Efficient sound-absorbing ceramsite

A technology of ceramsite and sound absorption, which is applied in the field of building materials, can solve the problems of sludge pollution in urban pollution, damage to the balance of the ecological system, and increase of production costs, so as to improve market competitiveness, save natural resources, The effect of sound absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

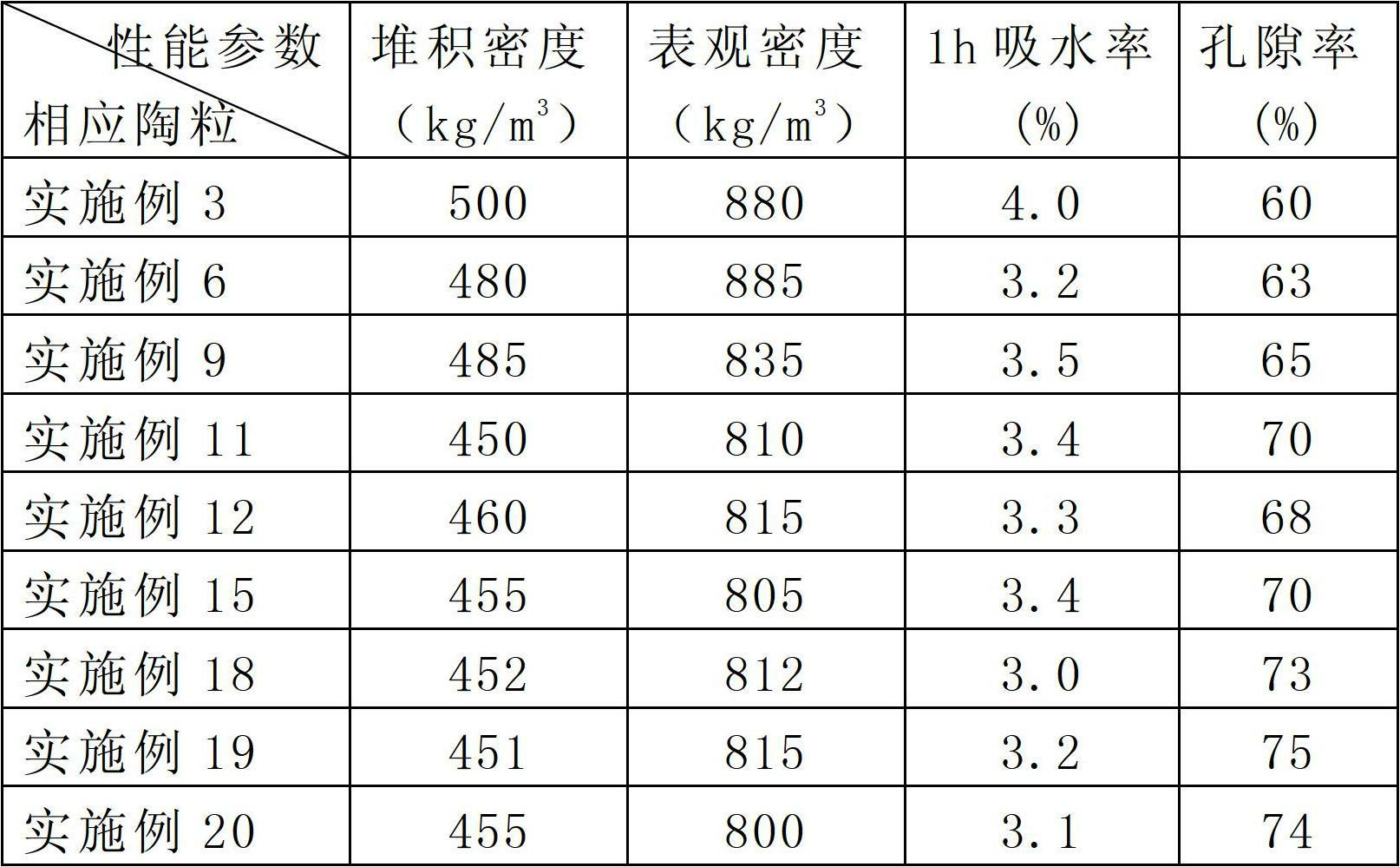

Examples

Embodiment 1

[0051] The high-efficiency sound-absorbing ceramsite is mainly made of the following raw materials in parts by weight:

[0052] Sludge: 80%; Shale: 8%; Fly ash: 5%; Admixture: 7.0%. The admixture has the ability to increase the porosity of the ceramsite.

[0053] The high-efficiency sound-absorbing ceramsite is prepared by the following method:

[0054] Weigh each raw material in the above weight percentage, put it into a mixer, knead evenly, put the above mixture into a crusher for crushing, age for 4 to 7 days, and then granulate to obtain pellets. The granulation described above is divided into secondary granulation. For the first time, it is granulated by double rollers for 5 to 8 minutes, and for the second time, it is granulated by a granulation roller for 4 to 10 minutes. The particle size of the pellets after granulation is 2 to 20mm. Then put the above pellets into the rotary kiln for preheating, the preheating temperature is 220°C-400°C, the preheating time is 15-2...

Embodiment 2

[0056] The high-efficiency sound-absorbing ceramsite is mainly made of the following raw materials in parts by weight:

[0057] Sludge: 60%; Shale: 20%; Fly ash: 15%; Admixture: 5.0%. The admixture has the ability to increase the porosity of the ceramsite.

[0058] The method for preparing the high-efficiency sound-absorbing ceramsite is consistent with the method in Example 1, and will not be repeated here.

Embodiment 3

[0060] The high-efficiency sound-absorbing ceramsite is mainly made of the following raw materials in parts by weight:

[0061] Sludge: 65%; Shale: 15%; Fly ash: 10%; Admixture: 10%. The admixture has the ability to increase the porosity of the ceramsite.

[0062] The method for preparing the high-efficiency sound-absorbing ceramsite is consistent with the method in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com