Patents

Literature

291 results about "Abrasive water jet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

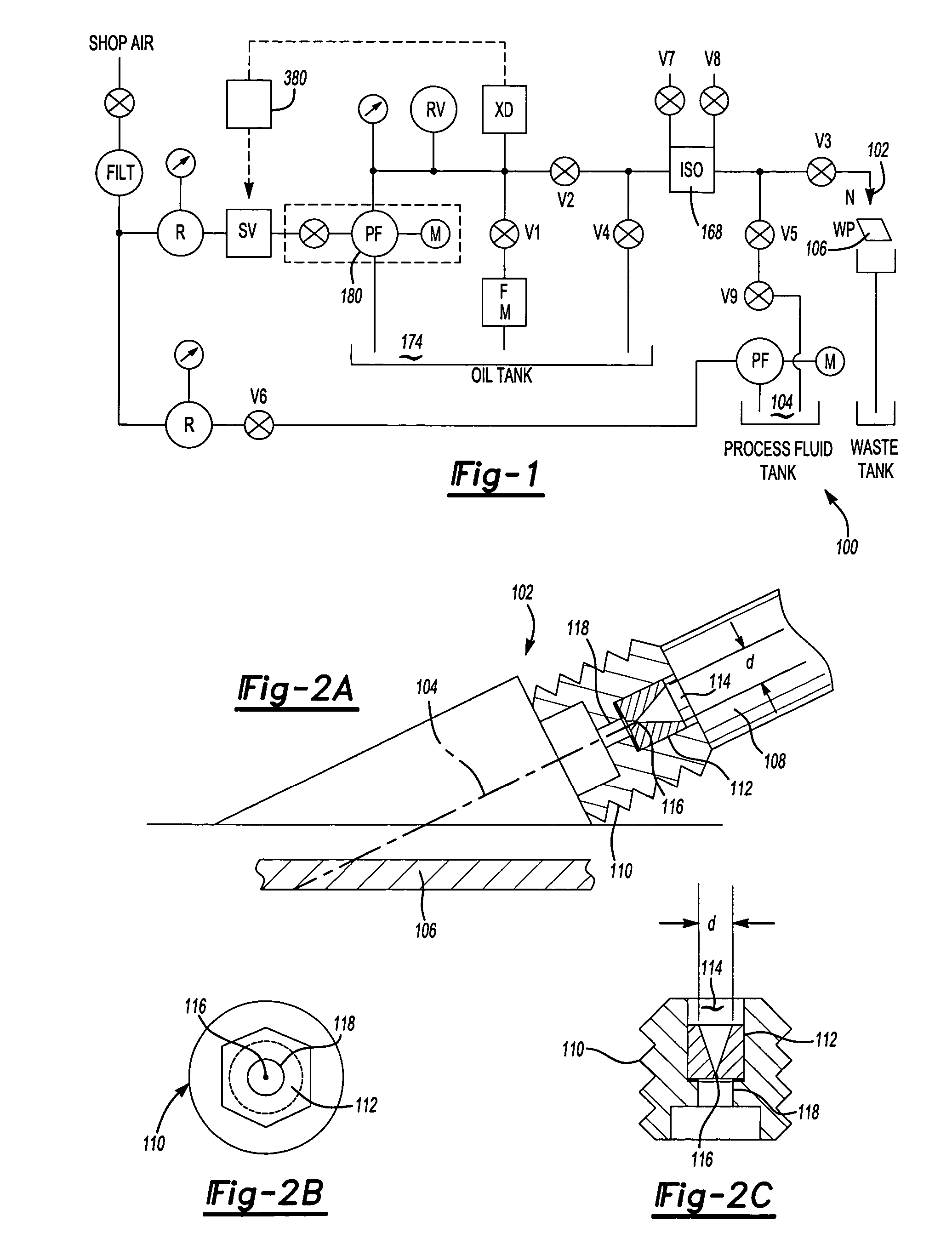

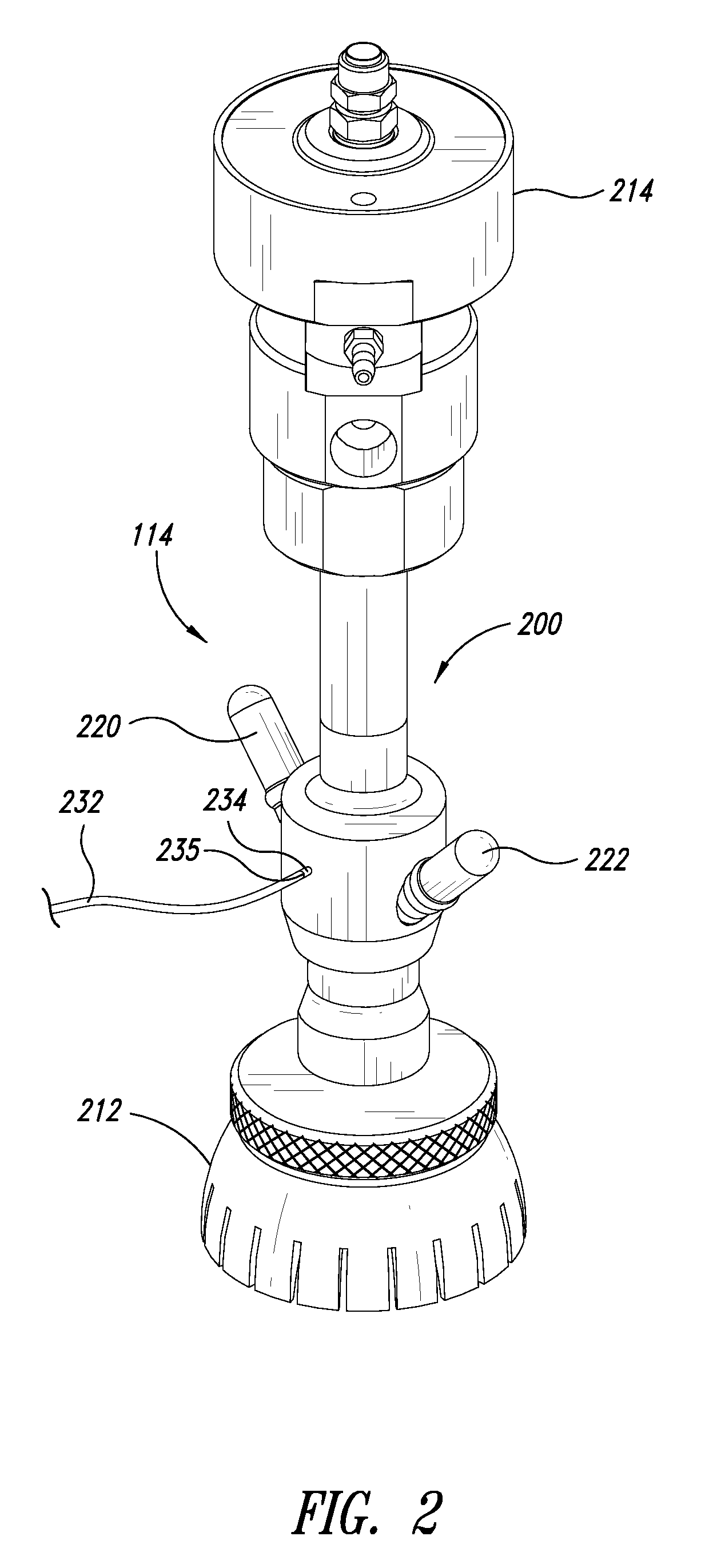

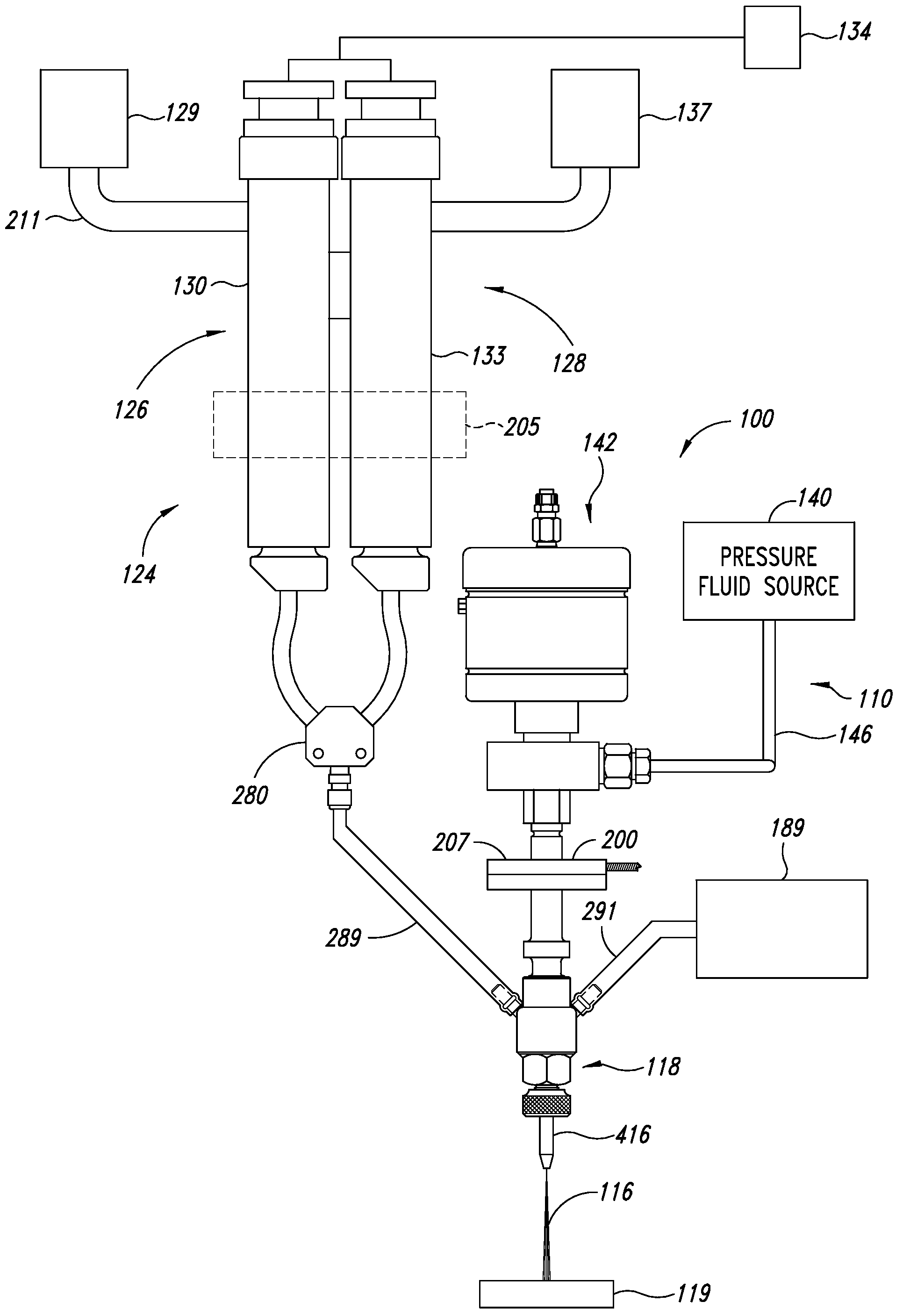

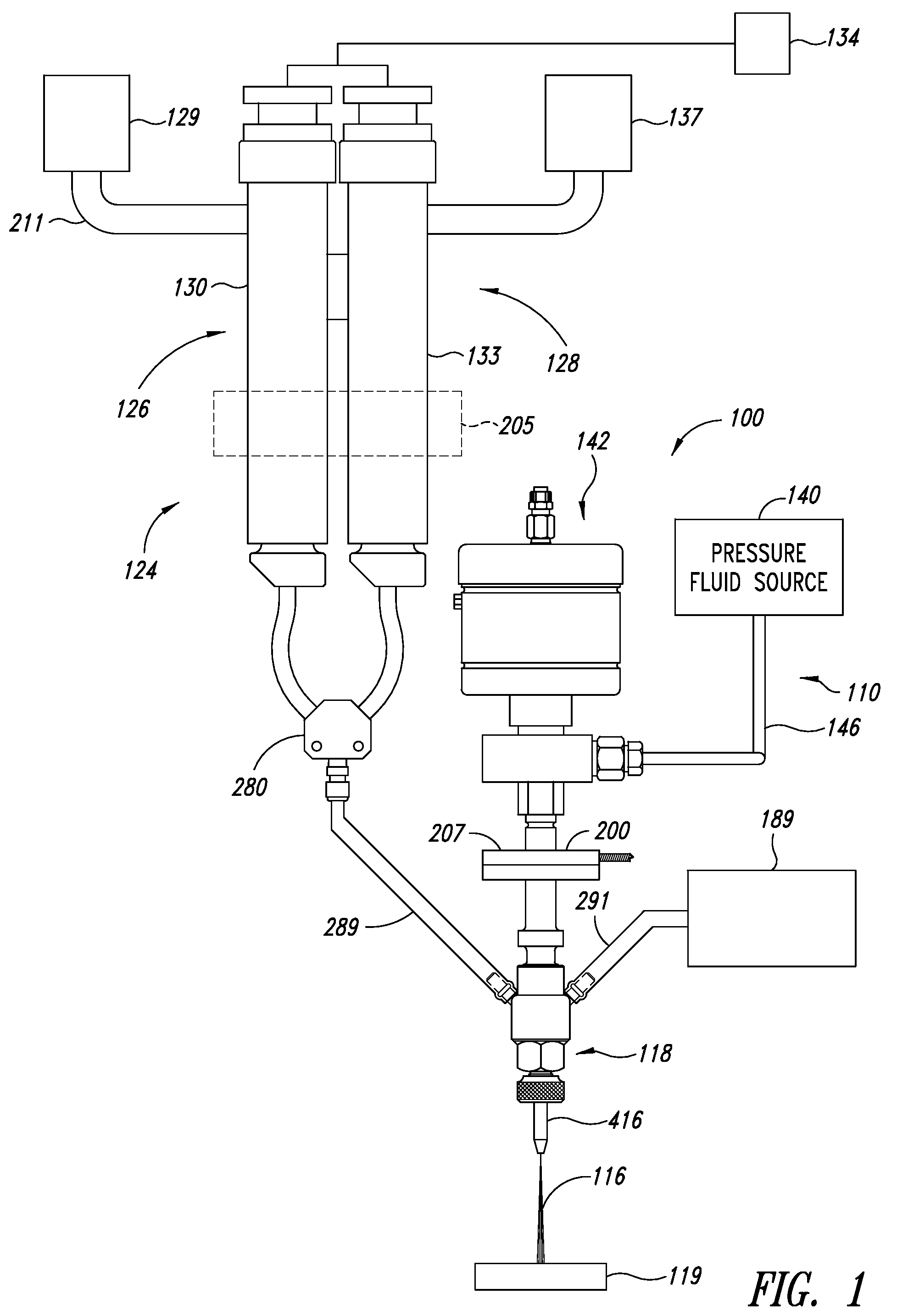

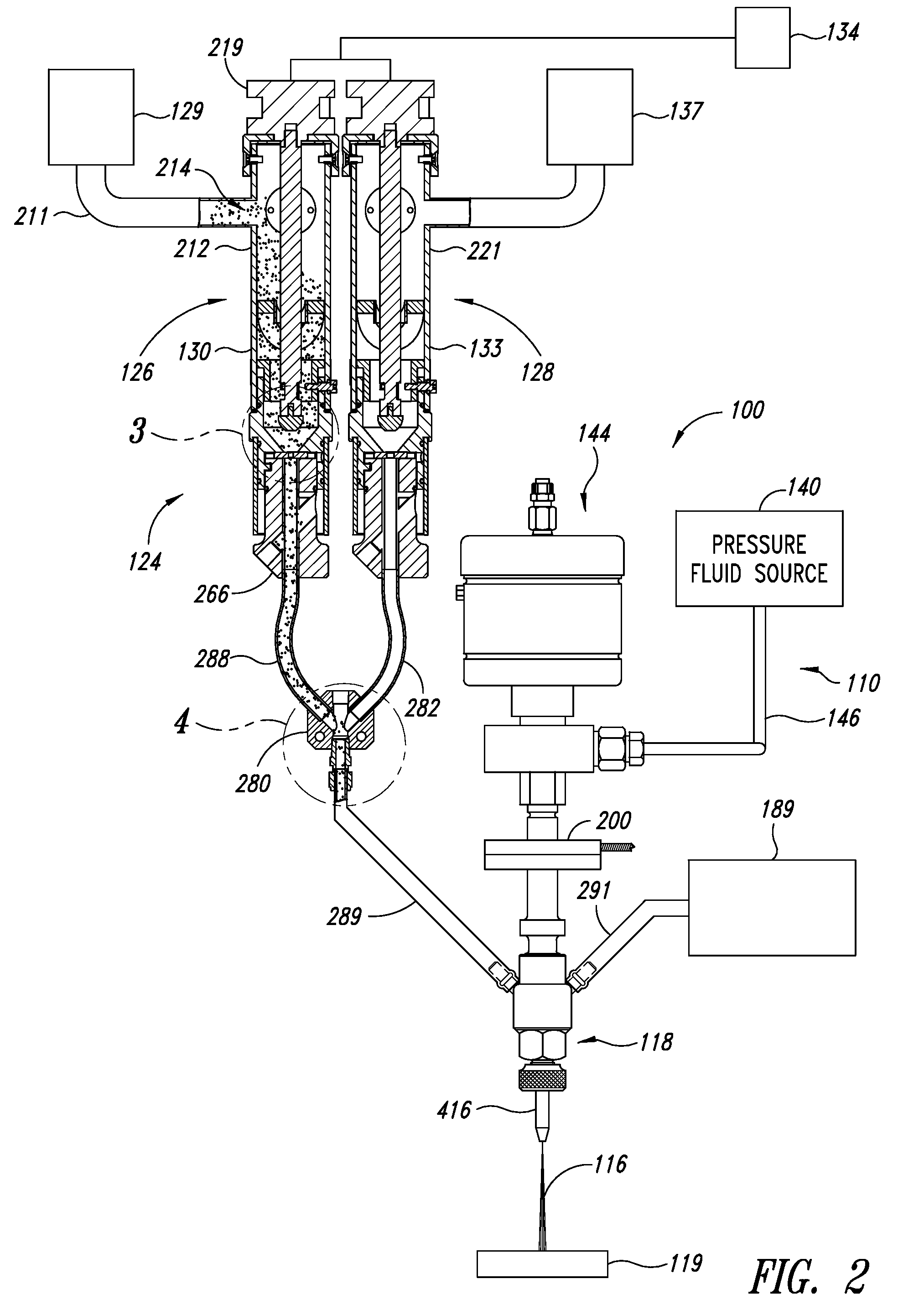

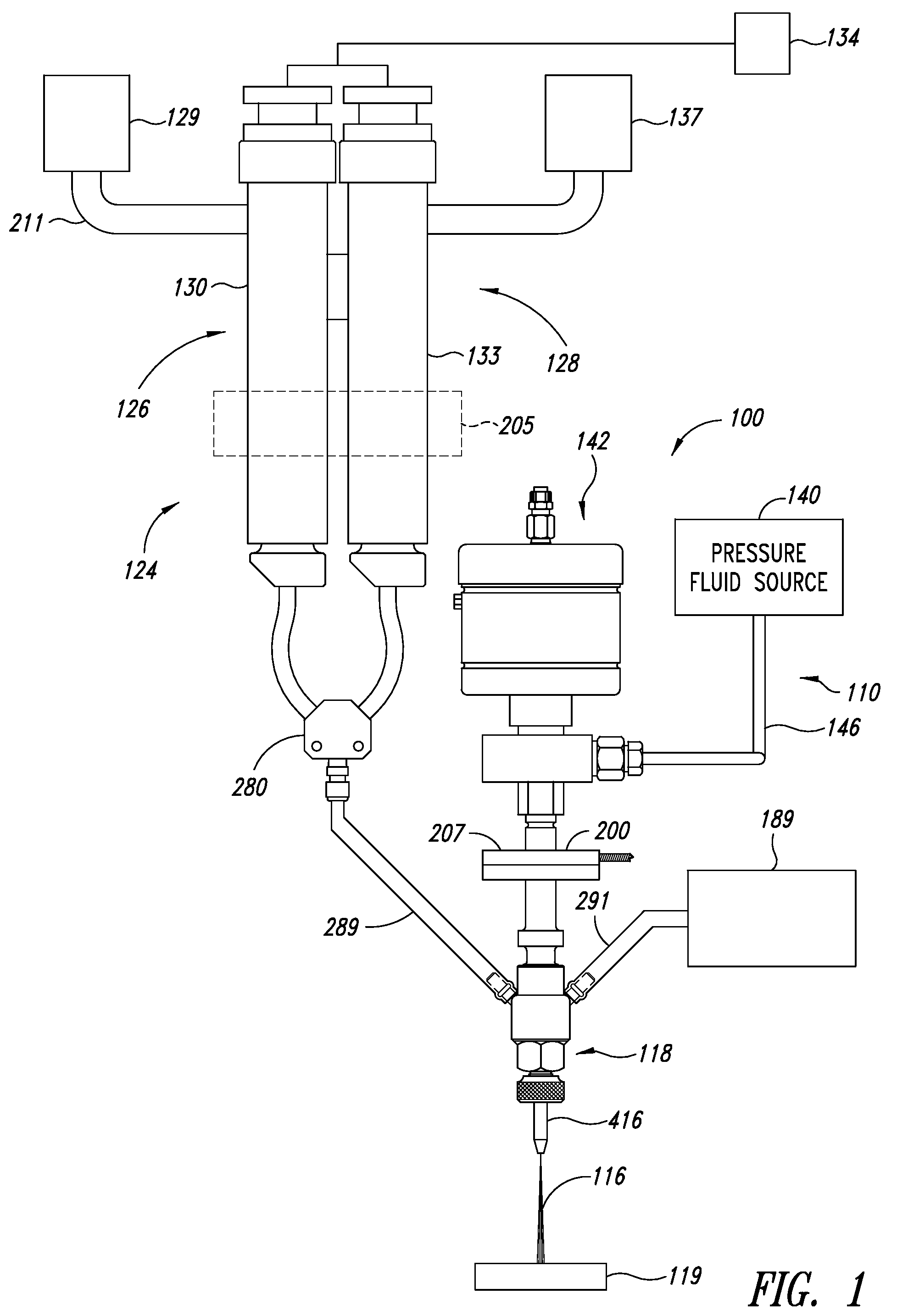

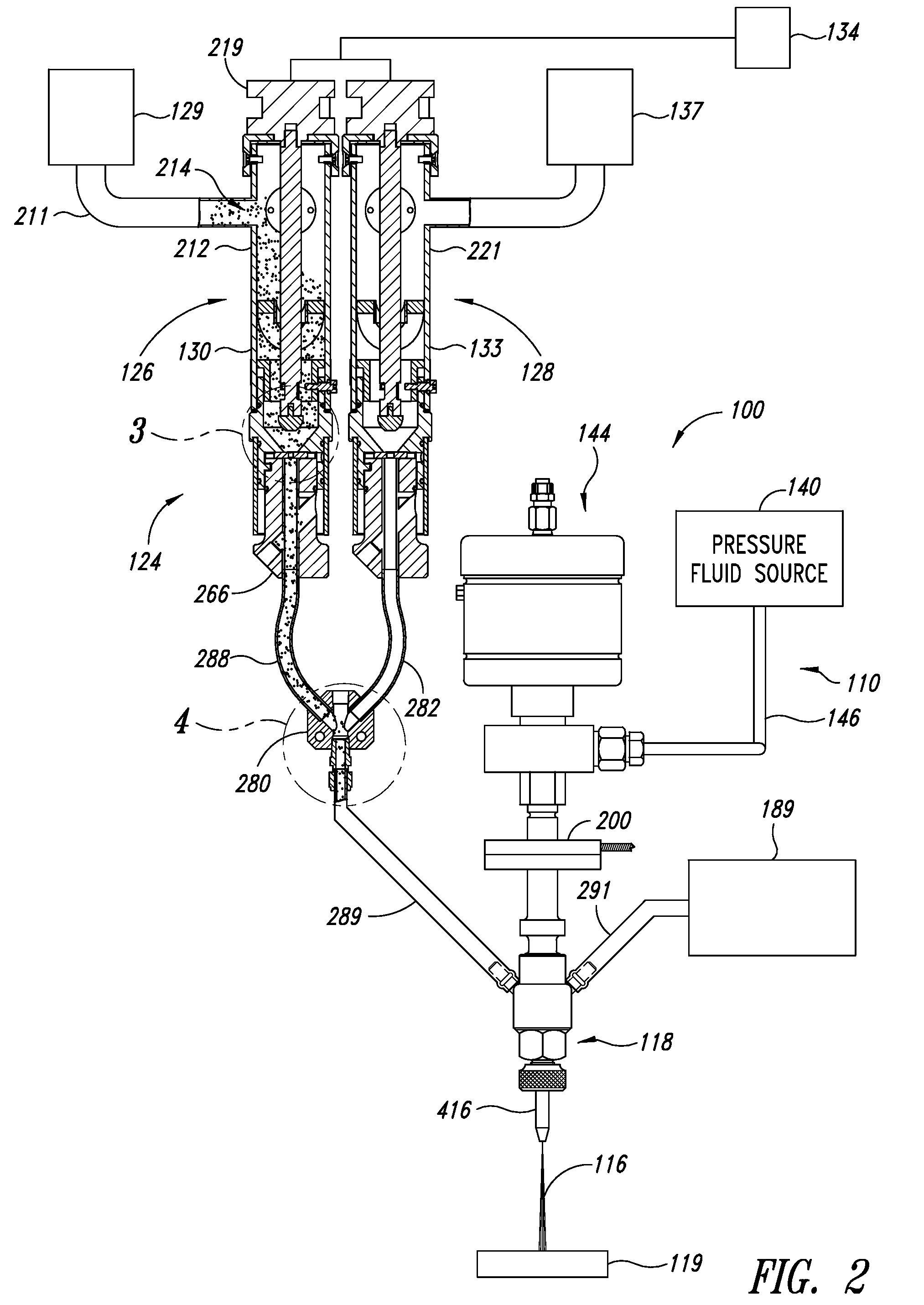

Suspended abrasive waterjet hole drilling system and method

ActiveUS7186167B2High viscosityVelocity increasesBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RTX CORP

