Patents

Literature

631results about How to "Low temperature requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

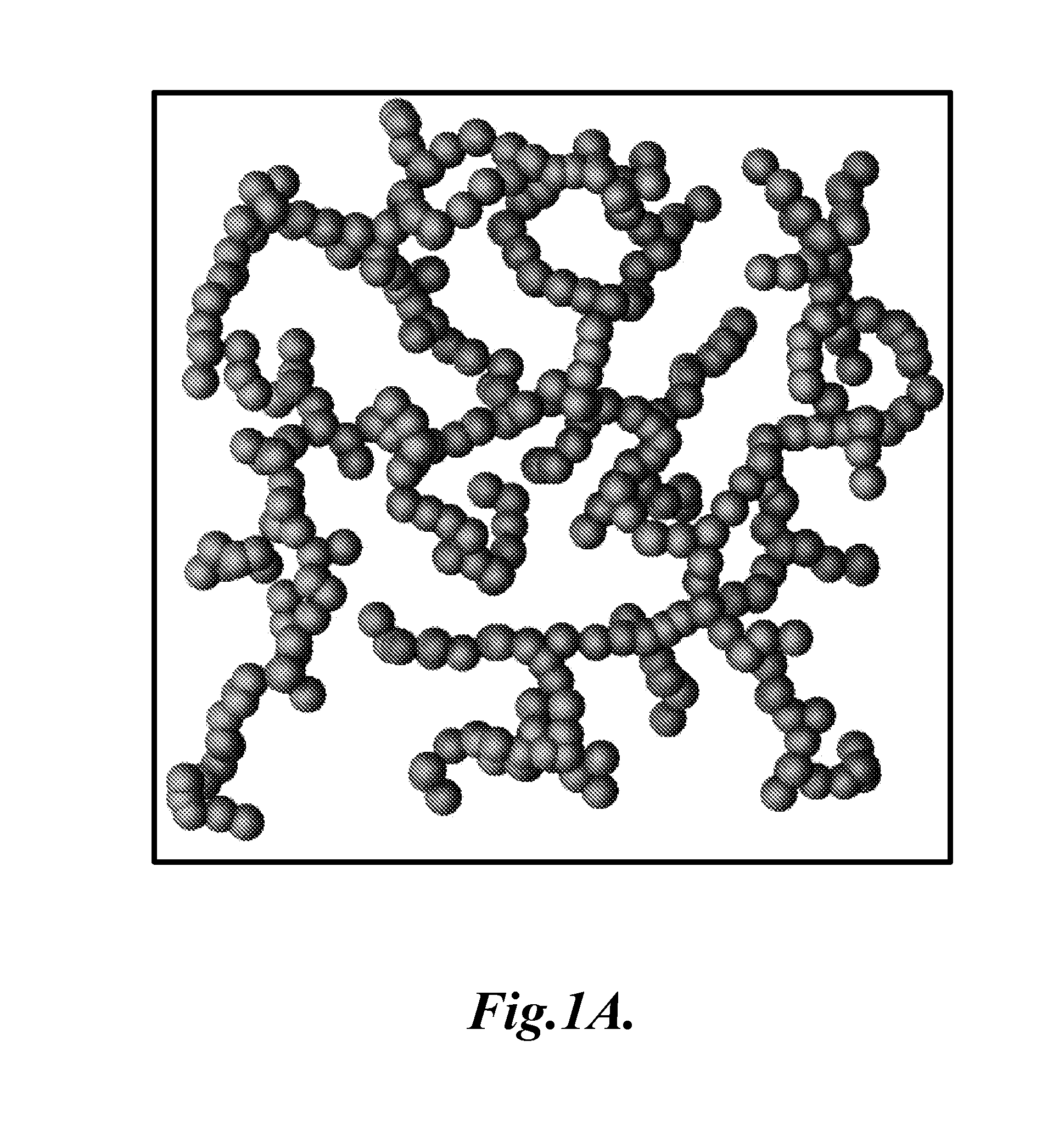

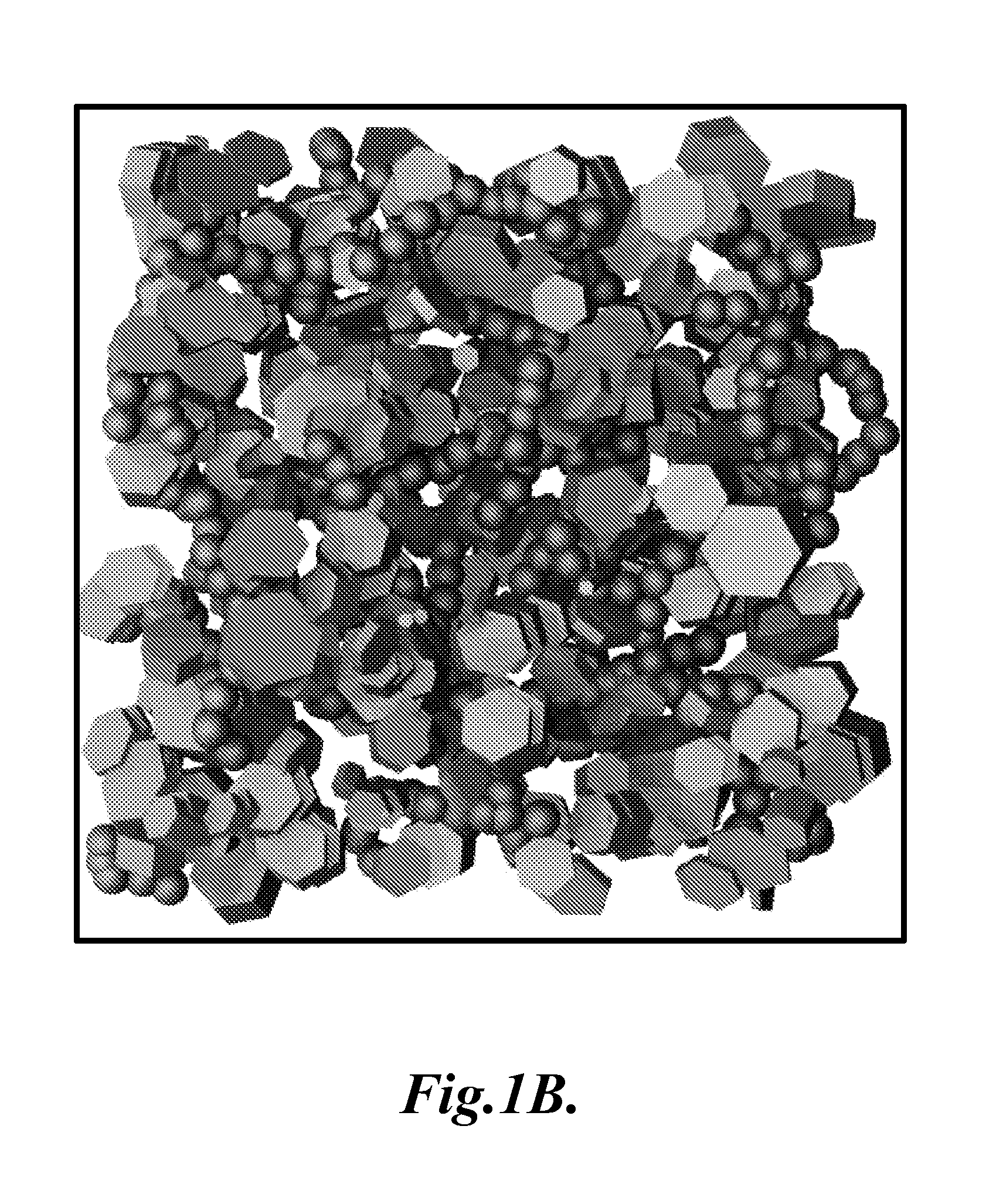

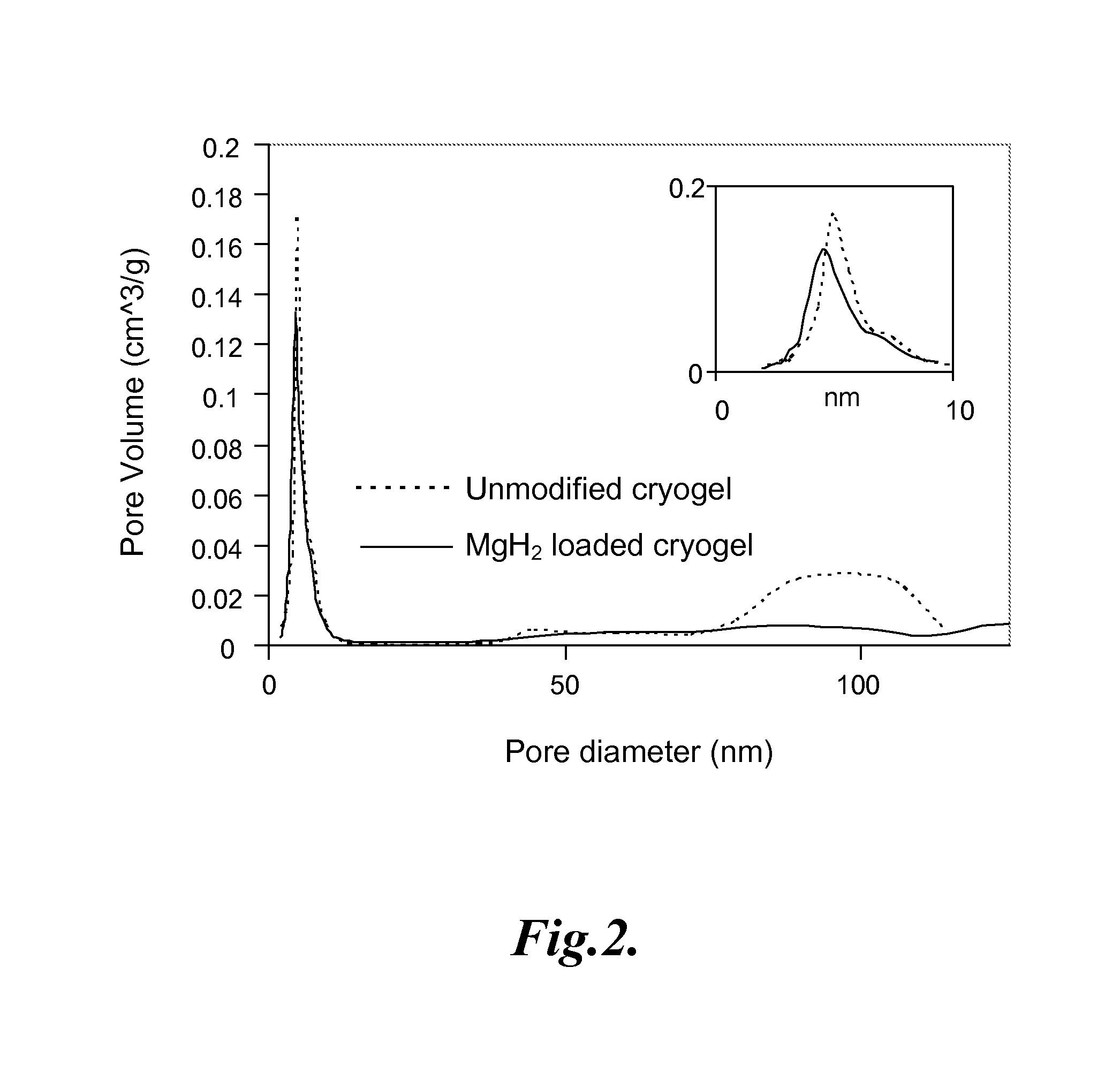

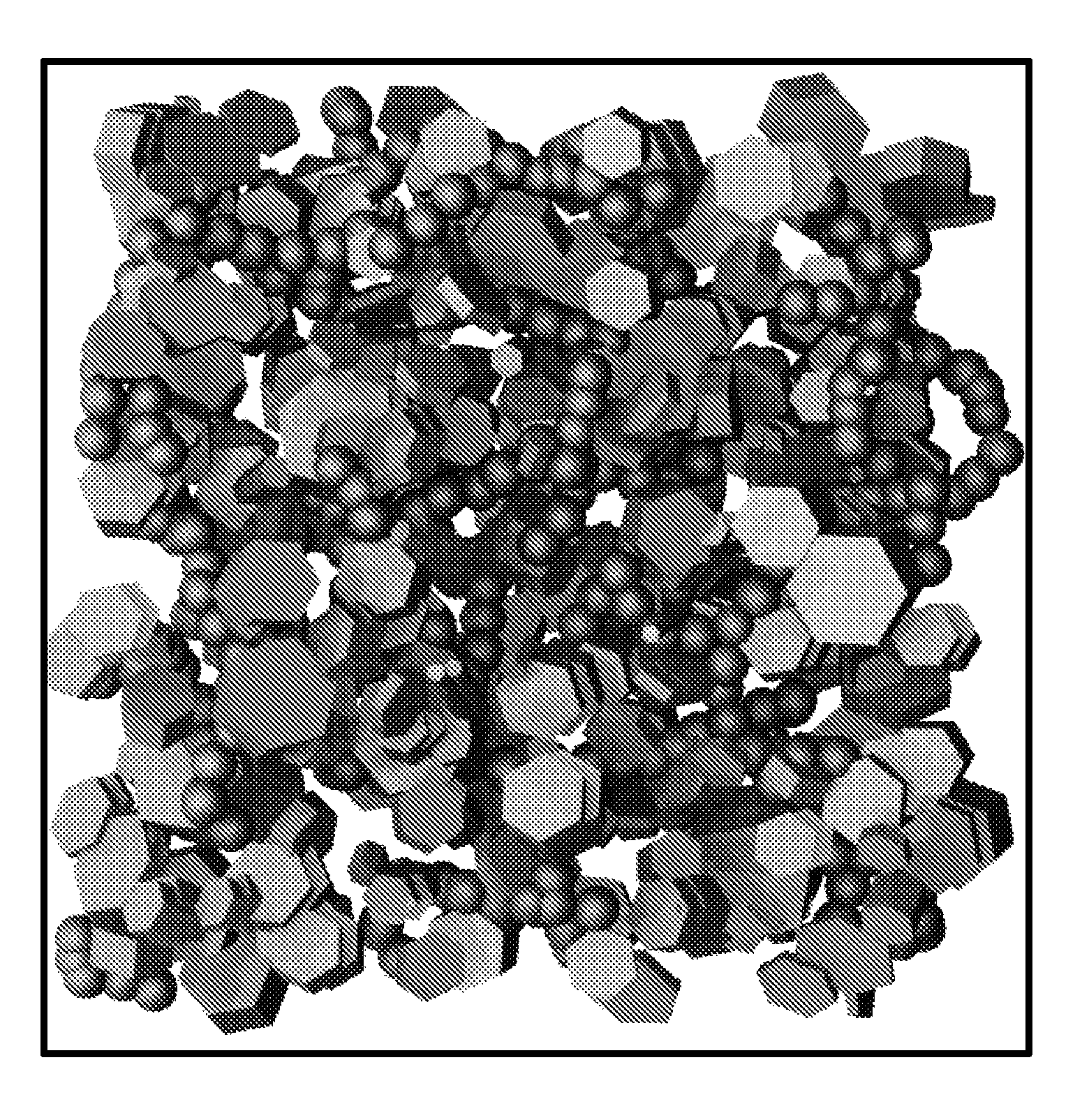

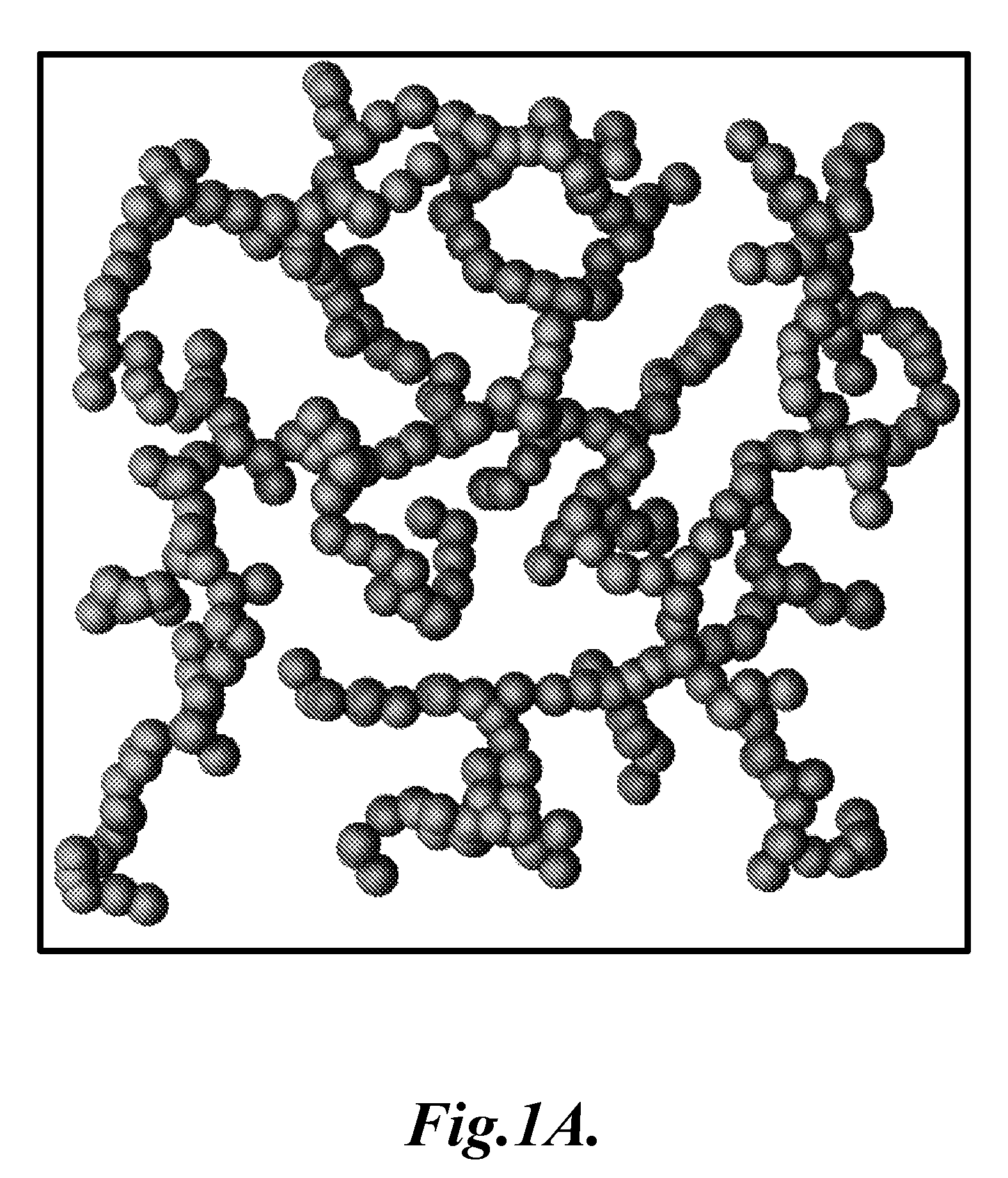

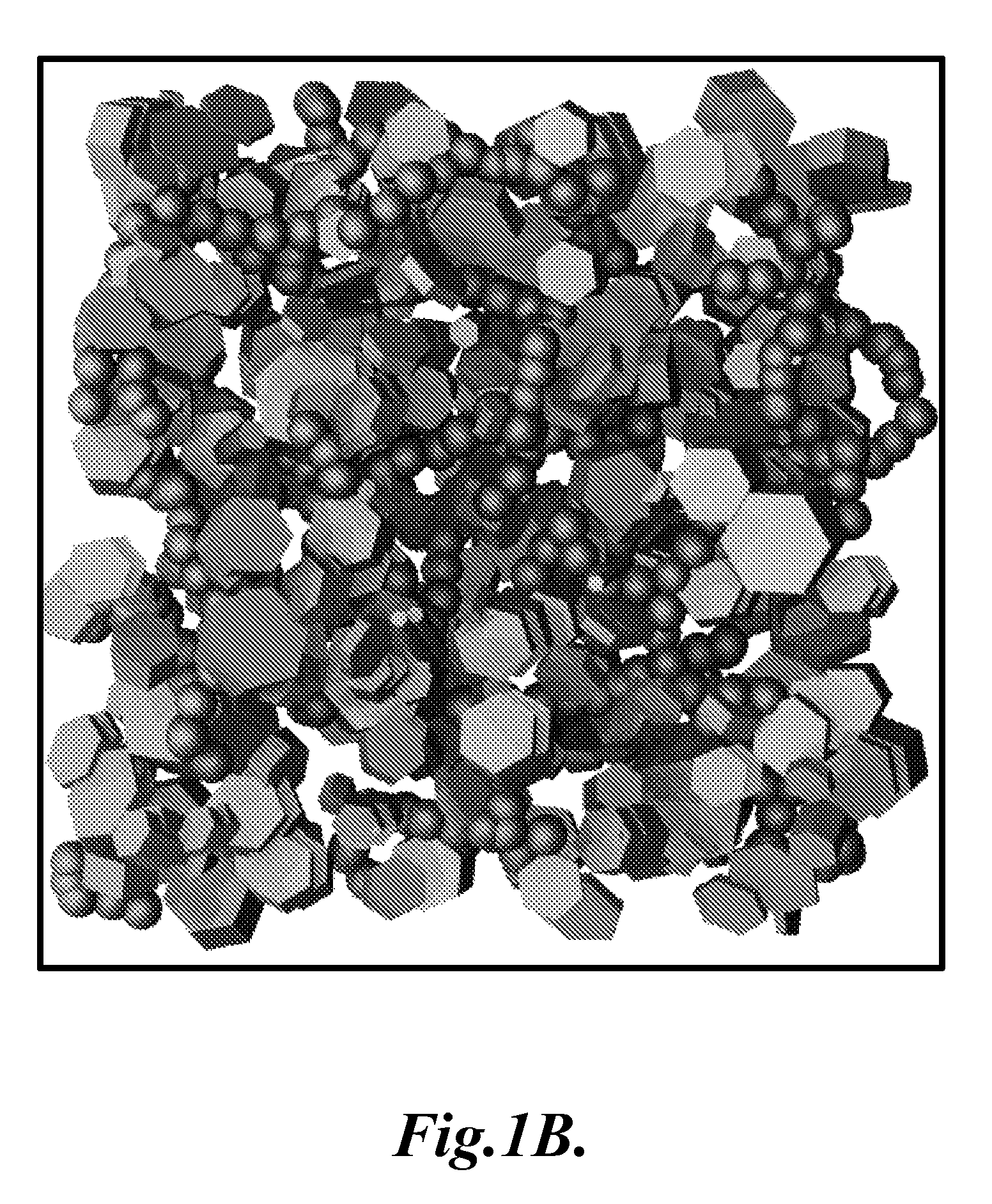

Carbon-based foam nanocomposite hydrogen storage material

ActiveUS20070292732A1Low temperature requirementReduces hydrogen releaseMaterial nanotechnologyHydrogenNanometreSolid-state

A carbon-based foam composite including a carbon-based foam and a solid state hydrogen storage material, methods for making the carbon-based foam composite, and methods for using the carbon-based foam composite. Representative carbon-based foams include cryogels, aerogels, and xerogels. Representative solid state hydrogen storage materials include metal hydrides and chemical hydrides.

Owner:UNIV OF WASHINGTON +1

Carbon-based foam nanocomposite hydrogen storage material

ActiveUS7816413B2Low temperature requirementIncreasing the amount of hydrogen released from the compositeMaterial nanotechnologyHydrogenNanometreChemical hydrides

