Drilling and bursting type heading machine

一种悬臂式掘进机、掘进机的技术,应用在截割机械、排料机械、土方钻采等方向,能够解决悬臂式掘进机效率低、爆破操作安全隐患大、工作条件恶劣等问题,达到降低开拓成本、结构紧凑、满足打孔和涨裂的需求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

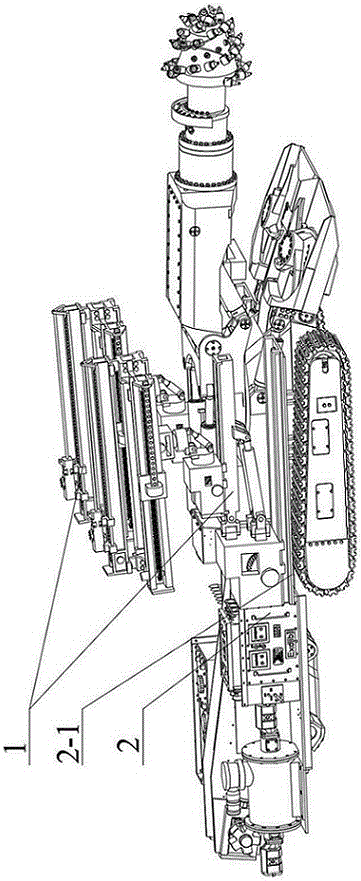

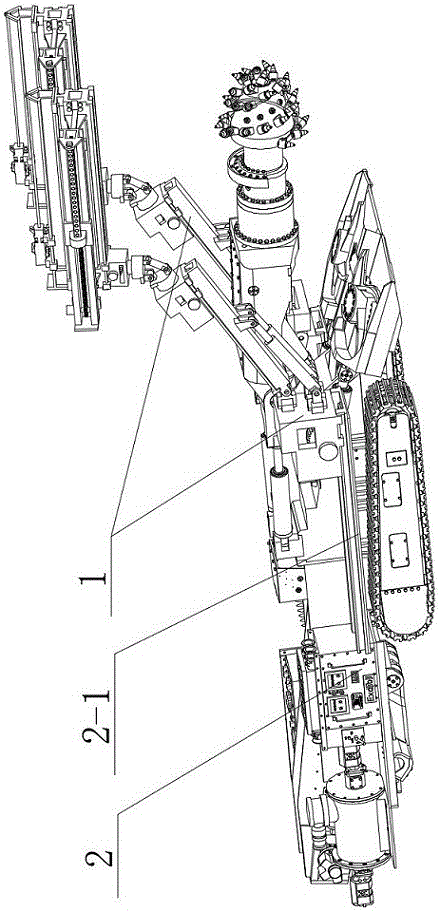

[0027] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the driving direction of the cantilever type roadheader is described as the front).

[0028] Such as figure 1 As shown, the drilling expansion type roadheader includes a drilling expansion device 1, an angle control device, a front and rear telescopic device and a cantilever type roadheader 2. The drilling expansion device 1 is installed on the front and rear moving parts of the front and rear telescopic devices through the angle control device. The device is installed on the cantilever type boring machine 2.

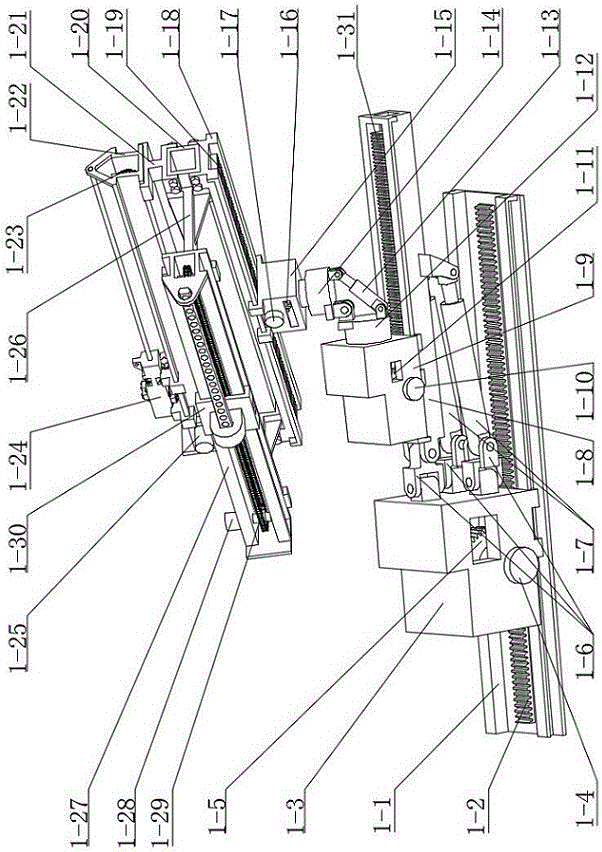

[0029] The drilling expansion device 1 includes a fixed frame 1-20, a rock drill component and an expander component, and the rock drill component and the expander component are respectively fixedly installed on the fixed frame 1-20;

[0030] Rock drilling machine components include connecting seat Ⅰ1-21, slide rail Ⅰ1-22-1, positioning guide plate Ⅰ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com