Patents

Literature

1478 results about "Emulsified oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsified Oils: Emulsified oils are small oil droplets in the wastewater ranging in size from 10 to 150 microns. Emulsified oils will not rise to the surface by gravity alone. Emulsified oils are either Mechanically emulsified or Chemically emulsified.

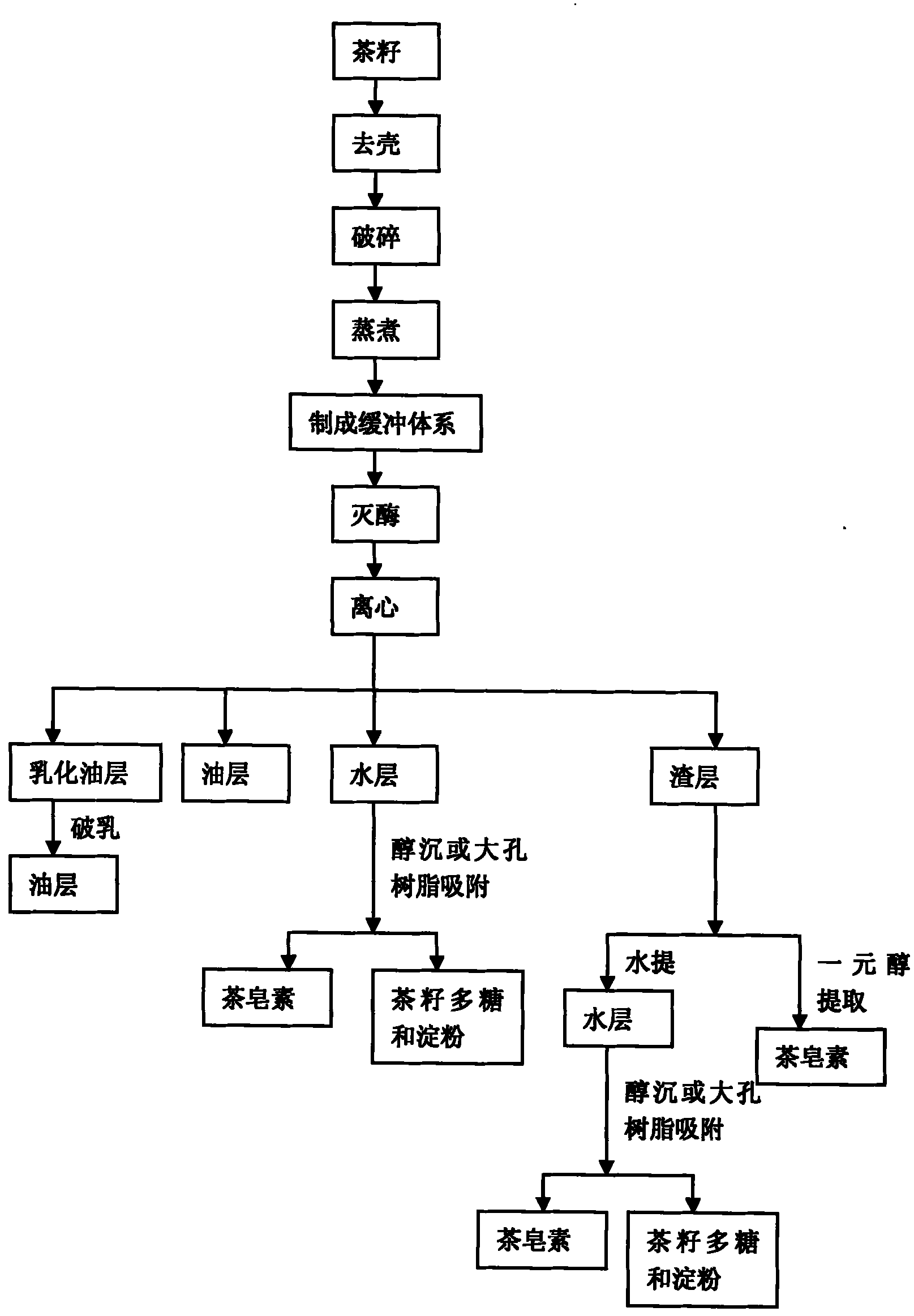

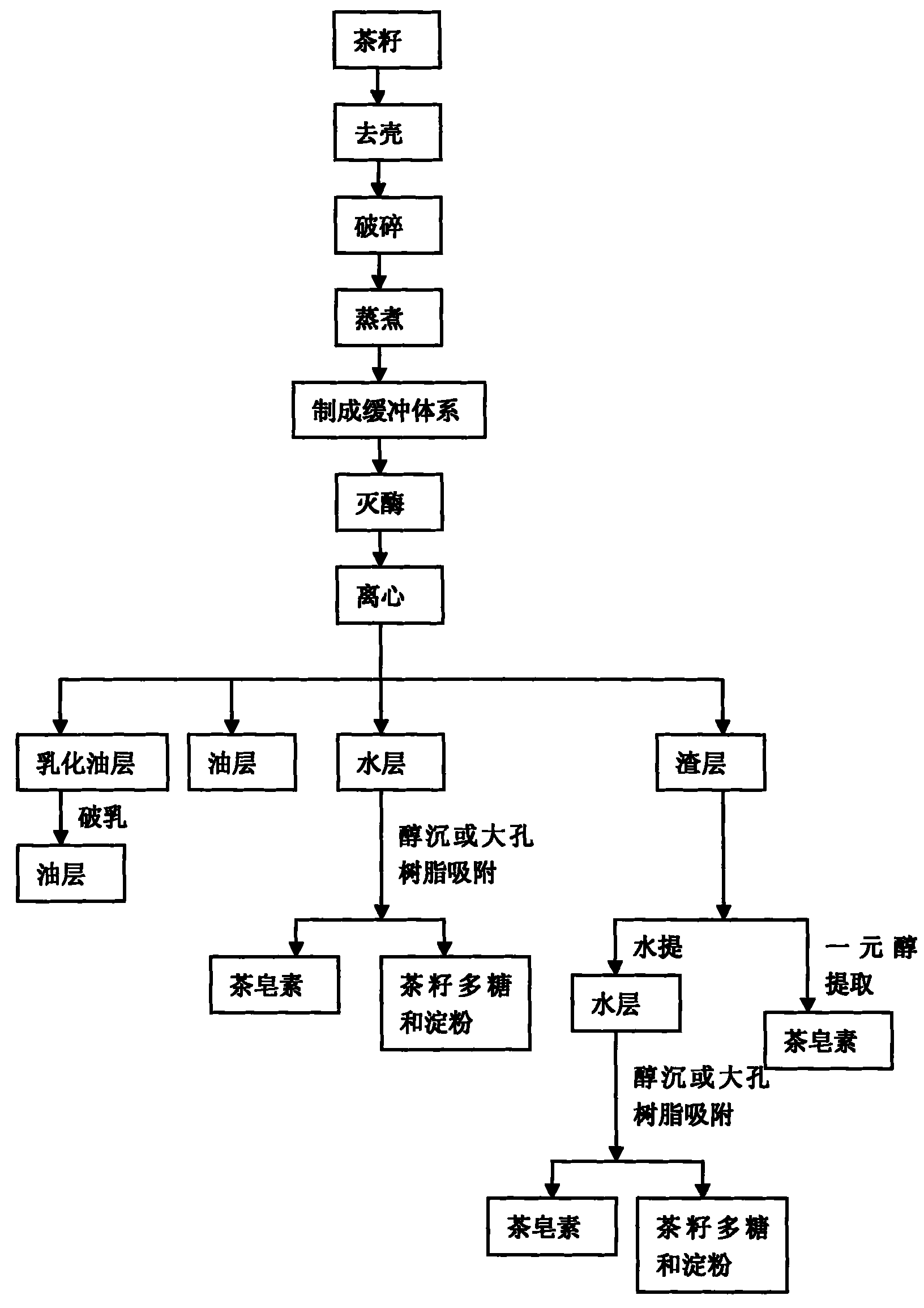

Comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds

InactiveCN101942355AHigh purityRealize comprehensive utilization and developmentSugar derivativesSteroidsOil processingSlag

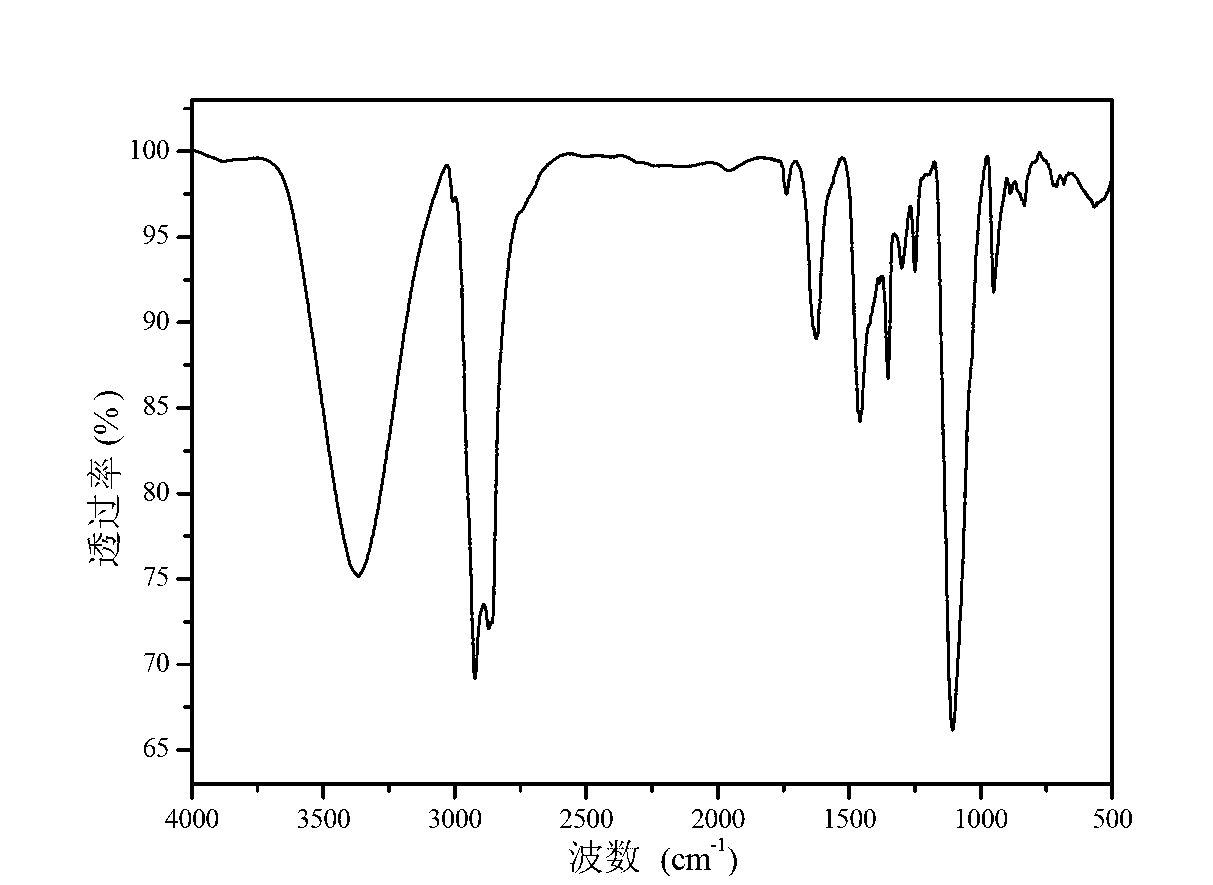

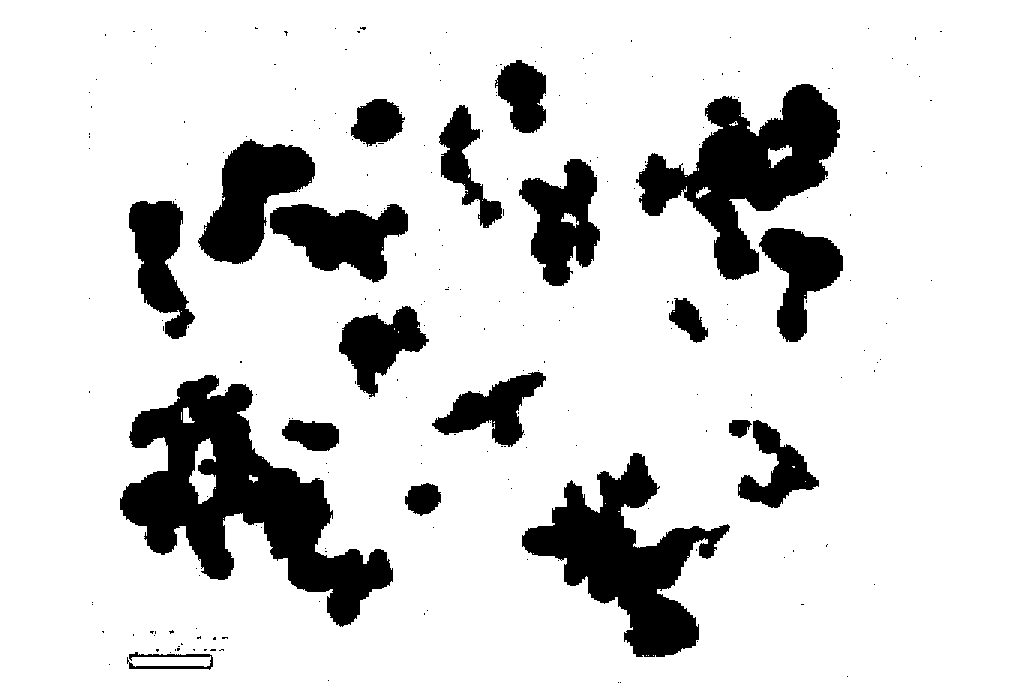

The invention discloses a comprehensive extraction method for extracting tea seed oil, tea saponin and tea seed polysaccharide from tea seeds or camellia seeds, belonging to the process fields of grain and oil processing and byproduct extraction. The method comprises the following steps of: with shelled tea seeds as a raw material, firstly, cooking to produce oil; then, adding an exogenous enzyme to obtain a boiled oil layer of a first level an emulsified oil layer, a water layer and a slag layer through zymolysis, blanching and still standing; demulsifying the emulsified oil layer to take boiled oil of a second level; mixing the oil layers of the two levels; centrifugalizing to obtain the tea seed oil; depositing the water layer in alcohol to separate the tea saponin and the tea seed polysaccharide; leaching the slag layer with water or monohydric alcohol to further separate the tea saponin and the tea seed polysaccharide; and purifying a clear solution which is leached with the water or the alcohol with a macroporous absorption resin chromatography column, eluting a resin adsorbate with a base and then an ethanol and collecting an ethanol eluant to obtain high-purity tea saponin. The tea seed oil, the tea saponin and the tea seed polysaccharide are synchronously prepared, thus the invention realizes that a tea seed or camellia seed resource is comprehensively extracted and utilized and has the advantages of simple process, less needed equipment and low cost.

Owner:SHANGHAI NORMAL UNIVERSITY

Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

The invention relates to a cold-rolled sheet rolling emulsified oil containing a modified nano copper and preparation method thereof, which belong to the field of organic chemistry. The emulsified oil comprises the following components, in percentage by weight: 54-80% of a base oil, 15-32% of an oiliness agent, 0.1-1% of a modified nano copper particle, 2-4% of an extreme pressure agent, 0.5-2% of an anti-rusting agent, 2-6% of an emulsifier, 0.4-1% of an anti-oxidant, 0.03-0.1% of an anti-foaming agent, and 0.2-0.6% of an anti-mildew agent. The cold-rolled sheet rolling emulsified oil containing the modified nano copper is diluted with water into a 2-6 wt% emulsion, and the emulsion is directly used in the cold rolling process of the strip steel and has very good lubrication, cleaning property of the rolling mill and annealing cleaning property, after annealing, the steel plate not subjected to degreasing has a clean surface without pollutants, so as to satisfy rolling production requirement under high pressure at high speed.

Owner:NORTHEASTERN UNIV

Method for producing composite silica particles

InactiveUS20120264599A1Improve utilization efficiencyLiquid surface applicatorsSilicaSilica particleSolvent

Disclosed is a method for producing composite silica particles and hollow silica particles that can improve the utilization efficiency of a hydrophobic organic substance. It is a method for producing composite silica particles each of which is provided with an outer shell part having a mesoporous structure formed from a silica-containing component and which includes a hydrophobic organic substance in the interior of the aforementioned outer shell part, and involves adding an aqueous solvent to the hydrophobic organic substance and emulsifying, and forming the outer shell part having the mesoporous structure formed from the silica-containing component on the surface of an emulsified oil droplet of the aforementioned hydrophobic organic substance.

Owner:KAO CORP

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:PNC BANK NAT ASSOC

Botany resource disinfectants for agricultural use an dits prepn. method

An efficient broad-spectrum low-poison vegetative agricultural bactericide in the form of emulsified oil, microemulsion, aquatic emulsion, or soluble liquid is prepared from asarum herb, turmeric and flavescent sophora root. Its preparing process is also disclosed.

