Patents

Literature

379results about How to "Guaranteed dust removal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

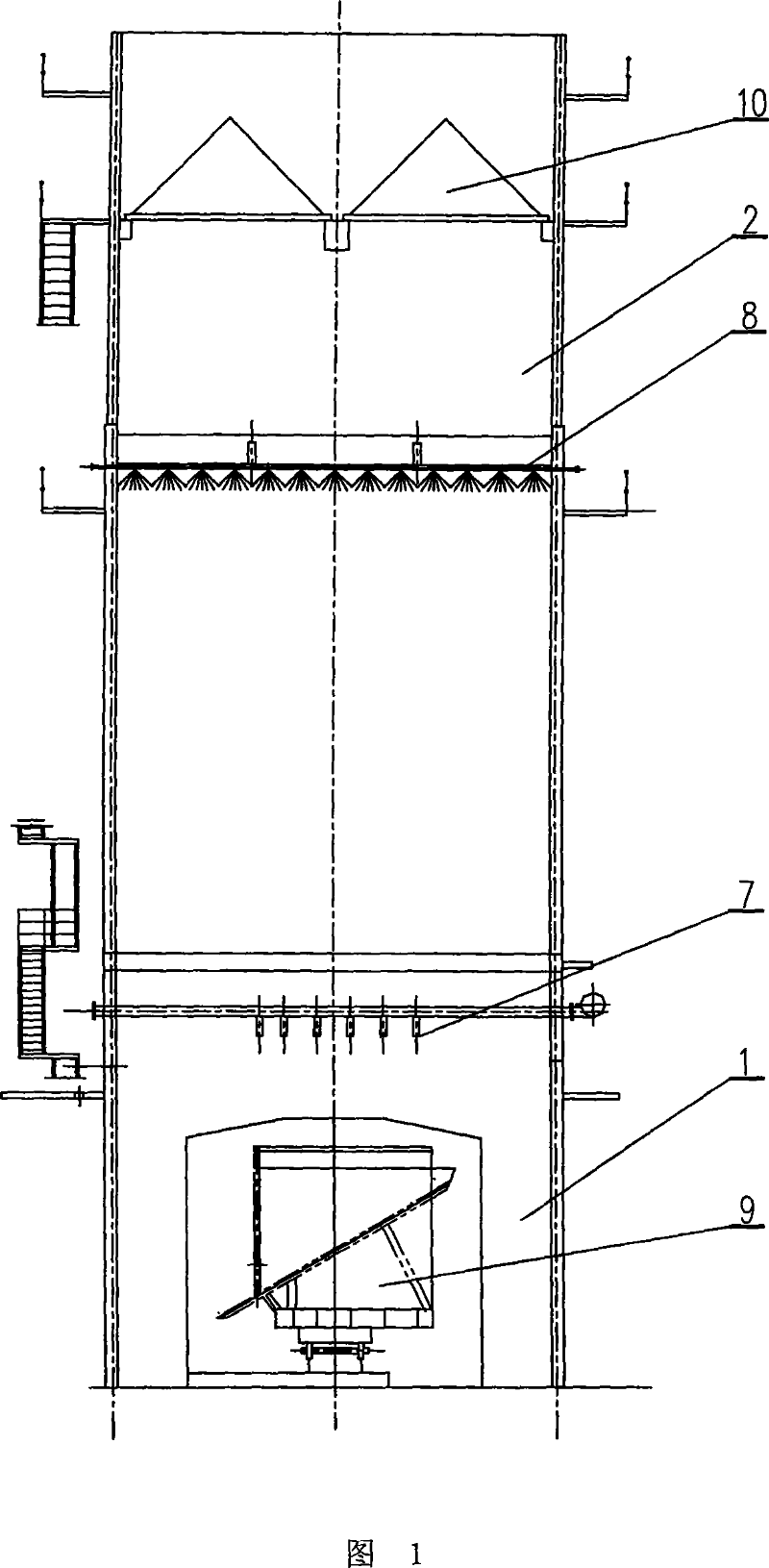

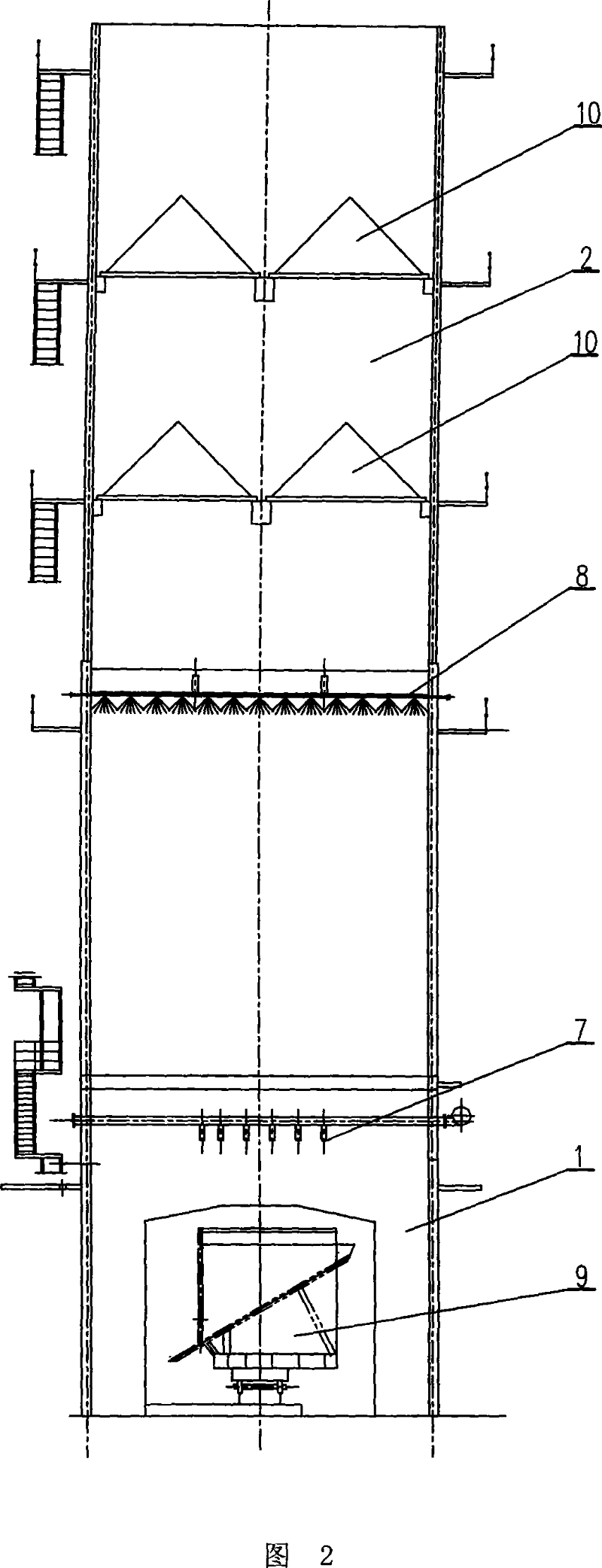

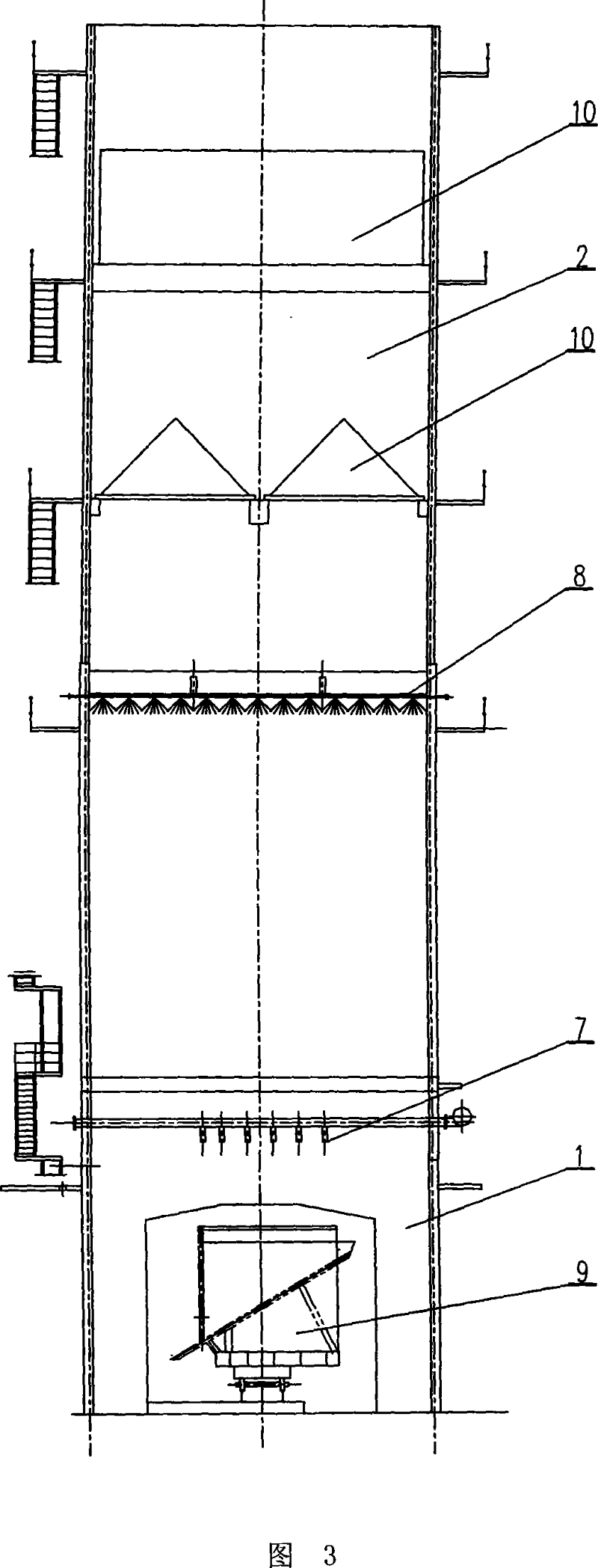

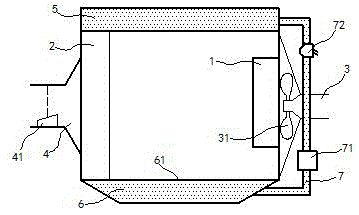

High-effective dust-removing coke quenching tower

ActiveCN101037603AEasy dust removal effectGuaranteed dust removal performanceCoke quenchingSingle stageTower

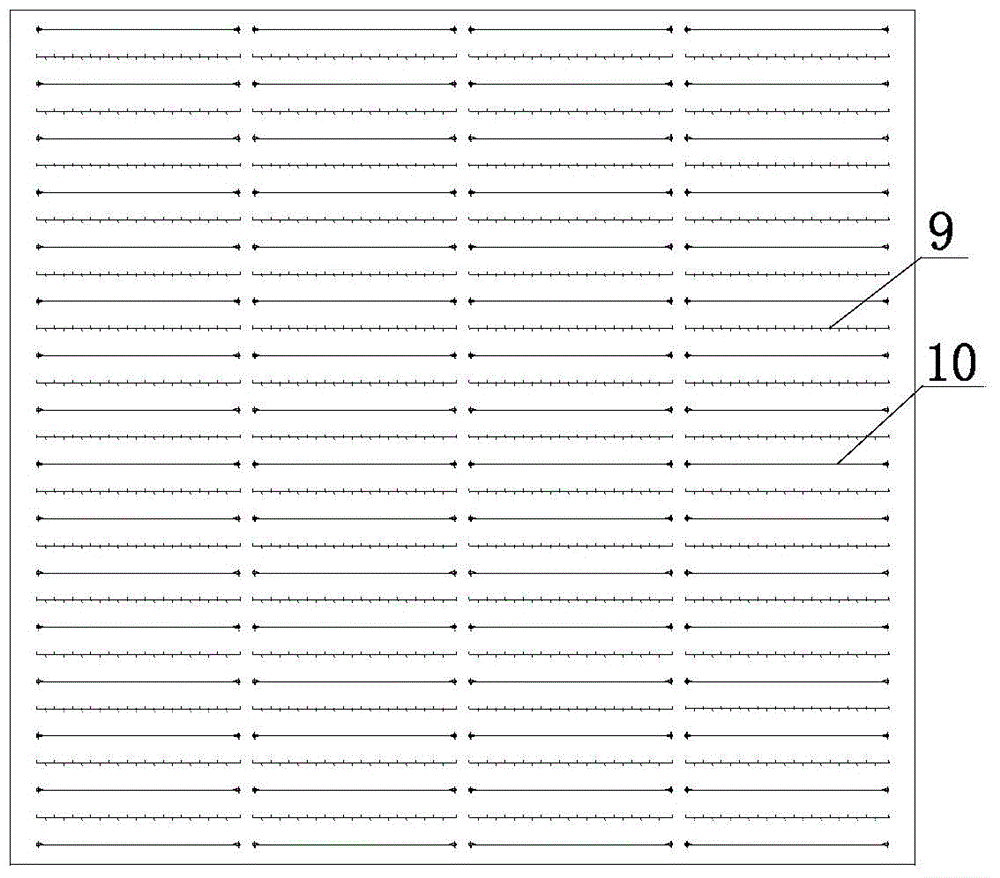

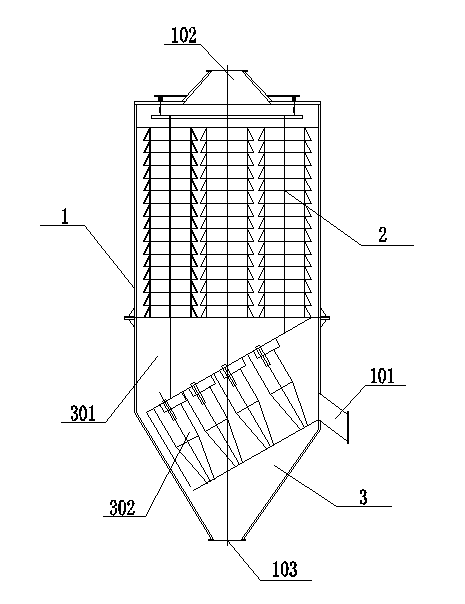

The invention relates to a highly effective dust removal coke quenching machine, which includes a coke quenching injection pipe, a washing and cooling device, and a dust removal device. The dust removal device, which is disposed single-stage or two-stage, includes a structural framework, a dust removal plate, a dust removal pipe and nozzles, wherein the dust removal plate, which is constituted of a heterotypic baffle sheet folded with a certain angle and a dust removal plate support, is disposed on the structural framework and forms angle of 45-60 DEG with horizontal plane; the dust removal pipe is equably equipped with a plurality of nozzles and is arranged parallel with the dust removal plate. Dust content of stream generated at coke quenching process is greatly reduced by water fog washing, cooling, gravitational settling and purifying of baffle plate type dust removal device, amount of coking powder discharged into air of per ton coke is lower than 50g. Moreover, the baffle plate employs industrial plastic, thereby possessing advantages of corrosion resistance, high strength, aging resistance, good dust removal effect, convenient installation and maintance, and easy cleaning.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

