Patents

Literature

501 results about "Vanadium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium carbide is the inorganic compound with the formula VC. It is an extremely hard refractory ceramic material. With a hardness of 9-9.5 Mohs, it is possibly the hardest metal-carbide known. It is of interest because it is prevalent in vanadium metal and alloys.

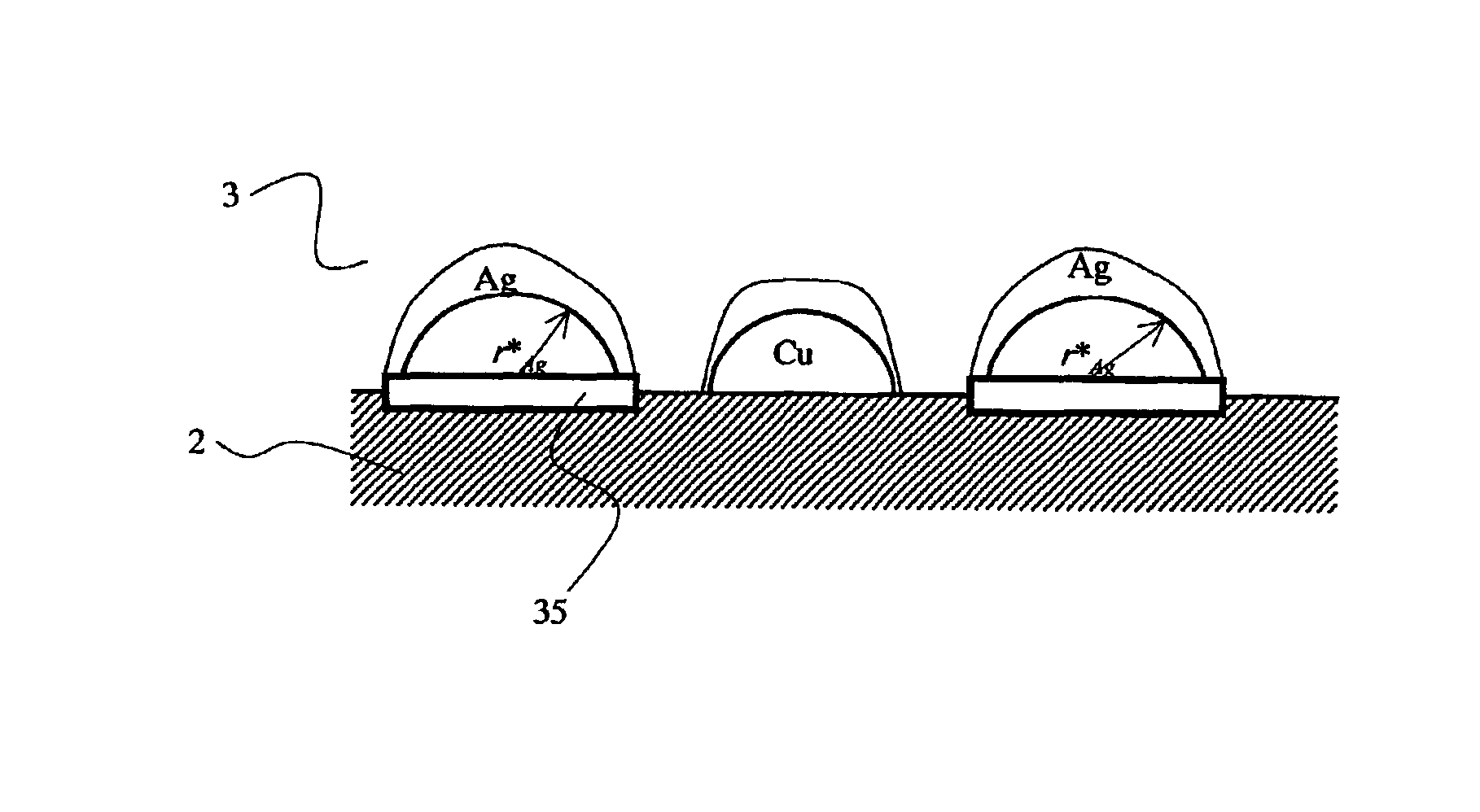

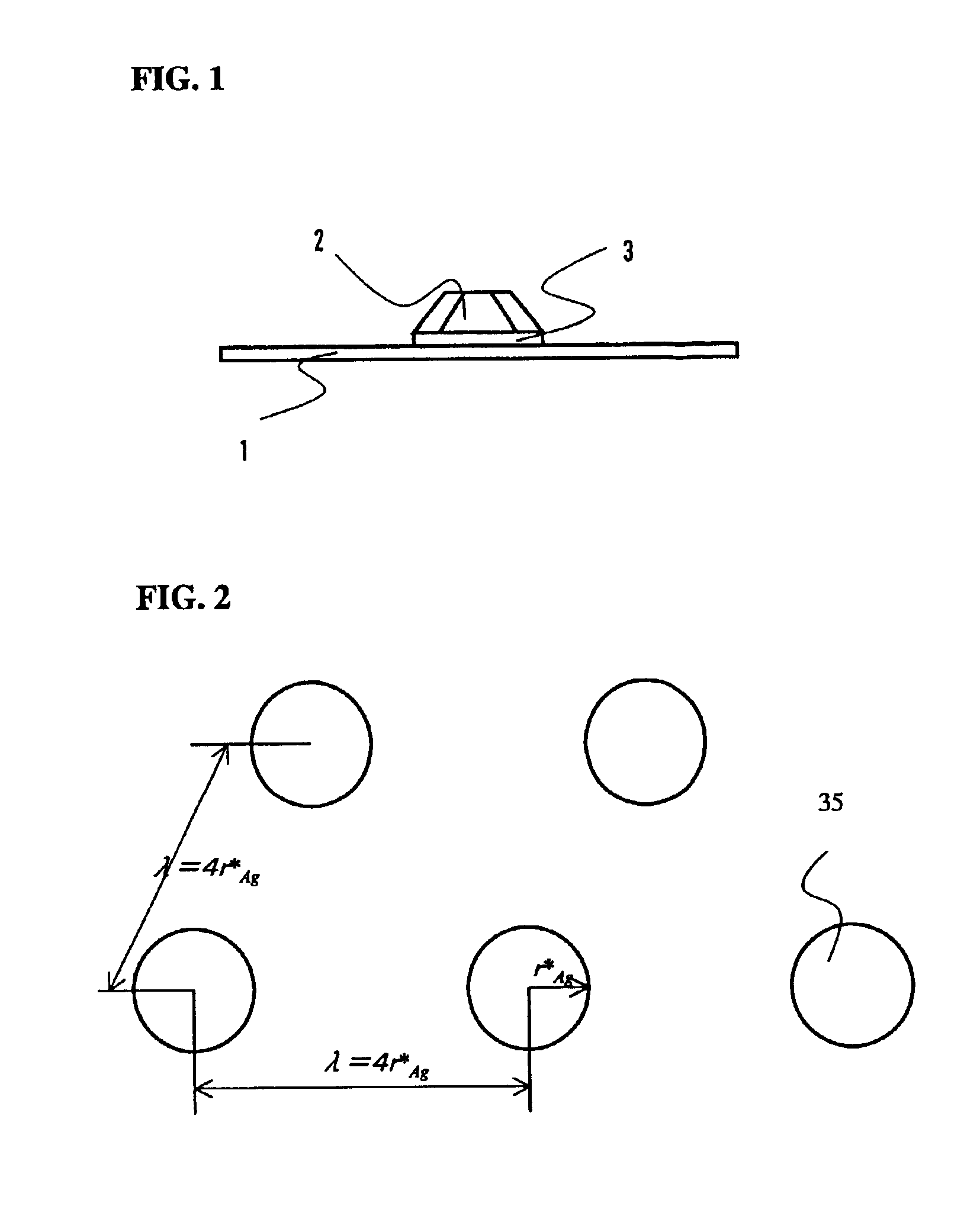

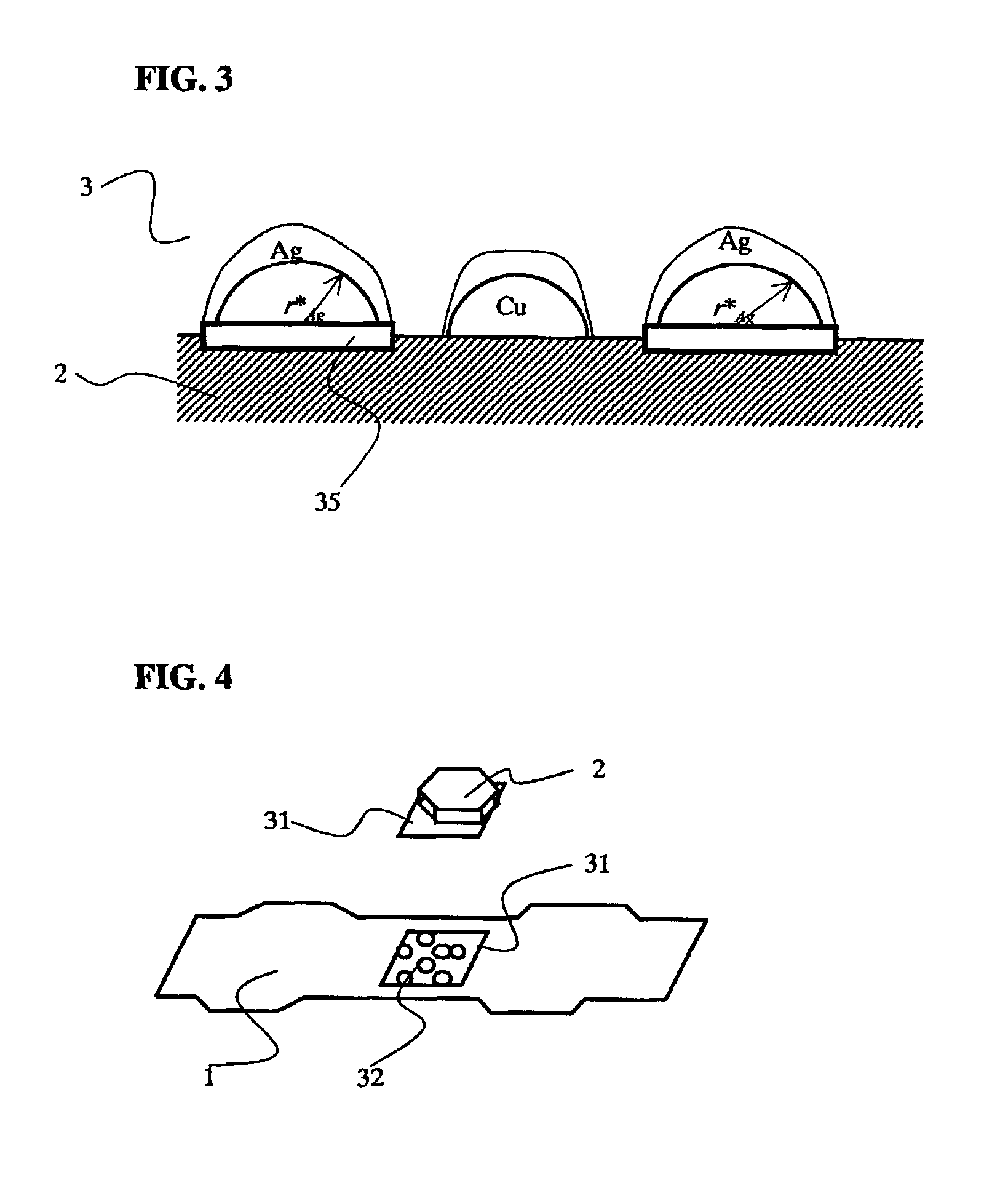

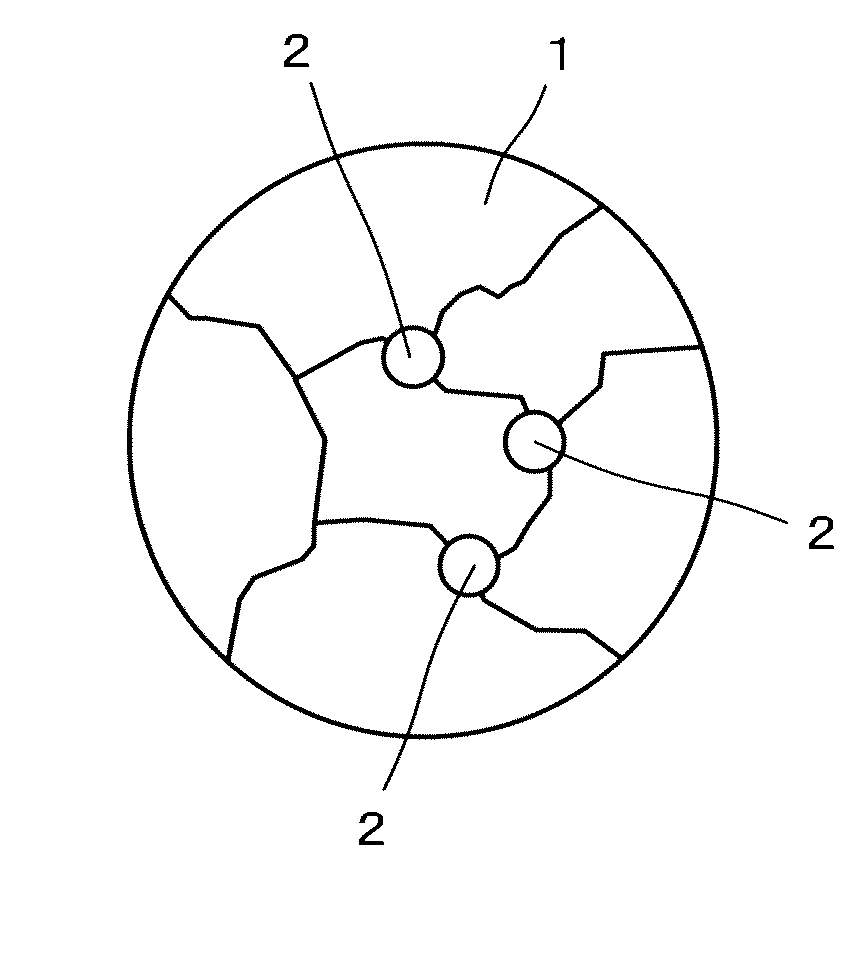

Brazing-filler material and method for brazing diamond

InactiveUS6889890B2Beautiful sceneryStable joint strengthLayered productsOther manufacturing equipments/toolsFilling materialsCopper

