightening temperature higher than 950 DEG C and square billet heating temperature of 1300-1340DEG C; (3) steel pipe molding: billet heating temperature of 1250-1300 DEG C, piercing temperature higher than 1200 DEG C, continuous rolling temperature higher than 1050 DEG C, and sizing and reducing temperature higher than 800DEG C; and (4) heat treatment: quenching temperature of 900-920 DEG C, tempering temperature of 500-600 DEG C and tempering time longer than 60 min. The product provided by the invention has yield strength of 125ksi, and -60DEG C impact energy greater than 40J.

Owner:ANGANG STEEL CO LTD

Welding method for Q460 high-strength steel tube of extra-high-voltage power transmission steel tube tower

ActiveCN102886593AReduced tendency to cold crackingGuarantee welding qualityArc welding apparatusTubular articlesSheet steelAlloy

The invention relates to a welding method for the Q460 high-strength steel tube of an extra-high-voltage power transmission steel tube tower, and the welding method comprises the following steps of: using a low-alloy high-strength steel plate having a yield strength of 460 MPa level, grinding the both sides of the low-alloy high-strength steel plate into single-surface grooves, bending the low-alloy high-strength steel plate into a primarily-formed steel tube with longitudinal slits, performing backing welding on welding joints, welding by means of CO2 gas shielded welding, and using JM68 welding wires; and continuously welding by means of submerged arc automatic welding during filling and covering, using CHW-S9 submerged arc welding wires, and using an SJ101 flux. According to the invention, aiming problems in welding for the Q460 high-strength steel tube, the CO2 gas shielded welding is combined with selection for the JM68 welding wires and reasonable welding parameters, and the CO2 gas shielded welding is combined with welding using the CHW-S9 welding wires and the SJ101 flux, thus improving the toughness and the quality of the welding joints, and increasing production efficiency and promoting the large-scale production simultaneously.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

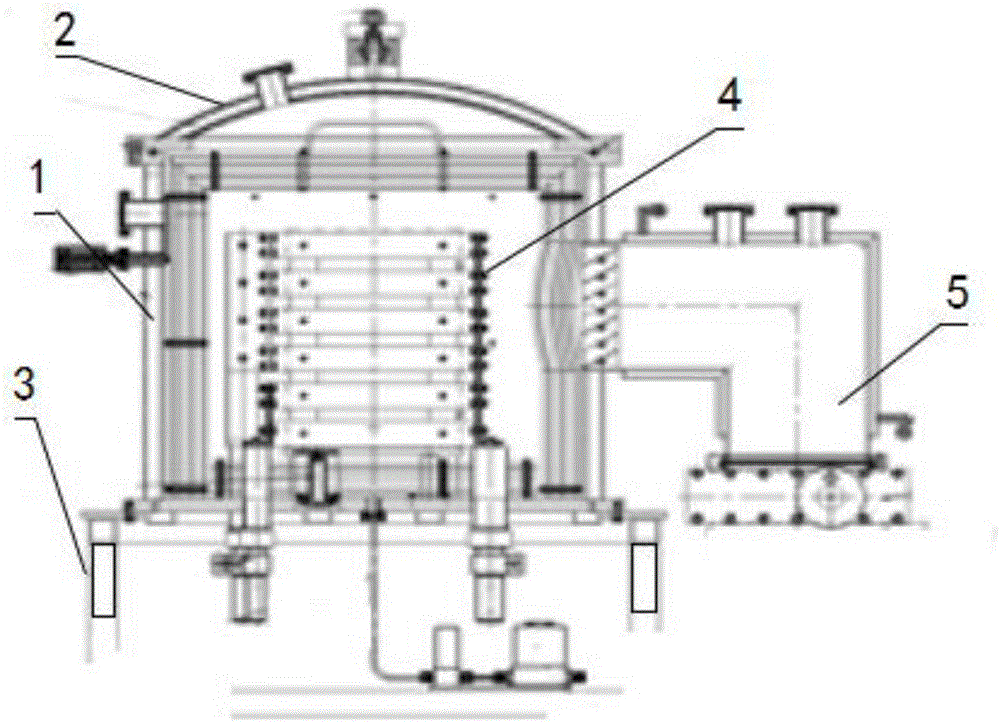

Selective laser melting material additive manufacturing IN718 component, system, and heat treatment method and device

ActiveCN106180719AReduce residual stressCorrosiveAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAlloy

The invention relates to a selective laser melting material additive manufacturing IN718 component, a system, and a heat treatment method and device. According to the IN718 component, during selective laser melting molding, the laser power ranges from 275 W to 800 W, the spot diameter ranges from 0.1 mm to 0.2 mm, the scanning speed ranges from 900 mm / s to 1400 mm / s, and the thickness of a powder laying layer ranges from 0.04 mm to 0.08 mm; the heat treatment method comprises the steps that the molded IN718 component is placed in a vacuum heat treatment furnace to be subject to vacuum annealing heat treatment. The heat treatment device comprises the vacuum heat treatment furnace. The system for the selective laser melting material additive manufacturing IN718 component comprises a 3D printer and further comprises the vacuum heat treatment furnace arranged behind the working procedure of the 3D printer. According to the system and the heat treatment method and device, residual stress generated in the printing process of the IN718 alloy component can be removed, a structure is obviously homogenized, corrosion resistance, toughness and the like are well improved, and the requirement of aerospace products for the IN718 alloy structural component can be met.

