Patents

Literature

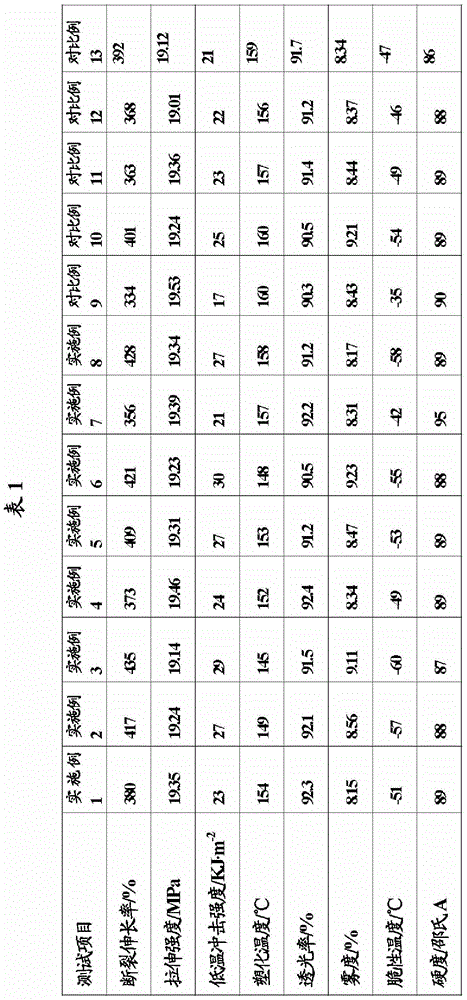

61results about How to "Reduce plasticizing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-odor flame retardant styrene-based resin composition and preparation method thereof

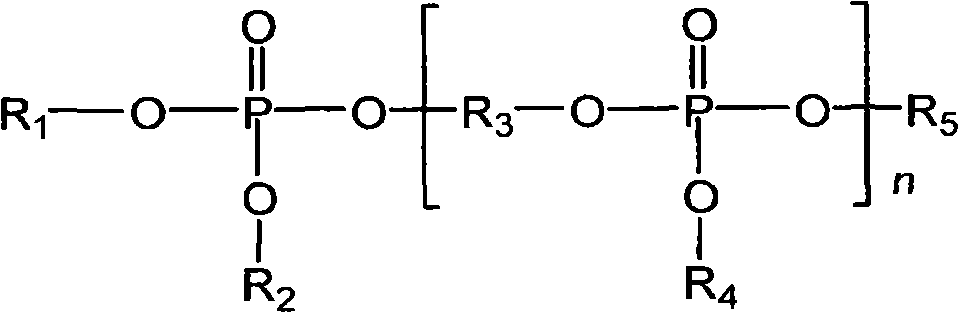

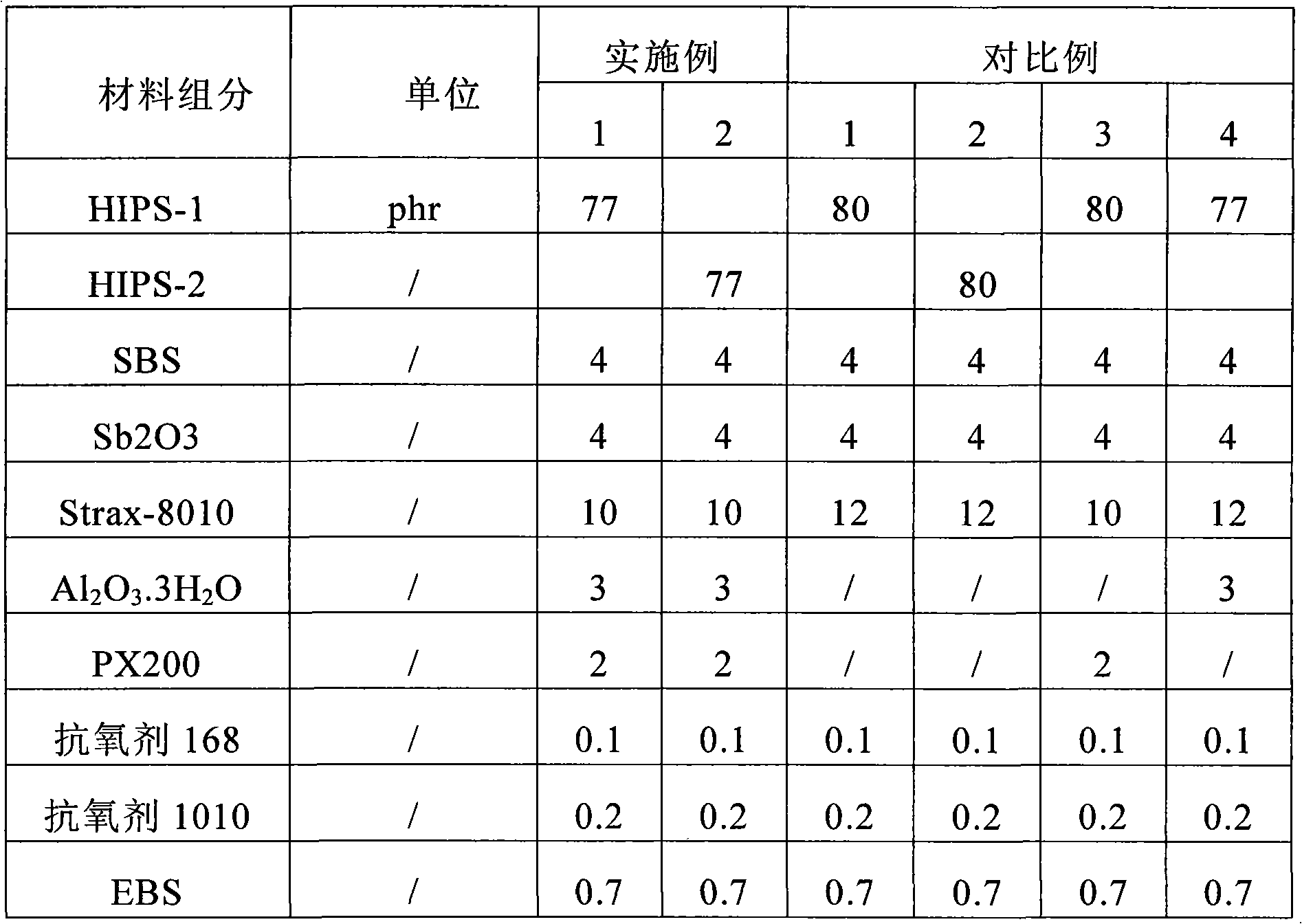

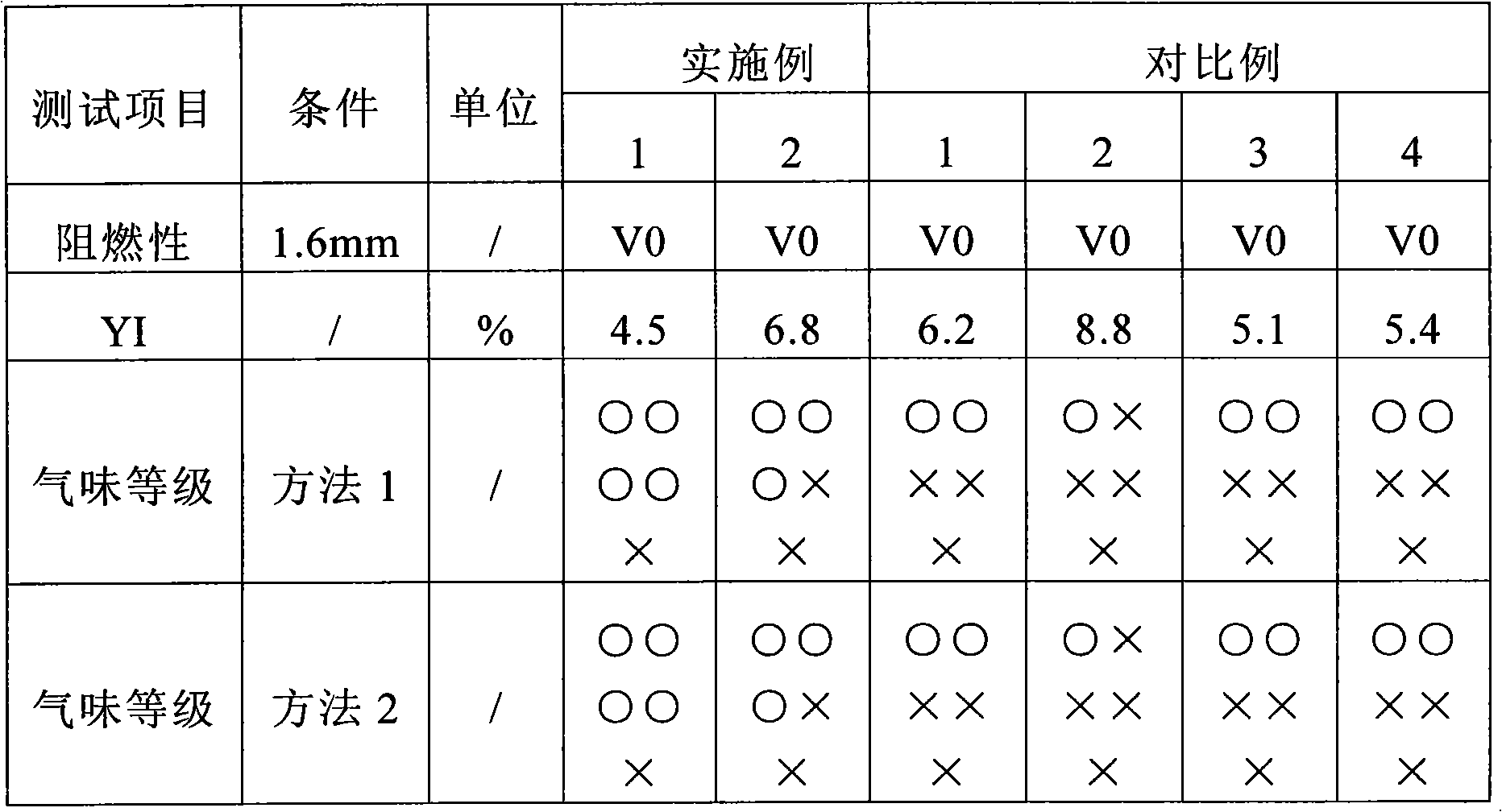

The present invention relates to a low-odor flame retardant styrene-based resin composition and a preparation method thereof. The composition comprises the following components, by weight, 60-80 parts of a styrene-based resin, 0-10 parts of an impact modifier, 8-20 parts of a bromine-based flame retardant agent, 1-5 parts of a flame retardant synergist, 0.5-5 parts of a compound containing phosphorus and 1-3 parts of a hydrated metal oxide. The preparation method comprises: adding the raw materials excluding the hydrated metal oxide to a high-speed mixer to carry out premixing to obtain a premixed material; adding the premixed material and the hydrated metal oxide to a twin screw extruder; carrying out treatments of conveying, melting, shearing, extruding, cooling and pelletizing to obtain the product. According to the present invention, the compound containing the phosphorus and the hydrated metal oxide are added, such that the odor of the flame retardant styrene-based resin composition is improved to the maximal degree; the plasticizing temperature of the material is reduced, the thermal stability of the material is improved, such that the discoloration risk due to decompositionof the flame retardant agent is reduced, and the odor of the halogen flame retardant styrene-based material during the forming process and the product using process is effectively reduced.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

