Mine abrasive water jet cutting method and device

A technology of abrasive water jet and cutting method, applied in abrasives, grinding/polishing equipment, metal processing equipment, etc., to achieve the effects of improved adaptability, improved effect, and reduced working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

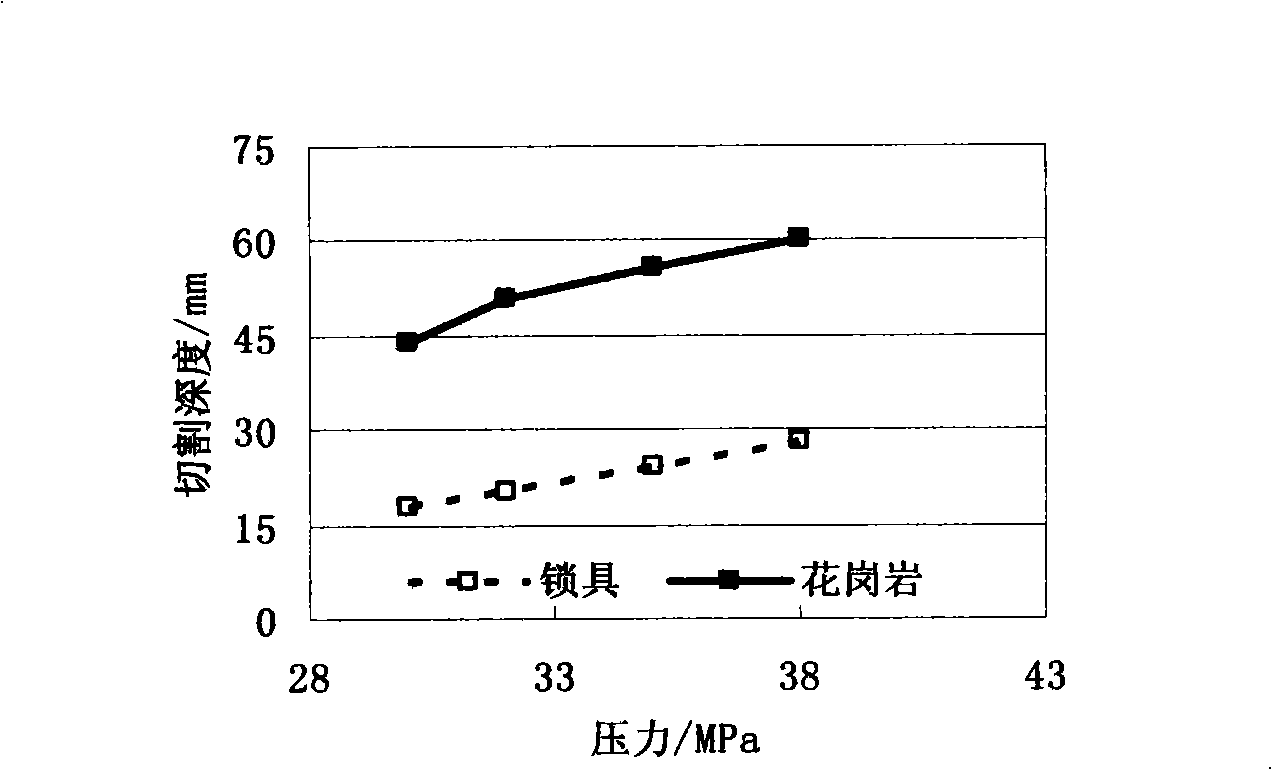

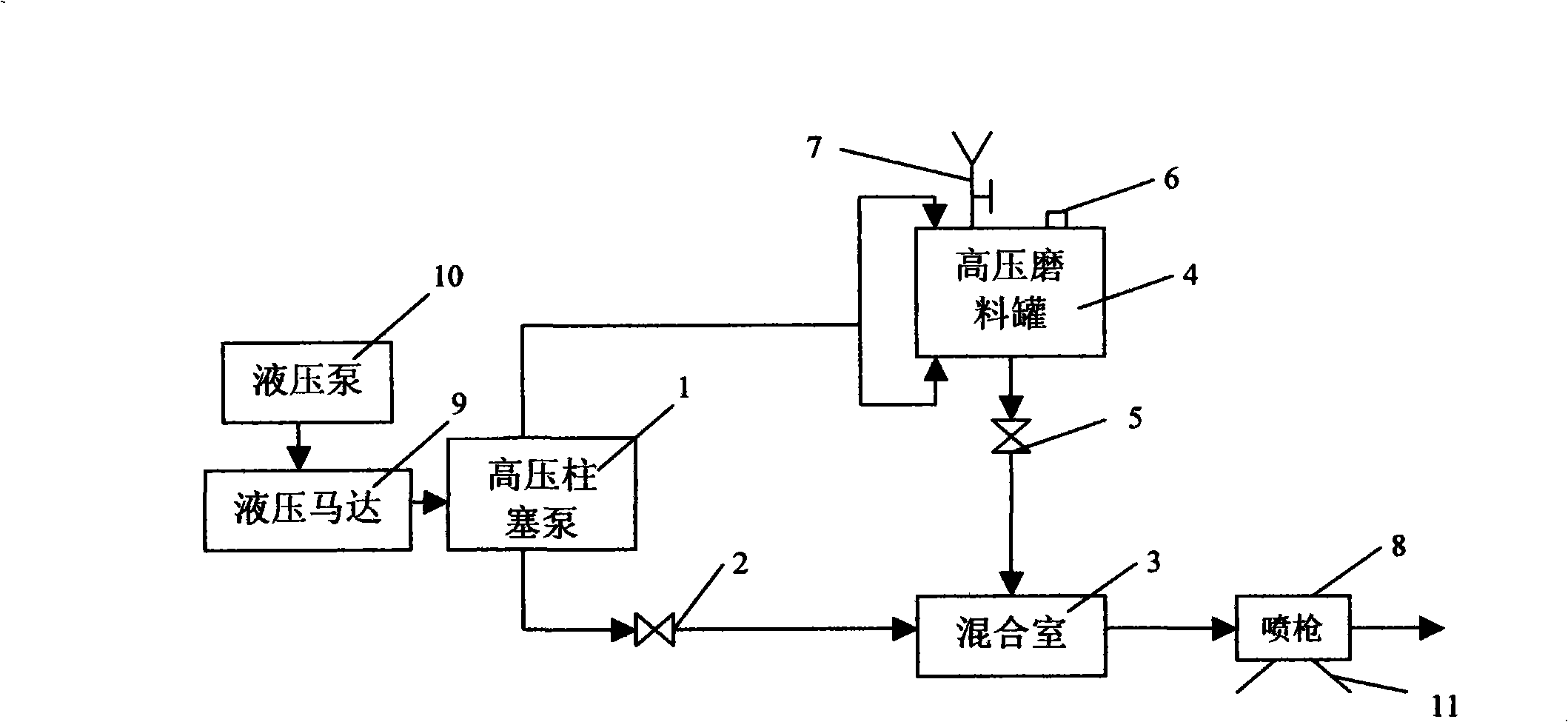

[0019] In the mine abrasive water jet cutting method described in the present invention, firstly, 80-mesh garnet is selected as the abrasive material, and the abrasive material itself is hard; then, the abrasive material and part of the high-pressure water are uniformly mixed in the container in the previous mixing method to form a suspension, Finally, the suspension is sent out from the container and mixed with the high-pressure water for cutting, and the high-pressure water for cutting and the suspension are ejected from the nozzle together to form a flow of abrasive particles with a very high speed-abrasive jet. The high-frequency impact and erosion effect can complete the cutting work on the surface to be cut. Among them, the pressure of the high-pressure water is 40MPa, the diameter of the nozzle is 0.8mm, and the amount of abrasive added generally does not exceed 20% of the capacity of the container. Of course, the abrasive can also be garnet between 60-80 mesh, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com