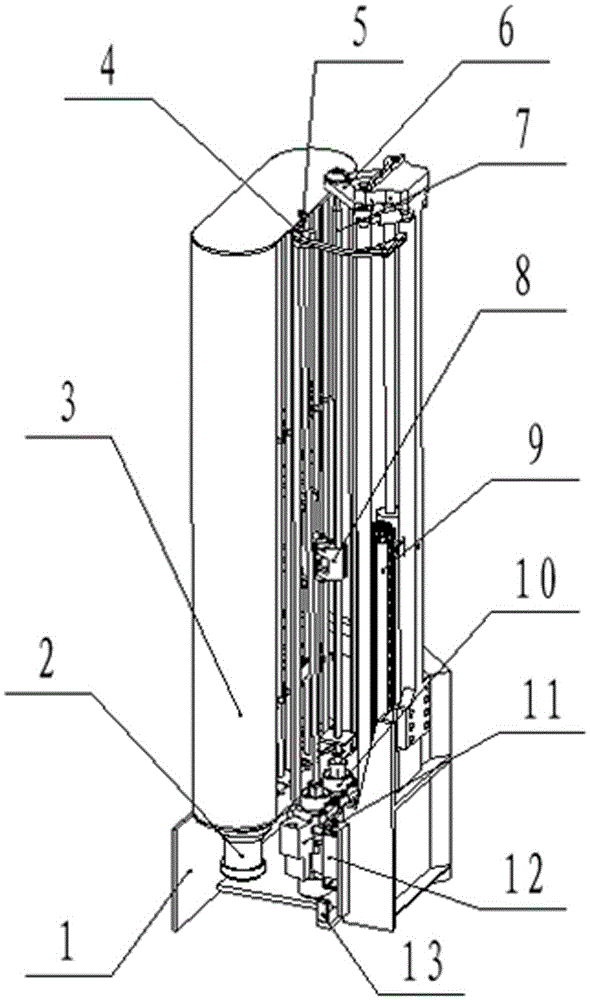

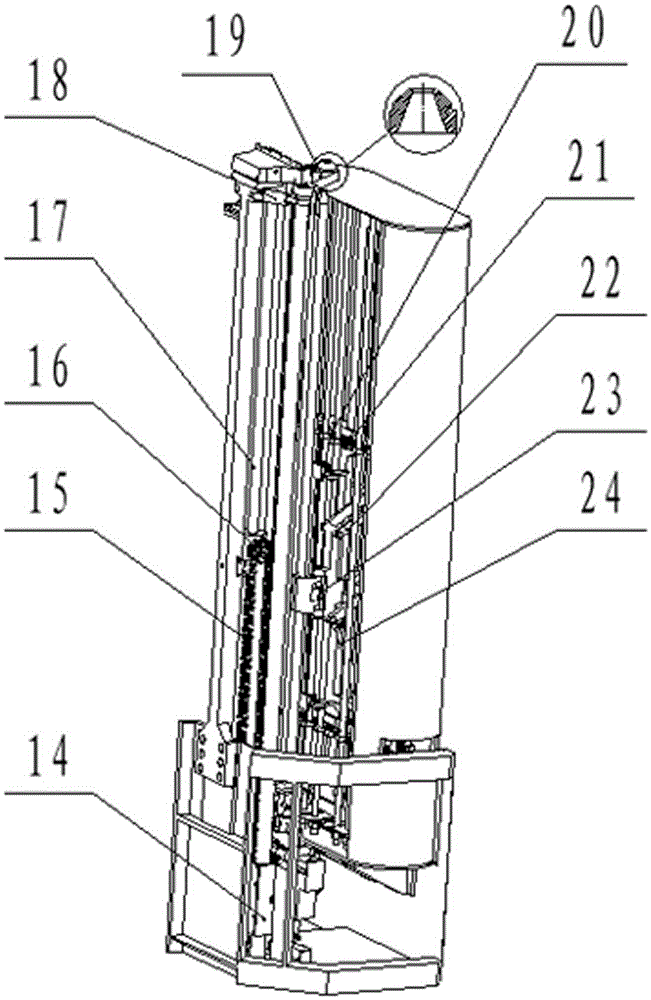

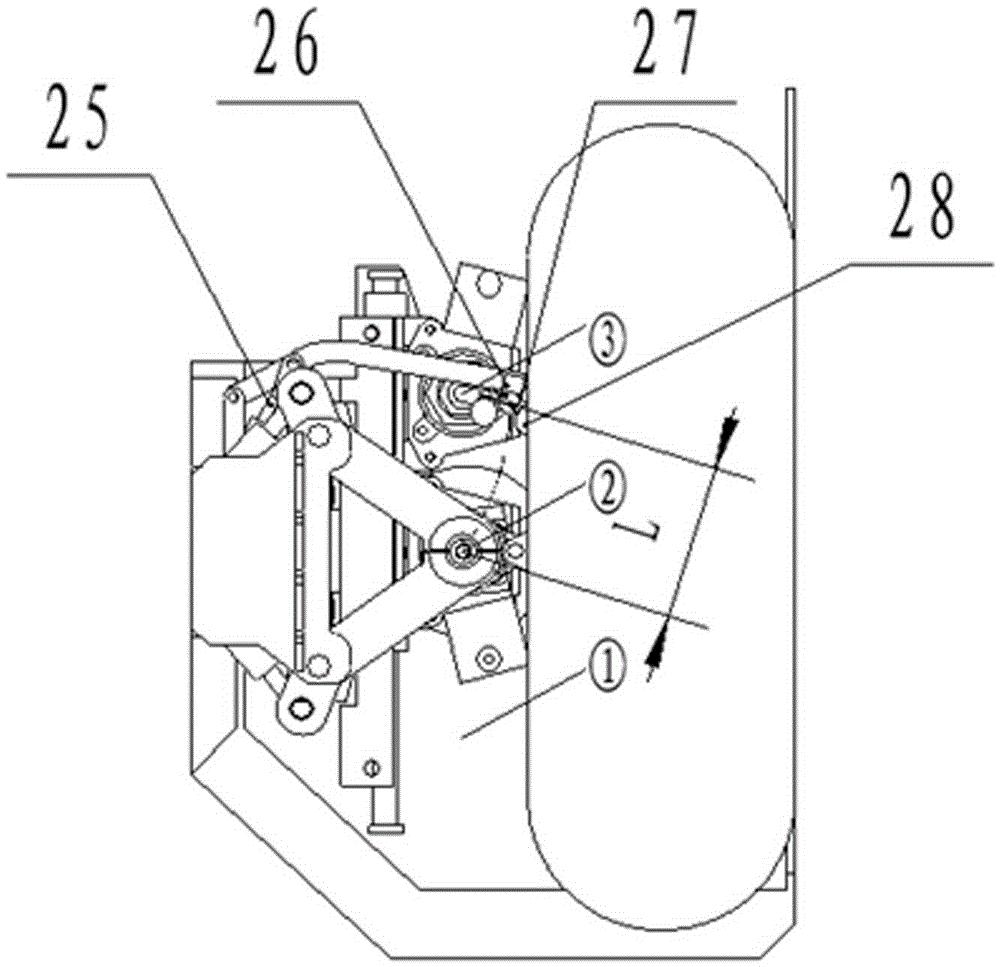

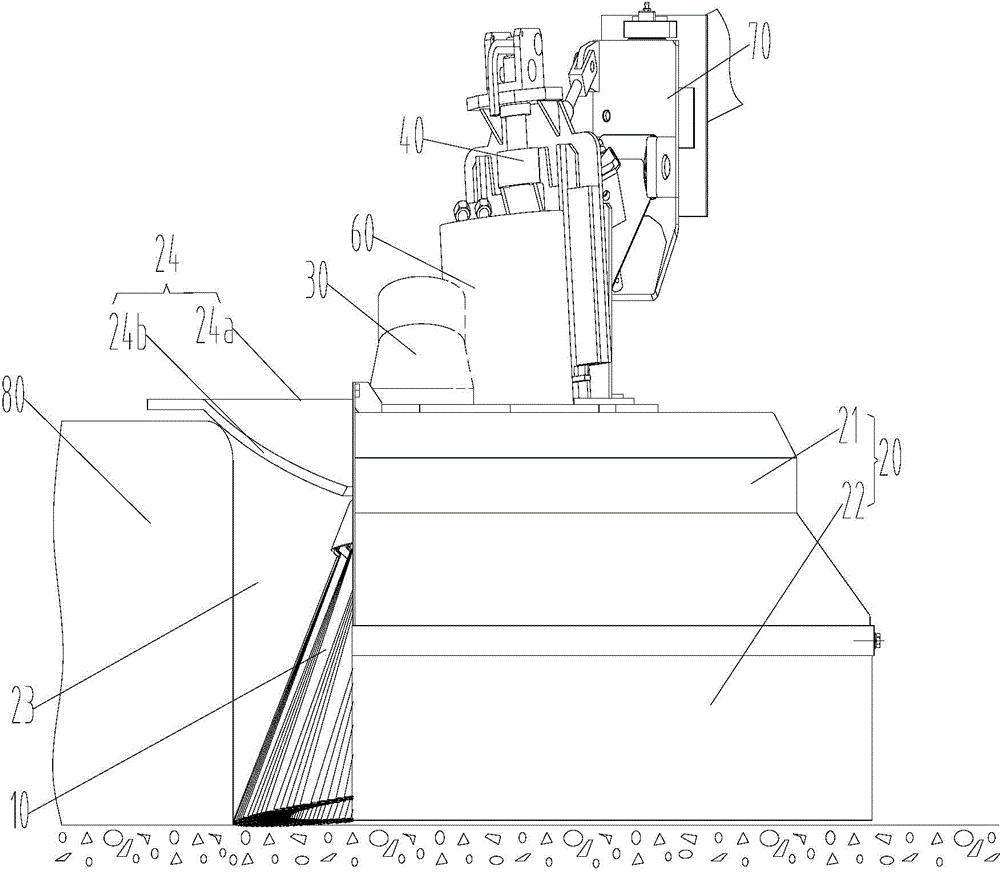

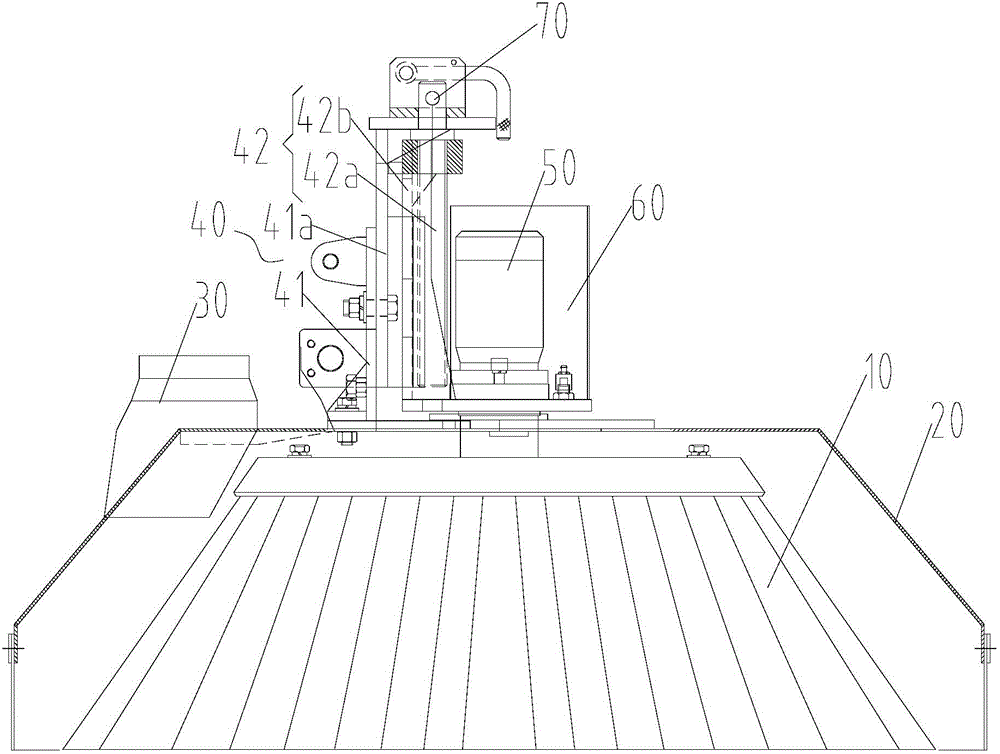

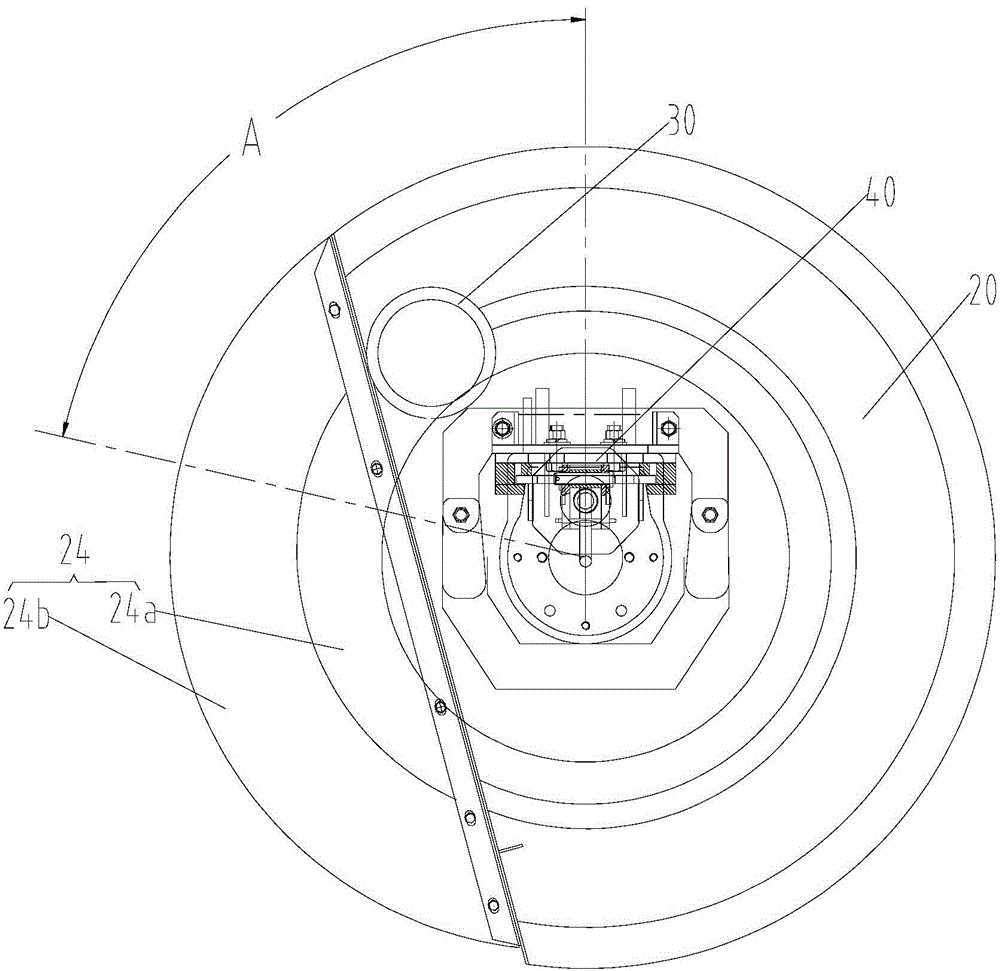

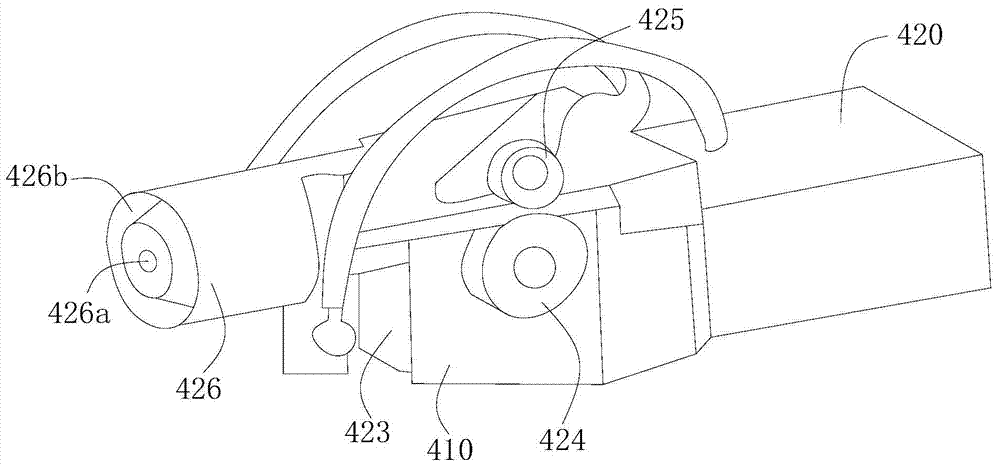

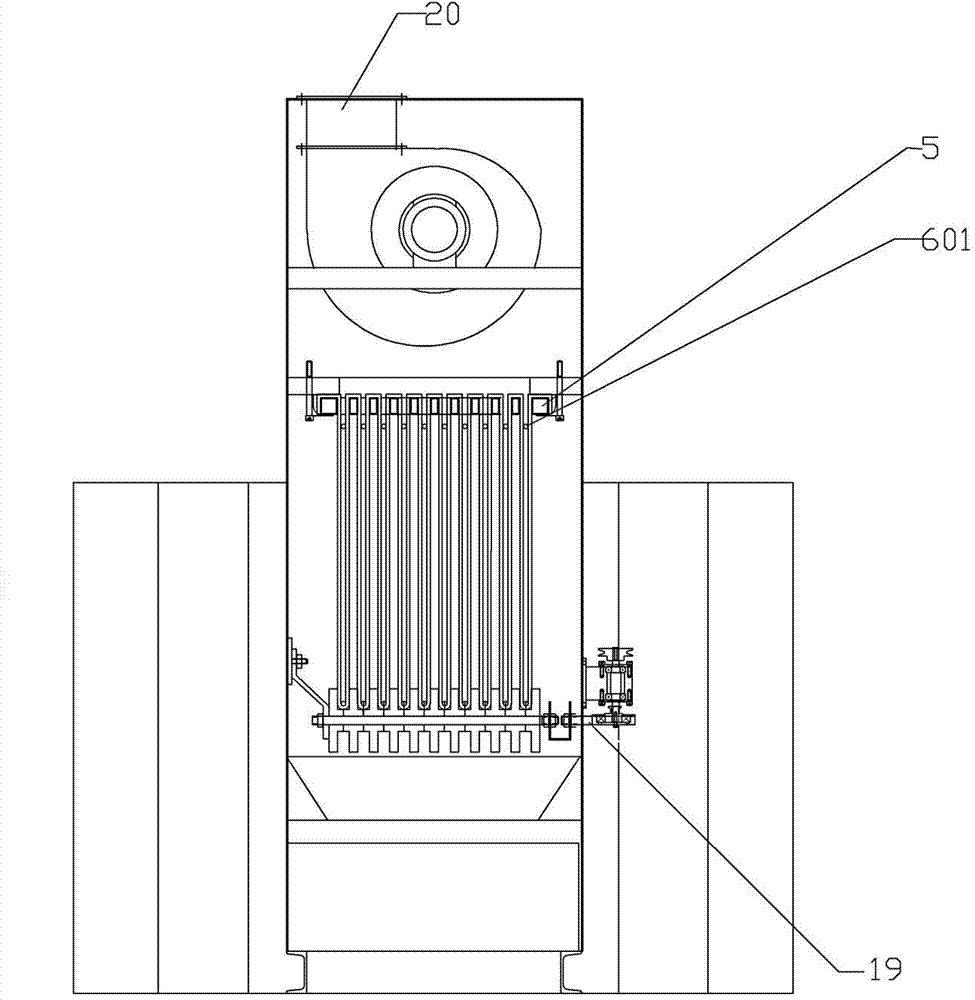

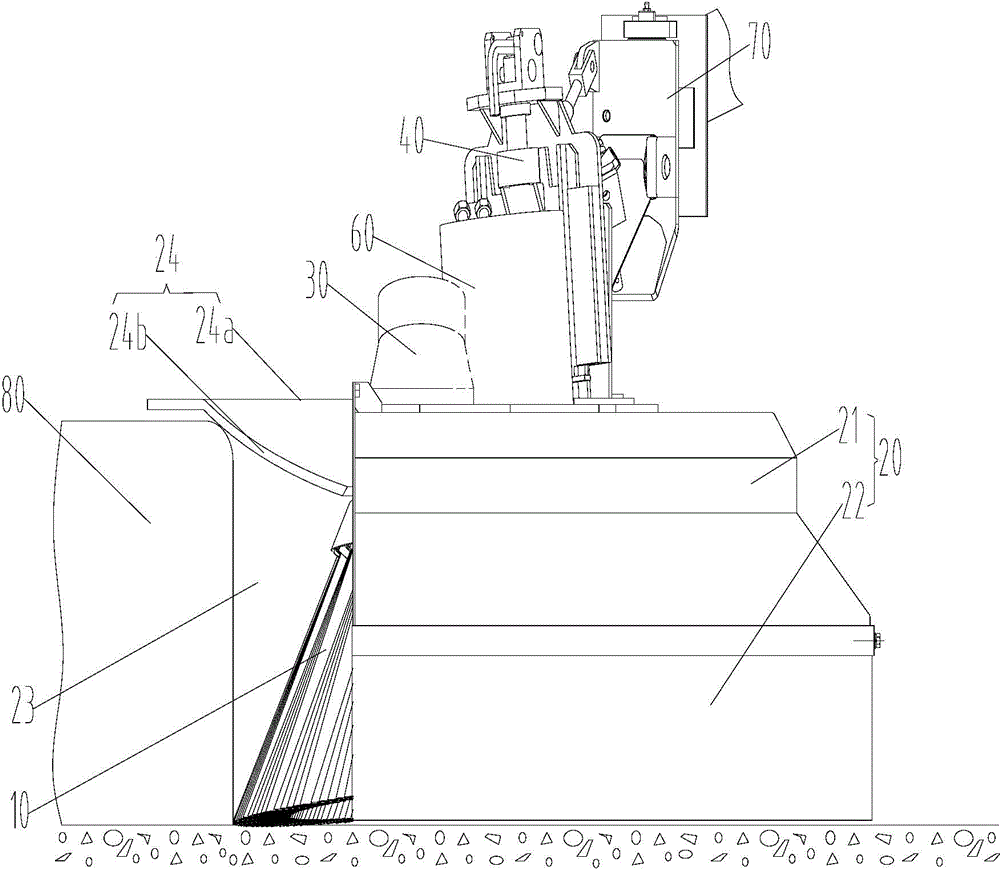

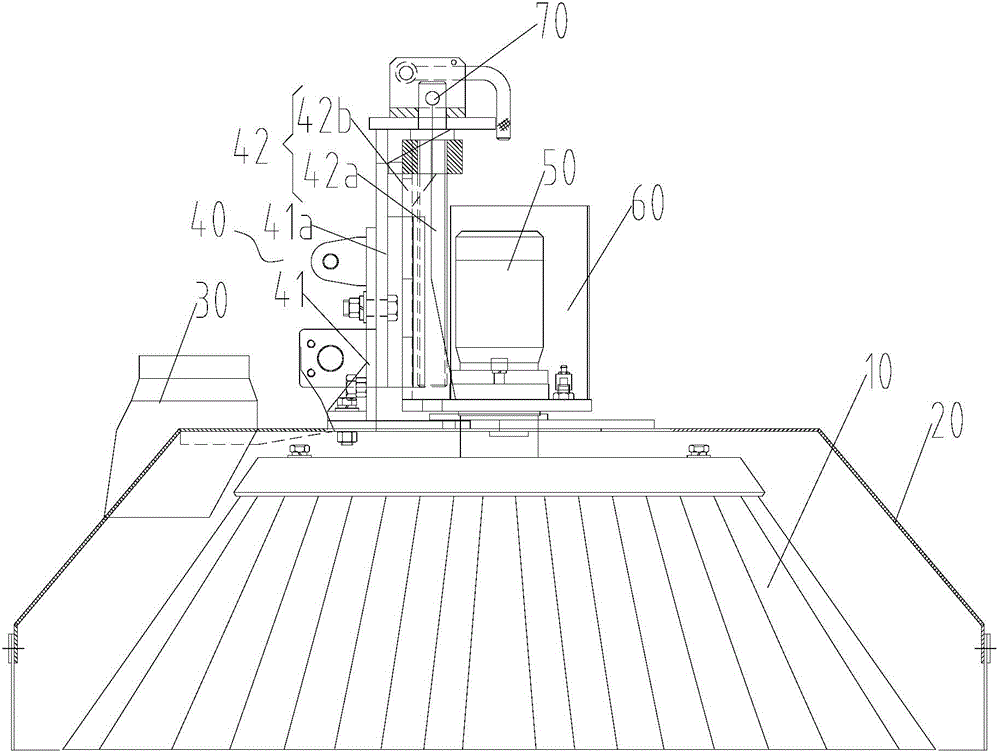

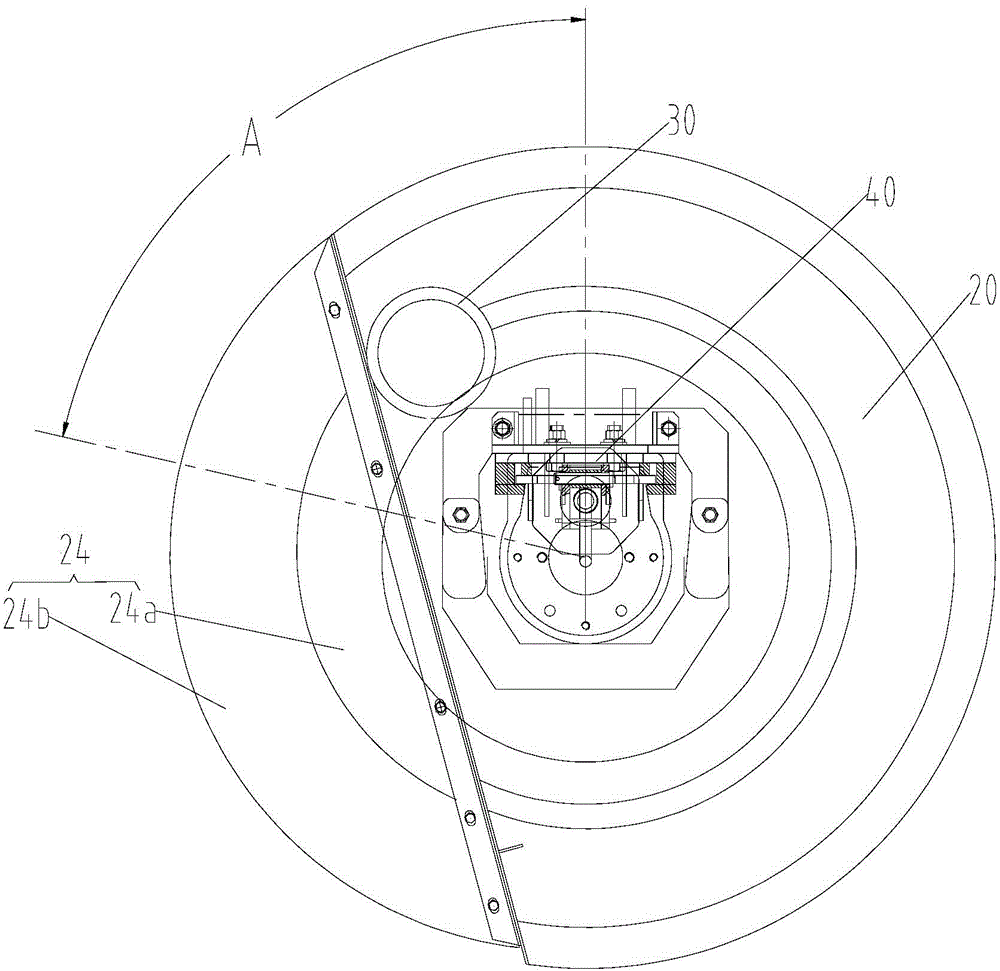

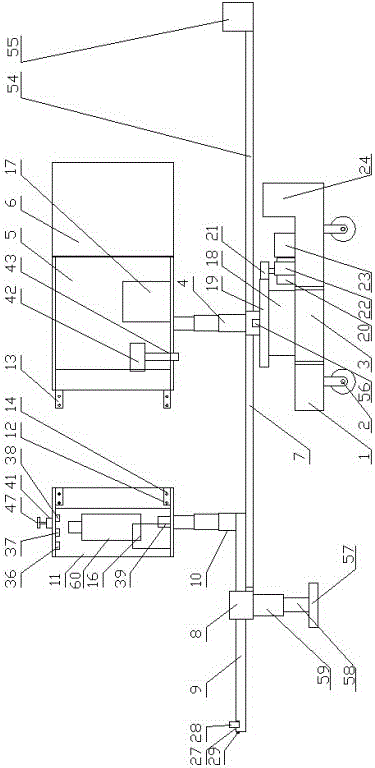

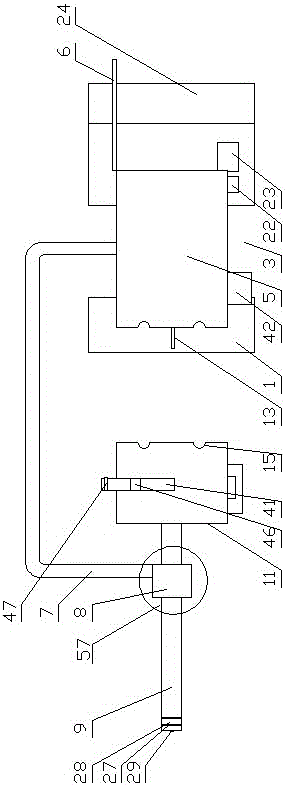

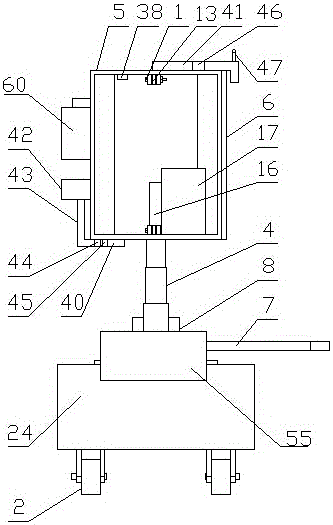

Double drilling-box switching type full-automatic roofbolter

ActiveCN105350992AHigh degree of automationFully automatedAnchoring boltsWorking environmentUltimate tensile strength

The invention belongs to the technical field of rock bolting equipment with the purpose of solving problems arising from a conventional anchor bolting mode such as low automation degree, great labor intensity of workers, a harsh working environment and poor safety. The invention provides a double drilling-box switching type full-automatic roofbolter. The double drilling-box switching type full-automatic roofbolter comprises a frame, a feeding mechanism, a large-capacity rock bolt bin, a drilling box switching mechanism, a drilling box accurate positioning mechanism, a manipulator, a steel pinching mechanism, a drilling rod positioning mechanism, a drilling box and an anchor drilling box. The drilling box and the anchor drilling box achieve drilling, installation and fastening of an anchor rod via the drilling box switching mechanism. The drilling box accurate positioning mechanism is utilized for achieving accurate positioning. The top of the large-capacity rock bolt bin is provided with the steel pinching mechanism and the drilling rod positioning mechanism so that accurate feeding of a drilling rod is ensured and higher drilling positioning is achieved. The roofbolter can be mounted to any equipment needing rock bolting. The double drilling-box switching type full-automatic roofbolter has a compact structure and does not any extra operation space or is protected by staff so that high equipment applicability is achieved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