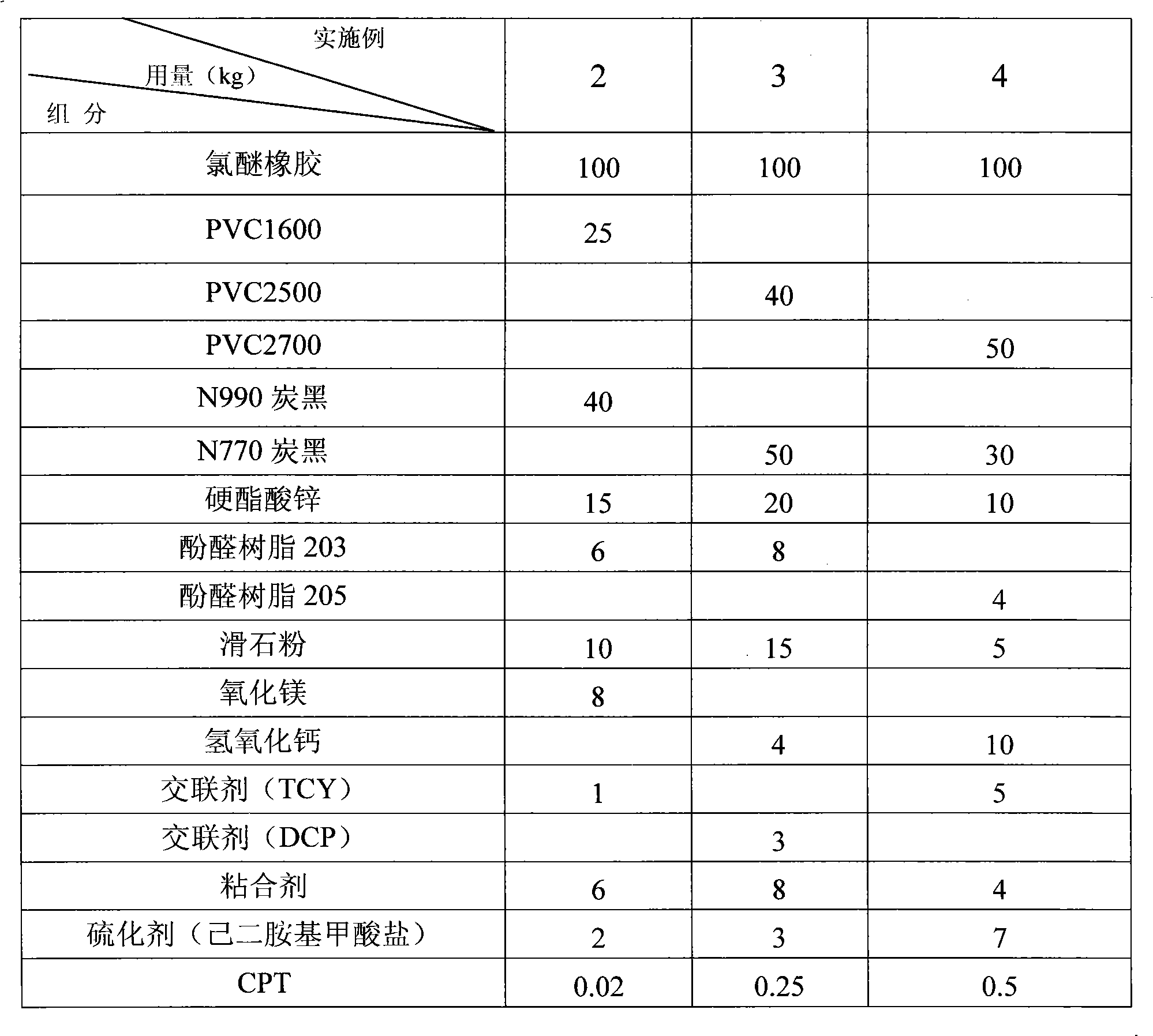

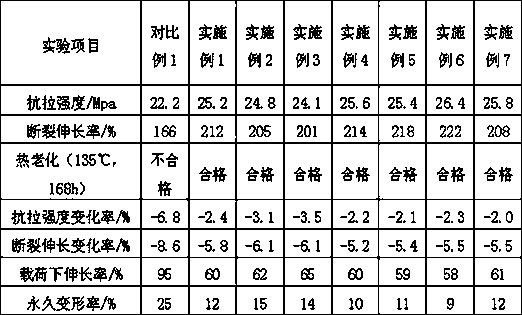

Material for anti-seepage rubber layer of inner tube of air conditioning hose and method for preparing same

The invention discloses a material for an anti-seepage rubber layer of an inner tube of an air conditioning hose and a method for preparing the same. The material comprises the following components in part by mass: 100 parts of epichlorohydrin rubber, 20 to 50 parts of PVC1300-2700, 10 to 20 parts of stabilizer, 5 to 15 parts of anti-aging agent, 4 to 8 parts of phenolic resin, 2 to 8 parts of barium / tin stabilizer, 30 to 50 parts of carbon black, 5 to 15 parts of talcpowder, 4 to 10 parts of acid acceptor, 1 to 5 parts of cross-linking agent, 4 to 8 parts of adhesive and 1 to 4 parts of vulcanizing agent. The method comprises the following steps of: placing the PVC and the components except the cross-linking agent and the adhesive in an internal mixer and plasticating the components for 8 to 16 minutes at the temperature of between 150 and 160 DEG C; placing the materials in an open mill, adding the cross-linking agent and the adhesive into the materials under the condition that the roller temperature is less than or equal to 60 DEG C, allowing the mixture to pass through the roller for 3 to 4 times in small thickness, triangularly packaging the mixture for 5 to 6 times and discharging sheets. The rubber material provided by the formula of the invention has the characteristics of freon resistance, novel refrigerant resistance, hot oil resistance, aging resistance and the like; and meanwhile, the process is simple and the manufacturing cost is low.

Owner:仝国磊

Modification method of phosphogypsum for PVC material production

InactiveCN105482503AImprove processing rheologyHigh strengthPigment treatment with non-polymer organic compoundsFilling materialsParaffin oils

The invention relates to the technical field of PVC production filling materials and especially relates to a modification method of phosphogypsum for PVC material production. The method comprises mixing fresh phosphogypsum and quicklime until pH is in a range of 6-8 so that phosphogypsum free water content is reduced, carrying out heating treatment through a stirring heater, controlling the temperature in a range of 150-180 DEG C so that the fresh phosphogypsum is transformed into semi-hydrated phosphogypsum, adding paraffin into the semi-hydrated phosphogypsum so that phosphogypsum plasticity and rheological properties are improved and the dry phosphogypsum adsorbs water to form crystal water with an unstable structure, carrying out dry grinding and screening so that crystal water in the phosphogypsum is exposed, related content of phosphogypsum impurities in unit volume is reduced and phosphogypsum whiteness is improved, and carrying out stir-frying at a temperature of 180-200 DEG C so that a part of crystal water in phosphogypsum is lost. The prepared phosphogypsum is a mixture of semi-hydrated gypsum, III-type anhydrite and II-type anhydrite, has high rheological properties and plasticity and improves PVC quality.

Owner:GUIZHOU KAILIN GRP CO LTD

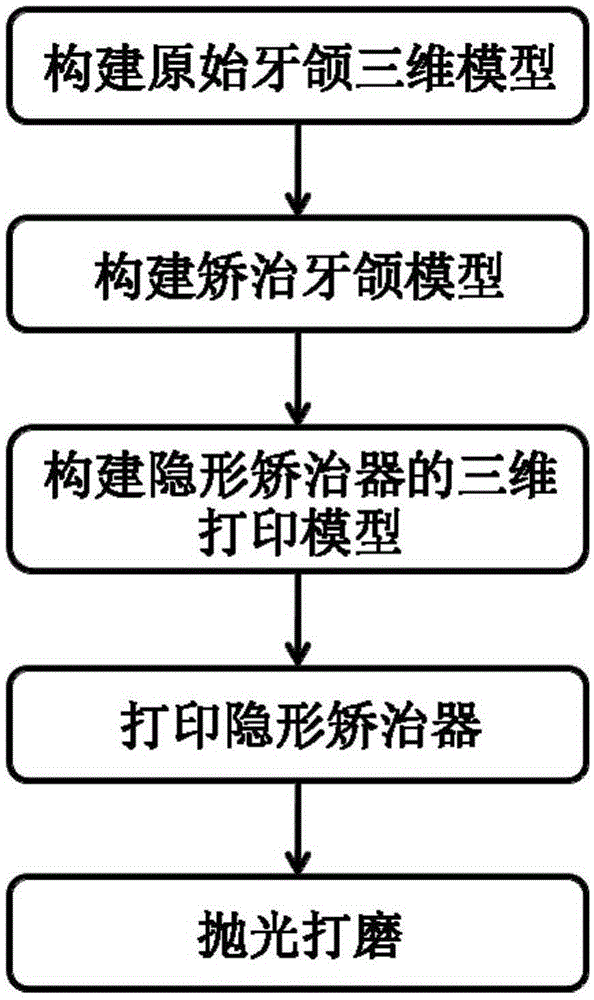

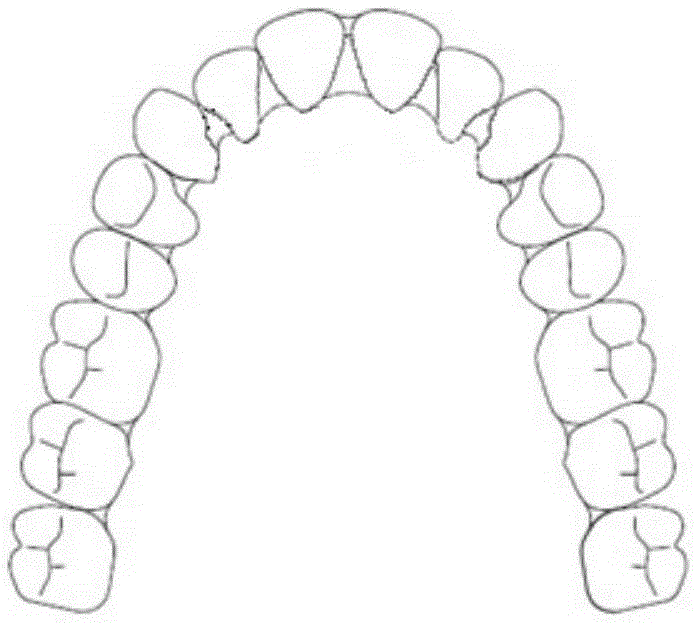

Manufacturing method of invisible tooth correcting treatment devices

InactiveCN105266906AReduce model materialSimplify production stepsOthrodontics3 dimensional printingObjective model

The invention discloses a manufacturing method of invisible tooth correcting treatment devices. According to the method, firstly, an original odonto-maxillary three-dimensional model of a patient is built through a correcting treatment objective and an original odonto-maxillary three-dimensional model; secondly, correcting treatment odonto-maxillary models in different stages of the correcting treatment process are built; then, corresponding three-dimensional printing models are built; corresponding invisible tooth correcting treatment devices are respectively printed out by medial polyethylene according to the three-dimensional printing models; and finally, the invisible tooth correcting treatment devices are polished and ground and are delivered to the patient to be used. By using the method, the invisible tooth correcting treatment devices are directly manufactured without using a solid body objective model, so that the consumption of a great number of light-cured resin materials is avoided; and the problems of high cost and complicated production process of the invisible tooth correcting treatment devices are solved.

Owner:肖然 +1

Efficient plasticizer

The invention discloses an efficient plasticizer. The efficient plasticizer comprises, by weight, 12-15 parts of sodium stearoyl lactylate, 10-15 parts of diacetyl tartaric acid ester of mono- and glycerides, 15-18 parts of glycerol monolaurate, 10-12 parts of glycerol ester of rosin, 8-10 parts of sodium polyacrylate, 6-8 parts of barium stearate, 8-10 parts of isopropanol, 6-8 parts of hyaluronic acid, 15-20 parts of tetrafluoroethylene, 12-15 parts of acetyl, 16-20 parts of carbitol, 20-22 parts of diethanol amine, 5-8 parts of phenoxy ethanol, 10-15 parts of acrylic modified alkyd resin, 12-15 parts of mercaptoacetic acid and 6-8 parts of chloroacetic acid. The efficient plasticizer has the advantages that plasticity and flexibility of plastic materials can be enhanced, environment protection performance is good, surface strength of the plastic materials can be also enhanced, environment pollution is reduced due to low plasticizing temperature, and product performance is improved.

