Patents

Literature

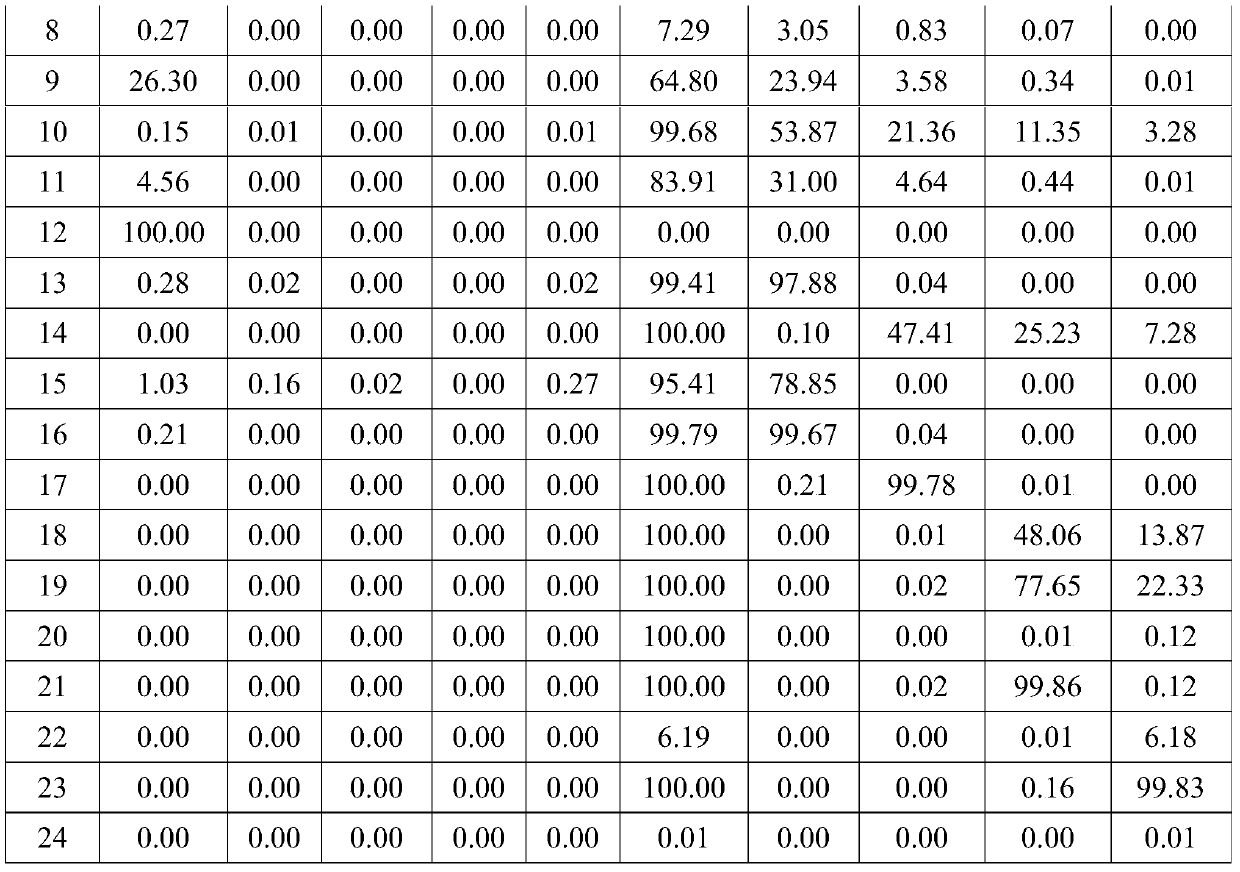

438results about How to "Reduce the difficulty of separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

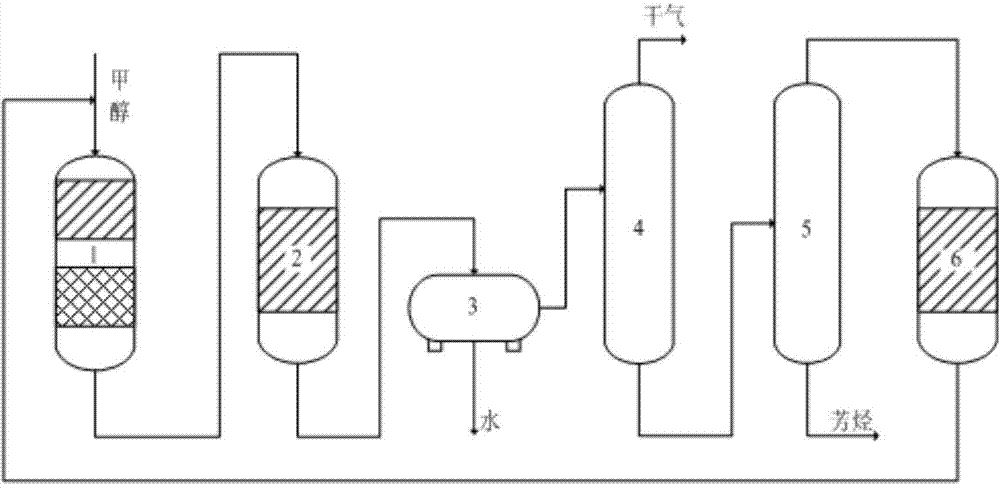

Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

InactiveCN101607858AHigh selectivityIncrease added valueMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveFixed bed

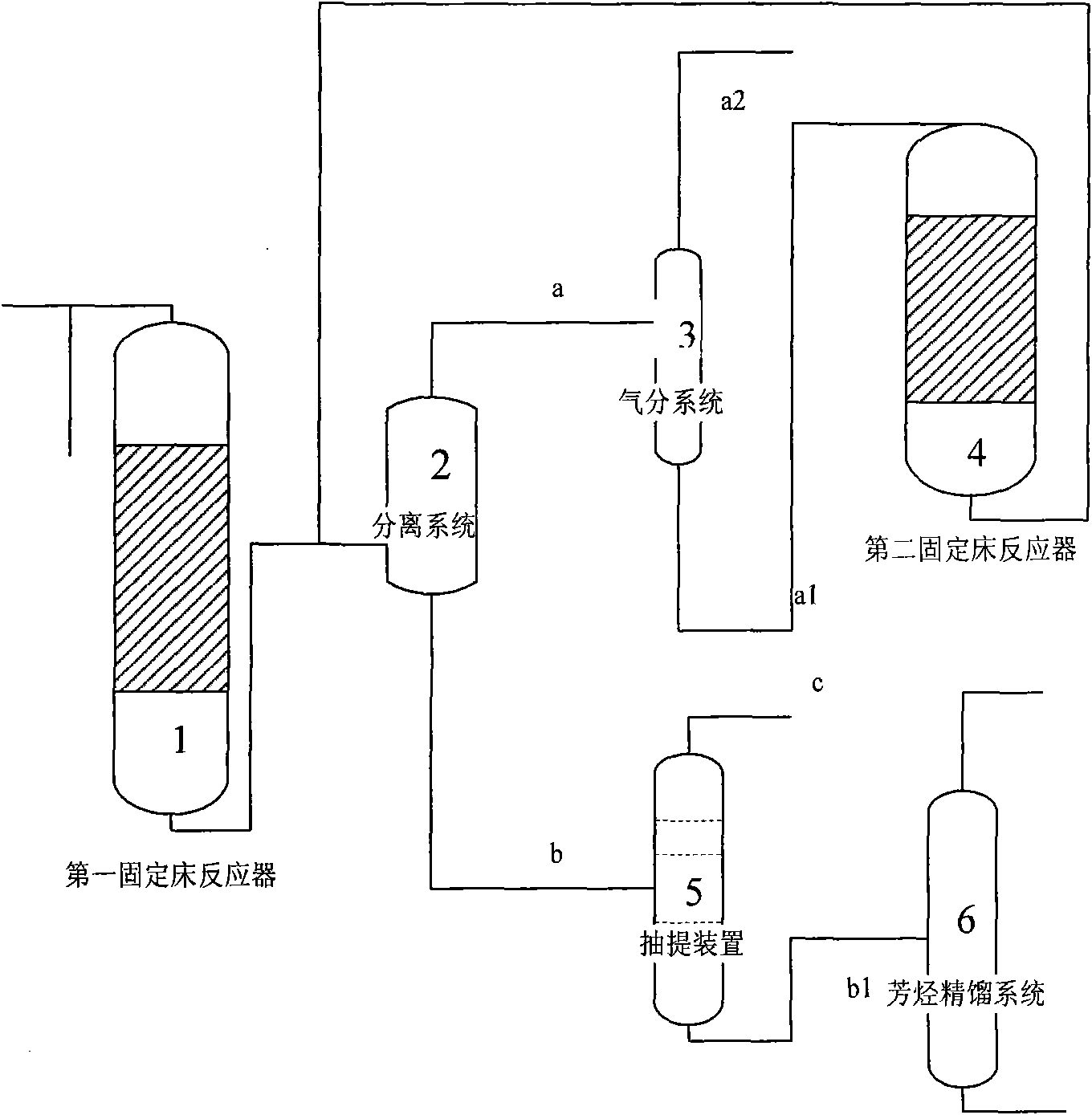

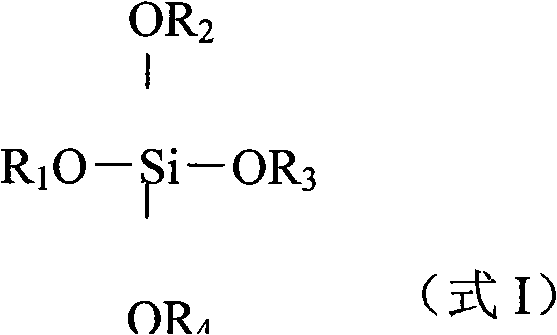

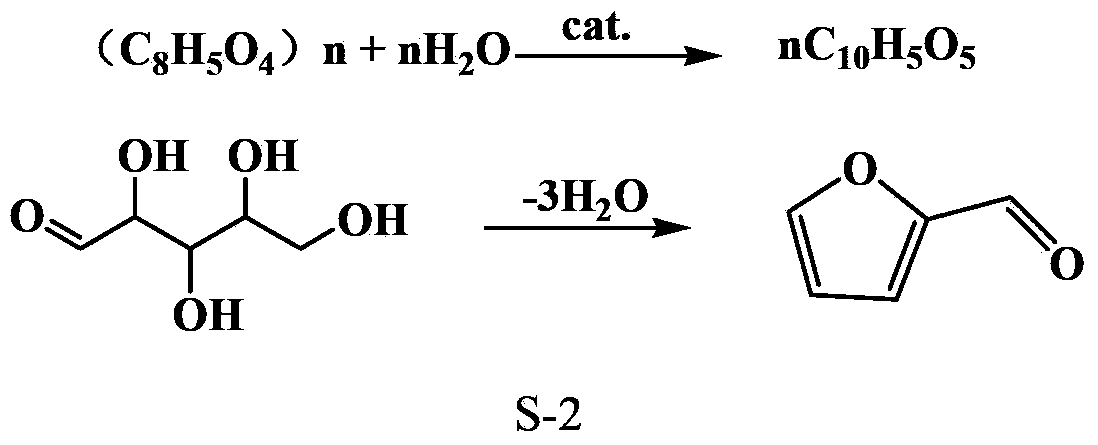

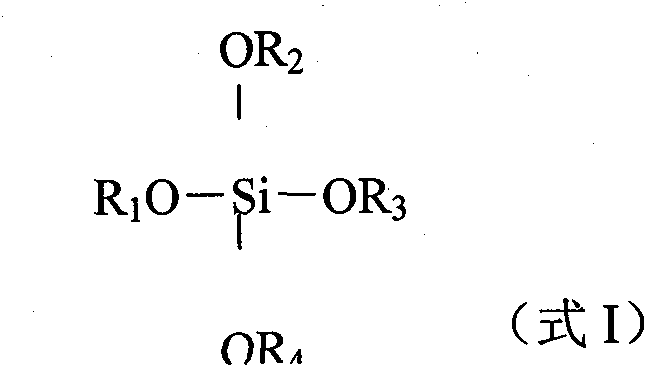

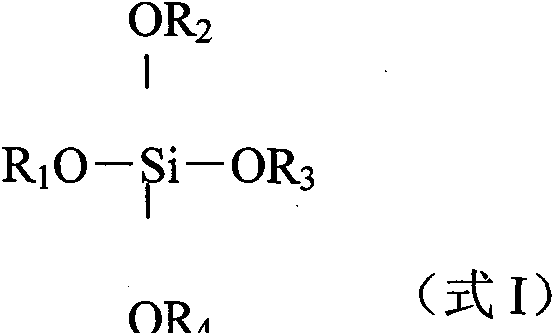

The invention discloses a method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol / dimethyl ether, comprising the following steps: 1) placing raw materials containing methanol or / and dimethyl ether, metals and molecular sieve based catalyst which is modified through silanizing in a first fixed bed reactor to perform catalytic reaction; 2) separating the products obtained in step 1) to obtain propylene, then placing propylene in a second fixed bed reactor with molecular sieve based catalyst which is modified by using metals to react, then performing aromatization on the obtained product in step 1) and obtaining aromatic hydrocarbons; then separating to obtain toluene and sending toluene back to the outlet of the first fixed bed reactor as a raw material. In the method, methanol is converted and prepared to aromatic hydrocarbons while propylene is produced at the same time and the content of paraxylene in aromatic hydrocarbons is high. In the products prepared by the method, the content of propylene can reach above 20%, the content of aromatic hydrocarbons can reach above 58wt% and the content of paraxylene in aromatic hydrocarbons is more than 35wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

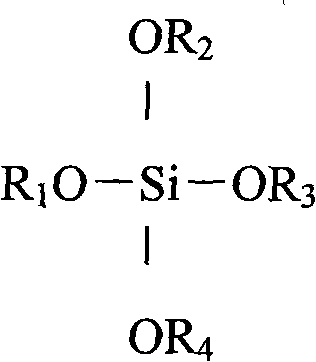

Micro-plastic separation method and device

ActiveCN106363835AImprove separation efficiencyShort processing timeSemi-permeable membranesPlastic recyclingFreeze-dryingVolumetric Mass Density

The invention belongs to the technical field of solid waste treatment and relates to a micro-plastic separation method and device. The micro-plastic separation method comprises the steps that (1) settlings of field natural water are collected; (2) the settlings of the field natural water is subjected to low-temperature drying and freeze-drying, and samples to be treated are obtained; (3) after a density solution is added into the samples to be treated, sufficient stirring is conducted until the samples to be treated are completely suspended in the density solution, and a non-sediment layer and a sediment layer are formed from top to bottom after still standing; and (4) the non-sediment layer is extracted and passes through a filter film, liquid passing through the filter film is repeatedly used, and objects isolated by the filter film include but limited to micro-plastic particles in the settlings of the field natural water. The provided micro-plastic pollutant separation method and device are capable of rapidly and effectively separating and extracting the micro-plastic particles in settlings of water such as rivers and lakes.

Owner:INST OF AQUATIC LIFE ACAD SINICA

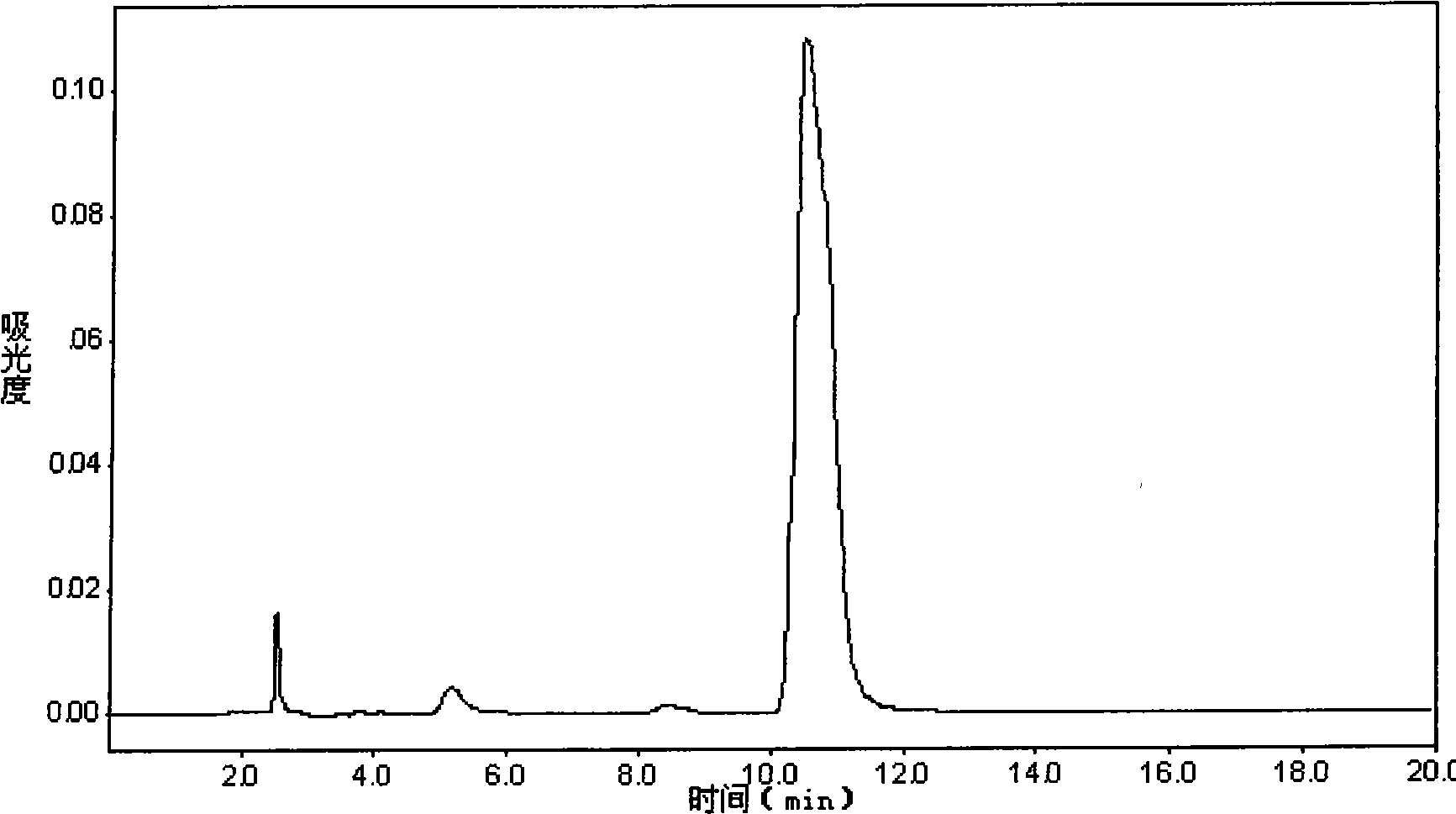

Lutein crystal preparing process from marigold flower

The present invention is the lutein crystal preparing process from marigold flower. Lutein ester is first extracted from marigold flower with non-polar solvent under heating condition and then saponified with alkali solution in stirring and heating condition; and the saponified product is diluted with deionized water and separated, washed and vacuum dried. After that, the obtained lutein crystal is re-crystallized in three-component solvent of tetrahydrofuran, deionized water and normal hexane or petroleum ether; and the lutein crystal is suction filtered, washed and vacuum dried. The present invention has low-toxicity solvent in small amount used, simple technological process, high extraction, rate, and high product purity. The product of the present invention may be used widely as feed coloring additive and food coloring agent and in medicine and health care article.

