Patents

Literature

166results about How to "Improve the sound absorption coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

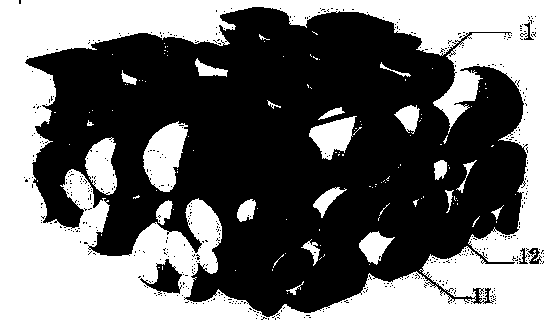

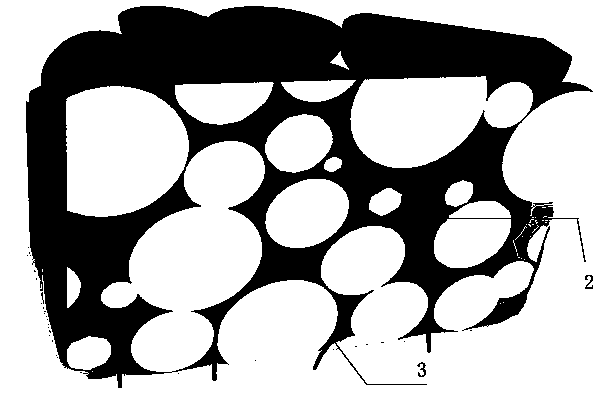

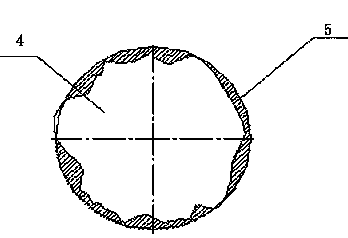

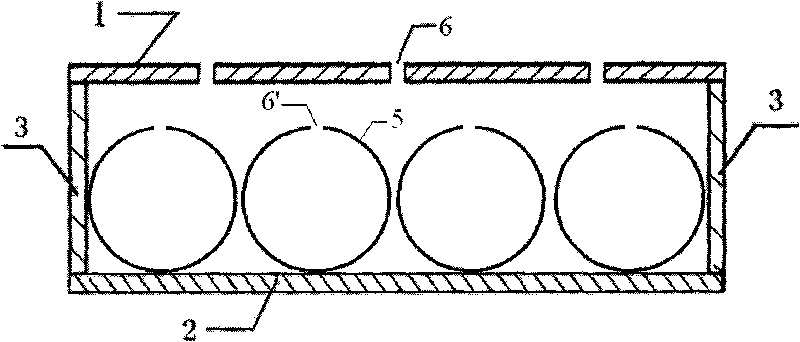

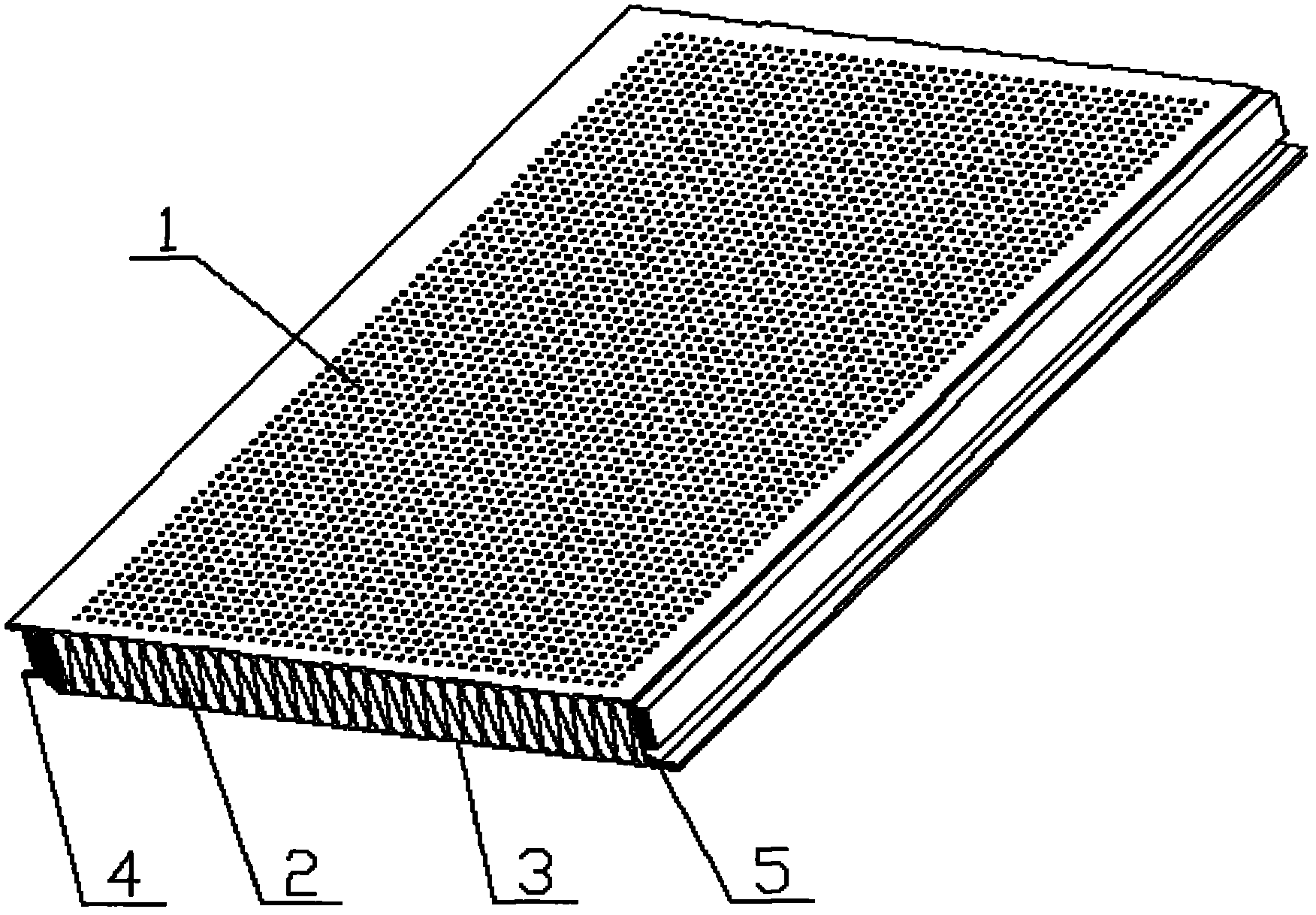

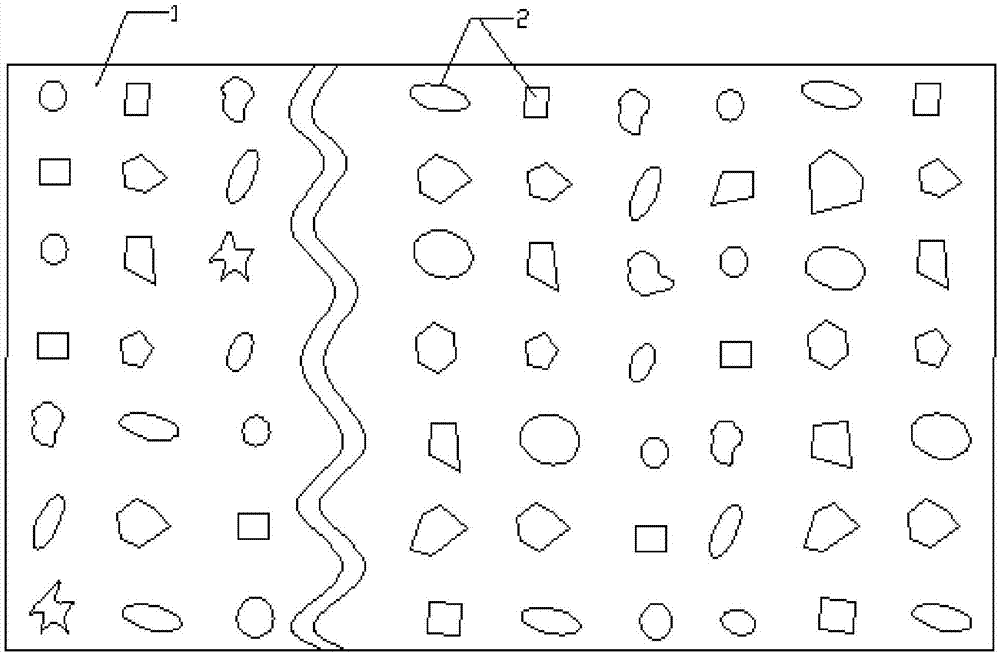

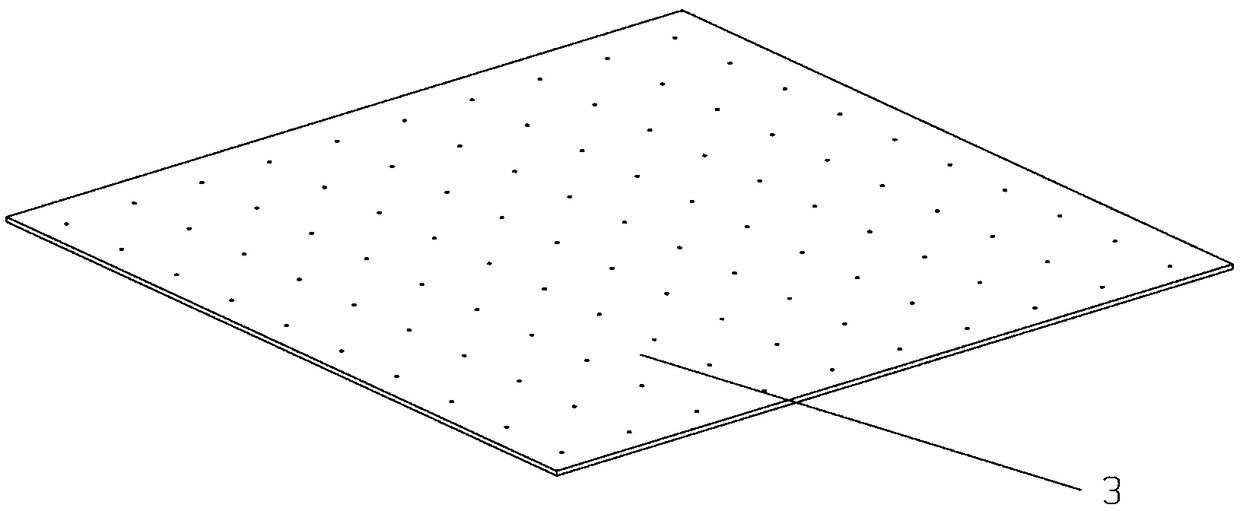

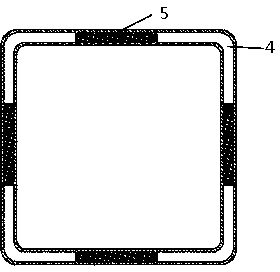

Micro-particle sound-absorbing board and preparation method thereof

ActiveCN104108902AGuaranteed structural strengthImprove the sound absorption coefficientSolid waste managementSound producing devicesFilm-coated tabletAngular coefficient

The invention discloses a micro-particle sound-absorbing board and a preparation method thereof. The micro-particle sound-absorbing board comprises a binding agent and sound-absorbing particles, wherein the outer surfaces of the sound-absorbing particles is coated with a layer of the binding agent; the angular coefficient of the particles coated with the binding agent is less than 1.3; the sound-absorbing particles comprise skeleton particles and filling particles; the skeleton particles are used for forming a skeleton of the sound-absorbing board; the filling particles enter pores among the skeleton particles to form sound-absorbing gaps; the average diameter of a cross section of the sound-absorbing gap is 0.07mm. Meanwhile, a two-section manufacturing process namely first-film-coating and second-curing-shaping of the sound-absorbing board can be used for avoiding an excessive amount of the binding agent from blocking the gap among the particles and further improving the angular coefficient of the particles. Therefore, the micro-particle sound-absorbing board and the preparation method of the micro-particle sound-absorbing board can be used for ensuring the structural strength of the sound-absorbing board and improving the sound-absorbing coefficient of the sound-absorbing board at the same time, and can obtain relatively good sound-absorbing effects.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

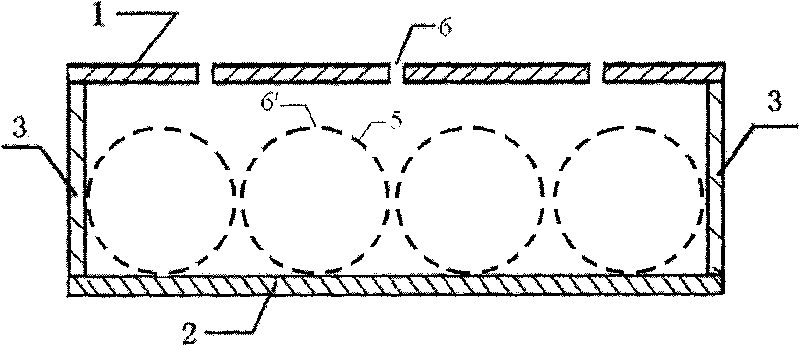

Composite sound absorbing device with built-in resonant cavity

ActiveCN101727894AIncrease sound resistanceIncrease acoustic reactanceSound proofingSound producing devicesResonant cavityResonance

The invention relates to a composite sound absorbing device with a built-in resonant cavity. The device comprises a perforated plate with a plurality of first holes, a back plate and a side plate, wherein a sealed cavity is formed by the perforated plate, the back plate and the side plate. The device is characterized in that at least one or more resonant cavities are placed in the sealed cavity; the resonant cavity is provided with at least one or more second holes; at least one of the second holes is communicated with the sealed cavity; the volume V of the resonant cavity is equal to 10mm3-1*1,010mm3, and the thickness of the wall of the cavity is 0.05 to 10 mm; and the aperture d, of the second hole on the cavity is equal to 0.05 to 100 mm, and the perforated percentage sigma, is 0.01 to 30 percent. The device forms acoustic scattering in the sealed cavity through the resonant cavity; and the second hole increases the acoustic resistance and the multi-cavity coupling resonance. The device has a flexible design and contributes to improving sound absorbing effect and expanding the sound absorbing frequency band.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