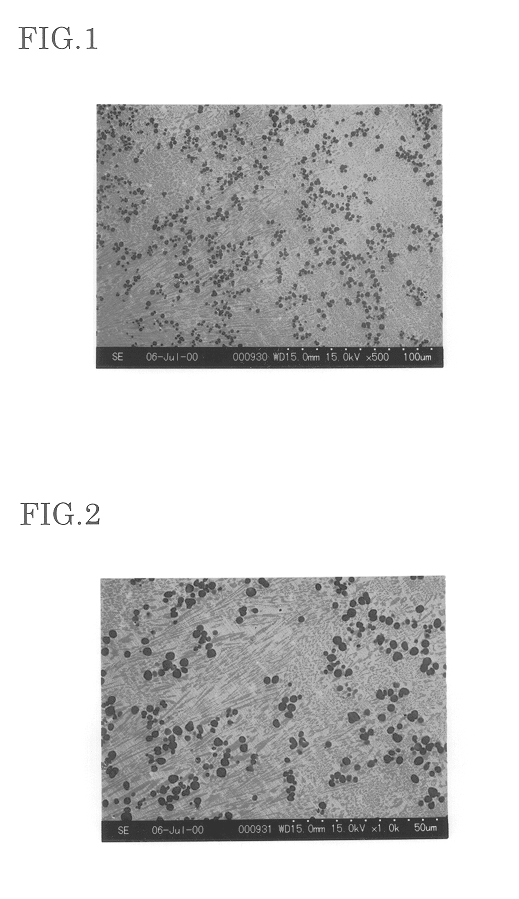

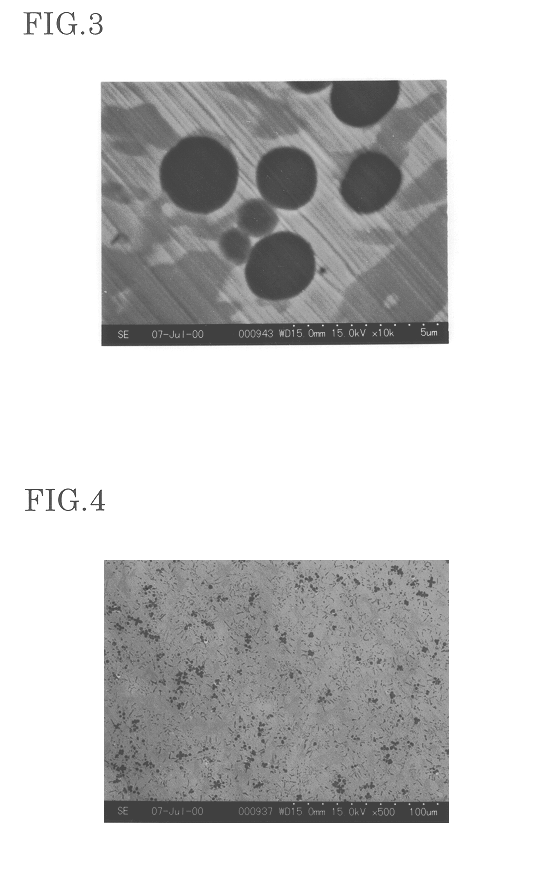

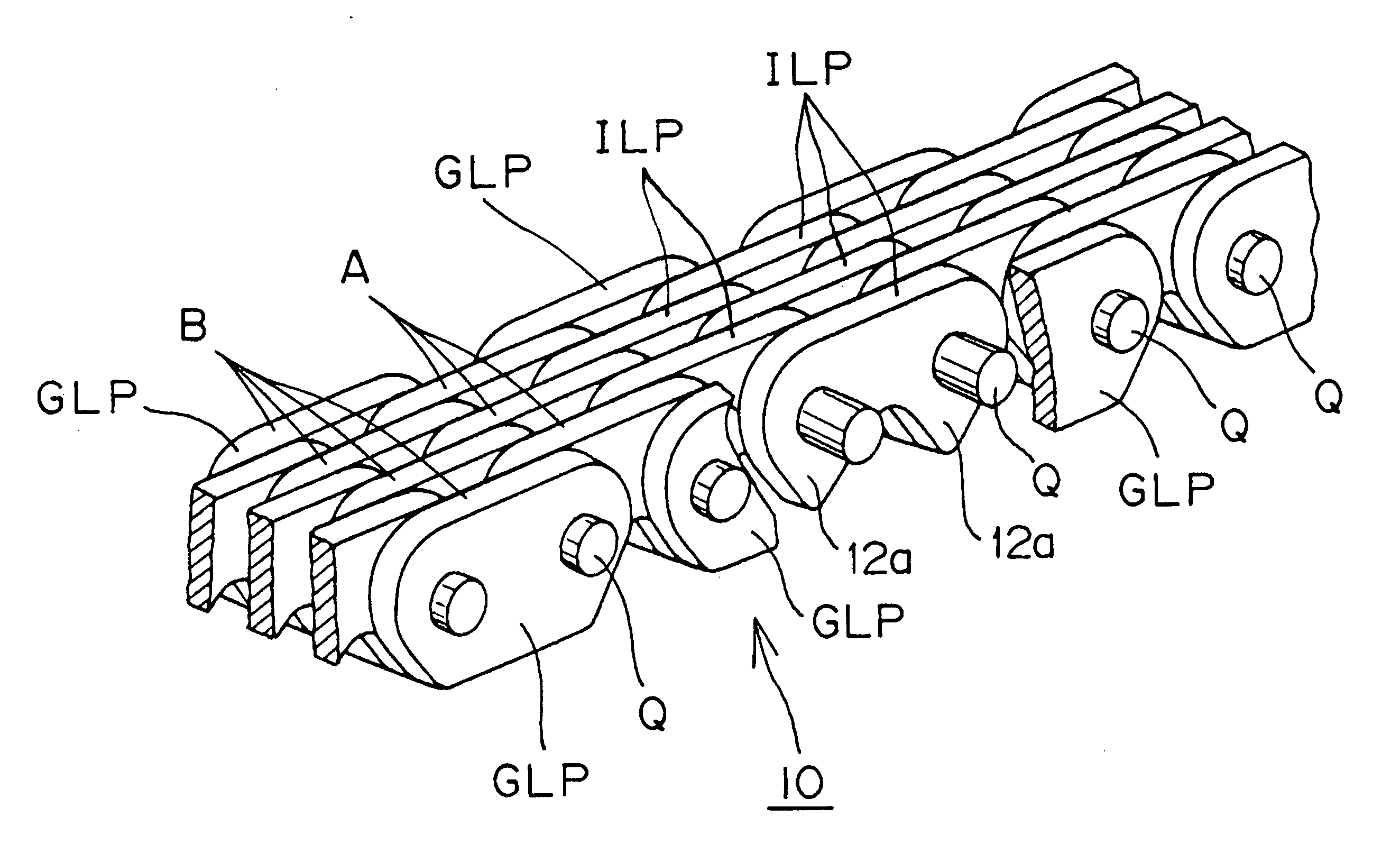

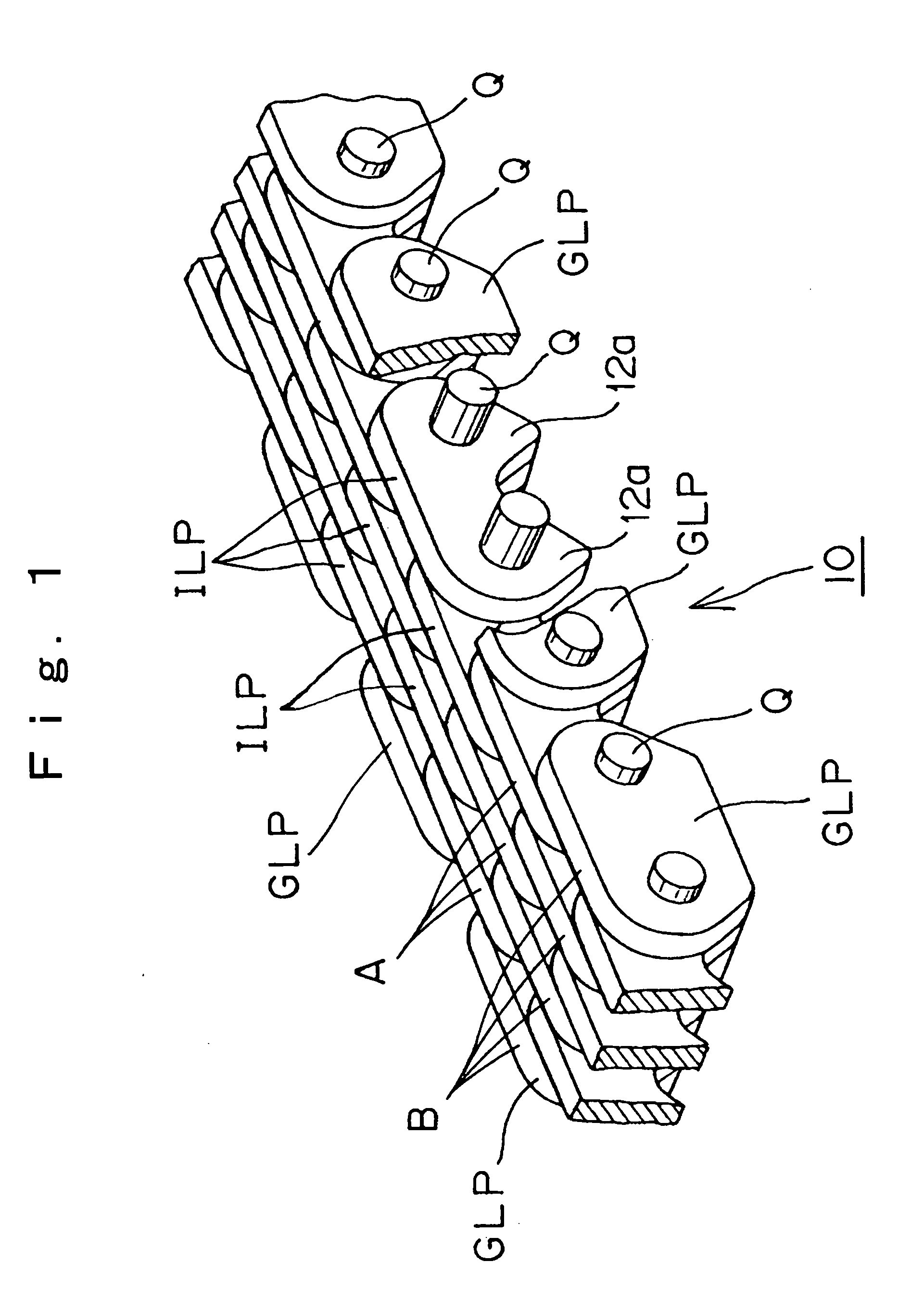

When a diamond is brazed to a metal substrate, while obtaining a stable joining strength, a joined interface of the diamond is not eroded to provide a good joint with a beautiful view. A brazing-filler material containing at least one selected from a group consisting of gold and silver, and copper as principal components, and further containing 0.001 to 5 mass % of vanadium is used. Preferably, a vanadium content is not more than 2.0 mass %, and more preferably not more than 0.5 mass %. Using this brazing-filler material, unidirectional solidification is performed from a side of diamond to form vanadium carbide in a joined interface in a shape of islands, and thereby an interface having a beautiful view with stable joining strength can be obtained. In addition, strong joining is possible also by a usual solidification method.

Owner:HOHOEMI BRAINS INC

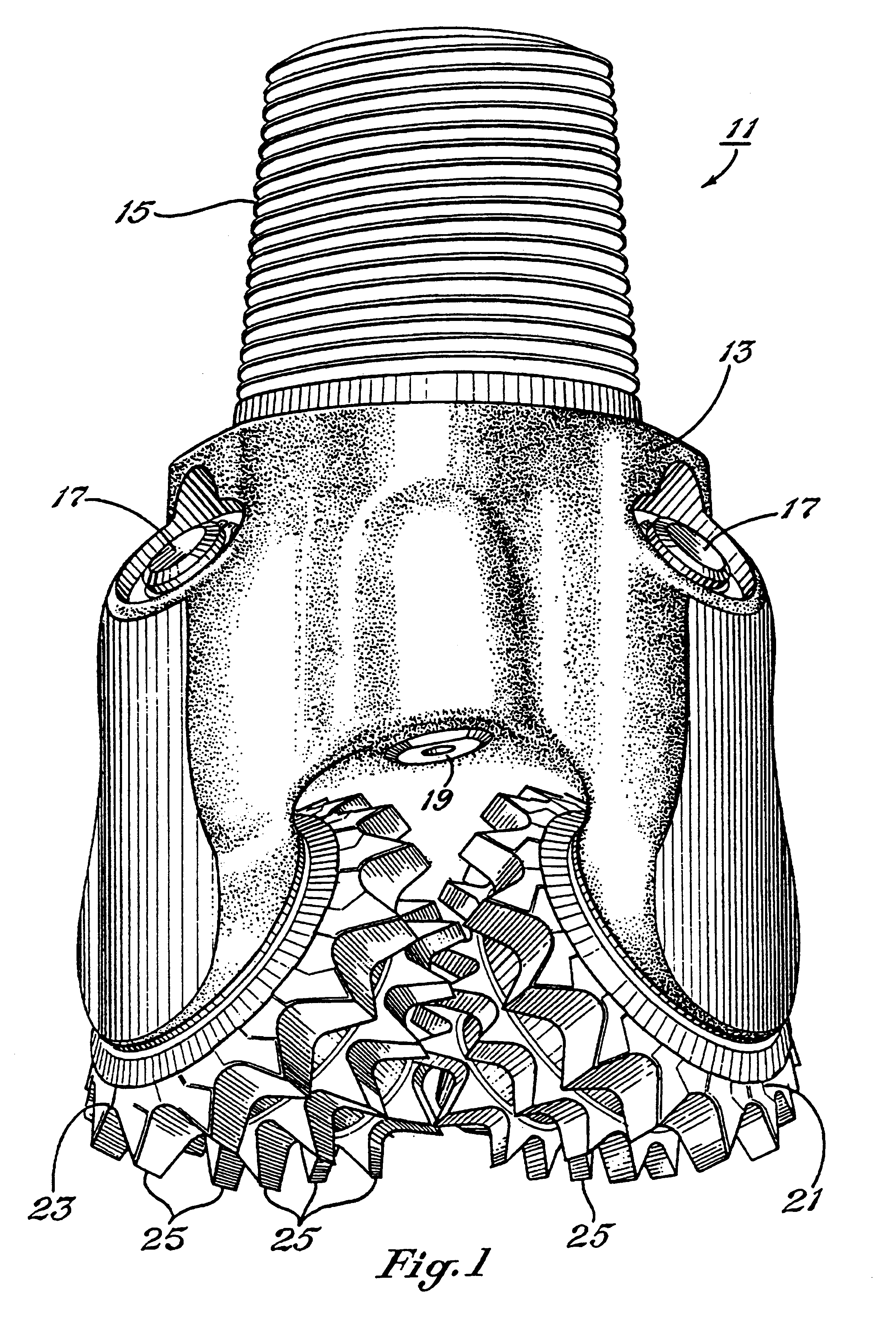

Hardfacing composition for earth-boring bits

InactiveUSRE37127E1Improve wear resistanceImprove fracture toughnessMolten spray coatingDrill bitsNiobiumVanadium carbide

A hardfacing composition comprises at least 60% by weight of hard metal granules including a quantity of sintered carbide pellets and a quantity of cast carbide pellets. The cast and sintered carbides are selected from the group of carbides consisting of chromium, molybdenum, niobium, tantalum, titanium, tungsten, and vanadium carbides and alloys and mixtures thereof. The balance of the hardfacing composition is matrix metal with traces of flux or deoxidizer, and alloying elements. All percentages given are pre-application ratios.

