Patents

Literature

9866results about How to "Corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

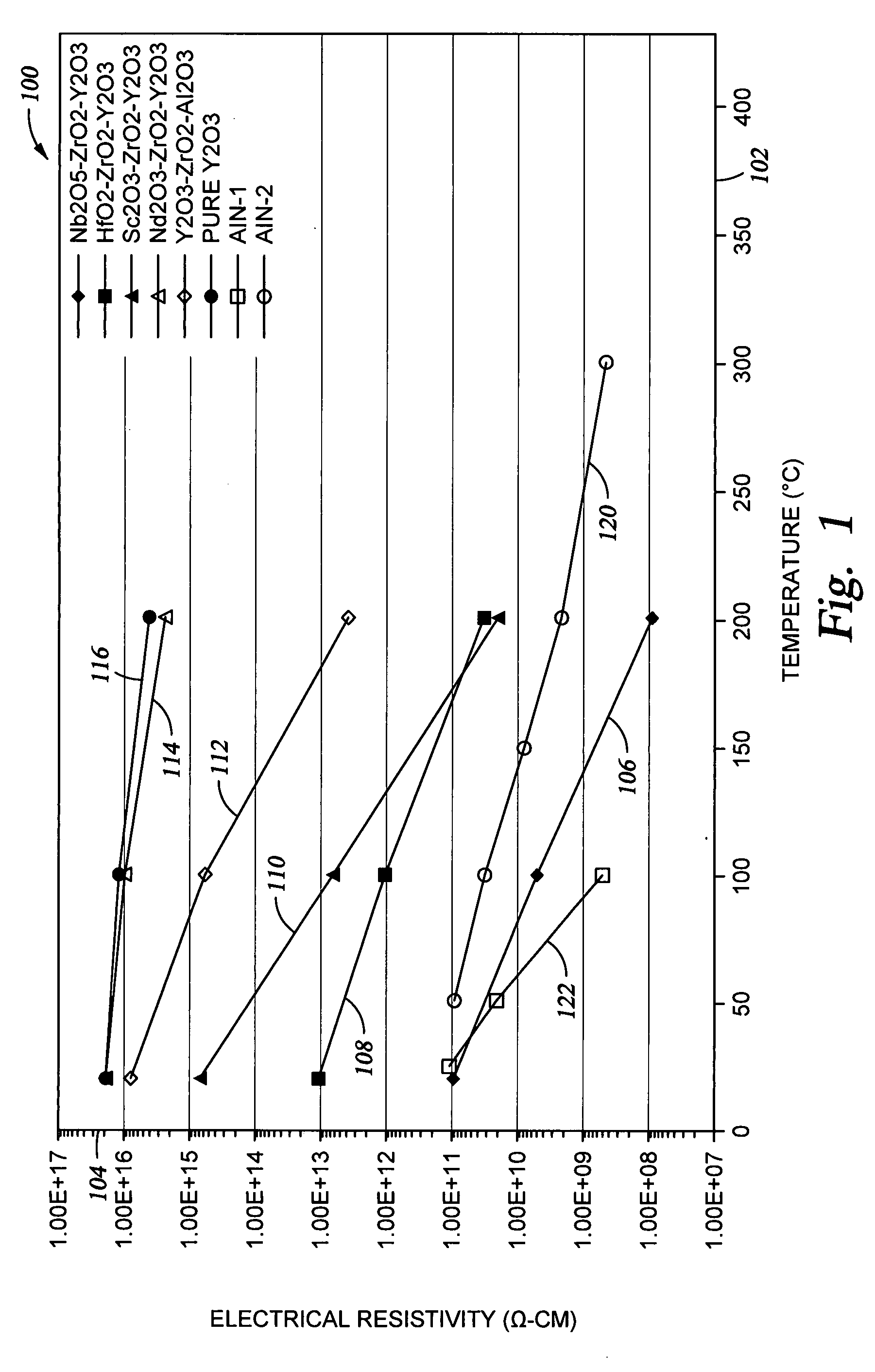

Plasma-resistant ceramics with controlled electrical resistivity

ActiveUS20090036292A1Improve plasma resistanceTailored mechanical propertiesSemiconductor/solid-state device manufacturingGlass/slag layered productsHalogenCeramic

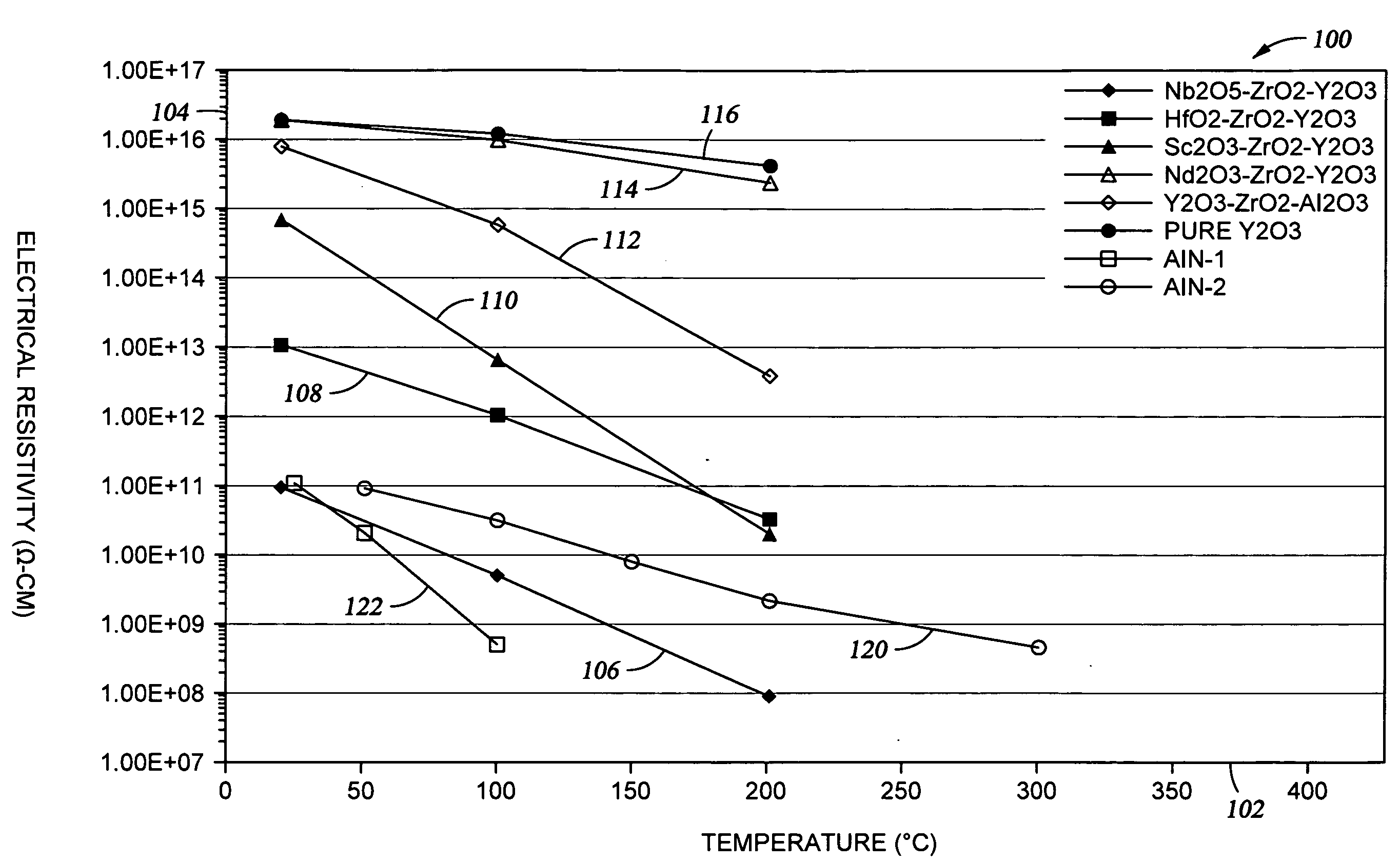

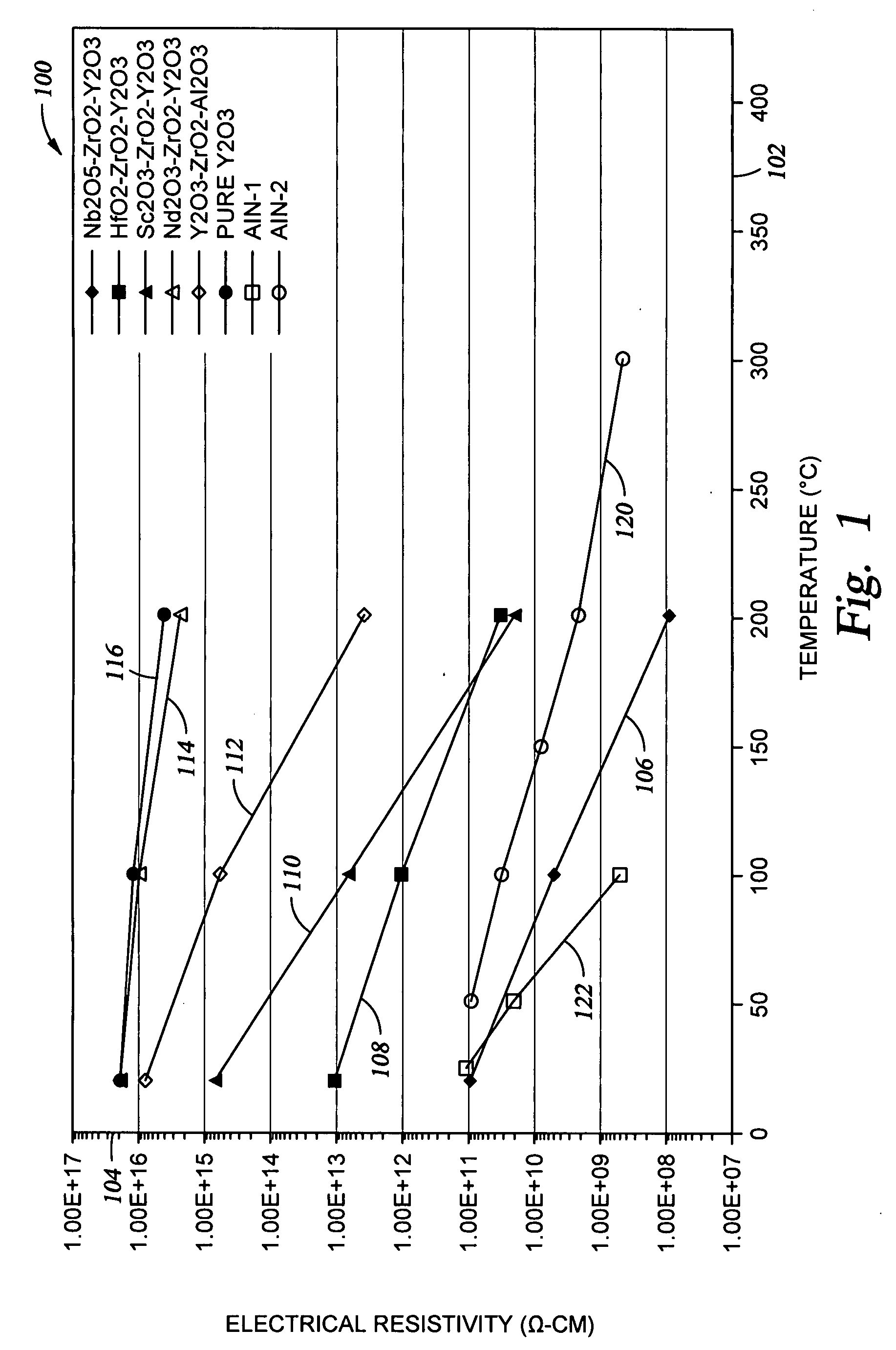

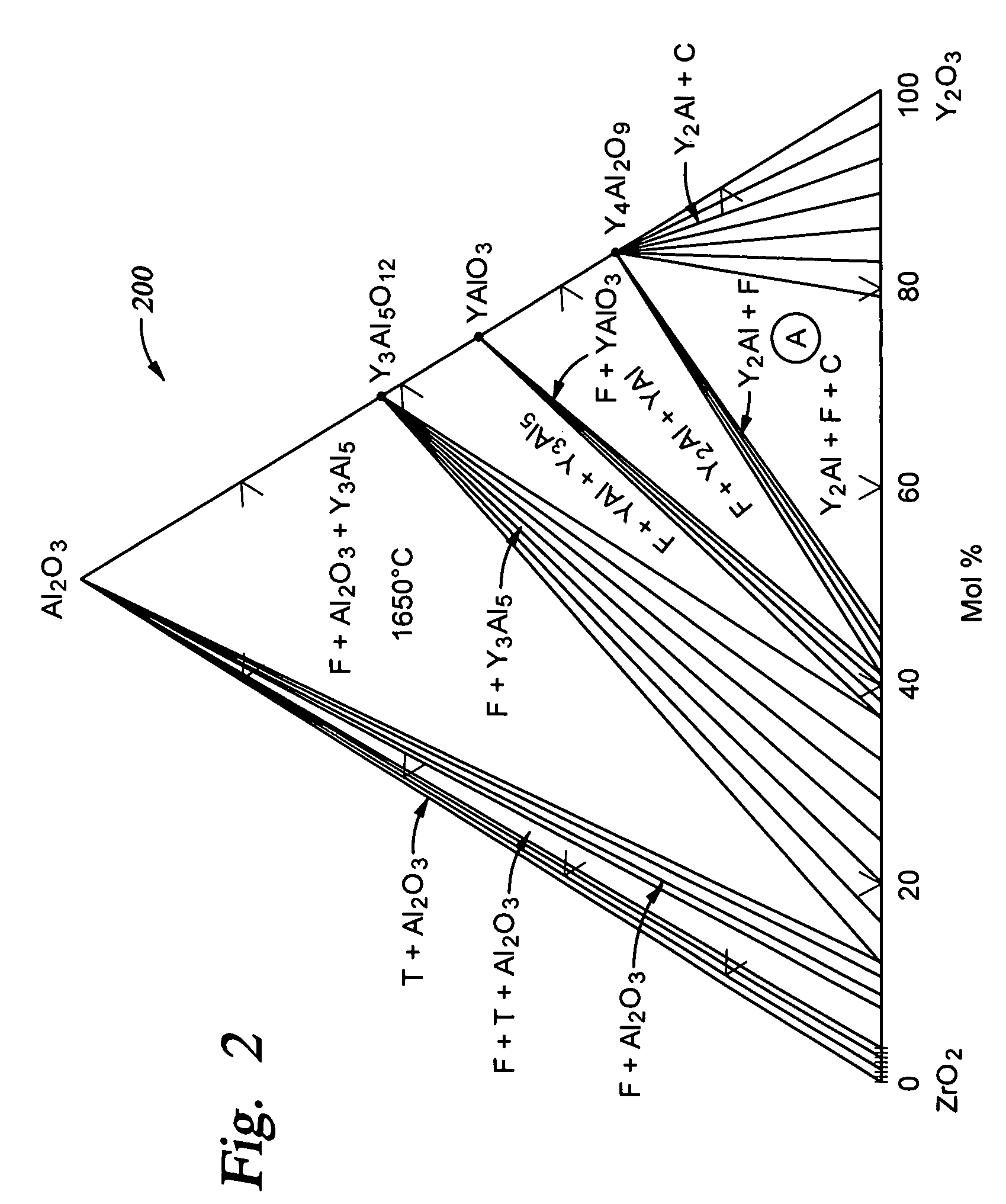

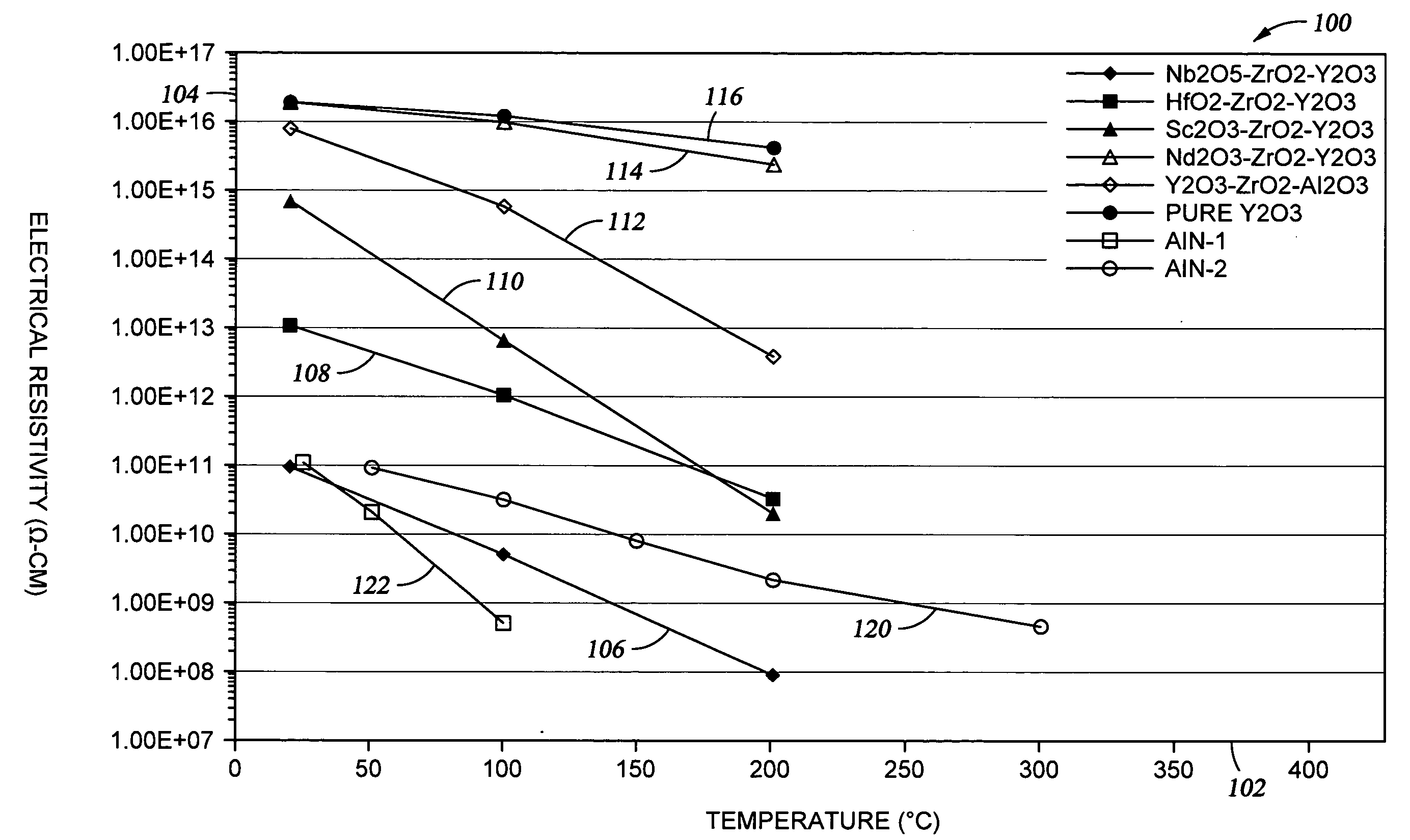

Specialty ceramic materials which resist corrosion / erosion under semiconductor processing conditions which employ a corrosive / erosive plasma. The corrosive plasma may be a halogen-containing plasma. The specialty ceramic materials have been modified to provide a controlled electrical resistivity which suppresses plasma arcing potential.

Owner:APPLIED MATERIALS INC

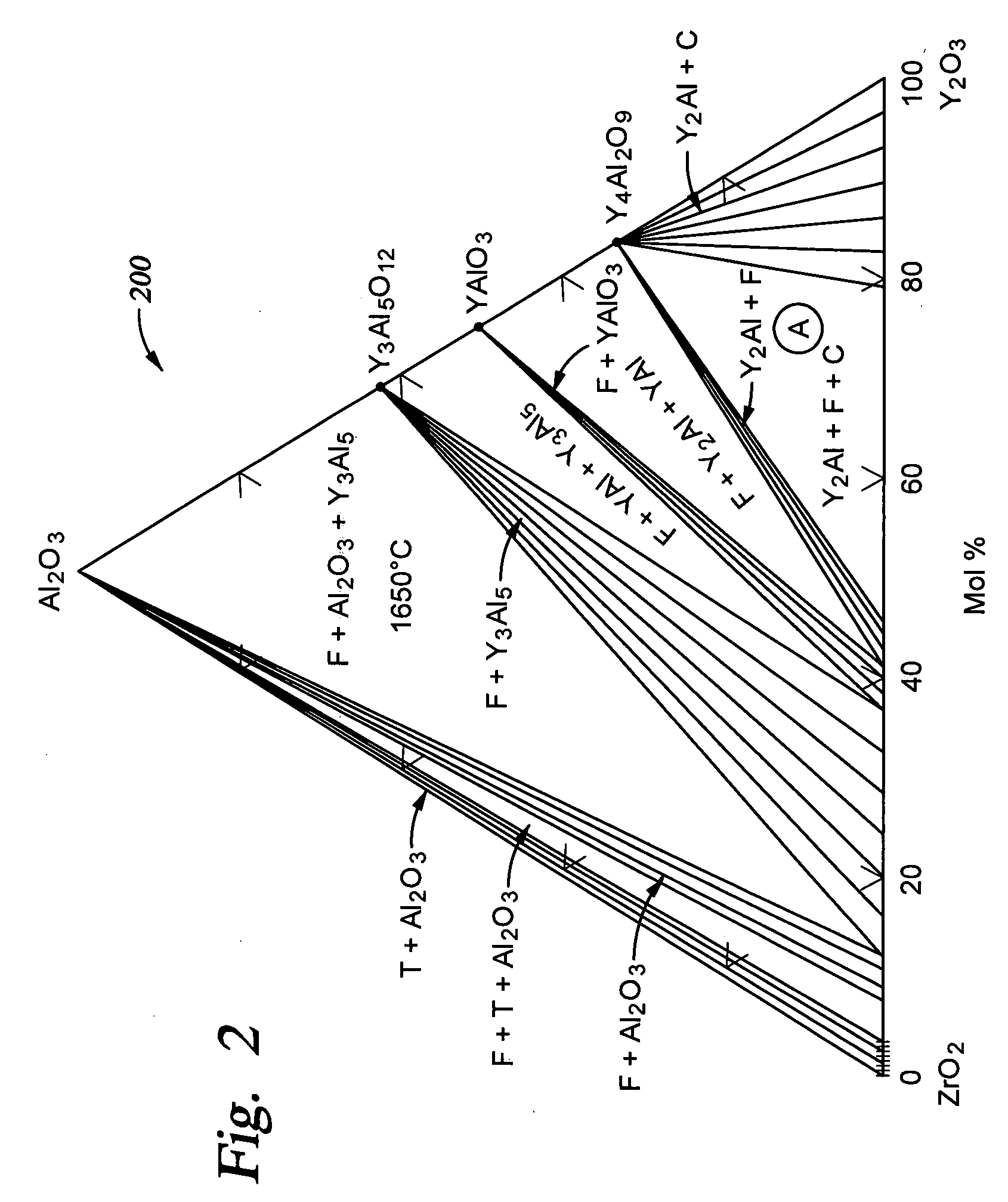

Method of coating semiconductor processing apparatus with protective yttrium-containing coatings

InactiveUS20080213496A1Improve plasma resistanceTailored mechanical propertiesMolten spray coatingVacuum evaporation coatingSolid solutionYttrium

Methods of applying specialty ceramic materials to semiconductor processing apparatus, where the specialty ceramic materials are resistant to halogen-comprising plasmas. The specialty ceramic materials contain at least one yttrium oxide-comprising solid solution. Some embodiments of the specialty ceramic materials have been modified to provide a resistivity which reduces the possibility of arcing within a semiconductor processing chamber.

