Patents

Literature

99 results about "Color additive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Under the Federal Food, Drug, and Cosmetic Act (Chapter VII, section 721), color additives, except for coal tar hair dyes, are subject to FDA approval before they may be used in food, drugs, or ...

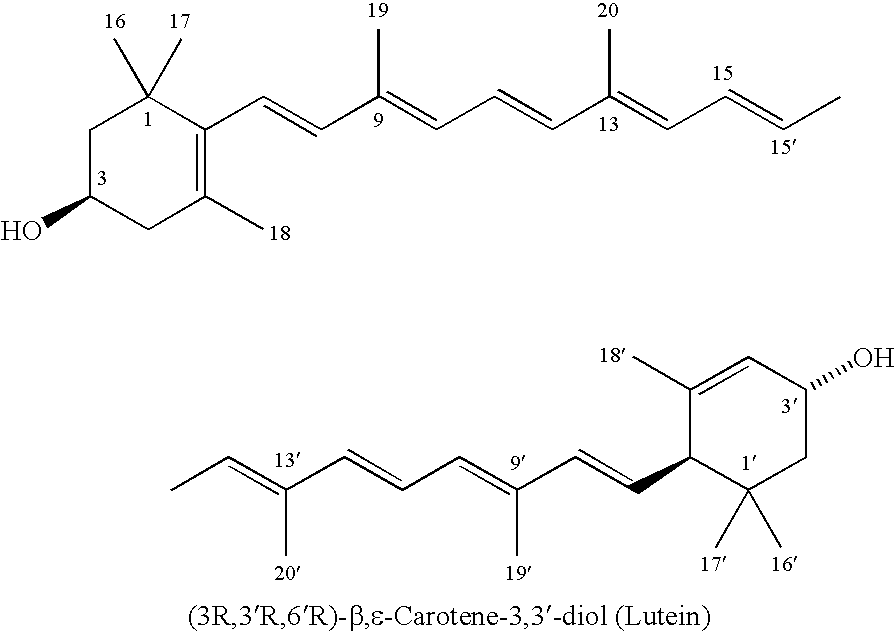

Process for extraction and purification of lutein, zeaxanthin and rare carotenoids from marigold flowers and plants

InactiveUS6262284B1Oxygen-containing compound preparationOrganic compound preparationBeta-CaroteneBeta-cryptoxanthin

A process for simultaneously extracting, saponifying, and isolating lutein and zeaxanthin, and a mixture of several rare carotenoids in high purity from plants without the use of harmful organic solvents. Lutein crystals containing 5% zeaxanthin were obtained from the dried petals of Marigold flowers Tagete erecla while zeaxanthin was isolated and purified from the berries of Lycium Chinese Mill (LCM berries). Similarly, this process has been employed to isolate and purify a mixture of lutein, beta-carotene, neoxanthin, violaxanthin, and lutein epoxide from green plants, preferably, kale, collard green, and spinach. These plants, to a lesser extent, also serve as a source of several rare carotenoids such as alpha-cryptoxanthin (Marigolds) and beta-cryptoxanthin (LCM berries). The purified carotenoids isolated by this process are free from impurities and serve as a safe source of nutritional supplement for human consumption as well as providing a suitable and effective color additive for human foods.

Owner:UNIV OF MARYLAND

Additive for Carbonated Beverage

It is intended to provide a carbonated beverage excelling in function as thirst-quenching beverage and taste through strengthening or sustaining of carbonated feel peculiar to carbonated beverage (brisk intense stimulation and sensation at pass through the throat, brought about by carbon dioxide gas, and sensation of coolness (refreshing sensation) produced by a combination of carbon dioxide gas and flavor) which after opening, rapidly drops depending upon a combination of employed raw materials, such as fruit juice, sweetener, color additives and flavoring, and upon evaporation of carbon dioxide gas. The drop of carbonated feel brought about depending upon a combination of raw materials, such as fruit juice and sweetener, can be relieved by adding to a carbonated beverage an additive for carbonated beverage comprising spilanthol or a spilanthol-containing plant extract or plant essential oil as an active ingredient. Further, the addition would help inhibit drop of carbonated feel brought about depending upon evaporation of carbon dioxide gas after opening and would help retain the taste and function as function as thirst-quenching beverage inherently to be had by carbonated beverage even after opening.

Owner:OGAWA & CO LTD

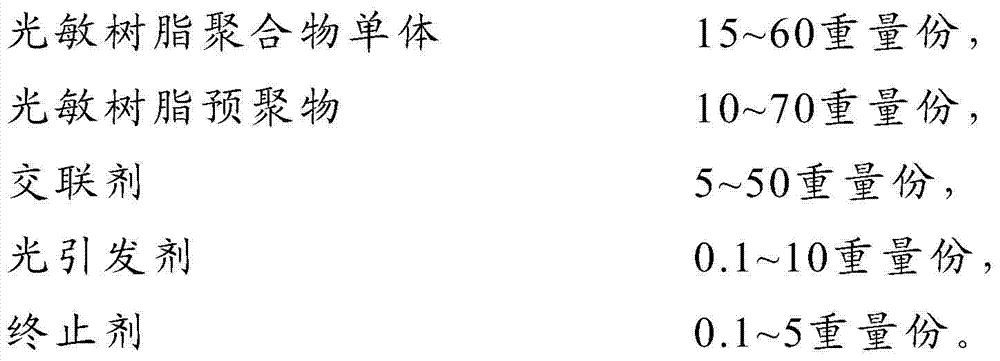

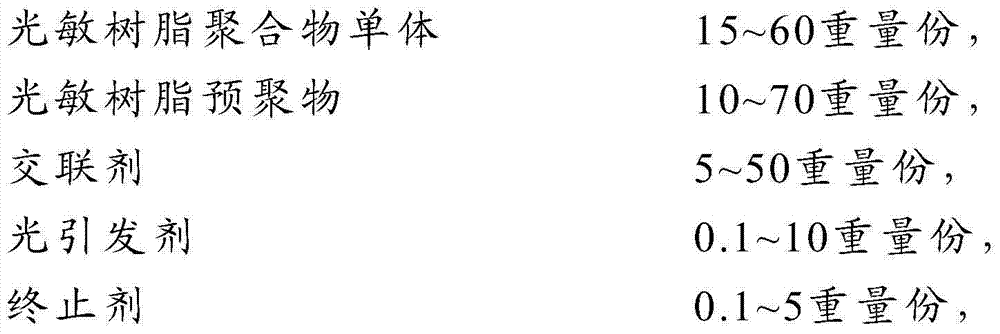

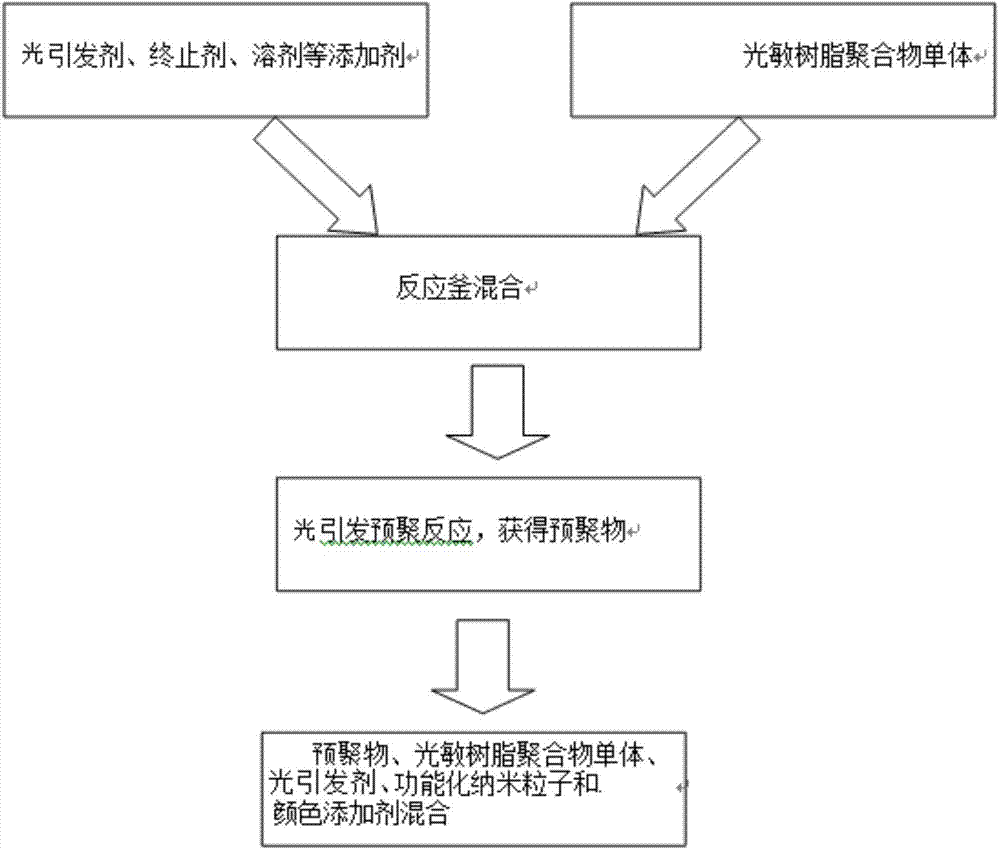

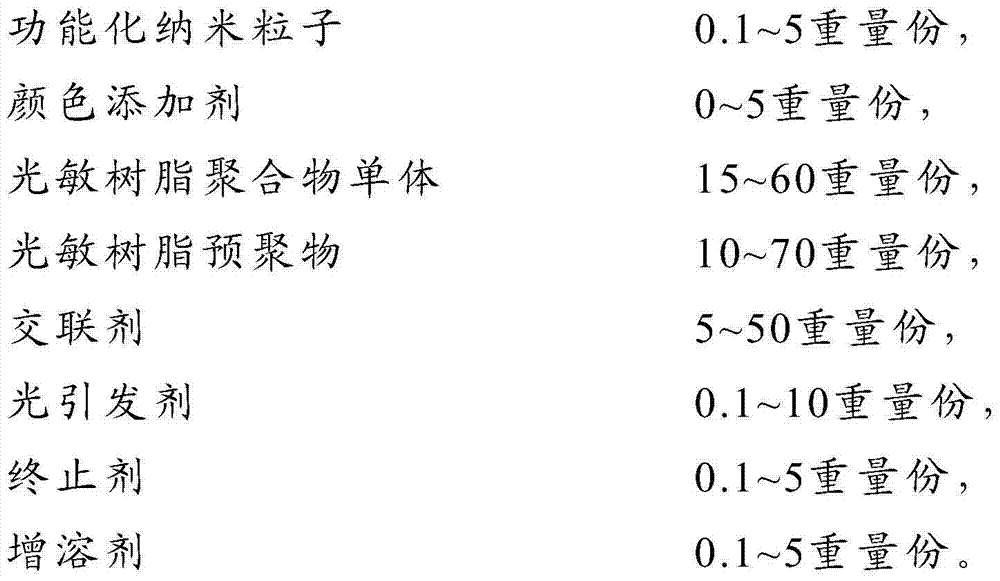

3D printing core material

InactiveCN104710548AImprove liquidityHigh speedAdditive manufacturing apparatusNanoparticle3d printer

The invention provides a 3D printing core material, which comprises photosensitive resin, a photoinitiator, a terminator, functional nanoparticles and a color additive, the fluidity and moulding speed of the prepared 3D printing core material is matched with a 3D printer, and the problems of low intensity and difficult coloring of the 3D printing material can be solved.

