Patents

Literature

281 results about "Lighter fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lighter fluid or lighter fuel may refer to: Butane, a highly flammable, colorless, easily liquefied gas used in gas-type lighters and butane torches. Naphtha, a volatile flammable liquid hydrocarbon mixture used in wick-type lighters and burners. Charcoal lighter fluid, an aliphatic petroleum solvent used in lighting charcoal in a barbecue grill.

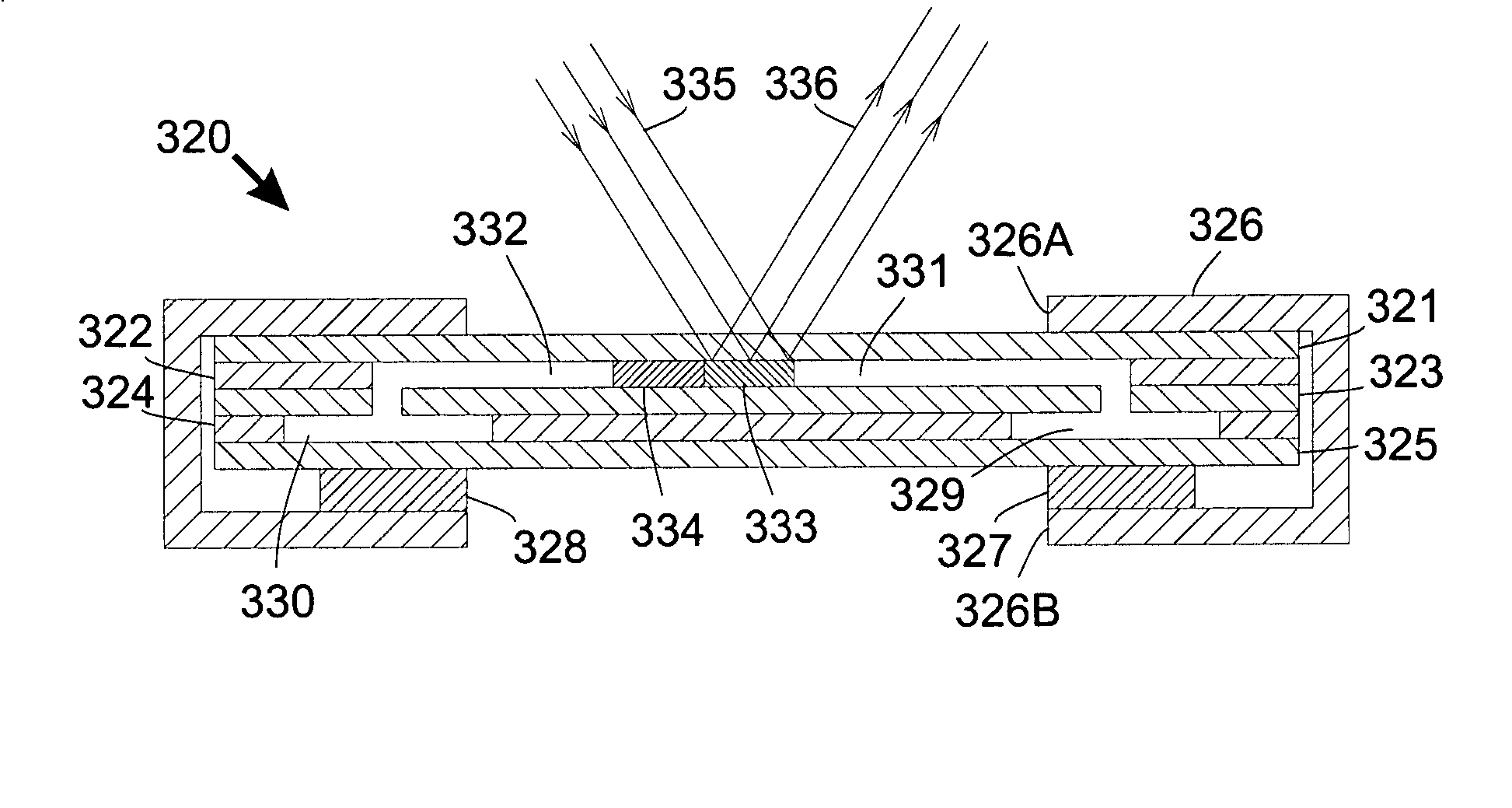

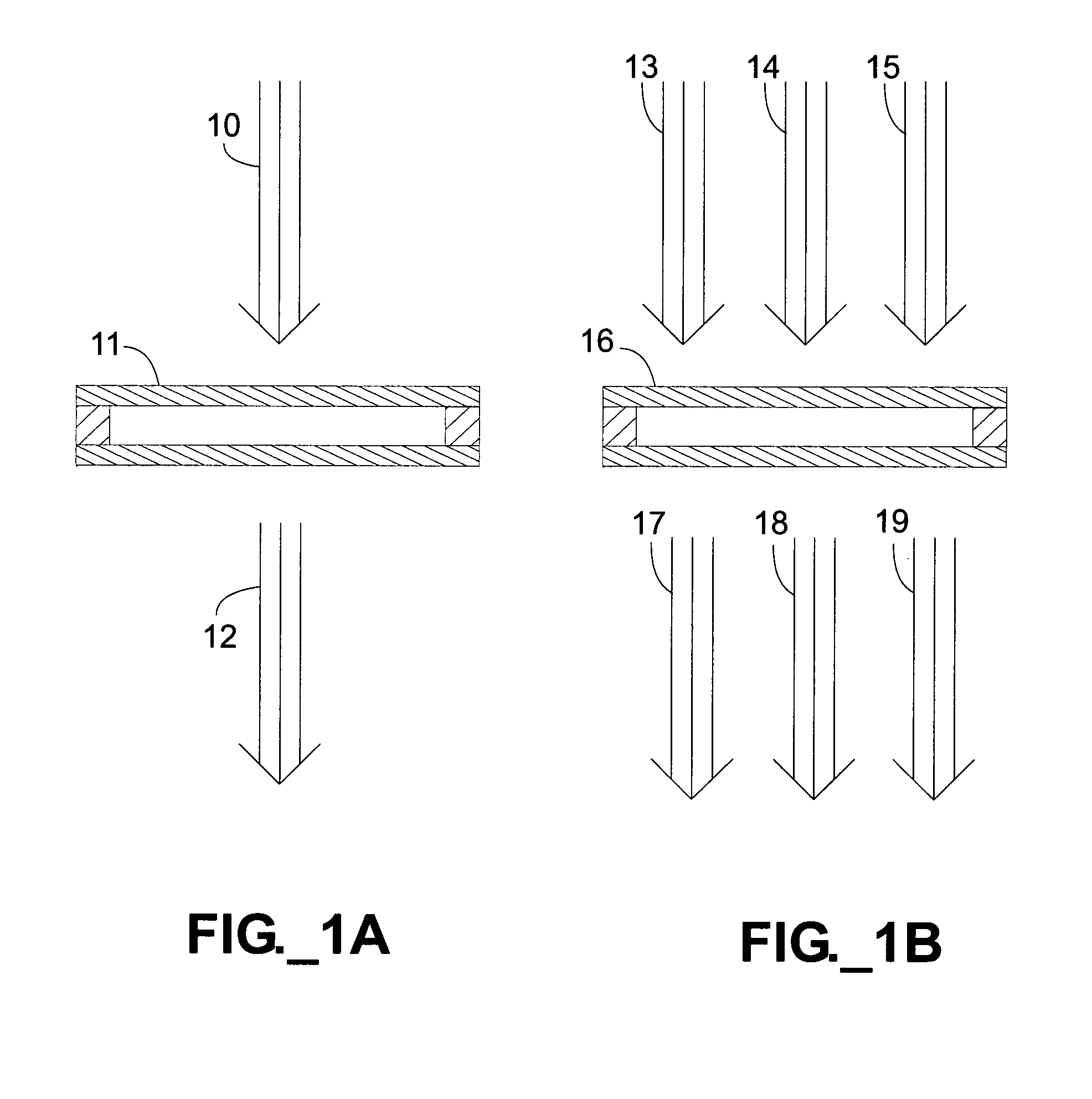

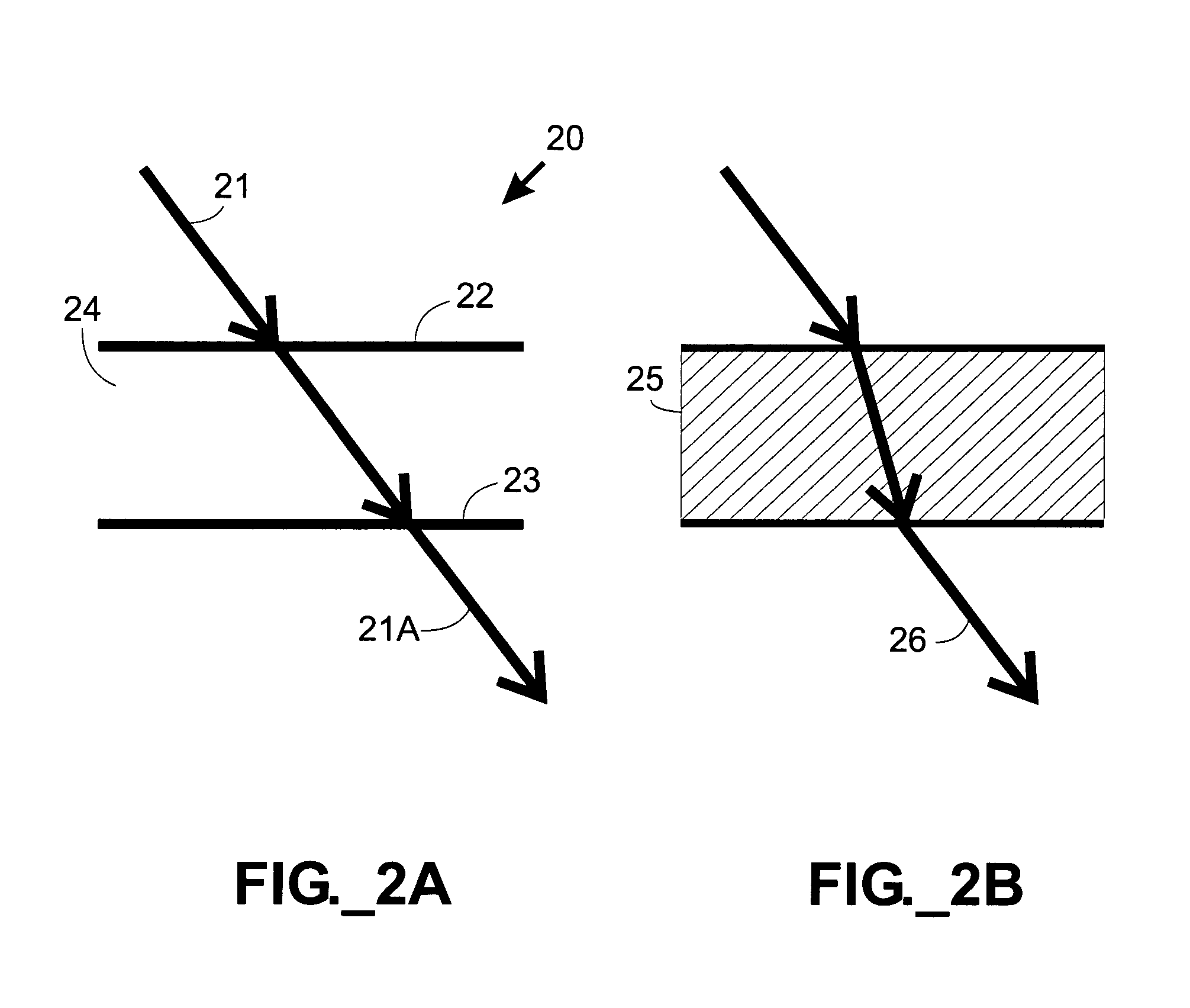

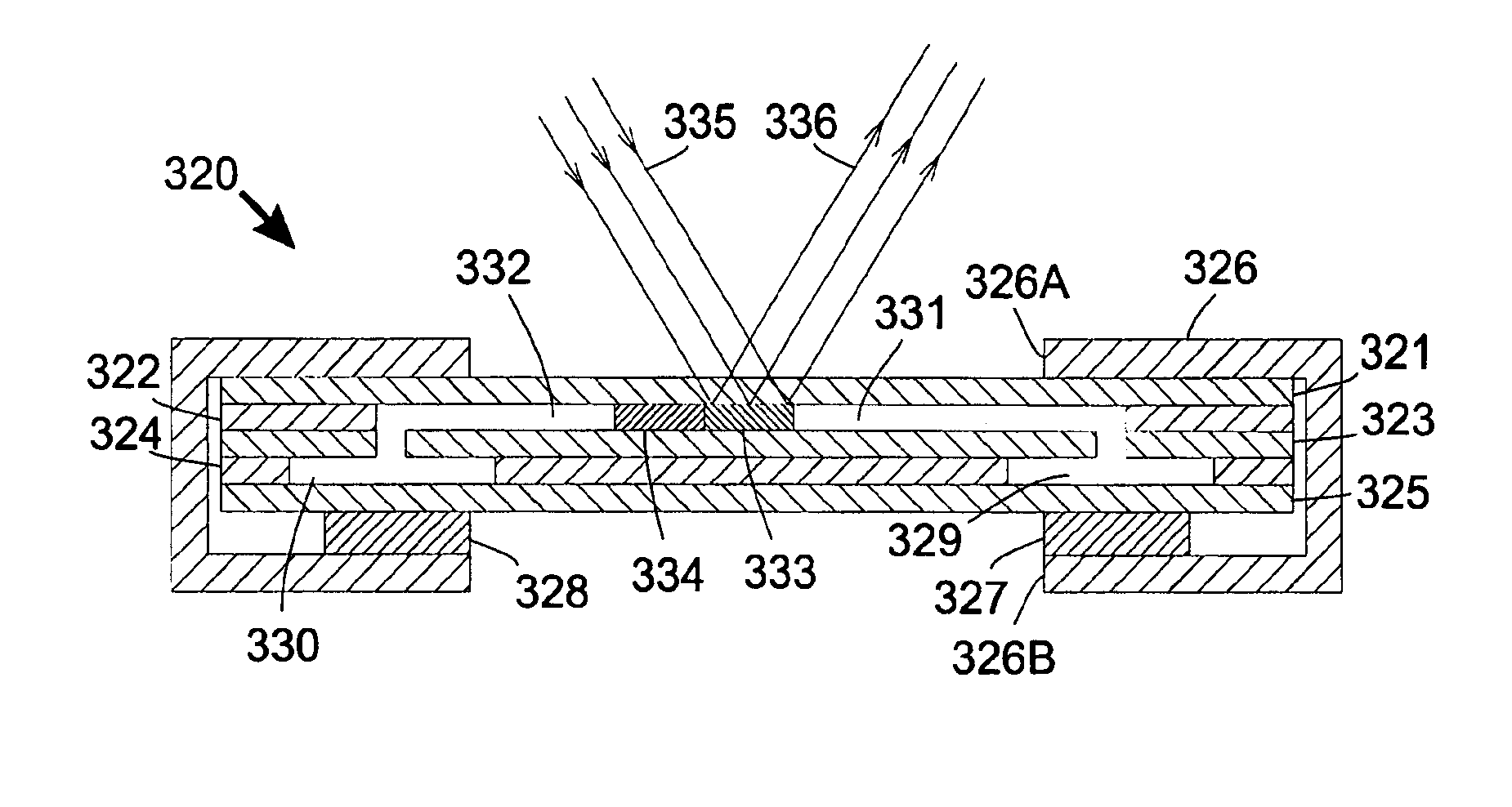

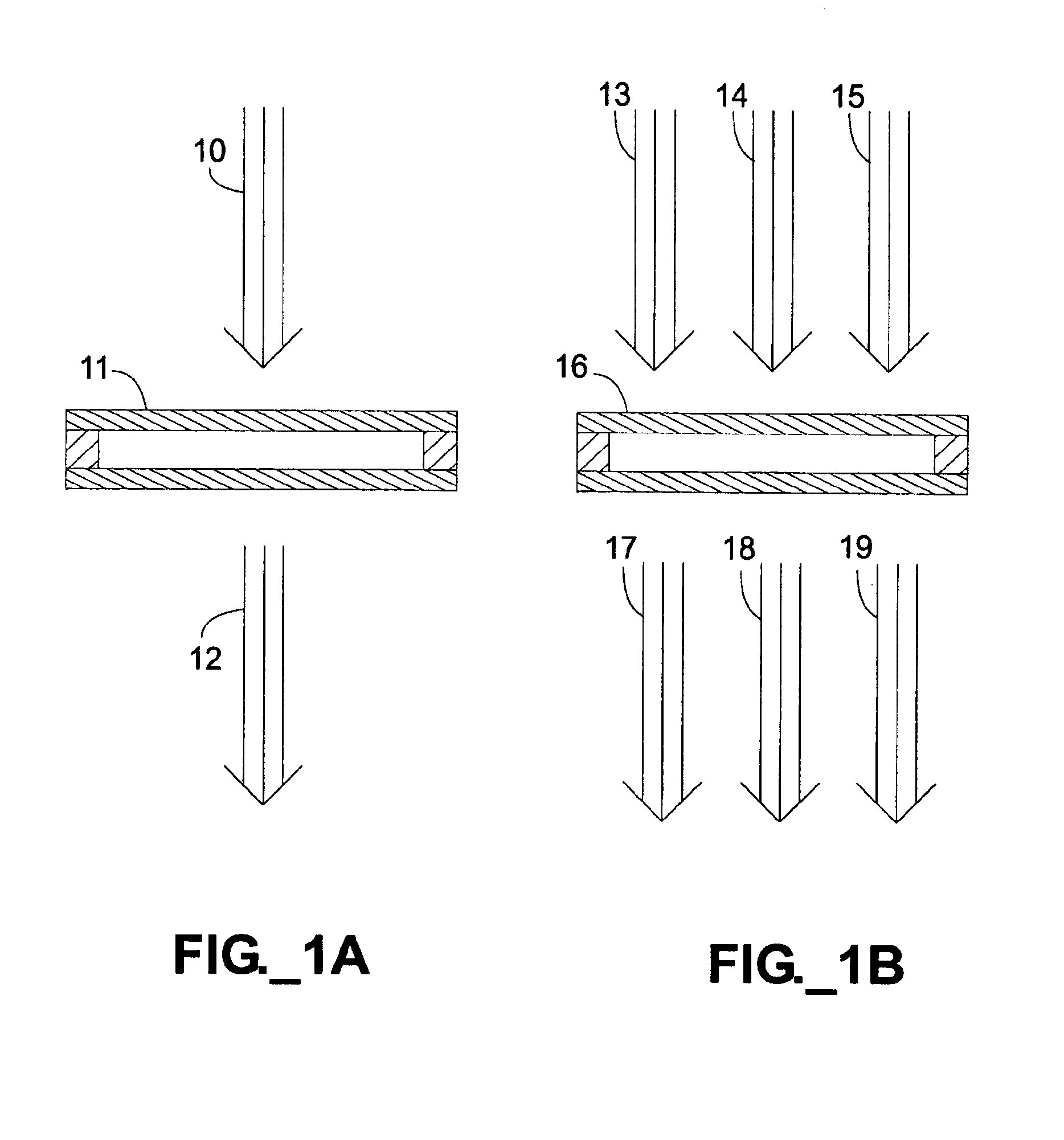

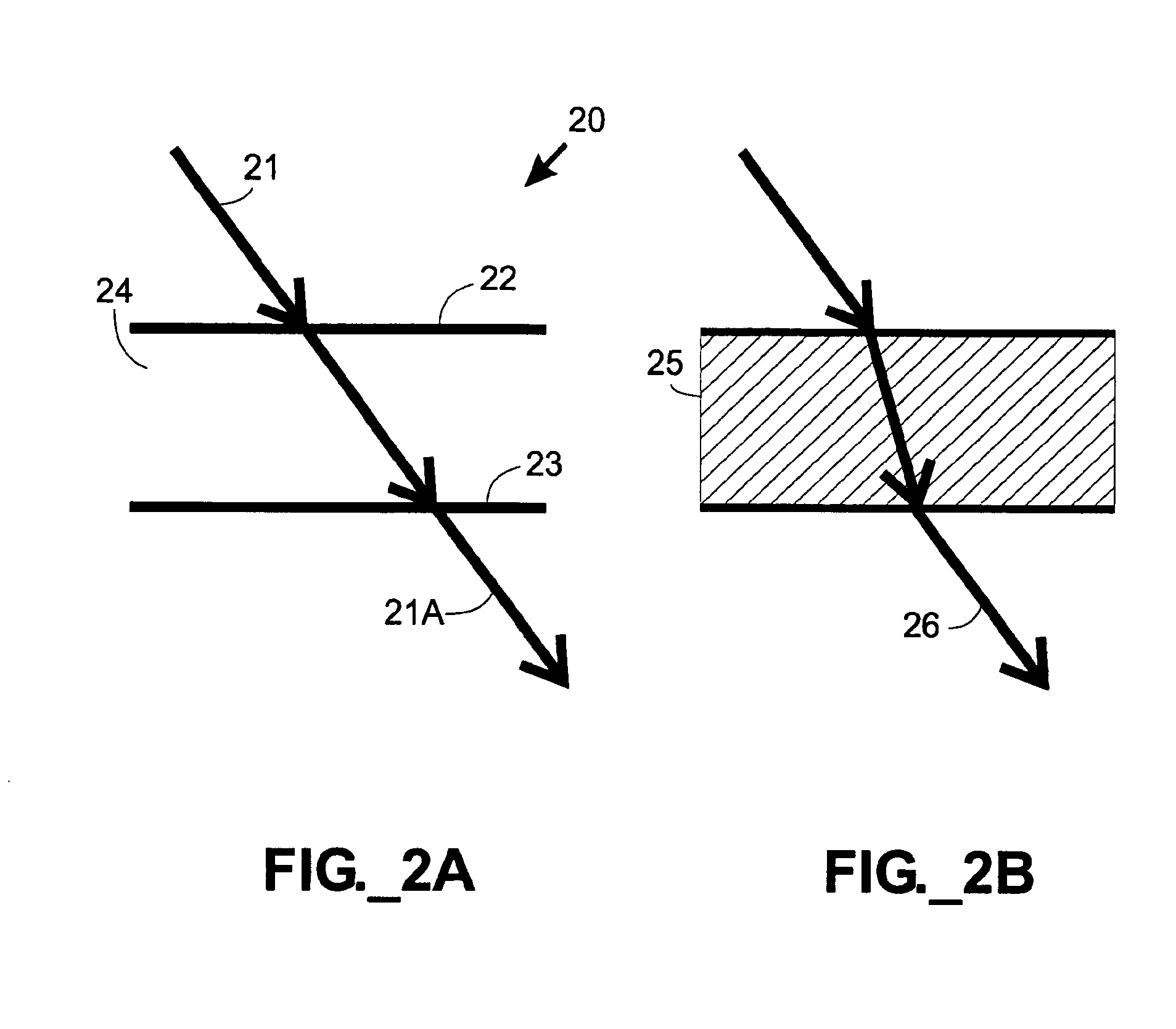

Optical devices with fluidic systems

Fluidic systems, including microfluidic systems, are used to manipulate light by light-fluid interaction so as to affect reflection, refraction, absorption, optical filtering, or scattering of the beam. One or more fluids may be provided to a channel or chamber and exposed to an incident beam, and the proportion of at least one of a plurality of fluids may be varied. Light may interact with a discrete fluid plug subject to movement within a channel. One or more flexible members may be employed, such as to provide a variable lens. Fluidic optical devices may be used in applications including optical switching, optical filtering, or optical processing. Multiplexed fluidic optical systems are further provided.

Owner:AGILENT TECH INC

Optical devices with fluidic systems

Fluidic systems, including microfluidic systems, are used to manipulate light by light-fluid interaction so as to affect reflection, refraction, absorption, optical filtering, or scattering of the beam. One or more fluids may be provided to a channel or chamber and exposed to an incident beam, and the proportion of at least one of a plurality of fluids may be varied. Light may interact with a discrete fluid plug subject to movement within a channel. One or more flexible members may be employed, such as to provide a variable lens. Fluidic optical devices may be used in applications including optical switching, optical filtering, or optical processing. Multiplexed fluidic optical systems are further provided.

