Patents

Literature

8308results about "Anchoring bolts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

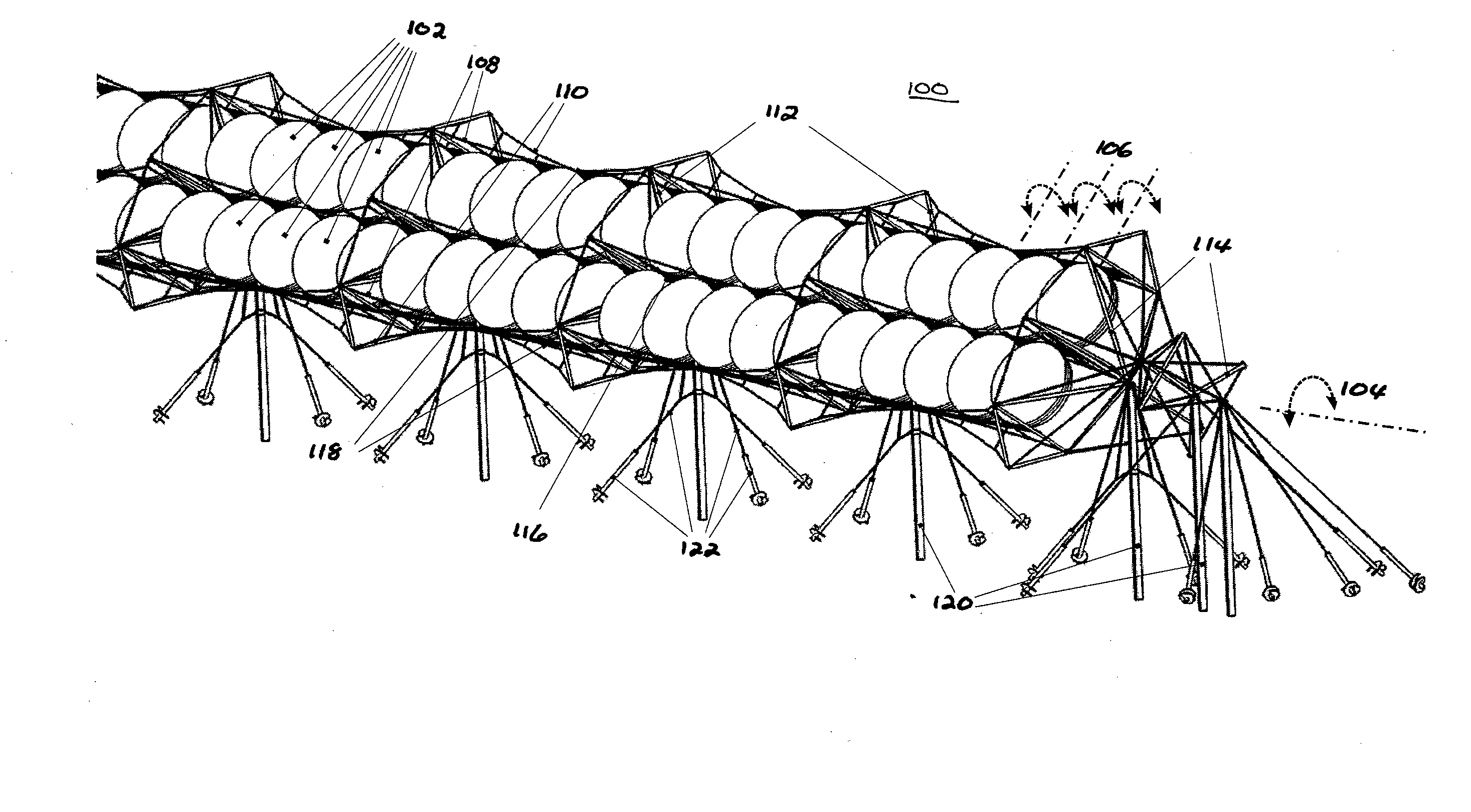

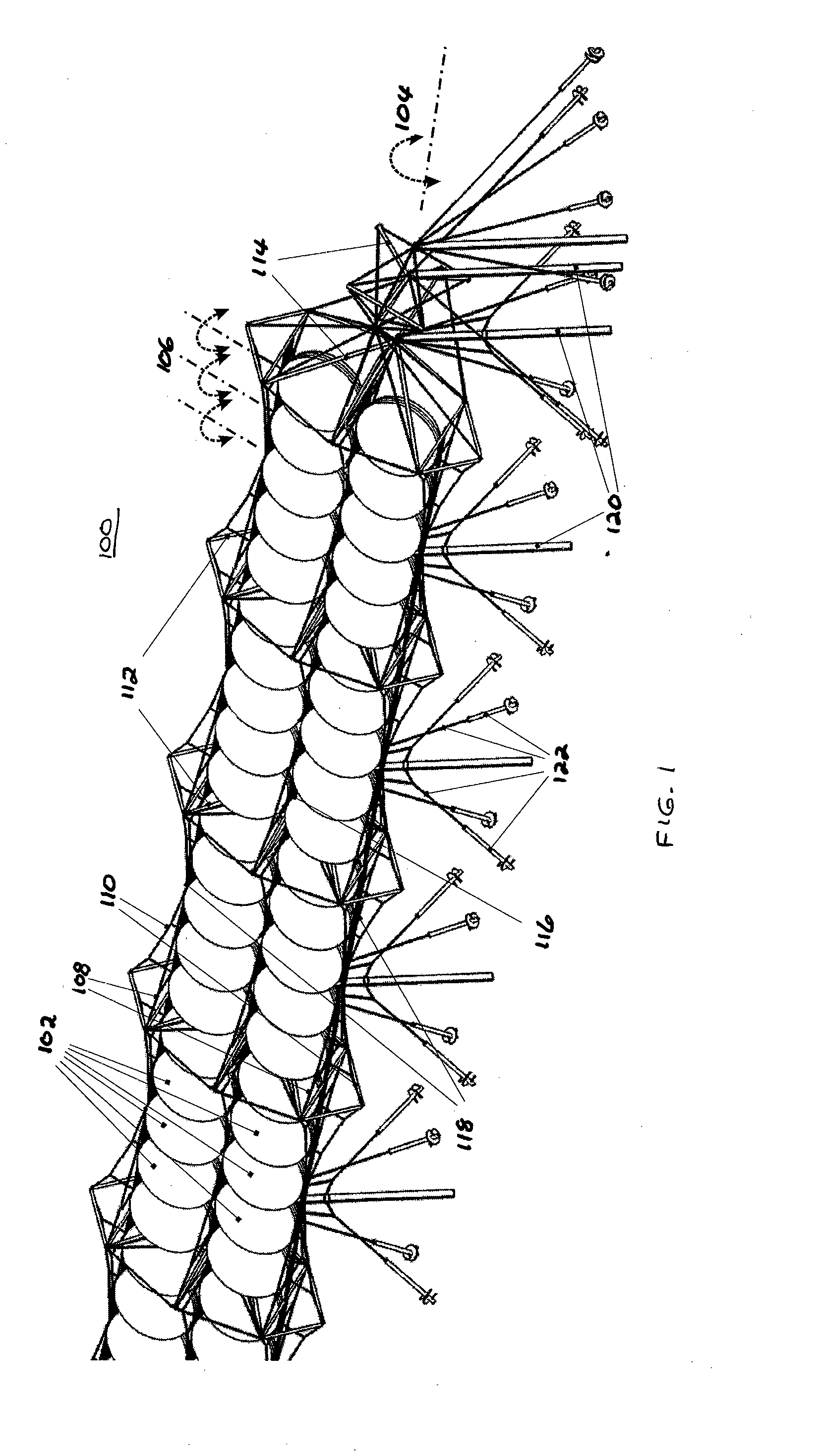

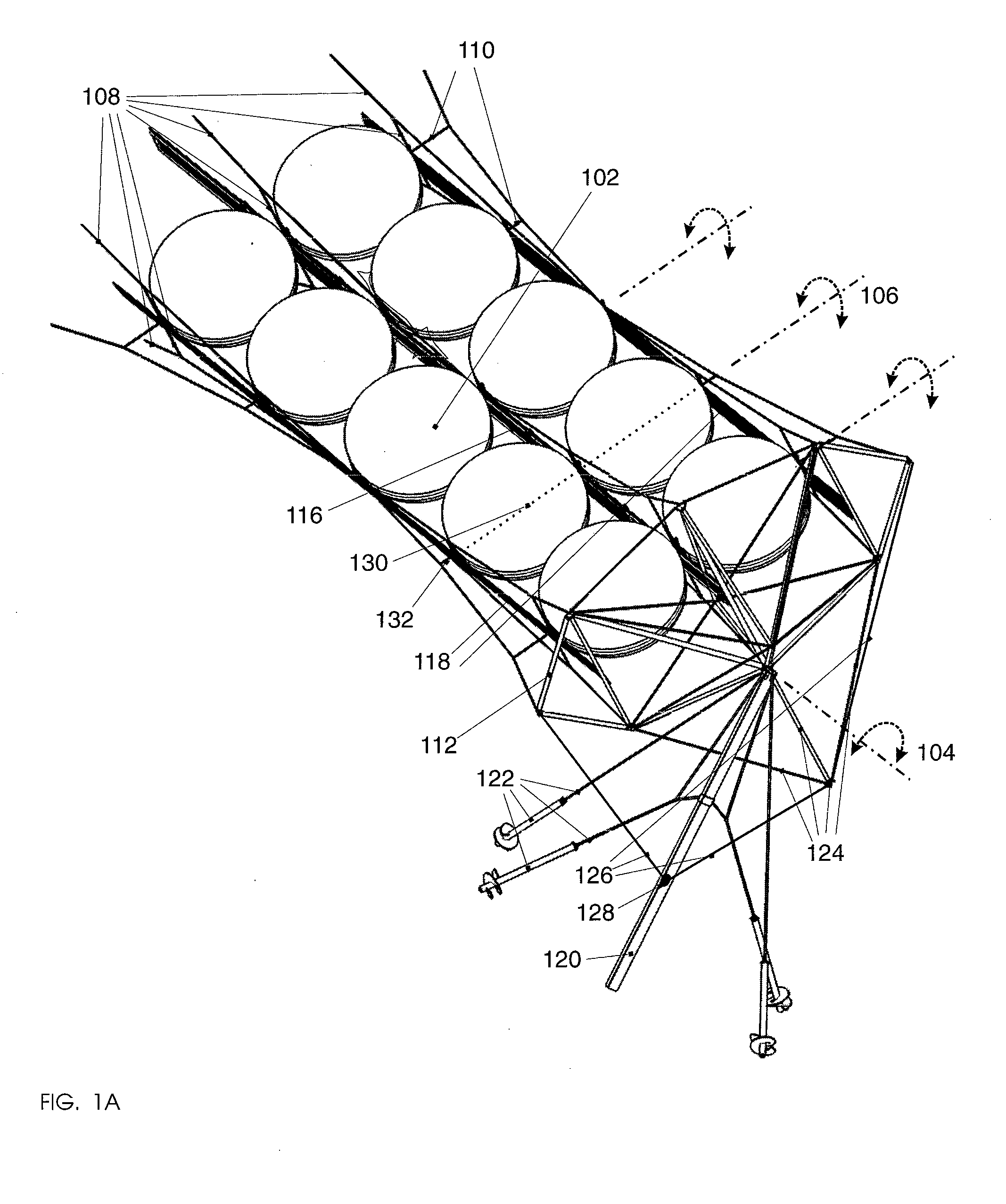

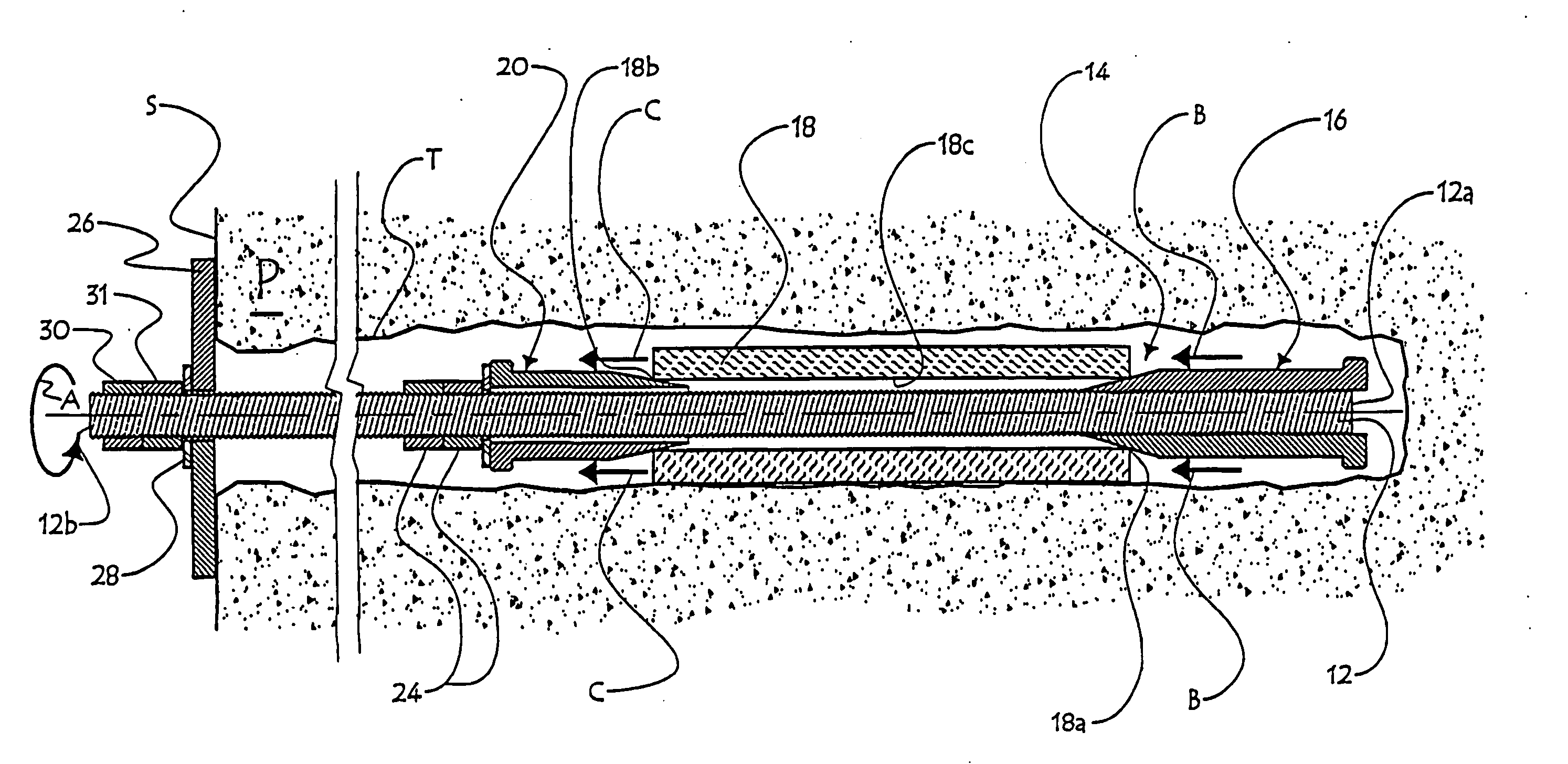

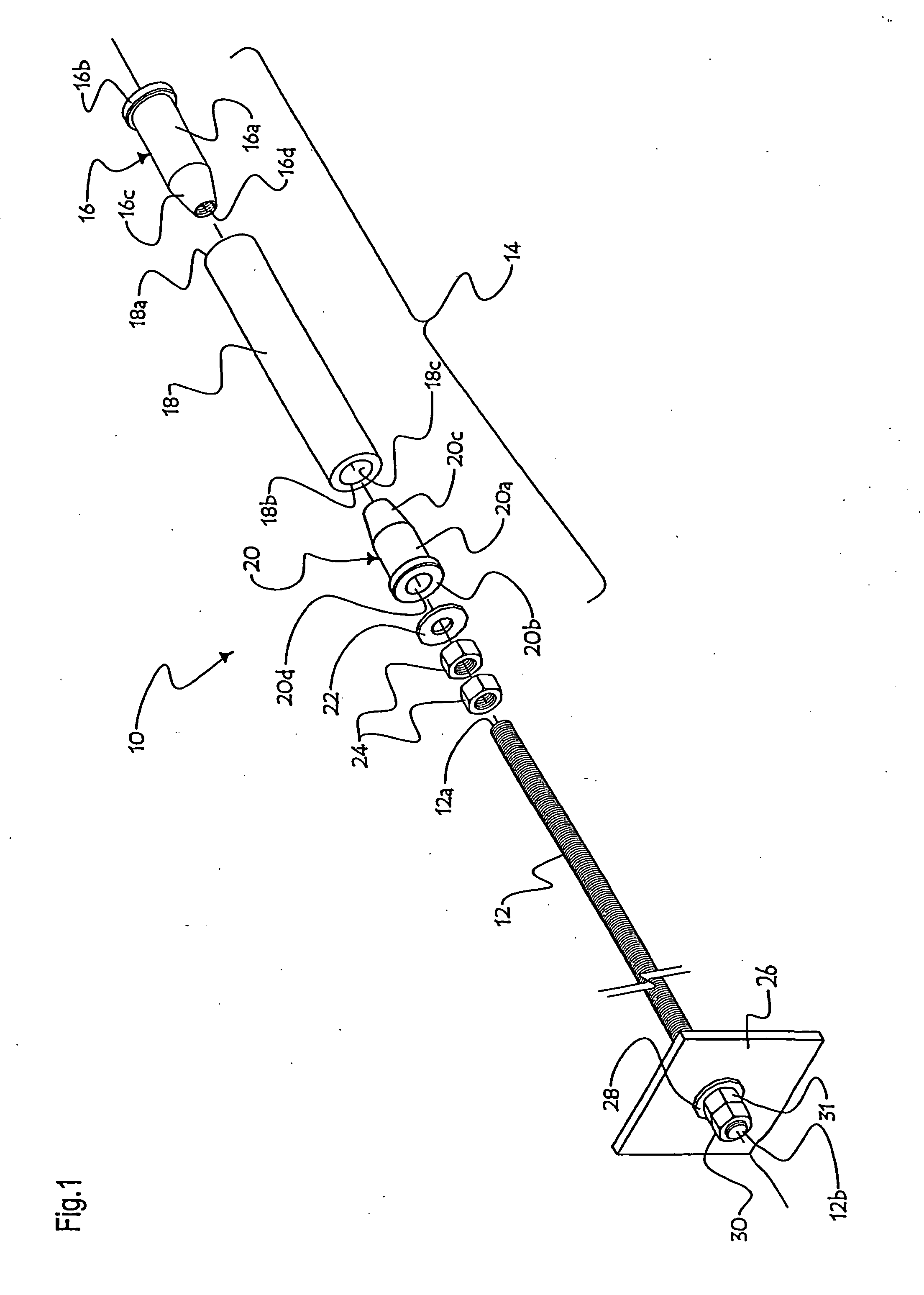

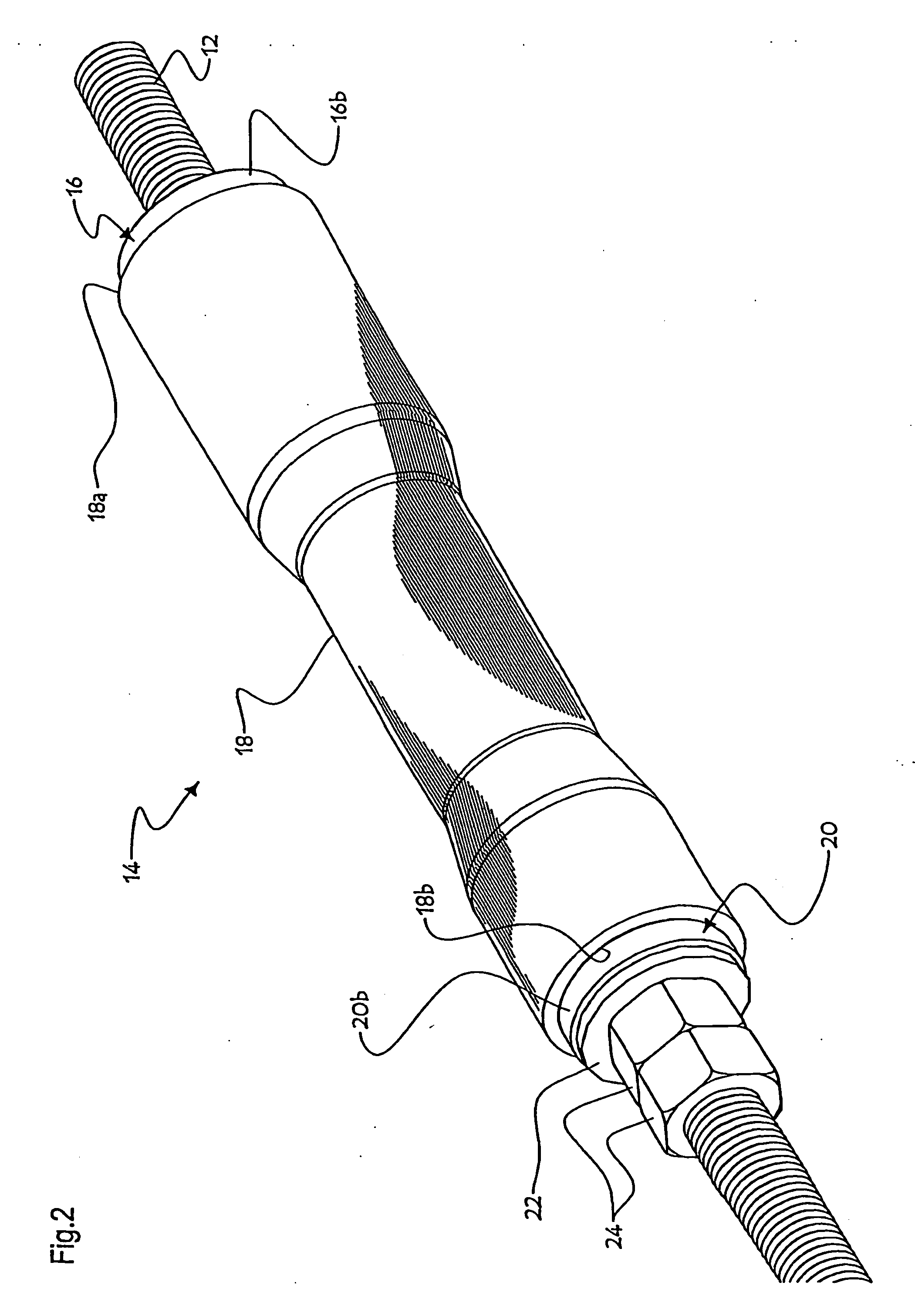

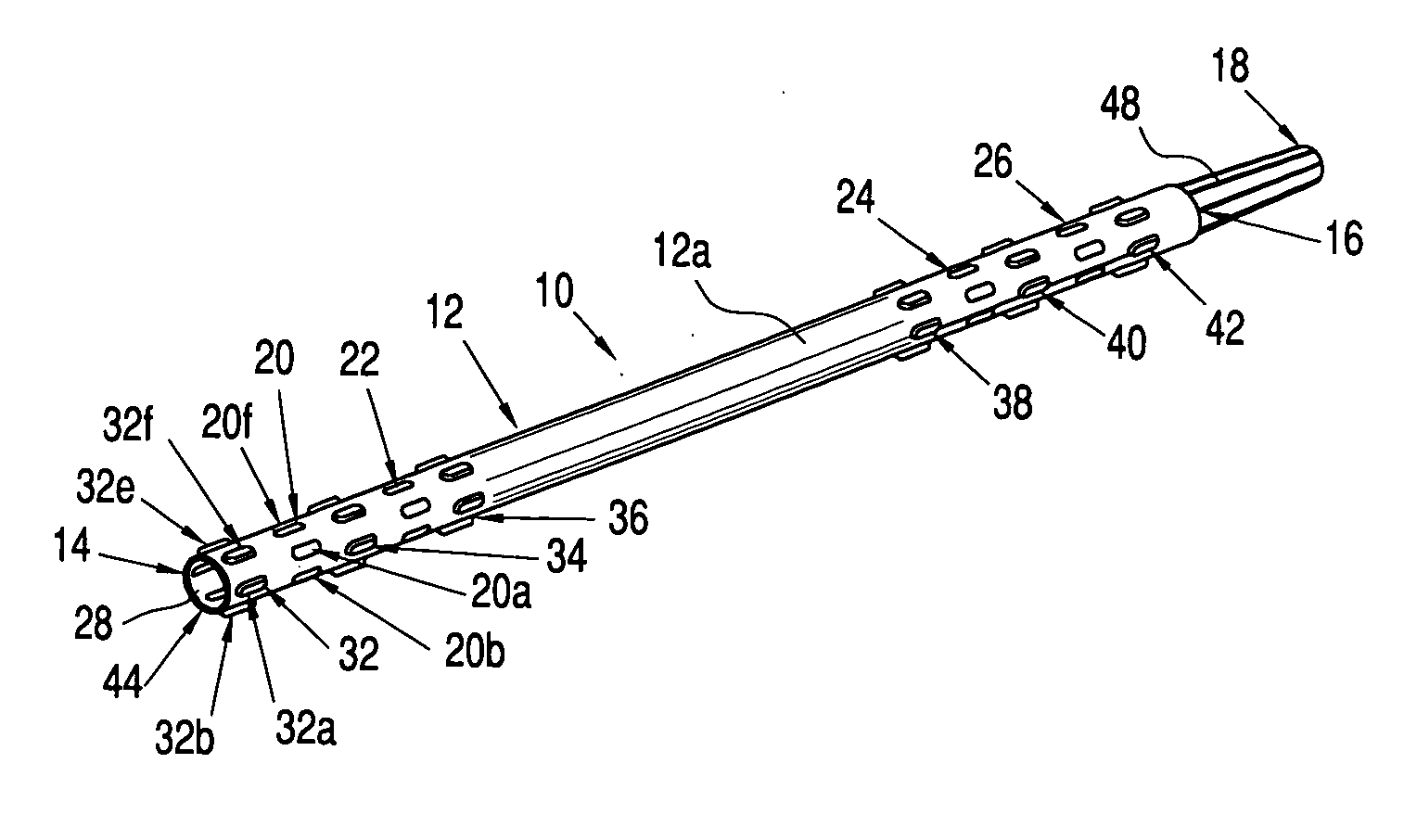

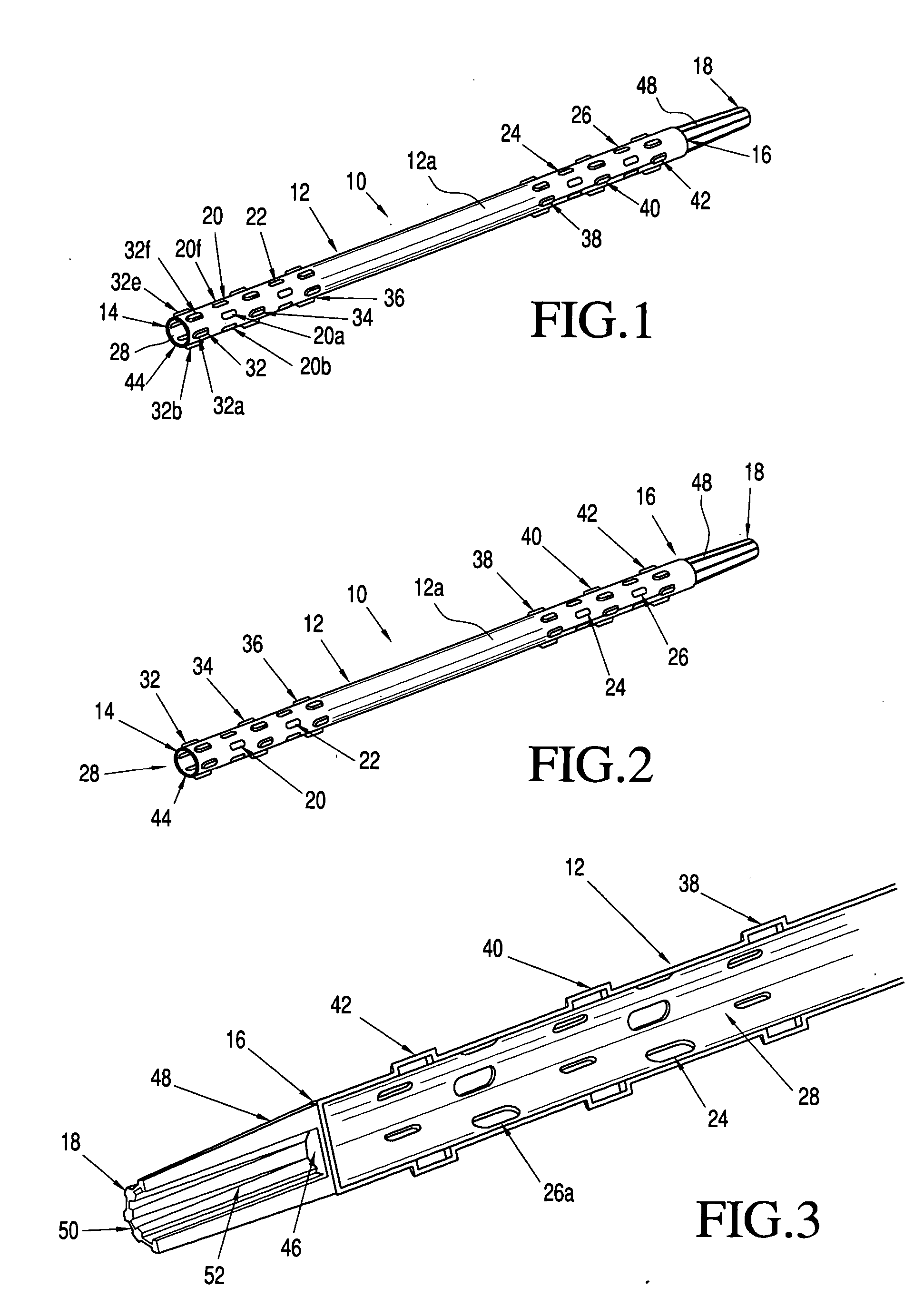

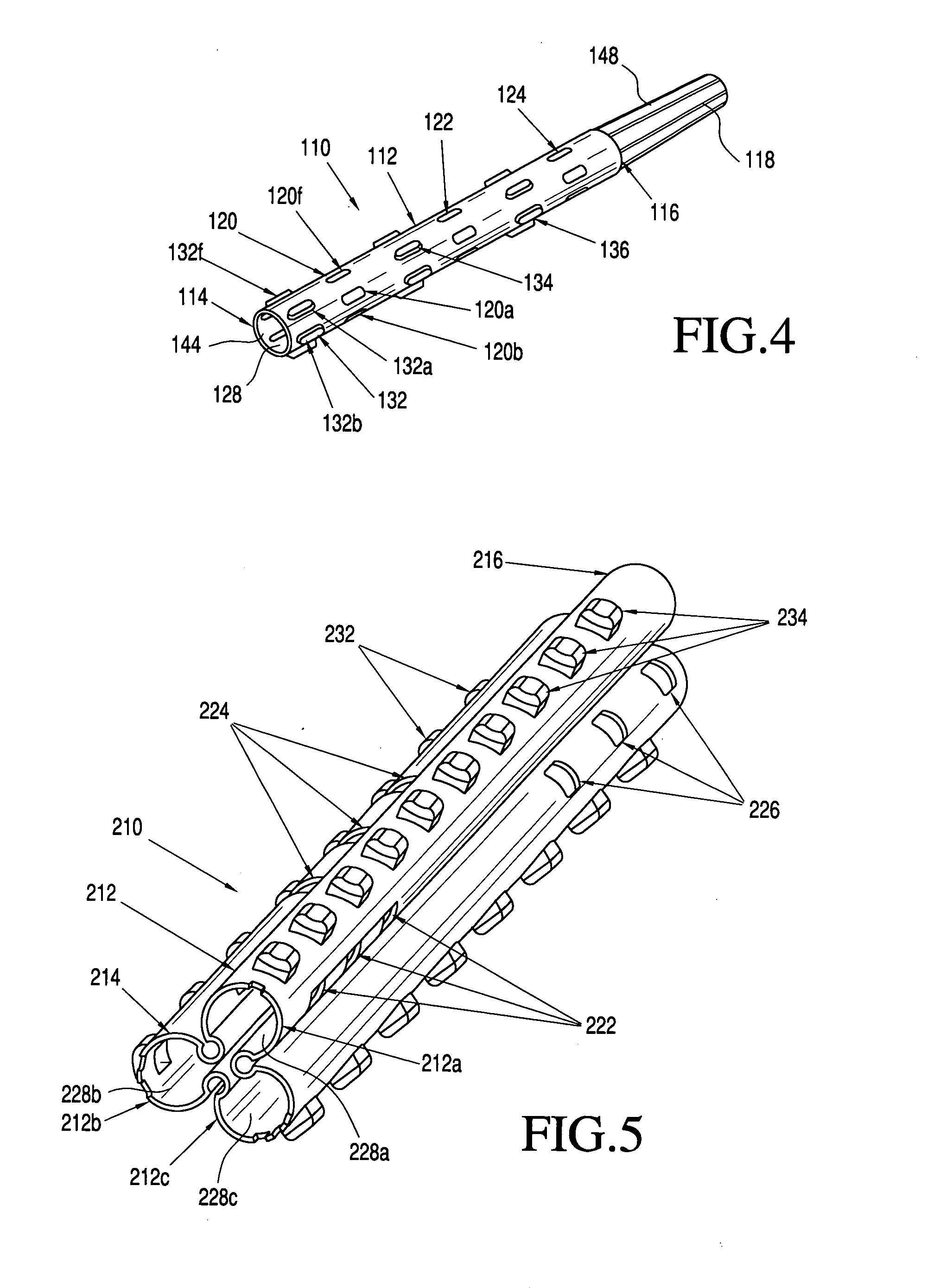

Rigging system for supporting and pointing solar concentrator arrays

InactiveUS20080168981A1Reduce bending forceConvenient and reliable cable-tension adjustmentPhotovoltaic supportsSolar heating energyTerrainRotational axis