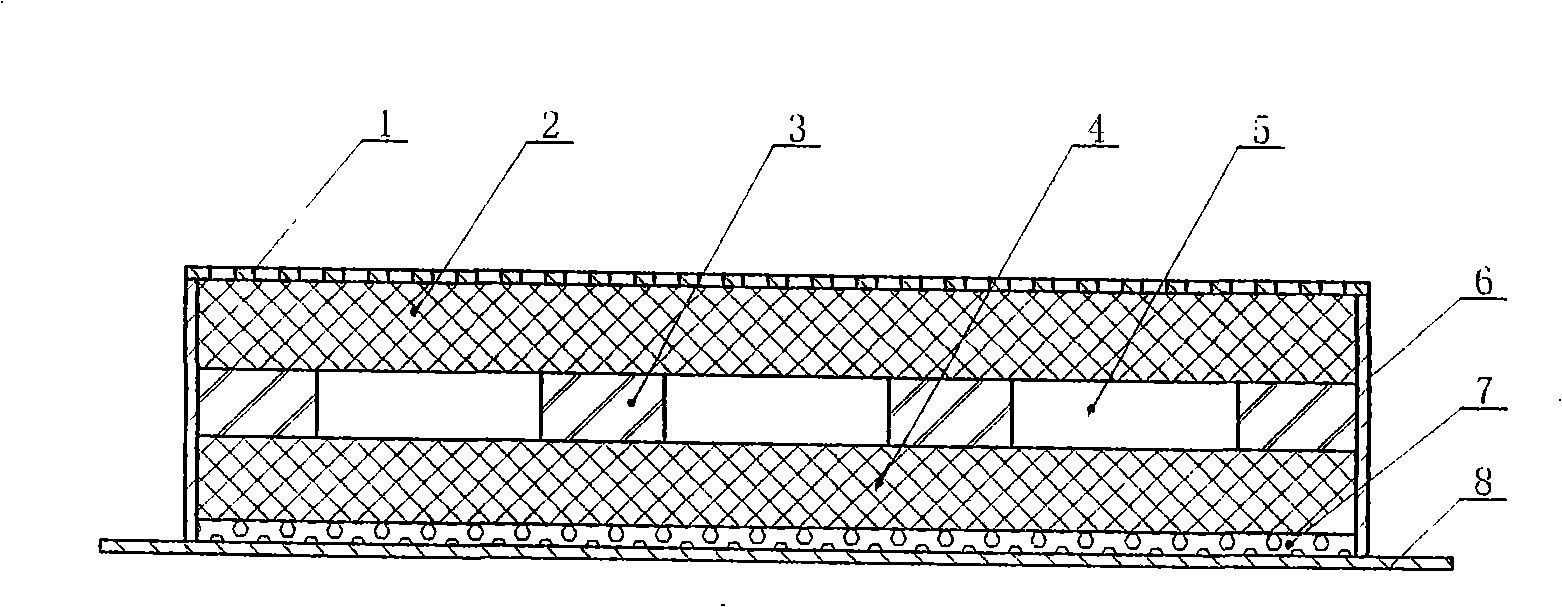

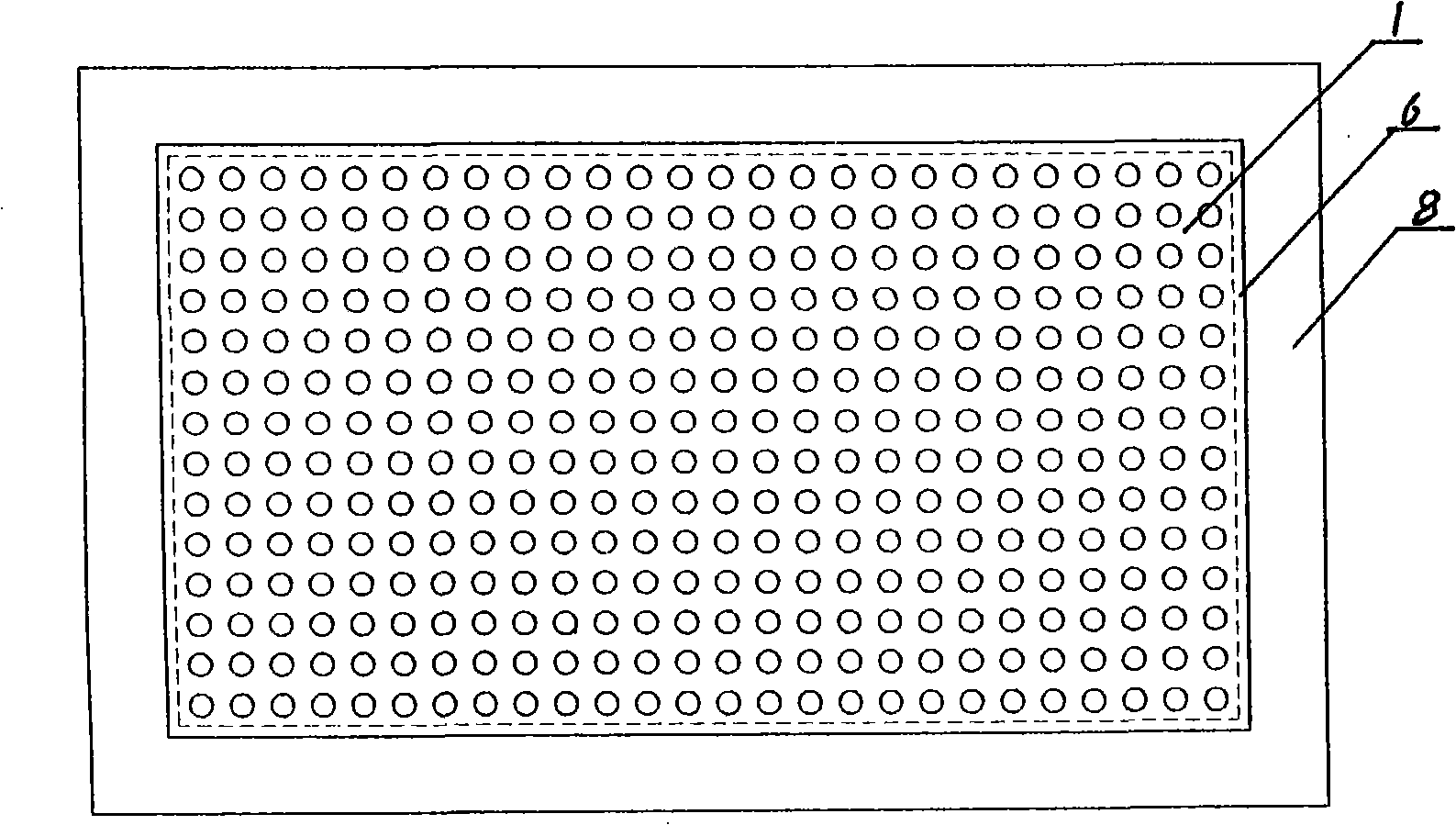

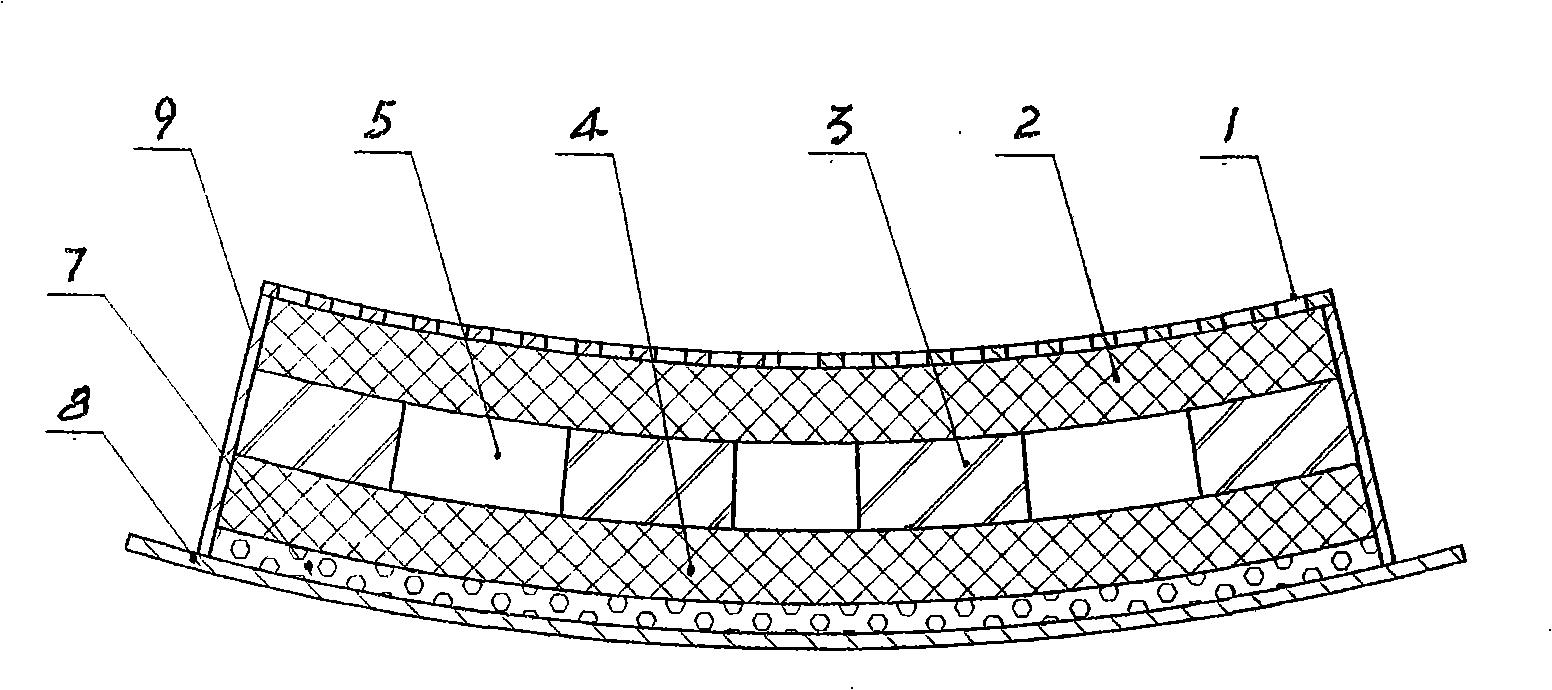

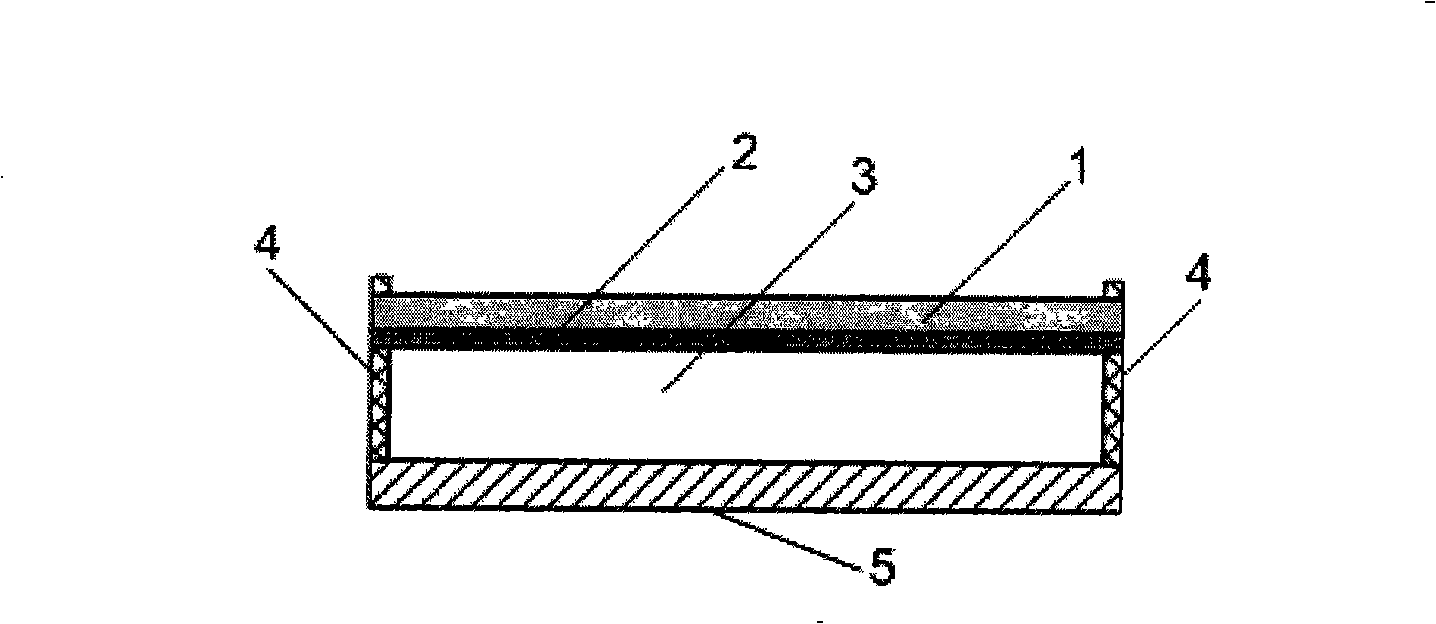

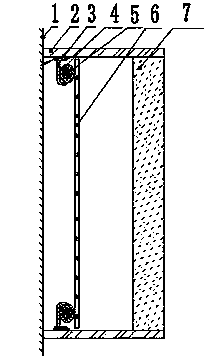

Sound insulation module on sound insulation apparatus of large noise equipment

InactiveCN101404159ASimple structureImprove the sound absorption coefficientSound producing devicesSteel platesWool

The invention provides a sound insulation module on the sound insulation device of large-noise equipment, which is widely applied to the noise disposal of large-noise equipment in the industries such as power, petrochemicals, metallurgy and the like. The module, from external layer to internal layer, sequentially comprises a sound insulation plate, a damping vibration layer and a sound-absorbing wool plate; from internal layer to external layer, the module sequentially comprises a porous sound-absorbing steel plate and a sound-absorbing wool plate; the circumference of the module is provided with reinforcing plates vertical to the porous sound-absorbing steel plate and the sound insulation plate; the sound insulation module is characterized in that a layer of sound insulation wool felt and a rectangular sound refluxing chamber are arranged between two sound-absorbing wool plates uniformly and intermittently. The sound insulation module prolongs the staying time of the sound in the sound refluxing chamber, enlarges the contact area between the noise and the wool plate and the wool felt, converts more sound energy into the heat energy inside the wool plate and the wool felt and improves the sound-absorbing coefficient of the material; the sound insulation quantity reaches more than 40dB, which is higher than the similar product by 15-35%.

Owner:JIANGSU ZHONGNENG POWER EQUIP

Method for producing damping porous denoise tunnel asphalt covering material

ActiveCN101173104AExcellent structural performanceImprove skid resistanceBuilding insulationsFiberSurface layer

The invention relates to a preparation method of a tunnel asphalt surface layer material. A preparation method for damping porous noise-reducing tunnel asphalt pavement material is characterized in that it comprises the following steps: 1) preparation of high-viscosity and high-elasticity modified asphalt: base asphalt according to the mass ratio of each component: modifier SBS : Activated rubber powder: Viscosifying compatibilizer: Antioxidant: Stabilizer=100: 6.0~18.3: 20.2~45.7: 1.2~3.7: 0.2~1.4: 0.4~1.9, select; obtain high viscosity and high elasticity modification Asphalt; 2) Add flame retardant to high-viscosity and high-elasticity modified asphalt, heat and melt high-viscosity and high-elasticity modified asphalt to add flame retardant, stir for 3-9 minutes, and stand at 150-170°C for 15-30 minutes to obtain Flame-retardant high-viscosity high-elasticity modified asphalt; 3) according to the mass ratio, mineral material: flame-retardant high-viscosity high-elasticity modified asphalt: fiber stabilizer = 100: 3.6~5.2: 0.1~0.4, choose; noise tunnel asphalt surface material. The invention has the functions of noise reduction, flame retardancy and anti-skid.

Owner:WUHAN MUNICIPAL CONSTR GROUP

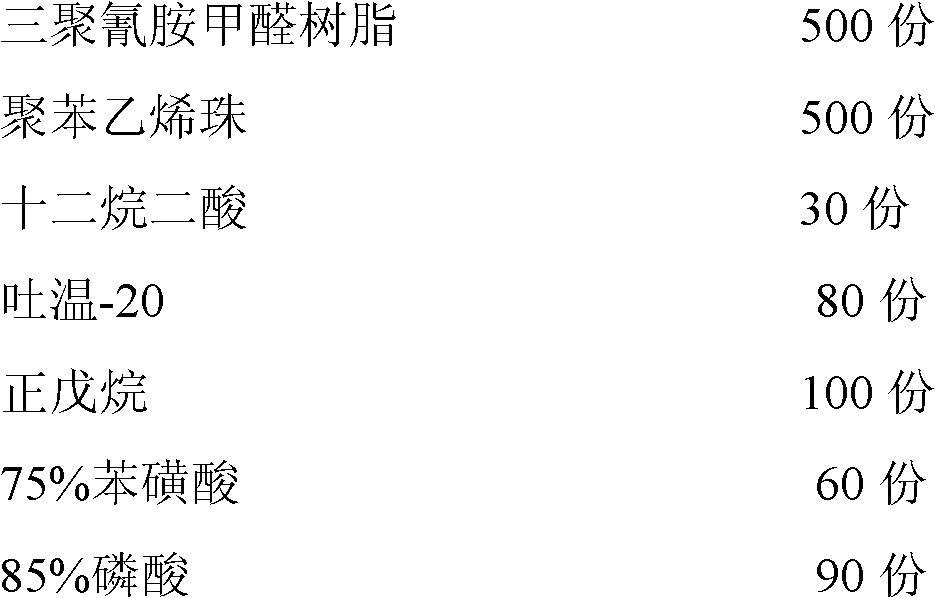

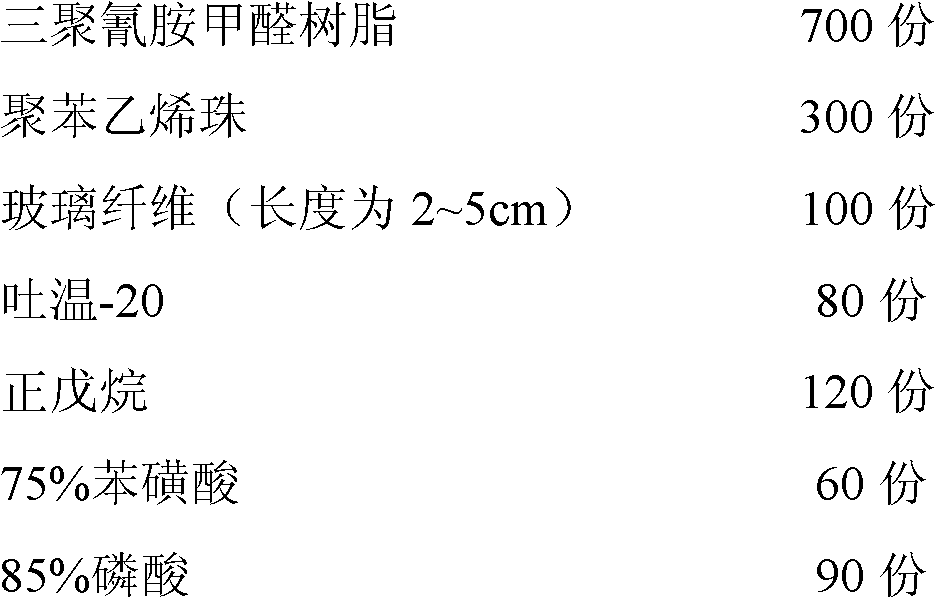

Macromolecular composite foam material as well as preparation method and application thereof

ActiveCN103374200AImprove flame retardant performanceImprove sound absorptionSynthetic resin layered productsIsolation effectFoaming agent

The invention belongs to the technical field of macromolecular materials and discloses a macromolecular composite foam material as well as a preparation method and application thereof. The material is formed by the following components in parts by weight: 50-500 parts of polystyrene bead, 500-950 parts of melamine formaldehyde resin, 100-200 parts of a foaming agent, 100-200 parts of a curing agent, 0-200 parts of a surface active agent, 0-150 parts of a flexibilizer and 0-200 parts of an additive. The preparation method comprises the following steps of: stirring 50-500 parts of polystyrene bead, 500-950 parts of melamine formaldehyde resin, 100-200 parts of foaming agent, 0-200 parts of surface active agent, 0-150 parts of flexibilizer and 0-200 parts of additive for 4-6 minutes, preheating the components for 5-10 min so that the temperature of a mixture is 30-40 DEG C, then adding 100-200 parts of curing agent, stirring for 1-2 minutes, pouring a second mixture into a preheated die for foaming and curing for 2-3 hours, thereby obtaining the macromolecular composite foam material. The invention also discloses application of the macromolecular composite foam material in serving as an insulation plate. The macromolecular composite foam material provided by the invention has high anti-flaming property and a good sound isolation effect.

Owner:HEFEI GENIUS NEW MATERIALS

Production method of centrifugal glass cotton-like fiber

InactiveCN103130410ALow densityLow thermal conductivityGlass making apparatusChemical reactionCentrifugation

The invention discloses a production method of a centrifugal glass cotton-like fiber. According to the production method of the centrifugal glass cotton-like fiber, materials of quartz sands, orthoclases, limestones, glass cullet, soda ashes, borax and the like are adopted, the materials are mixed in a reasonable proportion, glass liquids can be obtained after physical and chemical reactions through kiln high-temperature melting, and short glass fiber cotton aggregates can be thrown out through high-speed centrifugal injection. Material produced through the production method of the centrifugal glass cotton-like fiber has the advantages of being small in density, low in heat conductivity, high in acoustic absorptivity, flame-resistant, frost-resistant, and not prone to decay. The material is ideal heat preservation and heat insulation material, and is mainly used in the heat insulation process of building rail structures, industrial equipment, and pipe networks, and fireproofing and the like of the buildings. The material can further used as a sound absorber which absorbs and eliminates sounds, sound-absorbing barriers, sound-absorbing wall faces and the like.

Owner:吴振华

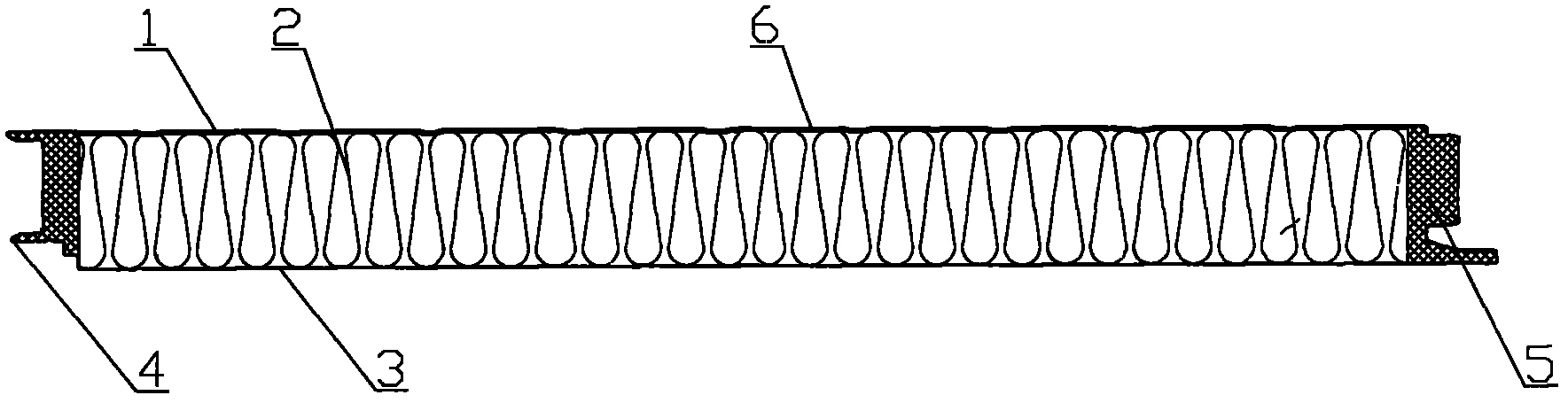

Compound sound insulation-absorption barrier board

ActiveCN101982613AGood hydrophobicityAvoid CapillarityNoise reduction constructionMicrometerAverage diameter

The invention discloses a compound sound insulation-absorption barrier board, comprising a front panel, a rear panel and a core material fixed between the front panel and the rear panel in a bonding manner, wherein, the core material is arranged in a strip shape, and the fiber direction of the core material is vertical to the front panel and the rear panel; multi-tongue rabbets are arranged at the two sides of the compound sound insulation-absorption barrier board at the joint of the front panel and the rear panel and can be spliced mutually; the front panel is a perforating panel; micropores are distributed on the perforating panel, wherein, the perforated rate of the micropores is more than 3% to 30%; the porosity of the core material is 97-98.4%; the average diameter of the fiber is 5-6 micrometers; the fiber length is 150-200 micrometers; and the noise enters into the core material through the micropores and is absorbed along the fiber direction of the core material. The compound sound insulation-absorption barrier board disclosed in the invention has the advantages of absorbing the noise in the environment, simultaneously insulating the noise, and avoiding the influence of the noise to the surrounding environment.