Owner:海宁凤鸣叶绿素有限公司

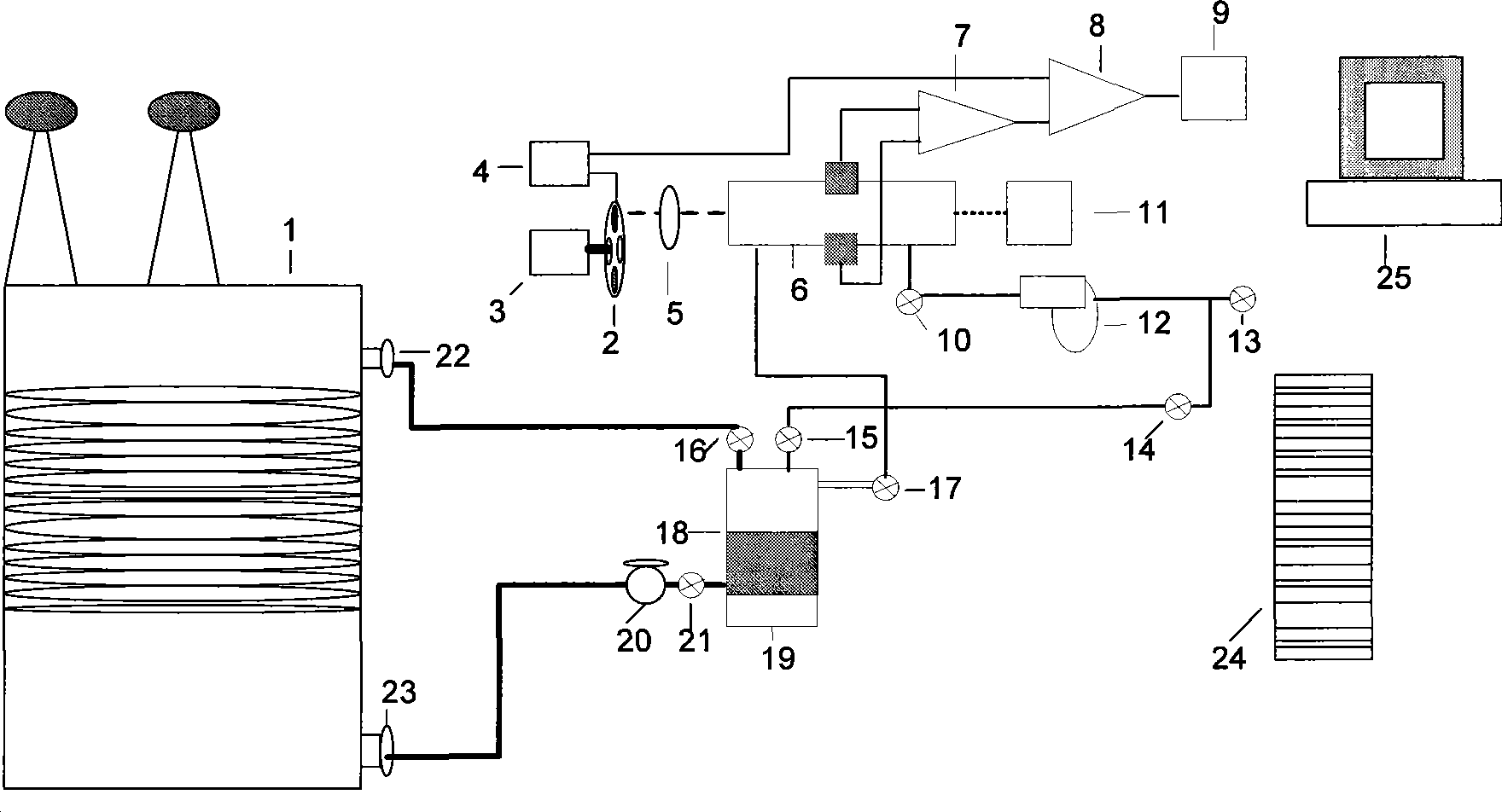

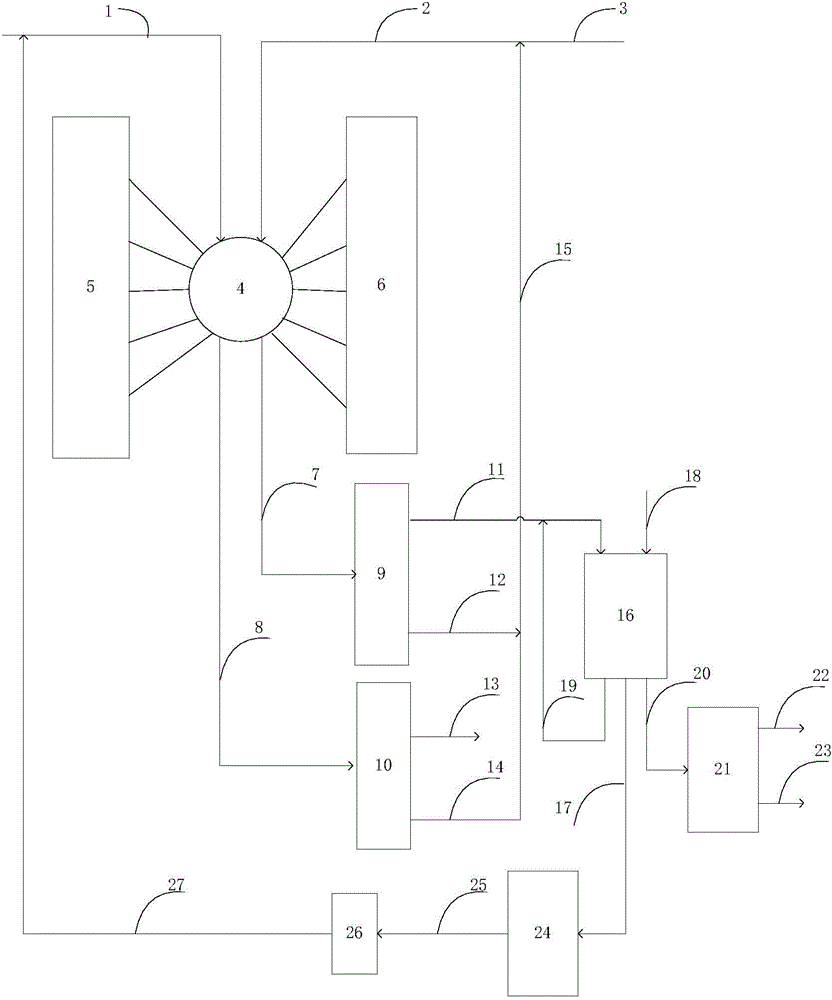

Online fault monitoring system for power transformer

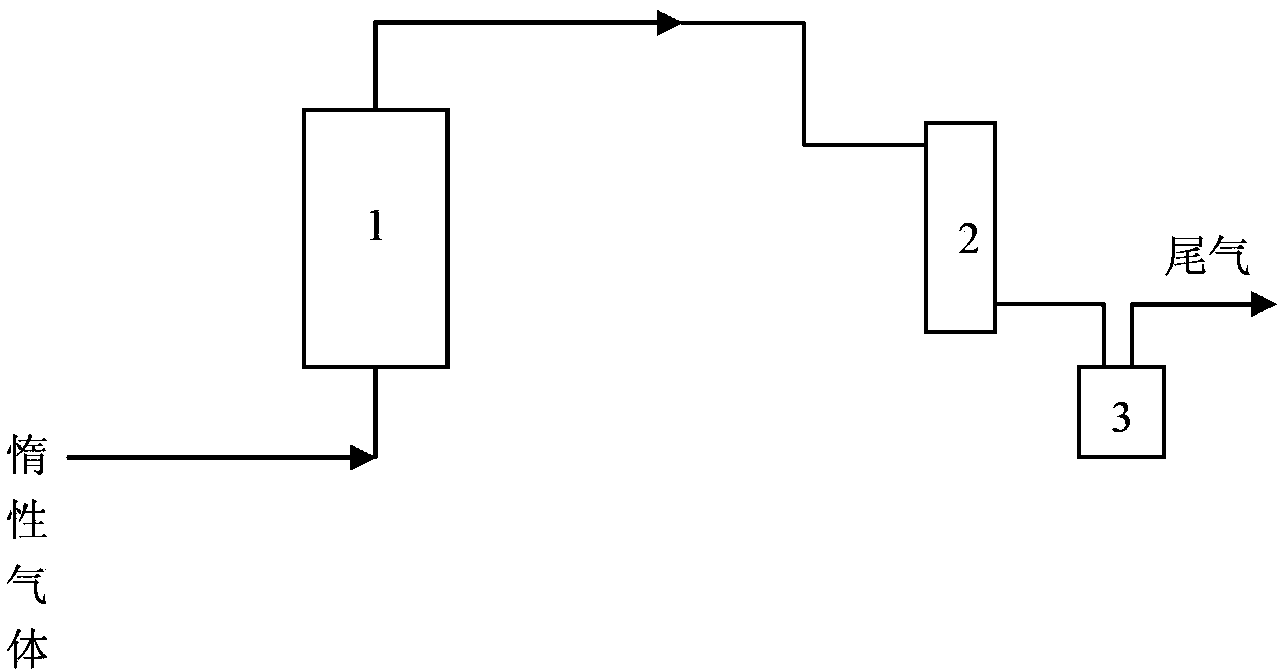

InactiveCN101498690AReduce the difficulty of separationReduce volumeUltrasonic/sonic/infrasonic wave generationPhotoacoustic spectroscopyTransformer

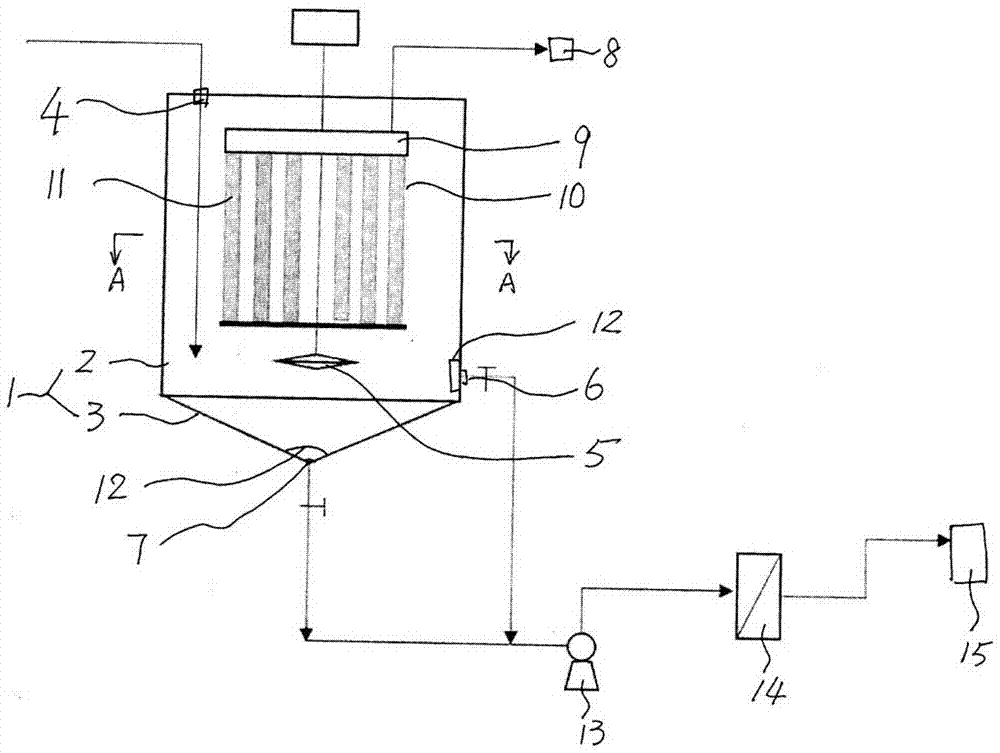

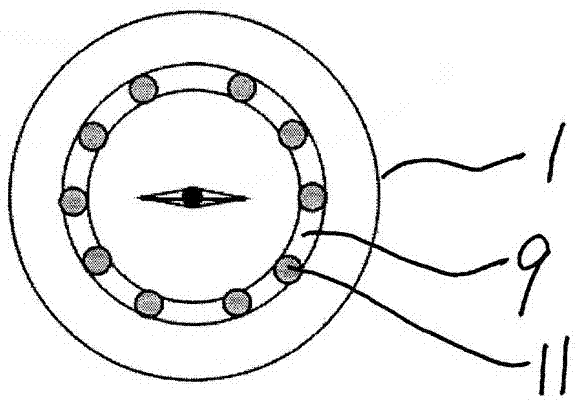

The invention relates to an online fault photoacoustic and spectroscopic monitoring system for a power transformer in the technical field of power engineering, comprising 7 tunable cascaded diode lasers, a gas and oil separating room, an optical-acoustic chamber, a lock-in amplifier, a power supply controller of the tunable cascaded diode lasers, a difference amplifier, a convex lens, a laser power meter, a digital recorder, an oil feed-back pump, an electric vacuum pump, a PLC and a computer. Ultrasonic degasification separation is performed for an oil sample in the gas and oil separating room, and fault gas is infused in the optical-acoustic chamber, after being directly modulated, a power supply can generate periodic vibration under the action of an infrared beam, thereby exciting to form a sound wave signal. After being detected by a rheomicrophone, the sound wave signal can be magnified by the lock-in amplifier and then is input in the digital recorder, thus the power transformer can be judged whether the current running state is fine according to the numerical value displayed on the digital recorder. Meanwhile, the data can be transmitted to a remote computer in a wire and wireless communication way.

Owner:SHANGHAI JIAO TONG UNIV

Extraction and purification process for cordycepin in cordyceps militaris link

InactiveCN101508715AMaintain biological activityHigh activitySugar derivativesOther chemical processesPurification methodsRotary evaporator

The invention provides an extraction and purification method of cordycepin from Cordyceps militaris, and belongs to the deep-processing technical field of agricultural products. The method comprises the following steps: crushing Cordyceps militaris raw material, mixing the raw material with water at 1:20 raw material / water ratio, performing ultrasonic extraction, and performing centrifugal filtration on obtained extracting solution and pouring in a macroporous resin column at the adsorption flow of 1.8BV / hr; taking 15% methanol aqueous solution as an eluant to perform resin column elution, and decompressing and condensing obtained eluent at the temperature of 60 DEG C by a rotary evaporator to obtain Cordyceps militaris cordycepin concentrate. The method can help realize aqueous solution extraction of the cordycepin from the Cordyceps militaris raw material at low temperature, and the extraction rate reaches 85%; and polysaccharide and protein can be removed from the extract by macroporous resin separation and purification, thus the content of the cordycepin in the extract can reach 10%. The cordycepin in the Cordyceps militaris product has high activity, can be taken as a raw material for producing cordycepin monomer and can also be directly taken as an additive of health products and functional food, thus the cordycepin has wide market development prospect.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for preparing eucalyptus and poplar mixture material bleached chemical thermomechanical pulp

ActiveCN101418531ASolve the shortage of resourcesFull penetrationPretreatment with water/steamNon-fibrous pulp additionAccelerantEnergy consumption

The invention belongs to the technical field of preparing bleached chemical thermomechanical pulp and in particular relates to a process method for preparing the bleached chemical thermomechanical pulp from eucalyptus and poplar. The process method adopts the eucalyptus and the poplar as raw materials to prepare the bleached chemical thermomechanical pulp; through the addition of a pulp grinding accelerant, the process reduces energy consumption of pulp grinding by 10 to 15 percent compared with the prior process for the bleached chemical thermomechanical pulp, reduces production cost, saves energy and simultaneously reduces the content of pulping fasciculus.

