Patents

Literature

125 results about "Neutralization method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Techniques of neutralization are a theoretical series of methods by which those who commit illegitimate acts temporarily neutralize certain values within themselves which would normally prohibit them from carrying out such acts, such as morality, obligation to abide by the law, and so on.

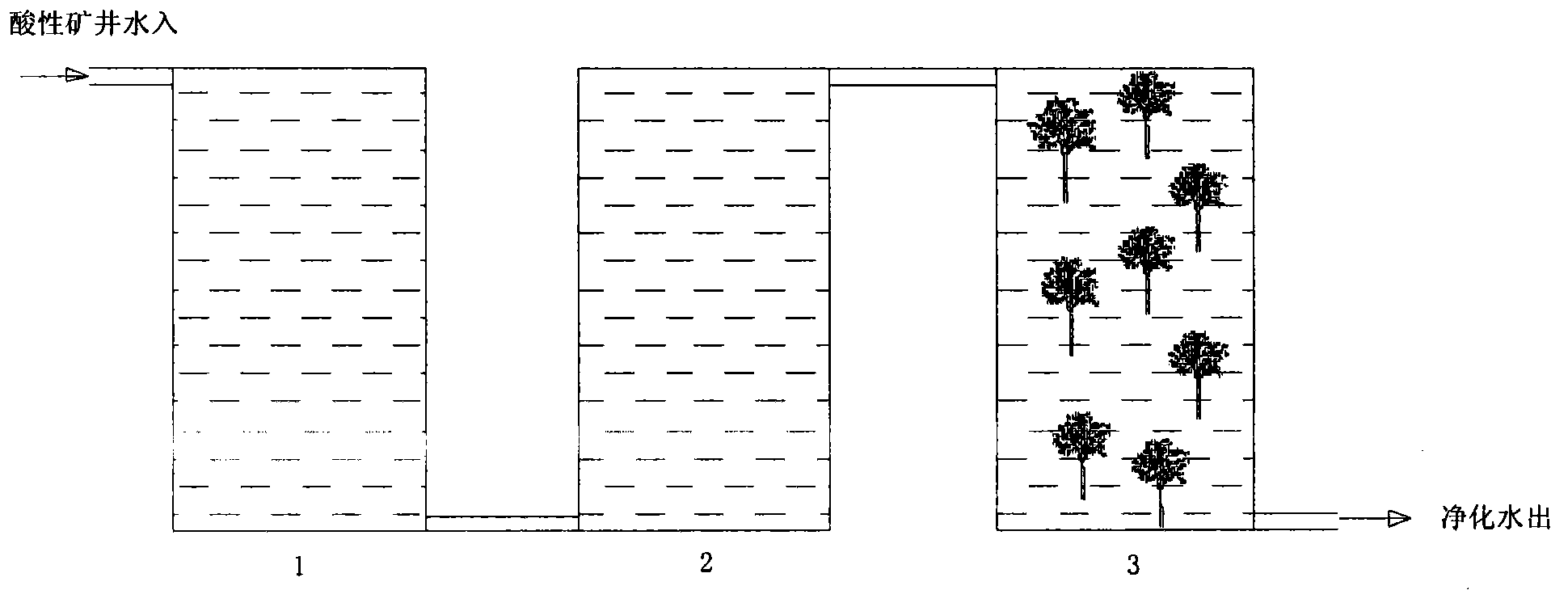

Ecological treatment method for acid mine water of coal mine

InactiveCN102701534AEasy to operate and manageReduce processing costsWaste water treatment from quariesMultistage water/sewage treatmentWater qualityCoal

The invention discloses an ecological treatment method for acid mine water of coal mine. The method comprises a pool or a pool group, a pond or a pond group and a wetland which are connected in series; a fine particle limestone filter material is arranged at the pool or the pool group, and the diameter of fine particles d is at most 3.0mm; the depth of the pool or the pool group is 3-10m, and the area of the pool depends on processed water quantity and water quality; processing 1000m3 / d of water needs the area of 10-30m2, and water flow passes through the filter material from bottom to top; thiobacillus ferrous oxide is put in the pond or the pond group, and the depth of the pond or the pond group is more than 1m; the area of the pond depends on processed water quantity, and processing 1000m3 / d of water needs the area of 50-100m2; the water temperature is 28-30 DEG C, the pH value is 2.0-2.3, and the quantity of strain inoculation is 10 percent; the water flow smoothly flows through the pond, and the flow speed is smaller than 0.2m / s2; water-resisting plants such as reeds, Typhaangustifolia or willows and the like are planted in the wetland; the area of the wetland depends on processed water quantity, and processing 1000m3 / d of water needs the area of 1000-2000m2; and the water flow slowly flows through the wetland, and the flow speed is smaller than 0.05m / s2. The method comprehensively applies a neutralization method, a bacterial method and a wetland method and utilizes the respective characteristics to process acid waste water with any concentration and any properties.

Owner:XIAN UNIV OF SCI & TECH

Explosive neutralization method and device

InactiveUS7331268B1Safe and effective neutralizationExplosive chargesAmmunitionEngineeringExplosive material

A method for neutralizing explosive ordnance is provided. According to an aspect of the method, an energetic charge is activated to produce a shockwave, which is imparted at an effective velocity and temperature on a gas to ionize the gas for creating plasma and to drive the plasma. The plasma is impacted on a casing of an ordnance containing an explosive to penetrate through the casing and, without or before causing an explosive event of explosive within the casing, substantially consume the explosive.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Composite improved matrix used for restoring ecology of gangue storage yard

The invention relates to a composite improved matrix used for restoring ecology of a gangue storage yard, and concretely relates to a composite improved matrix material used for restoring ecology of the gangue storage yard, which belongs to the mining wasteland ecological restoration technical field. The composite improved matrix solves the problems of high extra soil cost, severe site conditions, difficult viability of plants, easy failure by using a conventional alkali neutralization method and fertilizing treatment, easy generation of severe environmental influence and ecological harm due to large stacking of industrial and agricultural solid wastes of gangue, residual sludge, fly ash, phosphogypsum, culture manure and the like. The composite improved matrix is composed of residual sludge, fly ash, phosphogypsum, culture manure, soil and mushroom dreg, and moss according to a certain proportion. The composite improved matrix has the advantages of simple production, wide raw material source and good resource effect of refuse, and has good environmental benefit, economic benefit and social benefit.

Owner:GUIZHOU UNIV

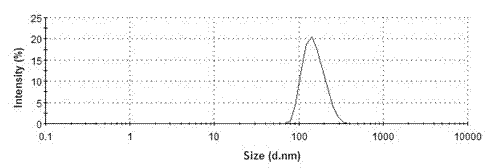

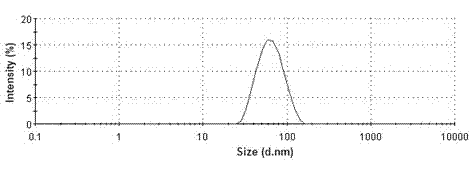

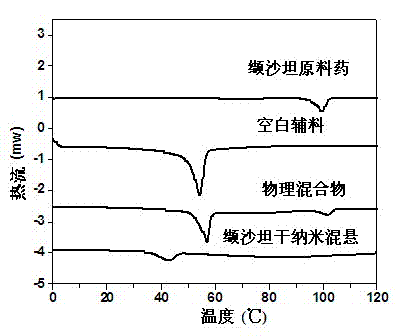

Valsartan spray-dried nanosuspension and preparation method of valsartan spray-dried nanosuspension

InactiveCN102920654AUniform particle sizeLarge particle sizePowder deliverySolution deliveryValsartanAnti solvent

The invention discloses a valsartan nanosuspension, a spray-dried power, and a preparation method of the valsartan nanosuspension and the spray-dried power. A valsartan spray-dried nanosuspension and a preparation method of the valsartan spray-dried nanosuspension belong to the field of nano-drug preparations. The valsartan spray-dried nanosuspension consists of 1 part of valsartan, 0.1-1 part of a stabilizing agent and 10-100 parts of a spray-drying protecting agent by mass; the valsartan spray-dried nanosuspension is prepared by an anti-solvent precipitation method and / or a high-pressure homogenizing method and / or an acid-alkali neutralization method in combination with a spray-drying technology. The drug particles in the spray-dried powder are reduced to a nano-grade, and the hydrophilicity, the in vitro dissolution rate and the bioavailability of the valsartan are greatly improved. The powder can be directly processed or be processed together an excipient into tablets, capsules and the like. The valsartan spray-dried nanosuspension has the advantages of simple preparation process, stable product quality and easy implementation of productization.

Owner:SHENYANG PHARMA UNIVERSITY

Iron removal process for copper cobalt ore leach liquor

ActiveCN101921914AIncreased Fe contentLow viscosityProcess efficiency improvementSlagMetal impurities

The invention relates to an iron removal process for copper cobalt ore leach liquor, belonging to the cobalt wet smelting industry. At present, the goethite method and the precipitate neutralization iron removal method are combined to remove iron, although the total quantity of iron slag can be reduced, the total quantity of the iron slag is still great because the precipitate neutralization method with high pH value is used for removing iron at a later stage. The process is characterized by comprising the following steps of: firstly, oxidizing the liquor before iron removal to oxidize ferrous iron in the liquor into ferric iron; then, removing most of iron impurities in the oxidized liquor before iron removal by using the goethite method in an iron removal tank, and removing the rest iron and other metal impurities in the liquor by the precipitate neutralization iron removal method; and filter pressing the obtained ore pulp by using a filter press to obtain filter liquor as liquor after iron removal. Under the premise of ensuring the iron removal effect, the iron content in the iron slag is increased by changing the slag form of scrap iron slag, and thus, the total quantity of the iron slag is reduced.

Owner:ZHEJIANG HUAYOU COBALT

Manufacturing method of chitosan hemostatic membrane with high water-absorbing swelling performance

InactiveCN102028966AImprove water absorptionGood adhesion to wound surfaceAbsorbent padsBandagesAcetic acidGlycerol

The invention discloses a manufacturing method of a chitosan hemostatic membrane with high water-absorbing swelling performance. The method comprises the following steps of: dissolving chitosan with the deacetylation degree of between 55 and 99 percent and the molecular weight of between 100,000 and 500,000 in an appropriate amount of dilute solution of methanoic acid, acetic acid or hydrochloric acid, preparing 0.5 to 5 percent (m / v) chitosan solution, standing and defoaming; injection the solution into a mold, covering a layer of one-way permeable membrane on the mold, soaking the mold in an alkali medium, preparing chitosan gel by a one-way penetration and neutralization method and washing the gel with a large amount of deionized water until the gel is neutral; performing N-position or O-position carboxylation, soaking the gel in 1 to 5 percent CaCl2 dilute solution for a short period of time, crosslinking appropriately, taking the gel out and washing; soaking the gel in 1 to 10 percent (m / v) glycerol solution for 1 hour, taking the gel out and draining; and drying and molding at the temperature of 60 DEG C so as to obtain the hemostatic membrane. Chitosan has excellent hemostatic effect and Ca2+ is one of blood coagulation factors and has the effect of promoting blood coagulation, so that hemostasis is promoted under the synergism of the chitosan and the Ca2+.

Owner:ZHEJIANG HAIZHI INVESTMENT MANAGEMENT

Lime milk neutralization method acid dipping-extraction vanadium extraction technology

The invention relates to a technology for extracting vanadium pentoxide from stone coal vanadium ore, comprising a lime milk neutralization method acid dipping-extraction vanadium extraction technology adopting a thickener production line and a lime milk neutralization method acid dipping-extraction vanadium extraction technology adopting a belt filter production line. The first technology adopts the working procedures of raw material pulverization, ball milling, sulfuric acid leaching, five-stage thickening washing separation, overflowing lime milk neutralization, single-stage thickening solid-liquid separation, overflowing reduction, pH value adjustment, extraction, reverse extraction, vanadium-contained solution oxidation, ammonia water precipitation, pyrogenation, and the like to obtain the vanadium pentoxide finished products, and the second technology adopts the working procedures of raw material pulverization, ball milling, sulfuric acid leaching, ore pulp lime milk neutralization, filtration washing, filtrate clarification washing, pH value adjustment, extraction, reverse extraction, vanadium-contained solution oxidation, ammonia water precipitation, pyrogenation, and the like to obtain the vanadium pentoxide finished products. The invention solves the problems of above-norm tailing wastewater NH3-N existing in the prior acid dipping-extraction vanadium extraction and has the advantages of high vanadium recovery rate, low production cost, good economic benefits and environment-friendly effect, and the like.

Owner:SHAANXI WUZHOU MINING +1

Neutralization method for treating alkali wastewater containing uranium

ActiveCN102491479AInhibit back dissolutionReach the efflux pH standardWater contaminantsWater/sewage treatment by neutralisationReaction temperatureDissolution

The invention provides a neutralization method for treating alkali wastewater containing uranium, which comprises the following steps: adding OH- in FeSO4 neutralized wastewater into the alkali wastewater containing uranium, wherein the molar weight of the added FeSO4 is 1 / 3-2 / 3 of that of the OH- in the alkali wastewater containing uranium, potential of hydrogen (pH) value of the wastewater is adjusted in a range of 7-9, the reaction temperature is 20-30 DEG C, and the reaction time is 1-3 hours; oxidizing and hydrolyzing Fe2+ under the action of air to produce Fe(OH)3 precipitation, wherein the Fe(OH)3 precipitation has positive electricity and can absorb uranium ions; 3 under the condition of ph 7-9, if the SO42- concentration is lowered than 1.0-2.0 grams per milliliter, adding Na2SO4to supplement SO42- and enable the SO42- concentration to be 1.0-2.0 grams per milliliter; and adding BaCl2 to remove radium and co-precipitate and produce Ba(Ra)SO4, wherein added BaCl2 quantity is controlled in a range of 0.02-0.06 gram per milliliter. The neutralization method is an important process in the treatment technology of the alkali wastewater containing uranium, and simultaneously achieves functions including neutralization, adsorption carrying for removing the uranium deeply, supplement of SO42- for removing the radium, inhibiting of precipitation re-dissolution, coprecipitation for removing the radium and the like.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

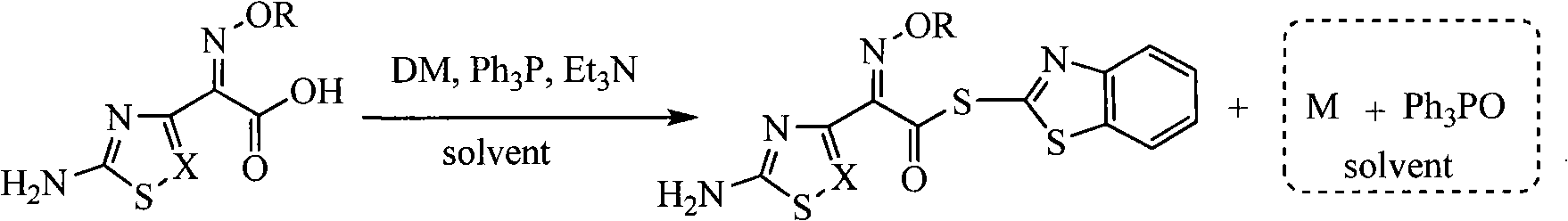

Process for recovering triphenyl phosphine oxide and 2-mercaptobenzothiazole from production waste liquid of cephalothin active ester

The invention discloses a method for recycling triphenyl phosphine oxide and 2-mercaptobenzothiazole from the production waste liquid of cephalosporin active ester, which includes the following steps: 1 to 10 percent sodium hydroxide solution is added drop by drop into the production waste liquid of the cephalosporin active ester under 0 to 80 DEG C; the pH value of the system is adjusted to be 10 to 12, and then the waste liquid is mixed fully for 0.5 to 6 hours, standing still and layering; an organic layer is decompressed to recycle an organic solvent; the solid waste slag is recrystallized directly to obtain the triphenyl phosphine oxide; the 2-mercaptobenzothiazole is extracted and obtained from water layer by a using acid neutralization method. The recycling method of the invention has the advantages of the simple operation, the high recycling rate, the good product purity, the good atom economy, etc., which effectively solves the problems existing in the prior art, such as the complicated operation, the high energy consumption, the low yield rate, the serious environment pollution, etc., thus having a wide implementary value and potential social economic benefits.

Owner:ZHEJIANG UNIV OF TECH +2

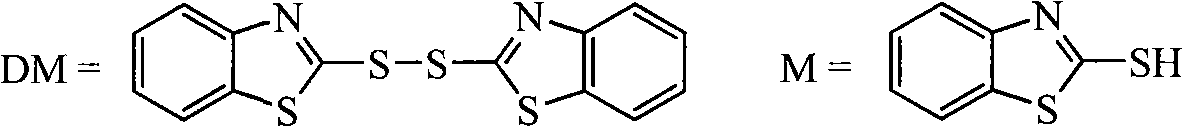

On-line sample dilution and neutralization test device

ActiveCN104897820AAccurate valueReliable test conditionsComponent separationPeristaltic pumpFour-way valve

The invention discloses an on-line sample dilution and neutralization test device which consists of a dilution device, a neutralizer, an instruction control device, a silica gel pipe and a control line, wherein an ultrapure water storage bottle and a sample bottle are connected to a peristaltic pump, an injection pump, a three-way mixer, an electric two-position four-way valve, a three-way mixer and the neutralizer through the dilution silica gel pipe; a control box is connected with the peristaltic pump, the injection pump, the three-way mixer, the electric two-position four-way valve and the neutralizer through the control main line in a control manner; automatic sample dilution and sample neutralization are completed on line through a pipeline and a circuit; samples are provided for a chromatographic analysis system to complete analysis. According to the on-line sample dilution and neutralization test device, the problem caused by ion pollution of an existing neutralization method is effectively solved; no suction pipe or no volumetric flask is used in the whole neutralization process any more, so that the pollution source is reduced, a precise value of experimental data measurement is guaranteed, and a reliable test condition is provided for research on ion chromatographic analysis of snow and ice samples.