Owner:司徒建辉

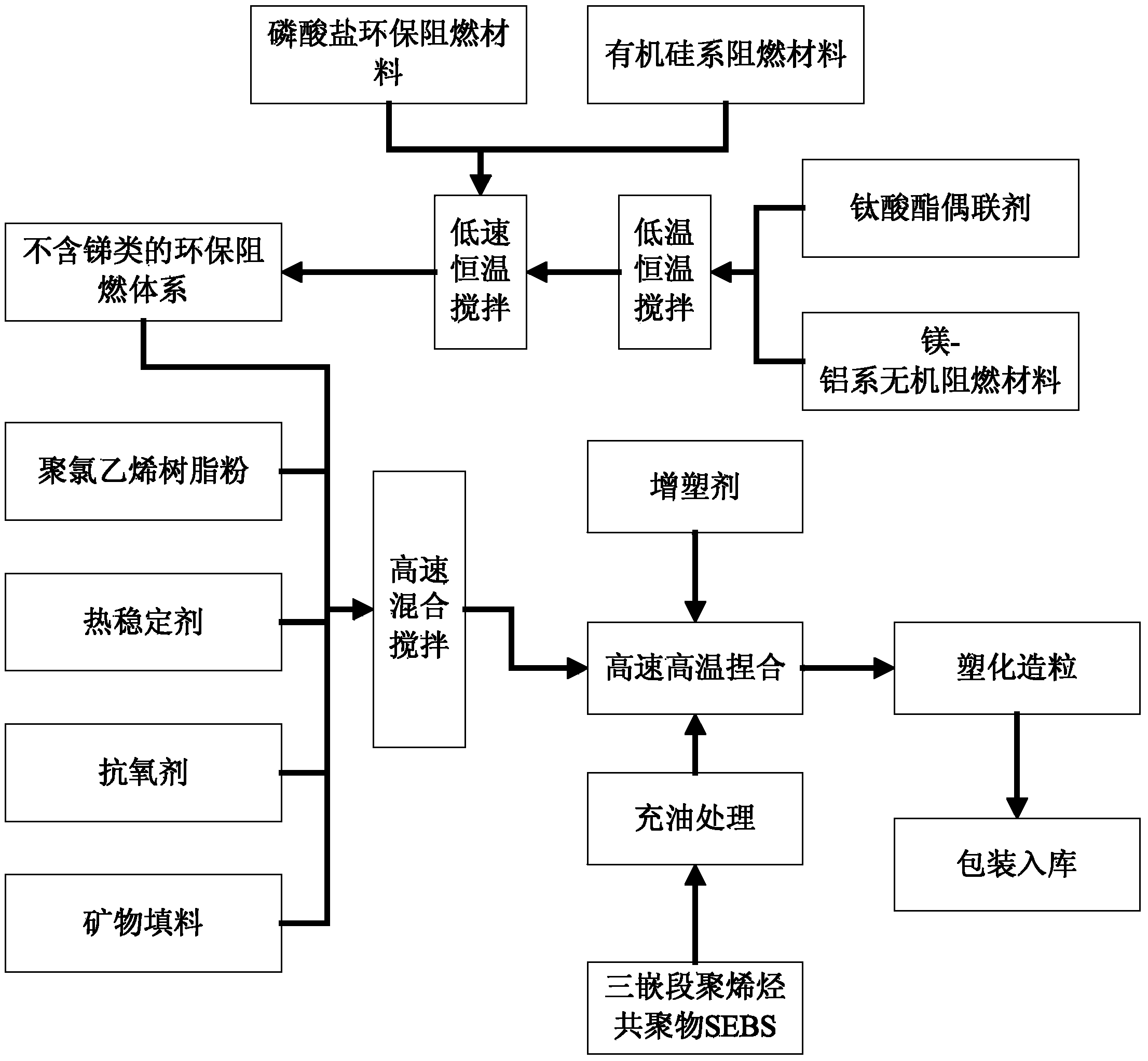

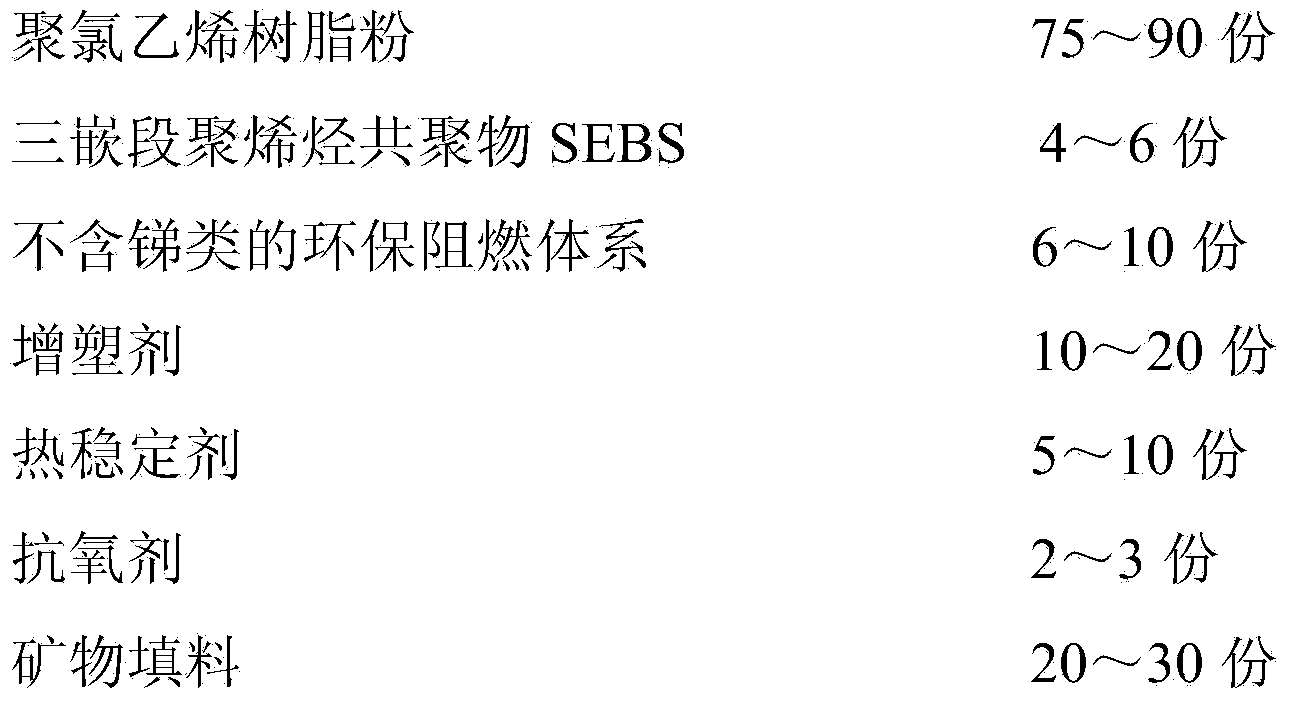

Full-fogging-surface flexible cable composite material and preparation method thereof

InactiveCN103849089AImprove the coiled state of molecular chainsLower glass transition temperaturePlastic/resin/waxes insulatorsPolyolefinPhosphate

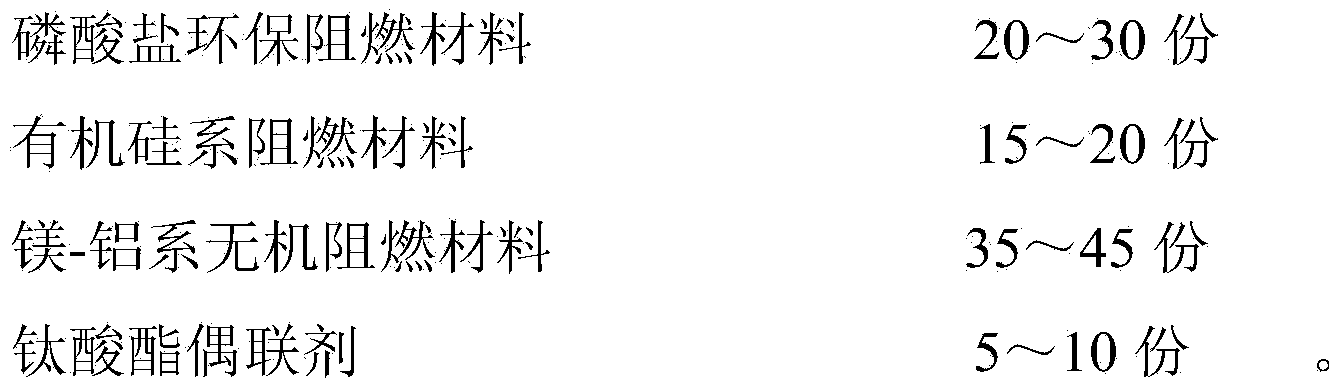

The invention discloses a full-fogging-surface flexible cable composite material which is prepared from the following active ingredients in parts by weight: 75-90 parts of polyvinylchloride resin powder, 4-6 parts of triblock polyolefin copolymer SEBS, 6-10 parts of antimony-free environmentally-friendly flame-retardant system, 10-20 parts of plasticizers, 5-10 parts of thermal stabilizers, 2-3 parts of antioxidant and 20-30 parts of mineral filler, wherein the antimony-free environmentally-friendly flame-retardant system is prepared from the following active ingredients in parts by weight: 20-30 parts of phosphate environmentally-friendly flame-retardant materials, 15-20 parts of organosilicone flame-retardant materials, 35-45 parts of magnesium-aluminum system inorganic flame-retardant materials and 5-10 parts of titanate coupling agent. The invention further discloses a preparation method for preparing the full-fogging-surface flexible cable composite material.

Owner:深圳市领亚电子有限公司

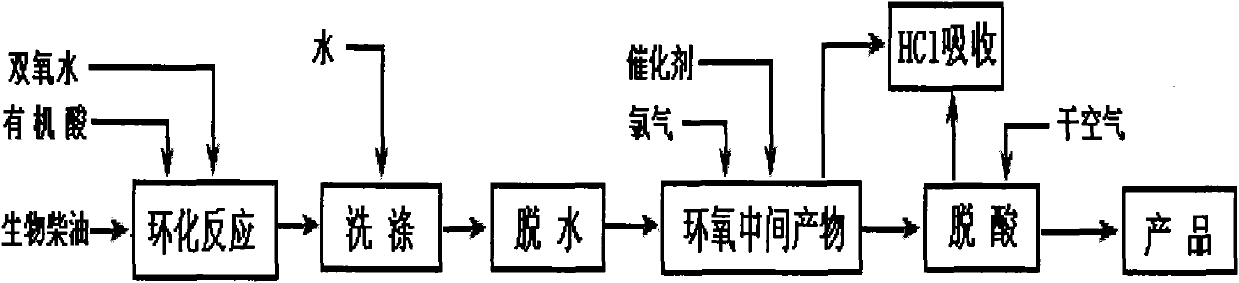

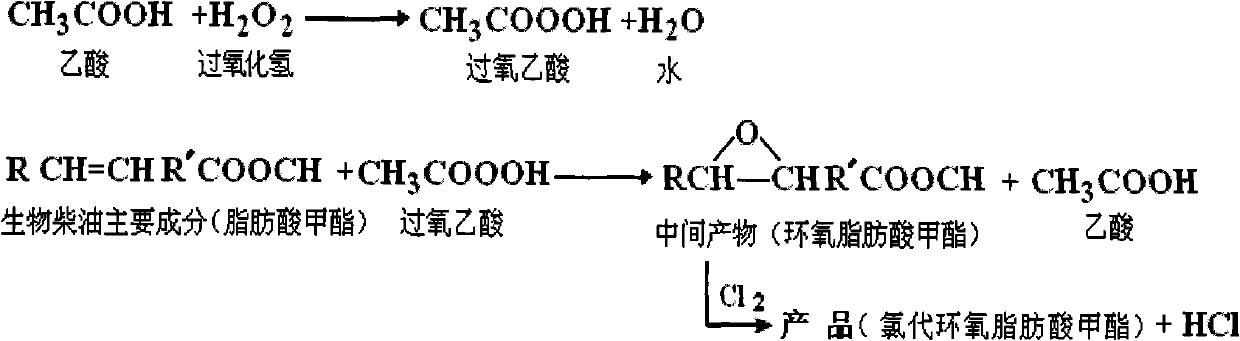

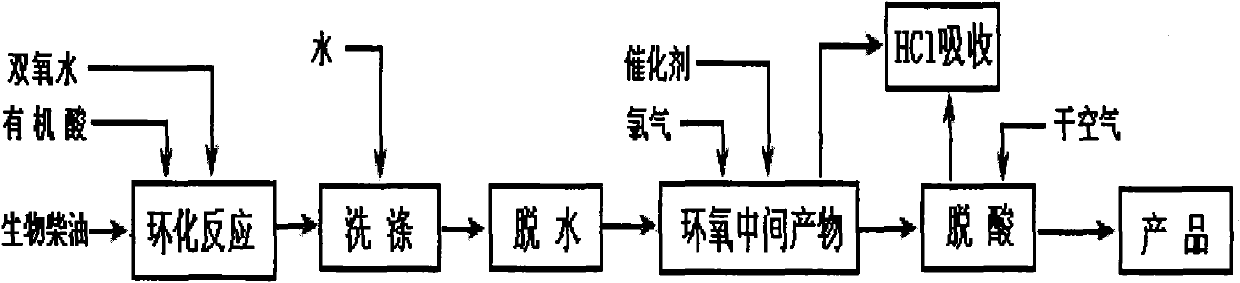

Method for preparing chloro-epoxy fatty acid methyl ester plasticizer

InactiveCN101948449AGood compatibilityReduce plasticizing temperatureOrganic chemistryEpoxyOrganic acid

