Patents

Literature

13776 results about "High pressure water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

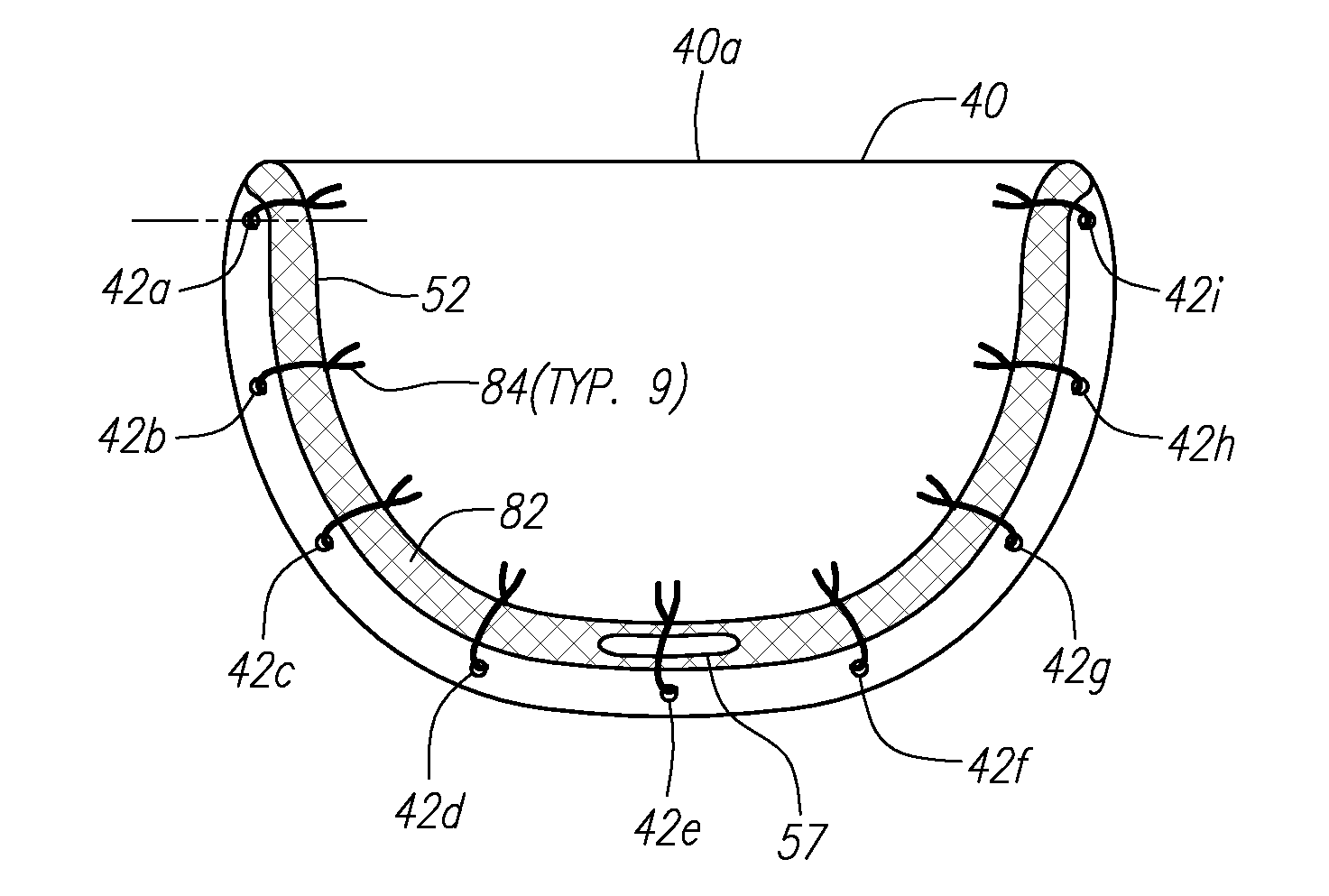

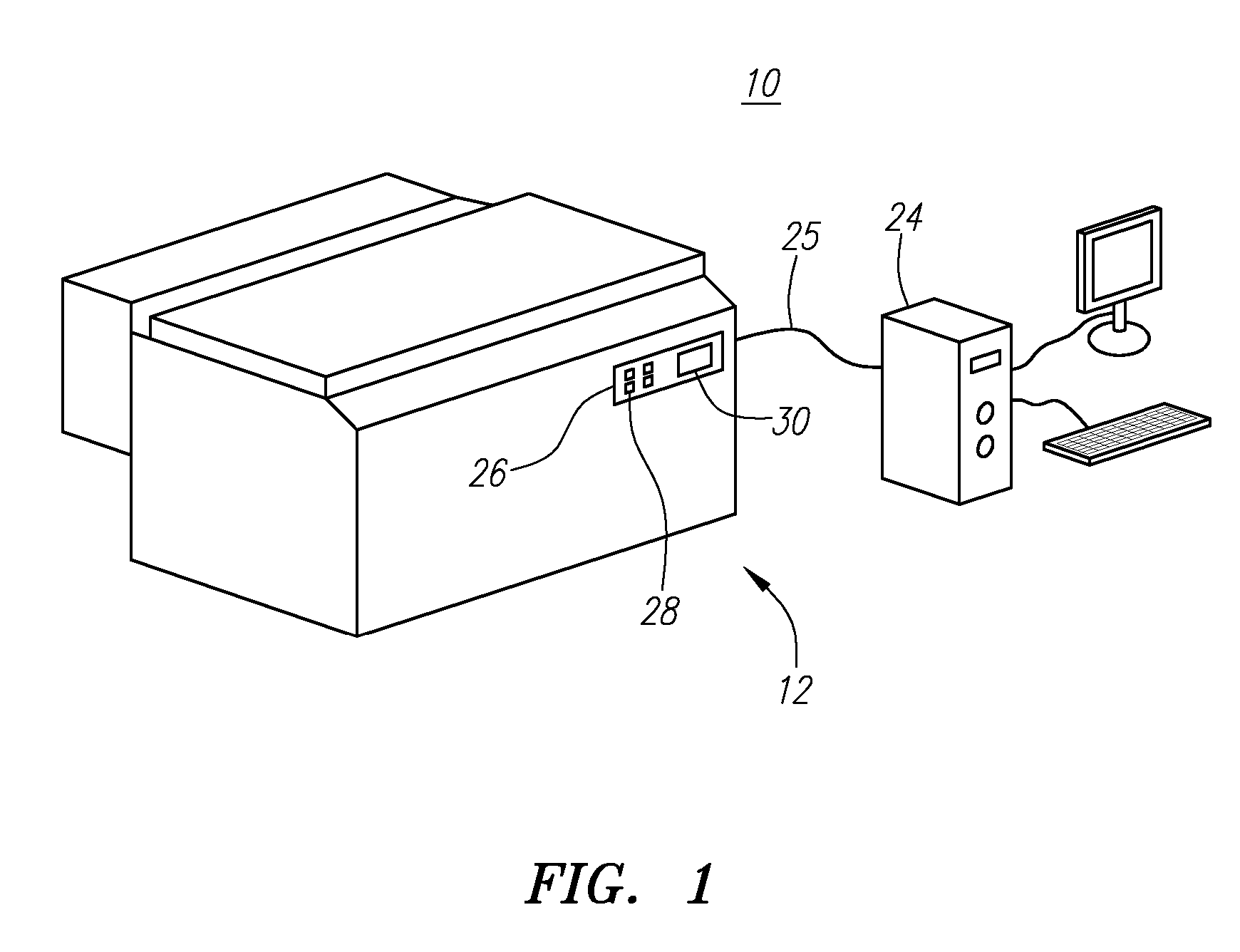

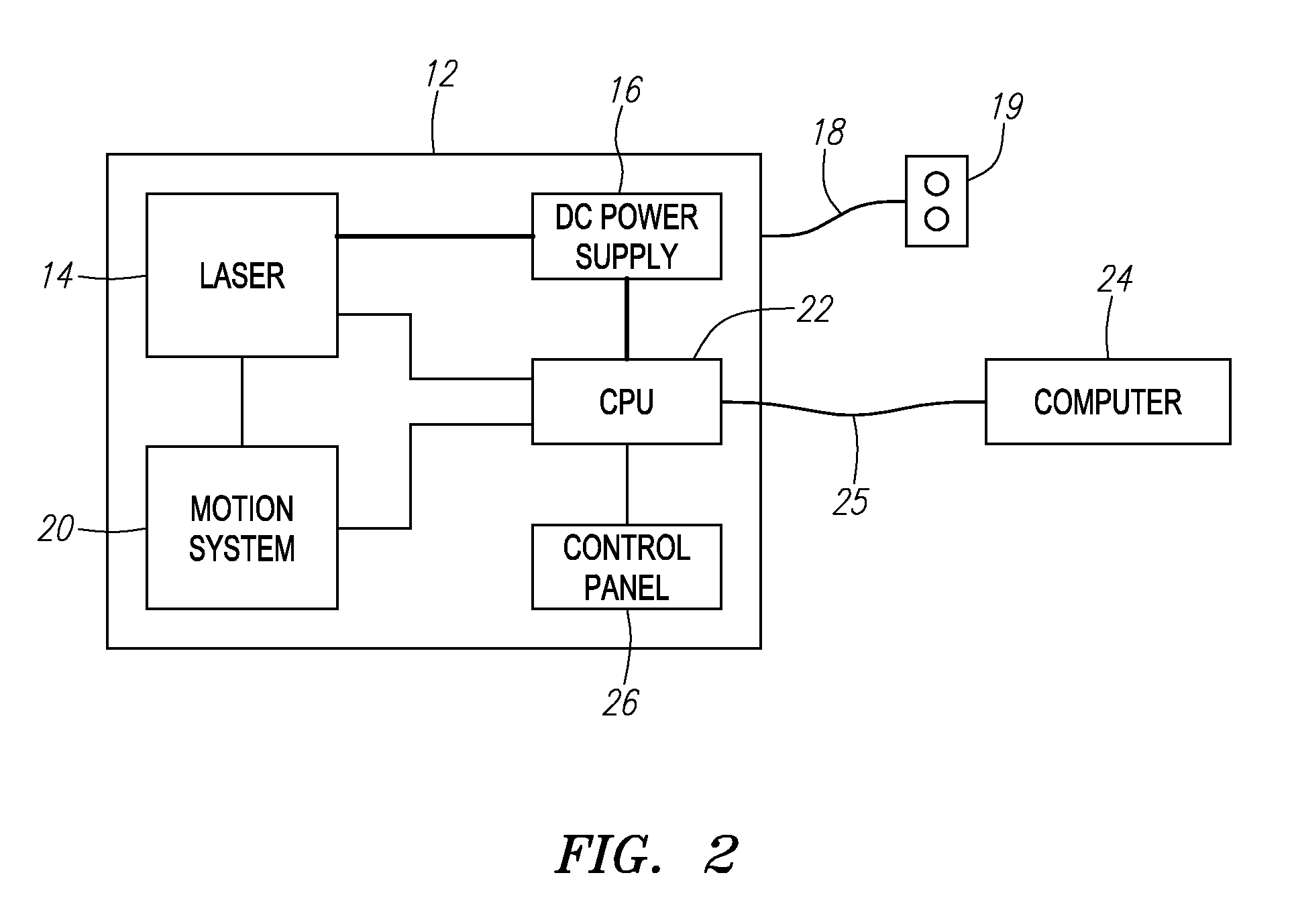

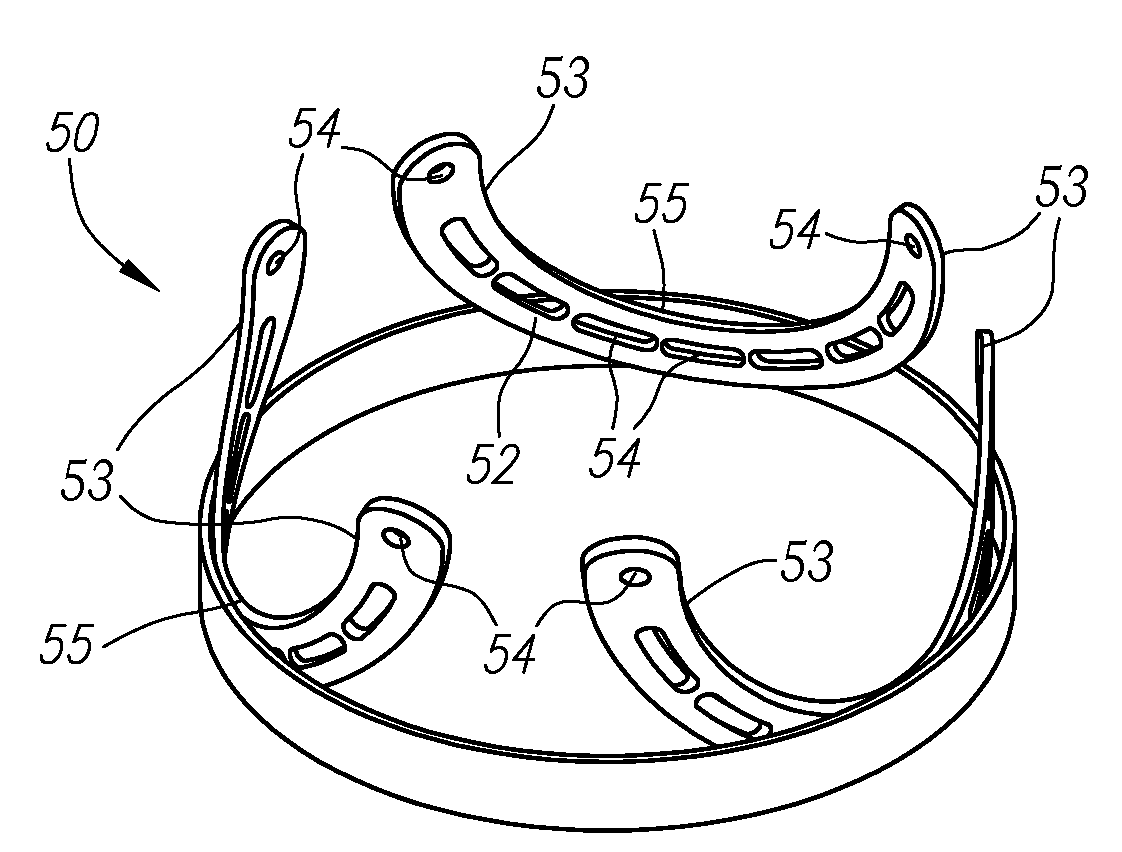

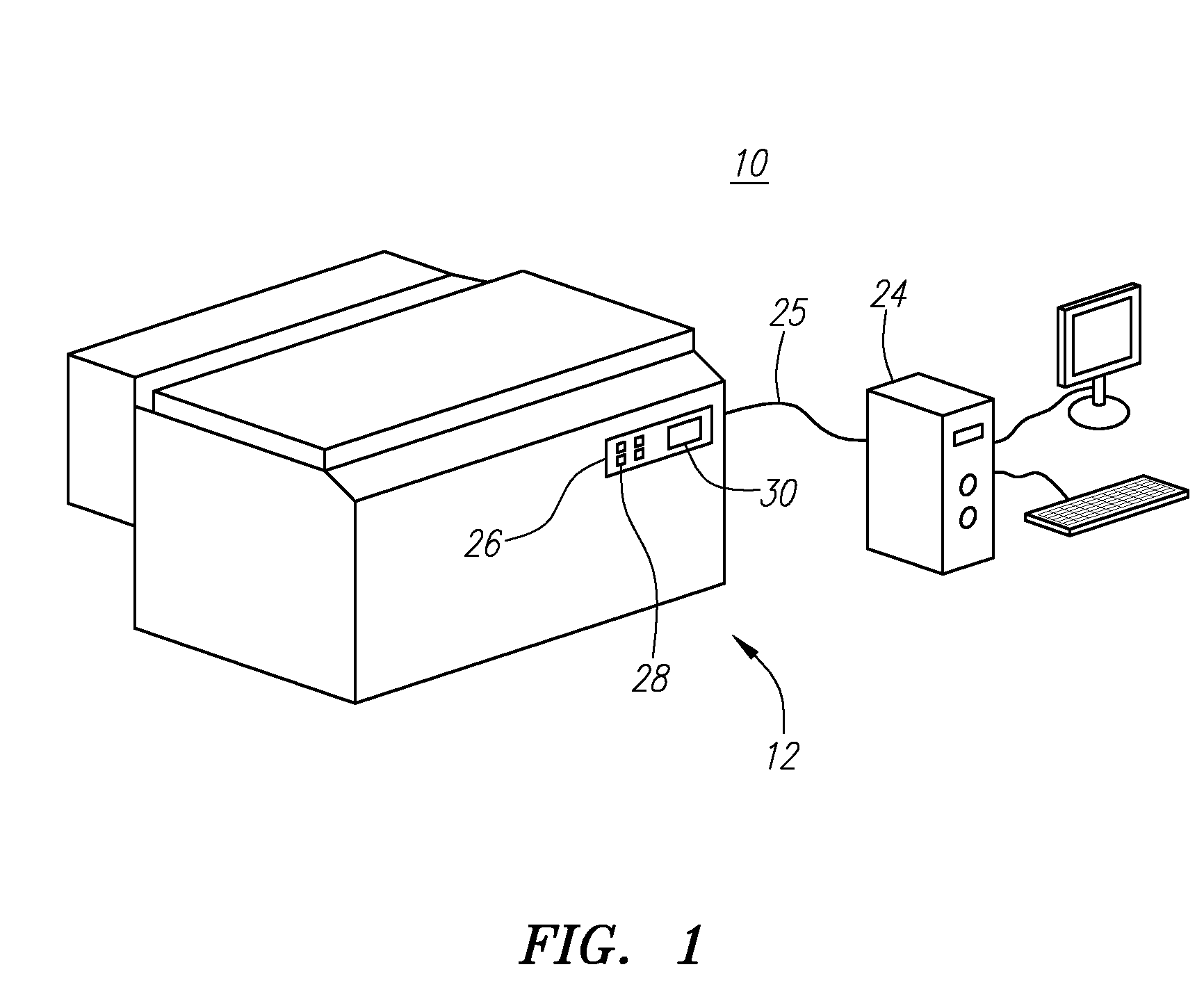

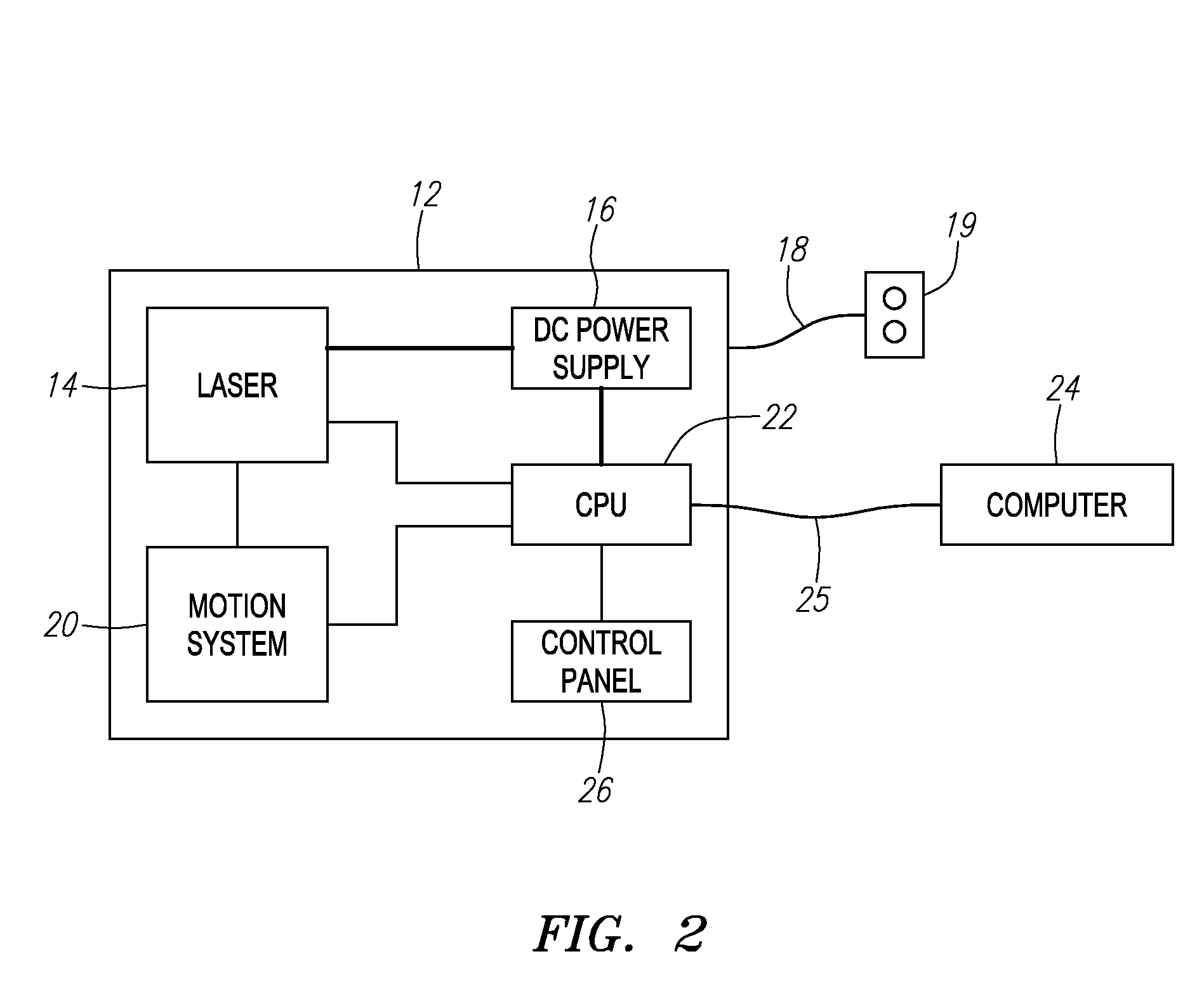

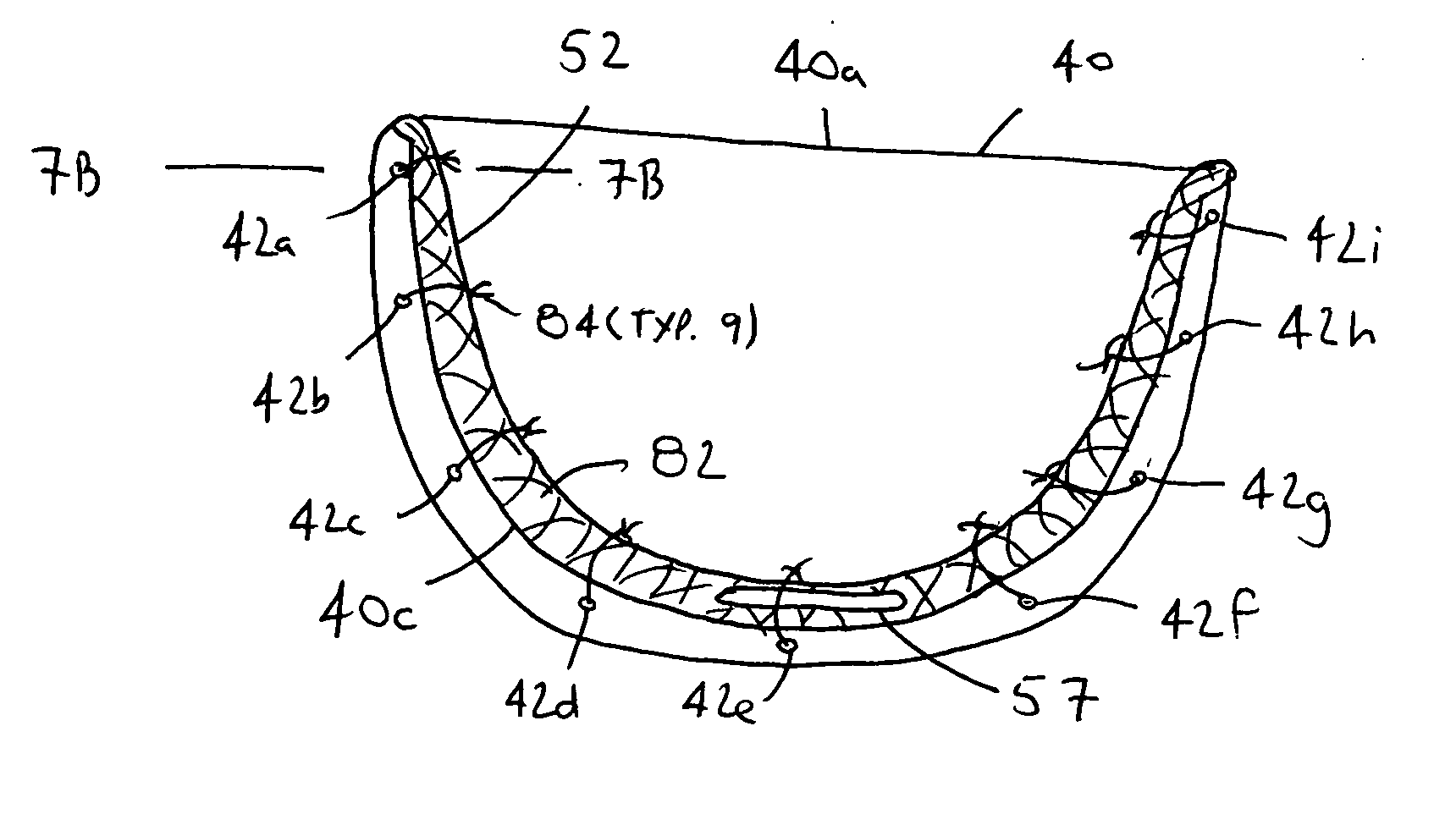

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

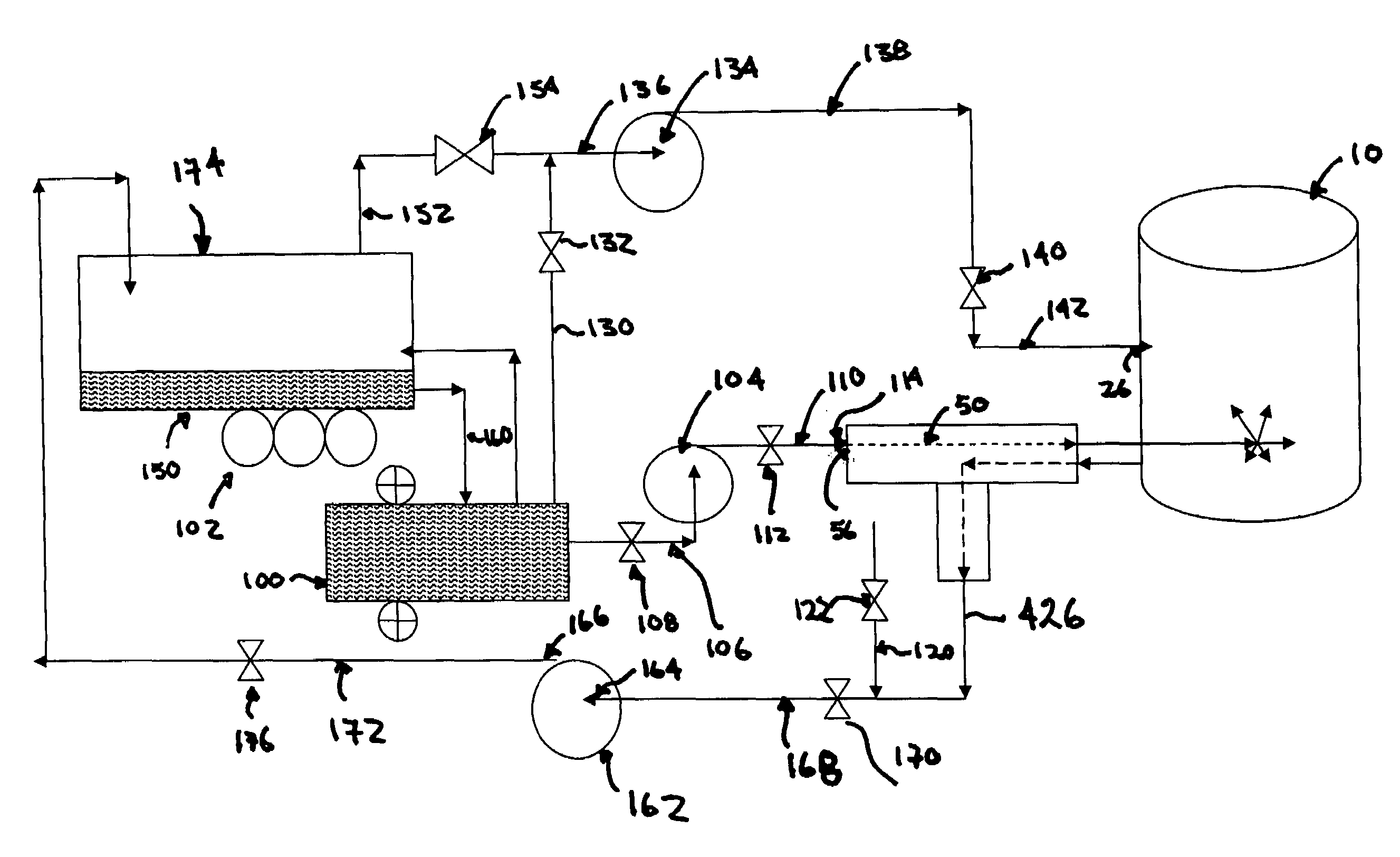

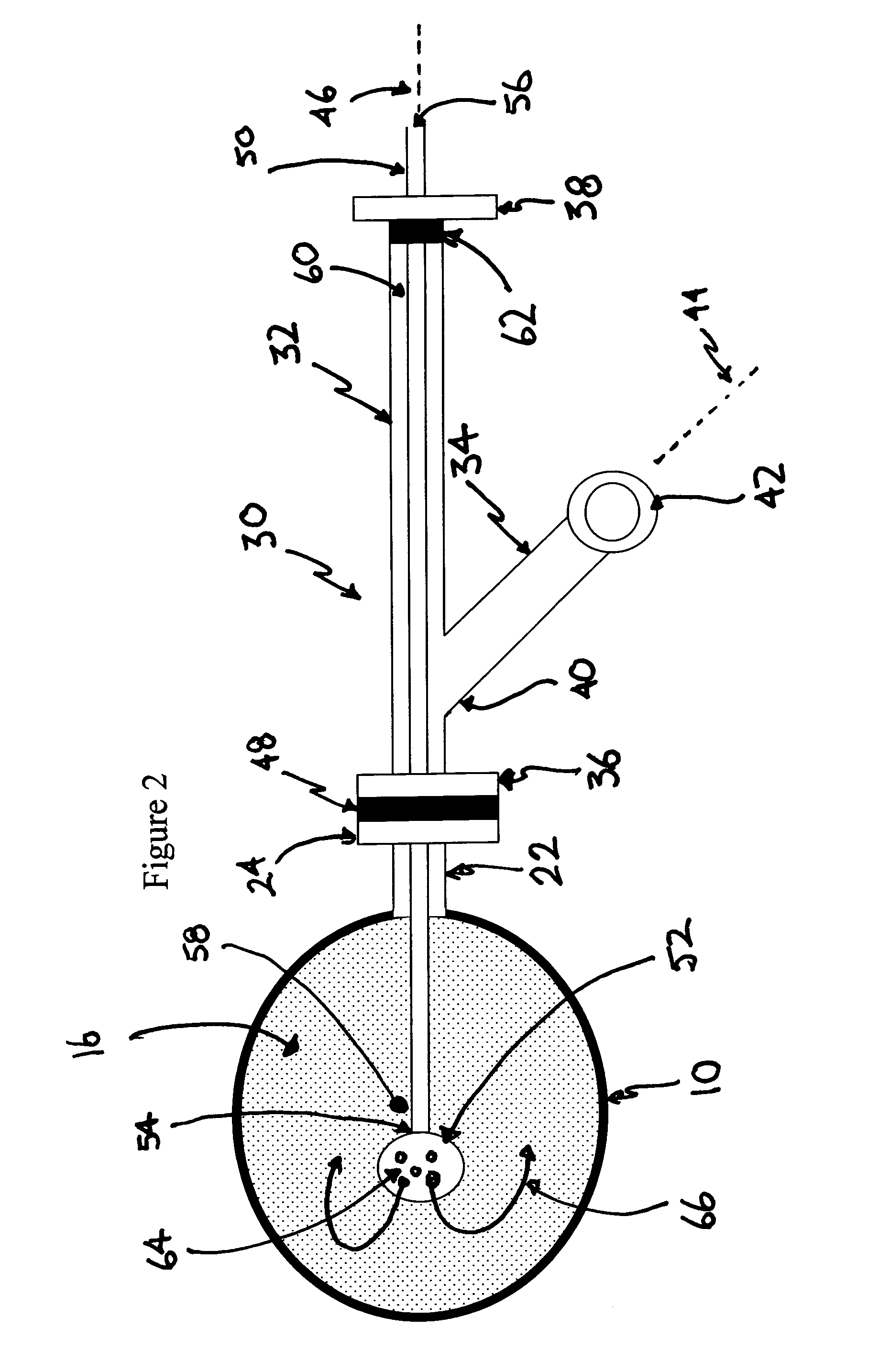

Trailer mounted mobile apparatus for dewatering and recovering formation sand

InactiveUS7240681B2Prevent leakageElectrostatic cleaningMultistage water/sewage treatmentDrive wheelHigh pressure water

An apparatus for removing formation sand from an oil storage tank. The apparatus is mounted to a truck towable trailer so that it may be transported to remote sites. Mounted to the truck towable trailer is a container adapted to accept and dewater a sand-water slurry pumped from the oil storage tank. The slurry is formed by injecting high pressure water from a water reservoir mounted to the truck towable trailer into the approximate centre of mass of the formation sand by way of a pipe having a nozzle generating a spherical spray pattern within the slurry. The pipe is forced into the slurry by way of a two counter-rotating drive wheels