Patents

Literature

107 results about "Zinc diethyldithiocarbamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc diethyldithiocarbamate is a Standardized Chemical Allergen. The physiologic effect of zinc diethyldithiocarbamate is by means of Increased Histamine Release, and Cell-mediated Immunity. The chemical classification of zinc diethyldithiocarbamate is Allergens.

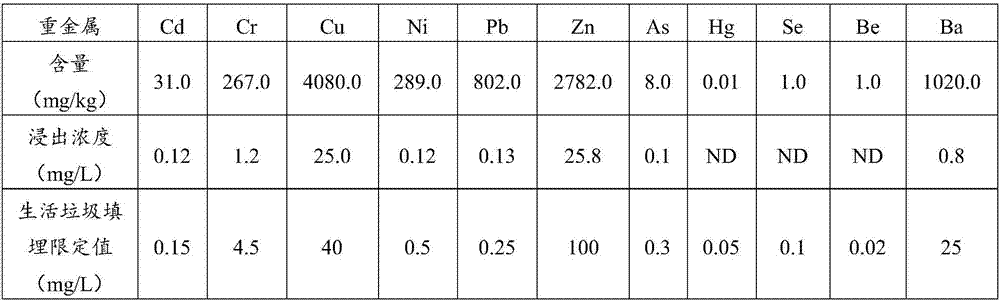

Heavy metal chelating agent for waste incineration fly ashes and preparation method for heavy metal chelating agent

InactiveCN106955451AImprove stabilityReduce dosageChemical protectionHeavy metal chelationSodium phosphates

The invention discloses a heavy metal chelating agent for waste incineration fly ashes. The heavy metal chelating agent for the waste incineration fly ashes comprises a compound chelating agent and a sodium hydroxide solution mixed with a weight ratio being 1:2-3, wherein the compound chelating agent comprises, by weight percentage, 60-90% of an organic chelating agent, and 10-40% of an inorganic chelating agent, the organic chelating agent is dithiocarbamates and is one or more selected from zinc diethyl dithiocarbamate, zinc dimethyl dithiocarbamate, sodium dibutyl dithiocarbamate or sodium dibenzyl dithiocarbamate, and the inorganic chelating agent is one or two selected from sodium sulfide and sodium phosphate. The heavy metal chelating agent for the waste incineration fly ashes is capable of reducing the leaching concentration of heavy metals and ensuring that a fly ash solidification sample block can meet the limit value of the leaching concentration. The invention further provides a preparation method for the heavy metal chelating agent for the waste incineration fly ashes.

Owner:湖南云平环保科技有限公司

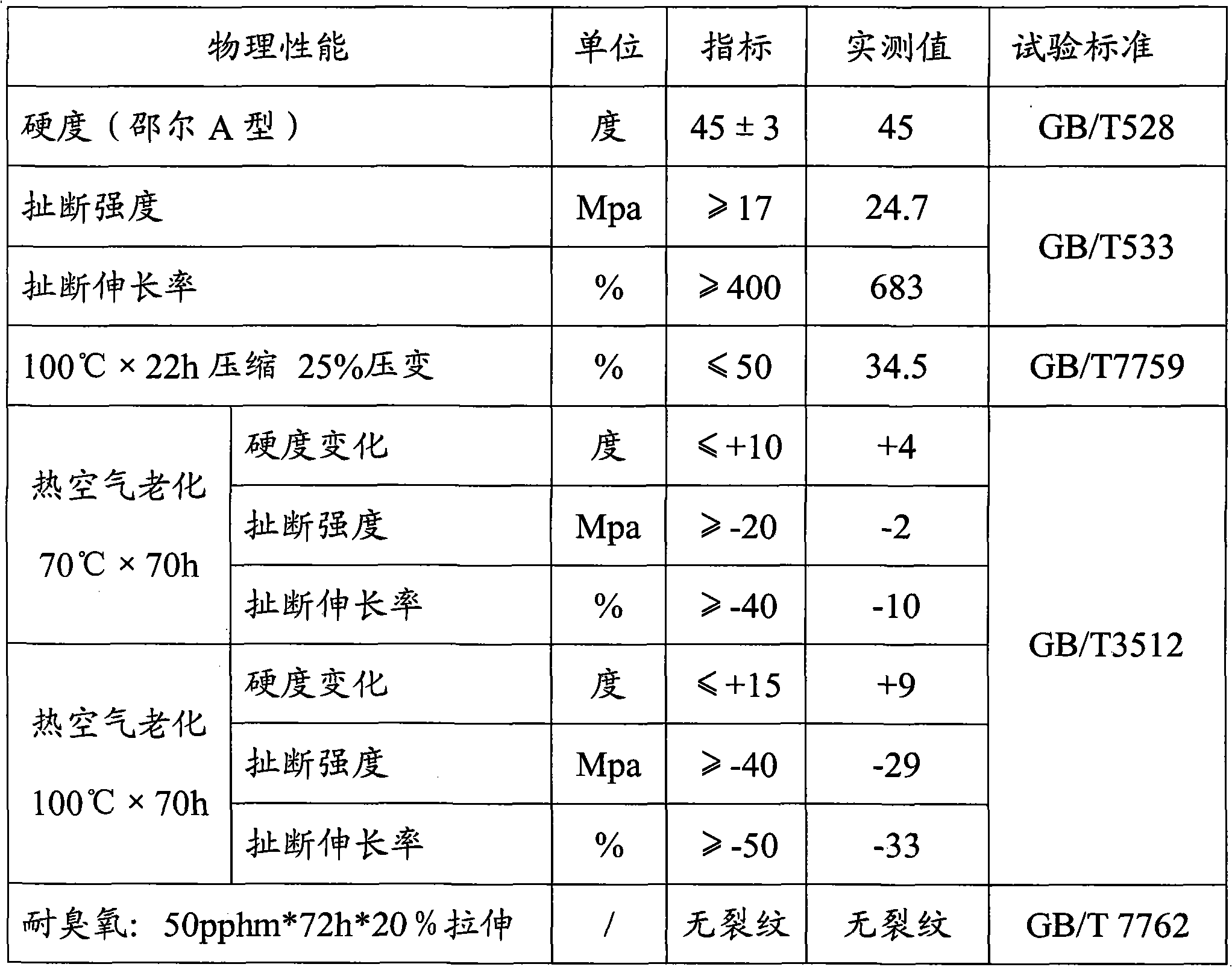

Preparation method of rubber for outer glue layer of power steering tube of automobile

The invention discloses a preparation method of rubber for an outer glue layer of a power steering tube of an automobile and belongs to the technical field of rubber parts for automobiles. The preparation method comprises the following steps: mixing chlorosulfonated polyethylene, fast extruding furnace black, carbon black prepared by a cracking process, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithiodibenzo thiazole, trioctyl trimellitate and strong magnesium powder in an external mixer, and after mixing, discharging rubber under a condition that the rubber temperature is 160 DEG C to prepare masterbatch; and putting the prepared masterbatch into the external mixer, adding trithiocyanuric acid and sulfur in the raw materials and mixing; and after mixing, sequentially extruding at a certain temperature interval to prepare the rubber for the outer glue layer of the power steering tube of the automobile. Compared with the rubber for the outer glue layer of the power steering tube of the automobile prepared in the prior art, the rubber prepared by the preparation method has the advantage that the heat resistance of the rubber is effectively improved by mutual synergistic effect among the raw materials and matching corresponding extrusion temperatures.

Owner:南京中配橡塑制品有限公司

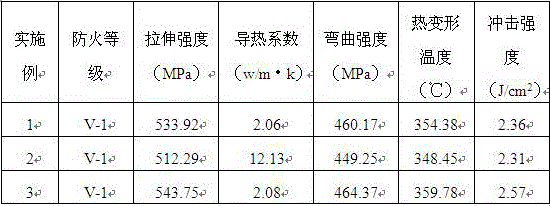

Engine mounting heat-resisting material and preparation method thereof

The invention discloses an engine mounting heat-resisting material and a preparation method thereof. The engine mounting heat-resisting material comprises the following raw materials in parts by weight: 70 to 80 parts of standard natural rubbers, 10 to 20 parts of butadiene rubbers, 5 to 10 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of 2,2,4-trimethyl-1,2-dihydro-chinoline polymers, 1 to 2 parts of N-isopropyl-N-phenylene diamine, 1 to 3 parts of composite paraffin, 25 to 40 parts of carbon black, 3 to 6 parts of complex calcium salt, 5 to 8 parts of white carbon black, 1to 3 parts of silane coupling agent, 1 to 2 parts of sulphur, 1 to 3 parts of zinc diethyl dithiocarbamate, and 1 to 3 parts of N-Cyclohexyl-2-benzothiazole. In the invention, an engine mounting material with good heat-resisting performance is prepared through a special refining process, has long service life and saves the using cost.

