Patents

Literature

2906results about How to "Improve fatigue strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

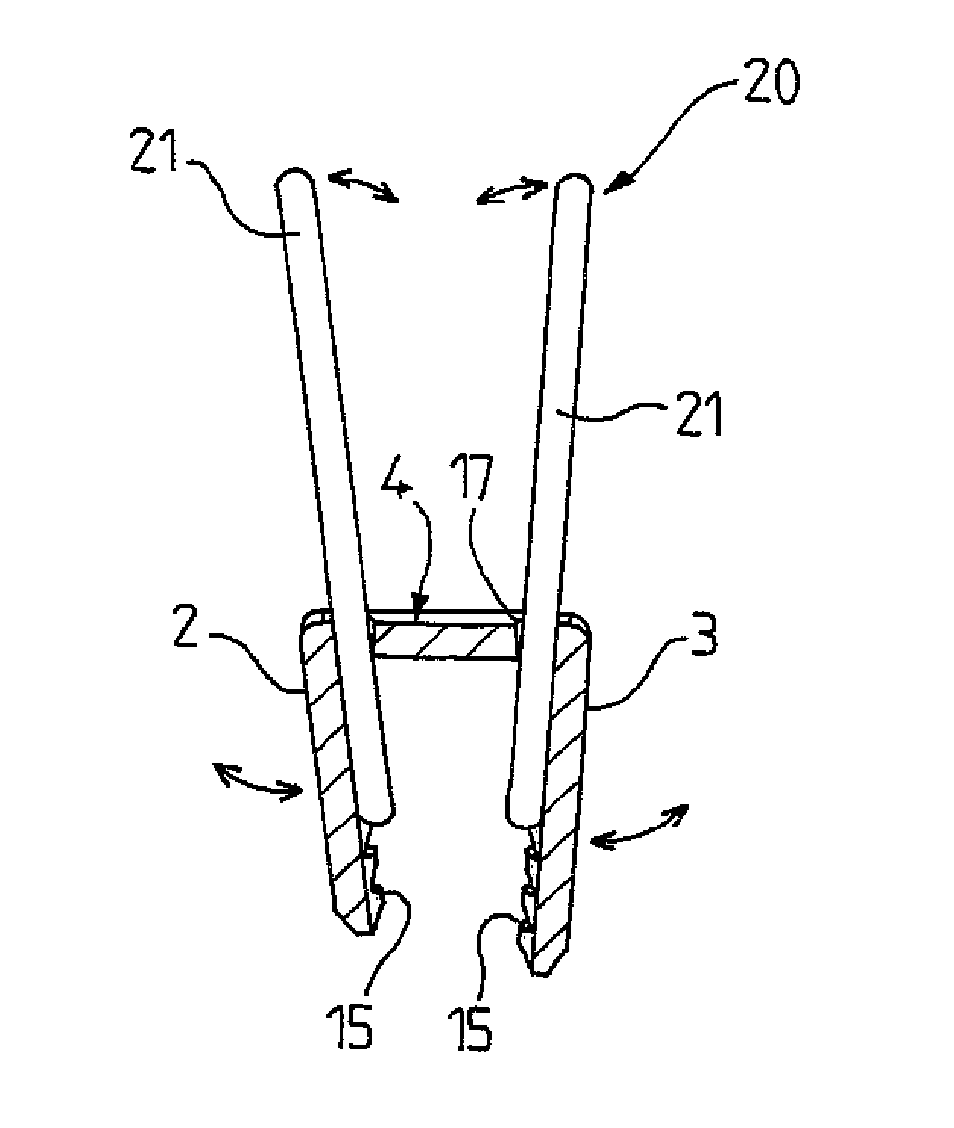

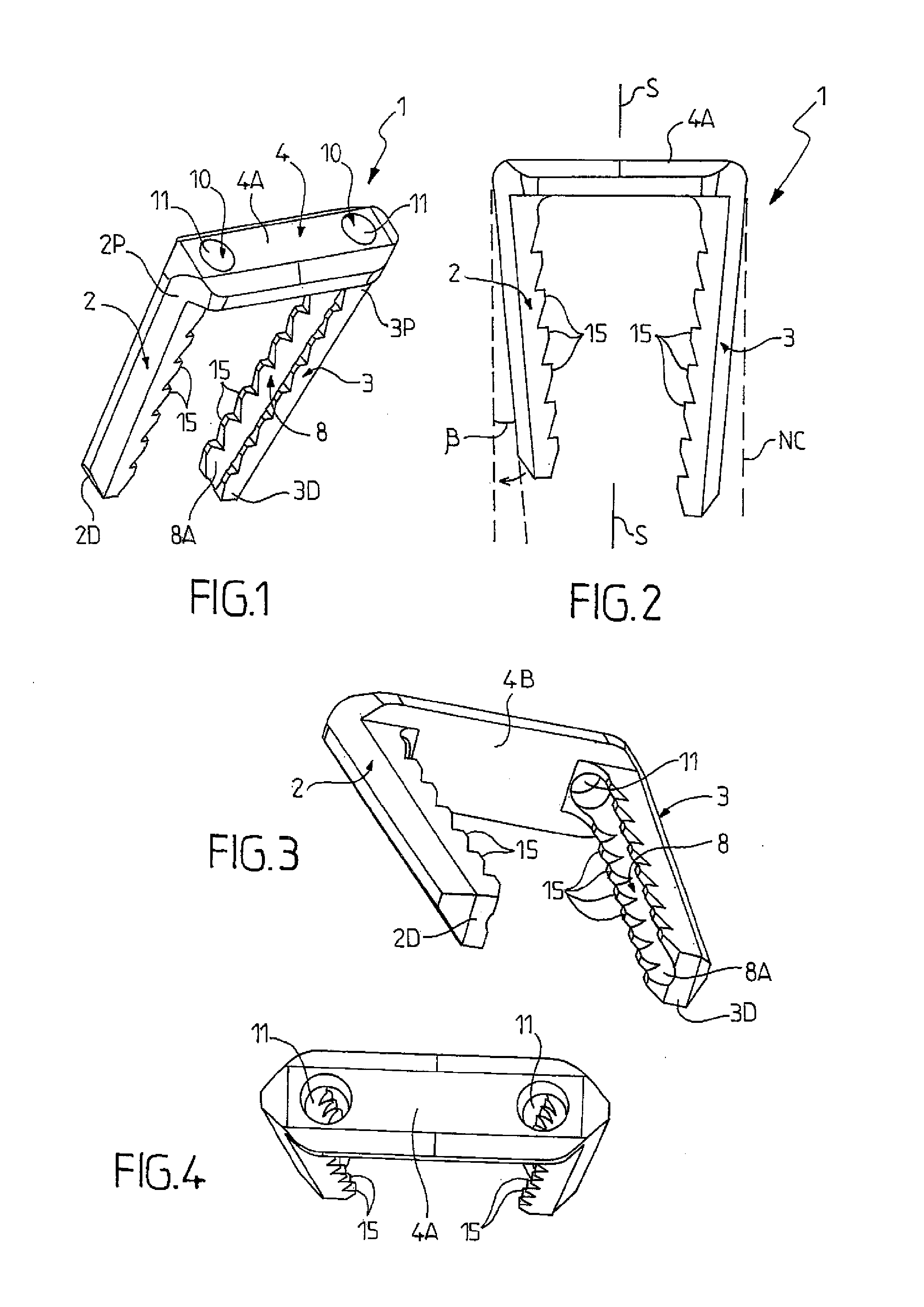

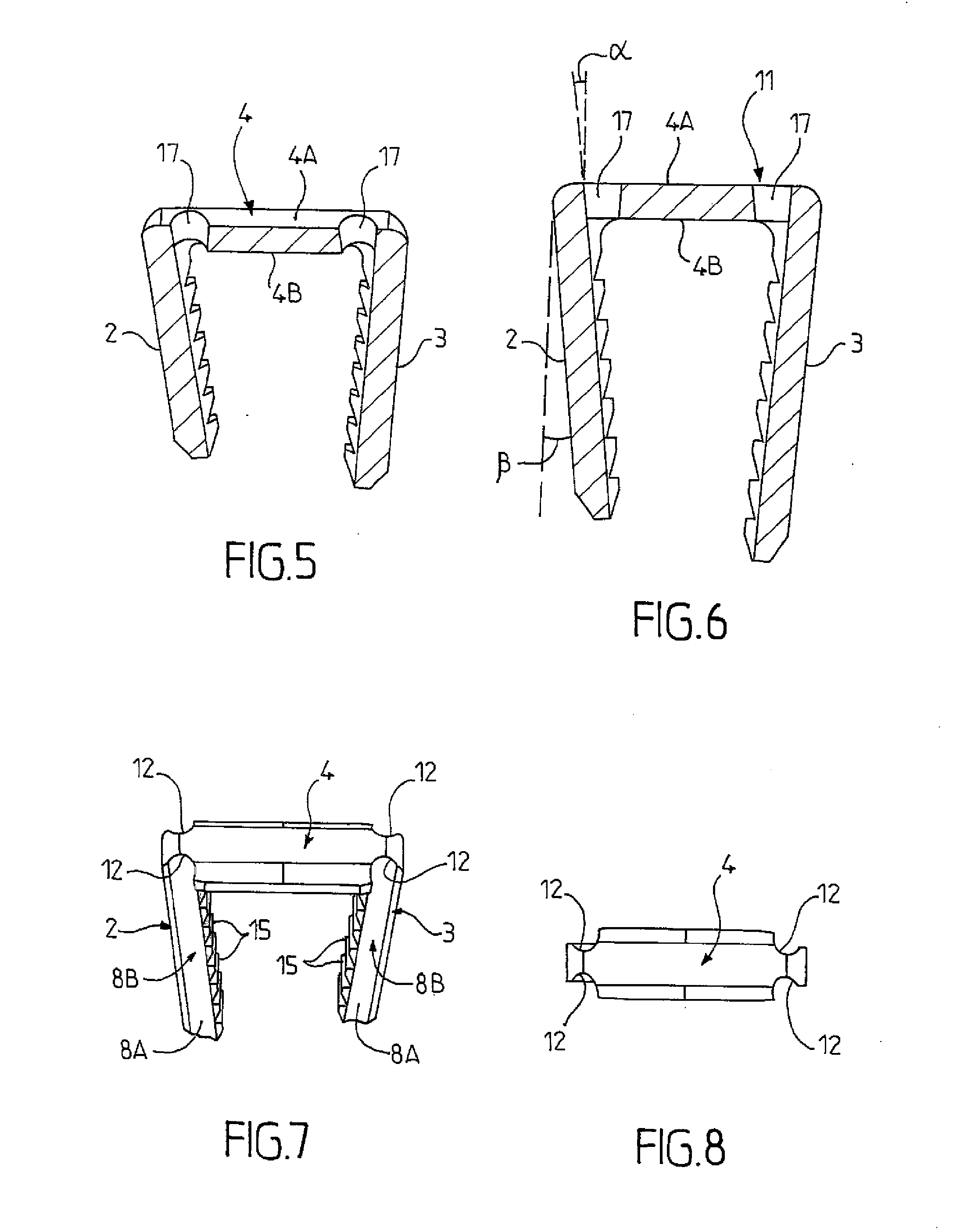

Compression Clip Having Convergent Legs

InactiveUS20150313592A1Easy to put into placeGood fatigue strengthStaplesJoint implantsBiological tissue

Owner:IN2BONES

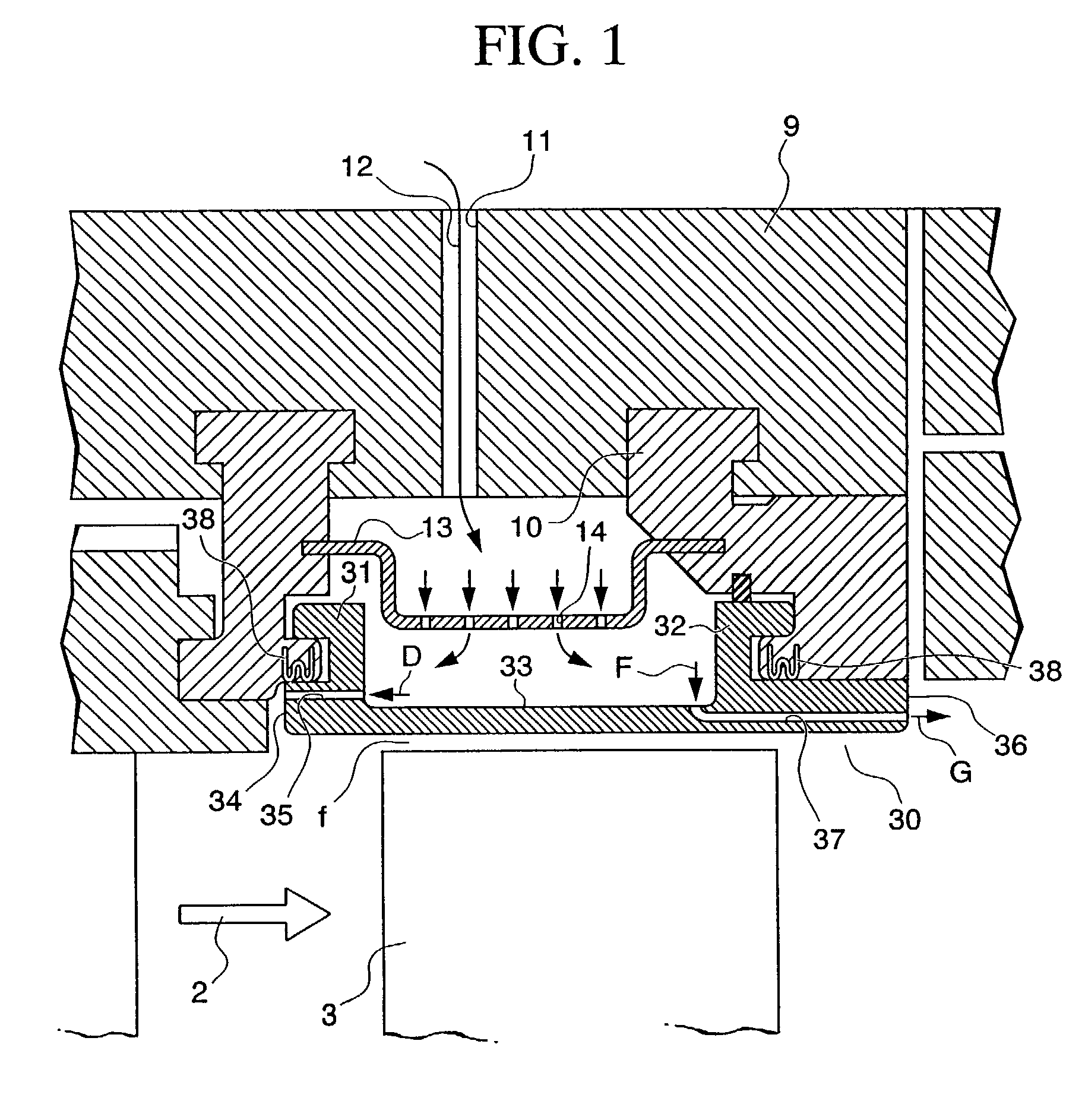

Ring segment of gas turbine

An object of the present invention is to provide a ring segment of a gas turbine in which the temperature is maintained low, damage due to high temperature oxidation is prevented, and high temperature deformation is prevented. In order to achieve the object, the present invention provides a ring segment of a gas turbine which comprises a blade ring, a main shaft and moving blades comprising a plurality of individual units which define an annular form by being arranged around the peripheral direction of the main shaft, and disposed so that its inner peripheral surface is maintained at a constant distance from the tips of the moving blades, wherein grooves which extend along the axial direction of the main shaft of the turbine are formed upon of the individual units so as mutually to confront one another; a seal plate which is inserted into each mutually confronting pair of the grooves so as to connect together the adjacent pair of individual units; and contact surfaces which are formed at positions more radially inward than the seal plates, which extend in the axial direction and the peripheral direction and which mutually contact one another.

Owner:MITSUBISHI HEAVY IND LTD

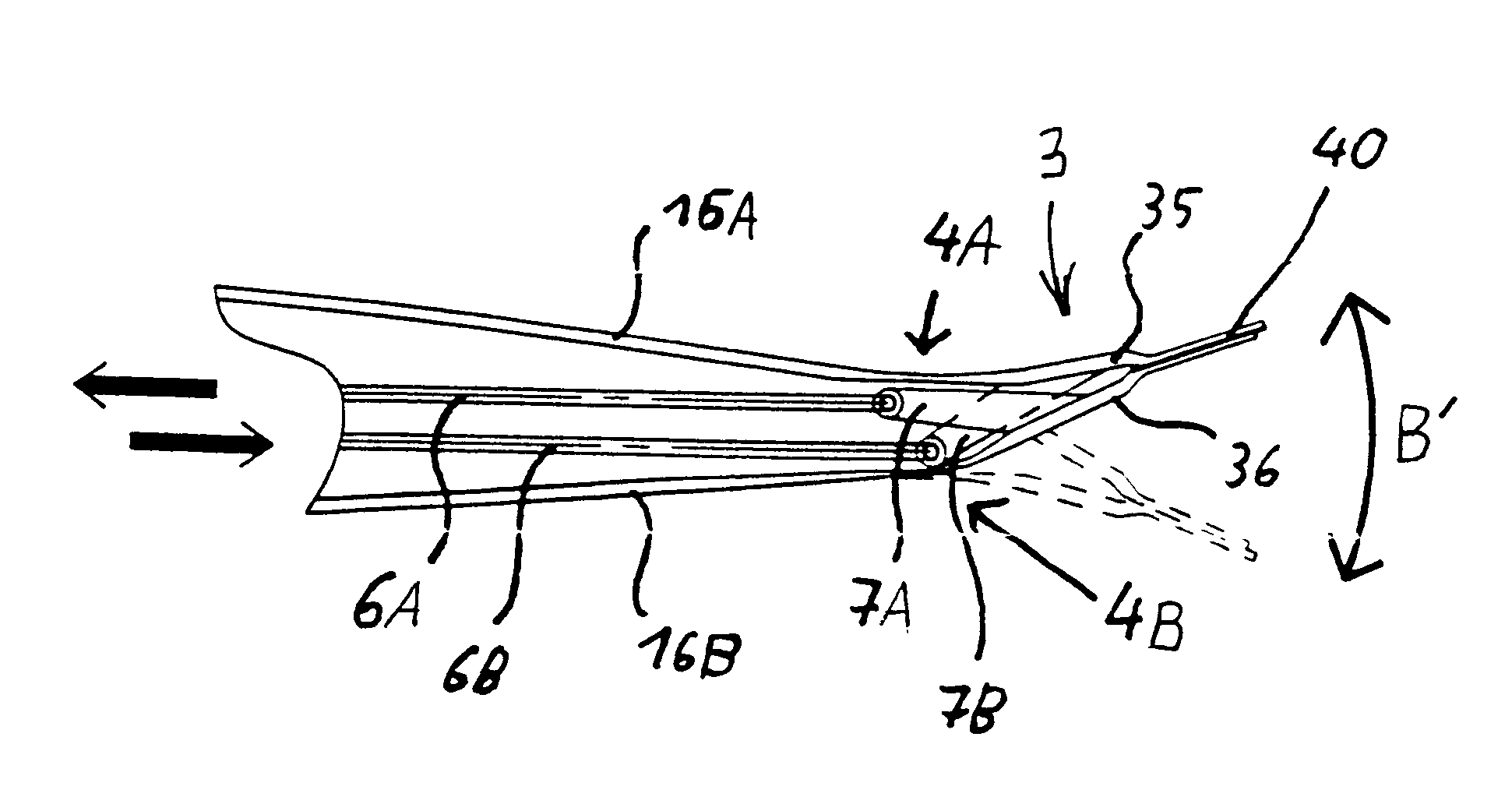

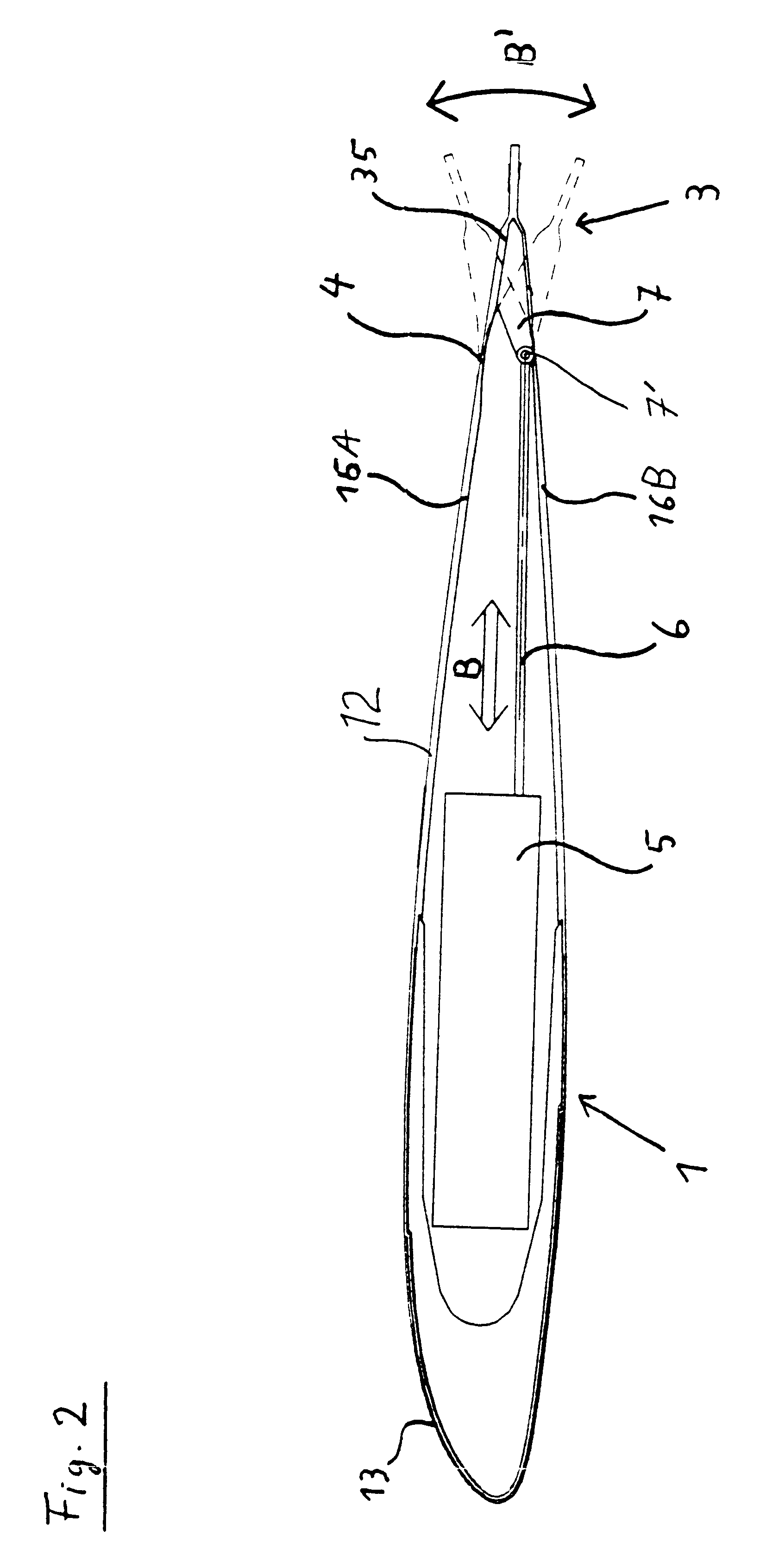

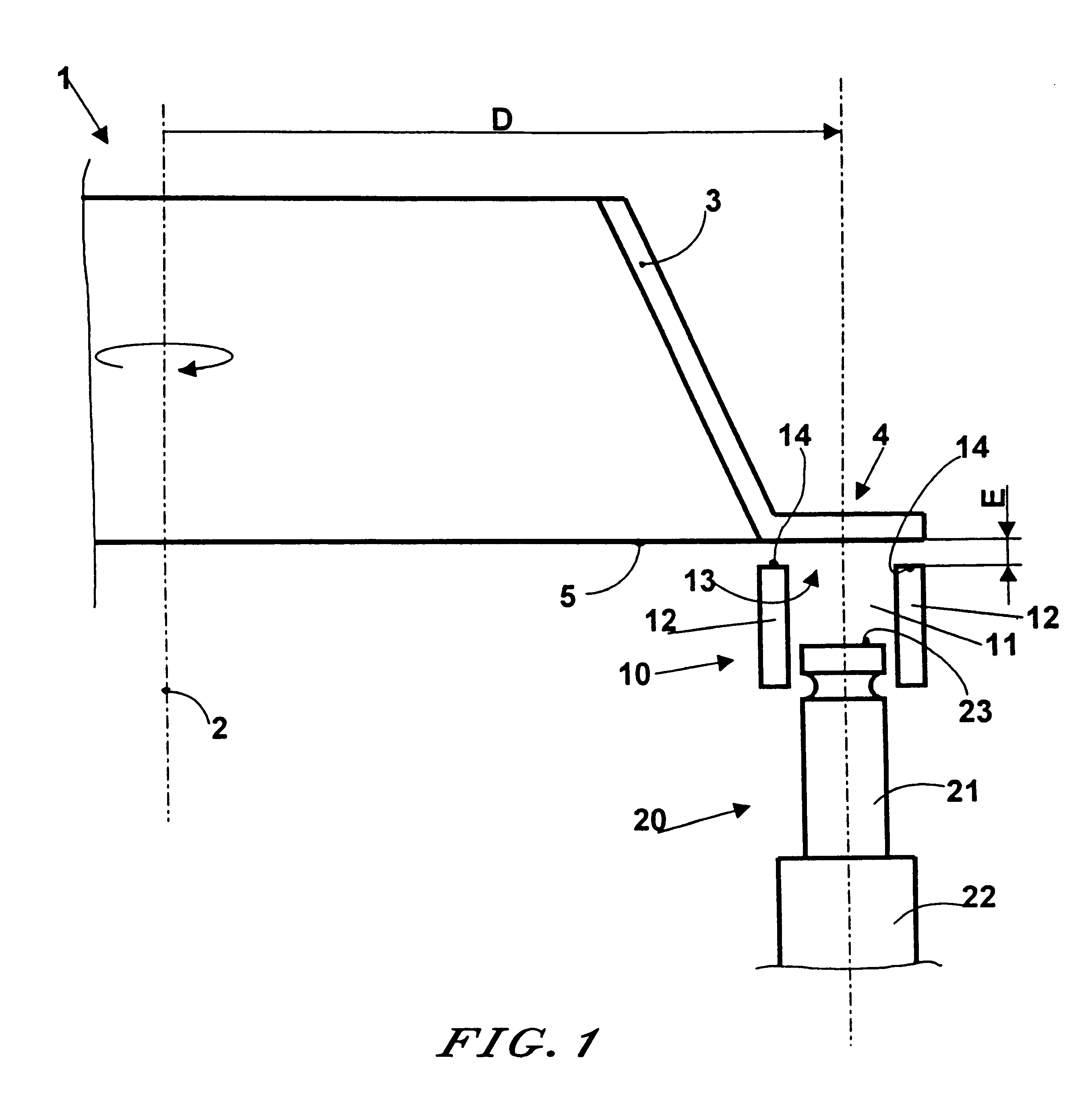

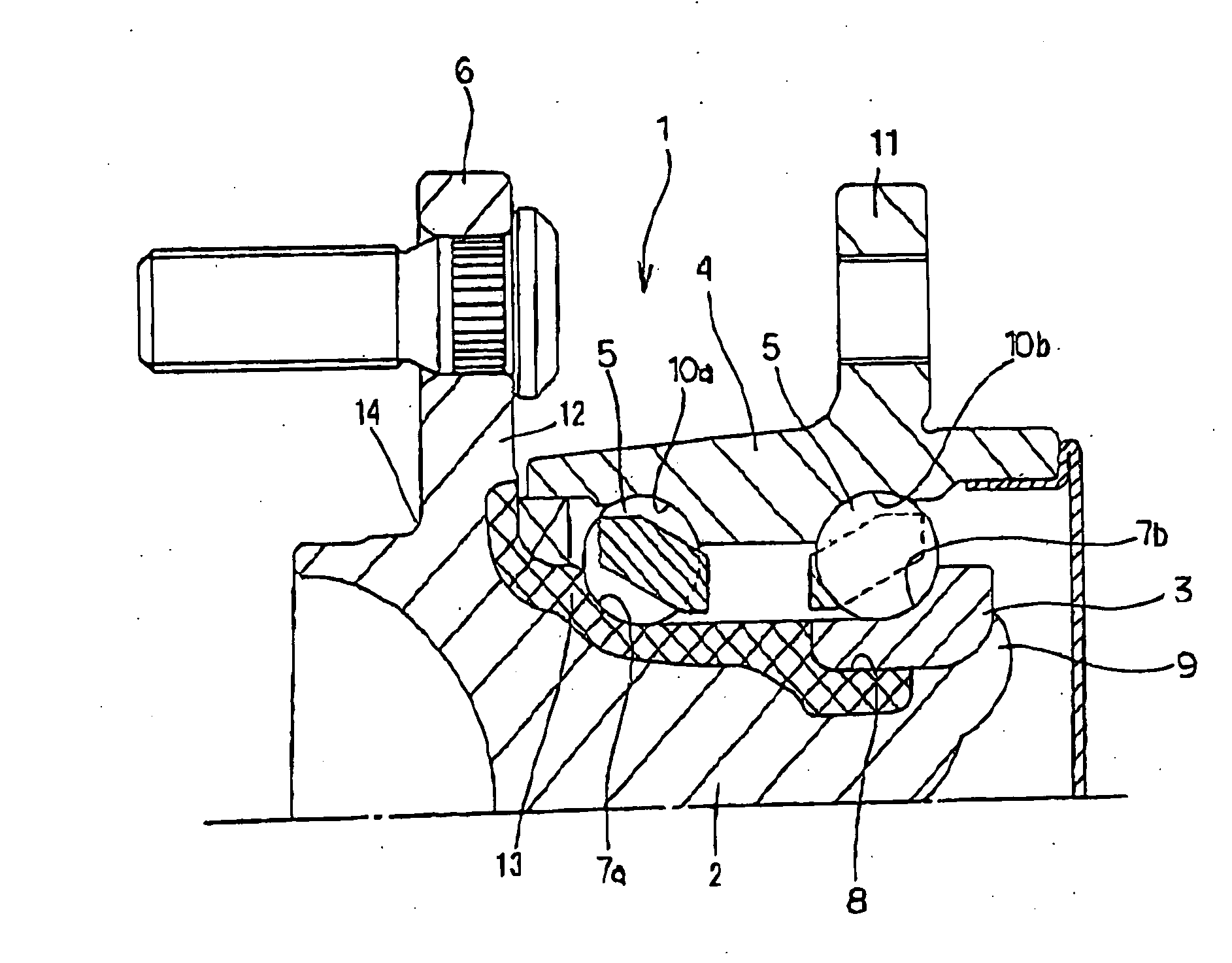

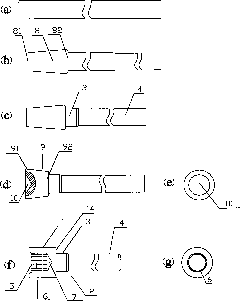

Helicopter rotor blade with a movable flap

InactiveUS6168379B1Durable and wear-resistant flexiblyImprove inspectionPropellersAircraft stabilisationPiezoelectric actuatorsFiber-reinforced composite

A helicopter rotor blade includes a main airfoil body (12) and a movable control flap (3) incorporated in the trailing edge profile of the airfoil body. The flap (3) is movably connected to the main airfoil body (12) by a flexibly bendable junction element (4), and is actuated by a piezoelectric actuator unit (5) via a push / pull rod (6) and a lever arm (7), whereby the control flap is deflected relative to the main airfoil body. The junction element (4) is preferably a continuous integral fiber-reinforced composite component having a flexible bending portion (42) with a reduced thickness in comparison to the adjoining portions, whereby the reinforcing fibers extend continuously through the joint in the direction of the connection between the main airfoil body and the flap.