The invention provides a method for preparing a chloro-epoxy fatty acid methyl ester plasticizer, which belongs to the field of preparation of plasticizers for organic chemical products. The method comprises the following steps: in the presence of C1 to C2 organic acids and hydrogen peroxide, carrying out epoxidation reaction so as to obtain epoxidation products; and then carrying out chlorination reaction on the obtained epoxidation products by using 2, 2'-azo-bis-isobutyronitrile or organic peroxides as a catalyst and using chlorine as a chlorinating agent so as to obtain the chloro-epoxy fatty acid methyl ester plasticizer. Compared with the traditional preparation methods, because the molecule of the plasticizer produced by using the method of the invention has ester groups and chlorine groups with strong polarity and the main bodies of aliphatic chains with weak polarity, the plasticizer has a good compatibility with polar polymers; and meanwhile, the method has the advantages ofsimple preparation process, low preparation cost and strong market competitiveness.

Owner:GUANGZHOU UNIVERSITY

Constitutes of technical formula in use for dipping plastic

InactiveCN1563178ASuspension evenly distributedReduce plasticizing temperaturePolyvinyl chlorideCadmium stearate

A process formula die carving includes compositions as the follows, 100 kg polyvinyl chloride in paste state, 80-100 kg dicapryl phthalate, 1-5 kg cadmium stearate, 1-5 g barium stearate, 0.5-2 kg bisphenol A and 0.01-1 kg dyestuff. The advantage of the present invention is using paste state polyvinyl chloride as main body, suspending each composition in dicapryl phthalate uniformly, plasticizing in not high temp and having excellent antidegradability.

Owner:ZHEJIANG UNIV

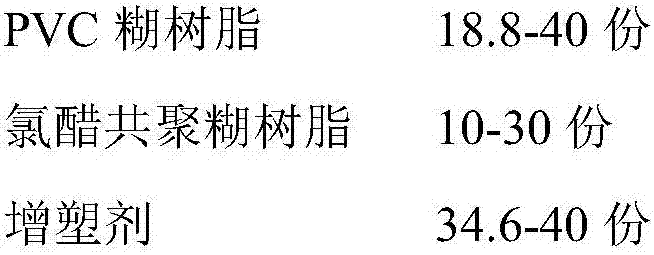

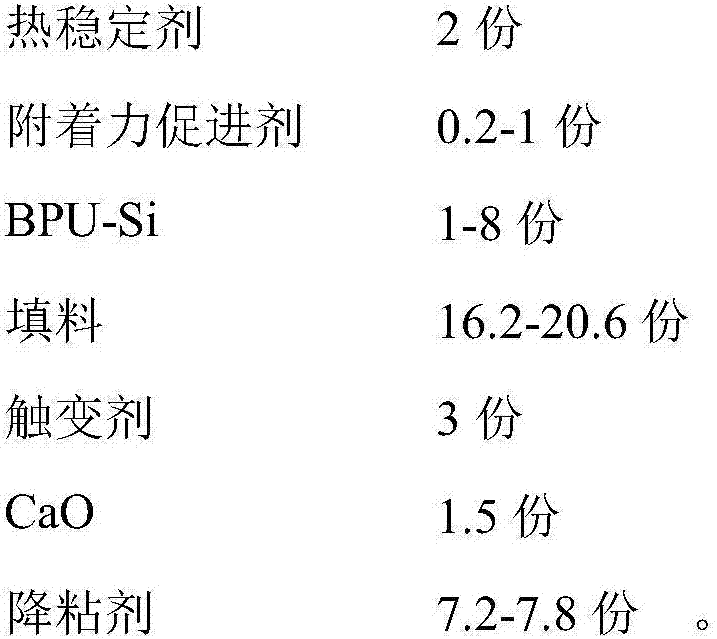

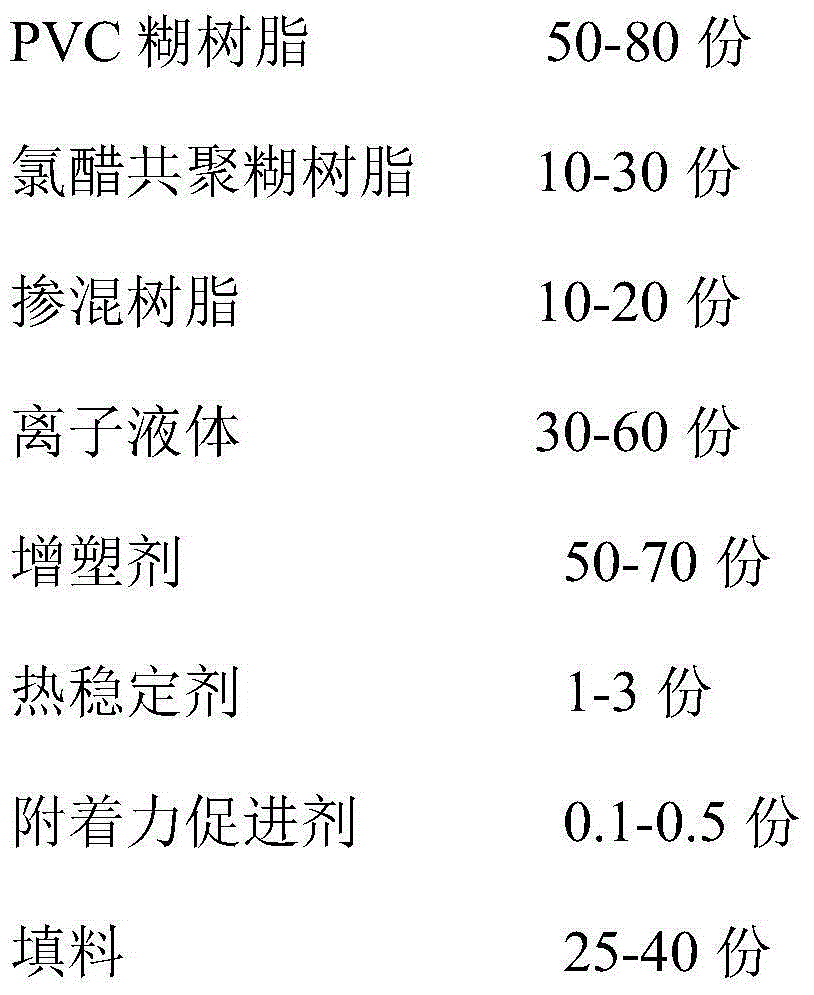

Environment-friendly low-temperature curing PVC plastisol and preparation method thereof

InactiveCN107474445AReduce volatilityHigh plasticizing efficiencyLow temperature curingMechanical property

The invention discloses environment-friendly low-temperature curing PVC plastisol and a preparation method thereof. The environment-friendly low-temperature curing PVC plastisol uses PVC paste resin, chloride vinyl acetate copolymerized paste resin, a plasticizer, a heat stabilizer, an adhesion promoter, BPU-Si, filler, a thixotropic agent, CaO, a viscosity reducer and the like as raw materials. The tensile strength of the prepared PVC plastisol can be up to 6-8 MPa, and the elongation at break can be up to 210%-270%. The adopted plasticizer is the novel environment-friendly plasticizer and has the advantages of being biodegradable, low in volatility, high in plastifying effect and the like. Under the synergistic effect of end-capped polyurethane and an adhesion promoter, the plastifying temperature (120-130 DEG C) of the plastisol can be effectively reduced, and the mechanical properties, elasticity and adhesion of the PVC plastisol are remarkably improved.

Owner:ANHUI UNIVERSITY

Foaming sound-proof acrylic resin vehicle bottom protective plastisol and preparation method thereof

The invention relates to foaming sound-proof type acrylic resin car-bottom protection plastisol and the preparation process thereof. The foaming sound-proof type acrylic resin car-bottom protection plastisol comprises components with following percentage by weight, 4-8% volatile solvent, 20-40% plasticizing agent, 20-35% acrylic polymer, 5-20% polyurethane resin, 0.2-1.5% foaming agent, 0.2-1.5% thixotropic agent and 15-45% filling. The preparation process comprises mixing raw materials under controlled temperature, stirring, grinding with a three roll mill, stirring under -0.05-0.1MPa, screening and obtaining finished products. The plastisol of the invention has excellent sound-proof effect, less construction usage, safe construction condition and low cost.