Owner:ASIMCO NVH TECH CO LTD ANHUI

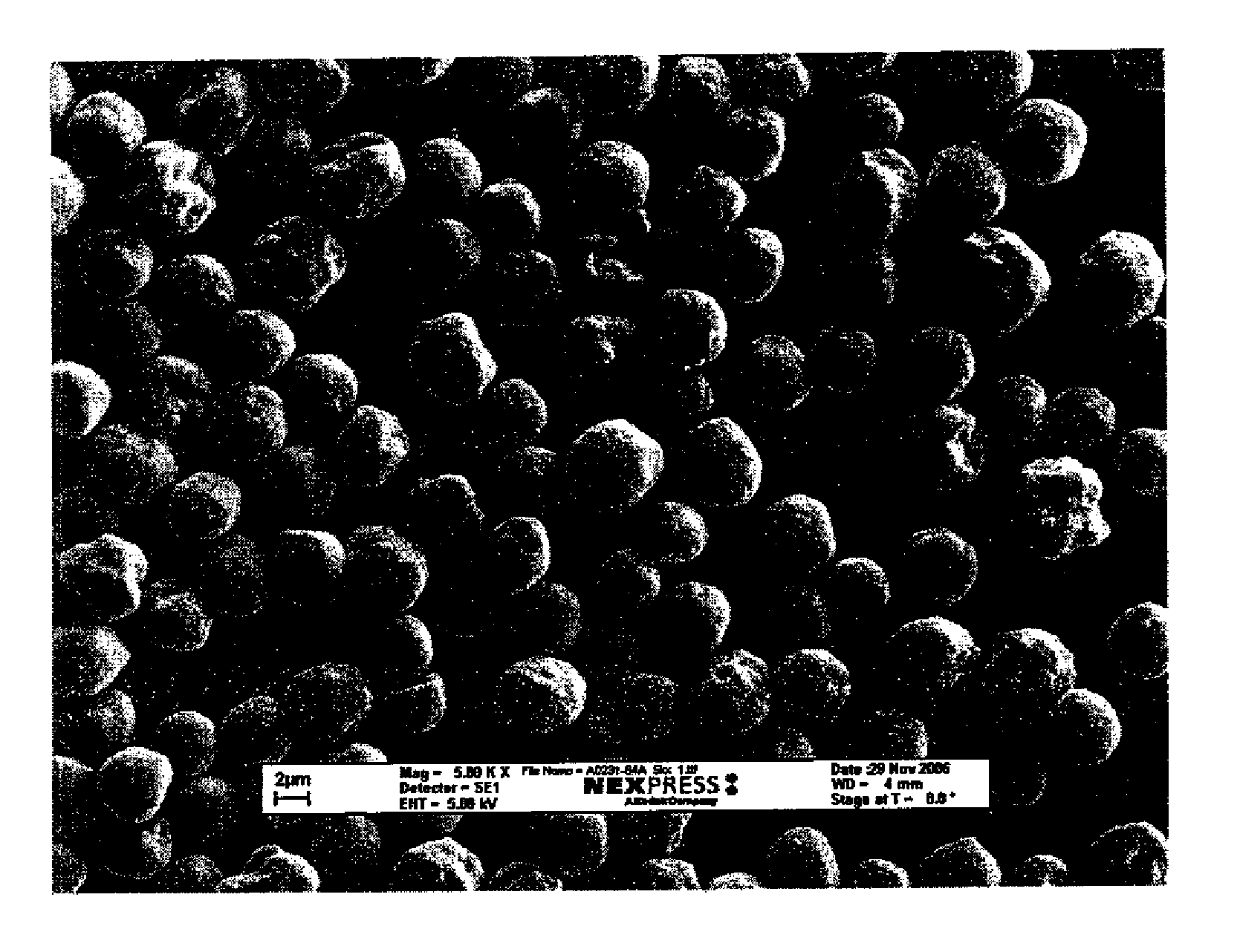

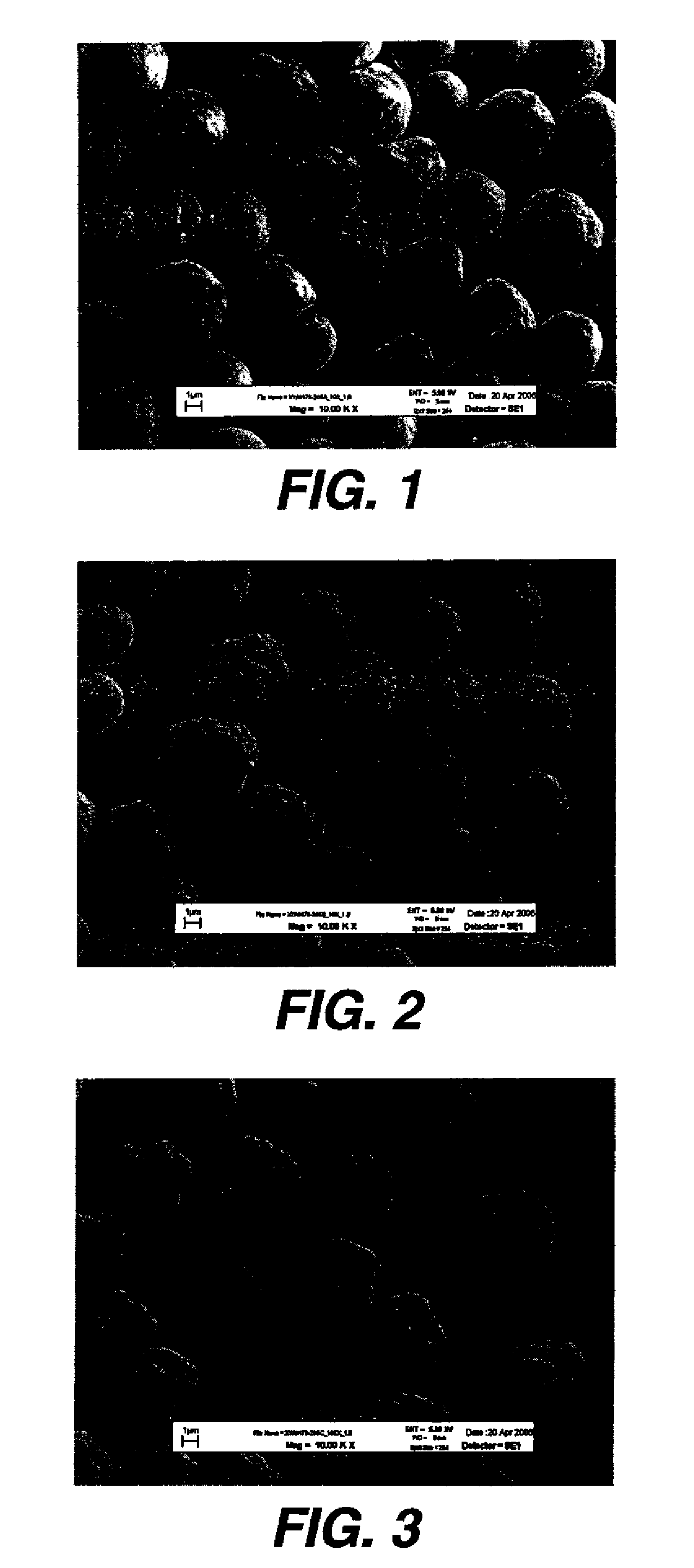

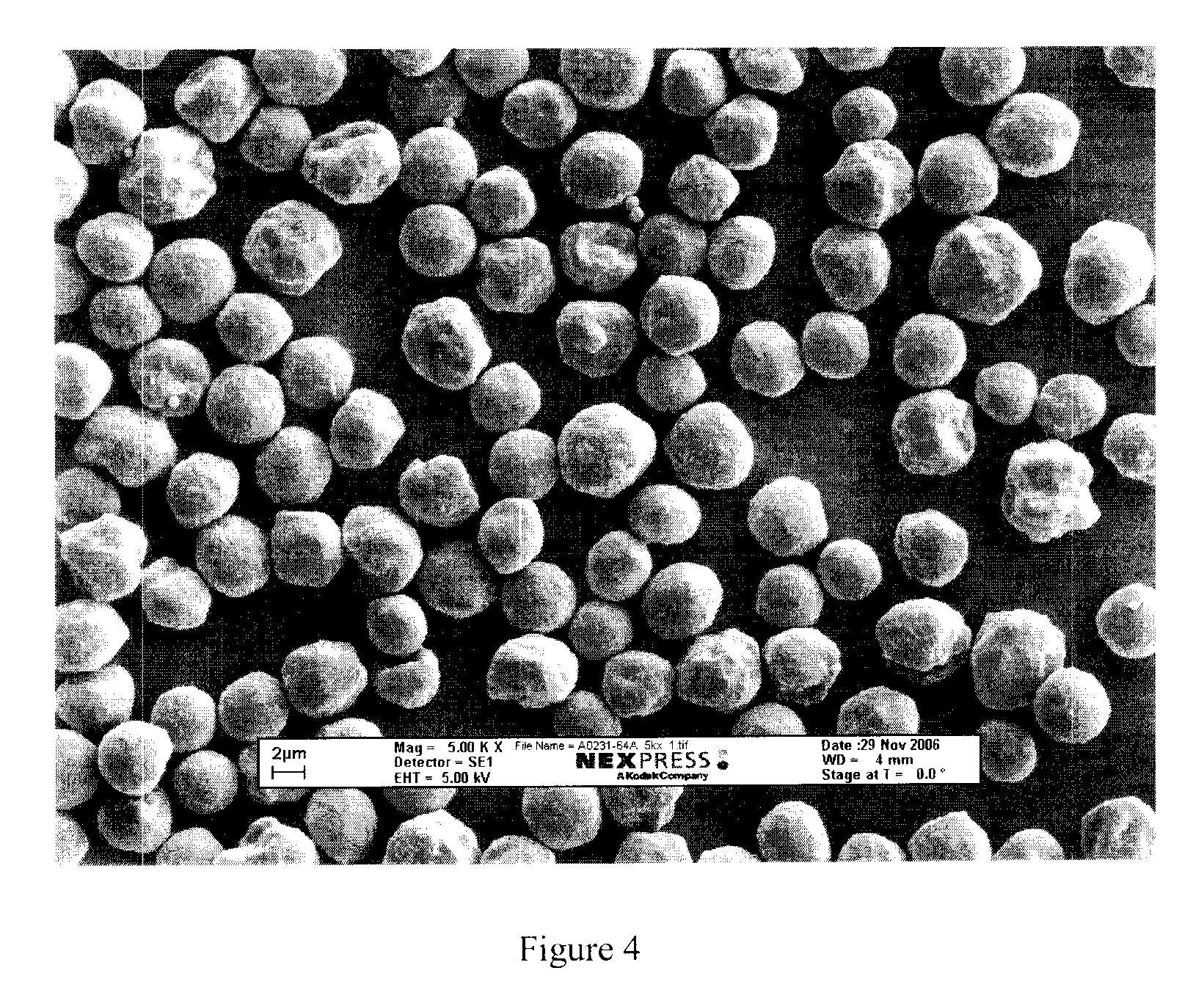

Toner particles of controlled morphology

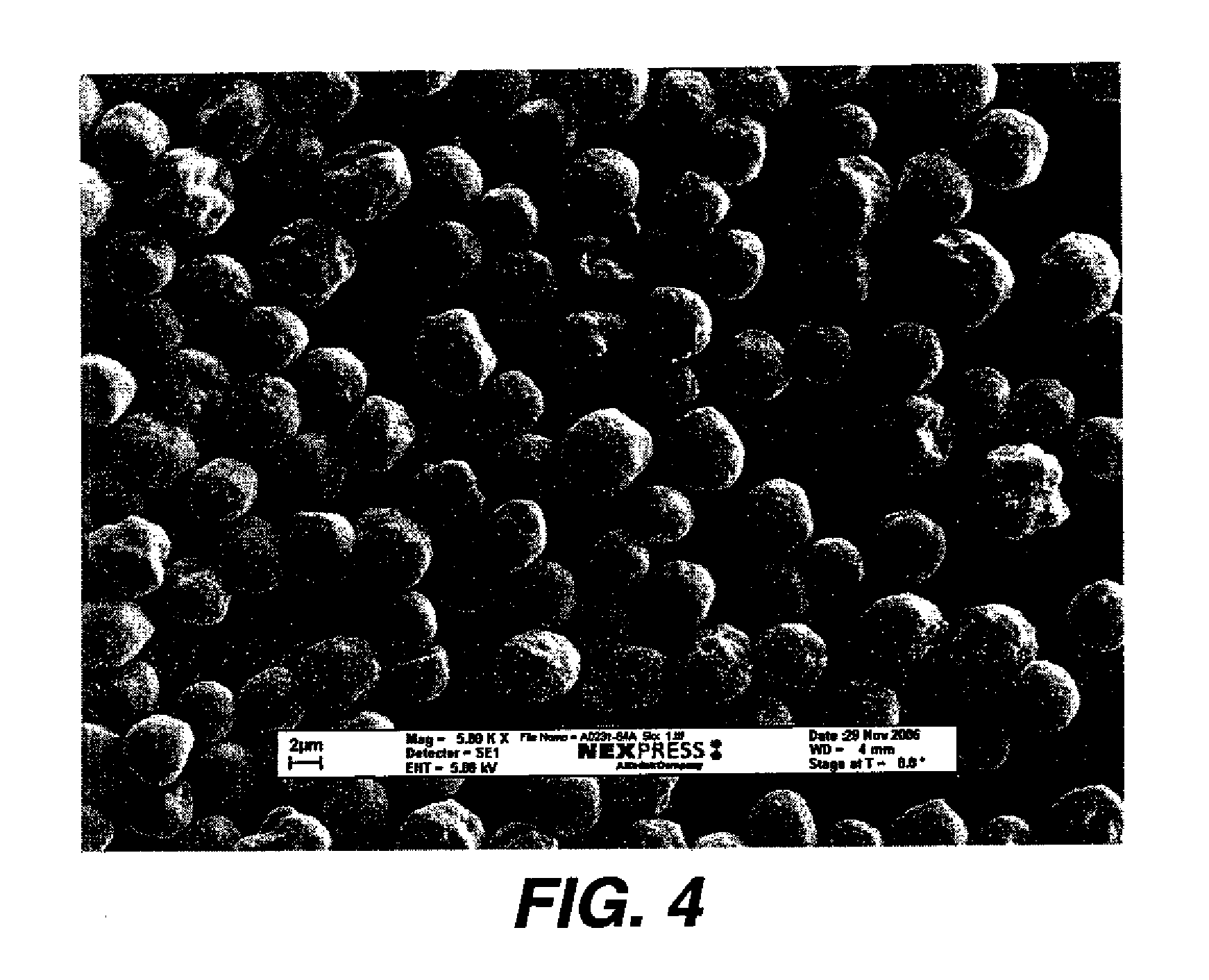

The present invention is a method for the preparation of electrostatographic toner that includes the following steps. A polymer material is dissolved in an organic solvent to form an organic phase that includes a metal complex of zinc dimethyldithiocarbamate; zinc diethyldithiocarbamate; dibenzyldithiocarbamate, zinc di-n-butyldithiocarbamate. The organic phase is dispersed in an aqueous phase that includes a particulate stabilizer to form a dispersion and the resultant dispersion is homogenized. The organic solvent is evaporated and the resultant product is recovered, washed and dried.

Owner:EASTMAN KODAK CO

Cold-resistant rubber

The invention belongs to the rubber field, and particularly relates to cold-resistant rubber. The cold-resistant rubber comprises the components in parts by weight as follows: 50-150 parts of epichlorohydrin rubber, 50-120 parts of natural rubber, 30-70 parts of silicone rubber, 20-60 parts of polyurethane rubber, 10-40 parts of ethylene propylene rubber, 10-30 parts of carbon black N100, 2-8 parts of pottery clay, 2-10 parts of sulfur, 1-5 parts of an aging-resistant agent, 1-10 parts of pottery clay, 1-5 parts of aromatic oil, 1-10 parts of white carbon black, 1-5 parts of an anti-scorching agent, 1-4 parts of nano-zinc oxide, 1-4 parts of zinc diethyldithiocarbamate, 1-4 parts of 2-imidazolidinethione, 1-10 parts of a plasticizer and 4-12 parts of a softening agent. The cold-resistant