Owner:AGILENT TECH INC

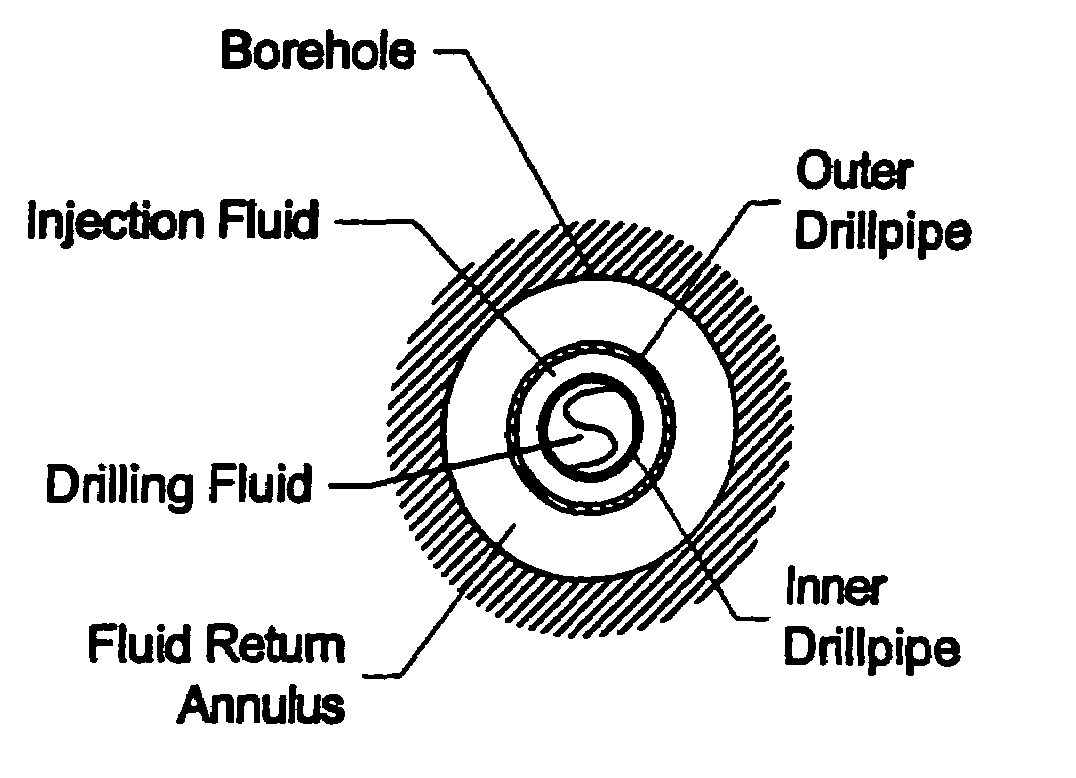

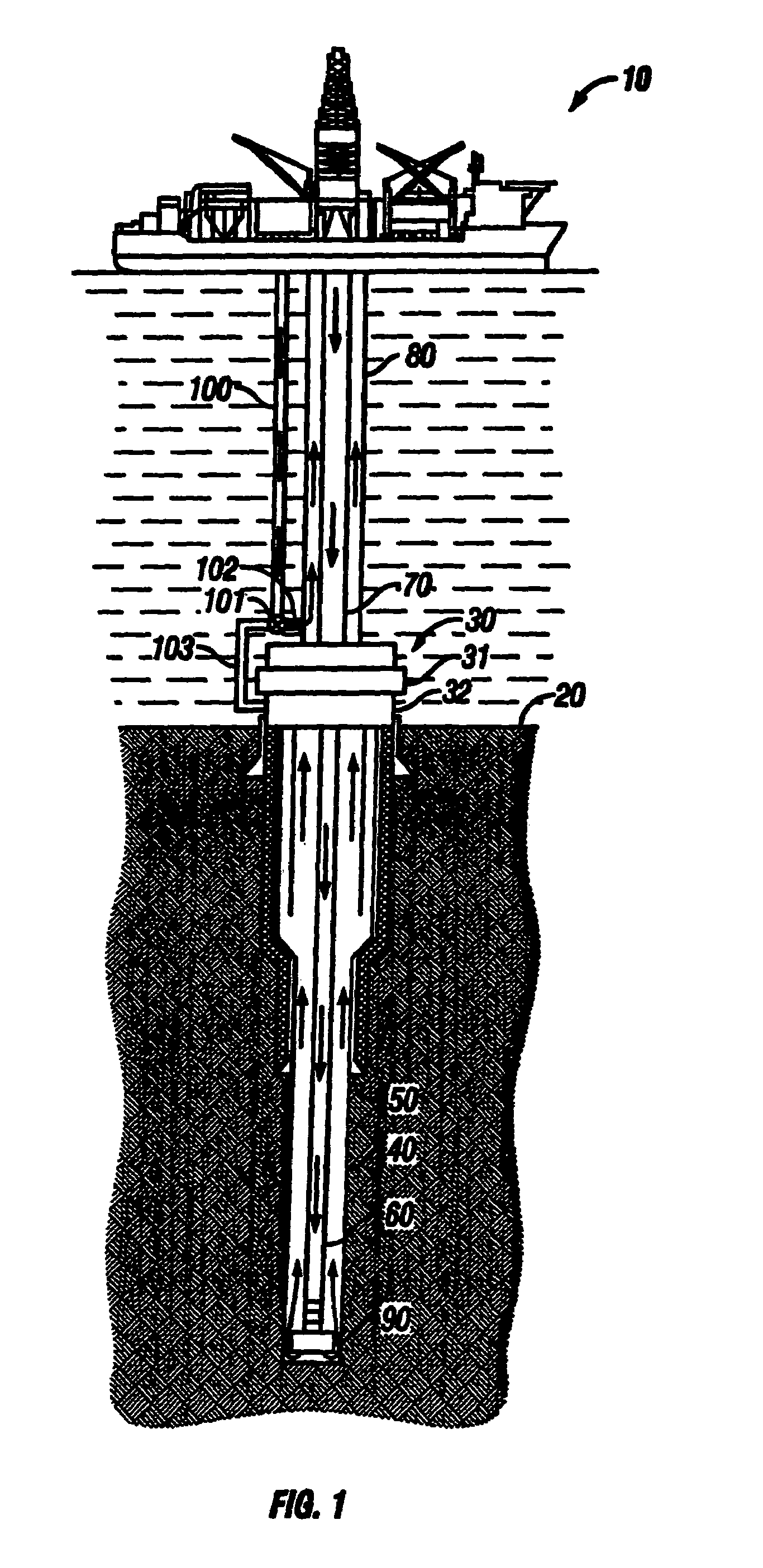

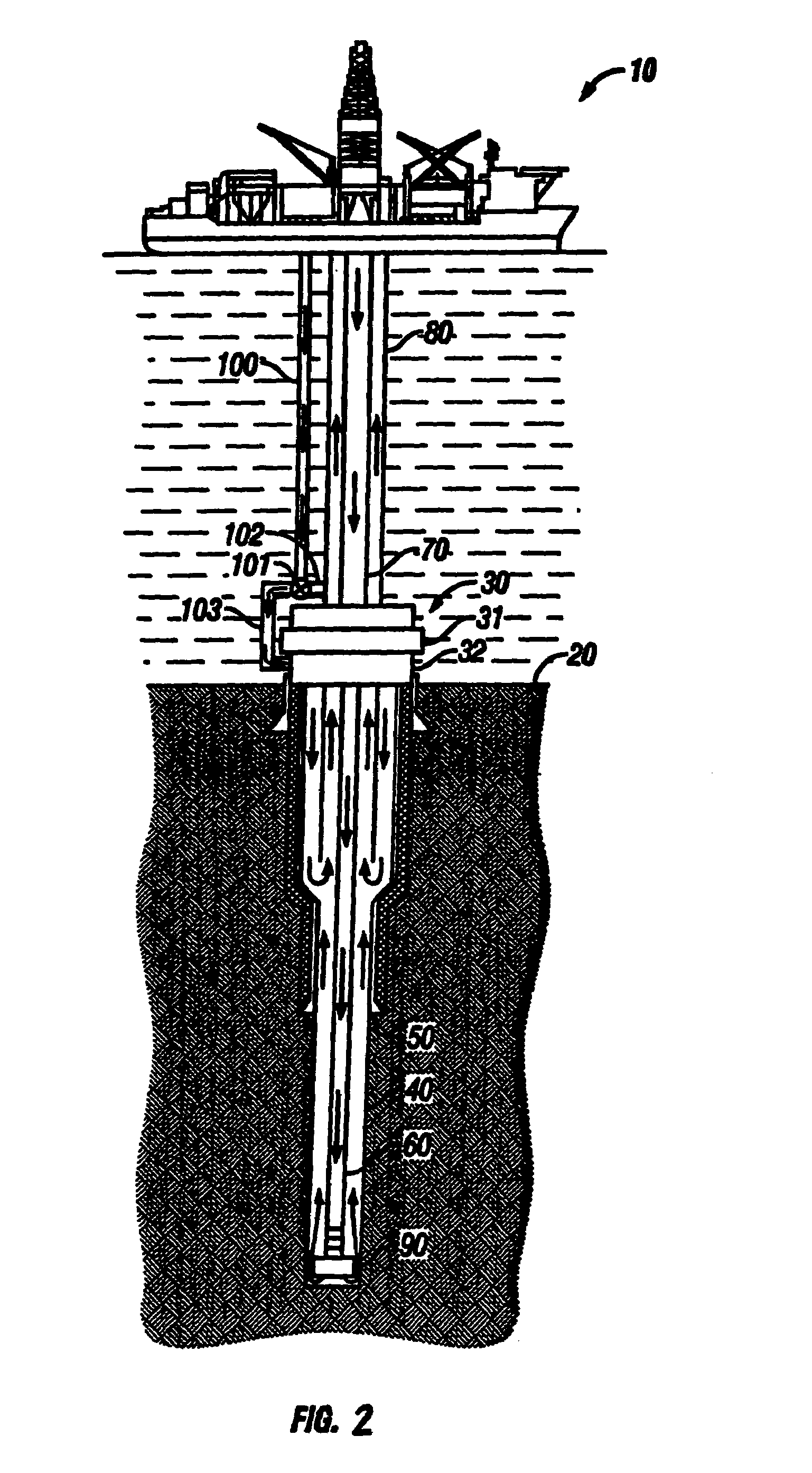

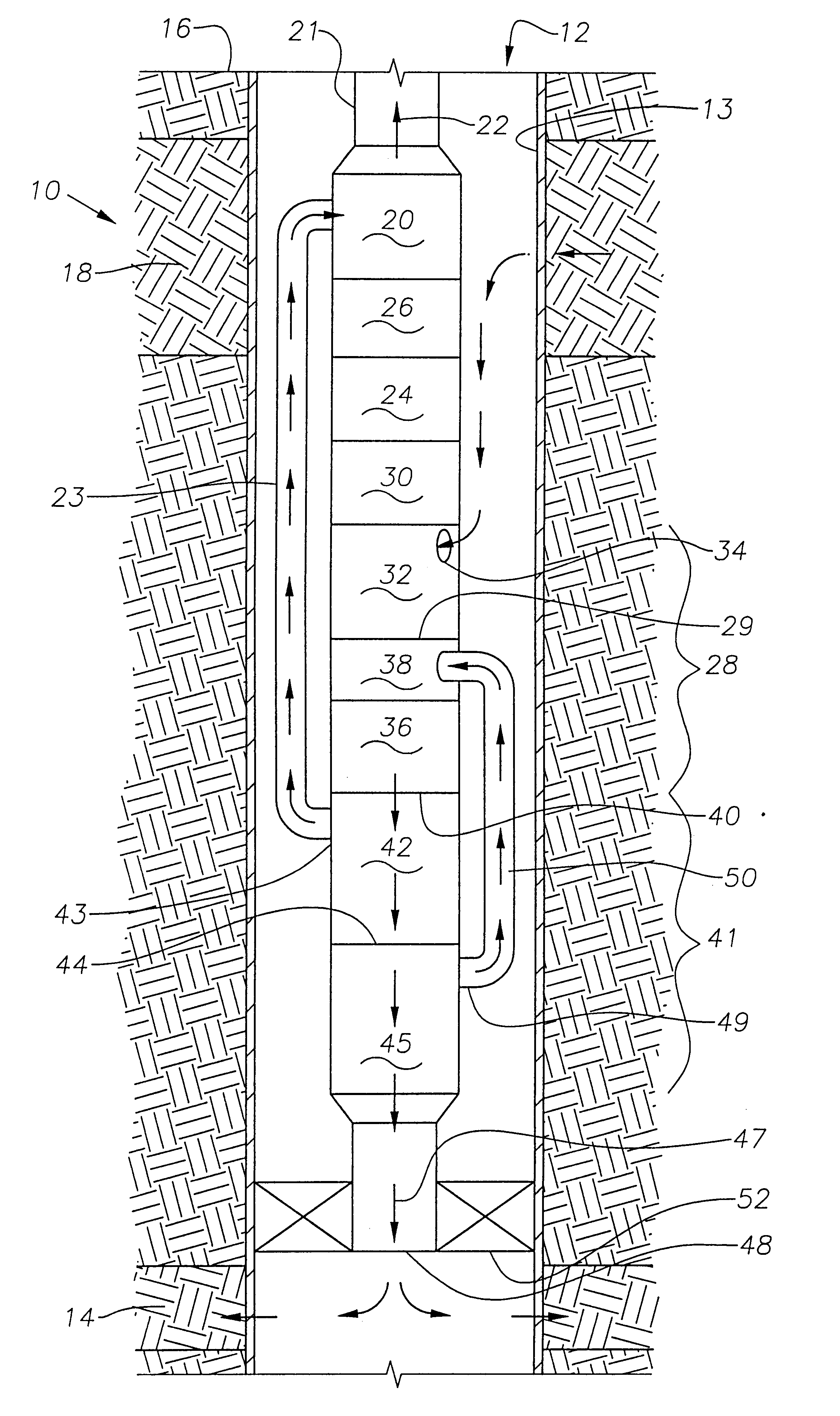

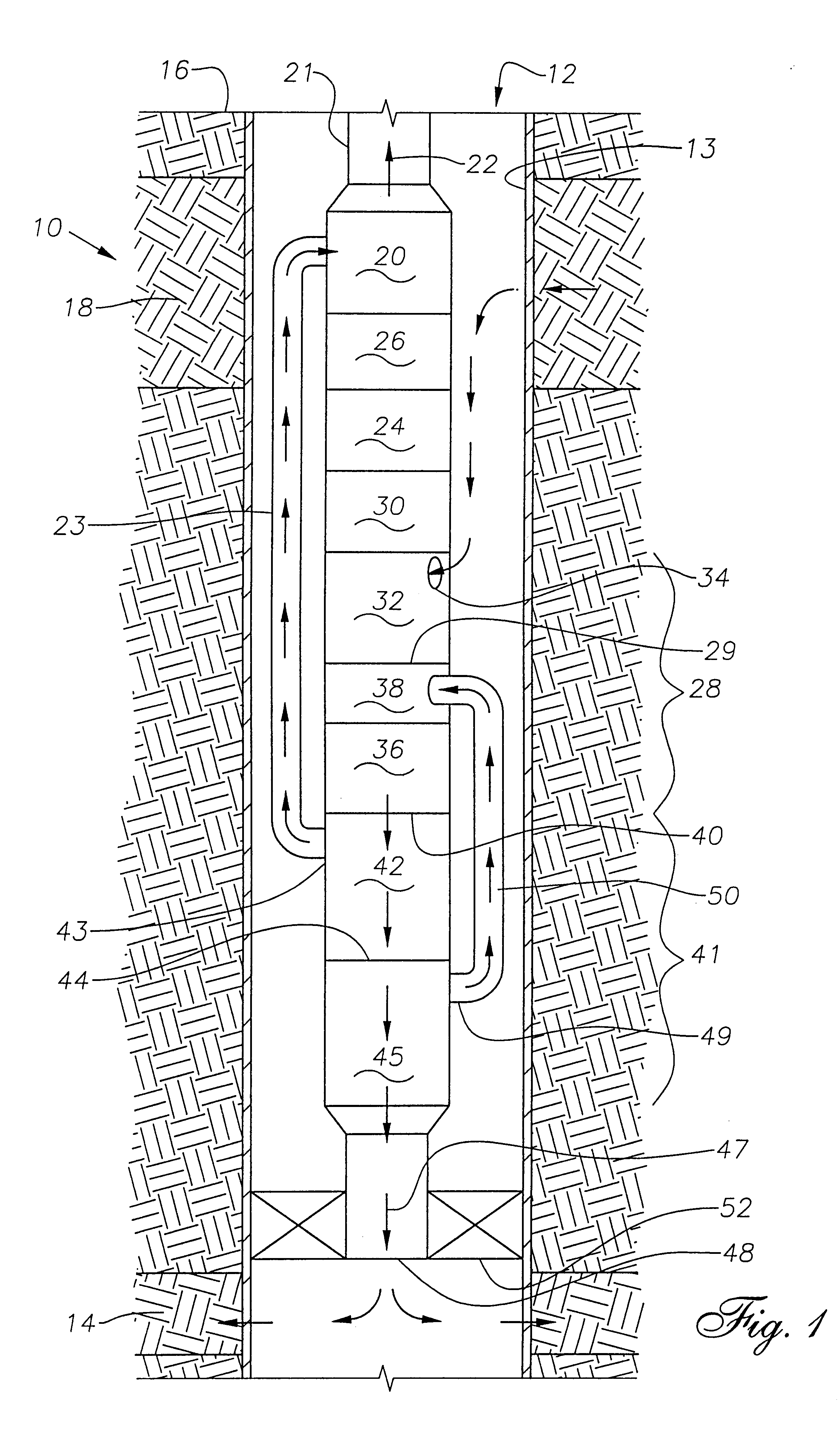

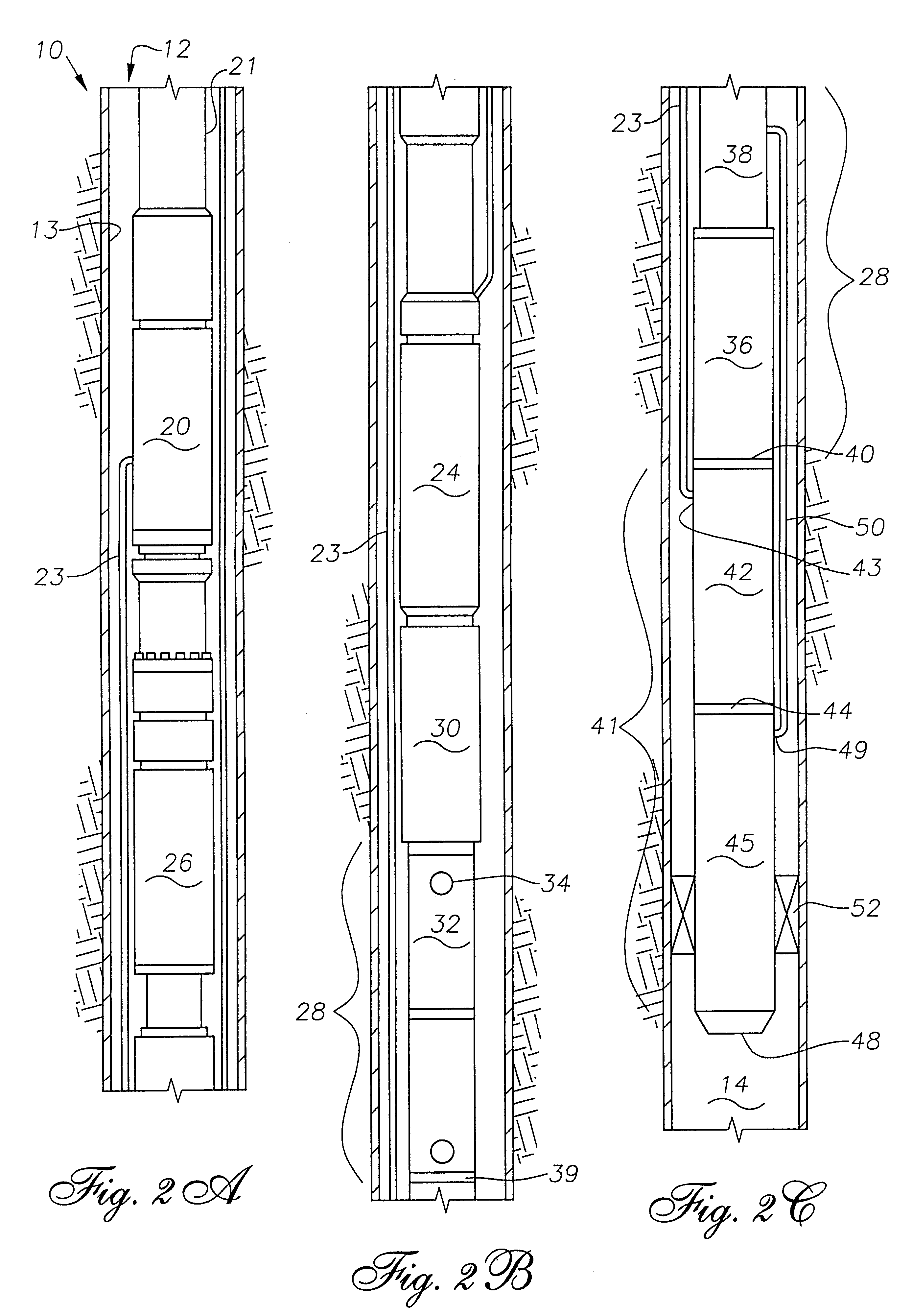

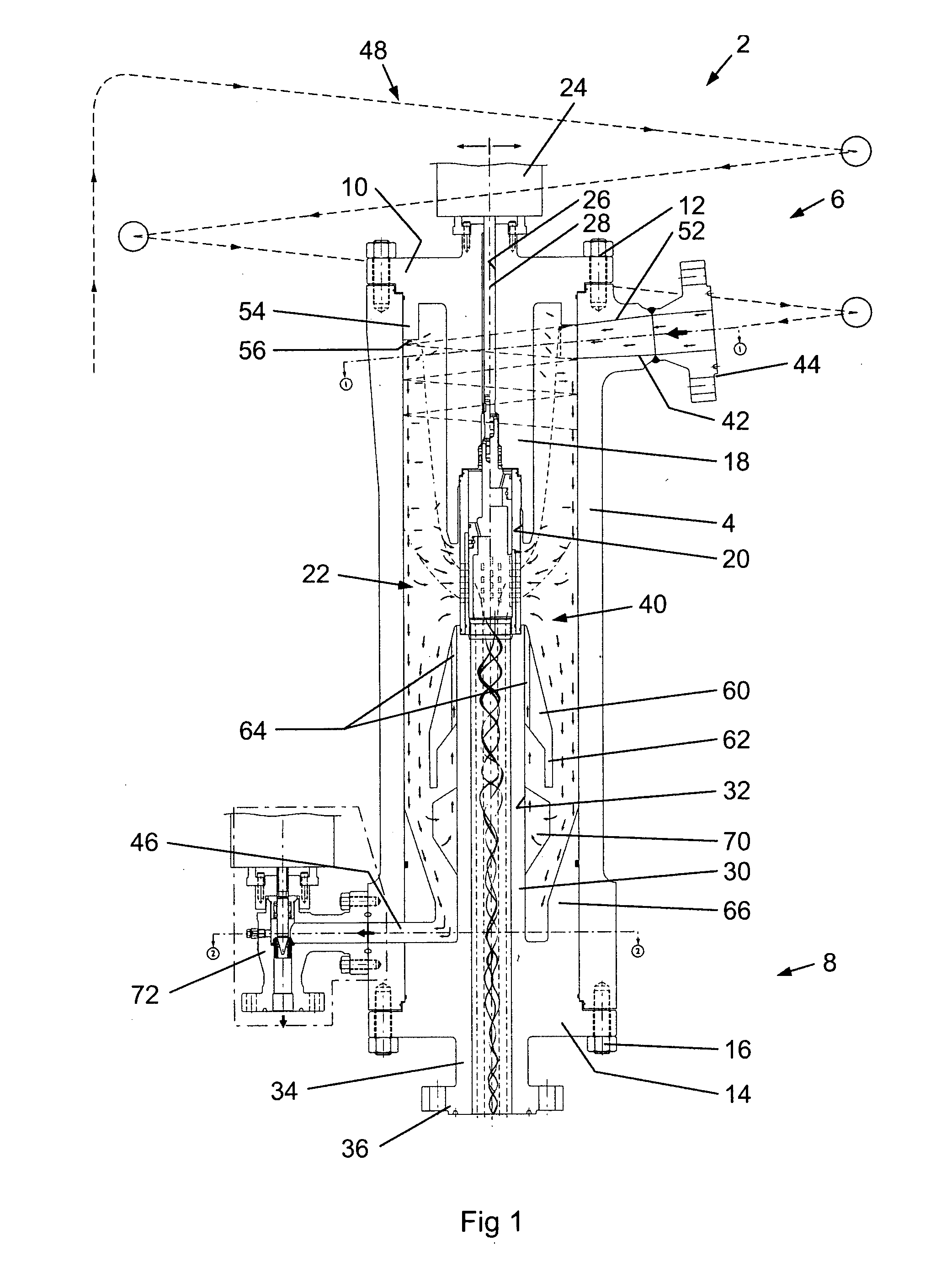

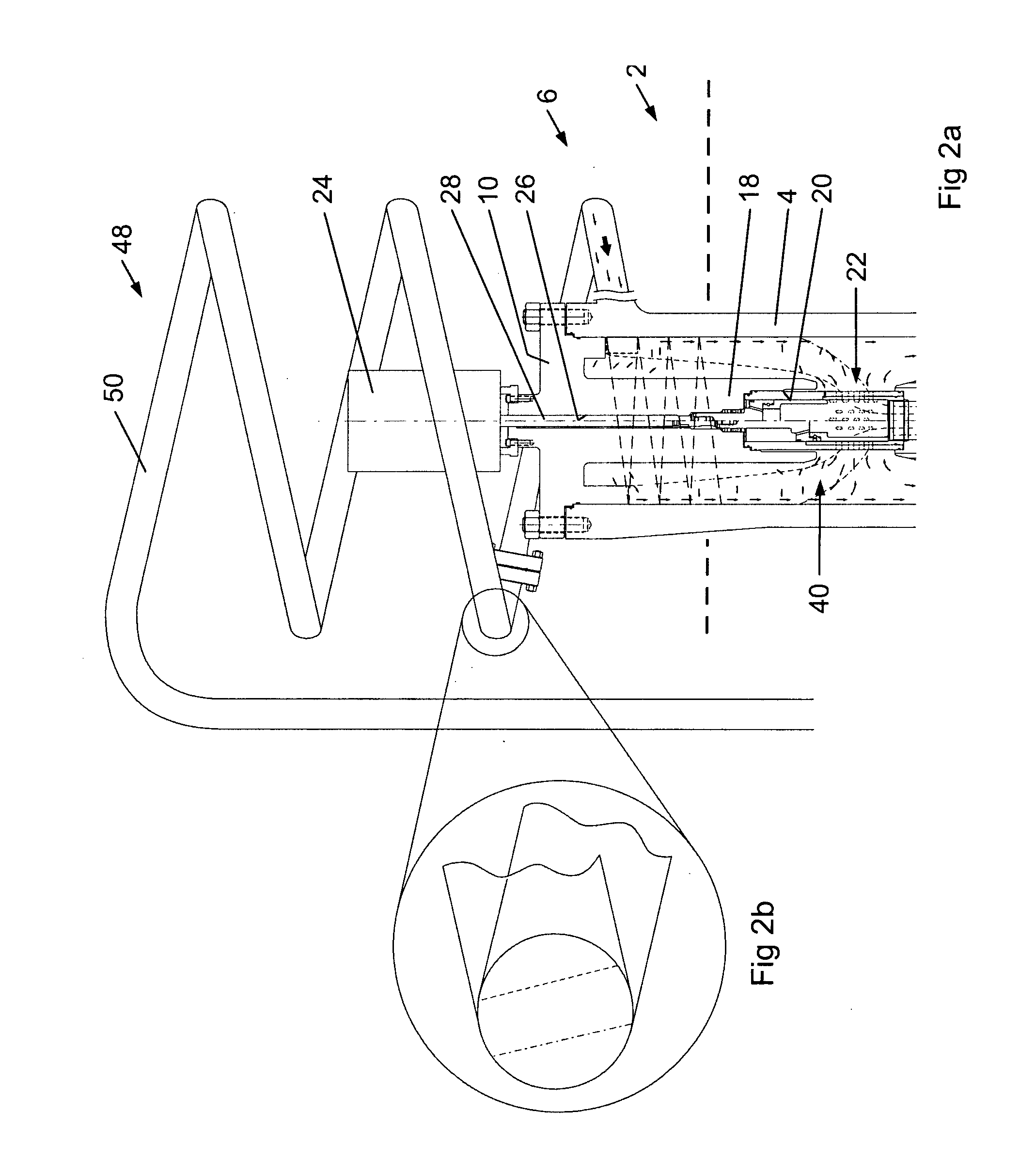

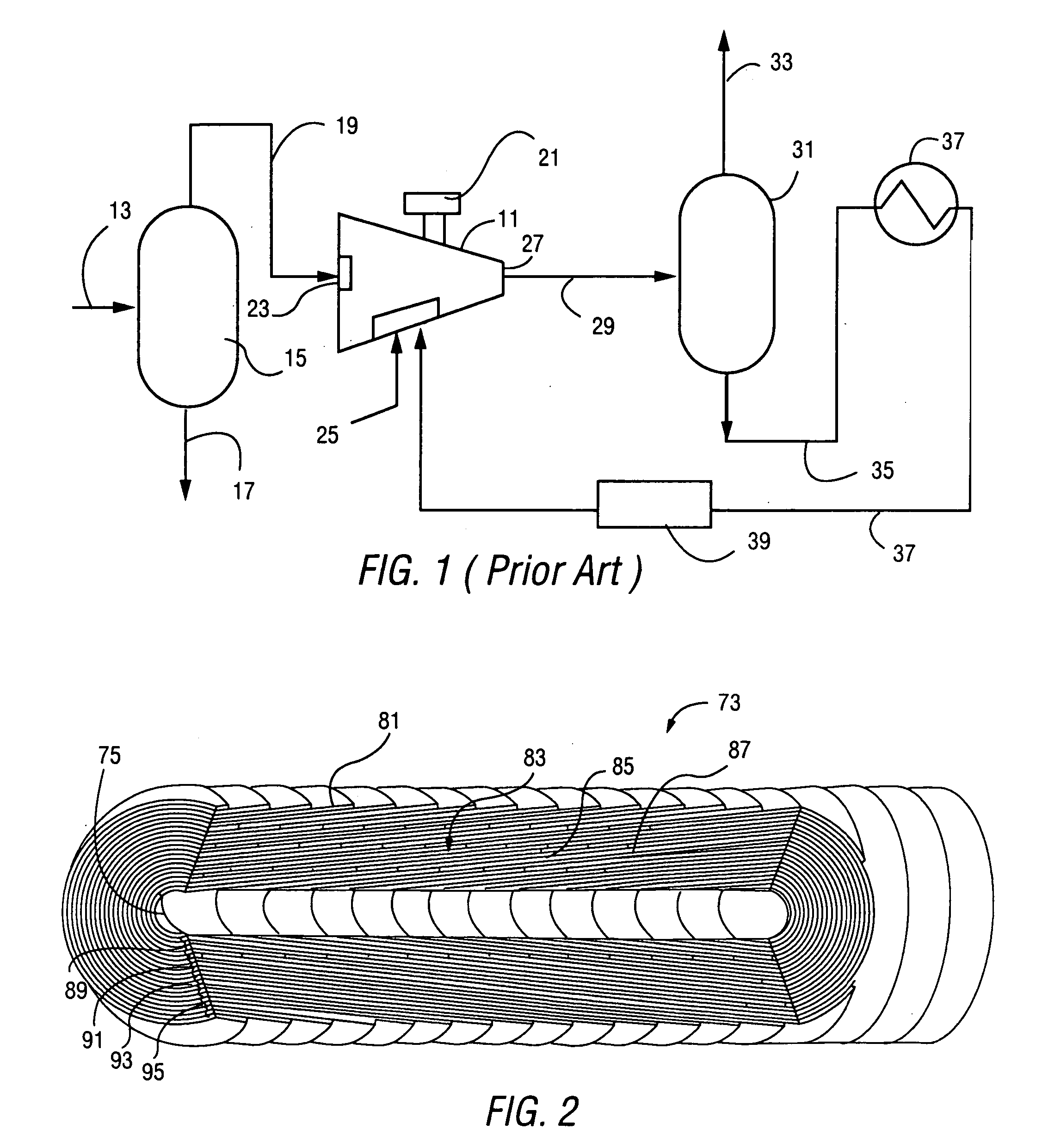

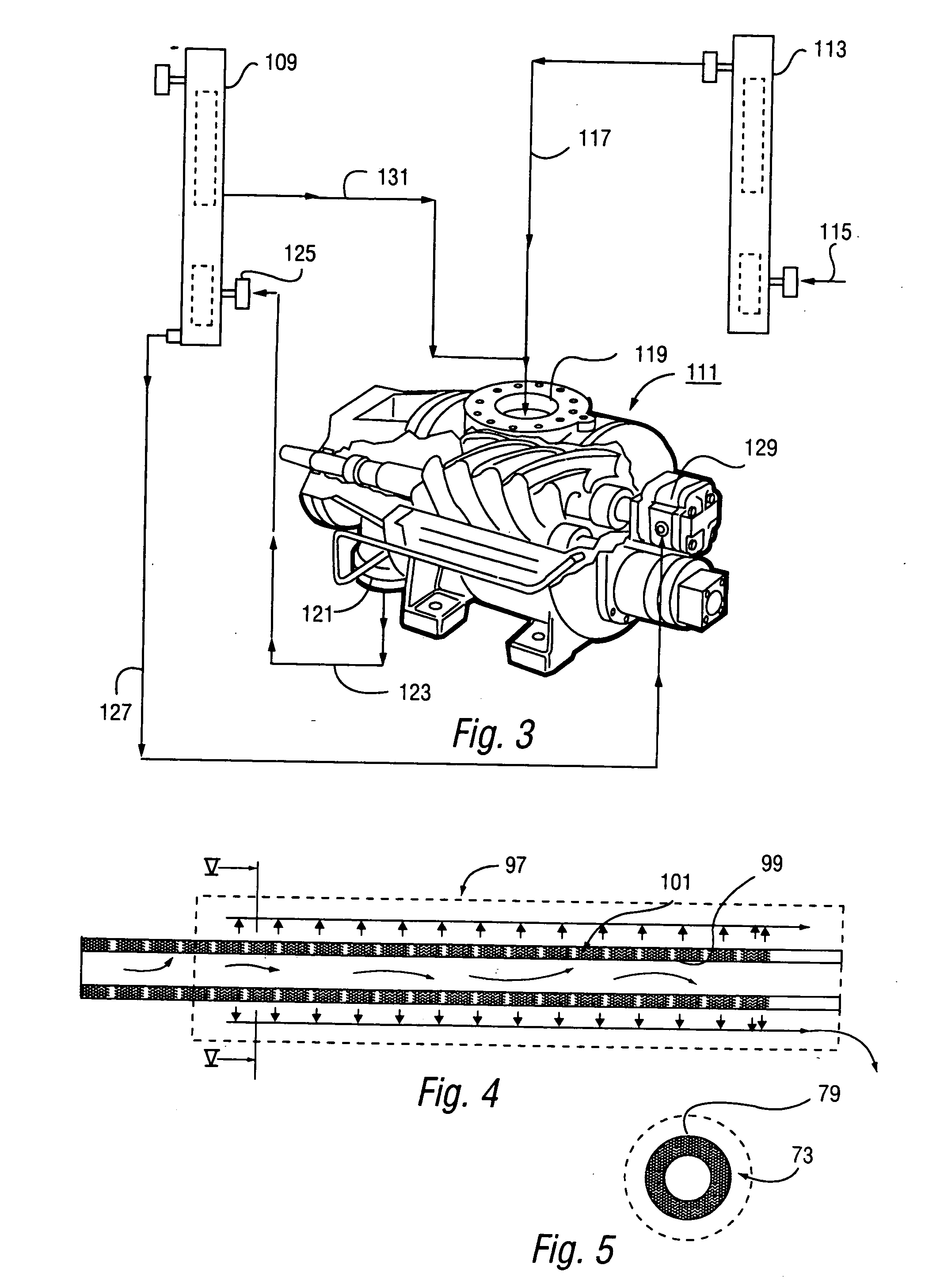

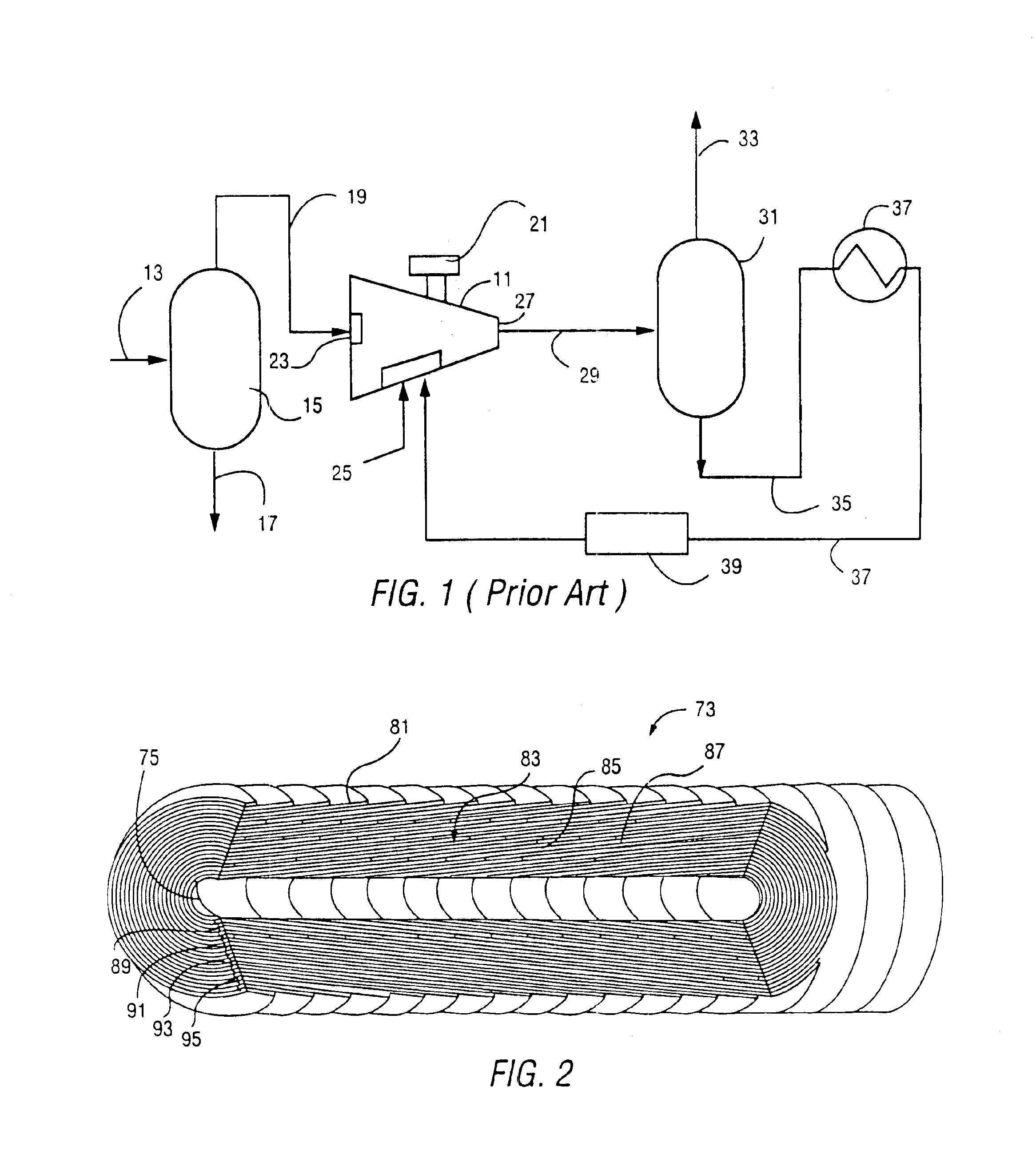

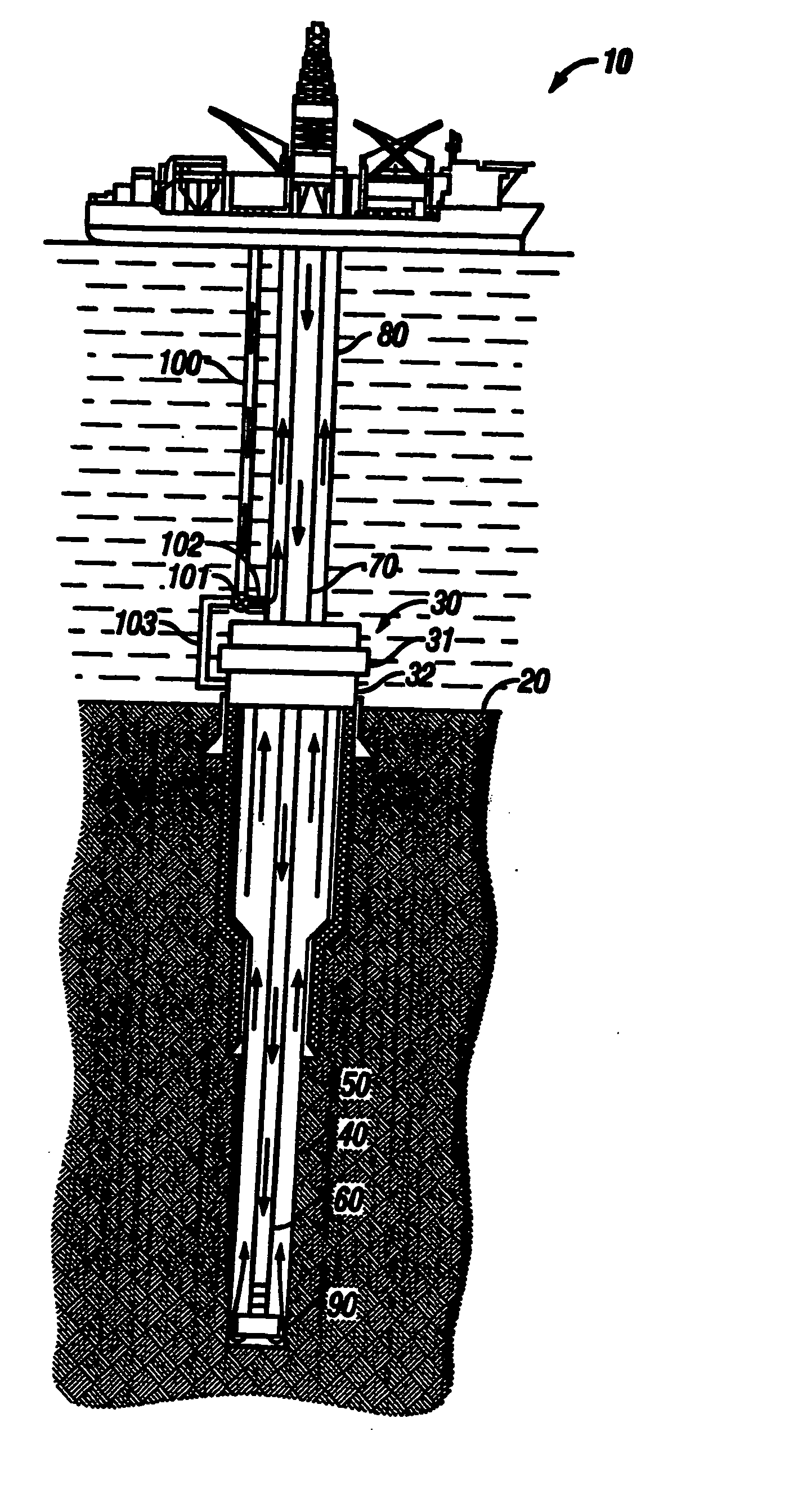

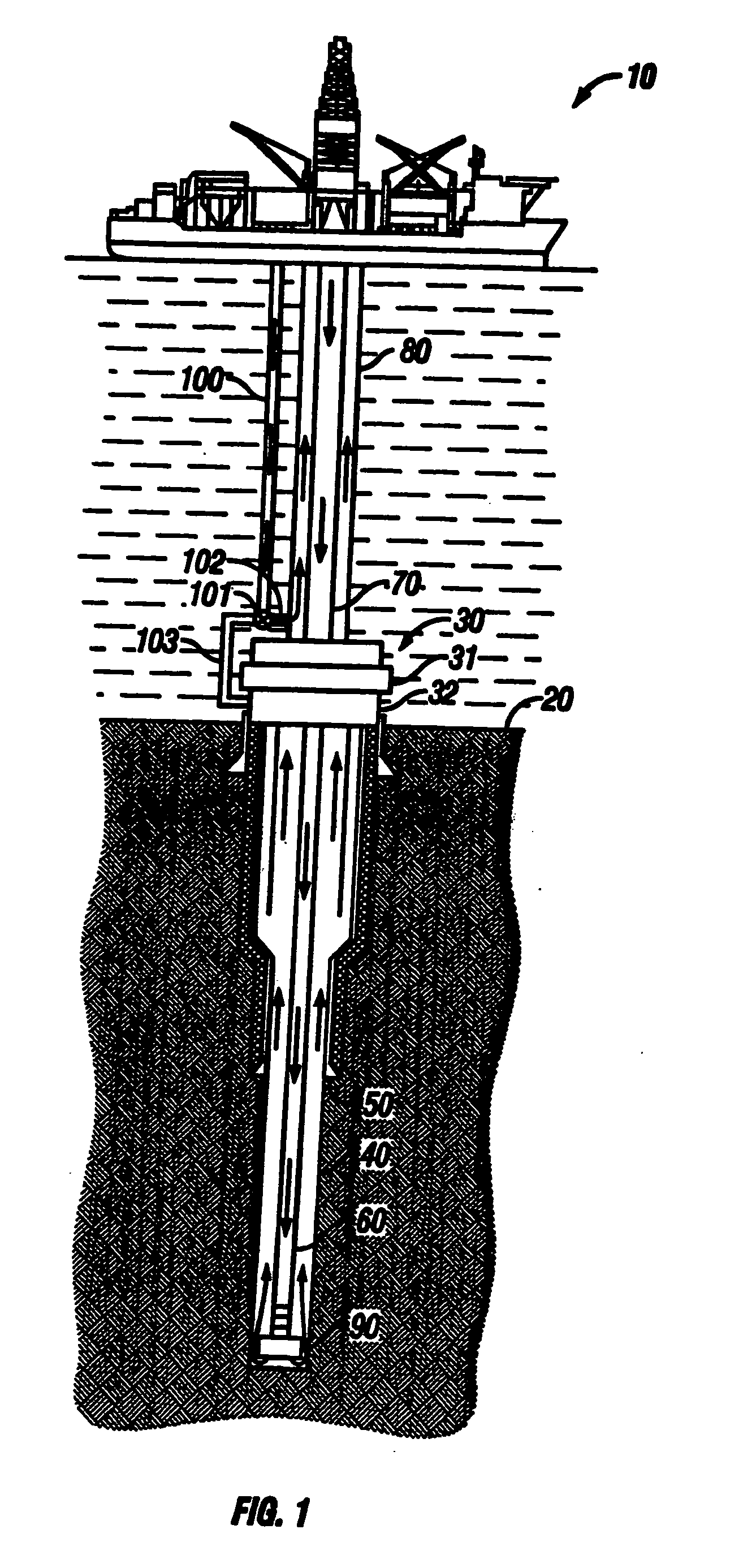

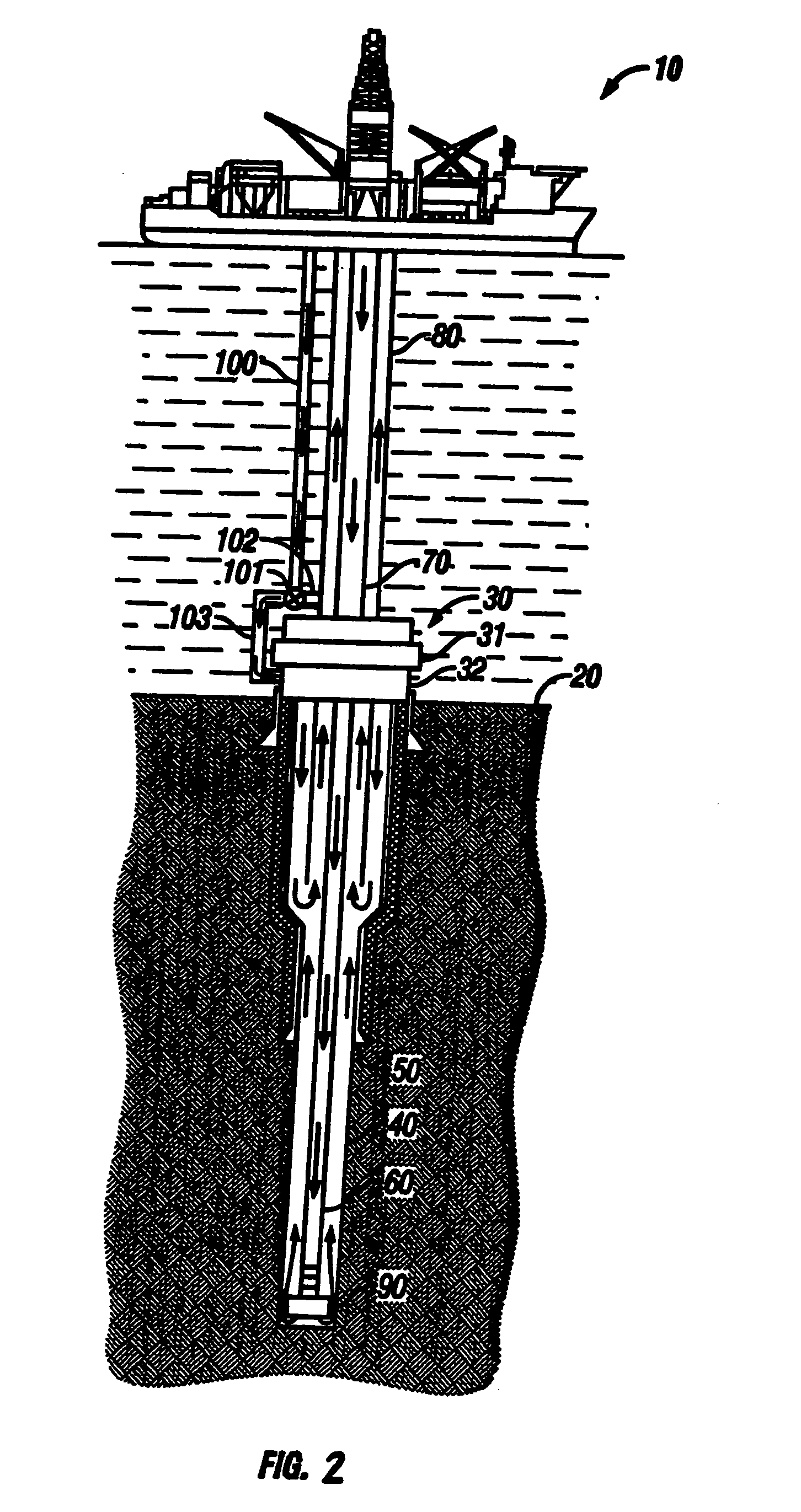

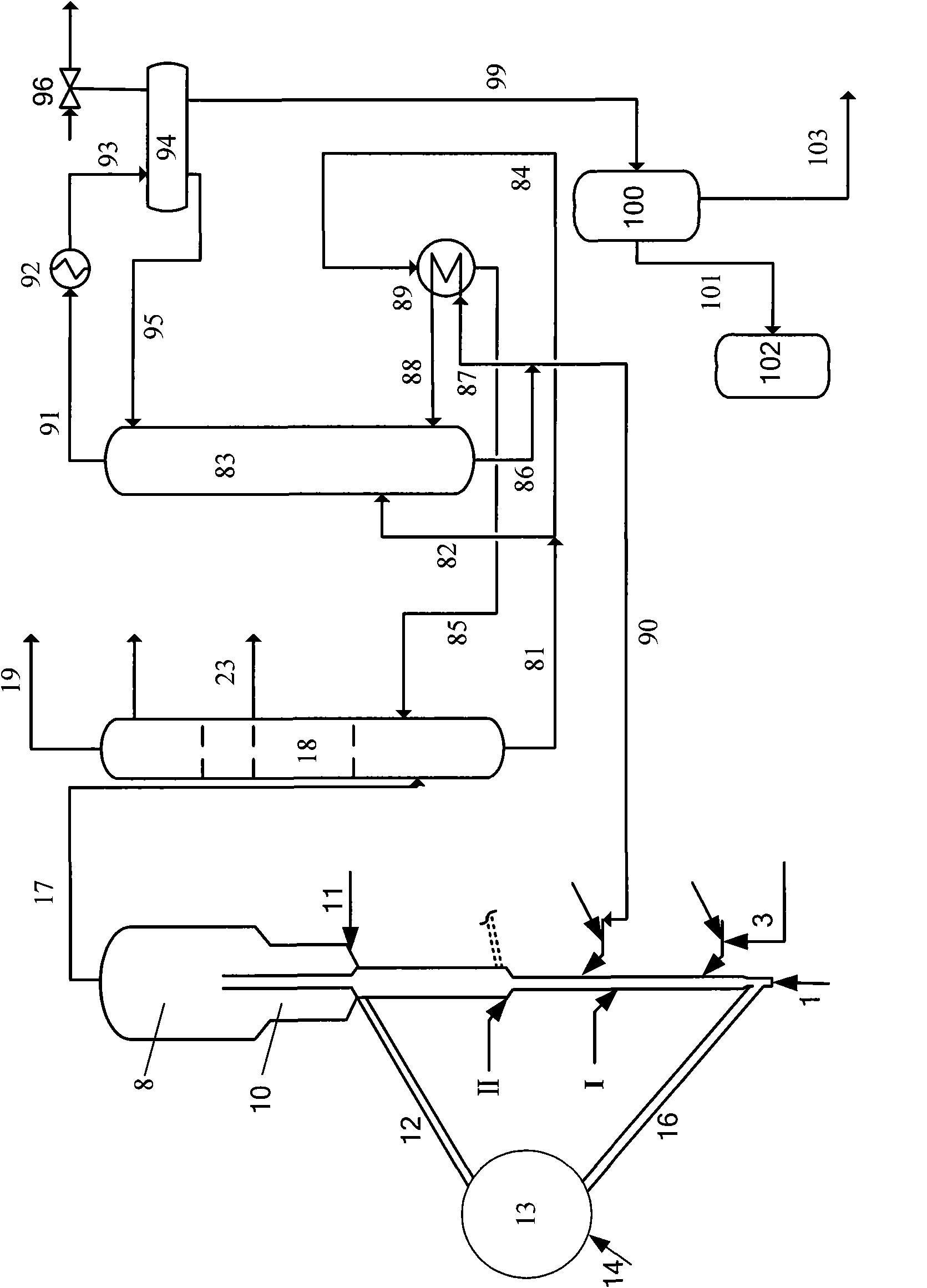

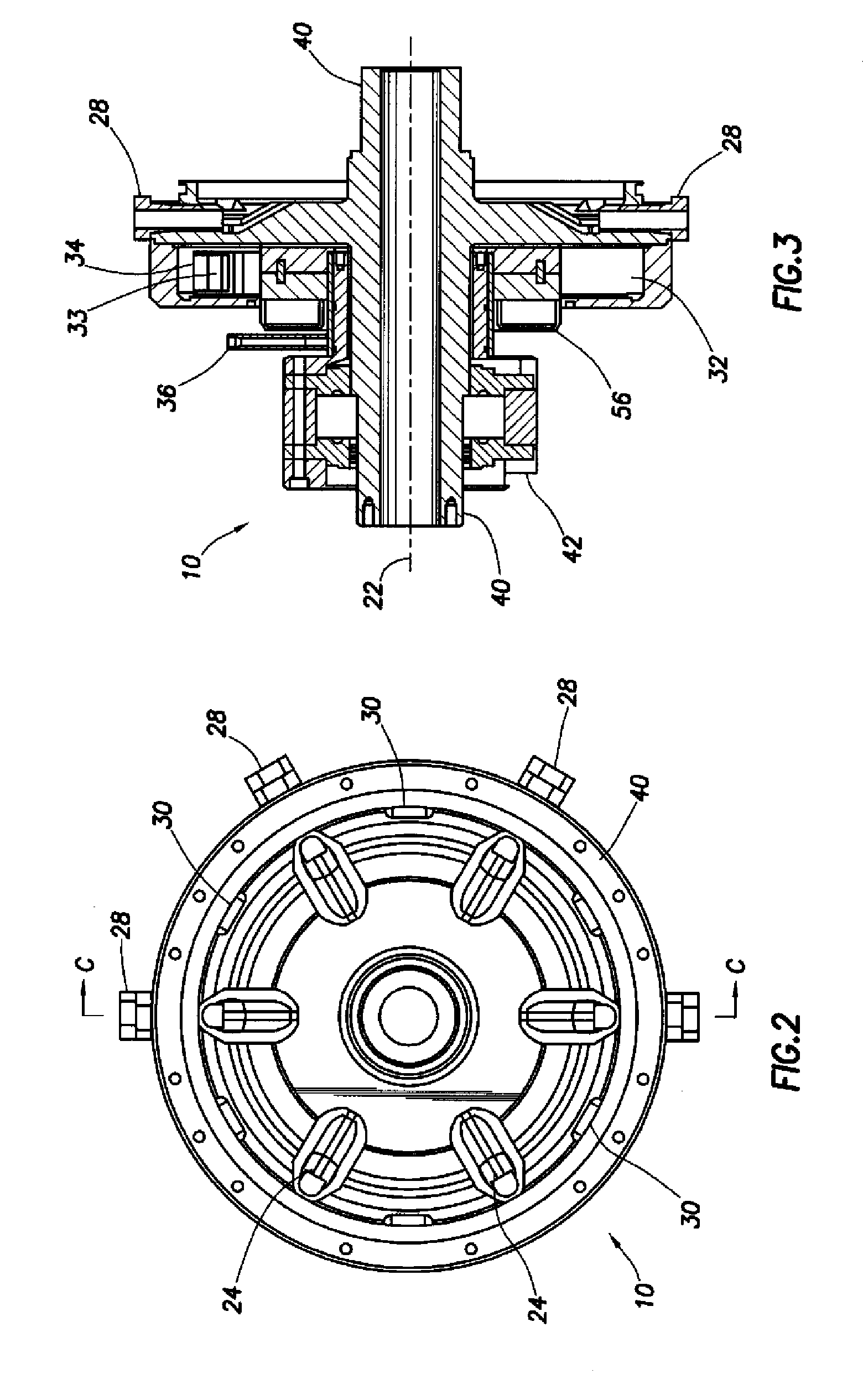

System for drilling oil and gas wells using a concentric drill string to deliver a dual density mud

InactiveUS7093662B2Decreasing/increasing densityHigh speedSurveyConstructionsSeawaterTreatment system

A system for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in offshore and land-based drilling applications is disclosed. The present invention combines a base fluid of lesser / greater density than the drilling fluid required at the drill bit to drill the well to produce a combination return mud in the riser. By combining the appropriate quantities of drilling mud with a light fluid, a riser mud density at or near the density of seawater may be achieved to facilitate transporting the return mud to the surface. Alternatively, by injecting the appropriate quantities of heavy fluid into a light return mud, the column of return mud may be sufficiently weighted to protect the wellhead. At the surface, the combination return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the drilling fluid from the base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