Owner:UNIV OF WASHINGTON +1

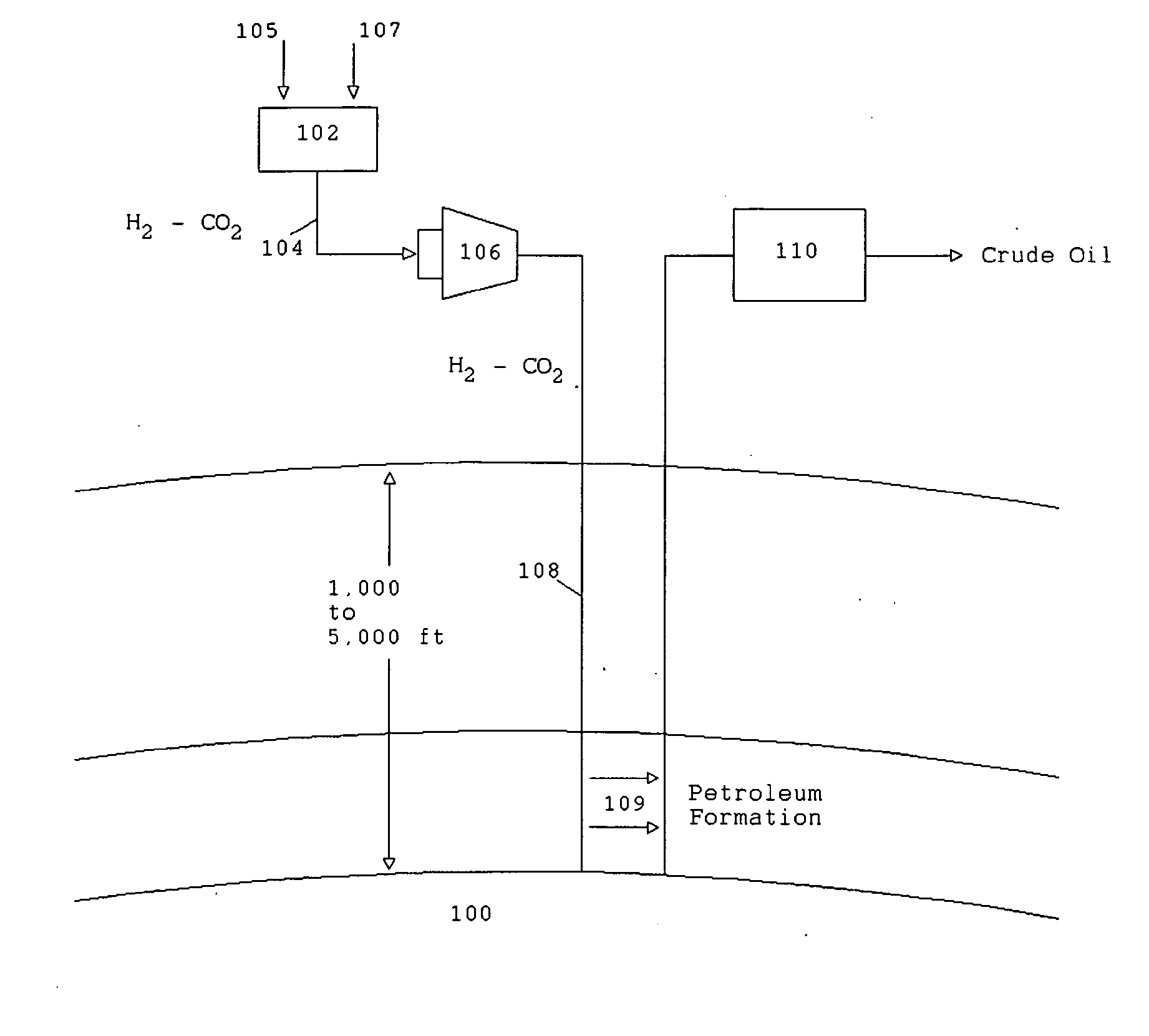

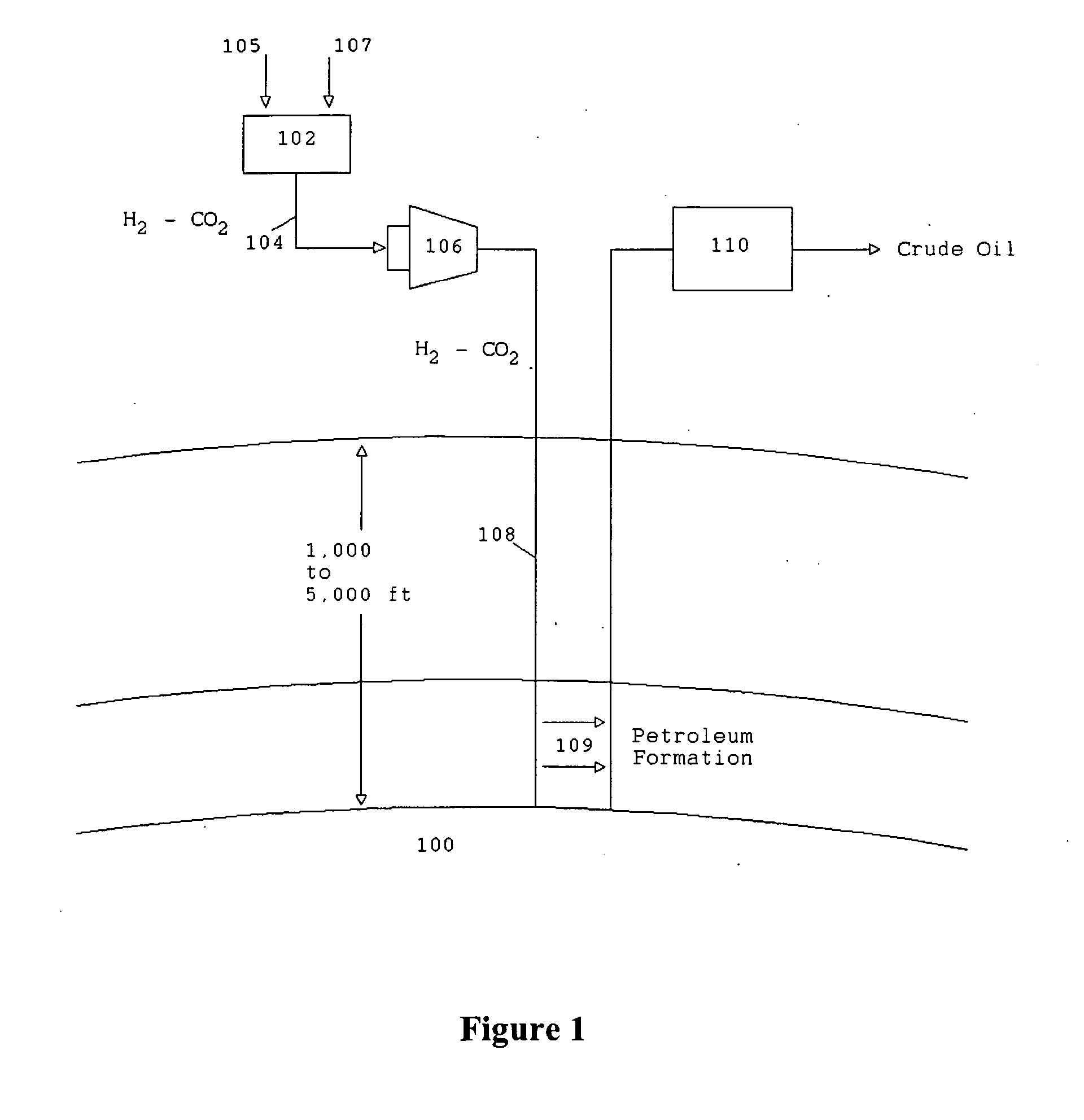

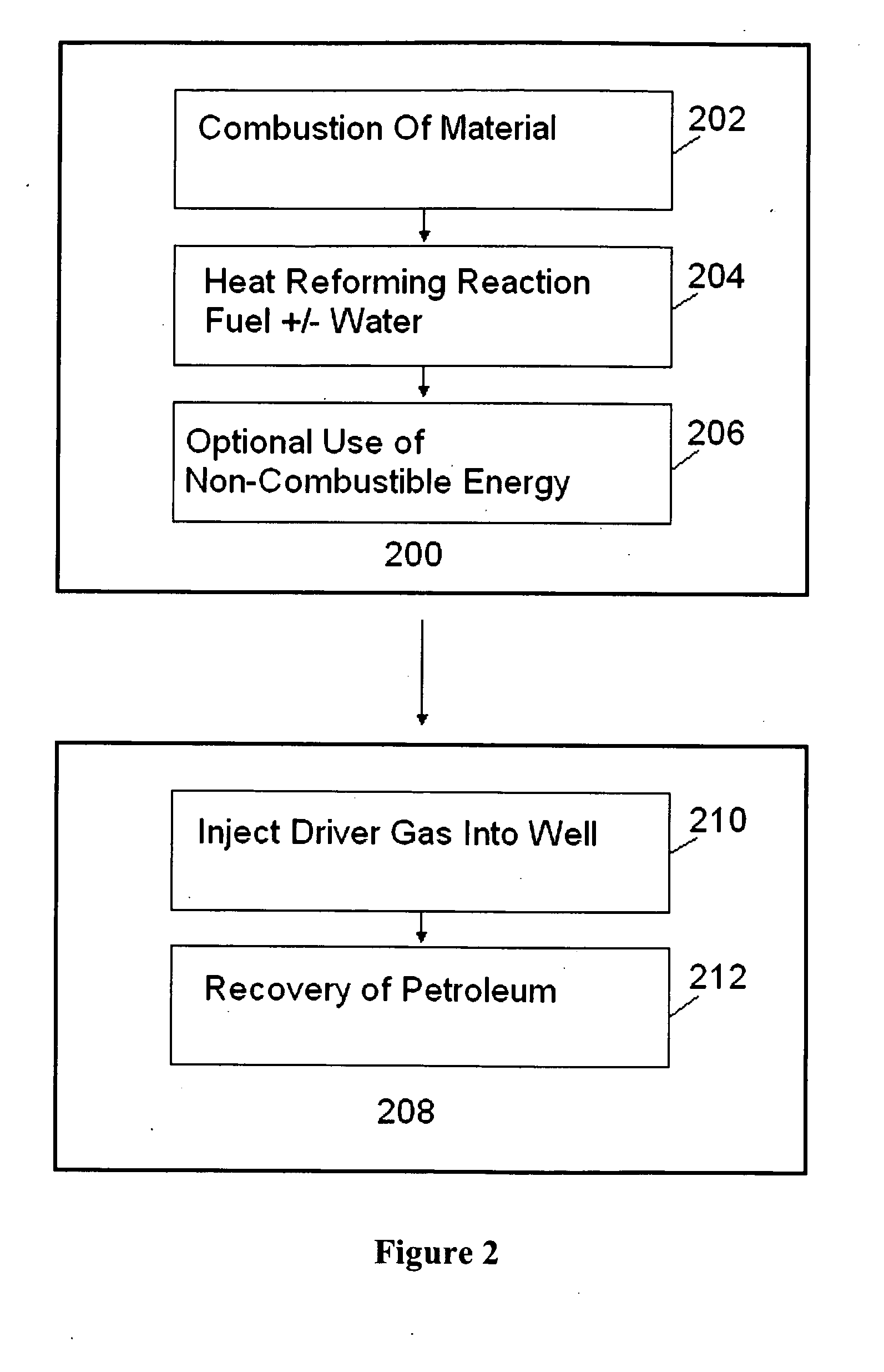

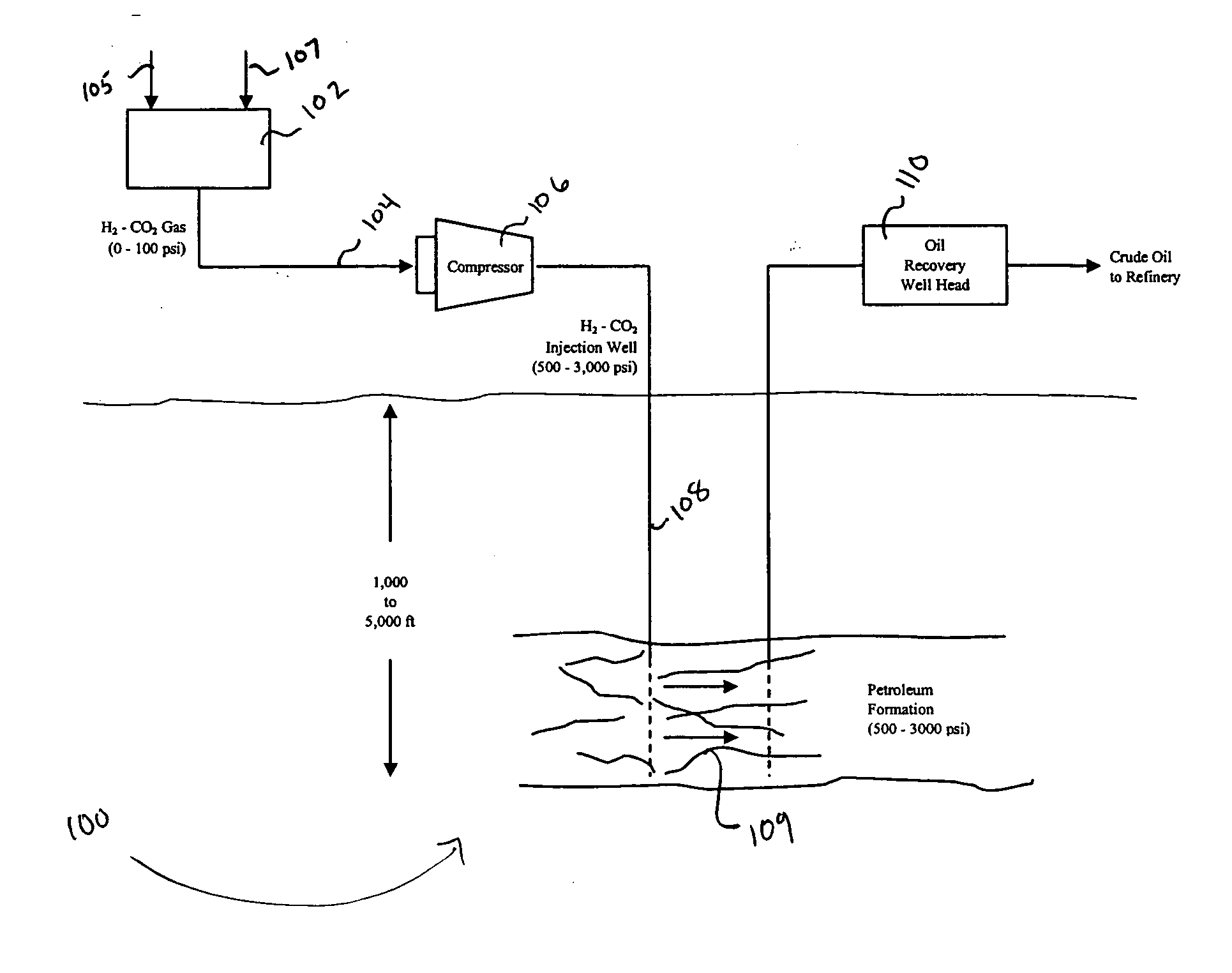

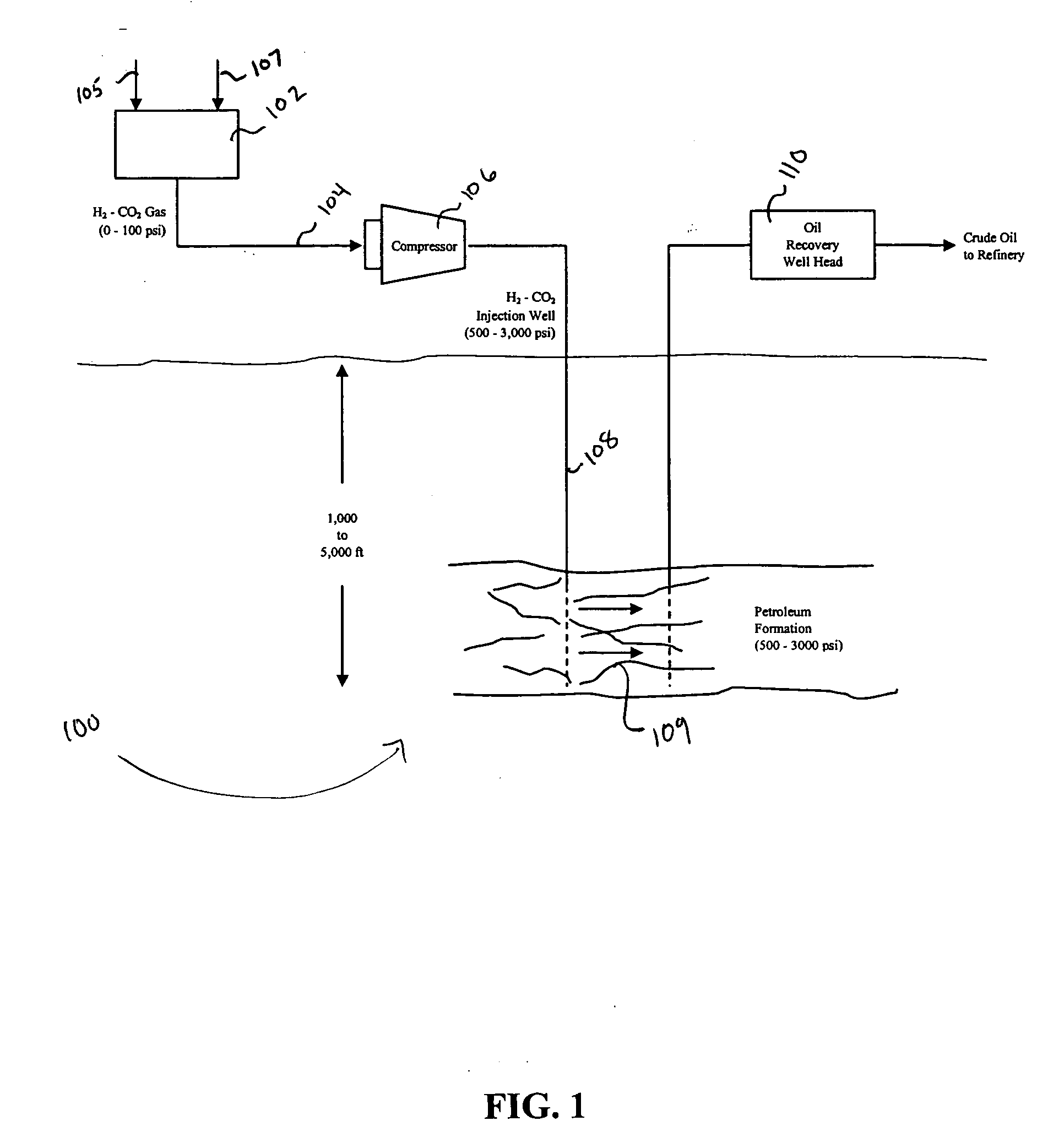

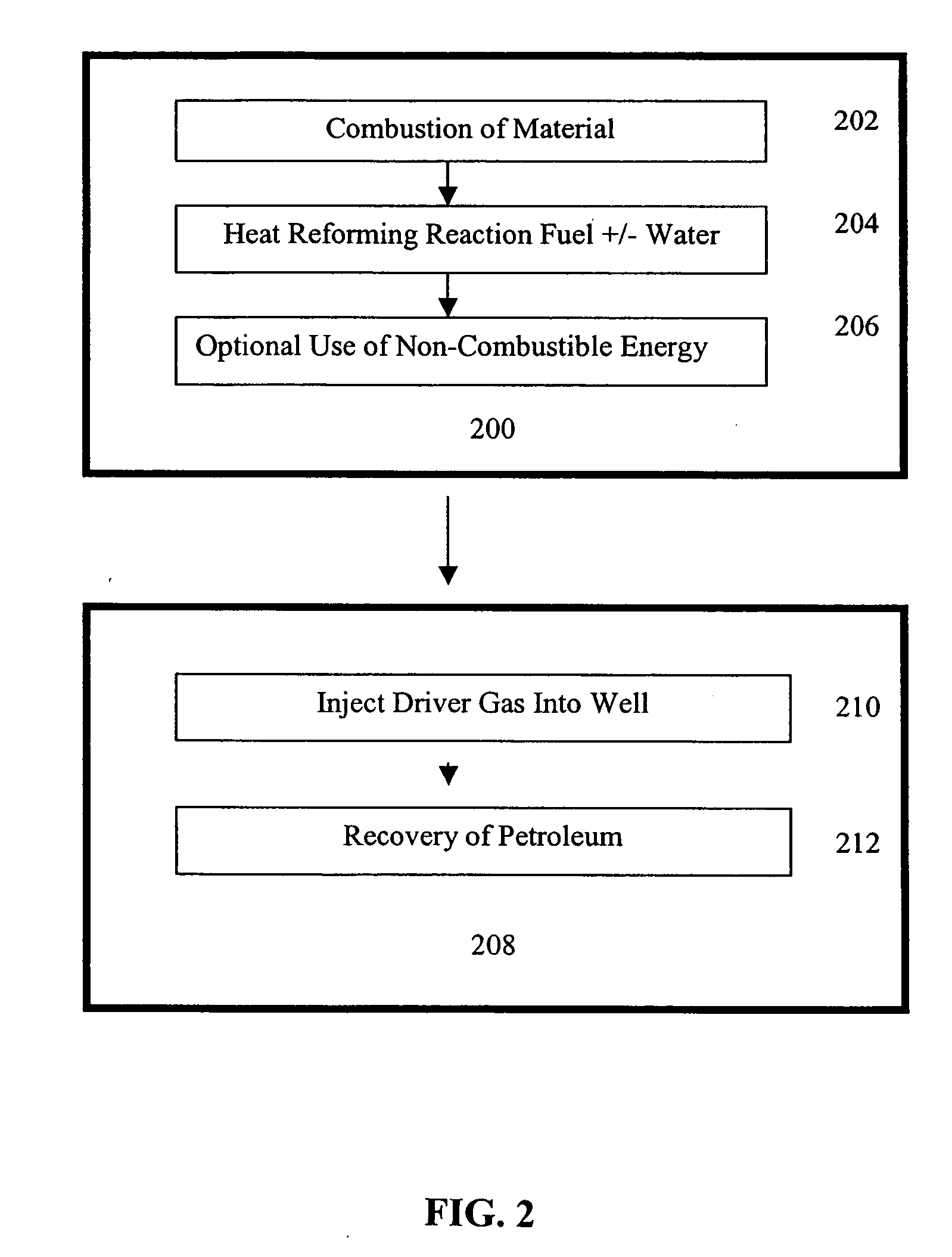

Apparatus and Method for Extracting Petroleum from Underground Sites Using Reformed Gases

InactiveUS20090236093A1Reduce temperature and amountLow temperature requirementDrilling rodsOther gas emission reduction technologiesProcess engineeringCoal

Provided herein are methods and apparatus for removing oil or natural gas from the ground. In one example, the method may include reforming a fuel source by reaction with water to generate driver gas, and injecting the driver gas into the oil well. The reforming operation may include causing the combustion of a combustible material with ambient oxygen for the release of energy; and heating a reforming reaction fuel and water sources, with the energy released from the combustion of the combustible material, to a temperature above that required for the reforming reaction wherein the fuel and water sources are reformed into driver gas. In one example, the amount of the combustible material combusted is sufficient to result in the release of enough energy to heat an amount of the reforming reaction fuel and water sources to the temperature above that required for the reforming reaction to proceed. The driver gas may be used to help extract oil from the ground and especially oil from depleted oil wells. It may also be used to drive natural gas trapped underground or in coal beds to the surface.

Owner:PIONEER ENERGY

Polyurethane resin composition, preparation method and application thereof

InactiveCN101735595AImprove water resistanceImprove featuresBallastwayTrack maintainencePolyolefinAlcohol

The invention provides a polyurethane resin composition, a preparation method and application thereof. The polyurethane resin composition comprises a component A and a component B, wherein the component A contains polyolein polyatomic alcohol, a plasticizer, an anti-settling agent and other auxiliary agents; the component B is isocyanate or prepolymer of the isocyanate; and the mass ratio of the A to the B is 10:1-1:10. A pouring material containing the resin composition can be used as a patching material for a cement road bed, a boss resin layer and a mortar packing layer of a railway plate-type unballasted track and has the advantages of high water resistance, ageing resistance and low temperature resistance, long service life and capability of being used at a low temperature.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

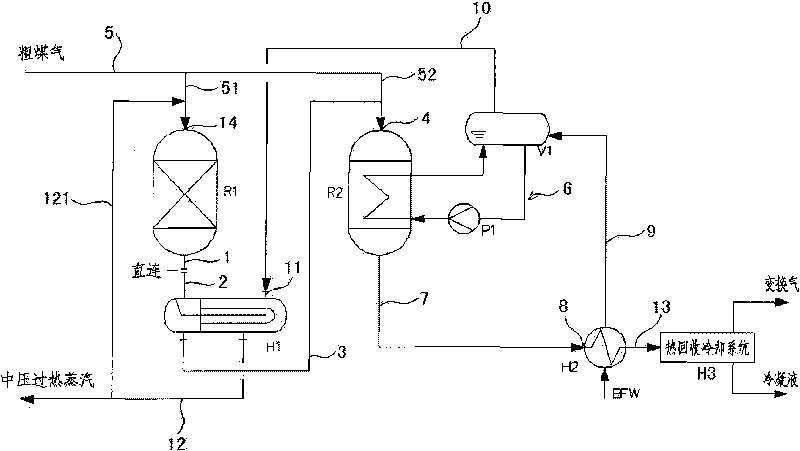

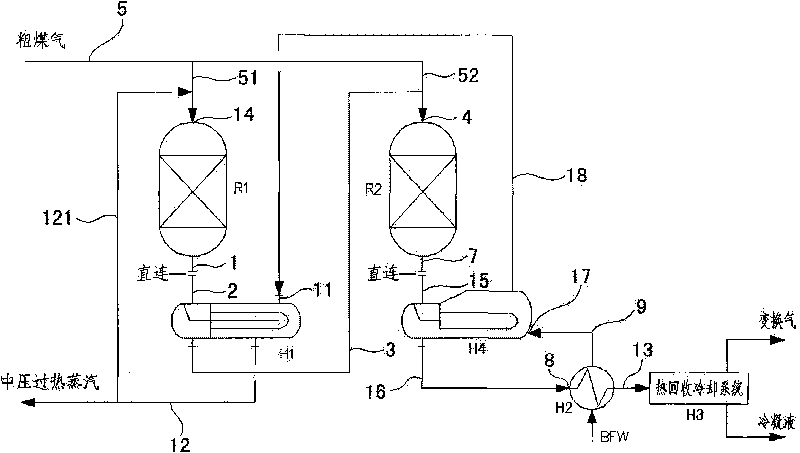

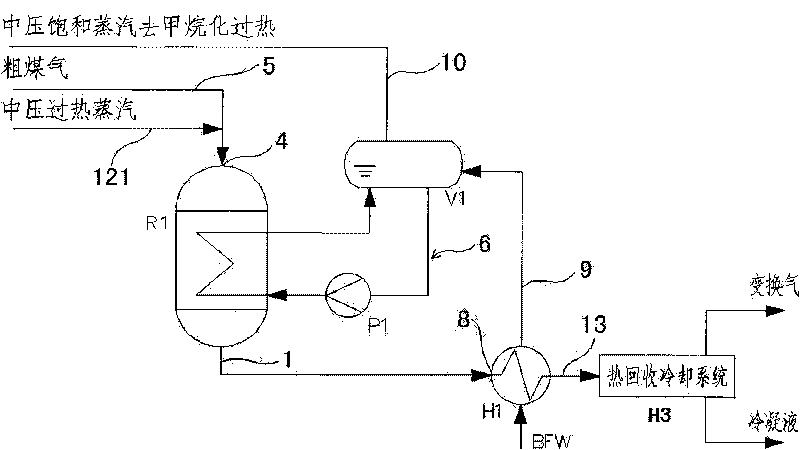

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

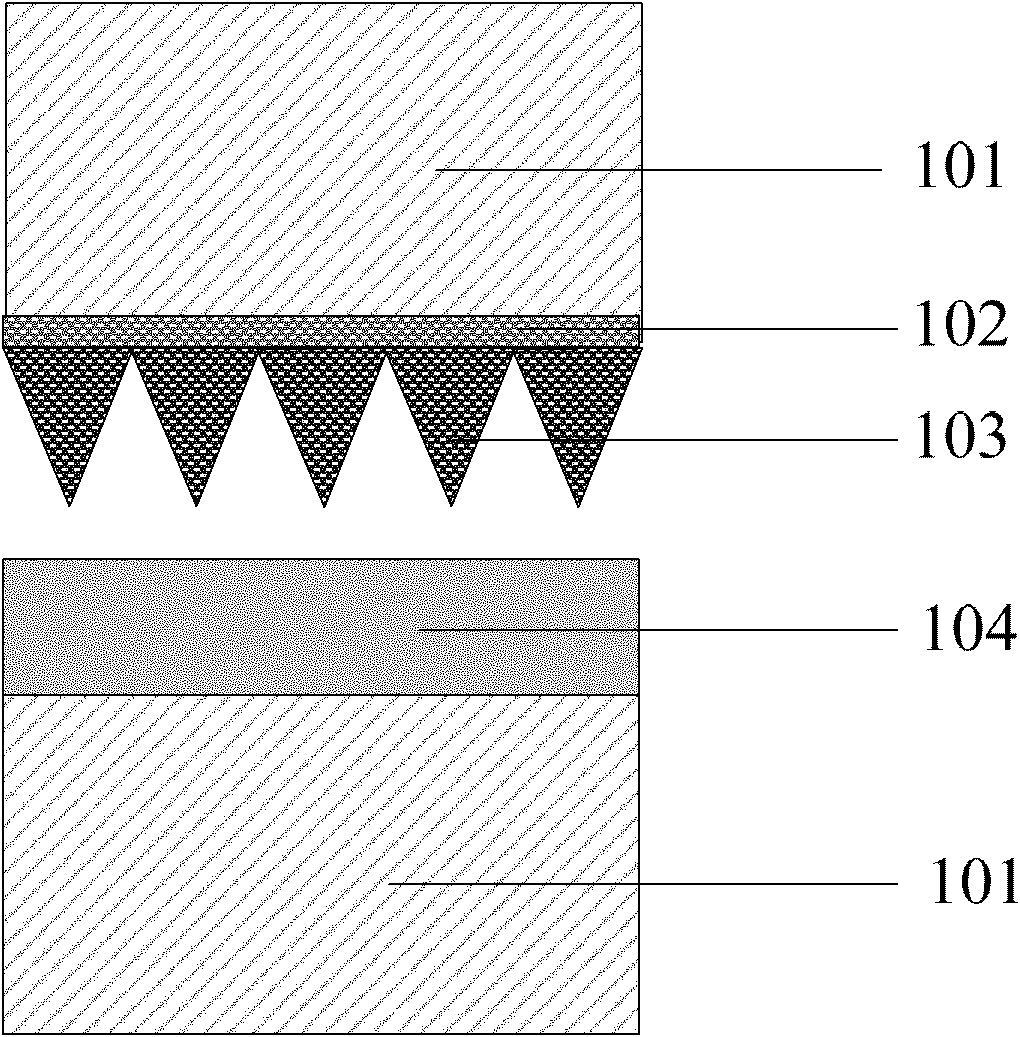

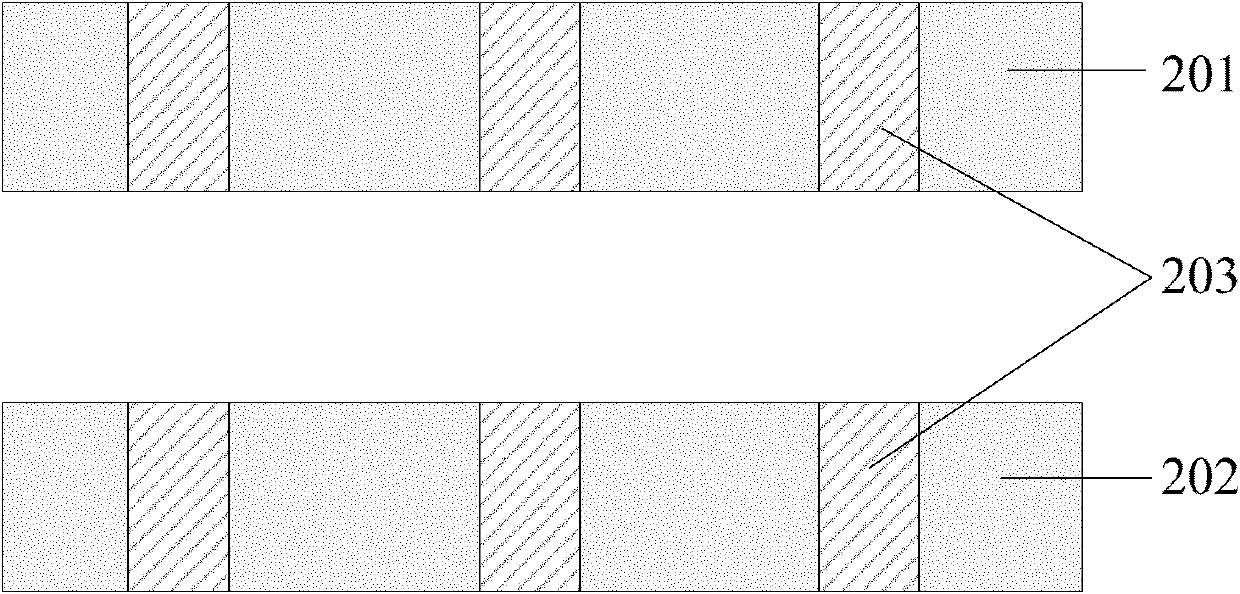

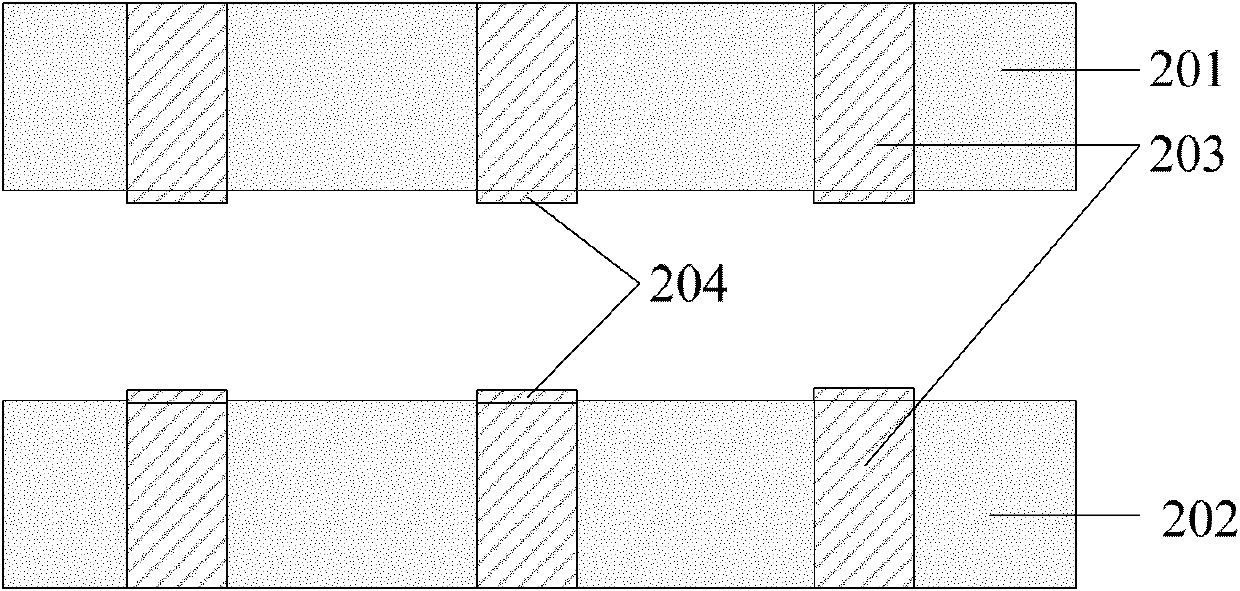

Multi-layer mixed synchronization bonding structure and method for three-dimensional packaging

ActiveCN102169845AGuaranteed accuracy requirementsSave time and costSemiconductor/solid-state device detailsSoldering apparatusDielectricHard metal

The invention relates to a multi-layer mixed synchronization bonding structure and a method for three-dimensional packaging. The method comprises the following steps of: forming a hard metal conical array on a surface of a metallic pad of a substrate to be mixed and bonded; forming a soft metal layer on the surface of the metallic pad of the other substrate to be mixed and bonded; forming dielectric adhesion layers on surfaces of non-metallic pads of the two substrates to be mixed and bonded; aligning the hard metal conical array with the soft metal layer, heating and pressurizing to make thehard metal conical array inserted into the soft metal layer, and combining the dielectric adhesion layers with each other to form a mixed pre-bonding structure; and then heating, forming an intermetallic compound in the hard metal conical array which is inserted into the soft metal layer, and solidifying and combining the dielectric adhesion layers. Compared with the conventional bonding method, the method provided by the invention has the advantages that: yield is high; bonding time is saved; cost is reduced; and the reliability of a product is improved at the same time.

