Patents

Literature

78 results about "Unidirectional solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

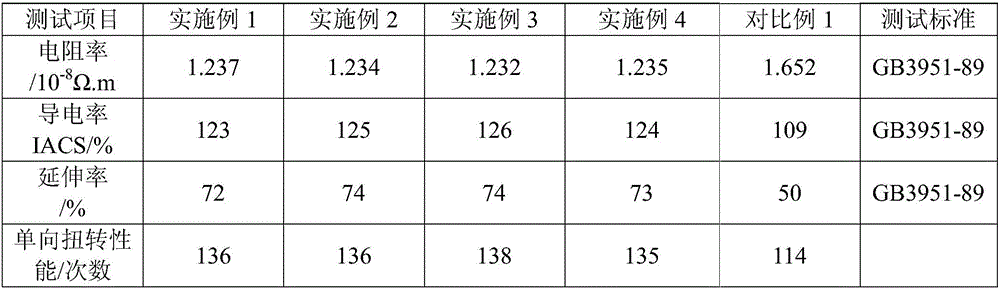

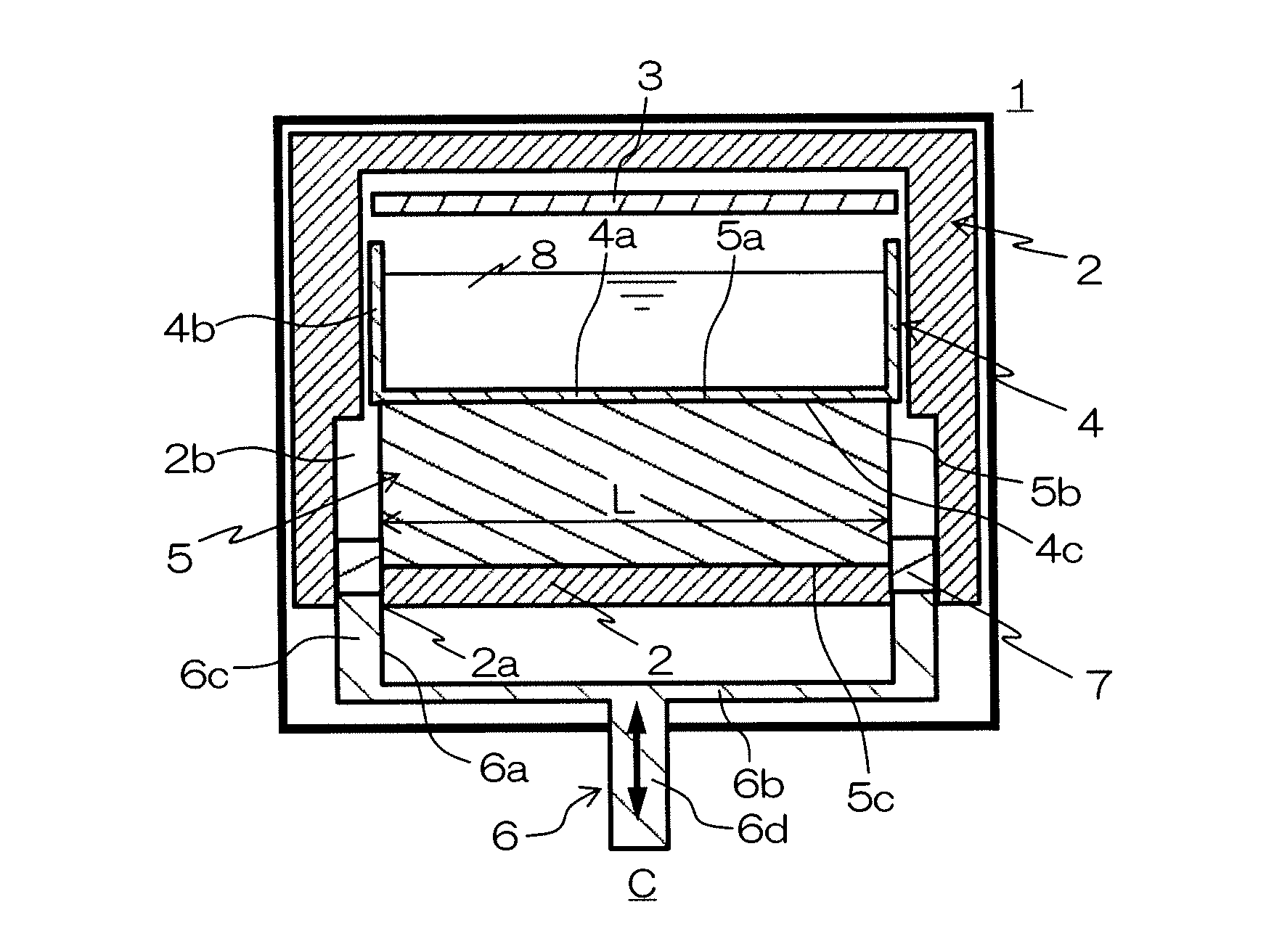

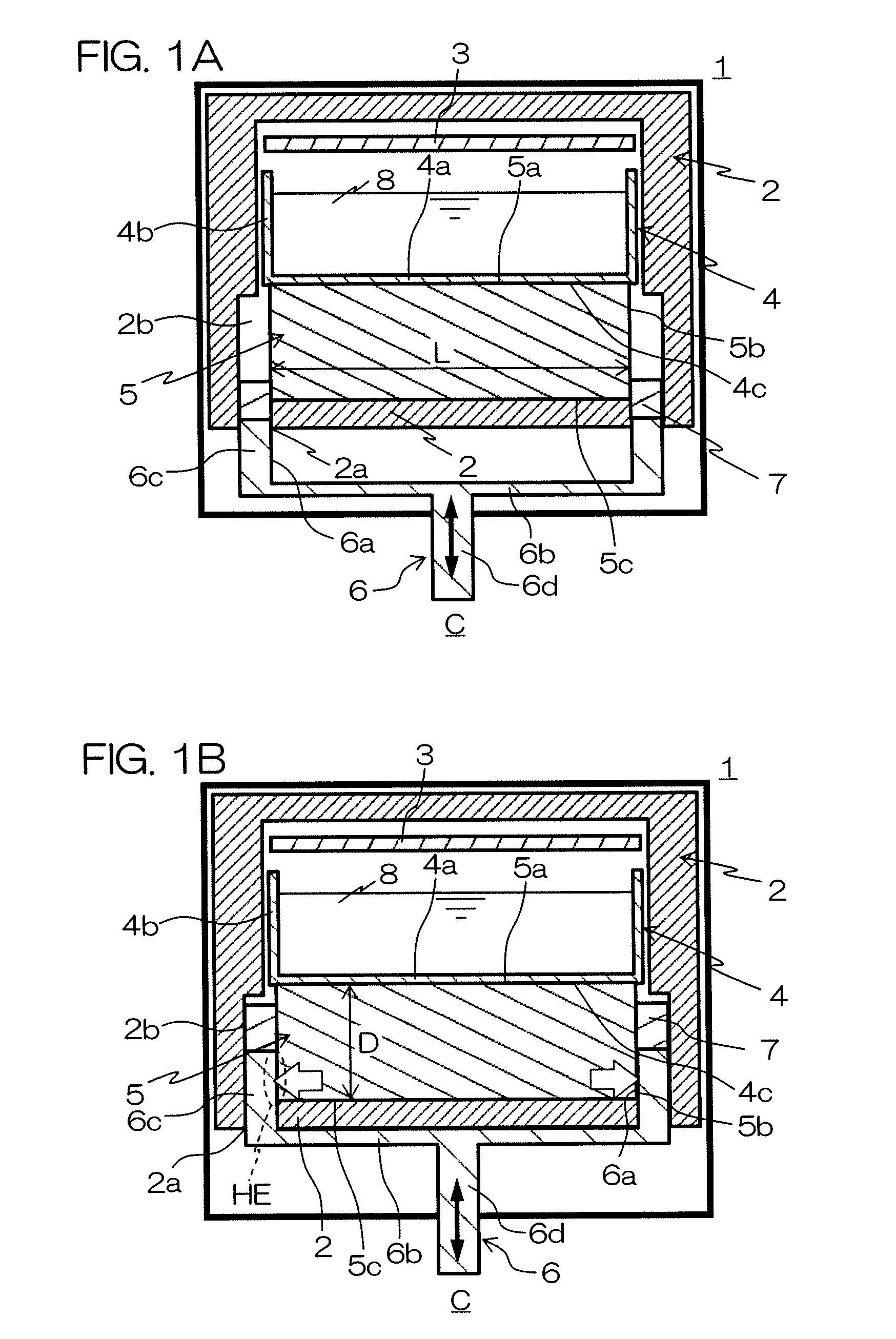

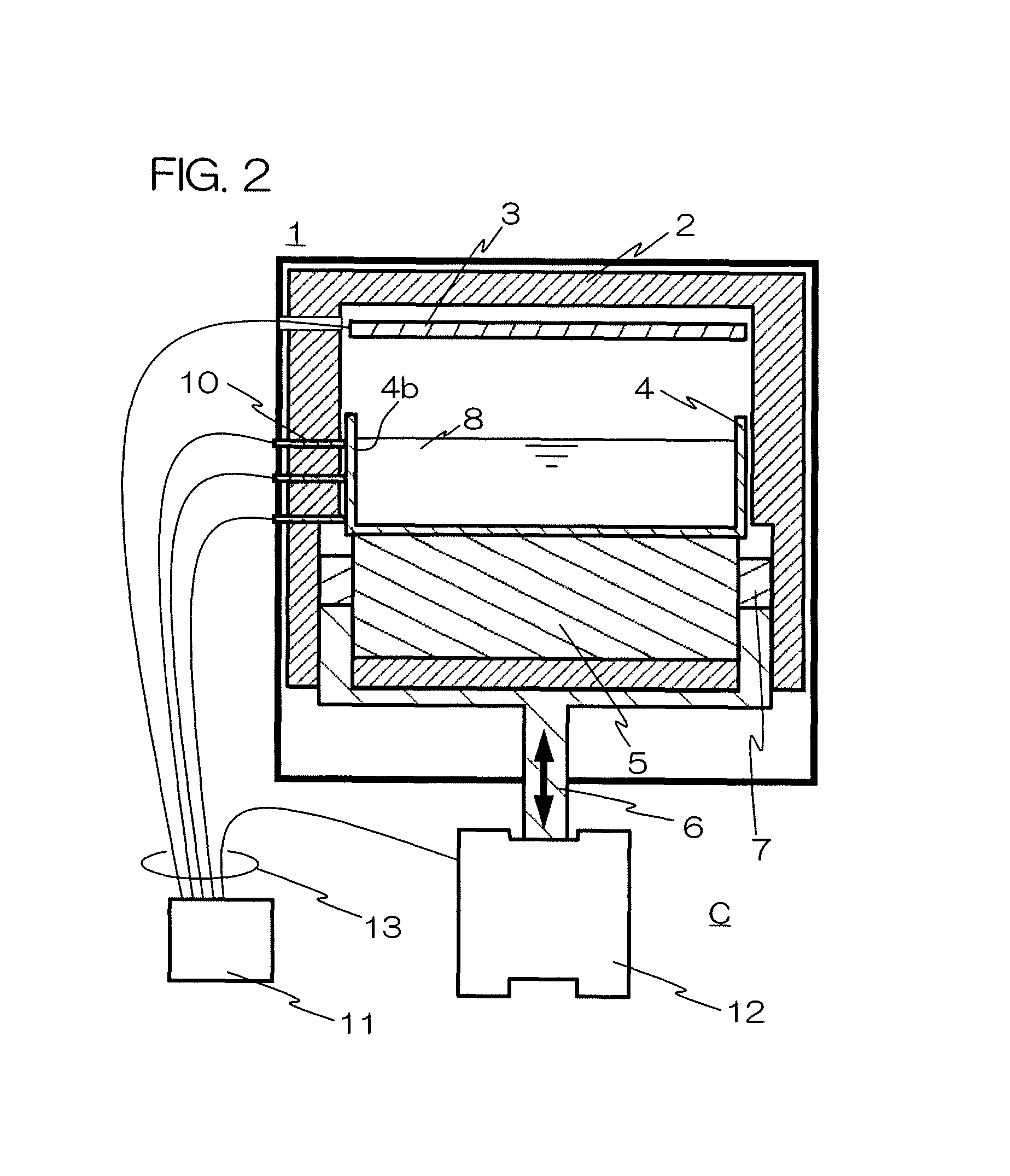

Silicon Casting Apparatus and Method of Producing Silicon Ingot

InactiveUS20070227189A1Good reproducibilityLow costFinal product manufactureGlass drawing apparatusIngotTemperature gradient

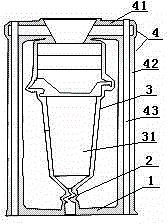

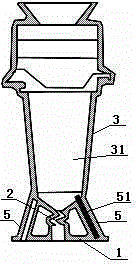

A silicon casting apparatus for producing polycrystal silicon ingot by heating a silicon melt (8) held in a mold (4) from above by a heater (3) and cooling it from below while changing the heat exchange area of a heat exchange region (HE), defined between a pedestal (5) having the mold (4) placed thereon and a bottom cooling member (6), in such a manner as to keep pace with the rise of the solid-liquid interface of the silicon melt (8), thereby causing unidirectional solidification upward along the mold (4); and a method of producing polycrystal silicon ingot using such apparatus. According to this production method, the temperature gradient given to the silicon melt (8) can be maintained at constant by adjusting the heat exchange area, so that polycrystal silicon ingot having good characteristics can be produced with good reproducibility.