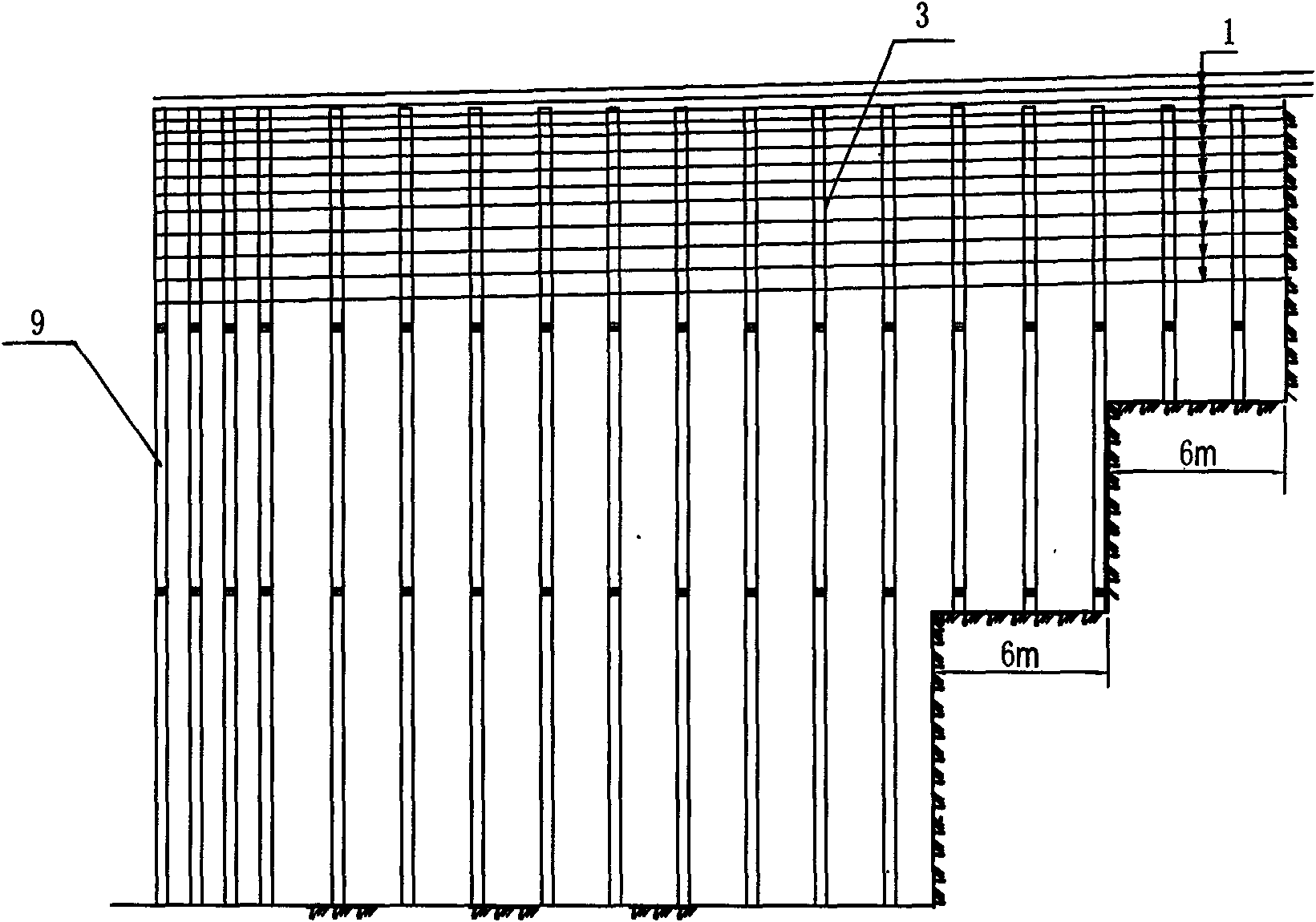

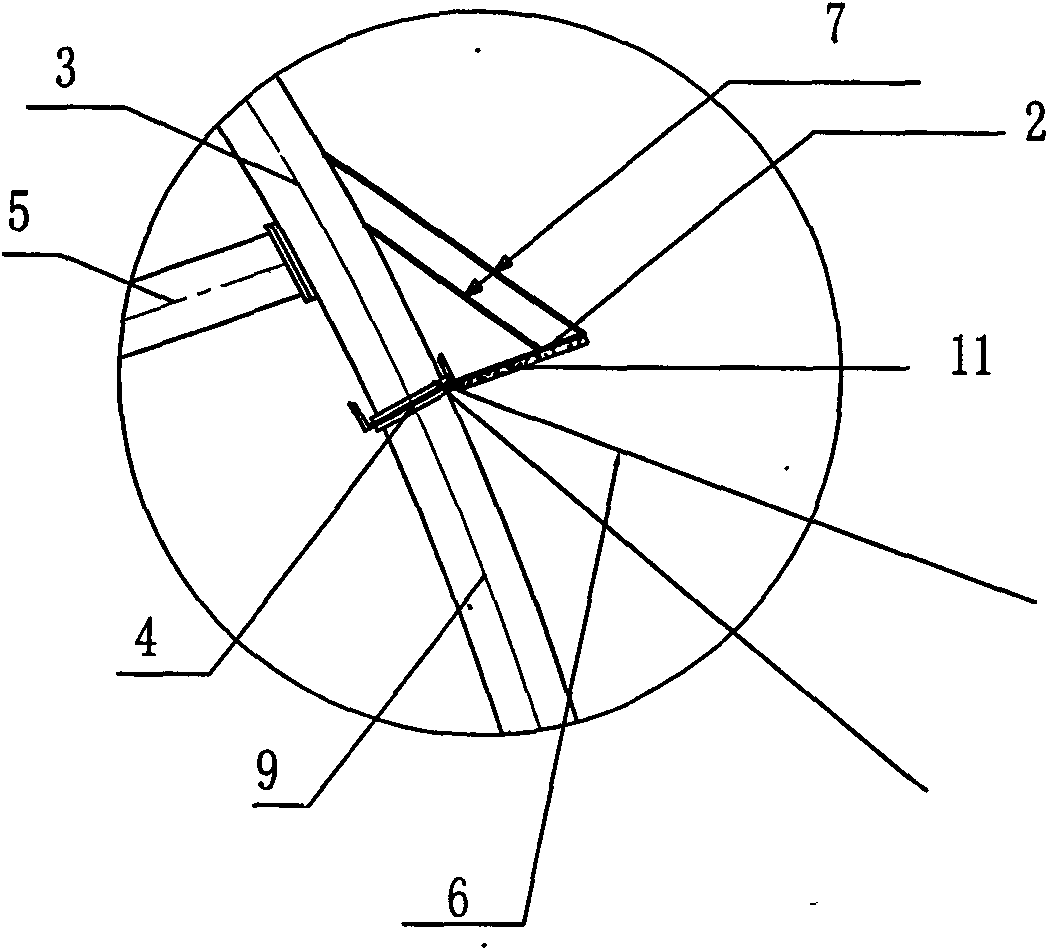

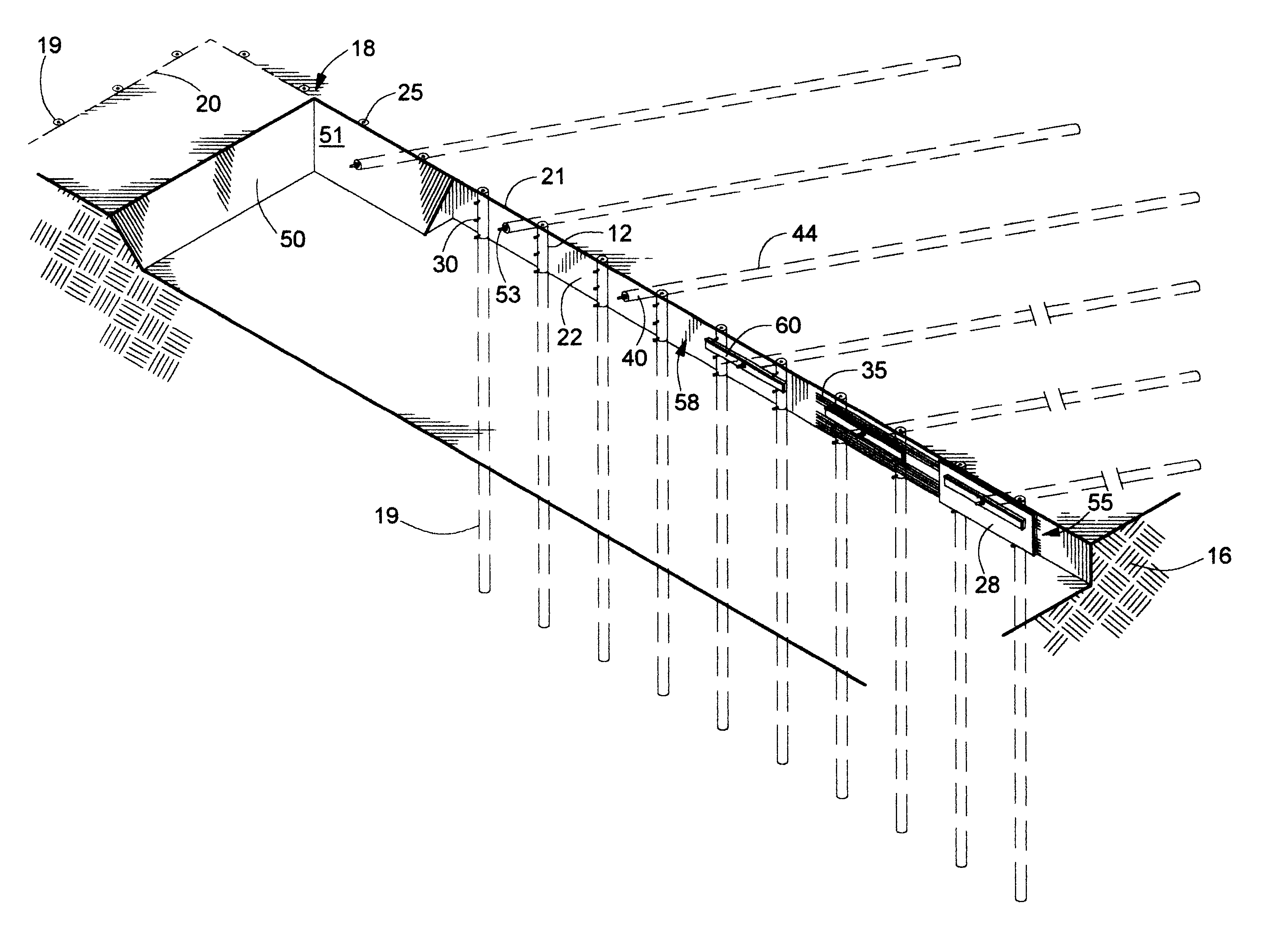

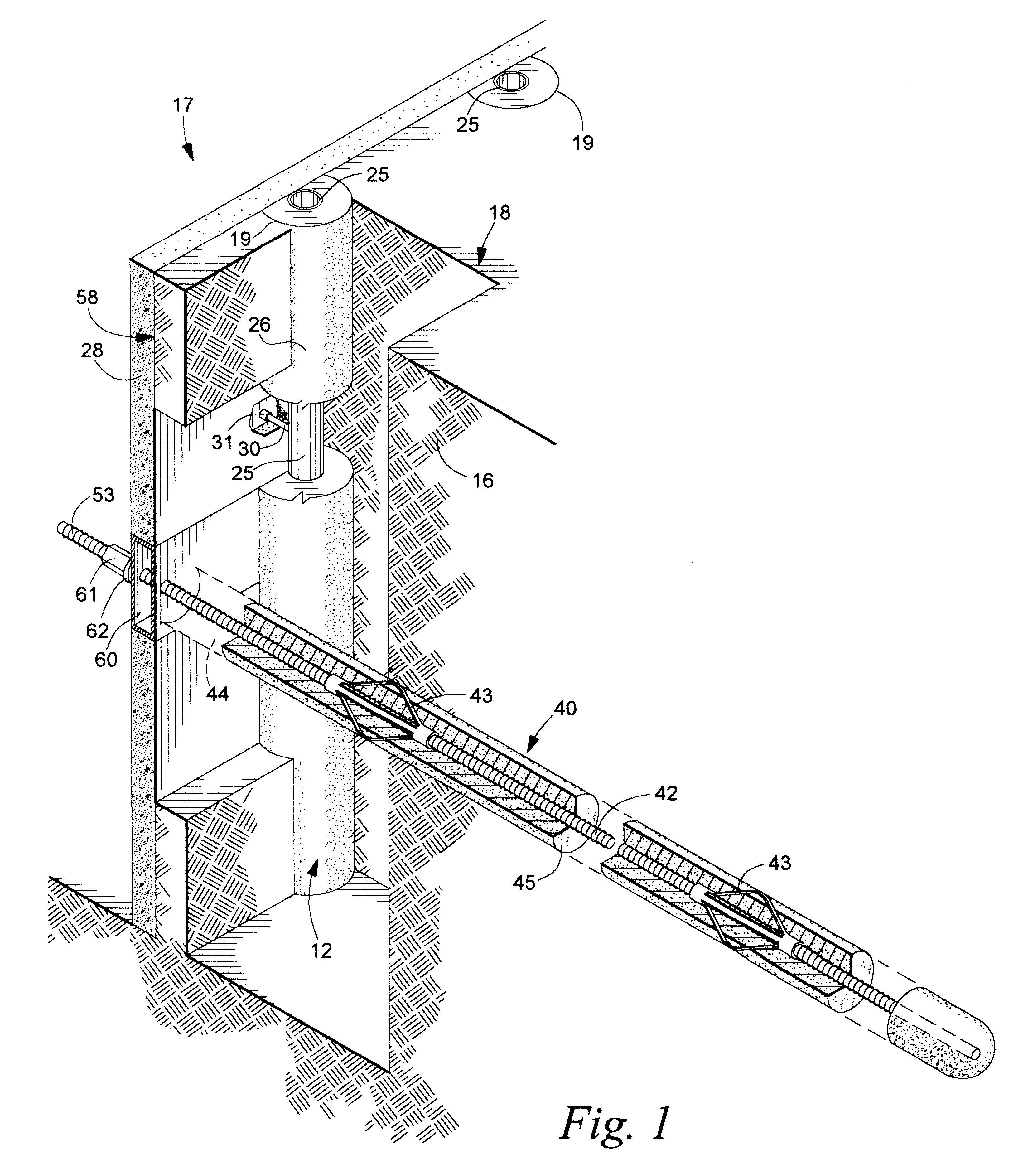

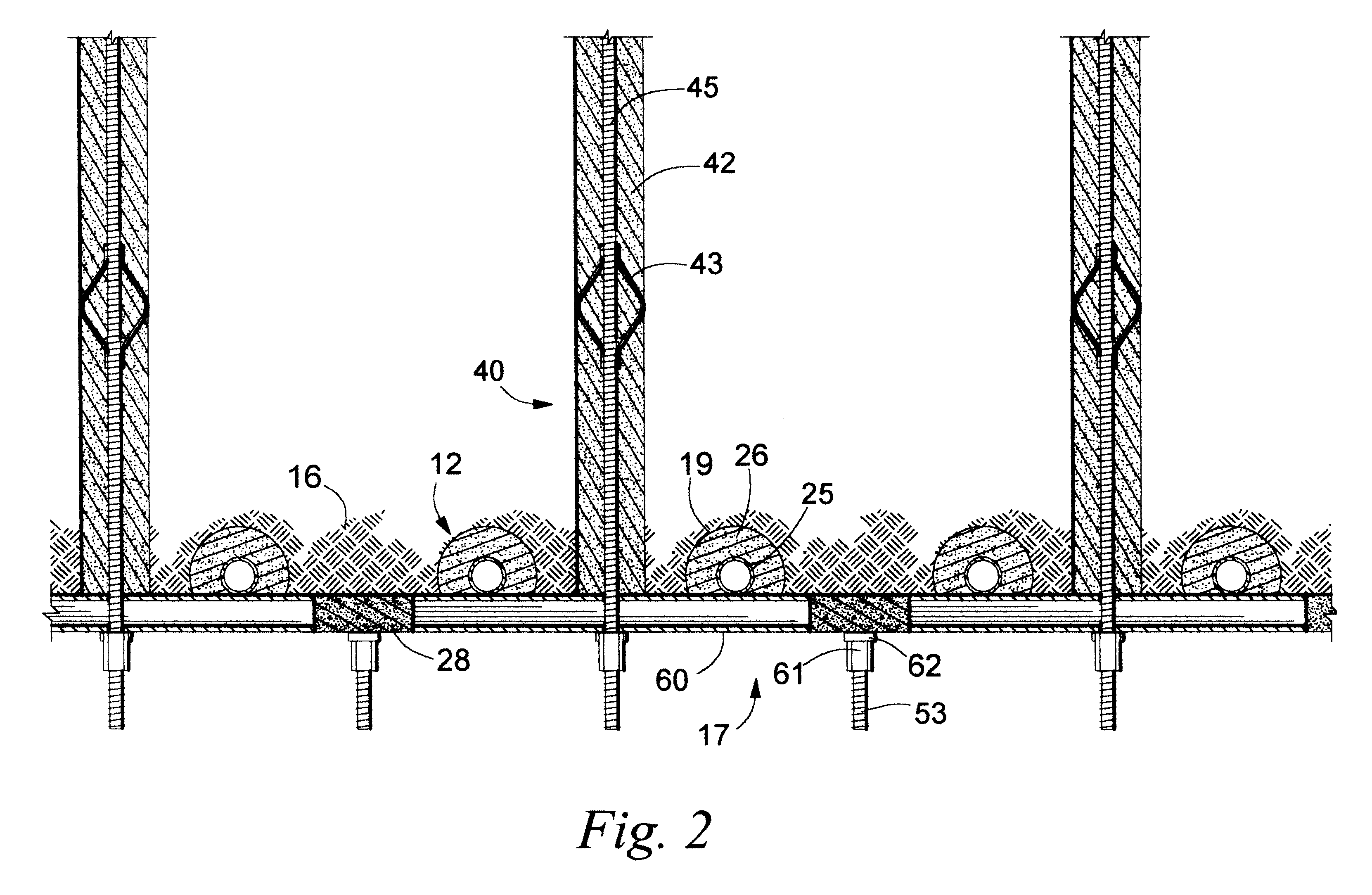

Embodiments in accordance with the present invention relate to the design of inexpensive mounting and pointing apparatuses for linear arrays of solar energy collectors and converters. Particular embodiments in accordance with the present invention disclose a rigging system comprising at least one, and preferably a plurality of, tensile cables onto which a plurality of solar modules are fastened. Such an arrangement provides a way of suspending solar modules over land, vegetation, bodies of water, and other geographic features without substantial perturbation of the underlying terrain. Certain embodiments comprise additional tensile cables fastened to the solar modules, such that differential axial motion of the cables produces a rotational motion component of the individual solar modules of the array. This rotational motion component effects an orientation control along one rotational axis.