Owner:APPLIED MATERIALS INC

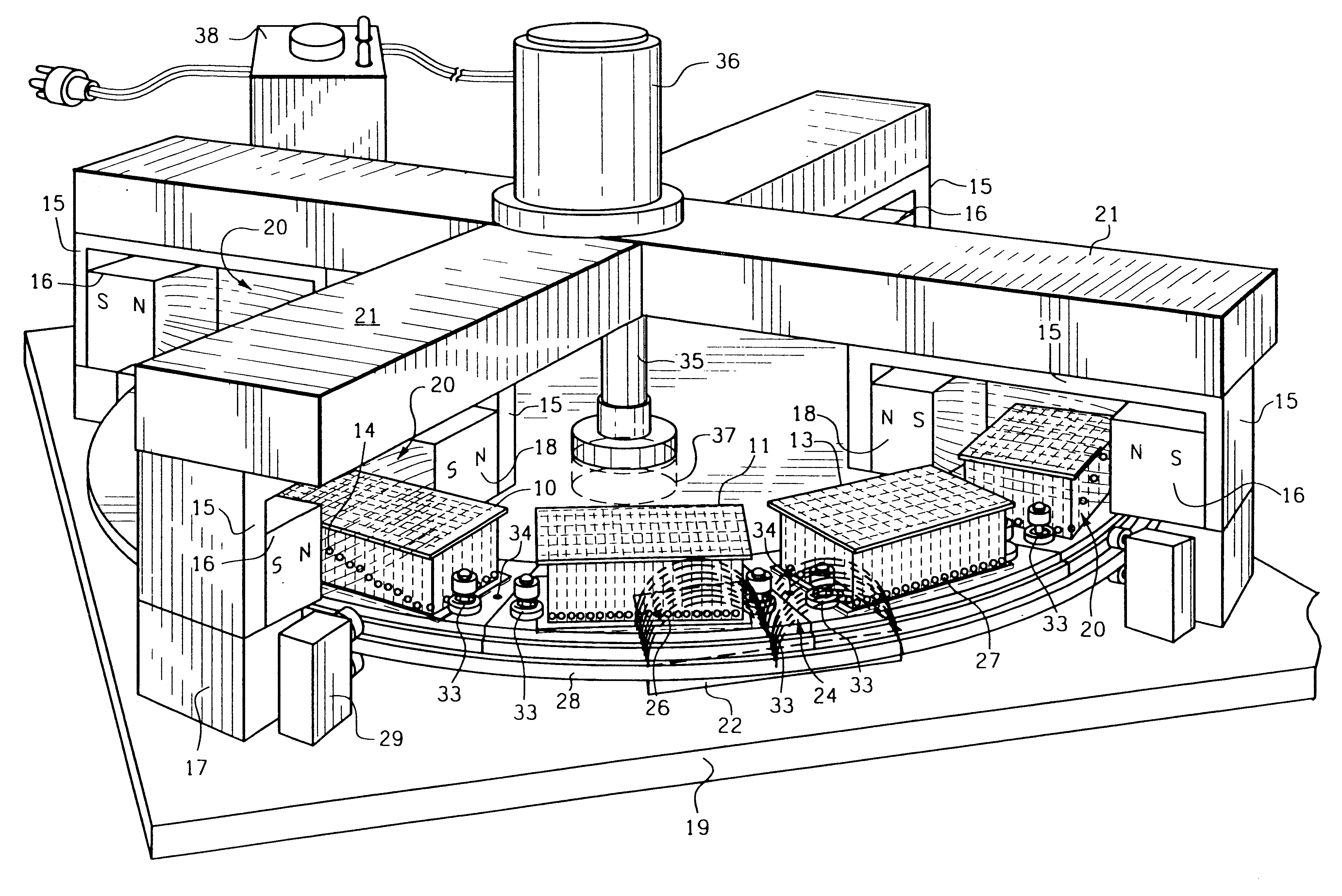

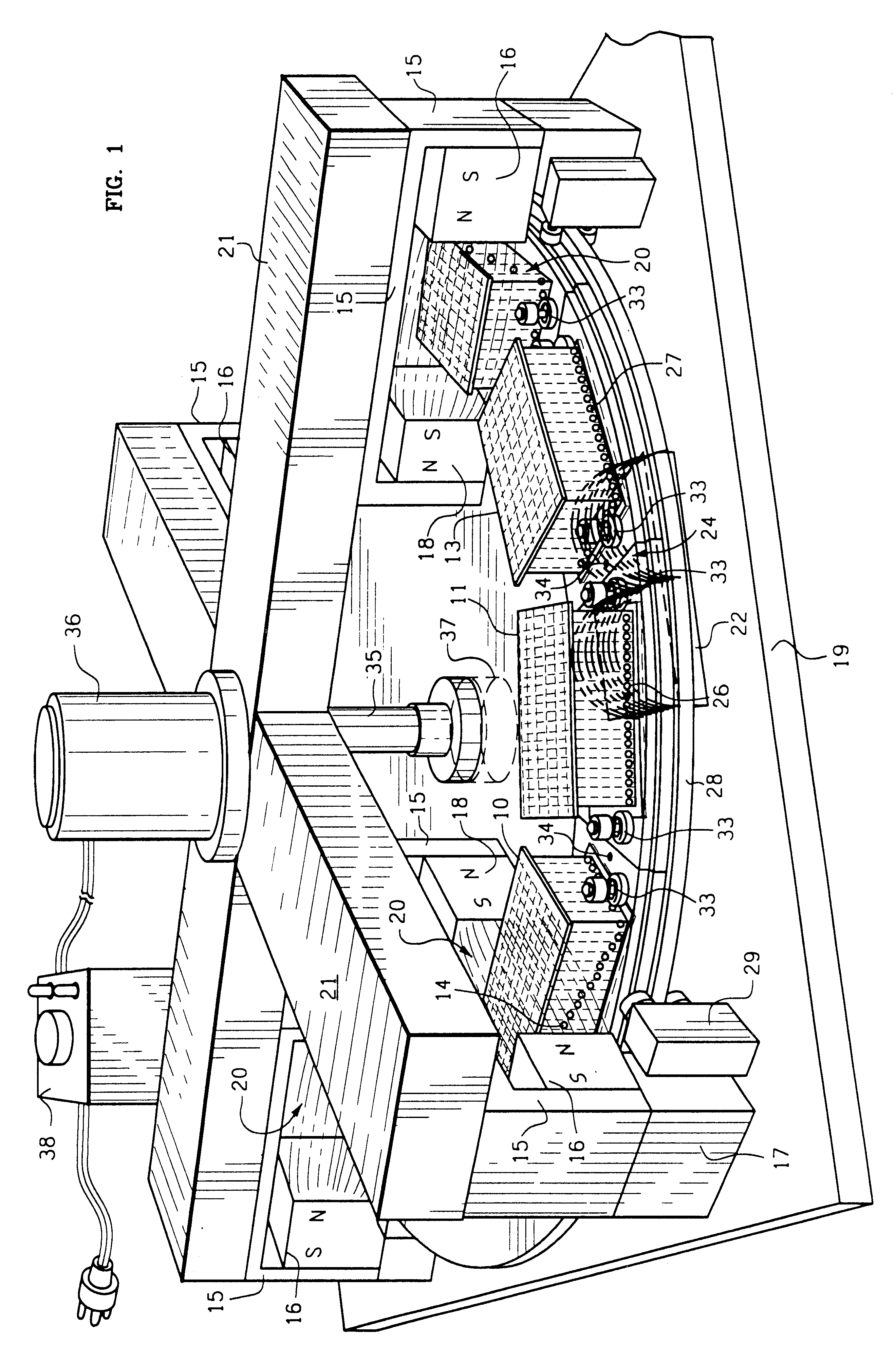

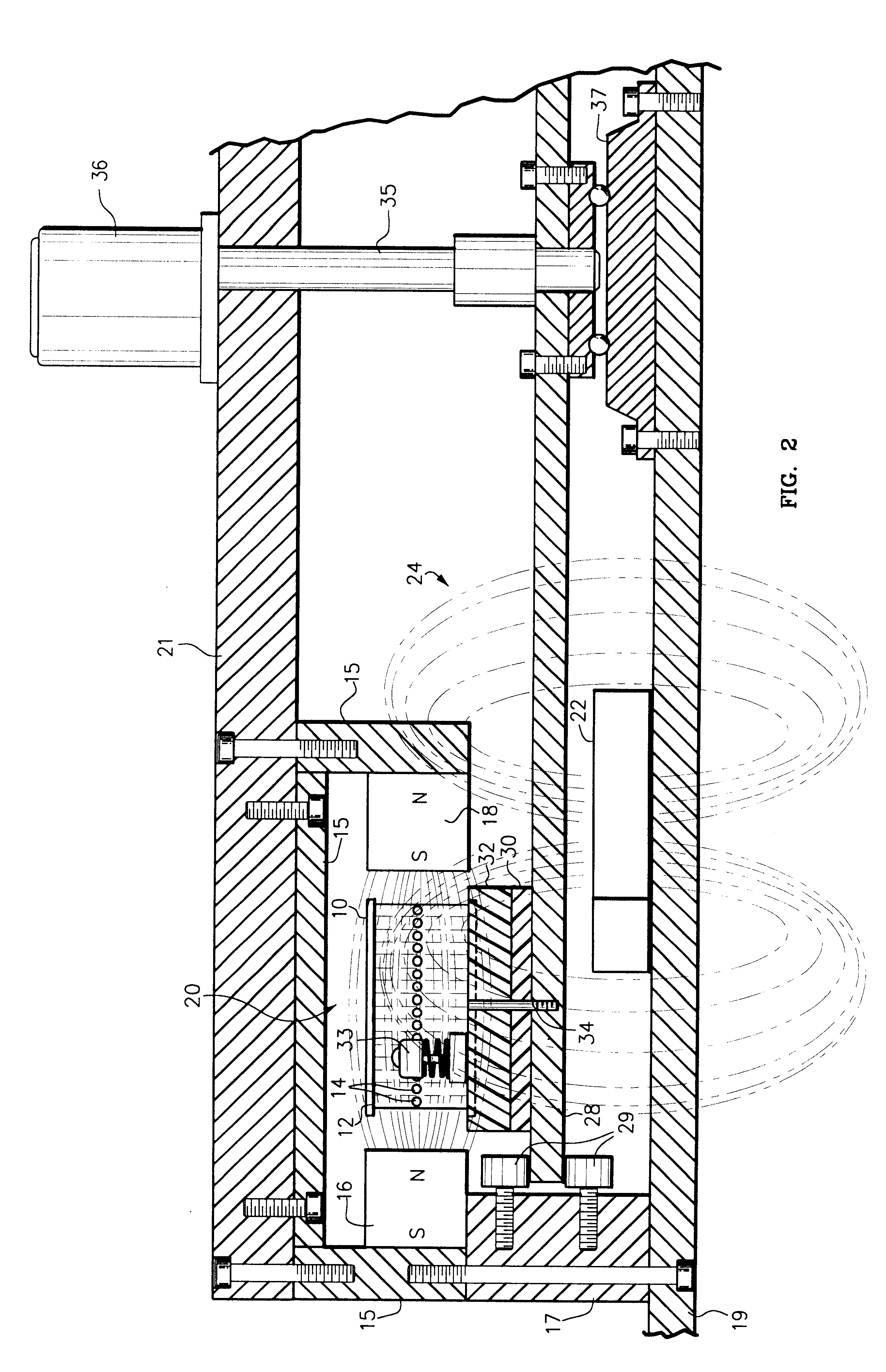

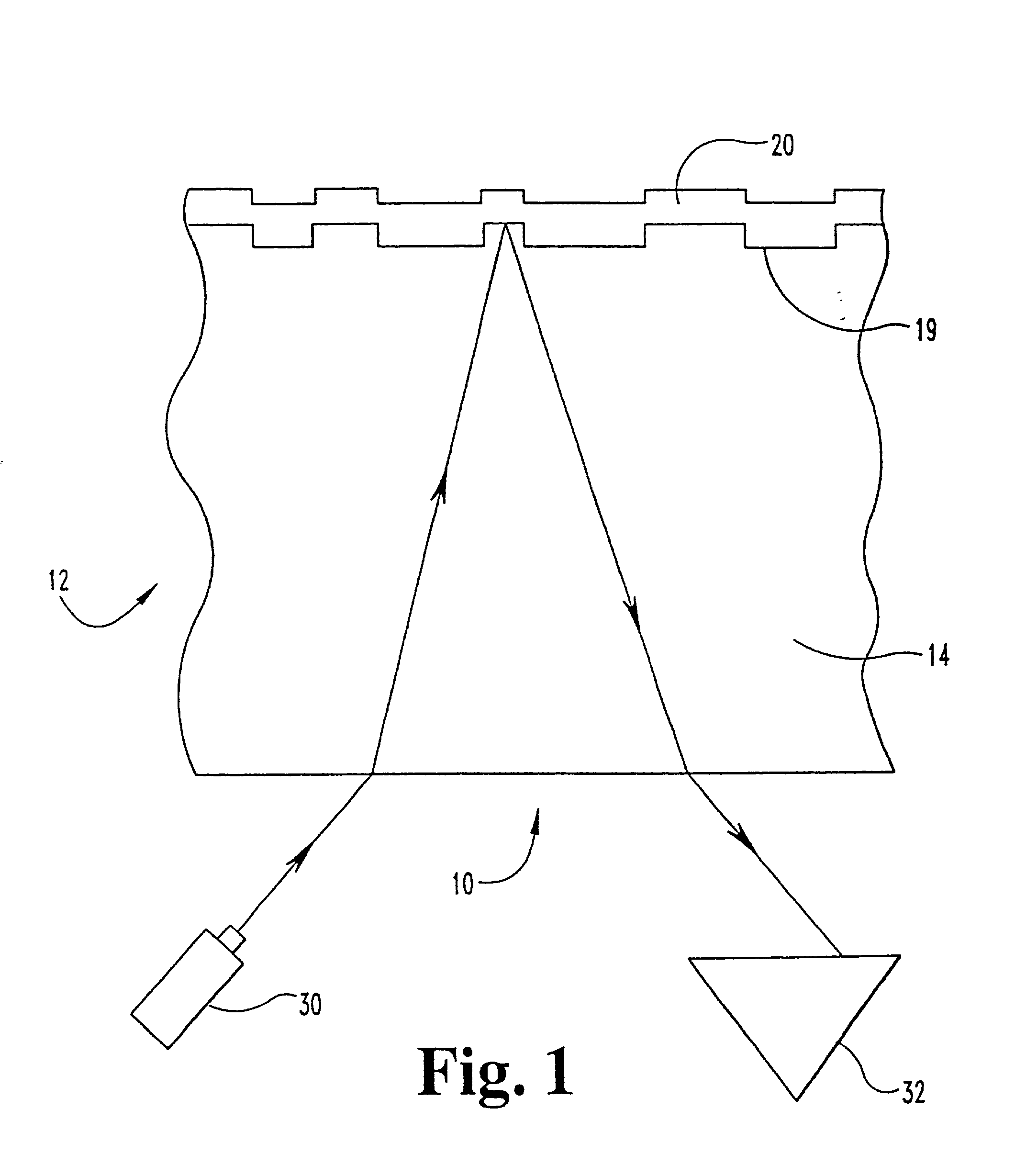

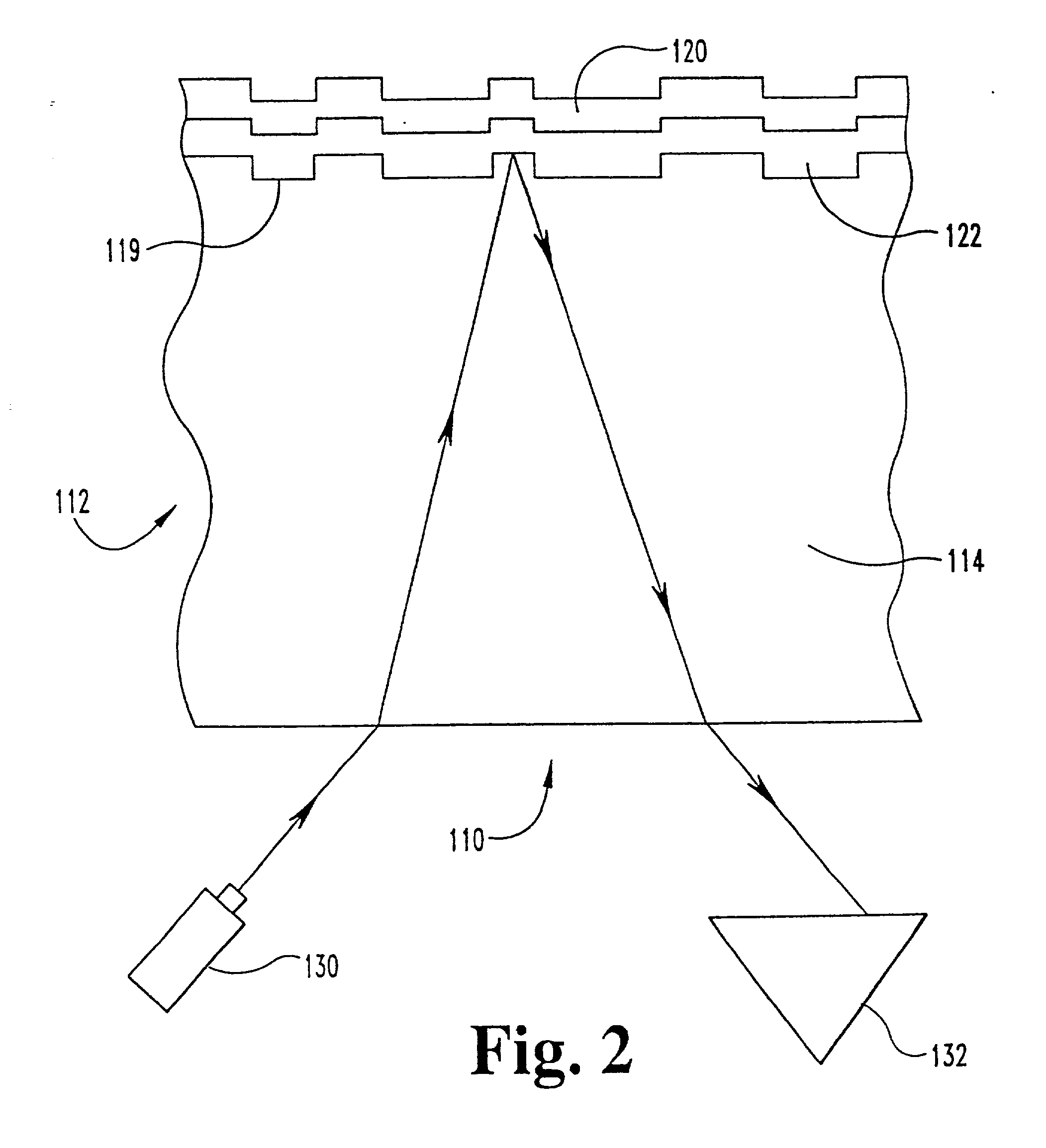

Magnetic levitation stirring devices and machines for mixing in vessels

InactiveUS6357907B1Increase surface areaIncrease aerationTransportation and packagingMaterial analysis by optical meansMagnetic polesMagnetic stirrer

The invention provides a simple method, devices and several machines for simultaneously stirring and aerating thousands of vessels or wells of microplates in a robust manner and with economy. This method uses the simple principle of magnetic stirrers being levitated vertically when passed laterally or vertically through a strong horizontal dipole magnetic field. The dipole magnetic fields may be produced by using permanent magnets, electromagnets or a modulating / reversing electro-magnetic field. Each vessel contains a magnetic ball, disc, bar, dowel or other shape (stirrers) which in their magnetic attraction to the dipole magnetic field will cause the stirrers to levitate up in the vessel as the stirrer's magnetic poles attempt to align with the center of the dipole's magnetic field. The stirrers will fall to the bottom of the vessel by gravity or by changing the relative position of the levitating magnetic field to pull them down, or by passing the vessel laterally over another magnetic field. The up and down movement of the stirrers provides a vigorous mixing of the contents of many vessels at same time. If the level of the vessel's meniscus is situated so the stirrers pass through it on their way up and down, the air / liquid interface is significantly increased thereby significantly increasing aeration of the liquid.

Owner:V & P SCI

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6280811B1Moderate to high reflectivityImprove corrosion resistancePhotosensitive materialsRadiation applicationsIridiumMagnesium

A copper-based or silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, palladium, copper, rhodium, ruthenium, osmium, iridium, beryllium and platinum. Alloy additions to copper include silver, cadmium, gold, magnesium, aluminum, beryllium, zirconium, and nickel. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