Owner:飞而康快速制造科技有限责任公司

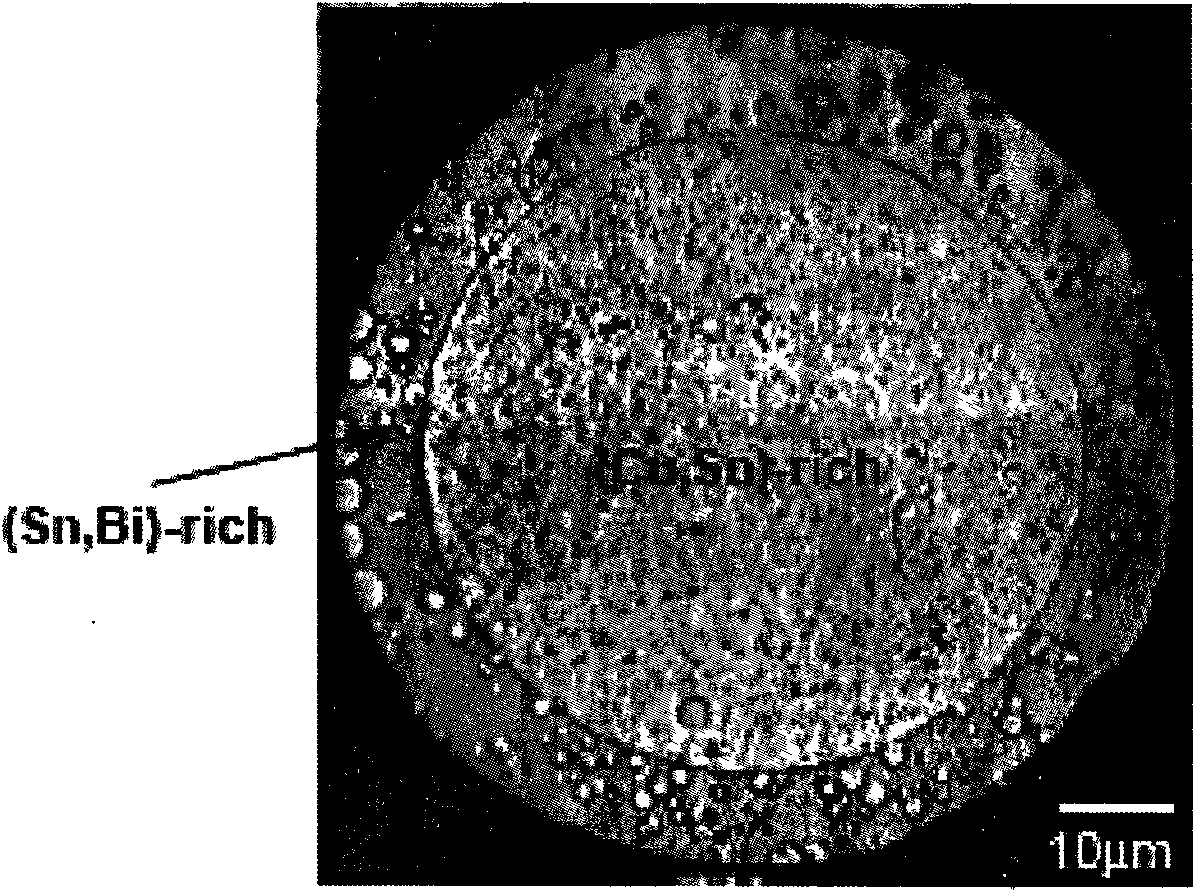

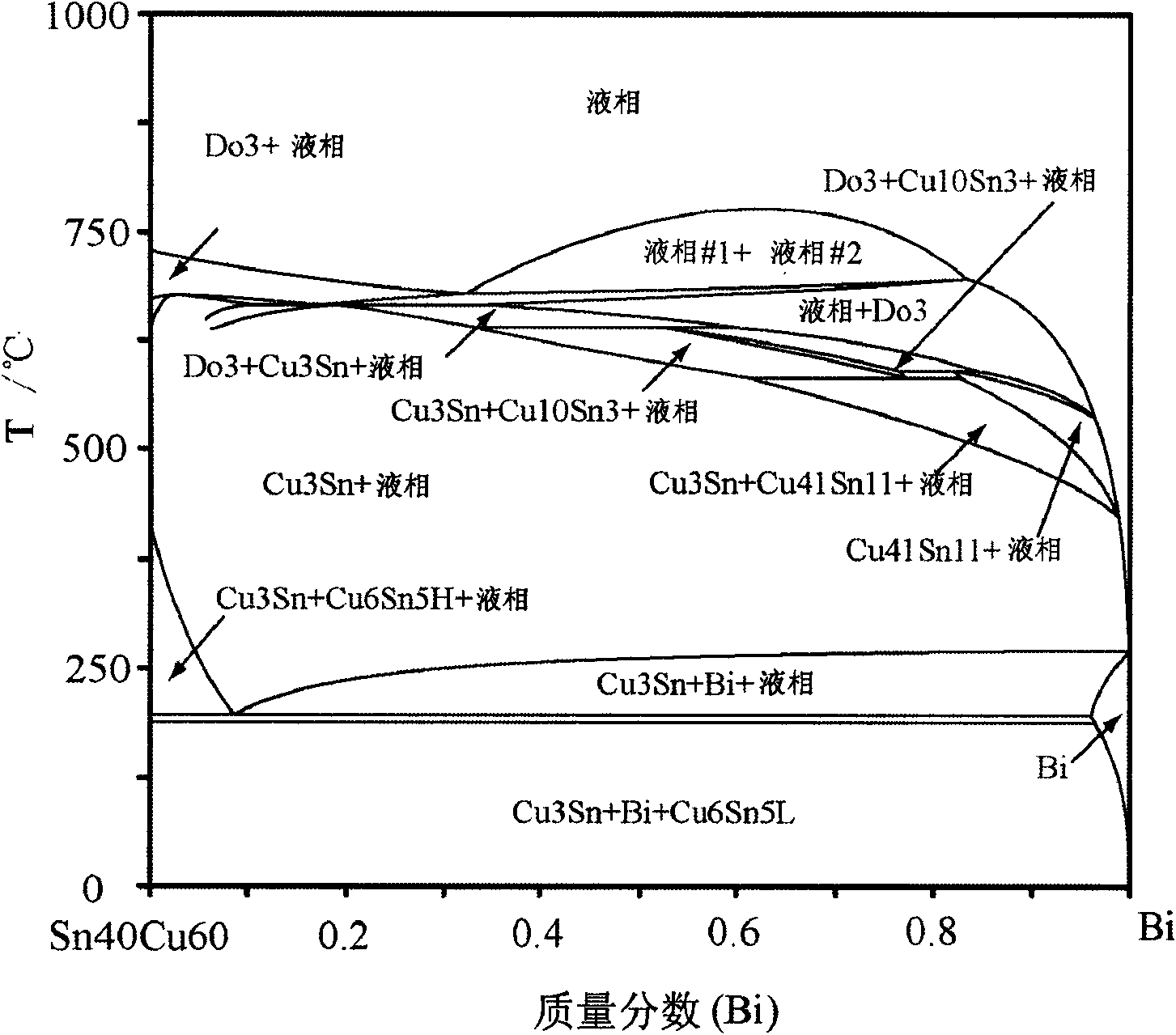

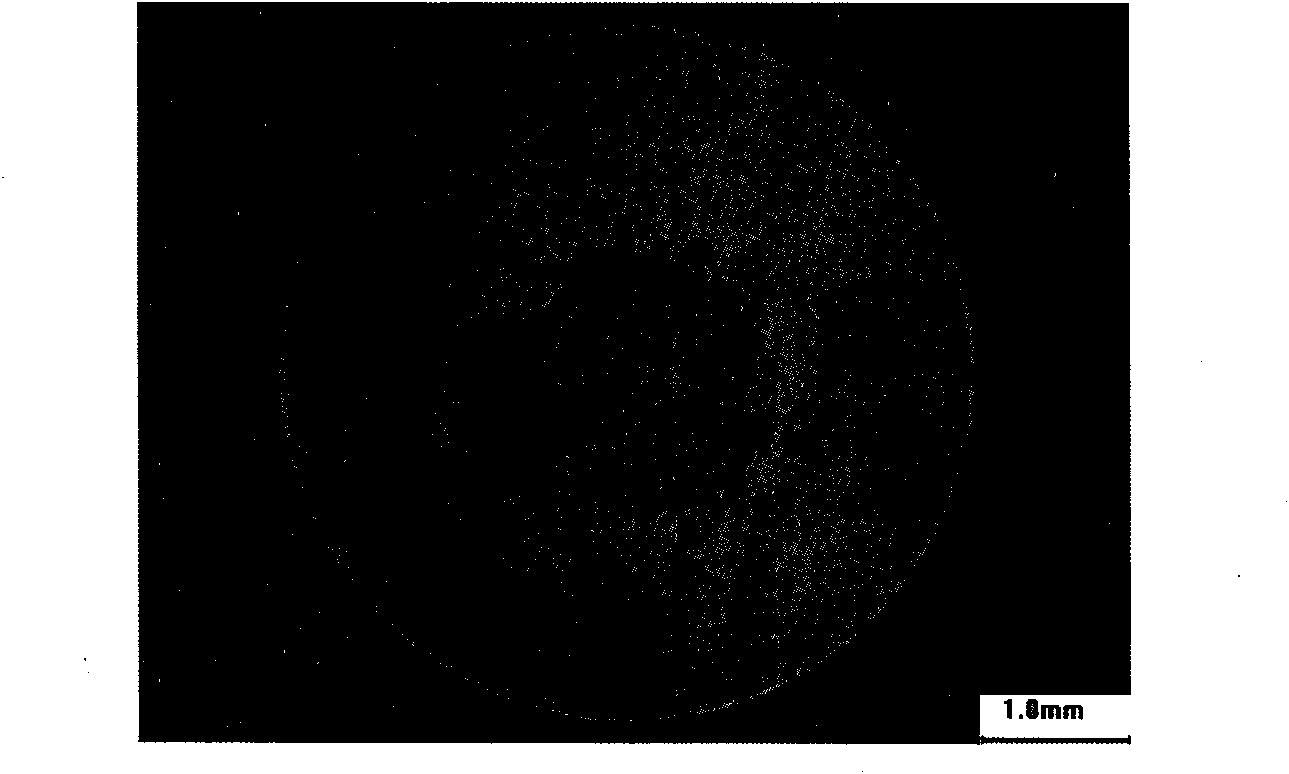

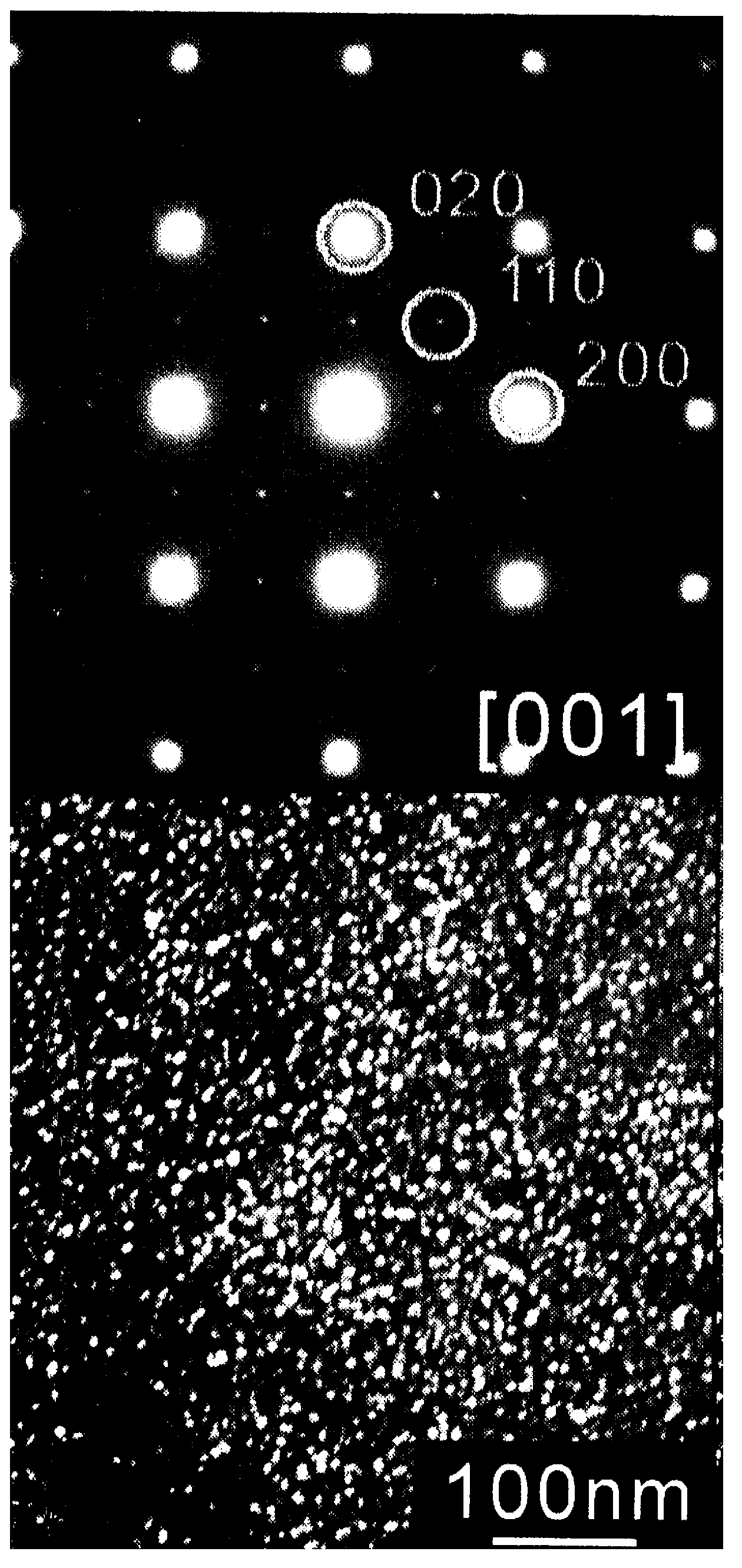

Nuclear shell structure Pb-free solder ball for electronic packaging and preparation method thereof

InactiveCN101642858AIncreasing the interfacial tension gradientEnhanced convectionWelding/cutting media/materialsSoldering mediaChemical compositionRare earth

The invention relates to a nuclear shell structure Pb-free solder ball for electronic packaging and a preparation method thereof, belonging to the technical field of Sn-based Pb-free brazing alloy. The solder ball contains the following chemical components by mass percent: 47-68% of Bi, 19-32% of Cu, 13-21% of Sn and 0.01-1% of rare earth metal. The diameter of the solder ball is 0.10-0.76mm. Thesolder ball has a nuclear shell structure, the nuclear core is a Cu-rich phase, and a layer of Sn-Bi-rich alloy is evenly coated on the shell. The Pb-free solder ball of the nuclear shell structure can be applied to BGA packaging. Peripheral low-melting point SnBi alloy mainly plays a role of connecting components in jointing, while internal high-conductivity Cu-based alloy plays a role of circuitconnection, which can meet the demands of high connection strength, high conductivity and high heat conductivity of electronic packaging.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Copper alloy and method for producing copper alloy