Owner:KYOCERA CORP

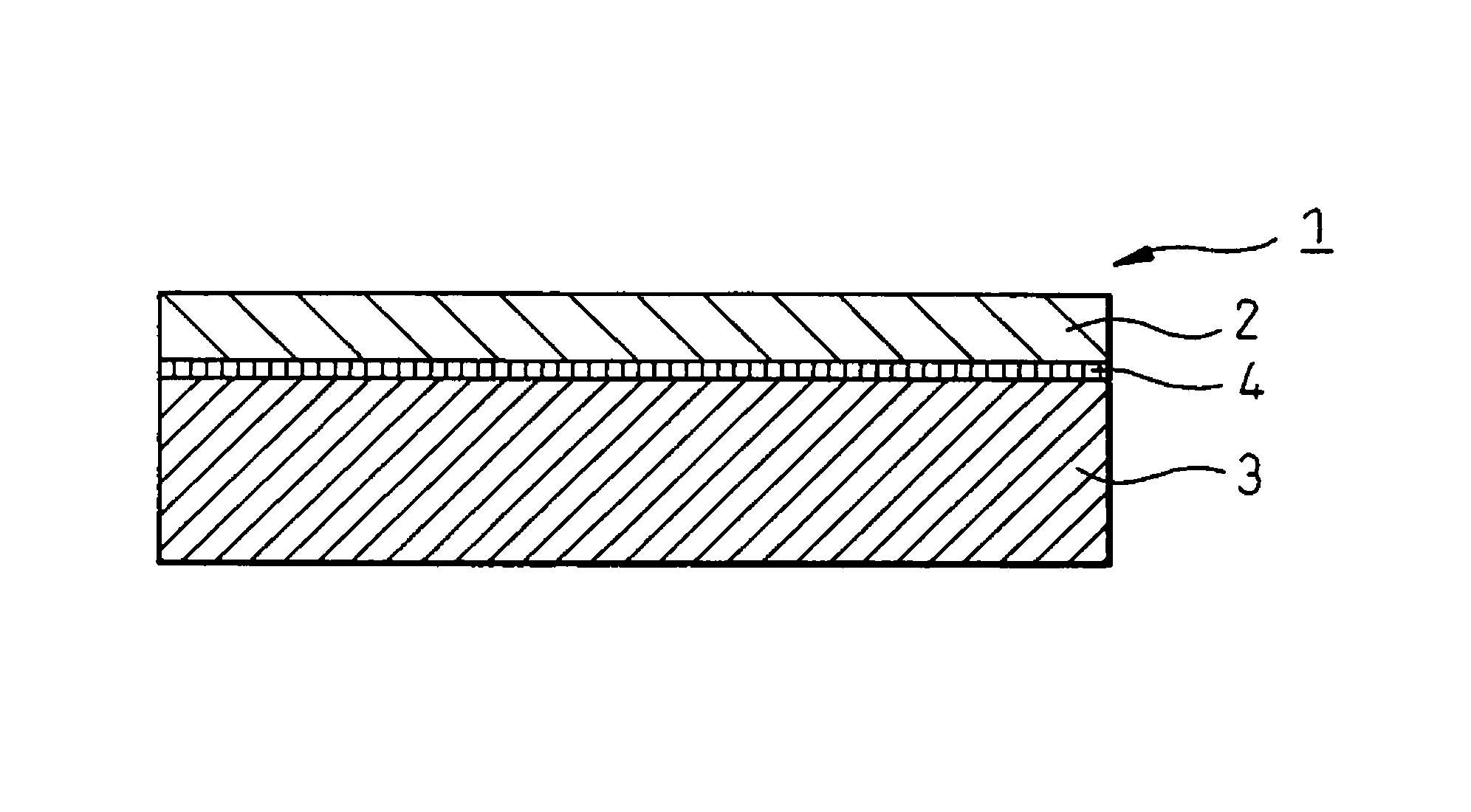

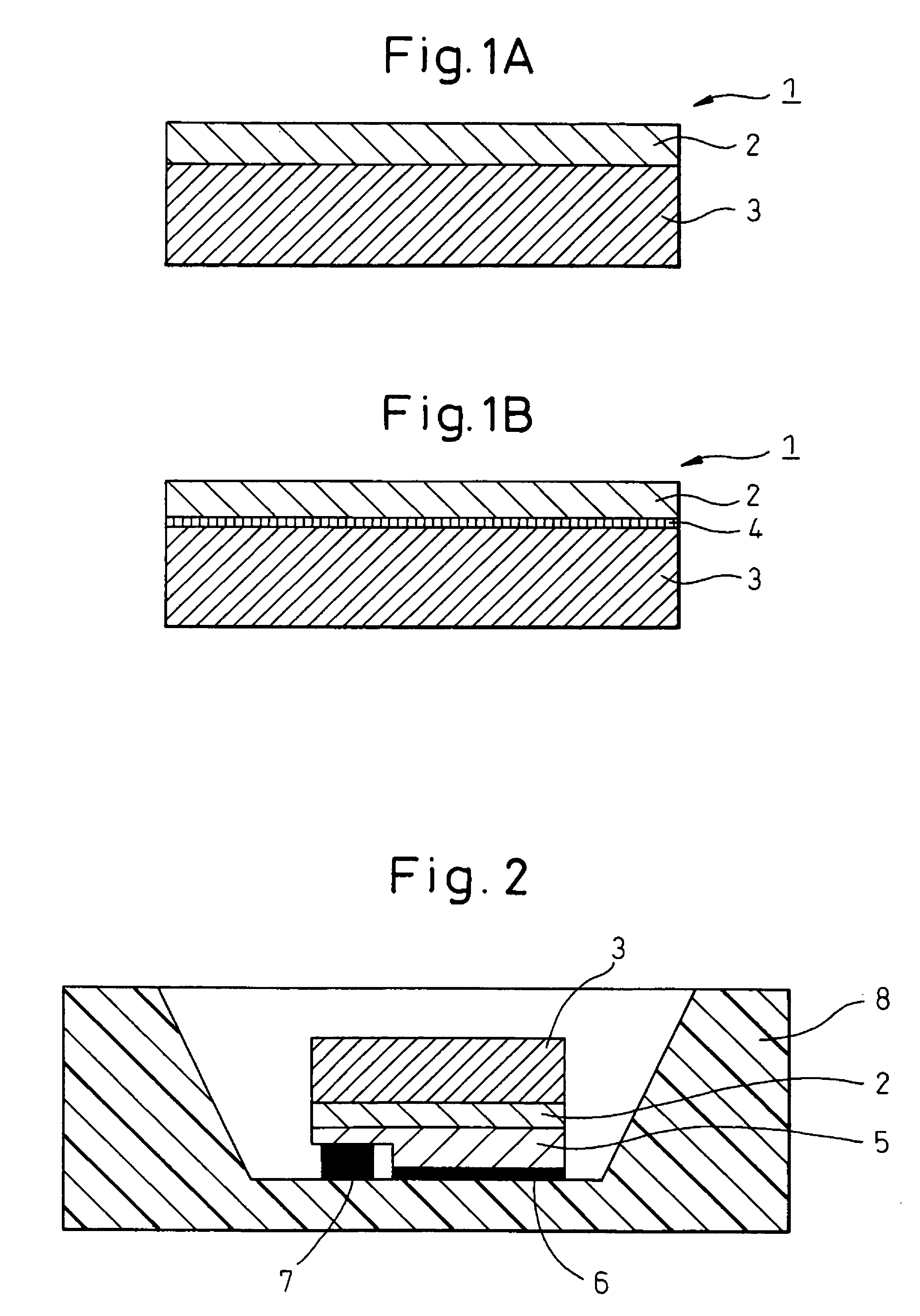

Ceramic composite material for optical conversion and use thereof

ActiveUS20060124951A1Improve thermal stabilitySolid-state devicesLuminescent compositionsCeramic compositeHeat resistance

