Patents

Literature

832 results about "Hard metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

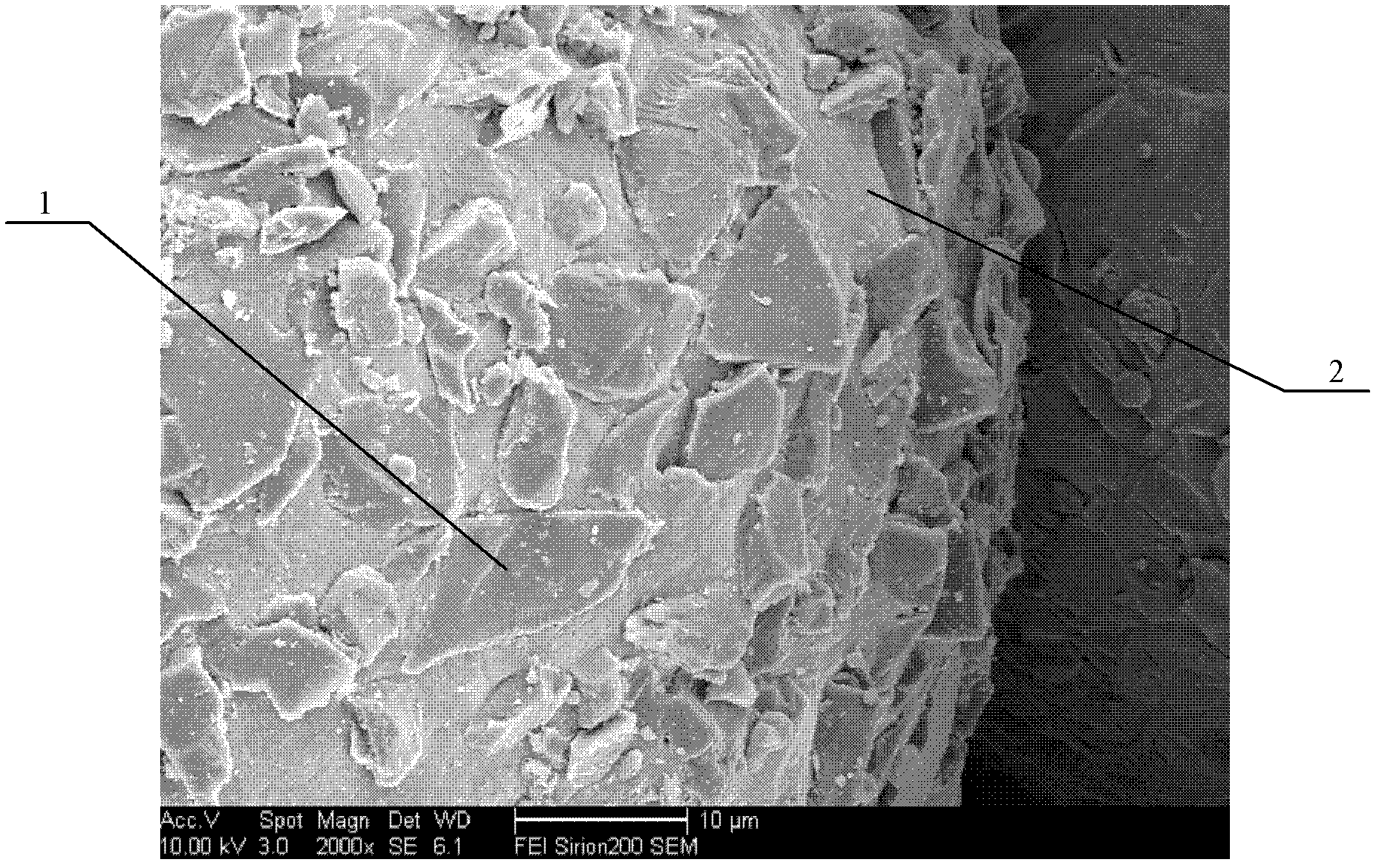

Hard Metals. Hard metals are primarily used as cutting tool for metal cutting. They consist of fine WC particles which act as the hard and abrasion-resistant component and are bonded with tough, comparatively soft, metallic cobalt (Co). The structure of two phase WC/Co hard metals is conventionally defined by key parameters such as.

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

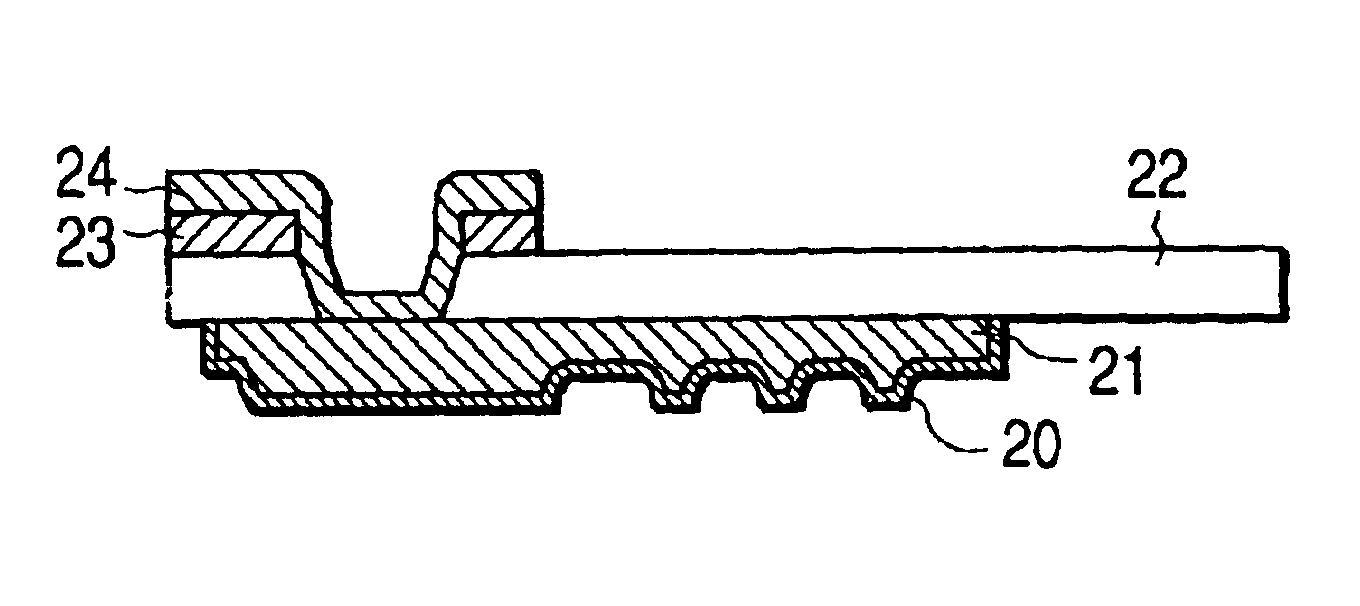

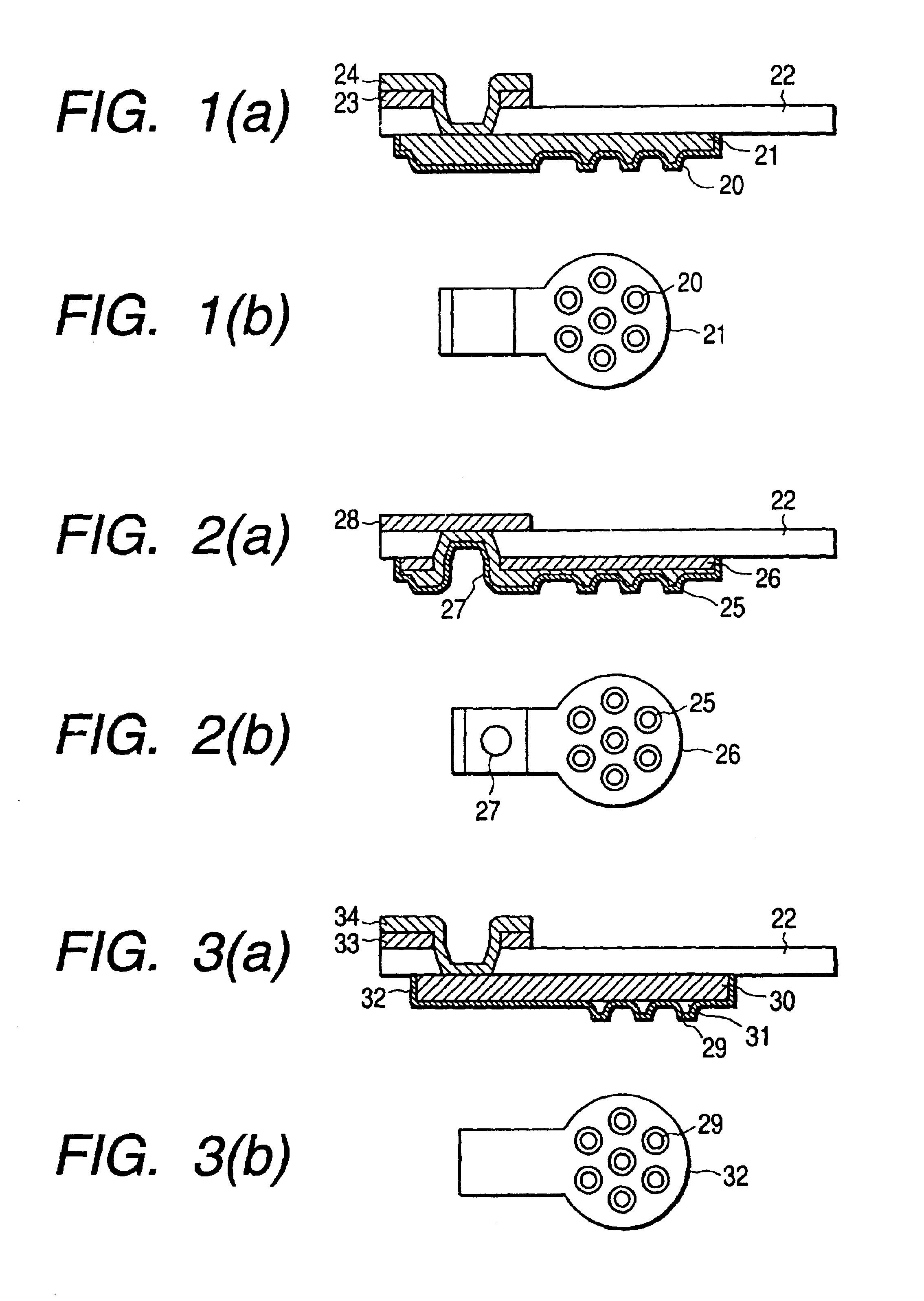

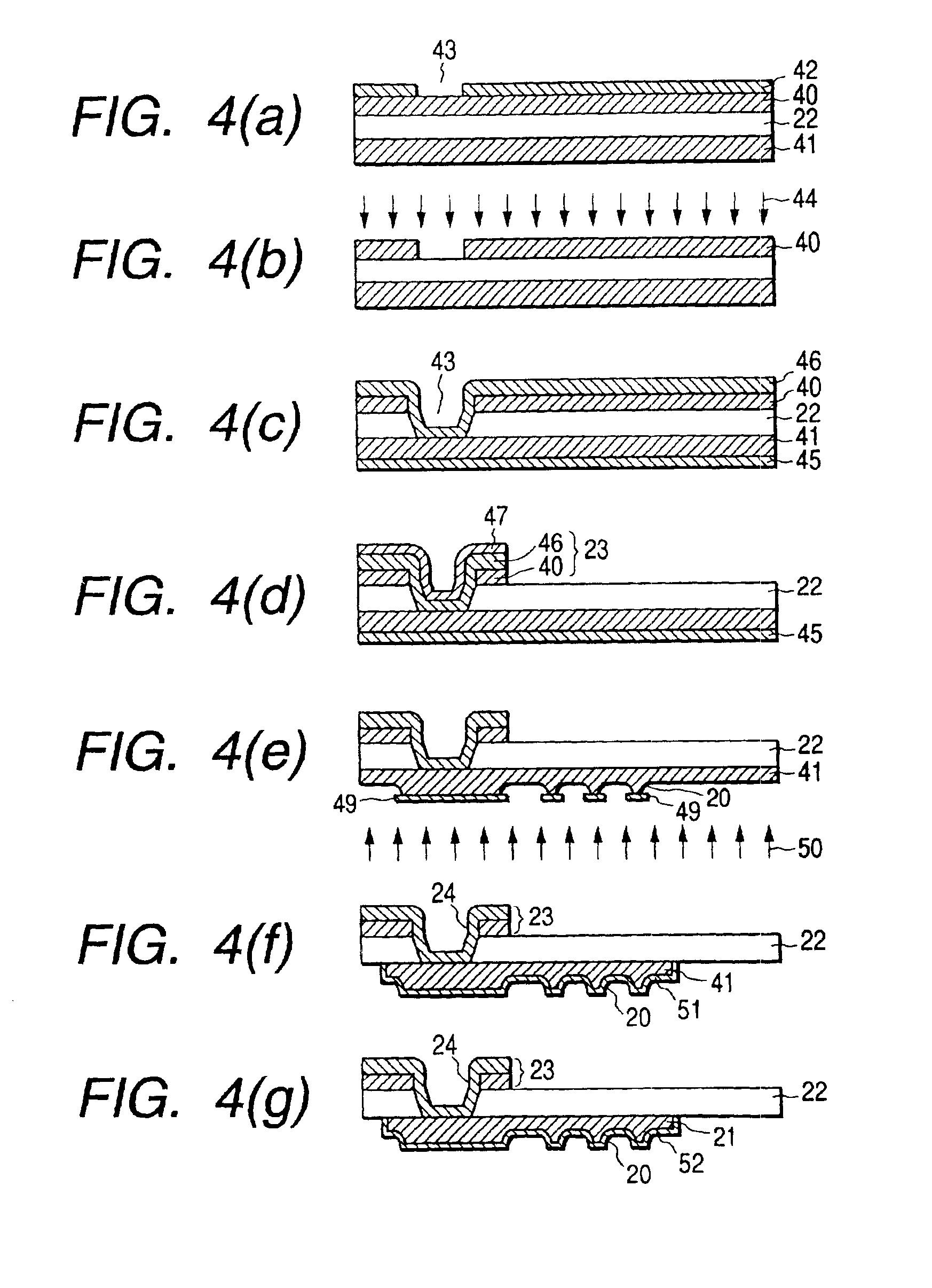

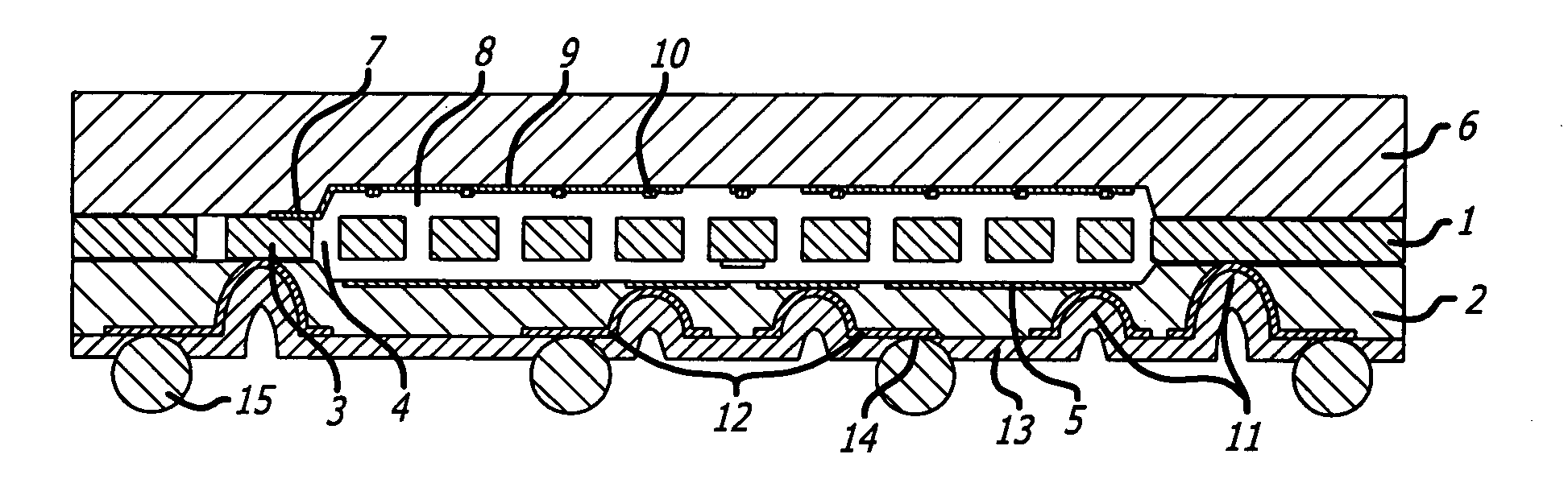

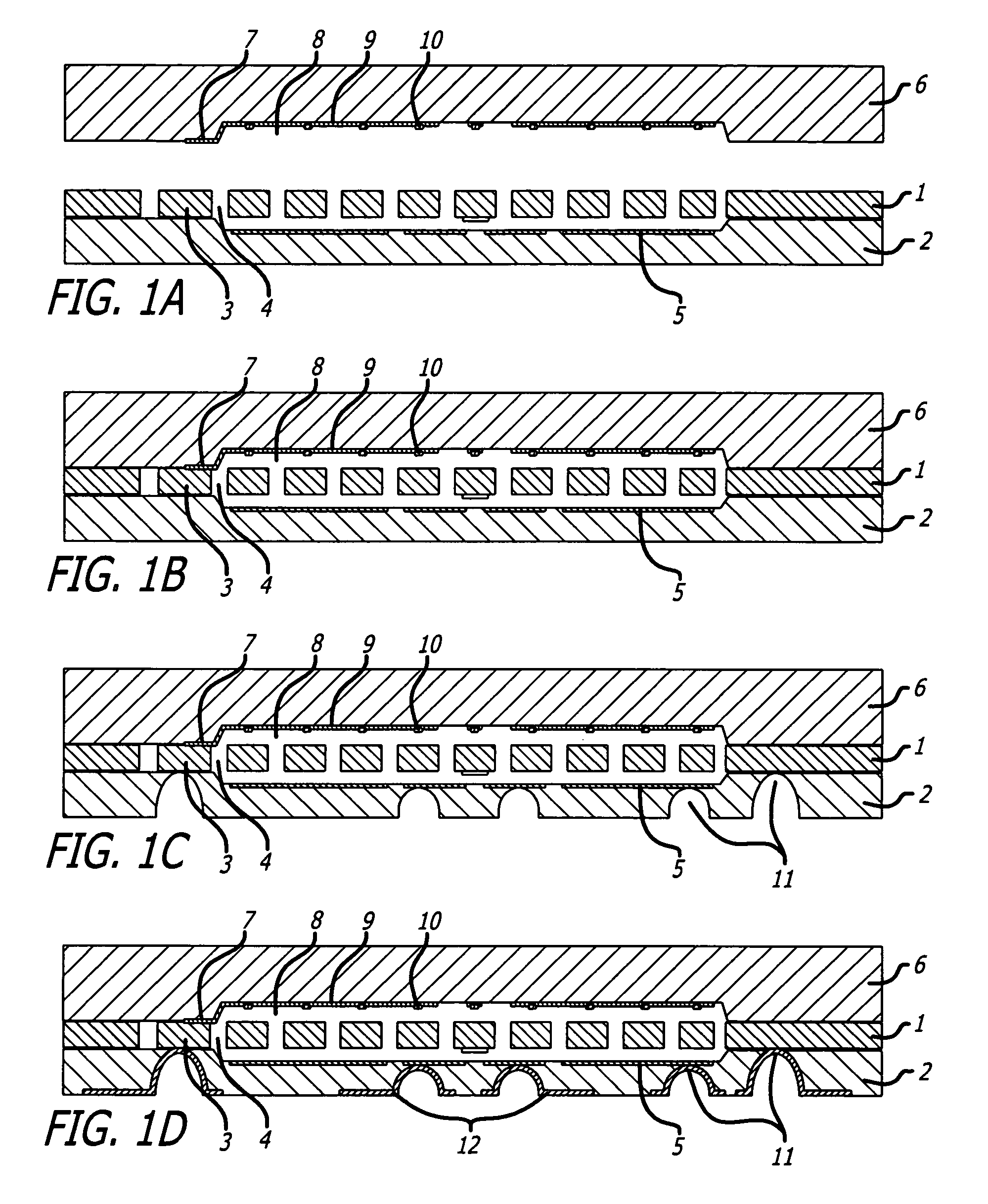

Probing device and manufacturing method thereof, as well as testing apparatus and manufacturing method of semiconductor with use thereof

InactiveUS6900646B2High densityImprove accuracySemiconductor/solid-state device testing/measurementElectronic circuit testingContact formationElectricity

A probing device for electrically contacting with a plurality of electrodes 3, 6 aligned on an object 1 to be tested so as to transfer electrical signal therewith, comprising: a wiring sheet being formed by aligning a plurality of contact electrodes 21, 110b, corresponding to each of said electrodes, each being planted with projecting probes 20, 110a covered with hard metal films on basis of a conductor thin film 41 formed on one surface of an insulator sheet 22 of a polyimide film by etching thereof, while extension wiring 23, 110c for electrically connecting to said each of said contact electrodes being formed on basis of a conductor thin film formed on either said one surface or the other surface opposing thereto of said insulator sheet of the polyimide film; and means for giving contacting pressure for obtaining electrical conduction between said extension wiring and said object to be tested by contacting tips of said projecting contact probe formed onto said each contact electrode through giving pressuring force between said wiring sheet and said object to be tested.

Owner:RENESAS ELECTRONICS CORP

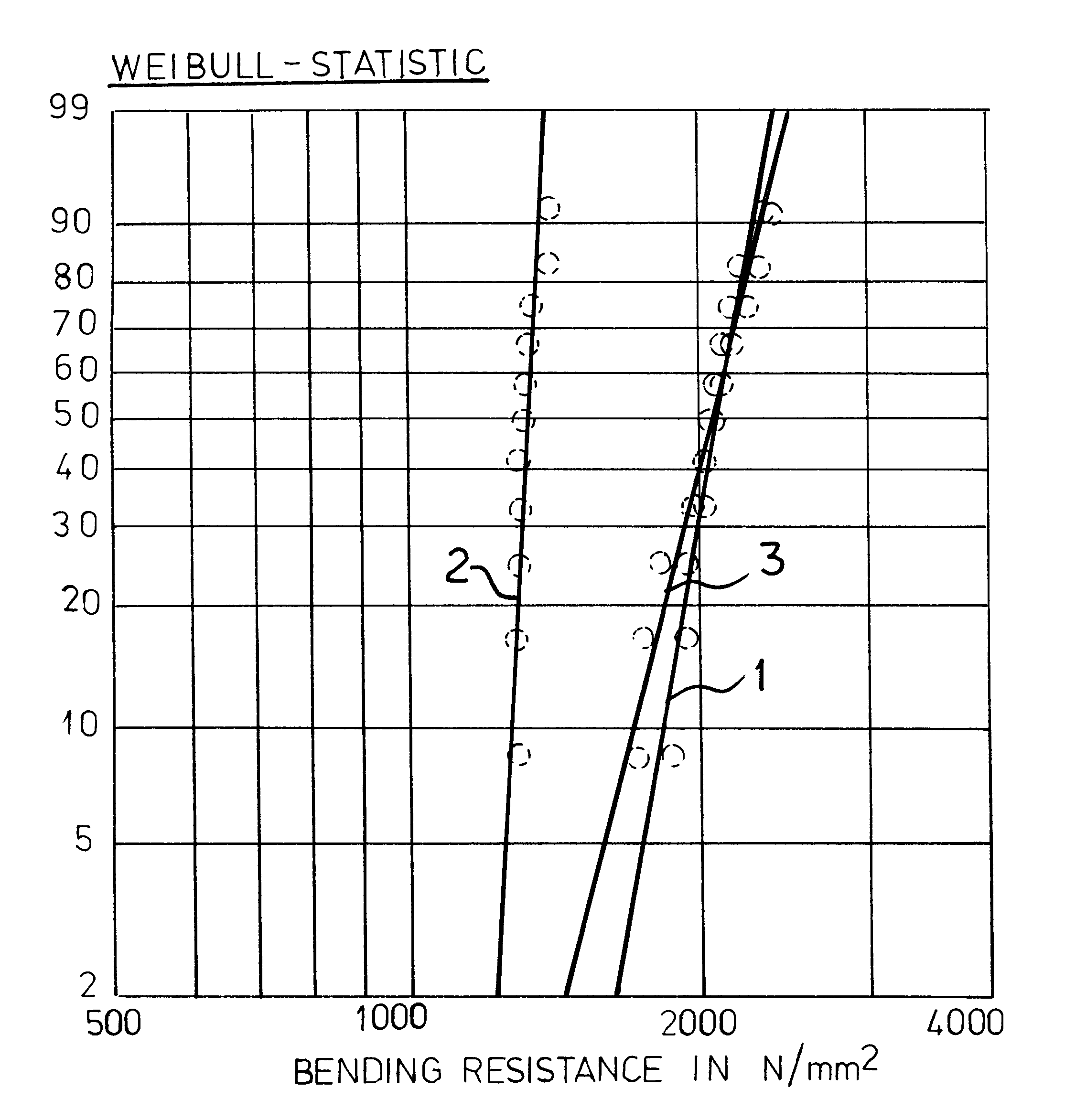

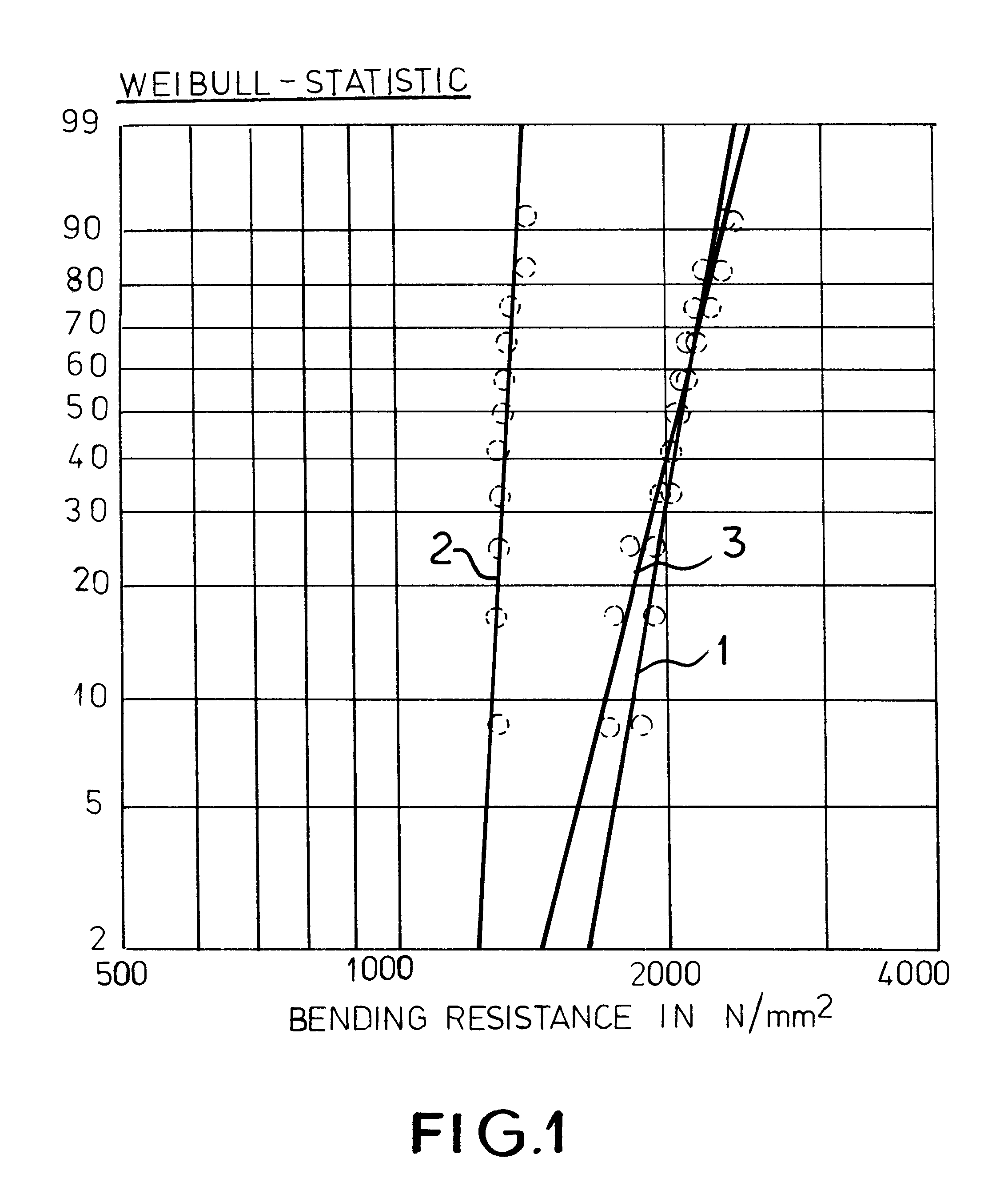

Composite and process for the production thereof

InactiveUS6124040AHigh hardnessHigh strengthVacuum evaporation coatingSputtering coatingHard metalCarbon nitride

PCT No. PCT / DE95 / 00548 Sec. 371 Date Nov. 20, 1997 Sec. 102(e) Date Nov. 20, 1997 PCT Filed Apr. 26, 1995 PCT Pub. No. WO96 / 33830 PCT Pub. Date Oct. 31, 1996The invention concerns composites substantially consisting of: a cermet material having a binder metal phase of between 5 and 30 mass % and the remainder comprising at least one carbon nitride phase; or a hard metal with a hard material phase of between 70 and 100 %, the remainder being a binder metal phase, with the exception of a WC-Co hard metal, with up to 25 mass % cobalt as binder metal; or a powder-metallurgically produced steel. The invention further concerns a process for producing this composite. In order to improve bending strength and hardness, sintering is carried out in a microwave field.