Owner:长白山皇封参业股份有限公司

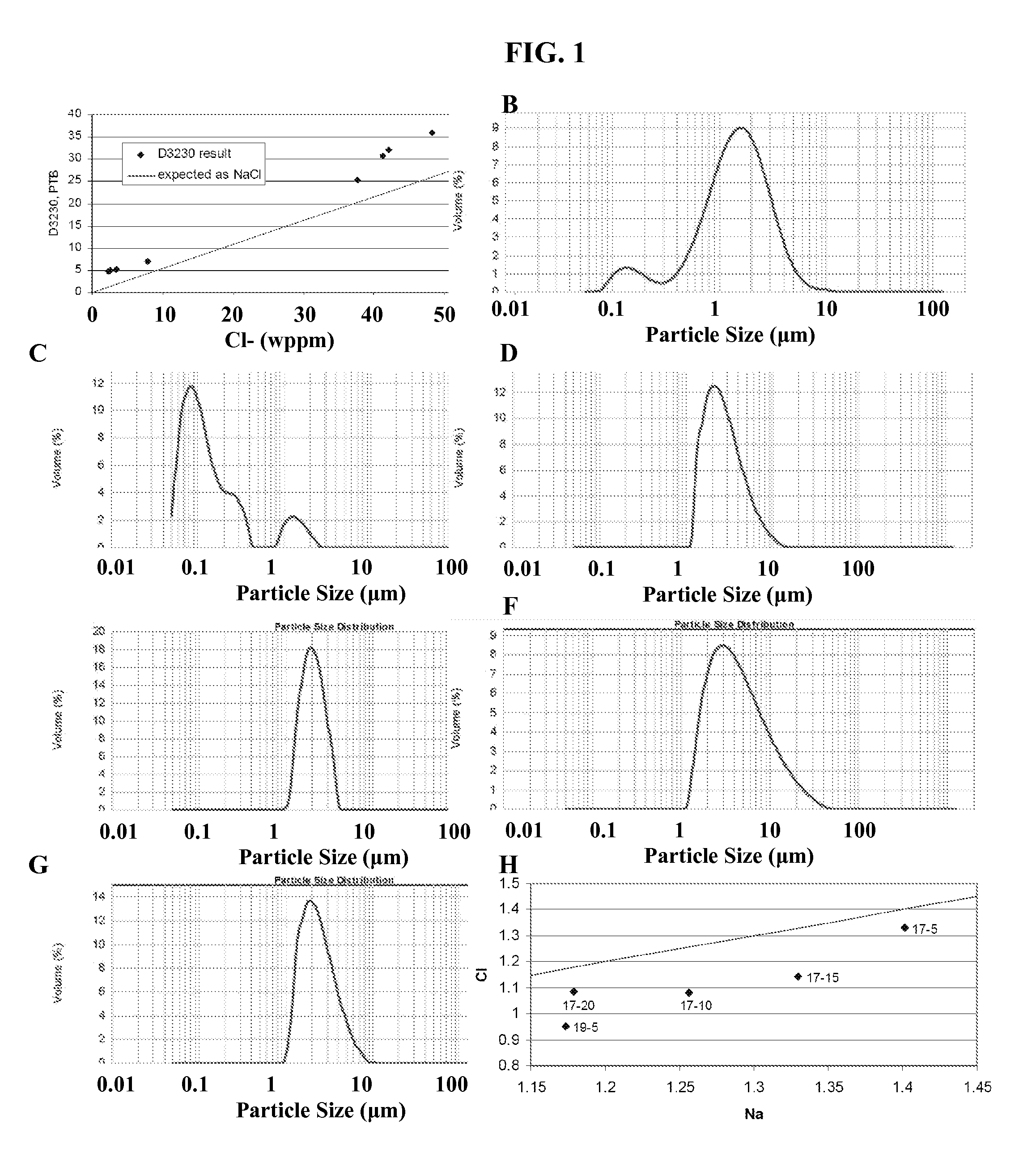

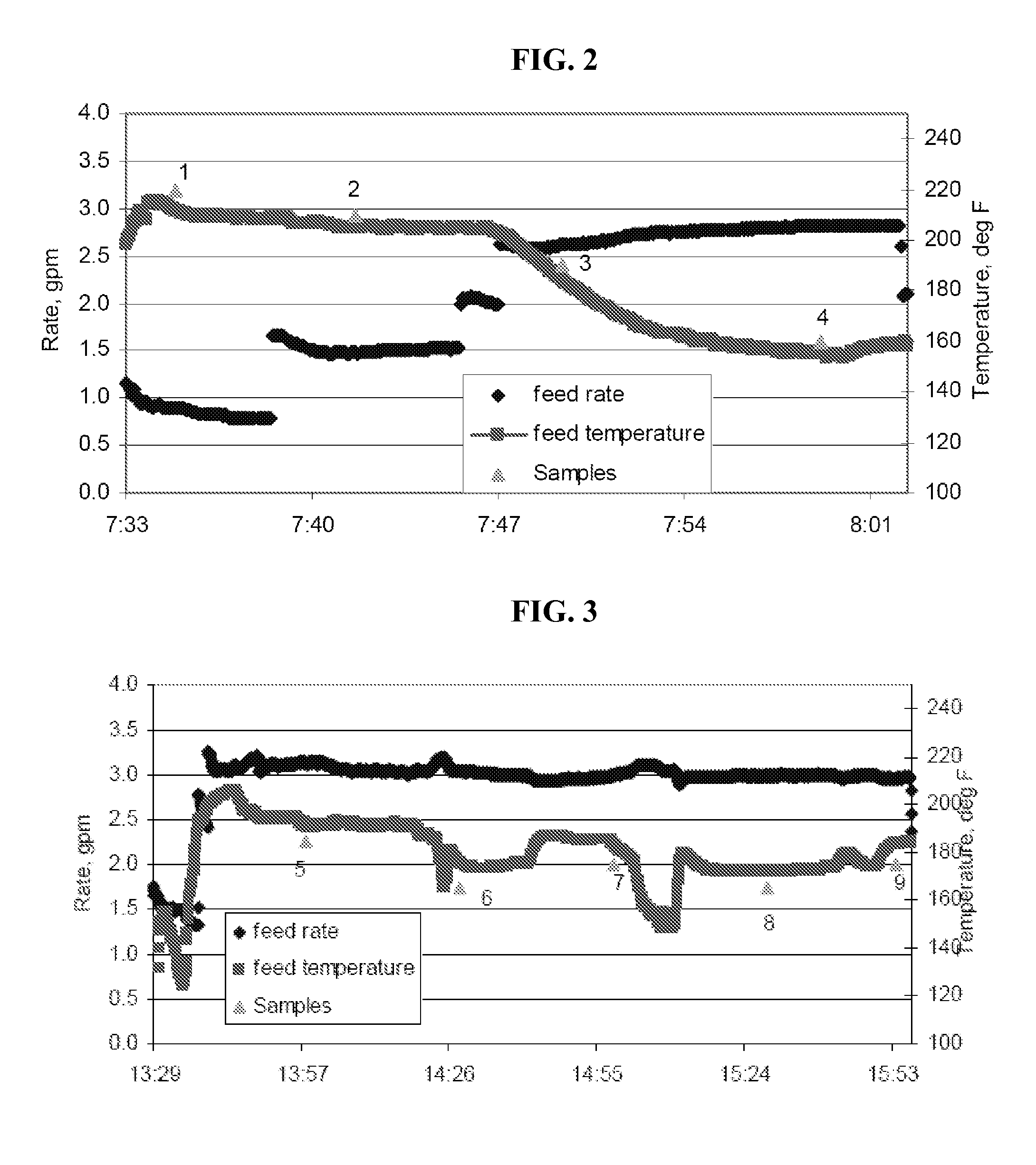

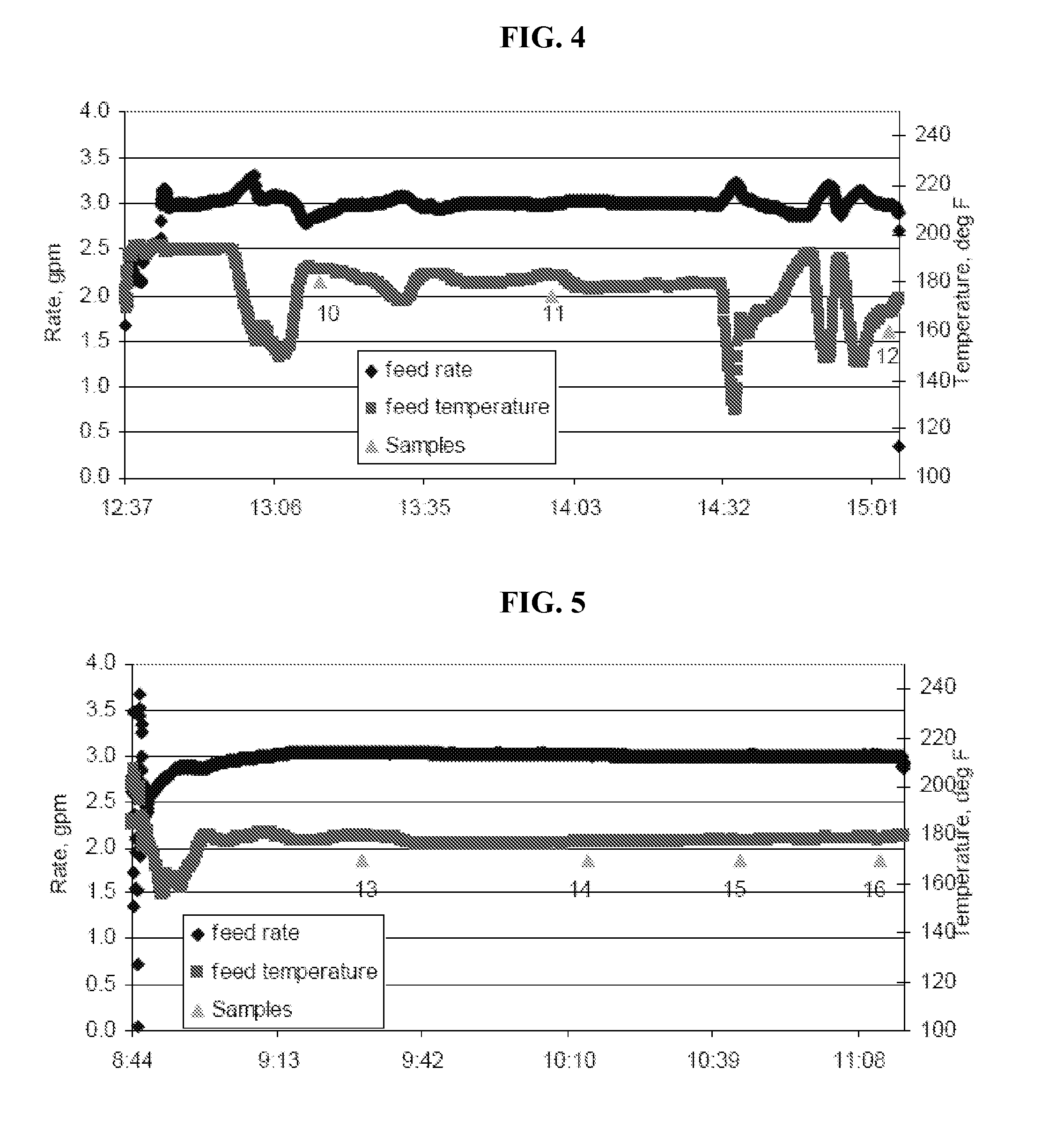

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

Caprotrahol and Bacillus subtilis compound agricultural chemicals

A compound agricultural chemical in the form of wettable powder, solution, microemulsion, suspension, water disperser, particle, emulsified oil, or aquatic emulsion for preventing and eliminating diseases and pests of rice, cotton, vegetables, fruit tree, etc, especially the green smut and sheath and culm blight of rice, is proportionally prepared from Bacillus subtitis, hexaconazole, functional assistant, filler and carrier.

Owner:JIANGSU SUBIN AGROCHEM

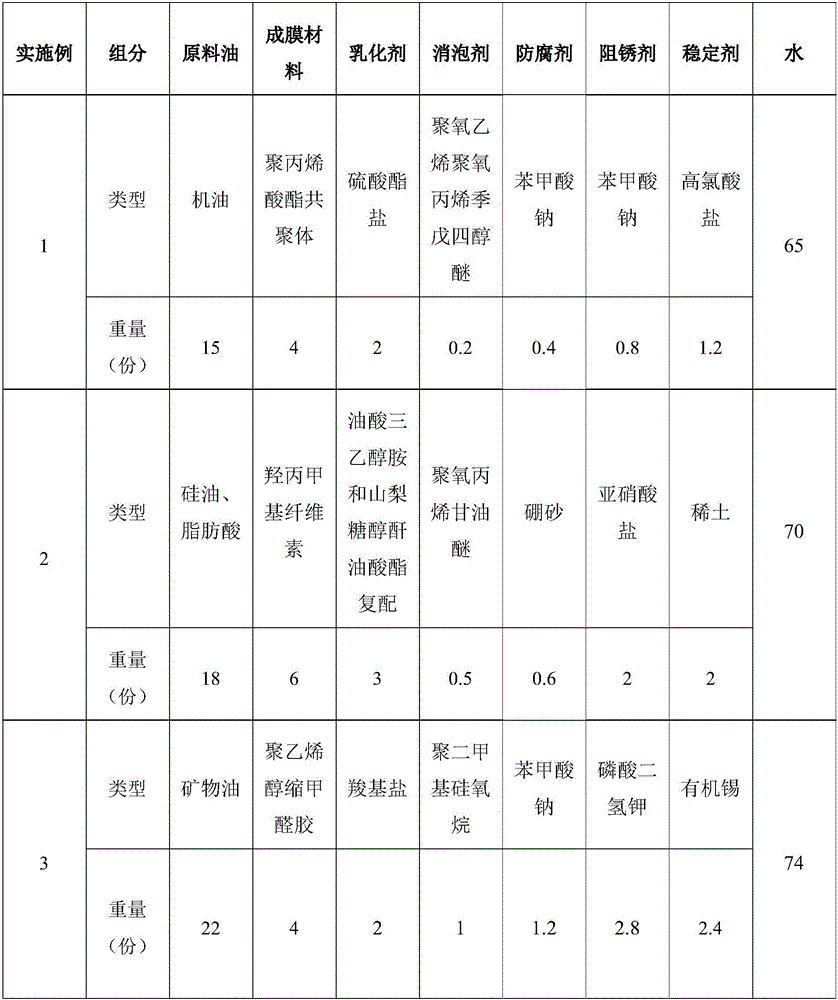

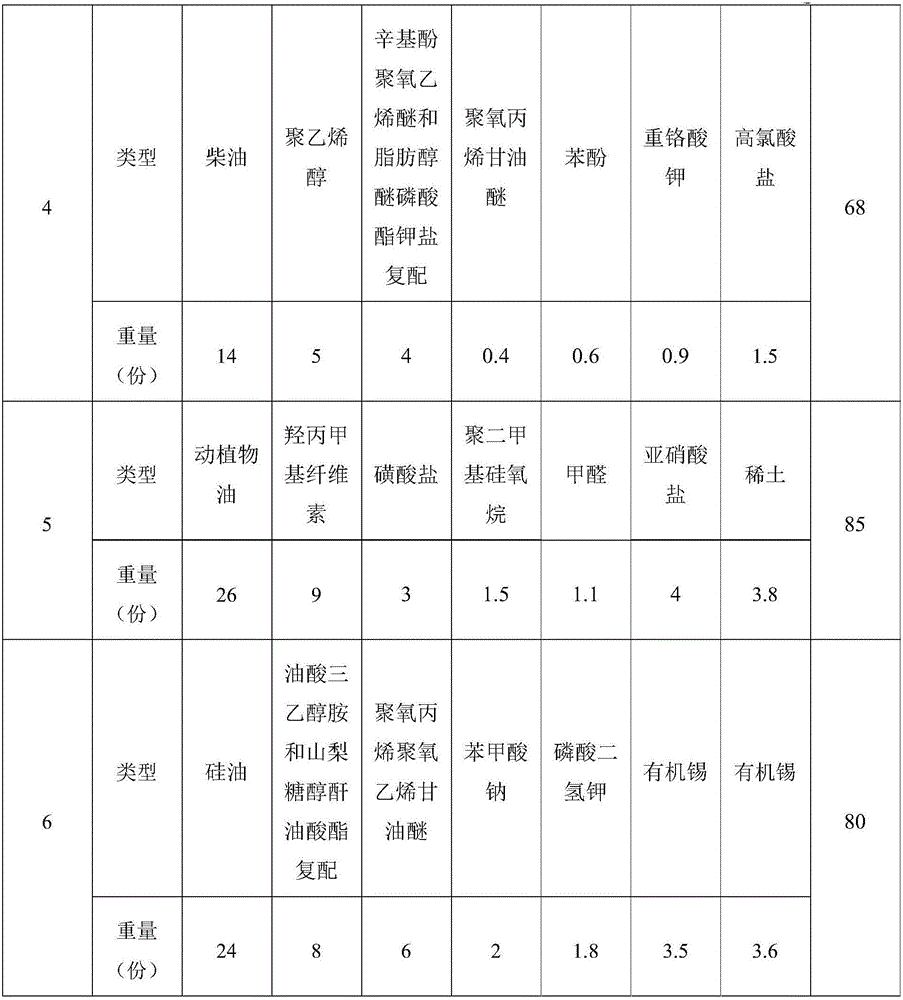

Emulsified oil-type release agent and preparation method thereof

InactiveCN106753724AGood release effectOilyCeramic shaping apparatusLubricant compositionControl systemPreservative

The invention provides an emulsified oil-type release agent. The emulsified oil-type release agent comprises, by weight, 10 to 30 parts of raw material oil, 1 to 10 parts of a film-forming material, 0.5 to 6 parts of an emulsifier, 0.1 to 2 parts of an antifoaming agent, 0.1 to 3 parts of a preservative, 0.5 to 5 parts of a rust inhibitor, 1 to 5 parts of a stabilizer and 60 to 90 parts of water, and the molecular weight of the film-forming material is less than 2000. The method comprises (1) orderly adding emulsified crude oil, an emulsifier and water into a reactor and carrying out stirring emulsification and (2) orderly adding auxiliary agents according to the amounts under the condition of stirring, controlling system pH and consistency of the system until the system forms a uniform liquid and stopping stirring to obtain the release agent. The emulsified oil-type release agent has the characteristics of good demolding effects, good oiliness, good smooth feeling, difficult adhesion to ash, mold cleaning easiness, smooth surface of the demolded concrete, simple processes, low cost and good feasibility to a wood mold, an aluminum mold and a steel mold.