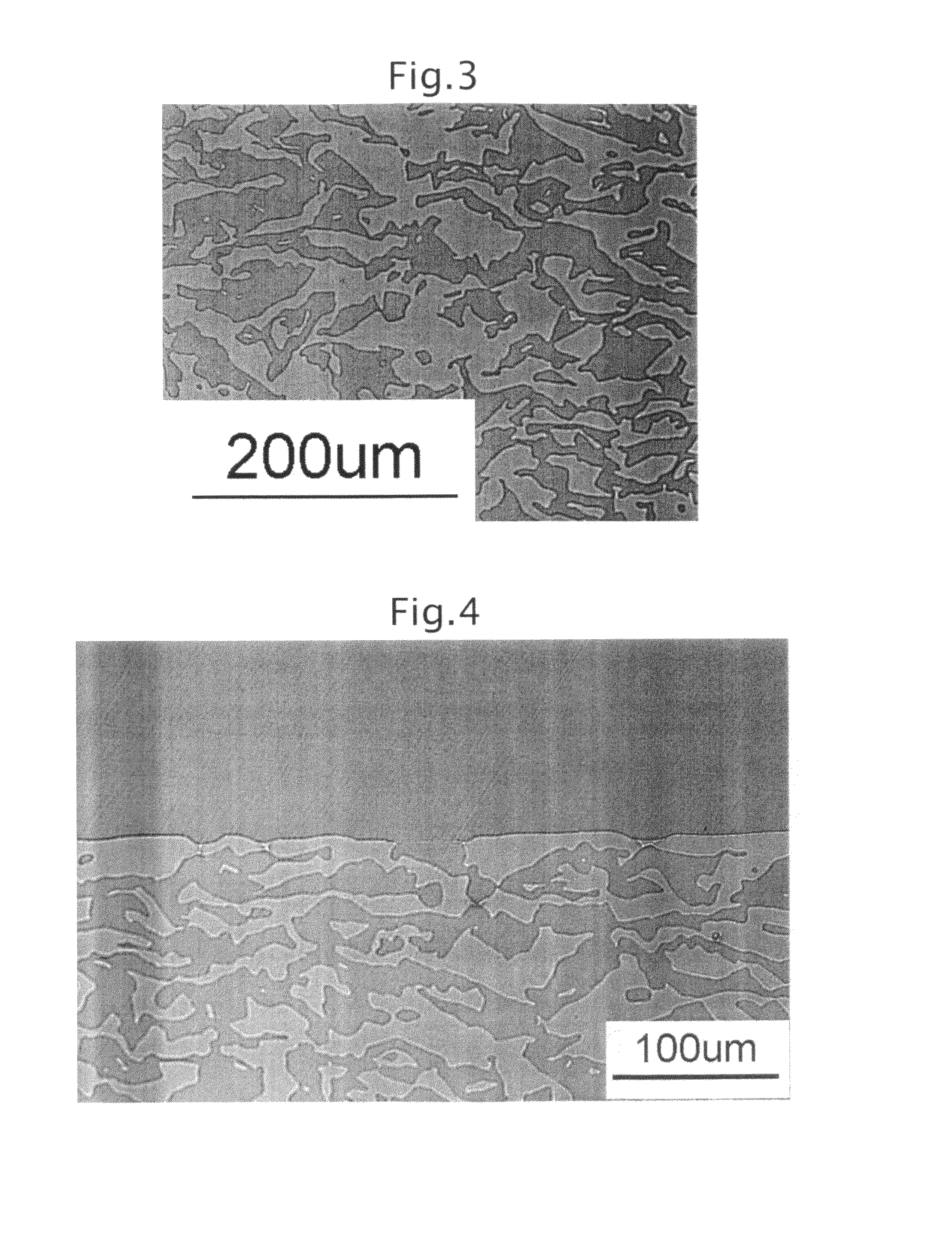

A ceramic composite material for light conversion, which is a solidified body comprising two or more matrix phases with respective components being two or more oxides selected from the group consisting of metal oxides and complex oxides each produced from two or more metal oxides, wherein at least one of the matrix phases is a phosphor phase containing an activated oxide. The solidified body is preferably obtained by the unidirectional solidification method. The ceramic composite material for light conversion is excellent in brightness, light-mixing property, heat resistance and ultraviolet light resistance.

