Noise reduction sound absorption layer

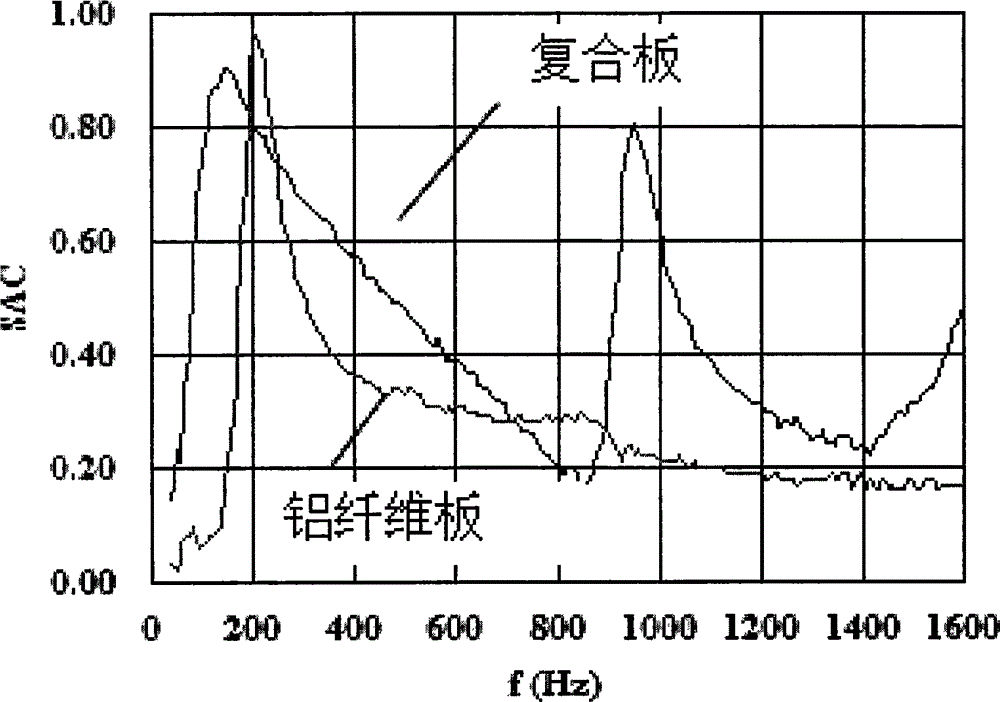

A sound-absorbing layer and noise reduction technology, applied in the field of noise damping, can solve problems such as affecting study work, narrow sound-absorbing frequency band, disturbing sleep, etc., to achieve improved sound-absorbing performance, excellent thermal conductivity, wide and efficient resistive sound-absorbing frequency band Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