Owner:湖南加美乐素新材料股份有限公司

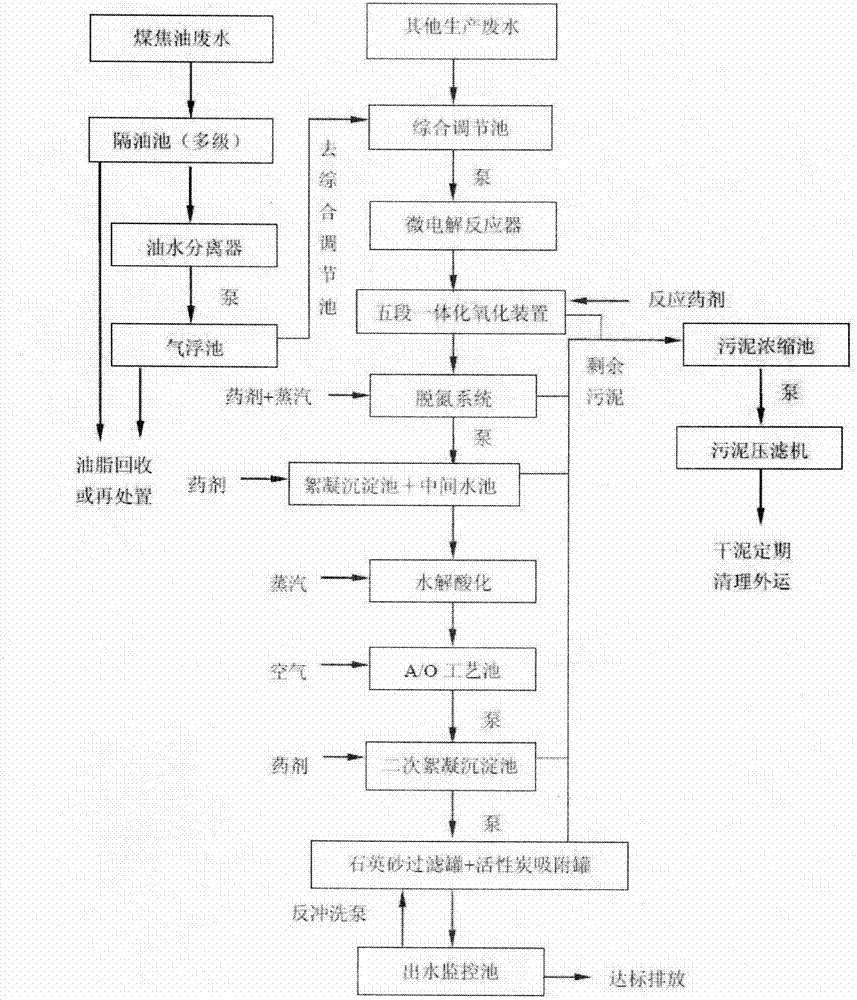

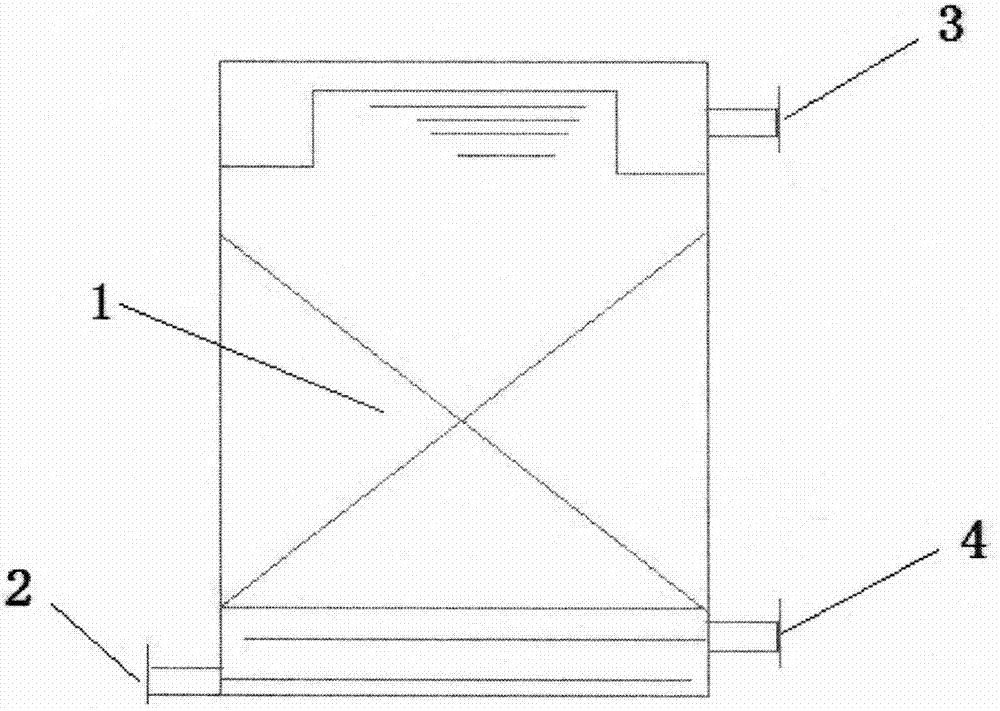

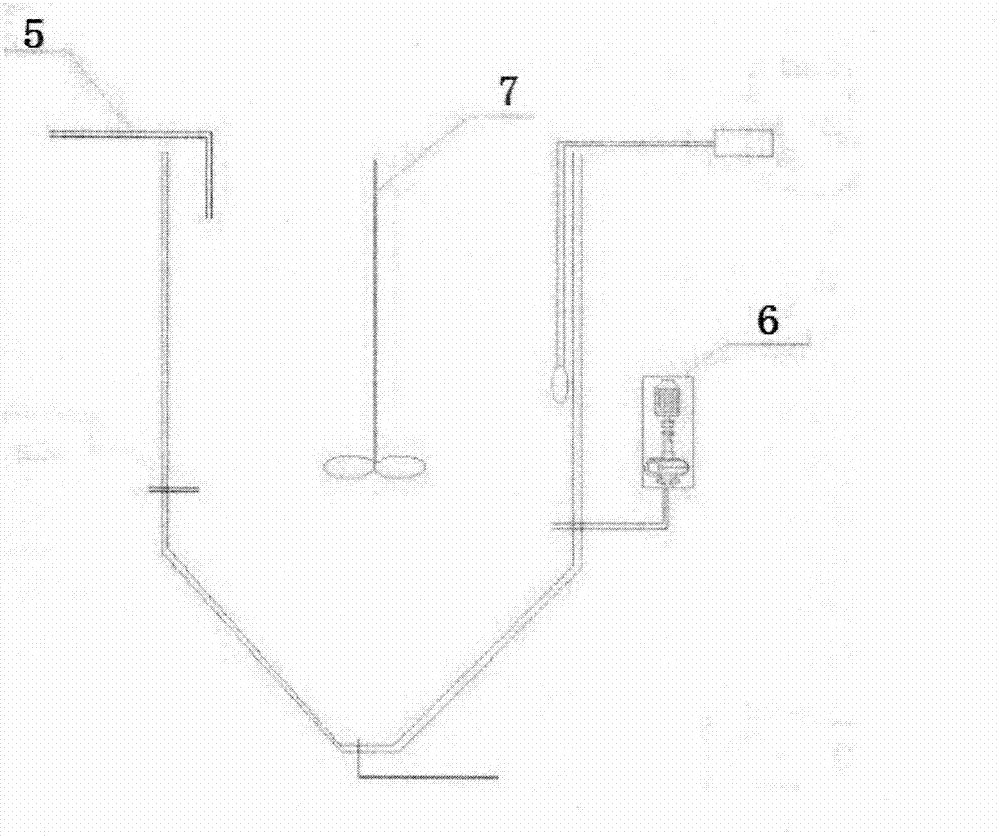

Complete equipment and process for processing coal tar wastewater

InactiveCN103113003AEasy to handleCreate economic valueMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention provides complete equipment and process for processing coal tar wastewater, and belongs to the technical field of environmental conservation. The process comprises the following steps of: adopting different removal principles according to different physicochemical properties of heavy oil, light oil and emulsified oil; scientifically and orderly removing the heavy oil, light oil and emulsified oil through three sets of environmental conservation equipment such as a multi-stage oil separator, an oil-water separator and an air floating tank gradually; combining a micro electrolysis reactor with a five-section integrated oxidization device; and firstly destroying a benzene ring by microelectrolysis, and then strongly oxidizing various organic matters through an oxidant, so that the COD (chemical oxygen demand) and the chromaticity are greatly reduced. Ammonia nitrogen can be efficiently removed by a denitrification system; the denitrification system is low on requirements of pH value and temperature, and low in operation cost; the denitrification system is arranged behind the five-section integrated oxidization device; the reaction change of power of hydrogen is fully considered; and the complete equipment complies with the scientific principle, and can be used for reducing feeding of acid and alkali, and lowering the operation cost.

Owner:NANJING ZIDU ENVIRONMENTAL PROTECTION SCI & TECH

Emulsified polymer drilling fluid and methods of preparation

A water-based polymer drilling fluid, containing effective quantities of surfactants having HLB numbers equal to or greater than approximately 7, emulsifies oil and bitumen contained in oil sand cuttings, resulting in the oil and bitumen being dispersed into the mud as an emulsion. This eliminates or significantly reduces the ability of the oil, bitumen, and cuttings to clog the well or stick to drill string components when drilling a well through oil-bearing sands, particularly sands containing highly viscous oil or bitumen. The emulsification process separates the sand particles from the oil and bitumen, such that the sand particles can be removed when the mud is run through a conventional shale shaker or other suitable apparatus.

Owner:SECURE ENERGY DRILLING SERVICES

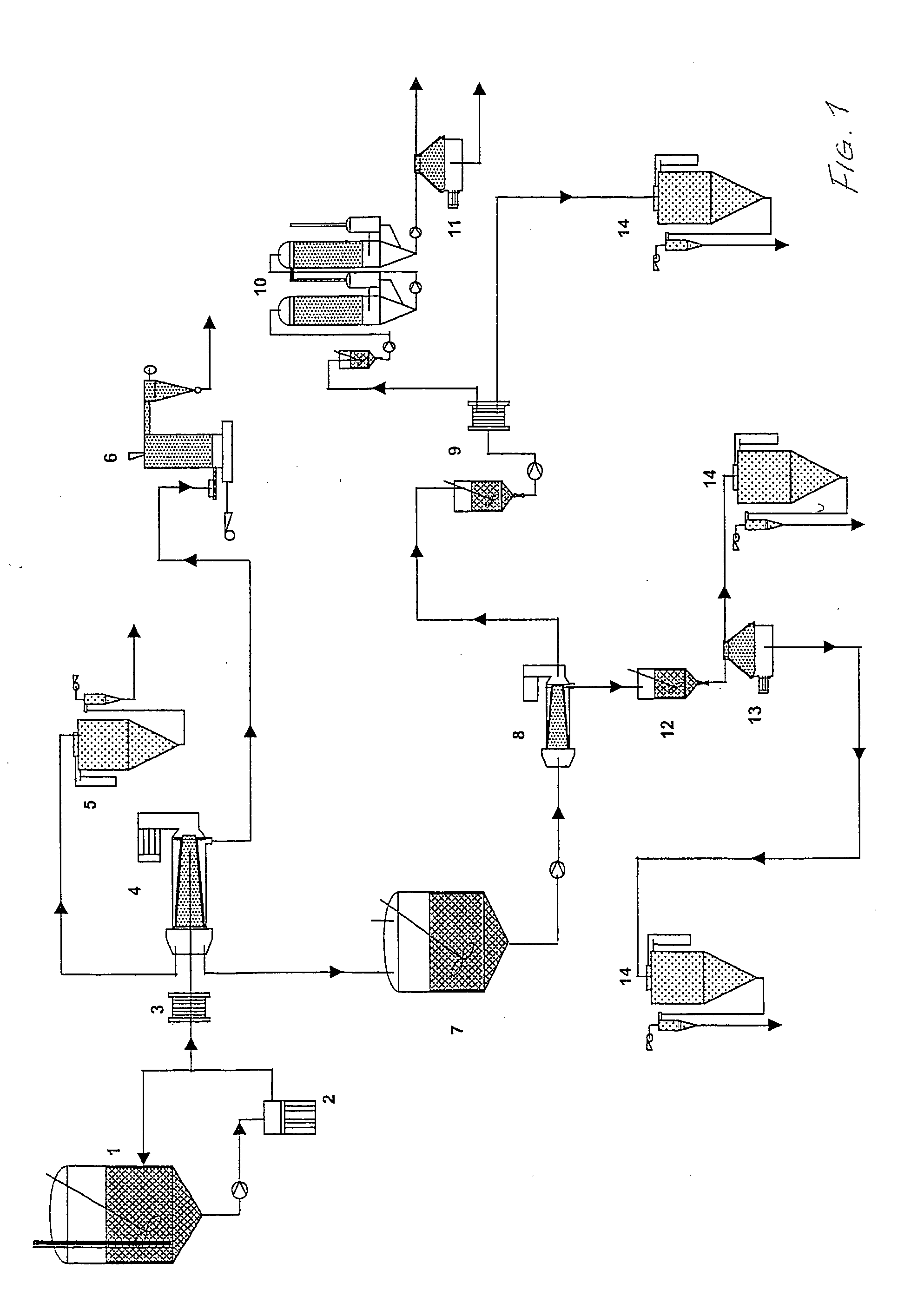

Process for the fractionation of oilseed press cakes and meals

A process for the fractionation of oilseed cakes and meals (e.g. rapeseed cake, soybean meal, and cottonseed cake) is disclosed. This invention describes a fractionation process, in which the said cake or meal is subjected to enzymatic treatment with polysaccharidases with intermittent wet milling, followed by heat treatment to facilitate separation of insoluble from soluble phase by centrifugal forces. Sequential centrifugation and ultrafiltration steps are carried out in order to yield a fibre-rich fraction, at least three protein-rich fractions, in the case of oilseed cakes at leas one emulsified oil fraction, a sugar-rich fraction, and a phytate-rich fraction. This invention also describes the use of the above-mentioned fractions in food, feed, nutraceutical and pharmaceutical applications.