Owner:BAKER HUGHES INC

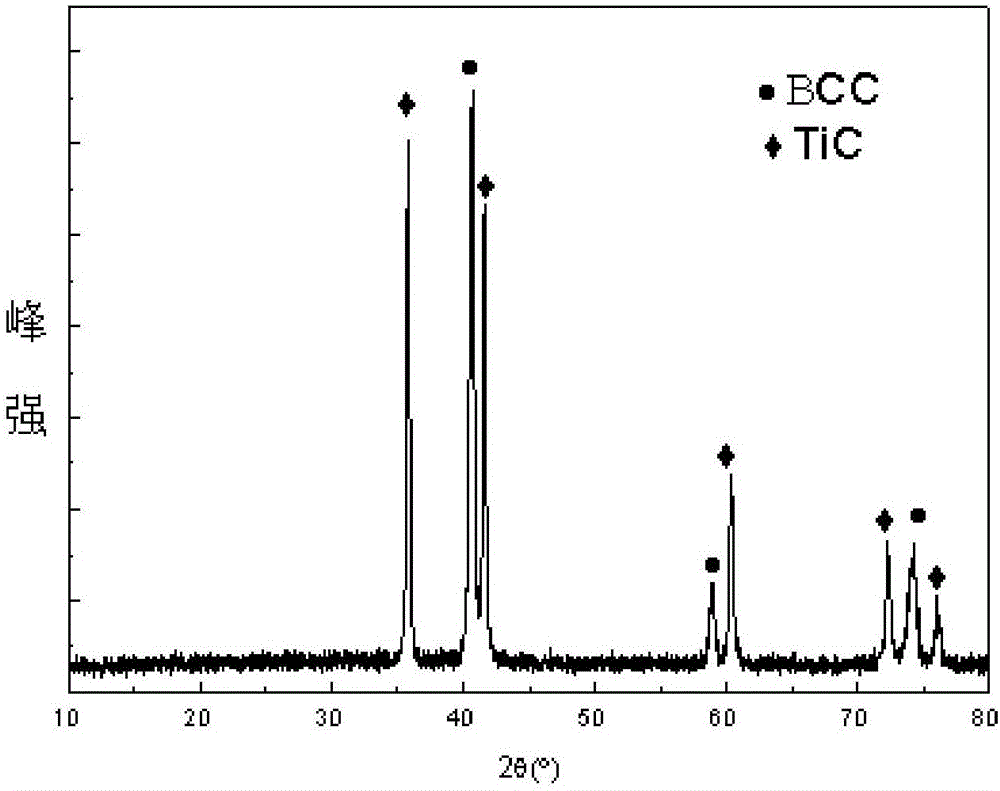

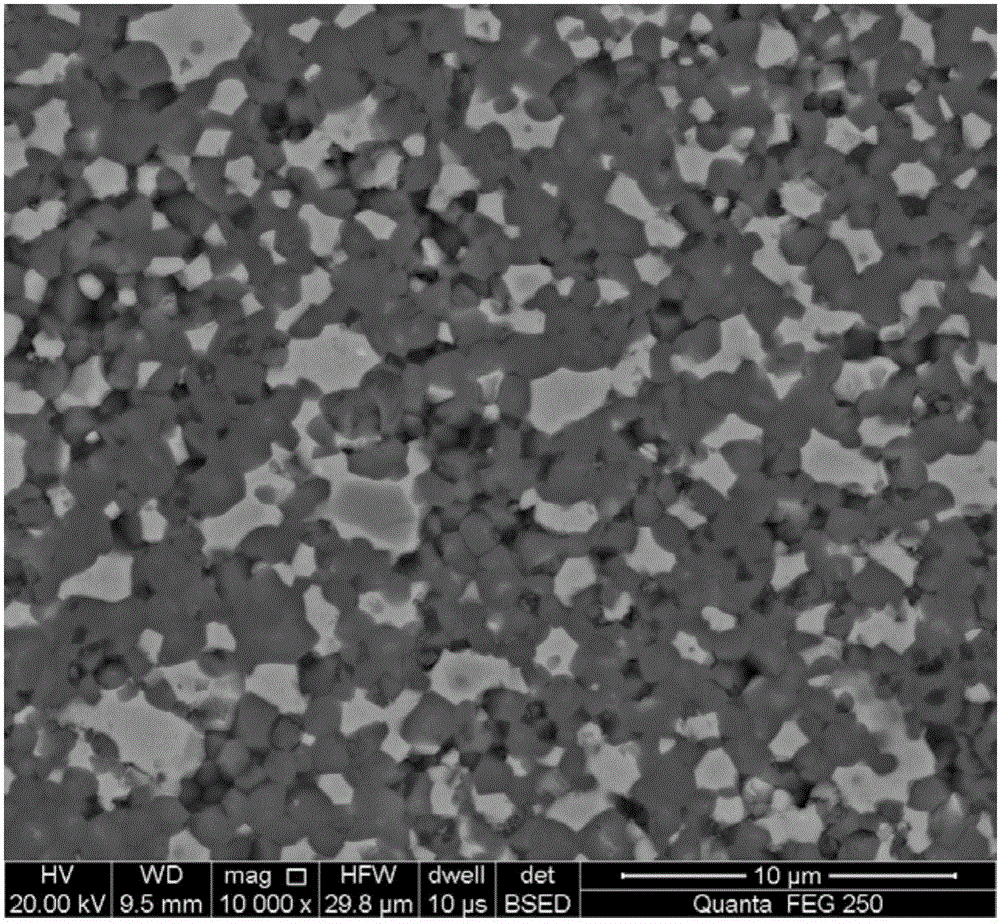

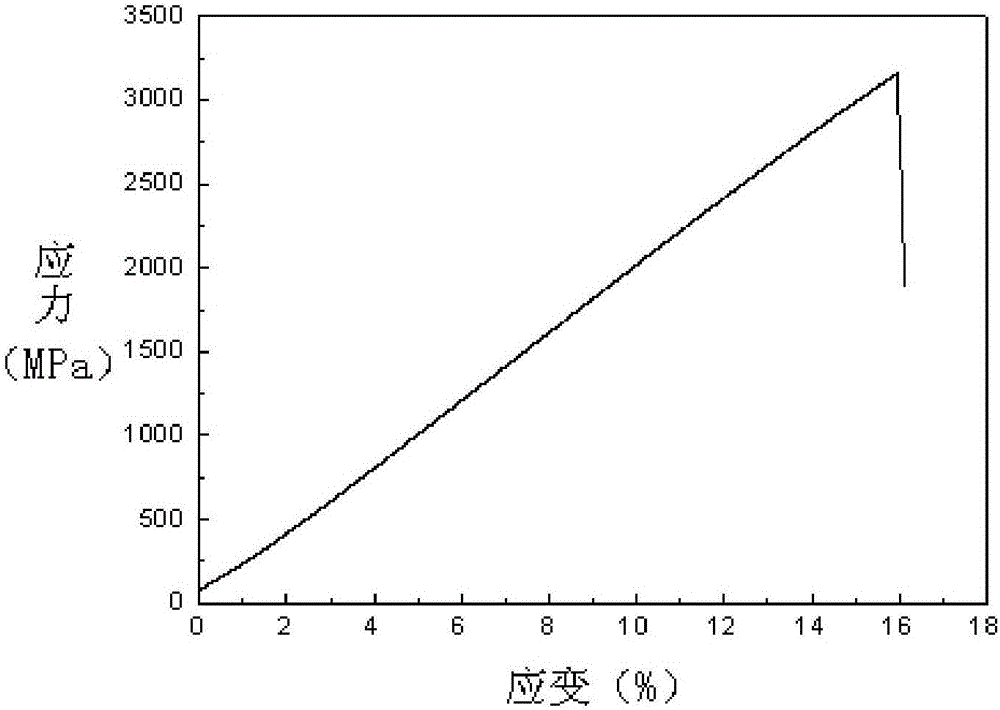

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

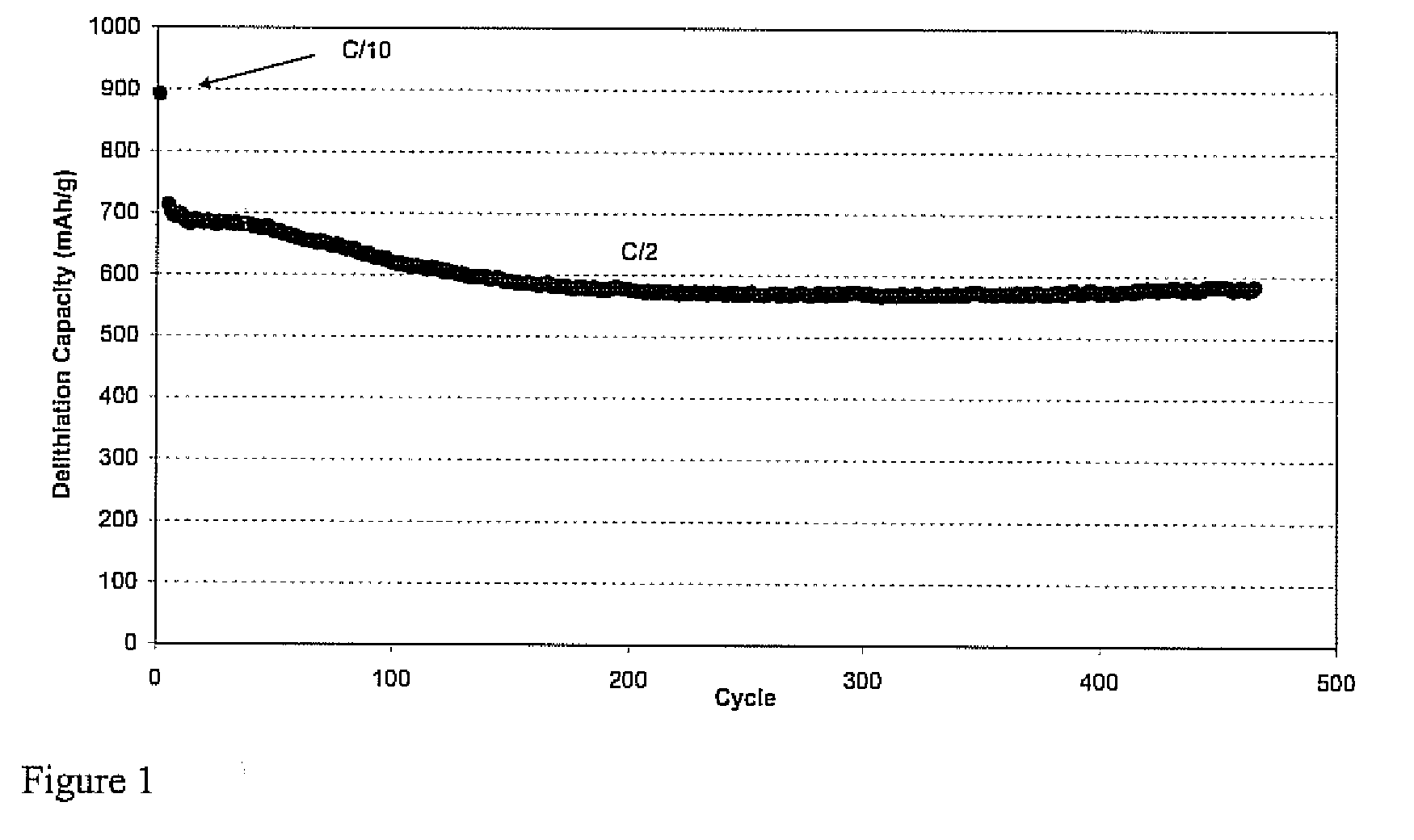

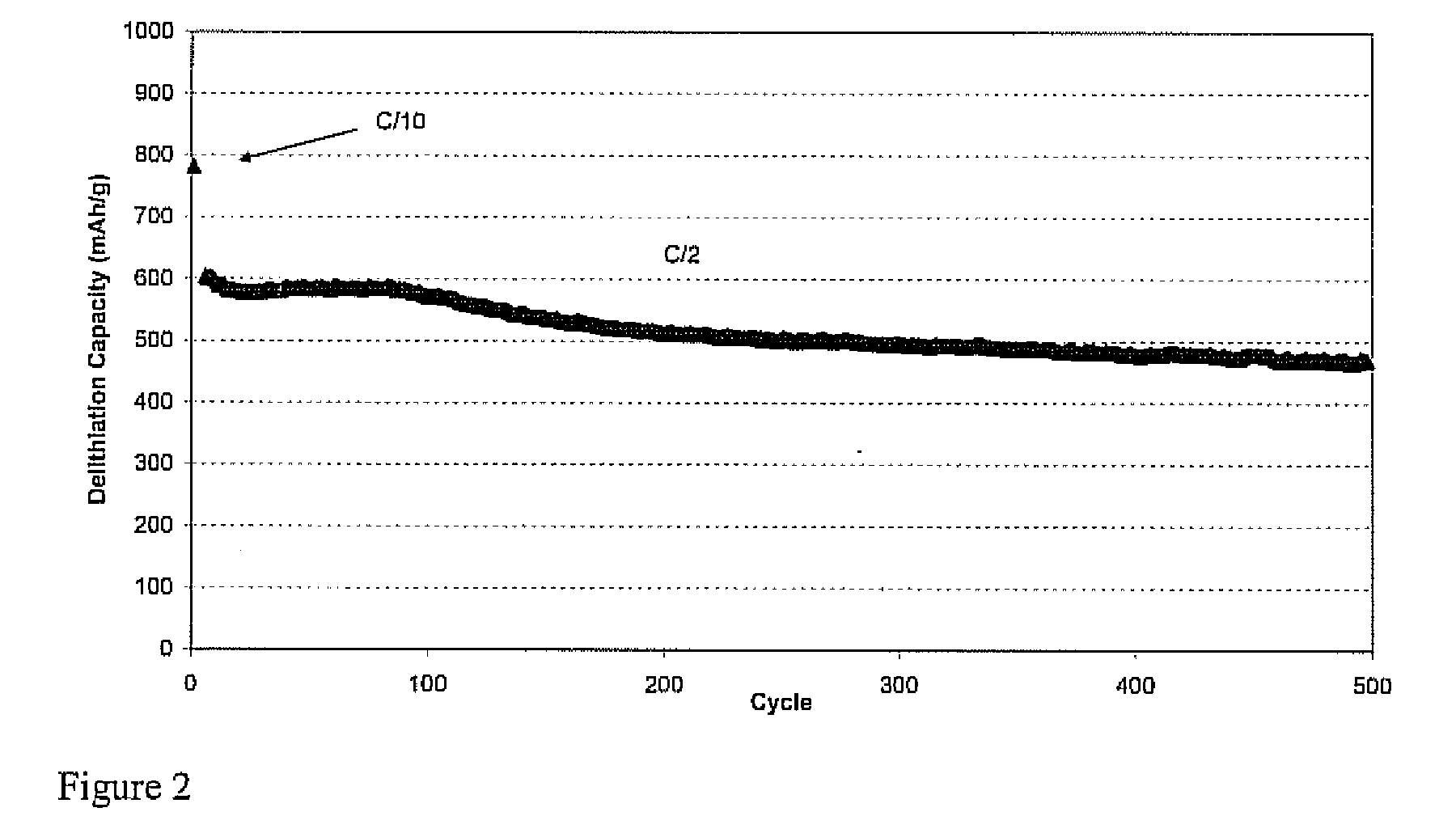

Silicon based composite material

A composite material having utility as an anode for lithium ion batteries comprises silicon, a transition metal, a ceramic and an electrically conductive diluent such as carbon. In particular instances, the ceramic is electrically conductive, and may comprise vanadium carbide or tungsten carbide. The transition metal may, in some instances, comprise iron. The material may be fabricated by grinding together a starting mixture of the components, and grinding may be accomplished in a high impact ball milling process, and the grinding step may cause partial alloying of the silicon with the metal and / or carbon. Further disclosed is a method for making the material as well as electrodes which incorporate the material.

Owner:A123 SYSTEMS LLC

Composite metal carbide wear-resistant coating and preparation process thereof

The invention relates to a composite metal carbide wear-resistant coating and a preparation process thereof, and belongs to a wear-resistant coating and a preparation process thereof. The composite metal carbide wear-resistant coating consists of adhesive coated tungsten carbide and other carbides, wherein the adhesive coated tungsten carbide has the grain size of WC-Co or WC-Ni; and the other carbides comprise chromium carbide, vanadium carbide, iron carbide, titanium carbide and the like. The preparation process comprises the following steps of: mixing the adhesive coated tungsten carbide and one or more kinds of the carbide powder; and performing spray coating (welding) or plasma spray coating (welding) on the surface of a medium-carbon steel part through supersonic flame to form the wear-resistant coating, wherein the carbon content of the medium-carbon steel is 0.35 to 0.55 weight percent (wt); the medium-carbon steel is subjected to the thermal refining state of quenching and high-temperature tempering; and the supersonic flame spray coating (welding) or plasma spray coating (welding) process sequentially comprises steps of performing sand blasting and rust removal on the surface of the medium-carbon steel, spraying a Ni-5 percent Al alloy adhesive coating and spraying a composite carbide wear-resistant coating. The composite carbide wear-resistant coating has Vickers hardness (HV) of 1,200 to 1,800, bonding force of more than 60 Mpa, and high mechanical property, wear resistance and corrosion resistance.

Owner:CHINA UNIV OF MINING & TECH +1

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

Enhanced metal ceramic abrasion-resistant composite material and preparation method thereof

The invention discloses an enhanced metal ceramic abrasion-resistant composite material and a preparation method thereof. The composite material is composed of, by mass, 25-35 parts of nano molybdenum carbide, 15-25 parts of nano ceramic powder, 10-15 parts of glass fiber, 5-10 parts of cobalt, 10-15 parts of chrome, 10-15 parts of titanium carbonitride, 1-3 parts of zirconium oxide, 3-5 parts of silicon oxide, 8-10 parts of cerium oxide, 1-3 parts of aluminium oxide, 5-10 parts of niobium carbide, 5-15 parts of silicon carbide, 1-3 parts of vanadium carbide, 4-9 parts of copper, 1-5 parts of titanium powder, 1-5 parts of coupling agents, 1-3 parts of antistatic agents and 1-3 parts of curing agents. The preparation method of the enhanced metal ceramic abrasion-resistant composite material just comprises mixing, drying, sintering and cooling. The metal ceramic composite material has good properties that the bending resistant strength is up to 2500 MPa and the Rockwell hardness is up to 93; in addition, the metal ceramic composite material also has good properties of abrasion resistance and high temperature resistance; the preparation method is simple and feasible and suitable for application and popularization on a large scale.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Ultra-fine hard alloy coated powder and method for preparing same

InactiveCN101186990AReduced tendency to aggregate and growWell mixedLiquid/solution decomposition chemical coatingCarbonizationTitanium carbide

The invention discloses a super-fine cemented carbide coating powder and process of preparation thereof. Super-fine hard-phase carbonization tungsten in the cemented carbide coating powder and other carbides such as titanium carbide, tantalum carbide, niobium carbide, vanadium carbide and / or chromium carbide are composed around by cobalt-phase ultra-fine powder particles. Karl Fischer's mean particle size of the super-fine cemented carbide coating powder is <=1 mu m. The super-fine tungsten carbide of the invention is put into the liquor of water-soluble metal cobalt-salt after being activated and dispersed with other hard-phase of carbide powder, the super-fine carbide powder and other hard-phase of carbide powder are taken as the core, chemical coprecipitation coating is employed in the reaction, and a uniform cobalt carbonate or cobalt hydroxide inhibitory coating is formed on the surface of the tungsten carbide powder and other hard-phase of carbide powder. The coprecipitation coating powder can be made into the super-fine cemented carbide coating powder by filtering, washing, and drying and low temperature reduction. The invention has the advantages of simple technique and low cost, which can take place the existing cemented carbide wet grinding mixture and the preparation method. High quality super-fine cemented carbide can be prepared by utilizing the powder of the invention.