Owner:南京波斯塔新材料科技有限公司

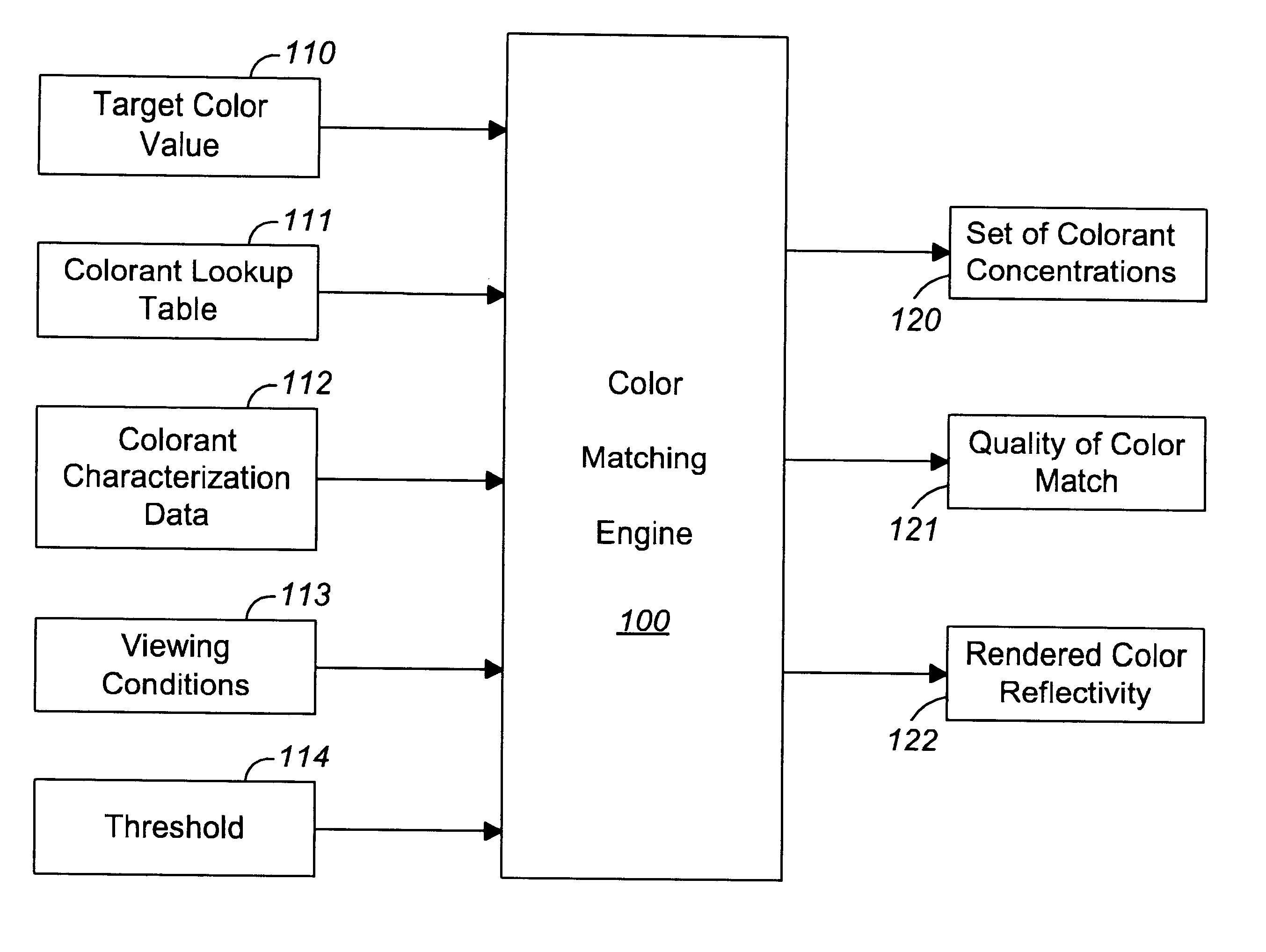

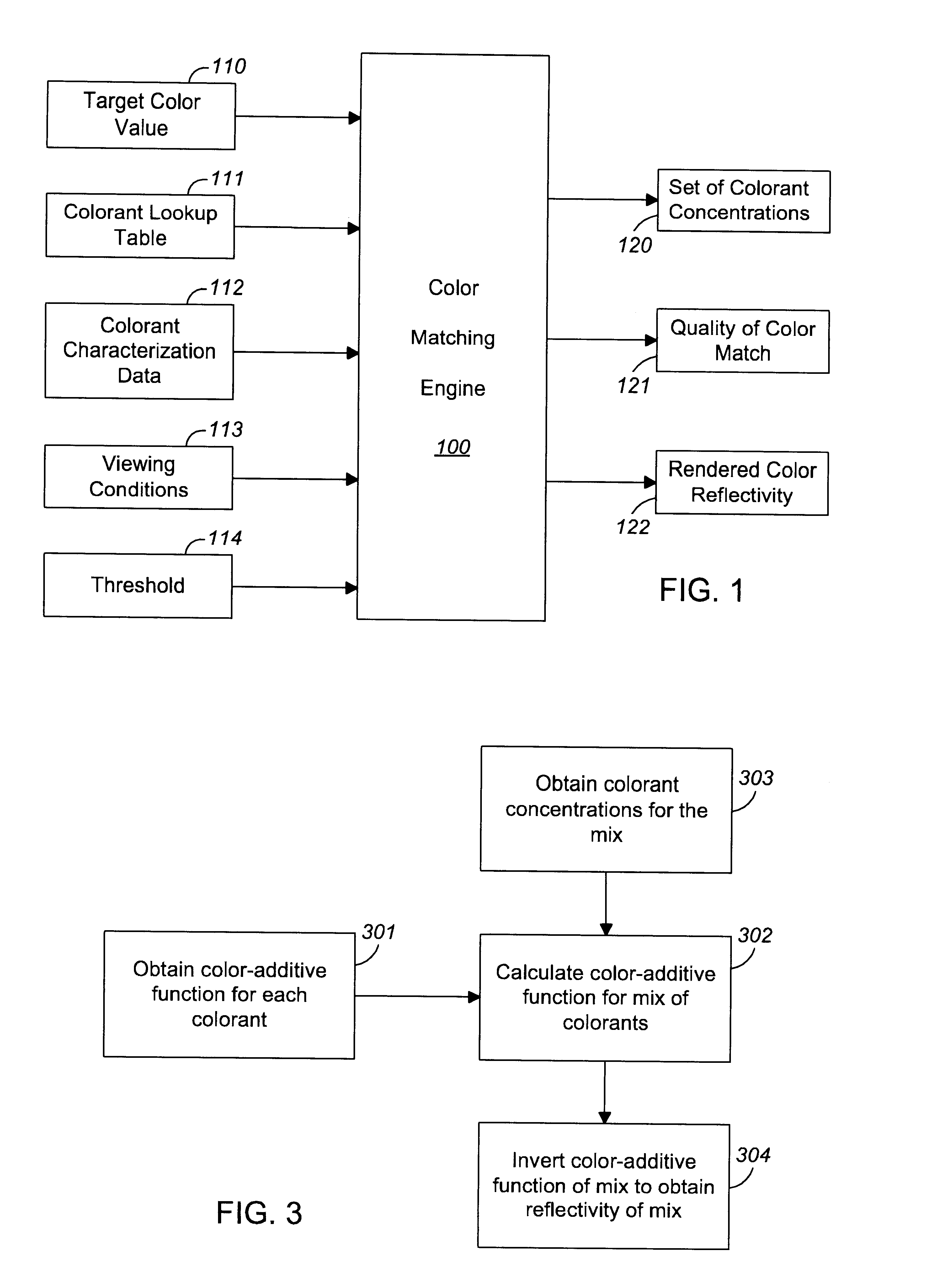

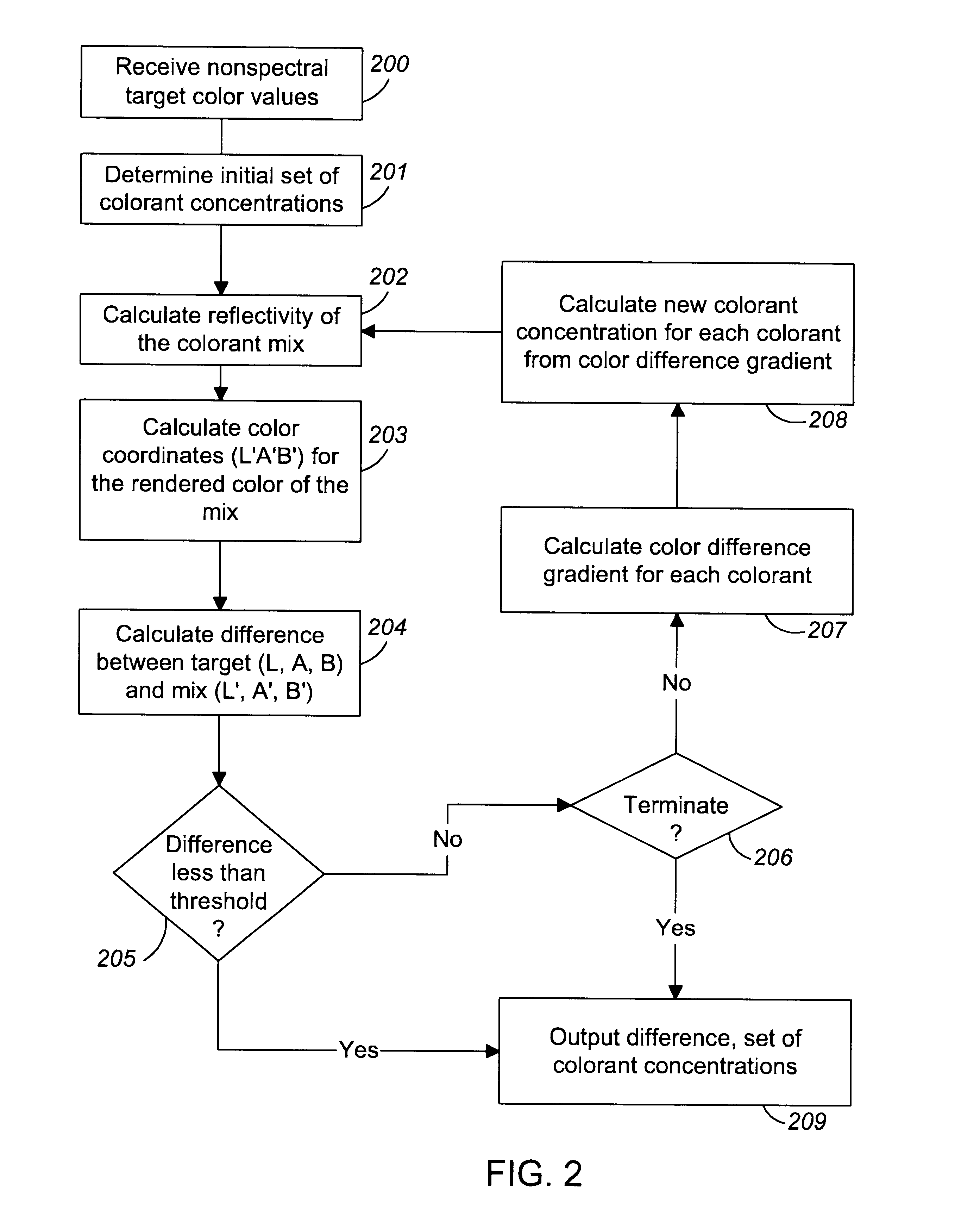

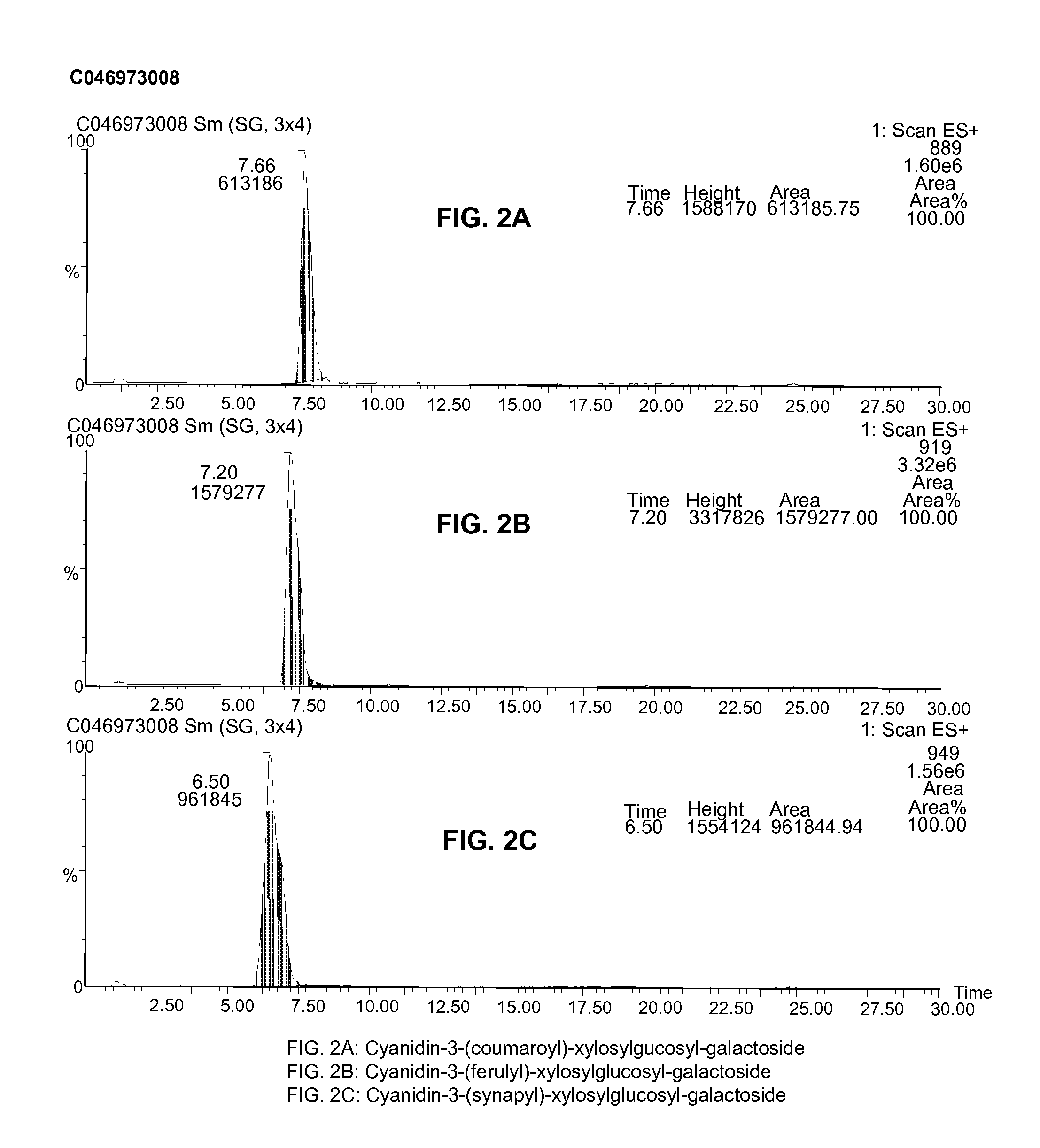

Spectral color matching to a device-independent color value

InactiveUS6646763B1Digitally marking record carriersVisual presentation using printersPattern recognitionTwo grid

Methods, systems, and apparatus for mapping a nonspectral representation of a target color, such as an input color tuple, to a set of concentration values for a set of device-specific colorants. The invention includes using the input color tuple to derive a first set of colorant concentration values from a color lookup table; and refining the first set of colorant concentration values by an iterative non-linear process to generate a final set of colorant concentration values. The first set of colorant concentration values can derived by using an input color tuple as an index to obtain grid-point concentration values at two grid points of the color lookup table and calculating the first set of colorant concentration values as a linear interpolation of the grid-point concentration values. In an implementation that provides a color function table of color-additive function values, the iterative non-linear process can include iteratively (a) calculating an interim color tuple from an interim set of colorant concentration values and the color function table, the initial interim set of colorant concentration values being the first set of colorant concentration values, and (b) deriving an interim set of colorant concentration values from a difference between the input color tuple and the interim color tuple. The calculations can include calculating a partial derivative of an error function from the difference between the input color tuple and the interim color tuple; and using the partial derivative to derive a successor interim set of colorant concentration values from a current interim set of colorant concentration values.

Owner:ADOBE SYST INC

Lutein crystal preparing process from marigold flower

The present invention is the lutein crystal preparing process from marigold flower. Lutein ester is first extracted from marigold flower with non-polar solvent under heating condition and then saponified with alkali solution in stirring and heating condition; and the saponified product is diluted with deionized water and separated, washed and vacuum dried. After that, the obtained lutein crystal is re-crystallized