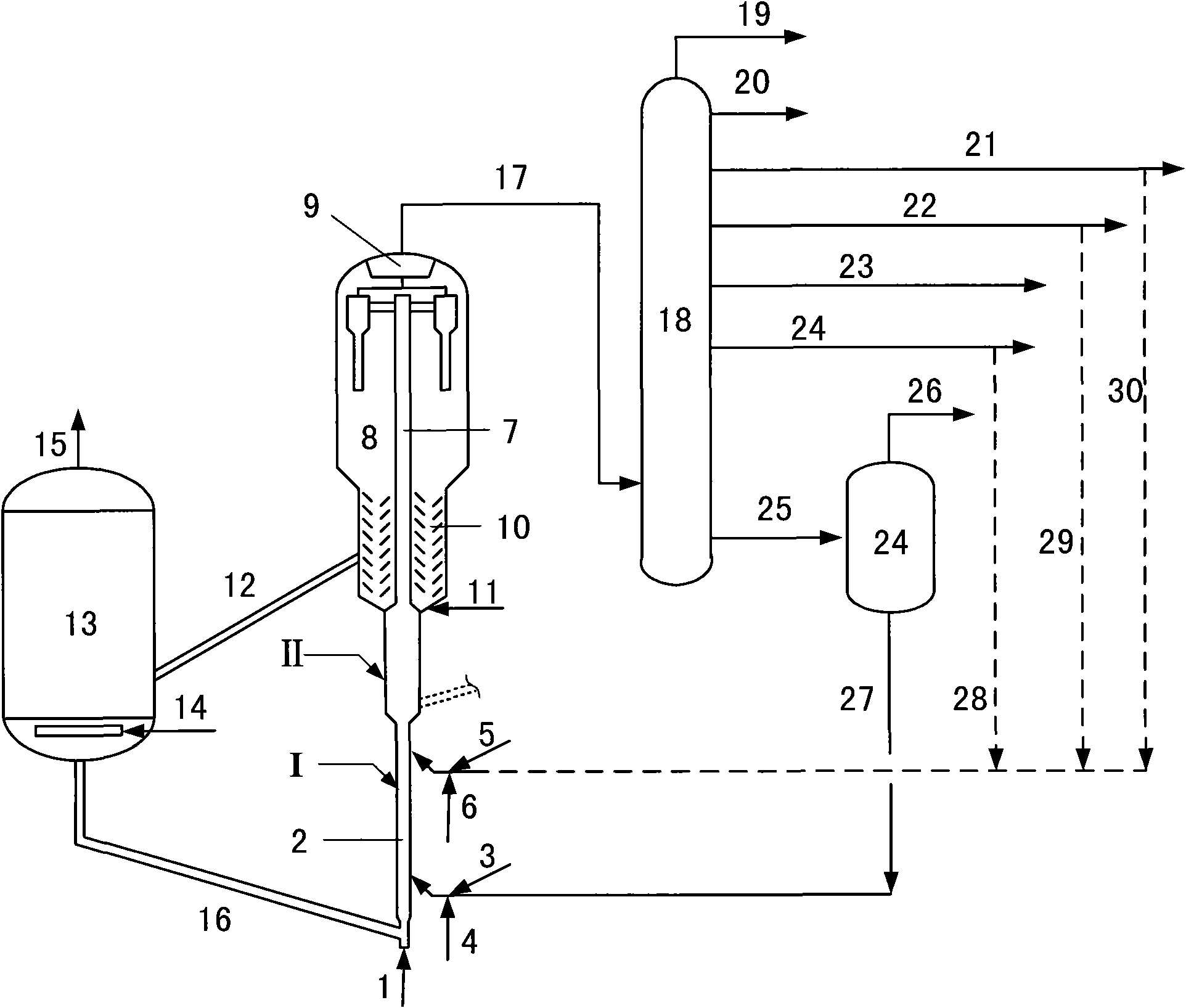

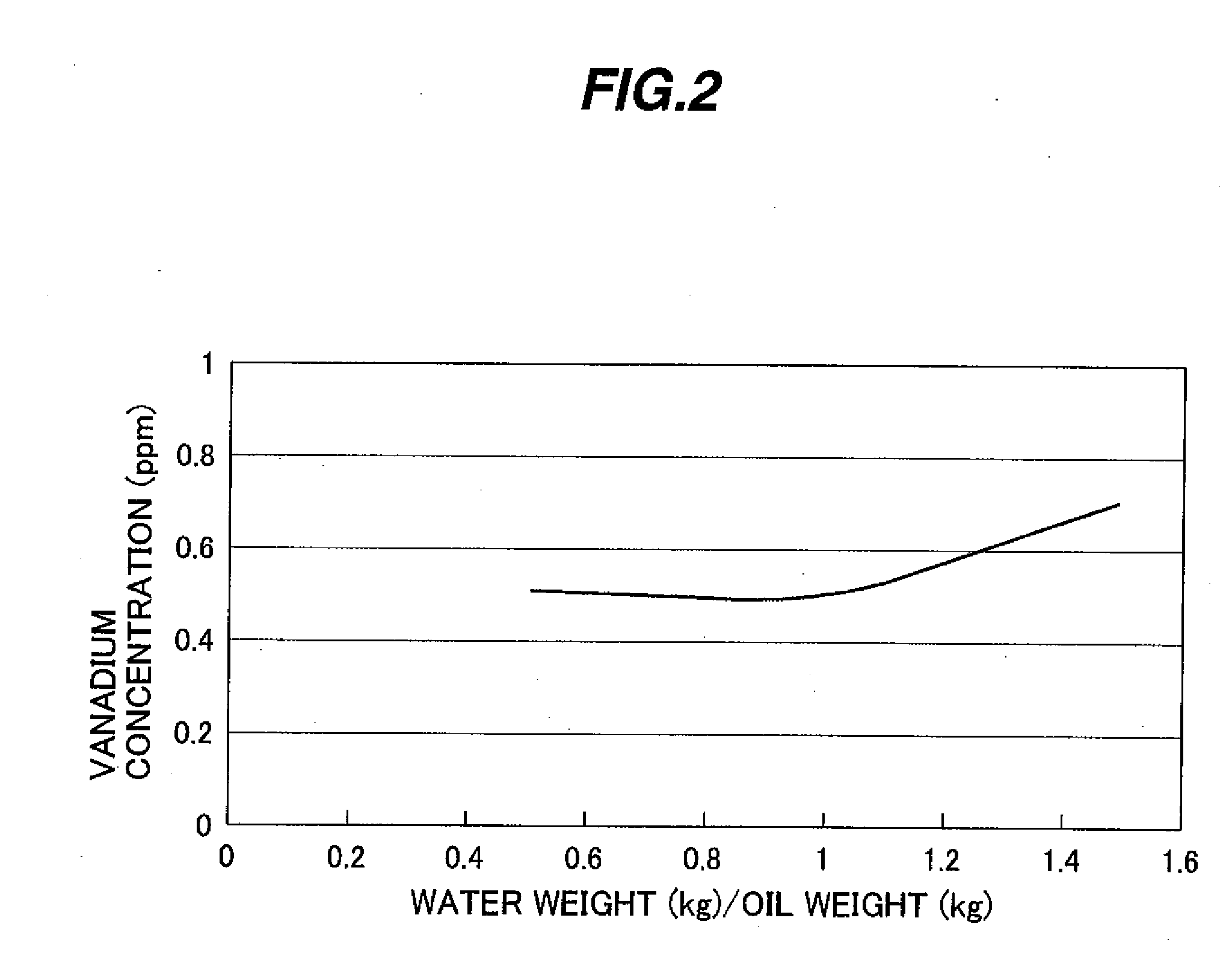

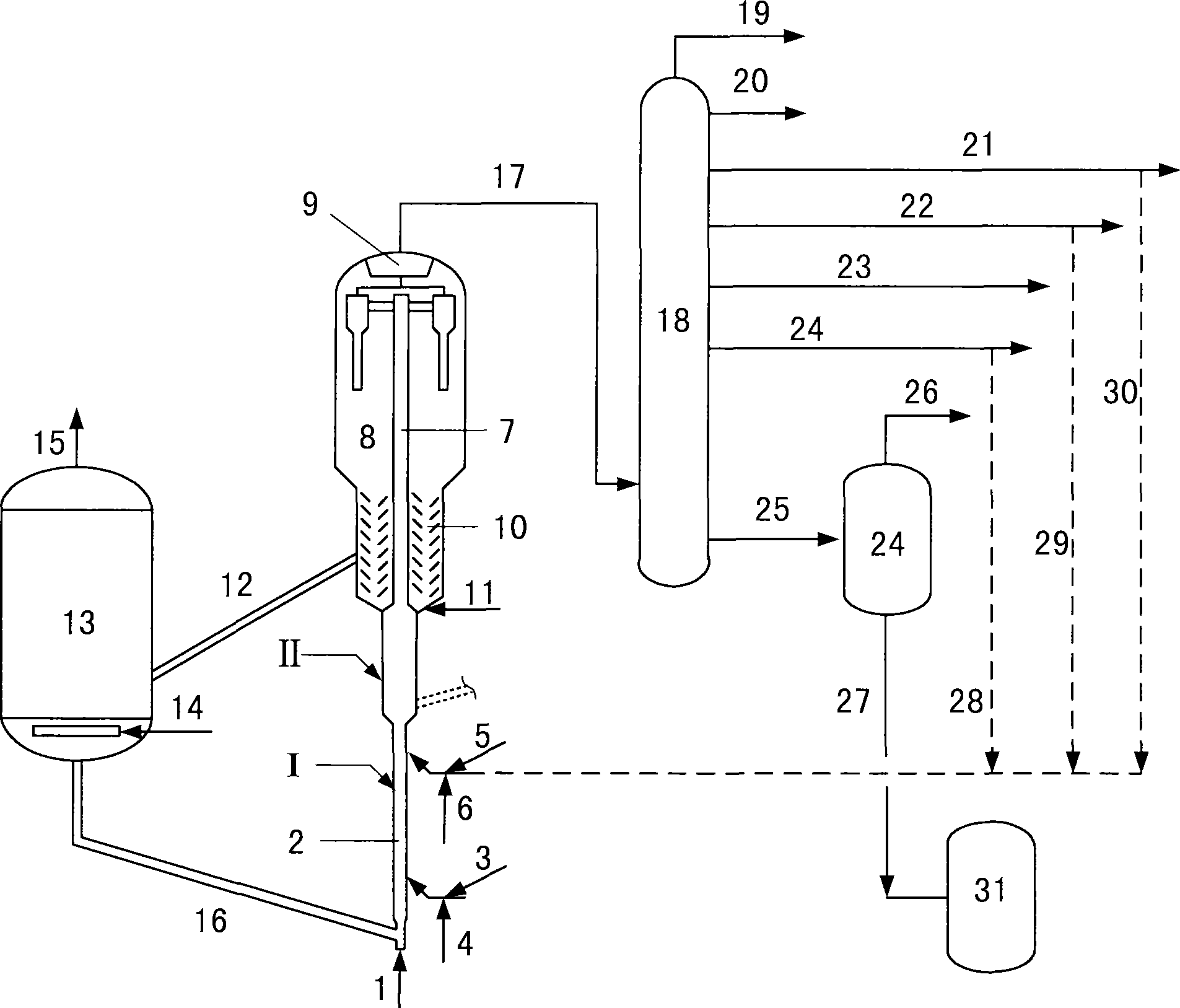

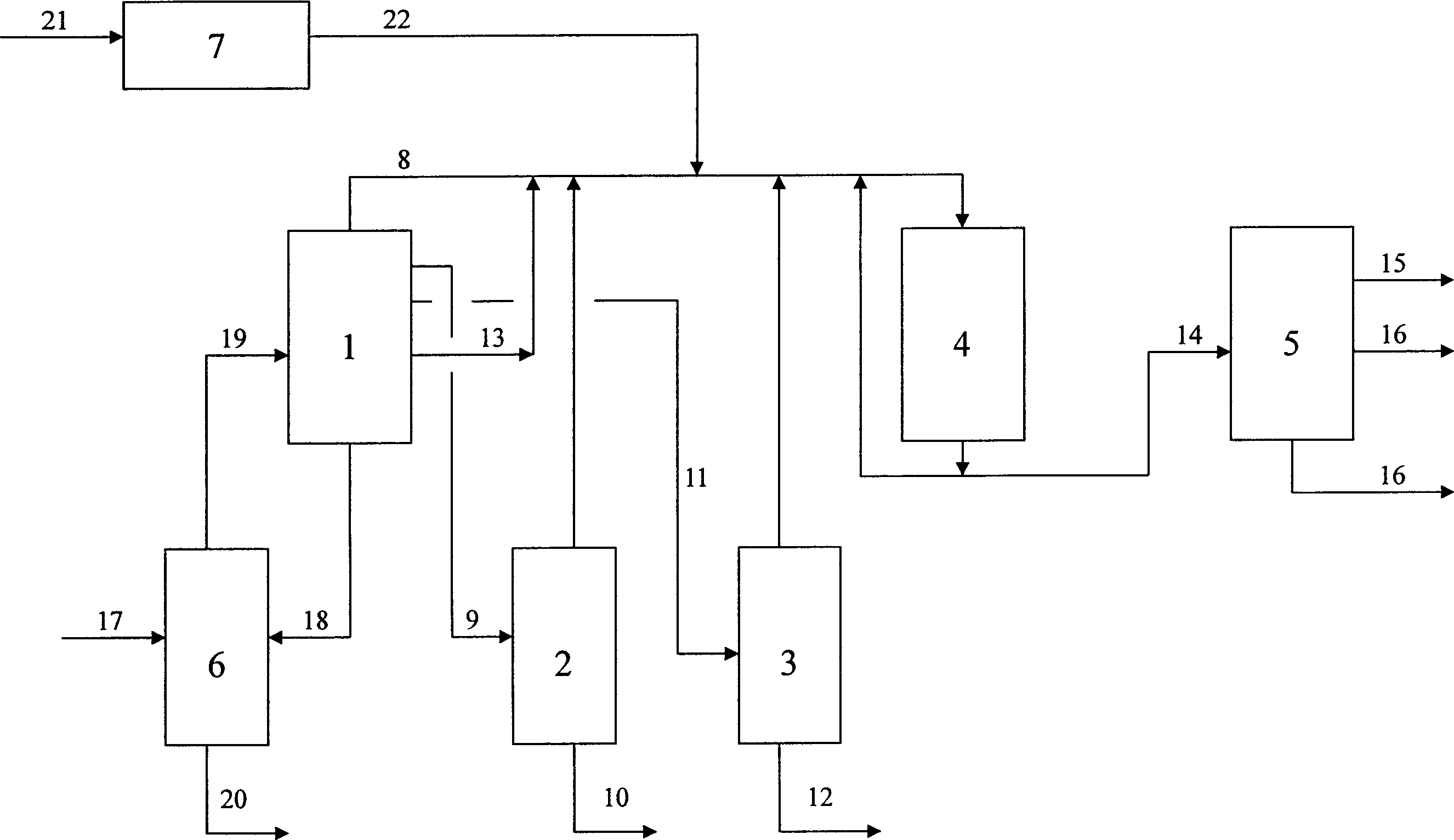

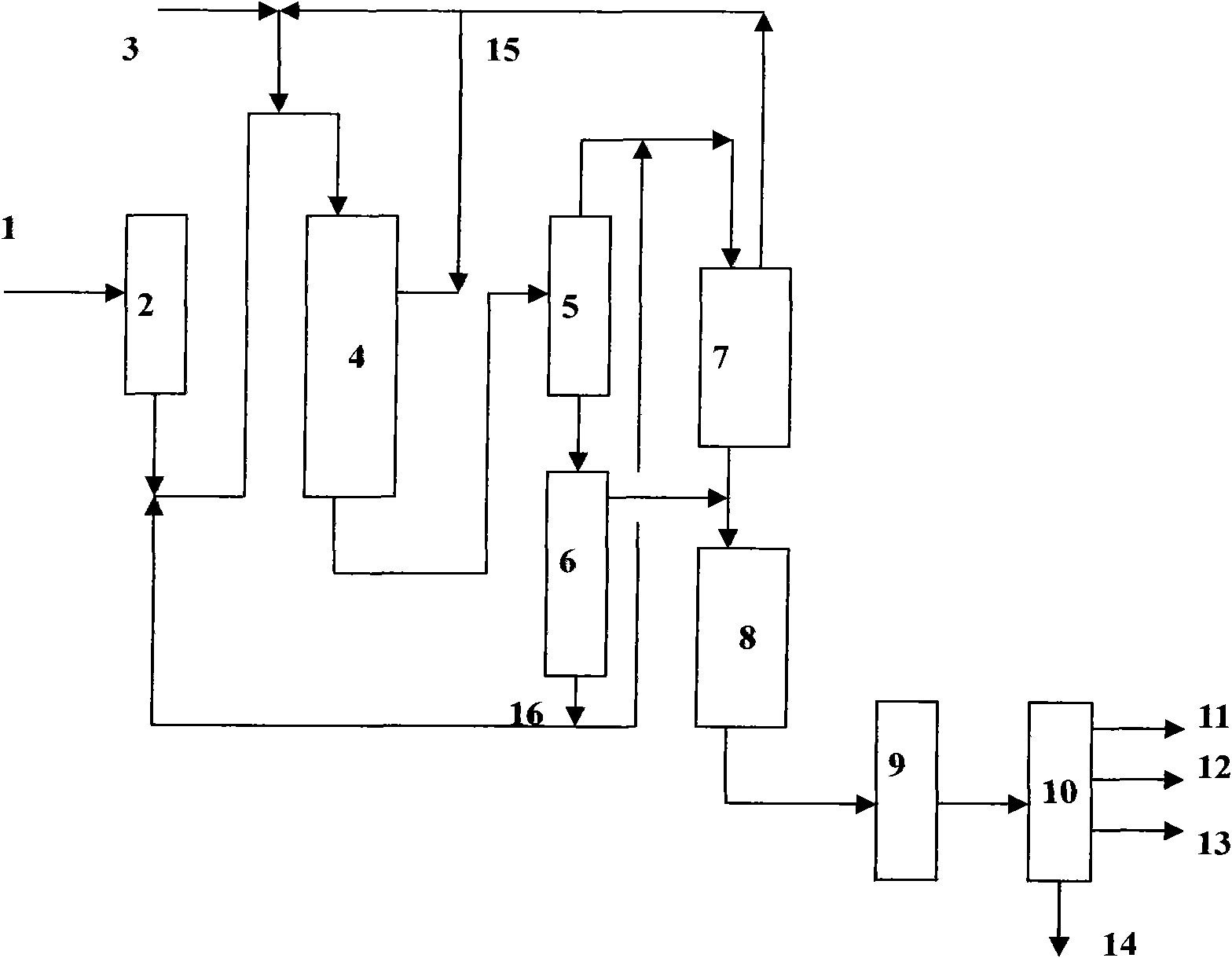

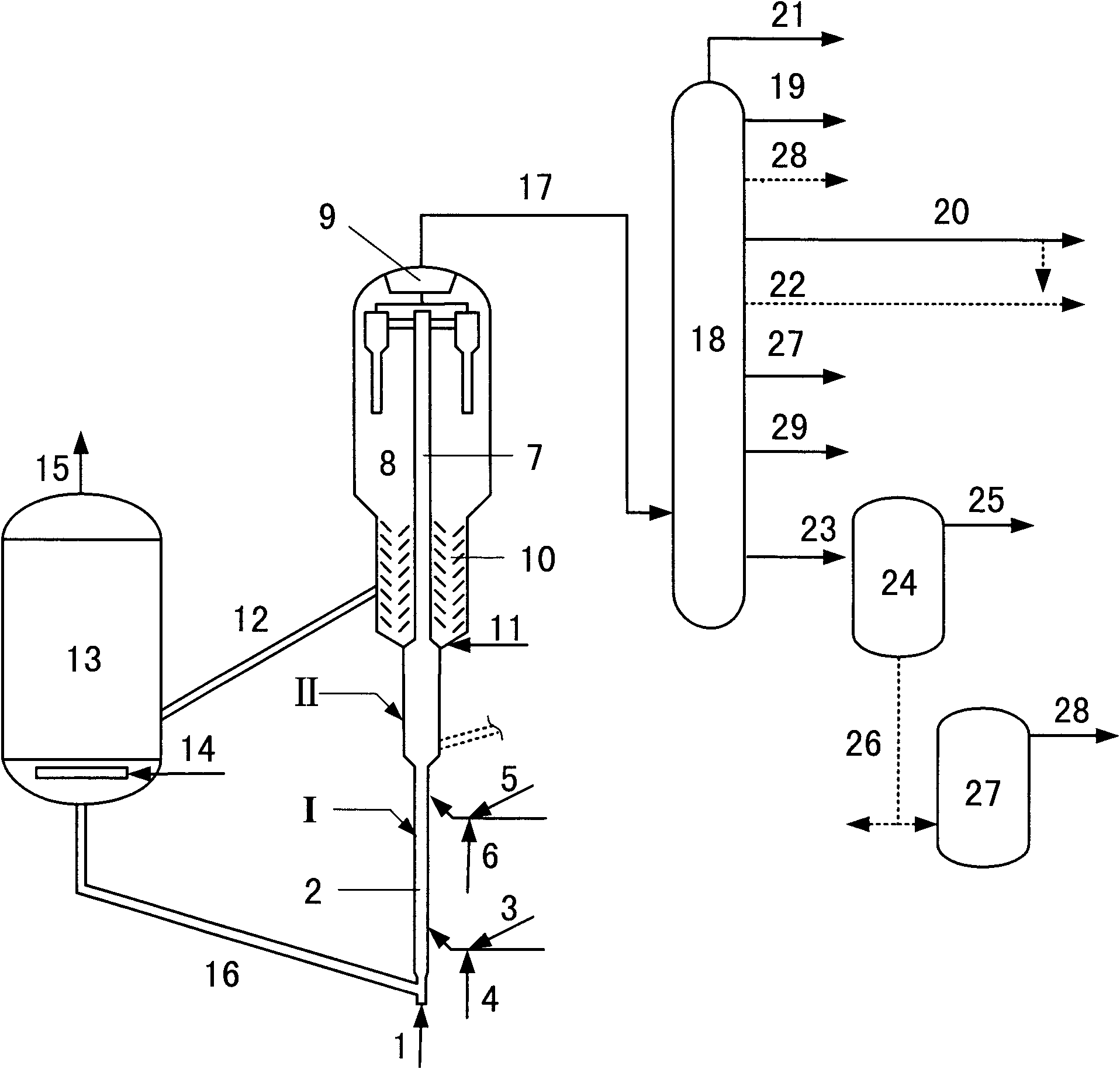

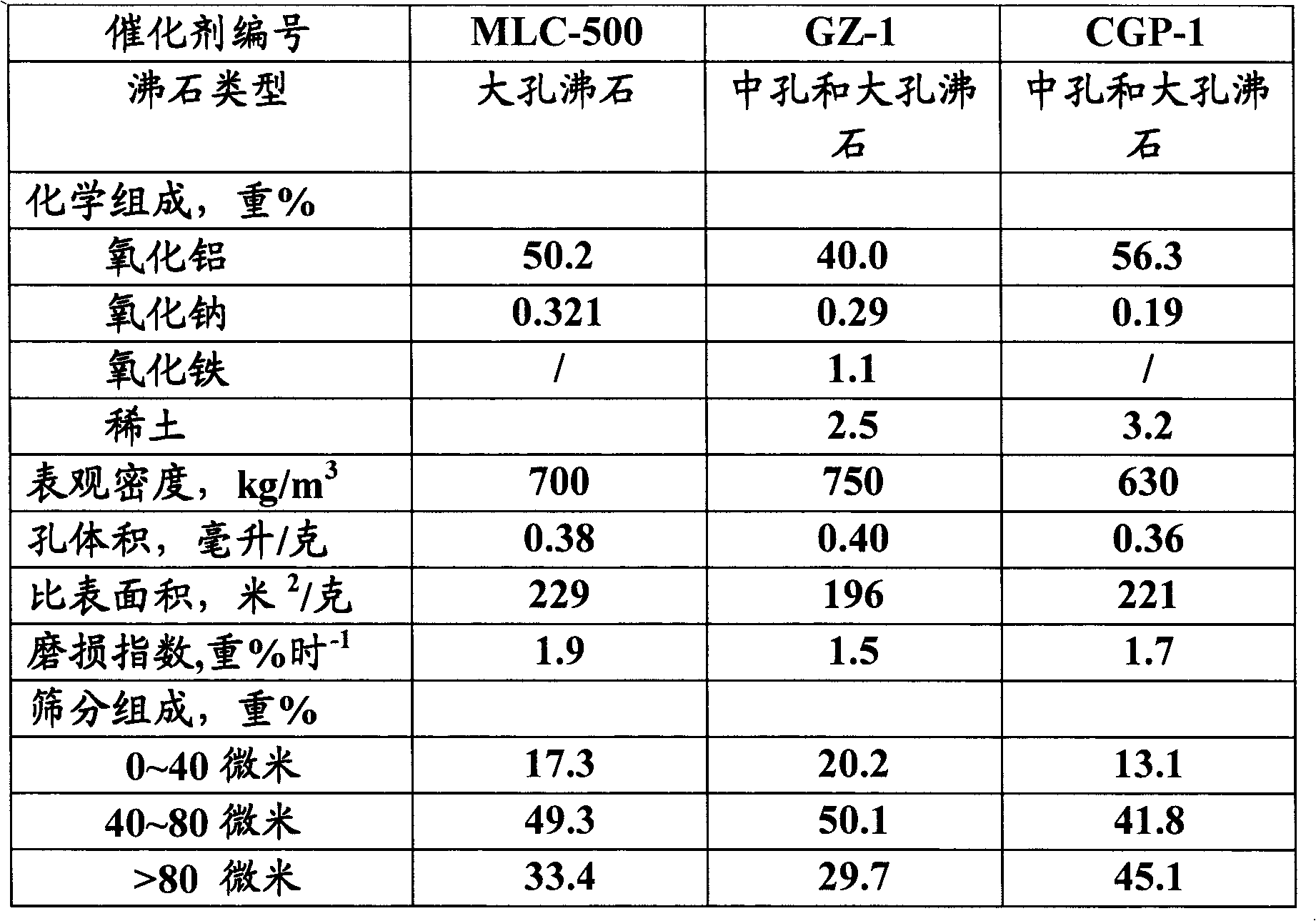

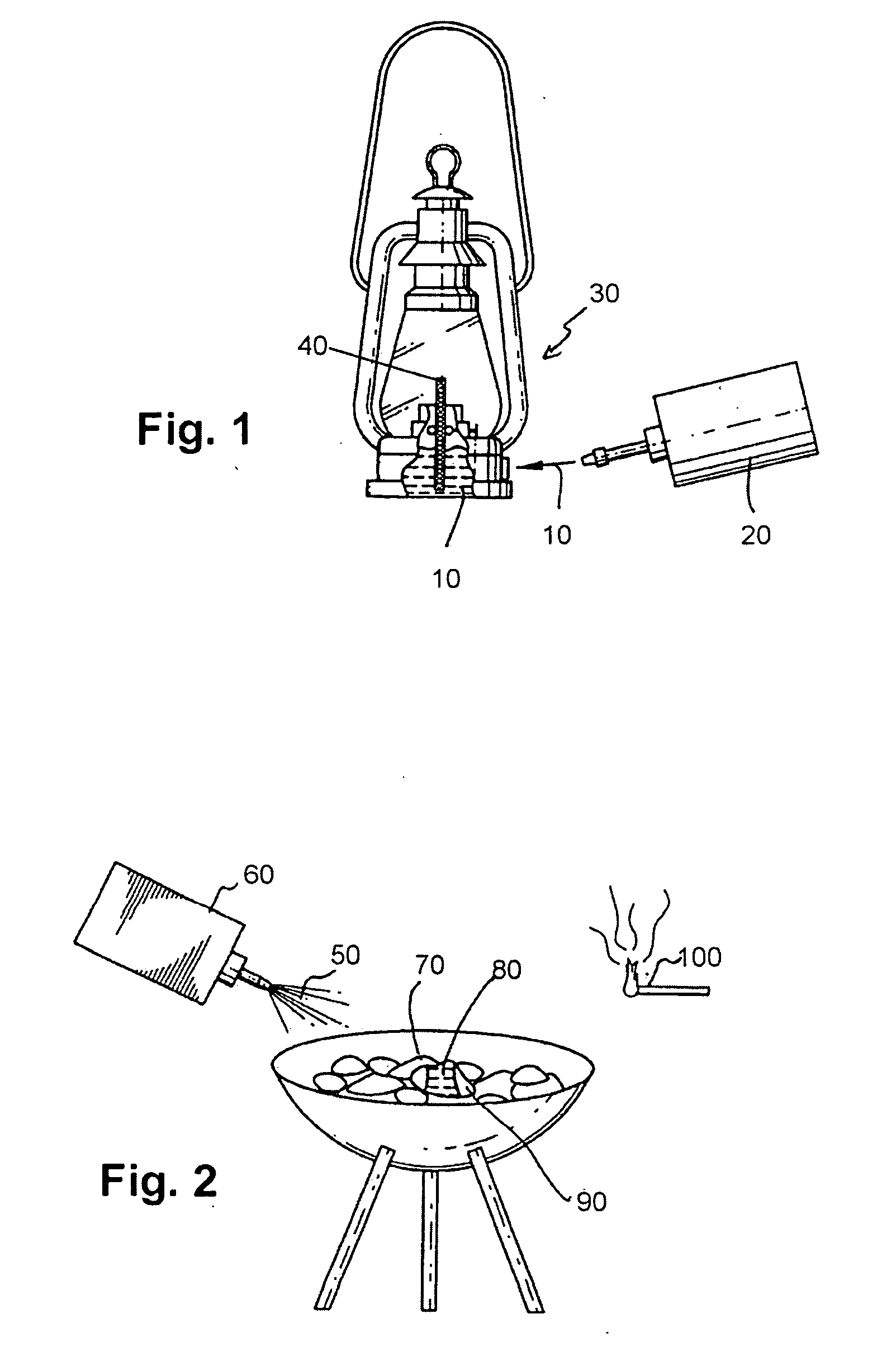

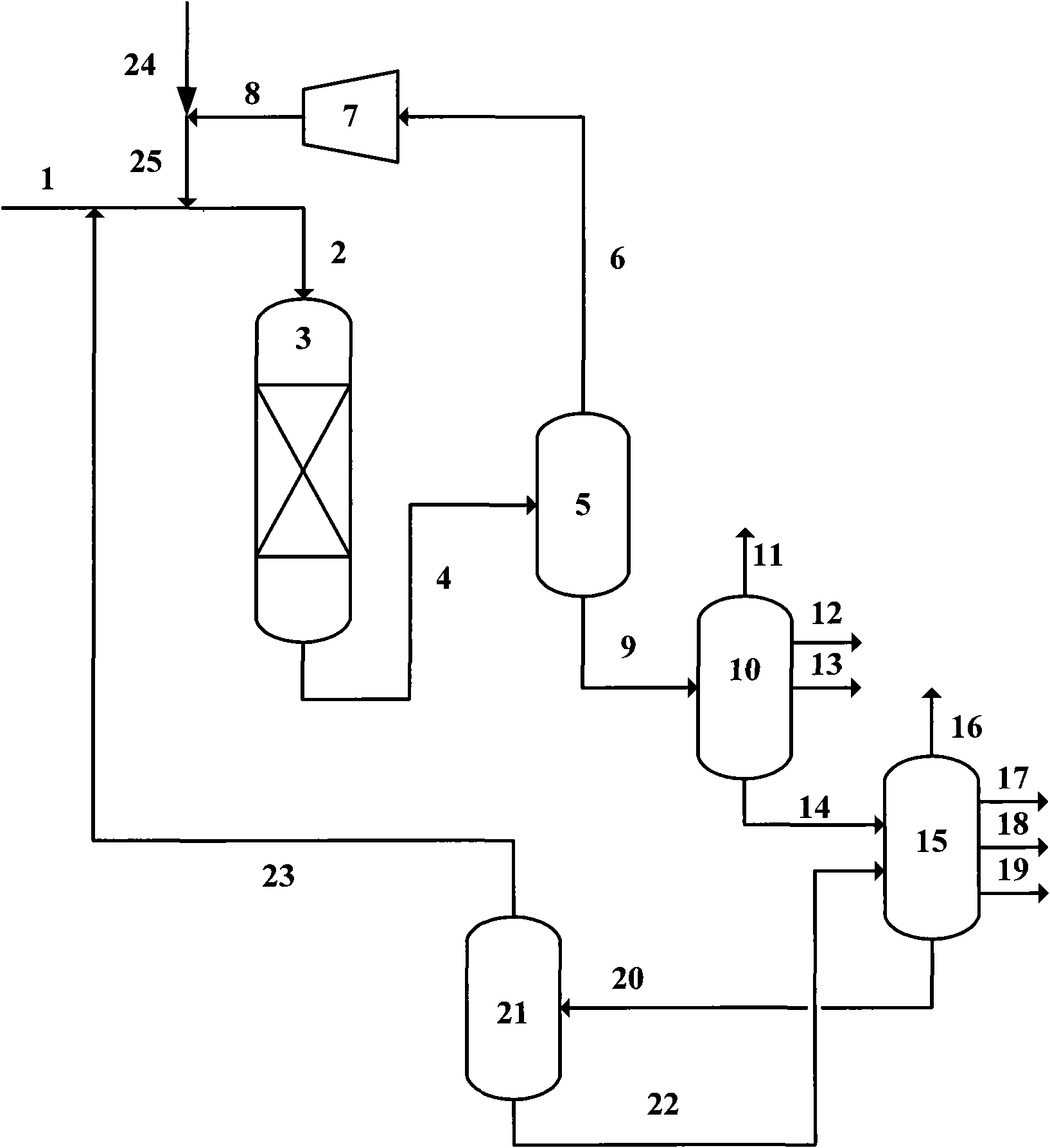

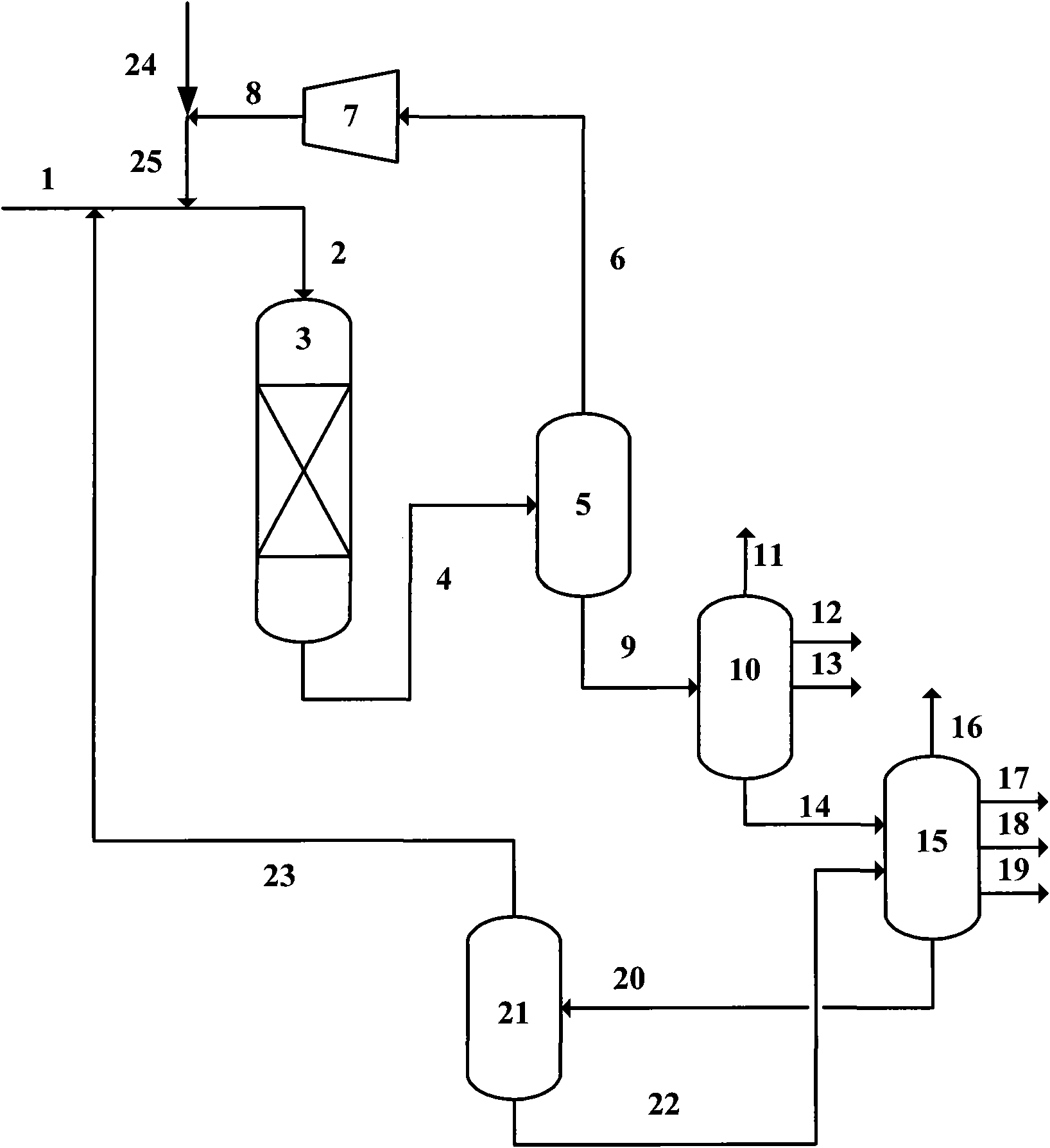

Method for preparing light fuel oil and propylene from inferior raw material oil

ActiveCN101942340AImproved raw material propertiesExtended operating cycleTreatment with plural serial stages onlyTreatment with hydrotreatment processesGas solidWax

The invention discloses a method for preparing light fuel oil and propylene from inferior raw material oil. The inferior raw material oil enters a first reaction area and a second reaction area of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst with coarse particle size distribution so as to perform primary reaction and secondary reaction respectively; after the reaction product and the spent catalyst undergo gas-solid separation, the spent catalyst is subjected to steam stripping and charring in turn and then returned to the reactor for recycling; and the reaction product is separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters at least one of hydrotreatment device, an arene extraction device and a hydrocracking device so as to obtain hydrogenated catalytic wax oil, raffinate oil and hydrocracking tail oil. The method improves the yield of the light oil, reduces the yield of oil slurry, realizes efficient utilization of petroleum resources, reduces the consumption of the catalyst, and reduces the catalyst content of the catalytic wax oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

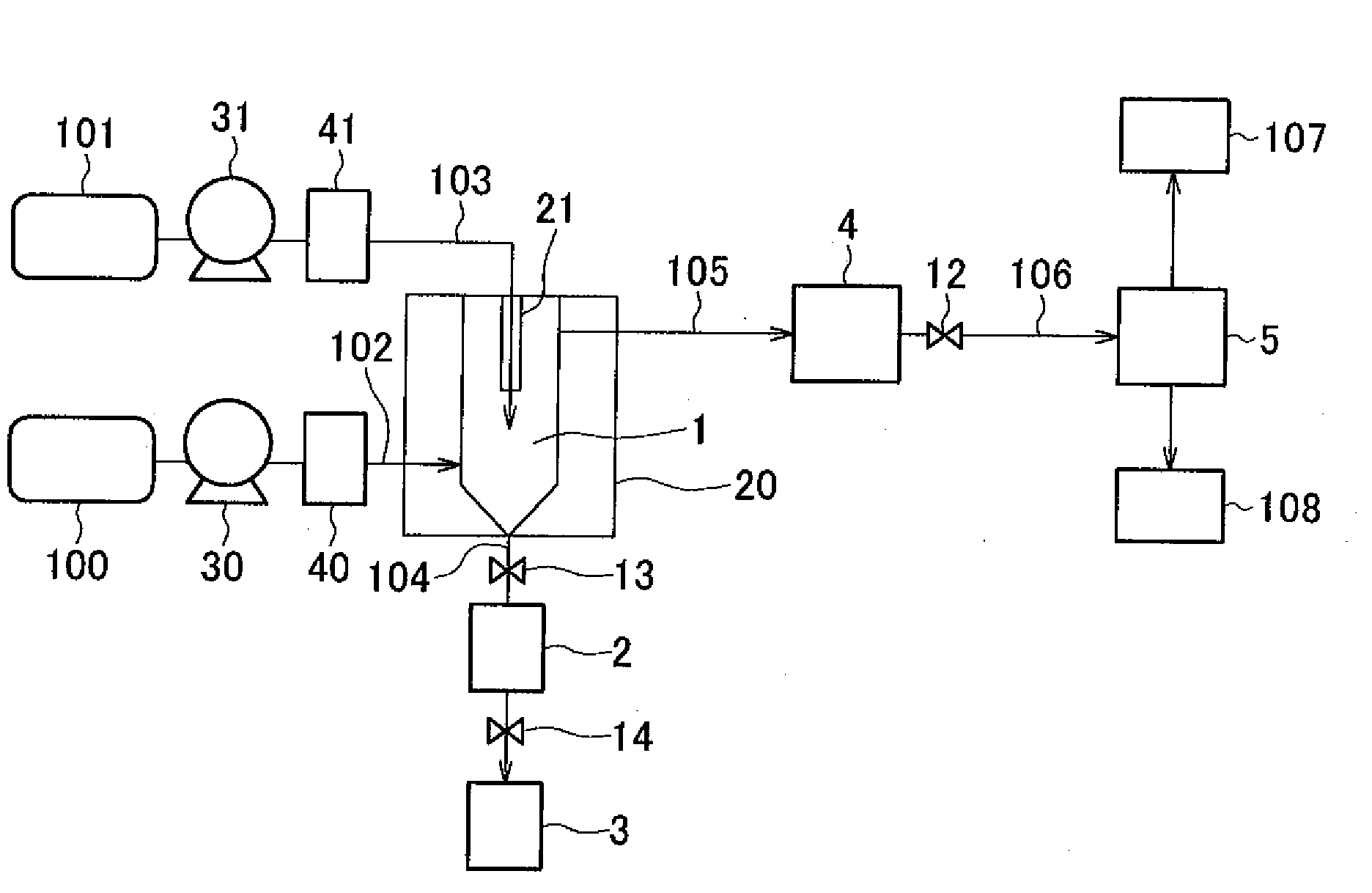

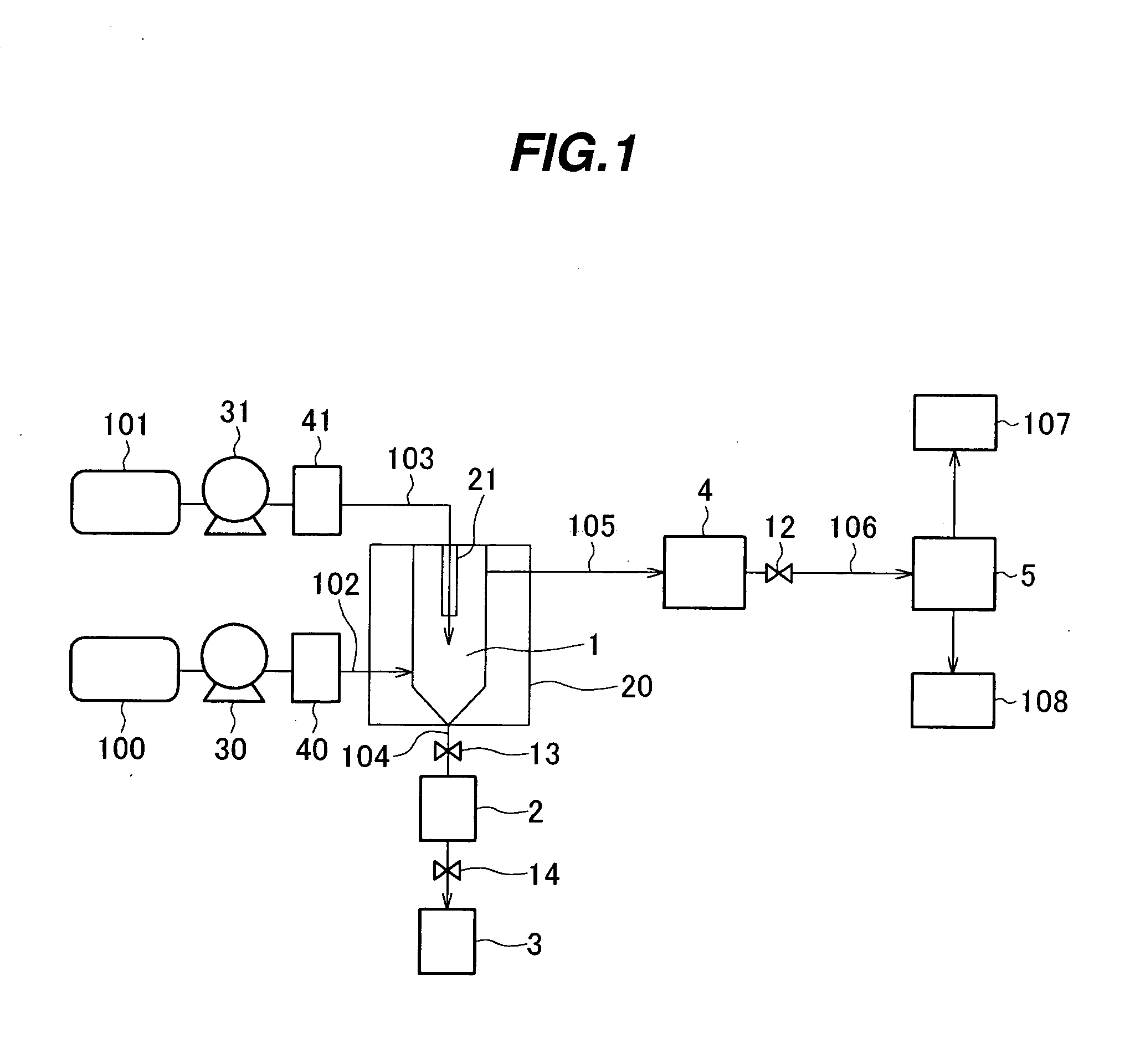

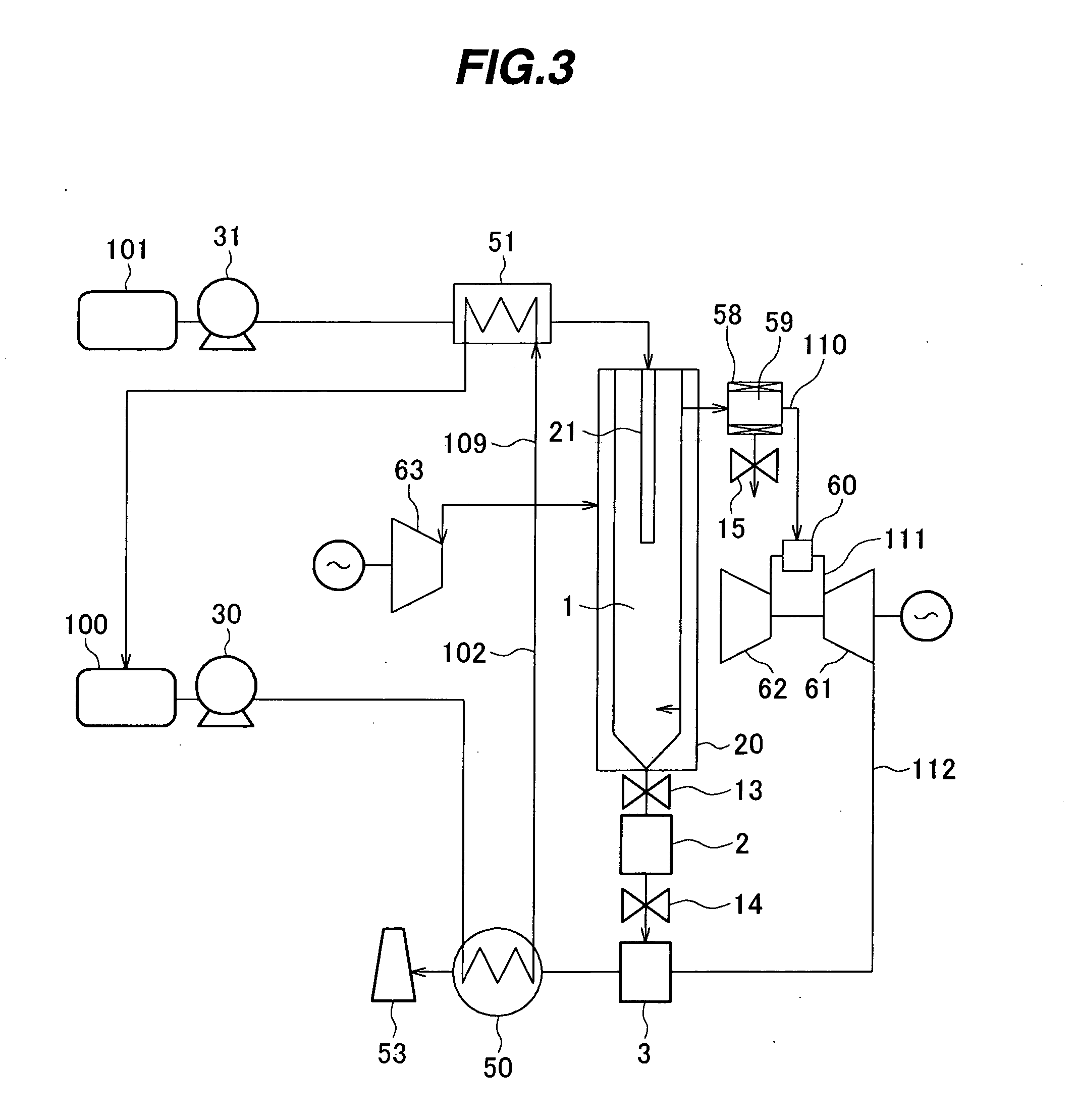

Heavy oil treating method and heavy oil treating system

InactiveUS20090032436A1Eliminate needMolecular sieve catalystsRefining with oxygen compoundsLighter fuelHigh pressure water