Owner:COOLEARTH SOLAR

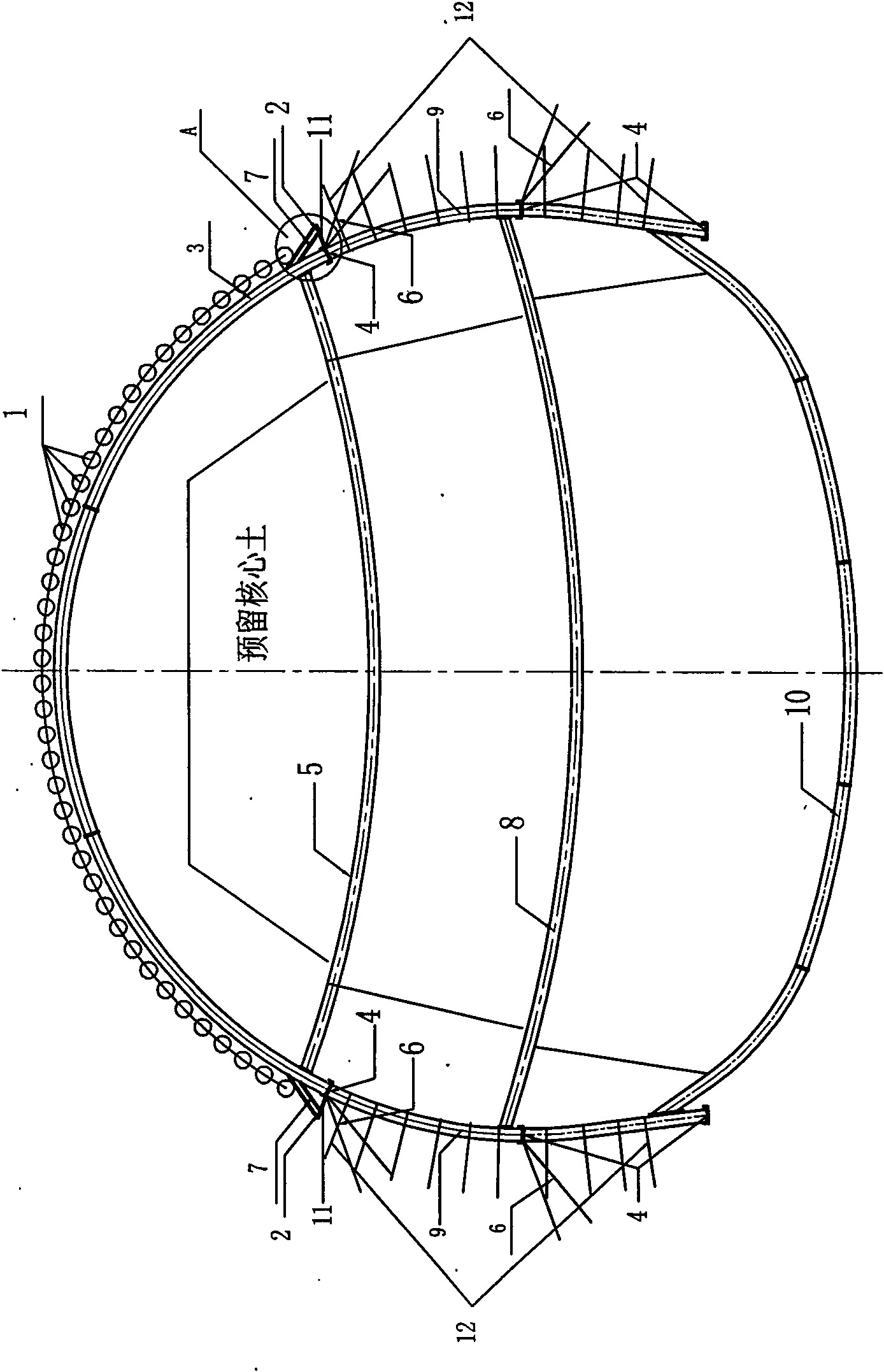

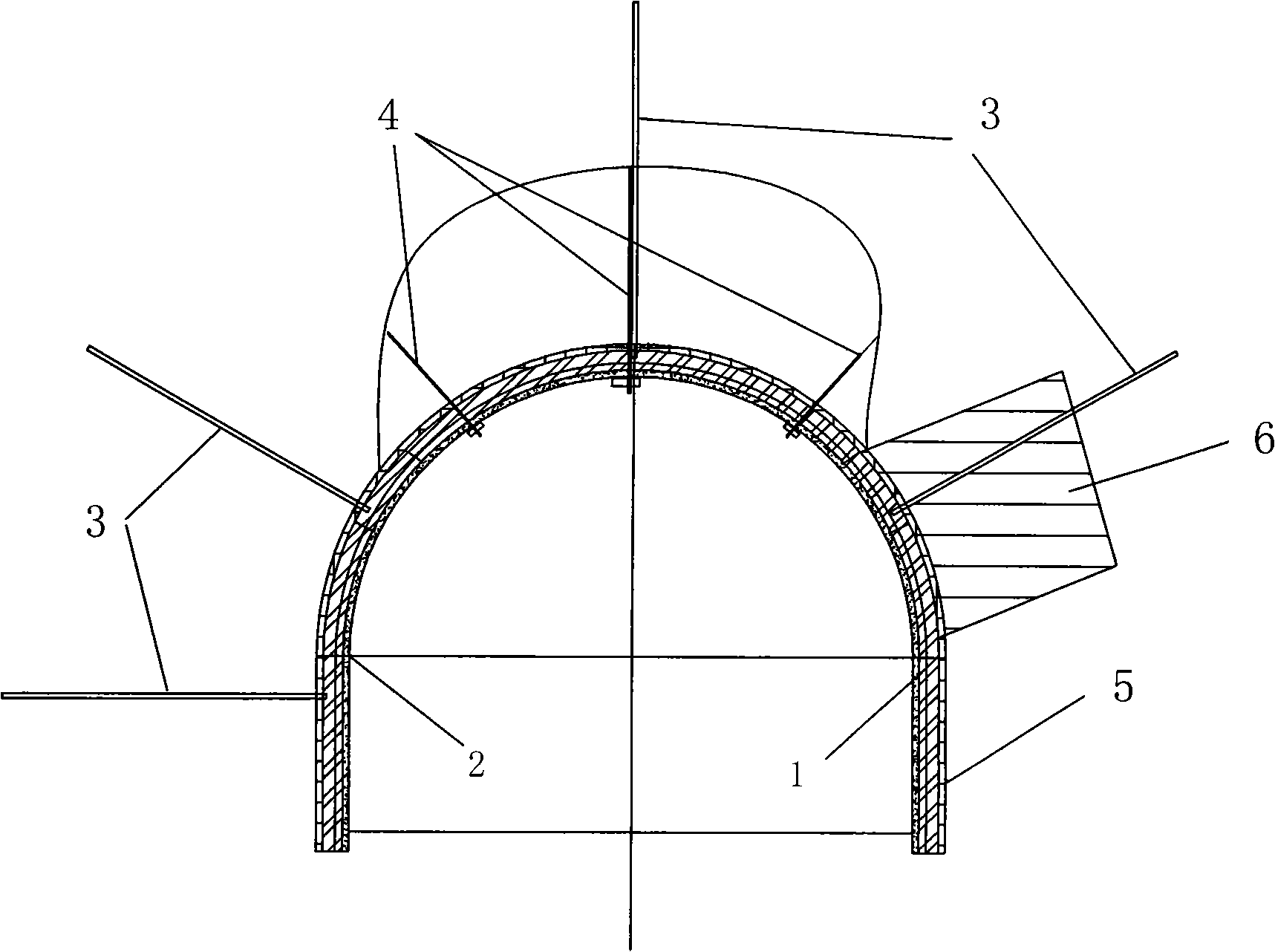

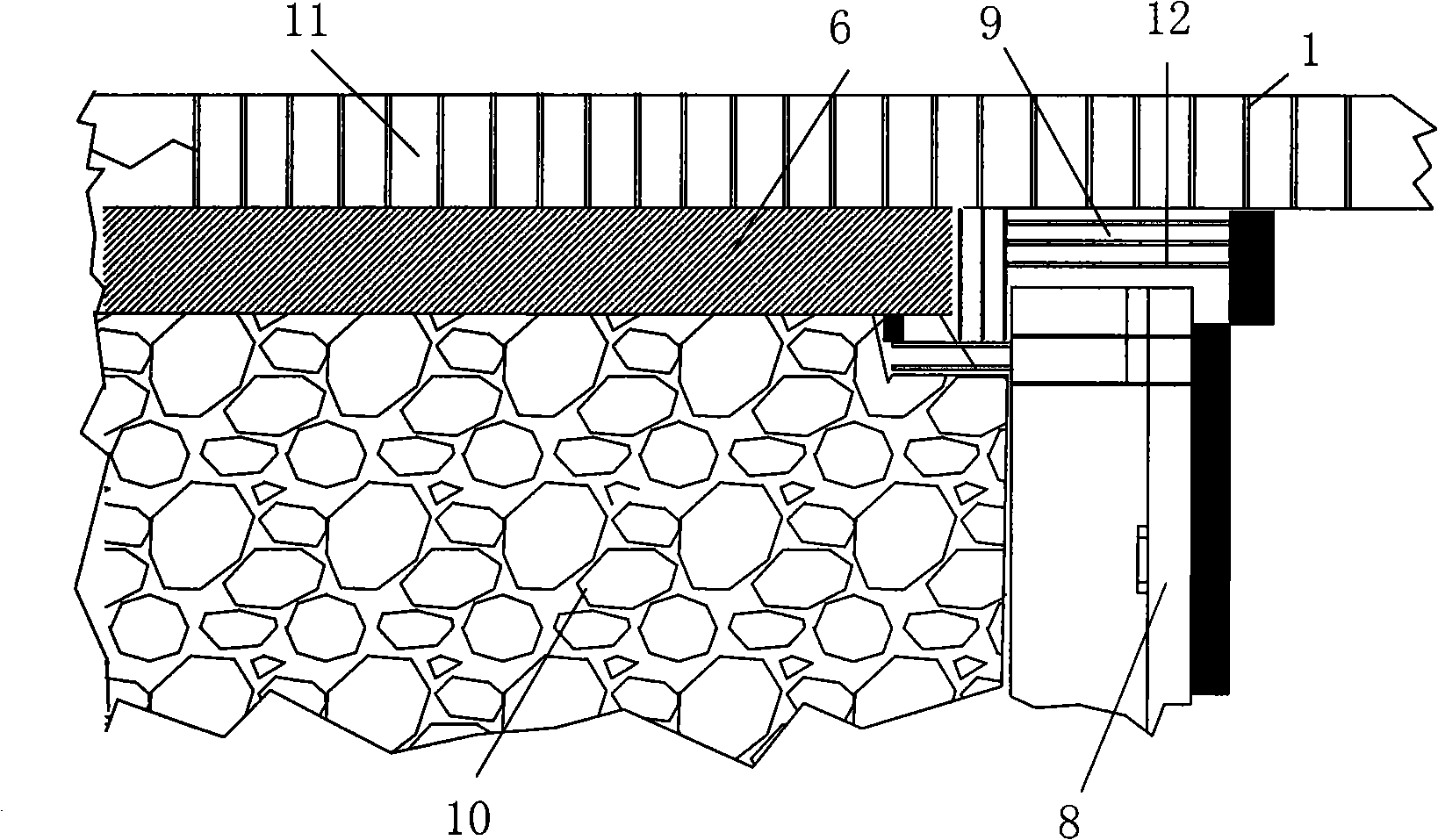

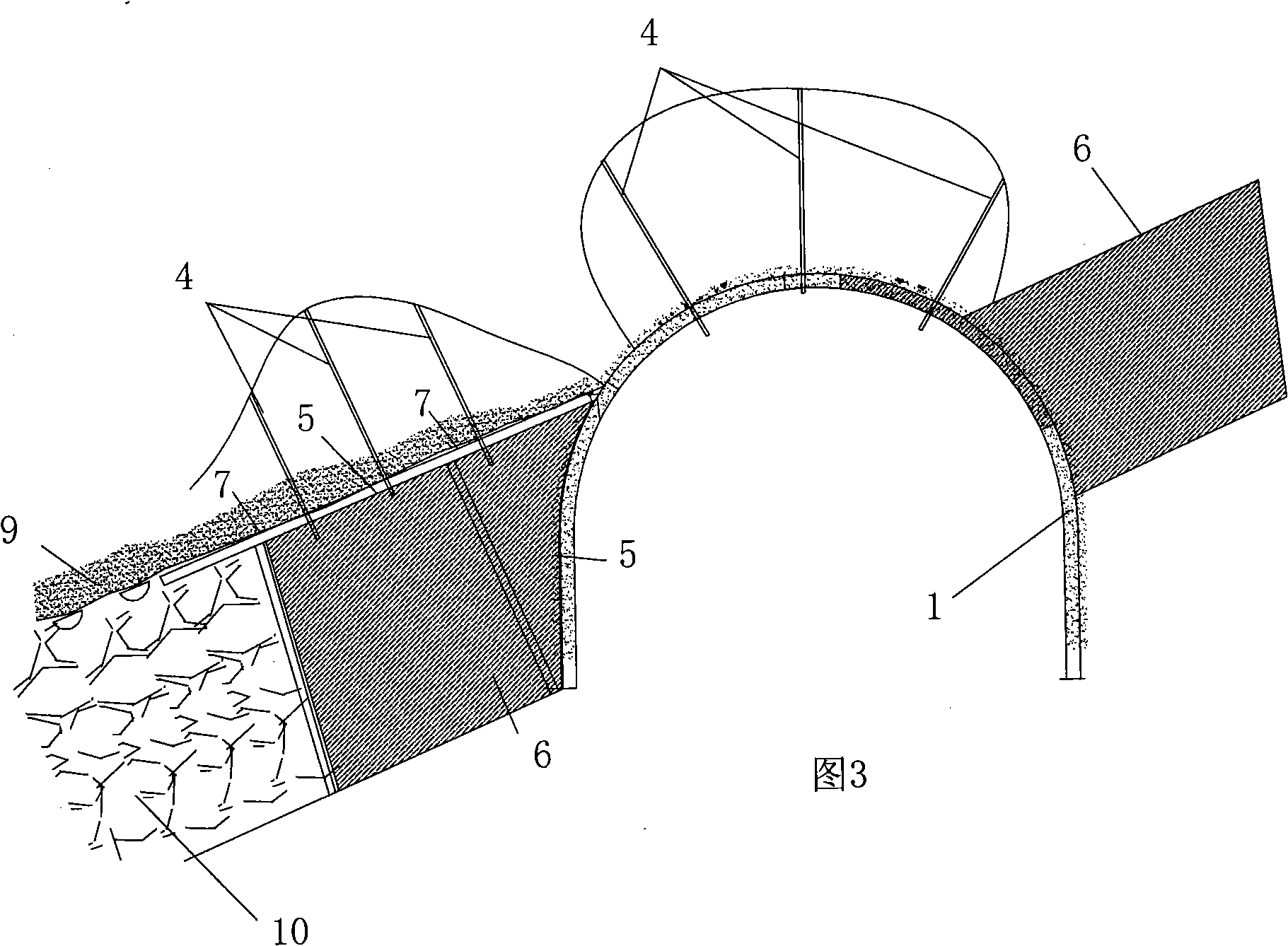

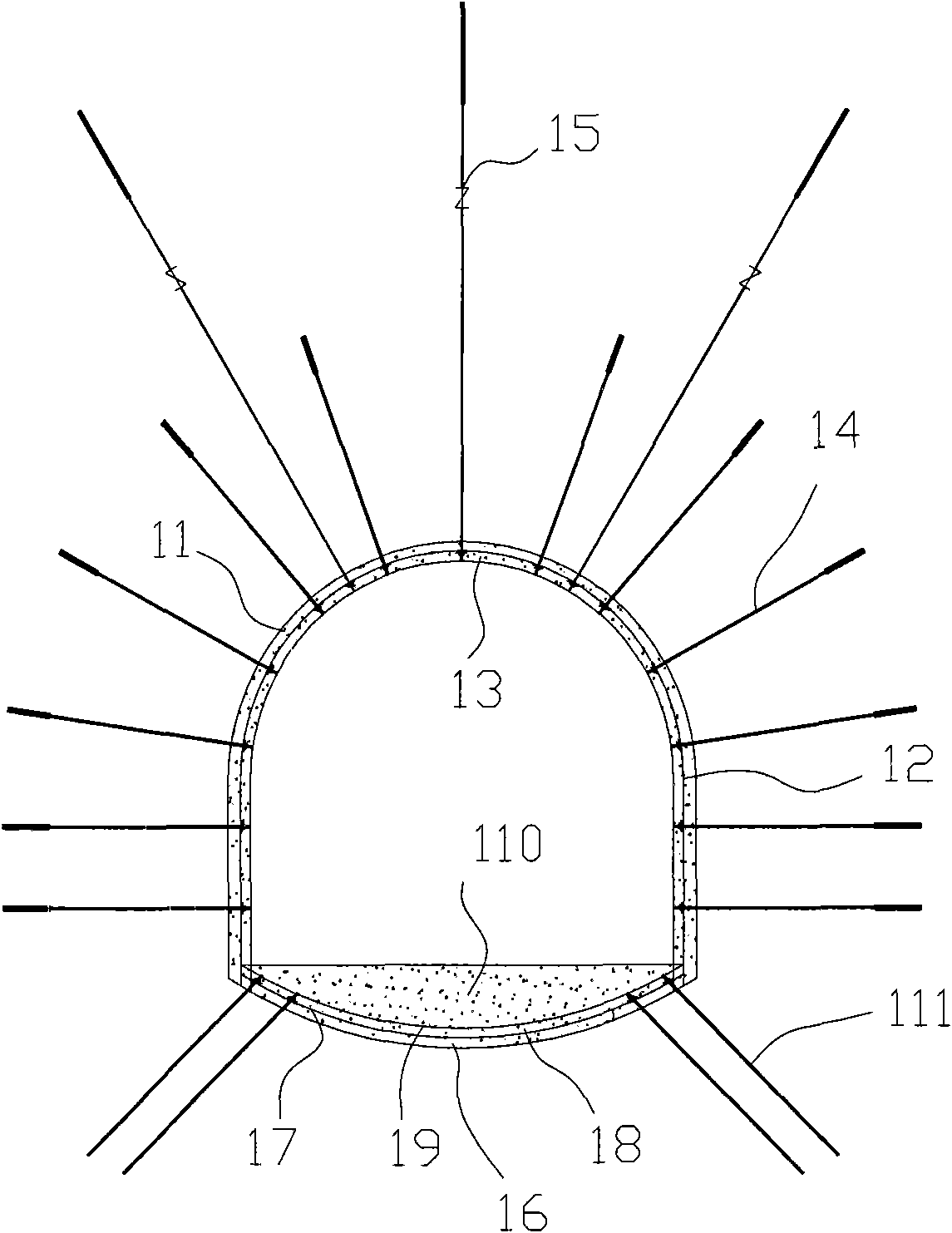

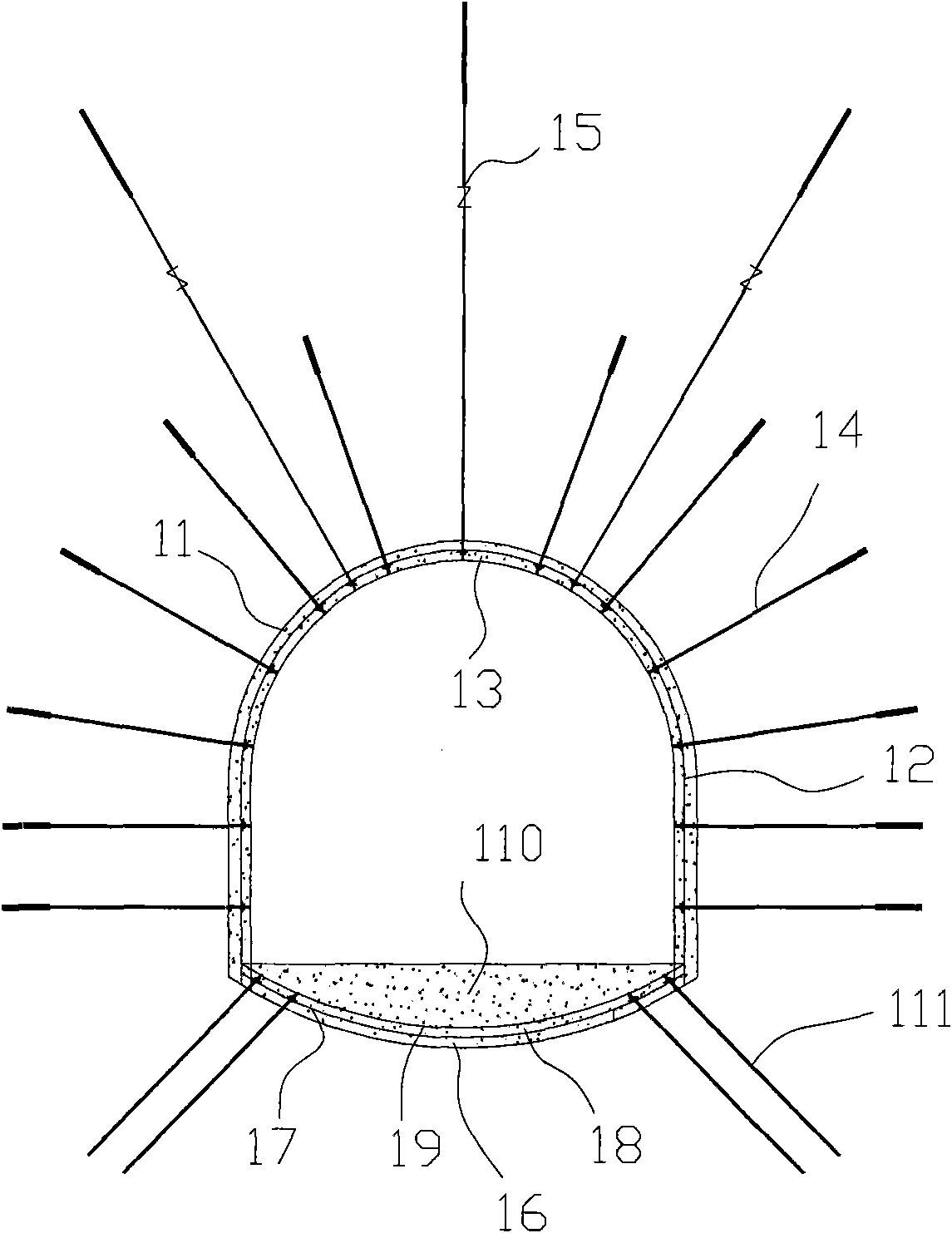

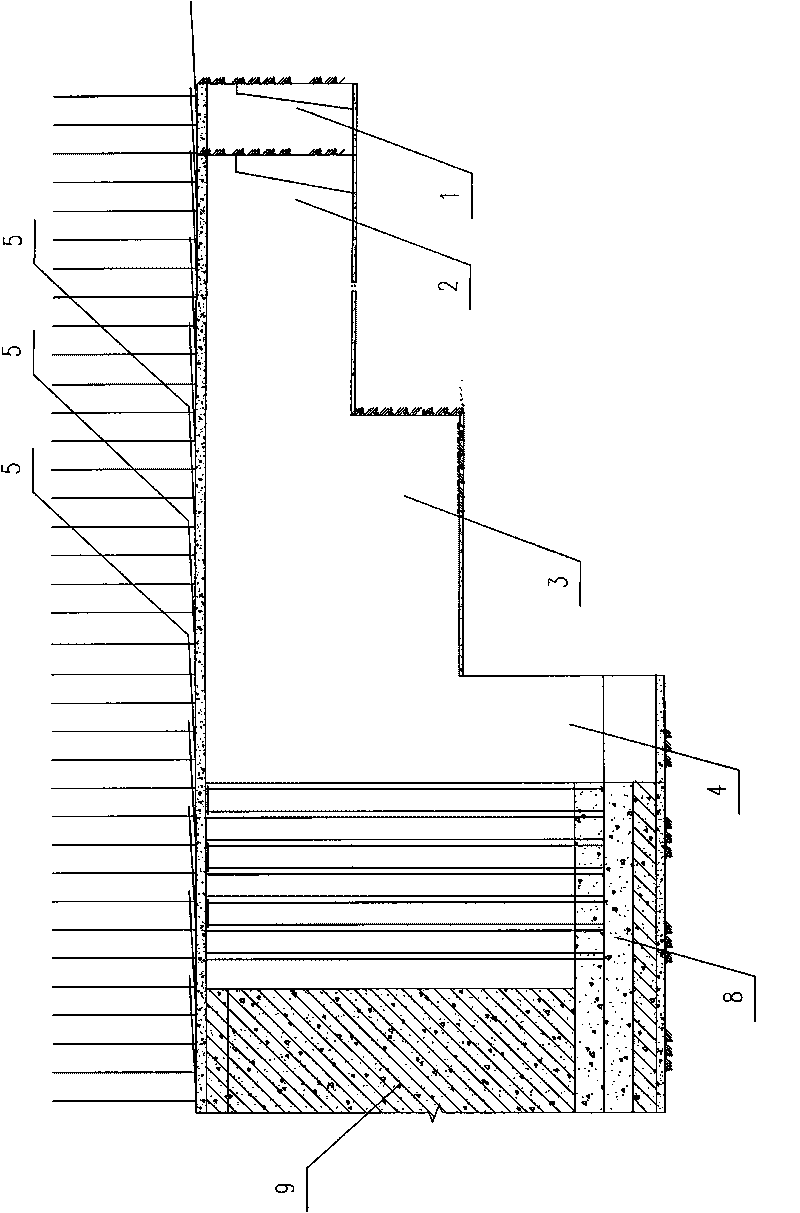

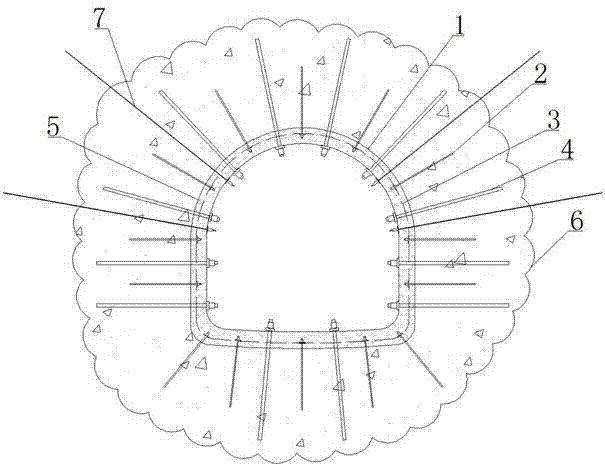

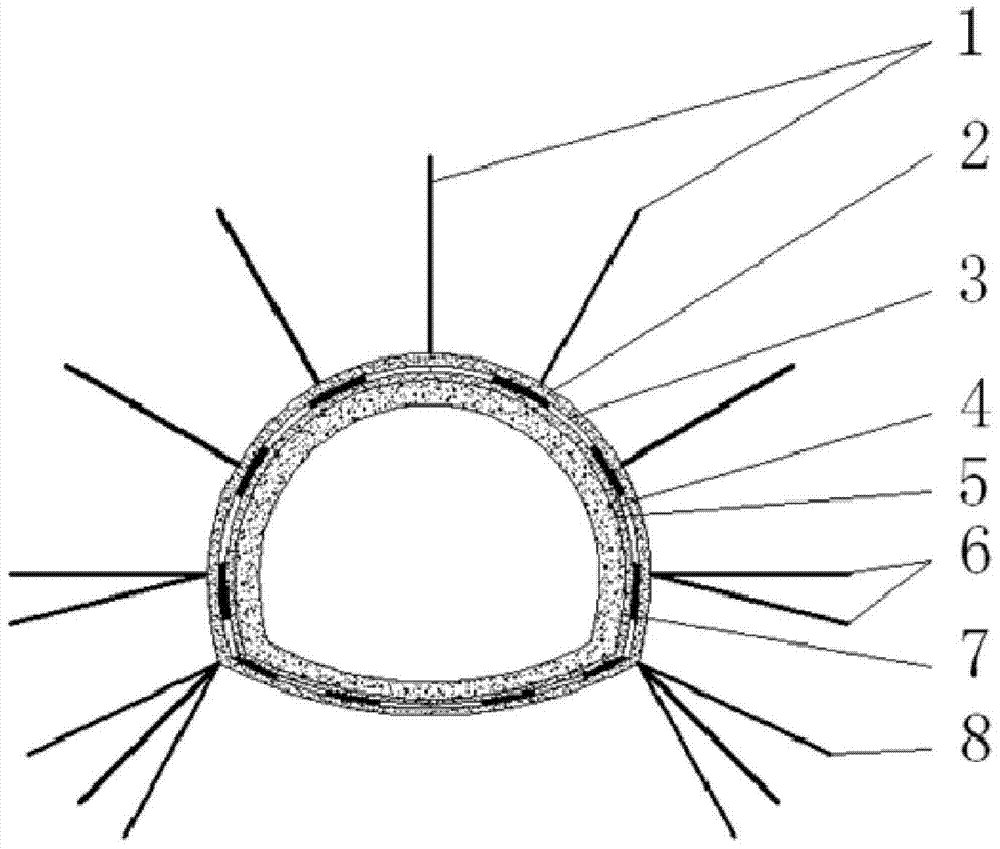

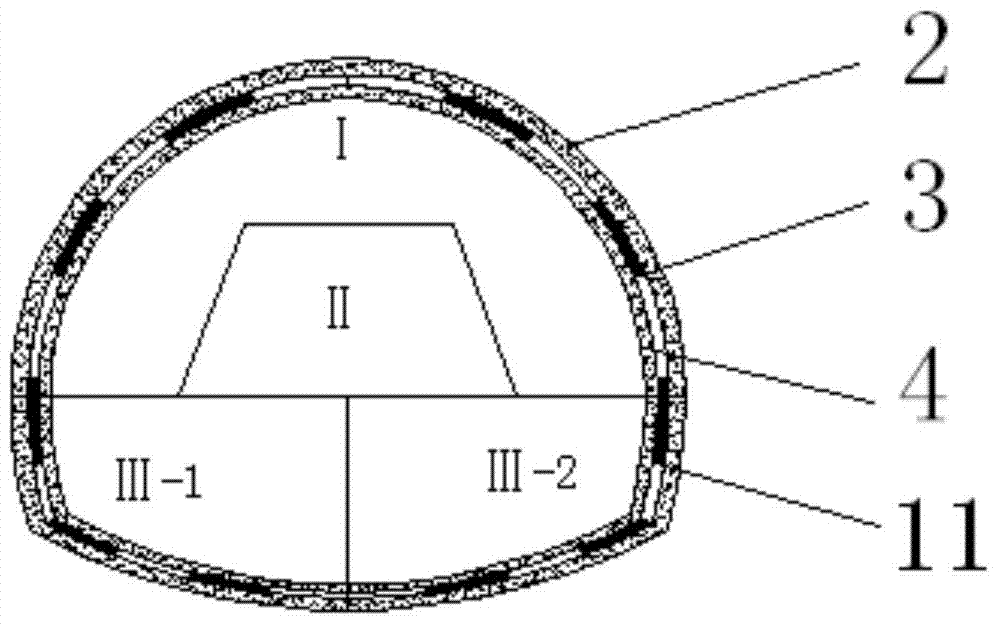

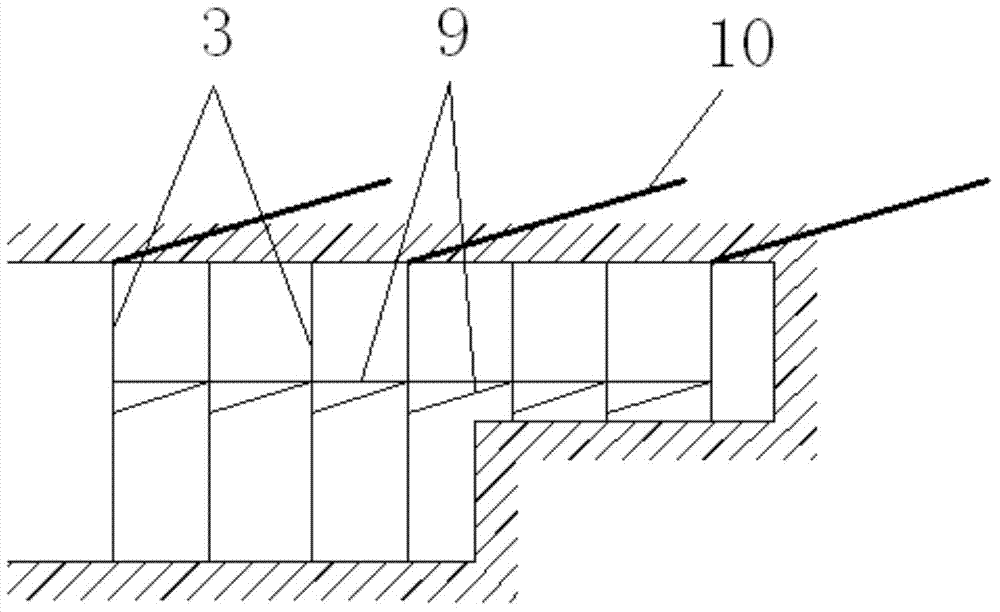

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

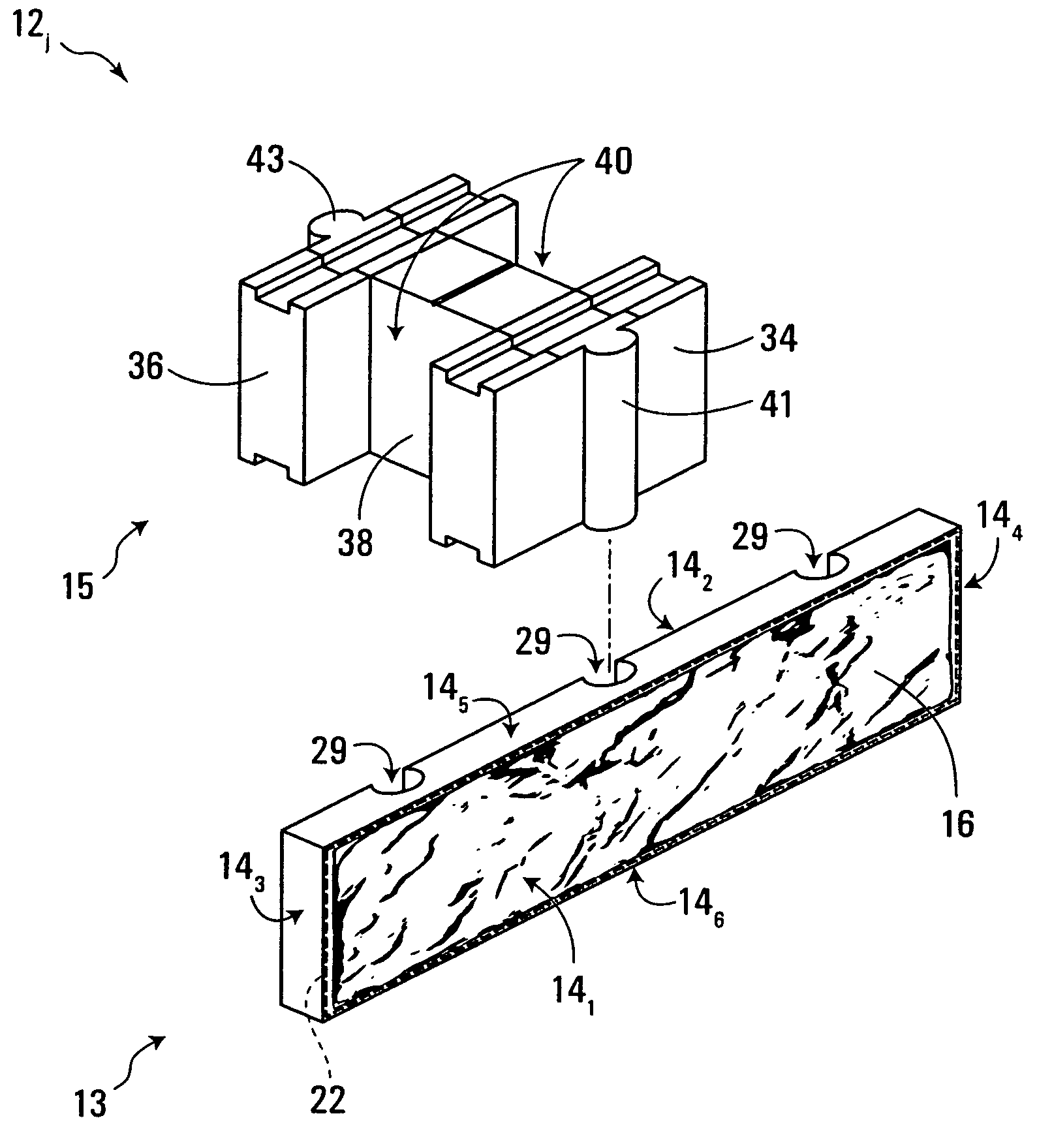

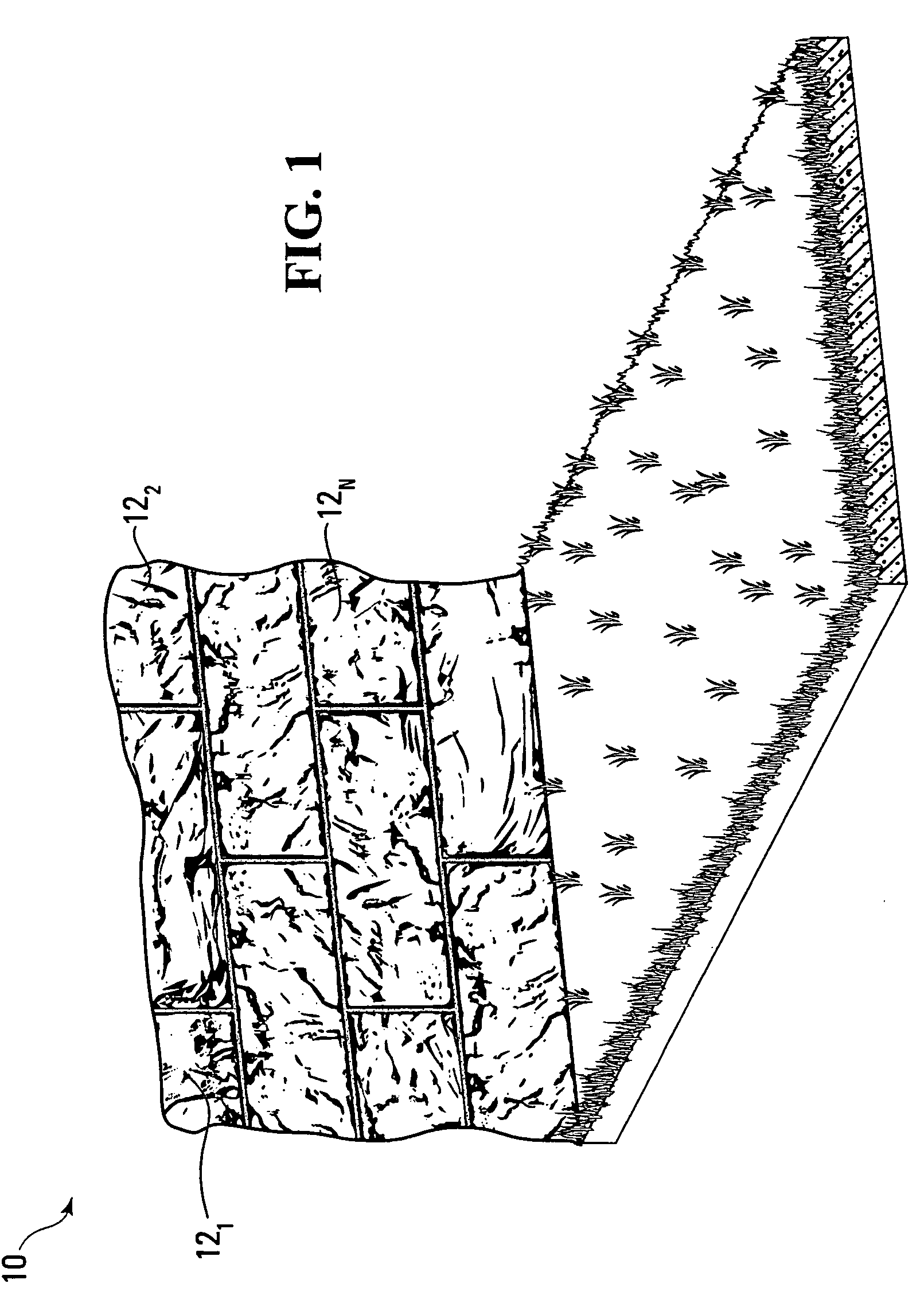

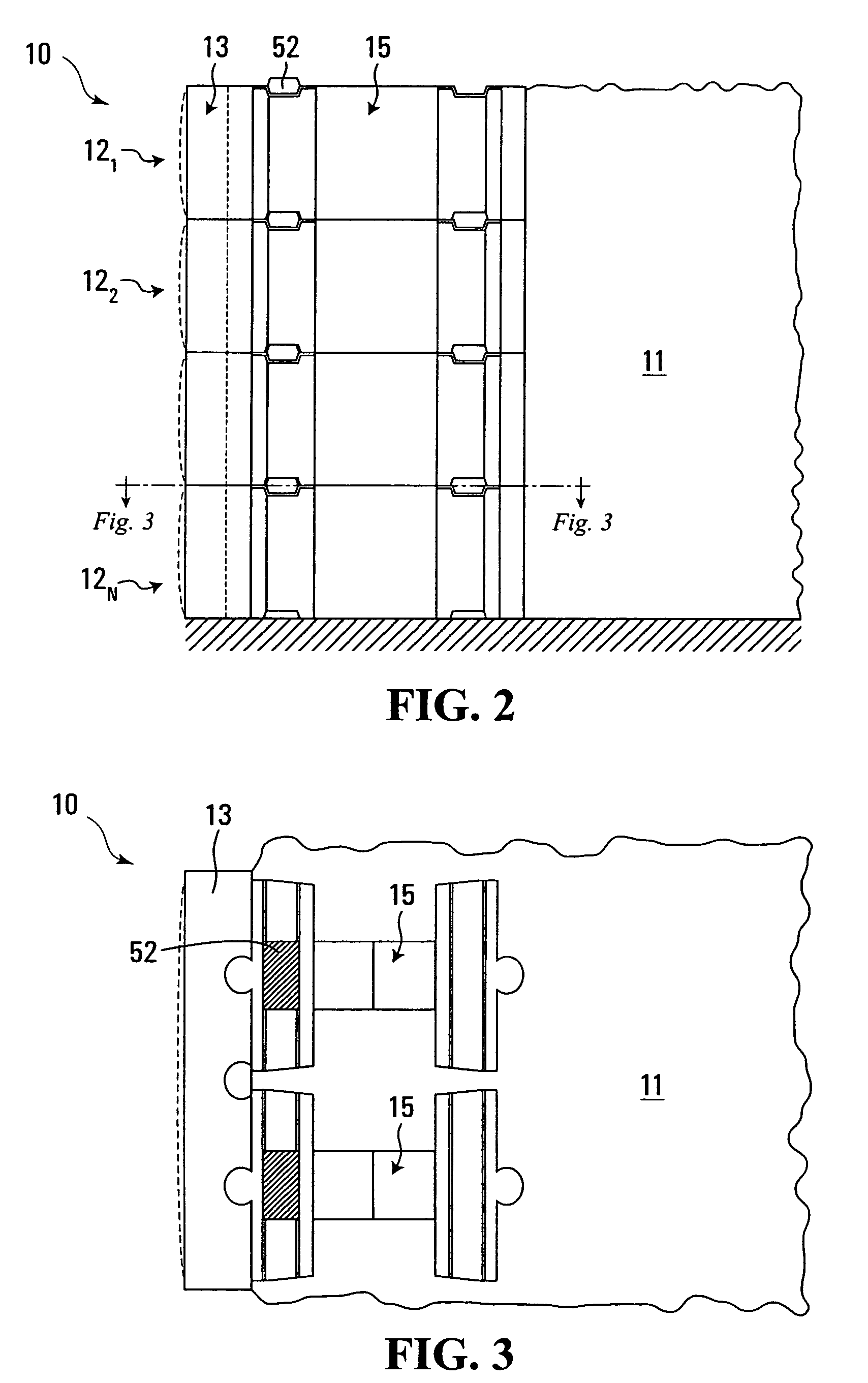

Multi-channel retaining wall block and system

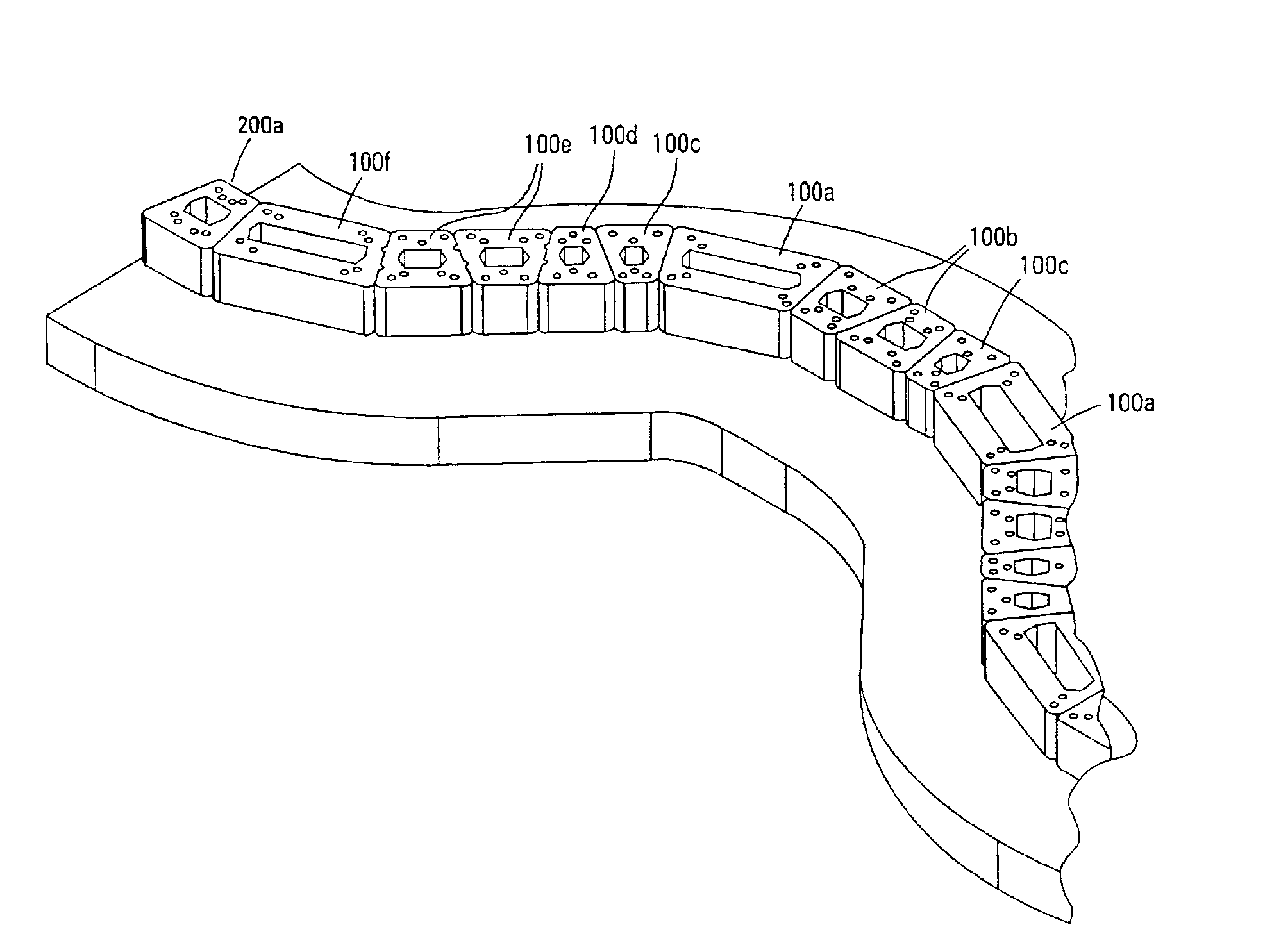

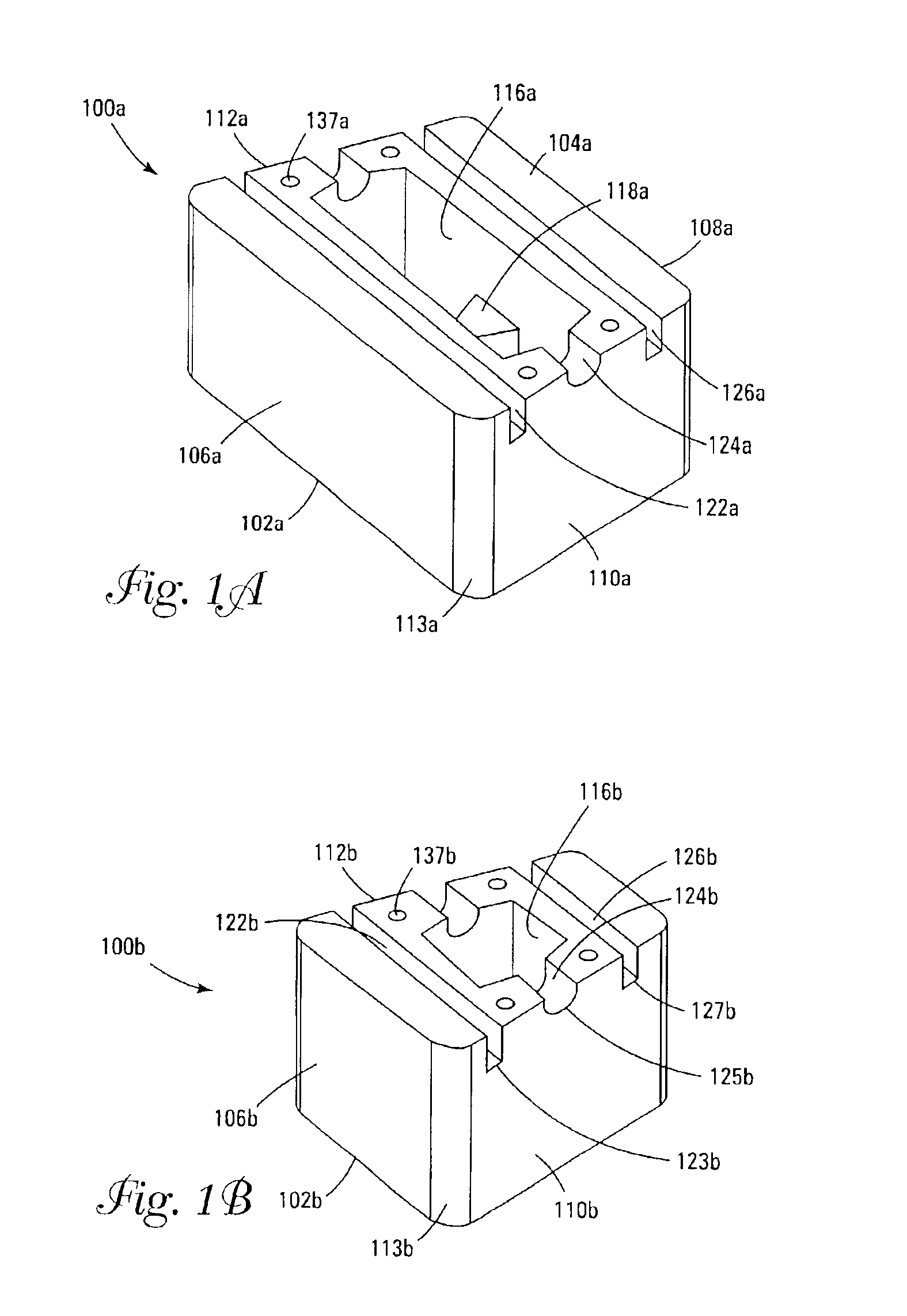

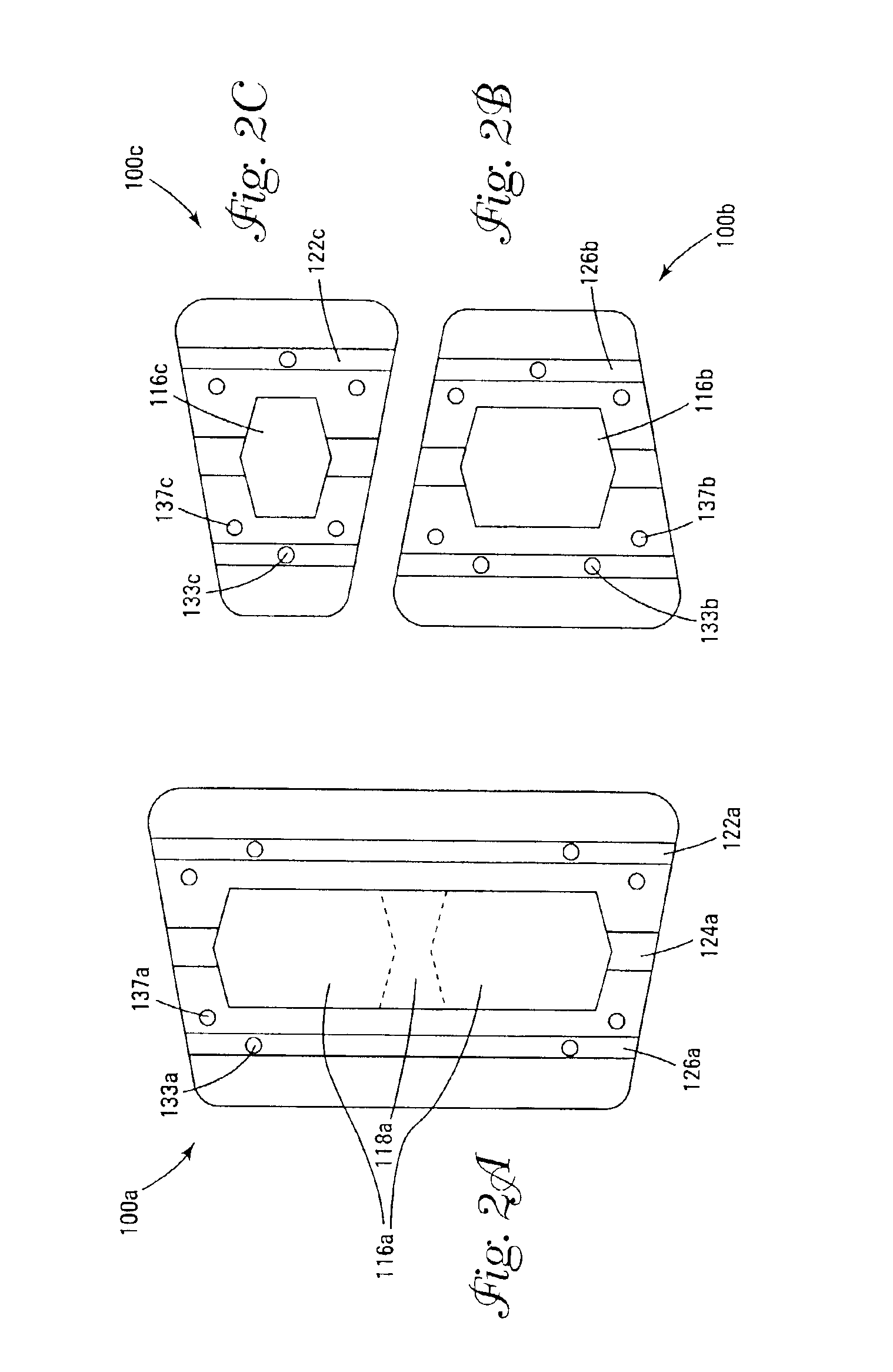

A retaining wall block system having multiple sizes and shapes of blocks with differently dimensioned, interchangeable front and back faces. The blocks are used to construct an irregularly textured wall having a weathered, natural appearance. Multiple channels in the lower face of the block are used to engage pins in pin-receiving apertures to form an attachment system. A side connection system is particularly useful for stabilizing free-standing walls. Horizontal reinforcing members are also used in the channels and vertical reinforcing members are used in cores of adjacent blocks for reinforcing a wall. Reinforcing geosynthetic materials can also be firmly held in a wall by means of the pins or by connectors adapted to fit in the block channels.