in three-component solvent of tetrahydrofuran, deionized water and normal hexane or petroleum ether; and the lutein crystal is suction filtered, washed and vacuum dried. The present invention has low-toxicity solvent in small amount used, simple technological process, high extraction, rate, and high product purity. The product of the present invention may be used widely as feed coloring additive and food coloring agent and in medicine and health care article.

Owner:海宁凤鸣叶绿素有限公司

Process for extraction and purification of lutein, zeaxanthin and rare carotenoids from marigold flowers and plants

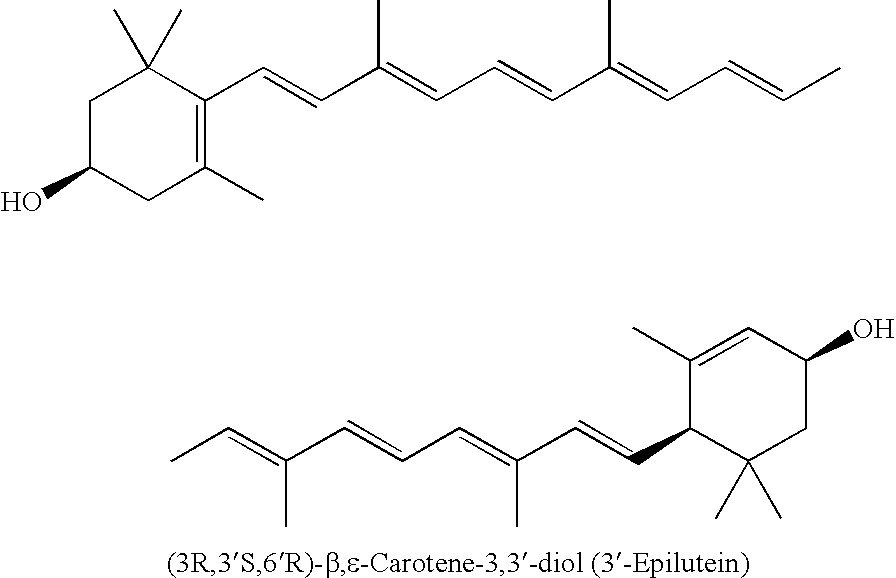

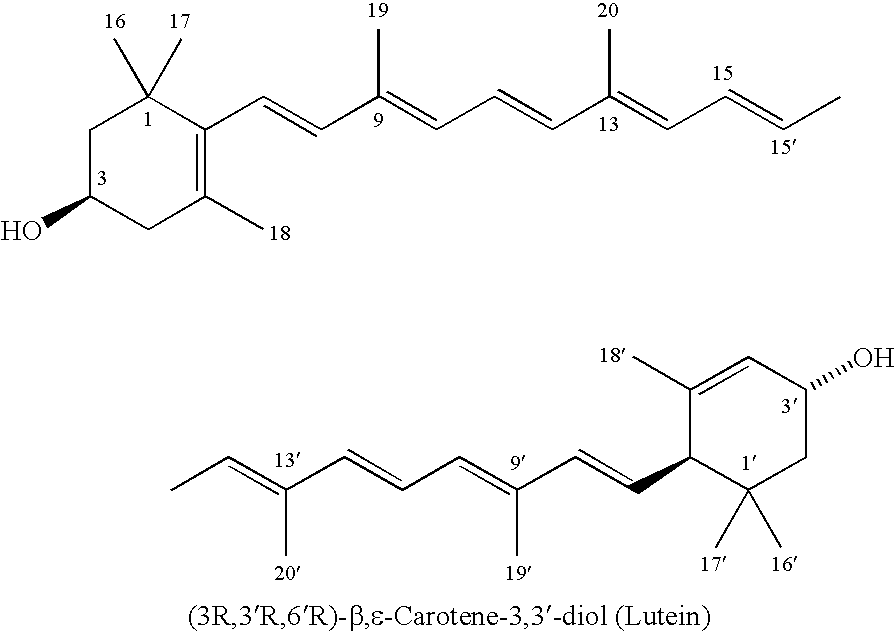

InactiveUS20050038271A1Method is feasibleInhibition of isomerizationOrganic compound preparationOrganic chemistry methodsLutein / zeaxanthinIsomerization

Owner:UNIV OF MARYLAND

Process for preparing reduced fat frozen potato strips

ActiveUS20060177544A1Beer brewingFruits/vegetable preservation by coatingAlternative methodsSuperheated steam

A method of preparing potato strips includes cutting potatoes into strips, blanching the strips, dipping the strips in an aqueous solution containing salt, color additives, SAPP or other additives, and drying the strips. The dry strips are parfried, partially deoiled, washed in water, cooled, exposed to superheated steam, dried in an impingement oven, cooled and frozen. The strips, before parfrying, may be coated with a batter. The frozen strips may be reconstituted by heating in an oven. In alternative methods, frozen strips are prepared with no or virtually no fat content.

Owner:LAMB WESTON INC

Process for extraction and purification of lutein, zeaxanthin and rare carotenoids from marigold flowers and plants

InactiveUS7173145B2Avoid isomerization and degradationSafely coloringOrganic compound preparationOrganic chemistry methodsZeaxanthinOrganic solvent

A process for extracting and isolating carotenoid esters or carotenoids in high purity from plants without the use of harmful organic solvents. Zeaxanthin esters were isolated and purified from the berries of Lycium Chinese Mill (LCM berries). The esters isolated according to the invention contain substantially no isomerized double bonds. The purified carotenoid esters or carotenoids isolated by this process are free from impurities and serve as a safe source of nutritional supplement for human consumption as well as providing a suitable and effective color additive for human foods.