Owner:NORTHWEST INST OF ECO-ENVIRONMENT & RESOURCES CAS

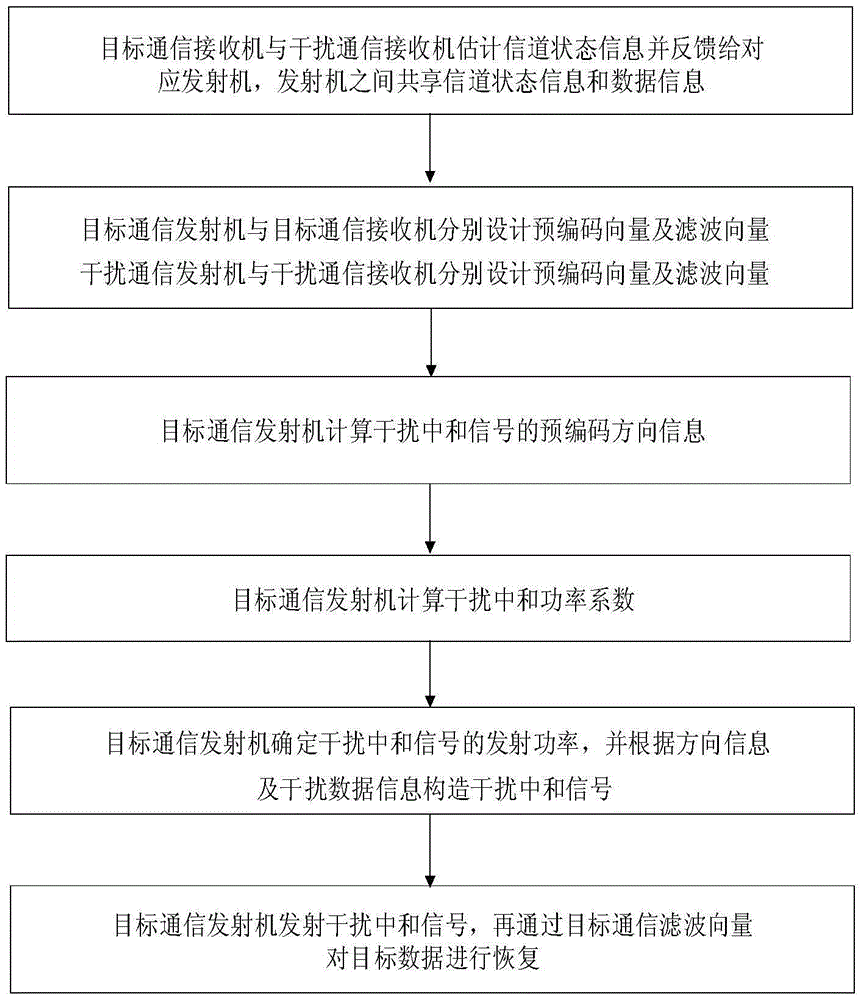

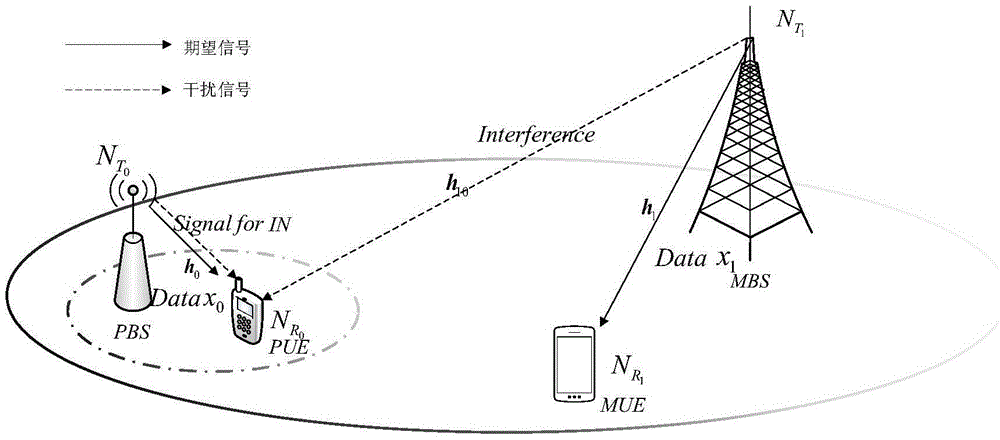

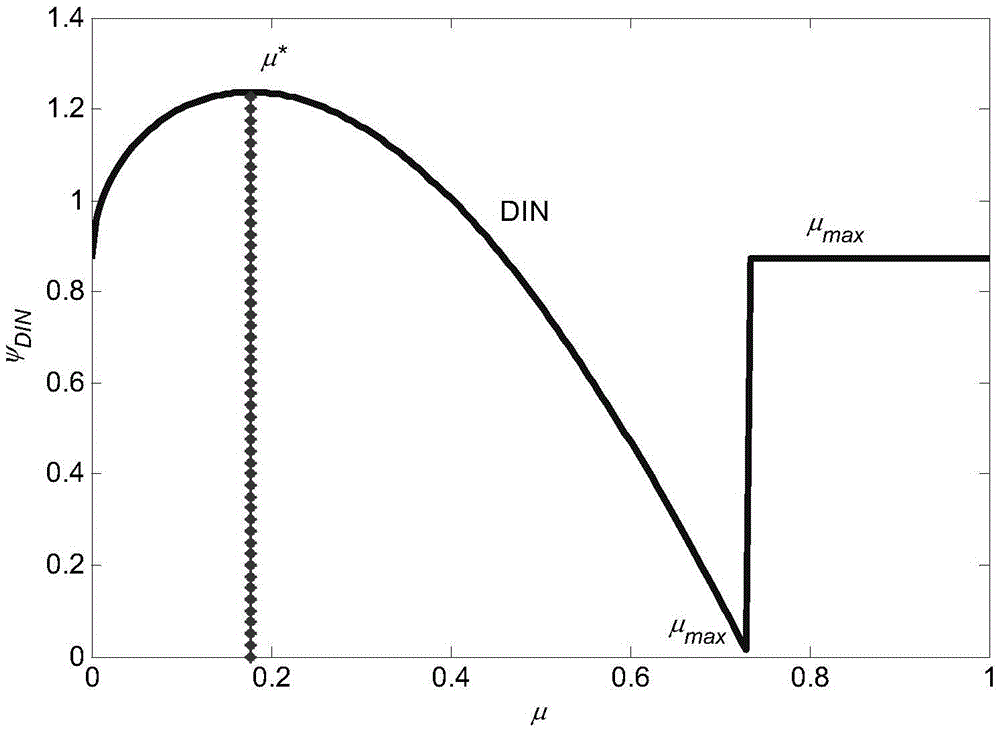

Interference neutralization method based on power dynamic allocation

ActiveCN105636215ARealize rational utilizationMaximize the noise-to-interference ratioHigh level techniquesWireless communicationSpatial correlationSignal-to-interference-plus-noise ratio

The invention discloses an interference neutralization method based on power dynamic allocation, which mainly solves the problem in the existing complete interference neutralization technology that the power overhead is too large so that the expected signal transmission power is reduced and the data rate is reduced. The technical scheme is that the method comprises the following steps: step 1, determining an optimum interference neutralization power coefficient by an interfered transmitter according to the strength of an expected signal and an interference signal and a spatial correlation of the expected signal and the interference signal; and step 2, constructing an interference neutralization signal by the interfered transmitter according to the optimum interference neutralization power coefficient, and transmitting the interference neutralization signal to a receiver, so as to partially or completely eliminate interferences, and make the interfered receiver recover expected data. The interference neutralization method based on the power dynamic allocation provided by the invention has the advantages that reasonable allocation can be performed on transmitting power of the interfered transmitter and the signal to interference plus noise ratio of the interfered receiver can be maximized, and the interference neutralization method can be used for data transmission.

