Patents

Literature

379results about How to "Fire-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct-compress EPS inorganic clad plate and exterior outer-insulating system and construction method thereof

InactiveCN101158213AAvoid field workRapid productionCovering/liningsSolid waste managementComposite plateWeather proofing

The invention discloses an external insulation system and a construction method of a straight compressing EPS inorganic composite plate. The external wall firstly pre-produces the straight compressing EPS inorganic composite plate or a straight compressing EPS inorganic composite decorative board in a factory and compresses an inorganic composite enhancement layer onto a single-side of an expanded EPS plate by using a mechanical method; the outer surfaces of a base course wall of a building all adopt the EPS inorganic composite plate which adheres to a leveling blanket through bonding sands; the slab joint is pointed by jointing material and the outside of the jointing material is sealed again by weather proofing sealant; and a finish is arranged at the lateral of the system. The invention is characterized by the anti-crack, the good durability, the reliability and safety, the low cost and the fast construction.

Owner:余景春

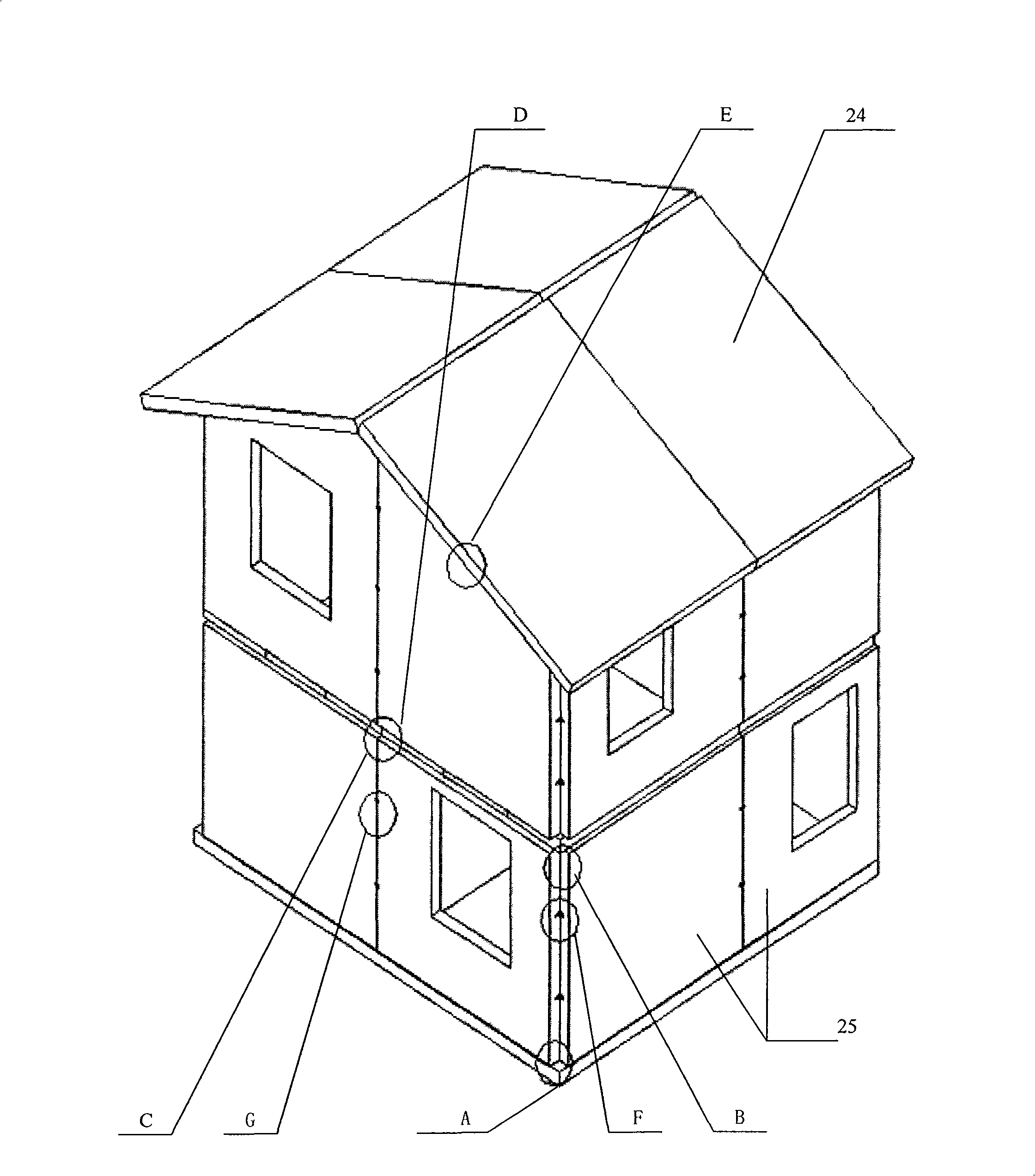

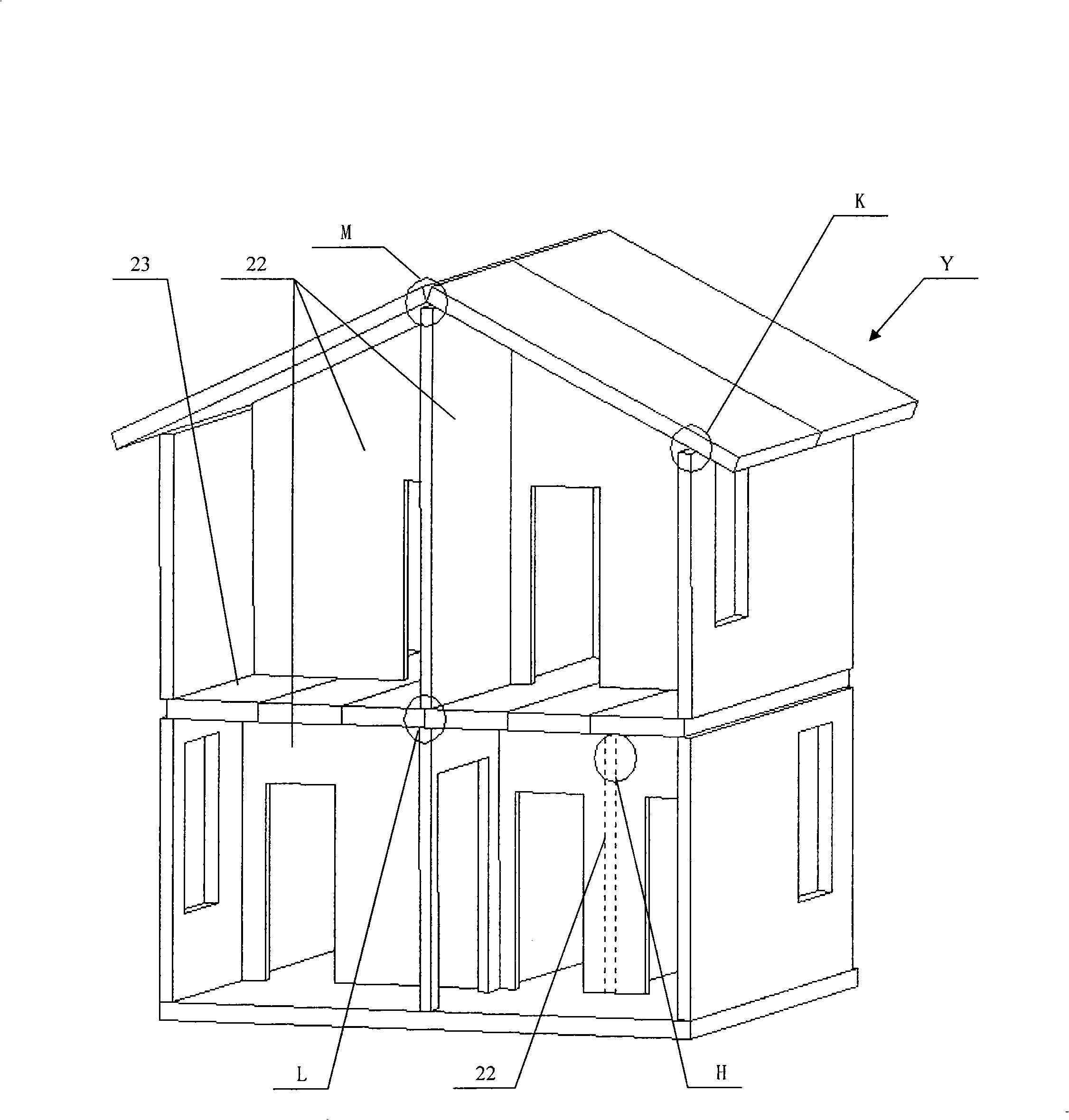

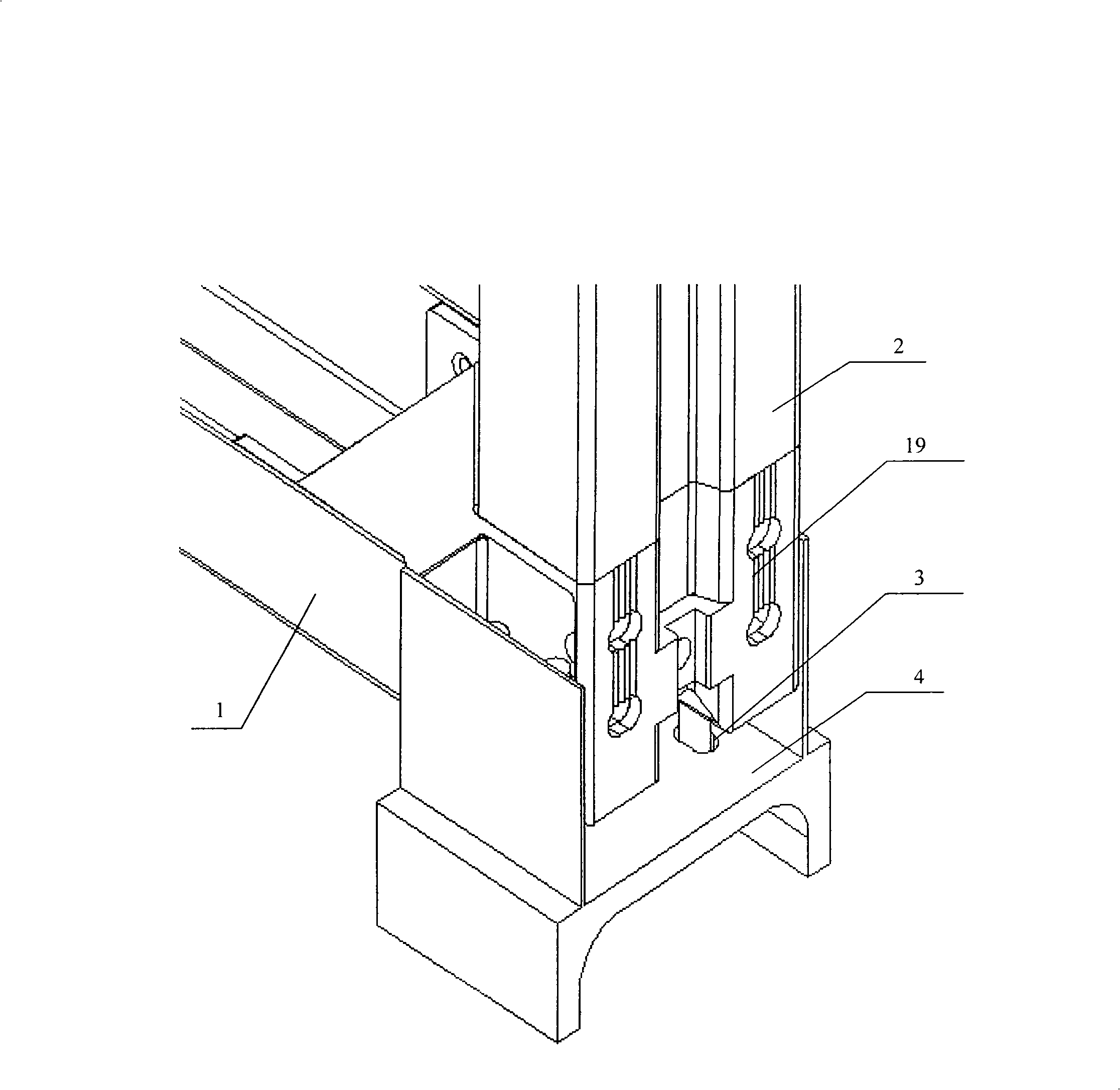

Architecture structure system assembled by composite building board and building method

ActiveCN101265723ARealize production integrationRealize industrializationRoof covering using slabs/sheetsWallsFloor slabFire resistance

The invention belongs to the architecture field, and particularly relates to an architecture structural system assembled by composite architecture boards and a construction method. The system comprises a load bearing partition plate performing functions as the beam and the column of a building and an external wall plate. Transverse frames performing the function of the beam, inner plate structure connectors and external structure connectors are arranged in a floor plate and a roof plate. The external structure connector comprises a wall bottom connector; an angle connector; a positioning connector; a connector connecting the floor plate, the external wall plate and the partition plate; a connector connecting the roof, the external wall and the gable wall; a ridge connector and so on. The invention is a plate-type total prefabricated housing construction technology, which has the comprehensive service performance of load bearing, shock absorption, hear and sound insulation, high efficiency, energy saving, durability and fire resistance, and conforms to the requirements of the green architecture. The method is capable of rapidly assembling and installing on the field and reducing the total cost of a house, as well as achieving the integration and the industrialization of the housing construction.