Owner:AIRBUS HELICOPTERS DEUT GMBH

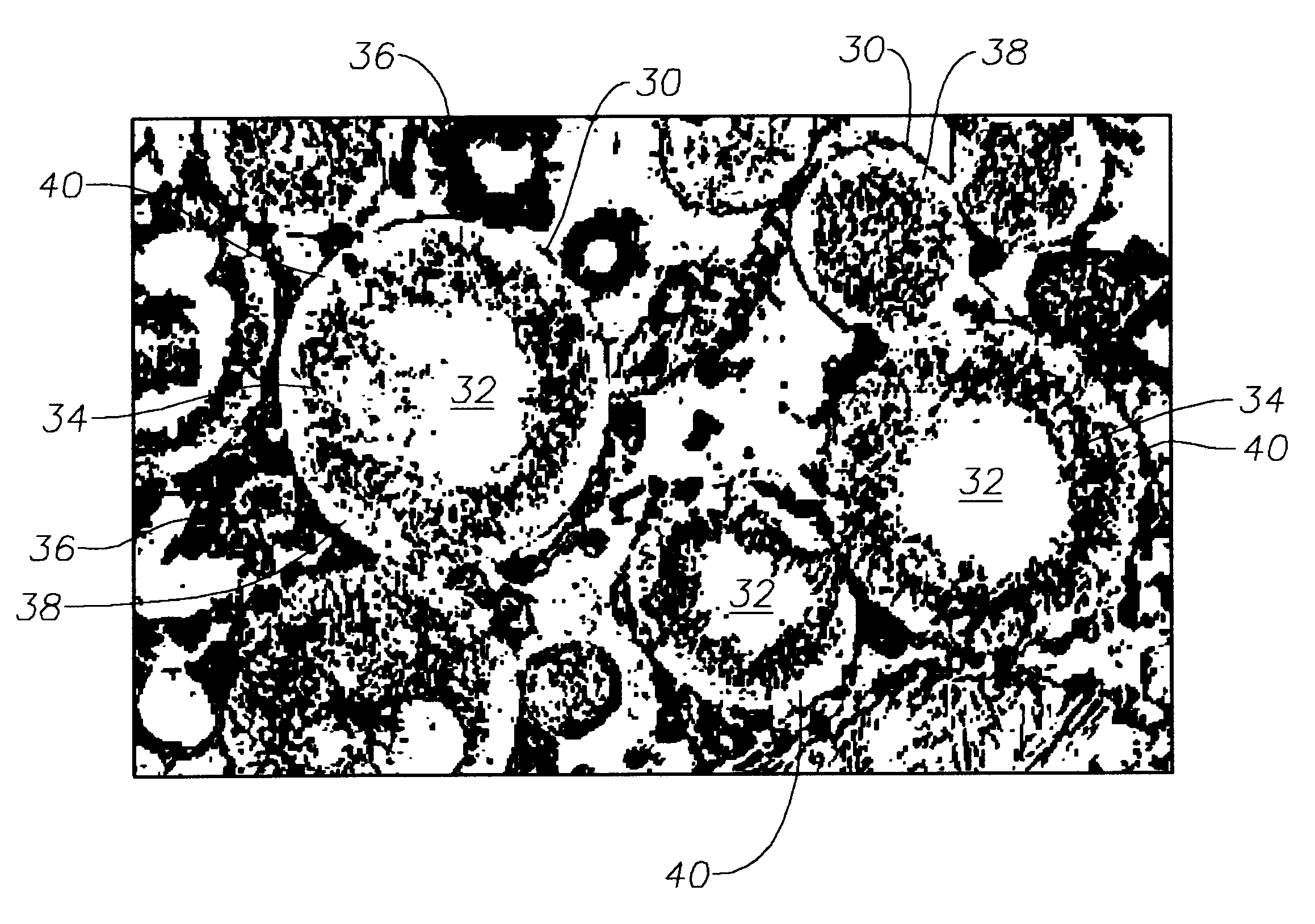

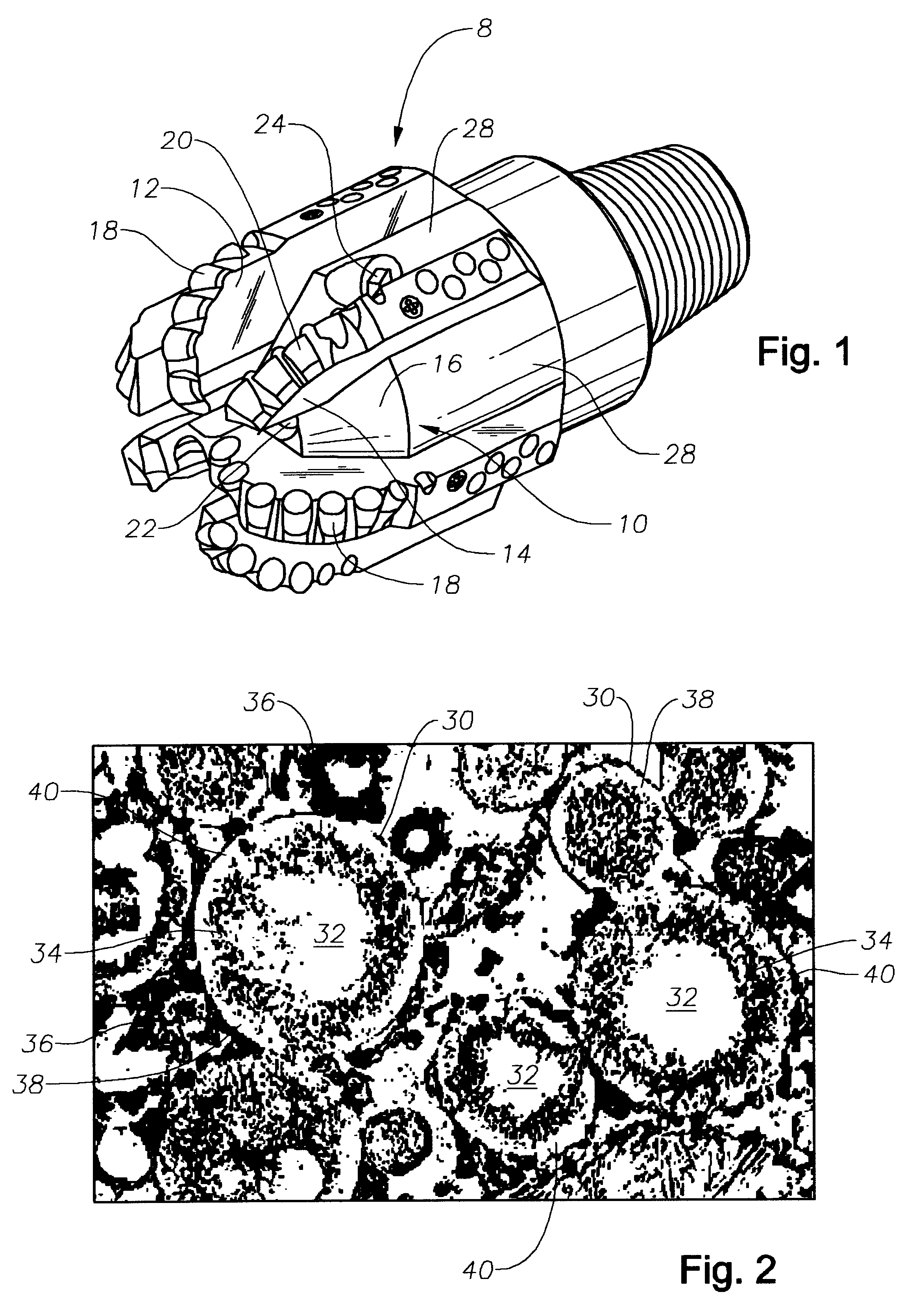

Wear resistant drill bit

InactiveUS6454028B1Improve wear resistanceHigh densityDrill bitsTransportation and packagingWear resistantSpherical shaped

A wear resistant drill bit of the matrix bodied type has a bit body comprising a tungsten carbide material bound with a binder material, wherein the tungsten carbide material includes at least some tungsten carbide particles of generally spherical shape. The tungsten carbide material includes particles having a relatively hard central core and a softer skin. The skin includes a large proportion of a high temperature phase of tungsten carbide.

Owner:CAMCO INT

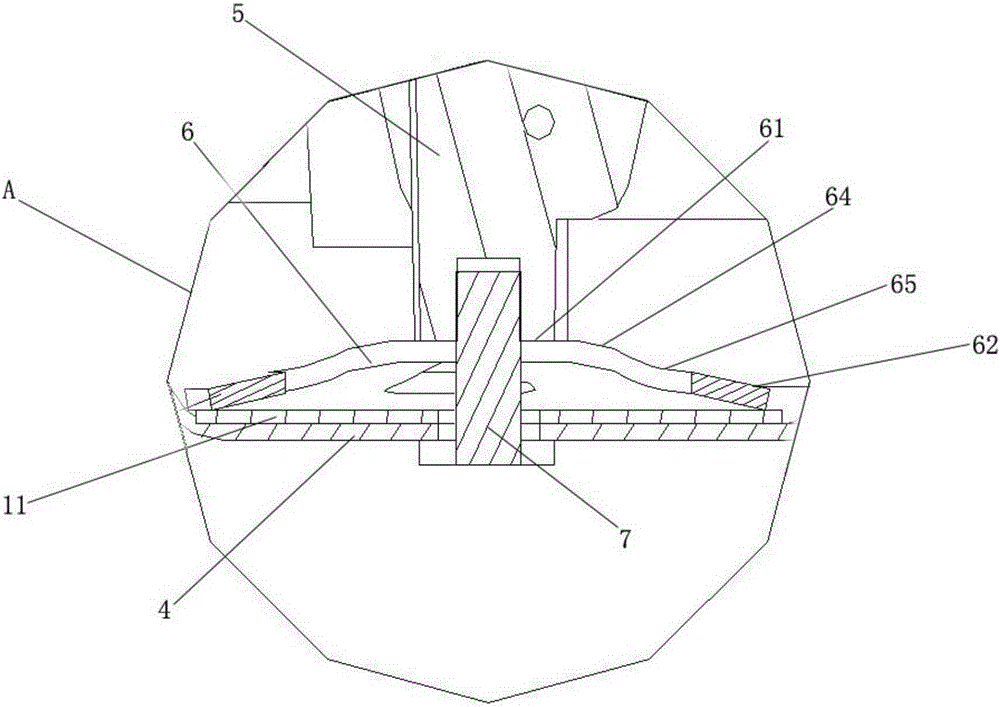

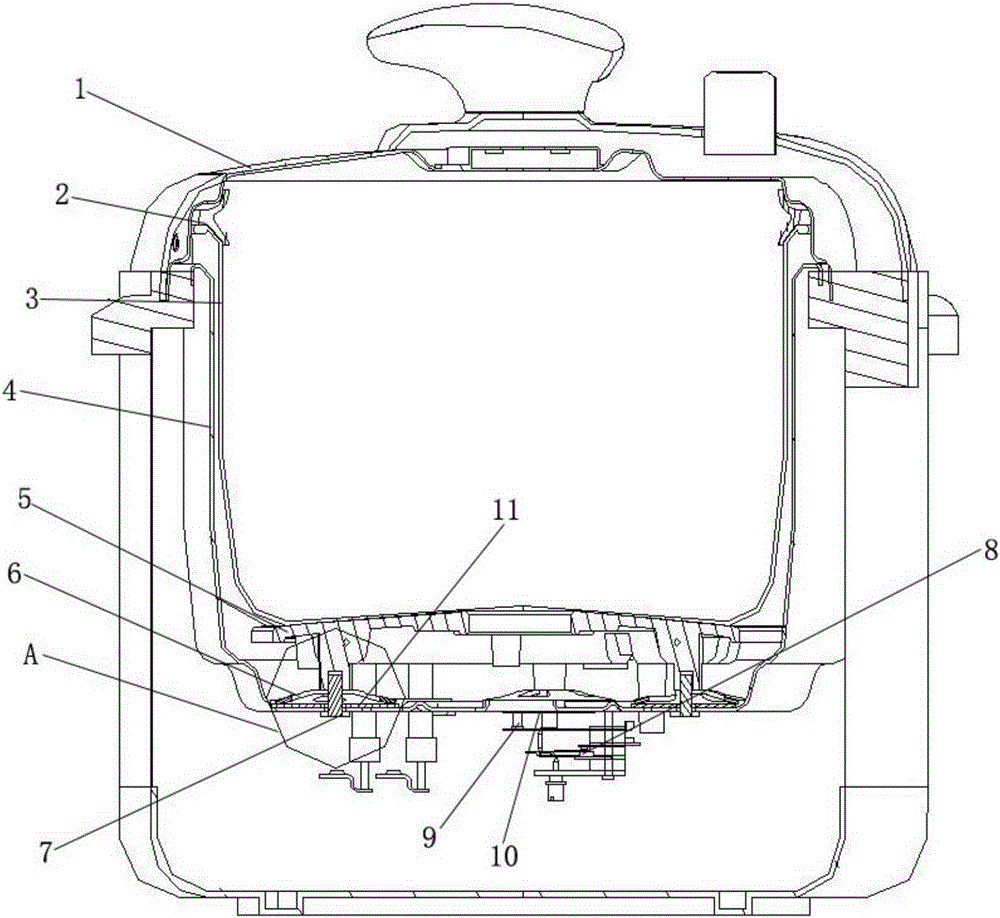

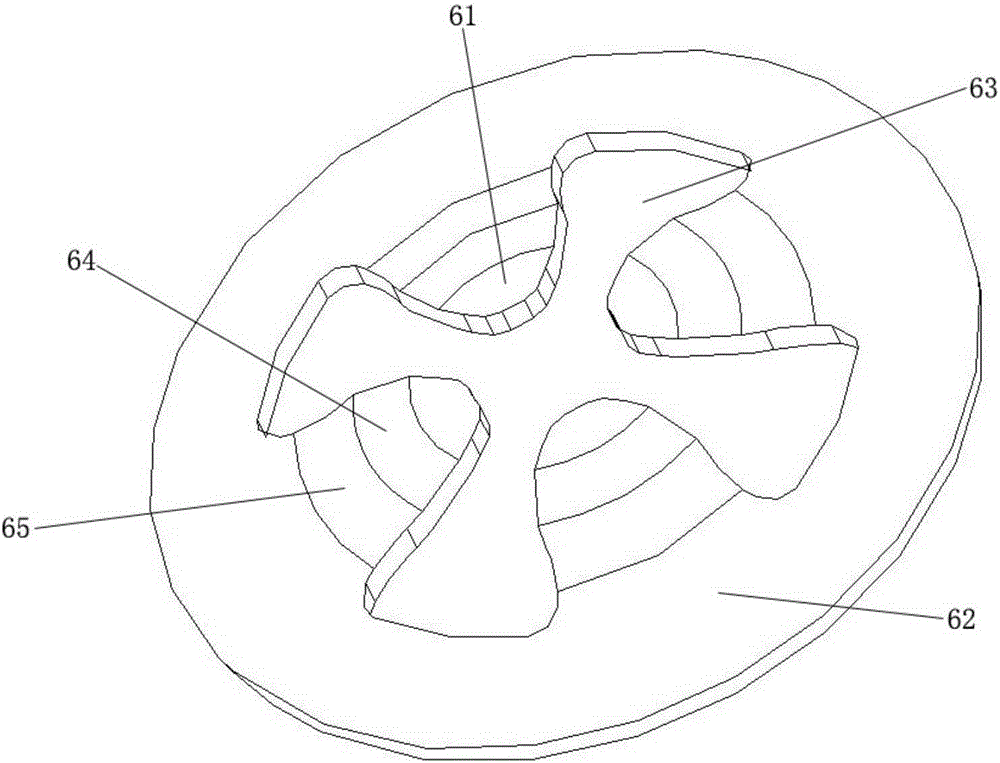

Pressure-control type electric pressure cooker

ActiveCN105286498AImprove stability and securitySimple structurePressure-cookersEngineeringPressure controlled ventilation

The invention discloses a pressure-control type electric pressure cooker. A sealed body is formed by sequentially connecting a pot cover, a seal ring, an inner pot and an outer pot; a plurality of belleville springs, which are provided with opening grooves, are arranged between a heating plate and the outer pot; upper supporting rings are formed by horizontally flanging the small-diameter ends of the belleville springs towards inner sides, and lower supporting rings are formed by the big-diameter ends of the belleville springs; an elastic deformation area is formed by a conical wall parts between each of the upper supporting rings and each of the lower supporting rings; the elastic deformation areas penetrate through the upper supporting rings in a radial direction and extend to conical body parts, and the opening grooves that contour lines projected on a horizontal plane are in a cross form are formed; the opening grooves are of gradually expanded structures with upsides smaller than downsides from openings to bottoms; the lower supporting rings are supported on the bottom of the outer pot; the upper supporting rings are propped against supporting legs of the heating plate; and the supporting legs and the belleville springs are integrally positioned with and connected to the outer pot by virtue of fixed screws. The amount of elastic deformation of the electric pressure cooker is effectively improved by virtue of the belleville springs, and the change in induction pressure of a pressure detection device is more conveniently to be detected, so that the precision and the safety stability of pressure control are improved.