ActiveCN103328665AImprove conductivityHigh strengthConductive materialMetal/alloy conductorsMetallurgyMaterials science

Provided is a copper alloy with an FCC structure, said copper alloy containing 3.0 to 29.5 mass% of Ni, 0.5 to 7.0 mass% of Al, and 0.1 to 1.5 mass% of Si, with the remainder comprising Cu and unavoidable impurities. By precipitating, at an average particle size of not more than 100 nm, an Si-containing L12-structured Gamma' phase in the parent phase of the copper alloy, the copper alloy is provided with excellent processability even at high temperatures, and is highly conductive. Furthermore, these characteristics can be controlled.

Owner:NIPPON SEISEN CO LTD +1

Steel strip for LED bracket and manufacturing method thereof

The invention provides a steel strip for an LED bracket and a manufacturing method thereof. The steel strip comprises the following chemical compositions by mass percent: 0.03%<=C<=0.07%, 0.01%<=Si<=0.03%, 0.2%<=Mn<=0.3%, 0%<P<0.02%, 0%<S<0.02%, 0.01%<=Al<=0.035% and the balance of Fe, as well as a trace of inevitable impurities. Repeated tests and trials show that the LED steel strip completely satisfies the quality requirements on the strength, the rigidity and the extensibility, which ensure that the LED bracket is free from cracks after being punched and bent for 6 times, and at present, the LED steel strip gains popularity of customers; and as the LED new material cold-rolled strip has a very wide development prospect, the popularization and application values are extremely high and the prospect is very wide.

