Patents

Literature

677 results about "Trioctyl trimellitate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trioctyl Trimellitate is a primary plasticizer for polyvinyl chloride resin and copolymer applications. It offers compatibility, excellent low temperature properties, ease of processing and a high degree of permanence.

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

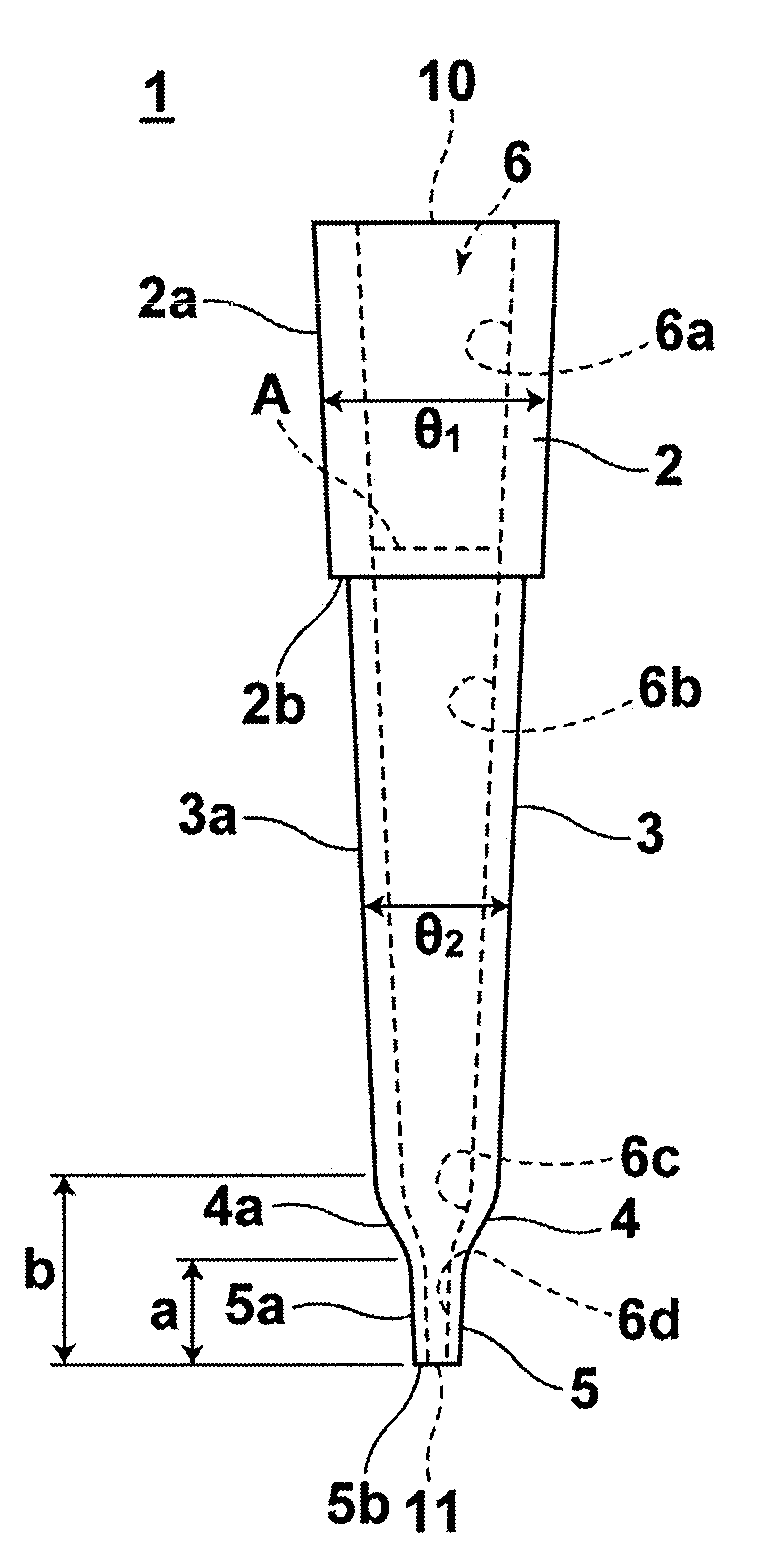

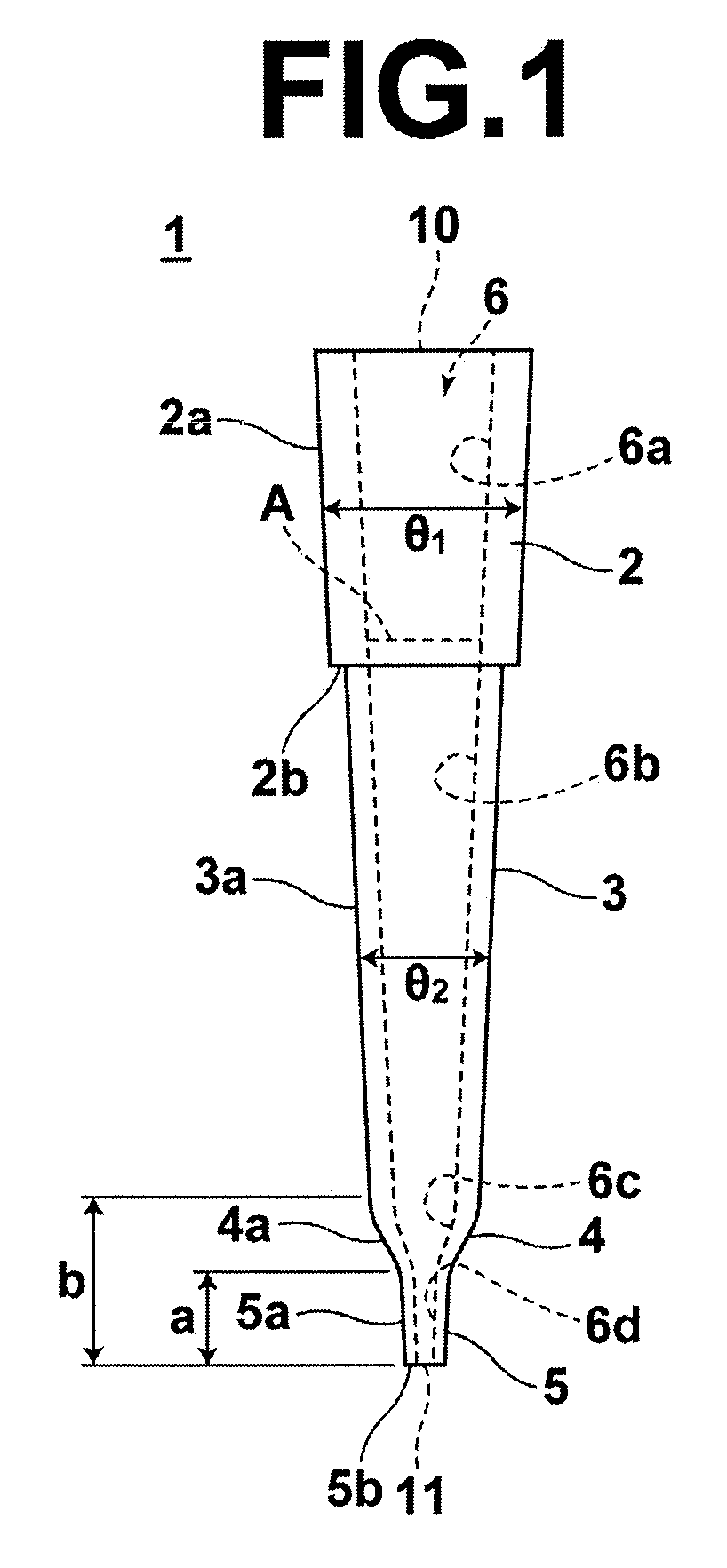

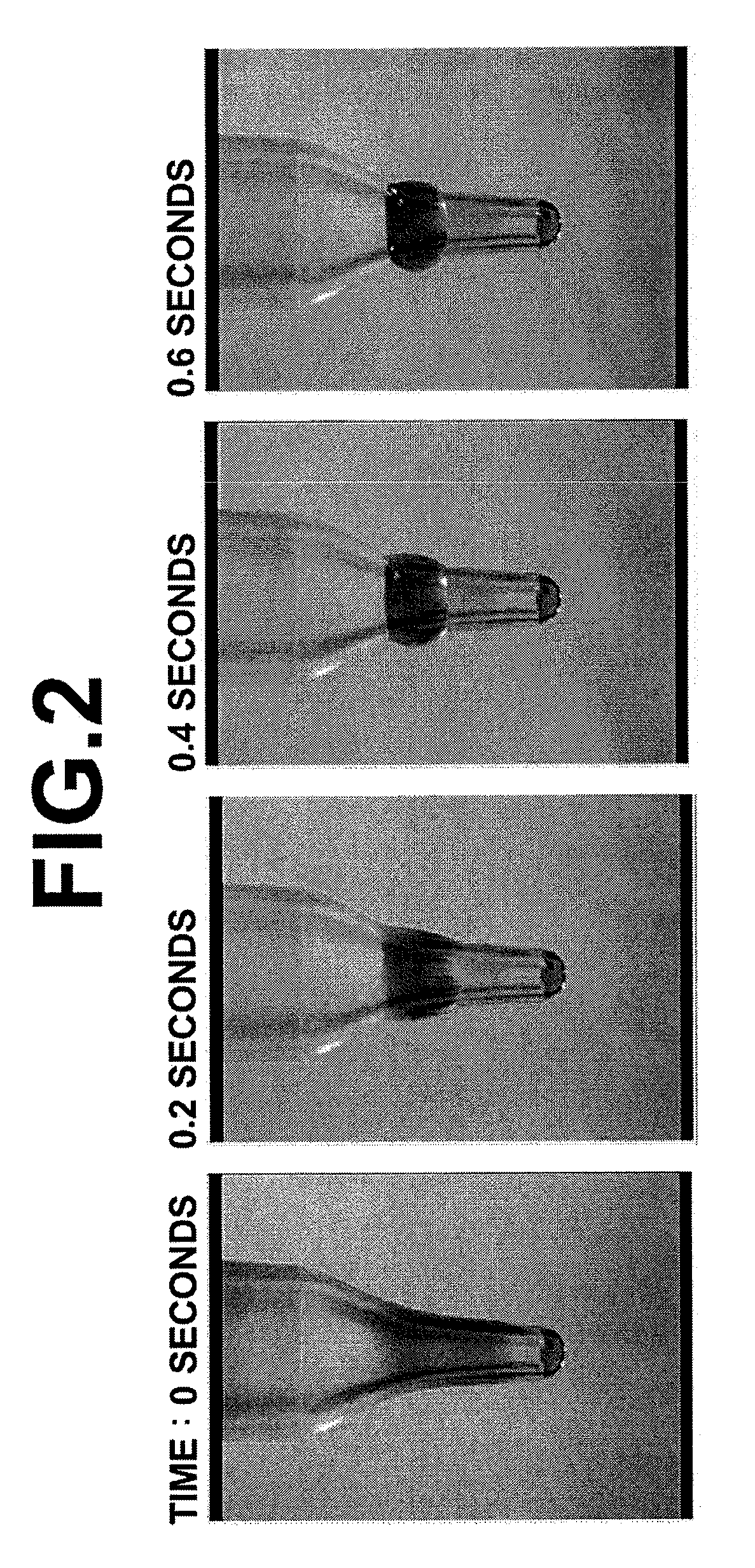

Pipette tip

InactiveUS20090202392A1Reliable distributionAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipette1,3-Butanediol

A pipette tip formed by a polypropylene substrate coated with a water repellent agent. The water repellent agent contains a silicone resin containing at least one specific substance selected from the group consisting of diisononyl phthalate, diisodecyl phthalate, trioctyl trimellitate and poly (1,3-butanediol adipate). The total mass of the specific substance is 1-30 mass % of the silicone resin.