Owner:HANGZHOU YONGYAO TECH

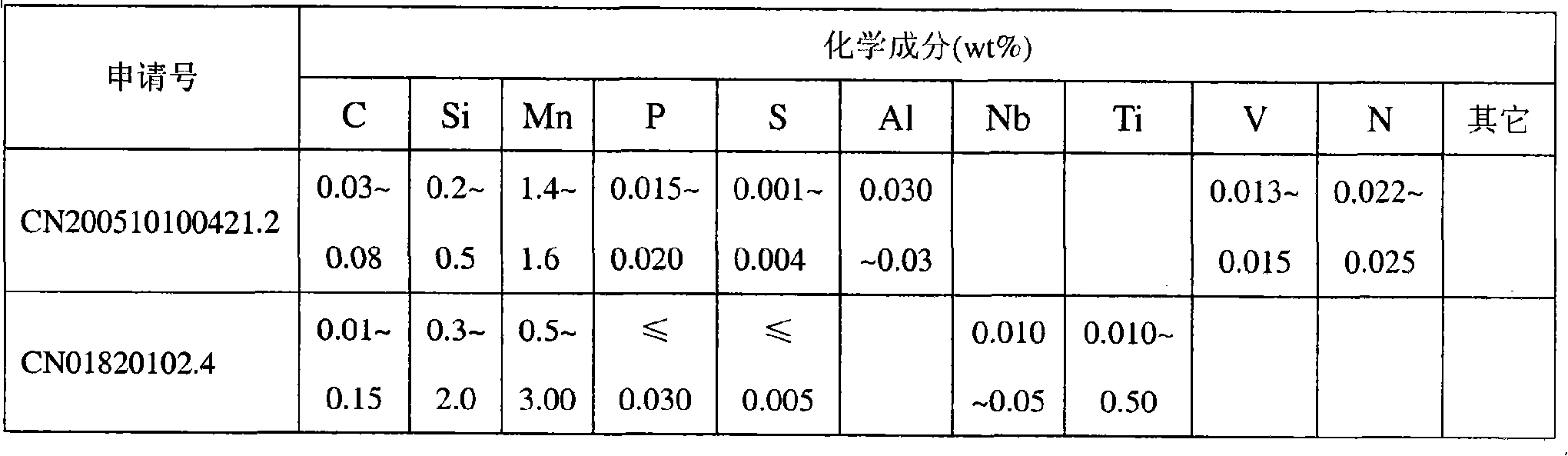

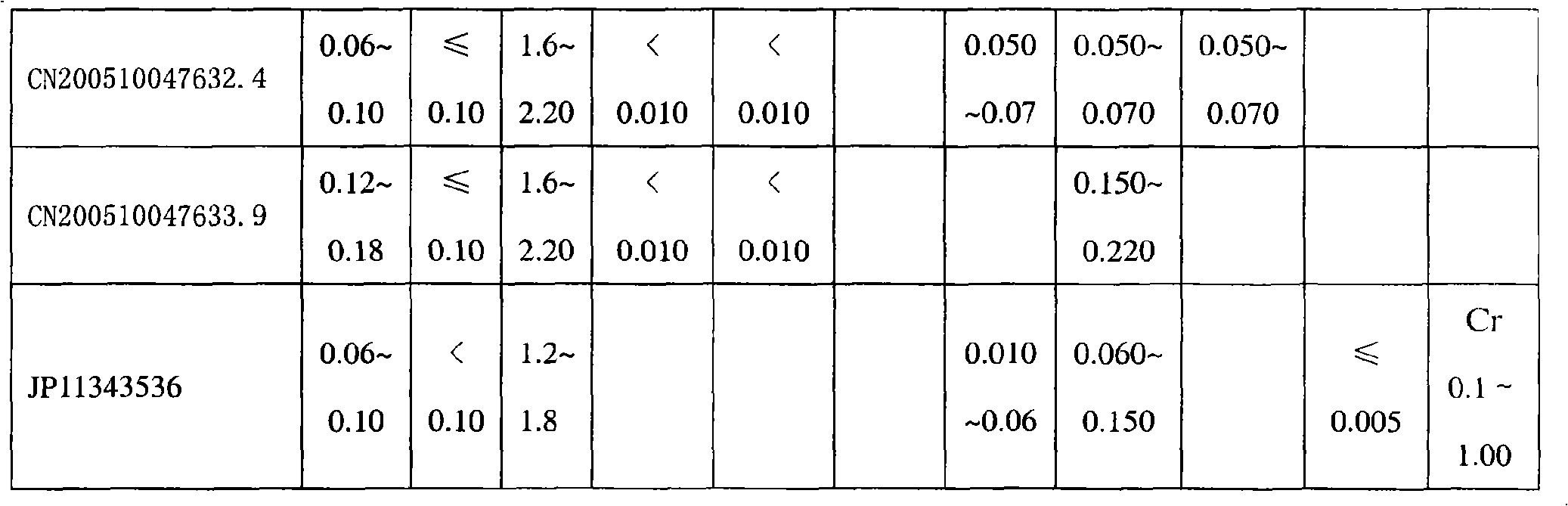

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

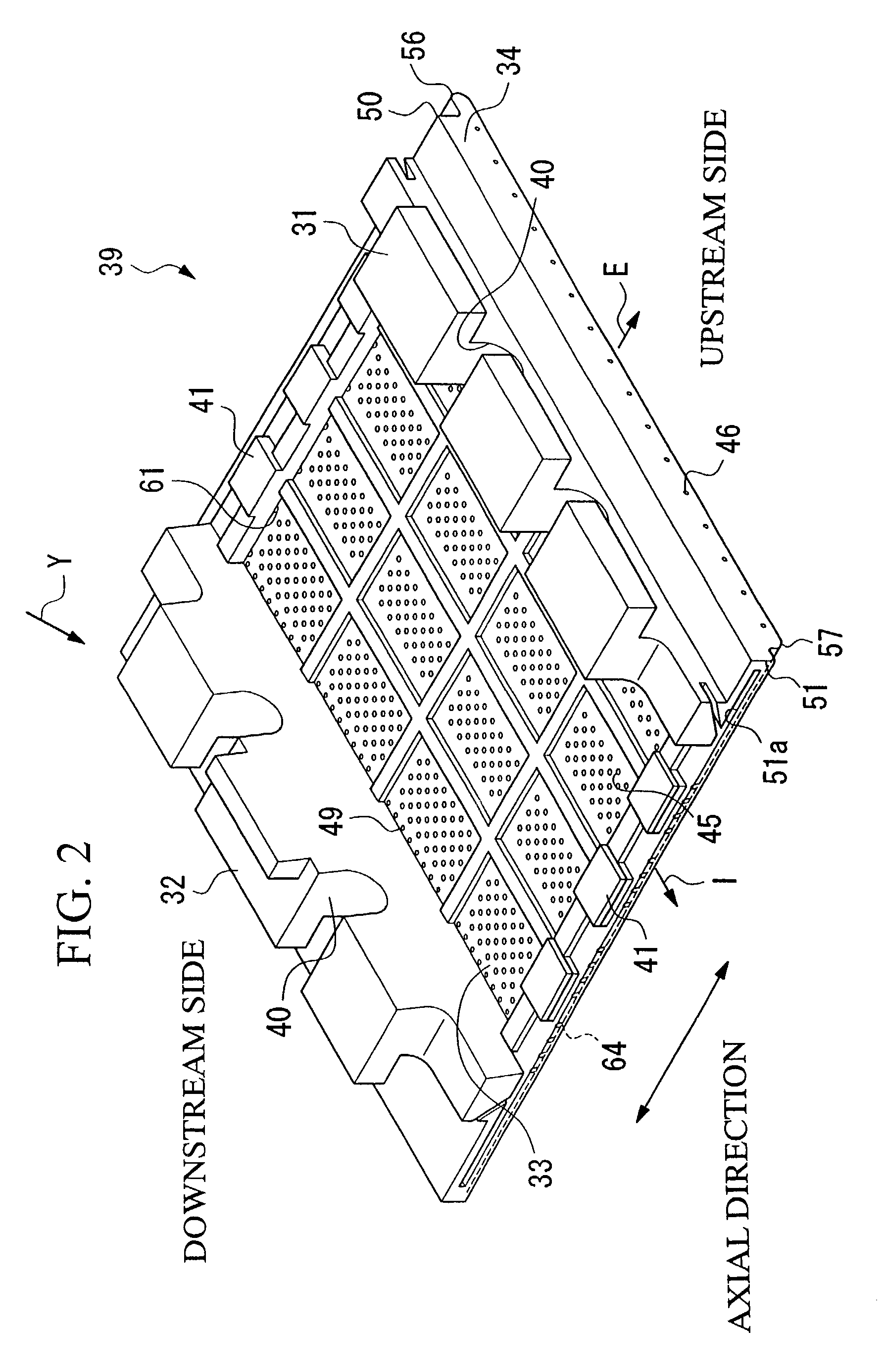

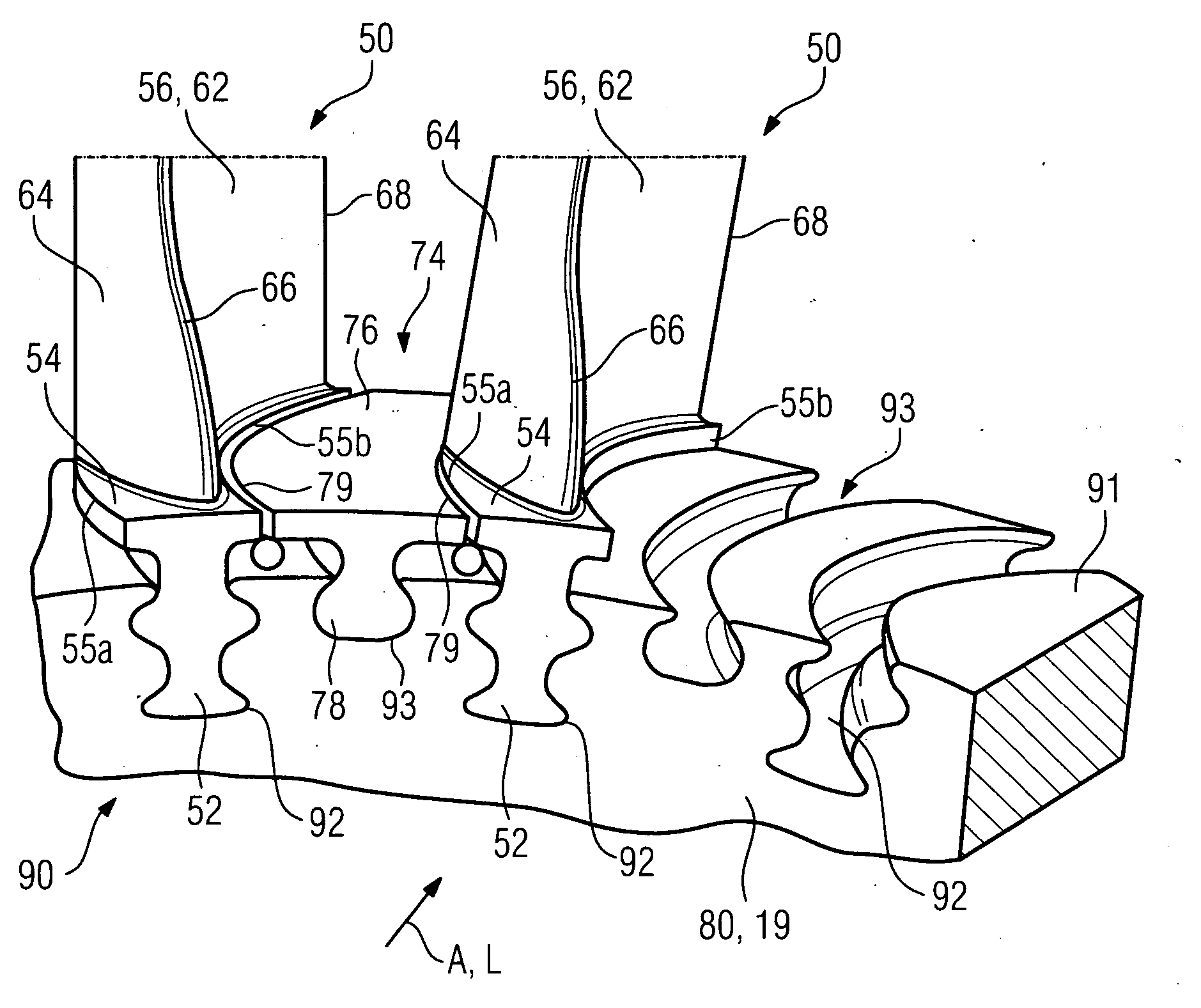

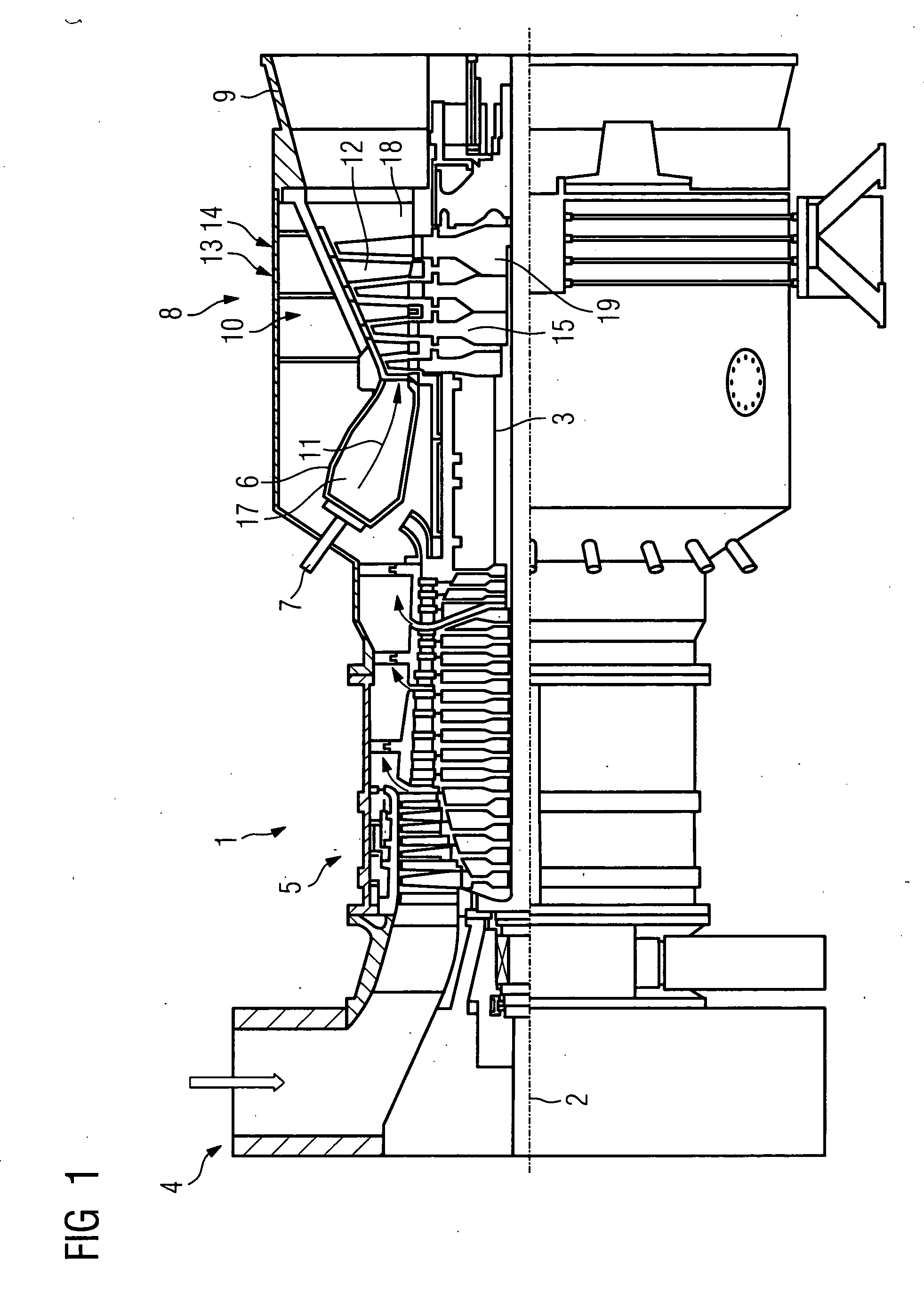

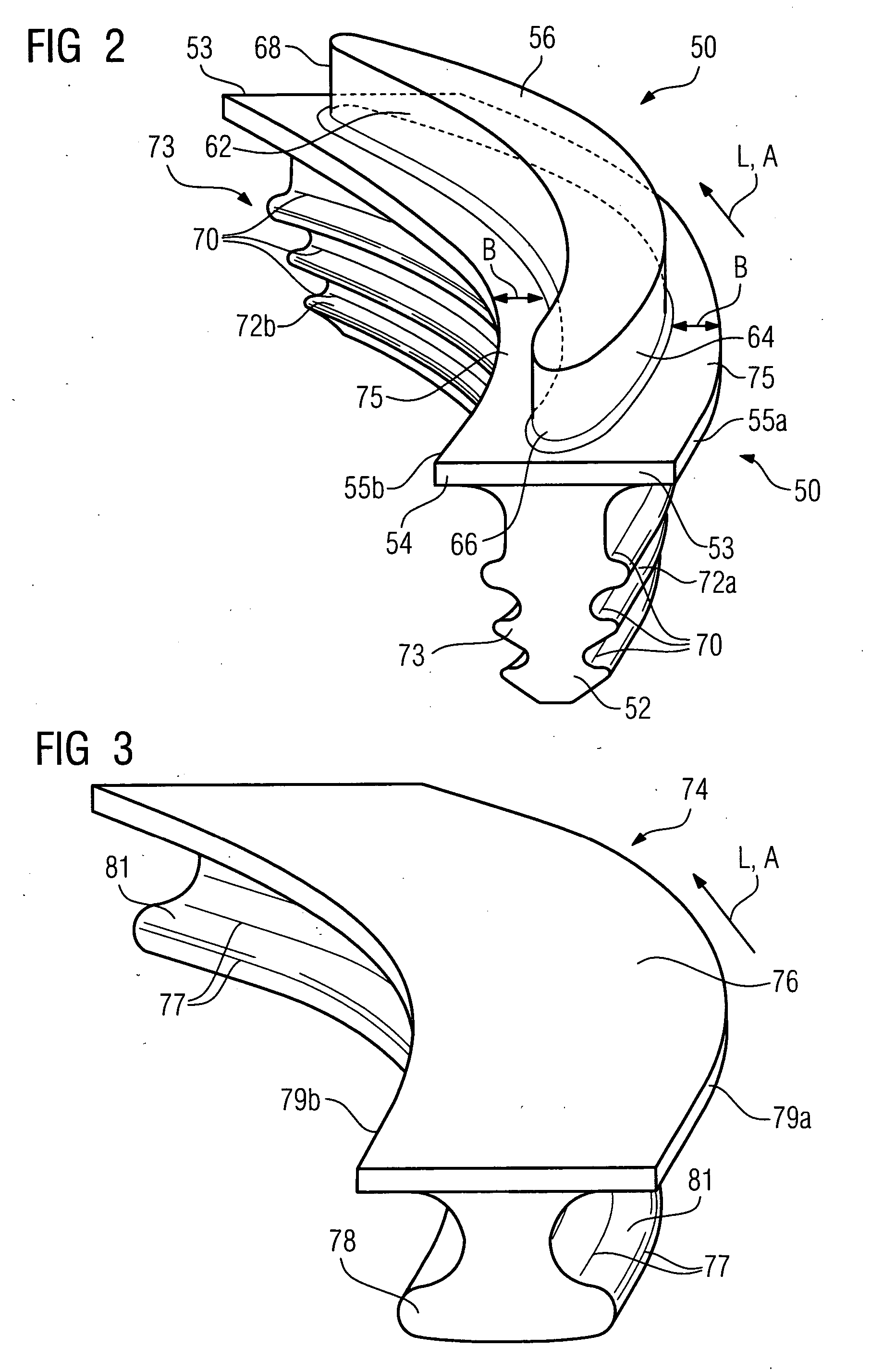

Gas turbine blade or vane and platform element for a gas turbine blade or vane ring of a gas turbine, supporting structure for securing gas turbine blades or vanes arranged in a ring, gas turbine blade or vane ring and the use of a gas turbine blade or vane ring

InactiveUS20070020102A1Improve efficiencyImprove gas efficiencyPropellersEngine manufactureAerospace engineeringGas turbines

The invention relates to a gas turbine blade or vane ring having a supporting structure and gas turbine blades or vanes secured to it. The gas turbine blades or vanes have a blade or vane root, which is successively adjoined by a platform and then a blade profile which is curved in the longitudinal direction, the blade or vane root running in the longitudinal direction of the blade profile, and the platform having two platform longitudinal edges which are bent parallel and run in the longitudinal direction. To provide an alternative gas turbine blade or vane ring with simplified assembly, it is proposed that the blade or vane root be shaped in such a manner that the suction-side or pressure-side blade or vane root surface of the associated platform longitudinal edge be curved convexly or concavely, respectively. Moreover, the invention relates to the use of a gas turbine blade or vane ring of this type.

Owner:SIEMENS AG

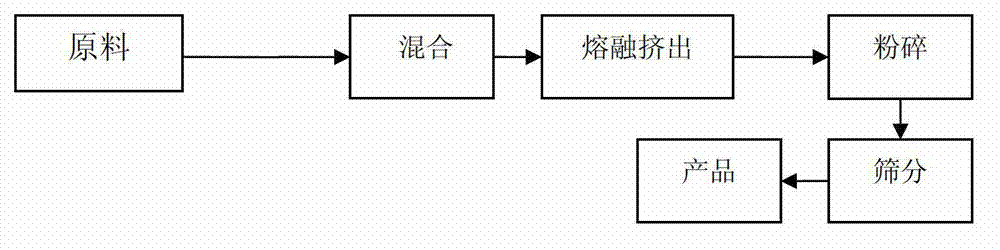

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

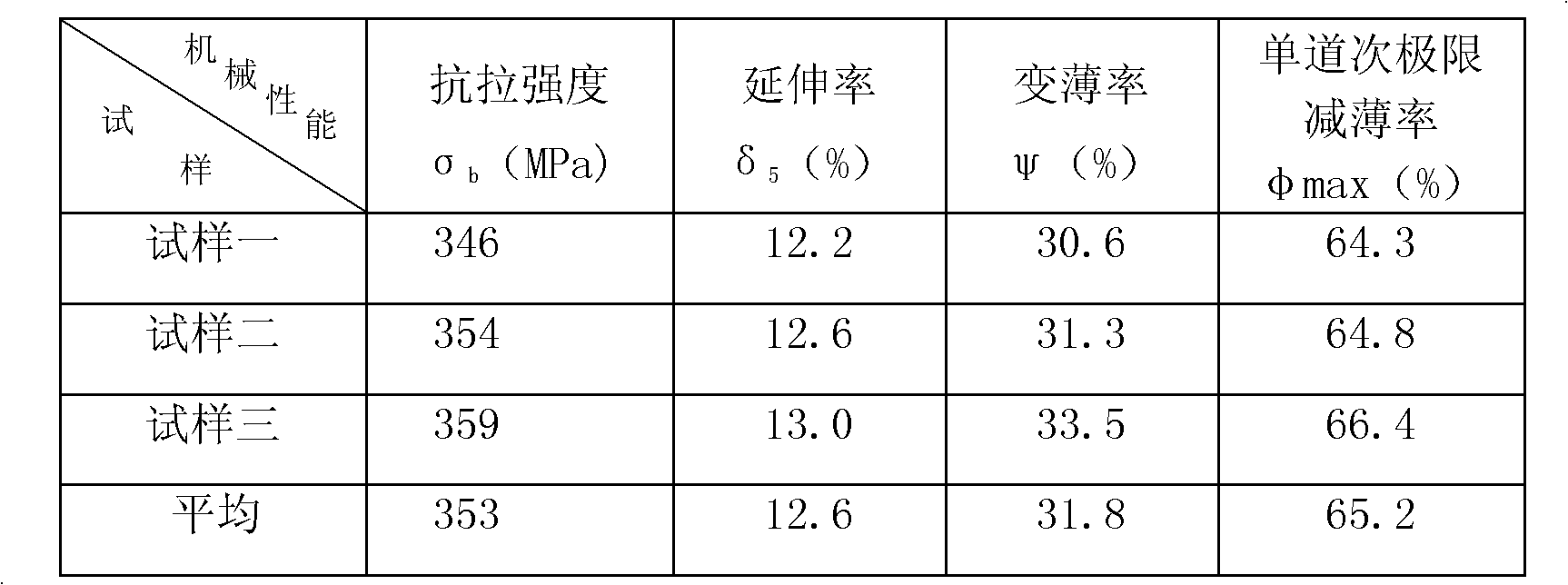

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

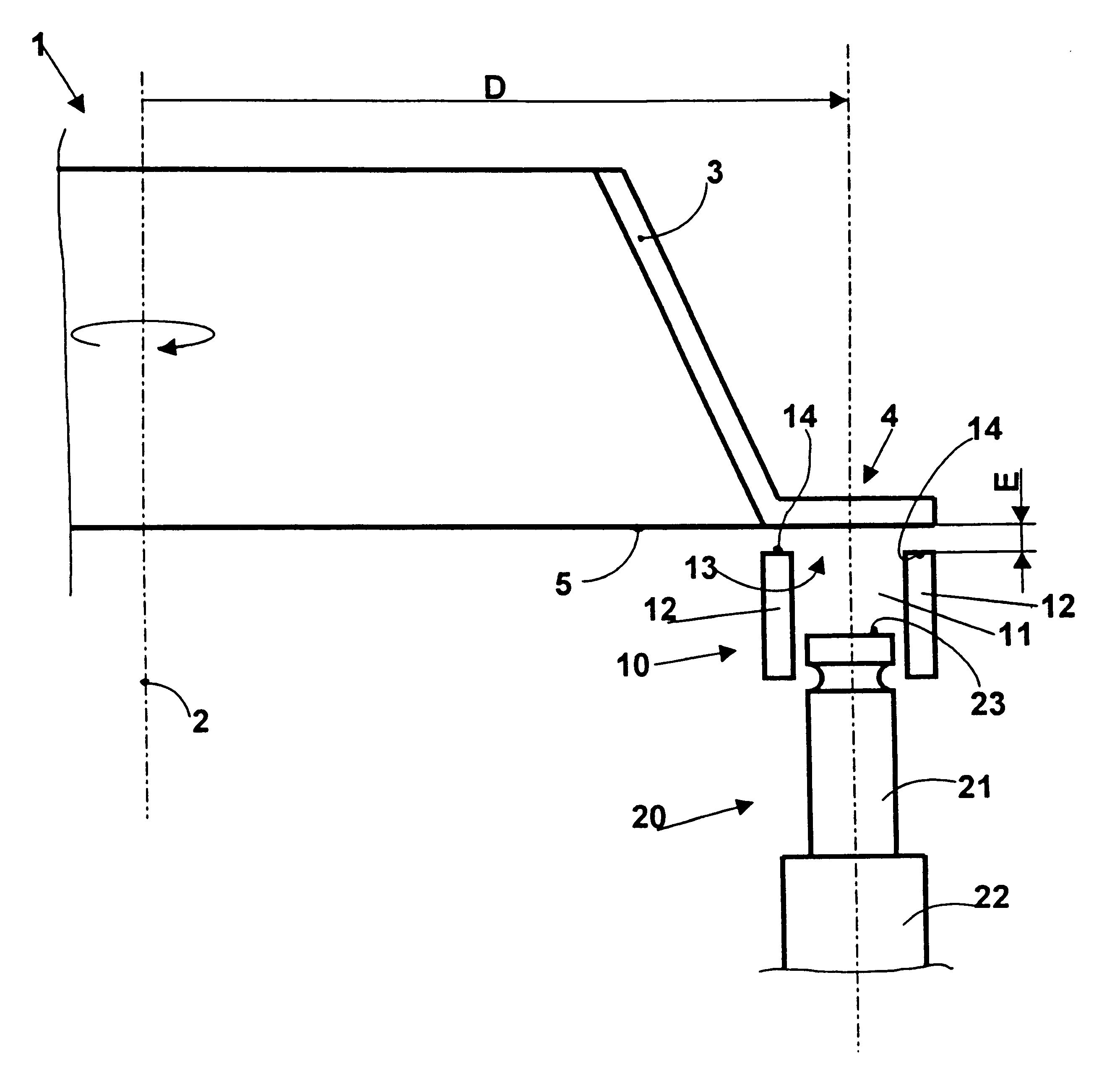

Method for the ultrasonic peening of large sized annular surfaces of thin parts

InactiveUS6289705B1Inhibits initiation and propagationImprove fatigue strengthBurnishing machinesVibratory devicesPeeningMaterials science

A method of so-called "ultrasonic" peening is described for peening large sized annular surfaces on thin parts. The method uses a microbead mist vibrated in a chamber with an opening so that the surface that is to be peened makes at least five movements past the opening of the peening chamber during peening so as to reduce deformation of the part.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