Owner:CENT INT GROUP

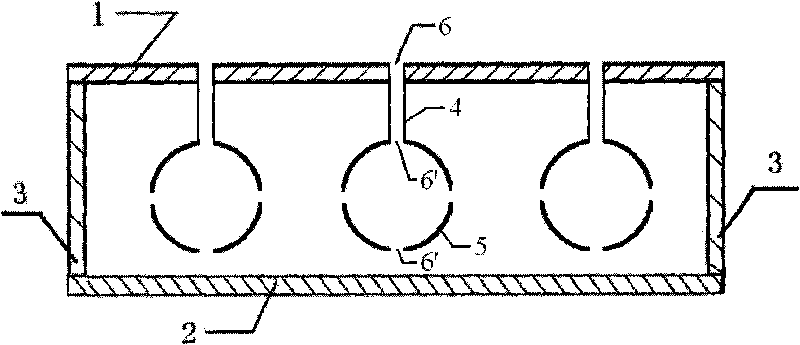

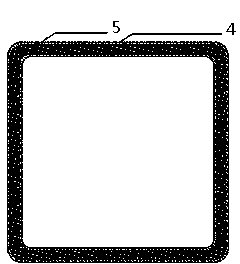

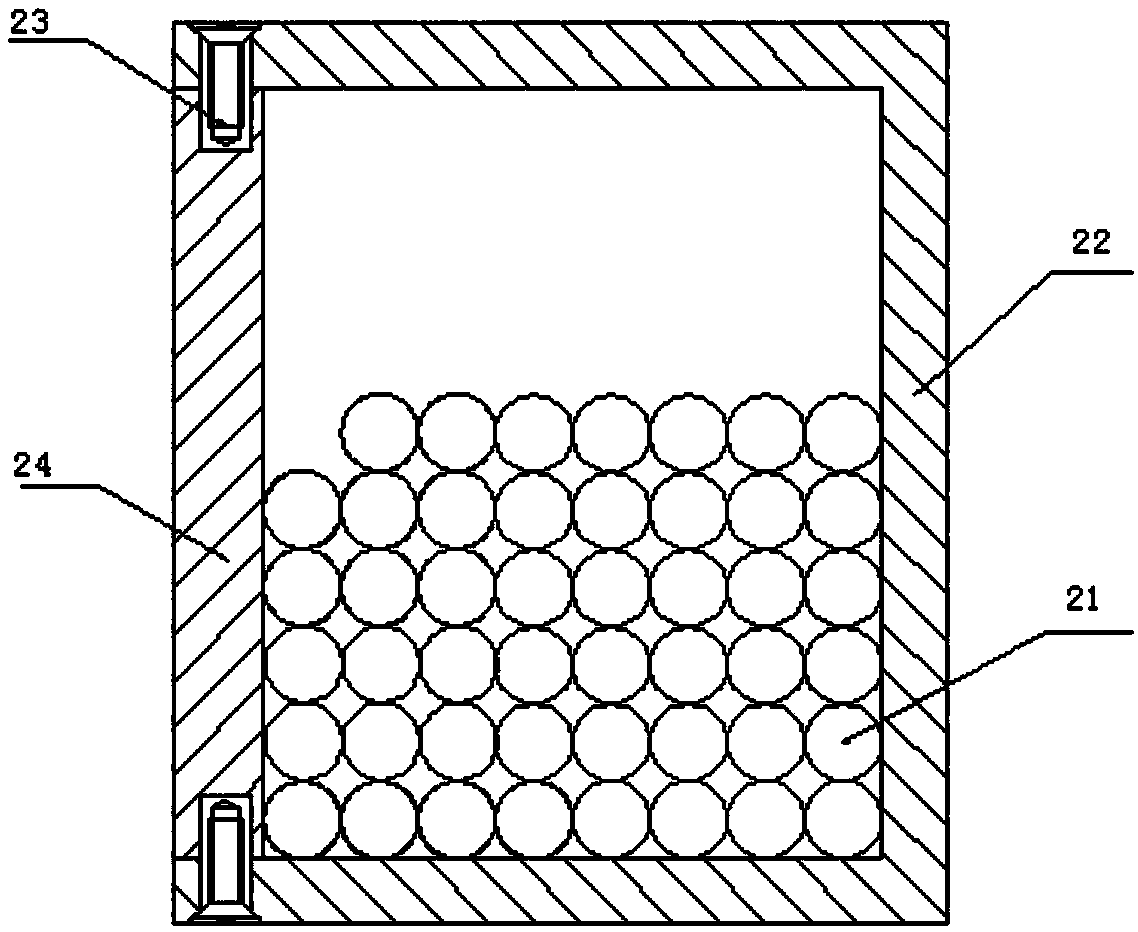

Perforated plate resonance sound absorption device possessing built-in cavity

InactiveCN105448287AImprove the sound absorption coefficientSound absorption frequency bandwidthSound producing devicesResonanceSolid particle

The invention discloses a perforated plate resonance sound absorption device possessing a built-in cavity. The device comprises a perforated plate and a plate rear cavity. A closed cavity is arranged in the perforated plate. An internal portion space of the cavity is filled with at least one of a liquid and a solid particle. In the invention, through arranging the closed cavity in the perforated plate and filling a sound absorption material in the cavity, a sound absorption coefficient of the perforated plate resonance sound absorption device is effectively increased and a sound absorption frequency band is widened. Under the condition that a volume is not increased, a suitable scope of the device is increased.

Owner:ZHEJIANG UNIV

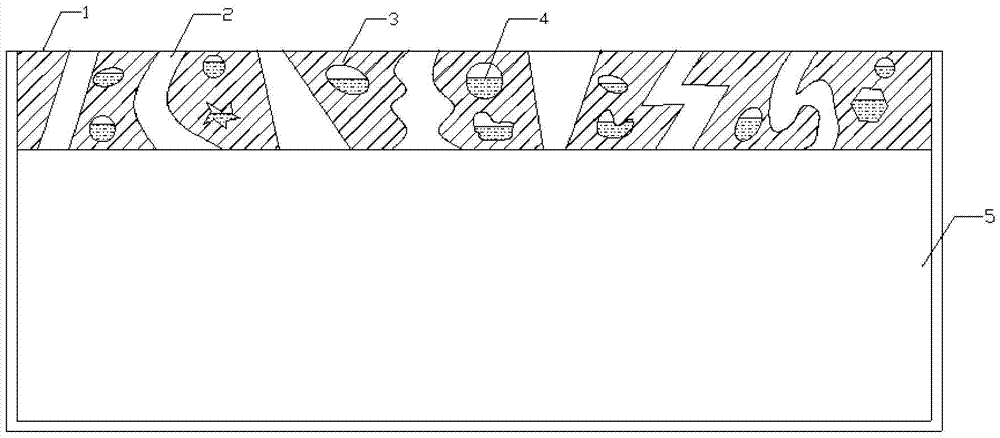

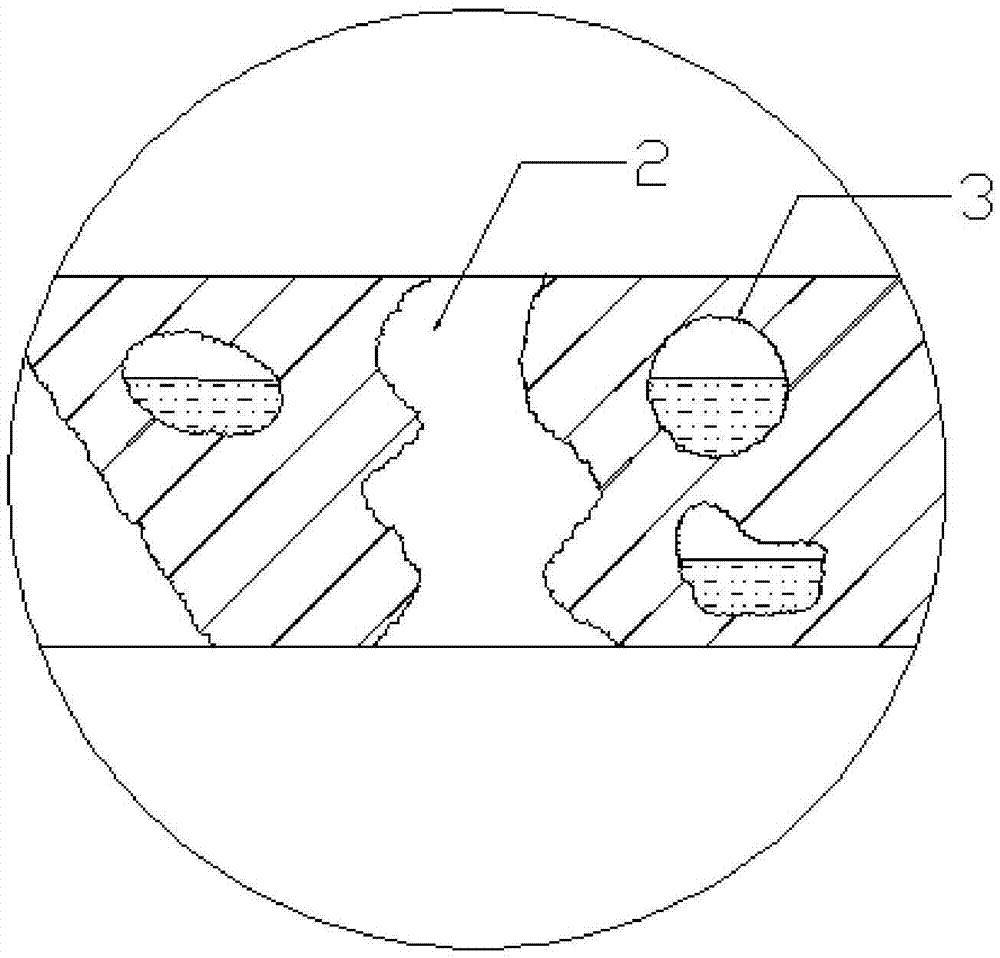

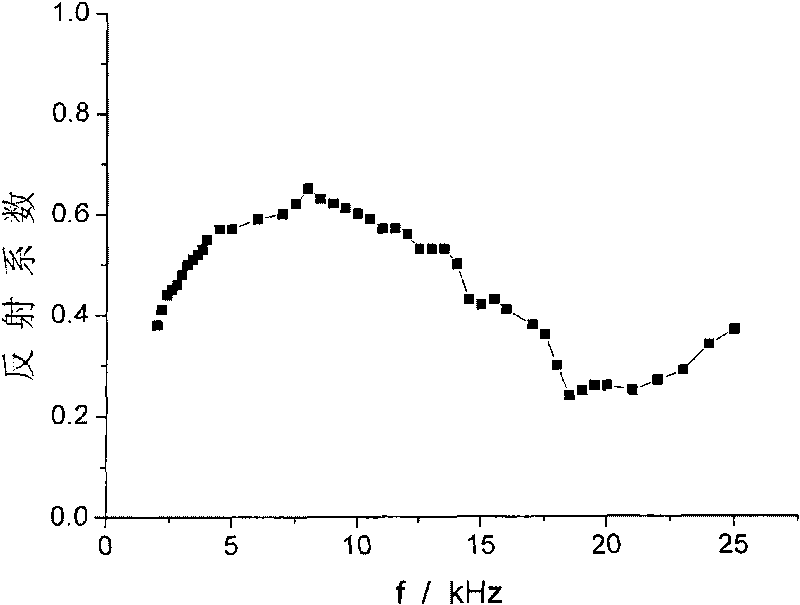

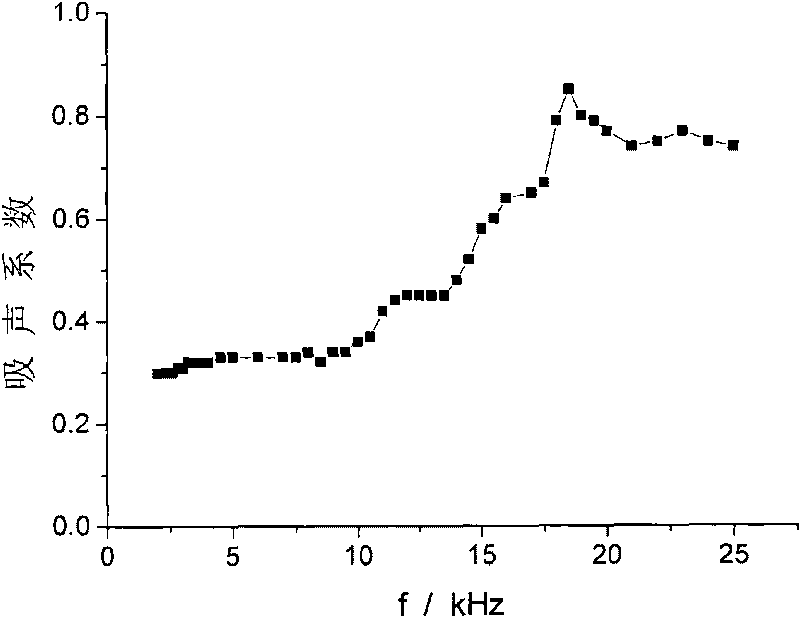

Low-density underwater sound absorbing plate and preparation method thereof

InactiveCN101719367AImprove the sound absorption coefficientLow densitySynthetic resin layered productsSound producing devicesVacuum pumpingUnderwater

The invention relates to a low-density underwater sound absorbing plate mainly used for an underwater sandwich structure core and a preparation method thereof. The sound absorbing plate effectively absorbs sound and has relatively low density. The sound absorbing plate is molded by separately pouring and curing an upper layer and a lower layer, wherein the upper layer comprises the following raw materials in percentage by weight: 55-75 percent of matrix resin, 10-20 percent of filler, 10-30 percent of curing agent and 1-5 percent of auxiliary agent; the lower layer comprises the following raw materials in percentage by weight: 40-65 percent of matrix resin, 15-30 percent of filler, 15-40 percent of cutting agent and 1-5 percent of auxiliary agent; the fillers contain hollow glass beads with grain sizes of 10-800 micrometers; and the thickness ratio of the upper layer to the lower layer is 1:(3-5). The preparation method comprises the following steps of: dewatering the raw materials of the upper layer and the lower layer; respectively proportioning and weighing the raw materials according to a range of 0.75-0.8 of the relative density of the whole plate and the content of the components of the upper layer and the lower layer; preheating the matrix resin of the upper layer and the lower layer; adding the fillers and then adding the auxiliary agents and the curing agents so as to ensure that the fillers are sufficiently dispersed in the matrix resin; initiating crosslinking and carrying out vacuum-pumping treatment on the raw materials; and then pouring the raw materials into a mold by adopting a layered pouring and curing method that the upper layer is firstly poured and then the lower layer is poured.

Owner:NAVAL UNIV OF ENG PLA

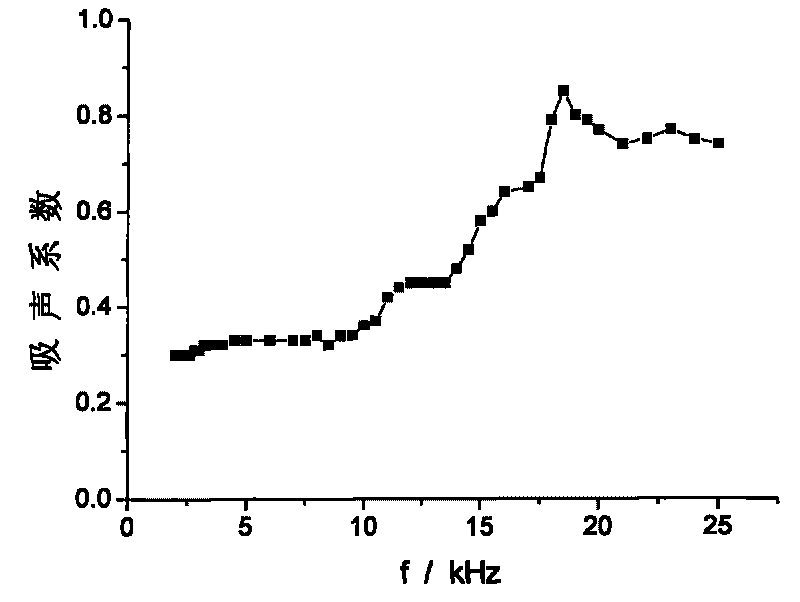

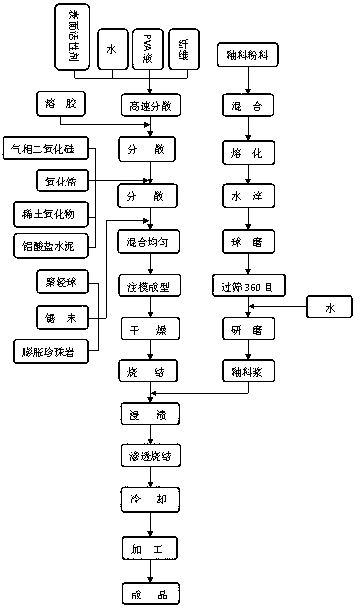

Ultra-microporous ceramic sound-absorbing material and preparation method thereof

ActiveCN103539482AExcellent acoustic absorption performanceHigh strengthCeramicwareFiberSound barrier

The invention discloses an ultra-microporous ceramic sound-absorbing material and a preparation method thereof. The ultra-microporous ceramic sound-absorbing material comprises water, polyvinyl acetate (PVA), composite sol, inorganic fiber, rare earth oxide or zirconium oxide, a microporous material, a pore-forming material and a surfactant, and ceramic glaze which is soaked in a matrix prepared from the above materials. The preparation method comprises the preparation steps of preparing slurry, performing injection molding, sintering, glazing the matrix, sintering and the like. The ultra-microporous ceramic sound-absorbing material disclosed by the invention has excellent sound-absorbing performance; zirconium oxide or / and rare earth oxide is added into the material, so that the whole material has high strength while maintaining excellent sound-absorbing performance; according to detection, the ultra-microporous ceramic sound-absorbing material disclosed by the invention has higher sound-absorbing coefficient compared with the conventional sound-absorbing material, and wide distributed frequency band, in particular, has high sound-absorbing coefficient in low-frequency band, so the material is particularly suitable for serving as the sound-absorbing material of a sound barrier of a high-speed rail.

Owner:CHENGDU ZHONGHONG RAIL TRANSIT ENVIRONMENTAL PROTECTION IND +1

Multi-layer noise elimination/vibration reduction structure and method for manufacturing noise elimination/vibration reduction structure through 3D printing technology

InactiveCN105458262AImprove the sound absorption coefficientIncreased sound absorption frequency bandwidthAdditive manufacturing apparatusGas based dampersEngineeringElectrical and Electronics engineering

The invention provides a multi-layer noise elimination / vibration reduction structure and a method for manufacturing the noise elimination / vibration reduction structure through the 3D printing technology, and relates to the field of material increase manufacture, vibration reduction and noise elimination. The multi-layer noise elimination / vibration reduction structure aims at solving the problem that a conventional noise elimination / vibration reduction structure material is narrow in application field. The noise elimination / vibration reduction structure is made from a metal base material. Except a base plate, micropores are formed in other components. Each layer of longitudinal partition plates are distributed between two side plates at equal intervals. Transverse partition plates are arranged between every two adjacent layers of longitudinal partition plates, and the height and width of a formed multi-layer cavity each change in a gradient mode. The method includes the steps of firstly, designing the size of the noise elimination / vibration reduction structure through computer simulation software according to actual working conditions; secondly, depositing molten powder on the surface of the base plate through the 3D printing technology, and printing the side plates, the longitudinal partition plates and the transverse partition plates. The noise elimination / vibration reduction structure is wide in application range and is formed at a time through 3D printing. The noise elimination / vibration reduction structure and the method are suitable for various fields of construction, navigation, aircrafts, power devices, transportation means and the like.