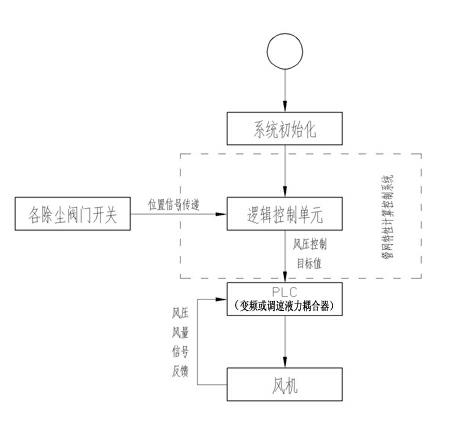

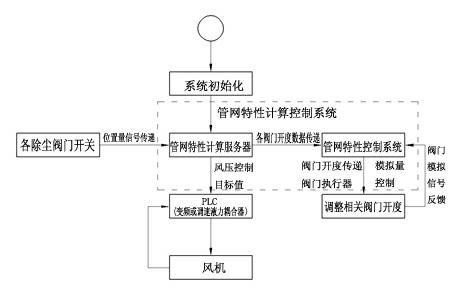

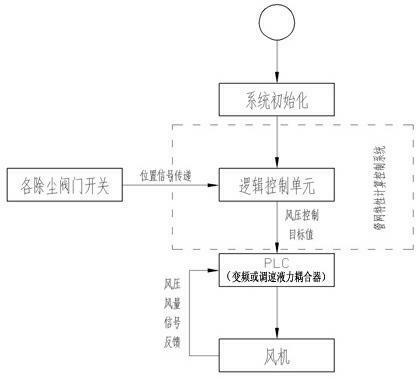

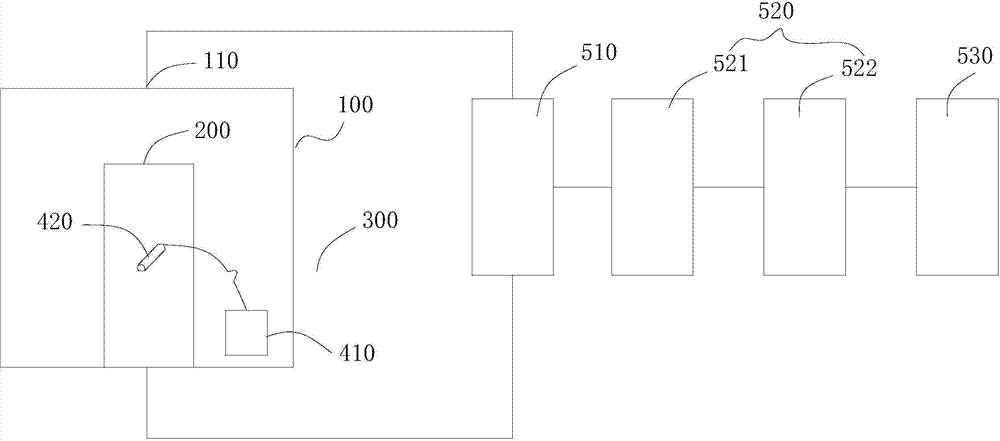

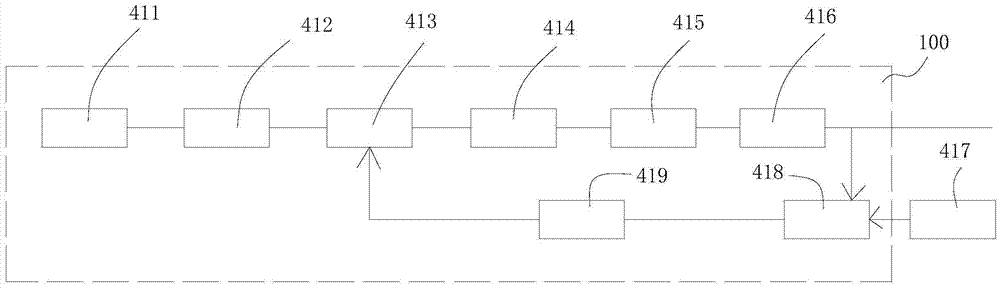

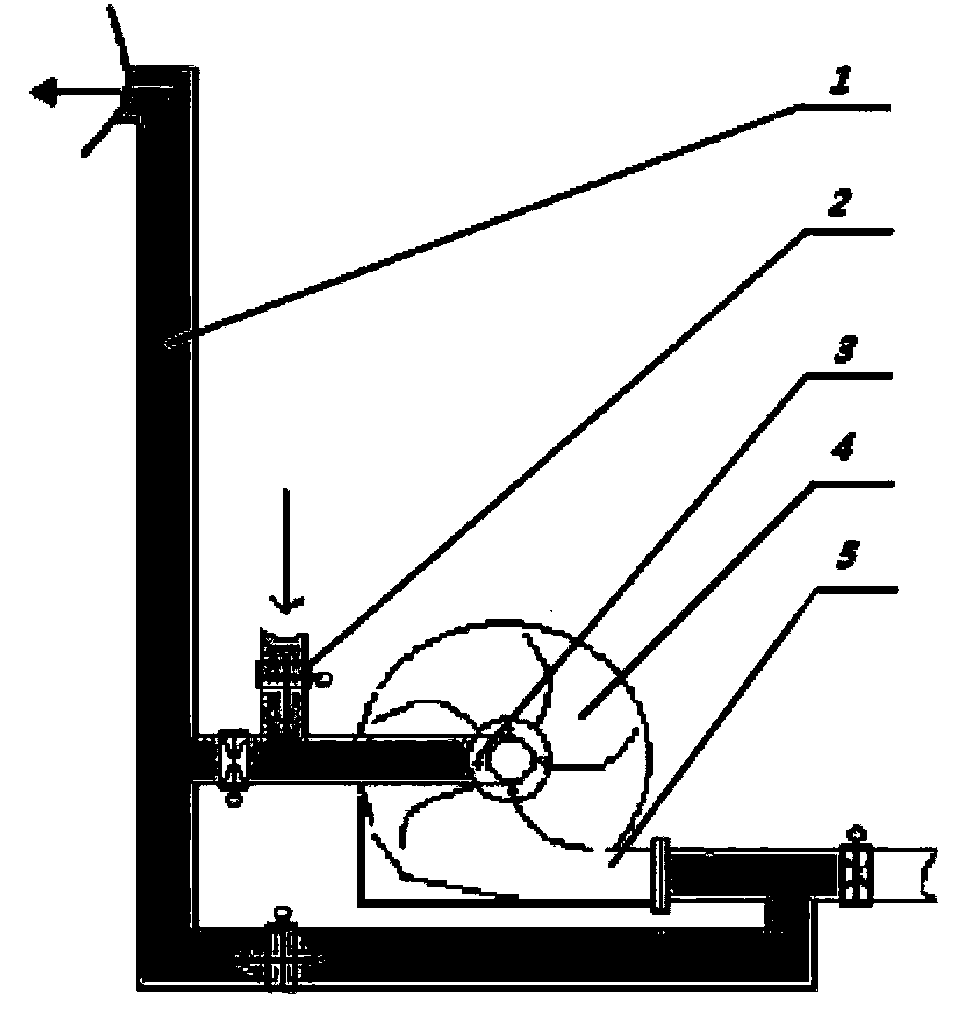

Air quantity automatic regulating method of variable working condition ventilating system

ActiveCN102635920AEasy constructionEasy to manageSpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerFluid coupling

The invention relates to an air quantity automatic regulating method of a variable working condition ventilating system, and belongs to the technical field of ventilating and dust removing. The technical scheme is as follows: the method comprises the following steps: inputting information of a dust removing pipe network and required air quantity of each dust collecting point into a pipe network property computing and controlling system, and determining the air pressure and air quantity of a fan according to the required air quantity of each dust collecting point in the ventilating and dust removing system under the existing working condition; and regulating the motor frequency or the number of turns of the fan automatically by a frequency converter or a speed-regulating fluid coupling and a PLC (programmable logic controller) control system according to the air pressure and air quantity which are provided by the pipe network property computing and controlling system as the standard, and performing the enclosed ring control of the fan according to the air pressure and air quantity signals fed back by a measuring sensor on the dust removing pipe network. According to the invention, the pipe network property computing and controlling system, the frequency converter or the speed-regulating fluid coupling and the PLC control system are separated, an individual functional module is formed respectively, and is convenient to construct and manage, the regulation of the fan property and the dust removing pipe network property as required according to the dust removing pipe network working condition variation is realized, and maximal energy conservation on the premises of guaranteeing the dust removing effect is realized.

Owner:唐山昊丰环保科技有限公司

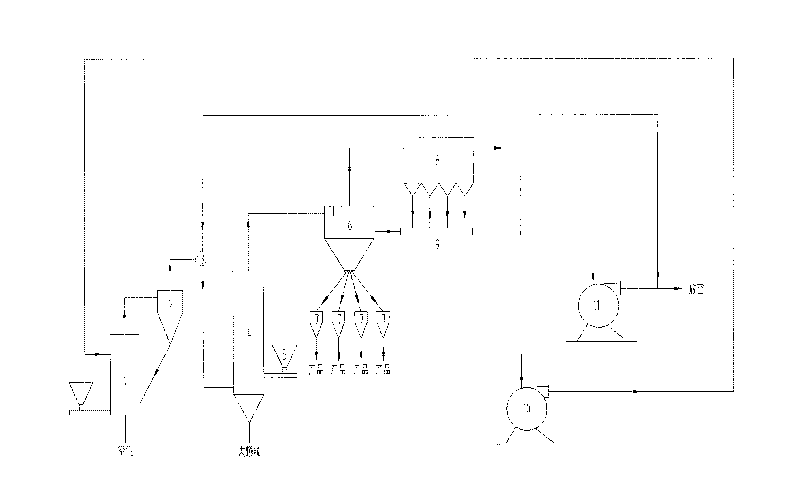

Smoke semi-closed circulating lignite straight pipe type airflow drying method

ActiveCN101726167AGood dispersionImprove dry strengthDrying solid materials with heatDrying gas arrangementsAir volumeDirect combustion

The invention relates to a smoke semi-closed circulating lignite straight pipe type airflow drying method, which ensures the safety and reliability of a device and makes the maximization of the device possible through direct combustion of lignite to generate smoke, once drying of a straight pipe type airflow dryer to meet the moisture requirement of a product, large-grain inertia setting, collection of a fine grain bag type dust collector, even blending of large grains and fine grains through a blending device, emptying and air quantity control through a mixed temperature fan and a booster fan.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

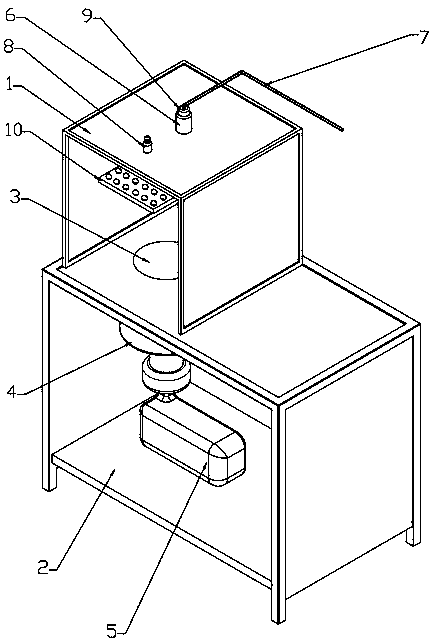

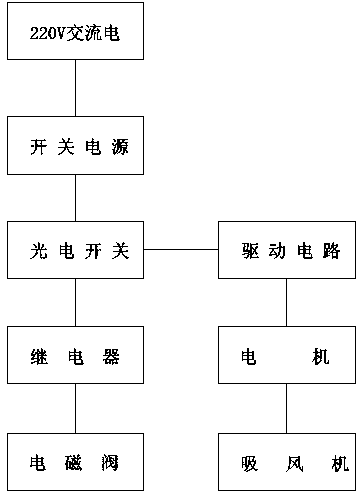

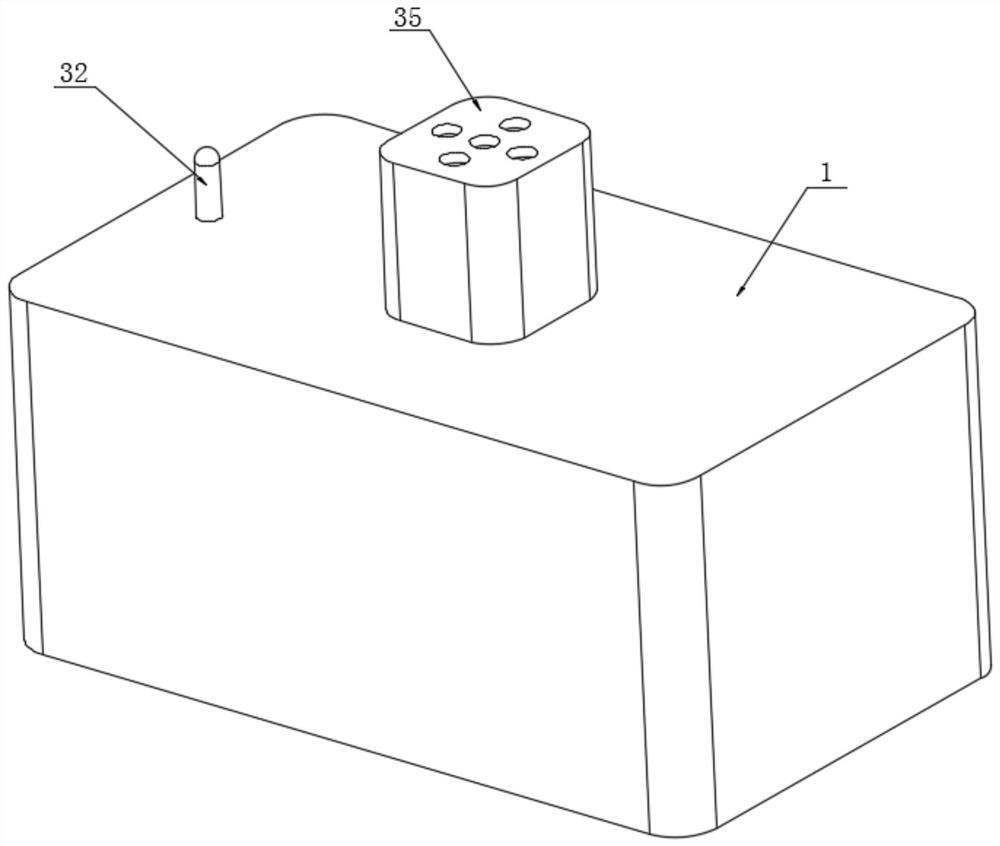

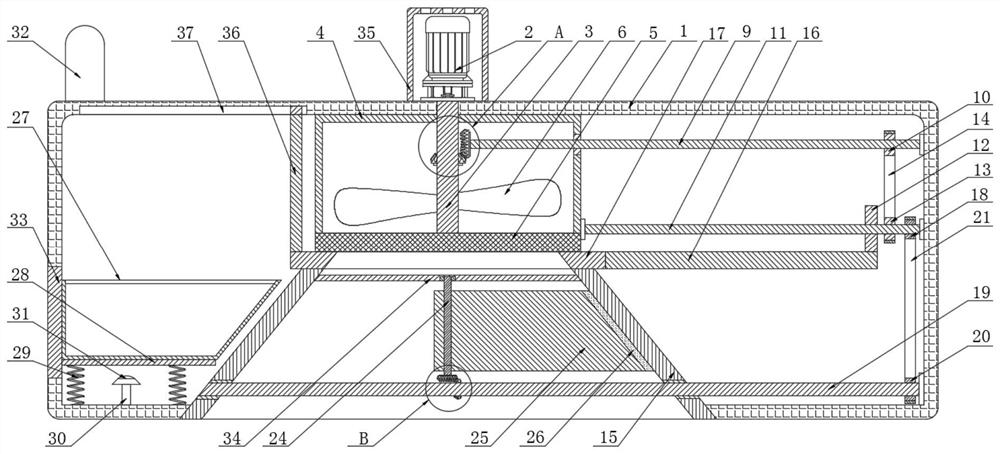

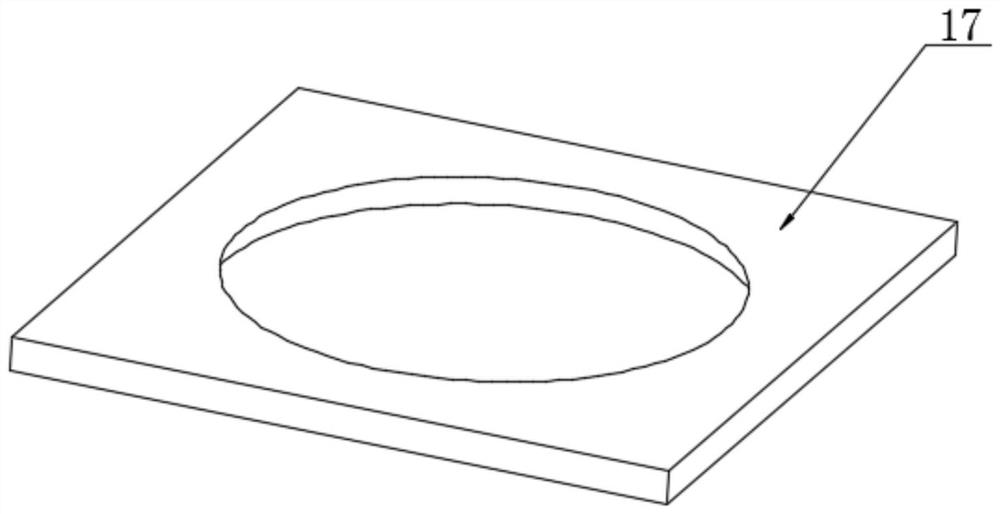

Dedusting device for intelligent electric meter

InactiveCN103551338AExquisite structureEasy to useDirt cleaningCleaning using gasesElectric machineryEngineering

A dedusting device for an intelligent electric meter comprises an upper box body and a lower box body, wherein the side of the upper box body and the side of the lower box body are provided with box covers. The bottom surface of the upper box body and the upper surface of the lower box body are fixed to be a whole and provided with a through opening. The lower box body is internally provided with a motor, a suction fan and a recycling bag, the upper end of the suction fan is communicated with the opening, the lower end of the suction fan is connected with the recycling bag, and the motor is connected with the suction fan through a wire. The upper box body is internally provided with a baffle, the baffle is parallel to the upper surface of the upper box body and is provided with a plurality of through holes, a dedusting air gun is arranged on the upper surface of the upper box body, a gun opening of the dedusting air gun penetrates through the upper surface of the upper box body to extend to be above the baffle, and an air inlet of the dedusting air gun is connected with an air inlet pipe. The dedusting device is ingenious in structure and convenient to use, not only guarantees dedusting effect, but also greatly improves dedusting efficiency, and is suitable for a dedusting process of electric meters of various models.

Owner:中电装备山东电子有限公司

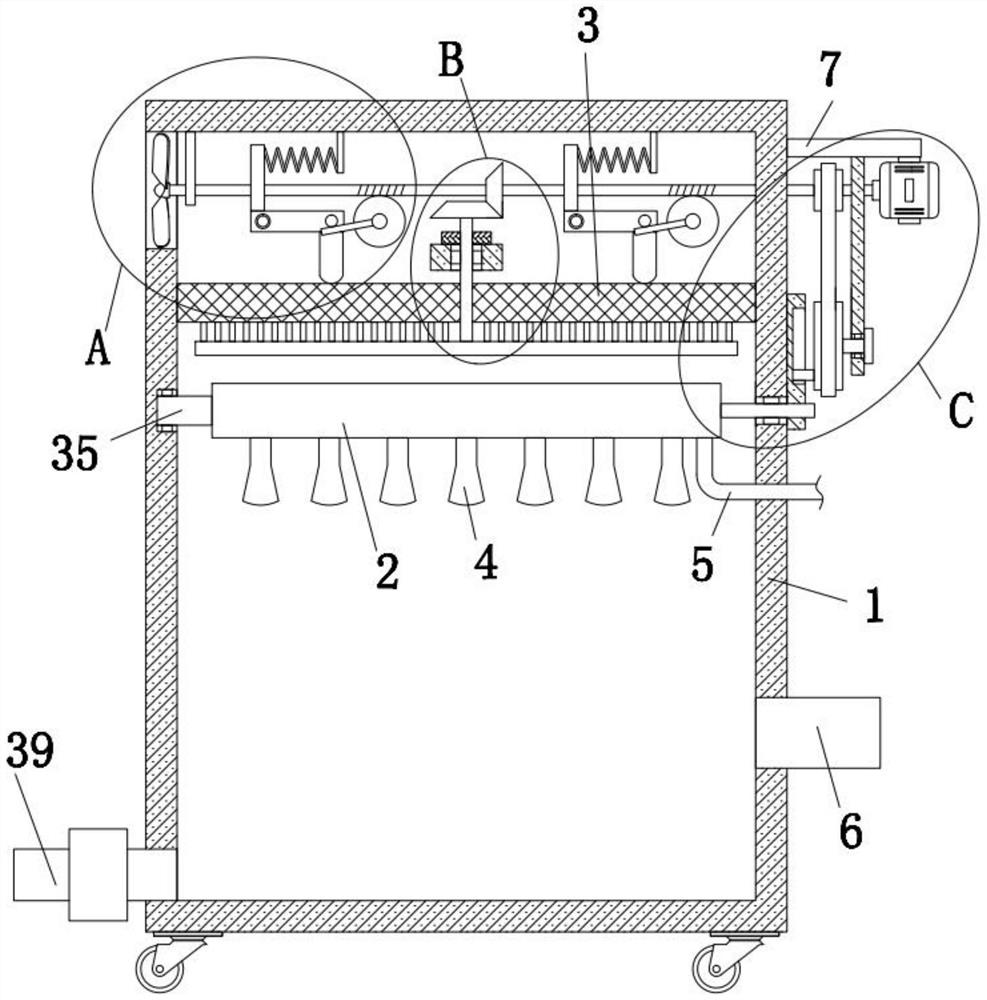

Environment-friendly forestry and agricultural residue treatment device

InactiveCN105642068AGuaranteed dust removal performanceCombination devicesAgricultural residueSedimentation

The invention discloses an environment-friendly forestry and agricultural residue treatment device which comprises a cyclone separator, a first filtering tank, a second filtering tank and a sedimentation basin, wherein a material feeding hopper is arranged at the top of the cyclone separator; a first filtering net hermitically connected with the inner wall is arranged at the position, which is close to the top, in the material feeding hopper; a material discharging channel is arranged at a position, which corresponds to the first filtering net, on the outer side wall of the material feeding hopper; a material discharging valve is arranged on the material discharging channel; a material outlet of the cyclone separator is communicated with the first filtering tank through a connection pipe; the first filtering tank and the second filtering tank are arranged in parallel, and are communicated through a connection pipe; partition plates hermitically connected with the inner side walls of the first filtering tank and the second filtering tank are arranged at the interior tops of the first filtering tank and the second filtering tank; spraying heads are further arranged at the interior tops of the first filtering tank and the second filtering tank and are communicated with the sedimentation basin through a water feeding pipe. The environment-friendly forestry and agricultural residue treatment device is good in dust collection effect, and resources can be saved.