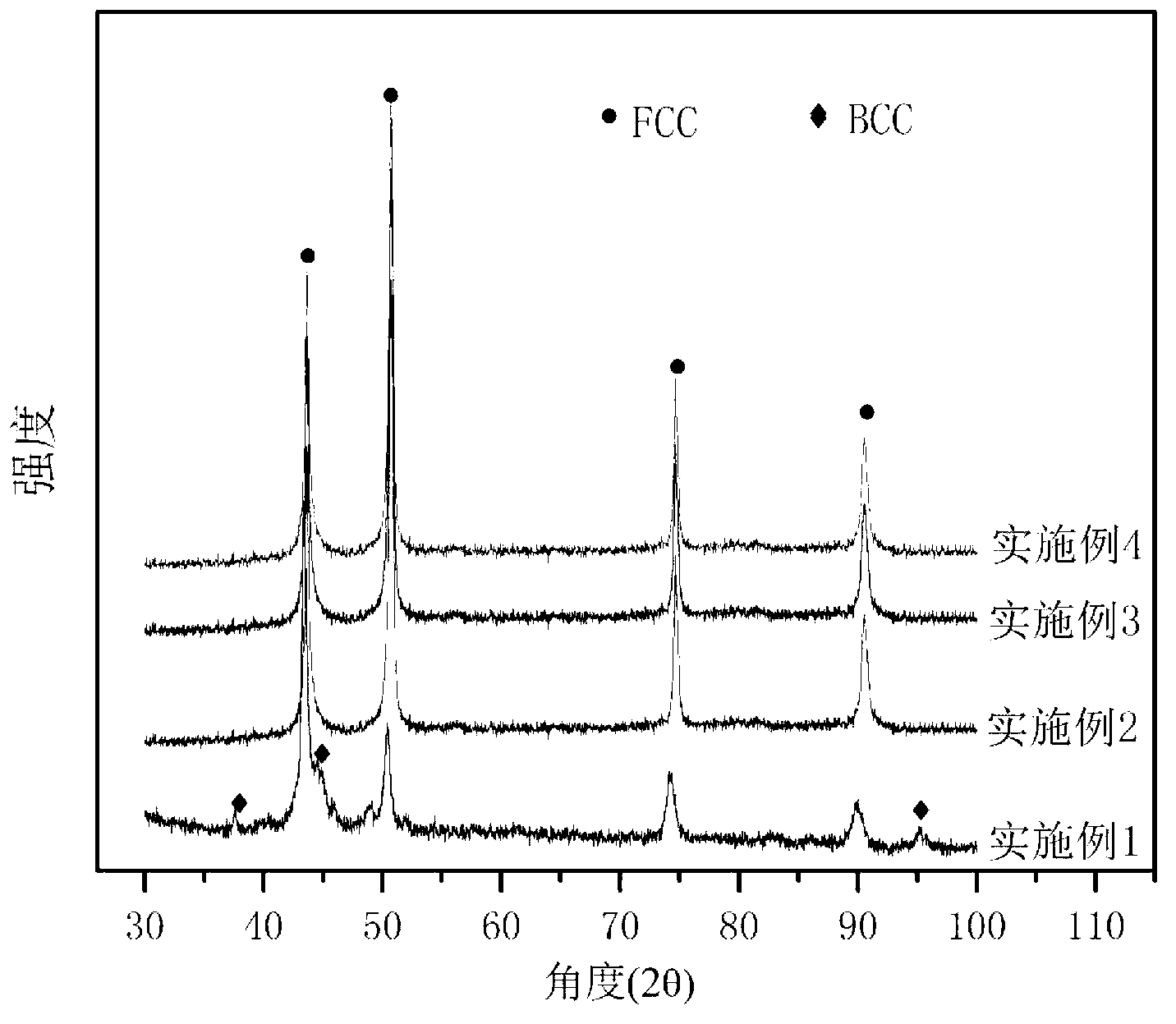

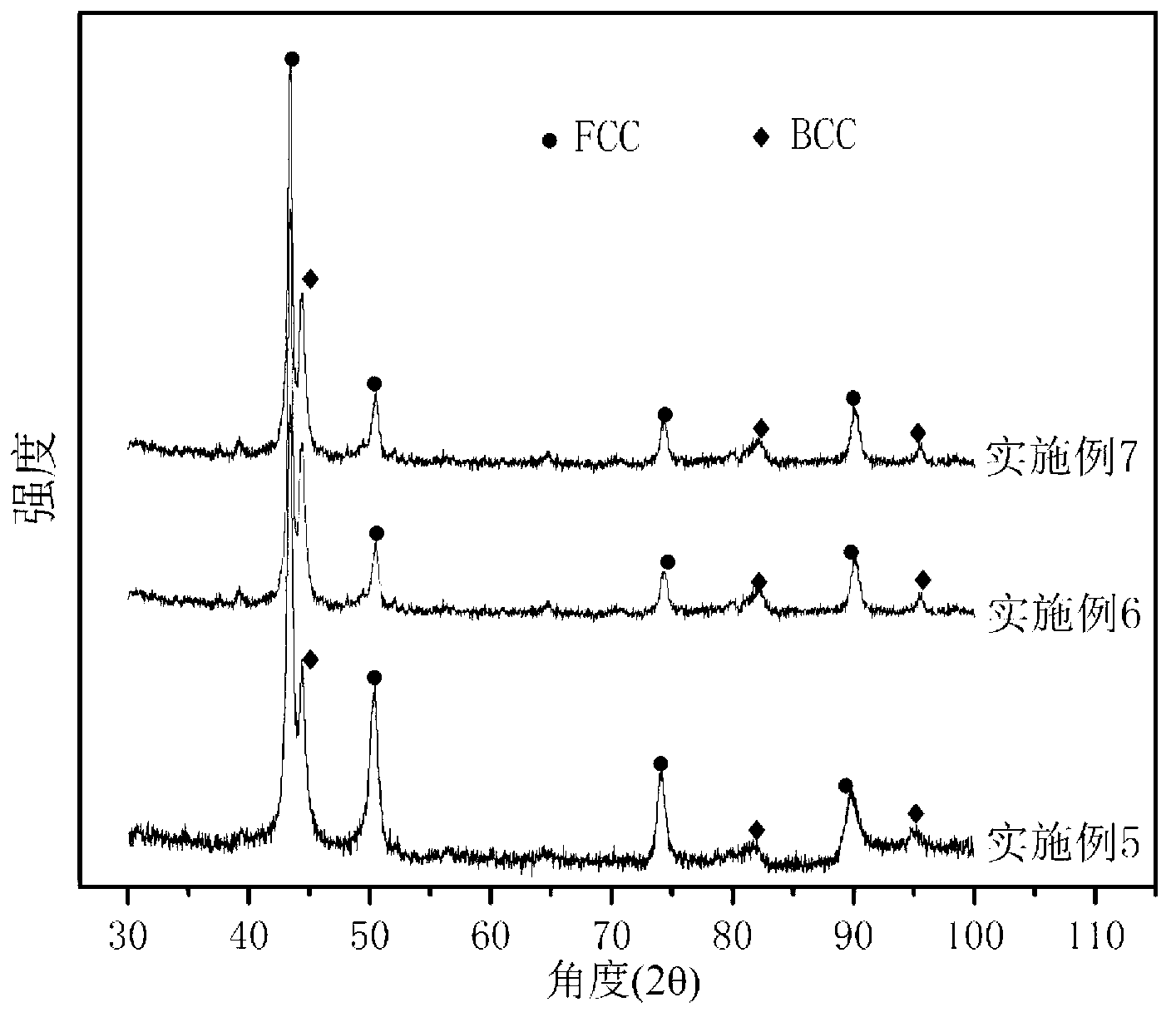

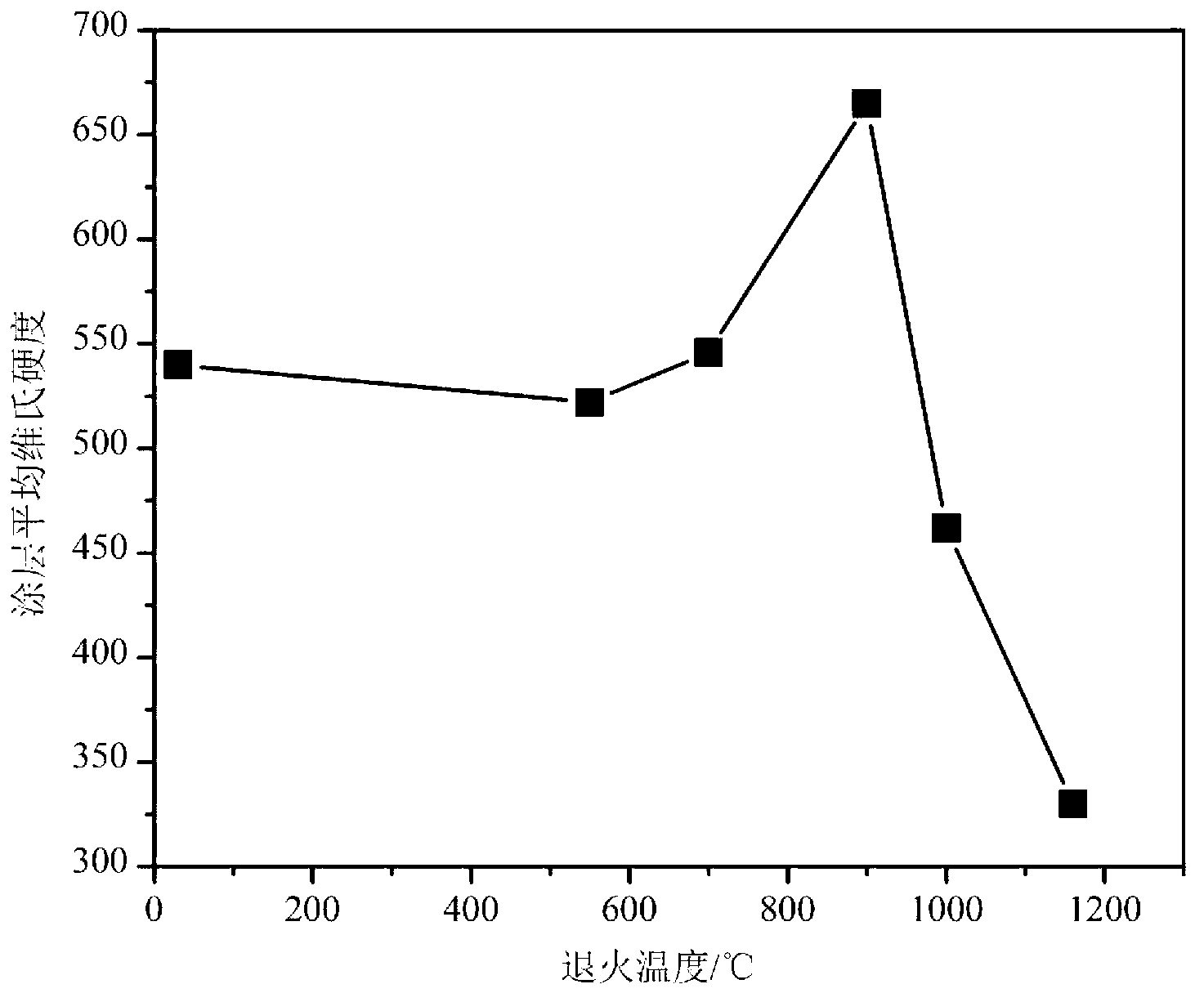

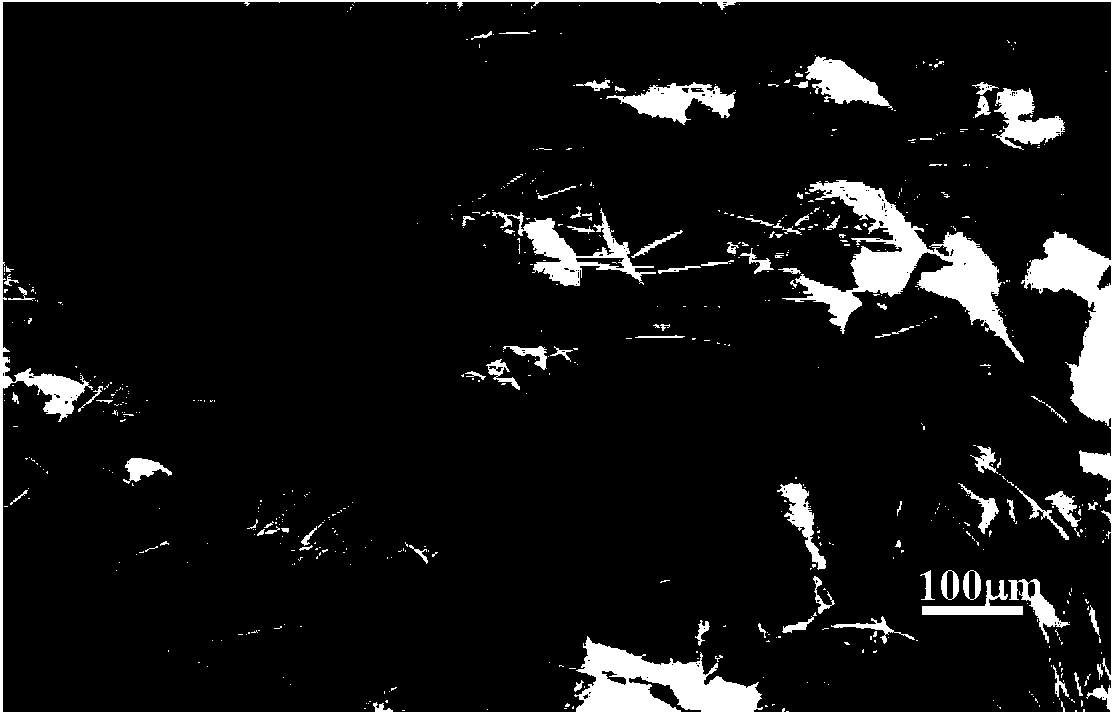

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6451402B1Good corrosion resistanceHigh reflectivityRecord information storageThin material handlingIridiumCorrosion

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, palladium, copper, rhodium, ruthenium, osmium, iridium, and platinum. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

Plant powder modified thermoplastic wood-plastic composite and preparation method and application

The invention discloses a plant powder modified thermoplastic wood-plastic composite and a preparation method and application thereof. The composite is composed of the following components by weight portion: 100 portions of thermoplastic resin, 1-400 portions of plant powder, 0.1-40 portions of dispersant, 0.5-60 portions of impact modifier, 0-100 portions of inorganic filler and 0-10 portions of antioxidant. Compared with wood, the plant powder modified thermoplastic wood-plastic composite prepared by the method has the advantages of durability, good dimensional stability, easy molding, small water absorption and corrosion resistance. Compared with plastics, the composite has the characteristics of low cost and high rigidity. The composite is suitable for a variety of injection molding parts, such as the shells of electrical equipment including TV, and the like.

Owner:KINGFA SCI & TECH CO LTD +1

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6544616B2Improve reflectivitySimilar sputtering characteristicMagnetic materials for record carriersVacuum evaporation coatingMetal alloyManganese

A silver-based alloy thin film is provided for the highly reflective or semi-reflective coating layer of optical discs. Alloy additions to silver include zinc, aluminum, zinc plus aluminum, manganese, germanium, and copper plus manganese. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

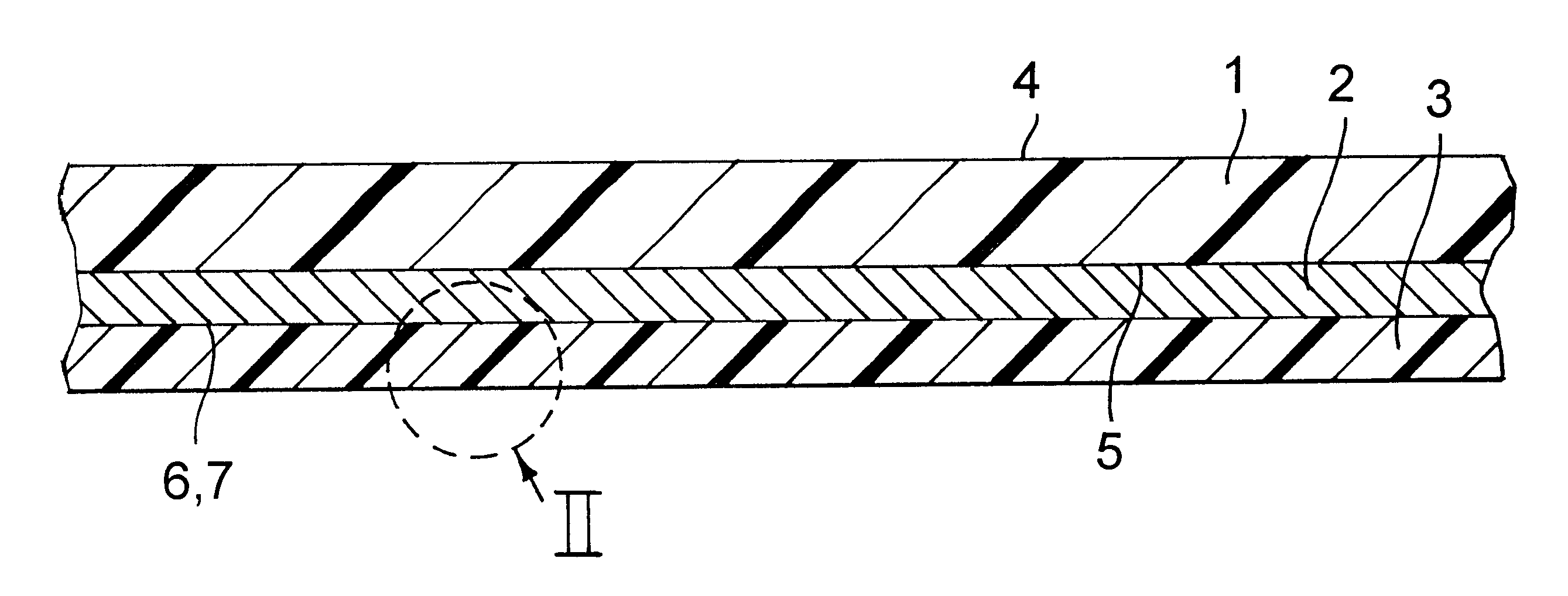

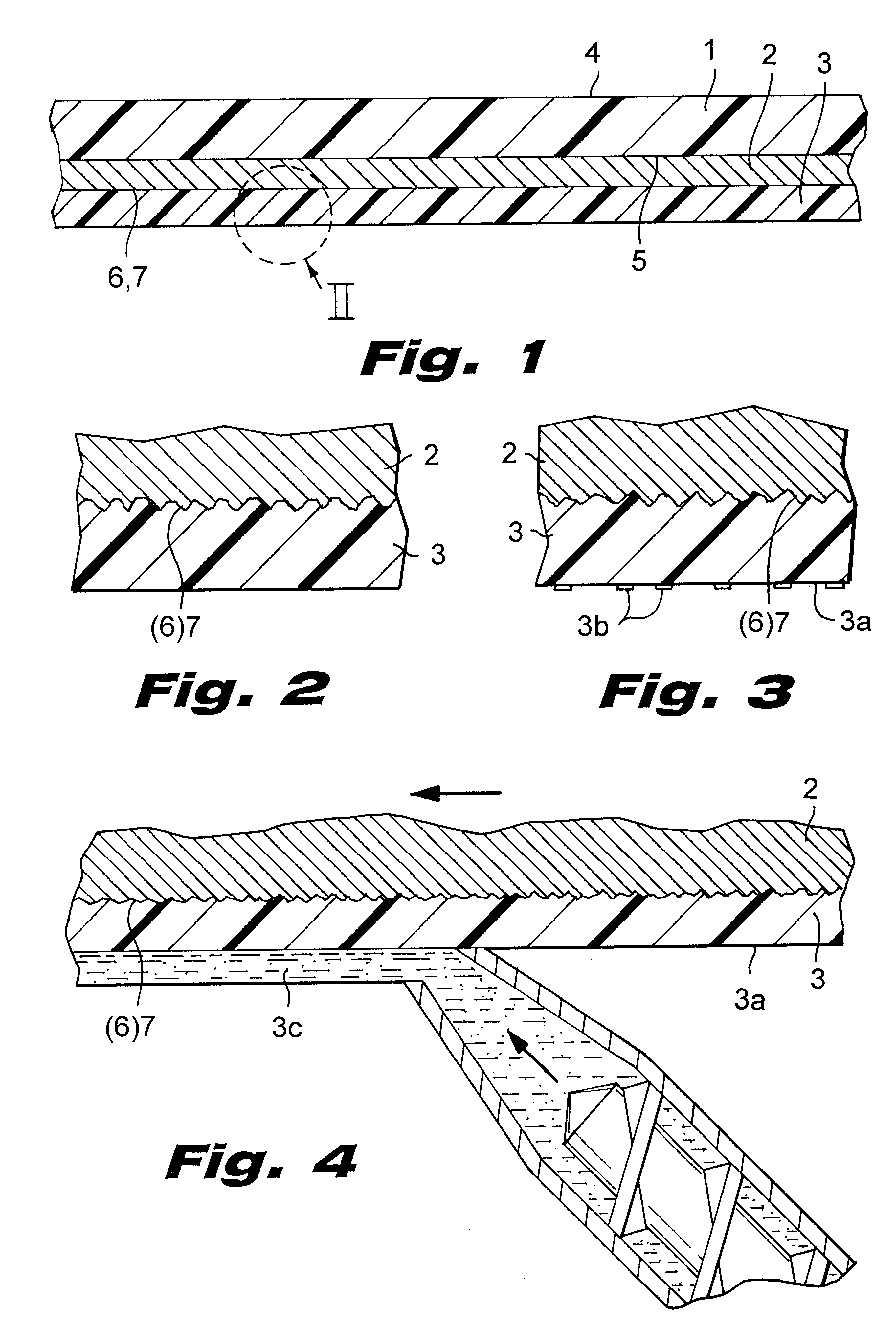

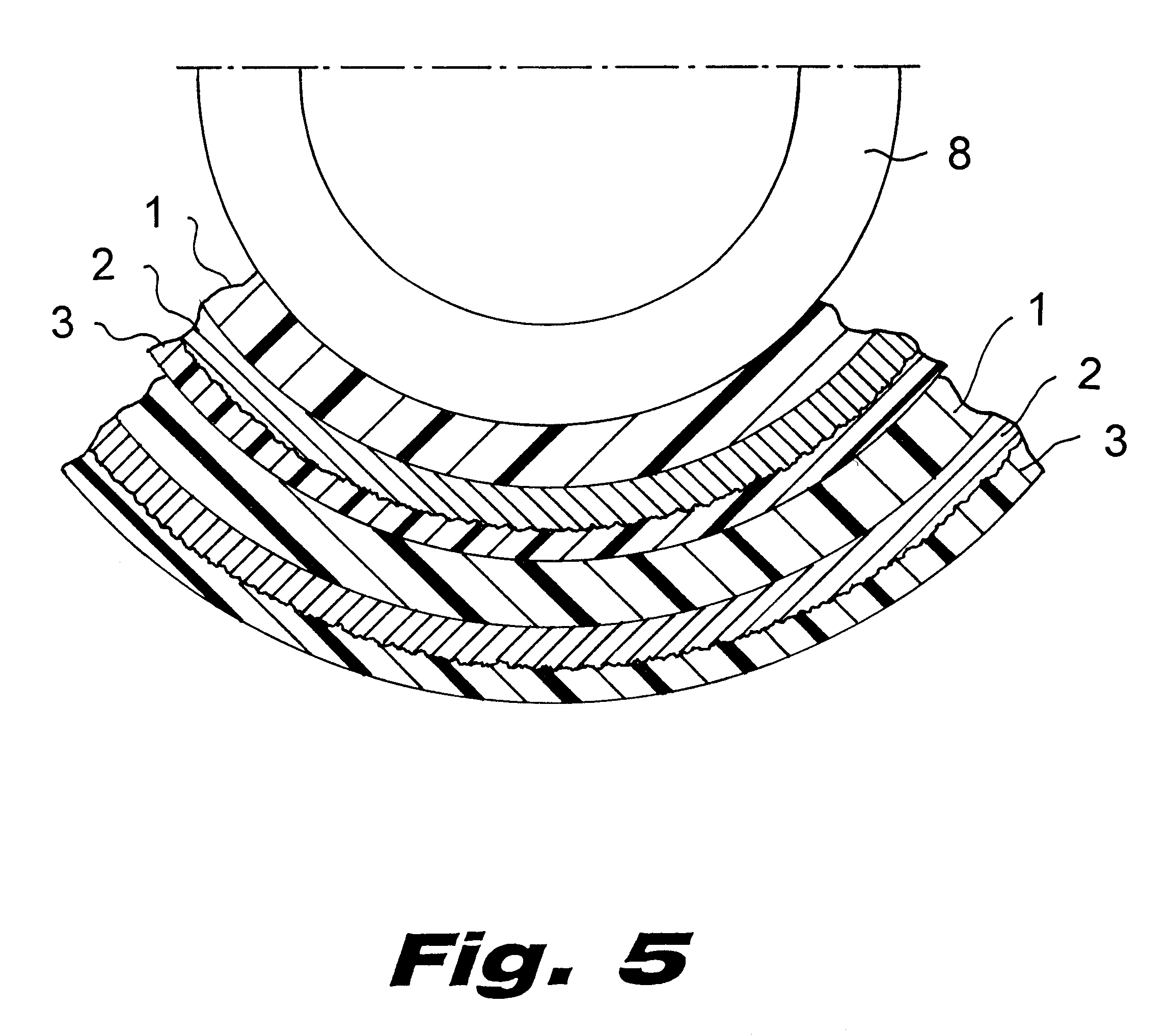

Fluid impermeable foil

A fluid impermeable foil for use in connection with the wrapping of foodstuffs, cosmetics and other products has a plastic substrate one side of which is coated with a film of metallic material, such as aluminum. The exposed surface of the metallic film is provided with a thin protective layer which contains a wax, a resin, a lubricant and / or another organic material and shields the metallic film from scuffing, corrosion and direct exposure to air and / or moisture. The metallic material of the film is vaporized onto the one side of the substrate, and the organic material of the protective layer is vaporized onto the exposed surface of the film in one or more stages as soon as the vaporization of metallic material upon the substrate is completed.

Owner:SCHMOOCK HELMUTH

Completely degraded plant powder modified thermoplastics composite material and preparation method thereof

ActiveCN101760037AHas physical and chemical propertiesEasy to processThermoplastic compositesPolypropylene

The invention discloses a completely degraded plant powder modified thermoplastics composite material and preparation method thereof, which consists of the components with the weight portions as follows: 100 portions of degradable thermoplastics resin, 1-400 portions of plant powder, 0.1-40 portions of dispersing agent, 0.5-60 portions of impact modifier, 0-40 portions of inorganic filler as well as 0.1-10 portions of stabilizing agent. The degraded thermoplastics resin has similar physiochemical performances with universal polyethylene and polypropylene, has excellent processing performances, and can be commixed with plant powder to prepare thermoplastics wood plastic composite materials. The obtained thermoplastics wood plastic composite materials can be completely degraded into carbon dioxide and water in natural environment under the effects of broadly existed microbes like germs, actinomycetes, etc. Compared with wood products, the composite material has the characteristics of good durability and dimensional stability, easy forming, small water absorbability, and corrosion resistance; compared with plastic, the composite material has the characteristics of low cost and high rigidity. The completely degraded plant powder modified thermoplastics composite material can be used for producing the shells of electric apparatuses like TV, sound, copier, printer, etc, and can also be applied on other workpieces used for injection.

Owner:GUANGDONG KINGFA TECH CO LTD +2

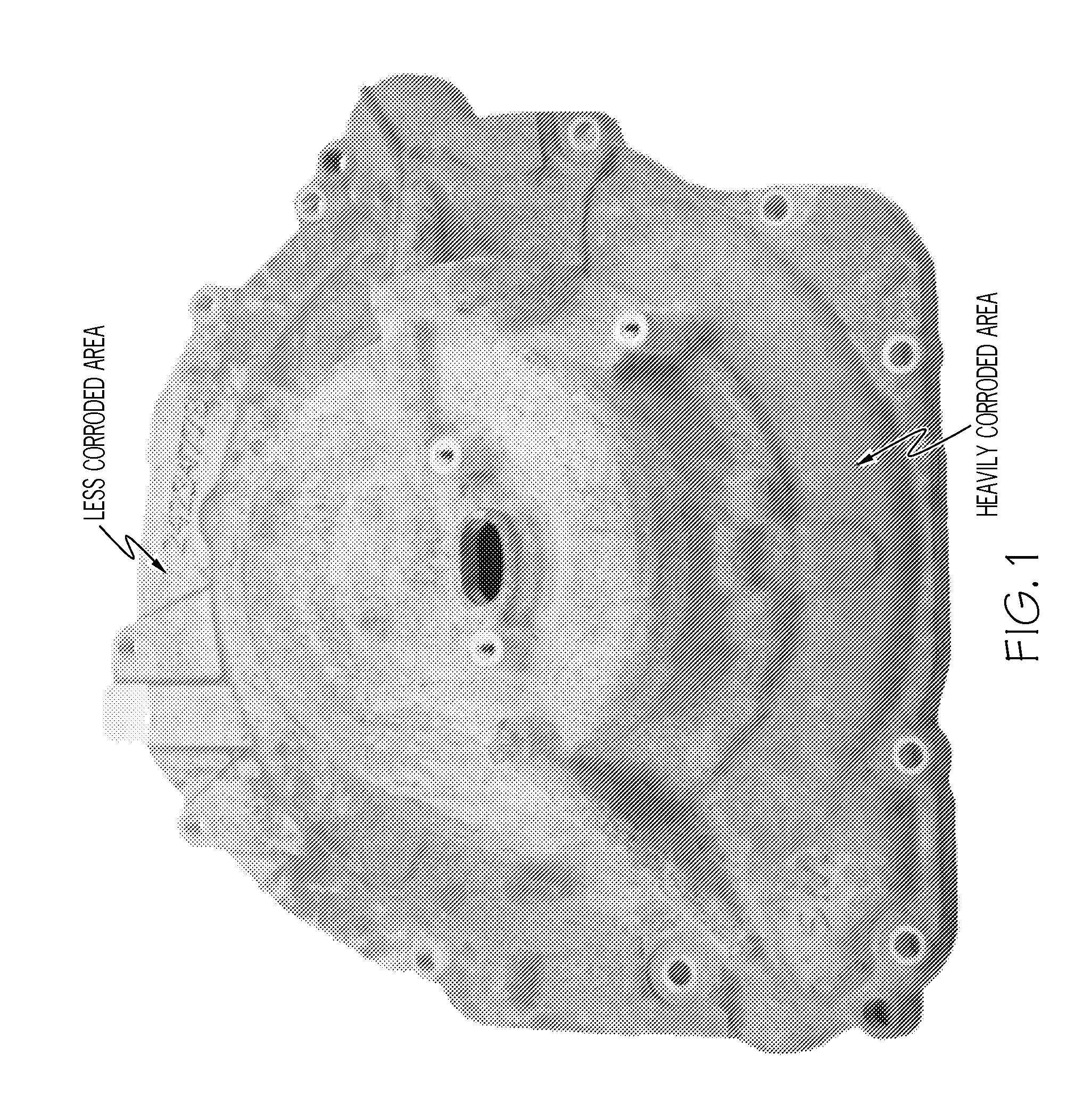

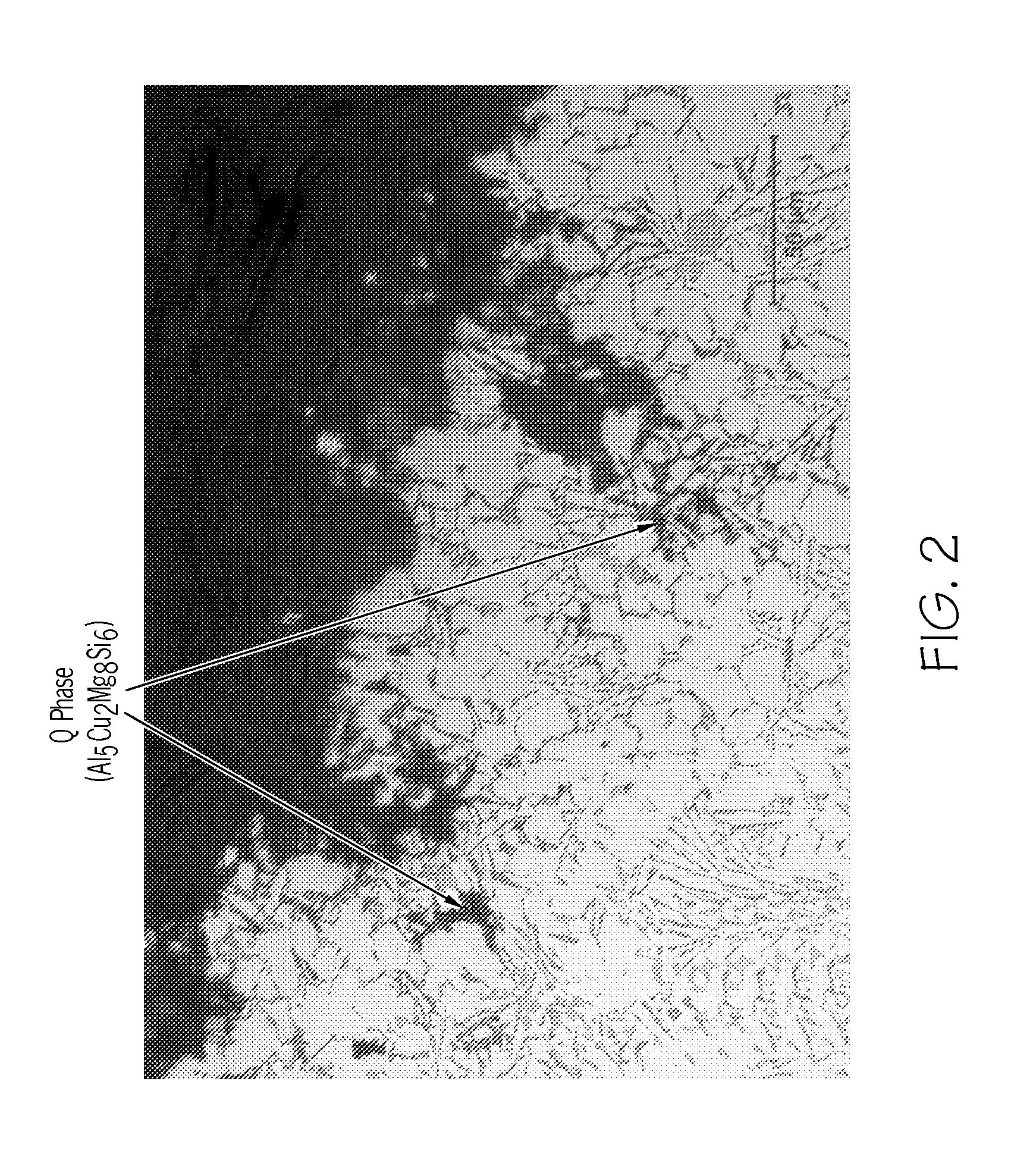

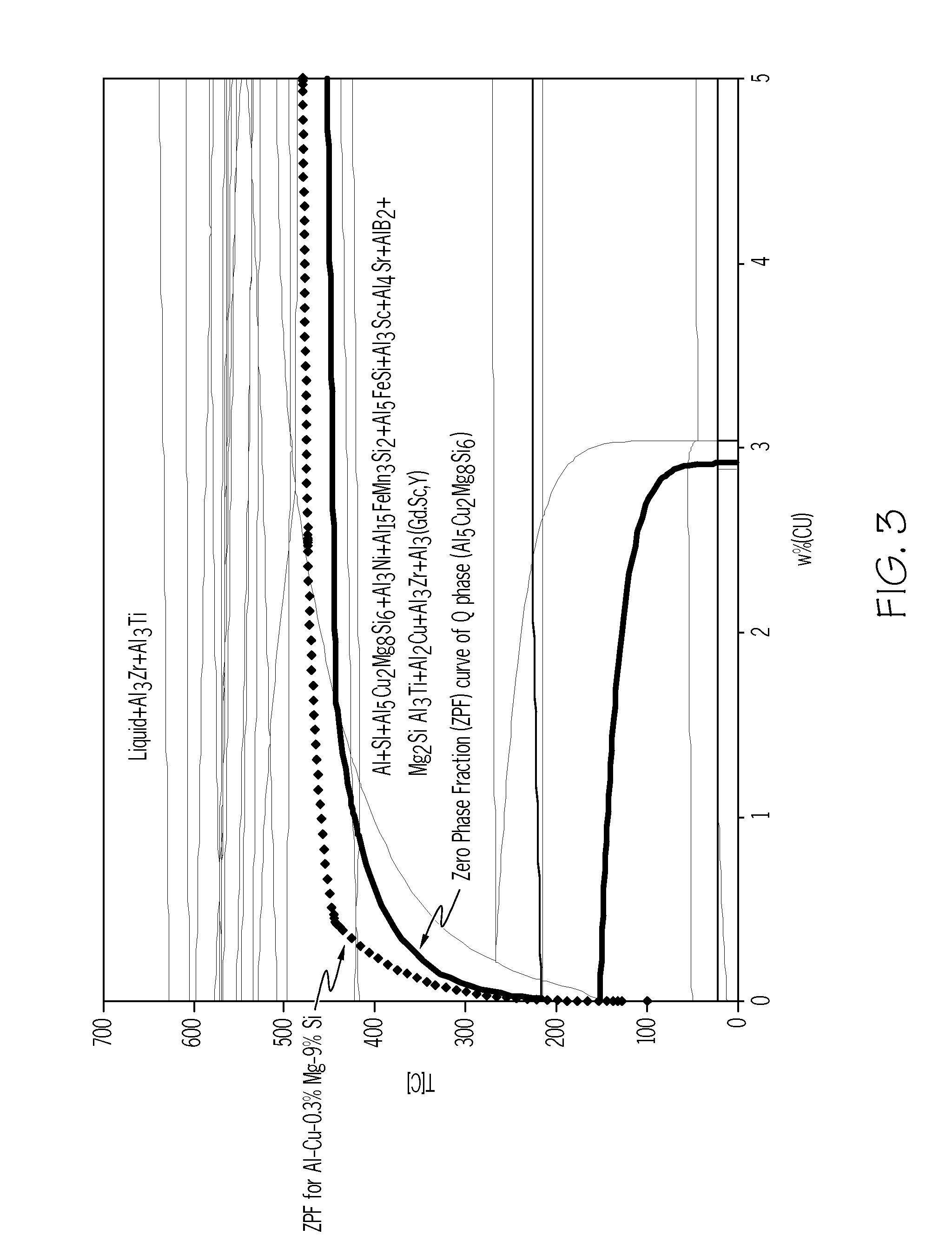

Cast aluminum alloys

ActiveUS20120000578A1Improve mechanical propertiesImprove corrosion resistanceAngiosperms/flowering plantsRare-earth elementIndium