Owner:CERTUS NETWORK TECHNANJING

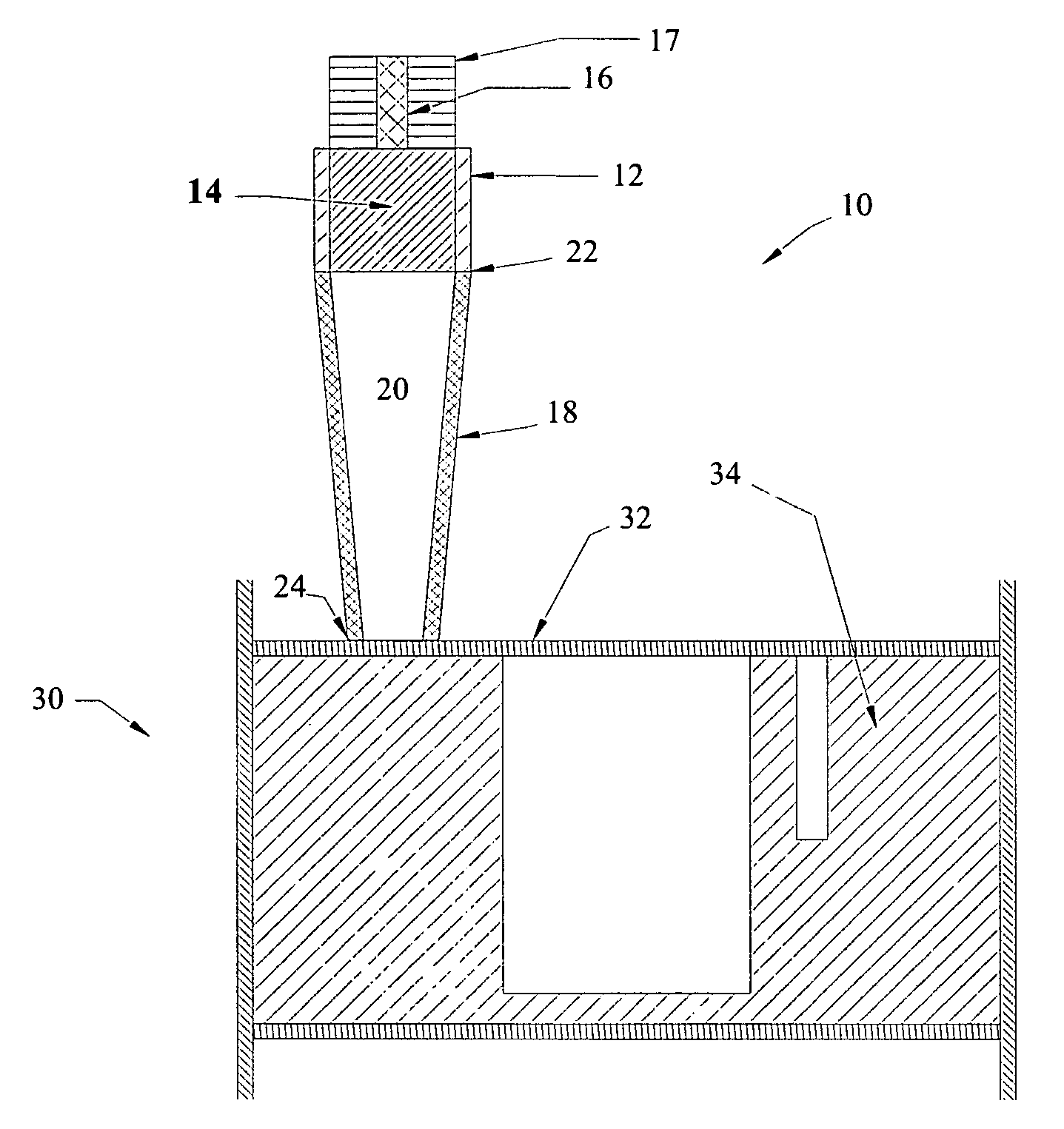

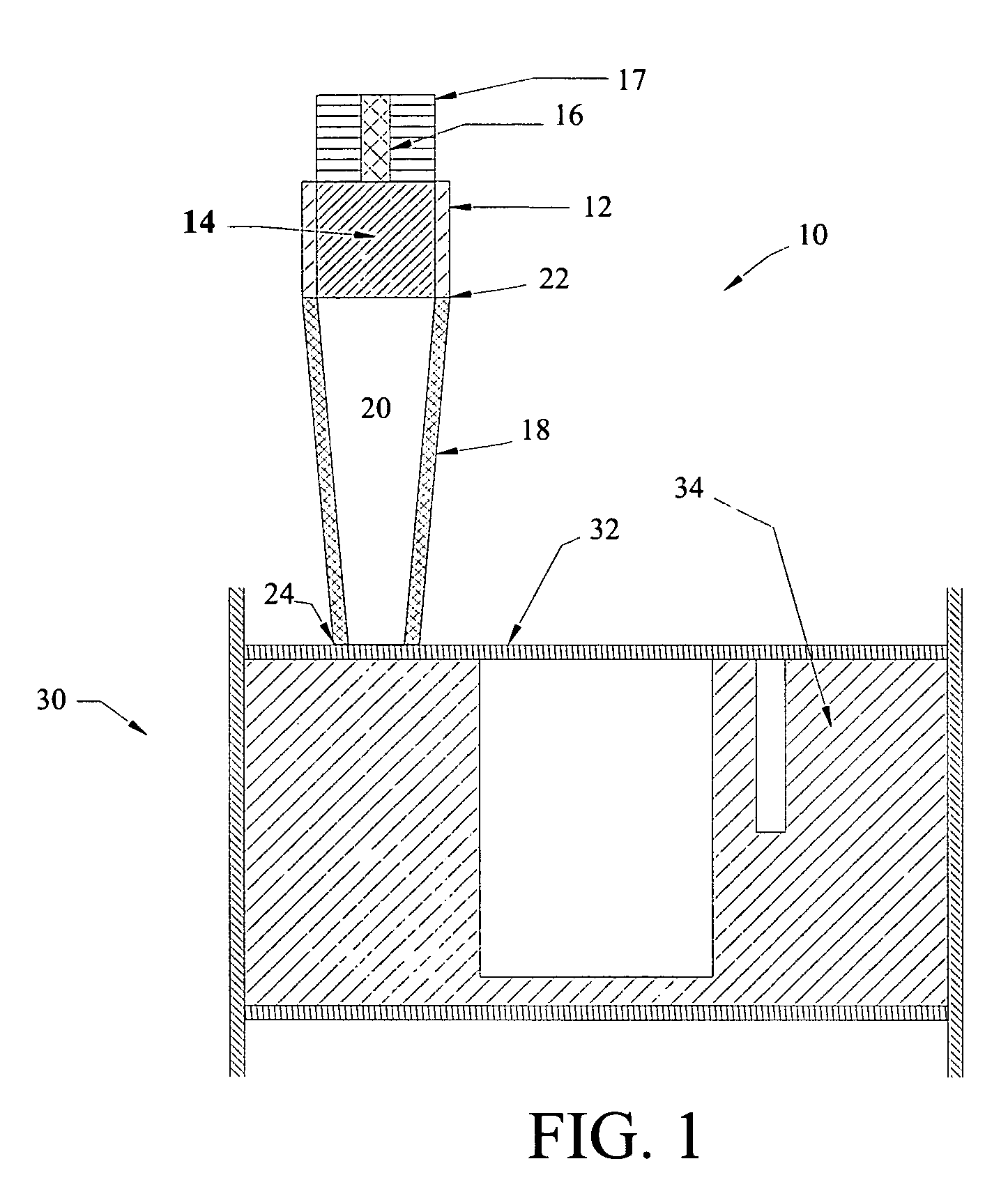

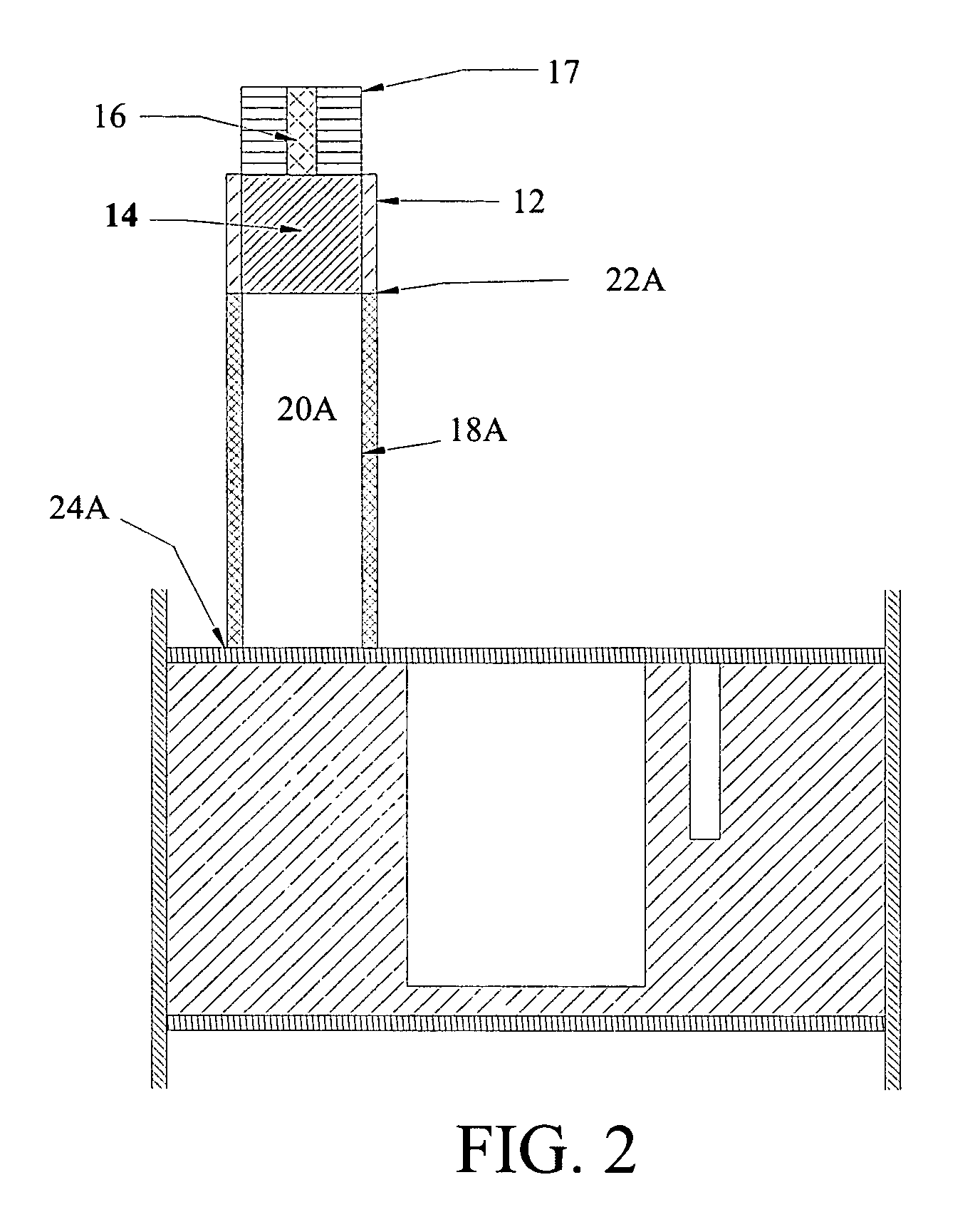

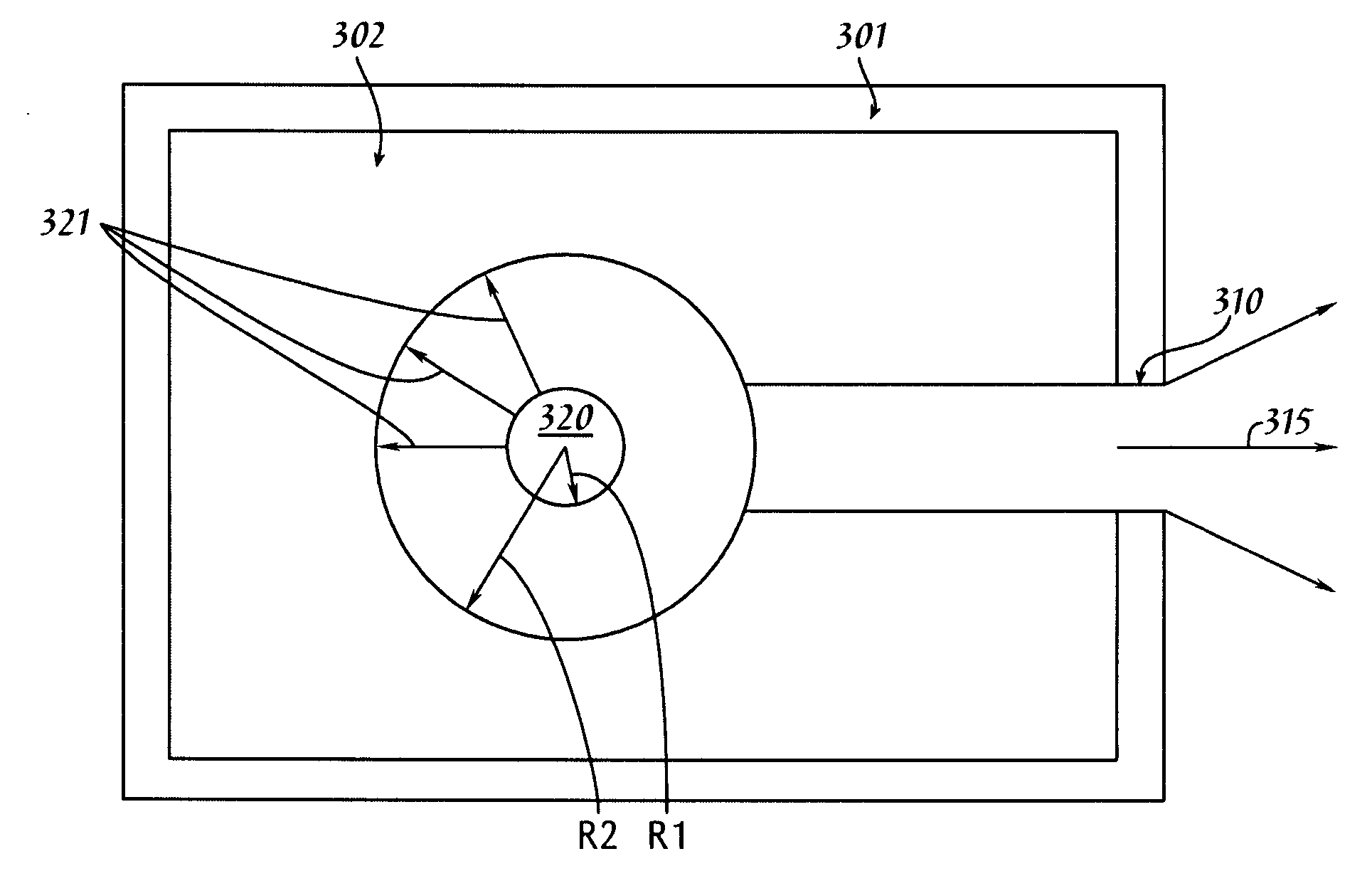

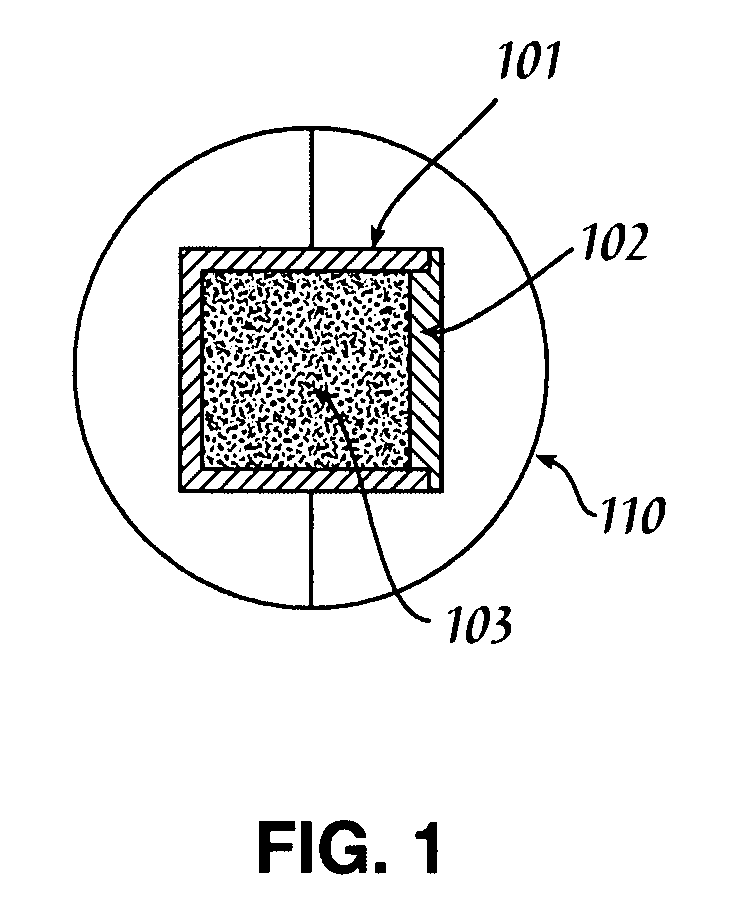

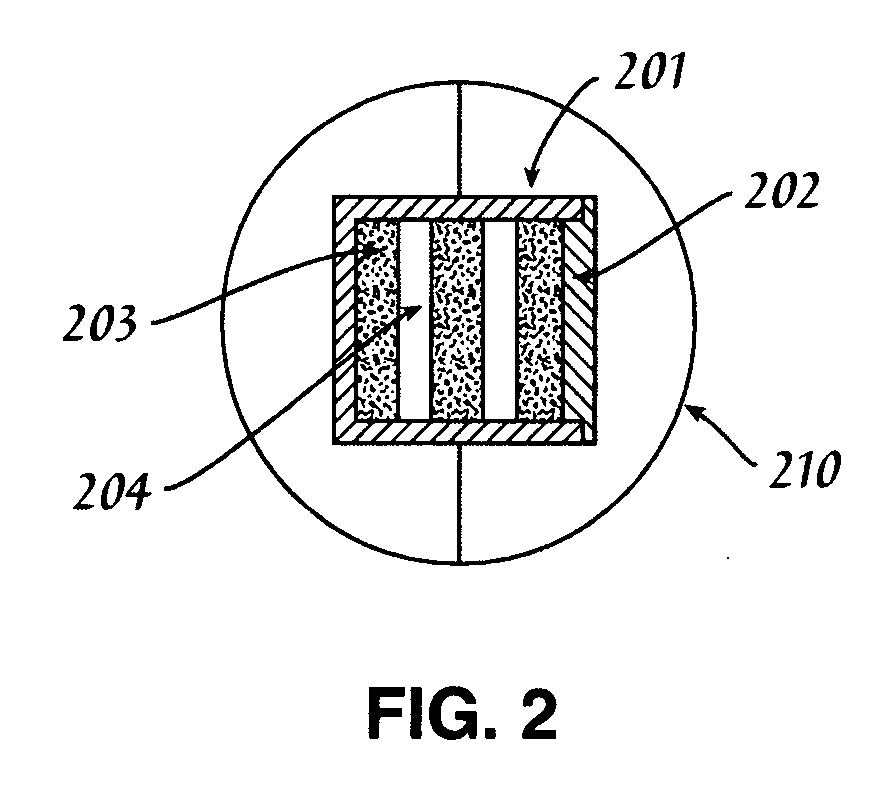

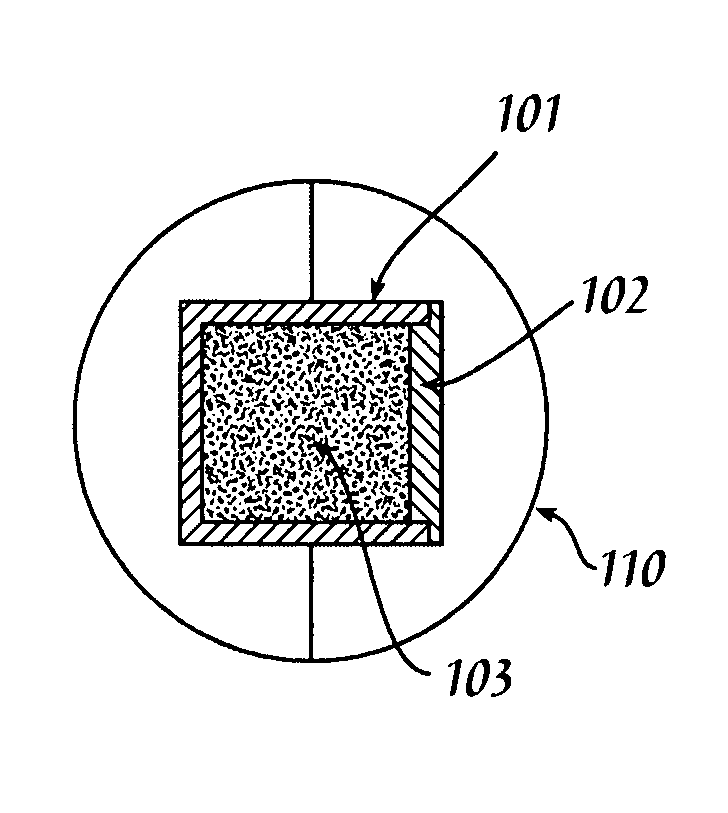

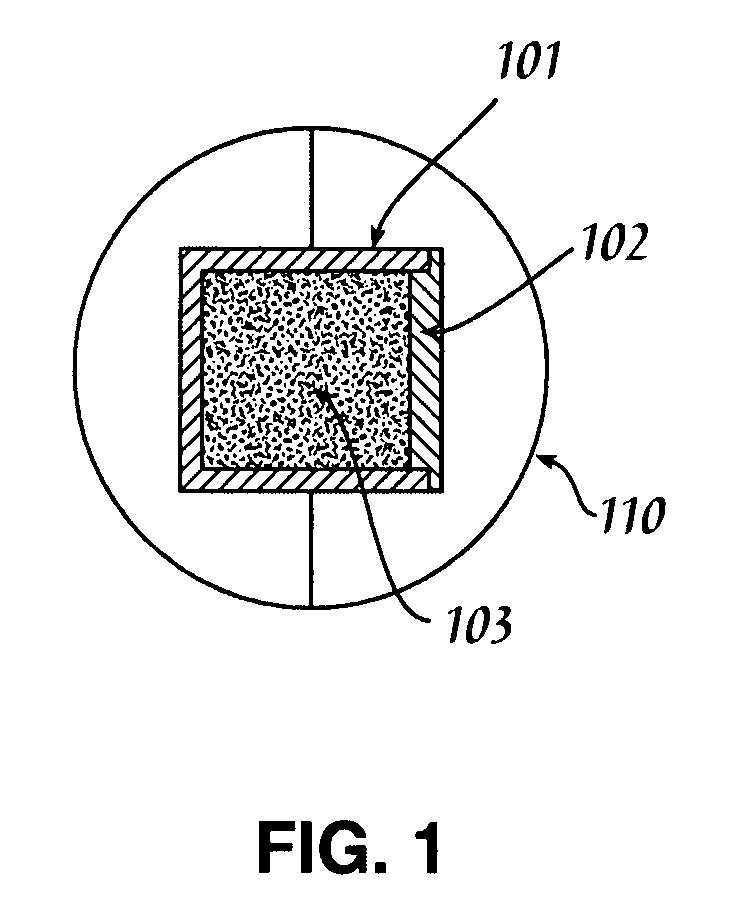

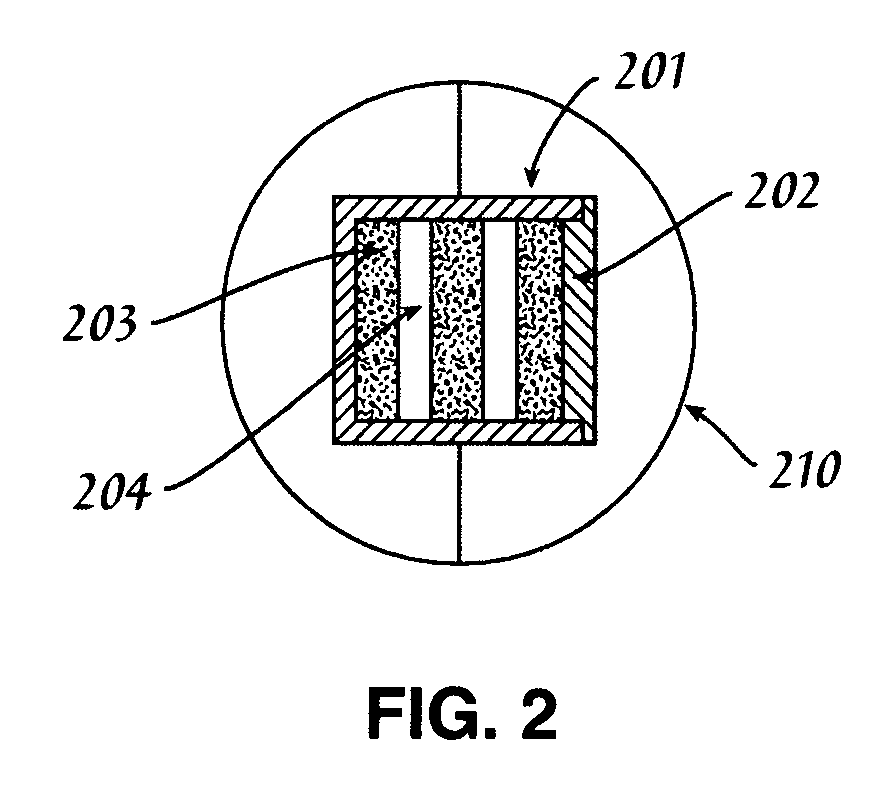

Ordnance neutralization method and device using energetic compounds

ActiveUS20080028922A1Safely neutralize ordnanceHigh equipmentAmmunition projectilesBlastingChemical compoundBomb device

This invention generally relates to a method and apparatus to neutralize ordnance, more specifically improvised explosive devices (IEDs) and unexploded ordnance (UXOs). The current invention provides a simple method to neutralize the ordnance by taking advantage of a new class of energetic materials that includes nano-thermites, binary thermites and additionally powdered thermites. In the invention, a projectile is loaded with the new class of energetic materials and fired into the ordnance. The impact causes the energetic materials to react in such a fashion that the explosive compound or other material within the IED or UXO is burned in a self-propagating mode without exploding. Hence, the ordnance is neutralized.