Owner:浙江龙盛薄板有限公司

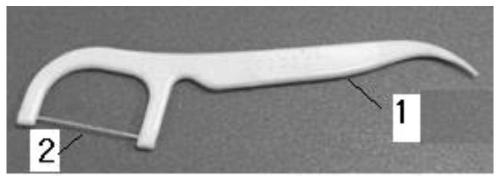

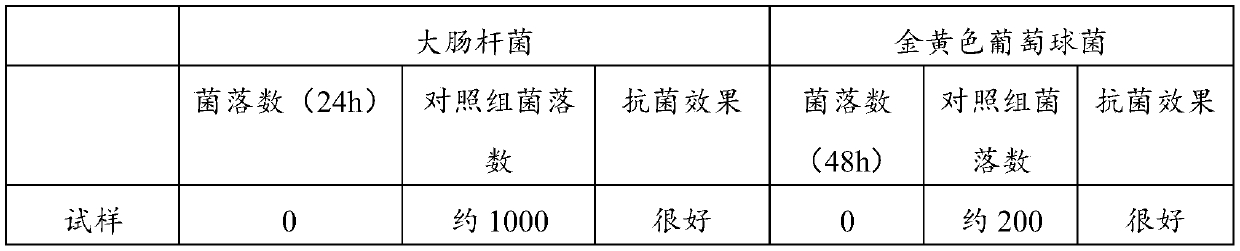

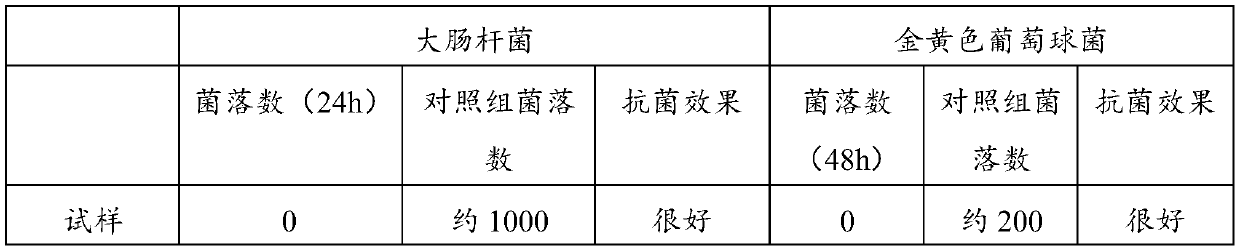

Full-biodegradable dental floss pick handle and preparation method thereof

The invention provides a full-biodegradable dental floss pick handle and a preparation method thereof. The handle is prepared through extrusion and injection molding from the following materials: 60-90 parts of polyglycolic acid, 5-30 parts of a toughening agent, 0.1-5 parts of a nucleating agent, 0.1-2 parts of a lubricant, 0.1-1 part of a compatilizer, and 0.1-3 parts of an antibacterial agent,wherein the toughening agent is at least one of poly(butylene adipate-co-terephthalate), poly(butylene succinate), polycaprolactone, polyhydroxyalkanoate, polypropylene carbonate, an acrylate degradable polymer and a maleic anhydride grafted degradable polymer, the nucleating agent is at least one of a sorbitol nucleating agent, a rosin nucleating agent, an organic phosphate nucleating agent and an inorganic nucleating agent, and the compatilizer is at least one of a silane coupling agent, an aluminate substance and a titanate substance. The handle meets the use requirements of the dental floss pick and can be fully biodegraded.

Owner:中科信晖(海南)新材料科技有限公司 +1

High-strength and high-elasticity-modulus casting Mg-RE alloy and preparation method thereof

The invention discloses a high-strength and high-elasticity-modulus casting Mg-RE alloy and a preparation method thereof. The casting Mg-RE alloy comprises 8-14wt% of Gd, 2-6wt% of Y, 1-5wt% of Zn, 0.5-2.5wt% of Si, 0.4-1wt% of Zr, the impurity elements of Fe, Cu and Ni and the balance of Mg, wherein the total content of the impurity elements of Fe, Cu and Ni is smaller than 0.02wt%. The preparation method includes the steps of smelting and heat treatment. According to the preparation method, Si is added and reacts with Mg and RE in an MG alloy to generate a high-elasticity-modulus Si-containing phase, meanwhile, Zn is added and reacts with Mg and RE in the Mg alloy to generate a stable eutectic phase, in this way, the crystallization range of an alloy melt is reduced, melt fluidity is improved, and accordingly through the following corresponding heat treatment process, the alloy has high room-temperature strength and elasticity modulus.

Owner:SHANGHAI JIAO TONG UNIV

Beta titanium alloy for fastener and manufacturing method

The invention discloses a Beta titanium alloy used for a fastener. The Beta titanium alloy comprises the following components, in weight percentage: molybdenum: 4 to 7 percent, niobium: 4 to 6.5 percent, chromium: 3 to 5 percent, tantalum: 1 to 3 percent, aluminum: 2 to 4 percent, iron: 1.0 percent or less, carbon: 0.1 percent or less, nitrogen: 0.05 percent or less, hydrogen: 0.015 percent or less, oxygen: 0.02 percent or less, balance titanium. A preparation method thereof is characterized in that after sponge titanium, pure aluminum, pure chromium, Ti-0.31Mo, Ti-0.53Nb and Al-0.80Ta are mixed and pressed with a pressing machine into block-shaped electrodes; a plurality of electrodes are welded with an ion welding machine into a long strip-shaped electrode which is taken as a consumable electrode and melted in a vacuum consumable arc furnace, the obtained casting ingot is again taken as the consumable electrode and melted for 2 to 3 times to acquire the product titanium alloy ingot. The invention has the advantages that the intensity is high, the low-cost large-scale production can be realized, the intensity requirements can be satisfied, the processing and modeling are easy, and the energy consumption is reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

5083 aluminum alloy plate for high-speed rail and production method thereof

The invention discloses a 5083 aluminum alloy plate for a high-speed rail and a production method thereof. The 5083 aluminum alloy plate for the high-speed rail is prepared from the following raw materials in percentage by weight: 0.20-0.30% of Si, 0.20-0.30% of Fe, 0.03-0.07% of Cu, 0.45-0.60% of Mn, 5.0-5.3% of Mg, 0.10-0.20% of Cr, 0.015-0.03% of Ti, 0-0.10% of Zn, and the balance of Al. The production method comprises the steps of preparing the raw materials, smelting, casting, sawing off the head, milling the surface, soaking, hot rough rolling, hot finishing, cold rolling, bending and straightening, annealing and slicing up. The method disclosed by the invention can be utilized to improve the fatigue strength, the tensile strength, the ductility and other properties of the 5083 aluminum alloy plate, so that the operating requirements on the 5083 aluminum alloy plate for the high-speed rail can be completely met.

Owner:郑州明泰交通新材料有限公司

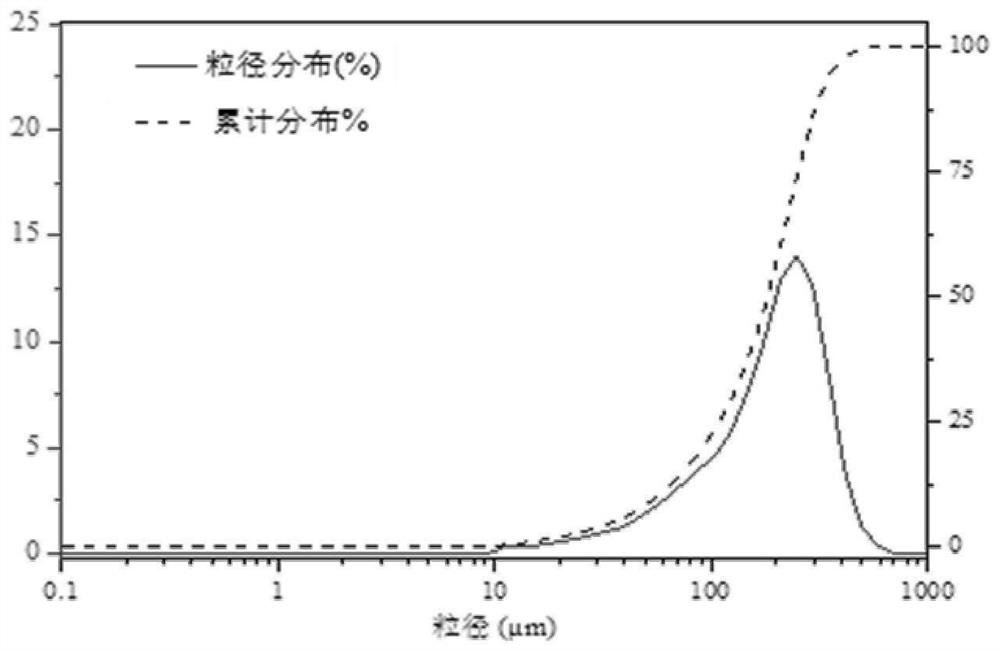

Tailing-based cementing material and preparation method thereof

ActiveCN111847924AWide variety of sourcesLarge reservesCement productionPregnant leach solutionCompressive resistance

The invention discloses a tailing-based cementing material and a preparation method thereof. The method comprises the following steps: drying a tailing raw material, and sequentially carrying out mechanical ball-milling activation treatment, thermal activation treatment and chemical agent activation treatment to obtain the tailing-based cementing material. According to the method, tailings are activated through a mechanical activation, thermal activation and chemical activation combined excitation method, the potential volcanic ash activity is utilized, the cementing material with better cementing performance is obtained, the maximum compressive strength of the solidified gel material can reach 10 MPa, the solidified gel material completely meets the underground filling technology, the solidified leachate meets the surface water quality IV type water standard, the method is simple in tailing treatment process, safe and free of pollution, and a brand-new thought can be provided for comprehensive utilization and resourceful treatment of tailings.