Owner:KEYSTONE RETAINING WALL SYST

Mechanical interlocking means for retaining wall

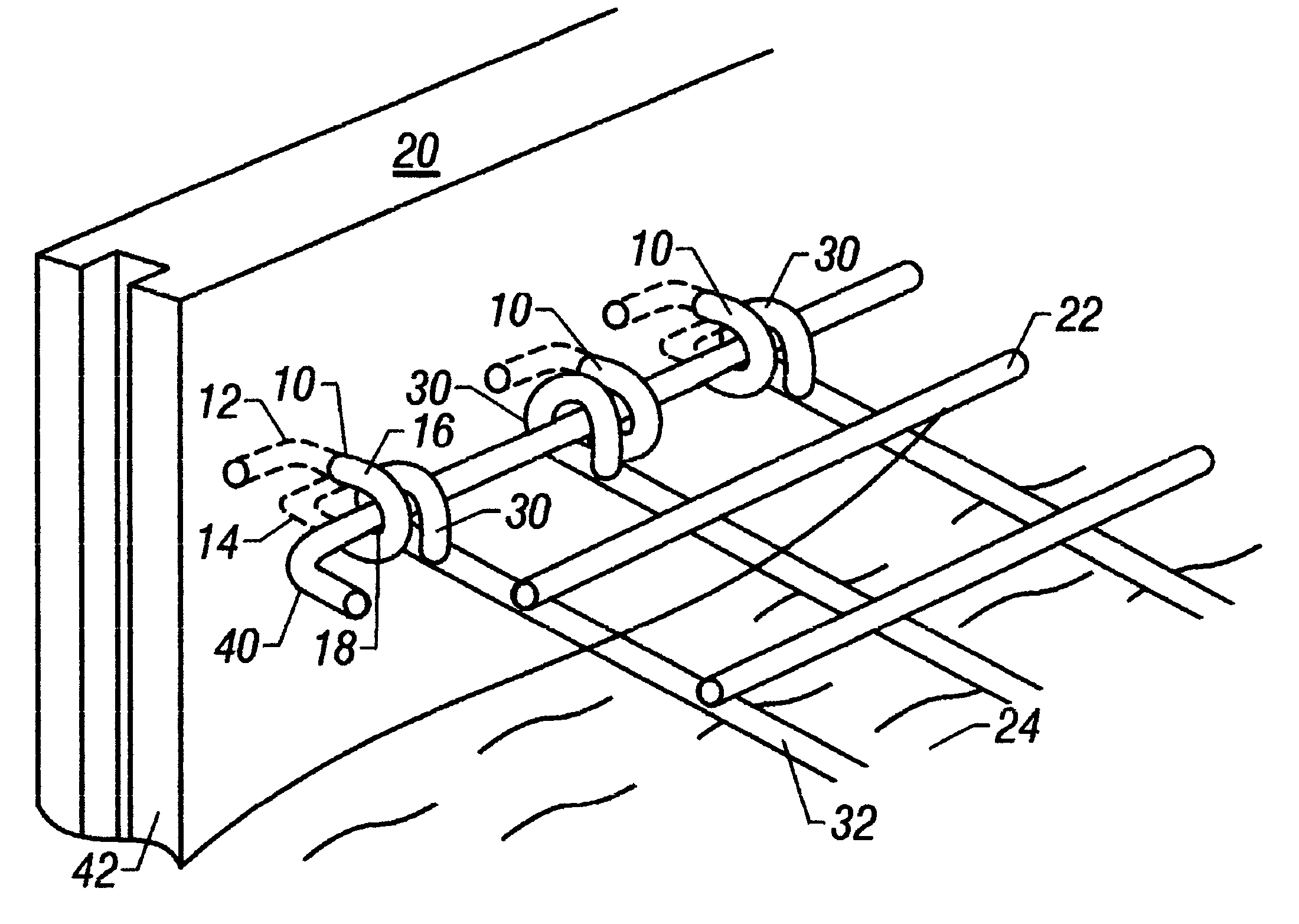

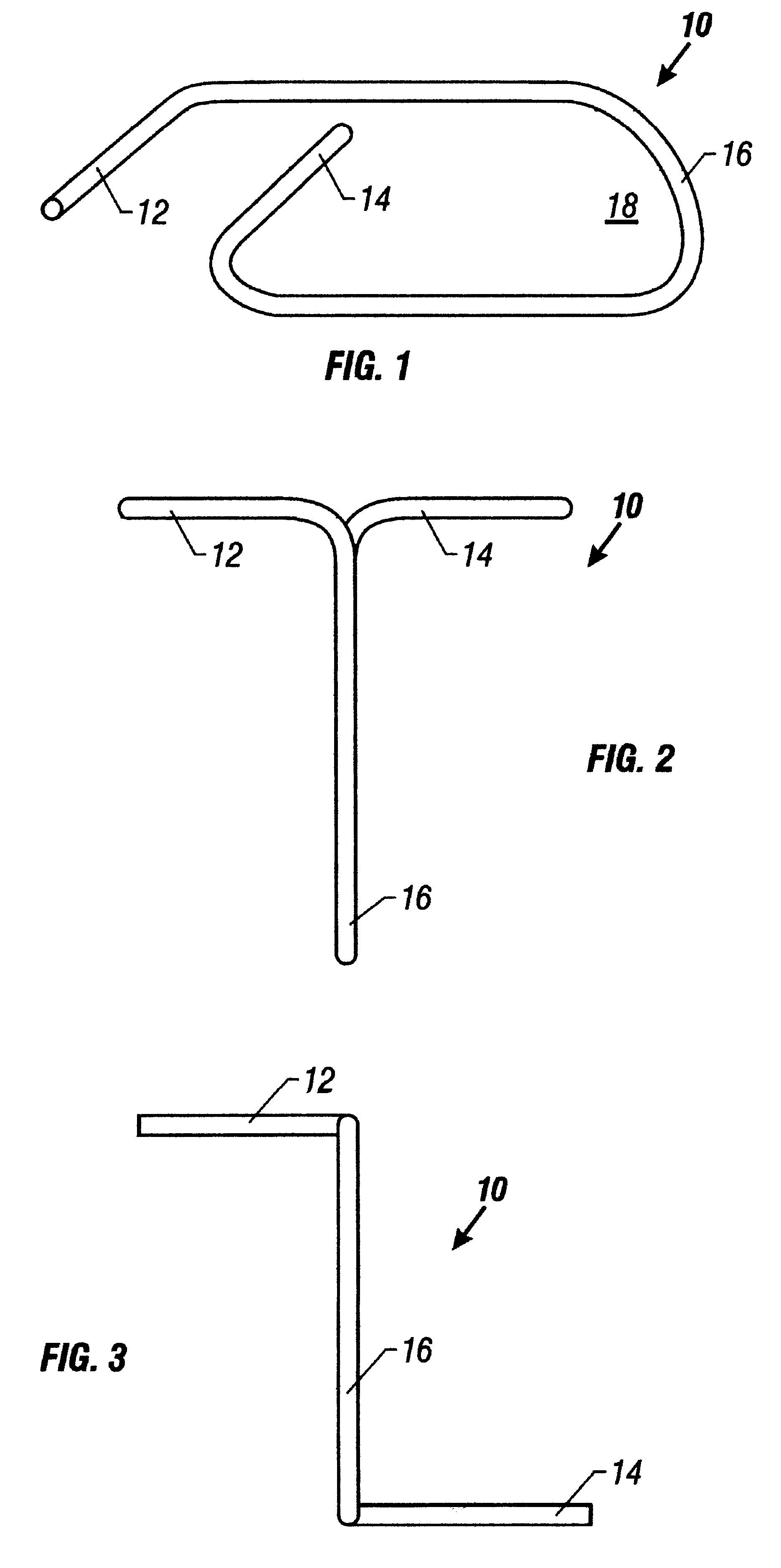

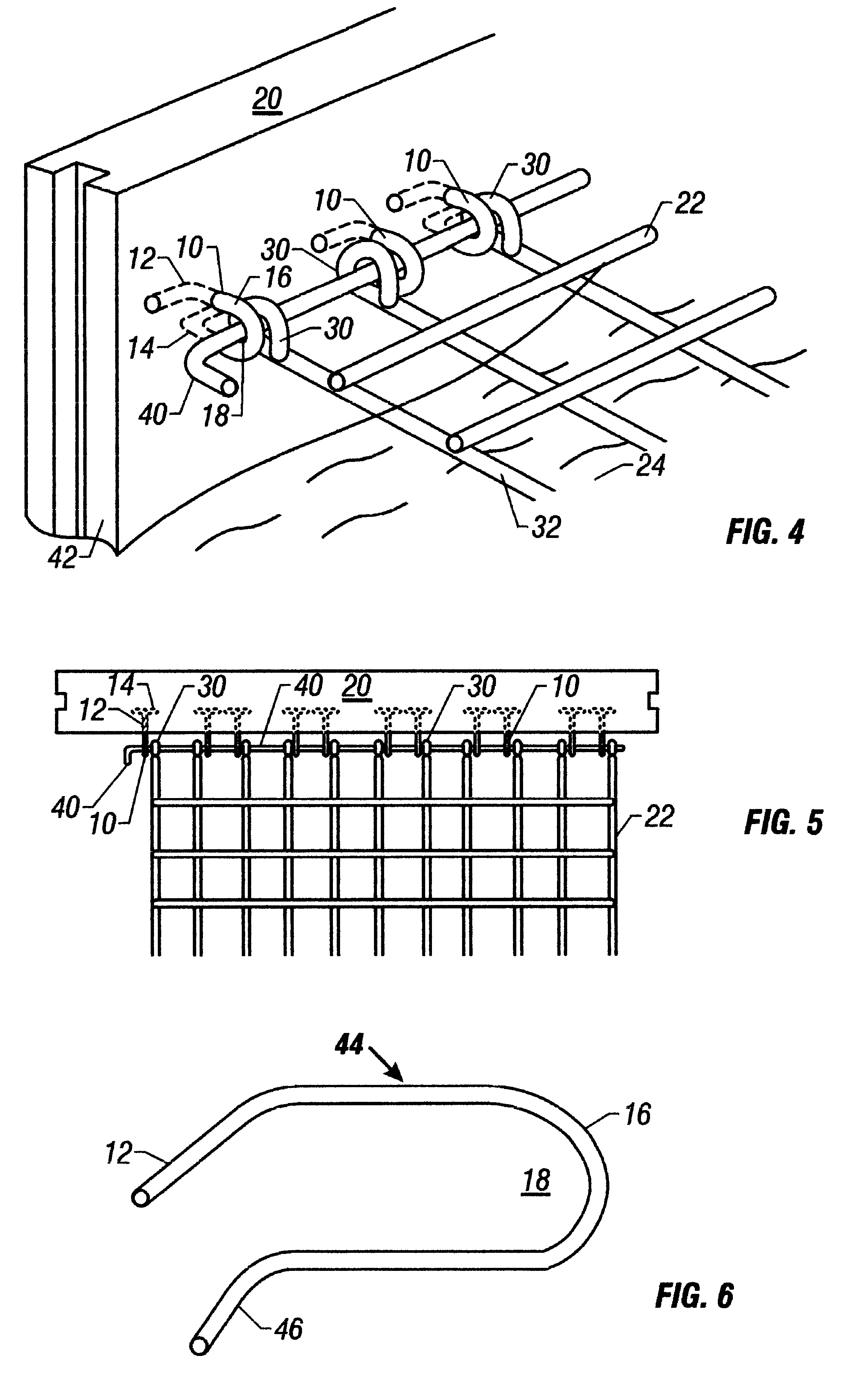

An improved method and system for attaching a welded wire grid-work panel to a plurality of face panels of a retaining wall. The method first begins by providing a plurality of stackable face panels, each face panel having a plurality of anchor links fixed within a back portion of the face panels. Each of the anchor links forms a vertical loop extending outwardly generally perpendicular to the back portion of the face panels. Additionally, each anchor link includes two legs extending laterally from each anchor link within the face panel. Next, a first tier of the face panels is disposed at the bottom of the embankment being erected. Soil is then back-filled behind the first tier of panels to a level of the anchor links disposed within the first tier of face panels. A welded wire grid-work panel, which extends perpendicularly from the back portion of the face panels into a soil embankment, is positioned so that a plurality of wire loops at the edge of the grid-work panel aligns with the vertical loops. A connector rod is extended through the vertical loops of the anchor links and the wire loops of the grid-work panel. Next, additional soil is back-filled behind the first tier of face panels and over the anchor links, vertical loops, wire loops, and grid-work panel to a level at a top edge of the first tier of face panels. The method is repeated until the desired height of the embankment is attained.

Owner:SCR STI LLC

Concrete block system

A dry-cast concrete block system for use in a structure. The dry-cast concrete block system comprises a support block comprising a first coupling part and a face block comprising a second coupling part. The first coupling part and the second coupling part enable the face block to be coupled to the support block. The face block comprises a surface adapted to be exposed when the face block is coupled to the support block and the dry-cast concrete block system is positioned in the structure. In one embodiment, at least a portion of the surface has a cast texture with a natural stone appearance. In one embodiment, the structure is a wall and the concrete block system is a wall block system. For example, the wall may be a retaining wall and the wall block system may be a retaining wall block system. In another embodiment, the structure is a column and the concrete block system is a column block system. In yet another embodiment, the structure is steps and the concrete block system is a steps block system.

Owner:OLDCASTLE BUILDING PROD CANADA INC

Quick supporting method for large-deformation roadway easy to fall, break and loosen and apparatus thereof

InactiveCN101852083AImprove stress statusStop looseningUnderground chambersMine roof supportsFiberSupporting system

The invention discloses a quick supporting method for large-deformation roadway easy to fall, break and loosen and an apparatus thereof. The method comprises the following steps of: (1) clearing away the loose stones on the wall of the surrounding rock of the roadway; (2) hanging a reinforcing steel bar mesh along the digging outline of the roadway and initially spraying one thin concrete layer; (3) arranging an anchor rod in the drill hole of the roadway wall; (4) arranging a side-wall steel grating arch to support the surrounding rock of the side wall; (5) arranging a top-supporting steel grating arch, touching the top and supporting the upper surrounding rock; (6) clearing away the floating slag at the bottom of the roadway, arranging a steel grating arch of the inverted arch, supporting and sealing the system into a ring; (7) carrying out the cement injection construction on the anchor rod; (8) welding the exposed part of the cement injected anchor rod on the steel grating arch to form a whole structure; and (9) multi-spraying concrete or steel fiber concrete along the roadway wall. The apparatus comprises an anchor rod, a side-wall steel grating arch, a steel grating arch of top arch, a steel grating arch of inverted arch, and a concrete spray layer of reinforcing steel bar. The invention has the advantage of remarkable support effect, simple method and convenient operation and solves the problem that the bracket and the surrounding rock are not adhered tightly.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

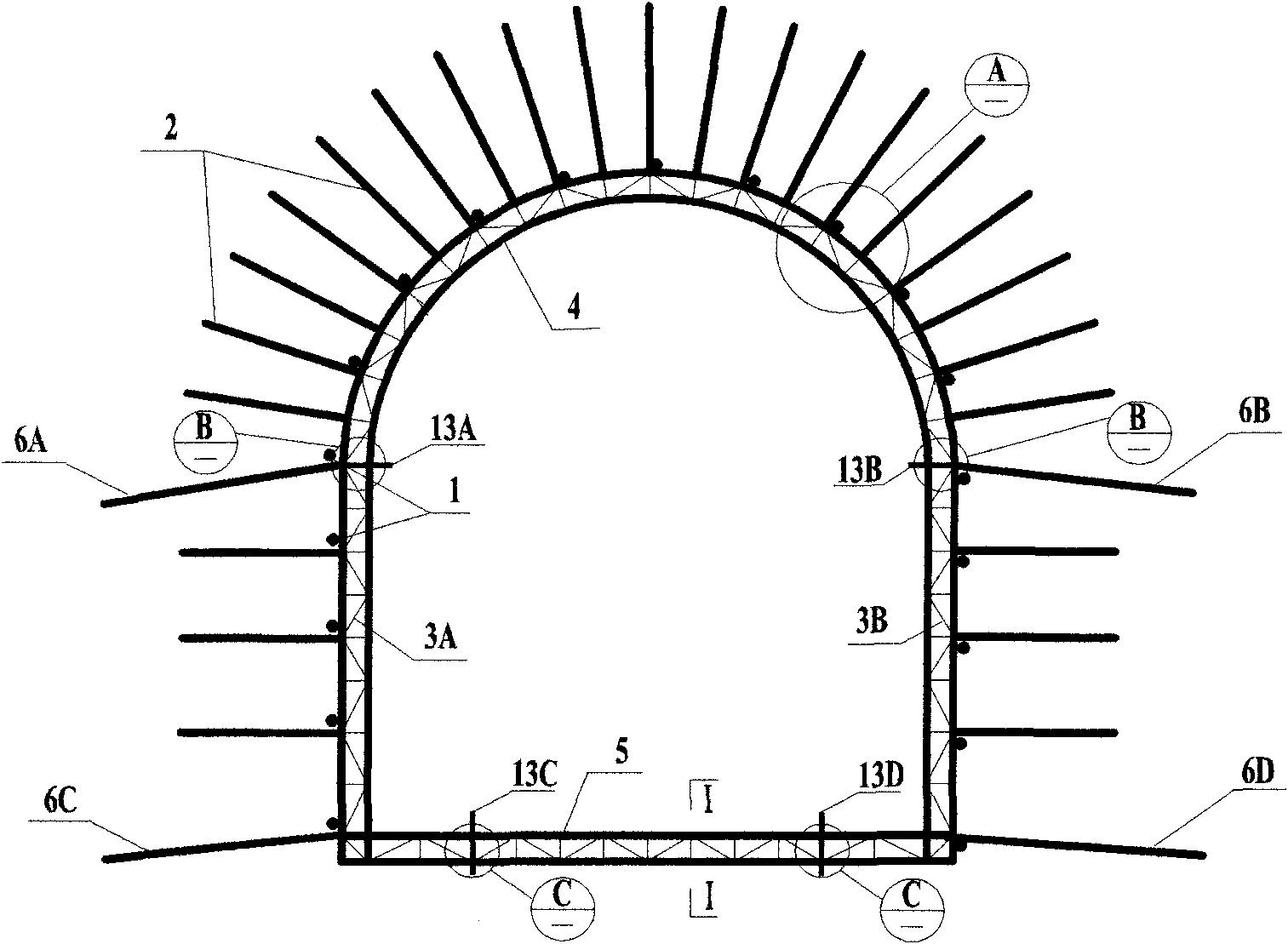

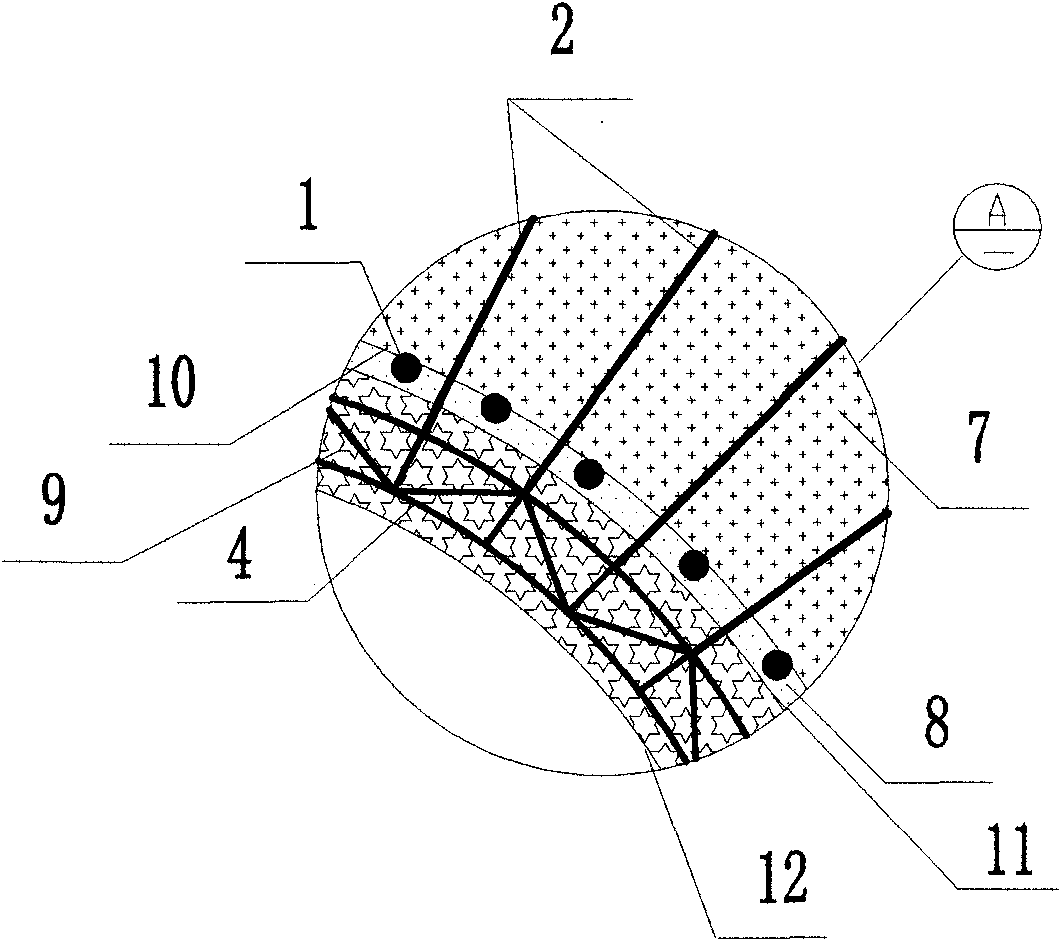

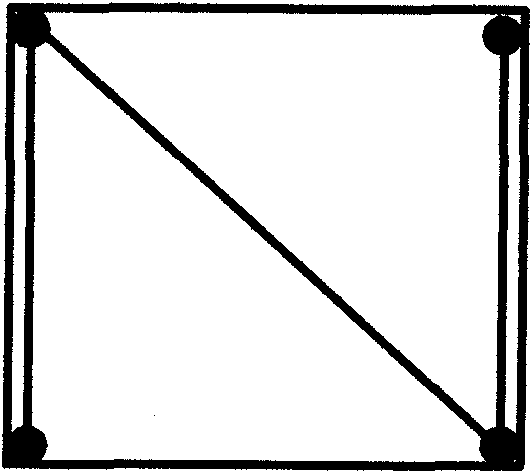

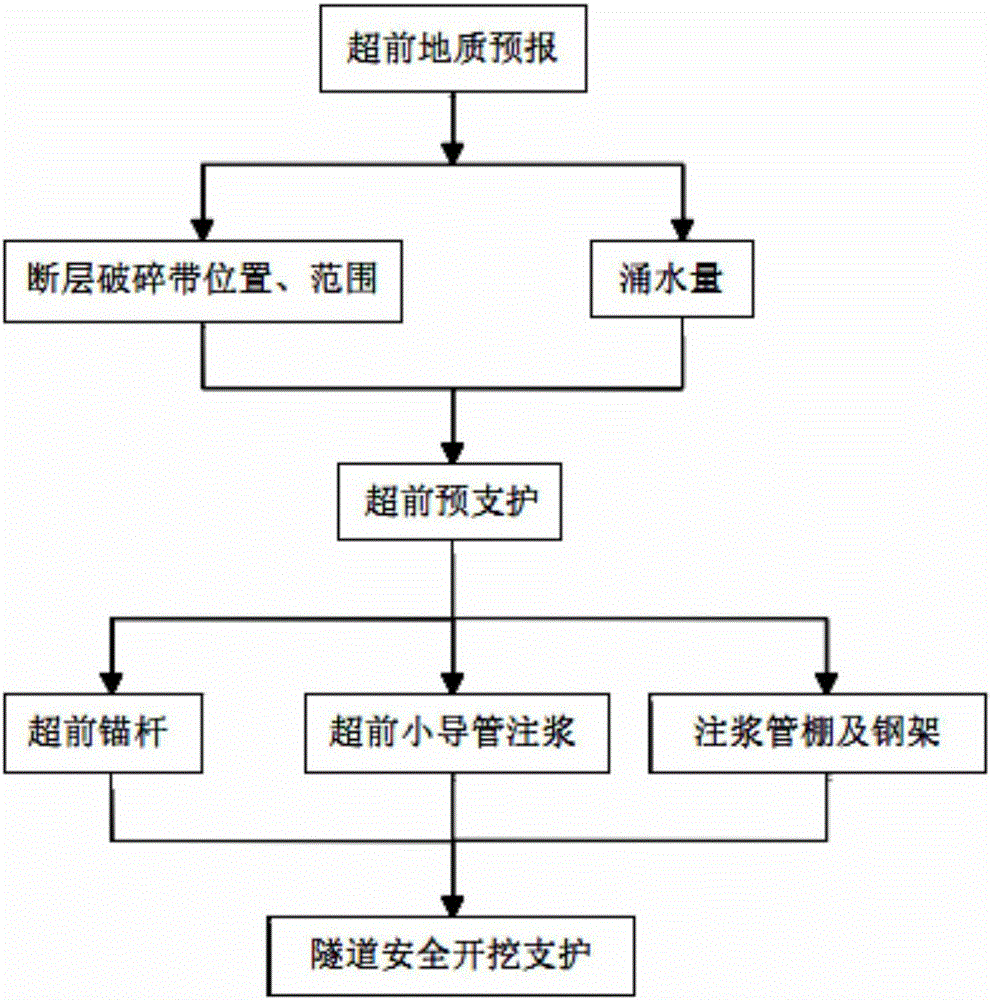

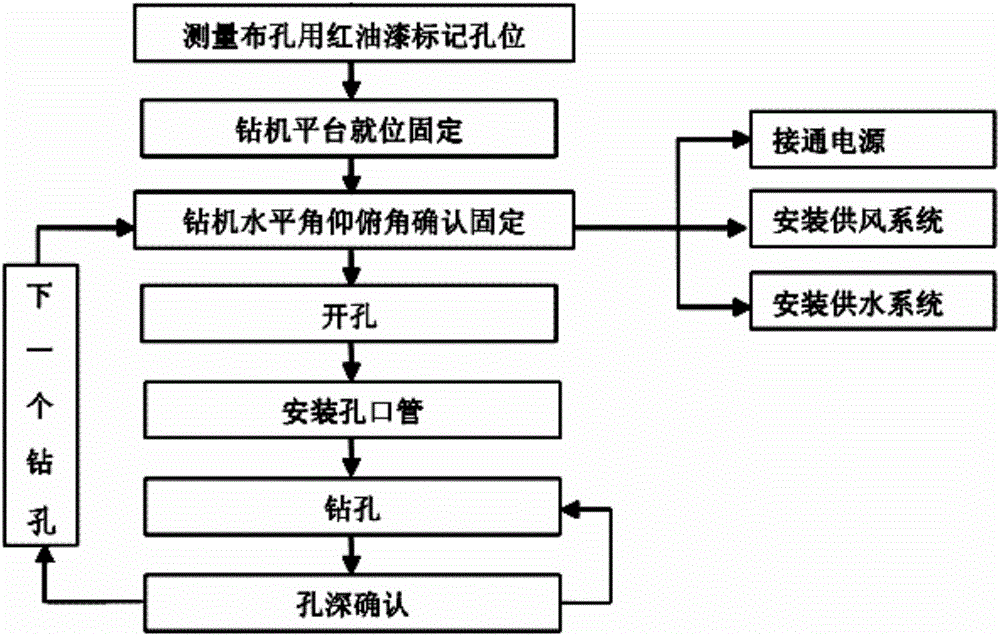

Construction method for fault fracture zone surrounding rock tunnel

InactiveCN106837352AEnsure safetyImprove applicabilityUnderground chambersTunnel liningGeomorphologyShortest distance

The invention discloses a tunnel construction method in a fault fracture zone, which comprises the following steps: a. adopting the method of combining geophysical prospecting and drilling and combining long-distance and short-distance to ascertain the geological situation in front, and carry out advanced geological prediction; b. adopting advanced Anchor construction, pre-grouting construction of the surrounding walls of small conduits in advance, and advance support construction of grouting pipe shed and steel frame, and advance pre-support; c. Tunnel excavation and support. It provides a theoretical basis for detecting the specific location, range and water inflow of the fault fracture zone; ensures the safety of tunnel construction; on the basis of analyzing the specific location and scope of the fault fracture zone and adopting a reasonable advanced pre-support method, comprehensive and specific According to the geological conditions, choose a reasonable tunnel excavation method. It has strong applicability for the construction of expressway tunnels crossing fault fracture zones; at the same time, it has reference and reference significance for the construction of railway, municipal and water conservancy tunnels (holes) with similar geological conditions.

Owner:CENT SOUTH UNIV +2

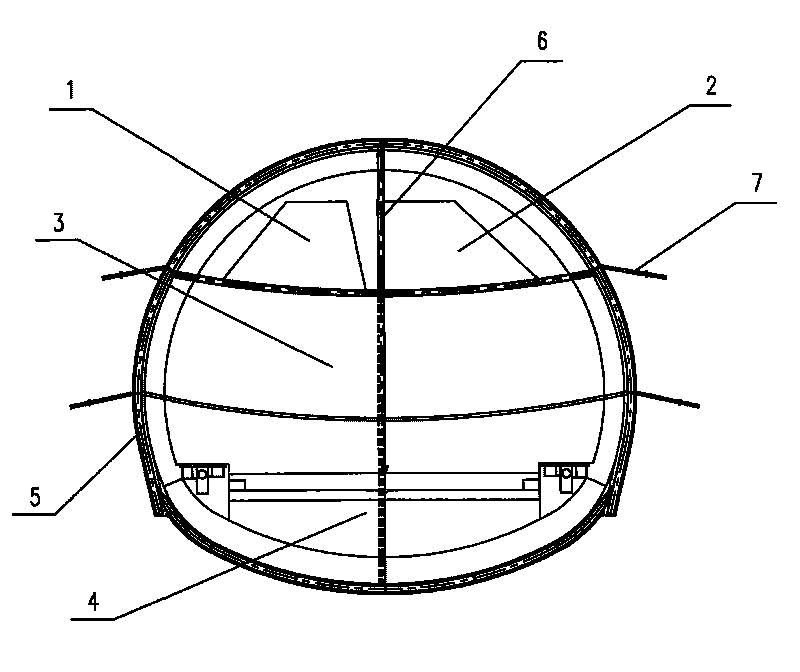

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

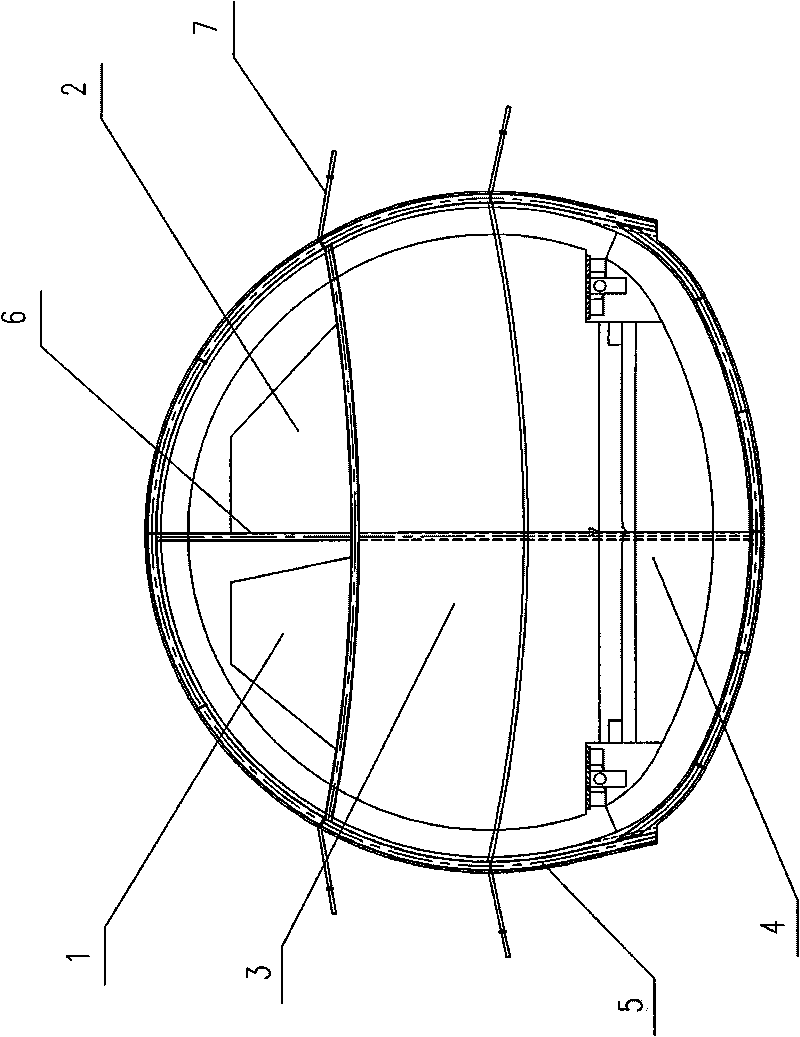

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Goaf surrounding rock around gob-side supporting method under three soft geological condition

ActiveCN101280684ASolve support problemsPromote safe productionUnderground chambersTunnel liningEngineeringTechnical support

Disclosed is a method for retaining roadway and supporting the surrounding rock in goafs under geological condition, which is characterized by first reinforcing and retaining roadway for the first time, then constructing the exceeded roadway and finally constructing and retaining roadway for the second time. The method of the invention forms an effective supporting for the secondary retaining roadway along the goafs, thus overcoming the difficulty in supporting roadway in a condition of multi mining activities. The roadway is primarily guaranteed perfect during the mining period and the amount of shrinkage is in the allowed control range, thereby providing technical support and guarantee for smoothly realizing the Y-type ventilation of the working face with high content of methane and promoting the safety production in mine wells.