Aluminum alloys having improved properties are provided. The alloy includes about 0 to 2 wt % rare earth elements, about 0.5 to about 14 wt % silicon, about 0.25 to about 2.0 wt % copper, about 0.1 to about 3.0 wt % nickel, approximately 0.1 to 1.0% iron, about 0.1 to about 2.0 wt % zinc, about 0.1 to about 1.0 wt % magnesium, 0 to about 1.0 wt % silver, about 0.01 to about 0.2 wt % strontium, 0 to about 1.0 wt % scandium, 0 to about 1.0 wt % manganese, 0 to about 0.5 wt % calcium, 0 to about 0.5 wt % germanium, 0 to about 0.5 wt % tin, 0 to about 0.5 wt % cobalt, 0 to about 0.2 wt % titanium, 0 to about 0.1 wt % boron, 0 to about 0.2 wt % zirconium, 0 to 0.5% yttrium, 0 to about 0.3 wt % cadmium, 0 to about 0.3 wt % chromium, 0 to about 0.5 wt % indium, and the balance aluminum. Methods of making cast aluminum parts are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS20020034603A1Improve reflectivitySimilar sputtering characteristicMagnetic materials for record carriersVacuum evaporation coatingManganeseHigh reflectivity

A silver-based alloy thin film is provided for the highly reflective or semi-reflective coating layer of optical discs. Alloy additions to silver include zinc, aluminum, zinc plus aluminum, manganese, germanium, and copper plus manganese. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

RFID tag assembly and method

InactiveUS20120217307A1Long rangeEasy to cutAntenna supports/mountingsSensing record carriersEngineeringCardboard

A method is disclosed of producing an RFID tag assembly including an associated antenna and attachment means suitable for attaching the tag assembly to a material. The material may be flexible such as fabric or relatively rigid such as cardboard. The method includes forming the associated antenna and the attachment means as a unitary conductive frame. An RFID tag assembly produced by the method is also disclosed.

Owner:TAGSYS

Foamed resin compositions for sealing subterranean zones

InactiveUS6069117AIncrease elasticityCorrosion resistanceOther chemical processesMixing methodsEpoxyMechanical property

The present invention provides improved foamed hardenable epoxy resin sealing compositions and methods which are particularly useful in the construction and repair of wells. The foamed epoxy resin compositions are corrosion resistant and have improved mechanical properties including elasticity and ductility.

Owner:HALLIBURTON ENERGY SERVICES INC

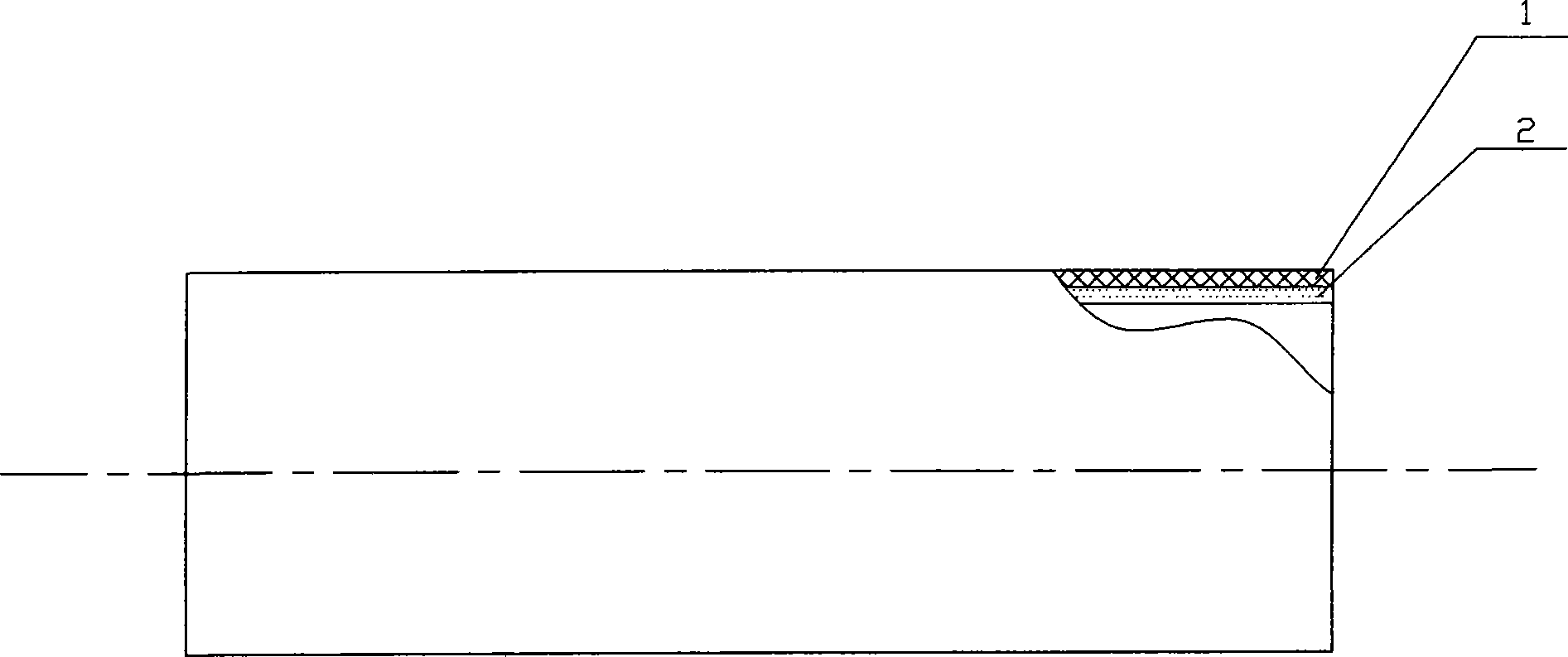

Single-surface glue water tape and making method thereof

The invention discloses a single-side glue water belt and a preparation method thereof; the water belt consists of a fiber knitting layer and a polyurea elastomer coating which is used as a lining layer which has the thickness of 0.5-1.0mm; high-strength aramids are preferably selected for the warp and woof of the knitting layer; the preparation method comprises the steps as follows: tabular knitting layer is knitted on a circular loom firstly; subsequently, isocyanate composition and resin composition are mixed and heated to 60-70DEG C and pressurized to 12-15MPa; subsequently, the mixture is sprayed at the internal side of the fiber knitting layer by a spraying gun, thus forming a polyurea elastomer coating which is then dried so as to gain the product; the water belt is used for delivering water or industrial liquids in the industries such as fire control or agriculture and industry, building and the like, has the advantages of wearability, anti-corrosion, anti-impact, long service life and the like, has simple preparation method, few equipment investment, high production efficiency and meeting the requirement of environmental protection.