Owner:BIOVELOP INT

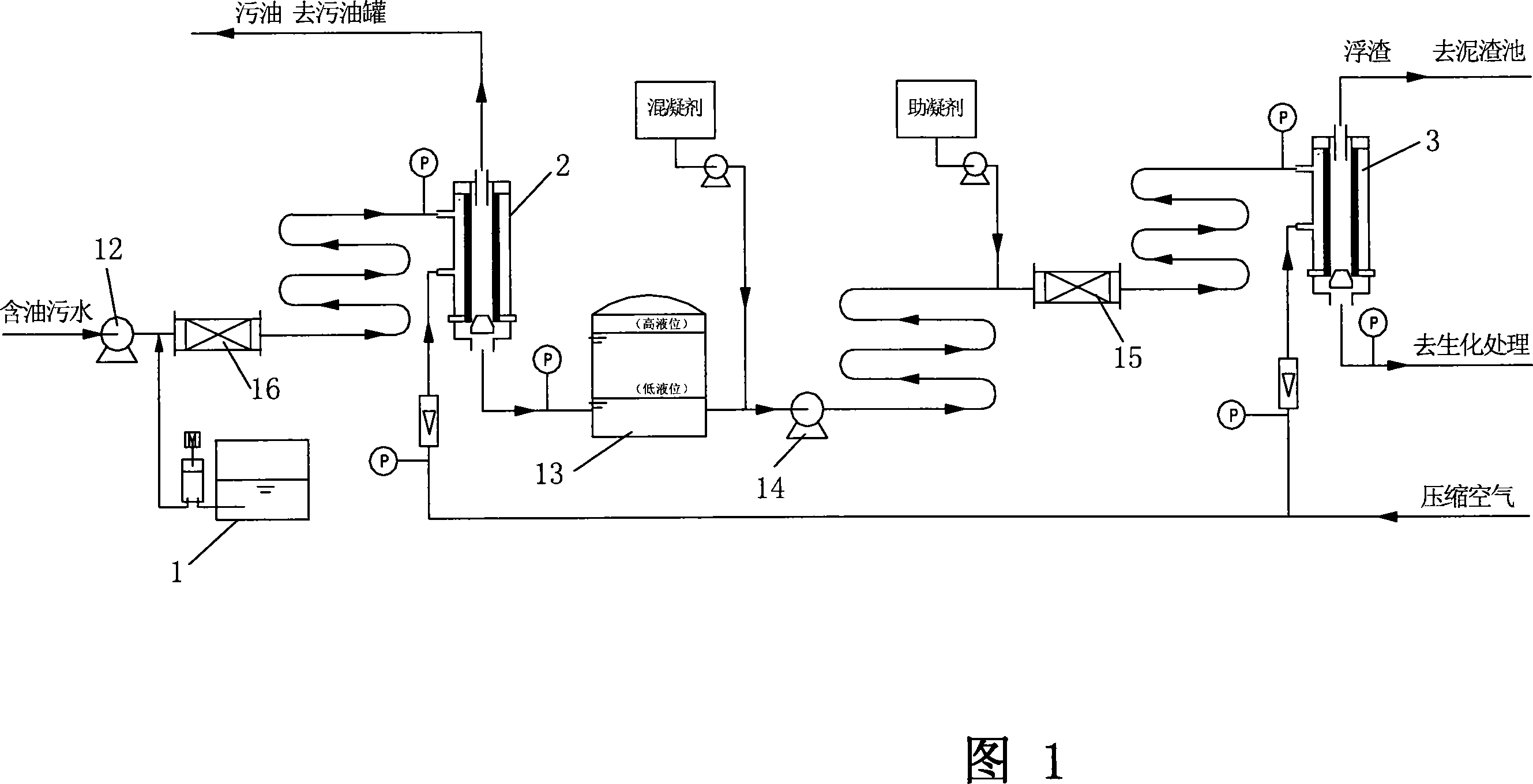

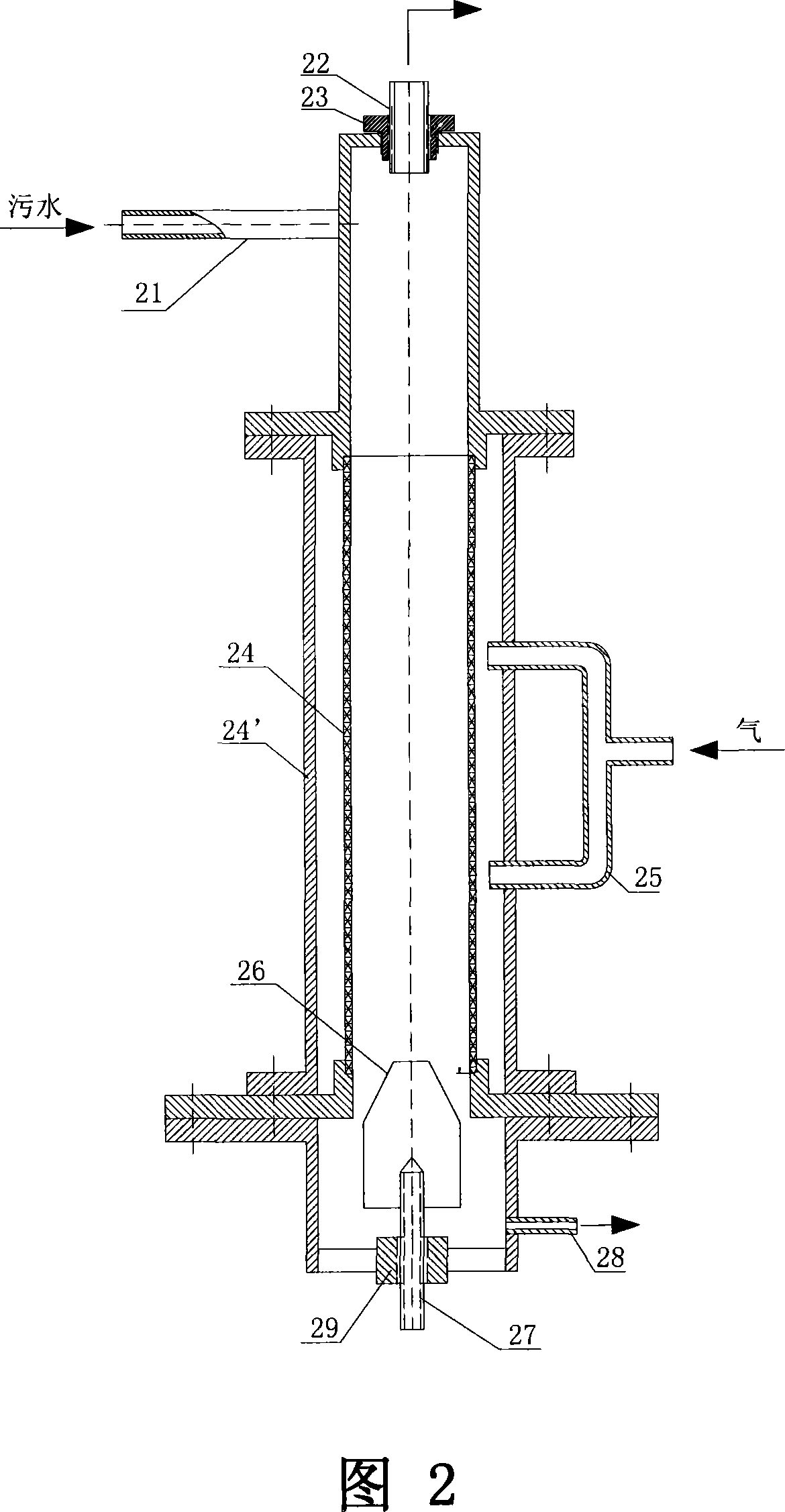

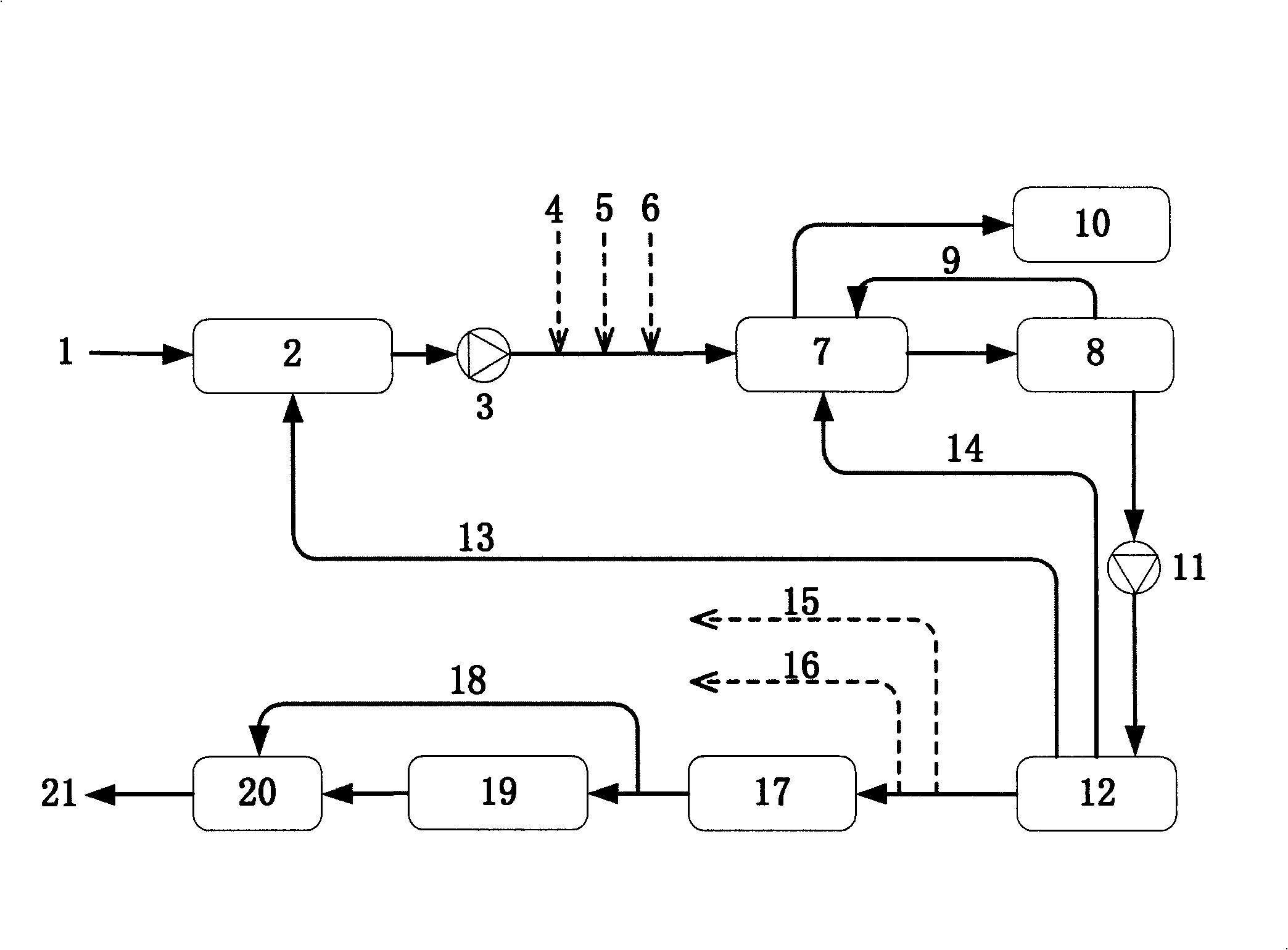

Method for treating oil refining sewage by employing multi-stage inflatable cyclonic current technology

InactiveCN101113035ADemulsification facilitates the realization ofShort stayWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesHigh concentrationEngineering

The invention provides a method for refinery waste water treatment by multi-stage air-sparged hydrocyclone technique, which can high effectively recycle floating oil, dispersed oil and emulsified oil of the refinery waste water, and eliminate most of suspension at the same time. The invention is mainly characterized in that: through setting at least two-stage air-sparged hydrocyclone, and combining the use of demulsifier, coagulant and coagulant aids, physiochemical treatment is carried out to high concentration oily waste water produced by all devices during the refinery process, and the releasing water after treatment can meet the biochemical stage water indices of normal waste water treatment field. The technique of the invention can substitute the physiochemical treatment stage (the first stage treatment) of the existing refinery waste water treatment process, and is characterized by high effect, occupying small land, and saving the investment, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Oral anti-calculus compositions and methods of use thereof

The present invention provides anticalculus oral compositions containing a plant oil mixture comprising a major oil constituent and a minor oil constituent in a proportion of at least 10 / 1 respectively. The major oil constituent comprises an edible vegetable oil and the minor oil consitutent comprises emulsifying oil, flavoring oil, antiseptic oil, anti-inflammatory oil, or a combination thereof.

Owner:TECH & MARKETING CONSULTING

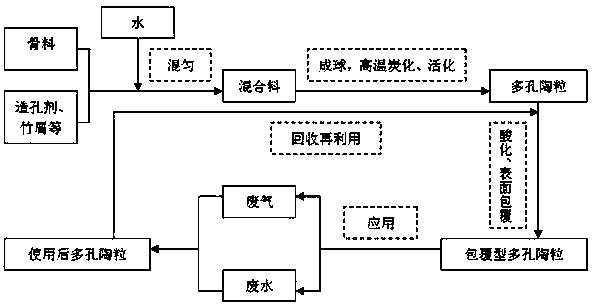

Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

ActiveCN104291797AImprove physical strengthGood processing effectCeramicwareExpanded clay aggregateHoneycomb

The invention provides bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as a preparation method and application of the bamboo-charcoal-shaped porous ceramsite. The preparation method of the bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron comprises the following steps: taking alpha-Al2O3 powder as ceramsite primary aggregate, clay and bentonite as auxiliary aggregates and surface-activated bamboo bits as bamboo charcoal preparation materials to combine with a pore forming agent to prepare pores without adding a sintering aid or a binder; adopting graded sintering at 400-600 DEG C to obtain bamboo-charcoal-shaped porous ceramsite by once molding; then, preparing the product bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron by virtue of a reducing coating process of the coating material, wherein the product bamboo-charcoal-shaped porous ceramsite is a deep dark small ball with a grain size of 2-10 mm, internally a porous honeycomb spherical structure with a surface pore size of 15-25 mu m, has water absorption of 20-35% and a specific surface area of 40-60m<2> / g. The preparation method disclosed by the invention is environmentally friendly simple and energy-saving in preparation process, various in treated pollutants, and suitable for treating non-biodegradable wastewater such as flue gas wastewater, heavy metal wastewater, phenol-containing wastewater, emulsified oil wastewater, note printing and printing and dyeing wastewater, and raw material are easily available.

Owner:FUZHOU UNIV

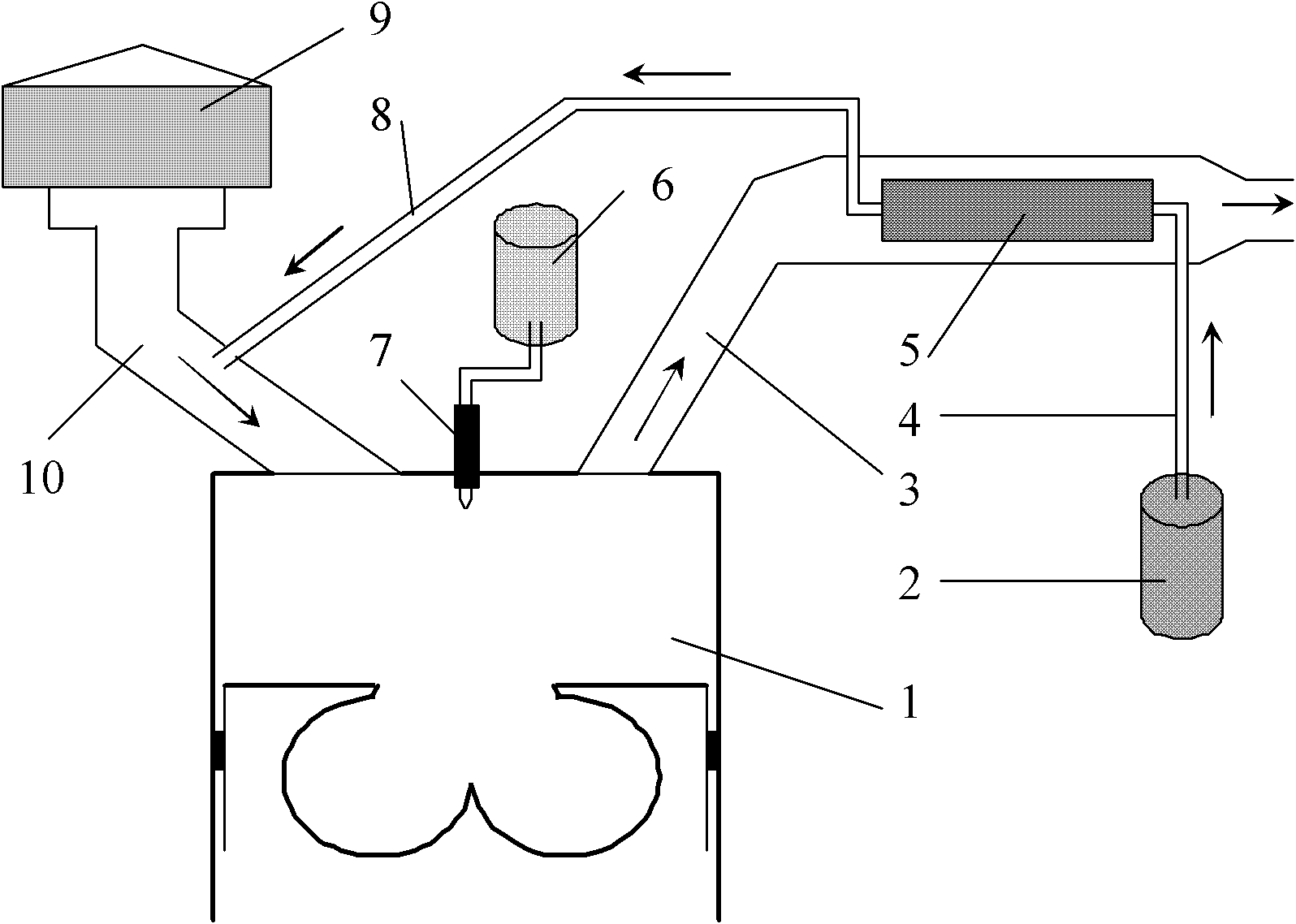

Method and device for reducing fuel consumption of diesel engine by catalytic decomposition of oxygen-containing fuel

InactiveCN102278240AEmission reductionReduce consumptionInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberExternal energy

A method and device for reducing fuel consumption of a diesel engine by catalytic decomposition of oxygen-containing fuel belong to the technical field of diesel engine combustion energy saving and emission reduction. In the present invention, the oxygen-containing fuel is fed into the catalytic reactor installed in the exhaust channel of the diesel engine, and the catalytic reactor is heated by the waste heat of the tail gas discharged from the combustion chamber, so that the oxygen-containing fuel is catalytically decomposed, and the generated hydrogen-rich and carbon monoxide-rich The decomposed gas enters the intake port, mixes with air, and enters the combustion chamber. At the same time, the emulsified oil is sprayed from the nozzle. The atomized emulsified oil evaporates, mixes, ignites and burns in the combustion chamber, and pushes the piston to do work. The system of the present invention makes full use of the waste heat of the exhaust gas of the diesel engine, and can realize the catalytic decomposition of the oxygen-containing fuel without providing energy from the outside. At the same time, combined with the use of emulsified oil, the comprehensive fuel saving rate of the diesel engine can reach 10-15%, and can be greatly improved. Reduce the emission of pollutants such as nitrogen compounds and soot, so as to achieve the purpose of energy saving and emission reduction.