Owner:UBE IND LTD

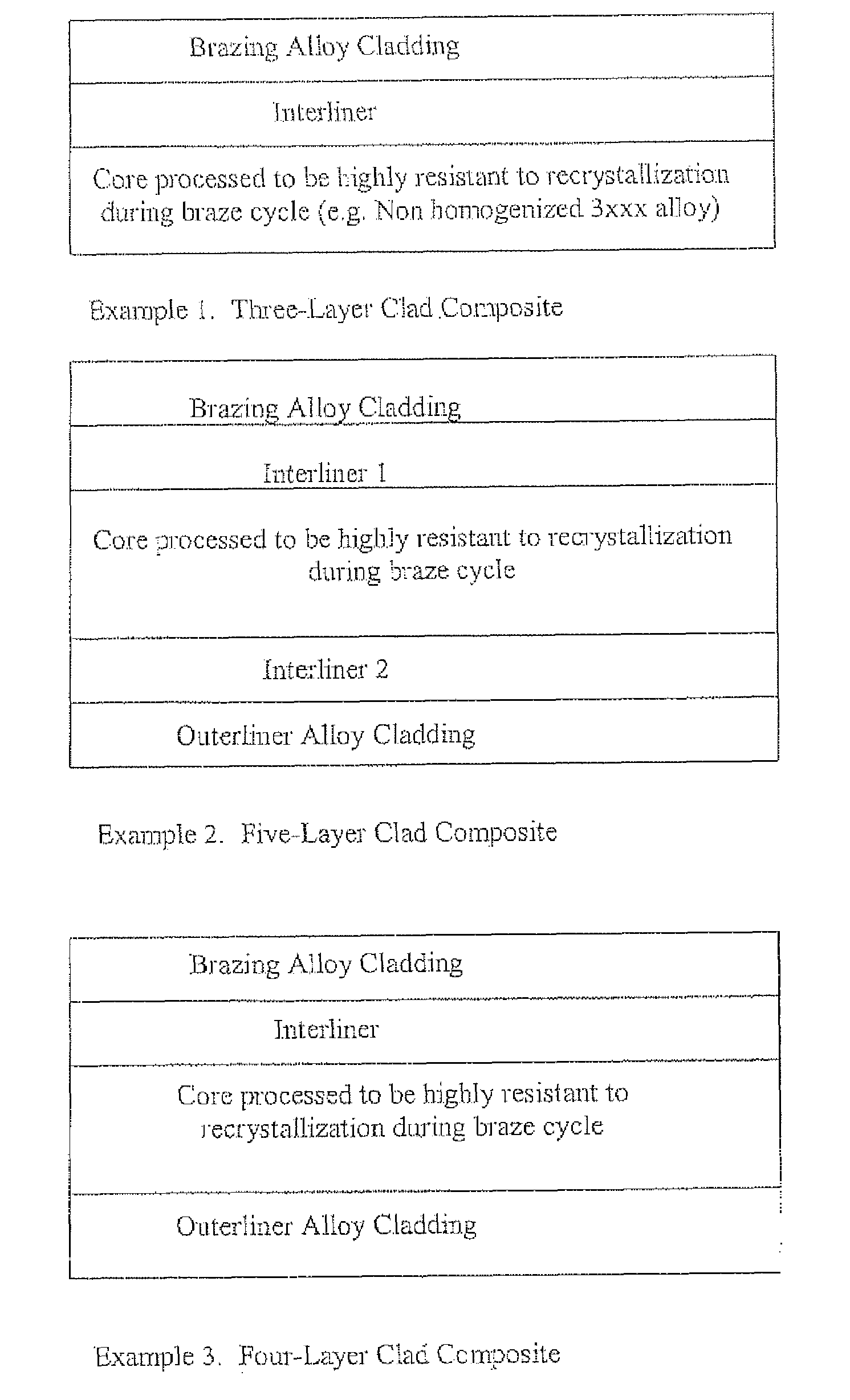

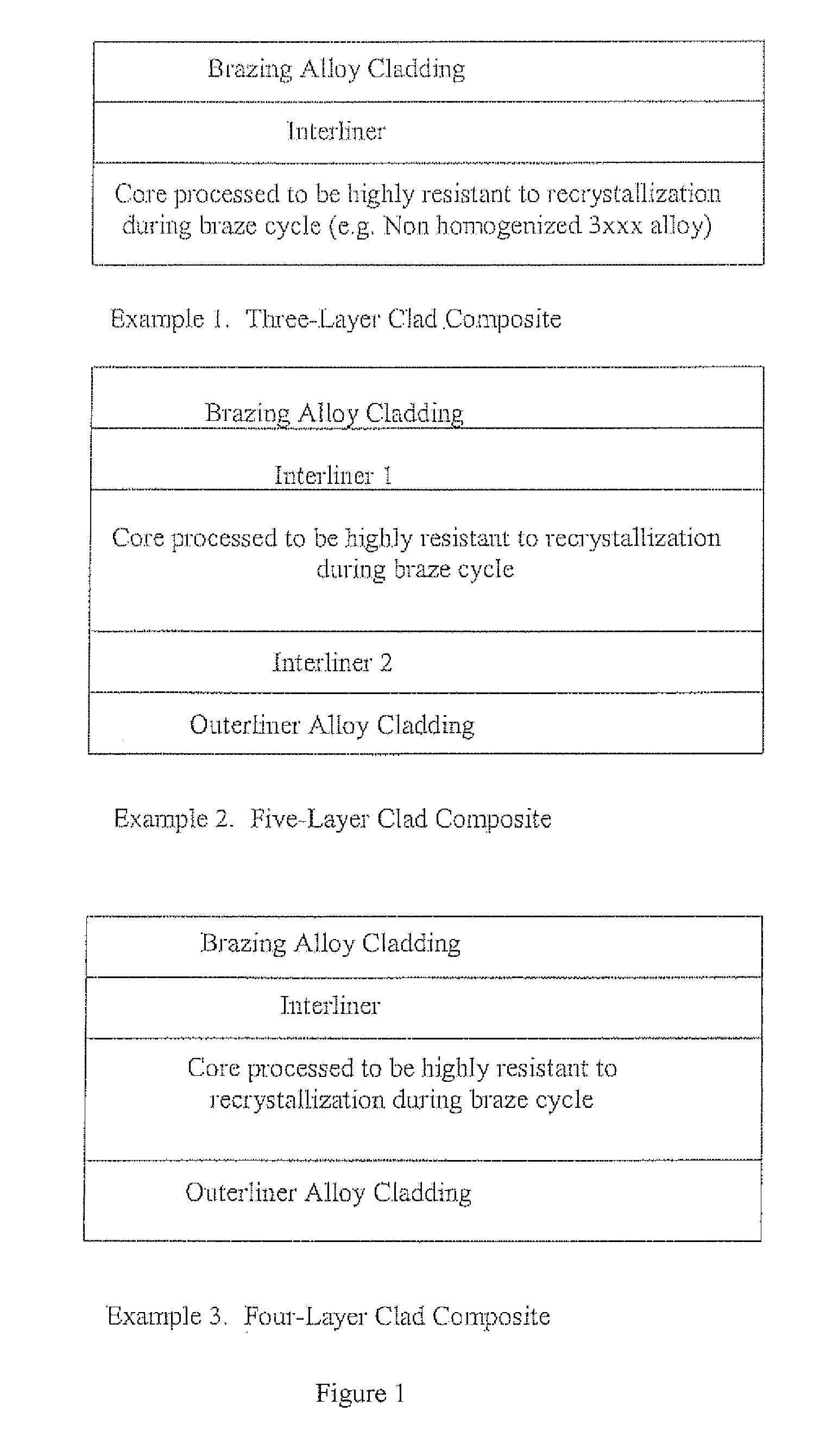