Owner:5ELEM HI TECH CORP

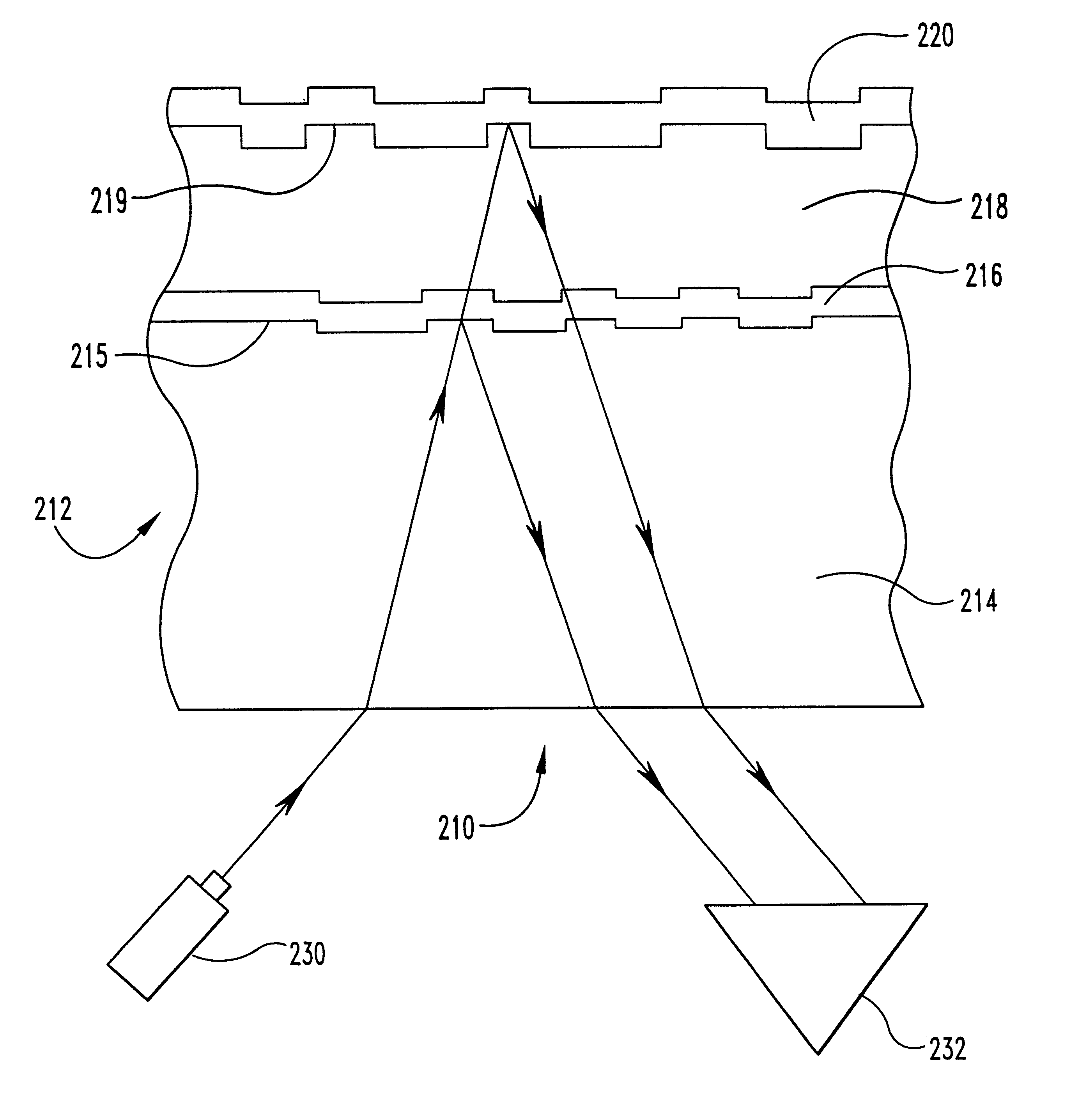

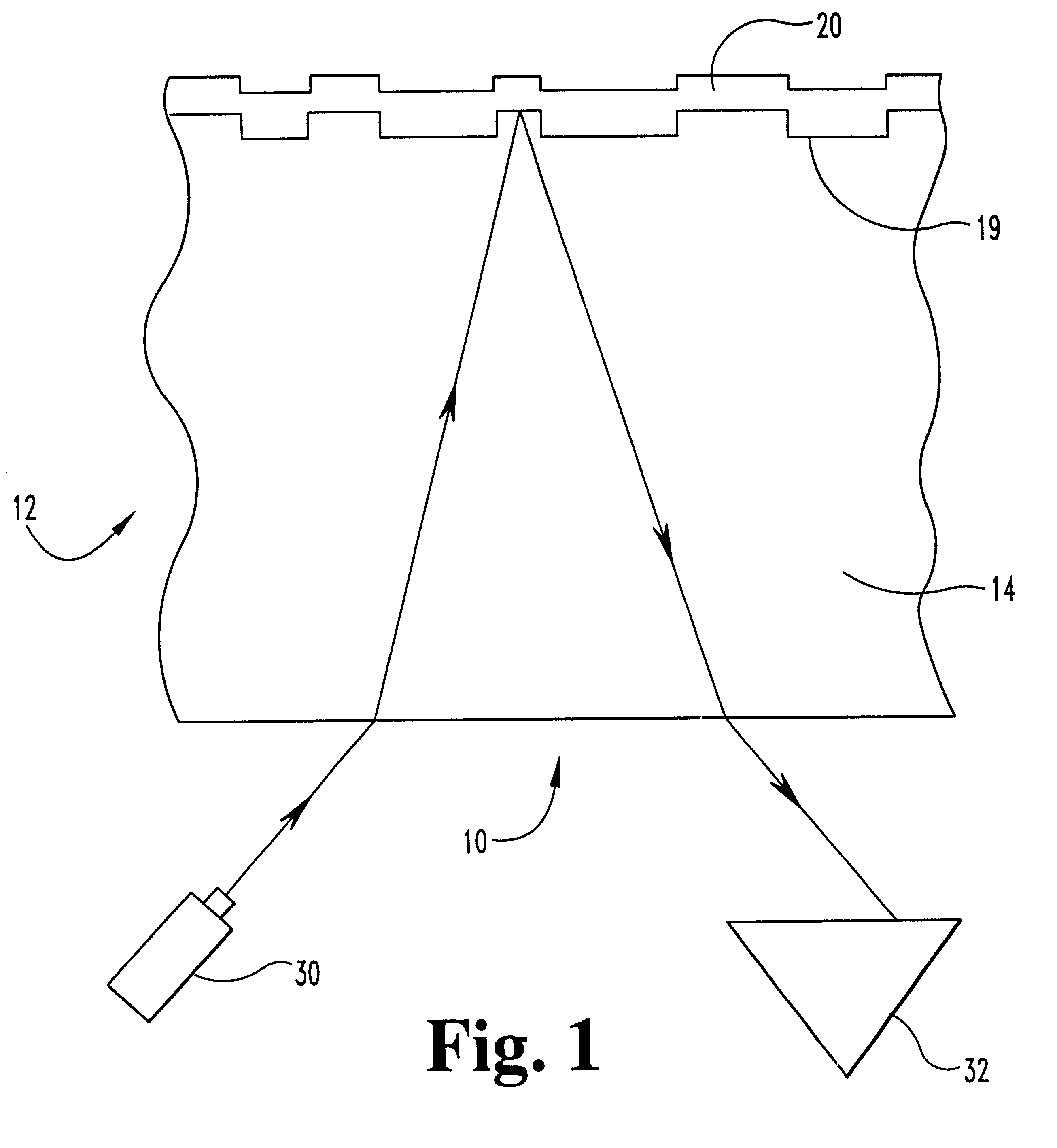

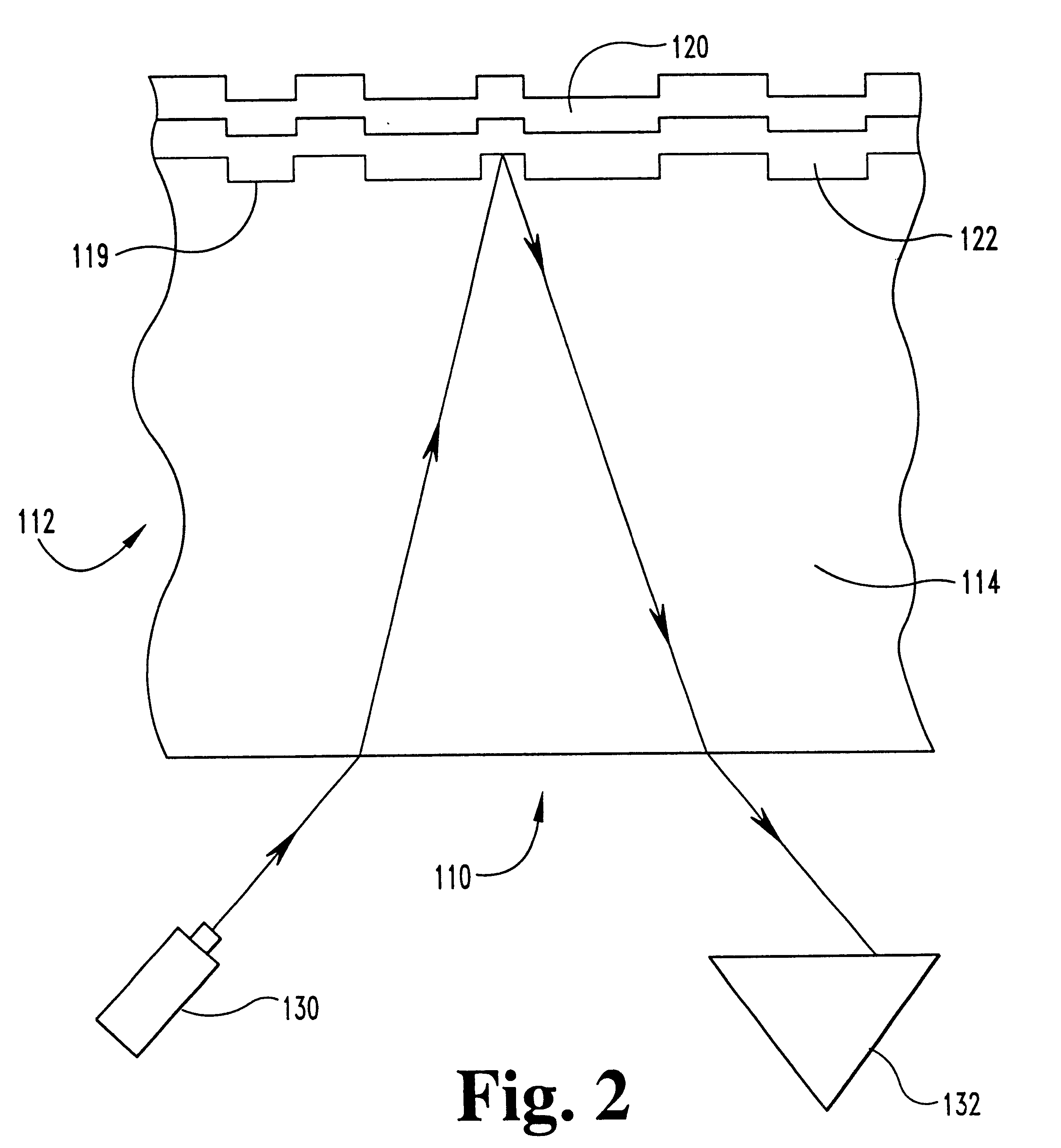

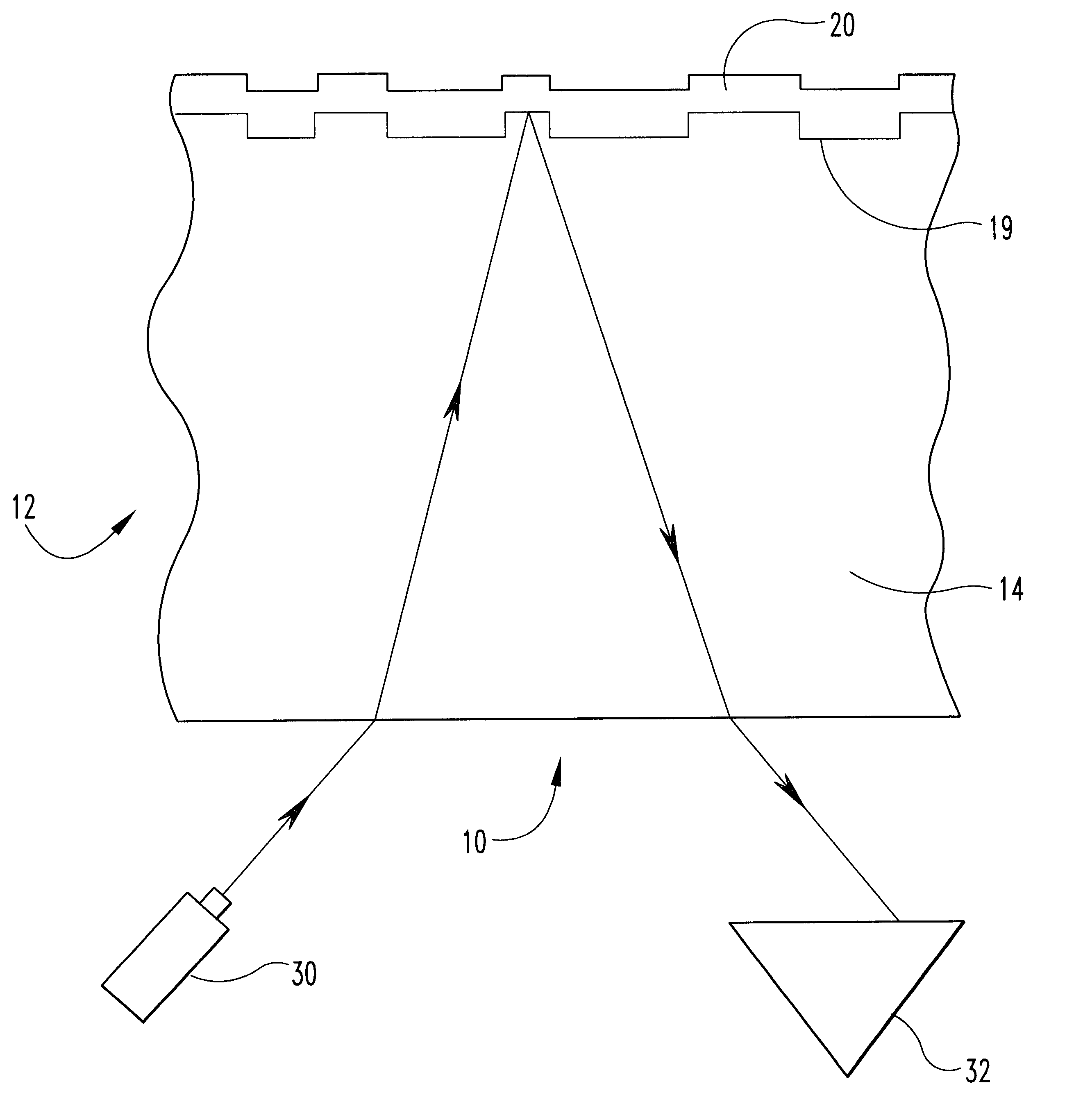

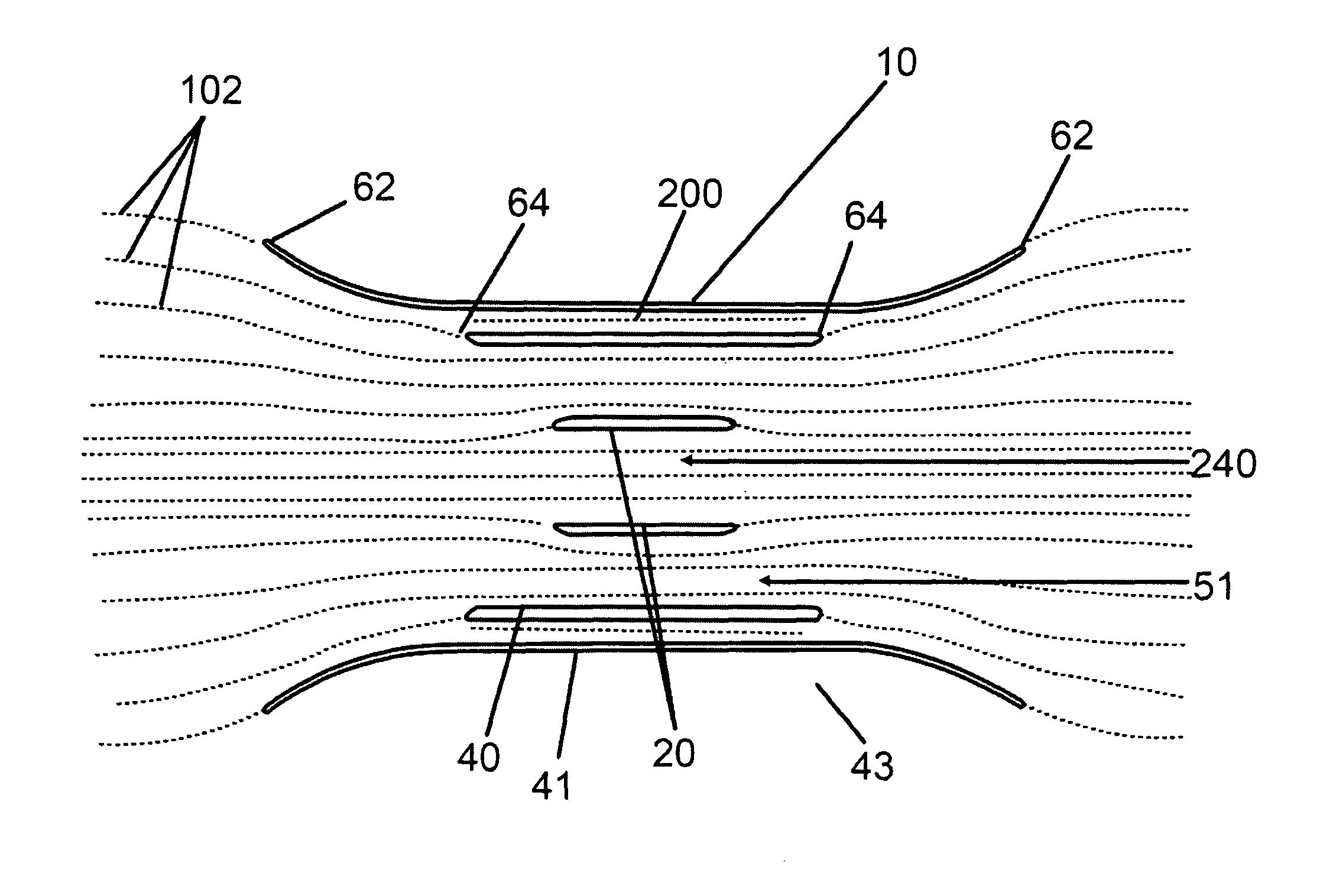

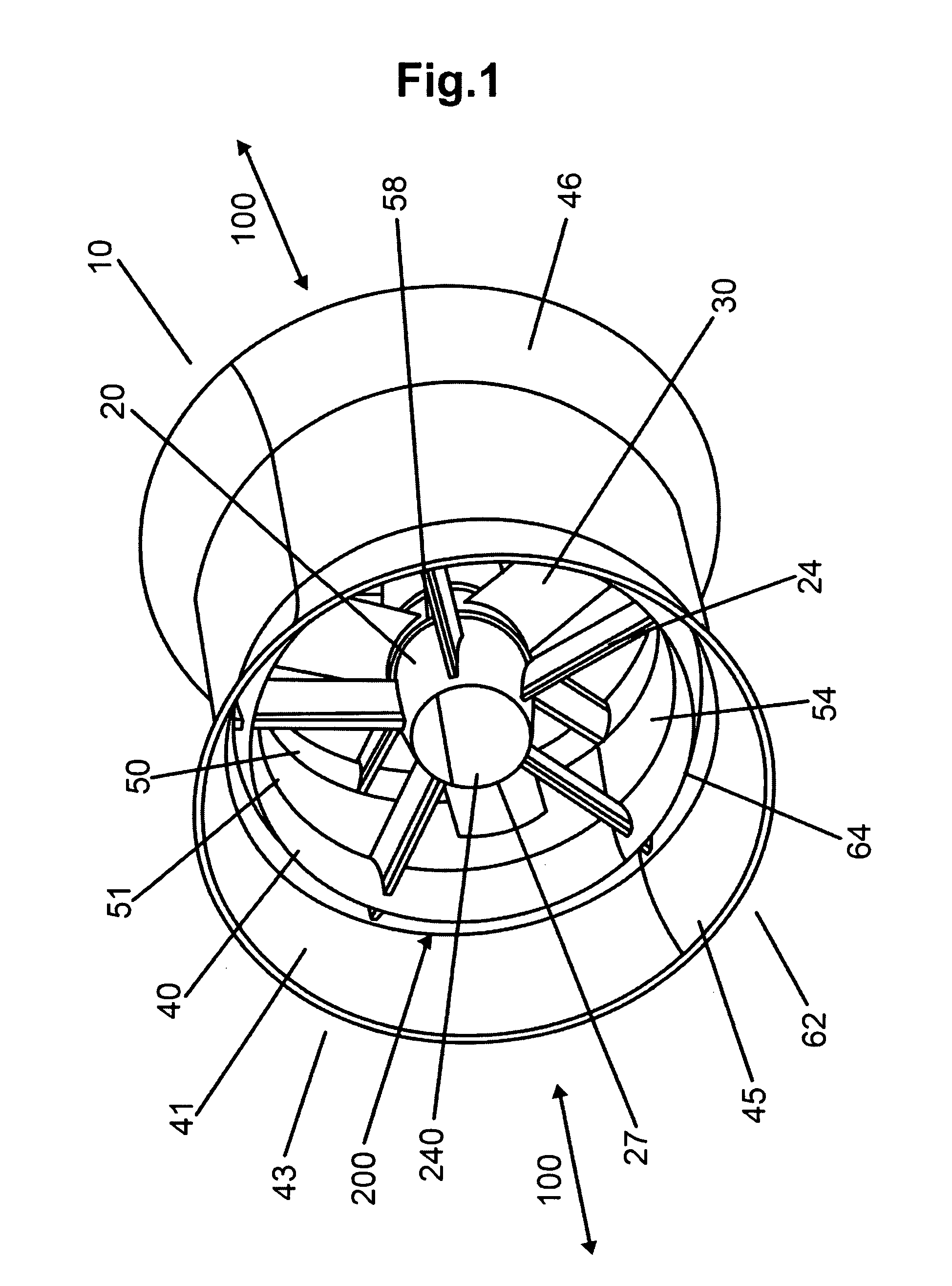

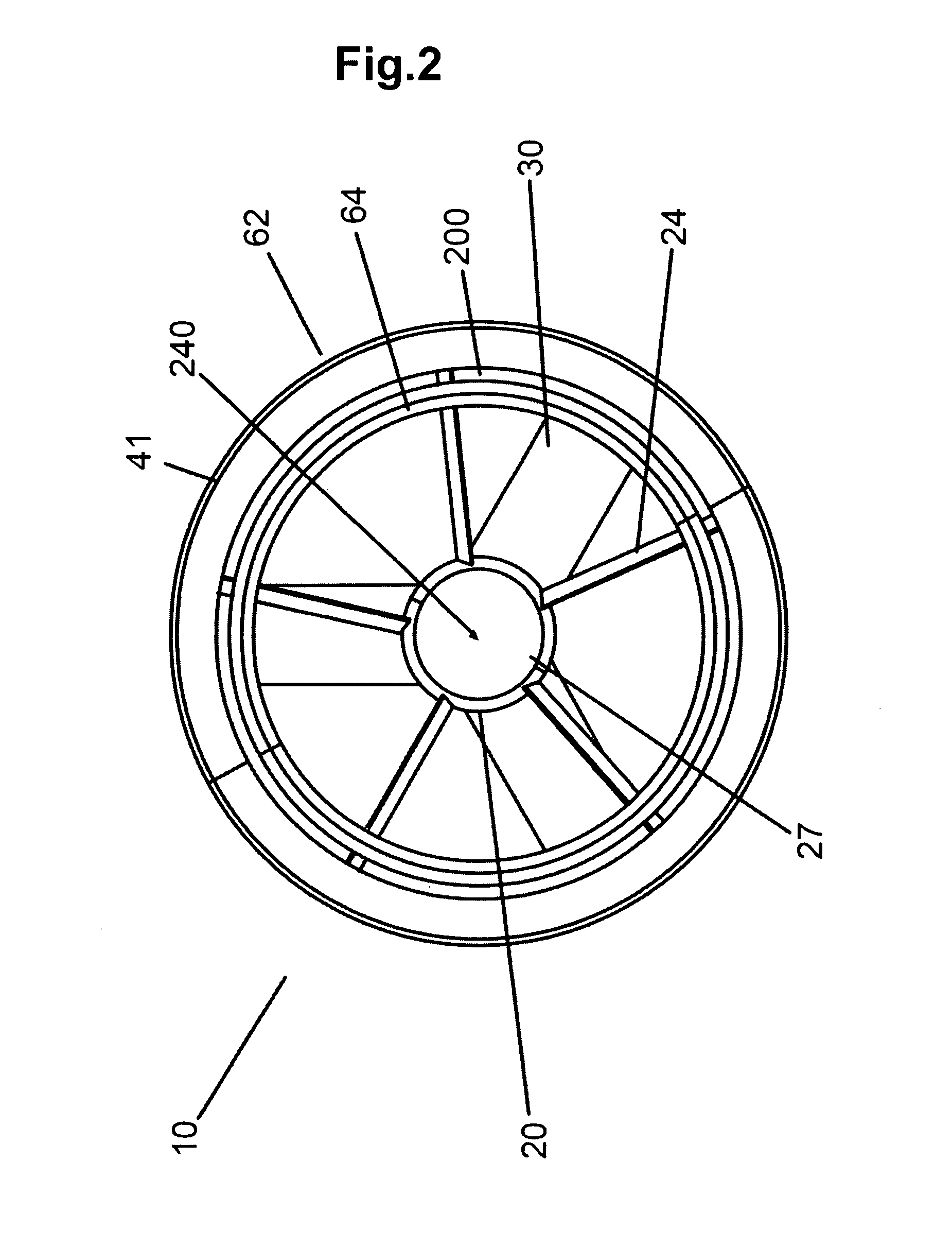

Flow enhancement for underwater turbine

InactiveUS7874788B2Improve turbine efficiencyImprove efficiencyWind motor controlPump componentsLeading edgeMarine engineering

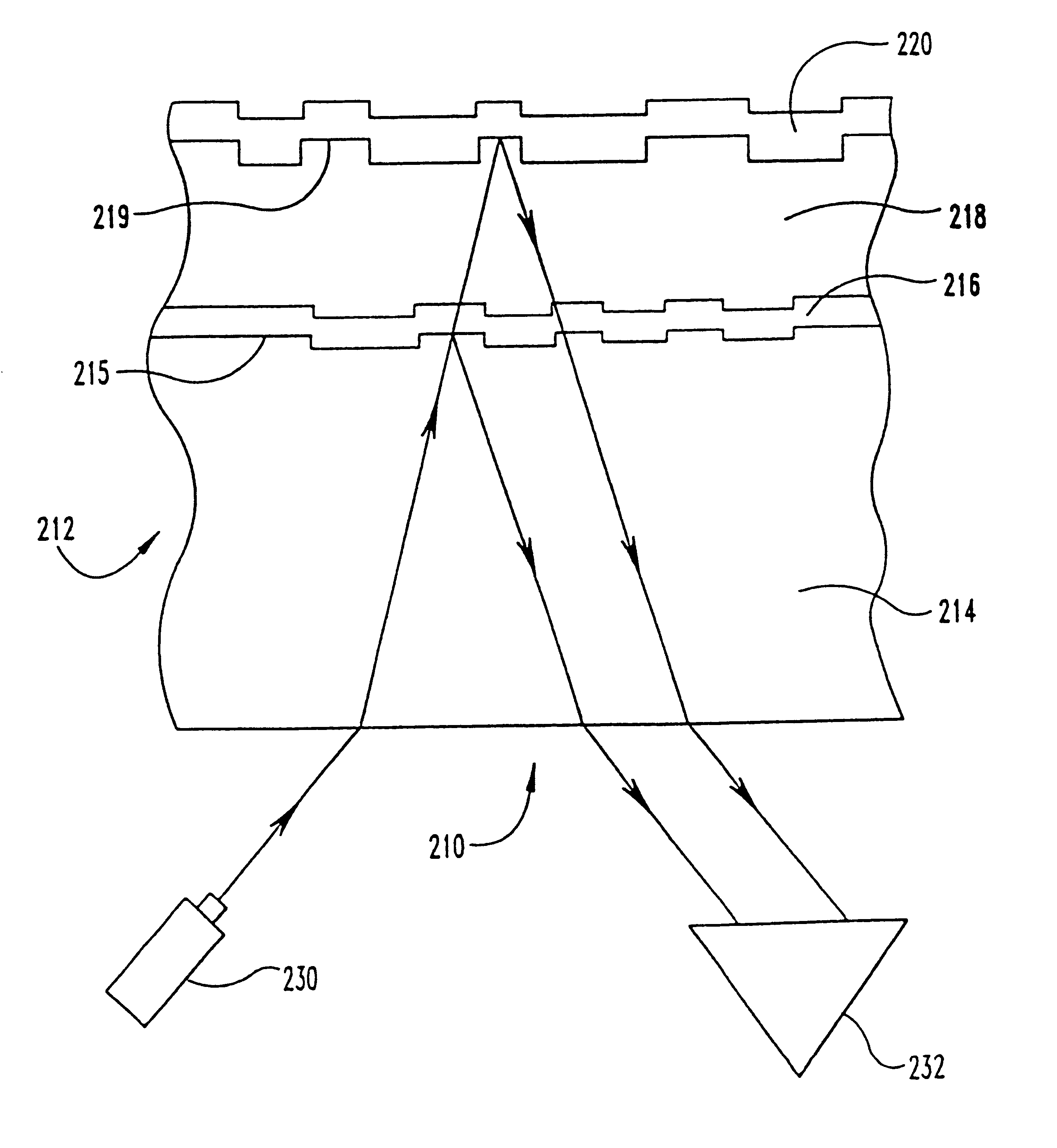

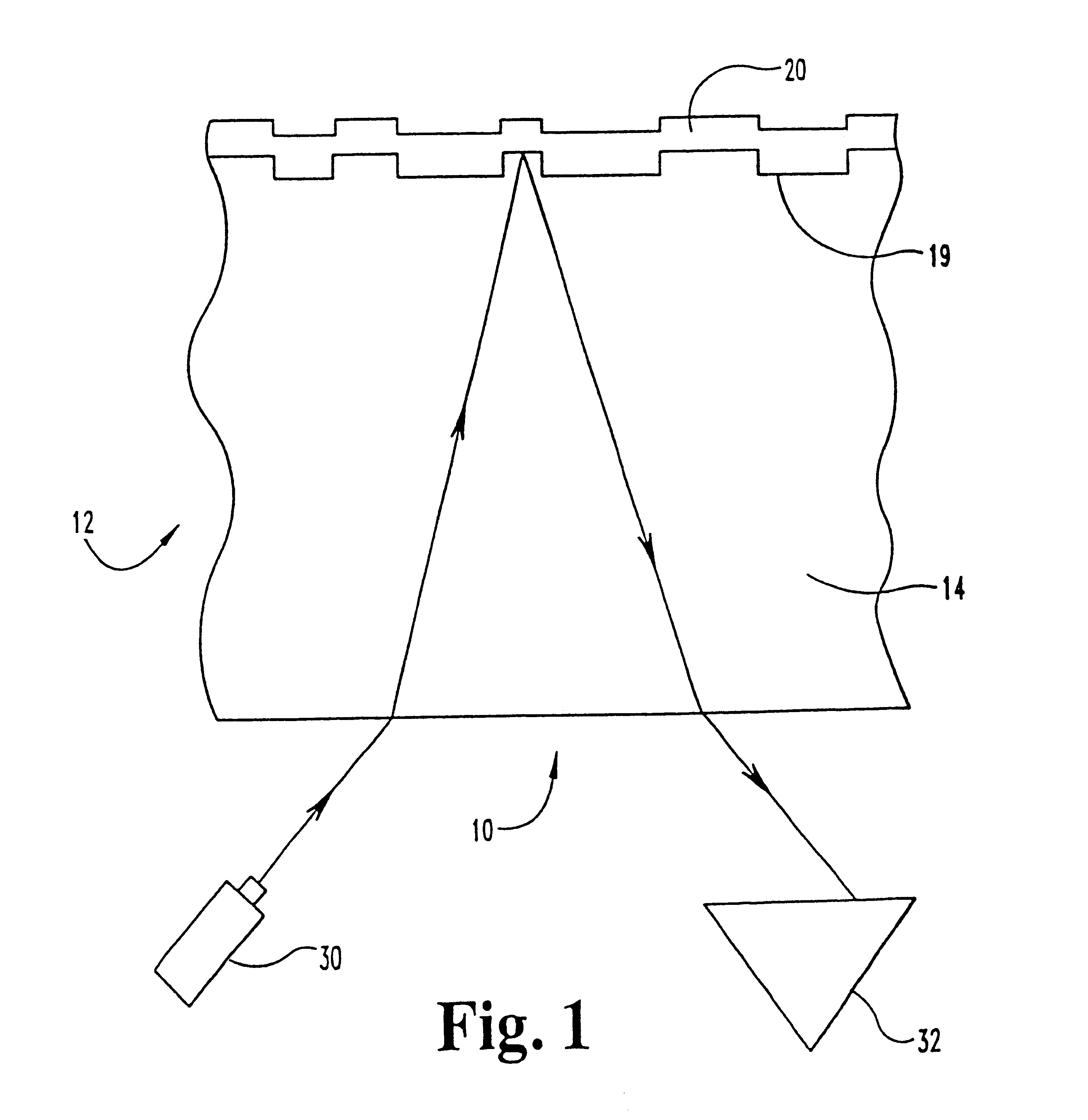

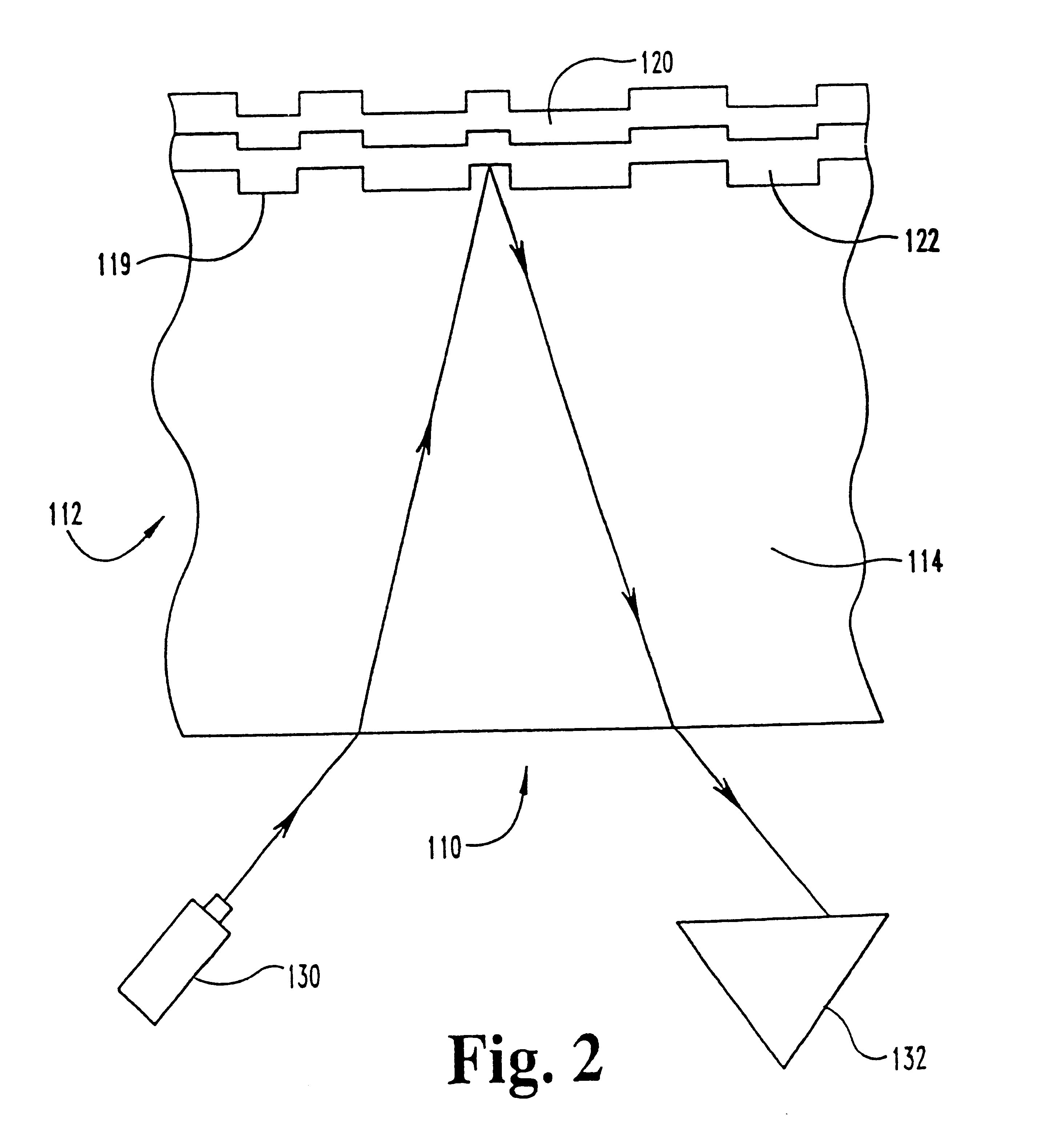

A flow enhancement improvement for an underwater turbine generator (10) is disclosed wherein a longitudinal hole (240) is disposed in the central area (26), typically a hub (20) of the generator (10), and a second, augmentor duct (41), preferably rigid, is disposed about the outer duct (40) or housing of the unit to create a slot (200) area. The slot (200) and hollow hub (20) create areas of smooth, laminar fluid flow. The leading edges of the hub (20) or central ring and the augmentor (41) and outer ducts (40) are elliptical to enhance the fluid dynamics of the structure.

Owner:CLEAN CURRENT PARTNERSHIP

Process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses

The invention discloses a process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses, wherein the method comprises the following steps: (1) weighing the raw materials according to the formula of a frosting liquid, mixing and stirring the raw materials evenly, curing the mixture for 24 -30 hours to prepare the frosting liquid; (2) after cleaning the glass to be frosted, carrying out protective treatment on one surface that is not needed to be frosted; (3) placing the protected glass into a pre-treatment liquor for further cleaning; (4) placing the treated glass into the cured frosting liquid to frost the glass for 30 -200 seconds, taking out the glass and cleaning the glass with water; and (5) placing the frosted glass into a polishing liquid to etch to obtain the anti-glare glass finished product. The invention solves the problem that the high-boron silicon and high-aluminium silicon glasses have large hardness and are difficult to be frosted; the process provided by the invention improves the hardness of the glass while guaranteeing the even frosting degree and good anti-glare effect; the product produced by the process provided by the invention has advantages of acid and alkali resistance and corrosion resistance.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS20020122913A1High reflectivityCorrosion resistancePhotomechanical apparatusRecord information storageIridiumCorrosion

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, palladium, copper, rhodium, ruthenium, osmium, iridium, and platinum. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

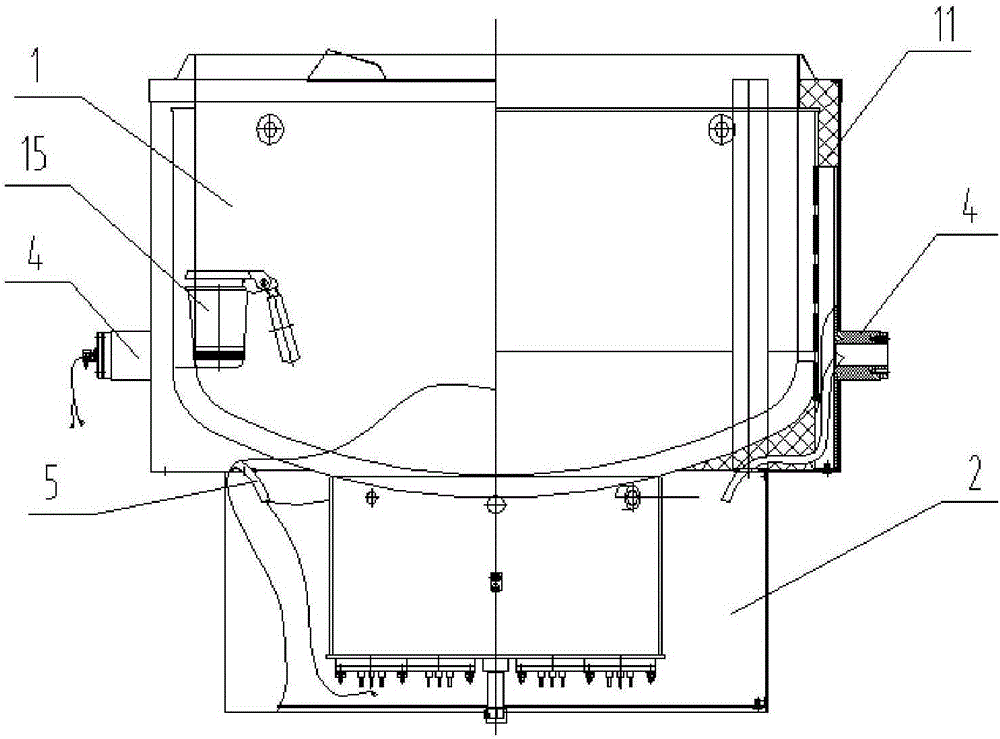

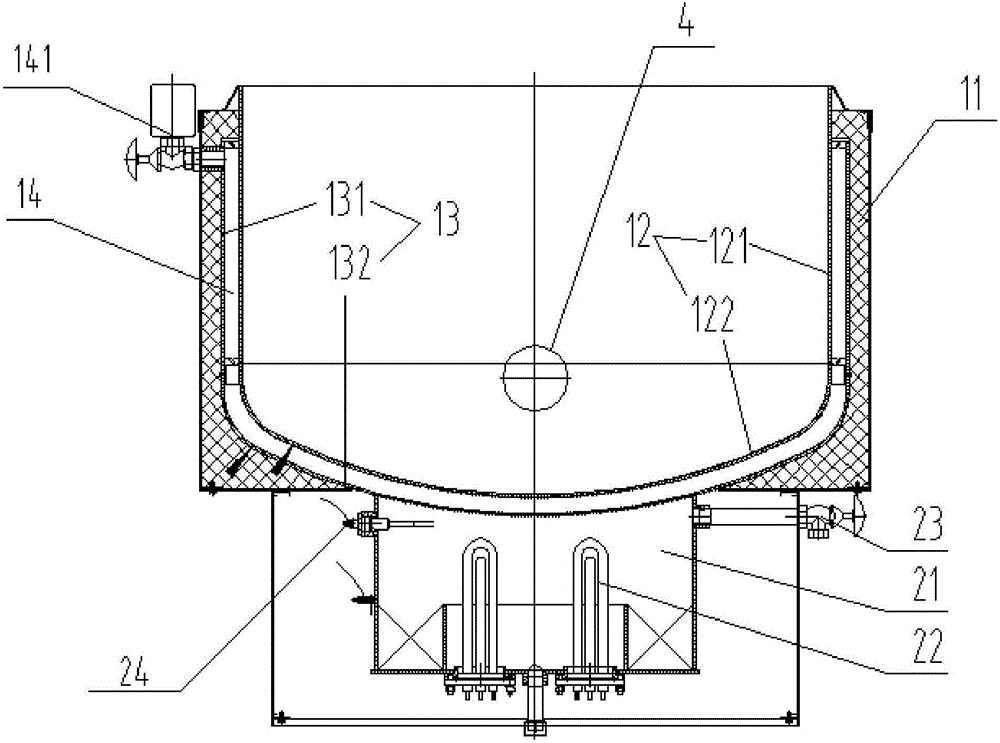

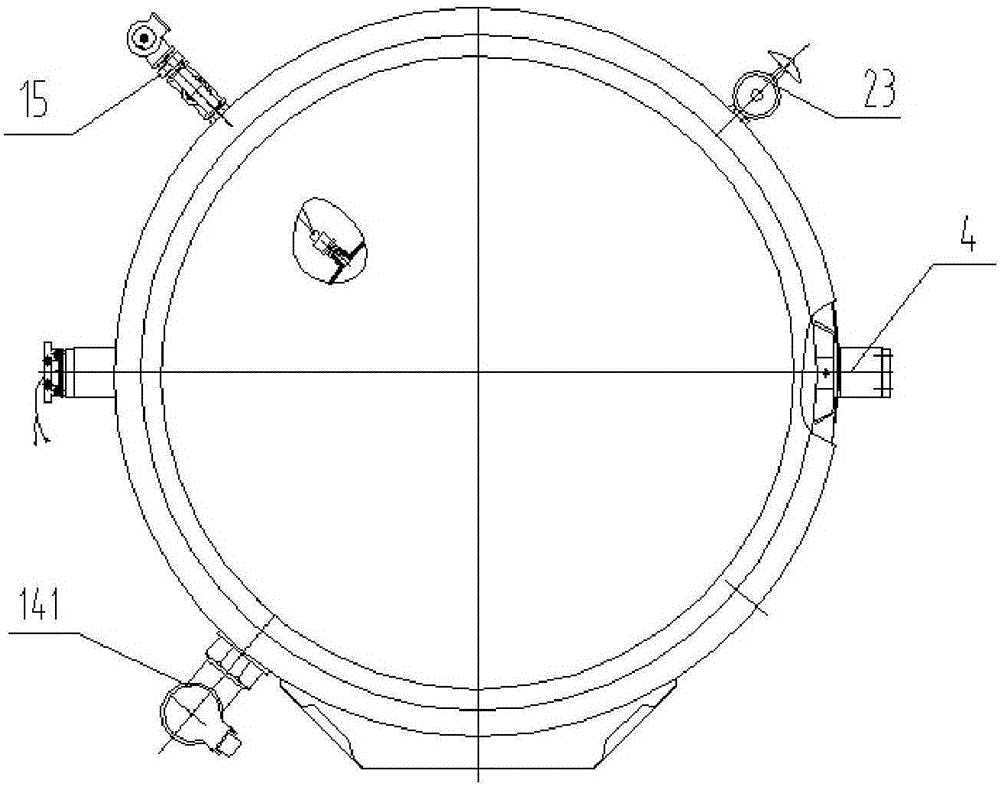

Sandwich type pressure cooker

InactiveCN106388572AEnsure safetyEasy to cleanPressure-cookersWarming devicesFood gradeBoiling point

The invention provides a sandwich type pressure cooker. The pressure cooker comprises a pot body; a heating tank is fixed at the bottom of the pot body; the pot body comprises an inner container and an outer container; a sealed sandwich layer is arranged between the inner container and the outer container to form a steam cavity; a first water inlet is formed in the upper end of the steam cavity; a first water inlet valve is fixed at the first water inlet; the heating tank is provided with a heating cavity which forms a sealed structure with the bottom of the outer container; a second water inlet is formed in a side wall of the heating cavity; a second water inlet valve is fixed at the second water inlet; a water level detector is further arranged on the side wall of the heating cavity; and a controller controls the opening and closing of the second water inlet valve through water level information detected by the water level detector. The pressure cooker is made of the dual-layer food-grade stainless steel pot body, and is easy to wash, corrosion-resistant and high in structural strength; and the sandwich layer is arranged between inner and outer pot bodies and is filled with high-temperature steam by heating, heat is generated by utilizing high pressure and the steam (the temperature of the steam is higher than the boiling point (100 DEG C) of water) of the sandwich layer, and the generated heat is used for heating food in the cooker through heat conduction of metal.

