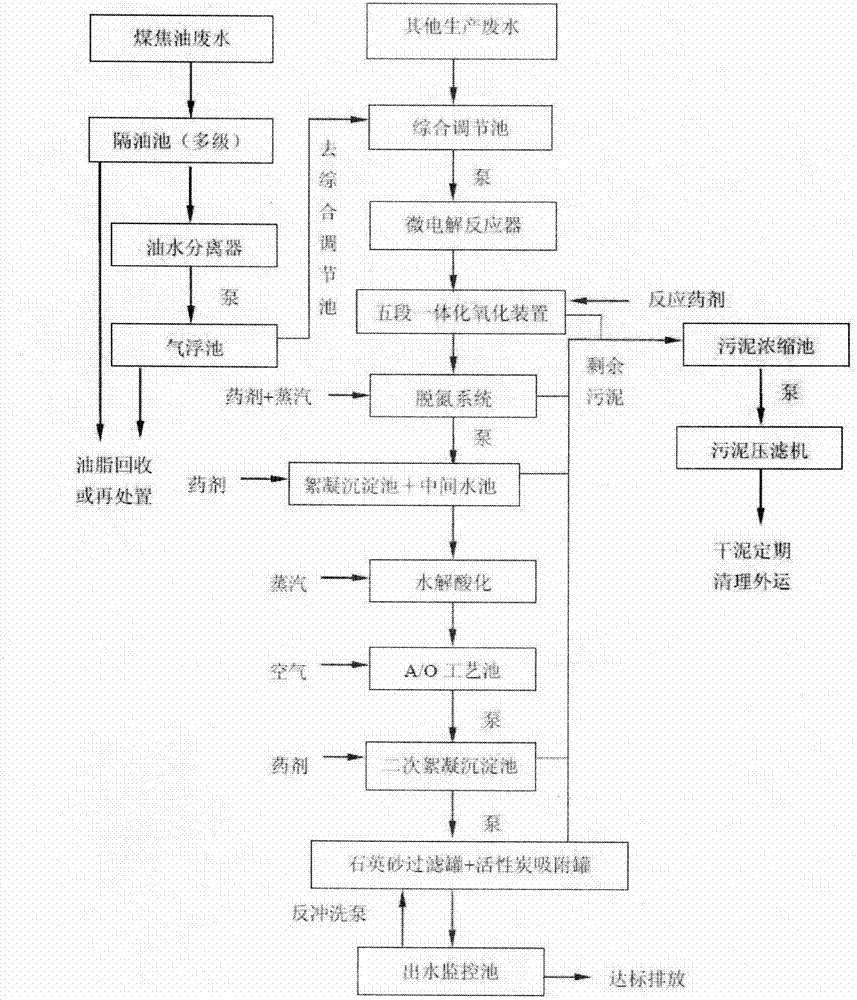

Complete equipment and process for processing coal tar wastewater

A sewage treatment and complete set of equipment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of demanding water inlet conditions, complex pollutant components, high organic matter content, etc. problems, to achieve the effect of reducing sludge disposal costs, high removal effect, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Referring to the accompanying drawings, the treatment process unit of the present invention will be described in detail.