Owner:HARBIN ENG UNIV

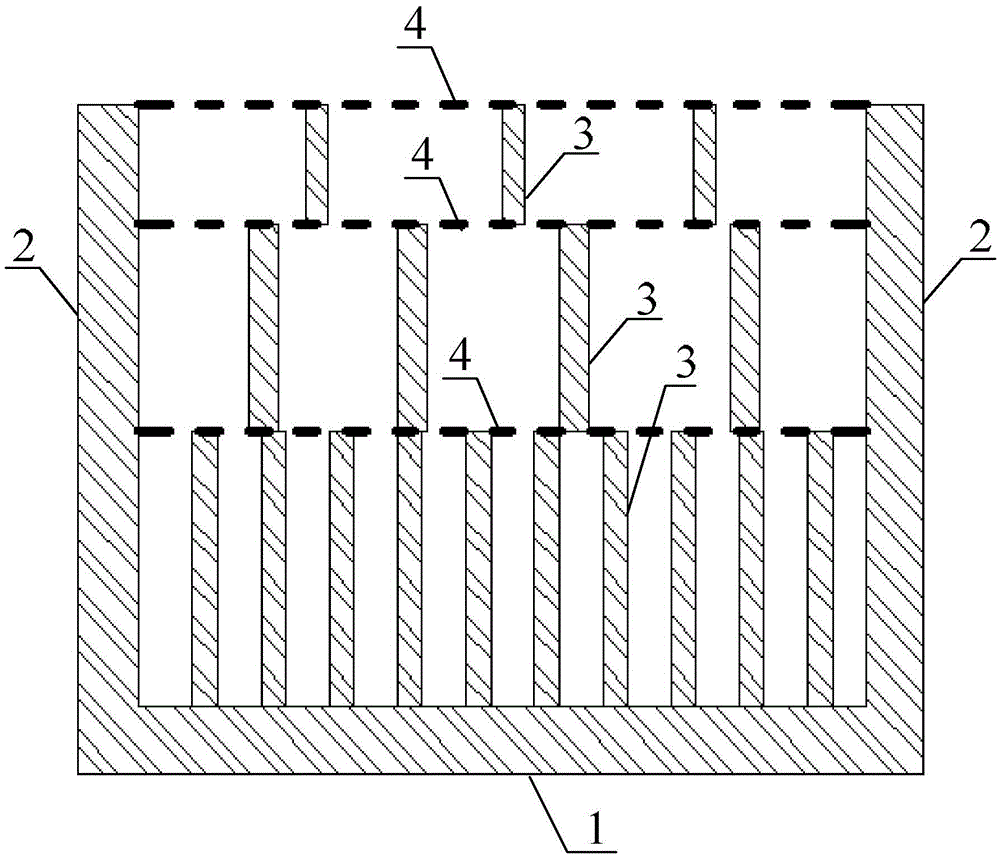

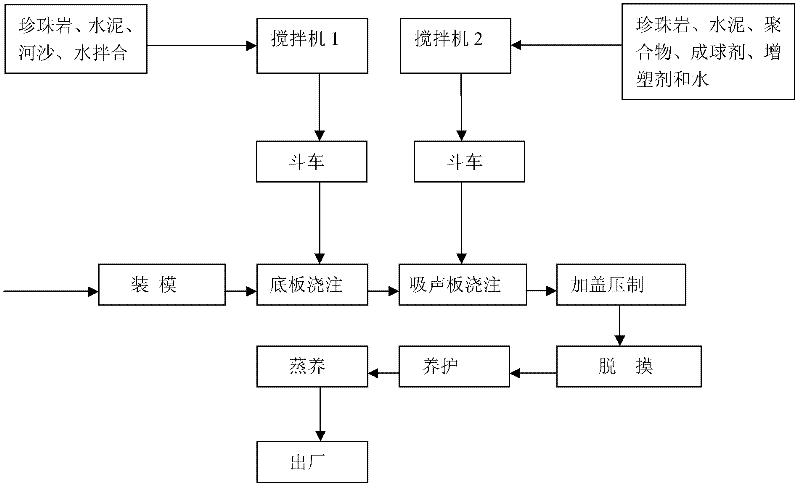

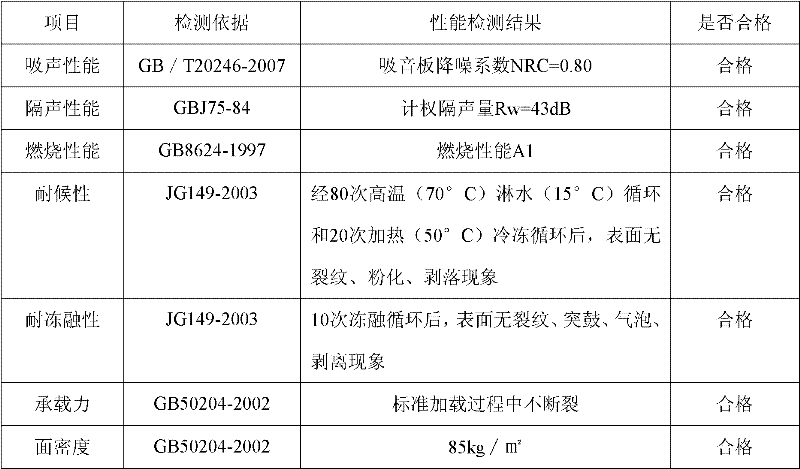

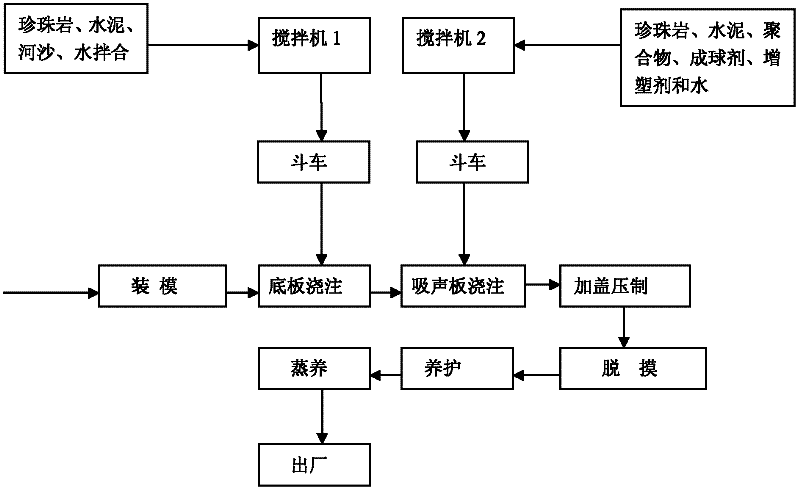

Porous perlite sound absorption material

The invention discloses a porous perlite sound absorption material used for building a sound absorption wall, characterized in that the porous perlite sound absorption material is prepared by the following procedures: blending and pelletizing the materials, pouring a soleplate, pouring a sound absorption plate, pressing, demolding, curing and vapor curing at 40 DEG C, and the like; the material is composed of the following ingredients in mass ratio: 1 part of perlite, 6 parts of 425 cement, 0.3 parts of high early strength cement, 0.1 part of polymer emulsion, 0.1 part of pelletizing agent, 0.01 part of plasticizer and 0.1 part of other accessory ingredients. The sound absorption material using perlite as aggregate disclosed by the invention has the advantages of excellent sound absorption effect, large anti-bending and anti-pressing strength, high sound absorption coefficient and wide sound absorption frequency band, and the sound absorption material has such excellent functions as fire resistance, moisture resistance, durability and innocuity, and the like, so that the sound absorption material has an extensive application prospect.

Owner:四川昊龙高科轨道交通新材料科技股份有限公司

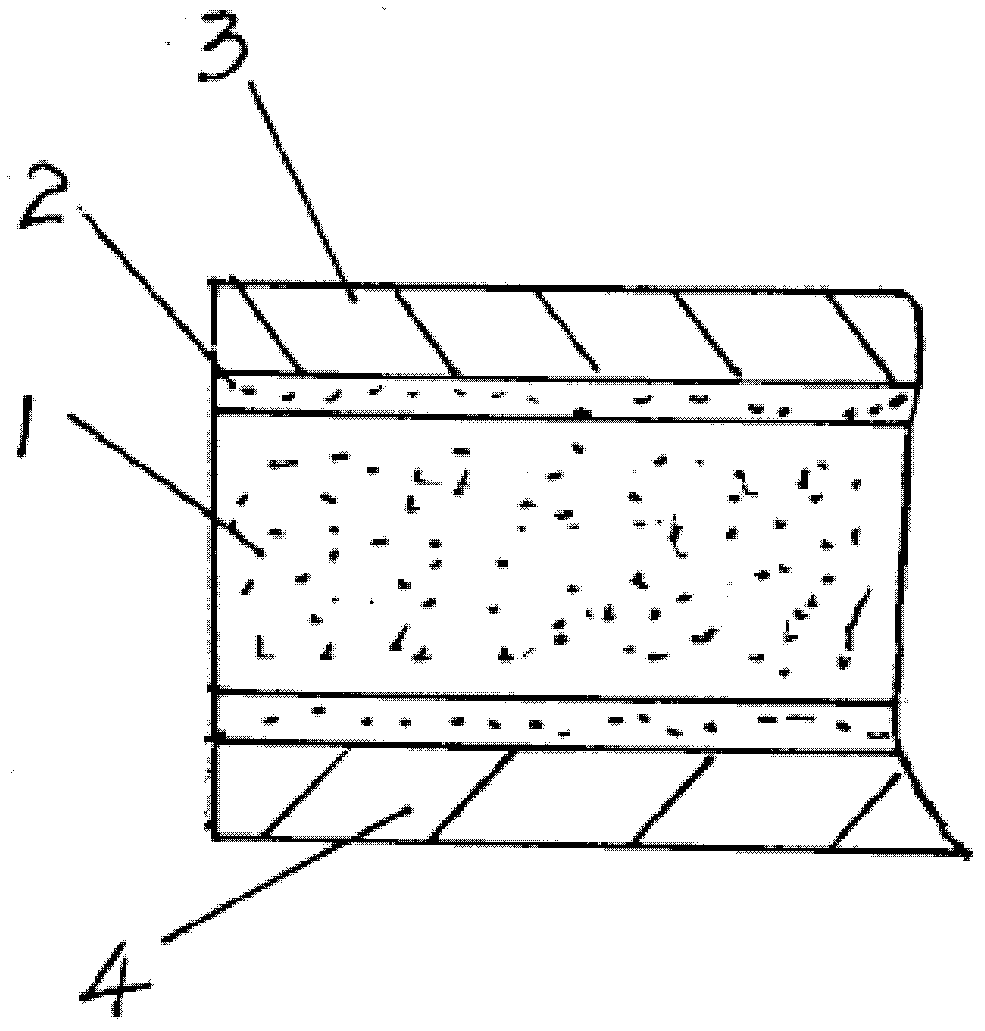

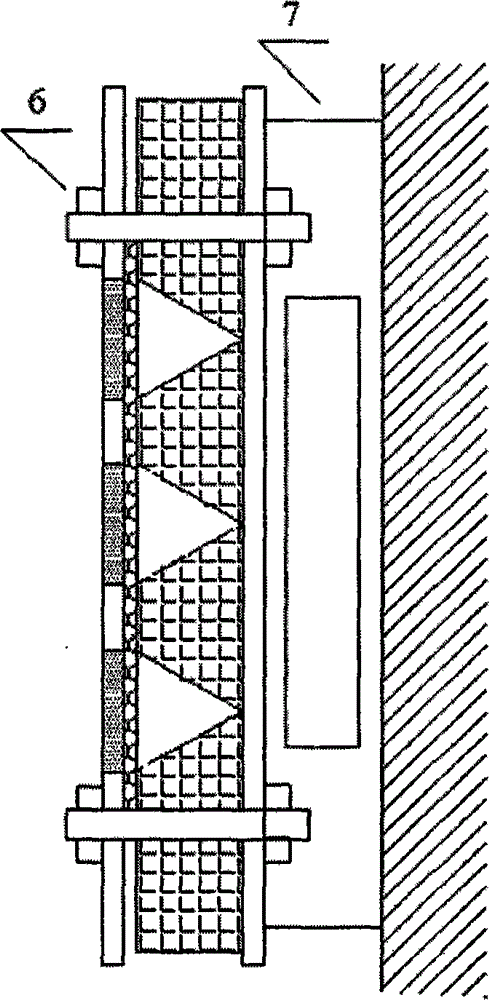

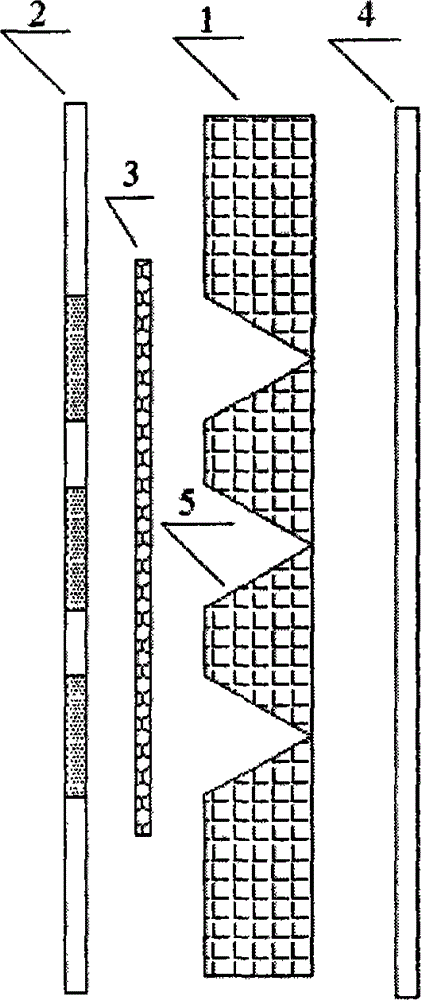

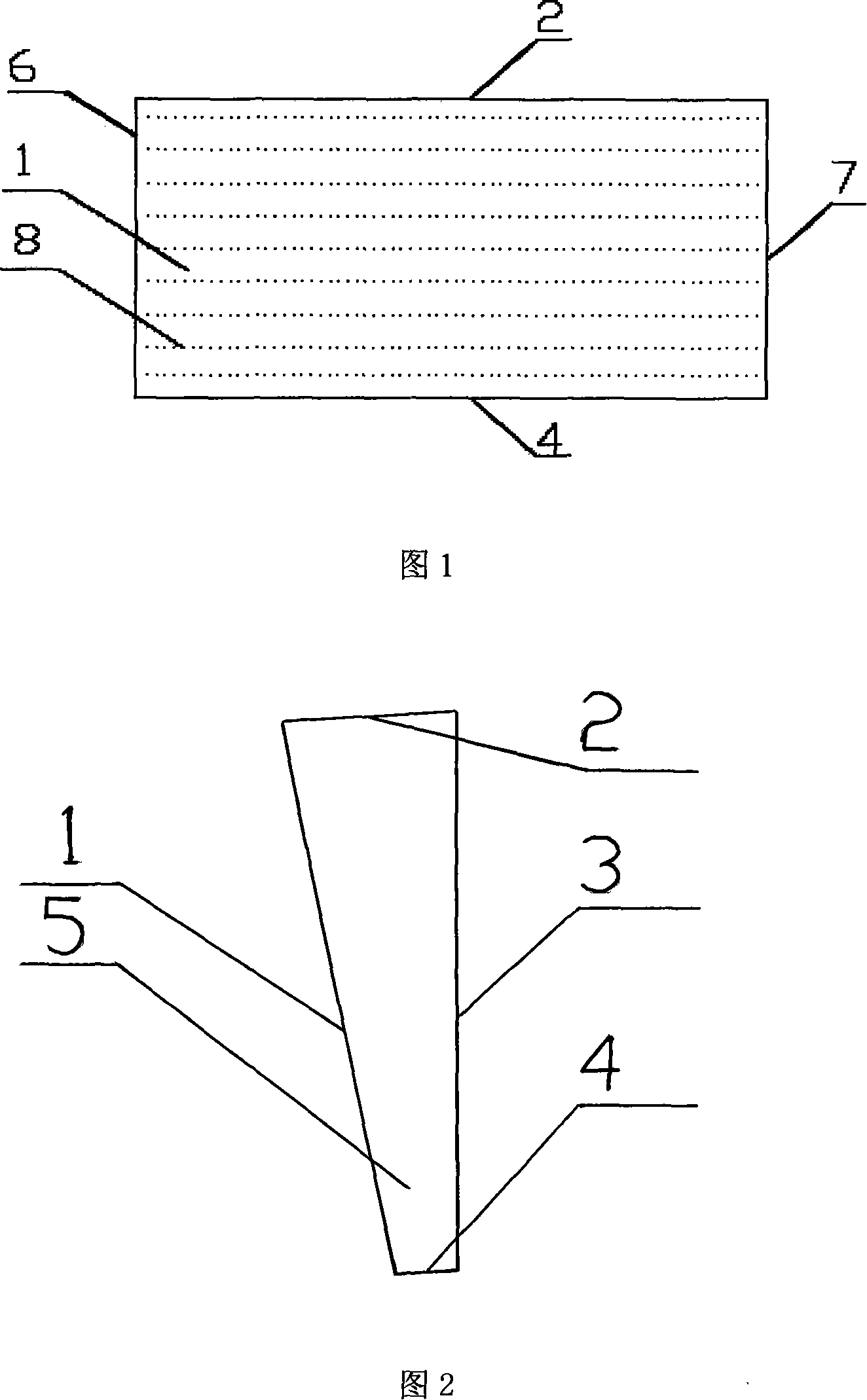

Noise reduction sound absorption layer

ActiveCN104485096AIncrease the barrier to spreadAchieve resistive sound absorption effectSound producing devicesFiberResonance

The invention provides a noise reduction sound absorption layer. The sound absorption layer comprises a keel and a sound absorption component, wherein the component comprises a micro-perforated panel 2, non-woven fabrics 3, a bi-component fiber mat 1 and a back plate 4, which are sequentially arranged along the direction from a noise source to a wall. The sound absorption principle of the noise reduction sound absorption layer couples the effects of bi-component resistive sound absorption and dual-layer resonance sound absorption; low-frequency noise of a substation transformer and a high-voltage reactor is effectively absorbed, and thus the target of reducing sensitive points on the boundary of a transformer substation and sensitive points out of the transformer substation is achieved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

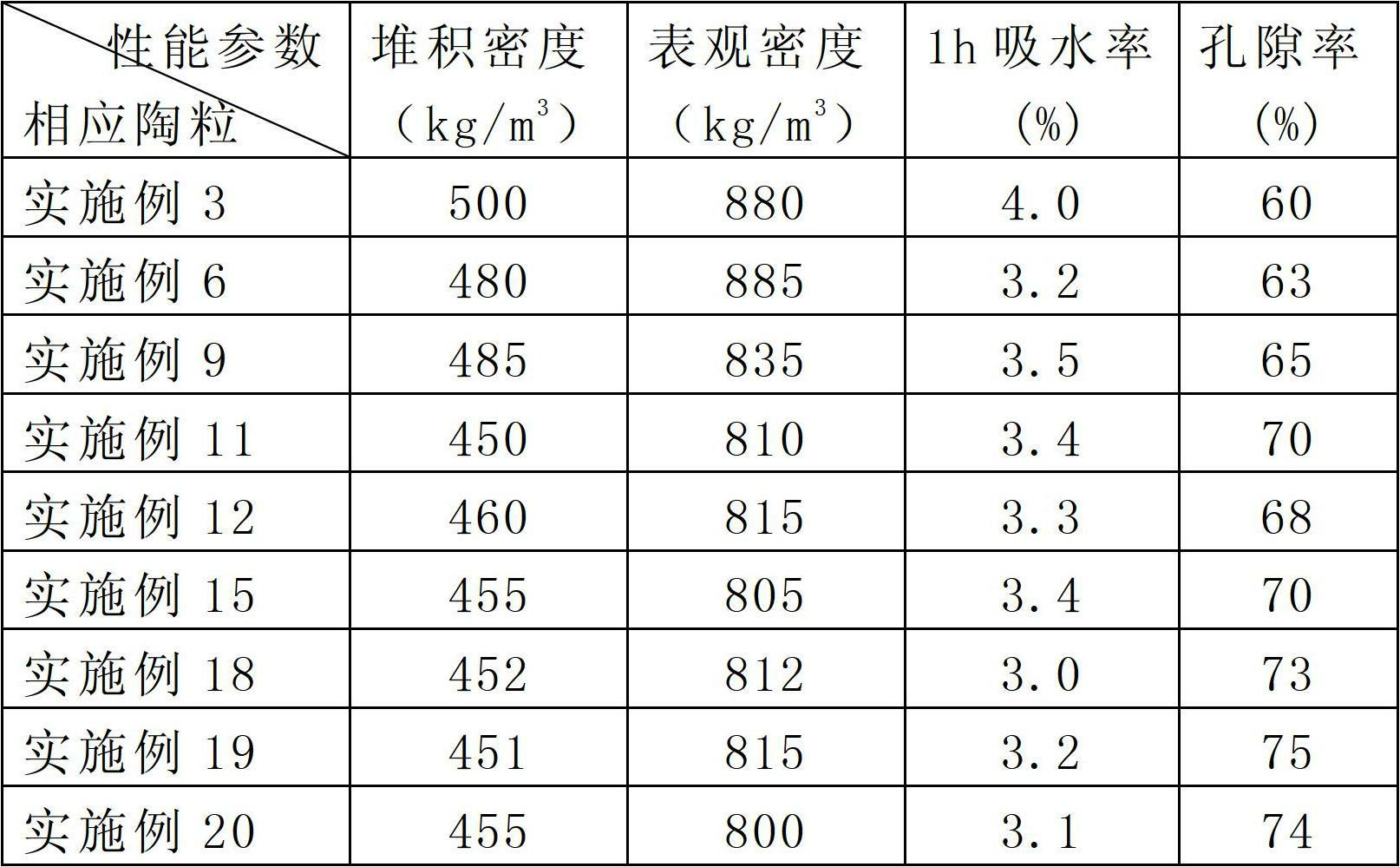

Efficient sound-absorbing ceramsite

InactiveCN102633491AImprove the sound absorption coefficientLightweight and high strengthCeramic materials productionCeramicwarePorositySludge