Owner:CUBIC DIGITAL TECH CO LTD

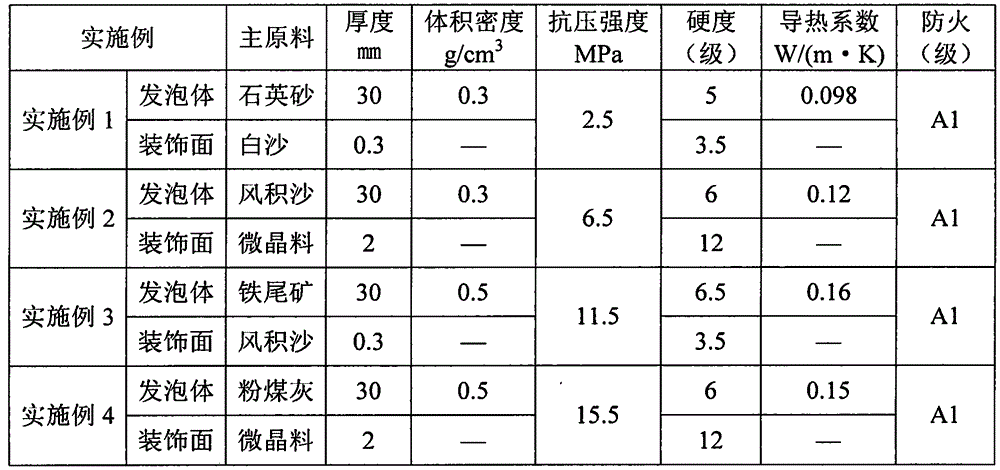

Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

ActiveCN104631688AProduced noRelieve pressureBuilding componentsCeramicwareWeather resistanceSurface layer

The invention discloses a microcrystalline foamed wall block produced by use of tailings and a manufacturing method of the microcrystalline foamed wall block. According to the microcrystalline foamed wall block, a decorative surface layer is sintered on a tailing microcrystalline foamed base body manufactured by use of a tailing composite material at a high temperature. The manufacturing method comprises the following steps: (1) preheating, namely increasing the temperature to the range of 800-950 DEG C and preserving heat for 10-40 minutes; (2) integrated sintering, namely increasing the temperature to the range of 1000-1350 DEG C and preserving heat for 30-120 minutes; (3) annealing cooling, namely cooling to below 280 DEG C and then taking out of a kiln; (4) naturally cooling to below 100 DEG C and then performing mold stripping, thereby obtaining a microcrystalline foamed wall block board; naturally placing the microcrystalline foamed wall block board for more than 60 hours to eliminate stress, and then grinding or polishing, cutting and drying to obtain the microcrystalline foamed wall block. The microcrystalline foamed wall block has a plurality of functions of high strength, fire resistance, heat preservation and thermal insulation, moisture and water proofing, decoration, light weight, weathering resistance, environmental protection and the like.

Owner:BEIJING HUIERJIU MATERIAL TECH

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

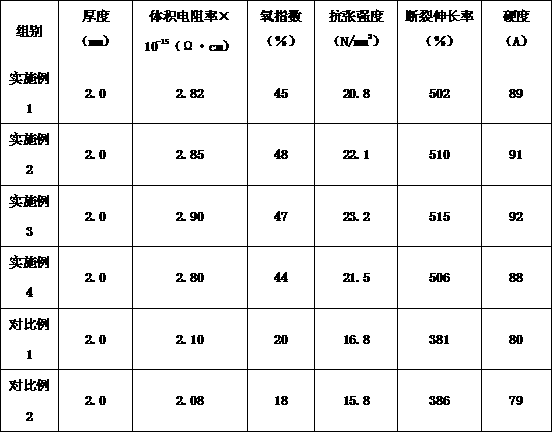

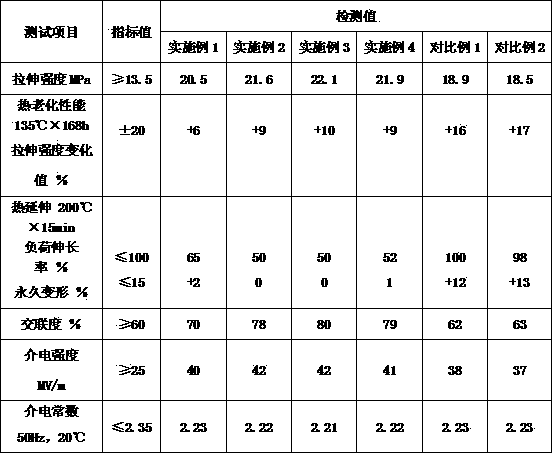

Cold-resistant rubber

The invention belongs to the rubber field, and particularly relates to cold-resistant rubber. The cold-resistant rubber comprises the components in parts by weight as follows: 50-150 parts of epichlorohydrin rubber, 50-120 parts of natural rubber, 30-70 parts of silicone rubber, 20-60 parts of polyurethane rubber, 10-40 parts of ethylene propylene rubber, 10-30 parts of carbon black N100, 2-8 parts of pottery clay, 2-10 parts of sulfur, 1-5 parts of an aging-resistant agent, 1-10 parts of pottery clay, 1-5 parts of aromatic oil, 1-10 parts of white carbon black, 1-5 parts of an anti-scorching agent, 1-4 parts of nano-zinc oxide, 1-4 parts of zinc diethyldithiocarbamate, 1-4 parts of 2-imidazolidinethione, 1-10 parts of a plasticizer and 4-12 parts of a softening agent. The cold-resistant rubber has the benefits as follows: compared with common rubber, the cold-resistant rubber has good cold-resistant performance and is suitable for continuous persistent use at the low temperature, and meanwhile, the rubber further has the advantages of high tensile strength, fire resistance, corrosion resistance and the like.