Owner:山东晨鸣纸业集团股份有限公司 +1

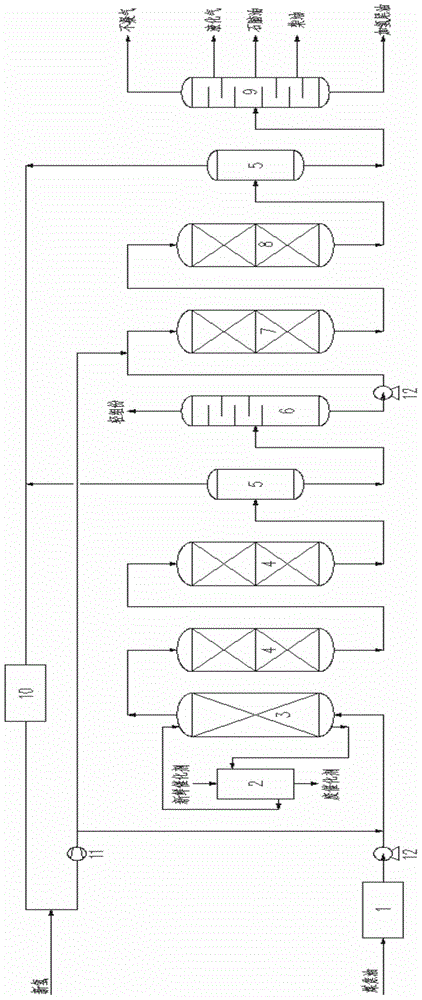

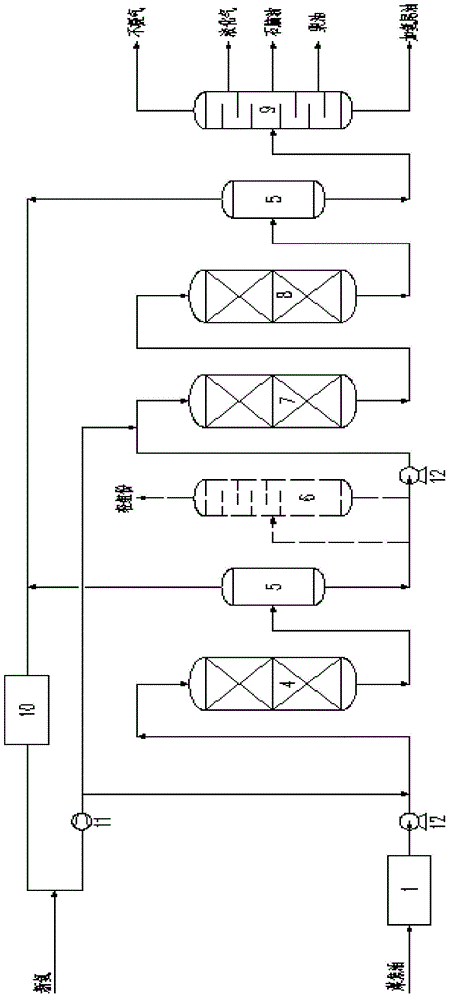

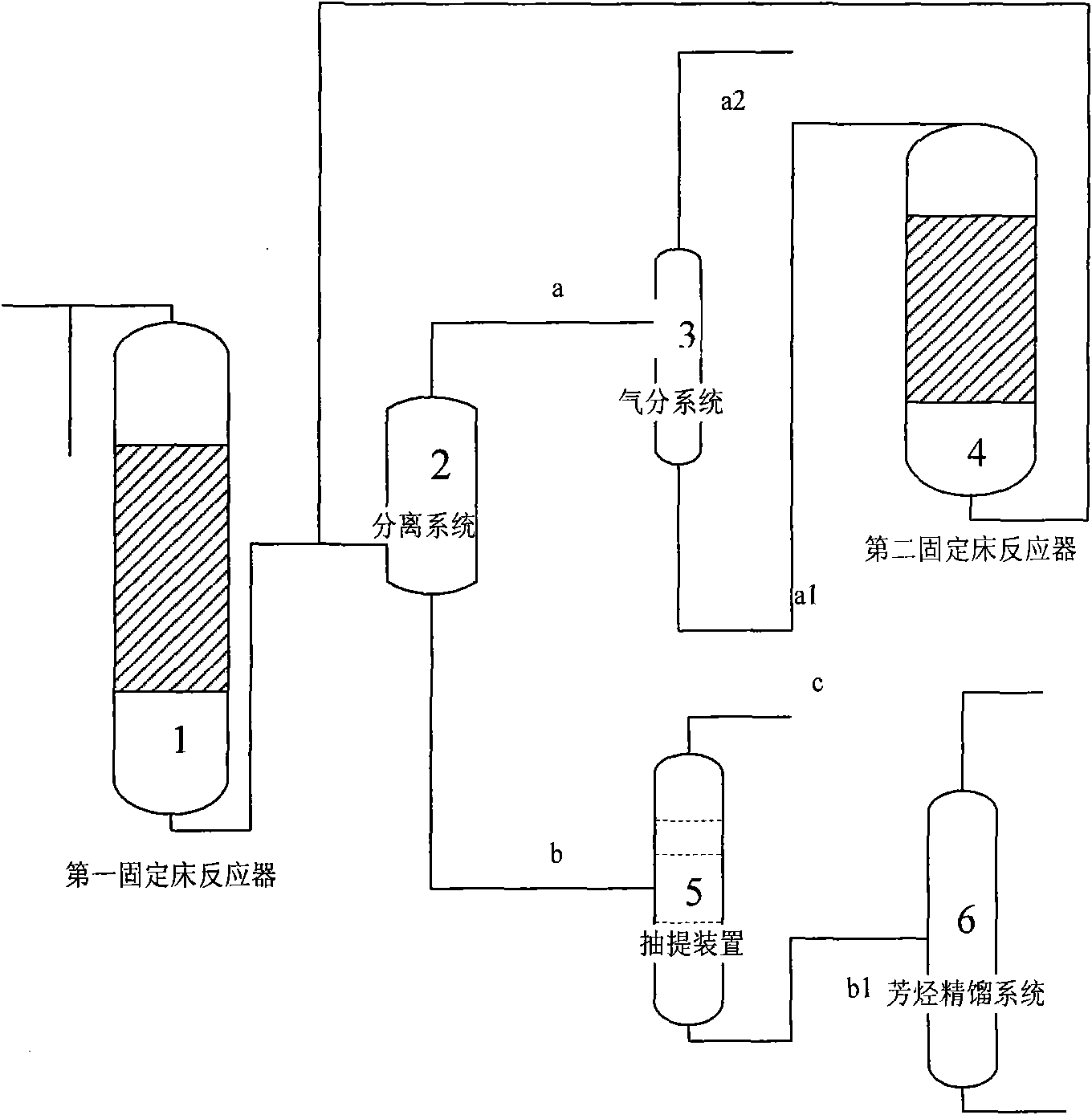

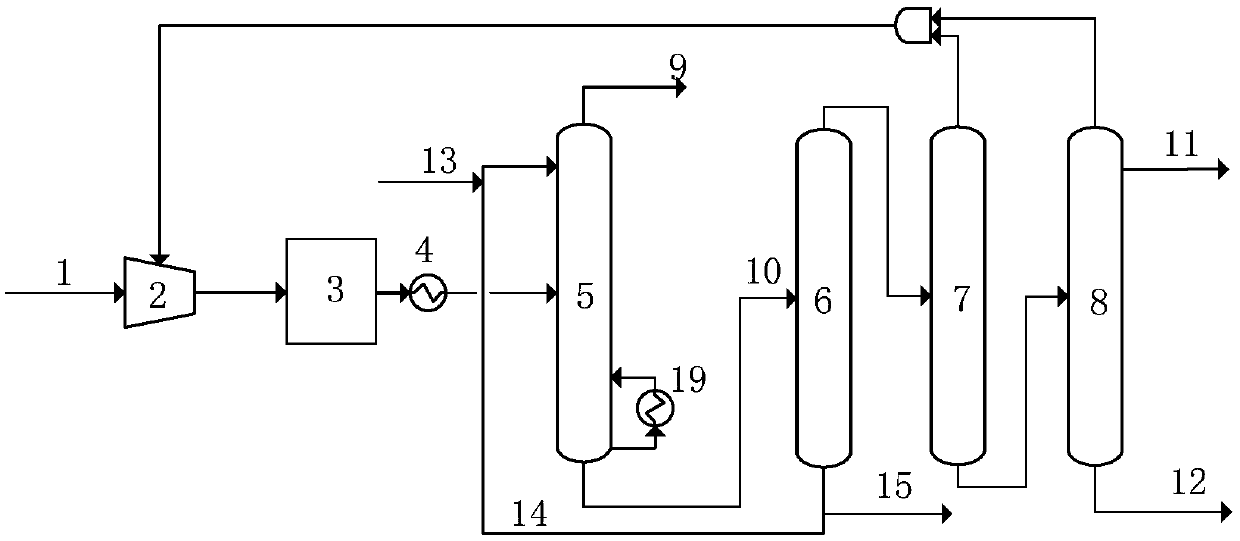

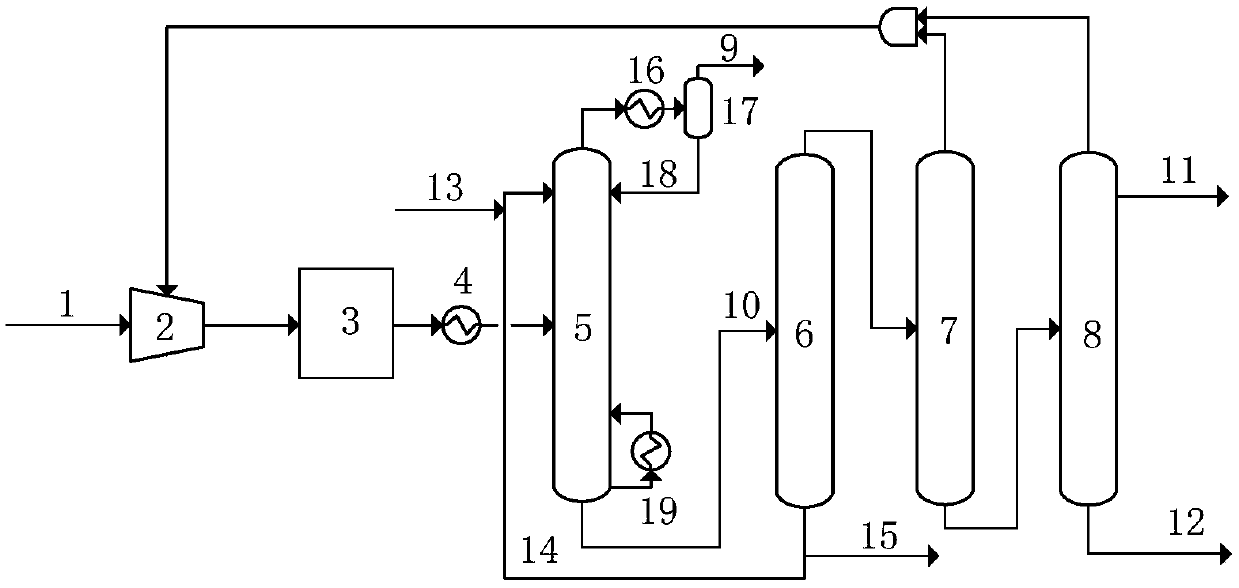

Combined coal tar whole fraction hydroprocessing system and application thereof

InactiveCN104862004AReduce the difficulty of separationTreatment with hydrotreatment processesFixed bedEngineering

The invention relates to a combined coal tar whole fraction hydroprocessing system and an application thereof. The system comprises a desalination dehydration impurity-removing refining system 1 which is connected with a hydrogen compressor 11 and an up-flow moving bed hydrofining reactor 3 respectively through one hydrogenation feeding pump 12, the up-flow moving bed hydrofining reactor 3 is respectively connected with a catalyzer on-line feeding system 2 and two series connection fixed bed hydrofining reactors 4, the fixed bed hydrofining reactors 4 are connected with separators 5, the separators 5 are respectively connected with a hydrogen refining system 10 and a flash tower 6, the flash tower 6 is connected with a fixed bed hydrocracking reactor 7 through the other hydrogenation feeding pump 12 and then sequentially connected with a fixed bed hydrofining reactor 8, the separators 5 and a fractionating tower 9. Compared with combined coal tar whole fraction hydroprocessing systems in the prior art, the combined coal tar whole fraction hydroprocessing system has the advantages that the process is simpler, the conversion rate is higher, operation is stable, product properties are good, and the system can be used for production processes of excellent light fuels by poor raw materials such as various coal tar, shale oil and residual oil.

Owner:袁继海 +2

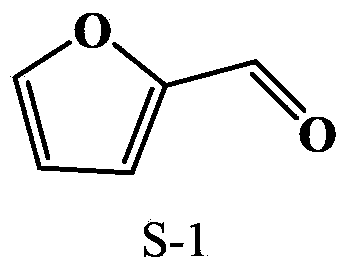

Method for preparation of furfural by biomass microwave mild pyrolysis

The invention discloses a method for preparation of furfural by biomass microwave mild pyrolysis. The method includes: 1) pretreating a biomass raw material by an inorganic acid catalyst or an inorganic salt catalyst; 2) taking microwave as a heat source, conducting mild pyrolysis on the biomass raw material pretreated in step 1), and subjecting the pyrolytic gas to condensation, thus obtaining furfural. The method provided in the invention has the advantages of simple process, high processing efficiency, short procedure and easy operation, short production cycle, and low cost.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

InactiveCN101607858BHigh selectivityIncrease added valueMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveAromatization

The invention discloses a method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol / dimethyl ether, comprising the following steps: 1) placing raw materials containing methanol or / and dimethyl ether, metals and molecular sieve based catalyst which is modified through silanizing in a first fixed bed reactor to perform catalytic reaction; 2) separating the products obtained in step 1) to obtain propylene, then placing propylene in a second fixed bed reactor with molecular sieve based catalyst which is modified by using metals to react, then performing aromatization on the obtained product in step 1) and obtaining aromatic hydrocarbons; then separating to obtain toluene and sending toluene back to the outlet of the first fixed bed reactor as a raw material. In the method, methanol is converted and prepared to aromatic hydrocarbons while propylene is produced at the same time and the content of paraxylene in aromatic hydrocarbons is high. In the products prepared by the method, the content of propylene can reach above 20%, the content of aromatic hydrocarbons can reach above 58wt% and the content of paraxylene in aromatic hydrocarbons is more than 35wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for preparing gentio-oligosaccharide by using immobilized beta-glucosidase

ActiveCN102321707AIncrease profitReduce the difficulty of separationHydrolasesMicroorganism based processesAlgluceraseGlycan

The invention discloses a method for preparing gentio-oligosaccharide by using immobilized beta-glucosidase. The method for preparing the gentio-oligosaccharide by using the immobilized beta-glucosidase comprises the following steps of: 1) preparing beta-glucosidase through solid-state fermentation of Aspergillus niger; 2) immobilizing the beta-glucosidase by a crosslinking-embedding method; and 3) producing the gentio-oligosaccharide by transforming glucose by using the immobilized beta-glucosidase. The recovery rate of enzyme activity of an immobilized enzyme prepared by the method is up to 60 percent, and the conversion rate of a substrate, namely the glucose converted by the immobilized enzyme is 45 percent; and the stability and pH tolerance of the immobilized enzyme are remarkably improved, the mechanical strength is high, the immobilized enzyme can be continuously and repeatedly used for 4 to 6 bathes, and the enzyme activity is kept unchanged. The utilization rate of the gentio-oligosaccharide produced by an enzyme method is improved, the production cost and difficulty in separation and purification of the gentio-oligosaccharide are reduced, and the method is suitable for large-scale continuous production and has a great significance for improving the technical level of the production of the gentio-oligosaccharide in China.

Owner:SHAANXI UNIV OF SCI & TECH

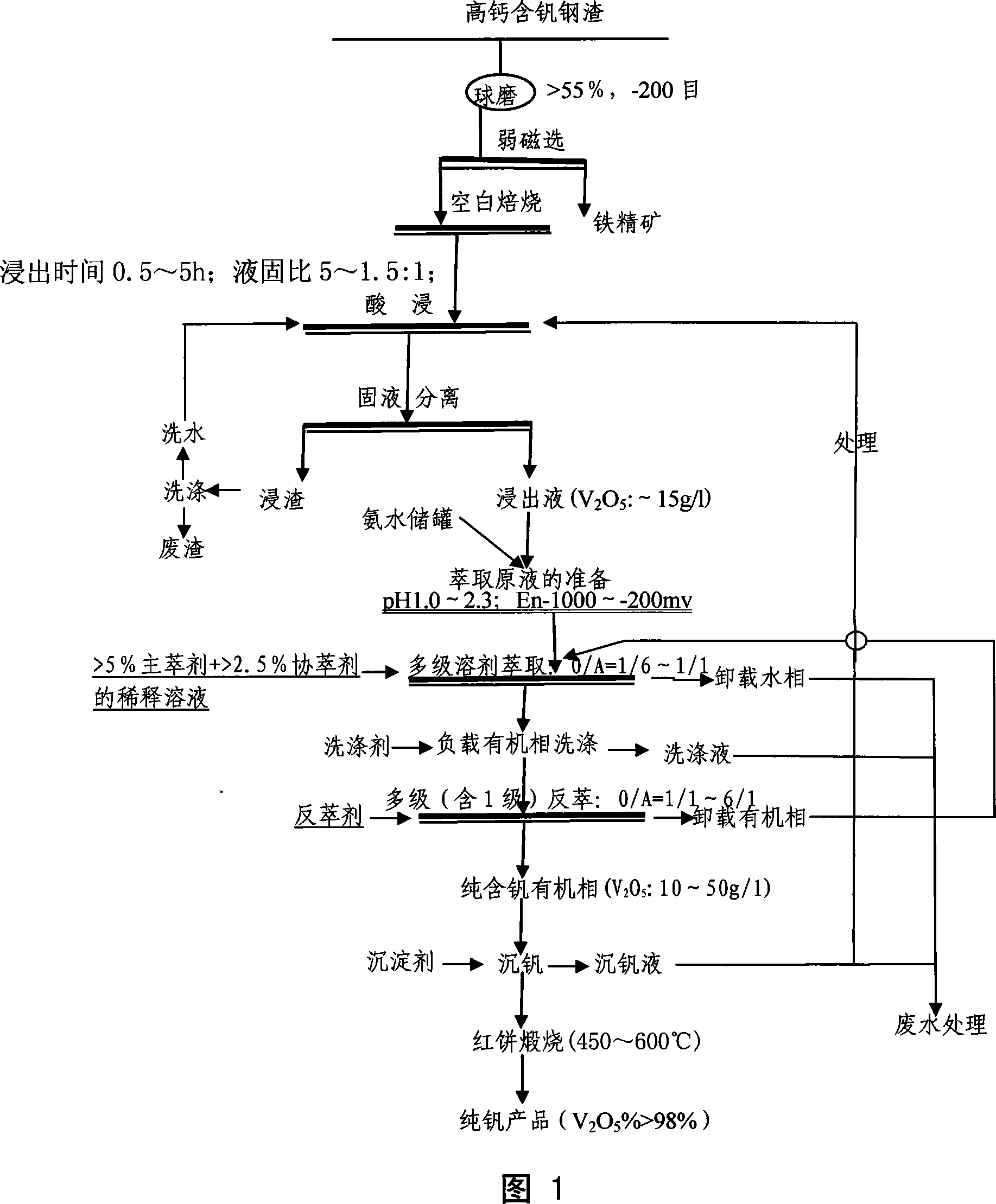

Technique for reclaiming vanadium and iron from high-vanadium high-iron steel slag

InactiveCN101121966AReduce accumulationReduce difficultySolid separationProcess efficiency improvementSlagOxidation reduction

A novel technology is used for recycling iron and vanadium from calcium-rich or iron-rich steel slag. The invention relates to a metallurgical method of extracting vanadium, in particular to a method that extracts vanadium or iron from abandoned steel slag with multidisciplinary technologies. The technology has the following procedures: (1) The calcium-rich or iron-rich steel slag is crushed, the iron contained in the steel slag is recycled by magnetic separation, and the material that will correspondingly change low-valent vanadium is roasted into high-valent vanadium contained in the material, or the material is first roasted and then magnetic separated; (2) the material is soaked with 95-98 percentage concentrated sulfuric acid, and then solid-liquid separation is conducted; (3) the acidity of lixivium is adjusted, to make sure the pH of the lixivium is in 1.0 to 2.3, and the oxidation-reduction potential is -1000 to 200mv; (4) Extraction above grade two is adopted, the extraction phase ratio O / A is 1 / 6 to 1 / 1, and then the aqueous phase unloaded; (5) the organic washing is applied in the load to remove iron, and the washing agent used is sulphate; (6) 0.25M to 1.5M alkaline solution is adopted as a stripping agent for back-extraction, with a phase ratio of O / A 1 / 1 to 6 / 1, so as to deposit vanadium contained in solution. The invention is characterized by simple technology, low cost, small environmental pollution and high recovery ratio in the process of extracting vanadium and iron from calcium-rich or iron-rich steel slag.

Owner:KUNMING UNIV OF SCI & TECH

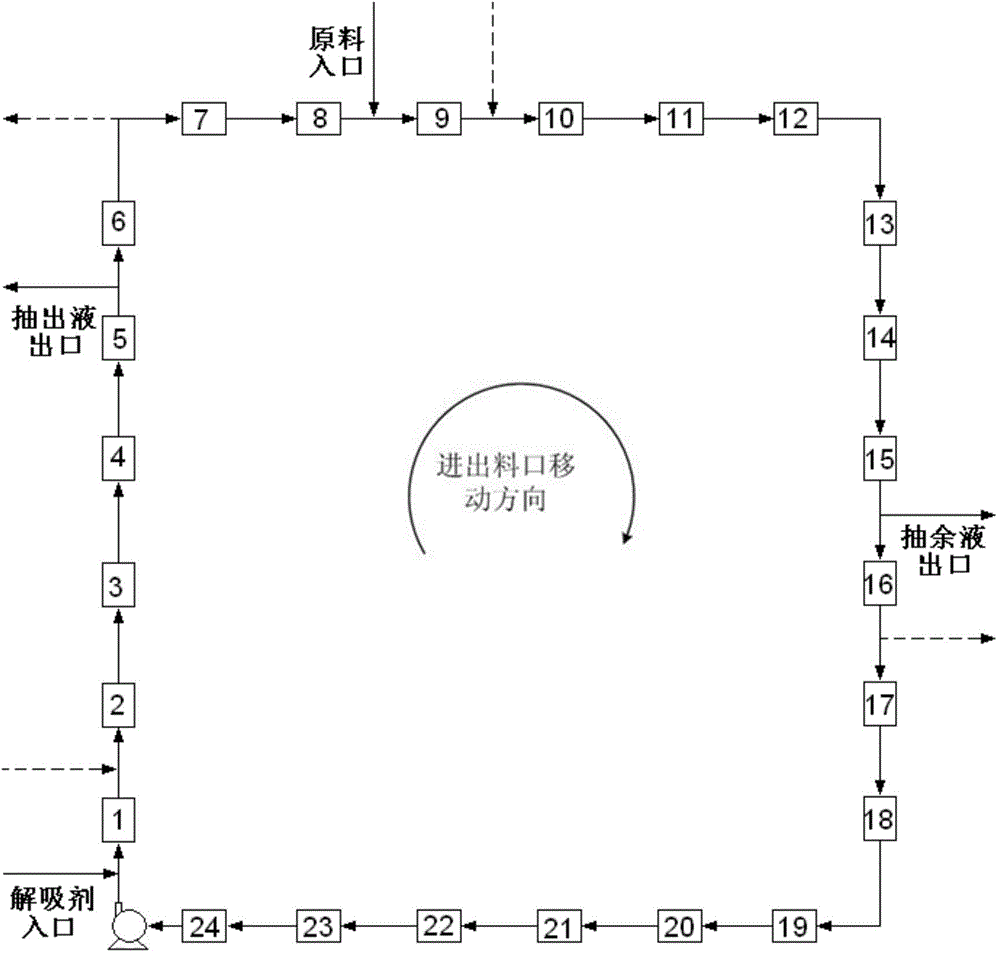

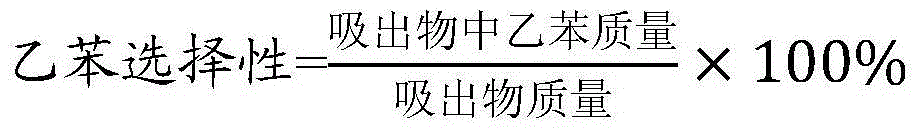

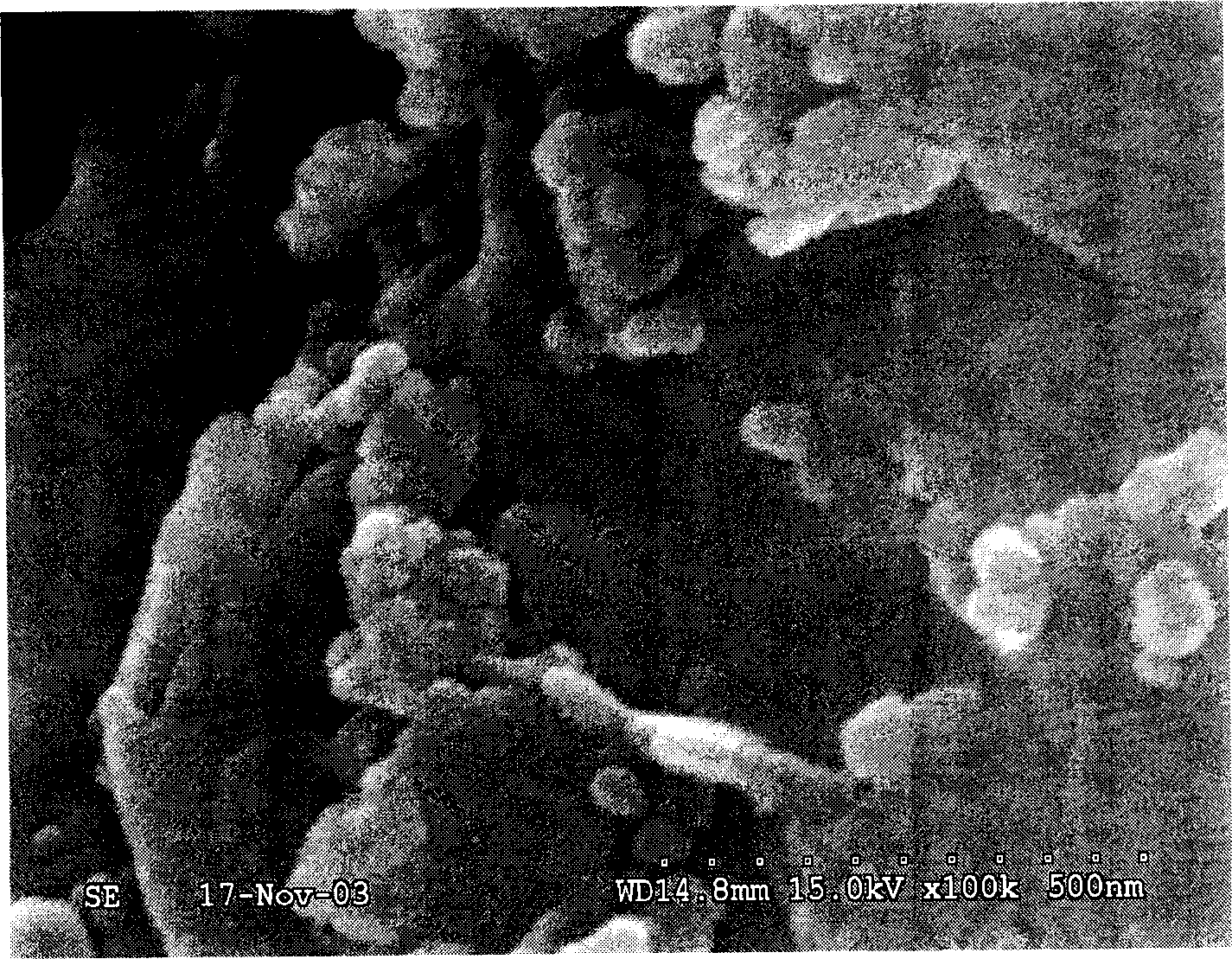

Method for adsorbing and separating paraxylene and ethylbenzene from C8 aromatic components

ActiveCN104418698AReduce the difficulty of separationHigh purityHydrocarbon by isomerisationAdsorption purification/separationO-XyleneIsomerization

The invention discloses a method for adsorbing and separating paraxylene and ethylbenzene from C8 aromatic components. The method comprises the following steps: performing liquid-phase adsorption and separation on C8 aromatic hydrocarbons, thereby obtaining extracted oil rich in paraxylene and raffinate oil rich in ethylbenzene, m-xylene and o-xylene; introducing the raffinate oil into a gas phase adsorption and separation column, adsorbing ethylbenzene from the raffinate oil under the conditions of 190-270 DEG C, 0.4-0.8MPa and gas phase, allowing the non-adsorbed components to flow out of the gas phase adsorption and separation column to serve as adsorption residues, and purging an adsorbent bed layer by using purge gas under the pressure not less than the adsorption pressure, wherein the purged intermediate components is used as gas phase adsorption feedstock; reducing the pressure to 0.1-0.3 MPa, introducing the purge gas to desorb the adsorbed ethylbenzene so as to obtain the aspirate, performing xylene isomerization on the adsorption residues, wherein the isomerization products are taken as raw materials of the above liquid phase adsorption and separation. According to the method, the high-purity paraxylene and ethylbenzene can be separated from the C8 aromatic components, the adsorption residues hardly contain ethylbenzene, and isomerization can be performed under the non-hydrogen and low-temperature conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Natural alta-mud modification method

ActiveCN1730426AHigh whitenessEliminate application conditions and region restrictionsClaywaresPolymeric surfaceSurface-active agents

The invention discloses a method for modifying natural alta-mud which comprises the following steps, (1) choosing and drying the raw ore, (2) coarse crushing, (3) charging water for slurrying, separating slurry from impurity substance, (4) charging strong alkali, modifying adjuvant, pH regulator, complexing agent and polymer surface active agent, (5) centrifugalizing, drying the suspending liquid, disintegrating and packaging.