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:TAKAHASHI HIROKAZU +6

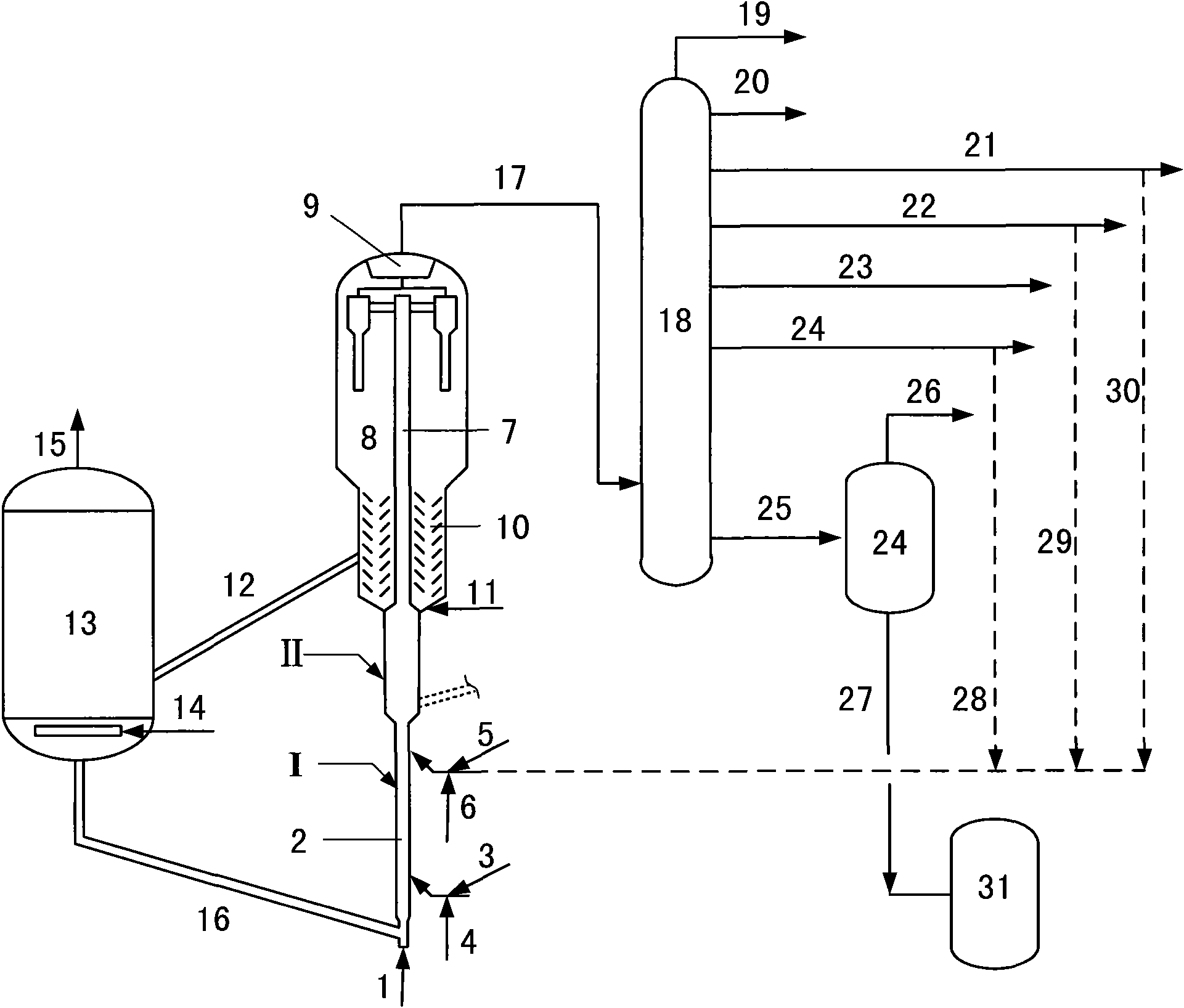

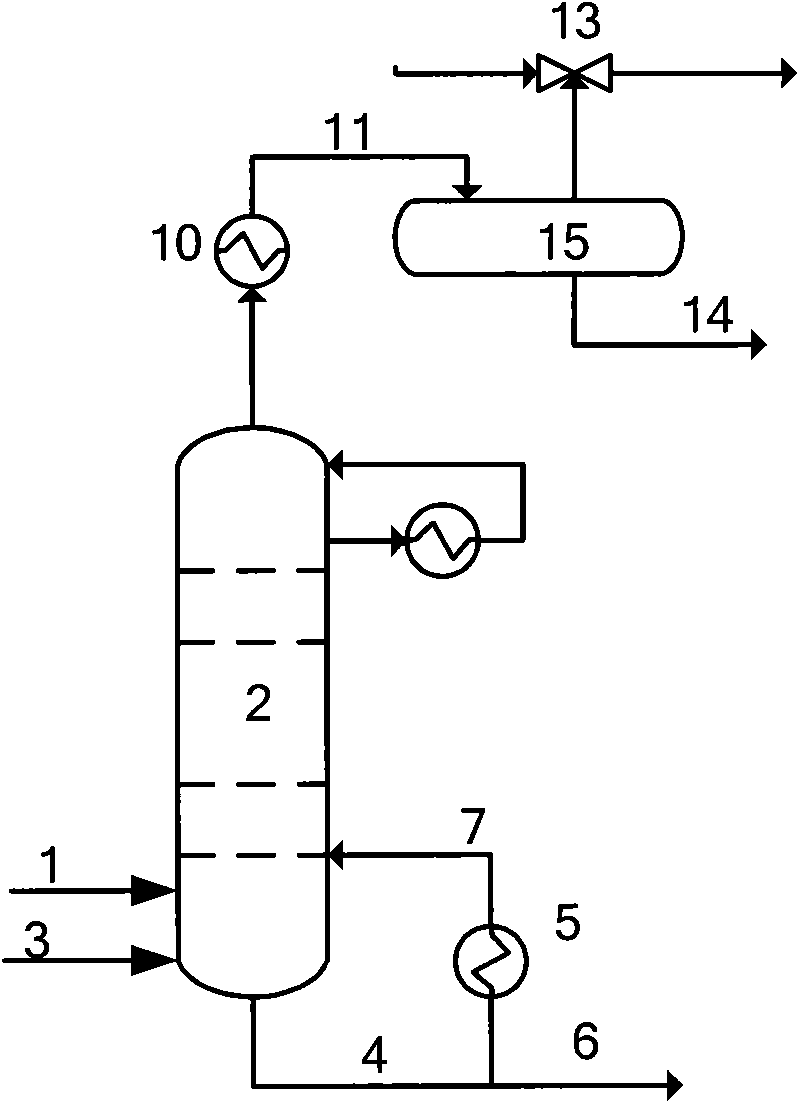

Method for preparing light fuel oil and propylene from poor-quality raw oil

ActiveCN101531924AImprove propertiesDry gas reductionTreatment with hydrotreatment processesSlurryFuel oil

A method for preparing light fuel oil and propylene from poor-quality raw oil comprises the following steps: the poor-quality raw oil sequentially enters a first reaction zone and a second reaction zone of a catalytic conversion reactor so as to be contacted with a catalytic conversion catalyst to generate first reaction and second reaction respectively, and after gas-solid separation is implemented to reaction products and spent catalyst, the spent catalyst returns to the reactor for recycling after steam stripping and burning; the reaction products are separated to obtain propylene, gasoline, heavy oil and other products, wherein the heavy oil is contacted with hydrogen and a hydrotreating catalyst for reaction, the obtained hydrogenated heavy oil circulates to the first reaction zone of the catalytic conversion reactor or / and other catalytic conversion devices for further reaction to obtain the target products of the propylene and the gasoline. The characteristic of the heavy oil obtained by hydrotreating after the mild catalytic conversion of the poor-quality raw oil is significantly improved, thereby significantly increasing light oil, reducing dry gas, reducing the yield of oil slurry and realizing the high-efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing chemical industry products and fuel oil from coal tar

InactiveCN1597866ATreatment with hydrotreatment processesTar working-up by distillationChemical industryLighter fuel

The invention is a method of producing chemical products and fuel oil by coal tar, relating to a method of producing chemical products and fuel oil by coal car, including vehicle fuel oil. And its characteristic: separating the coal tar into light and heavy fractions, where the light fraction includes light coal tar and tar pitch. The light fraction is used to produce light products by hydrofining or modifying. The processing of the tar pitch combines with coke furnace or delay coking, thus not only producing more chemical products such as phenol, naphthalene and gasoline, diesel oil / light fuel, etc, but also improving the coke quality of the coke furnace or directly producing low-ash content coke. Simultaneously, it adds an inhibitor to inhibit or slow down the coking in the furnace pipe or reactor, thus assuring long-term operation of the device.

Owner:山西东辉能源集团有限公司 +11

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil treating method and heavy oil treating system

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

Method for producing lightweight fuel oil by coal tar heavy fractioning hydrogenation

ActiveCN101240191AHigh yieldReduce loadTreatment with hydrotreatment processesCoal tar distillateNaphtha

The invention discloses a method for producing quality of light fuel oil through hydrogenation of heavy coal tar distillate. The method is that technics of refining hydrogen-hydrocracking portfolio is used, which includes: the heavy coal tar distillate and hydrogen mix and go into heydrogenation reaction zone, effluent after refining changes into naphtha, diesel oil and heavy distillate though a segregation system, the heavy distillate goes into hydrocracking reaction zone, the part or the all of the hydrocracking reaction effluent circularly are acted as incoming stock of the refining hydrogen, and the left part goes into the segregation system. Compares to the prior art, the invention broadens the raw material resource for producing the light fuel oil, promotes economical efficiency for production of the heavy coal tar distillate, provides a higher value-added application method for the heavy coal tar distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

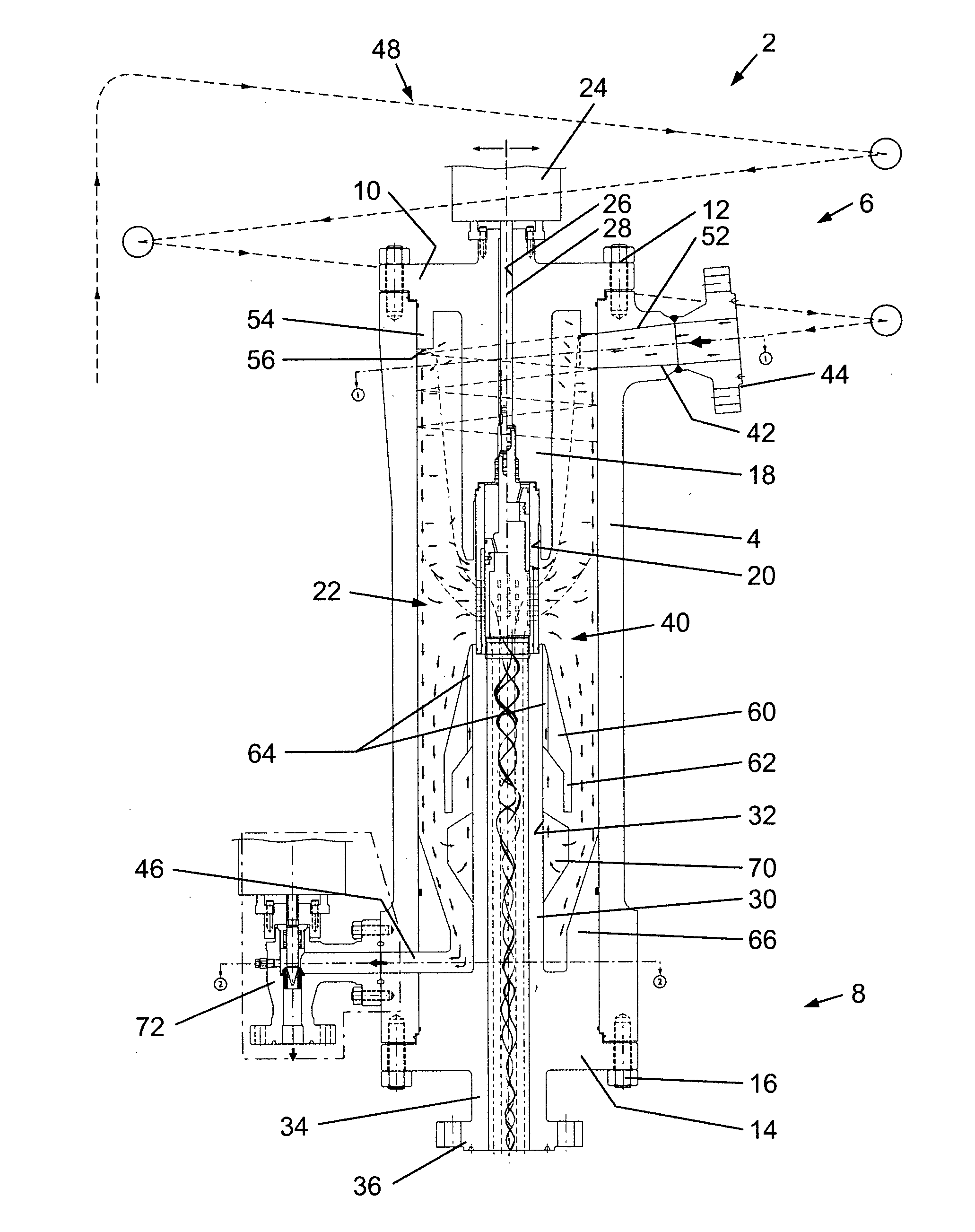

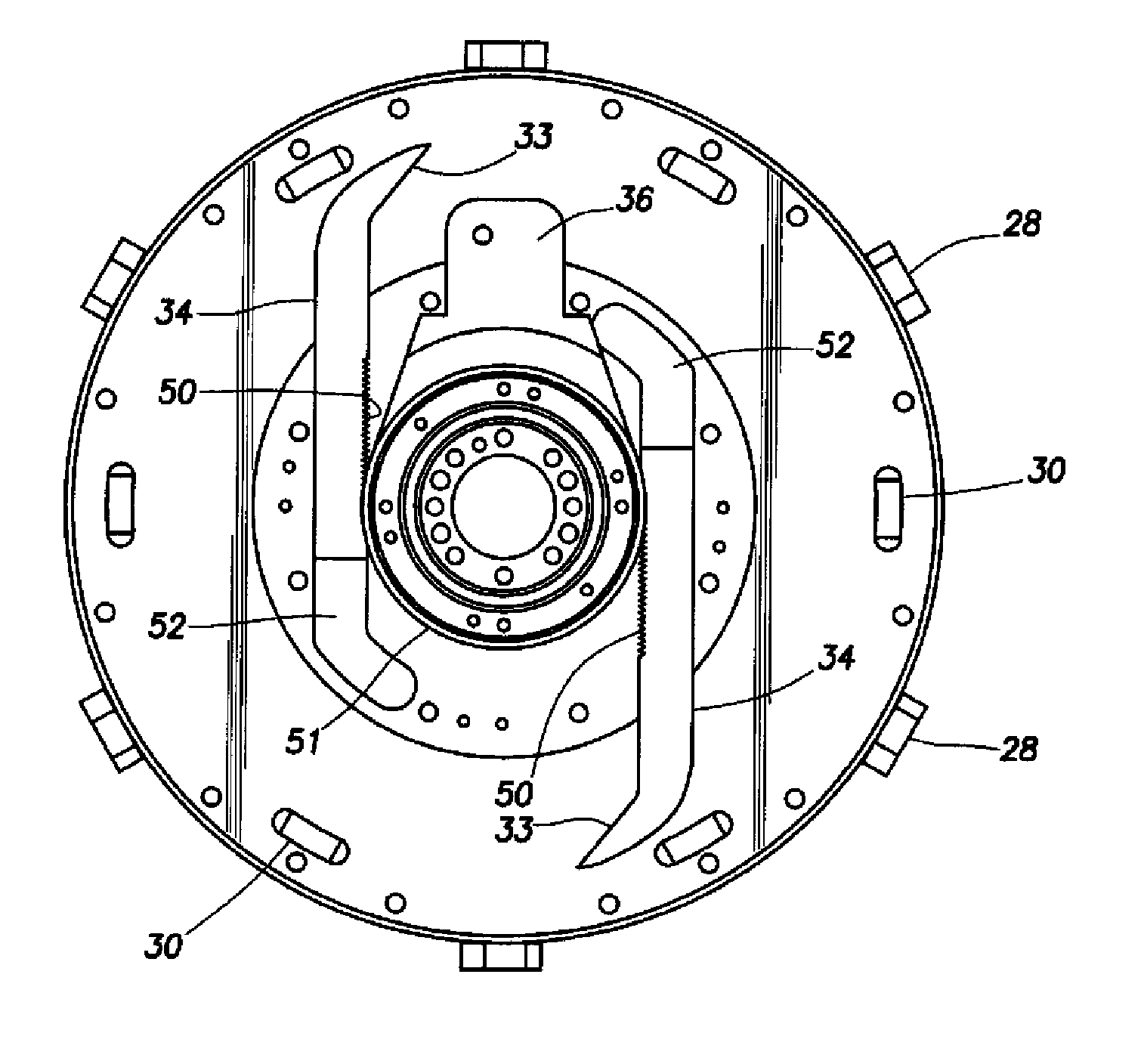

Inter-tandem pump intake

An assembly for use in a well containing a mixture of hydrocarbons and water wherein the assembly separates hydrocarbons or relatively lighter fluids from the mixture and injects water or relatively heavier fluids into the well. The assembly includes an upper pump that pumps the relatively lighter fluids to the surface. A tandem pump is positioned below the upper pump for pumping well fluids down to a downhole separator. An oil bypass tube is provided in communication with the tandem pump for transferring the relatively lighter fluids to the upper pump, for subsequent pumping to the surface. A recycle tube is also provided that communicates with the downhole separator and the tandem pump for transferring at least a portion of the relatively heavier fluids from the downhole separator to the tandem pump, for pumping the relatively heavier fluids back to the separator.

Owner:BAKER HUGHES INC

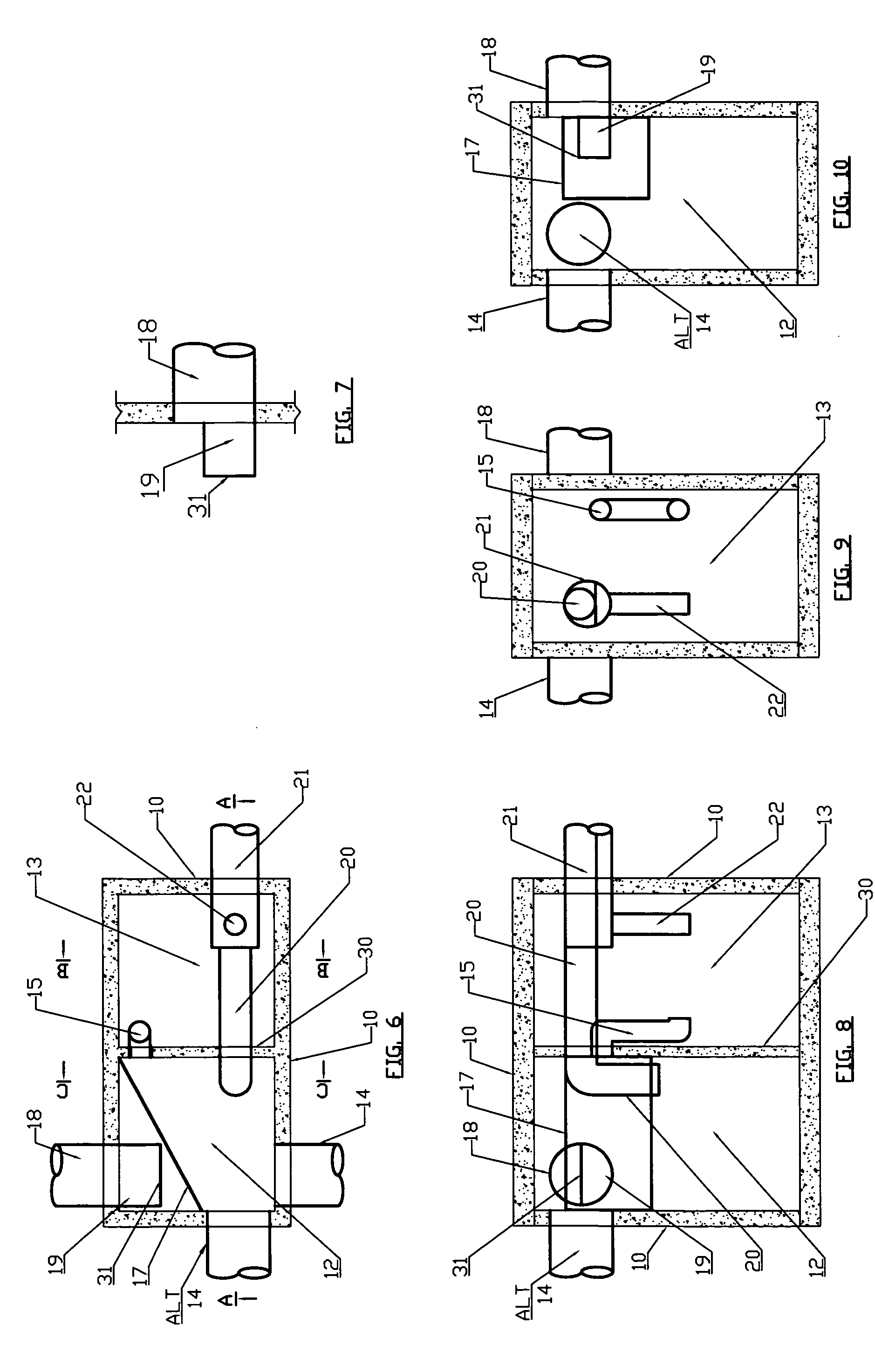

Choke Assembly

ActiveUS20120227813A1Reduce collisionReduce impactCircuit elementsSedimentation separationLighter fuelEngineering

A choke assembly comprises an inlet (48) for a multiphase fluid stream, the stream comprising a first relatively heavy fluid phase and a second relatively light fluid phase; a first fluid outlet (116); a choke element (22) disposed between the inlet and the first fluid outlet operable to control the flow of fluid between the inlet and the first fluid outlet; a separation chamber (40, 114) disposed to provide separation of phases in the fluid stream upstream of the choke element; and a second outlet (118) for removing fluid from the separation cavity. The choke assembly is of particular use in the control of fluid streams produced from a subterranean well, in particular oil and gas produced from a subsea well.

Owner:CAMERSON INT CORP

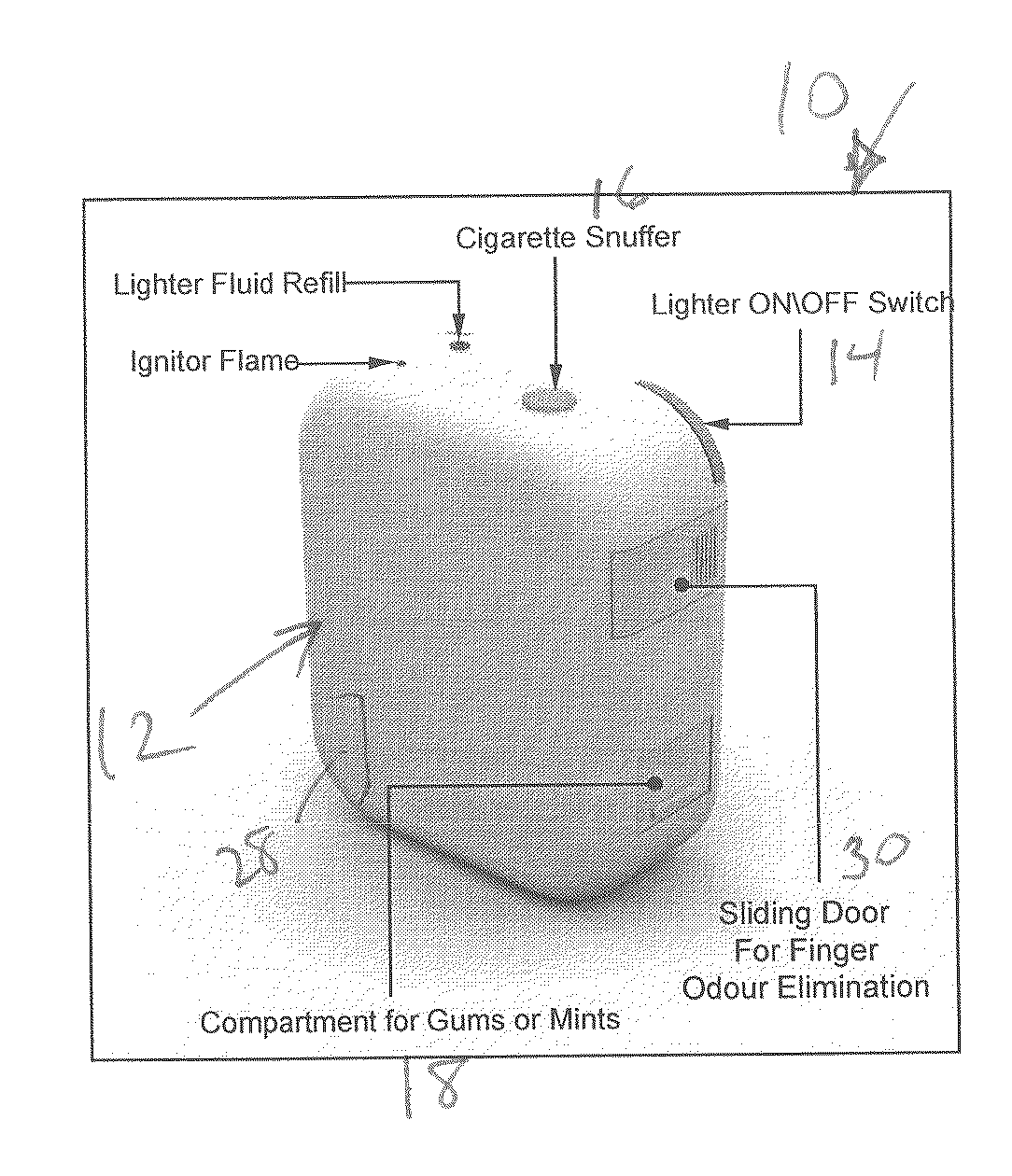

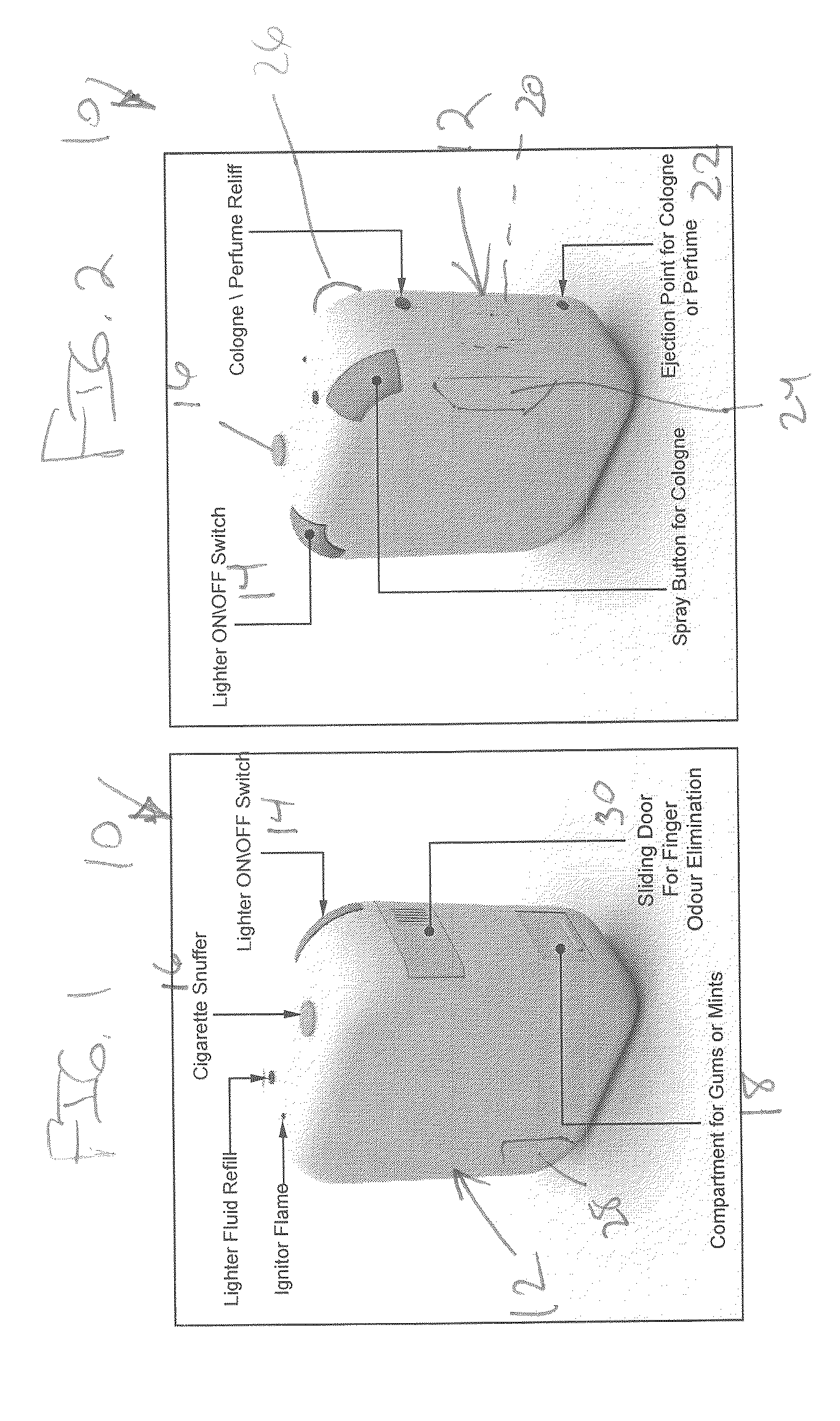

Cigarette storage system

A cigarette storage system for holding at least one cigarette is provided. The cigarette storage system comprises a case and an airtight storage formed in the case for holding the at least one cigarette. A lighter fluid reservoir is formed in the case with the lighter fluid reservoir having an amount of lighter fluid therein. A cigarette lighter fluidly cooperates with the lighter fluid in the lighter fluid reservoir with the cigarette lighter igniting the lighter fluid to produce a flame for lighting the at least one cigarette wherein a user can remove a cigarette from the airtight storage and ignite the cigarette with the cigarette lighter prior to smoking the cigarette.