Owner:TSINGHUA UNIV

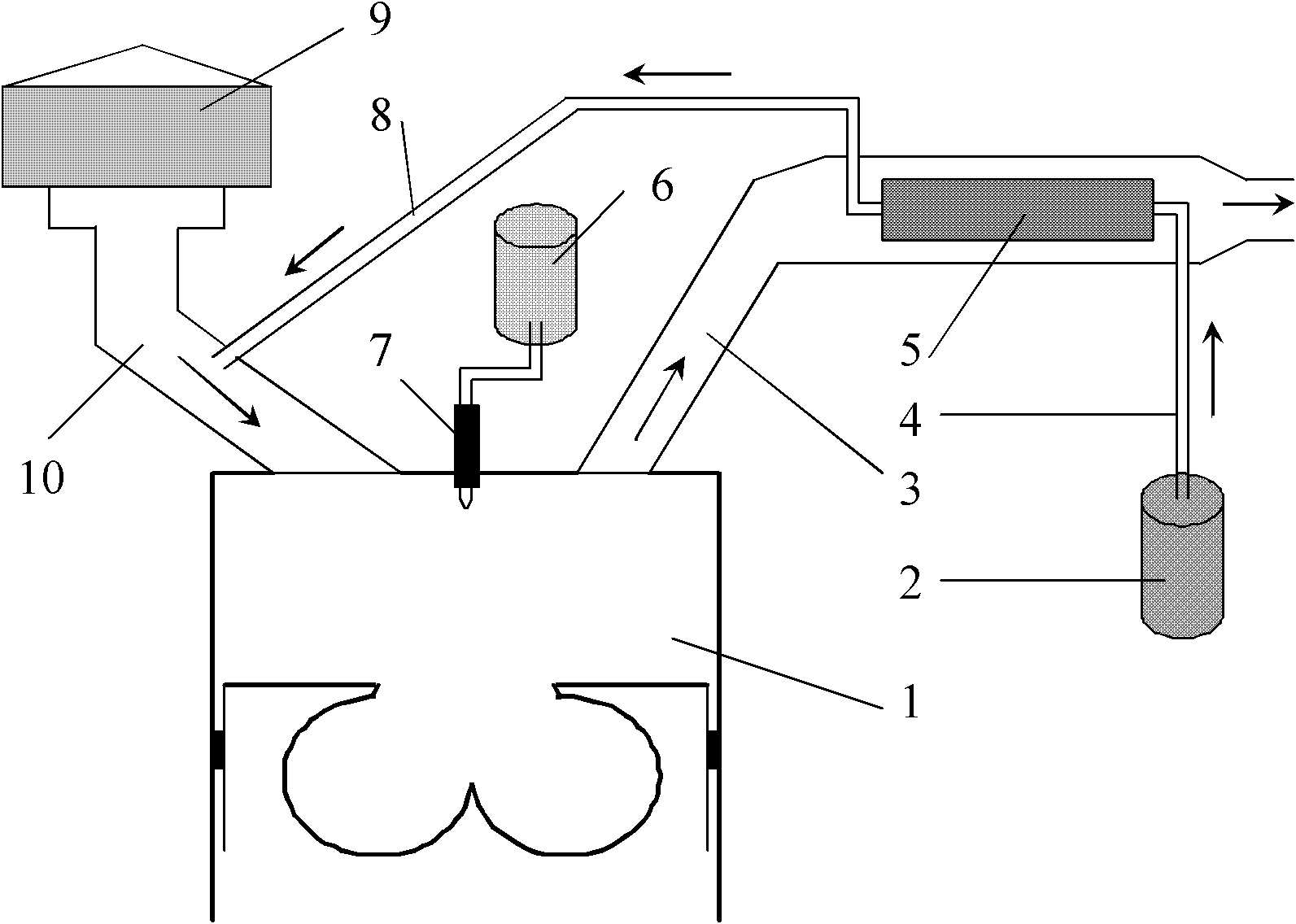

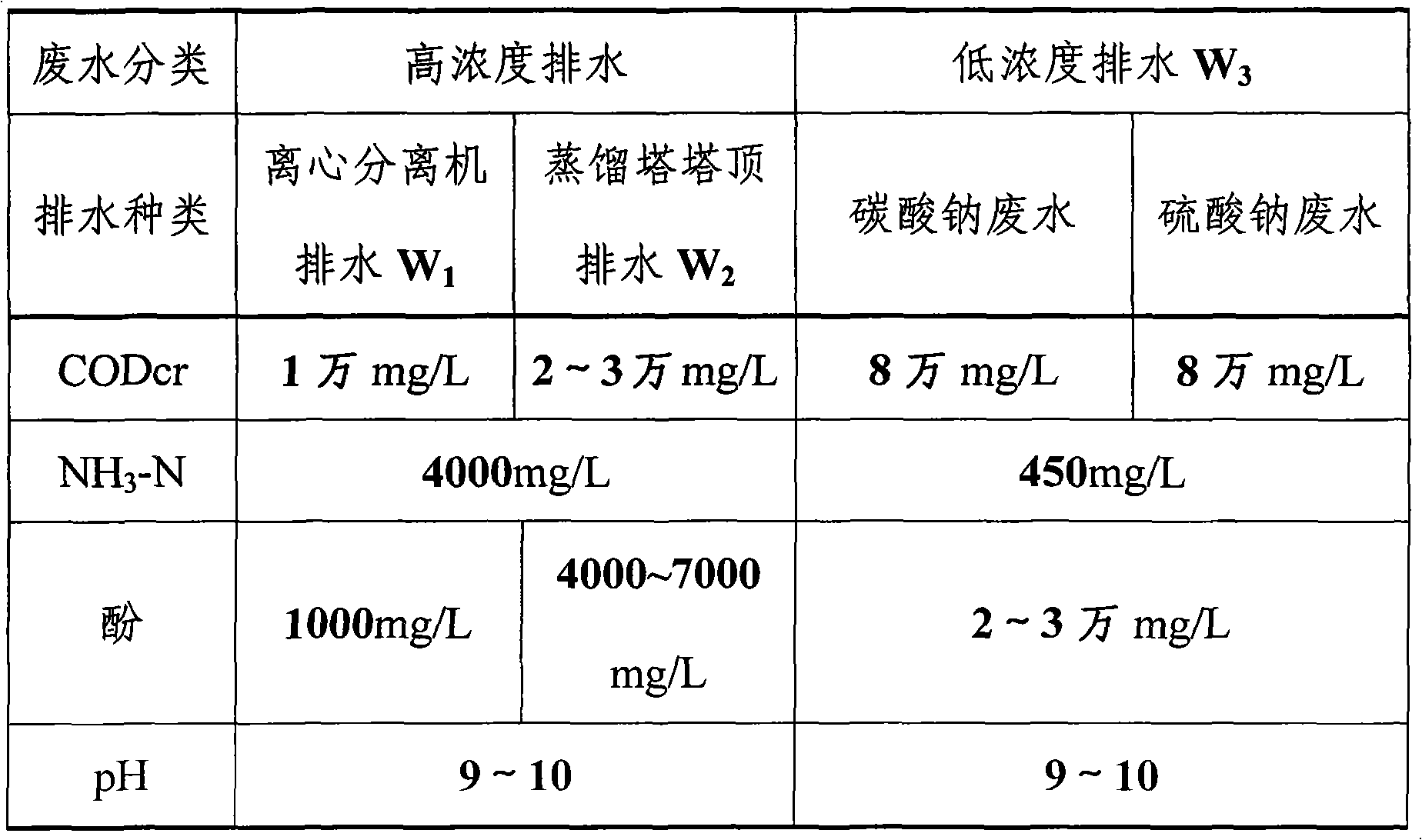

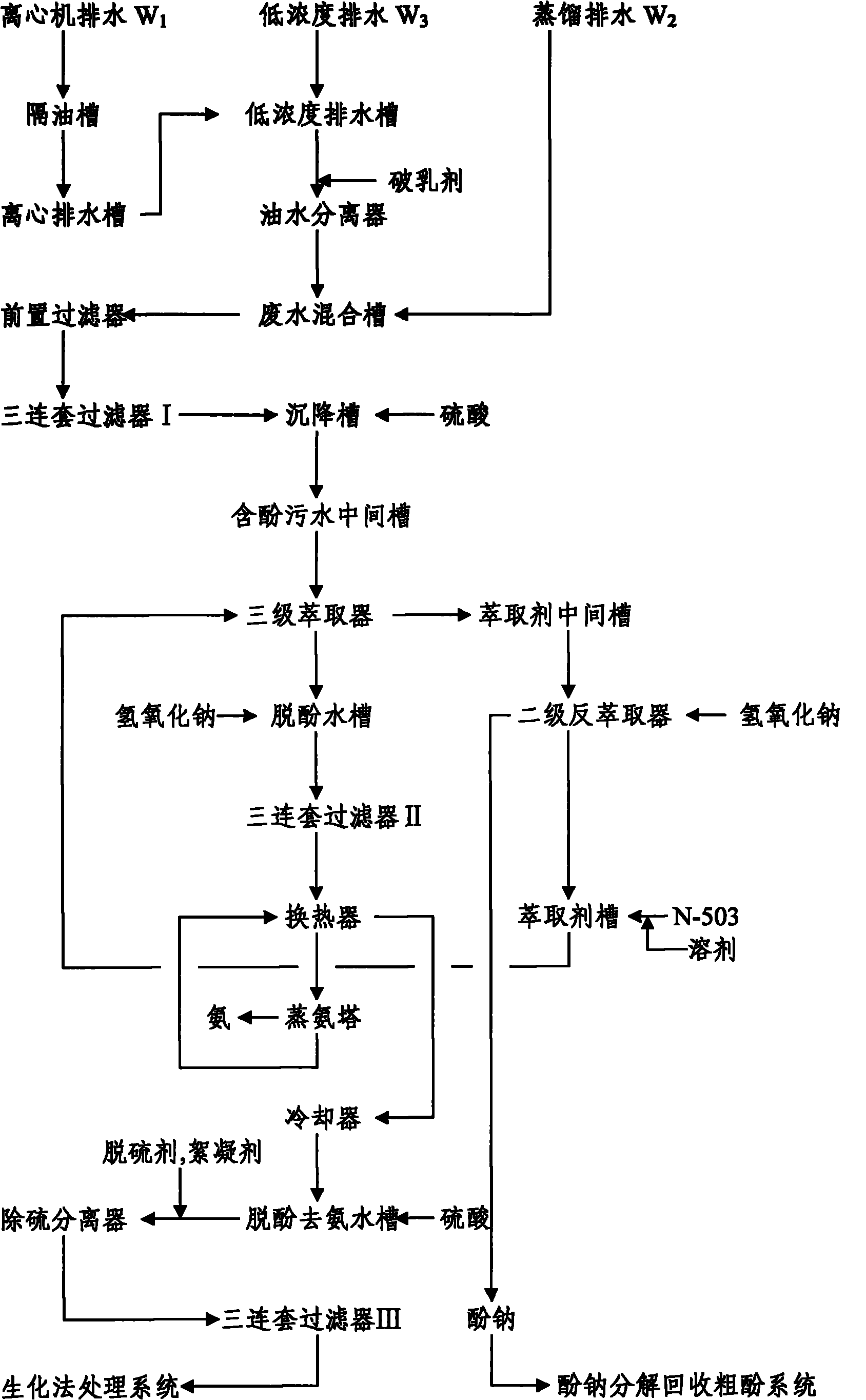

Coal tar processing wastewater treatment method and system

ActiveCN101875523AEfficient removalAchieve emission standardsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater qualityEconomic benefits

The invention relates to coal tar processing wastewater treatment method and system. The treatment method comprises materialization treatment comprising the following steps of: (1) removing free oil and emulsified oil which are contained in wastewater, filtering, regulating the pH value of the wastewater to 3-4, and then separating out depositions; (2) extracting and dephenolizing; (3) regulatingthe pH value of the dephenolized wastewater to 9-10, filtering, then carrying out steam stripping and deaminization by using steam, and besides, carrying out reextraction on extract phase containing phenol to respectively recover an extracting agent and phenate, and then recycling the extracting agent and decomposing the phenate to obtain crude phenol; and (4) cooling the deaminized wastewater, regulating the pH value to 7-8, and then filtering after adding a desulfurizing agent to remove sulfides. The water quality of the materialized wastewater achieves the requirement of a biochemical treatment system; meanwhile, the invention can recover a given amount of useful matter comprising the phenol, ammonia and the like and make the extracting agent recycled so that the economic benefit of wastewater treatment is improved.

Owner:高科环保工程集团有限公司

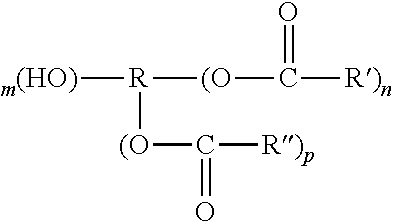

Hair care composition comprising a pre-emulsified formulation

A hair care composition comprising from about 0.25% to about 80% of a pre-emulsified emulsion comprising from about 0.005% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified oil in water emulsion is from about 20 nanometers to 20 microns; and a cationic surfactant system wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Method and device for treating a great variety of waste emulsion of high concentration using hyperfiltration membrane method

ActiveCN101311127AGood demulsification effectEasy to handleUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh concentrationLiquid waste

The invention discloses a method for treating the waste emulsion with high concentration and a plurality of varieties by an ultrafiltration membrane method and a device thereof, which belongs to the technical field of waste water and waste liquid treatment. The main technique of the invention is 'dissolved air flotation-ultrafiltration membrane-electrolysis floatation', which can effectively reduce the dosage of medicament and improve emulsion breaking effect by adopting an efficient dissolved air flotation system, moreover, the water for dissolved air flotation, which is taken from a subsequent intermediate water tank, can flexibly adjust and dilute the concentration of the waste water, thus improving the running stability and the shock resistant loading capability of the system. An ultrafiltration membrane with large flux, high separative efficiency and long service life is adopted in an ultrafiltration system to realize oil-water separation and to concentrate the emulsion for a plurality of times and then floating oil is recovered, the waste water generated in ultrafiltration washing is treated again after reflow, thus reducing waste liquid discharging. Electrolysis floatation can remove residual emulsified oil and dissolved oil in the waste water, thus further lowering the COD value of yielding water. When the quality of raw water is changed, an activated carbon adsorption unit can guarantee the quality of the yielding water to be standard. The method and the device of the invention can process waste emulsion with high concentration and a plurality of varieties and have simple and reasonable technique, good quality of yielding water, compact layout of the device, thus facilitating automatic control and realizing recovery of emulsion and recycle economy as well as changing waste to be profitable simultaneously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

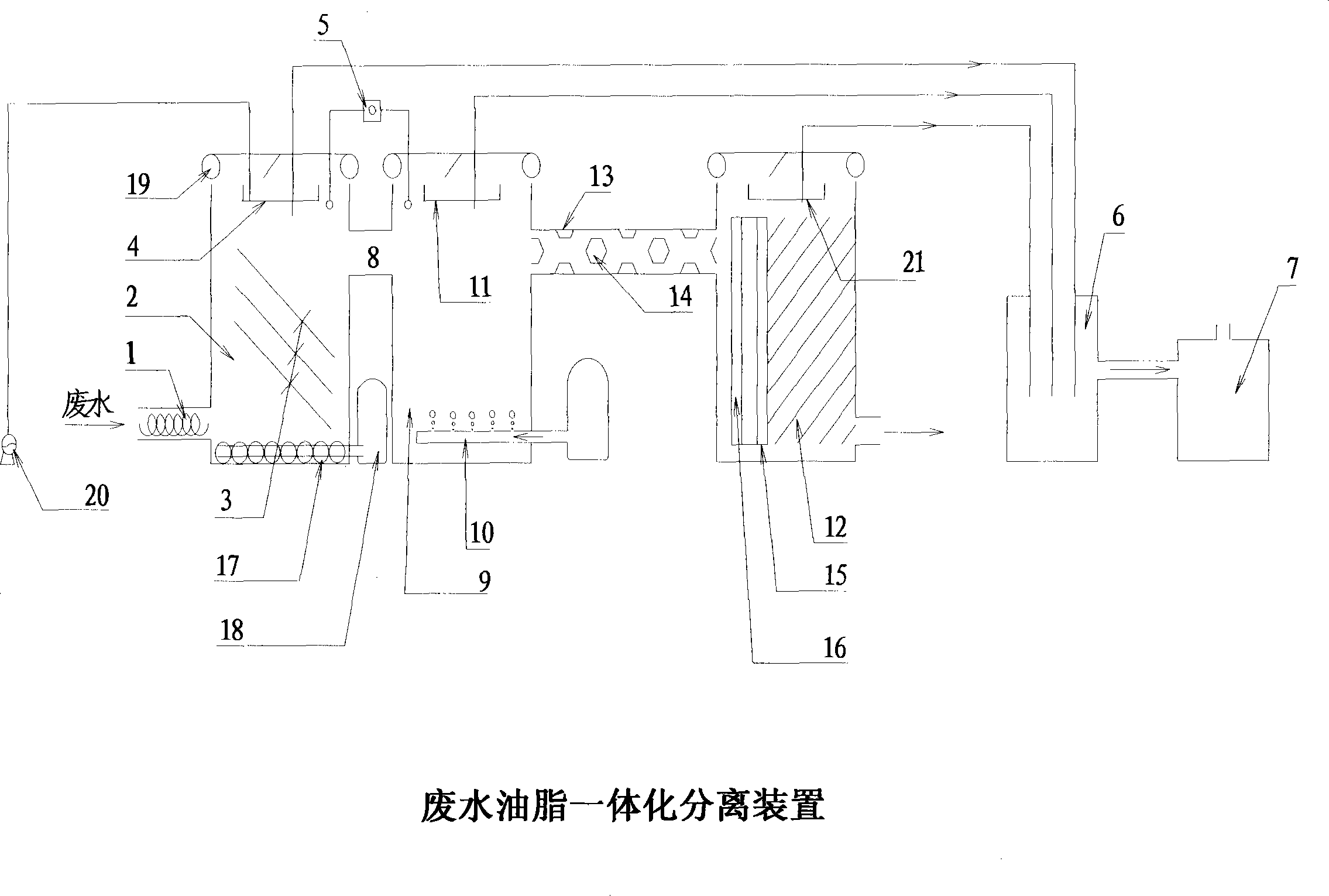

Integral separation device and method for kitchen garbage, waste-water and grease

ActiveCN101215020AEasy to separateLow costFatty/oily/floating substances removal devicesLiquid separationOil and greaseBiodiesel

Disclosed are an oil-water separation facility and a method for refuse waste-water of kitchens, which relate to the field of environment protection. The facility and method are composed of three portions which are respectively gravity oil slick, micro-airfloat oil skimming, thick granulating and the like in accordance with grease distribution shape and character of the refuse waste-water of kitchens, wherein the gravity oil removal section automatically excludes upper oil slick, emulsified oil, dispersed oil and the like float off via the micro-airfloat, thereby achieving separation of oil with smaller particles and water, after handling, oily wastewater left by the treatment of the above two sections further proceeds thick granulating process to lead micro-grease to assemble and form the grease with big particle diameter, then the grease with big particle diameter after floating upward is removed, thereby achieving being separated from water. The facility is capable of separating highly effectively the grease in sewage water, reducing organic loading of subsequent sewage water treatment, simultaneously the separated grease can be prepared into biological diesel fuels, soapstocks and the like, thereby improving resource recycling efficiency. The method has the advantages of feasible technique, cheapness and convenience, automation operation, which is not influenced by seasonal difference in temperature.