Owner:UNIV OF MARYLAND

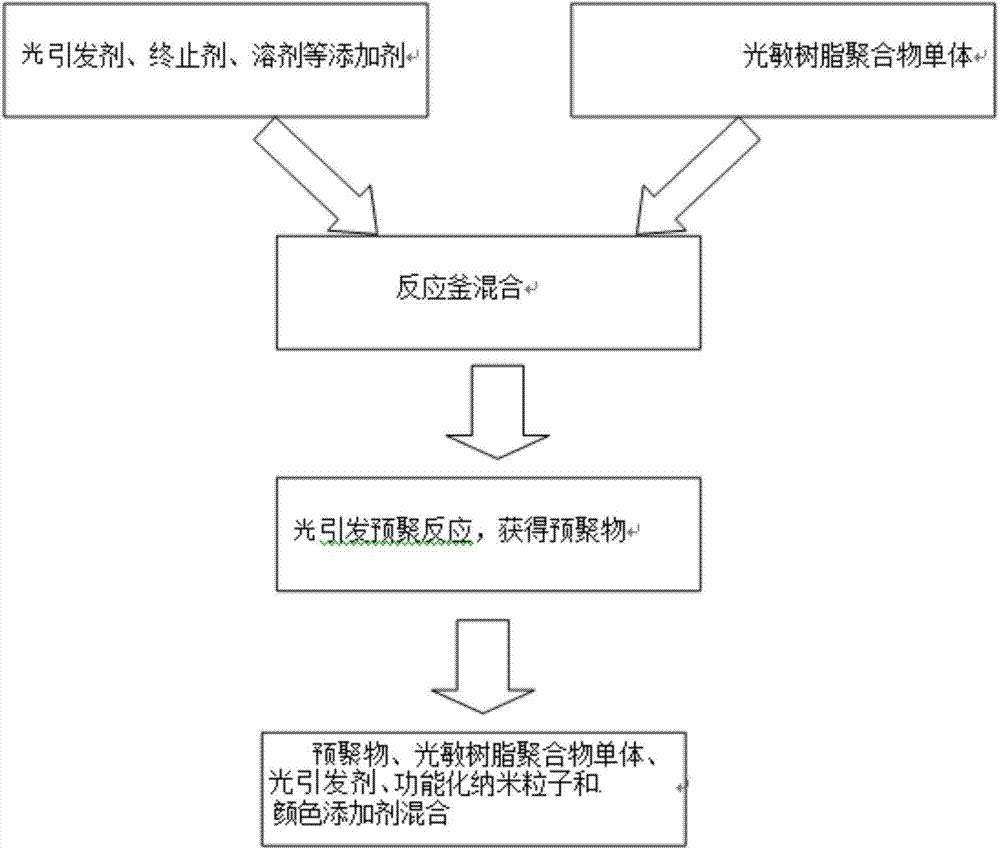

Preparation method of 3D printing material

The invention provides a method for preparing a 3D printing core material, when the 3D printing material is prepared, functional nanoparticles and a color additive are added in a photosensitive resin monomer, a photosensitive resin prepolymer, a photoinitiator and a terminator, the fluidity and moulding speed of the prepared 3D printing material is matched with a domestic 3D printer, and the problems of low intensity and difficult coloring of the 3D printing material can be solved.

Owner:南京爱特泰新材料科技有限公司

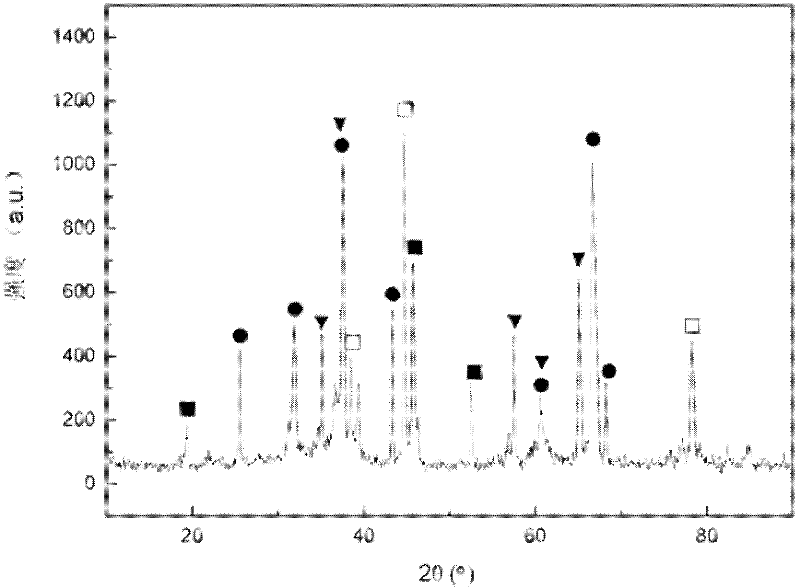

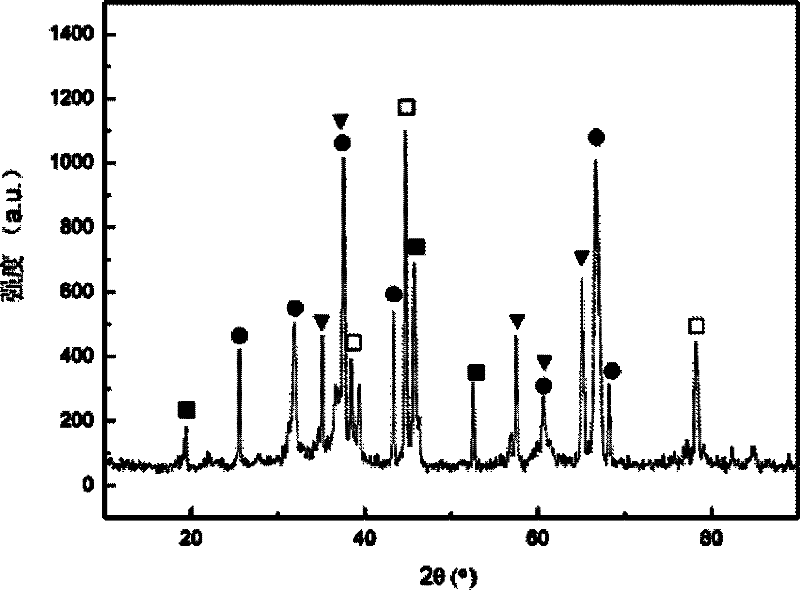

Synthetic fluorophlogopite and preparation method thereof

The invention provides synthetic fluorophlogopite which is colored fluorophlogopite. The synthetic fluorophlogopite is prepared by 100 parts by weight of fluorophlogopite basic raw material and 3-58 parts by weight of color additive, wherein the fluorophlogopite basic raw material is composed of the following ingredients in percentage by weight: 18-21% of K2SiF6, 28-31% of MgO, 8-13% of Al2O3, 2-5% of K2CO3 and 34-38% of SiO2; and the color additive is selected from one or more of the following ingredients in parts by weight: 5-15 parts of TiO2, 3-10 parts of Cr2O3, 5-15 parts of Fe2O3, 5-10 parts of CuO or 4-8 parts of CrO3. The synthetic fluorophlogopite provided by the invention has richful colors ad is capable of meeting the demands of various fields. The invention further provides a preparation method of the fluorophlogopite. By adopting the invention, the production cost can be greatly reduced, and the product quality is improved.

Owner:吕宝林

Fodder rich in Chinese herbal medicines and used for pork pigs

InactiveCN105166556APromote absorptionImprove disease resistanceAnimal feeding stuffBiotechnologyDisease

The invention provides fodder rich in Chinese herbal medicines and used for pork pigs. The fodder comprises basic materials, adjusting materials and a Chinese herbal medicine liquid, wherein the basic materials comprise 30-40 parts of rice, 25-30 parts of corn, 20-25 parts of wheat bran, 10-15 parts of fish meal, 10-13 parts of shrimp shells, 15-18 parts of potatoes, 10-13 parts of sweet potato leaves, 9-12 parts of folium artemisiae argyi, 8-13 parts of bone meal, 10-14 parts of broomcorn millet, 11-15 parts of buckwheat, 7-9 parts of cowpea, 6-10 parts of broad bean, 3-6 parts of water spinach, 4-7 parts of camellia japonica, 2-5 parts of water lettuce and 6-8 parts of clover. The fodder has the benefits as follows: the fodder is prepared from pure natural crops and the Chinese herbal medicines and doesn't contain color additives or hormone drugs, the quality of fed pork pigs is higher, the meat is firm and contains fewer fatty deposits, and the fodder can improve the absorption and digestion capability of pig intestinal tracts and enhance the disease resistance capability of the pork pigs.