rubber has the benefits as follows: compared with common rubber, the cold-resistant rubber has good cold-resistant performance and is suitable for continuous persistent use at the low temperature, and meanwhile, the rubber further has the advantages of high tensile strength, fire resistance, corrosion resistance and the like.

Owner:大连铁达塑胶制品有限公司

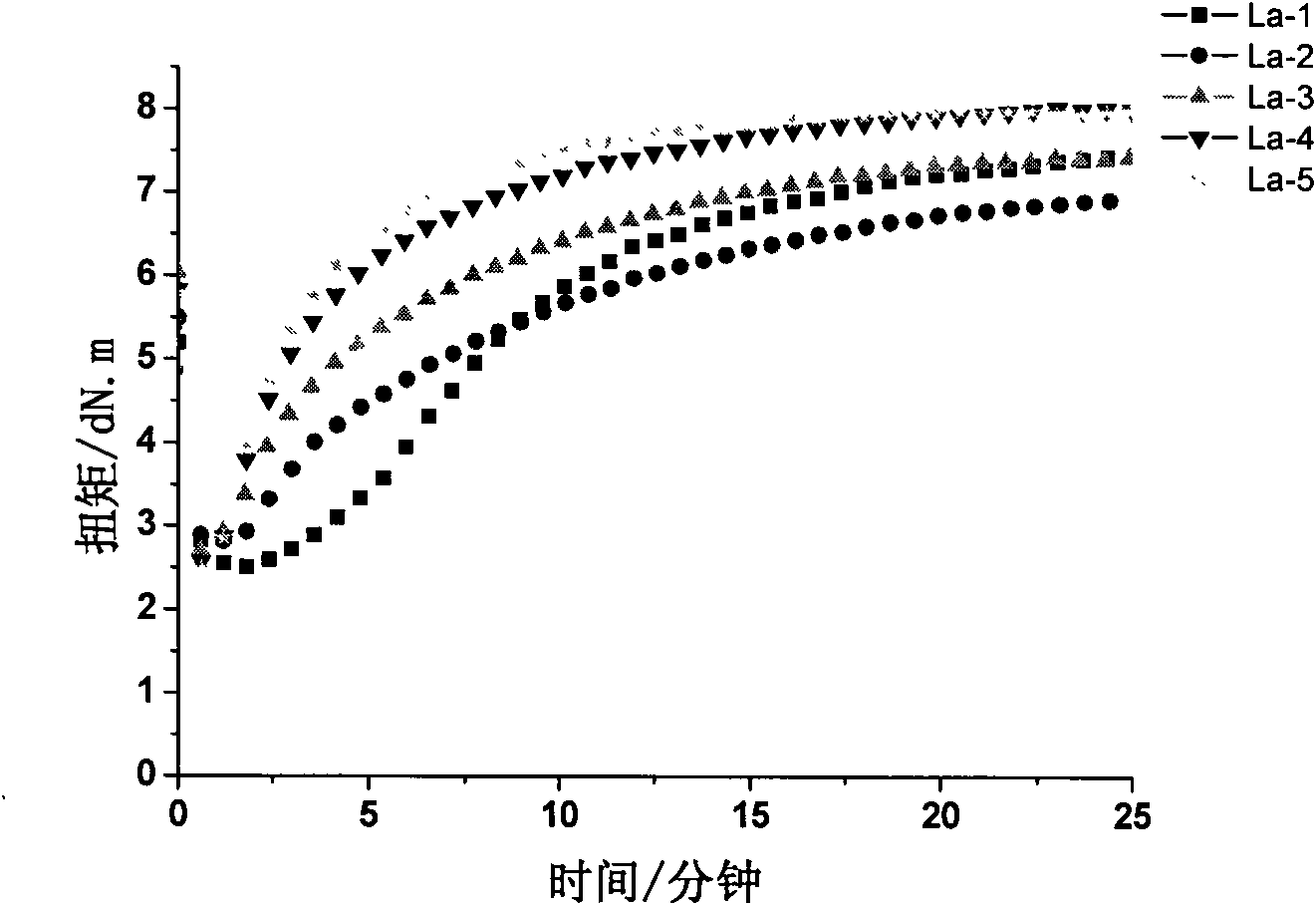

Rare earth rubber vulcanization accelerator, and preparation method and application thereof

ActiveCN101962452ASignificant vulcanization acceleration effectAccelerated vulcanization acceleration effectOrganic chemistryRare-earth elementVulcanization

The invention discloses a rare earth rubber vulcanization accelerator, and a preparation method and application thereof. The accelerator is prepared by compounding rare earth ions and carboxylic acid substituted dithiocarbamate, wherein the rare earth ions may be one or the mixture of more than one of 14 rare earth elements, except promethium which is a radioactive element, with the atomic numbers of 57 to 71 in the periodic table of elements. The rare earth vulcanization accelerator of the invention is added into a rubber formula without adding the vulcanization active agents of stearic acid and zinc oxide to achieve good vulcanization effect and prepare a rubber composite material with high comprehensive mechanical properties which are remarkably superior to those of the accelerator zinc diethyl dithiocarbamate (ZDC) commonly used in industry at present in the same proportion, is a carbamate rare earth compound of primary amine, does not produce nitrite in a vulcanization process, and is environmentally-friendly.