The invention relates to an efficient sound-absorbing ceramsite, belonging to the technical field of a building material. Aiming to solve the problems that city pollution can not be well solved, product properties are poor, the poor sound-absorbing effects are poor and the production cost is high in the prior art by mainly using the shale as ceramsite, can be solved, The invention provides the efficient sound-absorbing ceramsite, which is prepared from raw materials mainly consisting of raw materials of 60-80% of sludge, 5-20% of the shale, 5-20% of coal ash and 1.0-10% of additive. The efficient sound-absorbing ceramsite provided by the invention has the properties of wide sound-absorbing frequency band, fire resistance, good durability, freezing resistance, seismic resistance, high sound-absorbing coefficient, high porosity, light weight, high strength, heat resistance, anti-permeability and the like. The efficient sound-absorbing ceramsite further can be used for preparing a road barrier and a metro sound-absorbing material and has wide application prospect. Furthermore, the efficient sound-absorbing ceramsite provided by the invention mainly uses city sludge, so that not only can the problem of the city sludge be solved well, but also the overuse of a natural resource of the shale is reduced.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

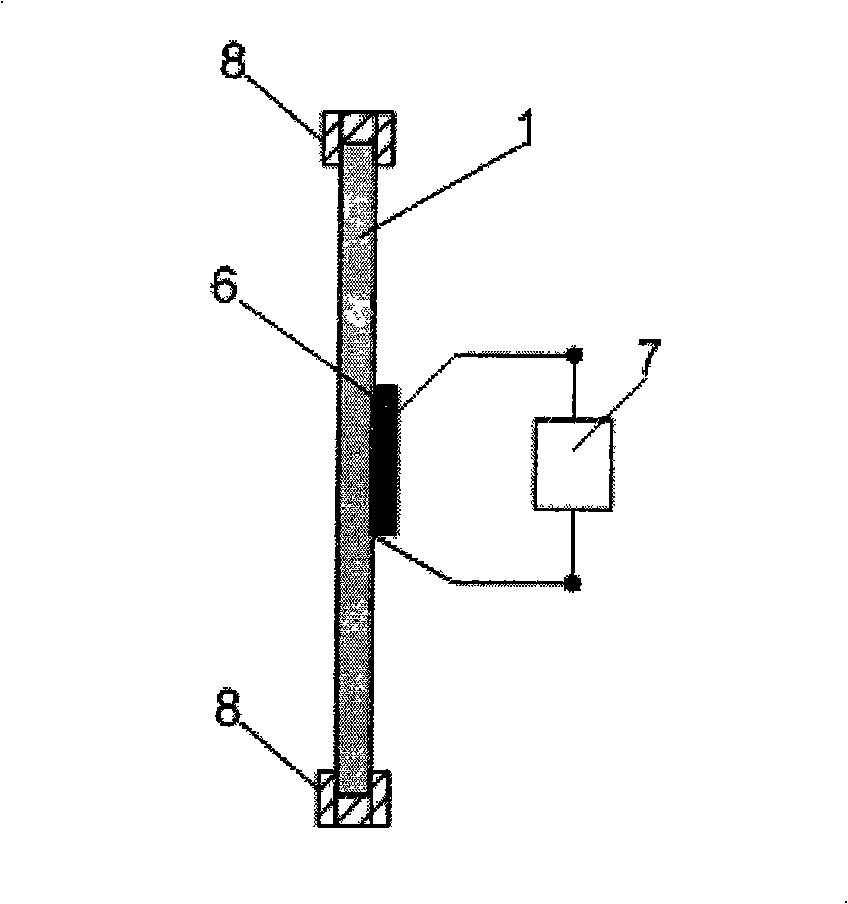

Resonance sound-absorbing structure for sheet

InactiveCN101329865AImprove the sound absorption coefficientIncrease widthSound producing devicesElectricityElectrical resistance and conductance

The invention relates to a thin plate resonance sound absorption structure which comprises a metal thin plate and a piezoelectric ceramic piece pasted on the metal thin plate. A resistor is connected between the two poles of the piezoelectric ceramic piece. The structure of the invention can fulfill the following technical effects of: being capable of effectively improving acoustical absorptivity at the basic frequency of the thin plate, tuning out another sound absorption peak through adjusting inductance and effectively widening the width of sound absorption frequency band through the combination of the sound absorption peak tuned out and the basic frequency sound absorption peak of the thin plate. Besides, the structure of the invention has light weight and small installation space and the acoustical absorptivity around the resonance frequency can reach more than 0.9.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

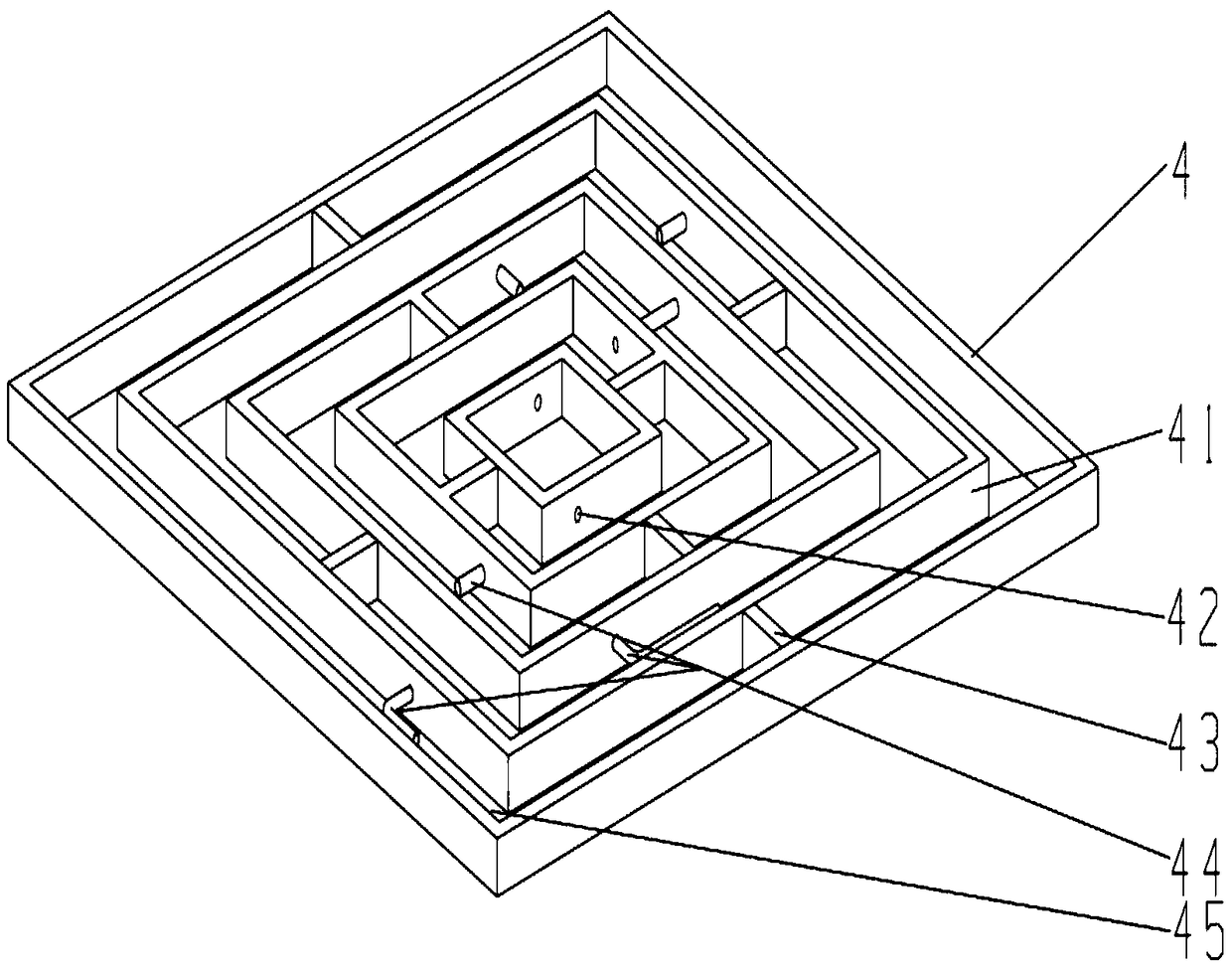

Sound absorption and insulation sandwich plate with labyrinth back cavity

ActiveCN108909083AImprove sound insulationResonant cavity increasedSynthetic resin layered productsSound producing devicesResonant cavityInsulation layer

The invention discloses a sound absorption and insulation sandwich plate with a labyrinth back cavity, and the sound absorption and insulation sandwich plate comprises the labyrinth back cavity. Perforated plates, damping elastic layers and mixed metal plates are in turn symmetrically superimposed on the front side and the back side of the labyrinth back cavity. The labyrinth back cavity is with.The shapes of the labyrinth back cavity, the perforated plates, the damping elastic layers and the mixed metal plates are regular shapes or irregular shapes, and the regular shapes include a circle, an ellipse and a polygon. The labyrinth back cavity, the perforated plates, the damping elastic layers and the mixed metal plates are sealed with damped slurry to prevent leakage, and are connected andfixed together by bolts. Incident sound waves can be reflected multiple times inside a sound insulation layer, the sound insulation quantity can be significantly improved; the resonant cavity can beincreased while increasing of the resonance efficiency, and the sound absorption coefficient is enhanced; the sound absorption frequency band is increased and broadened; and the sound absorption coefficient can be increased while adjusting of the absorption frequency band.

Owner:SOUTH CHINA UNIV OF TECH

High-strength environment-friendly fiber plasterboard and preparation method thereof

The invention discloses a high-strength environment-friendly fiber gypsum board and a preparation method thereof. Iron powder 10‑20 parts, fly ash 10‑20 parts, expanded perlite 8‑16 parts, tourmaline powder 6‑15 parts, glass fiber 10‑20 parts, aluminum silicate fiber 5‑15 parts, tea polyphenol 3 ‑8 parts, 1‑5 parts of adhesive, 4‑10 parts of water glass and 45‑65 parts of water. The invention provides a high-strength environment-friendly fiber gypsum board and a preparation method thereof. The fiber gypsum board has high strength, is not easy to crack, has a low thermal conductivity, and has the function of adjusting the indoor environment. At the same time, the fiber gypsum board has a simple preparation process and is easy to realize. Suitable for industrial production.

Owner:合肥慧林建材有限公司

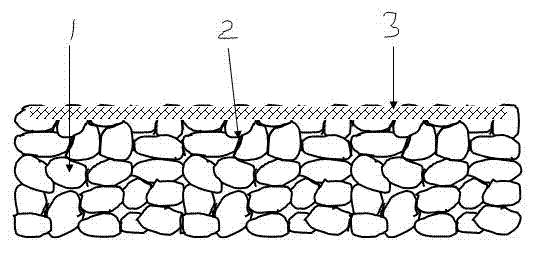

Special sound absorbing plate for polymerized-sand tunnel and preparation method thereof

ActiveCN103922648AImprove the sound absorption coefficientEasy to get materialsNoise reduction constructionWeather resistancePolymer chemistry

The invention discloses a special sound absorbing plate for a polymerized-sand tunnel and a preparation method thereof, and belongs to the field of special sound absorbing materials for reducing the noise of various tunnels. The special sound absorbing plate is mainly combined by three parts, i.e., sand grains, a silicon-based polymer and a steel mesh. The sound absorbing plate is formed by polymerization and pressing from the silicon-based polymer, and screened high-quality natural silicon-dioxide sand grains in combination with the stainless steel mesh. In the polymerization process, the silicon-philic end of the polymer and silicon dioxide on the surfaces of the sand grains are polymerized and dissolved, and the winding end of the polymer enables the sand grains to be close mutually; when the sand grains are contacted, dissolved silicon dioxide is mutually fused and penetrated so as to form good porous sound-absorbing performance. The special sound absorbing plate disclosed by the invention has the advantages that the requirements for physical and acoustic performances such as fire resistance, weather resistance, moisture resistance, safety, environment-friendly effect and high sound-absorbing performance and the like are met, and also has the advantages of convenience in material taking and low cost and the like.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

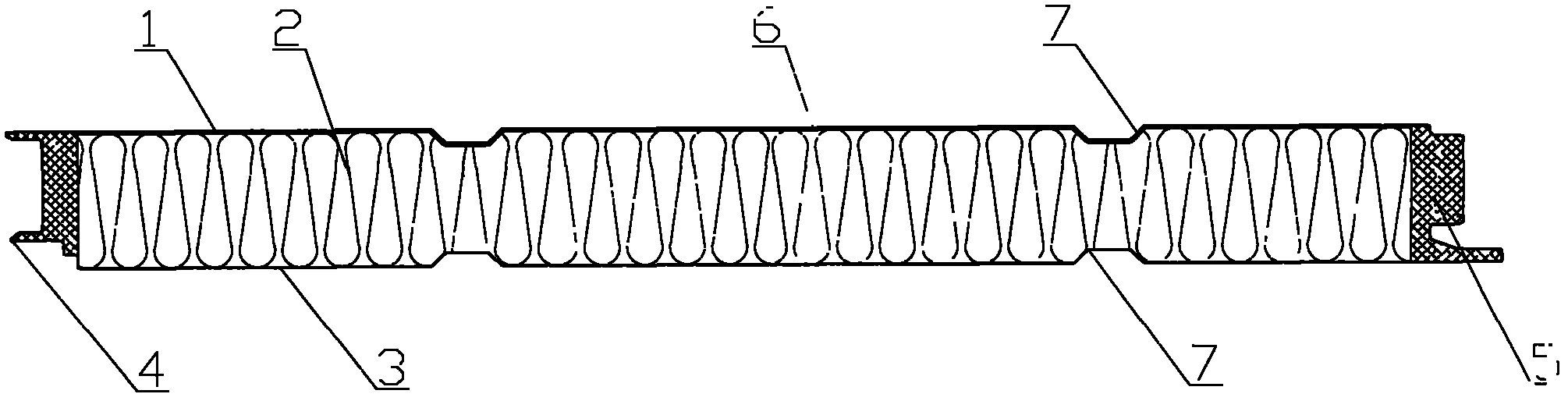

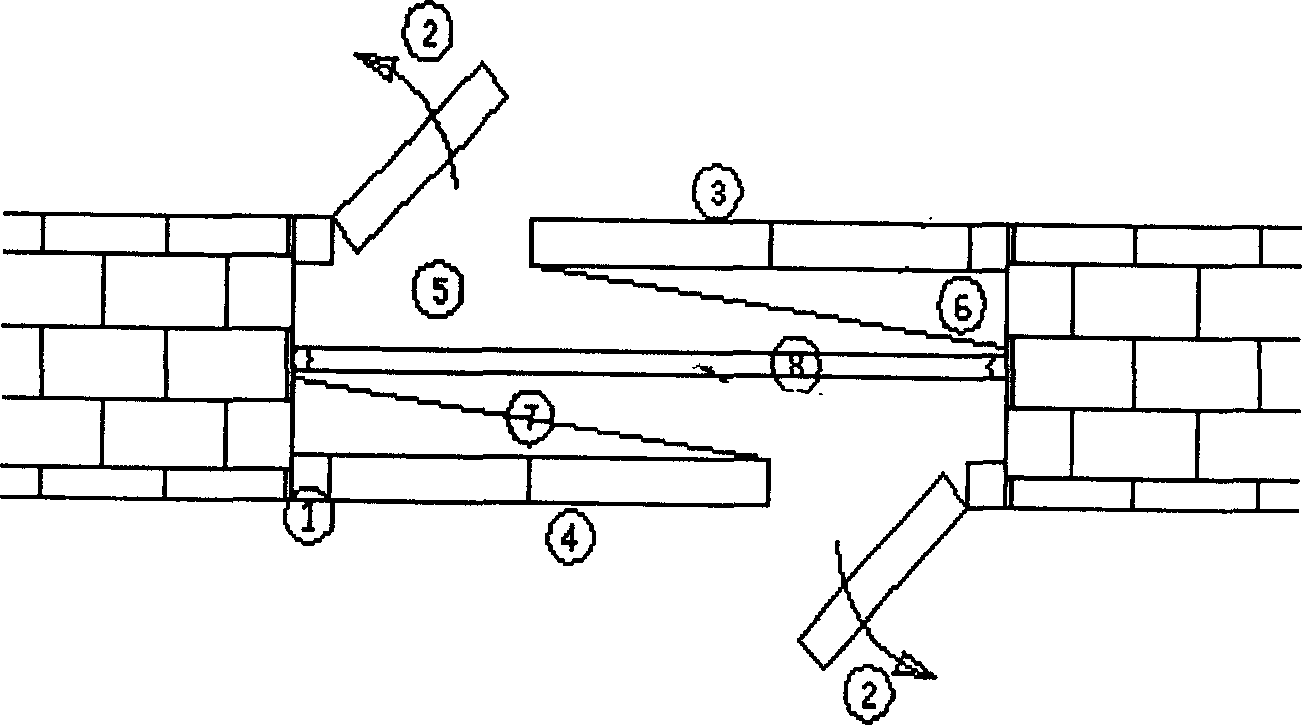

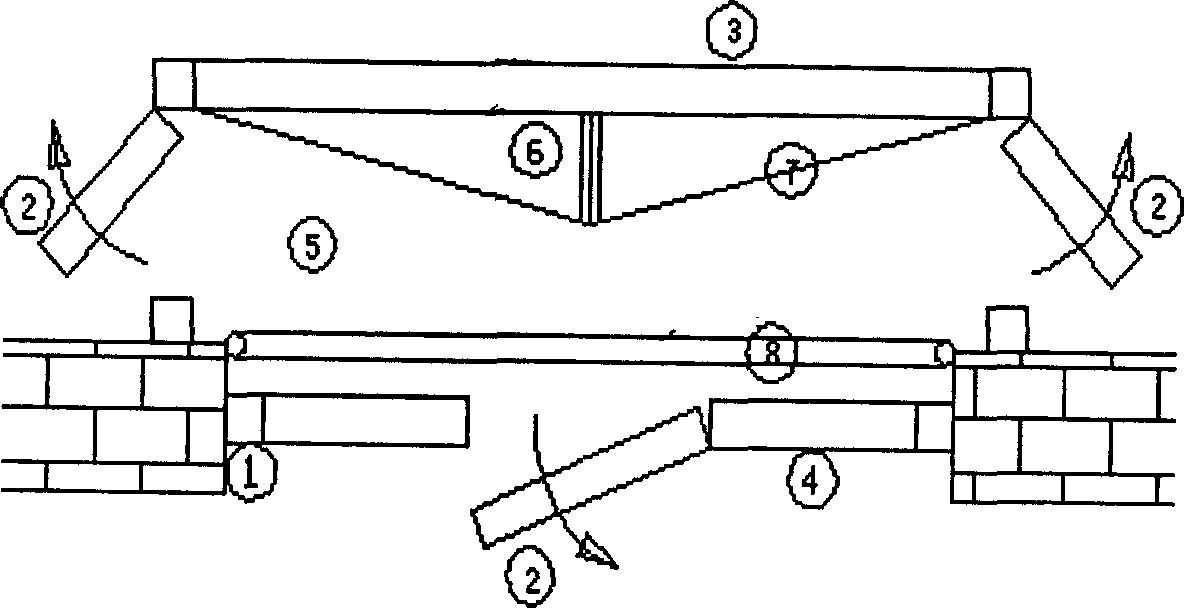

Gradual-change cavity microperforated broad band sound absorption type sound barrier

ActiveCN101139822AImprove the sound absorption coefficientSound absorption frequency bandwidthNoise reduction constructionSound barrierAbsorption factor

The invention belongs to the acoustical technical field and relates in specific to a novel non-fiber type and micropunched sound absorption type sound barrier body with transition cavity. The invention comprises a micropunched panel, a top face, a bottom face, a left end face, a right end face and a back plate; the micropunched panel, the top face, the bottom face, the left end face, the right end face and the back plate are connected to form a closed cavity; the cavity depth appears in a linear transition; the maximum depth is 2.5 to 3.5 times as the minimum depth. The micropunched panel is arranged with micropores with total occupied area of 0.5 percent to 3 percent of the panel area; the micropore aperture is 0.6 to 1.2mm. In actual use, it is only necessary to mount the invented device into a sound barrier vertical column or other places for sound absorption process. The invented device is characterized in being simple, easy and convenient manufacturing, thin shape and being light and having perfect sound absorption performances. Sound absorption band width with sound absorption factor higher than 0.4 exceeds 2 octaves. Therefore, the invention has advantages of broad application scope, easy purging, high-temperature resistance, and superior weather ability. Besides, the invented device can be completely recycled for use to thoroughly avoid the problem of secondary pollution, for which the invention has superior environmental protection function.