Owner:大连铁达塑胶制品有限公司

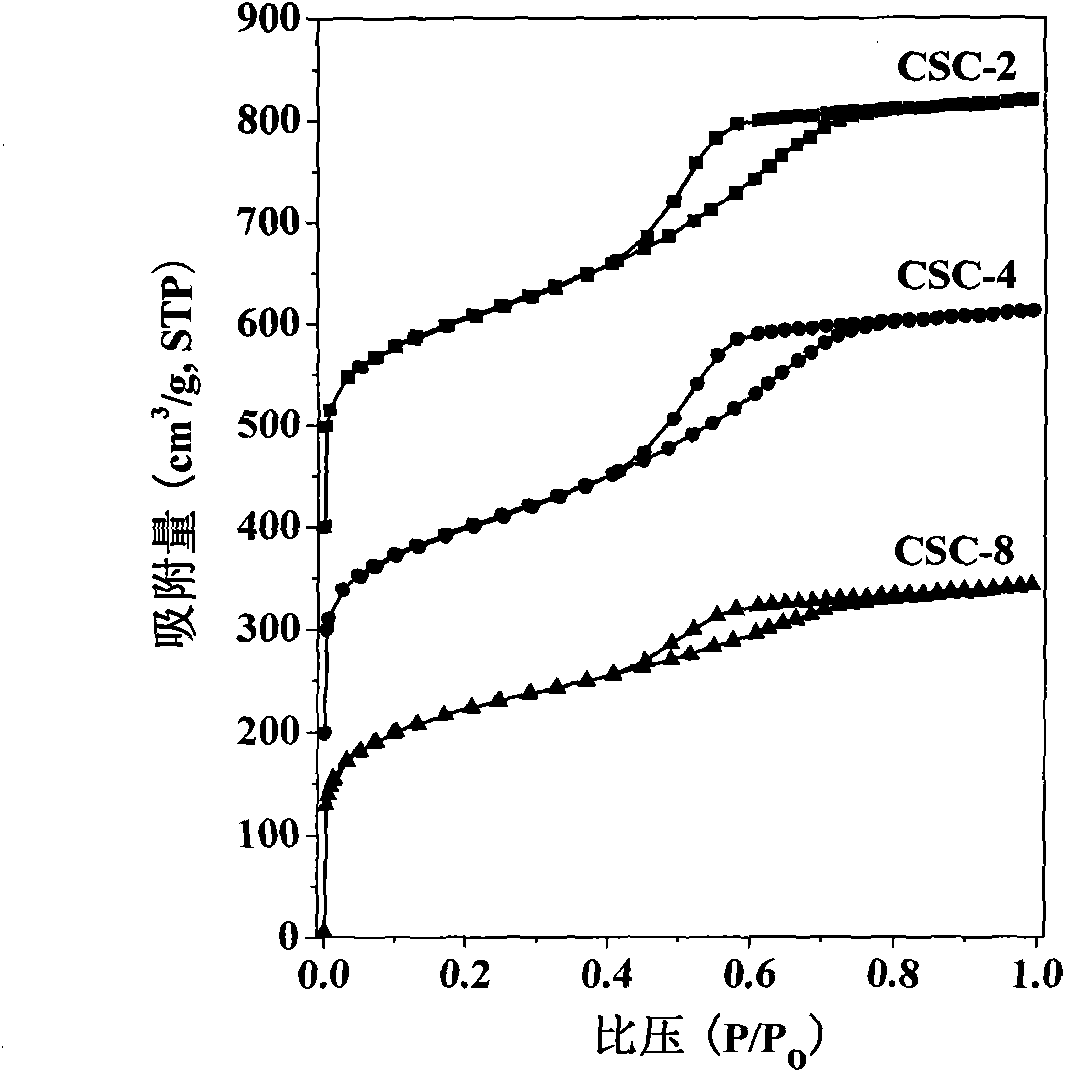

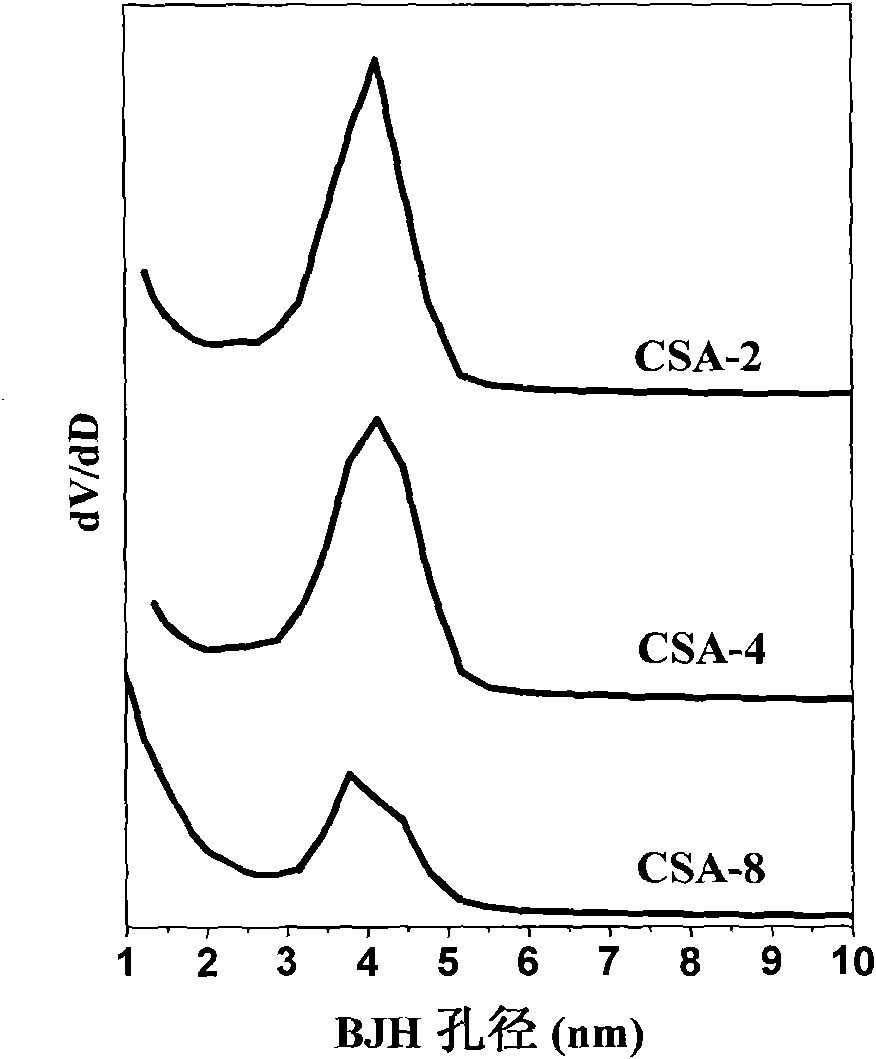

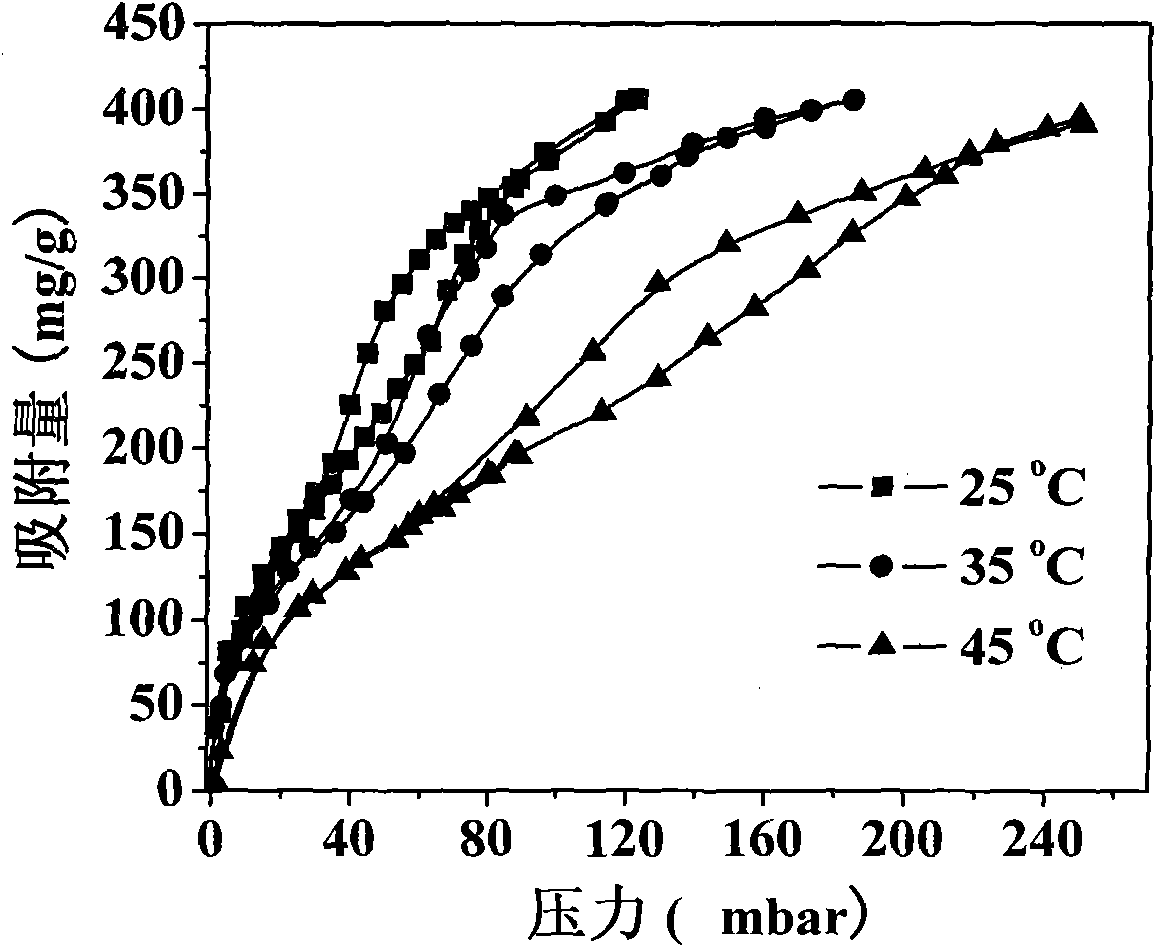

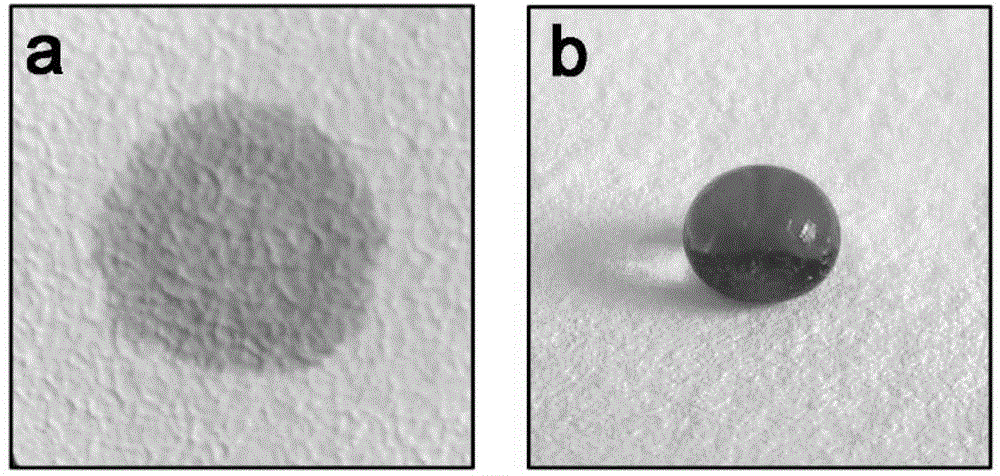

Active carbon-silicon aerogel complex for removing volatile organic pollutants

ActiveCN102125821AImprove adsorption capacityImprove desorption efficiencyOther chemical processesDispersed particle separationActivated carbonMass transfer resistance

The invention relates to an active carbon-silicon aerogel complex and a preparation method thereof, and belongs to the field of removal of volatile organic pollutants. The active carbon-silicon aerogel complex is prepared from active carbon granules serving as a skeleton structure and water glass serving as a silicon aerogel precursor by sol-gel reaction and normal-pressure drying. The active carbon-silicon aerogel complex is prepared from cheap raw materials, has a multistage pore structure, and is favorable for improving the adsorption quantity of volatile organic compounds (VOCs), reducingthe mass transfer resistance and improving the desorption efficiency.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

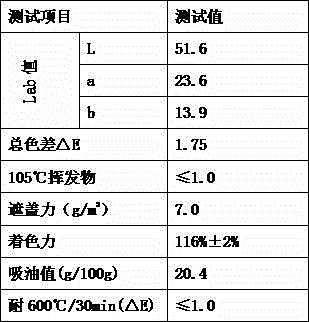

Fire-retardant black iron oxide pigment

InactiveCN103819940AEvenly dispersedGood anti-settling functionPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsChemistryBrown iron oxide

The invention relates to an iron oxide pigment, in particular to a fire-retardant black iron oxide pigment. The pigment provided by the invention is prepared from the following raw materials in parts by weight: 280 to 300 parts of black iron oxide, 5 to 8 parts of Na-montmorillonite, 1 to 2 parts of a silane coupling agent KH-5501-2, 3 to 5 parts of antimonous oxide, 4 to 6 parts of pyrophillite, 1 to 2 parts of calcium stearate, 3 to 5 parts of polyethylene wax, 1 to 2 parts of sodium dodecyl sulfate, 10 to 12 parts of coal ash, and 4 to 5 parts of an assistant. According to the pigment provided by the invention, the raw materials such as the polyethylene wax and the sodium dodecyl sulfate are used for improving the surface activity of a black iron oxide power; thus the distributing in a base material is more uniform, and the probability of sediment is low. The added raw materials such as Na-montmorillonite, antimonous oxide and pyrophillite ensure the black iron oxide pigment has the characteristics of fire resistance, flexibility, abrasion resistance, watertightness and damp resistance, and the like; during actual use, the fire-retardant black iron oxide pigment is safe and reliable, the covering power is large, and the application value is extremely high.

Owner:TONGLING RELY TECH

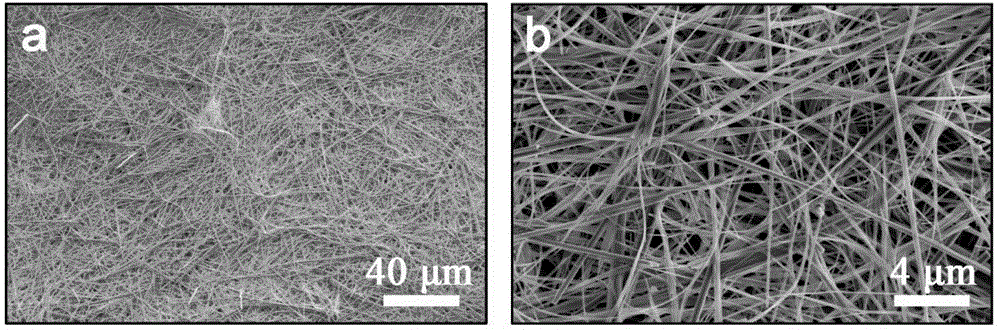

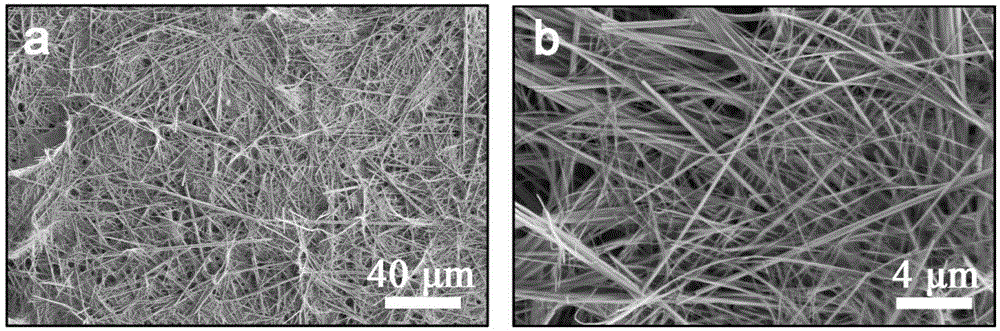

Hydroxyapatite overlength nanowire flameproof paper with waterproof function

ActiveCN106522015AWaterproofWith waterproof functionWater-repelling agents additionPaper/cardboardNanowireApatite

The invention relates to hydroxyapatite overlength nanowire flameproof paper with a waterproof function. The hydroxyapatite overlength nanowire flameproof paper with the waterproof function has super-hydrophobicity and fireproof and flame-retardant functions. The main component of the flameproof paper is hydroxyapatite overlength nanowire. The product also contains fatty acid salt or a perfluorinated compound modified on the hydroxyapatite overlength nanowire. The fatty acid salt or the perfluorinated compound carries out surface modification on the hydroxyapatite overlength nanowire. As hydroxyapatite overlength nanowire has rich surface reactive groups, the hydroxyapatite overlength nanowire is easy to undergo surface modification. Thus, the hydroxyapatite overlength nanowire is easy to combine with the fatty acid salt or the perfluorinated compound such that the hydroxyapatite overlength nanowire flameproof paper is endowed with an excellent waterproof function.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

