Sandstone acoustic board used in transformer substation

A technology of sound-absorbing panels and substations, which is applied in the field of sound-absorbing panels, and can solve problems such as not being able to meet the noise reduction requirements of substation sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

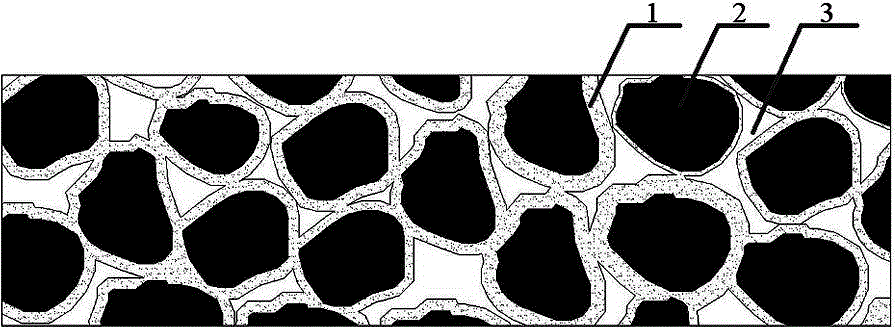

[0019] As shown in the accompanying drawings, an embodiment of a sandstone sound-absorbing panel for a substation of the present invention is formed by mixing and bonding natural clean sand 1 and an inorganic silicon-based solvent 2 that acts as a bond. As if welded together, there are irregular and interconnected tiny pores 3 in the whole composed of natural clean sand and inorganic silicon-based solvent. Because of the existence of tiny pores, when the noise passes through, the noise energy is converted into heat energy, thereby reducing noise.

[0020] The implementation of the sandstone sound-absorbing board used in substations of the present invention is made in the following way:

[0021] 1. Select natural clean sand with a fineness modulus of 1.5-2, and screen the impurities (soil, waste residue, etc.) in the natural sand;

[0022] 2. Select the inorganic silicon-based solvent and foaming agent, and the foaming agent should not chemically react with the inorganic silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com