Transparent cold-resistant polyvinylchloride modified material, and preparation method and application thereof

A technology of polyvinyl chloride and modified materials, applied in mechanical equipment, pipes, hoses, etc., can solve the problems of not guaranteeing the transparency of PVC, reducing plasticizing temperature and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

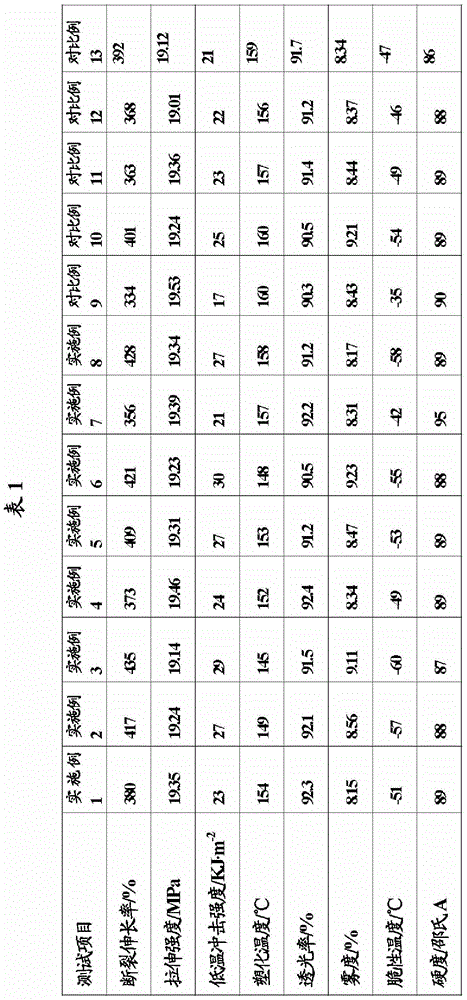

Examples

Embodiment 1

[0085] Polyvinyl chloride (brand SG3, with a weight average molecular weight of 170,000, purchased from Tianjin Organic Chemical No. ), as a calcium-zinc composite stabilizer (model: GX-082, purchased from Guangdong Dongzheng Chemical Co., Ltd.), as an auxiliary plasticizer, epoxy soybean oil (brand E-10, purchased from Guangzhou Xinjin Long Plastic Auxiliary Co., Ltd.) weighed in parts of 100 / 35 / 1.5 / 5, added to a high-speed mixer, first stirred at a low speed (300r / min) for 4 minutes, then stirred at a high speed (1000r / min) for 10 minutes, and reached the set temperature After 100°C, the mass was cooled to 60°C. Adding 10 parts of polyester TPU (brand NX-60A, purchased from Taiwan Coating Chemical Industry Co., Ltd.) and styrene-like (brand LE, weight-average molecular weight of 80,000, Henan Qin Yangxie Synthetic Material Factory) 3 parts, kept at 60-70°C and mixed for 5-10min to discharge. Then, the mixture was kneaded at a temperature of 165° C. for 10 min with a twin-r...

Embodiment 2

[0087] Polyvinyl chloride (brand SG4, with a weight average molecular weight of 145,000, purchased from Tianjin Organic Chemical No. ), as a stabilizer barium-zinc composite stabilizer (model: BZ-8056, purchased from Shenzhen Chuangbaoqi Co., Ltd.), as an auxiliary plasticizer epoxy soybean oil (brand E-10, purchased from Guangzhou New Jinlong Plastic Auxiliary Co., Ltd.) was weighed in parts of 100 / 35 / 2 / 5, added to a high-speed mixer, first stirred at a low speed (300r / min) for 4 minutes, and then stirred at a high speed (1000r / min) for 10 minutes to reach the set After the temperature was 100°C, the mass was cooled to 60°C. Adding wherein Shore hardness is 60A polyester TPU (brand NX-60A, purchased from Taiwan Coating Chemical Industry Co., Ltd.) 20 parts and styrene-like (brand C-10, weight-average molecular weight is 90,000, Henan Qinyang Hope Synthetic Material Factory) 5 parts, keep mixing at 60-70°C for 5-10min and discharge. Then, the mixture was kneaded at a tempera...

Embodiment 3

[0089] Polyvinyl chloride (brand SG4, weight average molecular weight is 145,000, purchased from Tianjin Organic Chemical No. 2 Factory), trioctyl trimellitate (brand TOTM, purchased from Wujiang Jinfeng Chemical Co., Ltd.) Barium cadmium zinc liquid composite stabilizer (model: BGX104-3, purchased from Rudong Lianfeng Chemical Co., Ltd.) as a stabilizer, epoxy soybean oil (brand E-10, purchased from Guangzhou City) as an auxiliary plasticizer Xinjinlong Plastic Auxiliary Co., Ltd.) was weighed in parts of 100 / 35 / 3 / 5, added to a high-speed mixer, first stirred at a low speed (300r / min) for 4 minutes, and then stirred at a high speed (1000r / min) for 10 minutes to reach the set After setting the temperature at 100°C, the material was cooled to 60°C. Then add 25 parts of polyester TPU (brand 460, purchased from U.S. Nuoyu Chemical Co., Ltd.) with Shore hardness of 70A and styrene-like (brand C-10, with a weight average molecular weight of 90,000, Henan Qinyang Hope Synthetic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com