Owner:WUHAN UNIV

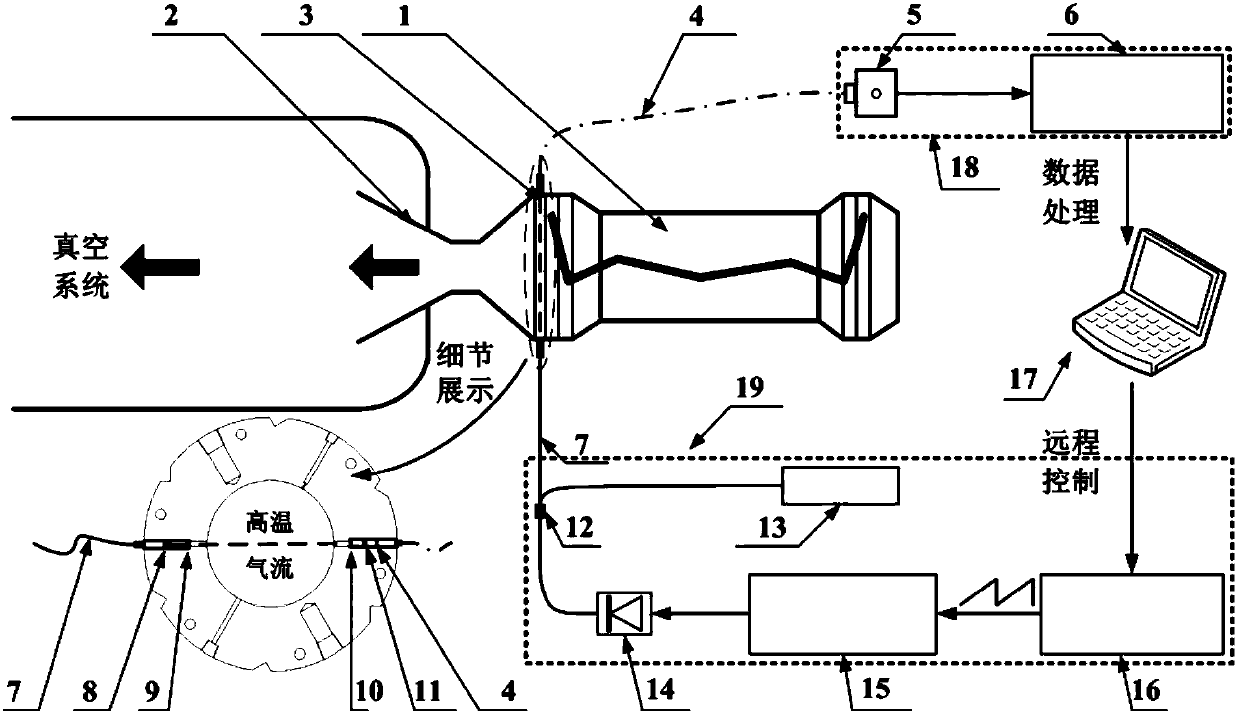

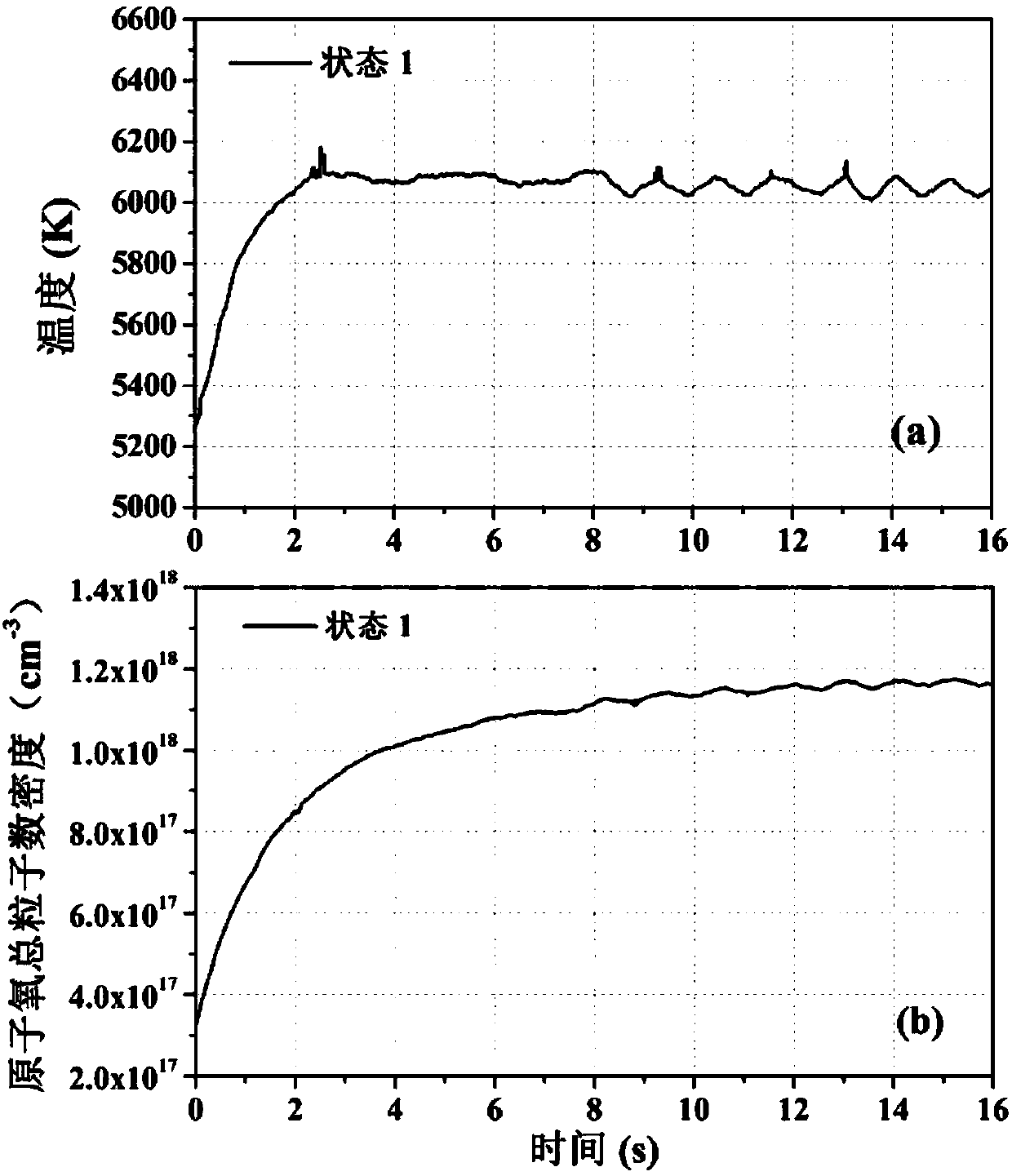

Laminated arc heater high-enthalpy airflow parameter diagnosis system

ActiveCN107907502ASolve difficult to applySolve the problem of plasma high temperature flow field diagnosisColor/spectral properties measurementsEngineeringOxygen

A laminated arc heater high-enthalpy airflow parameter diagnosis system is used for obtaining the airflow parameters (particle number density and static temperature) of a high temperature flow field in the ground heat protection test of an arc heater, and online diagnosing high temperature disassociated air test airflow in the arc heater by using an atom O (777.19 nm) spectral line to obtain the plasma airflow temperature and the atom oxygen particle number density in the arc heater. The system can be used as a routine way for the arc heater high-enthalpy airflow parameter diagnosis.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