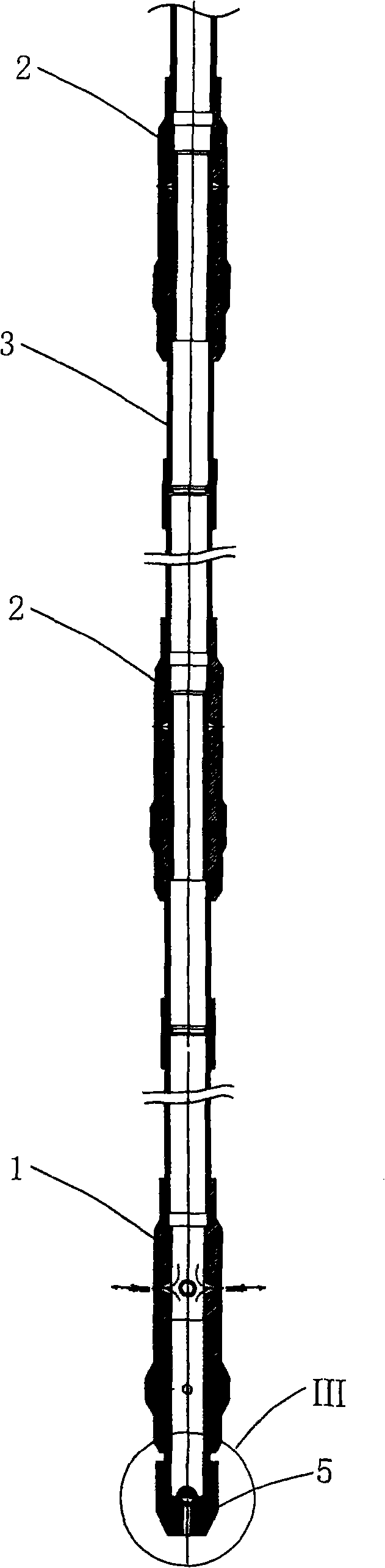

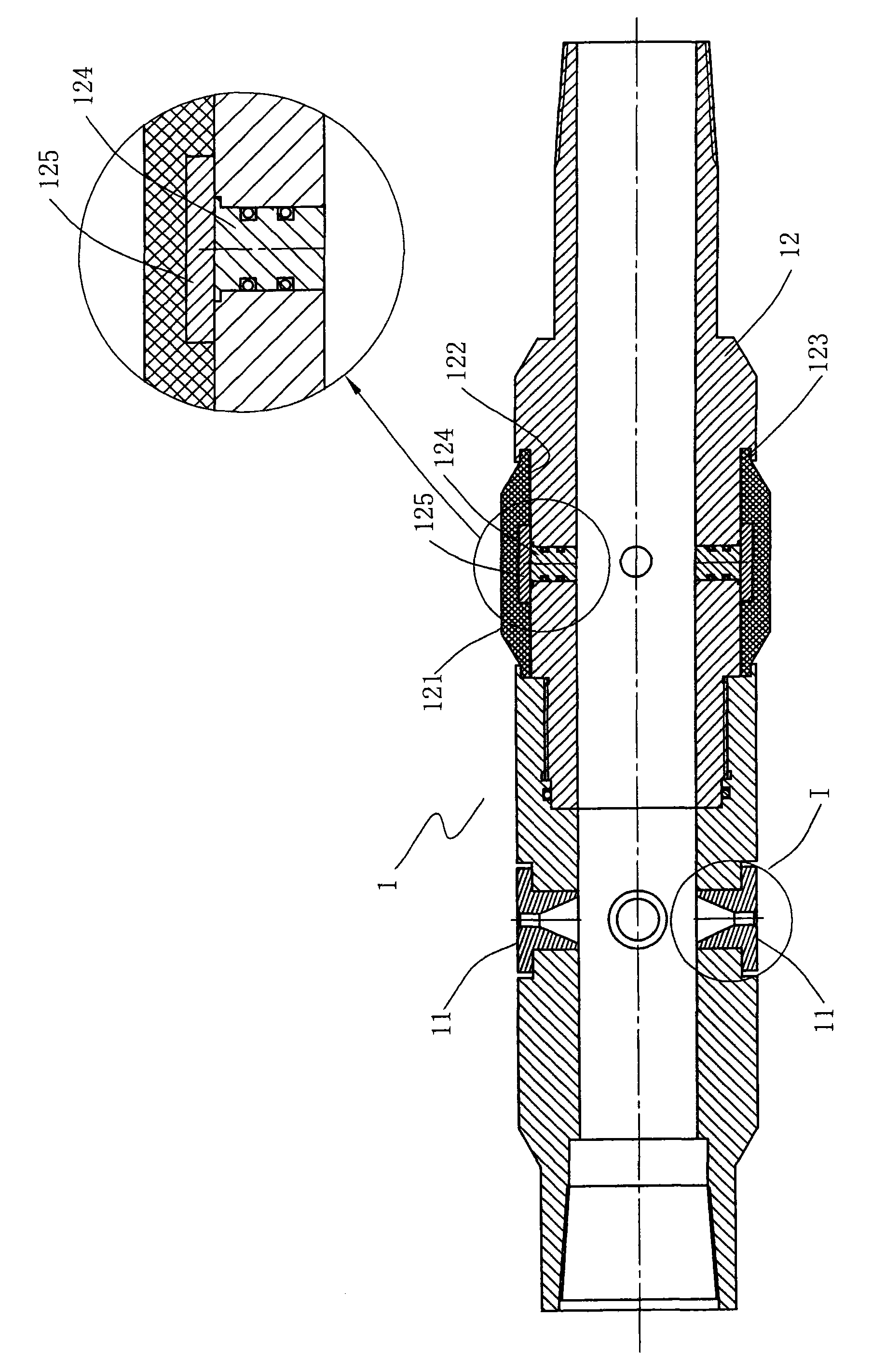

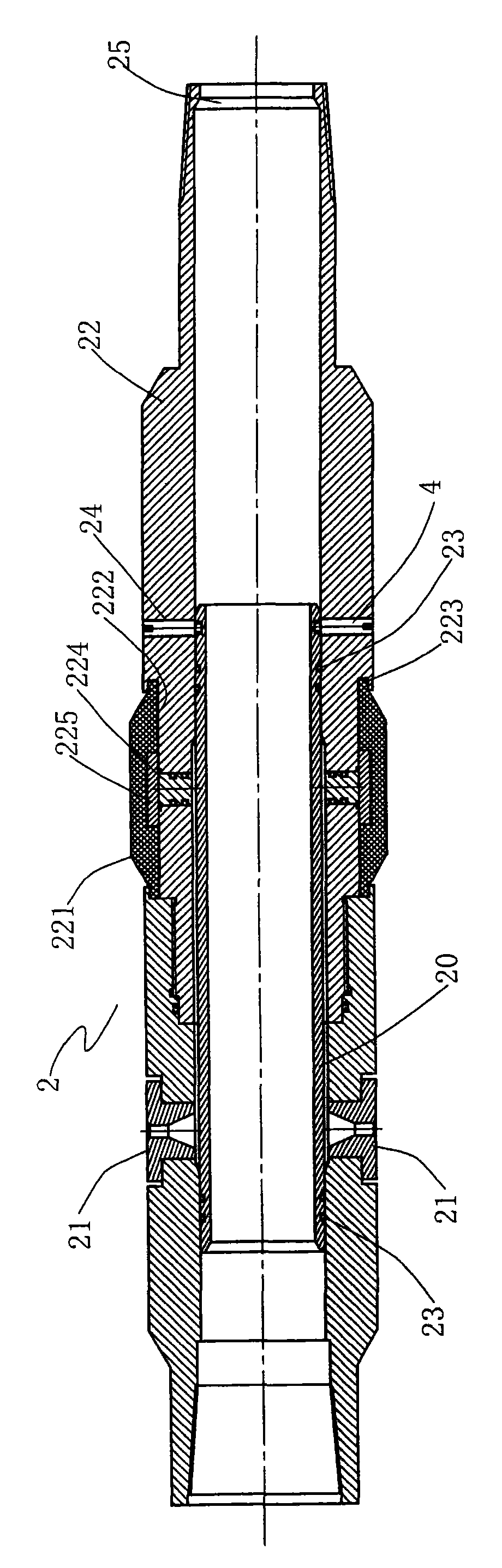

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

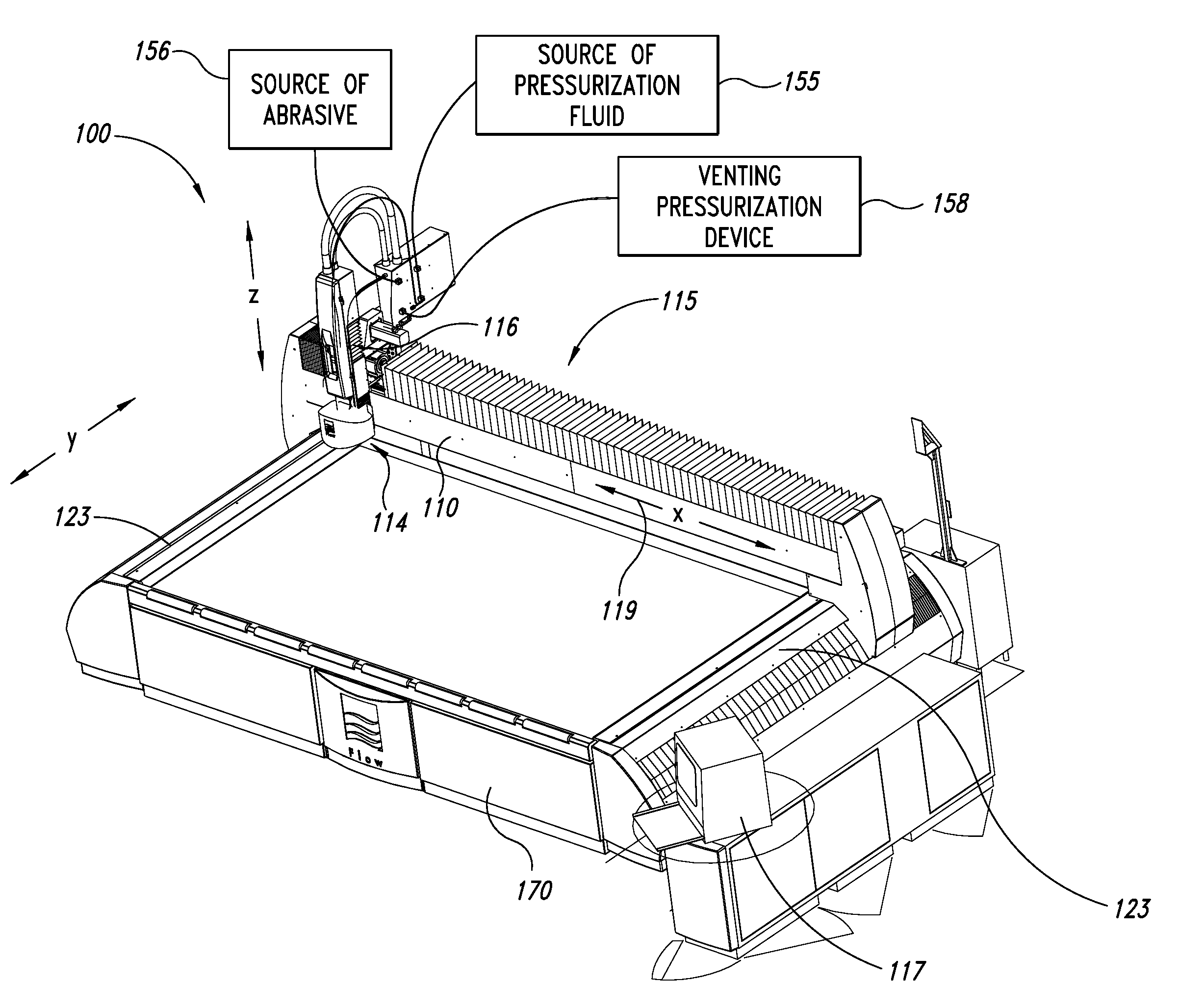

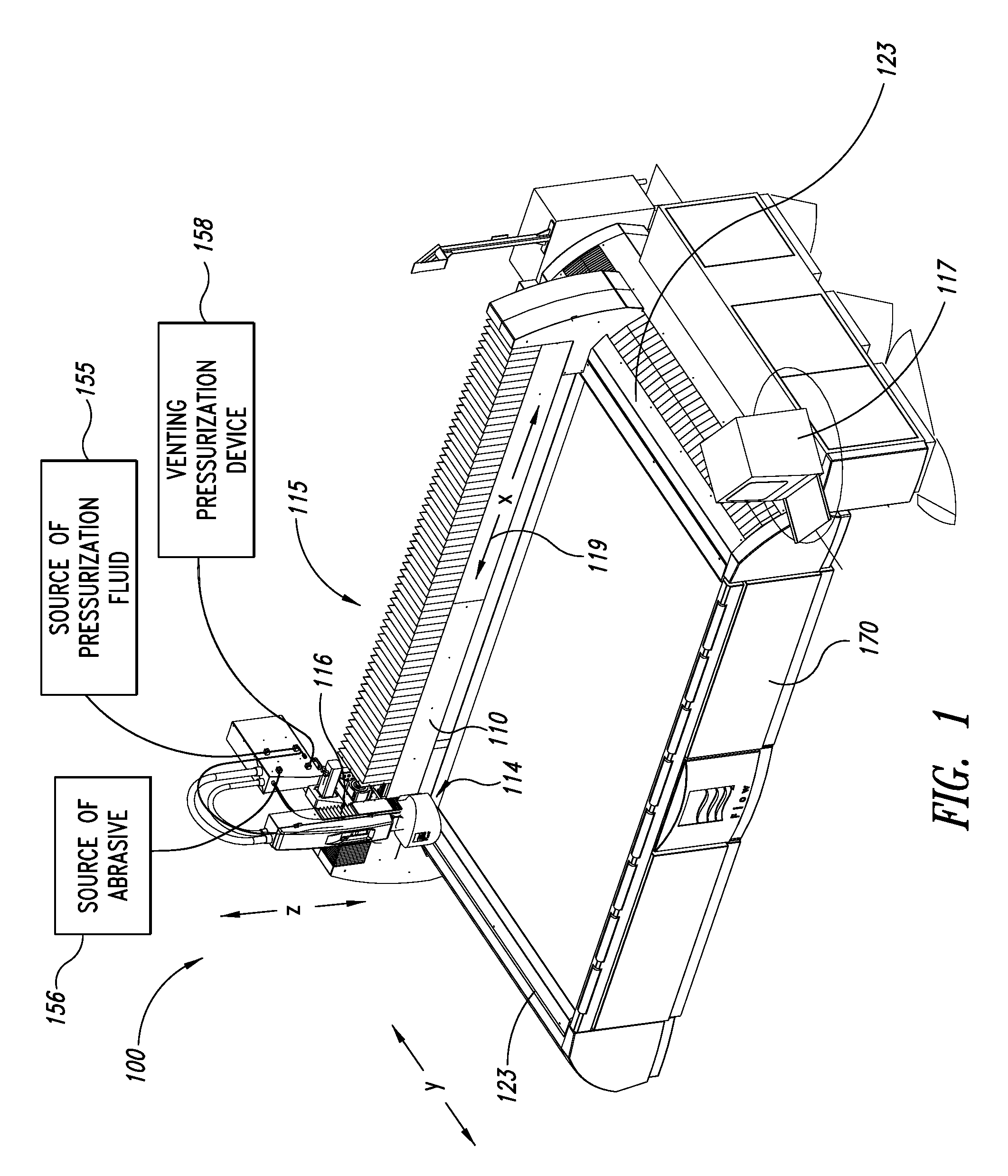

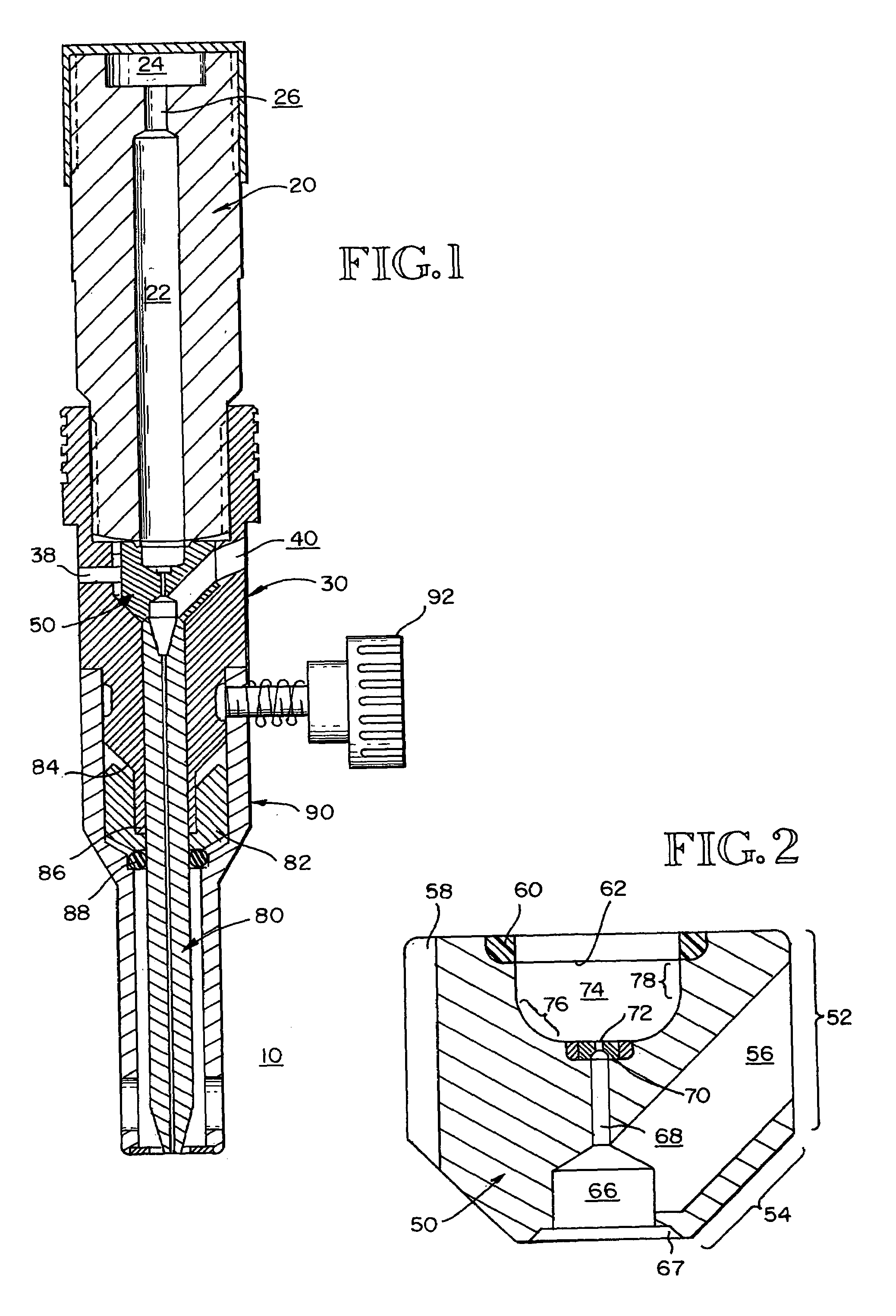

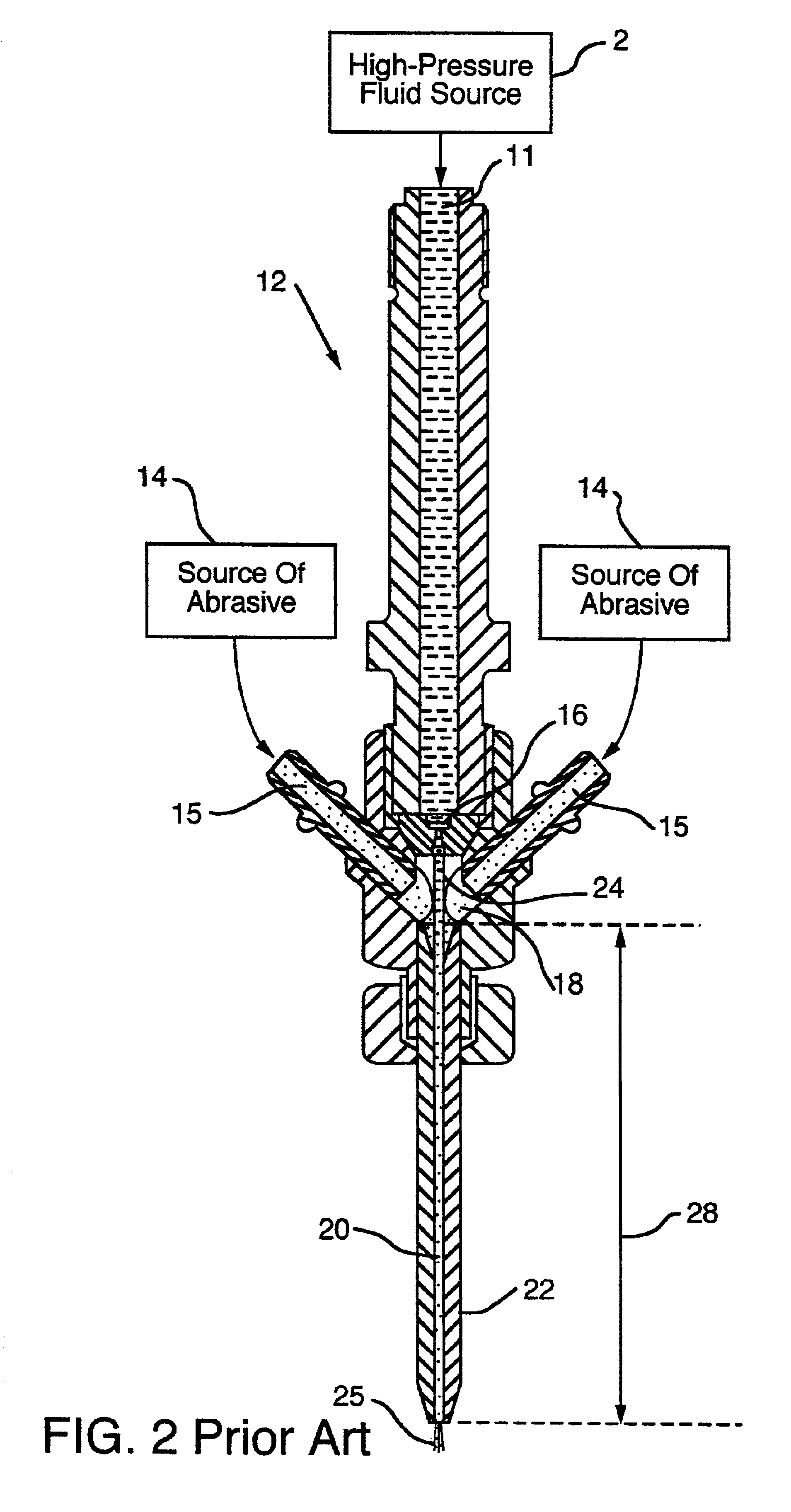

Vented cutting head body for abrasive jet system

An abrasive waterjet assembly has a cutting head assembly with a venting system for controlling the flow of abrasive within a cutting head body. The venting system includes one or more vents for regulating the pressure within a cutting head body to minimize, limit, or substantially eliminate any abrasive from reaching a jewel orifice. The vents include venting ports positioned between an orifice mount that retains the jewel orifice and a mixing region in which abrasive is mixed with a fluid jet produced by the jewel orifice. An isolator retained in the cutting head body further inhibits the upstream flow of abrasive, if any.

Owner:FLOW INT

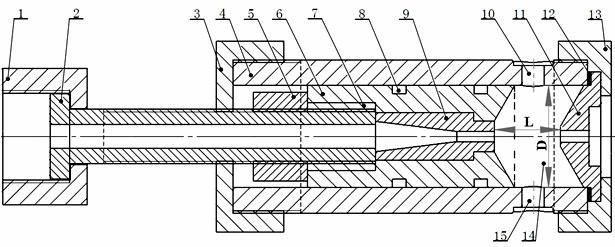

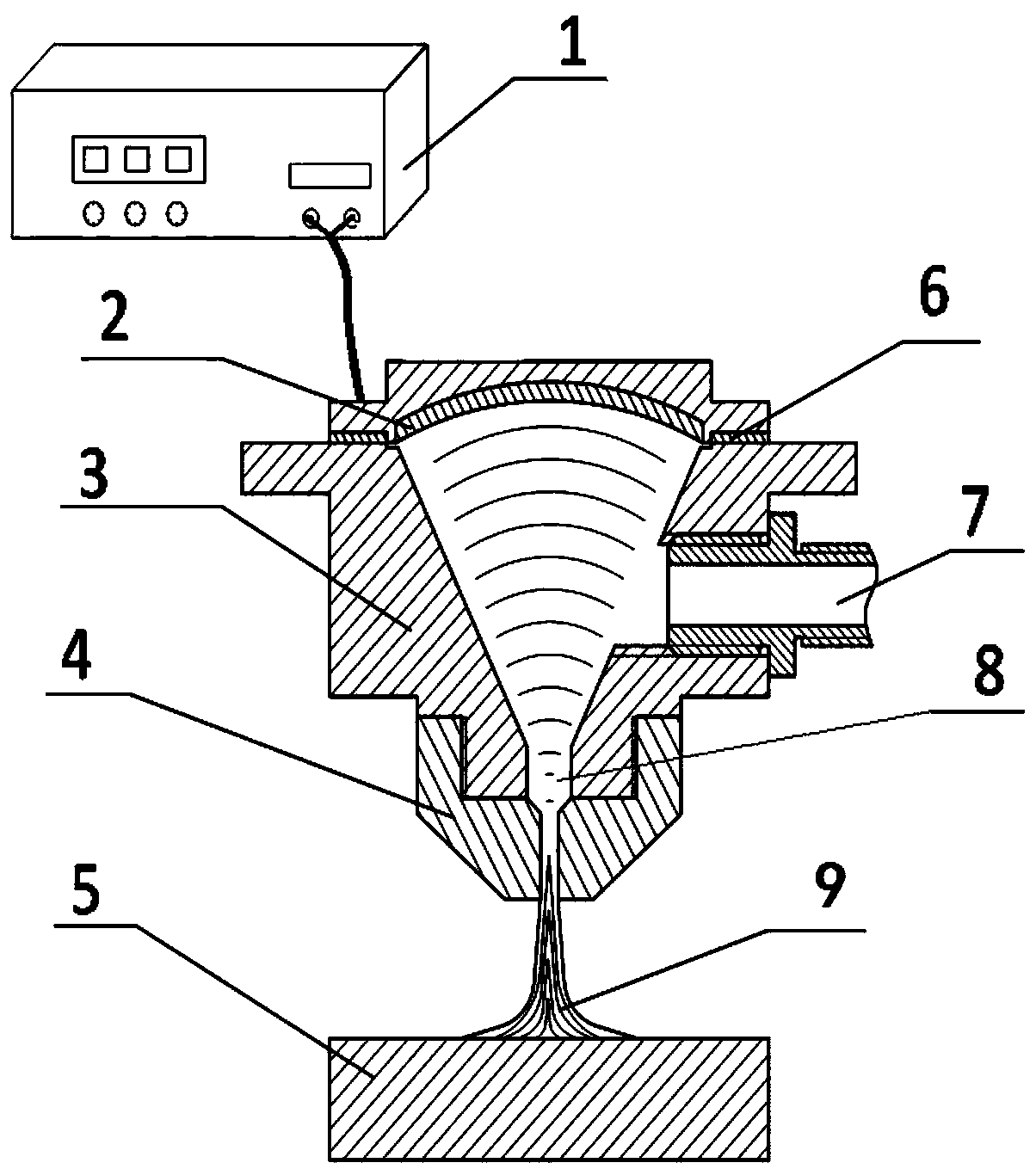

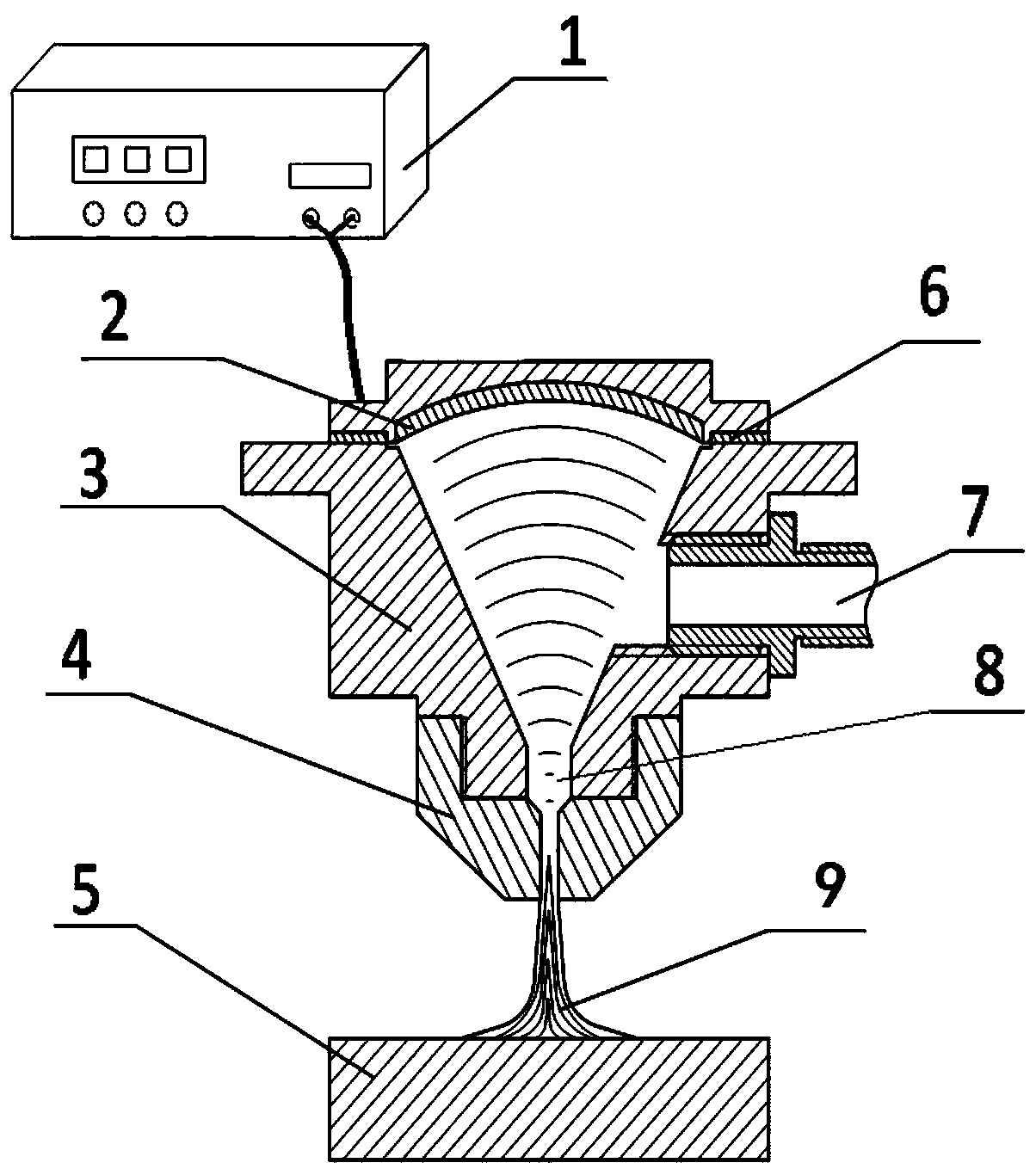

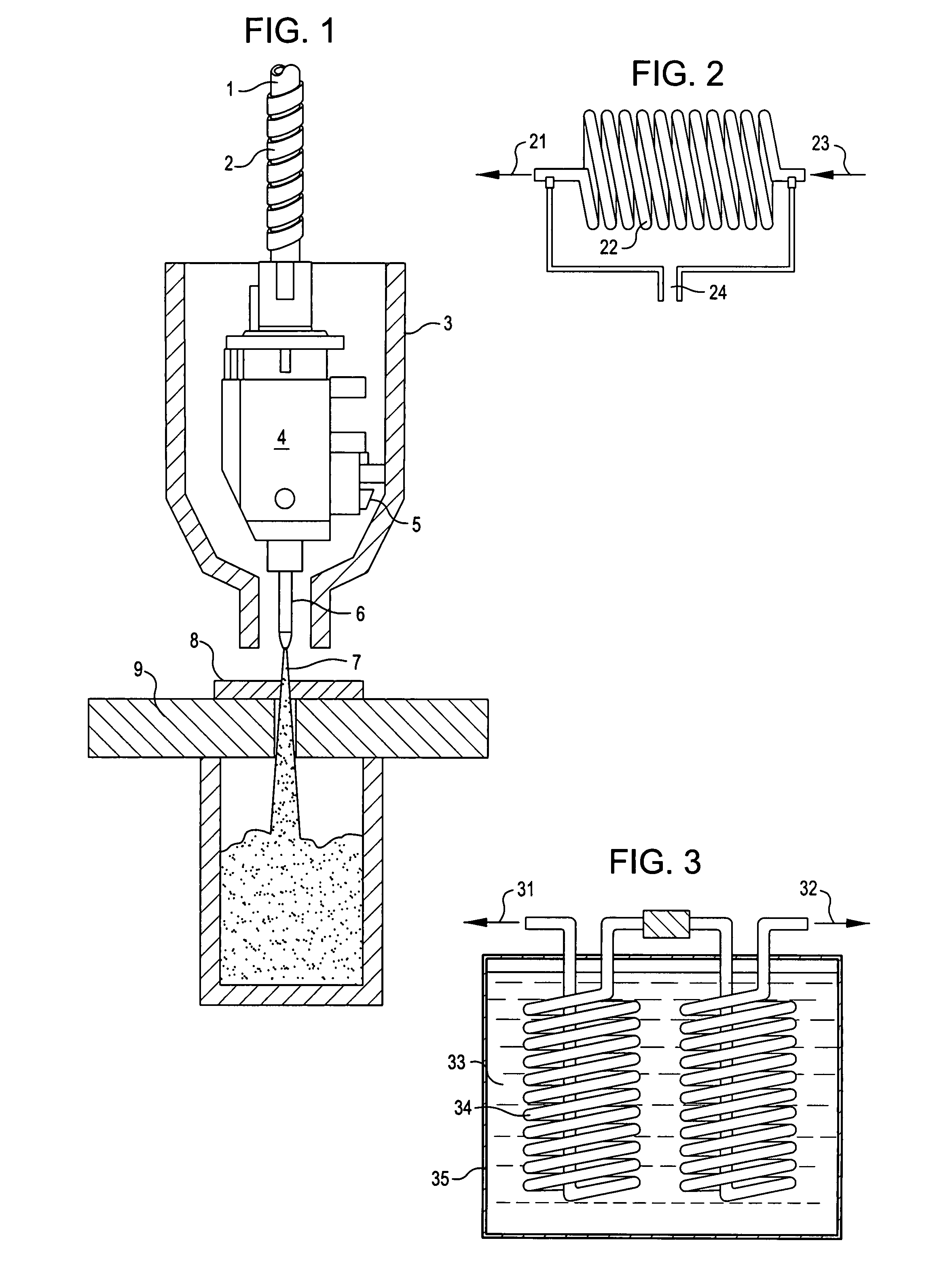

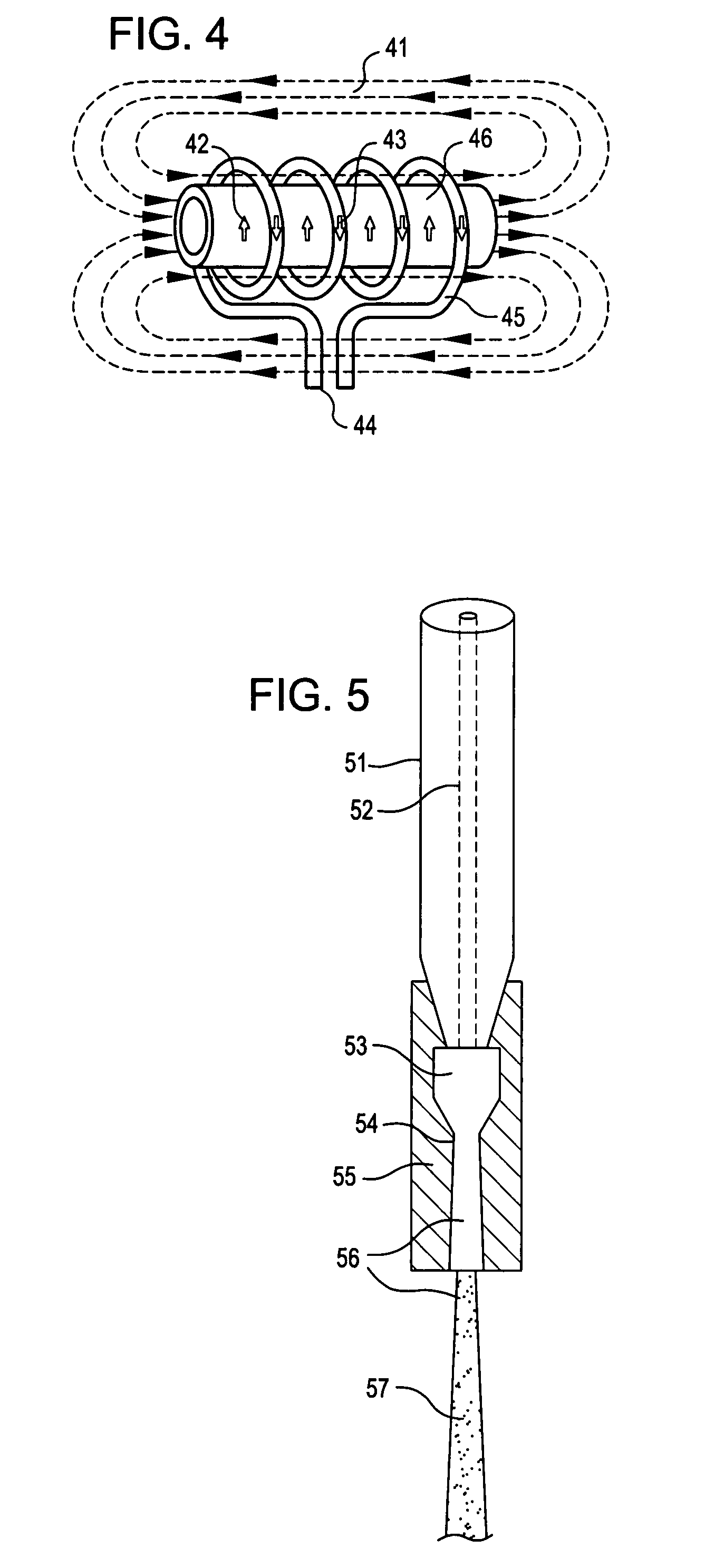

Multifunctional self-excited oscillation abrasive water jet generating device

ActiveCN102133562ASolve the difficult problem of performance optimization testSimple structureSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a multifunctional self-excited oscillation abrasive water jet generating device, which comprises an upstream nozzle, a downstream nozzle, an adjusting screw, a resonance cylinder, a first end cover and a second end cover. The device is characterized in that: the left part of the inner wall cavity of an upstream nozzle bush is provided with a metal threaded bush, and the outer wall of the upstream nozzle is matched with the inner wall of the resonance cylinder; the adjusting screw passes through a connecting screw cap and is sequentially in fit connection with the central hole of the first end cover, a locking screw cap and the metal threaded bush; the upstream nozzle is arranged on the right middle part of the inner wall cavity of the upstream nozzle bush, and the downstream nozzle is arranged between the right end of the resonance cylinder and the second end cover; the right end of the upstream nozzle, the left end of the downstream nozzle and the inner wall of the resonance cylinder positioned between the upstream nozzle and the downstream nozzle form a resonance chamber; and an air inlet formed on the resonance cylinder and an adjusting screw mounting hole are communicated with the resonance chamber. The device has simple structure, and is convenient for operation; the device has multiple testing functions; and compared with other jet generating devices, not only the experiment time can be greatly shortened, but also the experiment expenditure can be saved.