Owner:FOSHAN GAOMING DISTRICT HONGYE BREEDING CO LTD

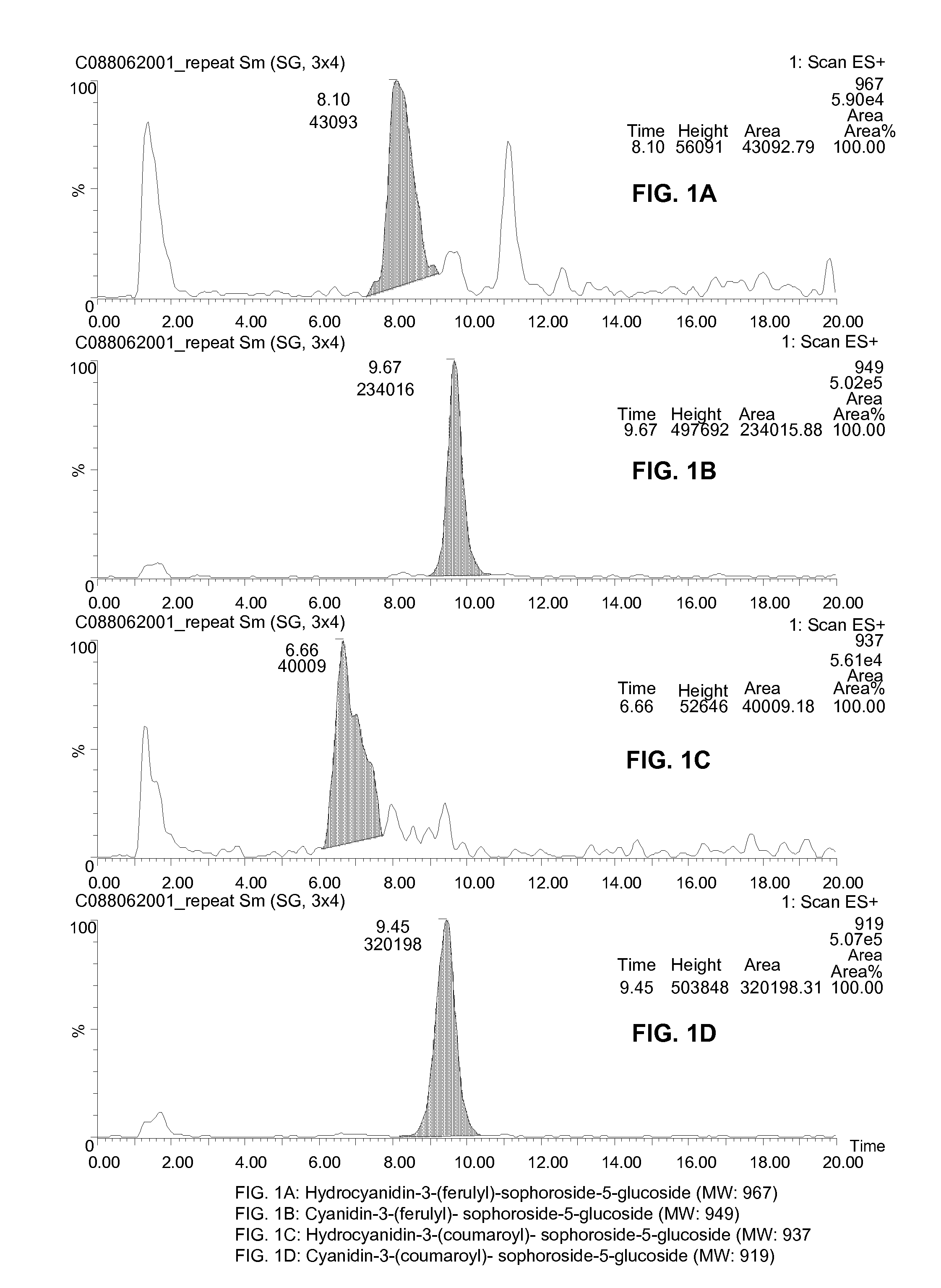

Methods for Creating Color Variation in Anthocyanins Produced by Cell Culture

Disclosed are methods for obtaining blue anthocyanin pigments and compositions including such pigments. This blue anthocyanin is present at an acidic pH (where anthocyanins are most stable) and may be used as a natural color additive. The methods can include cultivating a plant callus from a plant capable of producing anthocyanin in which the callus is treated with a blue anthocyanin-generating agent at a concentration sufficient to generate callus with blue anthocyanin pigments. The method can also include recovering the blue anthocyanin pigments from the culture. In an example, the blue anthocyanin-generating agent is ammonium molybdate.

Owner:DIANAPLANTSCIENCES SAS

Pearl rice flour and making method thereof

InactiveCN102038140ARich in colorHigh nutritional valueFood preparationAdditive ingredientSpherical shaped

The invention discloses pearl rice flour and a making method thereof. The major ingredients and the minor ingredient comprise one or more than one of rice, white flour, millet flour, potato flour, lotus root flour and beans; the color additive is natural pigment extracted from plants or vegetable juice extracted from vegetables; the weight of the major ingredients is 80-90%; the weight of the minor ingredients is 5-20%; and the weight of the color additive is less than 1%. The making method comprises the processes of soaking, washing the rice, dehydrating, pulverizing, stirring, shaping, drying, packing and the like. The rice in the major ingredient contain nutrition constituents, and the flour, the millet, the potatoes, the lotus root and the beans in the major ingredients also contain rich nutrition constituents, thereby improving the nutritional value of the food; and the added color additive is natural pigment extracted from plants or vegetable juice extracted from vegetables, thereby further enhancing the nutritional value and the healthcare effect of the food. The pearl rice flour boasts of spherical shape, crystal clear gloss and rich color, and the pearl rice flour has smooth mouth feel and is convenient to eat.

Owner:刘泉

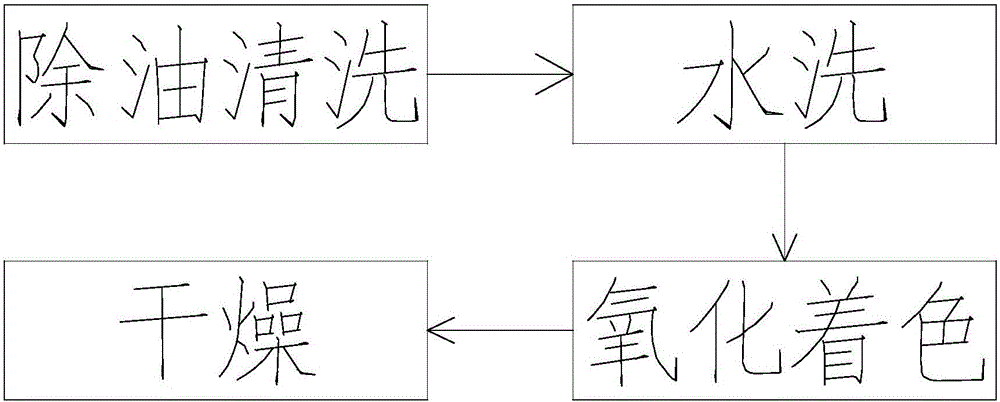

Method for growing blue ceramic film layer in situ on the surface of aluminum alloy and aluminum matrix composite material

InactiveCN102296339AElectrolyte stabilityHigh bonding strengthAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for in-situ growth of a blue ceramic film layer on the surface of an aluminum alloy and an aluminum-based composite material, relating to a method for preparing a blue ceramic film layer on an aluminum alloy and an aluminum-based composite material. The method solves the problem that the existing micro-arc oxidation method cannot prepare a blue ceramic film layer with uniform color on the surface of aluminum alloy and aluminum-based composite material, and the electrolyte used to prepare the blue ceramic film fails quickly and cannot be used repeatedly. 1. Prepare an electrolyte solution, which contains at least a main film-forming agent and a coloring additive, and the main film-forming agent is one of phosphoric acid, sulfuric acid and citric acid or a combination of several of them; 2. The cleaned aluminum base Fix the material in the electrolyte, turn on the power, and oxidize. The blue CoAl2O4 is evenly distributed in the blue ceramic film layer obtained on the surface of the aluminum substrate, and the blue color is uniform and beautiful. The bonding strength between the ceramic film layer and the aluminum substrate is high, and it has excellent wear resistance, corrosion resistance and heat resistance. The integrated preparation of decorative and structural coatings is realized.

Owner:HARBIN INST OF TECH

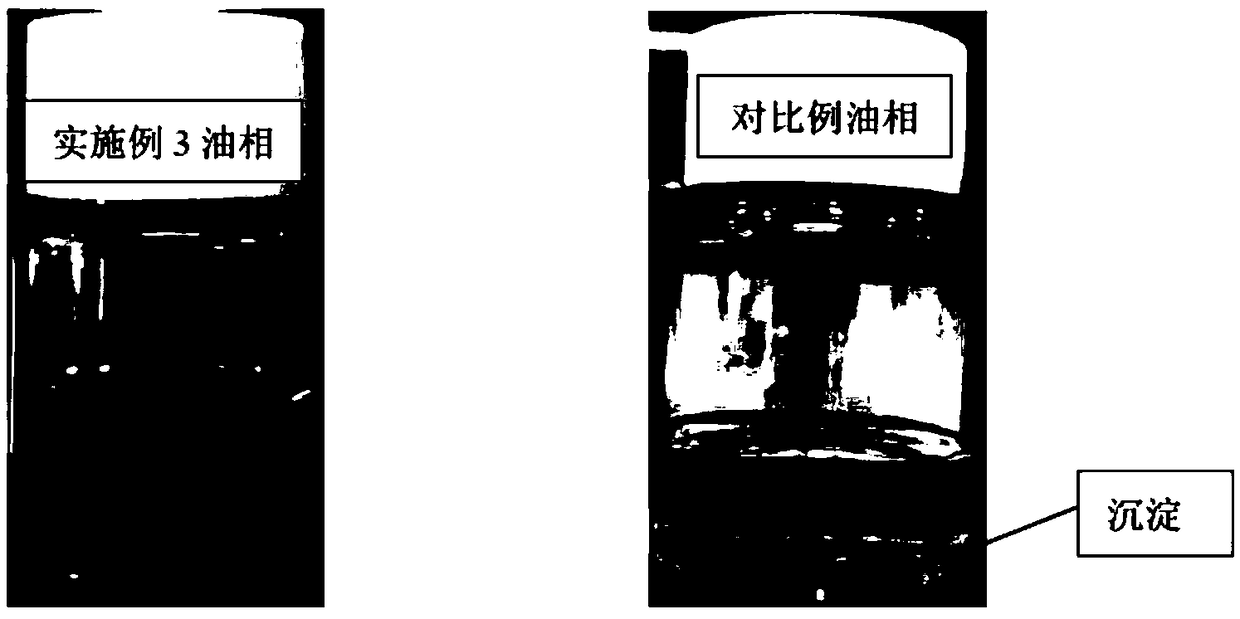

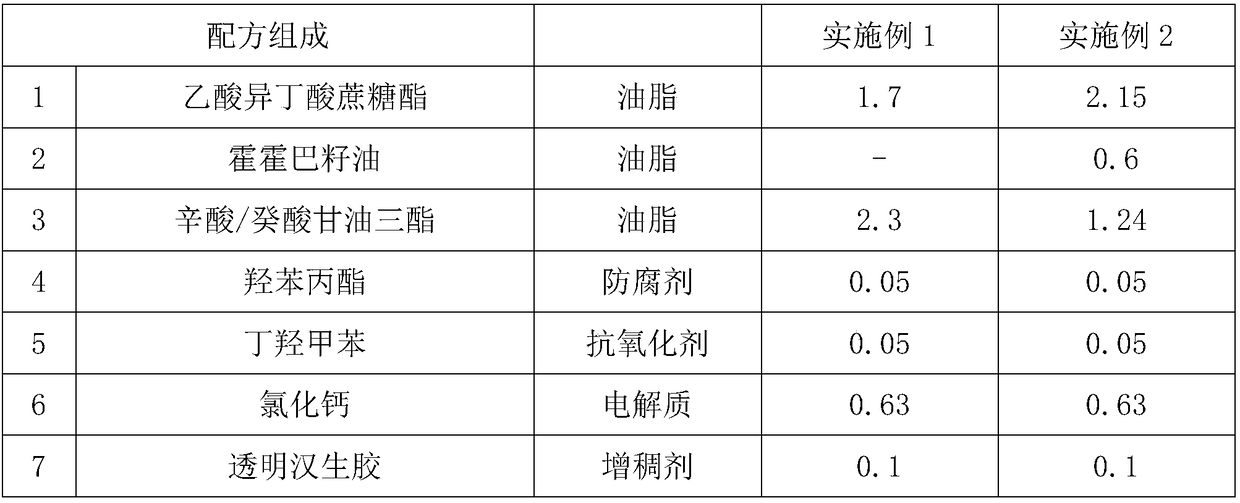

Suspended oil bead toning lotion containing sucrose acetate isobutyrate and preparation method thereof

ActiveCN108721132AIncrease choiceBig choiceCosmetic preparationsToilet preparationsOil and greaseMicroorganism

The invention discloses suspended oil bead toning lotion containing sucrose acetate isobutyrate and a preparation method thereof. The sucrose acetate isobutyrate is selected to be compounded with synthetic grease, vegetable grease and mineral oil; the selection range is wide; preservatives and oily color additives can be added; the oil phase selection space is large; the appearance colors are diversified; the efficacy selection range is wide; the microorganism risk can be relatively and effectively controlled; meanwhile, different kinds such as inorganic polymer types and natural rubber typesof water phase thickening agents can be selected; the selection of thickening system can be enlarged; meanwhile, different skin feeling can be given to the product.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