Owner:青海洁神环境科技股份有限公司

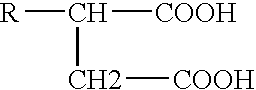

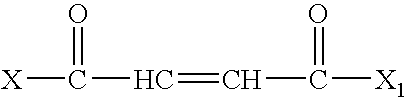

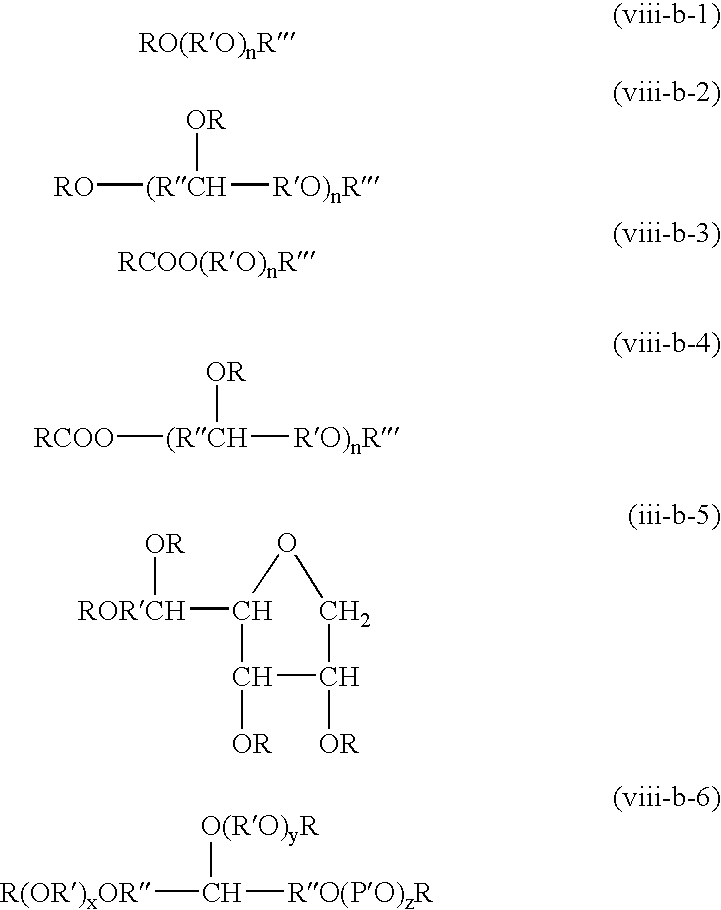

Viscous oil emulsification and viscosity reduction agent

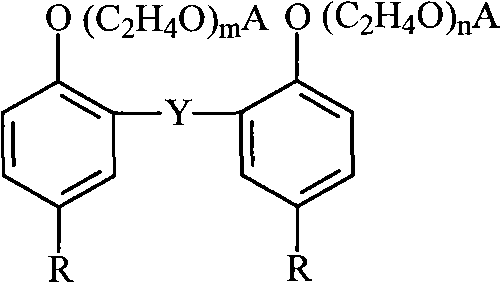

ActiveCN102876310AStrong resistance to mineral saltModerate cost of emulsificationDrilling compositionSalt resistanceAlcohol

The invention relates to a viscous oil emulsification and viscosity reduction agent. The emulsification and viscosity reduction agent comprises an anionic surfactant, a nonionic-anionic Gemini surfactant, a C1-C8 alcohol and water, wherein the weight ratio of the anionic surfactant to the nonionic-anionic Gemini surfactant to the C1-C8 alcohol is 1:0.1-40:0.01-10, and the water amount is 0.2-5000 times the total weight of the anionic surfactant, the nonionic-anionic Gemini surfactant and the C1-C8 alcohol. The emulsification and viscosity reduction agent has the advantages of no alkalis, strong mineral salt resistance, realization of emulsifying ultrahigh-viscosity viscose oil having above 30% of asphaltene, low viscosity of the emulsified oil, moderate emulsification cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods for removal of oil and other contaminants from water

The invention relates to compositions and methods for separating oil and other contaminants (particularly oleophilic compounds) from water and other carriers. The invention is particularly useful for separating oil and other oleophilic compounds from bilgewater and other wastewater. The compositions typically comprise a hydrocarbon resin and a drying oil. The compounds in the composition are typically combined in an organic solvent. For example, hydrocarbon resin and tung oil are optionally combined into a naphtha solvent. The invention is particularly useful for separating emulsified oil from water, whether oil in water emulsions or water in oil emulsions.

Owner:ROBERTS DAVID

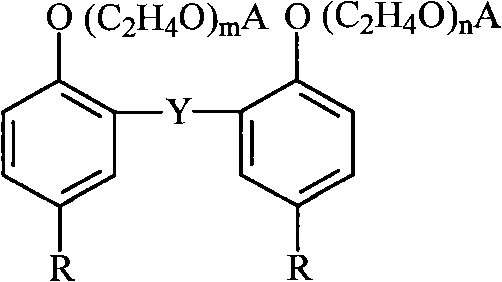

Technology of extracting oil and hydrolyzed protein from peanut using hydroenzyme method

InactiveCN1555714AQuality improvementOperational securityProtein composition from vegetable seedsEdible oils/fatsNutritive valuesAlkaline proteinase

A process for extracting oil and hydrolytic protein from peanut by water-enzyme method includes such steps as extracting emulsified oil by use of alkaline proteinase, and demulsifying it by freezing and thawing to obtain free oil while recovering hydrolytic protein powder in the form of micropeptide. Its advantages are high oil output and high nutritive value.

Owner:JIANGNAN UNIV

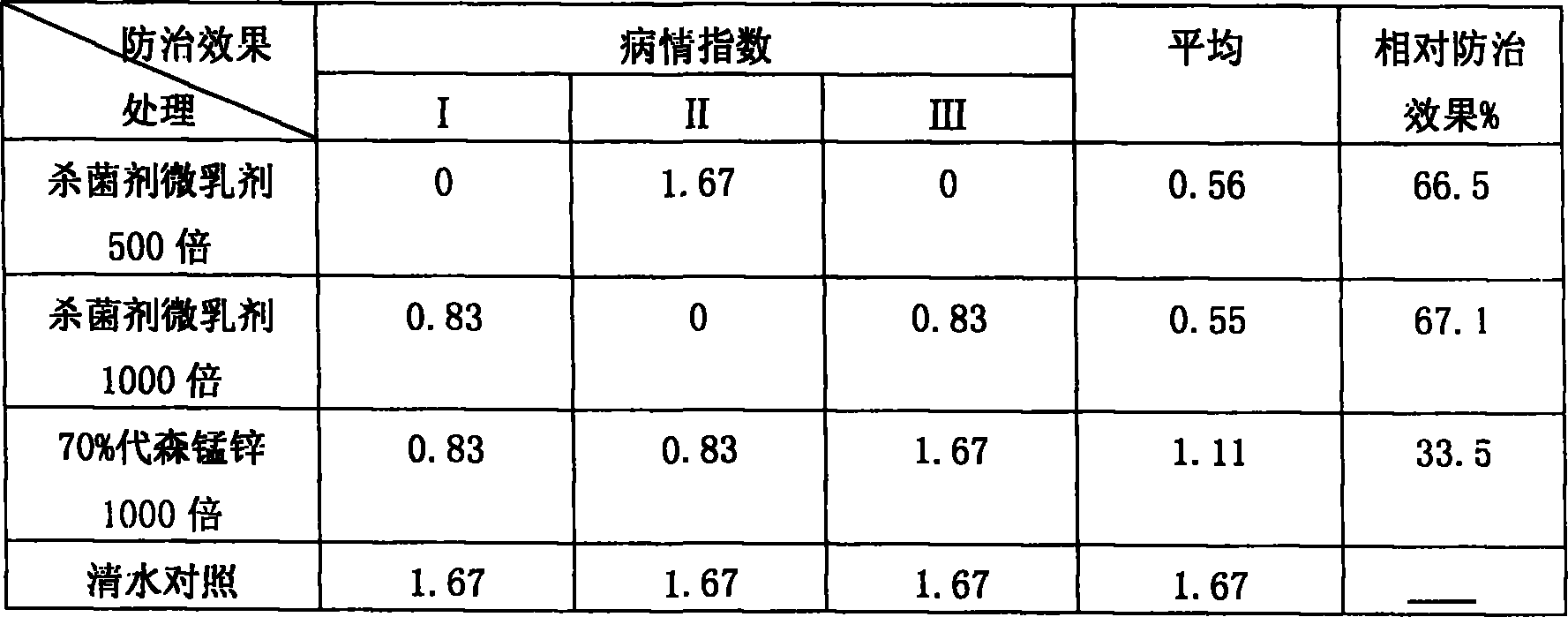

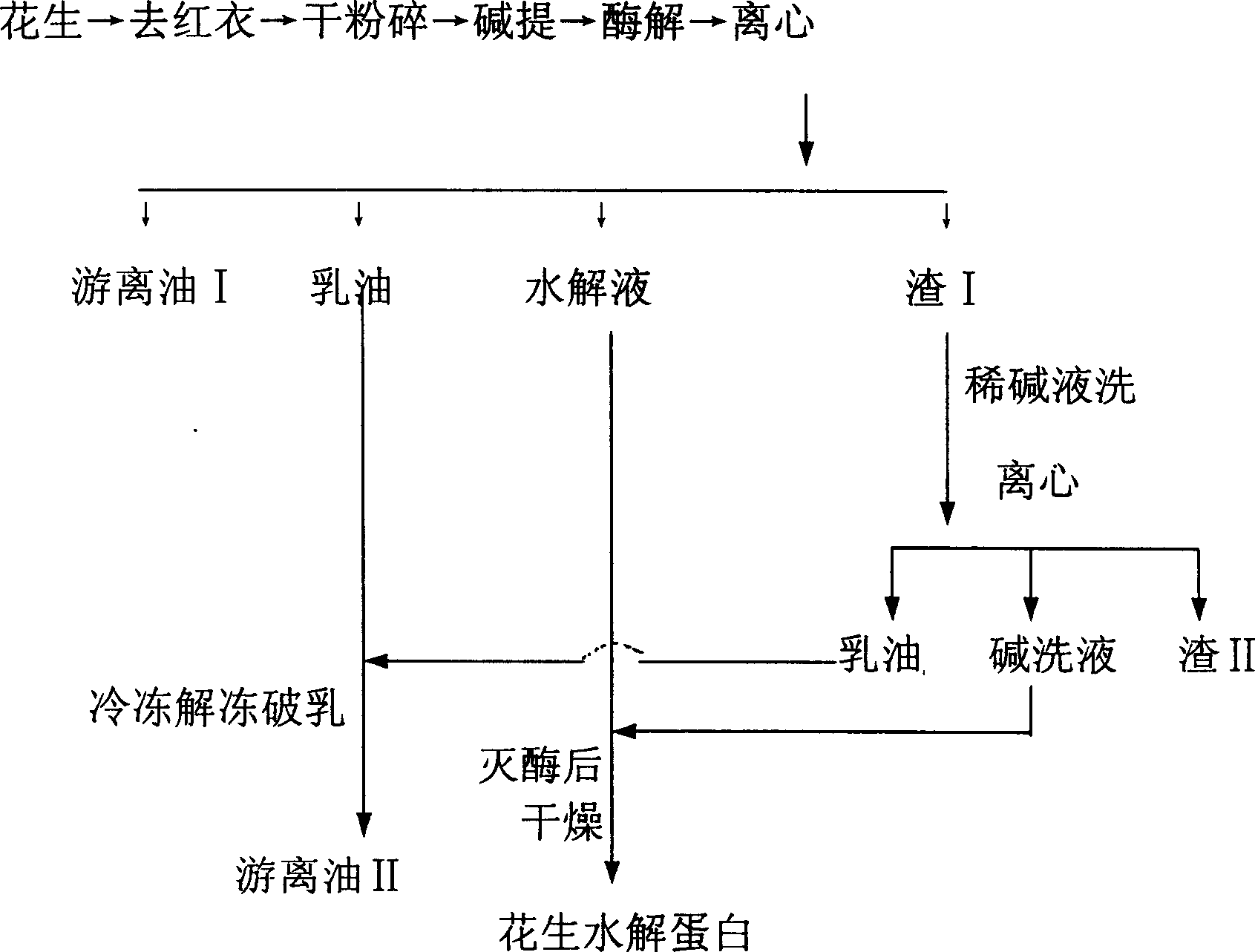

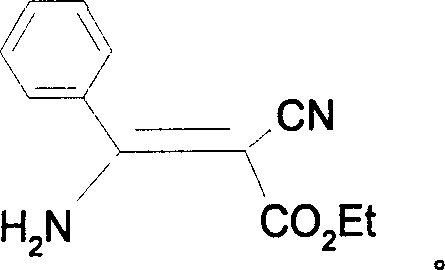

Application of 2-cydno-3-amino-3-phenylethyl acrylate for preventing and treating patty rice bakanae disease

An application of 2-cyano-3-amino-3-ethyl phenylacrylate in preventing and treating the foolish seedling disease of rice features that it is proportionally mixed with other bactericide as symergist to obtain the seed treating emulsion or emulsified oil for treating seeds of rice or spraying it on the leaves of rice.

Owner:JIANGSU PESTICIDE RES INST

Polypropylene hollow fiber ultrafiltration membrane coated with polymer composite coating

ActiveCN105080361AImprove antibacterial propertiesHigh strengthAntifouling/underwater paintsUltrafiltrationEpoxyFiber

The invention relates to a polypropylene hollow fiber ultrafiltration membrane coated with a polymer composite coating. The polypropylene hollow fiber ultrafiltration membrane comprises a water inlet surface and a water outlet surface which are respectively coated with a coating; the coating on the water inlet surface comprises the following raw materials: tricresyl phosphate, dioctyl phthalate, a modified polysiloxane polymer, polyether-ether-ketone (PEEK), methenamine and the like; and the coating on the water outlet surface comprises the following raw materials: allyl polyoxy alkyl epoxy ether, pentaerythritol, polyethylene glycol lauric acid diester, polyoxyethylene alkylamine, nano silver and the like. The polypropylene hollow fiber ultrafiltration membrane is capable of increasing the retention rate for macromolecular organic matter and emulsified oil, so that the COD removal rate of sewage is greatly increased, the electrostatic effect on the surface of the membrane is changed, the adsorption for contaminants of the surface of the membrane is prevented, the membrane can be continuously used for a long time under the condition of high membrane flux, and the service life of the membrane is prolonged. The addition of the nano silver effectively improves the antibacterial mildew properties of the membrane.