Owner:CHONGQING UNIV

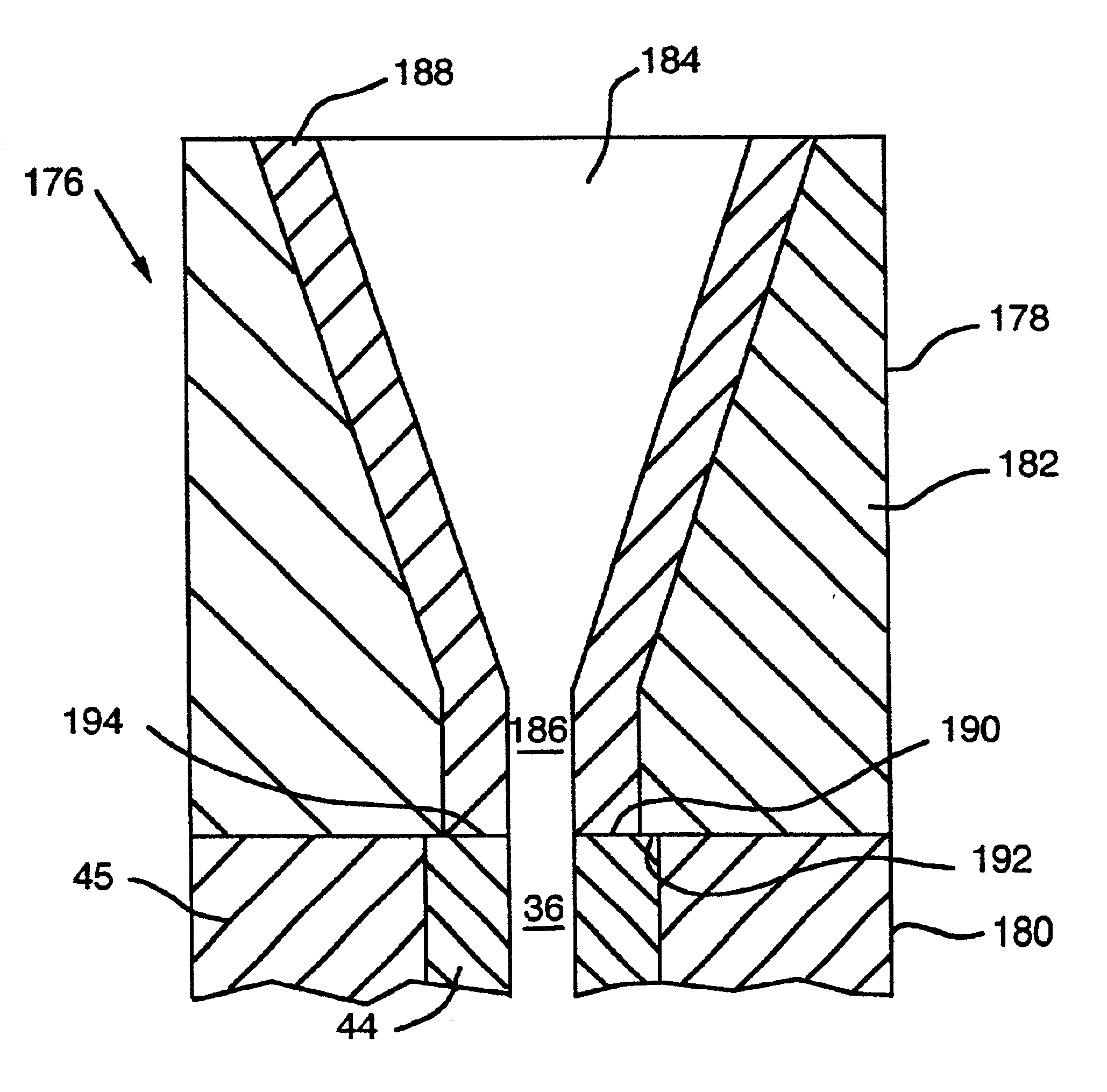

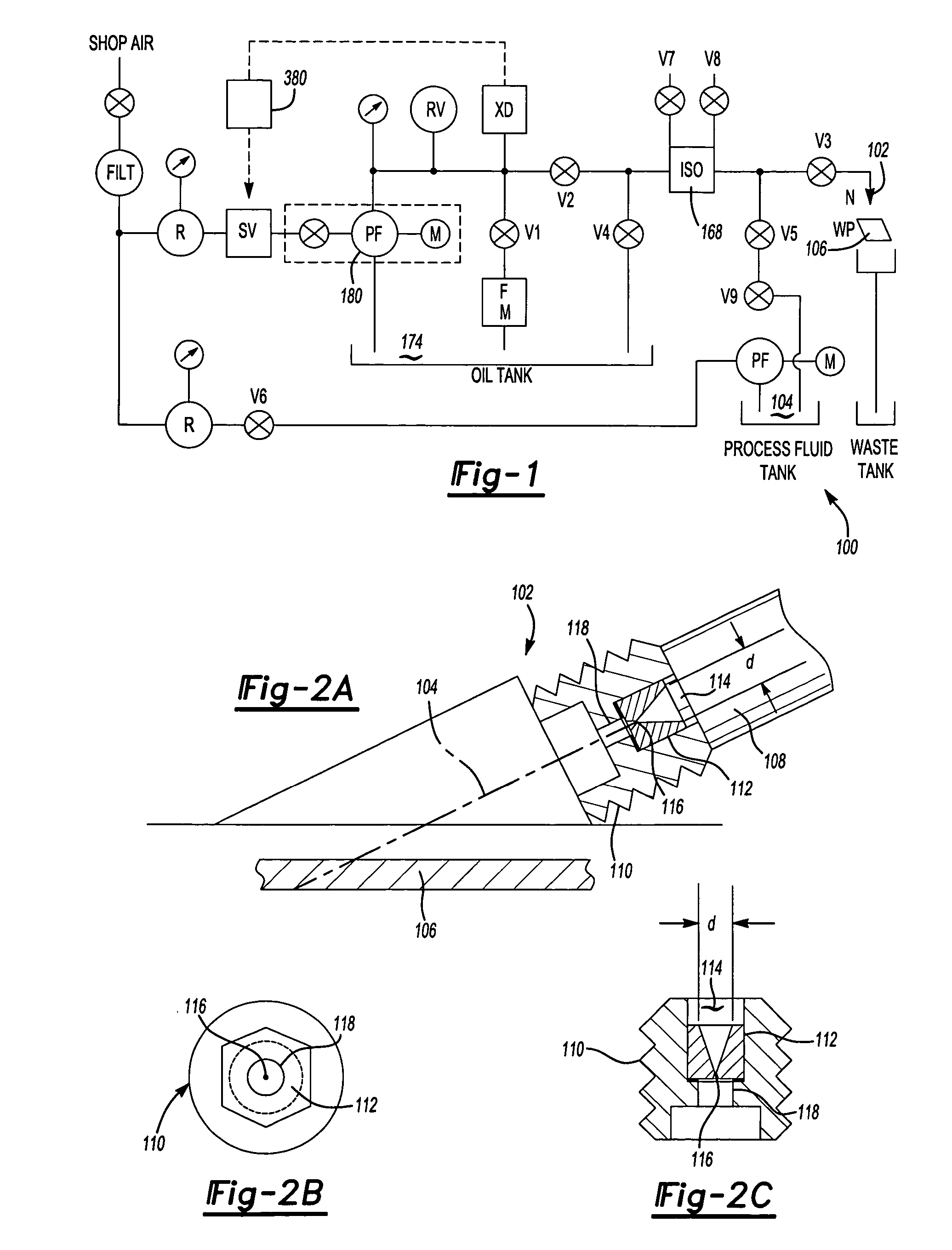

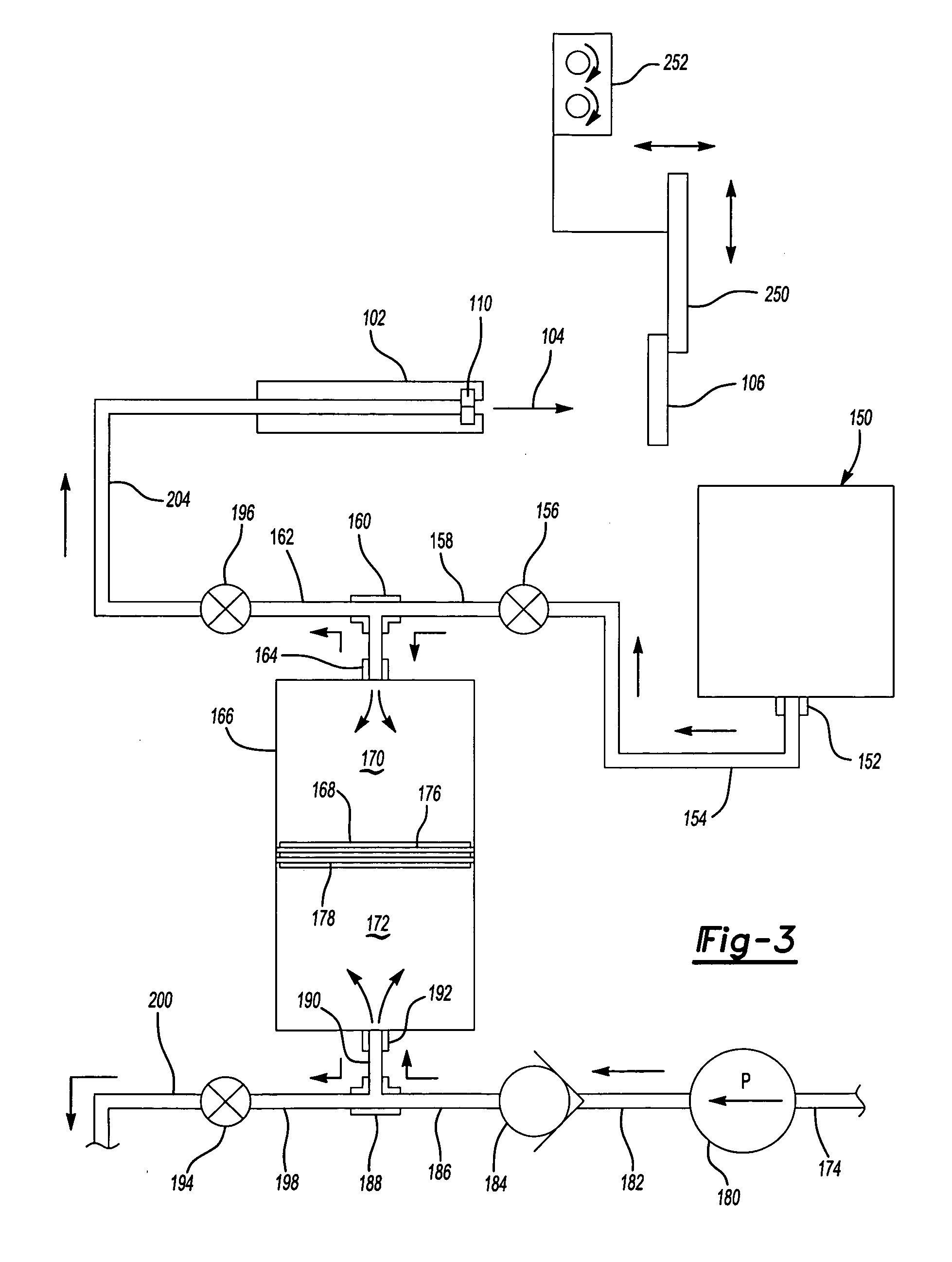

Processes and apparatuses for enhanced cutting using blends of abrasive materials

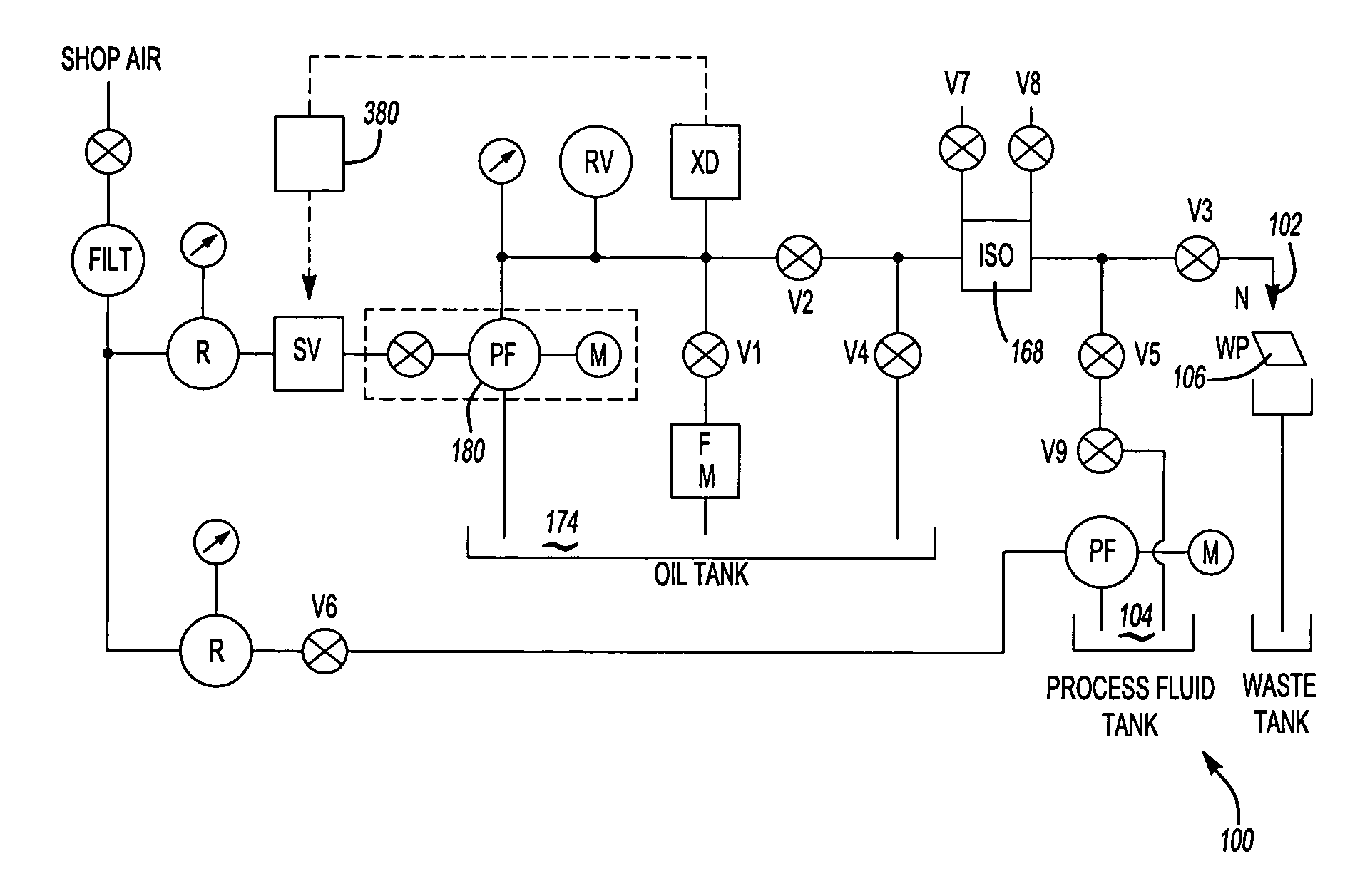

ActiveUS20100124872A1Composition is limitedBlast gunsControlling ratio of multiple fluid flowsEngineeringDelivery system

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT

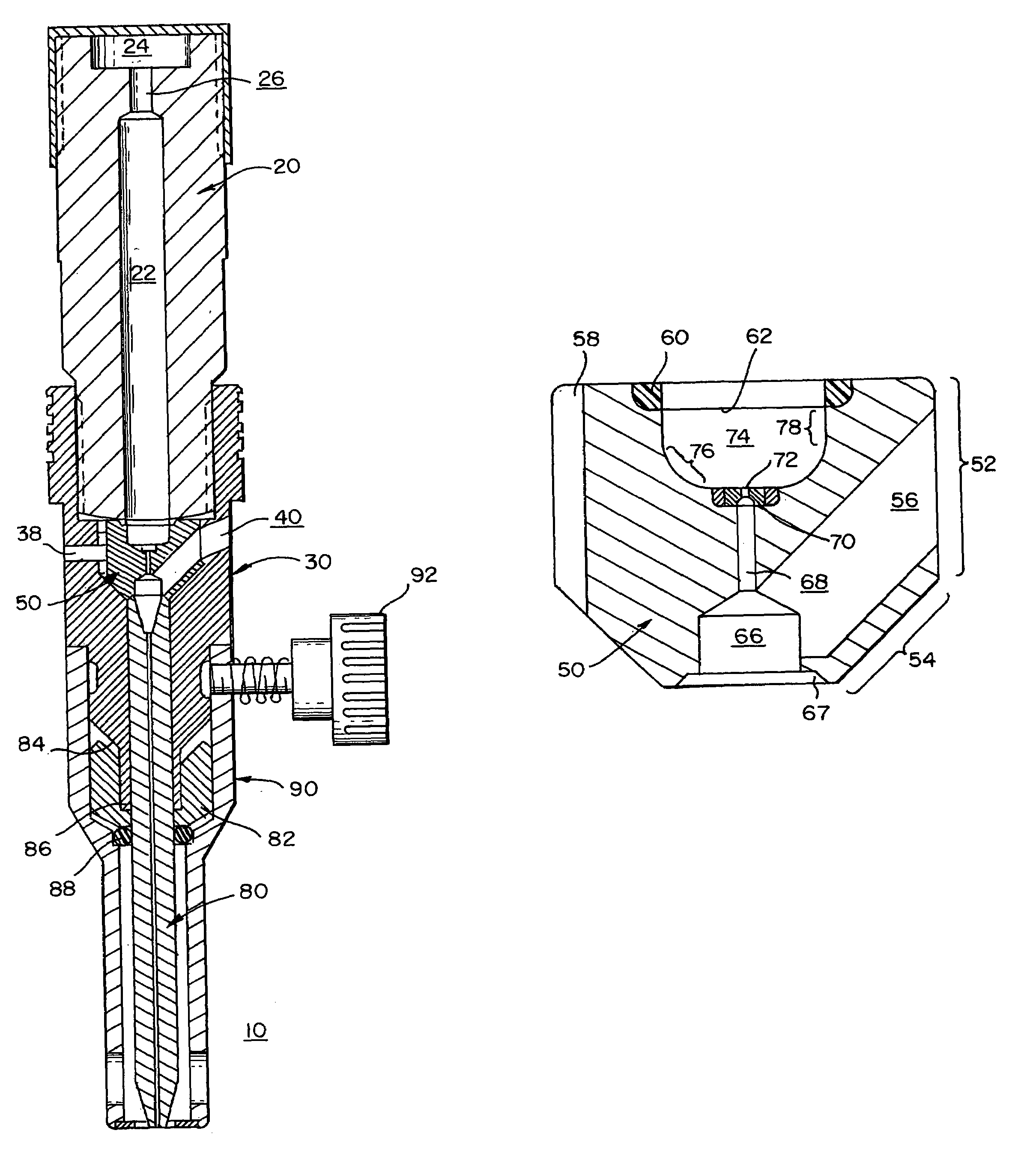

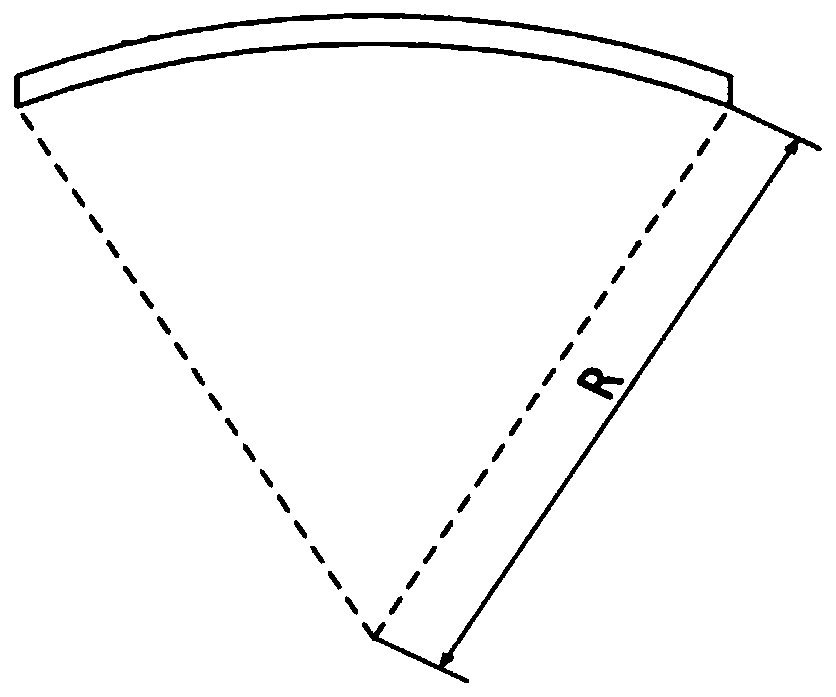

Orifice body with mixing chamber for abrasive water jet cutting

InactiveUS6932285B1Simple designImprove operationDrill bitsBlast gunsUltra high pressureHigh pressure

An improved orifice assembly for use with an ultra high pressure fluid jet cutting apparatus is disclosed. The improved orifice assembly generally includes an orifice body defining a central bore, a high pressure inlet cavity located at an upstream portion of the body, a mixing cavity located at a downstream portion of the body, and an abrasive material inlet bore that is in direct communication with the mixing cavity. The inlet or high pressure cavity preferably has a cylindrical cross section at the side wall portion and a generally flat bottom wall, with a constant radius transition portion between the side and bottom walls. A jeweled orifice is preferably located at the bottom wall and forms a portion thereof. A chamfer at the downstream portion of the mixing chamber permits appropriate coaxial alignment of a mixing tube with the jeweled orifice so as to preserve proper fluid flow characteristics. In addition, the incorporation of a soft seal between the mating surfaces of the inlet body and the orifice assembly permit easy user removal of these components from a cutting jet system.