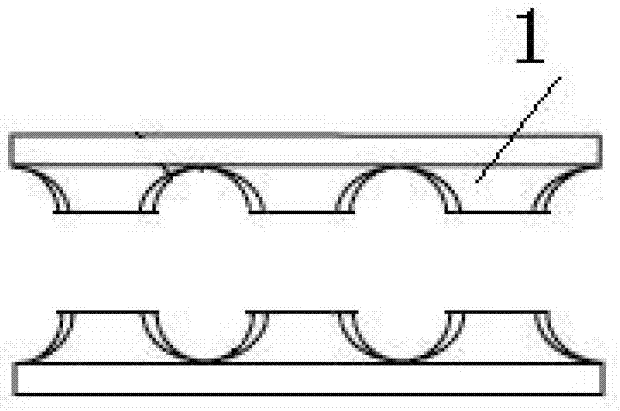

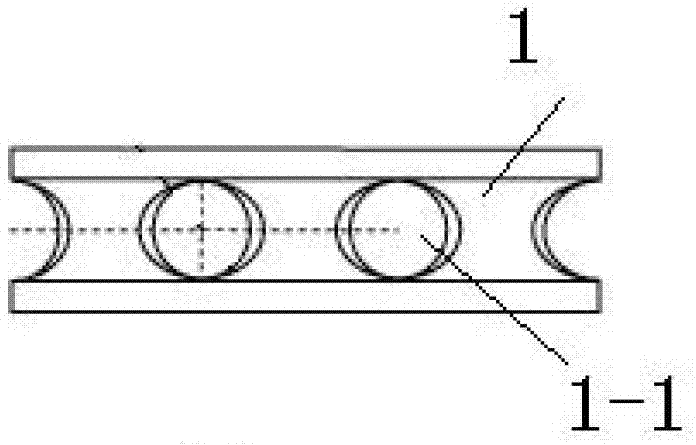

Cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, lattice composite wall and its manufacturing method

InactiveCN102731031AWith insulationWith sound insulationWallsBuilding material handlingReinforced concreteSlag

Disclosed are a cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, a lattice composite wall and its manufacturing method. The invention relates to the lattice composite wall shuttering, its manufacturing method, the lattice composite wall manufactured by the use of the shuttering and the manufacturing method thereof, so as to solve disadvantages of complicated operational processes and inflammable insulation materials in the prior art. The above purpose is realized by the following scheme: the shuttering comprises components of polyphenyl granules, cement, fly ash or slag, a shuttering bonding agent and water; the components are mixed with stirring to prepare a mixture of cement and polyphenyl granules; the shuttering bonding agent is diluted by the use of water, the solution of the shuttering bonding agent is added into the above mixture of cement and polyphenyl granules with stirring, the mixture is poured into a die, followed by compacting into half-plate cement polyphenyl granule concrete lattice composite wall shutterings; the two half plates undergo buckling and butt joint, and the composite wall is composed of the composite wall shuttering and a reinforced concrete core; and the several cement polyphenyl granule concrete lattice composite wall shutterings are respectively spliced in both vertical and transverse directions, steel bar is mounted in a core aperture, and self-compacting concrete is poured.

Owner:葛兆明 +1

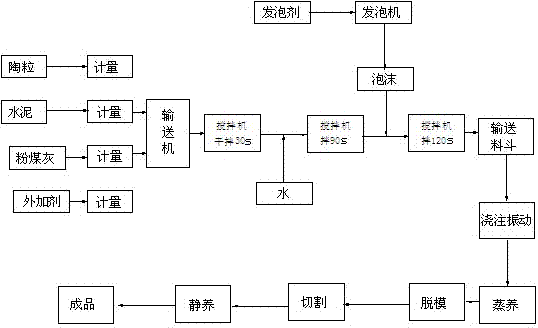

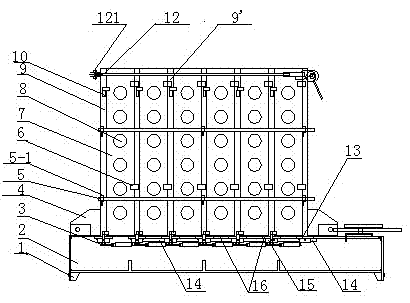

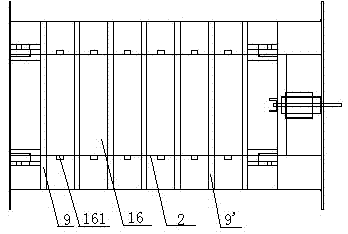

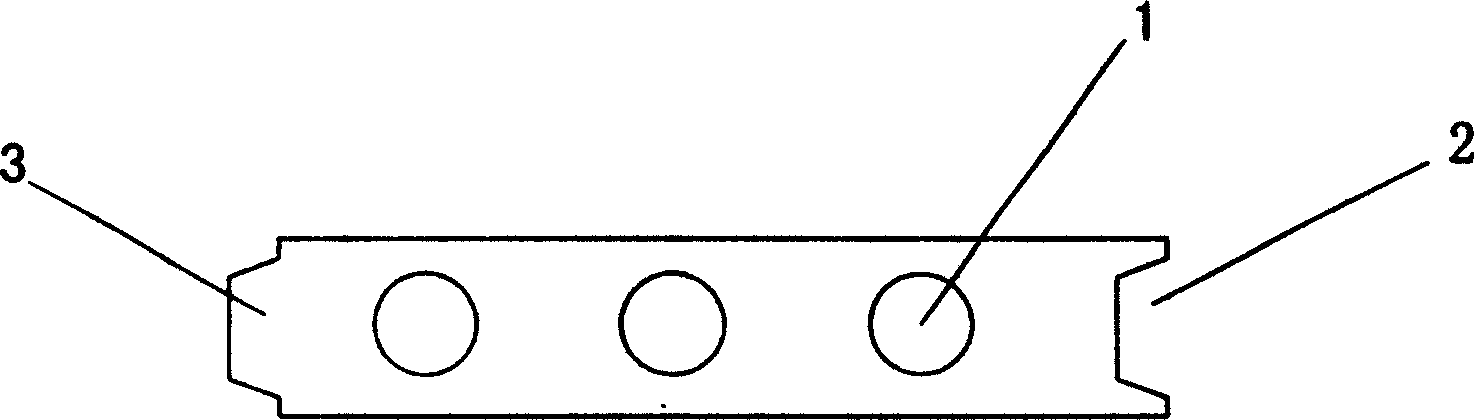

Energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould

ActiveCN102503522ALow water absorptionGood energy saving effectCeramic shaping apparatusCeramicwareCorrosion resistantEarthquake resistant

The invention relates to an energy-saving self-heat-insulation ceramsite building block and its manufacturing method and forming mould. The energy-saving self-heat-insulation ceramsite building block is made of, by weight, 35-50% of ceramsite, 20-29% of cement, 15-30% of coal ash, 0.5-1% of fibers, 2-5% of foaming agent, 0.3-0.5% of water reducing agent, 0.1-0.3% of waterproof agent and 0.2-0.5% of catalyst, wherein the volume of the ceramsite accounts for more than 80% of that of the whole building block. The manufacturing method of the building block includes steps of material selecting, metering, stirring, pouring, vibrating, steaming, tube drawing for demoulding, cutting forming and stacking for rest. The forming mould of the building block can be used for once forming of multiple medium-sized rectangular ceramsite building blocks, and each building block can be conveniently cut into standard small ceramsite building blocks. The energy-saving self-heat-insulation ceramsite building block is high in ceramsite content and has the advantages of light weight, warm retention, heat insulation, sound insulation, sound adsorption, low water adsorption, fire resistance, freezing resistance, quake proofing, corrosion resistance and the like.

Owner:NINGBO PINGHAI BUILDING MATERIALS

Heat insulation energy-saving material and preparation method thereof

InactiveCN107324776AExtended service lifeLow thermal conductivityCeramic materials productionClaywaresSodium silicateSodium carboxymethylcellulose

The invention discloses a heat insulation energy-saving material. The heat insulation energy-saving material comprises the following components in parts by weight: 60-80 parts of cement, 30-40 parts of mineral cotton, 20-30 parts of sodium silicate, 10-30 parts of natural zeolite powder, 10-20 parts of coal ash, 5-15 parts of mullite fibers, 3-8 parts of floating beads, 5-10 parts of polyvinyl alcohol, 2-8 parts of carboxymethyl cellulose, 5-10 parts of a nano inorganic oxide, 8-15 parts of glass beads, 3-8 parts of glass fibers and 4-10 parts of an additive. The heat insulation energy-saving material is prepared by such processes as grinding dispersion, high-temperature mixing, standing cooling, sieving separation, pressing molding and high-temperature sintering. The heat insulation energy-saving material has the advantages of fire resistance, long service life, small heat conduction coefficient, environmental friendliness and the like, and meanwhile, has good acid and alkali corrosion resistance and ultrahigh weatherability.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Efficient sound-absorbing ceramsite

InactiveCN102633491AImprove the sound absorption coefficientLightweight and high strengthCeramic materials productionCeramicwarePorositySludge

The invention relates to an efficient sound-absorbing ceramsite, belonging to the technical field of a building material. Aiming to solve the problems that city pollution can not be well solved, product properties are poor, the poor sound-absorbing effects are poor and the production cost is high in the prior art by mainly using the shale as ceramsite, can be solved, The invention provides the efficient sound-absorbing ceramsite, which is prepared from raw materials mainly consisting of raw materials of 60-80% of sludge, 5-20% of the shale, 5-20% of coal ash and 1.0-10% of additive. The efficient sound-absorbing ceramsite provided by the invention has the properties of wide sound-absorbing frequency band, fire resistance, good durability, freezing resistance, seismic resistance, high sound-absorbing coefficient, high porosity, light weight, high strength, heat resistance, anti-permeability and the like. The efficient sound-absorbing ceramsite further can be used for preparing a road barrier and a metro sound-absorbing material and has wide application prospect. Furthermore, the efficient sound-absorbing ceramsite provided by the invention mainly uses city sludge, so that not only can the problem of the city sludge be solved well, but also the overuse of a natural resource of the shale is reduced.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

Fire-resistant oil-resistant rubber

The invention relates to fire-resistant oil-resistant rubber which comprises the following raw materials in parts by weight: 10-150 parts of chloroprene rubber, 10-100 parts of fluorosilicone rubber, 1-5 parts of nano-zinc oxide, 1-4 parts of stearic acid, 10-25 parts of magnesium hydroxide, 1-5 parts of aluminum phosphate, 1-10 parts of sulphur, 1-4 parts of N-phenyl-alpha-phenylamine, 1-10 parts of calcium carbonate, 1-6 parts of hydroxyl silicone oil, 1-8 parts of hydrogen silicone oil, 1-5 parts of white carbon black, 1-15 parts of dimethyl silicon oil, 1-10 parts of dibutyl phthalate, 1-8 parts of zinc diethyl dithiocarbamate and 1-8 parts of 2-thiol group imidazoline. The fire-resistant oil-resistant rubber disclosed by the invention has the advantages of good oil-resistant property, high-temperature resistance, fire resistance, corrosion resistance and the like and can effectively meet the requirements of production and living.

Owner:罗云华

Shale ceramsite pervious ecological concrete

InactiveCN103936346AMeet the intensityHigh porositySolid waste managementPulverized fuel ashFire resistance

The invention provides a shale ceramsite pervious ecological concrete, which is obtained by stirring mixing of total cementitious materials, shale ceramisite, a water reducing agent and water. Specifically, the total cementitious materials include 22.4-34 parts by mass of cement, 5.6-8.7 parts by mass of coal ash and 1.5-4.2 parts by mass of silica fume. The mass part of the shale ceramisite is 35-95, the water reducing agent accounts for 0.2-0.4% of the mass of the total cementitious materials, and water accounts for 22-25% of the mass of the total cementitious materials. In addition to good water permeability, water absorption and breathability, etc., the shale ceramsite pervious concrete provided by the invention also has the characteristics of excellent heat preservation, shock absorption, fire resistance, water purification, gas purification and landscape effect, and can be widely used in the municipal field, the construction engineering field and water environment purification field.