Owner:WIDIA

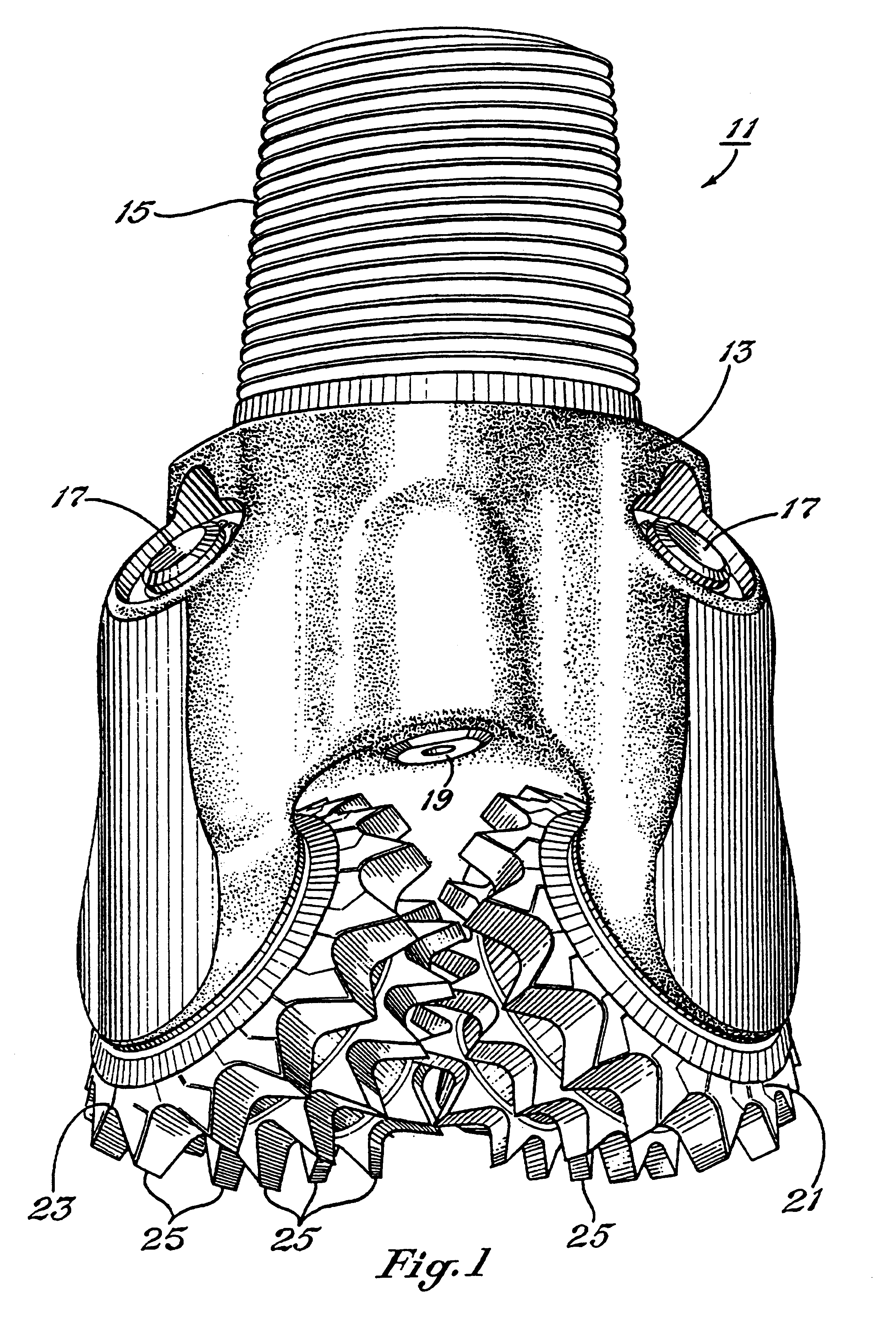

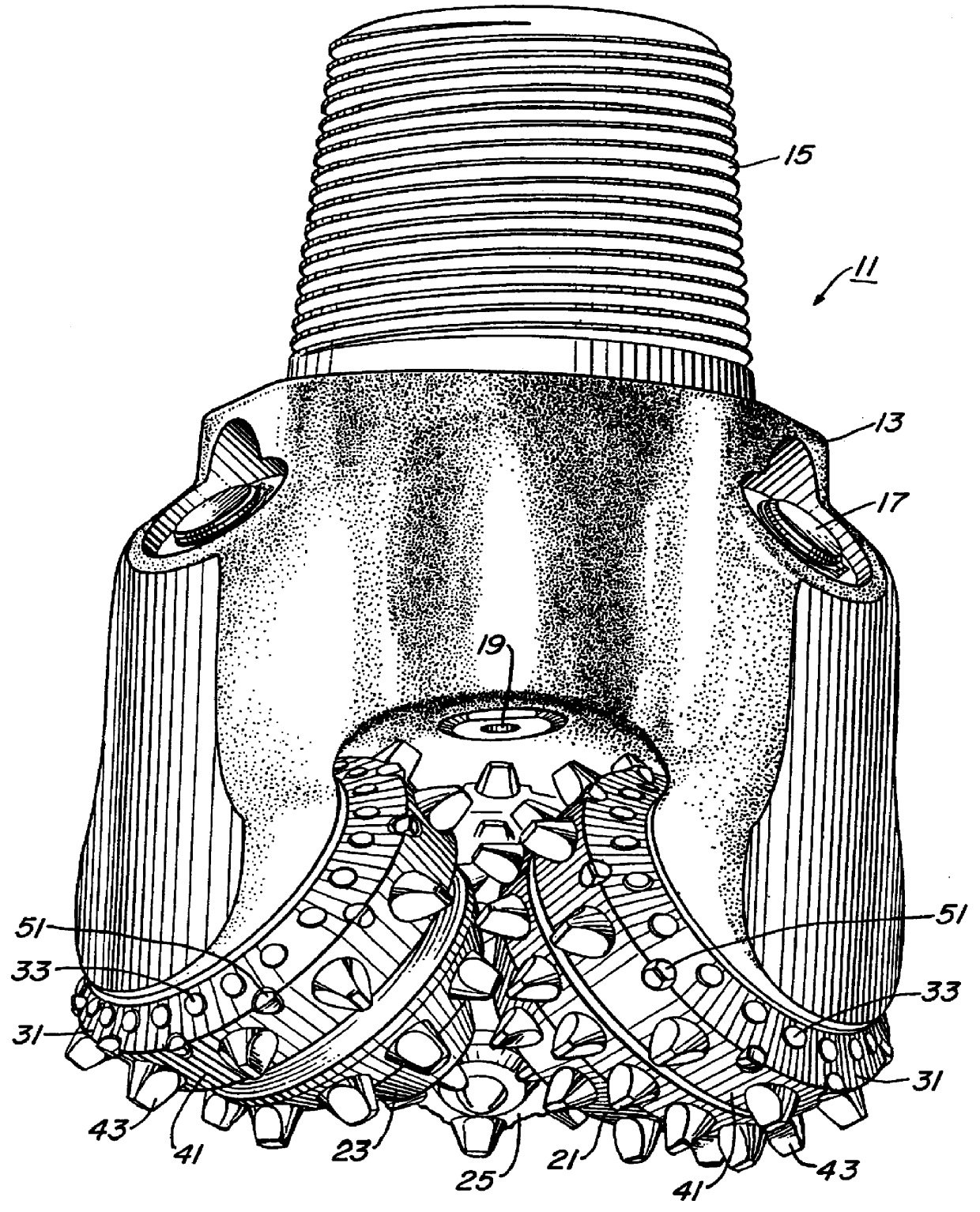

Hardfacing composition for earth-boring bits

InactiveUSRE37127E1Improve wear resistanceImprove fracture toughnessMolten spray coatingDrill bitsNiobiumVanadium carbide

A hardfacing composition comprises at least 60% by weight of hard metal granules including a quantity of sintered carbide pellets and a quantity of cast carbide pellets. The cast and sintered carbides are selected from the group of carbides consisting of chromium, molybdenum, niobium, tantalum, titanium, tungsten, and vanadium carbides and alloys and mixtures thereof. The balance of the hardfacing composition is matrix metal with traces of flux or deoxidizer, and alloying elements. All percentages given are pre-application ratios.

Owner:BAKER HUGHES INC

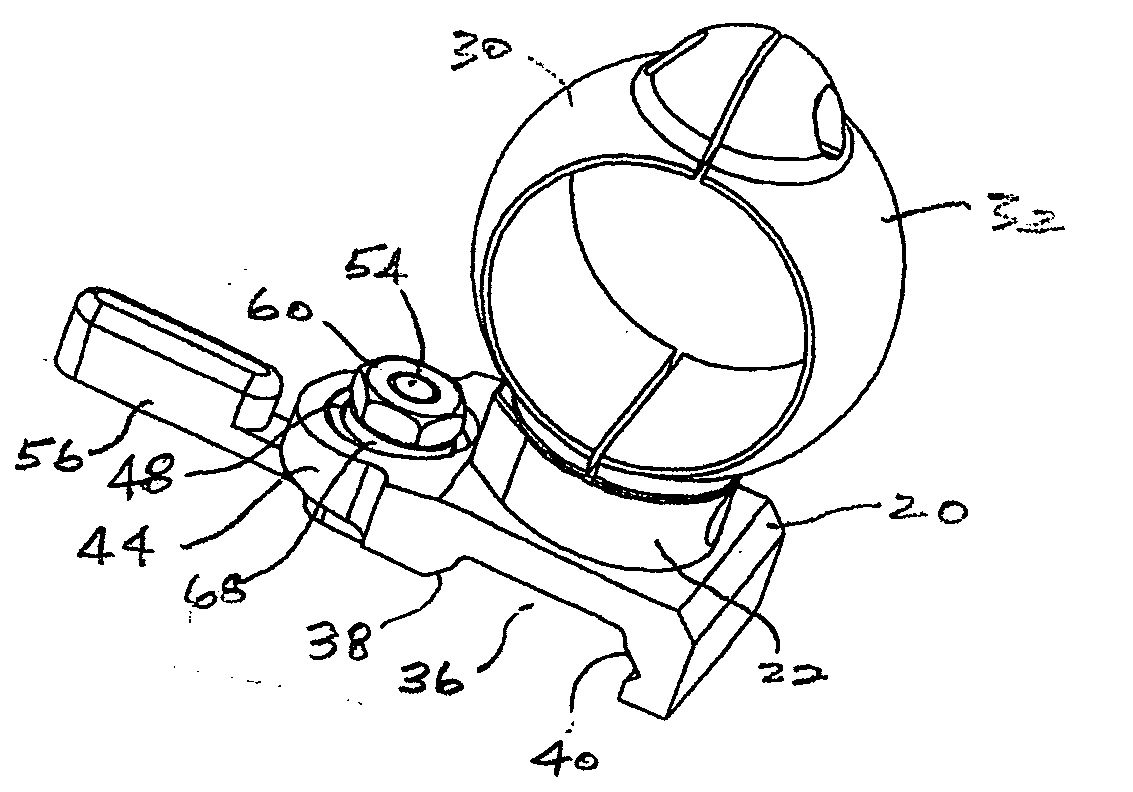

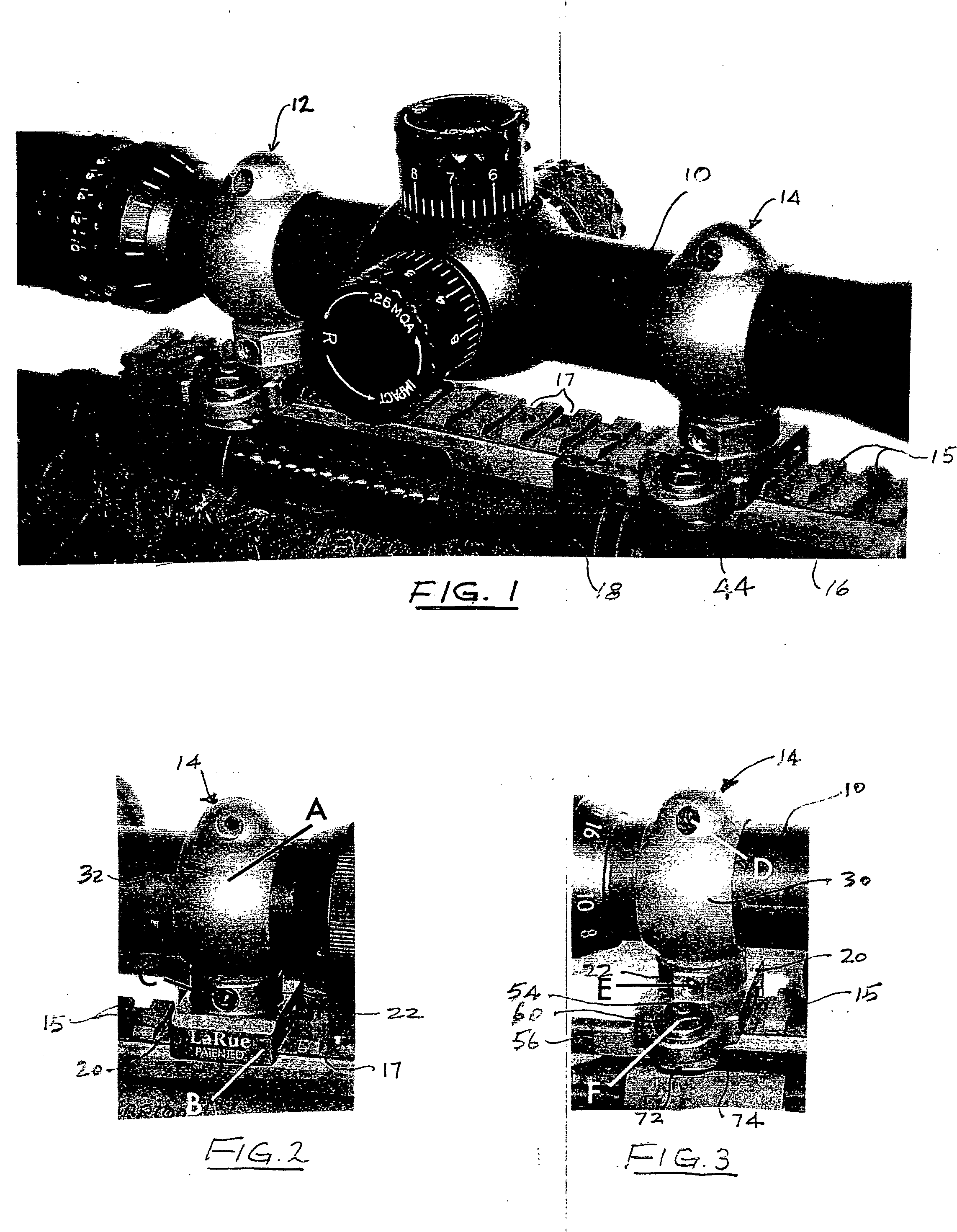

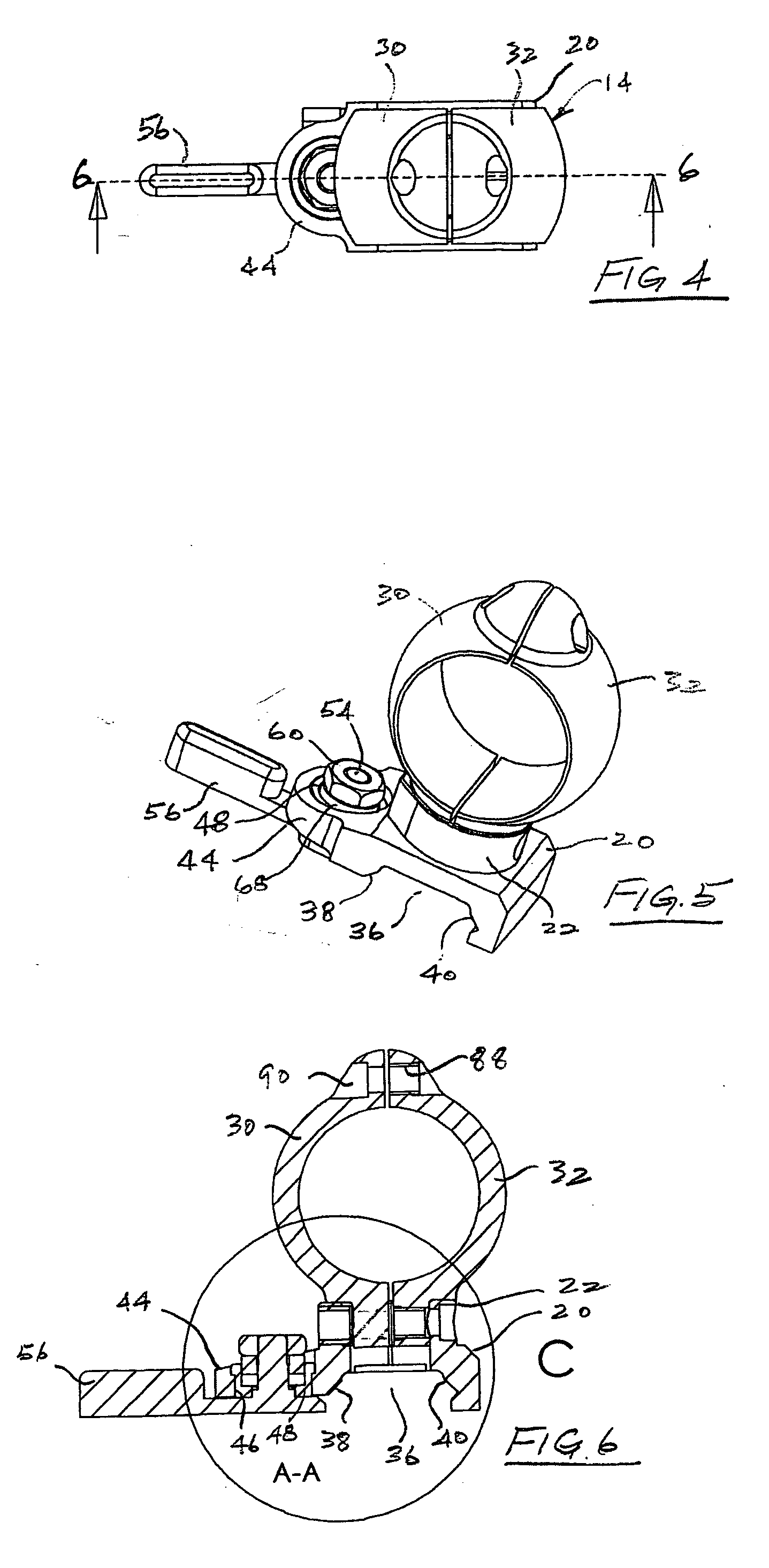

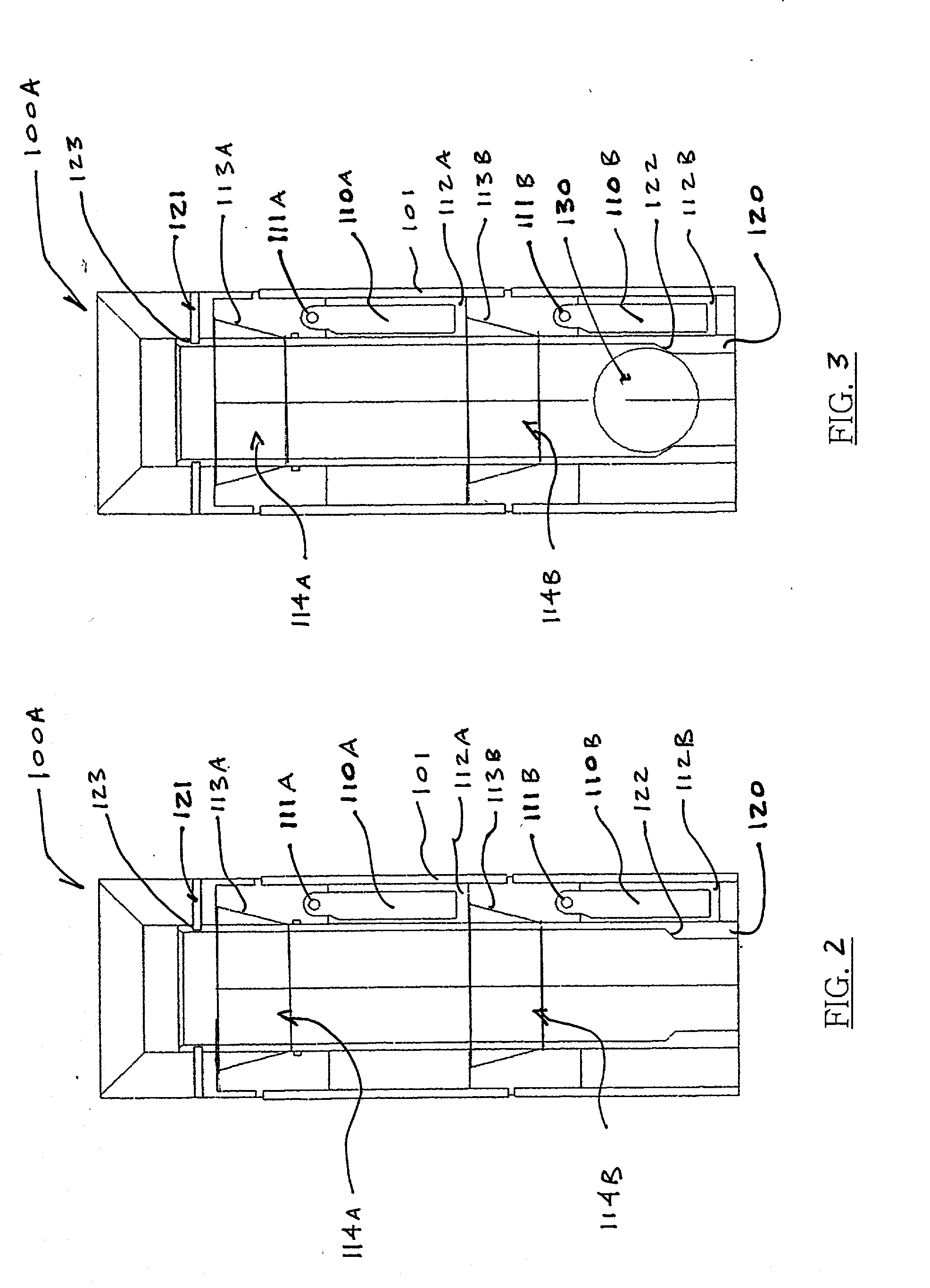

Adjustable throw-lever picatinny rail clamp

A throw-lever releasable mounting system for mounting a device in quick-release relation to a support member has a mounting base having a configuration fitting opposed angulated rail surfaces and having a locator key engaging a positioning slot of the rail. Each mounting base provides for mounting and stabilization of optics mounting rings. A locking platform projects from the mounting base and defines a locking opening having a circular hard metal insert therein that defines a receptacle receiving a resilient member and providing for location of the spline / spindle shaft of a rotatable locking plate. A locking plate of a throw-lever that is rotatable between locking and unlocking positions has angulated and curved cam surfaces for forcibly engaging correspondingly angulated surfaces of the rail to achieve cam energized precision locating and locking engagement with the rail. A non-circular section of a spline / spindle shaft of the throw-lever is receives a drive member in non-rotatable and linearly moveable relation. Resilient members are interposed between the drive member and the hardened insert and prevent free throw-lever movement at the release position thereof.