in frictional contact with the pipe. Included in the apparatus is a bifurcated conduit adapted for attachment to the storage tank drain port adapted for the injection of high pressure through one branch of the conduit and withdrawal of slurry from the other branch and into the container by way of a slurry pump. The dewatering of the slurry takes place by a plurality of screen filters mounted to the bottom, side and front inside walls of the container. Oil and water extracted from the slurry is recycled back into the storage tank for later removal and treatment. All pumps and conduits are mounted to the truck towable trailer so that the apparatus is self-contained.

Owner:SAIK LARRY

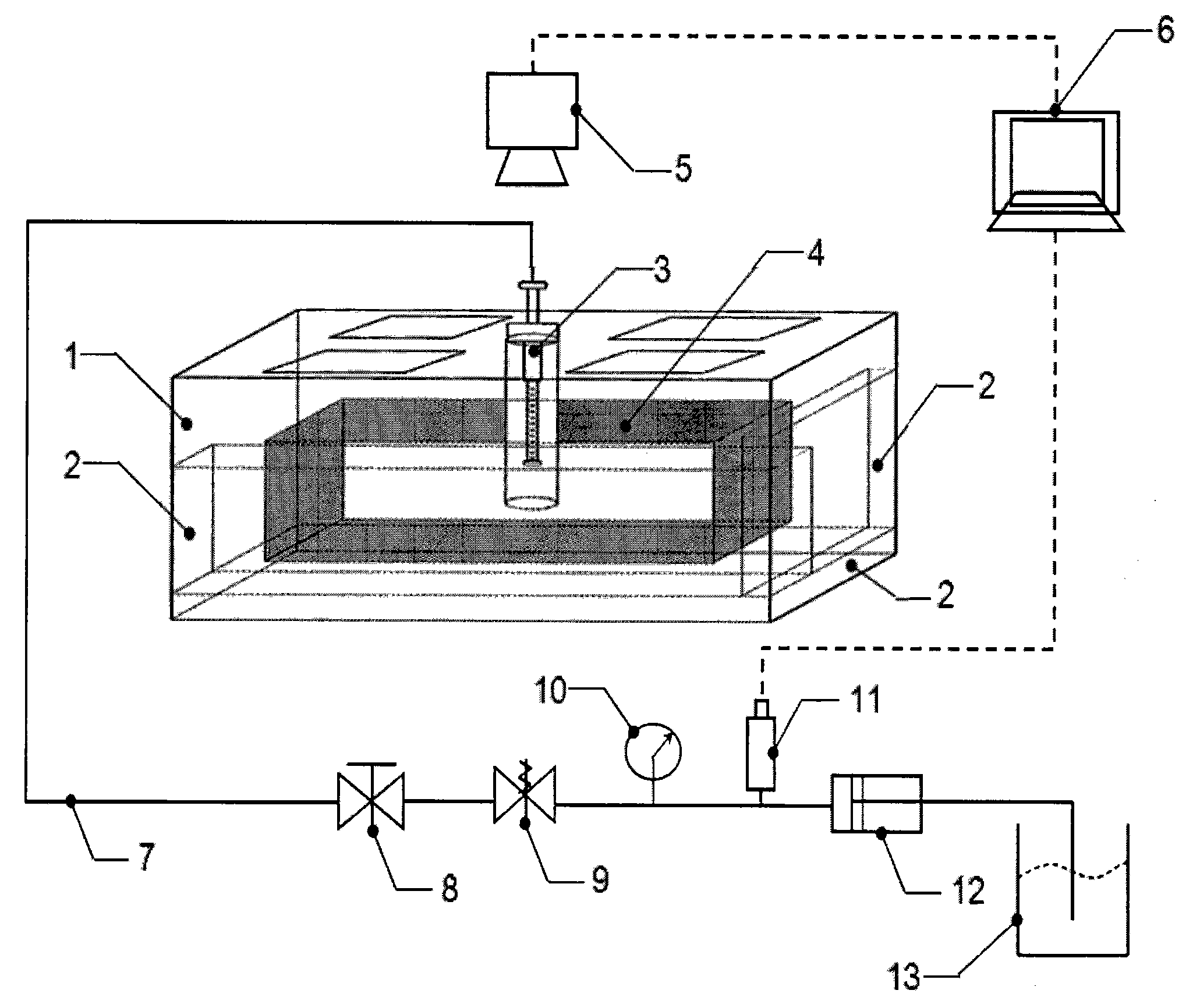

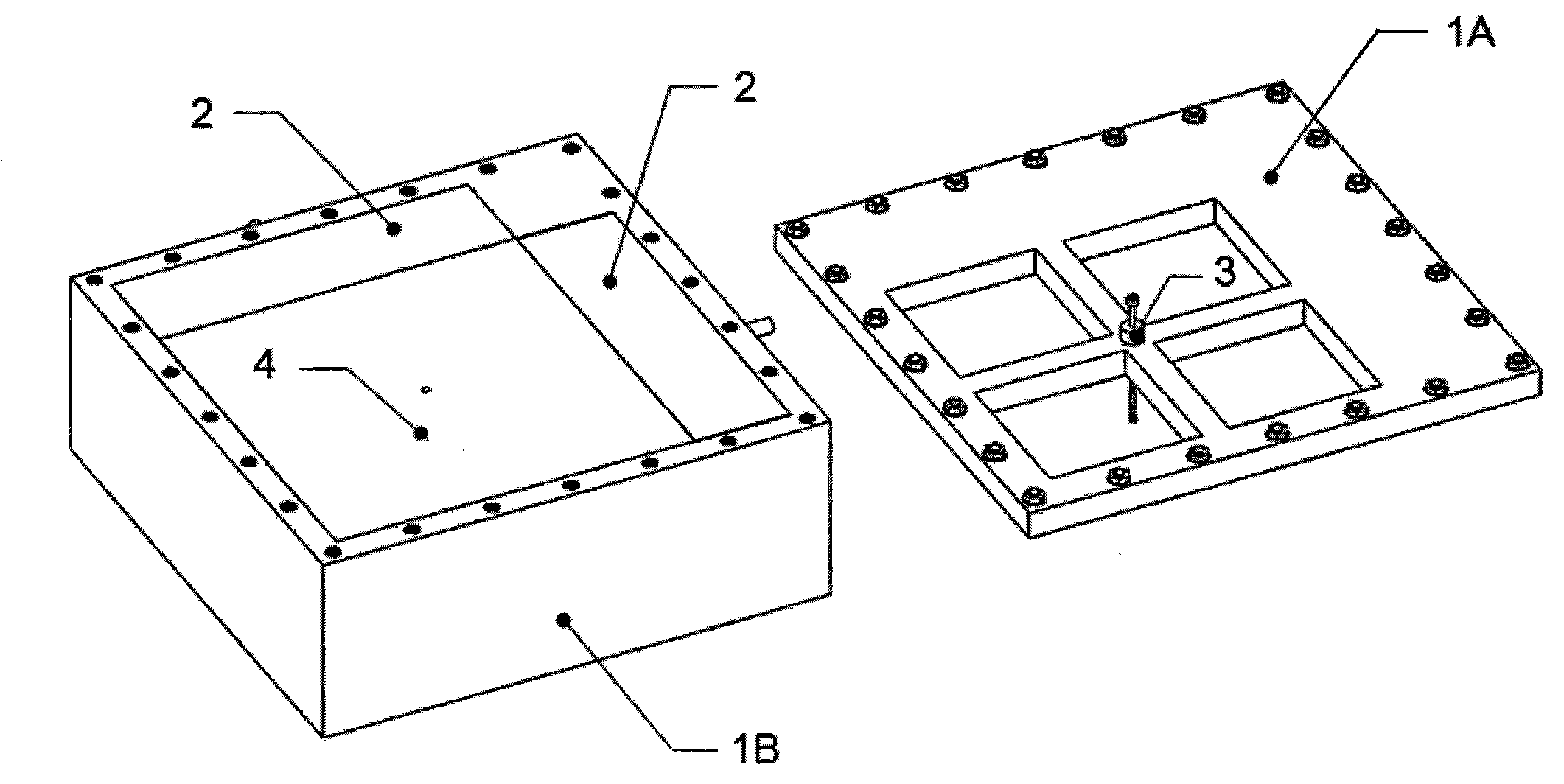

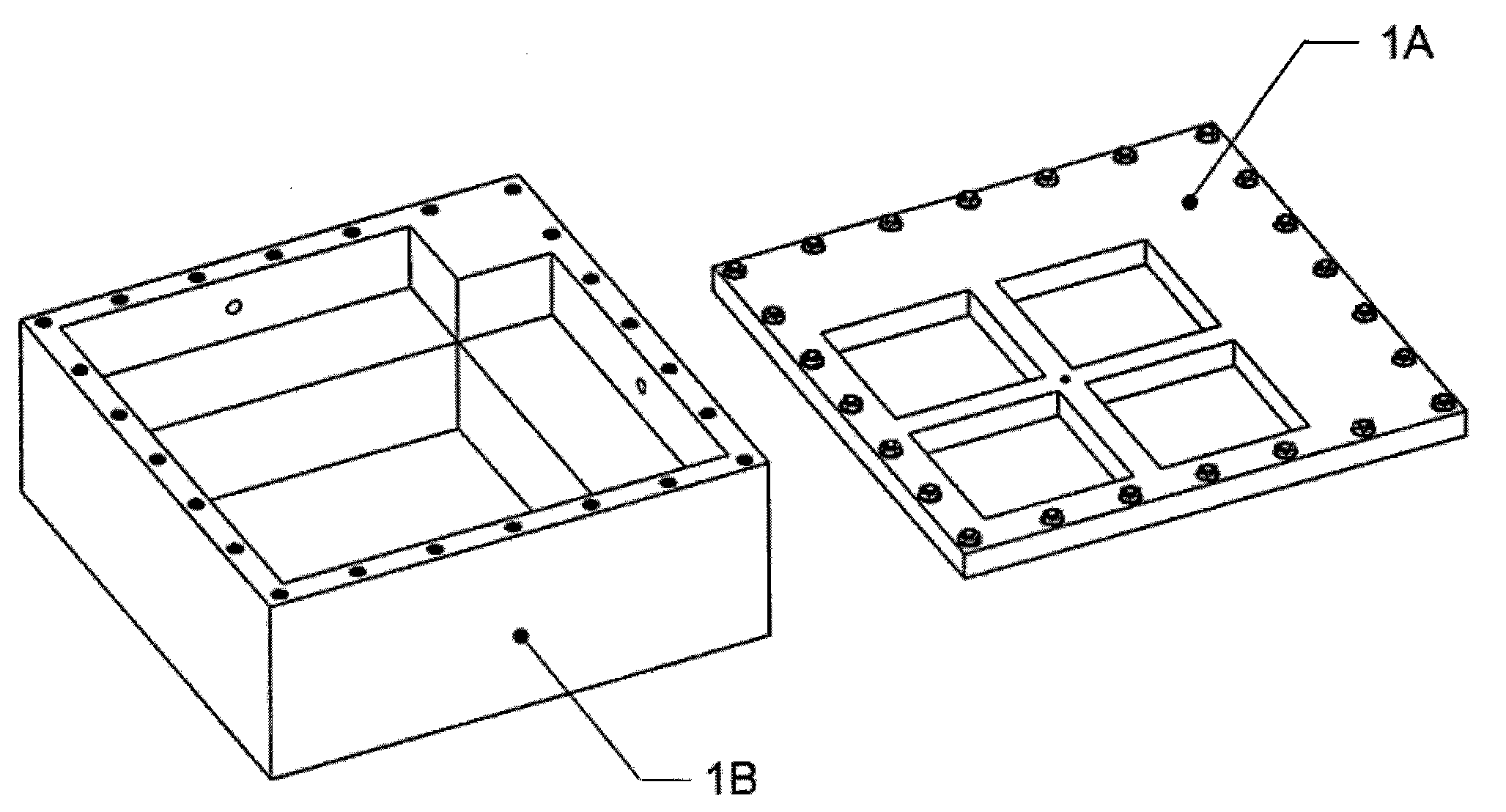

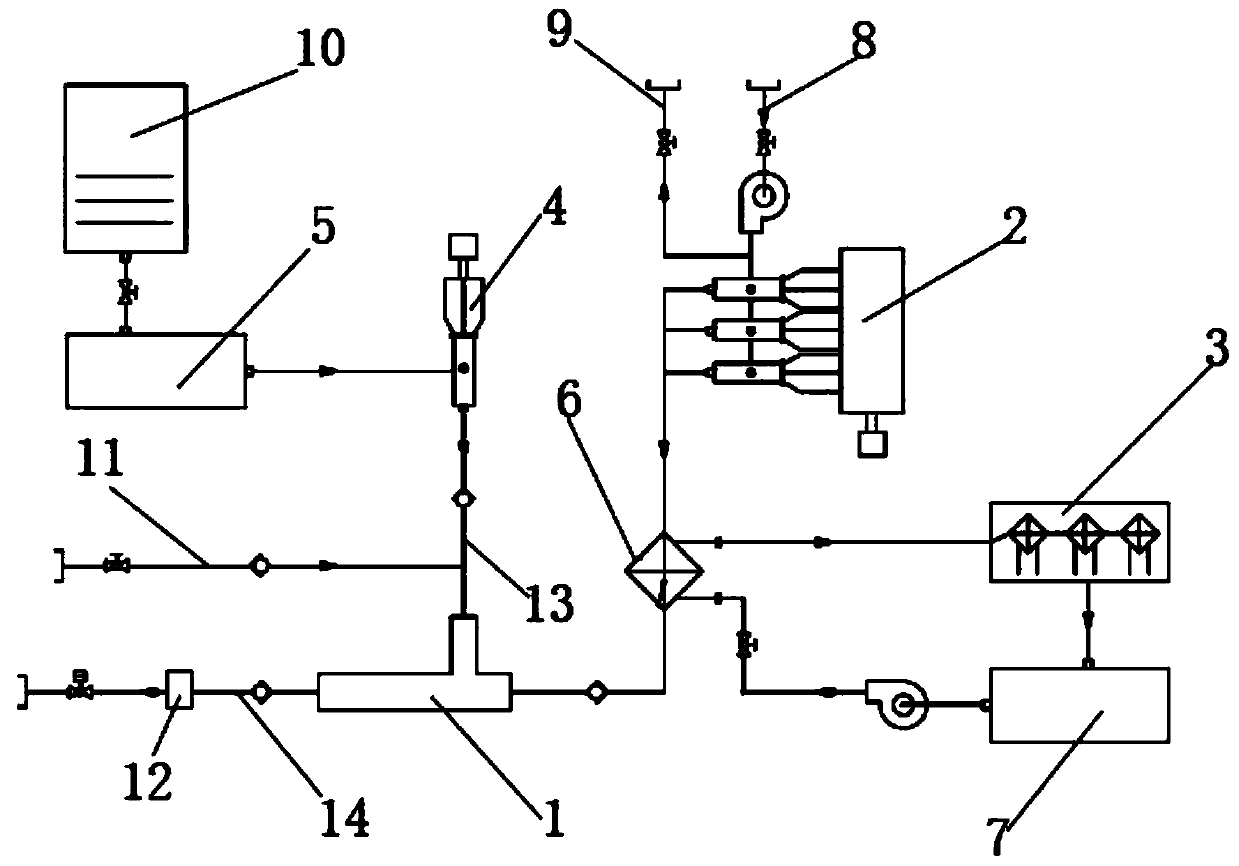

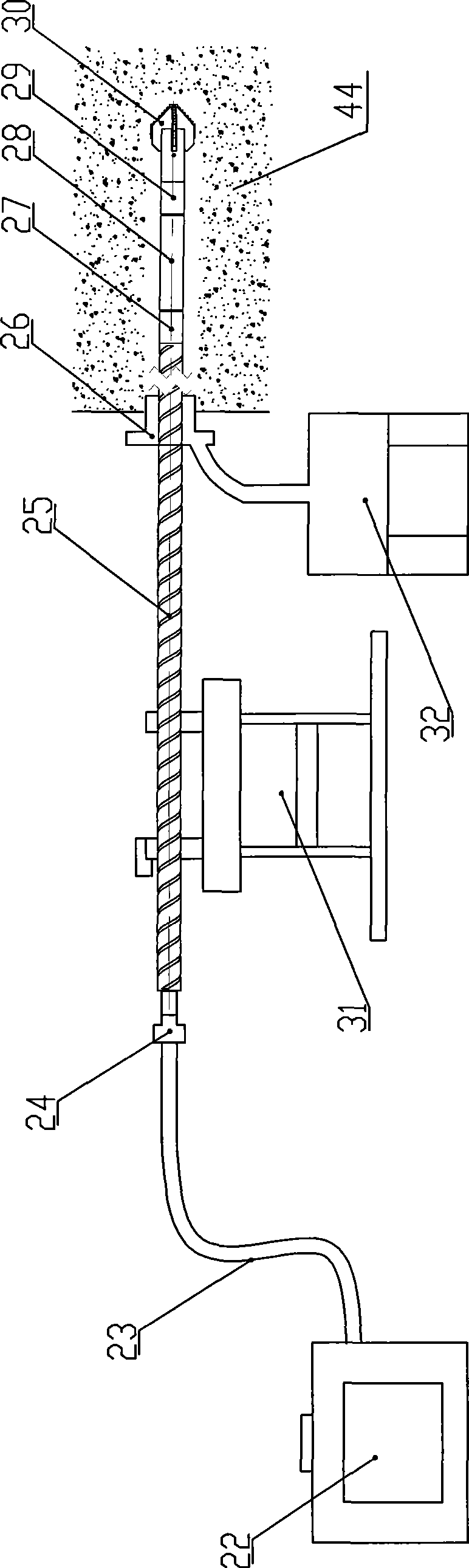

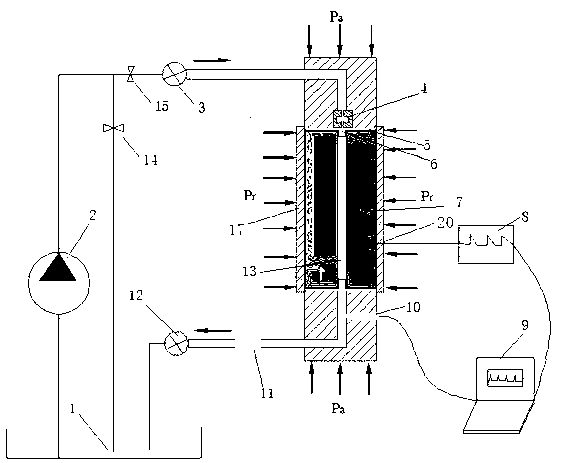

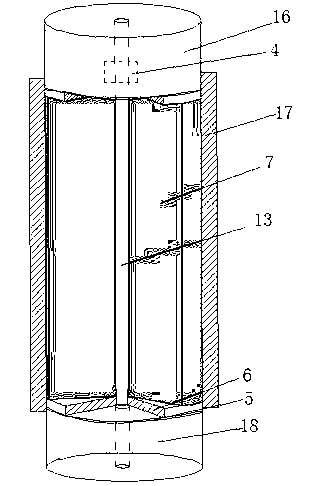

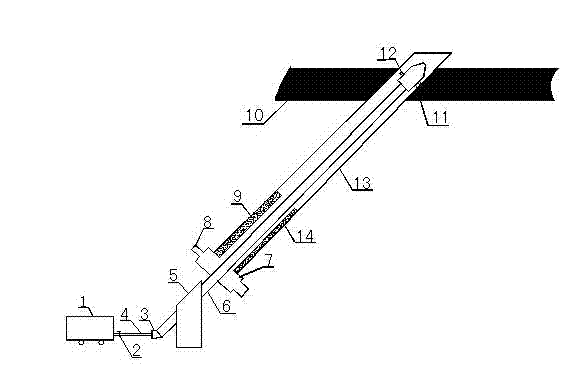

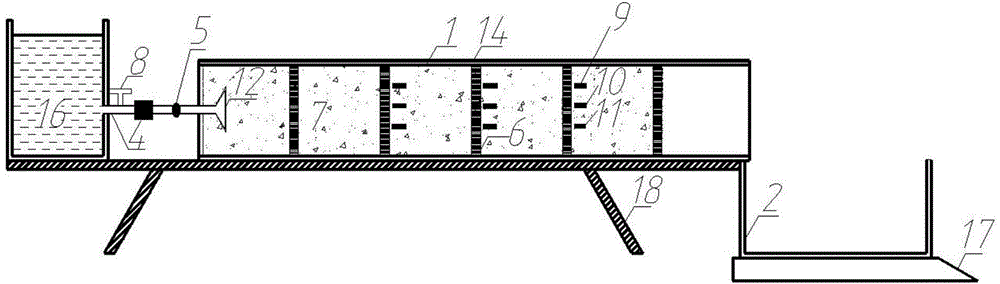

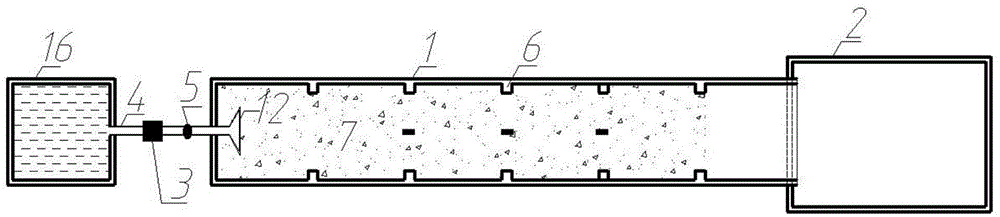

Oil-gas well hydraulically-created-fracture expansion visualization experiment method and oil-gas well hydraulically-created-fracture expansion visualization experiment device

ActiveCN103485759AFor the purpose of visualizationSurveyEarth material testingEpoxyHigh pressure water