Owner:SHAZC GRP CORP LTD

Sound absorption material

The invention discloses a sound absorption material. The sound absorption material is prepared form the following materials in parts by weight: octyl phenolic resin, stearic acid, powered carbon, talcum powder, vermiculite, stannous chloride, dibutyl phthalate, composite sol, inorganic fiber, rare earth oxide, zirconium oxide, a surfactant, aluminate cement and PVA aqueous solution. The sound absorption material has the advantages that zirconium oxide and rare earth oxide are added, so that the overall sound absorption material maintains good sound absorption property and also has high strength; octyl phenolic resin and complex sol are added, so that adhesive property of the sound absorption material is improved, and a sizing speed is high; powdered carbon, talcum powder and vermiculite are added, so that holes are formed in the surface of the sound absorption material while the sound absorption material is sized, sound absorption property is higher than sound absorption coefficient of a common sound absorption material, distribution frequency band is wide, especially the sound absorption coefficient in a low frequency band is high, a base material is small in size, and application property is excellent.

Owner:江苏鑫国精密模具有限公司

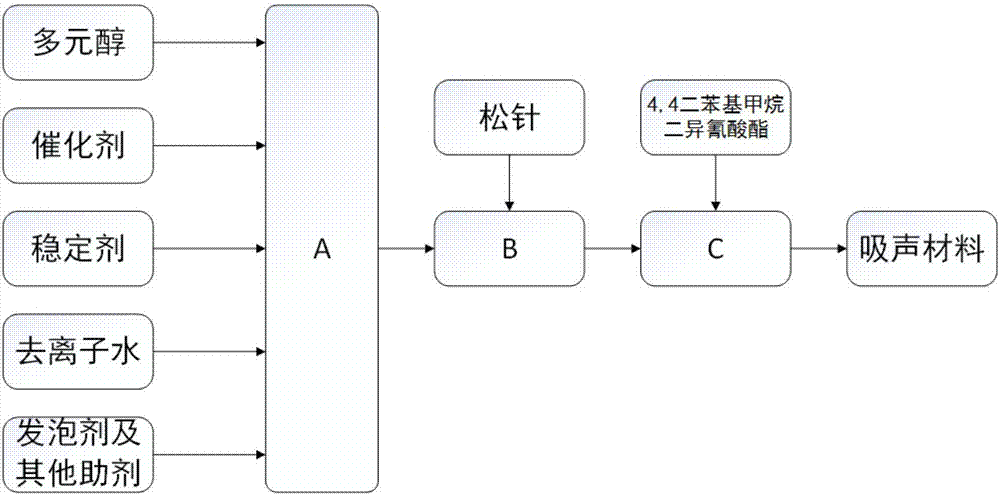

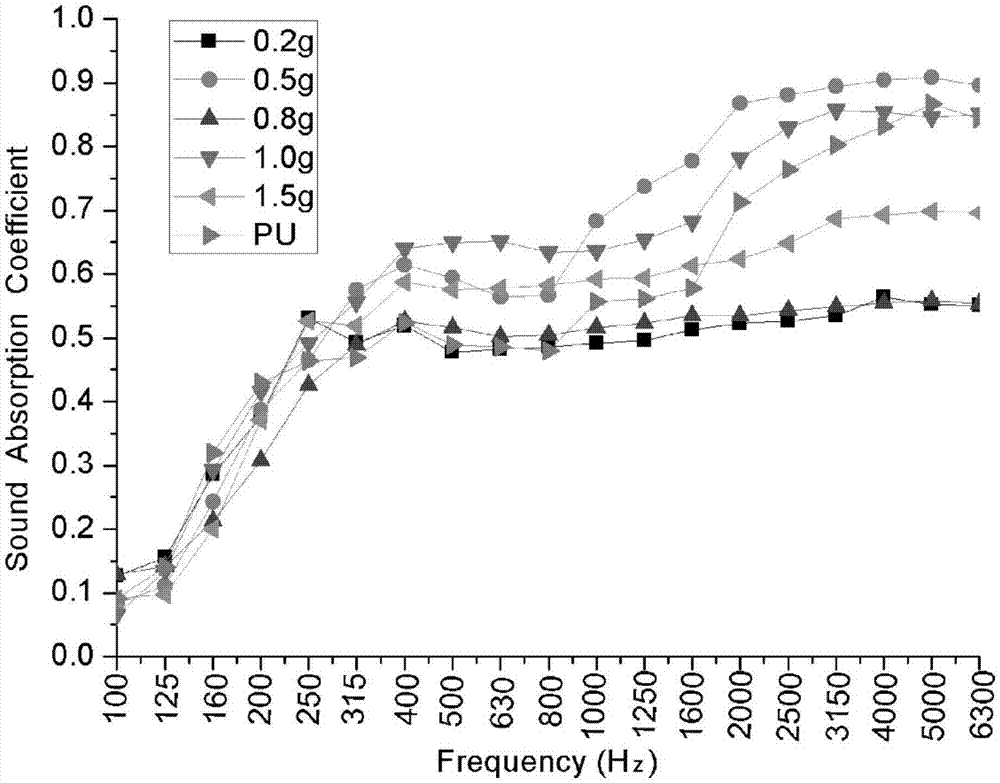

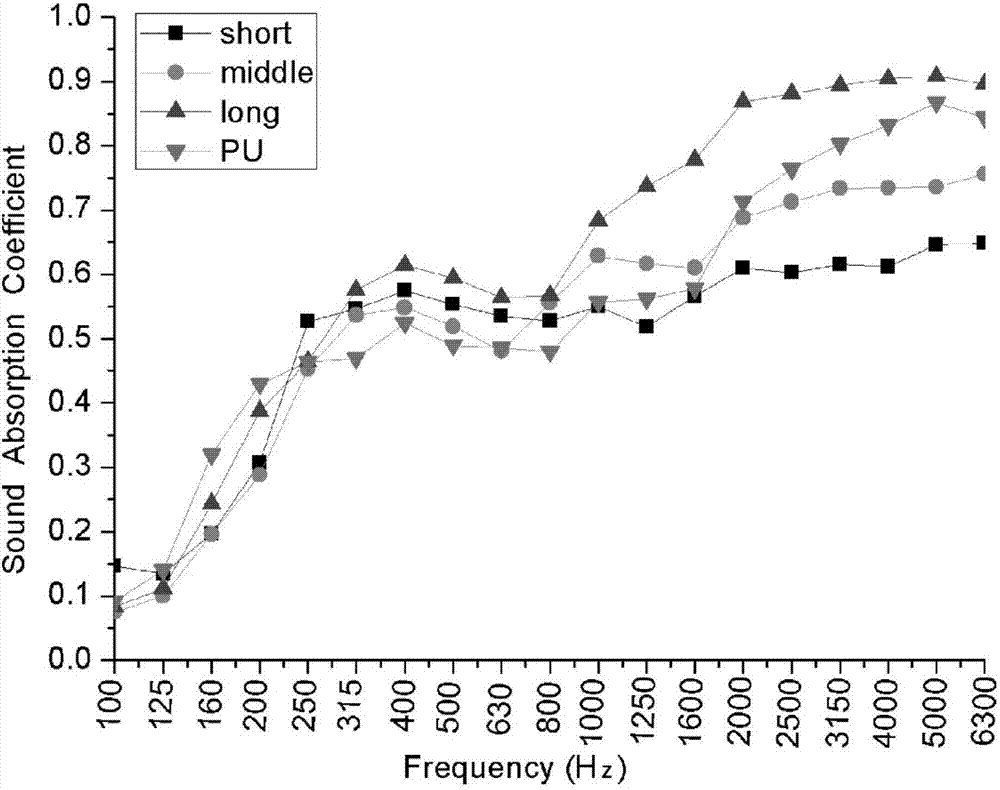

Polyurethane composite acoustic material and preparation method thereof

ActiveCN107312150AImprove low-frequency sound absorption characteristicsImprove degradabilityIonTriethanolamine

The invention belongs to acoustic packaging materials in the field of sound absorption material design, particular relates to a polyurethane composite acoustic material and a preparation method thereof. The material is prepared from the following components: 60 parts of polyether polyol 330N, 40 parts of polyether polyol 3630, 30 parts of 4,4 diphenylmethane diisocyanate, 3 parts of foaming agent deionized water, 3 parts of foaming agent triethanolamine, 5 parts of foaming agent dichlorofluoroethane, namely HCFC-141b, 0.05 part of catalyst A1, 1 part of catalyst A33, 1.8 parts of foam stabilizer and 0.2 to 1.5 parts of pine needle fragments with 1mm to 2mm or 3mm to 4mm or 5mm to 6mm. According to the polyurethane composite acoustic material and the preparation method thereof, a low-frequency sound absorption characteristic of polyurethane is improved by adding the pine needle fragments, the degradation capability of the polyurethane is increased through the addition of the pine needle fragments, and environmental pollution is reduced, thereby a problem that sound-absorbing materials at the prior art have poor sound absorption performance at the low frequency is solved.

Owner:JILIN UNIV

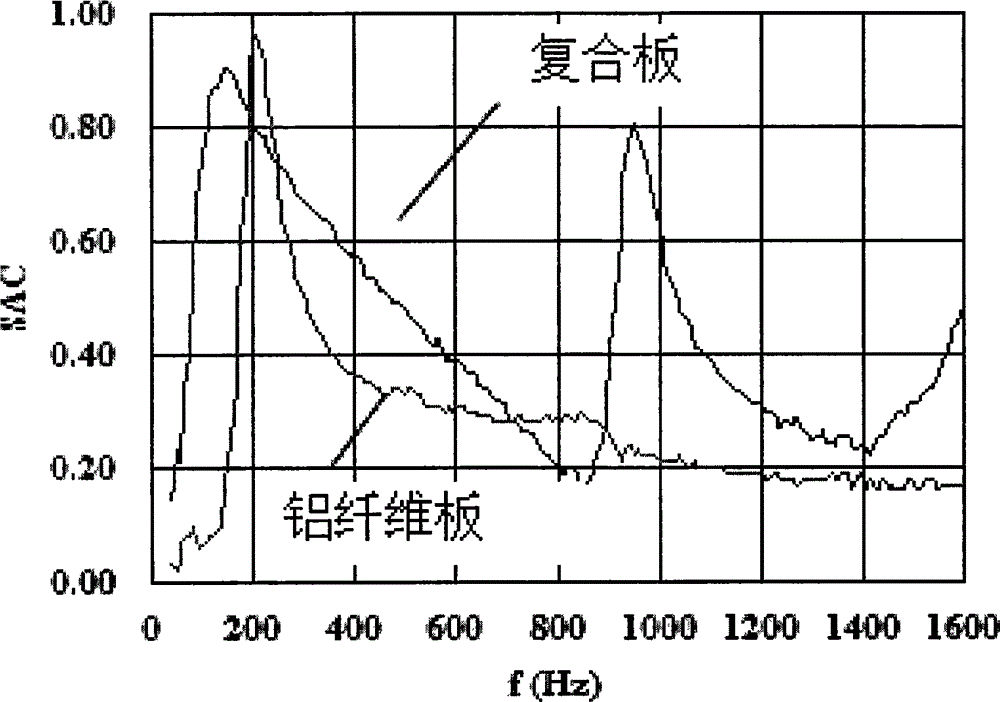

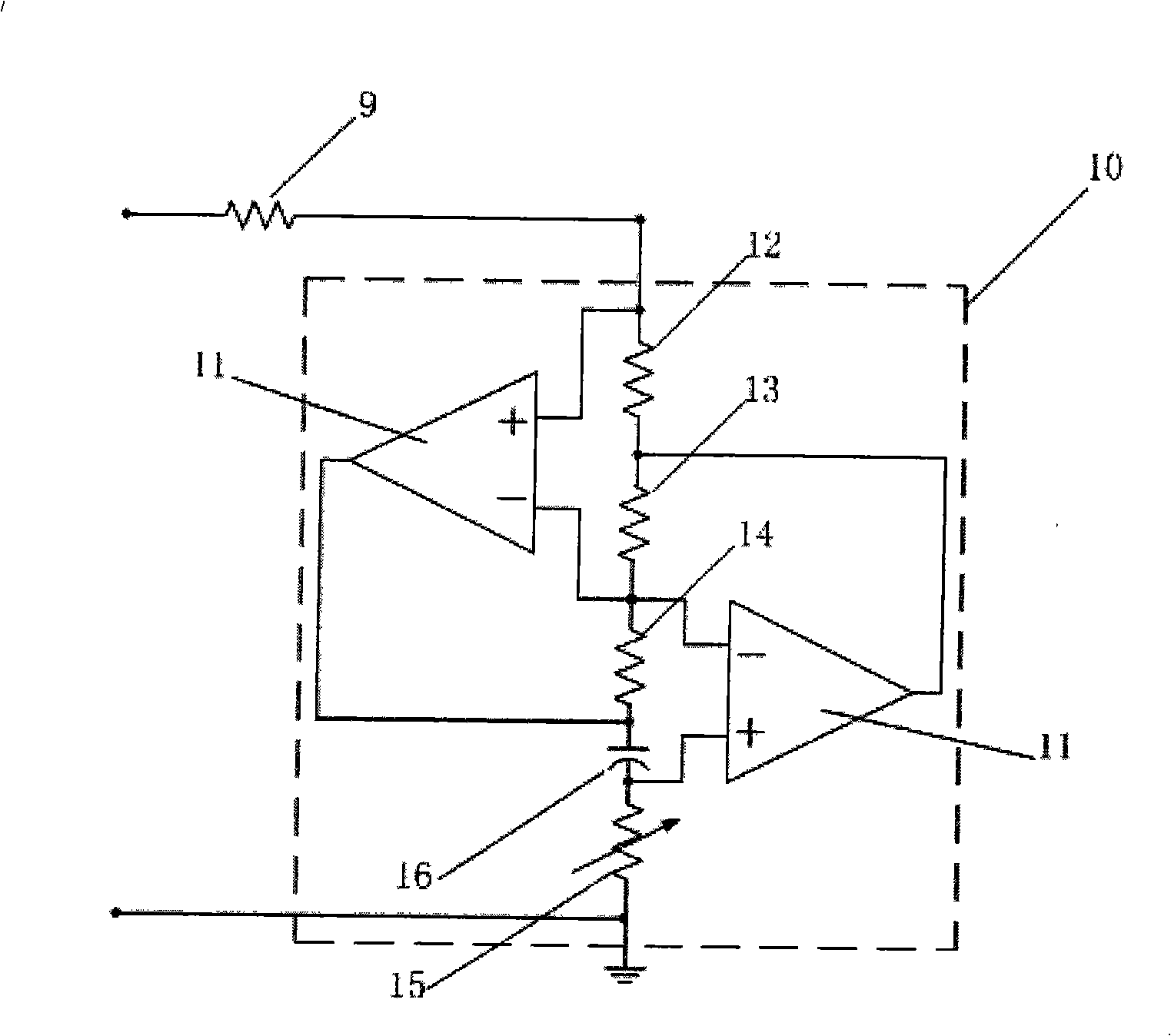

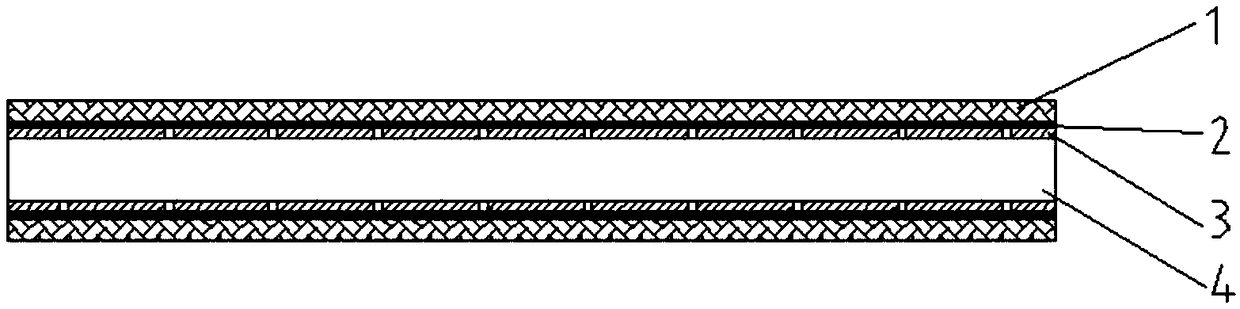

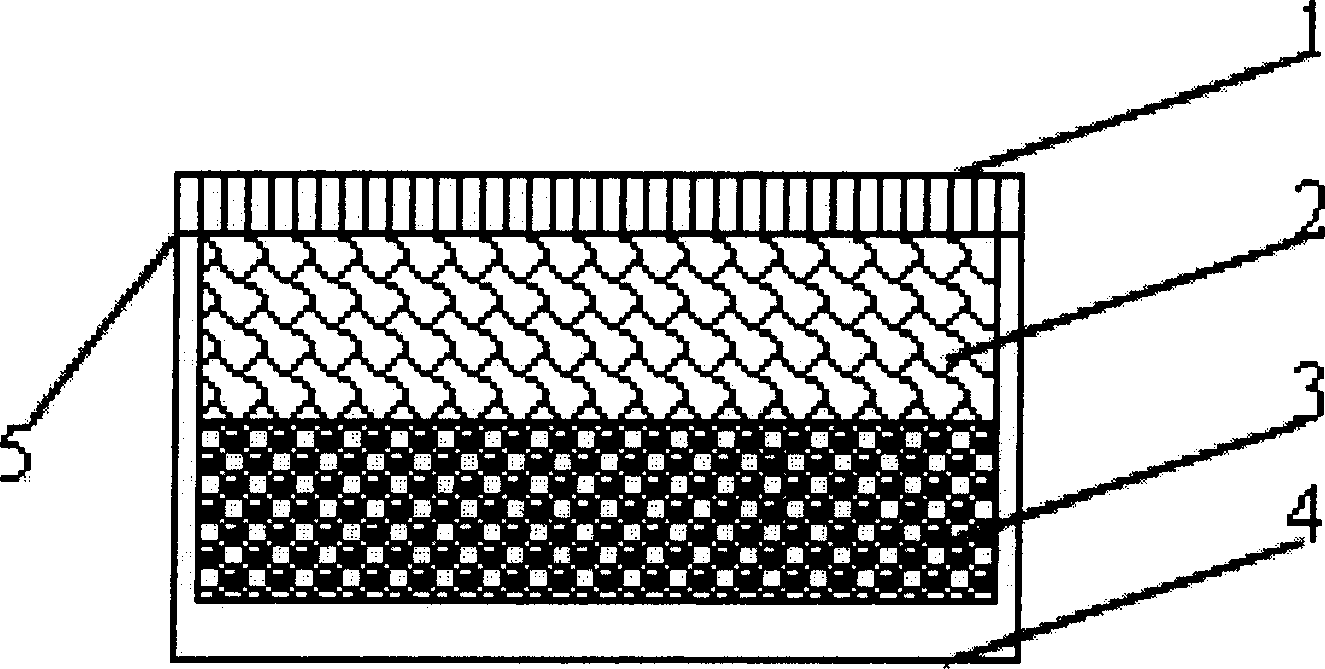

High molecular particle composite sound absorbing material, its mfg. method and uses