Owner:FUJIFILM CORP

Metal rust-preventive oil comprising butyl acrylate

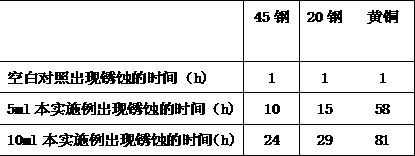

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

Medical polyvinyl chloride plastic and preparation process thereof

Owner:上海新上化高分子材料有限公司

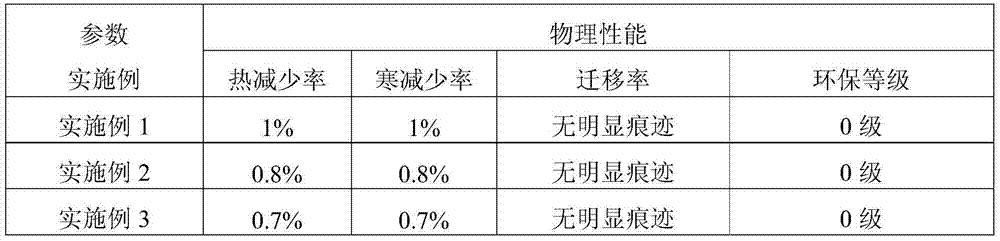

PVC (Polyvinyl Chloride) sealing strip and application thereof

ActiveCN103923412AImprove migration resistanceImprove heat resistanceDomestic cooling apparatusLighting and heating apparatusPolyesterElastomer

The invention discloses a PVC (Polyvinyl Chloride) sealing strip and an application thereof. The PVC sealing strip comprises 40-50 parts of PVC resin, 25-50 parts of plasticizer, 2-10 parts of elastomer, 2-5 parts of stabilizer, 15-25 parts of filler and 1-3 parts of lubricant, wherein the plasticizer is at least one of a diisononyl adipate plasticizer, a trioctyl trimellitate plasticizer, an epoxidized soybean oil plasticizer and a polyester plasticizer. The PVC sealing strip provided by the inveniton has high migration resistance, heat resistance, cold resistance and environmental friendliness performance.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

ActiveCN102964697AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses a nano-wollastonite powder modified ethylene propylene diene copolymer cable material, which is prepared FROM the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of butyl rubber BBK232, 10-15 parts of SG-3 PVC (polyvinyl chloride) resin, 10-15 parts of trioctyl trimellitate, 2-5 parts of propanediol sebacate polyester, 2-5 parts of epoxidized soybean oil, 5-10 parts of polyethylene wax, 0.2-0.5 part of bisphenol A, 1-2 parts of zinc stearate, 0.5-1 part of lead sulfate tribasic, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of wollastonite powder, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Polyimide resin diamond grinding wheel and preparation method thereof

ActiveCN102814763AHigh mechanical strengthImprove heat resistanceAbrasion apparatusGrinding devicesCorundumPolyimide

The invention discloses a polyimide resin diamond grinding wheel and a preparation method of the polyimide resin diamond grinding wheel. The polyimide resin diamond grinding wheel is prepared from the following components in parts by weight: 50-60 parts of diamond grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of garnet sand, 5-15 parts of polyimide resin powder, 2-6 parts of furfuryl alcohol, 1-2 parts of trioctyl trimellitate, 5-10 parts of cryolite, 5-10 parts of gypsum powder, 2-5 parts of nano siliceous shale powder and 2-5 parts of copper powder. According to the polyimide resin diamond grinding wheel and the preparation method of the polyimide resin diamond grinding wheel, as polyimide resin serving as a binding agent has higher mechanical strength and excellent heat resistance, the durability of the prepared resin grinding wheel is improved greatly; as ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, and cracks formed by rigid grinding are reduced, thereby the use efficiency and service life of the resin grinding wheel are improved further; and in addition, since copper power is added, fast heat dissipation effect is achieved, a great deal of heat generated in a cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is achieved.

Owner:安徽威铭耐磨材料有限公司

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

Preparation method of rubber for outer glue layer of power steering tube of automobile

The invention discloses a preparation method of rubber for an outer glue layer of a power steering tube of an automobile and belongs to the technical field of rubber parts for automobiles. The preparation method comprises the following steps: mixing chlorosulfonated polyethylene, fast extruding furnace black, carbon black prepared by a cracking process, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithiodibenzo thiazole, trioctyl trimellitate and strong magnesium powder in an external mixer, and after mixing, discharging rubber under a condition that the rubber temperature is 160 DEG C to prepare masterbatch; and putting the prepared masterbatch into the external mixer, adding trithiocyanuric acid and sulfur in the raw materials and mixing; and after mixing, sequentially extruding at a certain temperature interval to prepare the rubber for the outer glue layer of the power steering tube of the automobile. Compared with the rubber for the outer glue layer of the power steering tube of the automobile prepared in the prior art, the rubber prepared by the preparation method has the advantage that the heat resistance of the rubber is effectively improved by mutual synergistic effect among the raw materials and matching corresponding extrusion temperatures.