Owner:SILICON VALLEY BANK

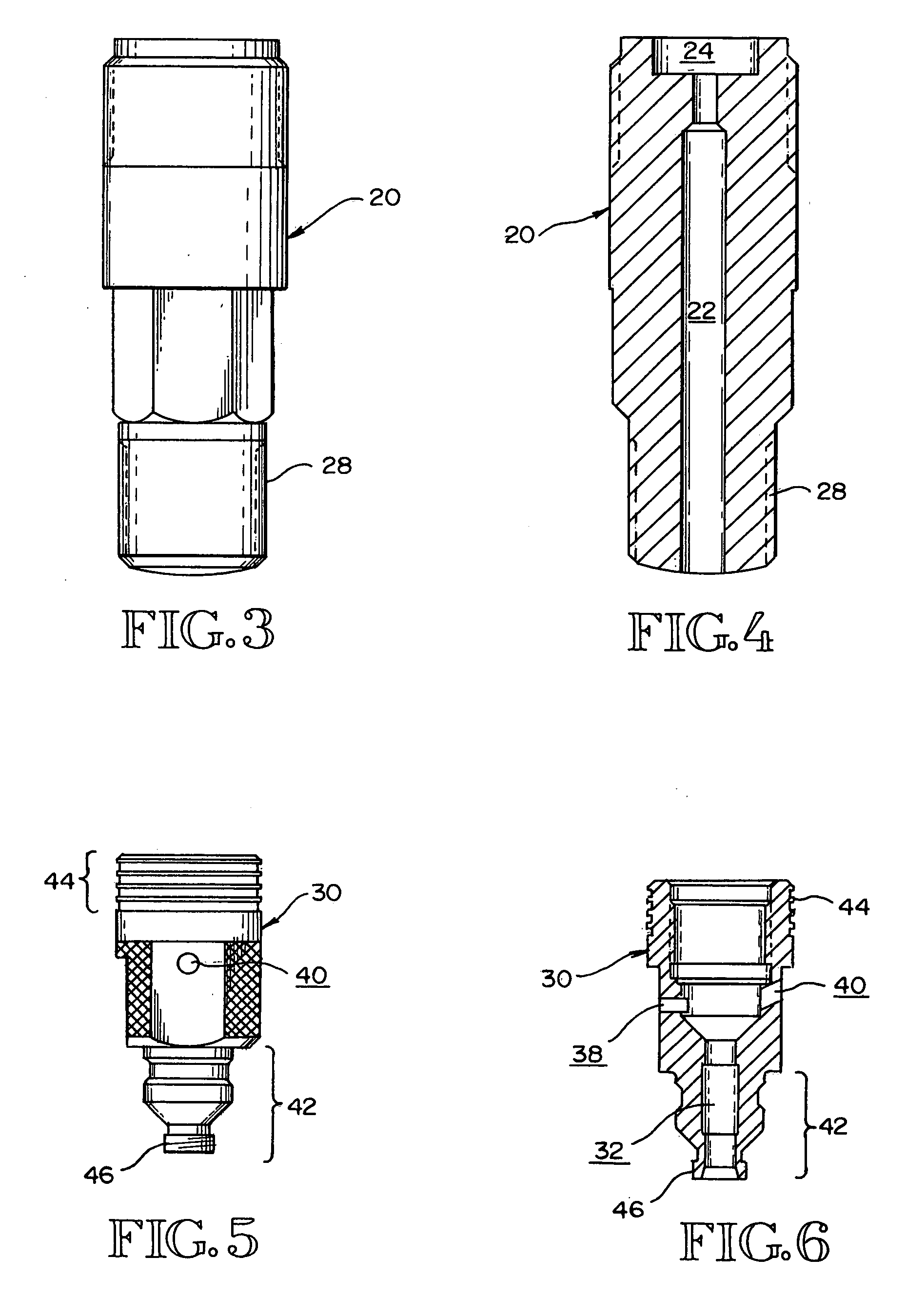

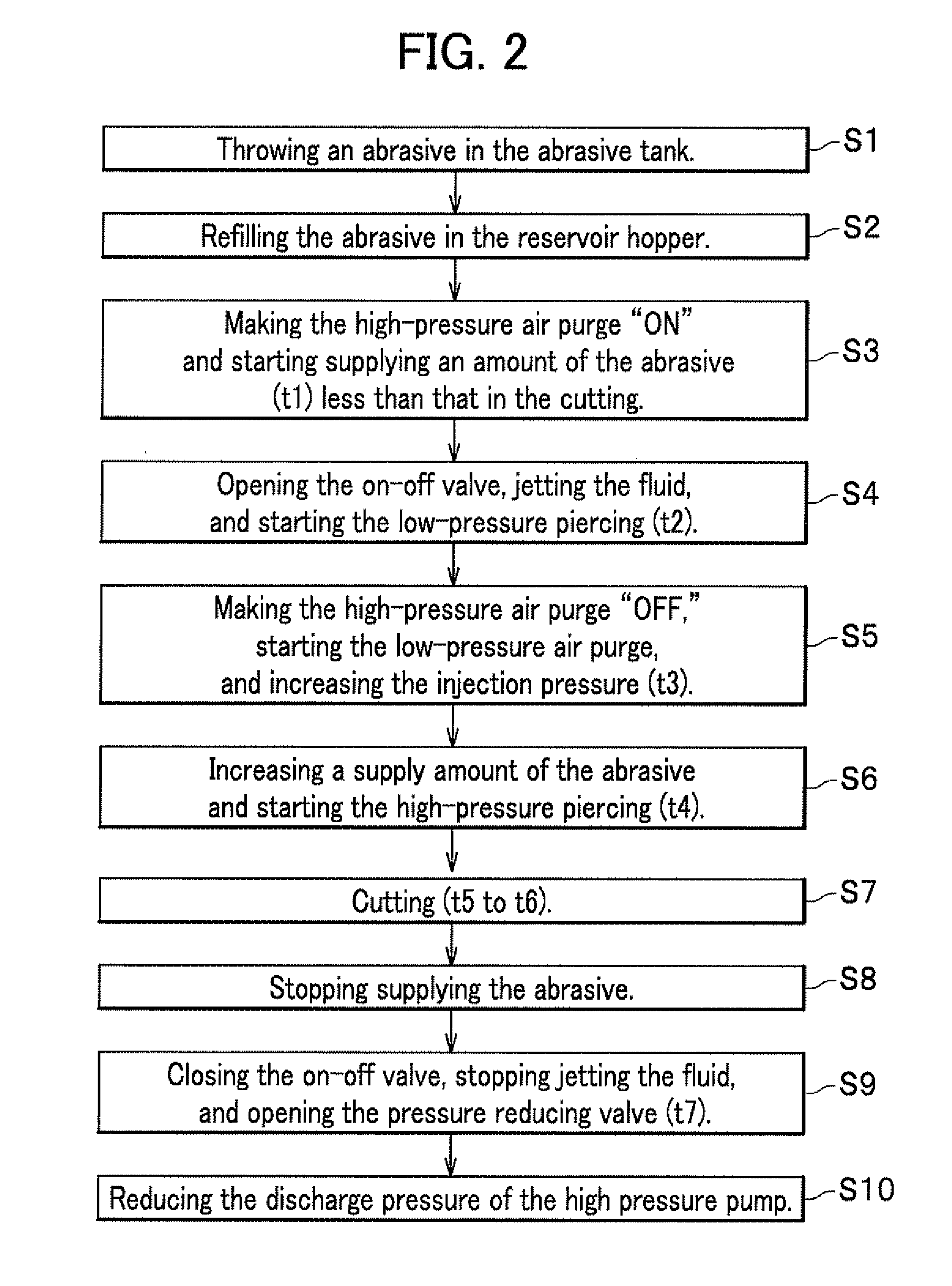

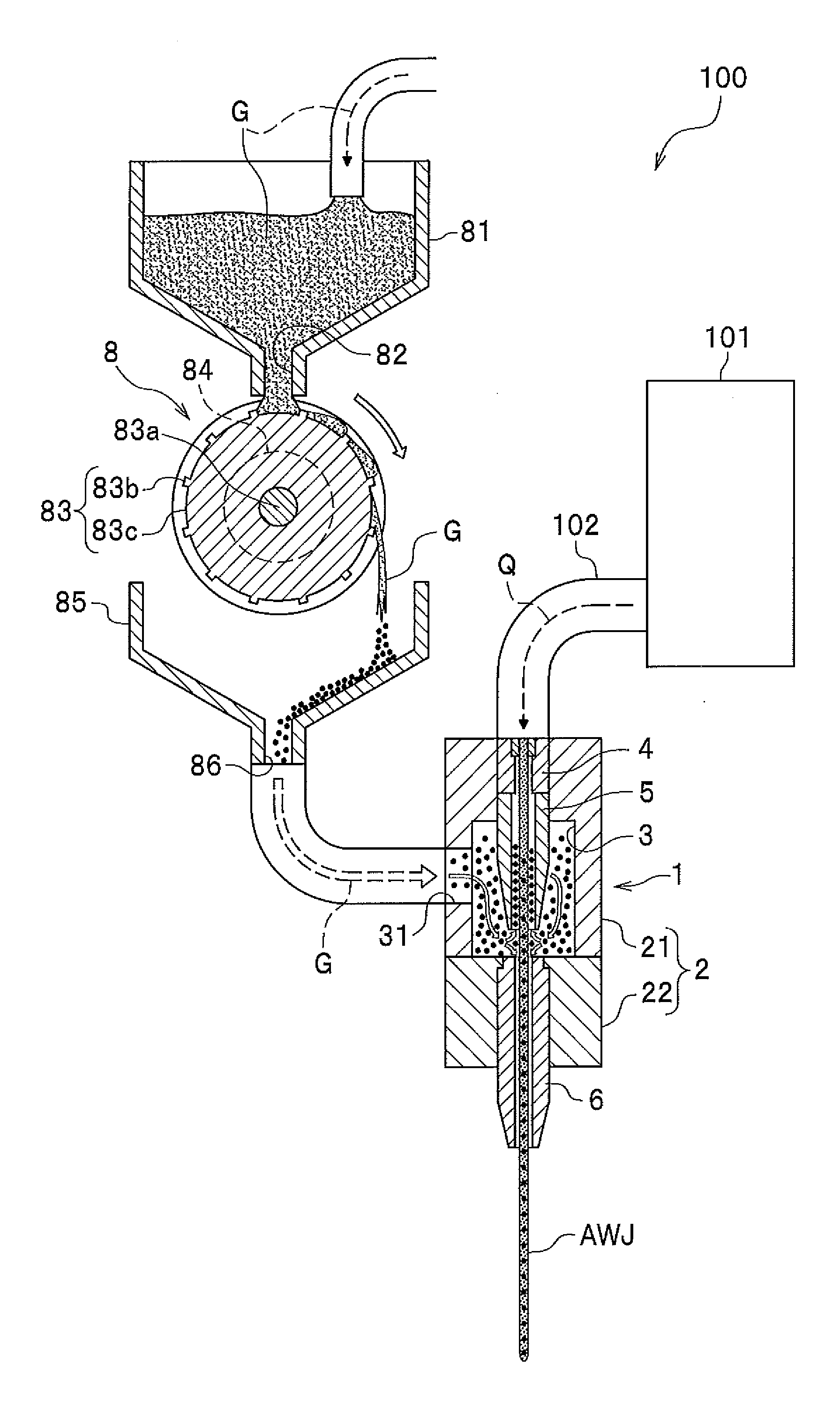

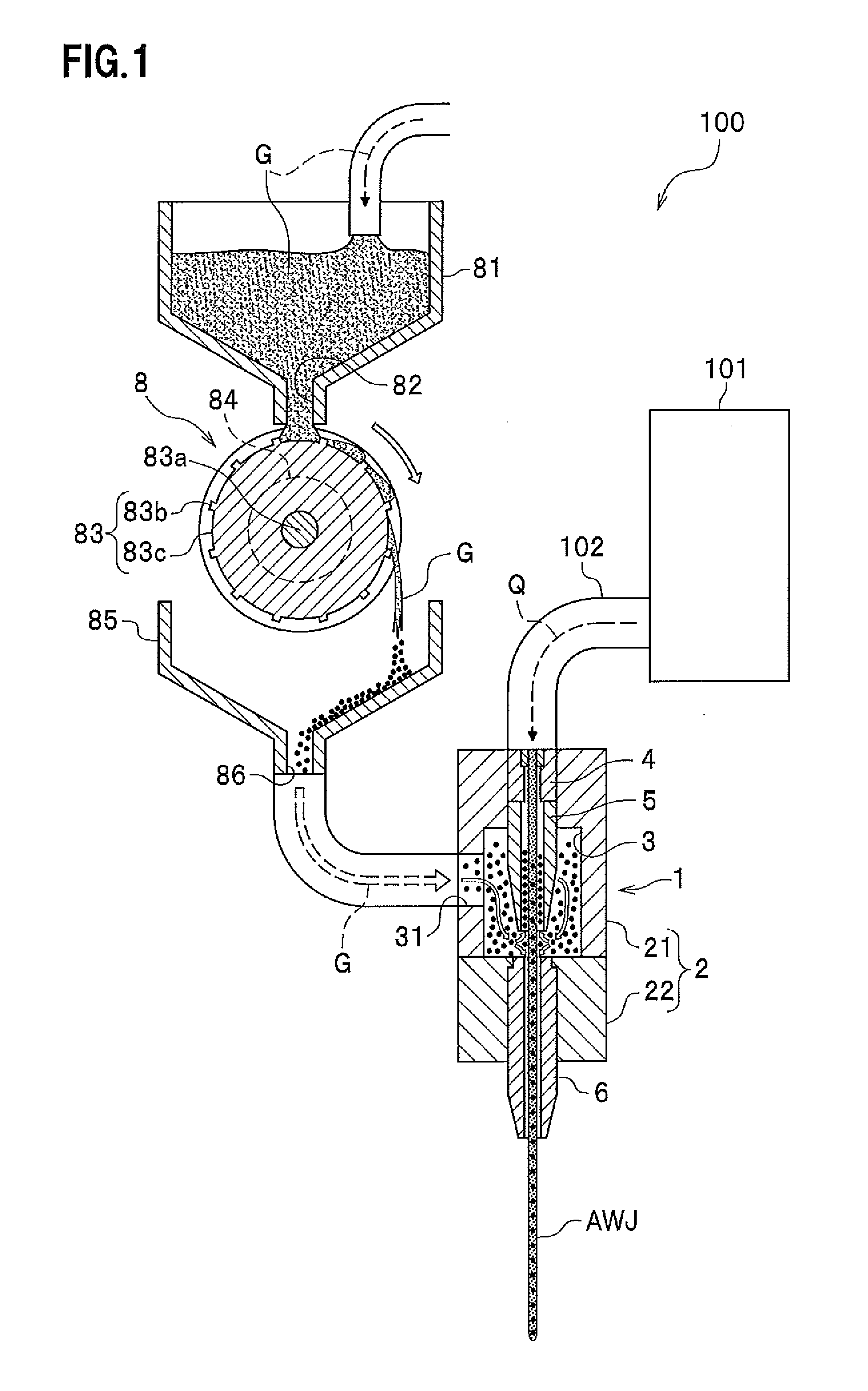

Abrasive water jet processing machine

InactiveUS20120196516A1Stable supplyPrevent backflowAbrasive feedersAbrasive machine appurtenancesInjection pressureEngineering

An abrasive water jet processing machine for jetting a fluid and performing a cutting includes a fluid supply device, an abrasive supply device, an injection pressure controller, wherein the abrasive supply device includes a reservoir hopper consisting of a pressure vessel for reserving the abrasive, an abrasive supply tube for communicating with the reservoir hopper and the nozzle, and an air purge device for supplying compressed air to the abrasive supply tube and the reservoir hopper; the injection pressure controller performs a two-stage control of controlling injection pressure in a piercing; and the air purge device includes a flow pressure controller for controlling flow pressure of compressed air passing through the abrasive supply tube, wherein the flow pressure controller controls the flow pressure in the piercing to be higher than that in the cutting.

Owner:SUGINO MACHINE

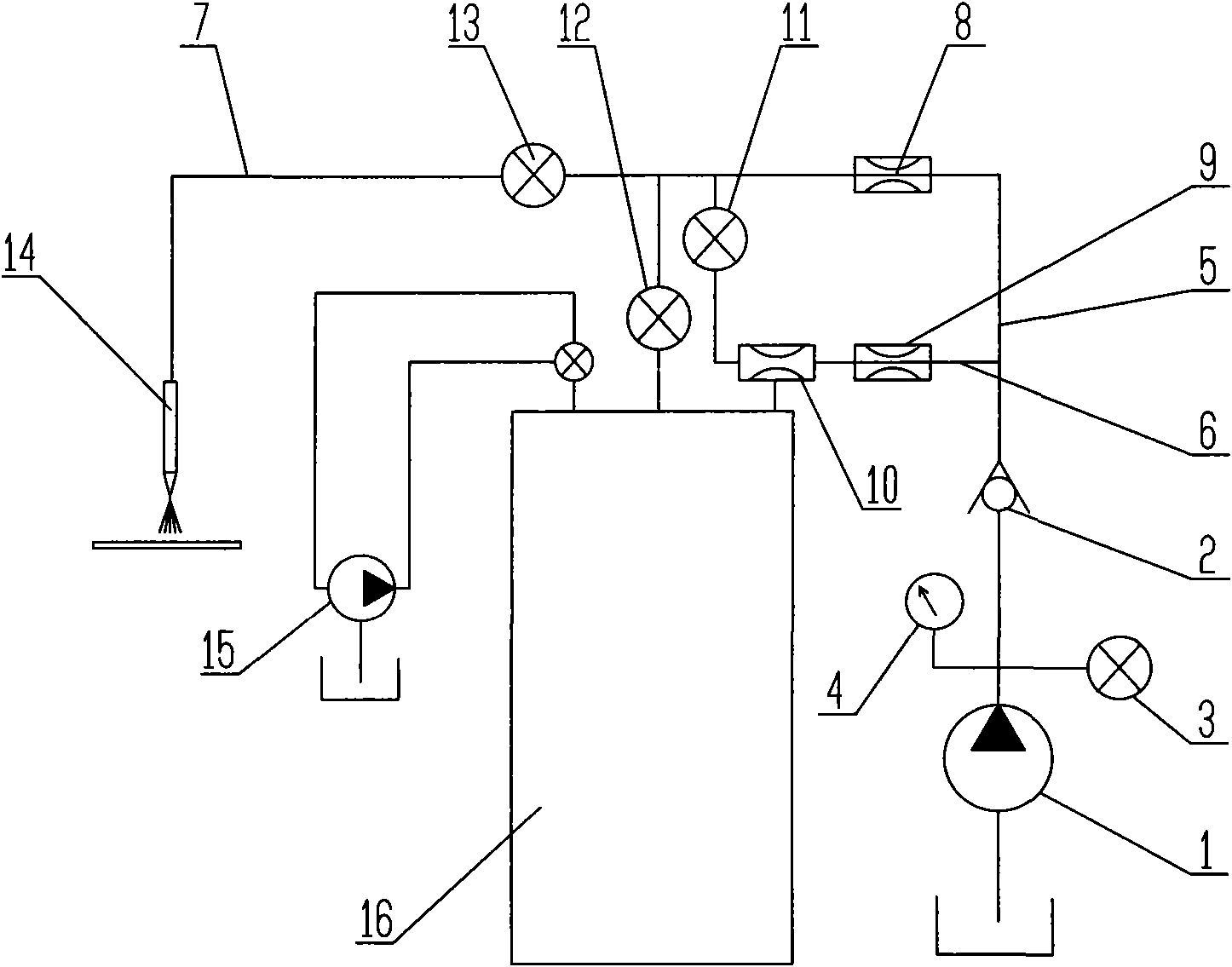

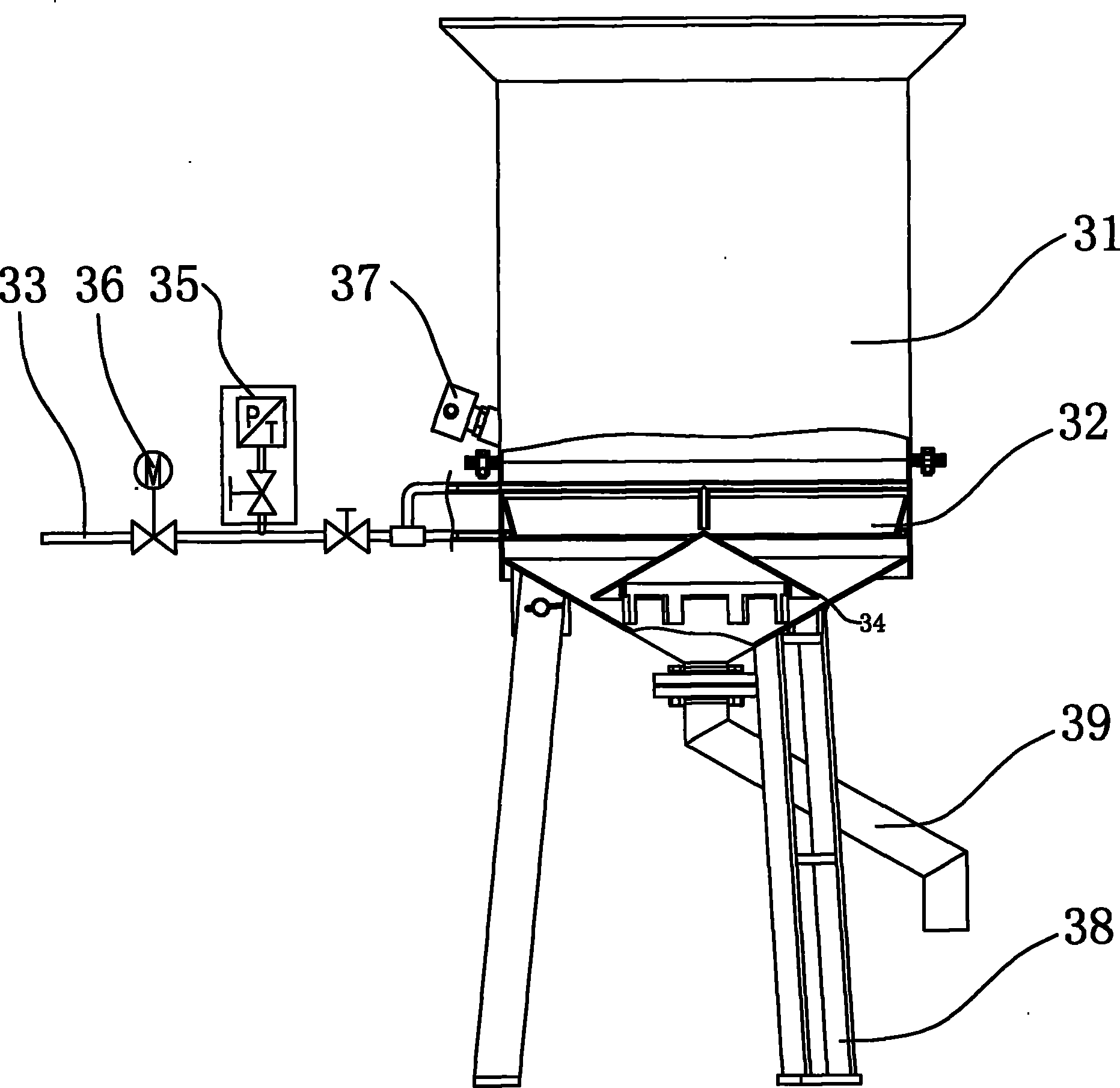

Abrasive automatic feeding device and using method

ActiveCN103100984AAchieve pure water jetRealize automatic feedingAbrasive feedersHigh pressure waterHigh pressure

The invention discloses an abrasive automatic feeding device for feeding abrasives through mixing abrasive water jet forward. The device is mainly composed of a hopper, a jet flow pump, a high-pressure abrasive tank, a valve seat installed on the upper part of the high-pressure abrasive tank and a mixing cavity installed on the lower part of the high-pressure abrasive tank; the valve seat is connected with a sand adding pipeline, a high-pressure water pipeline, a low-pressure water pipeline and a safety valve; and the mixing cavity is also connected with the high-pressure water pipeline, an abrasive pipeline and an abrasive water jet flow pipeline. Each flow inlet and each flow outlet as well as each functional component are connected through high-pressure pipelines which are internally provided with high-pressure ball valves, throttling valves and pneumatic ball valves for controlling the pipelines; the jet flow pump is arranged between a feeding pump and the sand adding pipeline; and through the negative pressure effect of the jet flow pump, the abrasive adding operation of the high-pressure abrasion tank is realized. Through the connection and disconnection combination of the high-pressure ball valves, throttling valves and pneumatic ball valves, the device can respectively achieve the three kinds of operations including pure water jet flow, automatic feeding and abrasive water jet flow, is simple in structure, is convenient to operate, is safe and reliable, and can be widely applied to a forward mixing abrasion water jet flow generation system.

Owner:CHONGQING UNIV

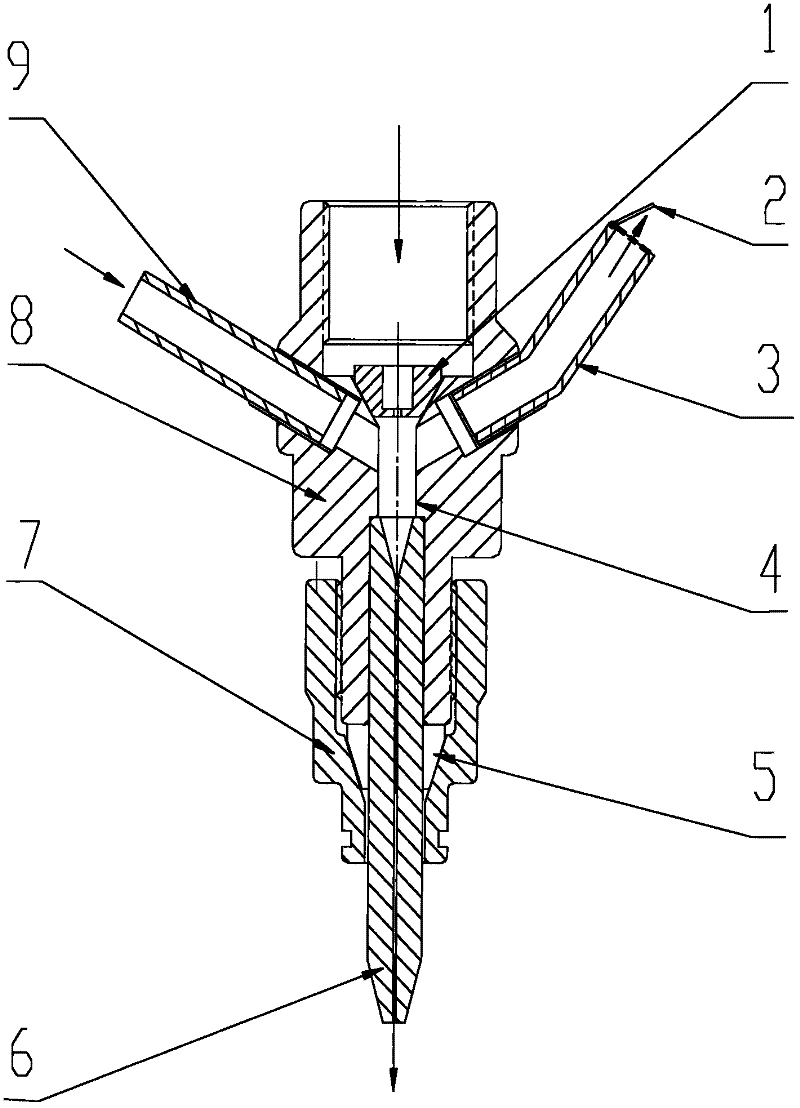

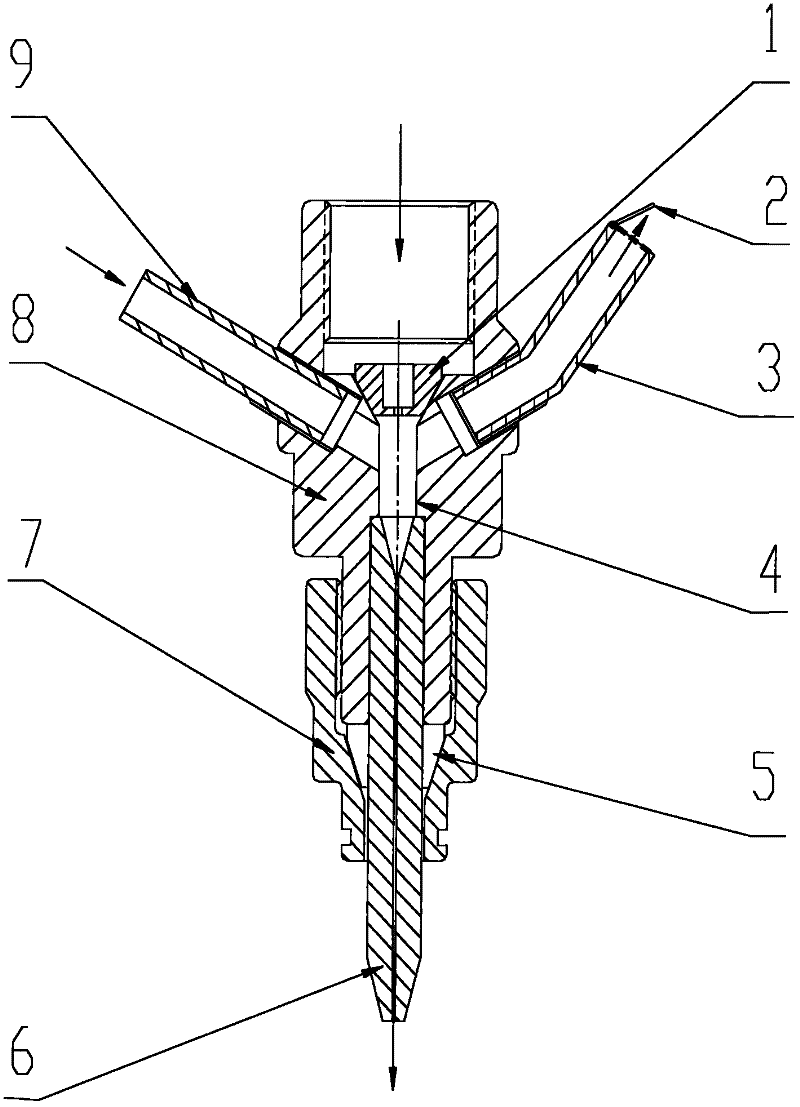

Abrasive water jet cutting spray head device

InactiveCN102363285AHigh working reliabilityKeep dryBlast gunsGrinding/polishing apparatusAbrasive blastingHigh pressure water

The invention discloses an abrasive water jet cutting spray head device. The center of a spray head body is provided with a through hole, one end of the spray head body is provided with a high-pressure water inlet, an abrasive blasting pipe is arranged in a central hole of the other end of the spray head body, and a spring chuck is arranged at the end of the installation section of the abrasive blasting pipe. A water jet nozzle is positioned in the high-pressure water inlet of the spray head body. An abrasive mixing cavity is formed in an inner hole of the spray head body between the water jet nozzle and the abrasive blasting pipe. The shell of the spray head body is provided with a return water outlet, and the return water outlet corresponds to an abrasive inlet. The included angle between the central line of the return water outlet and the central line of the spray head body is 15 to 30 degrees. The abrasive mixing cavity is formed in the inner hole of the spray head body between the water jet nozzle and the abrasive blasting pipe. By symmetrically and uniformly forming sand inlets and return water holes, the return water produced when the sand blasting pipe 6 is blocked is prevented from entering an abrasive supply valve, and the reliability and the machining efficiency in the cutting process are improved. The device is simple in structure, convenient to machine and easy to implement.

Owner:中船西安东仪科工集团有限公司 +1

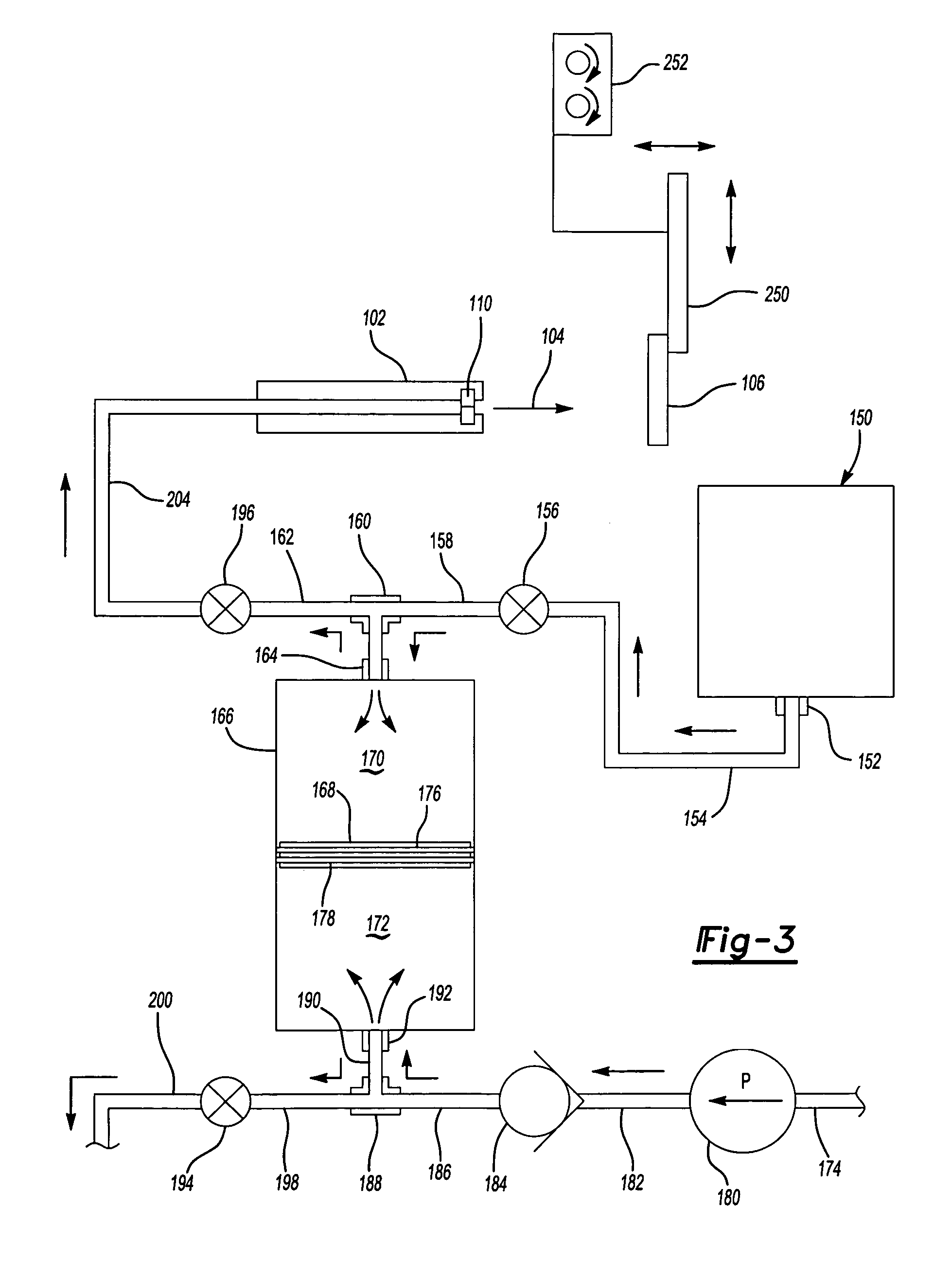

Method and apparatus for stripping holes in a metal substrate

ActiveUS20090270014A1Protect the wallMolten spray coatingEngine fuctionsForeign matterControl system

A method and apparatus for stripping foreign matter from holes in a substrate, such as a turbine component, which includes using a scanner to locate the hole and operating a water jet apparatus to direct a water jet or an abrasive water jet into the hole for stripping. A CAD model of the original turbine component may be used in the control system of the water jet apparatus to initially locate the scanner at the general or theoretical location of the hole. A reverse flow of low pressure water may be provided to further clear foreign matter from the hole.