Owner:LARUE MARK C

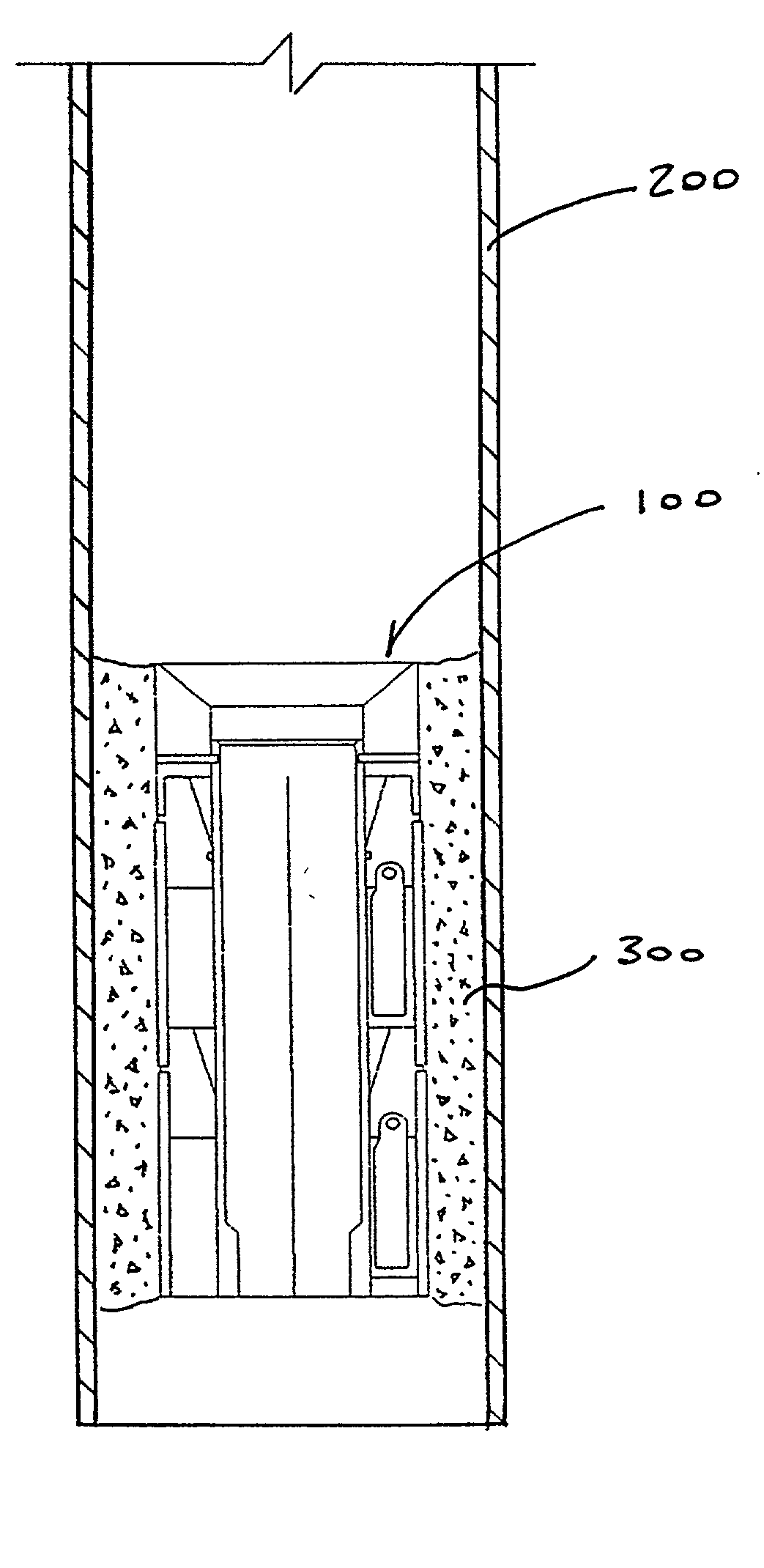

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

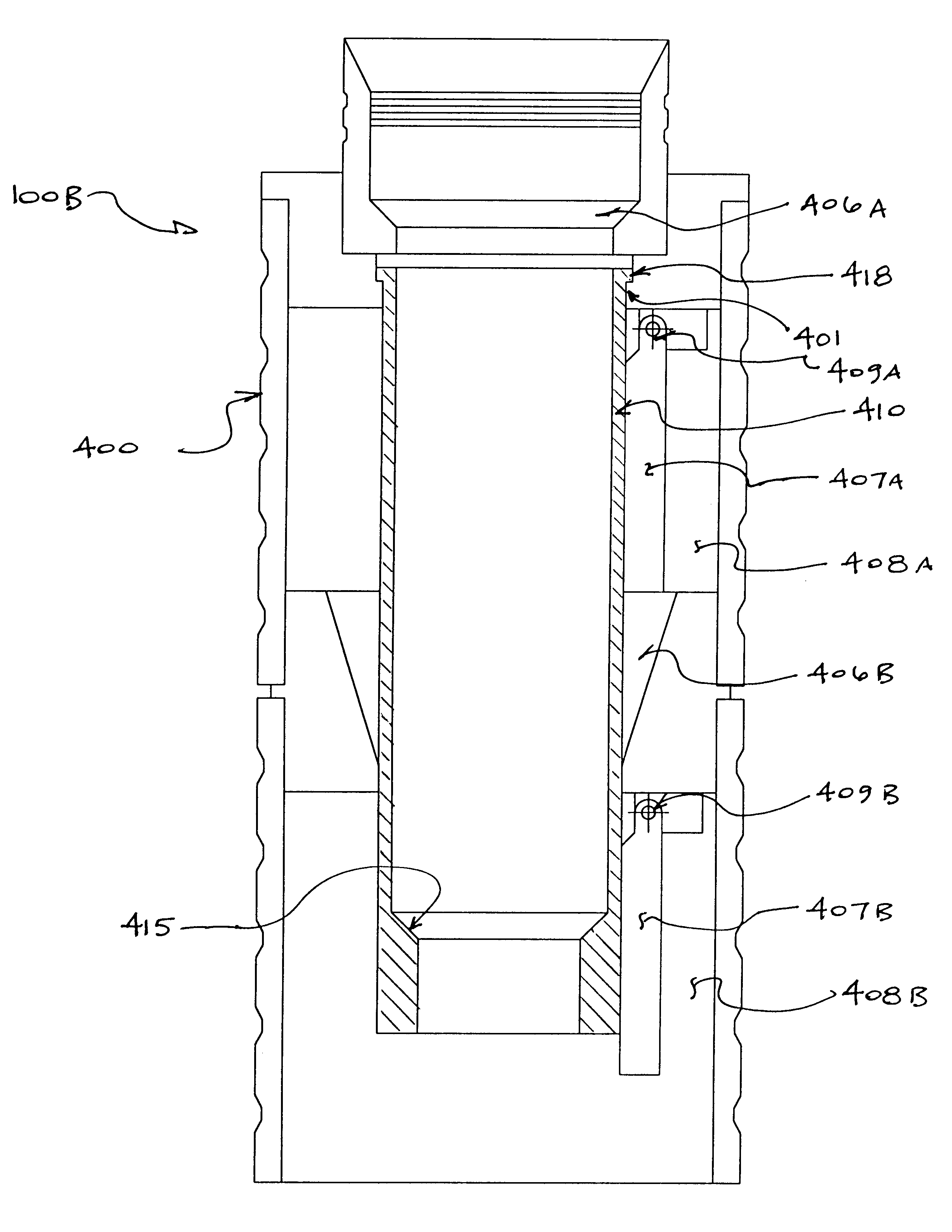

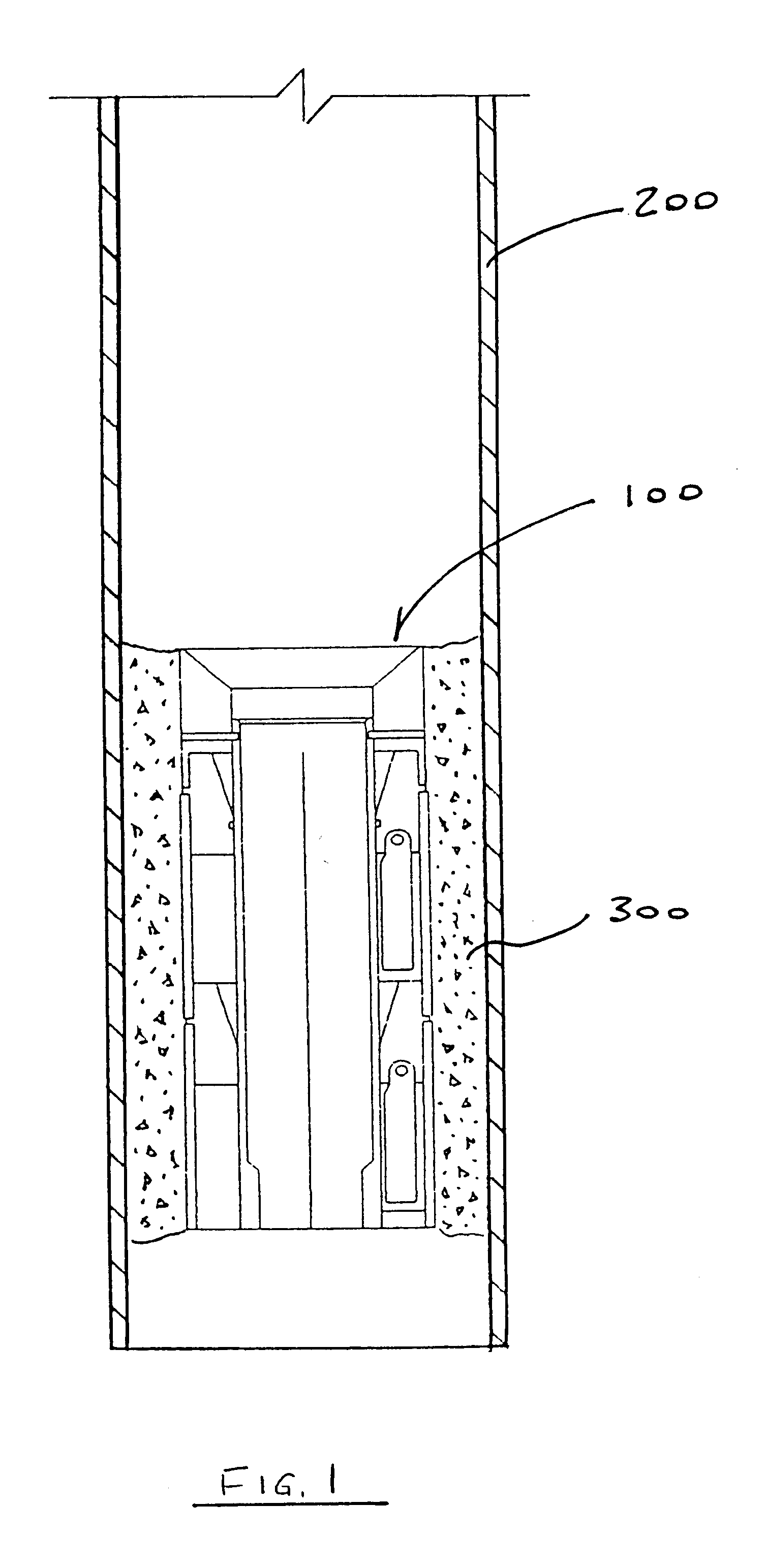

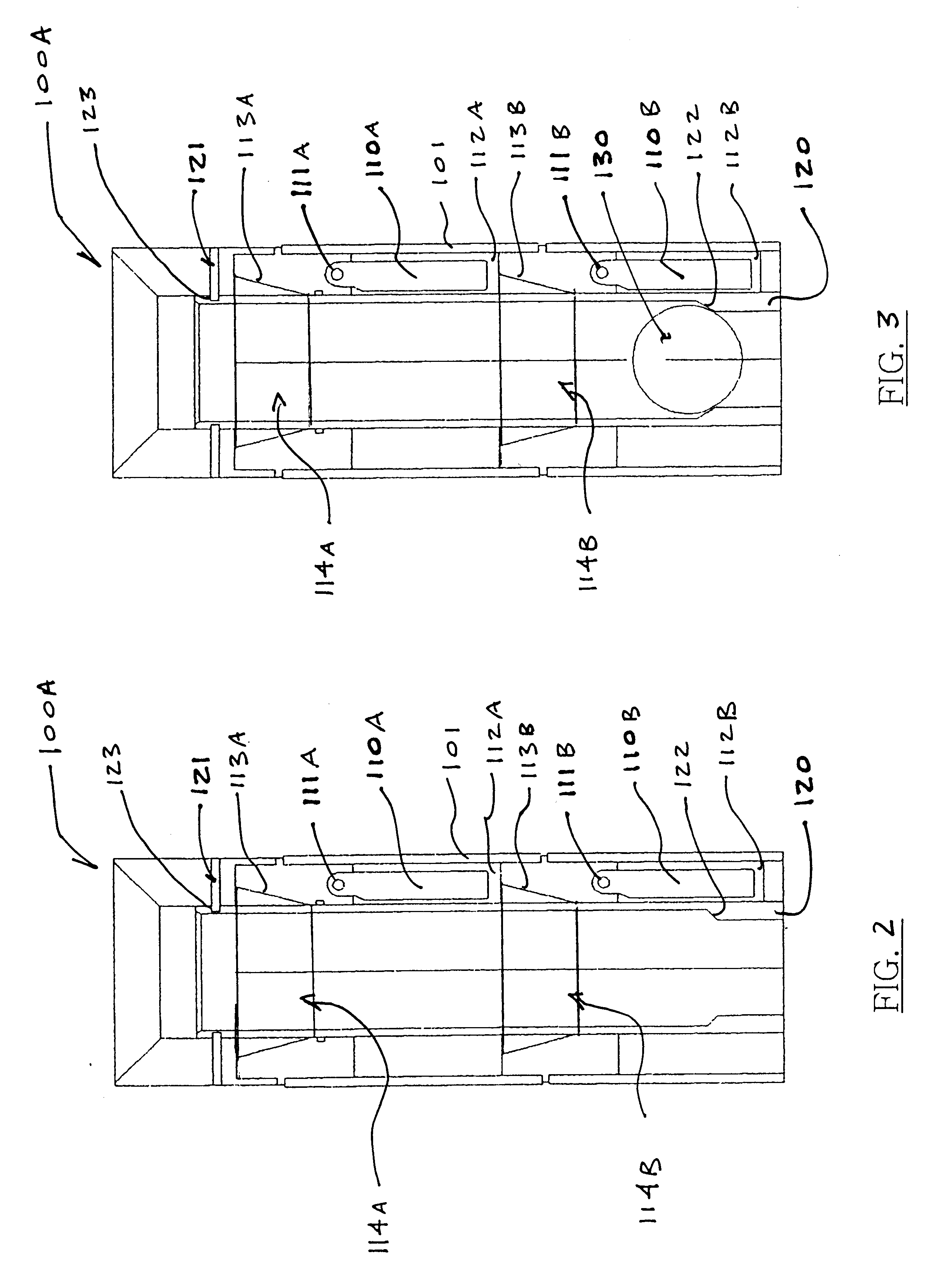

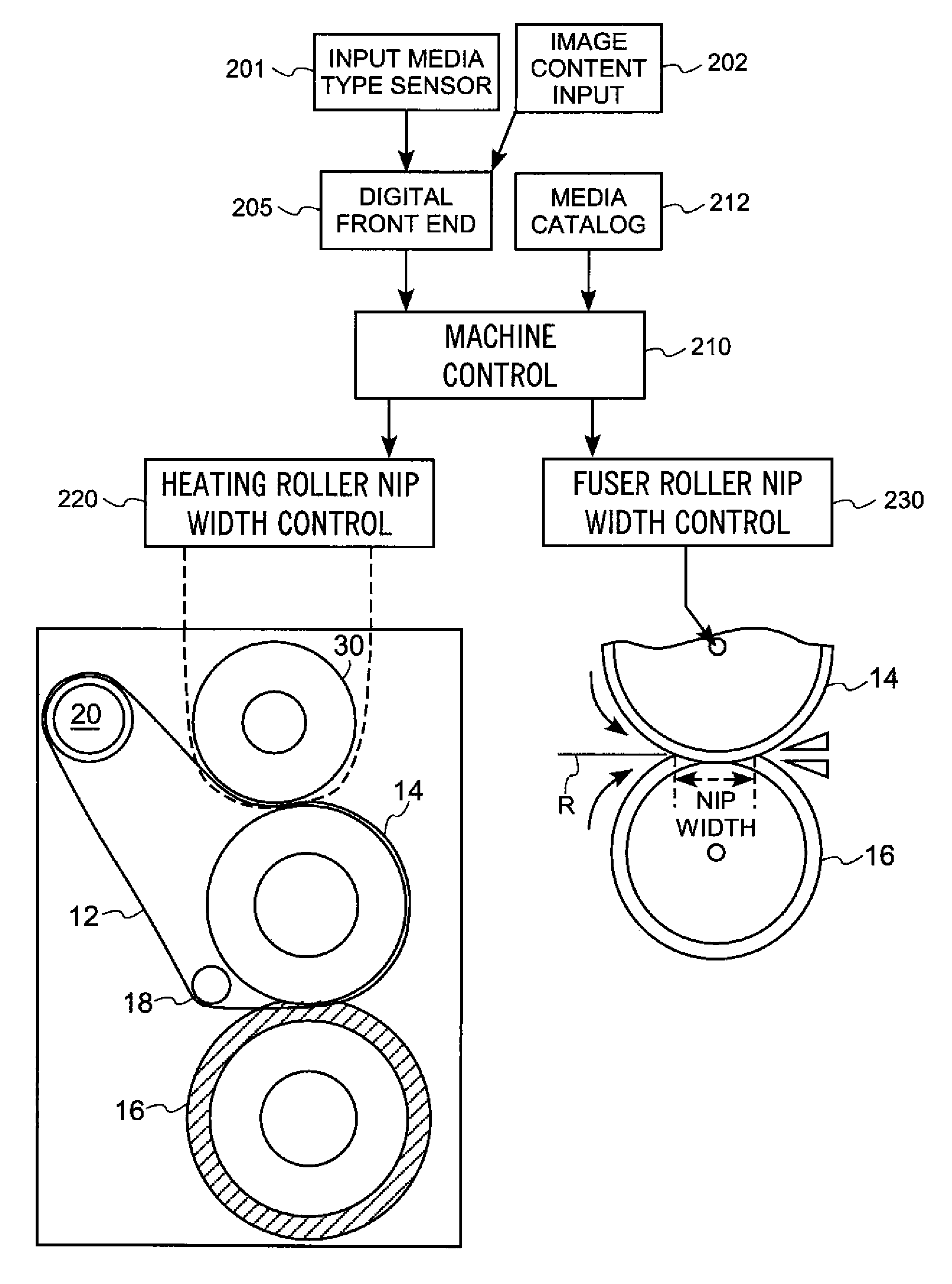

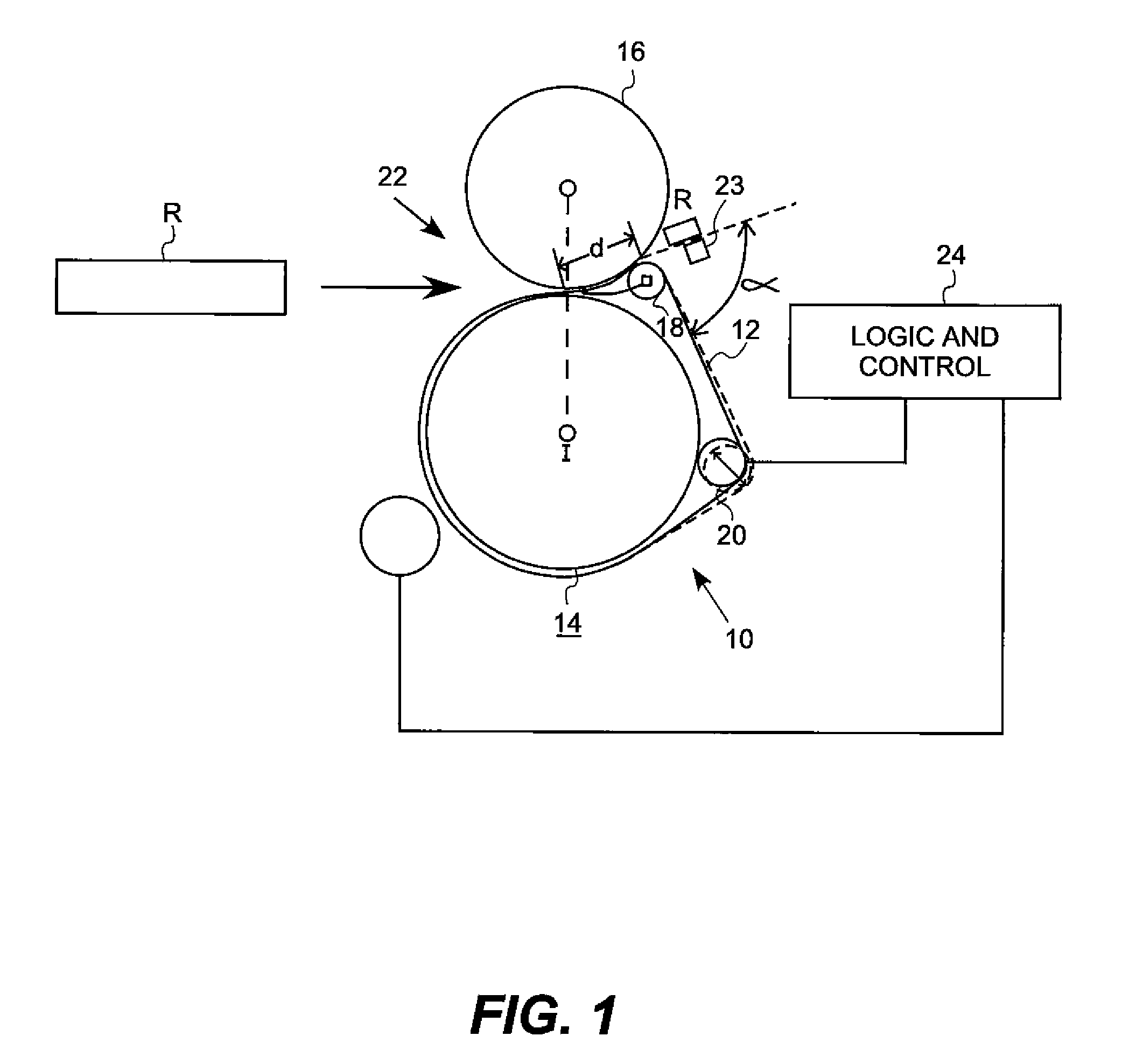

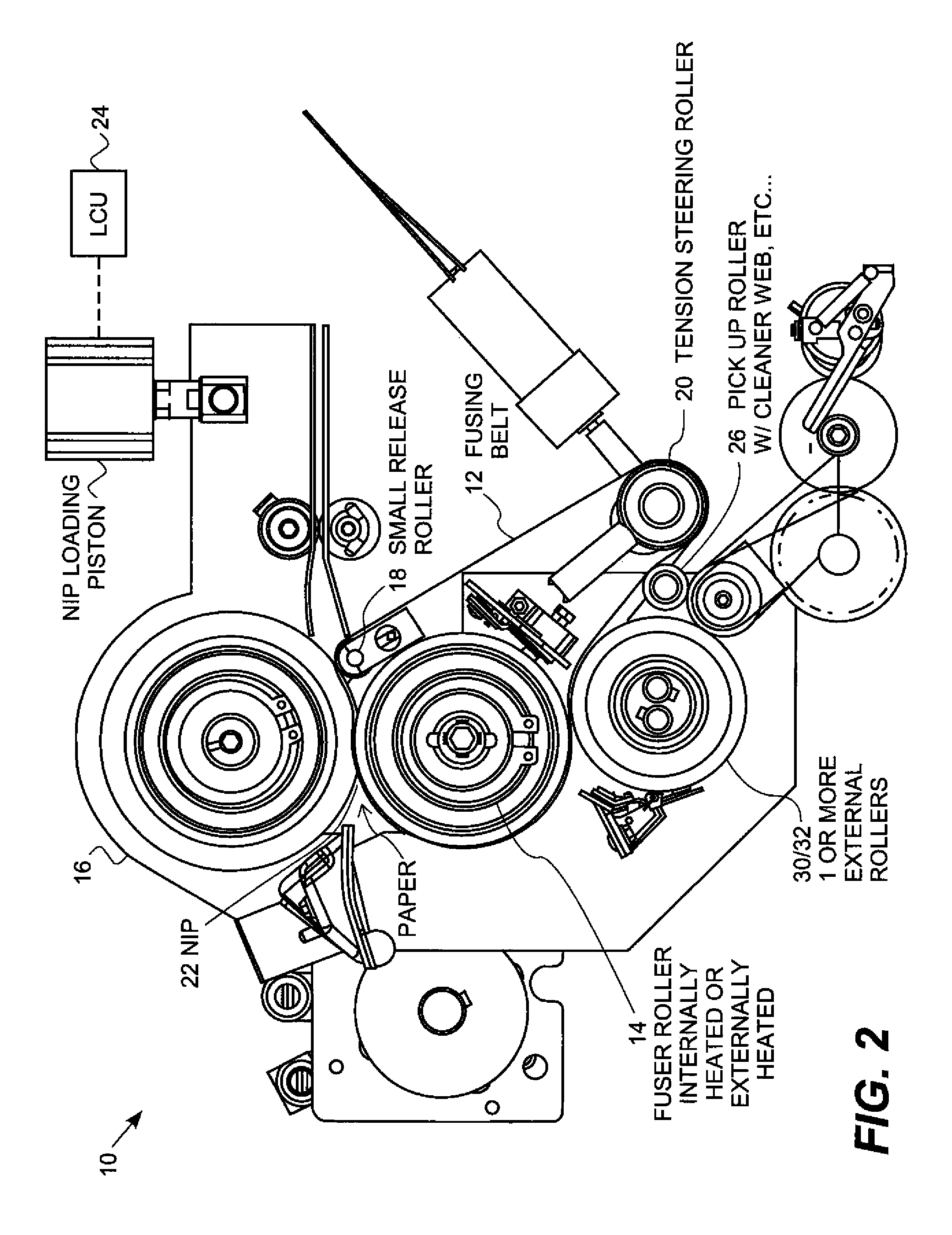

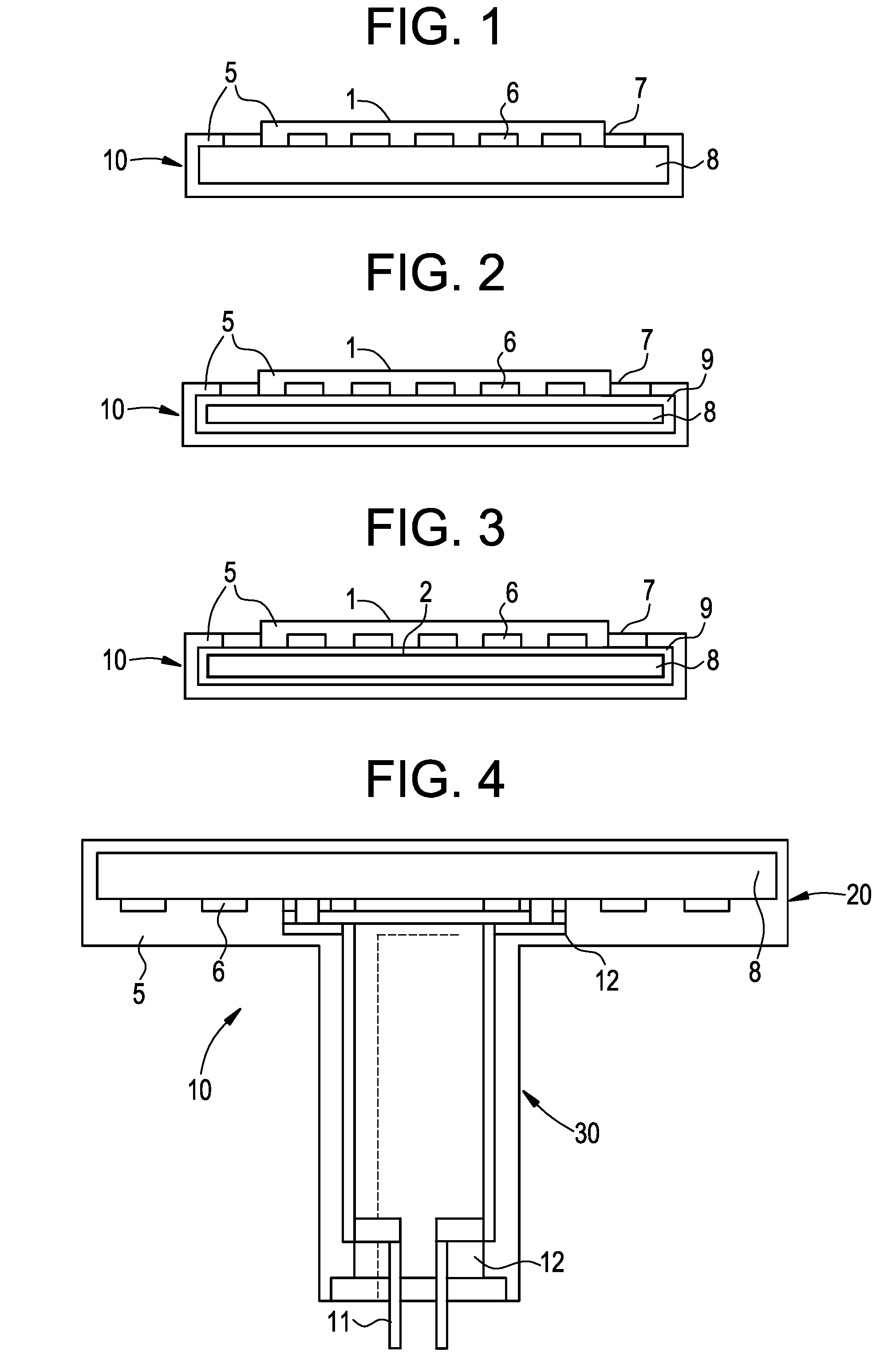

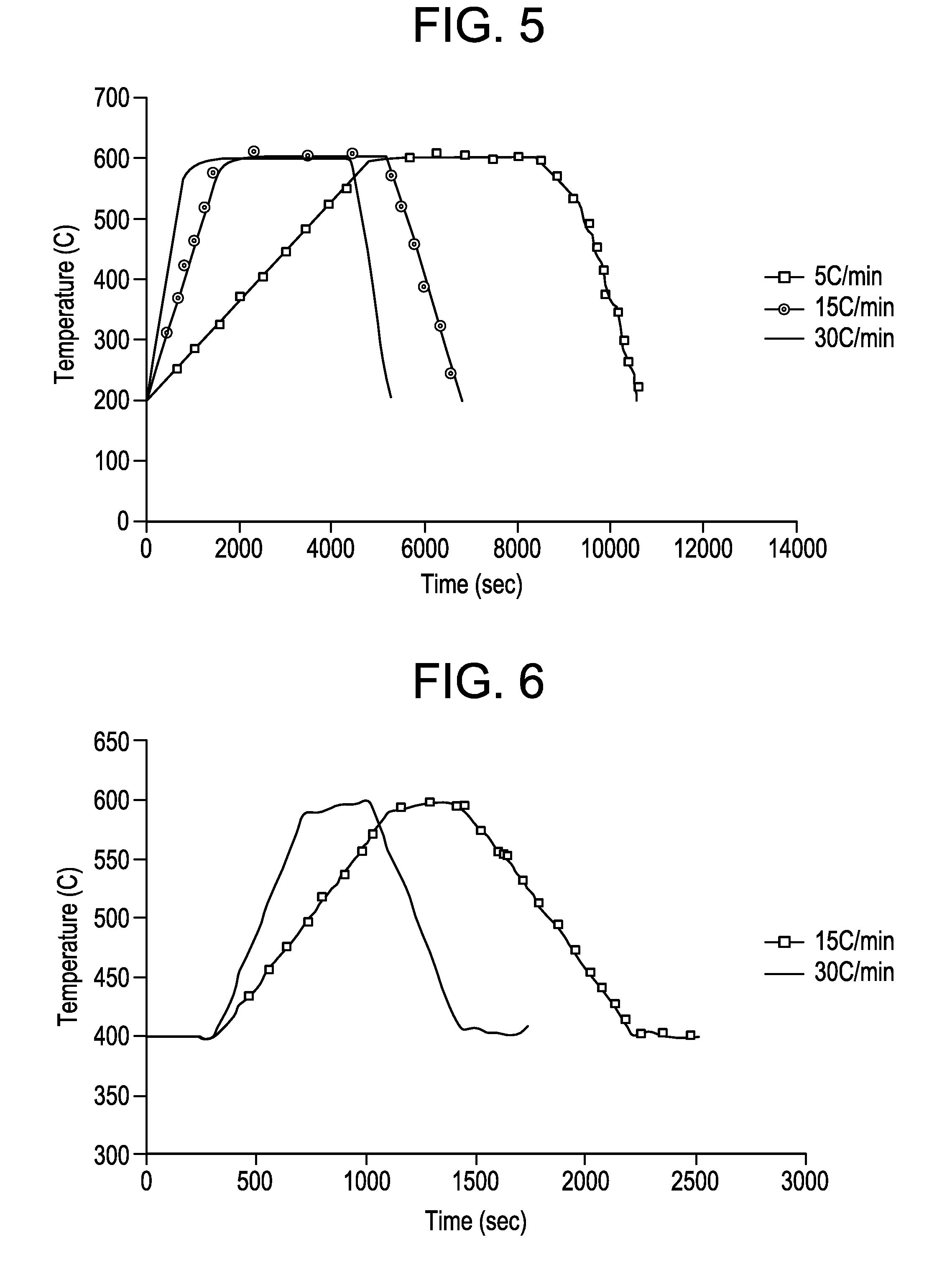

Fusing apparatus for high speed electrophotography system

ActiveUS8249480B2Improved controlled releaseAccuracy of releaseElectrographic process apparatusHard metalHard metals

A fuser and receiver release system and method are provided for improving the release of receivers in high speed of printing systems. This system controls the release of a receiver in conjunction with a fuser in a printing system, and specifically the efficiency and accuracy of the release system. One embodiment of this method includes a belt fuser that allows the separating of the heat transfer and release functions of the fuser such that fuser roller could be made of hard metal core that can be heated to high temperatures without the fear of delaminating elastomeric coatings which are common in roller fusing.

Owner:EASTMAN KODAK CO

Processing insert, and production of same

InactiveUS6350510B1Improve fracture resistanceAvoid disadvantagesVacuum evaporation coatingSputtering coatingHard metalCarbide

The invention pertains to a processing insert comprised of a body with a hard metal or ceramic substrate and with a multilayer coating and the manufacture of same. In order to have a highly fracture-tough insert with a relatively thick coating, it is suggested that an external layer (protective layer) be applied according to the CVD process, said layer being either a monophase or multiphase layer of Zr-based or Hf-based carbide nitride or carbonitride, and presenting internal compressive stresses. The layer(s) underlying the external layer, also applied according to the CVD process, also present(s), without any exception, internal compressive stresses, while at least one of them, maybe the only one laying under the protective layer is made of TiN, TiC and / or TiCN. The coating is applied according to a continuous CVD process at temperatures of 900° C. to 1100° C. and involves a specific modification of the gas compounds.