Owner:南京中配橡塑制品有限公司

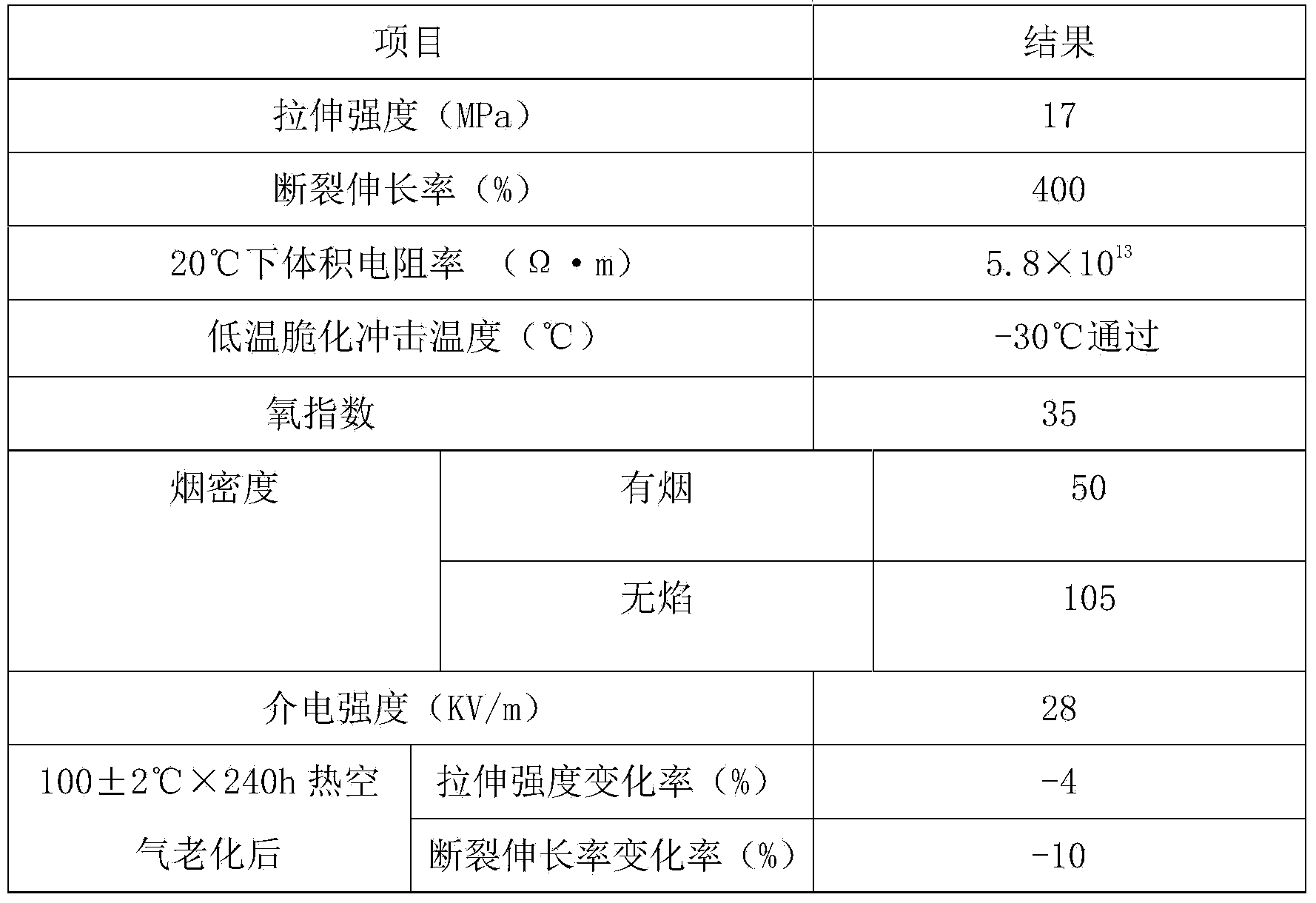

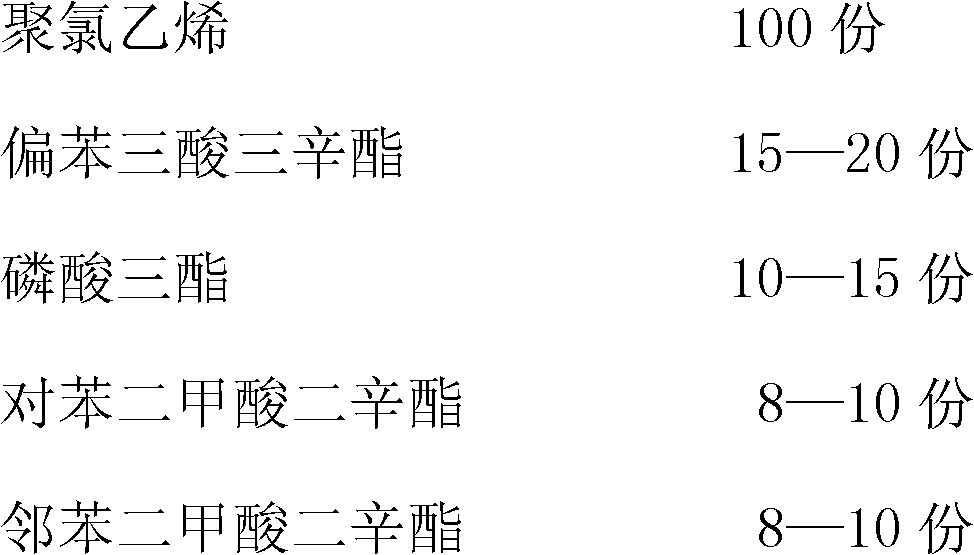

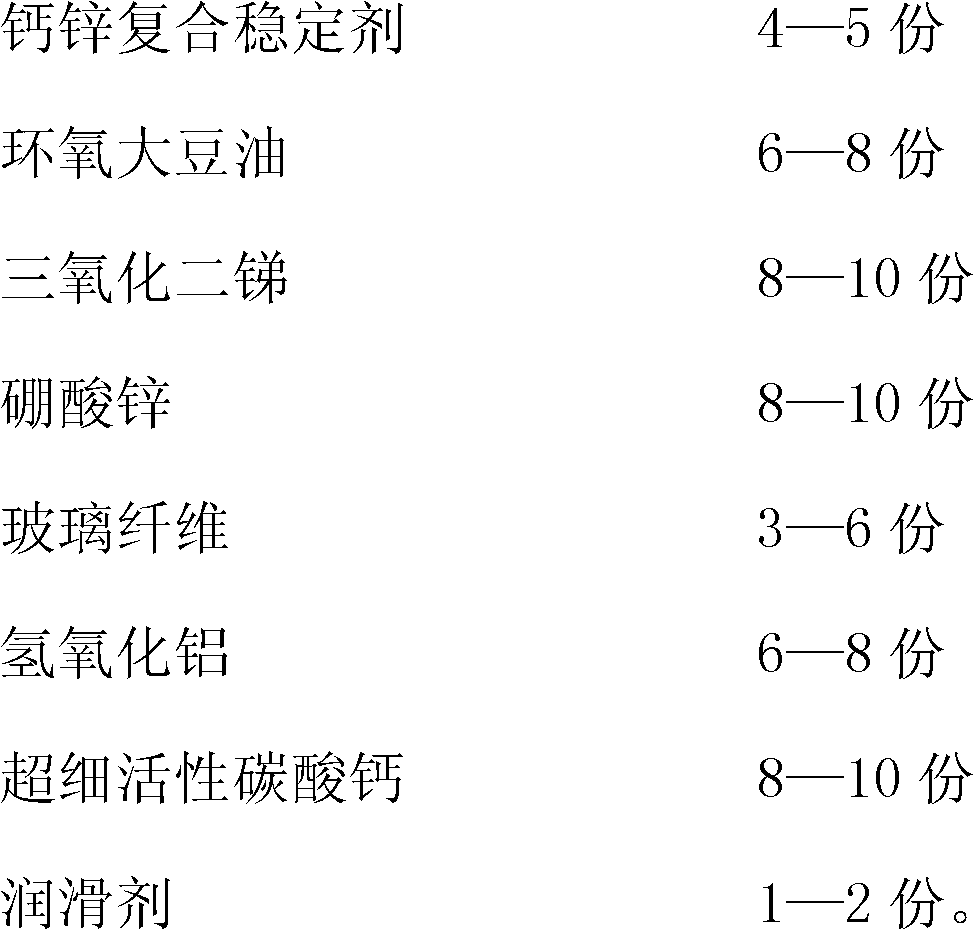

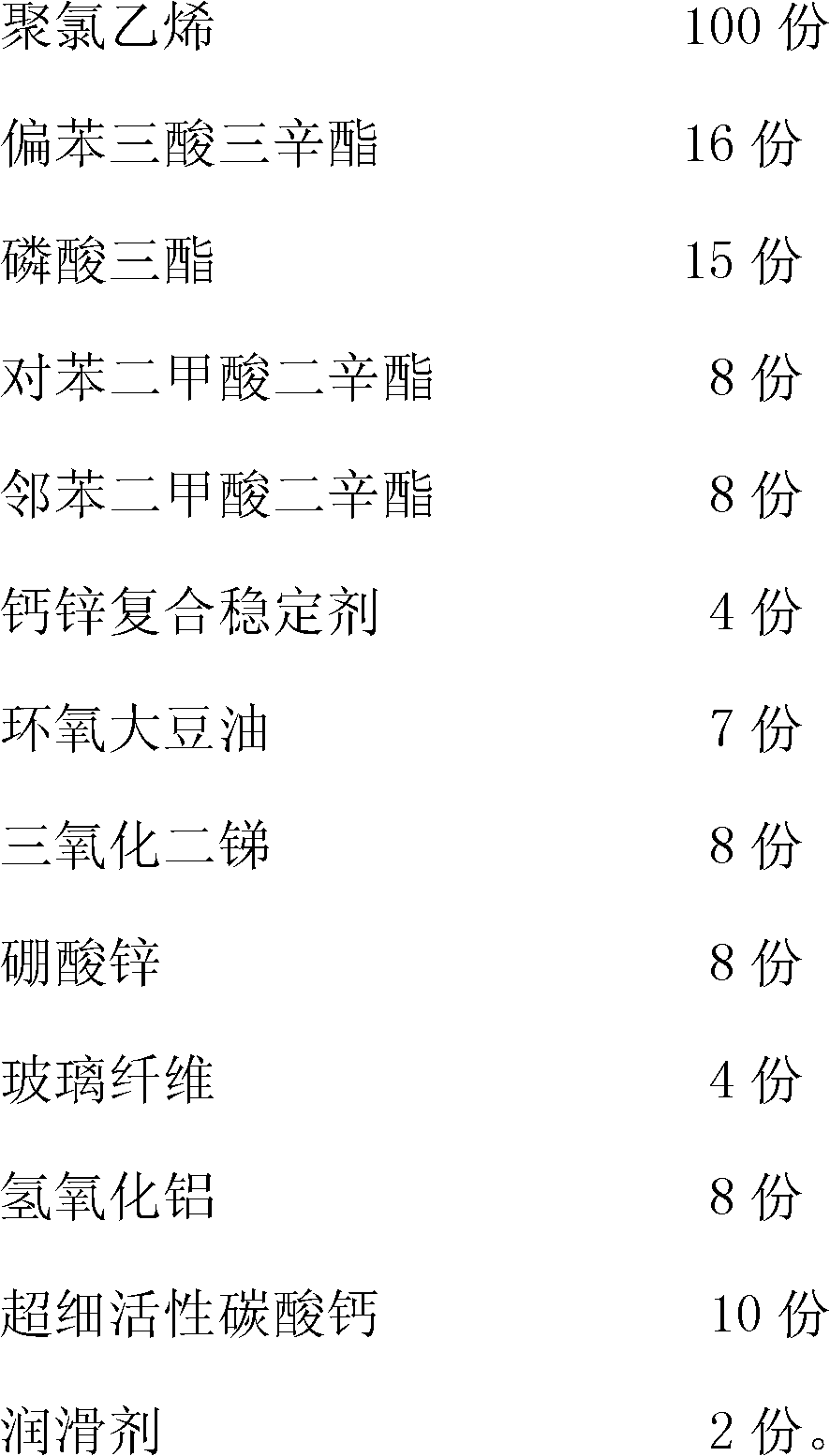

Polyvinyl chloride cable sheath material for CMR-grade high-flame-retardant environment-friendly coaxial cable

InactiveCN102161805AGood physical and mechanical propertiesEnvironmental protection is goodInsulated cablesInsulated conductorsAluminium hydroxideEngineering

The invention relates to a polyvinyl chloride cable sheath material for a CMR-grade high-flame-retardant environment-friendly coaxial cable, which is mainly prepared from the following components in parts by weight: 100 parts of polyvinyl chloride, 15-20 parts of trioctyl trimellitate, 10-15 parts of triphosphate, 8-10 parts of dioctyl terephthalate, 8-10 parts of dioctyl phthalate, 4-5 parts of calcium / zinc composite stabilizer, 6-8 parts of epoxy soybean oil, 8-10 parts of antimony trioxide, 8-10 parts of zinc borate, 3-6 parts of glass fiber, 6-8 parts of aluminum hydroxide, 8-10 parts of ultrafine activated calcium carbonate and 1-2 parts of lubricant. The sheath provided by the invention has the advantages of high strength, favorable shell forming property and durability in the burning process, excellent flame retardancy and environmental protection, and especially can satisfy the design requirements for CMR-grade high-flame-retardant fine coaxial cables.

Owner:LINAN PUFA CABLE MATERIAL

Twist-resisting polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995451AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterStearic acid

The invention discloses twist-resisting polyvinyl chloride synthetic leather which comprises a surface layer, a foaming layer, a bonding layer and fluffing cloth. The twist-resisting polyvinyl chloride synthetic leather is characterized by being prepared from the following components in parts by weight: 50-60 parts of SG-2 PVC (Polyvinyl Chloride) resin, 30-40 parts of SG-6 PVC resin, 20-25 parts of isophthalic ester, 10-15 parts of phthalic polyester, 10-15 parts of trioctyl trimellitate, 5-6 parts of PVC color cream, 1-2 parts of zinc stearate, 1-2 parts of protein powder, 20-25 parts of zinc oxide, 10-15 parts of magnesium oxide, 10-15 parts of N660 carbon black, and 5-10 parts of modified attapulgite. Through improvement of formula and process provided by the invention, the flexibility of the synthetic leather is enhanced, and the synthetic leather has a natural and comfortable handfeel similar to that of natural leather. The synthetic leather is not easy to damage or tear within 3-5 years.

Owner:HEFEI ANSHAN COATING FABRICS

Impact-resistant flame-retardant control cable

ActiveCN105244107AImprove brittlenessHigh tensile strengthInsulated cablesInsulated conductorsModified carbonEngineering

The invention discloses an impact-resistant flame-retardant control cable, comprising an insulating cable core, a shielding layer, an inner sheath, an armor layer and an outer sheath. The outer sheath is made of a modified polyvinyl chloride composite material. A raw material of the modified polyvinyl chloride composite material comprises: polyvinyl chloride, chlorinated polyethylene, styrene-butadiene block copolymer, 2,2,3,3,4,4,4-heptafluorobutyl acrylate, modified montmorillonite, expanded vermiculite, expansible graphite, polypropylene fiber, nano zinc hydroxystannate, a heat stabilizer, stearic acid, lanthanum stearate, epoxidized soybean oil, bis[2-(2-butoxyethoxy)ethyl]adipate, triphenyl phosphate, trioctyl trimellitate, hexaphenoxy cyclotriphosphazene, a modified carbon nano tube and an antioxygen. The impact-resistant flame-retardant control cable of the invention is good in flame resistance, excellent in impact-resistant performance and long in service lifetime.

