Method and device for surface processing of steel belt

A surface treatment device and technology for surface treatment, applied in workpiece surface treatment equipment, other manufacturing equipment/tools, metal rolling, etc., can solve problems such as a large amount of waste acid, difficult treatment, material corrosion, etc., and achieve less environmental pollution. , The effect of low labor intensity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

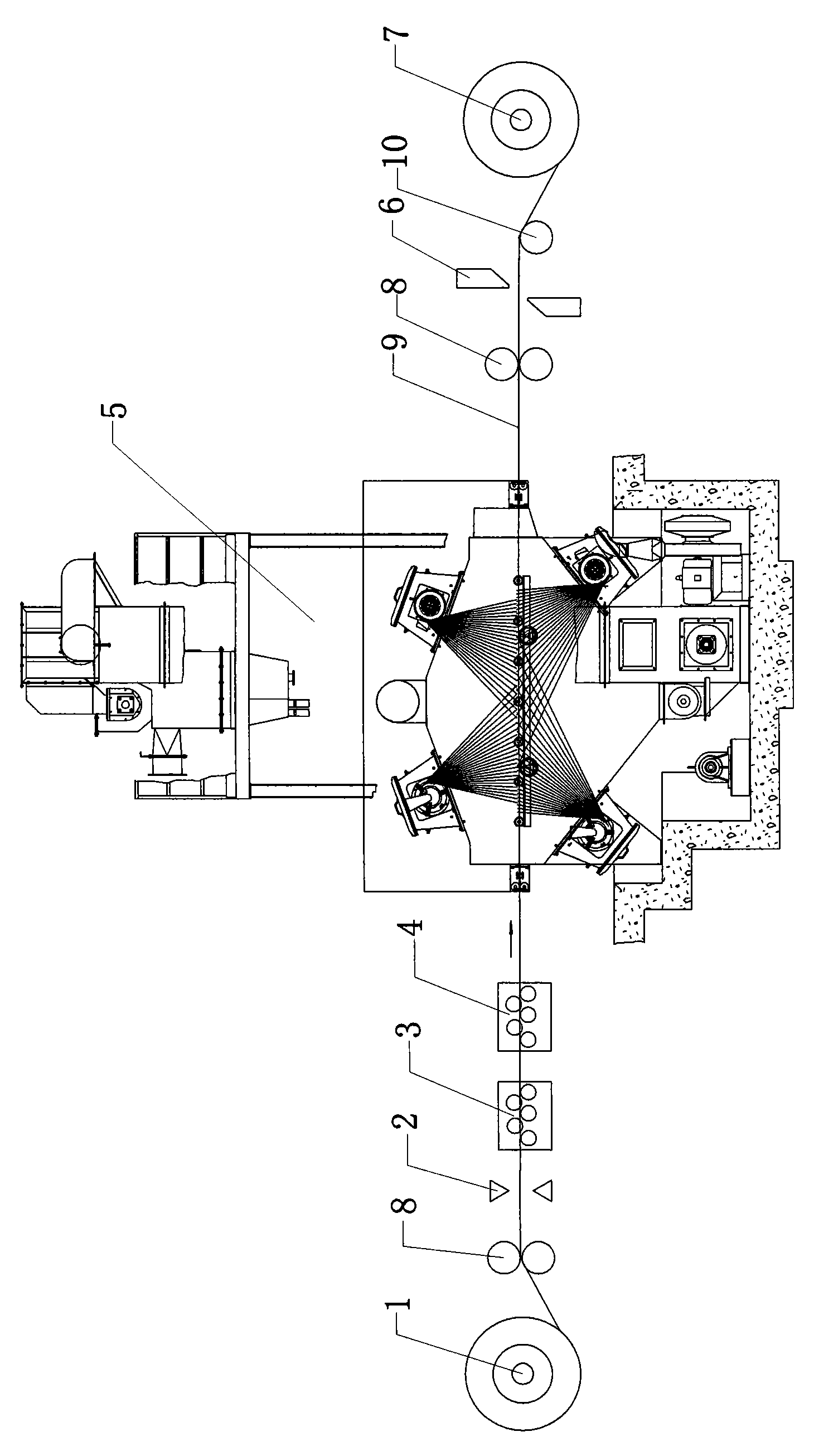

[0036] The steel strip surface treatment method and its device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] as attached figure 1 Shown, a kind of steel strip surface treatment method comprises the following steps:

[0038] (1) The steel strip 9 is uncoiled and conveyed by the feeding roller 8;

[0039] (2) Mechanical descaling: the steel strip 9 is sent into the multi-roller descaling machine 3, and the surface oxide layer of the steel strip 9 is removed through a plurality of upper and lower descaling passive rollers arranged in a staggered manner;

[0040] (3) Leveling, the steel strip 9 after mechanical descaling by the multi-roller descaling machine 3 is sent to the leveling machine 4 for leveling;

[0041] (4) Shot blasting treatment and cleaning: the leveled steel strip 9 is sent to the shot blasting machine 5, projectiles are projected onto the surface of the steel strip 9 at high speed, and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com