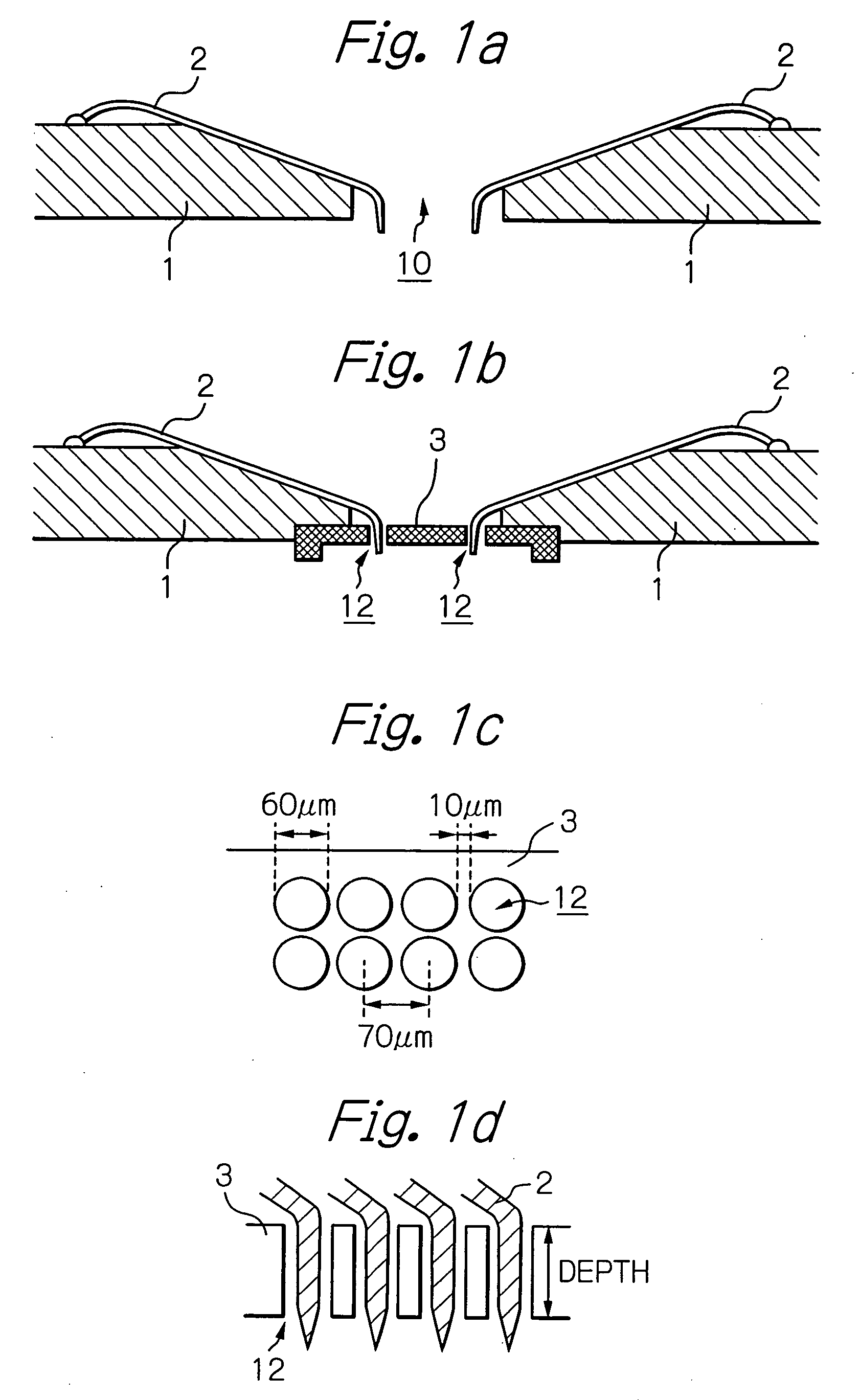

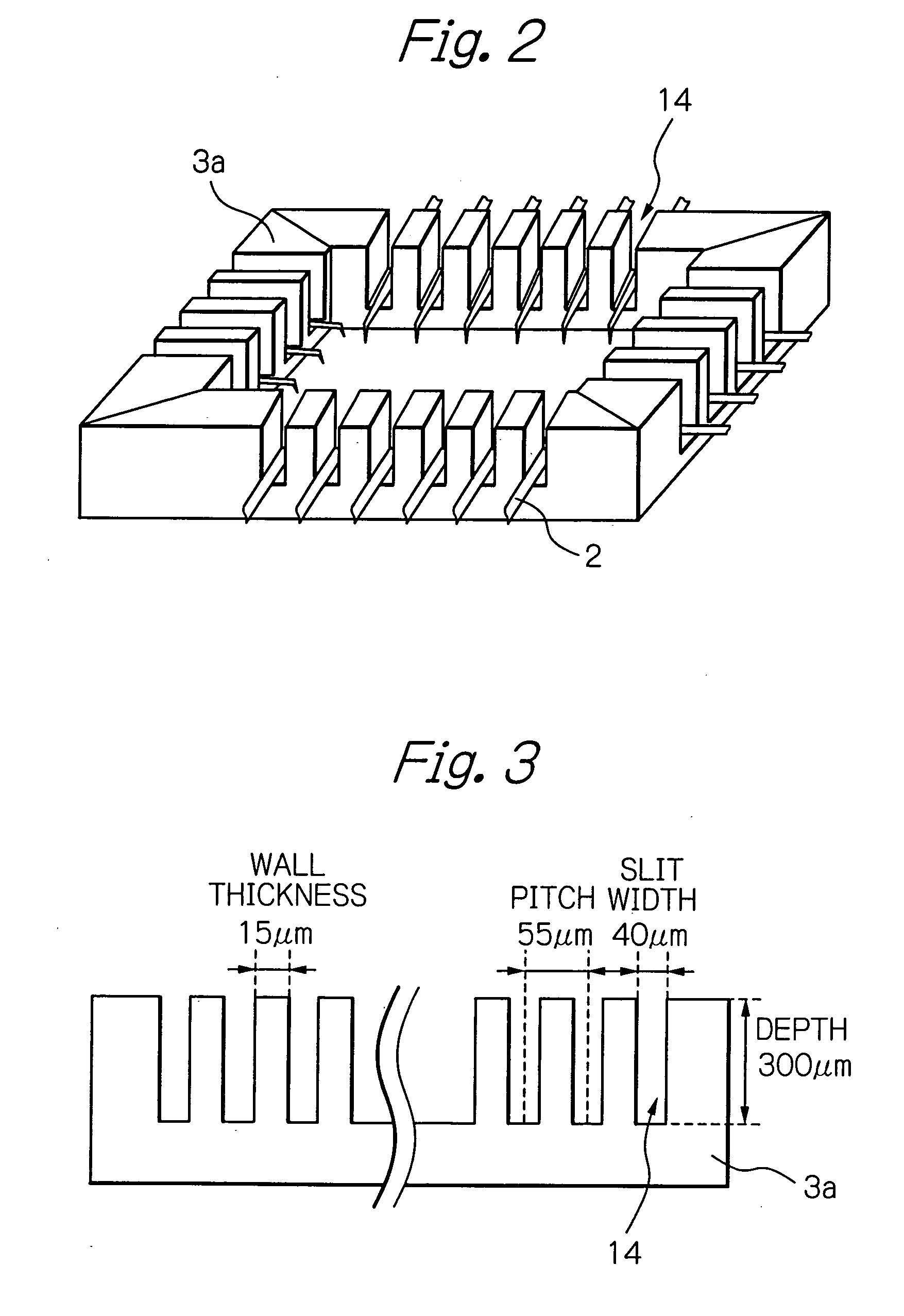

Electrolytic coloring liquid of aluminum profile and preparation method, application and application method thereof

InactiveCN104988556AUniform colorSmall color differenceSurface reaction electrolytic coatingColor additiveCatechol

The invention discloses electrolytic coloring liquid of an aluminum profile and a preparation method, application and application method thereof and belongs to the technical field of aluminum profile surface treatment. The electrolytic coloring liquid of the aluminum profile is composed of pure sulfuric acid, stannous mono-sulphate, nickel sulfate, coloring additives and water, the mass concentration of the pure sulfuric acid is 15-18 g / L, the mass concentration of the stannous mono-sulphate is 8-12 g / L, the mass concentration of the nickel sulfate is 15-30 g / L, and the mass concentration of the coloring additives is 20-30 g / L; the coloring additives are composed of D-tartaric acid, catechol, boric acid and sulfamic acid, and the coloring additives are composed of, by mass, 30%-40% of the D-tartaric acid, 30%-40% of the catechol, 20%-30% of the boric acid and 5%-10% of the sulfamic acid. By means of the electrolytic coloring liquid of the aluminum profile, a series of bright colors, namely light bronze to dark bronze to black, can be generated, the coloring of the aluminum profile is uniform, bright, little in chromatic aberration and good in reproducibility, a bath solution can keep clear and transparent for a long time, the dispersion capacity of the bath solution is great, the stability of tin ions is high, and the consumption is low.

Owner:马鞍山市华冶铝业有限责任公司

Red coloring agent for low-temperature colored glass, and preparation method and use method thereof

InactiveCN107651834AIncreased diffusion rateHigh stoichiometric ratioDecompositionReaction temperature

The invention belongs to the field of colored glass, and particularly relates to a red coloring agent for low-temperature colored glass, and a preparation method and a use method thereof. The red coloring agent is prepared from the following raw materials in parts by mass: 30 to 50 parts of a quartz powder, 10 to 30 parts of borax, 10 to 25 parts of sodium carbonate and 2 to 30 parts of a coloringadditive, by the steps of mixing the materials, founding at high temperature, performing water quenching and pulverizing, wherein the coloring additive is one of or a mixture of more than one of selenium powder, cuprous oxide and ferric oxide. A large amount of low-melting-point silicon oxide, borax and sodium carbonate are adopted in the coloring agent base material, so that the dispersing speedof the coloring agent in 1200-DEG C glass liquid is greatly enhanced and uniformly colored glass original liquid is formed. In the preparation process of the coloring agent, the composite powder is directly added into a high-temperature frit furnace to perform founding and the reaction temperature is increased from a room temperature to 1350 to 1500 DEG C instantaneously, so that decomposition, volatilization and composition segregation of the materials in the slow heating process are avoided, and a coloring agent product with high stoichiometric ratio and high high-temperature dispersion speed is obtained.

Owner:JIANGSU BAIFU TECH CO LTD

Fertilizer coloring agent and method for preparing same

InactiveCN101117448AGood lookingIncrease productionNatural dyesFertilizer mixturesPesticide residueDissolution

The invention relates to a fertilizer stain, which comprises colorant and toner, wherein the colorant is colored humic acids or colored humic acids salt substance, while the toner is colored foodstuff color additive and lignin as well as one sort or the mixture of a plurality of sorts of the salts; according to part by weight, 5 to 50 parts by weight account of the colorant, while 0 to 20 parts by weight of the toner. The method of preparation of the invention is as follows: firstly, the colorant and the toner are weighed according to proportion, or 0 to 20 parts by weight of dispersing agent and 0 to 20 parts by weight of solubilizer are weighed additionally; and then, method 1 including crushing, dissolution, toning and grinding or method 2 including dissolution, toning and grinding is adopted during production to obtain the natural fertilizer stain. The invention has the advantages of strong dyeing capacity, improving soil condition, reducing pesticide residue, protecting ecology environment, low cost, low dosage and non-pollution, etc.