Owner:蓝德能源科技股份有限公司

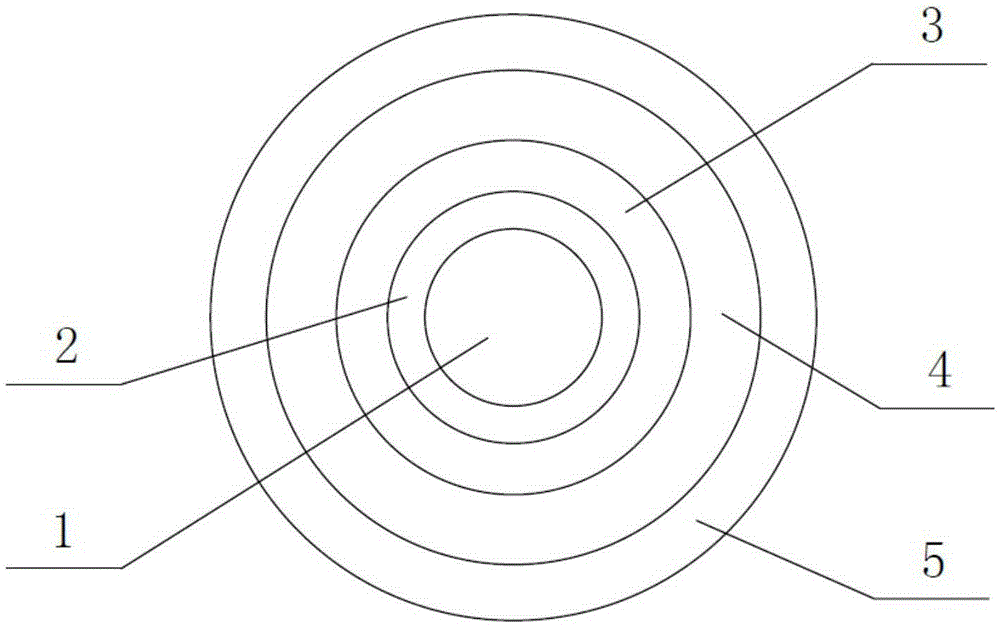

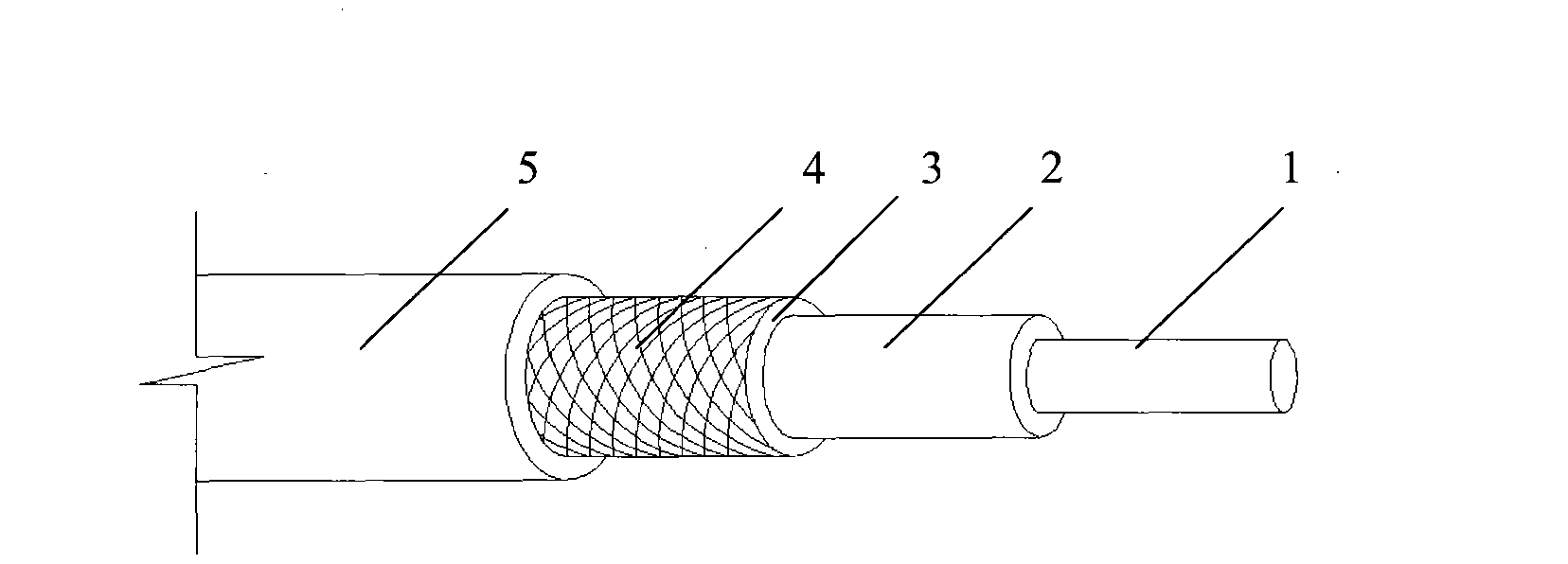

Environment friendly cold-resistant flexible sheath material and coaxial cable produced thereof

InactiveCN101492558AImprove cold resistanceGood flexibilityPlastic/resin/waxes insulatorsCoaxial cableSocial effects

An environmental protection cold resistance soft sheathing material is mainly prepared by the following materials according to the parts by weight: 40-45 pars of polyvinyl chloride, 5-7 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 8-10 parts of dioctylphthalate, 5-7 parts of phthalandione (2- propyl heptylasetate) diester, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, and 10-13 parts of refined calcium carbonate. The sheathing material has excellent cold resistance and environmental protection performance, low cost and high softness, and simultaneously the physical property of the sheathing material meets the European Union electronic apparatus ROHS commands and UL requirements. Based on the environmental protection cold resistance soft sheathing material, environmental protection cold resistance soft coaxial-cables which meet the UL requirements are successfully developed, thus technically solving the technical difficulties of softness, cold resistance, UL mechanical physical property and the like which are difficult to be achieved completely, meeting the strict requirements of the application of products on cold regions and having remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

PET (Polyethyleneglycol Terephthalate) fiber/glass fiber composite sound absorbing cotton and preparation method thereof

InactiveCN102965842AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesFiberPhosphoric Acid Esters

The invention discloses PET (Polyethyleneglycol Terephthalate) fiber / glass fiber composite sound absorbing cotton, which is prepared from the following raw materials in parts by weight: 70-80 parts of PET fiber, 40-50 parts of quartz glass, 15-20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 20-30 parts of peregal O-10, 80-100 parts of PP (Polypropylene), 30-40 parts of LDPE (Low-Density Polyethylene), 15-20 parts of calcium carbonate whiskers, 10-15 parts of modified diatomite, 2-3 parts of stearic acid, 5-8 parts of trioctyl trimellitate, 4-6 parts of ammonium polyphosphate, 2-3 parts of oxidized polyethlene wax, 1-2 parts of di(dioctyloxy pyrophosphate)ethylene titanium ester, 2-3 parts of zinc stearate, 1-2 parts of dimethyldimercaptoisooctylacetate tin, 0.5-1.5 parts of anti-aging agent RD, and 1-2 parts of antioxidant 1010. The sound absorbing cotton prepared in the invention has the advantages of high appearance flatness, uniform thickness, soft handfeel, high product viscosity, high tensile property, high sound absorbing performance, good flame retarding effect and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