Owner:HENAN POLYTECHNIC UNIV

Process for producing novel material with high functional capability from waste diatomaceous earth, and novel material with high functional capability from waste diatomaceous earth, and diatomaceous e

ActiveCN1968901ADurableNoise-absorbingSludge treatment by de-watering/drying/thickeningCovering/liningsAtmospheric airFiltration

There is provided a process for disposal of waste diatomaceous earth discharged from a filtration operation, etc. of various production plants, which process excels in handling easiness and in fuel cost for drying and realizes obtaining of high functional capability at low cost through, for example, holding and controlling of organic components, such as enzymes and yeasts, contained in waste diatomaceous earth and utilization of the functional capability thereof. Further, there is provided a diatomaceous earth composition for building containing a porous inorganic material such as fired diatomaceous earth and a cement for use as a coating material applied to panels, walls, etc. The composition is capable of preventing dew condensation, and is applicable without compulsory pressurization on a wood sheathing by means of coating roller, brush, spray coating, etc. Furthermore, the composition for building without exception is substantially from any color fade-out phenomenon due to coloring by natural soil grains. Still further, a certain effect of powerful photocatalyst redox reaction impact by titanium dioxide exposed to air on the decomposition of harmful pollutants of the atmospheric air is promising by causing the composition to contain a powdery porous inorganic mineral as a main component and titanium oxide as a pigment.

Owner:ISSI CORP +1

Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

InactiveCN107602106AImprove fire insulation and weather resistanceImprove fire performanceCeramicwarePore distributionEnvironmental resistance

The invention provides a graphene-based foamed ceramic insulation wallboard, which is made of the following components: potassium sodium feldspar, ceramic waste residue, graphene, vermiculite, high-temperature co-solvent, expanded graphite, zirconia, clay, stable agent and debonding agent. Using potassium sodium feldspar and ceramic waste slag as the base material, adding graphene and vermiculite to make the board more lightweight, high-strength, thermal insulation, and improve the performance of the board such as fire resistance, insulation and weather resistance, using expanded graphite as a foaming agent, using high temperature The foaming process can better control the density, pore distribution and pore size of the board, achieve better heat preservation and light weight effects, and make a board with remarkable anti-aging, corrosion resistance, heat insulation, sound insulation, waterproof and impervious, fireproof and fireproof. , lightweight, high-strength, non-cracking, green and environmental protection and other comprehensive performance in one foam lightweight wallboard.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

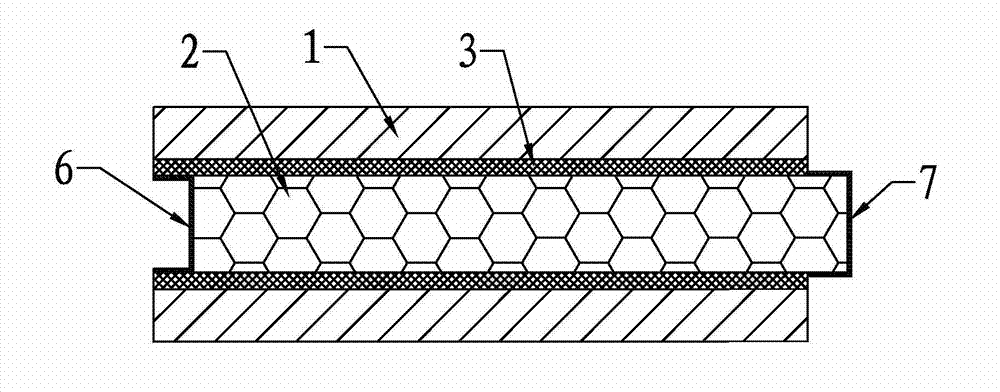

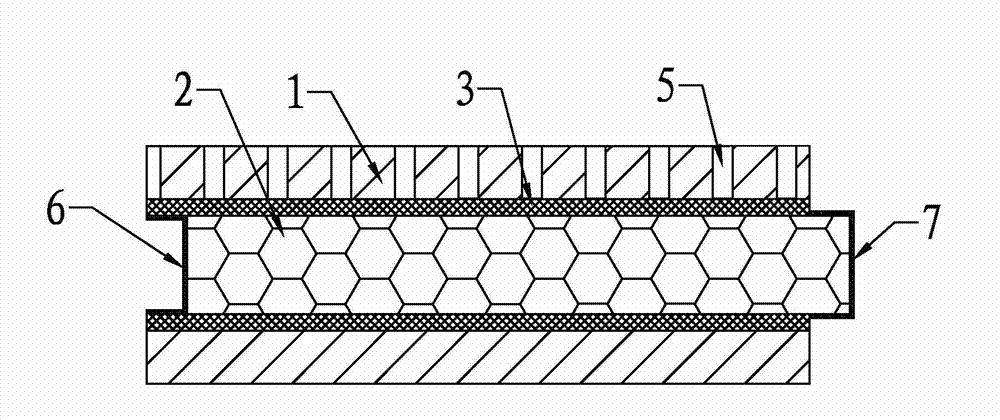

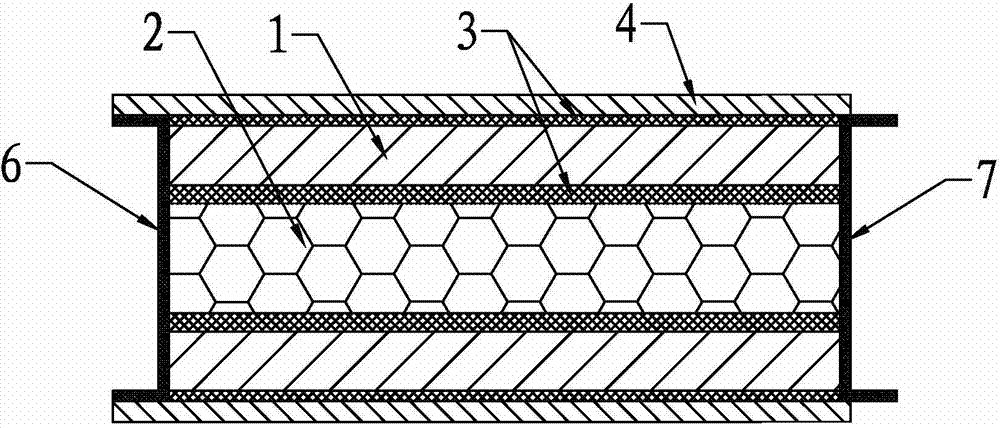

Sound-insulating fireproof wallboard

The invention discloses a sound-insulating fireproof wallboard which at least comprises a reinforced protection layer and an inorganic foaming material which is arranged in the reinforced protection layer in a clamped mode. The reinforced protection layer and the inorganic foaming material are bonded and fixed to each other through a bonding layer. The bonding layer comprises an adhesive and an anti-cracking fiber net. The anti-cracking fiber net is attached to at least one surface of the adhesive of the bonding layer. The reinforced protection layer has high strength so that the requirement that the wallboard serves as a main support of a wall can be met. The inorganic foaming material enables an inner layer of the wallboard to be a multifunctional composite layer which is light, capable of insulating and absorbing sound, and resistant to fire. According to the bonding layer, the anti-cracking fiber net is uniformly added to the adhesive, so that the bonding force of a contact surface between the bonding layer and the inorganic foaming material is increased, and the bonding strength of the bonding layer and the inorganic foaming material is enhanced. Due to the fact that the whole wallboard is made of an inorganic material, the wall cannot generate poisonous gas or smoke even if the wall is heated and burns, and the heat transfer performance of the whole wall is low.