Owner:长春依多科化工有限公司

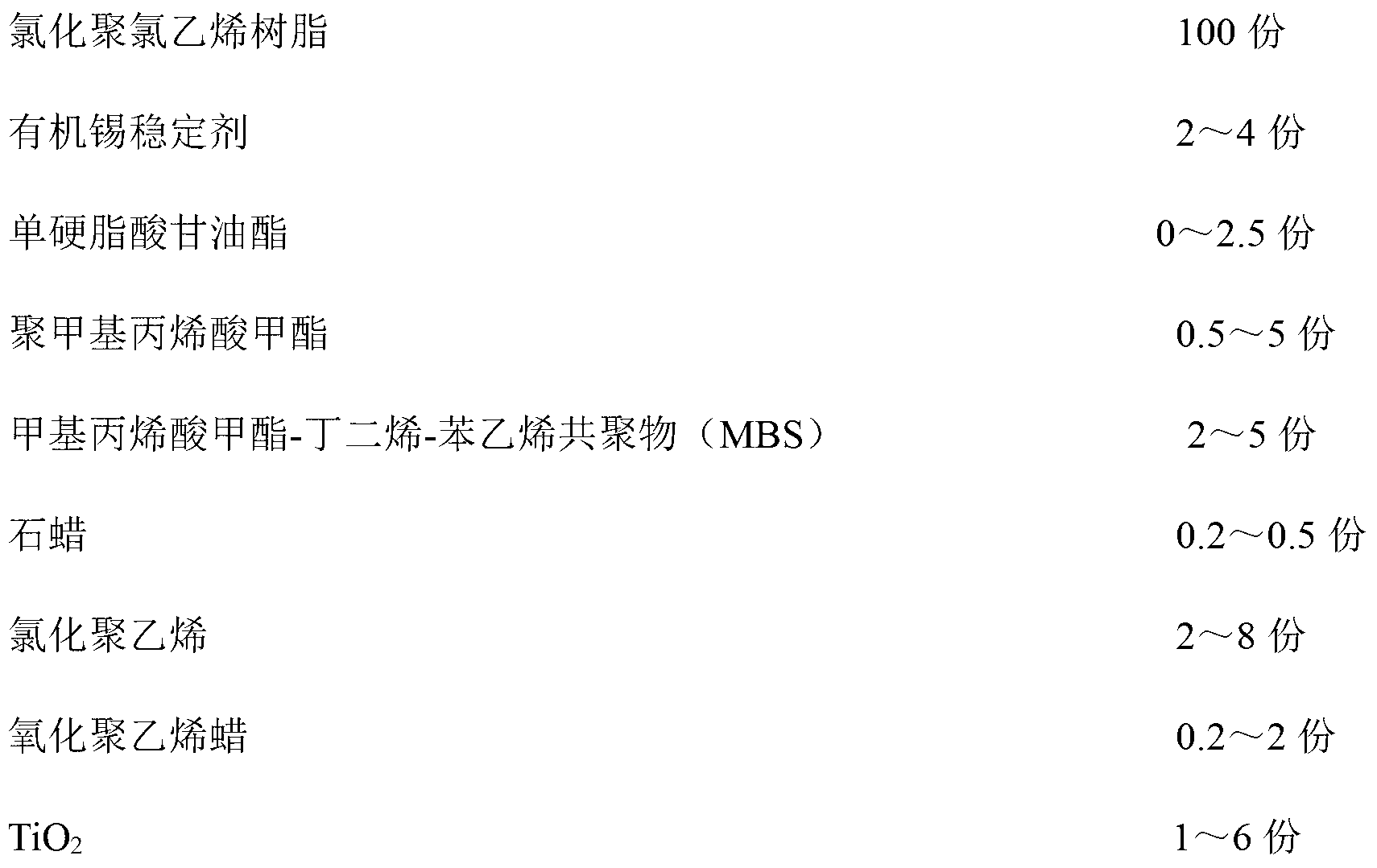

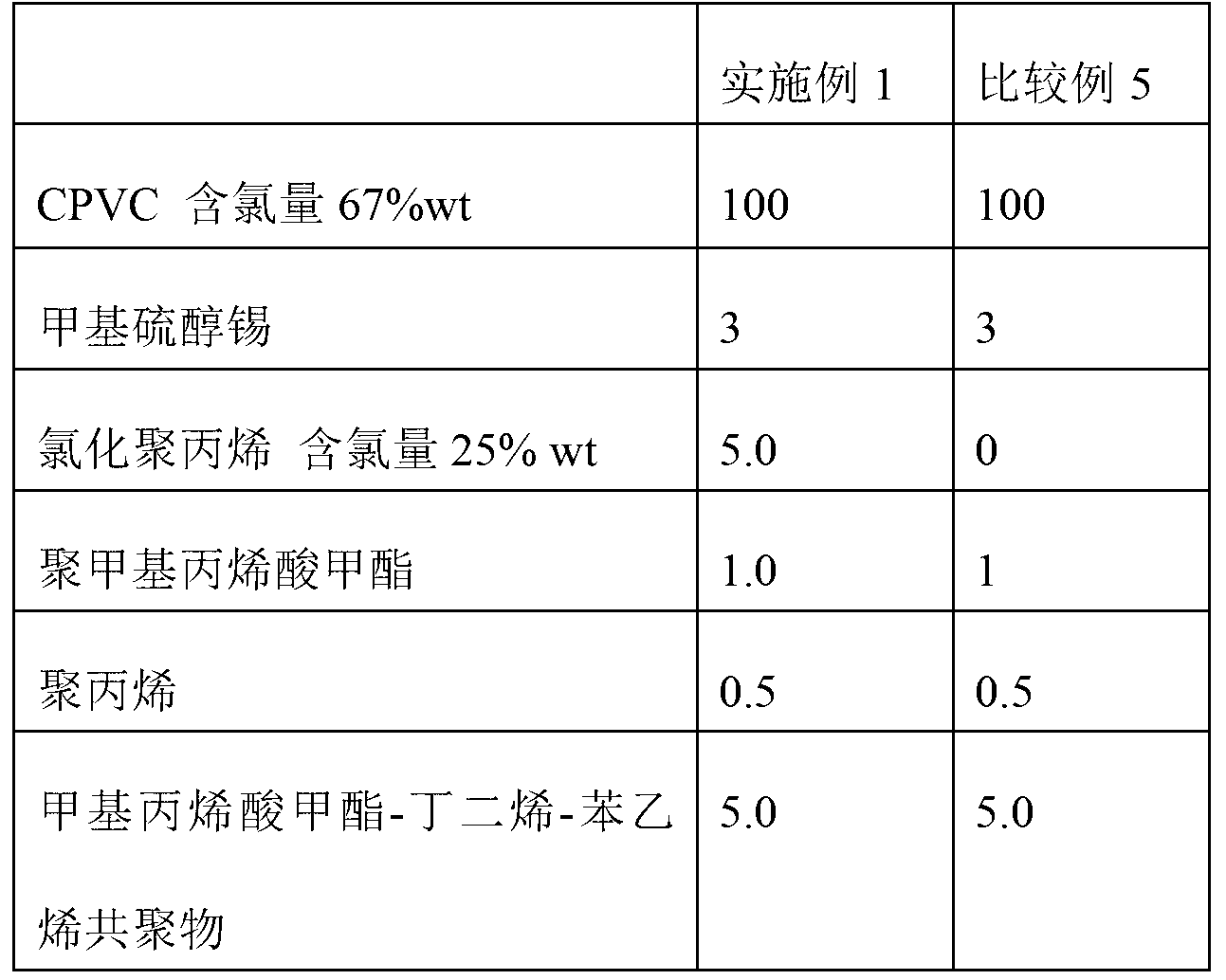

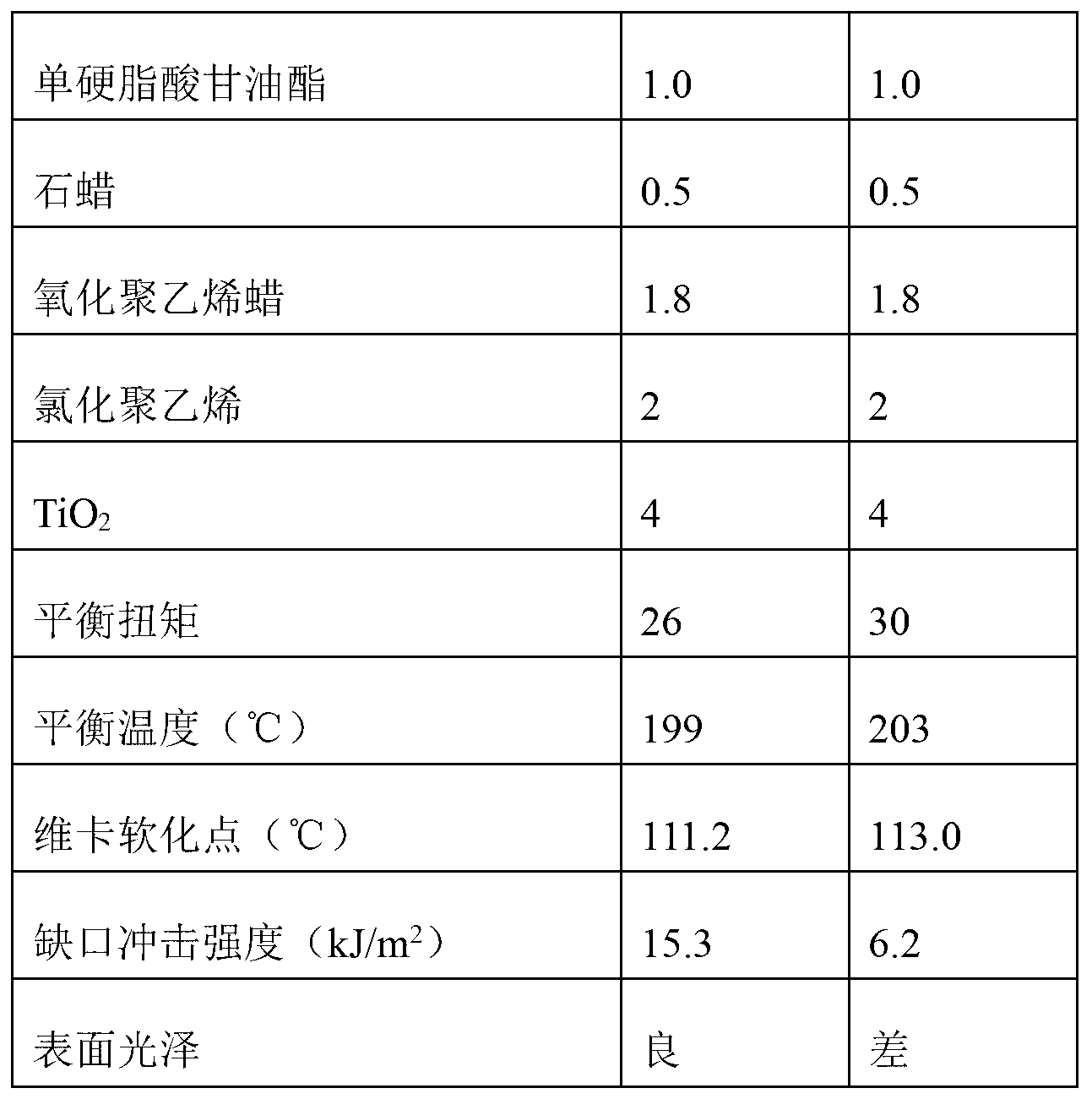

Chlorinated polyvinylchloride mixing material

InactiveCN103265780AImprove plasticizing effectExtended stabilization timePolymer scienceChlorinated polyvinyl chloride

The invention discloses a chlorinated polyvinylchloride mixing material, which comprises the following components, by weight, 100 parts of a chlorinated polyvinylchloride resin, and 0.5-10 parts of chlorinated polypropylene. According to the present invention, the chlorinated polypropylene is added to the chlorinated polyvinylchloride resin so as to increase a plasticizing performance of the chlorinated polyvinylchloride resin during a processing process, reduce a plasticizing temperature, and improve processability, such that the obtained mixing material has a good demolding performance, and performances of notched impact strength, tensile strength and the like of the product are improved.

Owner:SHANGHAI CHLOR ALKALI CHEM

Enclosed polyurethane performed polymer for formulating low-temperature plasticizing PVC plastic colloidal sols and method of producing the same

InactiveCN101402717AReduce plasticizing temperatureReduce the temperaturePolyurea/polyurethane coatingsPolymer scienceEnd-group

The invention relates to a close type polyurethane prepolymer used for preparing low temperature plasticizing PVC plastisol, which can improve the adhesion of the PVC plastisol on an electrophoresis paint plate and simultaneously reduce the plasticizing temperature of the PVC plastisol so as to reduce energy consumption. The polyurethane prepolymer is characterized in that: the polyurethane prepolymer is polymerized by polyisocyanate and a polyhydroxy compound with the generation terminal group of the semi-prepolymer of - NCO and a sealant is applied to blocking the semi-prepolymer so as to obtain the close type polyurethane prepolymer. The preparation method is as follows: 50 portions to 500 portions of a diluent are added into a three-necked reactor, stirred and heated to 75 DEG C to 80 DEG C, then 100 portions to 400 portions of polyisocyanate are added, 250 portions to 800 portions of the polyhydroxy compound are added slowly, reaction lasts for 3 hours to 4 hours, then 10 portions to 200 portions of the sealant and 0 portion to 2 portions of a catalyst are added slowly and the reaction lasts for 2 hours and 3 hours.