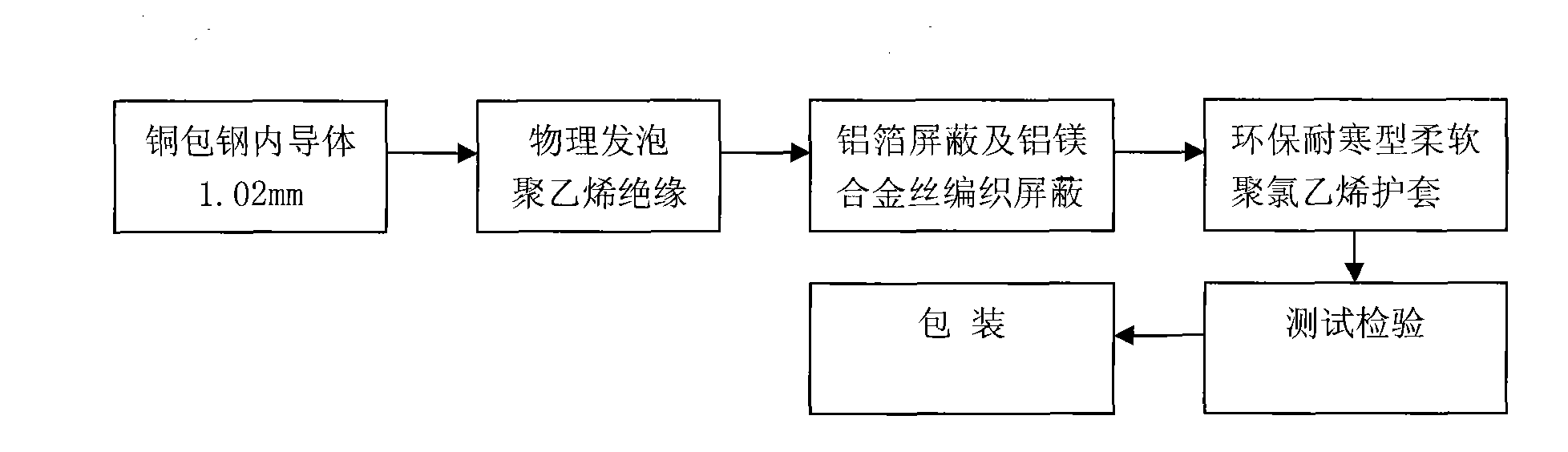

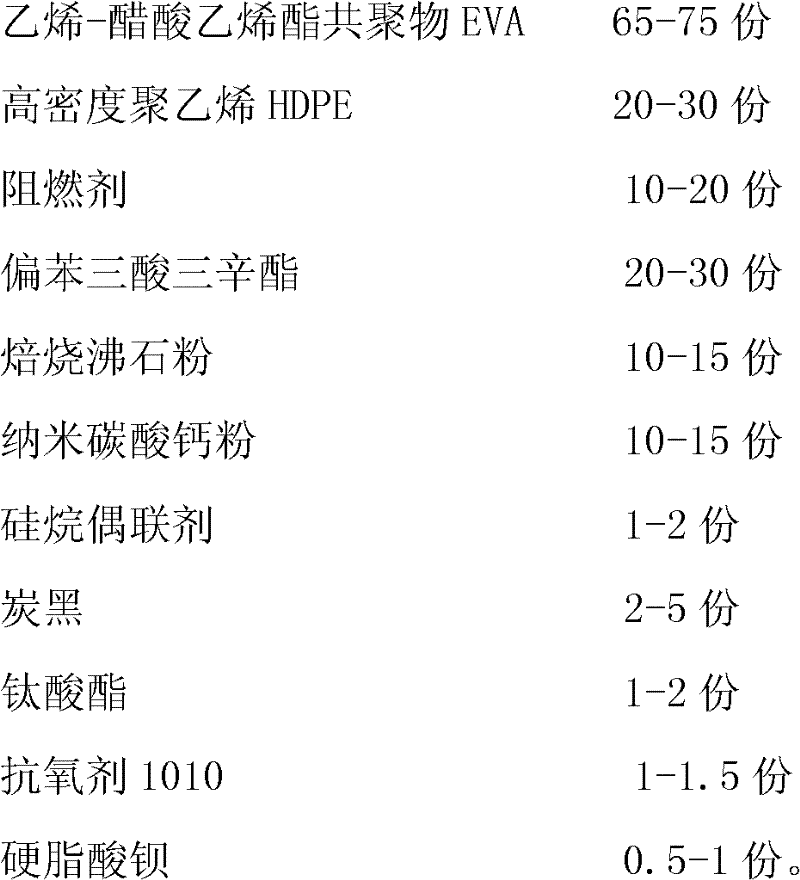

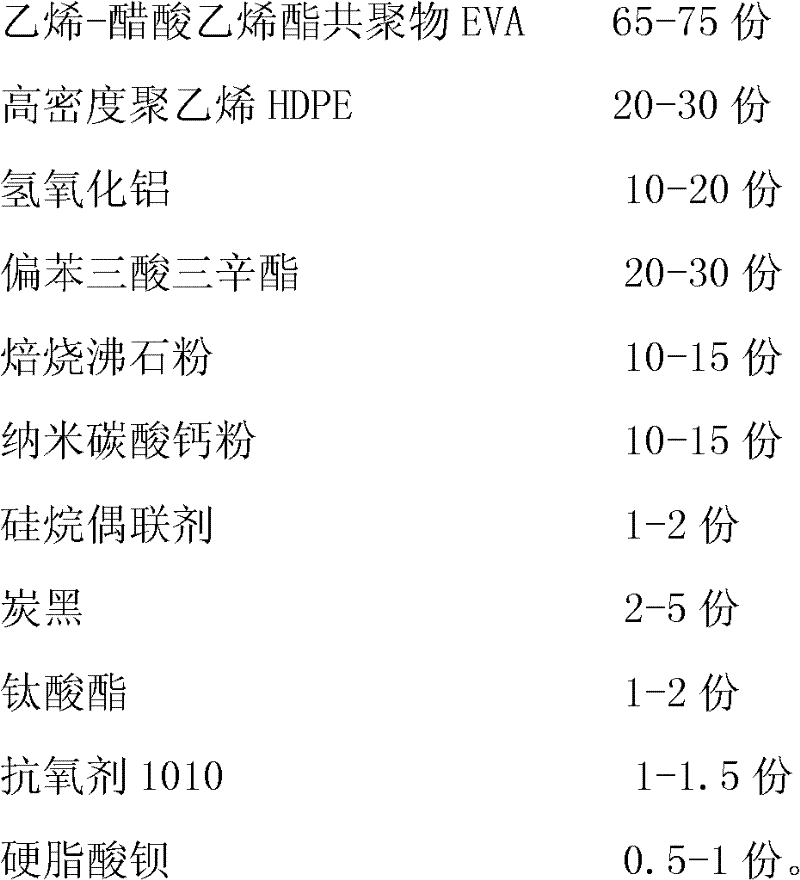

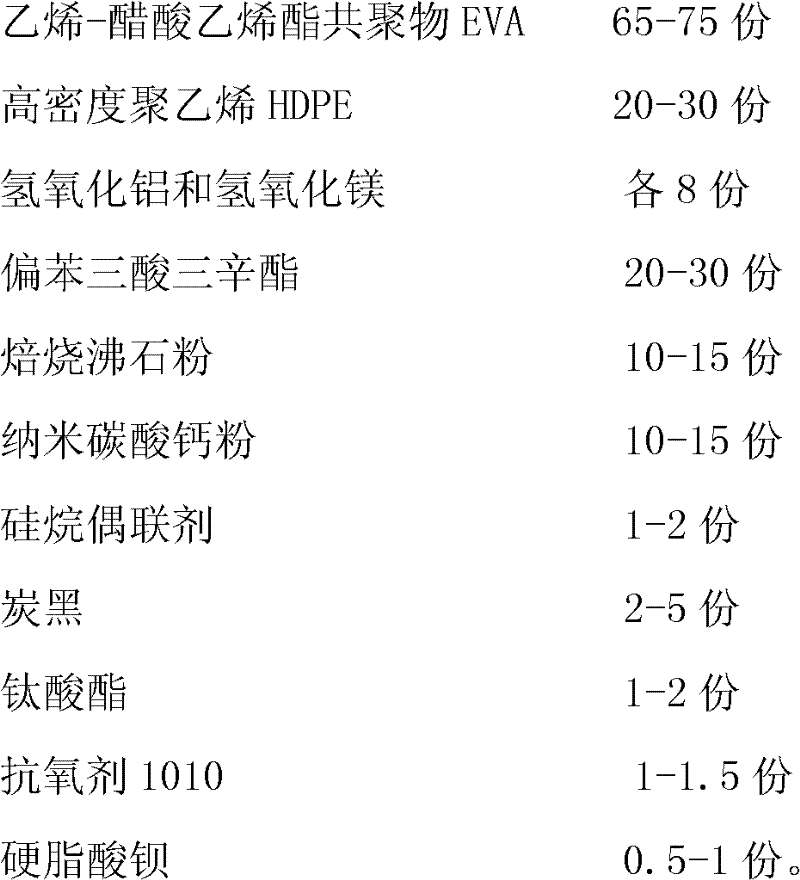

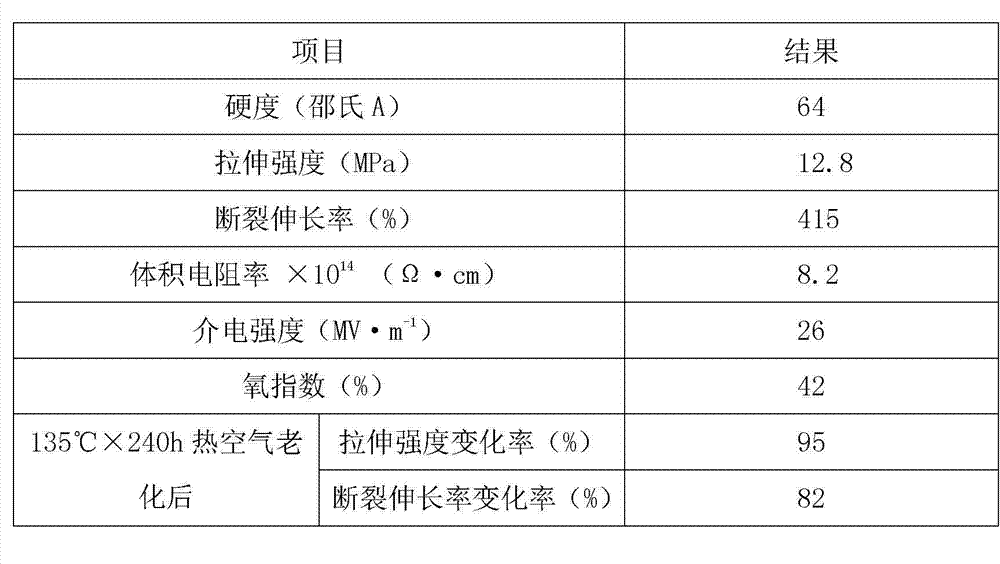

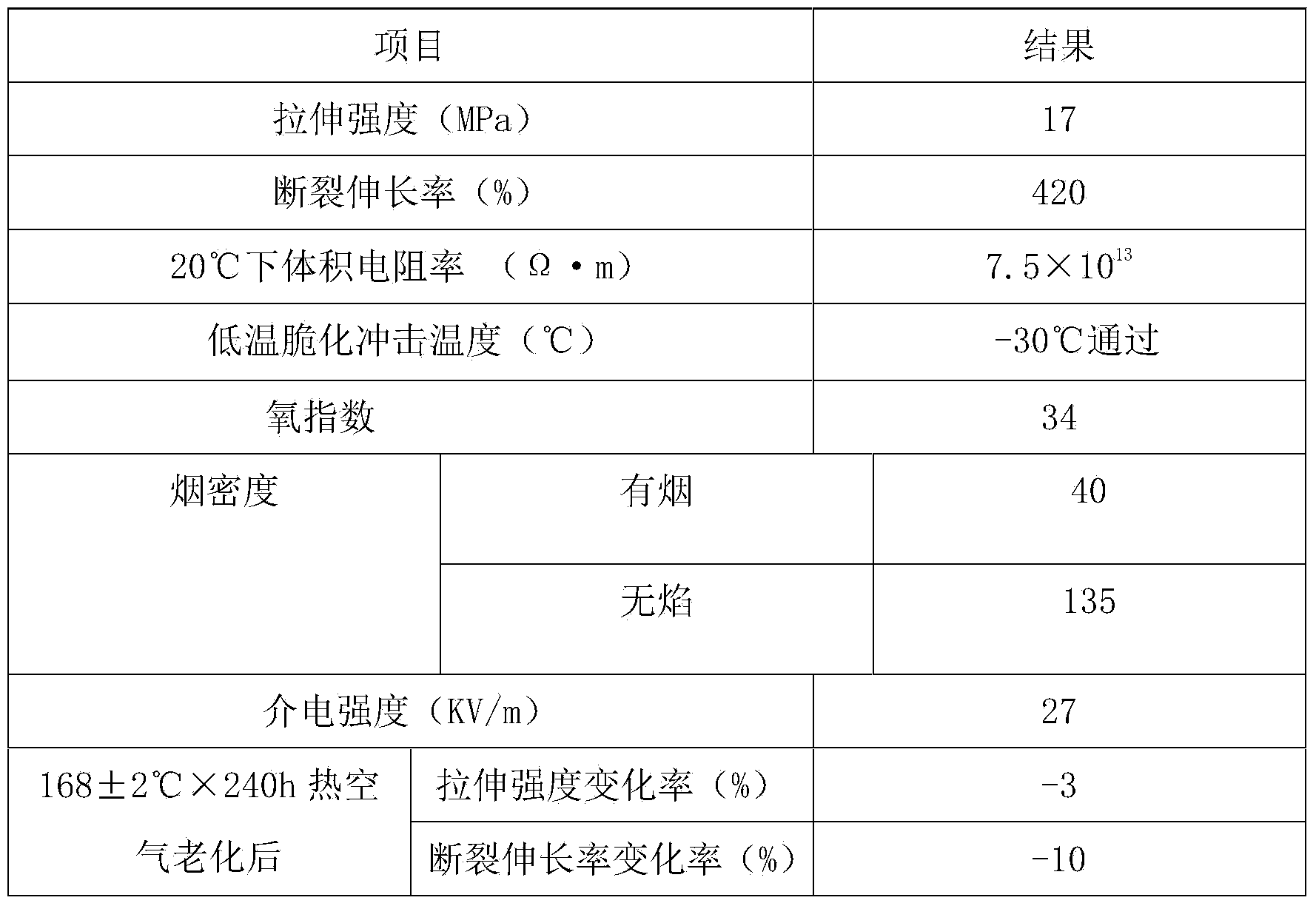

Polyvinyl chloride cable material and preparation method thereof

ActiveCN102382356AReasonable formulaImprove mechanical propertiesPlastic/resin/waxes insulatorsCarvacryl acetateFire retardant

The invention discloses a cable material and a preparation method thereof. The cable material is mainly prepared by composited materials including ethylene-vinylacetate co-polymer EVA, high-density polythylene HDPE, aluminum hydroxide, magnesium hydroxide, triotyl trimellitate, roasting zeolite powder, nano calcium carbonate powder, silane coupling agent, carbon black, titanic acid esters, oxidation inhibitor 1010 and barium stearate, which are all mixed according to a specific proportion of parts by weight. The preparation method is simple, convenient in operation and reasonable in formula of the composited materials, and the prepared cable material is high in mechanical performance and fire retardant property and resistant to high temperature, and is low in smoke and non-toxic when being burned.

Owner:ANHUI HUAYU PIPELINE MFG

High cold-resistance ethylene propylene diene copolymer insulated cable material and preparation method thereof

ActiveCN102964698AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsPolymer scienceBenzoyl peroxide

The invention discloses a high cold-resistance ethylene propylene diene copolymer insulated cable material and a preparation method thereof. The cable material is made of the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland 9650 ethylene propylene diene copolymer, 20-30 parts of active chlorine type acrylic rubber AR-400, 10-15 parts of duprene rubber CR121, 10-15 parts of di-butyl nylonic acid ester, 5-10 parts of trioctyl trimellitate, 5-10 parts of triethyl phosphate, 1-2 parts of sulphur, 2-4 parts of benzoyl peroxide, 1-2 parts of triallyl isocyanurate and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Environment-friendly heat-proof composite elastic cable material for cables and cords

Owner:SHANDONG HUANENG CABLE

Polyvinyl chloride (PVC) cable material for automobile data transmission wire

ActiveCN102964723AEliminate odorImprove wear resistancePlastic/resin/waxes insulatorsTerephthalic acidSILICONE DIOXIDE

The invention relates to a polyvinyl chloride (PVC) cable material for an automobile data transmission wire. The PVC material comprises the components based on parts by weight: 100 parts of SG3 type PVC resin, 25-30 parts of plasticizer 1, 3-5 parts of plasticizer 2, 10-12 parts of calcium carbonate, 8-12 parts of stabilizer, 0.8-1.2 parts of polyethylene wax, 2-4 parts of ACR impact modifier, 0.1-0.5 part of antioxidant, 2-3 parts of nano barium sulfate and 0.3-0.8 part of silicone powder, wherein the plasticizer 1 comprises one or two selected from trioctyl trimellitate or purified terephthalic acid dioctyl ester; the plasticizer 2 comprises one or two selected from epoxidized soybean oil and terephthalic acid dioctyl ester; and the silicone powder is silica powder treated by silicone. The PVC cable material has the temperature classification of 105 DEG C, thus having good processability under the condition of high-speed processing; and the obtained cable has excellent abrasion resistance and mechanical property, and the odor can be eliminated.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