Owner:罗广应

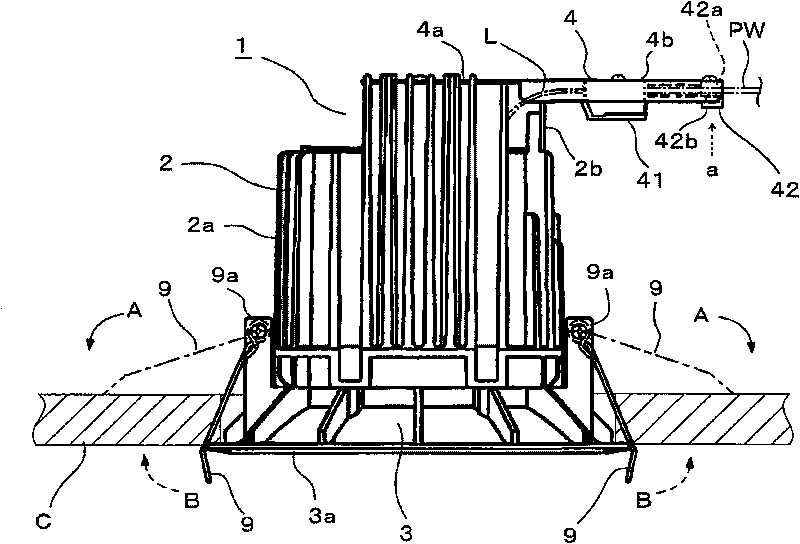

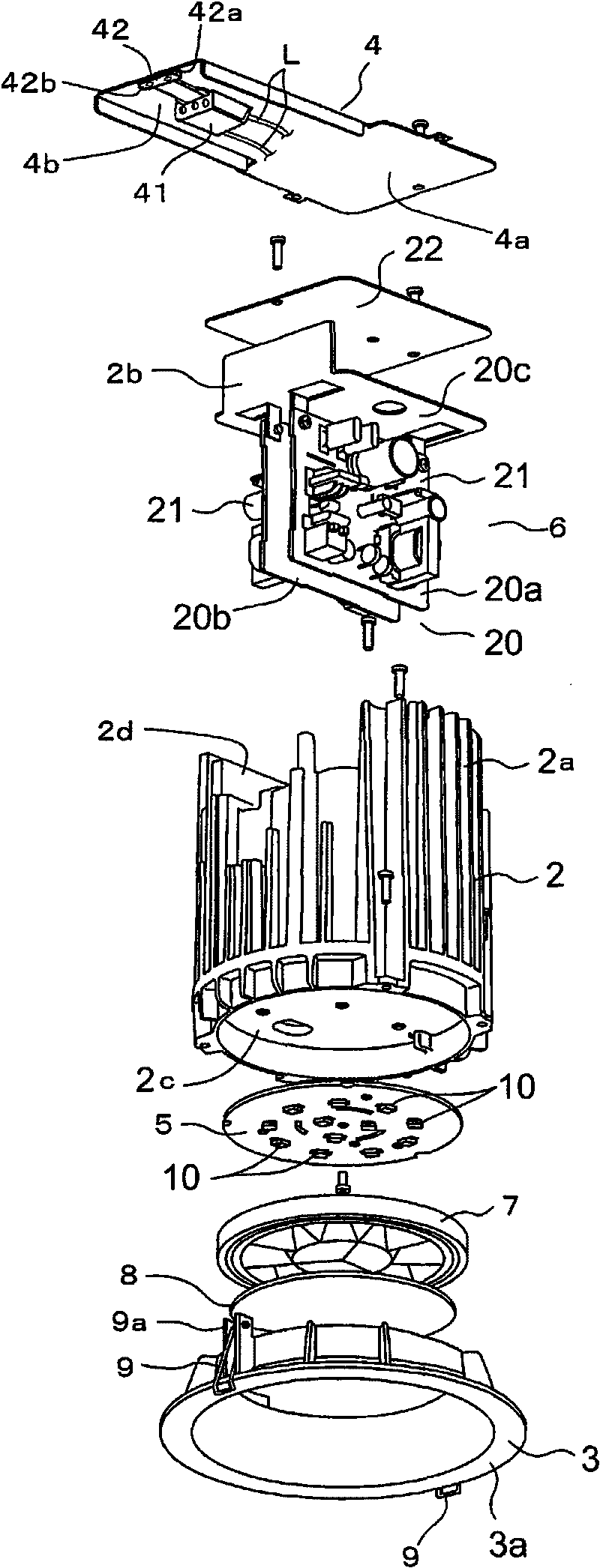

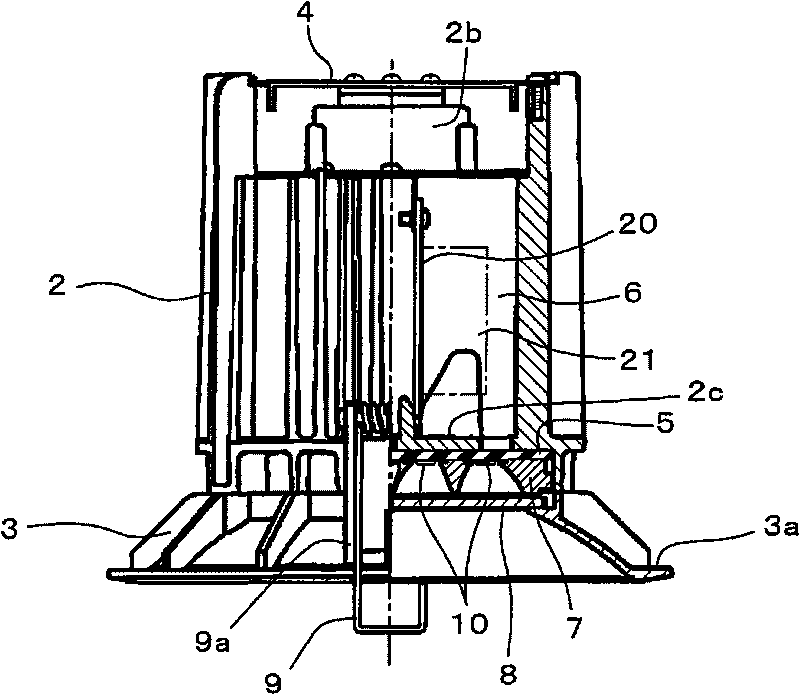

Recessed luminaire

InactiveCN101737689AImprove securityPrevent intrusionPoint-like light sourceLighting support devicesEngineeringFire resistance

A recessed luminaire includes a main body (1) including a light source (10), a terminal base attachment member (4), which is fire-resistant and extending laterally from the main body (1), and a terminal base (41), which is disposed on a lower surface of the terminal base attachment member (4) and to which power wires (PW) extending in parallel in a direction of extension of the terminal base attachment member (4) are connected.

Owner:TOSHIBA LIGHTING & TECH CORP +1

Cement reinforced composite heat preservation brickwork and its production method

InactiveCN1544379AEfficient use ofLight in massSolid waste managementCeramic shaping apparatusThermal insulationAdhesive

The invention relates to a building element, in particular a cement reinforced compound thermal insulation brick and process for preparing, wherein the brick is made from disintegrated agronomic crop stalks, 108 adhesive and cement through agitating homogeneously, die pressing and natural drying, the constituents by weight percentage are, agronomic crop stalks 70%-85%, 108 adhesive 0.4%-0.6%, and cement for the rest.

Owner:陈飙

Corundum micro-pore heat-insulating and fireproof material and preparation method thereof

InactiveCN102731118AReduce thermal stressImprove matrix strengthCeramicwareNano al2o3Temperature resistance

The invention relates to a corundum micro-pore heat-insulating and fireproof material and a preparation method thereof. The contents of raw materials of the corundum micro-pore heat-insulating and fireproof material are as follows: 40-50 wt% of corundum grain, 40-45 wt% of corundum fine powder, 5-10 wt% of active a-aluminum oxide micro-powder and 5-10 wt% r-aluminum oxide micro-powder, an additive, a dispersant account for 0.1-0.5 wt% of the above raw materials, nano aluminum oxide powder accounting for 0.1-1.5 wt% of the above materials and water accounting for 5-10 wt% of the above materials. The preparation method comprises the following steps of: dispersing the nano aluminum oxide powder into the water and dispersing under an ultrasonic vibration condition for 1-5 minutes to prepare a uniform suspension solution; then, gradually dropwise adding the suspension solution into a mixed material, and vibrating and molding; maintaining at a room temperature for 24-48 hours; de-molding and carrying out heat treatment at 1400-1600 DEG C; and keeping the heat for 1-5 hours. The corundum micro-pore heat-insulating and fireproof material and the preparation method thereof have the advantages of simple preparation process and lower energy consumption; a product has the advantages of small average hole diameter, high fireproof degree, great high-temperature resistance, low thermal conductivity and strong anti-corrosion resistance; and the product can be directly applied to a working layer of thermal equipment.

Owner:WUHAN UNIV OF SCI & TECH

Moldproof rubber

Owner:中山市和鑫橡塑电子有限公司

Preparation method for colorful polyurethane plastic and construction process for colorful polyurethane plastic track

ActiveCN104710593AHigh hardnessIncrease reaction rateWax coatingsGround pavingsAcrylic resinSports facility

The invention discloses a preparation method and a construction process for a colorful polyurethane plastic track, and belongs to the technical field of sports facilities. The preparation method for colorful polyurethane plastic comprises the following steps: uniformly stirring 10 to 15 parts of polyether polyol, 10 to 30 parts of hydroxylated acrylic resin, 10 to 30 parts of paraffin, 2 to 4 parts of a chain extender and 0.1 to 0.5 part of an age resistor, and raising temperature to 90 to 100 DEG C; adding 30 to 50 parts of a filler, 2 to 9 parts of a pigment and 0.1 to 0.5 parts of an age resistor, and performing uniform stirring; starting a colloid grinder to grind the materials into particle sizes of smaller than 400 meshes; continuing heating, and performing dehydration for 2 to 3 hours under the conditions of temperature of 90 to 100 DEG C and vacuum degree of lower than 0.095Mpa. According to the preparation method and the construction process, with the adoption of the high-functionality polyether polyol, reaction is accelerated, the hardness of a formed film is increased, and construction time is shortened; by the hydroxylated acrylic resin, high glossiness and higher weather resistance and color retention are achieved, and the service life is prolonged.