Owner:SOUTH CHINA UNIV OF TECH

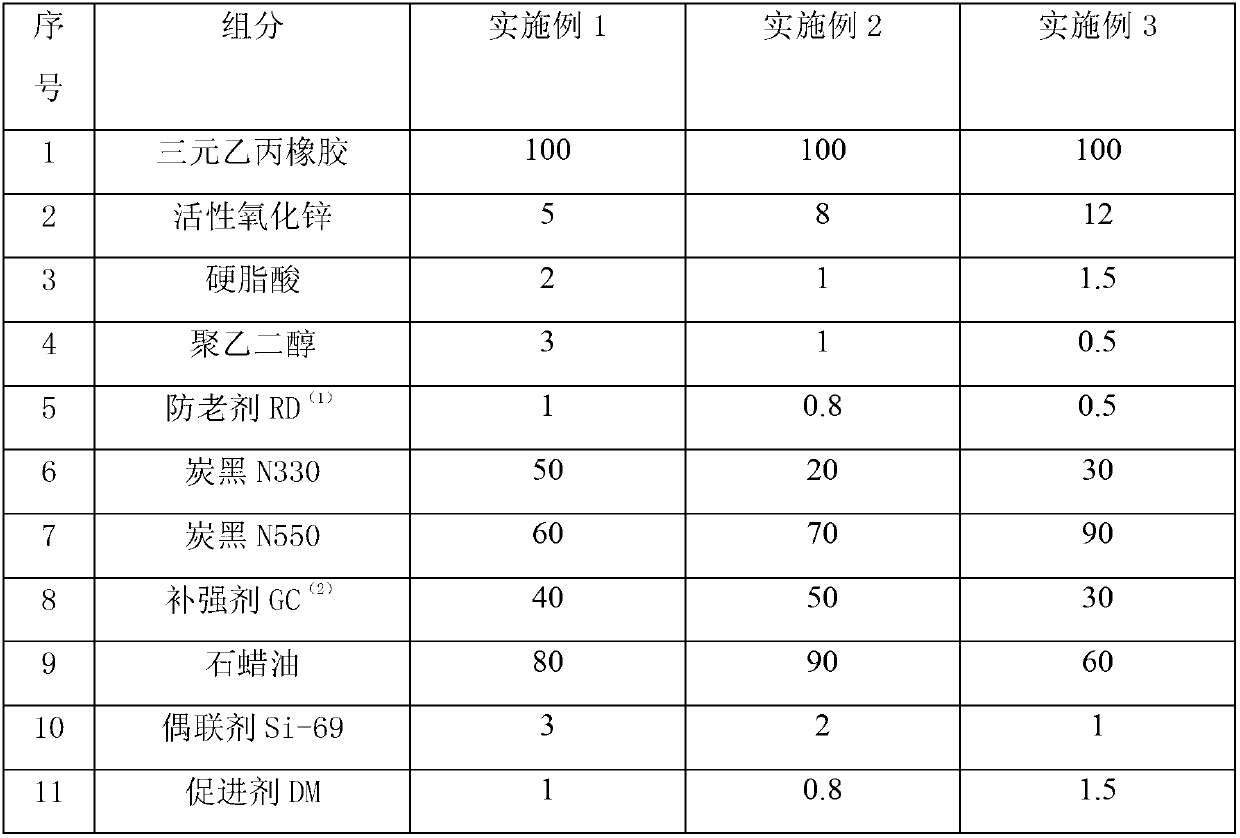

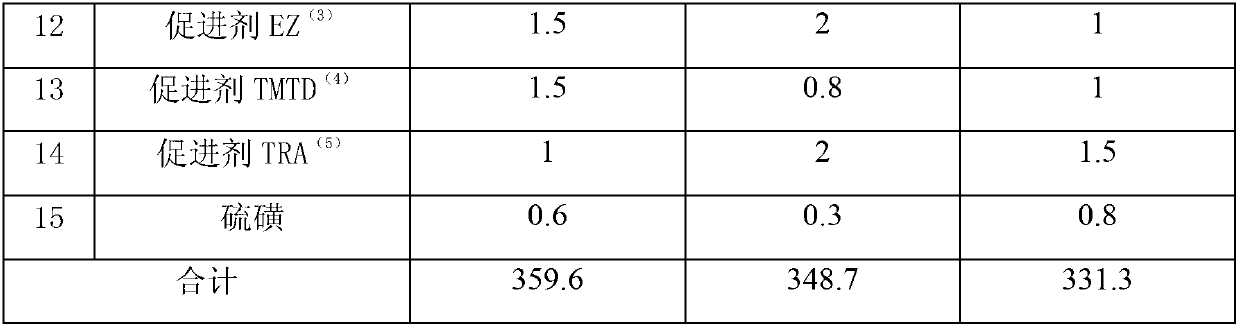

Ethylene propylene diene monomer (EPDM) composition for low-hardness glue injection

The invention relates to an ethylene propylene diene monomer (EPDM) composition for low-hardness glue injection. The composition comprises the following ingredients: EPDM rubber, activated zinc oxide, stearic acid, polyethylene glycol, 2,2,4-trimethyl-1,2-dihydroisoquinoline polymer, carbon black N330, carbon black N550, silicon dioxide hydrate, paraffin oil, coupling agent Si-69, accelerator DM, zinc diethyl dithiocarbamate, tetramethyl thiuram disulfide, bis(pentamethylene)thiuram tetrasulfide, and sulphur. According to the formula of the composition, the original hardness is low and is only about 50 degrees, the tensile strength and 100% stress at definite elongation are high, thermal air aging resistance property, the coldness resistance and low-temperature crispness are all excellent to meet the use requirement under low-temperature environment of different regions in winter, the lowest temperature can reach minus 45 degrees, glue injection technique is adopted to be capable of saving labor time and manual work. The composition formula can meet the requirements of RCF-510 grade material in MES MN300 standard.

Owner:TIANJIN PENGYI GRP CO LTD

Toner particles of controlled morphology

The present invention is a method for the preparation of electrostatographic toner that includes the following steps. A polymer material is dissolved in an organic solvent to form an organic phase that includes a metal complex of zinc dimethyldithiocarbamate; zinc diethyldithiocarbamate; dibenzyldithiocarbamate, zinc di-n-butyldithiocarbamate. The organic phase is dispersed in an aqueous phase that includes a particulate stabilizer to form a dispersion and the resultant dispersion is homogenized. The organic solvent is evaporated and the resultant product is recovered, washed and dried.

Owner:EASTMAN KODAK CO

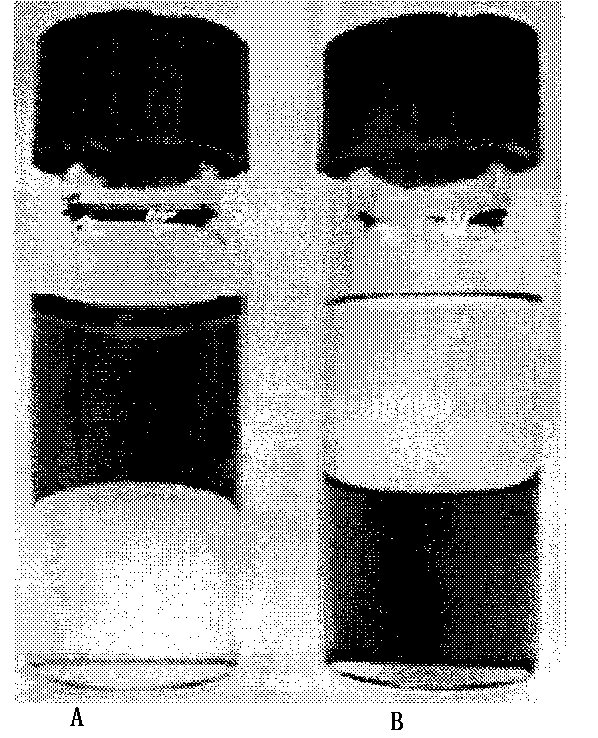

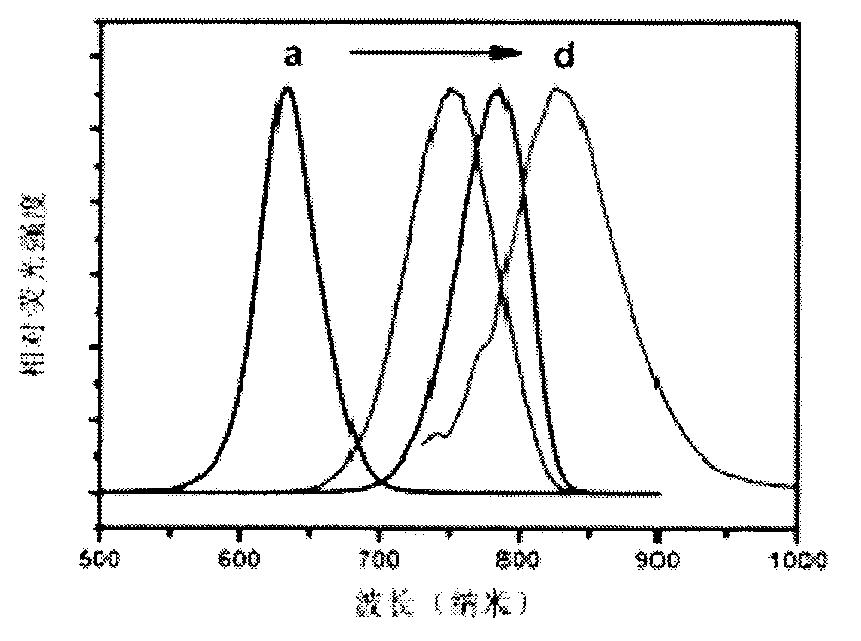

Water-soluble near-infrared quantum dot, preparation method and application thereof

ActiveCN103013520AReduce surface defectsHigh quantum yieldLuminescent compositionsQuantum dotWater soluble

The invention relates to a preparation method of a water-soluble near-infrared CdTeSe / ZnS quantum dot, a quantum dot prepared by adopting the preparation method and application of the quantum dot. According to the method, the emission wavelength of the quantum dot is regulated through regulating the proportion of Te, and the prepared quantum dot has a near-infrared fluorescence emission wavelength being 650-850nm. CdTeSe is cladded by using a single precursor zinc diethyldithiocarbamate, and is modified with imidazole polymers through hydration, so as to obtain the water-soluble quantum dot. The preparation method provided by the invention is convenient to operate and easy to control; and the reappeared water-soluble quantum dot has the advantages of easy labeling and good stability, and can be used in the fields such as biomarkers, fluorescence ion probes and semiconductor devices.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method for rubber for inner rubber layer of car power steering hose

The invention discloses a preparation method for rubber for the inner rubber layer of a car power steering hose, and belongs to the technical field of car rubber pieces. The preparation method comprises the following steps: adding chlorosulfonated polyethylene, fast extruding furnace black, cracking carbon black, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithio-dibenzo thiazole, trioctyl trimellitate and magnesium strong powder into an internal mixer for banburying; after banburying, discharging rubber at the rubber temperature of 160 DGE C to obtain a master batch; adding the prepared master batch into the internal mixer, and adding in trithiocyanuric acid and sulphur for mixing; after mixing, sequentially squeezing out within a certain temperature range to obtain rubber for the inner rubber layer of the car power steering hose. Compared with that manufactured rubber for an inner rubber layer of a car power steering hose in the prior art, the rubber adopts the synergistic effects of the raw materials and the corresponding squeezing temperatures to effectively improve the heat resistance property of the rubber.

Owner:南京中配橡塑制品有限公司

Modified rubber material

InactiveCN106633257AImprove flame retardant performanceHigh smoke suppression effectCarbon fibersPolymer science

The invention discloses a modified rubber material. The modified rubber material contains the following raw materials: epoxidized natural rubber, polyurethane rubber, graphene, tributoxyethyl phosphate, adipate, tri(2,4-di-tert-butylphenyl)phosphite, stearyl acrylate, maleic anhydride graft, magnesium hydroxide, kaolin, glass micro-beads, calcium cetyl sulfonate, zinc diethyl dithiocarbamate, chlorinated polyethylene, isoprene, brominated paraffin, polyvinyl chloride fibers, simethicone, carbon fibers, polyamide fibers, carboxyethyl cellulose, a surfactant, an initiator, a chain extender, a cross-linker, a degasifier, a leveling agent, a catalyst, an accelerant, a plasticizer, a dispersant, a tackifier, a curing agent, an antibacterial agent, an antioxidant, a photostabilizer, a thermal stabilizer, an age resister, an ultraviolet absorbent, a flame retardant and a smoke suppressant. The material disclosed by the invention is good in flame-retardant effect, high in shock resistance and high in toughness, can be extensively applied to the manufacturing of products such as tires, rubber tubes, rubber belts and cables and has remarkable economic and social benefits.

Owner:黄宇

Raw material dry state proportion for rubber latex for producing ultrathin condom and formulating vulcanization process thereof

The invention relates to a dried material ratio of rubber latex for producing ultra-thin condoms and a sulfuration technology for preparing the rubber latex. The dried weight ratios are respectively as follows: 1.20 portions of sulfur, 0.70 portion of ZnO, 0.40 portion of zinc diethyl dithiocarbamate, 1.00 portion of 2, 6-bis-tert buty-4-methyl phenol, 0.08 portion of KOH, 0.25 portion of fatty alcohol polyoxyethylene (20) ether, 0.05 portion of sodium hexametaphosphate, 0.10 portion of sodium methylene dinaphthyl sulphonate, 100.00 portions of natural rubber and 3.00 portions to 5.00 portions of modified rubber latex. The sulfuration technology comprises 10 steps and can be used for the preparation of the rubber latex for producing the ultra-thin condoms. The rubber latex can be used for the production of ultra-thin and ultra ultra-thin condom products with the thickness of about 0.050mm. Under the premise of guaranteeing the strength quality and meeting the national and international standards, the products have excellent comfortableness when in use, can realize effective contraception and also more effectively prevent the spread of diseases, such as AIDS, gonorrhea and chancroid and the like.