Owner:ANQING SANWEI ELECTRICAL

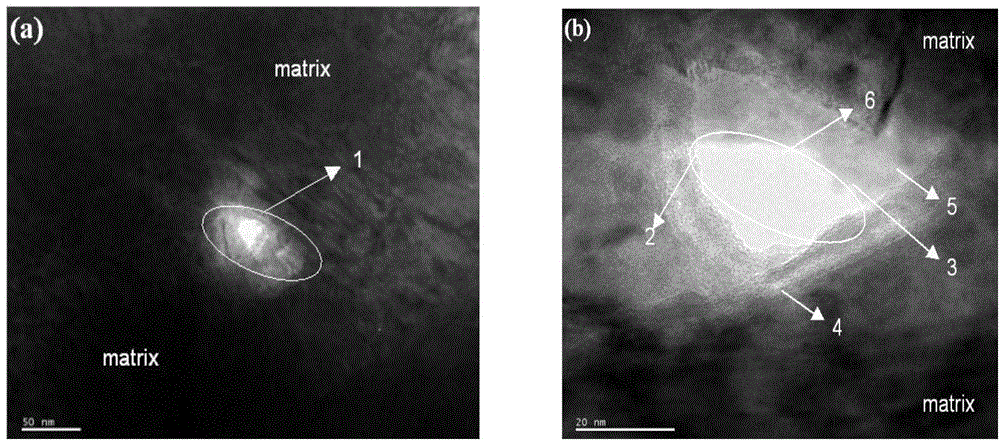

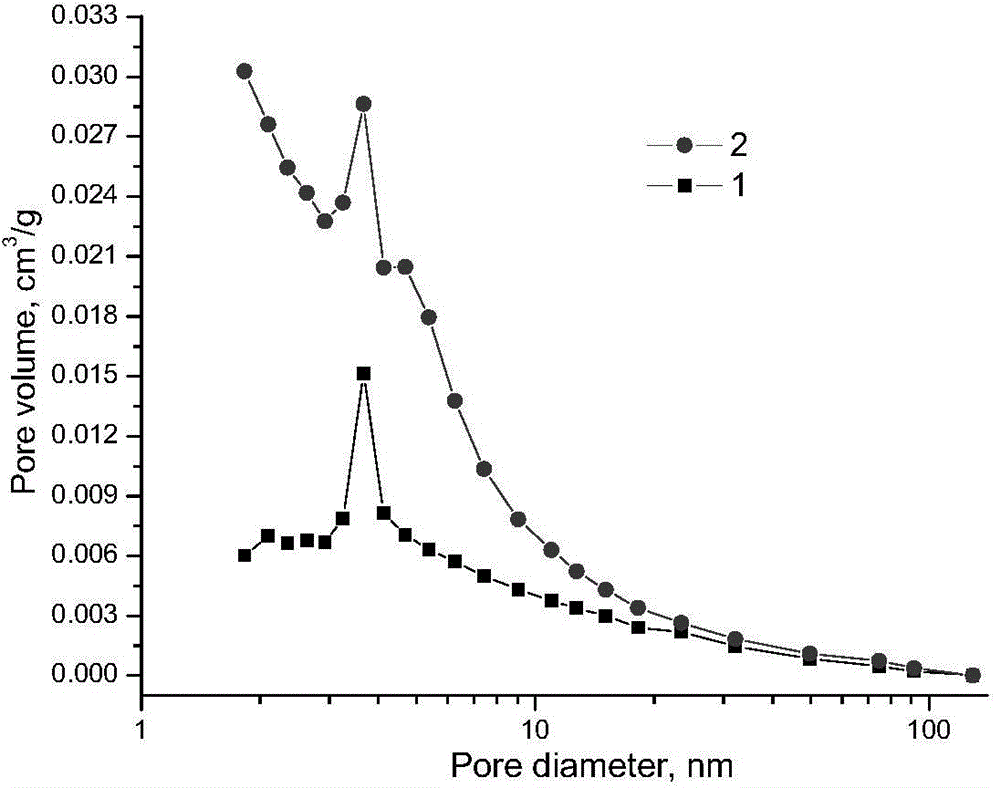

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

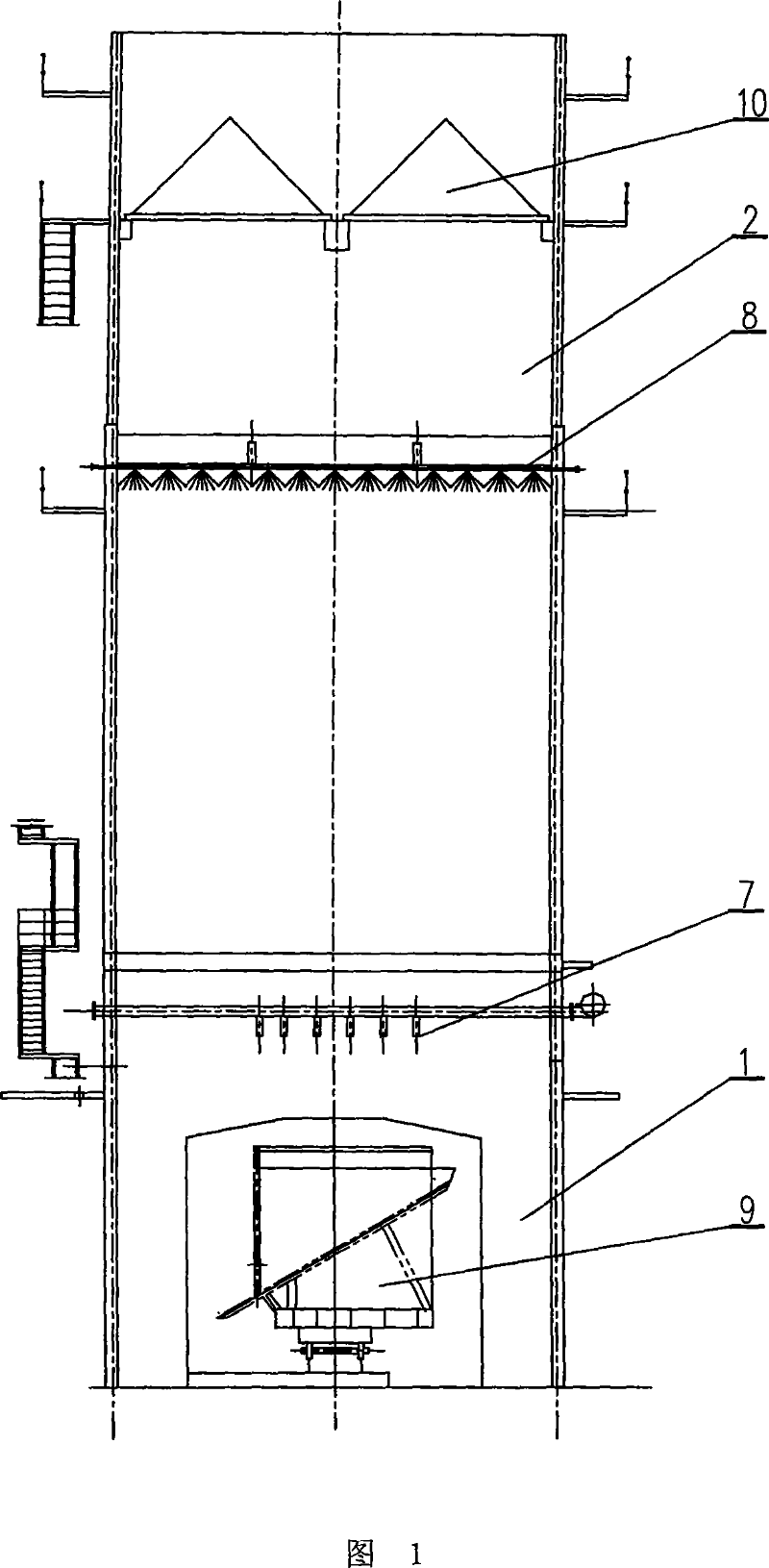

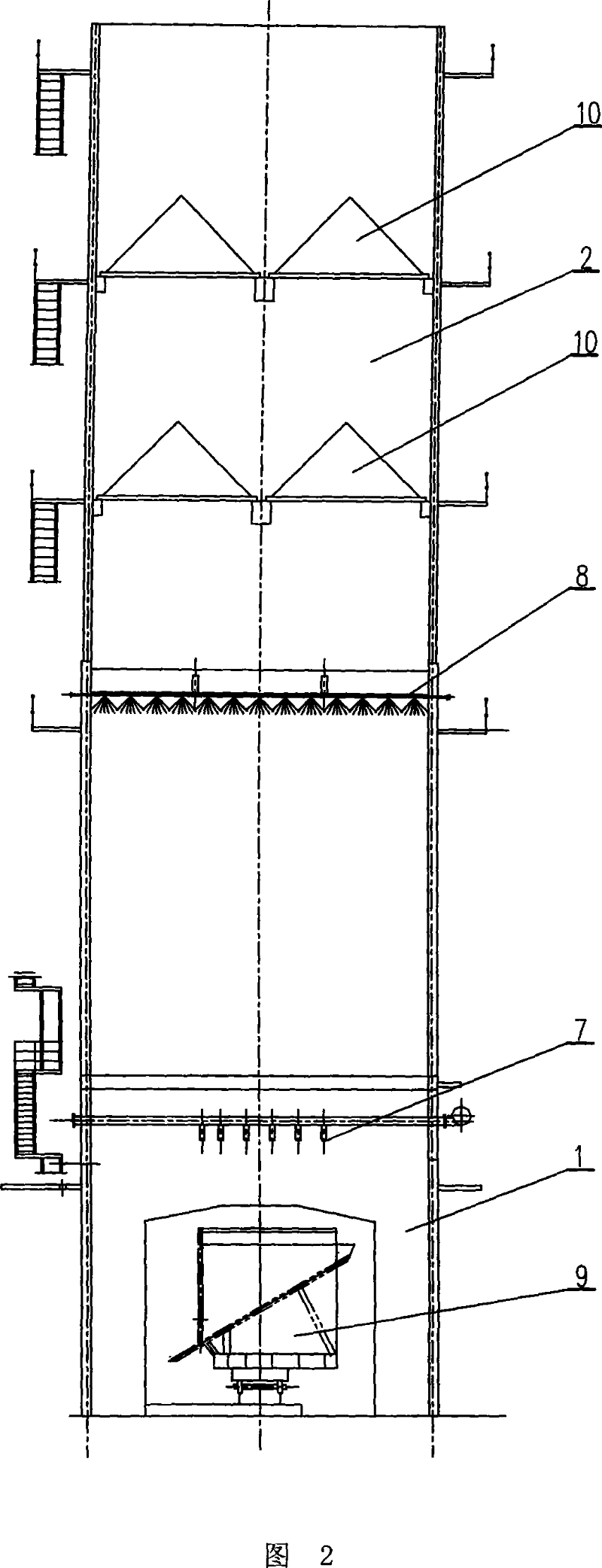

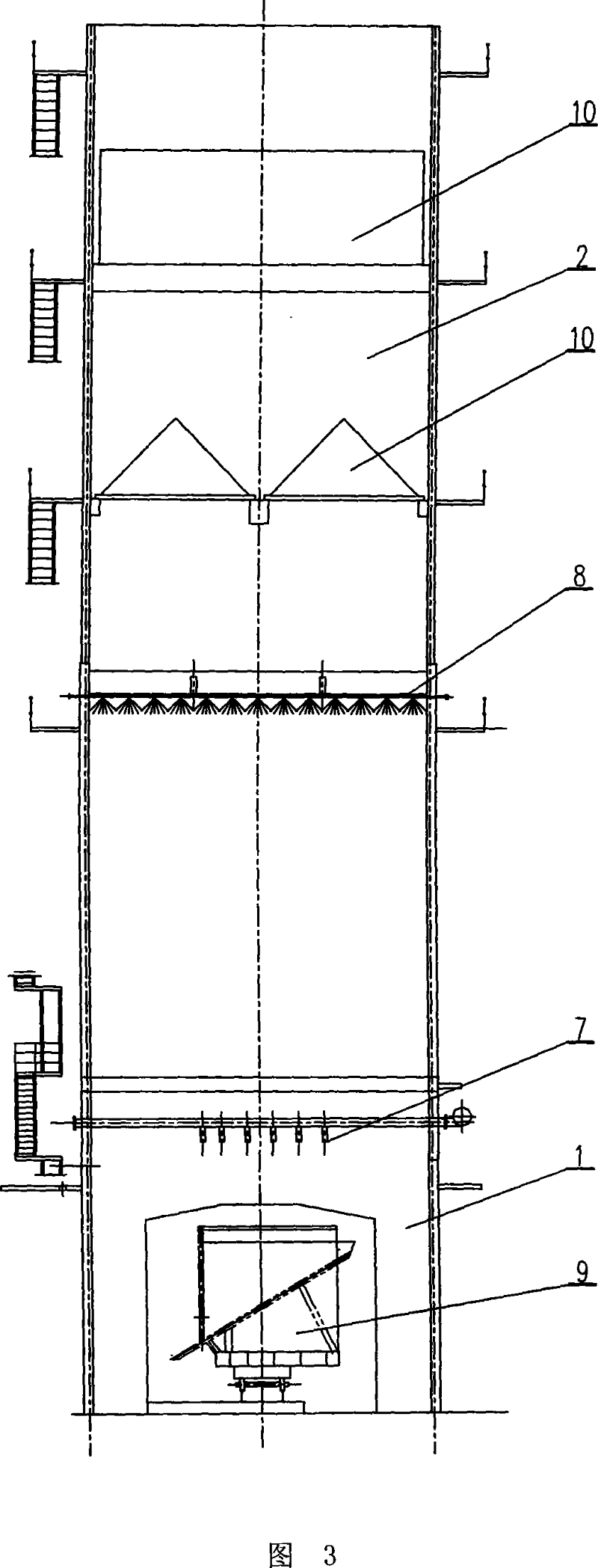

High-effective dust-removing coke quenching tower

ActiveCN101037603AEasy dust removal effectGuaranteed dust removal performanceCoke quenchingSingle stageTower

The invention relates to a highly effective dust removal coke quenching machine, which includes a coke quenching injection pipe, a washing and cooling device, and a dust removal device. The dust removal device, which is disposed single-stage or two-stage, includes a structural framework, a dust removal plate, a dust removal pipe and nozzles, wherein the dust removal plate, which is constituted of a heterotypic baffle sheet folded with a certain angle and a dust removal plate support, is disposed on the structural framework and forms angle of 45-60 DEG with horizontal plane; the dust removal pipe is equably equipped with a plurality of nozzles and is arranged parallel with the dust removal plate. Dust content of stream generated at coke quenching process is greatly reduced by water fog washing, cooling, gravitational settling and purifying of baffle plate type dust removal device, amount of coking powder discharged into air of per ton coke is lower than 50g. Moreover, the baffle plate employs industrial plastic, thereby possessing advantages of corrosion resistance, high strength, aging resistance, good dust removal effect, convenient installation and maintance, and easy cleaning.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

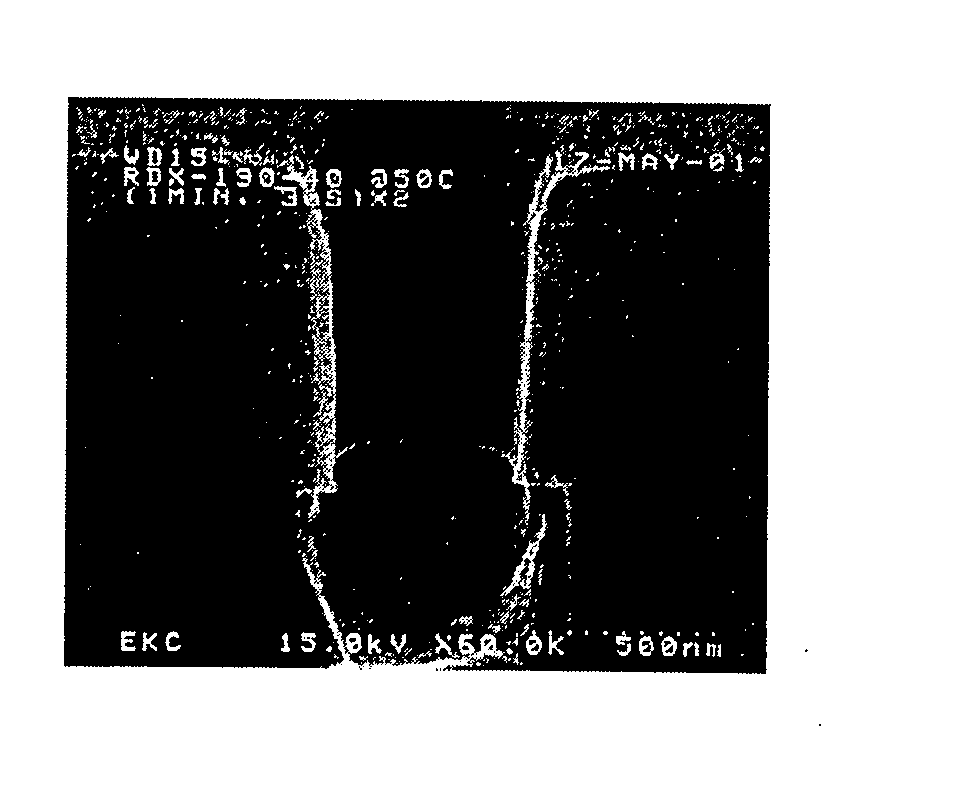

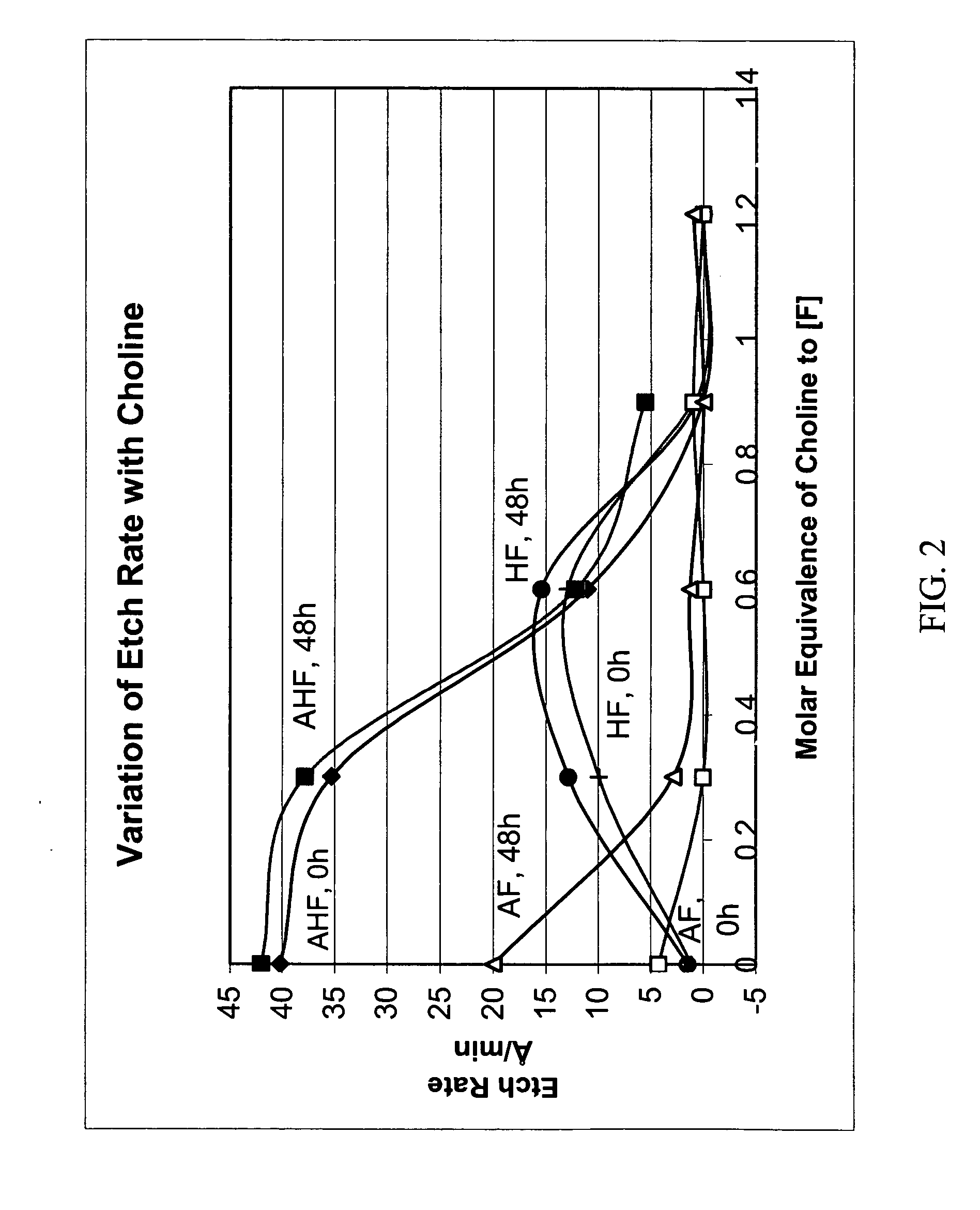

Compositions for cleaning organic and plasma etched residues for semiconductor devices

InactiveUS20050202987A1Increase capacityEasy to cleanSurface-active detergent compositionsNon-surface-active detergent compositionsResistDevice material

A composition for the stripping of photoresist and the cleaning of residues from substrates, and for silicon oxide etch, comprising from about 0.01 percent by weight to about 10 percent by weight of one or more fluoride compounds, from about 10 percent by weight to about 95% by weight of a sulfoxide or sulfone solvent, and from about 20 percent by weight to about 50 percent by weight water. The composition may contain corrosion inhibitors, chelating agents, co-solvents, basic amine compounds, surfactants, acids and bases.