Owner:HUAINAN MINING IND GRP +2

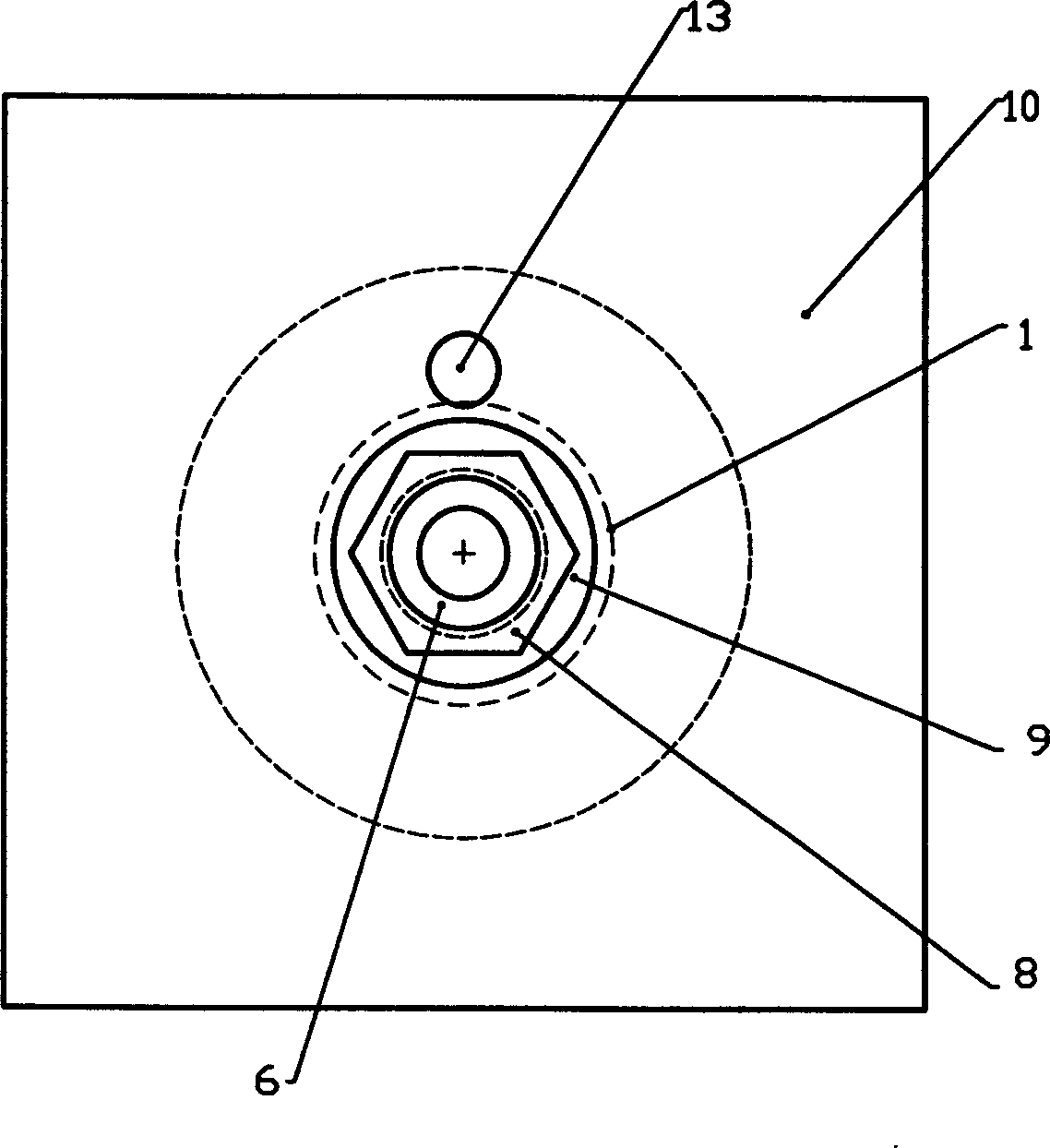

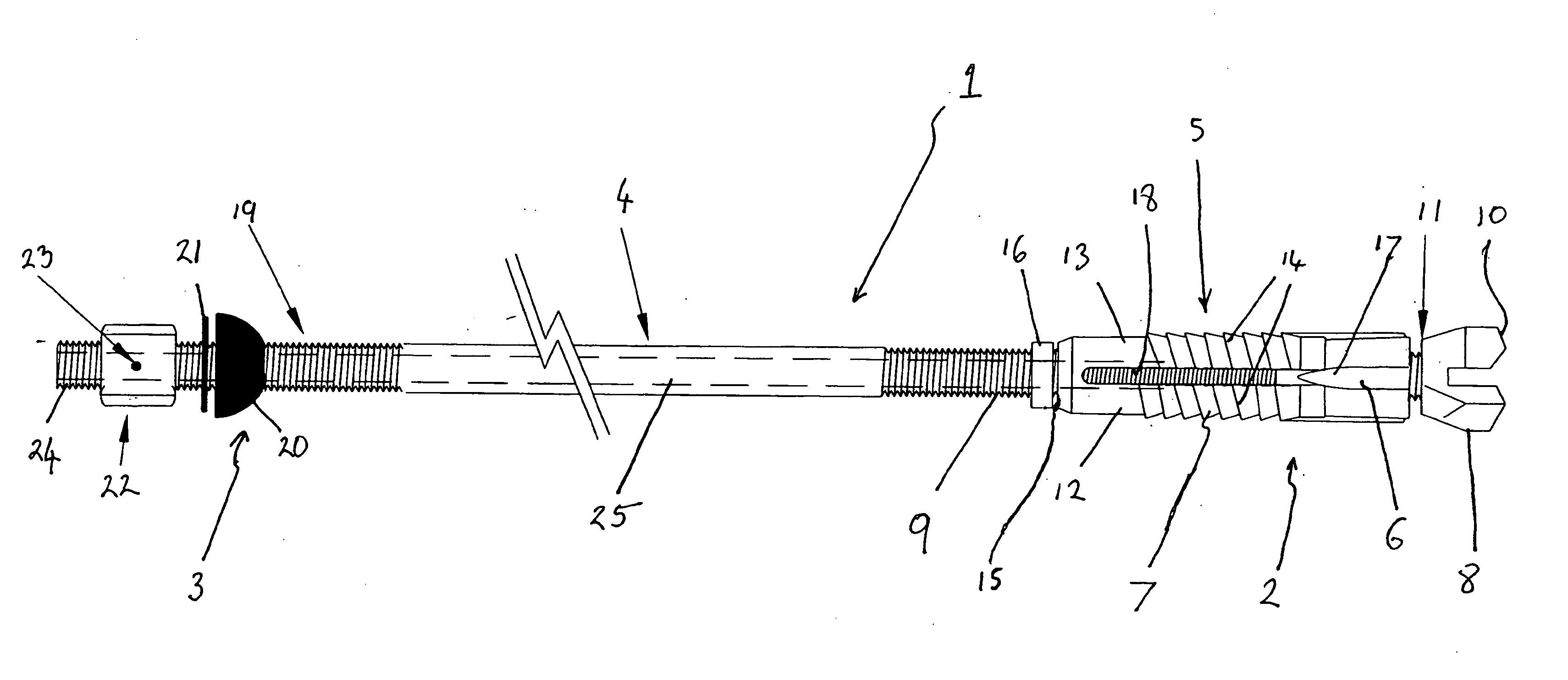

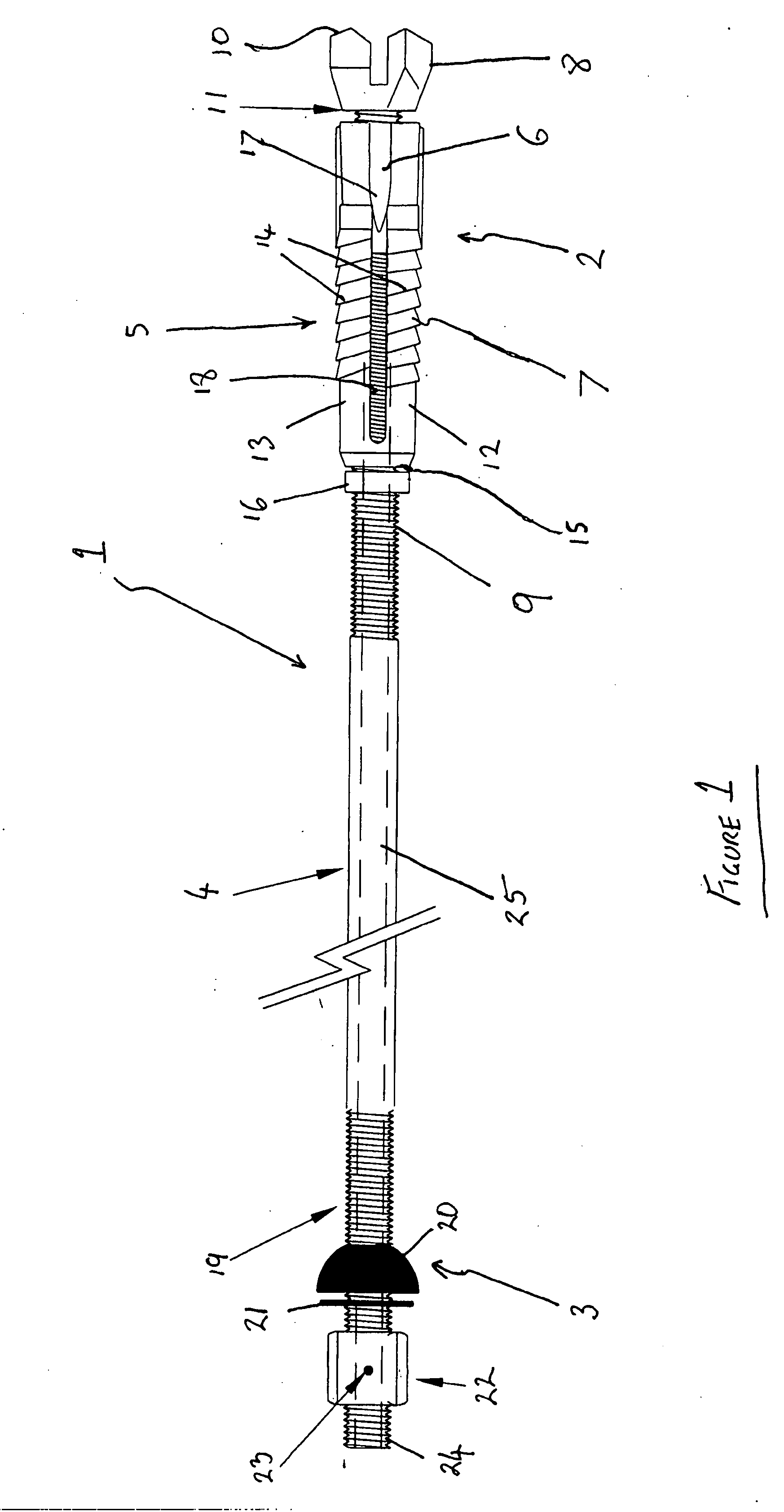

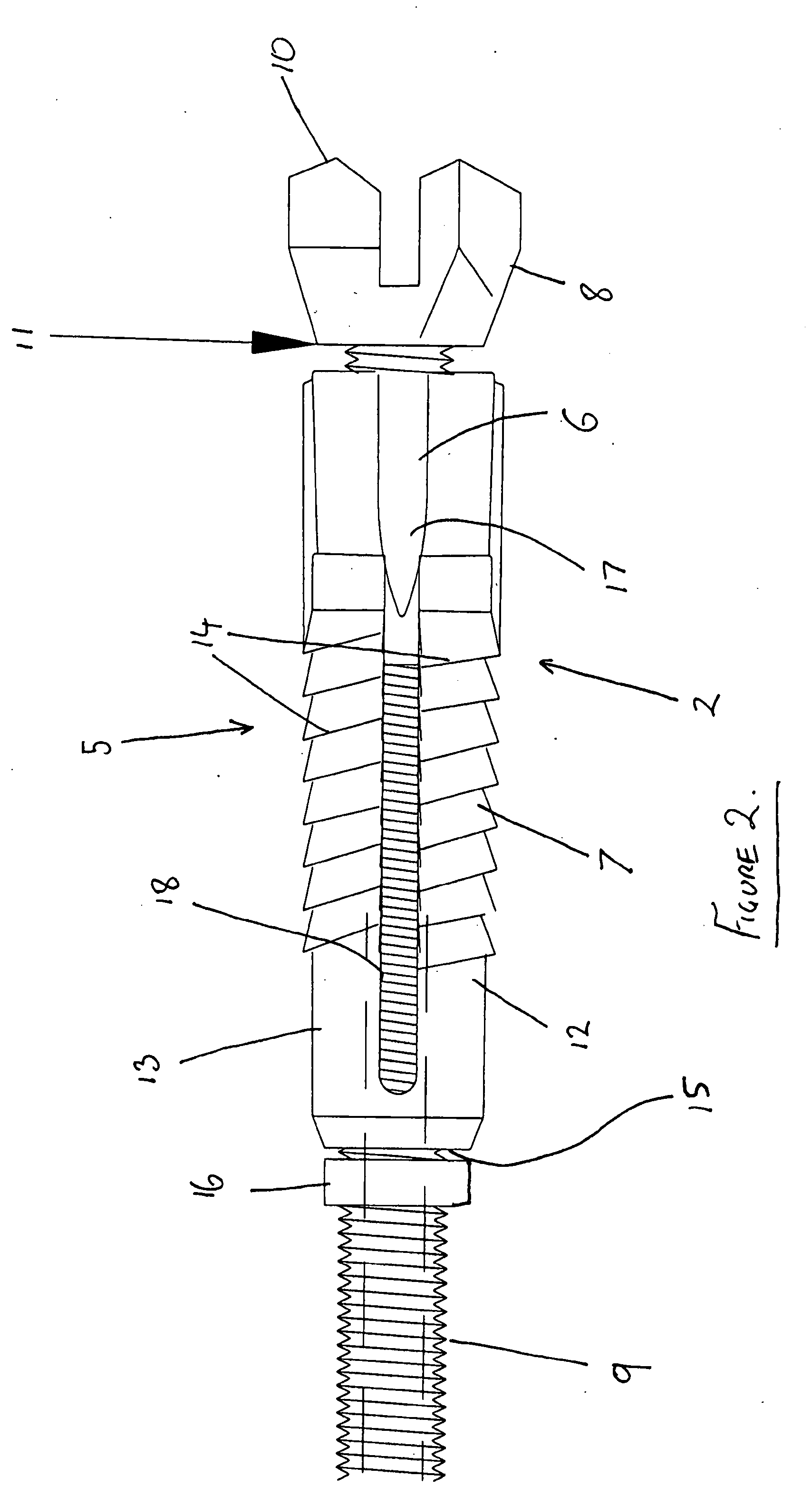

Anchor device with an elastic expansion sleeve

InactiveUS20070031196A1Strong loadIncrease the number ofArtificial islandsUnderwater structuresEngineeringRigid rod

The invention relates to an anchor device, for stabilizing an excavation wall and to be inserted into a hole, bored in an excavation wall. Said anchor device comprises a rigid elongated rod which defines a distal end, to be inserted into the bored hole and a proximal end, opposed to the distal end, a support member, mounted on the rod in the vicinity of the proximal end thereof and provided for resting against an outer surface of the wall of rock and an anchor head, mounted on the rod and to be inserted into the hole, bored in the excavation wall. Said anchor head comprises a flexible expandable member, mounted on the rod, made of plastic and capable of radially expanding and stretching and an activating member, movably mounted on the rod, said activating member being capable of moving relative to the rigid rod and to the expandable member and capable of contacting the same in order to exert a pressure. For anchoring the anchor head into the excavation wall at the bored hole, the activating member and the expandable member are displaced relative to one another, such as to contact each other and to allow the activating member to exert a pressure upon the expandable member, in order to cause the radial expansion of at least one portion thereof, so that said portion of the expandable member makes frictional contact on a part of the inner surface, defining the hole bored in the excavation wall.

Owner:BRUNEAU MARCELLIN

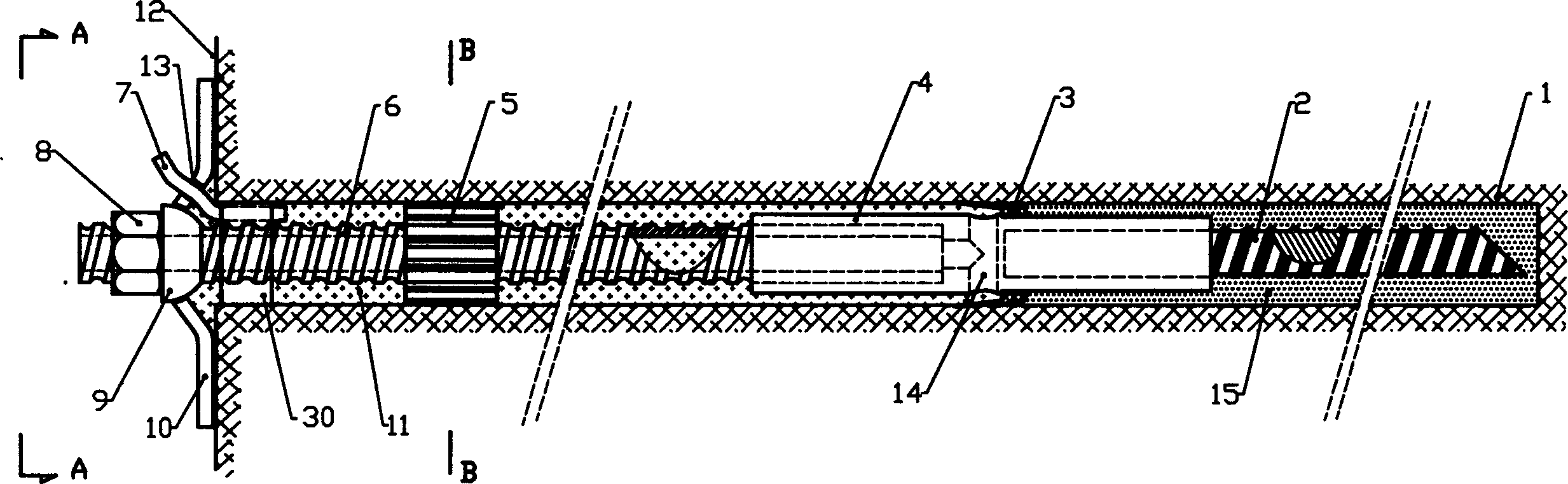

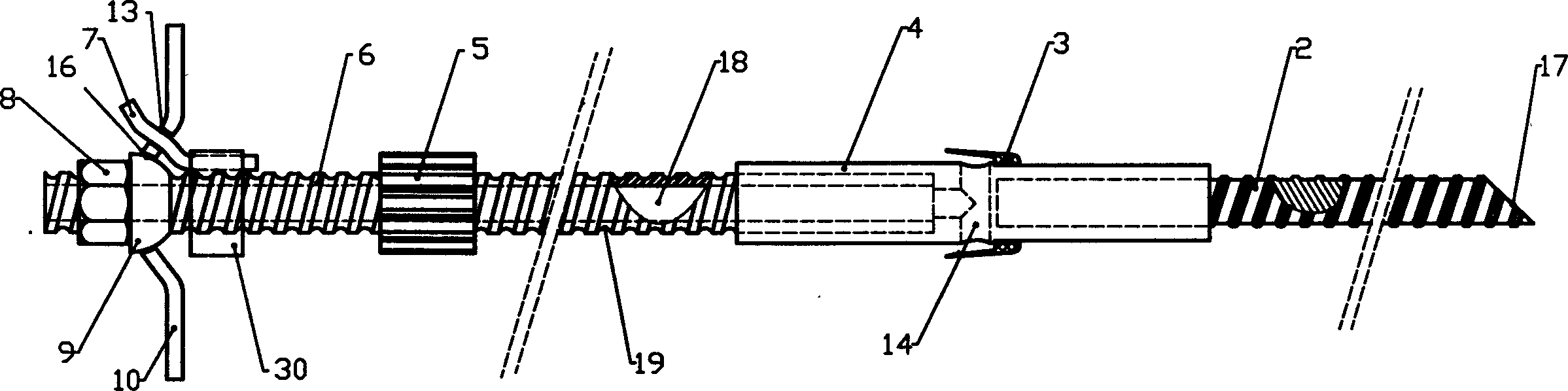

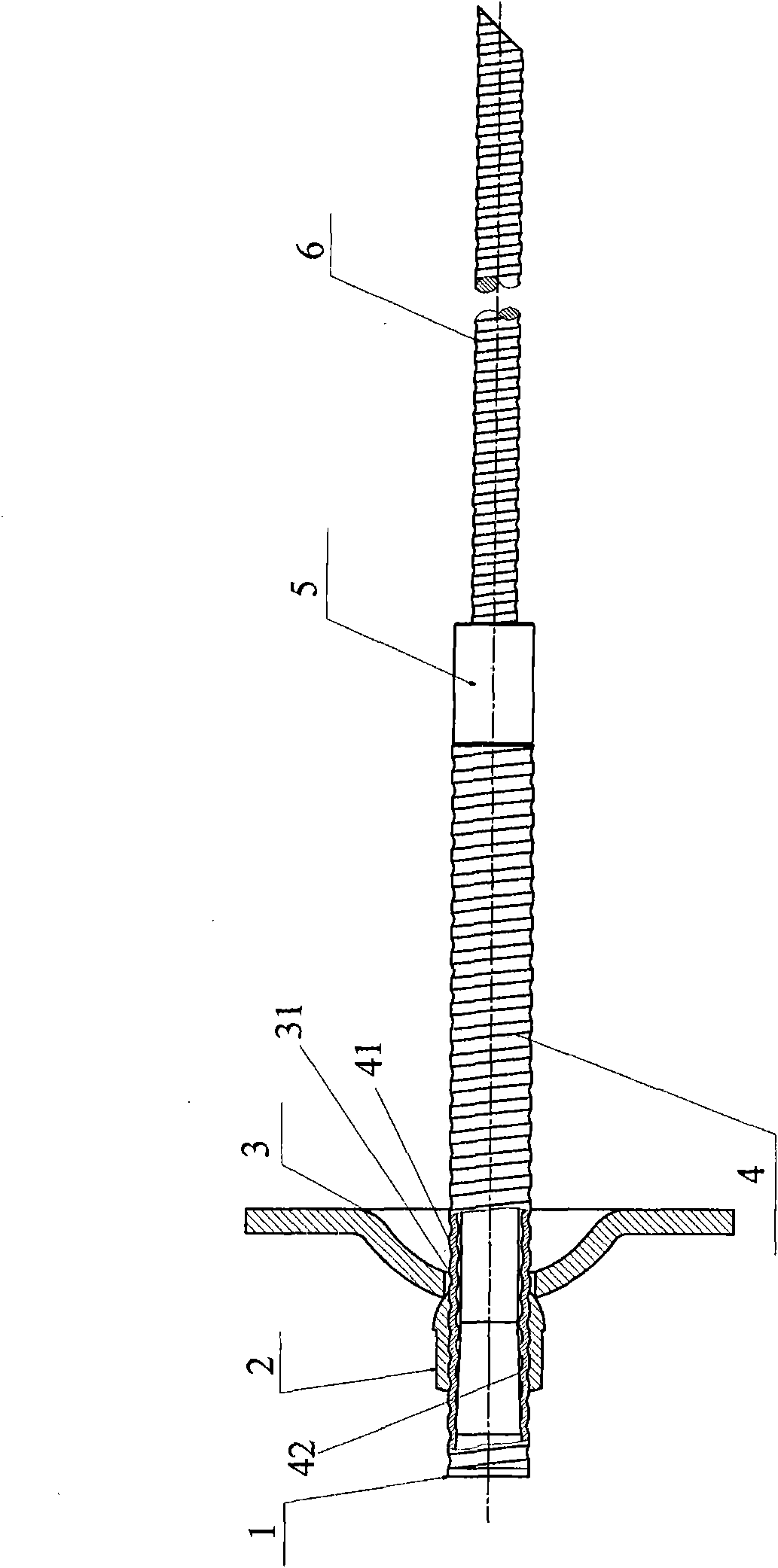

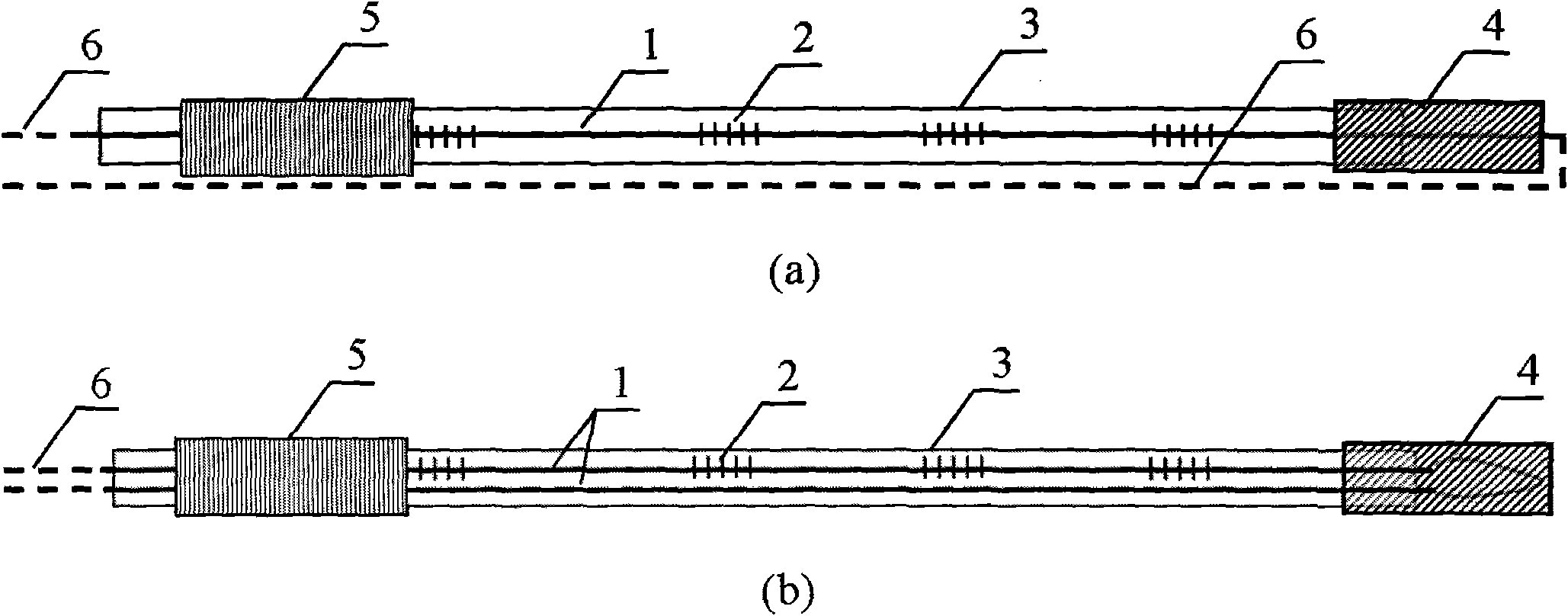

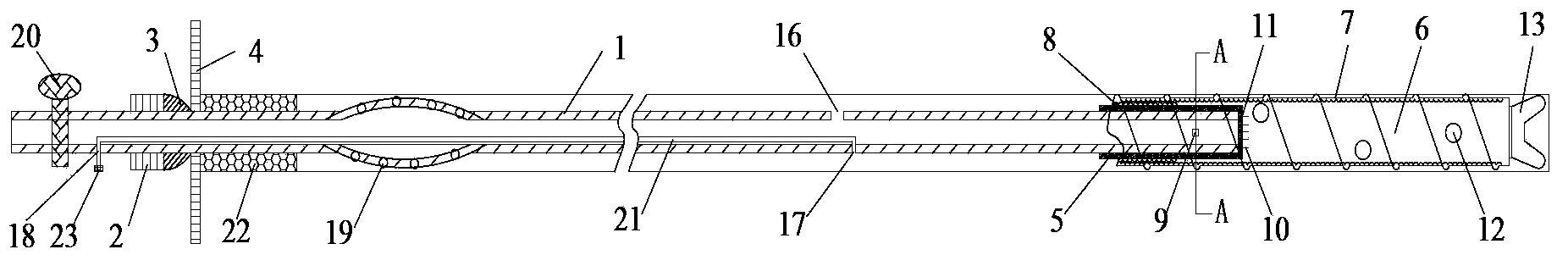

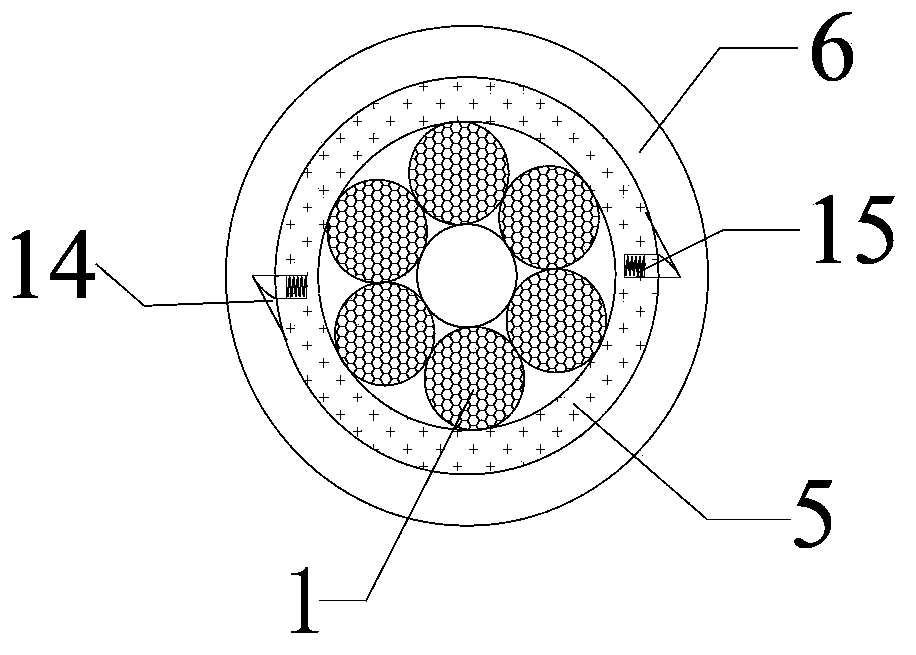

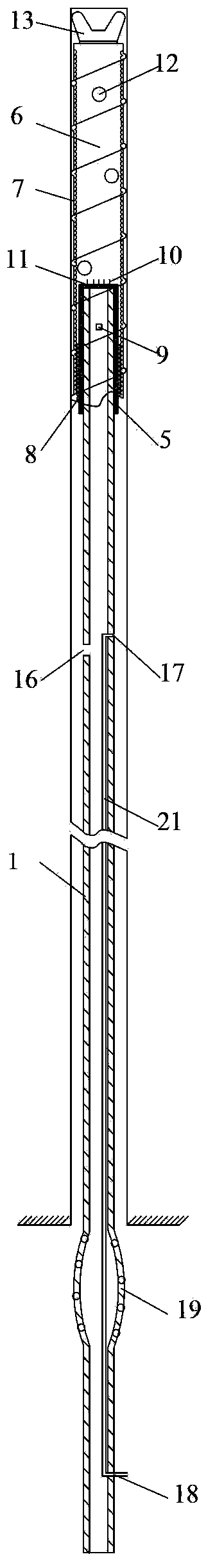

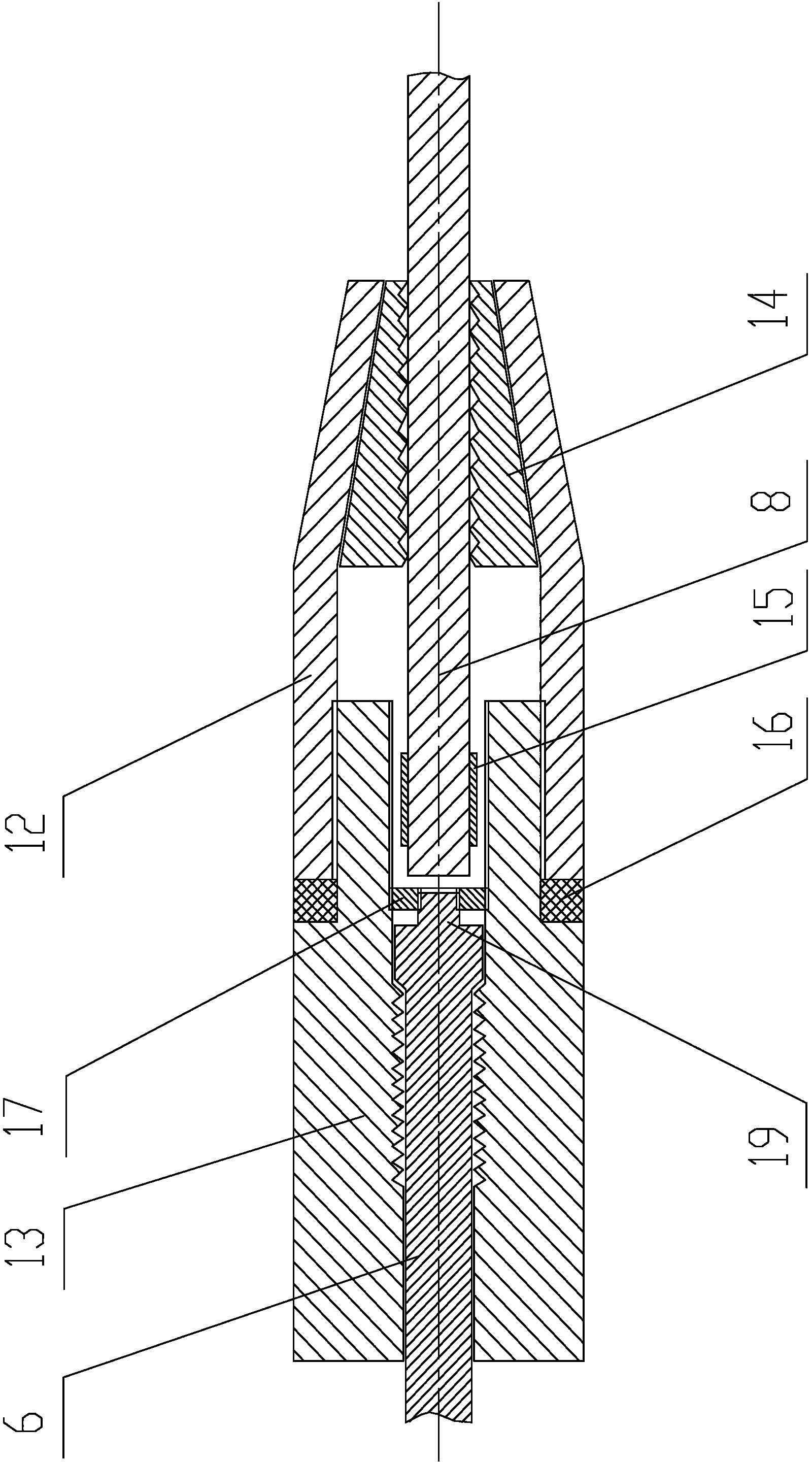

A pin timbering process and sectionalized hollow mud injecting stay bolt thereof

InactiveCN1464176AImprovement of Bolt Support MethodImproved support methodAnchoring boltsPre stressEngineering