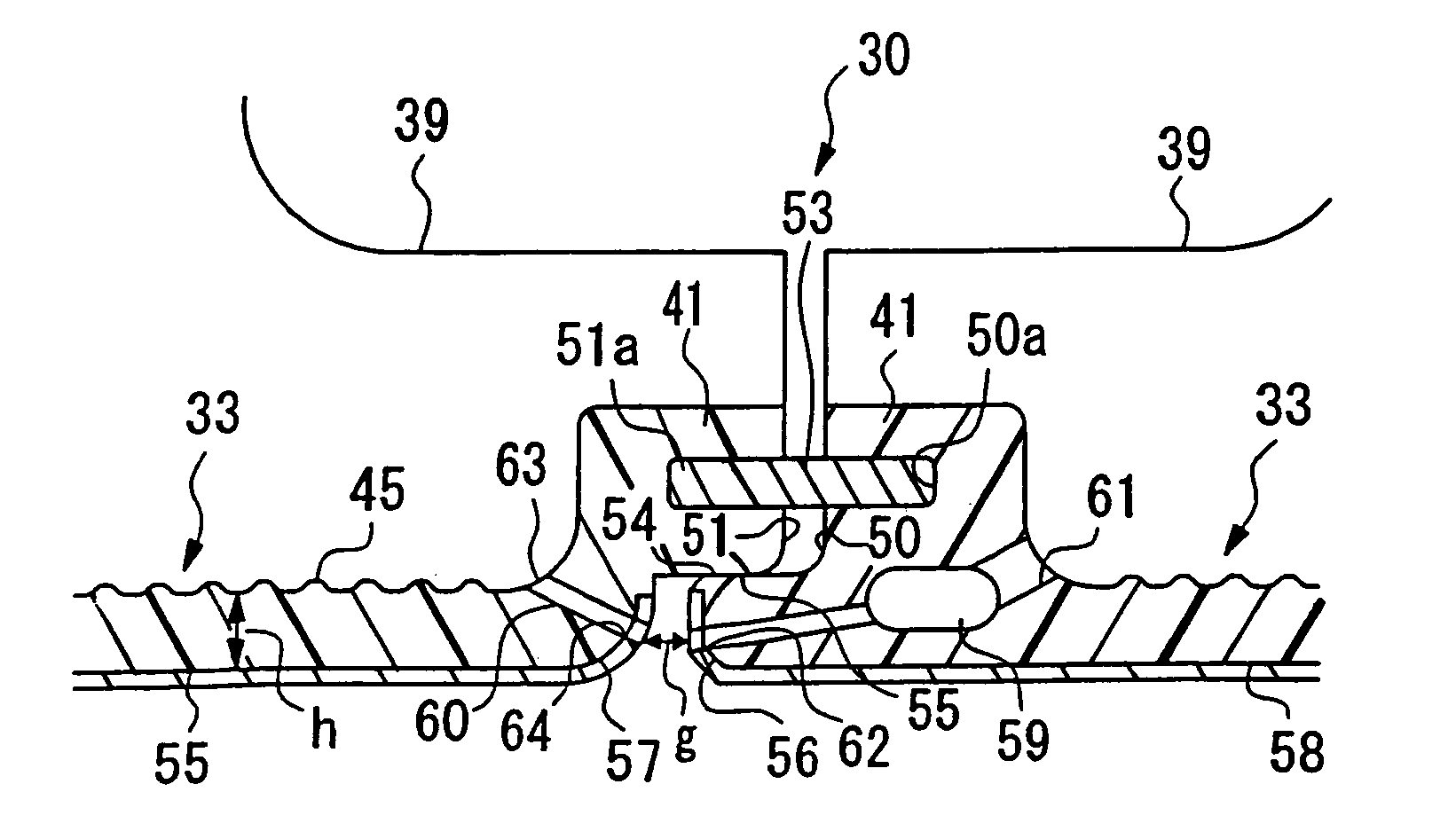

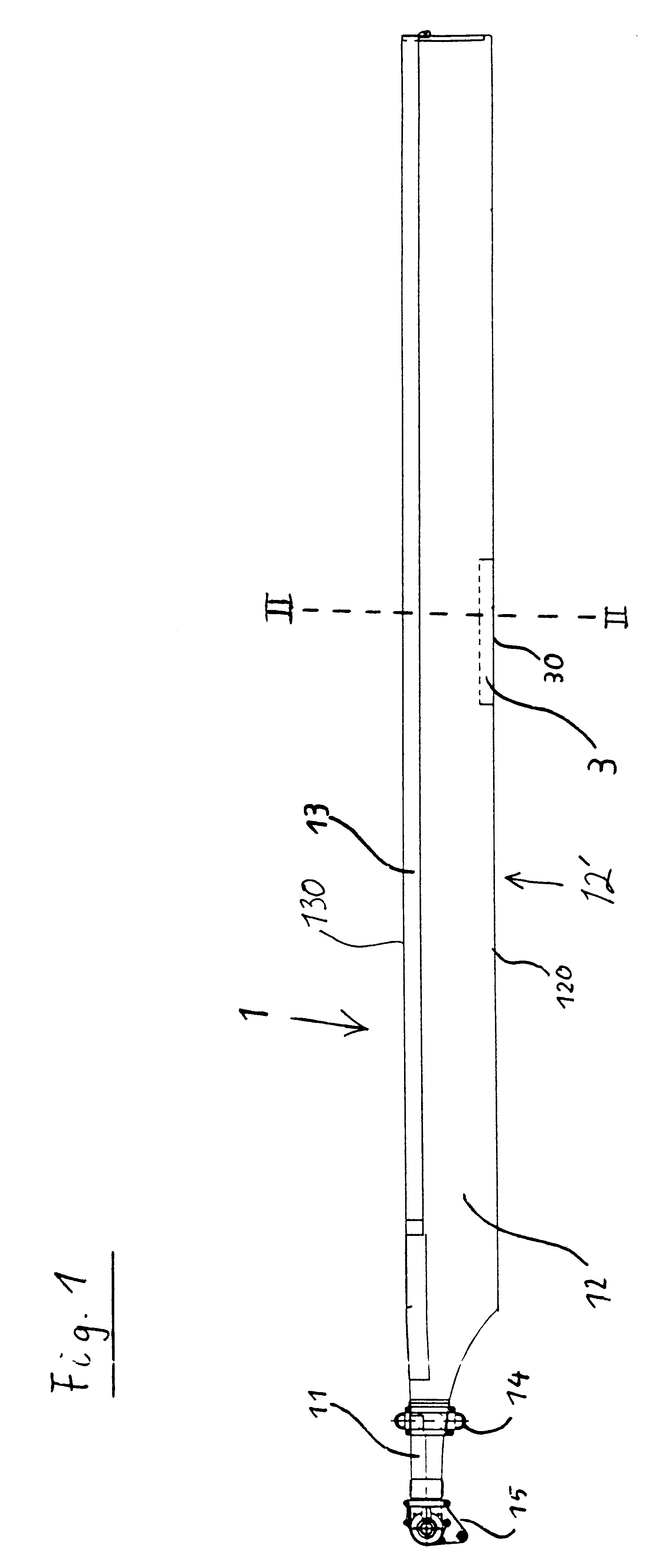

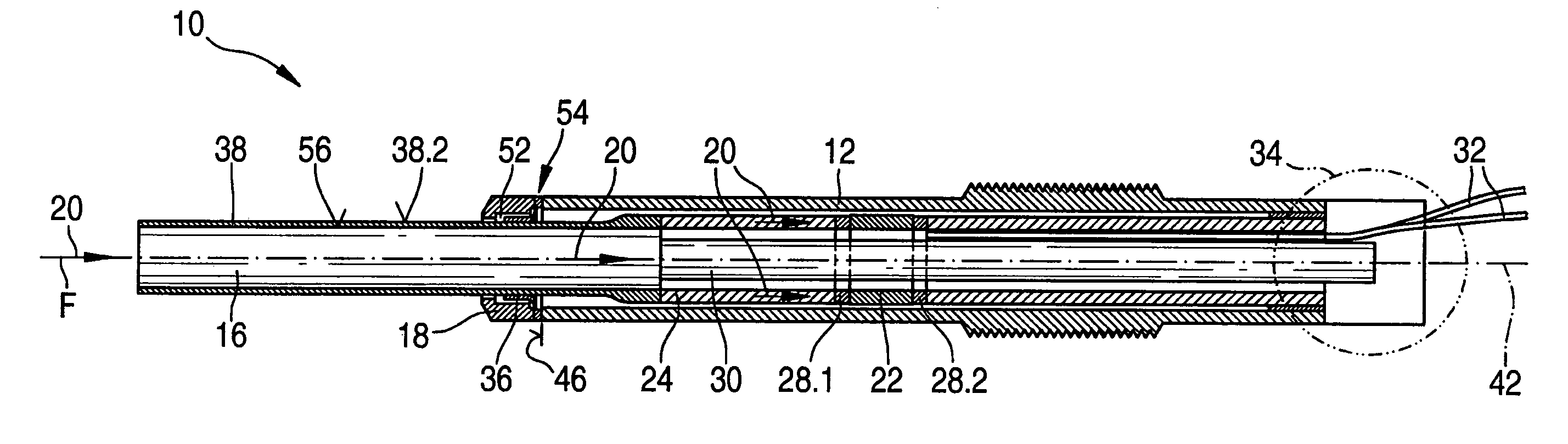

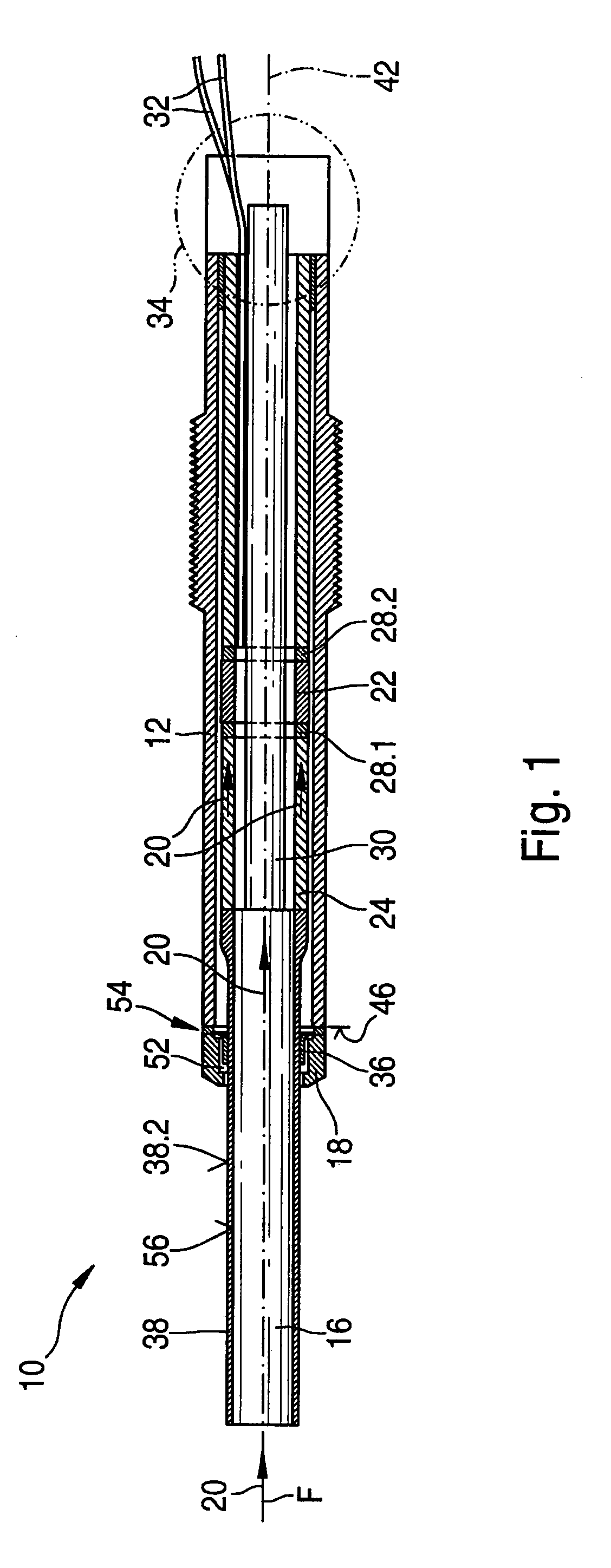

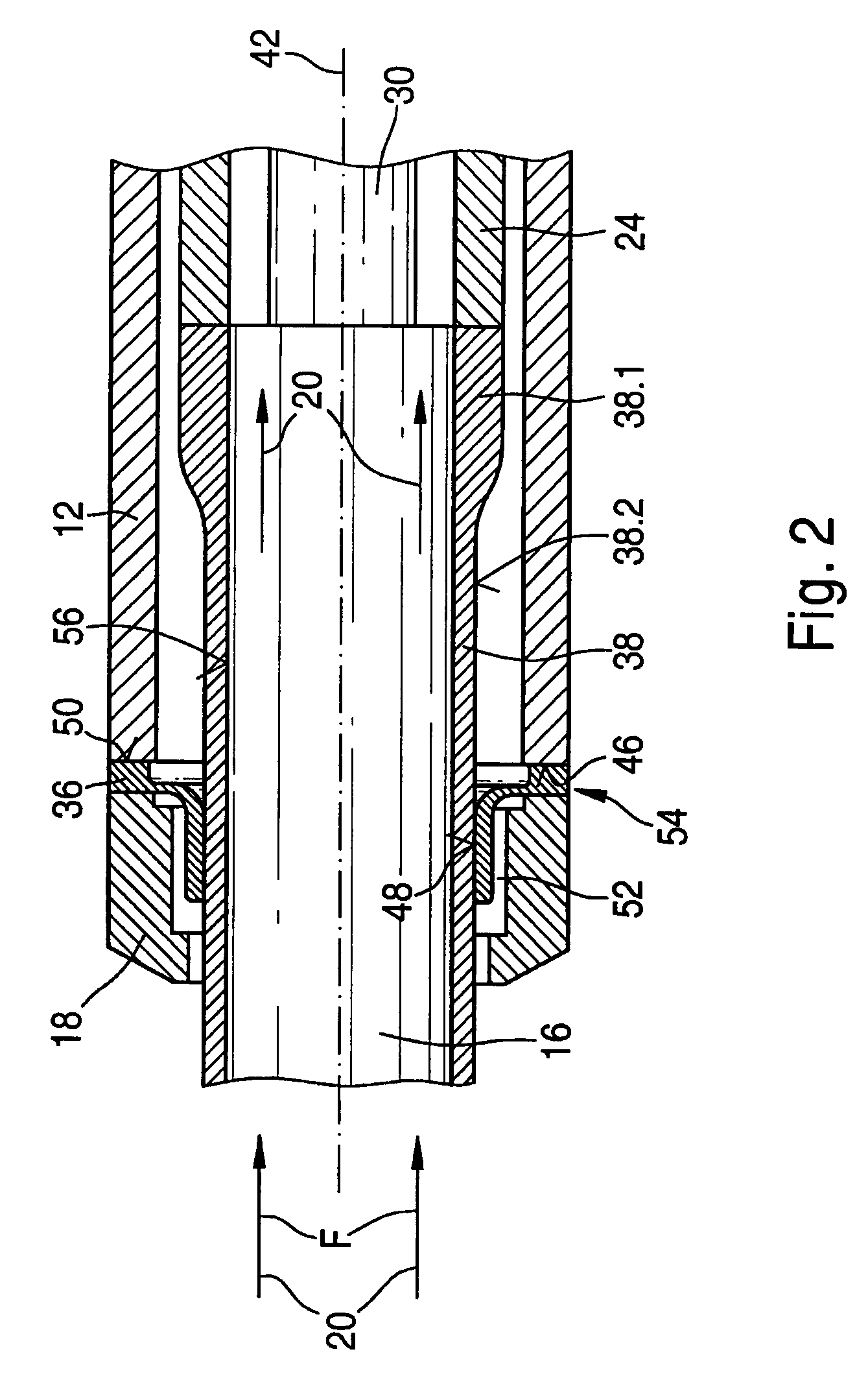

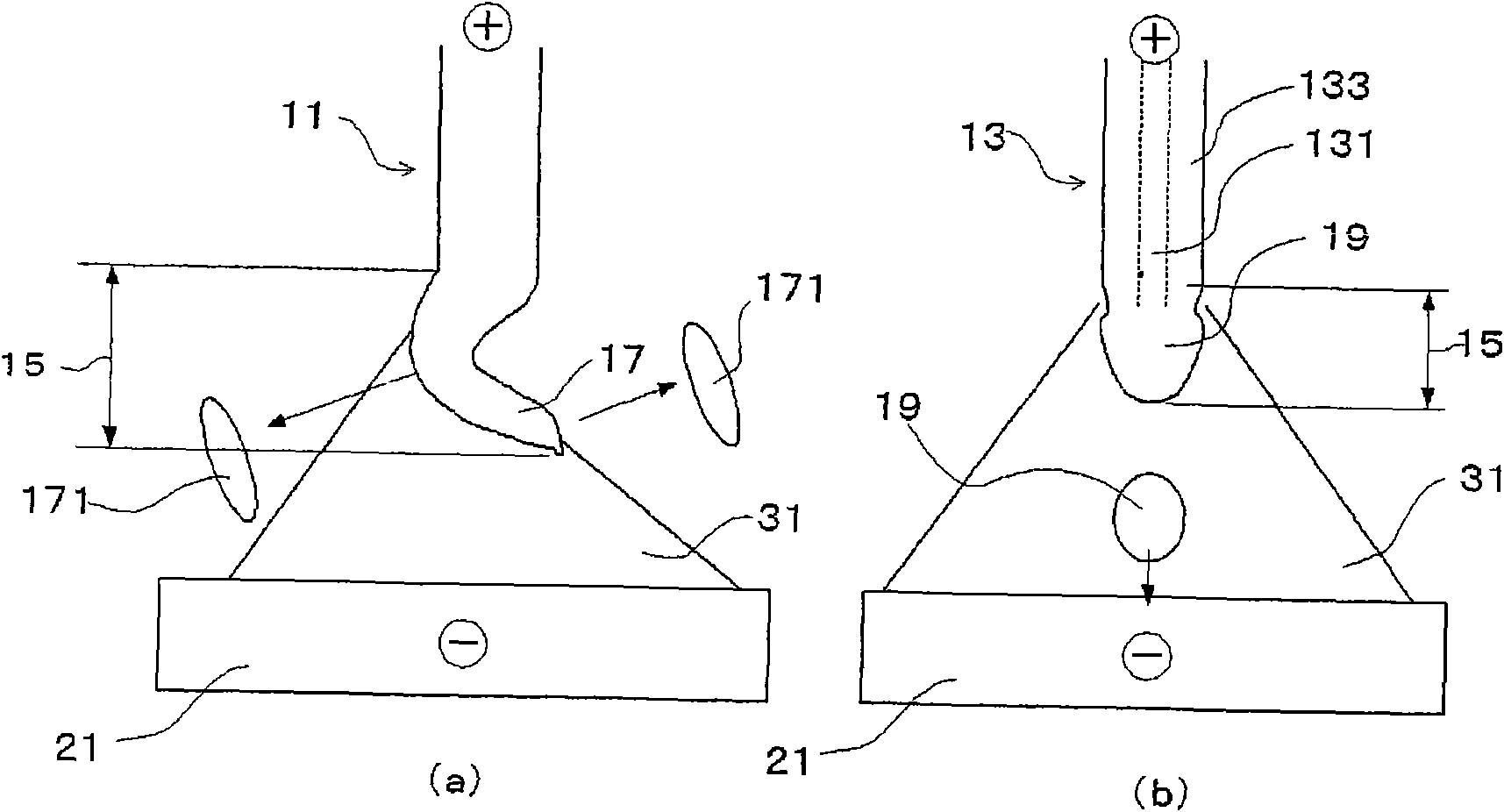

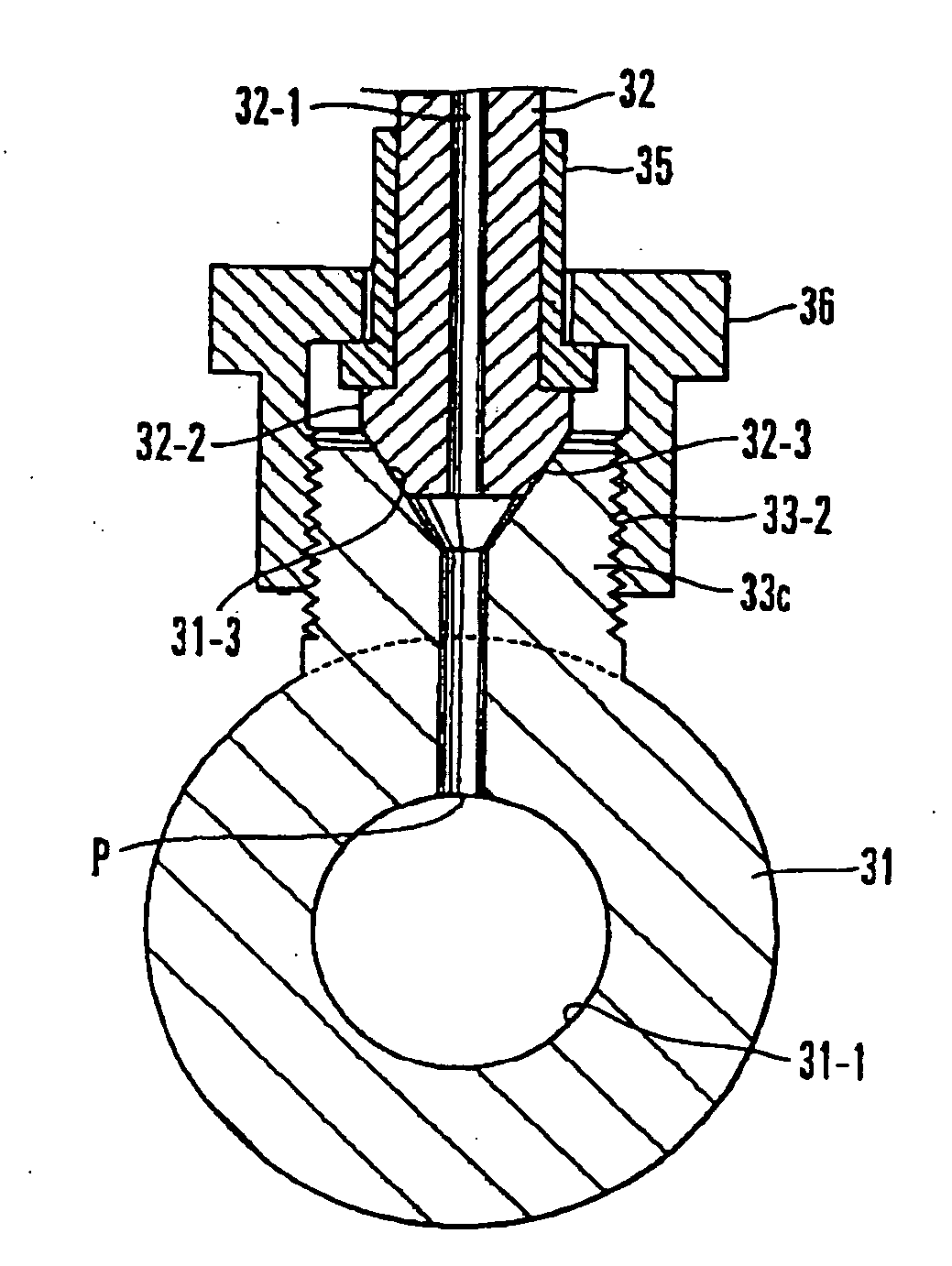

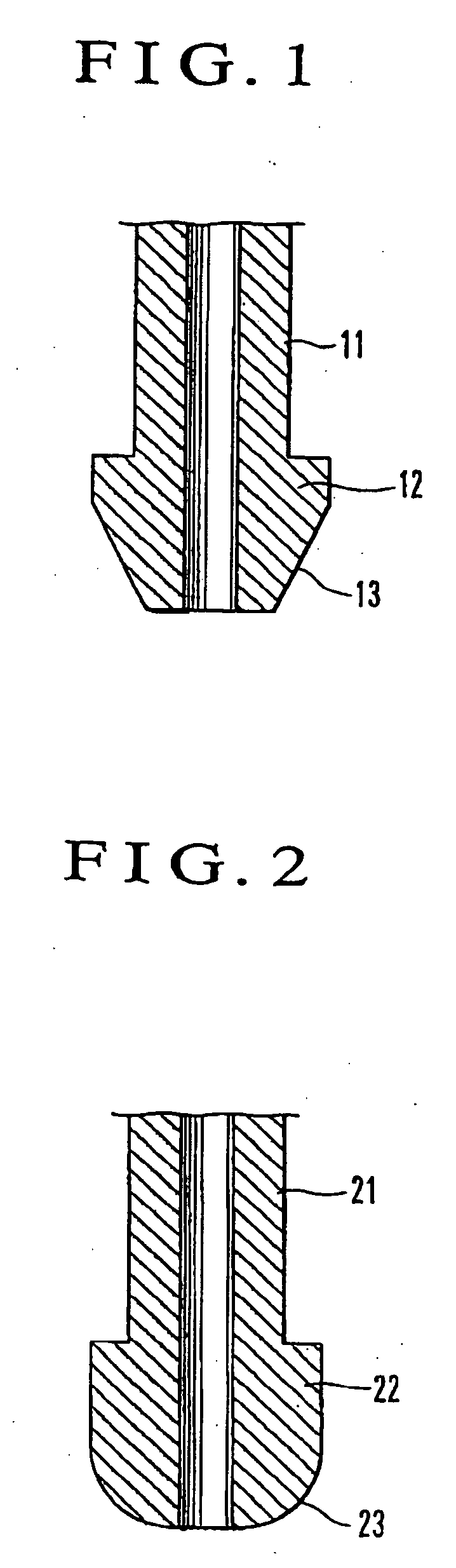

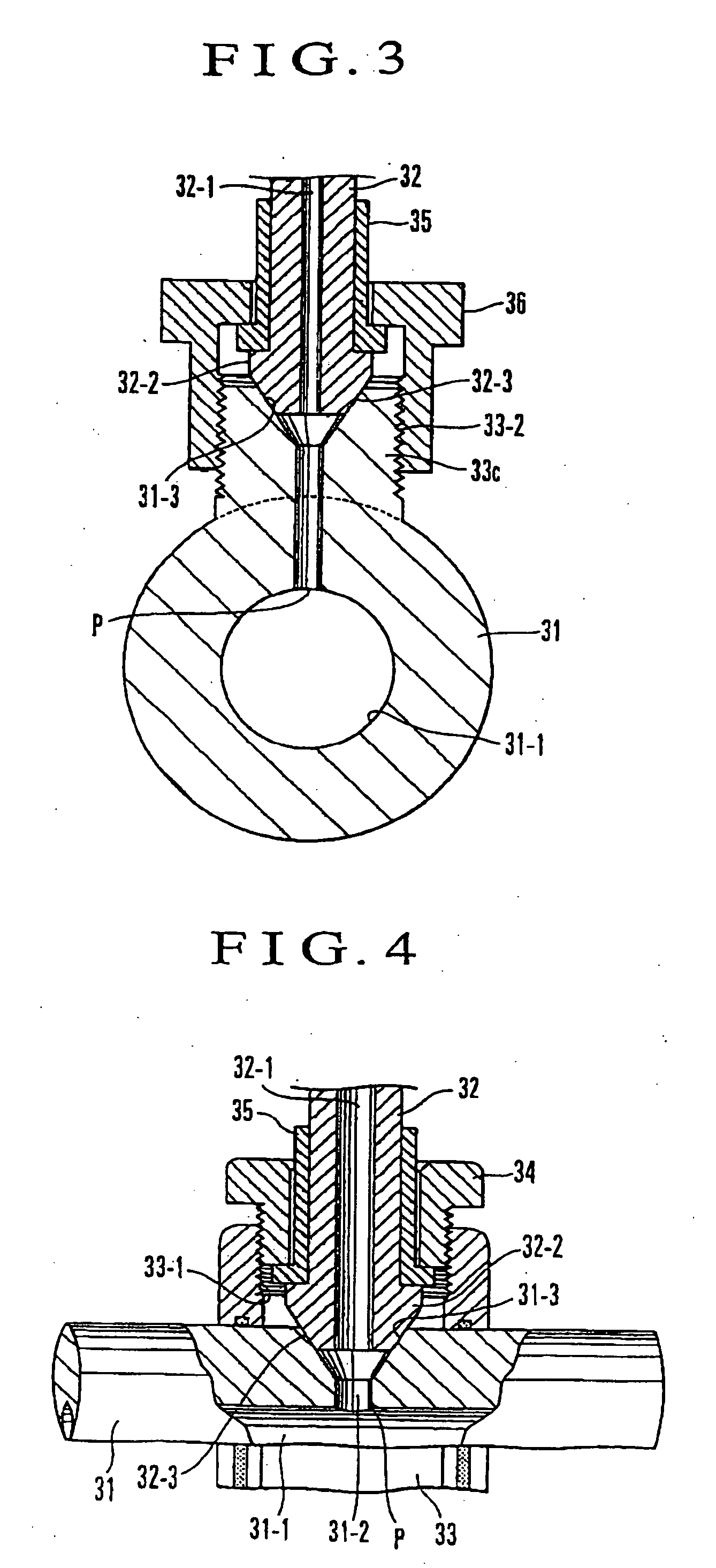

Pencil-type glow plug having an integrated combustion chamber pressure sensor

InactiveUS7581520B2Improve fatigue strengthAvoid failureIncandescent ignitionLamp incadescent bodiesCombustion chamberDiaphragm seal

A pencil-type glow plug for a self-igniting internal combustion engine is described. The pencil-type glow plug includes a plug body in which a combustion chamber pressure sensor is integrated, and a bar-shaped heating element that protrudes out from the plug body at one end, into the combustion chamber of the internal combustion engine. A force-measuring element of the combustion chamber pressure sensor is accommodated behind the heating element, which moves axially under the influence of force. The force-measuring element is sealed against combustion chamber gases by a steel diaphragm made of a stainless precipitation-hardened maraging steel.

Owner:ROBERT BOSCH GMBH

Rolling bearing

InactiveUS20030040442A1Reaction can be suppressedImprove fatigue strengthLiquid carbonaceous fuelsThickenersAlternatorRolling-element bearing

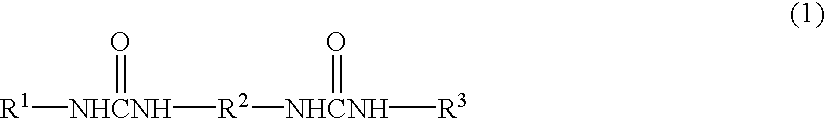

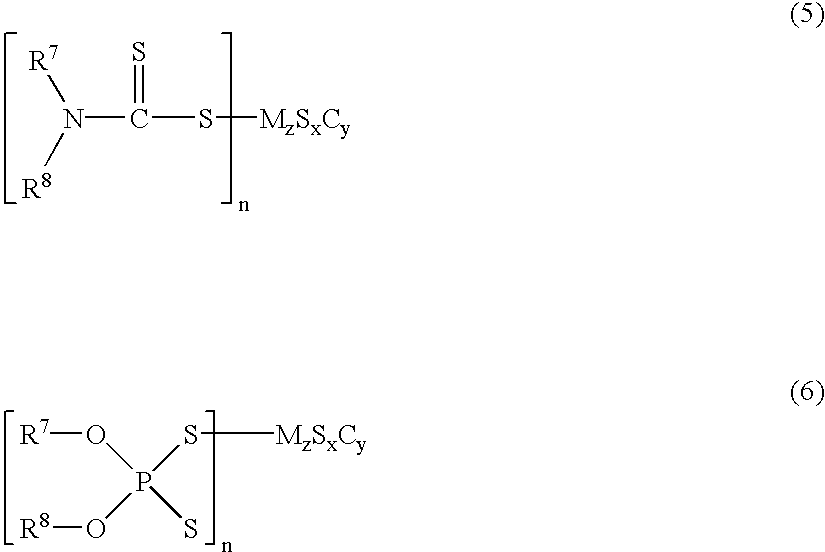

The invention aims to provide a rolling bearing that secures a sufficient bearing life economically even when used under such conditions that water from the outside or water formed by moisture condensation may seep into the lubricant or the bearing is affected by the vibrations, and particularly a rolling bearing suited to the electric parts and accessaries of au automobile engine, such as an alternator. To accomplish the object, the hydrogen ion exponent pH of the grease sealed into the inside of the bearing is adjusted in a range of from 7 to 13. For the same purpose, the hydrogen ion exponent pH of the grease is adjusted in a range of from 5 to 13 where a prescribed amount of an organic metal salt or ADTC is added to the grease, where a prescribed amount of an inorganic compound having an average particle size of 2 squarem or smaller is added to the grease, or where a diurea compound containing an aromatic amine or a mixture of the diurea compound is added to the grease as a thickener.