Owner:NAT CENT FOR ADVANCED PACKAGING

Apparatus and method for extracting petroleum from underground sites using reformed gases

InactiveUS20070227729A1Reduce temperature and amountLow temperature requirementDrilling rodsOther gas emission reduction technologiesCoalProcess engineering

Methods and apparatus for removing oil or natural gas from the ground. In one example, the method may include reforming a fuel source by reaction with water to generate driver gas, and injecting the driver gas into the oil well. The reforming operation may include causing the combustion of a combustible material with ambient oxygen for the release of energy; and heating a reforming reaction fuel and water sources, with the energy released from the combustion of the combustible material, to a temperature above that required for the reforming reaction wherein the fuel and water sources are reformed into driver gas. In one example, the amount of the combustible material combusted is sufficient to result in the release of enough energy to heat an amount of the reforming reaction fuel and water sources to the temperature above that required for the reforming reaction to proceed. The driver gas may be used to help extract oil from the ground and especially oil from depleted oil wells. It may also be used to drive natural gas trapped underground or in coal beds to the surface.

Owner:PIONEER ENERGY

Ionomer modified polypropylene compound for superior scratch performance,low blushing and molded in color with controllable gloss

InactiveUS20060020086A1Readily modified control glossNot deteriorate cycle timeIonomerPolymer science

The invention pertains to a polyolefin blend, which imparts superior physical properties, which may include enhanced scratch resistance, toughness and low temperature performance, and higher flexural modulus and rigidity. The blends in this invention impart improved performance and processability over existing products.

Owner:A SCHULMAN INC

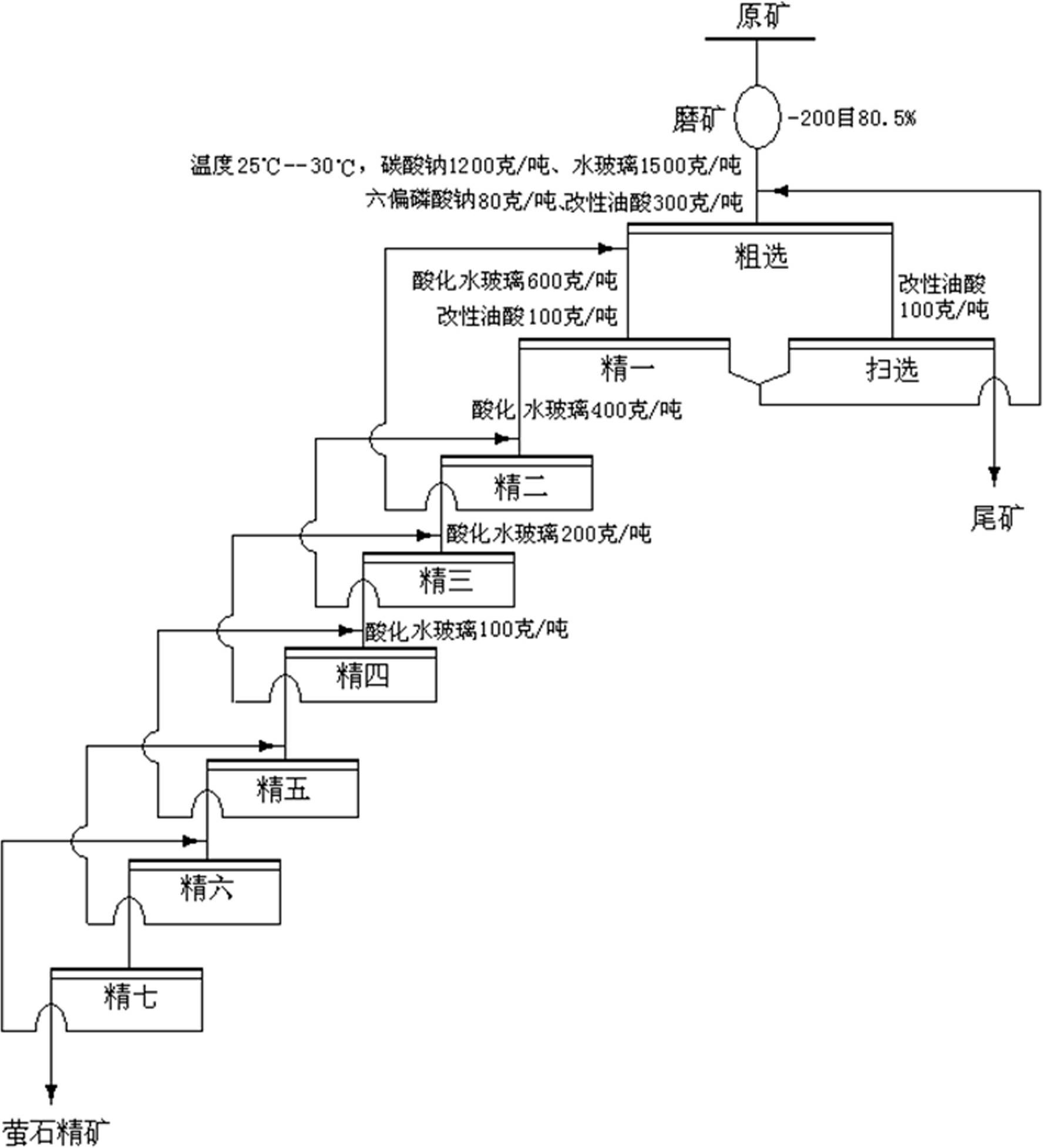

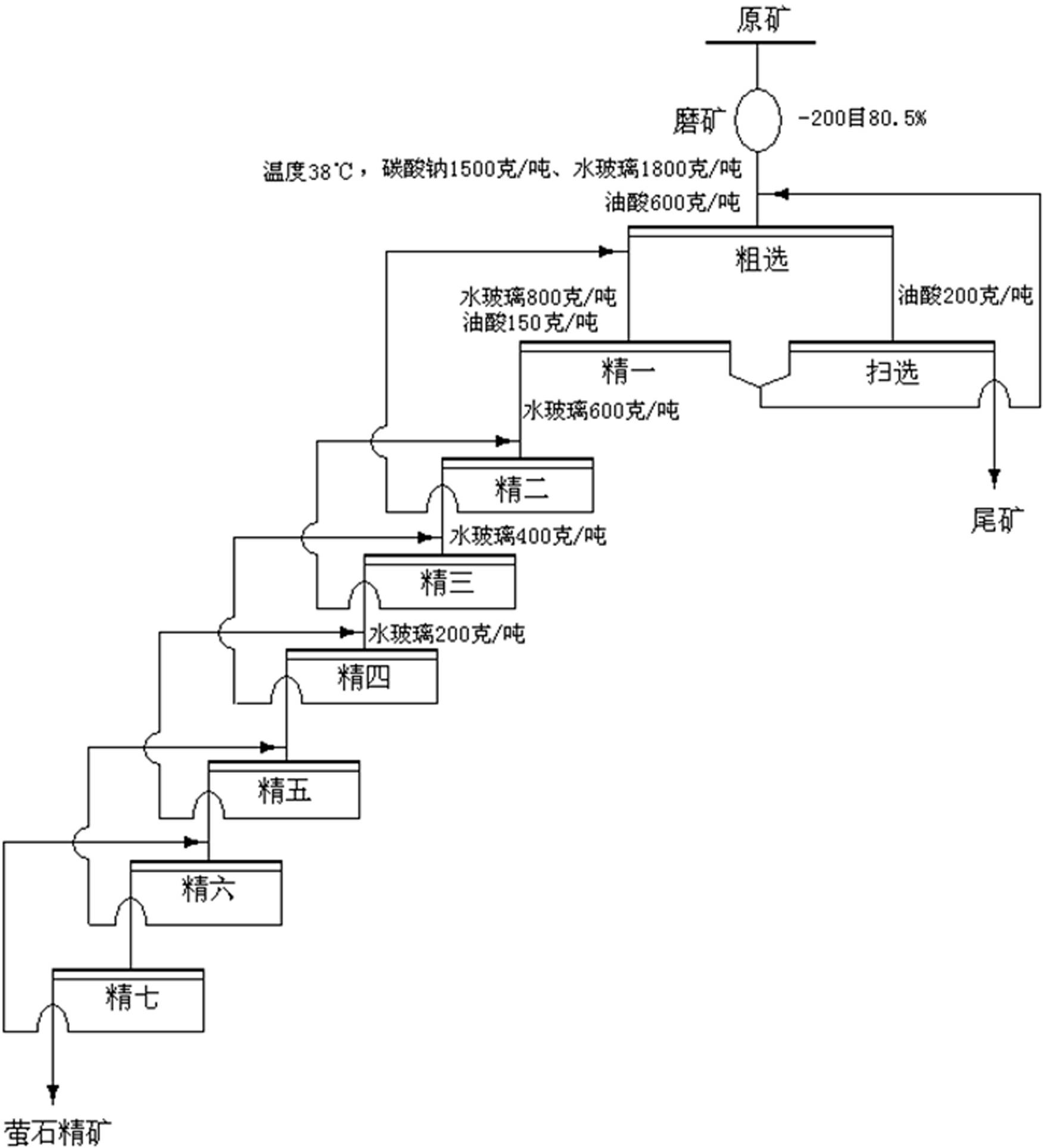

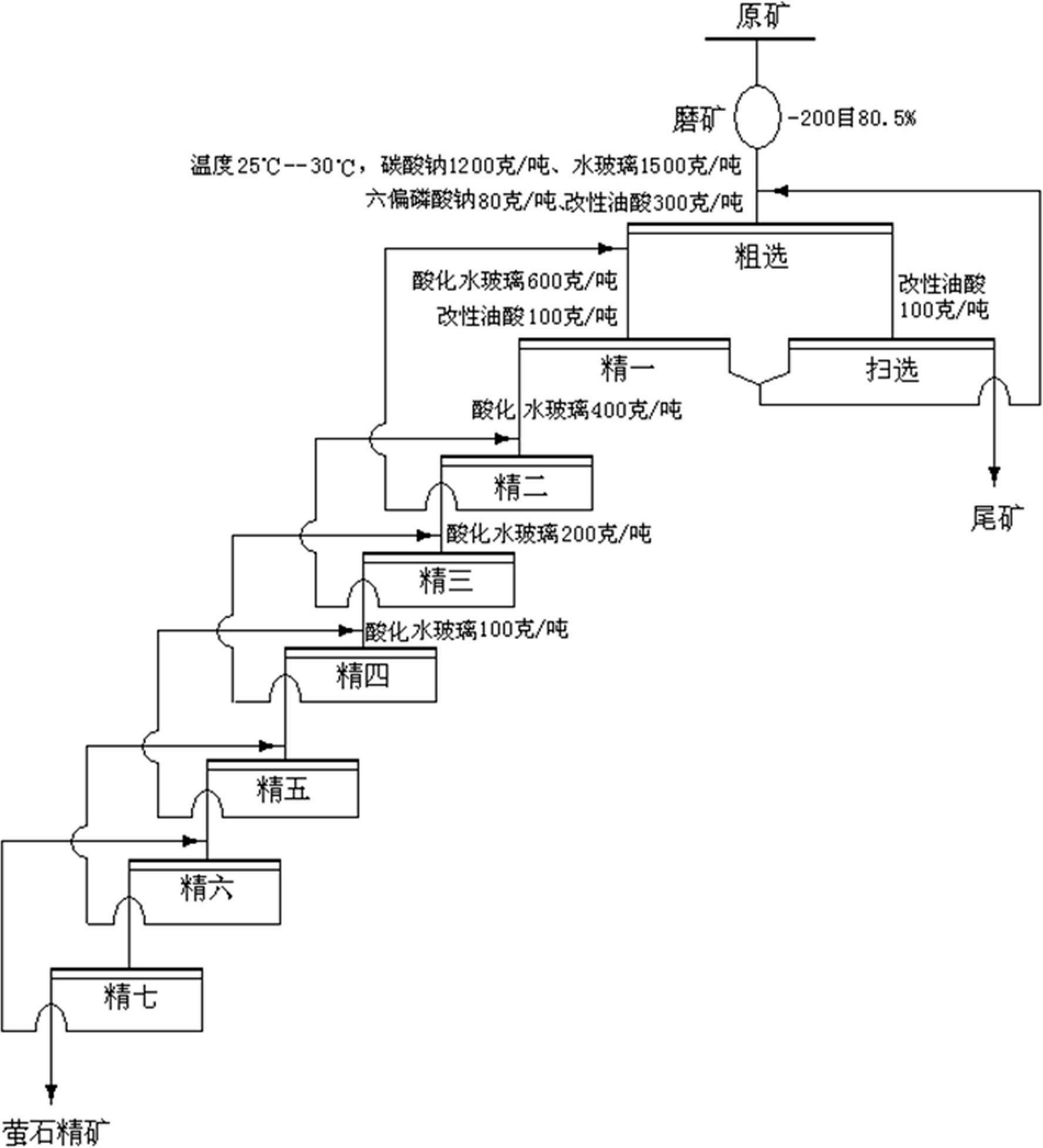

Mineral separation process of complex fluorite difficult to separate

The invention relates to a mineral separation process, in particular to a mineral separation process of complex fluorite difficult to separate. The process includes utilizing sodium hydroxide to treat oleic acid to obtain modified oleic acid, utilizing concentrated sulfuric acid to treat water glass and obtain acidized water glass, conducting ore grinding on fluorite ores according to the prior art, conducting coarse separation under the temperature of 25-30 DEG C, then conducting seven times fine separation on coarse separation foams and adding the acidized water glass into the foams in the first four times of fine separation to prepare fluorite concentrate. The process can improve separation efficiency of calcium fluoride, silica and calcite, improves quality and recycle rate of the fluorite ores, obtains high quality acid grade fluorite ores and resolves the problem of difficulty in separation of complex fluorite flotation, is remarkable in application effect in separation of the complex fluorite difficult to separate, has repeatability, simultaneously reduces requirements of fluorite mineral flotation for ore temperature, reduces energy consumption, reduces usage of collectingagent oleic acid, reduces environment pollution caused by exhaust of a large amount of waste water containing oleic acid and has better economical and social benefits.

Owner:BAIYIN NONFERROUS GROUP

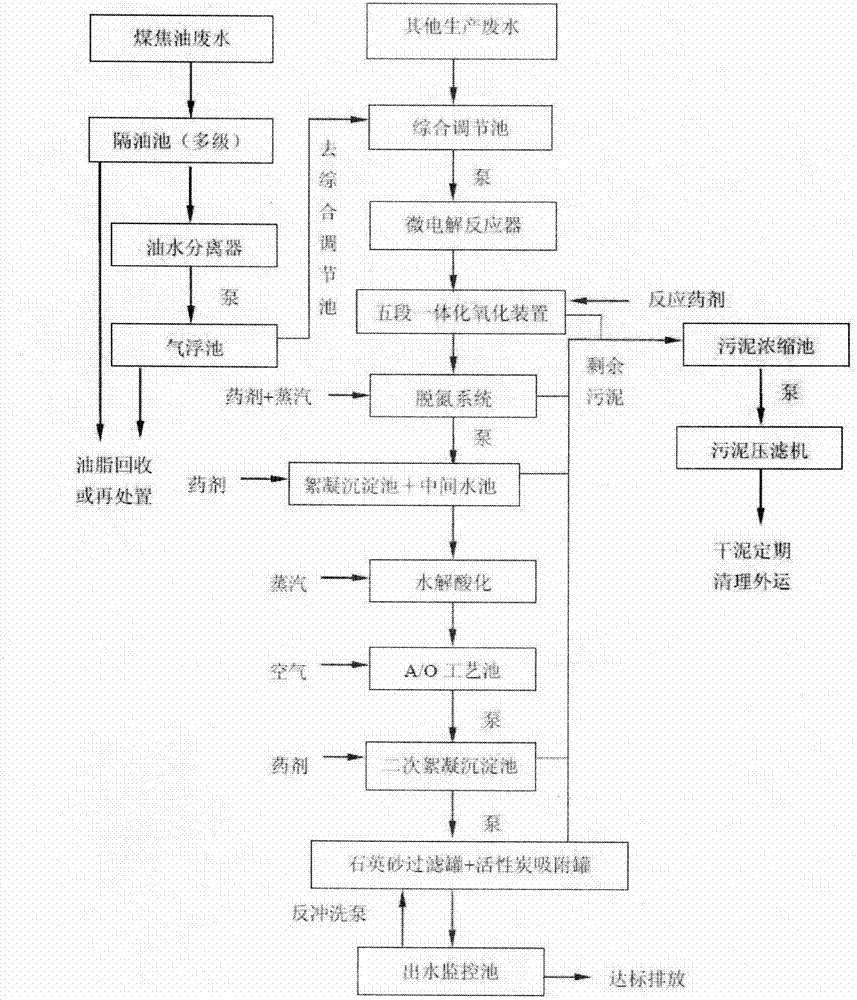

Complete equipment and process for processing coal tar wastewater

InactiveCN103113003AEasy to handleCreate economic valueMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention provides complete equipment and process for processing coal tar wastewater, and belongs to the technical field of environmental conservation. The process comprises the following steps of: adopting different removal principles according to different physicochemical properties of heavy oil, light oil and emulsified oil; scientifically and orderly removing the heavy oil, light oil and emulsified oil through three sets of environmental conservation equipment such as a multi-stage oil separator, an oil-water separator and an air floating tank gradually; combining a micro electrolysis reactor with a five-section integrated oxidization device; and firstly destroying a benzene ring by microelectrolysis, and then strongly oxidizing various organic matters through an oxidant, so that the COD (chemical oxygen demand) and the chromaticity are greatly reduced. Ammonia nitrogen can be efficiently removed by a denitrification system; the denitrification system is low on requirements of pH value and temperature, and low in operation cost; the denitrification system is arranged behind the five-section integrated oxidization device; the reaction change of power of hydrogen is fully considered; and the complete equipment complies with the scientific principle, and can be used for reducing feeding of acid and alkali, and lowering the operation cost.

Owner:NANJING ZIDU ENVIRONMENTAL PROTECTION SCI & TECH

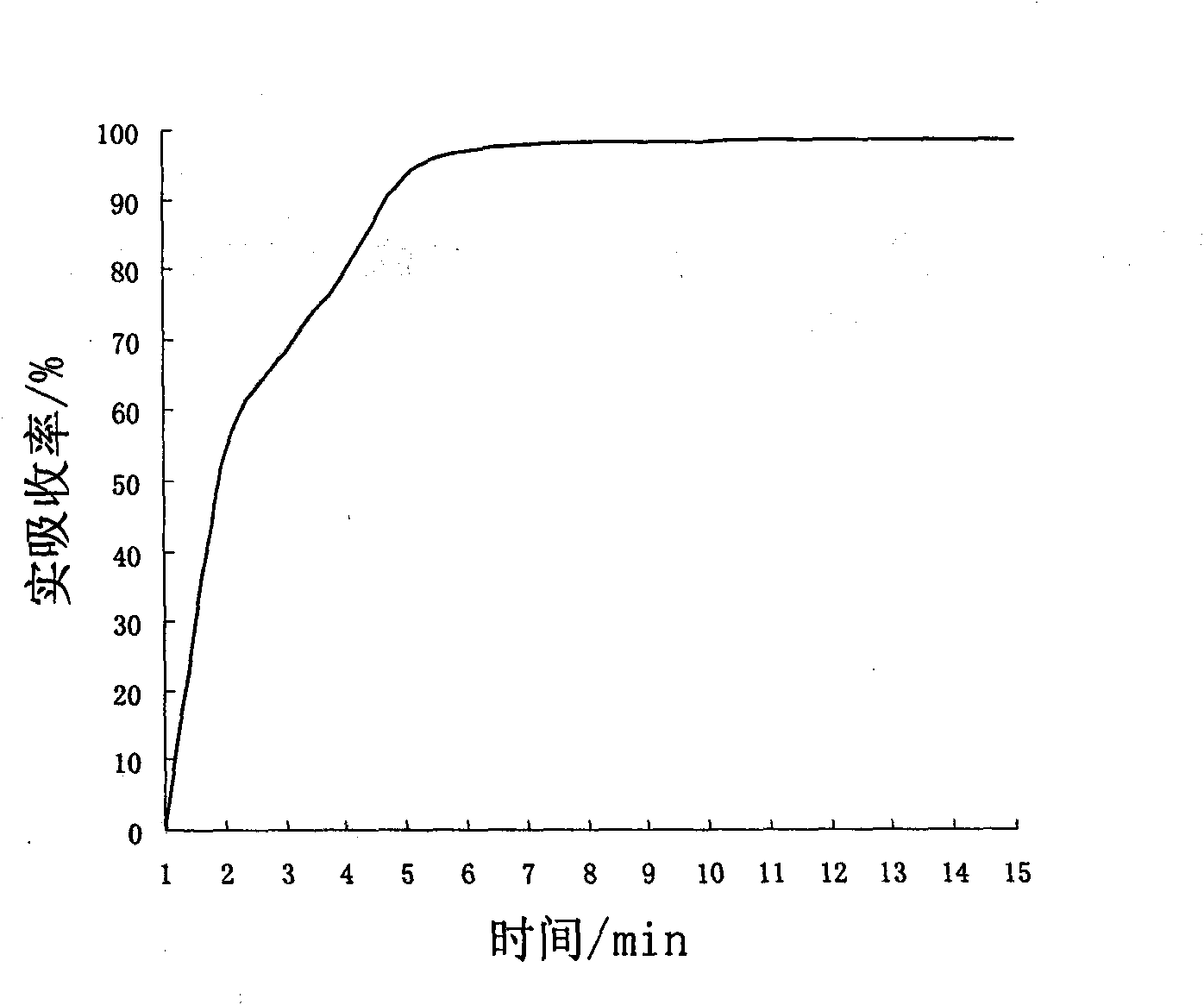

Additive for smelting aluminium alloy and preparation method and application method thereof

The invention relates to an additive for smelting aluminium alloy and a preparation method and an application method thereof, relating to the technical field of nonferrous alloy manufacturing with a special additive. The additive is composed of metal powder, cosolvent, heat-generating agent, detonating agent and moisture proof agent. The preparation method comprises the following steps: raw materials comprising the following by mass percentage, 70-81.5% of metal powder, 15-20% of cosolvent, 2-5% of heat-generating agent, 1-3% of detonating agent and 0.5-2% of moisture proof agent, are fully mixed evenly into compound powder with a ball mill, and the mixture is put into a mould, and is performed with cold pressing by a hydraulic pressure machine so as to obtain the additive for smelting aluminium alloy. The application method of the invention comprises the following steps: a graphite crucible filled with a pure aluminium pig is arranged in a resistance furnace to be heated until the aluminium pig is melted into aluminium liquid, and then the additive is added to react with the aluminium liquid so as to obtain aluminium alloy. Under the condition that the quality of aluminium alloy is not lowered, the additive solves the problems of high dissolving temperature, low absorptivity and unstable absorptivity of the additive.

Owner:HEBEI UNIV OF TECH

Method of Treating the Near-Wellbore Zone of the Reservoir

ActiveUS20120305255A1High Effective PermeabilityIncrease productivityFluid removalDrilling compositionParaffin waxPorosity

The invention describes a method for treating near-wellbore zones involving the steps of injecting a magnesium metal with a catalyst into the desired area of the formation to be treated. Subsequently, combustive-oxidizing solution (COS) is injected into the zone of the formation to be treated. The COS initially reacts with the magnesium, which in turn initiates a vigorous oxidation reaction of the COS. The reaction gases and heat produced by the COS oxidation reaction are harnessed to enhance the productivity of the well by creating fractures in the treatment zone and by melting of paraffin and resin deposits in the treatment zone. As a final step, acid is injected into the formation to react with the formation thereby further enhancing the porosity of the fractures. In one embodiment, the COS uses ammonium nitrate as the oxidizer, and in another, urea or ethylene glycol may be added as a reaction fuel.