Owner:GEORGE EDYTHE

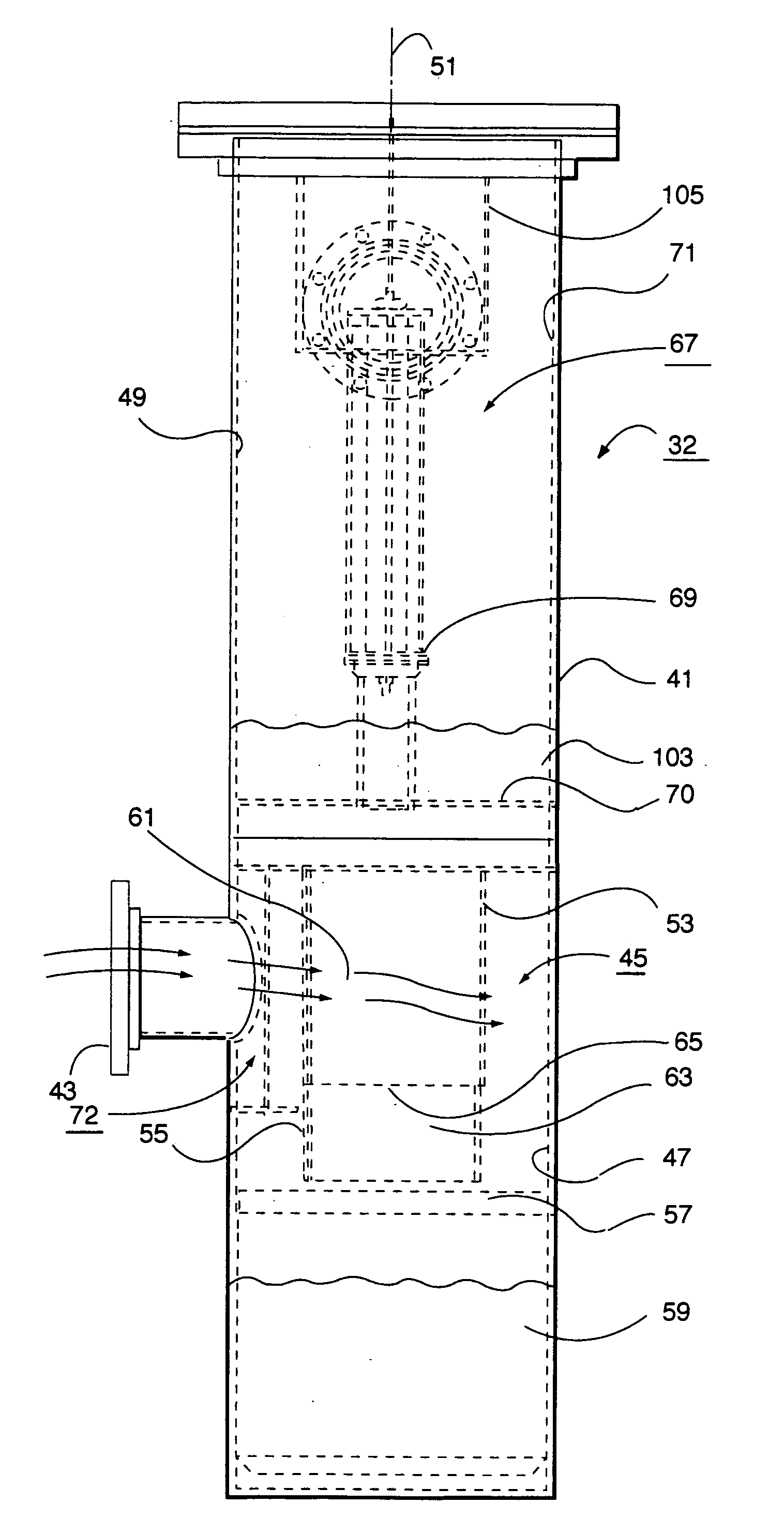

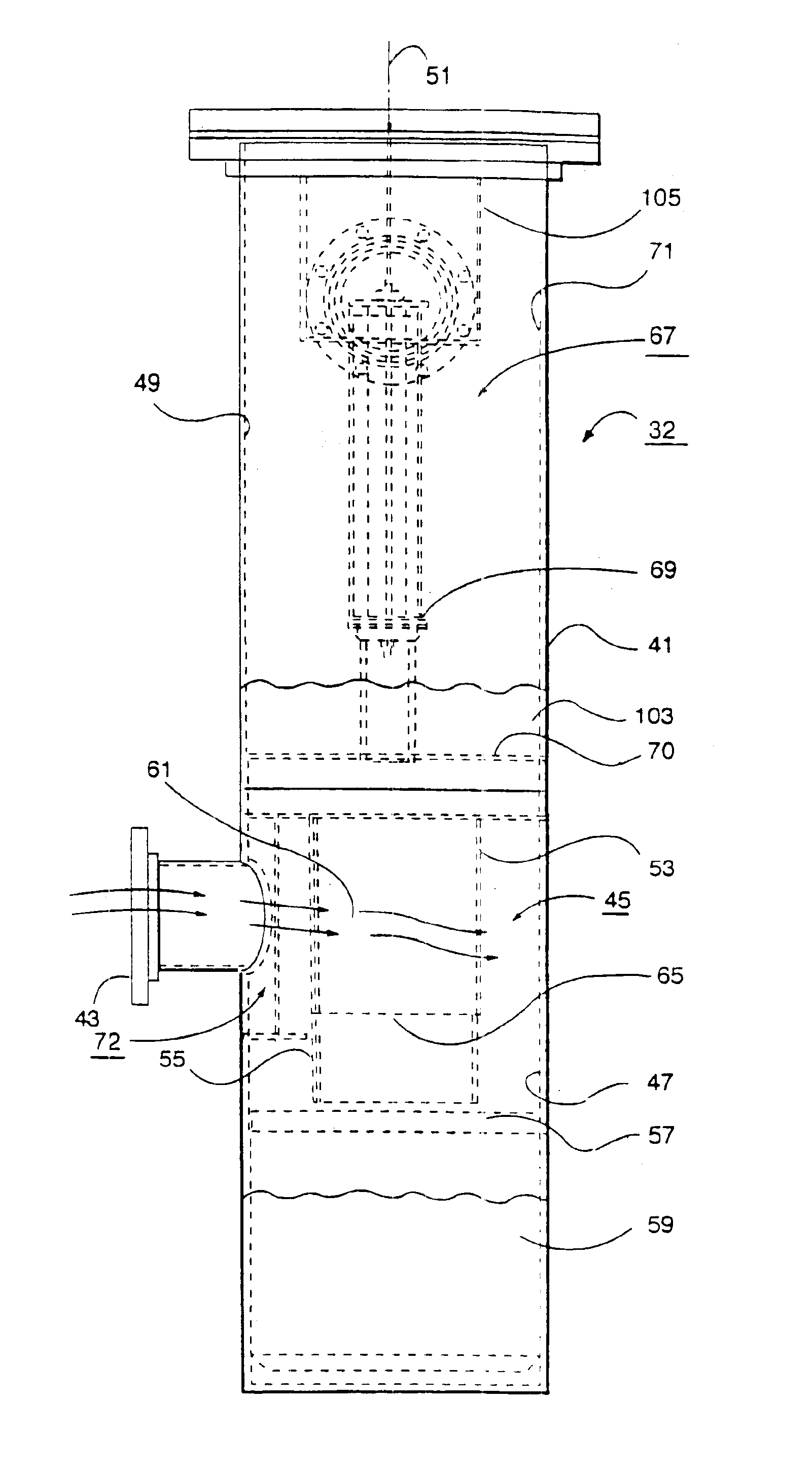

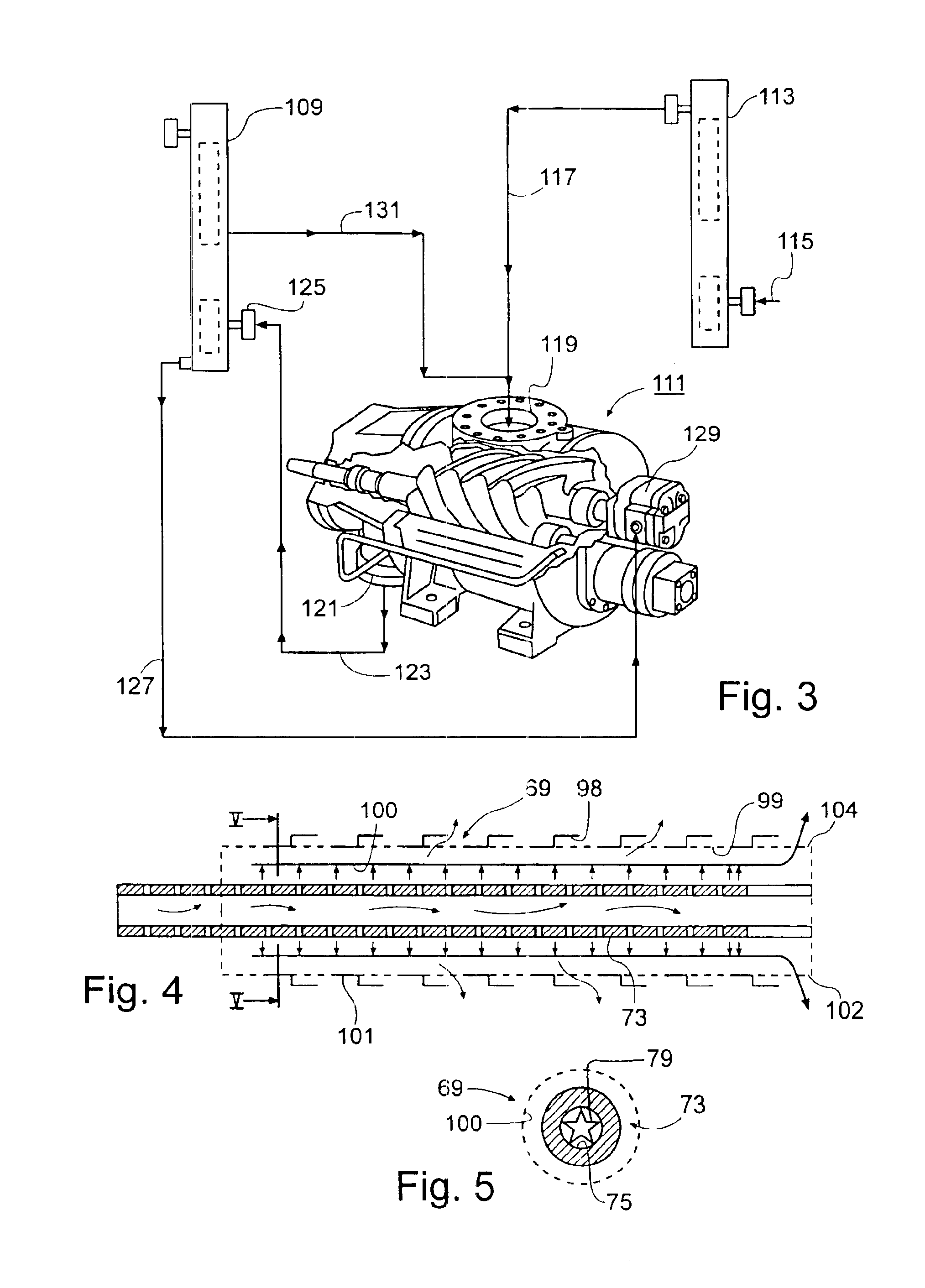

Filtration vessel and method for rotary gas compressor system

A filtration vessel is shown for use with a rotary screw compressor which receives a compressed liquid / gas mixture from the compressor. The vessel utilizes a first stage vortex knockout region to remove bulk liquids through a circular motion which imposes centrifugal forces on the gas and liquid mixture. A coalescer region located above the vortex knockout region receives the relatively lighter fluids and separates any remaining entrained liquids from the fluids. The discharge from the filtration unit is an essentially liquid free compressed gas. The liquid discharge, in the case of lube oil can be recirculated to the compressor for another cycle.

Owner:PARKER INTANGIBLES LLC

Filtration vessel and method for rotary gas compressor system

InactiveUS6858067B2Easy to separateCombination devicesDispersed particle filtrationLighter fuelFiltration

A filtration vessel is shown for use with a rotary screw compressor which receives a compressed liquid / gas mixture from the compressor. The vessel utilizes a first stage vortex knockout region to remove bulk liquids through a circular motion which imposes centrifugal forces on the gas and liquid mixture. A coalescer region located above the vortex knockout region receives the relatively lighter fluids and separates any remaining entrained liquids from the fluids. The discharge from the filtration unit is an essentially liquid free compressed gas. The liquid discharge, in the case of lube oil can be recirculated to the compressor for another cycle.

Owner:PARKER INTANGIBLES LLC

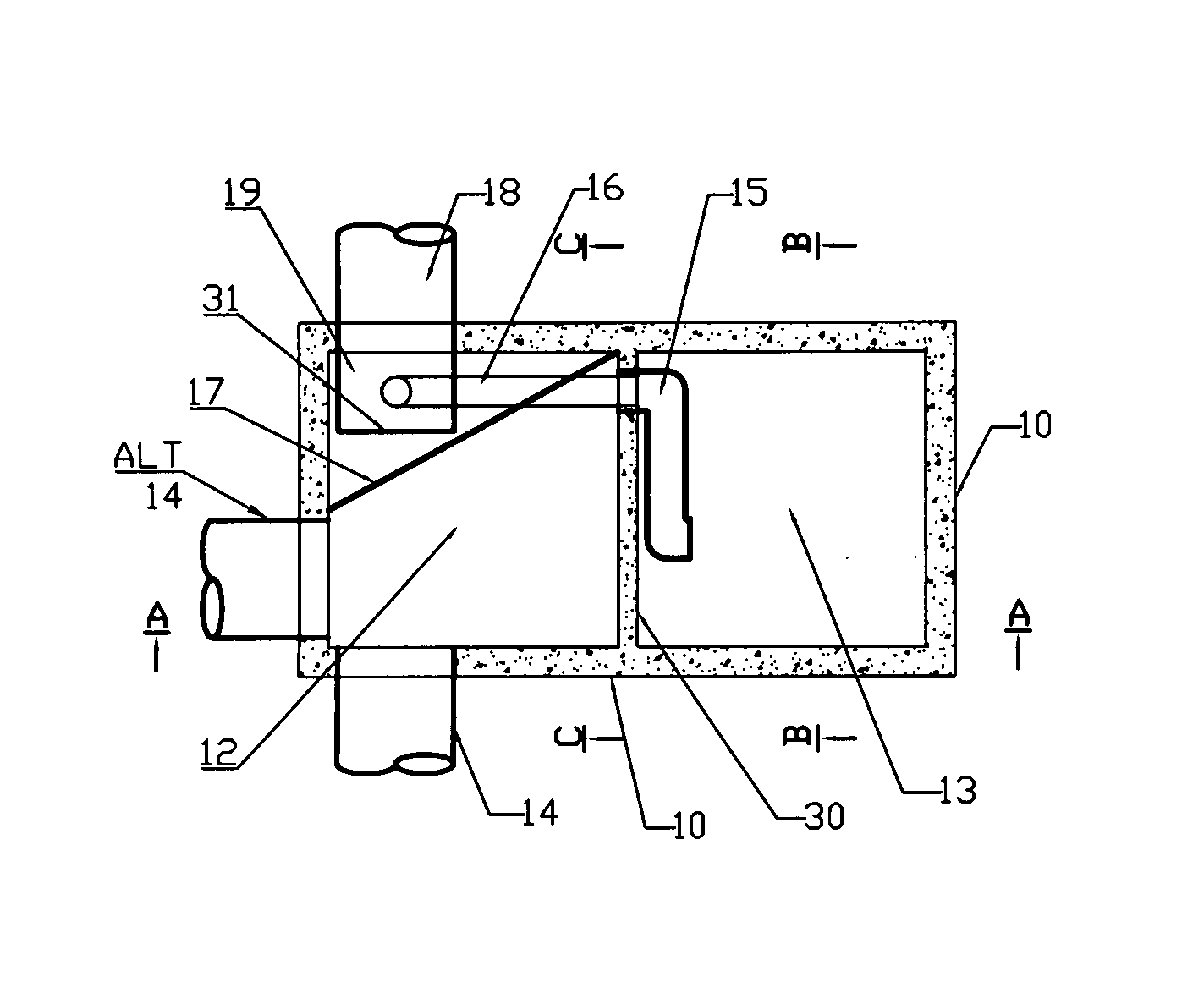

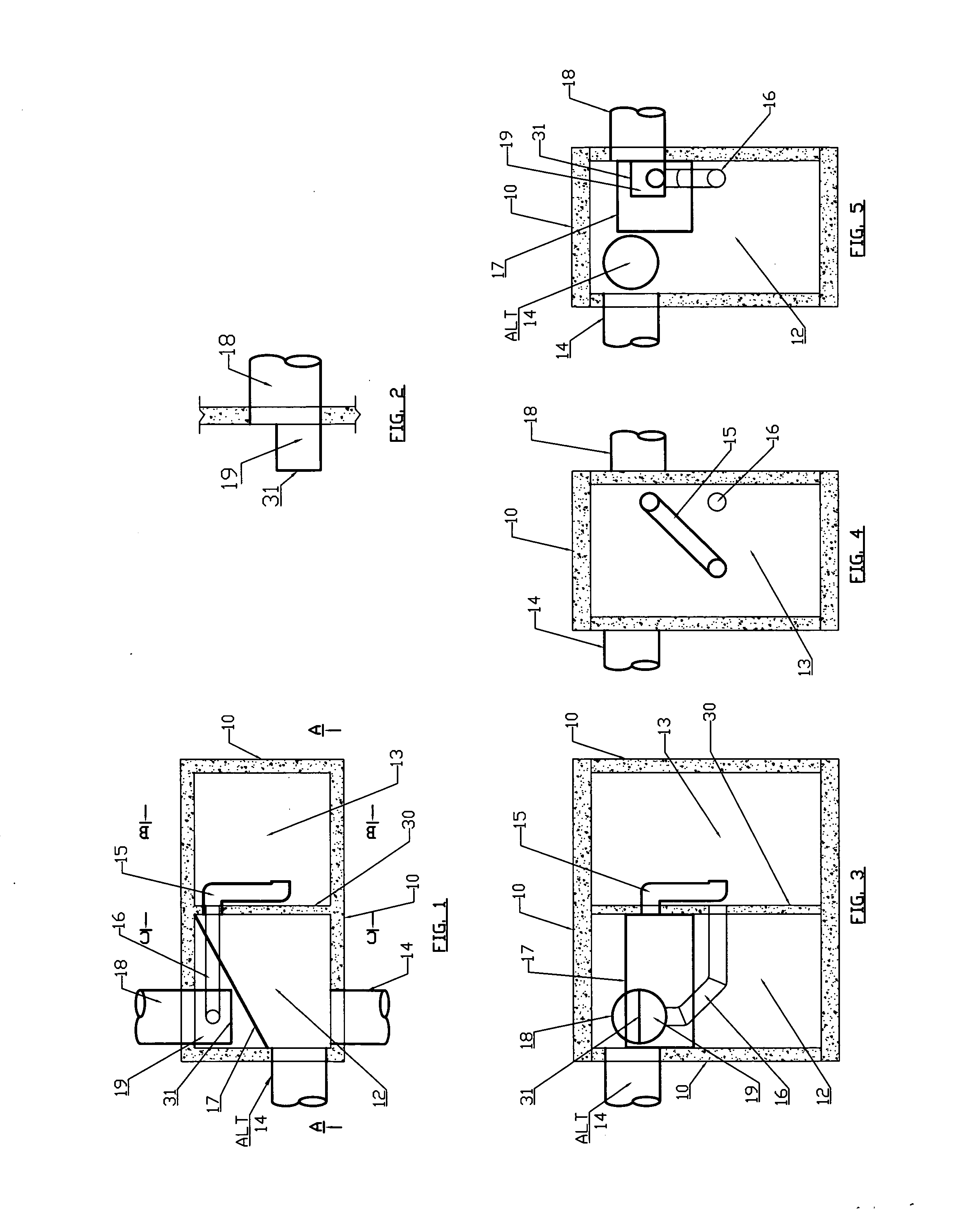

Apparatus for separating a light fluid from a heavy one and/or removing sediment from a fluid stream

InactiveUS20080217227A1Raise the water levelWater cleaningFatty/oily/floating substances removal devicesHigh elevationLighter fuel

An input chamber receives runoff water to be cleaned. Part of the way up the chamber wall is a restricted outlet which feeds a system for cleaning the water. At a still higher elevation another opening allows runoff water to flow to another cleaning system. Near the top of the chamber is an outlet pipe. A vertical baffle in front of the outlet cleans water that flows under the baffle on its way to the outlet. When the incoming flow rate is very high, water passes over the baffle to the outlet.

Owner:BAYSAVER TECH +1

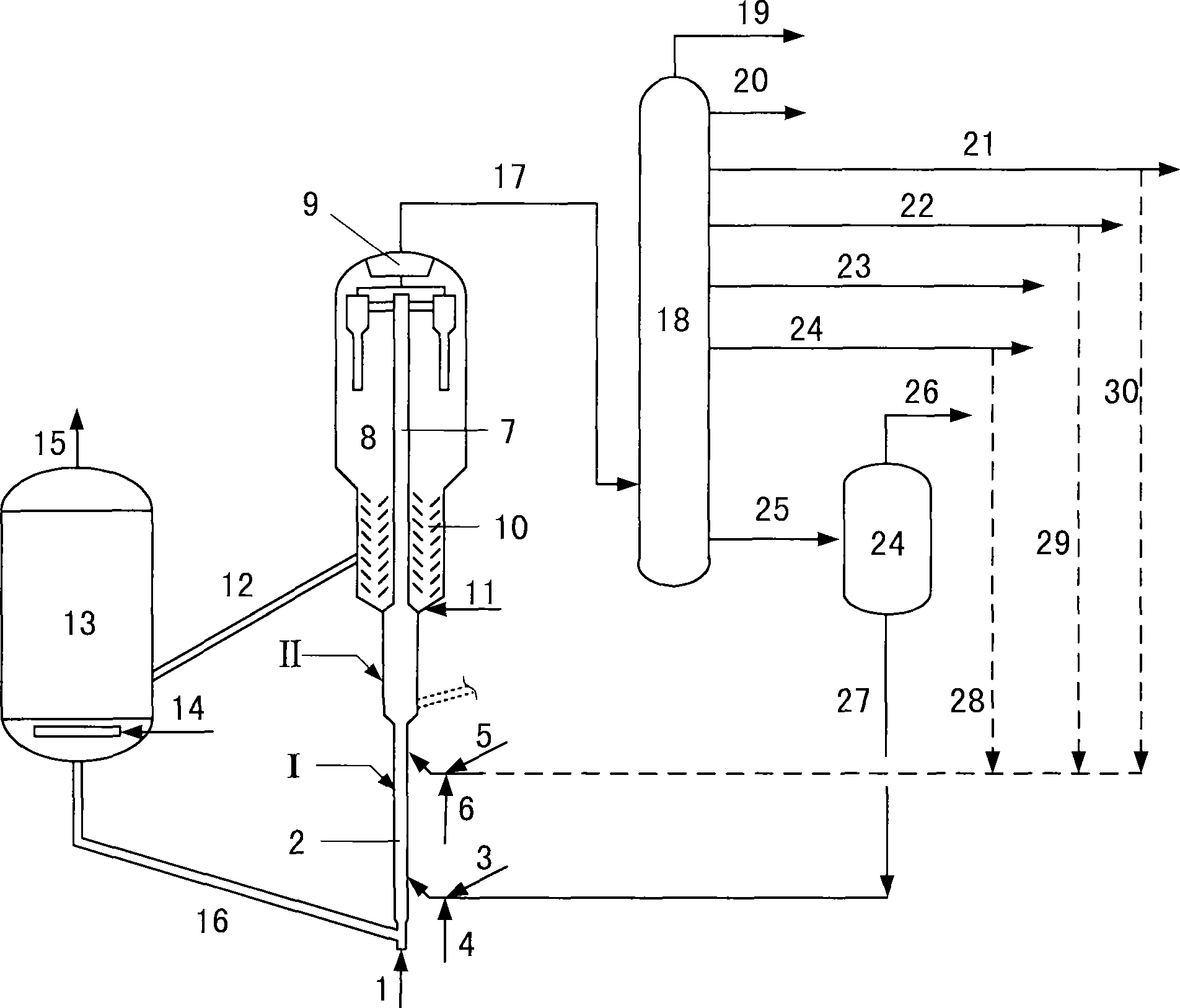

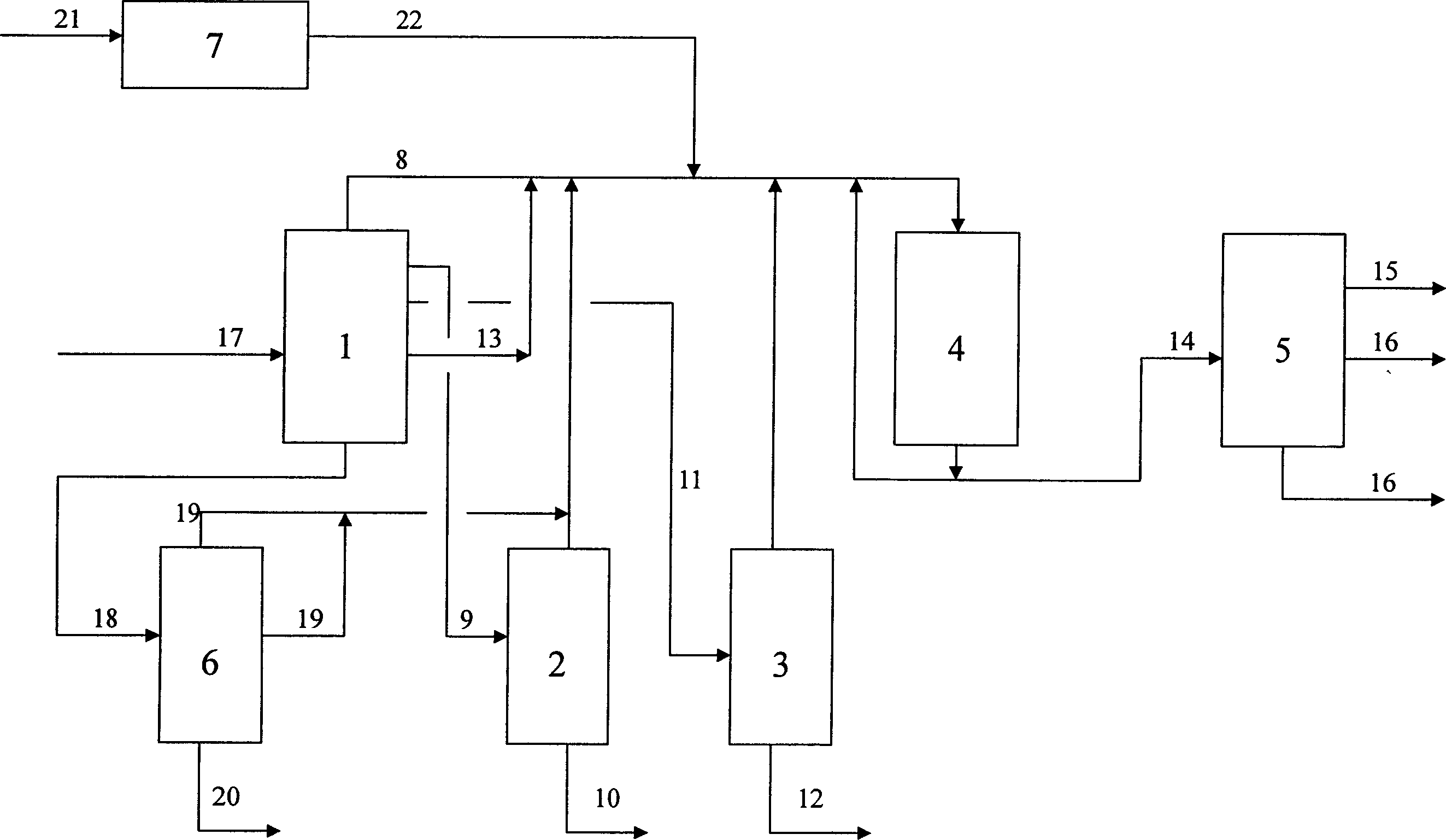

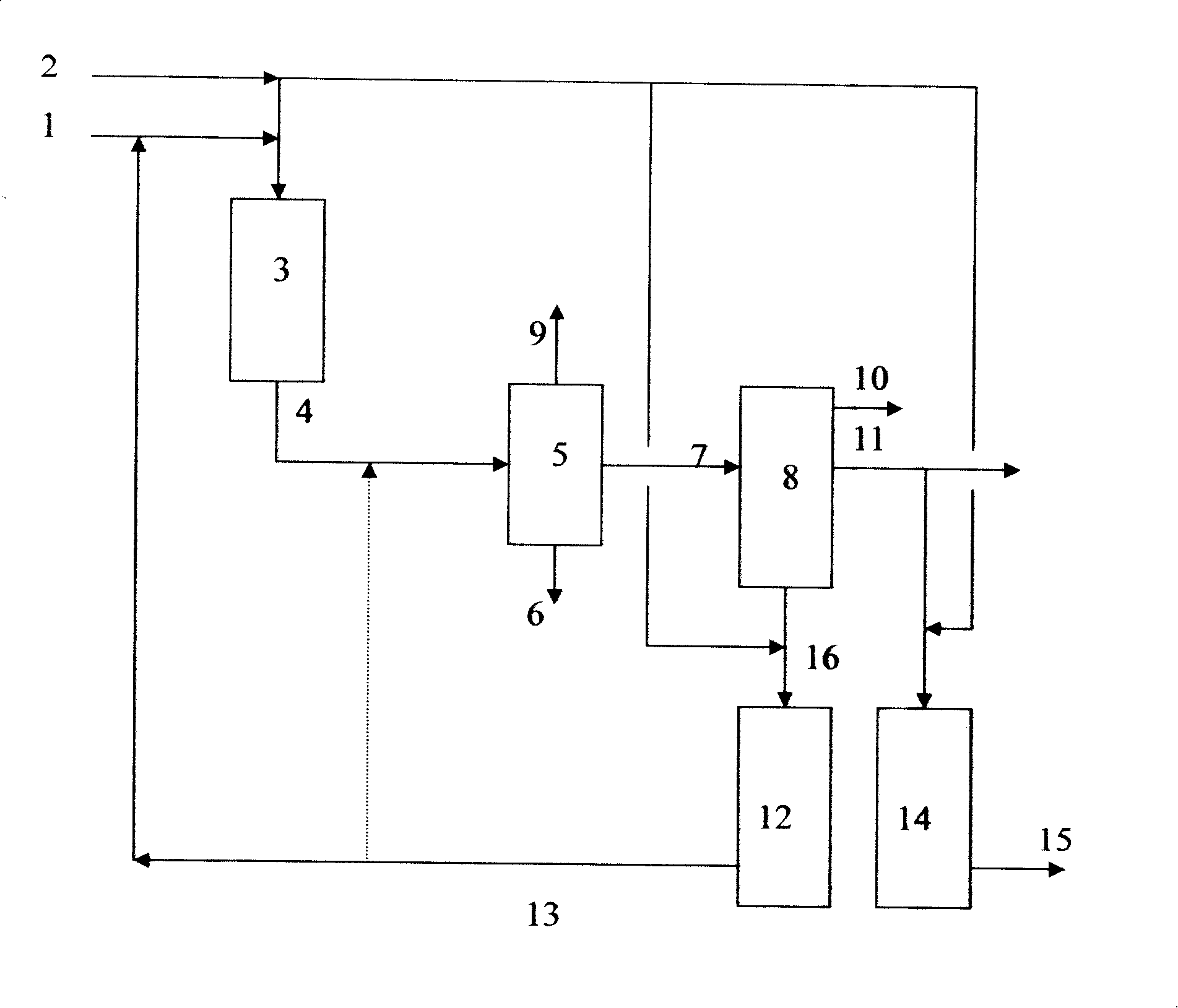

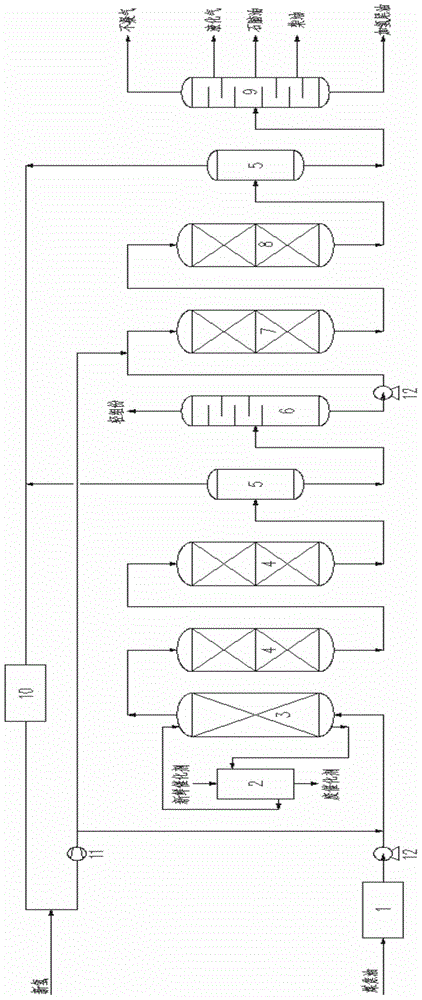

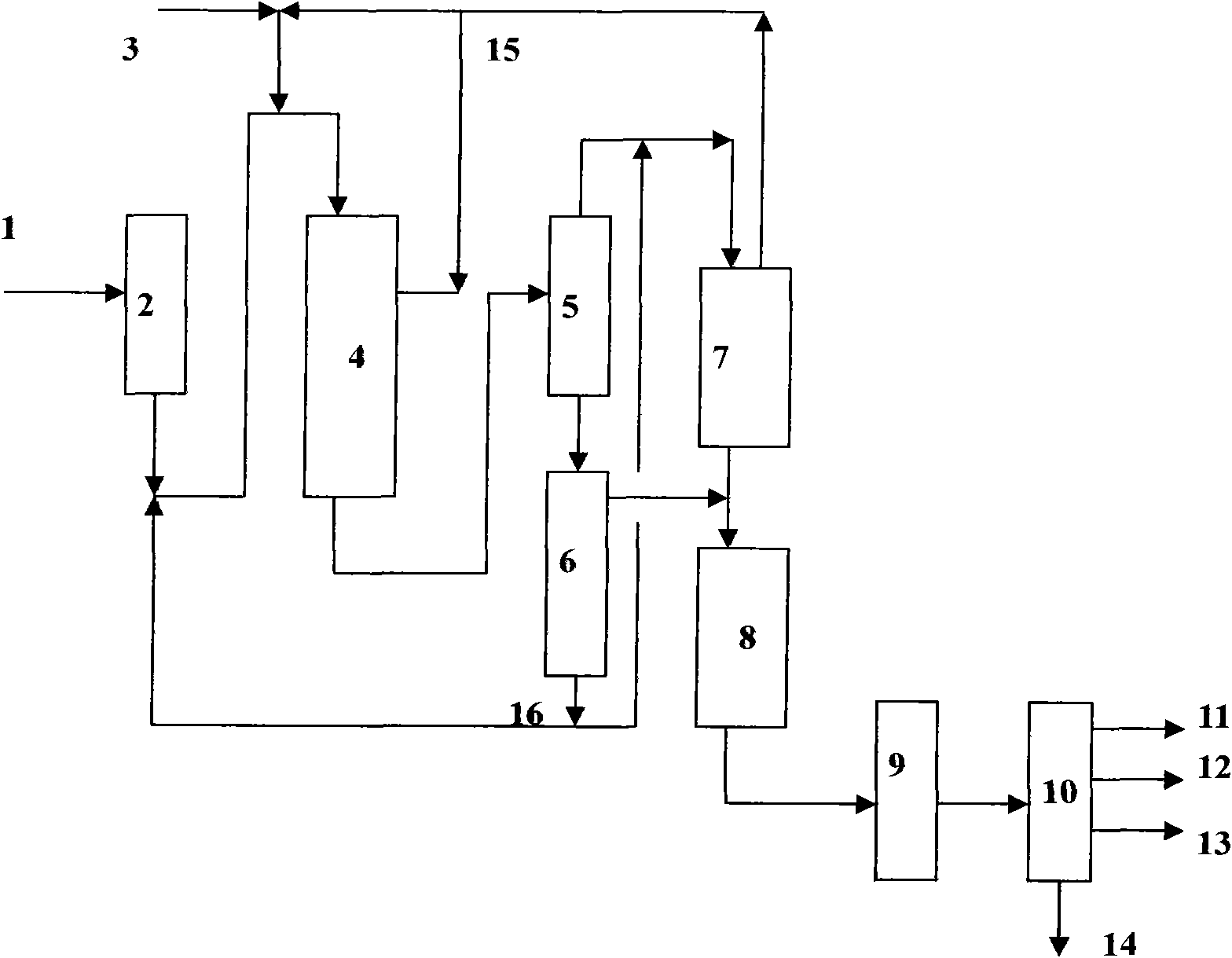

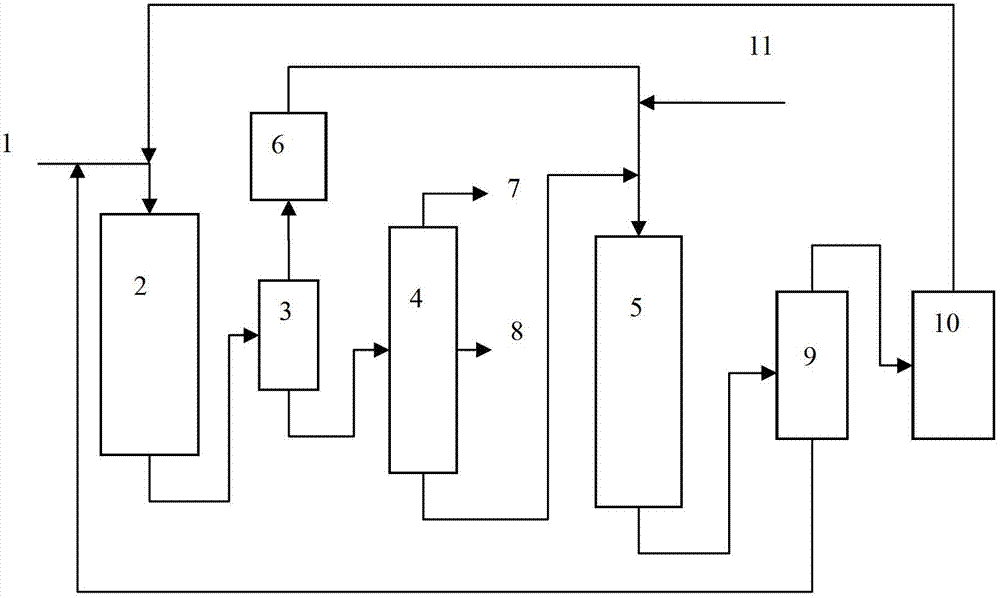

Combined coal tar whole fraction hydroprocessing system and application thereof

InactiveCN104862004AReduce the difficulty of separationTreatment with hydrotreatment processesFixed bedEngineering