Owner:CENT SOUTH UNIV +1

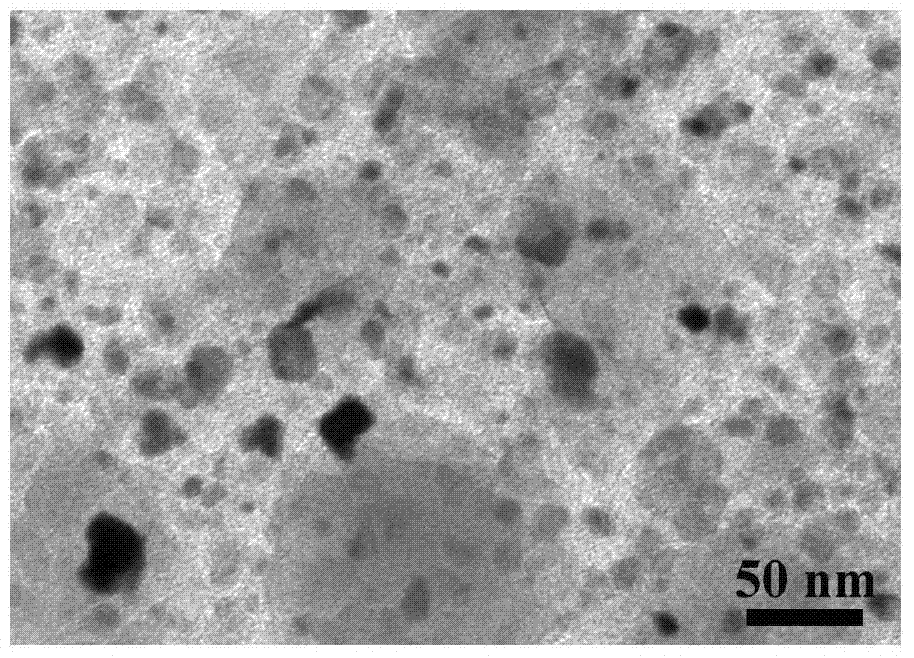

Nano-scale wolfram carbine composite powder and method of manufacturing the same

The invention provides a nanometer carbonized tungsten compound powder, which includes carbonized tungsten, vanadium carbide or / and chrome carbide, and a metallic element without binding phase exists in the compound powder. The preparation method of the nanometer carbonized tungsten compound powder is characterized in that the powdery ammonium tungstate, the carbonaceous reducing agent and the inhibitor are adopted as raw materials, the raw materials are dissolved in deionized water or distilled water and evenly stirred so as to obtain a solution, then the solution is heated and dried, the precursor powder is obtained finally, the precursor powder is put into a high-temperature reaction furnace, under the vacuum, argon or hydrogen atmosphere protection condition and the condition of 1,000 to 1,200 DEG C and 30 to 60 min, the carbonized tungsten compound powder with the average particle diameter less than 100 nm and even particle size distribution is obtained through carbonization. The method has the characteristics of low reaction temperature, short reaction time, low manufacturing cost, simple process and the like, which is suitable for the industrial production and used for the ultrafine hard alloy nanometer carbonized tungsten compound powder.

Owner:SICHUAN UNIV

Hard alloy

The invention discloses a hard alloy, which comprises a hard alloy matrix and further comprises a coating, wherein the hard alloy matrix is composed of metal carbide powder and a metal binder; the coating is coated on the hard alloy matrix; the metal carbide powder mainly comprises the following components in mass percentage: 40-50% of tungsten carbide, 5-10% of vanadium carbide, 3-8% of chromium carbide, 5-9% of titanium carbide, 6-11% of tantalum carbide, and 2-5% of niobium carbide, wherein the metal binder is cobalt the content of which is 12-18%. By means of the manner, the hard alloy disclosed by the invention has the characteristics of being low in cost, high in hardness, intensity, toughness and abrasive resistance, low in wear rate while cutting at high speed, and good in oxidation resistance, heat resistance and chemical stability and is applied to manufacturing cutter materials for high precision processing; in addition, the service life of cutters can be prolonged.

Owner:CHANGSHU LIONY METALS

Wood cutting tool material of Ti(CN) cermet and preparation method thereof

The invention provides a wood cutting tool material of Ti(CN) cermet and a preparation method thereof, relating to the technical field of wood cutting tool materials. The Ti(CN) cermet comprises 50 to 65% of Ti(CN) powder, 5 to 10% of cobalt powder, 5 to 10% of nickel powder, 8 to 15% of molybdenum powder, 10 to 20% of tungsten carbide powder, 4 to 8% of tantalum carbide powder and 0 to 1.0% of chromium carbide and vanadium carbide powder. The preparation method comprises the steps of preparation of materials, ball milling, spray drying, compacting, pressure sintering and obtainment of a finished product. Compared to other cutter materials, a cutter prepared in the invention has durability and a service life increased by 1 to 10 times, a cutting speed increased by 1.5 to 3 times and cost for cutting processing reduced by 20% to 40%, and has a wide application prospect in processing of wood composite materials by using cermet cutters.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

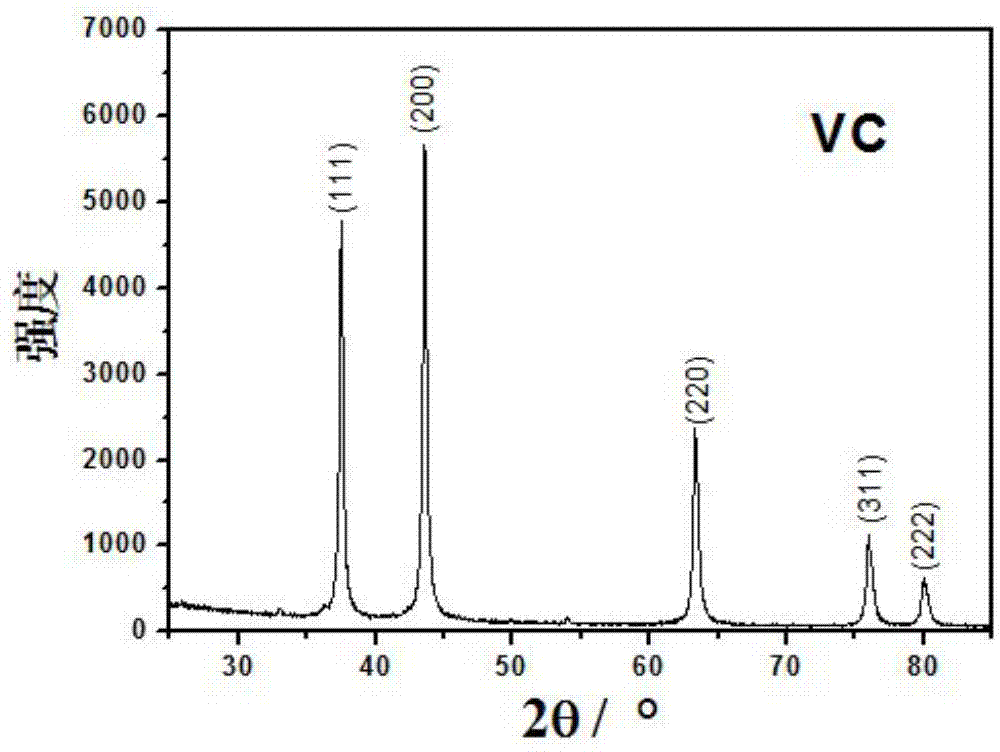

Process for preparing nano vanadium carbide powder

The invention discloses a preparing method of nanometer vanadium carbide powder, which is characterized by the following: dissolving raw material of powder-shaped ammonium vanadate, carbonaceous reducer and micro-dose rare earth as catalyst according to certain proportion in the deionized water or distilled water; stirring evenly; preparing solution; heating solution; drying; producing priority powder with vanadium source and carbon source; carbonizing priority powder in the high-temperature reactor protected by vacuum or gas for 30-60 min at 800-950 deg.c; obtaining vanadium carbide powder with even distributing grain (even grain is less than 100 nm).

Owner:SICHUAN UNIV

Vanadium-containing non-magnesium hard alloy and preparation method thereof

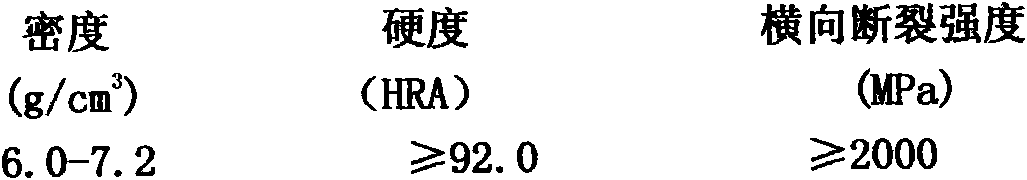

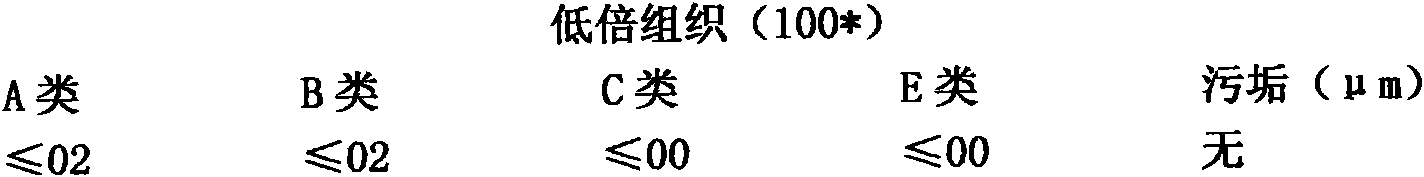

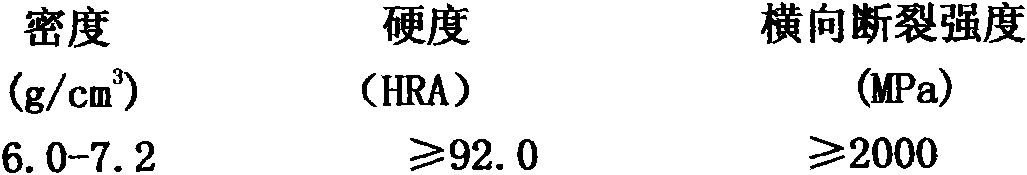

The invention relates to a nonmagnetic hard alloy material and a preparation method thereof. The alloy comprises (wt %) tungsten carbide 75-90, nickel powder 8-20, chromium carbide 0.5-3.0, and vanadium carbide 0.3-2.5. The preparation method comprises compounding, wet grinding, drying, pressing, sintering and checking, wherein in the wet grinding step, a nonmagnetic alloy lining board wet grinder is used, alcohol or acetone is added as grinding medium, nonmagnetic hard alloy balls is used as grinding material, the ratio of grinding medium to material is 5:1, the solid-to-liquid ratio is 350ml / Kg, and the wet grinding time is 48-56 hours; and pressure sintering is adopted. In the inventive nonmagnetic hard alloy material, fine-particle tungsten carbide powder (1.0-1.5 mum) is used as hard phase, so as to improve the hardness and abrasion resistance of the alloy. The nickel is used as binder, and a small amount of chromium carbide and vanadium carbide are added as tungsten carbide grain growth inhibitor, so as to refine tungsten carbide crystal grains, and further improve the hardness and abrasion resistance of the alloy. The pressure sintering technique accelerates densification speed during sintering process, effectively reduces porosity of the alloy, and remarkably improves the strength of the alloy.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

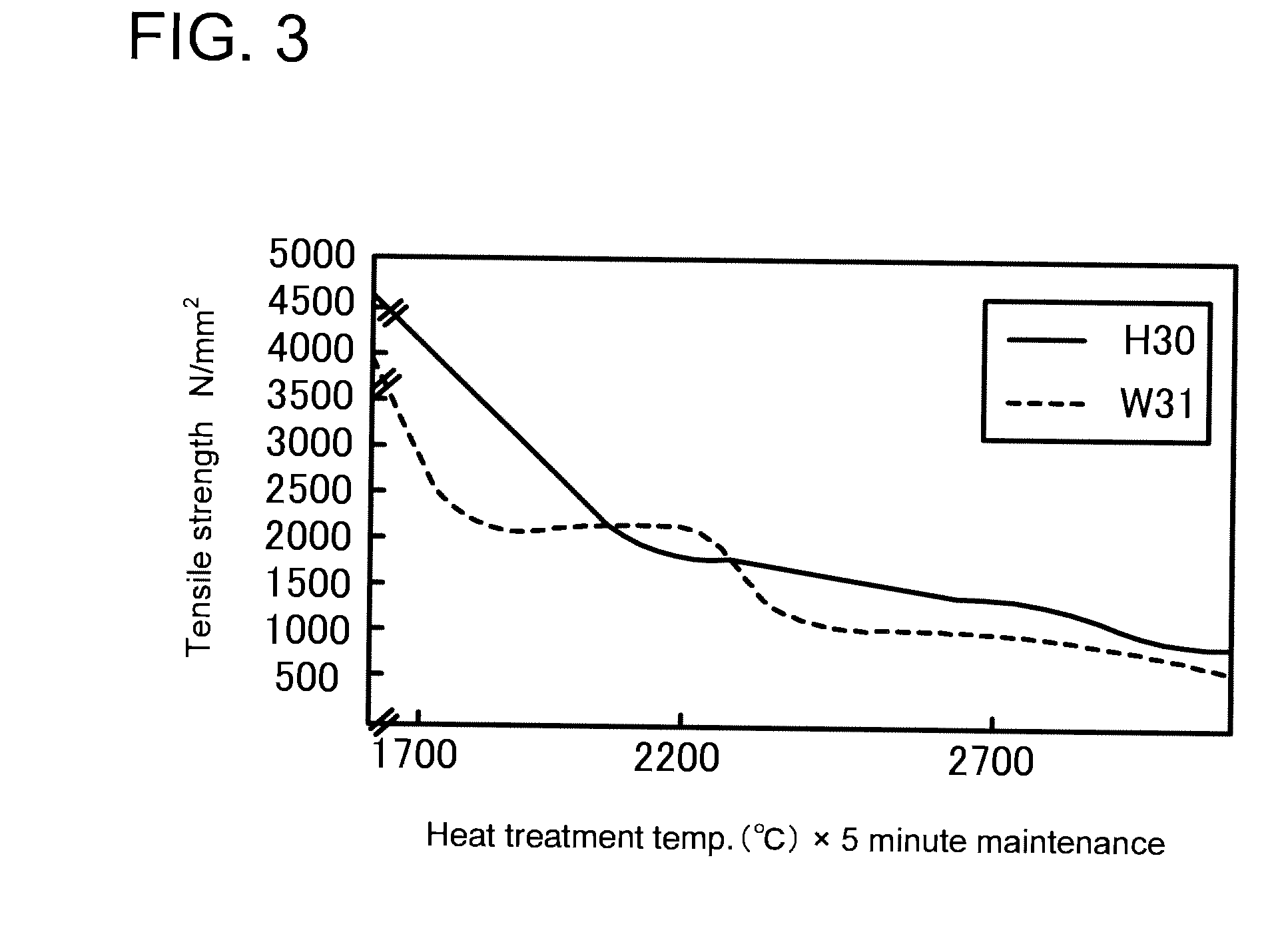

Preparation method for high-performance WC-Co nanocrystal cemented carbide

A disclosed preparation method for high-performance WC-Co nanocrystal cemented carbide comprises: taking nanometer tungsten carbide (WC) powder, ultrafine cobalt (Co) powder and ultrafine vanadium carbide (Cr2C3) powder as raw material powders, employing an alcohol wet grinding technology, and performing vacuum sintering and hot isostatic pressing sintering to prepare the WC-Co nanocrystal cemented carbide. By employing the above method for preparing nanocrystal cemented carbide, WC crystal grain structure is complete and clearly visible, by employing a method prescribed in ISO4499-2 for calculating two hundred or more WC crystal grains and averaging, the WC average crystal grain is less than 150 nm, the hardness HV30 is 1900 or more, the strength TRS is 4000 MPa or more and the metallographic structure is A02B00C00. The technology is simple, the process control is convenient, the production cost is low, and the prepared nanocrystal cemented carbide has the advantages of high densification degree and excellent performances.

Owner:XIAMEN TUNGSTEN

Cemented carbide blank suitable for electric discharge machining and cemented carbide body made by electric discharge machining

A cemented carbide blank suitable for fabrication by electric discharge machining that includes a carbide phase that includes tungsten carbide (and optionally vanadium carbide) present in an amount equal to between about 77.7 weight percent and about 93.6 weight percent of the cemented carbide blank. The cemented carbide blank further includes chromium present in an amount equal to between about 0.3 weight percent and about 1.5 weight percent of the cemented carbide blank, cobalt present in an amount equal to between about 8 weight percent and about 17 weight percent of the cemented carbide blank, nickel optionally present in an amount equal to 0 weight percent up to about 5 weight percent of the cemented carbide blank, and molybdenum present in an amount equal to between about 0.1 weight percent and about 1.0 weight percent of the cemented carbide blank. The cemented carbide blank having a magnetic saturation as measured according to ASTM B886-03 ranging between about 151×10−6 T m3 / kilogram cobalt and about 182×10−6 T m3 / kilogram cobalt.