Owner:NSK LTD

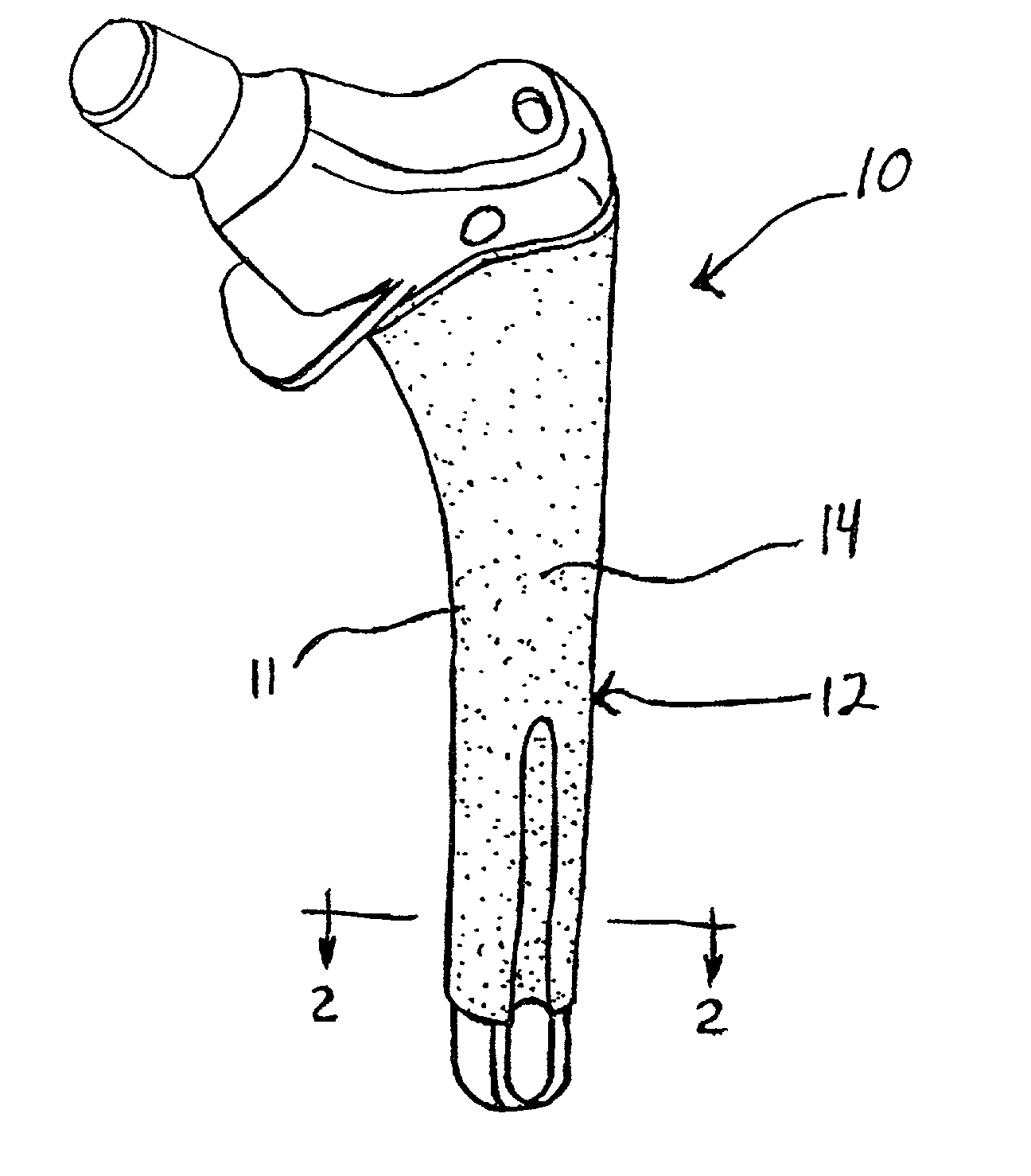

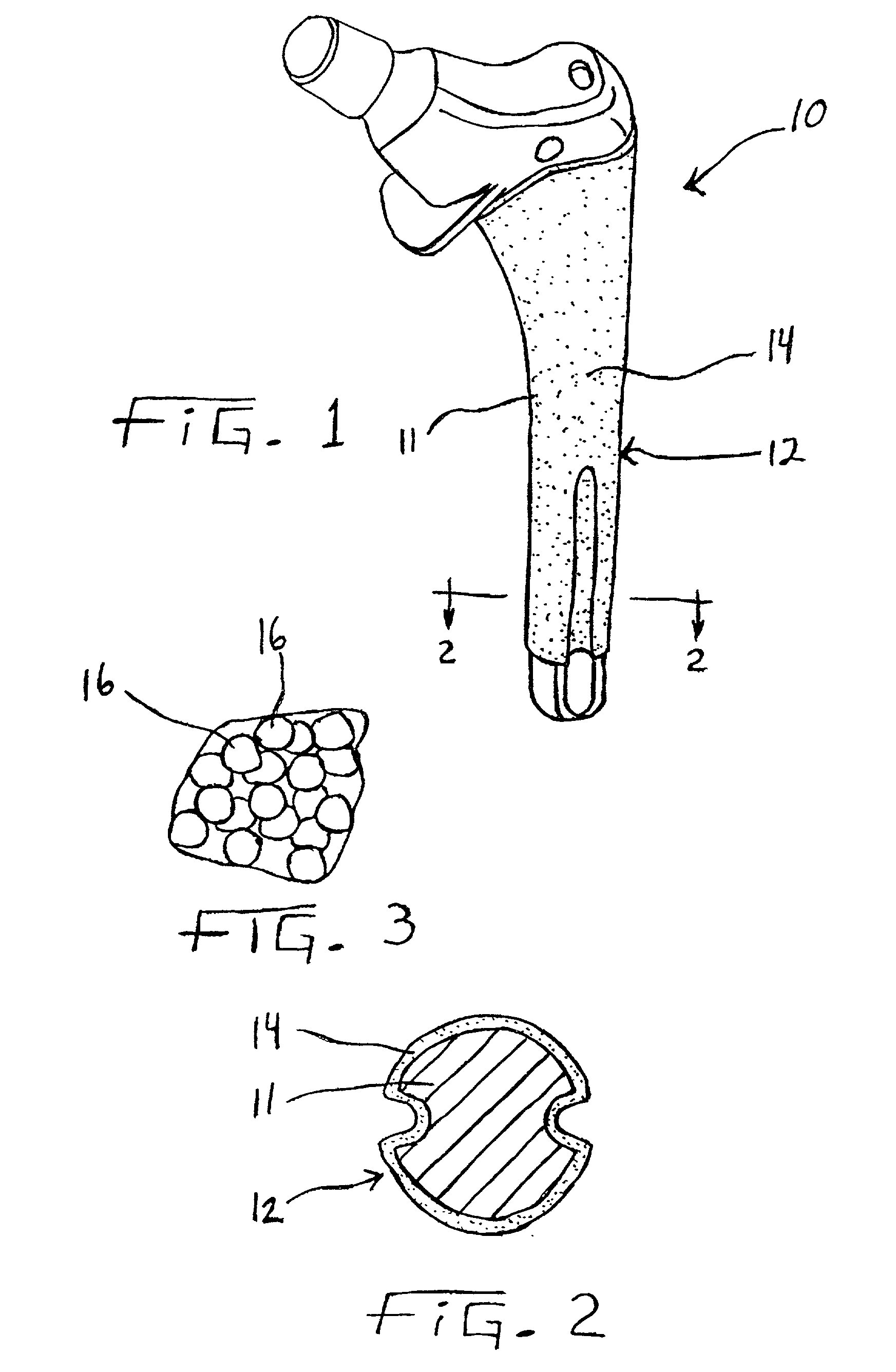

Enhanced fatigue strength orthopaedic implant with porous coating and method of making same

InactiveUS20020151983A1Improve fatigue strengthBone implantJoint implantsMetal particleBone ingrowth

A method for producing an orthopedic implant having enhanced fatigue strength. A forged implant substrate having an elongated stem is incorporated with a melting point lowering substance. Then, metal particles are sintered to the substrate, forming a porous layer on the substrate which enhances bone ingrowth or the mechanical interlock with bone cement. Advantageously, the sintering occurs at a lower temperature than if the substance were not incorporated into the substrate, which in turn results in an enhanced fatigue strength of the inventive implant. The fatigue strength of a forged or cast implant can also be improved by nitrogen diffusion hardening and / or thermally processing the implant after the porous coating is adhered by sintering. Further, the fatigue strength can be further improved by combining incorporating the melting point lowering substance with nitrogen diffusion hardening and / or aging treatment subsequent to sintering.

Owner:ZIMMER INC

Solid Particle Erosion Resistant Surface Treated Coat and Rotating Machine Applied Therewith

ActiveUS20090123737A1Improve fatigue strengthHigh erosion resistance and oxidation resistance and fatigue strengthLiquid surface applicatorsPump componentsAxial compressorSolid particle

A solid particle erosion resistant surface treated coat is provided by which a solid, particle erosion resistance is largely enhanced and a rotating member is given with an oxidation resistance without deteriorating a fatigue strength. Also, a rotating machine, such as a steam turbine, axial compressor or the like, applied with this coat is provided. The solid particle erosion resistant surface treated coat comprises a nitrided hard layer formed on a surface of base material and a PVD (physical vapor deposition) hard layer of at least one layer formed on the nitrided hard layer by a PVD method. The nitrided hard layer has a thickness of at least 30 μm. The PVD hard layer has a total thickness of at least 10 μm. Deformation of the base material by collisions by solid particles is prevented and crack of the coat comprising the nitrided hard layer formed on the base material and the PVD hard layer formed on the nitrided hard layer is prevented. Thereby, the solid particle erosion resistance is secured, life of the solid particle erosion resistant surface treated coat can be elongated and the oxidation resistance and fatigue strength are enhanced.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