Owner:WIDIA

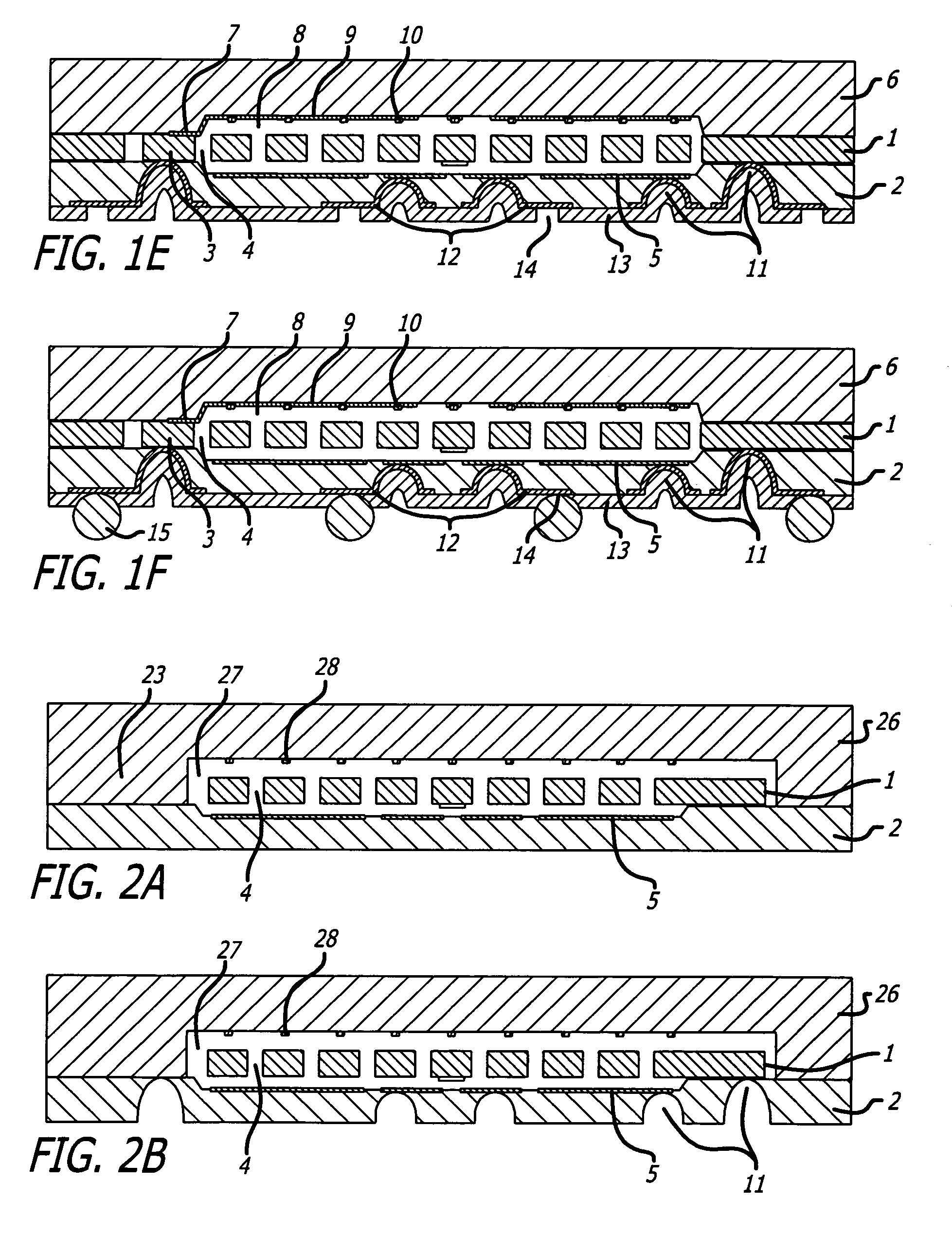

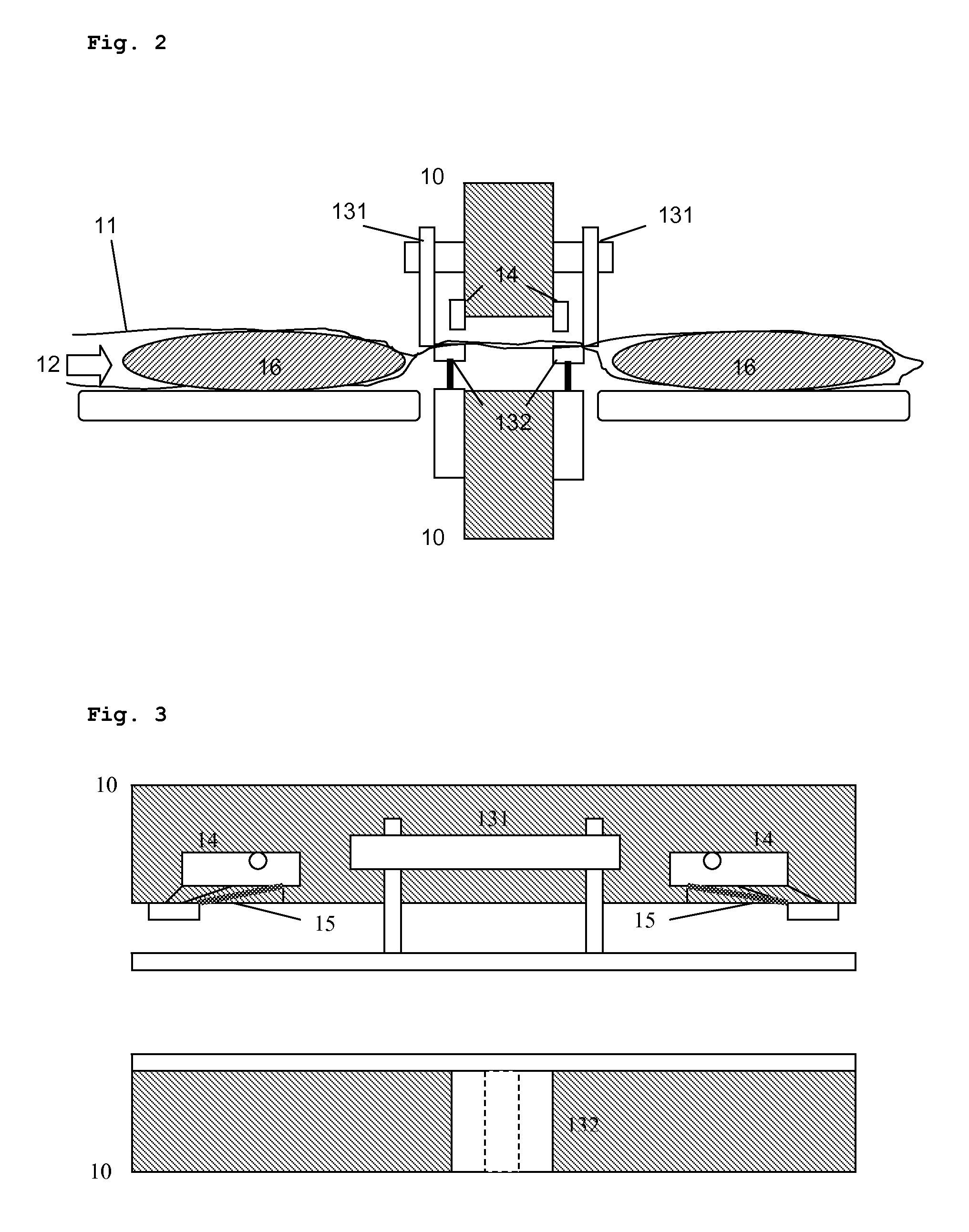

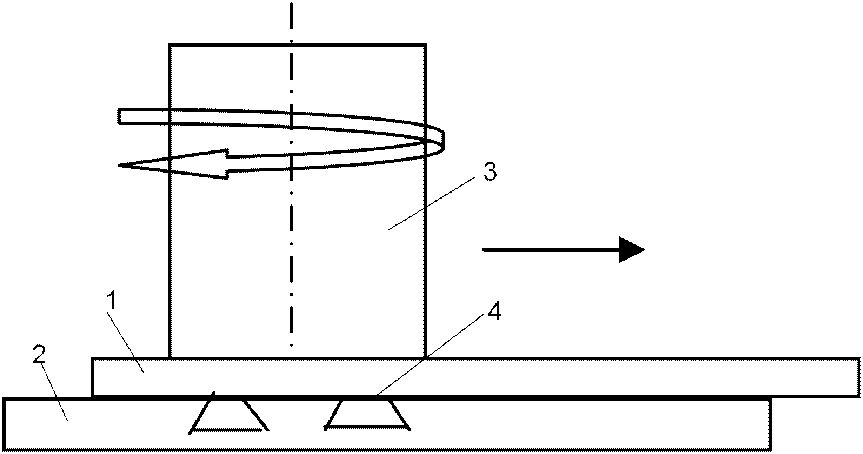

Friction stir welding tool

InactiveUS20100258612A1Easy to useReduce sensitivityWelding/cutting auxillary devicesAuxillary welding devicesHard metalTitanium carbide

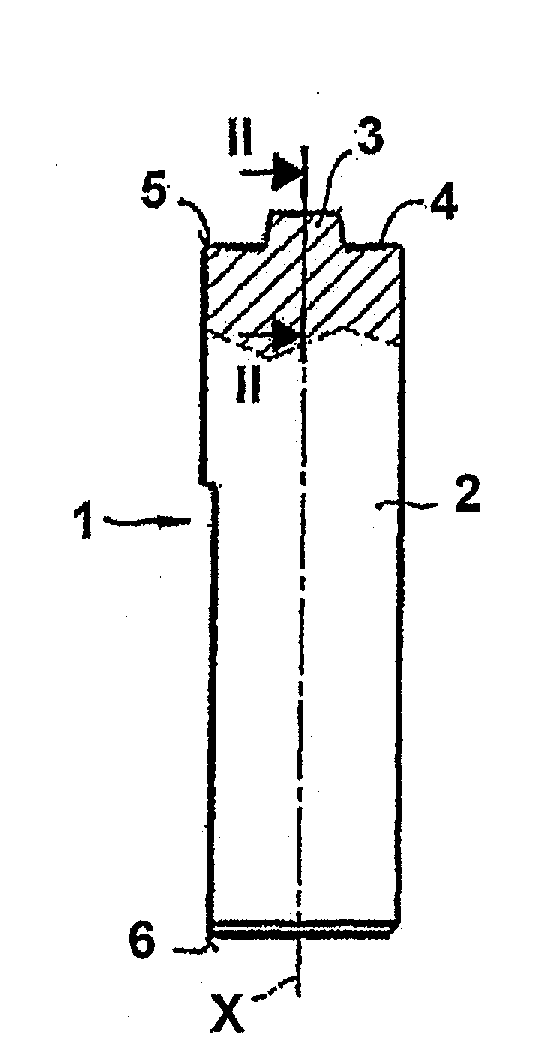

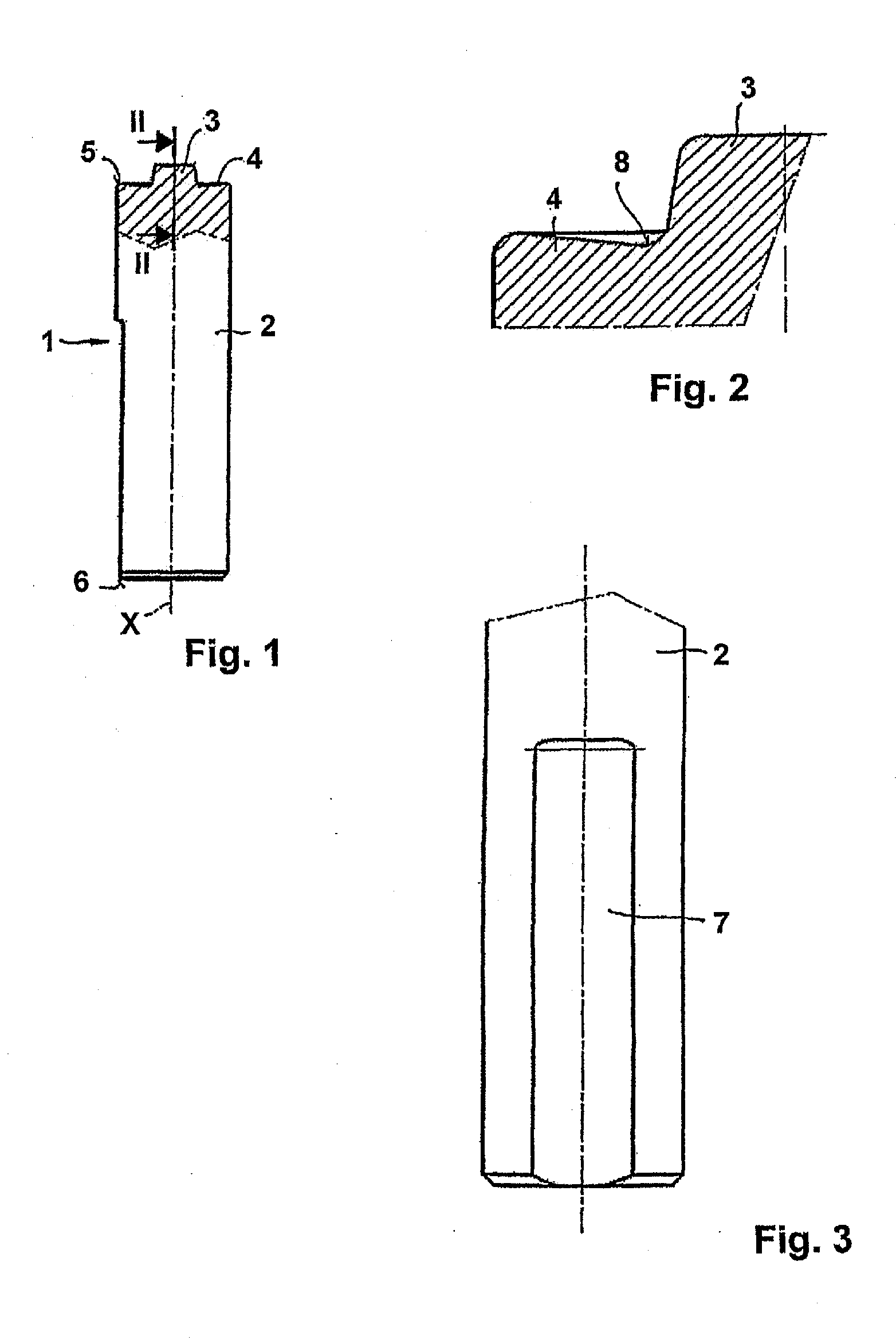

The invention relates to a friction stir welding tool (1) with an essentially cylindrical shank (2), which has a peg (3) with a smaller diameter projecting on one end (5) starting from a shoulder region (4) of the shank (2). According to the invention it is provided in order to create a friction stir welding tool (1) for welding steel, that the friction stir welding tool (1), at least in the region of the peg (3) and in the shoulder region (4), is made of a hard metal containing 80% by weight to 98% by weight tungsten carbide with an average grain size of more than 1 μm and up to 20% by weight cobalt as well as optionally a total of up to 18% by weight titanium carbide, tantalum carbide, niobium carbide and / or mixed carbides thereof and at least in one of the referenced regions has a coating of one or more layers.

Owner:BOEHLERIT GMBH & CO KG

Hard-material-coated bodies and method for their production

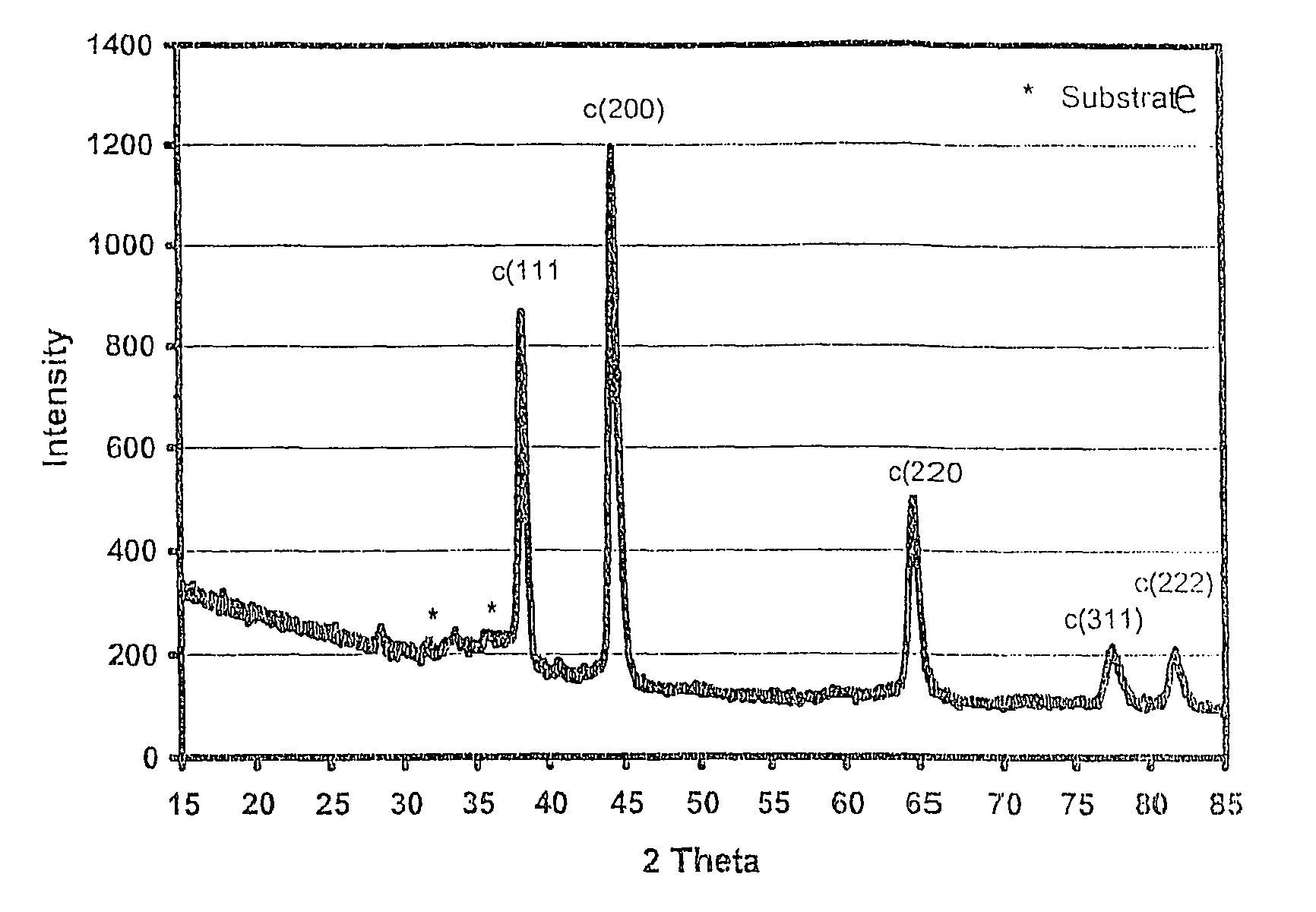

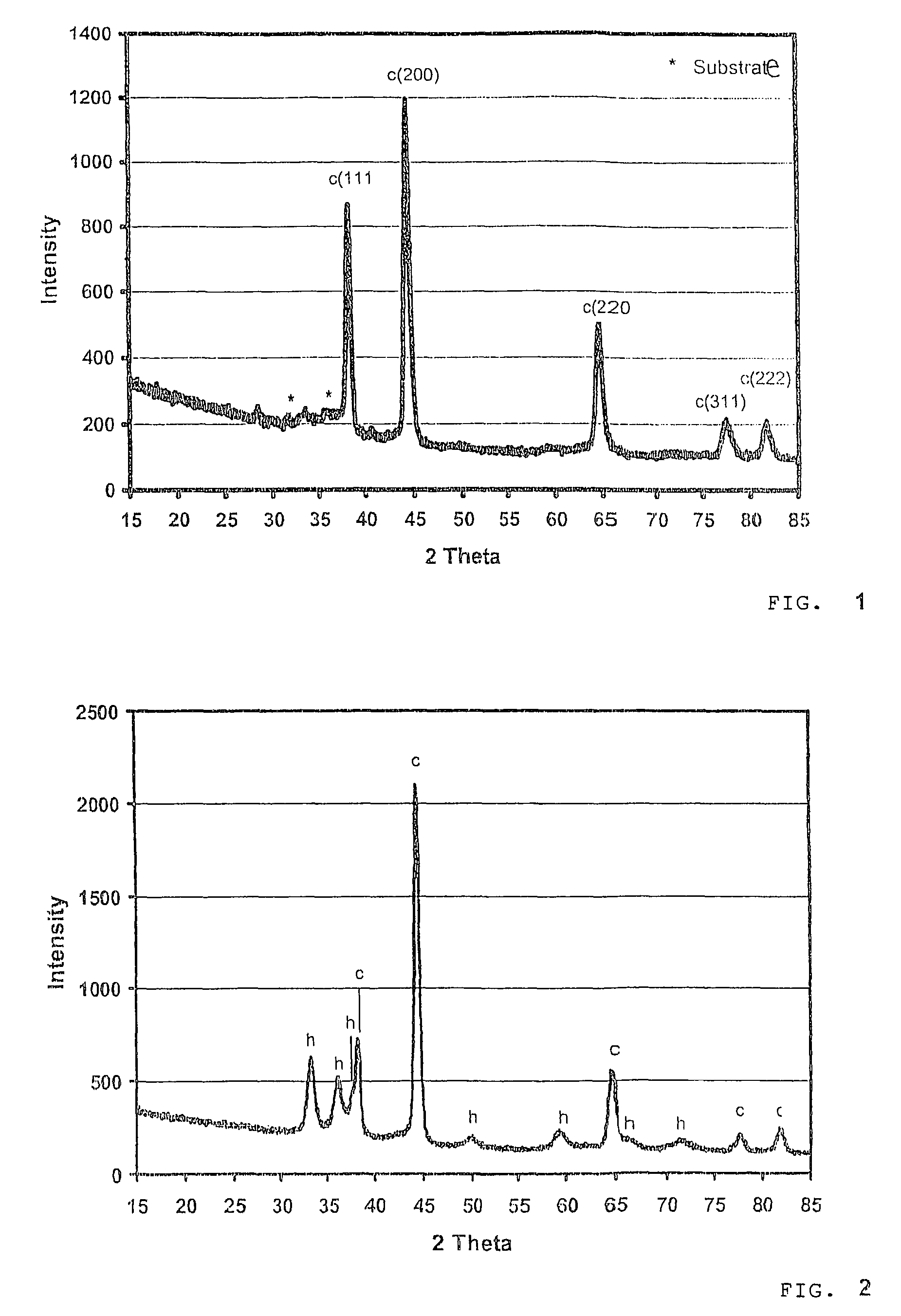

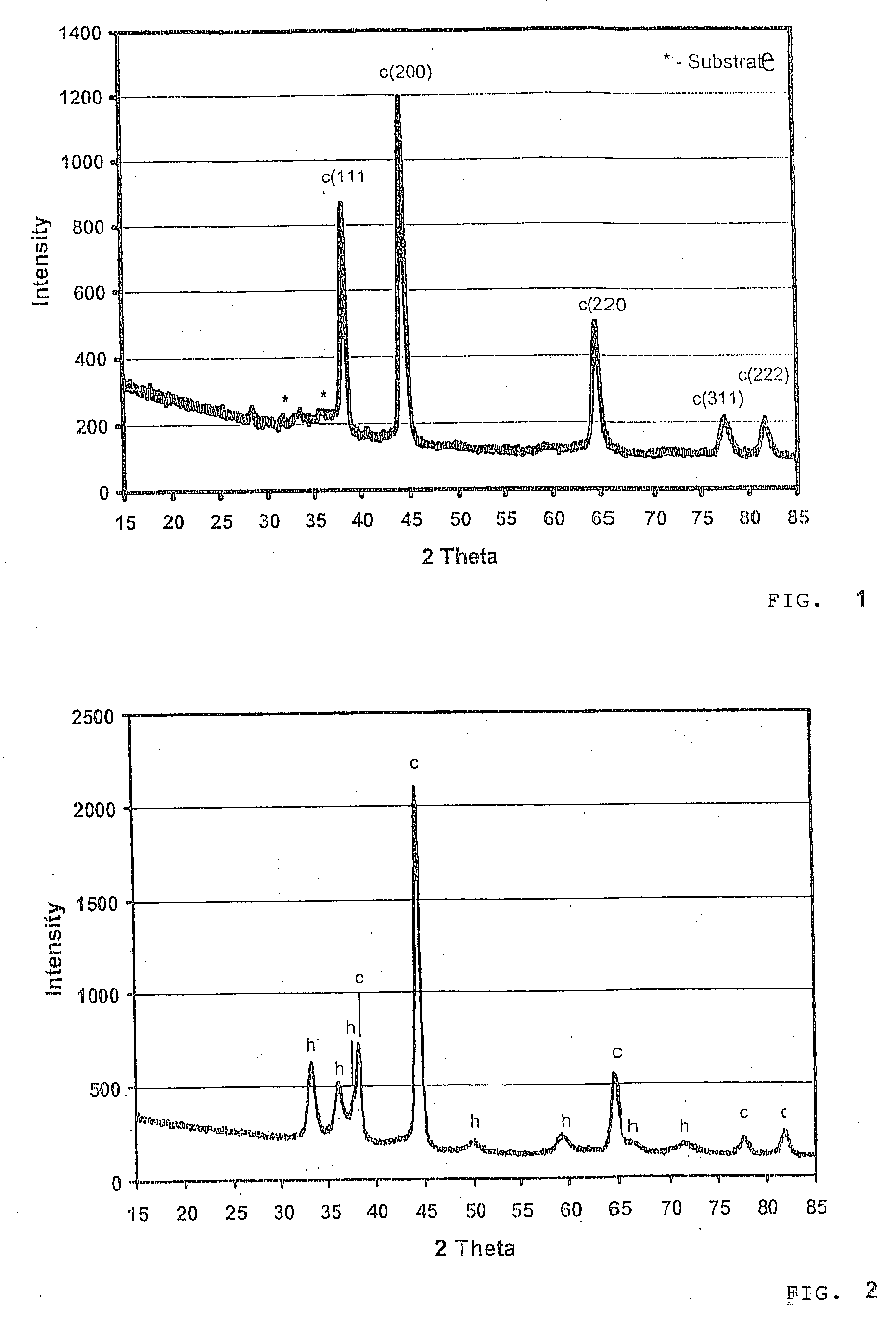

ActiveUS7767320B2Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Hard-Material-Coated Bodies and Method for Their Production

ActiveUS20090123779A1Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

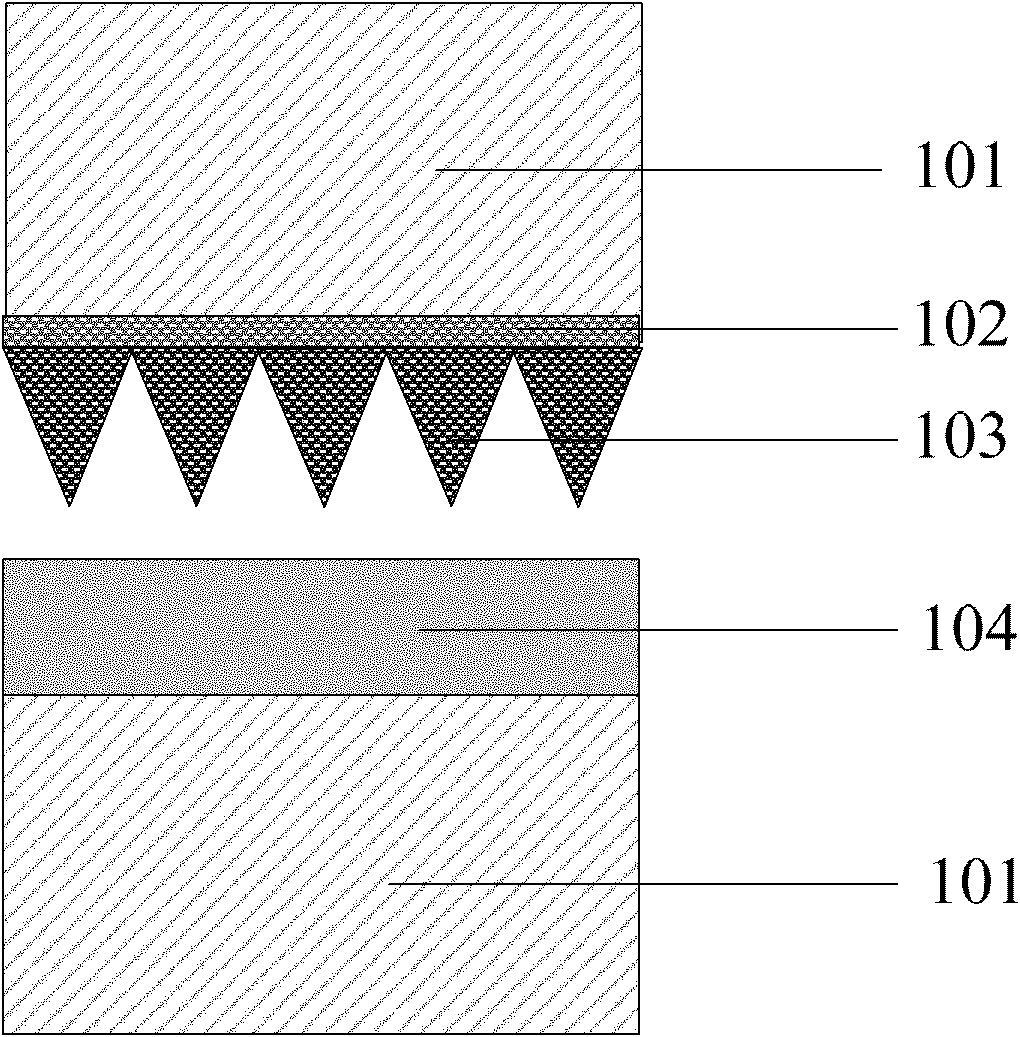

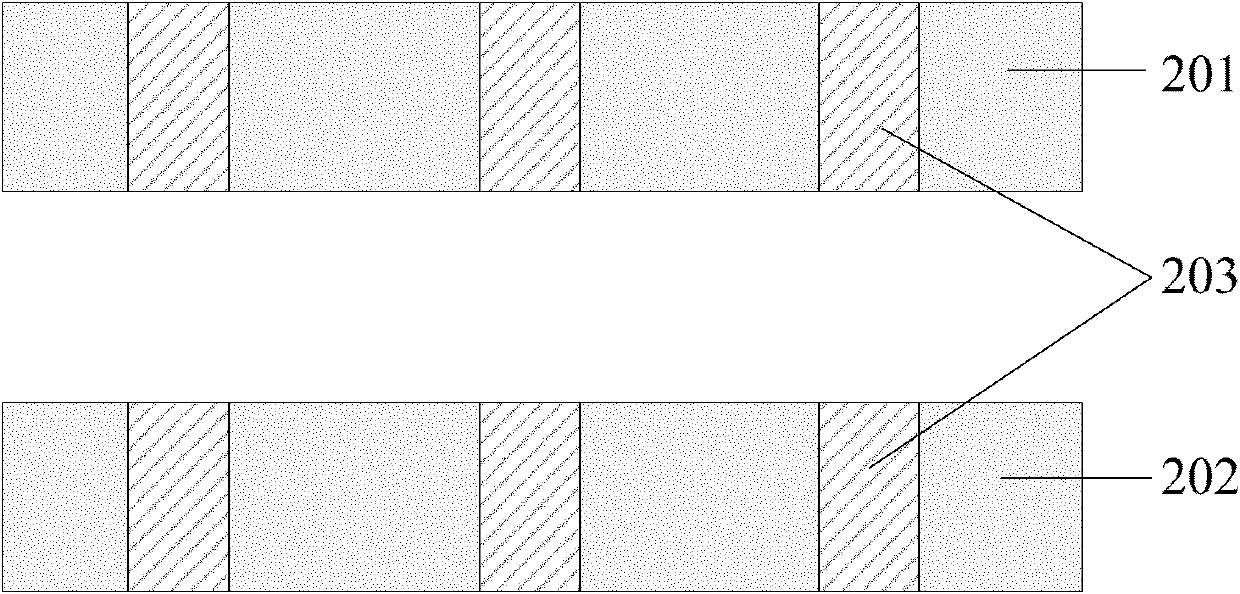

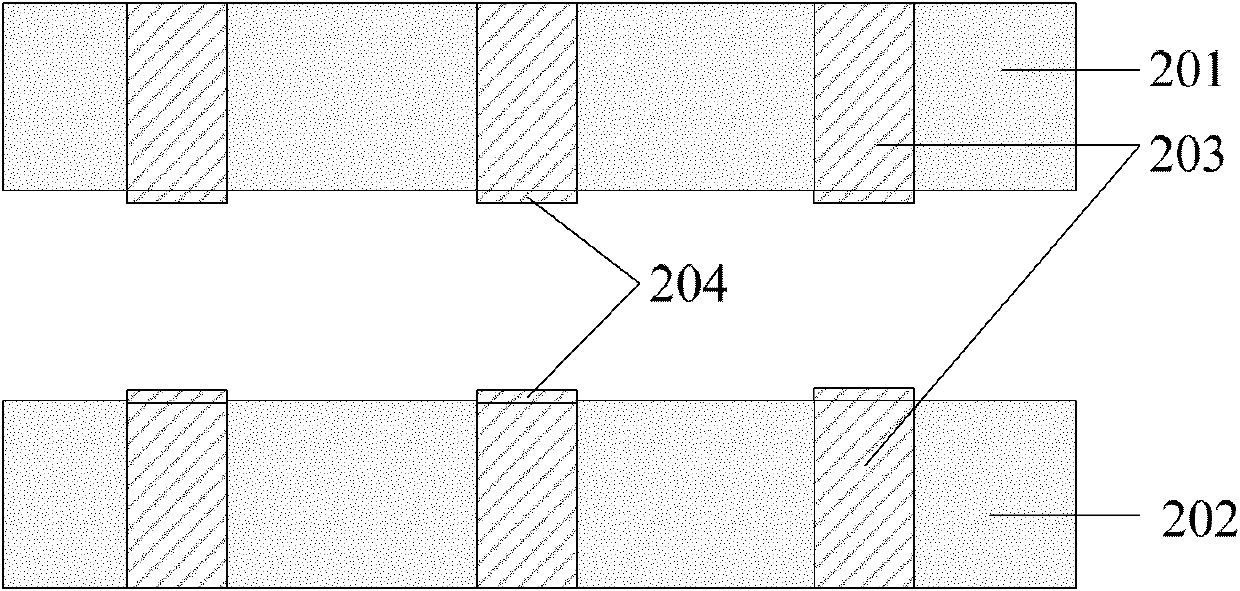

Multi-layer mixed synchronization bonding structure and method for three-dimensional packaging

ActiveCN102169845AGuaranteed accuracy requirementsSave time and costSemiconductor/solid-state device detailsSoldering apparatusDielectricHard metal

The invention relates to a multi-layer mixed synchronization bonding structure and a method for three-dimensional packaging. The method comprises the following steps of: forming a hard metal conical array on a surface of a metallic pad of a substrate to be mixed and bonded; forming a soft metal layer on the surface of the metallic pad of the other substrate to be mixed and bonded; forming dielectric adhesion layers on surfaces of non-metallic pads of the two substrates to be mixed and bonded; aligning the hard metal conical array with the soft metal layer, heating and pressurizing to make thehard metal conical array inserted into the soft metal layer, and combining the dielectric adhesion layers with each other to form a mixed pre-bonding structure; and then heating, forming an intermetallic compound in the hard metal conical array which is inserted into the soft metal layer, and solidifying and combining the dielectric adhesion layers. Compared with the conventional bonding method, the method provided by the invention has the advantages that: yield is high; bonding time is saved; cost is reduced; and the reliability of a product is improved at the same time.