Owner:KENNAMETAL INC

Ti(C,N) base metal ceramic and preparation method thereof

ActiveCN108950342AAdjust machinabilityMachinability satisfactionMilling cuttersWorkpiecesTitanium carbonitrideMolybdenum carbide

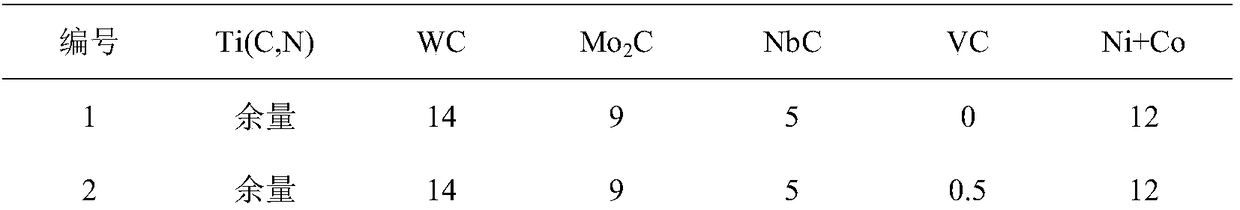

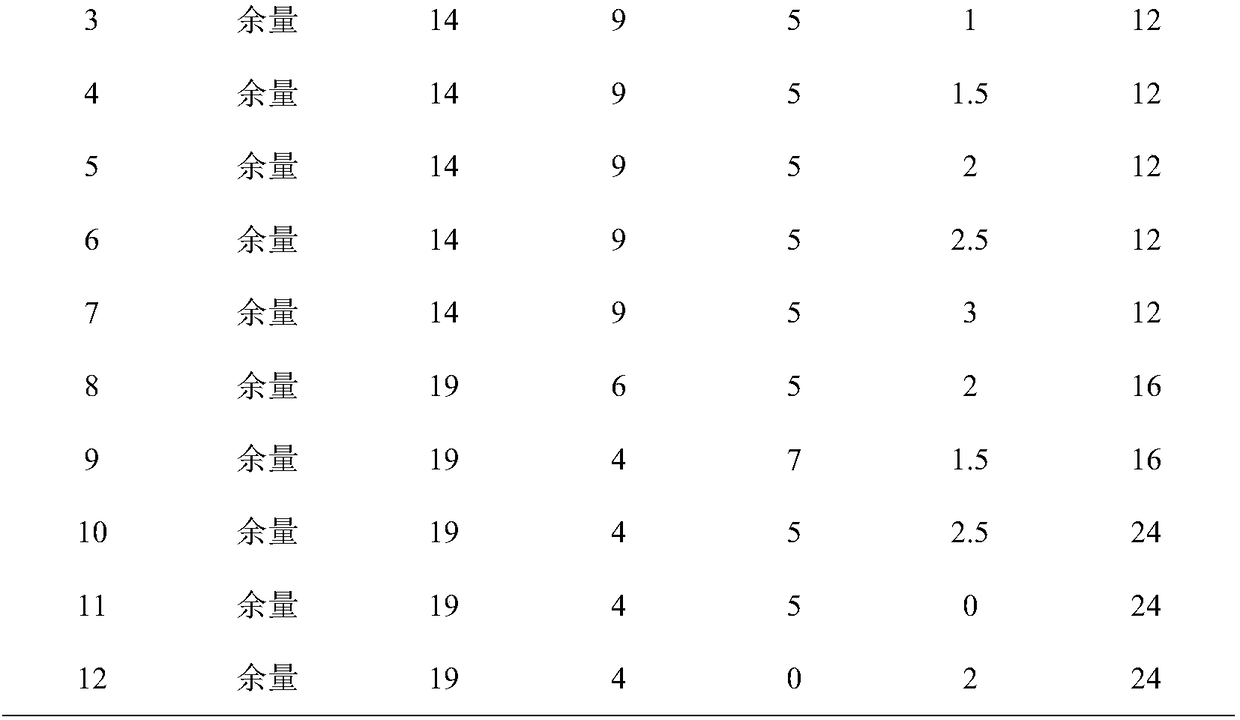

The invention discloses Ti(C,N) base metal ceramic and a preparation method thereof. Raw materials of the metal ceramic comprise titanium carbonitride Ti(0.5 of C and 0.5 of N), tungsten carbide WC, molybdenum carbide / molybdenum Mo2C / Mo, niobium carbide NbC, vanadium carbide VC, cobalt Co and nickel Ni powder, wherein the content of NbC ranges from 3 wt% to 15 wt%, the VC content is 0.3-3%, and the VC content changes along with the content of NbC. Hard phases formed by the materials are of two core-ring structures, one structure is a ring-shaped phase structure containing typical black core phases and inner ring phases, or outer ring phases and black core phases, and the other structure is a ring-shaped phase structure containing white core phases. The total credit of the black core phasesin the ring-shaped phase structure containing the black core phases and the inner ring phases, or the outer ring phases and the black core phases is 10-20%, the total credit of the inner ring phasesis 0.5-2%, and the total credit of the white core phases in the ring-shaped structure containing the white core phases is 5-10%. Chemical components of some or all white core phases are different fromthose of the inner ring phases, and the content of the Nb element in some or all white core phases is 30-40 wt% higher than the content of the Nb element in the inner ring phases. The Ti(C,N) base metal ceramic has thermal shock resistant performance and cutting performance.

Owner:CHINA THREE GORGES UNIV

Vanadium micro-alloyed 1300 Mpa-grade high-strength hot-rolled steel plate and production method of cold-rolled dual-phase steel plate

The invention discloses a vanadium micro-alloyed 1300 Mpa-grade high-strength hot-rolled steel plate and a production method of a cold-rolled dual-phase steel plate. The technical problem that the strength of the double-phase steel plate prepared by the existing method is insufficient is solved. According to the technical scheme, the 1300 Mpa-grade high-strength hot-rolled steel plate is formed through control cooling and through steel smelting and solidification, casting blank or hot continuous rolling after ingot casting cogging, after the hot continuous rolling is carried out at a certain temperature in a coiled mode, acid washing and room temperature cold rolling are carried out to 1-3 mm thick, then instant quenching is carried out at a certain temperature short-time heat preservationtime in a 720-780 DEG C two-phase region, and the vanadium micro-alloyed 1300 Mpa-grade high-strength dual-phase cold-rolled steel plate is prepared. According to the preparation process, nano-vanadium carbide particle precipitation strengthening and martensite phase change strengthening are combined, the strength of the existing dual-phase steel is remarkably improved, and meanwhile, the production efficiency is also guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