Owner:OPTOMEC INC

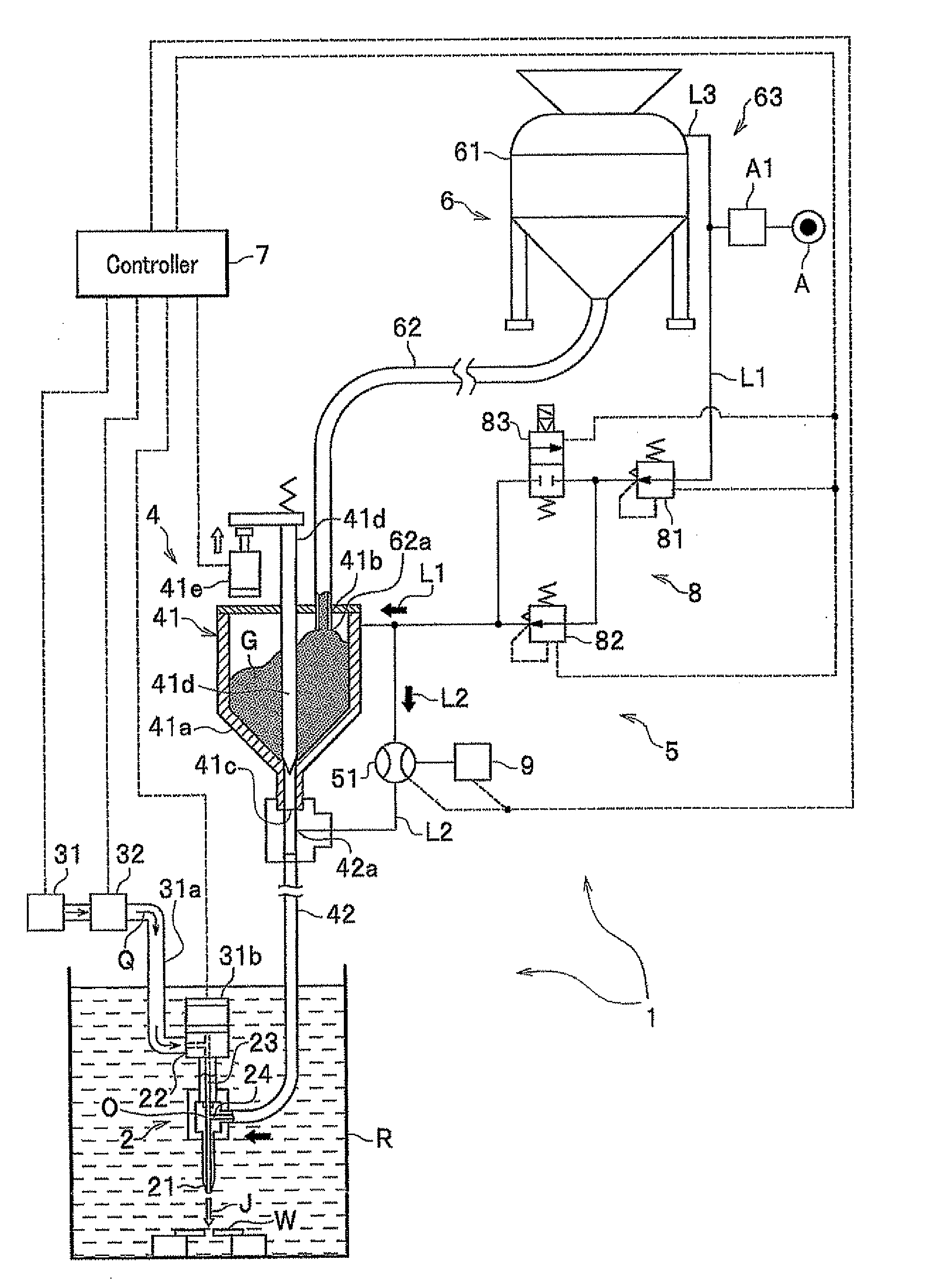

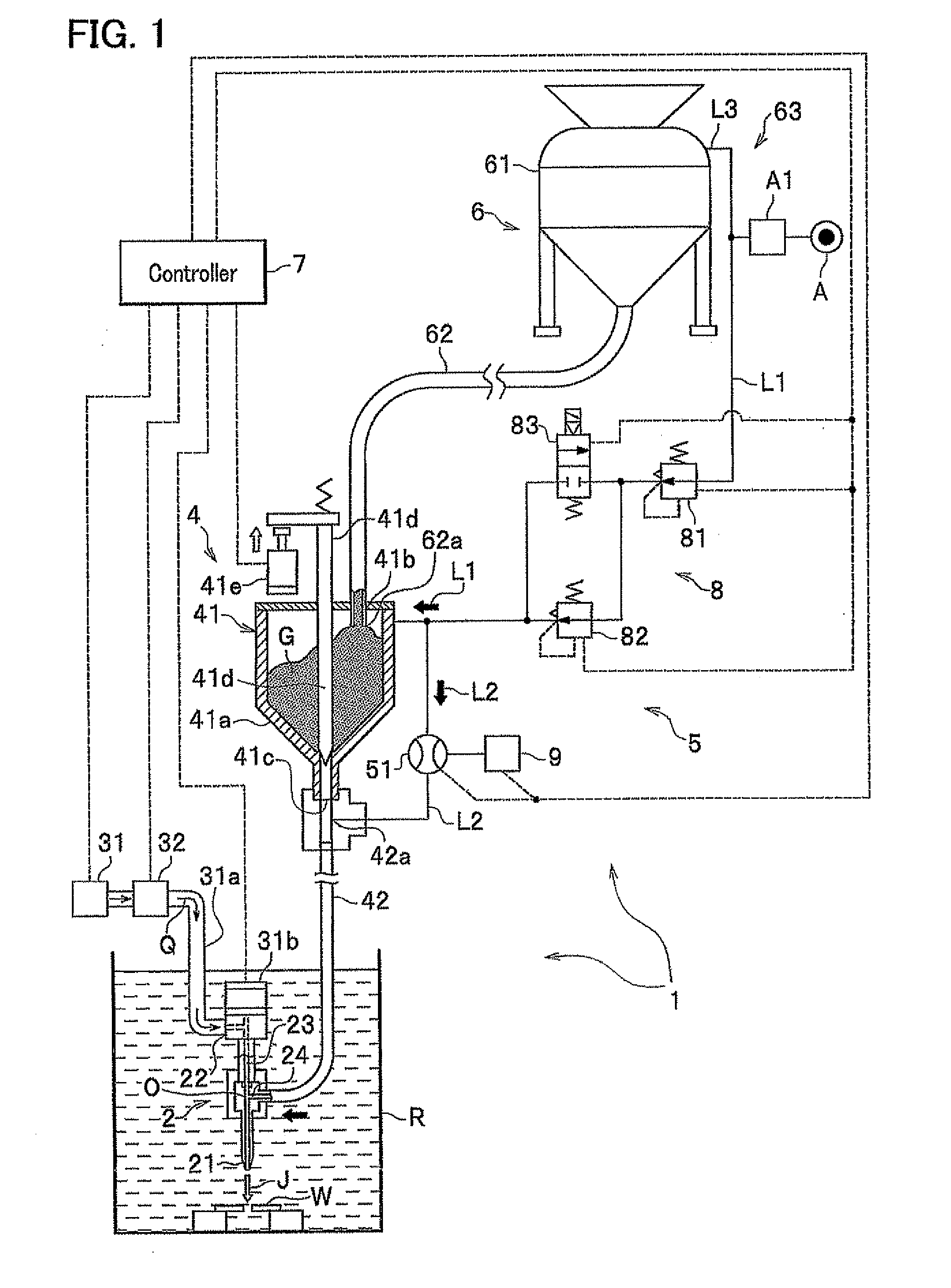

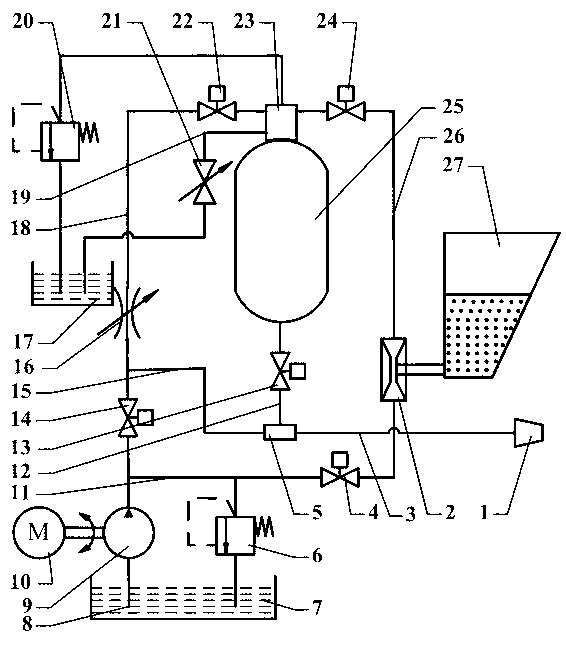

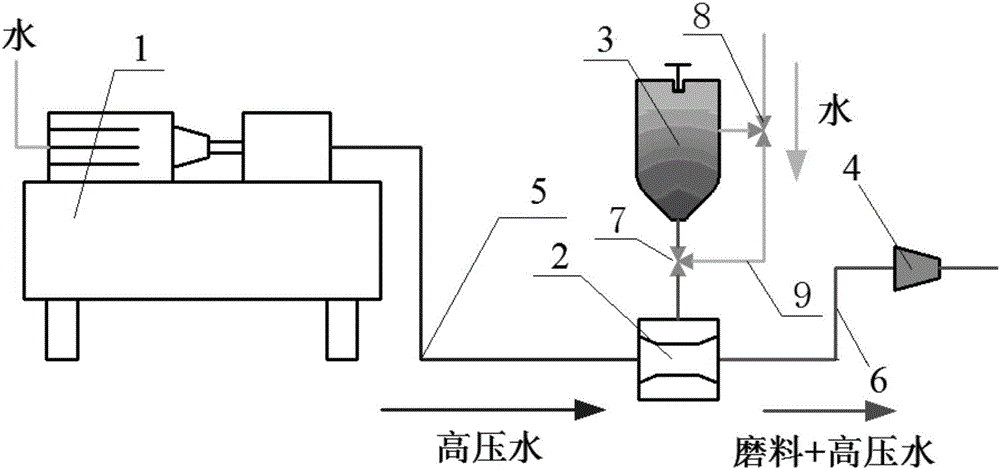

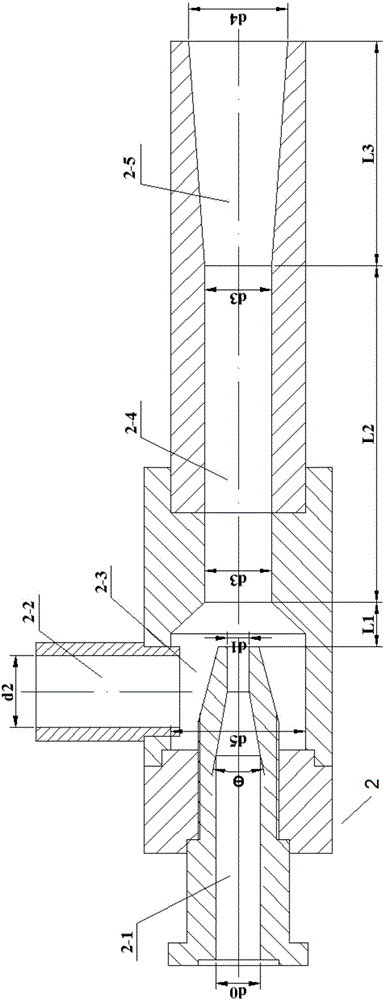

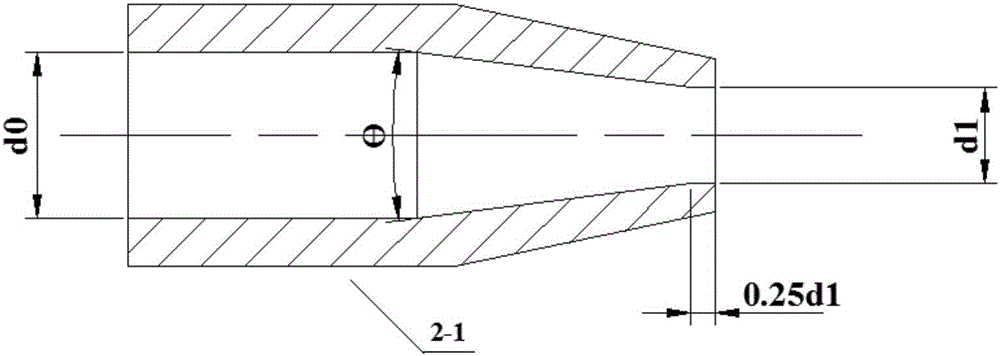

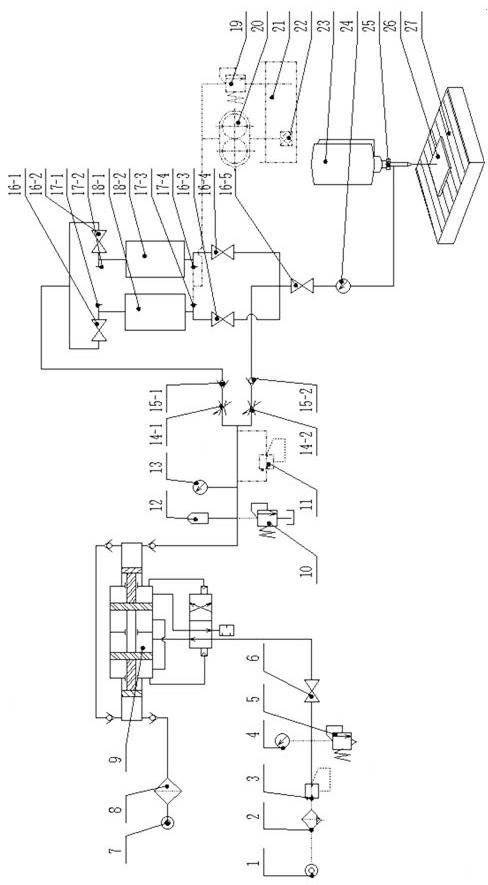

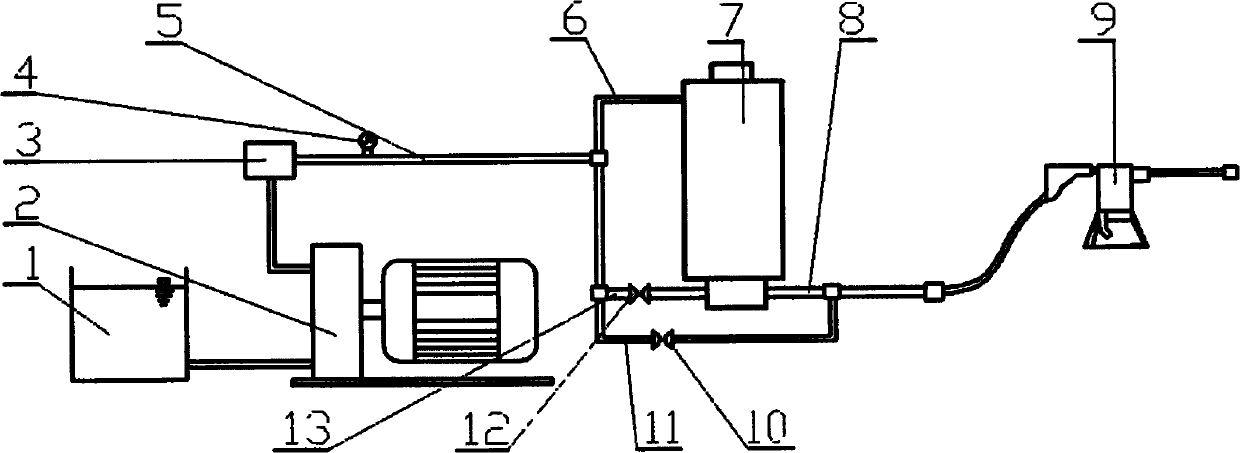

Pre-mixed abrasive water jet type continuous working system and method

ActiveCN106112821AJet stabilizationUninterrupted jetJet pumpsAbrasive feedersSpray nozzleHigh pressure water

The invention provides a pre-mixed abrasive water jet type continuous working system. The system comprises a jet pump, and a high pressure pump device for outputting high-pressure water, wherein the high pressure pump device is connected with the input end of the jet pump through a high-pressure water pipeline; an abrasive tank is connected to a material sucking port of the jet pump; the output end of the jet pump is connected with an abrasive jet nozzle through an abrasive water jet pipeline. The invention also provides a pre-mixed abrasive water jet type continuous working method. According to the system and the method, the abrasive can be quickly pumped and sucked under the entrapment effect of the jet pump as well as the weight effect of the abrasive; after being mixed with water, the abrasive is pressurized and accelerated through the abrasive jet nozzle, and then a pre-mixed abrasive water jet can be sprayed out; and the stable pre-mixed abrasive water jet can be formed on the premise that the abrasive in the abrasive tank for supplying the abrasive is continuously supplied. Therefore, the problem that the abrasive cannot be continuously supplied in the prior art can be solved.

Owner:CHONGQING UNIV

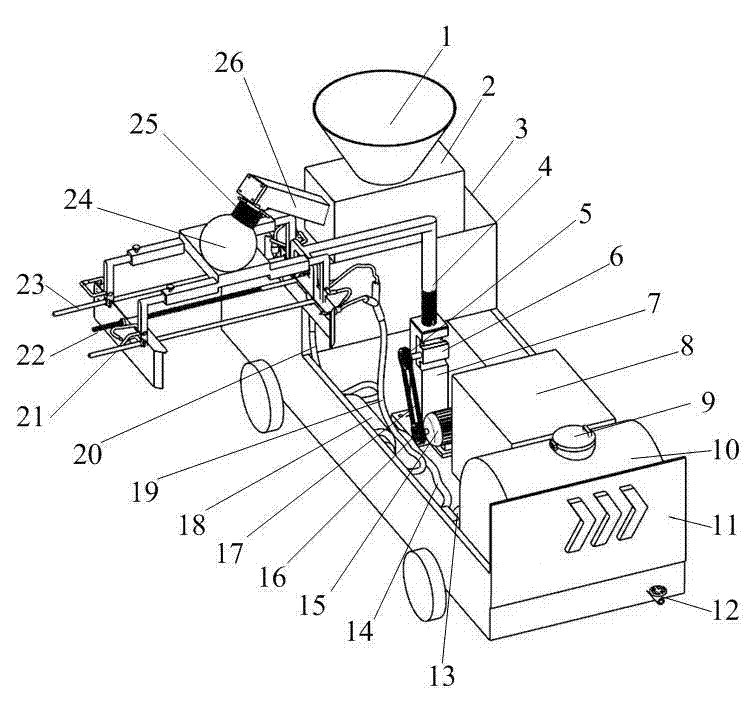

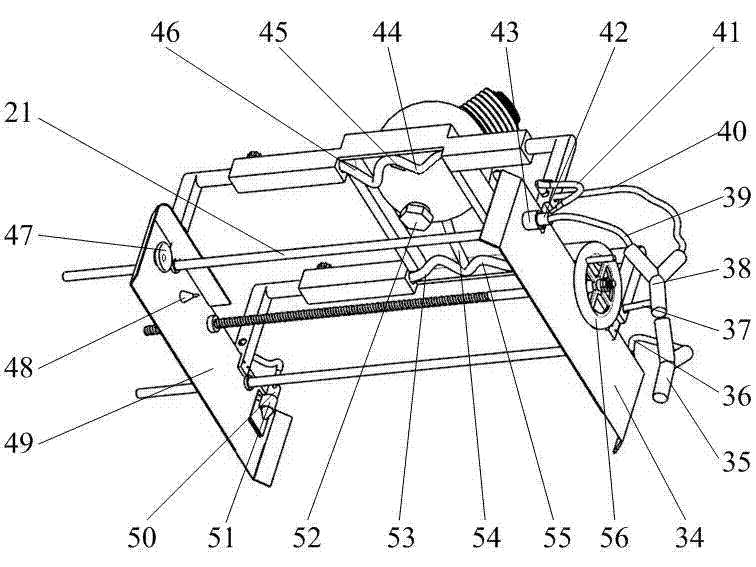

Green hedge trimmer with fertilizing and irrigating functions

InactiveCN103039279AGuaranteed lifeCleaningHedge trimming apparatusPressurised distribution of liquid fertiliserResource utilizationWater flow

The invention discloses a green hedge trimmer with fertilizing and irrigating functions. The green hedge trimmer with the fertilizing and irrigating functions is composed of a transport and power generation device, a support rotating lifting device, a water pressurization device, a fertilizer abrasive processing and distribution device and a water-fertilizer flow jetting trimming device. Compared to the prior art, the green hedge trimmer with the fertilizing and irrigating functions is characterized in that high pressure water jet flow is used as a trimming tool to achieve a green hedge trimming under the principle of high pressure abrasive water jet cutting with the auxiliary of processed fertilizer particles as an abrasive material, and the trimming way is novel and reliable; by utilizing the water and the fertilizer as a trimming tool, not only a trimming function is achieved, but also have cleaning, fertilizing and irrigating functions on the green hedge are achieved during the process of decompression and after decompression, so that the functions are various and the resource utilization rate is high; by utilizing an impact resistance and wear resistance impact resistant plate, a decompression on the no-loading high pressure jet flow is achieved, so that the service life of work pieces and the security of people can be effectively guaranteed; the utilization of a no-knife design avoids the problems of being easy to hit the knife and easy to knock against railings and the like in traditional designs, and is not only safe, easy to control, but also is low in the cost of using and maintaining.

Owner:SHANDONG UNIV OF TECH

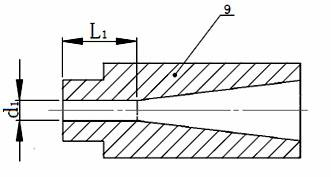

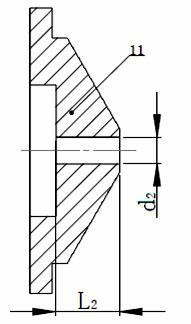

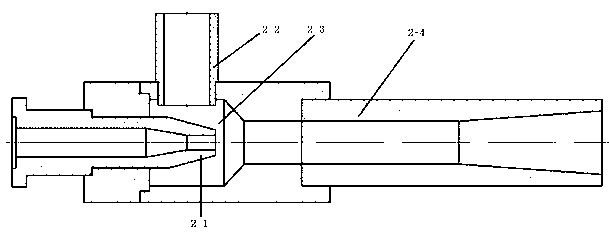

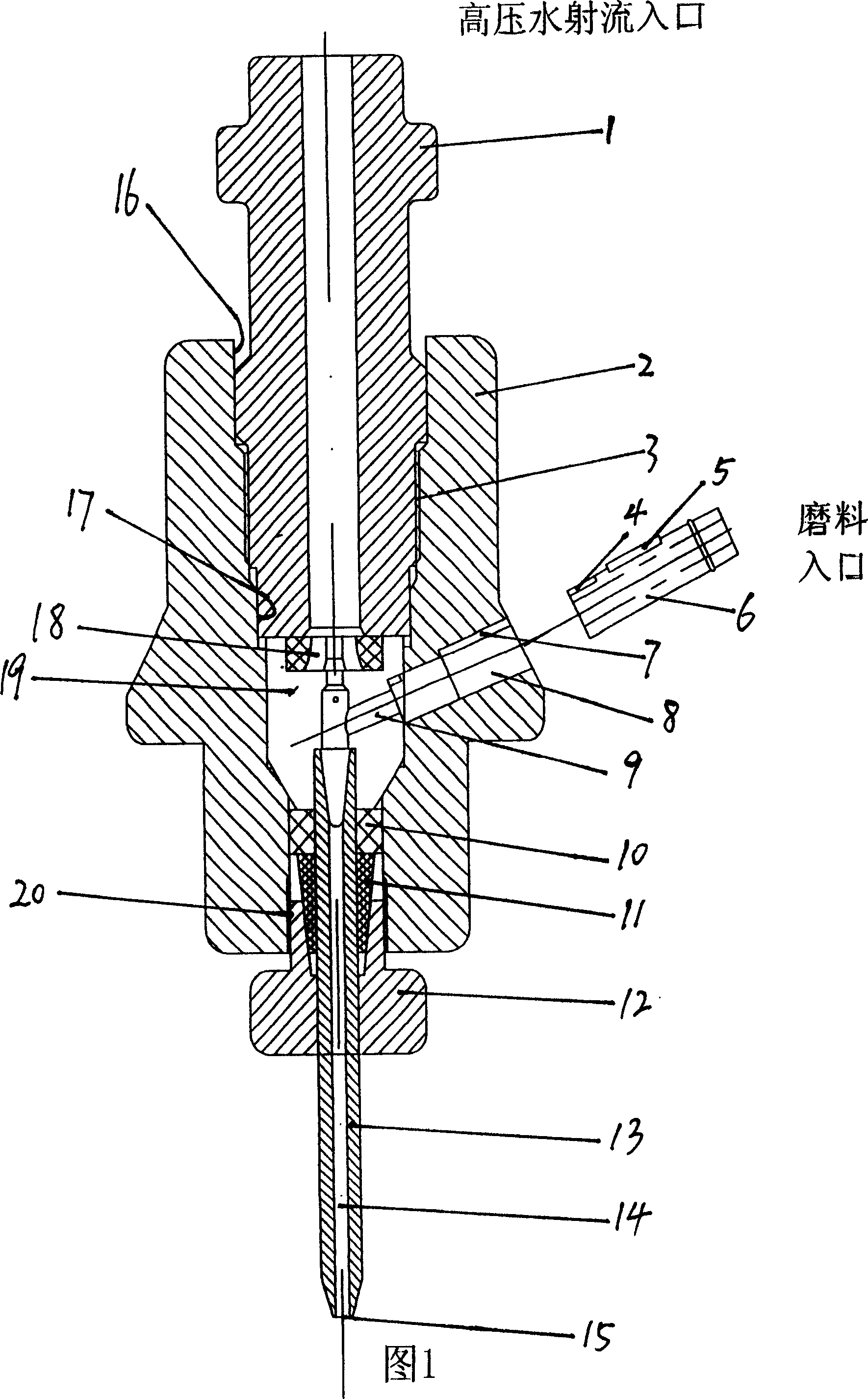

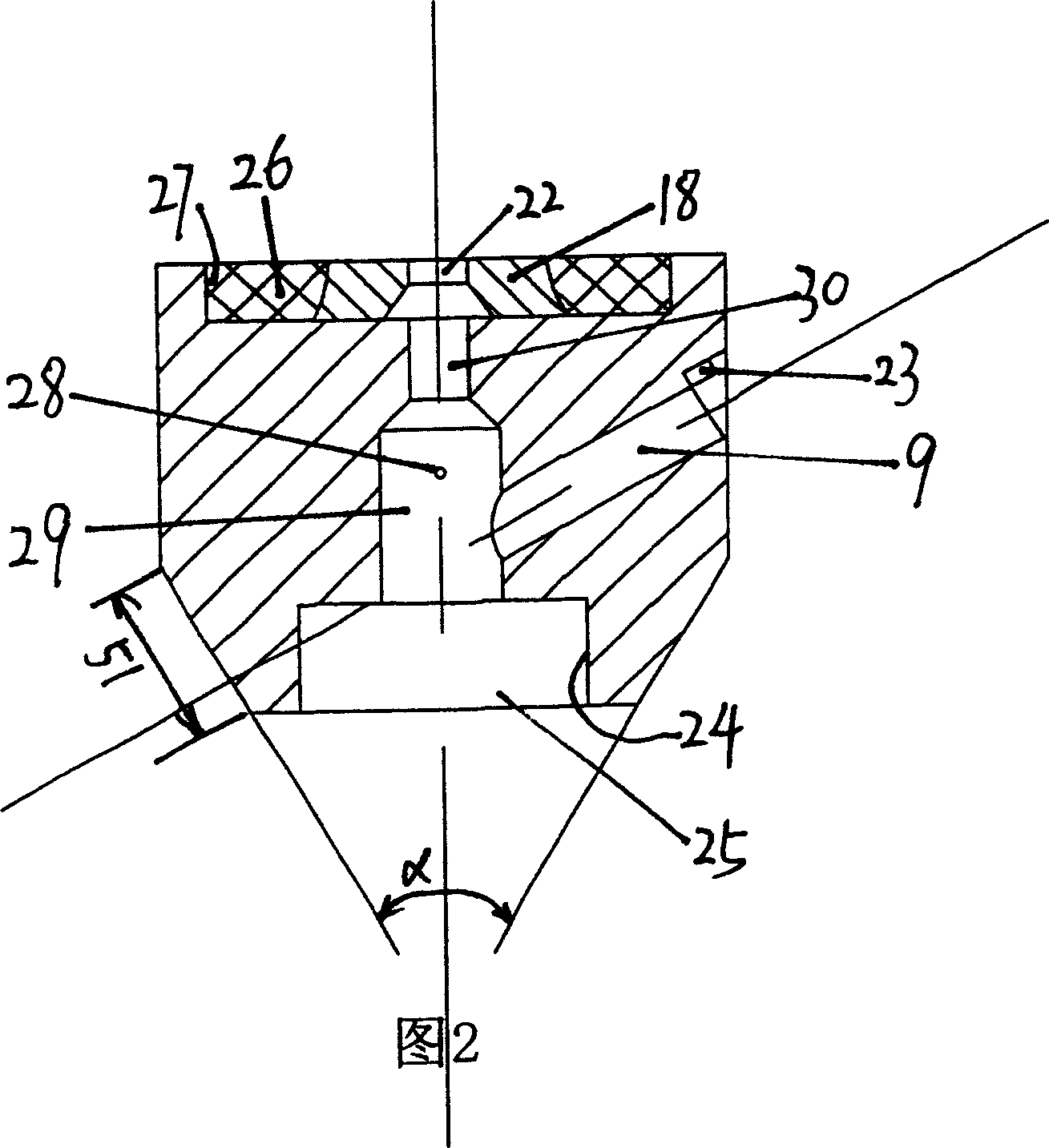

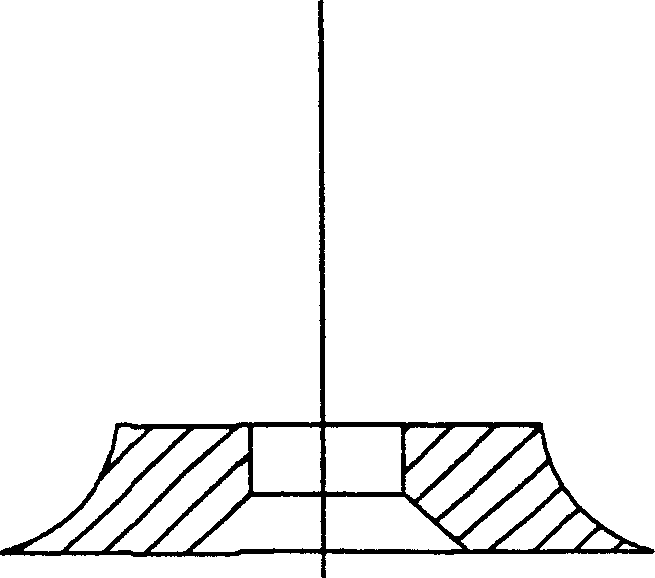

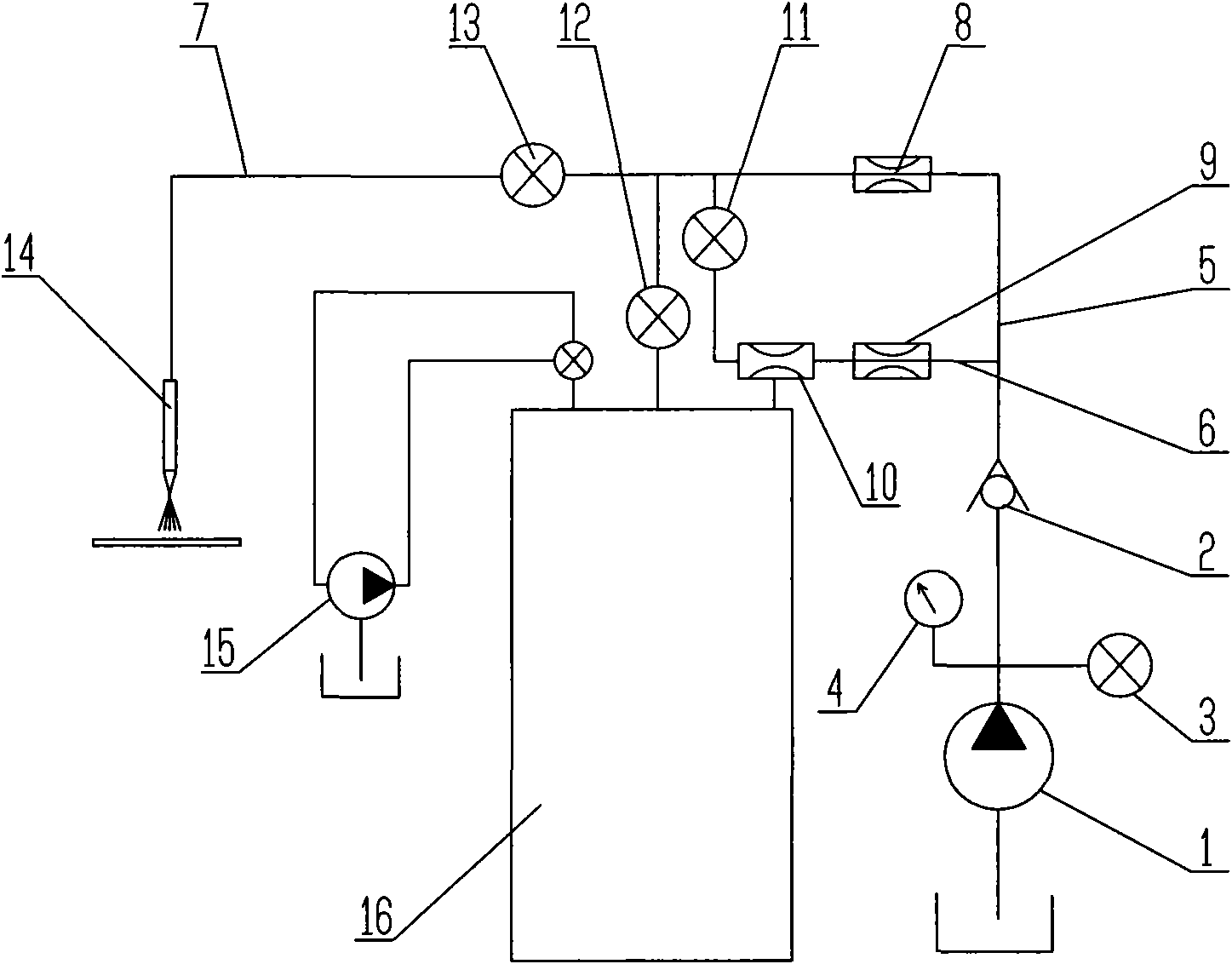

High-pressure abrasive material and water jet cutting head and blending tube

The invention provides a cutting muzzle and a mixing tube based on present abrasive water cutting muzzle. The invention has a mixing chamber inside the base of muzzle head and a conic part on the lower end of muzzle head; two guide surfaces on the cutting head to conform the axiality of muzzle body, muzzle head and base; and a taper locking device on the lower end of mixing tube. The invention can easily adjust the axiality of mixing tube and muzzle head to attain higher axiality. The invention has easy detachment of muzzle and mixing tube, lower cost which can save 10-20% power consumption, higher cutting efficiency, better quality, higher cutting speed, small kerf, and bigger cutting depth.