Owner:QINGDAO DOUBLE BUTTERFLY GROUP

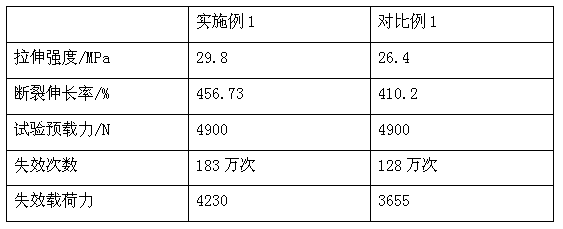

Fatigue-resistant rubber

ActiveCN103665459AImprove heat aging resistanceGood dynamic fatigue resistanceSodium stearateStearic acid

Owner:佛山市嘉翔新材料有限公司

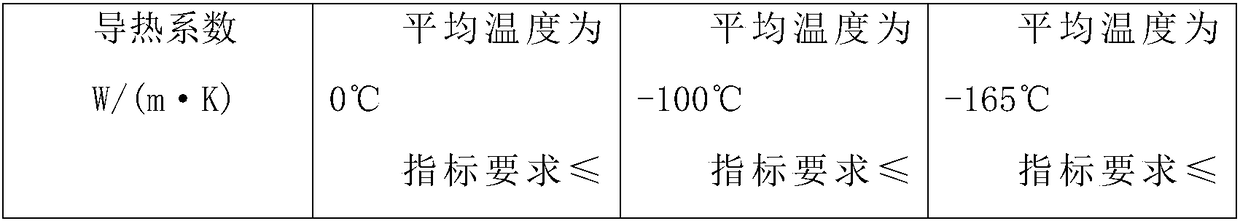

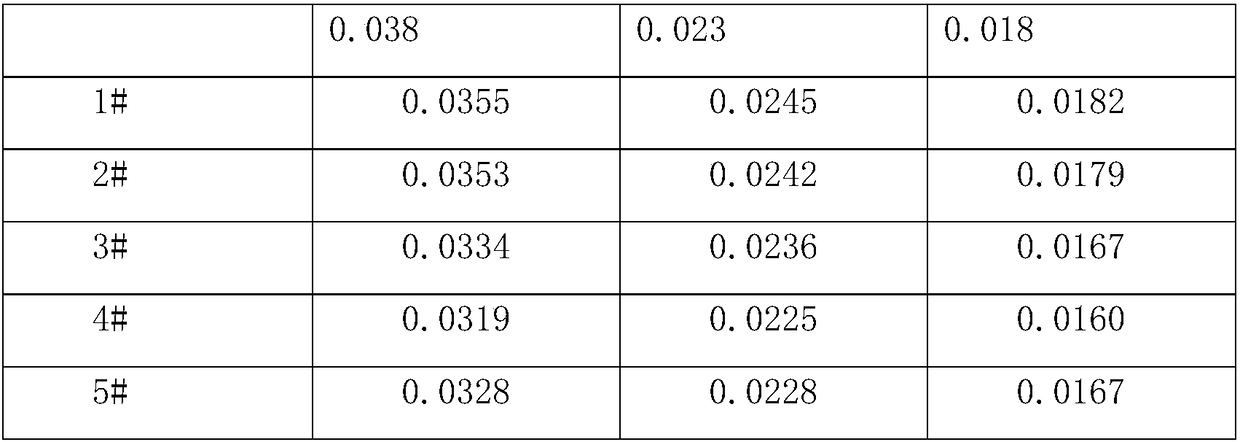

Cryogenic rubber thermal insulation material and preparation method thereof

InactiveCN108440849AGood flexibilityIncrease elasticityChemical industryThermal insulationPliability

The invention relates to a cryogenic rubber thermal insulation material and a preparation method thereof. The thermal insulation material is prepared from the following components in parts by weight:15-25 parts of EPDM (ethylene propylene diene monomer), 5-10 parts of IIR (isobutylene isoprene rubber), 5-10 parts of BR (butadiene rubber), 10-15 parts of a high-temperature foamer (AC), 5-8 parts of Sb2O3, 0.5-1 part of zinc oxide, 0.2-0.4 parts of sulfur, 10-15 parts of DOP (diocty phthalate), 0.2-0.4 parts of zinc diethyldithiocarbamate (E), 0.1-0.4 parts of an anti-aging agent (4020), 1.2-2parts of an antioxidant (AST-500). Flexibility and elasticity are improved by substituting a traditional rubber-plastic foam product for a full rubber foam product; meanwhile, with adoption of the preparation method, the product can be resistant to ultraviolet rays, and aging resistance is enhanced. Besides, an added microballoon foamer is adopted for changing the foam structure to lock the air, and the material is more energy-saving and thermal-insulating. The material can keep soft, bent and elastic at low temperature, and is the thermal-insulating, non-corrosive and environment-friendly product.

Owner:WINCELL INSULATION CO LTD

Production process of dithiocarbamate zinc salt rubber accelerator

InactiveCN108558722AAvoid it happening againSimple production processOrganic chemistryReaction temperatureZinc dibenzyldithiocarbamate

The invention provides an environment-friendly harmless new production process of a dithiocarbamate zinc salt rubber accelerator. The process comprises the following steps of S1. putting water and zinc oxide in a clean reactor and stirring; S2. putting organic amine, stirring for half hour and then adding CS2 dropwise, and controlling reaction temperature at 40DEG C or below; S3. stopping stirringwhen PH value is detected neutral; and S4. treating the paste to obtain znic dimethyldithiocarbamate (PZ), zinc diethyl dithiocarbamaate (ZDC), zinc dibutyl dithiocarbamate (BZ), 1,5-zinc sulfinyl dithiocarbamate (ZPD) and / or zinc dibenzyl dithiocarbamate (DBZ). The process optimizes the steps, and changes an original two-step method into a one-step method, thereby improving the efficiency and simplifying the production process. The processing process does not generate sodium chloride wastewater, thereby being environmentally friendly; and the product has higher performance, and zinc oxide does not contain chloride.

Owner:宜兴市鸿远精细化工有限公司

Modified anti-tear rubber

The invention discloses modified anti-tear rubber. The rubber is prepared from the following raw materials in parts by weight: 9 to 11 parts of stearic acid, 4 to 8 parts of butadiene-styrene rubber, 15 to 21 parts of chloroprene rubber, 6 to 10 parts of N115 reinforcing carbon black, 2 to 5 parts of a dispersing agent, 14 to 20 parts of tetrafluoroethlene propylene rubber, 7 to 10 parts of magnesium stearate, 3 to 10 parts of acrylate copolymer, 10 to 16 parts of epoxidized natural rubber, 1 to 5 parts of sulphur, 10 to 16 parts of zinc diethyl dithiocarbamate, 4 to 7 parts of sodium stearate, 1 to 3 parts of paste ash, 1 to 3 parts of an antifungus agent, and 13 to 20 parts of butadiene-acrylonitrile rubber. The rubber has the benefits that the rubber has good toughness and strength, good anti-tear property and good compression resistance.

Owner:QINGDAO GUOHANG XIANGYU TECH SERVICE

Rubber material for sealing automobile door and preparation method of rubber material

The invention provides a rubber material for sealing an automobile door. The rubber material is composed of the following components in parts by mass: 70-80 parts of natural rubber, 20-30 parts of hydrogenated butadiene-acrylonitrile rubber, 3-5 parts of stearic acid, 2-3 parts of methyl hydrogen silicon oil, 1.5-1.8 parts of light calcium carbonate, 0.4-0.6 part of oleic diethanolamide borate, 3-5 parts of drying alkyd resin, 1-2 parts of paraffin, 0.5-0.8 part of glass fiber, 0.8-1.2 parts of zinc diethyldithiocarbamate, 2-4 parts of acetyl peroxide, 8-10 parts of aluminum oxide, 10-15 parts of white carbon black, 0.8-1.5 parts of an anti-ageing agent and 1-3 parts of sulfur. The invention also provides a preparation method of the rubber material. The rubber material provided by the invention has favorable ageing resistance and sealing performance and can be favorably applied to sealing of the automobile door.

Owner:LIUZHOU YINGHANG AUTO PARTS

Foamed elastic cushion block for high-speed rail and preparation method thereof

The invention discloses a foamed elastic cushion block for a high-speed rail. The foamed elastic cushion block comprises the following components in parts by weight: 80-120 parts of EPDM (Ethylene-Propylene-Diene Monomer), 40-70 parts of carbon black, 10-30 parts of white carbon black, 1-3 parts of stearic acid, 3-7 parts of zinc oxide, 4-8 parts of coupling agent Si69, 10-30 parts of paraffin hydrocarbon oil, 1.0-2.0 parts of anti-aging agent RD, 0.5-1.5 parts of sulfur, 0.5-1.5 parts of accelerator TMTD (Tetramethyl Thiuram Disulfide), 0.5-1.5 parts of accelerator DPTT (Dipentamethylene Thiuram Tetrasulfide), 0.5-1.5 parts of accelerator DM (2,2'-dibenzothiazyl disulfide), 0.5-1.5 parts of accelerator EZ (Zinc Diethyldithiocarbamate) and 2-4 parts of foaming agent OBHS (4,4'-Oxybis(benzene sulfonyl hydrazide)). The strength of the foamed elastic cushion block can reach over 4 MPa, the dynamic multiplying power is less than 1.35; and the foamed elastic cushion block has the advantages of high strength, low dynamic multiplying power, superior heat resistance and weather resistance and good insulation performance, so that good vibration absorption and endurance performance are guaranteed.

Owner:ANHUI ZHONGDING SEALING PARTS

Ageing-resistant cable rubber

InactiveCN104817843AImprove antioxidant capacityStrong acid and alkali resistancePlastic/resin/waxes insulatorsPolymer scienceThiourea

Ageing-resistant cable rubber is produced from, by weight, 6-10 parts of ageing resister mercapto benzimidazole, 20-35 parts of butyl rubber, 3-8 parts of zinc diethyl dithiocarbamate, 15-25 parts of epichlorohydrin rubber, 6-8 parts of dioctyl phthalate, 7-13 parts of calcium carbonate, 5-8 parts of sulfur, 12-25 parts of chlorosulfonated polyethylene rubber, 2-3 parts of strengthening agent, 25-35 parts of silicone rubber, 4-6 parts of hydroxyl silicone oil, 5-7 parts of ethylene thiourea and 18-21 parts of 26-type nitrile butadiene rubber. The ageing-resistant cable rubber has the advantages of high resistance to oxidation, acid and alkali and higher ageing-resistant effect.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

High temperature resistant conductive rubber material

InactiveCN105367857AChanging the situation where only a single acetylene black is usedImprove conductivityRubber materialSilicone rubber

The invention discloses a high temperature resistant conductive rubber material and relates to the field of rubber. The high temperature resistant conductive rubber material comprises, by weight, 40-120 parts of chloroprene rubber, 50-150 parts of fluorinated silicone rubber, 30-50 parts of polyacrylate rubber, 1-4 parts of conductive particles, 10-30 parts of carbon black N300, 3-7 parts of conductive graphite, 4-20 parts of a reinforcing agent, 2-10 parts of calcium carbonate, 1-5 parts of an anti-aging agent, 3-5 parts of dibutyl phthalate, 1-4 parts of zinc diethyl dithiocarbamaate, 1-4 parts of 2-mercaptoimidazoline, 5-18 parts of a flame retardant, and 3-5 parts of a vulcanizing agent. According to the invention, a rubber material with good conductivity, high tensile strength, high temperature resistance and flame resistance can be produced.