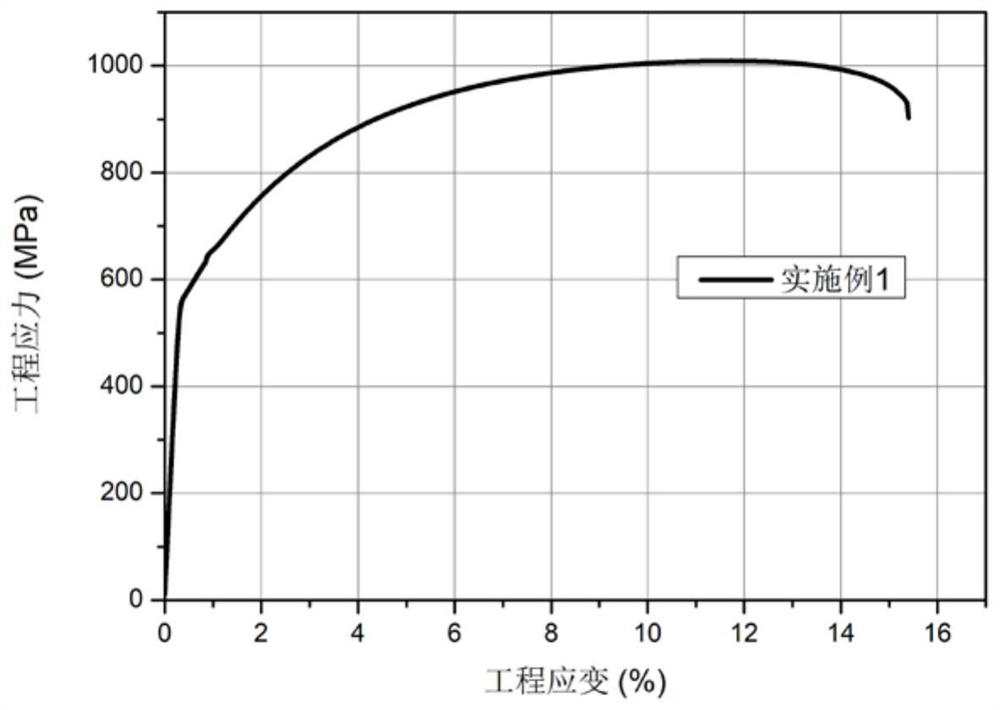

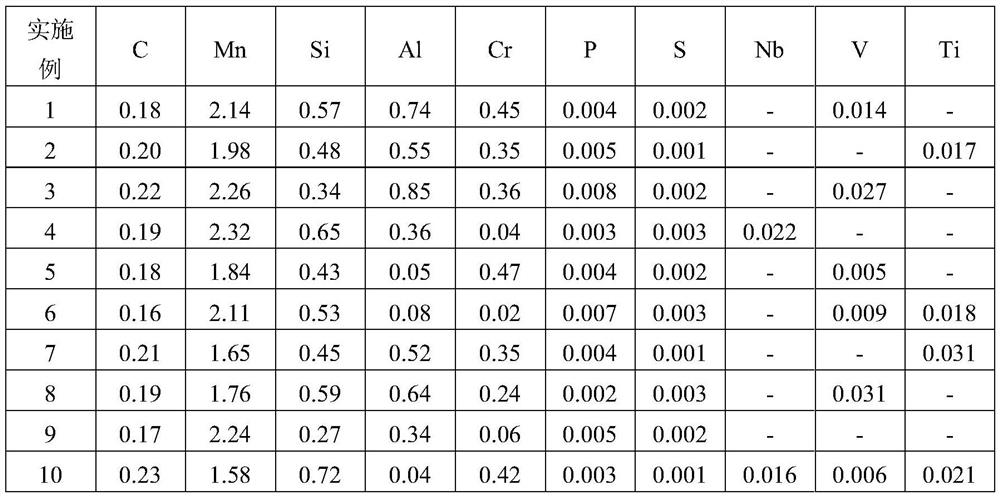

Alloyed hot-dip galvanized DH980 steel and preparation method thereof

ActiveCN112048680AReduce original costRealize industrial productionHot-dipping/immersion processesUltimate tensile strengthFatigue limit

The invention discloses alloyed hot-dip galvanized DH980 steel and a preparation method thereof. The steel comprises 0.16 %-0.23 % of C, 1.5 %-2.5 % of Mn, 0.2 %-0.9 % of Si, 0.02 %-0.9 % of Al, 0.02%-0.70 % of Cr, less than or equal to 0.01 % of P, less than or equal to 0.01 % of S, less than or equal to 0.05 % of Nb, less than or equal to 0.05 % of V, less than or equal to 0.05 % of Ti, and thebalance iron and inevitable impurities, wherein the proportion of (Si+Al) is 0.6 %-1.5 %. The heating temperature of a casting blank is 1150-1300 DEG C, the initial rolling temperature is 1000-1150 DEG C, the final rolling temperature is greater than or equal to 880 DEG C, and the coiling temperature is 500-700 DEG C; the cold rolling reduction rate is 40 %-80 %; and the annealing temperature is760-880 DEG C, the annealing time is 30-300 s, the galvanizing temperature is 450-470 DEG C, the alloying temperature is 470-530 DEG C, and the alloying heat preservation time is 5-60 s. According tothe steel and the method, the tensile strength of a finished steel sheet is 980-1100 MPa, and the high-cycle fatigue ultimate strength is larger than or equal to 370 MPa; and the reaming performance is excellent.