Owner:RIVERBEND

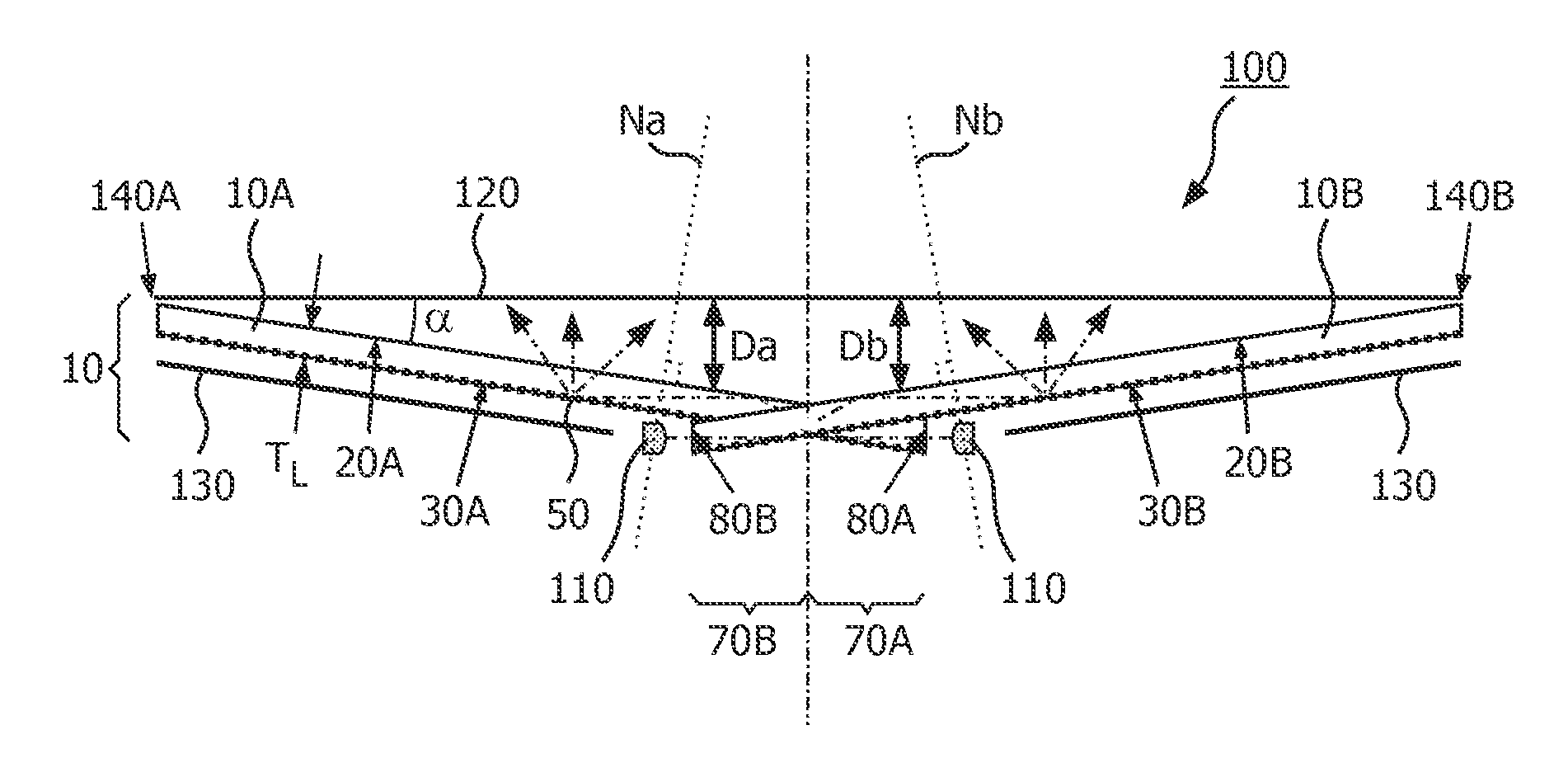

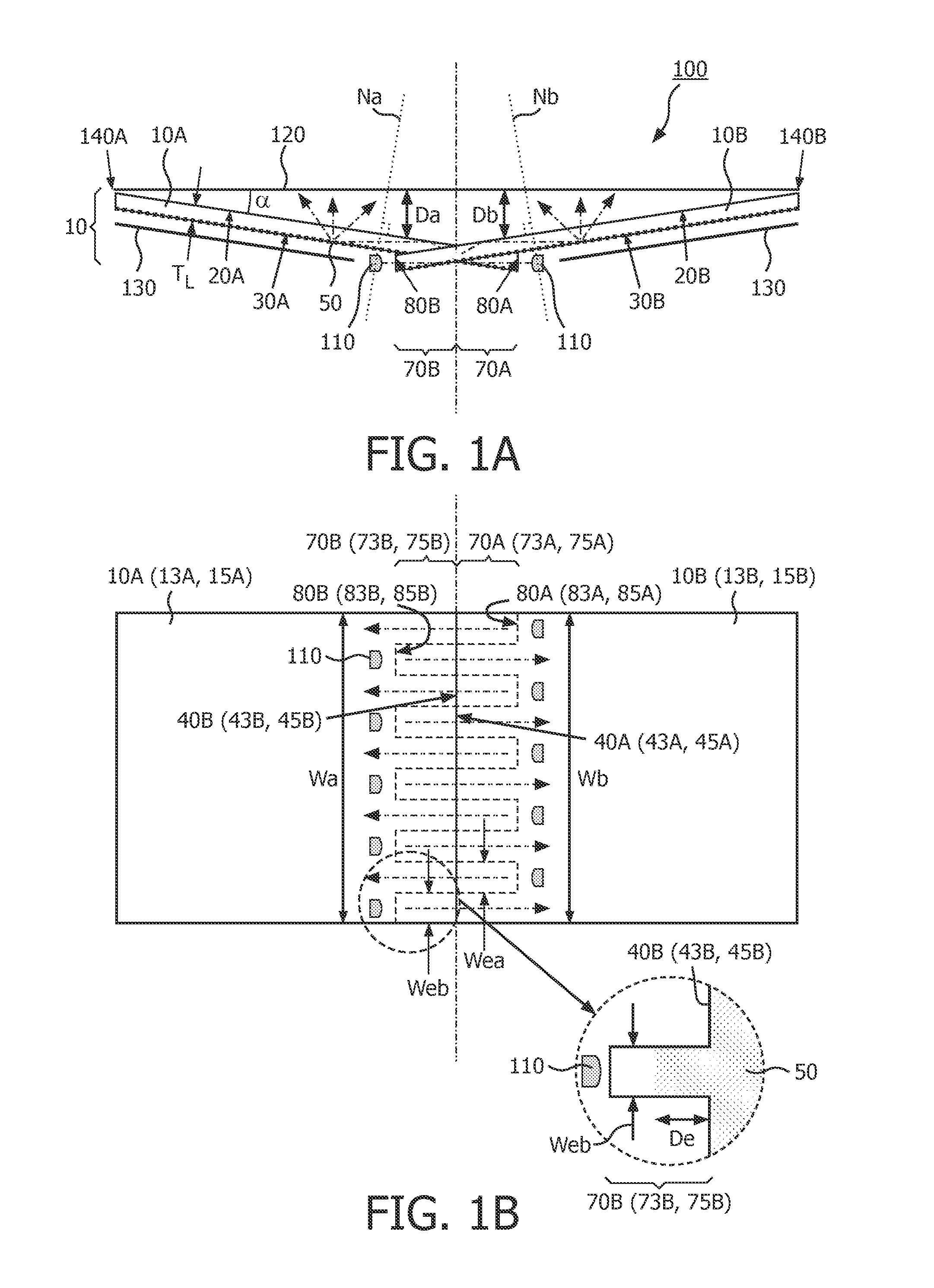

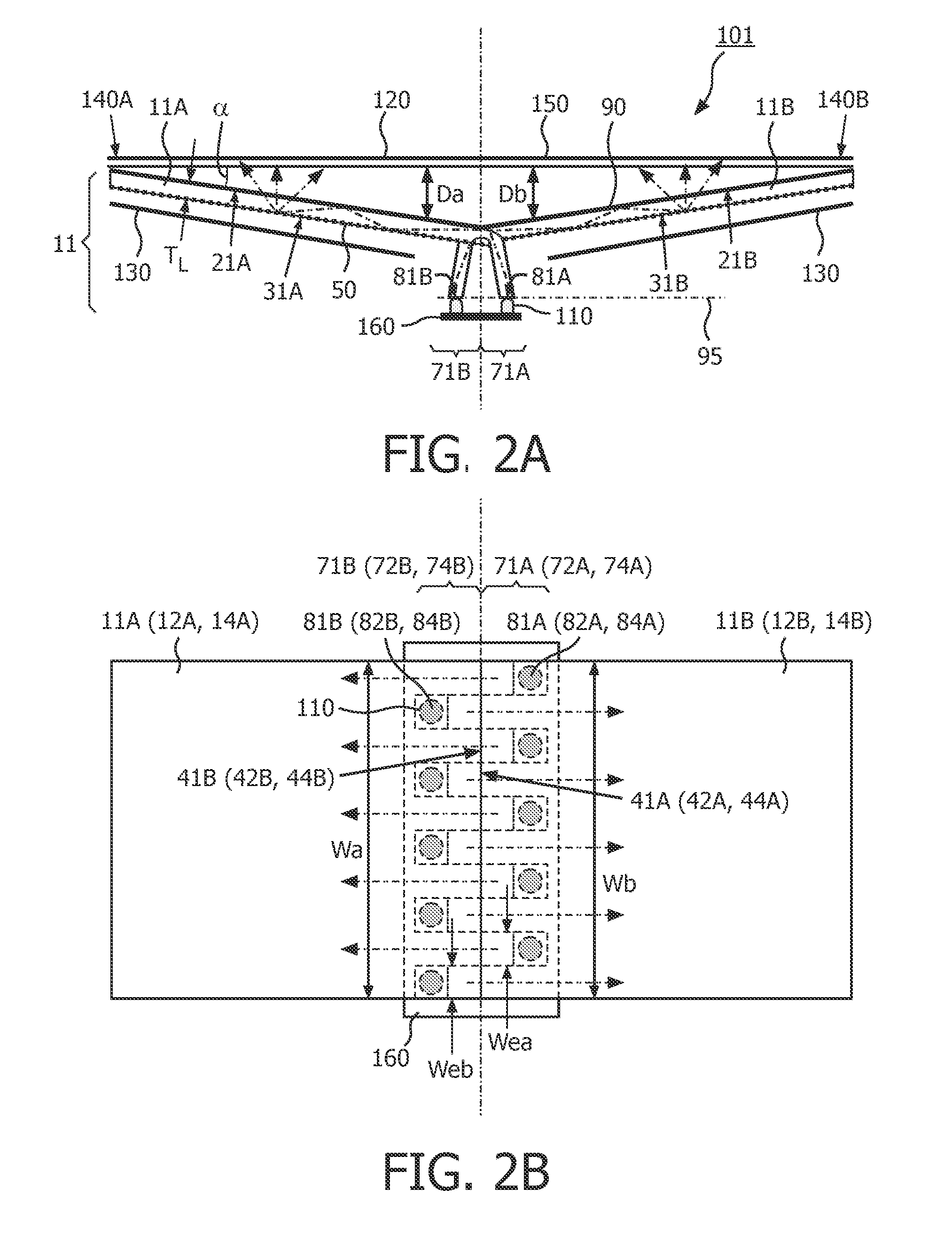

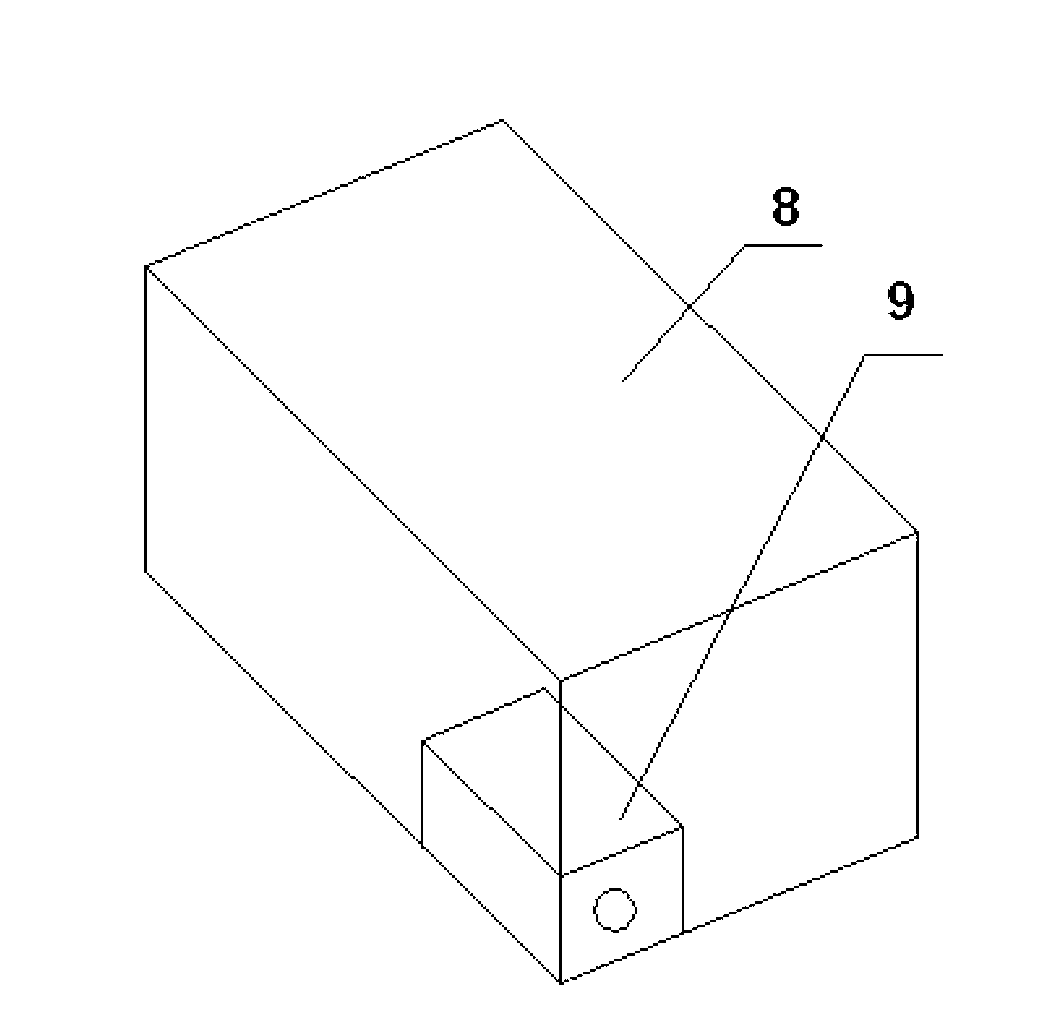

Light guide, illumination system, backlighting system and display device

InactiveUS20120155110A1Compact illumination systemImprove luminous efficiencyMechanical apparatusPlanar/plate-like light guidesLight guideDisplay device

The invention relates to a light guide (10) for illuminating a light output window (120) of an illumination system (100), the illumination system, a backlighting system (100) and a display device (200). The light guide comprises a first light guide part (10A) comprising a first light guide extension (70A) extending from a first edge wall (40A) of the first light guide part (10A), and comprises a second light guide part (10B) comprising a second light guide extension (70B) extending from a second edge wall (40B) of the second light guide part (10B), the first light guide extension (70A) being configured for positioning a first light input window (80A) at a side of the second light guide part (10β) facing a rear wall (30B) of the second light guide part (10B), the second light guide extension (70B) being configured for positioning a second light input window (80B) at a side of the first light guide part (10A) facing the rear wall (30A) of the first light guide part. An effect of the light guide according to the invention is that due to the configuration of the first light guide extension and the second light guide extension, the first light input window of the first light guide part is arranged behind the second light guide part, and the second light input window of the second light guide part is arranged behind the first light guide part.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

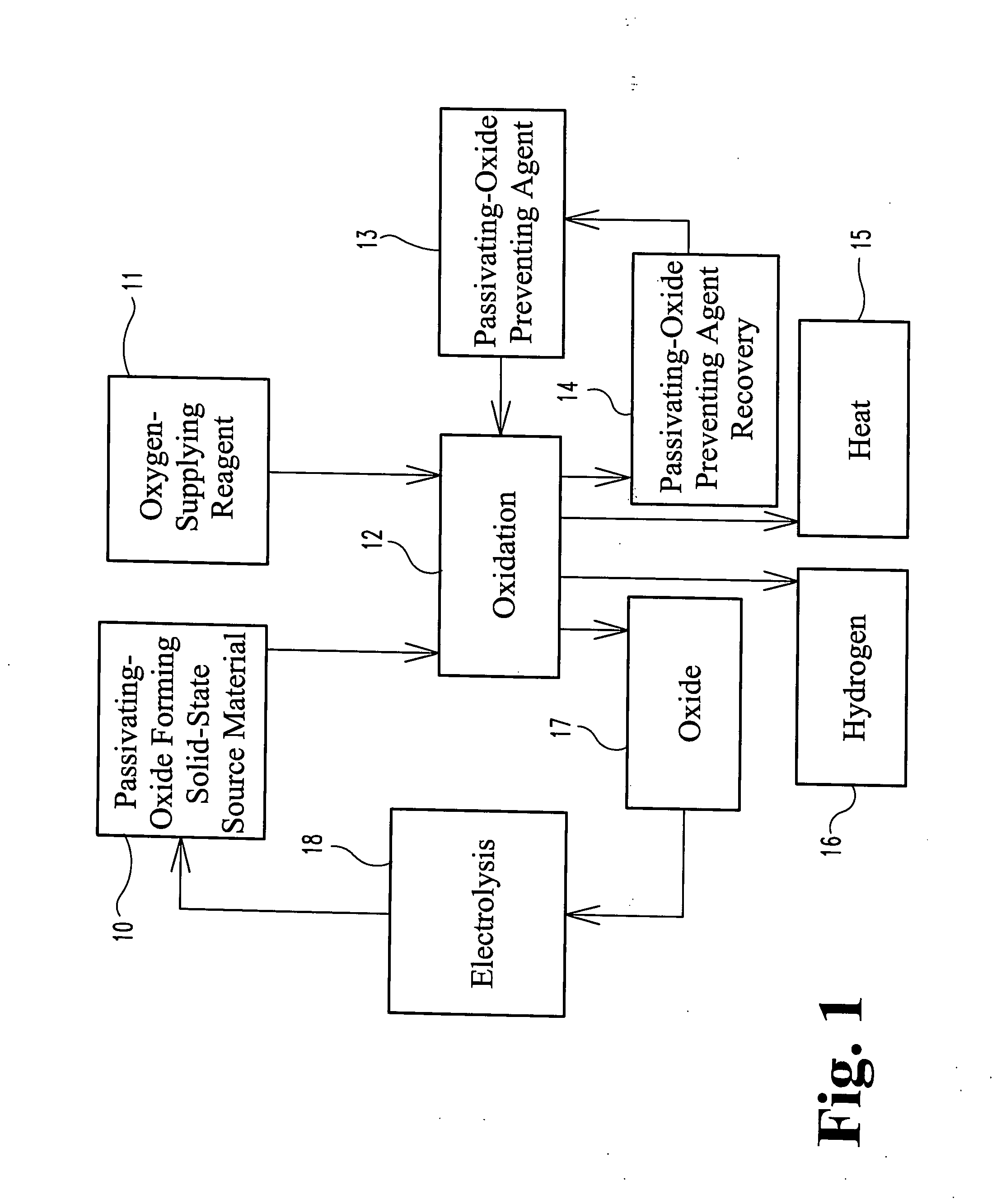

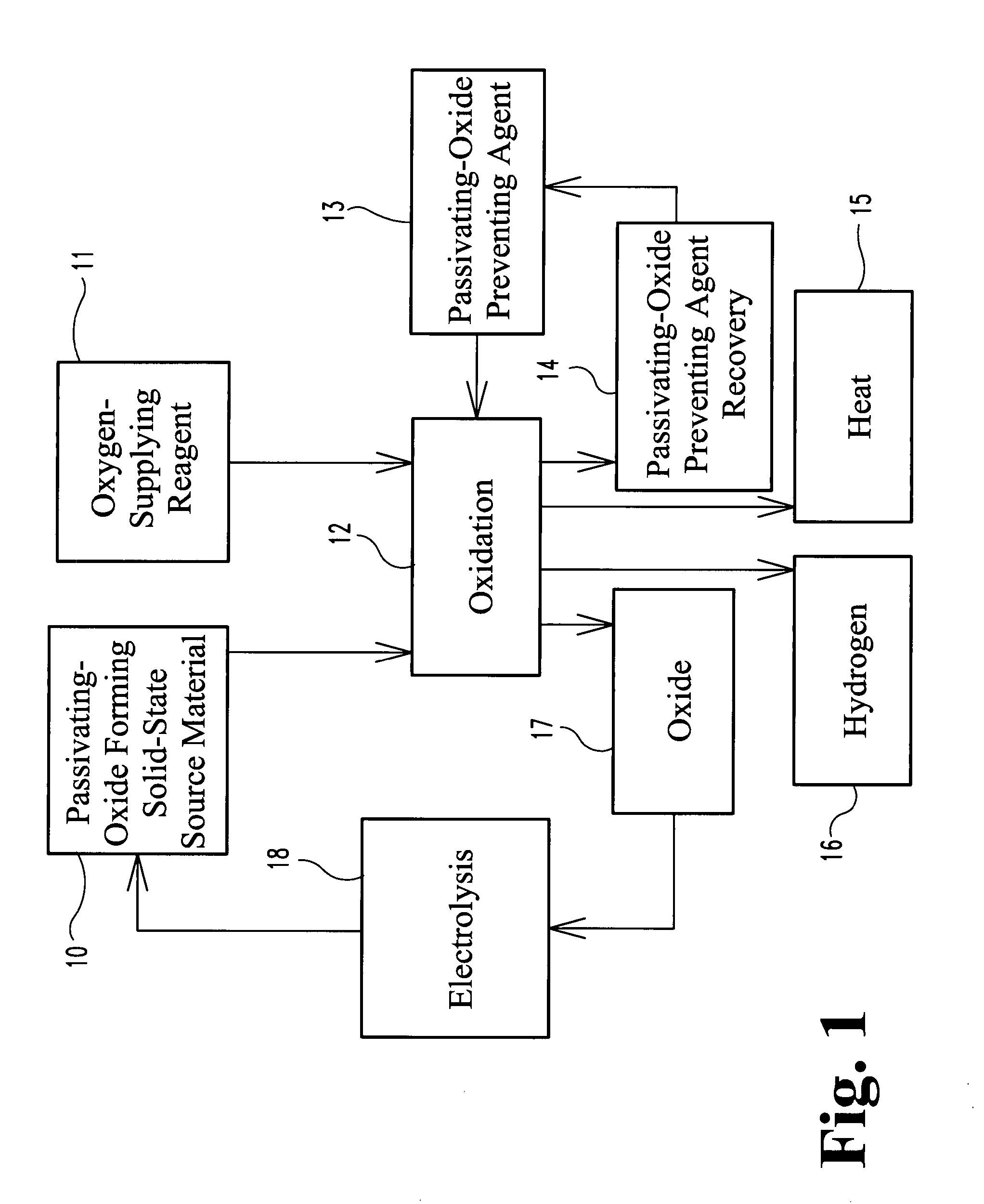

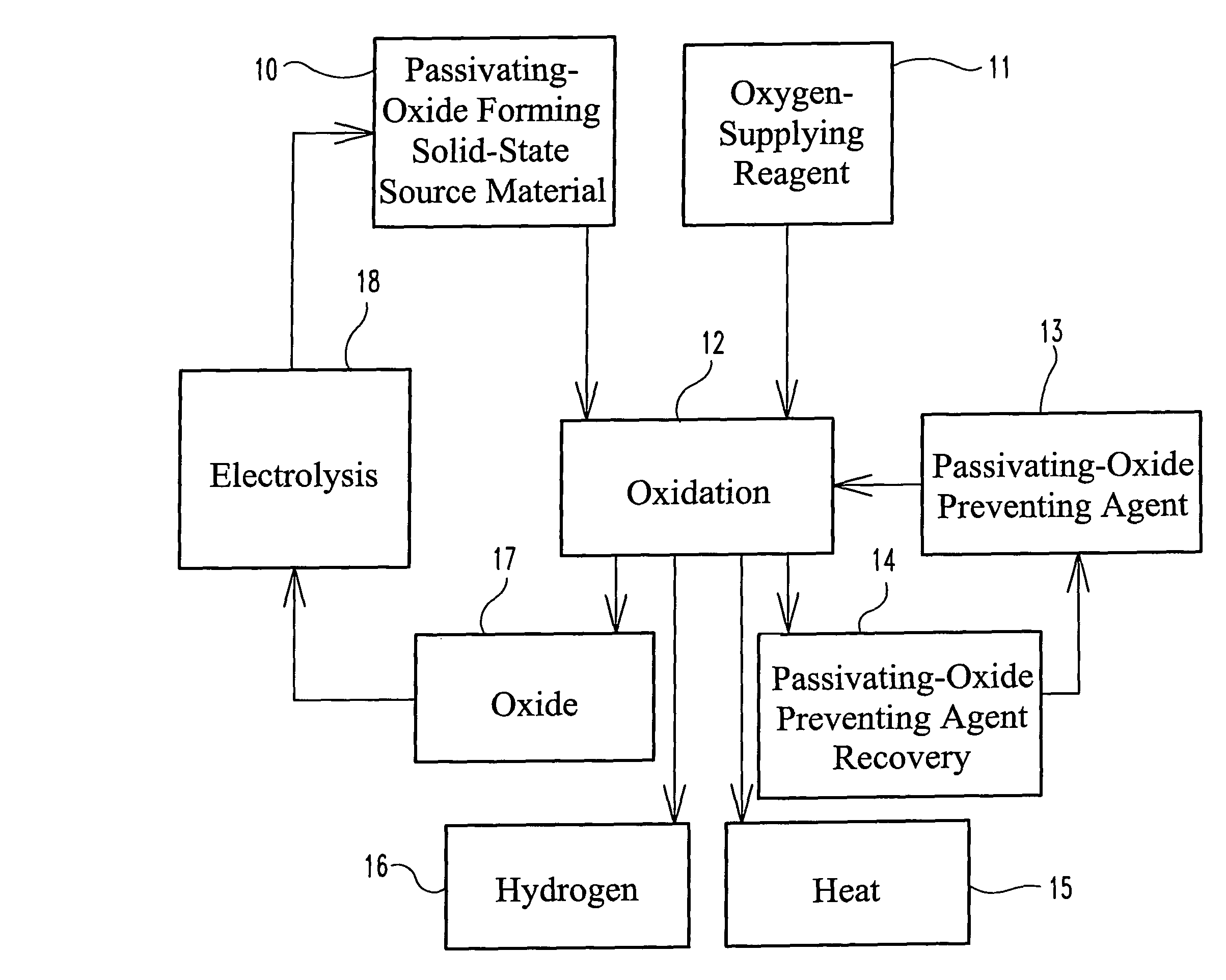

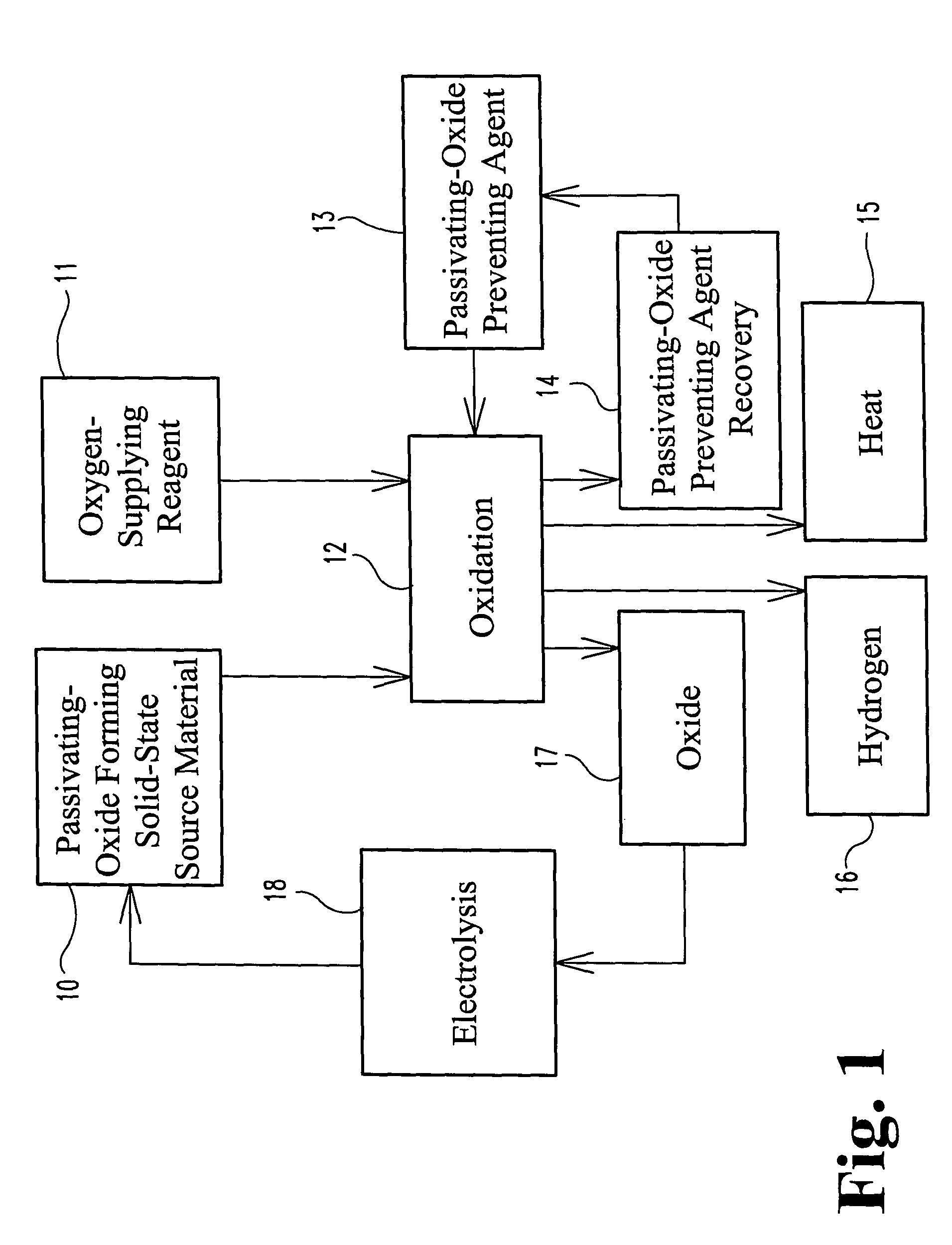

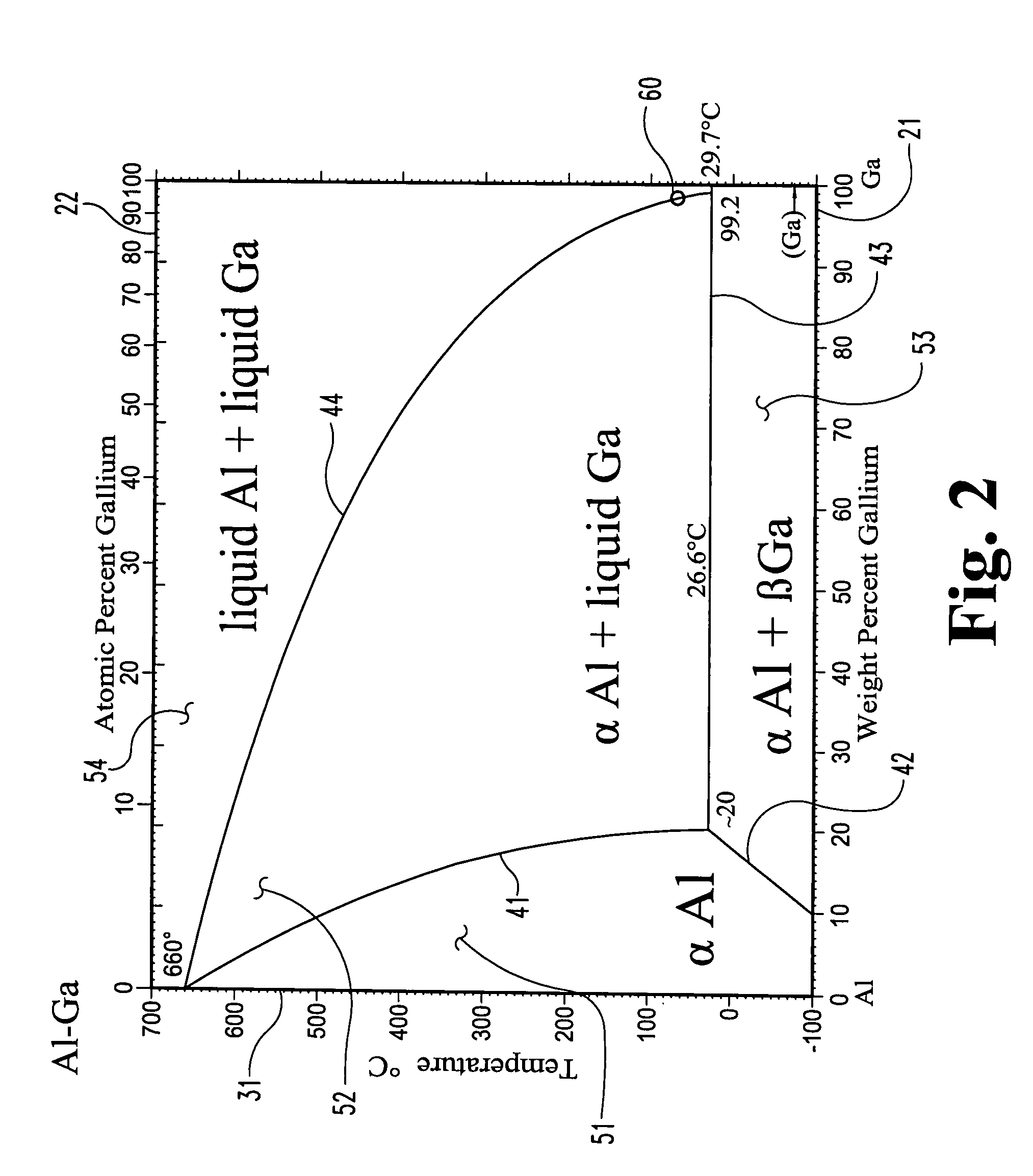

Power Generation From Solid Aluminum

ActiveUS20080063597A1Efficiently splitting water into hydrogenEfficient productionSolid fuelsWaste based fuelHydrogenSurface layer

A fuel for splitting water into hydrogen and an oxide component comprises a substantially solid pellet formed from a solid-like mixture of a solid-state source material capable of oxidizing in water to form hydrogen and a passivation surface layer of the oxide component, and a passivation preventing agent that is substantially inert to water in an effective amount to prevent passivation of the solid-state material during oxidation. The pellets are brought into contact with an alloy of the passivation preventing agent having a melting point temperature below that of the solid-like mixture to initiate the hydrogen-producing reaction at a lower temperature.