Owner:季桂金

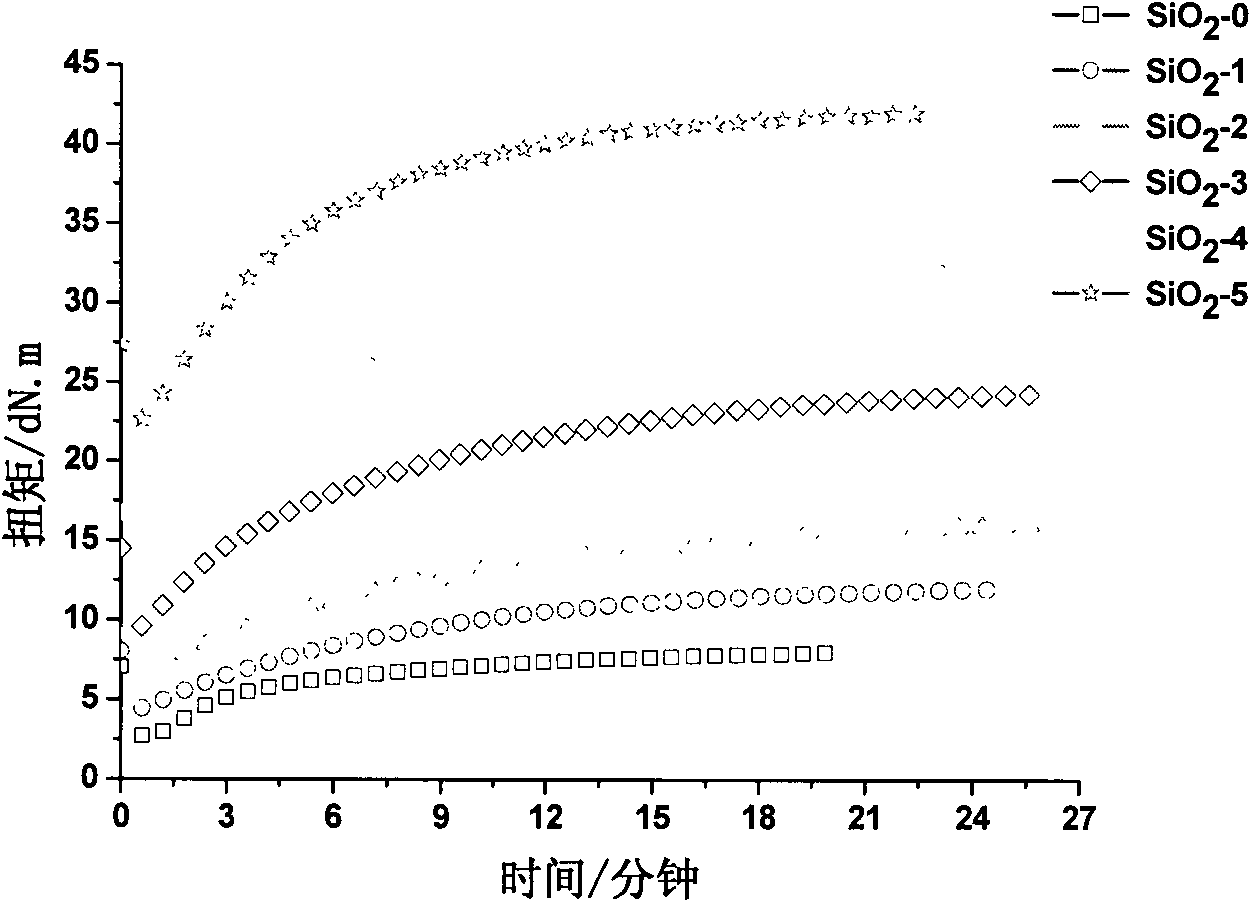

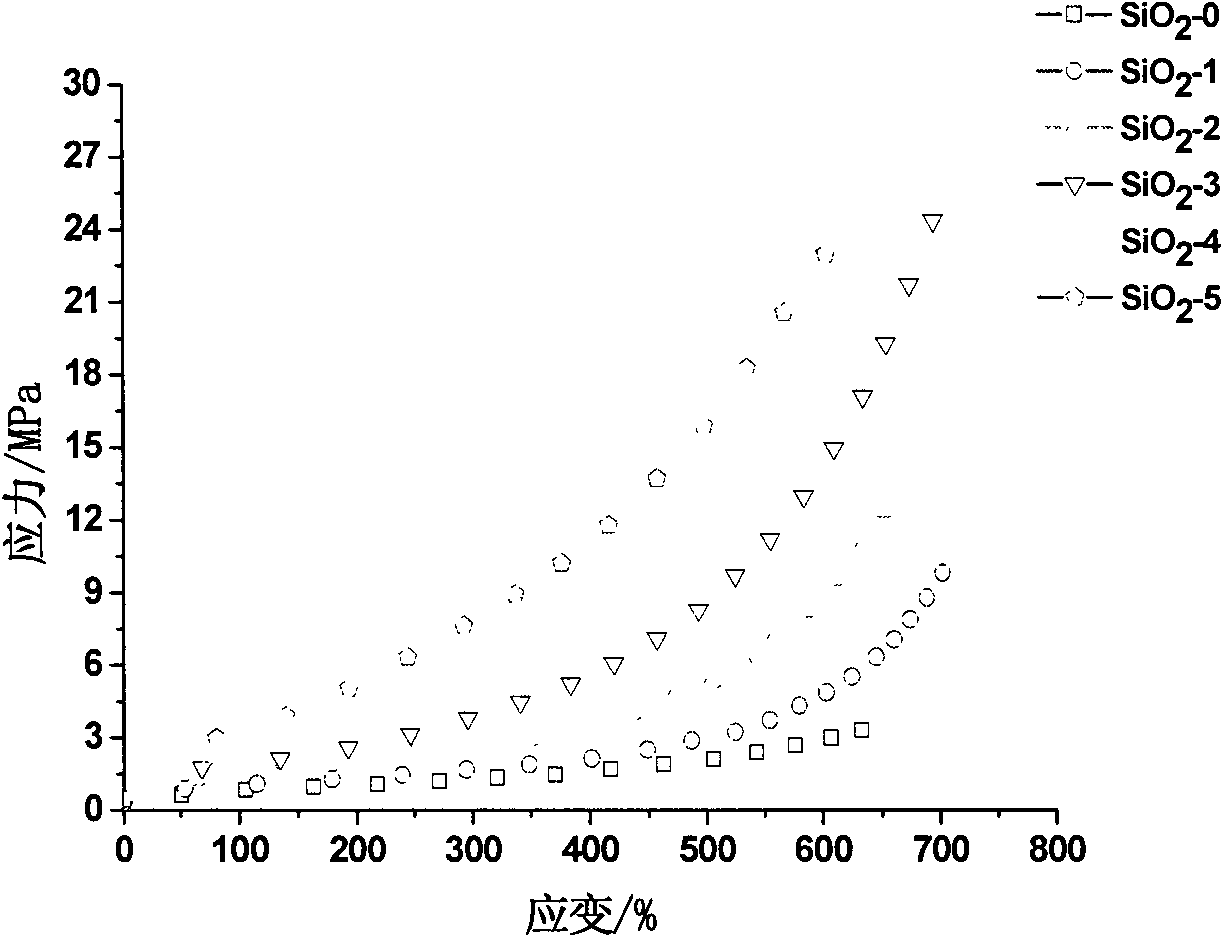

High-performance modified styrene butadiene rubber composition

The present invention discloses a high performance modified styrene butadiene rubber composition. The high performance modified styrene butadiene rubber composition is prepared from the following raw materials: styrene butadiene rubber, epoxidized natural rubber, a carbon nano-tube, modified montmorillonite, nano aluminium nitride, precipitation-method white carbon black, modified boehmite, nano aluminium hydroxide, nano magnesium hydroxide, stearic acid, sulfur, zinc oxide, organic silicon peroxide, polyvinyl alcohol, diphenyl phosphate, lanthanum stearate, an anti-aging agent RD, an anti-aging agent NBC, an anti-aging agent 4010NA, diethyl dithiocarbamate zinc, dithiocarbamate cerium formate glutamate, an accelerant DM and triethyl citrate. wherein a modifier of the modified boehmite is a mixture comprising one or more of methacrylic acid, itaconic acid, sorbic acid, maleic acid, arachidonic acid and linoleic acid. The high-performance modified styrene butadiene rubber composition provided by the present invention has high strength, good abrasion resistance, and excellent heat resistance and weather resistance.

Owner:合肥市再德高分子材料有限公司

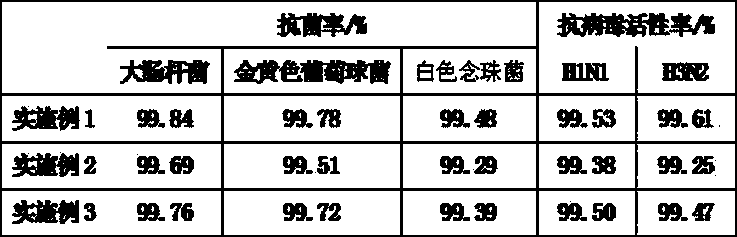

Active antibacterial and antiviral glove and preparation method thereof

InactiveCN111333929AAchieve long-lasting antibacterial and antiviral effectsGood compatibilityGlovesProtective garmentLatex gloveRubber material

The invention relates to an active antibacterial and antiviral glove. The glove comprises, by mass, 80 to 95 parts of a rubber material, 0.8 to 5 parts of sodium hydroxide, 0.3 to 1.8 parts of sulfur,0.4 to 3.5 parts of nano-silver, 0 to 1.5 parts of zinc diethyldithiocarbamate, 0 to 1.0 part of zinc di-n-butyl dithiocarbamate, 0 to 1.5 parts of titanium dioxide, 0.1 to 1 part of an organic antibacterial and antiviral agent and 0.1-1 part of a natural antibacterial and antiviral agent. The rubber glove can achieve the long-acting antibacterial and antiviral effects of a latex glove, and the wearing comfort is not affected.