Owner:CHENGDU PUJIANG KEXIAN TECH

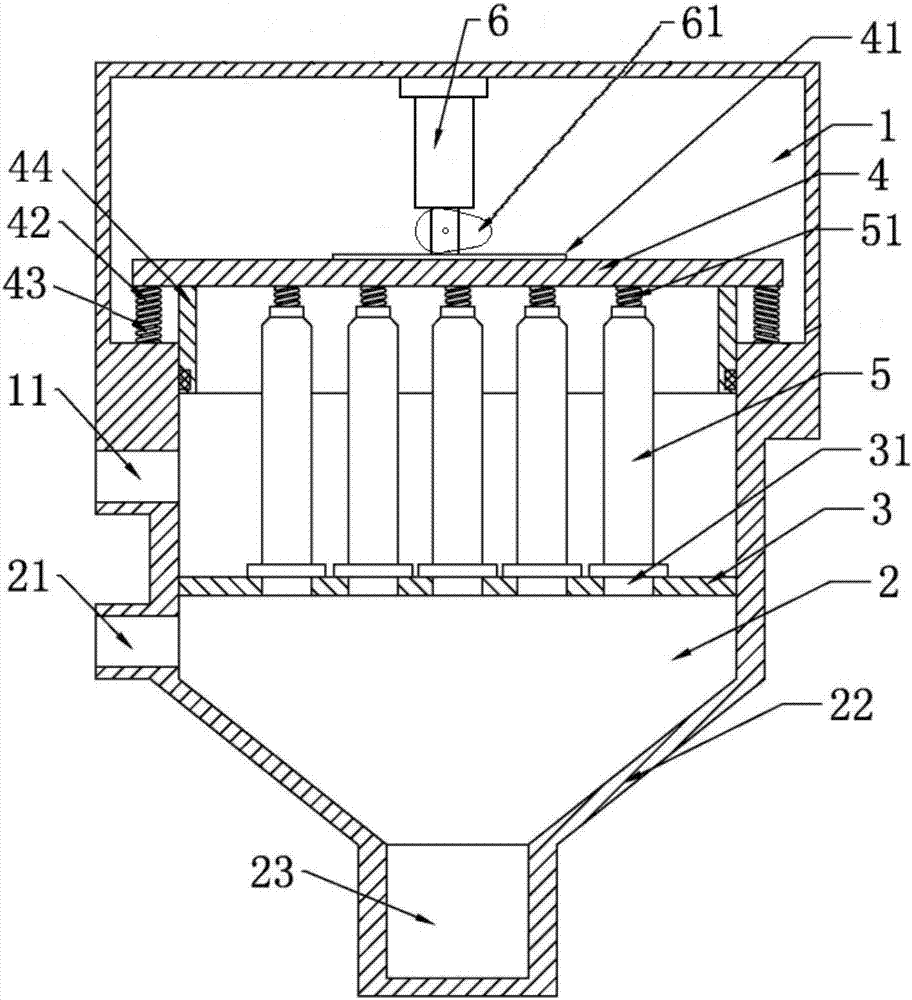

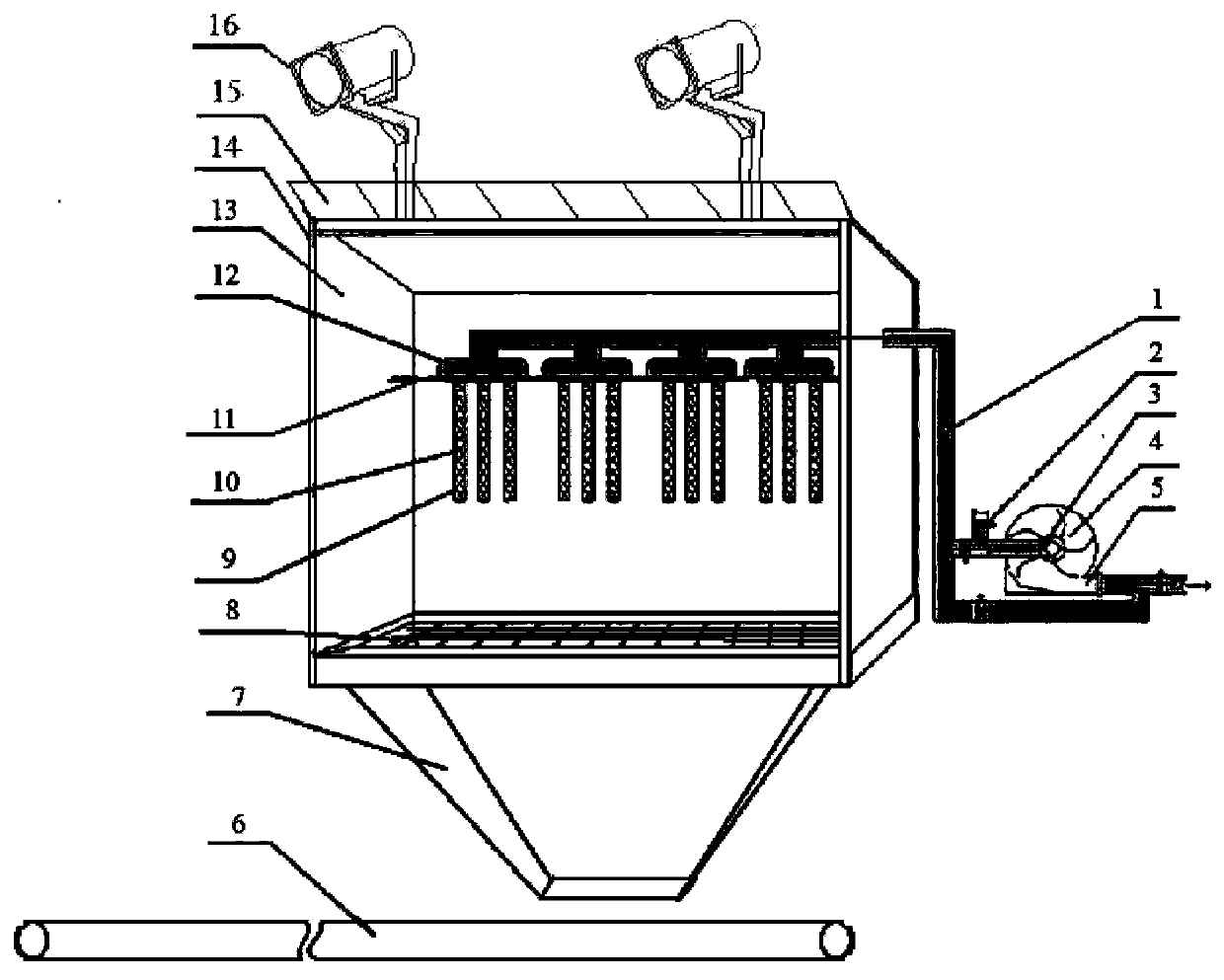

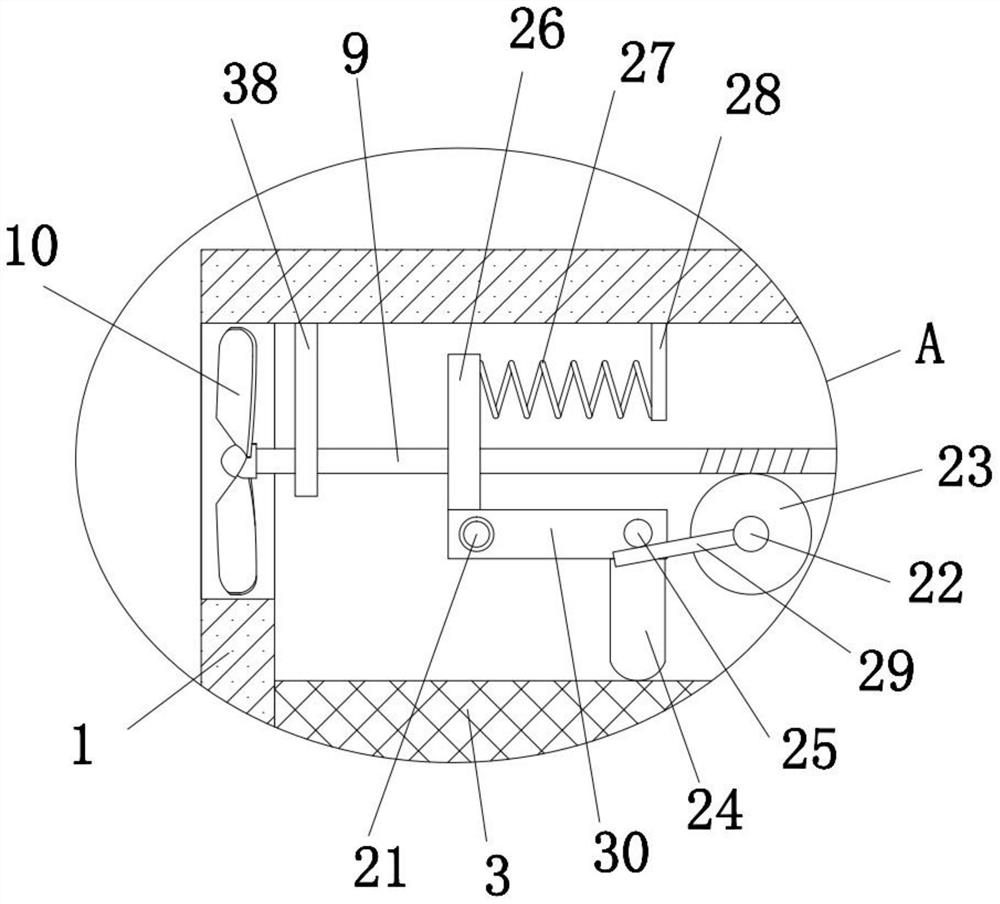

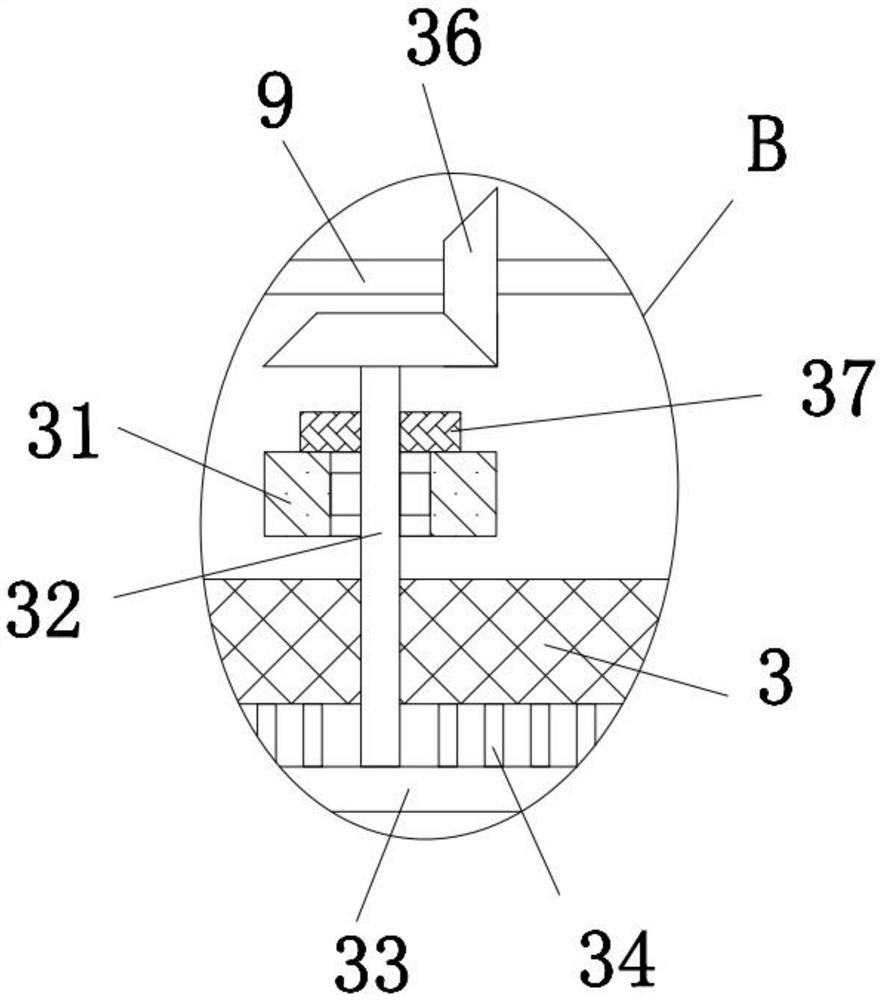

Filter bag dust-removing device

InactiveCN107511005AGuaranteed dust removal effectGood effectDispersed particle filtrationEngineeringCam

A filter bag dust-removing device comprises a dust-removing chamber, a dust gas chamber and filter bags, wherein a partition plate is arranged between the dust-removing chamber and the dust gas chamber, the filter bags are arranged above the partition plate and are installed in the dust-removing chamber through a suspension plate, the dust-removing chamber is provided with an air outlet, the dust gas chamber is provided with an air inlet, through holes are arranged in the partition plate; the dust-removing device further comprises a vibrating mechanism used for vibrating down fixed impurities attached in the filter bags, the vibrating mechanism comprises an air cylinder and a cam, a cylinder body end of the air cylinder is arranged in the top wall of the dust-removing chamber, an output shaft end of the air cylinder is connected with the cam and drives the cam to do rotating motion; the left end and the right end of the suspension plate respectively installed in the dust-removing chamber in an up and down telescoping manner through retractable hanging rods, reset springs are arranged outside the retractable hanging rods in a sleeving manner; the cam is linked with the suspension plate. The invention provides the filter bag dust-removing device which is longer in service life and better in dust-removing effect.

Owner:ZHEJIANG UNIV OF TECH

Road sweeper

ActiveCN105696506AGuaranteed cleaning efficiencyImprove reliabilityRoad cleaningRoad sweeperEngineering

The present invention provides a road sweeper, comprising a body, a first suction pipeline, sweeping devices, a second suction pipeline and a fan. The body is provided with a dustbin; the first end of the first suction pipeline extends towards the position below the body and the second end of the first suction pipeline extends into the dustbin; the sweeping devices are provided with dust collection air pipes; the second suction pipeline is independent of the first suction pipeline, the dust collection air pipes are communicated with the first end of the second suction pipeline, and the second end of the second suction pipeline extends into the dustbin; the fan is arranged on the body, the air inlet side of the fan is communicated with the dustbin, and thus a negative pressure zone is formed in the dustbin. By applying the road sweeper, accidents caused by icy roads due to water spraying for dust removal can be effectively avoided, and the reliability of road construction is improved on the premise of guaranteeing the dust removal effect. The road sweeper can be used in winter, thus effectively solving the problem that the equipment is idle.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

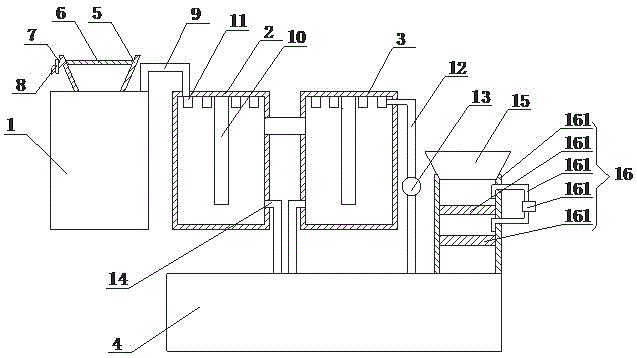

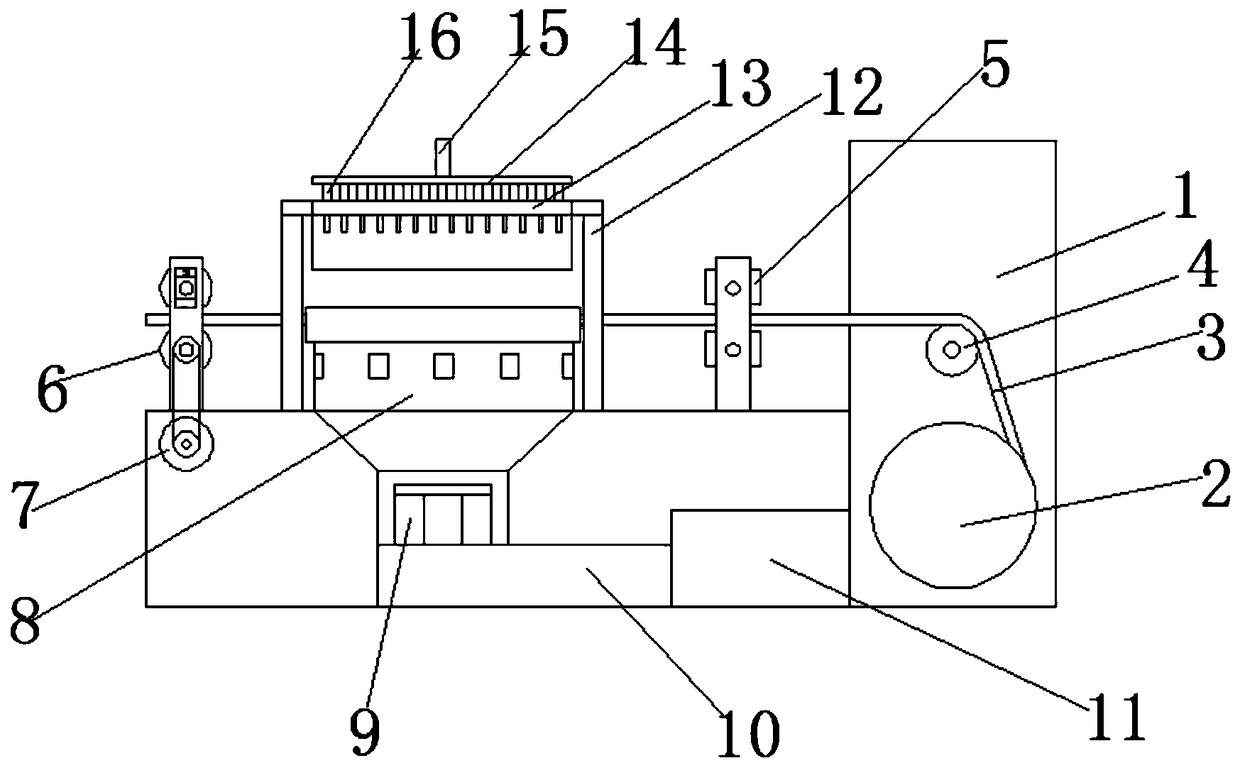

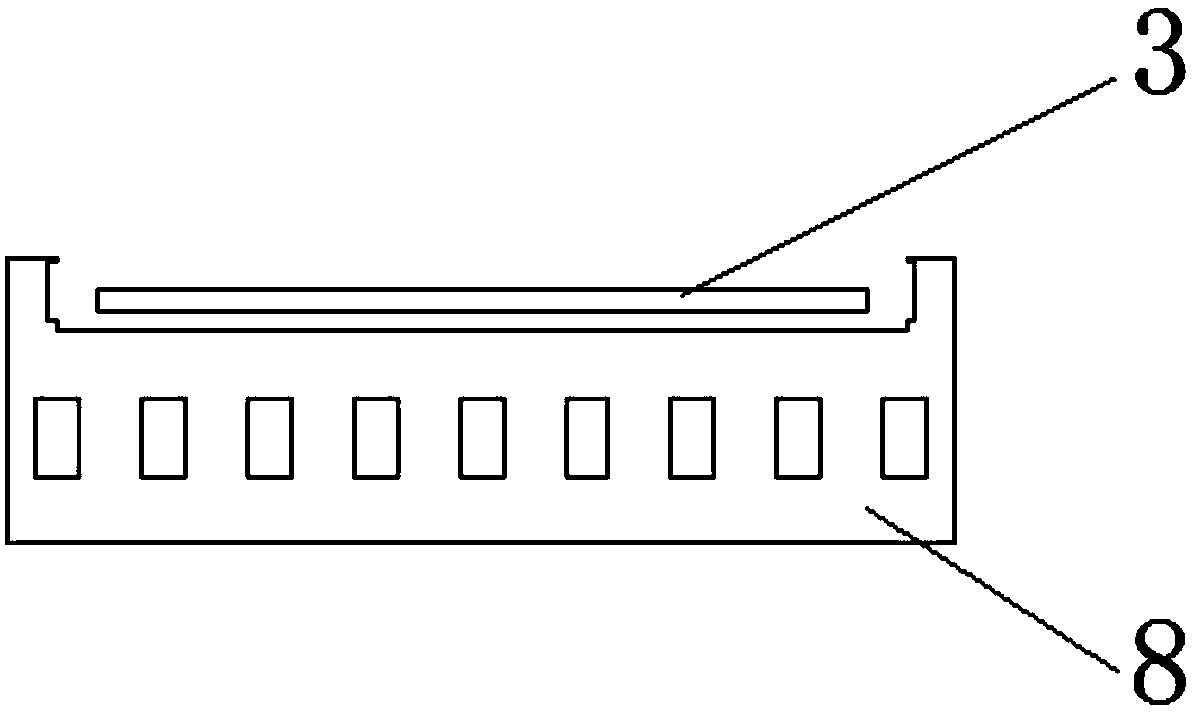

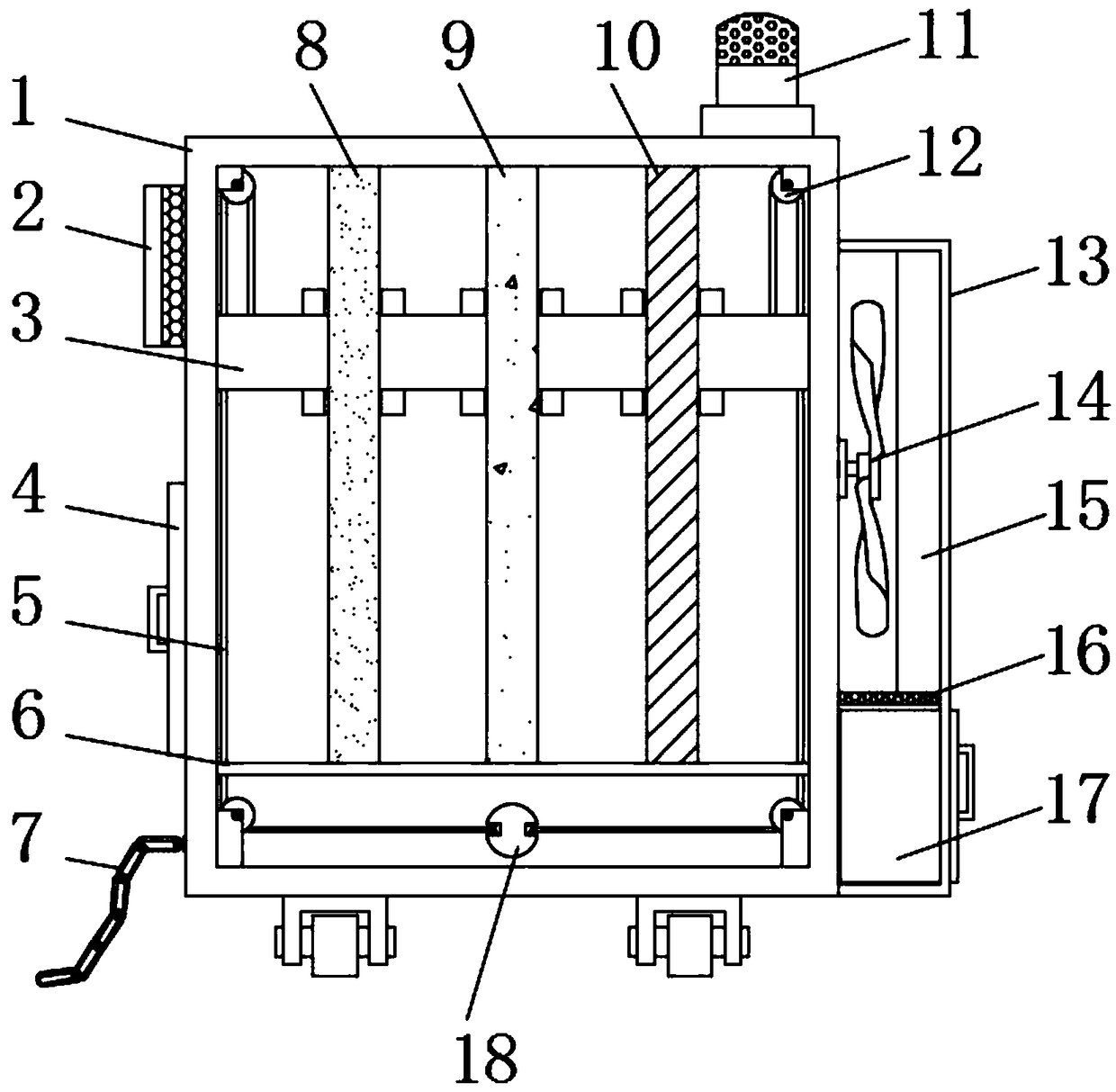

Substrate dust-removal device for processing diffusion diaphragm

InactiveCN109332299ASo as not to damageReduce wearDirt cleaningCleaning using gasesSolenoid valveAir filter

The invention discloses a substrate dust-removal device for processing a diffusion diaphragm. The substrate dust-removal device comprises an unwinding frame, a material reel, a substrate, a guiding roller, an electrostatic eliminator, traction rollers, a traction motor, a suction hood, an air filter, an exhaust pipe, a centrifugal fan, an injection frame, a spraying head fixing frame, a branch airpipe, a total air pipe and high-frequency solenoid valves. Through unwinding of the unwinding frame and cooperation of the guiding roller and the traction rollers, the substrate moves horizontally onthe top face of the dust-removal device at the constant speed, passes through the electrostatic eliminator firstly from right to left for electrostatic eliminating, and then enters the upper part ofthe suction hood, a controller controls the high-frequency solenoid valves to sequentially be closed and opened, thus high-frequency pulse airflow is formed to impact the surface of the substrate, dust is disengaged from the surface of the substrate, dust-containing gas is sucked by the suction hood, filtered by the air filter and then is discharged to the indoor space, in the whole process, the traction rollers and the guiding roller do not make contact with the surface of the substrate, abrasion of dust particles on the surface of the substrate is reduced, and the substrate is protected.