Owner:NCC NANO LLC

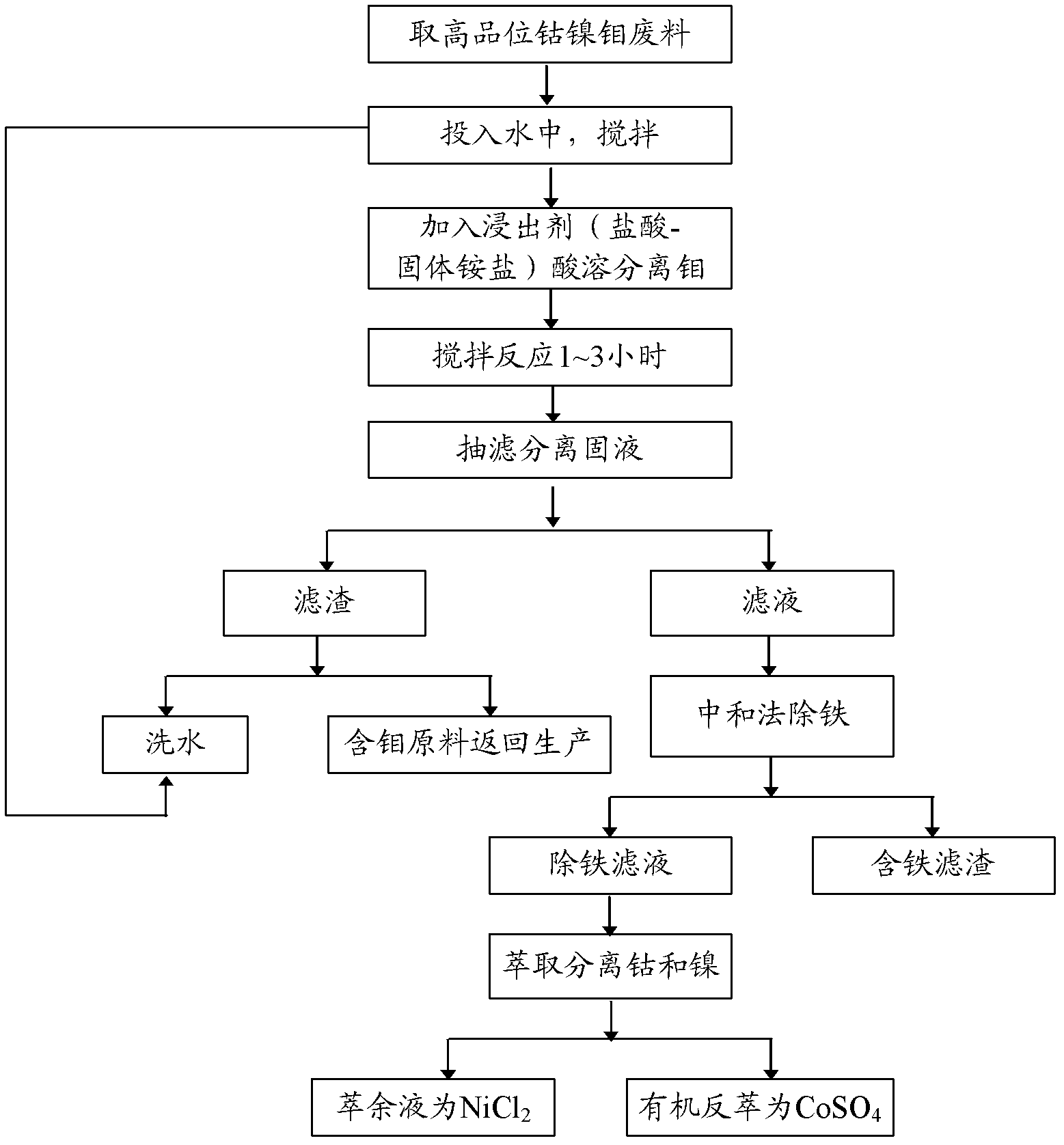

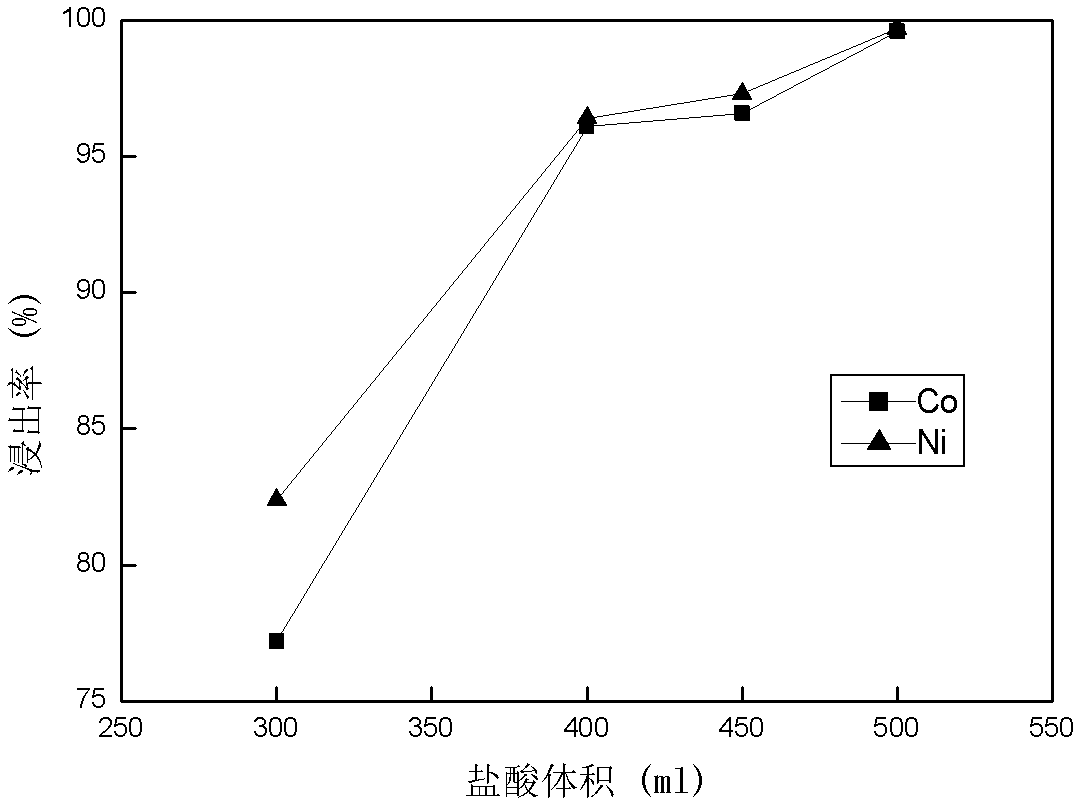

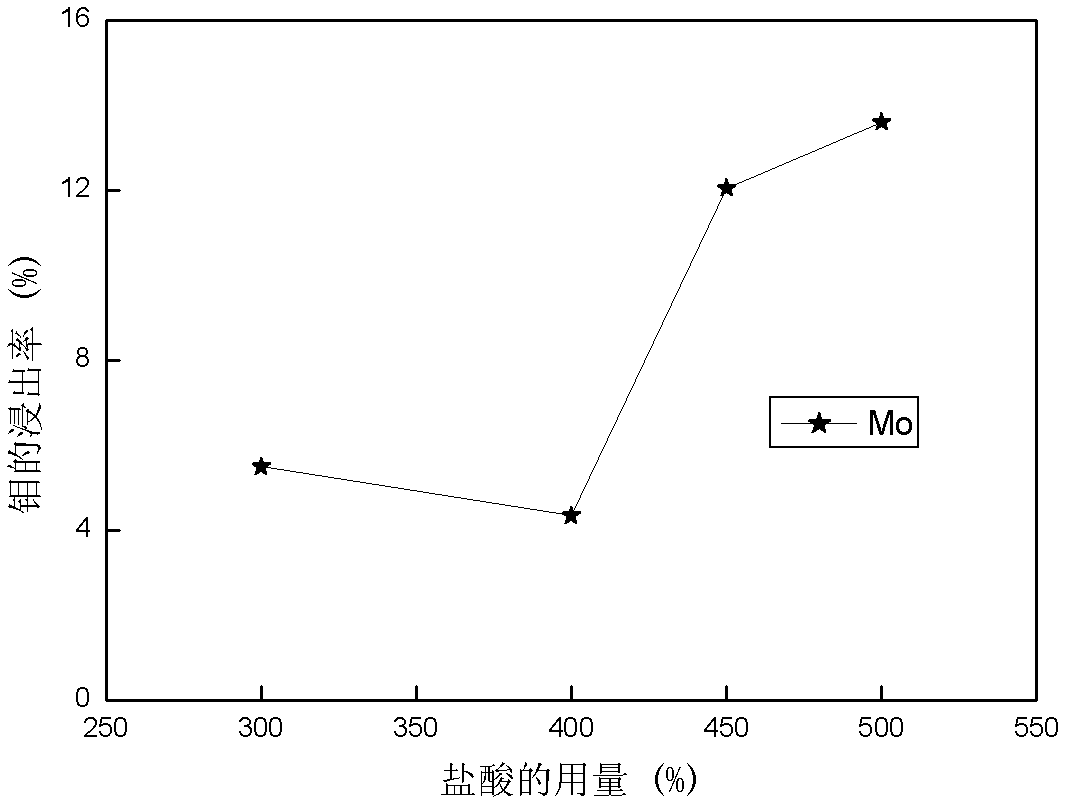

Method for selective leaching separation of cobalt, nickel and molybdenum from high grade cobalt-nickel-molybdenum waste material

ActiveCN102808082AImprove leaching rateLow leaching rateProcess efficiency improvementLoss rateAutomatic control

The invention provides a method for selective leaching separation of cobalt, nickel and molybdenum from a high grade cobalt-nickel-molybdenum waste material. The method comprises the following steps: (1) adopting an acid dissolution method to separate molybdenum; (2) adopting a neutralization method to separate iron; and (3) carrying out extraction to separate cobalt and nickel. For a high grade cobalt-nickel-molybdenum waste material, a hydrochloric acid-solid ammonium salt system is adopted as a leaching agent in the method of the present invention, a reasonable ratio of reactants is provided, cobalt and nickel are selectively leached while molybdenum is inhibited in residue, and a selective molybdenum and cobalt separation effect is significant. Iron removing rate and molybdenum removing rate in the filtrate containing cobalt and nickel are more than 99%, and cobalt loss rat and nickel loss rate are low, wherein the loss rates are respectively less than 2% and 18%. In addition, a solvent P507 is adopted to carry out extract separation of cobalt and nickel, such that selectivity is high, operation is simple and continuous, and automatic control is easy to perform. With the present invention, resources are saved to the maximal degree, adverse effects on environment are reduced, and great social benefits and economic benefits are provided.

Owner:GEM CO LTD +1

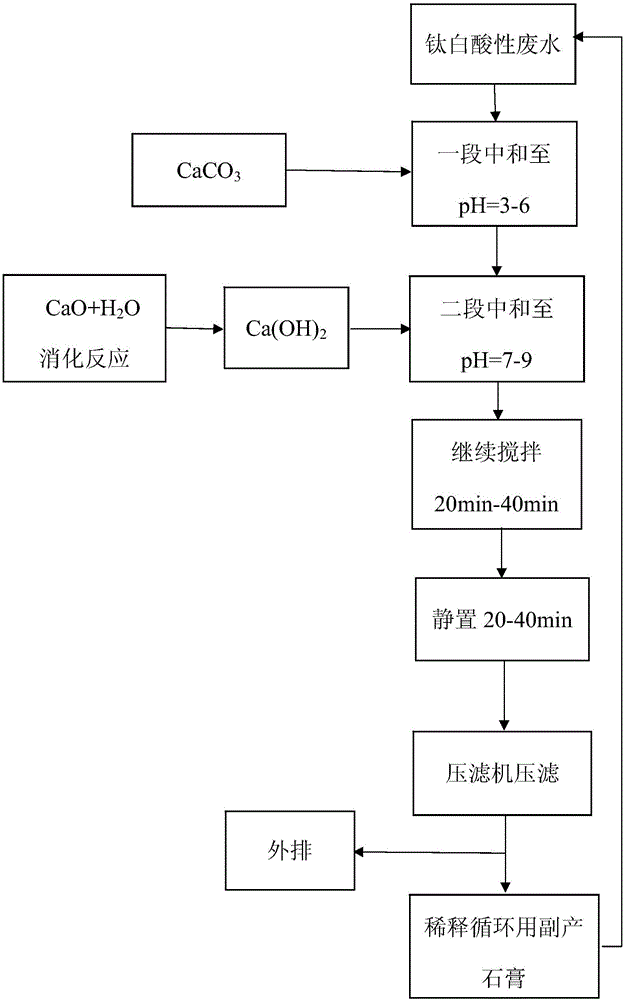

Titanium dioxide wastewater treatment method favorable for improving utilization ratio of calcium oxide and dehydration property of byproduct gypsum

ActiveCN106380018AIncrease profitImprove dehydration effectCalcium/strontium/barium sulfatesMultistage water/sewage treatmentCyclic processSeed crystal

The invention discloses a titanium dioxide wastewater treatment method favorable for improving the utilization ratio of calcium oxide and the dehydration property of a byproduct gypsum. The method comprises the steps of firstly utilizing calcium carbonate and calcium oxide to neutralize acid wastewater through a two-stage neutralization method, then partially reusing the generated byproduct gypsum to a next acid wastewater treatment process according to a seed crystal circulation principle, and circulating repeatedly. The reused byproduct gypsum can serve as seed crystal to improve the crystal growth of newly-generated gypsum, and the dehydration property of the byproduct gypsum is improved; in a circulation process, unreacted calcium oxide mixed in the byproduct gypsum can be released again and participates into neutralization reaction; thus, the utilization rate of the calcium oxide is improved.