Owner:同曦集团有限公司

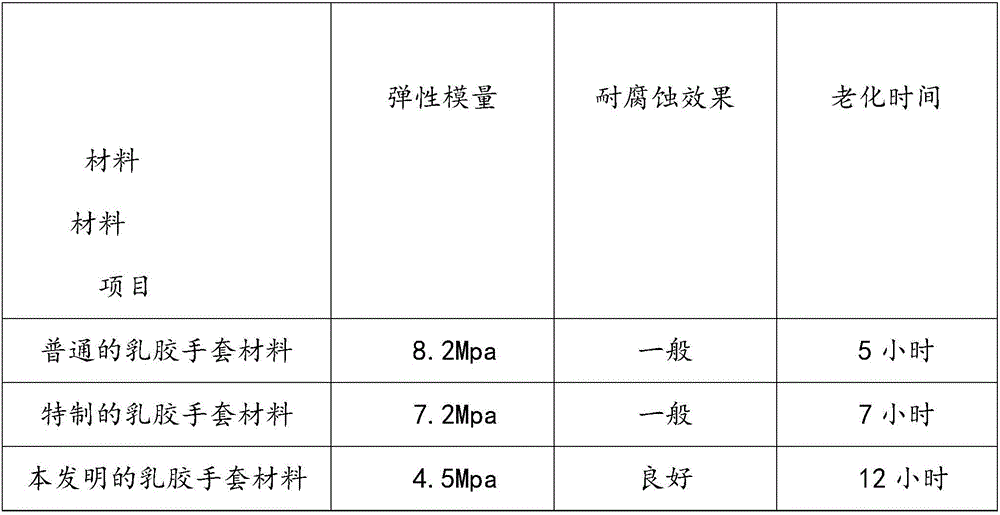

Pre-vulcanizing technology of latex medical gloves

InactiveCN106750617AIncrease elasticityGood anti-aging performanceDiethyl dithiocarbamatePolymer science

The invention discloses a pre-vulcanizing technology of latex medical gloves. The pre-vulcanizing technology comprises the following steps of (1) preparing a 10% potassium hydroxide solution; (2) preparing a 50% sulfur dispersion; (3) preparing a 30% zinc diethyl dithiocarbamate dispersion; (4) preparing a 50% zinc oxide dispersion; (5) preparing a 30% anti-aging agent dispersion; (6) weighing 100 parts of natural latex, 1 part of 10% potassium hydroxide solution prepared in step (1), 1 part of 50% sulfur dispersion prepared in step (2), 1 part of 30% zinc diethyl dithiocarbamate dispersion prepared in step (3), 0.72 part of 50% zinc oxide dispersion prepared in step (4), and 1.5 parts of 30% anti-aging agent dispersion prepared in step (5) in parts by mass, feeding into a vulcanizing tank, heating to 45 DEG C, warming for 12h, putting the warmed latex into the vulcanizing tank, and standing for 48h; (7) adjusting the raw material obtained in step (6), testing the total oxygen and chloroform numbers, and standing by further use. The latex raw material prepared by the technology has the advantages that the elasticity is good, the anti-corrosive property is realized, the anti-aging effect is good, and the service life is long.