Owner:ANGANG STEEL CO LTD

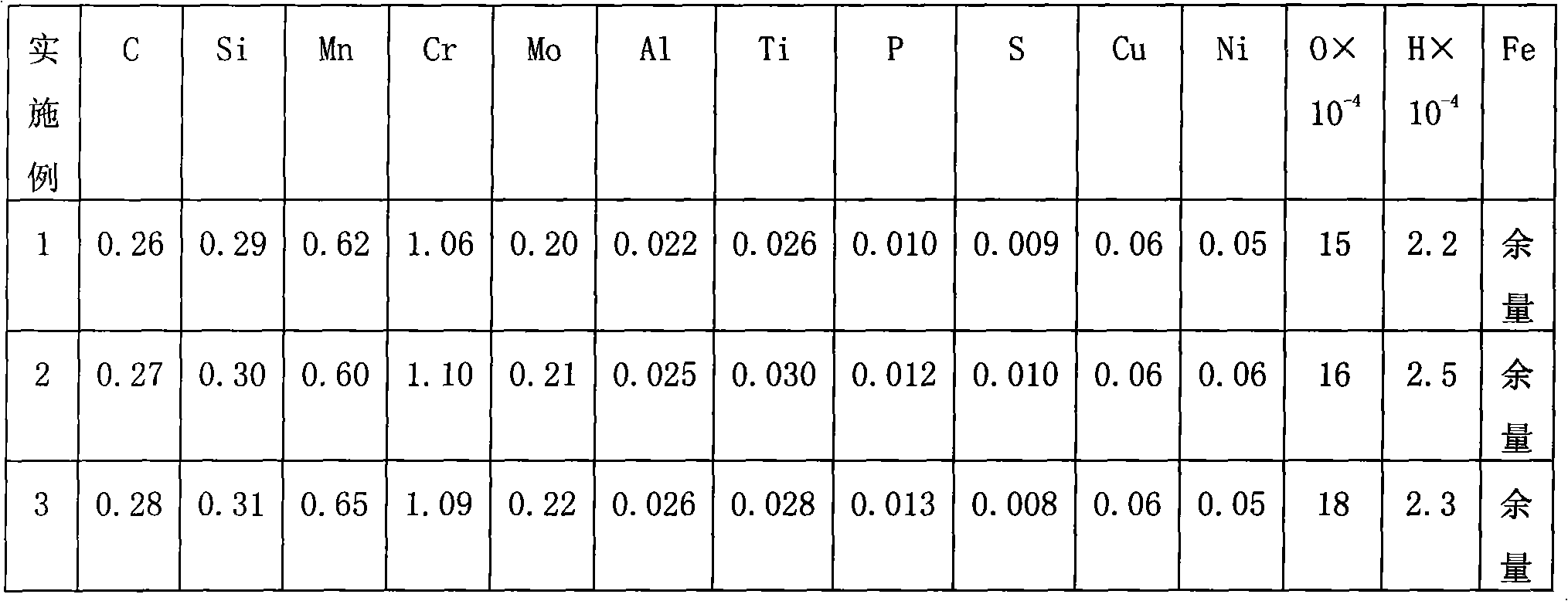

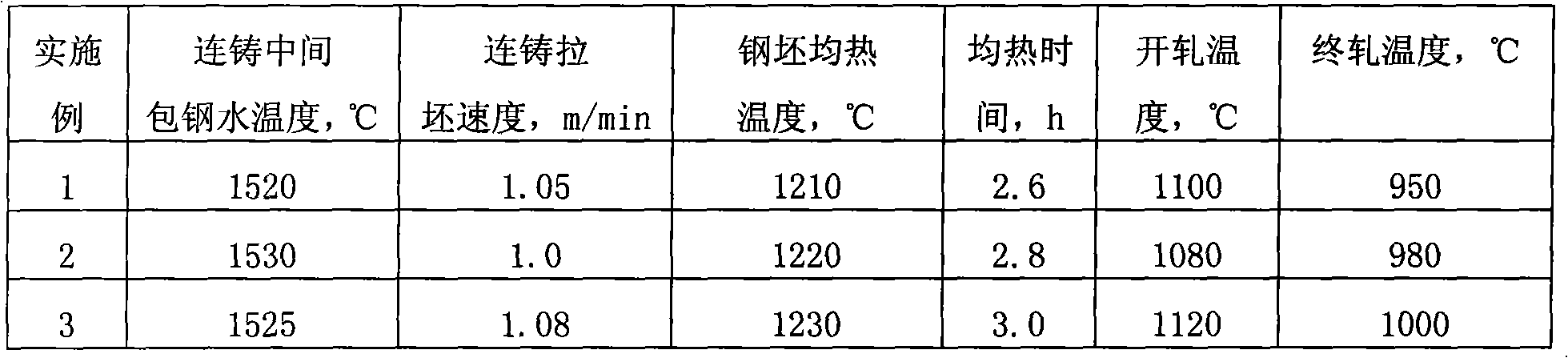

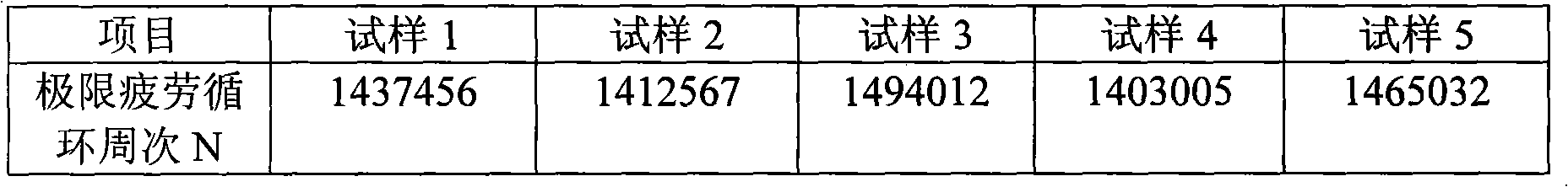

Multi-element alloyed ultrahigh-strength sucker rod steel and manufacturing method thereof

ActiveCN101962737AHigh strengthImprove performanceDrilling rodsDrilling casingsUltimate tensile strengthImpurity

The invention relates to a multi-element alloyed ultrahigh-strength sucker rod steel and a manufacturing method thereof. The sucker rod steel comprises the following components in percentage by weight: 0.25 to 0.29 percent of C, 0.17 to 0.37 percent of Si, 0.50 to 0.70 percent of Mn, 0.95 to 1.20 percent of Cr, 0.18 to 0.25 percent of Mo, 0.005 to 0.025 percent of P, 0.001 to 0.025 percent of S, 0.015 to 0.050 percent of Al, 0.015 to 0.050 percent of Ti, less than or equal to 20ppm of [O], less than or equal to 3ppm of [H], and the balance of Fe and inevitable impurities. The steel has excellent comprehensive performance and long fatigue life, and is suitable for oil recovery operation of heavy and overload oil wells.

Owner:SHANDONG IRON & STEEL CO LTD

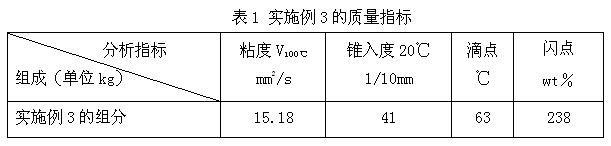

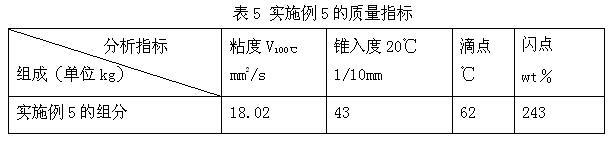

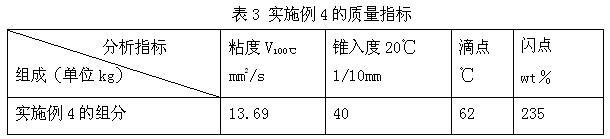

Integrated oil phase for emulsion explosive and preparation method thereof

InactiveCN102079681AGuaranteed emulsifying effectGuaranteed emulsification stabilityNon-explosive/non-thermic compositionsParaffin waxMicrocrystalline wax

The invention discloses an integrated oil phase for emulsion explosive and a preparation method thereof. The integrated oil phase for the emulsion explosive comprises the following components in part by mass: 10 to 18 parts of paraffin, 1 to 6 parts of microcrystalline wax, 45 to 65 parts of cerate and 25 to 35 parts of complex additive. The preparation method for the integrated oil phase for the emulsion explosive comprises the following steps of: preparing the components; adding the paraffin and the microcrystalline wax into an adjustable dehydrator, and heating for melting; adding the cerate, and fully stirring until the components are mixed and dissolved; raising the temperature for dehydration, and reducing the temperature; adding the complex additive, and stirring at a high speed until the components are mixed and dissolved; and filtering, discharging, cooling, forming and packaging. The integrated oil phase for the emulsion explosive integrates various components, has generality, and easily operates and controls the quality of the emulsion explosive, and can ensure the emulsifying property and emulsion stability in the production process of the emulsion explosive; the raw materials are easily obtained, low in cost and convenient to use; and the preparation method provides favorable guarantee for popularization and promotion in the industry.