Owner:SOUTH CHINA UNIV OF TECH

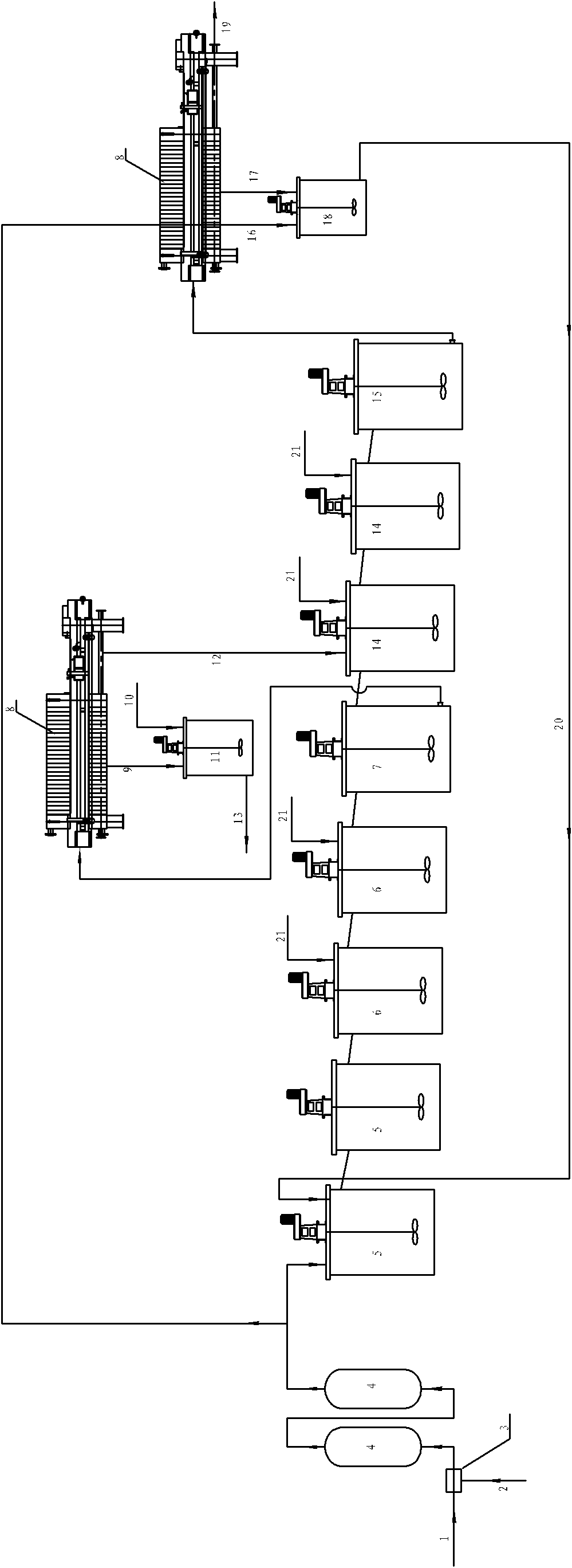

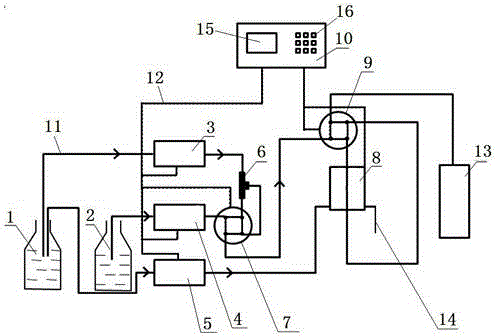

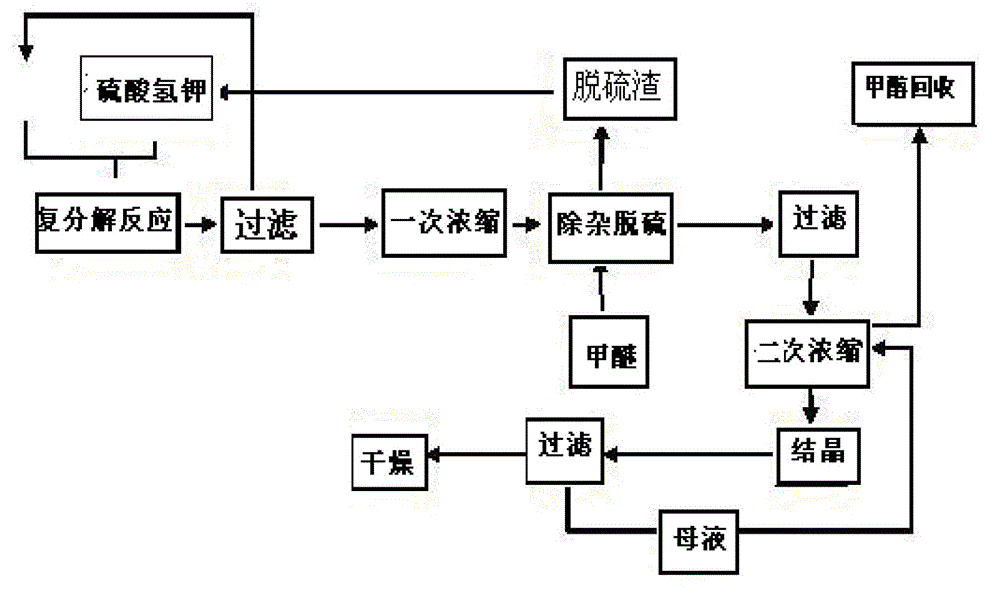

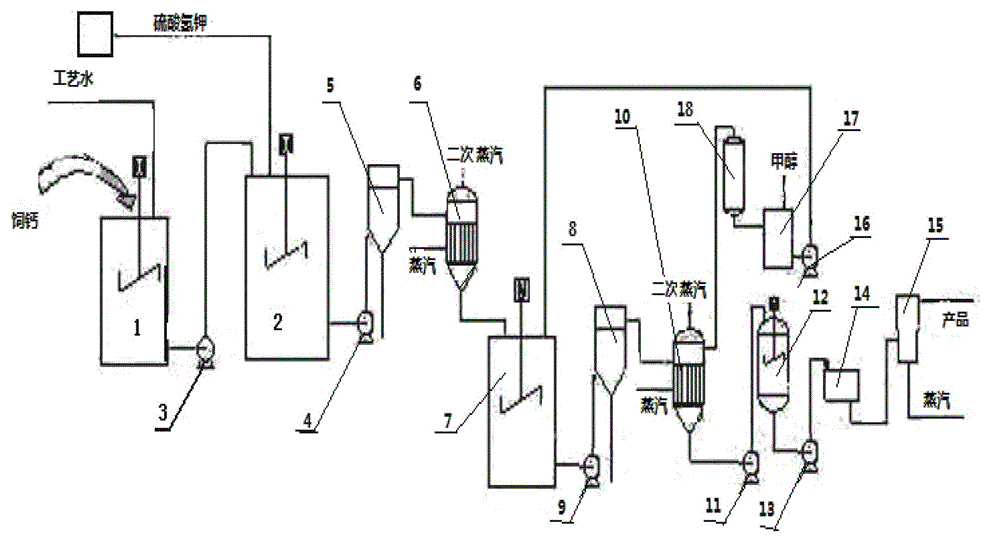

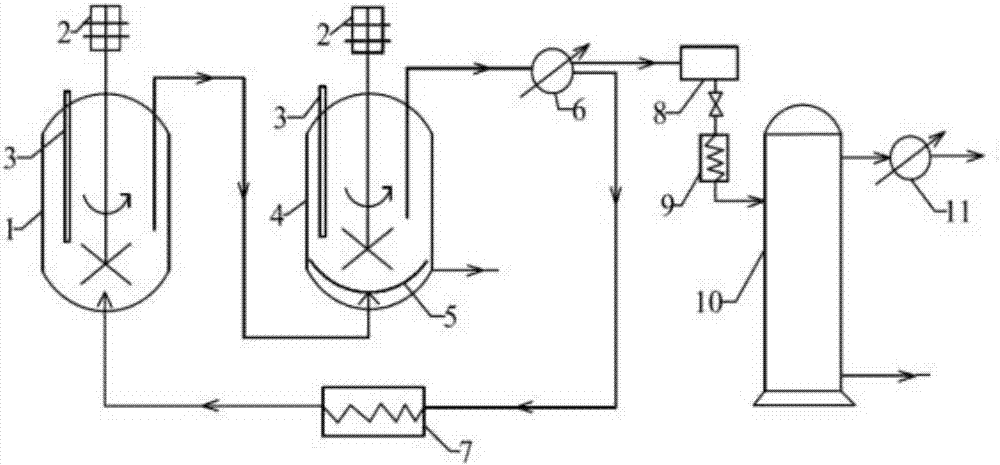

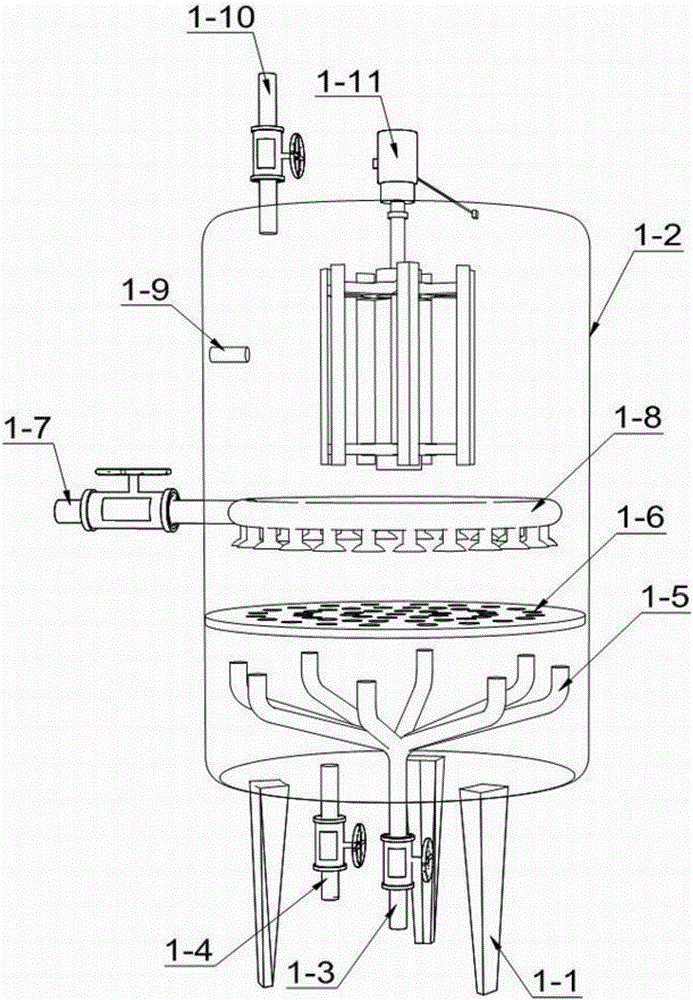

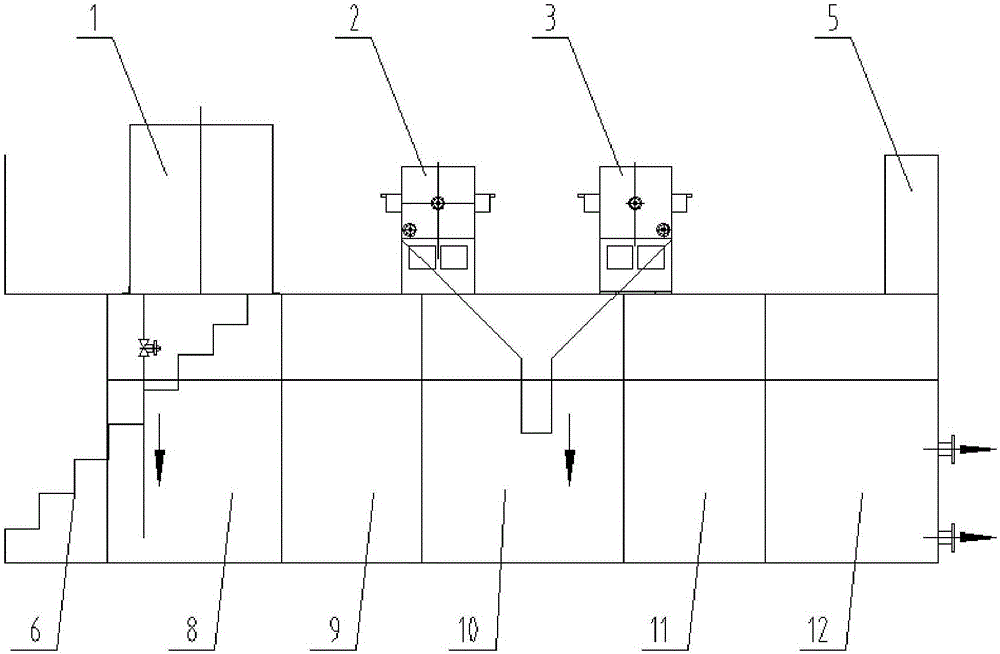

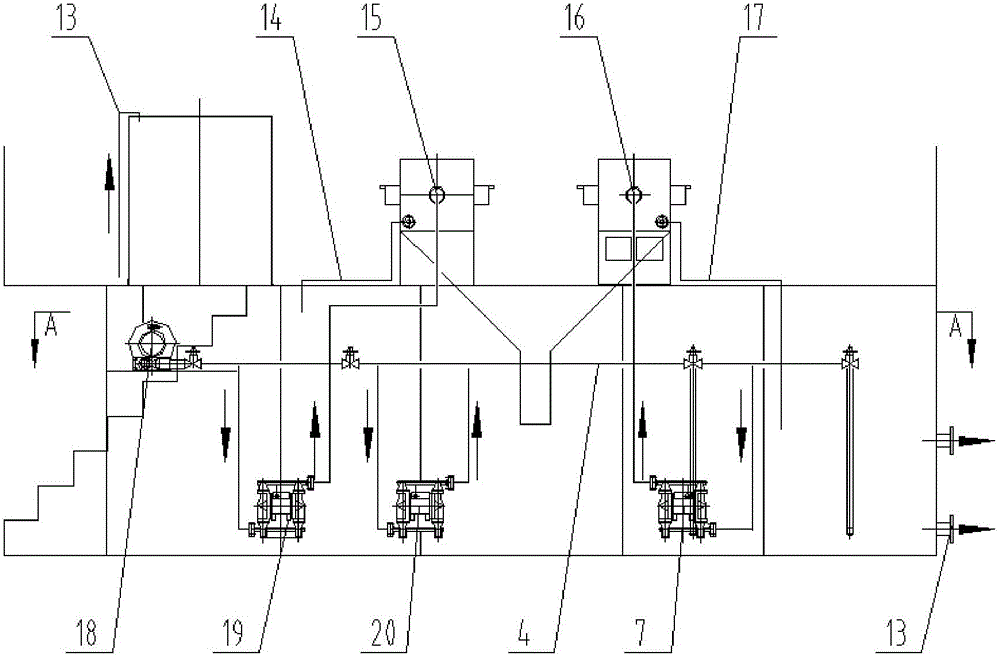

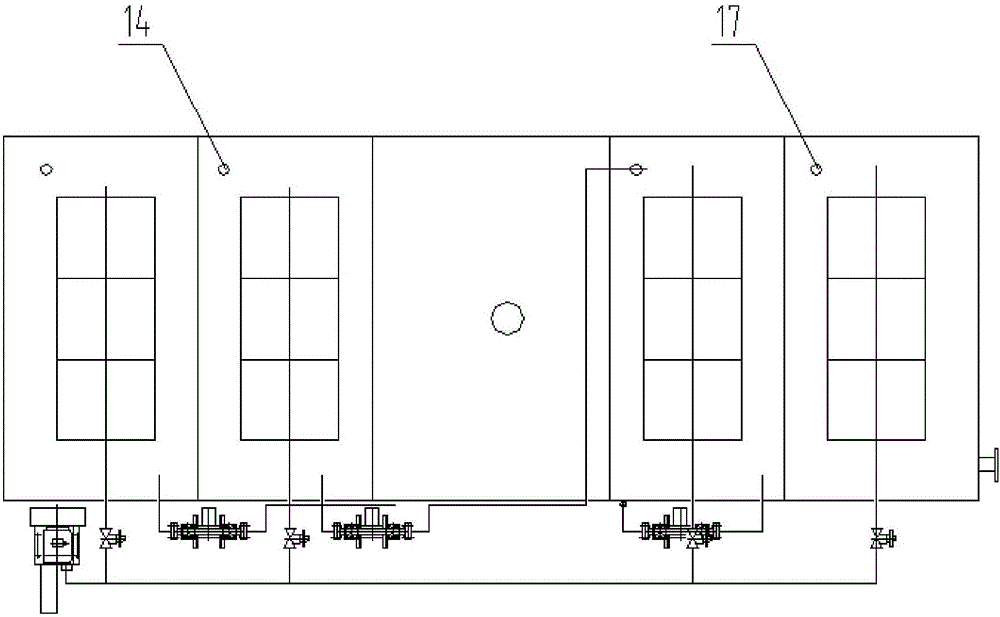

Production method of monopotassium phosphate

The invention discloses a production method of monopotassium phosphate. A production device comprises a feed calcium slurry tank (1), a reaction tank (2), a feed calcium slurry pump (3), a reaction slurry pump (4), a first automatic back washing surface filter (5), a primary evaporator (6), an impurity removal and desulfurization tank (7), a second automatic back washing surface filter (8), a slurry pump (9), a secondary evaporator (10), a mother solution pump (11), a crystallizer (12), a crystal mush pump (13), a flat plate scraper centrifuge (14), a drier (15), a methanol delivery pump (16), a methanol recovery storage tank (17) and a methanol condenser (18). With the adoption of the production device and a production technology flow, feed calcium hydrophosphate and potassium hydrogen sulfate generate replacement reaction, so that the content of a produced product can reach 98%, the cost is greatly lower than the production cost of a product obtained by a neutralization method production technology, and the production method is simple in technology and extensive in raw material source, and has broad market application prospects.

Owner:WENGFU (GRP) CO LTD

Preparation method of calcium propionate by egg shell

ActiveCN102675082AReduce processingHigh recovery rateCarboxylic acid salt preparationCarboxylic compound separation/purificationPropionatePropanoic acid

The invention discloses a preparation method of calcium propionate by egg shell. The preparation method of calcium propionate by egg shell includes egg shell pretreatment, shell membrane separation, neutralization reaction, purification reaction, filtration, pH adjustment, concentration, drying and the like. Shell membrane separation is performed under physical mixing by adding water. Based on a direct neutralization method, secondary neutralization reaction method using egg shell powder to prepare calcium propionate is established. Sodium carboxymethylcellulose is used as flocculant for purification. Therefore, the prior art problems that egg membrane separation is poor in effect, neutralization reaction is incomplete, utilization rate of propionic acid is low, product quality is instable and the like are solved.