The present invention is anchor support method and one kind of sectional hollow grouted anchor and has the features of first early strengthening locking and then grouting protection and prestressing. The sectional hollow grouted anchor consists of two sections including front solid rod and back hollow rod connected via connecting sleeve, the connecting sleeve has mortar blocking unit and hollow rod section has several centralizing units. There are side hole canal in the joint of the connecting sleeve and the hollow rod and hole canal in the support cushion for some pipe to pass through. The said anchor support method of the present invention is used for temporary and permanent fast support in both hard and weak rock formation conditions.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

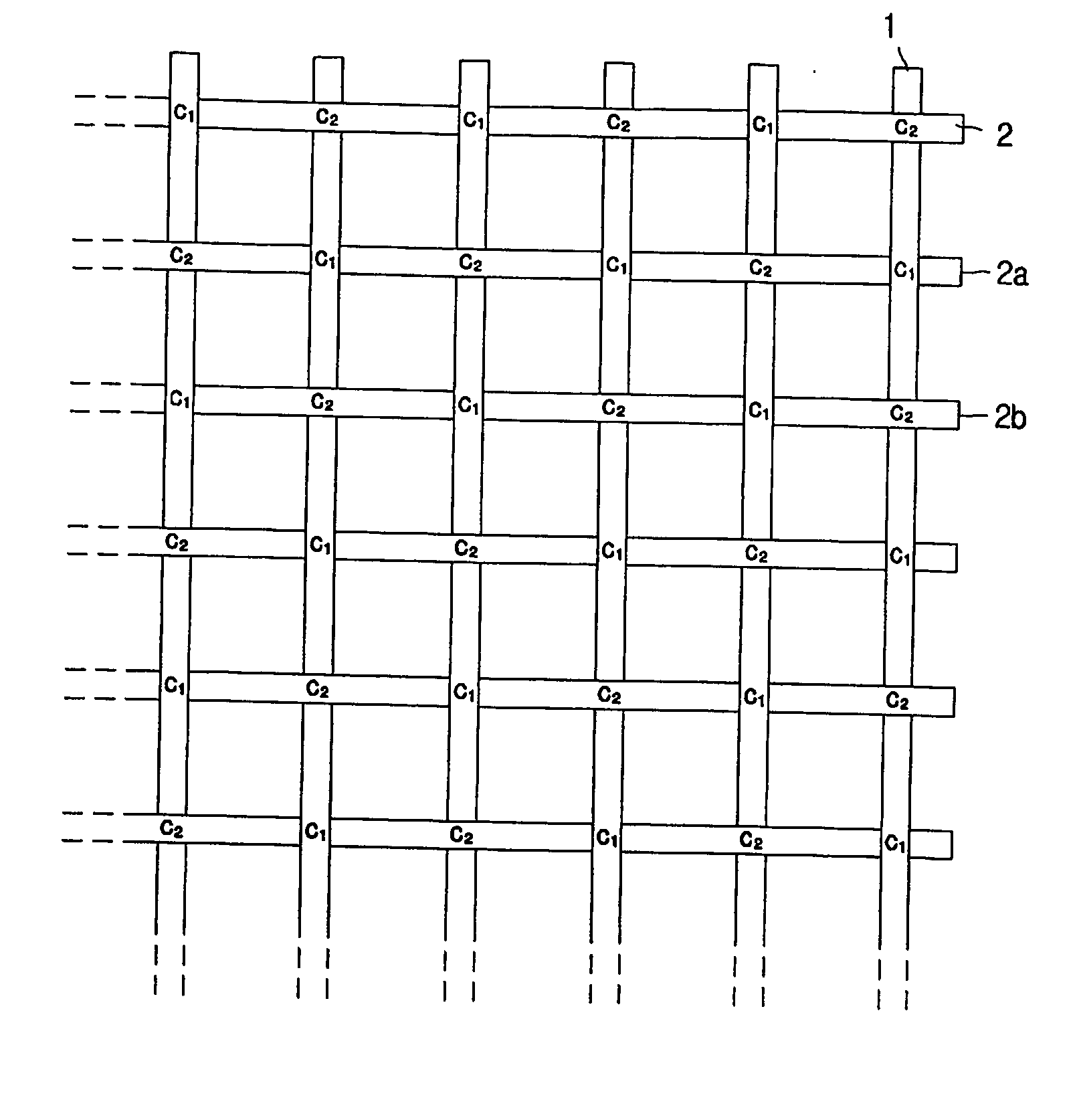

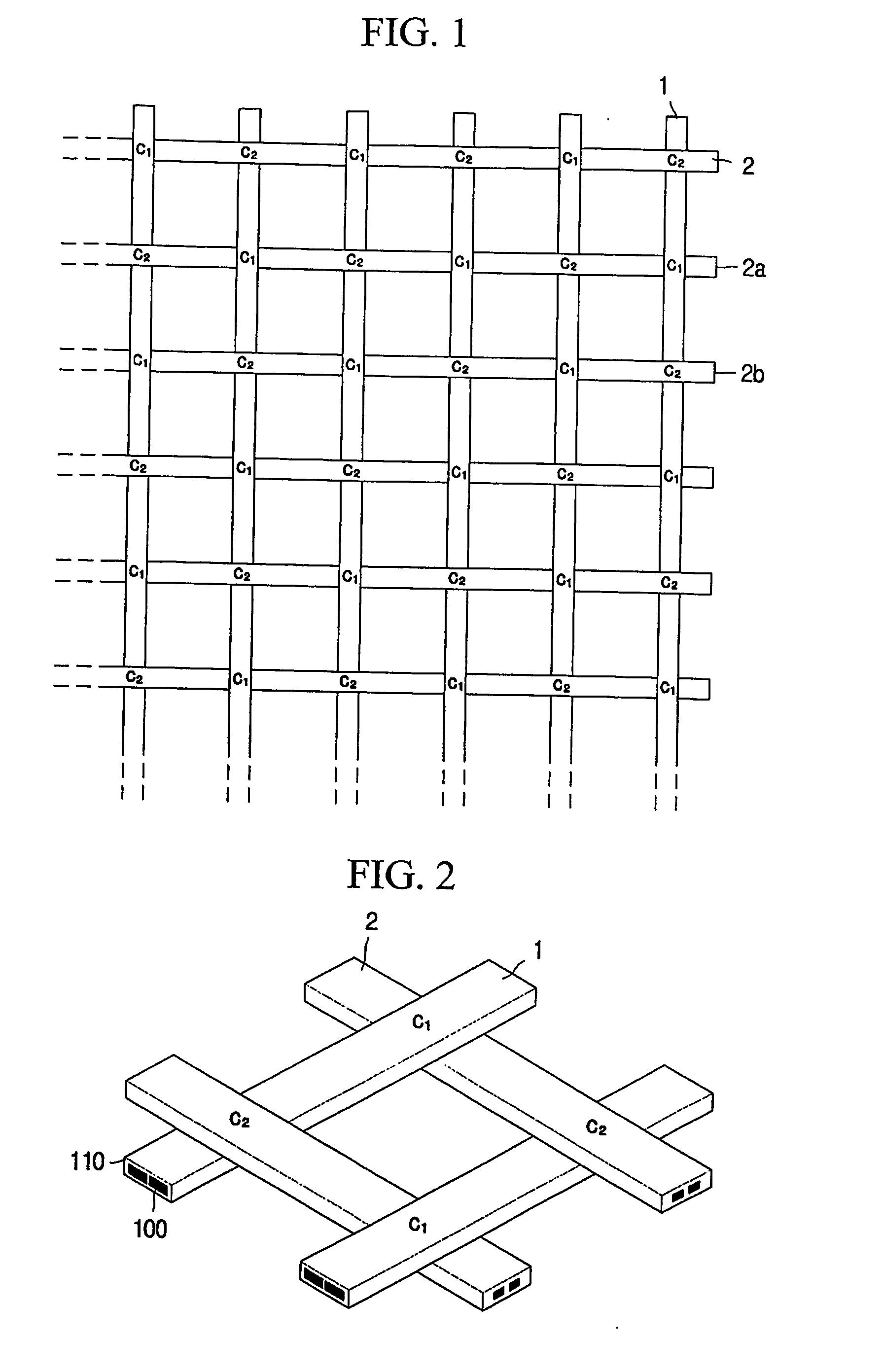

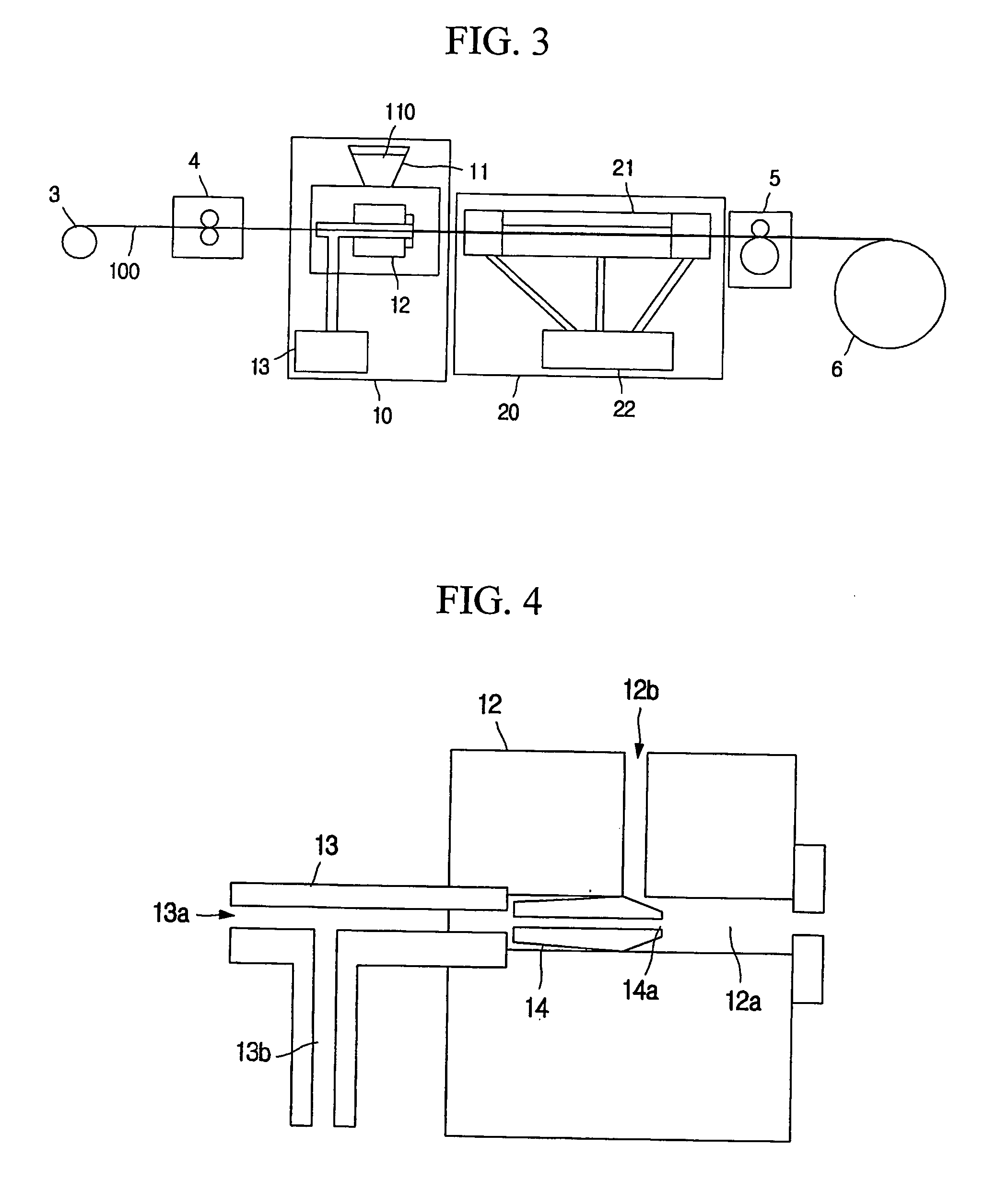

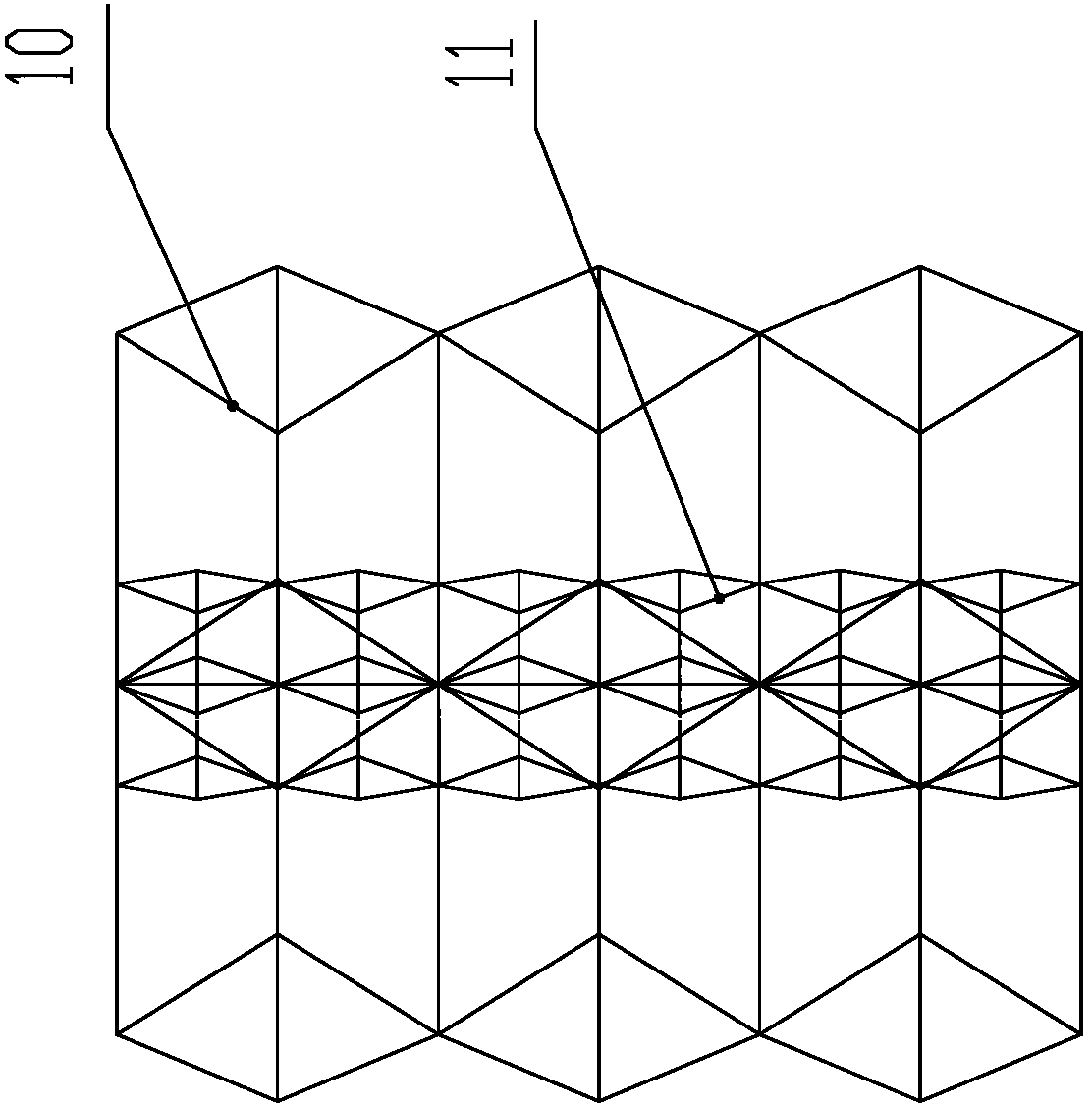

Geogrid composed of fiber-reinforced polymeric strip and method for producing the same

InactiveUS20060116040A1Increase resistance against vertical loadIncrease friction forceWarp knittingWelding/cutting auxillary devicesTensile strainGeogrid

A geogrid using fiber-reinforced polymeric strips and its producing method are disclosed. The geogrid of a lattice shape includes plural longitudinal fiber-reinforced polymeric strips longitudinally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin, and plural lateral fiber-reinforced polymer strip laterally arranged in parallel at regular intervals and formed by reinforcing fiber in a thermoplastic polymer resin. Each longitudinal fiber-reinforced polymer strip has at lease one first contact point crossed with the lateral fiber-reinforced polymer strip on the upper surface and at least one second contact point crossed with the lateral fiber-reinforced polymer strips on the lower surface. The contact points are fixed by welding the longitudinal and lateral fiber-reinforced polymer strips. The geogrid is excellent in installation capacity, frictional feature and shape stabilisation and shows high tensile strength and low tensile strain and low creep deformation.

Owner:SAMSANG CORP

Method for preventing and treating large deformation and collapse of softrock tunnel

ActiveCN101906977AImprove pullout resistanceGuaranteed stabilityUnderground chambersTunnel liningLarge deformationRock bolt

The invention relates to a method for preventing and treating large deformation and collapse of a softrock tunnel, which comprises the following steps: tunneling molding or enlarging a tunnel; primarily spraying the first layer of concrete, and hanging a side net and a top net at the first layer of concrete; arranging a constant-resistance large deformation rock bolt; multiply spraying the second layer of concrete; arranging a constant-resistance large deformation anchor cable on the top plate; digging and laying the first layer of base plate concrete; hanging a layer of backing screen on the first layer of base plate concrete, and arranging a base angle anchor rod at the base angle; laying the second layer of base plate concrete onto the grade level; setting a long-term ground pressure monitoring point, if the tunnel deforms to a certain preset valve, carrying out secondary support at the key position of the tunnel and carrying out pressurization and slip casting on surrounding rock. The invention can well ensure the stability of softrock tunnel under the condition of large deformation, in addition, the invention has the advantages of simple and practicable implement and lower cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

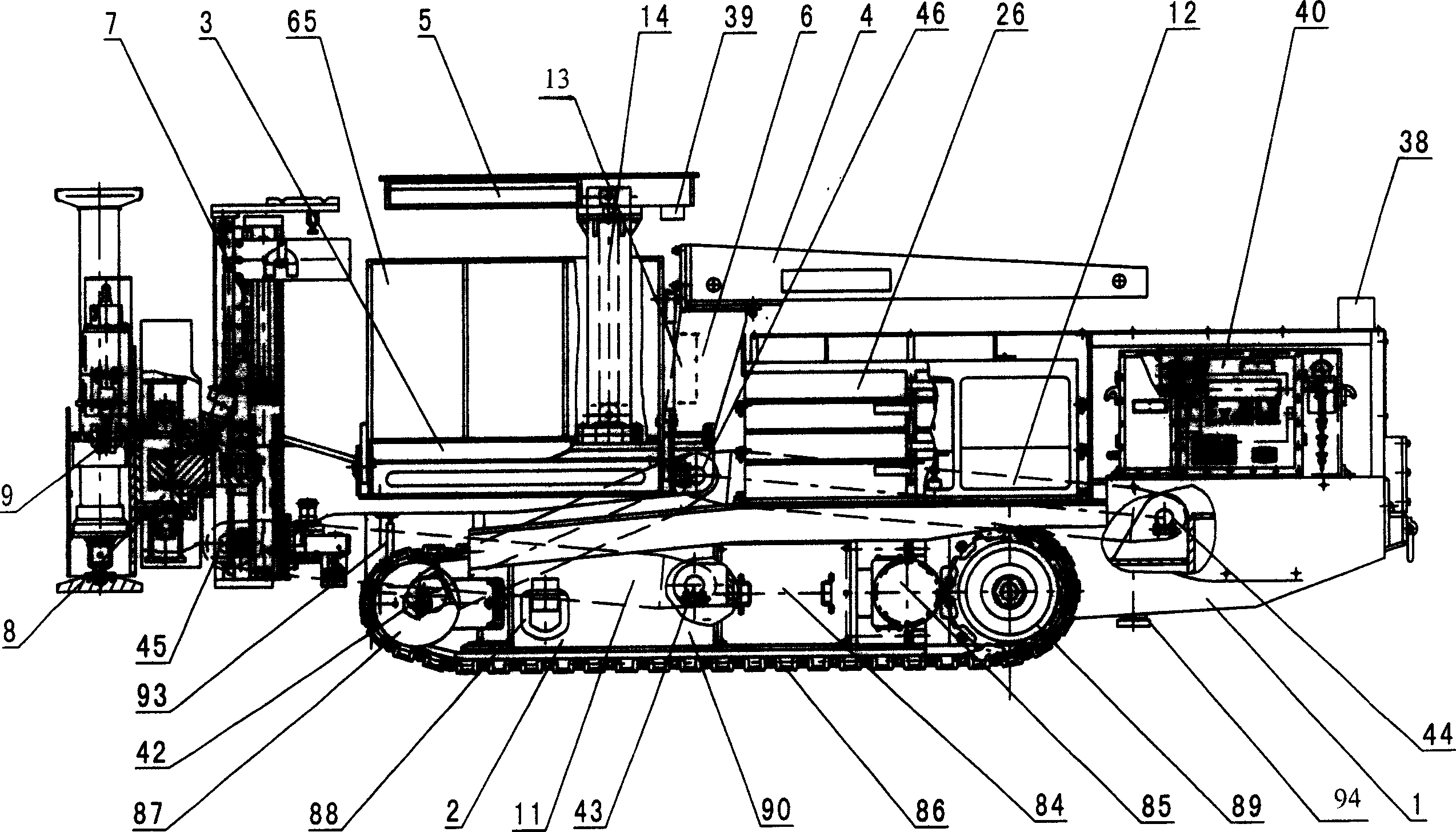

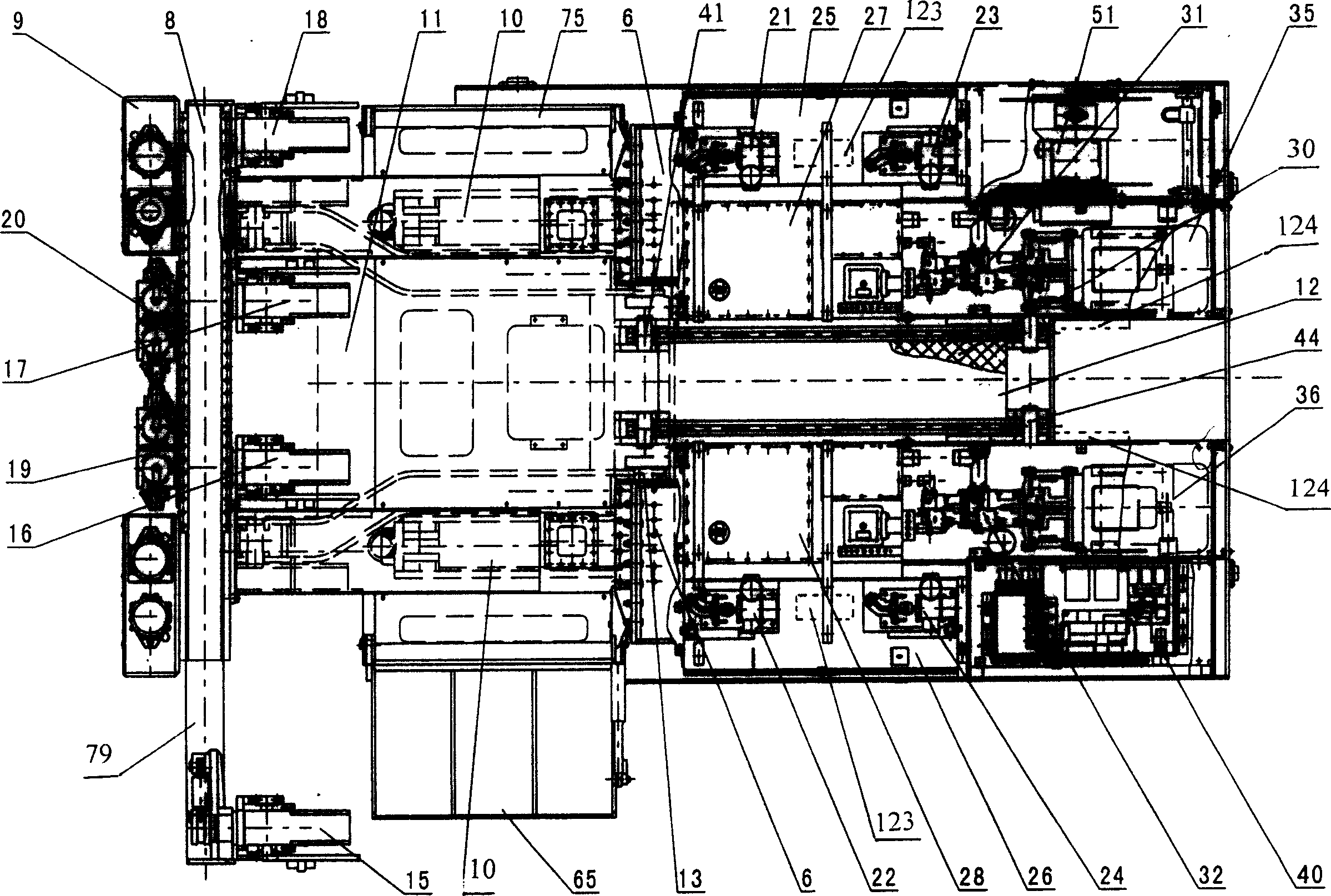

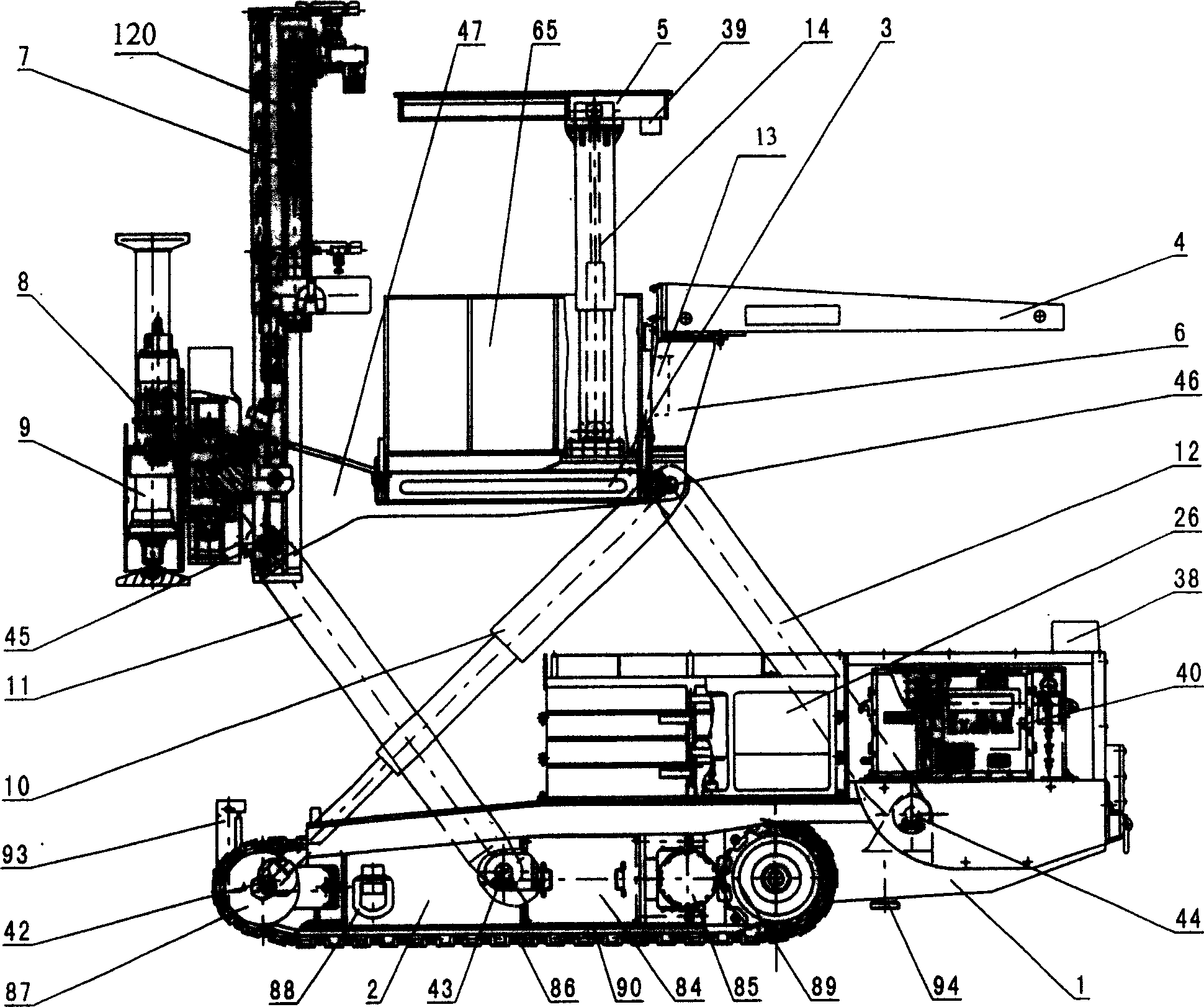

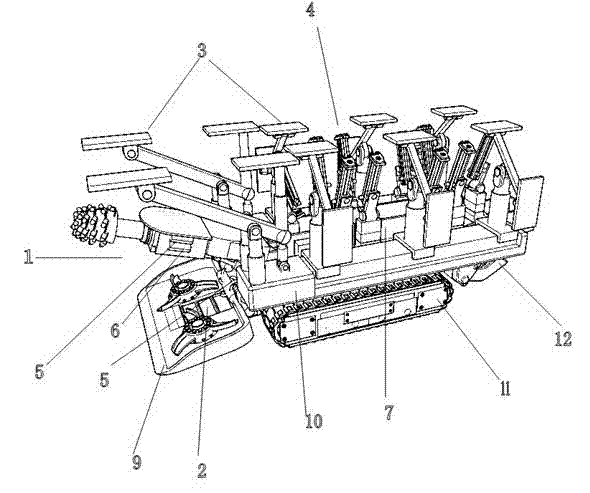

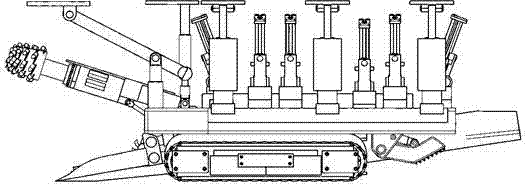

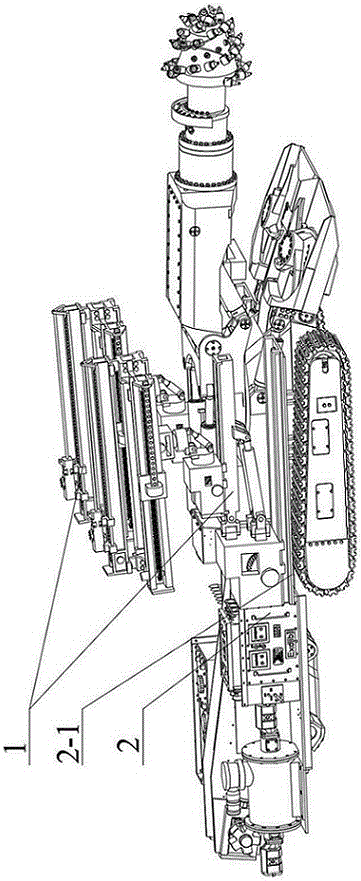

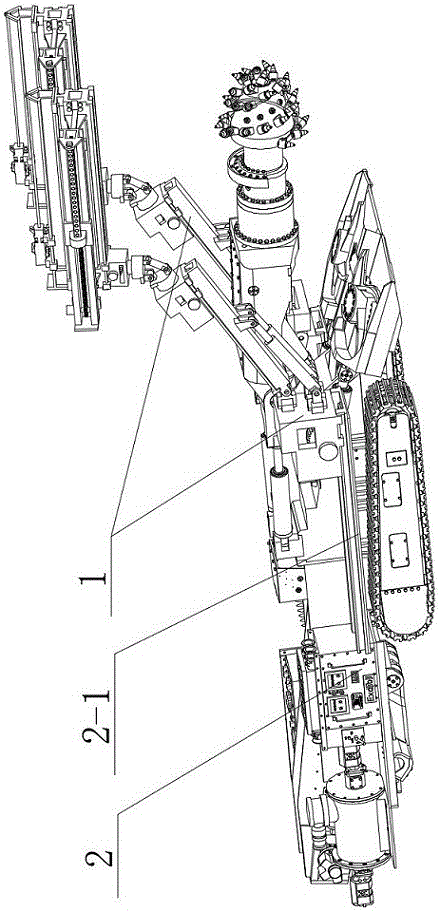

Crawler-type walking rockbolt drilling carriages

ActiveCN1584292AThe mechanical relationship is reasonableMechanizationAnchoring boltsDrilling machines and methodsElectric controlRock bolt

The present invention relates to a crawler running roof-bolting jumbo for coal extraction in the pit. It mainly includes machine seat, working table, running mechanism, lifting mechanism, hydraulic mechanism, dust-removing mechanism, cable-rolling mechanism, drilling cramp component, slideway component, support component and electric control box, said whole machine adopts hydraulic transmission, automatic dust-removing, automatic cable-rolling and crawler running modes, and utilizes the hydraulic oil cylinder to control parallelogram lifting movement and can make moving, lifting and multi-arm roof-bolt drilling works in the excavating tunnel. Said invention is reasonable in structure, large in load-bearing capacity, reliable and high in working efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