Owner:广州市高浦特光电科技有限公司

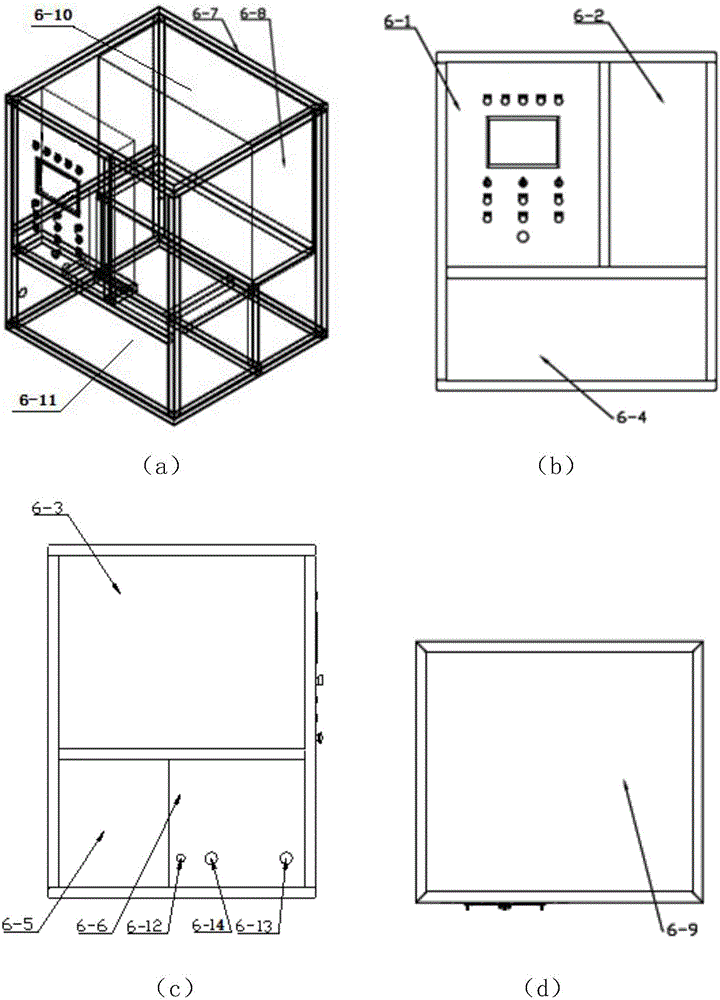

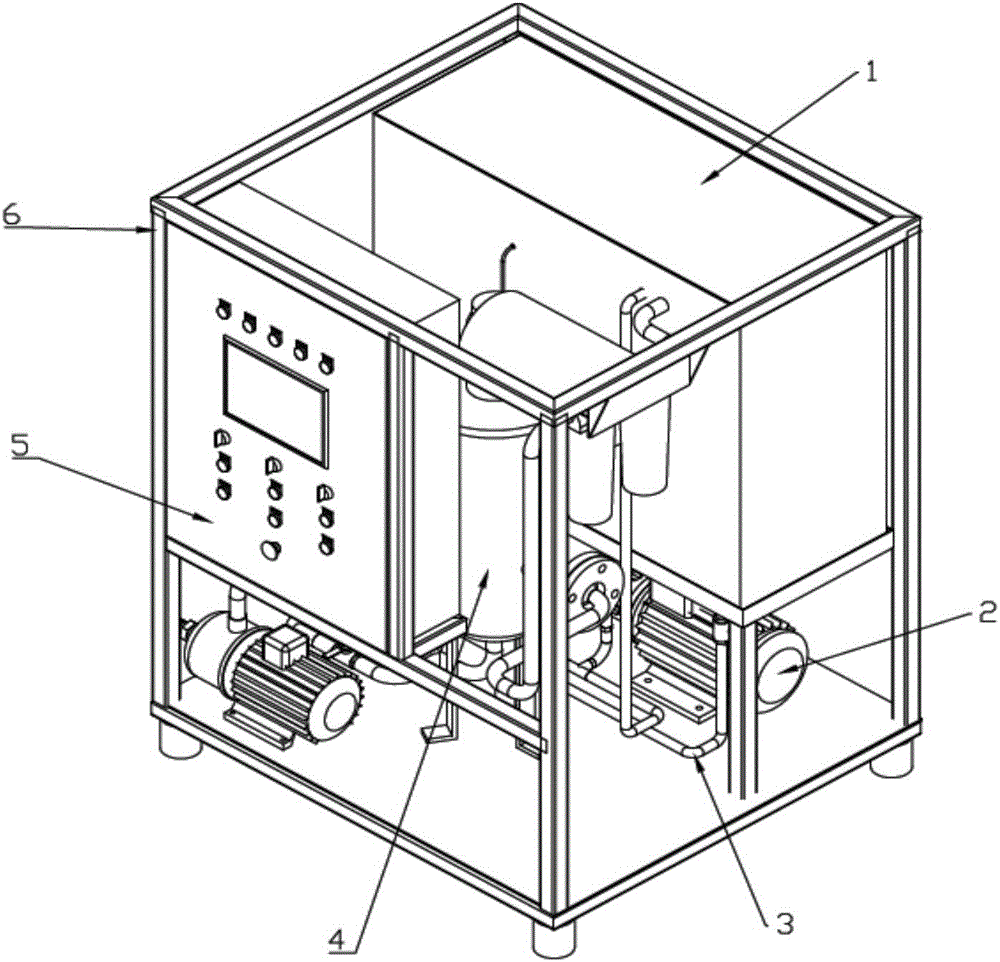

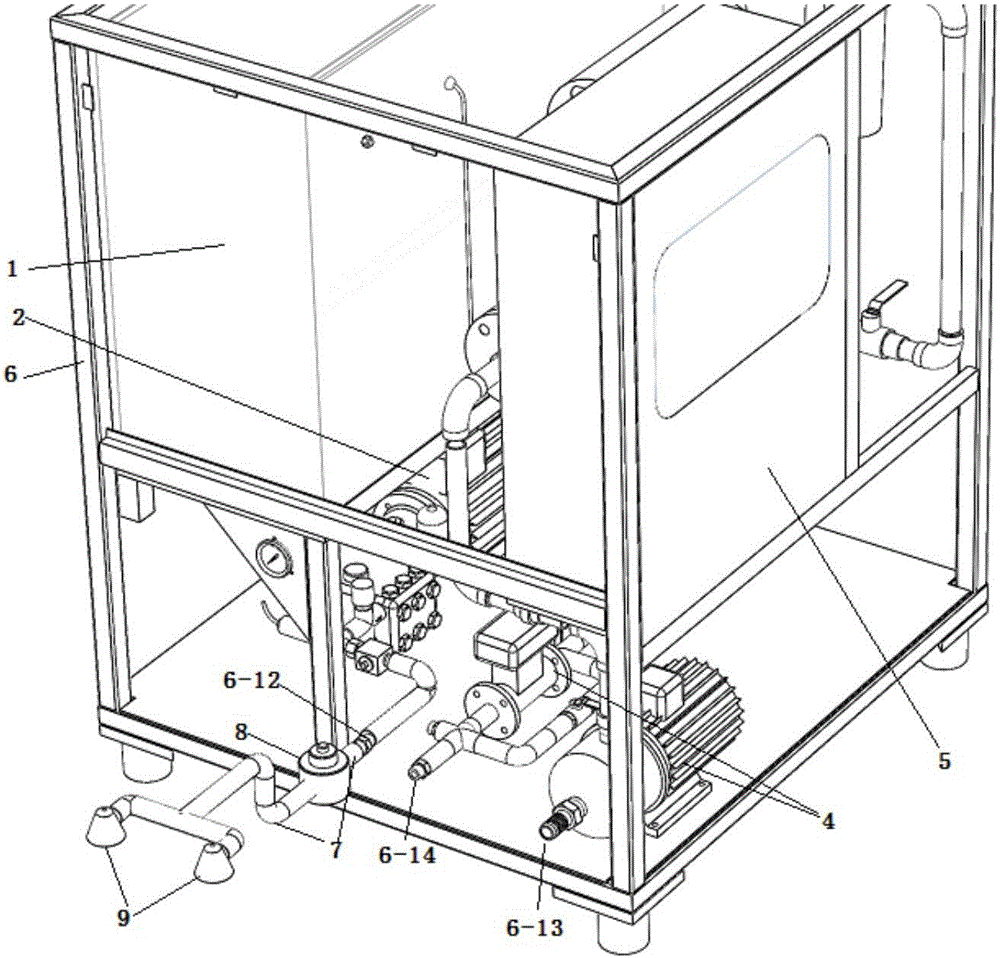

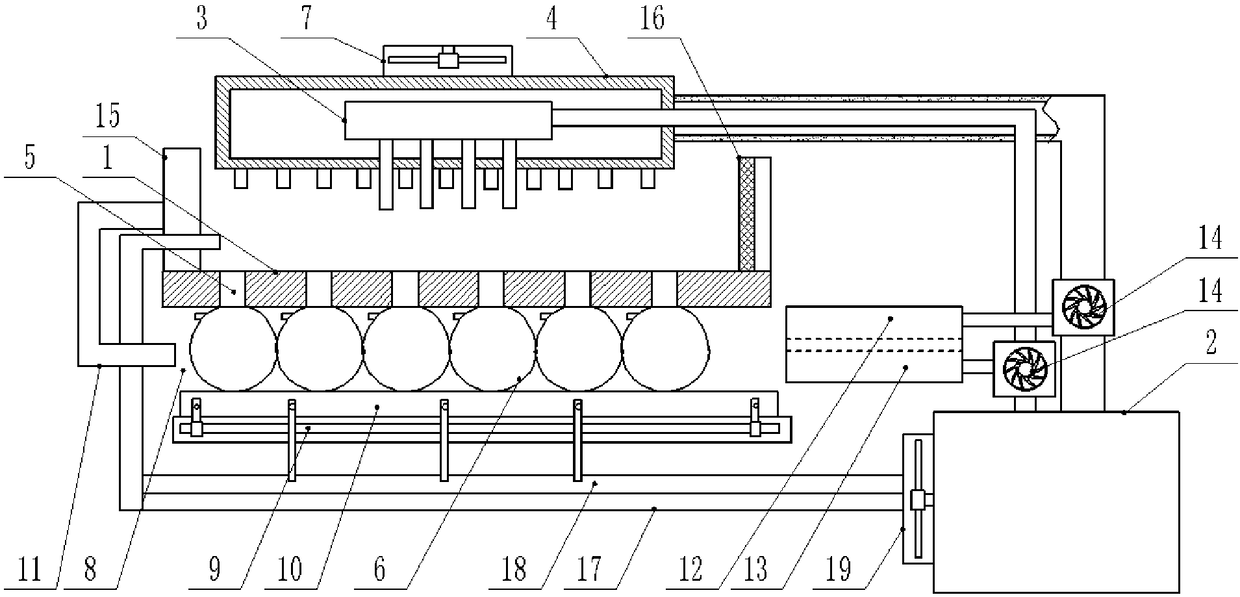

Integrated high-pressure fine water mist dust removal system

InactiveCN105999930AFine and uniform particle sizeHigh densityUsing liquid separation agentSeparation devicesWater storageWater source

The invention discloses an integrated high-pressure fine water mist dust removal system, which comprises a case, a water supplementing filtering device, a water storage device, a supercharging device, a control device and a spraying device, wherein the case is of a detachable structure; the water supplementing filtering device, the water storage device, the supercharging device and the control device are all integrated in the case; the spraying device is arranged on one side of the case; a water inlet of the water supplementing filtering device is connected with an external water source; the water storage device is used for storing filtered water; a water inlet of the supercharging device is connected with a water outlet of a water tank, and a high-pressure water outlet is connected to the spraying device; the supercharging device is used for pumping the water from the water storage device, and supercharging the water into a high-pressure spraying pipeline, and the water is sprayed and atomized into uniformly distributed micron-sized mist particles through a high-pressure centrifugal nozzle to implement dust settling and removal with high-pressure fine water mist. The system is compact in structure, small in occupied area and high in automation degree, and has good dust removal effects.

Owner:湖北嘉泓环保科技有限公司 +1

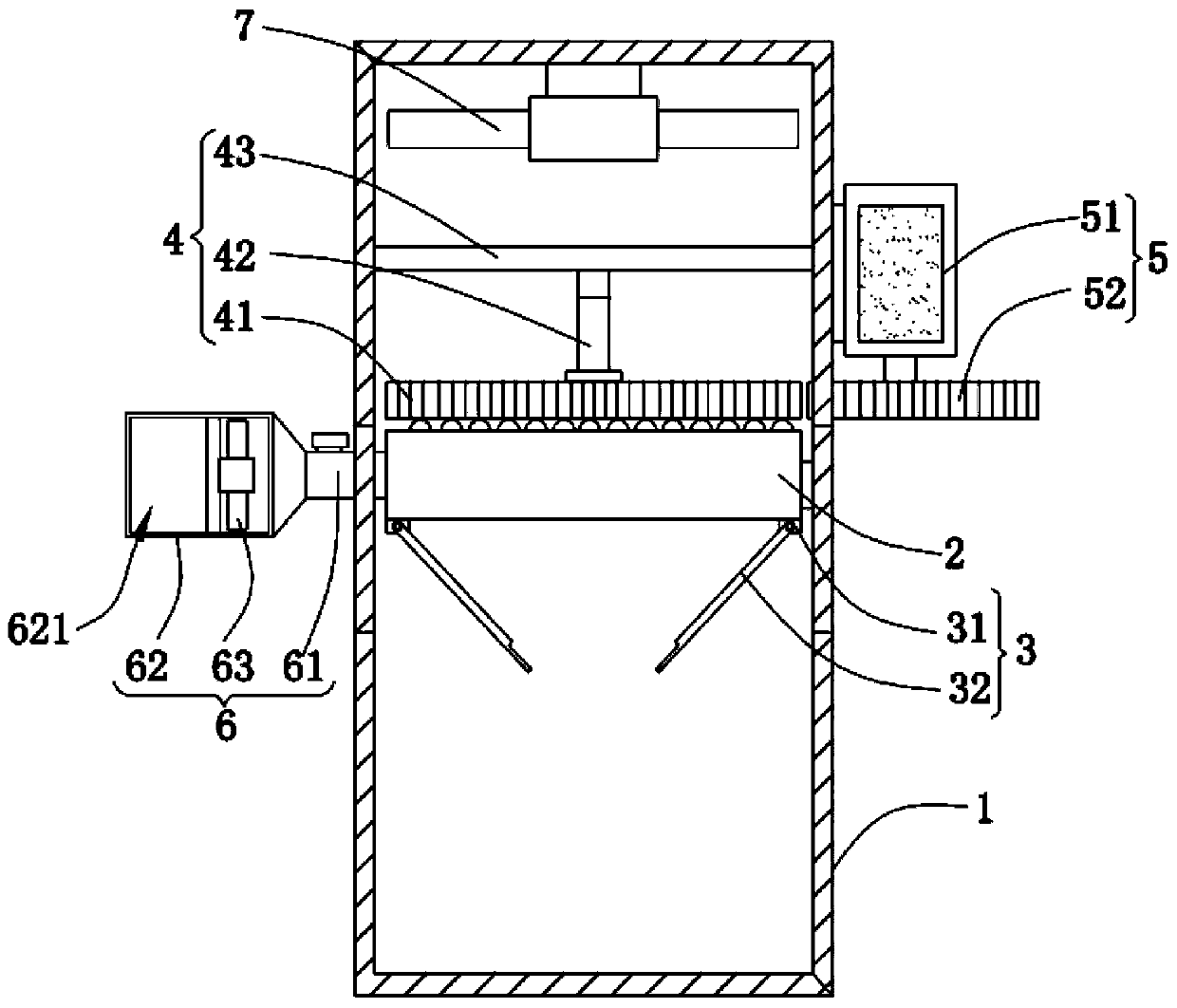

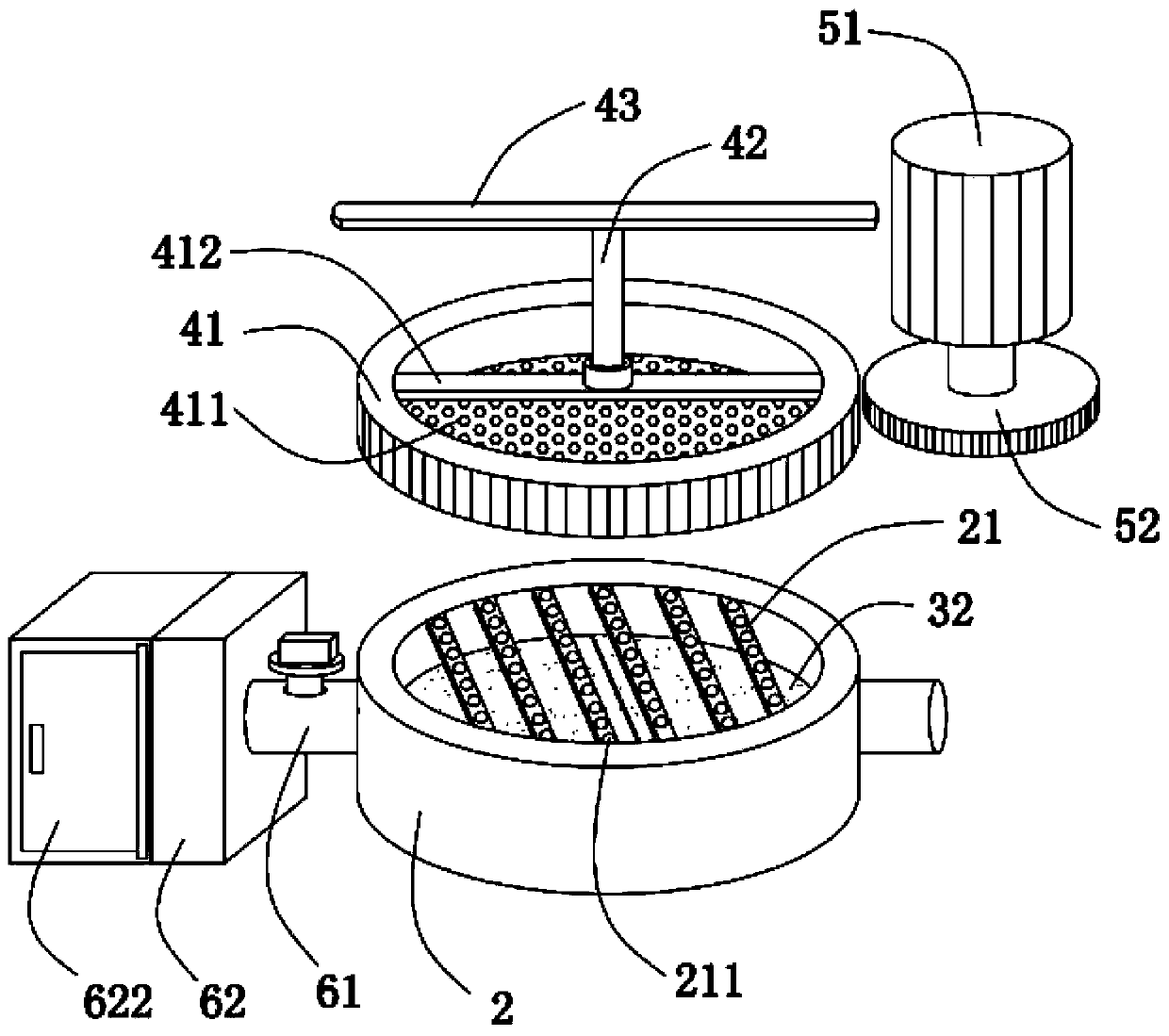

Electric automatic dust removal device capable of working continuously

InactiveCN111974107AEasy to cleanEasy to useDispersed particle filtrationTransportation and packagingElectric machineDust control

The invention discloses an electric automatic dust removal device capable of working continuously. The electric automatic dust removal device comprises a box body, a dust removing mechanism is arranged inside the box body, and the dust removing mechanism extends outside the box body; the dust removing mechanism includes a motor, the motor is fixedly arranged on the top of the box body, the motor is fixedly connected with a rotating rod through an output shaft, and the rotating rod is arranged at the top of the box body and extends into the box body; and a fixed box is fixedly arranged at the top of the inner cavity of the box body, and the rotating rod is arranged inside the fixed box. Through the design of the dust removing mechanism, dust can be absorbed to the bottom of a filter screen,and through the design of structures such as a reciprocating screw rod, a moving frame can move back and forth, then the dust at the bottom of the filter screen can be pushed toward one side of a wind cover, the normal use of the filter screen is ensured, so that the electric automatic dust removal device can work continuously, then the dust removal effect of the electric automatic dust removal device is ensured, and users can use conveniently.

Owner:安小钗

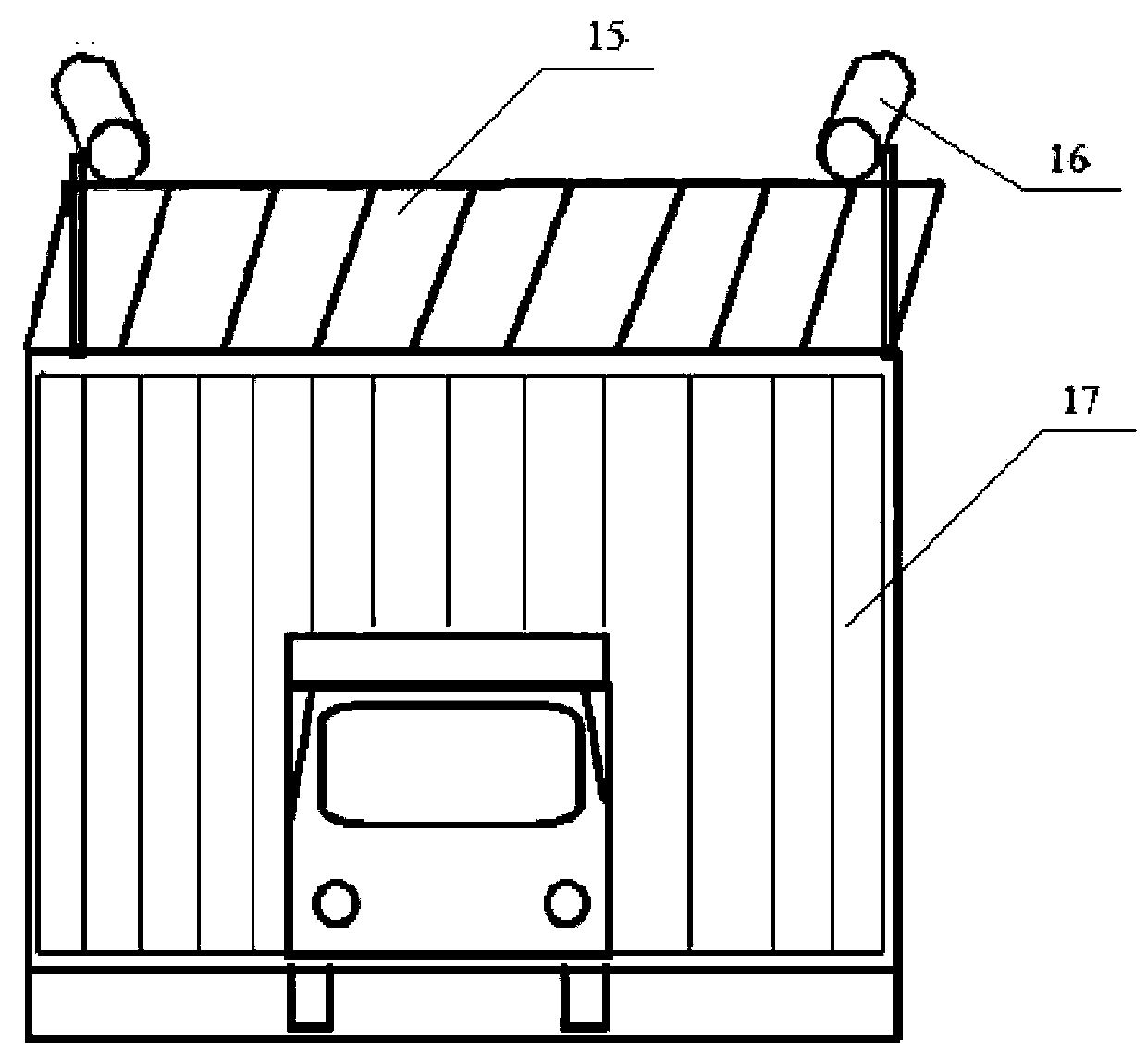

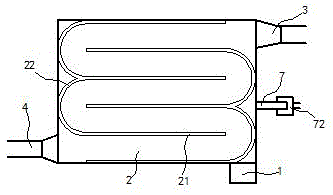

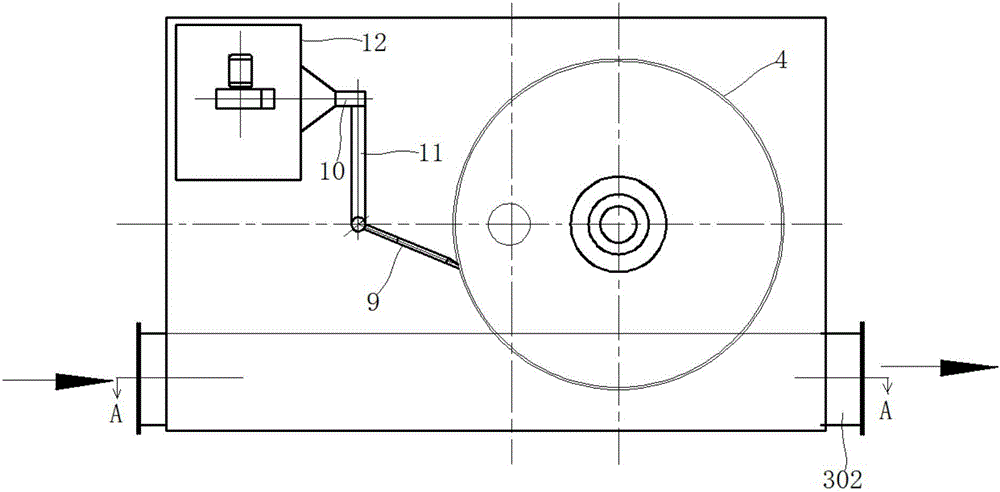

Simultaneous online zinc spraying and dust removal device for multiple microchannel aluminium flat pipes

ActiveCN103938146ADoes not affect setpointImprove anti-interference abilityCombination devicesMolten spray coatingPower flowEngineering

The invention discloses a simultaneous online zinc spraying and dust removal device for multiple microchannel aluminium flat pipes. The simultaneous online zinc spraying and dust removal device comprises spraying equipment, a spraying cabinet and a dust removal device, wherein the spraying equipment is arranged in the spraying cabinet, and an air outlet of the spraying cabinet is connected to the dust removal device; the multiple microchannel aluminium flat pipes enter into the spraying cabinet from one side of the spraying cabinet in parallel and exit out of the spraying cabinet from the other side of the spraying cabinet; the spraying equipment comprises a spraying main machine and a plurality of melting injection spray guns, the electric current parts of the plurality of melting injection spray guns are connected to the electric current output end of the spraying main machine, each melting injection spray gun is used for carrying out zinc spraying operation on each microchannel aluminium flat pipe, and the spraying main machine is provided with a power source part which comprises an input rectifying circuit, an input filter circuit, a power switch circuit, a voltage conversion and isolation circuit, an output rectifying circuit, an output filter circuit, an electric arc zone temperature detection sensor, a comparison circuit and a control circuit. The simultaneous online zinc spraying and dust removal device has a good spraying effect and low pollution to environments.

Owner:SHANGHAI LIANGSHI BLASTING & COATING EQUIP

Dedusting device for flour processing

InactiveCN108686435AEasy to moveImprove the bactericidal effectDispersed particle filtrationTransportation and packagingEngineeringElectric signal

The invention discloses a dedusting device for flour processing. The dedusting device comprises a device body and a cleaning plate, a dust detector is mounted on the surface of one side of the devicebody, and an air inlet is arranged on the surface, positioned on one side of the device body, below the dust detector. A dust filtering mechanism composed of a first filter net, a second filter net, athird filter net, the dust detector and the air inlet is adopted; when the circumstance that dust concentration is too high is detected by the dust detector, an electric signal is transmitted to an exhaust fan in the air inlet through the dust detector, and the exhaust fan starts to work; a hollow dust adsorption plate and an air suction port are arranged on the surface of the air inlet, so thatoutside dust can be sucked into the dedusting device to greatest extent and then is filtered through the first filter net, the second filter net and the third filter net, then dust-free air is discharged, so that the dust can be purified completely through multilayer filtering; a filter net is arranged in an air outlet, so that outgoing air can be ensured to be dust-free.