Owner:NAT CENT FOR ADVANCED PACKAGING

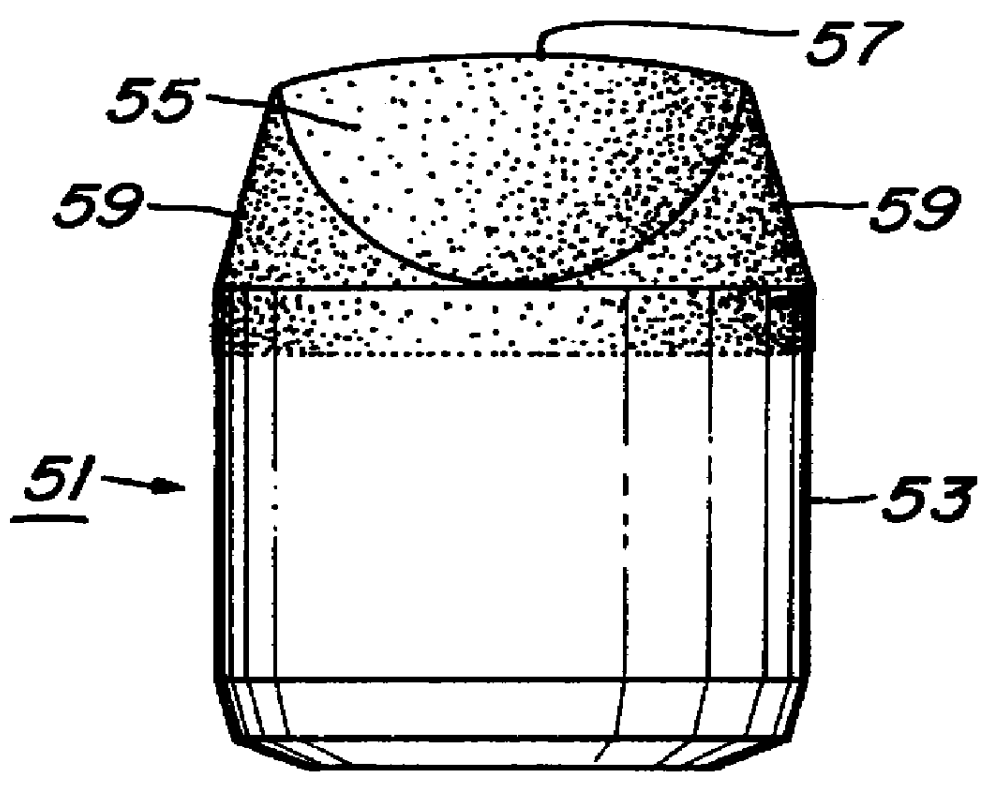

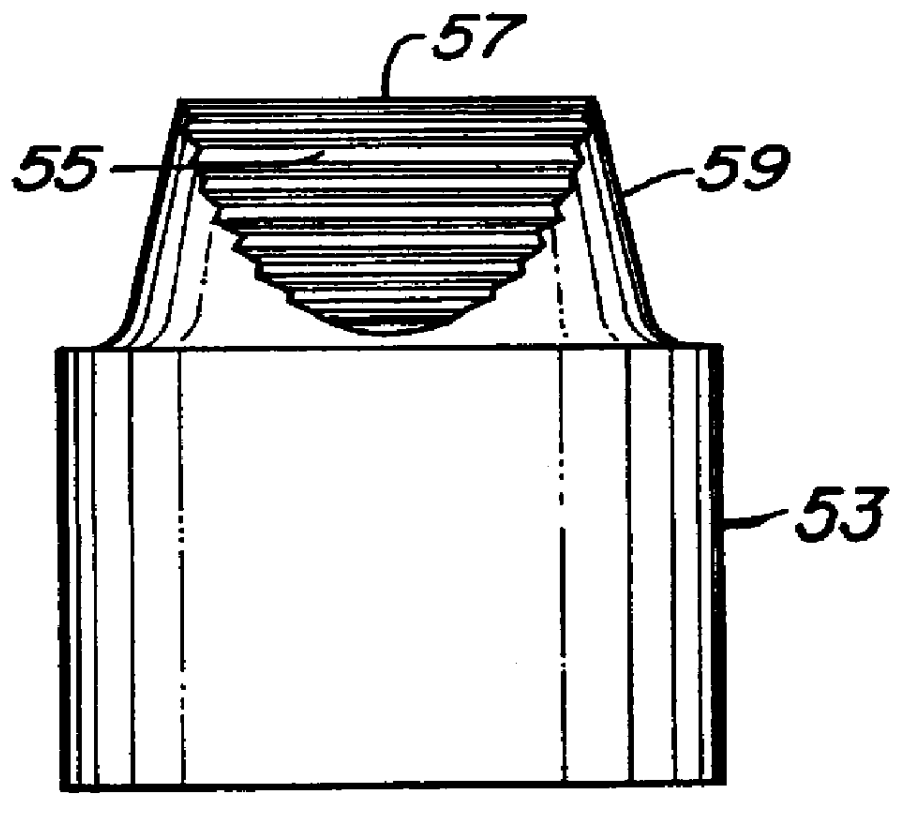

Earth-boring bit with super-hard cutting elements

An earth-boring bit has a bit body and at least one cantilevered bearing shaft depending inwardly and downwardly from the bit body. A cutter is mounted for rotation on the bearing shaft and includes a plurality of cutting elements. At least one of the cutting elements has a generally cylindrical body formed of hard metal with a convex cutting end. A plurality of recesses extend longitudinally from the apex to the junction. The recesses are shallow grooves symmetrically spaced about the axis. A layer of super-hard material is formed on the cutting end of the body and overlays the recesses formed thereon.

Owner:BAKER HUGHES INC

Wafer level packaging process

ActiveUS7393758B2Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesHard metalWafer stacking

Owner:MAXIM INTEGRATED PROD INC

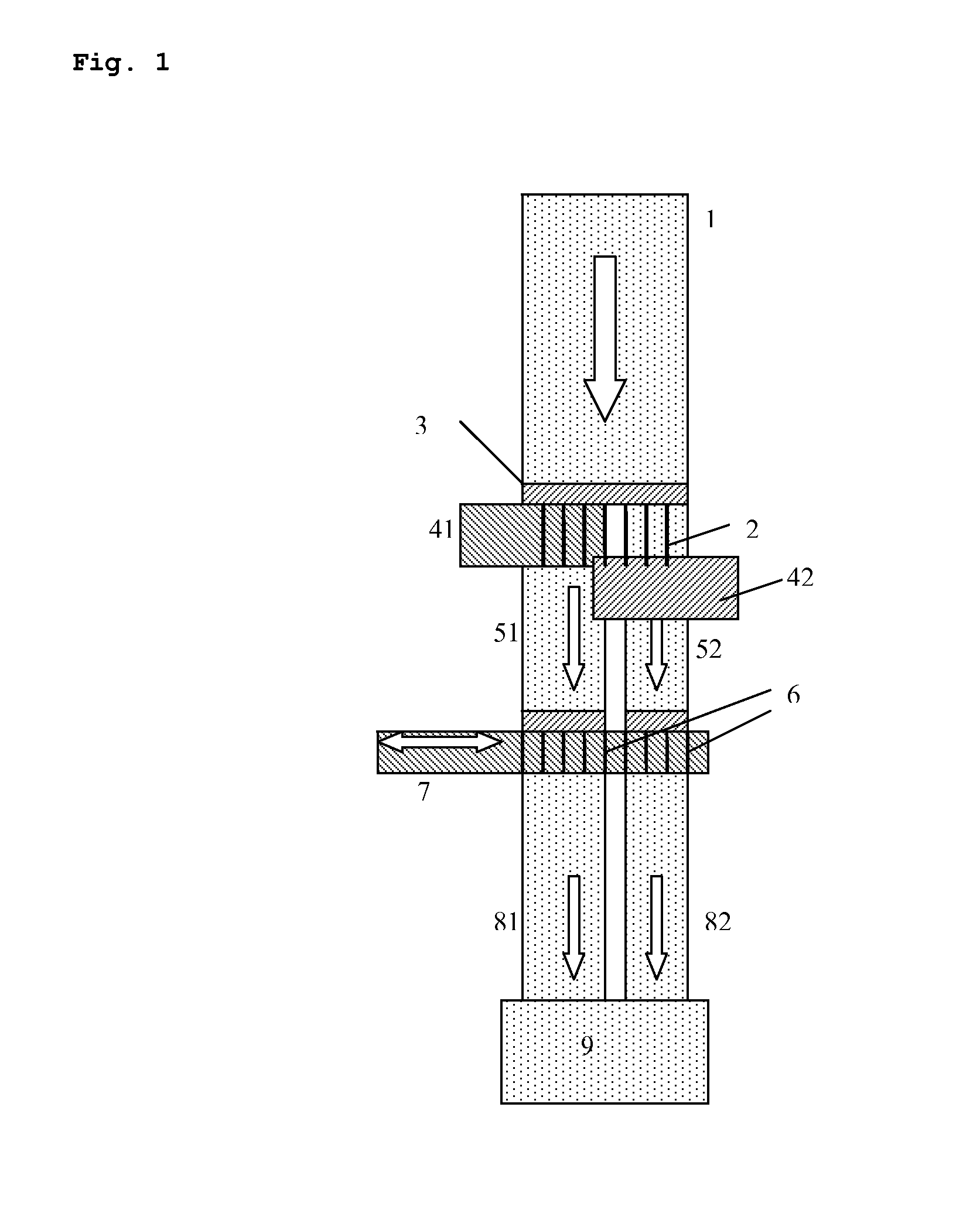

Method and device for dosing and packaging polysilicon chunks and dosing and packaging unit

ActiveUS20120198793A1Low costAccurate doseWrapper twisting/gatheringSolid materialHard metalProcess engineering

Disclosed is a method for dosing and packaging polysilicon chunks, wherein a product flow of polysilicon chunks is transported via a feed channel, separated by at least one screen into coarse and fine chunks, weighed and dosed to a target weight by a dosing balance, discharged via a discharge channel and transported to a packaging unit where a first plastic bag is filled with the polysilicon chunks and sealed, the plastic bag containing polysilicon chunks being packaged with a further plastic bag which is formed by a shaper and subsequently welded, wherein the at least one screen and the dosing balance at least partially include a hard metal on their surfaces and the shaper for forming the plastic bag includes a wear-resistant coating. Also disclosed are a dosing unit, a packaging unit and a device for dosing and packaging polysilicon chunks, which contains a dosing unit and a packaging unit.

Owner:WACKER CHEM GMBH

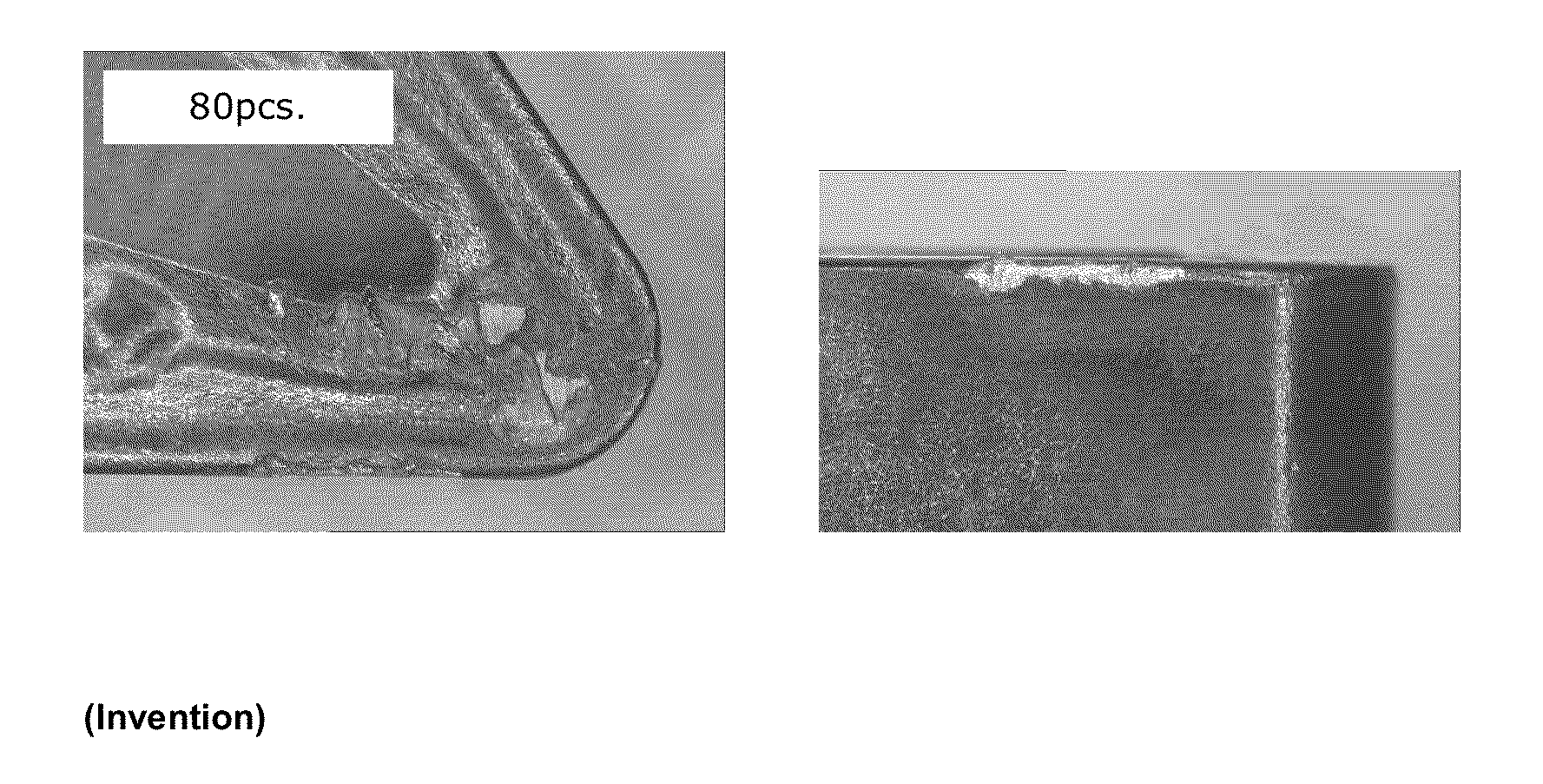

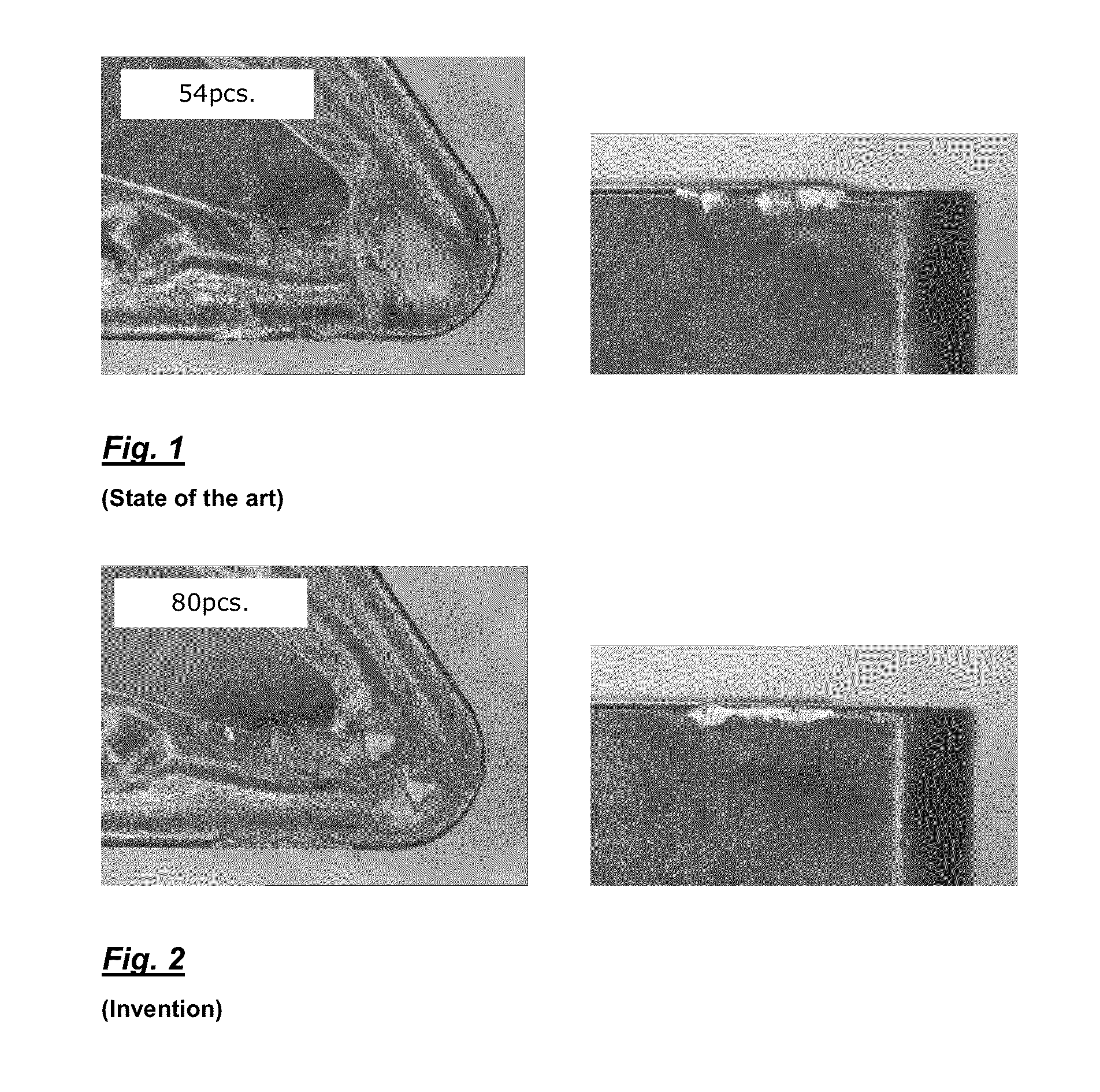

Cutting Insert and Method for Production Thereof

ActiveUS20140193624A1Advantageous or disadvantageous effects on the wear resistance of the cutting insertFatigue propertyPolycrystalline material growthLayered productsHard metalLayer thickness

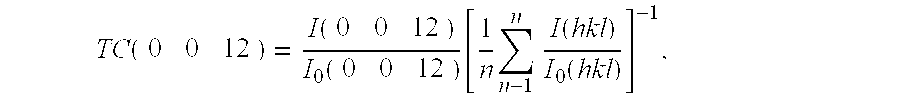

Cutting insert made of hard metal, cermet or ceramic substrate body with multi-layer coating applied thereto by CVD methods. The coating has a total thickness of 5 to 40 μm and, starting from the substrate surface, has one or more hard material layers, an alpha aluminium oxide (α-Al2O3) layer of a layer thickness of 1 to 20 μm and optionally at least portion-wise over the α-Al2O3 layer one or more further hard material layers as decorative or wear recognition layers. The α-Al2O3 layer has a crystallographic preferential orientation characterised by a texture coefficient TC (0 0 12)≧5 for the (0 0 12) growth direction.The α-Al2O3 layer has an inherent stress in the region of 0 to +300 MPas, and the substrate within a region of 0 to 10 μm from the substrate surface has an inherent stress minimum in the region of −2000 to −400 MPas.

Owner:WALTER AG

Tool with a molybdenum sulfide coating and method for producing the same

InactiveUS6521349B1Dense lattice structureHigh hardnessRecord information storageSolid state diffusion coatingGas phaseMetallic materials

The invention relates to a tool, especially a cutting insert for cutting metallic materials, consisting of a hard metal, cermet, ceramic or steel base body and at least one coating deposited thereon. This single coating or in the event that there are several layers, the outer layer or the layer below the outer layer, consists essentially of molybdenum sulphide. The invention also relates to a method for producing the molybdenum sulphide coating by chemical vapour deposition. According to the invention, the molybdenum sulphide coating contains a mixture of the sulphide phases MoS2 and Mo2S3 with an essentially random orientation (isotropic orientation) of the phase crystals. The coating is applied by means of a chemical vapour deposition procedure.