The invention relates to an oil-gas well hydraulically-created-fracture expansion visualization experiment method and an oil-gas well hydraulically-created-fracture expansion visualization experiment device. The device is composed of a rock sample chamber, a crustal loading unit, a simulation fracturing string, a high-speed camera, a high-pressure pumping unit, a data measuring and collecting unit and the like, and four transparent observation ports are formed on a top cover of the rock sample chamber. The method includes firstly, preparing a flat-plate-type rock sample, performing high-pressure-water cutting to preform a natural fracture, and filling the natural fracture with epoxy resin to form a filled-type fracture; secondly, performing water saturation on the rock sample for 3-5 days, and using epoxy resin to wrap the rock sample after water saturation; thirdly, loading three-axis stress on the rock sample, drilling a borehole under the condition that the three-axis stress is applied on the rock sample, and mounting the simulation fracturing string; finally, connecting a high-pressure pipeline with a constant-flux pump, pumping fracturing liquid, recording a fracture expansion path by the high-speed camera, and measuring pumping pressure changes by a pressure transmitter. By the method and the device, the hydraulically-created-fracture expansion path can be visualized on a plane, and a novel experiment method is provided for studying on a hydraulically-created-fracture expansion mechanism.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

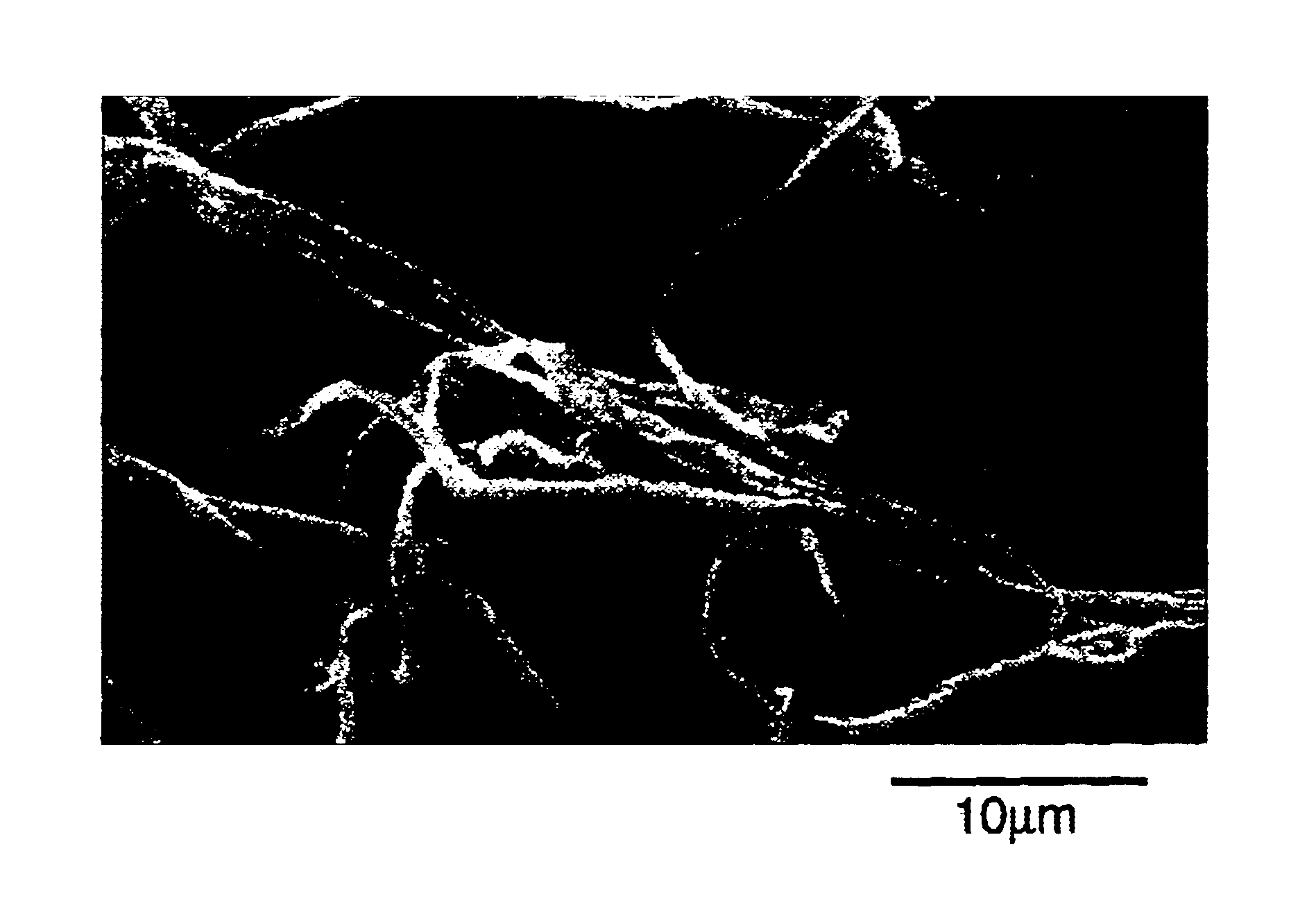

Aliphatic polyester microfibers, microfibrillated articles and use thereof

InactiveUS6890649B2Increase surface areaUseful applicationEngine sealsFilament/thread formingPolyesterParticulates

The present invention relates to aliphatic polyester microfibers, films having a microfibrillated surface, and methods of making the same. Microfibers of the invention can be prepared by imparting fluid energy, typically in the form of high-pressure water jets, to a highly oriented, highly crystalline, aliphatic polyester film to liberate microfibers therefrom. Microfibrillated films of the invention find use as tape backings, filters for particulate contaminants, such as face masks and water or air filters, fibrous mats, such as those used for removal of oil from water and those used as wipes, and thermal and acoustical insulation. Microfibers of the invention, when removed from the film matrix may be used in the preparation of woven or nonwoven articles and used as wipes for the removal of debris or dust from a surface. The microfibers and microfibrillated articles of the invention may be biodegradable, rendering them useful for geotextiles.

Owner:3M INNOVATIVE PROPERTIES CO

Device and method for preparing nitrogen foam cement

InactiveCN111206901ALow densityReduce energy consumptionSealing/packingHigh pressure waterNitrogen gas

The invention discloses a device and method for preparing nitrogen foam cement. The preparing device comprises a foam cement producer, a liquid nitrogen evaporator, a liquid nitrogen plunger pump, a foam liquid plunger pump, a foam liquid tank, a heat exchange system, a liquid nitrogen pipeline, a high-pressure cement paste pipeline, a first pipeline, a foam cement discharge pipeline and a densitydetecting device. The heat generated by a power unit, a hydraulic system and other devices in a nitrogen foam well fixing device is recovered through the heat exchange system, the recovered heat is used as a heat source of the liquid nitrogen evaporator, energy conservation and environment protection are realized, the energy utilization rate is high, and equipment input is low. Liquid nitrogen and foam liquid are pressurized through a high-pressure liquid nitrogen plunger pump and a high-pressure foam liquid plunger pump, the mixing uniformity is increased, and the density of foam cement is reduced. The density of the foam cement is detected in real time through the density detecting device, the flow of the liquid nitrogen and / or foam liquid is adjusted according to the density, and the density is simply controlled. By arranging a clear water tank, after operation ends, the equipment and pipelines are flushed, and the service life is polonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

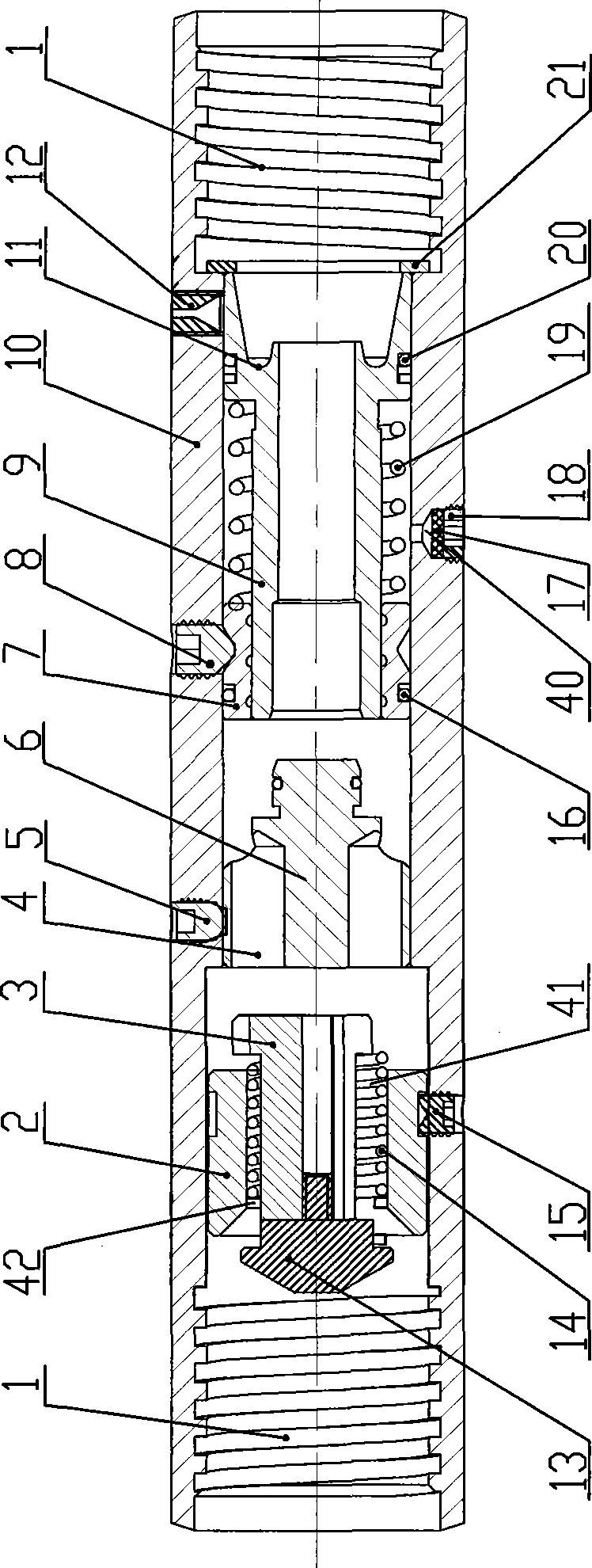

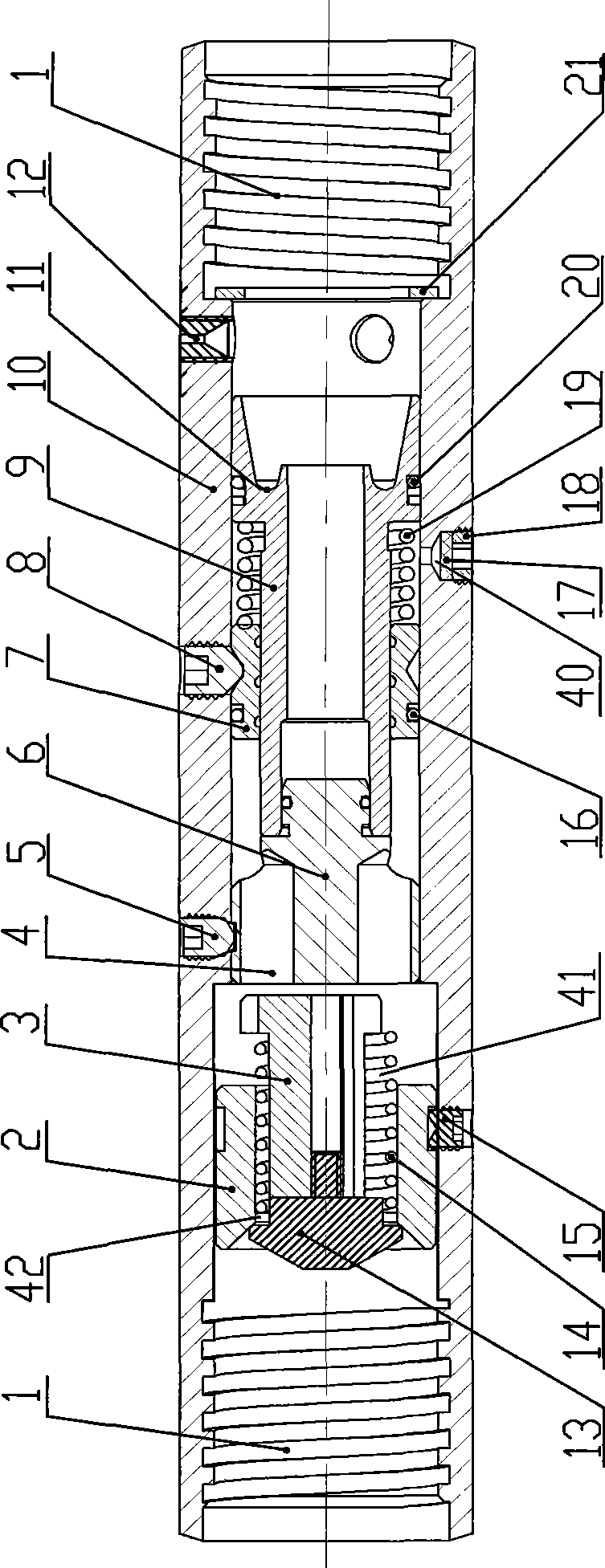

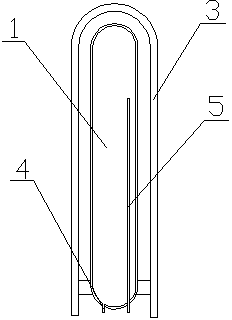

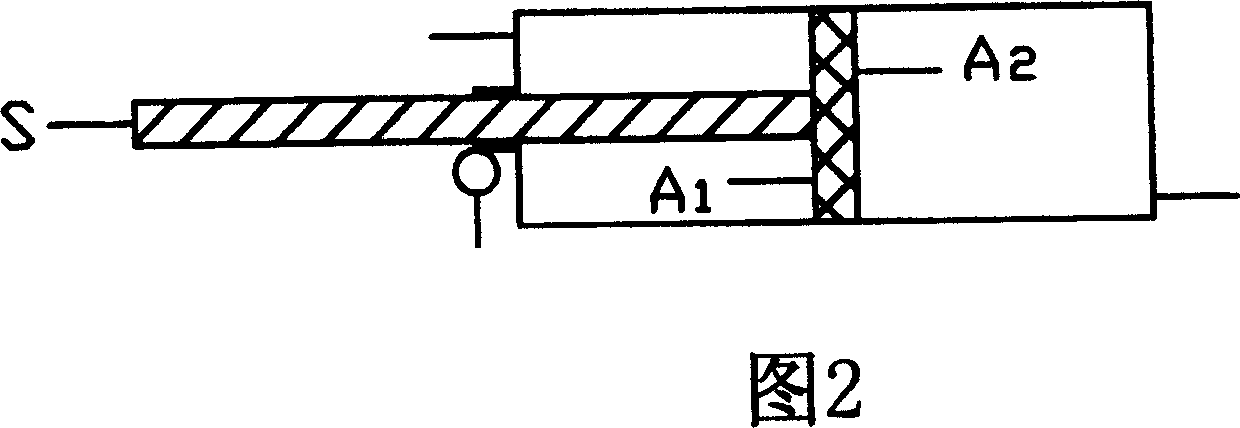

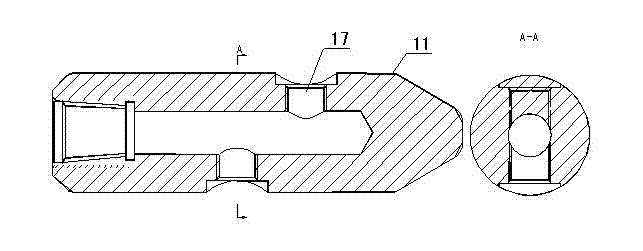

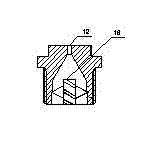

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

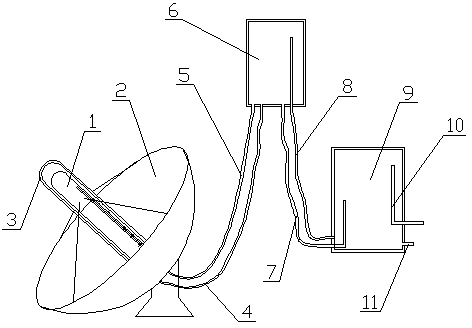

Solar energy storage and utilization device

InactiveCN104165347AAvoid lossImprove utilization efficiencySolar heating energySteam generation heating methodsWater storage tankHigh pressure water

A solar energy storage and utilization device comprises a metal inner container, a collecting lens, an energy storage tank and a water storage tank. A transparent vacuum tube is arranged outside the metal inner container; the bottom of the water storage tank and the bottom of the metal inner container are communicated through a water pipe I, the upper portion in the metal inner container and the bottom of the water storage tank are connected through a steam pipe I, and an exhaust pipe and a water supplementing pipe are arranged on the energy storage tank. According to the solar energy storage and utilization device, the transparent vacuum tube layer is arranged outside the metal inner container, received solar energy is stopped from being lost and thus the utilization rate of solar energy is substantially increased; meanwhile, the water storage tank and the energy storage tank are arranged so that solar energy received in good weather is stored in the energy storage tank in the form of high temperature and high pressure water and utilized in bad weather, the situation that an existing solar energy utilization device depends a lot on weather conditions is eliminated, and the application range of the solar energy utilization device is widened.

Owner:深圳市新浩建筑装饰工程有限公司

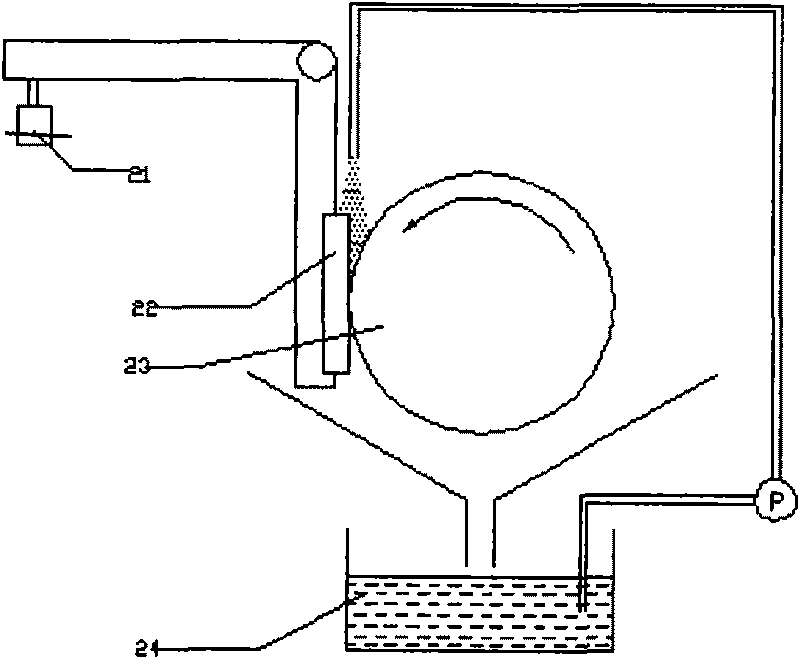

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254AChange mechanical propertiesImprove breathabilityFluid removalGas removalPulse pressureDischarge rate

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Fluid loss reducer for high temperature and high pressure water-based mud application

ActiveUS7101829B2Improve high temperature stabilityImprove shear resistanceOther chemical processesMixing methodsPolymer dissolutionWater based

The present invention concerns a water-based drilling mud for utilization in the drilling of oil wells comprising an aqueous phase wherein the aqueous phase contains an oil soluble polymer in the form of a gel as fluid loss reducer. The subject invention further reveals a process for preparing an oil soluble polymer fluid loss control agent comprising the steps of dissolving at least one polymer in a hydrocarbon oil to form a clear solution or a gel, adding an emulsifier to the solution or the gel, and keeping the mixture under conditions of agitation until a clear creamy mixture is obtained.

Owner:ELIOKEM

Experimental device and method for pulse hydrofracture transforming of shale gas storing layer

ActiveCN103196762AMonitor developments in real timeGenerating type of real-time monitoringSurface/boundary effectMaterial strength using repeated/pulsating forcesImpulse frequencyFracturing fluid

The invention relates to an experimental device and method for pulse hydrofracture transforming of a shale gas storing layer. The experimental device comprises a high pressure water pump, a fracturing fluid pond, a filtering device, a waterpower pulse generating device, a triaxial stress loading device, a pressure sensor, a sound emission device, a throttle valve, an overflow valve, a data collection recording system and a core test specimen. The device provided by the invention can simulate the operating environment of a shale sample under main operating parameter such as different pulse pressures and impulse frequencies on a certain confining pressure condition; moreover, the device can monitor a space-time developing rule of cracks and can test permeability change before and after fracture in real time; therefore, an experimental platform is provided for researching pulse hydrofracture of a shale gas storing layer. The experimental device provided by the invention has strong practicality, is easy to assemble, convenient to operate, is compact in structure, and can better imitate fracture damage and permeability change mechanism of a shale sample of the shale gas storing layer under the actions of static pressure and pulse hydrofracture.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

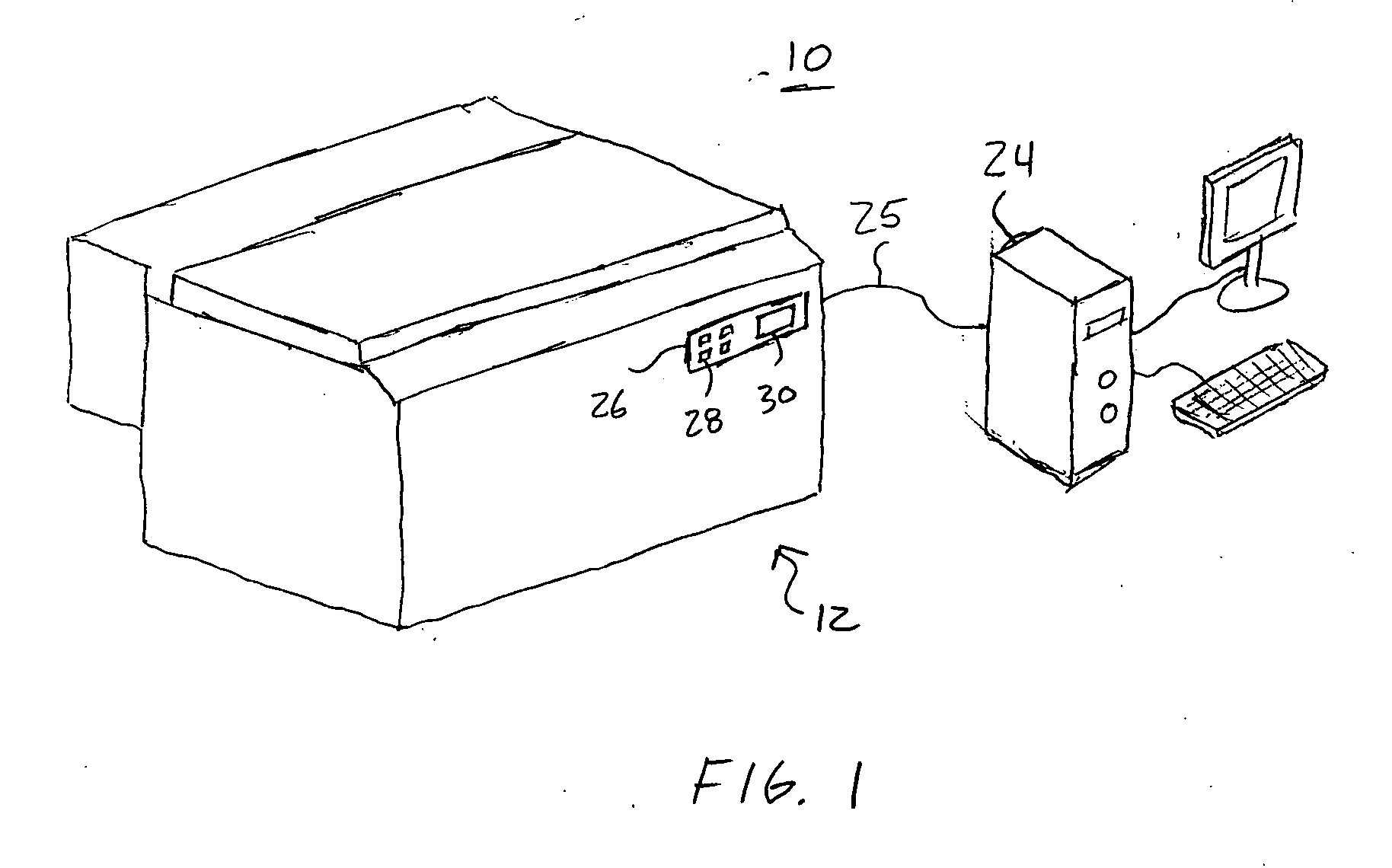

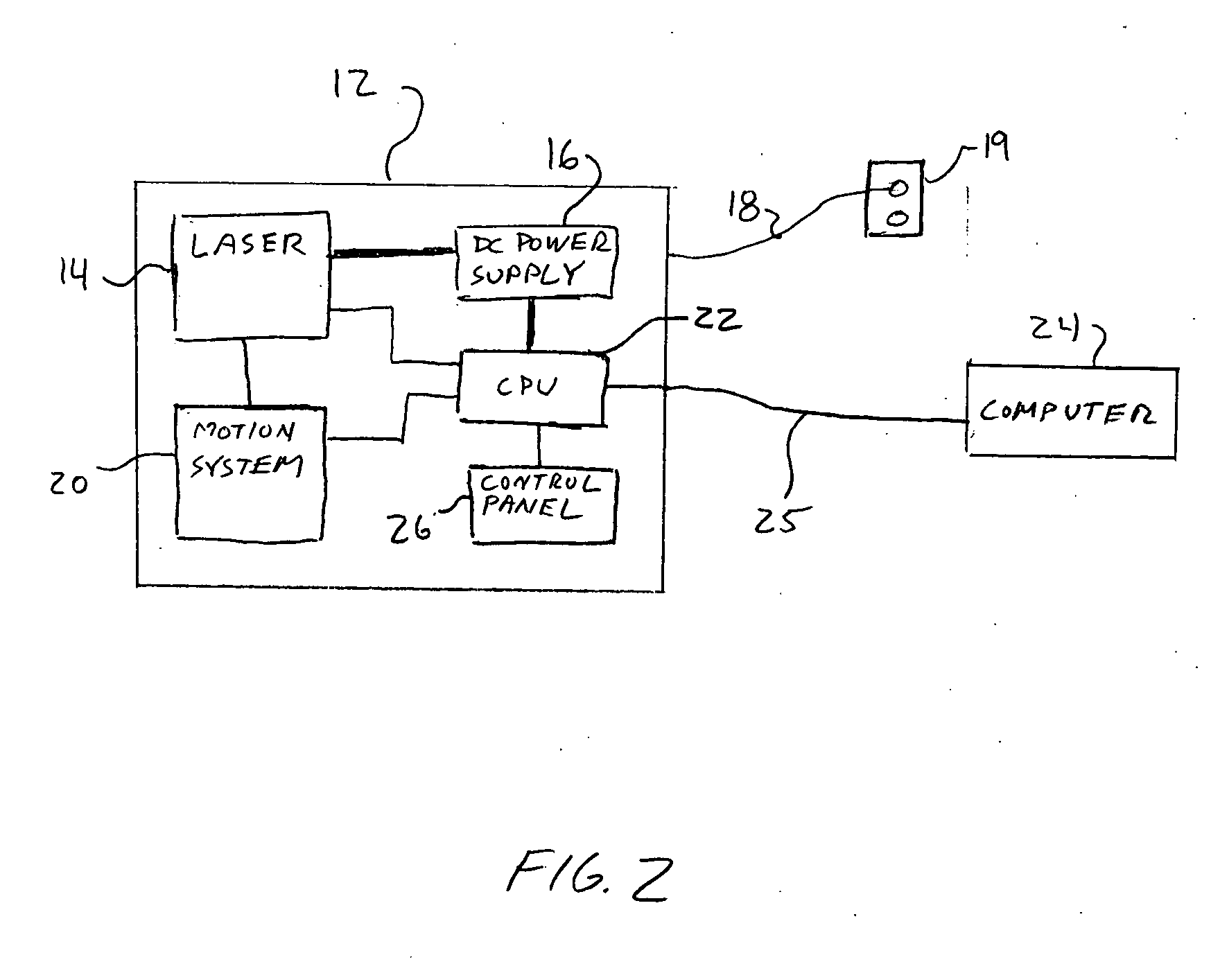

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

Method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing, and permeability increasing

InactiveCN101644166AImprove flow statusEasy to extractUnderground miningSurface miningHigh pressure waterHigh pressure

The invention discloses a method for extracting gas from high gas low permeability coal seam by punching, slotting, pressure releasing and permeability increasing, comprising the following steps: whena drill is drilled into a predetermined position of the coal seam, coal bodies at both sides of a drill hole are cut in the drill hole by high pressure water jet with a certain pressure and flow; a flat slot is formed at both sides of the drill hole; the cut coal bodies is led out the hole by the high pressure water jet. The exposed area of the coal body at the slotted part in the drill hole aregreatly increased, namely that an extremely thin protective layer is exploited with local scope of the flat slot, which enlarges effective influential range of pressure releasing, permeability increasing and gas discharging of the coal bodies in the drill hole, thus the air permeability of the coal bodies is increased about 200-300 times, the average amount of single-hole gas extraction reaches 0.3m<3> / min, the concentration of the gas extraction is 30-60%, gas drainage rate of working face of coal extraction is more than 50%, the number of drill holes for gas drainage is reduced by 10-20% after slotting, pressure releasing and permeability increasing. The method realizes the safety, high efficiency and uniform extraction of the gas from the high gas low permeability outburst coal seam, and changes high gas coal seam with outburst danger into low gas coal seam without outburst danger.