Owner:范志杰

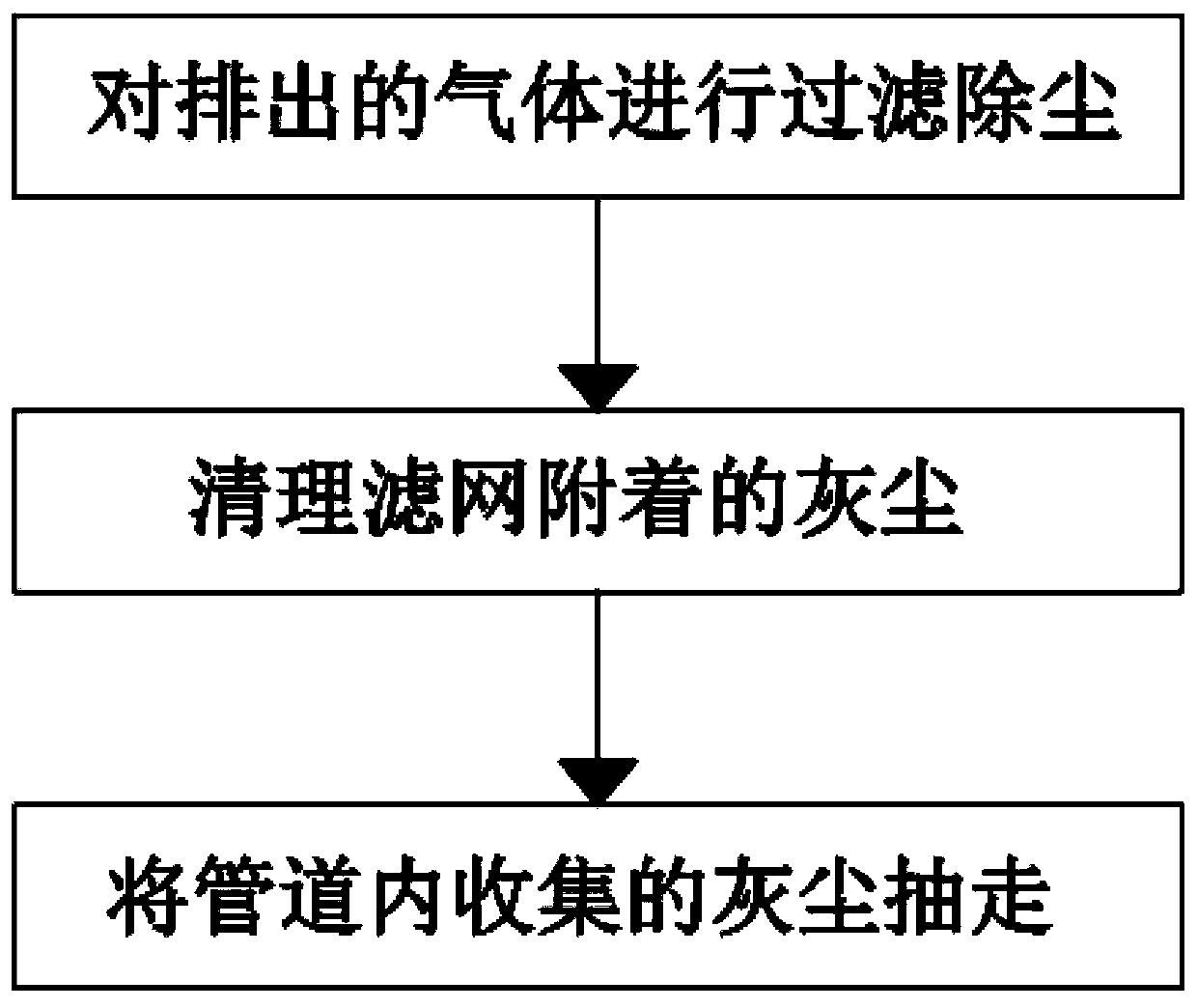

Automatic-cleaning industrial waste gas treatment equipment

InactiveCN107617276AExtended service lifeReduce frictionDispersed particle filtrationEngineeringToxic industrial waste

The invention provides automatic-cleaning industrial waste gas treatment equipment. The automatic-cleaning industrial waste gas treatment equipment comprises an exhausting pipe, a dust removal pipe, asealing mechanism, a dust suction mechanism, a dust removal mechanism, a driving mechanism and a second dust removal fan, wherein the dust removal pipe is fixed on the inner wall of the exhausting pipe, and scraping rods are arranged on the top surface of the dust removal pipe; convex heads are distributed on the surfaces of the scraping rods; the sealing mechanism comprises a rotating motor anda sealing baffle; the dust suction mechanism comprises a dust suction pipe and a dust collection tank; the dust removal mechanism comprises a ring gear, a transmission rod and a fixing rod, and the ring gear is arranged at the top of the dust removal pipe; a filter screen is arranged on the bottom surface of the ring gear, and a support rod is arranged on the top surface of the gear ring; and thedriving mechanism comprises a turning motor and a driving gear. The automatic-cleaning industrial waste gas treatment equipment has the beneficial effects that dust on the filter screen can be thoroughly discharged, the residue is avoided, and the service life is long.

Owner:长沙翼希网络科技有限公司

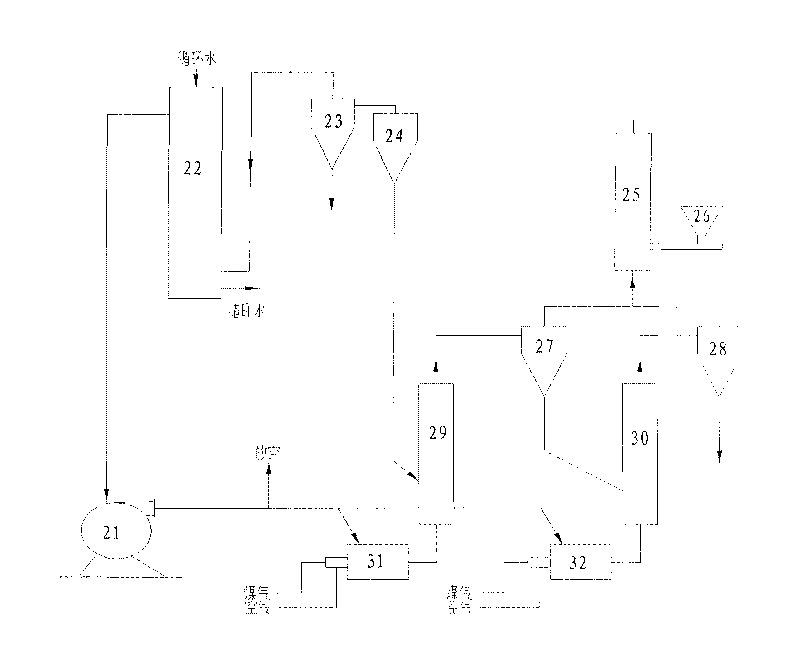

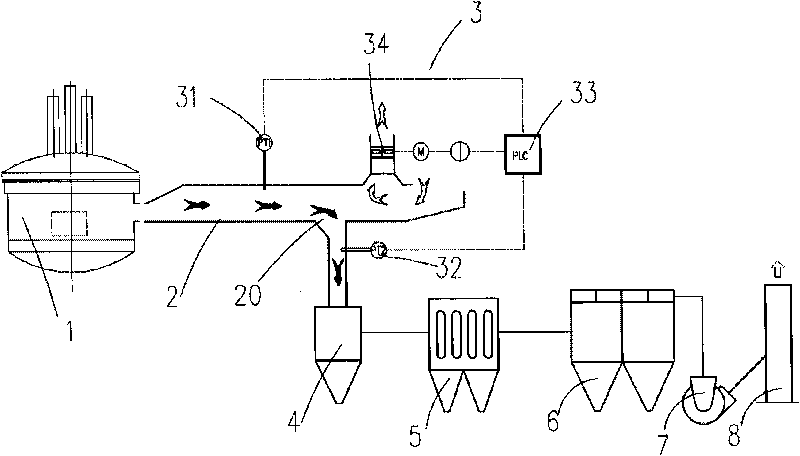

Electric furnace flue gas waste heat recovering and temperature regulating device

ActiveCN101718502AImprove operational safetyLess investmentControl devices for furnacesWaste heat treatmentTemperature controlAir volume

The invention relates to an electric furnace flue gas waste heat recovering and temperature regulating device comprising an electric furnace, a scrap steel preheating channel, a settling chamber, waste heat recovering equipment, a dust remover, a dust-removing blower and an exhaust stack. The scrap steel preheating channel is connected with the electric furnace; the settling chamber is connected with the preheating channel; the waste heat recovering equipment, the dust remover, the dust-removing blower and the exhaust stack are sequentially connected with the settling chamber; a temperature control device is arranged on the scrap steel preheating channel and comprises a first temperature sensor, a second temperature sensor, a PLC control system and a variable frequency fan, wherein the first temperature sensor is arranged between the electric furnace and the scrap steel preheating channel; the second temperature sensor is arranged between the preheating channel and the settling chamber; the PLC control system is arranged between the first temperature sensor and the second temperature sensor; and the variable frequency fan is connected with the PLC control system. The PLC control system can regulate the wind-drawing volume of the variable frequency fan according to temperature signals of the first temperature sensor and the second temperature sensor, thereby changing the amount of mixed cold wind entering into the waste heat recovering equipment and the flue gas temperature, achieving the purpose of regulating and controlling the flue temperature of an inlet of the waste heat recovering equipment and ensuring the operation stability and the safety of the waste heat recovering equipment.

Owner:南京东方源环境科技有限公司 +1

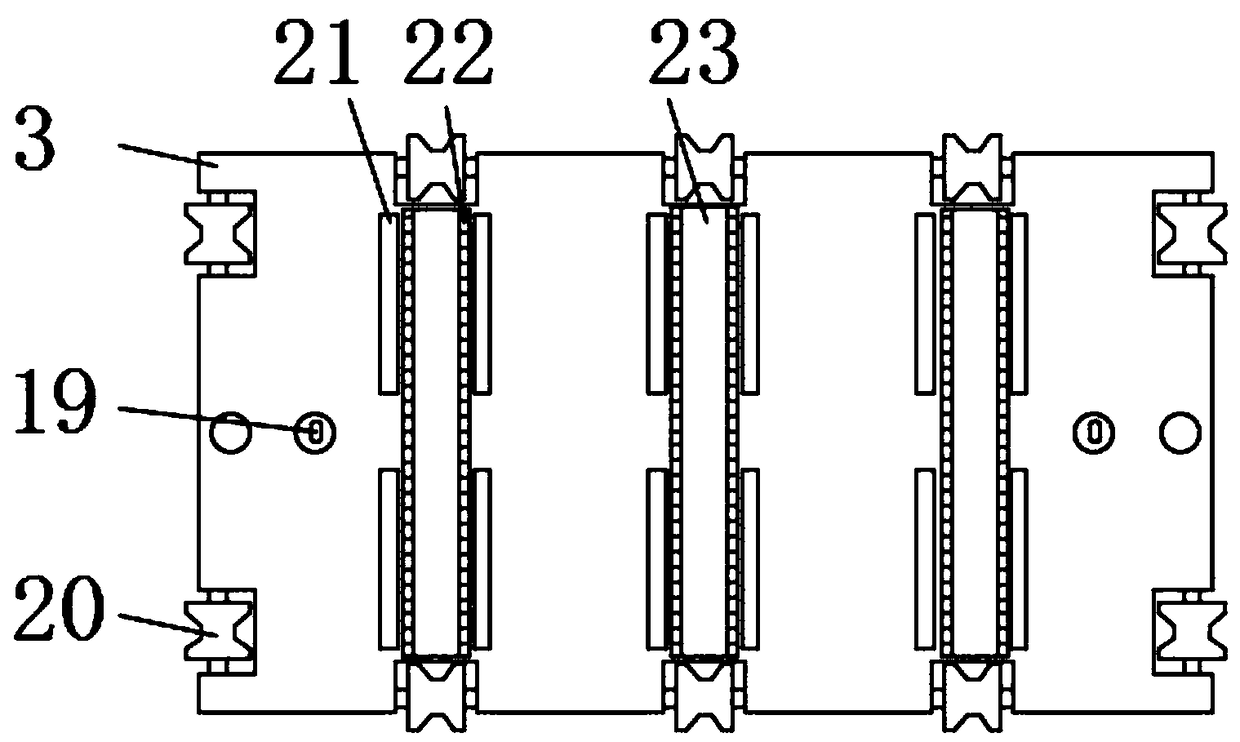

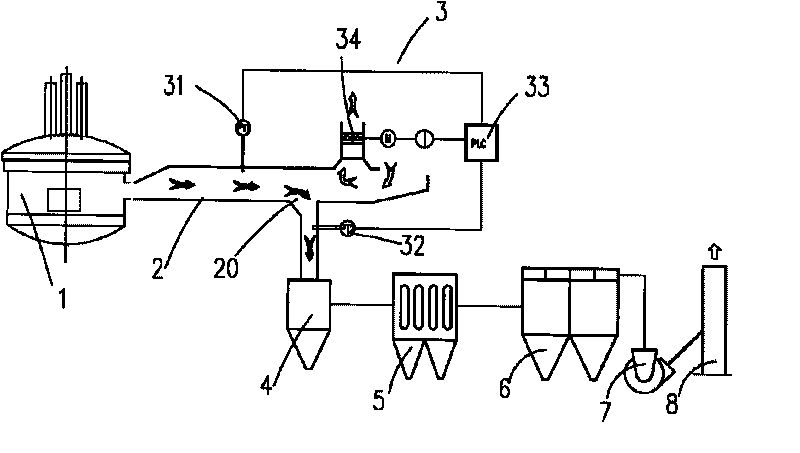

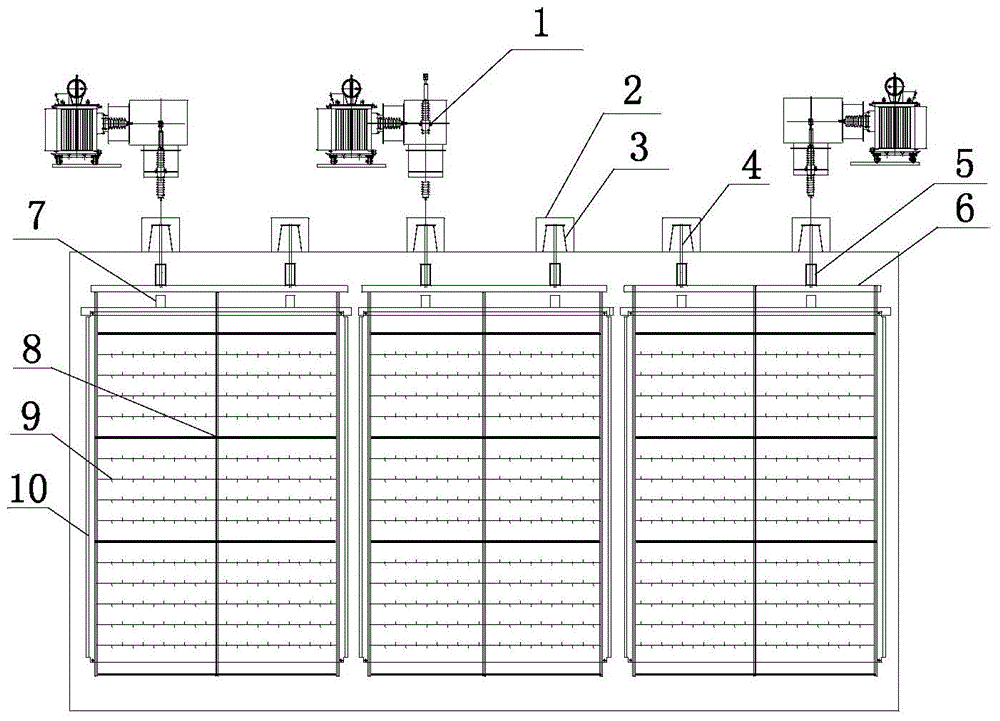

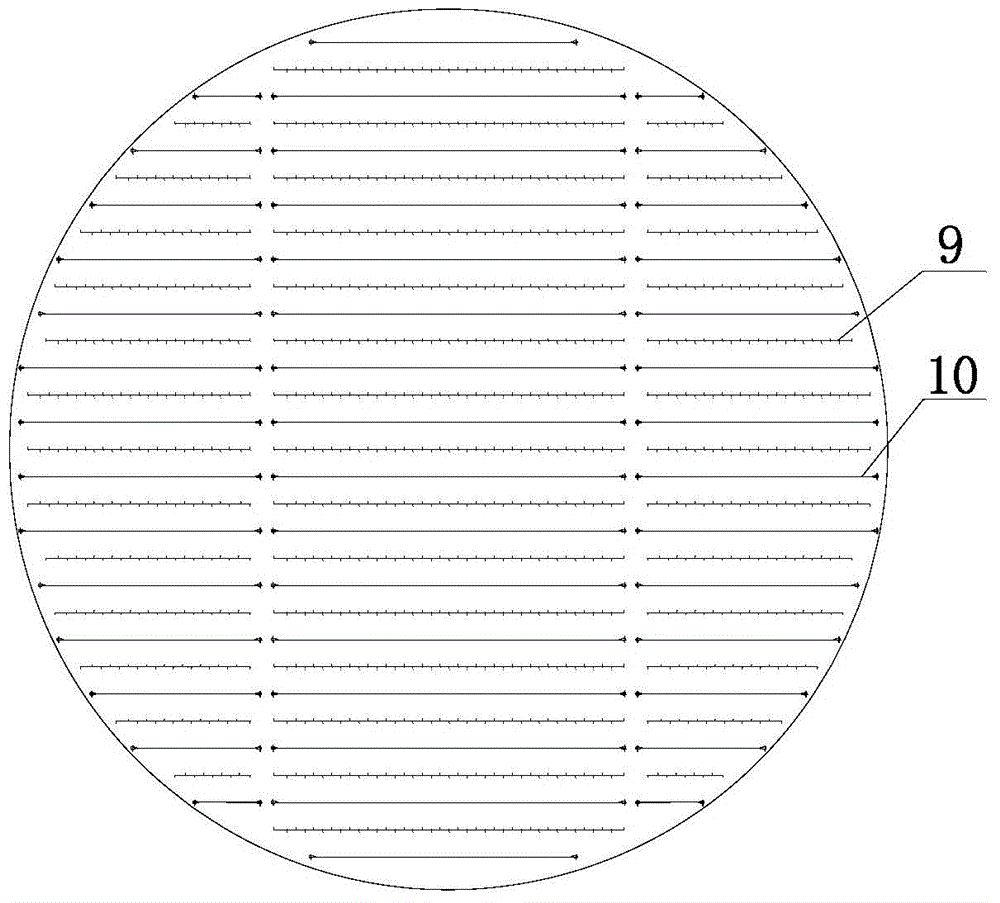

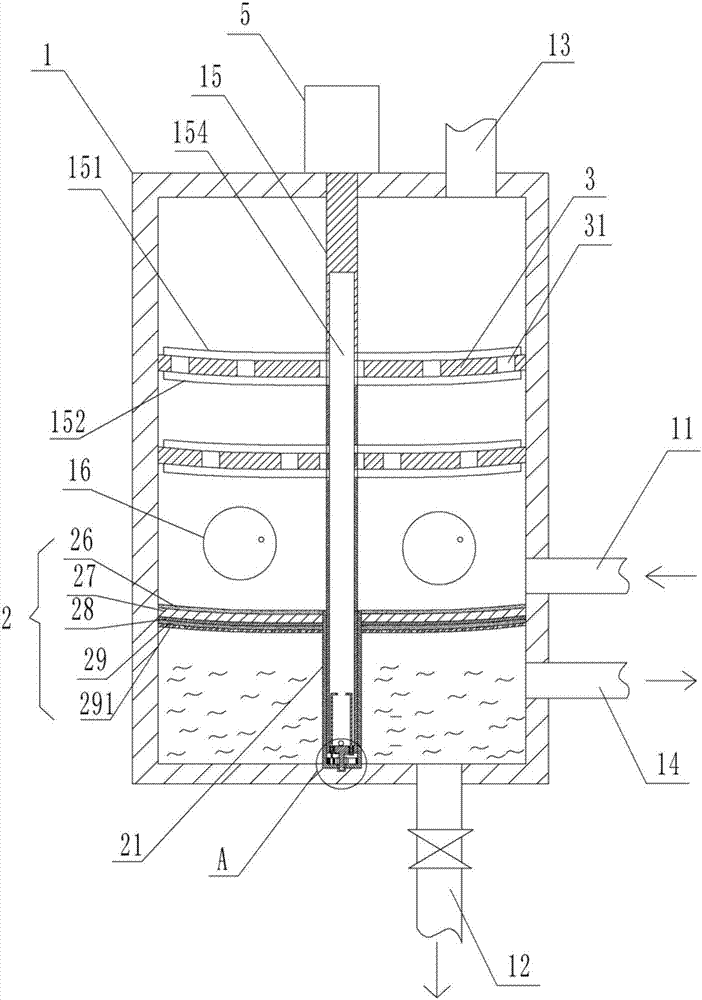

Subarea power supply system and subarea power supply method for wet electric precipitator

InactiveCN104525376ASafe and stable operationKeep a safe distanceExternal electric electrostatic seperatorElectric supply techniquesLow voltageHigh pressure

The invention provides a subarea power supply system and a subarea power supply method for a wet electric precipitator. The subarea power supply system for the wet electric precipitator comprises a plurality of electric field subareas, wherein each electric field subarea comprises a cathode hanger, a cathode frame, a cathode line, an anode beam and an anode plate. The system also comprises power supply sub-systems with the same number as the electric field subareas, wherein each power supply sub-system comprises a high-voltage power supply device, a low-voltage power supply device and an insulator box. Cathode structures between the electric field subareas are mutually separated from each other, and each electric field subarea is independently supplied by power. The subarea power supply method comprises the steps that: each electric field subarea is respectively and independently equipped with the high-voltage power supply device and the insulator box; the cathodes structures between different electric field subareas are mutually disconnected, and the safe distance is ensured, so that each subarea is independently discharged; the drying and insulation of high-voltage incoming lines is ensured by a continuous hot wind blowing mode. The subarea power supply system and the subarea power supply method provided by the invention have the advantages of effectively ensuring the safe and stable operation of the wet electric precipitator, effectively improving the dedusting efficiency, reducing the risk and reducing the high-voltage power supply load.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

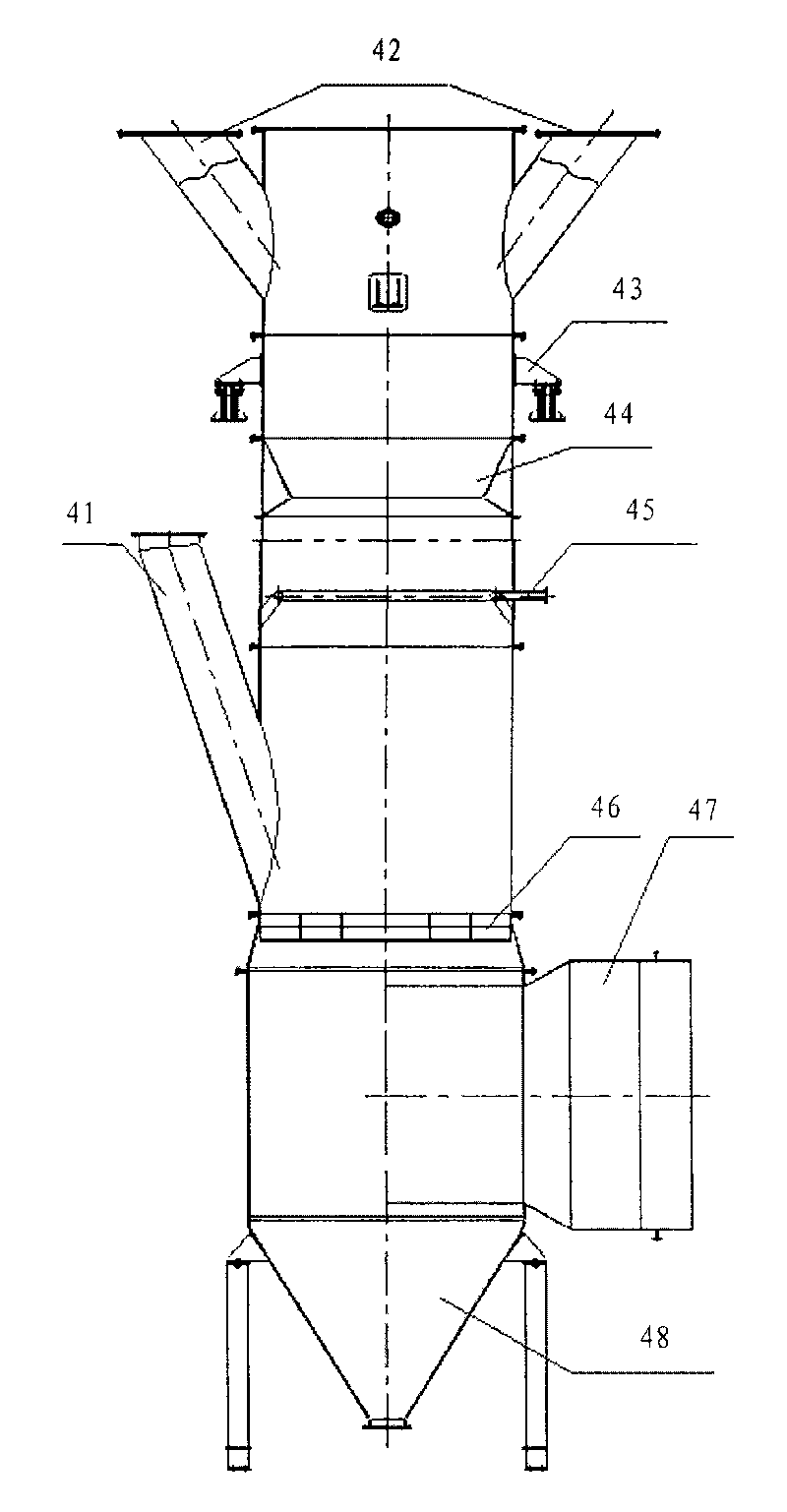

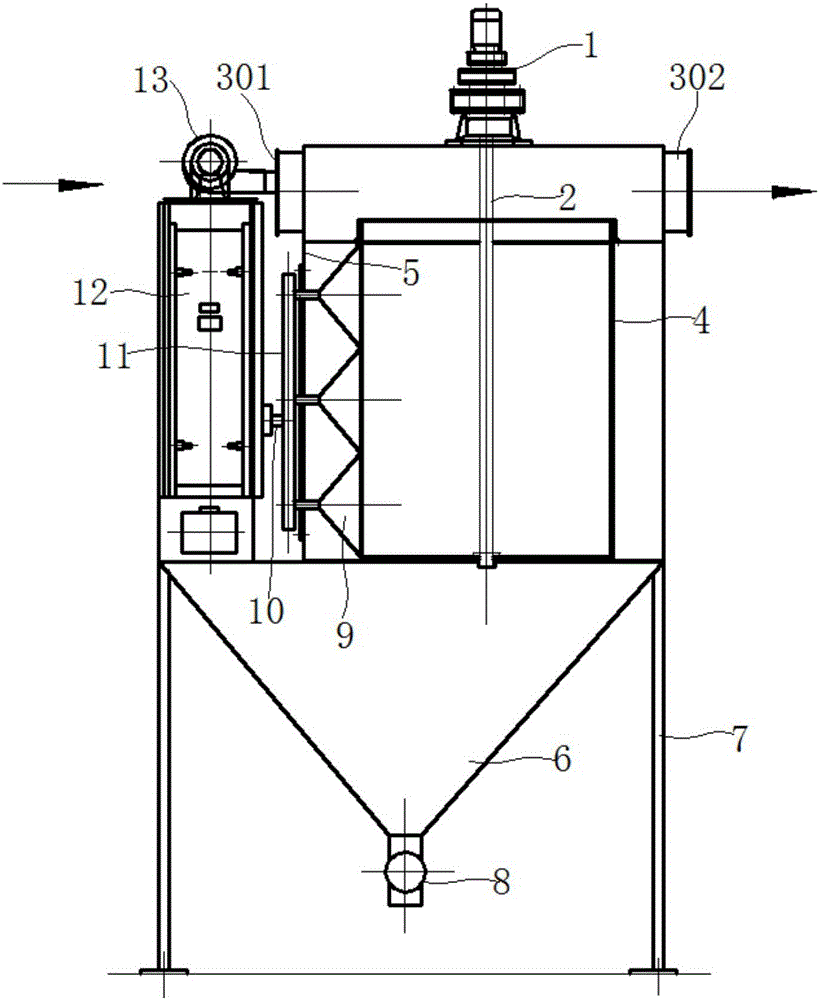

Vertical type electric dust collector integrated with gravity and cyclone dust collection