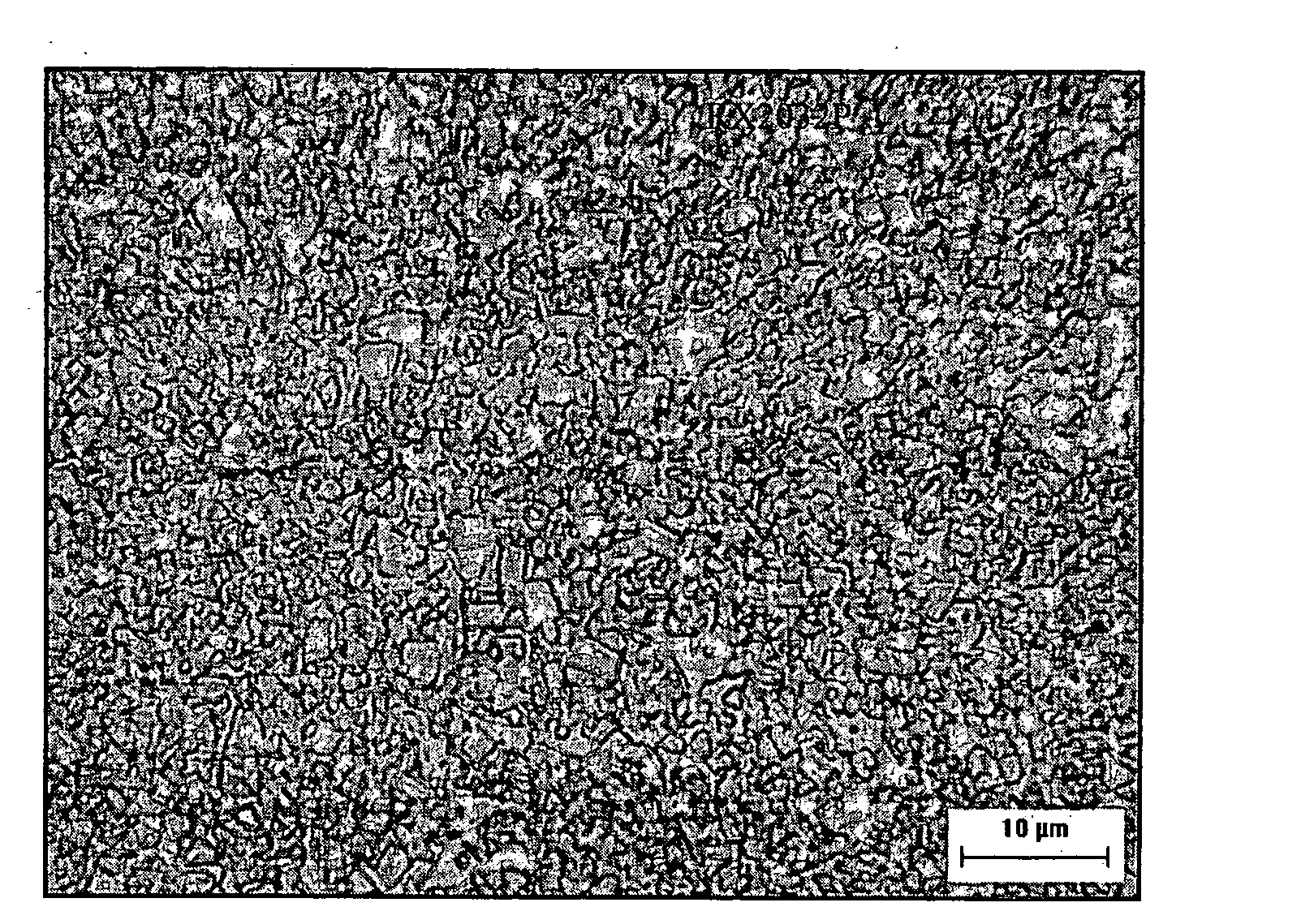

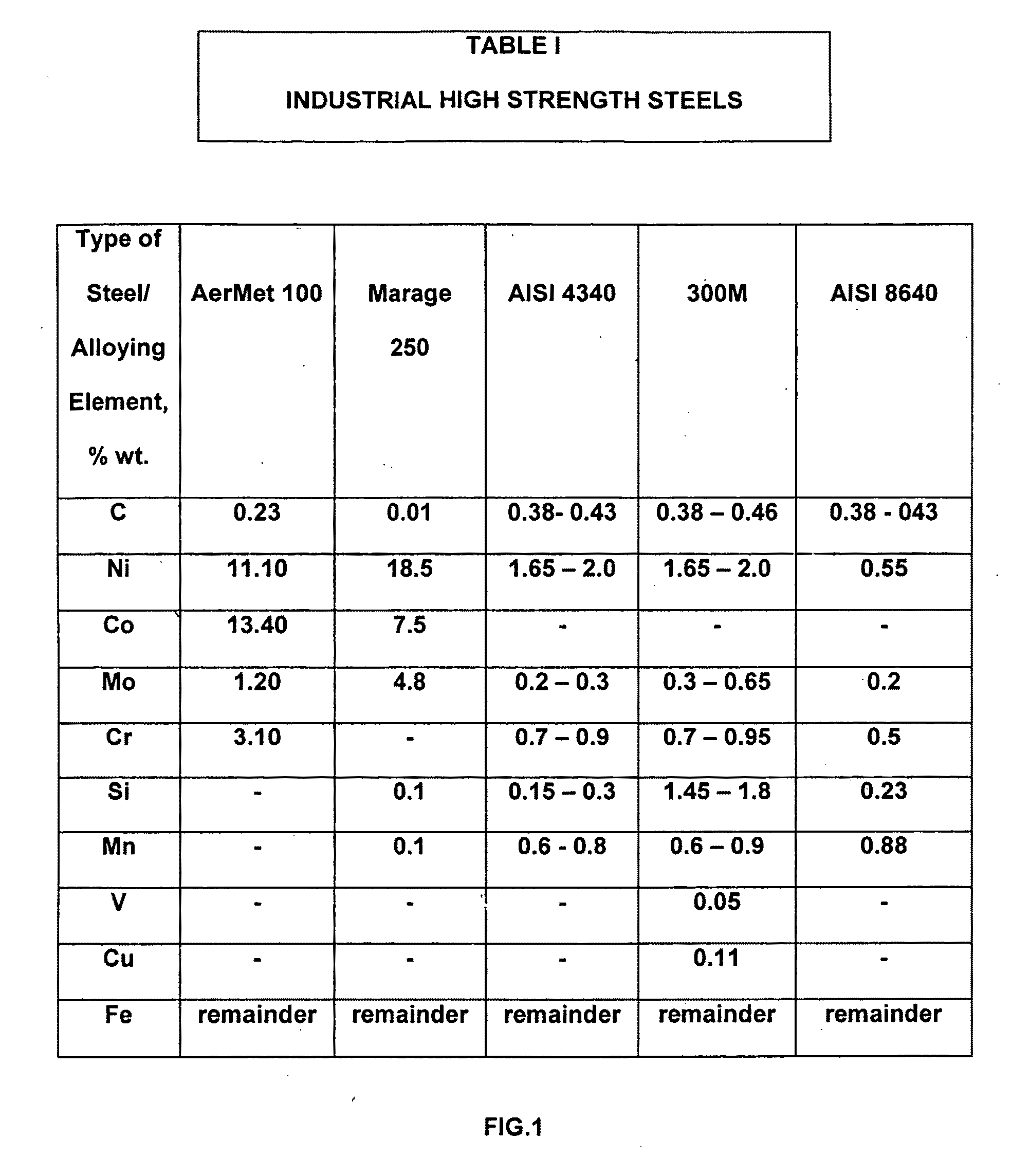

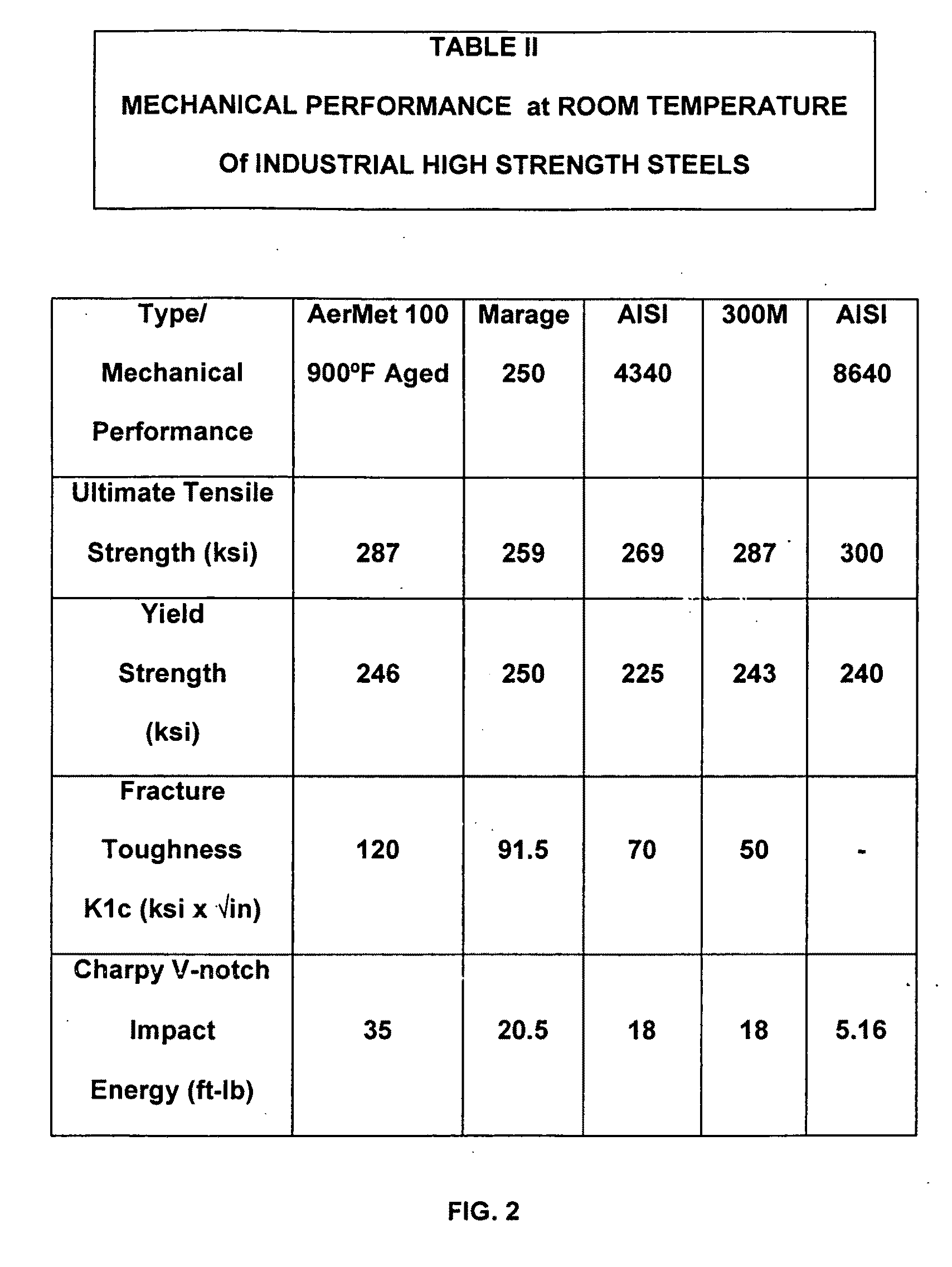

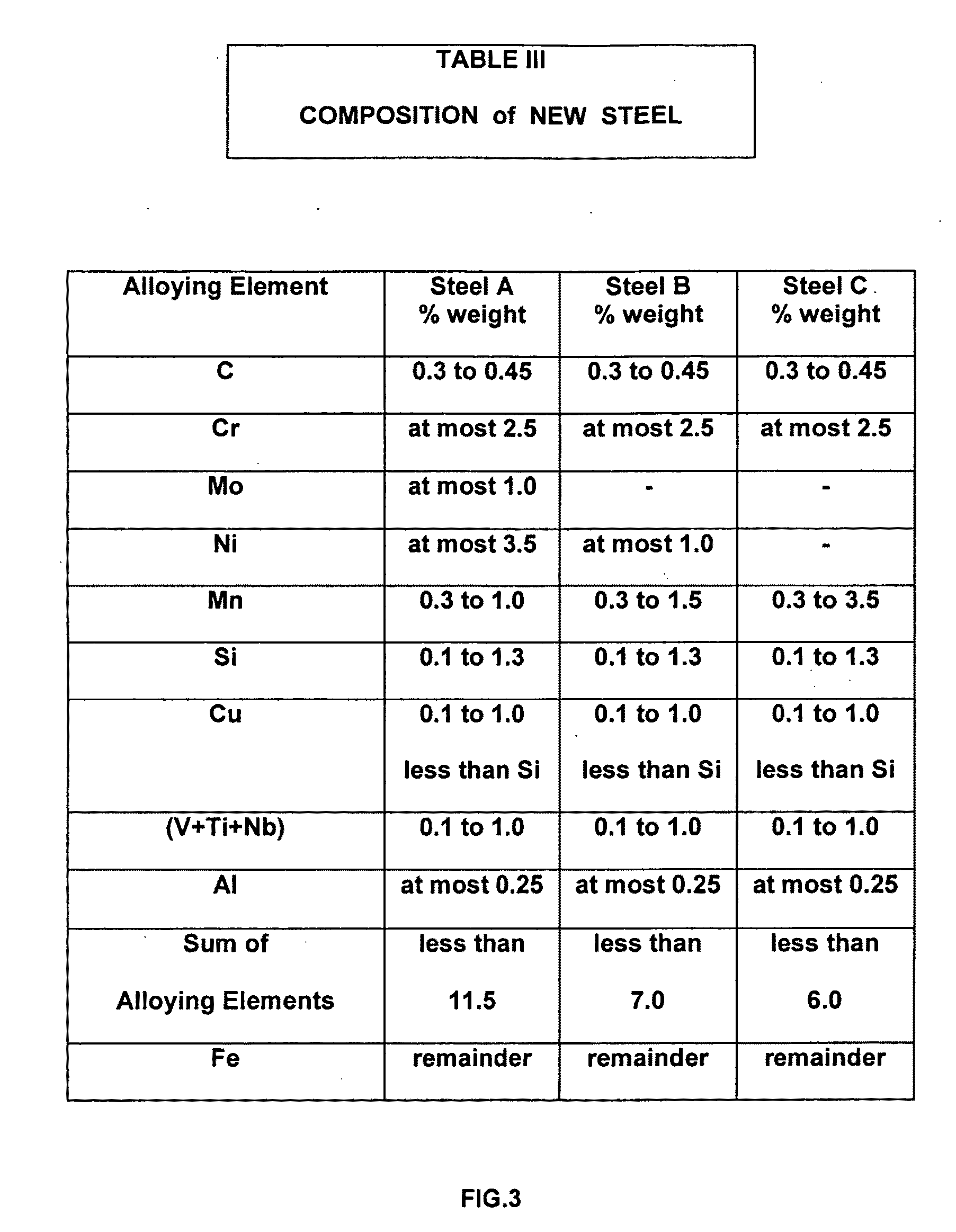

Method of designing a low cost, high strength, high toughness, martensitic steel and an article made thereof

InactiveUS20090291013A1Low costImprove toughnessHeat treatment process controlMathematical modelLaboratory scale

A method for designing a low cost, high strength, high toughness martensitic steel in which a mathematical model is used to establish an optimum low cost alloying concentration that provides specified levels of strength toughness. The model also predicts critical temperatures and the amount of retained austenite. Laboratory scale ingots of the optimum alloying composition were produced comprising by % wt. of about: 0.37 of C; 1.22 of Ni; 0.68 of Mn; 0.86 of Si; 0.51 of Cu; 1.77 of Cr; and 0.24 of V; and the balance Fe and incidental impurities were melted in an open induction furnace. After homogenized annealing, hot rolling, recrystallization annealing, and further oil quenching, refrigerating, and low tempering, a tempered martensite microstructure was produced consisting of small packets of martensitic laths, fine vanadium carbide, as centers of growth of the martensitic lathes, and retained austenite. Mechanical tests showed the following results: HRC of 52; UTS of 282 ksi; YS of 226 ksi; Charpy V-notch impact toughness energy of 31 ft-lbs. Energy consumption vacuum arc remelting (VAR) and electroslag remelting (ESR) were not required for improving strength and toughness.

Owner:FEDCHUN VLADIMIR A +1

Hard alloy, hard alloy cutter bar and manufacturing method thereof

The invention discloses a hard alloy, a hard alloy cutter bar and a manufacturing method thereof. The hard alloy comprises 80-90 parts by mass of tungsten carbide, 10-20 parts by mass of cobalt, 0.15-0.5 part by mass of tantalum carbide, 0.2-0.4 part by mass of chromium carbide and 0.1-0.3 part by mass of vanadium carbide. A cutter bar body (2) of a cutter bar made by the hard alloy is provided with a threaded hole (3) used for mounting a cutting tool (4). The manufacturing method of the cutter bar comprises the following steps of: adding the tungsten carbide, cobalt, chromium carbide, tantalum carbide and vanadium carbide into a ball mill according to the proportions of the ingredients, adding alcohol, mixing and grinding the ingredients, discharging, drying and sieving; adding a forming agent; pressing the ingredients to a blank; sintering the blank at a temperature of 1360-1450 DEG C to form the hard alloy cutter bar; conventionally polishing the surface of the hard alloy cutter bar; and electrosparking the tool bar and burning out the threaded hole.

Owner:CHANGSHA KENBEI TECH

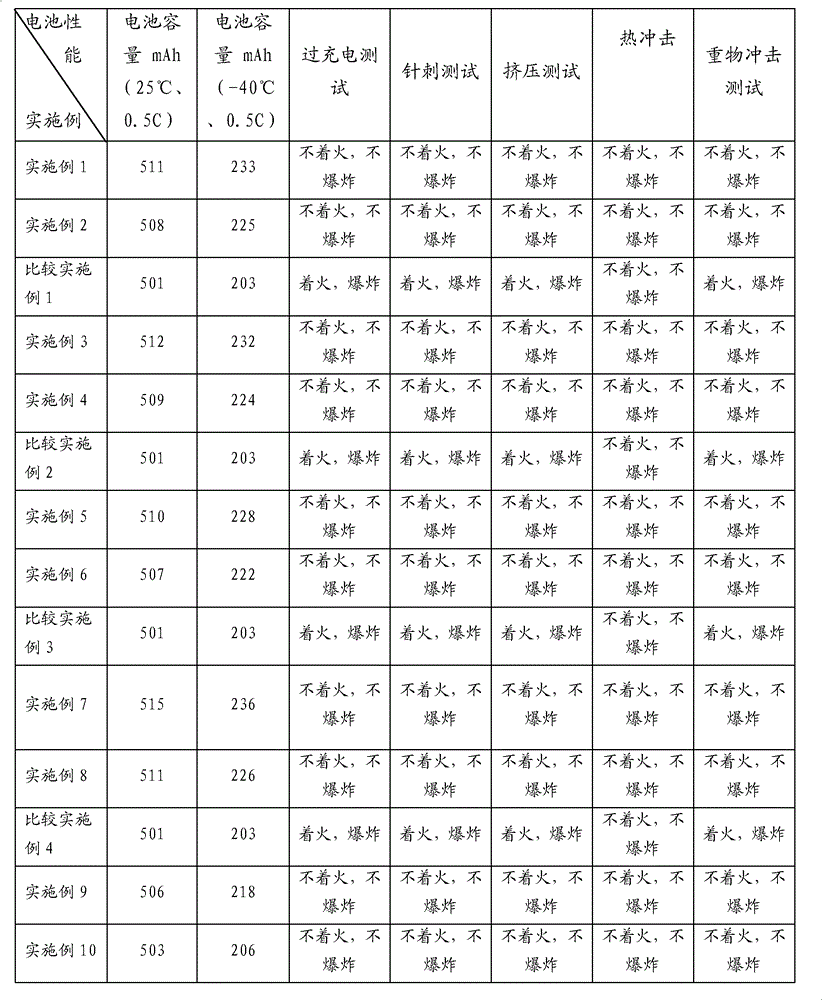

High capacity lithium ion battery containing metal conductive substances

ActiveCN102751530AImprove corrosion resistanceImprove antioxidant capacityCell electrodesSecondary cellsTitanium nitrideUranium carbide

The present invention discloses a high capacity lithium ion battery containing metal conductive substances. The battery comprises a positive electrode sheet, a negative electrode sheet, separation membranes, an electrolyte, a binder and a sealing material. A conductive substance of the positive electrode sheet comprises a metal carbide, a metal boride or a metal nitride. A conductive substance of the negative electrode sheet comprises a metal carbide, a metal boride or a metal nitride. The metal carbide is titanium carbonitride, tungsten carbide or titanium carbide, vanadium carbide, tantalum carbide, or a co-melting body of tungsten carbide and titanium carbide. The metal boride is a molybdenum boride, tungsten boride or vanadium boride. The metal nitride is titanium nitride, tungsten nitride or tantalum nitride. The conductive material of the positive electrode sheet further can contain powder metal, and the conductive material of the negative electrode sheet further can contain powdered metal, wherein the powdered metal is nickel powder, copper powder or chromium powder.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

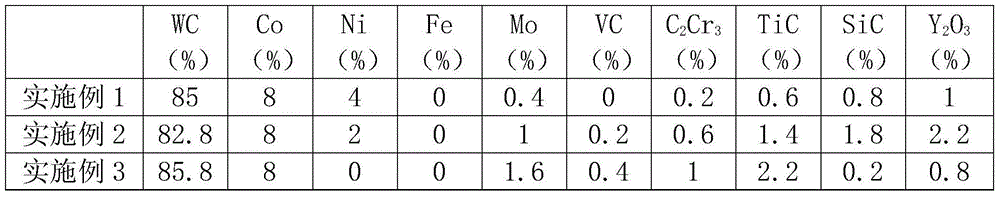

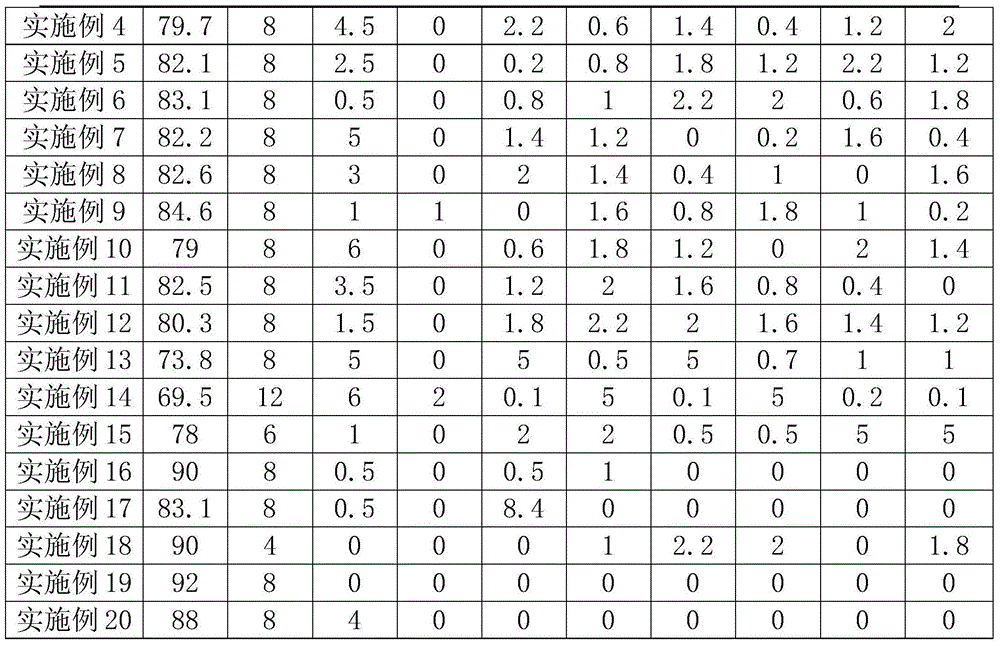

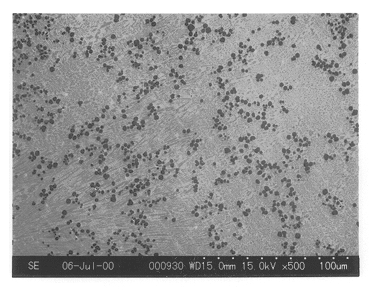

Tungsten carbide-based hard alloy and preparation method thereof

The invention relates to the technical field of alloy materials, in particular to a tungsten carbide-based hard alloy and a preparation method thereof. According to the tungsten carbide-based hard alloy, at least five of molybdenum powder, vanadium carbide, chromium carbide, titanium carbide, silicon carbide and yttrium oxide form a gain agent according to a certain proportion; the gain agent can inhibit the over-quick and / or irregular growth of tungsten carbide crystal grains so that the tungsten carbide-based hard alloy has high strength, toughness and plasticity; particularly, when the gain agent is used in a best proportion, the tungsten carbide-based hard alloy can have higher comprehensive mechanical properties and a better effect. The grain size of each substance is less than or equal to 1.2 micron, and the purity is over 99.9 percent, so that the substances are highly mixed; cobalt powder and nickel powder together form a bonding agent, so that other substances are in full contact with the bonding agent to increase a binding area and improve bonding force; therefore, the toughness of the tungsten carbide-based hard alloy can be improved. Paraffin is easily dispersed into a composite raw material by adding carbon tetrachloride solution of the paraffin into the composite raw material.

Owner:GUANGDONG UNIV OF TECH

Rare-earth modified tungsten hard alloy and preparation method thereof

The invention discloses a rare-earth modified tungsten hard alloy and a preparation method thereof. The rare-earth modified tungsten hard alloy is prepared by taking tungsten carbide, cobalt powder, vanadium carbide, chromium carbide, tantalum carbide, titanium carbide, rhenium powder, copper nitrate and yttrium oxide as raw materials through the steps such as powder preparation through atomization, alcohol mixing, wet type ball milling, normal-temperature static pressing, paraffin sizing, sintering in sections by using various excellent processes. The quality of the hard alloy is greatly improved, the production cost and consumption are reduced, the production efficiency is increased, and the rare-earth modified tungsten hard alloy is energy-saving and environment-friendly.

