Preparation method of white and yellowing resistant water-absorbent resin

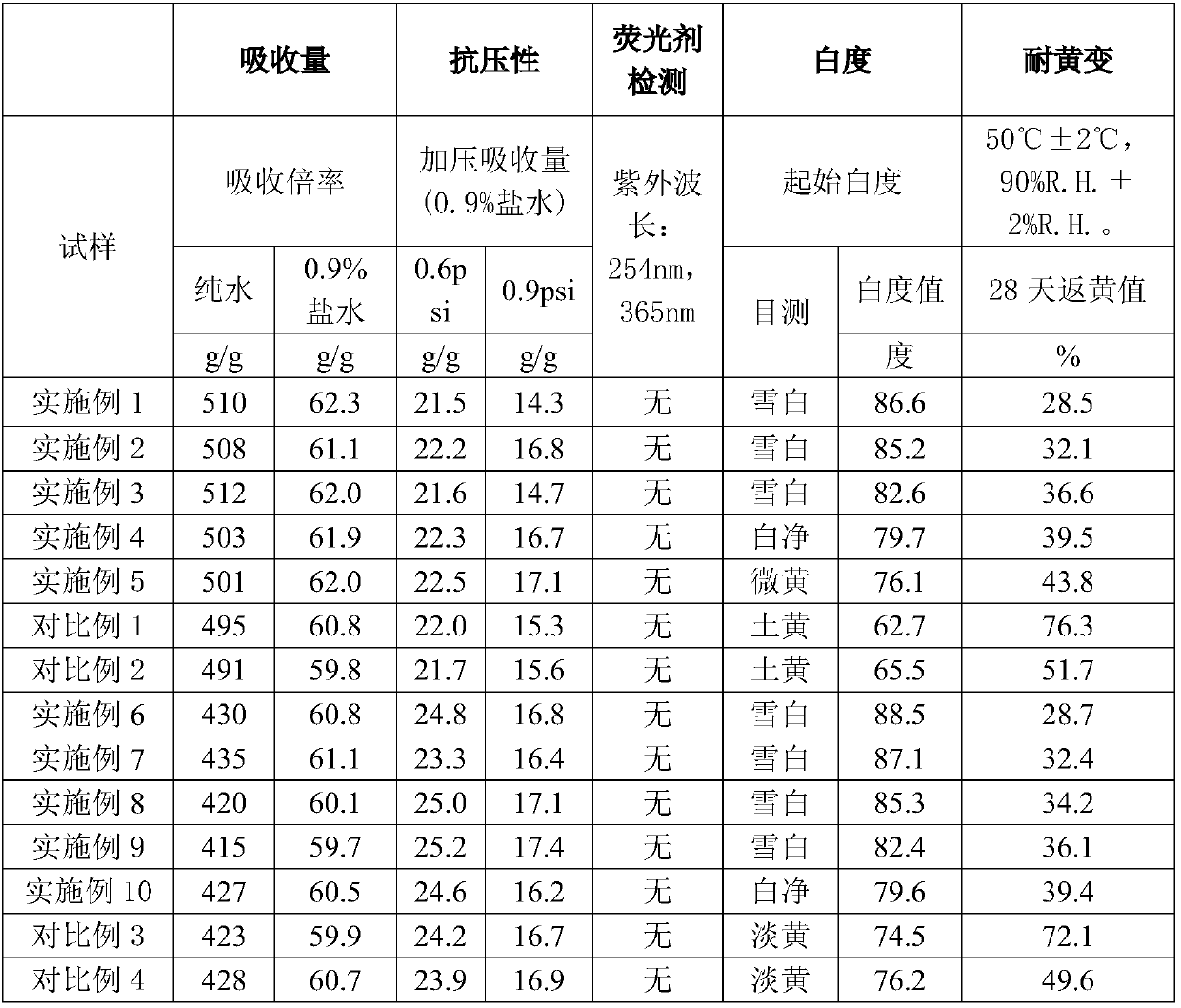

A technology of super absorbent resin and yellowing resistance, applied in the field of super absorbent resin, can solve the problems of easily violating the safety of sanitary products, and achieve the effect of improving initial whiteness and enhancing yellowing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The preparation method of the present invention is divided into two types: pre-neutralization method and post-neutralization method.

[0074]The pre-neutralization method is to first inject the acrylic acid aqueous solution into the reaction kettle with cooling and stirring devices, turn on the cooling water and the agitator, and slowly add the neutralizing liquid according to the total amount of the final neutralization degree of 70-80mol%, and control the neutralization. And heat release makes the material temperature lower than 40 ℃, the neutralization is carried out first, and then the internal crosslinking agent and reducing agent are added and mixed evenly. The mixed liquid is sent to the mixer to be fully mixed with the oxidant and other additives from another channel, and then flows to the polymerizer. After a few seconds, the free radical polymerization reaction initiated by the redox system occurs on the polymerizer to obtain a hydrogel; Extrusion and granulat...

Embodiment 1

[0078] A preparation method of a white, yellowing-resistant superabsorbent resin, comprising the following steps:

[0079] 1) Prepare polymerization grade refined acrylic acid, the content of polymerization inhibitor MQ is 138ppm; 200g.

[0080] 2) prepare neutralizing agent 45% sodium hydroxide aqueous solution, iron ion (as Fe 2 o 3 Total) content is 1ppm; 180g.

[0081] 3) Add 0.09 g of EDTA to 180 g of the above-mentioned neutralizing agent in a 45% aqueous sodium hydroxide solution, stir evenly, and prepare a neutralizing solution.

[0082] 4) Add the above-mentioned 200g of acrylic acid and 200g of deionized water into a 2000mL reaction flask equipped with a stirrer, a dropping funnel and a thermometer with a four-necked jacket, pass cooling water through the jacket of the flask, turn on the stirrer, and drip Add the above-mentioned neutralizing solution, and neutralize under the condition that the temperature of the material is controlled to be lower than 40°C; after...

Embodiment 2

[0084] With embodiment 1, difference is: acrylic acid polymerization inhibitor MQ content is 160ppm; Neutralizer 45% sodium hydroxide aqueous solution, iron ion (with Fe 2 o 3 meter) content of 2ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com