Suspended oil bead toning lotion containing sucrose acetate isobutyrate and preparation method thereof

A technology of isobutyric acid acetate and sucrose ester, which is applied in the field of cosmetics, can solve the problems that the antiseptic ability of the system cannot be further enhanced, oil-soluble preservatives cannot be added, toxicity or irritation increase, etc., and the risk of microorganisms can be controlled, and the appearance and color are diverse. The effect of chemicalization and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6-7

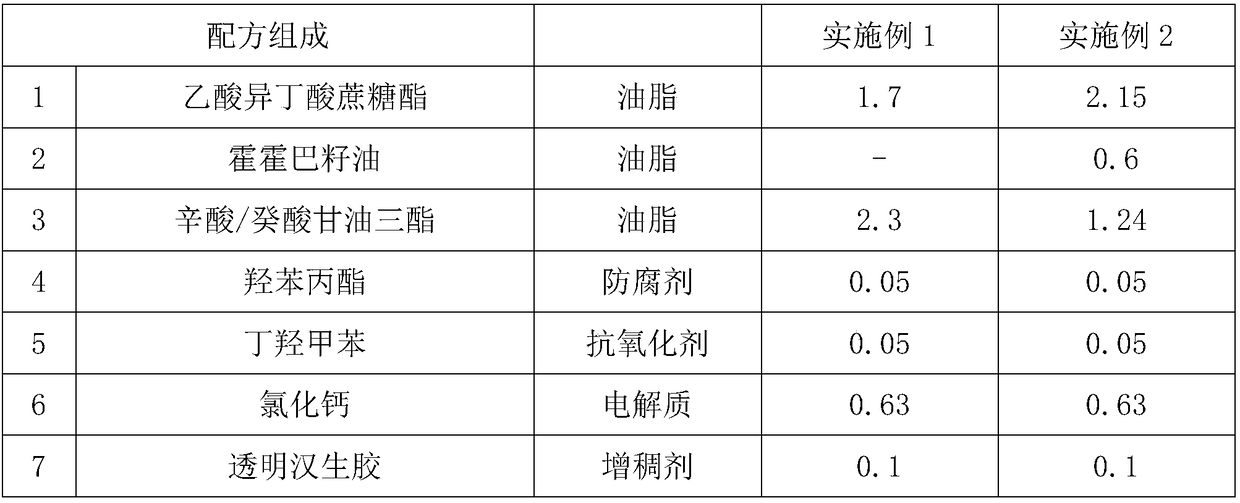

[0055]

[0056]

[0057] Preparation:

[0058] (1) Water phase: Add dehydroxanthan gum and gellan gum to glycerin and premix evenly to form a premixed phase; add water to the main kettle, add the premixed phase, methylparaben, and calcium chloride to room temperature water and stir and heat to 80 -85°C, full swelling, cooling to 60-65°C, adding electrolyte, cooling to 40-45°C, adding bis(hydroxymethyl) imidazolidinyl urea and ethanol, and detecting the density of the water phase;

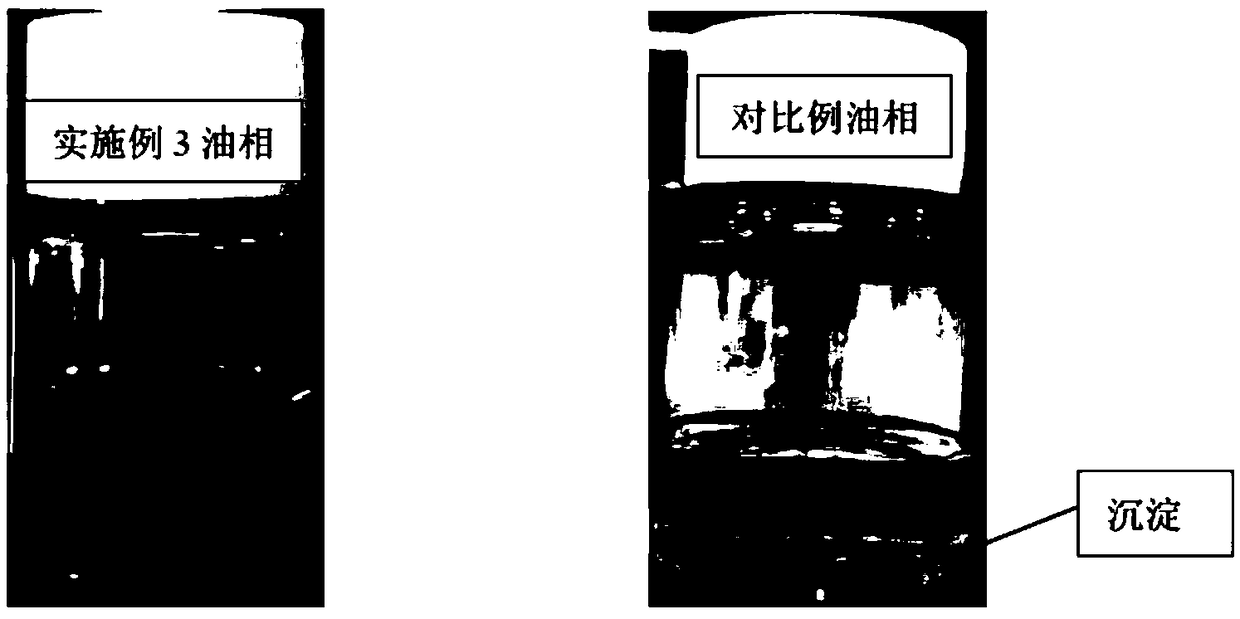

[0059] (2) Oil phase: According to the density of the water phase, calculate the amount of each liquid oil in the oil phase, and control ρ 油相 = ρ 水相 ±0.01, then add propylparaben and butylated hydroxytoluene, heat above 75°C until dissolved and transparent, cool down to 40-45°C, add color additives, and stir evenly;

[0060] (3) Finished product: Add the oil phase to the water phase of the main kettle under stirring until the oil droplets are suspended in the water phase, and the particle si...

Embodiment 8-12

[0062]

[0063]

[0064] Preparation:

[0065] Step (1) Water phase: add the thickener to the humectant and pre-mix evenly to form a pre-mixed phase, add water to the main kettle, add the pre-mixed phase, and add the water-based preservative to water at room temperature, stir and heat to 80-85°C, swell Fully, cool down to 60-65°C, add electrolyte, cool down to 40-45°C, add skin conditioner, and measure the density of the water phase;

[0066] Step (2) oil phase: according to the water phase density, calculate the consumption of sucrose acetate isobutyrate and other liquid oils in the oil phase, adjust ρ 油相 = ρ 水相 ±0.01, then add oil-phase preservatives and antioxidants, heat above 75°C until dissolved and transparent, cool down to 40°C±5°C, add color additives, and stir evenly;

[0067] Step (3) finished product: the water phase of the main kettle is stirred, and the oil phase is added until the oil droplets are suspended in the water phase.

[0068] Table 5 embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com