Owner:HUAZHONG AGRI UNIV

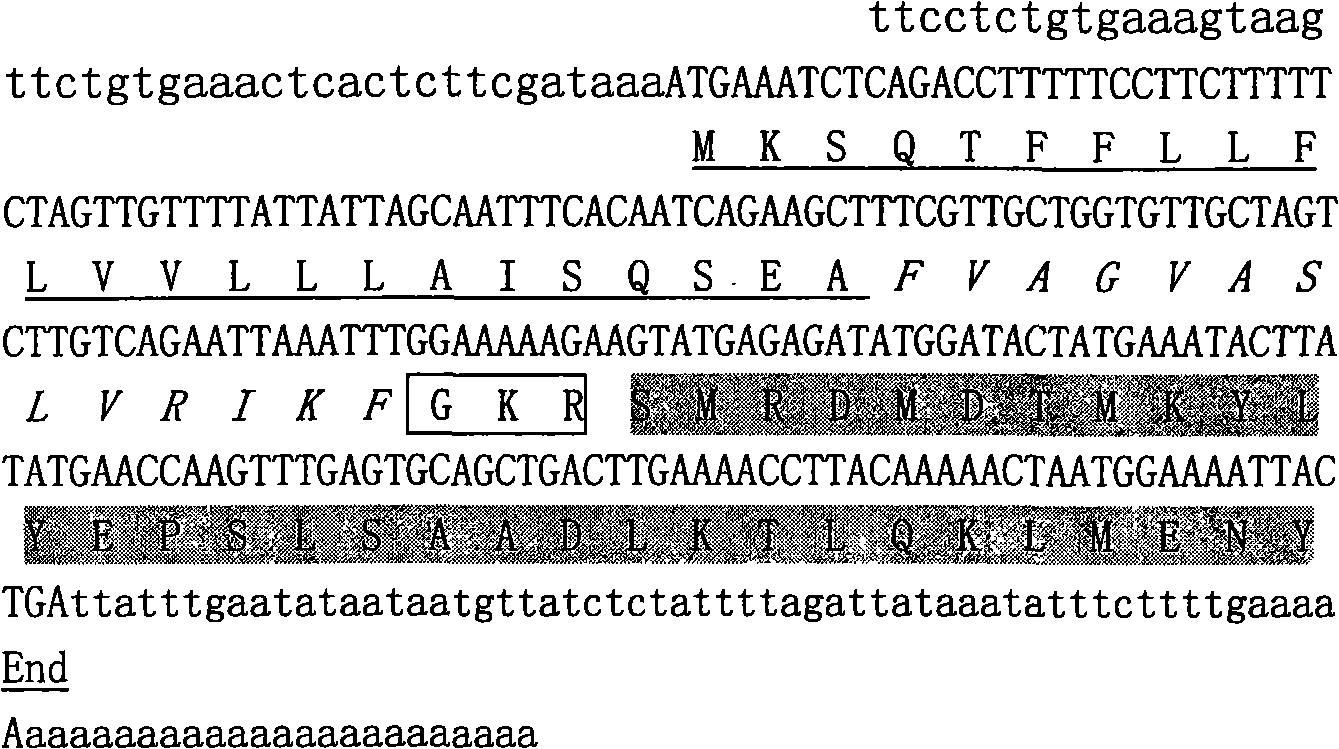

Polypeptides of anti-measles virus and human immunodeficiency virus and use

InactiveCN101284870AReduce manufacturing costGood water solubilityPeptide/protein ingredientsAntiviralsChemical synthesisDisease

The invention discloses scorpion toxin antiviral polypeptide and a use of the same. Scorpion toxin antivirotic polypeptide (AVP-W1) is obtained through a molecular biological and chemical synthesis method, and then the antiviral activity of the AVP-W1 on measles virus (MeV) and human immunodeficiency virus (HIV) is measured through adopting an antibody neutralization method; moreover, the measurement shows that the AVP-W1 can effectively inhibit virus infection at a low concentration. The AVP-W1 has a tremendous prospect in making applied medicine which can cure or prevent a disease caused by virus. Moreover, the antiviral peptide of the invention has high activity on MeV and HIV and a simple method, and can be developed as antiviral medicine.

Owner:WUHAN UNIV

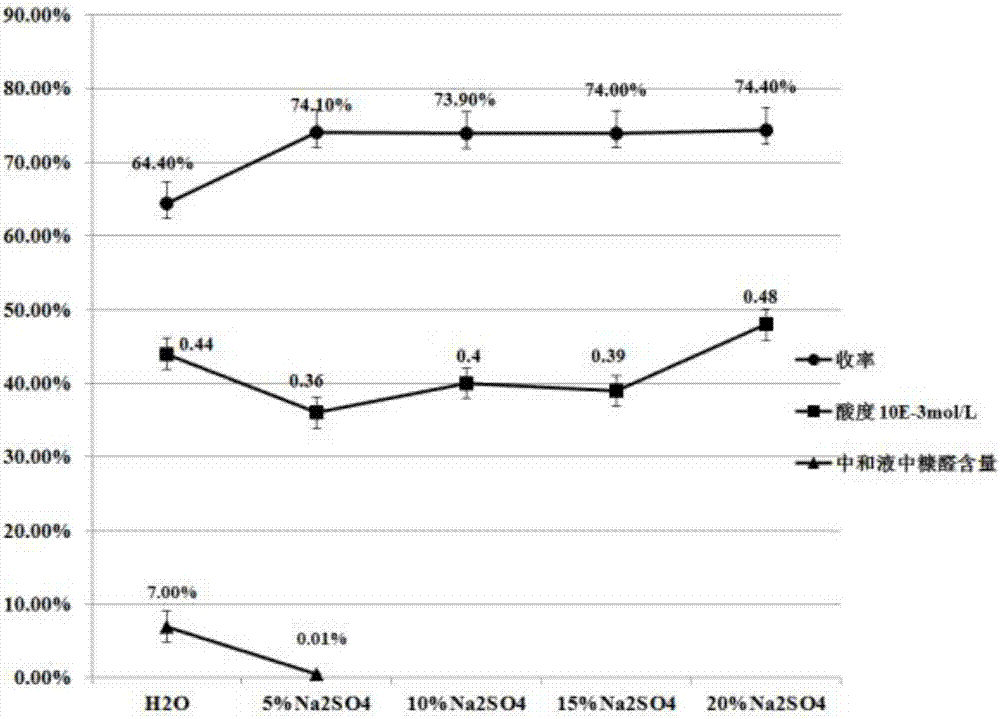

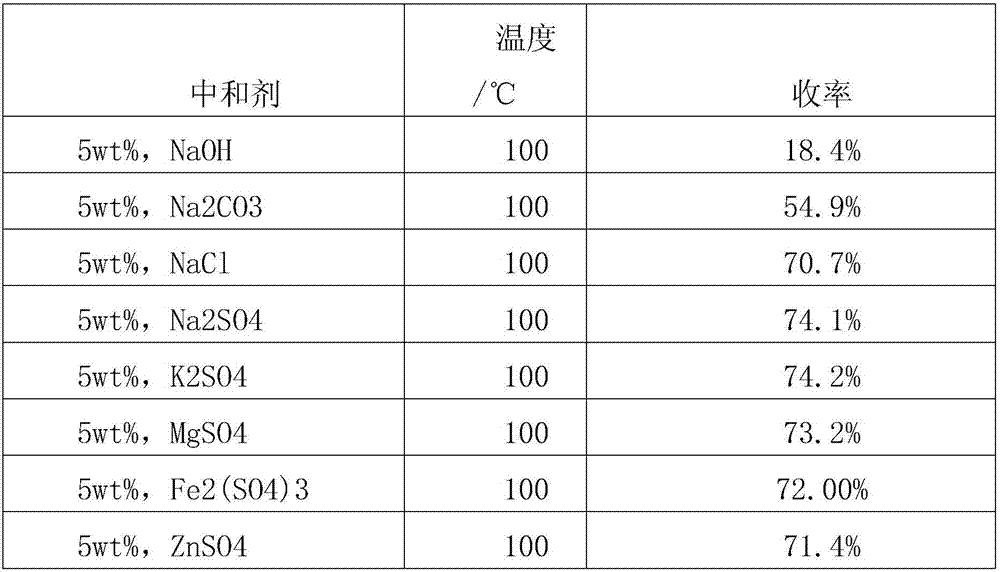

Method for improving furfural yield by furfural steam gas phase neutralization

ActiveCN107235939AIncrease concentrationReduce energy consumptionOrganic chemistryGas phaseWater vapor

The invention relates to a method for improving furfural yield by furfural steam gas phase neutralization. The method particularly includes the steps: firstly, dehydrating xylose by taking nitrogen as a steam stripping medium to prepare furfural steam; secondly, adding neutralizer solution prepared in advance into a neutralization reactor; thirdly, leading acid furfural steam distilled off from a dehydration reactor into a gas dispersing device at the bottom of the neutralization reactor, and performing reaction in the reactor after dispersion; leading furfural solution into a rectifying tower to obtain furfural with the purity of 99% or more. After the acid furfural steam passes the neutralizer solution, acid gas is absorbed by the neutralizer solution, and obtained acid solution can be returned into the dehydration reactor to serve as a catalyst for preparing the furfural after acidity is adjusted. The method has the advantages that the nitrogen is used for steam stripping, consumption of water vapor is reduced, the concentration and the purity of the furfural are improved, the acidity of the furfural steam is reduced by a gas phase neutralization method, corrosion of equipment is prevented, energy consumption of a rectifying section can be reduced, and continuous production of the furfural can be realized.

Owner:JILIN UNIV

Neutralization method of citric acid

InactiveCN101643411ASmall specific surface areaEasy to separatePreparation from carboxylic acid saltsOrganic compound preparationCitrate saltNeutralization method

The invention provides a neutralization method of citric acid, comprising the following steps: neutralizing once degerming clear solution of the citric acid with calcium carbonate and / or calcium hydroxide to pH 2-5 to generate precipitate containing citrate; carrying out solid-liquid separation and washing solid phase to obtain a solid phase containing the citrate, a liquid phase is solution containing the citric acid; secondarily neutralizing the solution containing the citric acid with the calcium carbonate and / or calcium hydroxide to pH 3-9 to generate the precipitate with the citrate; allowing the solid phase containing the citrate after separation to return for once neutralization, and allowing the liquid phase without the citric acid after separation to be discharged; and adding sulfuric acid into the solid phase containing the citrate obtained by once neutralization for acidolysis reaction to obtain acidolysis solution of the citric acid and calcium sulfate precipitate. The neutralization method of the invention has the advantages of good product quality, a small quantity of consumed water volume, small load on solid-liquid separation equipment and the like.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for treating waster water produced by production of acephate with ammonia neutralization process

InactiveCN101205103AReduce processing costsEfficient recyclingOrganic chemistryAmmonium sulfatesReaction temperatureRaffinate

The invention discloses a method for treating wastewater produced by using an ammonia neutralization method to manufacture acephate, which comprises the following steps: (1) sulphuric acid is added into the wastewater which is produced by using the ammonia neutralization method to manufacture the acephate to pH less than or equal to 5; reaction temperature is controlled below 50 DEG C; white crystal is separated; (2) by carrying out solid-liquid separation of the reaction product in the step (1), solid-phase white ammonium sulfate crystal is obtained; (3) by distilling liquid-phase reaction product left by the step (2), acetate solution is separated; (4) raffinate obtained from the step (3) is returned to the original system of compounding and extracting acephate, or is carried out burning treatment.The treatment method of the invention can greatly reduce cost for treating the wastewater of manufacturing the acephate and simultaneously realize efficient recycle and reuse by recycling the acetate in a way of industrial acetic acid with a recycling rate of 50 percent; and recycling ammonium in a way of ammonium sulfate chemical fertilizer with a recycling rate of 95 percent.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Ordnance neutralization method and device using energetic compounds

ActiveUS8505427B2Safely neutralize ordnanceHigh equipmentAmmunition projectilesBlastingNano-thermiteBomb device

This invention generally relates to a method and apparatus to neutralize ordnance, more specifically improvised explosive devices (IEDs) and unexploded ordnance (UXOs). The current invention provides a simple method to neutralize the ordnance by taking advantage of a new class of energetic materials that includes nano-thermites, binary thermites and additionally powdered thermites. In the invention, a projectile is loaded with the new class of energetic materials and fired into the ordnance. The impact causes the energetic materials to react in such a fashion that the explosive compound or other material within the IED or UXO is burned in a self-propagating mode without exploding. Hence, the ordnance is neutralized.

Owner:NCC NANO LLC

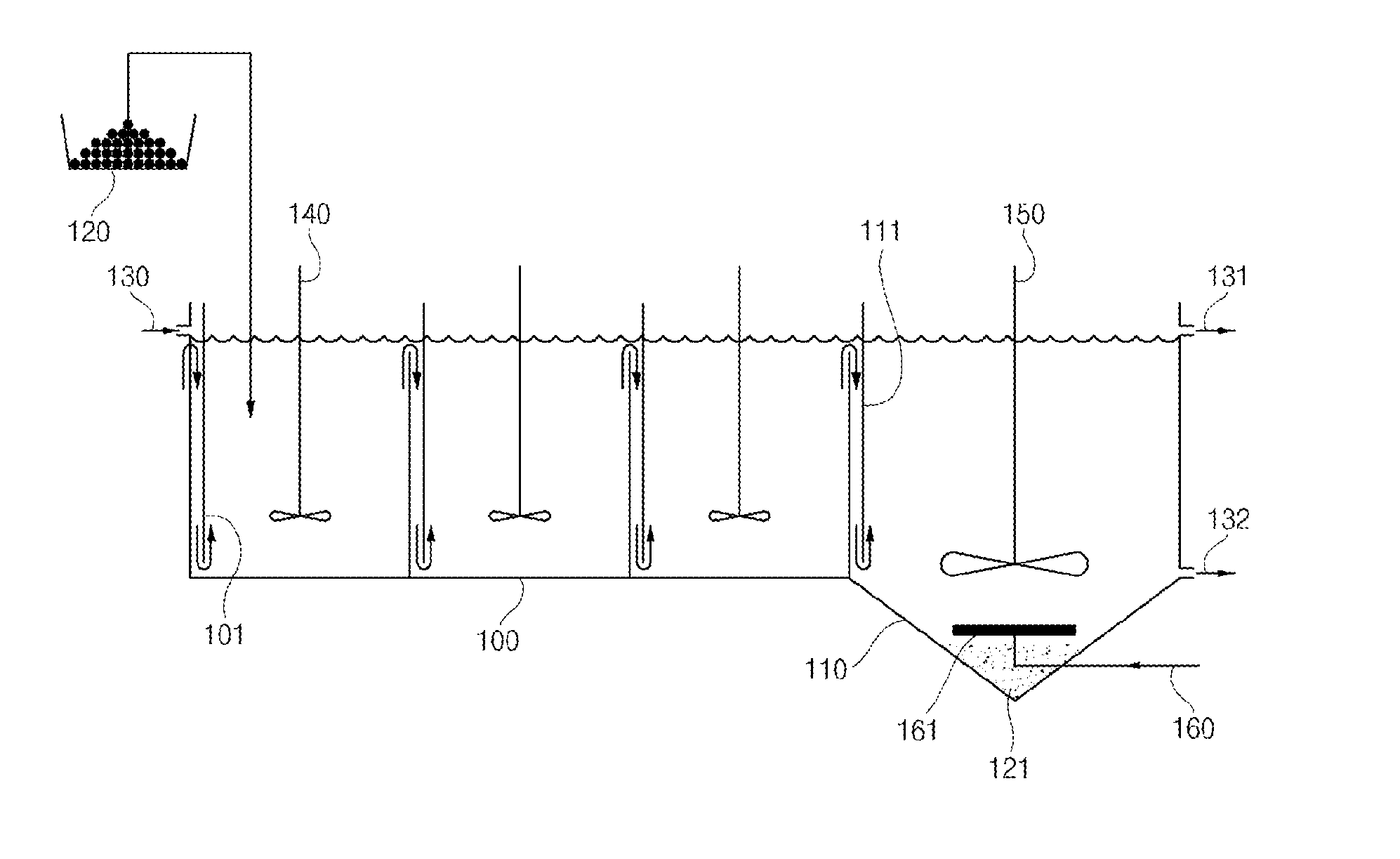

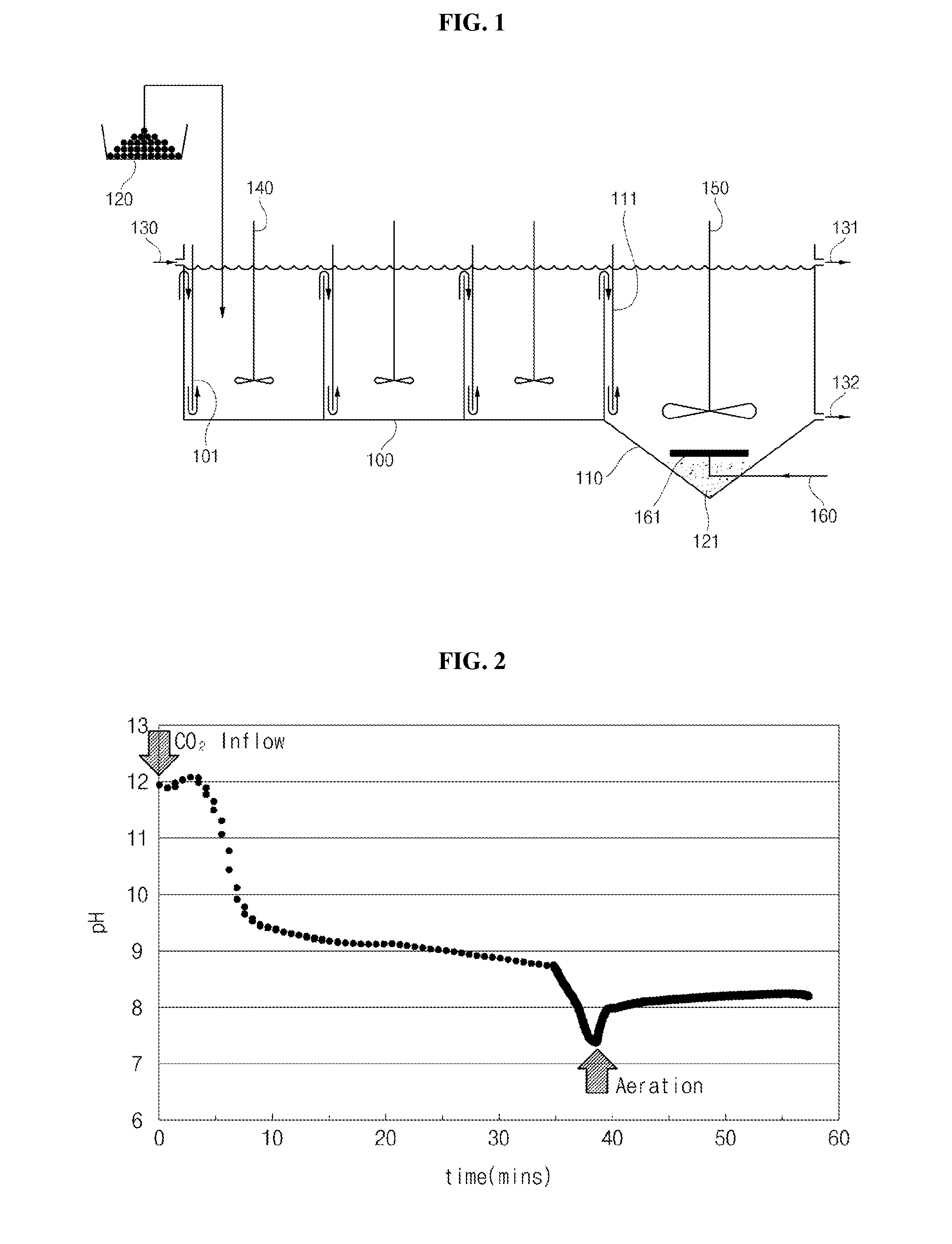

Apparatus for concentration reaction of carbon dioxide using magnesium ions in seawater, and method for sequestrating carbon dioxide in ocean using same