Owner:HUBEI FORBON TECH

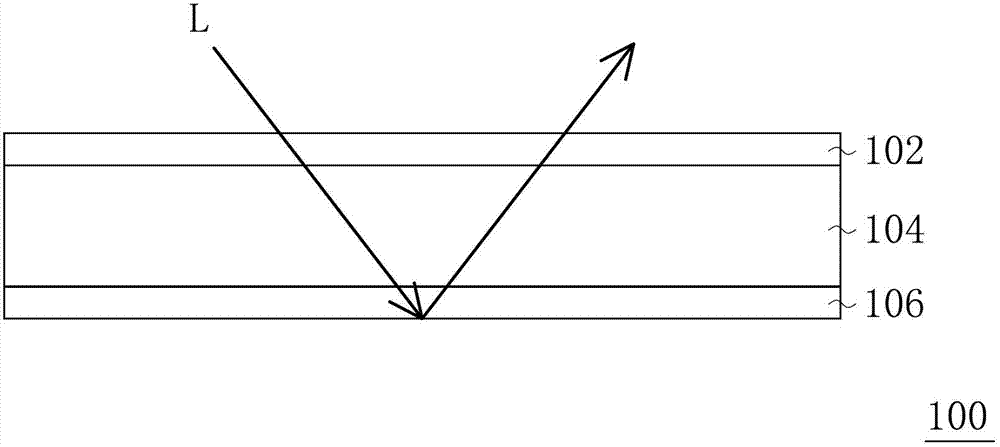

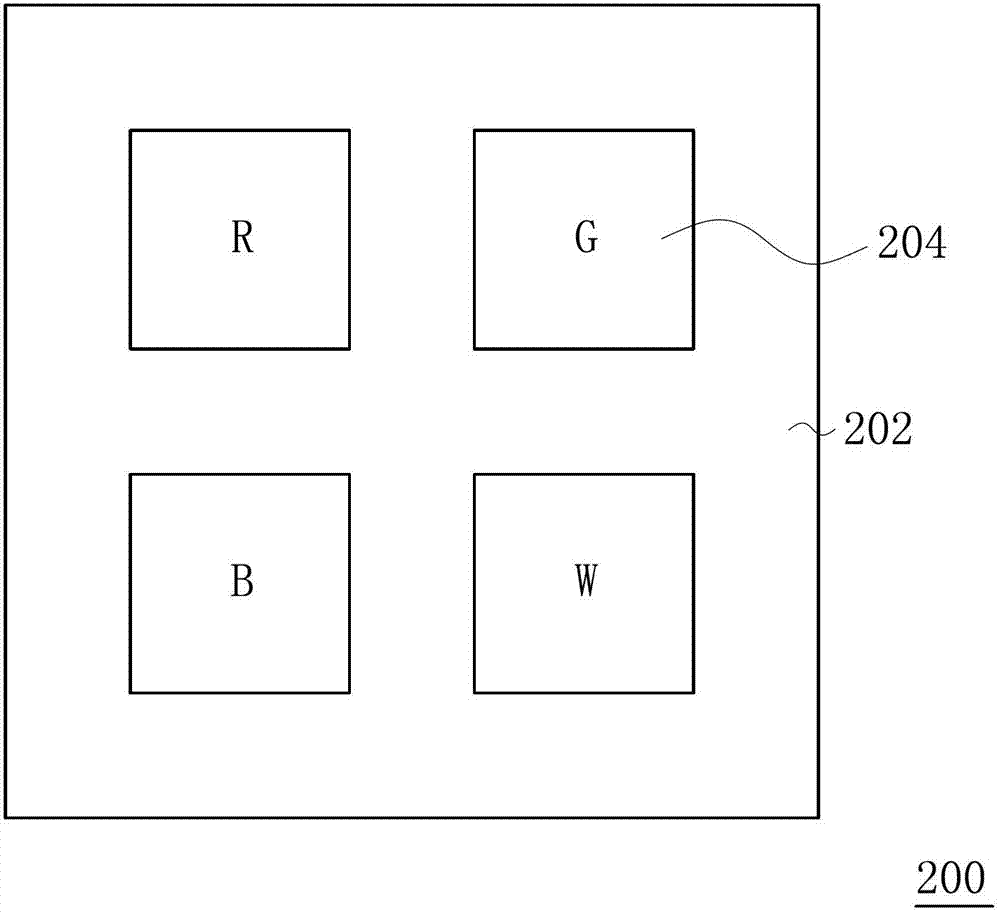

Color filter and color display device using same

InactiveCN102854555AHigh strengthIncrease display brightnessOptical filtersNon-linear opticsComputer graphics (images)Display device

A color filter includes a substrate and a plurality of pixel units. The substrate defines a plurality of pixel areas. Each pixel area has a plurality of first sub-pixel areas, and each first sub-pixel area has a first area and a second area. The pixel units are formed on the substrate corresponding to the pixel areas. Each pixel unit is disposed in a corresponding pixel area and includes a plurality of color subtractive filter films and a plurality of color additive filter films. The color subtractive filter films are disposed in the first areas of the first sub-pixel areas of the corresponding pixel area, and the color additive filter films are disposed in the second areas of the first sub-pixel areas of the corresponding pixel area. A color display device with the color filter is also disclosed. The color filter of the invention enhances the display brightness of the color display device and the color saturation during the display.

Owner:E INK HLDG INC

Color additive of cement concrete and color steel fibre concrete with said additive

The color additive consists of coloring agent, dispersant, composite early strength effective water reducing agent and swelling agent. Specifically, it consists of iron black or carbon black as coloring agent, calgon or STPP as dispersant, water reducing agent and potassium aluminum sulfate as swelling agent. The color additive can change the color of cement concrete and improve the performanceof cement concrete. Specially, when the cement concrete with the color additive is used in the extension joint of asphalt bridge surface of expressway, the less color difference can raise the safetyof running vehicles.

Owner:王文炳 +3

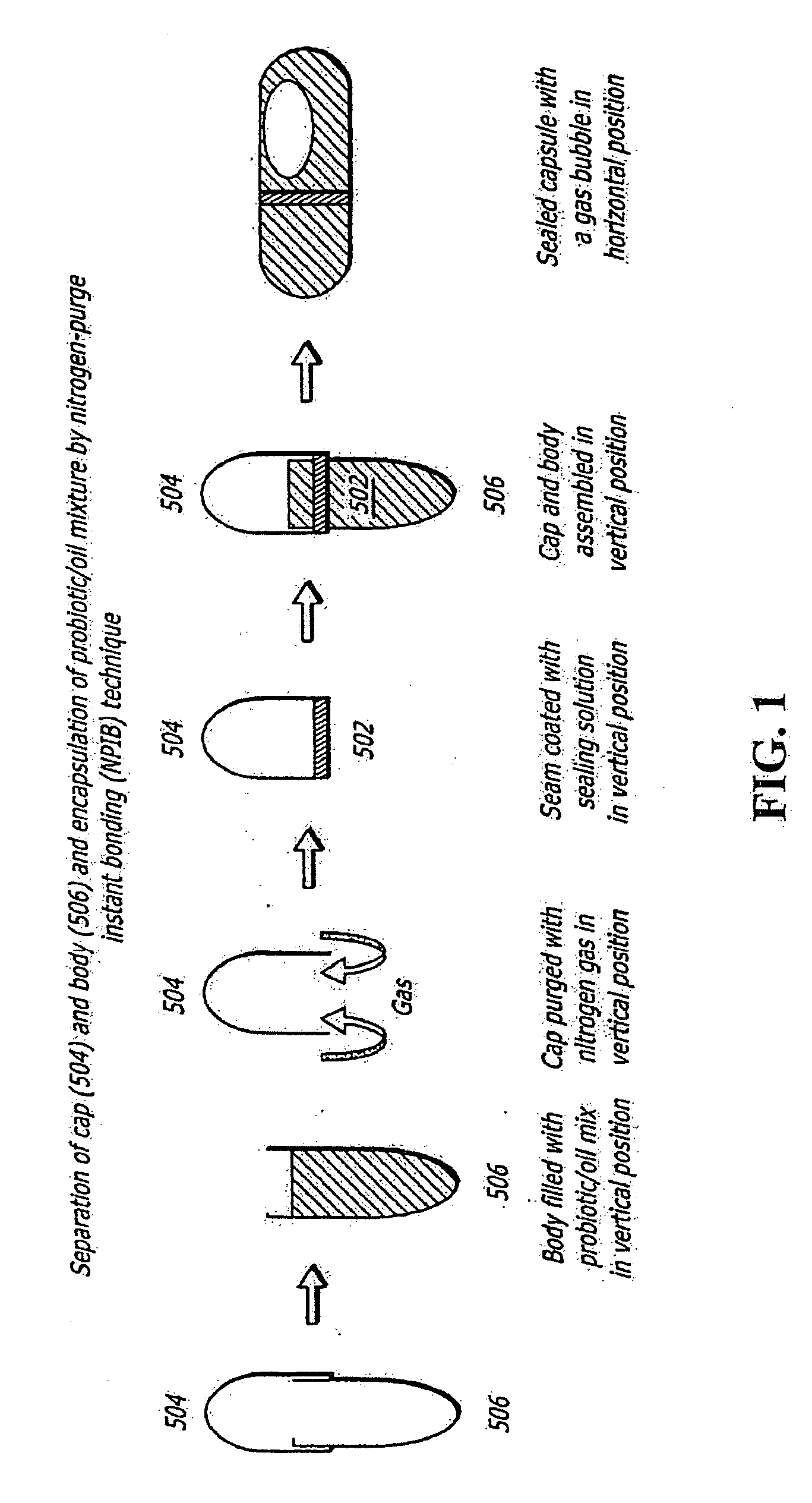

Methods and apparatus for sealing capsules

Methods and apparatus for providing a leak-proof seal for two-piece capsules containing oil-based liquids or other compositions by a two-stage process. The capsule cap and capsule body are combined by a nitrogen purge instant bonding (NPIB) system. An overlay medium is applied to selected portions of the capsule, including near the seam formed by the interconnection of the capsule cap and capsule body to provide a substantially leak-proof seal. The overlay medium is made from materials that make up the capsule cap and capsule body, including gelatin, starch, cellulose or polysaccharides, among others, which are dispersed in a hydro-alcoholic, aqueous or organic solution. The overlay medium includes additives to impart desired qualities to the capsule and include taste-enhancers, taste-maskers, odor-enhancers and odor-maskers. The additives may include color additives, aroma additives and taste additives.