Owner:CHINA UNIV OF MINING & TECH

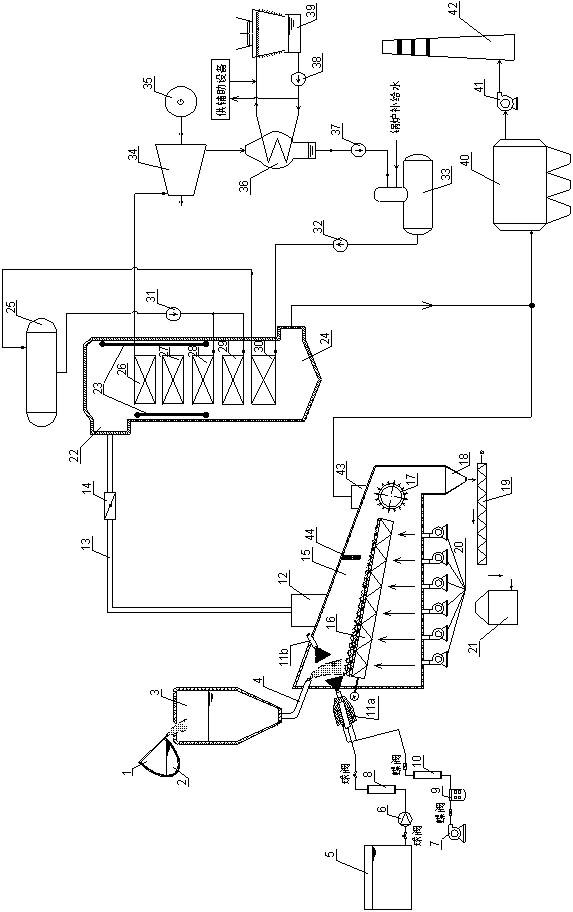

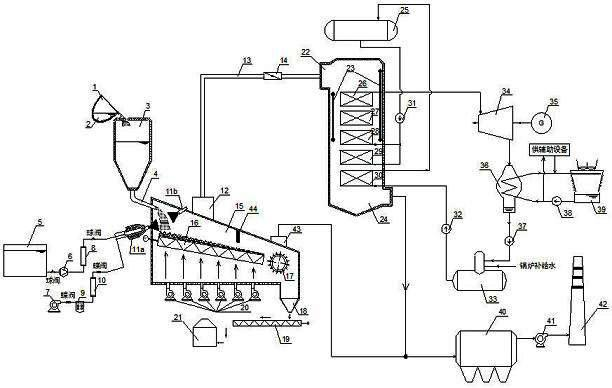

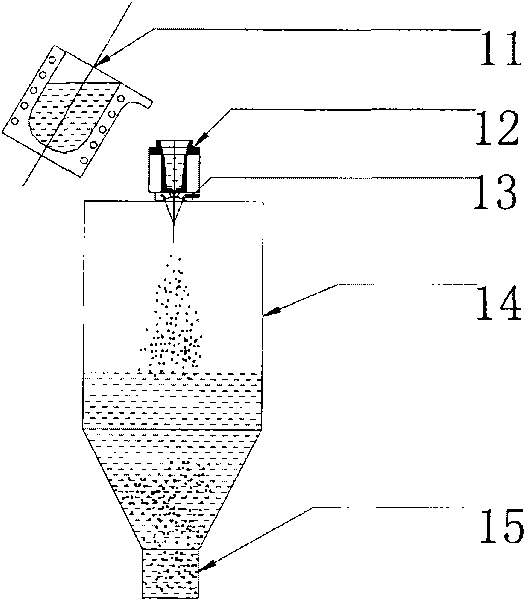

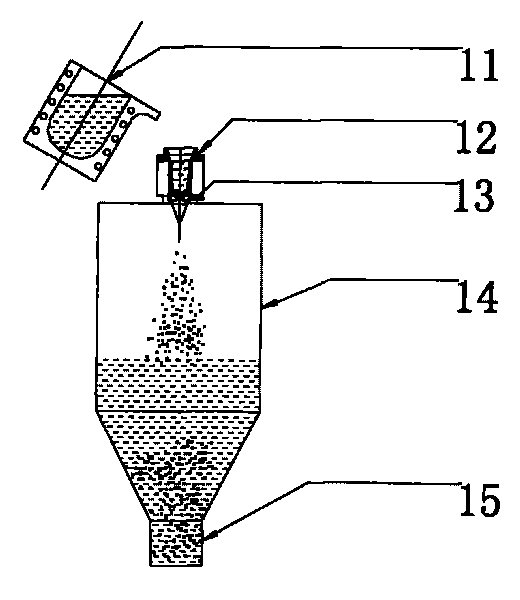

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

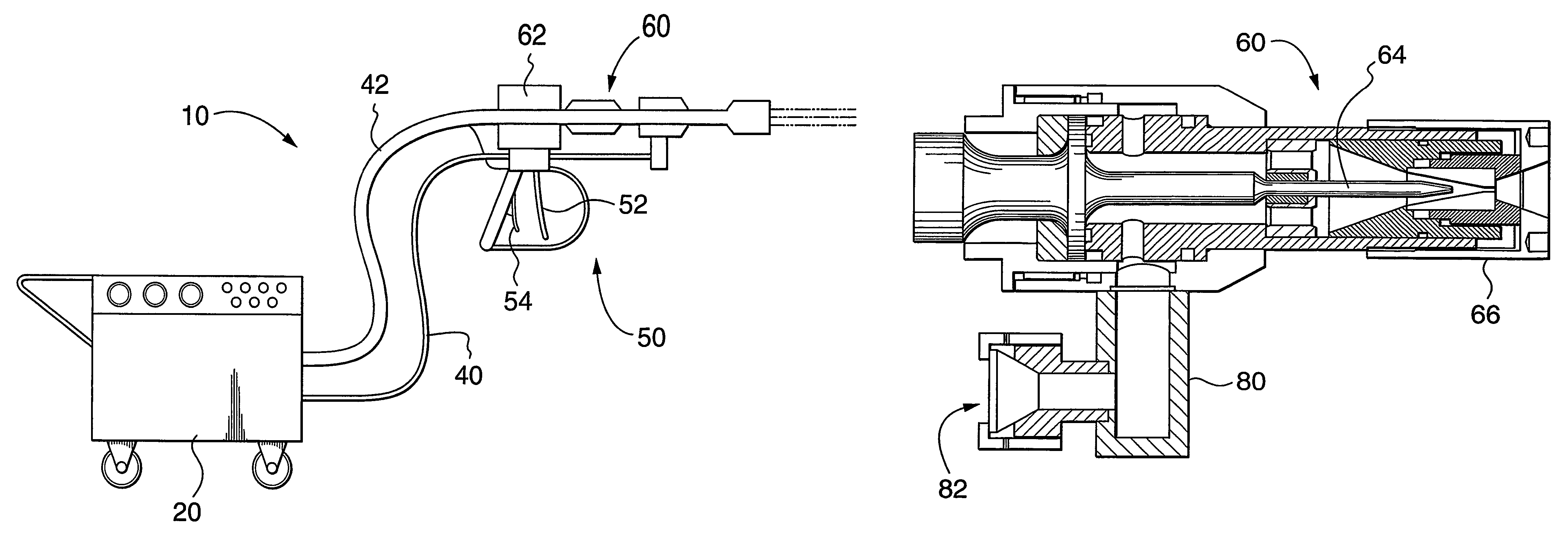

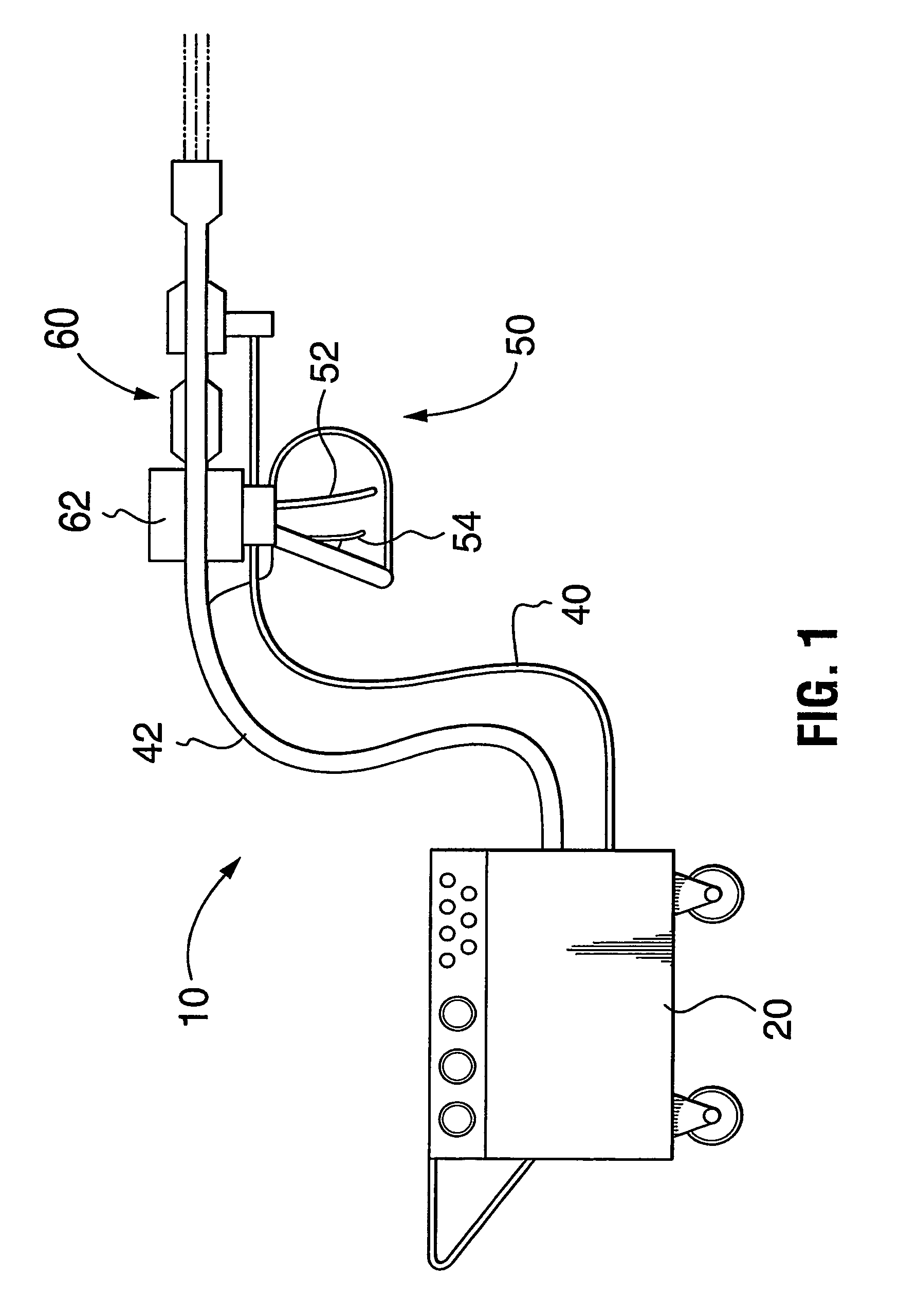

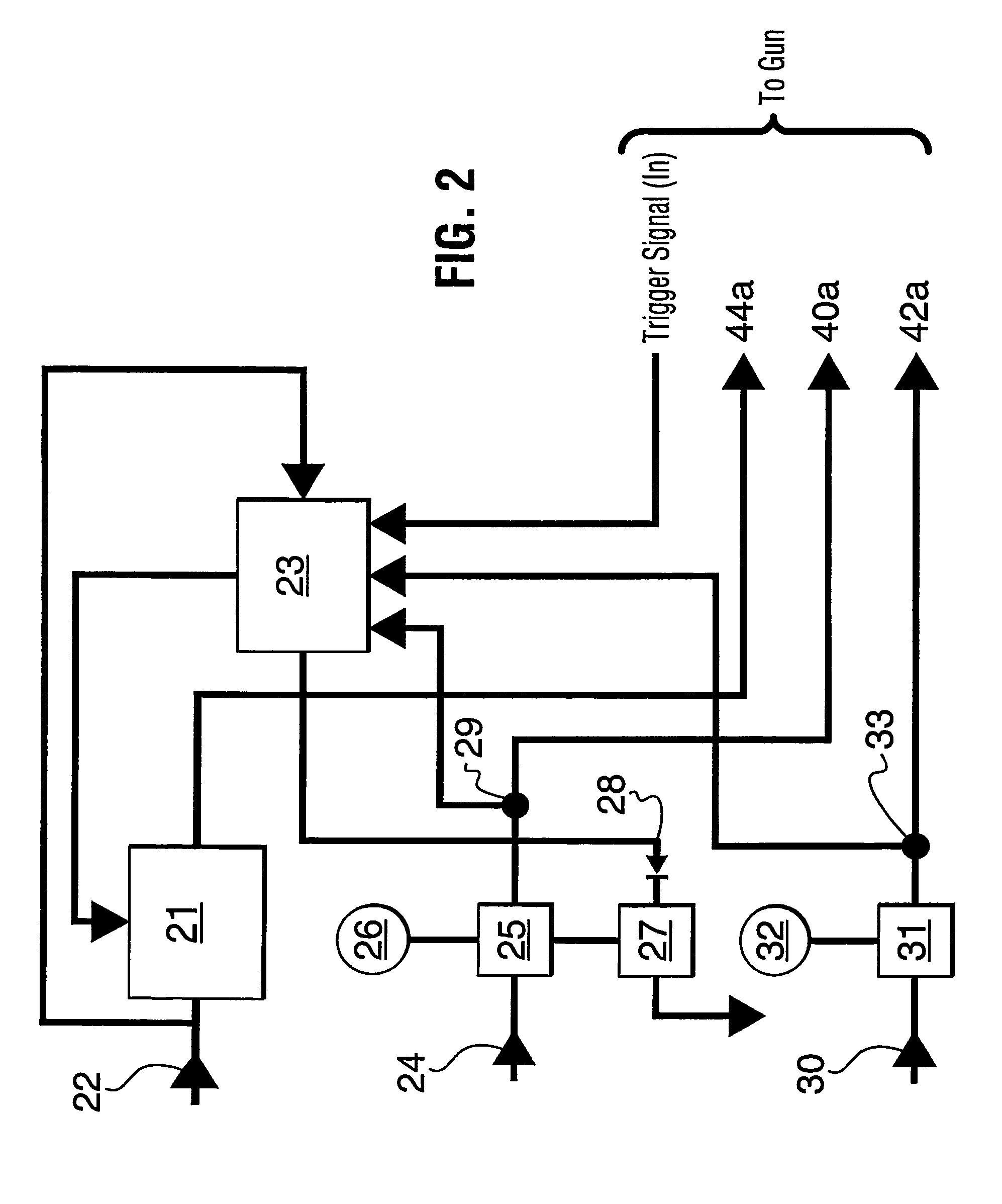

Ultrasonic waterjet apparatus

ActiveUS7594614B2Reduce cleaningReduce pressureLiquid surface applicatorsPiezoelectric/electrostriction/magnetostriction machinesSonic nozzleUltrasonic nozzle

An ultrasonic waterjet apparatus (10) has a mobile generator module (20) and a high-pressure water hose (40) for delivering high-pressure water from the mobile generator module (20) to a hand-held gun (50) with a trigger and an ultrasonic nozzle (60). An ultrasonic generator in the mobile generator module (20) transmits high-frequency electrical pulses to a piezoelectric or magnetostrictive transducer (62) which vibrates to modulate a high-pressure waterjet flowing through the nozzle (60). The waterjet exiting the ultrasonic nozzle (60) is pulsed into mini slugs of water, each of which imparts a waterhammer pressure on a target surface. The ultrasonic waterjet apparatus (10) may be used to cut and de-burr materials, to clean and de-coat surfaces, and to break rocks. The ultrasonic waterjet apparatus (10) performs these tasks with much greater efficiency than conventional continuous-flow waterjet systems because of the repetitive waterhammer effect. A nozzle with multiple exit orifices or a rotating nozzle (76) may be provided in lieu of a nozzle with a single exit orifice to render cleaning and de-coating large surfaces more efficient. A water dump valve (27) and controlling solenoid are located in the mobile generator module (20) rather than the gun (50) to make the gun lighter and more ergonomic.

Owner:PRATT & WHITNEY MILLTARY AFTERMARKET SERVICES

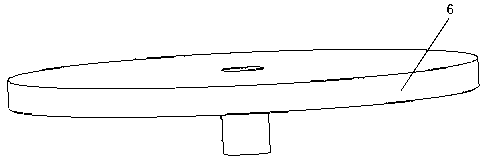

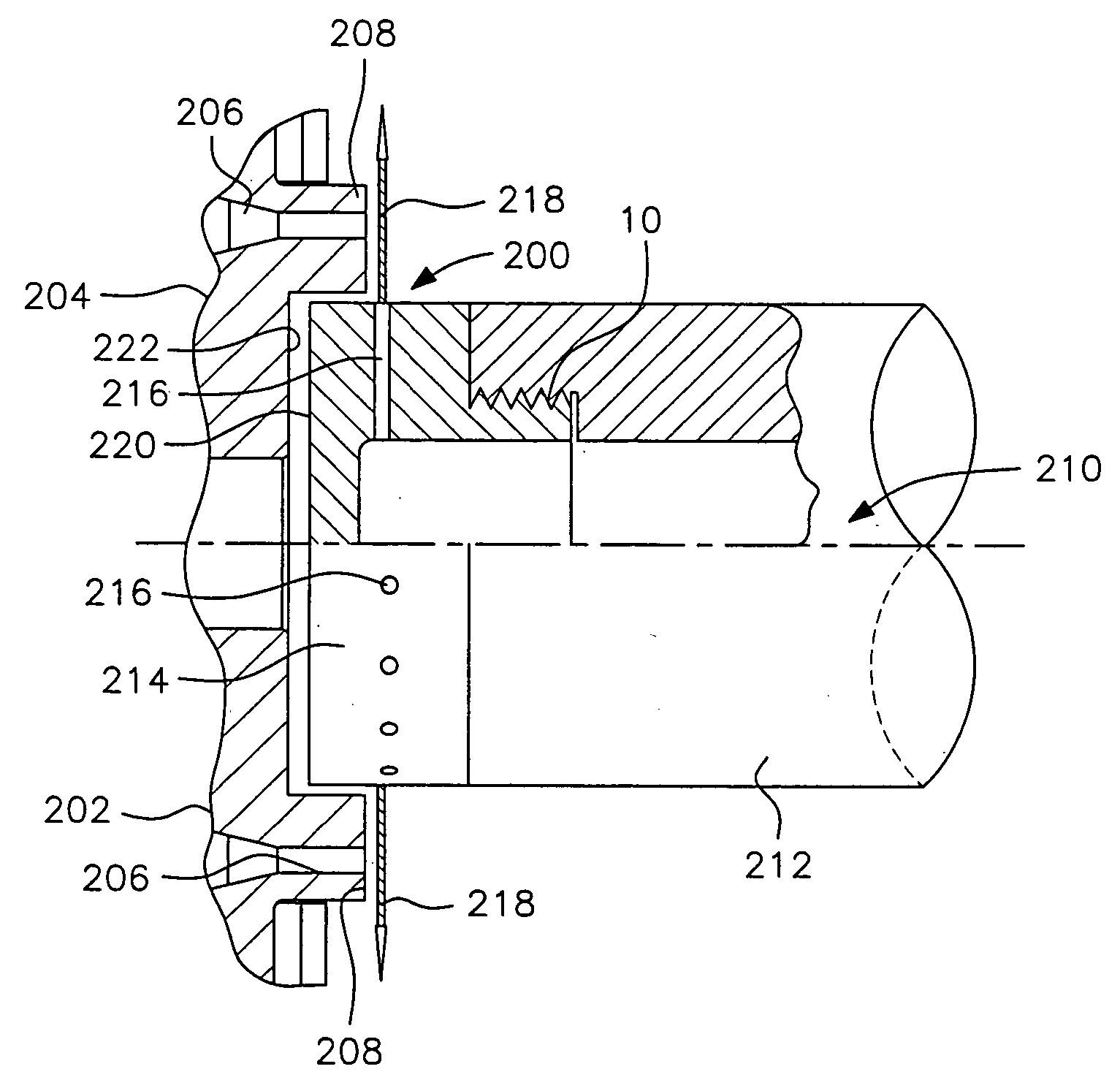

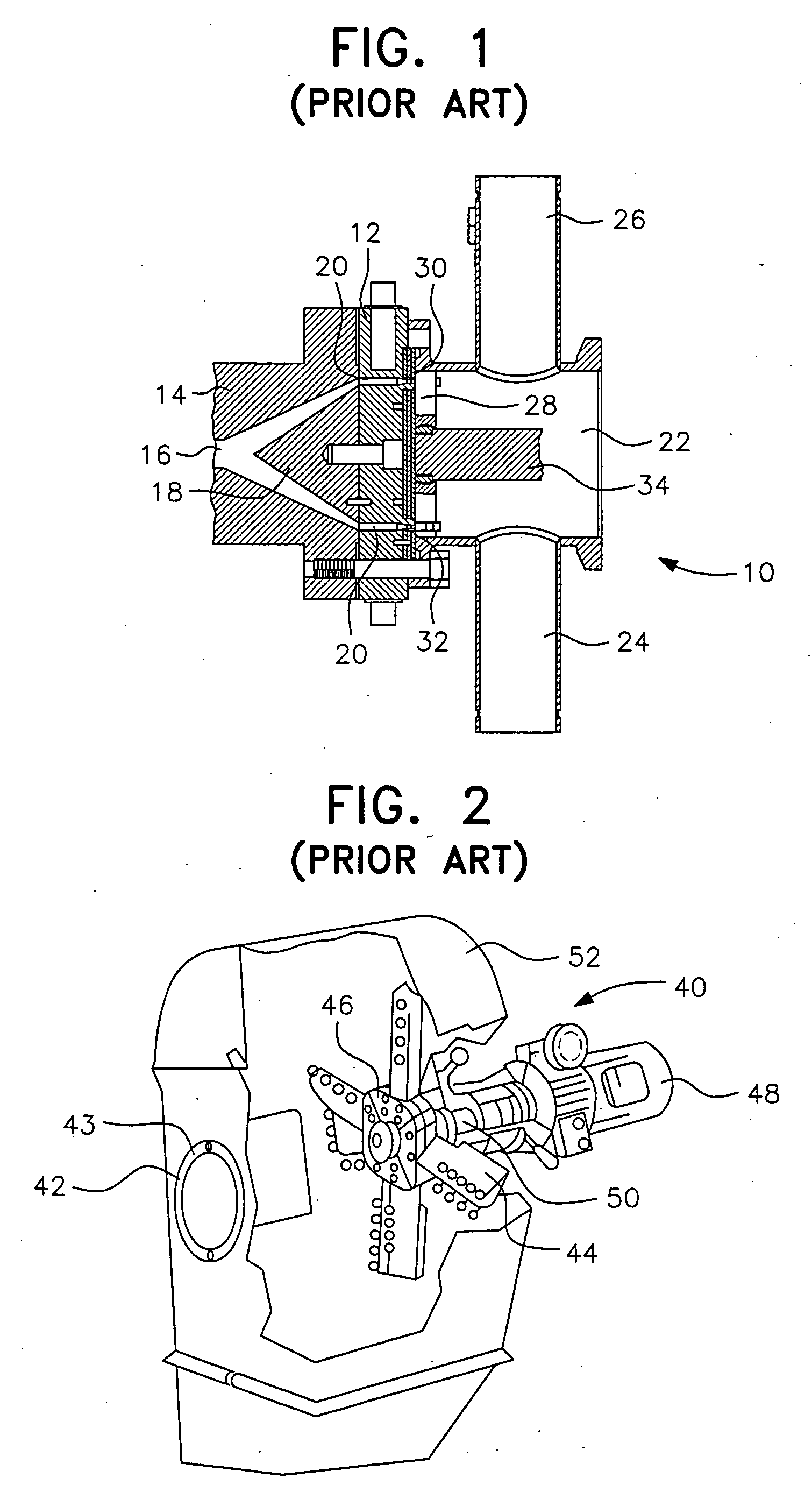

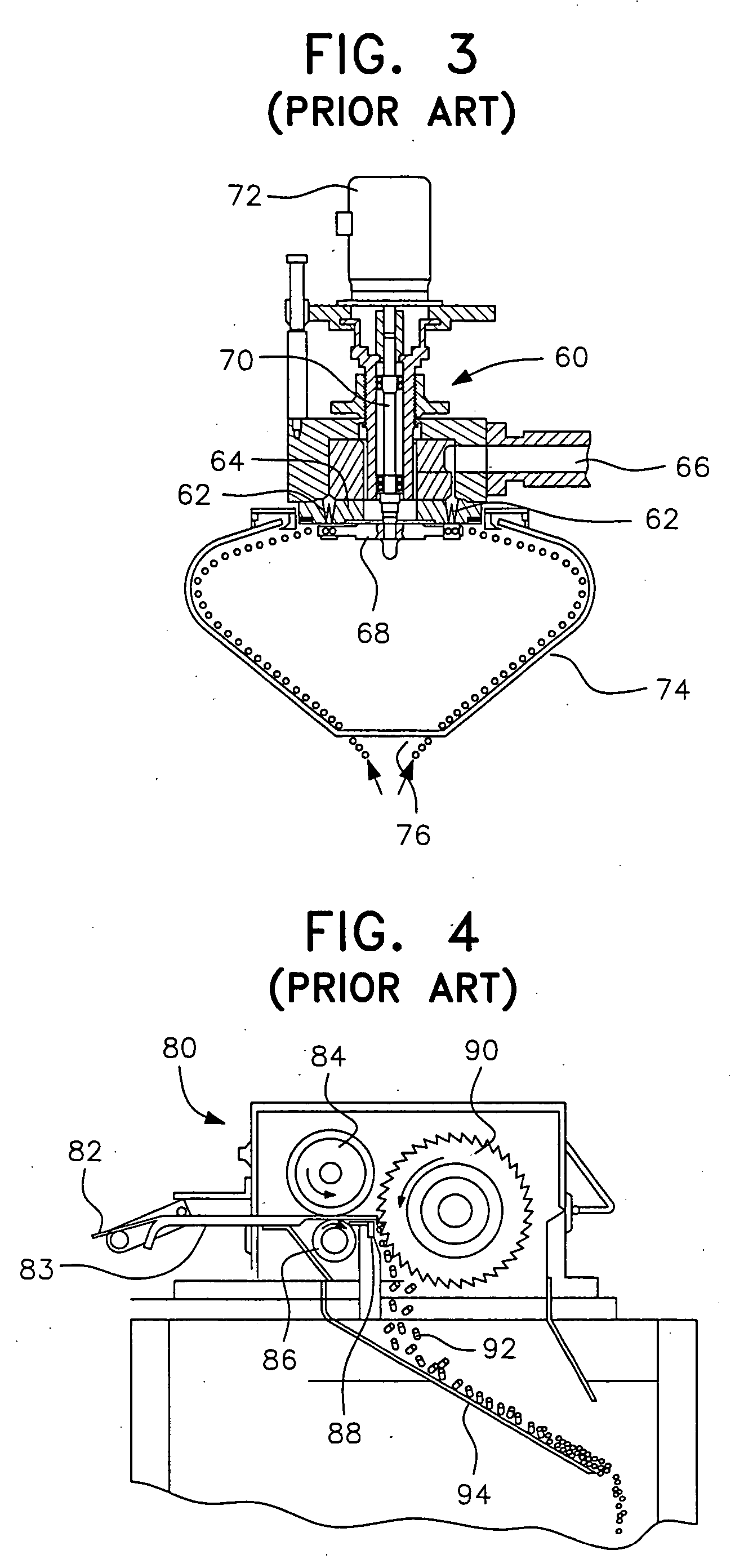

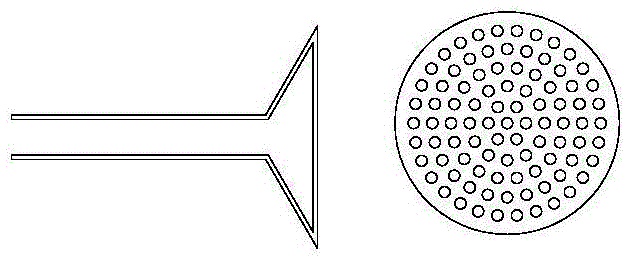

High pressure liquid jet cutting system and method for forming polymer pellets

InactiveUS20050077644A1Without unnecessary down timeContinuous operationMouldsConfectioneryWater basedLiquid jet

A system and method for pelletizing extruded materials, such as thermoplastic polymers in various pelletizing applications, including underwater, hot face, and strand pelletizing applications, utilizes a high pressure liquid delivered to one or more nozzles which direct a high pressure liquid jet cutting stream at the extruded polymer strand to cut the strand into pellets. The system and method are particularly applicable to underwater pelletizers utilizing water or water-based solutions. In a preferred underwater pelletizing embodiment, a plurality of nozzles are mounted on a rotating nozzle hub which is fed high pressure water through sealed hollow pelletizer and hollow motor shafts. The high pressure water jet cutting streams exiting the rotating nozzles are preferably in the form of a flat V-shaped spray with a spread angle of about 15° to about 45° and an approach angle between 0° and 60°, depending upon the pelletizing application.