Owner:JIANGSU UNIV

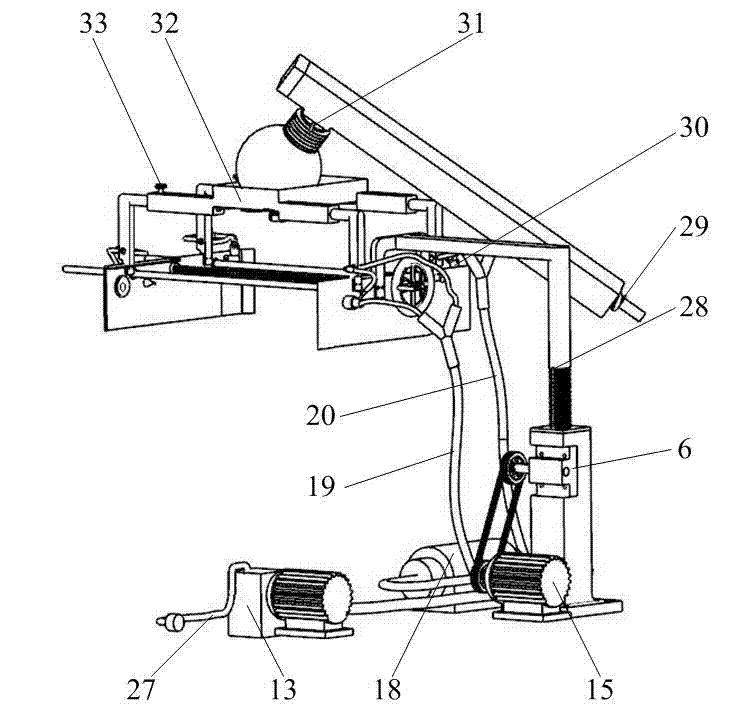

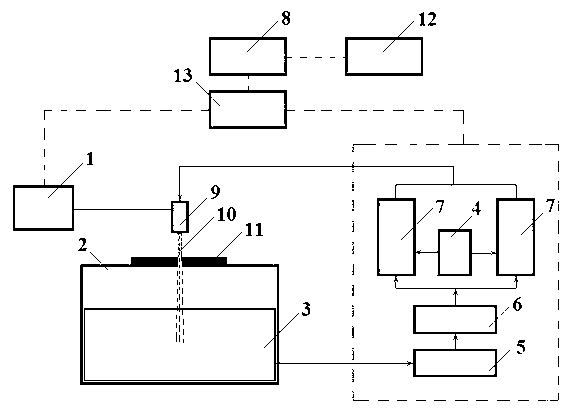

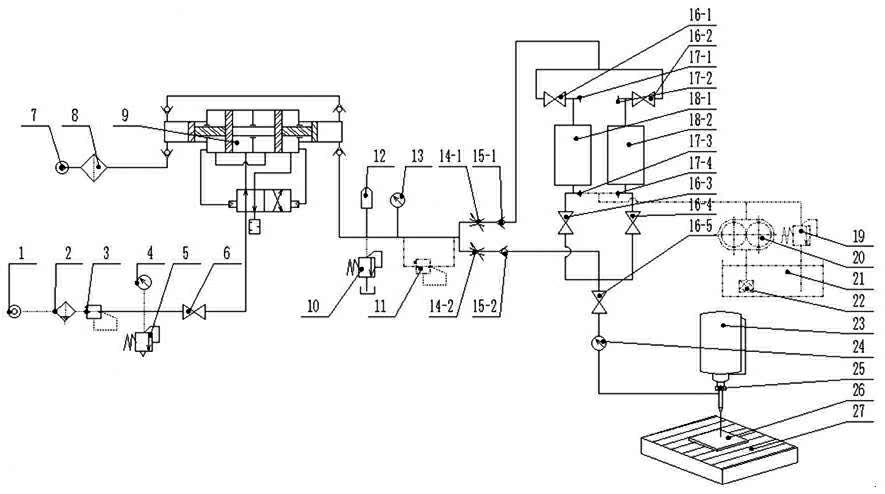

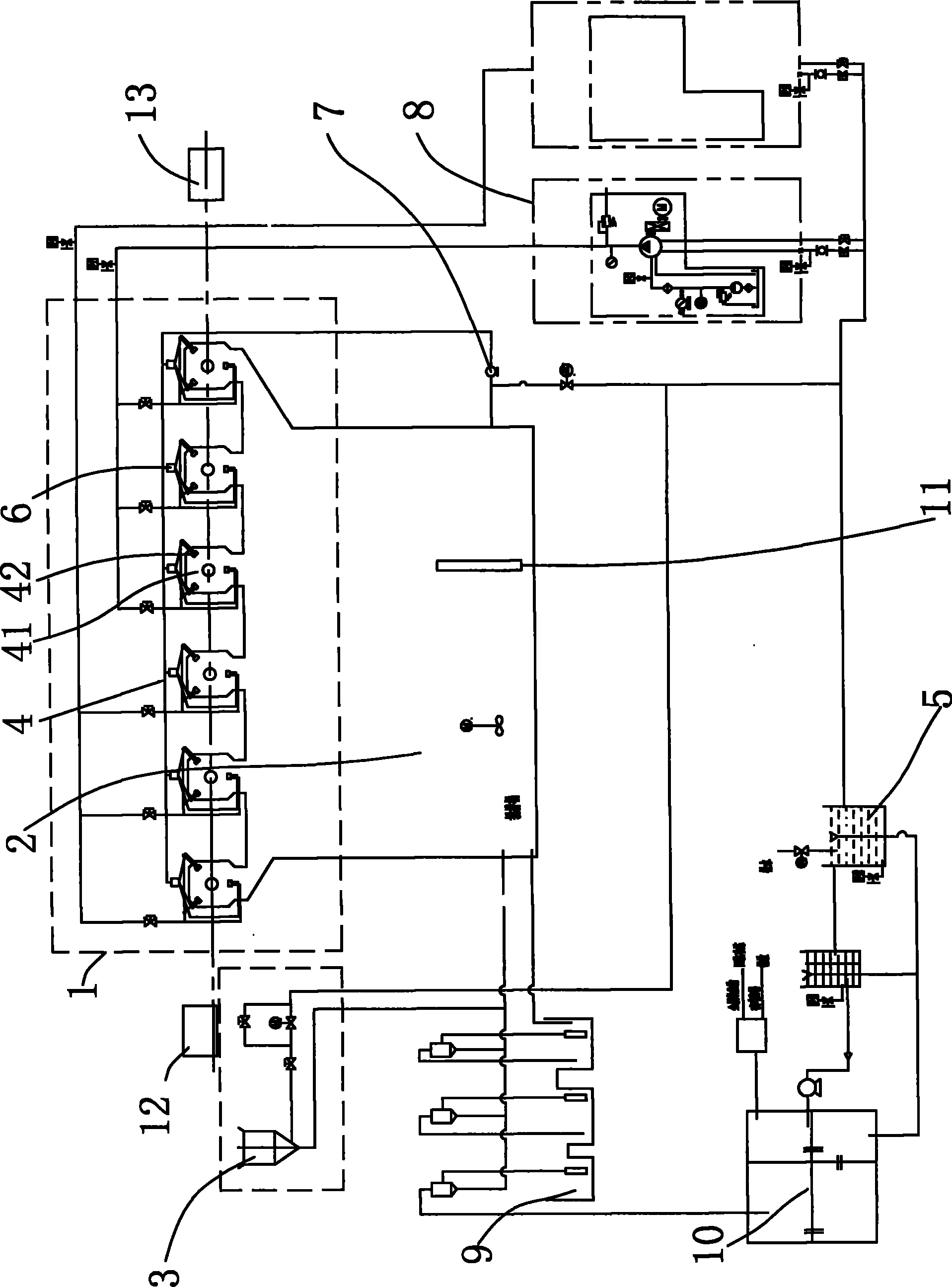

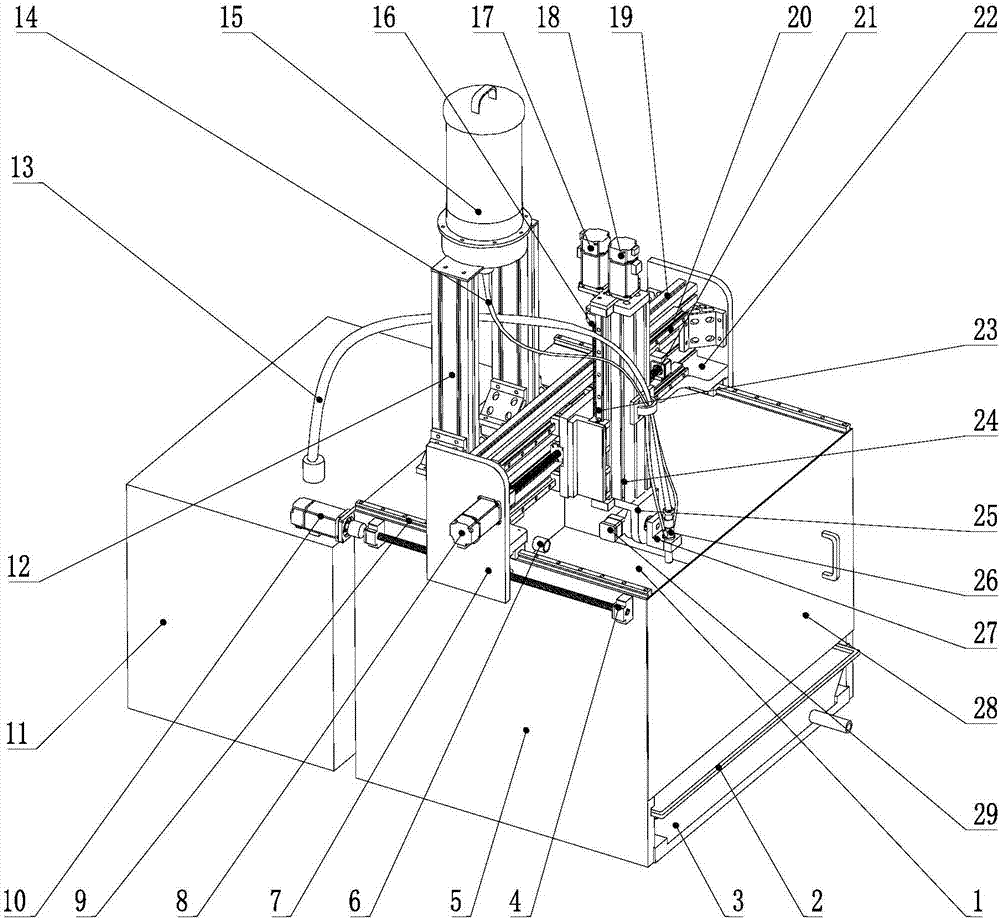

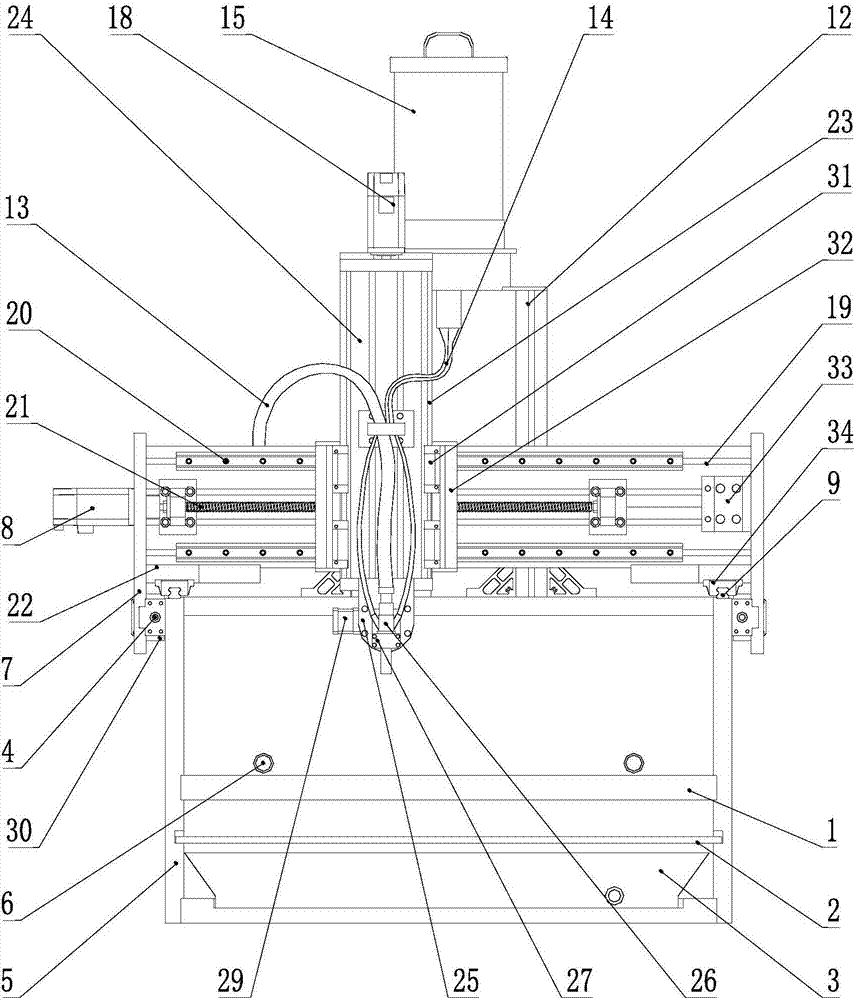

Pre-mixed abrasive water jet intelligent cutting machine

ActiveCN103128668AAchieve continuous supplyReduce lossAbrasive feedersAbrasive blasting machinesElectricityEngineering

The invention discloses a pre-mixed abrasive water jet intelligent cutting machine and belongs to the technical field of abrasive spray devices. The machine comprises a pre-mixed abrasive water jet system, a cutting system and a numerical control system, the pre-mixed abrasive water jet system and the cutting system are in electric connection with the numerical control system respectively, a recovered water tank is arranged below a workbench, the recovered water tank is connected with a screening device, the screening device is connected with an abrasive supply device, the abrasive supply device and a high pressure water generating device are respectively connected with an abrasive tank, a weight sensor is arranged at the bottom of the abrasive tank, a pressure sensor is arranged on a pipeline in front of a nozzle, and a positioning sensor is arranged on a guide rail. An abrasive in the high pressure abrasive tank is fluidized to an abrasive suspension through high pressure water, and a high-speed pre-mixed abrasive water jet is formed through the nozzle to transit pressure energy to kinetic energy, so the precise cutting of a material is completed under the control of the intelligent numerical control system, and the used abrasive can be recycled.

Owner:HOOTECH

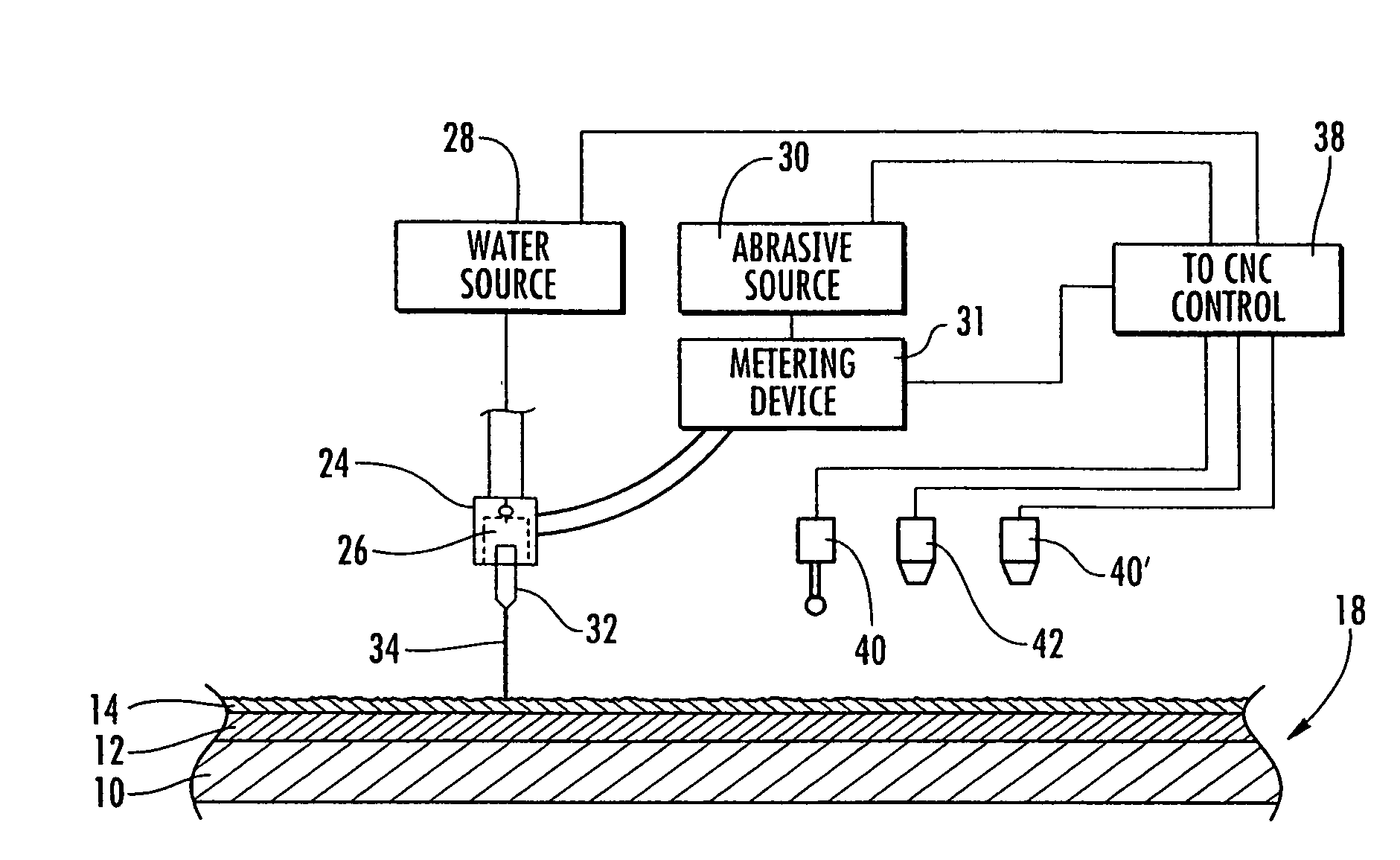

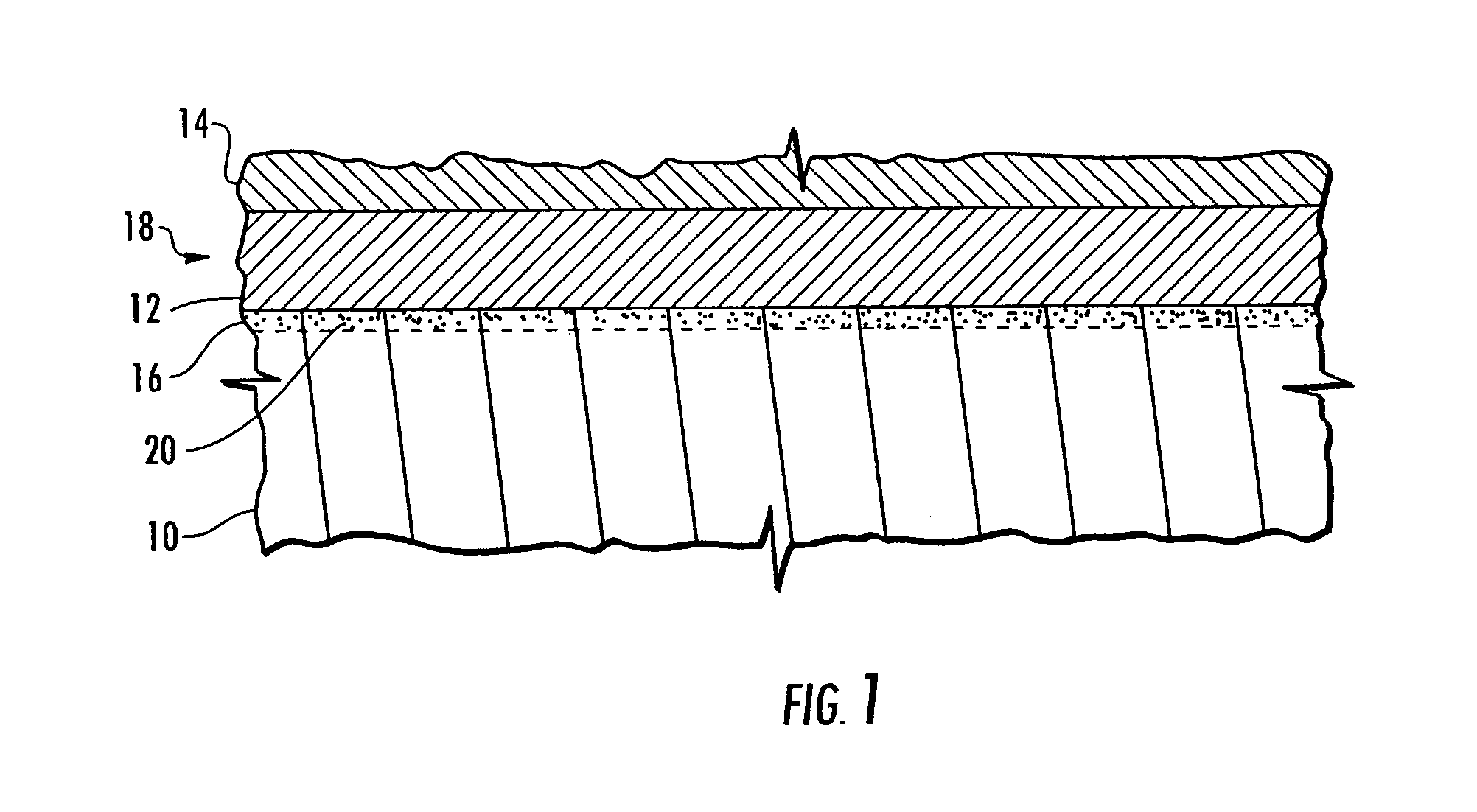

Method and apparatus for removing coatings from a substrate using multiple sequential steps

InactiveUS7896726B1High rateGrinding feed controlAutomatic grinding controlMaterial removalEngineering

A method and apparatus for removing a coating having an irregular surface configuration that includes mapping the irregular surface configuration, and using the mapping determination in controlling the operation of an abrasive water jet to provide increased material removal rates at the higher points in the irregular surface and decreased material removal rates at the lower points, and thereby even out the surface configuration of the coating. The method and apparatus also includes using a detection device for detecting the presence or absence of an element that is unique to a layer of a coating, and using the detection determination in controlling the operation of the abrasive water jet to stop material removal of the coating when the detection device determines there is an absence of the unique element.

Owner:OPTOMEC INC

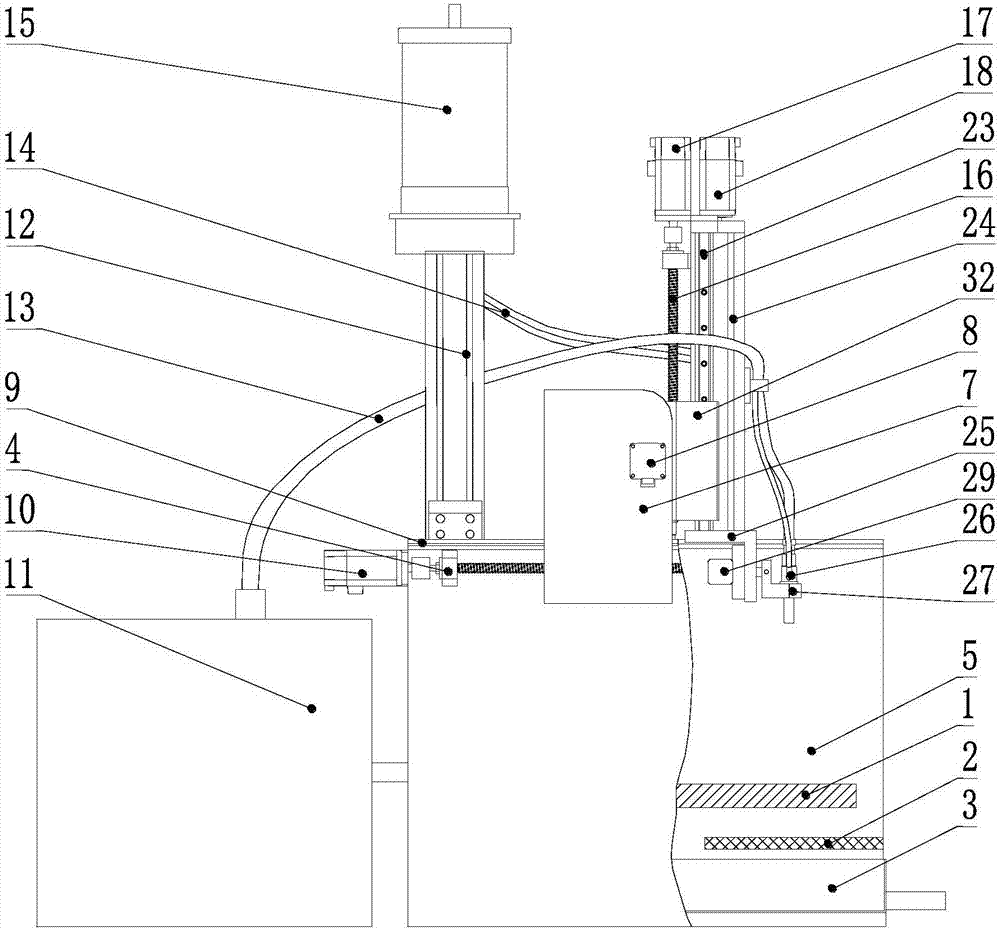

Micro abrasive water jet fine-finish device

InactiveCN102218707AIngenious designImprove performanceBlast gunsAbrasive feedersEngineeringHigh pressure

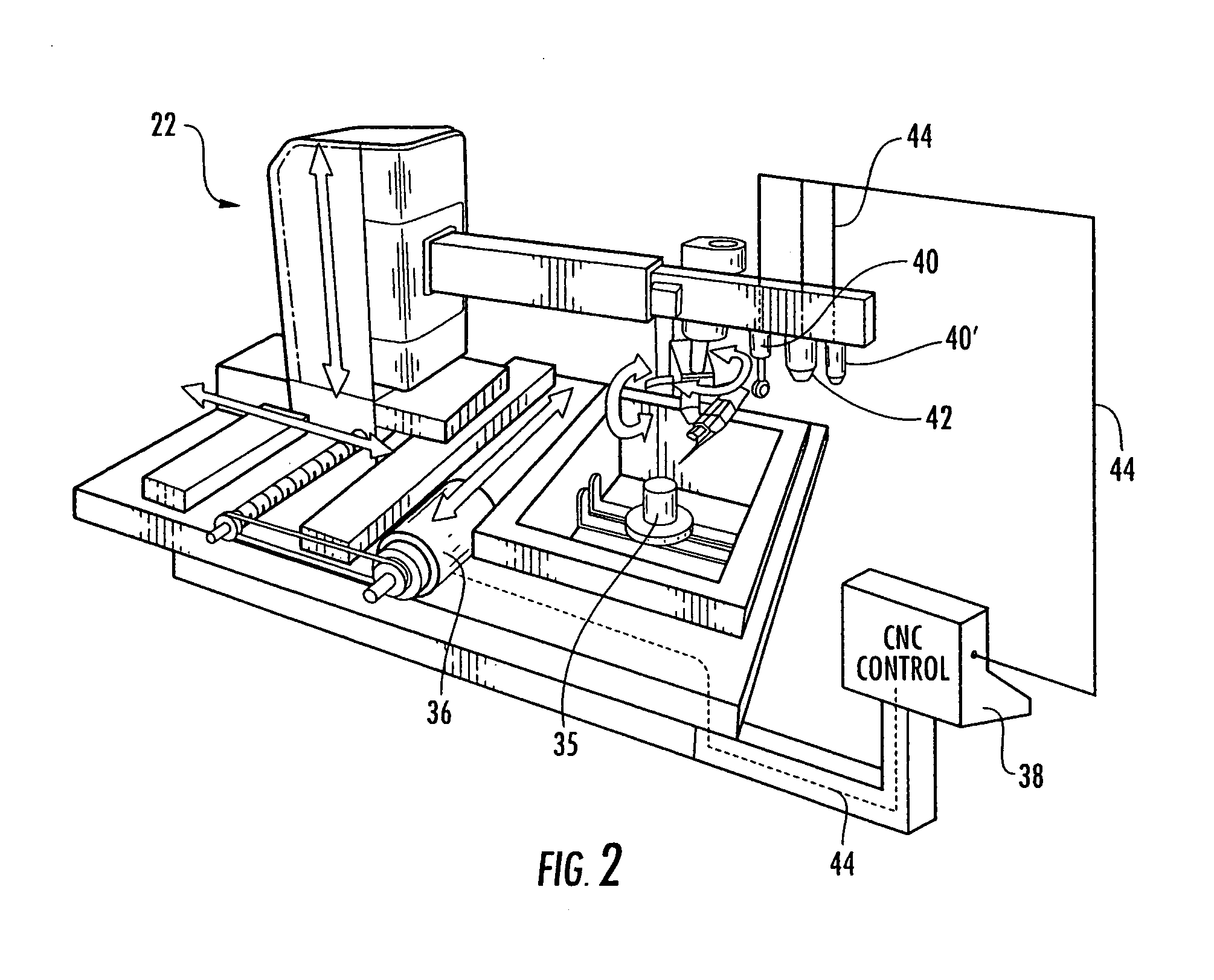

The invention provides a micro abrasive water jet fine-finish device, comprising a supercharging assembly (9), feeding assemblies (18, 19, 20 ) and a cutting head assembly (25), wherein, the feeding assemblies (18, 19, 20 ) are arranged on a frame and connected with the supercharging assembly (9) through a high pressure flexible pipe, the cutting head assembly (25) is arranged on a machining center (23), the cutting head assembly (25) is corresponding to a workpiece (26) in position, and the workpiece (26) is arranged on a bench (27) in the machining center (23). The micro abrasive water jet fine-finish device is suitable for precision finishing, and common cutting and boring, with high machining efficiency and good reliability. According to the invention, jet with small diameter is generated by method of suspension, so that the micro abrasive water jet fine-finish device is suitable for the generation of abrasive water jet which is capable of machining at any diameter of jet in industry, with the advantages of benefit design, excellent performance, being convenient and practical.

Owner:GUANGDONG UNIV OF TECH

Processes and apparatuses for enhanced cutting using blends of abrasive materials

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT CORP

Ultrasonic cavitation assistant jet polishing system and polishing method

PendingCN110026908AImprove removal efficiencyPrecise control of removal volumeAbrasive machine appurtenancesAbrasive blasting machinesNumerical controlUltrasonic cavitation

The invention discloses an ultrasonic cavitation assistant jet polishing system which is characterized by comprising an ultrasonic transducer and a shell; the shell is internally provided with a containing cavity with an opening formed in the upper end; an ultrasonic transducer sealing cover is arranged on an opening formed in the upper end of the containing cavity in a sealing manner; the side surface of the shell is provided with a polishing solution supply hole; the lower side of the shell is provided with a jet nozzle; and the polishing solution supply hole and the jet nozzle communicateswith the containing cavity. The invention further provides an ultrasonic cavitation assistant jet polishing method. The ultrasonic cavitation assistant jet polishing system can be installed on a numerical control machine tool spindle box or an industrial robot mechanical arm, and the ultrasonic transducer is utilized to enable a polishing solution to generate high-frequency vibration and produce cavitation bubbles, and the high-pressure and high-speed polishing solution is sprayed to the surface of a workpiece, so that the material removal efficiency of an abrasive water jet is improved. The ultrasonic cavitation assistant jet polishing system and method provided by the invention can be suitable for surface type finishing of a super-smooth surface and is also suitable for surface processing and manufacturing of a microscopic special morphology.

Owner:TIANJIN UNIV

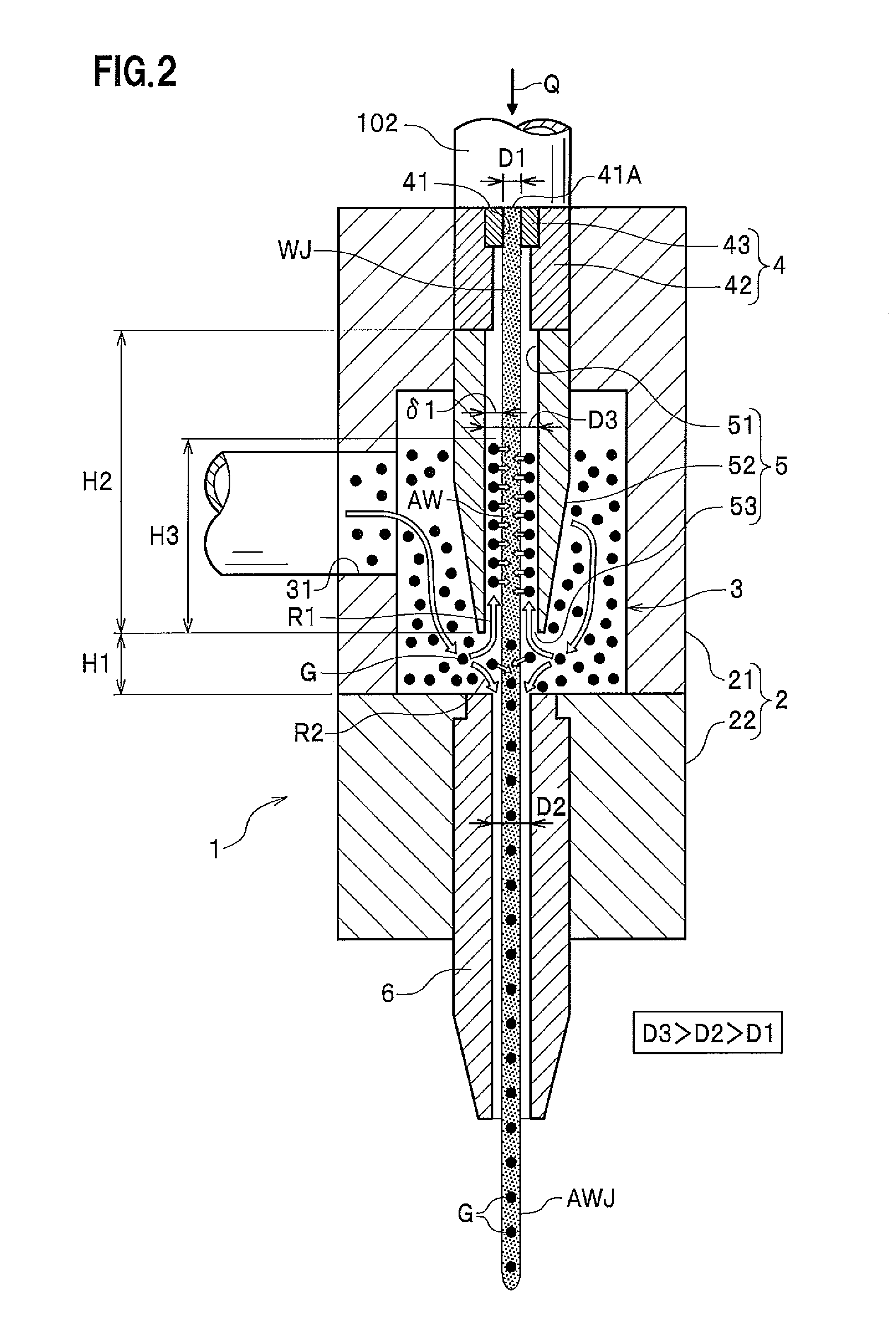

Abrasive water jet nozzle and abrasive water jet machine

Provided is an abrasive water jet nozzle comprising a mixing chamber for absorbing the abrasives with air through a supply port; a water nozzle; a mixing nozzle disposed on the downstream side against the water nozzle, to mix the abrasives in a water jet jetted out of the water nozzle, and to jet the water jet into the mixing chamber out of a through hole of the mixing nozzle; and an abrasive nozzle disposed on the downstream side against the mixing nozzle, to introduce the water jet thereinto to jet an abrasive water jet. A diameter of the through hole is larger than that of the water nozzle so that the abrasives in the mixing chamber are absorbed with air in a clearance between the through hole and the water jet passing through the through hole to mix the abrasives in the water jet.