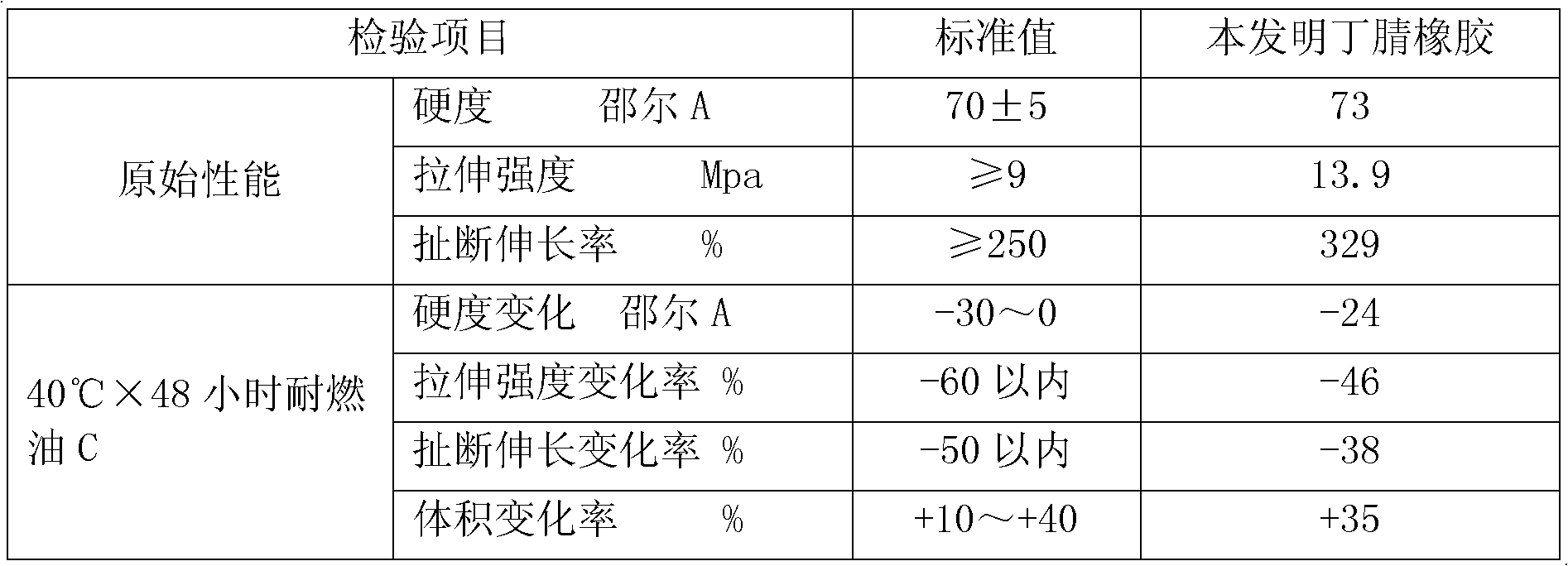

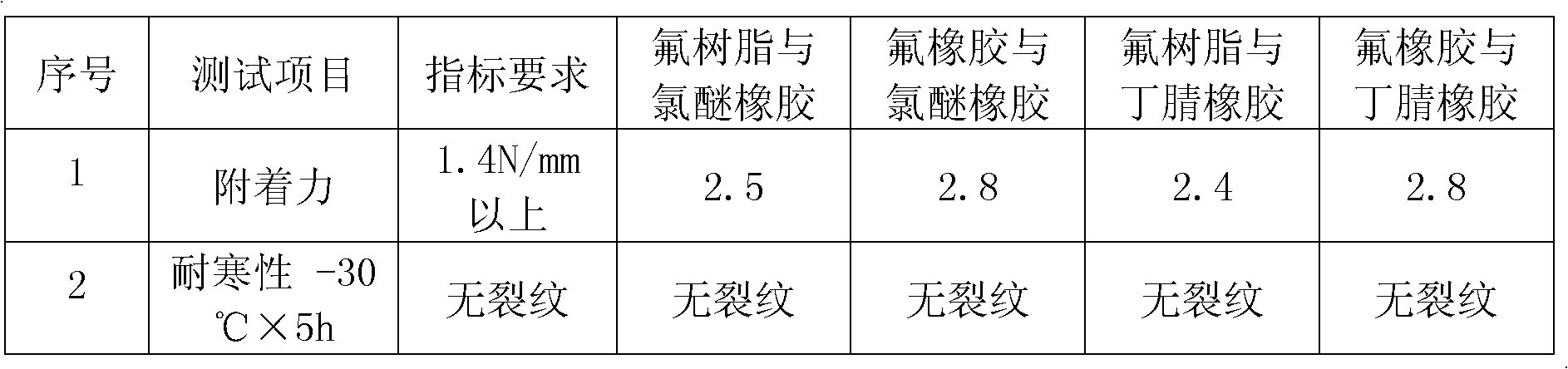

Nitrile-butadiene rubber bonded with fluororesin or fluororubber and application thereof in fuel pipe

ActiveCN102146173APerformance is not affectedAccelerated corrosionFlexible pipesPolymer scienceStearic acid

The invention relates to nitrile-butadiene rubber bonded with fluororesin or fluororubber and an application thereof in a fuel pipe. The rubber comprises the following components: raw nitrile-butadiene rubber, magnesium oxide, calcium hydroxide, stearic acid, an antiager RD, an antiager NBC, coumarone, an adhesive Ricobond 2031, fast extruding furnace black N550, high abrasion furnace black N330, white carbon black, trioctyl trimellitate, liquid nitrile-butadiene rubber 26, sulfur, an accelerator CZ and an accelerator TMTD (tetramethylthiuram disulfide). The experimental contrastive analysis on nitrile-butadiene rubber, epichlorohydrin rubber and ethyene-propylene rubber shows that the performances of the nitrile-butadiene rubber can fully meet the standard and the nitrile-butadiene rubber can replace epichlorohydrin rubber and ethyene-propylene rubber. A vehicle rubber pipe prepared from the nitrile-butadiene rubber can meet the normal production conditions and performance requirement, and simultaneously, the material cost can be reduced.

Owner:TIANJIN PENGYI GRP CO LTD

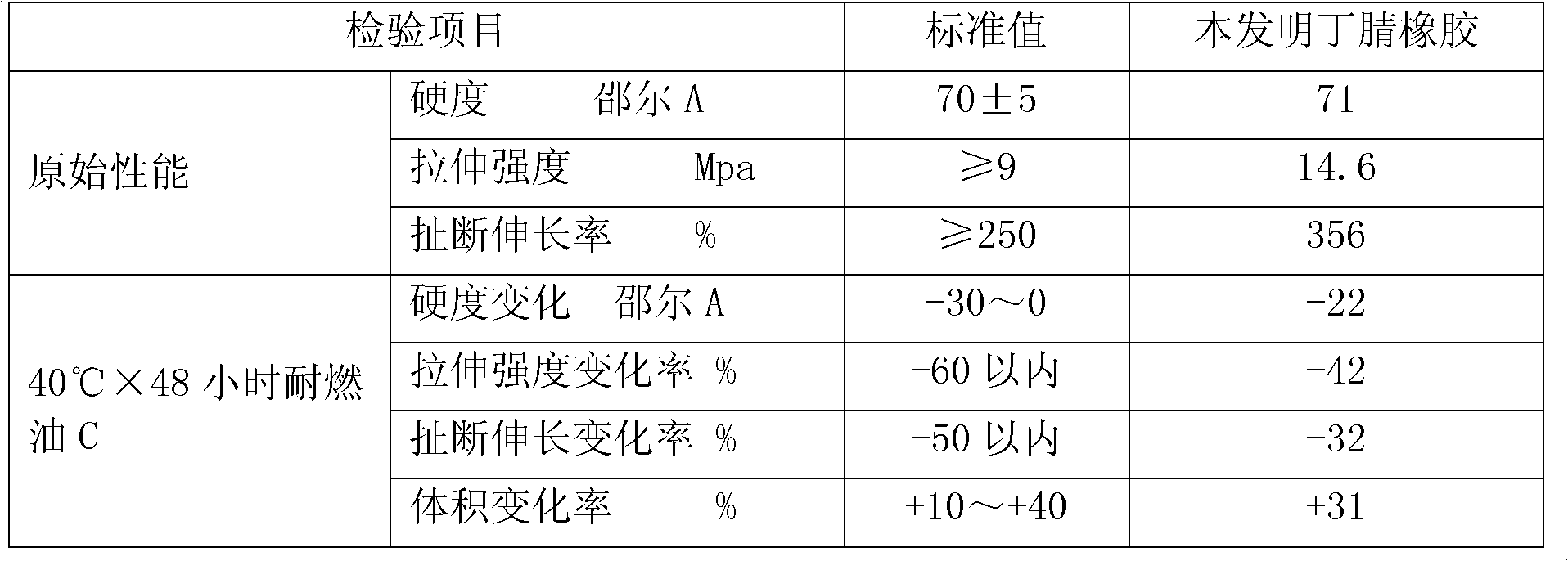

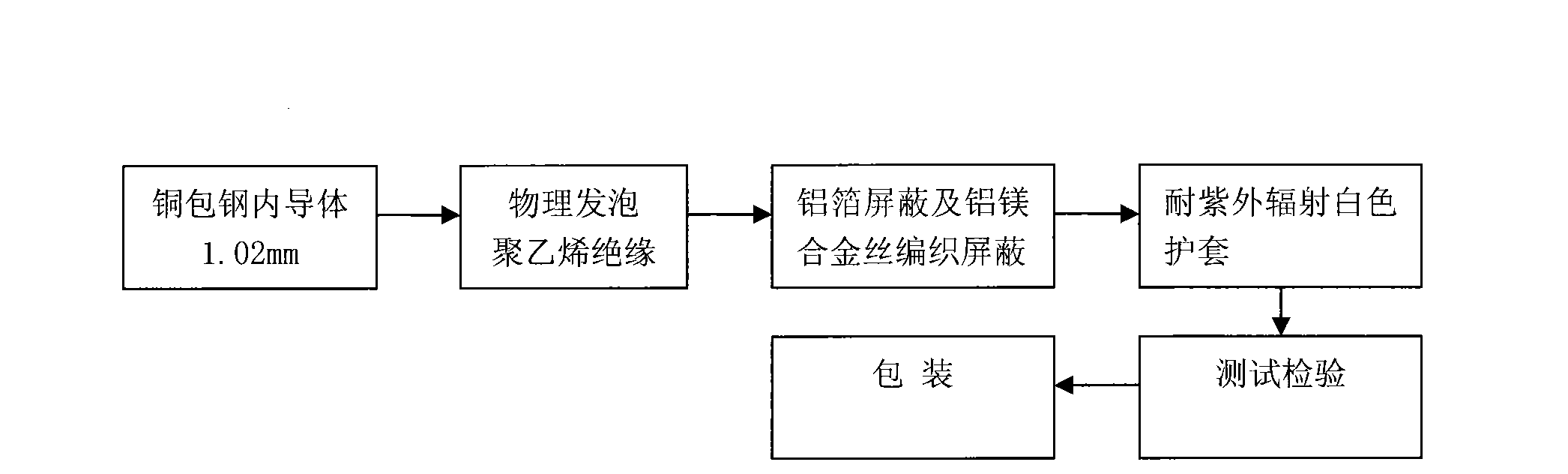

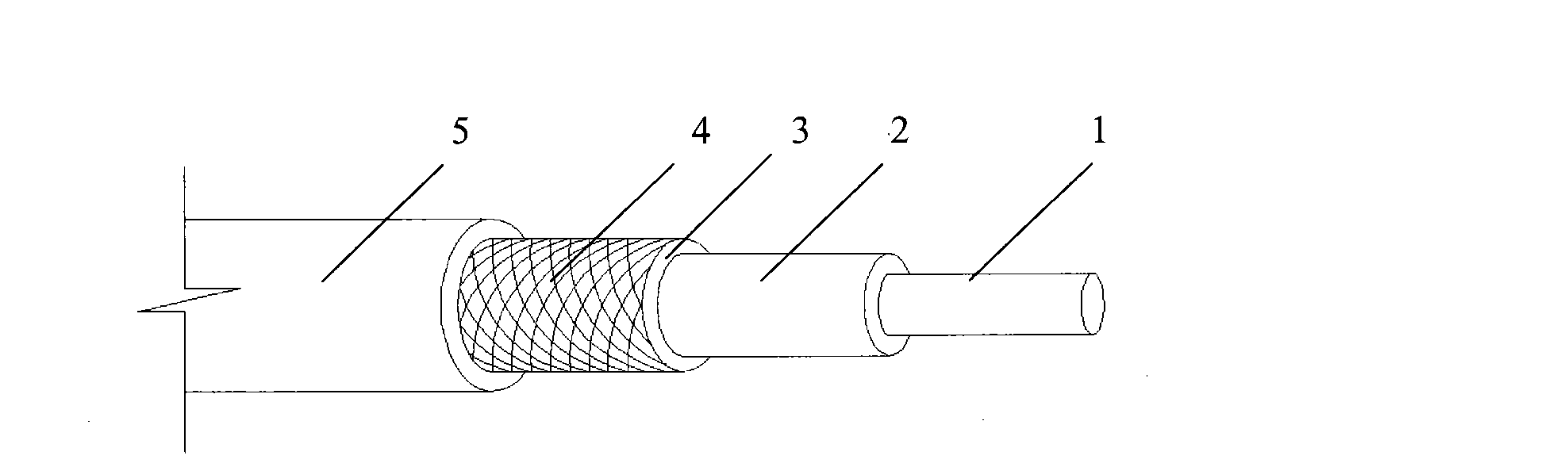

Ultraviolet light resistant ring protective cover material and white concentric cable produced thereof