Owner:赣州世瑞钨业股份有限公司

Stainless spheroidal carbide cast iron material

Owner:KAWANO YUTAKA +4

Nano zirconia and micron tungsten carbide toughened and enhanced metal ceramic die material and preparation method thereof

The invention relates to a metal ceramic die material and a preparation method thereof. The die material is formed by hot pressing and sintering micro TiC and TiN as matrix hard phases, added yttrium-stable nano ZrO2 and micro WC as enhanced phases, micro molybdenum and nickel as bonding phases and micro graphite and vanadium carbide as addictives. The preparation method comprises the following steps of: respectively dispersing the micro TiC, TiN, WC and micro ZrO2 powder; ball milling and drying to obtain the powder; and sintering by a hot pressing method. The method is beneficial to improving the strength and the toughness of the material and is simple in process and convenient in operation. The metal ceramic die material has favorable comprehensive mechanical properties and wear-resisting performance and can be used for fabricating squeezing dies, drawing dies, stamping dies and other wear-resisting parts.

Owner:QILU UNIV OF TECH

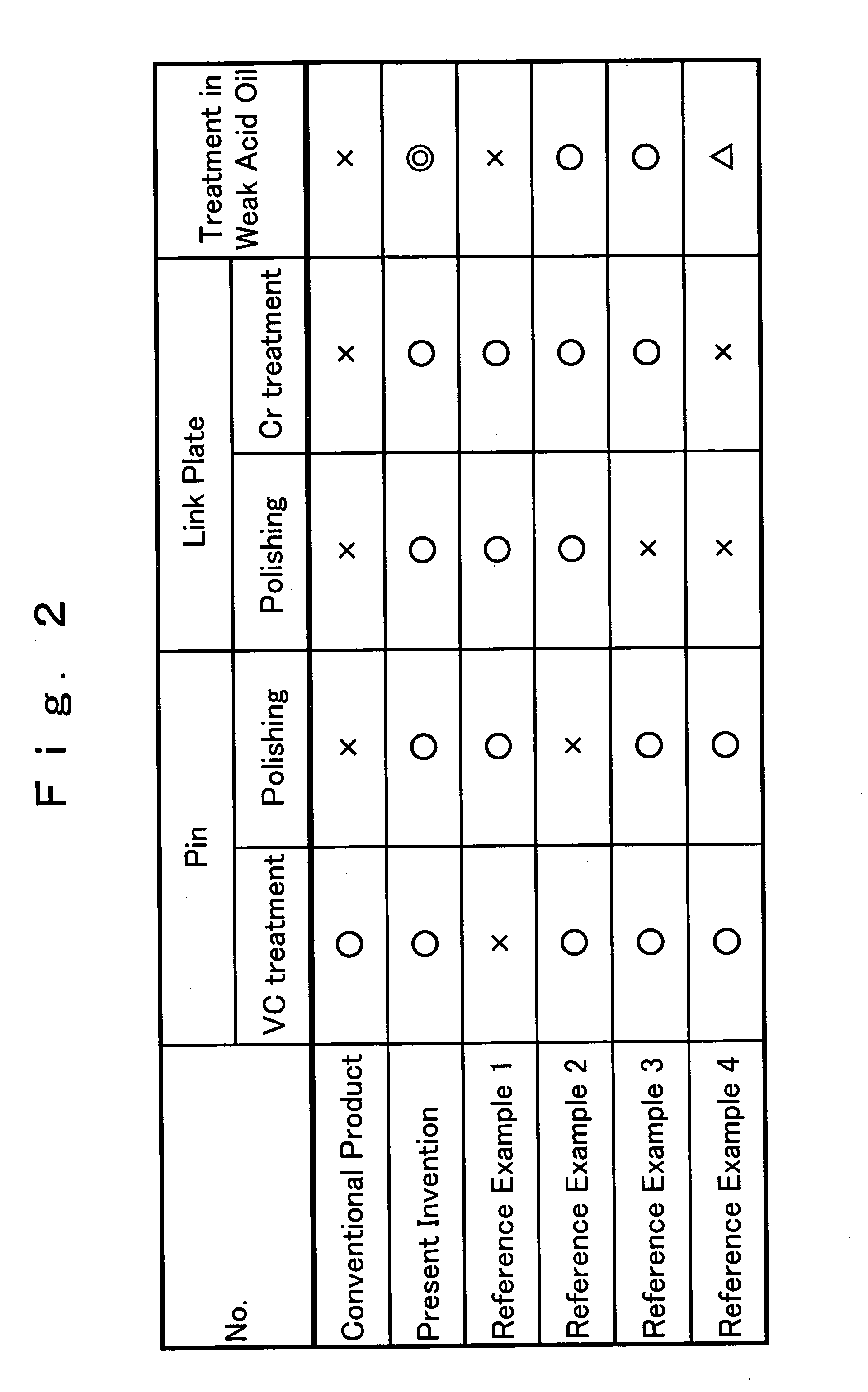

Silent chain and method of producing same

InactiveUS20060094551A1Corrosion resistanceResulting mutual contactDriving chainsMetallurgySurface roughness

Occasional abnormal wear elongation, which occurs in a silent chain when exposed to lubricating oil in a deteriorated condition due to oxidation, is avoided by polishing the inner link plates of the chain to a surface roughness of 0.5 μm Rz or less, chromizing the inner link plates, forming a vanadium carbide layer on the connecting pins of the chain, and then polishing the connecting pins to a surface roughness of 0.5 μm Rz.

Owner:TSUBAKIMOTO CHAIN CO

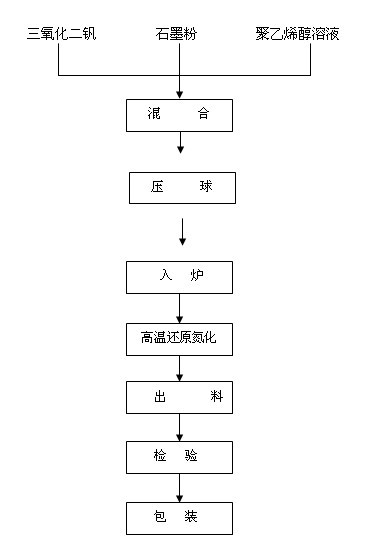

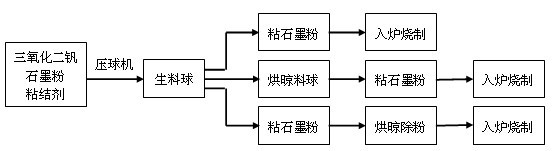

Method for anti-adhesion nitrogen increase in the process of producing vanadium nitride

ActiveCN102140587APrevents sinter sticking problemsHigh nitrogen contentPretreatment methodVanadium nitride

The invention relates to a method for anti-adhesion nitrogen increase in the process of producing vanadium nitride, and belongs to the technical field of vanadium nitride alloy production. The technical scheme comprises the following steps of: pretreating raw pellets before the vanadium nitride raw pellets enters a furnace to be fired, and putting the raw pellets into graphite powder, wherein a pretreatment method of sticking and coating the graphite powder on the surface is adopted, and the graphite powder is taken as an anti-adhesion material; and putting the raw pallets uniformly stuck with the graphite powder into a reaction furnace for firing. By the method, the problem of adhesion among products in the process of producing vanadium nitride can be effectively solved, the appearance quality of the products and the finished product ratio are improved, the surface area of nitriding reaction can be increased by 1 / 8 to 1 / 2 when the vanadium nitride pellets are fired, and the graphite powder on the surfaces of the pellets can consume partial residual oxygen and protect vanadium carbide / vanadium nitride in the pellets so as to prevent the vanadium carbide / vanadium nitride from being oxidized, improve the nitrogen content in the products and improve the grade and yield of the products. The method is suitable for all vanadium nitride production modes, particularly production of vanadium nitride by the most mature horizontal pusher kiln method at present.

Owner:HEBEI IRON AND STEEL

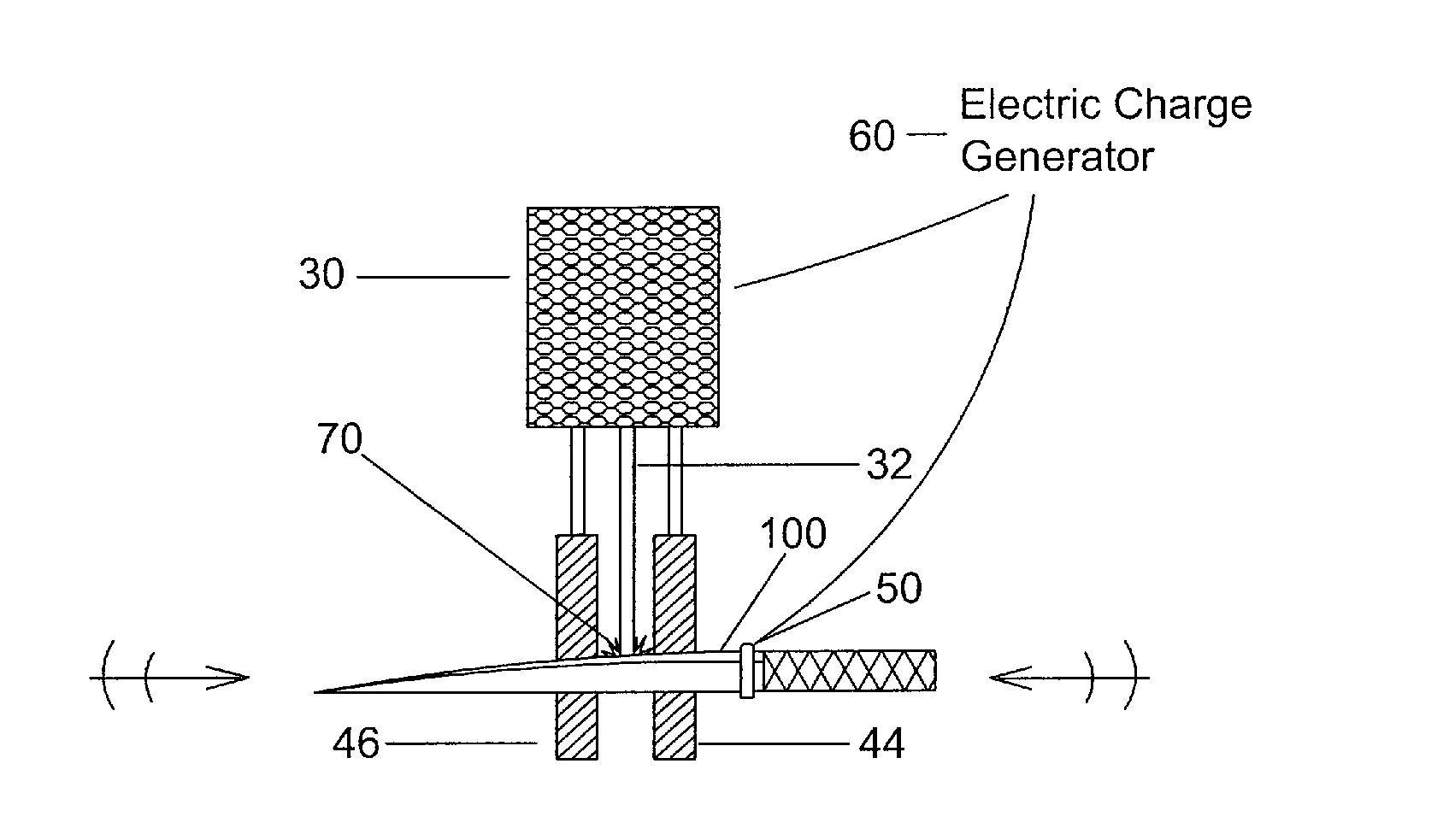

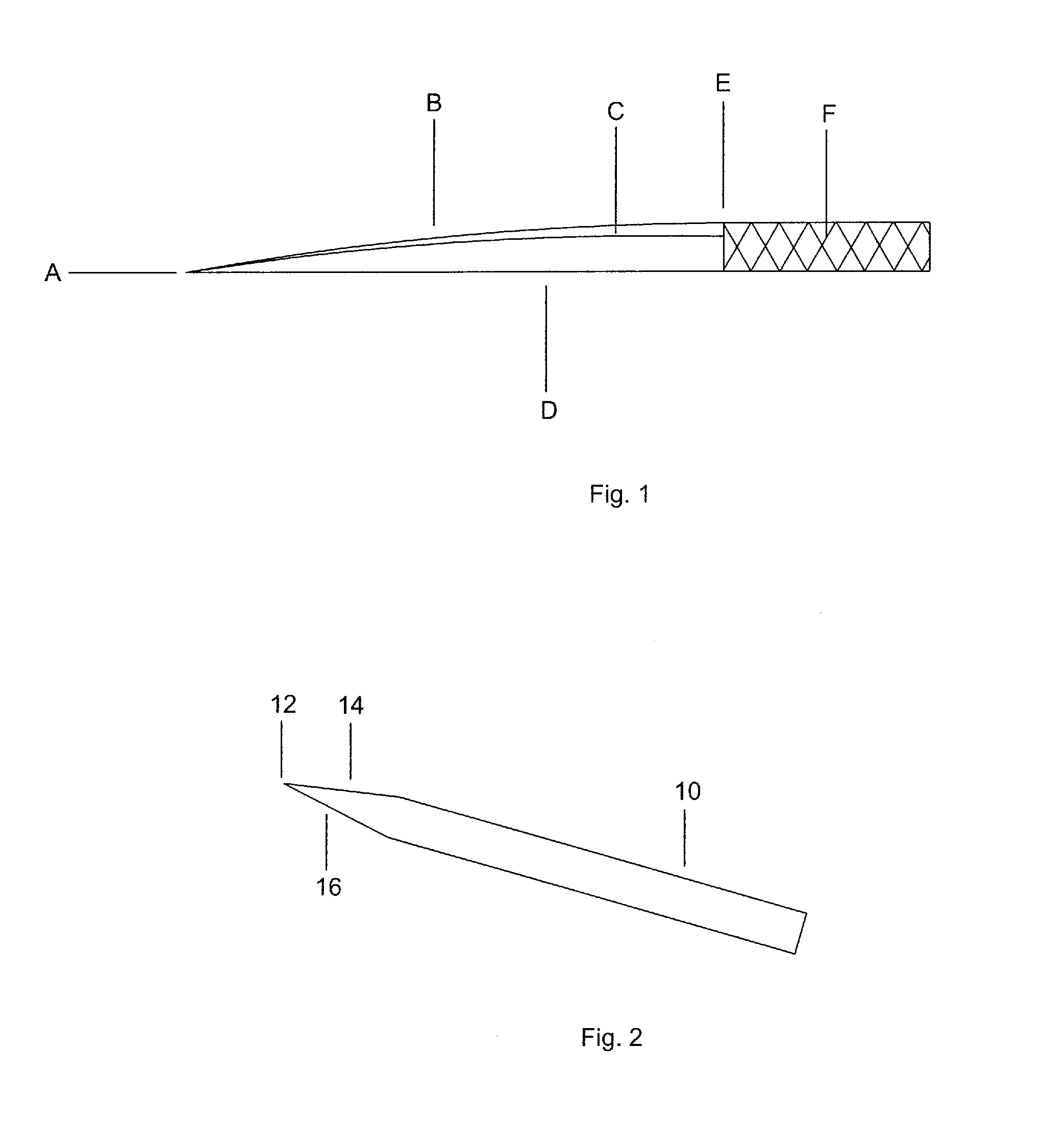

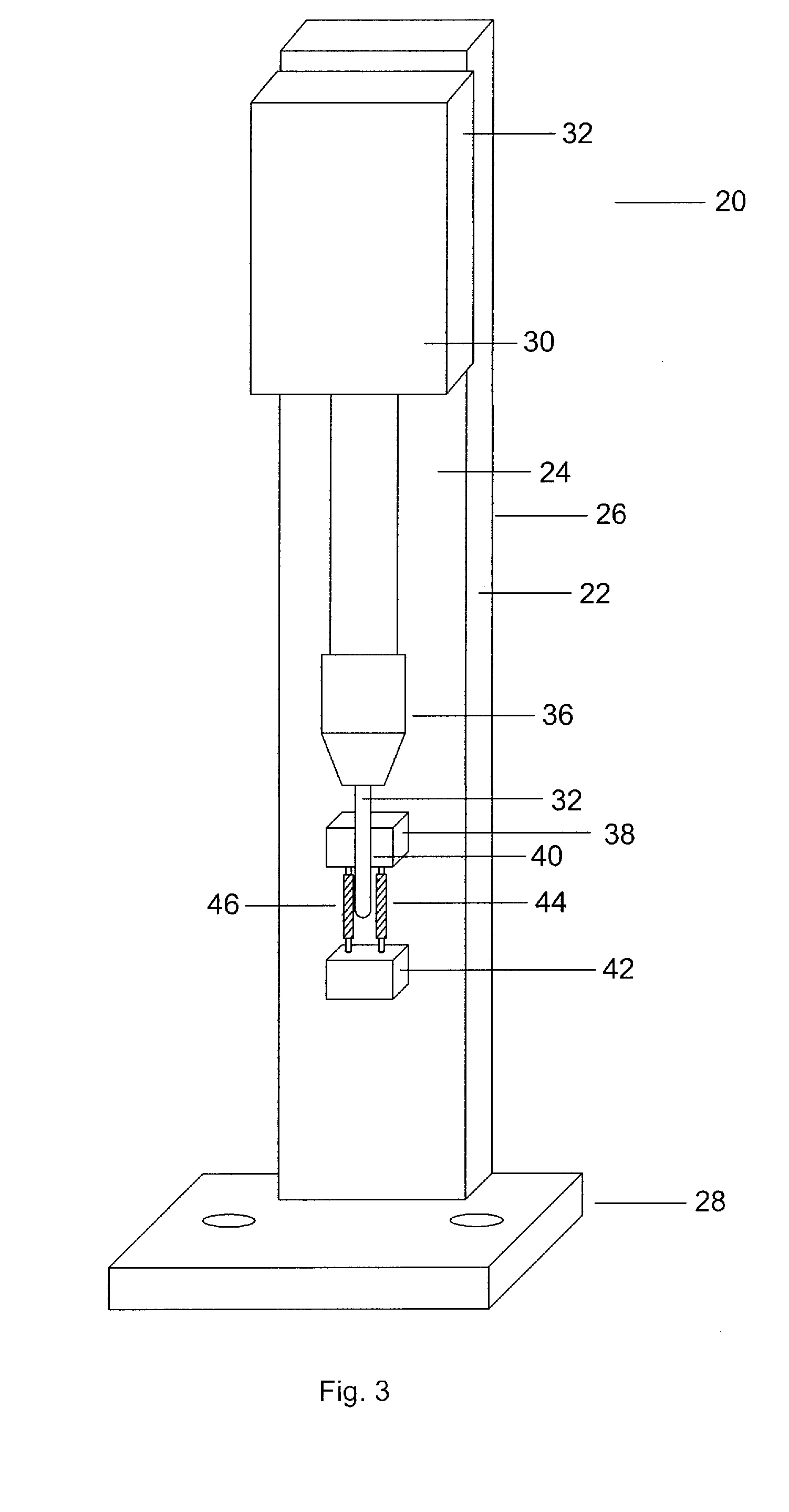

Apparatus and method of electronically impregnating a wear-resistant cutting edge