InactiveCN103252146AEMPGuaranteed dust removal performanceCombination devicesCyclonic separationSmall footprint

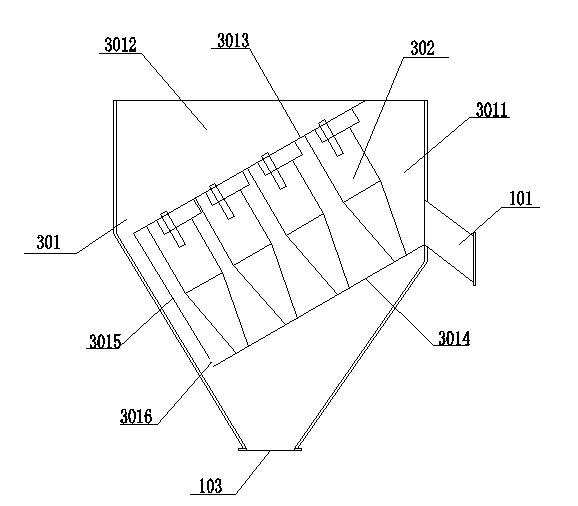

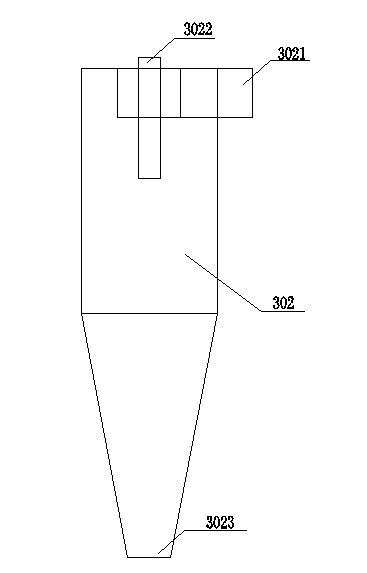

The invention relates to a vertical type electric dust collector integrated with gravity and cyclone dust collection. The vertical type electric dust collector comprises a shell, wherein an electric dust removal part is arranged in a cavity at the upper part of the shell, and a gravity and cyclone dust removal part is arranged in a cavity at the lower part of the shell and comprises a gravity settling chamber and cyclone separators arranged in the gravity settling chamber. According to the vertical type electric dust collector, the gravity and cyclone dust removal part in the cavity at the lower part of the shell is improved, and an internal space is reasonably partitioned into the gravity settling chamber and a cyclone separation chamber, so that the dusty gas can be effectively subjected to multistage processing, and the dust removal effect is guaranteed; and the gas processed by the gravity and cyclone dust removal part enters the electric dust removal part through a wind outlet of the gravity and cyclone dust removal part, is subjected to the dust removal again and is discharged after being subjected to electrostatic dust collection; and the whole electric dust collector has the advantages of high dust collection efficiency, low operation cost and small occupied area.

Owner:LUOYANG INST OF SCI & TECH

Dust removal device with air purification function and using method thereof

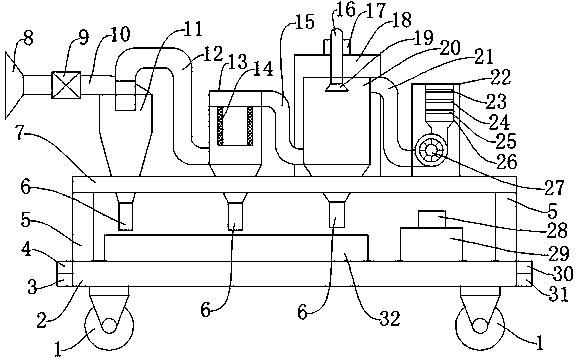

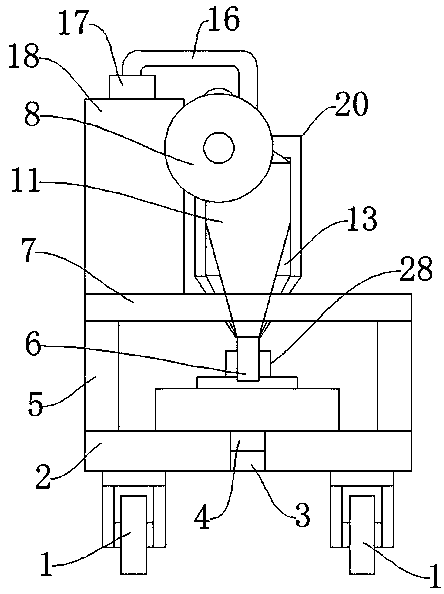

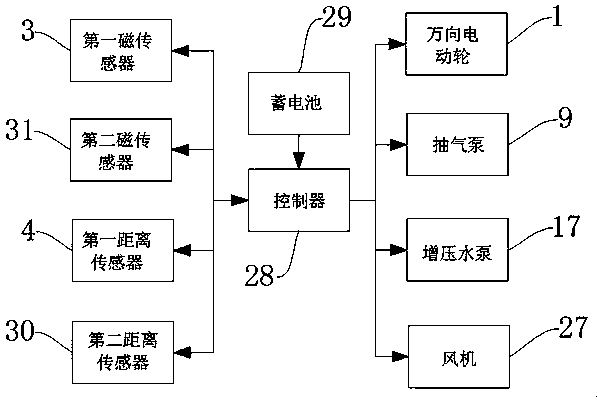

InactiveCN108479277AEfficient removalGuaranteed dust removal performanceCombination devicesDispersed particle filtrationHEPAParticulates

The invention discloses a dust removal device with an air purification function and a using method thereof. The dust removal device comprises universal electric wheels, a bottom plate and an air purification box, wherein the universal electric wheels are arranged at four corners of the bottom of the bottom plate; a first magnetic sensor is arranged on one side of the bottom plate; a first range sensor is arranged above the first magnetic sensor; a second magnetic sensor is arranged on one side, which is far away from the first magnetic sensor, of the bottom plate; a second range sensor is arranged above the second magnetic sensor. The dust removal device has the beneficial effects that 1, due to the arrangement of the universal electric wheels, the magnetic sensors and the range sensors, the dust removal device can be freely moved, and air in the range can be totally subjected to dust removal; 2, due to the arrangement of a cyclone dust collector, a bag type dust collector, a spray boxand the air purification box, multiple dust removal manners are adopted, and the dust removal effect is ensured; 3, due to the arrangement of an HEPA (High Efficiency Particulate Air) high-efficiencyfiltering net, a cold catalyst filtering net and an activated carbon filtering net, small solid particles, dust, odor, bacteria and the like in air can be effectively cleared.

Owner:张志锋

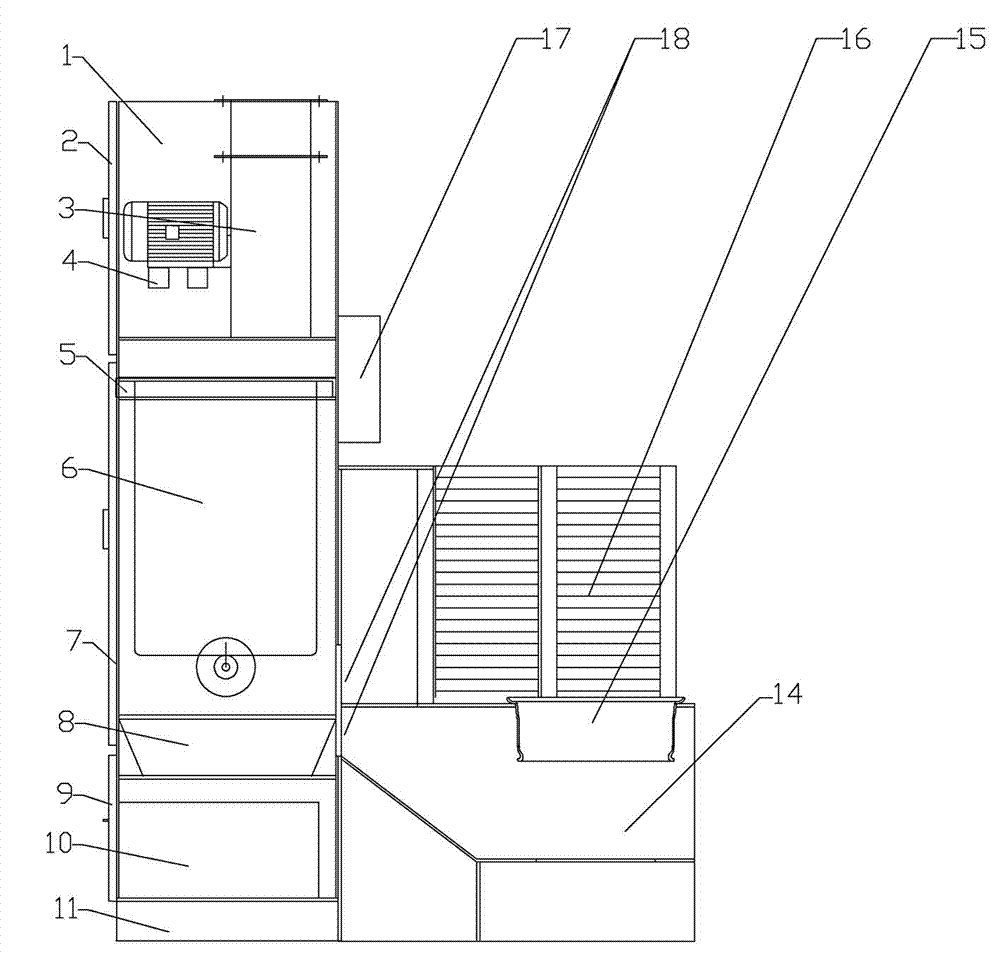

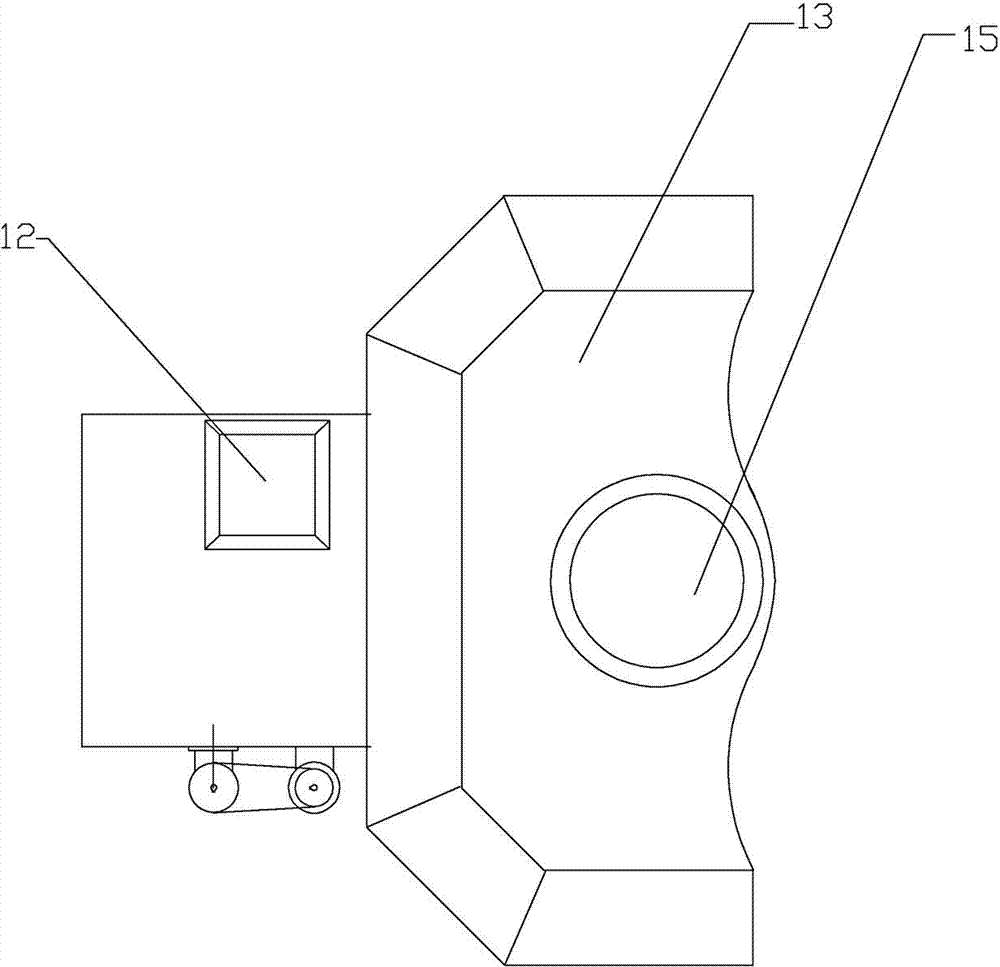

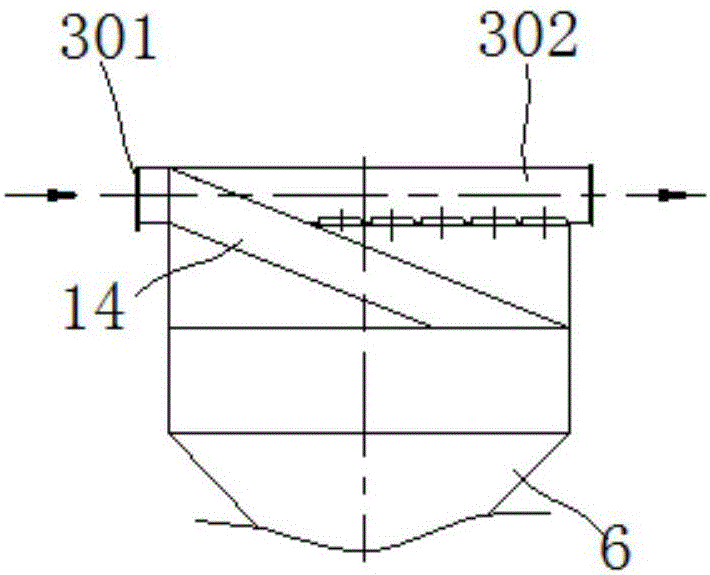

Collecting and dedusting device

InactiveCN104208954AControllable spillageReduce spillageDispersed particle filtrationDust controlEngineering

The invention discloses a collecting and dedusting device. The collecting and dedusting device comprises an unloading chamber (14) and is characterized in that the inside of the unloading chamber (14) is provided with a dedusting device for dedusting, the side portion of the unloading chamber (14) is provided with an air sucking dedusting device, which is connected with the dedusting device; the unloading chamber (14) also comprises a feeding port (13) at the side portion and a collecting hopper (7) at the bottom for collecting materials and dust. By means of a semi-tight structure, the collecting and dedusting device can achieve rapidity during unloading of a machine tool body and obtain dedusting effects. Meanwhile, the collecting and dedusting device is simple in structure, convenient to operate and good in dedusting effects.

Owner:GUANGXI DADU CONCRETE GROUP

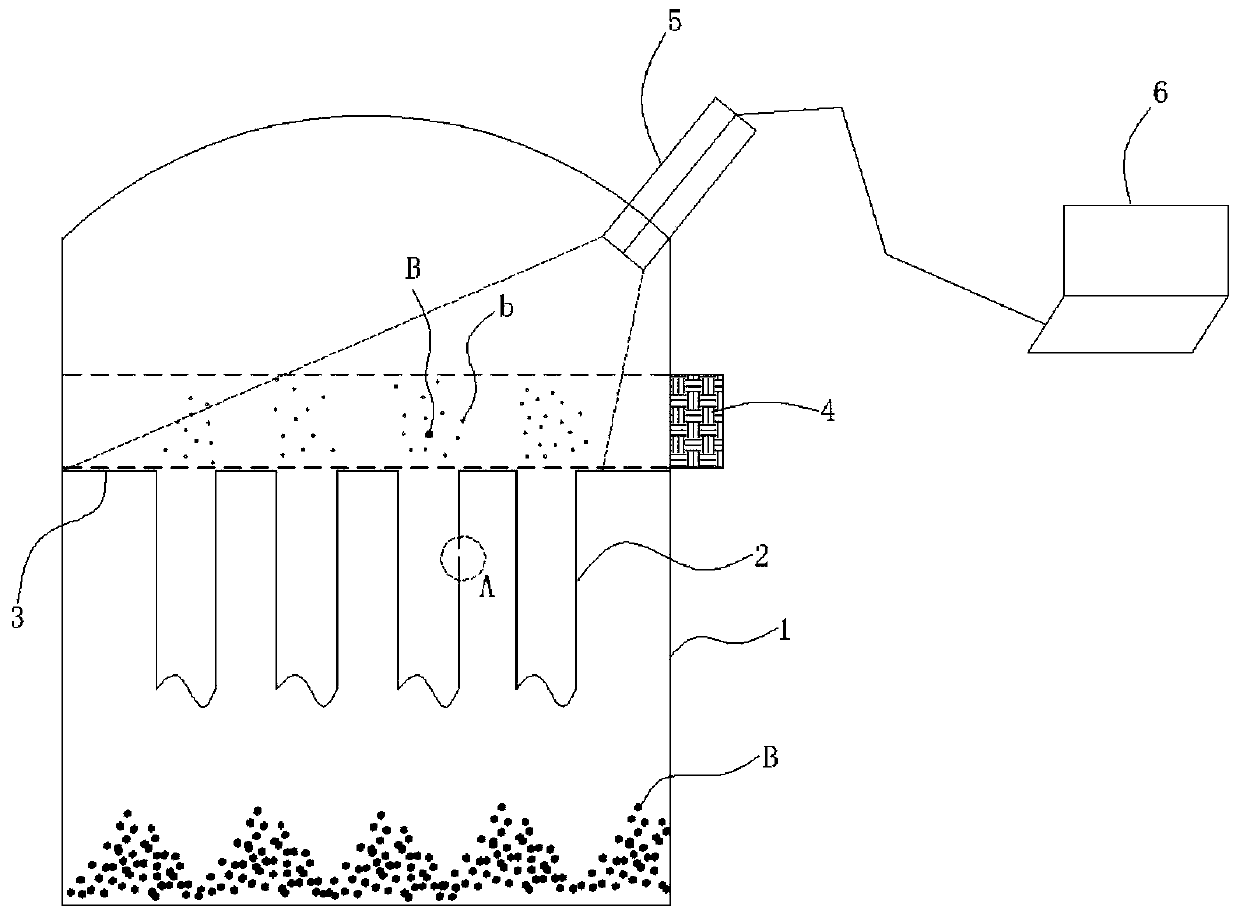

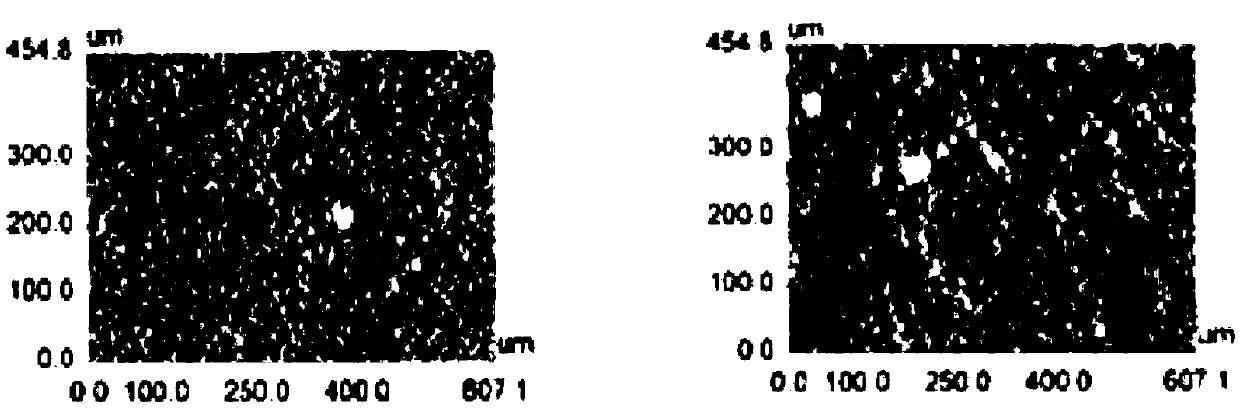

Online leak finding method for bag filter

PendingCN110404346AImprove work efficiencyImprove efficiencyDispersed particle filtrationBaghouseComputational physics

The invention discloses an online leak finding method for a bag filter. The method comprises the following steps: a light source, a camera and an image processor are arranged; the light source is fixedly mounted in the bag filter, and is located above a plurality of bag filter bags of the bag filter, lights emitted by the light source irradiate particle dusts filtered out by the bag filter bags, and the lights do not contact the flower plate of the bag filter; the camera is mounted above the light source, and shoots the particle dusts irradiated by the lights to obtain the images of the particle dusts above the bag filter bags; and the image processor analyzes the continuously obtained images, and if analysis shows the change abnormity of the density and the spot size of the particle dustsper unit area, the bag filter bag just below the particle dusts having the abnormal change is determined to be broken. The method has the advantages of high efficiency, accuracy, low cost and the like.