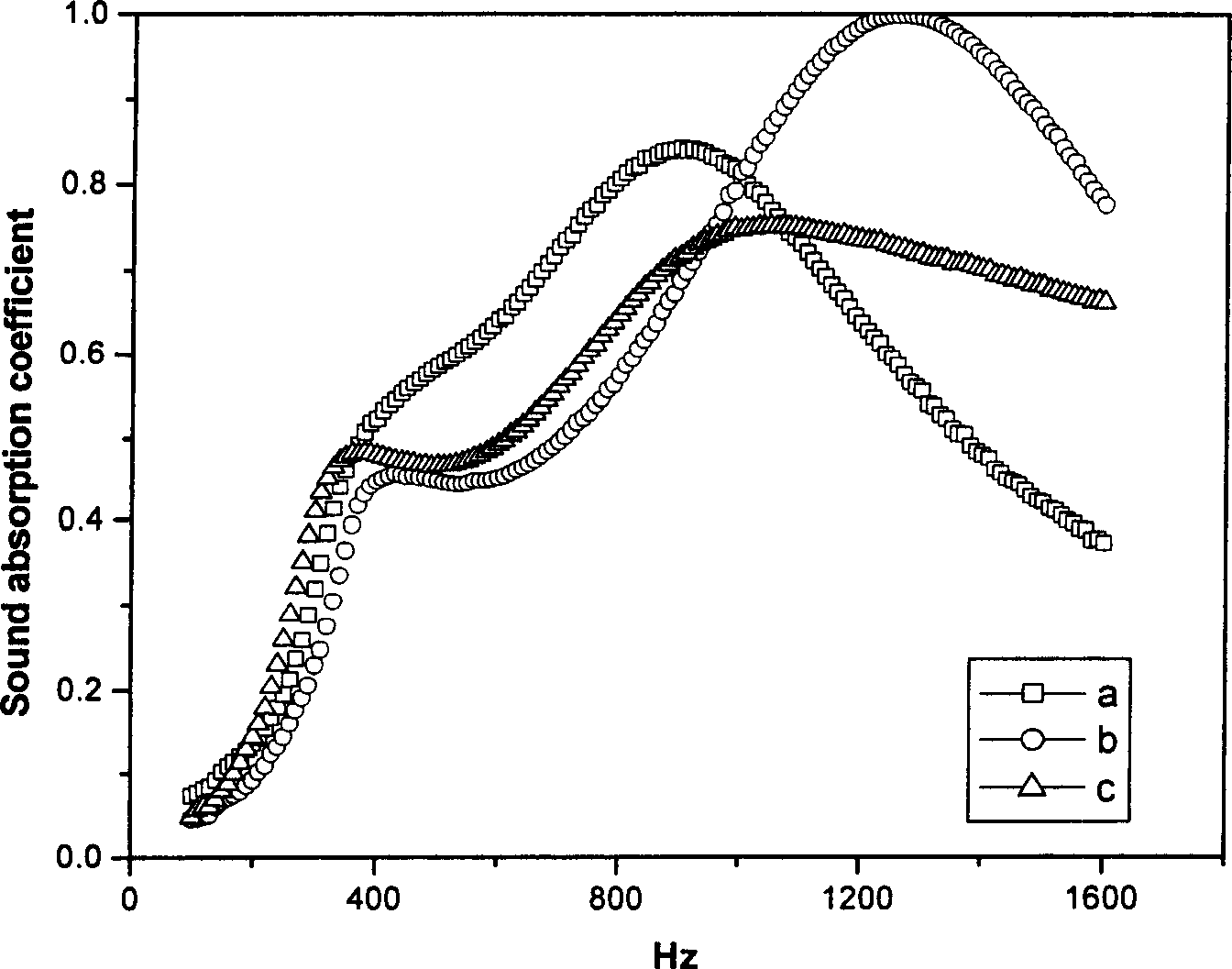

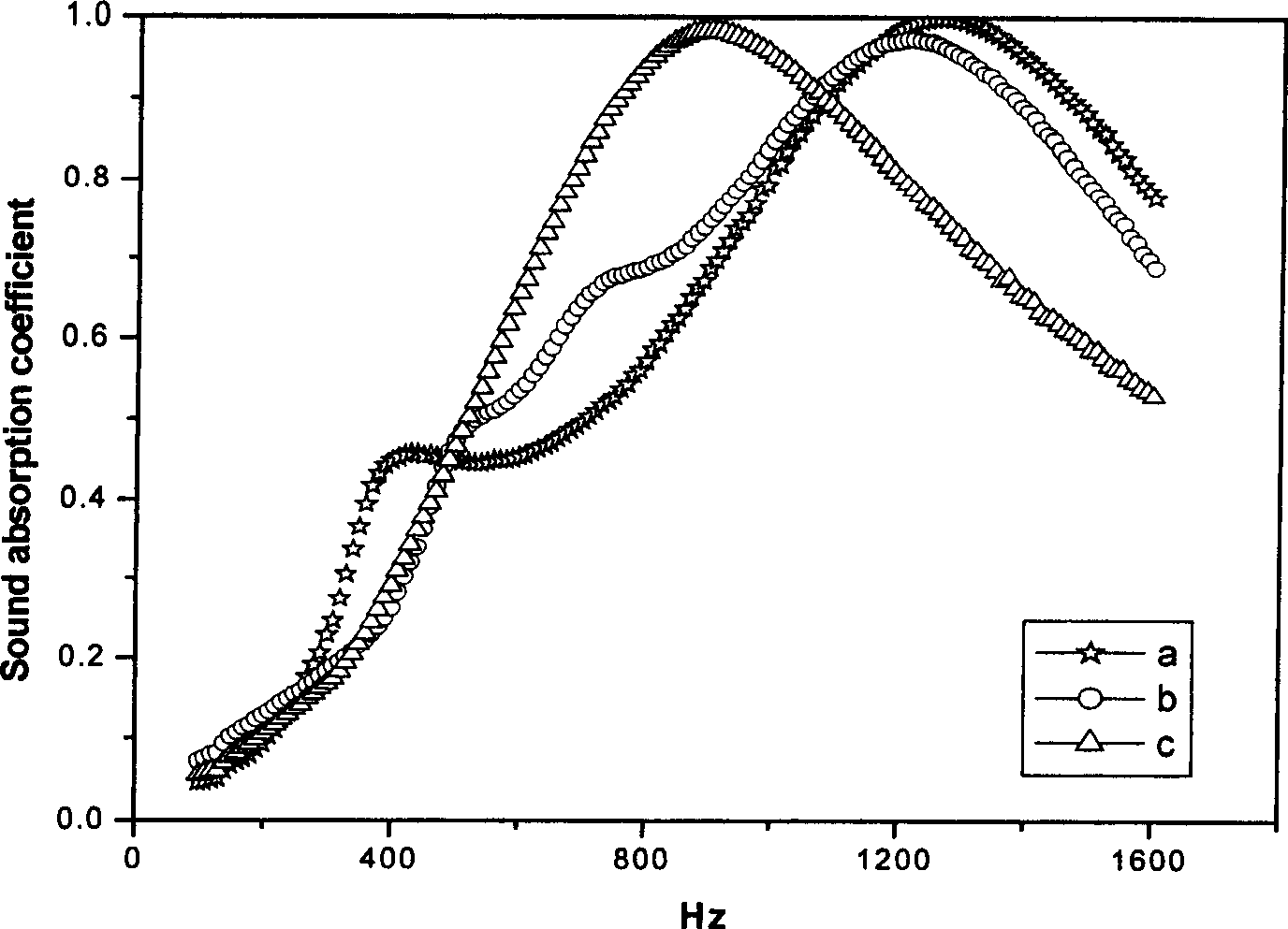

InactiveCN1835071ASound absorption frequency bandwidthImprove the sound absorption coefficient of middle and low frequencySound producing devicesAcoustic absorptionPorous layer

The invention is a high molecular sound absorbing composite and the preparing method and use thereof, characterized by comprising high molecular grain layer, high molecular porous layer and high molecular pierced layer, arranging the three layers of high molecular materials in a fixed die box in a mode of gradient variation of acoustic impedance and bonding the die box with surface layers of the high molecular material together. In a range of 300-2000Hz, it has average sound absorbing coefficient greater than 0.4, strong sound absorbing ability with the maximum sound absorbing coefficient up to 1.0, and wide sound absorbing frequency range, and its noise reducing coefficient is up to 0.68 and simultaneously it is thinner.

Owner:SICHUAN UNIV

Sound absorbing and insulating ventilation window

InactiveCN1702286AMeet ventilation requirementsGood sound insulation effectVentilation arrangementNoise insulation doors/windowsAcoustic absorptionEngineering

This invention discloses a venting noise insulation widow, which comprises a window frame fixed in the wall and a group of glass widow set in the frame, wherein the window frame including a garment frame set outside the wall and a core frame set inside the wall, and both the garment and core frame are set glass widow can be opened; between the garment and core glass widow forms the acoustic cavity, and a transparent acoustic element is arranged in it; the invention can be the sound lock mode and the resonant mode according to the requirement. Between the garment and core frame it can be set shade and heatproof curtain.

Owner:NANJING CHANGRONG ACOUSTIC INC

Energy conversion material of sound absorption

ActiveCN101093668AWide variety of sourcesSound absorption frequency bandwidthLamination ancillary operationsLaminationPorosityFiber

A material enabling to absorb sound and converting absorbed sound to be energy is prepared for using glue to directly stick butyl rubber plate with aluminium-fiber felt or laying unvulcanized butyl rubber plate and alminium-fiber felt in mould to stick said butyl rubber plate with aluminium-fiber felt after process flows of hot-pressing formation and rubber vulvanization as well as demoulding.

Owner:杜强华微(北京)高新材料科技有限公司

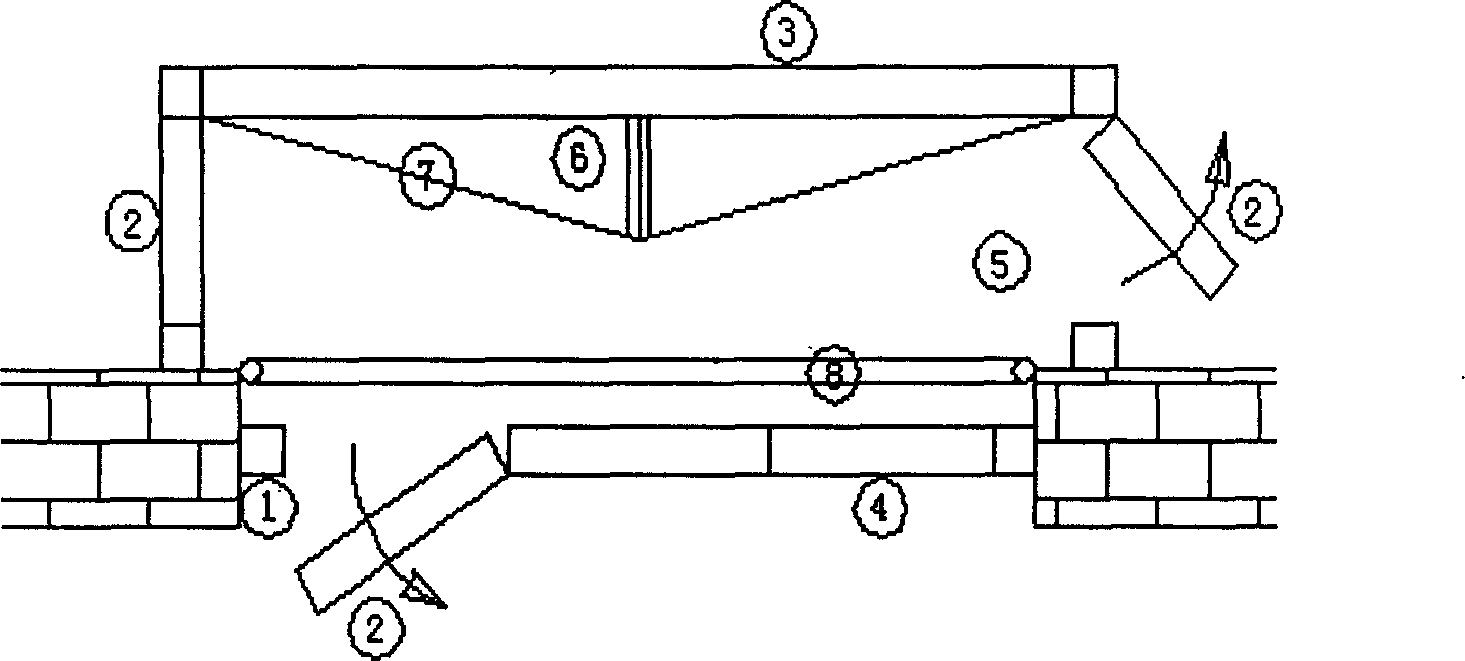

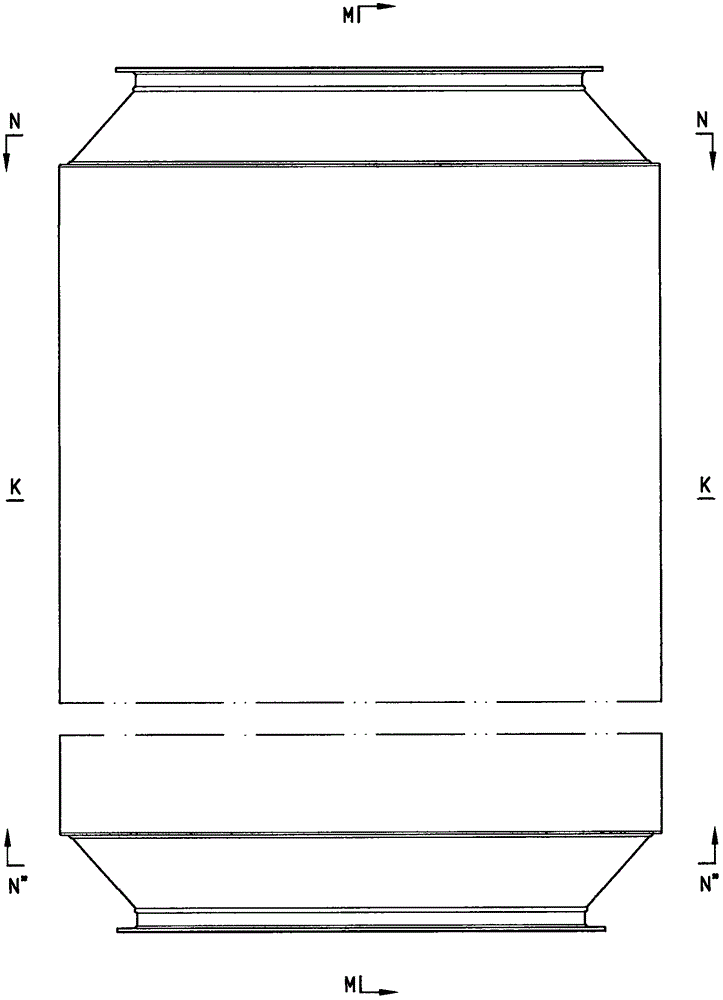

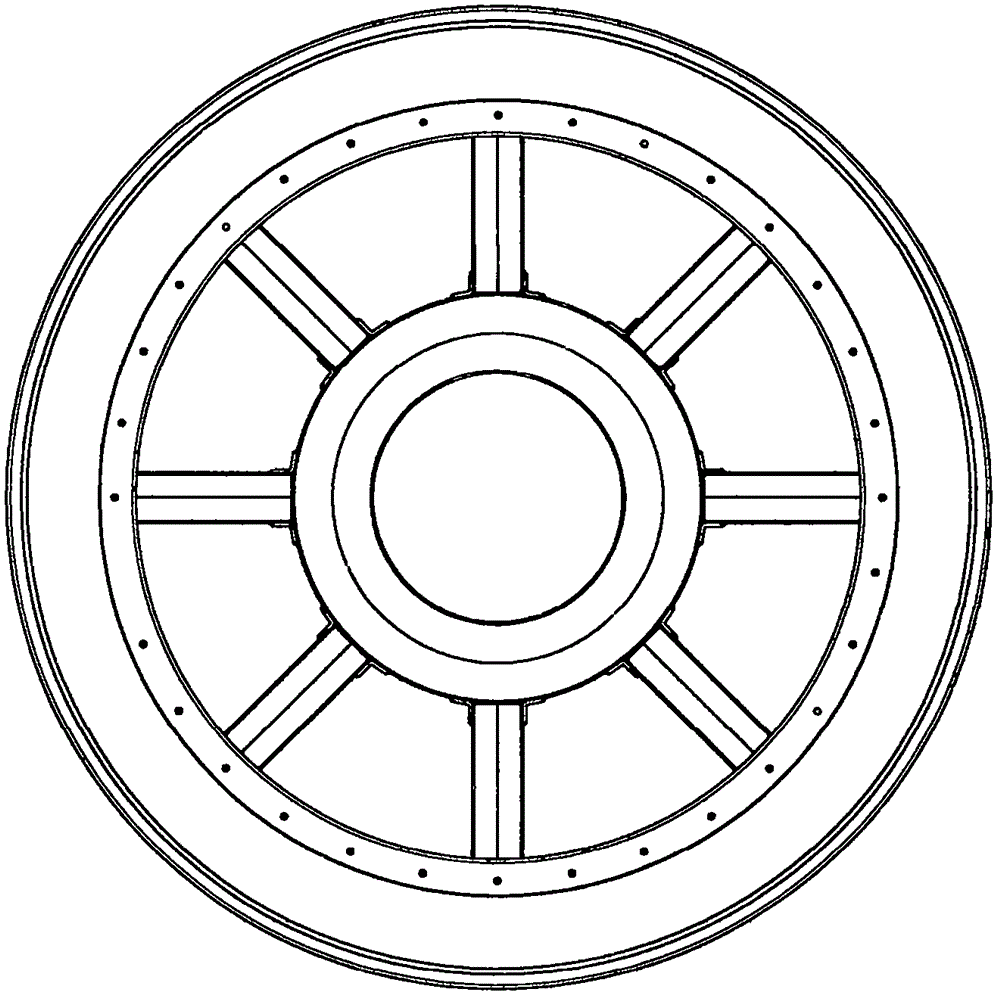

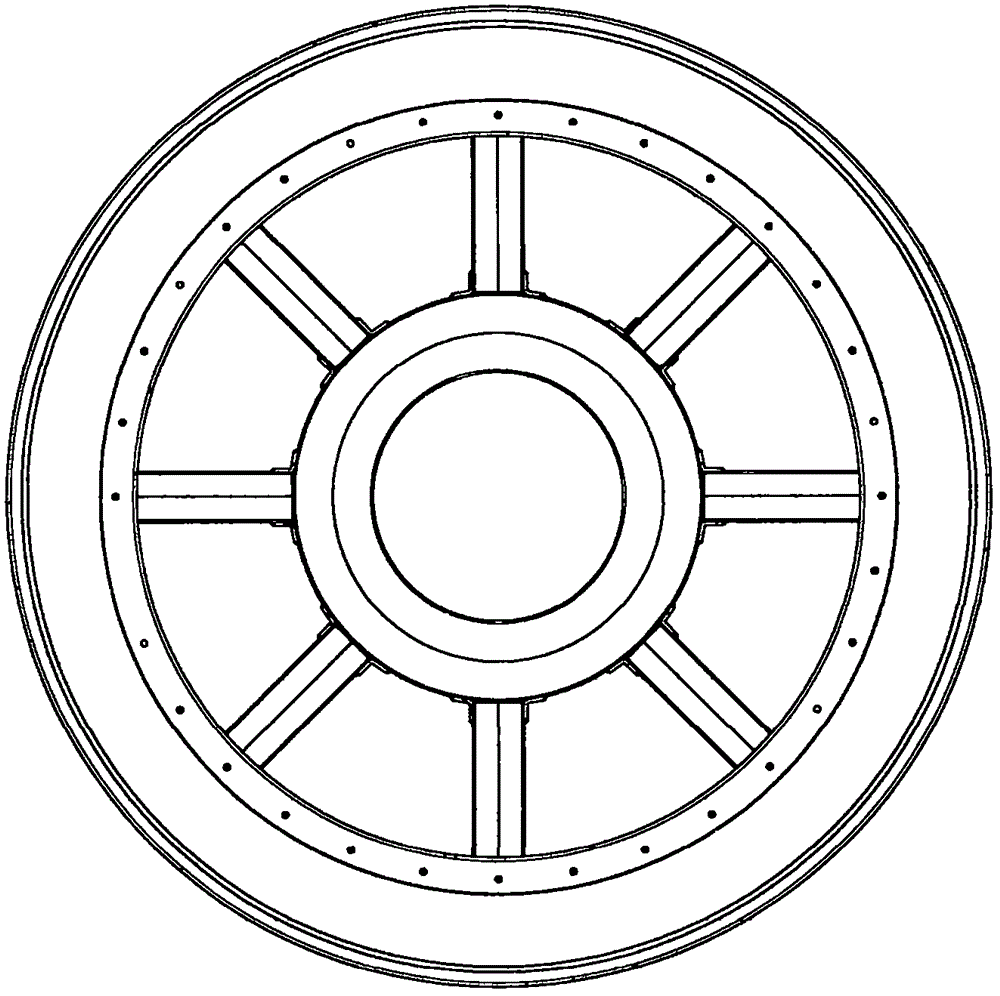

Fan silencer

InactiveCN105952687AImprove the sound absorption coefficientStable sound absorption coefficientPump componentsPumpsCooling towerKeel

The invention relates to a fan silencer which can be used in inlets, outlets, and ventilation exhaust channels of centrifugal fans, axial flow fans, and fan turbine engines, and can be used in outlets of cooling tower fans; and the fan silencer is excellent in sound attenuation and noise reduction, is large in acoustical absorption coefficient, is wide in noise elimination frequency band, is shock resistant, is small in wind resistance, is high temperature resistant, high pressure resistance, high humidity resistant, and is anti-freeze. The fan silencer is characterized in that a skeleton is properly welded to an inner wall of an outer cylinder; an outer cylindrical sound absorber is assembled and formed by welding and riveting fixation; the center of the outer cylinder is provided with a central cylindrical sound absorber attached to the skeleton; more than two radical radiation sheet type sound absorbers and more than two radical radiation sheet type sound eliminators are arranged between the central cylindrical sound absorber and the outer cylindrical sound absorber, the sheet type sound absorbers and the sheet type sound eliminators are evenly and alternatively arranged, the skeleton at two ends of the sheet type sound absorbers and the sheet type sound eliminators are tightly fixed on a central cylindrical sound absorber skeleton and an outer cylindrical sound absorber skeleton through fasteners, and are fixed and assembled with the central cylindrical sound absorber skeleton and the outer cylindrical sound absorber skeleton through welding and rivets to form a set of product.