Owner:WIDIA

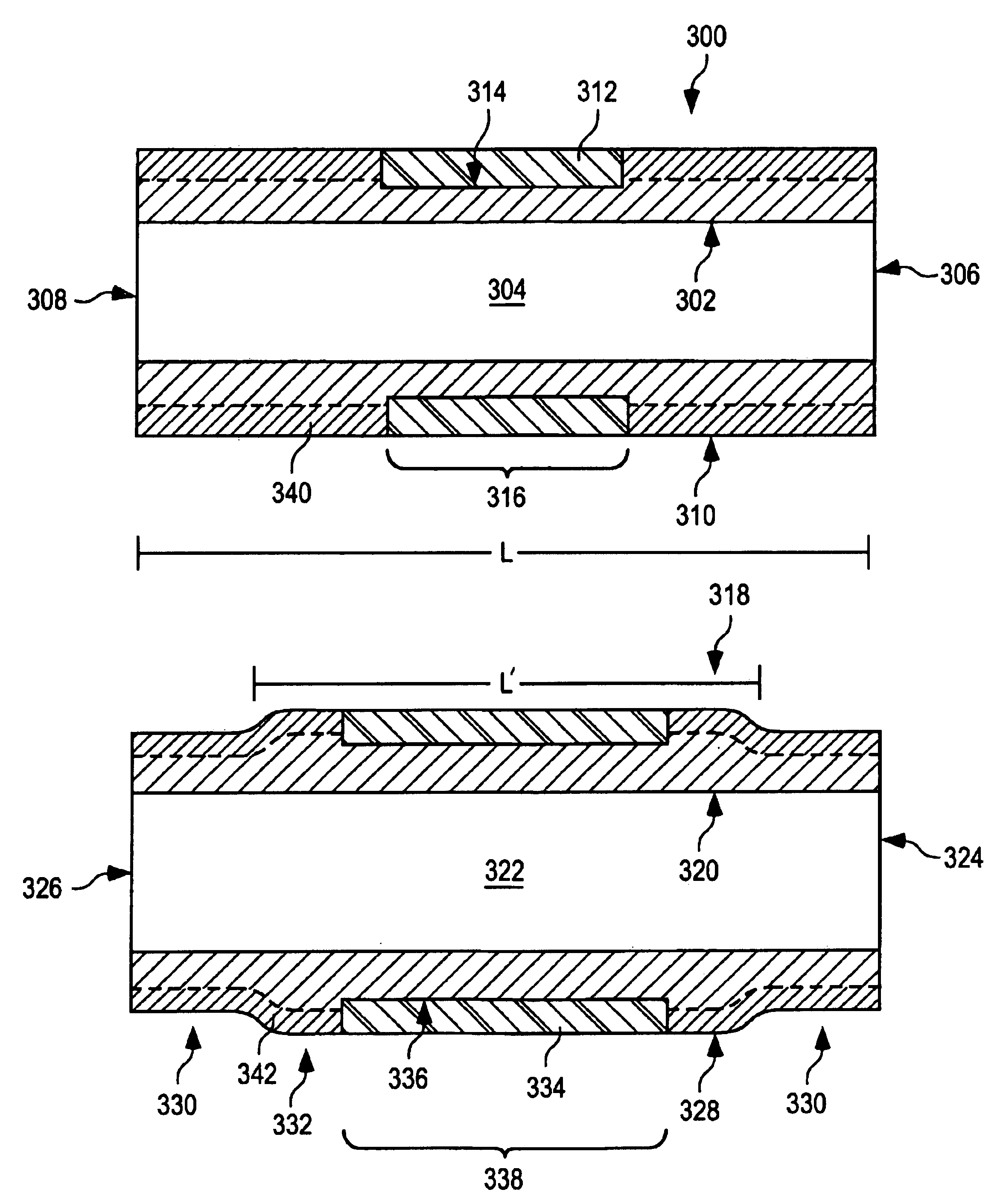

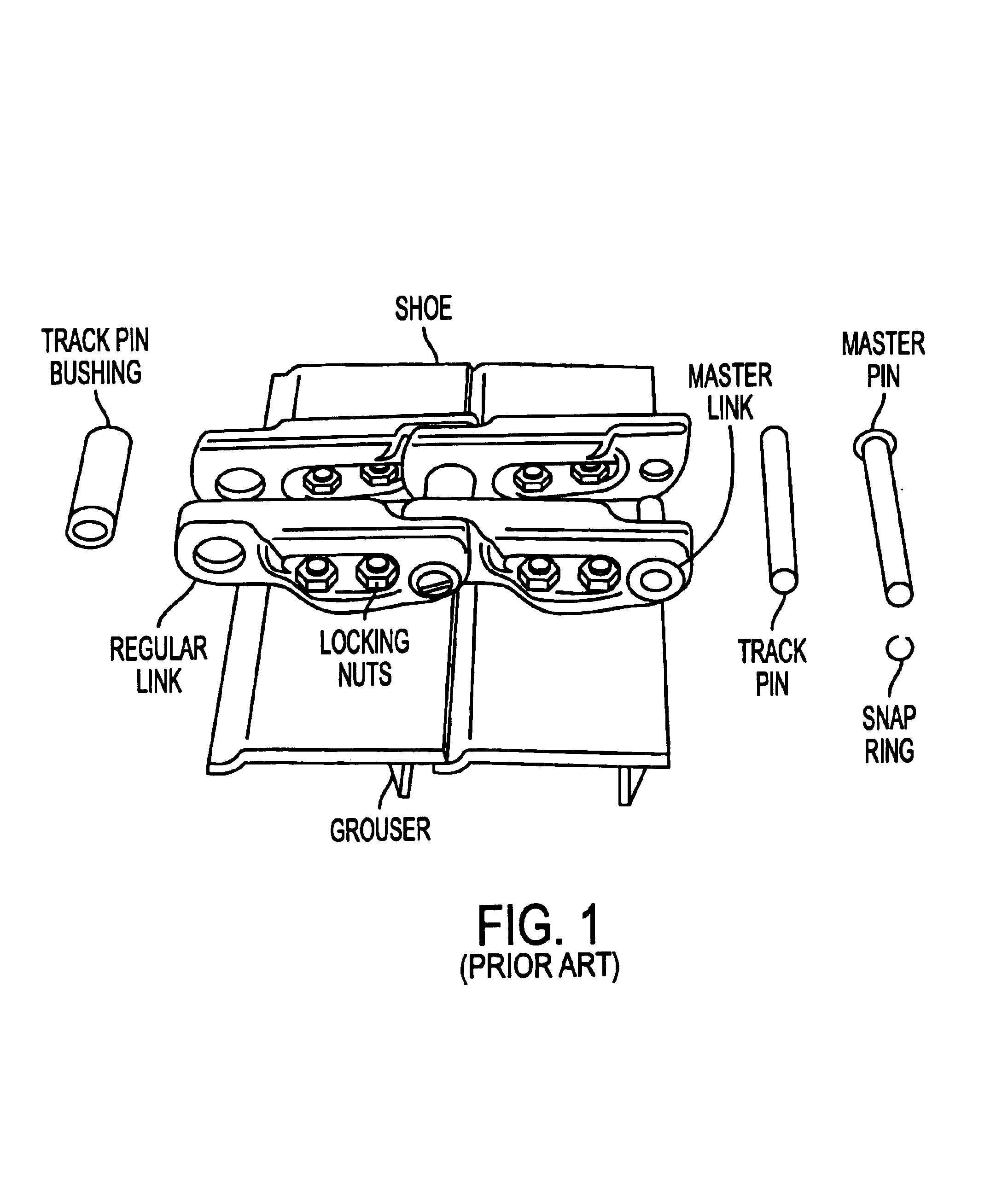

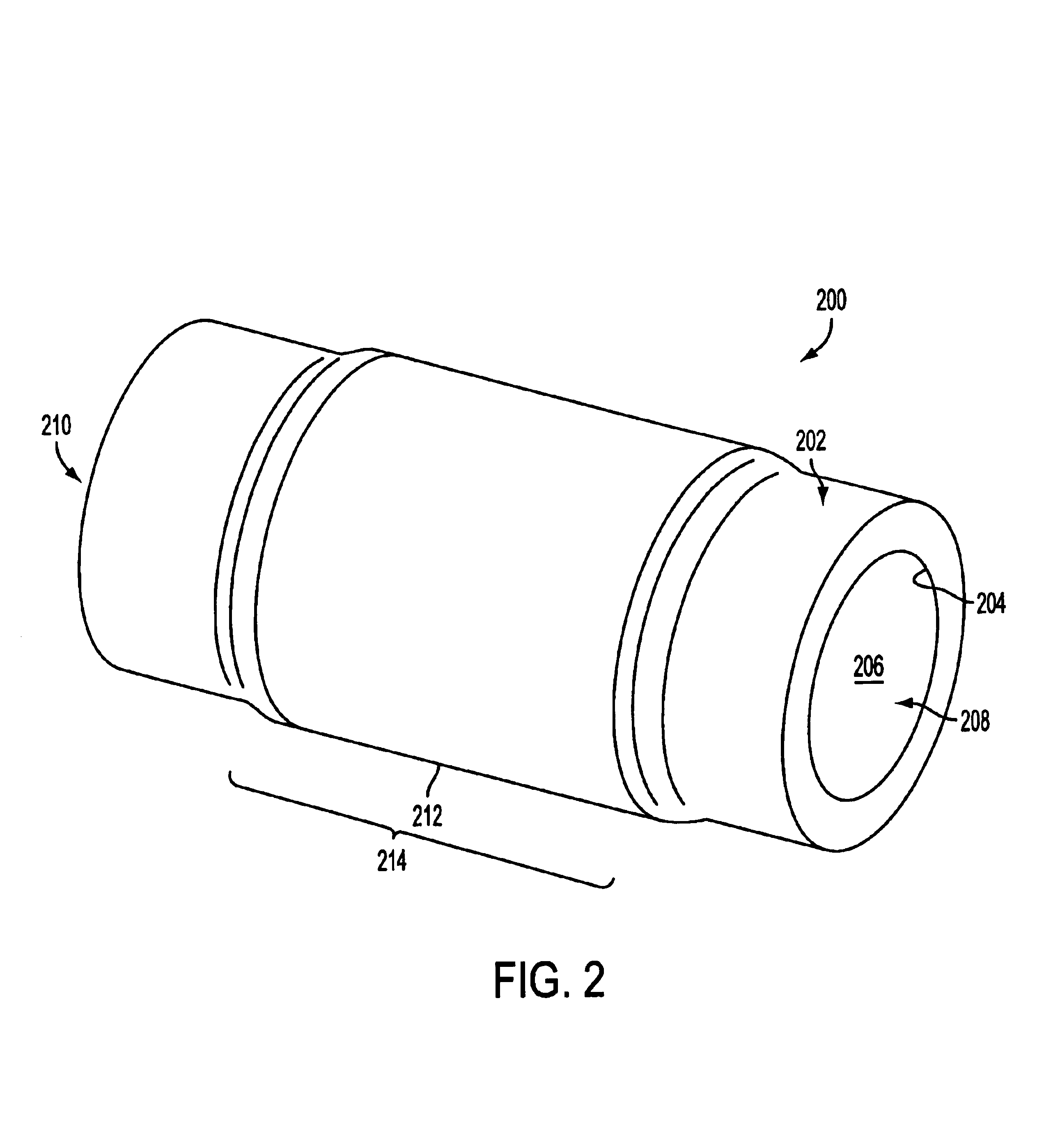

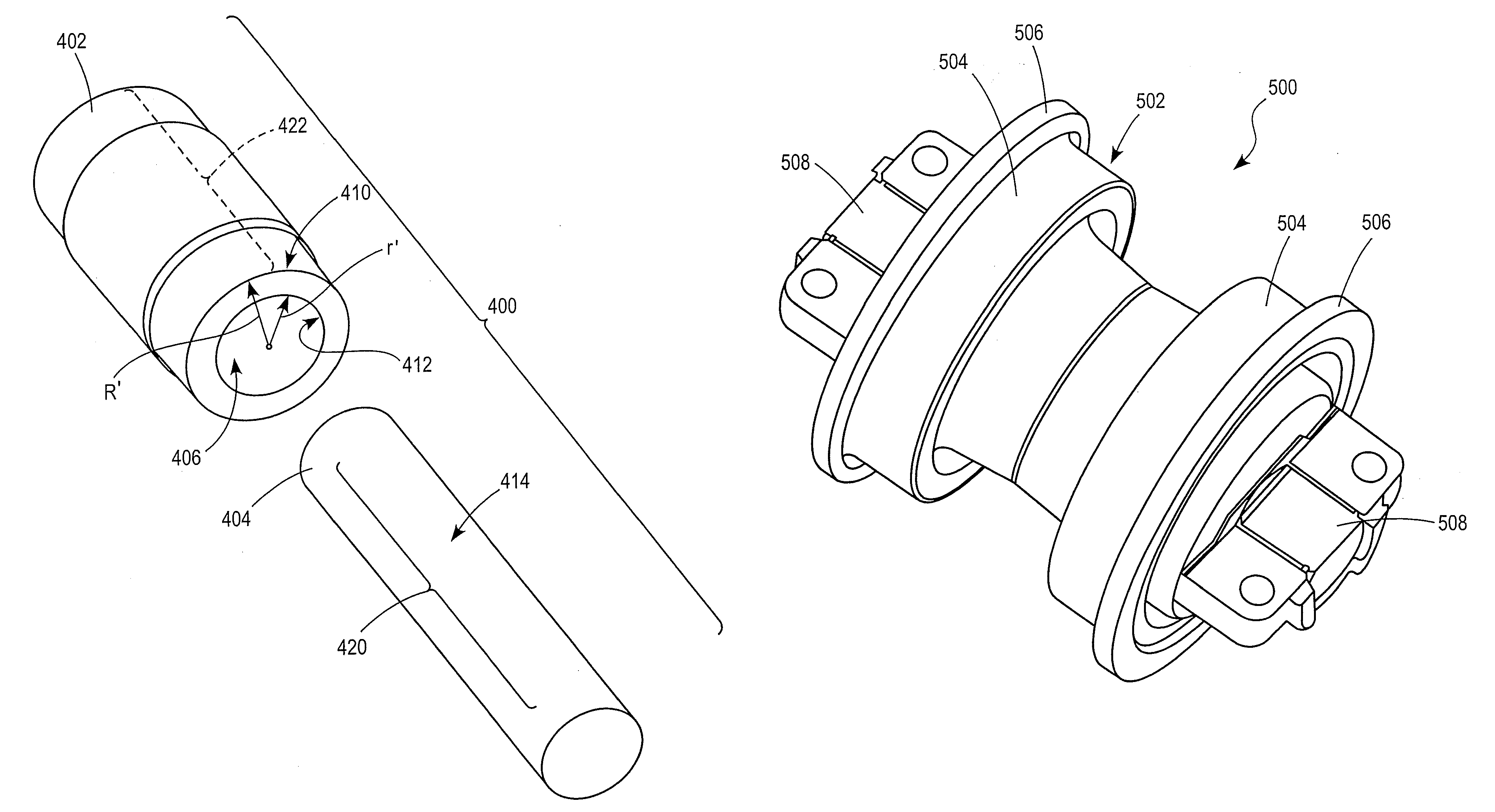

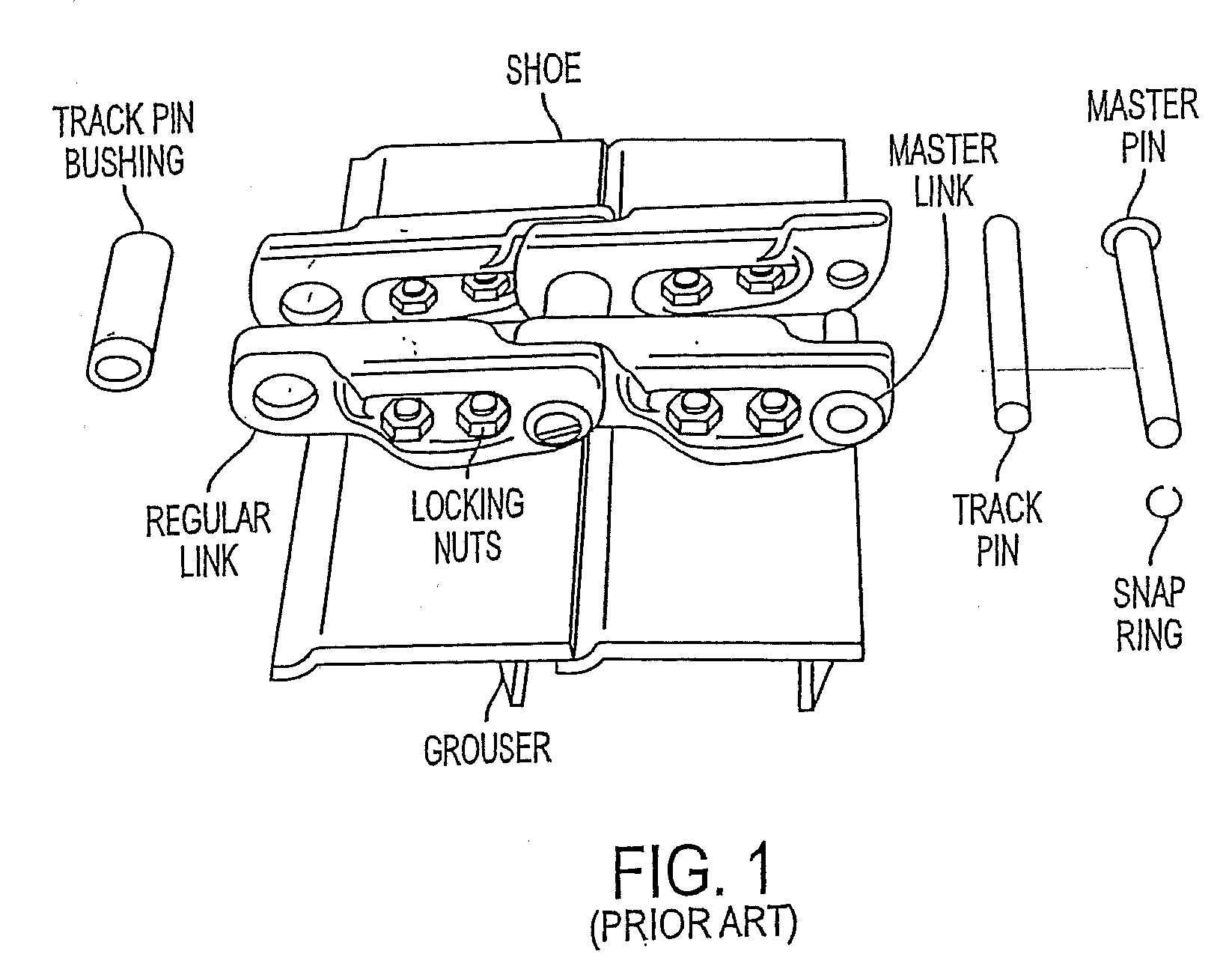

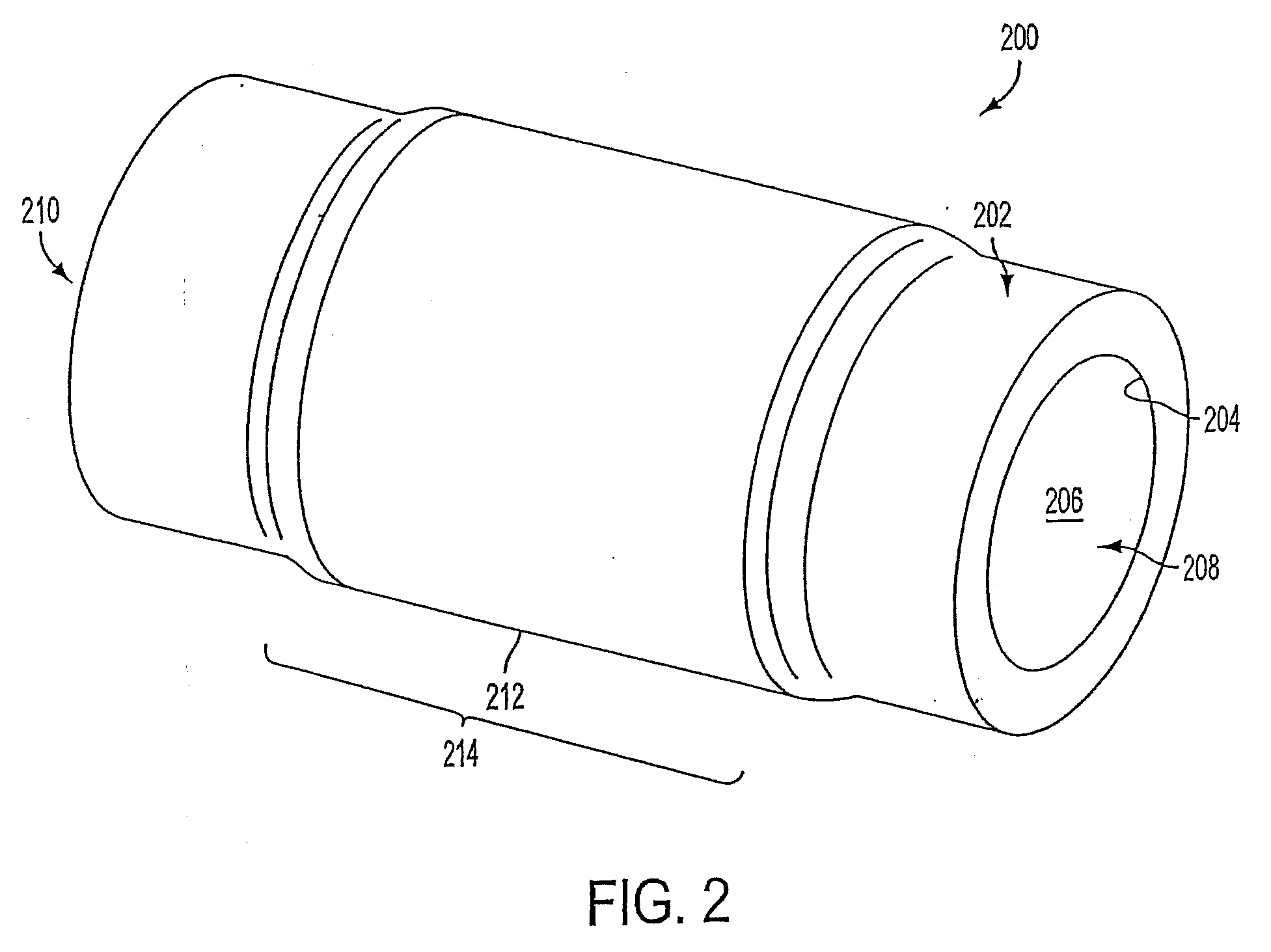

Track pin bushing having a metallurgically bonded coating

A track pin bushing for cooperating with a track pin in an endless track has a tubular body with a metallurgically bonded wear-resistant coating and a method for forming such a coated track pin bushing is taught herein. The tubular body, formed of an iron-based alloy, has an outer surface that is carburized and quenched, i.e., case-hardened, in at least a section thereof. At least a portion of the case hardened section has been removed to a depth sufficient to expose a non-carburized layer of the iron-based alloy. A hard metal alloy slurry is disposed on the non-carburized layer and forms a metallurgical bond between the non-carburized layer and the coated unfused slurry by fusing the hard metal alloy. The thickness of the unfused slurry is adjusted to be from 1.67 to 2.0 times a final thickness of the wear-resistant coating. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface with the wear-resistant coating corresponds to a contact surface adapted to engage with a drive sprocket in the endless track of the track-type vehicle.

Owner:DEERE & CO

Non-Carburized Components of Track-Type Machines Having A Metallurgically Bonded Coating

Undercarriage assembly components of track-type machines having a metallurgically bonded wear-resistant coating and methods for forming such coated undercarriage assembly components is taught herein. The bodies of the undercarriage assembly components, formed of an iron-based alloy, have a hard metal alloy slurry disposed on a surface or into an undercut or channel and then fused to form a metallurgical bond with the iron-based alloy. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof. The portion of the outer surface of the undercarriage assembly components having the wear-resistant coating corresponds to a wear surface of the component during operation of the endless track of the track-type vehicle.

Owner:DEERE & CO

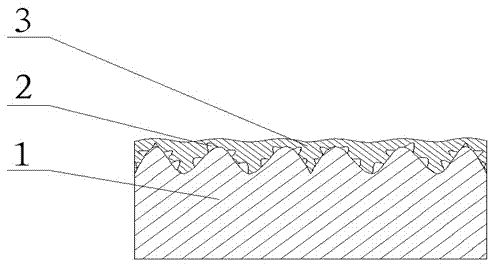

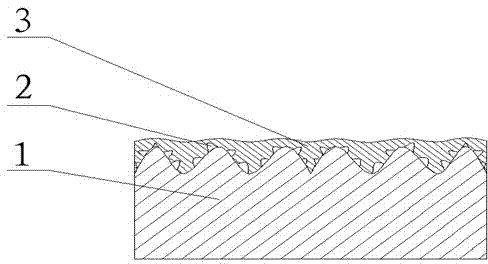

Nonstick cookware and manufacturing method thereof

The invention discloses nonstick cookware and a manufacturing method thereof, wherein the inner surface of the pot body of the nonstick cookware is provided with an uneven raised structure; a grain structure is distributed on the raised structure; and a nonstick coating covers outside the raised structure and the grain structure. The manufacturing method of the cookware comprises the following steps of: (1) forming the pot body of the cookware; (2) carrying out inner surface treatment on the pot body of the cookware to ensure that the uneven raised structure is formed at the inner surface of the pot body of the cookware; (3) carrying out meltallizing treatment on the cookware blank after being subjected to the roughening treatment to ensure that nanoscale hard metal-based or nonmetal-based grain structure is distributed on the raised structure of the pot body of the cookware; (4) spraying nonstick coatings on the inner surface of the pot body of the cookware after being subjected to the meltallizing treatment to ensure that the nonstick coating covers outside the raised structure and the grain structure; and (5) putting in a sintering channel at a temperature of 350-440 DEG C after the spraying to sinter for 5-20 minutes so as to obtain a finished product. The nonstick cookware disclosed by the invention is good in nonstick effect and abrasive resistance, simple in manufacturing process and suitable for large scale production.

Owner:谛卓(北京)咨询顾问有限公司

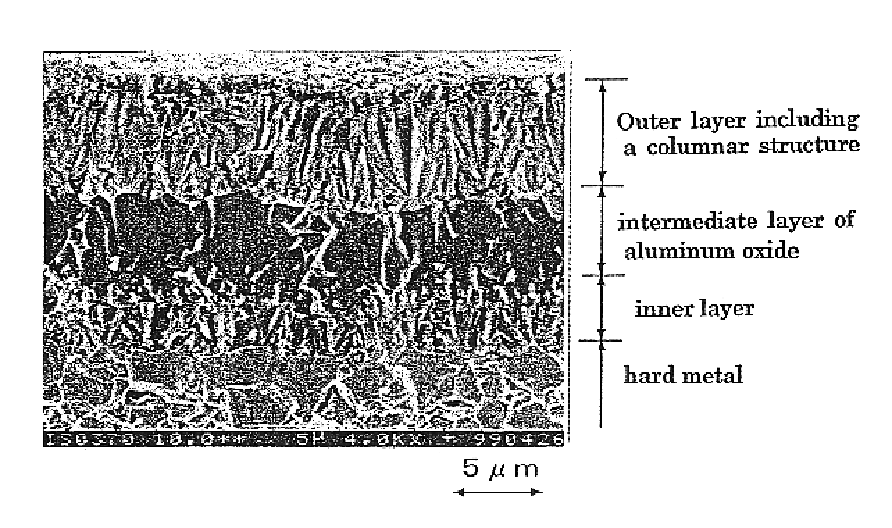

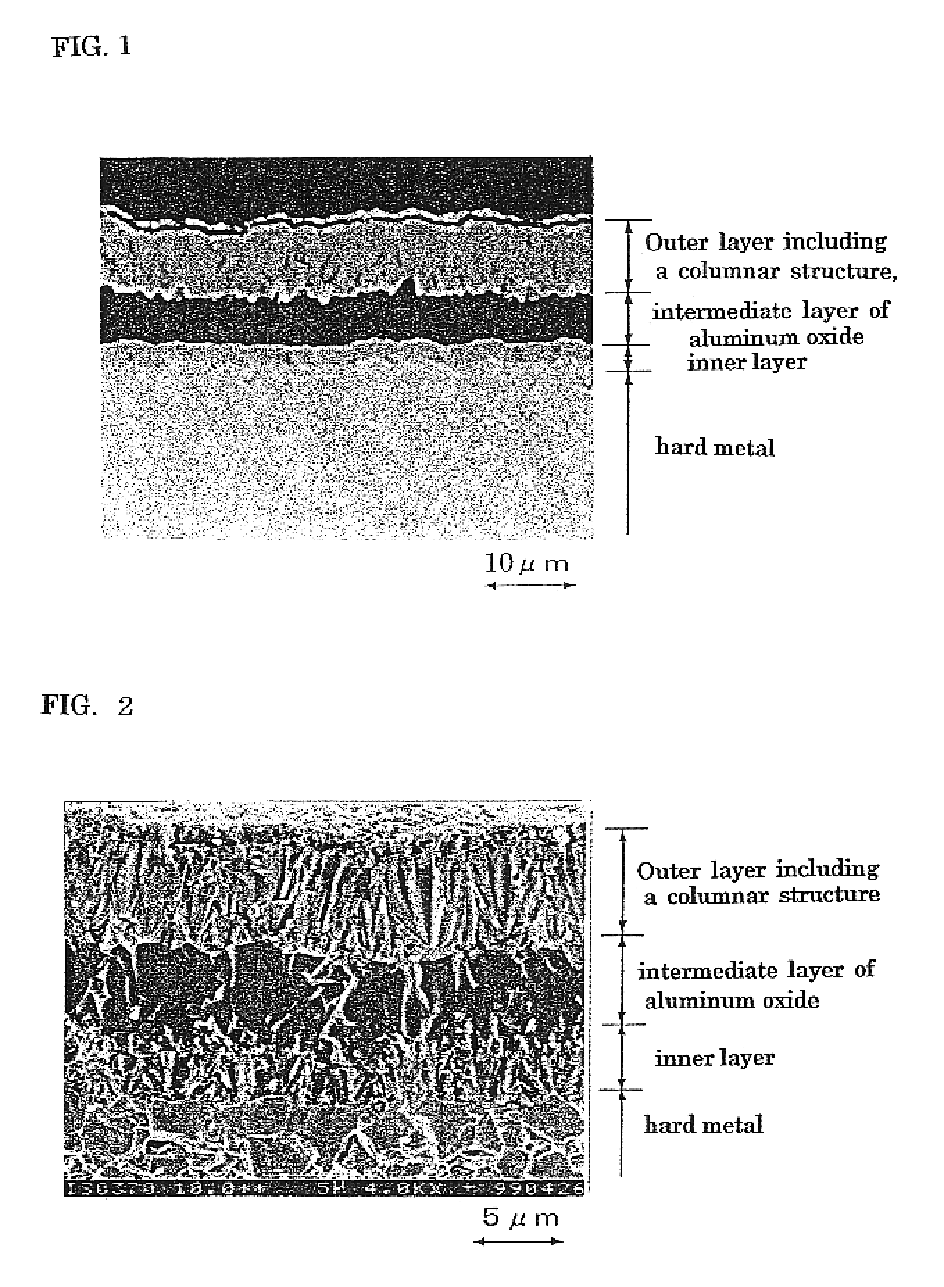

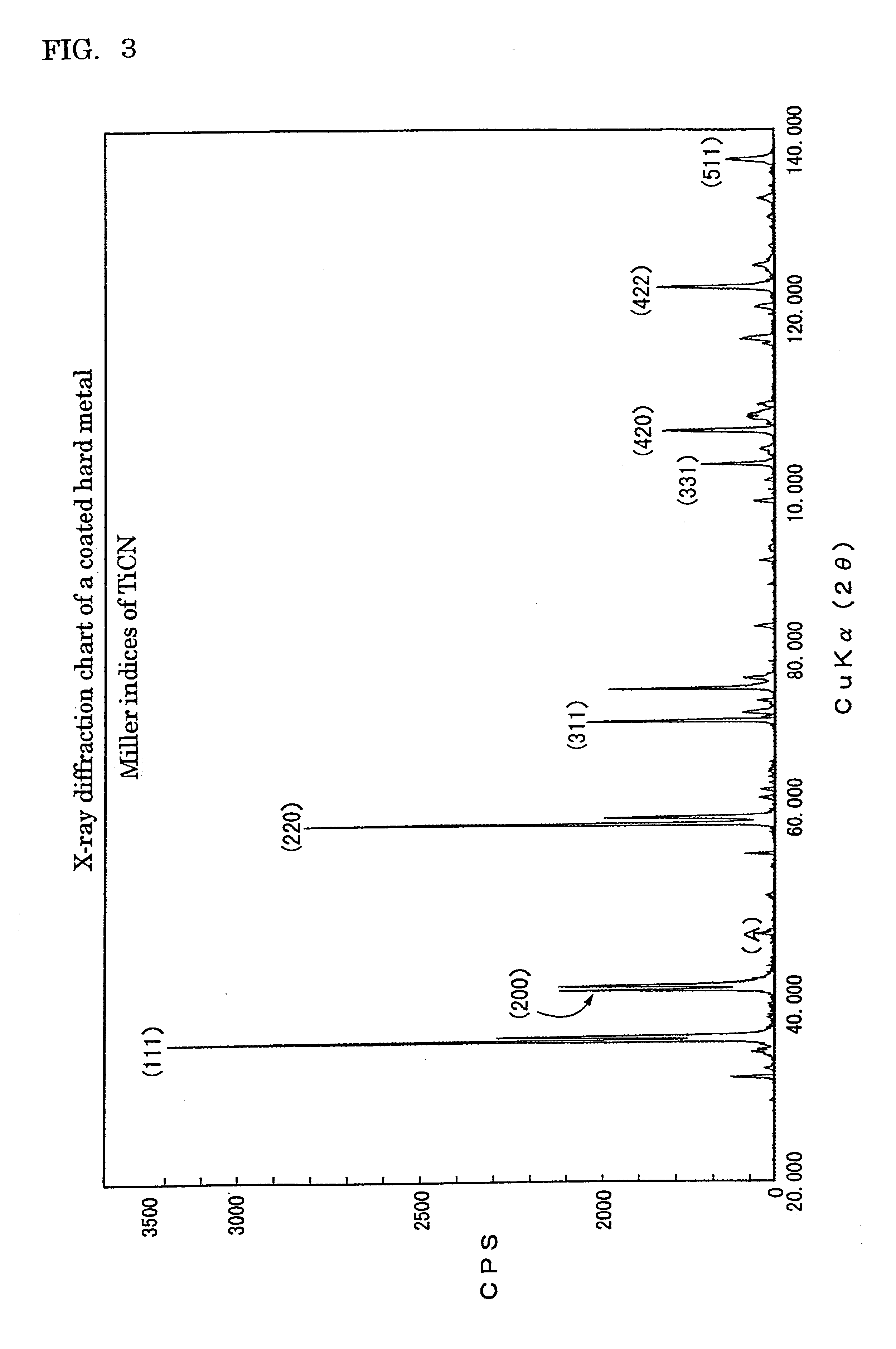

Coated hard alloy

A coated hard metal which has high resistance against wear, chipping, welding, and flaking is offered. The coated hard metal is provided with an inner layer, intermediate layer, and outer layer on the surface of the hard metal. The inner layer includes a layer comprising at least one member selected from the group consisting of (a) the carbides, nitrides, borides, and oxides of the elements belonging to the IVa, Va, and VIa groups in the periodic table and (b) the solid solutions of these. The intermediate layer includes a layer comprising at least one member selected from the group consisting of aluminum oxide, zirconium oxide, and their solid solution. The outer layer includes a layer of titanium carbonitride having a columnar structure. In a cross section showing the structure of the coated hard metal, the relation between "Amax," which signifies the maximum roughness at the outer face of the intermediate layer, and "Bmax," which signifies the maximum roughness at the outer face of the layer carbonitride having a columnar structure in the outer layer, satisfies equation 1.where 0.5 mum<Amax<4.5 mum, and 0.5 mum<=Bmax<=4.5 MUM.