ActiveUS20150191385A1Reduce disadvantagesActively copeGas treatmentLiquid degasificationHigh concentrationAtmospheric air

A method for sequestrating carbon dioxide in the ocean of the present invention coverts carbon dioxide into a high concentration of bicarbonate ions by using a neutralization method using calcium oxide commonly contained in alkaline industrial waste, prepares elution water for stably containing bicarbonate ions even when making contact with the atmosphere through aeration, and discharges the elution water into an area of the ocean of a relatively shallow depth to sequestrate carbon dioxide. According to the present invention, the present invention is a carbon dioxide storage method which uses alkaline industrial waste to carry out carbon dioxide ocean sequestration at relatively low cost, and can sequestrate carbon dioxide for a long time while minimizing bad environmental influences such as ocean acidification and the like, and is thus environmentally friendly. Therefore, it is possible to actively respond to carbon dioxide emission restrictions and simultaneously achieve economical efficiency by securing certified emission reductions henceforth.

Owner:KOREA ELECTRIC POWER CORP

Improved preparation method of mannityl nicotinate

The invention discloses a preparation method of mannityl nicotinate, which takes nicotinic acid, thionyl chloride and mannitol as main raw materials and comprises the steps of acylating chlorination, esterification, refining and the like, wherein the two reactions of acylating chlorination and esterification are finished by a 'one-pot method', and an alkaline neutralization method is adopted to sufficiently precipitate the product after the reaction; and in the refining process, a method of acid solution decoloration and alkaline precipitation taking water as a solvent is adopted to replace the existing traditional technology of adopting a large amount of class-two toxic solvent N,N-dimethylformamide to perform decoloration refining. Through the synthesis method disclosed by the invention, the separation and purification of intermediates are not required, and a crude product can be refined directly without drying, so that the operation steps are reduced, the production period is shortened, and the production cost is lowered, thus the method is suitable for industrial production.

Owner:HUAZHONG PHARMA

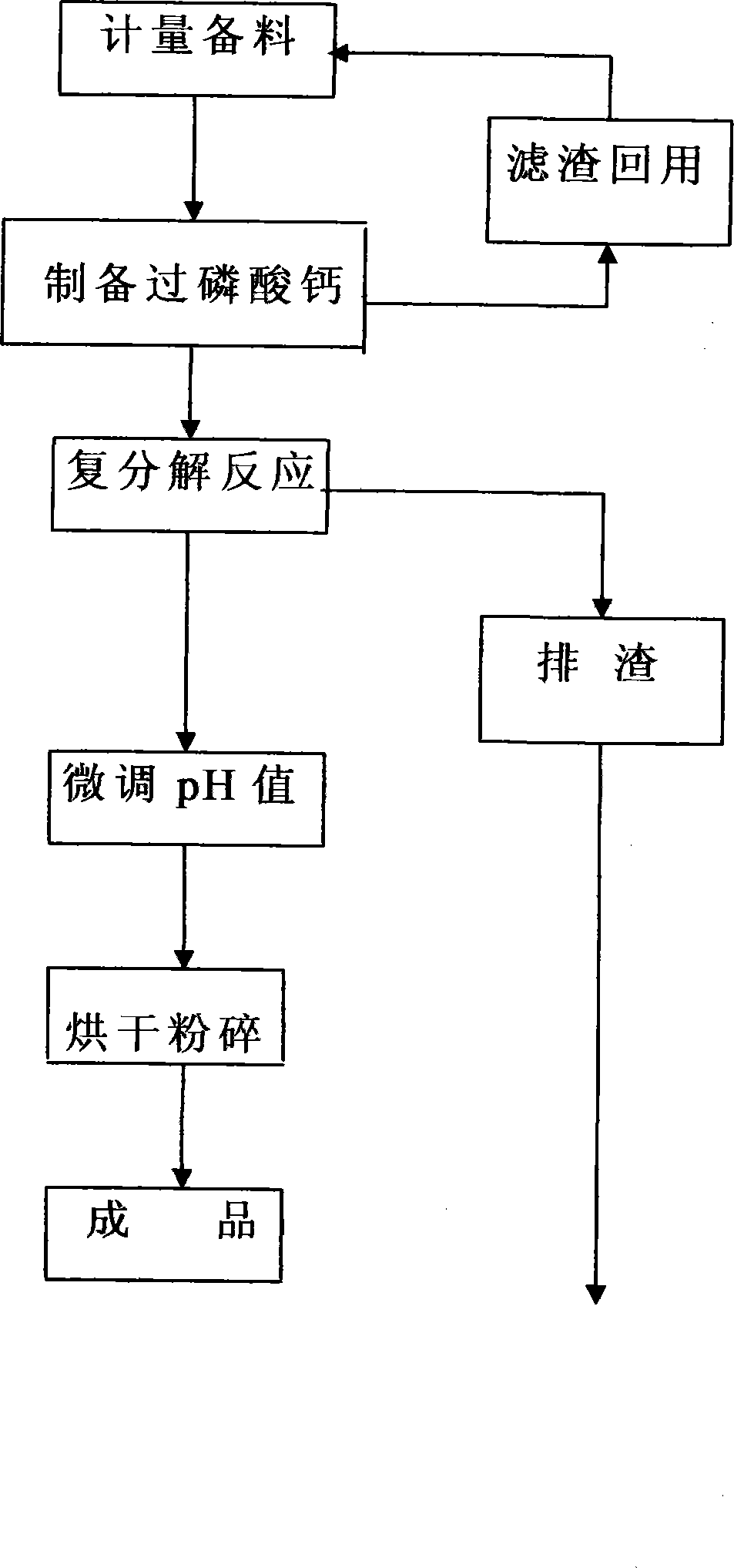

Method for producing monoammonium phosphate by metathesis method

The invention provides a method for manufacturing ammonium diacid phosphate by double decomposition, which follows the steps of material preparation by computation, calcium superphosphate preparation, double decomposition reaction, PH value vernier regulation and drying and grinding in sequence. The invention is remarkably characterized by that calcium superphosphate is prepared by firstly using rock phosphate and sulfuric acid and then carried out the double decomposition reaction with ammonium sulfate to manufacture ammonium diacid phosphate products, which avoids the defect in traditional 'neutralization method' that large quantity of metal ion such as iron, aluminum and magnesium are precipitated as the form of hydrogen phosphate of water insoluble and large quantity of phosphorus element are drained away; the thickness of hydrogen ion in original state of reaction liquid and the water solubility of dihydric phosphate such as iron, aluminum and magnesium are preserved. The method can use low, middle and high grade of phosphorite as material and manufacture ammonium diacid phosphate products with a quality that can realize or higher than the international II class standard; the total yield of phosphorus reaches up to 95 percent; the consumption of sulfuric acid material reduces by 30 percent; the method has a good effect of energy saving and emissions reduction and remarkable economic efficiency.

Owner:四川省犍为明丰化工有限公司

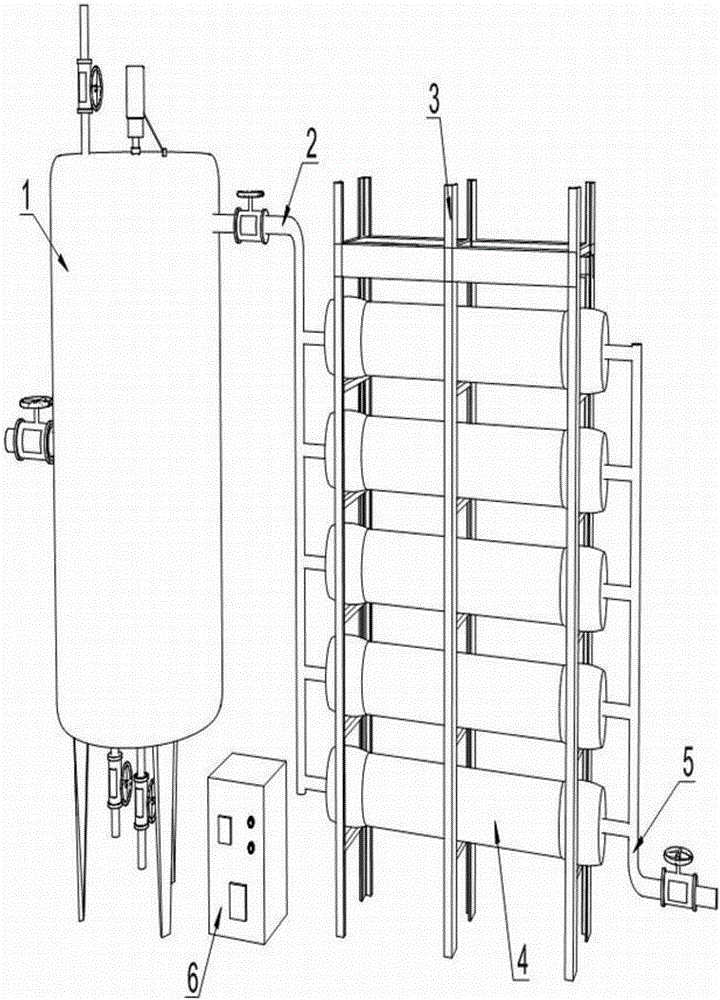

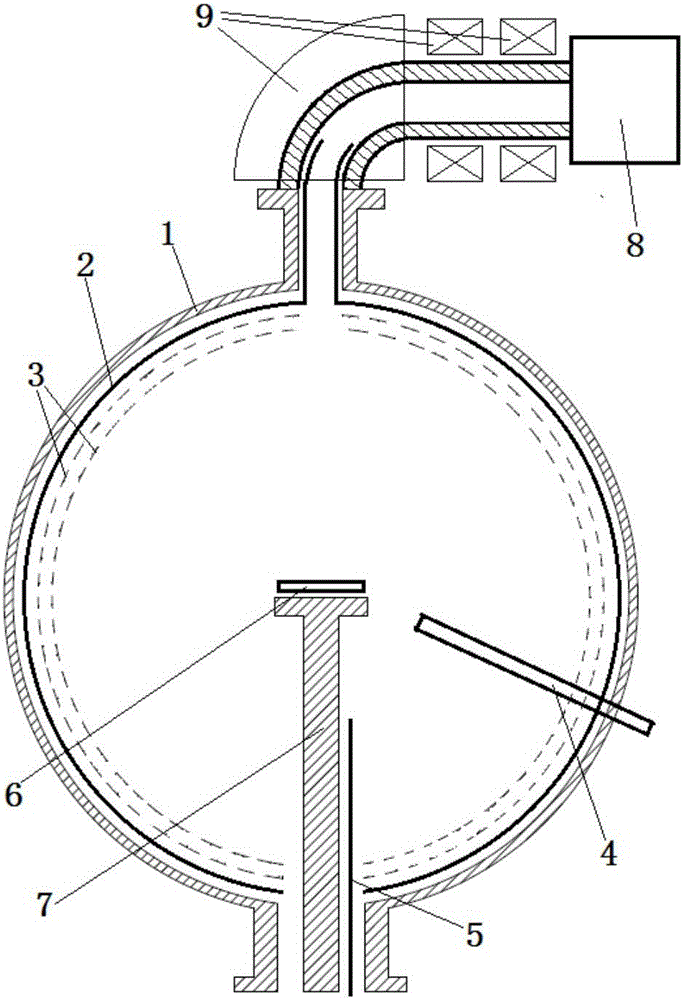

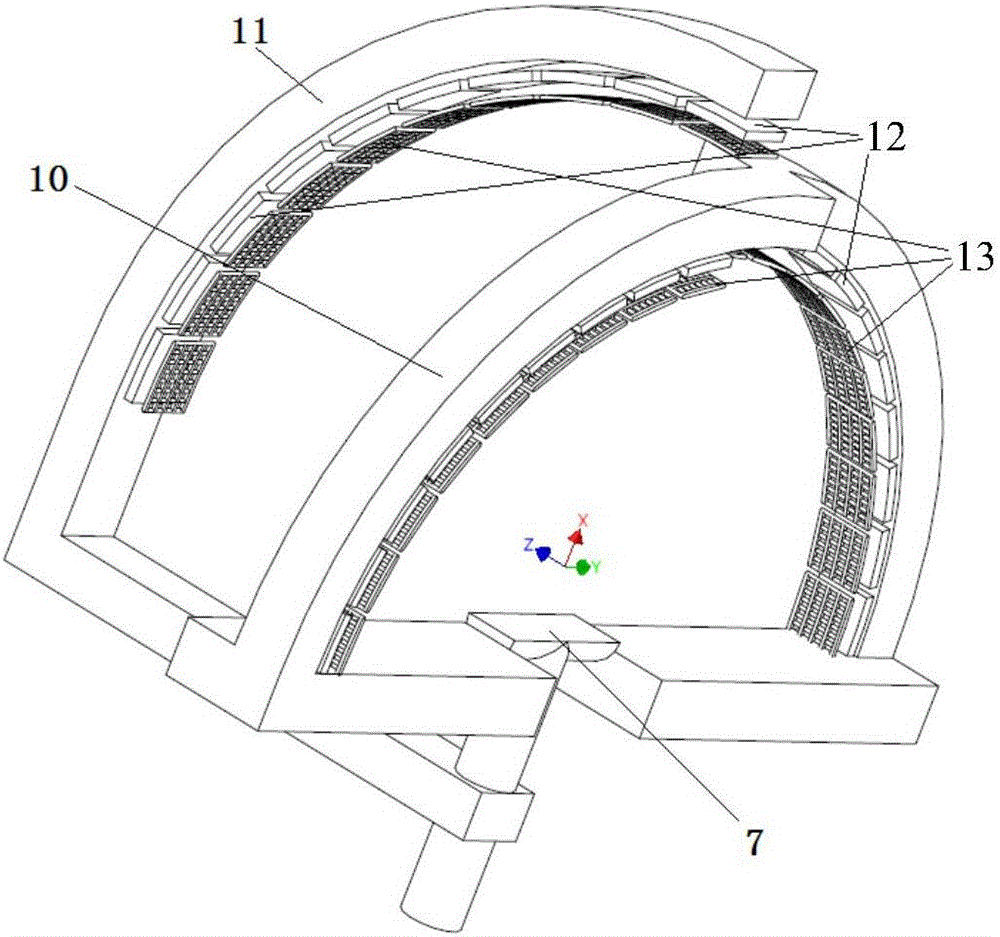

Sewage purification device and purification method based on chemical neutralization method and nanofiltration technology

ActiveCN106365351AImprove purification effectCompact and reasonable structure designTreatment involving filtrationWater distributersPurification methodsControl system

The invention discloses a sewage purification device and purification method based on a chemical neutralization method and a nanofiltration technology. The sewage purification device comprises a chemical neutralization and purification unit, a series connection bent pipe, a formed steel supporting frame, nanofiltration bins, a water outlet pipe and a control system, wherein the nanofiltration bins are positioned on the surface of the formed steel supporting frame and are uniformly arranged in the vertical direction; the control system is arranged at one side of the formed steel supporting frame; the chemical neutralization and purification unit is positioned at one side of the formed steel supporting frame; the chemical neutralization and purification unit is communicated with the nanofiltration bins through the series connection bent pipe; the surface of the series connection bent pipe is provided with an electromagnetic valve, and the electromagnetic valve is in wire control connection with the control system; the water outlet pipe is arranged at one side of the nanofiltration bins; and the surface of the water outlet pipe is provided with another electromagnetic valve, and the electromagnetic valve is in wire control connection with the control system. The sewage purification device and purification method based on a chemical neutralization method and a nanofiltration technology have the advantages of novel and reasonable structure, high purification efficiency and wide application range.