Owner:山东世纪联合新材料科技有限公司

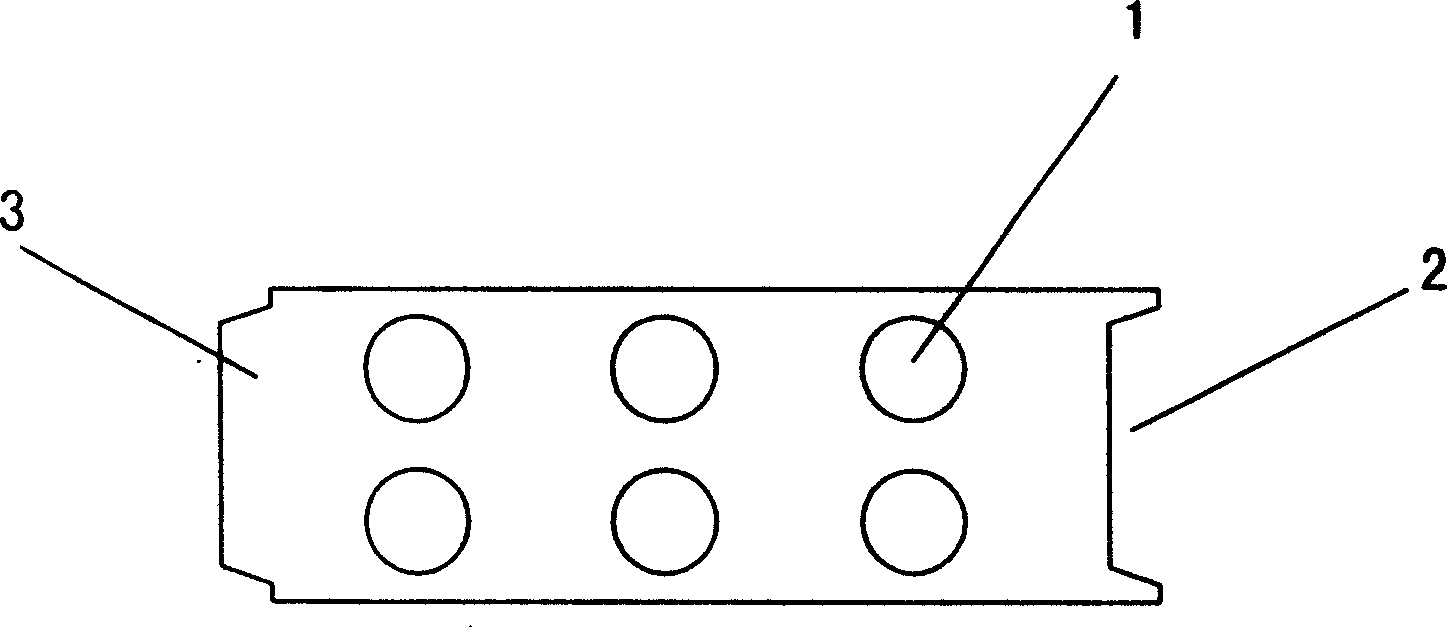

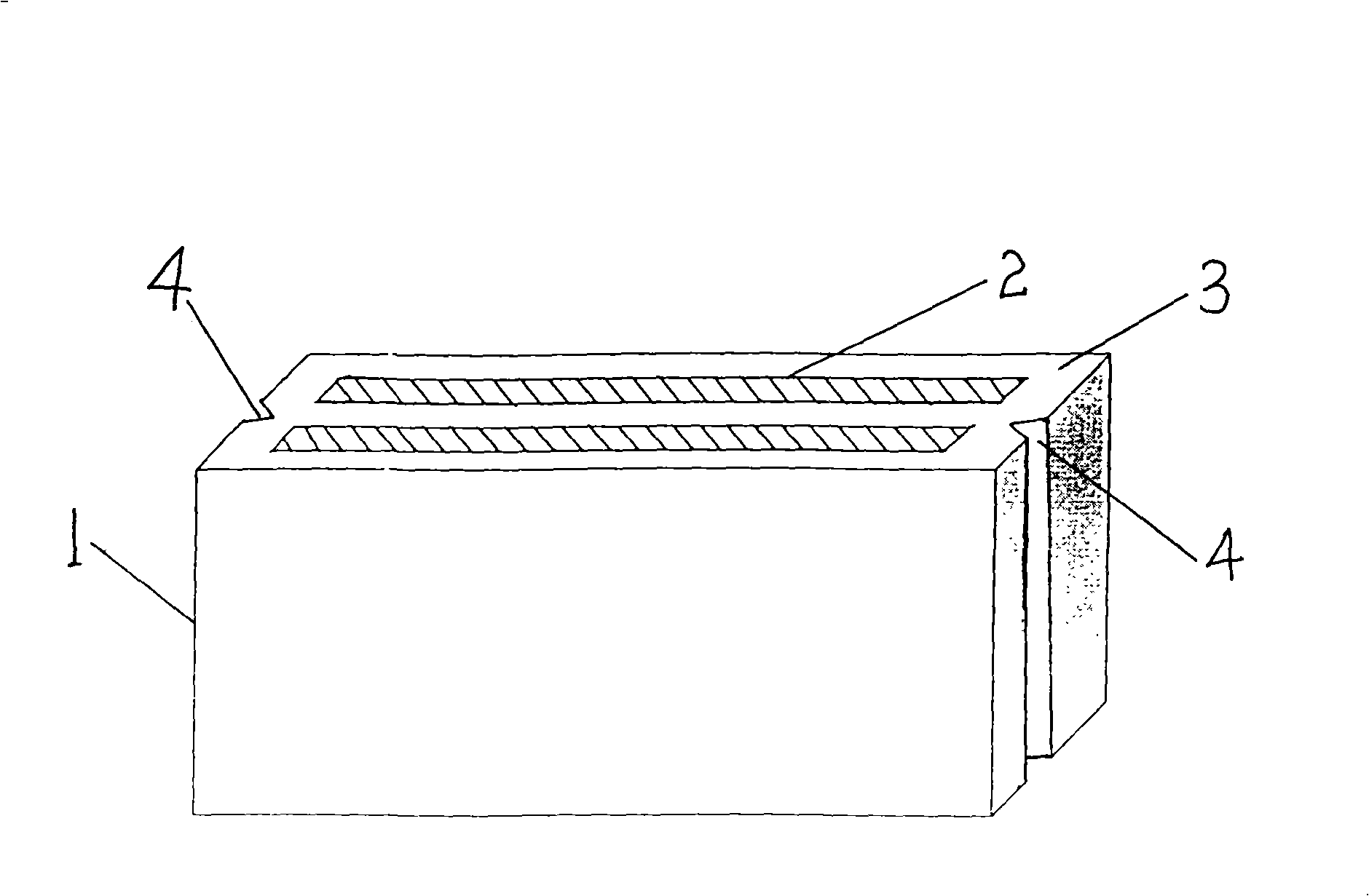

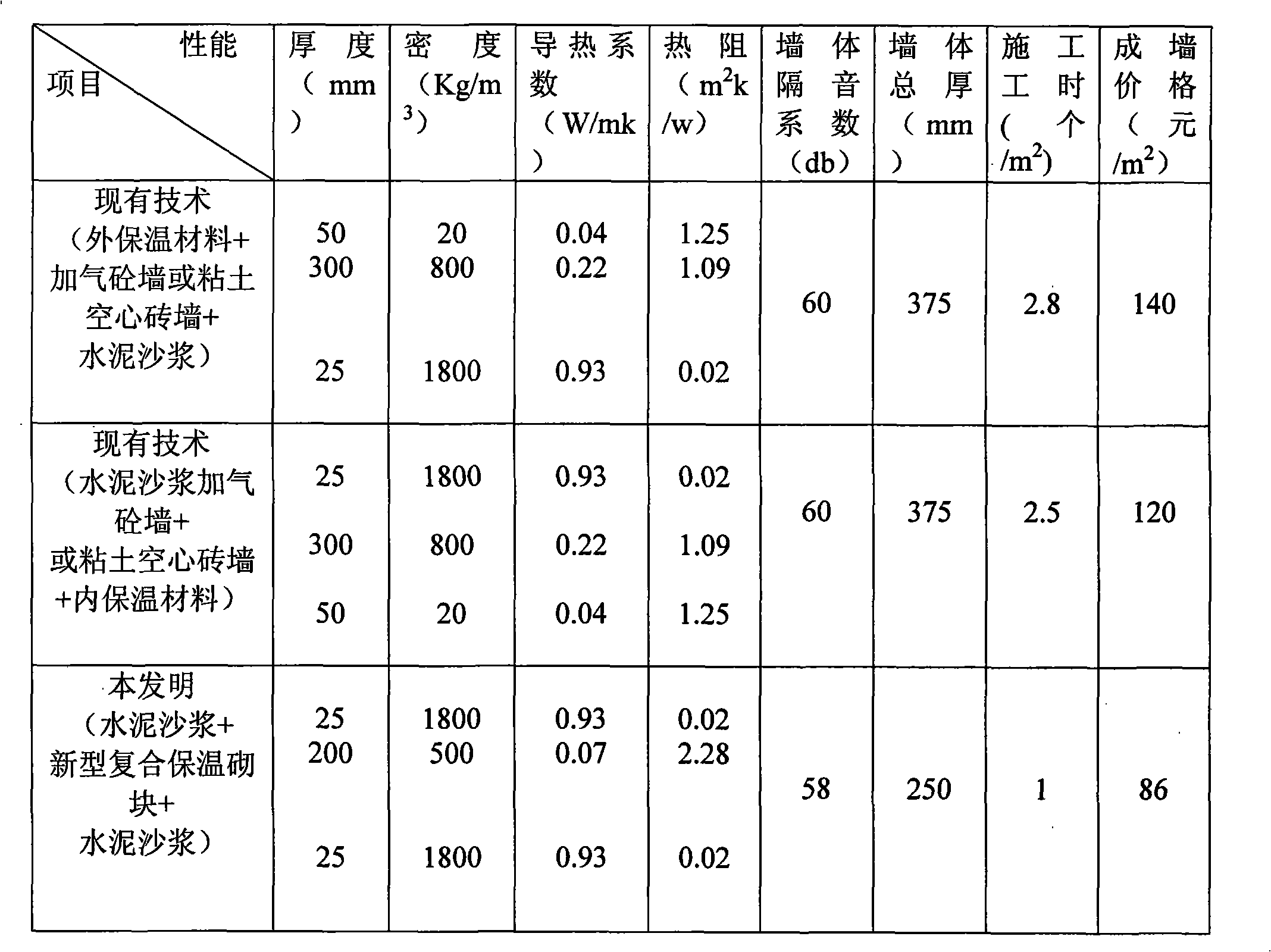

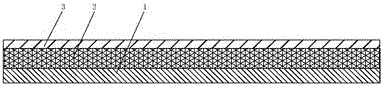

Novel composite thermal insulation building block and producing method thereof

InactiveCN101294434AGood sexStrong bondConstruction materialSolid waste managementThermal insulationMortar joint

The invention discloses a novel composite thermal insulation block and a manufacturing method thereof. The novel composite thermal insulation block is mainly characterized in that the block body consists of an insulating layer and a reinforcing layer; the reinforcing layer made of cement mortar mixture is poured outside the insulating layer; either of two end faces vertical to the insulating layer arranged on the block body is provided with at least one mortar joint groove. The manufacturing method of the composite thermal insulation block is that a polystyrene plate is divided into appropriate sizes according to the size of a mould, and the divided polystyrene plates are fixed in the mould; pasty mixture prepared with water is foamed with a foaming machine and a foaming agent, is injected in an agitator, and is mixed and agitated with the mixture; the foamed mixture is injected into the fixed mould of the polystyrene plate; and the top is screeded, naturally air-dried or oven-dried; and standing for curing is carried out. Compared with the prior art, the novel composite thermal insulation block has the remarkable characteristics of light weight, fireproofing, flame resistance, sound insulation, quick construction, increased utilization area, shock resistance and so on.

Owner:薛锋堂

Anticorrosive and environmentally-friendly water-based coating and preparation method thereof

InactiveCN109021788AAvoid pollutionAvoid wastingFireproof paintsAntifouling/underwater paintsWater basedEpoxy

The invention discloses an anticorrosive and environmentally-friendly water-based coating. The coating is mainly prepared from, by weight, 40-50 parts of waterborne epoxy resin, 30-50 parts of a basematerial, 5-10 parts of a filler, 4-6 parts of modified graphene oxide, 1-2 parts of a photocatalyst, 1-3 parts of an emulsifier, 2-3 parts of a silicone acrylate leveling agent, 3-5 parts of sodium diisooctyl sulfosuccinate, 2-5 parts of an NXZ defoamer, 2-3 parts of hydroxyethyl cellulose, 20-30 parts of deionized water and 0.5-1 part of 2-amino-2-methyl-1-propanol. The invention also disclosesa preparation method of the coating. The preparation method comprises the following steps: emulsification of the waterborne epoxy resin, preparation of a filler mixture, preparation of a base materialmixture, and uniform grinding and stirring. Potassium silicate, sodium silicate and silica sol are compounded as a base material, the waterborne epoxy resin is used as an emulsion, and water as a dispersion medium, so environmental pollution and resource waste caused by using of an organic solvent are avoided, and the coating has no pollution in the production or use process, and has excellent environmental protection performance and mechanical performances.

Owner:SHENZHEN NANSHUO MINGTAI TECH CO LTD

Sanding-free high-pressure decorative panel for cladding and production method thereof

InactiveCN106113864ASuitable for precision machiningReduce the impactLamination ancillary operationsSpecial paperMelamine formaldehyde resinEngineering

The invention relates to the field of an indoor decorative material and specifically relates to a sanding-free high-pressure decorative panel for cladding and a production method thereof. The sanding-free high-pressure decorative panel comprises a sanding-free base plate and a decorative layer, wherein the decorative layer is arranged on the sanding-free base plate; the sanding-free base plate is made of kraft paper which is soaked in thermoset modified melamine resin and then coated with a sanding-free release agent on the back; the decorative layer is formed according to the steps of soaking the decorative paper in thermoset melamino-formaldehyde resins, drying and then coating the thermoset melamino-formaldehyde resins; the sanding-free base plate and the decorative layer are once molded and formed under the conditions of high temperature and high pressure. The decorative panel provided by the invention can be heated, coats an irregularly shaped wood substrate and then can be molded; sanding is not required; the sanding-free high-pressure decorative panel has the characteristic of bending radius less than or equal to 0.7mm, is fit for precision machining of decorative panel with radian requirements on later corner and edge sealing and has the advantages of fire resistance, water resistance, moisture resistance, dry heat resistance, impact resistance, pollution resistance, corrosion resistance, scraping resistance, ageing resistance, beautiful appearance, durability, high size stability, high bonding strength and zero pollution of organic solvents including benzene in paint.

Owner:HENAN YONGWEI SECURITY

Method for recycling dust generated by casting waste sand regeneration

The invention discloses a method for recycling dust generated by casting waste sand regeneration. According to the method, firstly, a dust removal system is used for collecting high-value dust and low-value dust in groups according to effective values of the dust; then composite powder for modeling is generated through compounding, activation, drying and pulverizing after the high-value dust is sieved by a powder concentrator, and sludge generated through wet regeneration by the low-value dust, blast furnace slag and casting waste sand is subjected to raw material pretreatment, compounding, shaping, prebaking, baking, cooling and screening to generate light ceramsites; the high-value dust is dust generated during regeneration of unbaked casting waste sand, and the low-value dust is dust generated during regeneration of baked casting waste sand. The recycling method can achieve the purpose of full recycling of the casting waste sand, and has the advantages that the operation is simple,more energy is saved, and the environment is protected better.