Owner:SUMITOMO ELECTRIC IND LTD

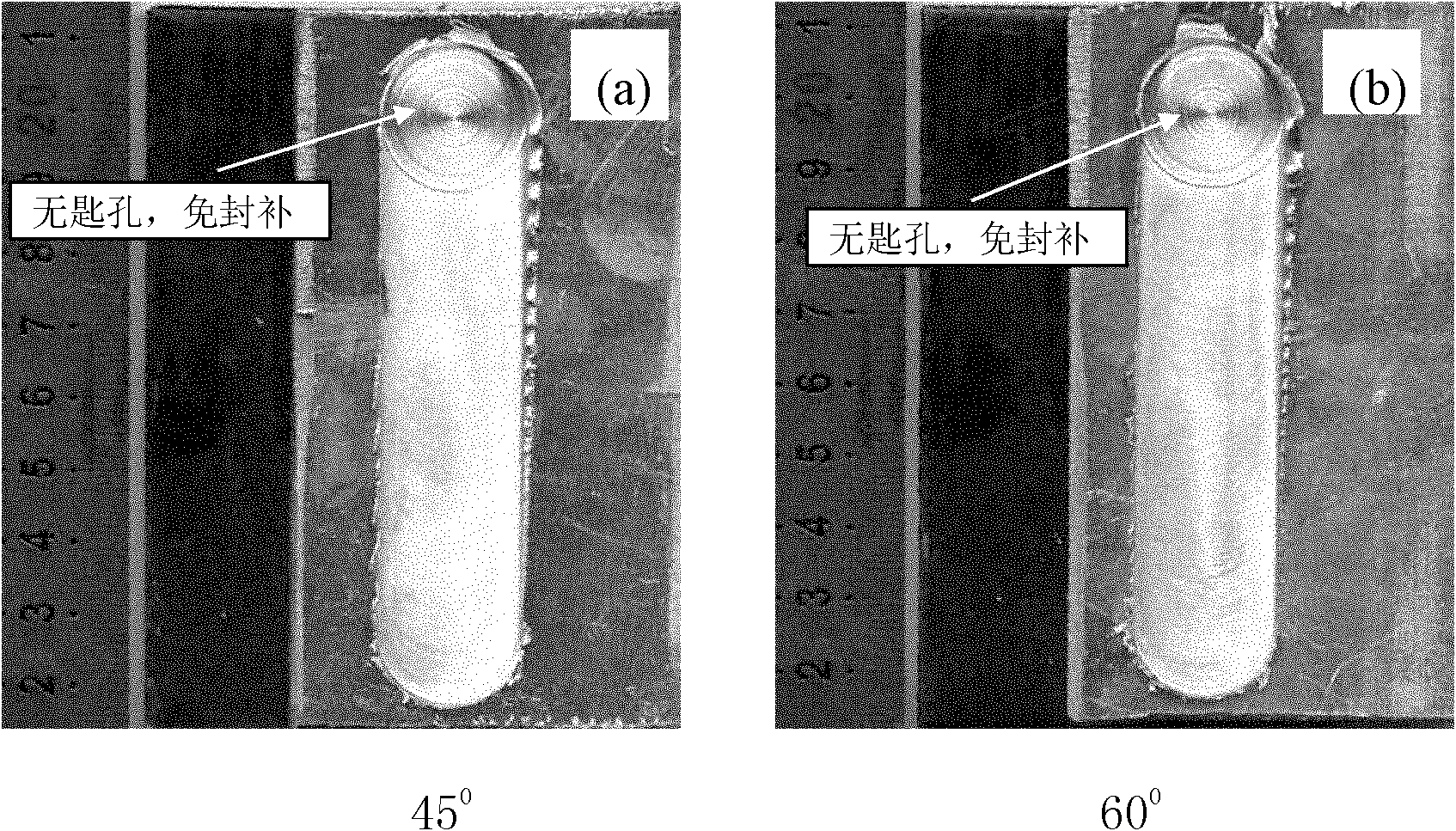

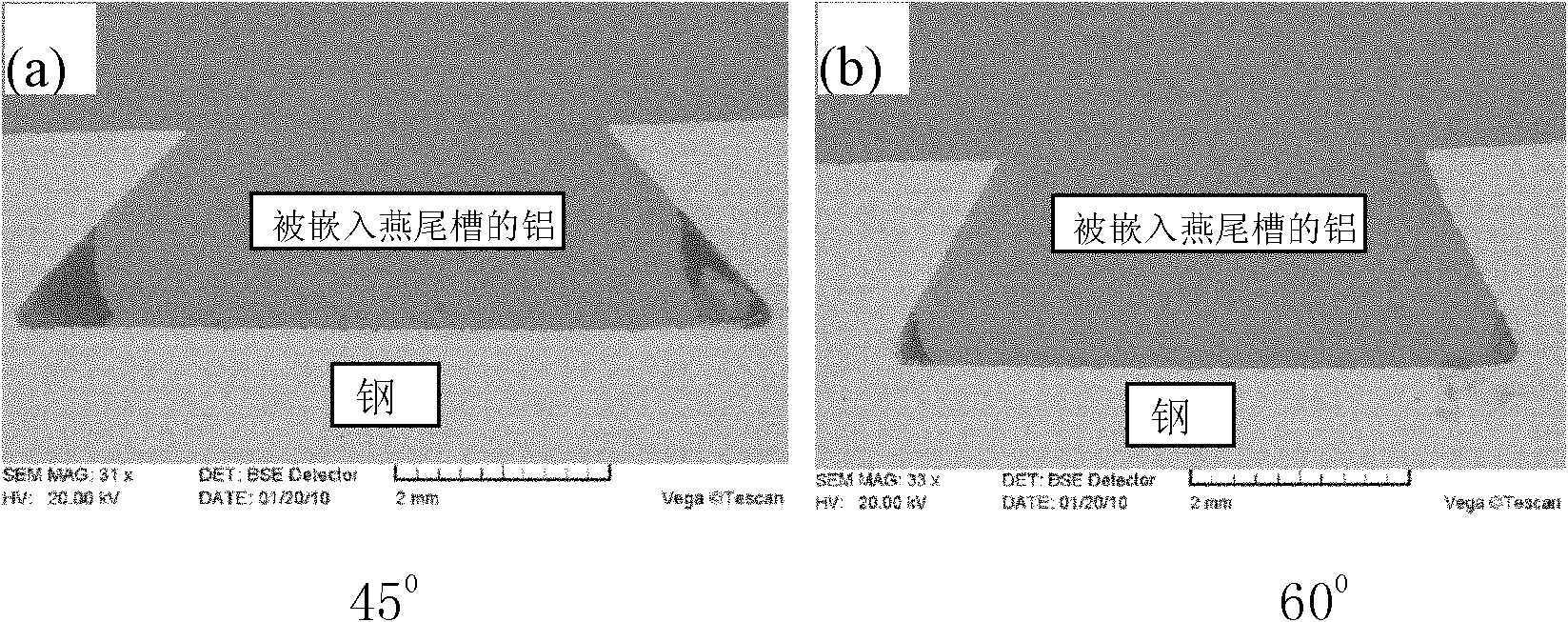

Embedded stirring and rubbing slit welding method

InactiveCN102120287AImprove bindingSignificant energy savingNon-electric welding apparatusNeedle freeHard metal

The invention discloses an embedded stirring and rubbing slit welding method for dissimilar metals, which is especially suitable for large-area lap connection of aluminum or magnesium or harder metal materials. The embedded stirring and rubbing slit welding method comprises the steps of: firstly, processing one or more dovetail grooves on a second harder base material; secondly, assembling according to a lap connection form, and placing an aluminum plate on the upper sides of the dovetail grooves of the second harder base material; using a needle-free stirring head and installing in an inclining manner; starting the stirring head to rotate and enabling the stirring head to be in contact with the upper surface of the aluminum plate, wherein the pressing depth of the stirring head is limited to about between 0.1mm and 2mm and a welding interface needs not to be penetrated; after rubbing and preheating for several seconds at the starting end, moving the rotating stirring head or operating platform so that the aluminum plate is helically extruded in a groove of a lower plate and the welding or cladding is completed. Compared with the resistance slit welding, the method disclosed by the invention has remarkable energy saving advantage. Compared with the traditional stirring rubbing welding, the method disclosed by the invention has the advantages of no keyhole and no abrasion to needles by the harder base material. The method can be used for welding, and can also be used for preparing a bimetal composite plate.

Owner:西安英特金属复合材料有限公司

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

Cutting tool comprising a multiple-ply pvd coating

The invention relates to a tool comprising a substrate that consists of hard metal, cermet, ceramic, steel or high speed steel, and a multiple-ply coating that is applied using the PVD method and has a total thickness of 1 (mu)m to 20 (mu)m, said multiple-ply coating comprising a connecting layer and a wear-resistant layer deposited directly onto said connecting layer, characterised in that the connecting layer has a multiple-ply design and is deposited by means of cathodic vacuum arc vapour deposition (arc PVD), plies of said connecting layer which lie one immediately over the other having different compositions, and each of the multiple plies of said connecting layer being formed from carbides, nitrides, oxides, carbonitrides, oxycarbides, carboxy nitrides of at least two different metals selected from Ti, V, Cr, Zr, Nb, Mo, Ru, Hf, Ta, W, Al, Si, Y, Li and B, and solid solutions thereof; and said wear-resistant layer having a single or multiple-ply design and being deposited by means of high-power impulse magnetron sputtering (HIPIMS), each of said one or more plies of the wear-resistant layer being formed from carbides, nitrides, oxides, carbonitrides, oxycarbides, carboxy nitrides of at least two different metals selected from Ti, V, Cr, Zr, Nb, Mo, Ru, Hf, Ta, W, Al, Si, Y, Li and B and solid solutions thereof.

Owner:WALTER AG

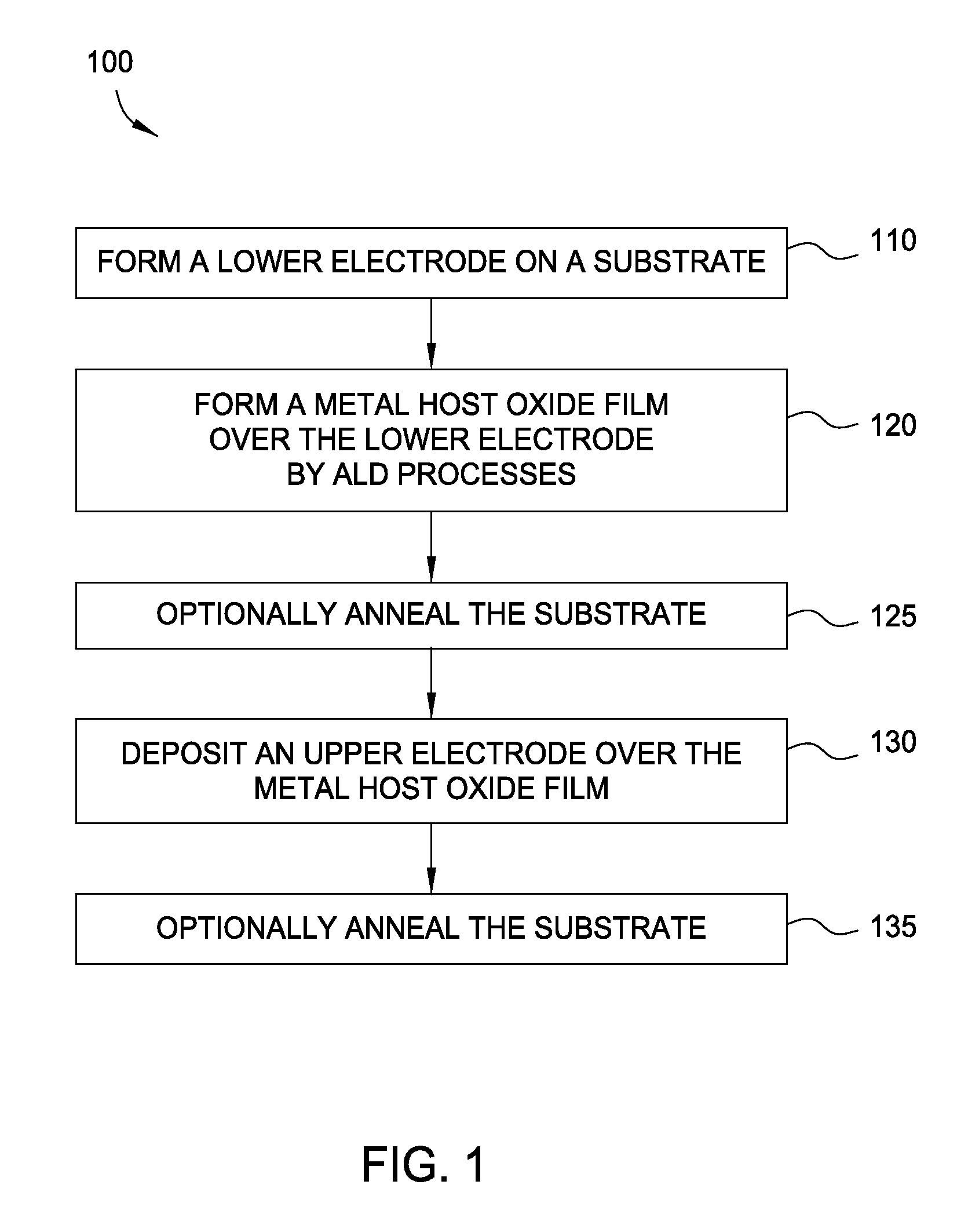

Atomic layer deposition of metal oxides for memory applications

ActiveUS20130034947A1Easy to controlGood reproducibilitySolid-state devicesSemiconductor/solid-state device manufacturingHard metalPhysical chemistry

Embodiments of the invention generally relate to nonvolatile memory devices and methods for manufacturing such memory devices. The methods for forming improved memory devices, such as a ReRAM cells, provide optimized, atomic layer deposition (ALD) processes for forming a metal oxide film stack which contains at least one hard metal oxide film (e.g., metal is completely oxidized or substantially oxidized) and at least one soft metal oxide film (e.g., metal is less oxidized than hard metal oxide). The soft metal oxide film is less electrically resistive than the hard metal oxide film since the soft metal oxide film is less oxidized or more metallic than the hard metal oxide film. In one example, the hard metal oxide film is formed by an ALD process utilizing ozone as the oxidizing agent while the soft metal oxide film is formed by another ALD process utilizing water vapor as the oxidizing agent.

Owner:SANDISK TECH LLC +2

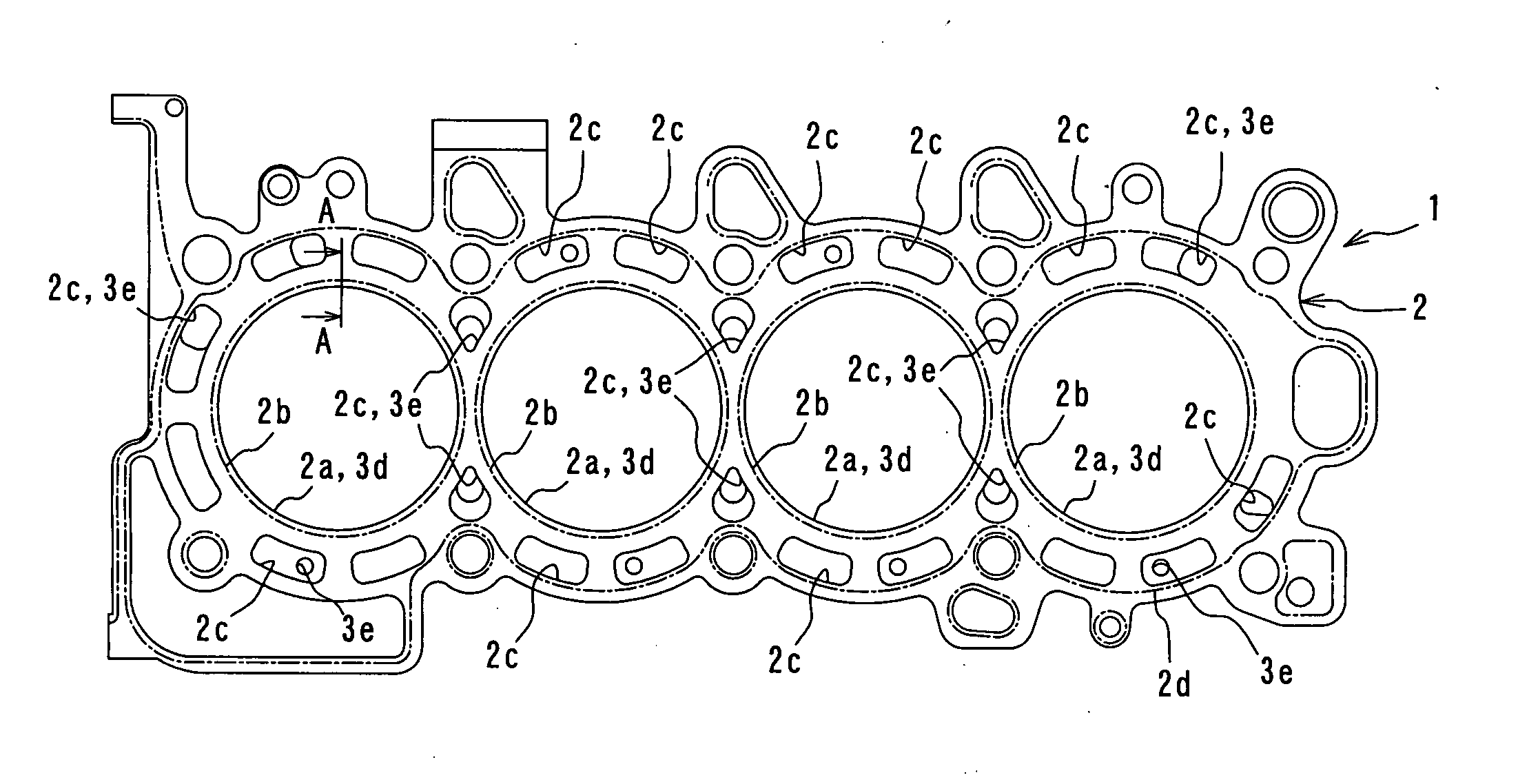

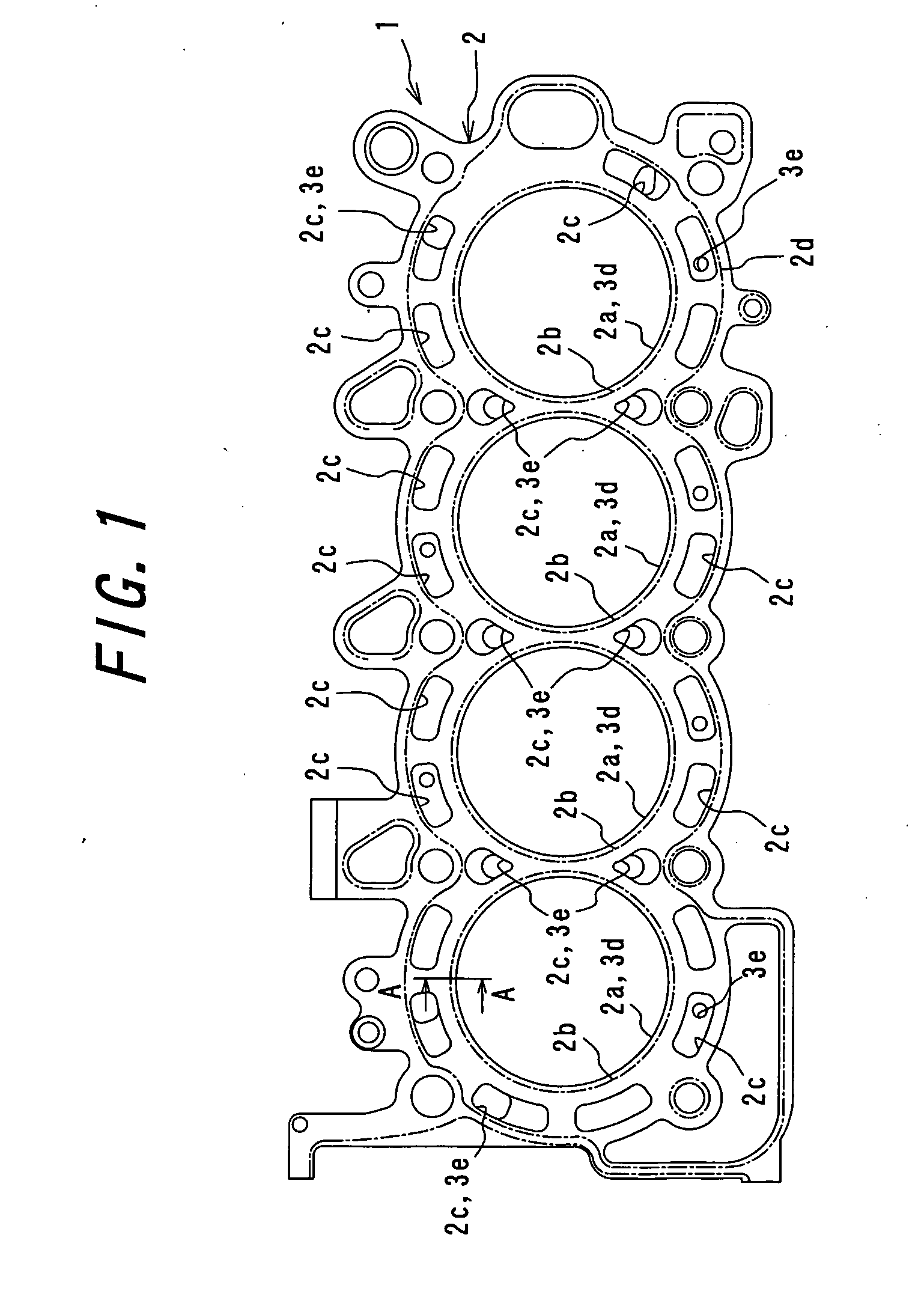

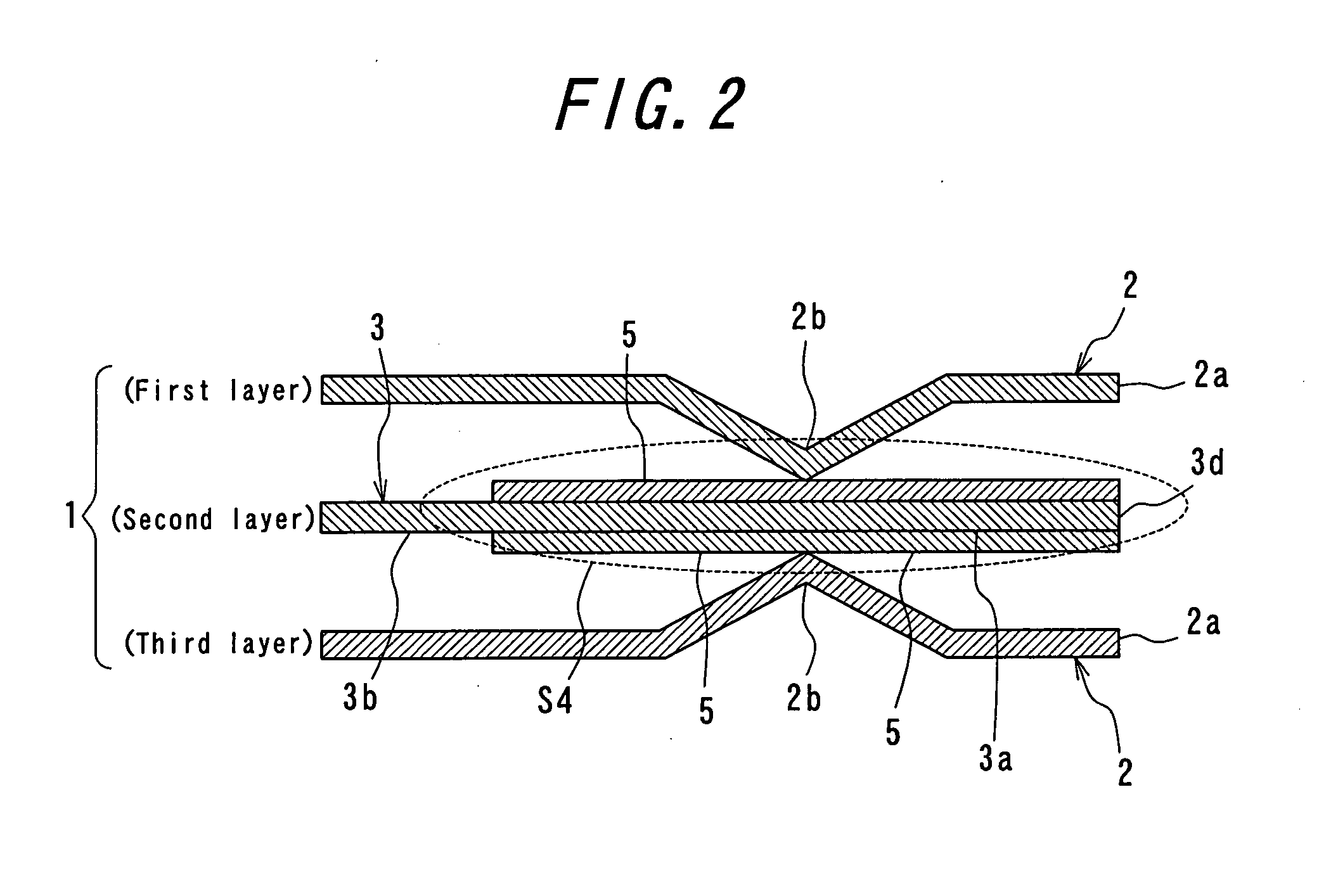

Metal gasket for cylinder head

InactiveUS20060232017A1Easy to adjustLine pressureEngine sealsSealing arrangements for enginesCylinder headHard metal

A metal gasket for a cylinder head has two base plates each constructed from a metal plate and layered over each other, an auxiliary plate constructed from a metal plate and interposed between the base plates, and hard metal-plated layers. The base plates each have cylinder holes, annular beads, coolant holes, and an outer peripheral bead. The cylinder holes correspond with the bore of each cylinder. The annular beads have an angled cross-sectional shape. The coolant holes correspond with a coolant jacket of the cylinder block and with a coolant hole of the cylinder head. The outer peripheral bead has a cross-sectional shape sloping on one side and surrounds the beads and the coolant holes. Each of the layers is extended from a position more radially inward than an annular bead of a base plate to a position radially outward.