Owner:匡建钢

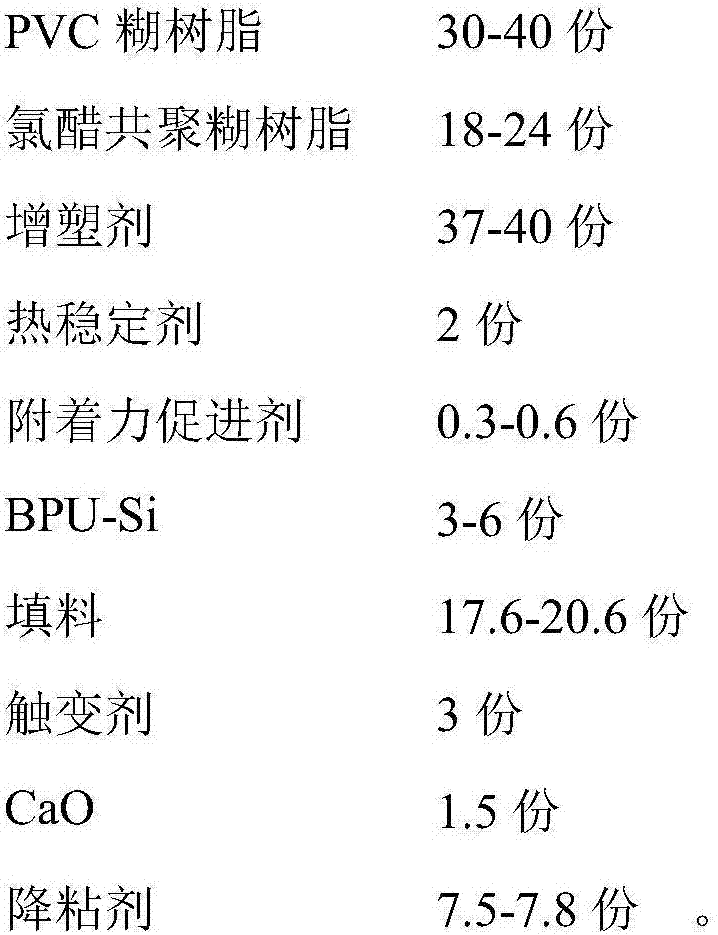

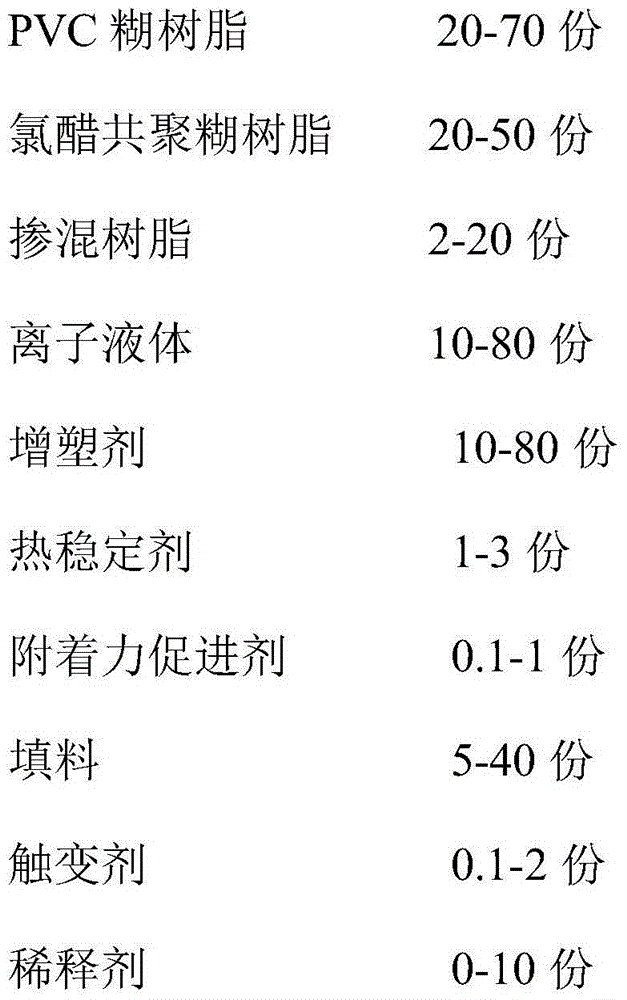

Low temperature plasticized polyvinyl chloride plastisol and preparation method thereof

InactiveCN106147068AReduce plasticizing temperatureSimple preparation processPolyvinyl chlorideIonic liquid

The invention provides low temperature plasticized polyvinyl chloride plastisol. The low temperature plasticized polyvinyl chloride plastisol comprises, by weight, 20-70 parts of PVC paste resin, 20-50 parts of vinyl chloride-vinyl acetate copolymer paste resin, 2-20 parts of mixed resin, 10-80 parts of an ionic liquid, 10-80 parts of a plasticizer, 1-3 parts of a heat stabilizer, 0.1-1 part of an adhesion promoter, 5-40 parts of a filler, 0.1-2 parts of a thixotropic agent and 0-10 parts of a diluent. The low temperature plasticized polyvinyl chloride plastisol effectively reduces a plastisol plasticizing temperature to 120-130 DEG C, utilizes the nontoxic and nonvolatile ionic liquid so that environment protection and operation personnel safety are guaranteed, and can be prepared through simple processes without a special additional technology.

Owner:SHANGHAI CHLOR ALKALI CHEM

PVC injection molding material and PVC injection molding method capable of forming high-light mirror surface effect on surface of product

InactiveCN107746520AImprove appearance qualityPromote plasticizationMolten stateDioctyl terephthalate

The invention discloses a PVC injection molding material and a PVC injection molding method capable of forming a high-light mirror surface effect on the surface of a product. The PVC injection moldingmaterial comprises the components in percentage by weight: 30-50% of PVC resin, 15-25% of dioctyl terephthalate, 18.5-38% of calcium carbonate, 2-8% of stabilizer and 1.5-2% of methyl methacrylate and acrylonitrile copolymers. The injection molding method comprises the steps: firstly, uniformly stirring the components; heating the components to be in a molten state; closing a mold; carrying out filling, carrying out injection molding by an injection molding machine, wherein the injection molding pressure at the first stage is 15-30Bar, the flow at the first stage is 15-35mm / s, the injection molding time at the first stage is 2-5s, the injection molding pressure at the second stage is 15-30Bar, the flow at the second stage is 20-40mm / s, the injection molding time at the second stage is 1-3s, the injection molding pressure at the third stage is 10-25Bar, the flow at the third stage is 10-25mm / s, and the injection molding time at the third stage is 2-4s; maintaining the pressure; carrying out cooling; and carrying out demolding. By using the injection molding method disclosed by the invention, a high-light mirror surface effect can be formed on the surface of the product, the requirement of a terminal client to the appearance of the product can be met, and meanwhile, the competitiveness of the product on the market can be improved.

Owner:常熟利星光电科技有限公司

Transparent cold-resistant polyvinylchloride modified material, and preparation method and application thereof

ActiveCN105273328AHigh transparencyReduce hardnessFlexible pipesPlasticizerThermoplastic polyurethane

The invention relates to a polyvinylchloride (PVC) modified material. Every unit of the material comprising 100 parts by weight of polyvinylchloride resin comprises, by weight, (A) 1-10 parts of quasi-styrene which is a graft copolymer of rubber or elastomer and alpha-methyl styrene, (B) 5-30 parts of thermoplastic polyurethane, (C) a thermal stabilizer, (D) a plasticizer and (E) an optional auxiliary plasticizer. According to the polyvinylchloride modified material, on a basis that good transparency of polyvinylchloride resin is substantially maintained, the plasticizing temperature is reduced and the cold resistance is improved, such that comprehensive performances of the material are improved. The invention also relates to a method for preparing the polyvinylchloride modified material. The method comprises the steps of melting and kneading all components of the polyvinylchloride modified material. The PVC modified material is transparent and environment-friendly. The plasticizing temperature is greatly reduced, and the material also has good cold resistance. Therefore, the material can be used for preparing transparent environment-friendly PVC soft products used under low-temperature environments.

Owner:BEIJING UNIV OF CHEM TECH +1

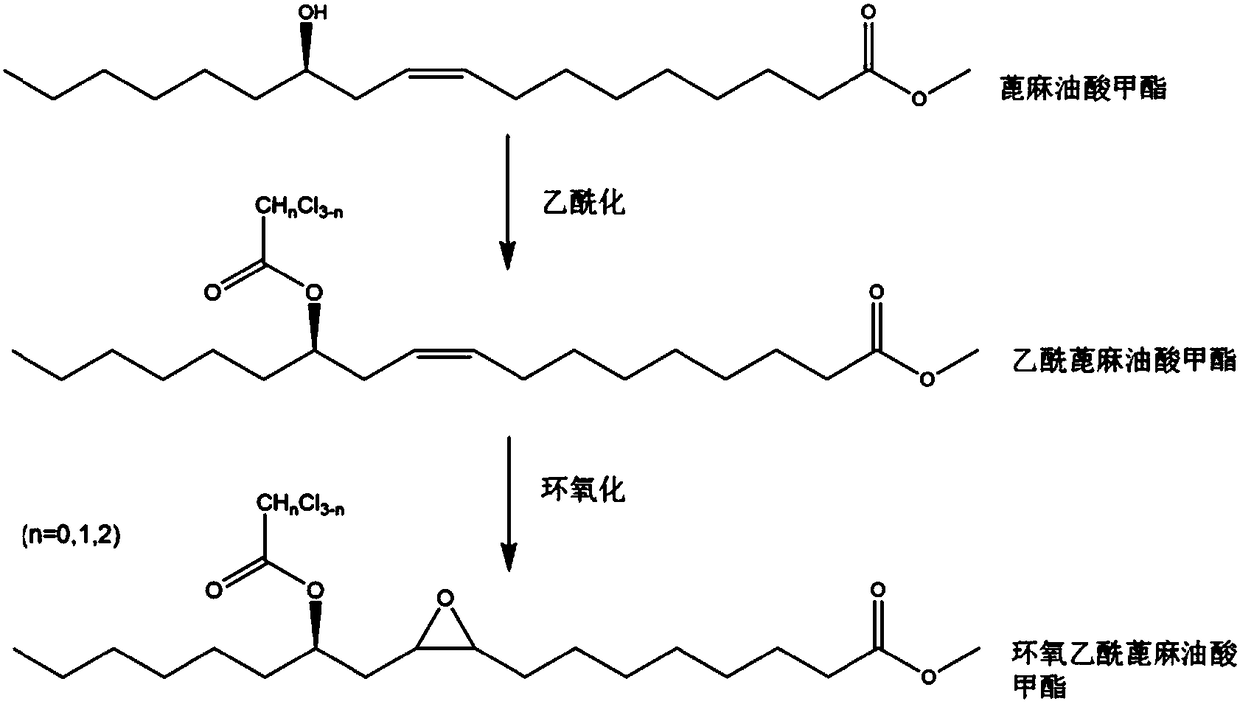

Method for improving compatibility of epoxidized methyl acetylricinolate plasticizer and PVC (Polyvinyl Chloride) resin

The invention discloses a method for improving the compatibility of an epoxidized methyl acetylricinolate plasticizer and PVC (Polyvinyl Chloride) resin. The method is characterized in that a utilizedacetylation reagent contains chlorine atoms with a certain quantity; the compatibility of the epoxidized methyl acetylricinolate plasticizer and the chlorine-containing PVC resin can be remarkably improved, so that the transferring resistance of the plasticizer is improved, and the flexibility and durability of a PVC product are improved. The plasticizer prepared by the method disclosed by the invention has no toxin and is environmentally friendly, can be used for replacing or partially replacing a phthalate plasticizer to produce products including polyvinyl chloride artificial leather, foodpackages, medical devices and the like, and has a wide application prospect.

Owner:SICHUAN UNIV

Environment-friendly plasticizer

The invention discloses an environment-friendly plasticizer being prepared by mixing the following components, by weight: 13-14% of flexible polyvinyl chloride, 0.3-2% of roseolic acid, 10-20% of polyethylene glycol, 10-20% of acetalized polyvinyl alcohol, and the balanced being trimethylene ether. The environment-friendly plasticizer is reasonable in formula, is low in cost, is low in plasticizing temperature, is good in adhesion, is low in residual viscosity and is strong in weather resistance.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

High temperature resistant PVC reinforced hose and preparation method thereof

The invention provides a high-temperature-resistant PVC enhanced hose which comprises an inner tube and an outer tube. The inner tube or the outer tube is prepared from, by mass, 100 parts of PVC, 1.5-3 parts of heat stabilizer, 20-35 parts of trioctyl trimellitate, 5-15 parts of polyester plasticizer, 2-3 parts of toughening modification agent, 10-20 parts of calcium carbonate filler, 1-3 parts of antioxidant and one part or less of toner. Correspondingly, the invention further provides a preparation method of the high-temperature-resistant PVC enhanced hose. The prepared high-temperature-resistant PVC enhanced hose is excellent in heat stability, breaking tenacity and tensile strength; compared with PVC resin in the prior art, the high-temperature-resistant PVC enhanced hose is excellent in performance, nontoxic and environmentally friendly, meets the requirements of national laws and regulations and industrial standards, and has the quite considerable application market.

Owner:PROSPER IND

Constitutes of technical formula in use for dipping plastic

InactiveCN1268683CSuspension evenly distributedReduce plasticizing temperaturePolyvinyl chlorideCadmium stearate

A process formula die carving includes compositions as the follows, 100 kg polyvinyl chloride in paste state, 80-100 kg dicapryl phthalate, 1-5 kg cadmium stearate, 1-5 g barium stearate, 0.5-2 kg bisphenol A and 0.01-1 kg dyestuff. The advantage of the present invention is using paste state polyvinyl chloride as main body, suspending each composition in dicapryl phthalate uniformly, plasticizing in not high temp and having excellent antidegradability.