Owner:北京京盛国泰科技有限公司

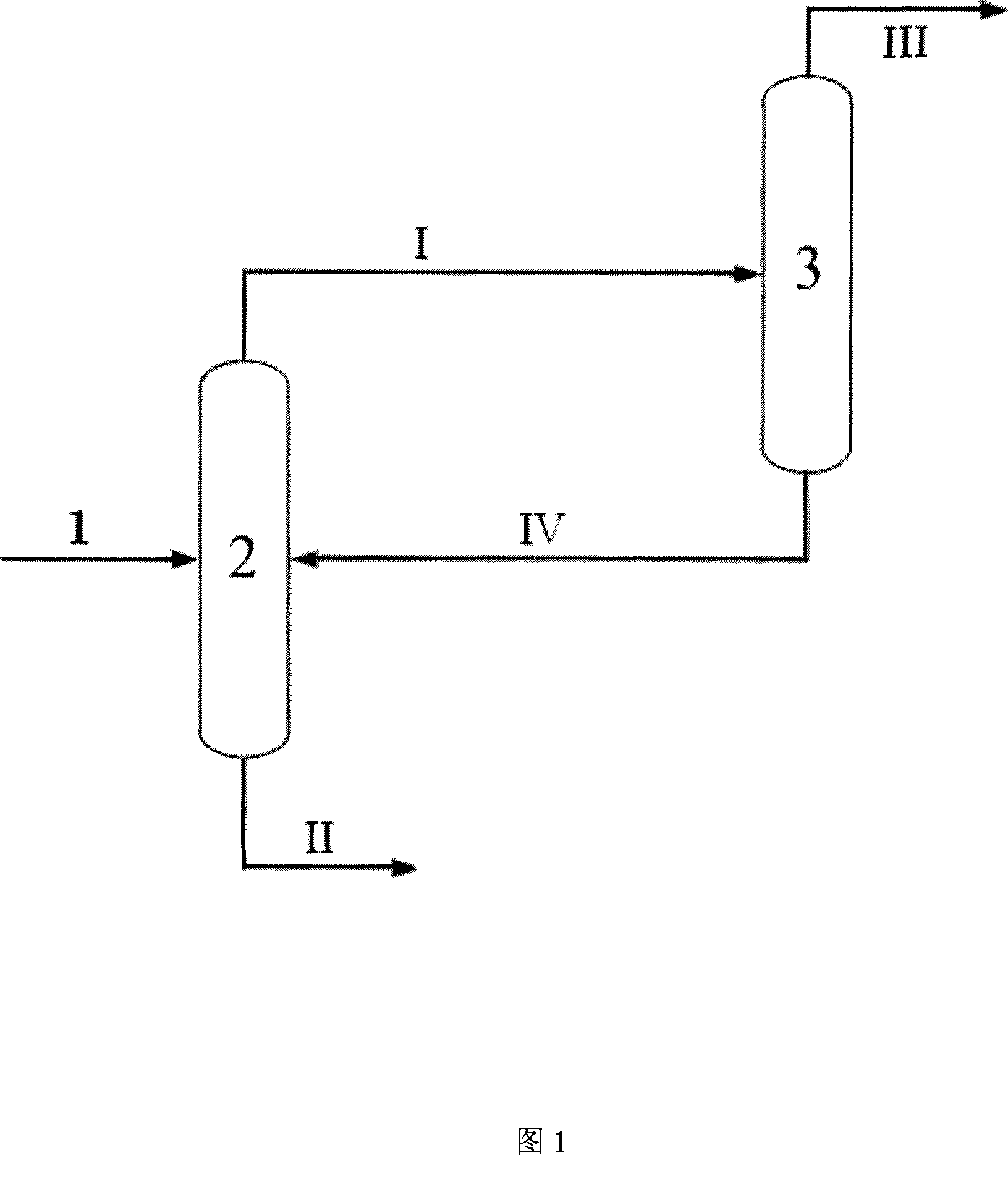

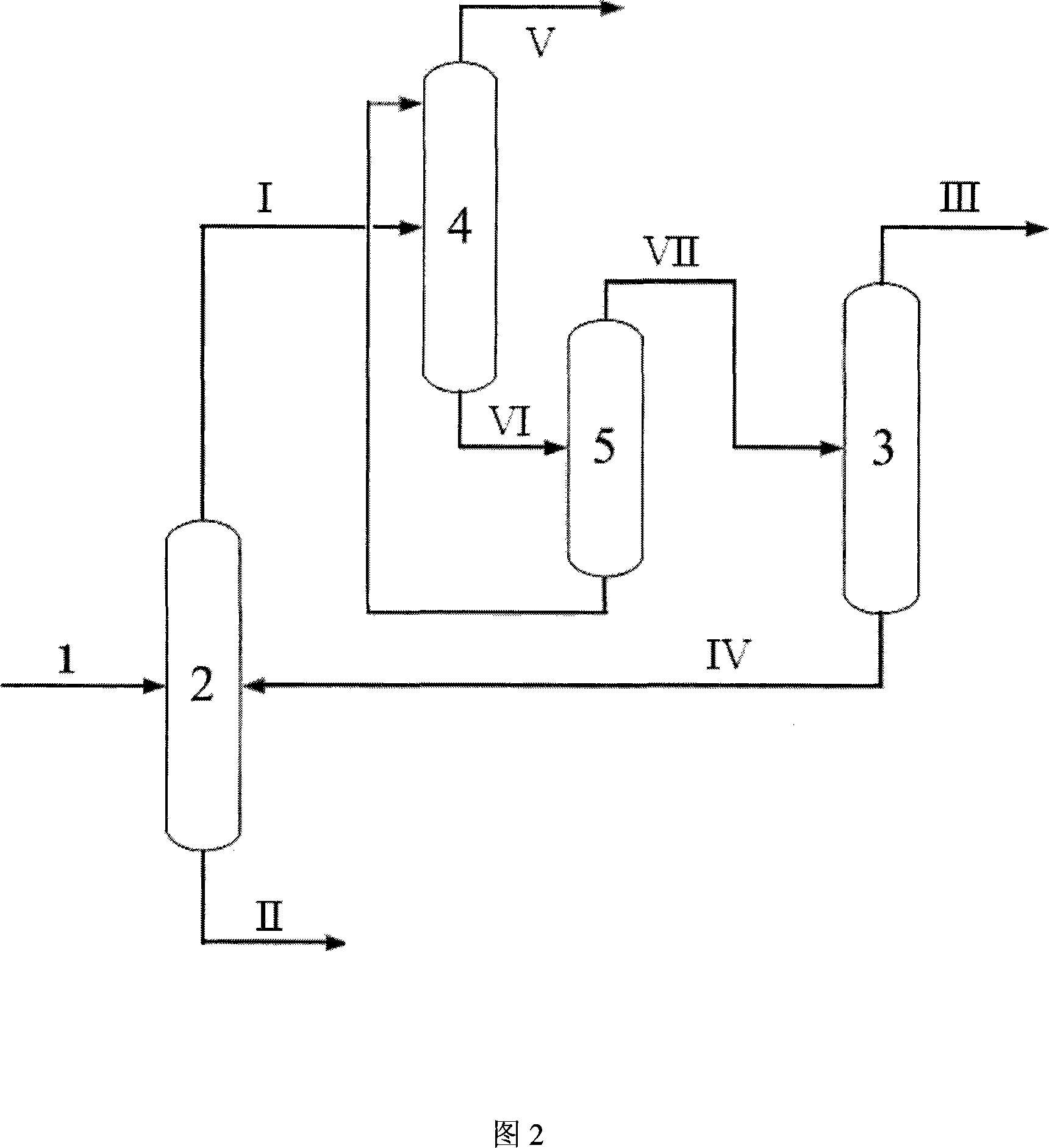

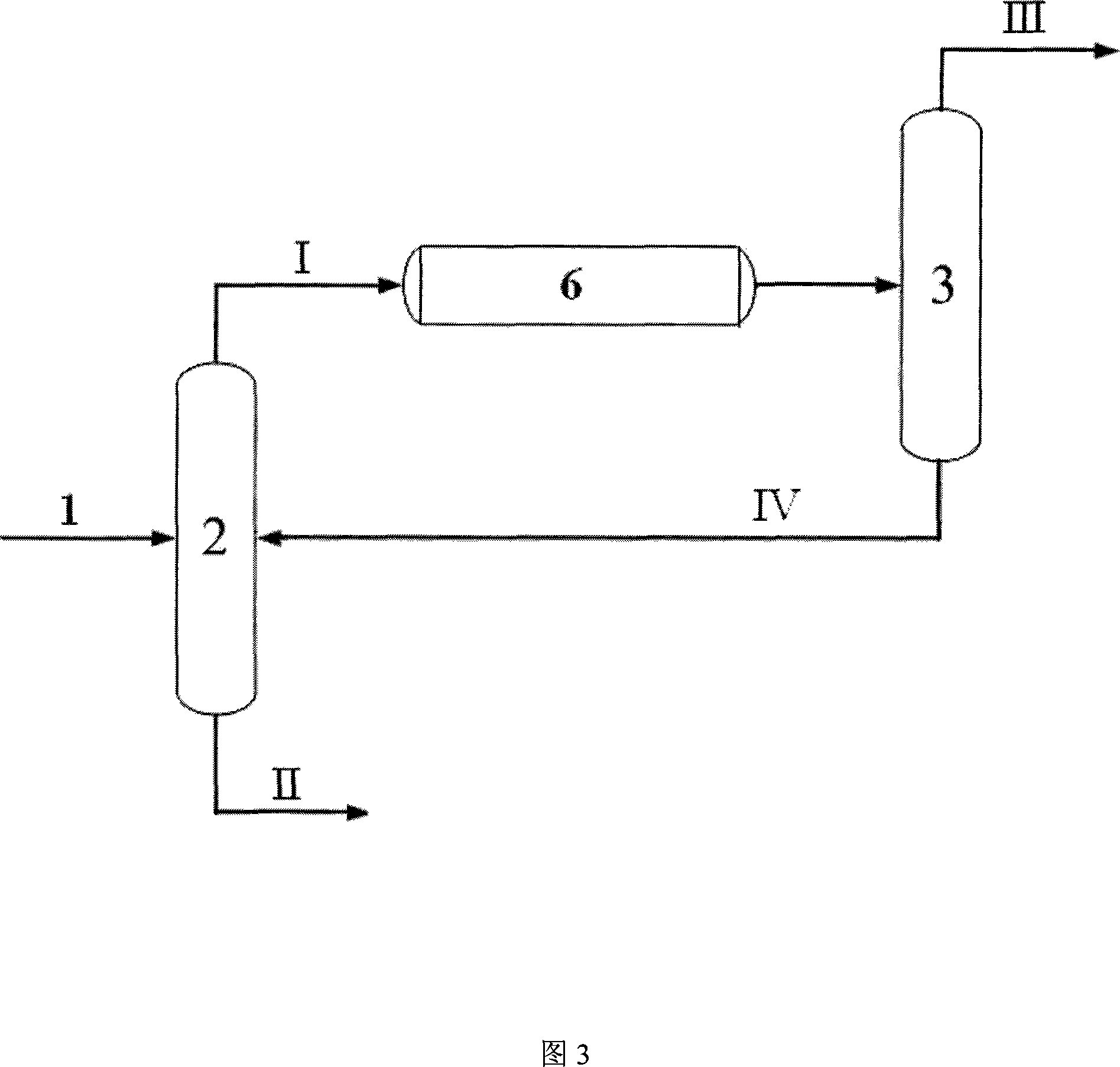

Method for separating isoprene by combined rectification

ActiveCN101104573APrevent self-aggregationAvoid lostDistillation purification/separationComing outBoiling point

The invention relates to a combined isoprene rectification and separation method, mainly aimed at solving the problems in prior art that when to separate and crack the diolefin in c_5 fraction, the raw materials have to enter a thermal dimerization reactor first, resulting in great losses of isoprene and cyclopentadienyl, and that because the boiling points of isoprene and cyclopentadienyl are nearly the same, the cyclopentadienyl affects the purity of the product isoprene and a part of cyclopentadienyl is lost, and particularly the problem that the isoprene knockout tower has high temperature and is energy-consuming. The invention makes the c_5 materials enter the isoprene knockout tower2 from the middle; after separation, material flow I containing isoprene comes out from the top of the tower and the material flow II containing cyclopentadienyl comes out from the bottom of the tower for later processing. Then the material flow I enters the cyclopentadienyl recycling tower from the middle part, after separation the material flow III coming out from the top of the cyclopentadienyl recycling tower enters the follow-up isoprene refining process and the cyclopentadienyl material flow coming out from the bottom of the cyclopentadienyl recycling tower circulates to the middle part of the isoprene knockout tower2. With such technique proposal, the invention solves the problems, thus the invention can be applied to the industrial production of separating the diolefin in c_5 fraction.

Owner:SINOPEC SHANGHAI ENG

Coenzyme composition preparing method

InactiveCN101023968ALower requirementAvoid destructionMetabolism disorderPlant ingredientsActivated carbonUltrafiltration

The present invention relates to a preparation method of coenzyme compound. Said invention adopts mature technical processes of temperature difference wall breakage and reduced pressure concentration, and utilizes the steps of ultrafiltering separation, column chromatography to make purification, concentration and precipitation so as to obtain the invented coenzyme compound.

Owner:NANTONG XINPING GARMENTS

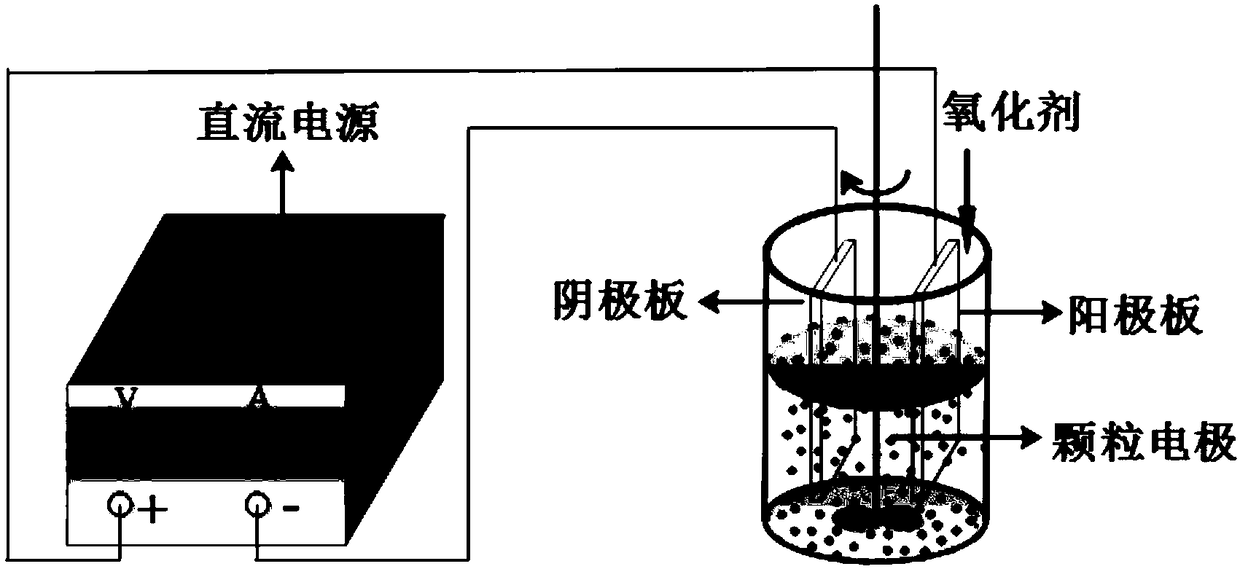

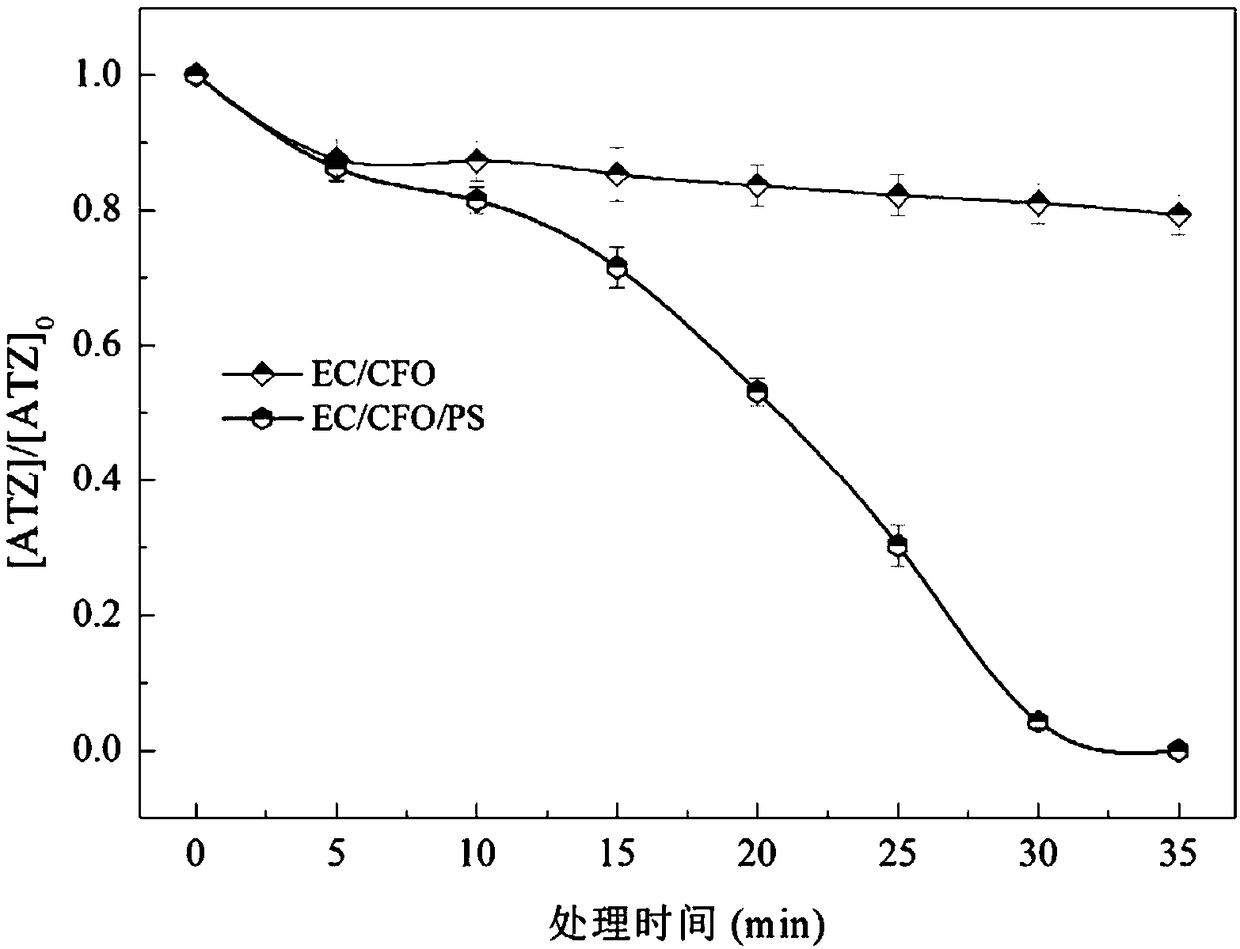

Method for processing refractory wastewater by three-dimensional electrode coupled with oxidant

ActiveCN108928890AImprove activation efficiencyImprove processing efficiencyWater contaminantsWater/sewage treatment by neutralisationPersulfateMaterials science

The invention belongs to the field of refractory wastewater treatment, and provides a method for processing refractory wastewater by a three-dimensional electrode coupled with an oxidant. The method comprises the following operation: adding the refractory wastewater with a pH value of 3-11 to be processed into a wastewater processing container provided with a slab anode and a slab cathode, addingthe oxidant and a particle electrode into the wastewater processing container, performing stirring to make the particle electrode in a fluidized state, starting a direct-current power supply connectedwith the slab anode and the slab cathode, and performing treatment for 15-60 min under the condition of a current density of 2-20 mA / cm<2> to complete the treatment of the refractory wastewater, wherein the particle electrode is magnetic spinel type ferrite MFe2O4 nanoparticles, and the oxidant is at least one selected from the group consisting of a persulfate, hydrogen peroxide and ozone. The method provided by the invention can effectively improve the degradation efficiency and degradation effect of the refractory wastewater while reducing the treatment costs of the wastewater.