Owner:NIPPON LEAKLESS IND CO LTD +1

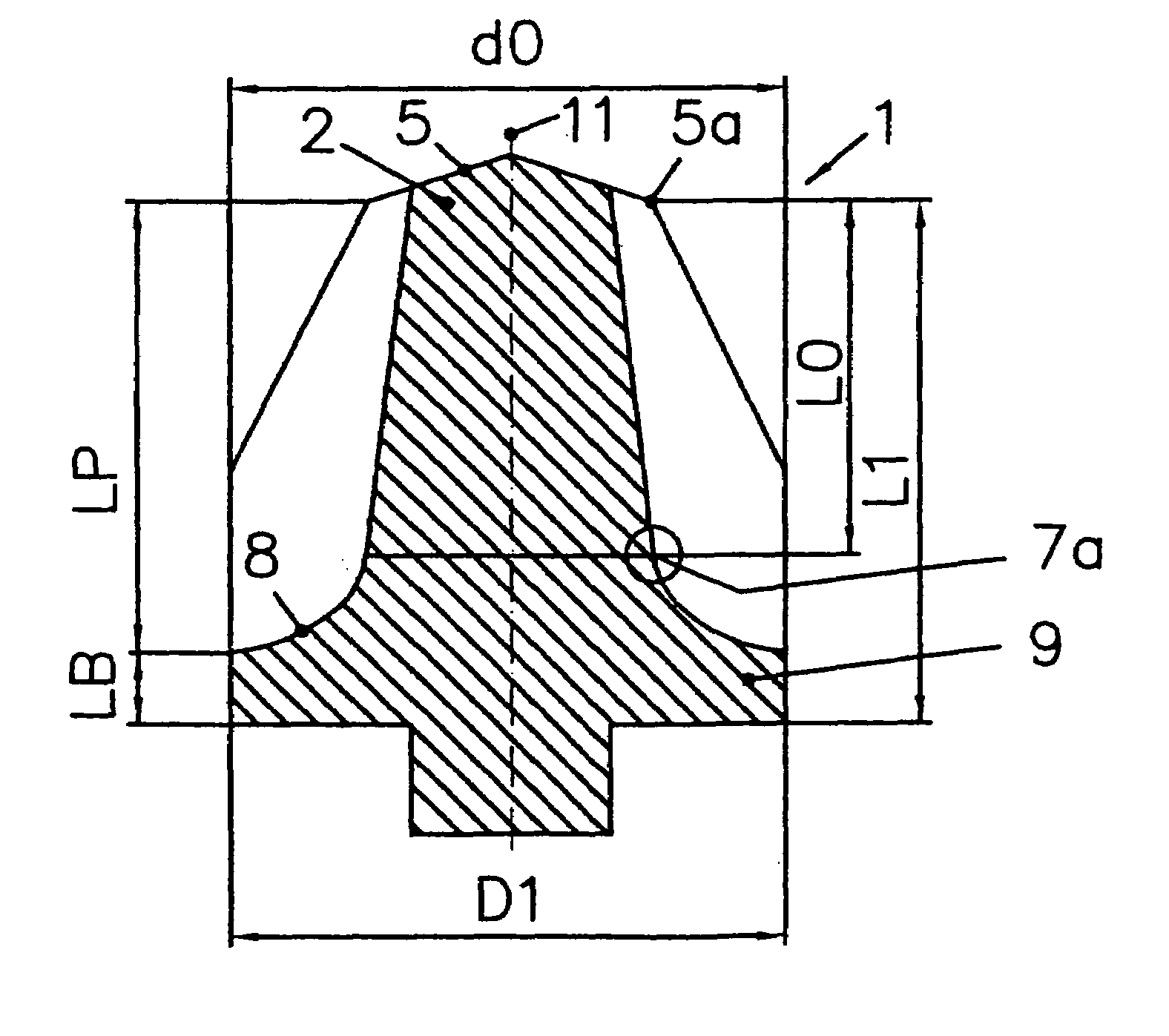

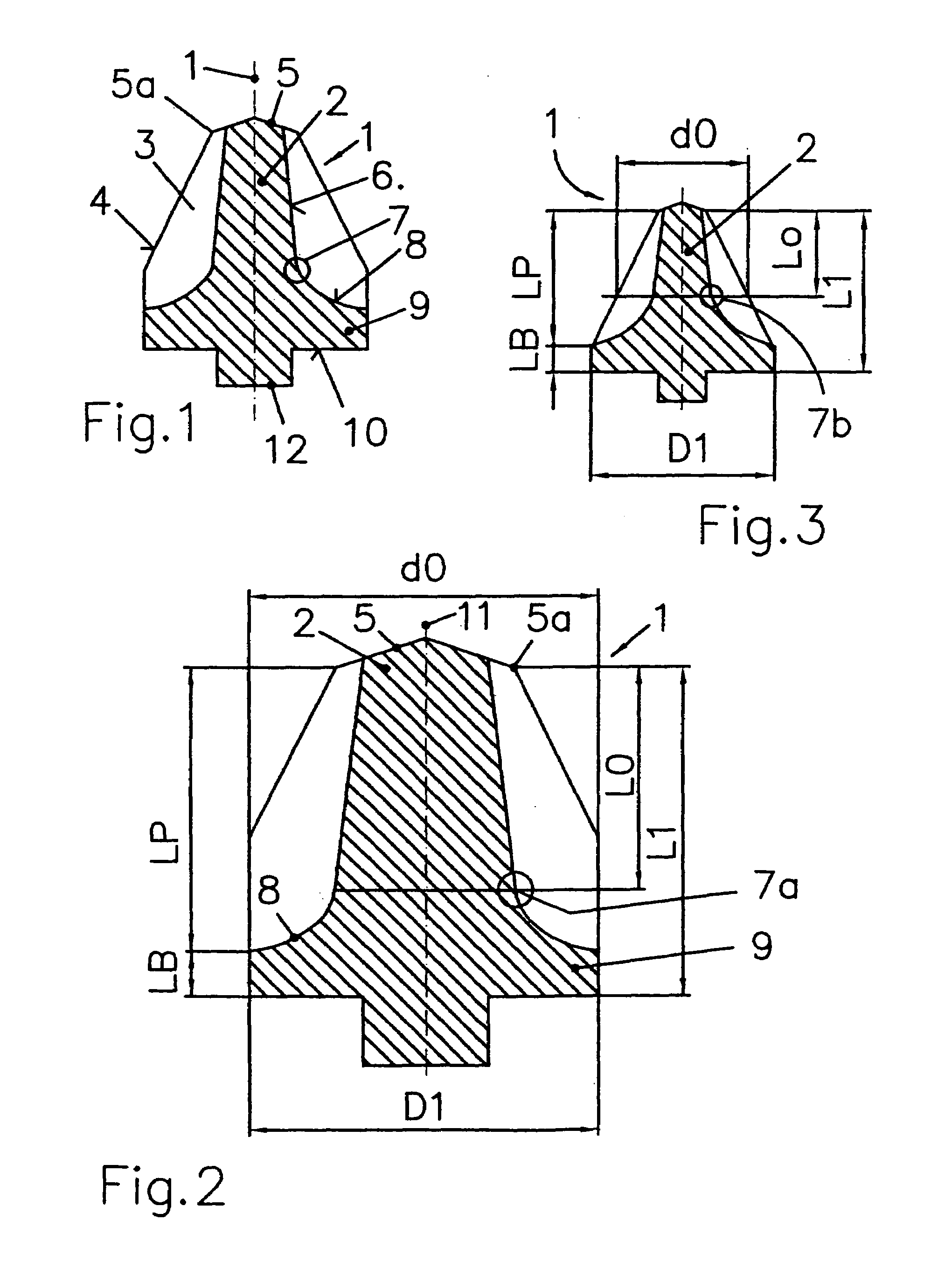

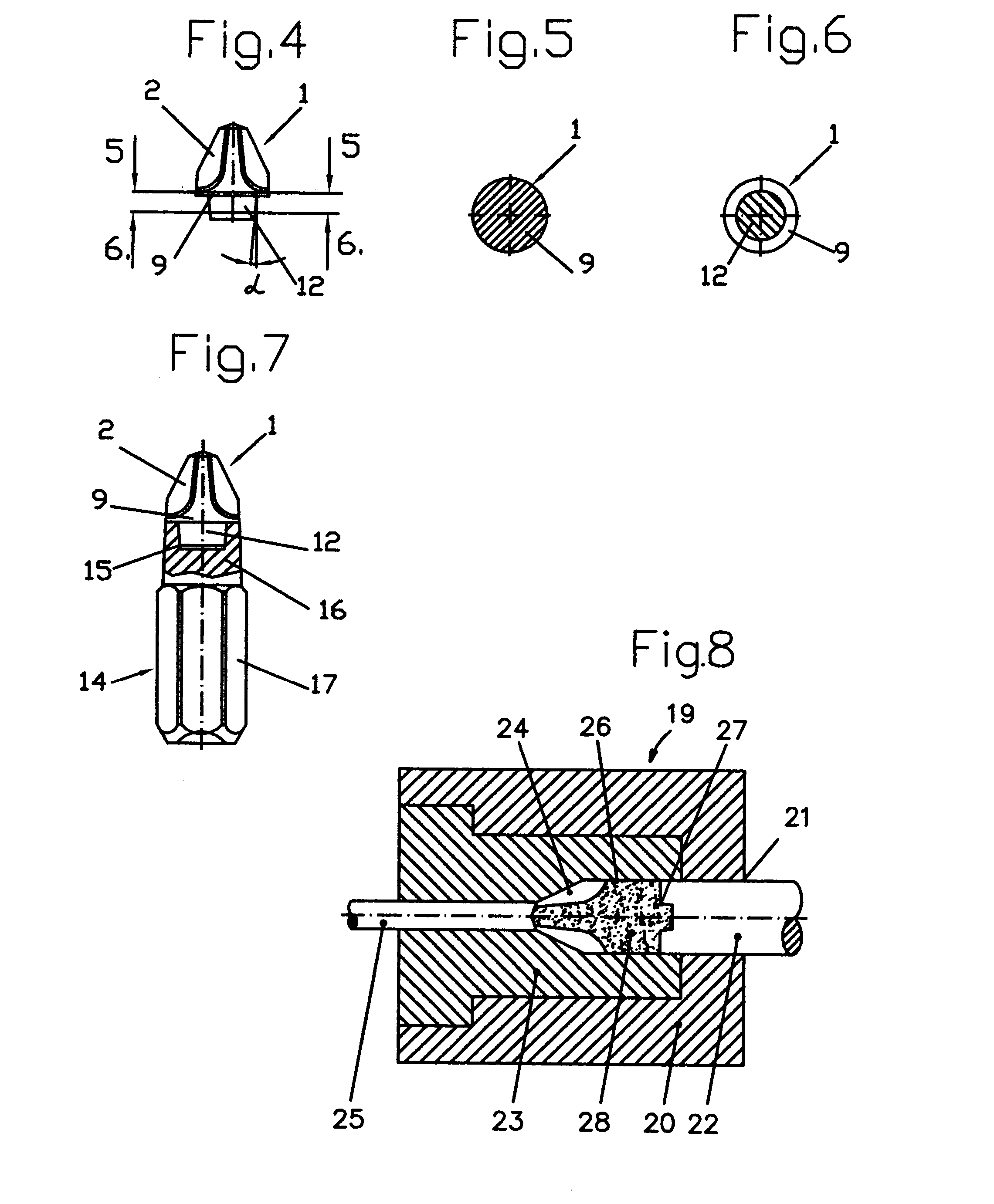

Screwdriver bits

InactiveUS7168348B2Interfere with homogeneityUniform and precise and superior densificationSpannersWrenchesCompression moldingHard metal

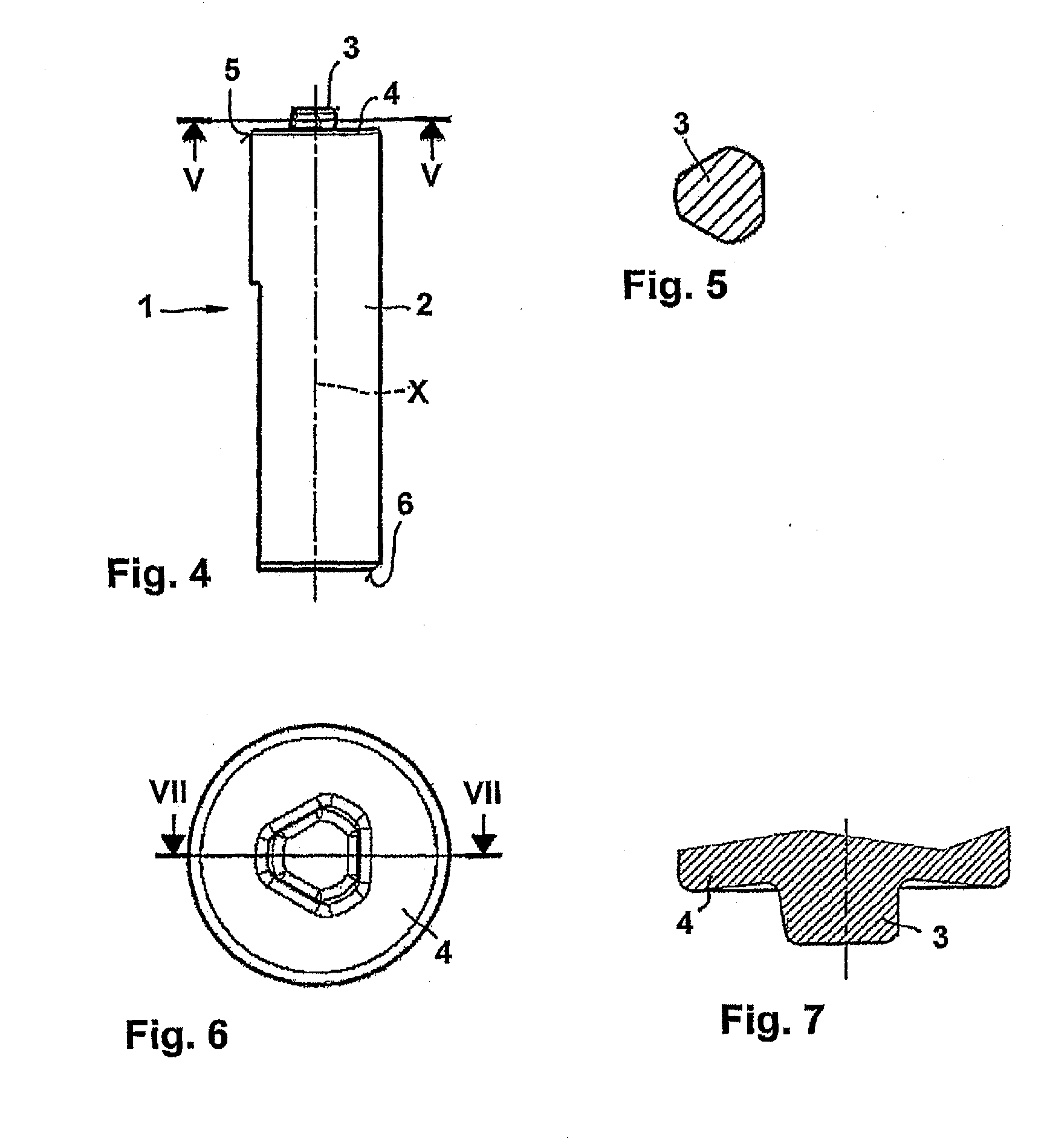

The invention pertains to a screwdriver bit with a drive section (14) and a front section (1) that contains a profiled penetrating section (2) and is manufactured by compression molding and subsequently sintering a hard metal powder, where the front section is connected to the drive section. Thus, according to the invention, the length of the front section (1) is not greater than 2.5-times the length of the penetrating section (2) and / or the ratio of the length of the front section (1) to the diameter or the width across corners of the penetrating section (2) is not greater than 2.2 (FIG. 7).

Owner:FELO WERKZEUGFAB HOLLAND LETZ

Etch resistant wafer processing apparatus and method for producing the same

InactiveUS20070138601A1Liquid surface applicatorsSemiconductor/solid-state device detailsThin film electrodeHard metal

A wafer processing apparatus is fabricated by depositing a film electrode onto the surface of a base substrate, the structure is then overcoated with a protective coating film layer comprising at least one of a nitride, carbide, carbonitride or oxynitride of elements selected from a group consisting of B, Al, Si, Ga, refractory hard metals, transition metals, and combinations thereof. The film electrode has a coefficient of thermal expansion (CTE) that closely matches the CTE of the underlying base substrate layer as well as the CTE of the protective coating layer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

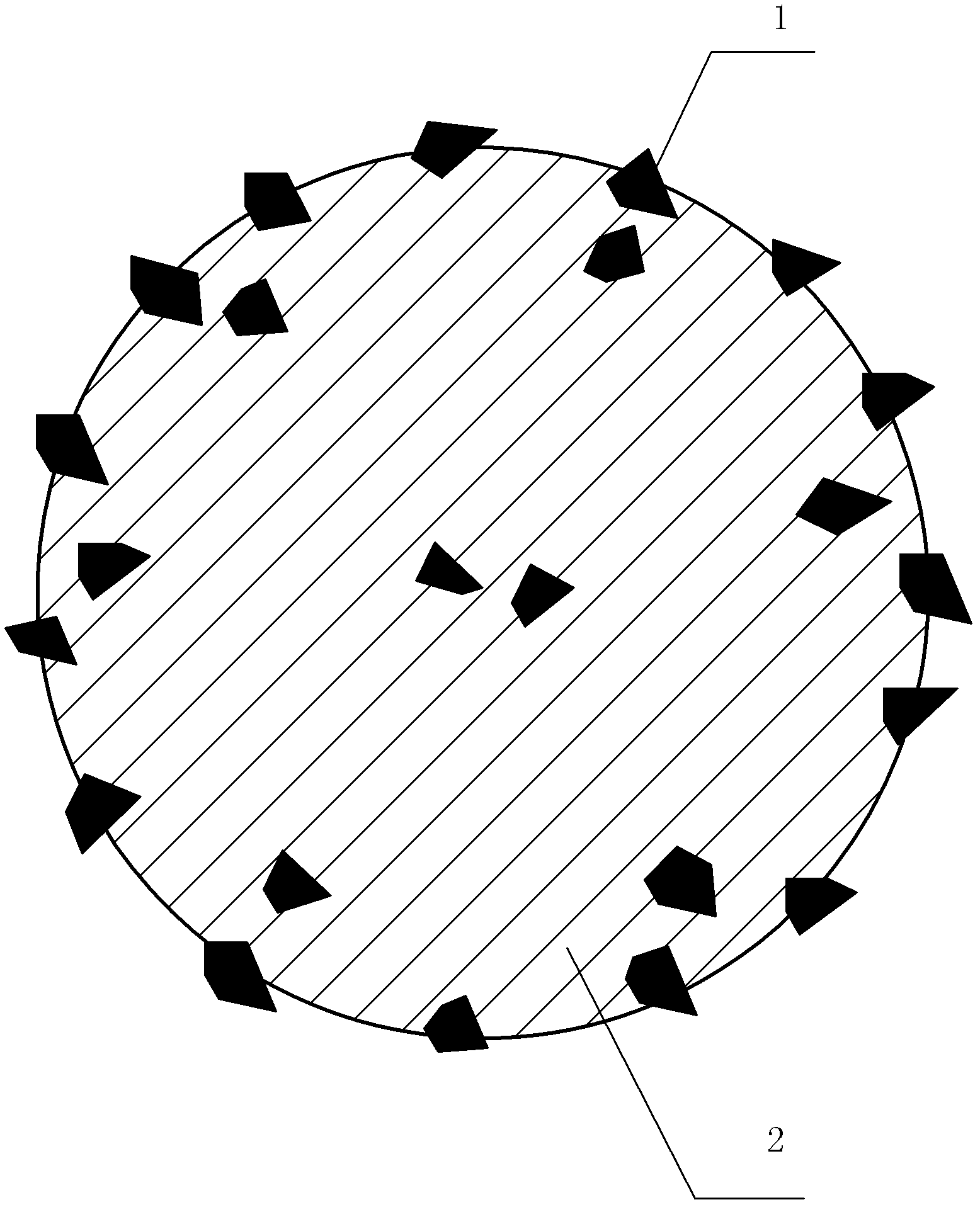

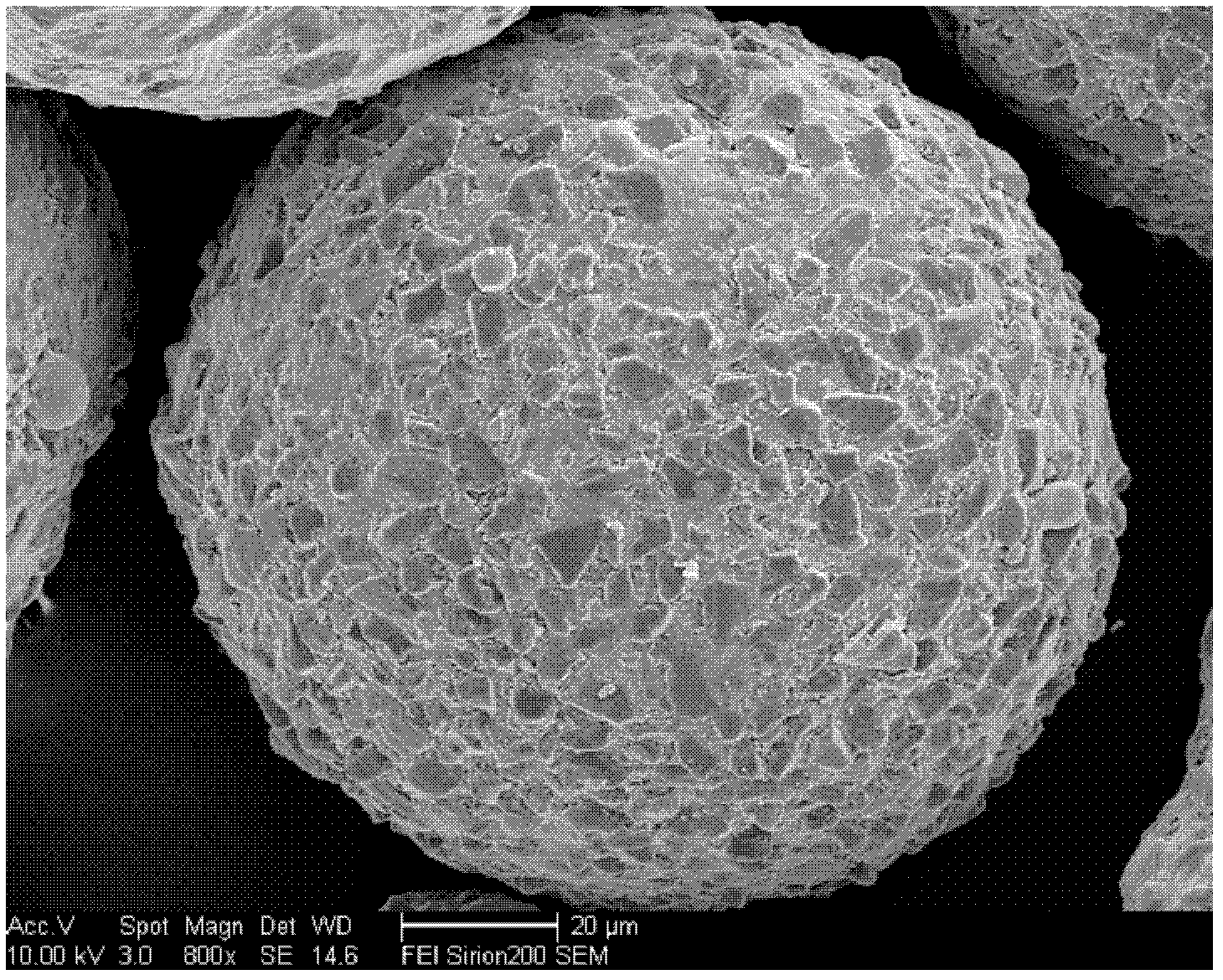

Structural and Morphological Control Method of Magnetic Abrasives Prepared by Gas Atomization Rapid Solidification

InactiveCN102277132AImprove bindingExtended service lifeOther chemical processesHard metalSpherical shaped

The invention relates to a method for controlling the structure and shape of magnetic abrasives prepared by a gas atomization quick-setting method. By controlling the melting temperature of the ferromagnetic metal at 50-280° C. above the melting point of the corresponding ferromagnetic metal and controlling the injection velocity of the powder-mixing airflow at 0.7-3.0 MPa, the obtained magnetic abrasive has a regular spherical structure. Its hard abrasive is evenly distributed on the superficial layer of the metal body and is firmly combined with the metal body for a longer service life. Hard abrasive particles are mainly distributed in the superficial layer of the ferromagnetic metal body, only a small amount is distributed in the center of the metal body, and almost not distributed in the middle layer between the superficial layer and the center. The cutting edge of the hard abrasive protrudes outside, and the outermost cutting edge is of equal height to the surface of the metal body; it has a strong ability to grind the workpiece to be processed, and can also significantly improve the processing quality of the surface of the workpiece to be processed; guide The high magnetic rate significantly enhances the grinding ability of the processed workpiece and improves the processing efficiency.

Owner:SHANDONG UNIV OF TECH

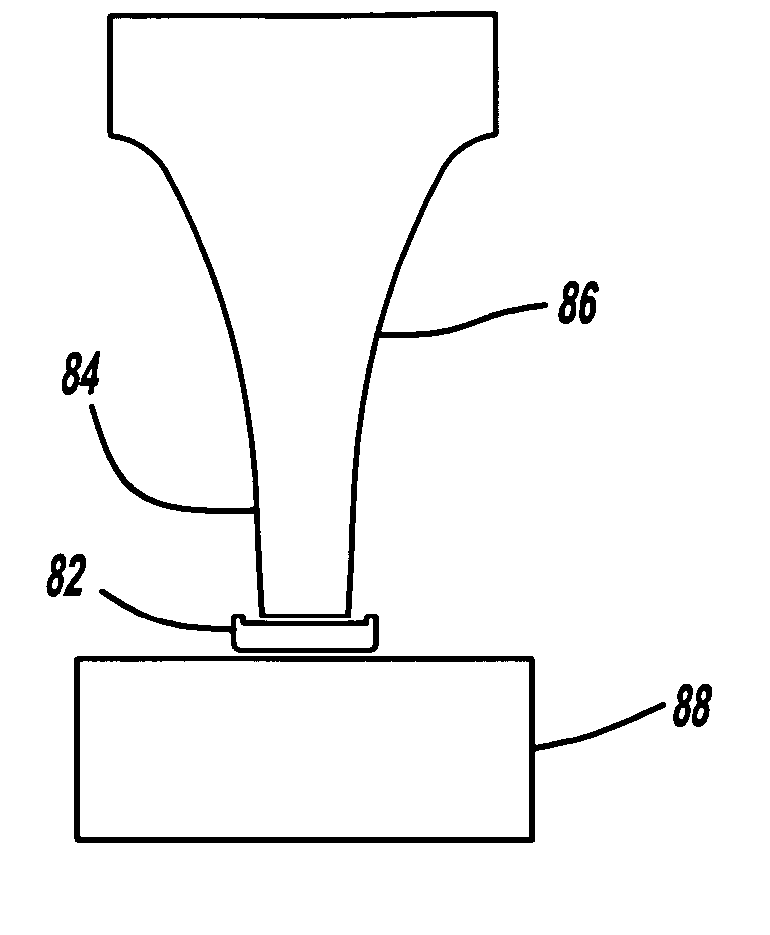

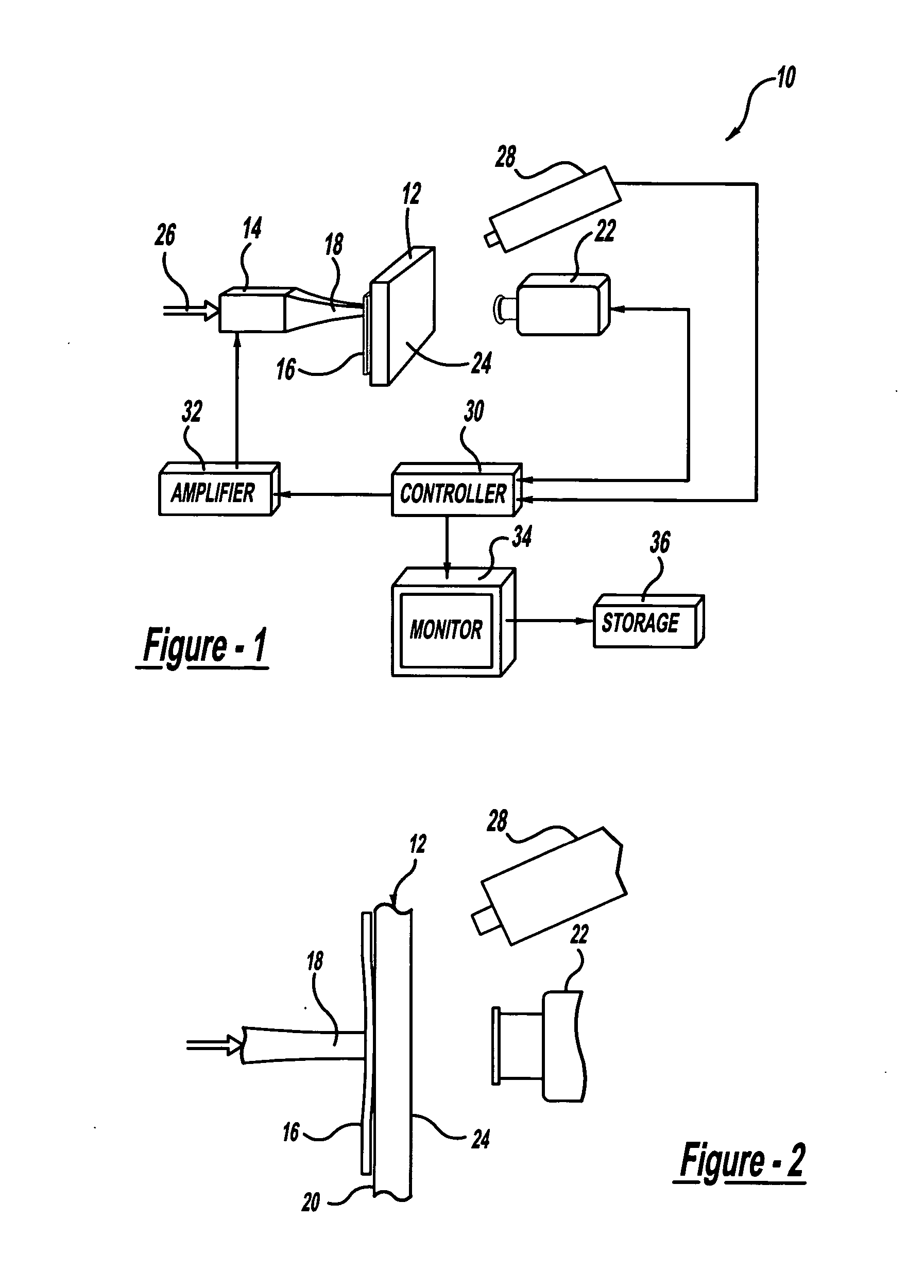

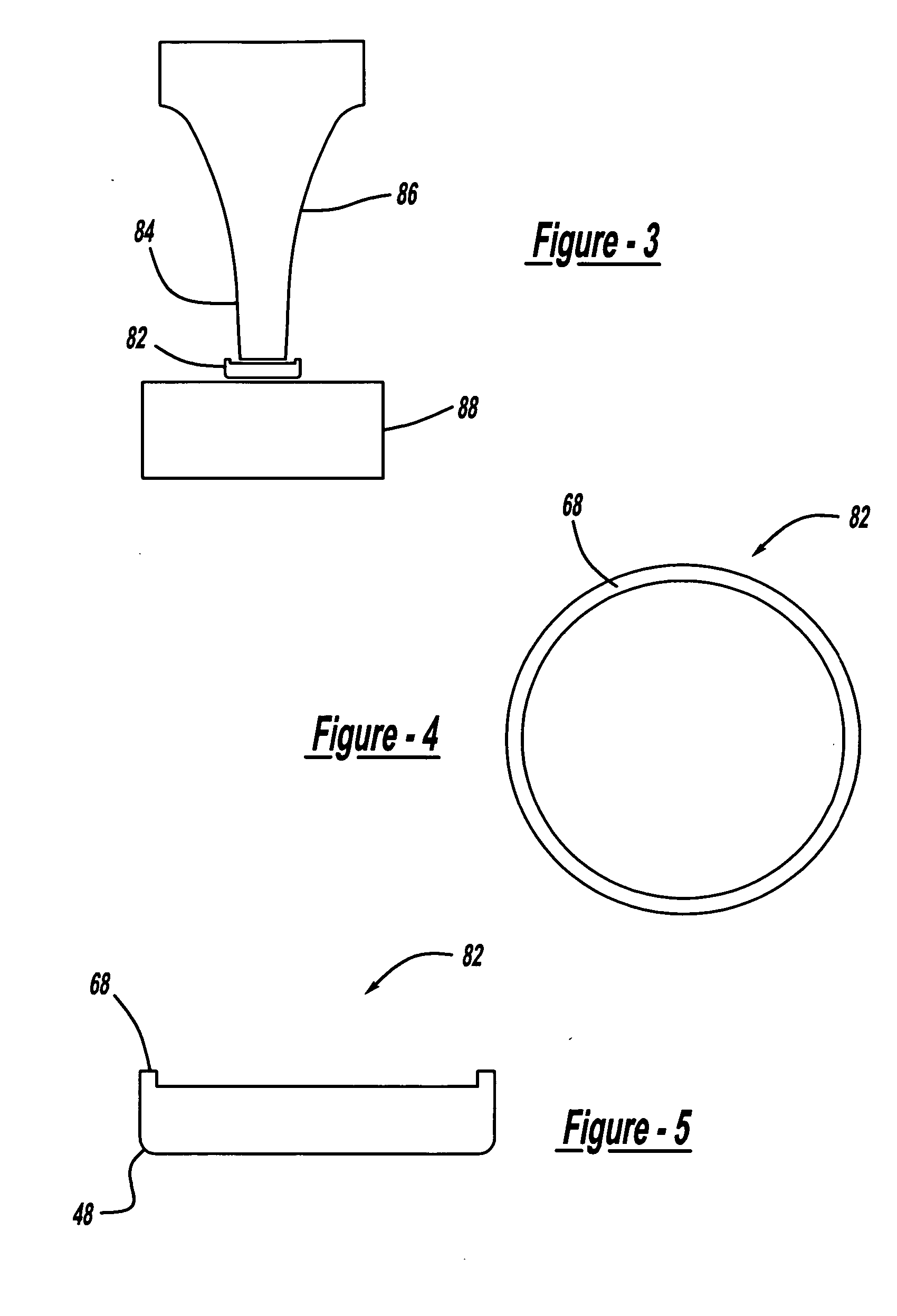

System and method for generating chaotic sound for sonic infrared imaging of defects in materials

ActiveUS20050151083A1Material analysis using sonic/ultrasonic/infrasonic wavesRadiation pyrometryThermal energyCamera image

A defect detection system for thermally imaging a structure that has been energized by sound energy. The system includes a transducer that couples a sound signal into the structure, where the sound signal causes defects in the structure to heat up. In one embodiment, a hard metal disk is positioned between the transducer and the structure to help couple the sound energy from the transducer into the structure. A predetermined force is applied to the transducer and a pulse duration and a pulse frequency of the sound signal are selected so that the sound energy induces acoustic chaos in the structure, thus generating increased thermal energy. A thermal imaging camera images the structure when it is heated by the sound signal.

Owner:WAYNE STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com