Owner:GALA INDUSTRIES INC

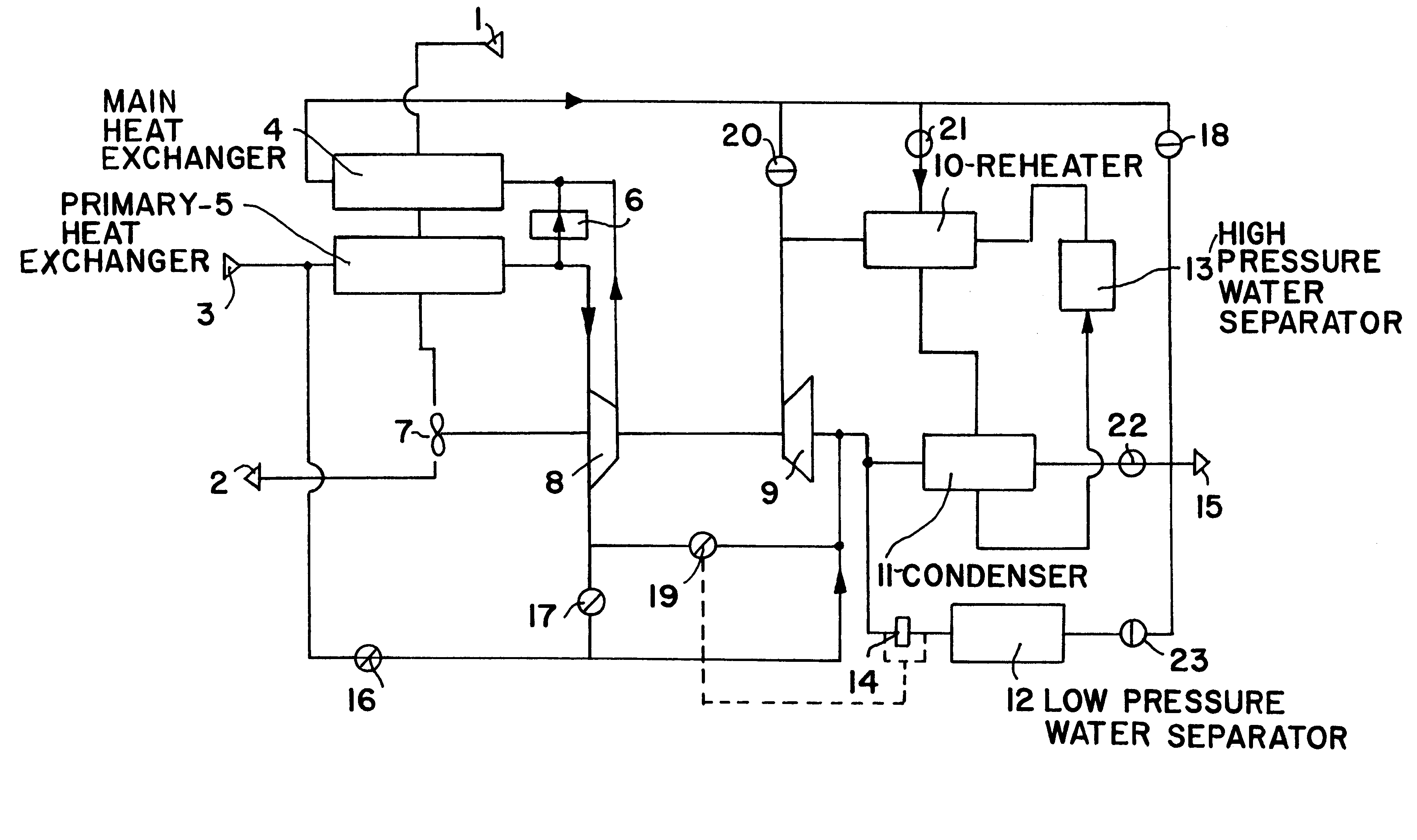

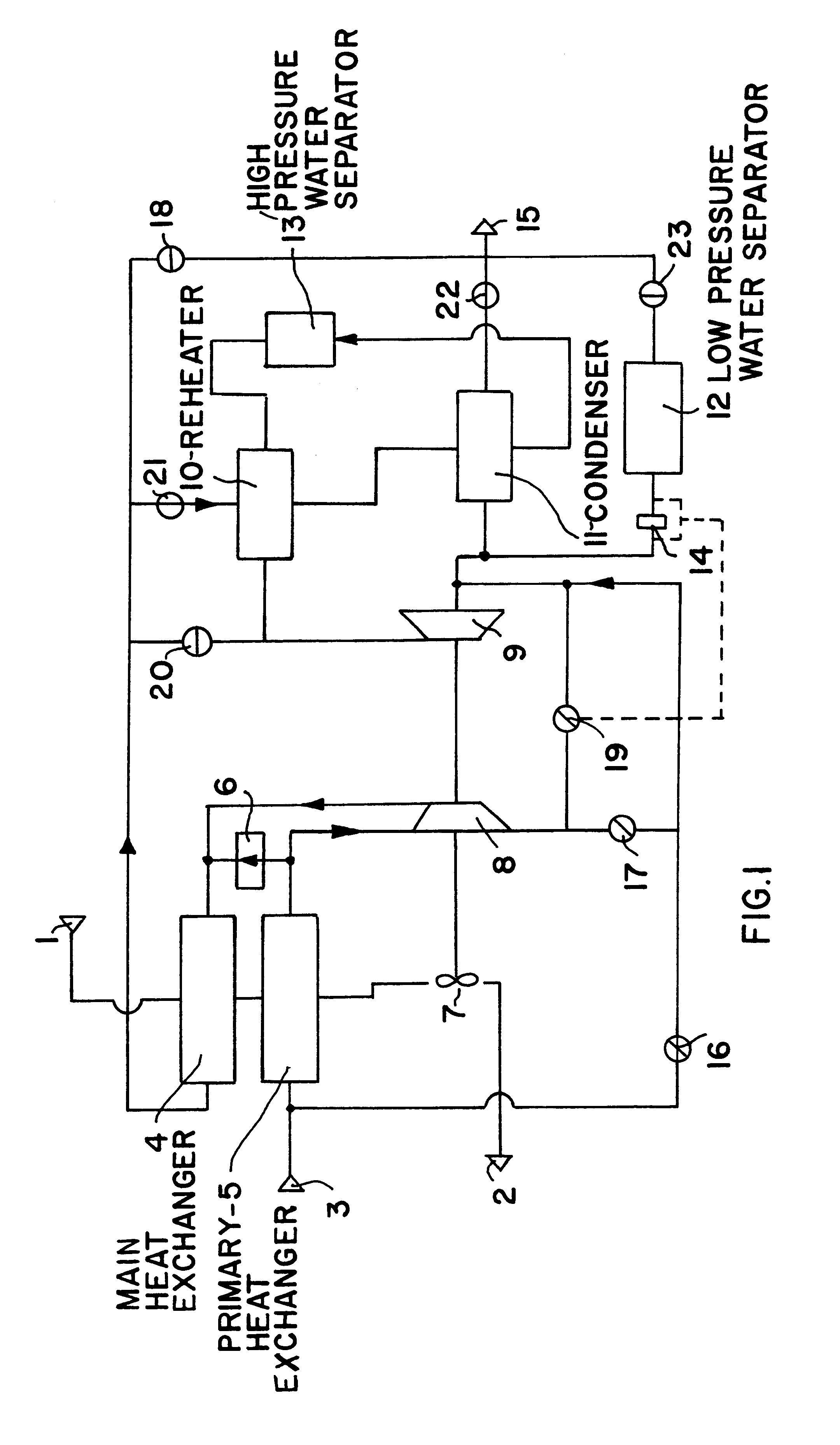

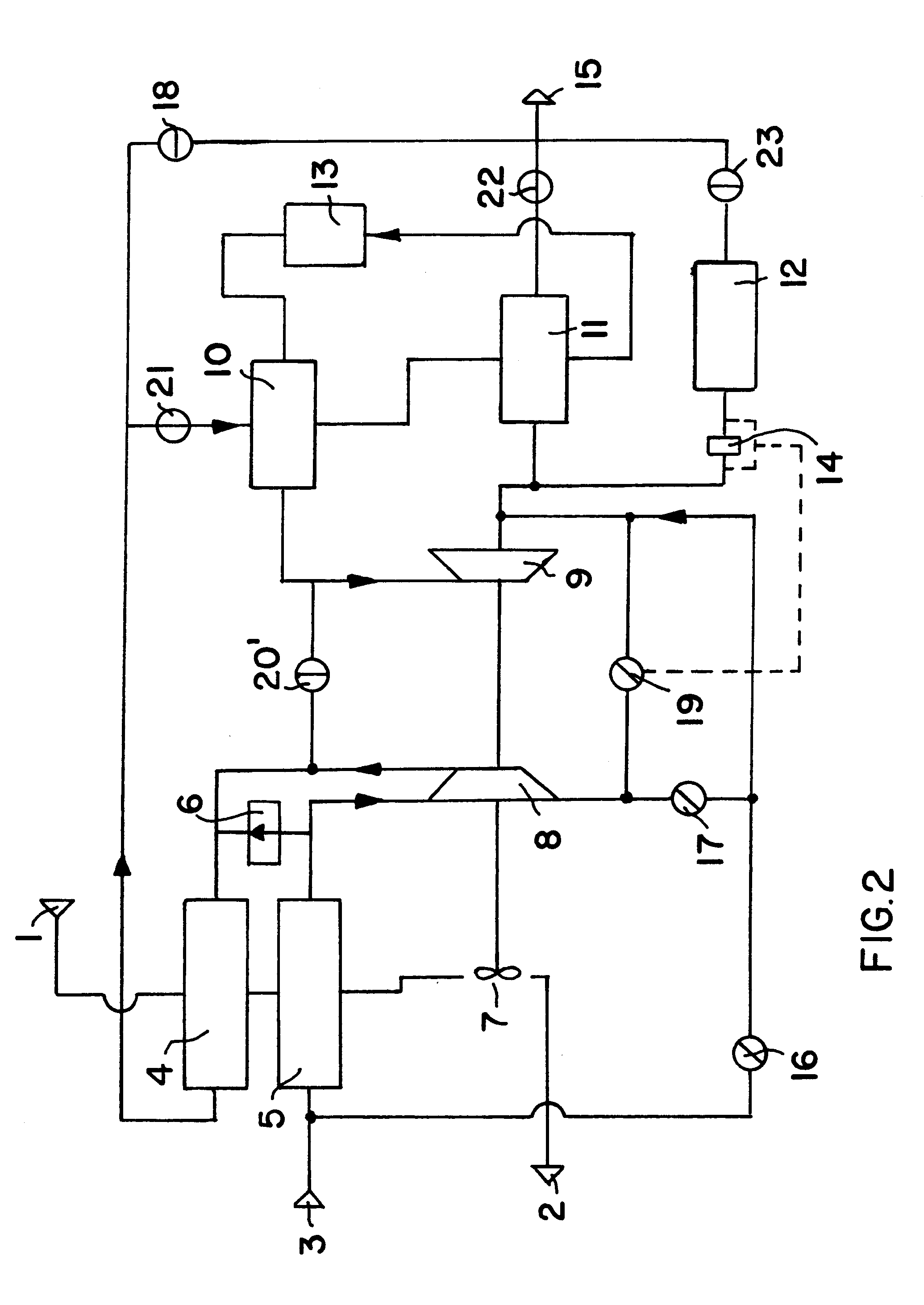

Aircraft air-conditioning apparatus with water separators

InactiveUS6295822B1Efficiently usMinimize the numberDomestic cooling apparatusAir-treatment apparatus arrangementsNacelleFlight vehicle

A system for air-conditioning the cabin of a passenger aircraft using externally provided fresh air as well as bleed air tapped from the engine of the aircraft includes at least one heat exchanger (4, 5), a blower (7), a compressor (8), an expansion turbine (9), a condenser (11), a reheater (10), a first high pressure water separator (13), and a second low pressure water separator (12). The several components are connected to each other by air lines such as air ducts, with control valves interposed therein. Two separate air-flow paths representing two different sub-systems are formed. A first air-flow path uses the high pressure water separator while a second air-flow path uses the low pressure water separator. These two air-flow paths or sub-systems can be operated separately and independently of each other by appropriately switching respective shut-off valves. In this manner, the operation of the air-conditioning system can be adaptively switched to achieve an optimal operation under different operating conditions of the aircraft and different air-conditioning requirements.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

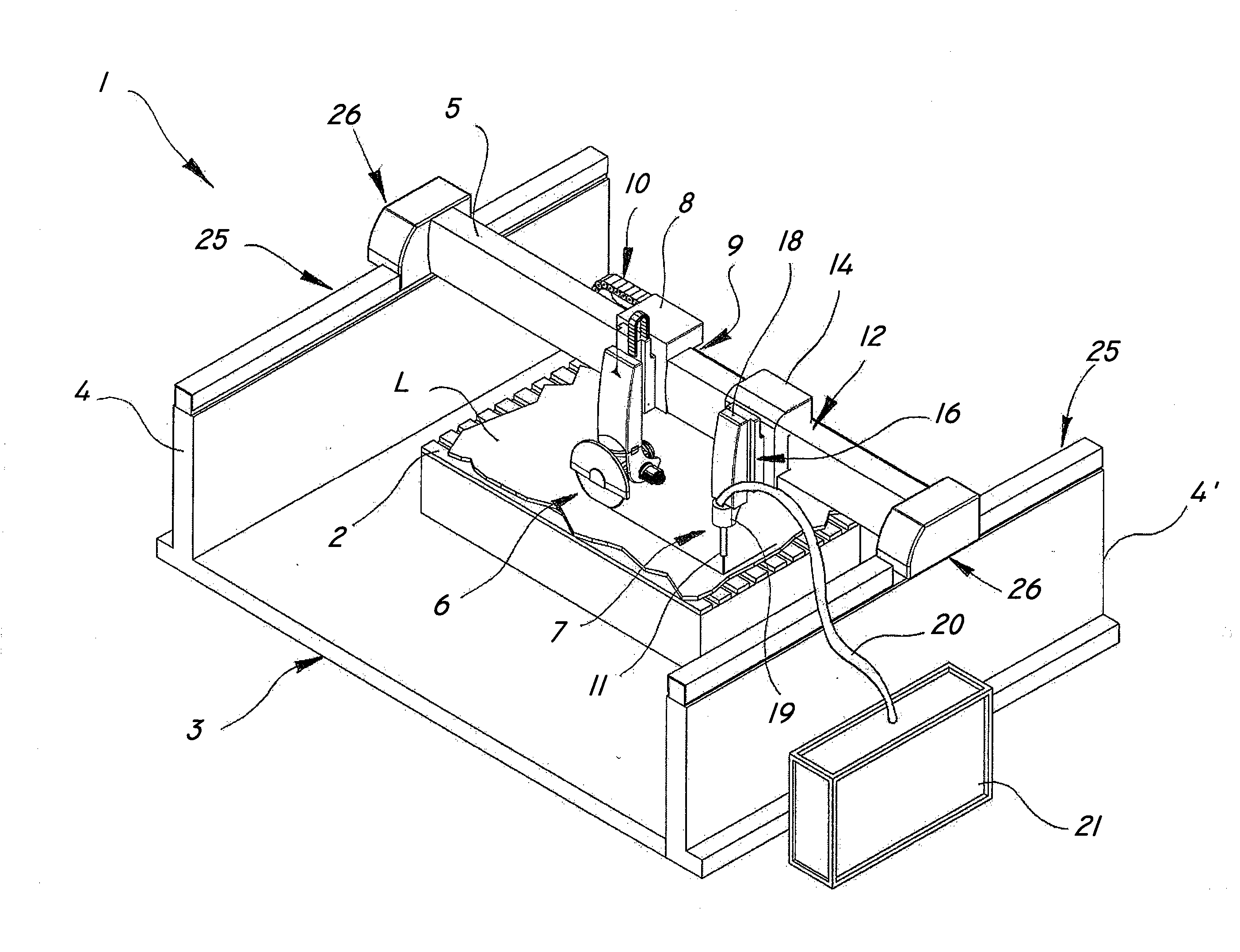

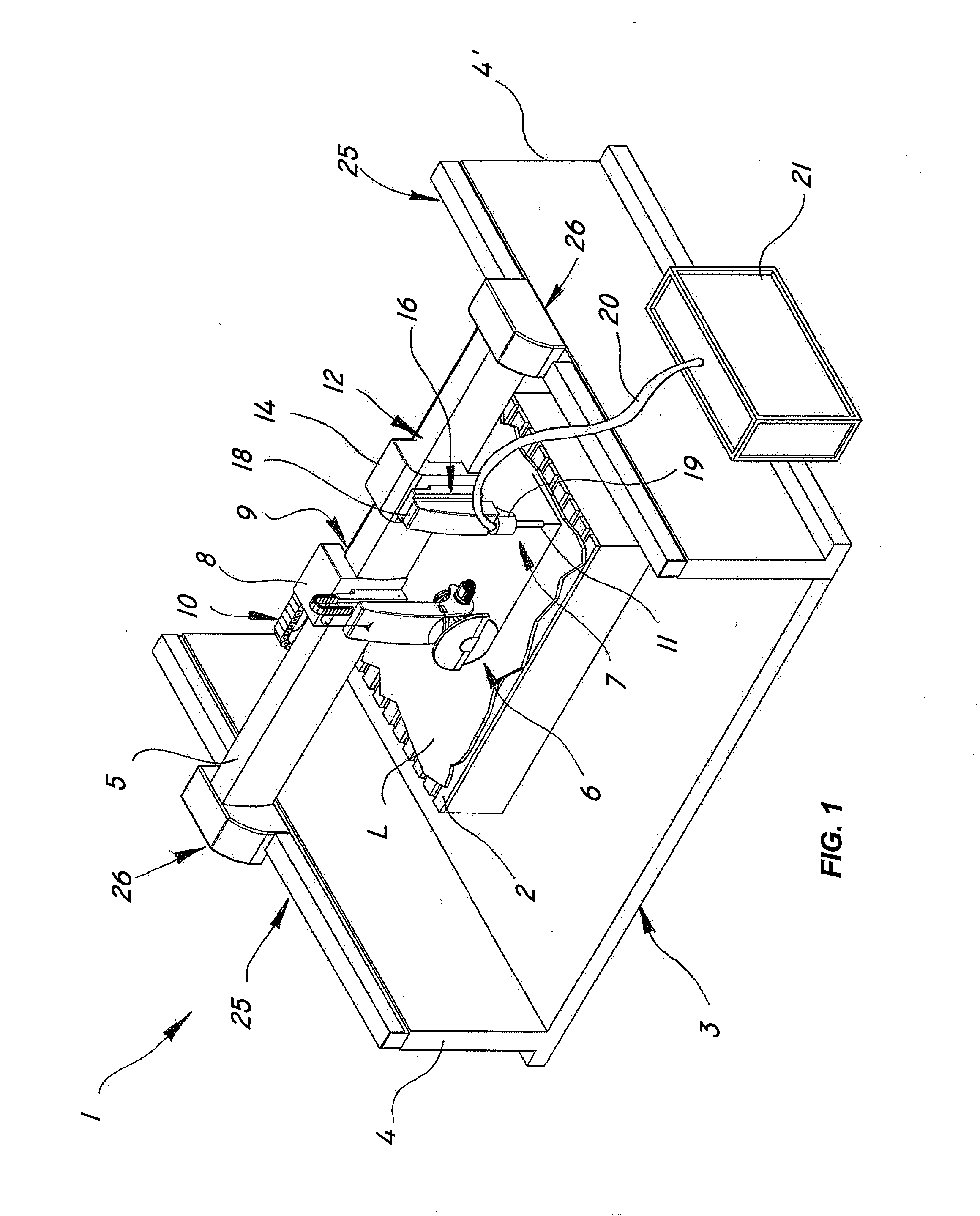

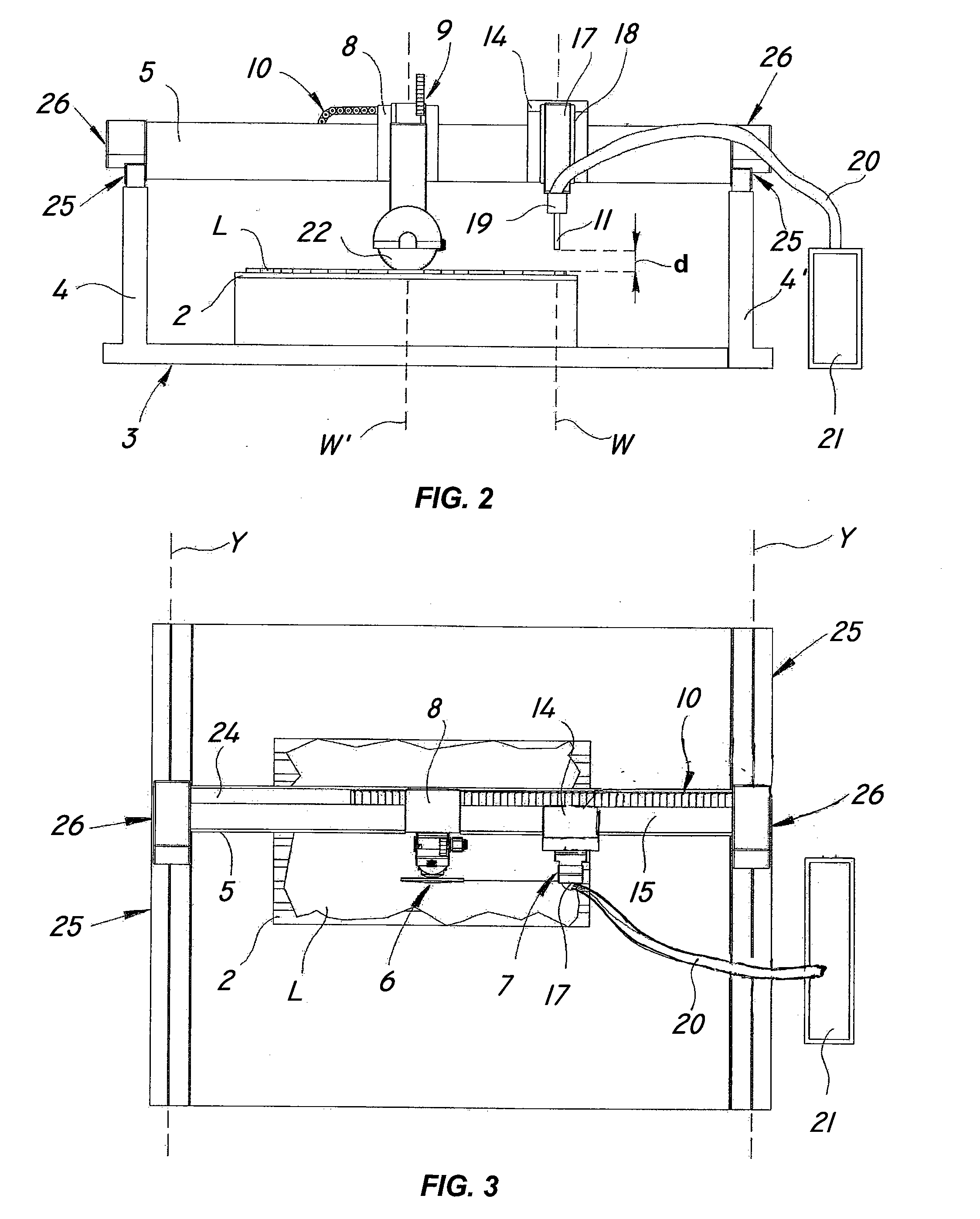

Multiple-tool machine for combined cutting of slabs of hard material

InactiveUS20080110311A1Improve efficiencyCost effectiveMetal sawing devicesGuide fencesClassical mechanicsStringer

The present invention relates to processing of hard materials, and more particularly relates to a multiple-tool machine for the combined cutting of slabs of hard materials such as stone, marble, granite, concrete, wood, metal, glass and the like. One embodiment of the present invention includes a support surface for receiving a slab; a load-bearing frame with a longitudinal beam extending over the support surface; a first disk blade cutting tool mounted on a first slide and movable along a first guide connected to the beam; a first motion imparting device for moving the first slide; a second cutting tool with a nozzle for high-pressure waterjet cutting, which is mounted in sliding relationship to a second guide coupled to the beam; and a second motion imparting device, other than the first motion imparting device, for translating the second cutting tool independently of the first cutting tool.