Owner:SICHUAN UNIV

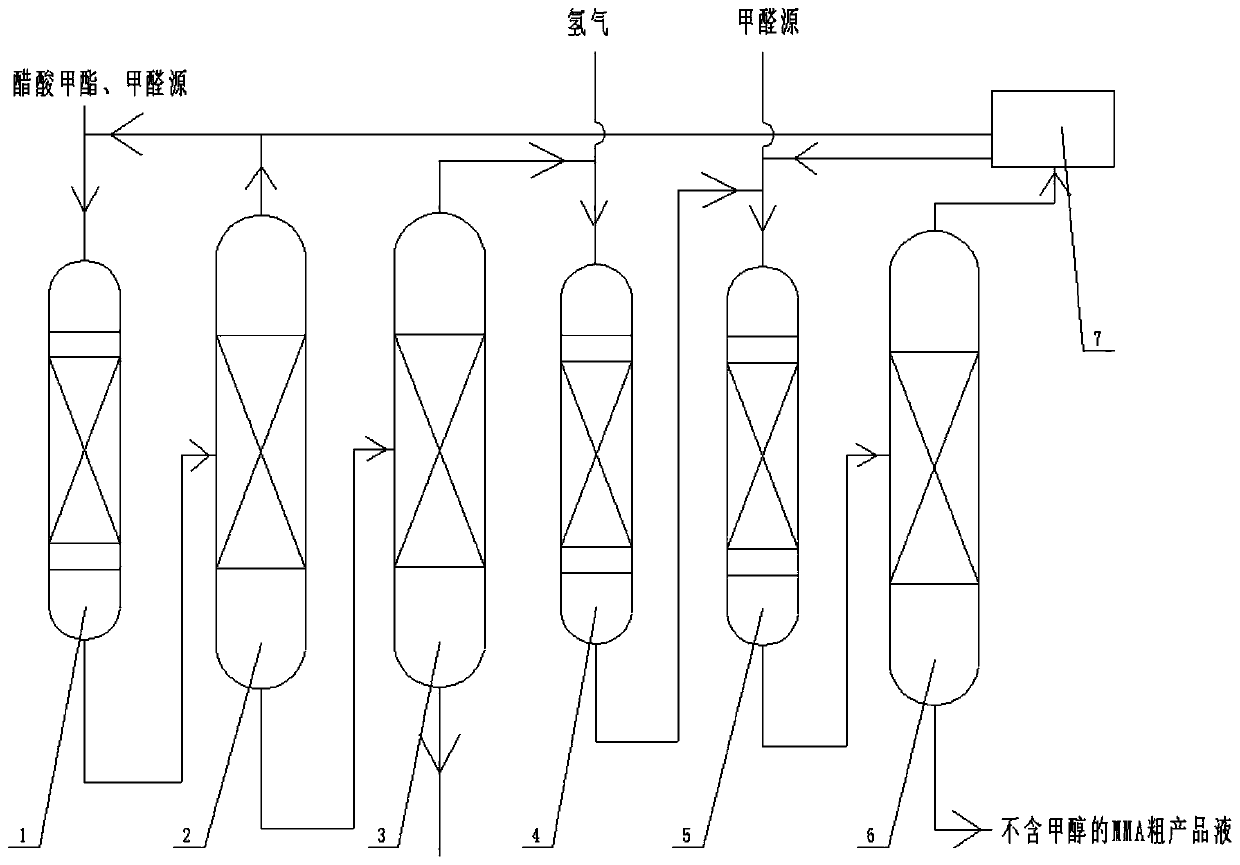

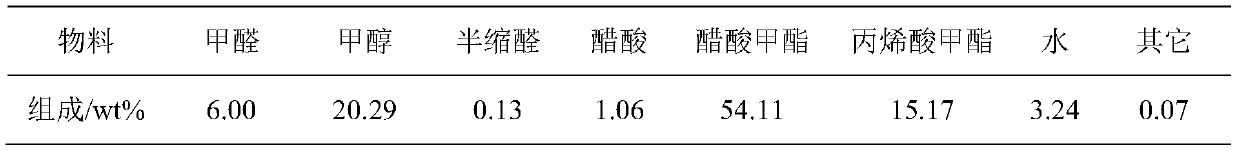

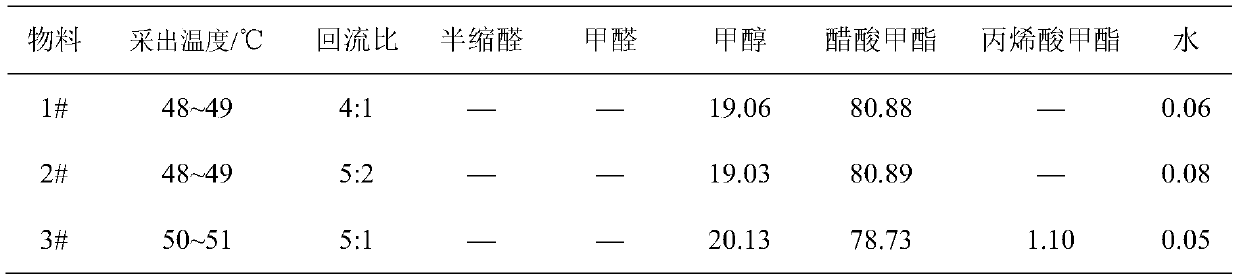

Methyl methacrylate synthesis process

ActiveCN110981727AReduce cycle energy consumptionCracking the separation puzzleOrganic compound preparationCarboxylic acid esters preparationPropanoic acidHydrogenation reaction

The invention discloses a methyl methacrylate synthesis process comprising the steps: carrying out condensation reaction on the reaction raw materials, liquefying and separating out a mixture of methanol and methyl acetate, circulating, separating out a mixture of methanol and methyl acrylate, carrying out hydrogenation reaction to obtain a mixture of methanol and methyl propionate, carrying out areaction on the mixture with a formaldehyde source, liquefying a reaction product gas flow, separating out a mixture of methanol and methyl propionate to obtain a methanol-free MMA crude product liquid, separating the mixture of methanol and methyl propionate, and respectively circulating. According to the method, the mixture of methanol and methyl acetate, the mixture of methanol and methyl acrylate and the mixture of methanol and methyl propionate are gradually separated in an azeotropic manner, so that the energy consumption of methanol separation circulation is reduced; methanol and methyl acrylate azeotrope is used as a raw material to be fed into a hydrogenation reactor, so that the separation difficulty is reduced; formaldehyde is separated from the methanol-free MMA crude productliquid, and the difficulty of further refining is lower; the separation problem of a methanol-containing multi-component complex easily-polymerized system is effectively solved, and a powerful supportis provided for MMA synthesis of a methyl acetate route.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

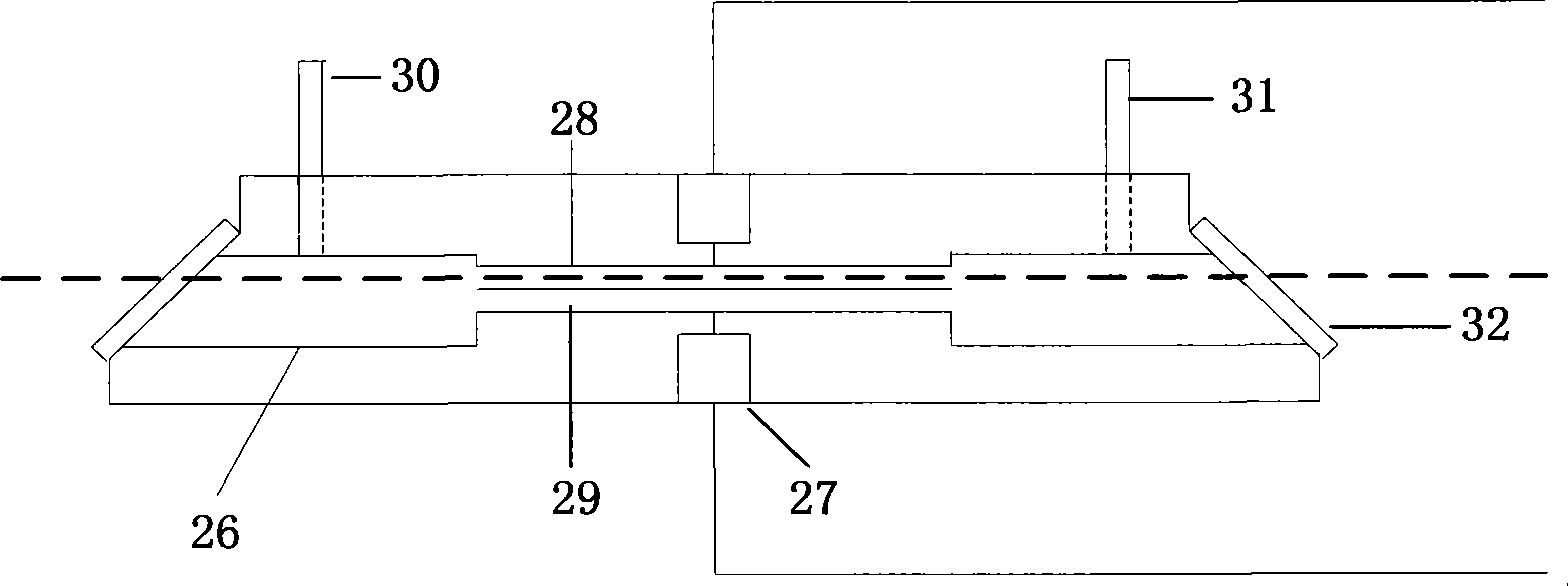

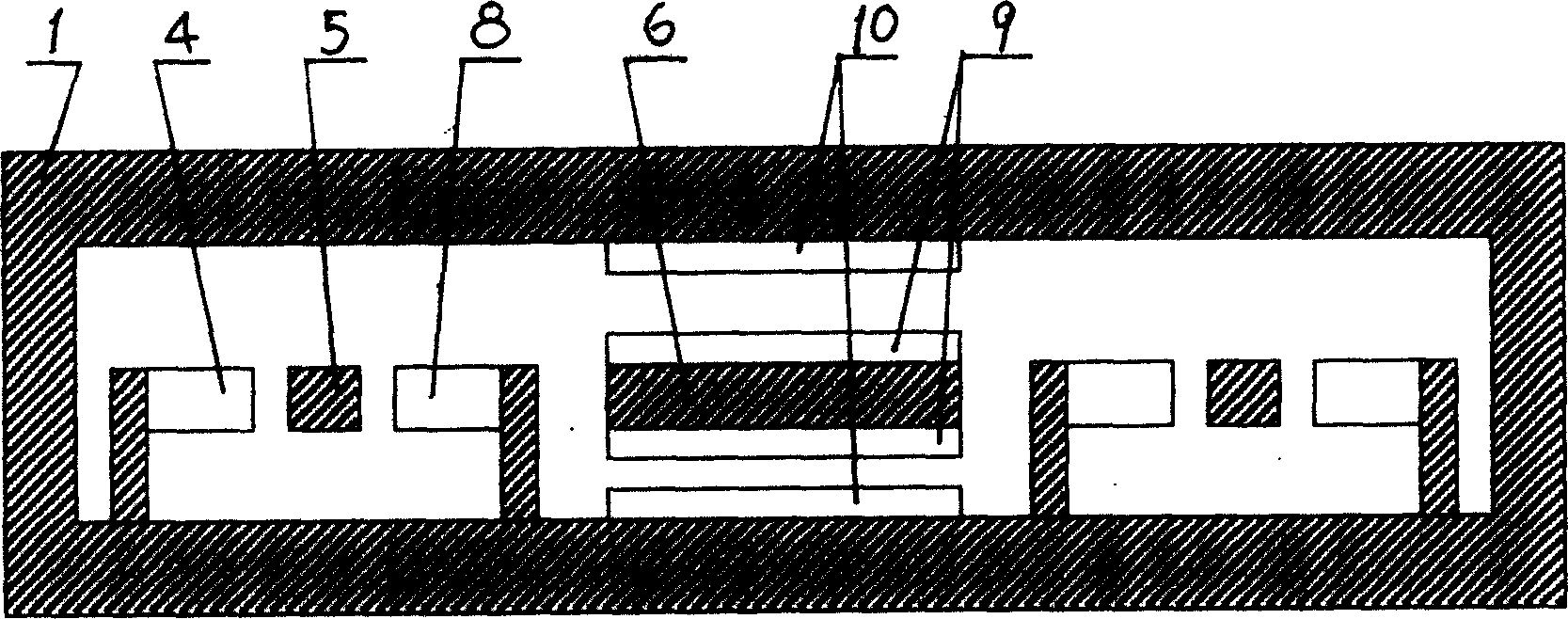

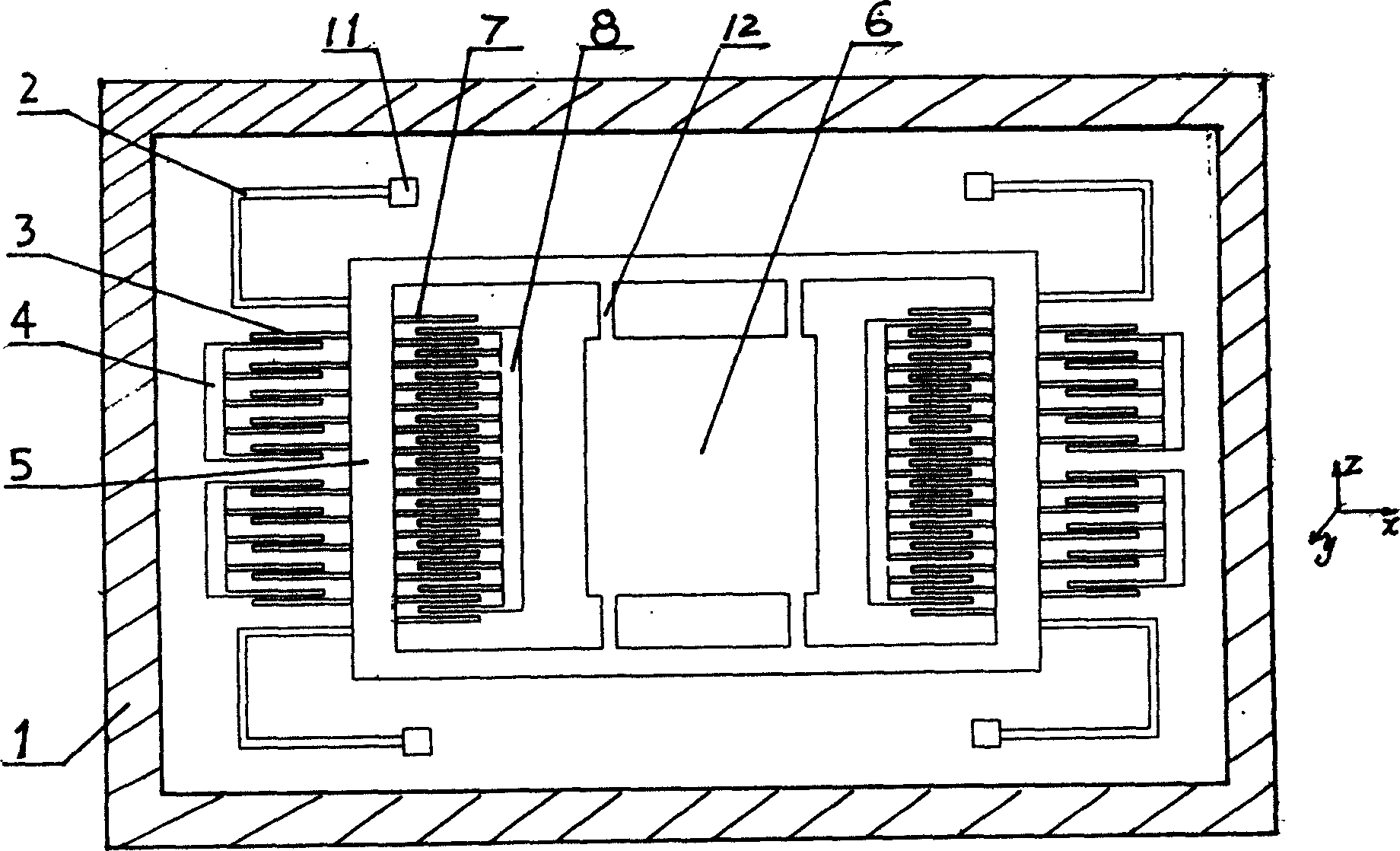

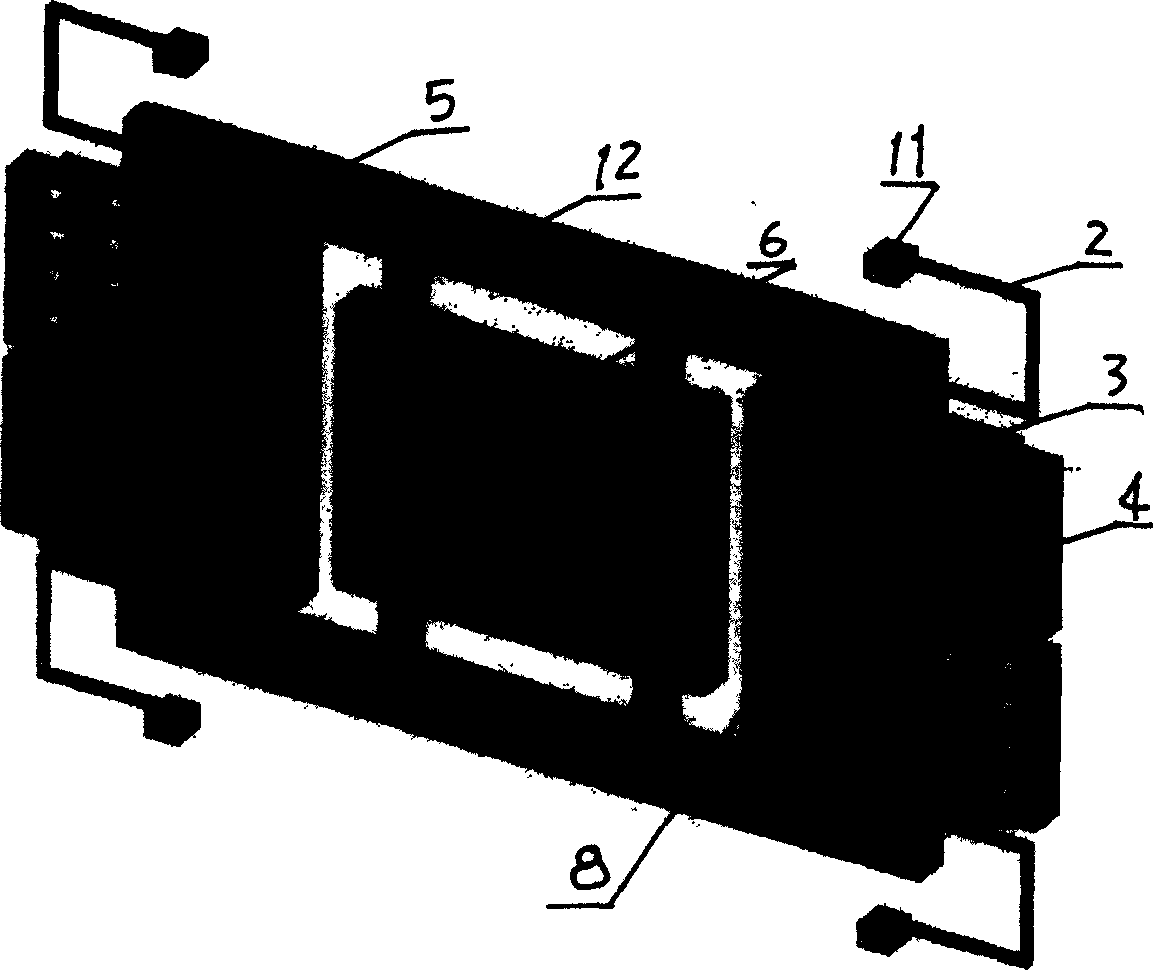

Single chip double inertia parameter accelerometer gyroscope

InactiveCN1648673AHigh sensitivityReduce the difficulty of separationSpeed measurement using gyroscopic effectsAcceleration measurement using gyroscopesGyroscopeAccelerometer

The present invention relates to accelerometer gyroscope, and is an especially single chip double inertia parameter accelerometer gyroscope. The single chip double inertia parameter accelerometer gyroscope includes casing, mass block, which consists of outer frame and mass block core inside the outer frame, anchored with elastic beam to the casing bottom, comb capacitor fixed on two sides of the mass block with sensing comb teeth fixed onto the outer side walls of the outer frame, comb driver fixed in the inner side walls of the outer frame, and electrodes fixed to the top and bottom ends of the mass block core and the top and bottom of the casing. The present invention can detect two kinds of inertia parameters integrally, may sense the linear acceleration and angular acceleration in the same direction and is practical.