Owner:SUGINO MACHINE

Device for cutting and cleaning pre-mixed high pressure suspension grinding material water jet

InactiveCN101811287AReduce wearWith anti-blocking functionAbrasive feedersAbrasive blasting machinesIsolation valveEngineering

The invention discloses a device for cutting and cleaning a pre-mixed high pressure suspension grinding material water jet, comprising a grinding material refilling device, a grinding material supplying device, a high pressure pump system, a grinding material isolating valve and a nozzle. The outlet of the high pressure pump system is divided into two paths, a main pipeline reaches a filling isolating valve and the nozzle through a throttle valve, a branch pipeline converges with the main pipeline through the throttle valve, an ejector and a grinding material supplying valve in sequence, the ejector is also connected with the grinding material supplying device through the pipeline, and the grinding material isolating valve is installed on the pipeline between the grinding material supplying device and the main pipeline at the back of the throttle valve. The invention has the anti-plugging function, effectively avoids the problem that the pressure changes in the working process or the grinding material possibly plugs the pipeline and the nozzle when the device is turned off, greatly reduces the abrasion to the filling isolating valve, can generate a stable and uniform high pressure suspension grinding material water jet in quantification according to different needs, and has remarkable cutting and cleaning effects.

Owner:任保林

Method of making an abrasive water jet with superhard materials

InactiveUS6924454B2Increase speedReduce sensitivityBlast gunsVacuum evaporation coatingSuperhard materialAbrasive water jet

Methods for making abrasive water jet mixing tubes with superhard materials are presented. Also presented are methods for making a tubular elongate superhard material bodies.

Owner:KENNAMETAL INC

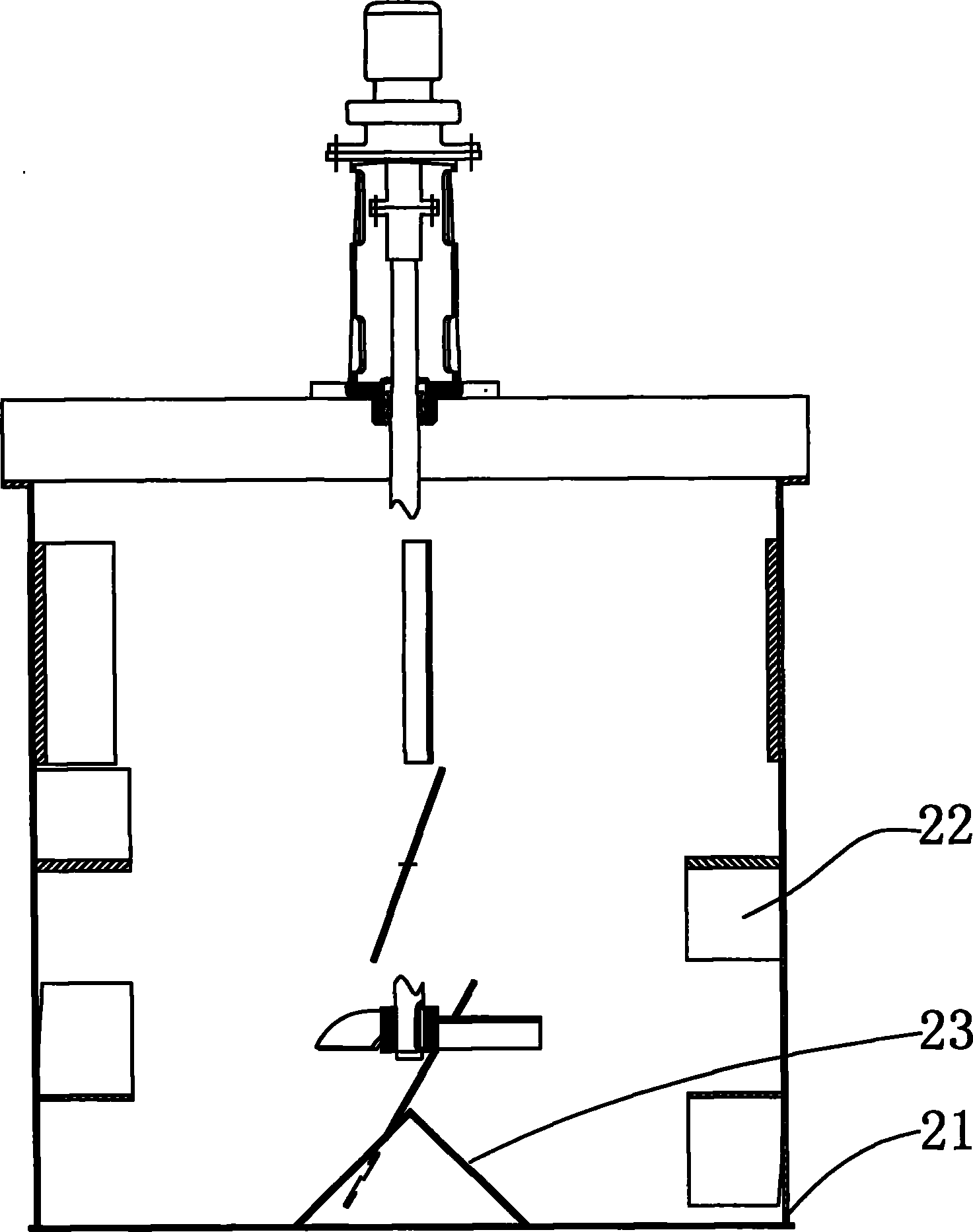

Method and equipment for removing scale on metal wires or metal bars by grinding material water jet

The invention discloses a method for removing scale on metal wires or metal bars by grinding material water jet, which comprises the following steps: 1) preparing a grinding material by mixing sand and water in a preset proportion; 2) pumping the prepared grinding material into a splitter by a mortar pump and then allowing the prepared grinding material to enter a jetting cavity; and simultaneously, pressurizing the water by a high-pressure pump to change the water into high-pressure water and convey the water into the jetting cavity, and impacting the grinding materials by taking the high-pressure water as motive power to remove scale through jetting. Special scale removal equipment provided by the method comprises a mixing tank positioned below a scale removal box, an automatic fluidifying and sanding-up device for sanding up sand to the mixing tank, a jetting device and a water box, and also comprises a sand separator positioned in the scale removal box, a high-pressure pump for generating the high-pressure water and the mortar pump for conveying the grinding materials to the sand separator. The grinding materials are impacted by taking high-pressure water as the motive power to remove the scale on the metal wires or the metal bars, and the method and the equipment have the advantages of improving the working efficiency effectively, relieving the labor strength of workers, along with quick cleaning speed, difficult blocking of sprayers, good scale removal effect, no damage to metal matrixes and no environmental pollution.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

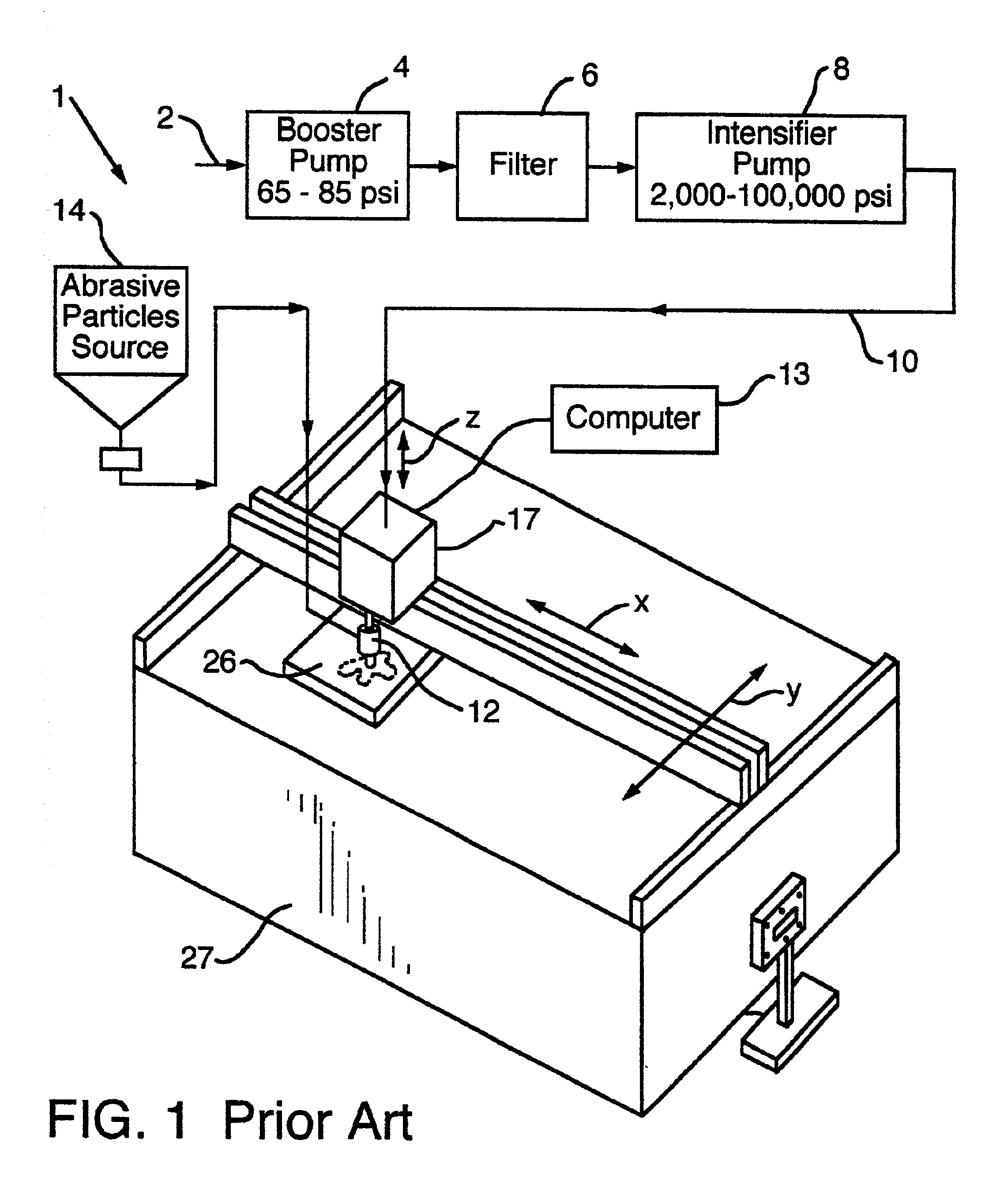

Flash vaporizing water jet and piercing with flash vaporization

ActiveUS7815490B2Minimizing nonuniform secondary damageMore portableGrinding feed controlAutomatic grinding controlLiquid jetSlurry

A flash vaporizing liquid jet cutting tool and method for piercing with minimal damage to the cut material. The liquid is preferably superheated water, typically with abrasive particles added after the jet is expressed through a nozzle (abrasive water jet, AWJ) or with abrasive particles added before the jet is expressed through a nozzle (abrasive slurry jet, ASJ). In piercing, only a portion of water that has not changed phase enters into the cavity or must leave the cavity and the piercing pressure, which can damage the material, is therefore reduced.

Owner:OMAX CORP (US)

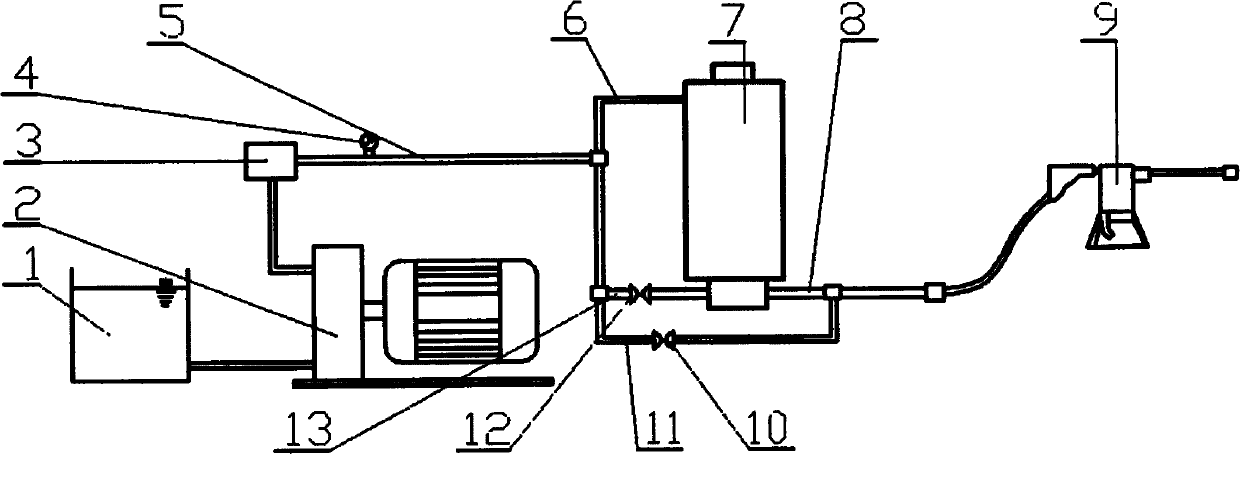

Portable abrasive water jet cutting machine used in coal mine

InactiveCN102166733AImprove protectionNothing producedAbrasive feedersAbrasive blasting machinesBarrel ShapedPulp and paper industry

The invention relates to a portable abrasive water jet cutting machine used in a coal mine. A water tank is connected with a water pump, a pressure adjustment valve and a pressure gage in sequence through a water pipe in series; the water pipe is divided into three branched water pipes; a first branched water pipe is connected with the upper end of a barrel-shaped abrasive jar; a second branched pipe is connected with the lower end of the abrasive jar through an abrasive flow regulating valve; a third branched water pipe is connected with a mixing pipe through a water adjusting valve; the mixing pipe extends forwards to be connected with a spray gun; and the abrasive water is jetted out through the spray gun to cut the objects, thus achieving the purpose of the cutting operation. A cold cutting technique of the abrasive water jet is adopted in the cutting machine, thus overcoming the dangers caused by the condition that the gas exists in various hot cutting technique; and the cutting machine is light, is not hot, is smokeless, smell-less, and nontoxic and has no gas generation, is beneficial for protecting the environment, and is suitable for carrying out the safe cutting operation under the inflammable and explosive dangerous occasions and the like.

Owner:徐州中矿永宏科技有限公司

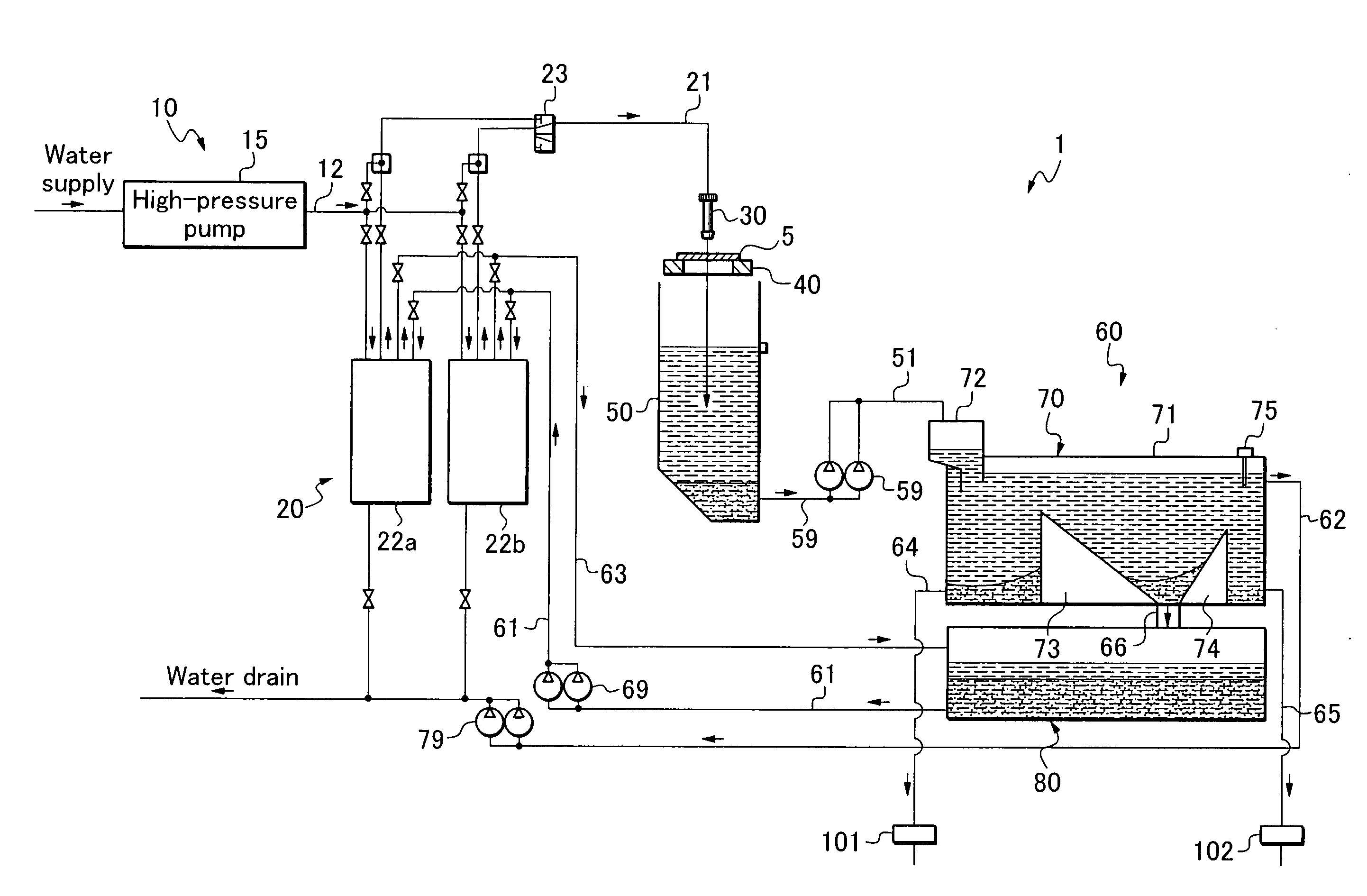

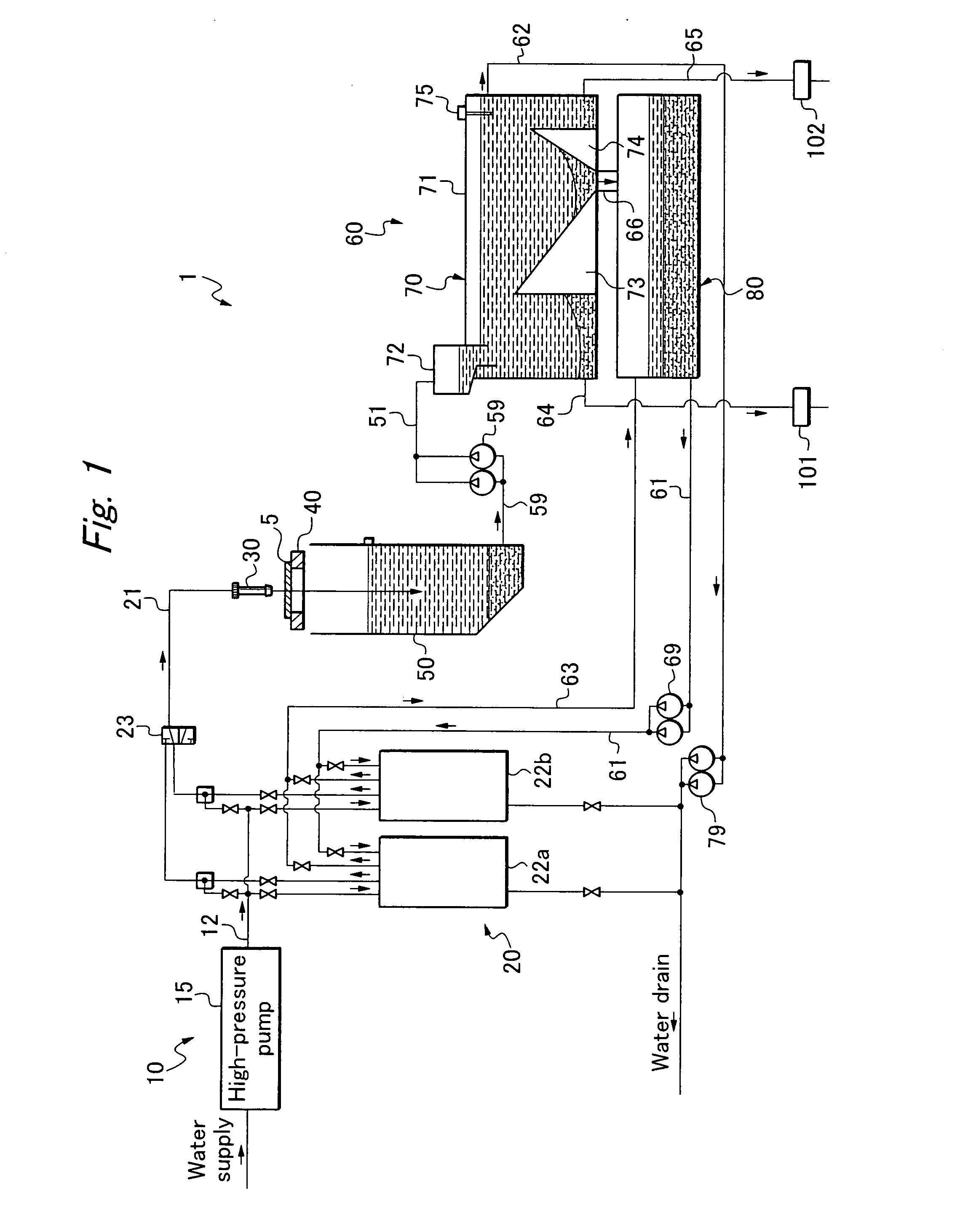

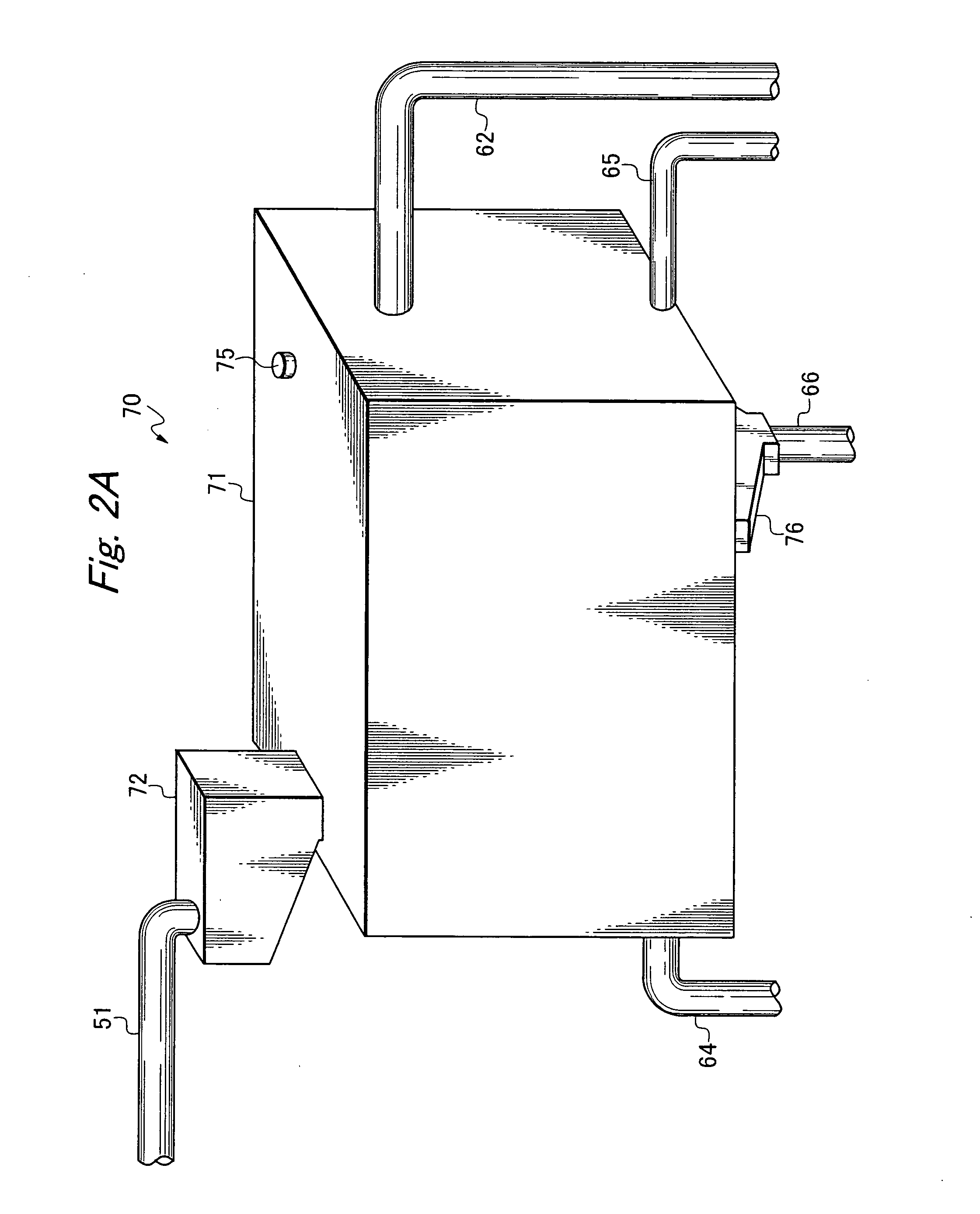

Abrasive water jet cutting machine

InactiveUS20070037495A1Promote recoveryUniform particle sizeAbrasive machine appurtenancesAbrasive blasting machinesLiquid jetHigh pressure

To provide an abrasive water jet cutting machine in which an abrasive recovery unit can be continuously used without needing maintenance, and an abrasive having a uniform grain size can be easily recovered, the machine has a catch tank for receiving a high-pressure abrasive mixture liquid jetted from a jet nozzle, and an abrasive recovery unit that recovers abrasive having a grain size in a reusable predetermined range from the abrasive mixture liquid transported from the catch tank, and transports abrasive mixture liquid including recovered abrasive into an abrasive-mixture-liquid retention tank; wherein the abrasive recovery unit has an abrasive sorting tank which flows the abrasive mixture liquid transported from the catch tank in an approximately horizontal direction, and sorts abrasive depending on grain size by using difference in sedimentation rate depending on grain size, and recovers the abrasive having the grain size in the reusable predetermined range.

Owner:DISCO CORP

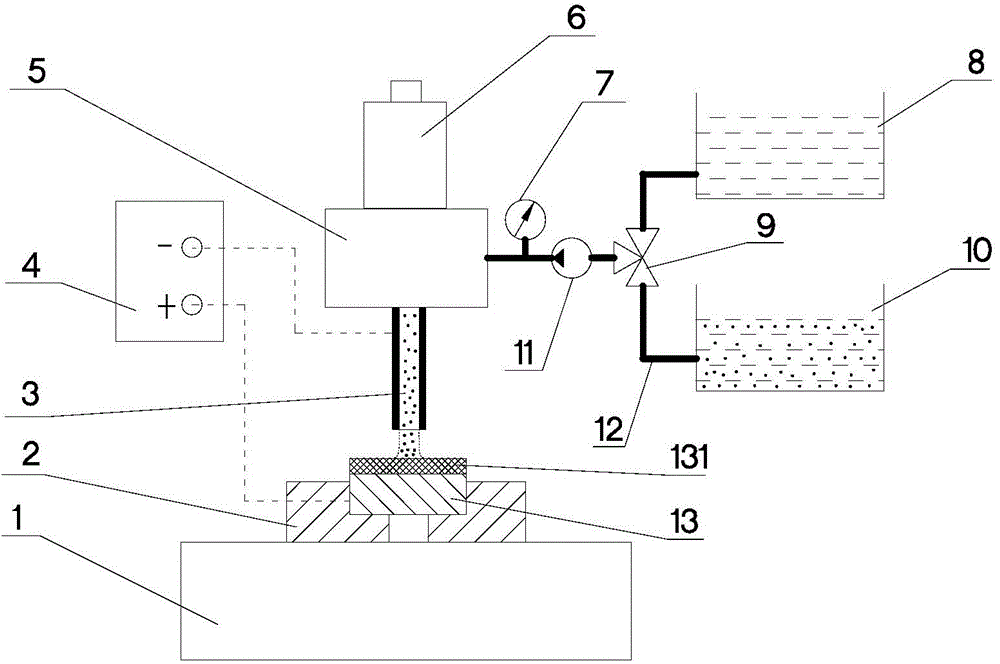

Abrasive water jet-electrolysis composite pass making method and device for metal part with thermal barrier coating

InactiveCN104907650ASimple processProcessing quality is easy to guaranteeElectrolysisThermal barrier coating

The invention discloses an abrasive water jet-electrolysis composite pass making method and device for metal part with thermal barrier coating. The method comprises the steps that a thermal barrier coating pass with the nonconducting workpiece surface is machined by using an abrasive water jet, and after a metal base body is exposed, a metal base body pass is machined by using electrolysis. The device comprises a workbench, a fixture, a tool electrode, a liquid inlet connector, a servo feeding device, an abrasive working liquid box, an electrolysis working liquid box, an infusion pump, a power source, an electromagnetic valve, a pressure regulating device and an infusion pipe. According to the method, it can be guaranteed that under the condition that a tool and the tool electrode are clamped and positioned at one time, the thermal barrier coating pass and the metal base body pass are sequentially machined, the position of the machined thermal barrier coating pass is coincided with the position of the machined metal base body pass, and the machining quality is easy to guarantee. According to the device, it can be guaranteed that abrasive water jet machining and electrolysis machining are carried out on same machining equipment, and the implementation of the method is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