Owner:SIMEC SPA

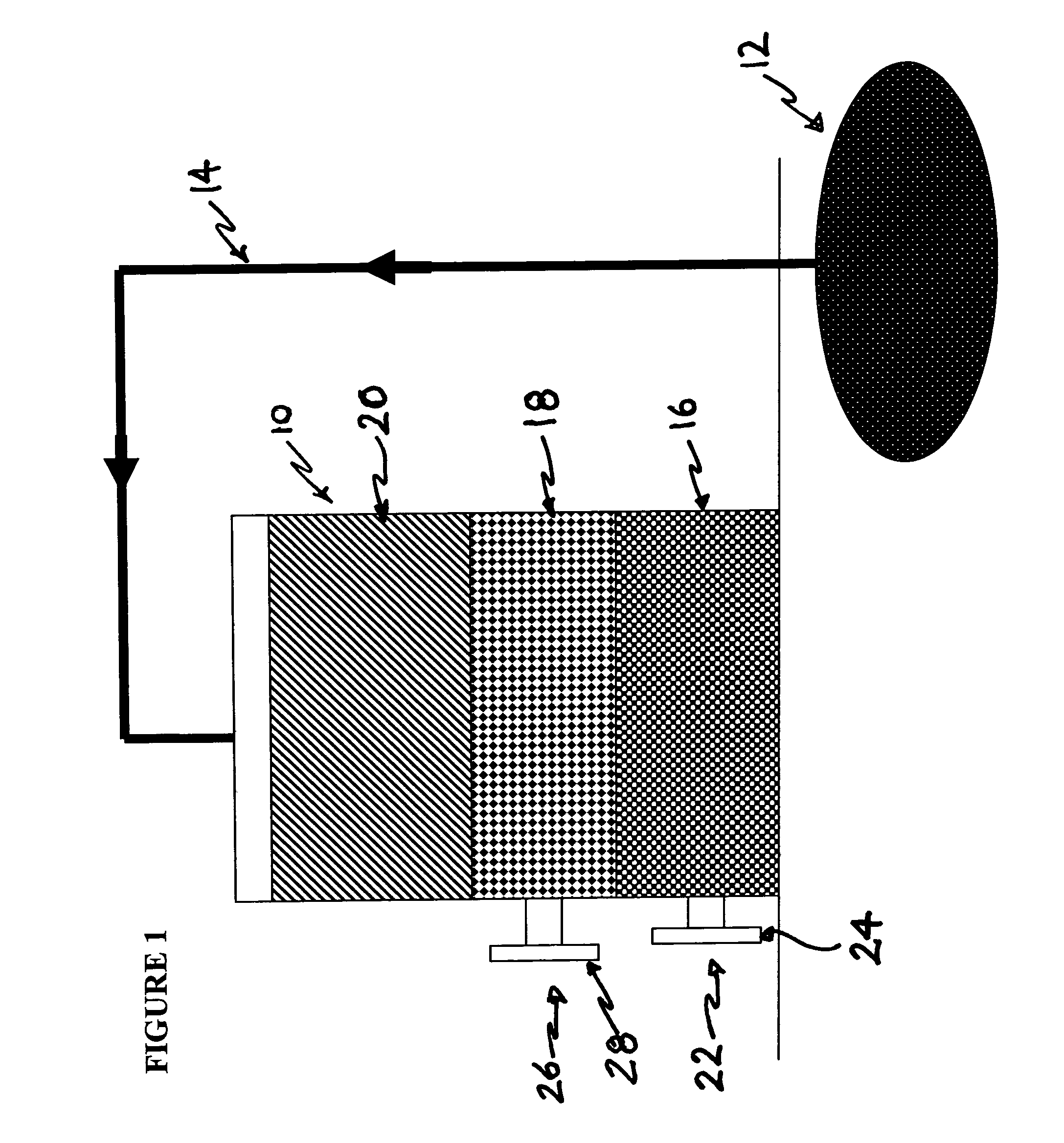

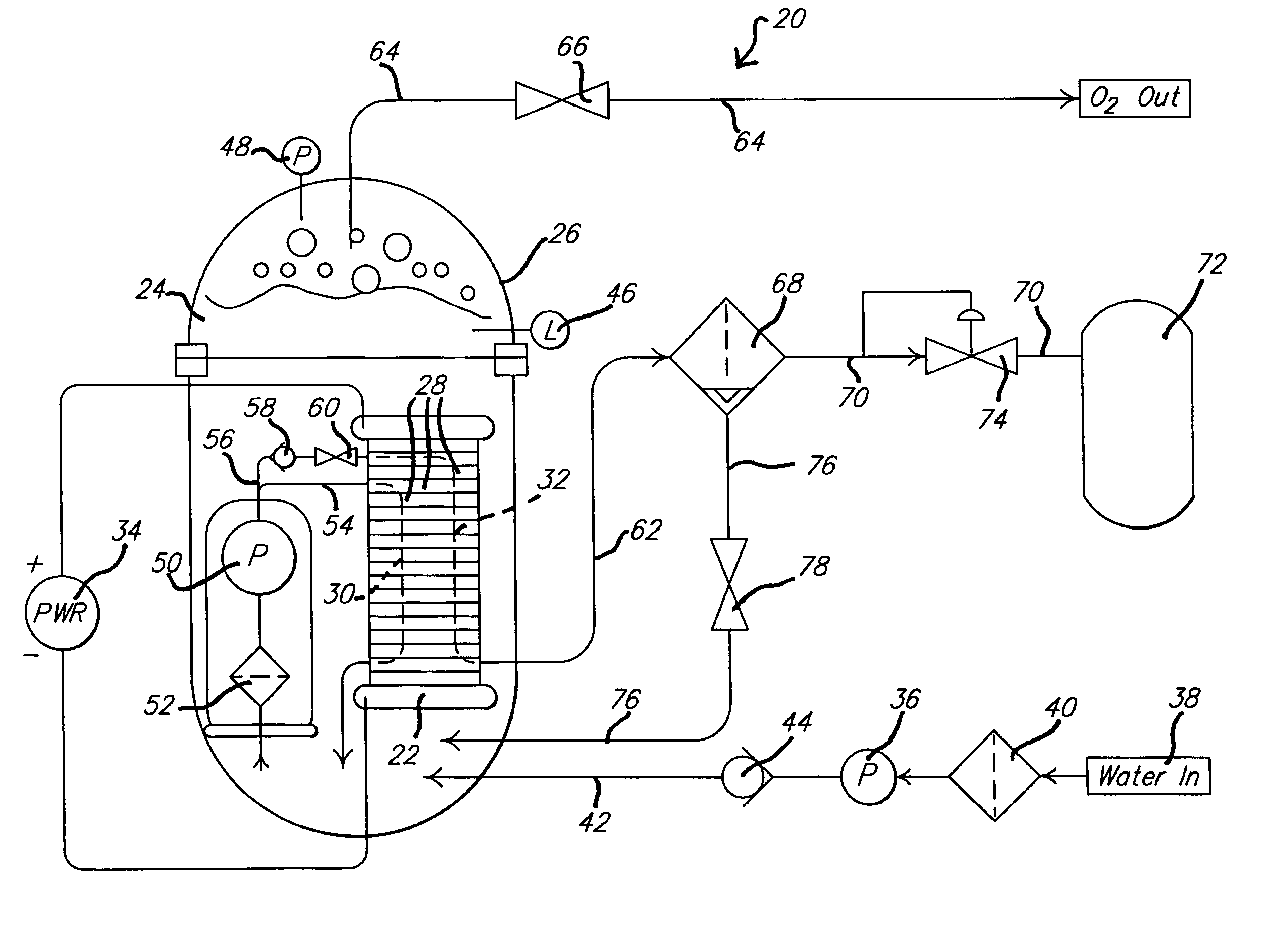

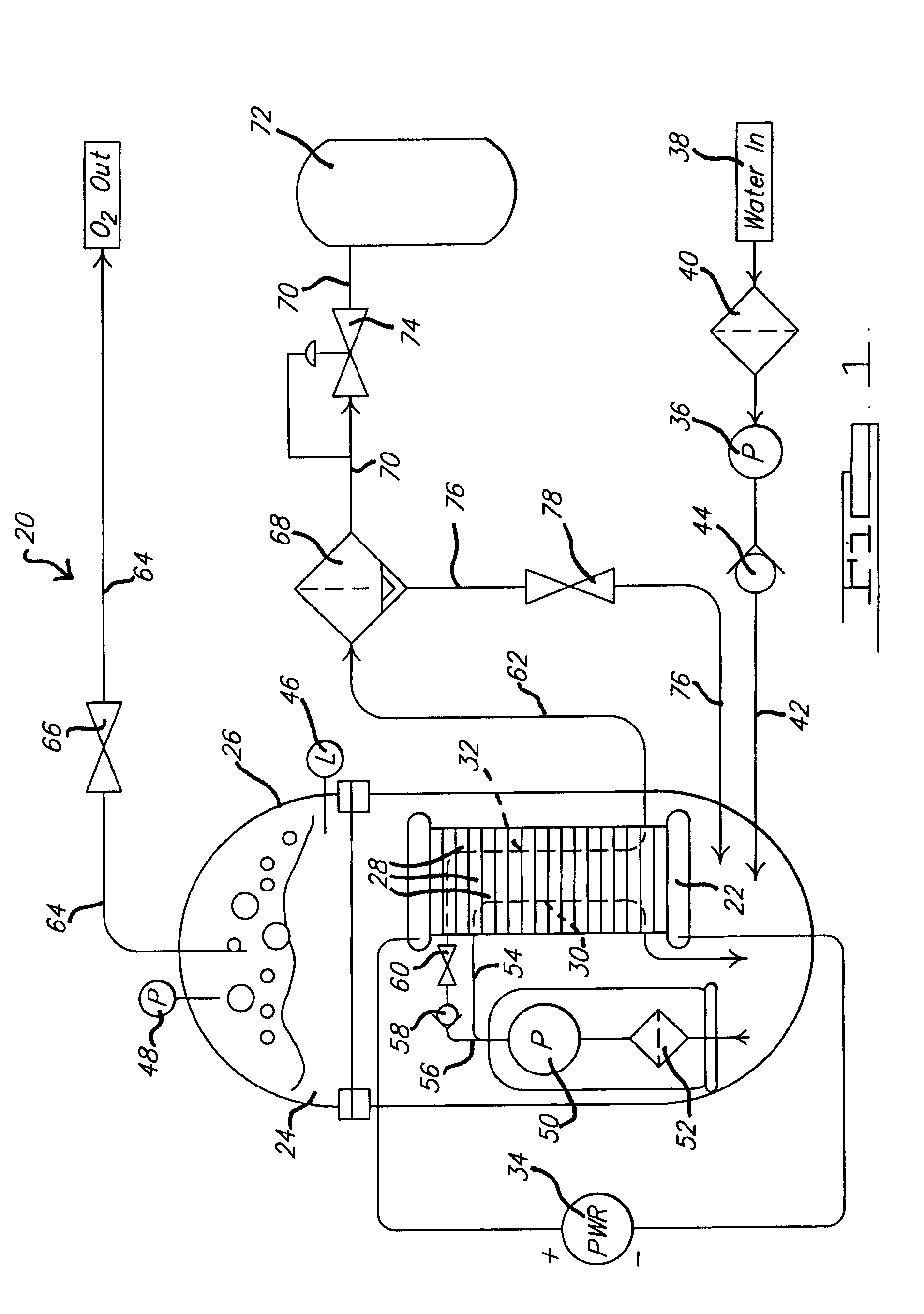

Electrolyzer system to produce gas at high pressure

ActiveUS20050072688A1Increase pressureCellsPhotography auxillary processesElectrolysisHigh pressure hydrogen

An apparatus and method to produce hydrogen gas a high pressure is disclosed. An electrolyzer is located inside a pressure vessel that is pressurized with high pressure water. The high pressure water is provided to both the anode and cathode sides of the electrolyzer by a pump in the pressure vessel Oxygen produced at the high pressure on the anode side of the electrolyzer is vented directly into the pressure vessel while hydrogen produced at the high pressure on the cathode side is routed to a separator and is deadheaded. The high pressure hydrogen is periodically routed from the separator to a storage tank by a pressure regulator.

Owner:GM GLOBAL TECH OPERATIONS LLC

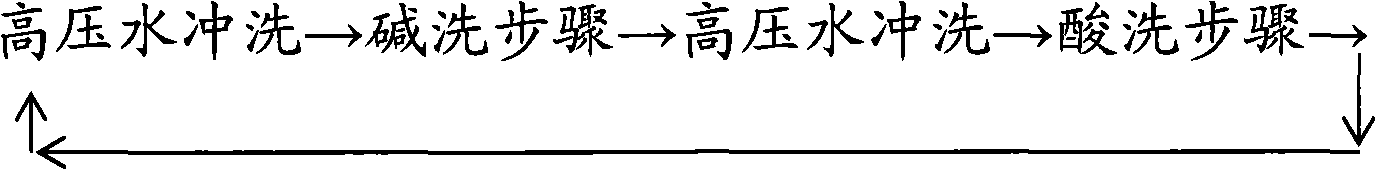

Cleaning agent and cleaning process of GGH heat exchange component

ActiveCN101555441AQuick washWash thoroughlyDispersed particle separationInorganic non-surface-active detergent compositionsStrong acidsHigh pressure water

The invention provides a cleaning agent and a cleaning method of a GGH heat exchange component applying the same. The cleaning agent comprises alkaline cleaning solution and acidic cleaning solution, wherein the alkaline cleaning solution contains 1.6 weight percent to 11.0 weight percent (wt, same below) of alkali, 0.7 to 2.4 of penetrating agent, 1.2 to 3.5 of scale dissolver, 0.3 to 1.2 of surfactant, 0.2 to 1.3 of remover b and the balance of water; and the acidic cleaning solution contains 2.6 to 5.5 of strong acid, 0.7 to 2.4 of penetrating agent, 0.3 to 1.2 of latent solvent, 0.2 to 0.6 of inhibitor, 0.2 to 1.3 of remover a, and the balance of water. The washing process comprises an alkaline cleaning step, an acid cleaning step and a high-pressure water flushing step between the alkaline cleaning step and the acid cleaning step. The cleaning process and the cleaning agent of the GHH heat exchange component have the advantages of quick and thorough cleaning, low cost, environmental protection, and the like.

Owner:CHINA SHENHUA ENERGY CO LTD +3

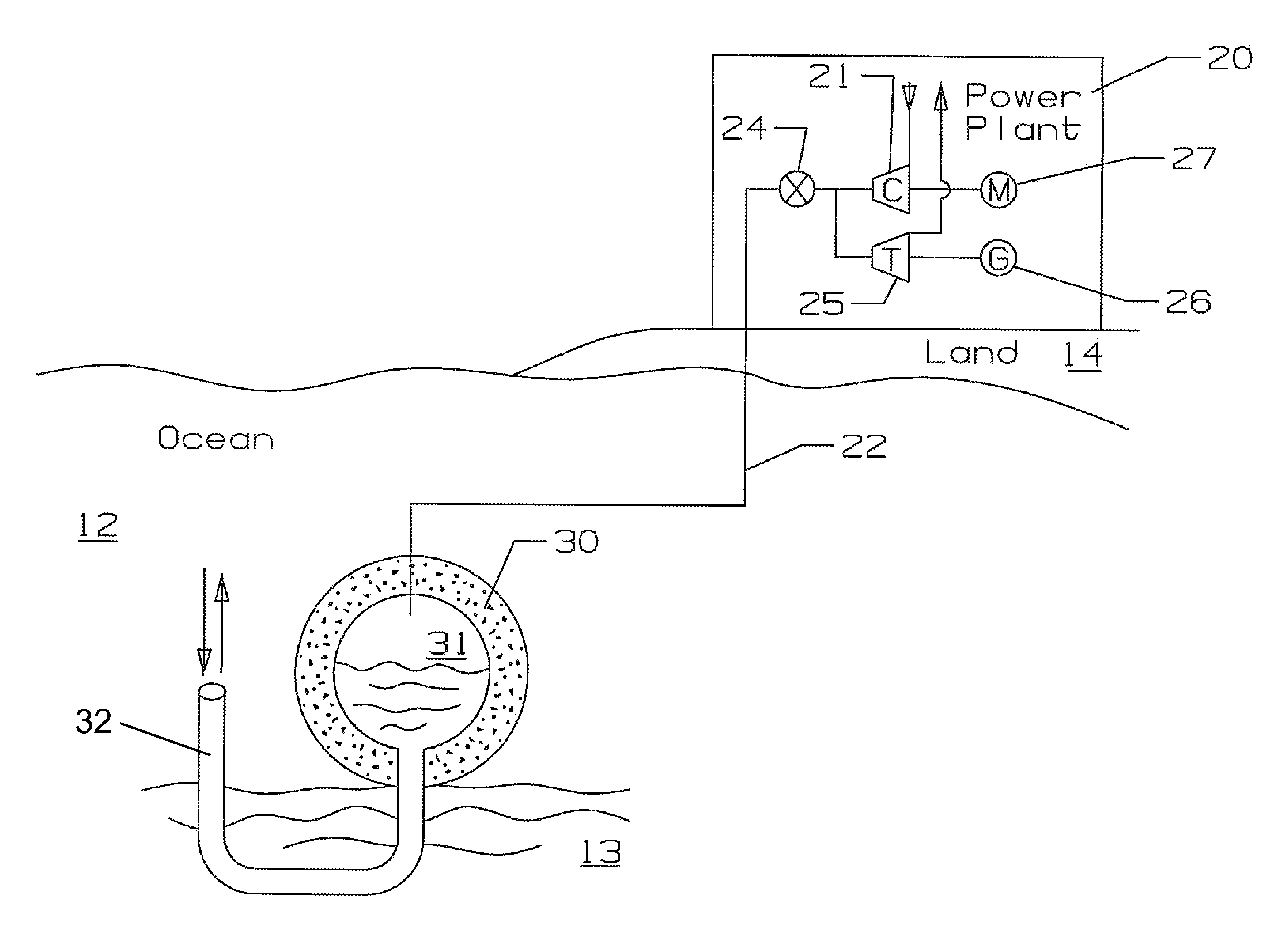

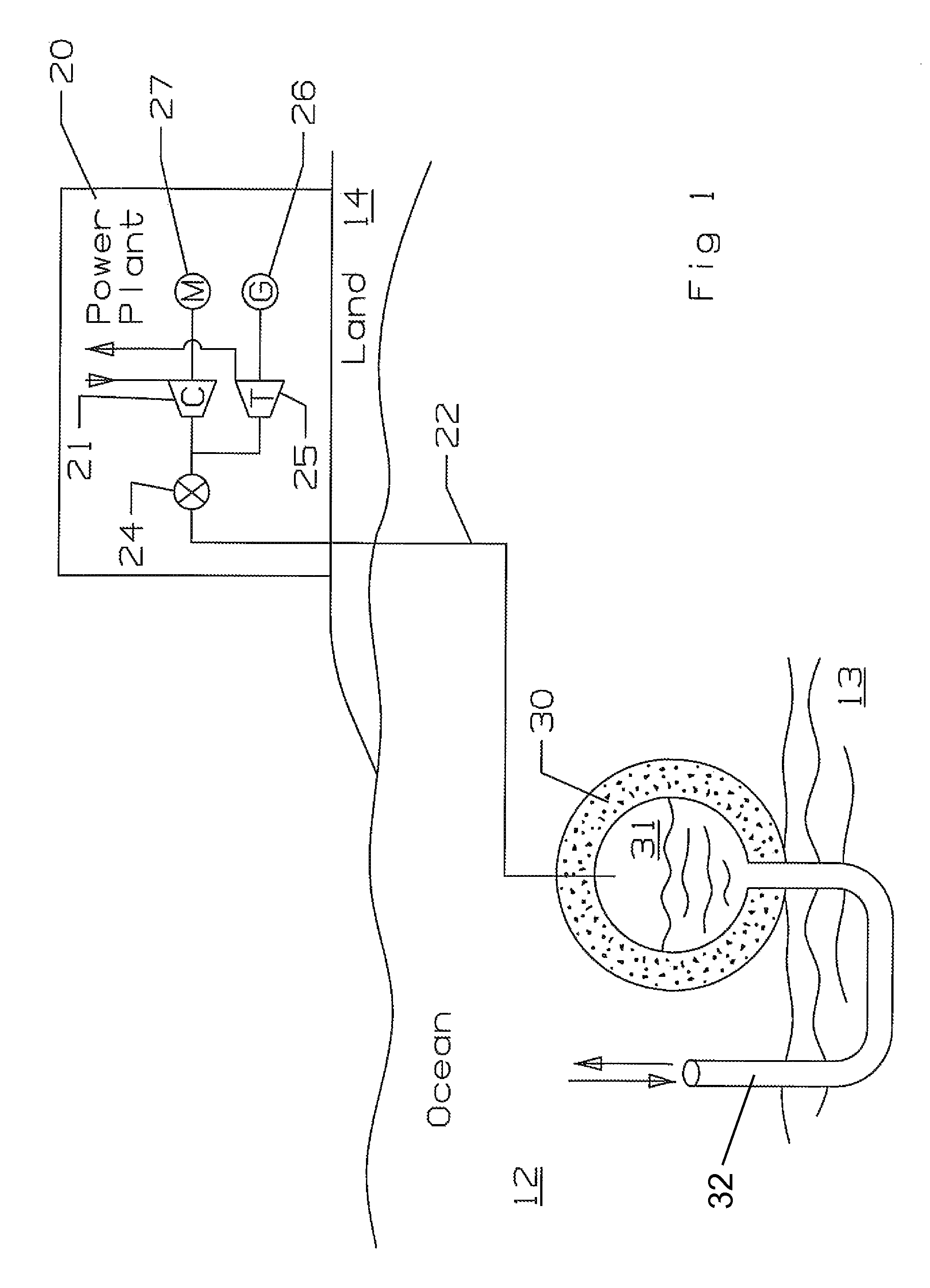

Power plant with energy storage deep water tank

A power plant that is used for storing energy during a low demand and returning the energy to a power plant during high or peak demand. A concrete tank is placed on the bottom of a deep body of water. A compressed air line connects the tank to a compressor and turbine assembly on land at the power plant. An electric motor drives the compressor to supply compressed air to the tank and displace the water within the tank during the low demand period. At high demand, the compressed air is allowed to flow through the turbine that drives an electric generator to produce electric power. The tank includes a water outlet pipe for the tank is displaced of the high pressure water and to allow the water to flow into the tank and displace the compressed air under high pressure to drive the turbine.

Owner:FLORIDA TURBINE TECH

Pre-alloying powder for diamond tool and manufacturing method thereof

The invention relates to pre-alloying powder for a diamond tool and a manufacturing method thereof. The pre-alloying powder adopts Fe phase or Cu phase as the main phase. The pre-alloying powder is characterized in that: trace B strengthens crystal boundary and refines crystal particles; Ni, Co and Me (at least one of Mn, Cr, Si, Ti, V, W and Mo is selected) are adopted as strengthening elements; and Sn, P and C further adjusts an alloy structure. The pre-alloying powder is prepared by the high-pressure water atomization powdering technology. The manufacturing method is characterized in that: alloy liquid is smashed by high-pressure water which is preferential for many times, the meso-position diameter D50 of the powder measured by a laser particle-size meter is within 7 to 18mum, and the preference is within 7 to 13mum; the full oxygen content measured by a full oxygen analyzer is smaller than or equal to 0.35% (mass), and the preference is smaller than or equal to 0.25% (mass).