[0034] 1. Preprocessing part

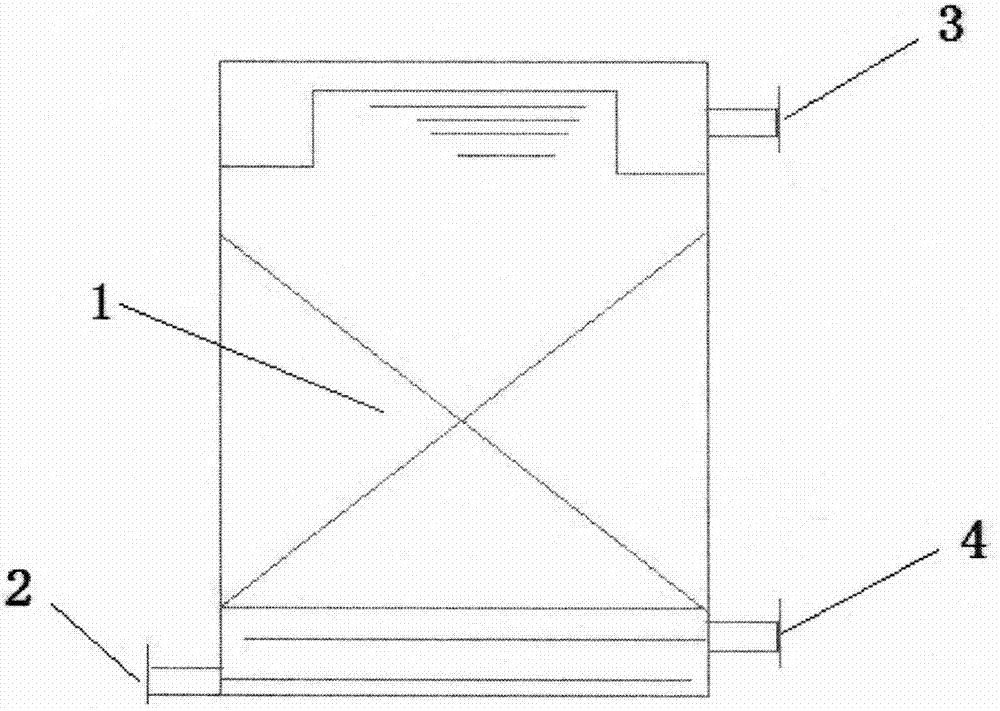

[0035] ①Grease trap (multi-stage)

[0036] Function: The grease trap is a treatment structure that uses the difference in specific gravity between oil and water to separate and remove suspended oil with large particles in sewage.

[0037] Design parameters: design effective volume: 48.0m 3 ;Hydraulic retention time (HRT): 6.0h. The net size of the structure: L×B×H=3000×12000×2500 (mm), the effective water depth is 1.4m. Structural form: underground steel-concrete structure (pool wall anti-corrosion treatment). Quantity: 1 seat.

[0038] Supporting main equipment: oil skimmer: non-standard design and manufacture, quantity 2 sets. Oil discharge pump: Q=10m 3 / h, H=10m, N=1.5kw, quantity 2 sets (prepare one).

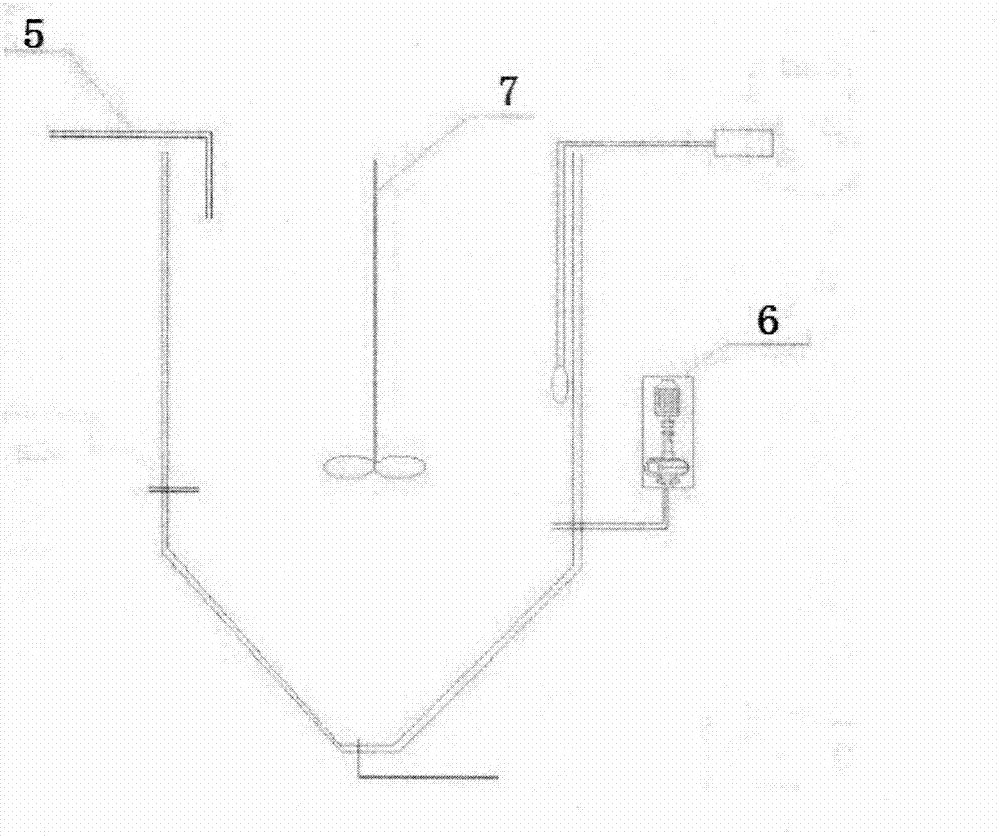

[0039] ②Comprehensive adjustment pool

[0040] There is unevenness in sewage discharge during factory pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com