Owner:ZHONGBEI UNIV

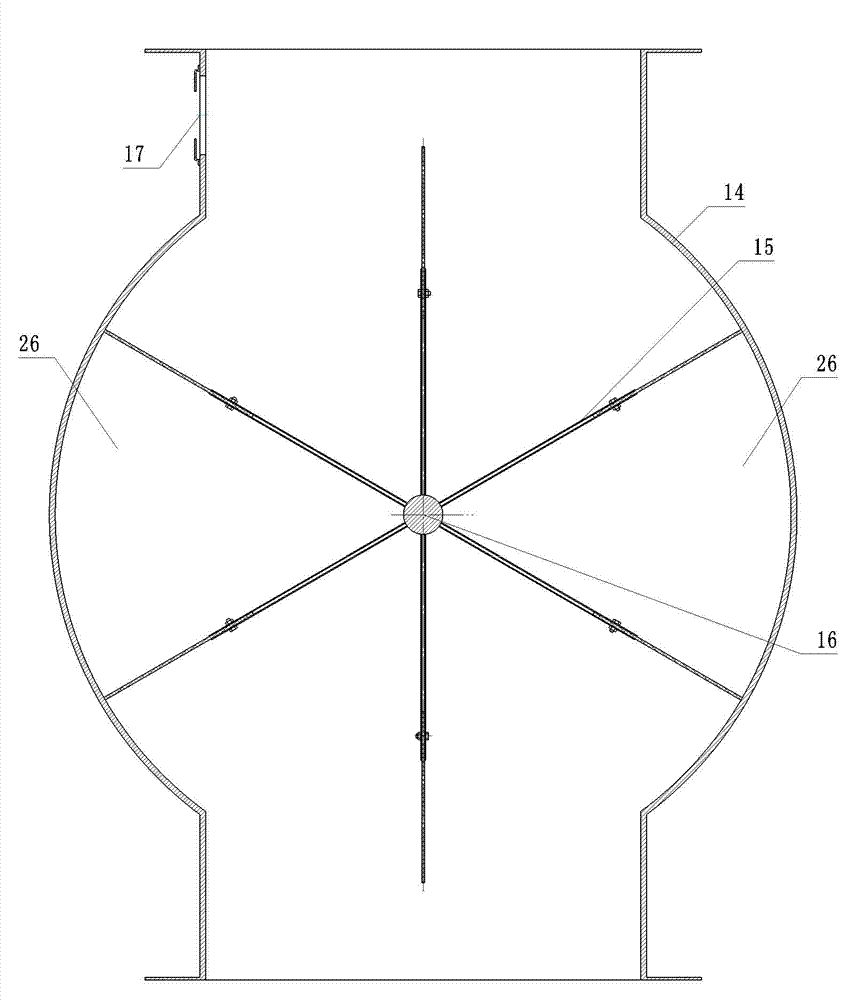

Method and special device for heterogeneous catalyzed synthesis of triacetonamine

ActiveCN107033066AHigh yieldReduce the difficulty of separationOrganic chemistryChemical/physical/physico-chemical stationary reactorsHindered amine light stabilizersTriacetone amine

The invention belongs to the technical field of preparation of hindered amine light stabilizer midbody and pharmaceutical midbody triacetonamine, and particularly relates to a method and a special device for heterogeneous catalyzed synthesis of triacetonamine. The technical scheme is that a cone base reaction kettle consisting of a straight cylinder section and a cone cylinder section is applied, and a water knockout drum formed by a tubular type membrane tube is arranged in the cone base reaction kettle; heterogeneous catalyst and acetone are added in the reaction kettle; after stirring and heating, ammonia gas is filled for reaction; the procedures of separating water by the water knockout drum, cooling, stopping mixing, separating water and standing are carried out, and reaction fluid is discharged and filtered to obtain a crude product of triacetonamine; finally, the crude product is rectified to obtain the high-purity triacetonamine product. In the invention, the heterogeneous catalyst is applied to replace the homogeneous catalyst, thus the separating difficulty of the catalyst is reduced, the high saline-alkali waste water generated from separation process of homogeneous catalyst is avoided; the reaction water is separated from the reaction process, the yield of triacetonamine is improved, and the water separating cost of the rectifying technique is reduced. The content of organic matters in separated water of the water knockout drum is low, and water disposal cost is reduced.

Owner:HENGSHUI KAIYA CHEM

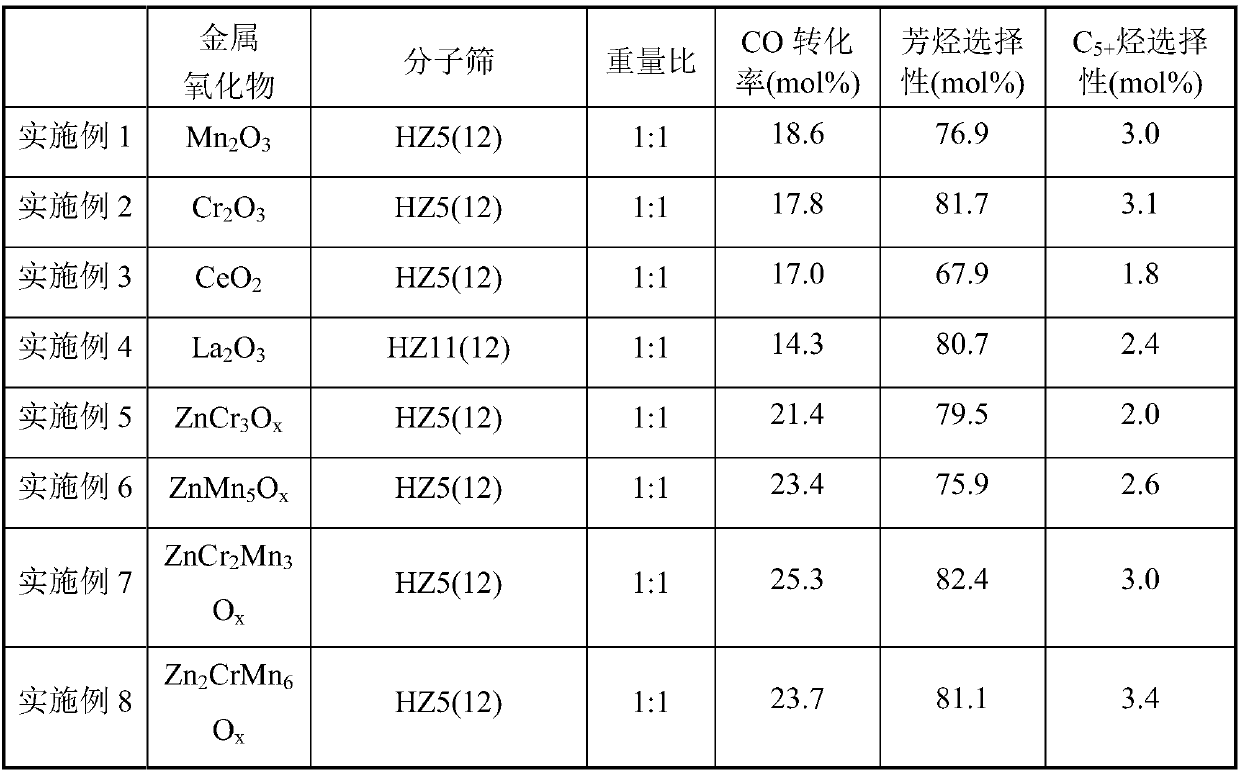

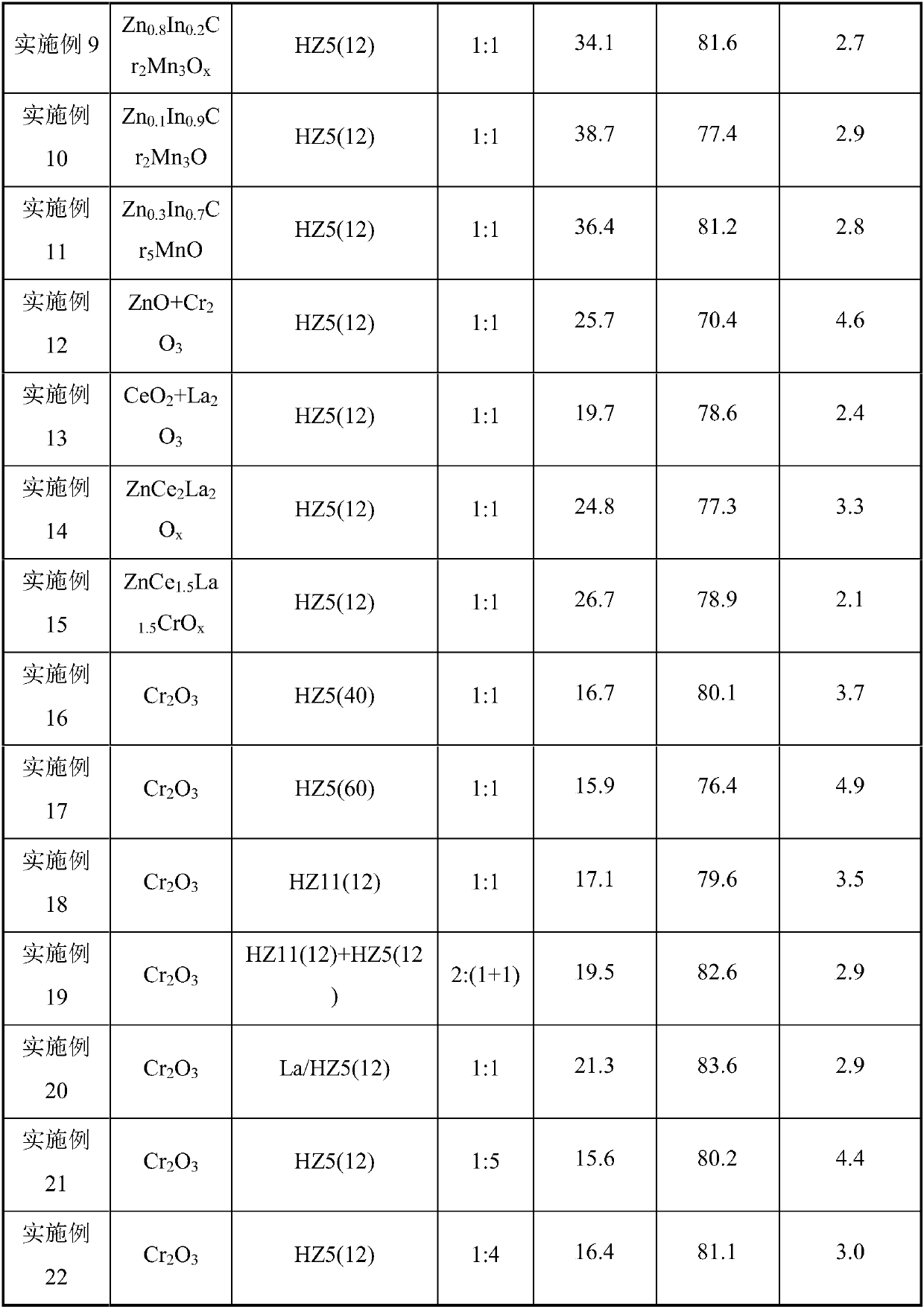

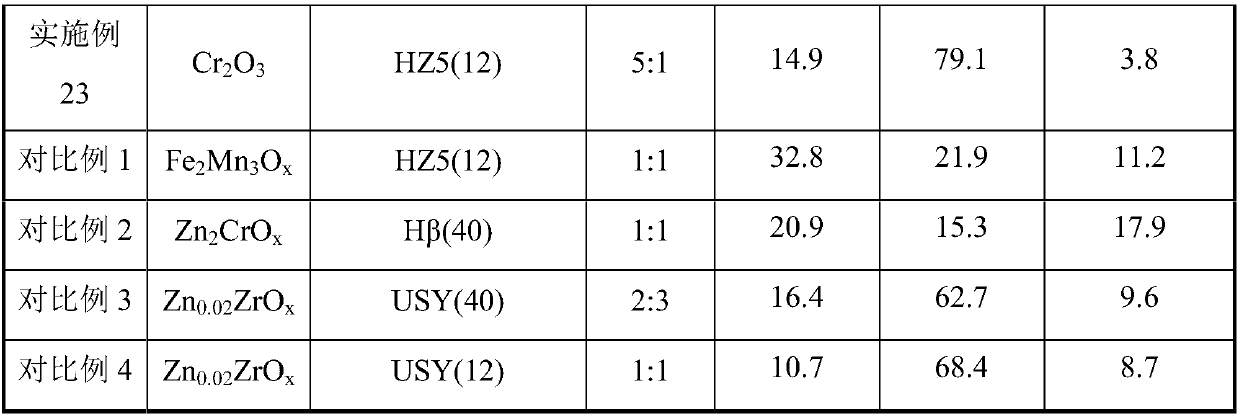

Catalyst system for preparing hydrocarbons and use thereof

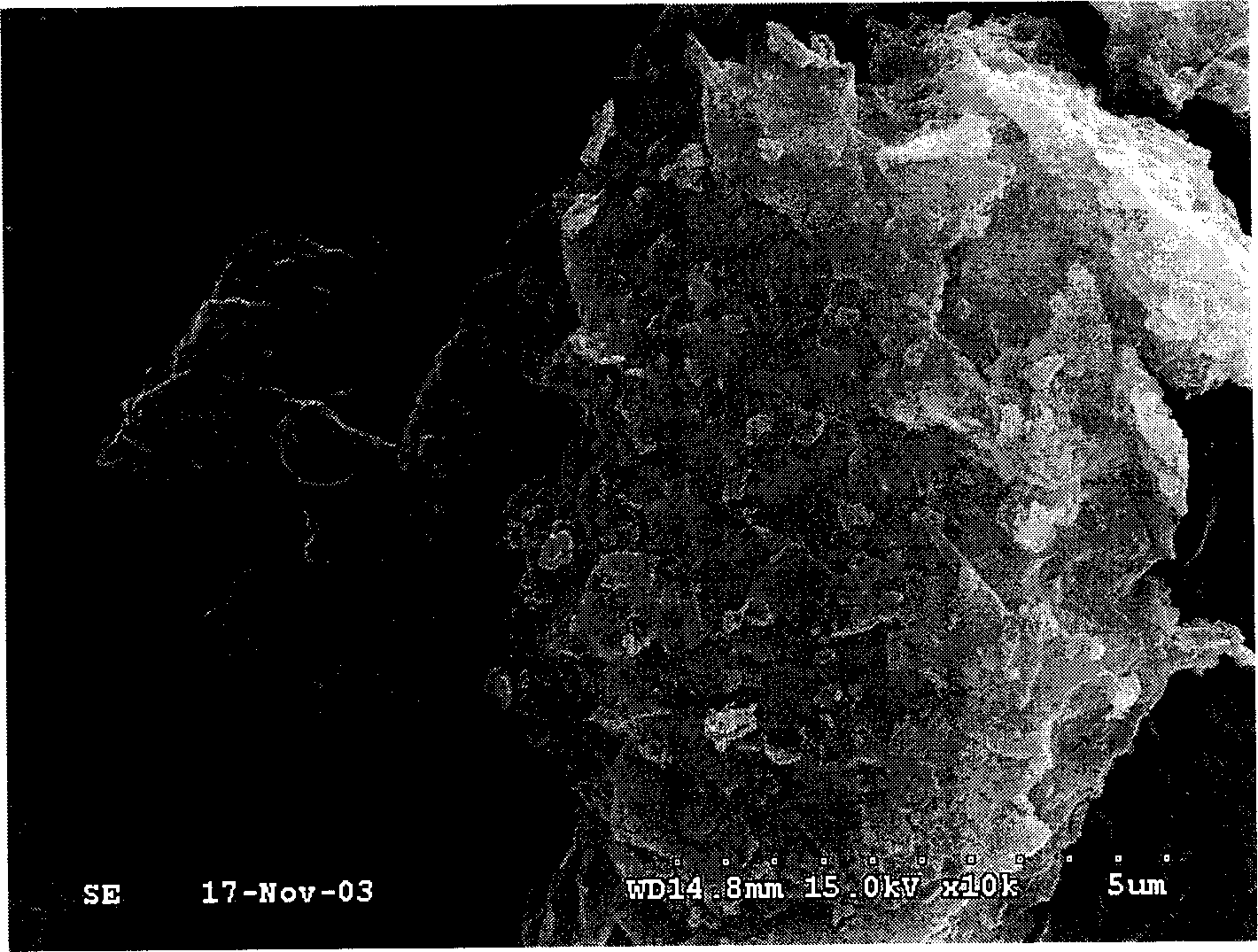

ActiveCN109701602AEasy to combineLow selectivityMolecular sieve catalystsCatalyst activation/preparationSolid acidZSM-5

The invention discloses a process for producing of aromatic hydrocarbons and co-production of light hydrocarbons through synthesis gas conversion and a catalyst used in the process; a catalyst systemhas synthesis gas conversion activity and aromatic hydrocarbon / light hydrocarbon synthesis activity. The synthesis gas conversion activity is provided by a metal oxide catalyst, the aromatic hydrocarbon / light hydrocarbon synthesis activity is provided by a solid acid catalyst including a ZSM-5 or ZSM-11 molecular sieve and modified molecular sieve. The active component of the metal oxide is preferably selected from one or at least one of Cr, Zr, Mn, Ce, La, Ti, In and Zn. The silicon-aluminum ratio of the ZSM-5 or ZSM-11 molecular sieve / the modified molecular sieve ranges from 12-250. Thecatalyst form comprises a composite catalyst or a multi-section catalyst system. Under the conditions that the molar ratio of H2 to CO in the raw material is 0.25-5.0, and / or the reaction temperatureis 300-500 DEG c and / or the pressure is 0.5-10.0 MPa, and / or the volume space velocity is 1000-20000 h<-1>, the synthesis gas can be efficiently converted in one-section or multi-section catalyst systems to generate aromatic hydrocarbon and light hydrocarbon products. The process is a non-fischer-tropsch route, and is a novel route for producing of the aromatic hydrocarbons and co-production of the light hydrocarbons through synthesis gas conversion by virtue of a one-step method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ethyl acetate and/or isopropyl acetate

InactiveCN102757341AReduce concentrationInhibition of the alignment reactionOrganic compound preparationCarboxylic acid esters preparationEsterification reactionReaction system

The invention provides a preparation method of ethyl acetate and / or isopropyl acetate. Catalytic dry gas from an oil refinery is used as a dilute ethylene and / or dilute propylene raw material and is introduced into a reaction system with a strong solid acidic catalyst to perform an addition esterification reaction so as to produce ethyl acetate and isopropyl acetate. The dry gas required by the method directly comes from a dry gas desulfurization treatment device of the refinery, the addition reaction pressure is low, continuous production of the ethyl acetate and isopropyl acetate can be realized by using dilute ethylene and / or dilute propylene, i.e., low-concentration ethylene and / or propylene, serving as raw material(s), the device investment is saved, the energy consumption is low, and the preparation method belongs to an advanced technology for new utilization of the catalytic dry gas.