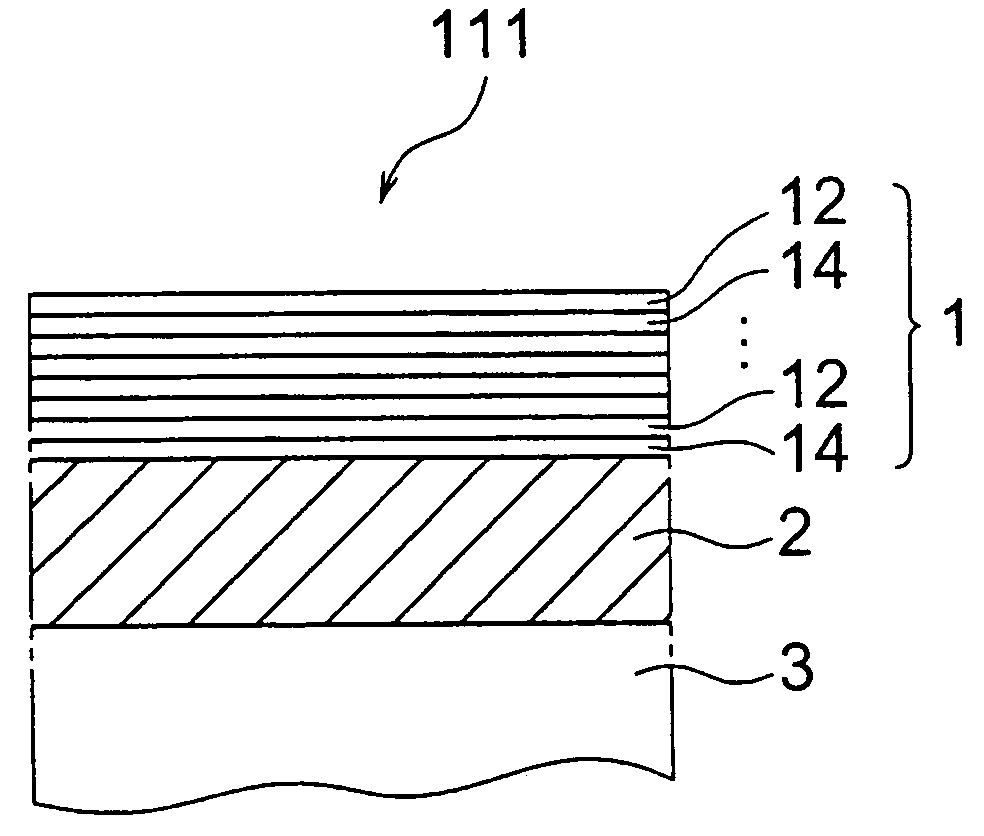

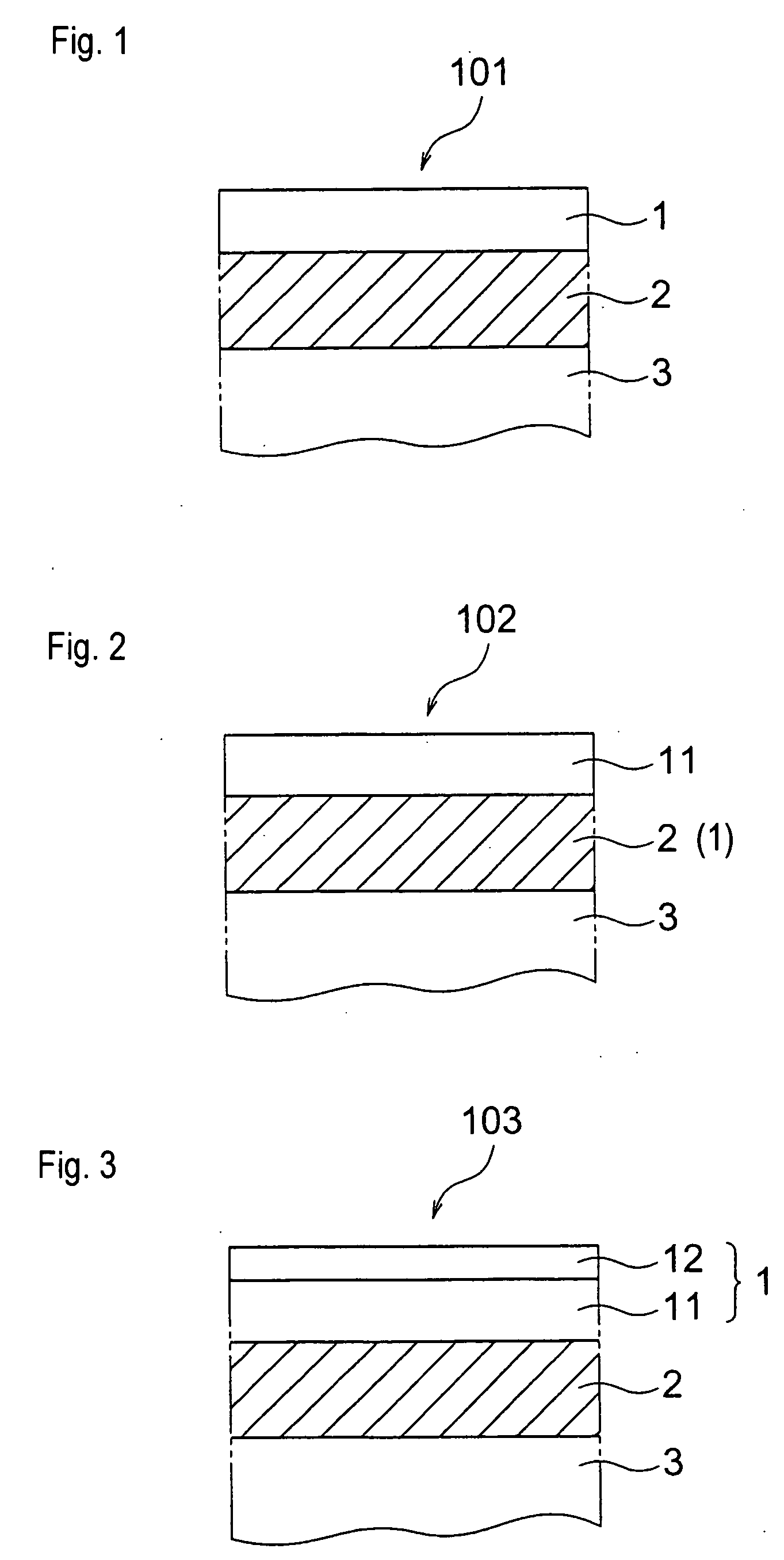

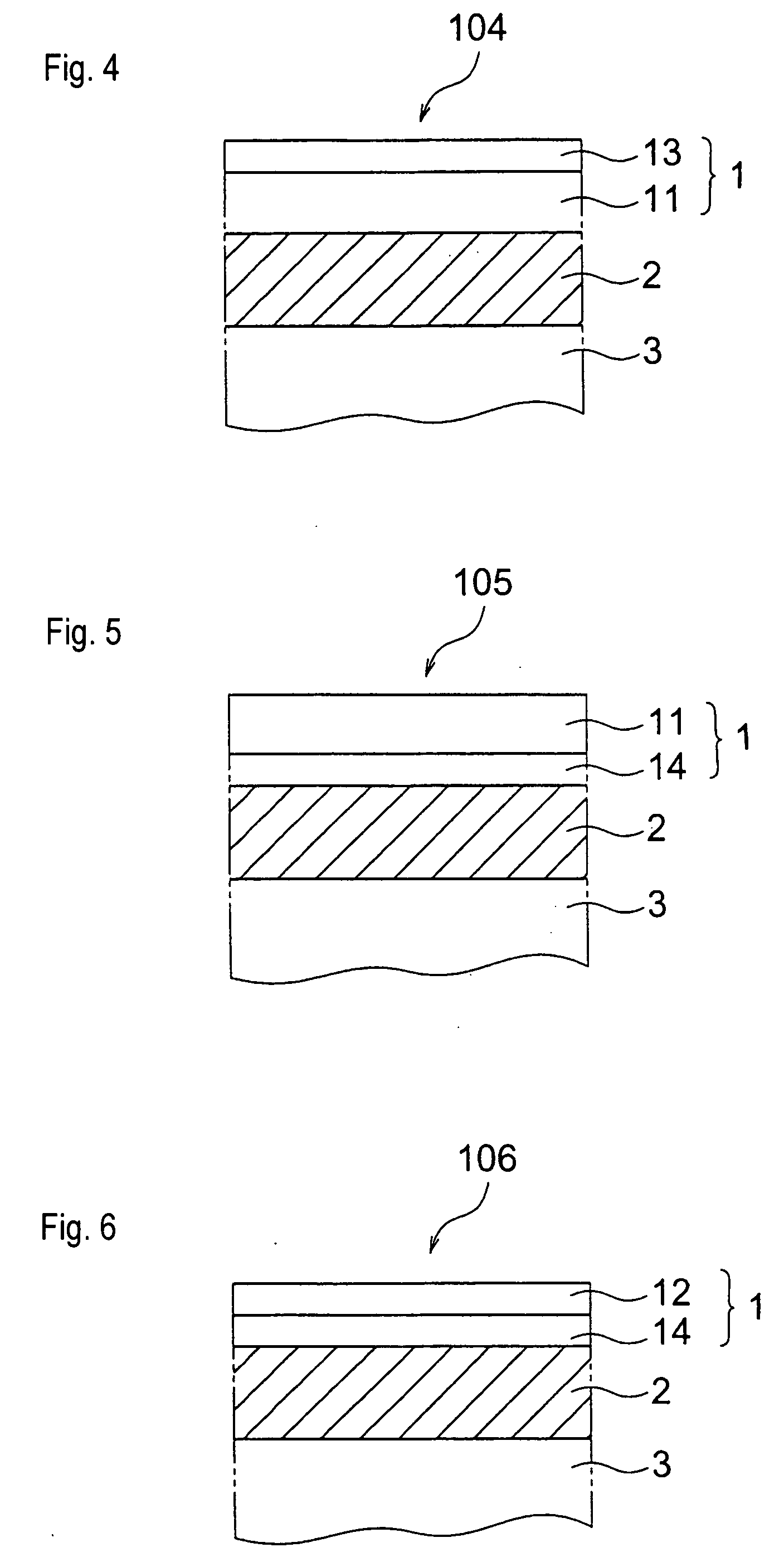

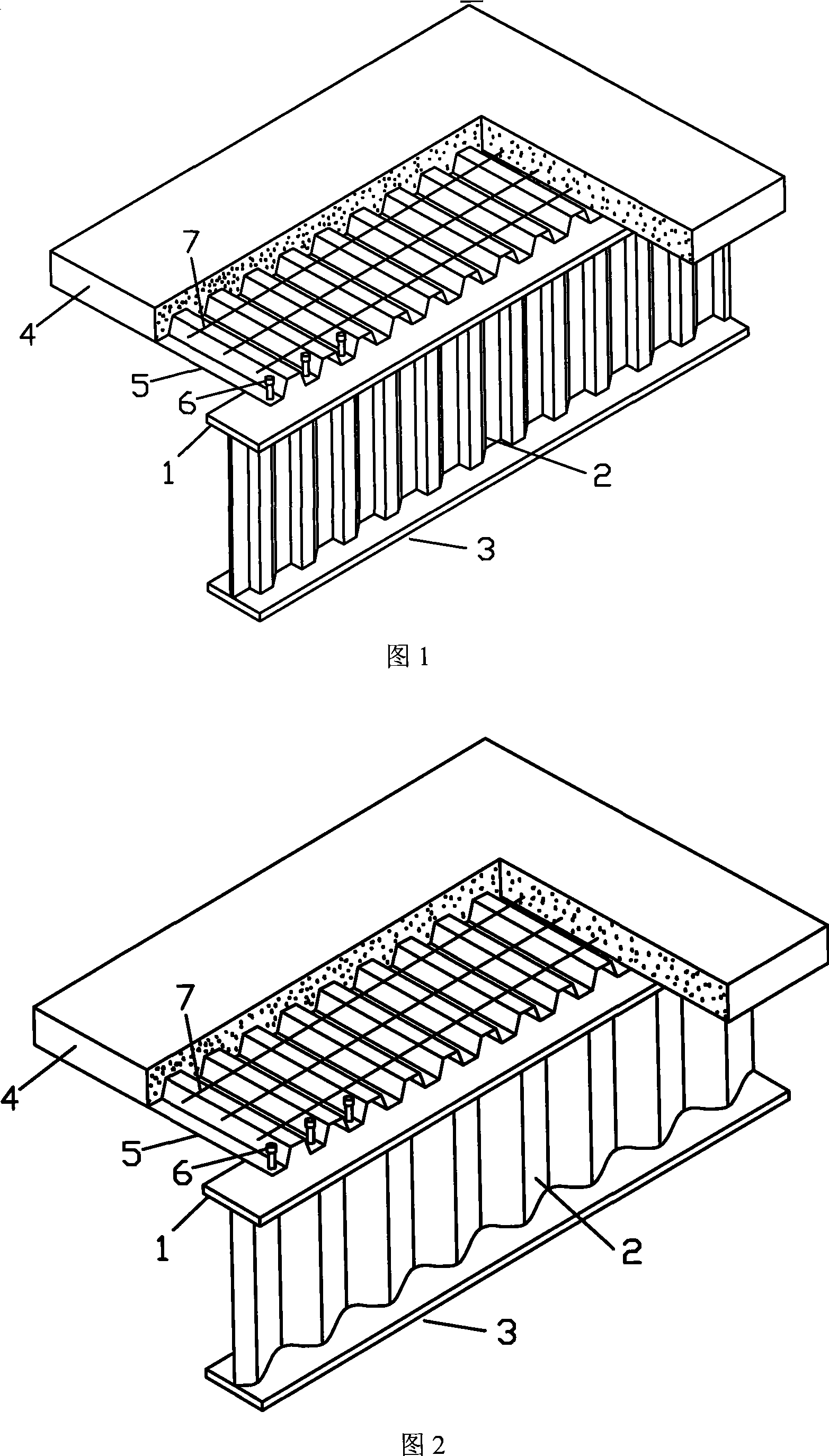

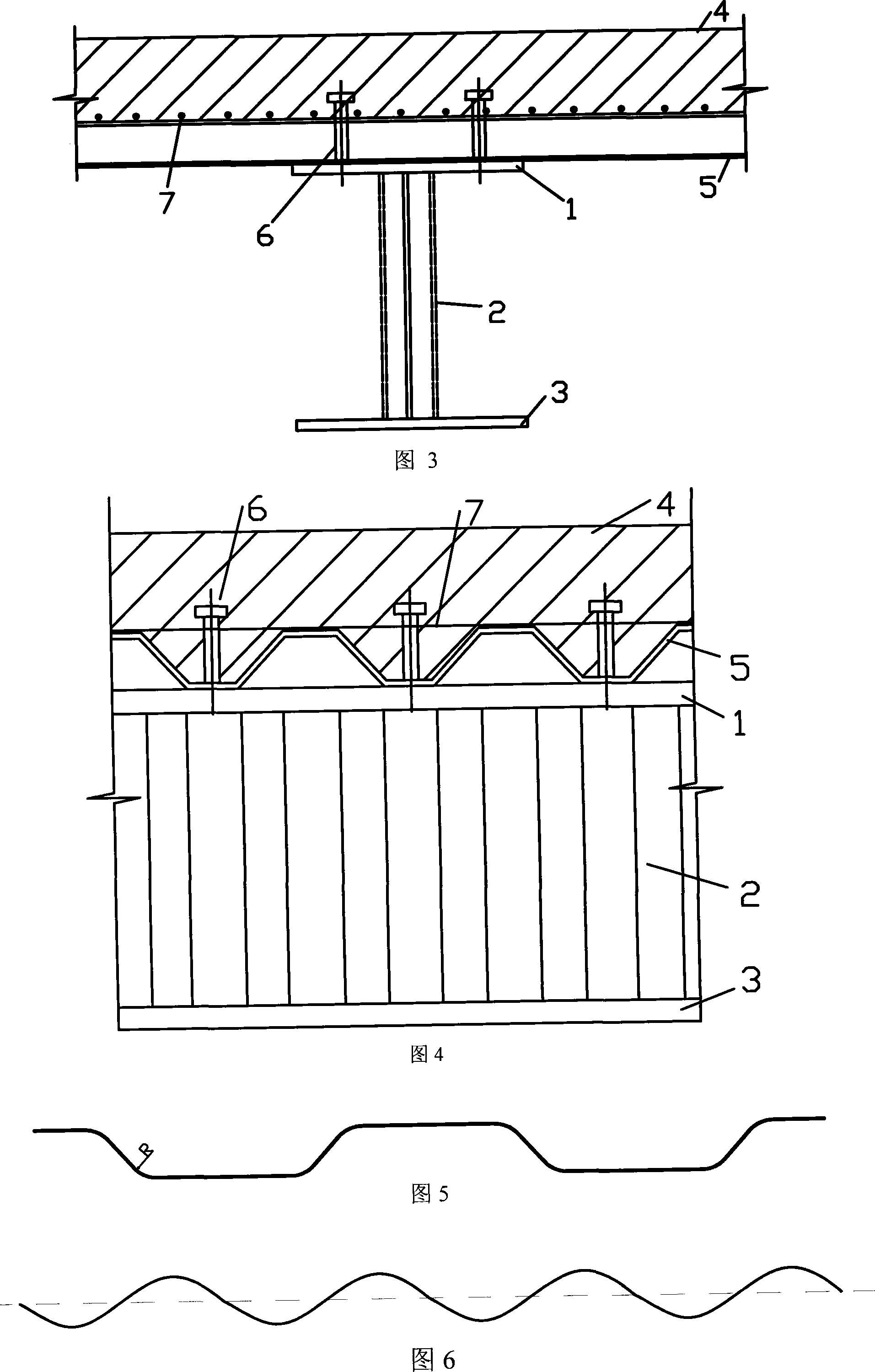

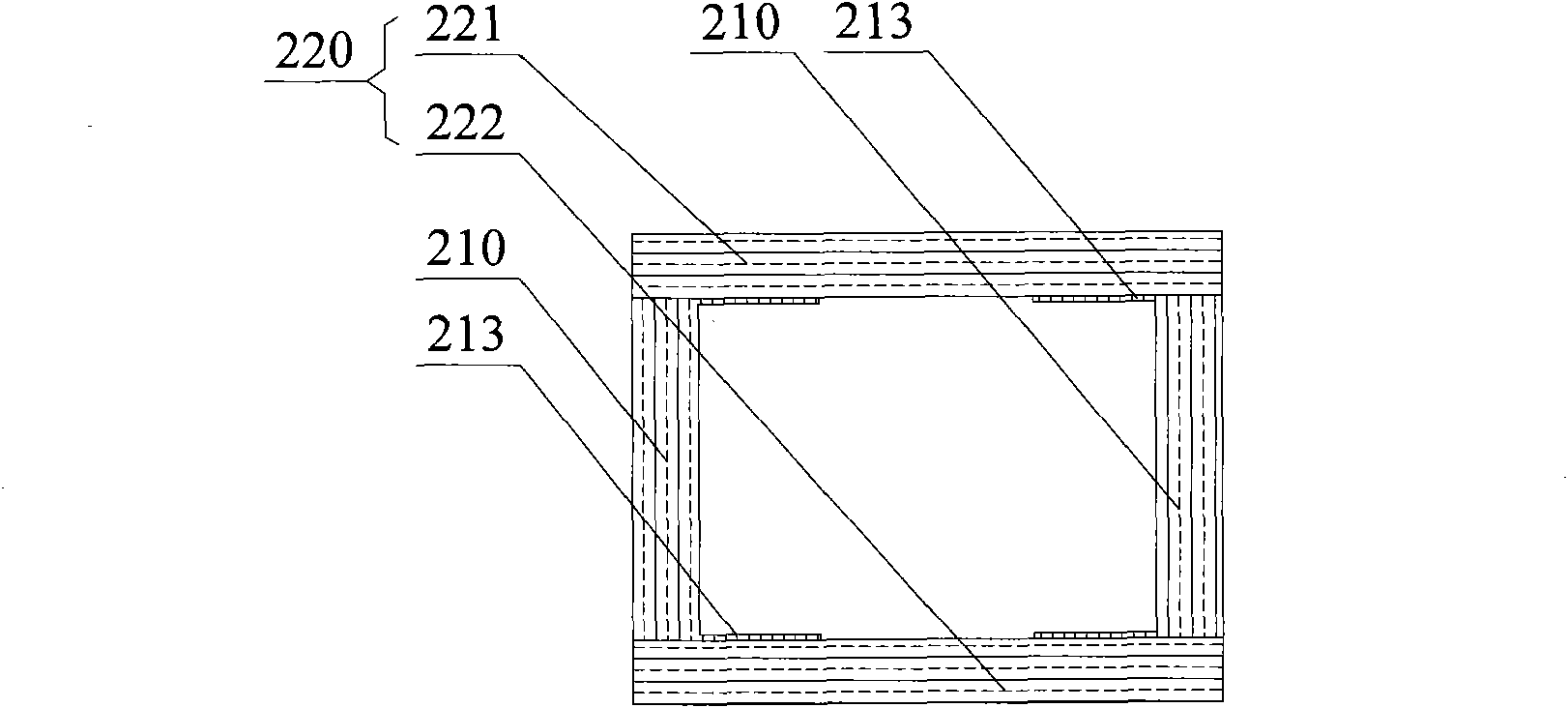

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

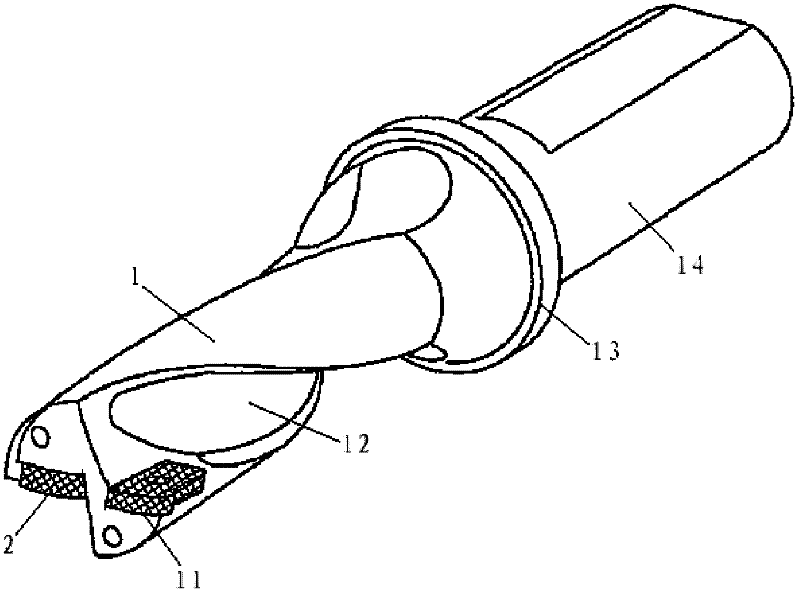

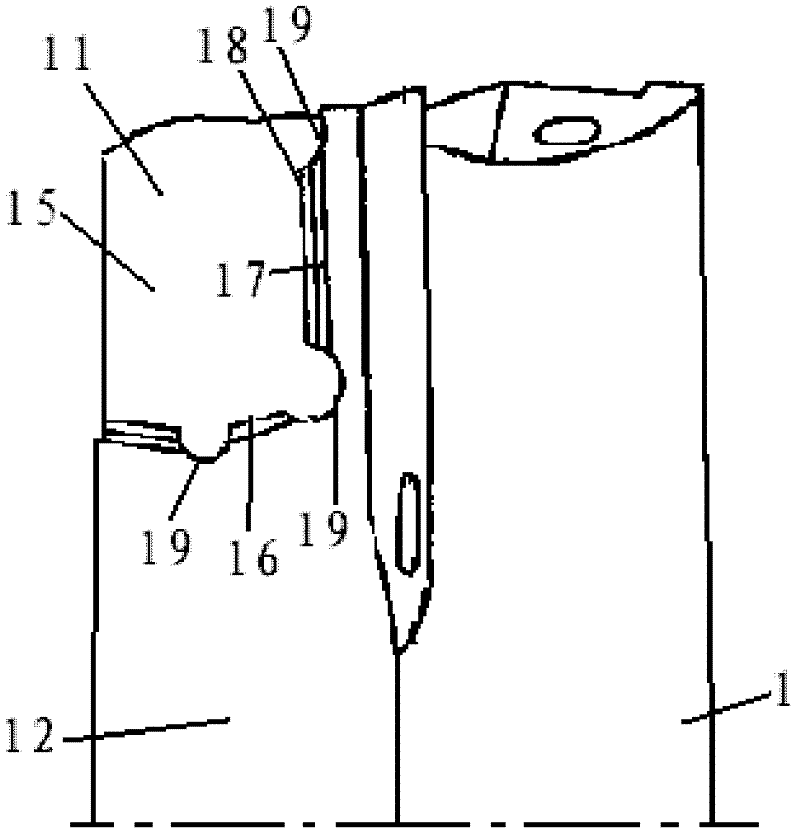

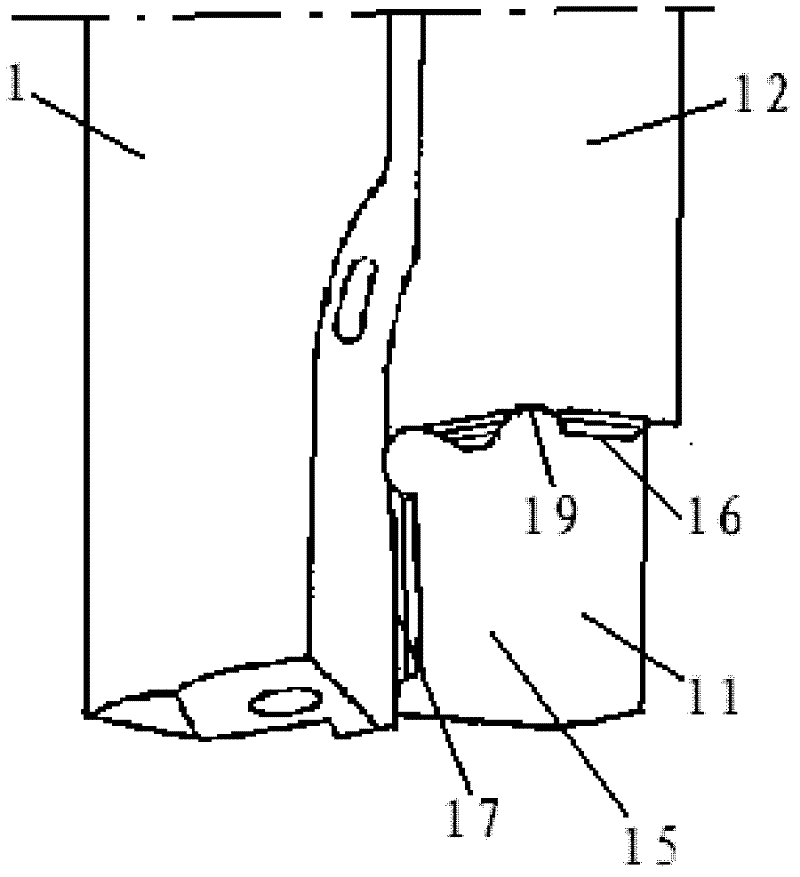

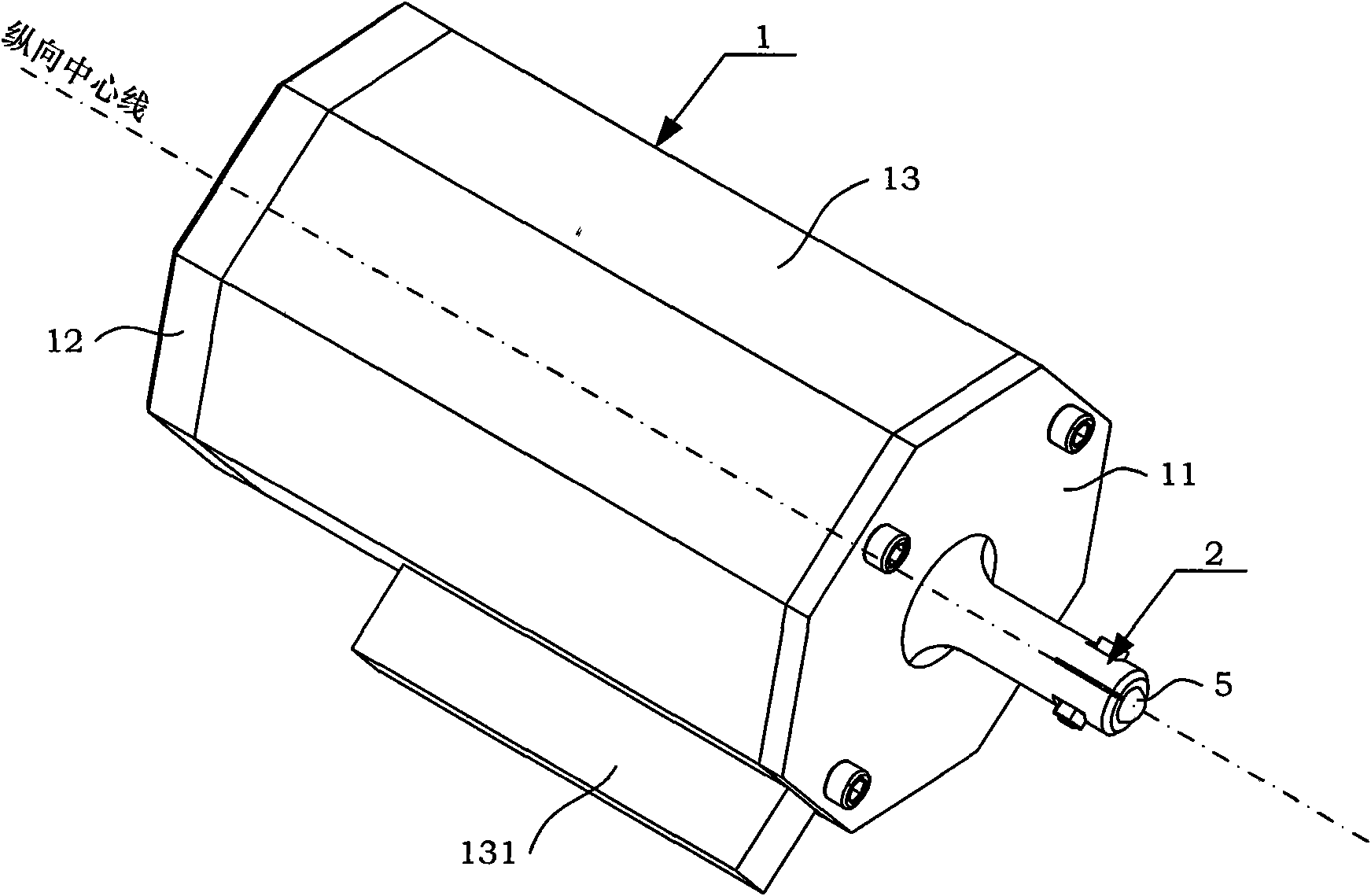

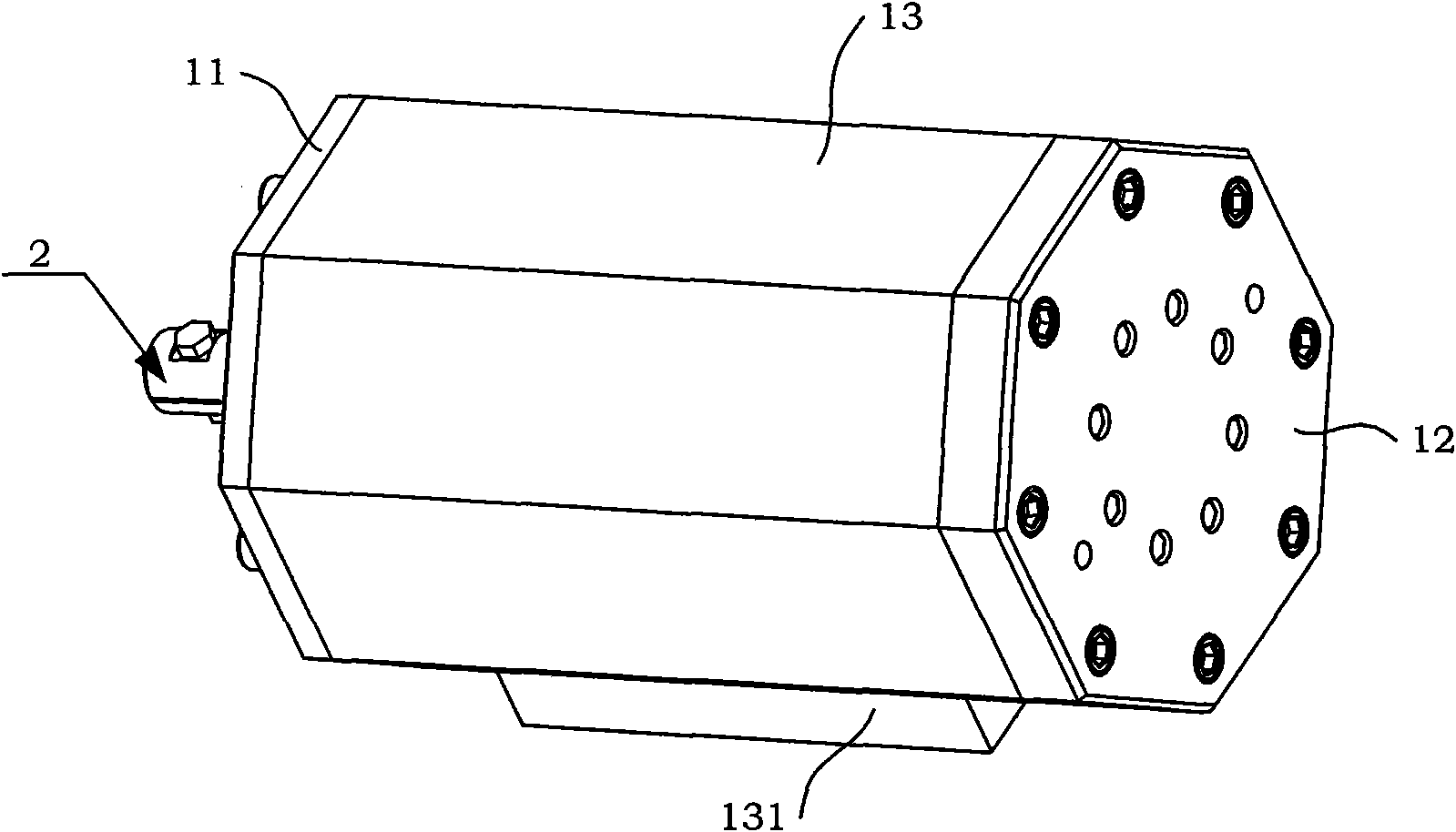

Cutting tool used for metal processing

InactiveCN102335778AHigh hardnessImprove fatigue strengthTransportation and packagingTrepanning drillsMetal workingEngineering

The invention discloses a cutting tool used for metal processing, which comprises a cylindrical tool rest (1) and at least one blade (2), wherein the tool rest (1) is provided with blade bearings (11) for containing at least one blade (2); the rear end of each blade bearing (11) is provided with a cuttings channel (12) which is favorable for cuttings to fall off by the tool rest (1); each blade bearing (11) is a groove and is provided with three supporting surfaces for abutting against the blade (2), wherein the three supporting surfaces are respectively a cutting supporting surface (15), a longitudinal supporting surface (16) and a radial supporting surface (17); and at least one of the longitudinal supporting surface (16) and the radial supporting surface (17) is provided with at least one circular-arc notch (19). The hardness of the material is improved by the design on the tool rest structure, and therefore the tool has high fatigue strength. Meanwhile, material surface polishing is used to lower the possibility of forming fissures. In addition, the cutting tool has the advantages of simple structure and low cost and is convenient to manufacture.

Owner:四川欧曼机械有限公司

Steel having excellent machinability for mechanical structure

InactiveCN102985577AImprove fatigue strengthExcellent machinabilityIncreasing energy efficiencyMetallurgyMachinability

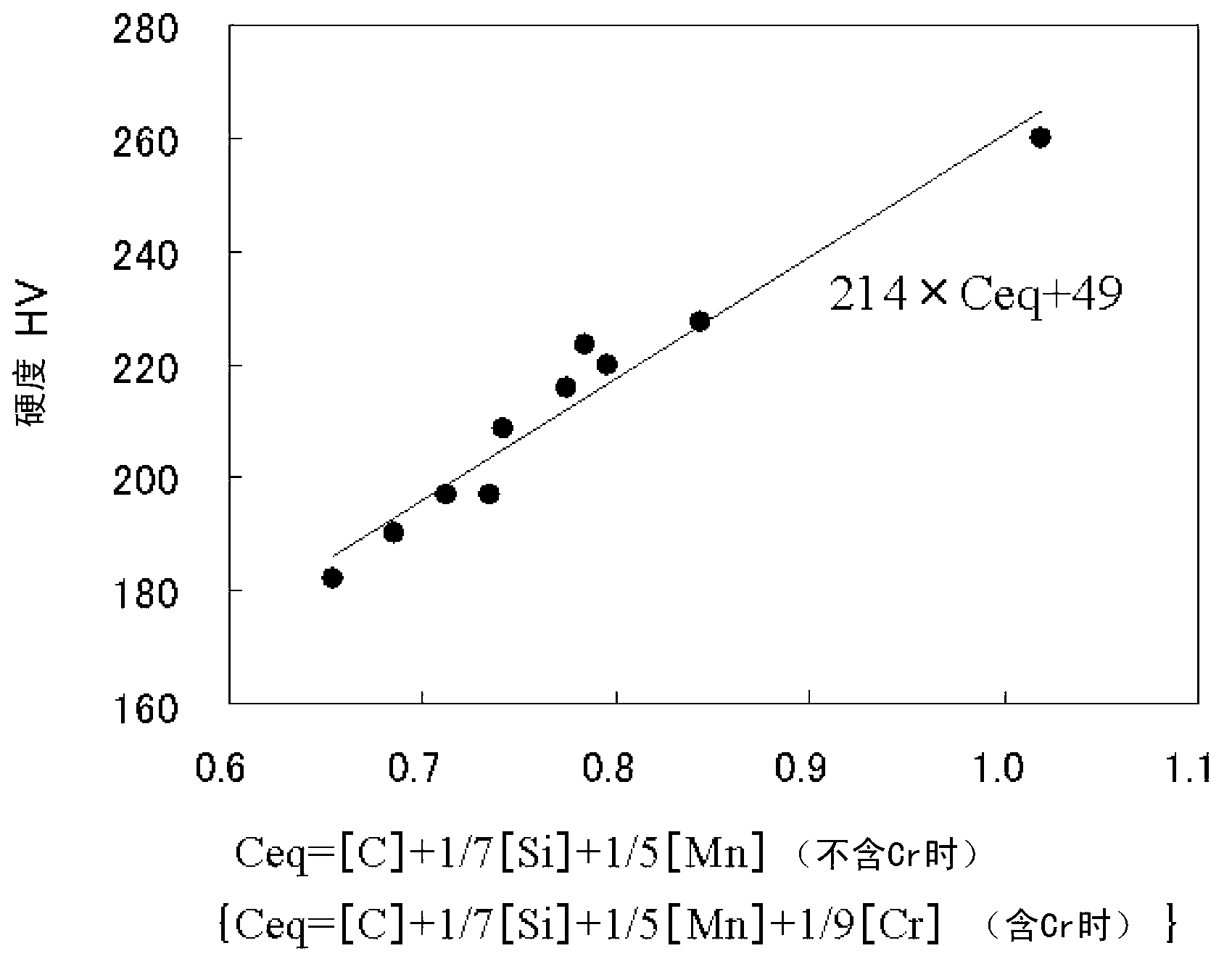

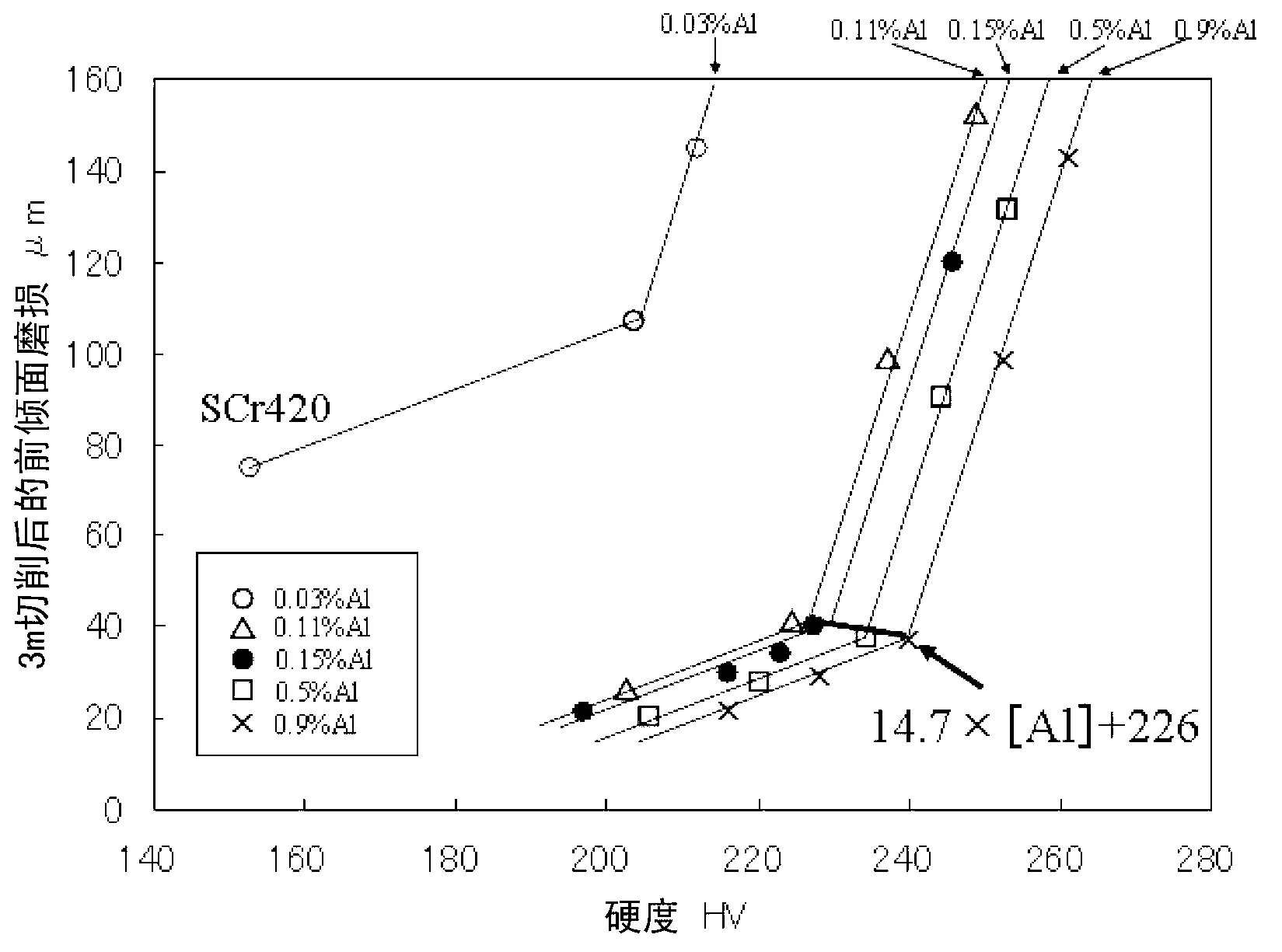

Provided is a steel for a mechanical structure, which comprises, by mass%, 0.40% to less than 0.75% of C, 0.01% to 3.0% of Si, 0.1% to 1.8% of Mn, 0.001% to 0.1% of S, greater than 0.1% to 1.0% of Al, 0.001% to 0.02% of N, no more than 0.05% of P, and residual Fe and inevitable impurities as the balance, and which satisfies 139.38<=214[C]+30.6[Si]+42.8[Mn]-14.7[Al]<=177 and 0.72<=[C]+1 / 7[Si]+1 / 5[Mn]<1.539.