InactiveCN101492557AExcellent resistance to UV radiationEnvironmental protection is goodPlastic/resin/waxes insulatorsUltraviolet lightsSocial effects

An ultra violet radiation resistant environmental protection sheathing material is mainly prepared by the following materials according to the parts by weight: 40-50 pars of polyvinyl chloride resin, 6-8 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 7-9 parts of dioctylphthalate, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, 8-10 parts of refined calcium carbonate, 8-10 parts of titanium dioxide, and 0.3-0.5 parts of ultraviolet absorbent. The invention technically solves the difficult point of compound formulation of the ultra violet radiation resistant white sheathing material, greatly increases the resistance to ultra violet radiation performance of the product, has strong practicability and lays the material foundation for the design and development of resistance to ultra violet radiation coaxial-cables. Based on the resistance to ultra violet radiation white polyvinyl chloride sheathing material, the resistance to ultra violet radiation environmental protection sheathing material technically solves the technical difficulties of resistance to ultra violet radiation performance, softness, UL mechanical physical property, ROHS environment requirements and the like which are difficult to be achieved completely, meets the strict requirements of the application of products on tropical and subtropical regions and has remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

Port machine cable storage basket sling cable sheath rubber and preparation method thereof

InactiveCN102093645AImprove mechanical propertiesImprove anti-agingPlastic/resin/waxes insulatorsParaffin waxEngineering

The invention discloses a port machine cable storage basket sling cable sheath rubber and a preparation method thereof, belonging to the field of cables. The sheath rubber comprises the following components: 26.5 parts of chlorinated polyethylene 352, 2.5-3 parts of magnesium oxide, 0.3-0.5 part of antioxidant RD, 0.25-0.5 part of paraffin wax, 3.5-4.0 parts of DOS (Dioctyl Sebacate), 2.0-2.5 parts of TOTM (Trioctyl Trimellitate), 1.5-2.0 parts of white carbon black, 1.2-1.5 parts of diantimony trioxide, 1.2-1.5 parts of chlorinated paraffin 70, 0.3-0.5 part of lead stearate, 0.2-0.4 part of three salts, 6-8 parts of calcined clay, 0.2-0.3 part of A-172, 3-4 parts of high-abrasion carbon black, 3-4 parts of semi-reinforcing carbon black, 0.85-1 part of DCP (Dibasic Calcium Phosphate) and 1-1.5 parts of triallyl cyanurate (TAC). The preparation method of the port machine cable storage basket sling cable sheath rubber comprises the following steps of: firstly, blending the chlorinated polyethylene 352, adding the magnesium oxide and the like, blending and stirring uniformly; pouring filtered rubber into an internal mixer, adding the DCP and the TAC, blending uniformly, and blanking; and making the mixture into five triangular packages in an open mill, rolling for five times and delivering out sheets. The sheath rubber has excellent mechanical properties and good corrosion resistance and aging resistance.

Owner:JIANGSU YUANYANG DONGZE CABLE

High-hardness, wear-resistant and heat-resistant material for cell phone cases

The invention discloses a high-hardness, wear-resistant and heat-resistant material for cell phone cases. The high-hardness, wear-resistant and heat-resistant material comprises the following raw materials in parts by weight: 80-120 parts of modified ethylene propylene diene monomer, 30-50 parts of styrene-butadiene rubber, 30-50 parts of epoxy resin, 30-50 parts of coumarone resin, 20-50 parts of polycarbonate, 5-15 parts of wollastonite, 2-8 parts of nano calcium carbonate, 1-5 parts of magnesium carbonate, 3-6 parts of trioctyl trimellitate, 4-8 parts of 2,6-di-tert-butyl-4-methylphenol, 2-9 parts of dicumyl peroxide, 3-4 parts of phthalic anhydride, 2-6 parts of an anti-stress-cracking agent, 2-6 parts of a lubricant, 1-5 parts of a flame retardant, 2-6 parts of a foaming agent and 2-5 parts of a toughening agent. The high-hardness, wear-resistant and heat-resistant material for the cell phone cases, disclosed by the invention, is high in hardness and good in wear resistance and heat resistance.

Owner:安徽酷米智能科技股份有限公司

Environment-friendly polyvinyl chloride cable sheathing compound

InactiveCN101638499AEnvironmental protection is goodExcellent resistance to moisture absorptionPlastic/resin/waxes insulatorsMoisture absorptionAntimony trioxide

The invention relates to an environment-friendly polyvinyl chloride cable sheathing compound mainly comprising the following materials in parts by weight: 40-45parts of polyvinyl chloride resin, 5-7parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 8-10parts of acetyl tributyl citrate, 5-7 parts of DX-360, 4-6parts of Ca-Zn composite stabilizing agent, 1-1.5 parts of epoxidized soybeanoil, 1-1.5 pats of diantimony trioxide, 10-30 parts of magnesium hydroxide and 10-13parts of fine calcium carbonate. The environment-friendly polyvinyl chloride cable sheathing compound technically satisfies European Union ROHS and REACH index requirements, resists ultraviolet irradiation, and the like, increases stability and anti-moisture absorption, prolongs a storage period and has high practicability, wide development prospect and large market potential. The environment-friendly polyvinyl chloride cable sheathing compound is successfully developed to supply raw material guarantee for designing and selecting an environment-friendly cable product which can simultaneously satisfy the European Union ROHS and REACH requirements, promotes the stable sustainable development of linked industries and conforms the development direction of products of new and high technologies of China.

Owner:王一群

Wear-resistant shock-absorbing foaming rubber material

The invention discloses a wear-resistant shock-absorbing foaming rubber material comprising the following raw materials in parts by weight: 58-62 parts of natural rubber, 36-42 parts of polyurethane rubber, 46-50 parts of butyl rubber, 13-17 parts of a foaming agent OBSH, 5-8 parts of a foaming agent ADC, 15-19 parts of sodium bicarbonate, 4-7 parts of zinc oxide, 3.3-3.8 parts of sulfur, 1.8-2.1 parts of a promoter DM, 2.1-2.4 parts of a promoter DOTG, 32-35 parts of sepiolite powder, 33-37 parts of modified kaolin, 22-28 parts of mica powder, 3-6 parts of styrene bromide, 2-4 parts of antimony trioxide, 5-8 parts of zinc borate pentahydrate, 9-13 parts of trioctyl trimellitate TOTM, 8-11 parts of chlorinated paraffin, 1.2-1.8 parts of an anti-aging agent MBZ and 2.1-2.4 parts of an anti-aging agent BLE. The wear-resistant shock-absorbing foaming rubber material disclosed by the invention has excellent wear resistance and high elasticity, and can be used for effectively absorbing shock.

