Multi-layer noise elimination/vibration reduction structure and method for manufacturing noise elimination/vibration reduction structure through 3D printing technology

A vibration-damping structure and technology, which is applied in the direction of gas shock absorbers, additive processing, etc., can solve the problems of narrow application fields of noise-absorbing/vibration-damping structures, and achieve a large sound absorption coefficient, not easy to aging, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

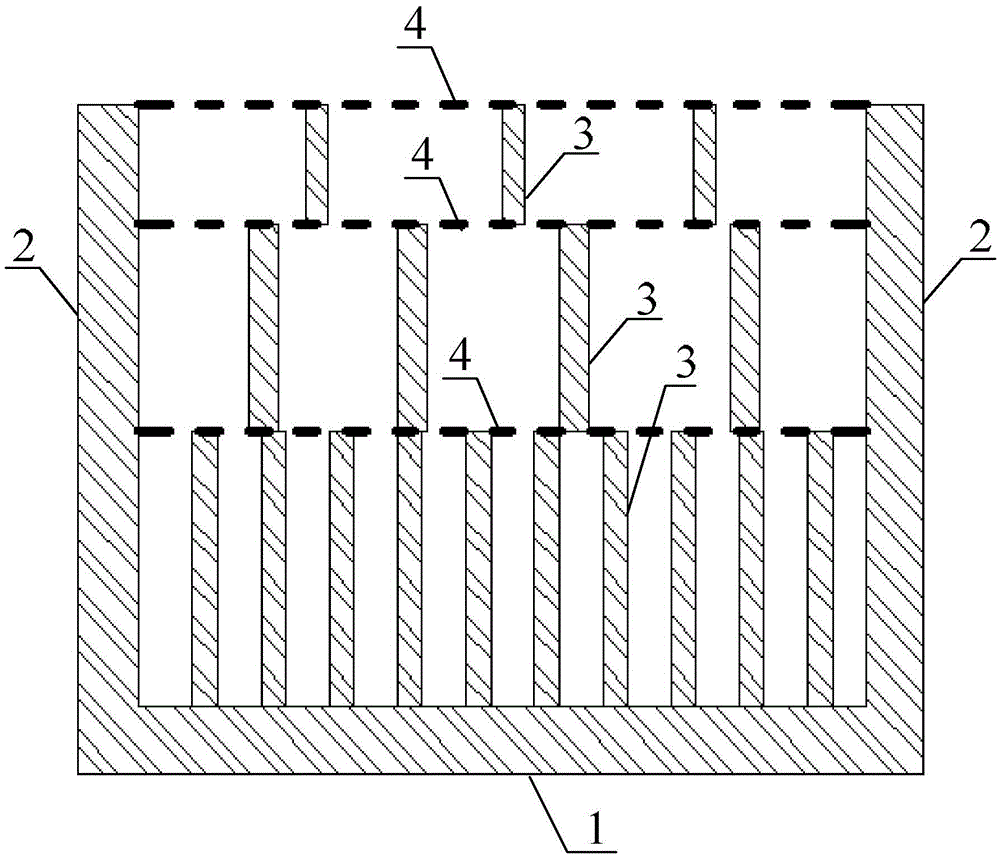

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of multi-layer noise elimination / vibration reduction structure described in this embodiment mode, comprises bottom board (1), two side boards (2), multi-layer vertical partition board (3) of different heights and multiple A transverse partition (4), the bottom plate (1), side panels (2), longitudinal partitions (3) and transverse partitions (4) are all metal-based materials, and the side panels (2) , The longitudinal partition plate (3) and the transverse partition plate (4) are provided with a plurality of micropores;

[0016] Two side plates (2) are located on both sides of the bottom plate (1);

[0017] The longitudinal partition boards (3) are parallel to the side boards (2), and each layer of longitudinal partition boards (3) is equally spaced between two side boards (2), and between two adjacent layers of longitudinal partition boards (3) Between them is a transverse partiti...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the multi-layer noise reduction / vibration reduction structure described in Embodiment 1. In this embodiment, the heights of the multi-layer cavities are sequentially decreased and the widths are sequentially increased. .

specific Embodiment approach 3

[0020] Specific Embodiment 3: This embodiment is a further limitation of the multi-layer noise reduction / vibration reduction structure described in Embodiments 1 and 2. In this embodiment, the side panels (2), longitudinal partitions (3) And the microholes on the transverse partition plate (4) include circular holes and non-circular holes, the aperture of the circular holes is less than 1 or equal to mm, and the single hole area of the non-circular holes is less than or equal to 0.785mm 2 , the hole spacing is less than or equal to 17mm, and the porosity is 1%-10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com