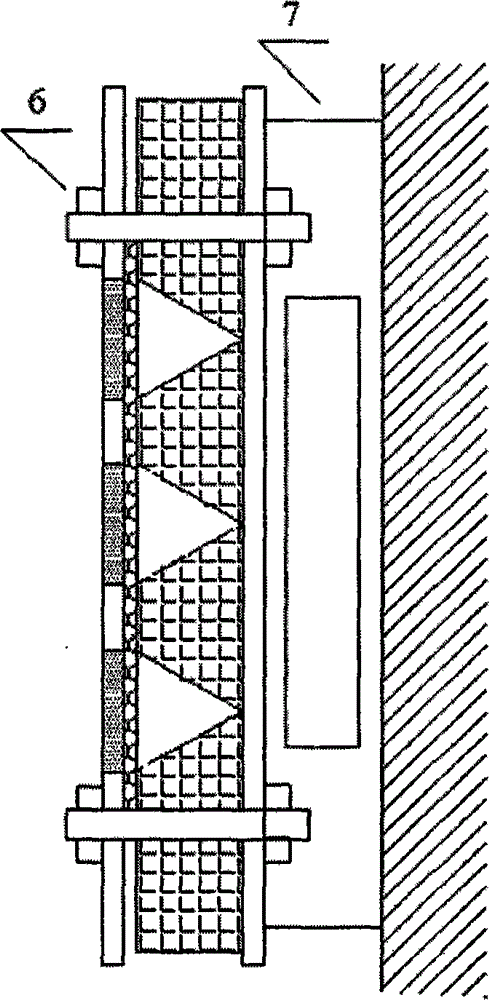

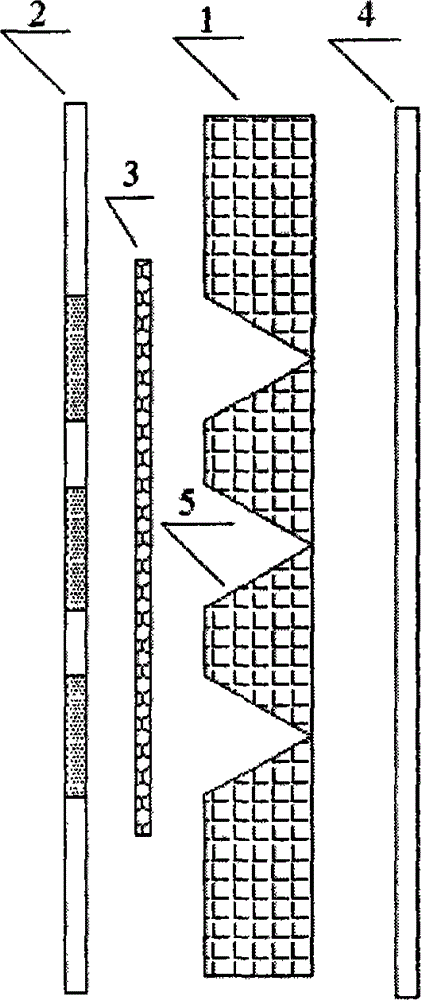

[0068] Such as figure 1 As shown, in the noise-reducing sound-absorbing layer of the present invention, the sound-absorbing layer includes a hexahedron composed of resonant sound-absorbing components, the surface of the hexahedron perpendicular to the base plane is the keel, and the plane parallel to the base plane of the hexahedron is the resonant sound-absorbing component, and the resonant sound-absorbing component The acoustic component includes a micro-perforated plate 2 , a non-woven fabric 3 , a bicomponent fiber mat 1 and a back plate 4 arranged sequentially from the noise source toward the wall.

[0069] The thickness of the air layer formed by the back plate 4 and the base surface is 180mm.

[0070] The length and width of the micro-perforated plate 2, the two-component fiber mat 1 and the back plate 4 are respectively equal to the parallel surface of the wall, and the length of the non-woven fabric 3 and the parallel surface of the wall is 60% of the length of the mi...

Embodiment 2

[0080] Such as figure 1 As shown, in the noise-reducing sound-absorbing layer of the present invention, the sound-absorbing layer includes a hexahedron composed of resonant sound-absorbing components, the surface of the hexahedron perpendicular to the base surface is the keel, and the surface parallel to the base surface of the hexahedron is a resonant sound-absorbing component, and the resonant sound-absorbing component The acoustic component includes a micro-perforated plate 2 , a non-woven fabric 3 , a bicomponent fiber mat 1 and a back plate 4 arranged sequentially from the noise source toward the wall.

[0081] The thickness of the air layer formed by the back plate 4 and the base surface is 40mm.

[0082] The length and width of the micro-perforated plate 2, the two-component fiber mat 1 and the back plate 4 are respectively equal to the parallel surface of the wall, and the length of the non-woven fabric 3 and the parallel surface of the wall is 80% of the length of the...

Embodiment 3

[0092] A noise-reducing and sound-absorbing layer includes a keel and a sound-absorbing component, and the component includes a micro-perforated plate 2, a non-woven fabric 3, a bicomponent fiber mat 1 and a back plate 4 arranged in sequence from the noise source to the wall.

[0093] An air layer with a thickness of 100 mm is formed between the sound-absorbing member and the base surface.

[0094] The length and width of the micro-perforated plate 2, the two-component fiber mat 1 and the back plate 4 are respectively equal to the parallel surface of the wall, and the length and width of the non-woven fabric 3 and the parallel surface of the wall are equal to the length and width of the micro-perforated plate 2. 70% of the width.

[0095] The non-woven fabric 3 is polypropylene fiber cotton with a thickness of 0.6 mm.

[0096] Two-component fiber mat 1 is processed by blending aluminum fibers with a diameter of 40 μm and polyester fibers with a diameter of 40 μm, and the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com