Intelligent fiber reinforced plastic (FRP) anchor rod

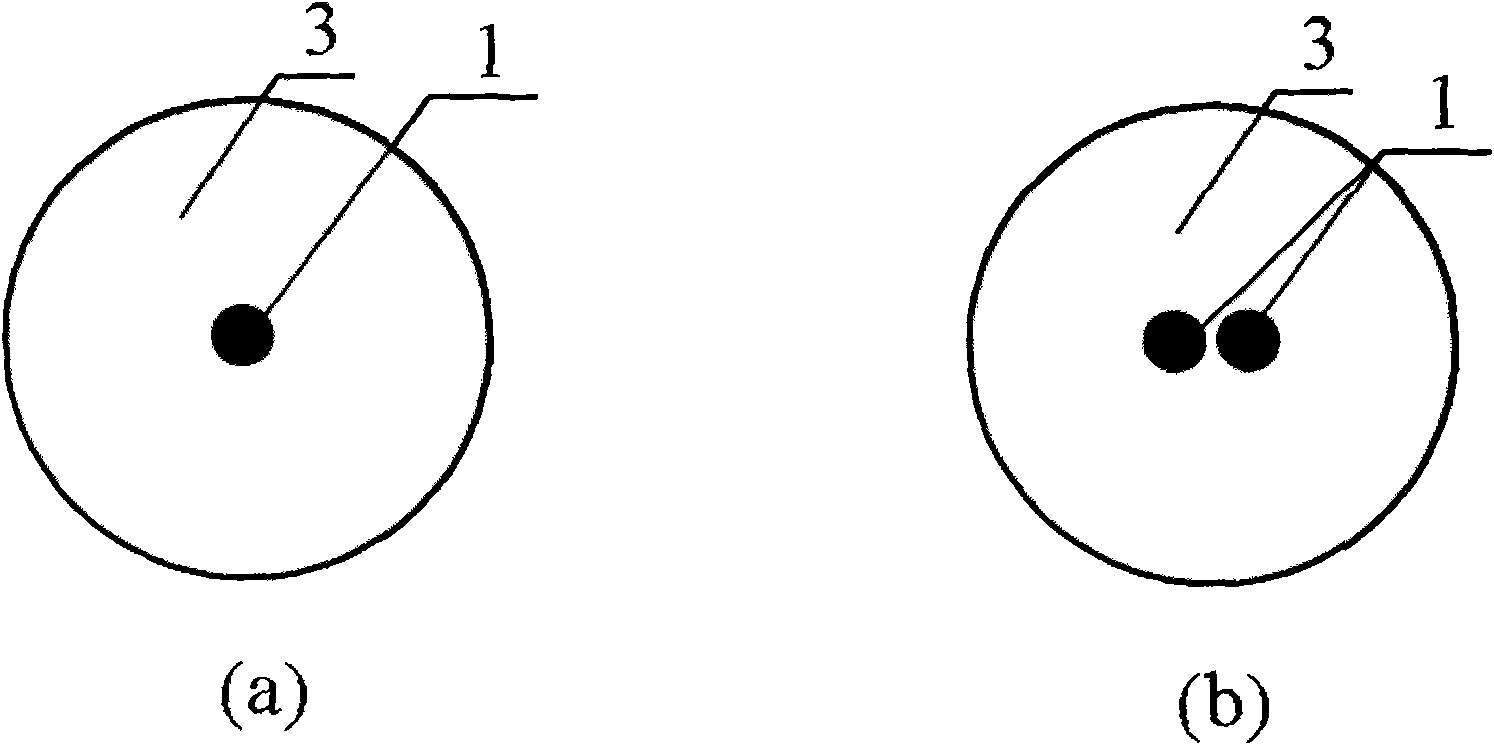

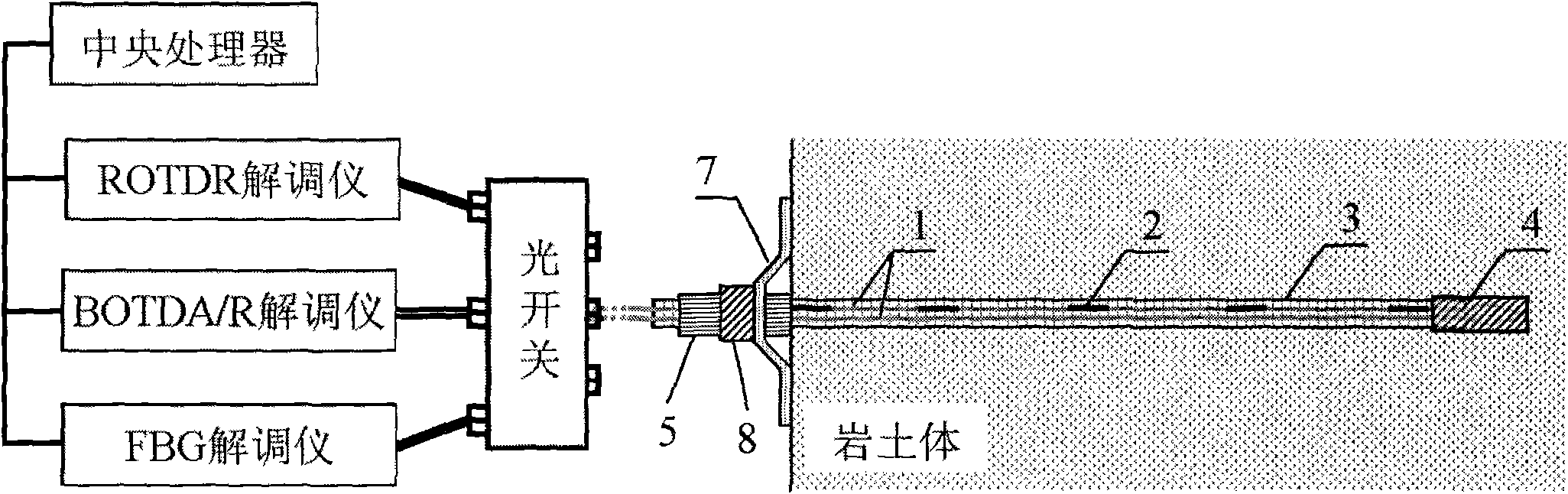

ActiveCN102140796AMonitoring the anchorage environmentMonitor the environmentFoundation testingBulkheads/pilesGratingFiber Bragg grating

The invention provides an intelligent fiber reinforced plastic (FRP) anchor rod, and belongs to the technical field of safety monitoring of geotechnical engineering. The intelligent FRP anchor rod is characterized in that the rod body is sequentially equipped with a fiber-fiber Bragg grating (FBG) sensor and an FRP wrapping layer from inside to outside, wherein the fiber-FBG sensor refers to a single-mode fiber in which one or more FBGs are written, or two parallel sensing fibers (including one common single-mode fiber and one single-mode fiber in which one or more FBGs are written). In the invention, the fiber-FBG sensor respectively transmits the sensed temperature or strain optical signals to a Raman optical time-domain reflectometry (ROTDR) demodulator, a Brillouin optical time-domainanalysis / reflectometry (BOTDA / R) demodulator and an FBG demodulator through optical switch connection and conversion. The intelligent FRP anchor rod has the beneficial effects that the embedded fiber-FBG sensor integrates test advantages of an ROTDR temperature measurement technology, a BOTDA / R test technology and an FBG test technology, thus improving reliability for long-term test of ambient temperature and strain state of the anchor rod.

Owner:DALIAN UNIV OF TECH

Method and apparatus for a shoring wall

InactiveUS6299386B1Improve face stabilityLarge and costly foundationArtificial islandsExcavationsSoil nailingRebar

A retaining element system is provided that improves face stability in poorer quality soils that are not suited to conventional soil nailing. The method includes inserting retaining elements substantially vertically into an earthen mass to shore the face of an excavation. The earthen mass can be any material or combination of materials, such as soil, clay or rock that requires excavation for the installation of a shoring wall. The plurality of retaining elements are placed side by side in a substantially linear arrangement. A plurality of soil nails are then inserted into the excavation plane, at the approximate midpoint between a pair of adjacent retaining elements. An exposed tip portion of each soil nail attaches to a wale, which is a substantially horizontal element that contacts a retaining element on both sides of each soil nail. The wale can be a beam, bracket, or a set of concrete reinforcement bars. The beam or bracket can either be a structural member, formed of steel or the like, or alternatively formed from a precast concrete. The concrete reinforcement bars can then receive a concrete fill to form a solid wale structure. Face stability is achieved with the pre-installed retaining elements, which with the wales provide complete facing support.

Owner:BYRNE R JOHN +1

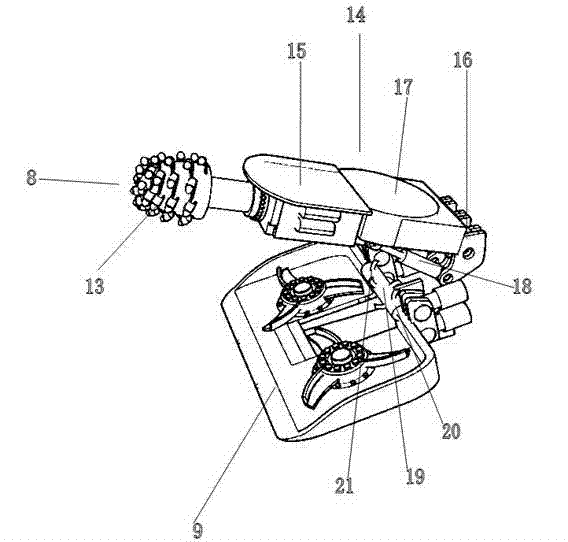

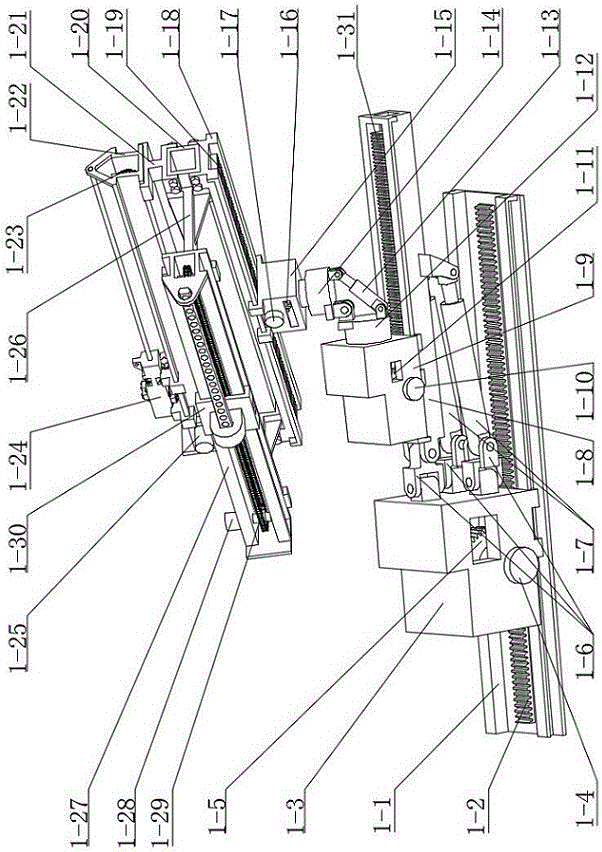

Fully automatic drilling anchor work vehicle

ActiveCN108104853AReduce volumeLess interferenceDrilling rodsConstructionsHydraulic cylinderEngineering

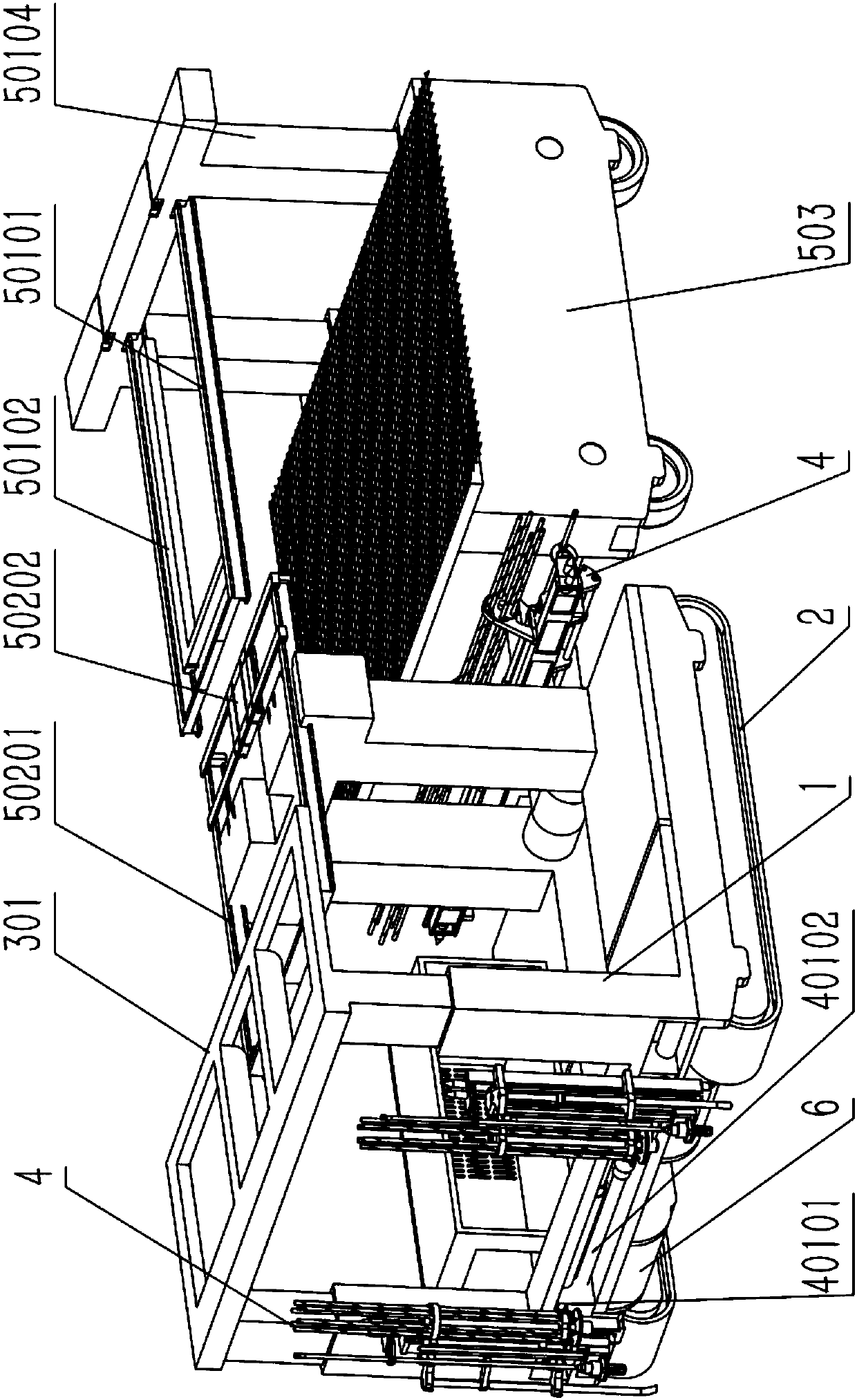

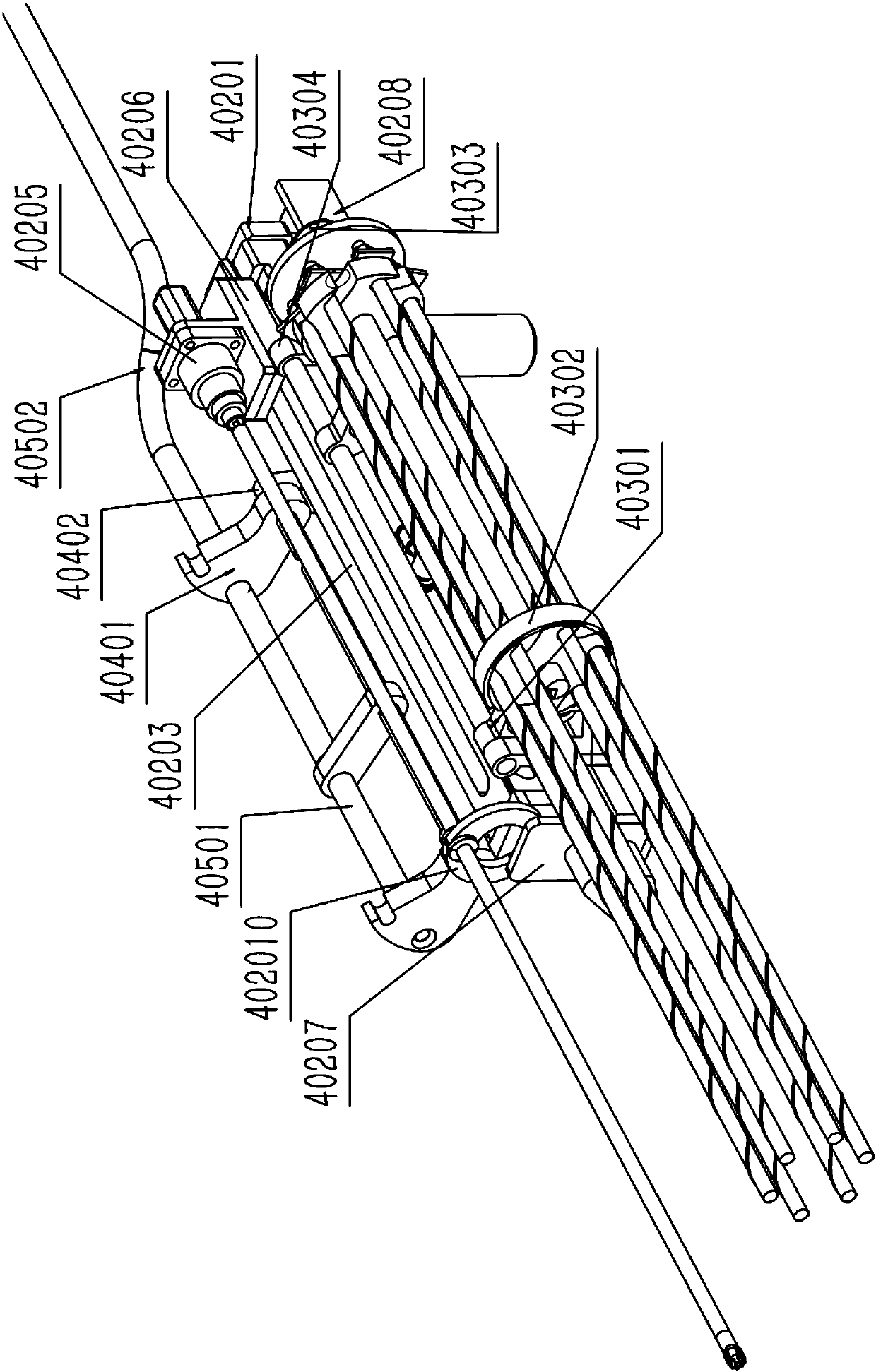

The invention discloses a fully automatic drilling anchor work vehicle integrating processes of anchor net paving, anchor hole drilling, anchoring agent injecting and installing of anchor bolt, and relates to the field of coal mine downhole tunnel support. The fully automatic drilling anchor work vehicle solves the existing problem of misalignment of digging and supporting caused by complicated process and low efficiency of tunnel support operation. The fully automatic drilling anchor work vehicle is characterized by comprising a vehicle body, a self-walking mechanism, a temporary support mechanism, an anchor drilling automation device, and an anchor net storing and a conveying mechanism. The anchor net is grabbed and conveyed to a temporary support frame by the anchor net conveying mechanism from an anchor net storage vehicle, and is supported by the temporary support frame to complete the anchor net laying work; and the anchor drilling automation device realizes the left-right and up-down displacement by the double-acting hydraulic cylinder in a car body sliding slot, and the rotation of the anchor drilling automation device is realized by a swing motor. According to the fully automatic drilling anchor work vehicle, the automatic laying of a back anchor net can be completed, mechanized support and automatic support of a top anchor rod and a side anchor rod can be realized, and the fully automatic drilling anchor work vehicle is matched with tunneling equipment to realize the parallel operation of digging and supporting anchor.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Excavation construction method of ultra-shallow buried uneven weathered stratum of tunnel

The invention relates to an excavation construction method of an ultra-shallow buried uneven weathered stratum of a tunnel. A segmented step method is used for construction, and a tunnel section is divided into a left side of an upper station, a right side of the upper station, a middle station and a lower station; each segment of step is sequentially constructed circularly, one-time excavation length of each segment of step is not larger than 30m preferably, and a middle partition wall is changed into a straight wall from the traditional curved wall at the left side of the upper station. Thus, for the uneven weathered stratum in the shallow buried area of wall rocks, the dynamic construction method using the segmented step method has little process interference, reduces the construction cost, has simple operation, safety, reliability, less temporary support, low fund investment and high construction speed, is suitable for large machinery for construction, and ensures that the whole construction process is in a safe, stable, high-quality and high-speed controllable state.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Unmanned roadway driving and anchoring all-in-one machine

InactiveCN104500086AImprove adjustabilityFlexible cuttingMine roof supportsTunnelsSupporting systemControl system

The invention discloses an unmanned roadway driving and anchoring all-in-one machine. The unmanned roadway driving and anchoring all-in-one machine comprises a driving system, a conveying system, a temporary support system, an anchoring system, a driving all-in-one machine water system, a sensing system and an electrical control system. A feed moving roller at the connection portion between a shovel of the driving system and the front end of the conveying system can prevent feed clogging at the shovel and the front end of a scraper conveyor. The temporary support system is uniform in supporting, can move relative to the driving and anchoring all-in-one machine to achieve no-deferring synchronization of driving, supporting and anchoring and can be adapted to the round, uprightly oval, approximately oval or rectangular cross section of a roadway to be applicable to driving and supporting operations of roadways of a variety of ground pressure and directions. The sensing system and the electrical control system of the driving and anchoring all-in-one machine can effectively collect and process information such as, light, distance, humidity and gas and the electrical control system performs automatic or remote manual analysis so as to achieve unattended operations in the working process and greatly improve the safety factor of the operations.

Owner:SHANXI DATONG UNIV

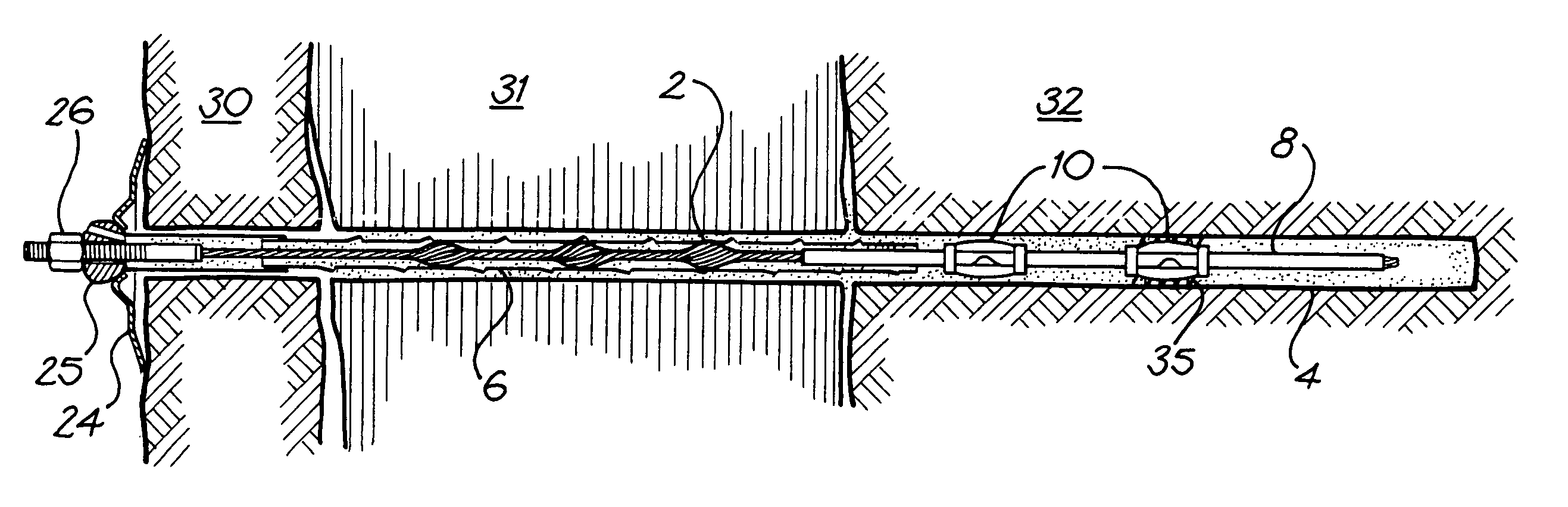

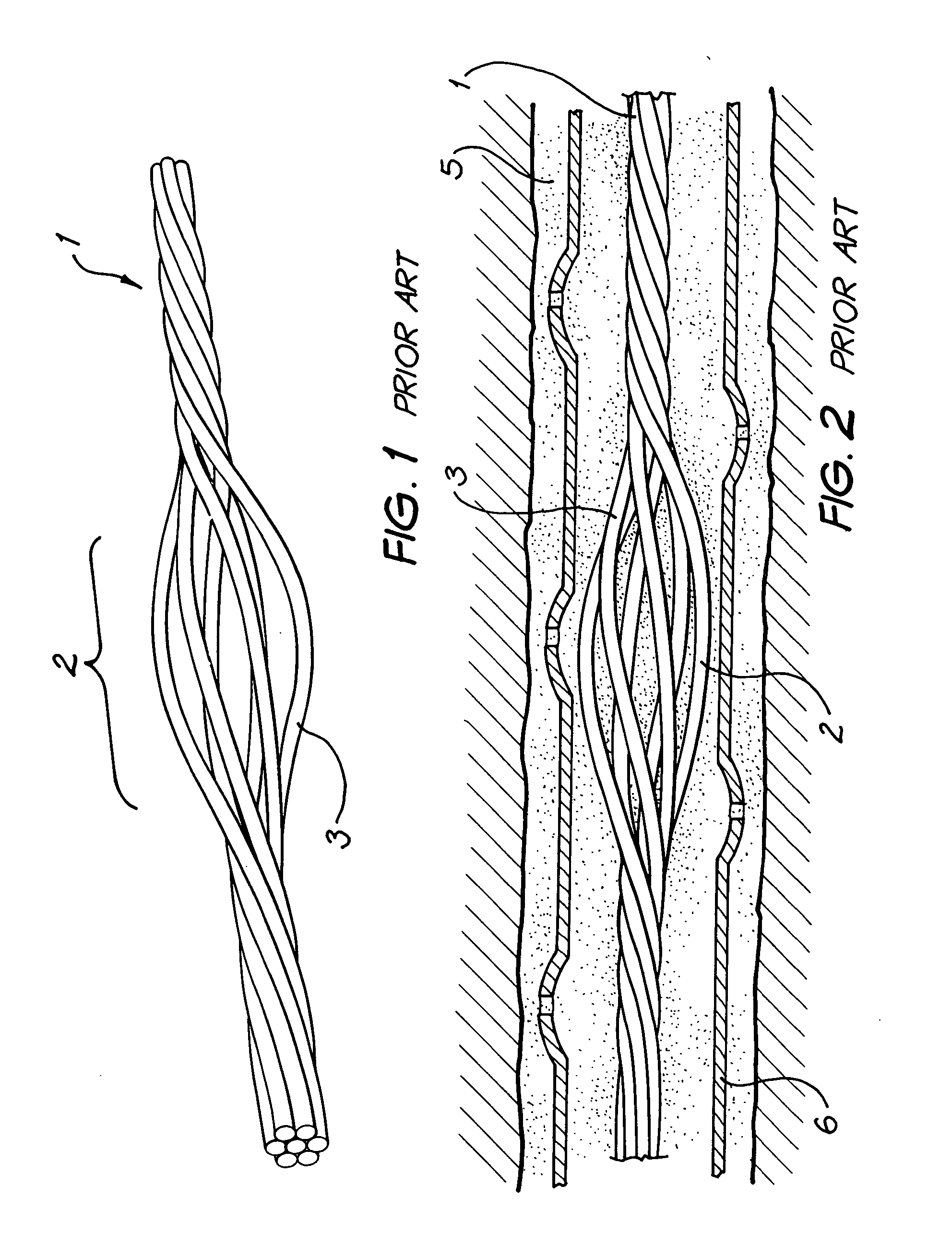

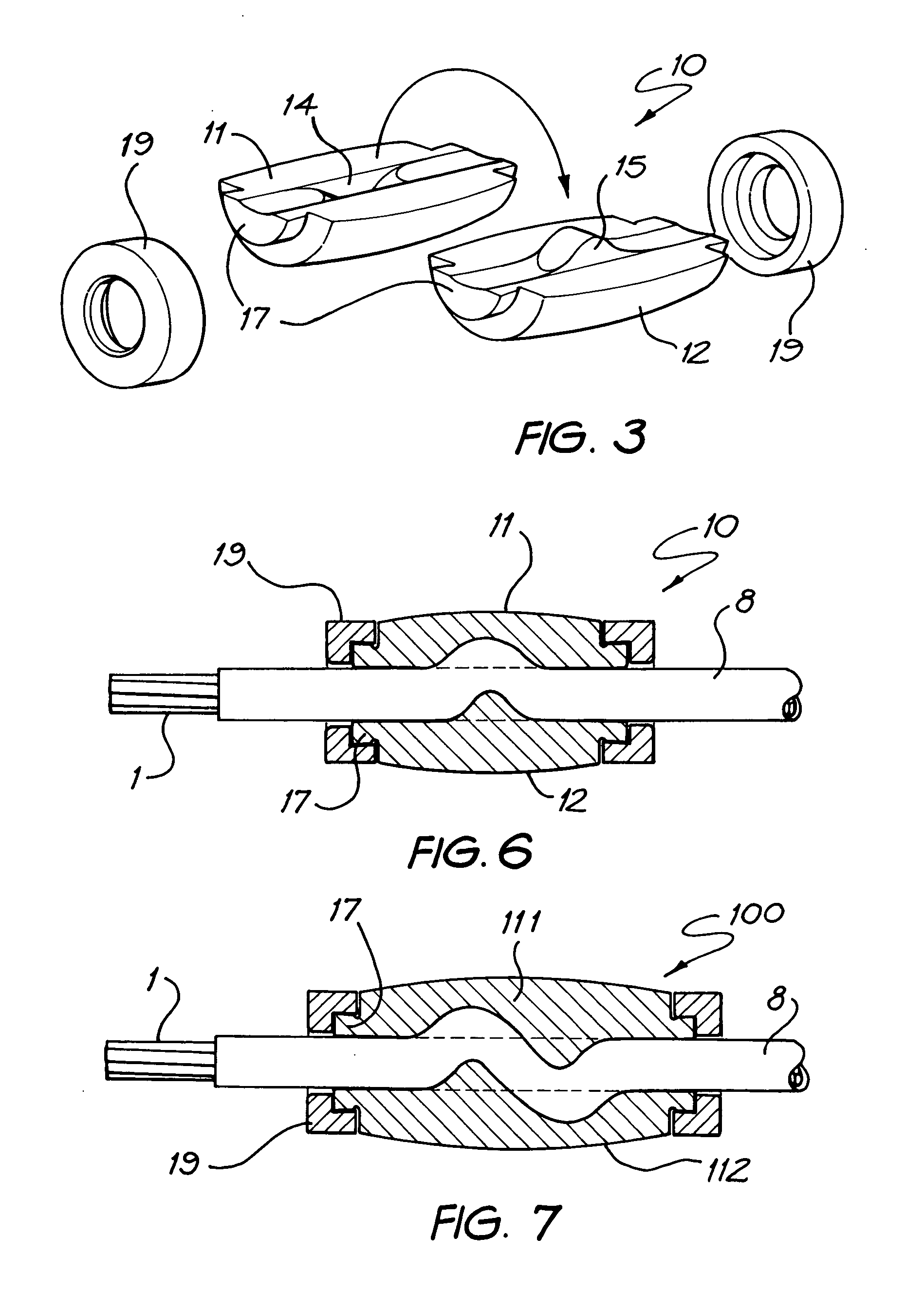

Yielding strata bolt

The present invention discloses a rock bolt having a tendon (1, 201) which is able to yield and thereby control movement of unstable rock strata into which the bolt is installed. The tendon has a portion which is provided with a grout slippage mechanism, preferably in the form of a tube (8) which surrounds the tendon. A two part grout anchor (10, 100, 200) is clamped to the tendon. The grout anchor is embedded in grout and is therefore essentially immovable. The tendon passing through the anchor is worked and thereby dissipates energy. The tendon can be either a multi-strand cable (1) or a solid bar (200). Various forms of anchor (10, 200) are disclosed with either complementary recess(es) (14) and protrusion(s) (15) or opposed protrusions (115) which form pinch point(s). A one piece grout anchor (300) is also disclosed.

Owner:FERGUSSON JEFFREY ROBERT

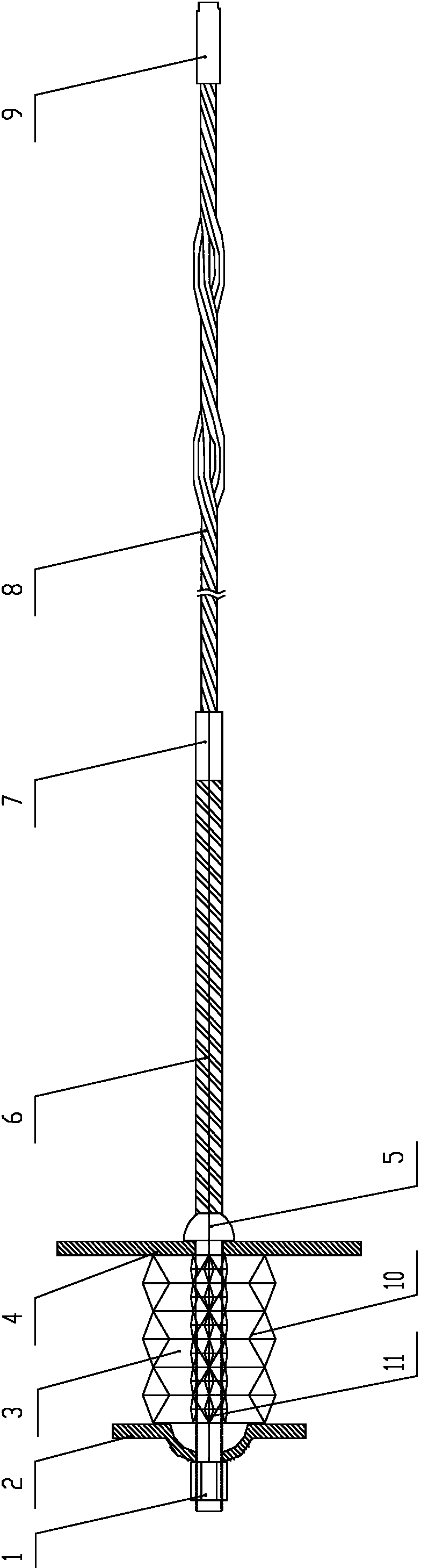

Prestressed drilling, anchoring and grouting anchor cable and support method

ActiveCN103382847AImprove stabilitySolve difficult access problemsAnchoring boltsUltimate tensile strengthMetal nail

Disclosed are a prestressed drilling, anchoring and grouting anchor cable and a support method. The prestressed drilling, anchoring and grouting anchor cable comprises a hollow grouting anchor cable, a sleeve, a lock, a washer and a tray, the hollow grouting anchor cable is provided with a sleeve head, a drill bit is arranged at the front end of the sleeve, and the sleeve is provided with an anchoring hole and a thread. The hollow grouting anchor cable drives the sleeve to drill holes and advances inwards through the thread in reverse rotation, a metal nail at the front end of the sleeve head punctures an anchoring agent package inside the sleeve, anchoring agents are mixed and then discharged through the anchoring hole in the sleeve, the gap between the sleeve and a drill hole wall is filled with the anchoring agents, and the anchoring function is achieved. An exhaust pipe is arranged in the anchor cable, the anchor cable is provided with a plurality of lantern-shaped grouting sections, and grout vent holes are formed in the lantern-shaped grouting sections. The prestressed drilling, anchoring and grouting anchor cable integrates drilling, exhausting, grouting and anchoring, the tail of the grouting anchor cable is firstly tensioned and fastened, grouting is then performed, an anchored body becomes reinforced pre-tightening force concrete, loose coal rocks are drilled, anchored, grouted and supported once, the problem that the anchor cable does not easily enter drilled holes in the loose coal rocks due to sticking and hole collapse is solved, the support strength of surrounding rocks of a roadway is enhanced, and the carrying capacity of a rock mass is improved. The prestressed drilling, anchoring and grouting anchor cable is simple in structure, low in cost, easy in construction and fine in support effect.