Owner:ADVANCED TECH BAZHOU SPECIAL POWDER CO LTD

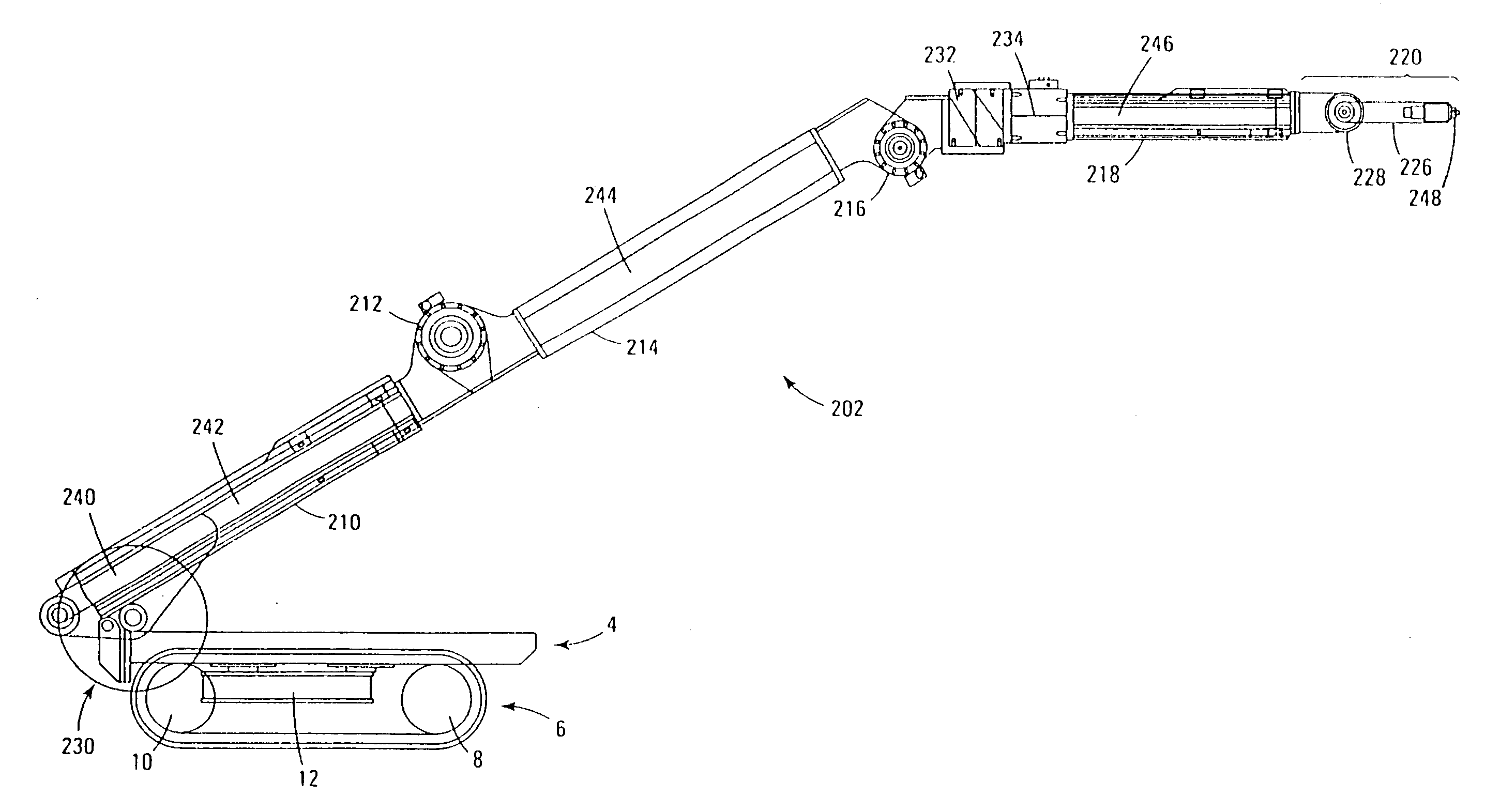

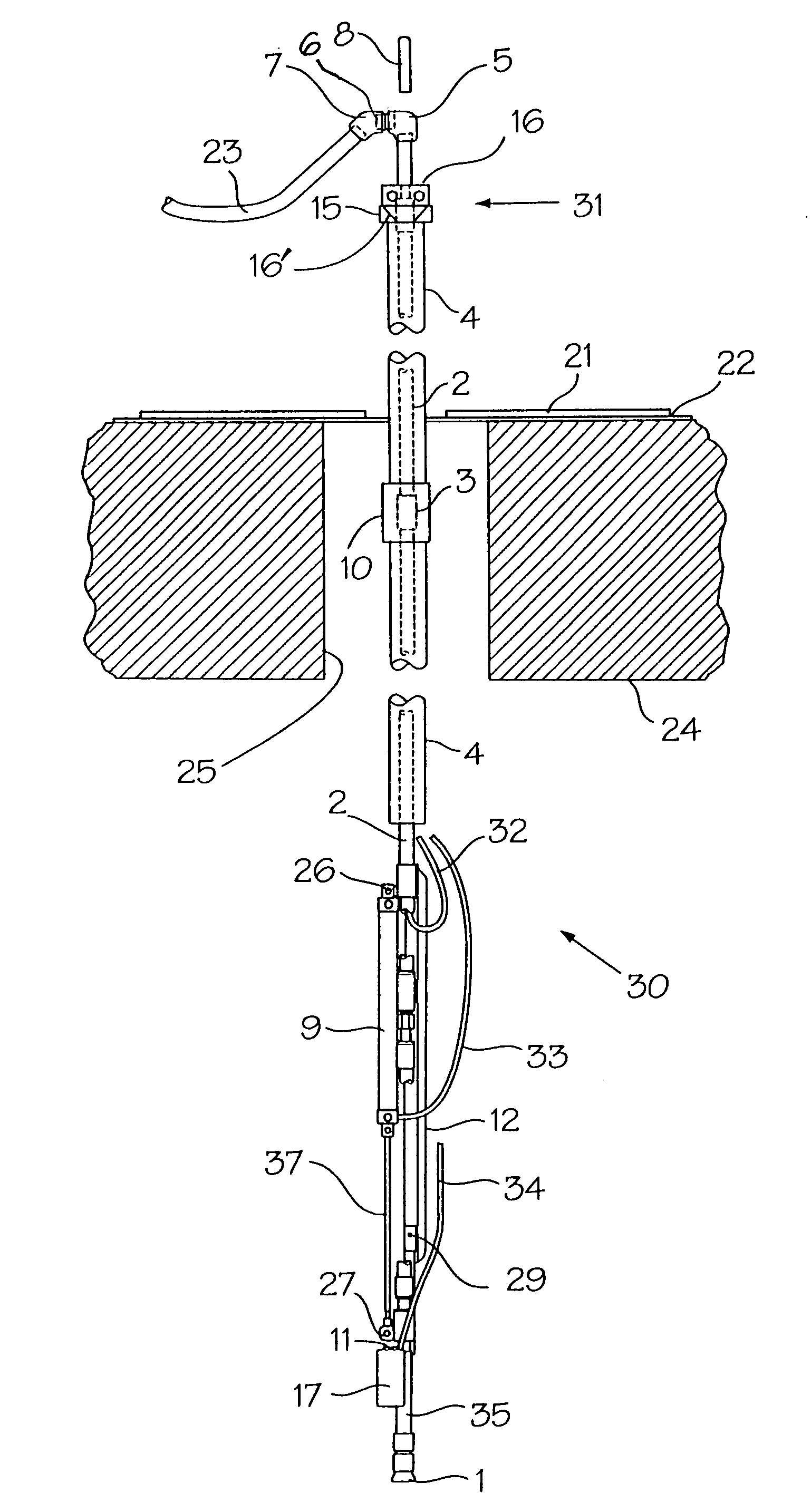

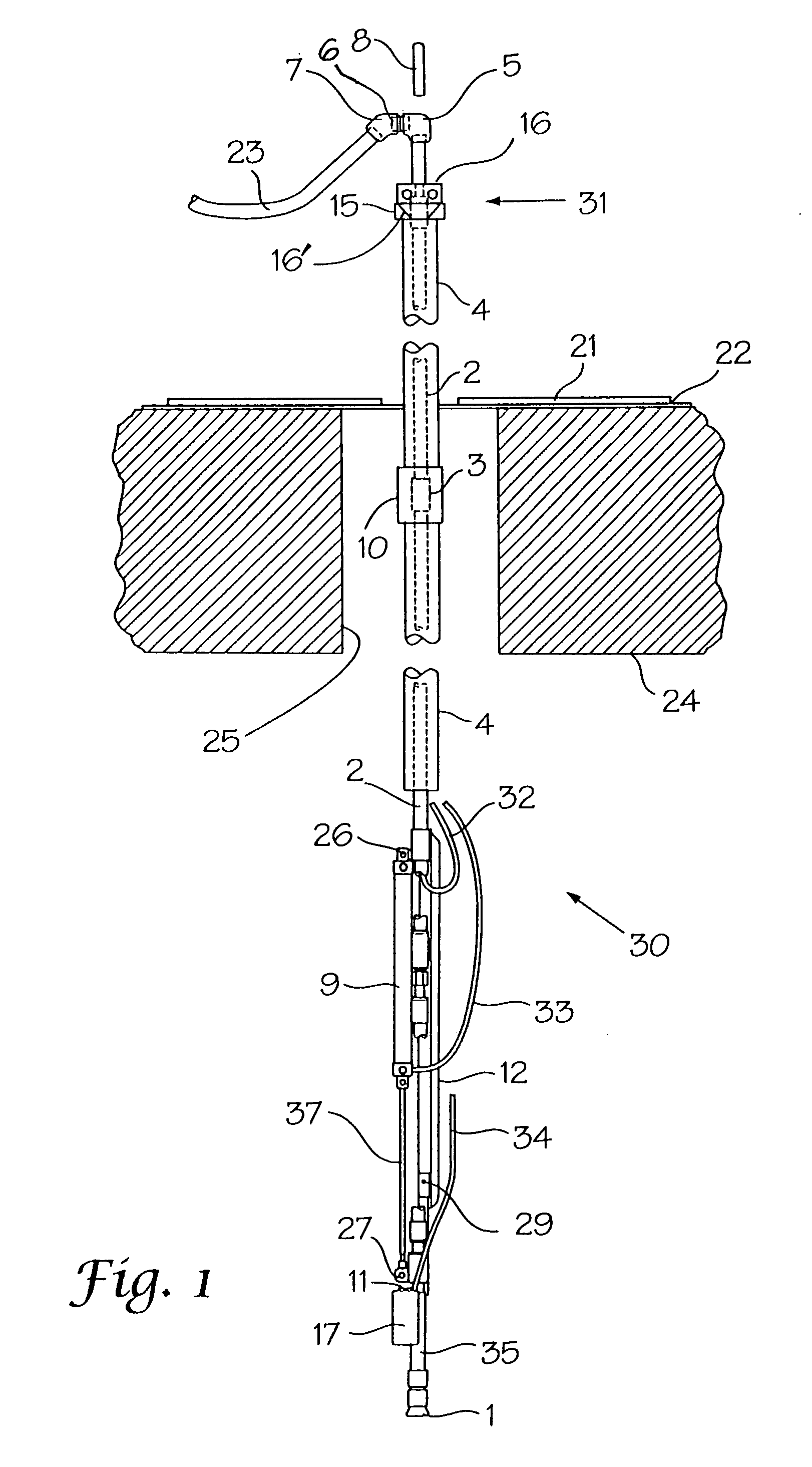

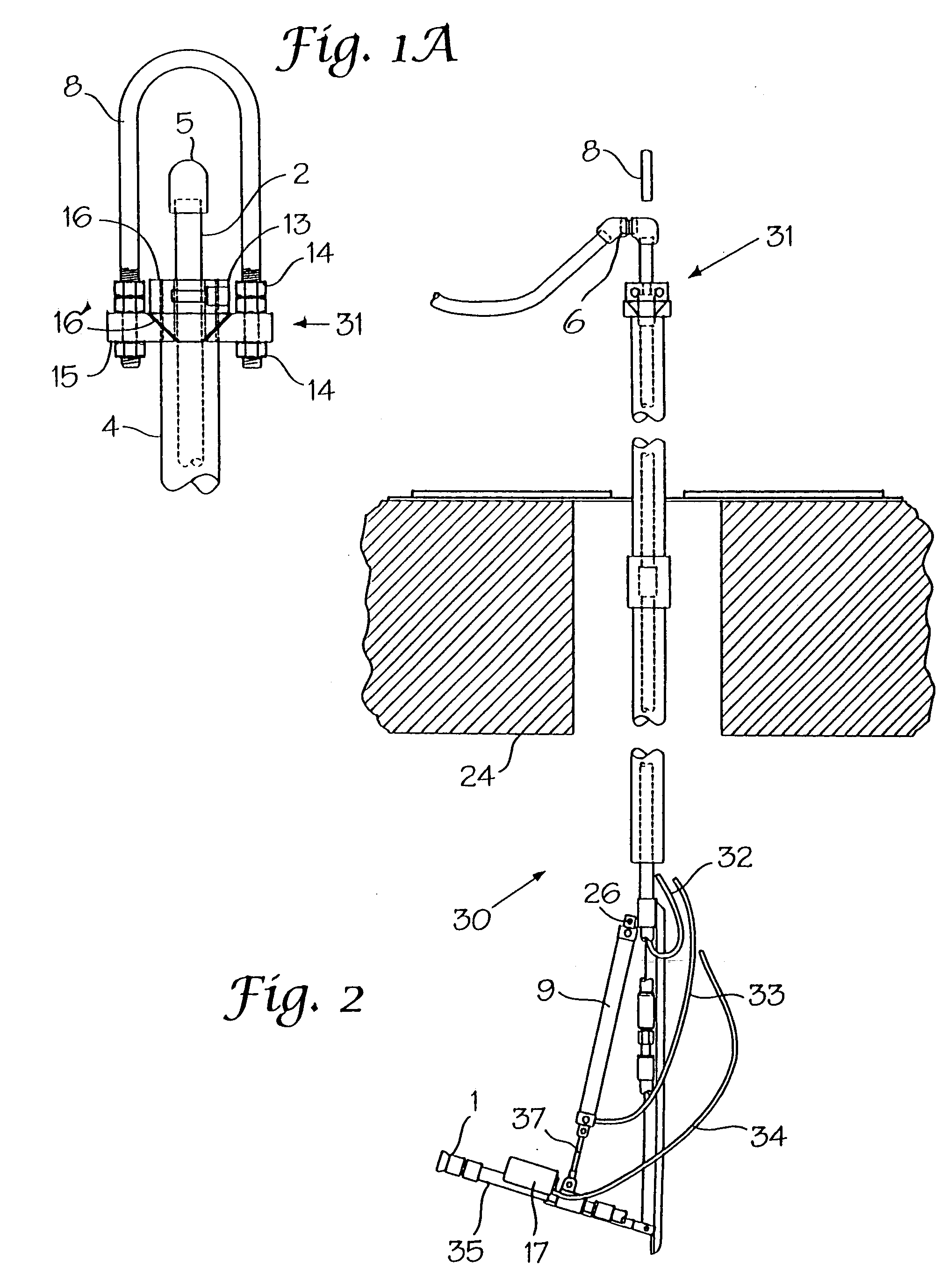

On-site land mine removal system

InactiveUS20090223355A1Reduced effectivenessReduce eliminateDefensive equipmentDefence devicesLiquid jetDetonation

A method of deactivating land mines buried in ground comprises projecting high-pressure water jets into ground, cutting through ground with the high-pressure water jets, and making at least one cut through a land mine or cutting through at least one land mine that had been under the ground, the cutting of the land mine reducing the performance of the land mine. The method may reduce the performance of the land mine by rendering the land mine inactive to normal detonation procedures for the land mine. To reach as many surface areas on the buried landmines, it is preferable that at least two high-pressure water jets are spaced apart are used to cut through the ground. The method may be practiced with the high-pressure water jet being carried on a vehicle and cutting is done in a line that is formed at least in part by movement of the vehicle over the ground while the high-pressure water jet is cutting ground. An apparatus for the reduction in effectiveness of land mines buried in ground may comprise a self-contained push-cart unit or a unit attached or attachable to a vehicle. A complete system could comprise a vehicle having a source of liquid, a high-pressure pump to move the liquid under high pressure, a nozzle directing a liquid jet path for the liquid, a support for the nozzle, abrasive delivery system, and nozzle being controllable to direct the liquid towards the ground while the nozzle is fixed relative to the vehicle.

Owner:MANDERS STEPHEN M

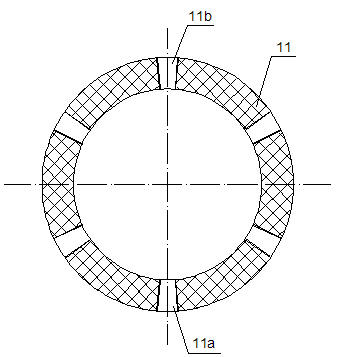

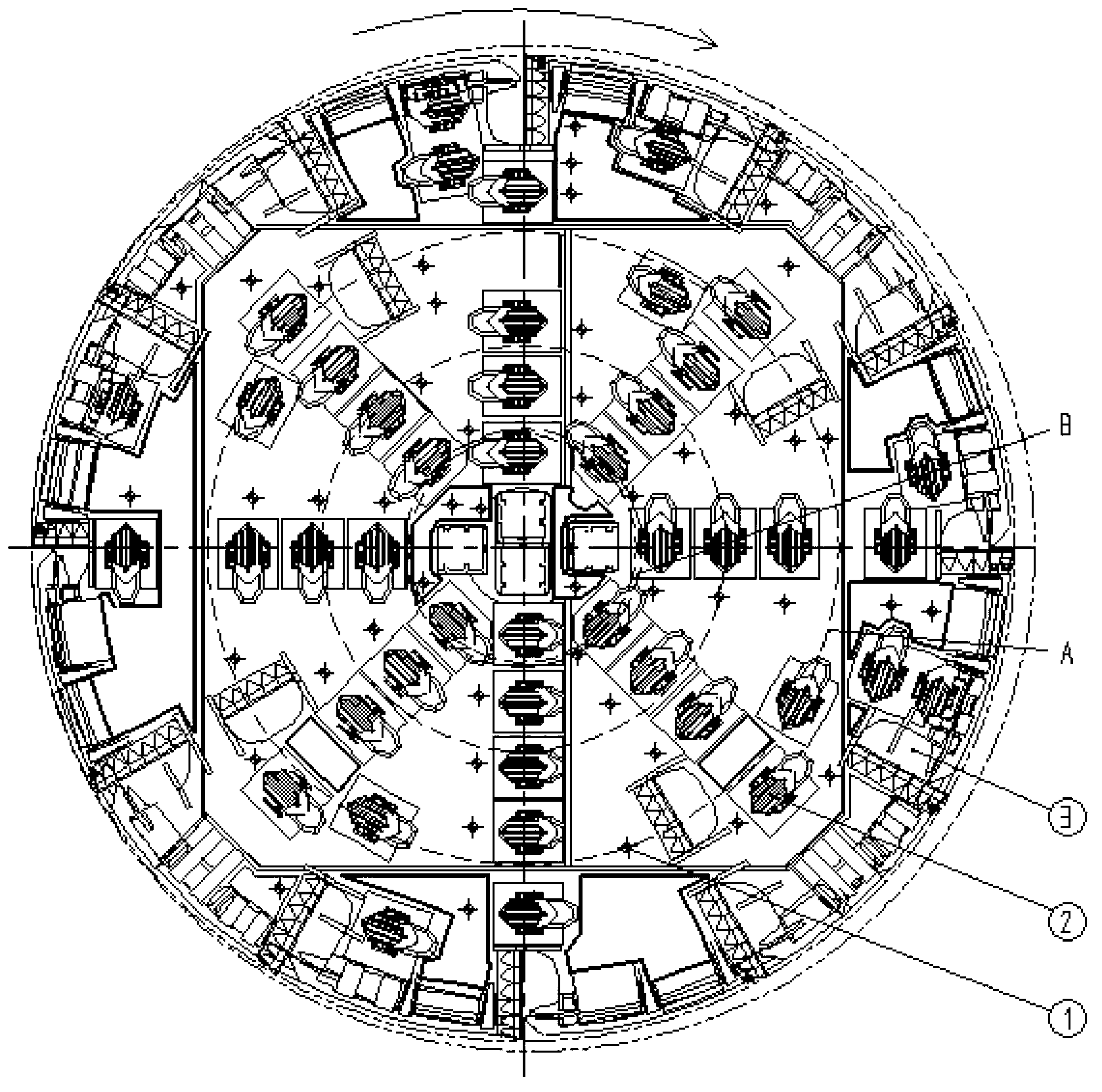

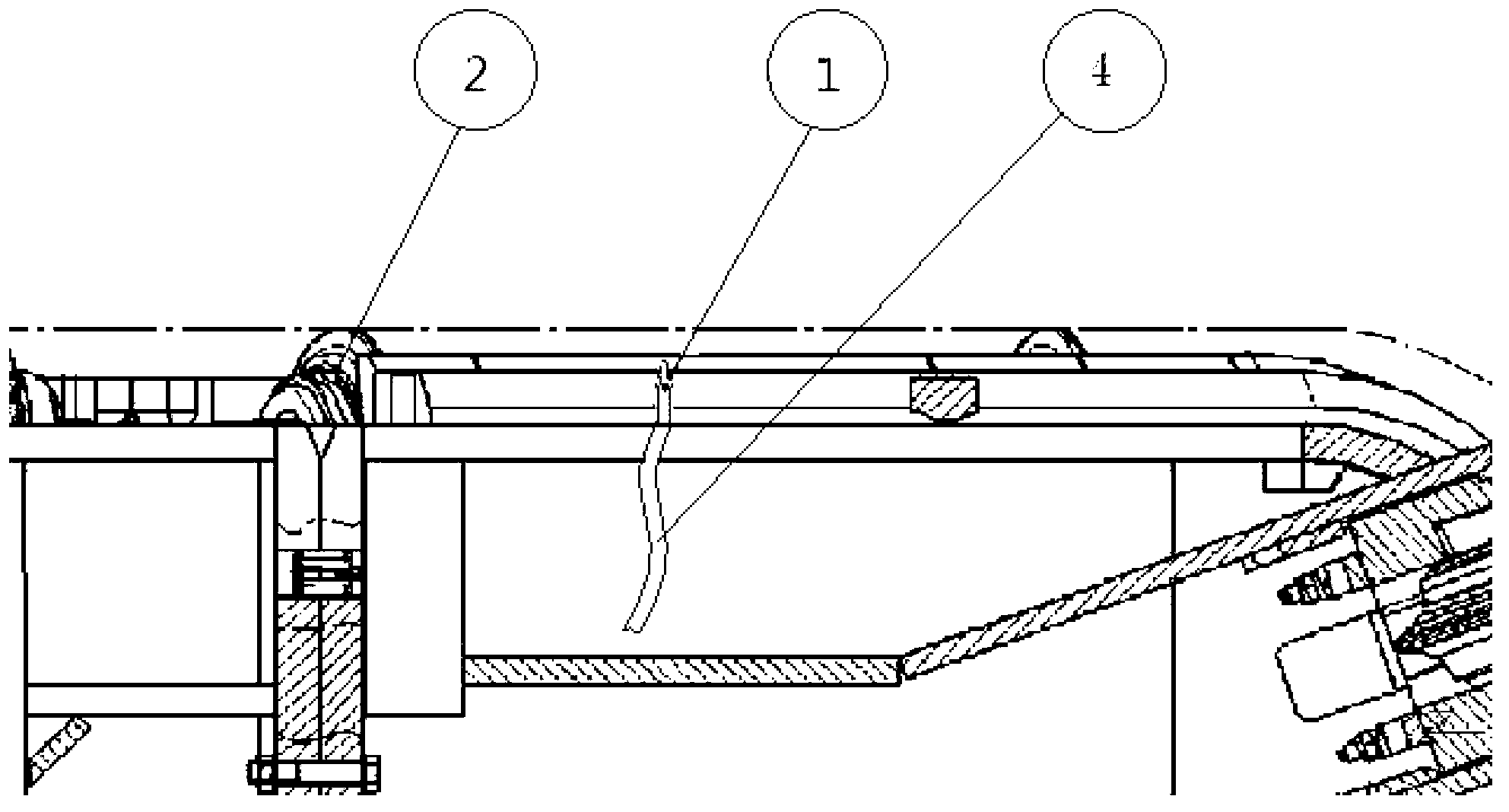

Distribution method and distribution structure of high-pressure water jet in heading machine cutterhead

The invention relates to a distribution method and a distribution structure of high-pressure water jet in a heading machine cutterhead belonging to the field of the machine design, and in particular relates to a distribution method and a distribution structure of high-pressure water jet in the heading machine cutterhead. The distribution method in the heading machine cutterhead is free from changing the structural form of the existing rock heading machine cutterhead body and the layout and installation way of a hobbing cutter and a material collection port in the cutterhead, and a plurality of high-pressure water nozzles are distributed on the blank position of the end surface of the existing cutterhead structure. The heading machine cutterhead structure consists of the plurality of high-pressure water nozzles, a hobbing cutter, a material collection port and a plurality of water pipes. The rock heading machine cutterhead structure combining the high-pressure water jet and the hobbing cutter utilizes the high-pressure water to force rock joints to expand, so that the rock is easy to crush, the abrasion of the hobbing cutter is reduced, the construction efficiency is improved, and the construction cost is reduced. The water flow formed after the high-pressure water compresses the rock covers an entire digging surface, so that the working surface of the hobbing cutter and the heading machine cutterhead can be cooled, and a dustproof cooling effect on the construction environment can be realized.