Owner:PURDUE RES FOUND INC

Method for preparing lignin nanoparticles by taking papermaking black liquid as raw material

The invention discloses a method for preparing lignin nanoparticles by taking papermaking black liquid as a raw material and belongs to the field of nanometer material chemistry. The preparation method comprises the following steps of: carrying out acidification or ultra-filtration purification on the papermaking black liquid taken as the raw material so as to remove insoluble impurities and a lower molecular compound; dissolving purified lignin in an alkaline solution; adding sulfuric acid, nitric acid or hydrochloric acid at a certain speed so as to form lignin colloid; and carrying out freeze drying to obtain the lignin nanoparticles, wherein the particle sizes of the lignin nanoparticles are in the range being 50-280 nm. The obtained lignin nanoparticles have good dispersion property and absorption property and are expected to be applied to a dispersing agent for wastewater treatment and systems such as dyes, pesticides and coal-water slurry. The preparation method disclosed by the invention is simple and practicable and has good application prospect; and a solvent used in the method is water which has no negative effect on environments.

Owner:GUANGXI UNIV

Power Generation From Solid Aluminum

InactiveUS20080056986A1Control of reactionProduction controlEnergy inputBlast furnace detailsChemistrySource material

A fuel for splitting water into hydrogen and an oxide component comprises a substantially solid pellet formed from a solid-like mixture of a solid-state source material capable of oxidizing in water to form hydrogen and a passivation surface layer of the oxide component, and a passivation preventing agent that is substantially inert to water in an effective amount to prevent passivation of the solid-state material during oxidation. The pellets may be introduced into water or other suitable oxidizer in a controlled rate to control the rate of reaction of the source material with the oxidizer, and thereby control the rate of formation of hydrogen. Methods are described for producing the solid-like mixture in varying weight percent of source material to passivation preventing agent.

Owner:PURDUE RES FOUND INC

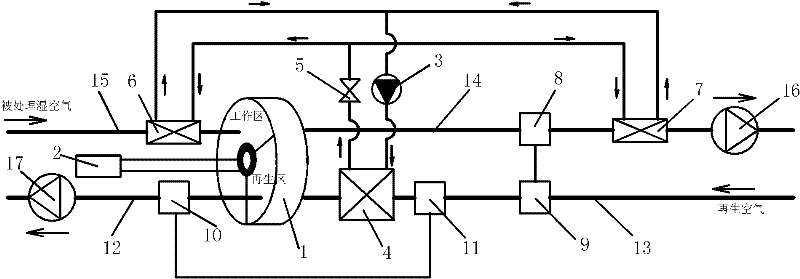

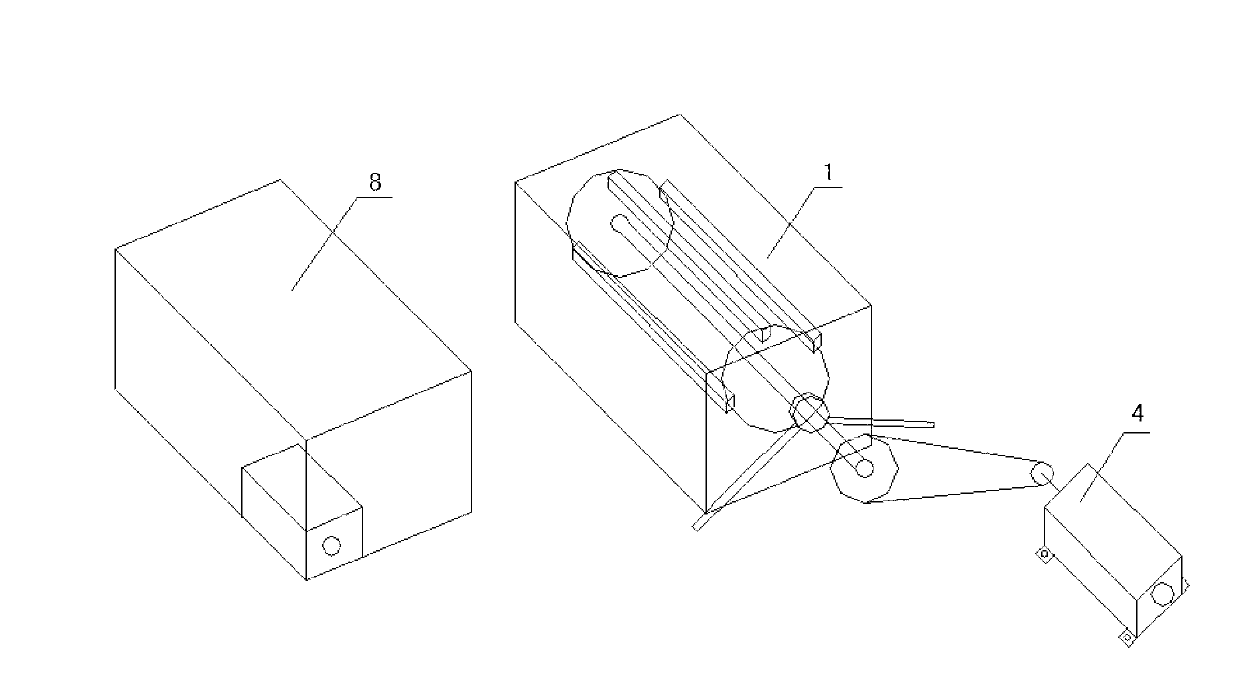

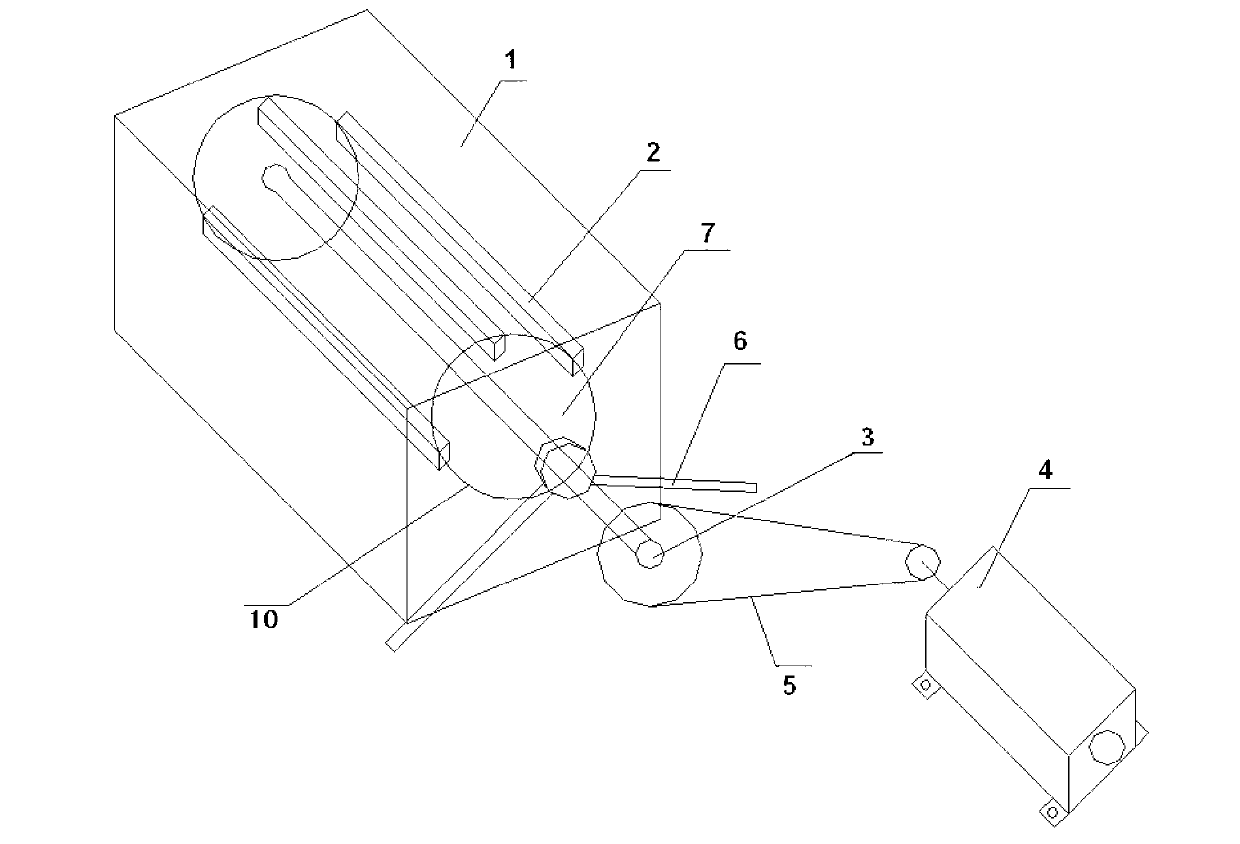

Rotary Dehumidification and Air Conditioning System Using Heat Pipe Heat Recovery and Ultrasonic Enhanced Regeneration

ActiveCN102261703AReduce heating energy consumptionImprove work efficiencyDucting arrangementsHeat recovery systemsHigh energyEngineering

The invention discloses a runner dehumidification air-conditioning system adopting heat pipes for heat recovery and adopting ultrasound for enhancing regeneration, which comprises an ultrasonic dehumidification runner, an ultrasonic generator, a compressor, a condenser, a throttle valve, a first evaporator, a second evaporator, a first heat pipe, a second heat pipe, a regenerated air outlet channel, a regenerated air inlet channel, a processed air outlet channel, a processed air inlet channel, a processed air feeder and a regenerated air exhaust fan, wherein the ultrasonic dehumidification runner comprises a local radiation rod-shaped ultrasonic transducer, moisture-absorbing material, a partition plate and a housing; and the local radiation rod-shaped ultrasonic transducer comprises an outer cover plate, an inner cover plate and a piezoelectric ceramic wafer. The characteristic of high energy efficiency of a medium-high temperature heat pump is utilized for heating regenerated air, the characteristic of high heat conduction of heat pipe elements is utilized for recycling latent waste heat, the ultrasonic regeneration enhancing technology is utilized for reducing the requirements of a runner dehumidizer on the temperature of the regenerated air, and the energy-saving purpose of the dehumidification air-conditioning system is finally achieved.

Owner:博拓(苏州)新能源技术有限公司

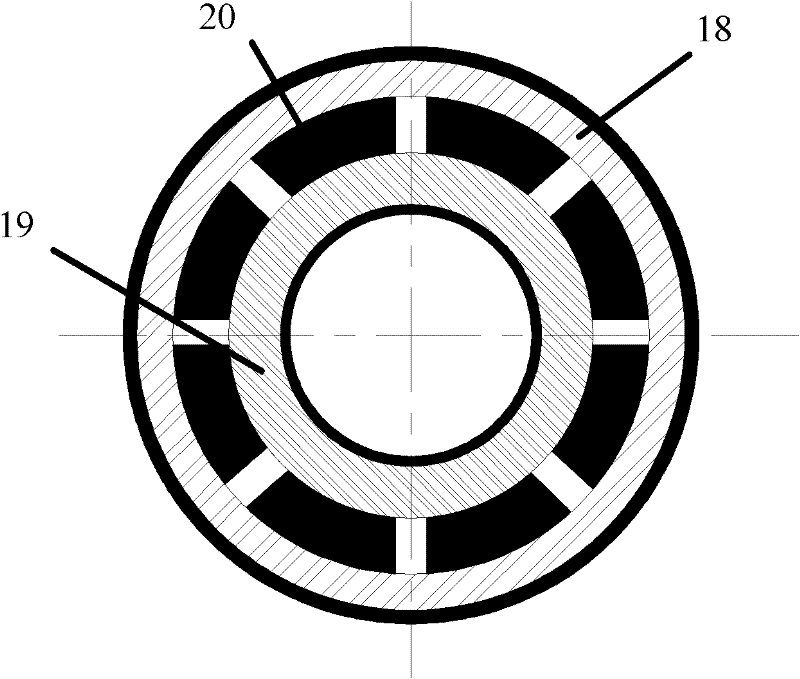

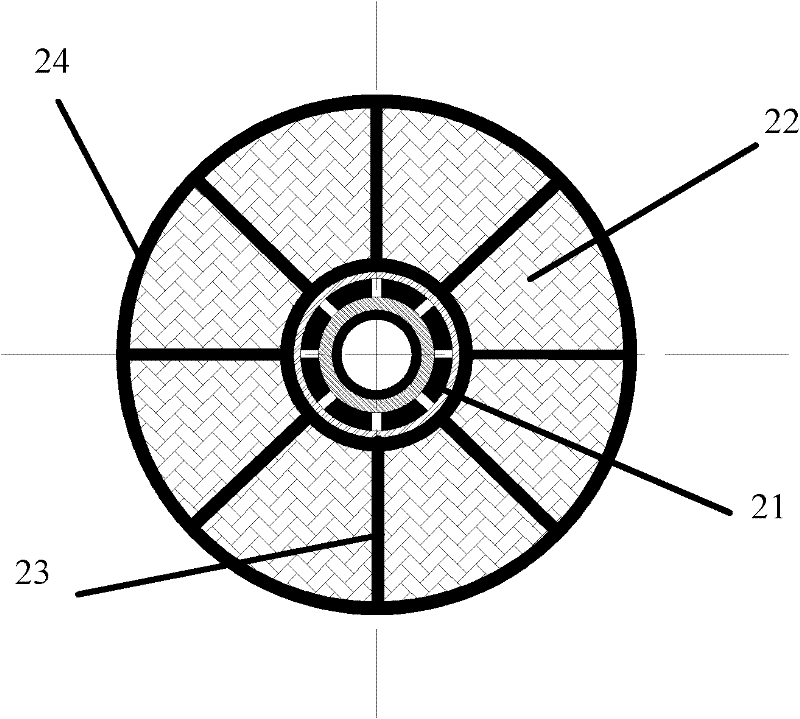

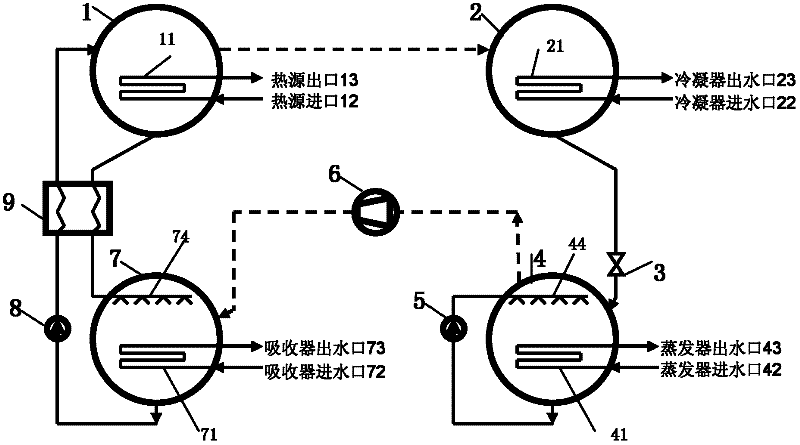

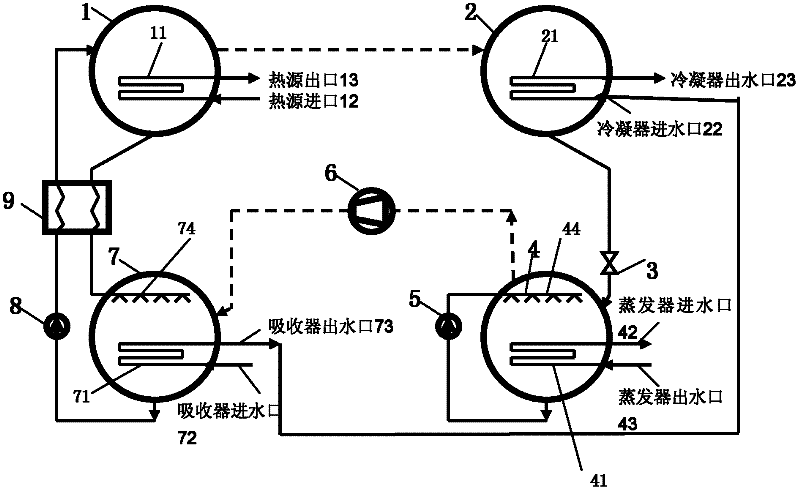

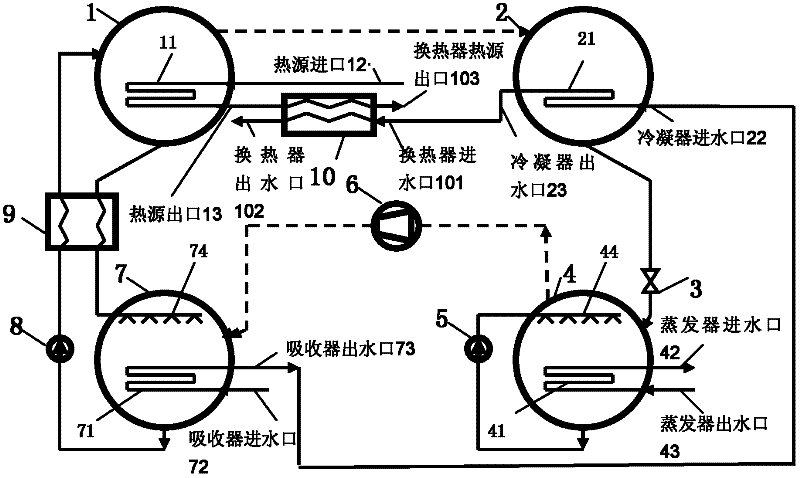

Lithium bromide absorption-compression type series boosting refrigeration/heating pump system

InactiveCN102230686AReduced temperature level requirementsLow temperature requirementFluid circulation arrangementAbsorption compressionLithium bromide

The invention discloses a lithium bromide absorption-compression type series boosting refrigeration / heating pump system. A refrigerant steam outlet of a generator (1) is connected with a refrigerant steam inlet of a condenser (2); a liquid refrigerant outlet of the condenser (2) passes through a throttling element (3) and is connected with a liquid refrigerant inlet of an evaporator (4); a liquid refrigerant outlet of the evaporator (4) passes through a refrigerant circulation pump (5) and is connected with a sprayer I (44); a refrigerant steam outlet of the evaporator (4) passes through a compressor (6) and is connected with a refrigerant steam inlet of an absorber (7); a dilute solution outlet of the absorber (7) passes through a solution circulation pump (8) and a solution reheater (9) sequentially and is connected with a dilute solution inlet of the generator (1); and a condensed solution outlet of the generator (1) passes through the solution reheater (9) and is connected with a sprayer II (74). The lithium bromide absorption-compression type series boosting refrigeration / heating pump system has the characteristics of lower requirement on the temperature of a heat source, reduction in the compression ratio of the compressor and the like.