Owner:CHINA UNIV OF MINING & TECH

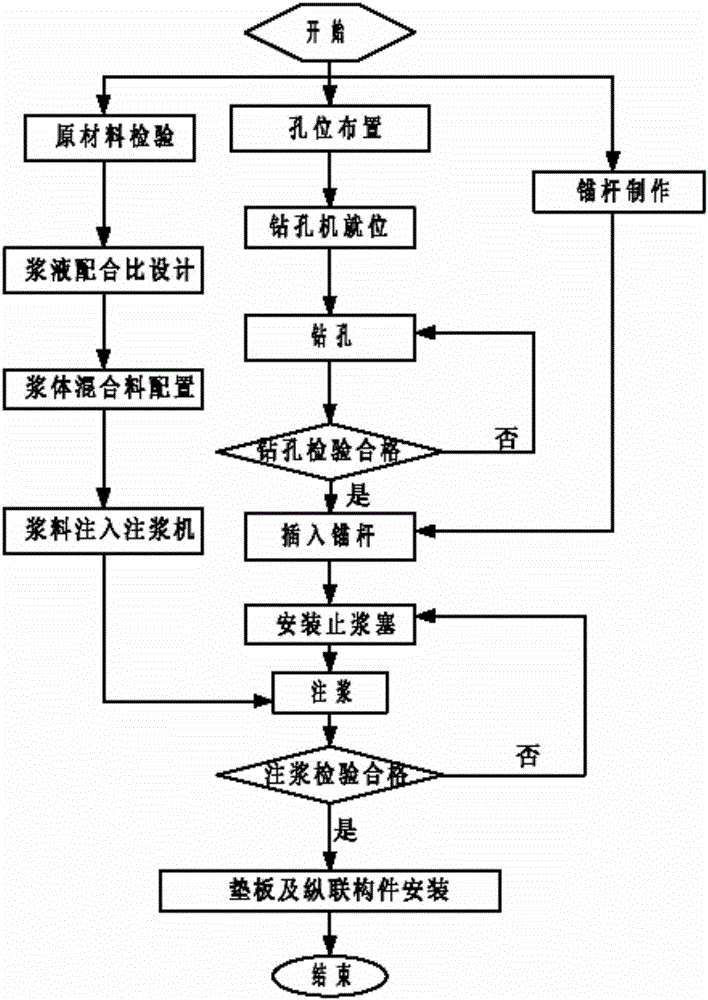

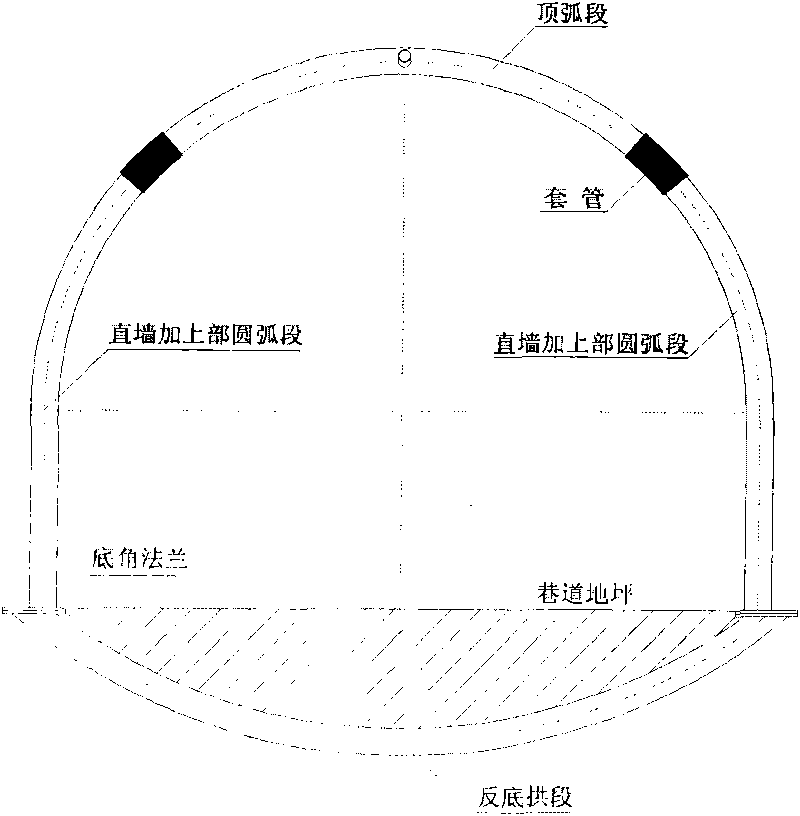

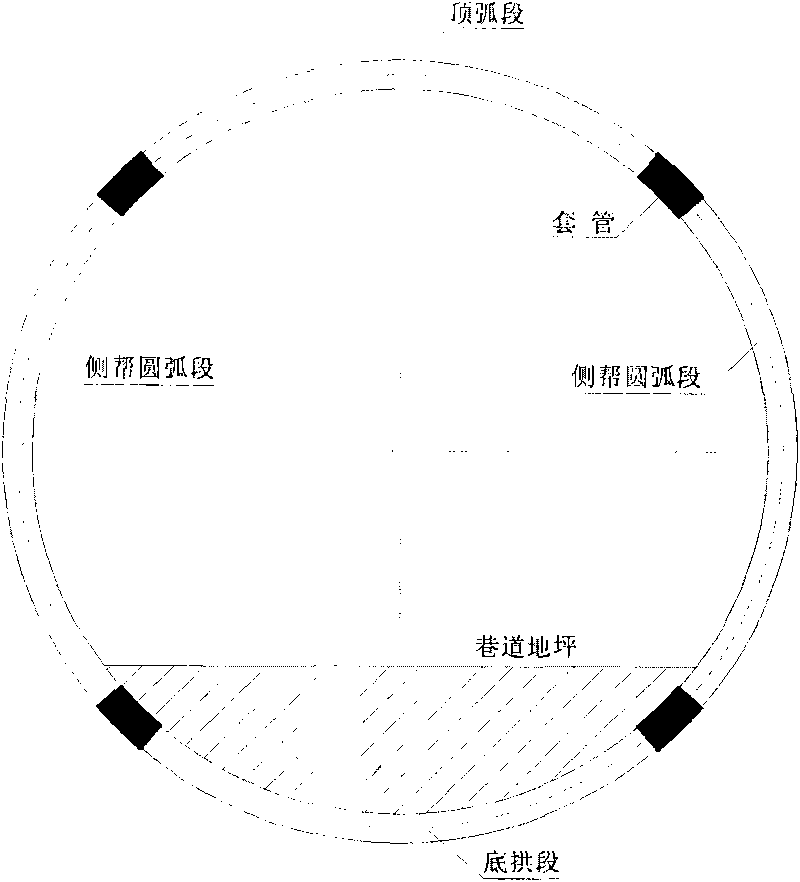

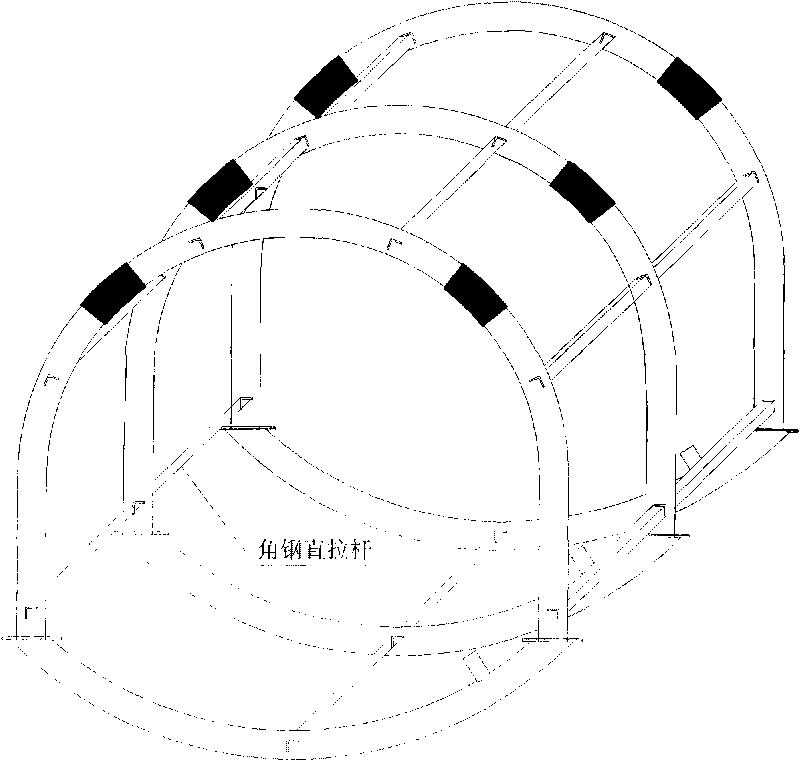

Supporting and reinforcing structure of coal mine tunnel and construction technology thereof

InactiveCN103195441AEven by forcePrevent weatheringUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses a supporting and reinforcing structure of a coal mine tunnel and a construction technology thereof. The supporting and reinforcing structure of the coal mine tunnel comprises a lane, wherein a grid-shaped reinforced layer is arranged on the inner wall of the lane, an anchor rod is arranged on the grid node portion of the reinforced layer, the inner end of the anchor rod is anchored in surrounding rock of the lane, and an anchor plate and a nut of the anchor reinforced layer are arranged at the outer end of the anchor rod. A concrete spraying layer covered on the reinforced layer and arranged at the outer end of the anchor rod is further arranged on the inner wall of the lane, a grouting anchor rod is arranged in the surrounding rock of the lane, an anchor cable is further arranged in the surrounding rock of the lane, the inner end of the anchor cable is anchored in the surrounding rock of the lane, and the outer end of the anchor cable is anchored on the outer side of the concrete spraying layer through a tray and a tensioning lock. The supporting and reinforcing structure of the coal mine tunnel integrates the surrounding rock of the lane in cementing mode with the initiative supporting theory as the guidance, prestress is reserved in the rock body, and stress is released and superimposed slowly, so that self integral strength and stability of soft rock and coal body are improved, the surrounding rock in a release ring of the lane can form a structure relatively homogenous and stable, and the aim of reinforcing and protecting the soft rock lane can be achieved within a long time.

Owner:PINGDINGSHAN TIANAN COAL MINING

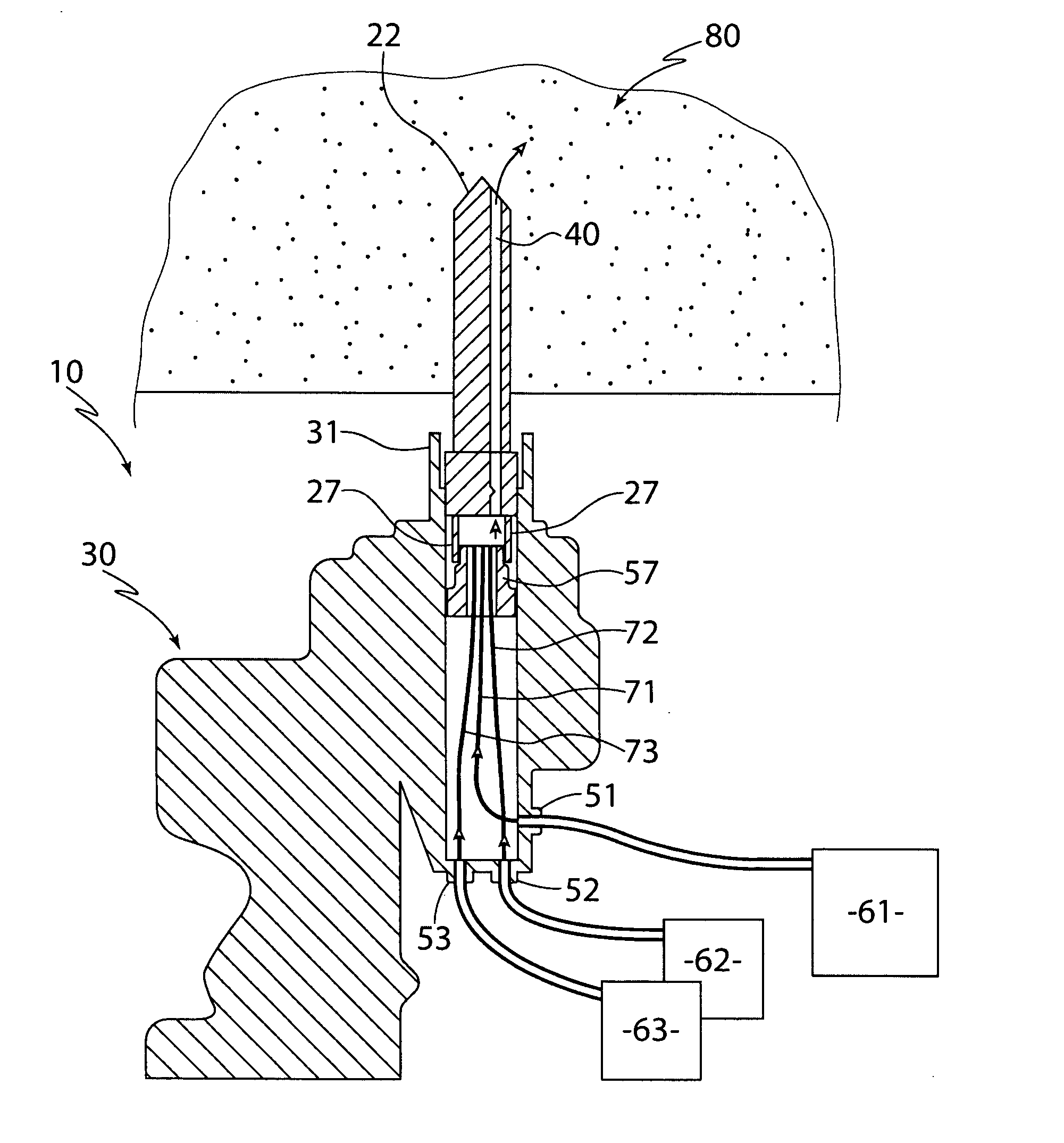

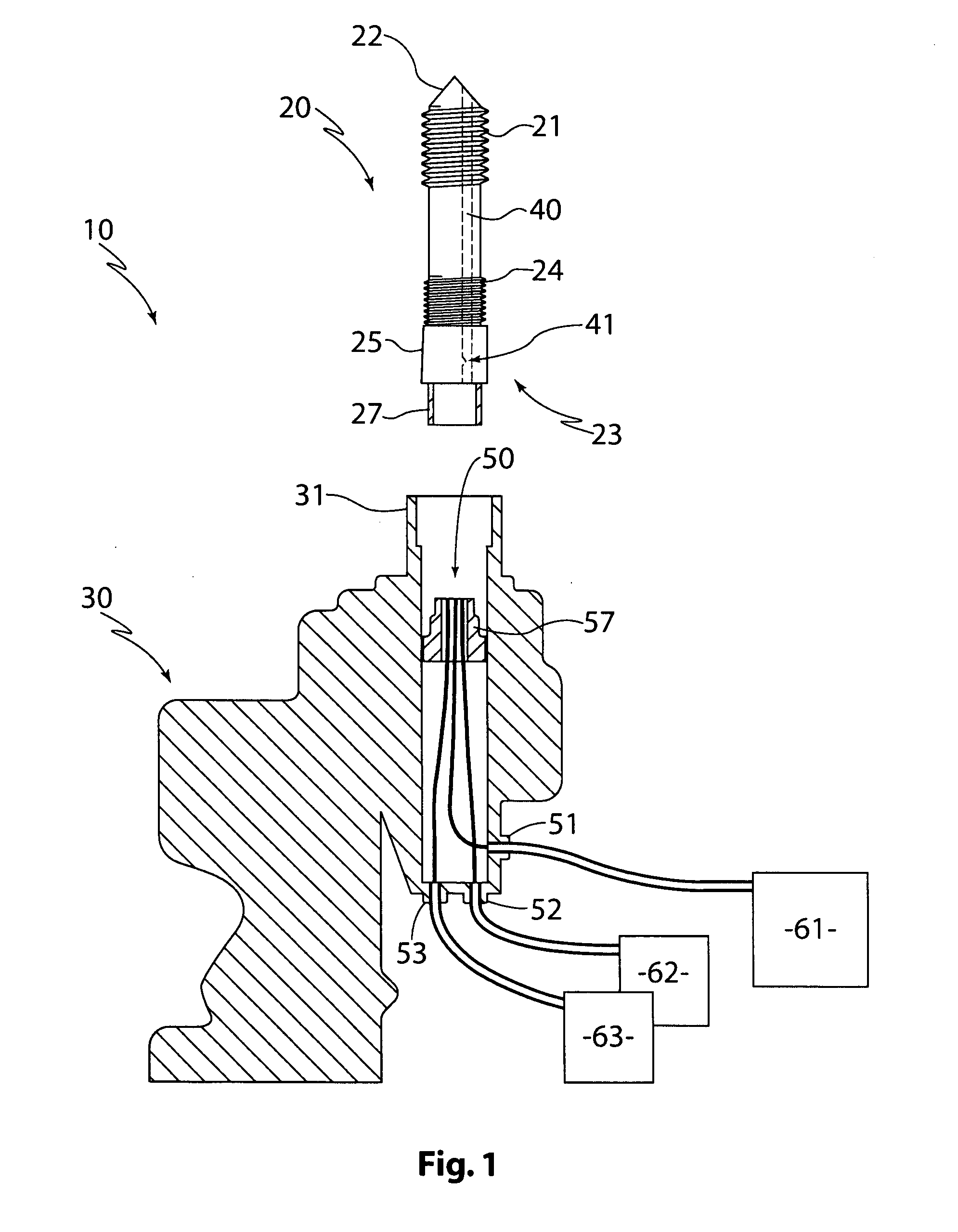

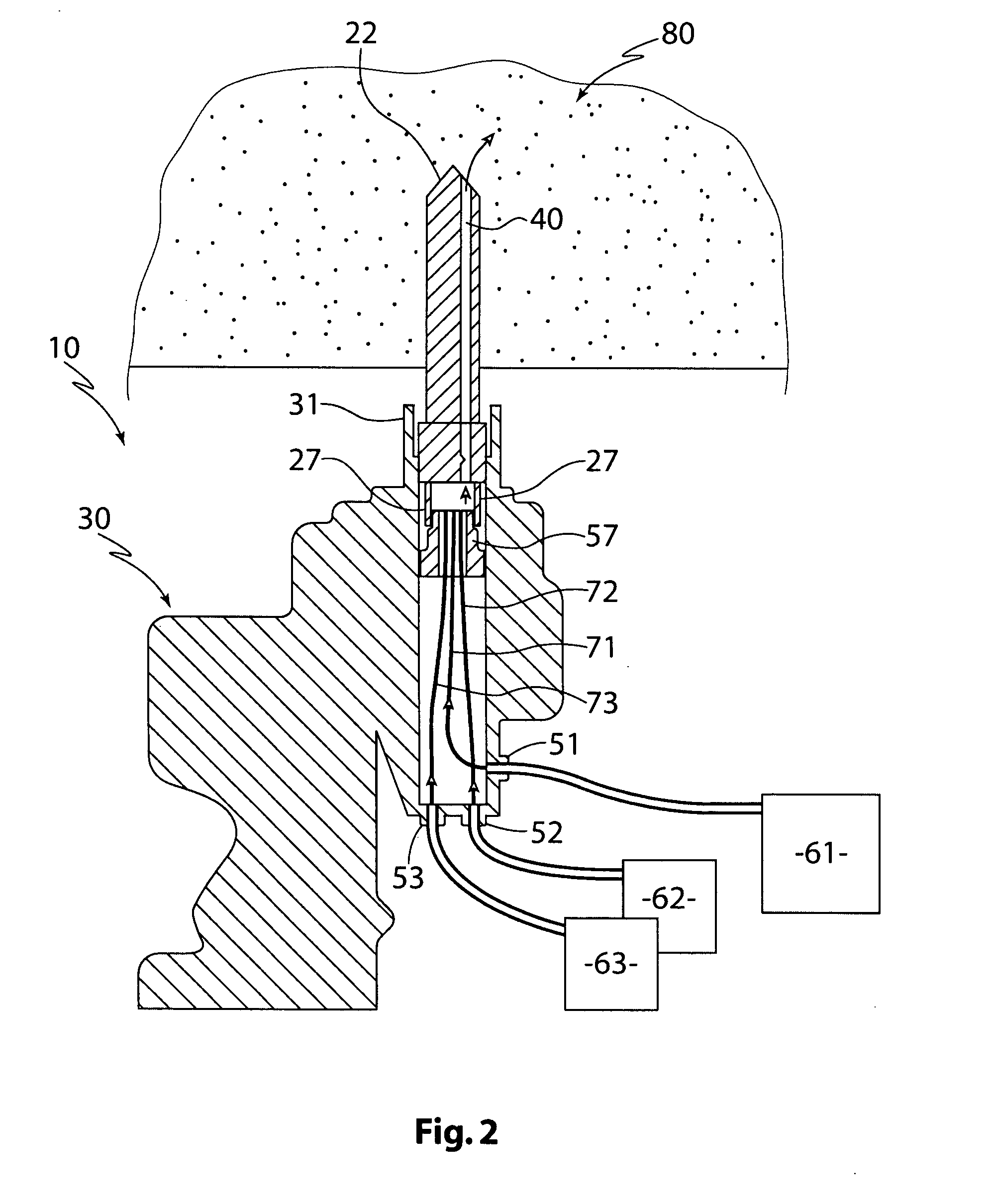

Self drilling rock bolting

The present invention relates to self drilling rock bolting. In particular, the invention concerns both a drilling apparatus for rock bolting, and a rock bolt for use with the drilling apparatus. The drilling apparatus comprises within it a fluid injector having an upper part that mates with a self-drilling rock bolt for boring a hole. The injector includes three fluid inlets, three fluid outlets in the upper part, and three fluid conduits extending from respective inlets to respective outlets. The self drilling rock bolt comprises an elongate body having a leading end with a cutting tip, and around the tip a thread with a coarse pitch. The bolt also has a trailing end with an integral collar for fluid connection to a channel that extends axially through the body of the rock bolt to the leading end. Above the collar is a thread with a fine pitch. In other aspects the invention concerns a system comprising the drilling apparatus in combination with a rock bolt and a method for rock bolting using the system. The invention has application, but not exclusively, to rock bolting to stabilise the roof and walls of underground coal mines.

Owner:ALMINCO

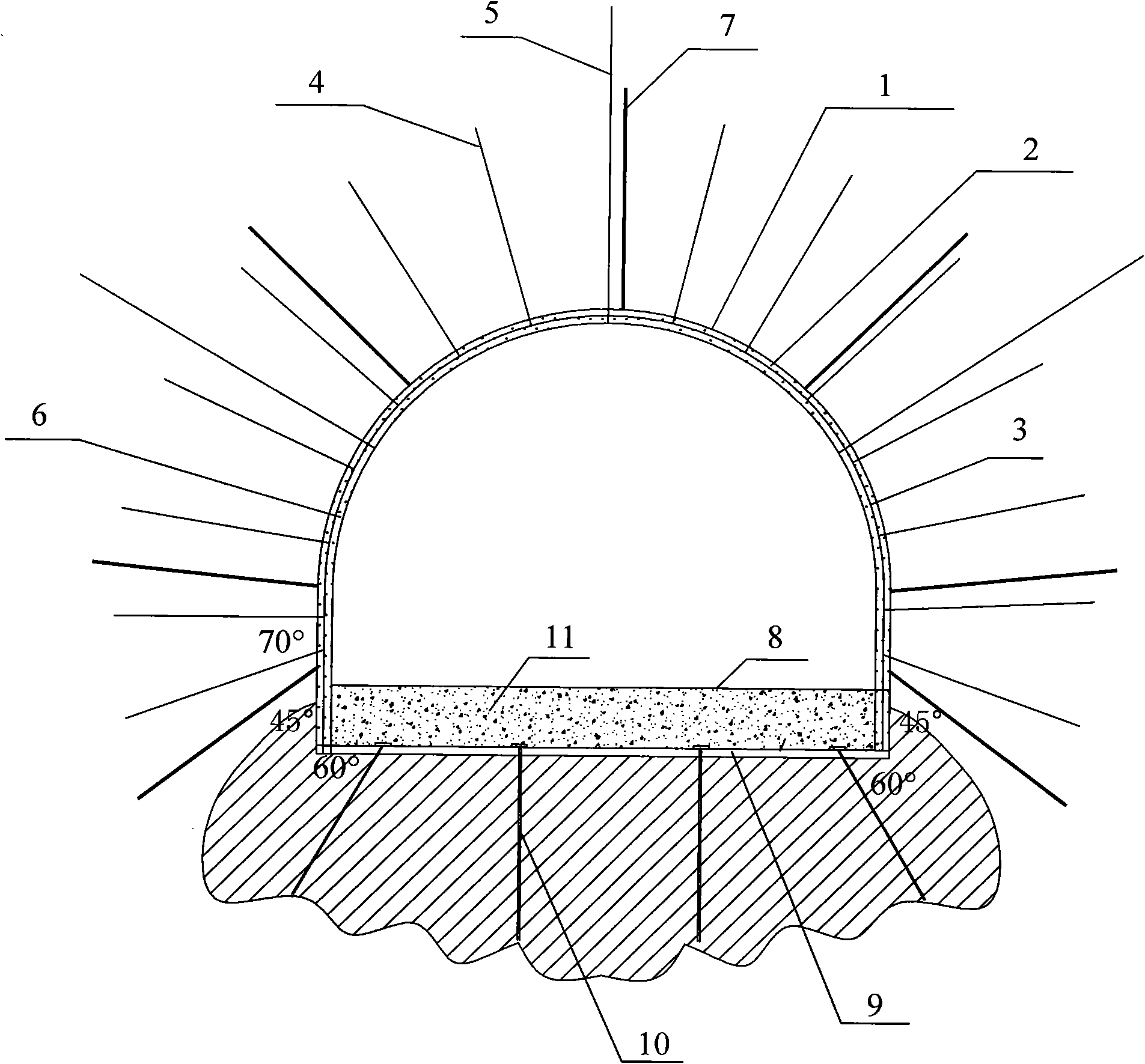

Soft rock large-deformation tunnel supporting system and construction method thereof

InactiveCN104847374AEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

The invention discloses a soft rock large-deformation tunnel supporting system and a construction method thereof. The system comprises a forepoling, a preliminary bracing, a waterproof layer, a secondary lining and other main structures, wherein the structures are constructed in sequence according to construction procedures. Surrounding rock is reinforced through advanced small pipe grouting by means of the forepoling, the preliminary bracing comprises lengthened anchor rods, a primary spraying layer, steel arches and a re-jetting layer, feet-lock bolts are further arranged at the positions of an upper bench and arch feet to be welded to the steel arches, the adjacent steel arches are connected through longitudinal connecting ribs, and the secondary lining is constructed at last to form the supporting system. The steps are simple and linked with one another, supporting lag caused by idling of labor force is avoided, and large-deformation of tunnels is well controlled.

Owner:CHANGAN UNIV

Abdicating buffer energy-absorbing shock-proof anchor rod cable for coal mine

ActiveCN103016035AEnhance the role of stabilizing deep rock massWith steel flexible coupling characteristicsAnchoring boltsSlurryThin walled

The invention provides an abdicating buffer energy-absorbing shock-proof anchor rod cable for a coal mine and belongs to the technical field of coal mine support safety. The anchor rod cable provided by the invention comprises pre-tightening nuts, a tray, an abdicating buffer energy-absorbing device, a backing plate, a slurry stop plug, a high-strength twisted steel anchor rod, an abdicating joint sleeve, a stranded wire anchor cable and a anchor cable cap, wherein the abdication jointing sleeve comprises an anchor cable joint sleeve, an anchor rod joint sleeve, a wedge-shaped cushion block, a anchor cable end part stripping-prevention protective sleeve, a rubber sleeve and an installation nut, the abdication buffer energy-absorbing device is of a thin wall tubular structure with folding grains and comprises an outer cylinder and a locating sleeve; the slurry stop plug, the backing plate, the abdication buffer energy-absorbing device and the tray are sequentially sleeved on the front end of the rod body of the high-strength twisted steel anchor rod and are fastened by virtue of the pretensioning nuts; the anchor cable joint sleeve and the anchor rod joint sleeve are connected through threads; the anchor rod joint sleeve is sleeved at the tail end of the high-strength twisted steel anchor rod and is connected with the stranded wire anchor cable by virtue of the wedge-shaped cushion block.

Owner:LIAONING TECHNICAL UNIVERSITY

Drilling and bursting type heading machine

ActiveCN105804764AImprove drilling efficiencyLow drilling efficiencyDisloding machinesSlitting machinesHydraulic motorHydraulic cylinder

The invention discloses a drilling and bursting type heading machine which comprises a drilling and bursting device, an angle control device, a front-back telescopic device and a cantilever type heading machine body. The drilling and bursting device is installed on a front-back moving component of the front-back telescopic device. The front-back telescopic device is installed on the cantilever type heading machine body. The drilling and bursting device comprises a fixing frame, a rock drill component and a bursting device component, wherein the rock drill component and the bursting device component are fixed to and installed on the fixing frame. The angle control device comprises an installation base, an auxiliary rotary hydraulic motor, an adjusting hydraulic cylinder and a main rotary hydraulic motor. When the front-back moving component of the front-back telescopic device completely stretches out, the distance between the front end of the drilling and bursting device and a working surface is smaller than the distance between the front end of a cutting head of the cantilever type heading machine body and the working surface. The drilling and bursting type heading machine is compact in structure, a hard rock stratum with the rock stratum hardness being larger than 10 can be rapidly drilled and burst on the premise that the energy consumption is not increased, and accordingly the purposes of improving the heading efficiency and reducing potential safety hazards are achieved.

Owner:CHINA UNIV OF MINING & TECH

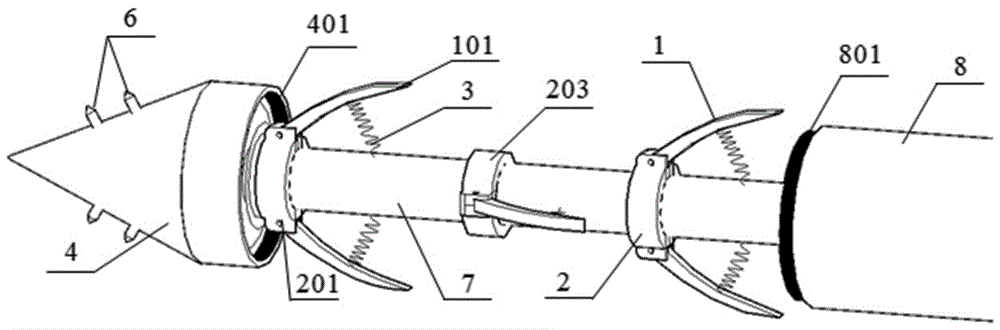

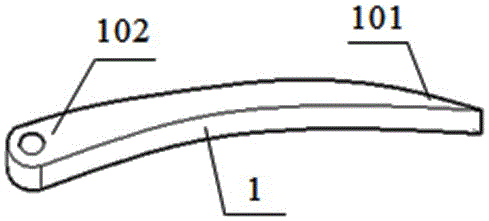

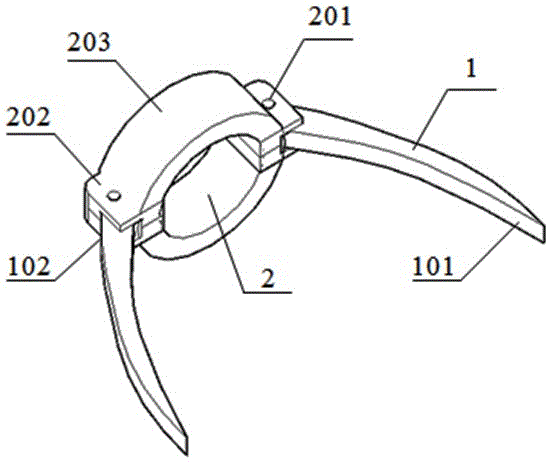

Fishbone-shaped anchor rod

InactiveCN106567384AAvoid scratchesReduce contact areaAnchoring boltsBulkheads/pilesPull forceEngineering

The invention relates to a fishbone-shaped anchor rod. The fishbone-shaped anchor rod comprises an anchor head, an anchor rod body and a sleeve pipe. A movable conical propelling body is arranged in the anchor head and connected to the front end of the anchor rod body through a thread. The anchor head is connected to the front end of the sleeve pipe through a thread. Spine holes are evenly distributed in the anchor head and internally provided with short-rod-shaped anchor head bore spines. Two or more pairs of fishbone-shaped blade mechanisms are evenly distributed on the anchor rod body. Each blade mechanism comprises blades and a clamp. When the fishbone-shaped anchor rod is not used, the blades are folded, abut against the anchor rod body and are located in the sleeve pipe. When the fishbone-shaped anchor rod is used, a roof bolter rotates forwards, and the fishbone-shaped anchor rod is drilled into rock soil. Pressure is exerted on the rear end of the anchor rod body, the propelling body in the anchor head extrudes the anchor head bore spines out of the anchor head, and the anchor head bore spines are embedded in a rock soil body. The roof bolter rotates reversely till the sleeve pipe is separated from the anchor head. Then, outward pull force is provided for the anchor rod body till the blades evenly distributed on the anchor rod body are in a completely unfolded state. Finally, a grouting machine is aligned with the anchor rod body and pours cement paste into the anchor rod body till a cavity between the anchor rod body and the rock soil body is completely filled. Then, installation of the anchor rod body is finished.

Owner:HEFEI UNIV OF TECH

Masonry wall anchoring device, system, and anchoring method

InactiveUS20050097849A1Prolong lifeEarthquake proof and more resistant to damage and failureConstruction materialBuilding repairsEngineering

Owner:HAYES JOHN T

Rock bolt

The present invention relates to rock bolts which may be used in mining applications. The rock bolt of this invention includes a mechanical anchoring arrangement to facilitate retaining the rock bolt in a borehole, and also a drill bit to enable self drilling of the rock bolt. Rotation of the rock bolt about an axis of the rock bolt in a first direction causes the drill bit to drill into rock and to create a borehole to receive the rock bolt. Subsequently, rotation in the opposite direction actuates a mechanical anchoring arrangement to anchor rock bolt.

Owner:FCI HLDG DELAWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com