Owner:VITA HERB NUTRICEUTICALS

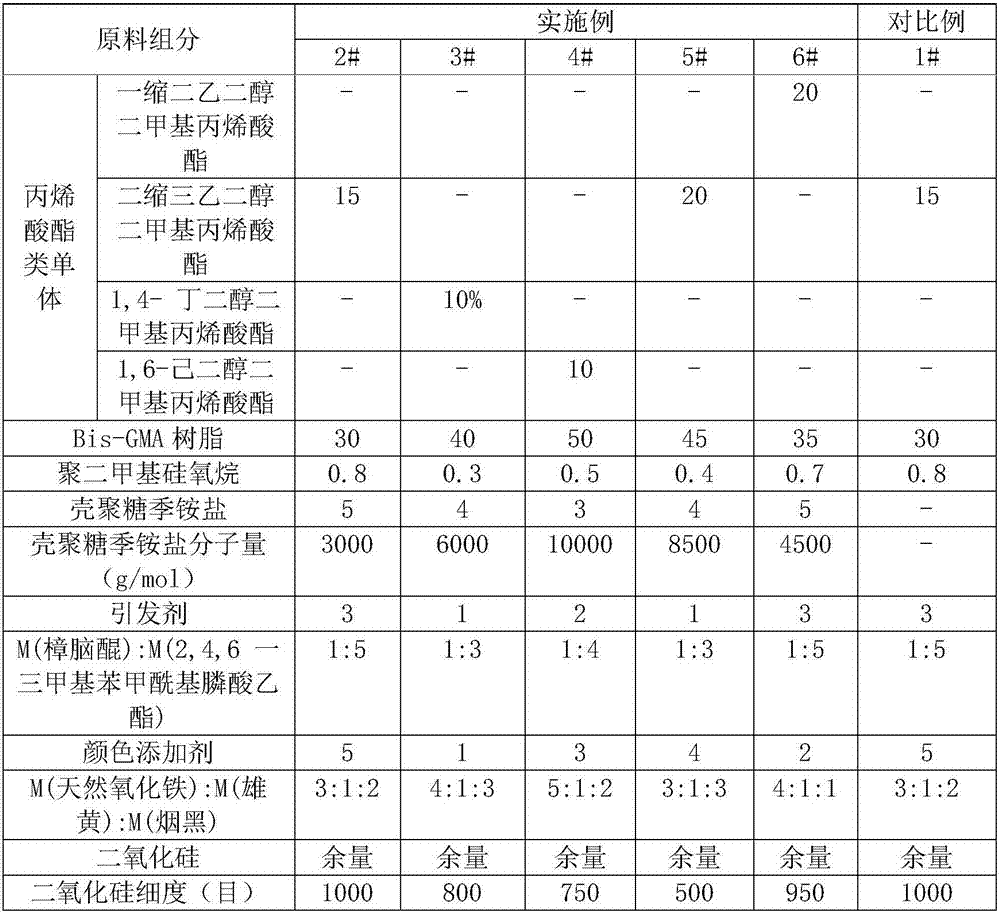

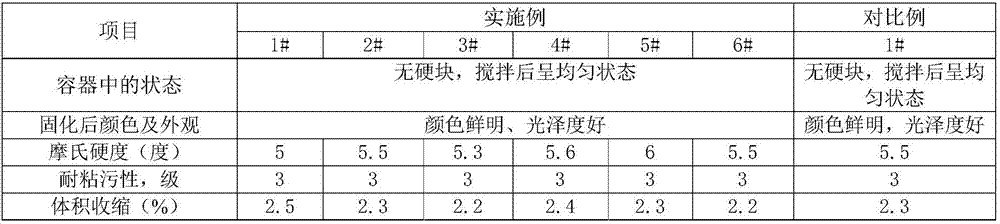

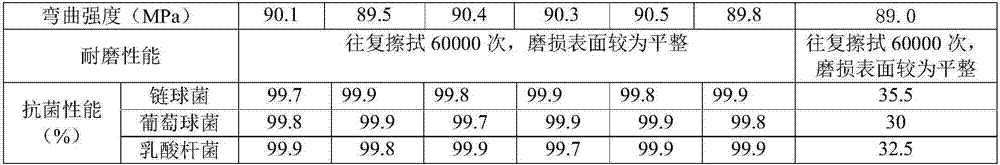

3D printing antibacterial repair dental medical material and preparation method thereof

InactiveCN107320342ALow costOvercome efficiencyImpression capsAdditive manufacturing apparatusBiocompatibility TestingEngineering

The present invention relates to the technical field of 3D printing molding materials, particularly to a 3D printing antibacterial repair dental medical material and a preparation method thereof, wherein the 3D printing antibacterial repair dental medical material comprises, by weight, 10-20% of an acrylic monomer, 30-50% of a Bis-GMA resin, 0.3-0.8% of a defoaming agent, 3-5% of an antibacterial agent, 1-3% of an initiator, 1-5% of a color additive, and the balance of silica. According to the present invention, the tooth part printed from the 3D printing antibacterial repair dental medical material has advantages of low cost, high printing precision, good wear resistance and long service life; by selecting the chitosan quaternary ammonium salt, the 3D printing antibacterial repair dental medical material has good biocompatibility and good antibacterial effect, and the disadvantages of sterilization ability reducing, easy adsorption loss, easy drug-resistance generation and the like of the high traditional quaternary ammonium salt having the high mineralization degree can be overcome; and the preparation method has advantages of simple and easy-performing molding method, convenient operation, and wide material source.

Owner:苏州汉力新材料有限公司

Machinable ceramic

A high-strength machinable ceramic capable of high-precision fine machining has a coefficient of thermal expansion close to that of silicon and preferably a uniform blackish color which facilitates image processing of machined parts. The ceramic comprises a main constituent and a sintering aid. The main constituent comprises 30–59.95 mass % of boron nitride, 40–69.95 mass % of zirconia, optionally up to 20 mass % of silicon nitride and 0.05–2.5 mass % (calculated as an element) of at least one coloring additive, which is selected from C, Si, elements of Groups IIIA–IVB in the fourth period, elements of Groups IVA–VB in the fifth period, elements of Groups IVA–VIB in the sixth period of the long form periodic table, and compounds of these elements.

Owner:FERROTEC CERAMICS CORP

Preparation method for black micro arc oxidation film layers of surfaces of pure aluminum and aluminum alloys

InactiveCN106637341ATo achieve a variety of colorsMeet decorative needsAnodisationSodium molybdatePlasma electrolytic oxidation

The invention discloses a preparation method for micro arc oxidation black ceramic films of pure aluminum and aluminum alloys and belongs to the technical field of surface treatment of the pure aluminum and the aluminum alloys. Sodium tungstate, sodium molybdate and ammonium metavanadate serve as color additives. In the alkaline electrolyte taking phosphate as a main salt, coloring is conducted while the pure aluminum or the aluminum alloys are subjected to micro arc oxidation by setting up electrical parameters adaptable to the electrolyte. The black ceramic films prepared through the preparation method for the micro arc oxidation black ceramic films have the characteristics that hardness is high, abrasion resistance and corrosion resistance are very good, the color is even and blackness is high, and the application prospects are wide.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Colored esmolol concentrate

A concentrated esmolol formulation is provided that is distinguishable from a diluted form of the concentrated esmolol formulation. In one embodiment, the concentrated esmolol formulation allows identification of the concentrate even after transfer of the concentrate out of a labeled primary container. The concentrated esmolol formulation can include from about 25 to about 1000 mg / ml of esmolol hydrochloride, a buffering agent and a color additive. Any number of color additives may be included such as indocyanine green, phenopheylene, hemoglobin, cyanocobalamine, patent blue, and indigo carmine vitamin B2 and naturally occurring vitamins and minerals. The amount included in the formulation is highly dependent on the color additive selected. The color additive should be included in an amount sufficient to easily distinguish the concentrated esmolol formulation from at least about a 1:4 dilution of the concentrate. Also, a medical product is provided that includes a colored concentrated esmolol housed in a container, and a package housing the container and instructions. The instructions can notify that a color additive has been added to the concentrated esmolol formulation to aid in differentiating it. Additionally a method of allowing easy identification of a concentrated esmolol formulation is provided. The method includes providing a colored concentrated esmolol formulation that has from about 25 to about 1000 mg / ml of esmolol and a color additive.

Owner:BAXTER INT INC +1

Process for preparing reduced fat frozen potato strips

ActiveUS7560128B2Beer brewingFruits/vegetable preservation by coatingAlternative methodsAqueous solution

A method of preparing potato strips includes cutting potatoes into strips, blanching the strips, dipping the strips in an aqueous solution containing salt, color additives, SAPP or other additives, and drying the strips. The dry strips are parfried, partially deoiled, washed in water, cooled, exposed to superheated steam, dried in an impingement oven, cooled and frozen. The strips, before parfrying, may be coated with a batter. The frozen strips may be reconstituted by heating in an oven. In alternative methods, frozen strips are prepared with no or virtually no fat content.

Owner:LAMB WESTON INC

Method for preventing discoloration in vegetable processing

InactiveCN102090579APrevent browningPrevents changes in chlorophyllFood preparationBiotechnologyVegetable processing

The invention discloses a method for preventing discoloration in vegetable processing, which relates to the technical field of vegetable discoloration prevention. The method comprises the prevention of browning and the prevention of change of chlorophylls, wherein the prevention of the browning further comprises the prevention of enzyme browning and the prevention of nonenzymic browning. The method has the advantage of effectively preventing the browning in the vegetable processing and the change of the chlorophylls in a plurality of ways under the condition of no color additive, and ensures good effects.

Owner:李文忠

Natural stone oven for roasting nuts and methods associated therewith

InactiveUS20160338400A1Control tackinessLow viscosityDomestic stoves or rangesStoves/ranges shelves or racksFood flavorHealth benefits

It has been discovered that a natural stone oven possesses certain advantages in its use in producing a natural nut foodstuff having improved taste and health benefits. Natural stone has a unique ability to heat and flavor food, particularly nuts, when used as an oven at the appropriate temperature since stone has a natural flavoring effect. The use of the stone oven additionally facilitates the production of nut foodstuff without the necessity of using oils, fats, non-natural flavor or color additives or other non-natural additives which are associated with roasting nuts by other mass producers of the same.

Owner:YNUTS LLC

Process for isolation, purification, and recrystallization of lutein from saponified marigold oleoresin and uses thereof

A method of isolating, purifying and recrystallizing substantially pure lutein, preferably from saponified marigold oleoresin in its pure free form, apart from chemical impurities and other carotenoids. Lutein may be used as an analytical standard or in cancer prevention trials and as a safe and effective color additive for human food.

Owner:CATHOLIC UNIV OF AMERICA

Preparation method of instant burdock snack food

InactiveCN105494862AKeep the natural fragranceRetain propertiesFood ingredient as colourConfectioneryReady to eatPreservative

The invention discloses a preparation method of instant burdock snack food. According to the preparation method, fresh harvested two-year yellow burdock is selected and subjected to peeling, slicing, color protecting, brittleness-keeping, sugaring, drying and coating with sugar, and an instant burdock product is obtained. The prepared burdock has flexibility and chewiness produced through drying and sugaring, the product flavor is pure and fresh, earthy smell and obvious traditional Chinese medicine smell of the burdock are removed, natural fragrance and specific flavor of the burdock are reserved, the sweetness is appropriate, sweet greasy feeling is avoided, the product is portable and is ready-to-eat, coloring additives and antiseptic substances are not added in a production process, the product is safe and sanitary, and the shelf life of the product is prolonged through drying and vacuum packaging.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com