Owner:广州市纳清环保科技有限公司

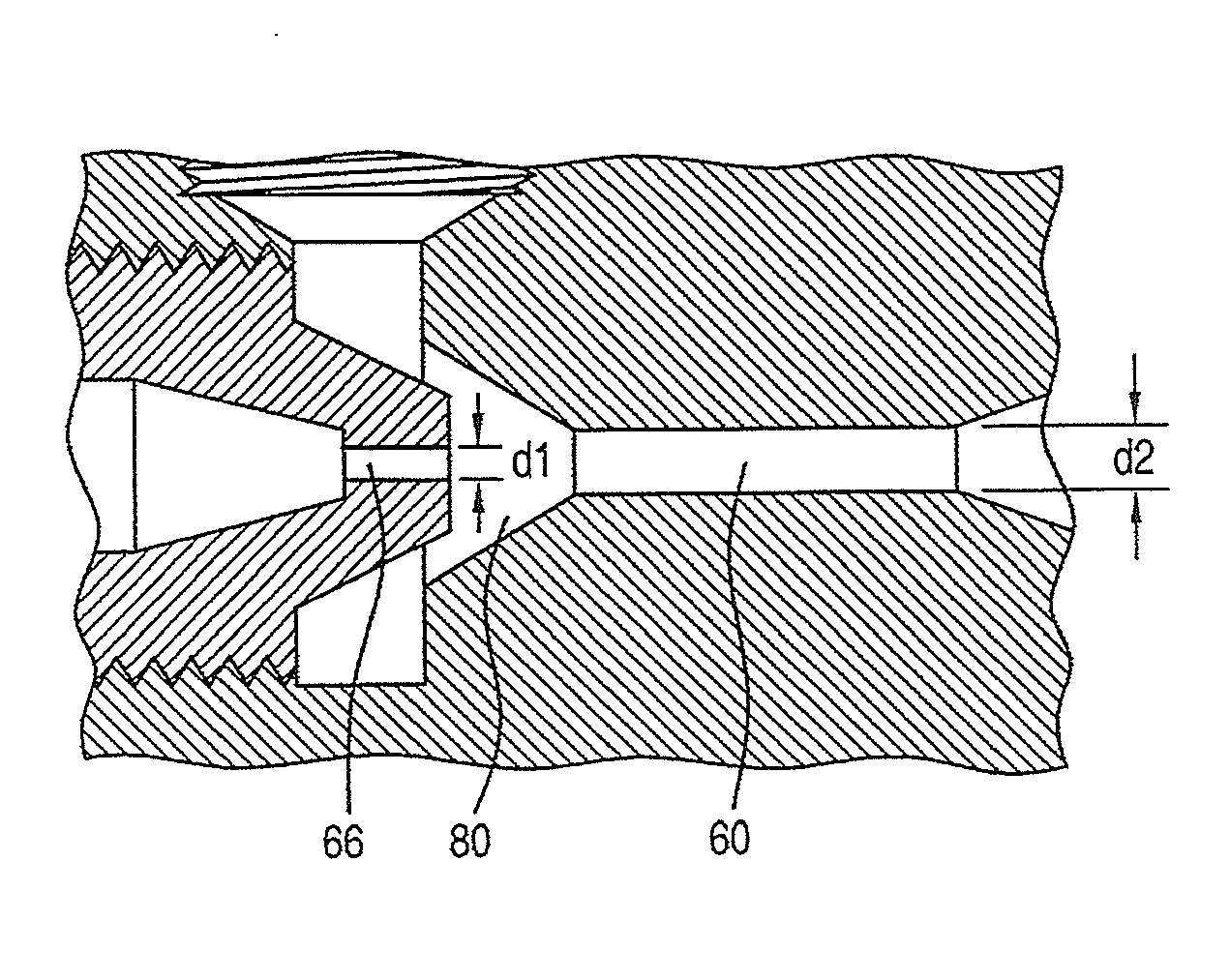

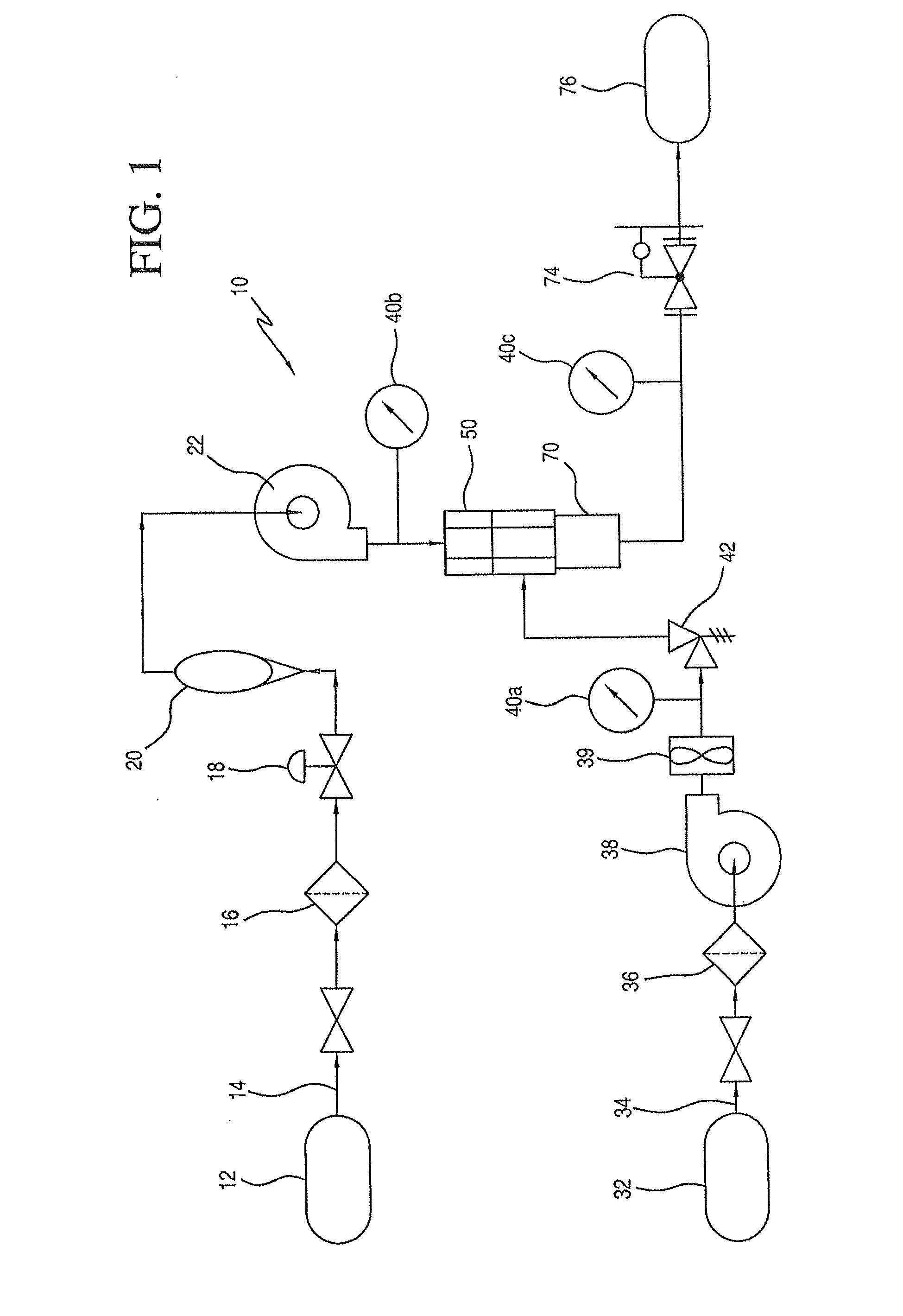

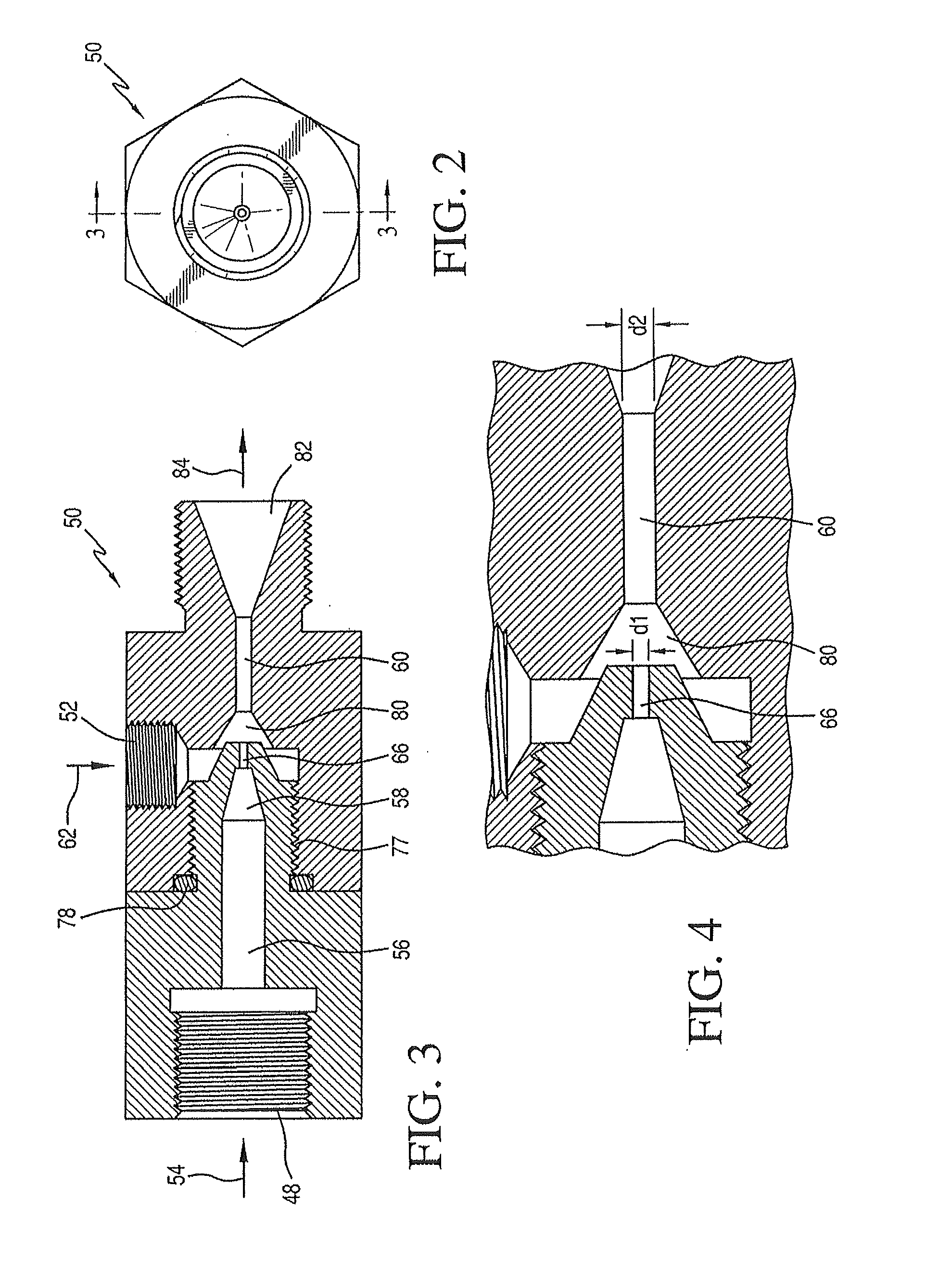

Apparatus, system and method for emulsifying oil and water

ActiveUS20120103546A1Well as runnability of machineReduce sizeLiquid surface applicatorsNon-macromolecular adhesive additivesEmulsionPaperboard

An apparatus, system and method for emulsifying oil and water, such as for emulsifying a sizing agent for use in treating paper or paperboard, introduces a continuous phase under pressure through a continuous phase nozzle of a venturi apparatus and into a mixing section. A dispersed phase is introduced optionally under pressure into the mixing section of the venturi apparatus. The emulsion formed in the mixing section is directed through a mixed phase nozzle and out of the venturi apparatus. The mixed phase nozzle diameter of the venturi apparatus is larger than the continuous phase nozzle diameter at a ratio of greater than 1:1 and less than 4:1.

Owner:SOLENIS TECH CAYMAN

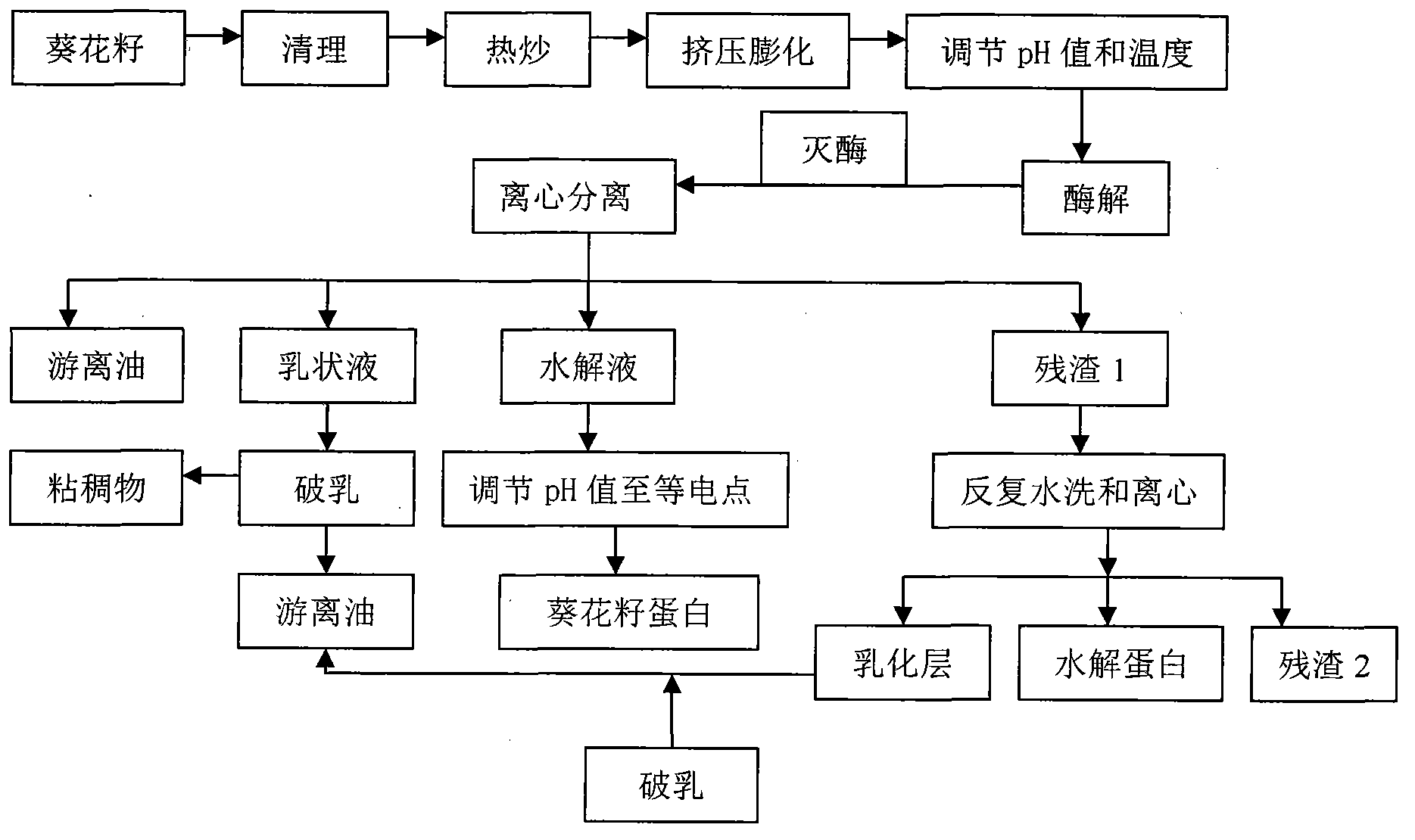

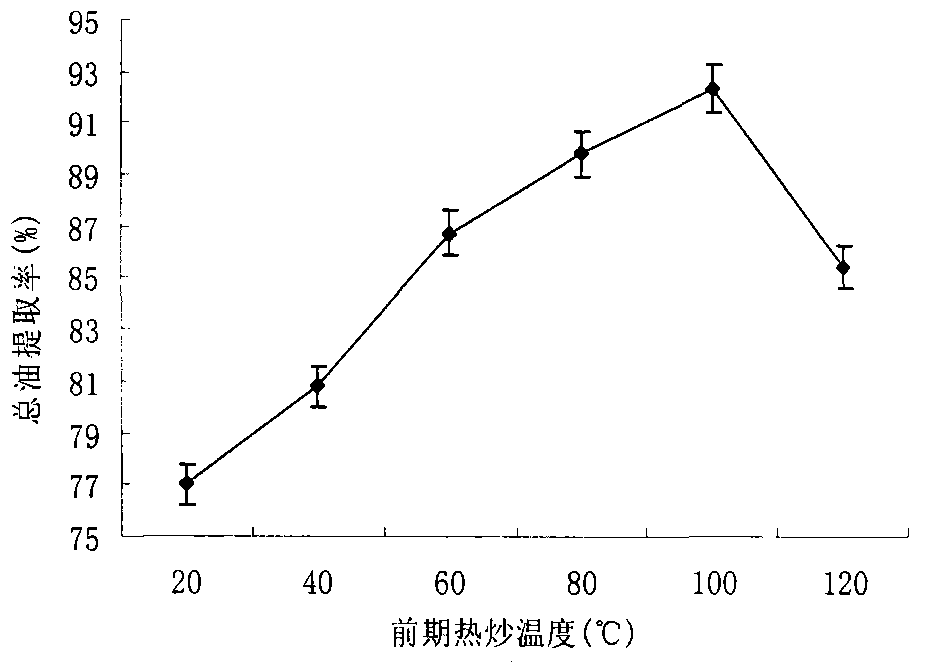

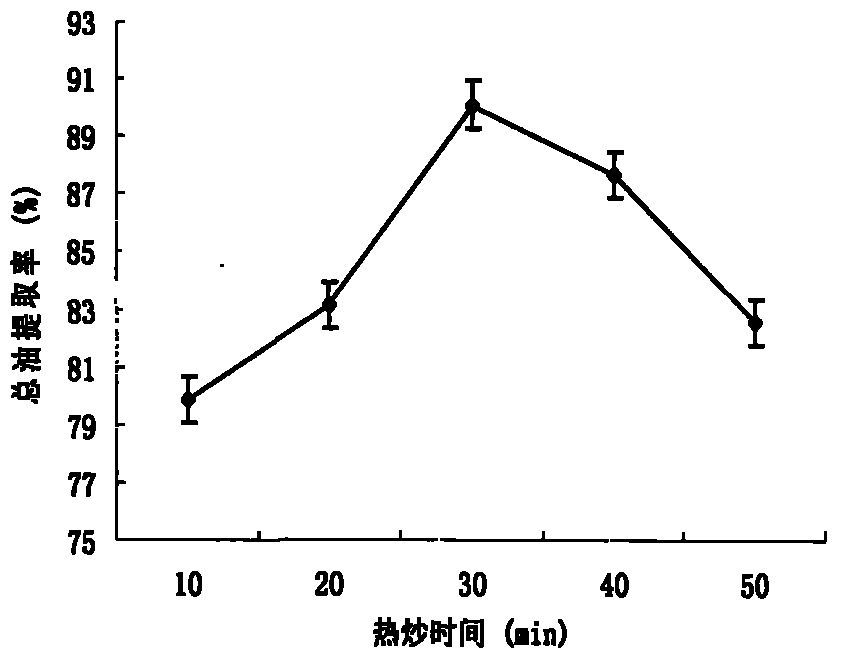

Method for extracting fragrant sunflower seed oil

InactiveCN102703206ALess residueLess investmentFatty-oils/fats refiningFatty-oils/fats productionCelluloseHydrolysate

The invention discloses a method for extracting a fragrant sunflower seed oil and belongs to the extraction processing technique of plant fat. The method comprises the following steps: (1) frying cleaned sunflower seeds; (2) carrying out extrusion puffing pre-treatment to the fried sunflower seeds to obtain pressed fragrant sunflower oil and a puffed product; (3) mixing the puffed product obtained in the step (2) with water to obtain mixed solution, adding compound cellulose to the mixed solution to enzymatically hydrolyze and obtain an enzymatic hydrolysate; (4) enzyme-inactivating the enzymatic hydrolysate and centrifugally separating to obtain the free fragrant sunflower seed oil. According to the method of extracting the fragrant sunflower seed oil, the sunflower seed oil is separated in a method of combining frying, extrusion puffing pretreatment and bio-enzyme; after the emulsified oil subjected to separation is demulsified, the oil of high quality can be obtained without refining and has high nutritional value; the total oil extraction rate is up to 96.98 percent; the action conditions are mild and degradation products in the system are not reacted with the extract, so that the qualities of various components can be protected effectively.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

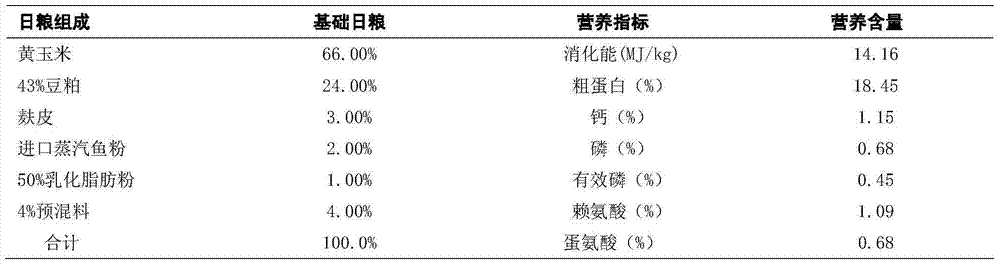

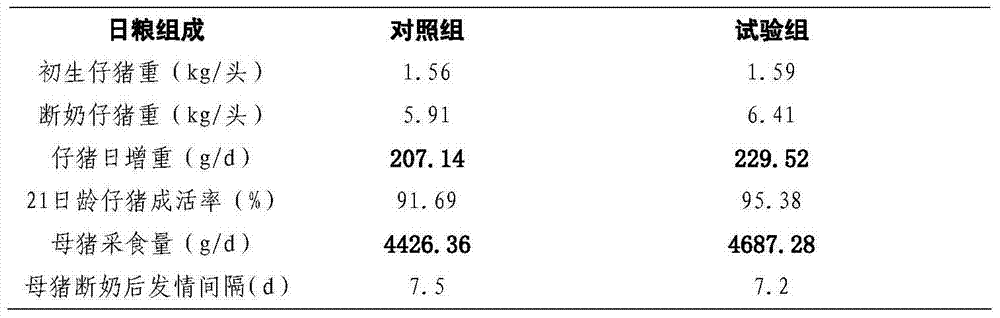

Preparation method of lactating sow feed

The invention discloses a preparation method of a lactating sow feed. The preparation method comprises the following specific steps: soaking soybeans in water, grinding the soaked soybeans into thick liquid by a grinding miller, raising the temperature, cooking and cooling to prepare soybean milk dregs; mixing the soybean milk dregs, alfalfa meal, corn flour, brown sugar, a composite bacterial liquid and a compound enzyme according to a ratio; carrying out solid fermentation and enzymolysis, and then drying the substance to obtain a soybean-grass fermentation material; uniformly mixing the soybean-grass fermentation material, corn, broken rice, bean pulp, fish meal, emulsified oil powder, helianthus tuberosus powder, seaweed, composite Chinese herbal medicines and 4% of premix sold in the market, so as to obtain the lactating sow feed capable of calling food, promoting lactation and resisting constipation. The lactating sow feed disclosed by the invention is rich in emulsified fat, yeast protein, active oligopeptide, short-chain dextrin, glucose, soybean and helianthus tuberosus oligosaccharides, lactic acid, probiotics and unstated prolactin, good in palatability, balanced in amino acid, high in nutrition, low in probability of digestion, low in anti-nutritional factor content, and capable of obviously promoting sow ingestion, simulating lactation and preventing constipation.