Owner:EKC TECH

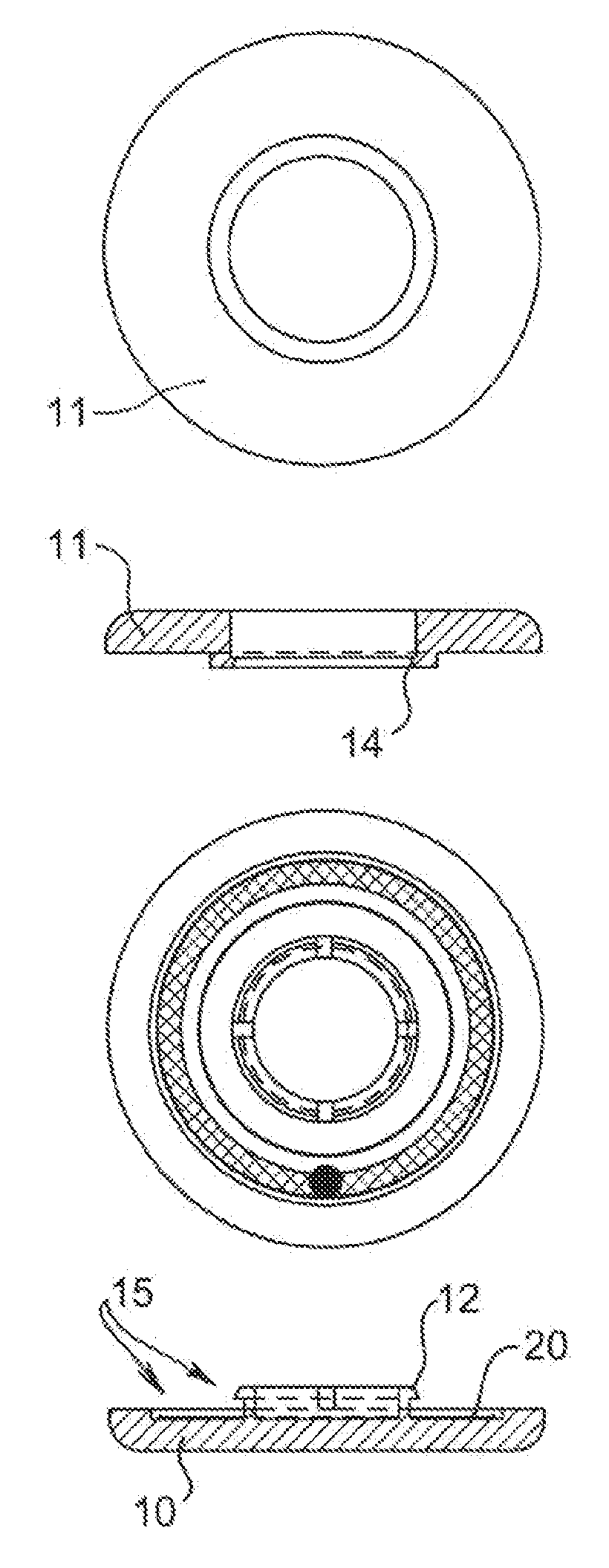

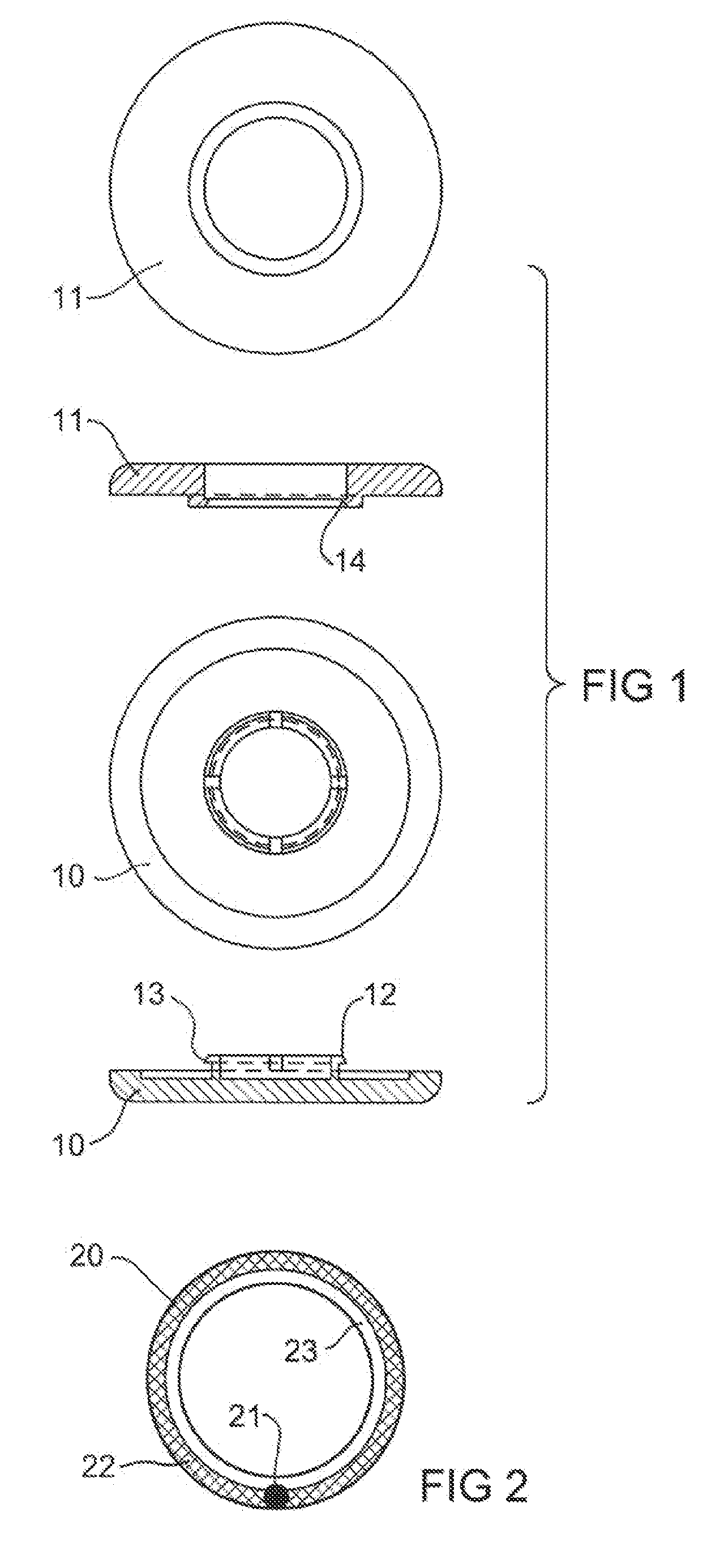

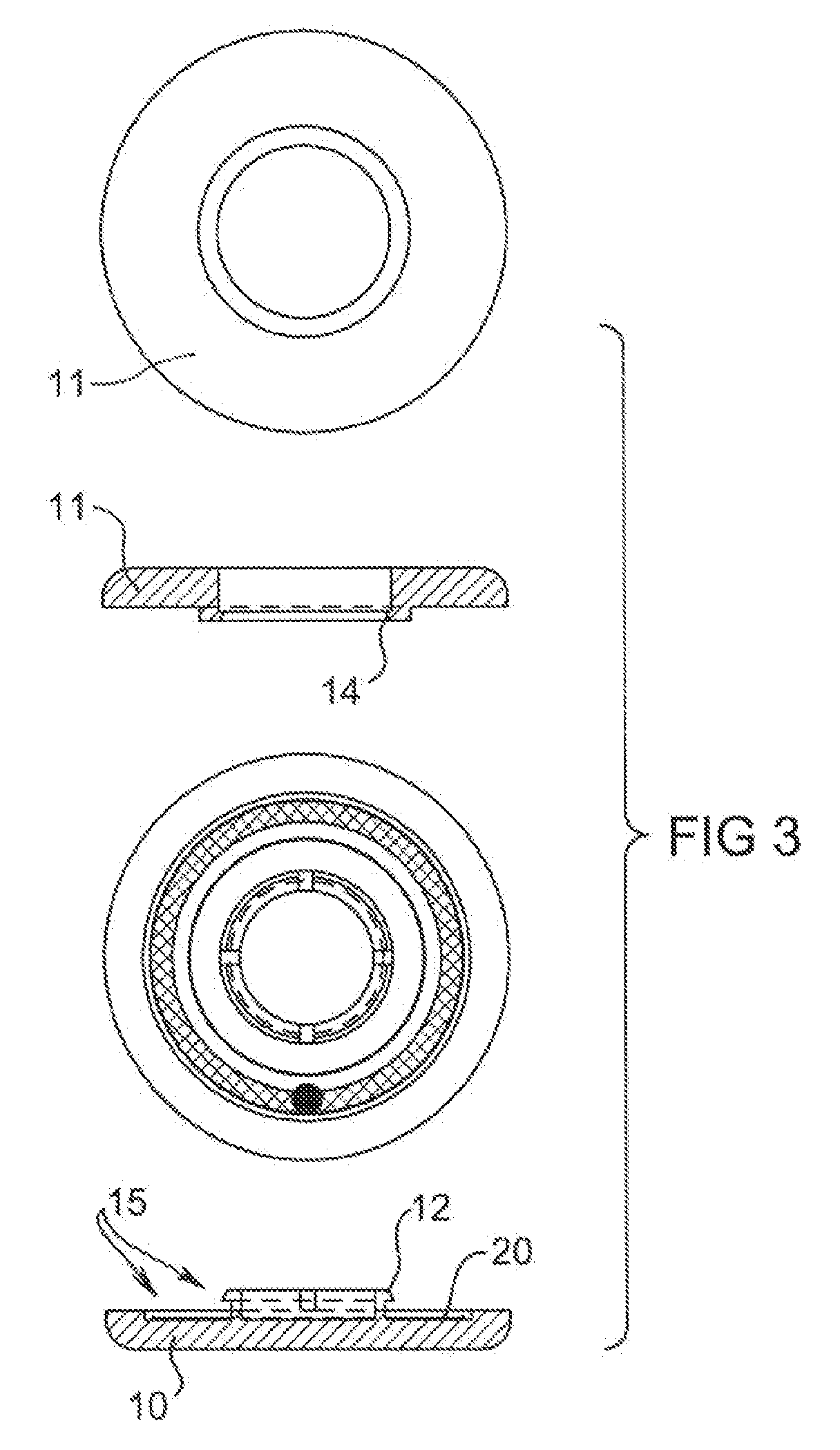

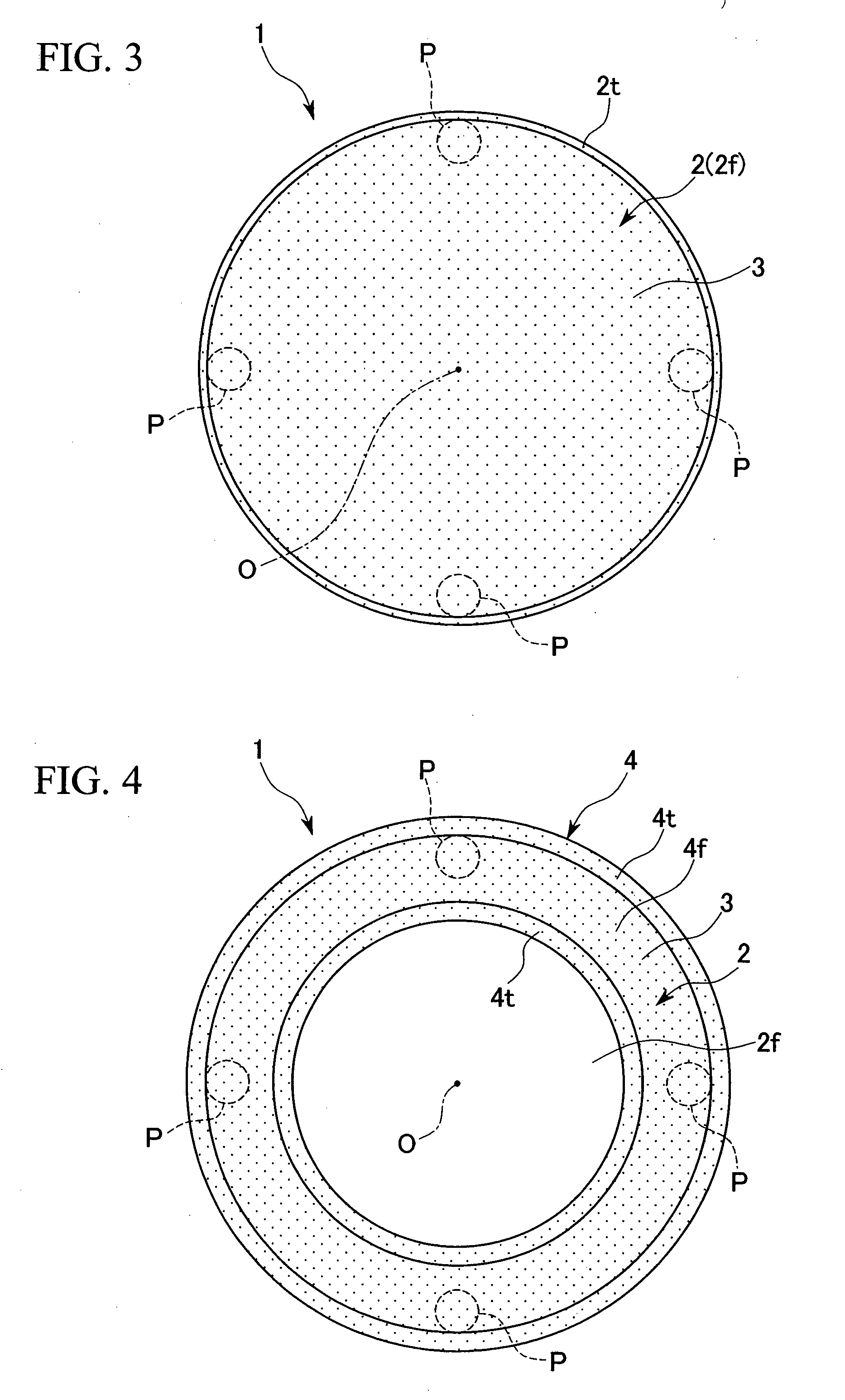

CMP conditioner

ActiveUS20060079162A1Avoid it happening againCorrosion resistanceRevolution surface grinding machinesGrinding drivesMechanical engineeringDiamond grit

A CMP conditioner is provided in which diamond grit that is adhered to a conditioning surface so as to face and be in contact with a polishing pad of a CMP apparatus is adhered such that 111 surfaces of crystal surfaces of the diamond grit are substantially parallel with the conditioning surface and face in a direction faced by the conditioning surface.