Owner:NIPPON STEEL CORP

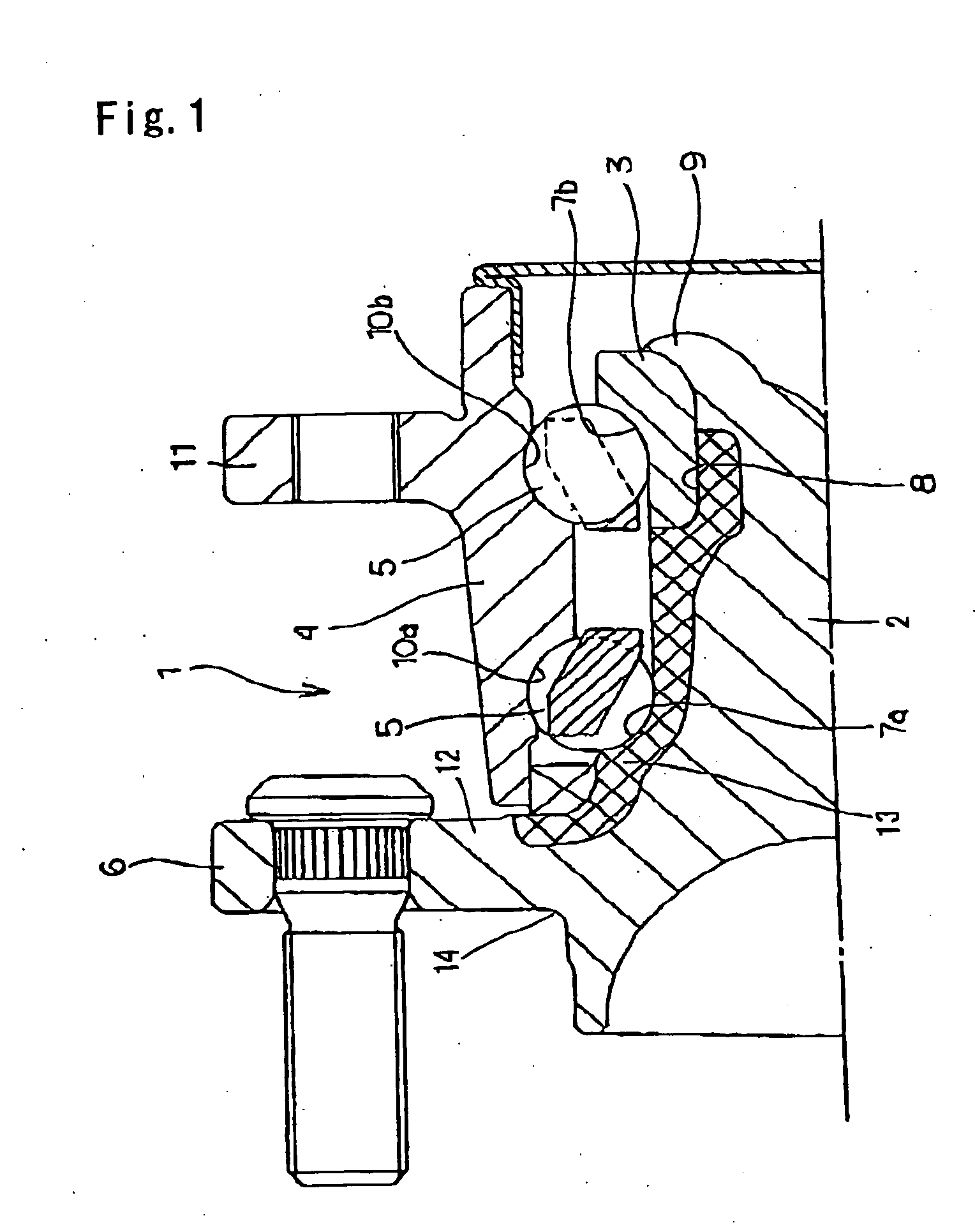

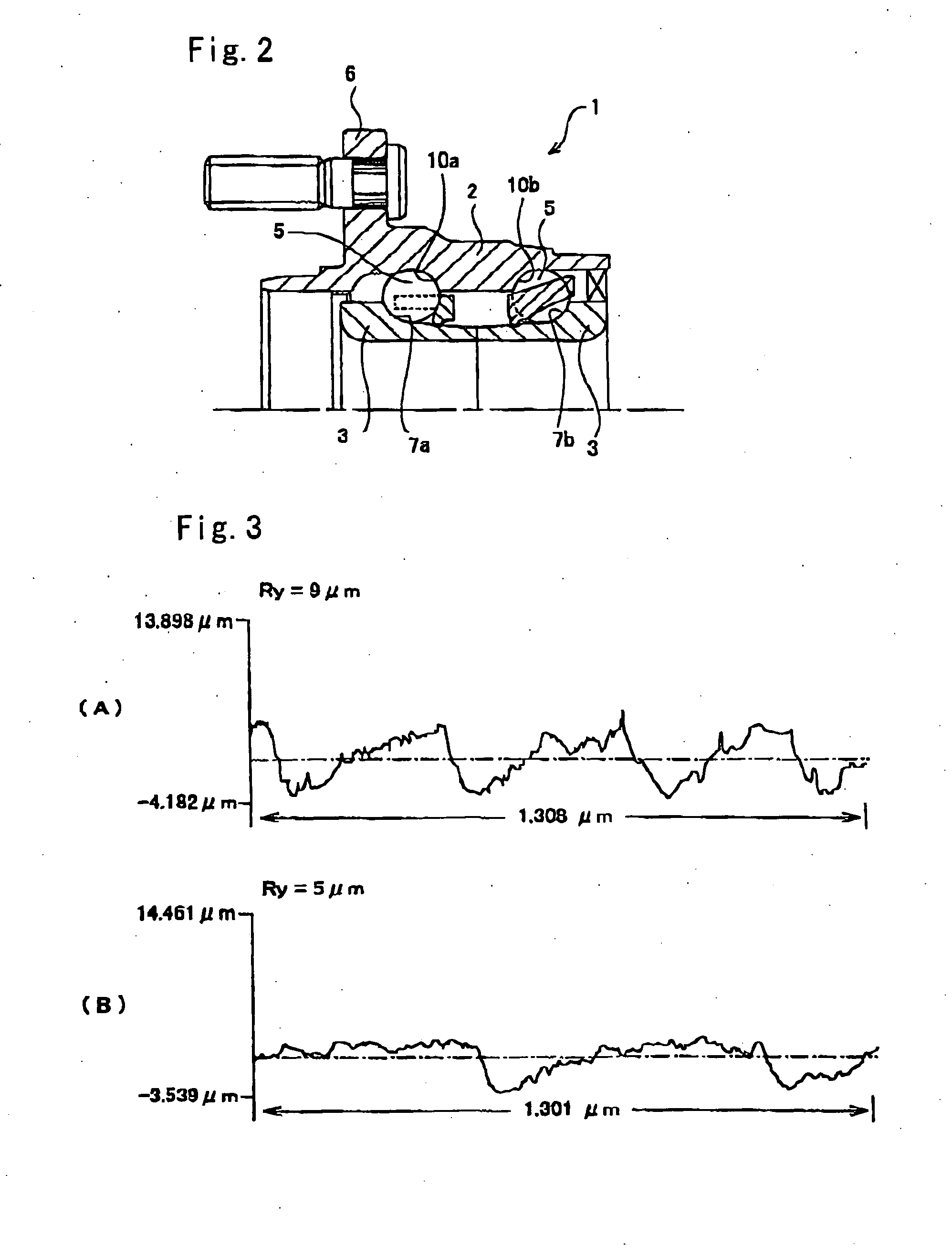

Wheel-support rolling bearing unit

InactiveUS20050141799A1Reduced deformabilityEasy to crackRolling contact bearingsBearing assemblySurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

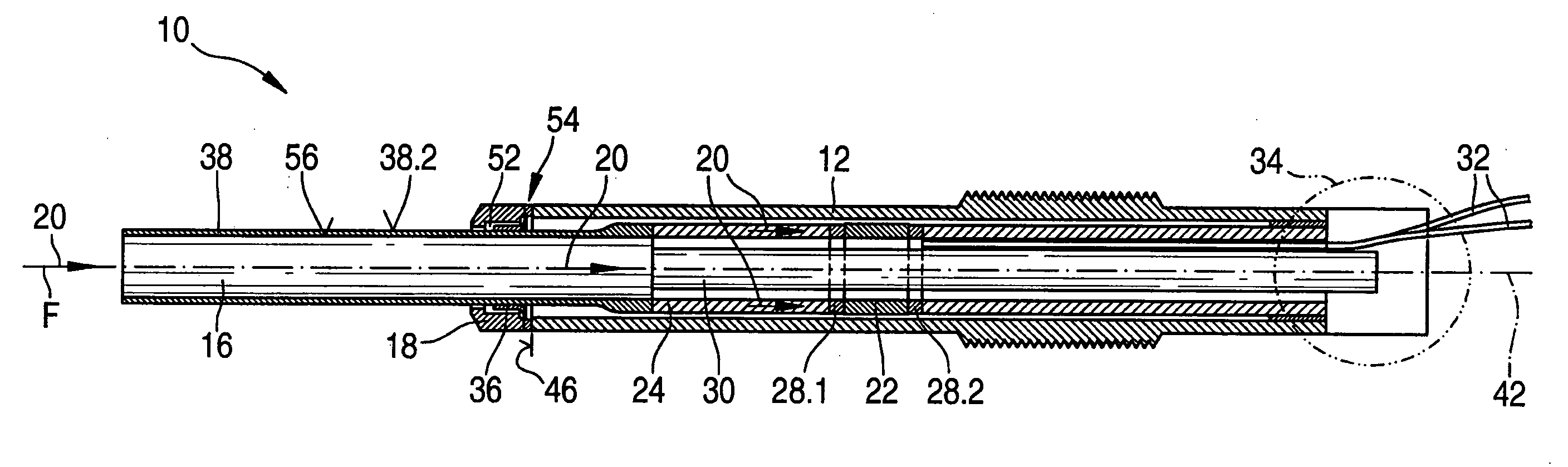

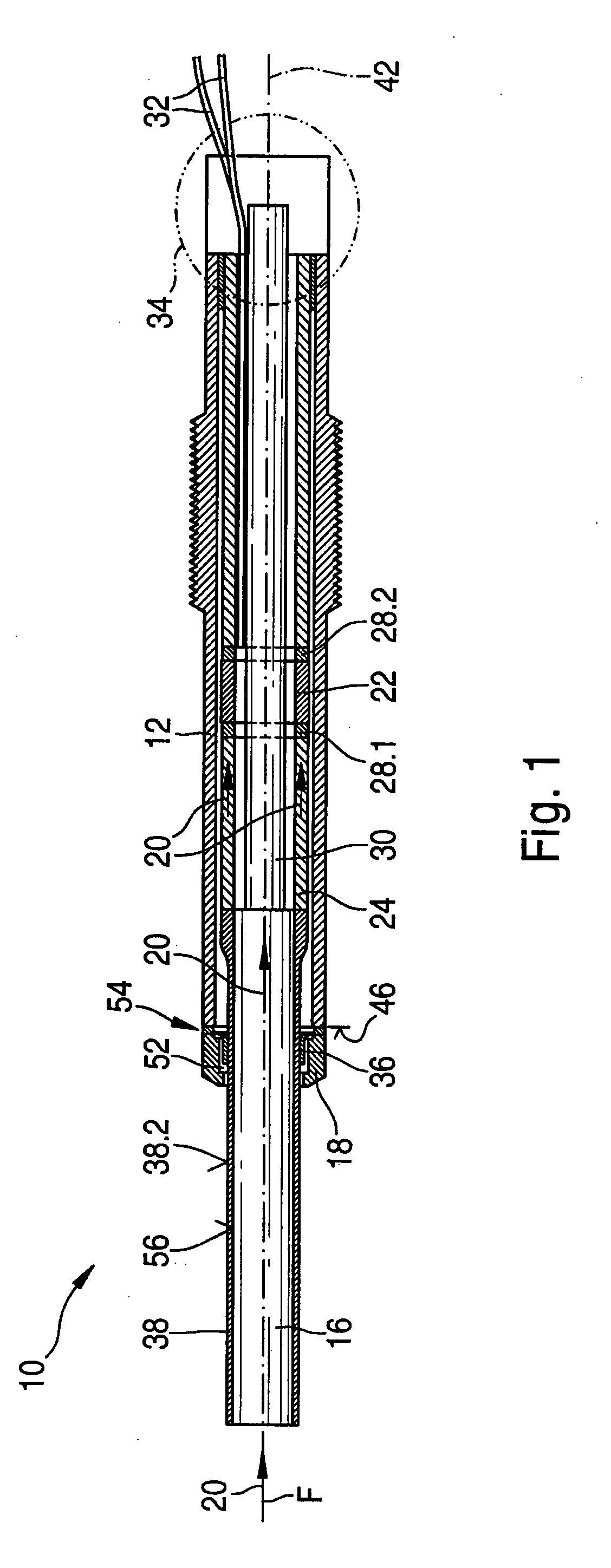

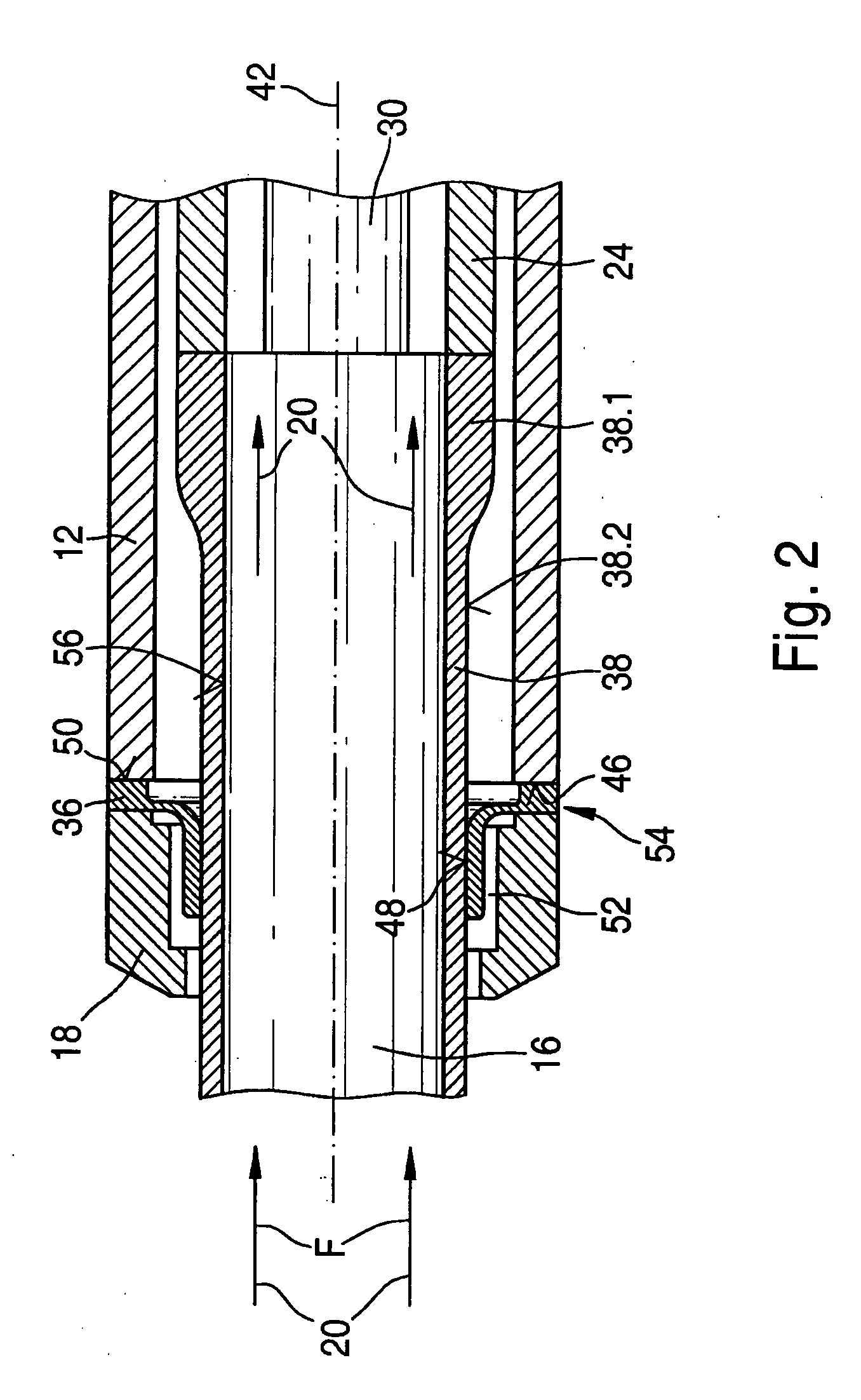

Pencil-Type Glow Plug Having an Integrated Combustion Chamber Pressure Sensor

InactiveUS20080302323A1Improve fatigue strengthAvoid failureIncandescent ignitionLamp incadescent bodiesCombustion chamberEngineering

A pencil-type glow plug for a self-igniting internal combustion engine is described. The pencil-type glow plug includes a plug body in which a combustion chamber pressure sensor is integrated, and a bar-shaped heating element that protrudes out from the plug body at one end, into the combustion chamber of the internal combustion engine. A force-measuring element of the combustion chamber pressure sensor is accommodated behind the heating element, which moves axially under the influence of force. The force-measuring element is sealed against combustion chamber gases by a steel diaphragm made of a stainless precipitation-hardened maraging steel.

Owner:ROBERT BOSCH GMBH

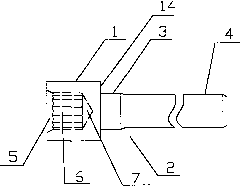

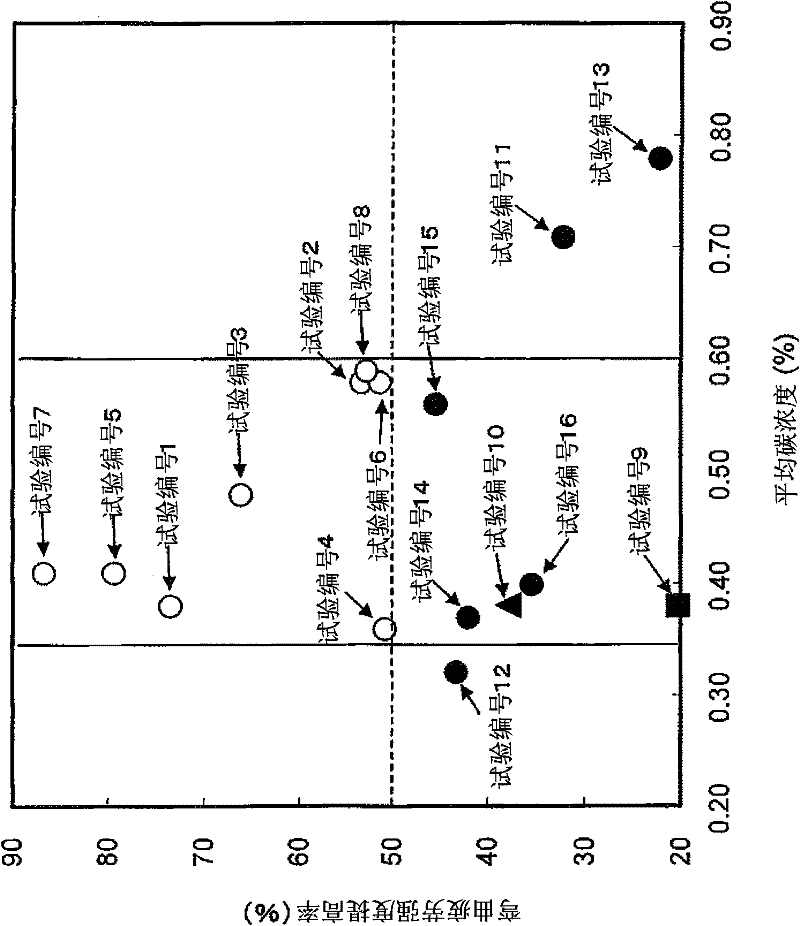

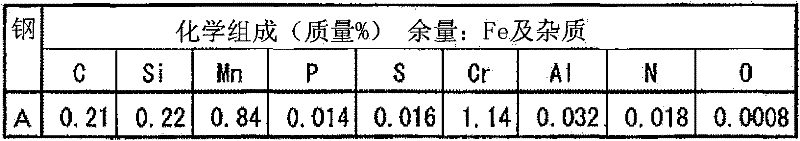

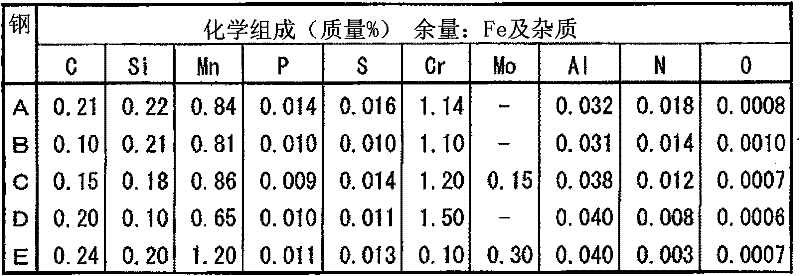

Carburized component and manufacturing method therefor

ActiveCN102459678AImprove fatigue strengthSolid state diffusion coatingFurnace typesNiobiumManganese

Provided is a carburized component having excellent fatigue strength in the "low-to-mid-cycle regime." Said carburized component comprises a steel having a chemical composition as follows: the base steel contains 0.15-0.25% carbon, 0.03-0.50% silicon, more than 0.60% and up to 1.5% manganese, no more than 0.015% phosphorus, 0.006-0.030% sulfur, 0.05-2.0% chromium, no more than 0.10% aluminum, no more than 0.03% nitrogen, and no more than 0.0020% oxygen; the steel also contains specific amounts of molybdenum, copper, nickel, boron, titanium, niobium, and / or vanadium as necessary; and the remainder comprises iron and impurities. The surface hardened layer of the carburized component fulfills the following conditions: (a) the mean carbon concentration up to a depth of 0.2 mm from the outermost surface is between 0.35% and 0.60%; (b) the surface roughness Rz is at most 15 [mu]m; and (c) the compressive residual stress at the outermost surface of the component is no more than -800 MPa, thecompressive residual stress 100 [mu]m from the outermost surface of the component is no more than -800 MPa, and Ir is at least 80,000, where Ir is the integral of sr(y) dy from 0 to 100, y being the depth in [mu]m from the outermost surface of the component up to a depth of 100 [mu]m and sr(y) being the residual stress at a depth y.

Owner:NIPPON STEEL CORP +1

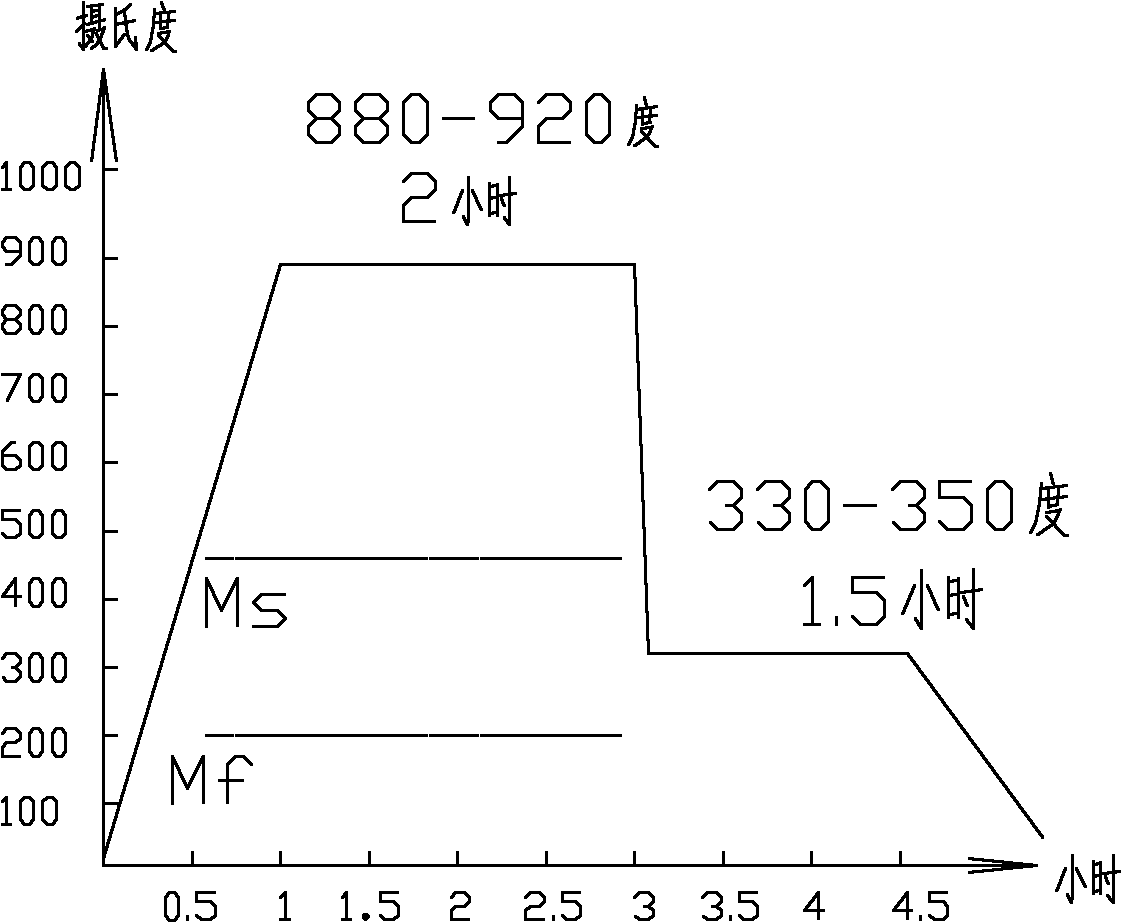

Cemented quenching heat treatment method of automobile engine gears

InactiveCN104195567APlane warpage reductionReduce manufacturing costSolid state diffusion coatingFurnace typesFurnace temperatureCarbon potential

A cemented quenching heat treatment method of automobile engine gears comprises a step of carrying out cemented quenching treatment on the forged, pre-heated, machined and hobbed gears. Cemented quenching treatment comprises the following steps that (a) the gears are arranged in a tooling set with a middle round rod in a stacked manner, a cover plate is configured above the gears, and a gear string is formed; (b) multiple gear strings are fed into an Aichelin5 / 3 type multi-purpose furnace to be carburized and quenched, wherein the carburizing and quenching step specifically comprises the stages that firstly, the gear strings are heated to 800 DEG C, then, heat preservation is carried out on the gear strings for 0.2 hour, the carbon potential is 0.3 percent; then, the gear strings are heated to 900 DEG C to be carburized, the strong carburization potential is 1.1 percent, the strong carburization time is 130 minutes; the gear strings are subjected to diffusion, the diffusion carbon potential is 0.7 percent, and the diffusion time is 90 minutes; the gear strings are cooled along with the furnace temperature, and are cooled to 810 DEG C, heat preservation is carried out on the gear strings for 0.2 hour, the carbon potential is 0.7 percent; the gear strings are fed into a front chamber to be quenched, the quenching oil temperature is 50 DEG C, the quenching time is 20 minutes, rapid stirring reaches 1200r / min and the time is five minutes, slow stirring reaches 1100r / min and the time is 15 minutes; and the quenched gear strings are taken out of the furnace; (c) the quenched gear strings taken out of the furnace are cleaned, and low-temperature tempering is further carried out.