Owner:FLSUGARPEPTIDE BIOLOGY ENG

Fuel composition having a fuel, water, a high molecular weight emulsifier, and a surfactant including natural fats, non-ionic and ionic surfactants, co-surfactants, fatty acids and their amine salts, or combinations thereof

InactiveUS20060162237A1Reduce interfacial tensionReduce molecular weightTransportation and packagingMixingActive agentEnvironmental engineering

The invention provides an emulsified water in oil composition comprising: A) a fuel; B) a water; C) a high molecular weight emulsifier; D) a surfactant having a molecular weight of about less than or equal to about 950 g / mol wherein the surfactant comprises: i) natural fats; ii) non-ionic and ionic surfactants; iii) co-surfactant; iv) fatty acids and their amine salts; or v) combinations thereof; and E) optionally ammonium nitrate.

Owner:MULLAY JOHN J +5

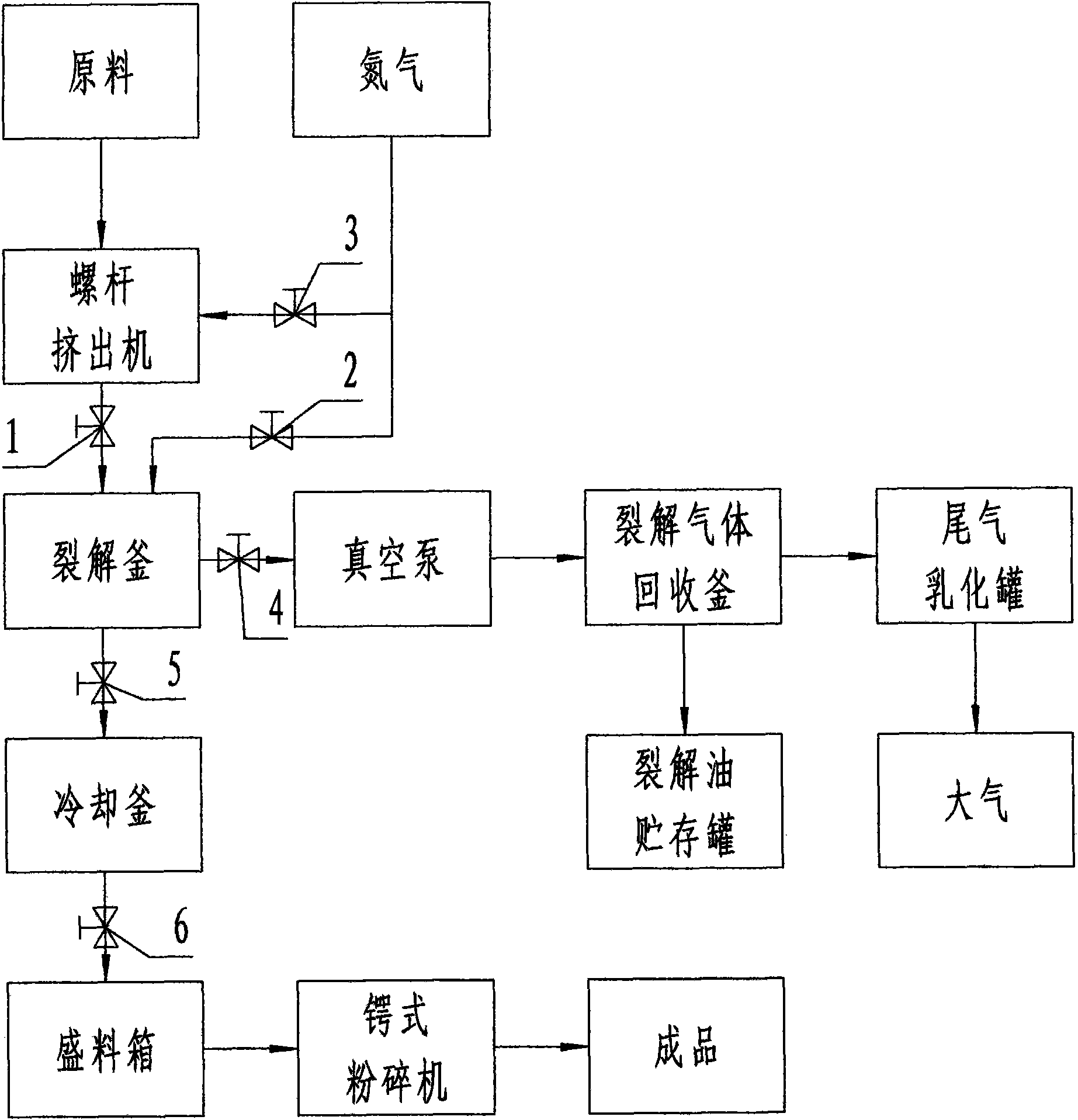

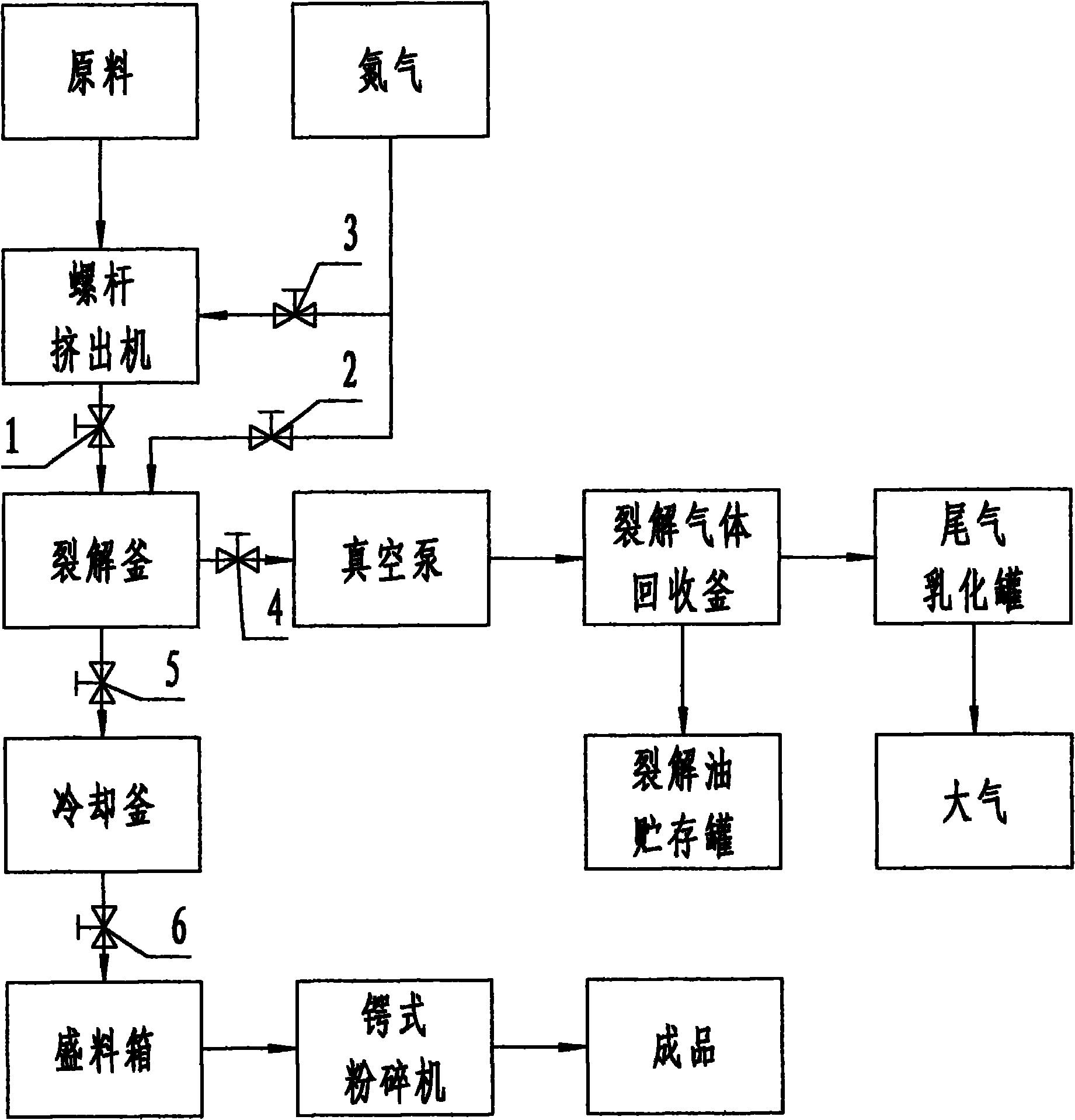

Simple method for preparing polyethylene wax from waste plastic

The invention discloses a simple method for preparing polyethylene wax from waste plastic, which comprises raw materials, nitrogen, equipment and process flows. The method solves the problems that the prior art is not suitable for private small enterprises to implement on-site reclamation, treatment and utilization by adopting the technical problem that the conventional equipment is matched with simple and feasible process flows of extrusion of a screw extruder, feeding of a cracking kettle, cracking, distillate oil reclamation, emulsified oil reclamation, cooling and crushing, wherein the conventional equipment comprises the screw extruder, the cracking kettle with an electric heater and a stirrer, a stainless steel cooling kettle with a stirrer and a cooling jacket, a stainless steel accommodating tank with an open upper part, a jaw crusher, a vacuum pump, a stainless steel cracking gas reclamation kettle with a cooling jacket, a stainless steel cracking oil storage tank and a stainless steel tail gas emulsifying tank. The simple method for preparing the polyethylene wax from the waste plastic fulfills the purpose of suitability for on-site reclamation, treatment and utilization for the private small enterprises through the conventional equipment and the simple process.

Owner:NINGBO CREATE NEW MATERIAL

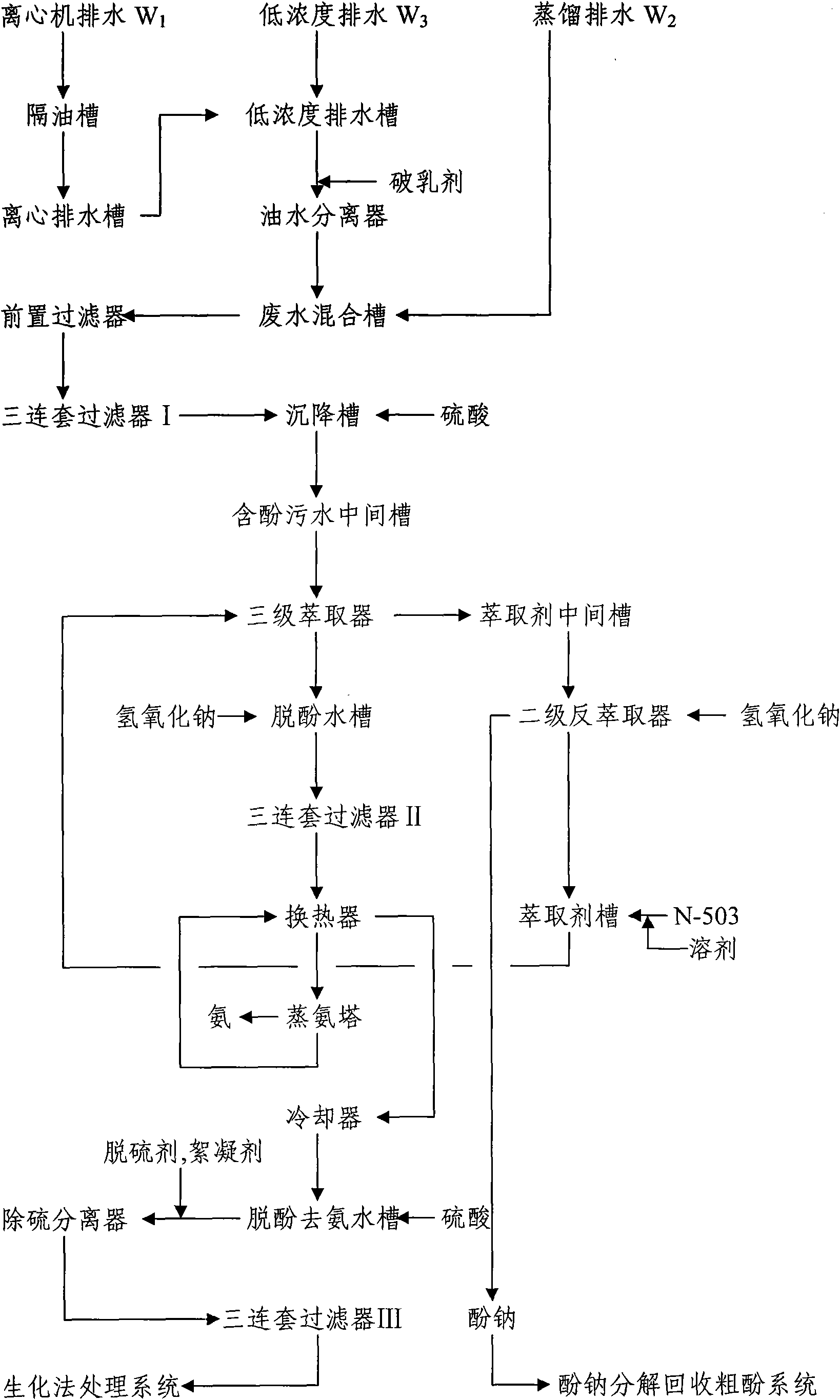

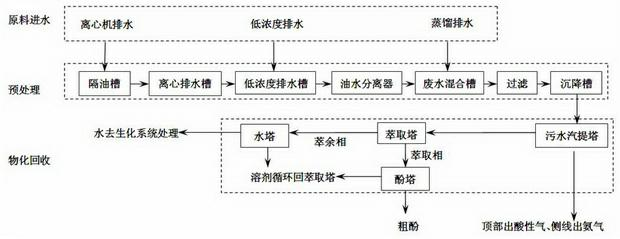

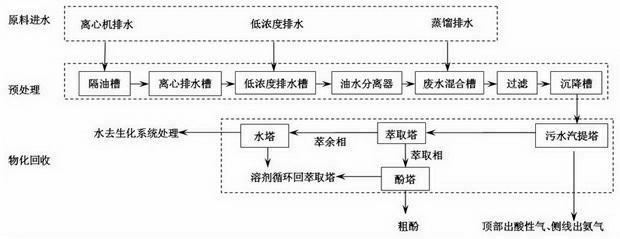

Separation treatment method for waste water in coal tar machining process

InactiveCN102674609AEasy to handleEmission complianceMultistage water/sewage treatmentWater/sewage treatment by heatingWastewaterProcess engineering

The invention discloses a separation treatment method for waste water in a coal tar machining process. The separation treatment method mainly comprises the following steps of: at first, pre-treating the waste water in the coal tar machining process to remove free oil and emulsified oil, and then entering a waste mixing groove; secondly, further removing oil matter by filtering and entering a subside for removing depositions through settling, so as to obtain oil-removed waste water; removing hydrogen sulfide and amine after the oil-removed waste water enters a sewage steam stripping tower, and extracting after acid-removed and amine-removed waste water enters an extraction tower; recovering crude carbolic acid and an extracting agent after an extract phase enters a phenol tower; separating the extracting agent from water after a residual extract phase enters a water tower; and processing after the water enters a follow-up biochemical system. The separation treatment method provided by the invention firstly removes acid and anime of the waste water, provides a good acid-alkali condition for follow-up solvent extraction and dephenolization, and has no need of adding a great amount of the acid and alkali in a treatment process. Meanwhile, byproducts, such as the crude carbolic acid, the anime, the hydrogen sulfide and the like, can be recovered. The water quality of the treated waste water can meet the water inlet requirements of the normal biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com