Owner:CHINA PETROCHEMICAL CORP

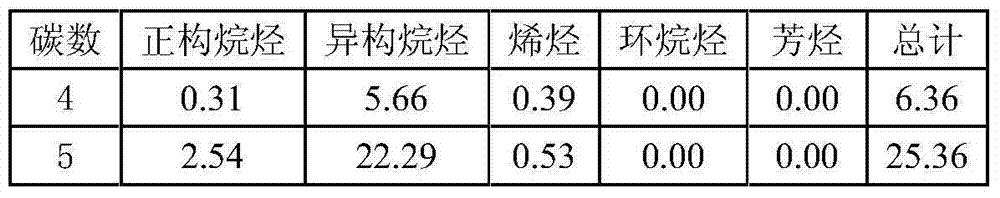

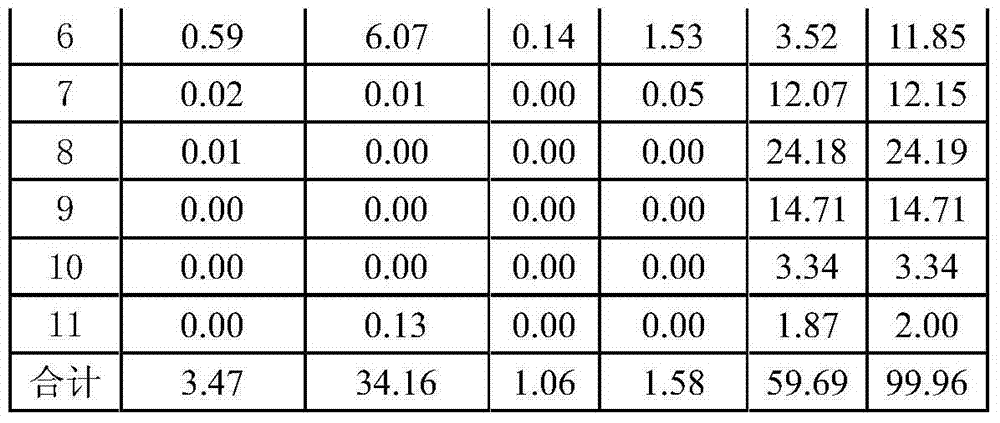

Technical method for preparing aromatic hydrocarbon through methanol aromatization

ActiveCN103864561AGuaranteed selectivityReduce the difficulty of separationHydrocarbon from oxygen organic compoundsHydrocarbonsAlkaneFixed bed

The invention relates to a technical method for preparing aromatic hydrocarbon through methanol aromatization. The technical method is characterized by comprising the steps: firstly, reacting methanol in a fixed-bed reactor filled with a methanol hydrocarbonylation reaction catalyst and an olefin aromatization catalyst, enabling the reacted product to enter a reactor filled with a non-aromatic cracking agent, reacting, separating the product to obtain dry gas, C<3+> non-aromatic hydrocarbon and aromatic hydrocarbon, wherein the dry gas and the aromatic hydrocarbon are output from the system as products, the C<3+> non-aromatic hydrocarbon is dehydrogenated after entering a dehydrogenation reactor, the dehydrogenated C<3+> non-aromatic hydrocarbon returns a methanol hydrocarbonylation reactor for continuing reaction. Through the technique, the methanol conversion, olefin aromatization, non-aromatic cracking and alkane dehydrogenation technology are combined, so that no only can the yield and selectivity of aromatic hydrocarbon be improved, but also the separation difficulty of aromatic hydrocarbon can be lowered. Through the technique, the total yield of the aromatic hydrocarbon (based on mass of methanol) can achieve 30-34%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

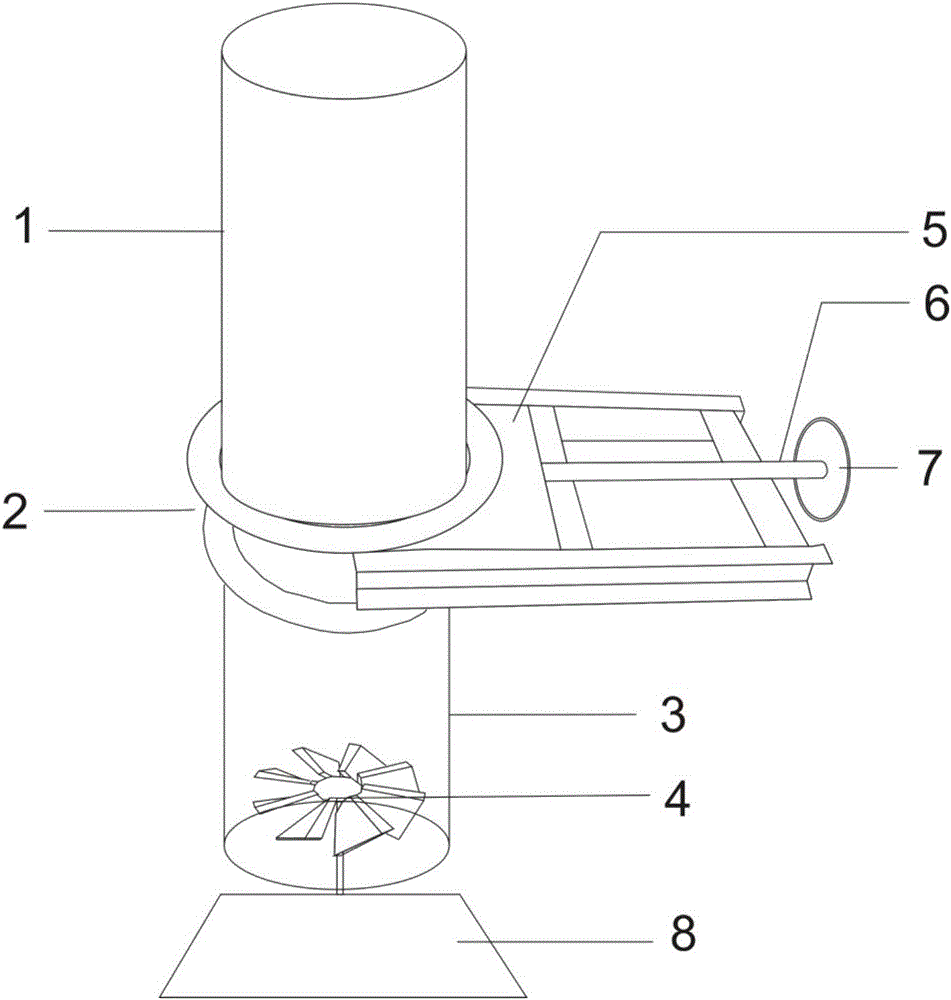

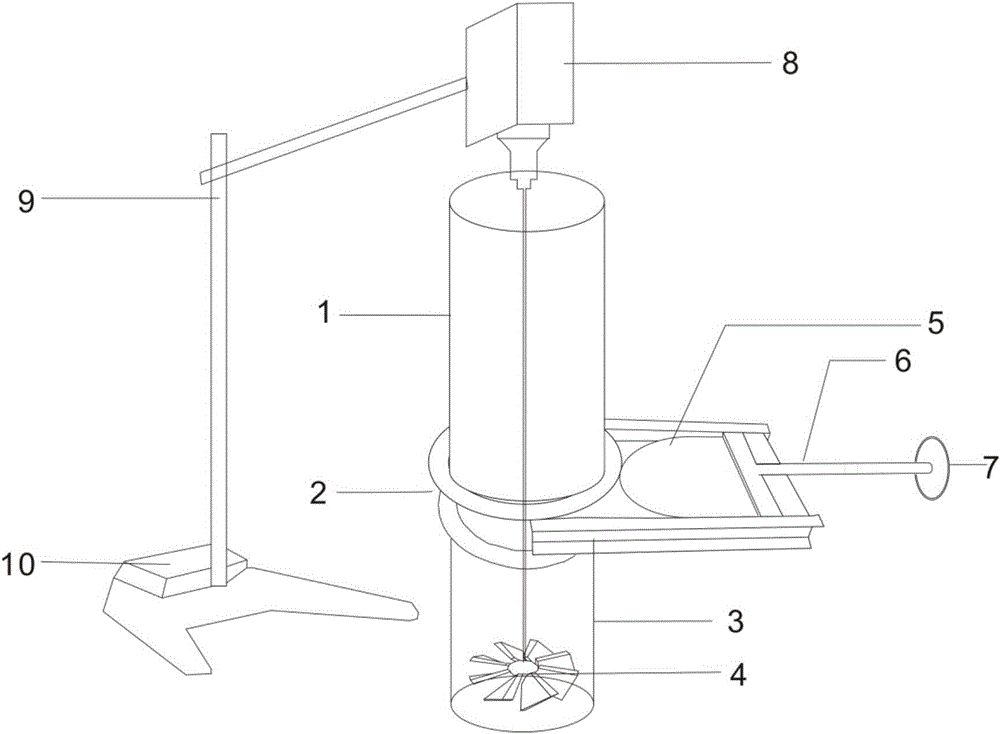

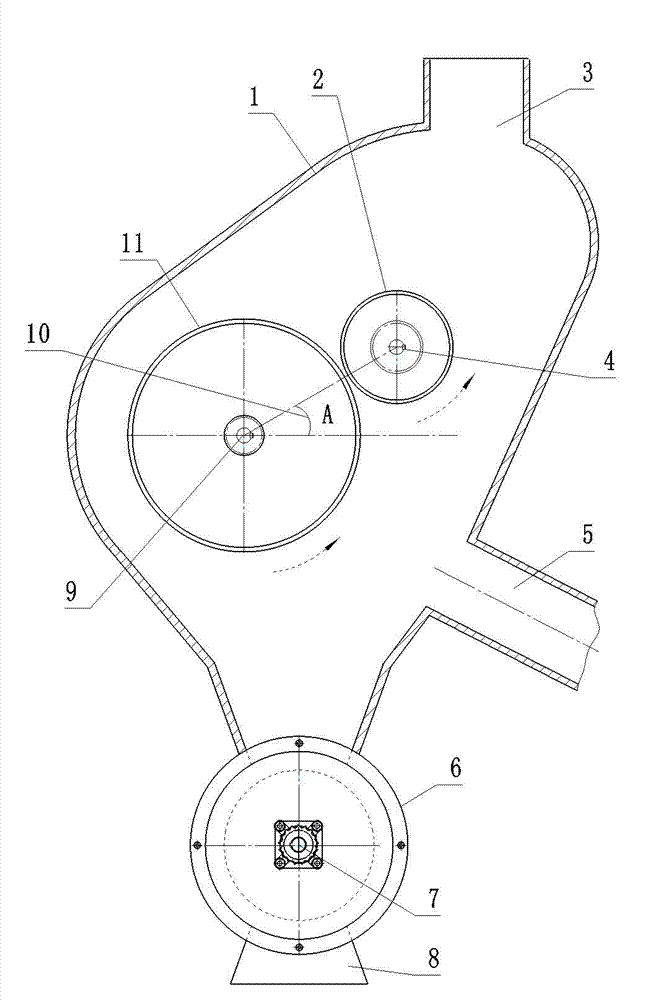

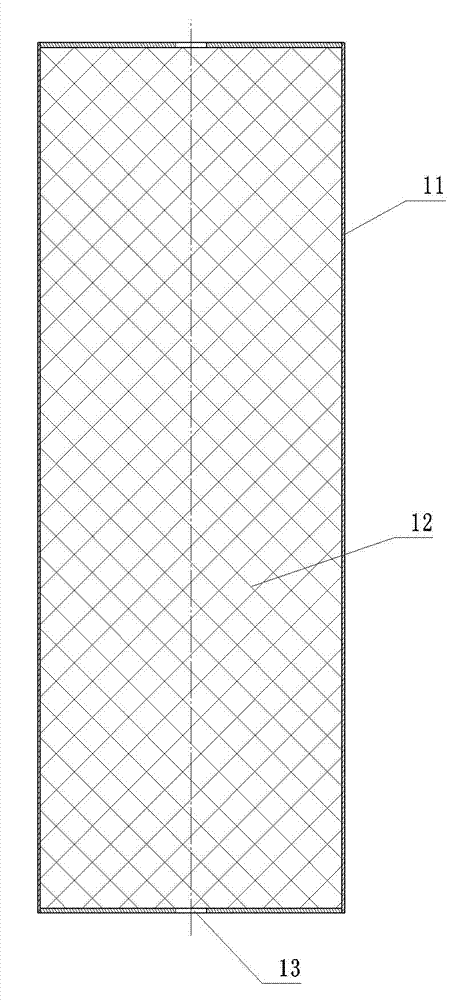

Matched plastic film residue separation device for cotton picker

ActiveCN103111419AAchieve separationEfficient separationGas current separationPicking devicesEngineeringFan blade

The invention relates to a matched plastic film residue separation device for a cotton picker. The matched plastic film residue separation device comprises a separation chamber. A large net-shaped roller, a small net-shaped roller and an air-lock valve area arranged in the separation chamber. A cotton flow inlet, a plastic film residue outlet and a seed cotton outlet are arranged on the separation chamber. The large net-shaped roller and the small net-shaped roller are both of internal hollow structures, gauzes are arranged at the peripheries of outer layers of the net-shaped rollers, and the small net-shaped roller is arranged obliquely above the large net-shaped roller and close to the plastic film residue outlet. When the matched plastic film residue separation device works, the large net-shaped roller and the small net-shaped roller rotate in a counterclockwise mode. The air-lock valve structurally and mainly comprises a casing, an air-lock valve rotating shaft and a fan blade arranged on the air-lock valve rotating shaft. In an initial stage for picking cotton, sundries in seed cotton can be removed, so that a serial of related work procedure links of opening, removing residues and the like can be eliminated after seed cotton is harvested, and energy consumption is reduced. The device can greatly reduce sundry separation difficulty and is simple in structure, economical and practical.

Owner:SHIHEZI UNIVERSITY

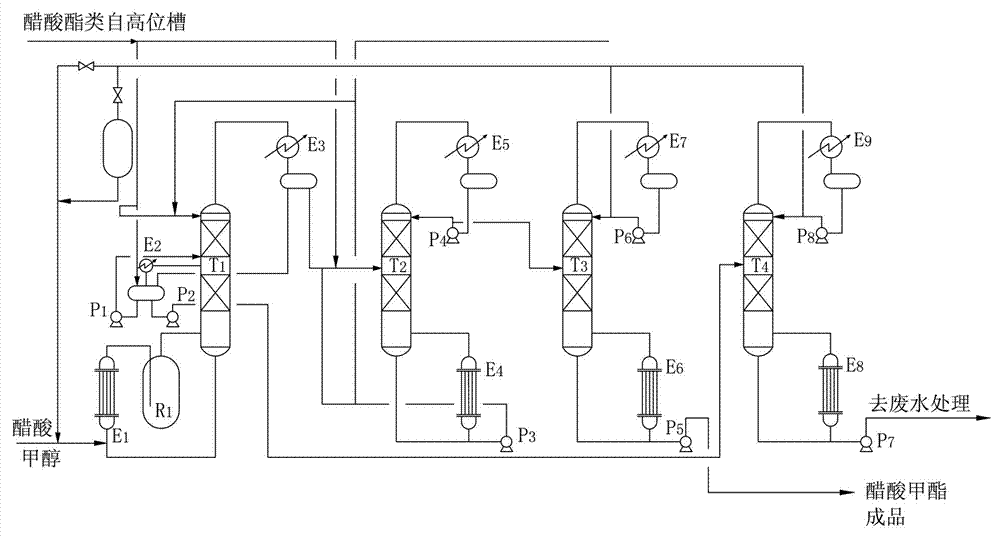

Novel technique for producing methyl acetate

InactiveCN103113222AEasy and efficient to prepareReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationOrganic solventFoaming agent

The invention discloses a novel technique for producing methyl acetate. Acetate is refluxed to carry residual excessive water in the esterifying kettle away in the industrial production process; and a continuous process, comprising reaction rectification, acetate recovery, methyl ester rectification, wastewater treatment and the like, is utilized to conveniently and efficiently prepare the high-purity methyl acetate. The method overcomes the defects of difficulty in separating and purifying the product methyl acetate in the process of producing methyl acetate by esterifying reaction of acetic acid and methanol. The technique has the advantages of low equipment requirement, low energy consumption and simple technique. The product prepared by the method is suitable for organic solvents, polyurethane foam foaming agents, thinners and the like required in the production process of resins, coatings, inks, paints, adhesives and leather.

Owner:谦信化工集团有限公司

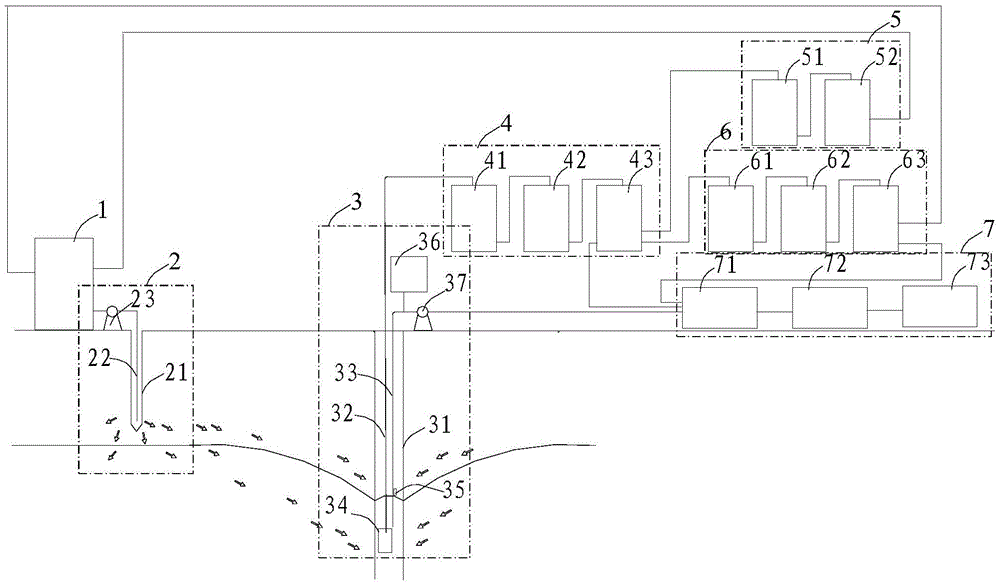

In-situ remediation system and remediation method for organic pollution site of light non-aqueous phase liquids (LNAPLs)

ActiveCN105521990AReduce drawingImprove recycling efficiencyContaminated soil reclamationIn situ remediationEnvironmental engineering

The invention discloses an in-situ remediation system and remediation method for an organic pollution site of light non-aqueous phase liquids (LNAPLs). The in-situ remediation system comprises a soil eluting remediation system and a solar power supply system. The soil eluting remediation system comprises a medicine storage device, a medicine injecting device, an extracting device, an eluant separating device, a groundwater processing device and an eluant recycling device. The medicine storage device is connected with the medicine injecting device, the groundwater processing device and the eluant recycling device. The extracting device is connected with the eluant separating device. The eluant separating device is connected with the groundwater processing device and the eluant recycling device. The solar power supply system comprises a solar power supply battery set, a storage battery set, a solar controller and an inverter. The in-situ remediation system is small in energy consumption, low in cost, high in pollutant removal rate, good in extract separating effect and high in recycling efficiency of groundwater and eluant.