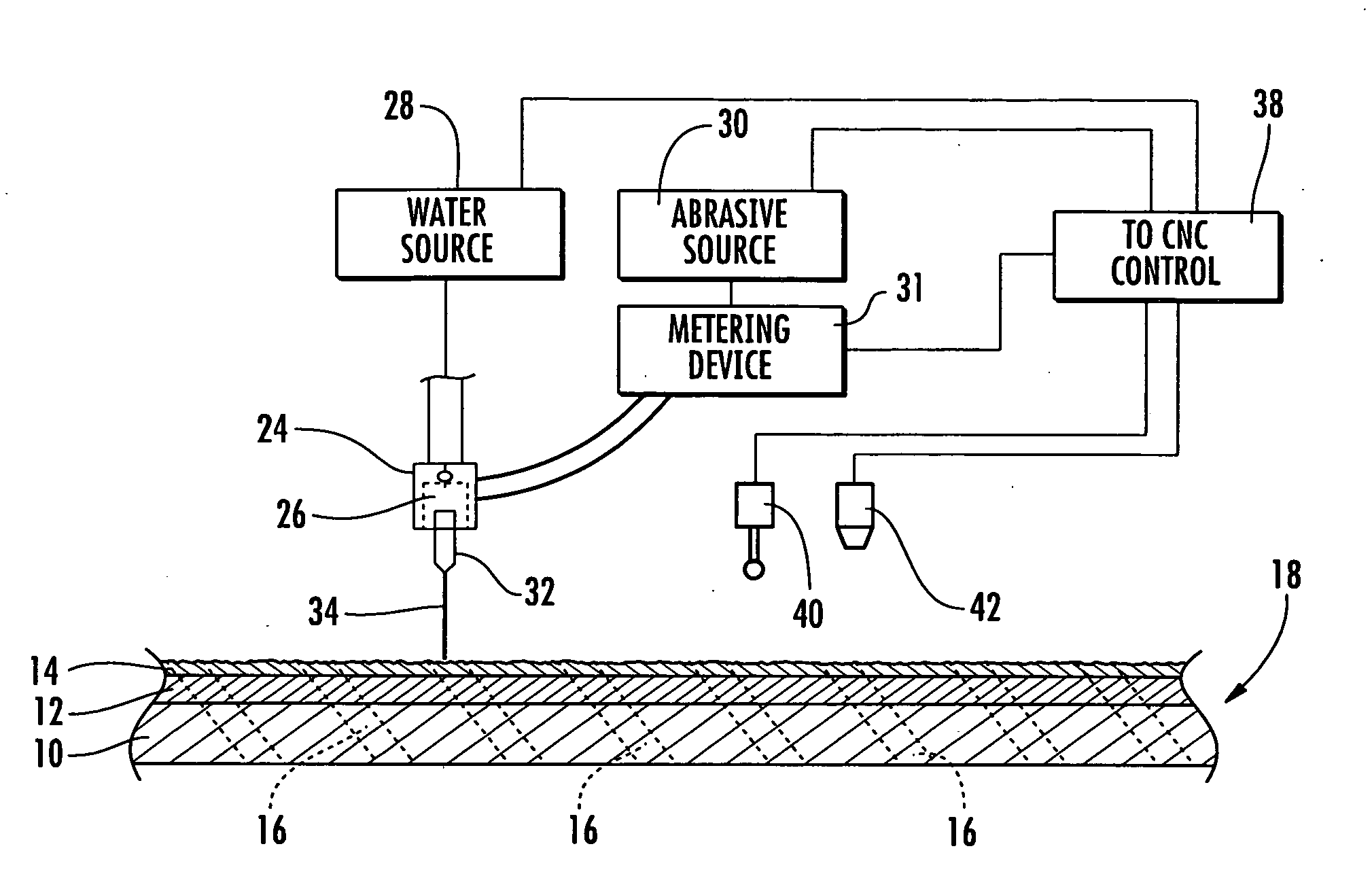

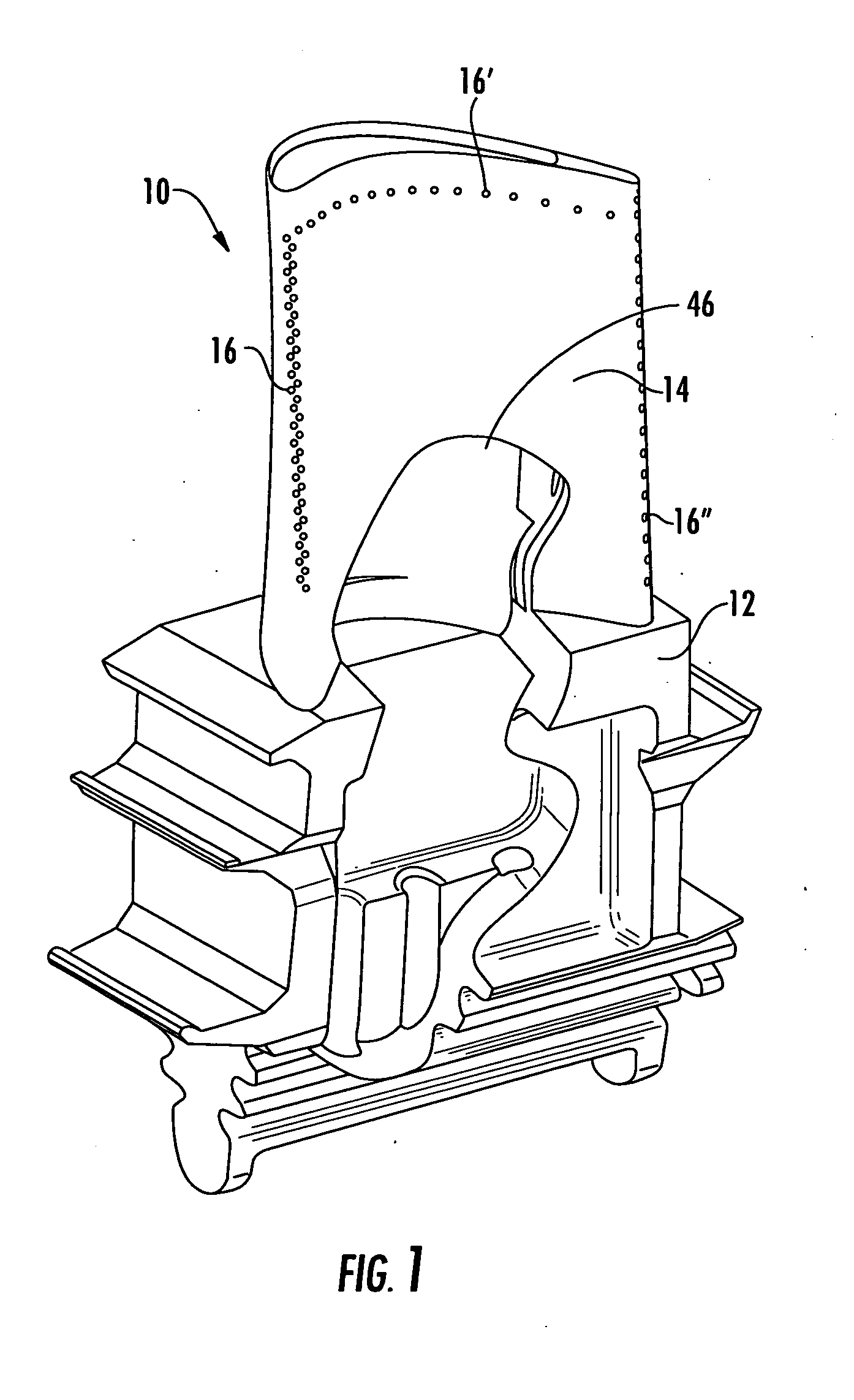

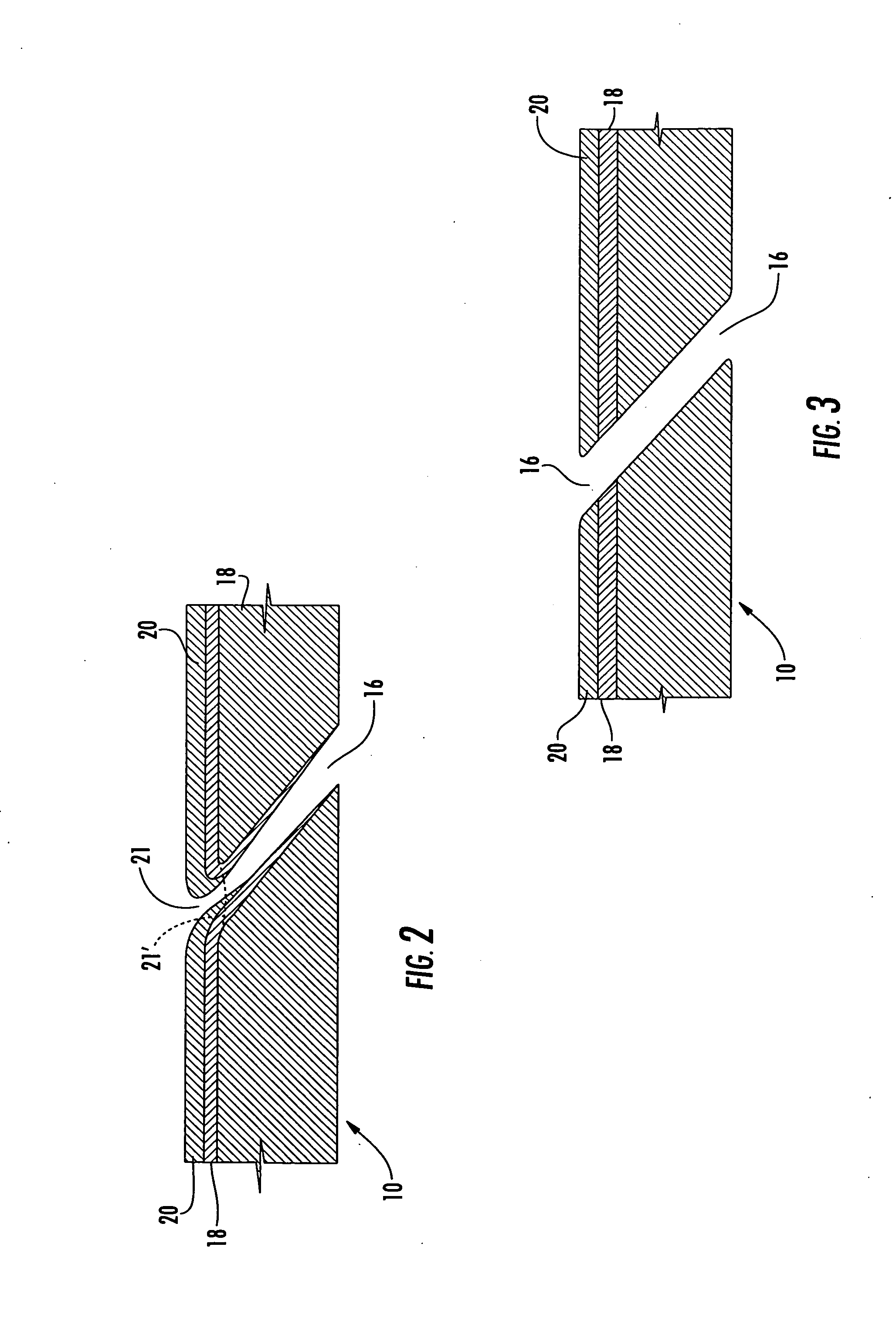

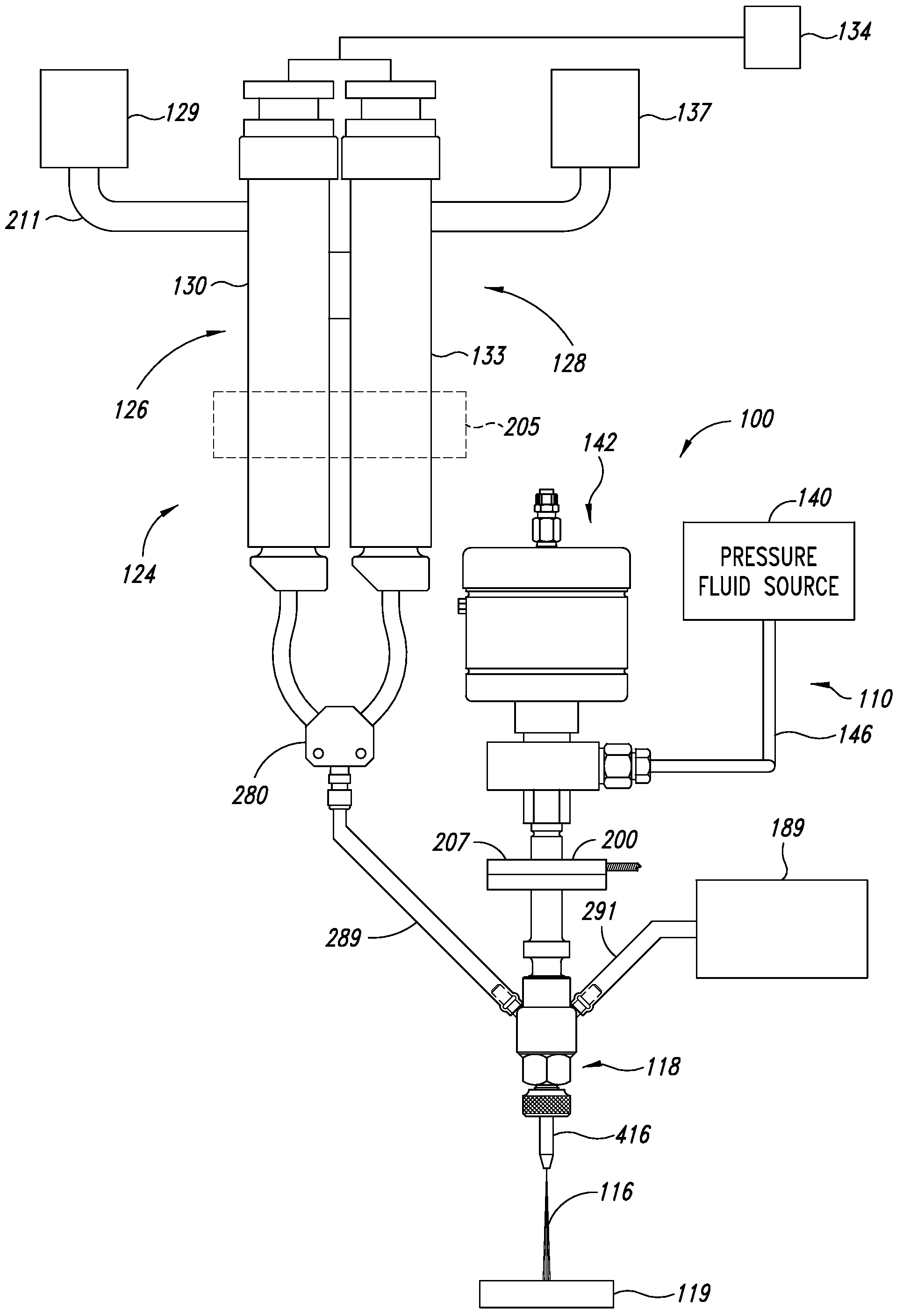

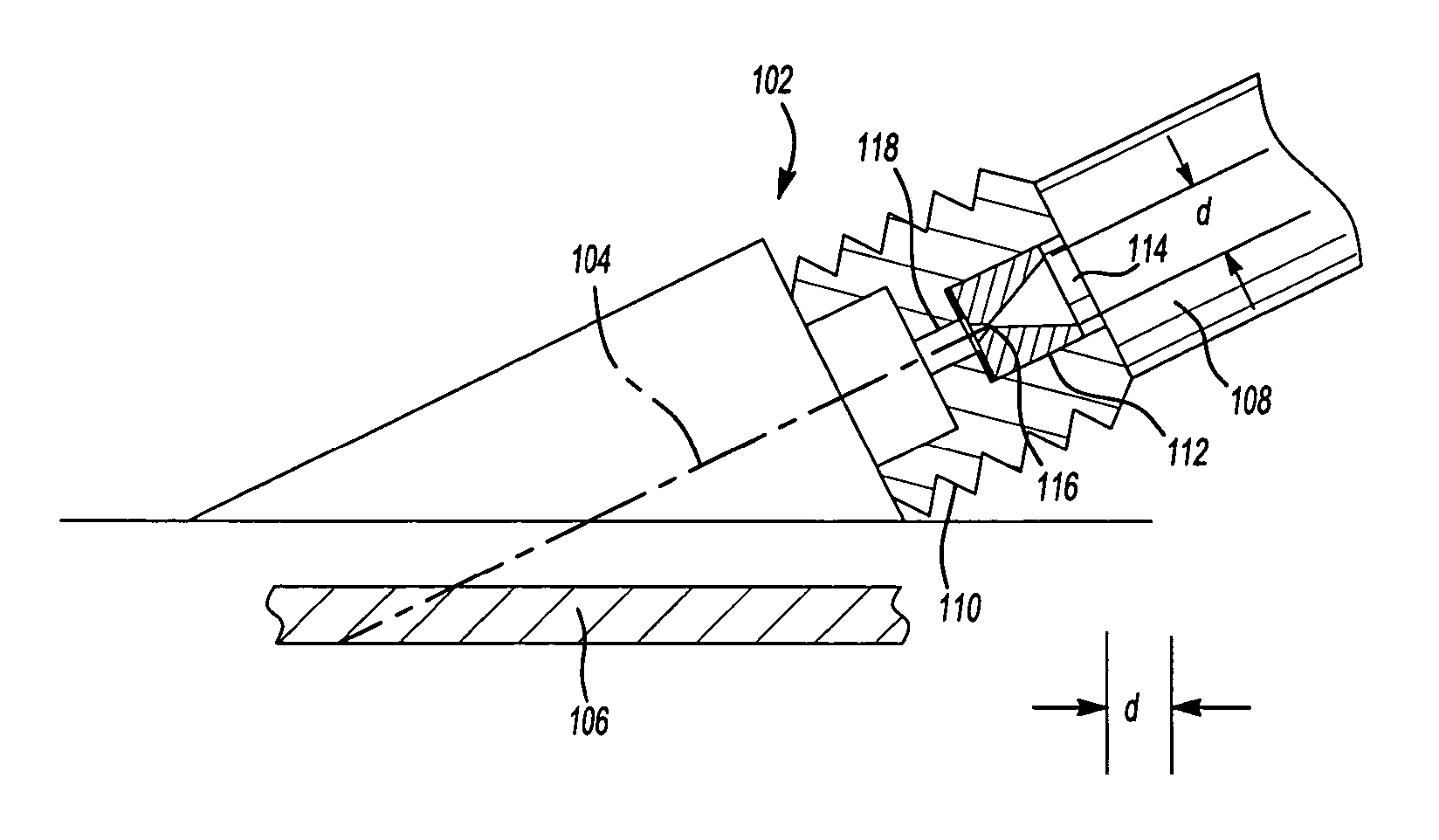

Suspended abrasive waterjet hole drilling system and method

ActiveUS20050230152A1Increase viscosity of fluidHigh abrasive particle velocityBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RAYTHEON TECH CORP

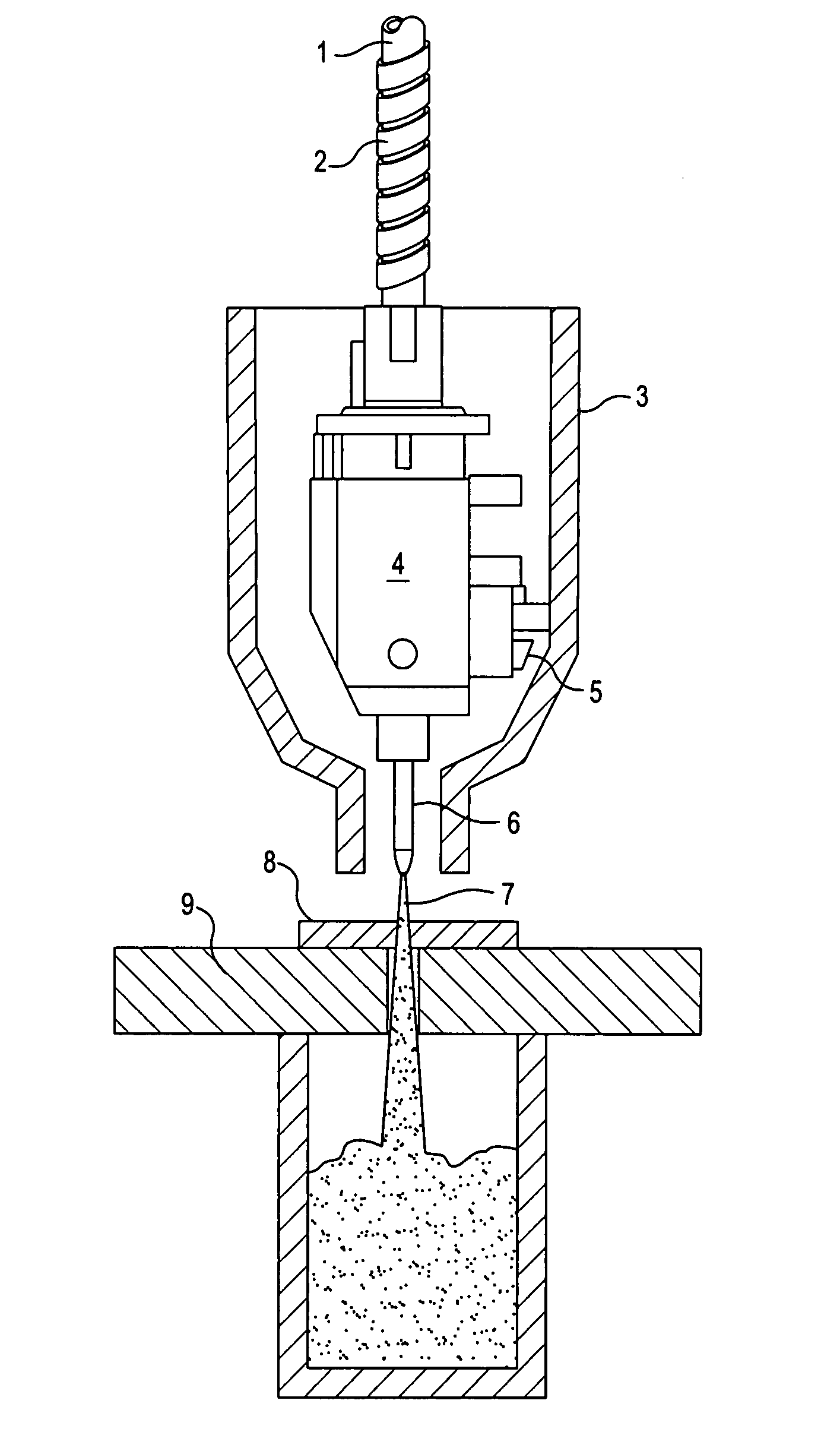

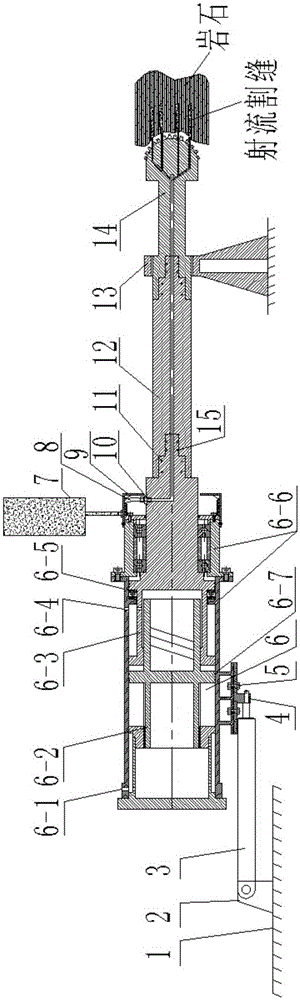

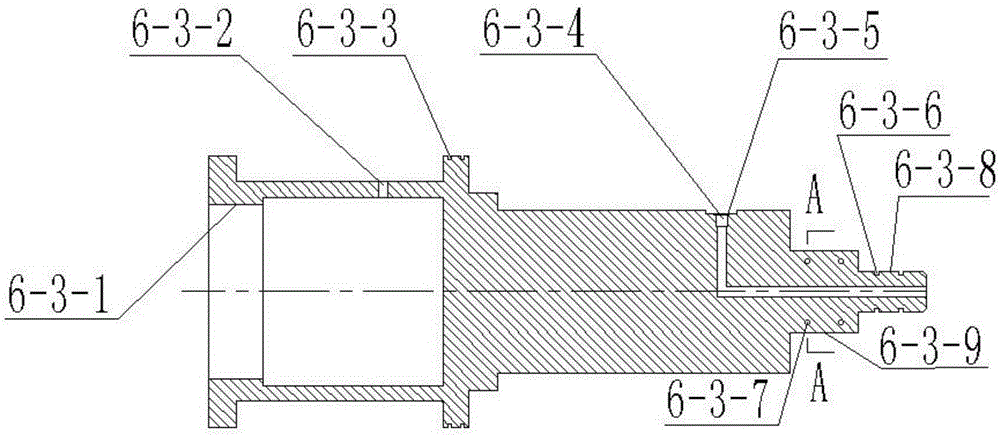

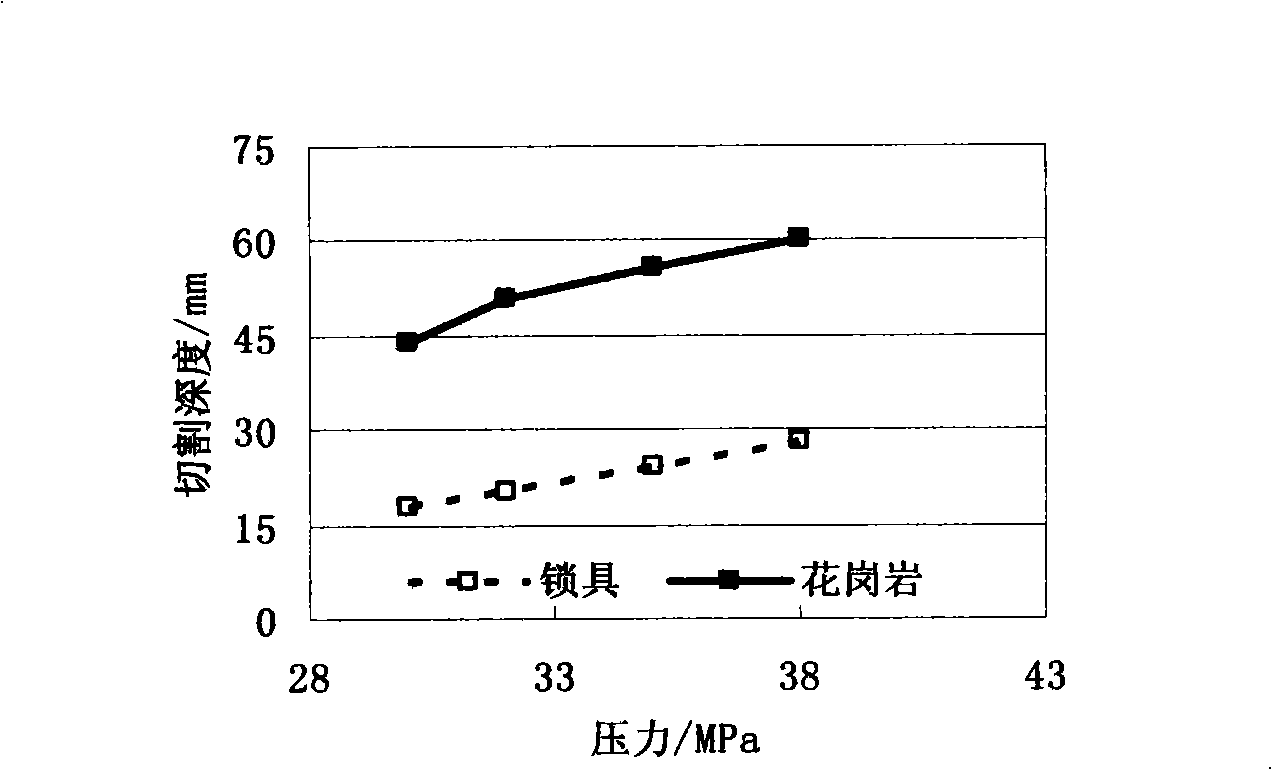

Ultrahigh-pressure swirling abrasive water jet drilling machine

ActiveCN105239928AImprove sealingRealize drilling and cuttingDrilling rodsLiquid/gas jet drillingHigh pressure waterHardness

The invention discloses an ultrahigh-pressure swirling abrasive water jet drilling machine comprising an oil cylinder supporting seat and a drill rod supporting seat which are fixed on a supporting platform. A cylinder body of a propelling oil cylinder is hinged to the oil cylinder supporting seat while a piston rod of the same is connected with a connecting block, the connecting block is connected with a rotary oil cylinder shell, an output shaft of a rotary oil cylinder is connected with the rear end of a universal drill rod, the front end of the universal drill rod is connected with the rear end of a drill bit and arranged in a mounting hole of the drill rod supporting seat, one end of a self-contraction-release high-pressure hose is connected with an outlet of an ultrahigh-pressure abrasive water jet generation system, the other end of the self-contraction-release high-pressure hose is connected with a hydraulic joint, the output shaft of the rotary oil cylinder, the universal drill rod and the drill bit are provided with inner runners which are mutually communicated, and the hydraulic joint is communicated with a nozzle on the drill bit through the inner runners. The ultrahigh-pressure swirling abrasive water jet drilling machine is driven in a fully hydraulic manner and is simple and compact in structure, the propelling oil cylinder and the rotary oil cylinder are small in size and high in power, high-pressure water sealing is simple and reliable, and drilling cutting of rock high in Protodikonov's hardness coefficient can be realized by aid of ultrahigh-pressure abrasive jet.

Owner:CHINA UNIV OF MINING & TECH

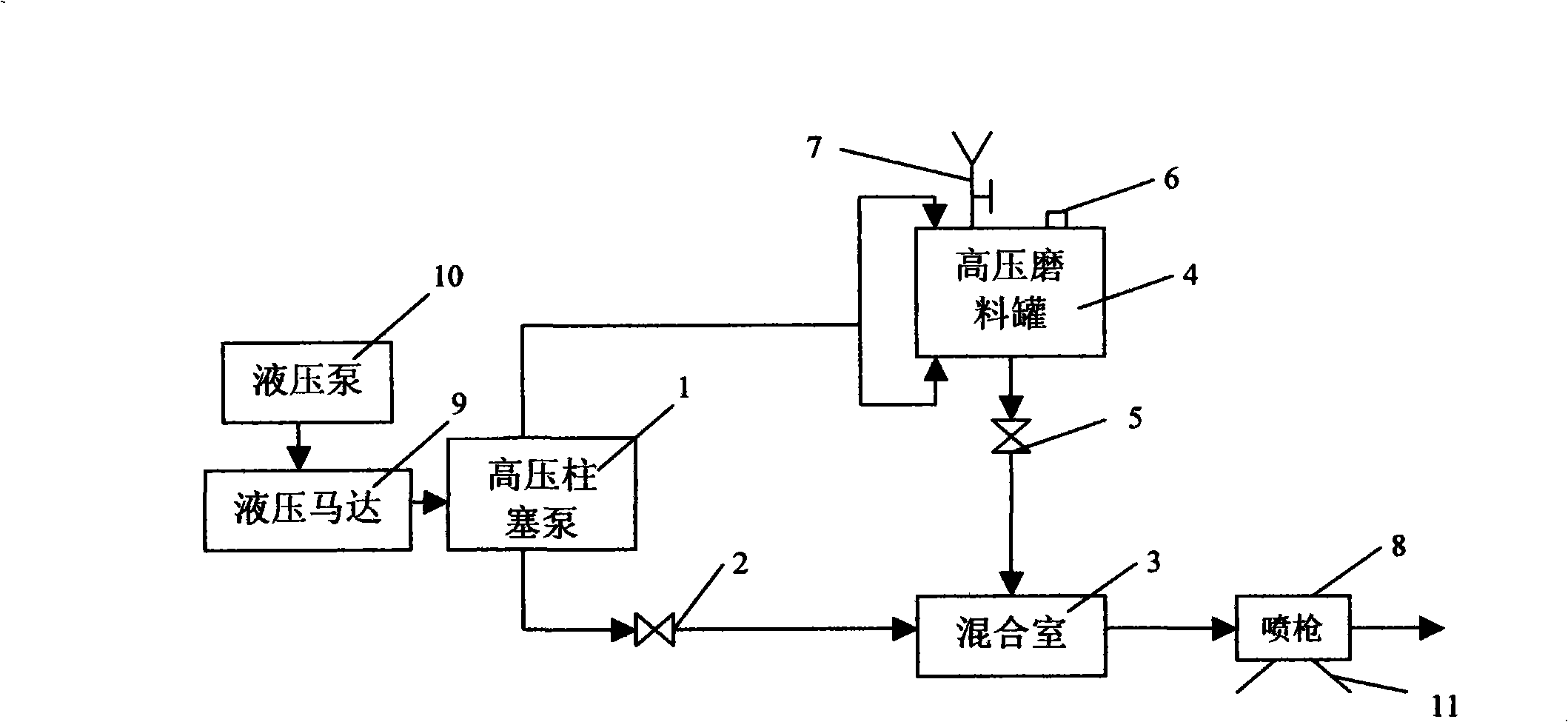

Mine abrasive water jet cutting method and device

InactiveCN101537600ALow priceWell mixedAbrasion apparatusGrinding/polishing apparatusGas explosionAbrasive water jet

The invention discloses a mine abrasive water jet cutting method and a device. The method comprises the steps of mixing the abrasive with partial high-pressure water in a forward mixing manner in a high-pressure abrasive tank to form uniform suspension, and then mixing the suspension with cutting high-pressure water in a mixing chamber, and jetting the mixture from the spout of a spray pistol in an accelerative manner to form abrasive particle flow-abrasive jet to cut the object to be cut at an extremely high speed. The abrasive particle of the forward mixing manner has long acceleration time, obtains huge energy, and has good cutting effect. The entire device has quick cutting speed without sparkle in the cutting process, does not cause gas explosion, has low cost, and is free from pollution and extremely suitably used for cutting in complex environment in mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Five-axis numerical control abrasive water jet automatic polishing machine

InactiveCN106976020AGuaranteed machining accuracyStable temperatureBlast gunsAbrasive feedersNumerical controlMotor drive

A five-axis CNC abrasive water jet automatic polishing machine, including a base, a workbench is installed inside, a filter screen and a liquid collection box are arranged under the workbench; a beam is installed above the base, and a longitudinal beam is installed on the side of the beam , the longitudinal beam can move left and right and up and down on the beam, the nozzle support is installed at the end of the longitudinal beam, and the support is fixedly connected with the rotating shaft inside the longitudinal beam, driven by the servo motor at the top of the longitudinal beam to realize the rotation of the nozzle support, the support Abrasive water jet nozzle is installed on the top, and the nozzle is driven by a worm gear motor, which can swing left and right; the high-pressure water generation system is located on the back of the base, and is connected to the water inlet of the nozzle mixing chamber through a high-pressure water pipe; the abrasive supply system is installed on the base at the rear of the beam On, the abrasive is delivered to the sand inlet of the nozzle mixing chamber. The invention can realize the surface polishing processing of any three-dimensional curved surface, especially for the precision processing and surface treatment of complex curved surfaces and tiny surfaces, and has the effects of high precision, precise control of removal amount and the like.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com