Owner:ZHEJIANG SCI-TECH UNIV

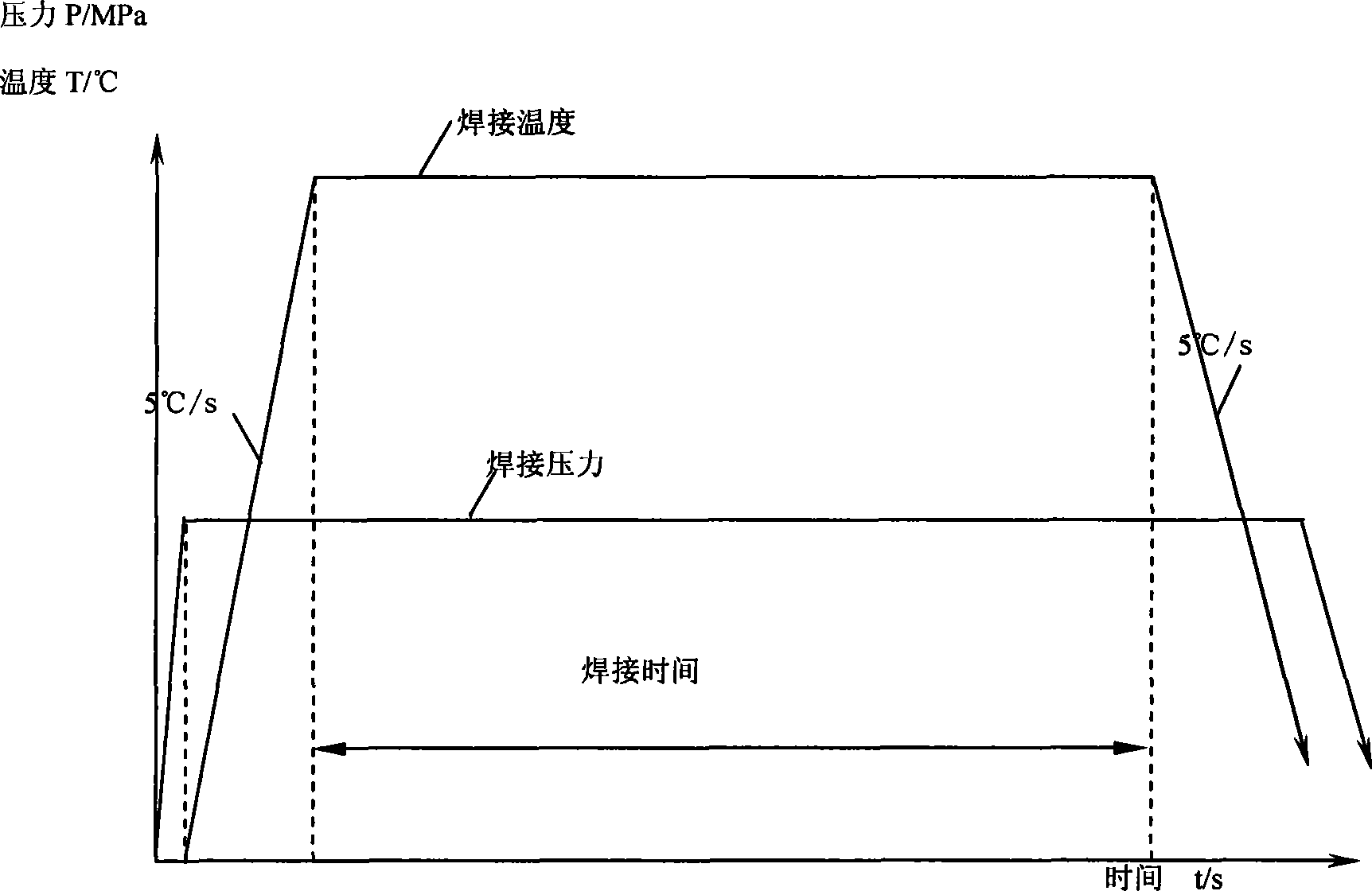

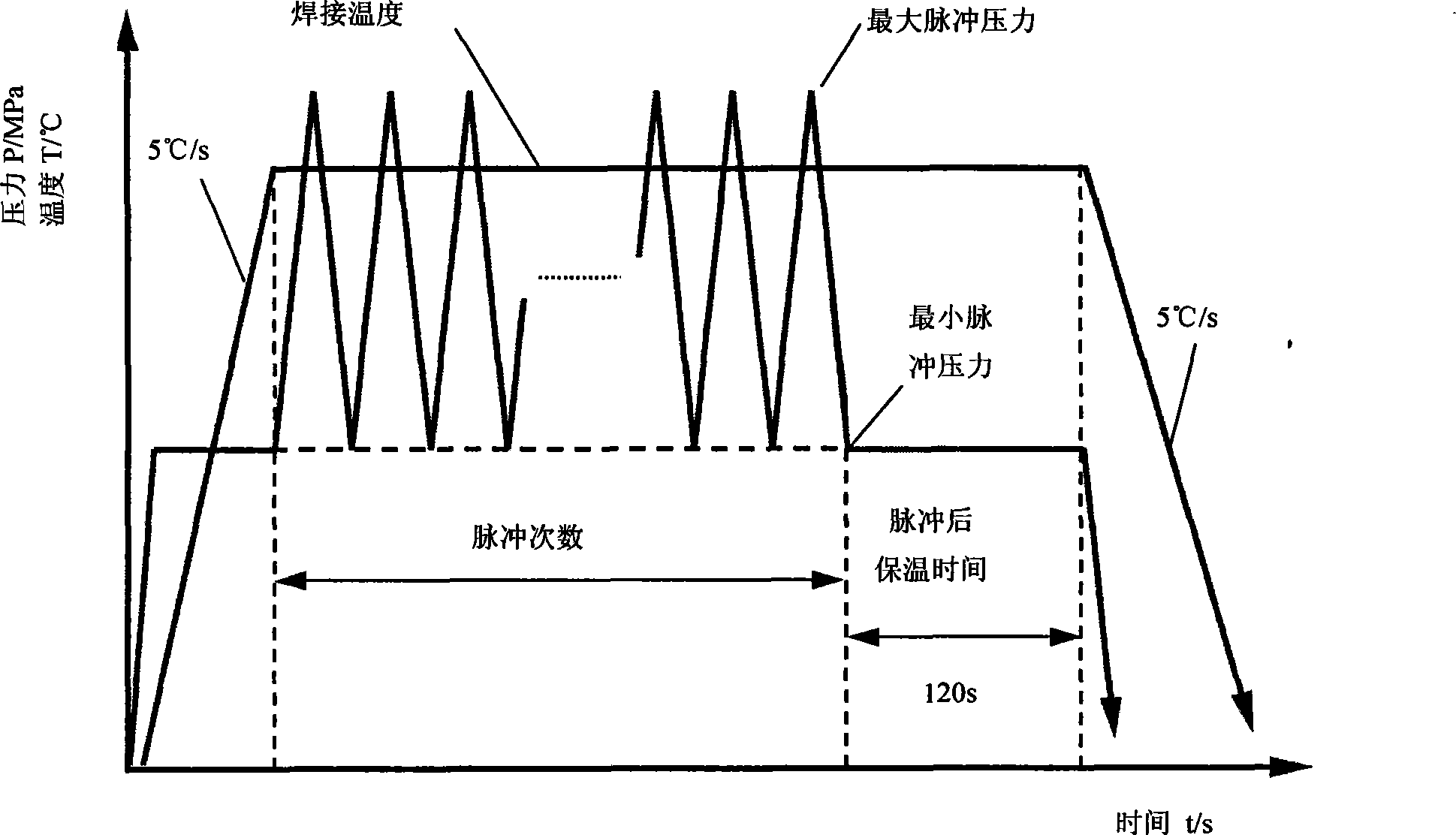

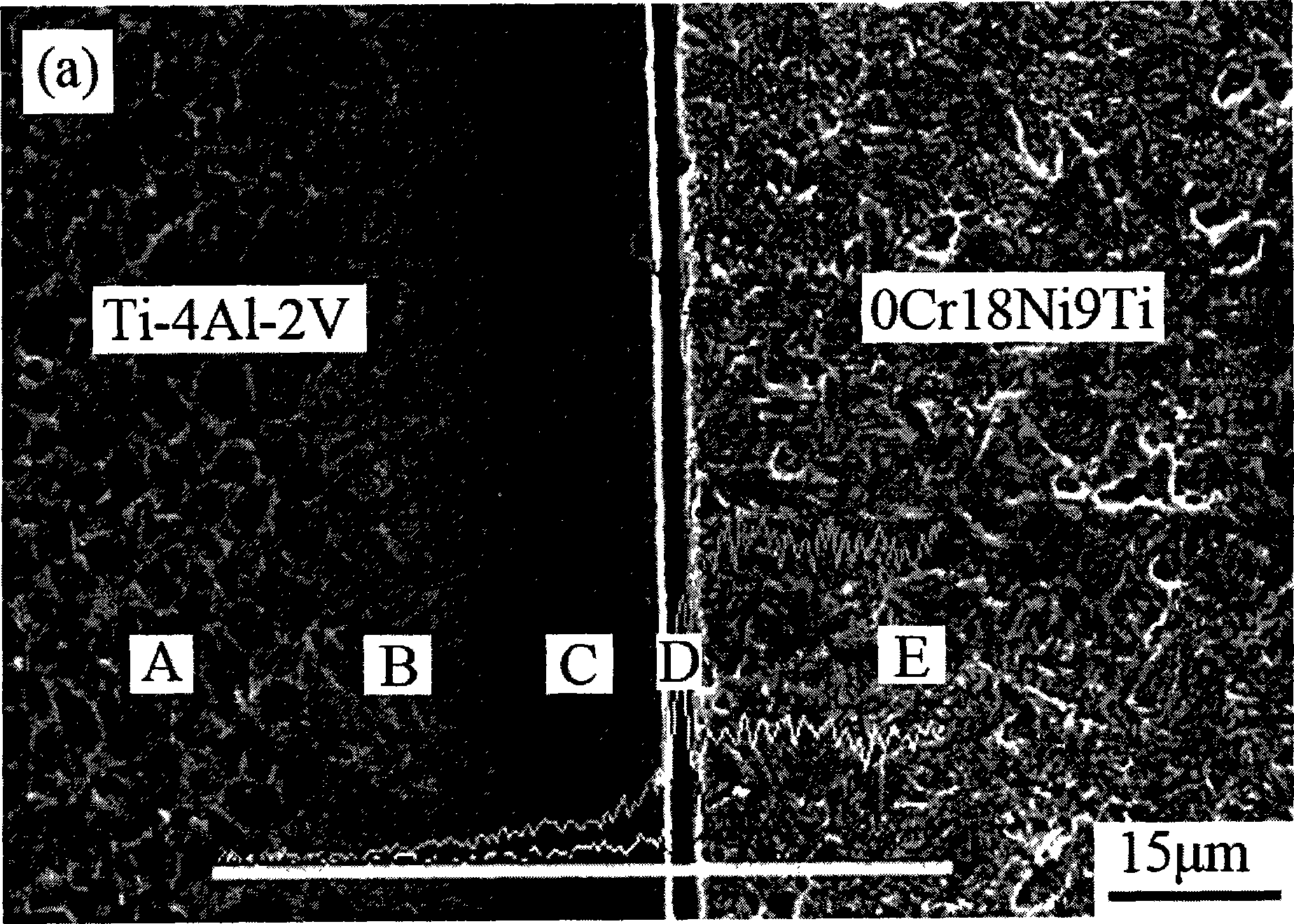

Self-nano-structure diffusion welding technique for titanium alloy and stainless steel surface

InactiveCN101244483AIncrease the diffusion coefficientImprove mechanical propertiesPolishing machinesNon-electric welding apparatusNano structuringTitanium alloy

The invention discloses a titanium alloy and stainless steel surface self-nanocrystallization diffusion welding craft; wherein, the same diameter titanium alloy and stainless steel rod are selected; the surface self-nanocrystallization of the end face of the welding terminal is processed; the constant temperature and constant pressure diffusion welding or the impact pressurizing diffusion welding are processed. The titanium alloy and stainless steel surface self-nanocrystallization diffusion welding craft has the advantages of raising the diffusion coefficient of the titanium alloy and stainless steel in the process of diffusion welding, shortening the welding time, raising the welding efficiency, reducing the thickness of intermetallic compounds layer, refining the joint crystalline grain, and raising the mechanical property of the diffusion welding joint of titanium alloy and stainless steel.

Owner:CHONGQING UNIV

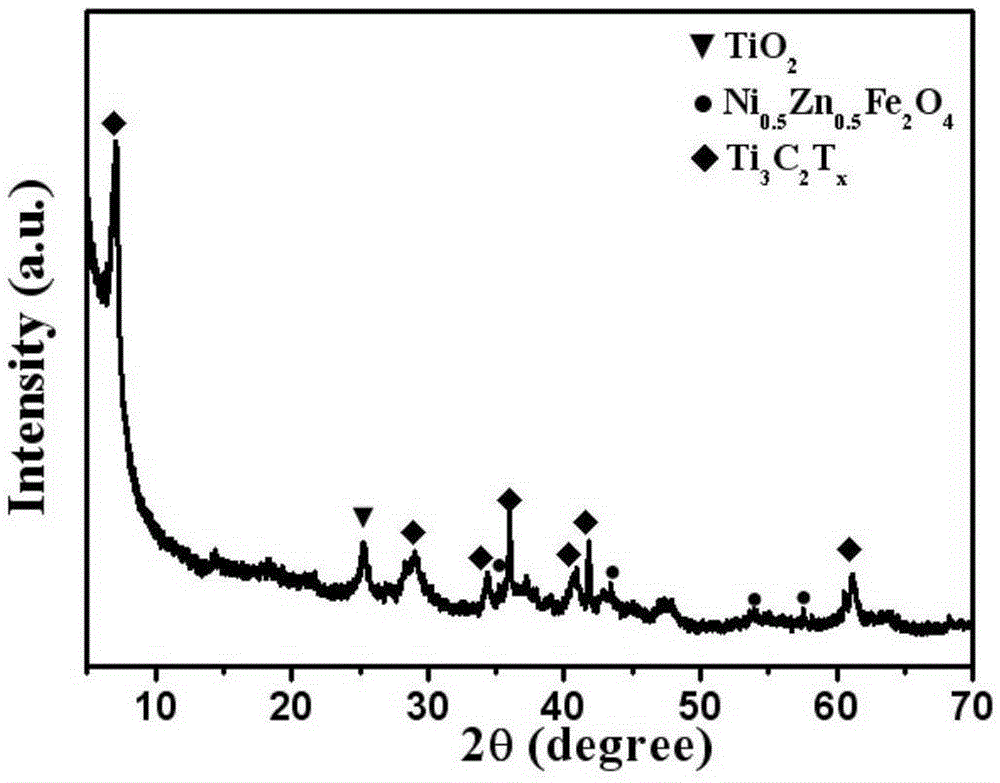

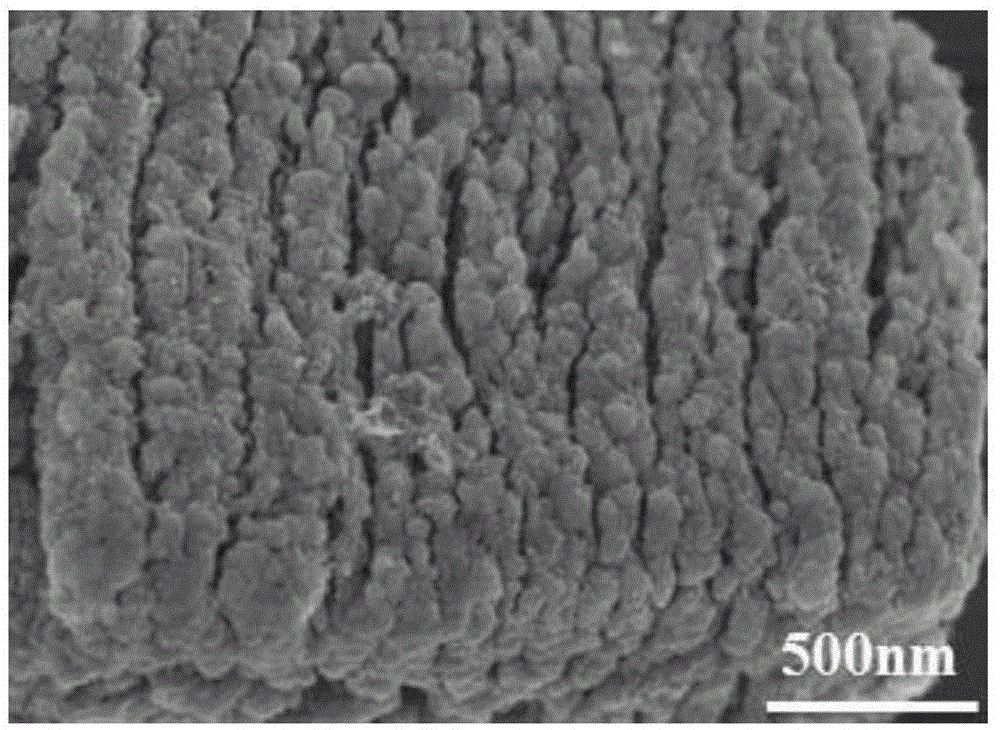

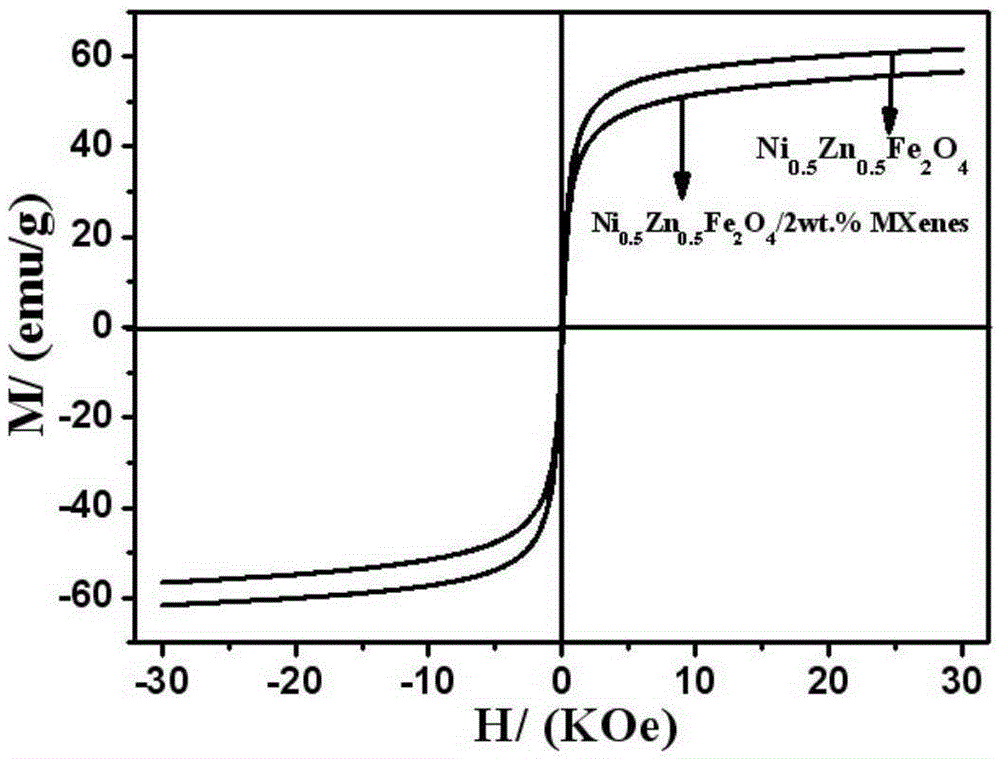

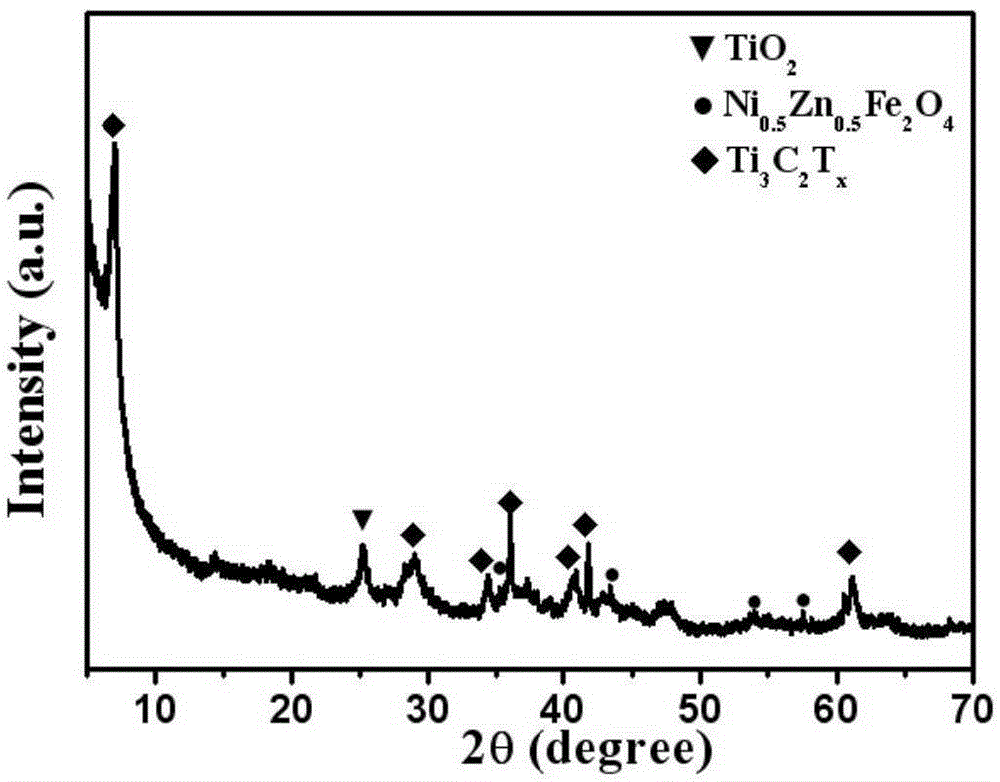

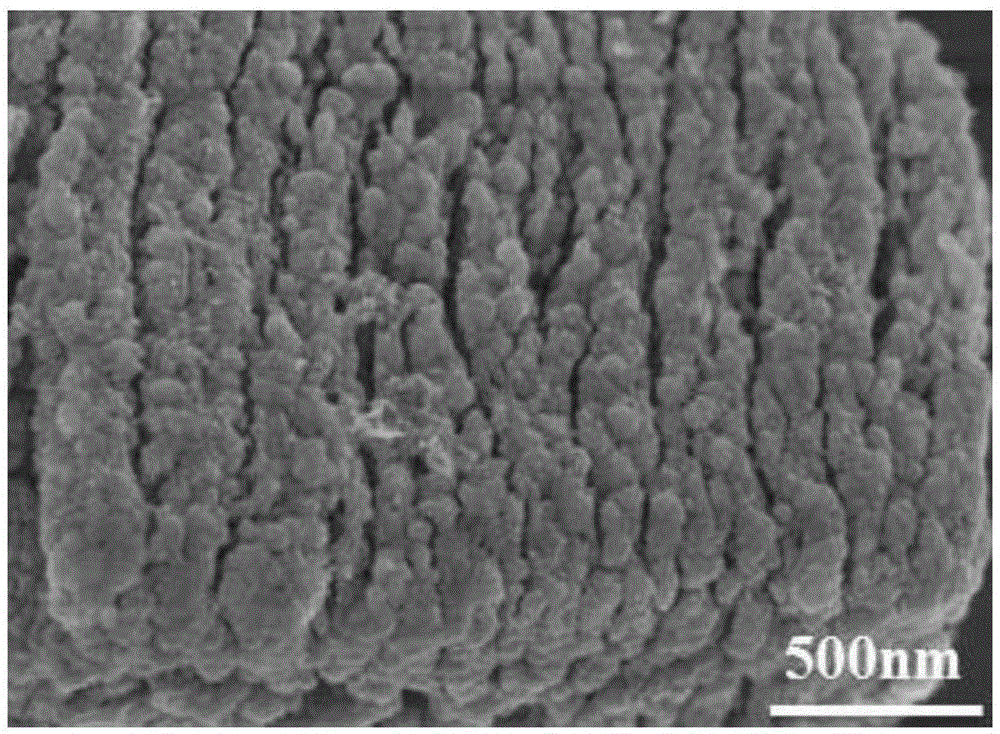

Ferrite material and MXenes composite material and preparation method and application thereof

ActiveCN105418072AGood electrical conductivityHigh conductivity at room temperatureElectromagnetic interferenceImpedance matching

The invention provides a ferrite material and MXenes composite material. Ferrite molecules are dispersed in a lamellar structure of MXenes. The ferrite material and MXenes composite material has good electrical conductivity, and accordingly, even when the temperature is lower than 260K, the ferrite material and MXenes composite material can still keep a certain electrical conductivity; the ferrite material and MXenes composite material good in impedance matching performance can be applied to various electronic parts and components such as anti-electromagnetic interference antennae, filters and inductance components by serving as a wave-absorbing material and is particularly applicable to wave absorption at low temperatures.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of aluminum or aluminum alloy super-hydrophobic surface

The invention relates to a preparation method of aluminum or aluminum alloy super-hydrophobic surface. The method comprises the followings: using ethanol and deionized water sequentially to ultrasonically cleaning an aluminum or an aluminum alloy piece; taking oxalic acid aqueous solution as electrolyte, an aluminum or aluminum alloy piece as an anode, and graphite as a cathode, carrying out oxidation in electrifying and water bathing, constructing a pyramidal surface with a micro-nano composite structure in one step, then cleaning the aluminum or aluminum alloy piece again, and drying; and decorating the aluminum or aluminum alloy piece after anode oxidation by adopting a low surface energy material, and then drying, namely the super-hydrophobic surface is obtained. By adopting the anode oxidation technology, a duality composite structure with a pyramidal micron structure and a nanowire can be constructed under high current in one step, the method used is simple and convenient, the technology is mature, and the preparation time is reduced greatly; and temperature requirements for anode oxidation are very low, and the preparation can be performed under low temperature and constant-temperature conditions. The contact angle of the prepared super-hydrophobic surface to water can reach more than 155 degrees.

Owner:HARBIN INST OF TECH

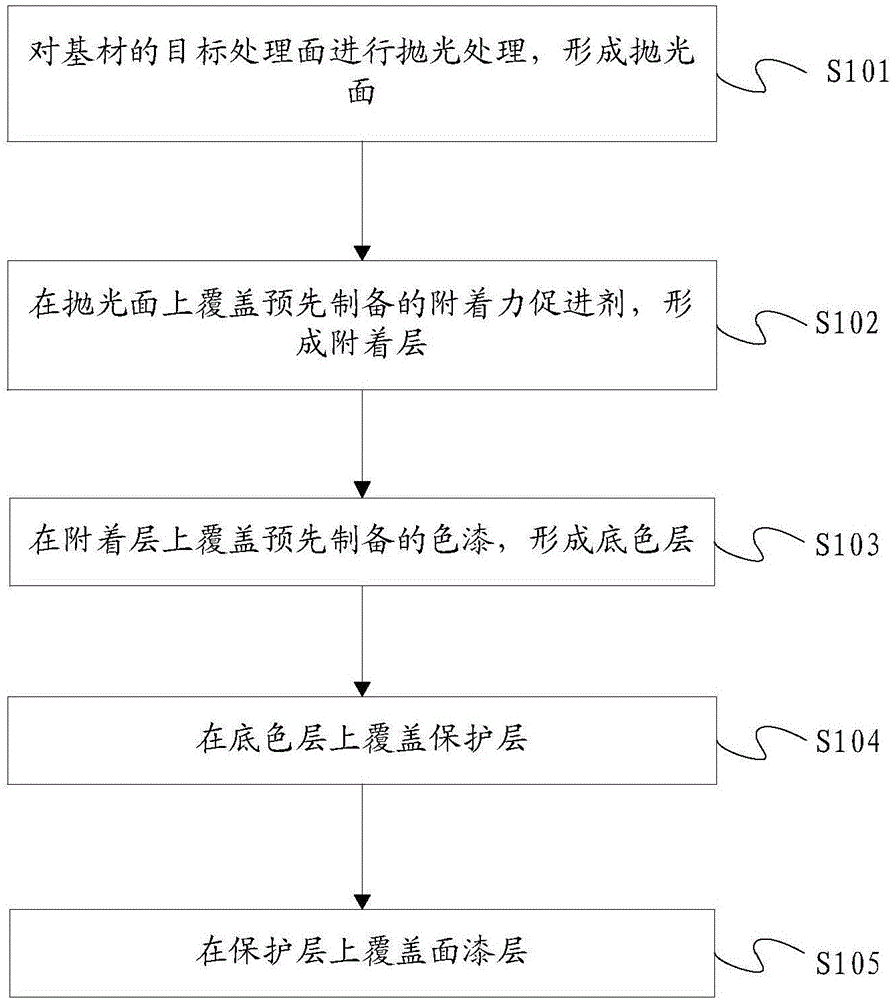

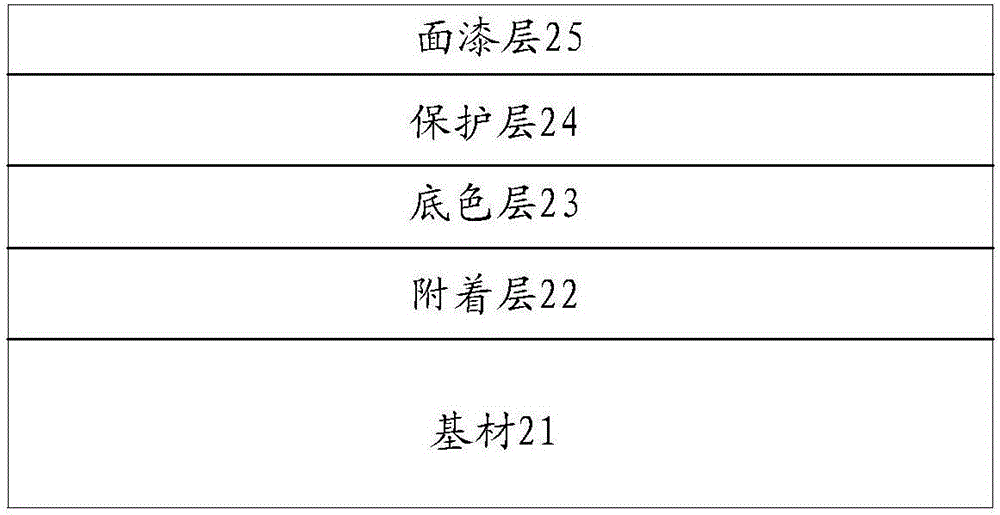

Substrate surface processing method, shell and terminal

The invention discloses a substrate surface processing method, a shell and a terminal. When the surface of a substrate is processed, a target processing surface of the substrate is firstly polished to form a polished surface, the polished surface is covered with a pre-prepared adhesion promoter to form an adhesion layer, the adhesion layer is covered with pre-prepared colored paint to form an underpainting layer, the underpainting layer is covered with a protection layer, and the protection layer is covered with a topcoat layer. The obtained finished product has good texture, and substrate processing steps are simple and easy to implement; compared with the prior art, when a layer structure is formed on the substrate, the substrate surface processing method is low in temperature requirement, low in production equipment requirement, low in production cost and high in production efficiency.

Owner:依偎科技(南昌)有限公司

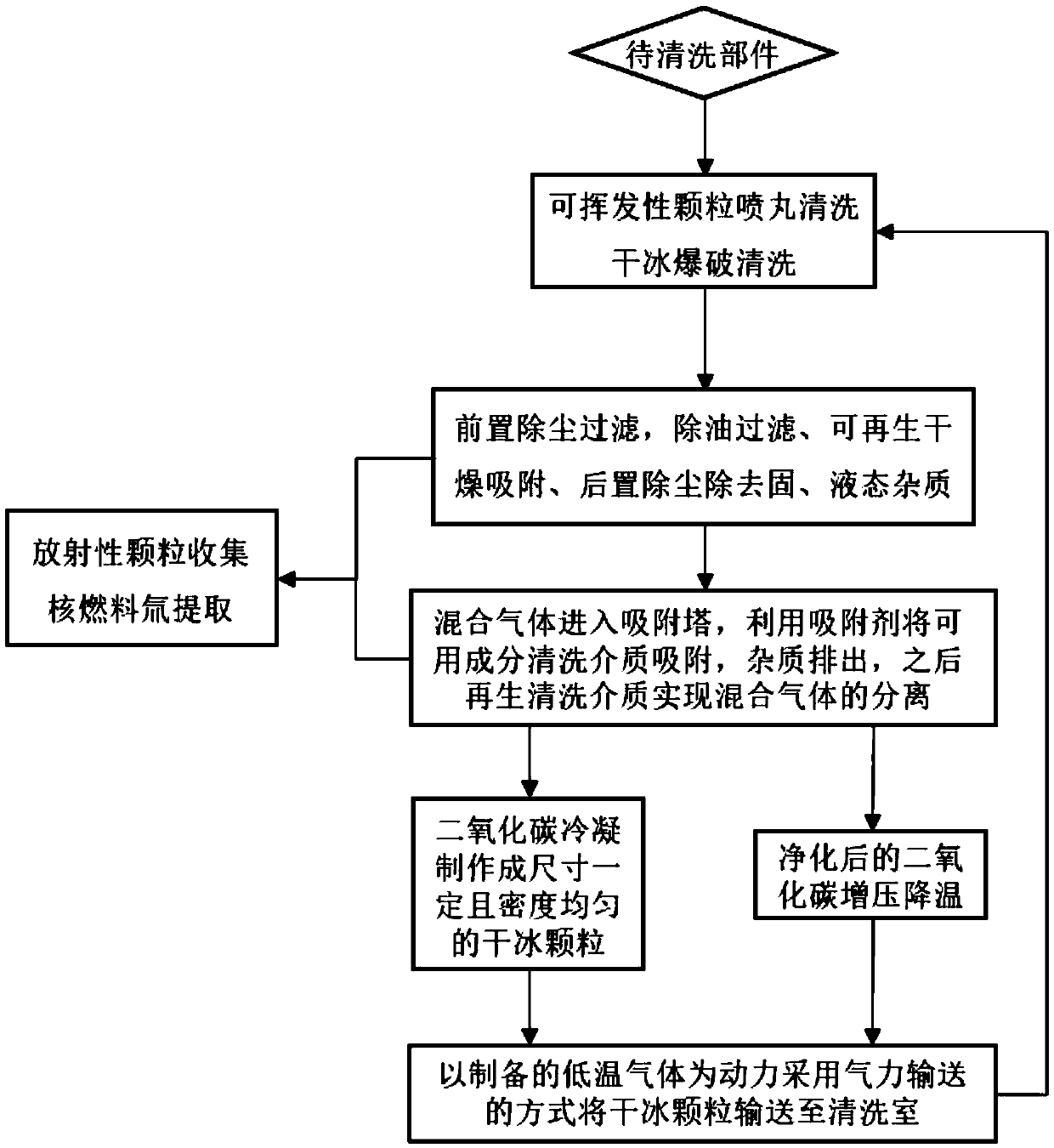

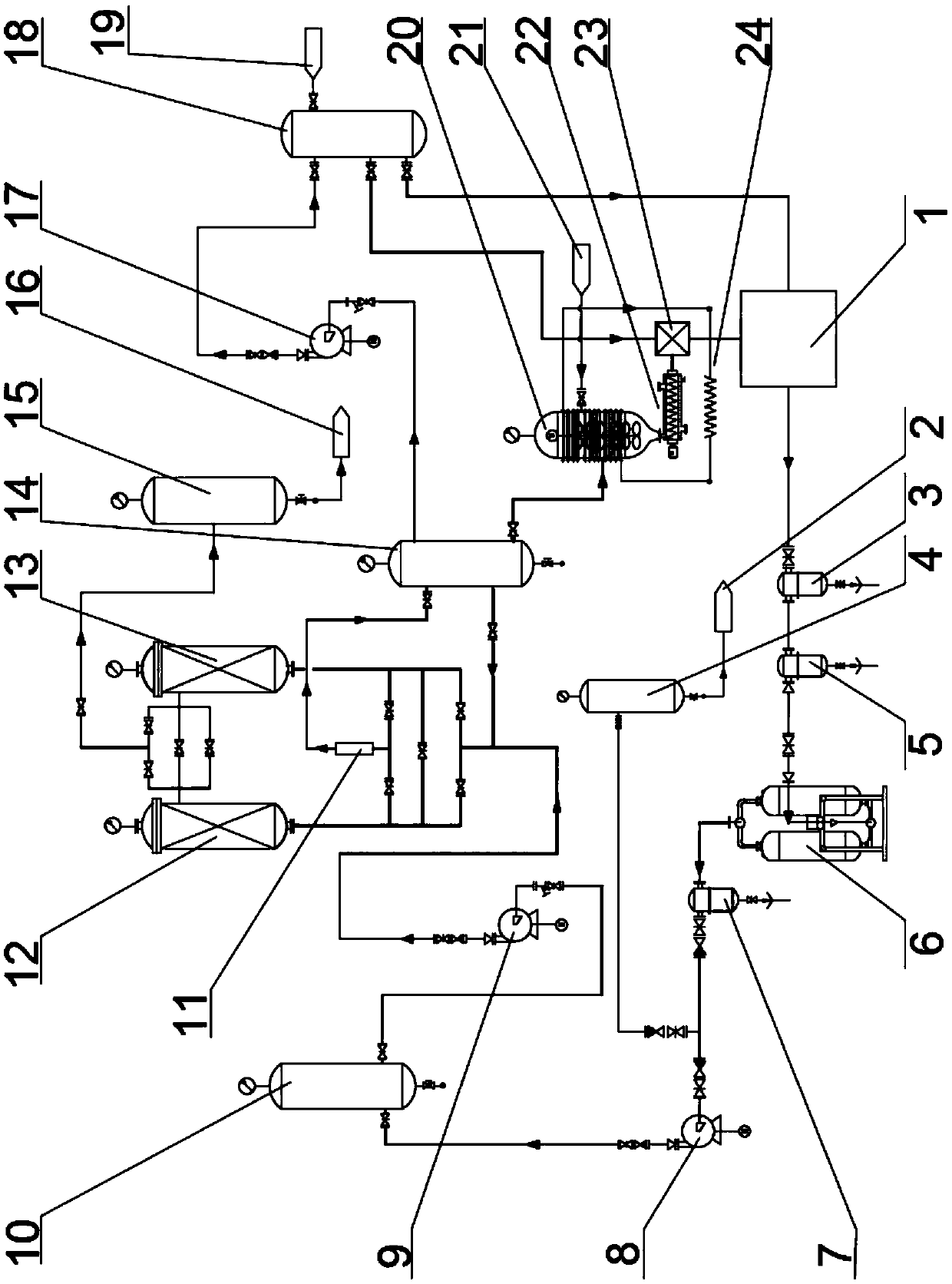

Cleaning waste gas pressure swing adsorption purification and recycling method and device for fusion reactor hot room

ActiveCN105513661AMinimize wasteAchieving classification of by-productsGas treatmentDispersed particle filtrationRadioactive gasCarbon dioxide

The invention relates to a cleaning waste gas pressure swing adsorption purification and recycling method and device for a fusion reactor hot room. The method includes the technological process of cleaning and contaminating, solid and liquid impurity filtration and purification, cleaning medium adsorption separation and regeneration, low-temperature power gas preparation, volatilizable particle regeneration and volatilizable particle remote-distance pneumatic transport. Fusion reactor hot room cleaning waste gas containing radioactive particles and radioactive gas is processed in a low-risk mode through a multiple filtration and pressure swing adsorption method, and separation, classified collection and recycling of radioactive particles, radioactive gas tritium and a cleaning medium carbon dioxide gas are achieved. The purity of regenerated products is high, no external heat source heating is needed, the gas temperature change range is small, the device is more economical and saves more energy, the service life of adsorbent is long, the device maintenance is easy and convenient, automatic production can be completely achieved, and the method and the device are suitable for the hot room environment remotely controlled and operated.