Owner:MITSUBISHI MATERIALS CORP

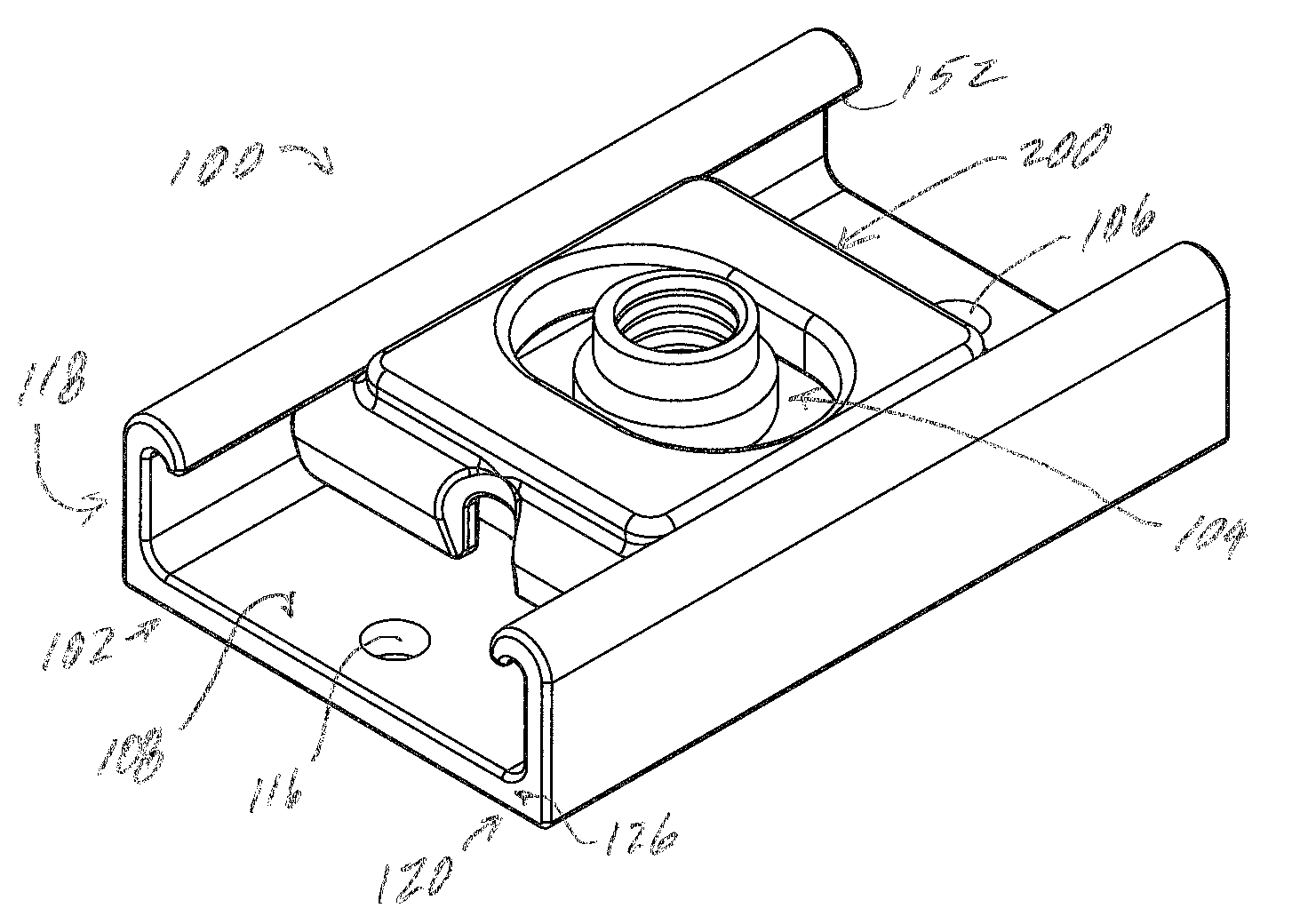

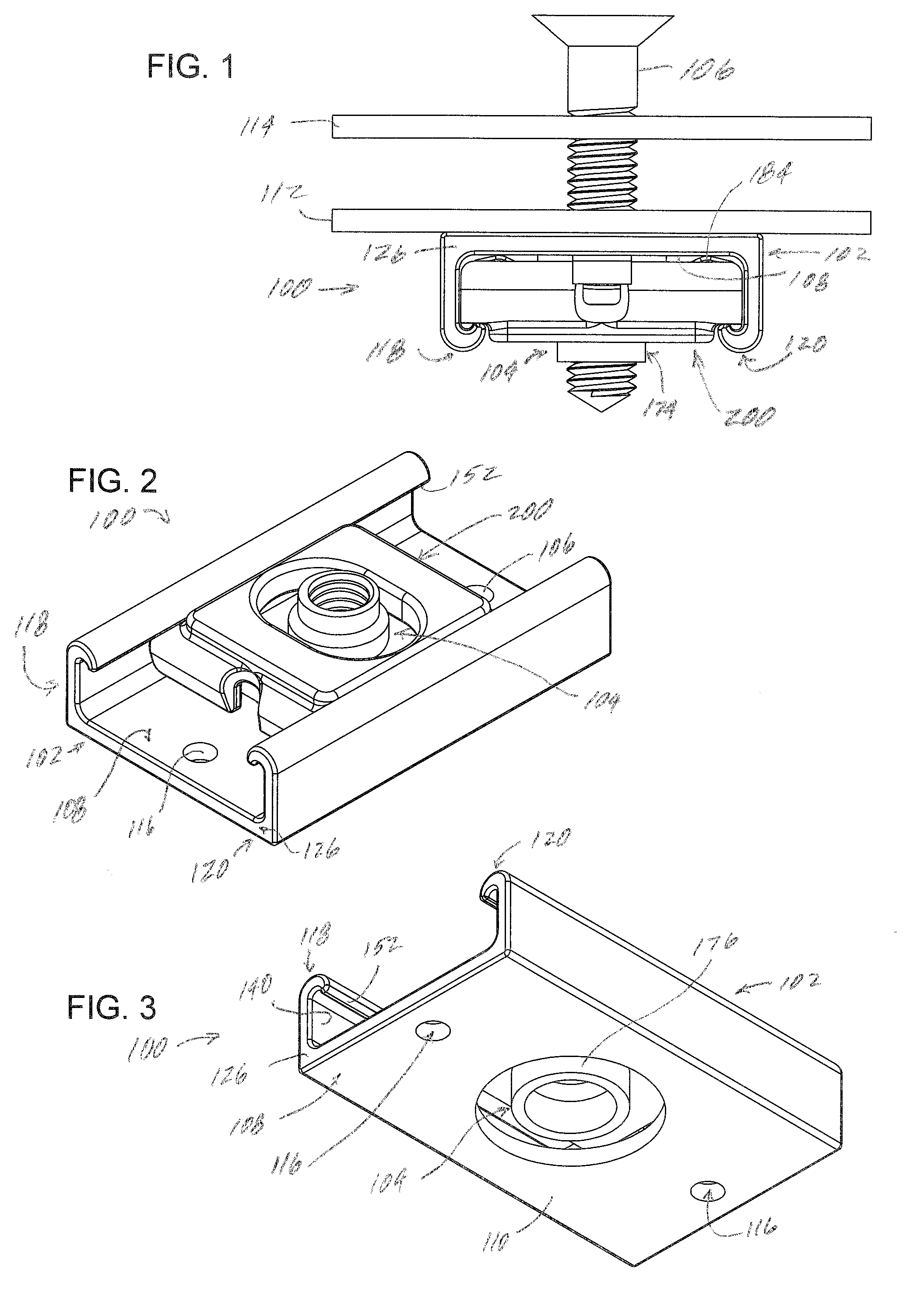

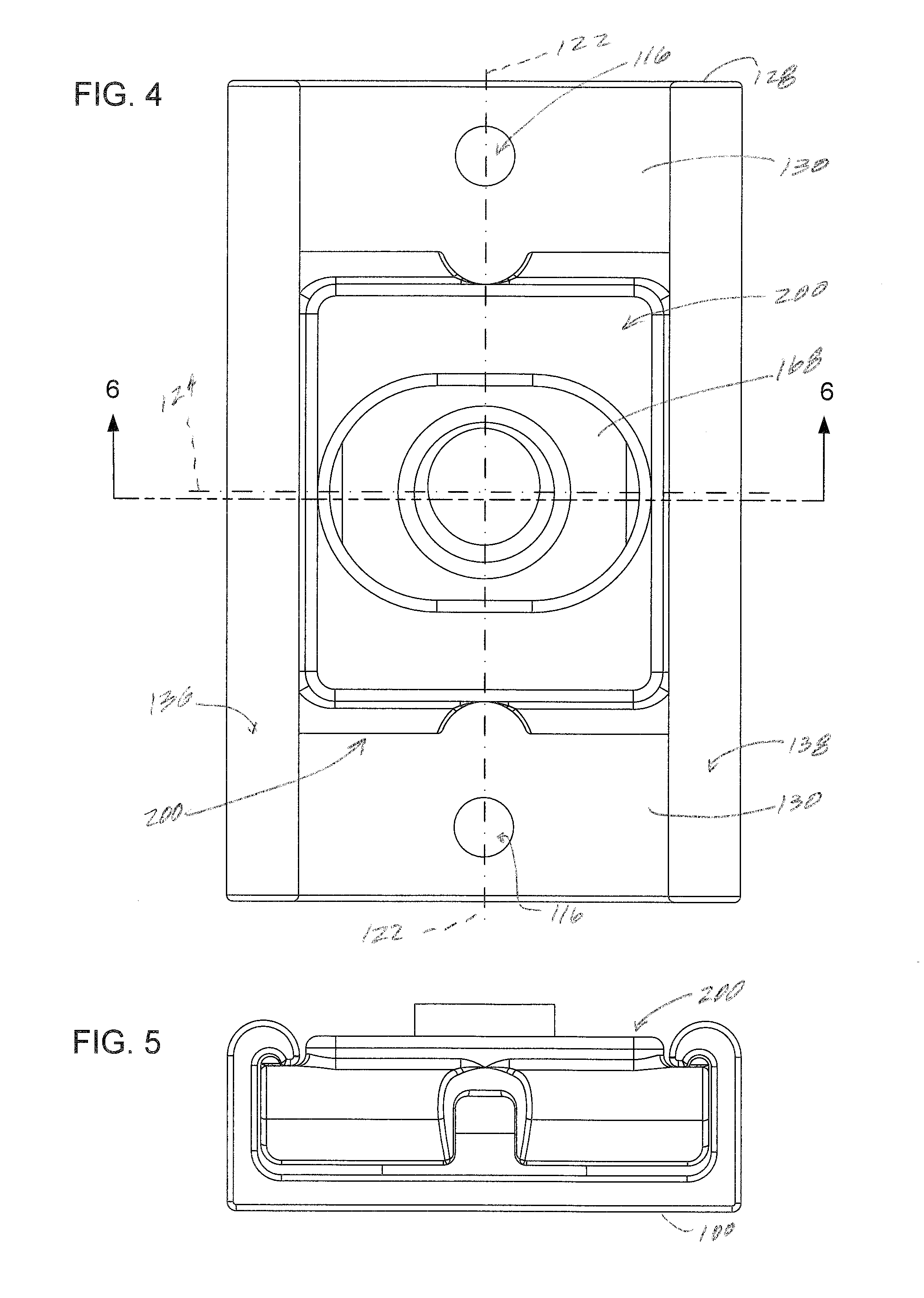

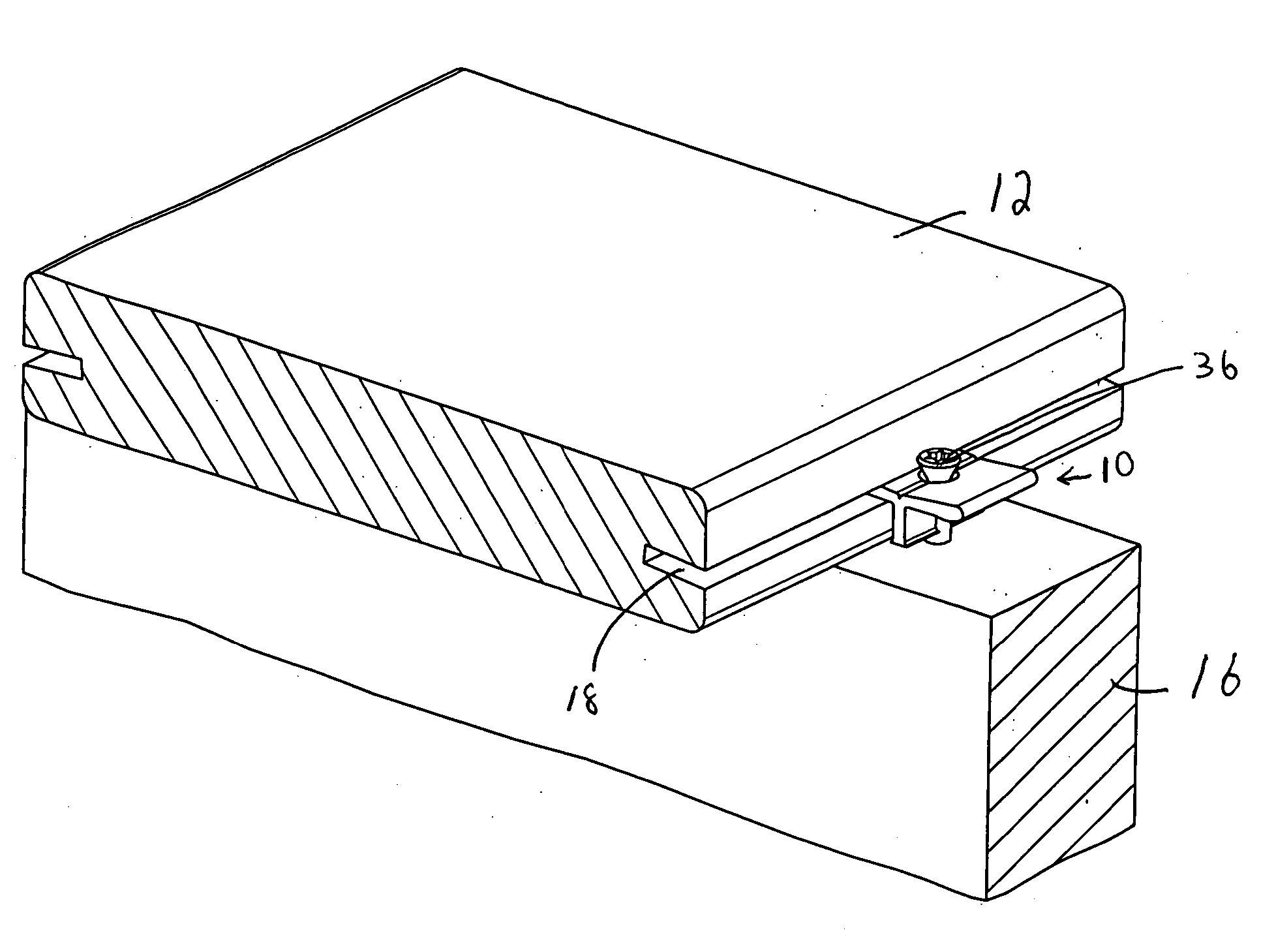

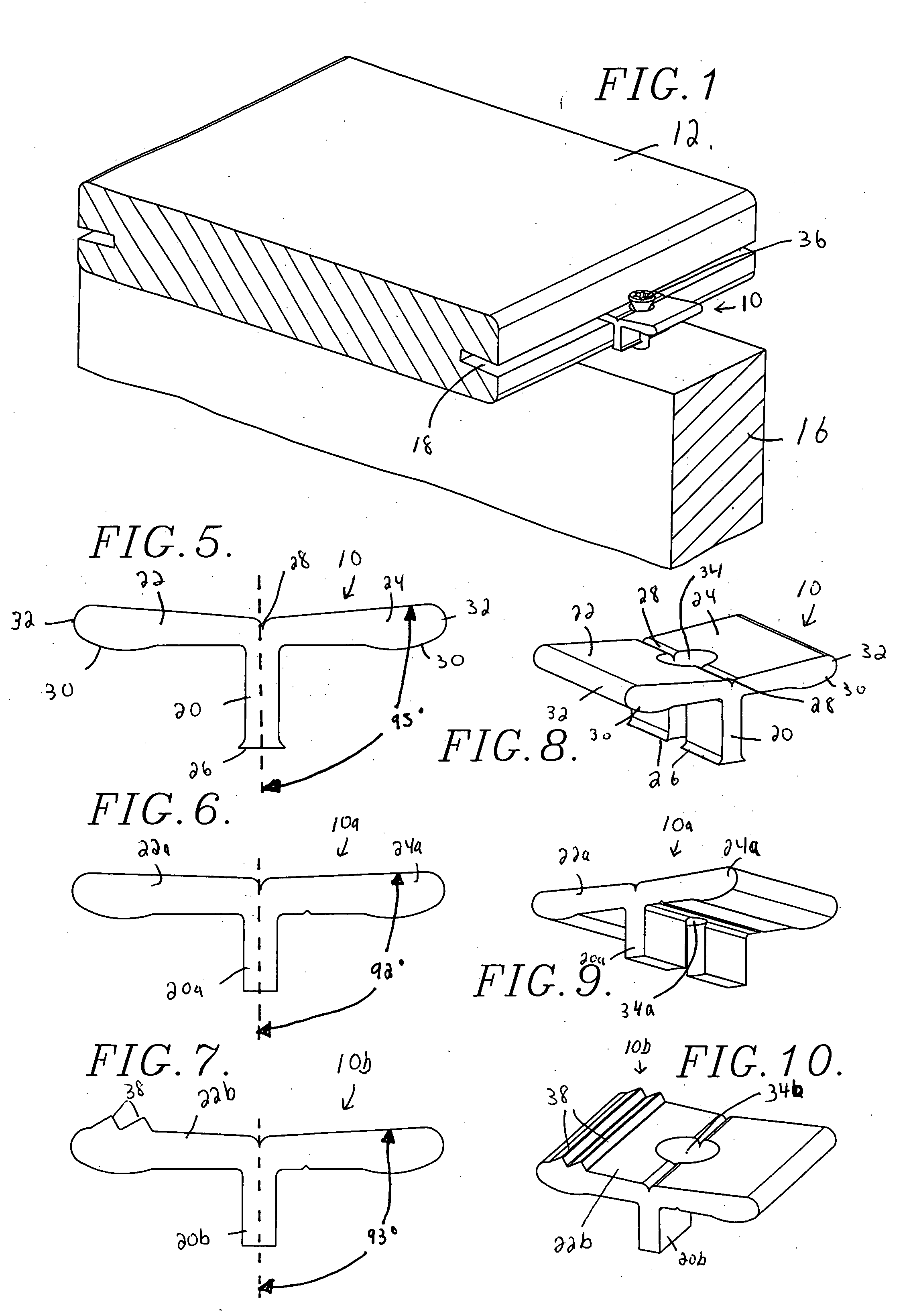

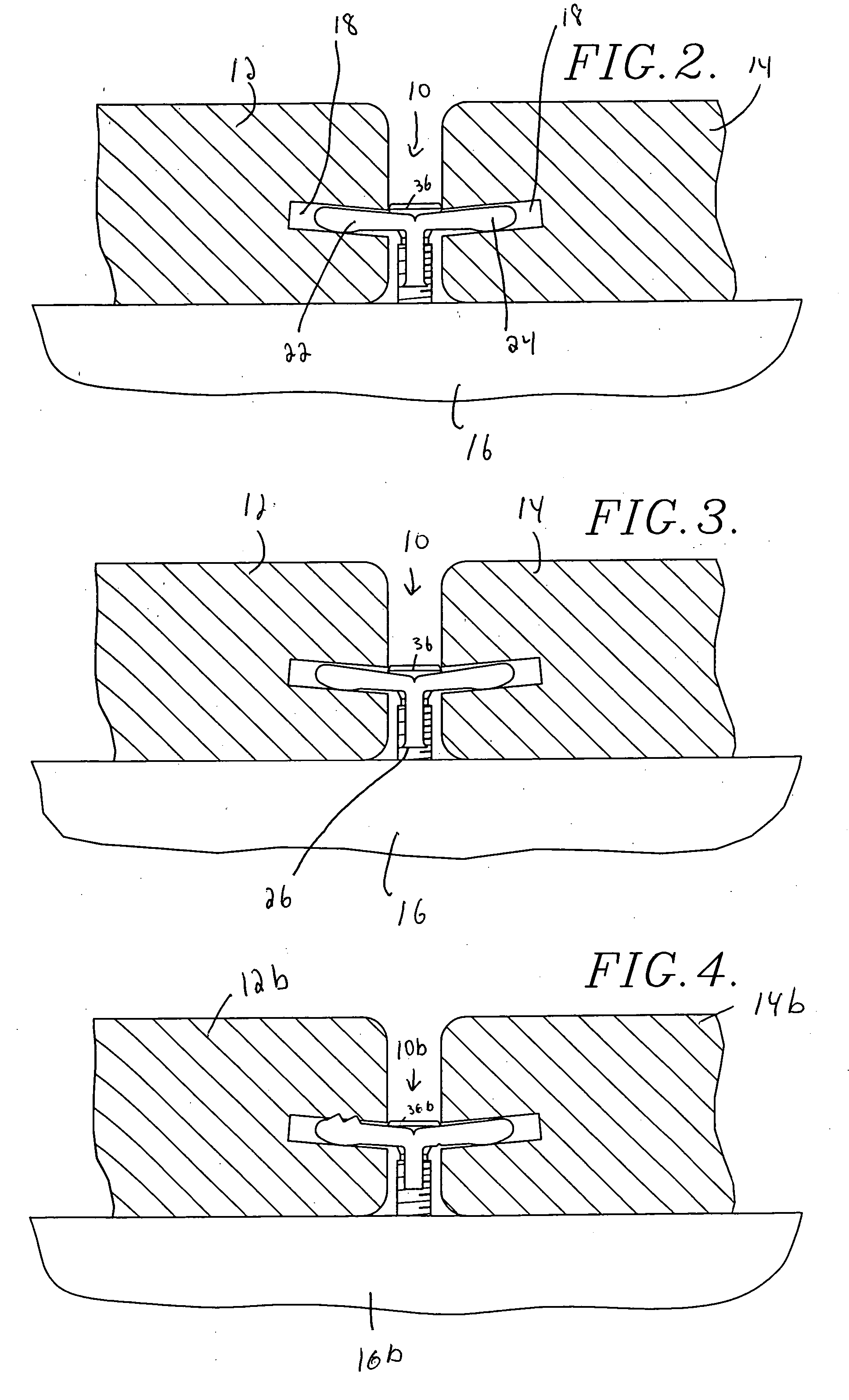

Floating nut plate

ActiveUS20090129885A1Simple processEasy to manufactureCandle holdersLighting support devicesEngineeringPlate method

Methods relating to and apparatus such as floating nut plates may include complementary surfaces limiting movement of a retainer toward or away from side walls of a receiver, such as wherein a nut element is positioned between the retainer and the receiver. One of the complementary surfaces may be a groove formed in the retainer. In one configuration, the receiver and / or retainer are non-metal.

Owner:MONADNOCK

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6764735B2Improve reflectivitySimilar sputtering characteristicPhotomechanical apparatusRecord information storageIridiumHigh reflectivity

Owner:TARGET TECH

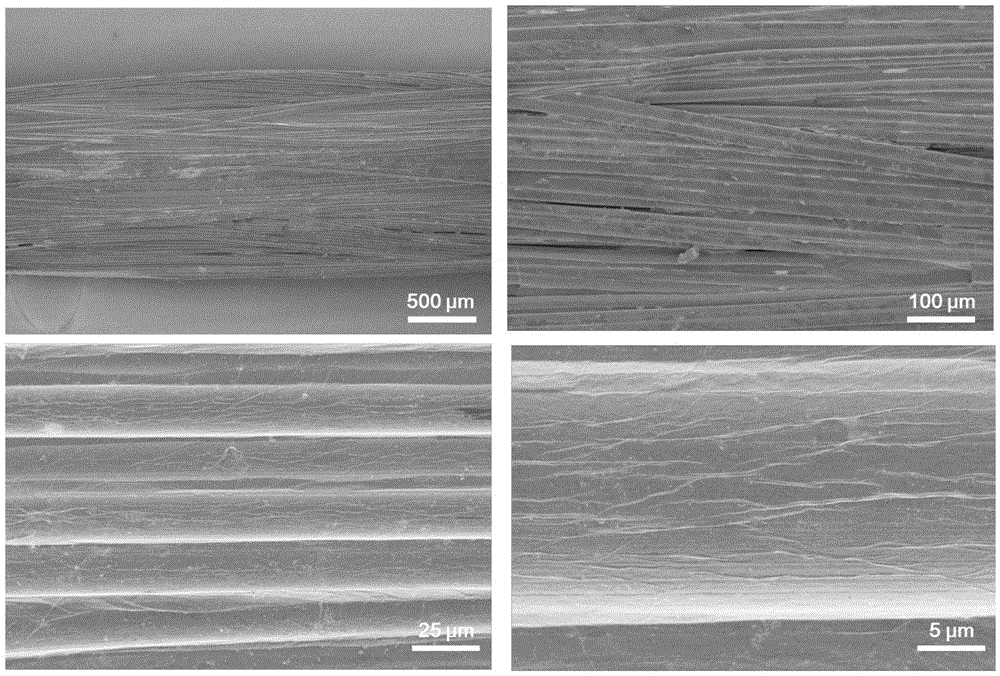

Preparation method of graphene composite conductive fiber

The invention discloses a preparation method of a graphene composite conductive fiber and relates to the technical field of graphene. The method comprises the following steps: processing a common textile polymer fiber with an organic solvent to remove impurities such as an oiling agent on the fiber surface; dipping the textile polymer fiber into an alkali liquor and an oxidized graphene solution, and enabling the fiber surface to fully contact the oxidized graphene; and dipping the dried fiber with an oxidized graphene coating into a solution containing a reducing agent to obtain the graphene composite conductive fiber. By adopting a simple dip coating method, the obtained composite fiber has mechanical property, high temperature resistance and flexibility performance of a traditional high polymer material and also has good conductivity. The method is easy to operate, environment-friendly and convenient to industrialize.

Owner:宁国市龙晟柔性储能材料科技有限公司

Deck clip

InactiveUS20060059822A1Effective movementEasy to installCeilingsSheet joiningJoistMarine engineering

A deck clip comprises a generally vertically extending leg; and a pair of arms extending from an upper edge of the leg. Each arm is configured for insertion into a slot of a deck board and presents an enlarged lobe. When the deck clip is screwed to a deck joist, the lobes grip the deck boards and hold them tight against the joist. The shape of the lobes increases the gripping force between the lobes and the deck boards as adjacent boards are hammered or otherwise pushed together. The lobes facilitate the gripping of the boards and help maintain the desired gap between adjacent boards for the life of the deck.

Owner:WOOD HAVEN

Composite material with anti-bacterial and purifying functions and preparation method of composite material

ActiveCN104607039AImprove adsorption capacityImprove decomposition rateWater/sewage treatment by irradiationDispersed particle separationDecompositionRare earth

The invention relates to a composite material with anti-bacterial and purifying functions and a preparation method of the composite material, and belongs to the technical field of environmental-friendly materials. The composite material with the anti-bacterial and purifying functions comprises raw materials in parts by weight as follows: 70-95 parts of a mineral composite adsorption material, 3-25 parts of a photocatalytic degradation material, 2-15 parts of a rare earth inorganic anti-bacterial material and 1-10 parts of an additive, wherein the mineral composite adsorption material is prepared from sepiolite, diatomite, medical stone and attapulgite; the photocatalytic degradation material is prepared from titanium oxide, tourmaline and far infrared ceramic powder; the rare earth inorganic anti-bacterial material is prepared from zinc oxide, cerium oxide and silver oxide; the additive is a mixture of activated carbon, carboxymethylcellulose and pumice powder. The composite material with anti-bacterial and purifying functions has high adsorption and decomposition rate, can be resistant to water and damp and has excellent anti-bacterial effect. Meanwhile, the invention provides the preparation method. According to the preparation method, the cost is low, the amount of produced wastewater is low, and powder is simple and convenient to apply.

Owner:淄博木齐新材料科技有限公司

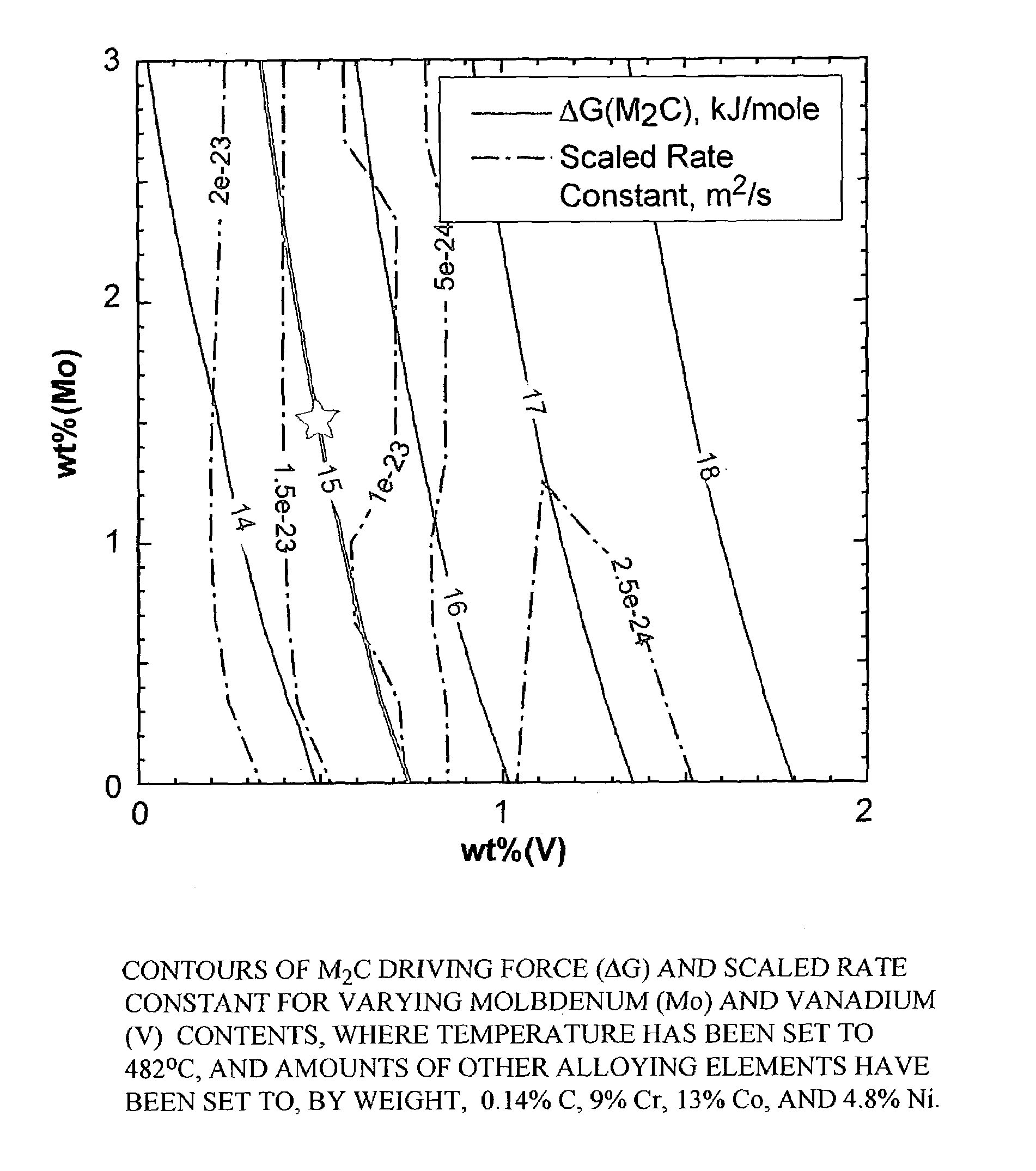

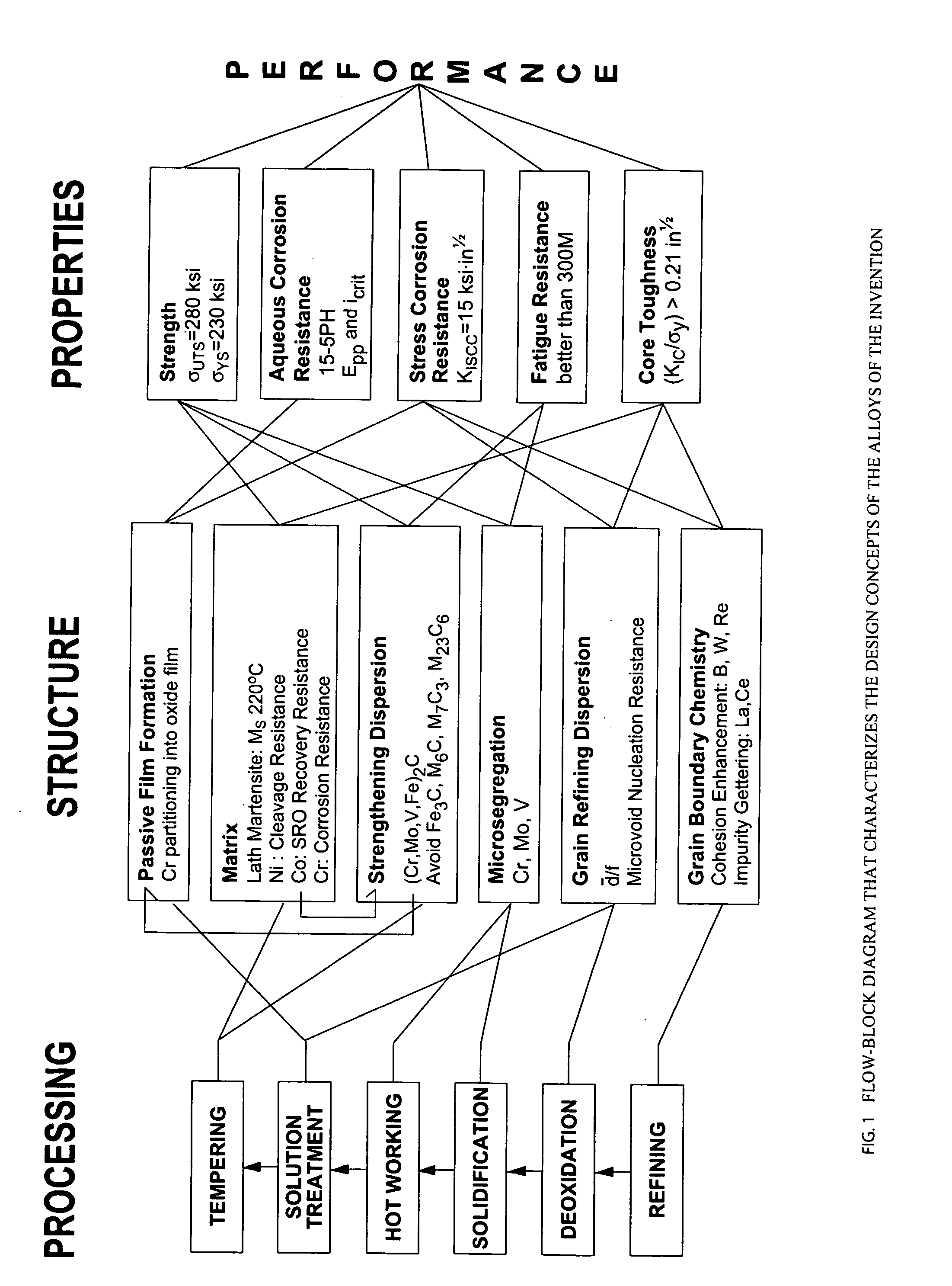

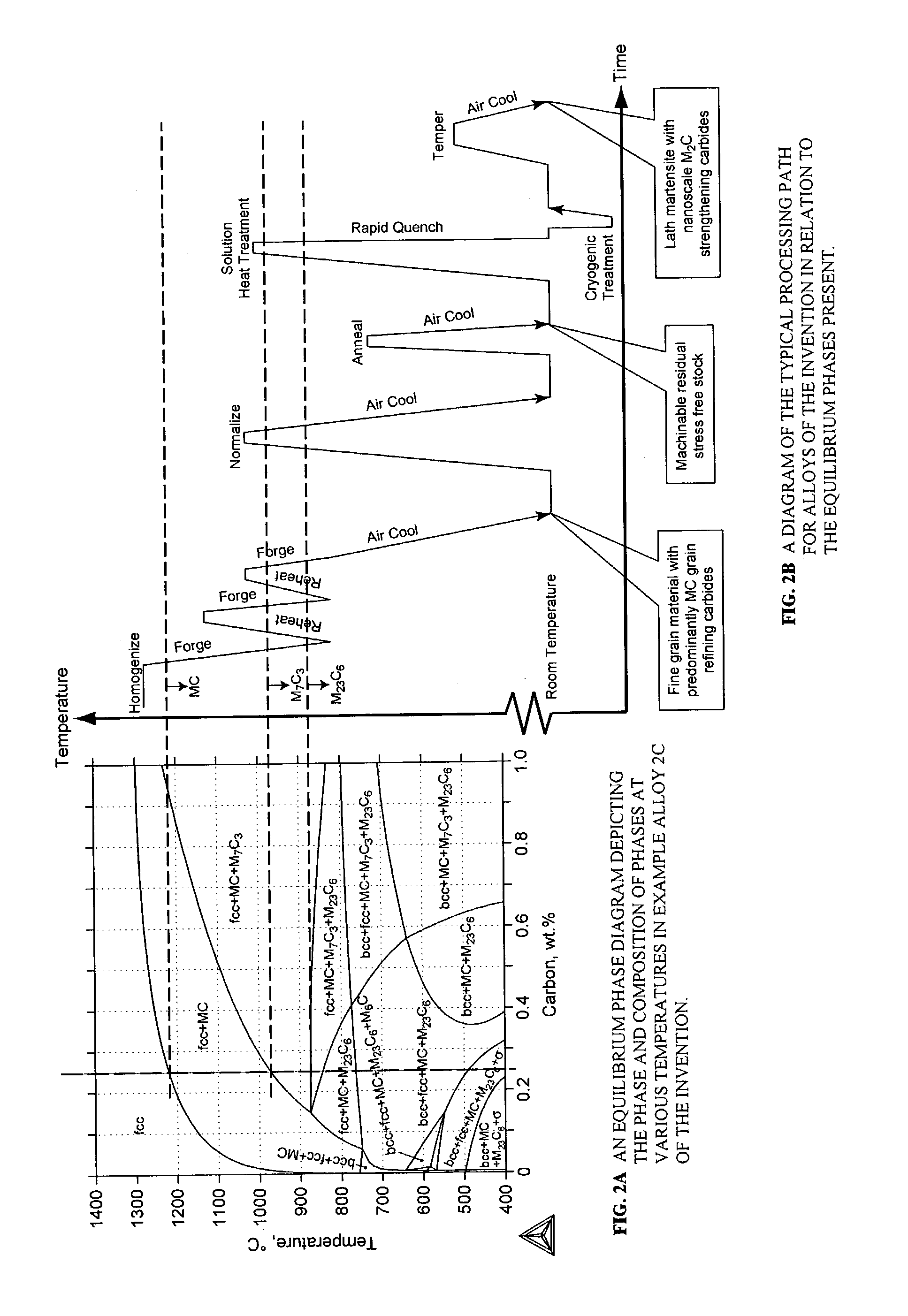

Nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steels

InactiveUS7160399B2Simple working processHigh strengthFurnace typesHeat treatment furnacesCobaltMaterials science

A nanocarbide precipitation strengthened ultrahigh-strength, corrosion resistant, structural steel possesses a combination of strength and corrosion resistance comprising in combination, by weight, about: 0.1 to 0.3% carbon (C), 8 to 17% cobalt (Co), 0 to 10% nickel (Ni), 6 to 12% chromium (Cr), less than 1% silicon (Si), less than 0.5% manganese (Mn), and less than 0.15% copper (Cu), with additives selected from the group comprising about: less than 3% molybdenum (Mo), less than 0.3% niobium (Nb), less than 0.8% vanadium (V), less than 0.2% tantalum (Ta), less than 3% tungsten (W), and combinations thereof, with additional additives selected from the group comprising about: less than 0.2% titanium (Ti), less than 0.2% lanthanum (La) or other rare earth elements, less than 0.15% zirconium (Zr), less than 0.005% boron (B), and combinations thereof, impurities of less than about: 0.02% sulfur (S), 0.012% phosphorus (P), 0.015% oxygen (O) and 0.015% nitrogen (N), the remainder substantially iron (Fe), incidental elements and other impurities. The alloy is strengthened by nanometer scale M2C carbides within a fine lath martensite matrix from which enhanced chemical partitioning of Cr to the surface provides a stable oxide passivating film for corrosion resistance. The alloy, with a UTS in excess of 280 ksi, is useful for applications such as aircraft landing gear, machinery and tools used in hostile environments, and other applications wherein ultrahigh-strength, corrosion resistant, structural steel alloys are desired.

Owner:QUESTEK INNOVATIONS LLC

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS20070281176A1Cost-effective and convenient processIncrease stiffnessMaterial nanotechnologyRodsThermal dilatationMetal coating

Fine-grained (average grain size 1 nm to 1,000 nm) metallic coatings optionally containing solid particulates dispersed therein are disclosed. The fine-grained metallic materials are significantly harder and stronger than conventional coatings of the same chemical composition due to Hall-Petch strengthening and have low linear coefficients of thermal expansion (CTEs). The invention provides means for matching the CTE of the fine-grained metallic coating to the one of the substrate by adjusting the composition of the alloy and / or by varying the chemistry and volume fraction of particulates embedded in the coating. The fine-grained metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling. The low CTEs and the ability to match the CTEs of the fine-grained metallic coatings with the CTEs of the substrate minimize dimensional changes during thermal cycling and prevent premature failure.

Owner:INTEGRAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com