The invention relates to a combined coal tar whole fraction hydroprocessing system and an application thereof. The system comprises a desalination dehydration impurity-removing refining system 1 which is connected with a hydrogen compressor 11 and an up-flow moving bed hydrofining reactor 3 respectively through one hydrogenation feeding pump 12, the up-flow moving bed hydrofining reactor 3 is respectively connected with a catalyzer on-line feeding system 2 and two series connection fixed bed hydrofining reactors 4, the fixed bed hydrofining reactors 4 are connected with separators 5, the separators 5 are respectively connected with a hydrogen refining system 10 and a flash tower 6, the flash tower 6 is connected with a fixed bed hydrocracking reactor 7 through the other hydrogenation feeding pump 12 and then sequentially connected with a fixed bed hydrofining reactor 8, the separators 5 and a fractionating tower 9. Compared with combined coal tar whole fraction hydroprocessing systems in the prior art, the combined coal tar whole fraction hydroprocessing system has the advantages that the process is simpler, the conversion rate is higher, operation is stable, product properties are good, and the system can be used for production processes of excellent light fuels by poor raw materials such as various coal tar, shale oil and residual oil.

Owner:袁继海 +2

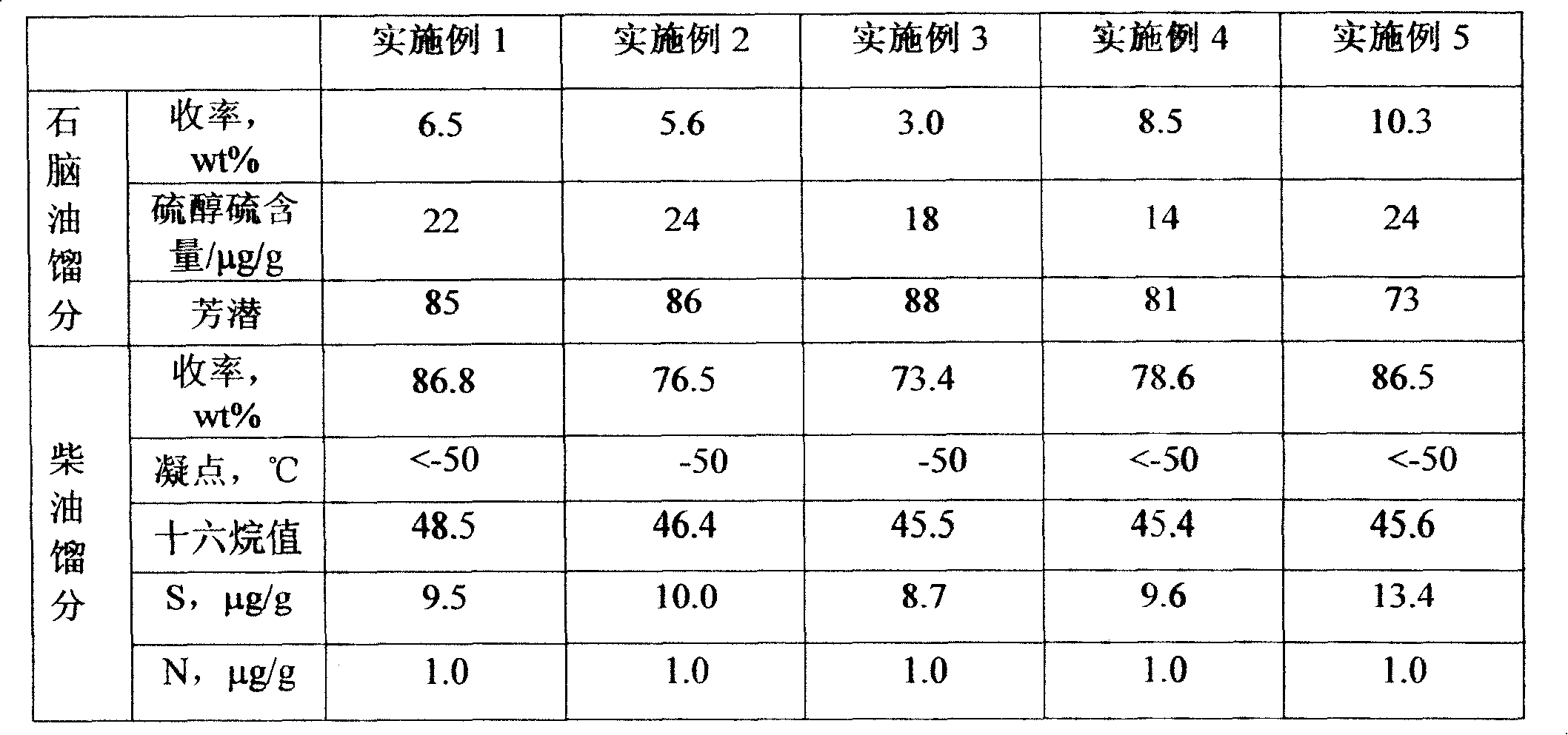

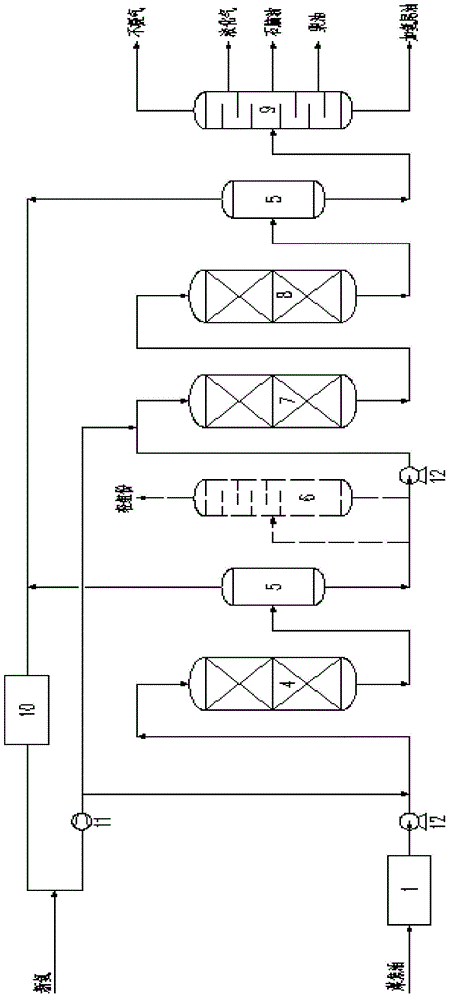

Hydrocracking method for blending ethylene tar

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technique for coproducing methanol from coke oven gas and fuel products by hydrogenating coal tar prepared from tail gas of methanol preparation

InactiveCN101239887ATo achieve the effect of energy saving and emission reductionOrganic compound preparationHydroxy compound preparationNitrogen gasHeat energy

The invention relates to a hydrogenation process for preparing oil products from coal tar which is generated together with exhaust gas synthesized during preparation of methanol from a coke oven and coal gas. Methanol is prepared from coal gas which is the by-product of the coke oven, large amount of relief gas and nitrogen gas during the methanol preparation process, hydrogen is extracted from the relief gas and used as one of the materials for hydrogenation preparing light fule oil from tar, nitrogen is extracted as the material of a coke dry quenching unit, the heat energy generated during the coke dry quenching process is used for generating electric power. With the recycling of coke oven coal gas, the prior exhaust gas which is directly exhausted or burnt is changed into a high-value product, such as electricity, methanol, light fuel oil, advanced charcoal material, etc., at the same time, the object of energy conservation can be realized.

Owner:QITAIHE BAOTAILONG COAL CHEM IND

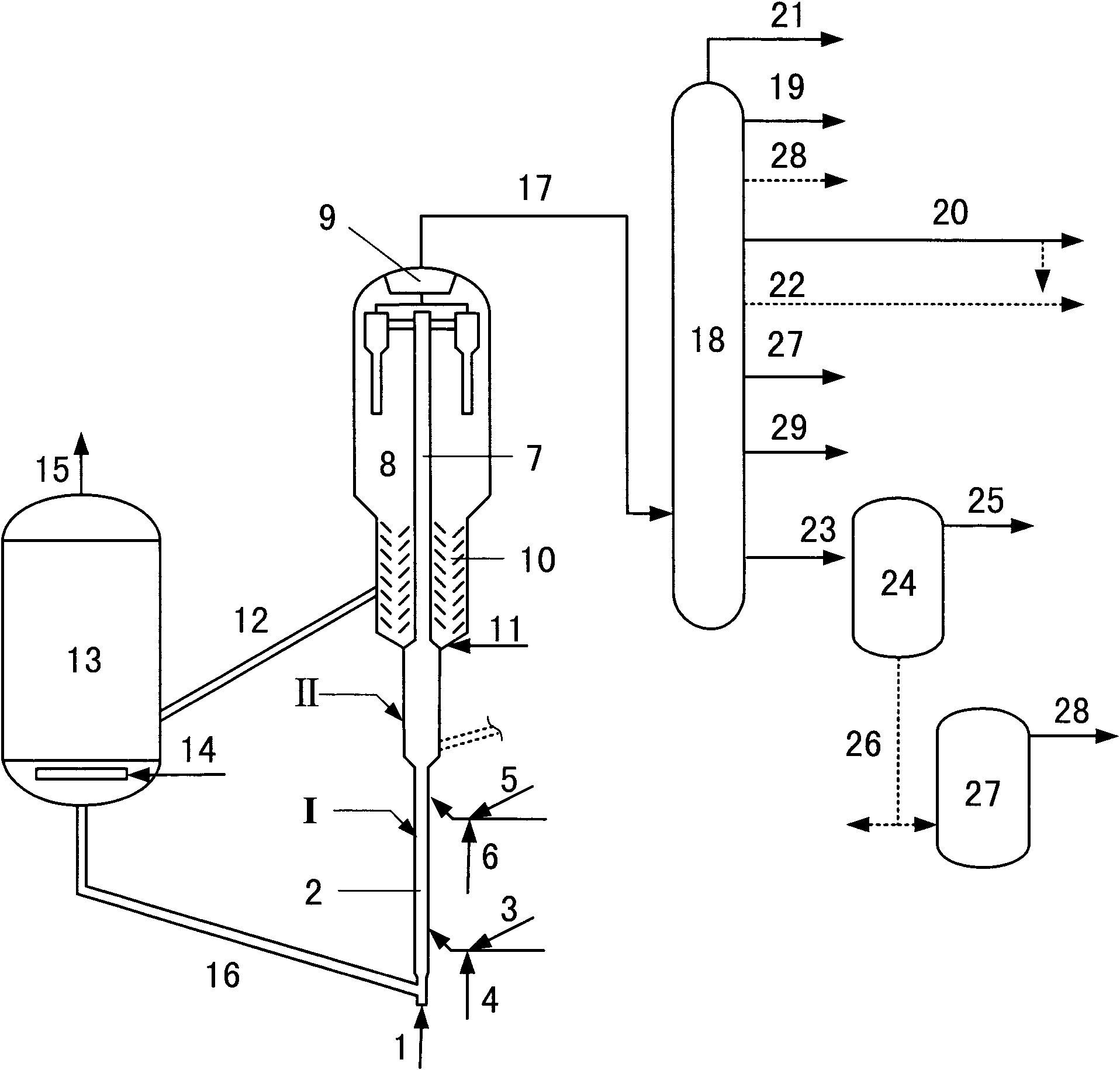

Lighter fluid composition

InactiveUS6843812B2Clean burningLow VOC emissionSolid fuelsLiquid carbonaceous fuelsCross-linkMethanol

A lighter fluid composition usable for starting barbecues and the like that comprises naturally occurring combustible materials, which is clean burning and results in low volatile organic compound (VOC) emission during combustion, which is biodegradable and easily disposable, and which burns with a pleasant aroma and does not impart any unpleasant hydrocarbon odor or flavor to food cooked on a barbecue. The composition preferably comprises between approximately 0.5 weight percent and approximately 90 weight percent of a terpene or terpenoid oil, and between approximately 0.5 weight percent and approximately 98.5 weight percent of short chain alcohol, between approximately 0.5 weight percent and approximately 60 weight percent of water, between approximately 0.1 weight percent and approximately 10 weight percent of surfactant, and between approximately 0.5 weight percent and approximately 10 weight percent of thickening agent. The preferred terpene preferably comprises d-limonene or a citrus derived oil containing d-limonene such as cold-pressed orange oil. The preferred alcohols are methanol and ethanol. The preferred surfactant is a non-ionic detergent or detergents, and the preferred thickener is a pH controllable slightly cross-linked polyacrylic acid material.

Owner:STEPHANOS PRODROMOS PERICLES

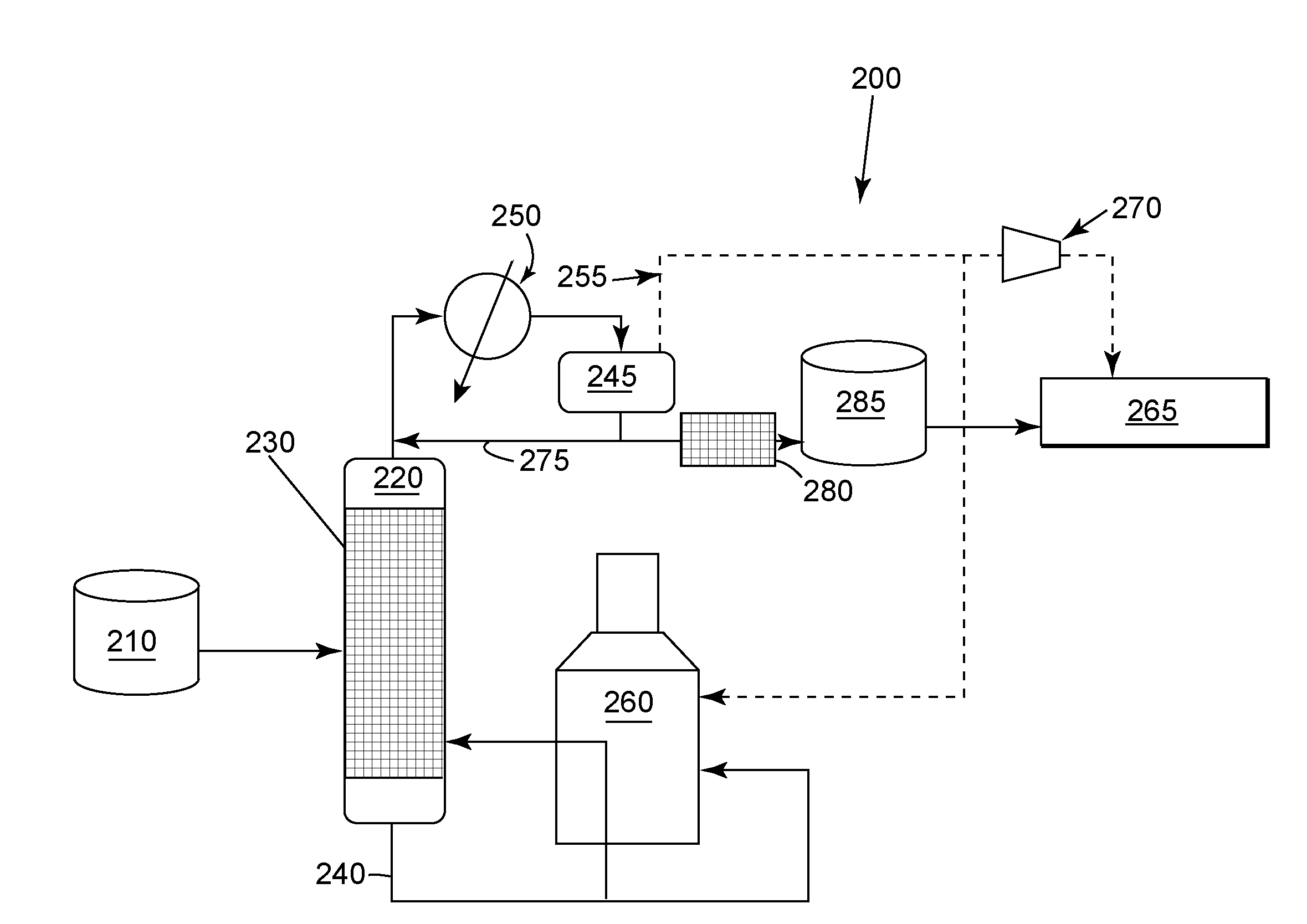

System for drilling oil and gas wells using a concentric drill string to deliver a dual density mud

A system for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in offshore and land-based drilling applications is disclosed. The present invention combines a base fluid of lesser / greater density than the drilling fluid required at the drill bit to drill the well to produce a combination return mud in the riser. By combining the appropriate quantities of drilling mud with a light fluid, a riser mud density at or near the density of seawater may be achieved to facilitate transporting the return mud to the surface. Alternatively, by injecting the appropriate quantities of heavy fluid into a light return mud, the column of return mud may be sufficiently weighted to protect the wellhead. At the surface, the combination return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the drilling fluid from the base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

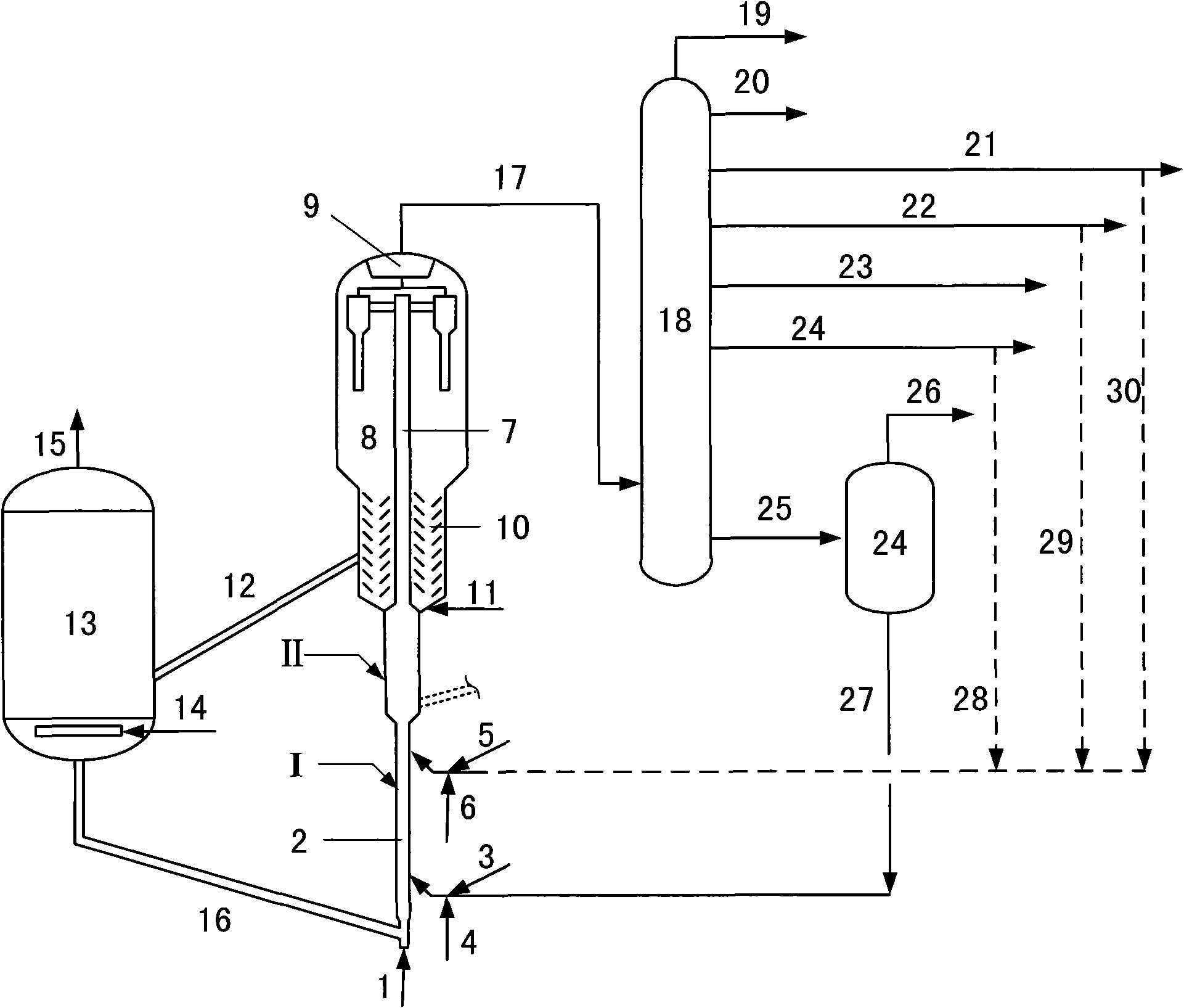

Method for preparing high-quality fuel oil from inferior crude oil

ActiveCN101993726AImproved raw material propertiesExtended operating cycleTreatment with hydrotreatment processesChemical recyclingWaxLighter fuel

The invention discloses a method for preparing high-quality fuel oil from inferior crude oil. The inferior crude oil enters first and second reaction zones of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst and respectively perform primary reaction and secondary reaction, and after a reaction product and a spent catalyst are subjected to gas-solid separation, the spent catalyst is stripped and scorched in turn and is returned to the reactor for recycling; the reaction product is separated to obtain propylene, light fuel oil, catalyzed wax oil and other products, wherein the catalyzed wax oil enters a hydrocracking device and is separated to obtain products such as gasoline, an aviation fuel, diesel oil, hydrocracked tail oil and the like; and the hydrocracked tail oil is circulated to the first reaction zone of the catalytic conversion reactor and / or other catalytic conversion devices for further reaction to obtain a desired product, namely the light fuel oil, and a byproduct, namely the propylene. By the method, a diesel cetane number is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lamp oil composition and lighter fluid composition

InactiveUS20050115145A1SaferEasy to manufactureCapillary burnersLiquid carbonaceous fuelsAlcoholLighter fuel

Lamp oil compositions including methyl palmitate, methyl stearate, myristyl alcohol, an alcohol with less than six carbons, preferably ethyl alcohol, and fragrance. Also disclosed herein are lighter fluid compositions which include methyl laurate, methyl stearate, ethyl alcohol and fragrance.

Owner:LUMETIQUE

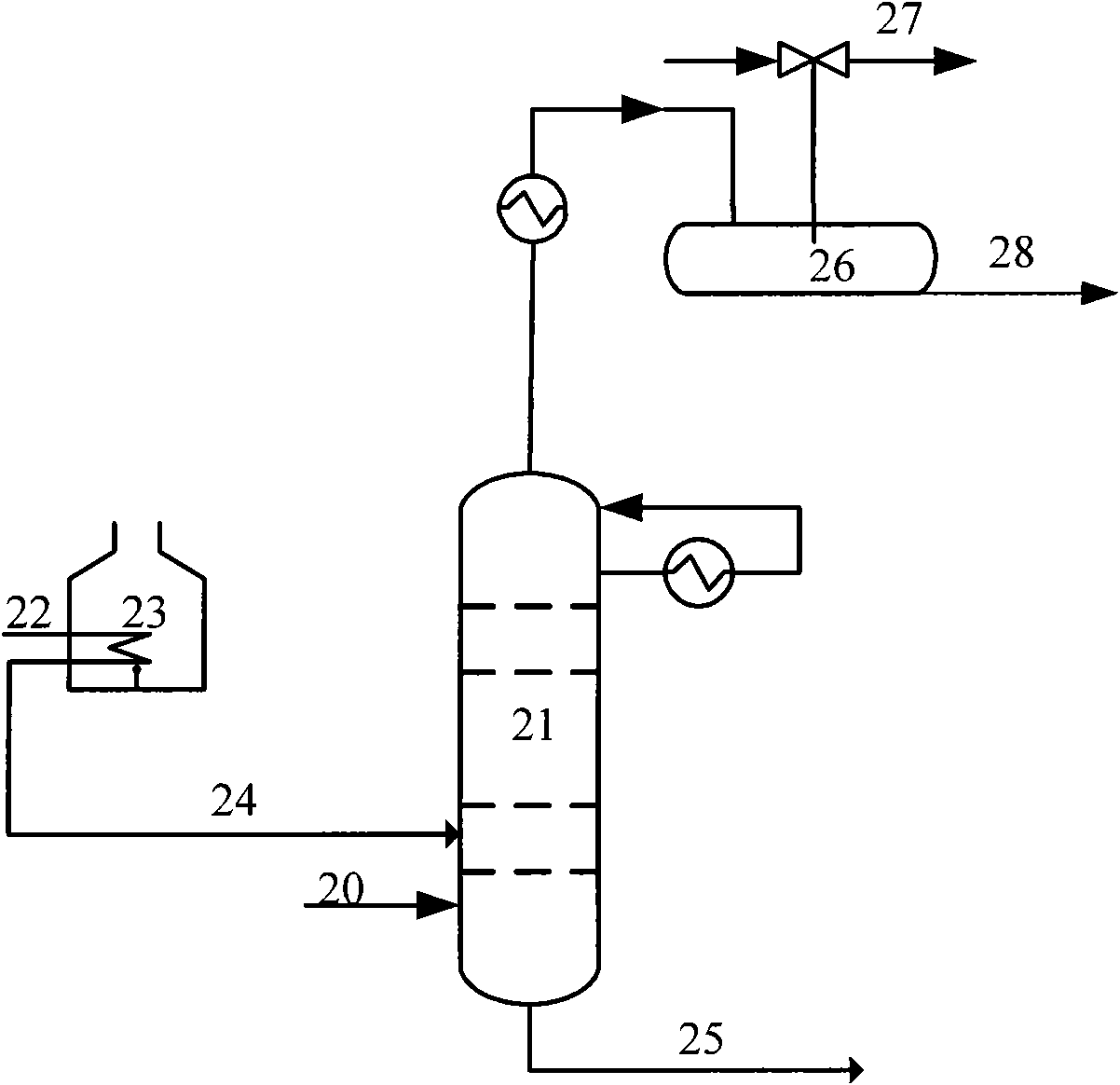

Catalytic conversion method for converting low-quality heavy oil into light clean fuel oil

ActiveCN101899323AImprove separation efficiencyEasy to separateTreatment with plural serial stages onlyVacuum distillationDistillationSolid particle

The invention discloses a catalytic conversion method for converting low-quality heavy oil into light clean fuel oil, which comprises: (1), introducing low-quality raw material oil into a catalytic cracking reactor having two reaction areas for performing a cracking reaction, wherein the reaction conditions in the catalytic cracking reactor ensure the catalytic wax oil obtained by the reaction is12 to 60 weight percent based on the weight of the low-quality raw material oil; (2) introducing the catalytic wax oil carrying catalyst particles into a reduced-pressure distillation tower, and separating a catalytic wax oil light fraction from the top of the tower; (3) hydrogenating the catalytic wax oil light fraction to obtain hydrogenated catalytic wax oil; and (4) circulating the hydrogenated catalytic wax oil to a catalytic conversion device for further reaction to obtain a light fuel oil target product. The method provided by the invention has the advantages that: due to the catalyticcracking of the low-quality heavy oil raw material, the catalytic wax oil yield is high, and the dry gas yield and cock yield are low; after solid particle removal and hydrogenation, the obtained catalytic wax oil can be introduced back to the catalytic cracking device for recycling, so the light oil yield of the whole process is increased by 5 to 15 percent and oil slurry yield is reduced; and thus, the high-efficiency use of oil resources is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrogenation process of coal tar

ActiveCN102851071AHigh yieldOvercome expensiveTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention discloses a two-stage hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrotreating reaction section, and carrying out a hydrotreating reaction on the coal tar by contacting with a hydrotreating catalyst in the presence of hydrogen and under hydrogenation conditions; (b) carrying out gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, in order to distillate out a light fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section, and carrying out a hydrocracking reaction on the heavy fraction by contacting with a hydrocracking catalyst in the presence of hydrogen and under hydrogenation cracking conditions; and (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a). Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