Owner:ZHEJIANG UNIV

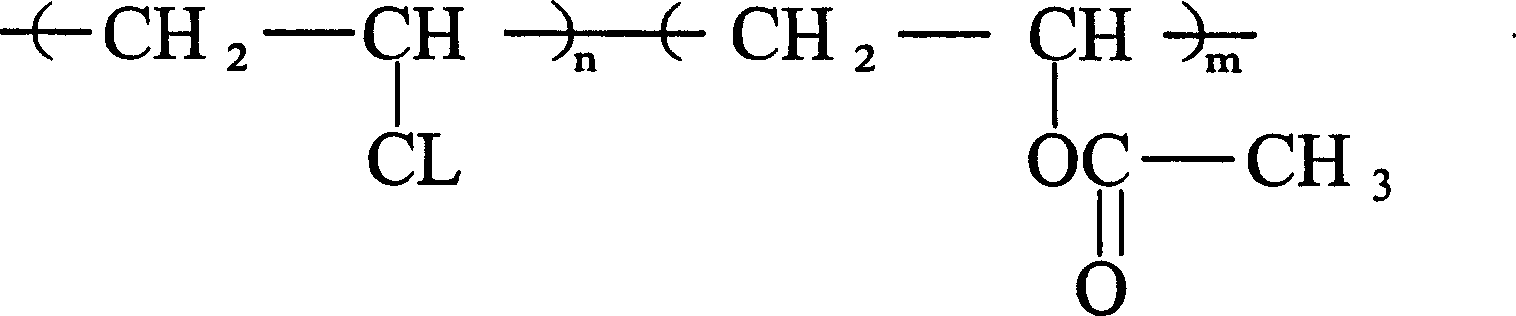

Prepn. of vinyl chloride-vinyl acetate copolymer resin

Owner:上海天原集团天原化工有限公司

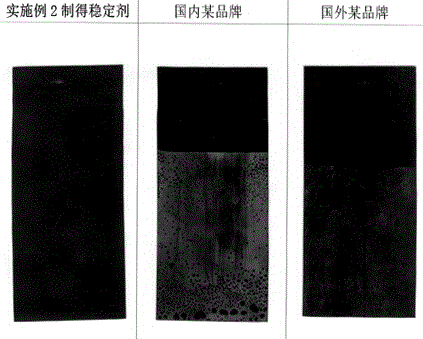

Environment-friendly stabilizer with low processing temperature and simplicity in plasticization for wires and cables

The invention discloses an environment-friendly stabilizer with low processing temperature and simplicity in plasticization for wires and cables. The stabilizer is prepared from the following components by weight: 45-220kg of a fatty acid calcium-zinc composition, 10-100kg of calcium stearate, 1-10kg of an antioxidant 1076, 3-21kg of stearoylbenzoylmethane, 30-100kg of hydrotalcite, 5-120kg of 2-oxazolidinone and 20-200kg of inorganic hydroxides. The stabilizer disclosed by the invention is used for manufacturing wire and cable colloidal particles, the processing temperature of the stabilizer is 20-30 DEG C lower than that of a compound lead stabilizer, the temperature of each section can be controlled to be 120-130 DEG C for a conical twin-screw extruder, and the energy can be saved; the colloidal particles are good in plasticization, and the wire surface is bright; and moreover, the produced colloidal particle Congo red time is longer than or equal to 60 minutes, and the product is excellent in humidity resistance, particularly is not separated out on a black wire, is good in flowing property and suitable for highly filling wires and also can be applied to medium / low-temperature wires specified in GB8815.

Owner:广东森德利环保新材料科技有限公司

Environment-friendly solar heat absorption paint

InactiveCN106189611AImprove stabilityGood weather resistanceAntifouling/underwater paintsPaints with biocidesOctanoic AcidsCarbon nanotube

The invention discloses an environment-friendly solar heat absorption paint. The solar heat absorption paint is prepared from, by weight, 25-35 parts of acrylate modified composite emulsion, 2-6 parts of a fluorocarbon surfactant, 2-8 parts of a nanometer titanium dioxide and carbon nonatube mixture, 7-12 parts of a curing agent, 35-55 parts of an absorbent, 10-20 parts of a solvent, 5-8 parts of a film forming agent, 0.1-0.3 part of a humidifying agent, 0.3-0.7 part of a dispersing agent, 0.5-0.7 part of a thickening agent and 0.4-0.7 part of a plasticizer. The plasticizer is prepared from, by weight, 20-30 parts of phthalic anhydride acetate, 10-20 parts of polyvinyl chloride, 1-10 parts of glycol acetate, 10-40 parts of methylmethaerylate and 20-40 parts of octanoic acid acetate. According to the environment-friendly solar heat absorption pain, by modifying acrylic acid, the prepared paint can have good weather resistance and waterproof performance under the outdoor condition, the preparing process is simple and easy to understand, and the heat absorbing efficiency of the heat absorption paint can be ensured.

Owner:NANNING KEYU ENERGY TECH CO LTD

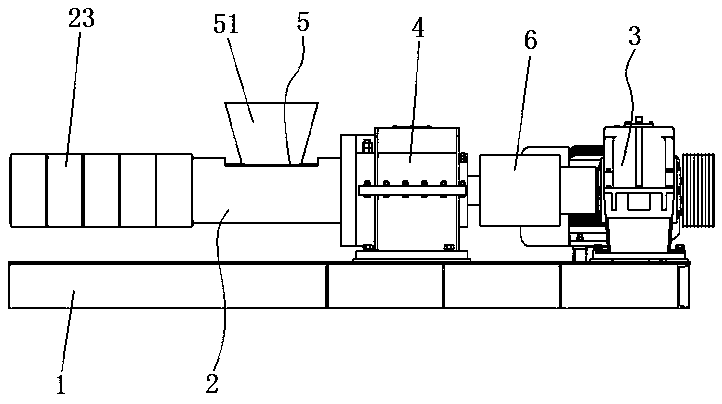

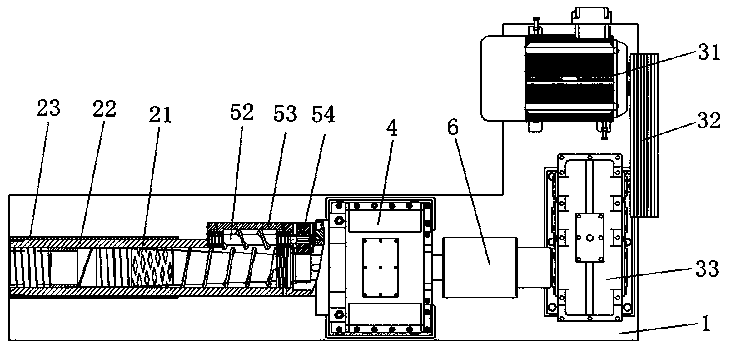

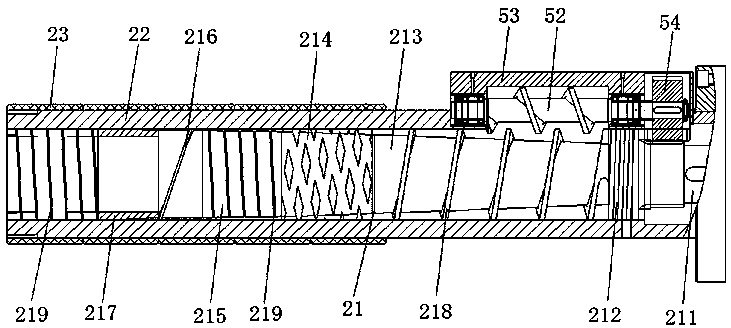

Foaming waste low-temperature cracking extruding machine and extruding method

The invention discloses a foaming waste low-temperature cracking extruding machine and an extrusion method, and belongs to the field of waste plasticizing extrusion. The foaming waste low-temperaturecracking extrusion method comprises the steps that a, a foaming waste cracking extrusion system is established, the foaming waste cracking extrusion system comprises a driving mechanism, an extrusionmechanism, and a feeding mechanism, and the feeding mechanism is connected with the extrusion mechanism; the extrusion mechanism comprises an extrusion screw and a screw barrel, the screw barrel is provided with a heating part, and the driving mechanism is connected with the extrusion screw in a transmission mode; and the extrusion screw comprises a connecting section, a feeding compression section, a crushing section, and a grinding section; b, the screw barrel is preheated by the heating part; c. the extrusion screw is driven through the driving mechanism to idle at a speed of no more than 40r / min; rotation speed of the extrusion screw is increased, preliminary feeding is conducted, and at the same time, the driving mechanism provides a low-temperature of 165 to 190 degrees; d, after discharging is normal, the extrusion screw rotates at a speed of 40 r / min to 50 r / min and keeps feeding; and e, discharged materials are collected. According to the foaming waste low-temperature crackingextruding machine and the extrusion method, low-temperature plasticizing extrusion is realized, waste recycling utilization rate is high, and effects of energy saving and environmental protection areachieved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Plastic water pipe material and preparation method of same

The invention provides a plastic water pipe material and a preparation method of same, and relates to the technical field of plastic pipes. The plastic water pipe material includes, by weight, a composite stabilizer, ACR resin, stearic acid, PE wax, titanium dioxide, PVC-SG5 resin, nano active calcium carbonate, phenolic resin, chlorosulfonated polyethylene rubber, quartz glass fibers, glass wool, magnesia, silicon micro-powder, a flame retardant, an antioxidant, a compatilizer, a plasticizer, and a curing agent. The preparation method includes the steps of: (1) weighing raw materials; (2) mixing the raw materials; (3) performing plasticization and granulation; (4) extruding the pipe base material; (5) performing vacuum cooling shaping to obtain the pipe; and (6) drawing the pipe. The preparation method solves the problems of poor flame-retarding function, low strength and toughness and poor anti-aging property of plastic water pipe materials in the prior art.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Wallpaper containing a volcanic rock-polylactic acid porous fiber modified acrylic resin emulsion coating

InactiveCN105507078AExtended service lifeImprove performanceCoatings with pigmentsPaper/cardboardAcrylic resinCellulose acetate

The invention discloses wallpaper containing a volcanic rock-polylactic acid porous fiber modified acrylic resin emulsion coating. A cellulose acetate-copolymerized modified waterborne acrylic resin emulsion is adopted as a resin adhesive in coating slurry used for the wallpaper, and is stable in performance and free of toxic compounds slow in volatilization such as formaldehyde. The formed coating is smooth and elastic and has waterproof, antifouling and antibacterial functions and other functions. Compared with traditional PVC paste, plasticizing temperature of the coating is lower, and the coating is more energy-saving and environmental friendly. Graphene-doped volcanic rock-polylactic acid porous fibers have functions of high strength, heat preservation, thermal insulation, sound absorption, porosity, formaldehyde removing, and the like. Adsorbability with a substrate is improved. The service lifetime of the wallpaper is effectively prolonged. The wallpaper has a certain indoor air cleaning function.