Owner:DALIAN UNIV OF TECH

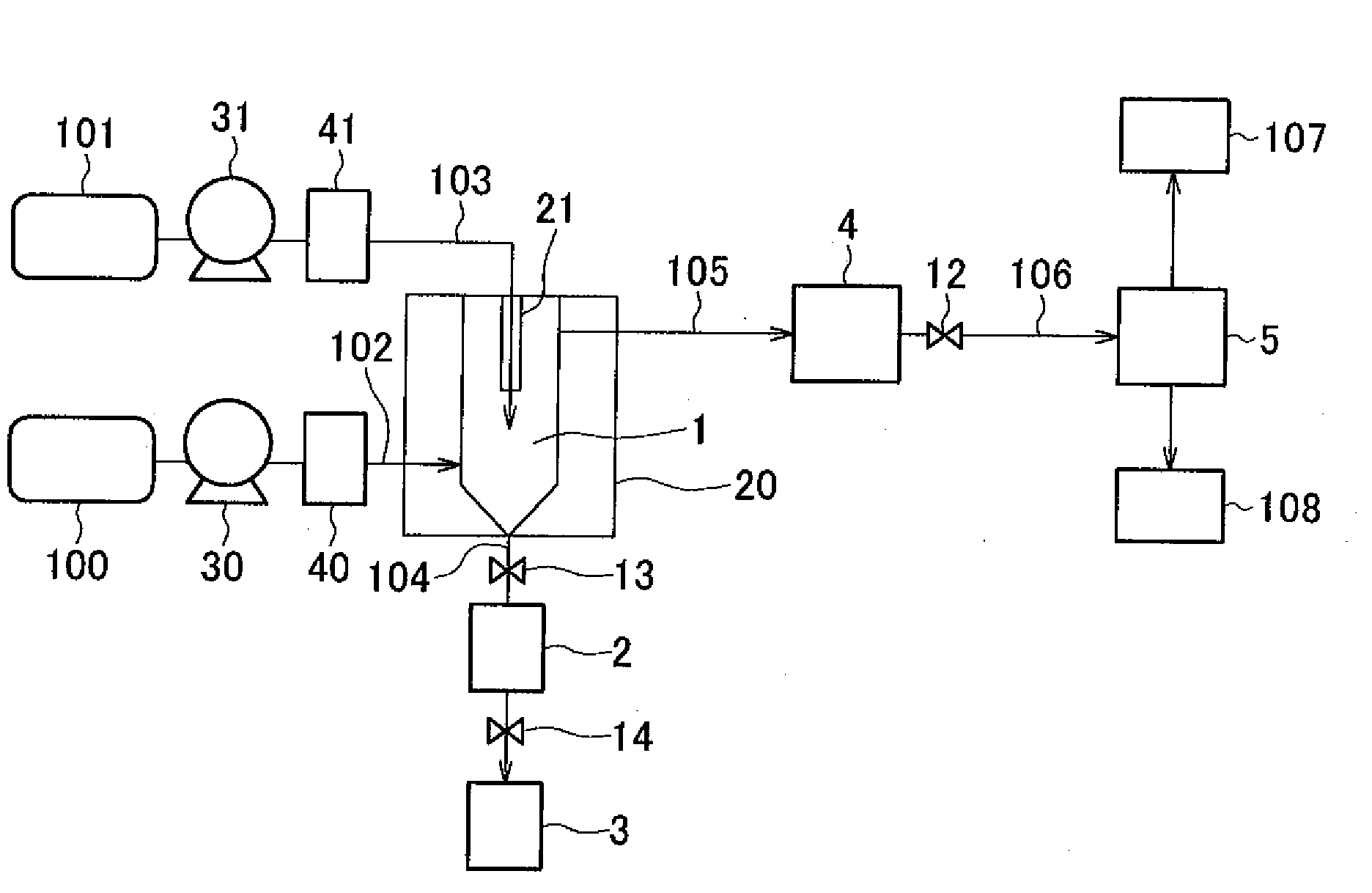

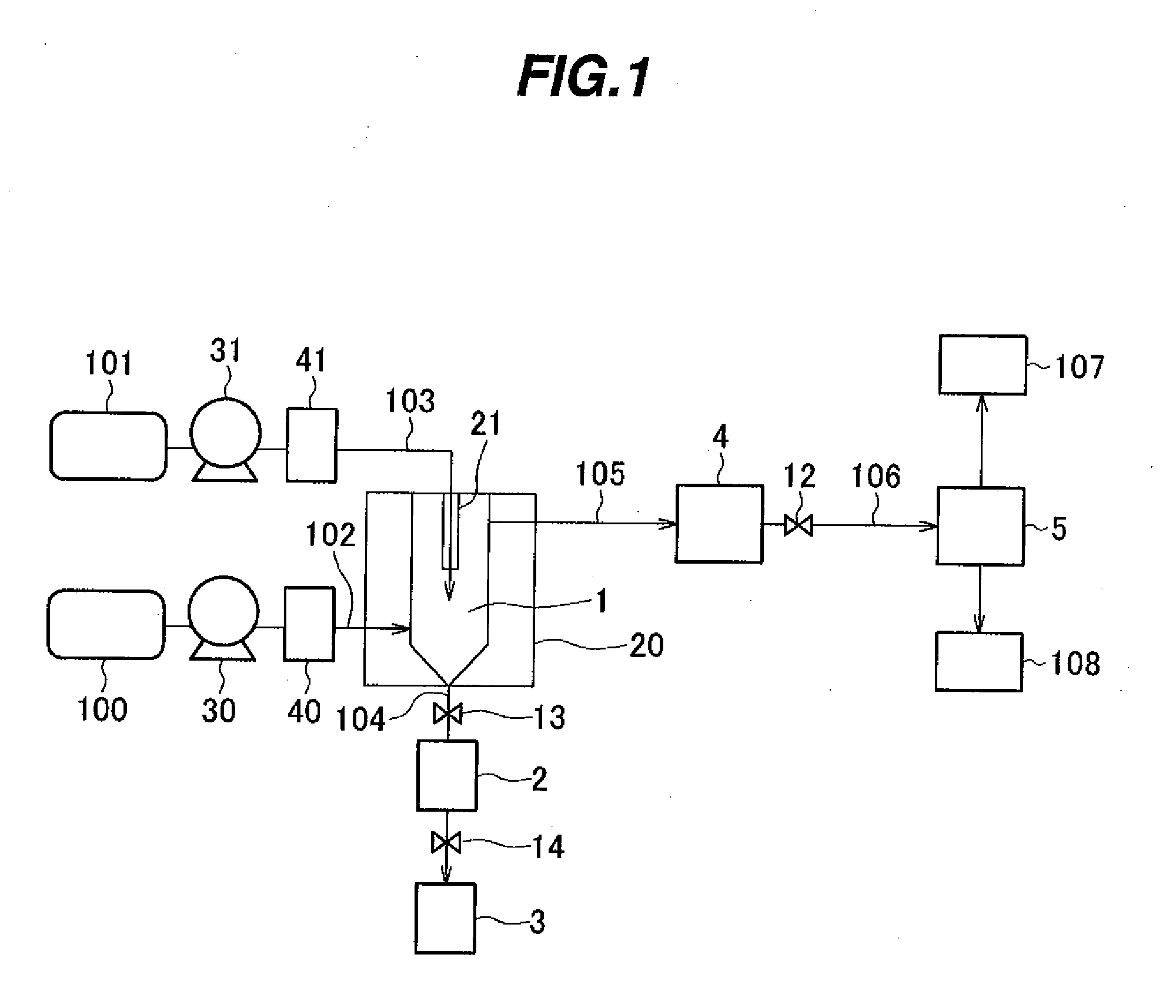

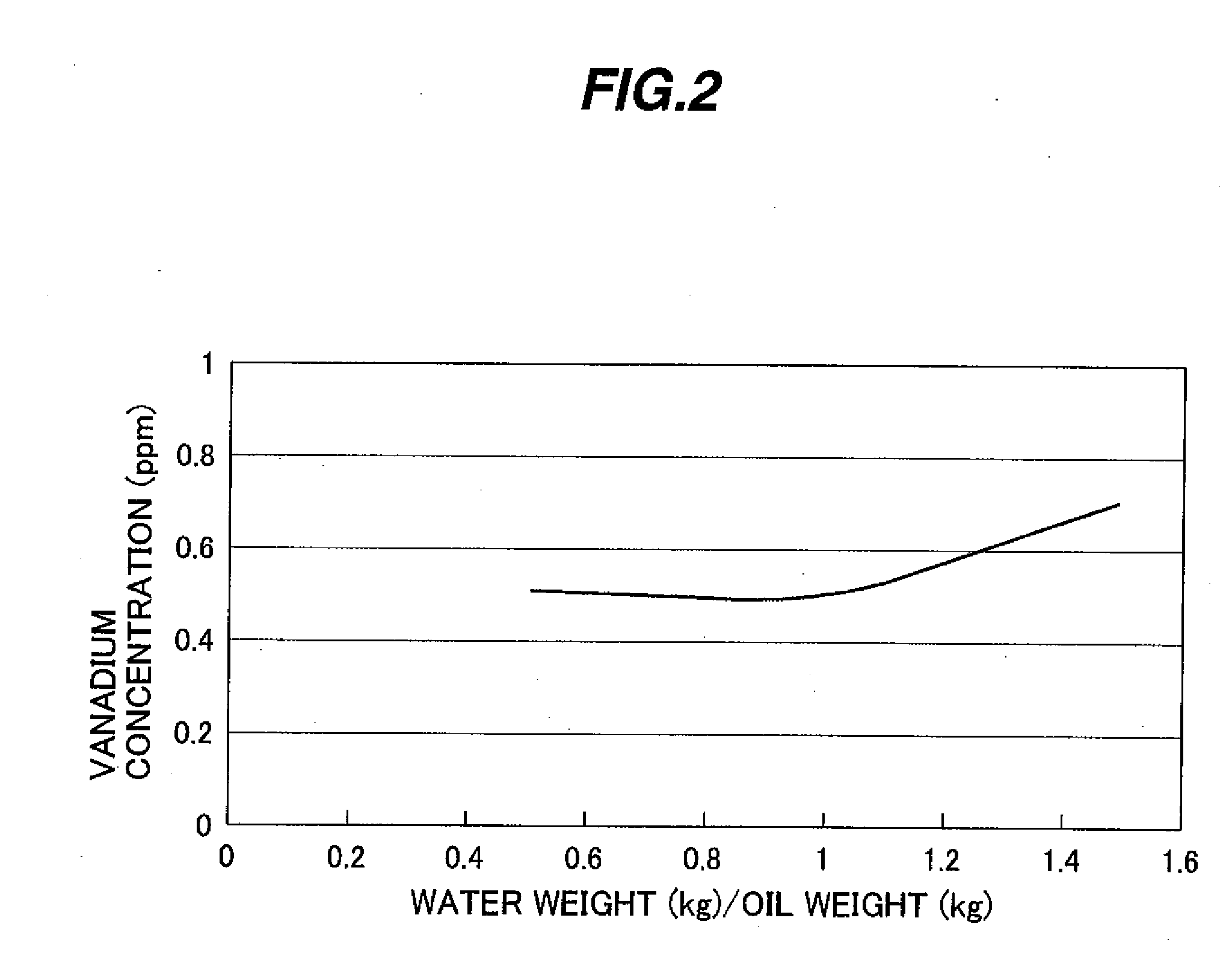

Heavy oil treating method and heavy oil treating system

InactiveUS20090032436A1Eliminate needMolecular sieve catalystsRefining with oxygen compoundsLighter fuelHigh pressure water

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:TAKAHASHI HIROKAZU +6

Strong brine energy recovery device based on reverse osmosis desalination technology

InactiveCN100341609CGuaranteed uptimeReduce consumptionGeneral water supply conservationReverse osmosisHydraulic cylinderSaline water

This invention discloses energy-recovery device for strong brine based on desalination technique by reverse osmosis, which comprises hydraulic cylinder with guide bar connected to piston; water inlet three-way solenoid valve with one end connected to end of guide bar, and other two ends connected separately to water outlets of low and high pressure water-feed pumps; drainage three-way solenoid valve with one end connected to the hydraulic cylinder end far away guide bar, and other two ends connected to strong brine discharge pipes of reverse osmosis membrane; sensor, to obtain the position signal of piston; controller, to control the synchronized open and shut of two aforementioned three-way solenoid valves. It has high efficiency, runs stably, switches quickly and fit to spread in industry.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

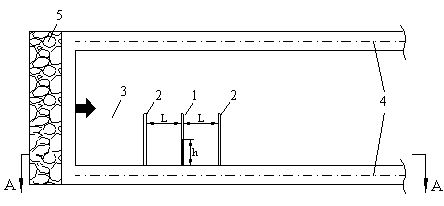

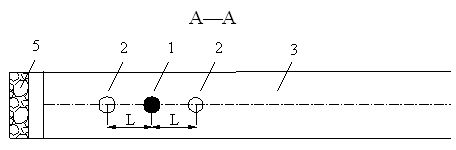

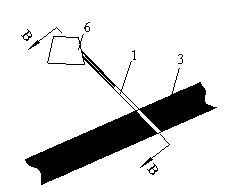

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

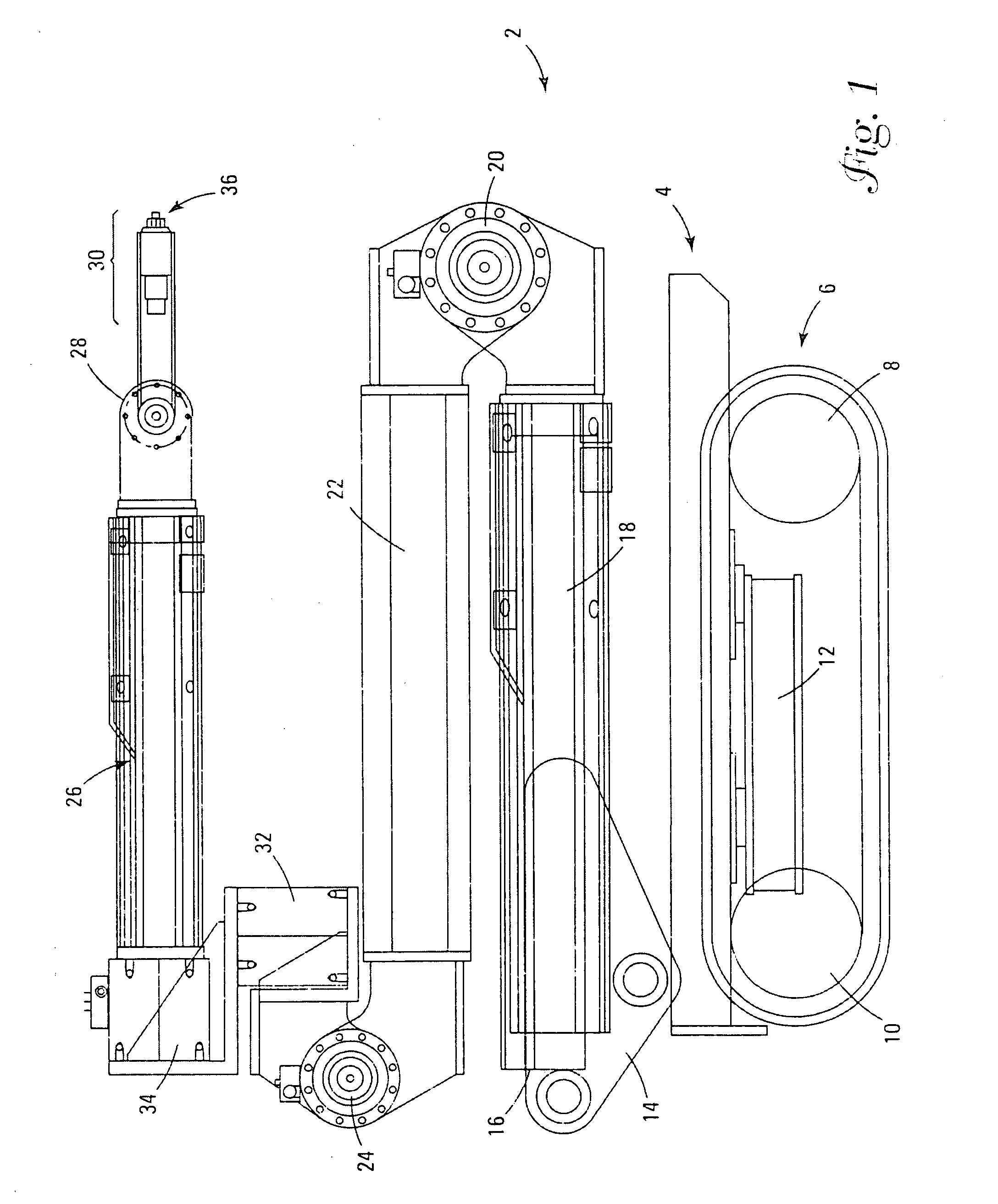

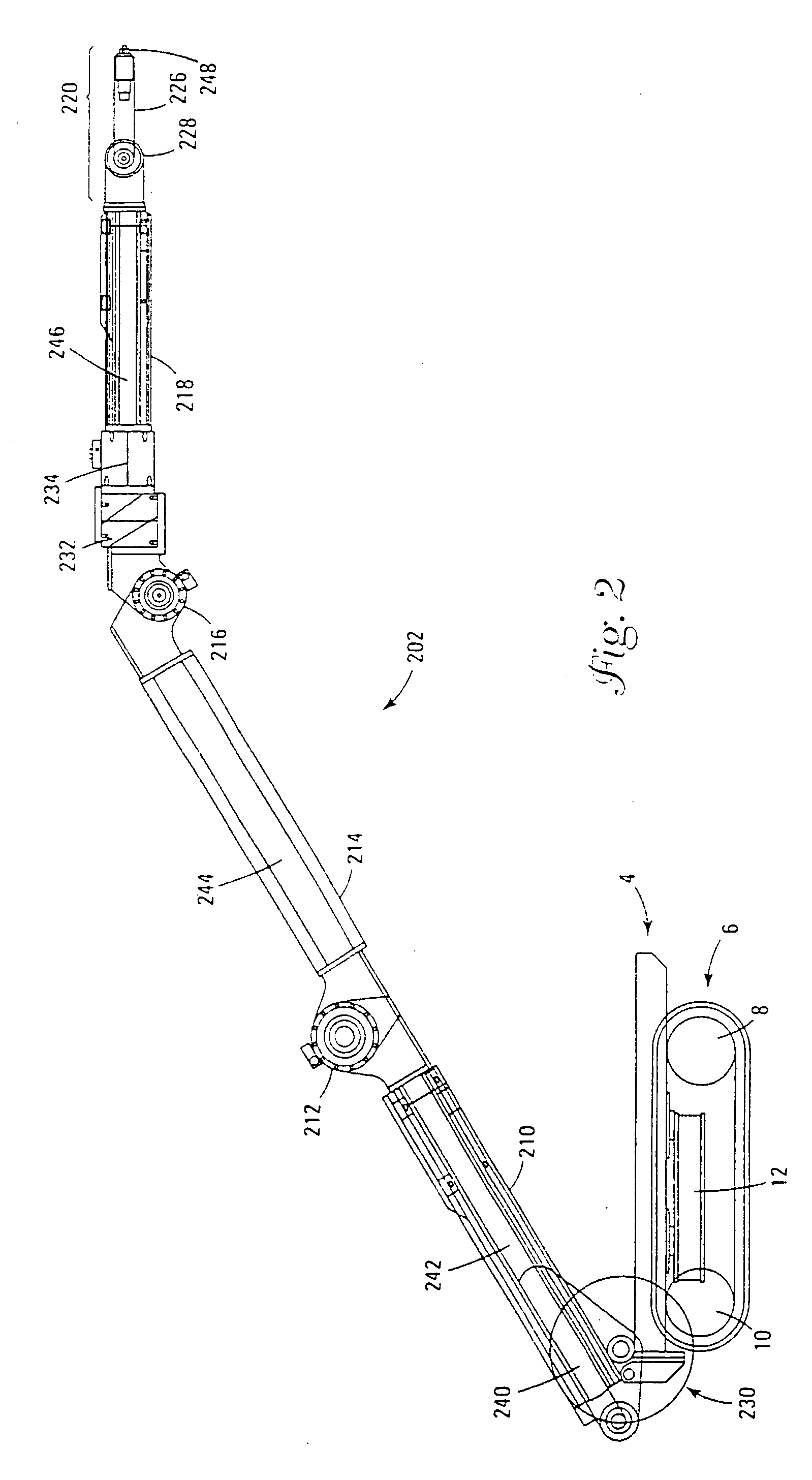

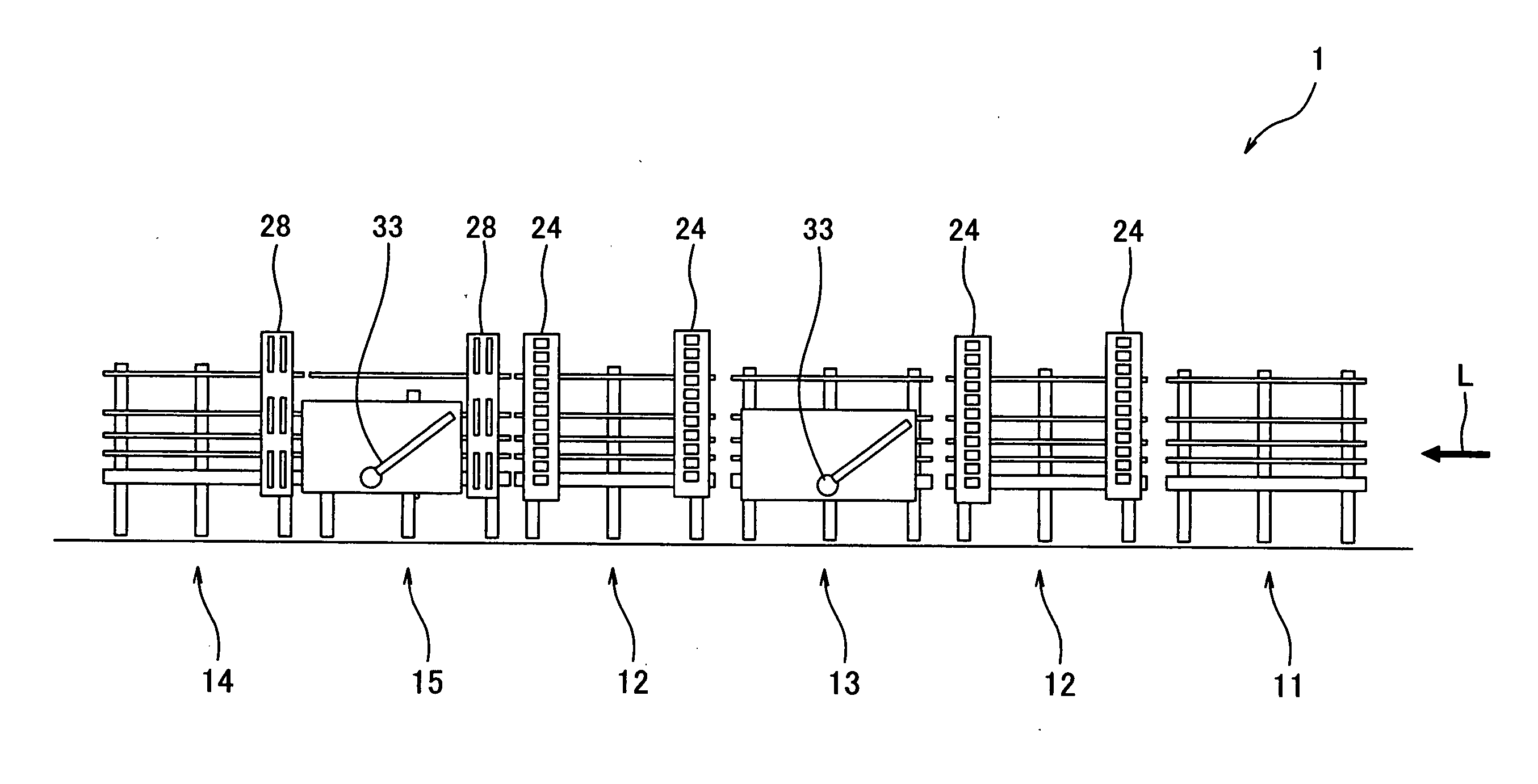

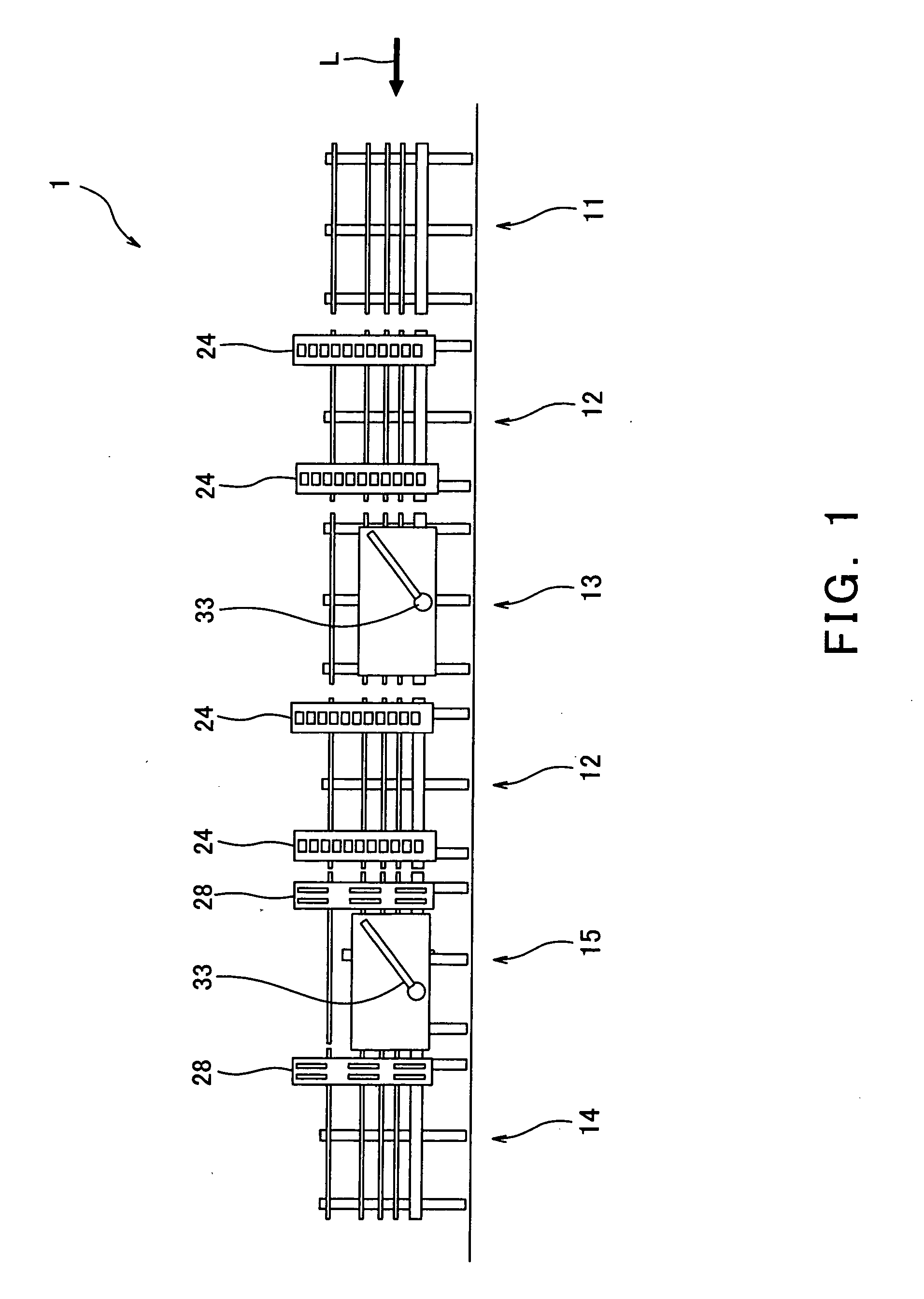

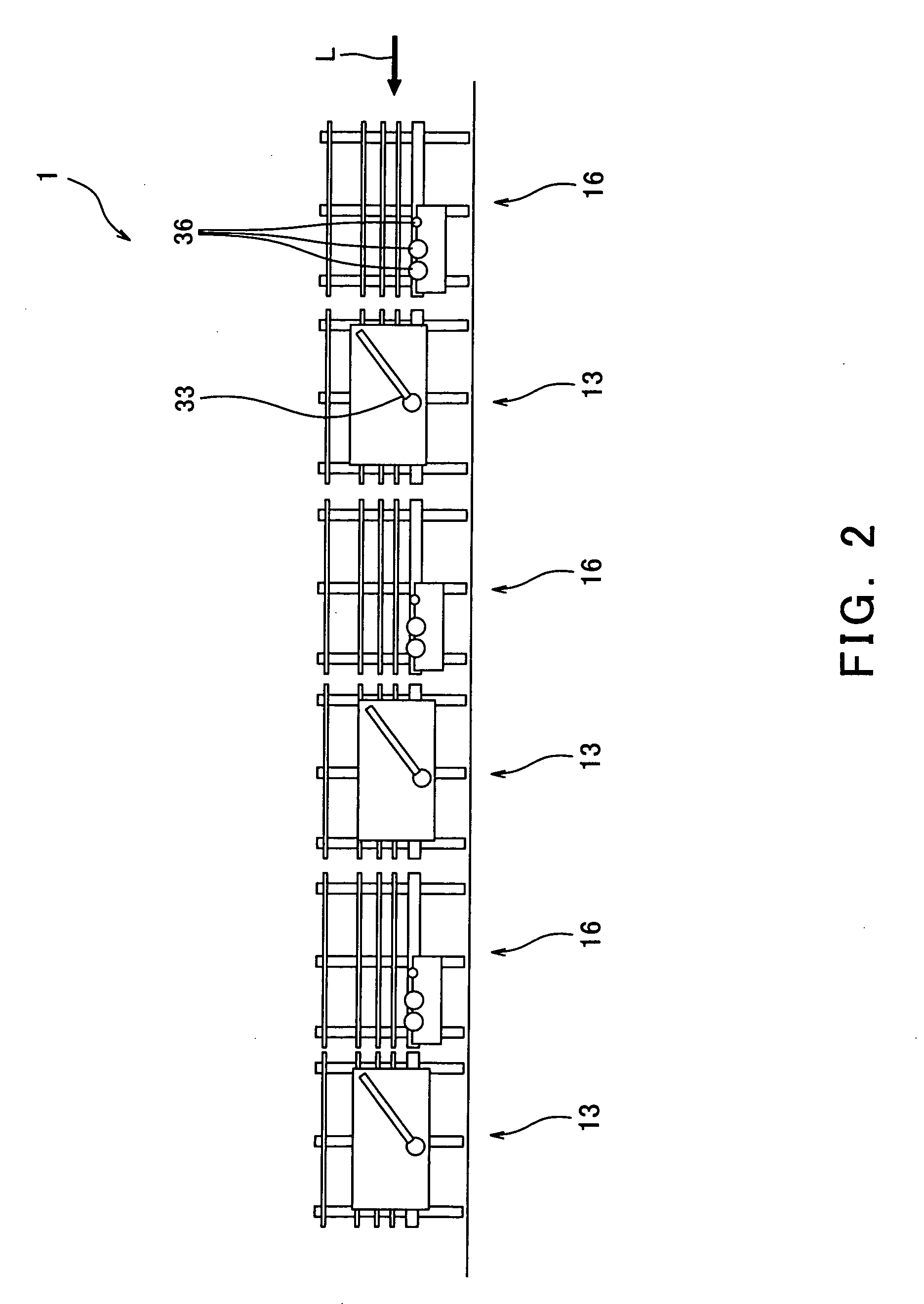

Plate Material Vertical Processing Line

ActiveUS20070271756A1Quality improvementSave installation spaceCharge manipulationSupporting framesHigh pressure waterHigh pressure

A plate material vertical processing line that is capable of subjecting large-sized and thinned glass plates to scribing, venting, etc without degrading their quality, comprises a plurality of processing devices each having a modular structure; wherein each of the processing devices includes a platform; a belt conveyor that is mounted on the platform and is configured to convey a glass plate placed in a substantially upright position while supporting a lower end of the glass plate; and a fluid guide that is mounted on the platform and is configured to apply a fluid pressure to a surface of the glass plate to support the glass plate in the substantially upright position and in a non-contact state; and wherein the processing devices include a combination of at least two processing devices selected from a scribing device, a venting device, a chamfering device, a cleaning agent washing device, a water washing device, a high-pressure water spray device, and a glass plate turn device.

Owner:KAWASAKI HEAVY IND LTD

Directed spray mast

InactiveUS20050045751A1Removed flexiblyEasy to insertHollow article cleaningLiquid spraying apparatusSprayerSpray nozzle

Disclosed is an elongated, tubular, compact high pressure sprayer apparatus for insertion into an access port of vessels having contaminated interior areas that require cleaning by high pressure water spray. The invention includes a spray nozzle and a camera adjacent thereto with means for rotating and raising and lowering the nozzle so that areas identified through the camera may be cleaned with a minimum production of waste water to be removed.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

Visual model testing device and method for simulating water gushing in tunnel

ActiveCN104807960AObserving the Progressive Destruction ProcessEasy to fillMaterial analysisModel testingMonitoring system

The invention discloses a visual model testing device and method for simulating water gushing in a tunnel. The device comprises a model test box, a water tank, a high-pressure water pump, a flow meter, a runoff flow and filling collecting device, a digital photographing non-contact measuring system, an osmotic pressure monitoring system, a fiber grating displacement monitoring system and the like. The testing device is characterized in that the catastrophe evolution process of water gushing in the tunnel is simulated, and anti-gushing rock mass crack growth and water gushing channel formation during water gushing can be directly observed. The device can quantitatively research water gushing behavior of the tunnel under different water pressure, different lithological characters and different thicknesses of anti-gushing rock masses, acquire coupling information of multiple fields such as stress fields, displacement fields, seepage fields and the like during water gushing of the tunnel, determine formation processes and forms of water gushing channels under the effect of different factors, disclose mechanical characteristics and evolution laws in anti-gushing rock mass structure progressive failure processes and provide an effective basis for the tunnel water gushing disaster incoming criterion and the minimum safe thickness analysis method.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com