Owner:NINGGUO NINGSHENG RUBBER PROD

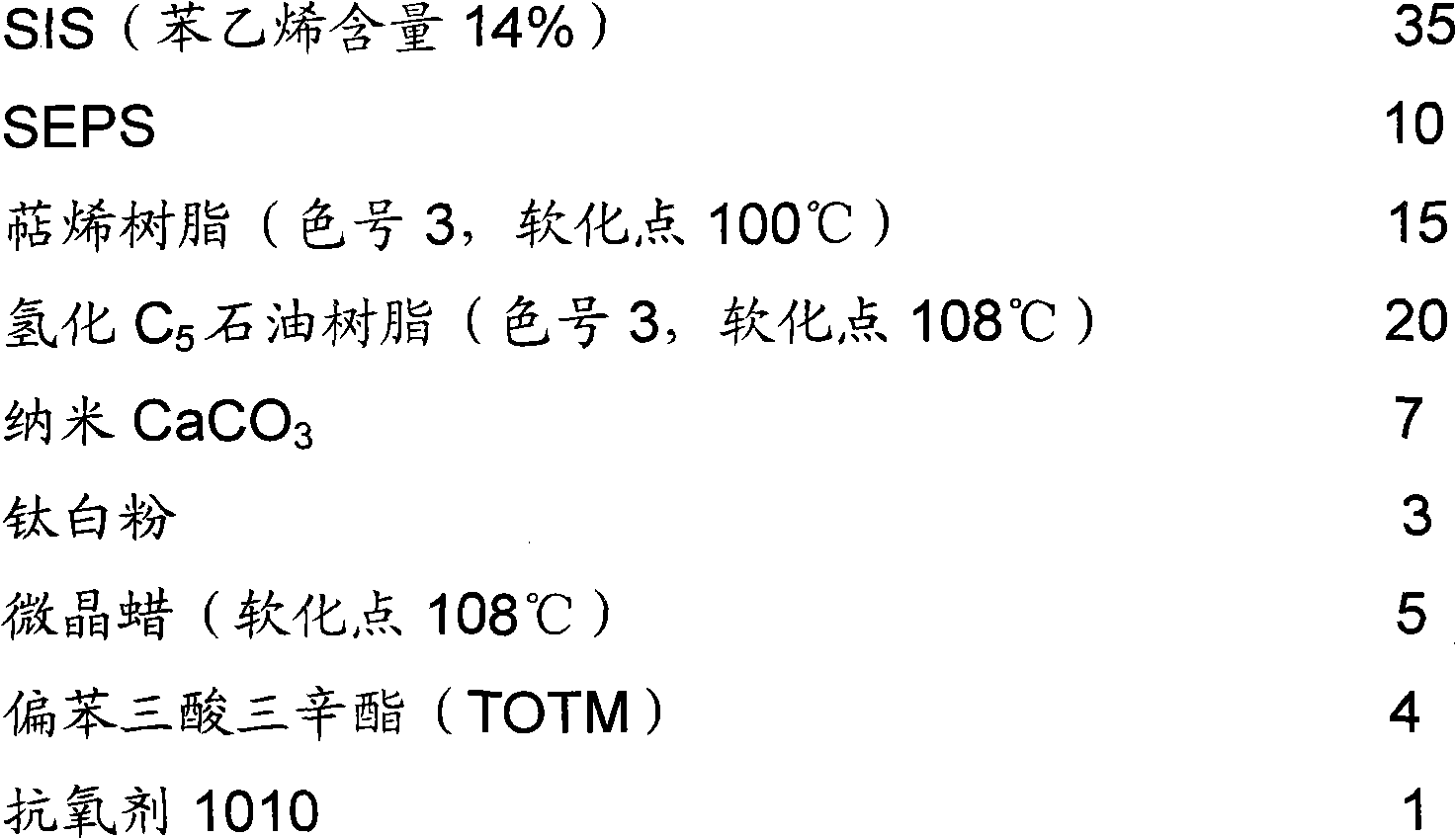

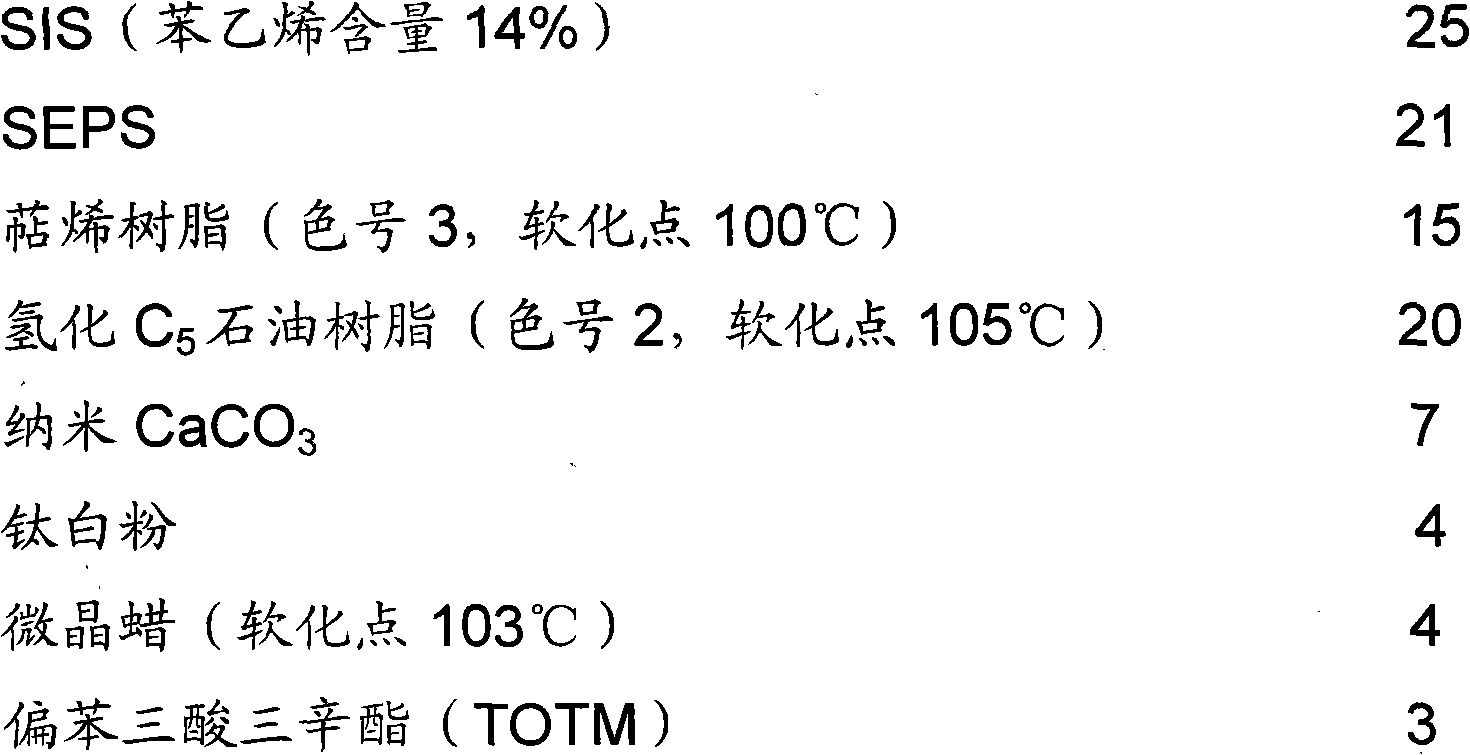

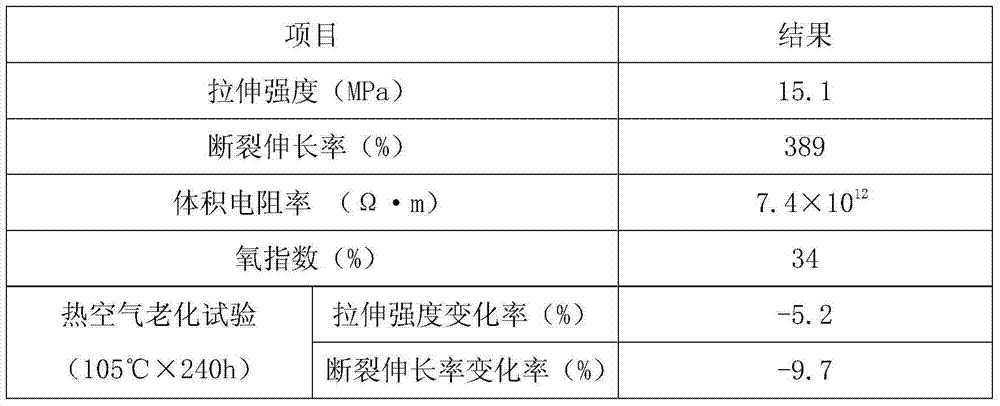

Hot-melt pressure sensitive adhesive for automobile interior part

ActiveCN102061140AExcellent bonding and sealing performanceImprove production efficiencyMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMicrocrystalline waxAntioxidant

The invention discloses a hot-melt pressure sensitive adhesive for an automobile interior part, which is used for bonding and sealing automobile body metals, plastics and rubber interior parts. The hot-melt pressure sensitive adhesive comprises the following components in percentage by weight: 25-35 percent of styrene-isoprene-styrene segmented copolymer, 10-25 percent of styrene-ethylene-propylene-styrene segmented copolymer, 30-45 percent of tackifying resin, 3-8 percent of nano CaCO3 or Al2O3, 3-8 percent of titanium white, 3-8 percent of microcrystalline wax used as a process auxiliary agent, 2-5 percent of trioctyl trimellitate used as a plasticizer and 0.5-1 percent of antioxidant. The preparation process of the hot-melt pressure sensitive adhesive comprises the following steps of: sequentially adding the materials into a horizontal kneading machine in proportion for heating and kneading; injecting the materials into a square die for molding; cooling and demoulding; and packaging with release paper. The hot-melt pressure sensitive adhesive has the advantages of high temperature resistance, high bonding strength, excellent bonding and sealing properties, good flexible elasticity, high production efficiency, simple operation, no spray gun blockage and environmental protection.

Owner:中国航天科技集团公司第四研究院第四十二所

High-weatherability chlorinated polyethylene power cord sheath material and preparation method thereof

InactiveCN103540044AGood weather aging resistanceNo deformationRubber insulatorsInsulated cablesMicrocrystalline waxTriallyl isocyanurate

The invention discloses a high-weatherability chlorinated polyethylene power cord sheath material and a preparation method thereof. The high-weatherability chlorinated polyethylene power cord sheath material is prepared from the following substances in parts by weight: 70-90 parts of chlorosulfonated polyethylene rubber, 20-30 parts of ethylene-propylene-diene monomer rubber, 10-15 parts of SEBS (styrene-ethylene / butylene-styrene), 3-5 parts of high-activity magnesium oxide, 2-4 parts of microcrystalline wax, 15-20 parts of talcum powder, 20-30 parts of carbon black N550, 5-10 parts of black bacon rubber, 2-3 parts of triallyl isocyanurate, 0.5-1 part of 1, 3-bis(t-butylperoxy isopropyl) benzene, 10-15 parts of trioctyl trimellitate, 8-12 parts of dioctyl phthalate, 1-2 parts of antioxidant 168 and the like. The sheath material disclosed by the invention has excellent weatherability and anti-aging property, can be used in an environment with the temperature from -50 DEG C to 105 DEG C for a long time without deforming or cracking, has excellent electrical insulation, tensile strength, oil resistance, resistance to acid and alkali corrosion, environmental friendliness, and flame retardancy, is durable, safe and reliable, and has a broad market prospects.

Owner:天长市富达电子科技股份有限公司

High strength wear resistant rubber material

The invention discloses a high strength wear resistant rubber material, which comprises the following raw materials: epoxy natural rubber, ethylene propylene diene monomer, butyl rubber, nano zinc oxide, sodium stearate, novel modification fortifier, carbon black N330, sulfur, promoter DM, promoter DOTG, meerschaum powder, grinded polypropylene fiber, mica powder, molybdenum disulfide, silane coupling agent KH-792, trioctyl trimellitate (TOTM), chlorinated paraffin, antioxidant 1010, and antioxidant 264. The high strength wear resistant rubber material has the advantages of good elasticity, high strength, good wear resistant performance, and long service life.

Owner:宁国市开源橡塑汽车零部件有限公司

Method for producing trioctyl trimellitate with trimellitic acid

ActiveCN101429126ATemperature is not harshLower requirementOrganic compound preparationCarboxylic acid esters preparationTrimellitic acidOctanol

The invention relates to a method for producing trioctyl trimellitate through using trimellitic acid. Intermediate products of trimellitic acid and methanol in the process of producing the trimellitic anhydride are esterified to generate trimethyl trimellitate; the trimethyl trimellitate and 2-ethylhexanol (commonly called asoctanol) are subjected to ester exchange to produce trimellitate (2-ethyl) trihexyl ester (trioctyl trimellitate). The method of methyl esterification and ester exchange can reduce requirement on a technology and equipment so that the intermediate product of the trimellitic acid in the process of producing the trimellitic anhydride is flexibly utilized.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

Aerated concrete block reinforced by fibers and preparation method thereof

An aerated concrete block reinforced by fibers comprises the components, in parts by weight: 18-22 parts of cement, 15-18 parts of quick lime, 12-15 parts of gypsum, 30-35 parts of fly ash, 0.2-0.3 part of an aluminum powder, 2-3 parts of triethanolamine, 8-10 parts of glass fibers, 2-3 parts of sodium sulfate, 2-3 parts of sodium hydroxide, 10-12 parts of asphalt, 3-5 parts of sodium persulfate, 2-3 parts of foots, 1-2 parts of ferrocene, 8-10 parts of an alum powder, 2-3 parts of trioctyl trimellitate, and 30-40 parts of diatomite. The glass fibers are employed in the raw materials, and thereby significantly increasing the strength of the block; and at the same time, the glass fibers have low cost, and thus can be popularized and promoted.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

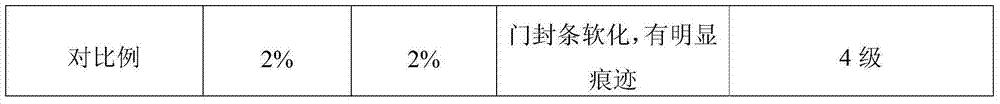

Heat-resistant polyvinyl chloride material, preparation method thereof and wire

ActiveCN104804332AImprove low temperature brittlenessIncrease costPlastic/resin/waxes insulatorsElastomerHeat stability

The invention provides a heat-resistant polyvinyl chloride material which is prepared from the following raw materials: 100 parts of polyvinyl chloride resin powder, 45-52 parts of trioctyl trimellitate and 22-31 parts of a filling agent which comprises calcium carbonate and kaoline, 3-8 parts of Ca-Zn composite stabilizer, 4-7 parts of ethylene-n-butyl acrylate-hydroxy elastomer and 1.5-5 parts of a flame retardant; the flame retardant comprises Sb2O3 and / or an Sb2O4 substitute. The heat-resistant polyvinyl chloride material provided by the invention is higher in low-temperature fragility and lower in cost; furthermore, the heat-resistant polyvinyl chloride material is higher in mechanical physical performance and heat stability. An experiment result shows that the low-temperature fragility of the heat-resistant polyvinyl chloride material is -11 DEG C to -21 DEG C. The invention further provides a preparation method of the heat-resistant polyvinyl chloride material and a wire.

Owner:FUTONG GROUP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com