Owner:HANGZHOU ADVANCE GEARBOX GRP

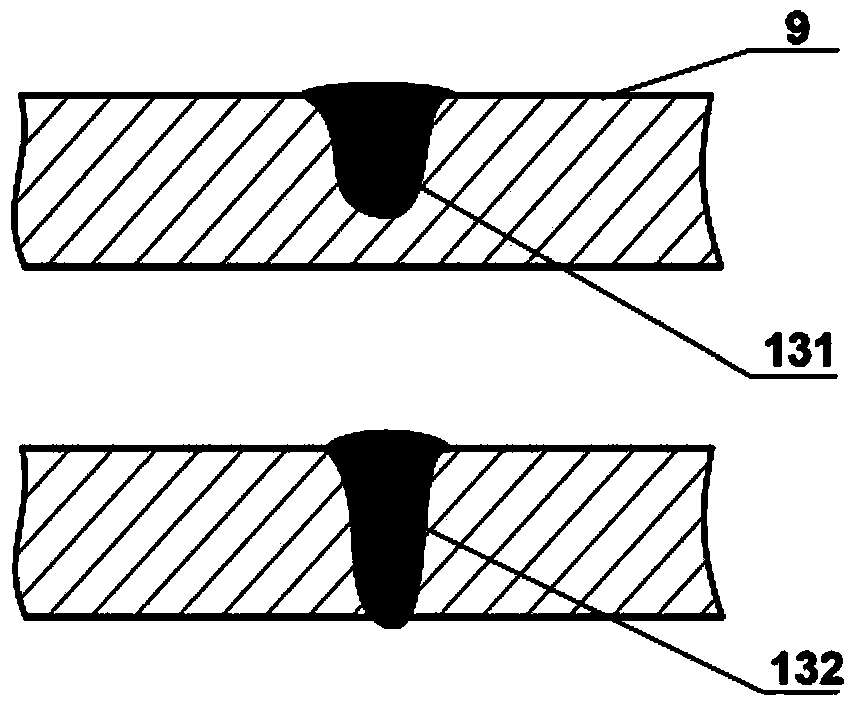

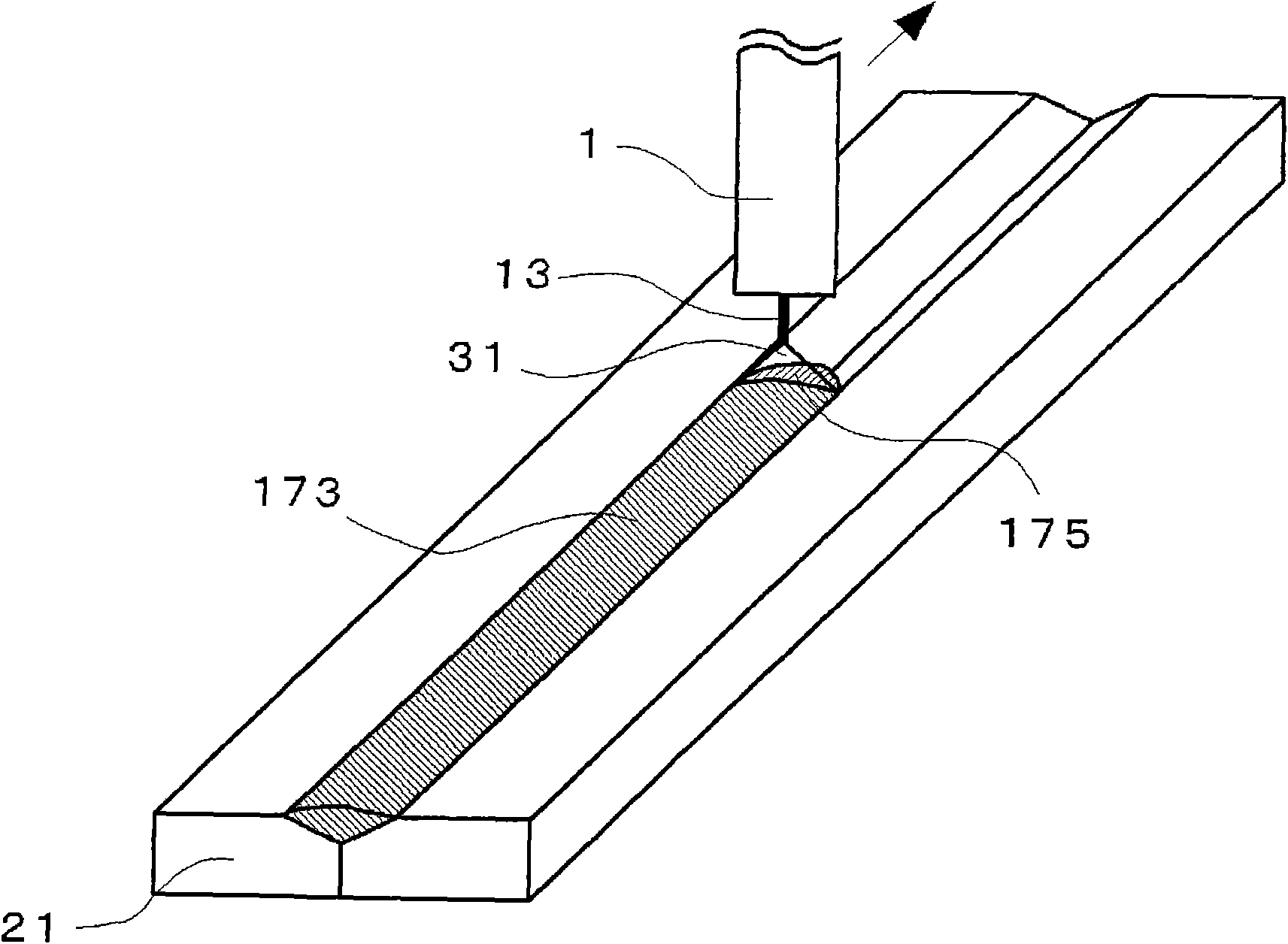

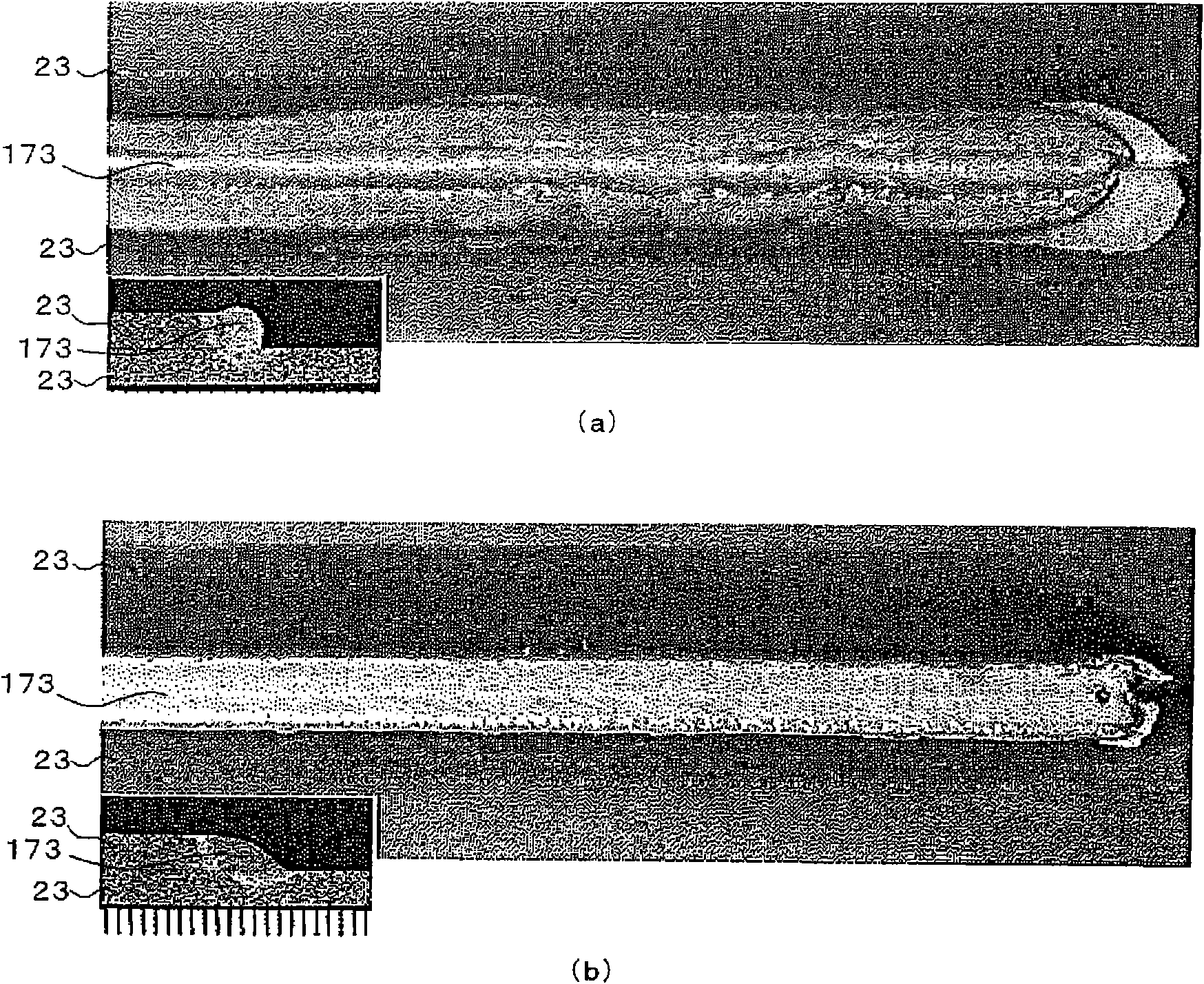

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

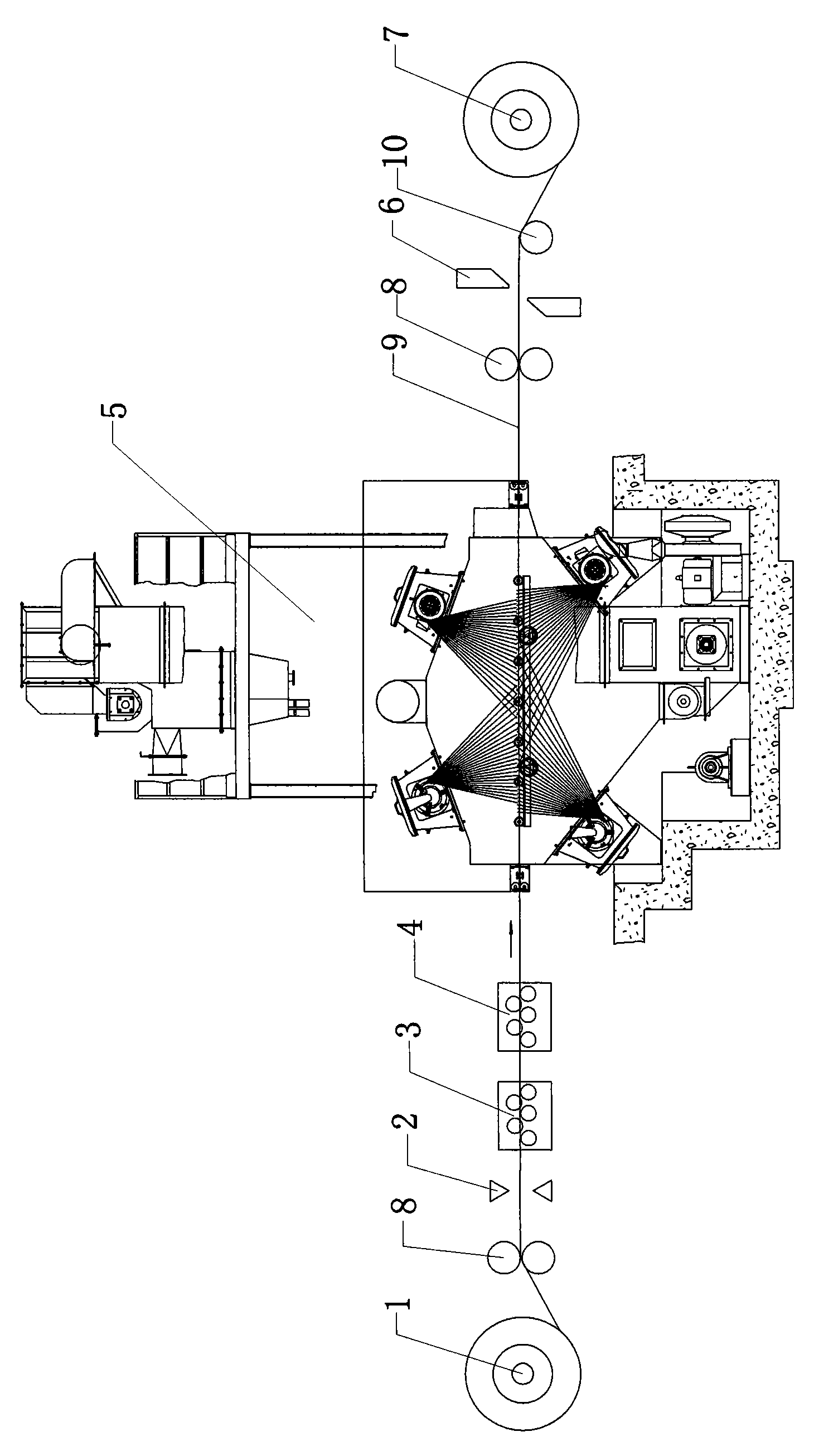

Method and device for surface processing of steel belt

InactiveCN101633111AGood effectImproves fatigue strength and corrosion resistanceWork treatment devicesOther manufacturing equipments/toolsPopulationSurface finishing

The invention relates to a method and a device for surface processing of a steel belt. The physical method instead of the chemical method adopted in the prior art processes the surface of the steel belt. The method mainly comprises the following steps of: uncoiling of the steel belt, mechanical scale removal, flattening, shot blasting and cleaning, coiling. Corresponding to the steps, the device comprises an uncoiling machine, a welding machine, a multi-roll type scale remover, a flattening machine, a shot blasting cleaning machine, a shearing machine and a coiling machine, which are arranged from front to back in sequence; and conveying rolls for conveying the steel belt are arranged between the uncoiling machine and the welding machine and between the shot blasting cleaning machine and the shearing machine respectively. The device has the advantages of simple structure, good surface processing effect, high cleaning efficiency, safety and environmental protection, low cost, small floor area, long service life of the steel belt and easy population.

Owner:王志强

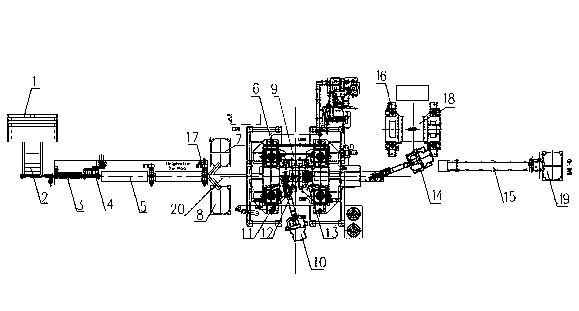

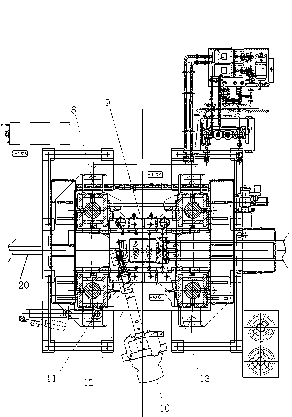

Production device and production technology for non-quenched and tempered steel forge piece automatic forging

InactiveCN103230997AEmission reductionImprove electricity efficiencyHandling devicesEngineeringUltimate tensile strength

The invention relates to the technical field of metal hot processing, in particular to the technical field of production device and production technology for non-quenched and tempered steel forge piece automatic forging. The device comprises a forging system, a feeding system and a discharging system, wherein the feeding system is arranged at the front end of the forging system, the discharging system is arranged at the rear end of the forging system, the forging system comprises an electric heating furnace connected with rear part of the feeding system, a forging pressing machine is connected with the rear part of the electric heating furnace, an edge trimmer is connected with the rear part of the discharging system, and the discharging system is connected with the rear part of the edge trimmer. According to the device provided by the invention, defects in the prior art is overcame, the full automatic line technology that the forge piece is heated once and is controlled by one worker is realized, is energy-saving and cost-reducing, labor saving, the outer surface and the inner quality of the forge piece is improved, and the service life is prolonged; as the mechanical property of each part of the forage is close to one anther, the forge piece quality and safety performance are improved, and the non quenched and tempered steel forging piece is high in tensile strength, fatigue strength and machinability.

Owner:ANHUI ANHUANG MACHINERY

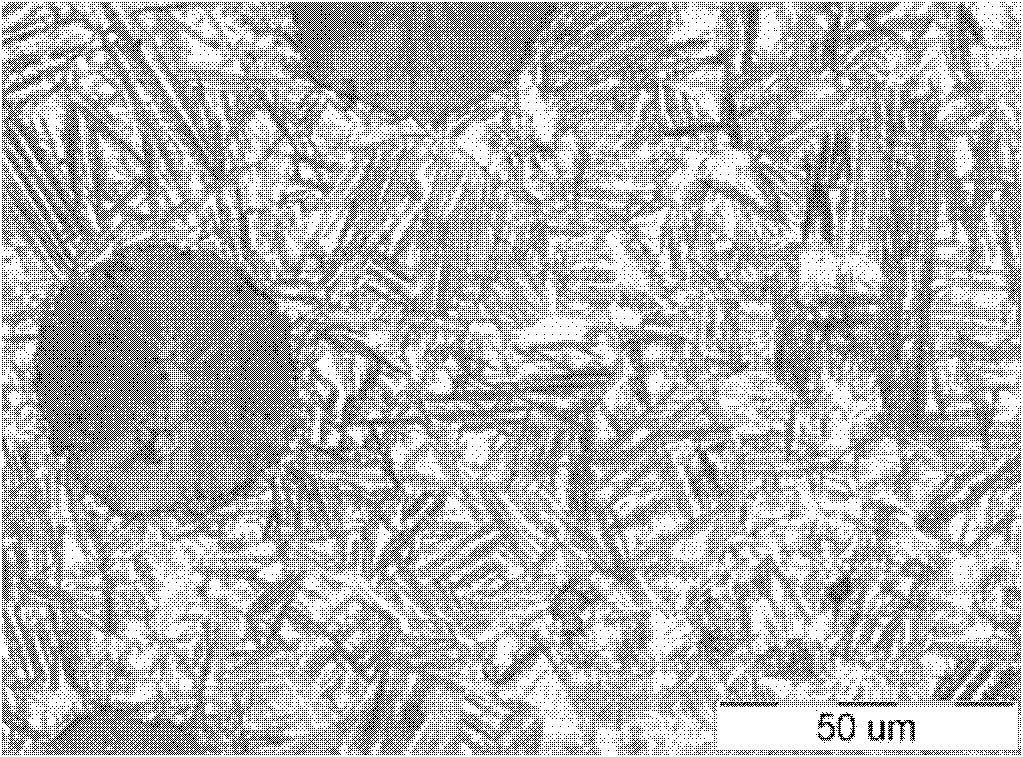

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

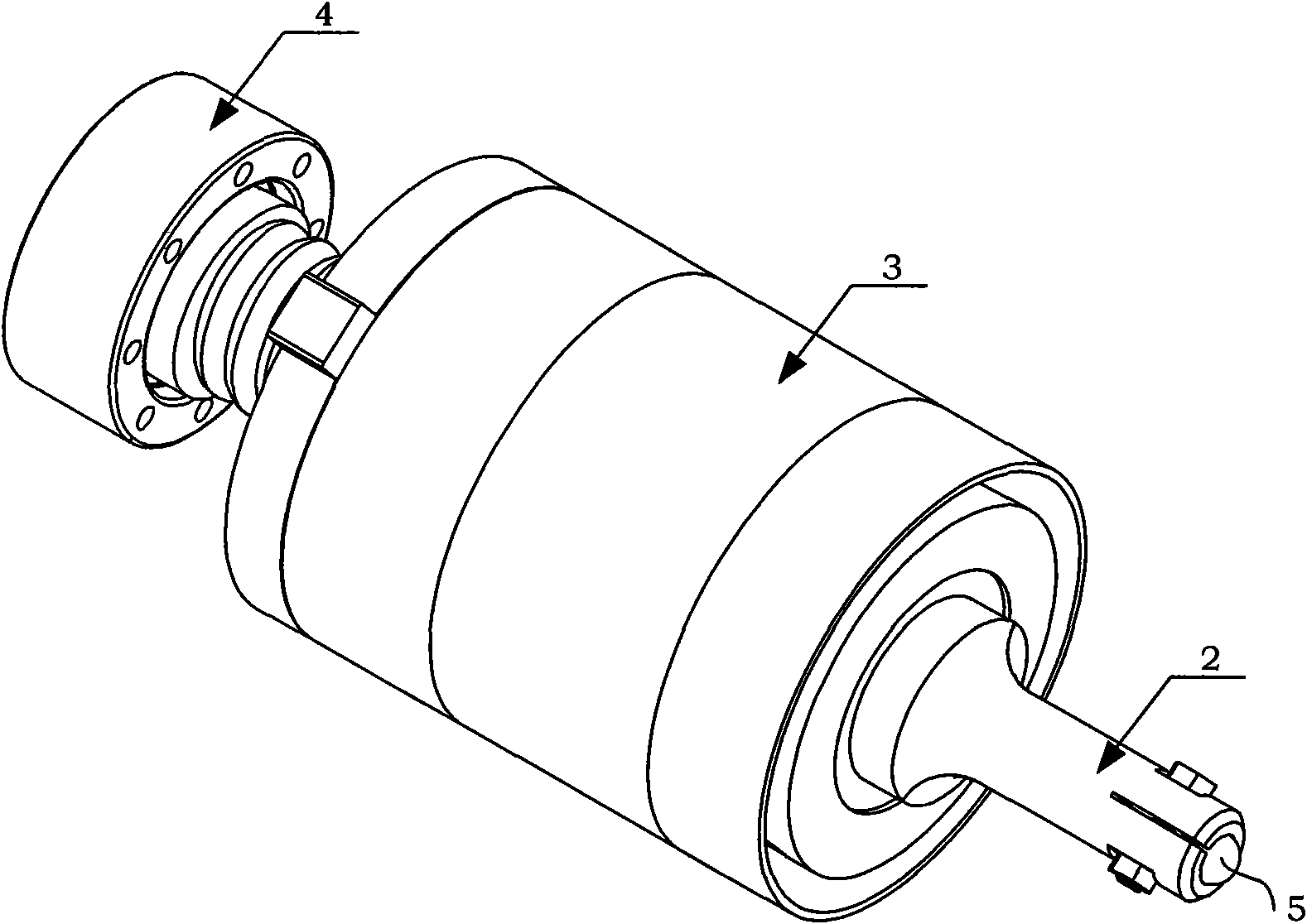

Ultraphonic elliptical vibration and extrusion processing device based on double-excitation longitudinal bending elliptical energy converter

InactiveCN101633048AExtended service lifeReduce or even avoid sliding frictionAuxillary equipmentMechanical vibrations separationEllipseEnergy converter

The invention discloses an ultraphonic elliptical vibration and extrusion processing device based on a double-excitation longitudinal bending elliptical energy converter, comprising a shell assembly, a vibration assembly, a sliding assembly and a pressure assembly, wherein the sliding assembly is sleeved on the excircle surface of the vibration assembly; the pressure assembly is arranged on the tail part of the vibration assembly; and the assembled vibration assembly, the sliding assembly and the pressure assembly are arranged in the shell assembly. The structure of the ultraphonic elliptical vibration and extrusion processing device is designed by combining a flexible extrusion requirement with a langevin energy converter principle, when the ultraphonic elliptical vibration and extrusion processing device is adopted to carry out extrusion processing, the double-excitation longitudinal bending elliptical energy converter of the ultraphonic elliptical vibration and extrusion processing device can drive a cutter to cautiously take longitudinal bending elliptical vibration, tracks of the longitudinal bending elliptical vibration are tangent with tracks of the turning motion of a workpiece and is reverse to the turning direction of the workpiece, when the turning speed of the longitudinal bending elliptical vibration is equal or approximately equal to the turning speed of the workpiece, the cutter is equivalent to make pure rolling on the surface of the workpiece so that relative sliding between the cutter and the processing surface disappears, and the mechanical abrasion caused by sliding friction is effectively prevented, and the purpose of prolonging the service life of the cutter is achieved.

Owner:BEIHANG UNIV

Pure argon gas shielded welding mig flux-cored wire and mig arc welding method

ActiveCN101559544AHigh strengthImprove fatigue strengthArc welding apparatusWelding/cutting media/materialsSlagArc welding

A pure Ar-MIG welding wire for welding steel according to the present invention is formed of a flux-cored wire. The flux-cored wire is formed in the manner that a formation formed by welding a carbon steel hoop into a pipe shape or a seamless pipe is used as an outer sheath, the outer sheath is filled with a flux, and a wire drawing process is performed. The flux accounts for 7 to 27 mass% of the total wire mass. The wire contains graphite in the amount of 0.16 to 2.00 mass% on the basis of the total wire mass and iron powder in the amount of 20 mass% on the basis of the total flux mass. According to the construction, neither expensive metal resource nor a greenhouse effect gas is used, slag and fume generation is inhibited, and a weld joint having a high static tensile strength and fatigue strength can be obtained.

Owner:KOBE STEEL LTD

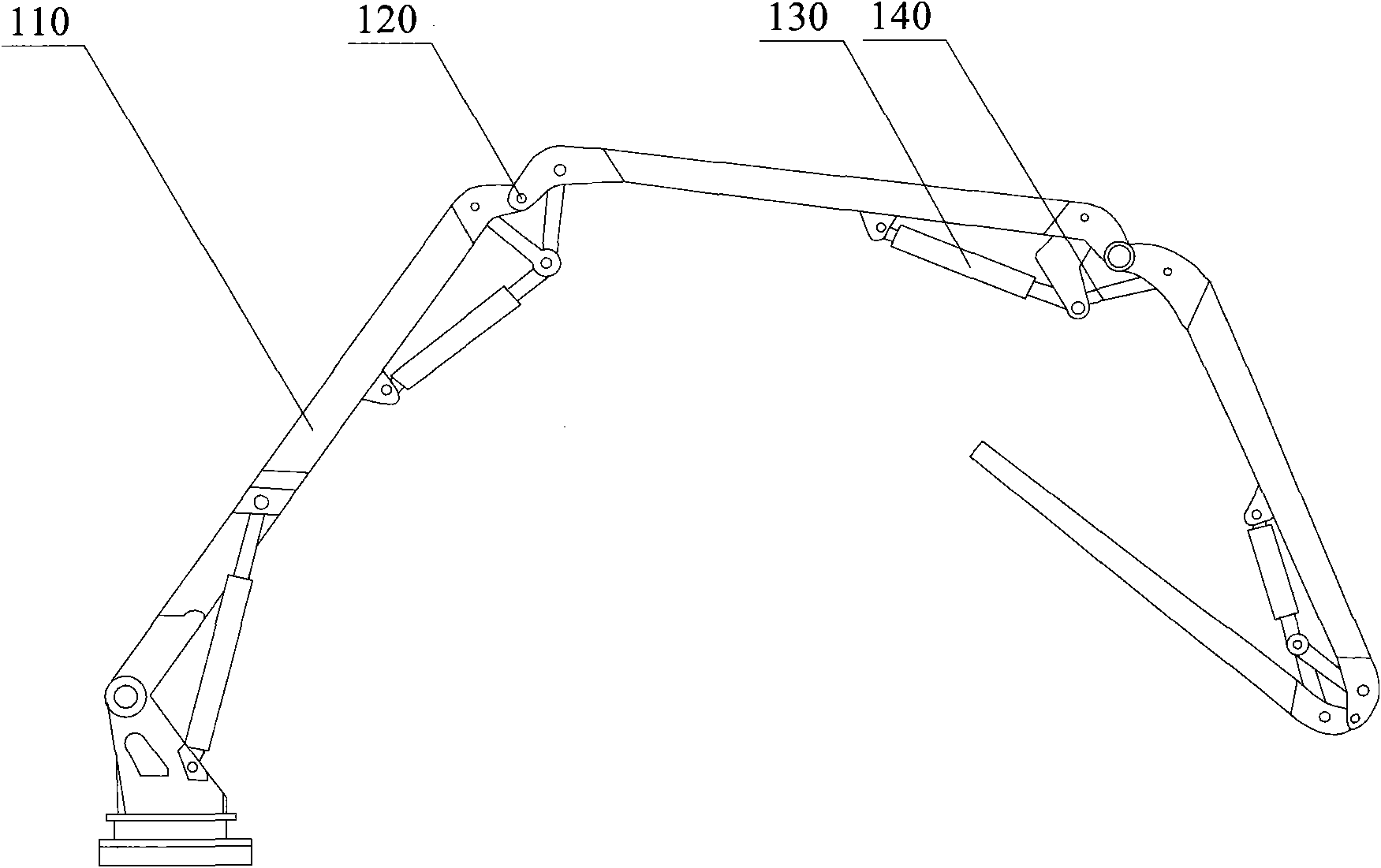

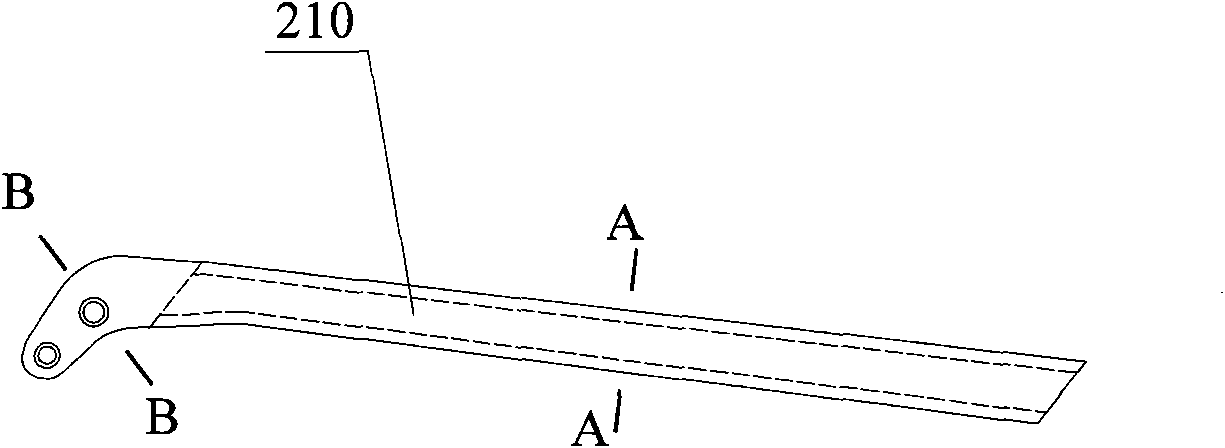

Joint arm of cloth arm bracket and manufacturing method thereof as well as concrete conveying machine

The invention discloses a joint arm of a cloth arm bracket and a manufacturing method thereof and also relates to a concrete conveying machine provided with the joint arm. The joint arm of the cloth arm bracket comprises a transverse plate and a vertical plate, wherein in the longitudinal direction, the transverse plate and the vertical plate extend along the same direction; in the transverse section, the transverse plate extends horizontally, and the vertical plate extends vertically; the side of the vertical plate has flanging, and the side of the vertical plate and the horizontal flanging are fixed with the transverse plate; and the transverse plate and the vertical plate are respectively provided with a composite material layer which comprises resin and fiber. The joint arm can maintain less weight while ensuring higher strength and fatigue resistance, and also can reduce the adverse effect for the joint arm caused by welding; furthermore, the joint arm provided by the invention also has damping performance and corrosion resistance, thus prolonging the service life of the joint arm.

Owner:SANY HEAVY IND CO LTD (CN)

High-pressure fuel pipe for diesel engines

InactiveUS20050127665A1Improve fatigue resistanceFine surfaceFluid pressure sealed jointsJoints with sealing surfacesCavitationAlloy

There is provided a high-pressure fuel pipe for diesel engines, which is excellent in inner-pressure fatigue resistant property, vibrational fatigue resistant property, cavitation-resistant property, seat surface crack resistant property, and bending shape stability, and capable of thinning and lightening. A high-pressure fuel pipe for diesel engines, composed of a low alloy transformation inducing plastic type strength steel containing residual austenite of 5 to 40 wt %, and wherein an inner surface of a flow passage has a crack depth of 20 μm or less, and plastic working is applied to an inner surface of a flow passage.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com