Owner:潘泉方

Variable-damping mechanical impedance combined sound absorption structure

InactiveCN104464709AWide sound absorption frequency rangeReduce thicknessSound producing devicesDamping factorCompound structure

The invention discloses a variable-damping mechanical impedance combined sound absorption structure. The structure comprises a wall face and a sound absorption material, wherein a support is horizontally installed on the wall face, a bracket is welded to the inner side face of the support and stuck to one side of a viscoelastic hose, a variable-damping mechanical impedance plate is stuck to the other side of the viscoelastic hose, and damping liquid is injected in the viscoelastic hose. The structure can control changes of a damping coefficient and guarantee that a high sound absorption coefficient is achieved at a low frequency, and meanwhile a good sound absorption band width is achieved. Due to combination of variable mechanical impedance and the sound absorption material, the whole combined sound absorption structure is wide in sound absorption audio frequency and has good sound absorption property at low, medium and high frequencies. The variable-damping mechanical impedance sound absorption structure is small in thickness, needed space is small, medium and high frequency sound absorption does not need large thickness, the small thickness of the whole structure is important and excellent property of the combined structure, and the limited-space and high-sound-absorption requirement engineering problem is solved.

Owner:JIANGSU UNIV

Sandstone acoustic board used in transformer substation

InactiveCN104692824AChange structureChange the way of production and processingCeramicwareFiberAcoustic absorption

The invention relates to a sandstone acoustic board used in a transformer substation. The main body of the sandstone acoustic board comprises natural clean sand and a mixed layer, wherein the natural clean is wrapped with the mixed layer; the mixed layer comprises an inorganic silicon based solvent and a foaming agent and plays a bonding role; and irregular micro pores communicated with one another are formed in the main body. A manufacturing method of the sandstone acoustic board comprises the following steps: 1, selecting the natural clean sand, and screening out impurities from the natural clean sand; 2, selecting the inorganic silicon based solvent and the foaming agent; 3, mixing the inorganic silicon based solvent, the foaming agent and the natural sand; 4, pouring the mixture of the inorganic silicon based solvent, the foaming agent and the natural sand into a mould, performing shaking to flatten the mixture in the mould to form the board; 5, curing the board with spray water at 15-35DEG C for not less than 7 days; and 6, demoulding when the sandstone board is strong enough so that the sandstone board loses no edge and corner during moving. According to the sandstone acoustic board and the manufacturing method thereof, since traditional fiber extrusion solidification is changed into natural sand gravel aggregation arrangement, the acoustic absorption coefficient of the sandstone acoustic board is high at a low frequency below 500Hz, and the sandstone acoustic board is especially suitable to use in the transformer substation.

Owner:STATE GRID CORP OF CHINA +2

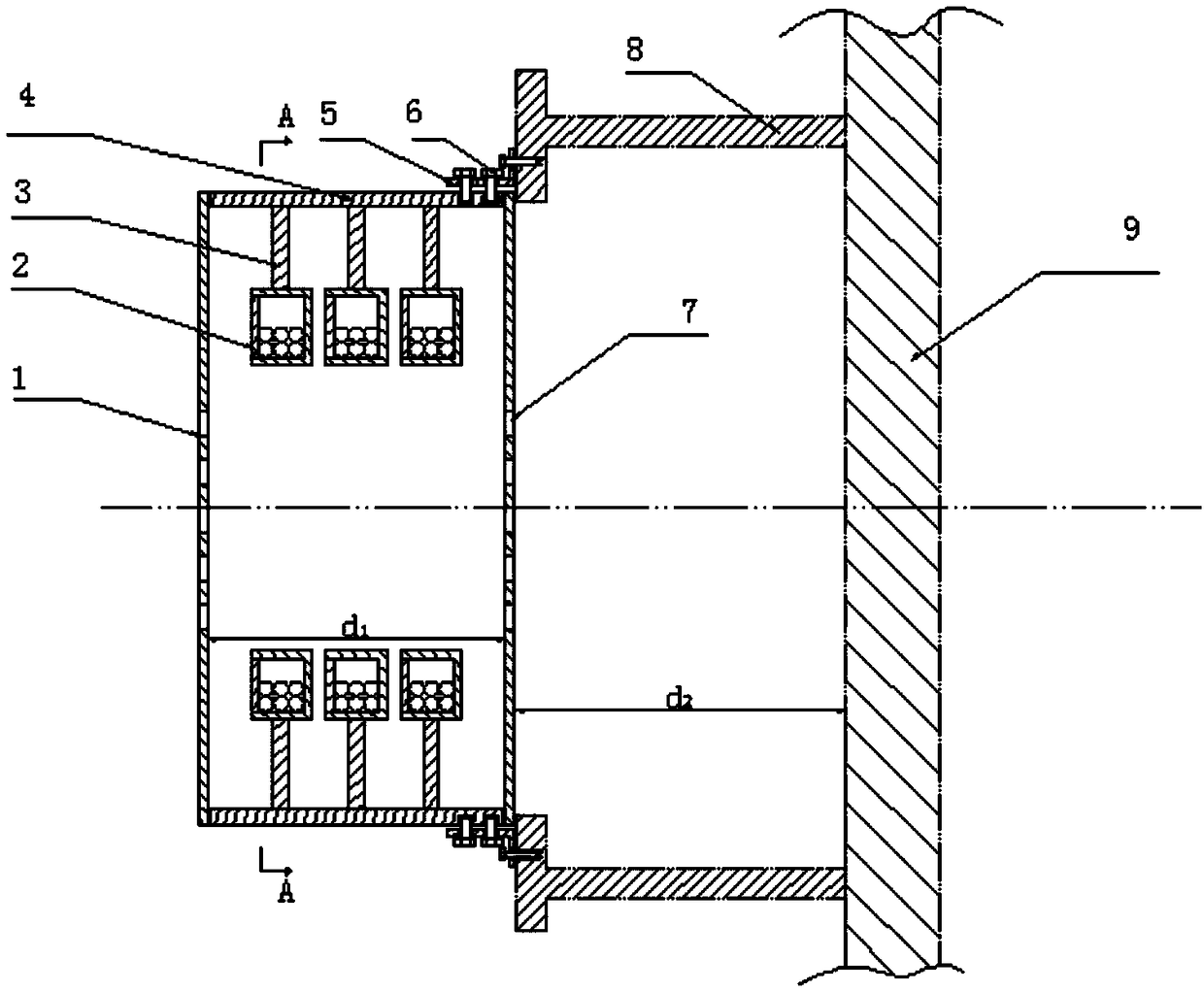

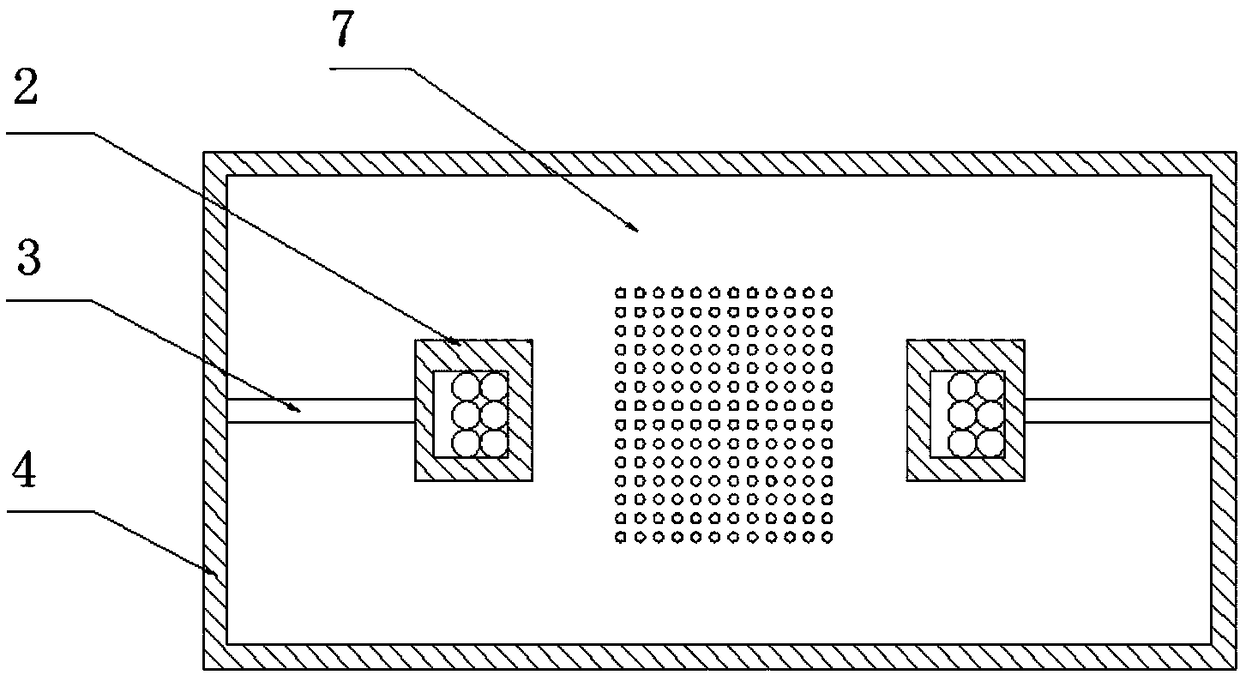

A composite structural member for reducing noise and vibration in a ship cabin

ActiveCN109018193AReduce vibrationEnhanced Damping ControlHull panellingsMicro perforated plateWorking environment

The invention discloses a composite structural member for reducing noise and vibration in a ship cabin., The member comprises a outer layer micro-perforated plate, a framework and an inner layer micro-perforated plate, all of which are connected through connecting parts and enclosing walls for a chamber. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedlyconnected and combined into a double-layer micro-perforated cavity through a frame, and a plurality of rows of multi-layer particle dampers are fixedly connected on two side walls corresponding to the frame in the cavity through elastic connecting rods. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedly connected to each other through a frame. The invention can optimize the sound absorption coefficient of the micro-perforated plate without changing the cabin structure, broaden the sound absorption frequency band, improve the sound absorption effect,reduce the vibration of the cabin structure, and create a good cabin working environment. Moreover, the invention has the advantages of compact structure and convenient installation. It has a good prospect of engineering application.

Owner:JIANGSU UNIV OF SCI & TECH

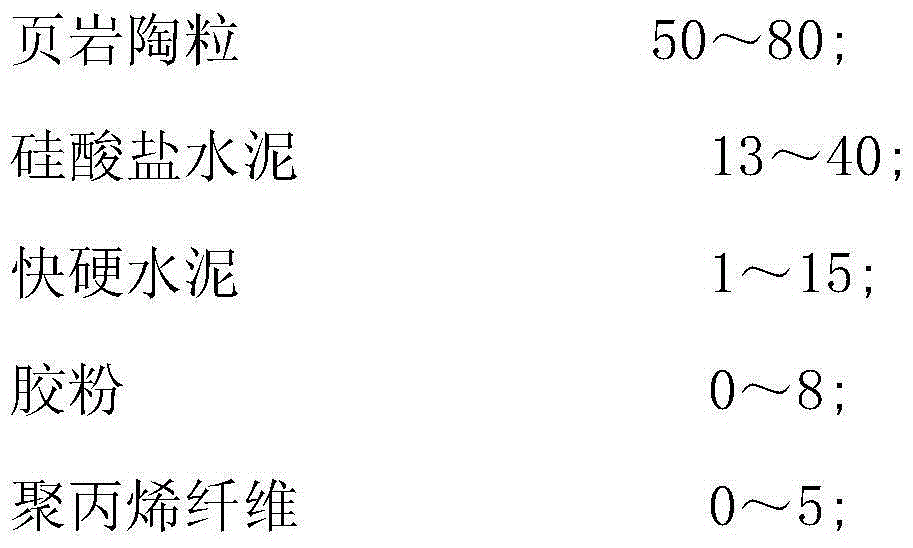

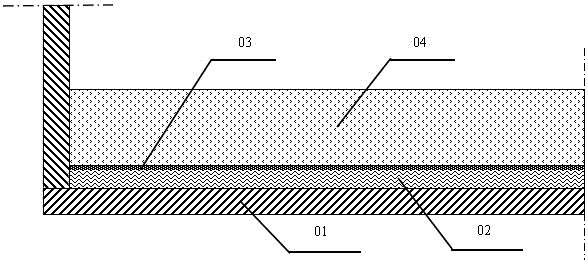

Railway traffic sound-absorption and -insulation fireproof light-weight water-permeable material and preparation method thereof

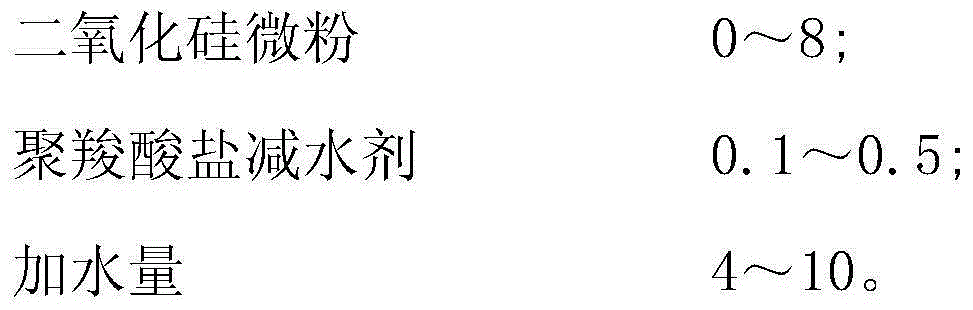

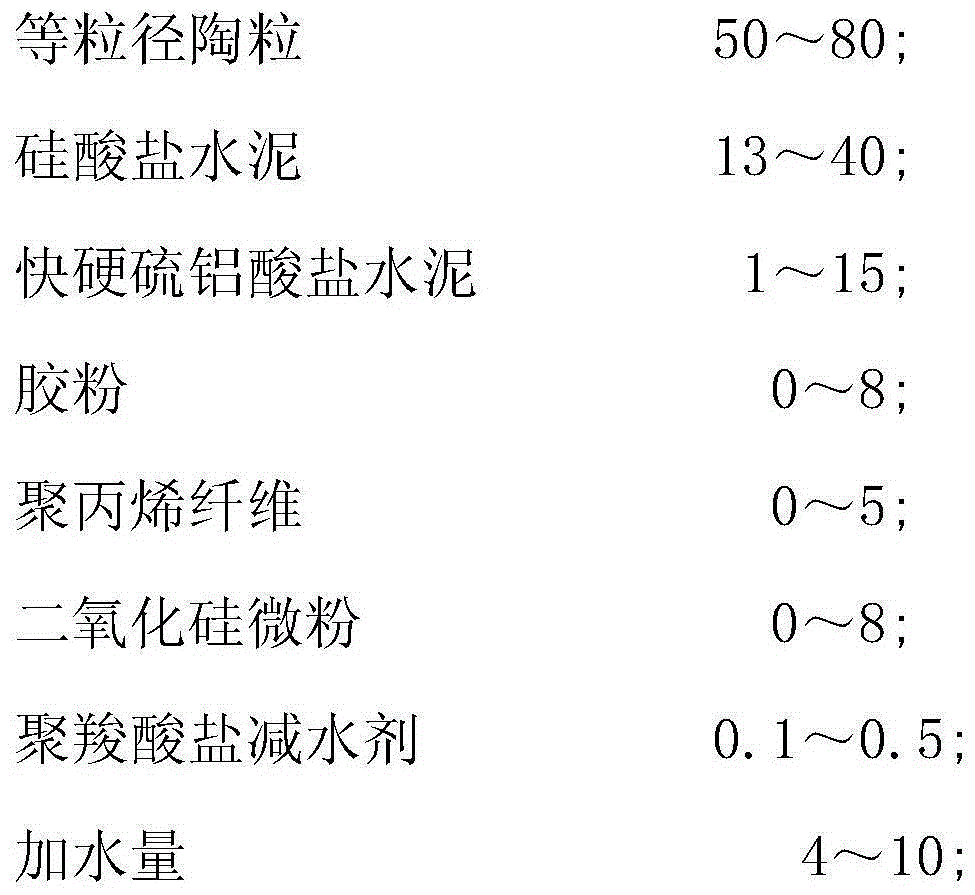

InactiveCN105130343AReduce the impactReduce secondary noise pollutionAcoustic absorptionExpanded clay aggregate

A railway traffic sound-absorption and -insulation fireproof light-weight water-permeable material and a preparation method thereof. The invention belongs to the environment-protective technical field of fireproofing, sound absorption and insulation, and noise reduction in railway traffic. The material is prepared with calcined shale ceramic granules as an aggregate and Portland cement and quick-hardening sulphoaluminate cement as cementing materials with various additives. The aggregate in equal granular size, the Portland cement and quick-hardening sulphoaluminate cement as the cementing materials, rubber powder, polypropylene fiber, silicon dioxide micro-powder and a polycarboxylate water reducing agent are mixed to prepare a material, wherein the material includes, by weight, 50-80 parts of the ceramic granule in equal granular size, 13-40 parts of the Portland cement, 1-15 parts of the quick-hardening sulphoaluminate cement, 0-8 parts of the rubber powder, 0-5 parts of the polypropylene fiber, 0-8 parts of the silicon dioxide micro-powder, 0.1-0.5 parts of the polycarboxylate water reducing agent and 4-10 parts of water. When being used, the material just needs to be stirred uniformly with tap water for carrying out die casting or pave casting.

Owner:BEIJING ALLIED RONGDA CONSTR MATERIAL

Marine noise reduction structure

InactiveCN103950508AImprove corrosion resistanceNon-combustibleHull decksHull panellingsGlass fiberAluminum foil

The invention provides a marine noise reduction structure. A hollow special-shaped glass fiber cloth, an aluminum foil and a dressing layer are sequentially laid on a horizontal steel deck. By virtue of adopting a composite structure, vibration and noises of a ship can be greatly weakened or eliminated. The hollow glass fiber cloth has the advantages of non-combustible property, verminproof property, heat resistance, corrosion resistance, high strength, high sound absorption coefficient and the like. Due to the aluminum foil, the corrosion resistance of a material is greatly improved, the water vapor obstruction effect is enhanced, the tensile strength is better, and the veneering is relatively stiff, smooth and flat; the dressing layer comprises an inorganic binder and a dressing main body and can be used for effectively protecting the deck and achieving antirust and antiwear effects.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com