Owner:ANHUI SOYA DECORATIVE MATERIALS

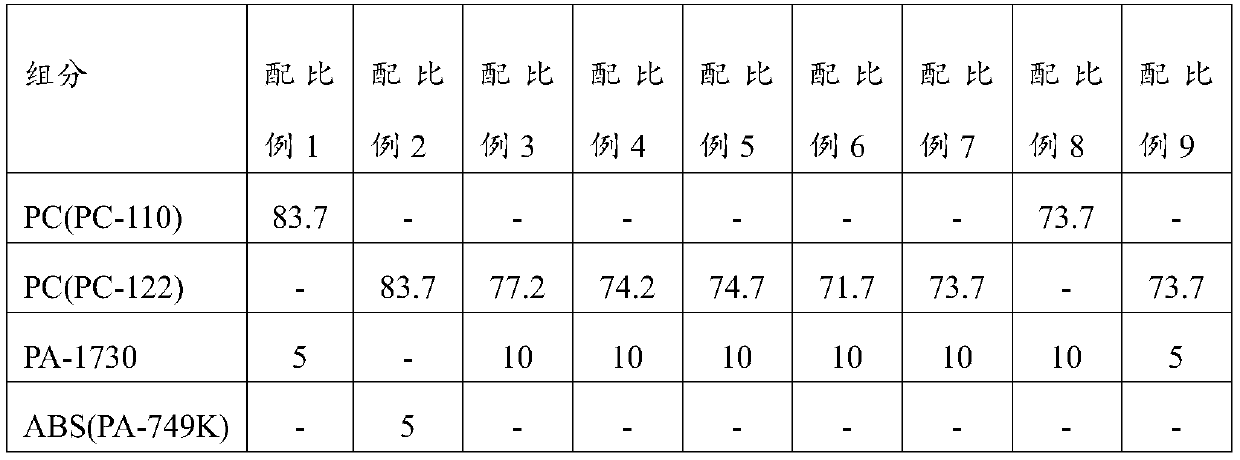

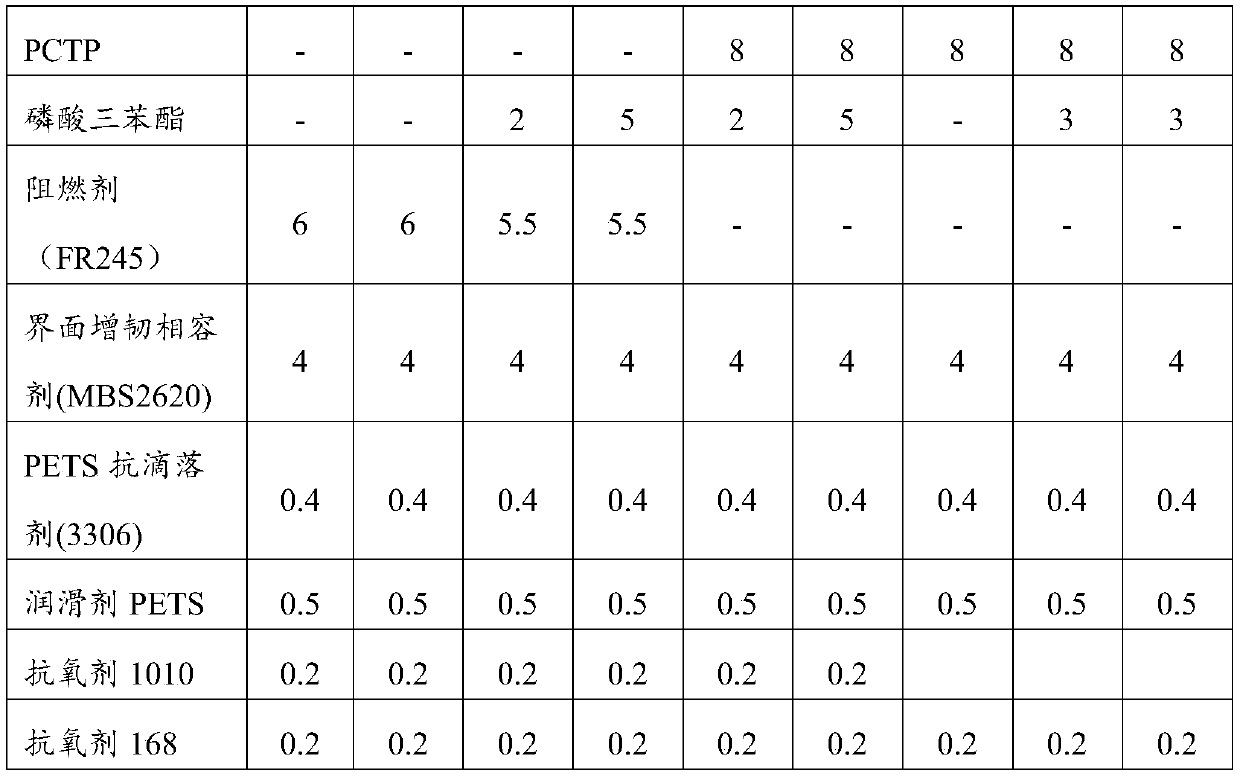

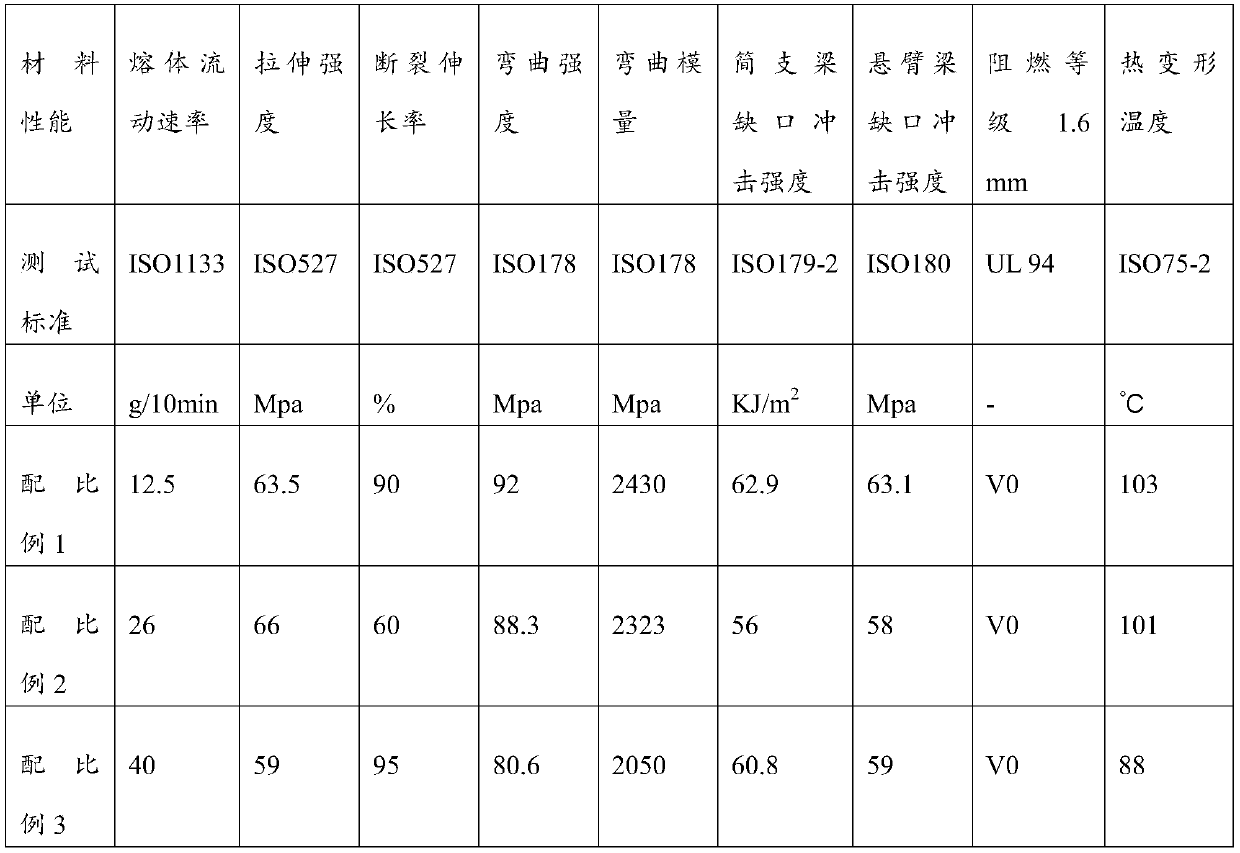

Flame-retardant blister PC/ABS alloy material as well as preparation method and application thereof

The invention discloses a flame-retardant blister PC / ABS alloy material as well as a preparation method and application thereof, and belongs to the technical field of organic synthetic materials. Theflame-retardant blister PC / ABS alloy material comprises the following components in parts by weight: 73 to 74 parts of PC-122, 9 to 11 parts of PA-1730, 3 to 5 parts of an interface toughening compatilizer, 7 to 9 parts of a phosphonitrile flame retardant, 2.5 to 3.5 parts of a plasticizing flame retardant synergist, 0.3 to 0.5 part of an anti-dripping agent, 0.45 to 0.55 part of a lubricating agent and 0.15 to 0.25 part of an antioxidant. The plasticizing flame-retardant synergist is triphenyl phosphate or diphenyl phosphate. The PC / ABS alloy material provided by the invention is relatively good in comprehensive performance, relatively good in plastic uptake and high in saturation degree.

Owner:青岛中新华美塑料有限公司

Electric wire and cable material and preparation method of same

The invention provides an electric wire and cable material and a preparation method of same and relates to the field of electricity materials. The electric wire and cable material includes, by weight, polyvinyl chloride resin, methyl vinyl silicon rubber, ethylene-vinyl acetate copolymer, nano-active calcium carbonate, color powder, polyethylene wax, talcum powder, ceramic fibers, floating beads, brown corundum, a plasticizer, a compatilizer, a flame retarding agent, an antioxidant, a photostabilizer, and a thermal stabilizer. The preparation method includes the steps of: 1) weighing raw materials; 2) stirring the raw materials in a high-speed mixing machine; 3) stirring the raw materials in a cold-stirring machine; 4) feeding the raw materials in a granulator. The preparation method solves the problems of insufficient flame-retarding property, mechanical strength, toughness and anti-aging property of electric wire and cable materials in the prior art.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

High-stability foaming plate and preparation method thereof

The invention discloses a high-stability foaming plate which is prepared from the following raw materials in parts by weight: 100 parts of PVC (polyvinyl chloride) resin, 4 parts of composite stabilizer, 4 parts of ACR-401D accelerator, 6 parts of foaming regulator, 0.8 part of foaming agent, 1 part of PE (polyethylene) wax and 30 parts of light calcium carbonate, wherein the PVC resin is a P-700 type PVC resin of which the gelation speed is high, the processing temperature is relatively low, the product quality is stable and the density is easy to control during processing; the foaming regulator is a high molecular weight polymer which is prepared from acrylate monomers through multi-stage emulsion polymerization and has a multilayer structure, and the foaming regulator is JHB-42 or JHB-100; and various assistants are added into the formula system to effectively lower the plastication temperature, promote the plastication effect, improve the plastication efficiency, enhance the melt intensity, reduce the melting pulsation, prevent the melt fracture and obviously improve the surface smoothness of the product. Thus, the product quality is ensured, and the product grade is improved; and meanwhile, the relationship between the formula cost and the comprehensive cost can be wholly mastered to achieve optimal economic benefits.

Owner:王程皓

Wallpaper containing compound modified acrylic resin emulsion coating and being capable of shielding electromagnetic radiation

The invention discloses a piece of wallpaper containing a compound modified acrylic resin emulsion coating and being capable of shielding electromagnetic radiation. The cellulose acetate copolymerized modified water-based acrylic resin emulsion is served as a resin adhesive applied to a coating sizing agent of the wallpaper, so that the performance is stable, no chronic volatile toxic compound, such as, formaldehyde, and the like, is contained, the formed coating is smooth and elastic, and the wallpaper has the functions of water resistance, dirt resistance, bacterial resistance, and the like; the plasticizing temperature of the wallpaper is 120-150 DEG C lower than the plasticizing temperature of the traditional PVC thickener; the nanometer nickel-containing superfine aluminum silicate-polylactic acid porous fiber has excellent dispersibility and suspension property and has the effects of reinforcing, extinction, weather resistance, electromagnetic radiation shielding, and the like; the use property of the wallpaper is effectively improved.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Endothermic coating for solar water heater

InactiveCN108384357AEnvironmentally friendlyLow costPolyurea/polyurethane coatingsRadiation-absorbing paintsPolyvinyl chlorideSolar water

The invention relates to an endothermic coating for a solar water heater. The coating is prepared from the following components in parts by weight: 33-42 parts of an acrylate modified composite emulsion, 1-3 parts of a silane coupling agent, 2-5 parts of titanium dioxide, 1-2 parts of organic bentonite, 8-14 parts of a curing agent, 43-62 parts of an absorbent, 13-17 parts of a solvent, 6-9 partsof a film-forming agent, 2-4 parts of a humidity-controlling agent, 4-8 parts of a dispersing agent, 2-4 parts of a thickening agent, 3-7 parts of dibutyl phthalate and 1-5 parts of acetone; and a plasticizer comprises the following components in parts by weight: 11-23 parts of phthalic anhydride acetate, 12-15 parts of polyvinyl chloride, 3-7 parts of ethylene glycol acetate, 13-23 parts of polyvinyl chloride, and 1-10 parts of ethylene glycol acetate. The prepared solar endothermic coating provided by the invention has the advantages of environmental protection, low costs, low plasticizing temperature, good binding performance, low residual viscosity, and stronger weather resistance.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com