Owner:KUNSHAN YUSHUN ENVIRONMENTAL PROTECTION TECH CO LTD

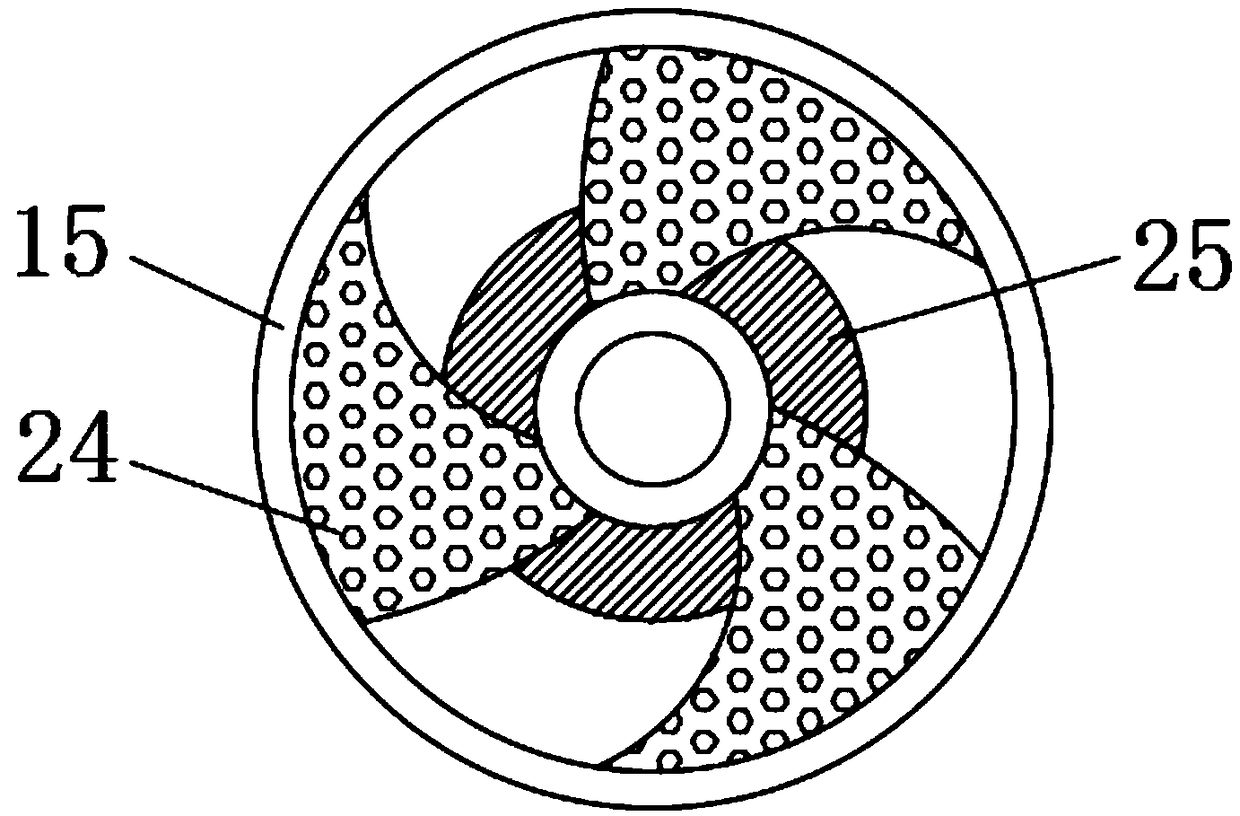

Dust removal sedimentation device

ActiveCN107875769AAvoid wastingFully contactedUsing liquid separation agentFiltration circuitsSolid componentWastewater

The invention relates to the technical field of apparatuses for discharging solid components in exhaust gas, and especially provides a dust removal sedimentation device. The device includes a dust removal barrel on which an air pipe, a sewage draining pipe, an exhaust pipe and a clear liquid discharge pipe are disposed. A rotary shaft, which is driven by a power device, is arranged in the dust removal barrel. A filter plate and a dust removal plate are arranged in the dust removal barrel. A support column is fixedly connected to the bottom surface of the filter plate. A rotary chamber is formed in the support column. The rotary shaft is rotationally connected to the chamber wall of the rotary chamber. Bar-shaped grooves, in which water absorption layers are disposed, are arranged in both the upper and the lower surfaces of the dust removal plate. An annular water pipe is arranged in the dust removal plate. An upper scraping bar and a lower scraping bar are fixedly connected to the rotary shaft, wherein scraping grooves are arranged in the side walls of the upper scraping bar and the lower scraping bar. A sewage draining chamber is located inside the rotary shaft, wherein a discharge outlet is formed in the chamber wall of the sewage draining chamber. A stirring structure is arranged in the sewage draining chamber. A stirring hole is formed in the bottom surface of the rotary shaft. An elastic structure is arranged inside the stirring hole. The dust removal sedimentation device can avoid residual dirt on a water baffle, and also can precipitate wastewater.

Owner:遵义双河生物燃料科技有限公司

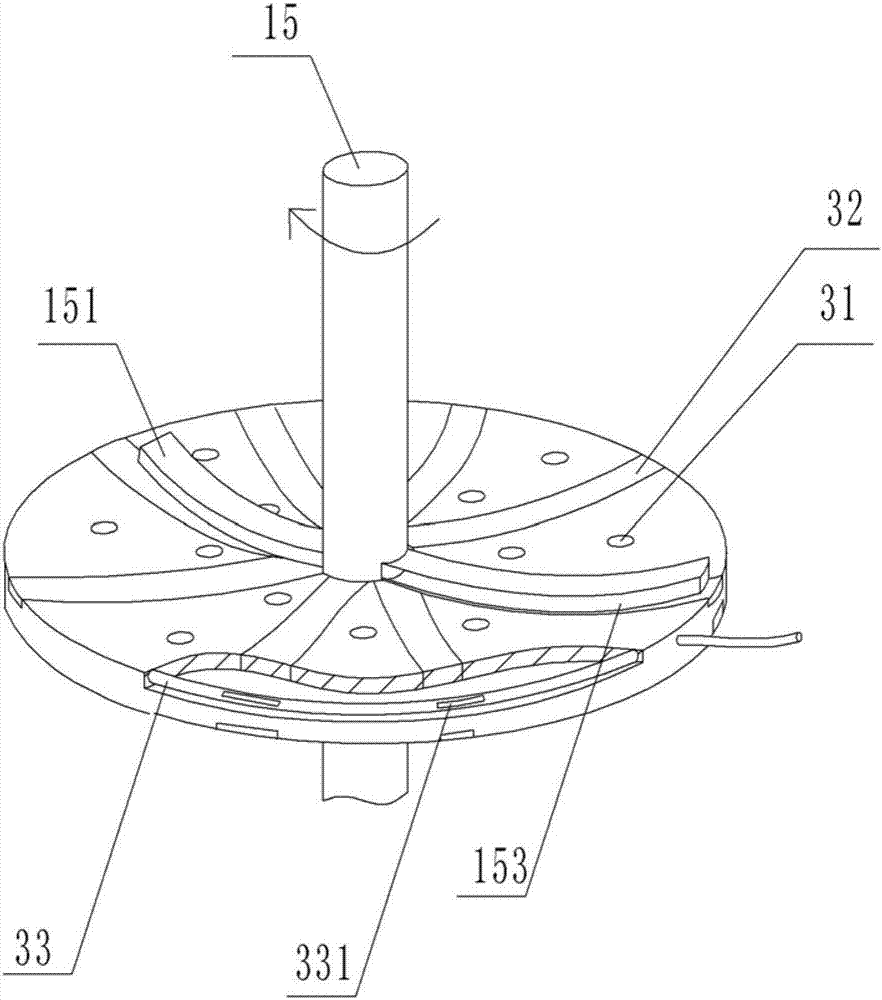

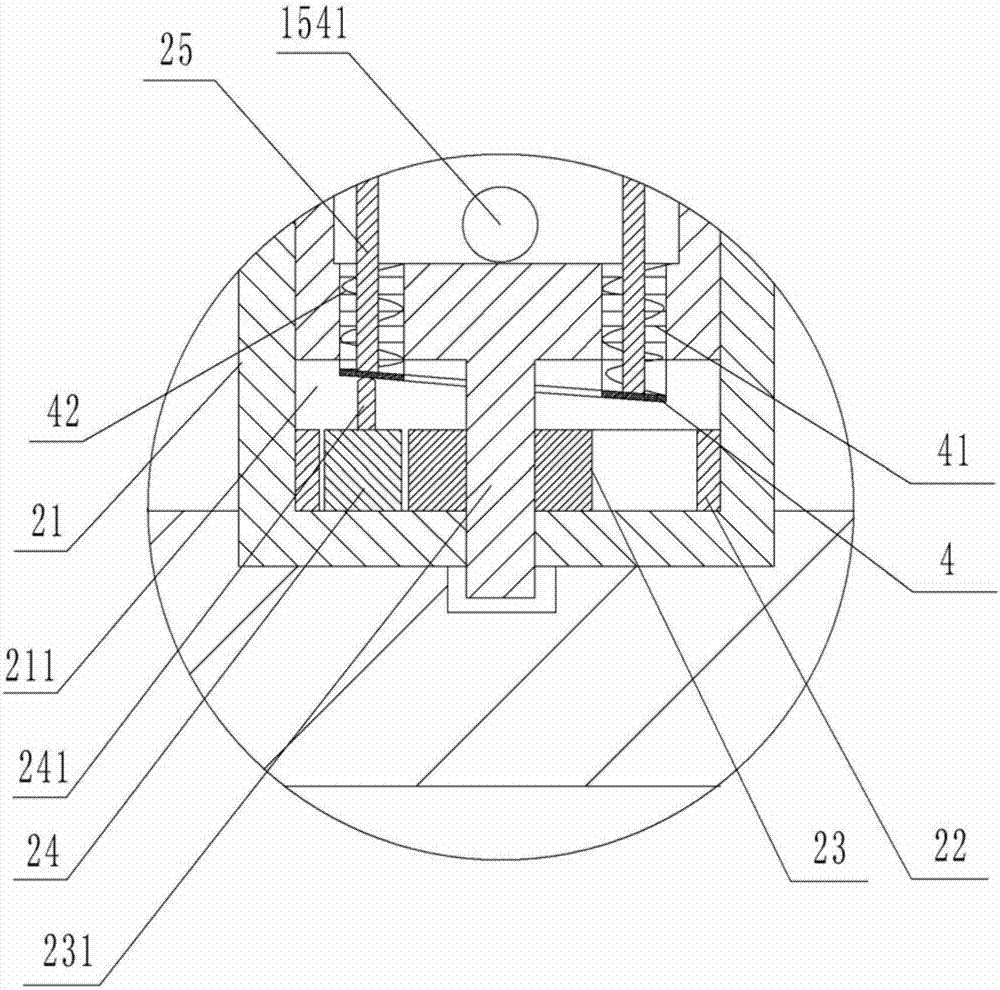

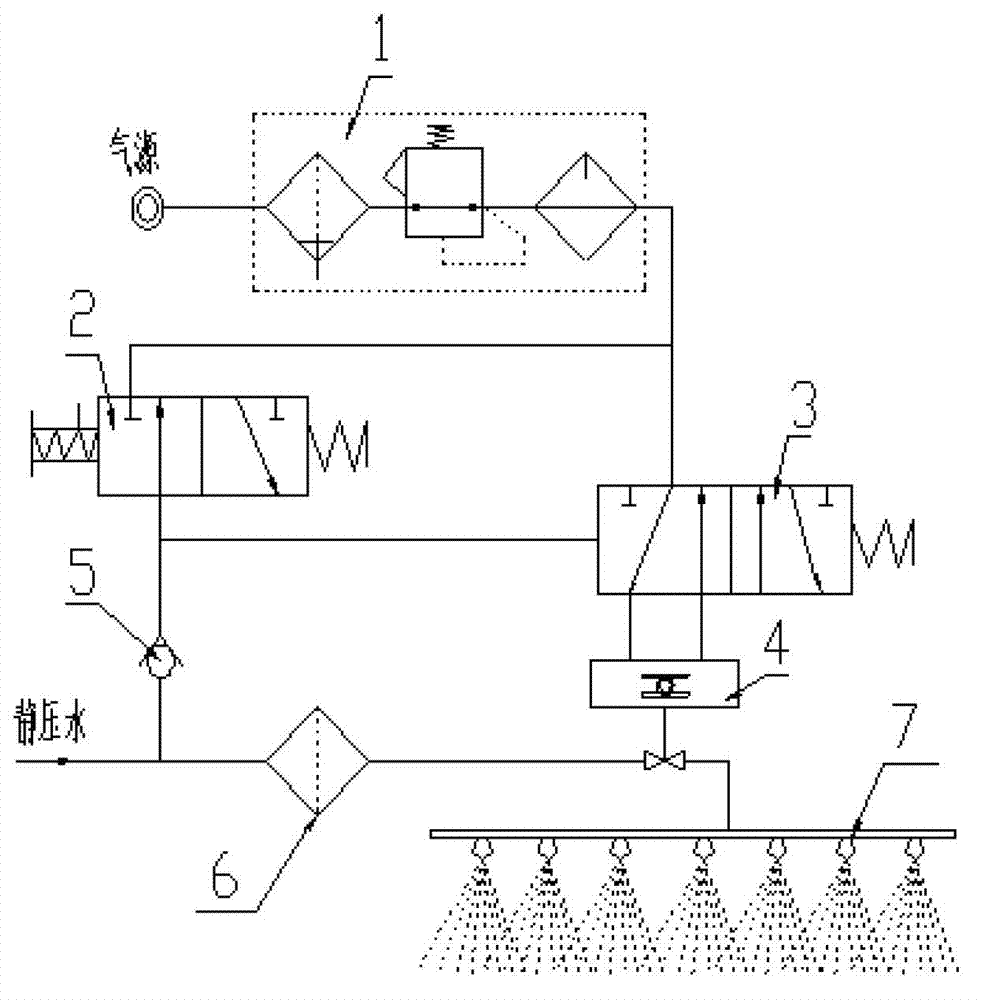

Wind/water linkage spraying and dust falling device

InactiveCN103046945AReduce labor intensityFully combinedDust removalFire preventionWater channelEngineering

The invention discloses a wind / water linkage spraying and dust falling device. The device consists of a pneumatic triple piece, a self-locking button, a two-position five-way reversing valve, a pneumatic ball valve, a check valve, a filter and a nozzle, wherein the compressed air is fed into the self-locking button and the reversing valve through the pneumatic triple piece. When the spraying is required, the self-locking button is pressed, one channel of the compressed air enters a static pressure water pipeline through the check valve, the reversing valve is reversed through the other channel, the pneumatic ball valve is opened, and the compressed air and the static pressure water enter the nozzle through the filter and the pneumatic ball valve and form the mist to be spayed out. When the spraying is not required, the self-locking button is unlocked, the compressed air is cut off, the reversing valve is reset, the pneumatic ball valve is closed, the water channel is cut off and the spraying stops. By the aid of the device, the liquid sprayed by the nozzle forms the mist effect, the liquid is combined with the dust completely, the dust falling effect is good, the compressed air serves as the switching power, and the labor intensity is reduced.

Owner:SHANXI LUAN HUAXIN TECH DEV

Processing device for plank

PendingCN108499772AImprove practicalityQuick adjustment to useSpraying apparatusElectrostatic cleaningEngineeringWood plank

The invention relates to the field of plank painting processing equipment and discloses a processing device for a plank. The processing device for the plank comprises a conveying platform and an oil paint box. The oil paint box is connected with a main spray head and an auxiliary spray head. The main spray head is located in the auxiliary spray head, the width of the main spray head is smaller than that of the auxiliary spray head, and a blower is arranged above the conveying platform. The conveying platform is provided with a plurality of through holes, and the through holes are connected with an air bag. An air flow channel for air flow to pass through is arranged below the conveying platform, the bottom of the air flow channel is provided with a sliding groove, the air flow channel is internally provided with an arc-shaped elastic piece, and the two ends of the elastic piece are both connected into the sliding groove in a sliding manner. The two ends of the air flow channel are connected with an air inlet pipe and an air outlet pipe correspondingly. The air outlet pipe is internally provided with an upper air outlet pipe and a lower air outlet pipe, the upper air outlet pipe isinternally provided with a pressure valve, an air flow drive painting mechanism is connected between the lower air outlet pipe and the main spray head, and an air flow drive painting mechanism is connected between the upper air outlet pipe and the auxiliary spray head. By means of the processing device for the plank, the problem that the painting range of a painting head cannot be adjusted can besolved, painting processing for planks with different specific specifications is achieved, and the practical effect of the device is enhanced.

Owner:重庆木头木脑文化创意有限公司

Workpiece grinding dust remover

InactiveCN102895824AClean up in timeReduce labor intensityDispersed particle filtrationReciprocating motionGrinding wheel

The invention discloses a workpiece grinding dust remover, comprising a grinding platform and a dust removal unit that are connected as a whole, wherein the grille interior of the grinding platform is provided with a run-through dust-loaded air cavity, grating blades of the grille is arranged horizontally, the dust removal unit comprises a case having a dust-loaded air inlet and an air outlet, a fan, a filter bag hanging bracket and a filter bag are arranged in the case, the upper end of the filter bag is arranged on the filter bag hanging bracket, the dust-loaded air cavity is communicated with the dust-loaded air inlet of the dust removal unit, a rapping unit for driving the filter bag to swing is arranged below the filter bag, the rapping unit comprises a power transmission mechanism and a vibrating shaft which is driven by the power transmission mechanism to make straight reciprocating motion, the surface of the vibrating shaft is sleeved with a filter bag vibrating rack which is provided with filter bag cavities that axially arranged at intervals, and the lower end of the filter bag is arranged in the filter bag cavity. According to the invention, the dust on the filter bag can be automatic removed in time, the labor intensity of personnel is reduced, the change of the grille direction can isolate splashed ash and spark reflection, and the safety and health of the personnel can be protected.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Flour processing dust removal equipment and using method thereof

InactiveCN112354312AAvoid cloggingGuaranteed dust removal effectCombination devicesEngineeringStructural engineering

The invention relates to the technical field of flour processing dust removal, and discloses flour processing dust removal equipment and a using method thereof. The flour processing dust removal equipment comprises a box body, a spraying barrel and a filtering net, the bottom of one side of the box body communicates with one end of a dust suction pipe, and the filtering net is fixedly installed inthe box body; the bottom of the spraying cylinder communicates with one end of a water inlet pipe and a plurality of spray heads, one end of a rotating shaft is fixedly mounted on one side of the spraying cylinder, the box body rotationally sleeves the outer side of the rotating shaft, a rotating plate fixedly sleeves the outer side of the rotating shaft, a connecting groove is formed in one sideof the rotating plate, and a fixing plate is fixedly mounted at the top of one side of the box body. The equipment is reasonable in design, sprayed water mist makes full contact with dust through reciprocating rotation of the water mist spraying barrel, the dust removal effect is improved, a knocking plate is driven to intermittently impact a filter screen to drive the filter screen to vibrate, meanwhile, a brush is driven to rotate to clean the filter screen, the filter screen is prevented from being blocked, and the dust removal effect is guaranteed.

Owner:宿州市超王面业有限责任公司

Liquid-level electrostatic precipitator

InactiveCN105583078AImprove adsorption capacityGuaranteed dust removal performanceExternal electric electrostatic seperatorElectrode constructionsEngineeringElectrostatic generator

The invention relates to a liquid-level electrostatic precipitator. The liquid-level electrostatic precipitator comprises an electrostatic generator, an air inlet, a dust removal cavity and an exhaust port, wherein a liquid storage cavity is mounted at the top of the dust removal cavity; a dust collection cavity is mounted at the bottom of the dust removal cavity; dust removal plates are distributed in the dust removal cavity in parallel at the equal interval; all the dust removal plates are connected by the aid of arc-shaped tiles and assembled to form an S-shaped channel; upper ends of the dust removal plates penetrate through the bottom of the liquid storage cavity and extend into a dust removal liquid, and lower ends of the dust removal plates are fixed on a dust collection screen; the dust collection cavity and the liquid storage cavity are connected by the aid of a flow guide pipe; a driver and a dust separator are sequentially connected onto the flow guide pipe in series; a discharge piece is mounted at the air inlet and electrically connected with one electrode of the electrostatic generator, and all the dust removal plates are electrically connected with the other electrode of the electrostatic generator. The precipitator is novel in structure and can work continuously for a long time, and the working efficiency is effectively improved; meanwhile, the dust removal work is simple and efficient.

Owner:马海霞

Road sweeper

InactiveCN105672179AGuaranteed cleaning efficiencyImprove reliabilityRoad cleaningRoad sweeperEngineering

The invention provides a road sweeper which comprises a sweeper body, material suction pipelines, sweeping devices and a draught fan. The sweeper body is provided with a dustbin; the first ends of the material suction pipelines extend to the positions below the sweeper body, and the second ends of the material suction pipelines extend into the dustbin; each sweeping device is provided with a dust suction air pipe, and each dust suction air pipe is connected with the pipe wall of the corresponding material suction pipeline and communicates with the corresponding material suction pipeline; and the draught fan is arranged on the sweeper body, the air inflow side of the draught fan communicates with the dustbin, and a negative pressure region is formed in the dustbin. By the adoption of the road sweeper, the safety accidents caused by road freezing due to the fact that water is sprayed to reduce dust can be effectively avoided; and on the premise that the dust removing effect is guaranteed, the road operation construction reliability is improved. The road sweeper can be used in winter, so that the problem that equipment is idle is effectively solved.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Intelligent transformer overhaul integration device

The invention discloses an intelligent transformer overhaul integration device, which comprises a platform, a rotary mechanism and a walking mechanism, wherein the rotary mechanism is arranged at the upper part of the platform; the walking mechanism is arranged at the bottom of the platform; grooves are formed in the left side and the right side of the platform; a right ascending and descending rod is arranged at the upper part of the rotary mechanism; a right overhaul box body is arranged on the top of the right ascending and descending rod; a half frame-shaped support frame is arranged in a position, near the edge, of the upper part of the rotary mechanism; the end part of the half frame type support frame is provided with a fixed sleeve; a cantilever is glidingly arranged in the fixed sleeve; a left ascending and descending rod is fixedly arranged on the upper surface of the right end of the cantilever; the top of the left ascending and descending rod is provided with a left overhaul box body; a balance mechanism used for regulating the balance is arranged on a rotary gearwheel; and an emergency temperature lowering mechanism is arranged on the outer wall of the left overhaul box body. The intelligent transformer overhaul integration device solves the problem of online monitoring of the oil temperature of cooling oil of a transformer is solved; the transformer can realize online temperature lowering and overhaul, so that the transformer realizes emergency temperature lowering; the temperature of the transformer can be lowered before the overhaul; the overhaul after the dismounting of the transformer is not needed; and the work efficiency is improved.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Continuous dust removal regeneration filtration dust remover

ActiveCN105749649AExtended service lifeClean dust evenly and continuouslyCombination devicesDispersed particle filtrationFiltrationEngineering

The invention discloses a continuous dust removal regeneration filtration dust remover and belongs to the technical field of dust removal devices.The dust remover comprises a dust remover box, a filter barrel, a driving device for driving the filter barrel to rotate, a dust collecting hopper and a dust removal device.The dust collecting hopper is arranged below the dust remover box, and the filter barrel is installed inside the dust remover box.The dust removal device comprises a dust suction nozzle, the dust suction nozzle is attached to the surface of a filter material of the filter barrel in the height direction of the filter barrel, a rapping device is arranged on the dust suction nozzle, and the surface of the filter material of the filter barrel is rapped through the rapping device.The dust remover is excellent in dust removal performance, low in resistance and stable and reliable in operation, is ideal upgrading technical equipment, and can be widely used for purifying dusty air in places of ground surface purification breaking, screening and transferring of a metal mine concentrating plant and also used for downhole working face airflow purification and purification of dusty air in downhole breaking chambers, winzeloading and unloading mines, downhole mine bins and secondary breaking roadways.

Owner:安徽天顺环保过滤材料有限公司

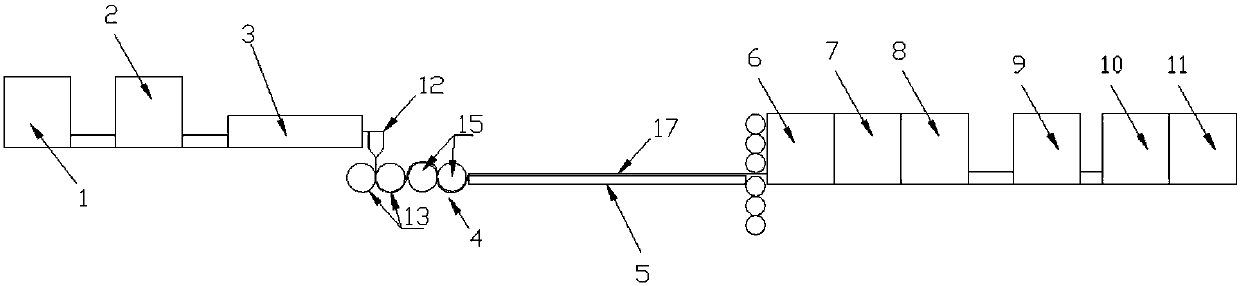

Preparing system and method of PMMA light-guide-stage transparent membranes

PendingCN107813512ALess interferenceReduce the impactOptical articlesCleaning using toolsLight guideMembrane surface

The invention discloses a preparing system of PMMA light-guide-stage transparent membranes. The preparing system comprises a washing device, a drying device, an extruding device, a polishing device, aconveying device, a relay type membrane surface dust removal device, a film pasting device, a first cutting device, a traction device, an edge cutting device, a second cutting device and a piece loading device which are sequentially arranged and further comprises negative-pressure chip sucking devices arranged on the discharging sides of the first cutting device, the edge cutting device and the second cutting device correspondingly. Squeezing rollers below a mouth die of the extruding device are a pair of flexible rollers. The relay type membrane surface dust removal device comprises an upperdust removal roller set and a lower dust removal roller set which are arranged on the two faces of the membranes. The negative-pressure chip sucking devices each comprise a plurality of negative-pressure chip sucking parts arranged on one face or two faces of a to-be-cut product. Ultra-thin and ultra-wide PMMA membranes can be produced, inner stress of prepared products is evenly distributed, andthus the products are not prone to being cracked. Meanwhile, the very small thickness tolerance (smaller than 1.5%) and extremely perfect optical quality can be obtained, and the defect that powderedscraps press the appearances of the products to be damaged is effectively overcome.

Owner:JIANGSU HANYANG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com