ActiveUS20110078909A1Improve cutting effectQuick wearElectrode vibration holdersOther manufacturing equipments/toolsCarbide coatingWear resistant

An apparatus and method for treating a cutting edge with a carbide coating to form a high endurance cutting edge that is self sharpening. The cutting edge has one side of its bevel treated with an electronically impregnated coating to create a wear resistant surface employing Tungsten, Titanium or Vanadium Carbide. The coating providing an abrasion resistant cutting edge and creates a differential hardness on the total cutting edge thereby extending its cutting ability through a wear-resistant surface on its treated face and a faster wear on the untreated surface causing the cutting edge to be self sharpening.

Owner:LAMBERT GEORGE H

Method for preparing coarse-grain hard alloy

The invention relates to a method for preparing a coarse-grain hard alloy. The method comprises the following steps of: fully mixing the following raw materials in percentage by weight: 93.18 percent of coarse-grain tungsten carbide powder WC, 6 percent of cobalt powder, 0.12 percent of radium powder, 0.2 percent of rhenium powder, 0.1 percent of vanadium carbide, 0.1 percent of chromium carbide, 0.1 percent of tantalum carbide, 0.1 percent of titanium carbide, 0.1 percent of nickel powder and the like; performing wet grinding; drying; and forming, and sintering to obtain the coarse-grain hard alloy. The method is characterized in that: the coarse-grain tungsten carbide powder is not doped with alkali metal ions such as Li, Na, K and the like serving as grain growth agents, and is produced by hydrogen reduction at high temperature, and a production process for the coarse-grain tungsten carbide powder comprises the following steps of: mixing blue tungsten oxide powder and nano carbon black, performing high temperature carbonization, crushing, sieving, blending, detecting, sieving, and packaging to obtain the coarse-grain tungsten carbide powder. The coarse-grain hard alloy is higher in strength and high temperature resistance.

Owner:周毅

Method for producing nano-sized vanadium carbide powder

The invention relates to a method for producing nano-sized vanadium carbide powder, belonging to the technical field of preparing ceramic powder. The method comprises the following processes: (1) mixing a vanadium source, a carbon source and an auxiliary into a solution according to a certain proportion; (2) heating the solution, so that the solution is volatilized, concentrated and decomposed to obtain precursor powder containing the vanadium source and the carbon source; and (3) reacting the precursor powder for 1-5 hours at the temperature of 700-1300 DEG C under certain atmosphere. The method is simple in technology, low in cost, and easy to industrialize, and the obtained vanadium carbide powder has a particle size of less than 50nm, and good dispersity.

Owner:UNIV OF SCI & TECH BEIJING

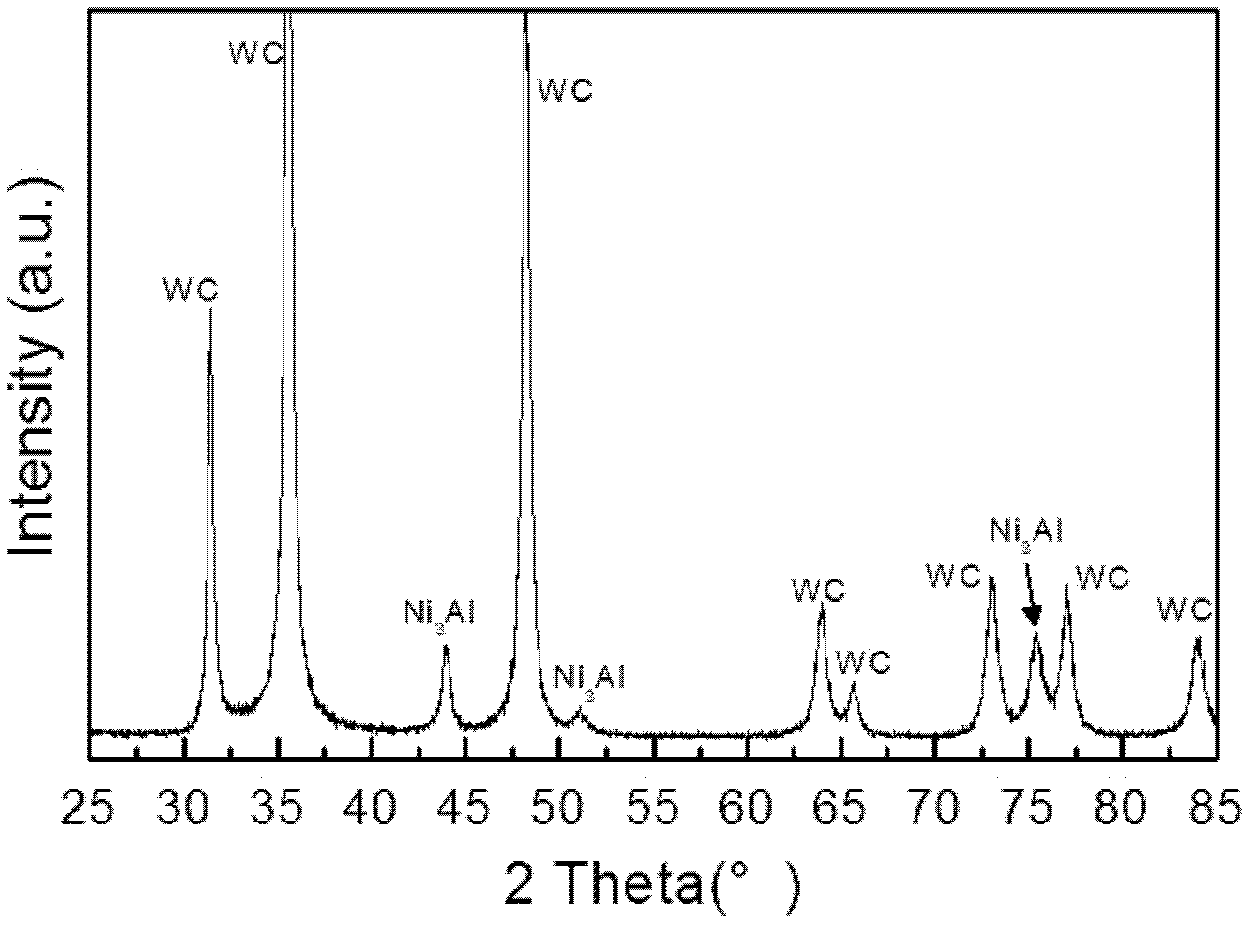

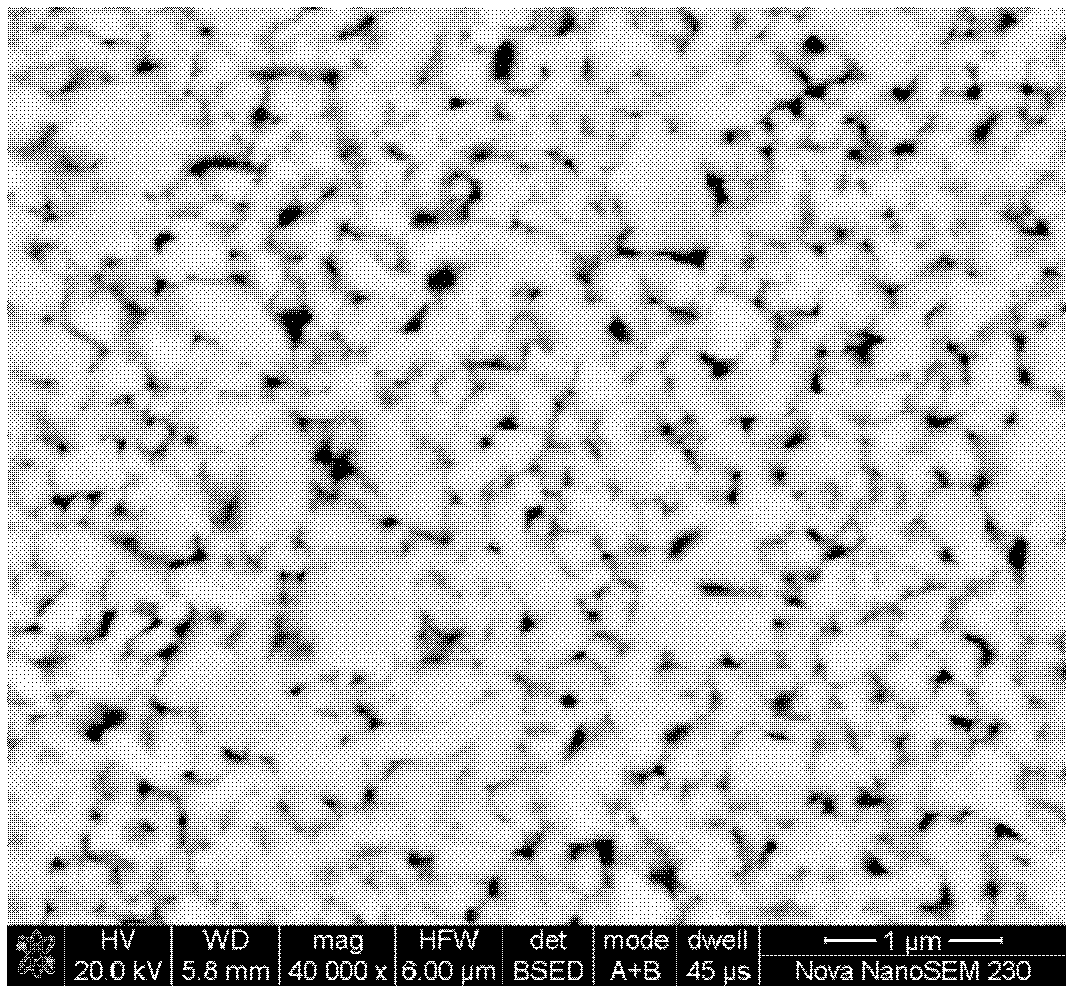

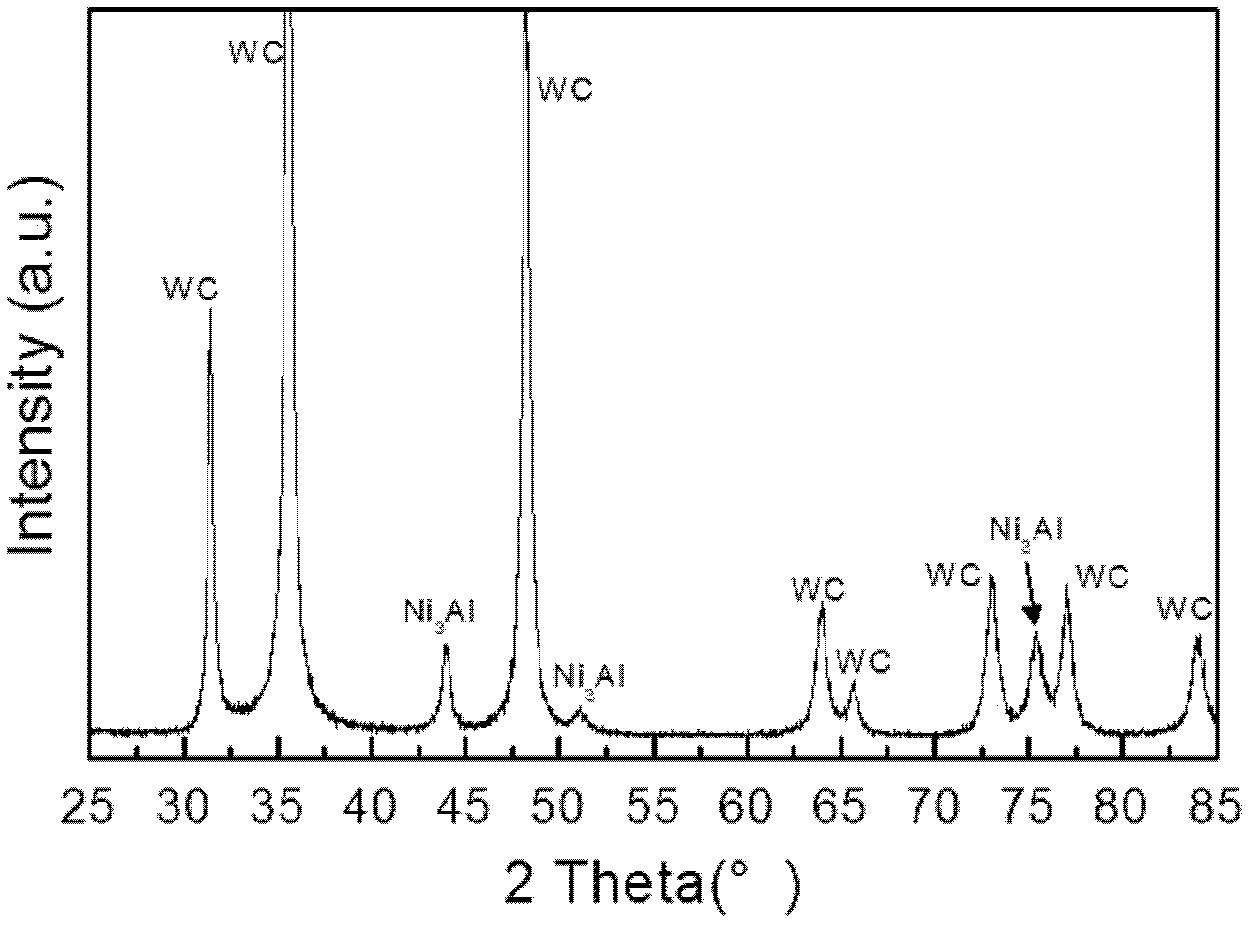

Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy and preparation method thereof

The invention provides a Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy and a preparation method thereof, and belongs to the field of high-performance structural materials. The hard alloy comprises the following components in percentage by mass: 0.01 to 0.1 percent of rare earth hexaboride (ReB6), 0.05 to 0.5 percent of chromium carbide (Cr2C3), 0.05 to 0.5 percent of vanadium carbide (VC), 5 to 40 percent of nickel aluminum (Ni3Al) and the balance of tungsten carbide powder. The method comprises the following steps of: weighing the tungsten carbide powder, nickel powder, aluminum powder, ReB6 powder, Cr2C3 powder and VC powder with certain granularity in a weight percent ratio, uniformly mixing the powder by a mixing method, and pressing by a compression molding process to obtain a blank with a certain shape; and degreasing the blank, putting into a low-pressure sintering furnace, sintering, and cooling with the furnace to obtain the Ni3Al bonded ultra-fine grained tungsten carbide-based hard alloy. The alloy prepared by the method is fine grained and has a uniform structure, high density and strength, corrosion resistance and high-temperature resistance, the process is simple, preparation cost is low, and industrial production can be implemented.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com