Owner:浙江卓亿工贸有限公司

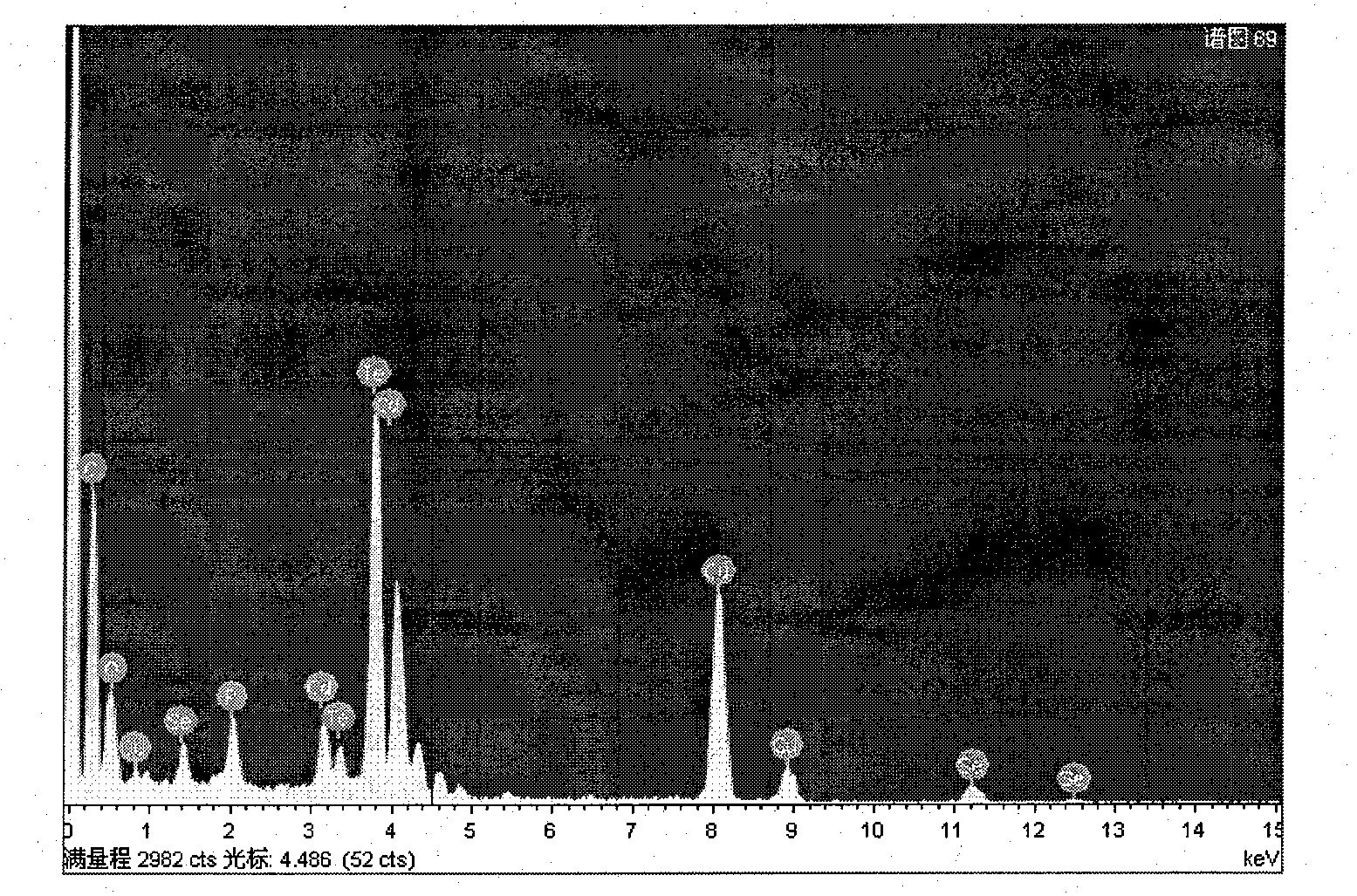

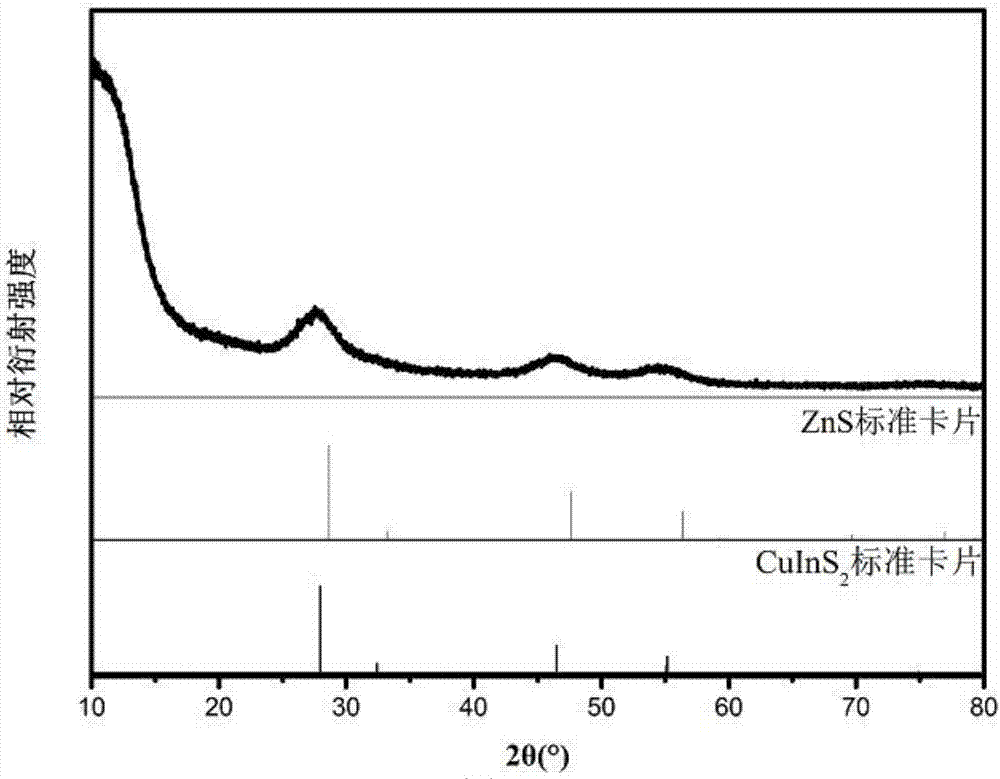

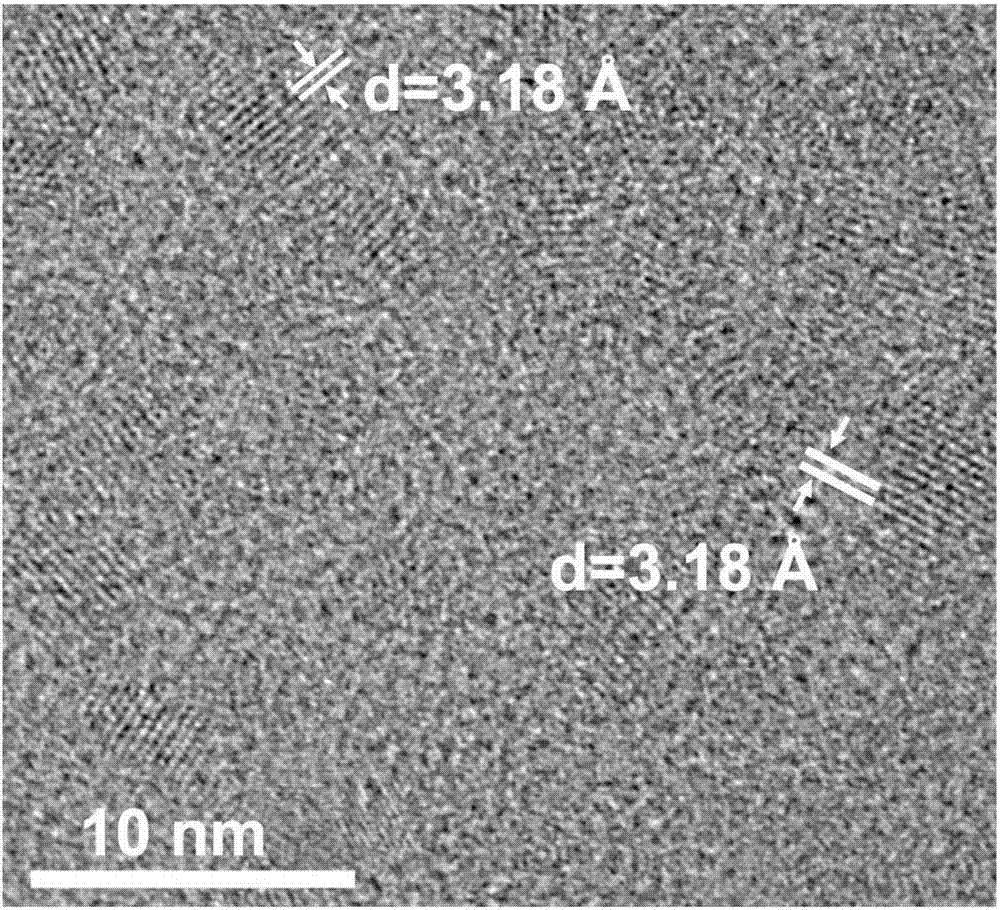

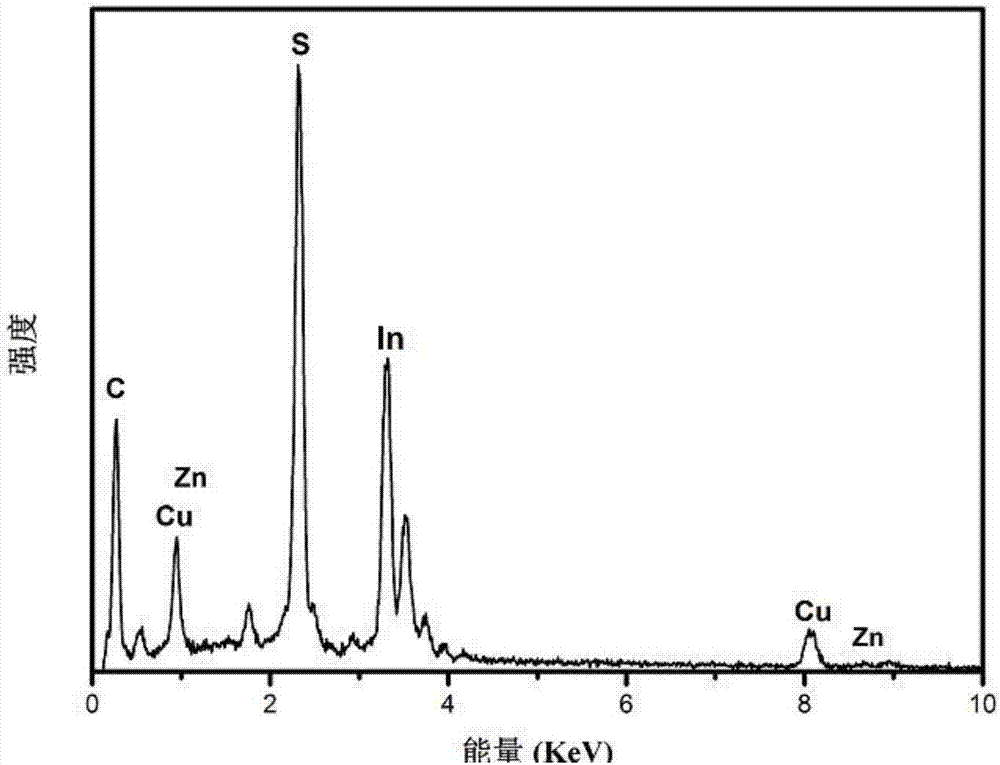

Method for synthesizing zinc-doped copper-indium-sulfur (Zn-doped CuInS2) quantum dots

InactiveCN107418564AGood dispersionThe control method is simple and convenientMaterial nanotechnologyLight-sensitive devicesIndiumSynthesis methods

The invention provides a method for synthesizing zinc-doped copper-indium-sulfur (Zn-doped CuInS2) quantum dots. The method is characterized in that by using copper diethyldithiocarbamate as a copper source, indium diethyldithiocarbamate as an indium source, zinc diethyldithiocarbamate as a zinc source, oleylamine as a ligand and a solvent, one-step reaction is conducted to prepare the Zn-doped CuInS2 quantum dots. The Zn-doped CuInS2 quantum dots prepared according to the invention have the size of 4 to 5nm and a good photoelectric property, and are suitable for preparing a quantum dot sensitized solar cell. According to the invention, the zinc content of the quantum dots can be changed by changing the quantity of the zinc source; compared with pure CuInS2 quantum dots, the Zn-doped CuInS2 quantum dots obtained by the method have fewer internal defects; compared with a thermal injection method, the method provided by the invention has the advantages of simple and easy operation, simpler process, shorter synthesis cycle, good production controllability and repeatability and low cost, and the method provided by the invention is suitable for industrialized production, and has a wide application prospect in the solar cell.

Owner:WENZHOU UNIVERSITY

High-strength moldproof rubber material

The invention belongs to the field of rubber, and particularly relates to a high-strength moldproof rubber material. The moldproof rubber comprises the following components in parts by weight: 80-180 parts of epoxidized natural rubber, 50-180 parts of ethylene propylene diene monomer, 5-10 parts of nano zinc oxide, 2-4 parts of sodium stearate, 15-30 parts of carbon black N100, 4-12 parts of carbon black N330, 4-15 parts of mold preventive, 2-10 parts of sulfur, 3-5 parts of anti-aging agent, 2-6 parts of paraffin, 2-5 parts of aromatic oil, 3-5 parts of white carbon black, 3-5 parts of anti-scorching agent, 2-4 parts of dibutyl phthalate, 1-4 parts of zinc diethyl dithiocarbamate, 2-4 parts of 2-mercaptoimidazoline and 5-10 parts of plasticizer. Compared with the existing rubber, the moldproof rubber provided by the invention has the following beneficial effects: the added mold preventive composition greatly improves the moldproof effect; and meanwhile, the rubber also has the advantages of high tensile strength, fire resistance, corrosion resistance and the like.

Owner:QINGDAO BOYANG BIOTECH

Preparation method for rubber for automobile exhaust pipe lifting ring

The invention discloses a preparation method for rubber for an automobile exhaust pipe lifting ring and belongs to the technical field of rubber pipe products for an automobile. The preparation method comprises the following steps: EPDM and chlorosulfonated polyethylene rubber are put into an internal mixer for plastication, intermediate super carbon black N200, general furnace black N660, indirect zinc oxide, 2-thiol group benzimidazole, 2,2'-dithio-dibenzo thiazole, paraffin oil and strong magnesium powder are added, and mixing is performed to obtain a mixed material; the mixed material is put into vulcanization equipment, zinc diethyl dithiocarbamaate, zinc stearate, trithiocyanuric acid and sulphur are added, vulcanization is performed sequentially at four temperature intervals. Compared with the preparation method for rubber for the automobile exhaust pipe lifting ring in the prior art, the preparation method disclosed by the invention has the advantage that by using the synergistic effect of all raw materials, the heat resistance of the automobile exhaust pipe lifting ring is improved effectively and meanwhile the ageing resistance of the automobile exhaust pipe lifting ring is also improved when the raw materials are used for preparing the automobile exhaust pipe lifting ring.

Owner:LIUZHOU YINGHANG AUTO PARTS

Ozone-resistant rubber

InactiveCN104045863AExcellent ozone resistanceExtended service lifeRubber materialDiethyl dithiocarbamate

The invention relates to an ozone-resistant rubber which is prepared from the following raw materials in parts by weight: 40-60 parts of natural rubber, 10-25 parts of ethylene propylene diene monomer, 6-10 parts of zinc diethyl dithiocarbamate, 8-11 parts of anti-aging agent, 3-6 parts of PVC (polyvinyl chloride) powder, 6-9 parts of nickel dibutyldithiocarbamate, 9-12 parts of microcrystalline wax and 5-7 parts of N-tert-butyl-2-benzothiazolylsulphenamide. The rubber material can enhance the ozone resistance of the manufactured automobile shock-absorption part rubber, thereby prolonging the service life.

Owner:QINGDAO JIZHI ENERGY SAVING ENVIRONMENTAL PROTECTION

Polyisoprene articles and process for making the same

The invention disclosed herein relates to an improved process for making elastomeric polyisoprene articles. In particular, the process of the invention is a system which produces synthetic polyisoprene articles exhibiting tensile strength properties similar to that of solvent-based processes using natural rubber latex. The process comprises an accelerator composition at the pre-cure stage comprising a dithiocarbamate, a thiazole and a guanidine compound. In a preferred embodiment, the accelerator composition comprises zinc diethyldithiocarbamate (ZDEC), zinc 2-mercaptobenzothiazole (ZMBT) and diphenyl guanidine (DPG), in conjunction with a stabilizer, such as sodium caseinate. The invention also includes an elastomeric polyisoprene product made by the process, such as a surgeon's glove.

Owner:ALLEGIANCE CORP

Stable wear-resisting rubber

The invention discloses a stable wear-resisting rubber, which is prepared from the following raw materials in parts by weight: 10-20 parts of chloroprene rubber, 6-8 parts of naphthenic oil, 3-7 parts of zinc oxide, 7-11 parts of solution-polymerized styrene butadiene rubber, 4-9 parts of a carbon fiber, 3-9 parts of a tackifier, 4-8 parts of hydroxyl silicone oil, 5-7 parts of zinc diethyl dithiocarbamate, 4-9 parts of an accelerant, 1-5 parts of lead monoxide, 3-8 parts of a scorch retarder, 5-11 parts of 2-thiol imidazoline and 6-11 parts of an active agent. The stable wear-resisting rubber disclosed by the invention has good abrasive resistance and good elasticity, and can be used as sealing elements in various connections.

Owner:QINGDAO MEIJIALONG PACKAGING MACHINERY

Continuous pore rubber-plastic slow-rebound foaming material and preparation method thereof

The invention discloses a continuous pore rubber-plastic slow-rebound foaming material. The continuous pore rubber-plastic slow-rebound foaming material comprises a main material, resin, a filler, a plasticizer, a lubricant, sulfur, a vulcanizing agent, a vulcanization active agent, an accelerator and a foaming agent; the main material is 50 parts to 70 parts of nitrile rubber; the resin is 30 parts to 50 parts of PVC resin; the filler comprises 0 to 30 parts of carbon black, 40 parts to 80 parts of powdered steatile and 60 parts to 70 parts of active aluminum hydroxide; the plasticizer comprises 10 parts to 30 parts of dioctyl phthalate and 10 parts to 50 parts of chlorinated paraffin; the lubricant comprises 1 part to 2 parts of stearic acid, 1 part to 2 parts of paraffin, 1 part to 2 parts of polyethylene glycol, and 1.5 parts to 2.5 parts of sulfur; the accelerator includes 1 to 3 parts of mercaptobenzothiazole, 0 to 1.5 parts of dipentylene thiuram tetrasulfide, 0.2 parts to 1.5 parts of zinc diethyldithiocarbamate and zinc dibutyl dithiocaarbamate; the vulcanization active agent includes 1 part to 3 parts of stearic acid and 1 part to 10 parts of zinc oxide; and the foaming agent includes 5 part to 25 parts of stearic acid and 1 parts to 10 parts of low-temperature complex foaming agent ACP-J. The steps and the finished product have characteristics of high quality, good process quality control, high production efficiency, and low energy consumption.

Owner:湖南广裕新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com