Owner:徐州筱翔知识产权服务有限公司

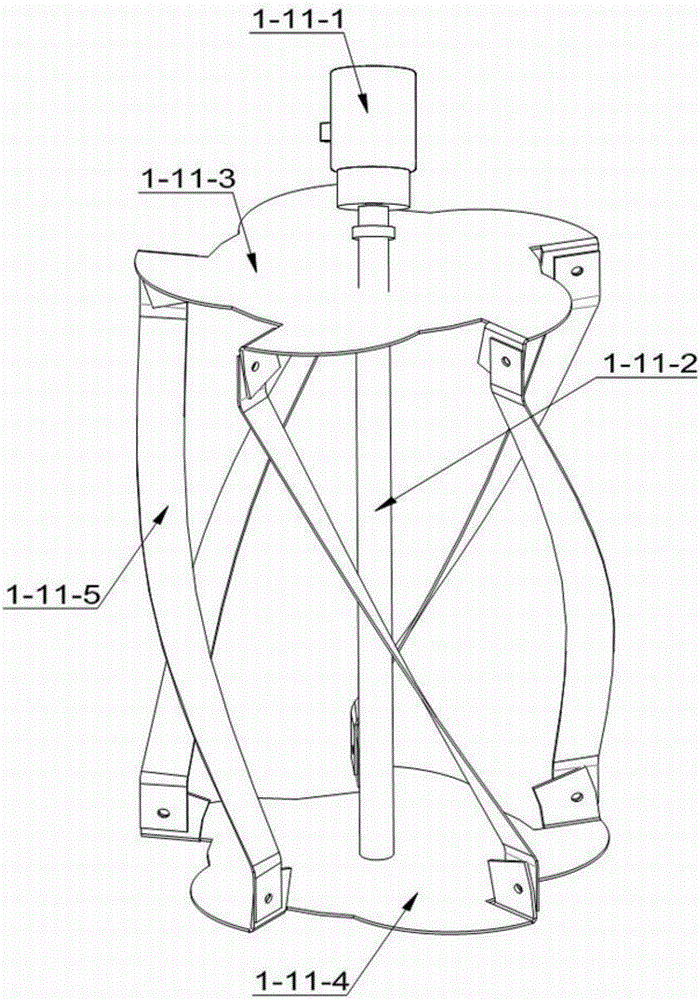

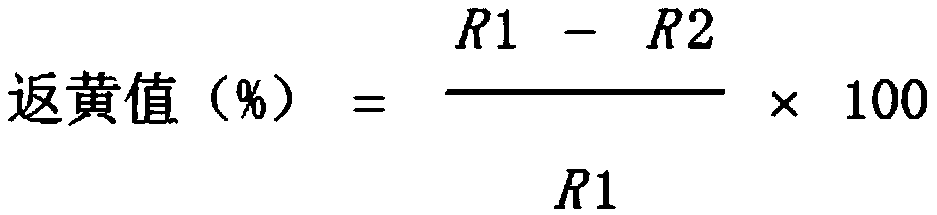

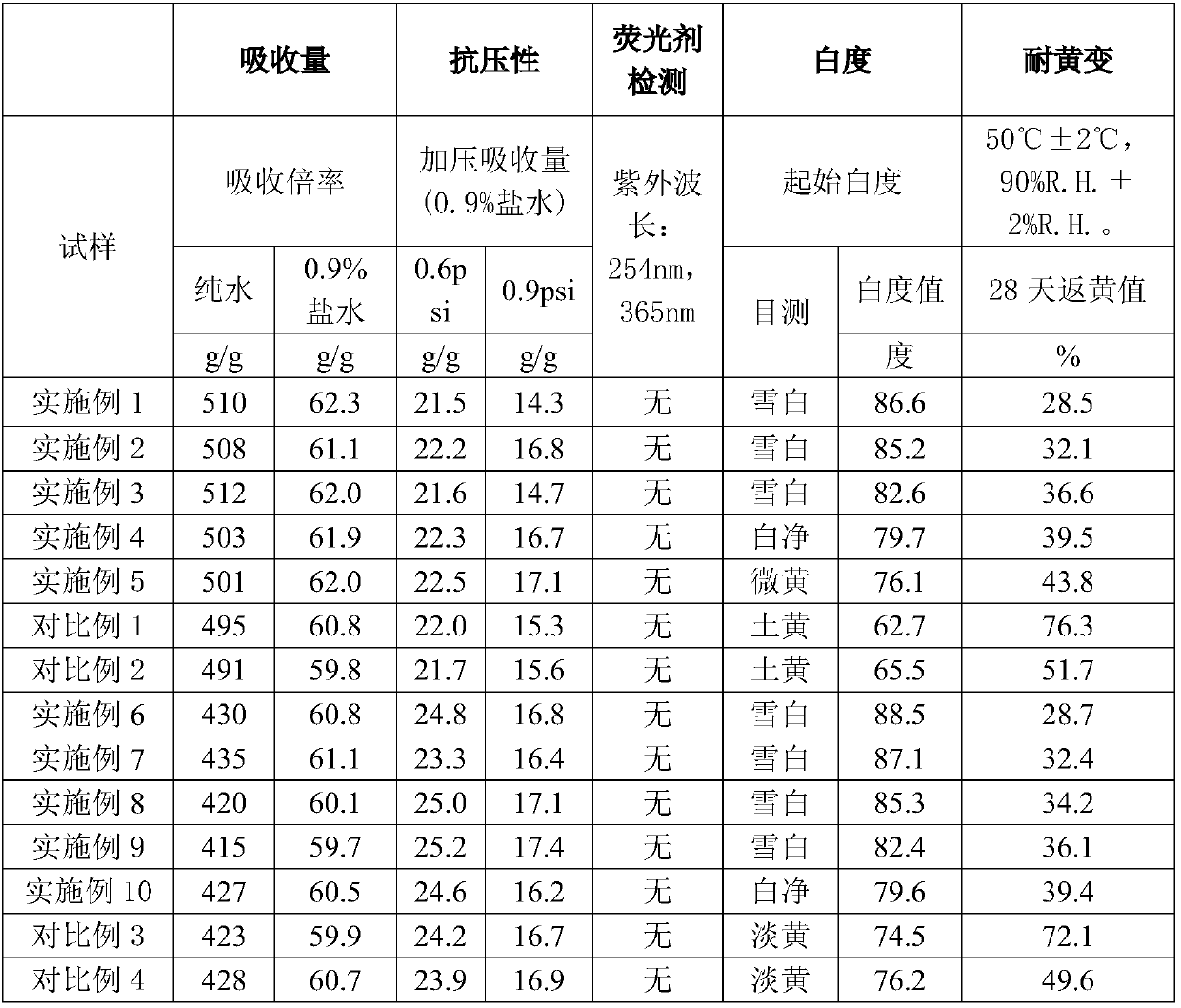

Preparation method of white and yellowing resistant water-absorbent resin

The invention discloses a preparation method of a white and yellowing resistant water-absorbent resin. The preparation method is a pre-neutralization method or a post-neutralization method, wherein the pre-neutralization method comprises the following steps: adding acrylic acid into a neutralization solution to be neutralized, carrying out a radical polymerization reaction to obtain sodium polyacrylate and polyacrylic acid hydrogel of a certain neutralization degree, performing squeezing granulation on the hydrogel in the presence of a soluble reducing agent, and performing after-treatment toobtain a super absorbent resin; and the post-neutralization method comprises the following steps: carrying out a radical polymerization reaction on an aqueous solution of acrylic acid so as to obtainpolyacrylic acid gel, and adding a neutralization solution into the polyacrylic acid gel to carry out a neutralization reaction; and adding the soluble reducing agent to perform squeezing granulation,and performing after-treatment, thereby obtaining the super absorbent resin. According to the preparation method disclosed by the invention, the initial whiteness of the product can be effectively improved, and the yellowing resistance of the product can also be effectively enhanced.

Owner:刘常红

Composite carrier of exhaust gas cleaning catalyst and preparation method of carrier

InactiveCN102962104AIncrease the areaLarge hole volumeCatalyst carriersDispersed particle separationSodium aluminateCerium

The invention discloses a composite carrier of an exhaust gas cleaning catalyst and a preparation method of the carrier, and relates to the preparation method of a composite material for cleaning and catalyzing automobile exhaust. The composite carrier is characterized by comprising the components of 34-75% of aluminum oxide, 12.5-35% of cerium oxide and 12.5-31% of zirconium oxide. The preparation process comprises the steps of: preparing a pseudo-boehmite base material by a sodium aluminate solution sulfuric acid neutralization method, and then merging and precipitating cerium-zirconium mixed soluble salt solution and a precipitator on the surface of the pseudo-boehmite base material, thus obtaining the composite carrier material which is large in specific surface area, and good in oxygen storage capacity, and has the capability of keeping high specific surface area and high oxygen storage capacity stability at high temperature by aging, drying and roasting, wherein the specific surface area can be up to 113m<2> / g after sintering for 12 hours at 1000 DEG C. The preparation method is simple in production process, and the prepared composite carrier material has excellent property and can be used as a coating carrier of a high-performance exhaust catalyst.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

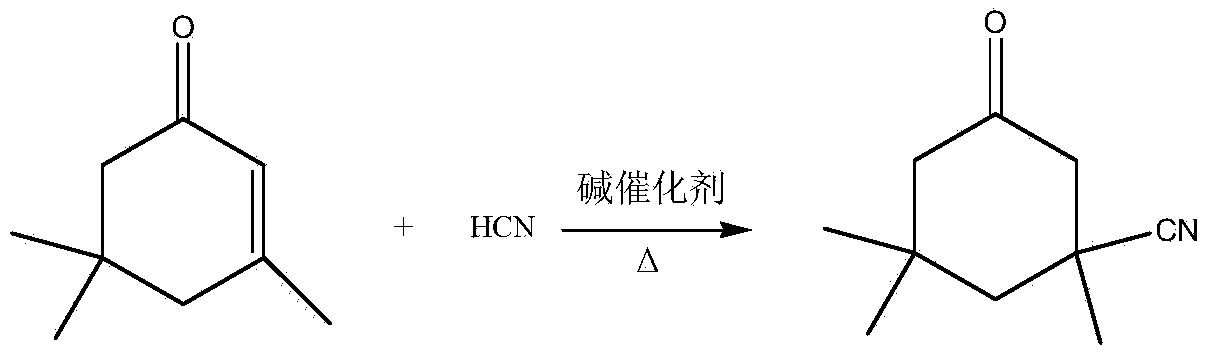

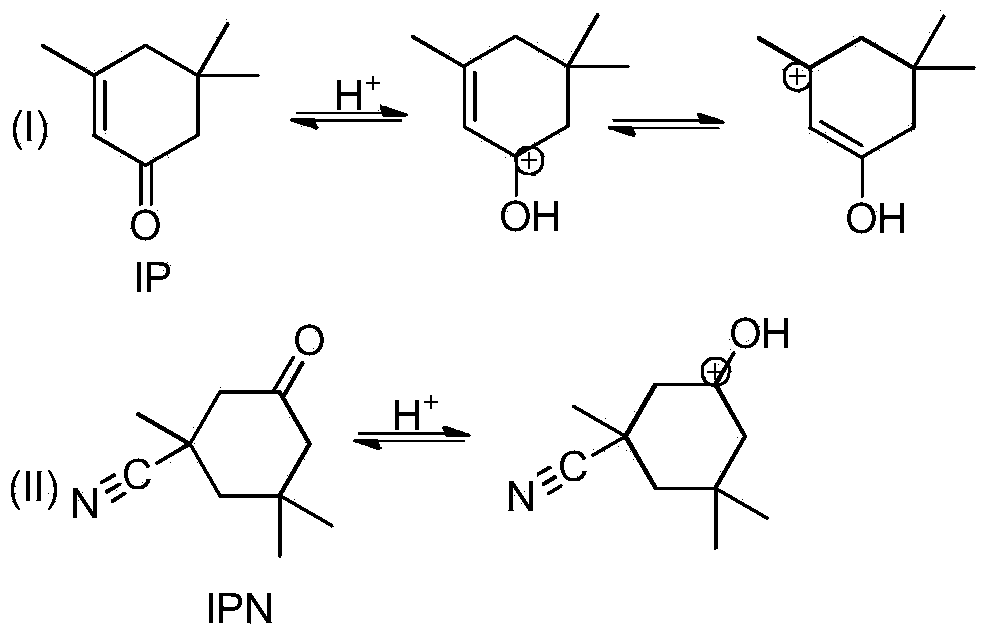

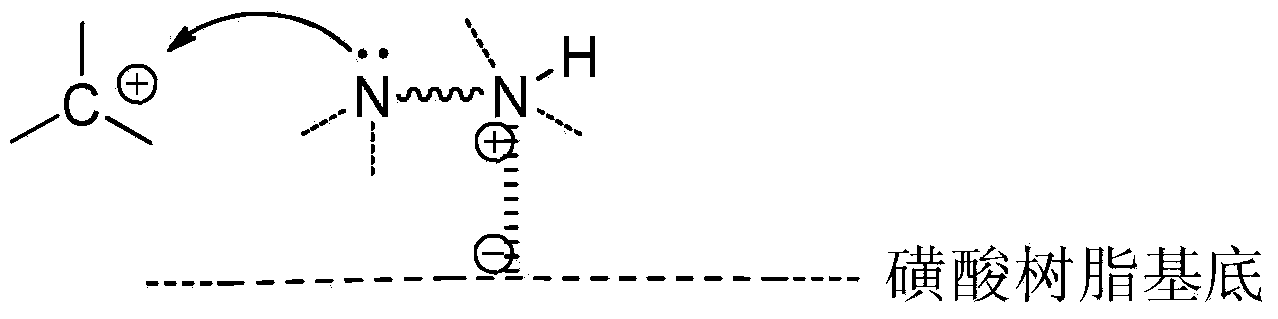

Improved method for treatment of isophoronenitrile reaction solution

ActiveCN104230756AEasy to getGuaranteed uptimeCarboxylic acid nitrile purification/separationEnvironmental resistanceIsophorone

The invention provides a method for treatment of a reaction solution obtained in preparation of isophoronenitrile from raw materials, namely isophorone and hydrocyanic acid under the catalysis of an alkaline catalyst. By adopting a two-step neutralization method, the reaction solution of isophoronenitrile is relatively stable, the influence of a salt produced in a neutralization process on a subsequent separation system is avoided and the stability in operation of a device is increased; furthermore, decomposition and polymerization reactions of isophoronenitrile and the reaction speed of polymerization of isophorone in the neutralization process and subsequent rectification separation of the reaction solution of isophoronenitrile are greatly reduced, the product yield is further improved, the unit consumption of materials is reduced by above 5%, the solid and waste content in a high polymer is reduced by above 80%, and a series of production, safety, environmental production and other problems caused by production of hydrocyanic acid in a rectification system are avoided.

Owner:WANHUA CHEM GRP CO LTD +1

Chemical nickel-plating waste liquor treatment method and system

PendingCN106587455AReduce COD valueReduce energy consumptionPhotography auxillary processesWater treatment compoundsBarium saltExisting Treatment

The invention provides a chemical nickel-plating waste liquor treatment method and system. The chemical nickel-plating waste liquor treatment method comprises the steps of adjusting the pH value of chemical nickel-plating waste liquor to 8-8.5; adding soluble barium salt to conduct a complex breaking reaction, and adjusting the pH value of the solution to 11-12, and then conducting coagulating settling to obtain first mixed liquor; conducting solid-liquid separation on the first mixed liquor to obtain first filtrate; conducting subsequent purification treatment on the first filtrate to realize recycling and discharging. The chemical nickel-plating waste liquor treatment system comprises a complex breaking device and a first pressure filter connected with each other. By means of the chemical nickel-plating waste liquor treatment method and system, complex nickel in the chemical nickel-plating waste liquor can be destroyed to generate free nickel ions, so that nickel in the waste liquor is completely removed through a neutralization method. Compared with existing treatment methods, the purification effect is greatly improved.

Owner:重庆中农环保建设股份有限公司

Secondary electron measurement device

ActiveCN106770411ABombardment damage is smallAvoid surface damageMaterial analysis using wave/particle radiationMeasurement deviceSecondary electrons

The invention belongs to an electron measurement technology and particularly relates to a secondary electron measurement device. According to the device, a plasma generation device is arranged in a vacuum cavity, charges accumulated on the surface of an insulated sample during secondary electron measurement are neutralized by plasma, and total current measurement and angle distribution measurement of secondary electrons can be realized; secondary electrons of a reverse-shooting electronic gun can be collected. The problem of surface damage of the insulated sample with a positive ion implantation and neutralization method in the prior art is solved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com