Owner:UNIV OF SCI & TECH OF CHINA

Composite bulk material of resin, ferrite and MXenes and preparation method and application thereof

ActiveCN105295303AGood electrical conductivityGood impedance matching performanceComposite materialMXenes

The invention discloses a composite bulk material of resin, ferrite and MXenes. Ferrite molecules are dispersed in a laminated structure of the MXenes to form powder particles, and the powder particles are evenly dispersed in the resin to form the bulk material. On the one hand, the composite bulk material has the advantages of the ferrite material and the advantages of the MXenes, has good conductivity, can still keep certain conductivity when the temperature is lower than 260 K, and meanwhile has good impedance matching performance, and therefore the composite bulk material can be applied as a wave-absorbing material, and is especially suitable for being applied to the low-temperature condition; on the other hand, the resin is introduced into the composite bulk material, the powder particles are evenly dispersed in the resin, the composite bulk material is formed and has the advantage of being easy to form and process, and meanwhile, due to the fact that the curing temperature of the resin is lower than the sintering temperature of the powder particles, the problem that the powder particles are easily oxidized at high temperature is effectively solved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Glass fiber infiltration agent composition

The invention relates to a combination of glass fiber infiltration agent, which comprises a film forming agent, a coupling agent and other promoters. The film forming agent is unsaturated and polyester type, and the unsaturated polyester is made into emulsion by emulsification, wherein, the unsaturated polyester is made from carboxyl sulfonate, polyol and polybasic acid by catalysis; the catalyst is titanate esters agent; the preparation technique includes the steps: 1 to 10 weight portions of carboxyl sulfonate and 50 to 150 weight portions of polyol react under the temperature of 150 to 200 DEG C; after being cooled, the obtained material is added with 40 to 95 weight portions of polybasic and titanate esters catalyst that is 0.05 to 1 percent of the mass of the film forming agent to react under the temperature of 160 to 230 DEG C; then the obtained material are cooled, crushed and made into emulsion; at last the emulsion is mixed with the coupling agent and other promoters to produce the infiltration agent. The invention has the advantages that: the unsaturated polyester emulsion is adopted as matrix and the sulfonate monomers with hydrophilicity is used for preparing the film forming agent, so the film forming agent has self-emulsifying function and can be dissolved in solution more easily; in addition, the titanate esters is employed as catalyst, which avoids the occurrence of polyester gel and better protects of glass fiber.

Owner:上海新天和树脂有限公司 +2

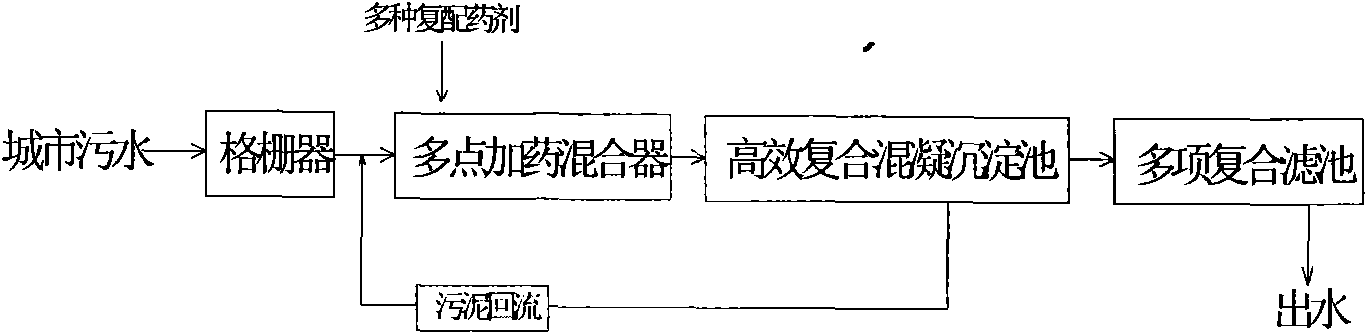

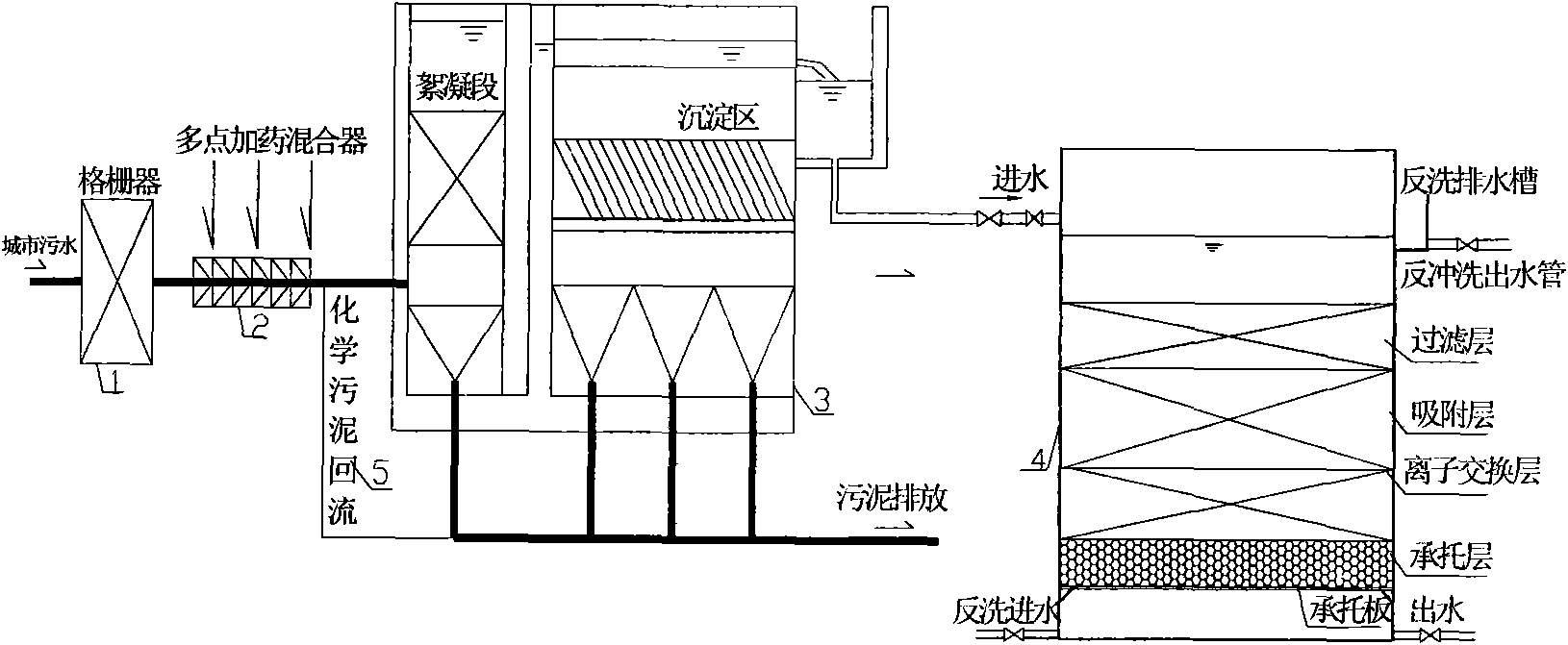

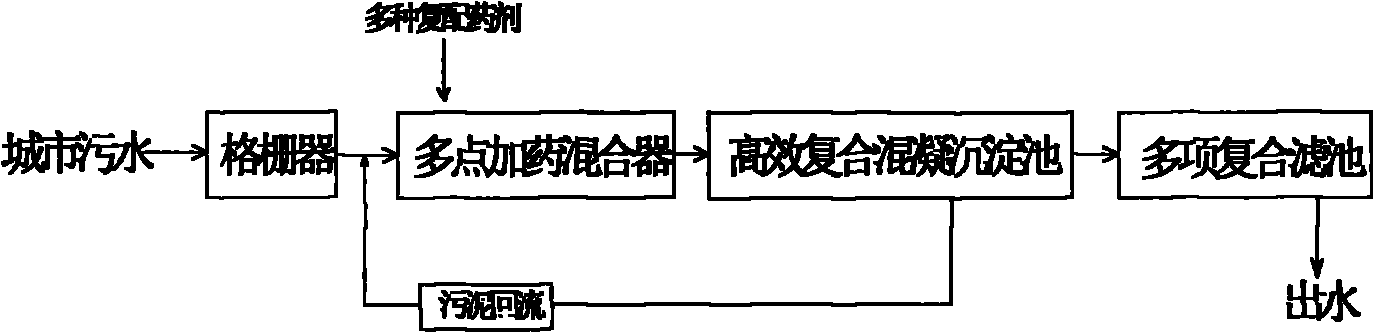

Composite technology for treatment of urban wastewater in complete set of physical and chemical methods

InactiveCN101880101AEnhanced mass transferAchieve efficiencyWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiltrationSludge

The invention provides a composite technology for treatment of urban wastewater in a complete set of physical and chemical methods. When the urban wastewater flows into the system, large-particle impurities are basically removed through a grille, the wastewater is then rapidly mixed with a plurality of compound medical preparations and returning chemical sludge in a multi-point dosing mixer and then flows into an efficient complex coagulation-precipitation system for flocculation and precipitation, the supernate after precipitation flows into a multi-phase composite filter, and water is finally discharged after filtration, ion exchange and adsorption. The chemical sludge can be further used for processing building materials after stabilization, acidification, alkalization and chemical phosphorus recovery, thereby realizing the utilization of the sludge resource. The invention has the advantages of low requirements for the ambient temperature and flexible starting and operation. Compared with the complex process for advanced treatment with serial combination of the traditional secondary biological treatment, coagulation, precipitation and filtration, the invention shortens the overall treatment flow, and effectively reduces the infrastructure investment cost.

Owner:王鹤立

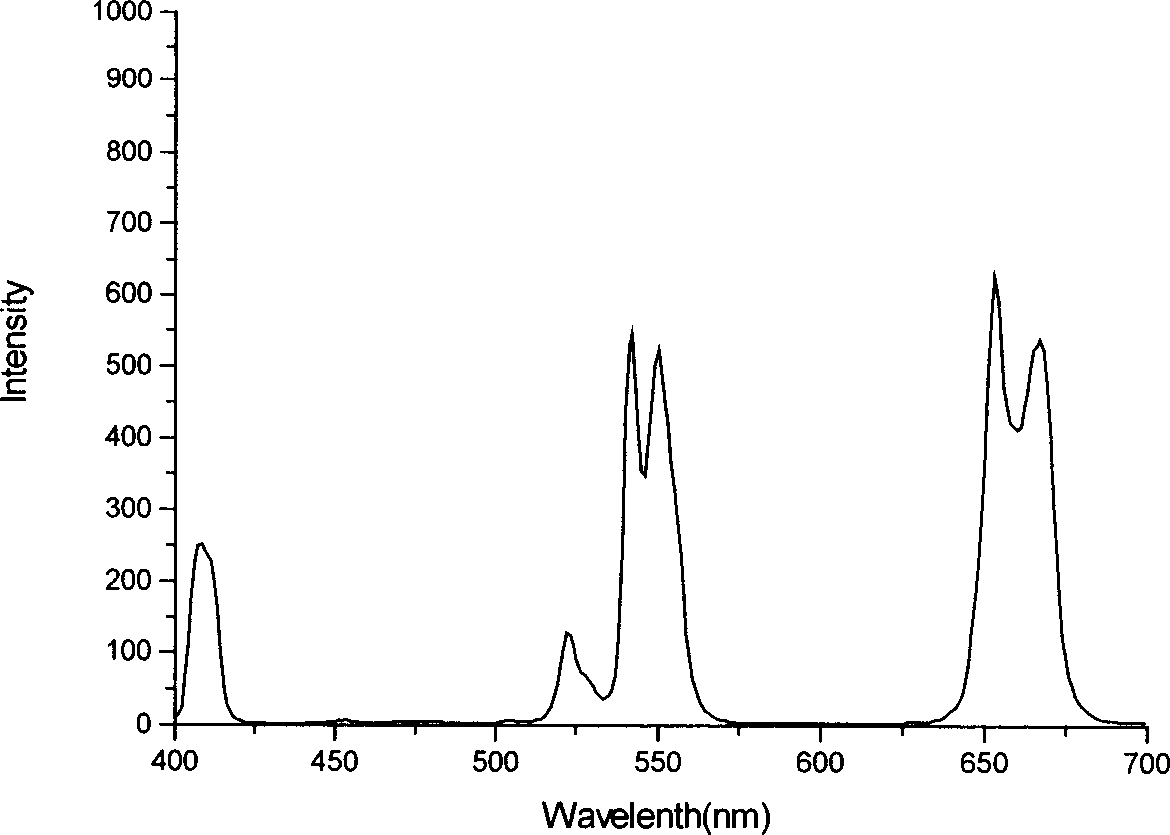

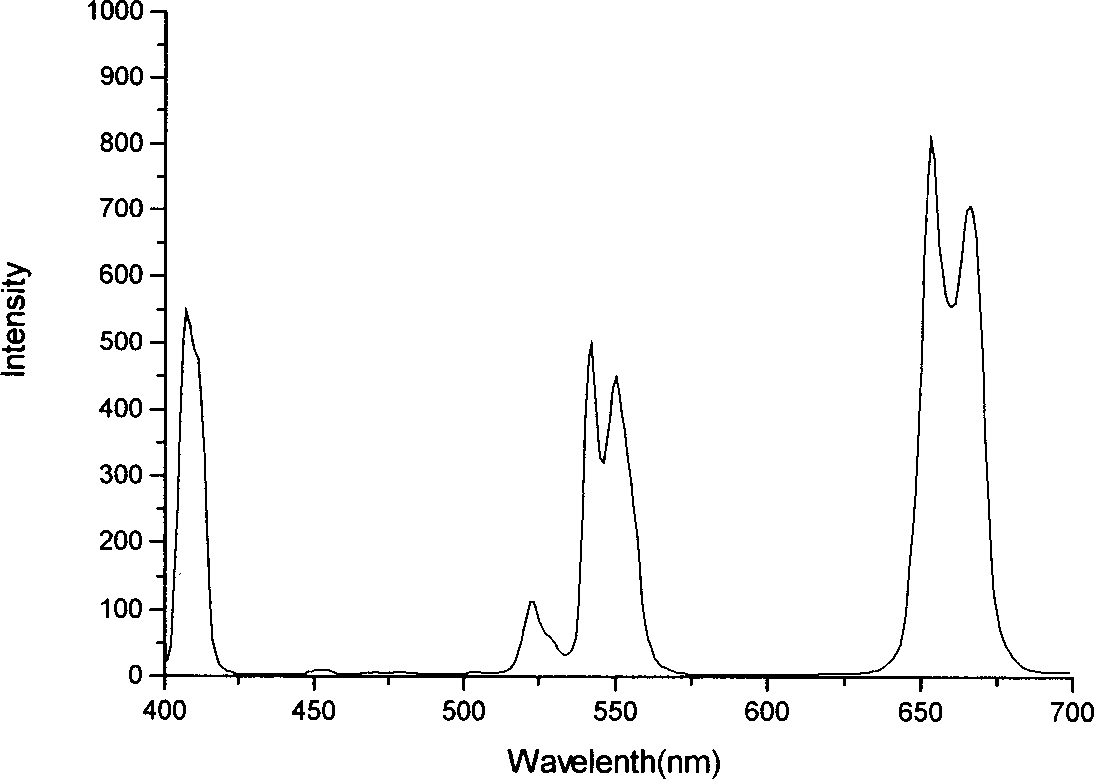

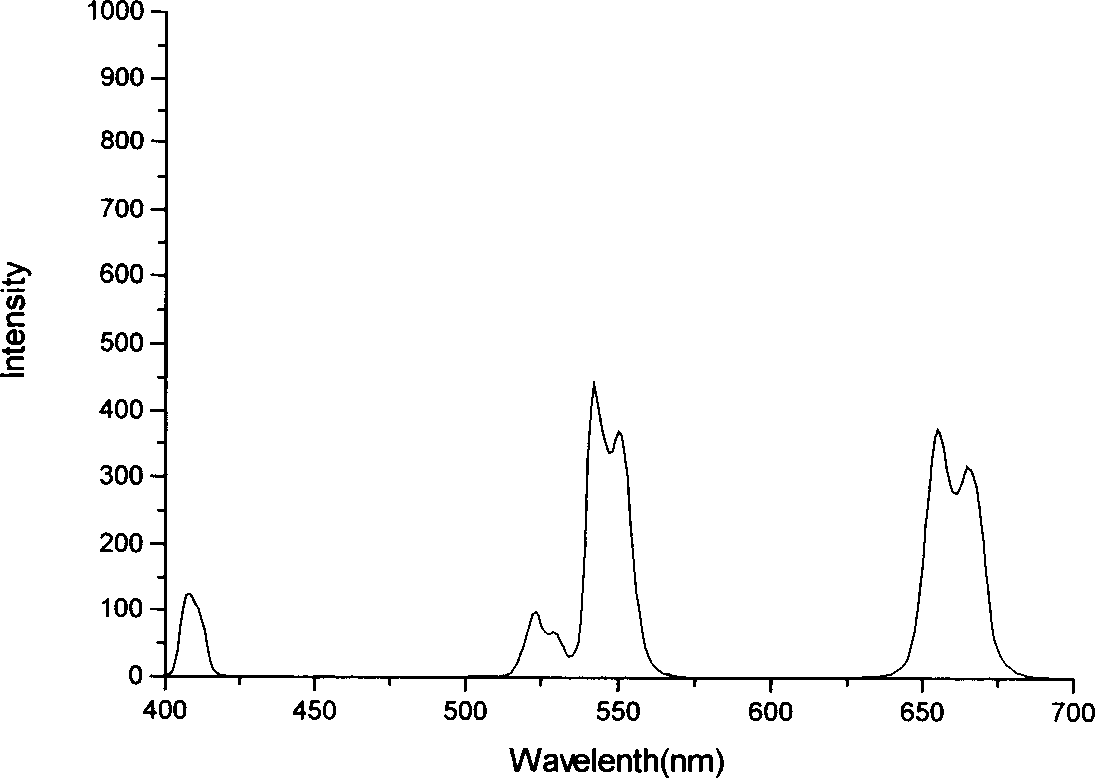

Infrared upward rotating marking material and its prepn. method

InactiveCN1415693AImprove conversion efficiencyMaintain stabilityLuminescent compositionsRare earthLength wave

A dual-wavelength infrared up-conversion material for label or antiforge purpose is a RE compound doped composite fluoroxidie ceramics material while can generate one or two or more kinds of wavelength-fixed visible light under the radiation of 980-nm near infrared light. Its advantages are high up-conversion efficiency and stability and simple preparing process.