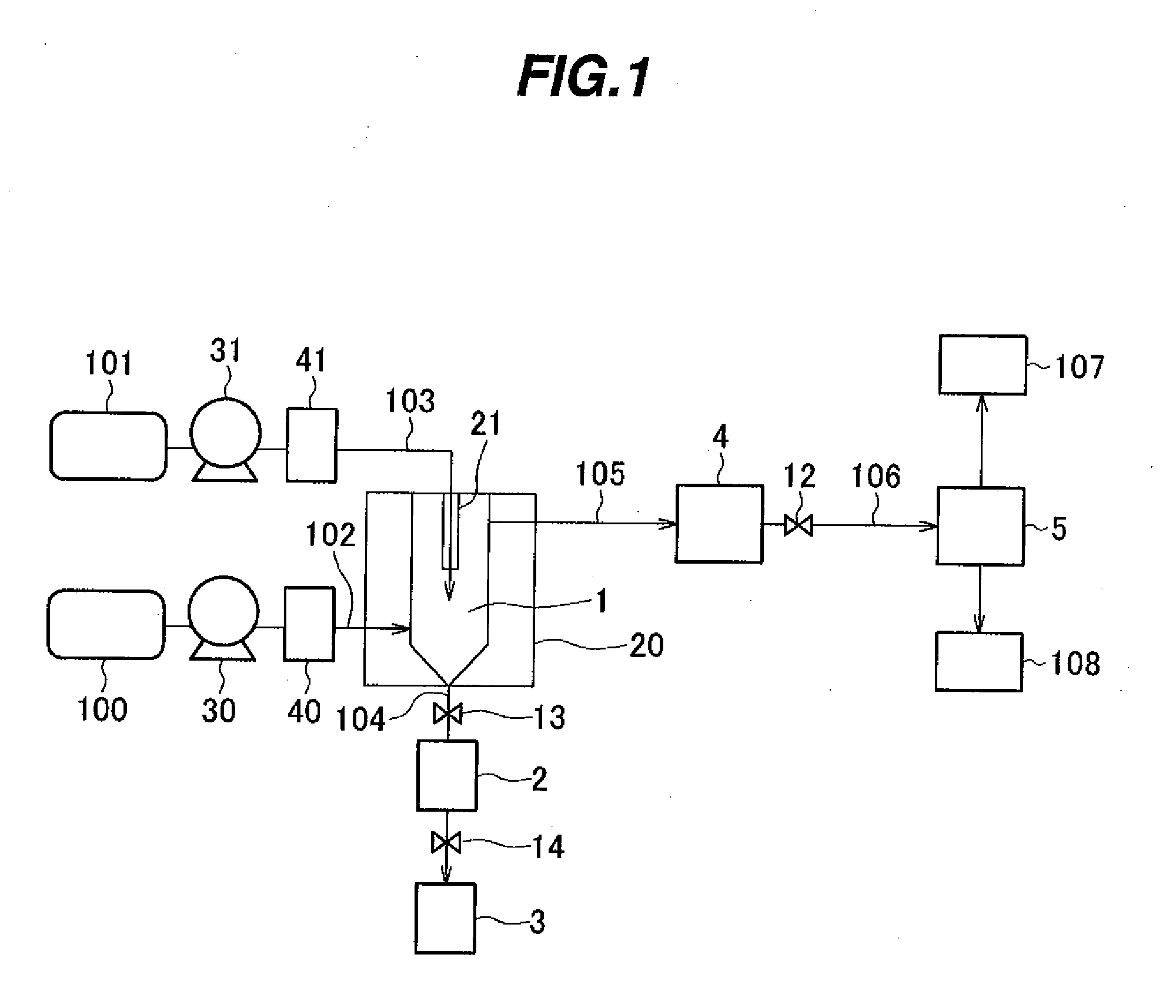

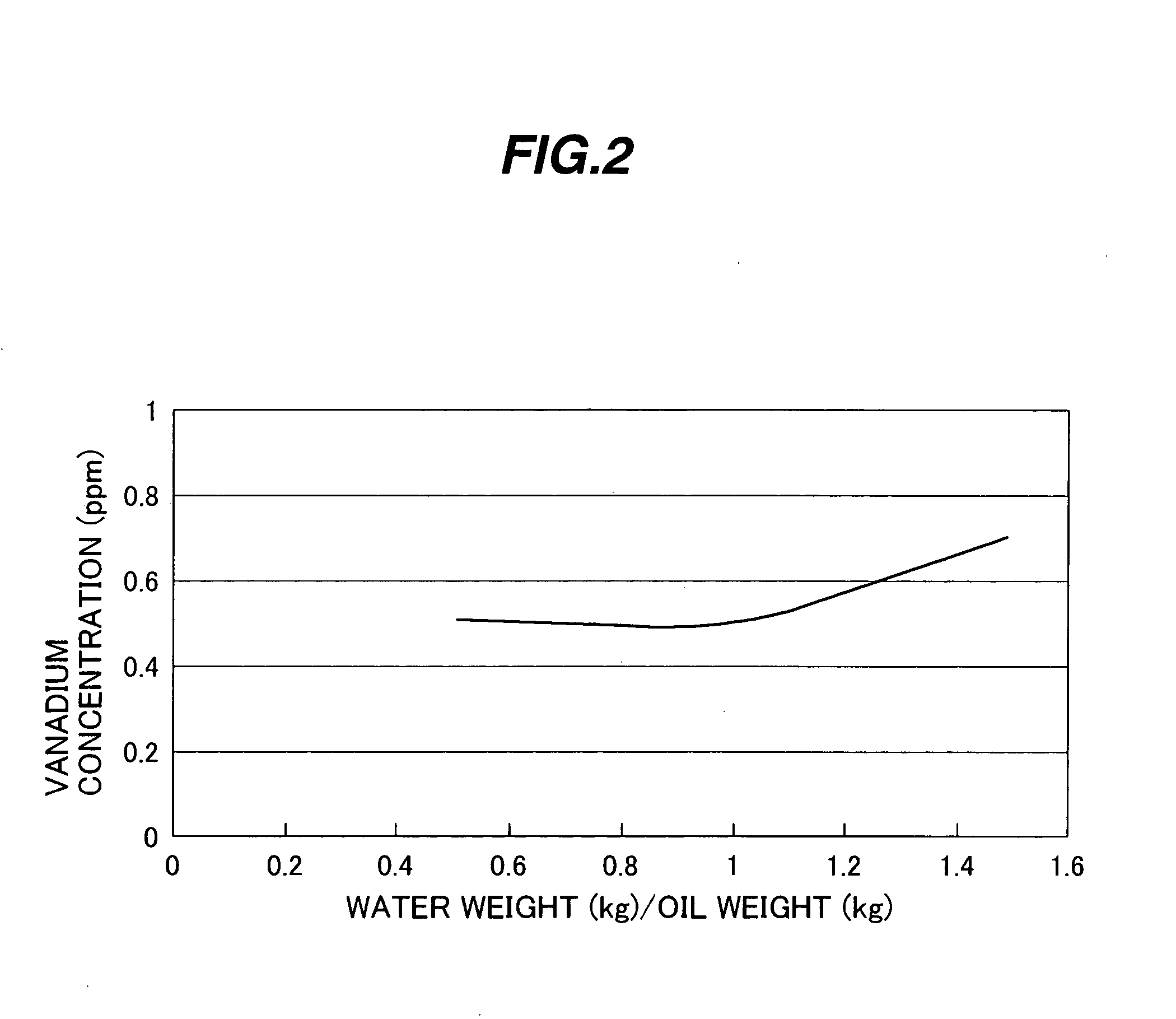

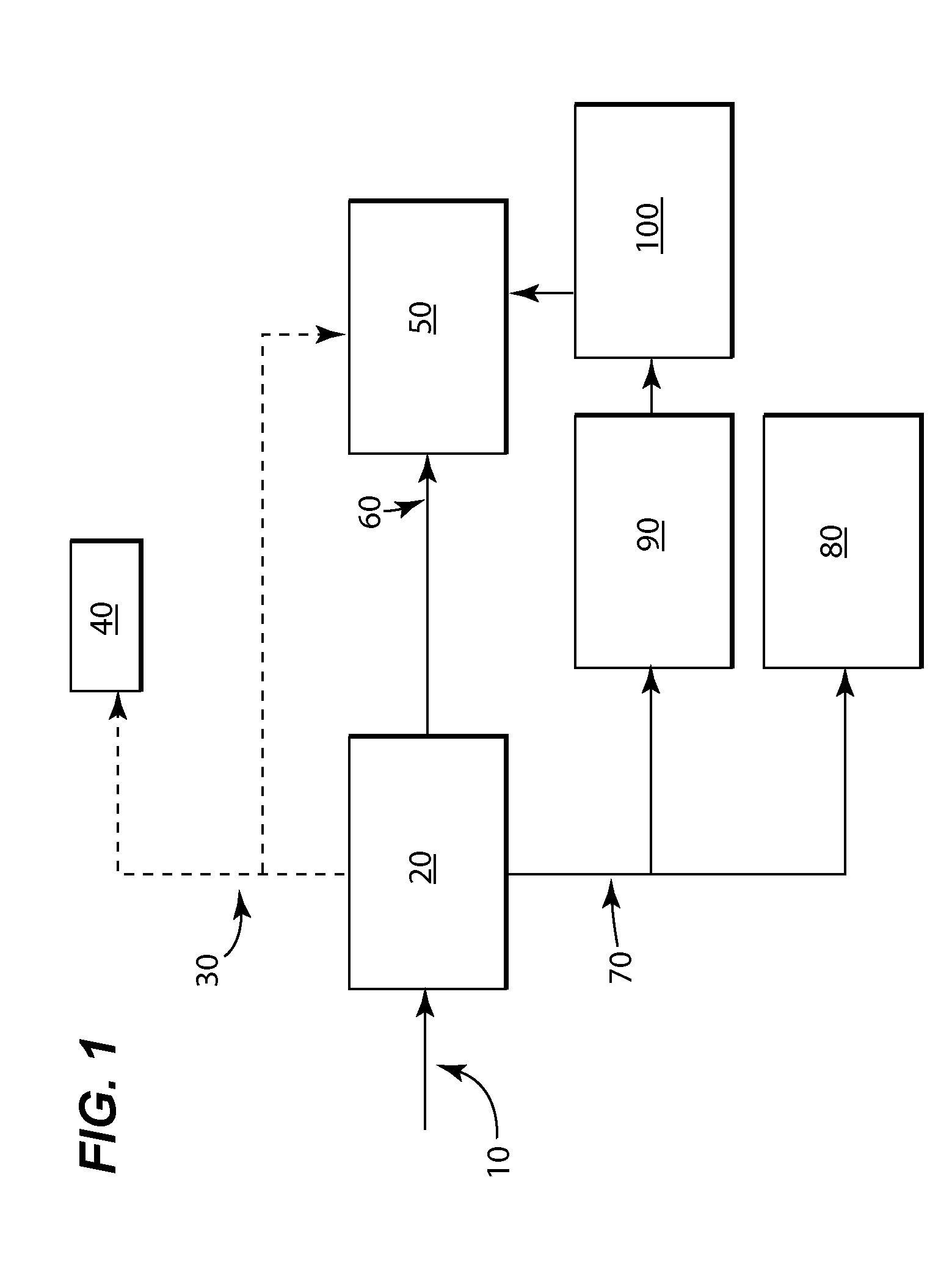

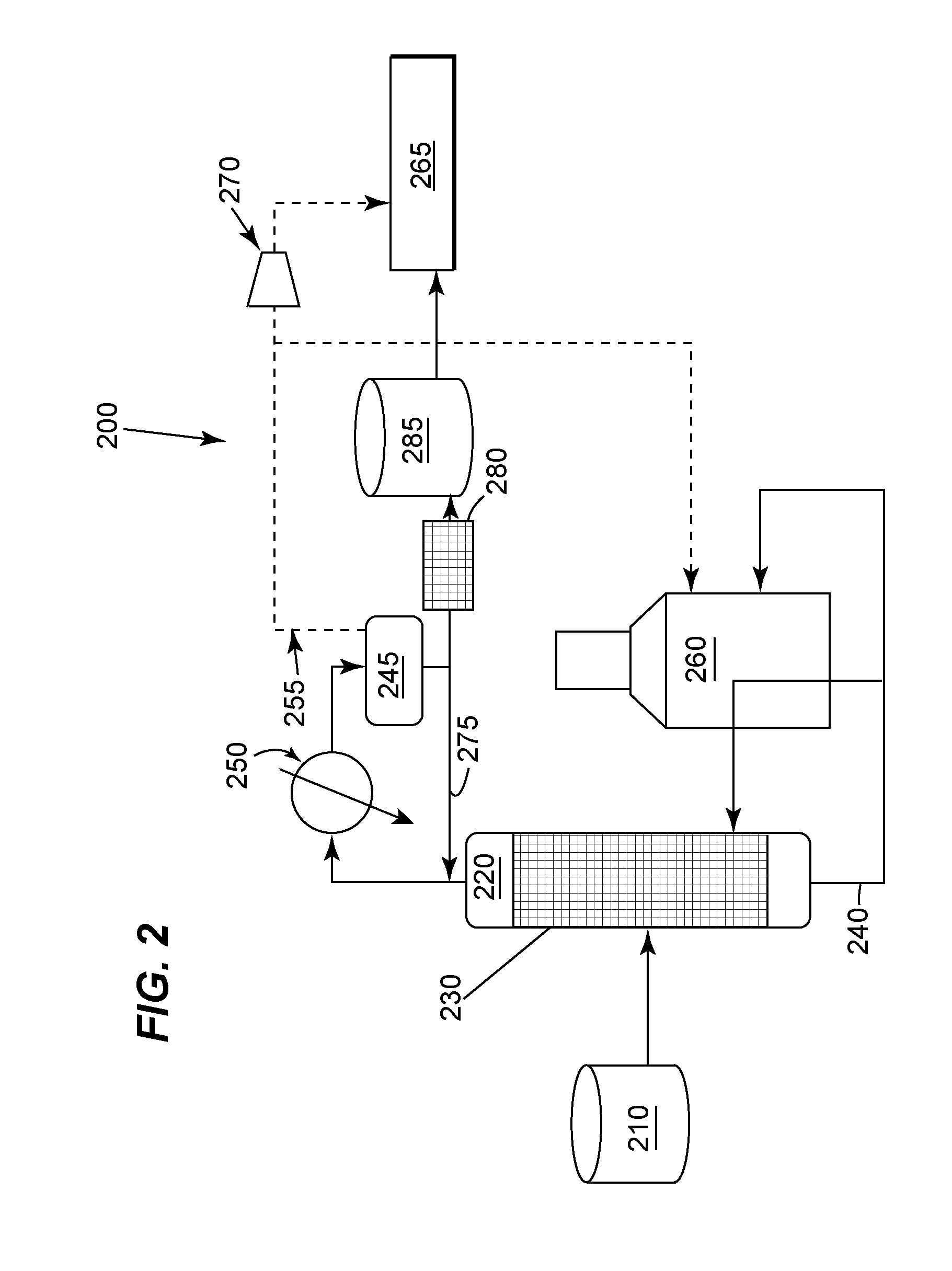

Methods and systems for removing vanadium from low-grade fuels

ActiveUS20090057202A1Efficient methodHydrocarbon distillationSolid sorbent liquid separationLighter fuelLower grade

A method for treating fuel containing vanadium including extracting vanadium from the fuel with an adsorption material and fractionating the fuel into a light oil fraction and a heavy fuel fraction. The light fuel fraction has a reduced amount of vanadium. Systems for fuel preparation are also provided.

Owner:GENERAL ELECTRIC CO

Method producing light fuel oil and propylene from poor residual oil

ActiveCN102373084AEfficient use ofTreatment with hydrotreatment processesChemical recyclingLighter fuelFuel oil

The invention discloses a method producing light fuel oil and propylene from poor residual oil, wherein residual oil raw materials and the extract oil of catalytic cracking heavy oil aromatics extraction are reacted in a residual oil hydrogenation unit, the obtained hydrogenation residual oil and the extract oil of the catalytic cracking heavy oil aromatics extraction enter a catalytic cracking device to react, the obtained catalytic cracking heavy oil enters an aromatics extraction device, then the raffinate oil and the extract oil are obtained after the treatment, the obtained extract oil is circulated to the residual oil hydrogenation unit, and the raffinate oil is circulated to the catalytic cracking device. The method organically combines hydrotreatment, catalytic cracking and aromatics extraction technologies, and produces propylene and light fuel oil from poor raw materials to the maximum extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

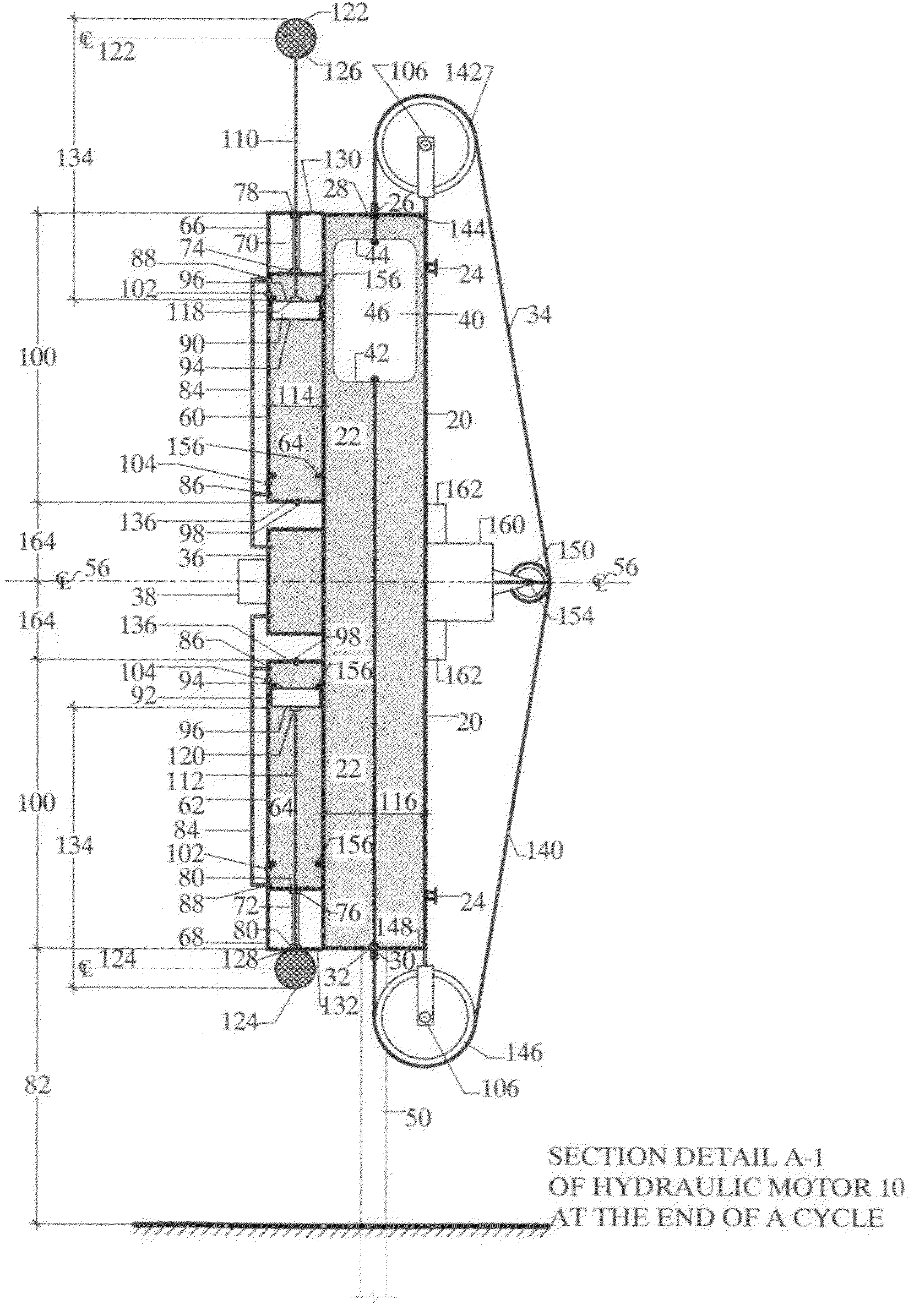

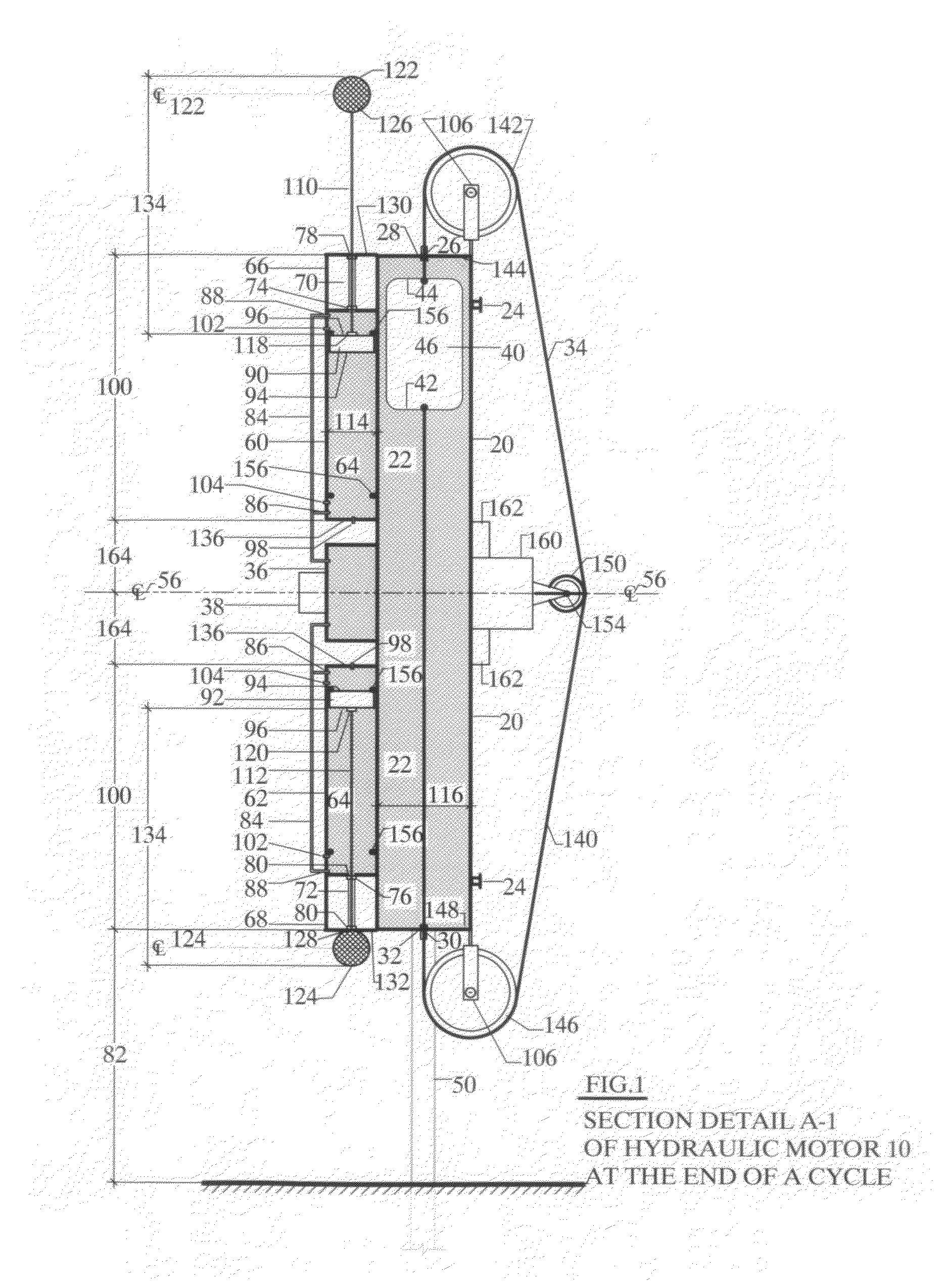

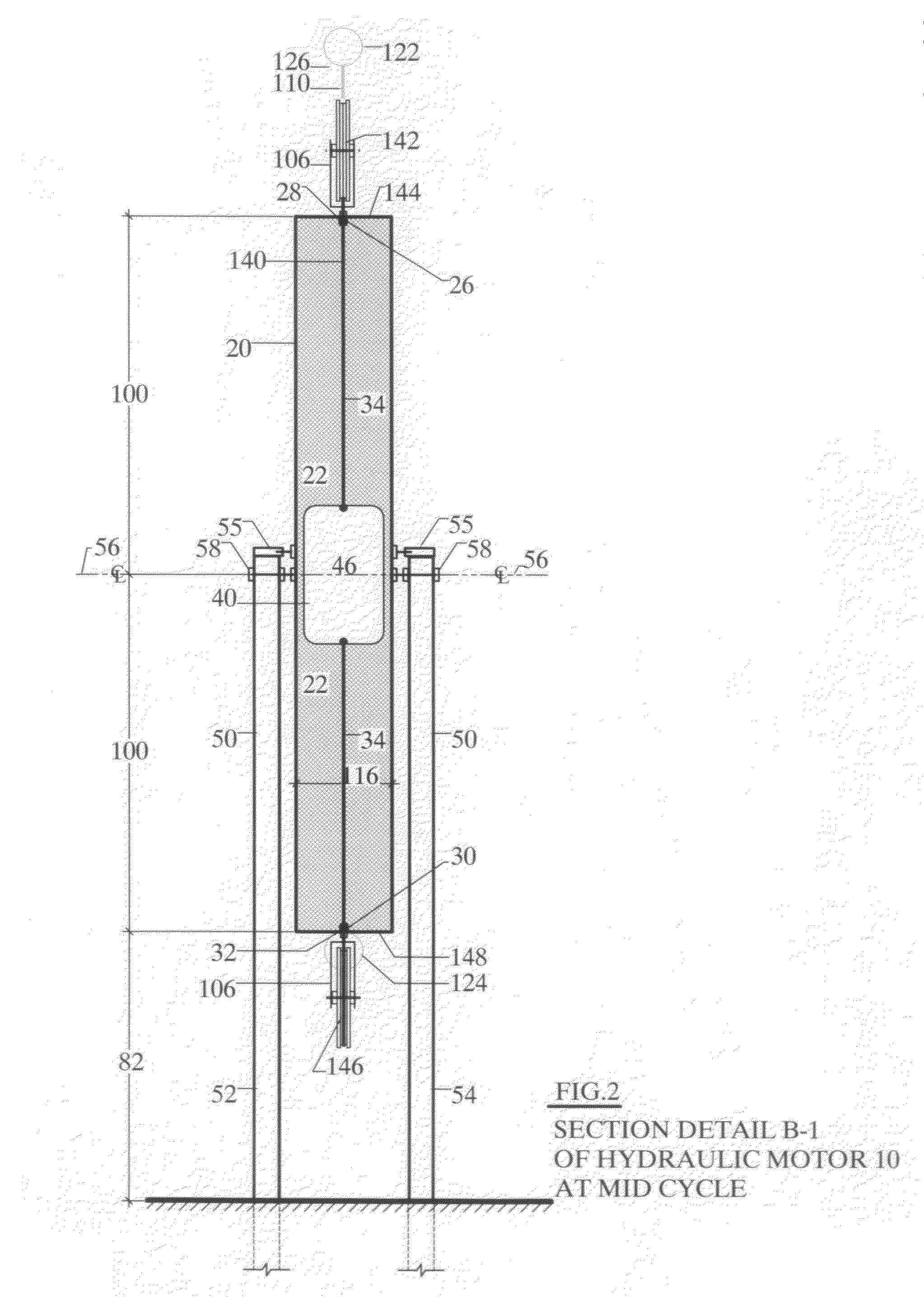

Hydraulic motor using buoyant and gravitational forces to generate kinetic energy

A motor mounted on a structural support with a pivot at its center line which comprises a cylindrical vessel for holding a fluid in a closed system and in which a buoyant cylinder containing a lighter fluid is allowed to free float so that a cable attached to either end of the buoyant cylinder may be used to transfer energy to a energy storage unit, a crank or a generator. Two moment arms having a weight attached at the exterior end and inside attachably connected to the surface of two drive pistons that operate in pressure tanks which force a compressed gas against the pistons through pre-sequenced automatic activated valves to extend or retract the moment arms at the end of a cycle. The motor then becomes top heavy and rotates 180 degrees by gravity and relocks in place to repeat the cycle.

Owner:DAVIS STEPHEN E

Fuel composition comprising alkyl ester

Use of a composition comprising a base formulation of one or more alkyl esters of a C6-C16 carboxylic acid or mixtures thereof as a fuel composition is provided. The use of the fuel composition is specifically provided for use as a lamp fuel, a lighter fuel, and / or a fuel for cooking, heating or cooling. Specifically, use of a composition as a lamp fuel is provided, wherein the composition comprises by weight 35-45% C8 methyl esters, 25-35% C10 methyl esters, 15-25% C12 methyl esters, and / or 5-15% C14 methyl esters. Also provided is a method for producing a fuel composition comprising the steps of a) providing a vegetable oil, b) preparing alkyl esters of carboxylic acids comprised in said vegetable oil by esterification and / or transesterification, c) optionally isolating one or more of said alkyl esters of said carboxylic acids, wherein said alkyl esters of carboxylic acids comprised in said vegetable oil and / or said one or more isolated alkyl esters constitute said fuel composition.

Owner:AGOWA IP

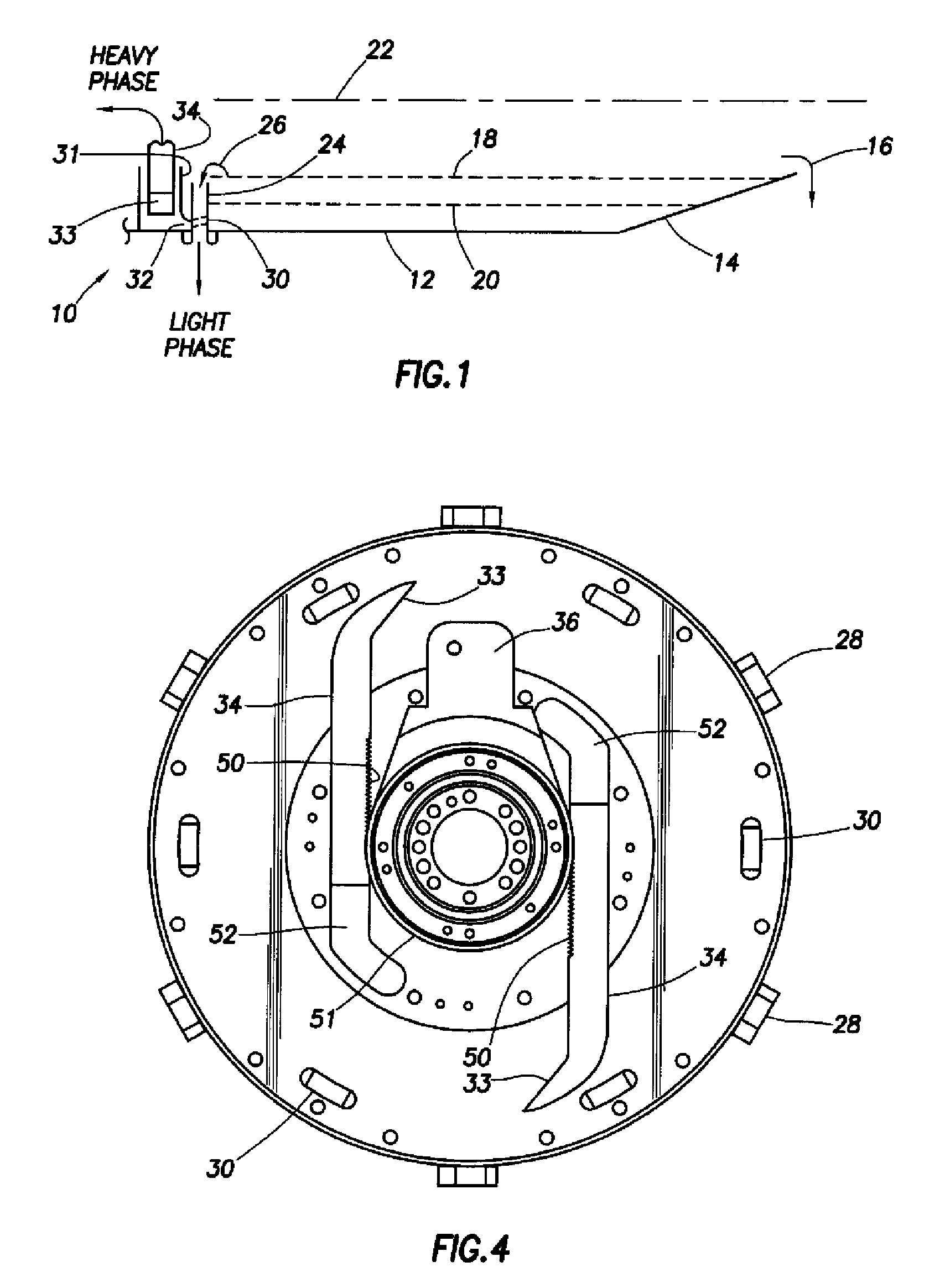

Three Phase Decanter Centrifuge

A three-phase decanting centrifuge is provided. Solids are removed from a slurry in the centrifuge in the conventional manner, as described above. The liquid separated from the slurry moves into a fluids reservoir. Centrifugal action classifies the fluids, with lighter fluids (typically oil) radially closer to the axis of rotation of the machine, while the heavier fluids are radially farther from the axis, i.e. at the bottom of the reservoir. Lighter fluids flow out a plurality of overflow tubes. Heavier fluids flow through a plurality of ports into a heavy fluids reservoir to be skimmed out by a pair of radially actuatable skimmer tubes. The skimmer tubes are preferably automatically operated based on the light transmissivity of the lighter and heavier fluids discharged from the machine.

Owner:HUTCHISON HAYES PROCESS MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com