Owner:广西兰科资源再生利用有限公司

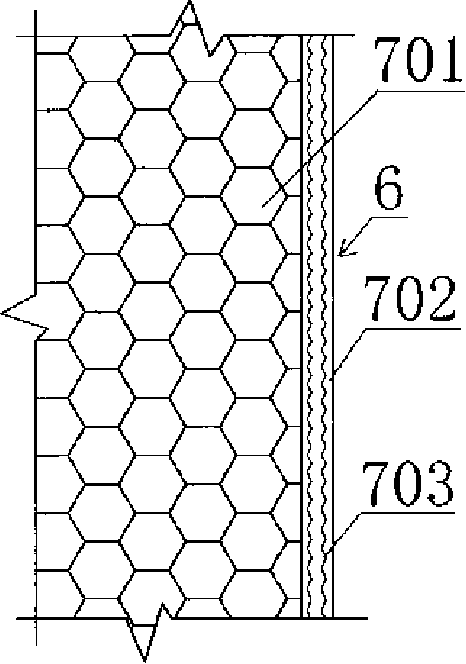

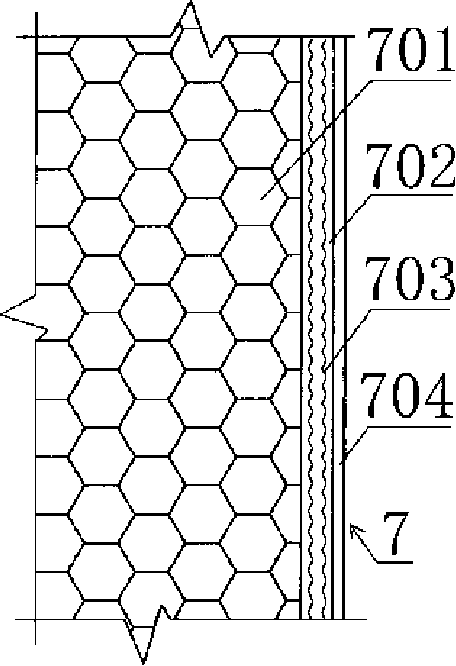

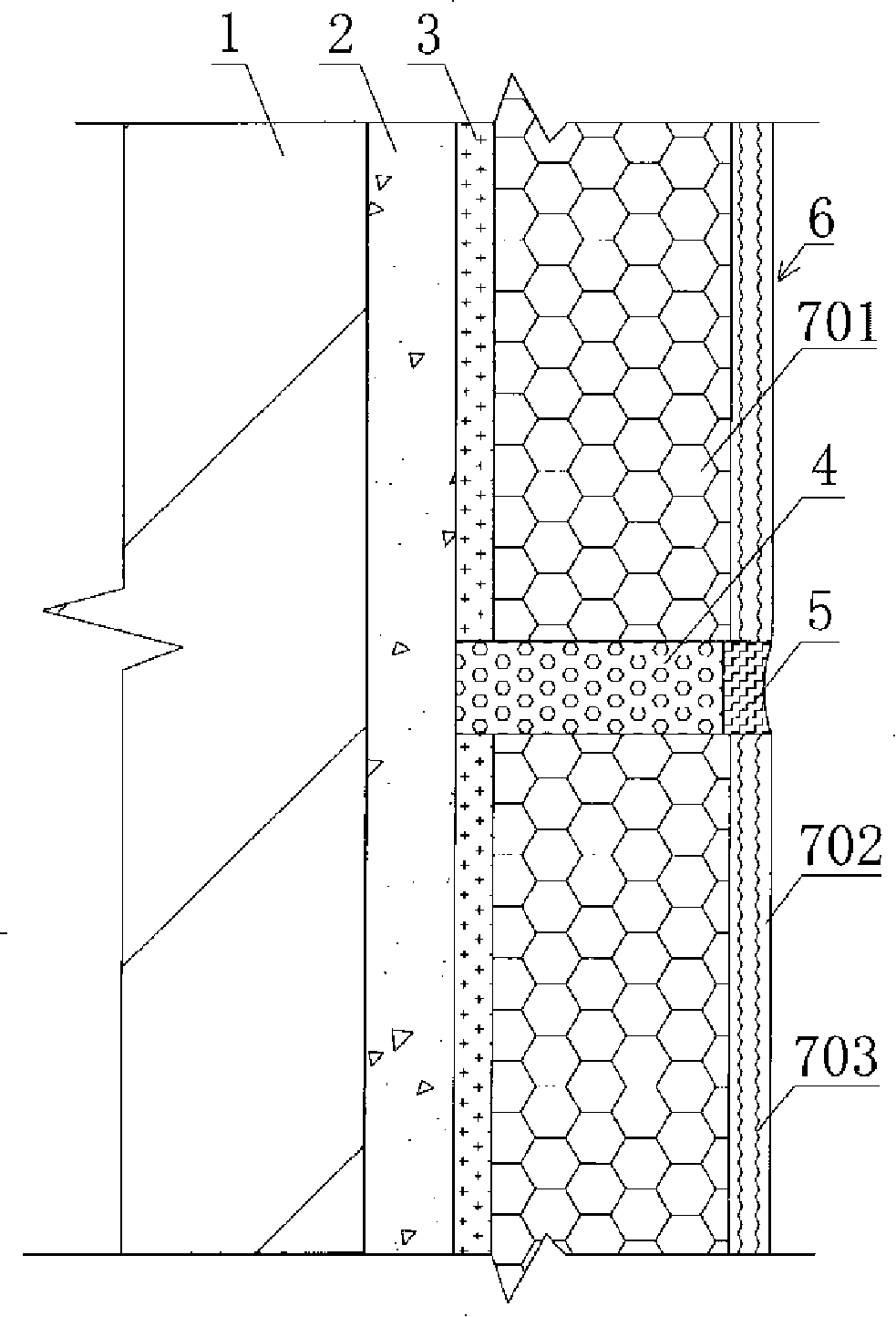

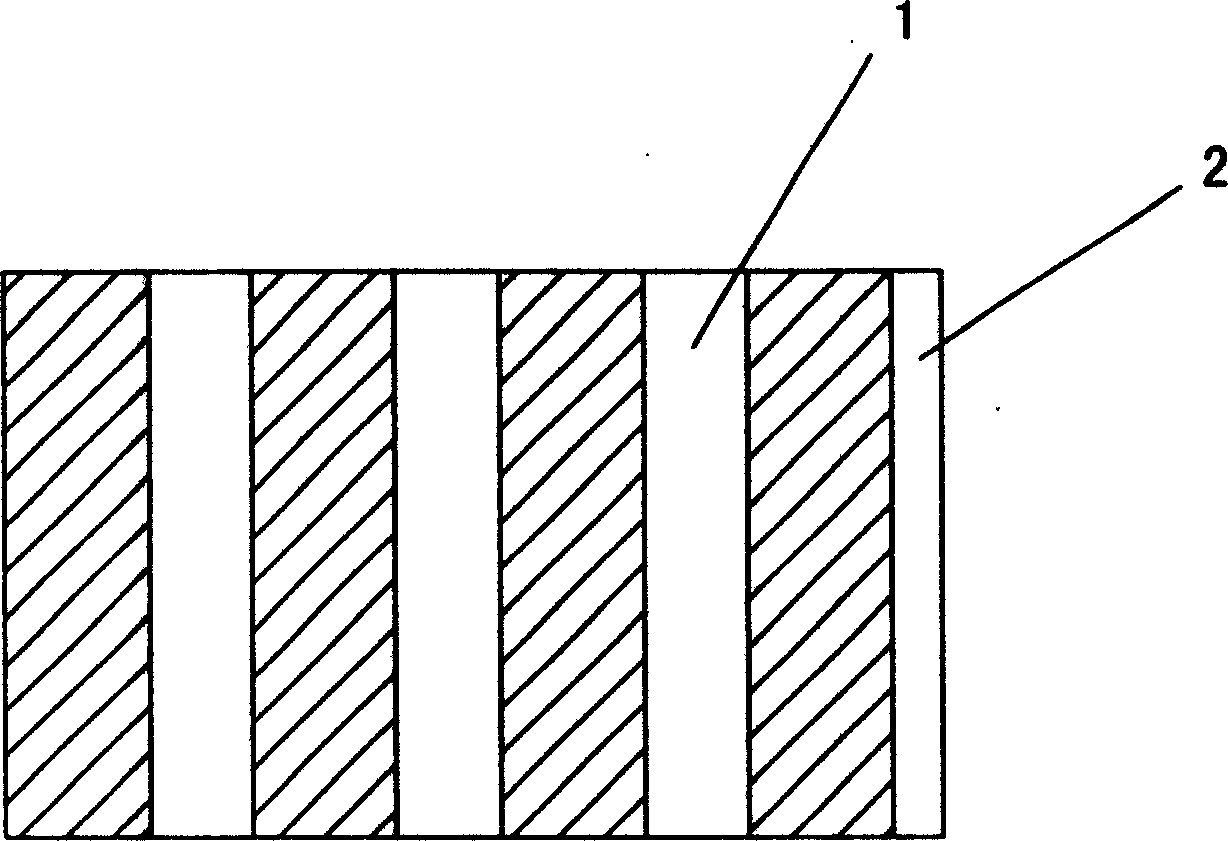

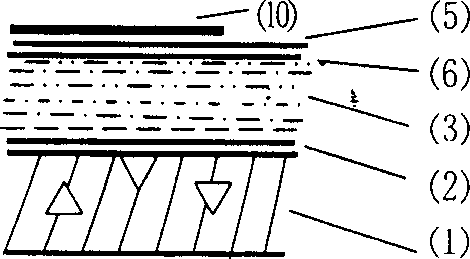

Thermal insulation system structure for mineral wool coated building

InactiveCN1807789AWith sound absorptionFire-resistantCovering/liningsWallsAbnormal shapedThermal insulation

The invention relates to a thermal-insulation system which coats the mineral wool on the construction. It comprises a construction base on which the waterproof agent is plated to form a damp-proof layer; a mineral wool thermal-insulation layer is plated on the damp-proof layer; a protective layer is laid on the thermal-insulation layer; and a ornament layer is arranged outside the protective layer. The invention can apply multi-floor and high buildings, public buildings and the workshops, especially applying variable irregular surfaces, and it can directly plate mineral wool on the surface of construction base with demanding the flatness. The thermal-insulation layer has lower heat conductive parameter, the burning property is A level, the sound adsorption effect is 1 level, the fiber is three-dimensional arranged, and the integrated property is better without any connection slit. It can meet the energy-saving demands of different areas to realize high social and economic benefits.

Owner:韩春贵

Insulating fireproof radiation-resistant shielded cable material and preparation method thereof

InactiveCN105367884ALow priceWith insulationRubber insulatorsPlastic/resin/waxes insulatorsShielded cableAntioxidant

The invention discloses an insulating fireproof radiation-resistant shielded cable material and a preparation method thereof. The insulating fireproof radiation-resistant shielded cable material is prepared from EPDM, ethylene-vinyl acetate copolymer, polyvinyl chloride, phenol-formaldehyde resin, polydimethylsiloxane, glass fiber, plasticizer, a vulcanizing agent, a coupling agent, an anti-aging agent, a stabilizing agent, a flame retardant and an antioxidant. Raw materials are compounded according to a ratio and then poured into a high-speed mixer to be mixed; after the raw materials are evenly mixed, the raw materials are poured into a twin-screw extruder to undergo melt extrusion, and air-cooled granulation is performed. All ingredients of the cable material have respective independent effects and advantages and are also matched with each other to form a whole, so that the cable material is insulating, fireproof and resistant to radiation, has a shielding function and is excellent in performance. Moreover, the raw material cost is low, and thus the product cost is low. A manufacturing process is simple.

Owner:陈薇

Corrosion resistant aerated building block and making method thereof

InactiveCN105272337AImprove mechanical propertiesImprove fire resistanceCeramicwareCrack resistanceSlag

The invention discloses a corrosion resistant aerated building block and a making method thereof. The corrosion resistant aerated building block is made from, by weight, 23-27 parts of waste concrete, 28-36 parts of quartz sand, 16-29 parts of pine sawdust, 13-21 parts of porous ceramsite, 18-34 parts of zirconium-silicon slag, 32-46 parts of high sulfate resistance Portland cement, 17-33 parts of pumice, 14-26 parts of kyanite, 22-34 parts of marine dredged sludge, 11-22 parts of desulfurized gypsum, 19-28 parts of calcium carbide slag, 10-15 parts of hawthorn fruit seed powder, 8-12 parts of sodium polystyrene sulfonate, 3.5-5 parts of calcium hydride and a proper amount of water. The aerated building block has the advantages of strong corrosion resistance, strong resistance to acids, alkali, salts and other corrosive media, high strength, good durability, impermeability, low heat conduction coefficient, good crack resistance, safety, environmental protection and durability.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

Foamed thermal insulation material fired by coal water slurry gasification waste residue and preparation method thereof

ActiveCN107602079ALow costImprove insulation effectCeramic materials productionCeramicwareCoal waterThermal insulation

The invention discloses a foamed thermal insulation material fired by coal water slurry gasification waste residue. The foamed thermal insulation material is formed by uniformly mixing coal water slurry gasification waste residue and a high-temperature phase change material in proportion and then firing. The preparation method of the foamed thermal insulation material comprises the following steps: heating a mixture to the temperature of 700-800 DEG C at constant heating rate within 30-60 minutes, keeping constant temperature for 15-30 minutes, so that the coal water slurry gasification wasteresidue is fully foamed and expanded, then heating to the temperature of 900-1000 DEG C at the constant heating rate within 10-30 minutes, keeping constant temperature for more than 30 minutes, so that the high-temperature phase change material adhered to the foamed coal water slurry gasification waste residue is fully molten and liquefied at continuous high temperature and coal water slurry foamsare bonded into a whole, and naturally cooling and sizing. The foamed thermal insulation material disclosed by the invention has the advantages that a thermal insulation material is fired by utilizing the characteristic that the coal water slurry gasification waste residue can be foamed and expanded at the temperature of higher than 700 DEG C, and the problems of appropriation of land and environmental pollution due to accumulation of the coal water slurry gasification waste residue are solved; and the thermal insulation material produced by utilizing the coal water slurry gasification wasteresidue and the high-temperature phase change material has the advantages of fire resistance, durability, light weight, waterproofness, good thermal insulation performance, high strength and the like.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com