Owner:SUZHOU UNIV +1

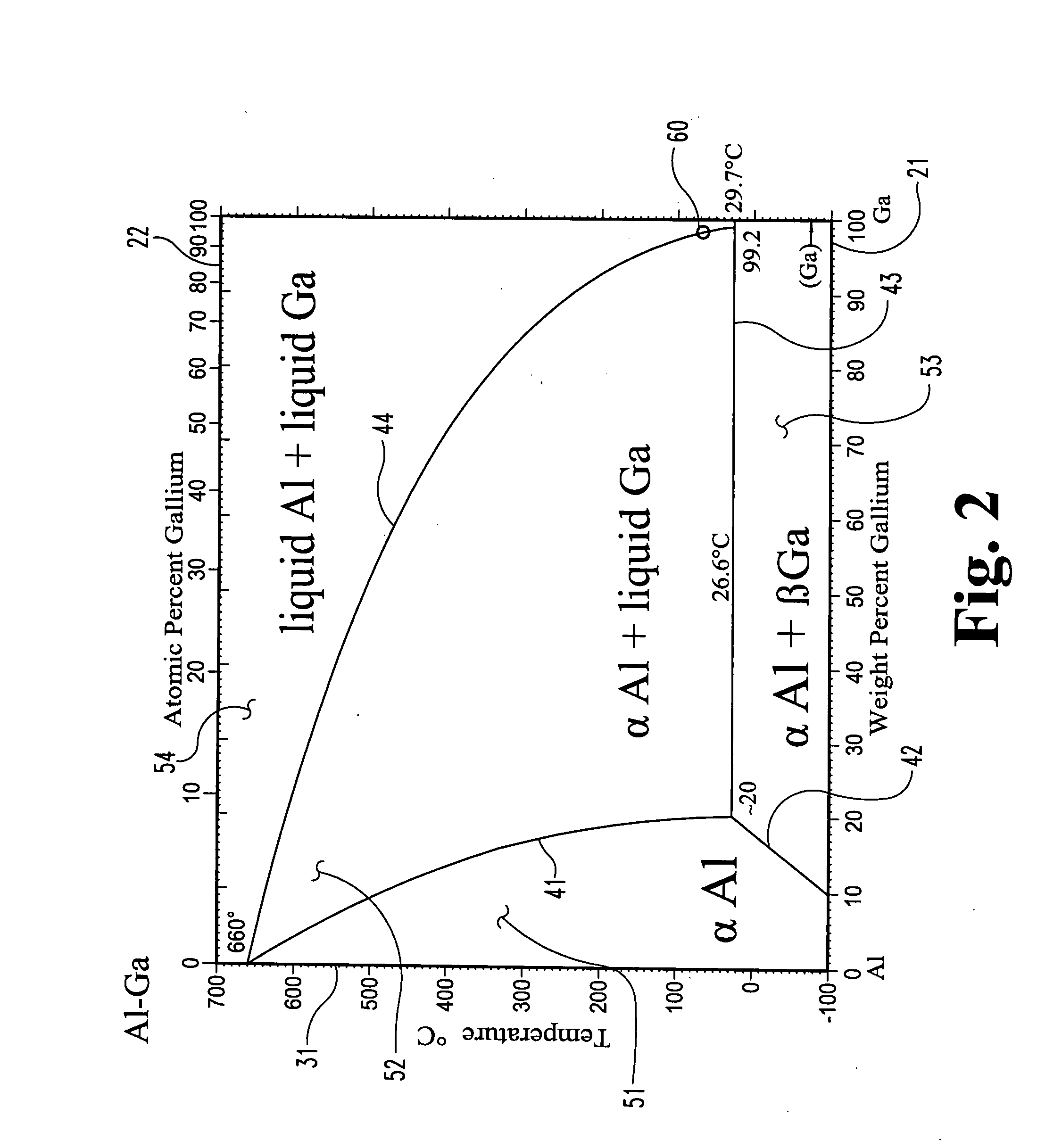

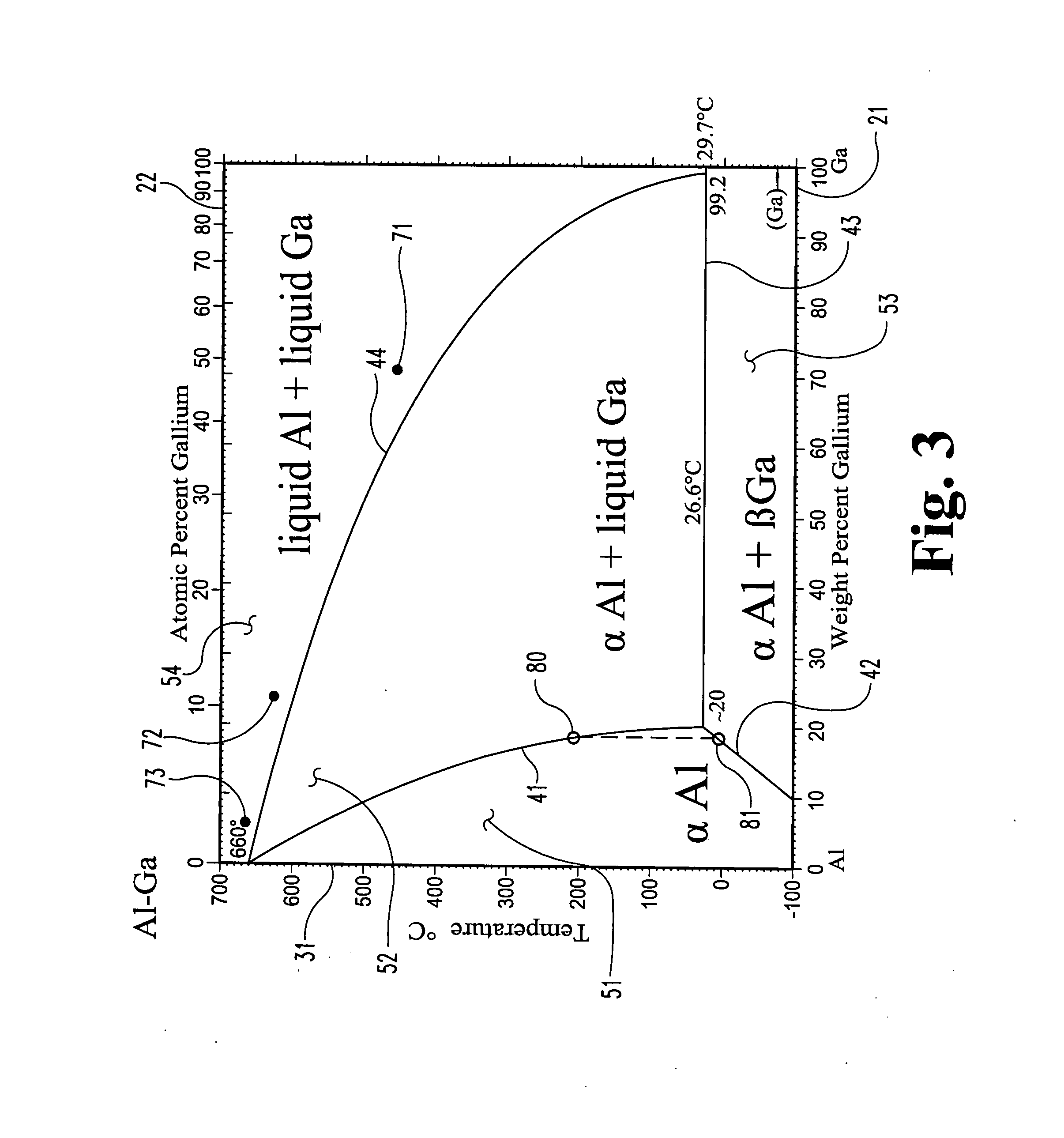

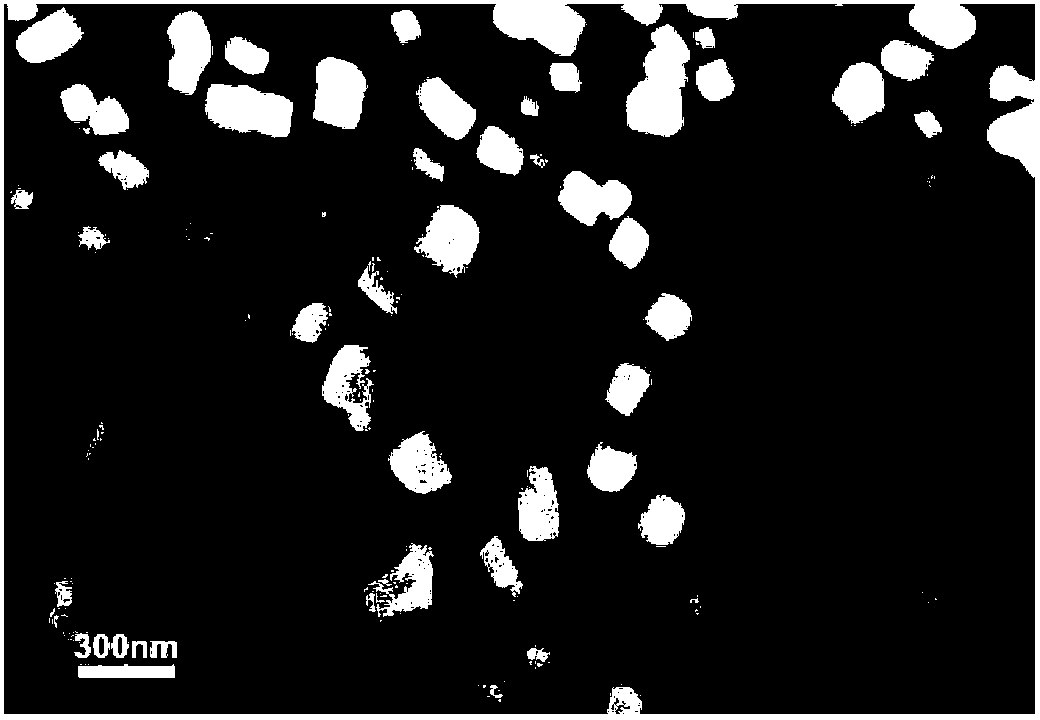

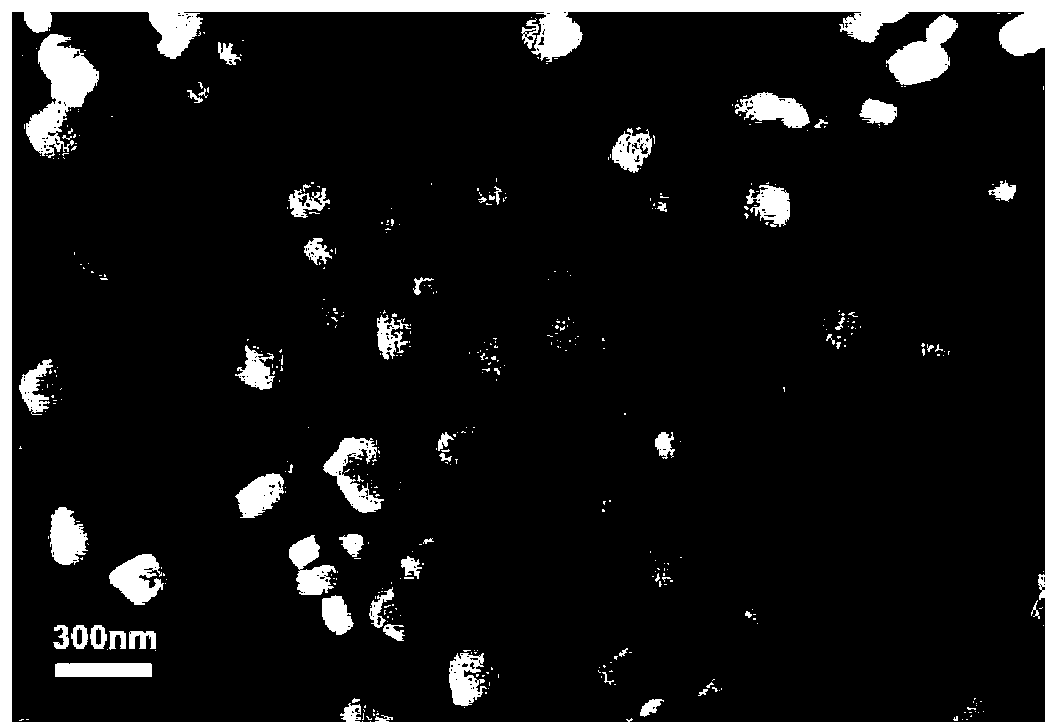

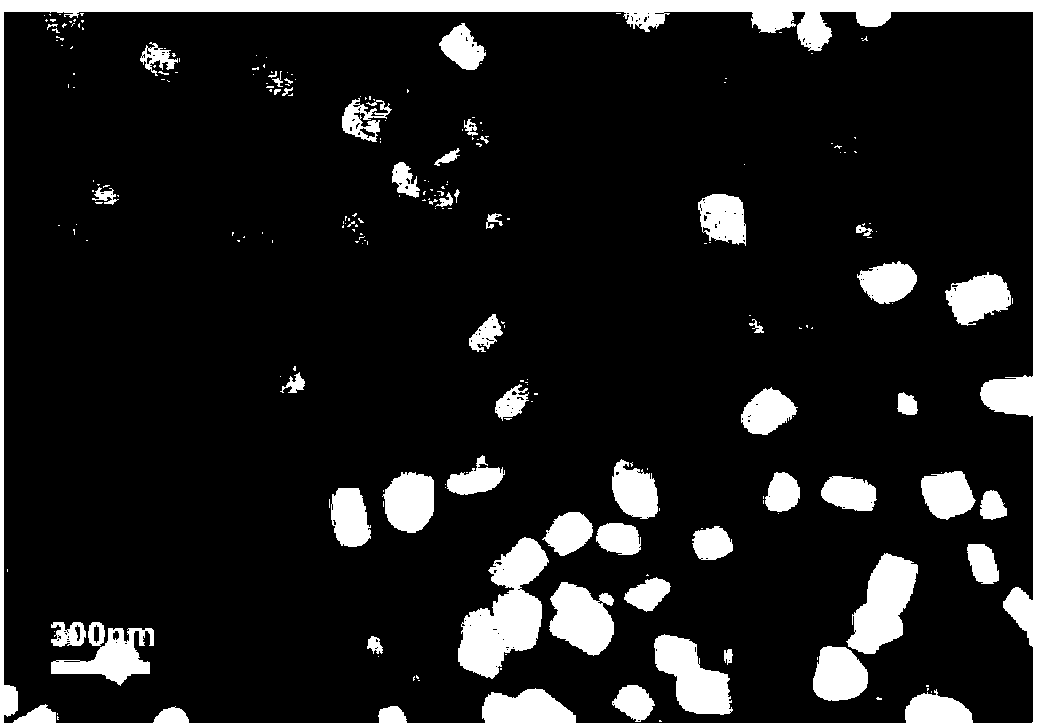

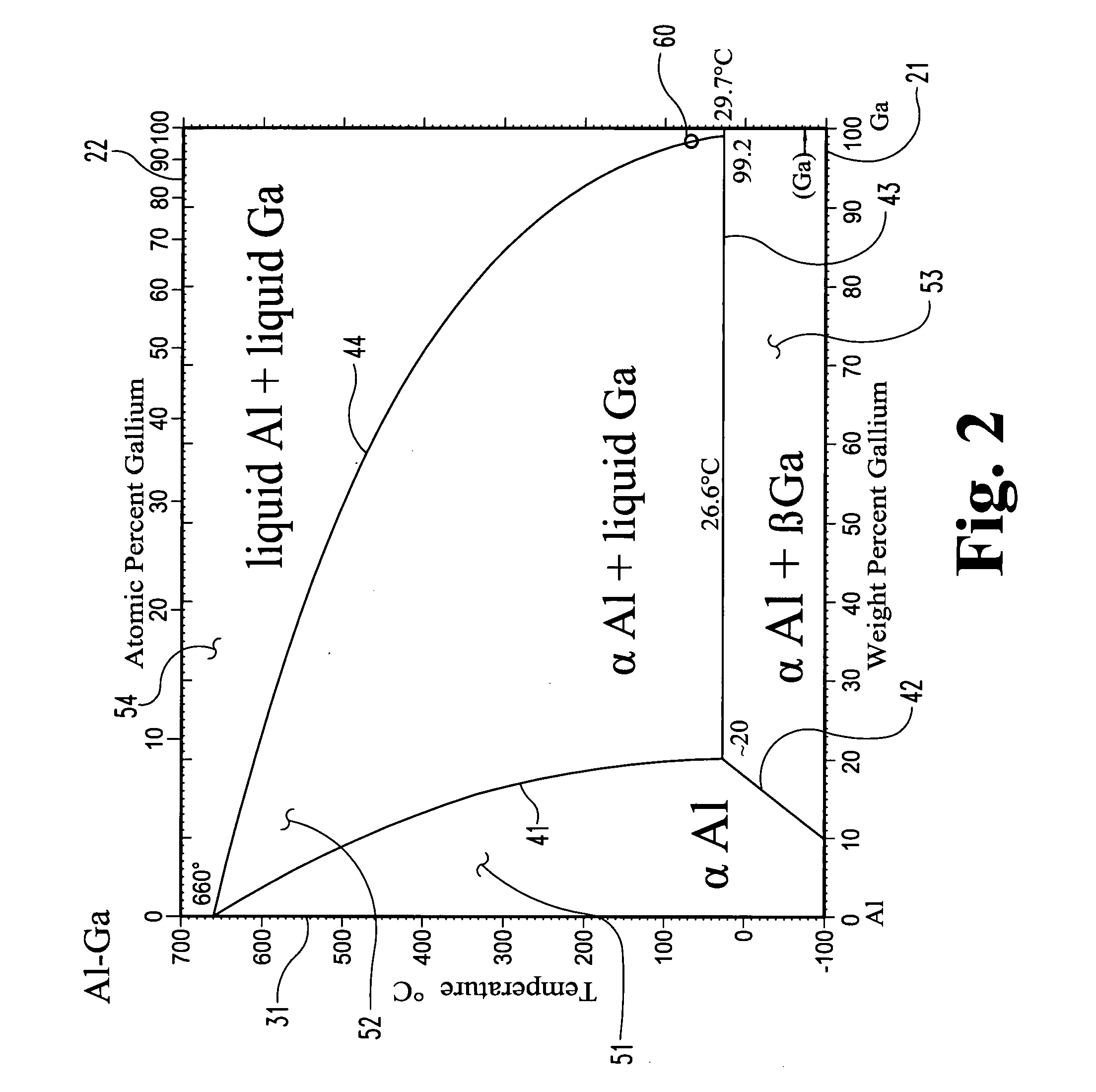

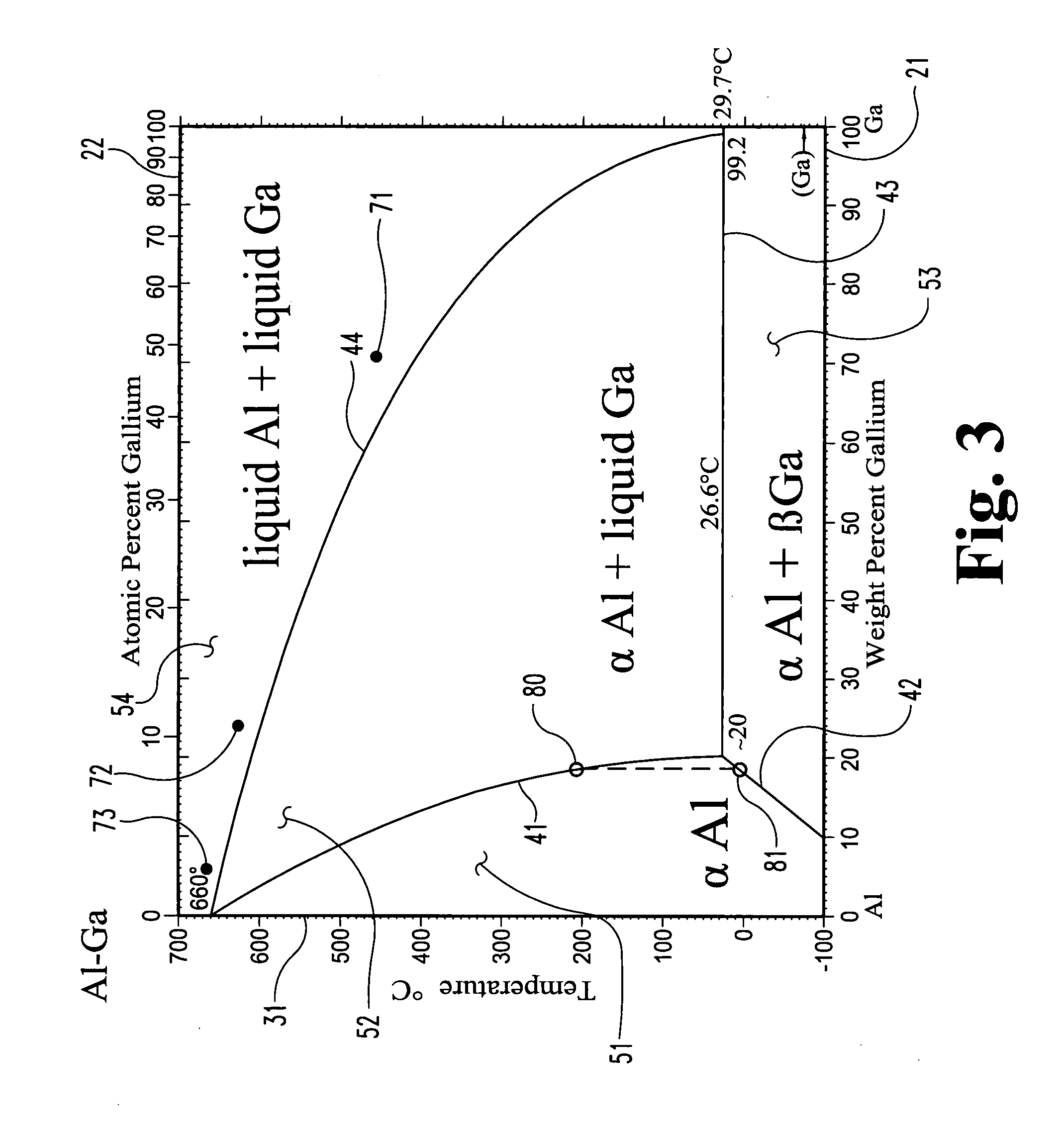

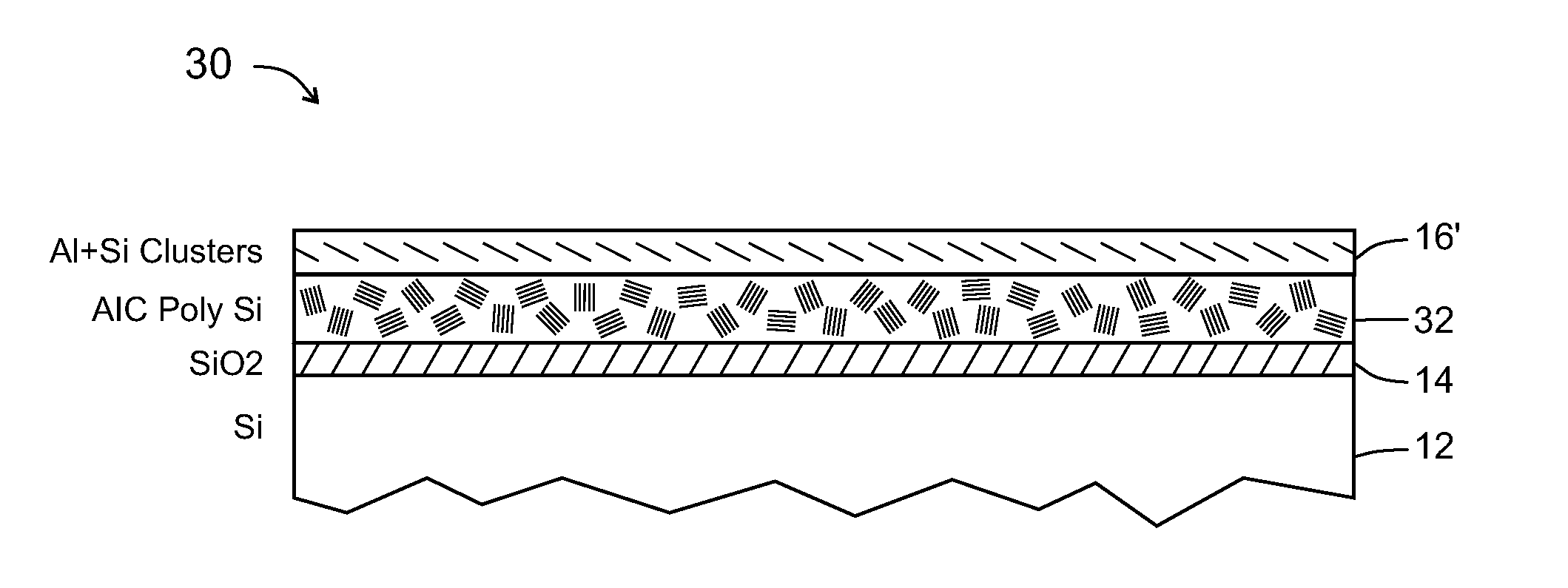

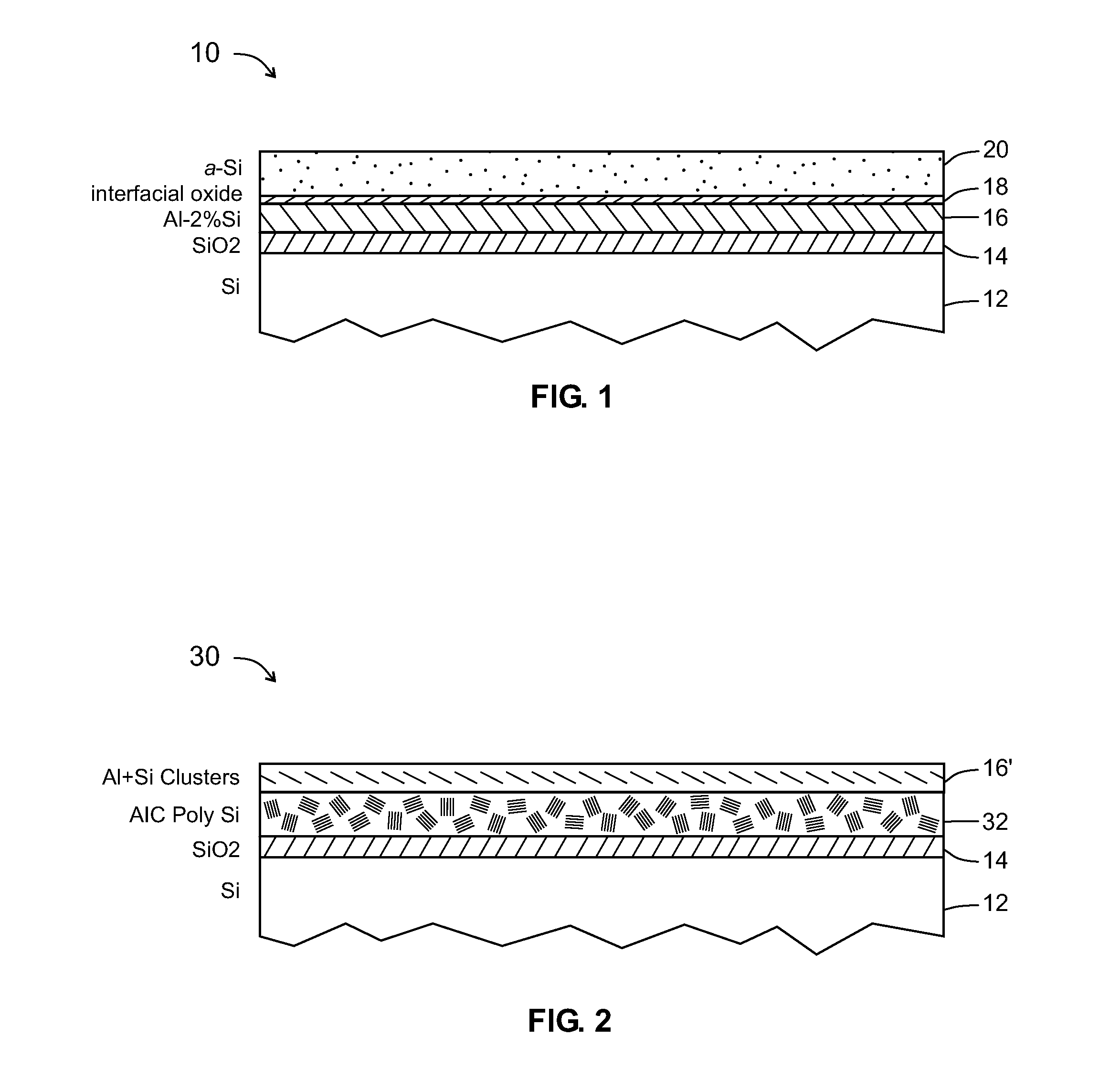

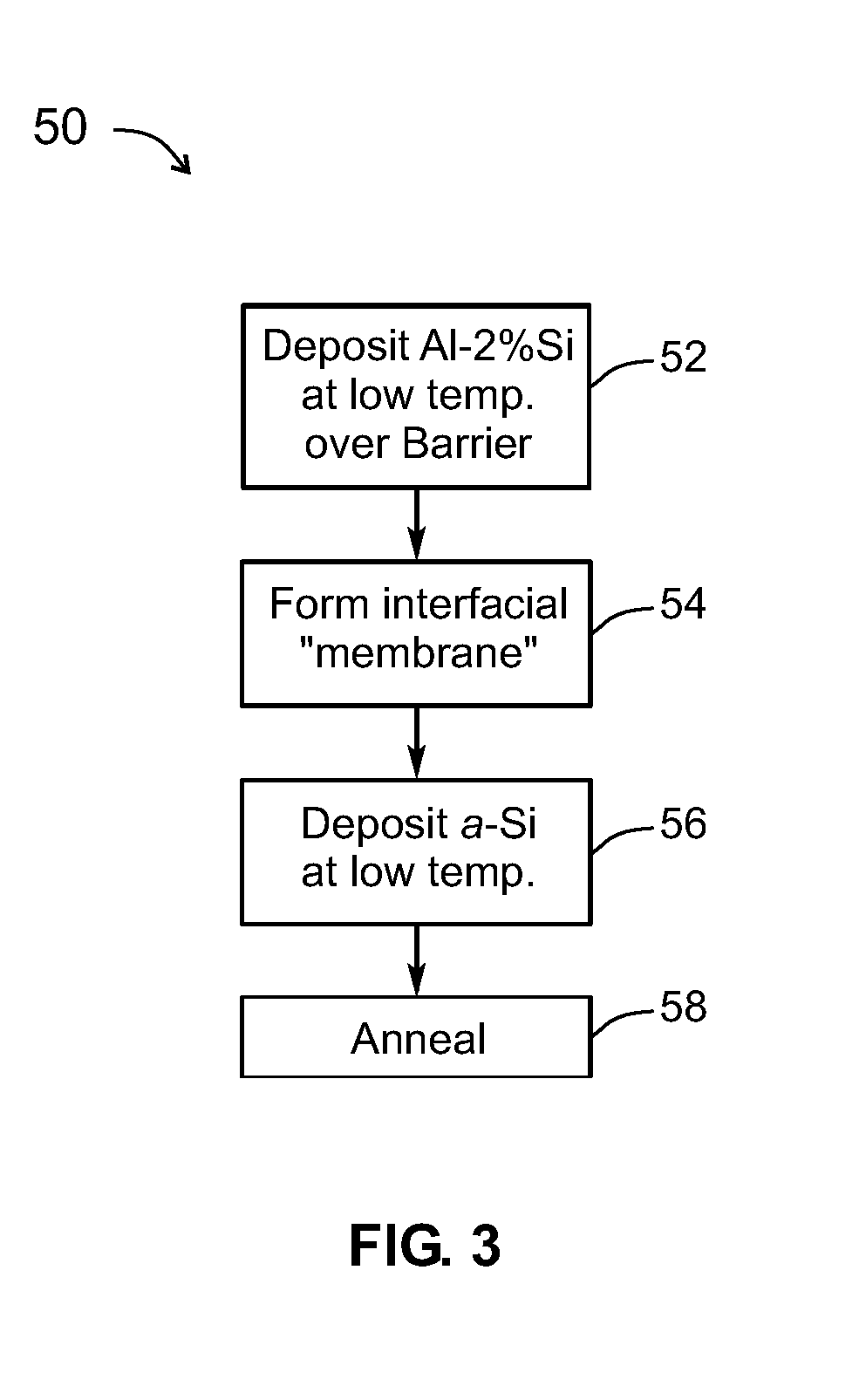

Low-temperature formation of polycrystalline semiconductor films via enhanced metal-induced crystallization

ActiveUS20100184276A1Enhance formationLow temperaturePolycrystalline material growthFrom solid stateMetal-induced crystallizationAmorphous semiconductors

A method for forming polycrystalline semiconductor film from amorphous semiconductor film at reduced temperatures and / or accelerated rates. The inclusion of a small percentage of semiconductor material, such as 2% within the metal layer, reduces the temperatures required for crystallization of the amorphous semiconductor by at least 50° C. in comparison to the use of the metal layer without the small percentage of semiconductor material. During a low temperature isothermal annealing process adjacent Al-2% Si and a-Si films undergo a layer exchange resulting in formation of a continuous polycrystalline silicon film having good physical and electrical properties. Formation of polycrystalline-semiconductor in this manner is suitable for use with low temperature substrates (e.g., glass, plastic) as well as with numerous integrated circuit and MEMs fabrication devices and practices.

Owner:RGT UNIV OF CALIFORNIA

Power generation from solid aluminum

ActiveUS8080233B2Improve abilitiesIncrease contentSolid fuelsWaste based fuelAlloyMelting Point Temperature

A fuel for splitting water into hydrogen and an oxide component comprises a substantially solid pellet formed from a solid-like mixture of a solid-state source material capable of oxidizing in water to form hydrogen and a passivation surface layer of the oxide component, and a passivation preventing agent that is substantially inert to water in an effective amount to prevent passivation of the solid-state material during oxidation. The pellets are brought into contact with an alloy of the passivation preventing agent having a melting point temperature below that of the solid-like mixture to initiate the hydrogen-producing reaction at a lower temperature.

Owner:PURDUE RES FOUND INC

Momordica grosvenori drying process and momordica grosvenori drying equipment

InactiveCN103271139APrevent oxidationGood energy saving effectFruit and vegetables preservationFood treatmentChemistrySiraitia grosvenorii

The invention discloses a momordica grosvenori drying process which comprises the following steps: cleaning fresh momordica grosvenori, putting the momordica grosvenori in steam at the temperature of 90-110 DEG C to deactivate enzyme for 2-3 minutes; freezing the momordica grosvenori subjected to enzyme deactivation under the condition of the temperature of 30-35 DEG C below zero for 1-1.5 hours, and performing vacuum low-temperature dehydration on the momordica grosvenori in vacuum microwave drying equipment for 30-35 minutes; and finally, drying the treated momordica grosvenori under the conditions of the temperature of 30-50 DEG C and the humidity of 10-15 percent for 6-10 hours. According to the improved momordica grosvenori process, the momordica grosvenori processing yield and the momordica grosvenori processing quality are improved, the cost and the energy are saved, and the momordica grosvenori is industrially processed and dried in a large scale.

Owner:梁光庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com