Owner:浙江博世华环保科技有限公司

Purification method for coal tar soft pitch

InactiveCN102839008AImprove solubilityHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionPurification methodsCentrifugation

The present invention relates to a purification method for coal tar soft pitch. The method is characterized by comprising: stirring and uniformly mixing coal tar soft pitch with a softening point of 30-60 DEG C and a solvent according to a mass ratio of 1:0.5-1.5 at a temperature of 120-300 DEG C; carrying out thermal and adding the resulting material to a continuous centrifuge; carrying out continuous centrifugation separation at the same temperature to obtain a supernatant and residue; carrying out vacuum distillation on the supernatant; removing the solvent to obtain the purified pitch; and recovering the solvent to reuse. The method of the present invention has the following advantages and effects that a dissolution property of the soft pitch in the solvent and a process yield can be significantly improved, difficulties of mixing and separation are significantly decreased, and operation and maintenance are convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

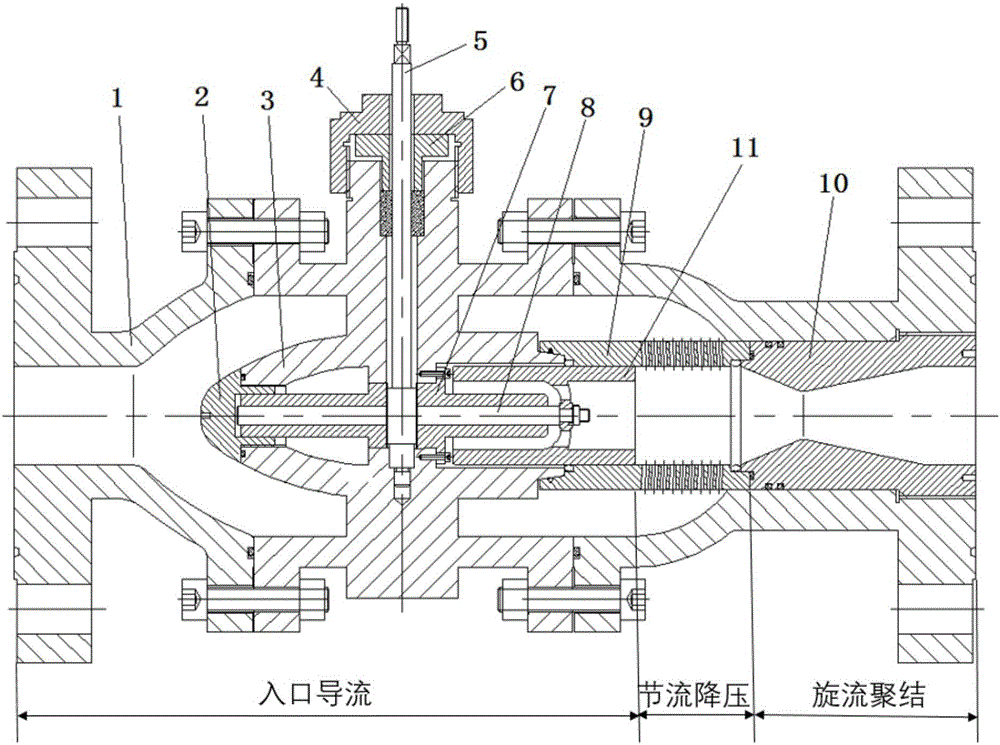

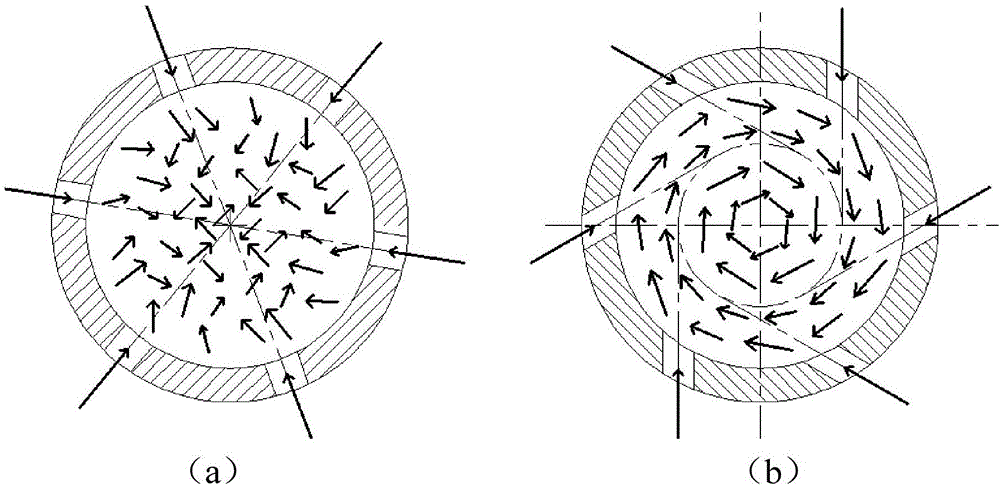

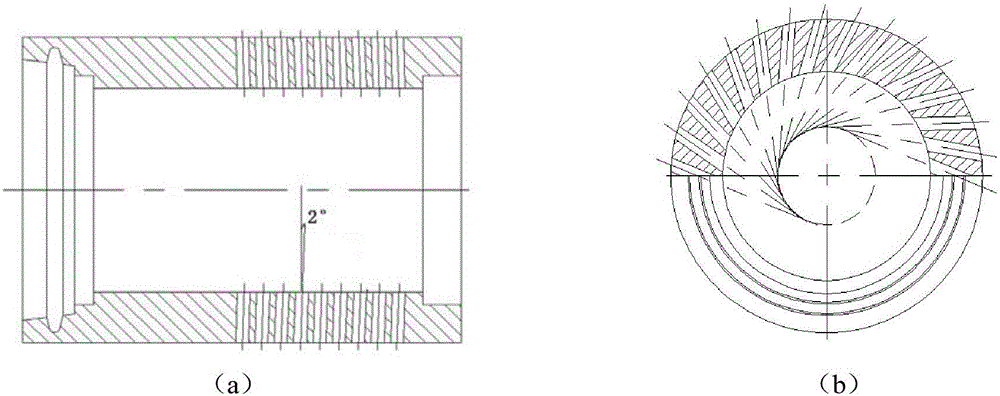

Low shearing plunger type throttling valve used for oil production gathering and transporting

InactiveCN106439137AEnhance swirl effectReduce random vortex motionEqualizing valvesSafety valvesBase functionOil water

The invention discloses a low shearing plunger type throttling valve used for oil production gathering and transporting. Based on a rotational flow agglomeration and unit mass energy dissipation rate control technology, orifices of a valve cage are designed to be in the tangential direction, a rotational flow chamber which is converged firstly and expanded afterwards is connected behind the orifices, the basic function of flow and pressure adjustment can be achieved on the plunger type throttling valve, meanwhile, the velocity gradient and the turbulence energy dissipation rate in a flow field are reduced, the shearing force of the orifices for fluid is reduced, the liquid drop breaking degree is lowered, and the subsequent oil water separation difficulty is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

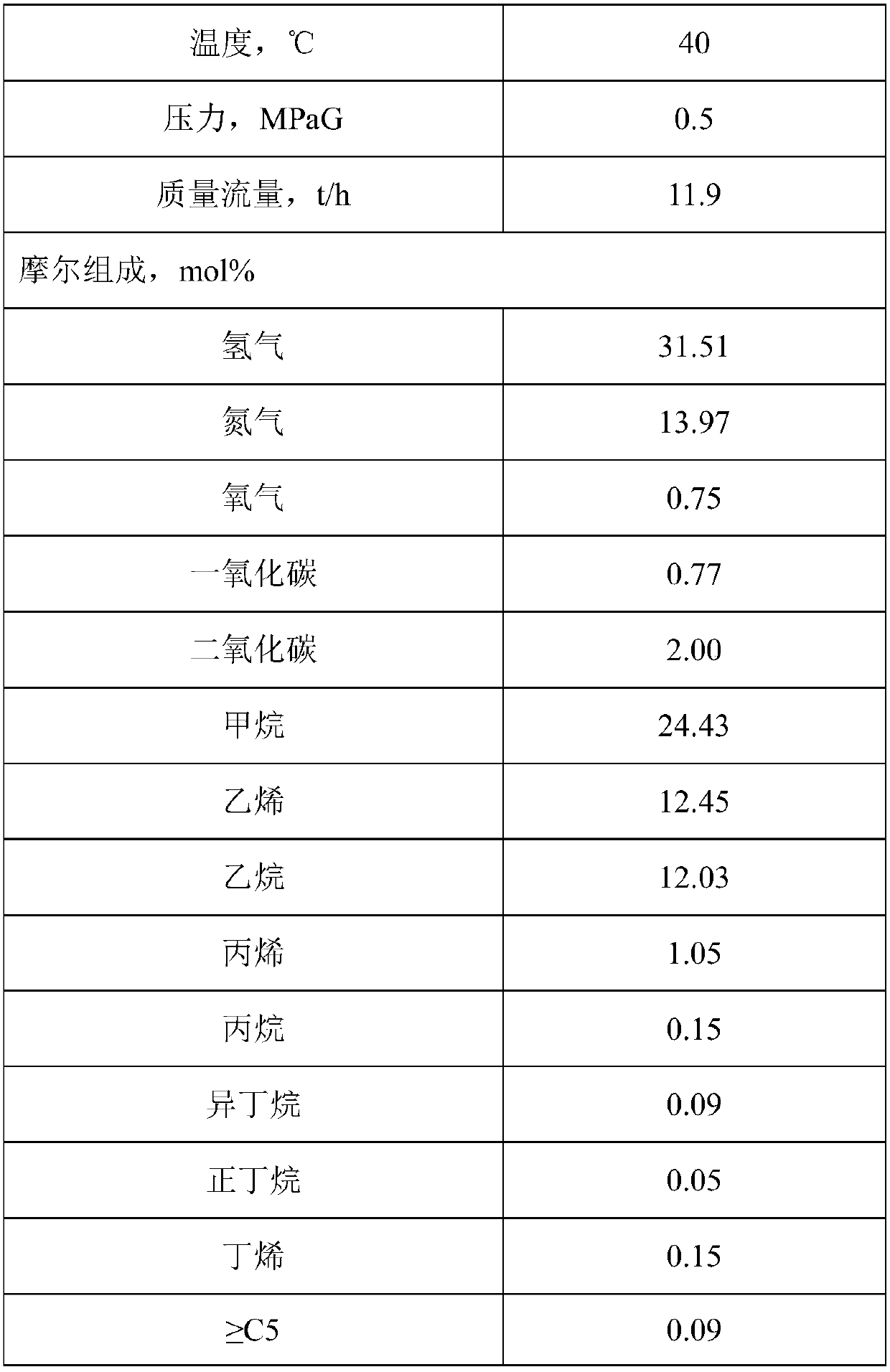

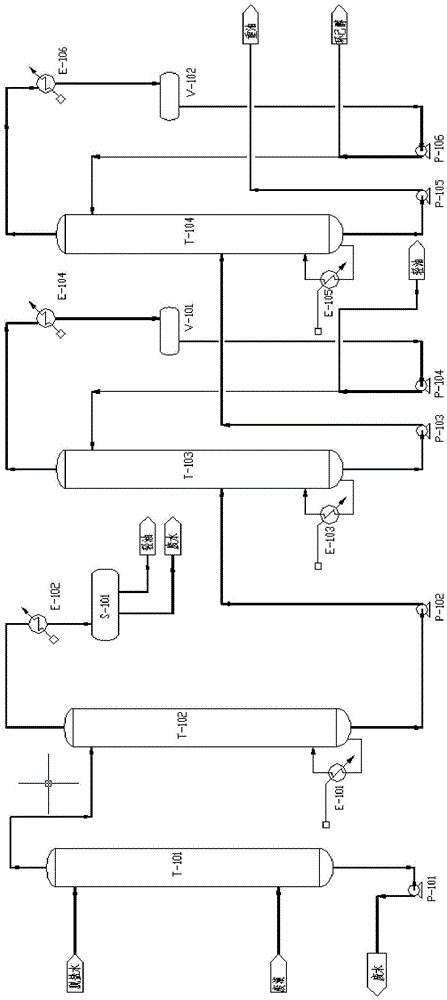

Method and device for separating ethylene from refinery plant dry gas

ActiveCN111320523AAvoid dependenceRaise the condensation temperatureDistillation purification/separationFractional condensation purification/separationProcess engineeringPropane

The invention belongs to the field of chemical engineering, and particularly discloses a method and a device for separating ethylene from refinery plant dry gas. The method comprises the steps of compression, purification, cooling, absorption, propane removal, methane removal, and ethylene refining. The method is based on a shallow cold oil absorption technology, directly produces a polymer-gradeethylene product from refinery plant dry gas on the premise that the refrigeration process is simplified, the cold consumption is reduced and the investment is saved, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

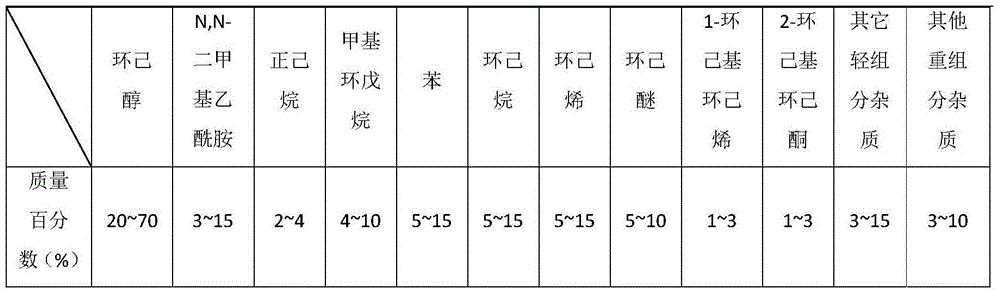

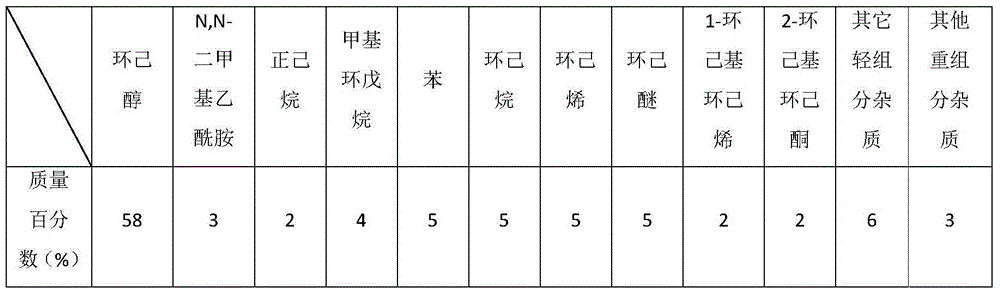

Method for recycling cyclohexanol from cyclohexanone device waste liquid

ActiveCN104909984AReduce the difficulty of separationWill not cause pollutionOrganic compound preparationHydroxy compound separation/purificationCyclohexanoneDehydrogenation

The invention belongs to the technical field of organic chemistry, and relates to a method for separating and recycling cyclohexanol from a cyclohexanone device waste liquid. The method is characterized by comprising the steps of carrying out a series of treatment such as washing, drying, dehydrogenation and refining on the waste liquid, separating to obtain a cyclohexanol product with mass concentration more than 90 percent, wherein the yield of the cyclohexanol in the waste liquid reaches 90 percent or more. By adopting the technological method, the utilization rate of the cyclohexanol is effectively increased, and the discharging volume of the waste liquid can be reduced.

Owner:CHINA TIANCHEN ENG +1

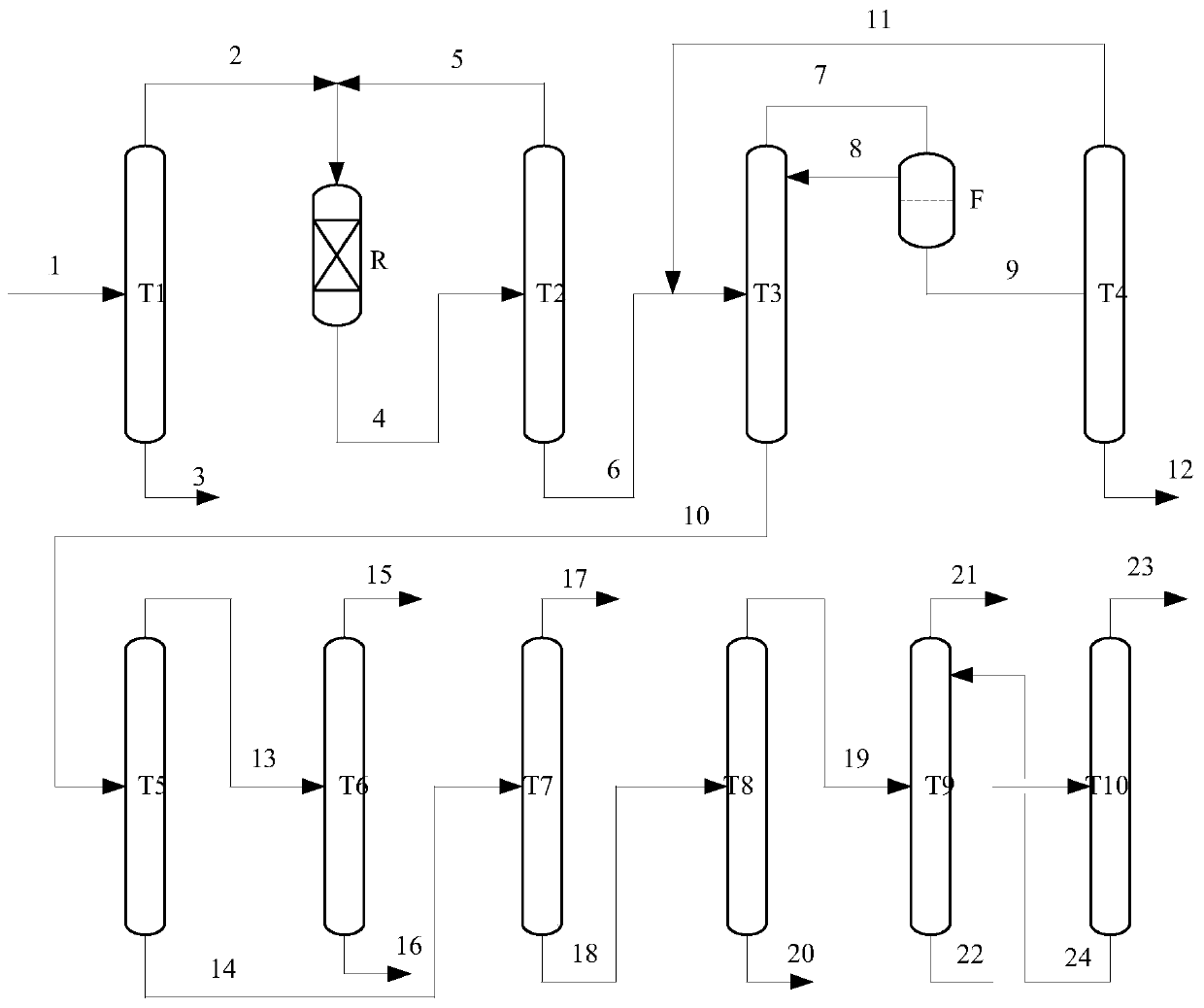

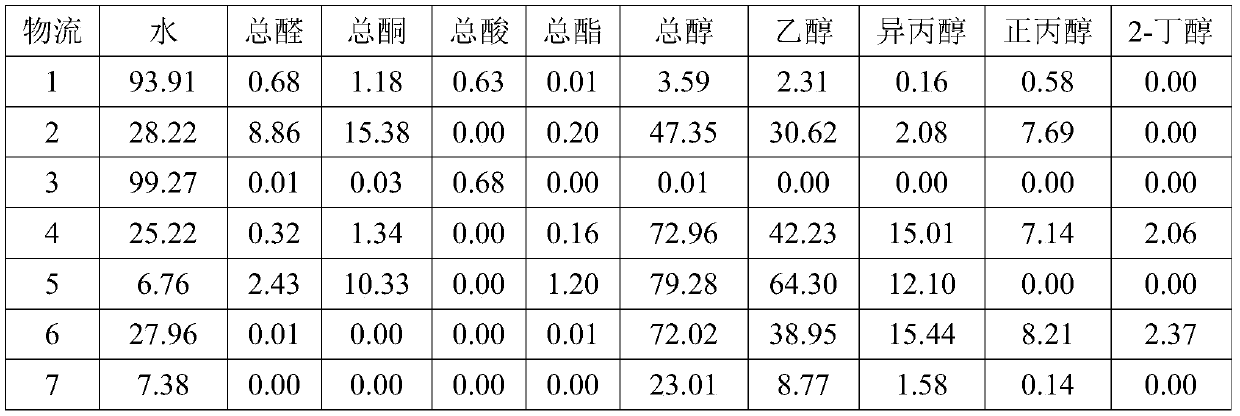

Method for treating oxygen-containing organic matters in Fischer-Tropsch synthesis reaction water

ActiveCN110818531ASimple compositionReduce the difficulty of separationOrganic compound preparationDistillation regulation/controlKetoneKeto acid

The invention relates to a method for treating oxygen-containing organic matters in Fischer-Tropsch synthesis reaction water. According to the method, Fischer-Tropsch synthesis reaction water is subjected to following treatment steps: (a) primary separation, concentration and separation, (b) carbonyl compound hydrogenation, (c) carbonyl compound cutting, (d) mixed alcohol dehydration, (e) solventrecovery, (f) ethanol separation, (g) methanol removal and separation, (h) isopropanol separation, (i) propanol cutting, (j) n-propanol separation, and (k) 2-butanol separation to obtain basic organicchemicals such as ethanol, isopropanol, n-propanol, 2-butanol and a mixed alcohol. Compared with the prior art, the method has the advantages that the concentrated Fischer-Tropsch synthesis water rich in alcohols, aldehydes, ketones, acids, and esters is directly hydrogenated into a mixed alcohol water solution, the separation technological process is simple, and the product purity is high.

Owner:YANKUANG ENERGY R&D CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com