Owner:GUANGDONG SUNION CHEM & PLASTIC

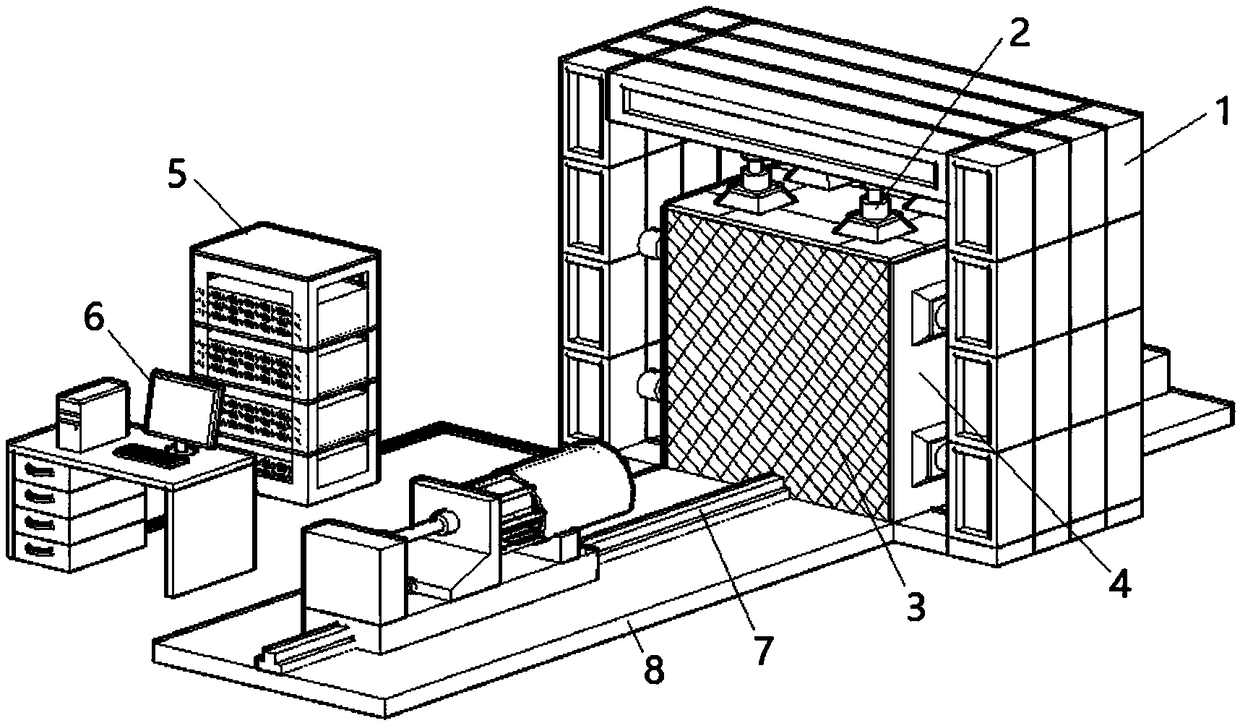

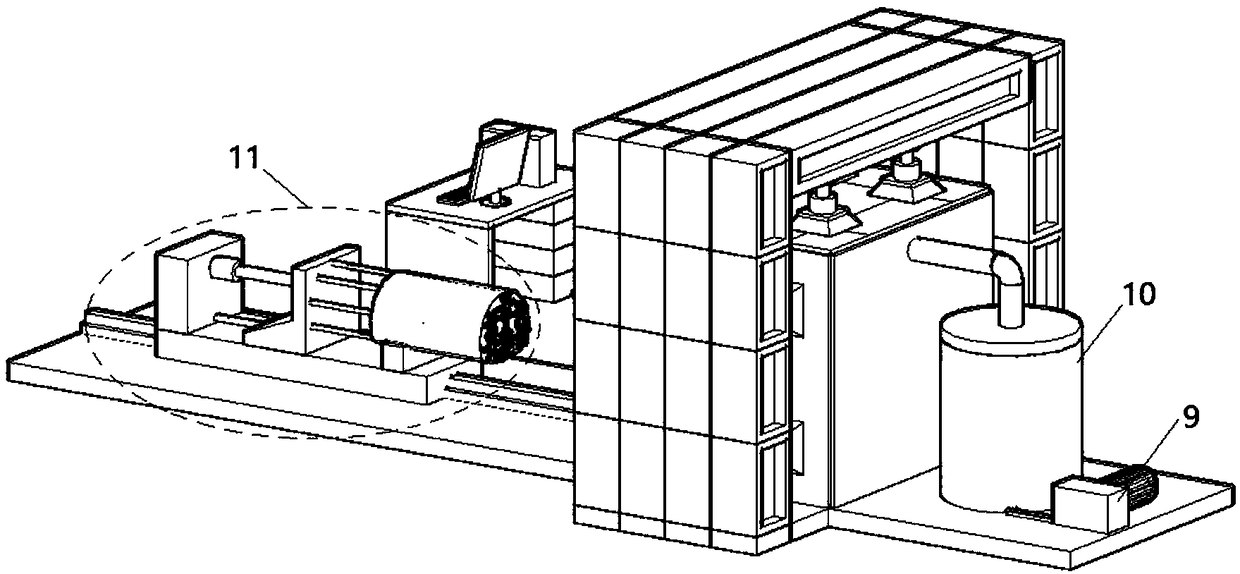

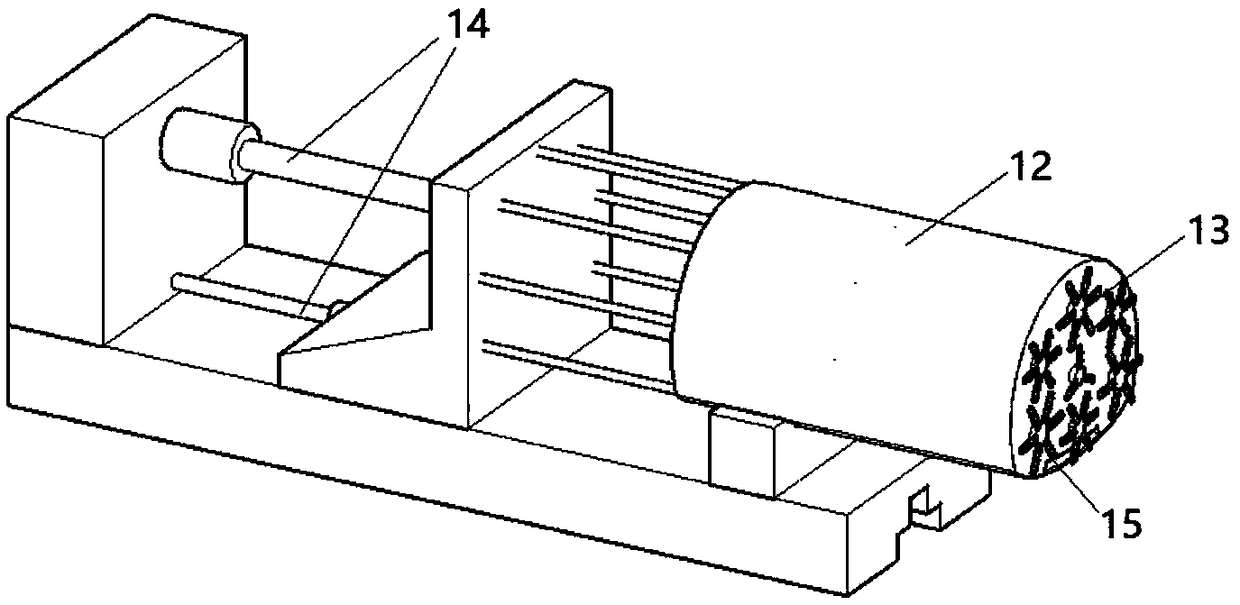

Block fracture rock mass excavation disturbance and digging machine shield stress monitoring model test system and method

InactiveCN108225929AEasy to cutMeet the intensityMaterial strength using tensile/compressive forcesThermometers using physical/chemical changesGeophysicsRock breaking

The invention discloses a block fracture rock mass excavation disturbance and digging machine shield stress monitoring model test system and method. The method comprises the following steps: a fractured rock mass is prefabricated by adopting a mold, and moreover, a cutter is used for carrying out cutting to produce needed fractures; a hydraulic loading system adopts a model test bed as a counterforce structure to apply pressure on the fractured rock mass and simulate real stress; a water pressure simulation system adds water into the fractured rock mass and realizes the influence of underground water on the destabilization process of the fractured rock mass; a digging excavation system pushes jacks under the control of a motor to control a cutterhead to carry out rock breaking and diggingon a part to be excavated; a monitoring system monitors the change of a stress field of the fractured rock mass in the process of digging excavation; and moreover, monitoring elements are arranged onthe surface of a digging machine shield to monitor the stress of the shield in the process of digging.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com