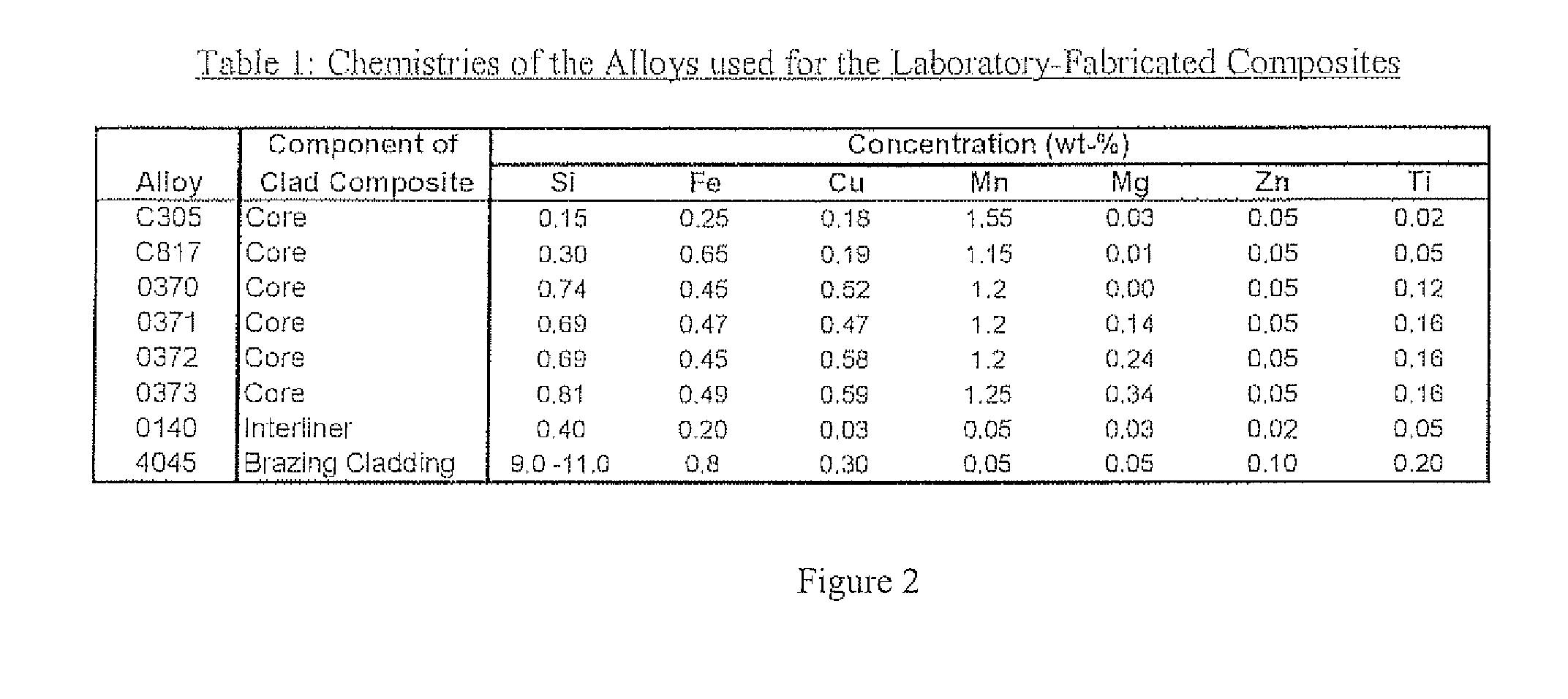

Recovered high strength multi-layer aluminum brazing sheet products

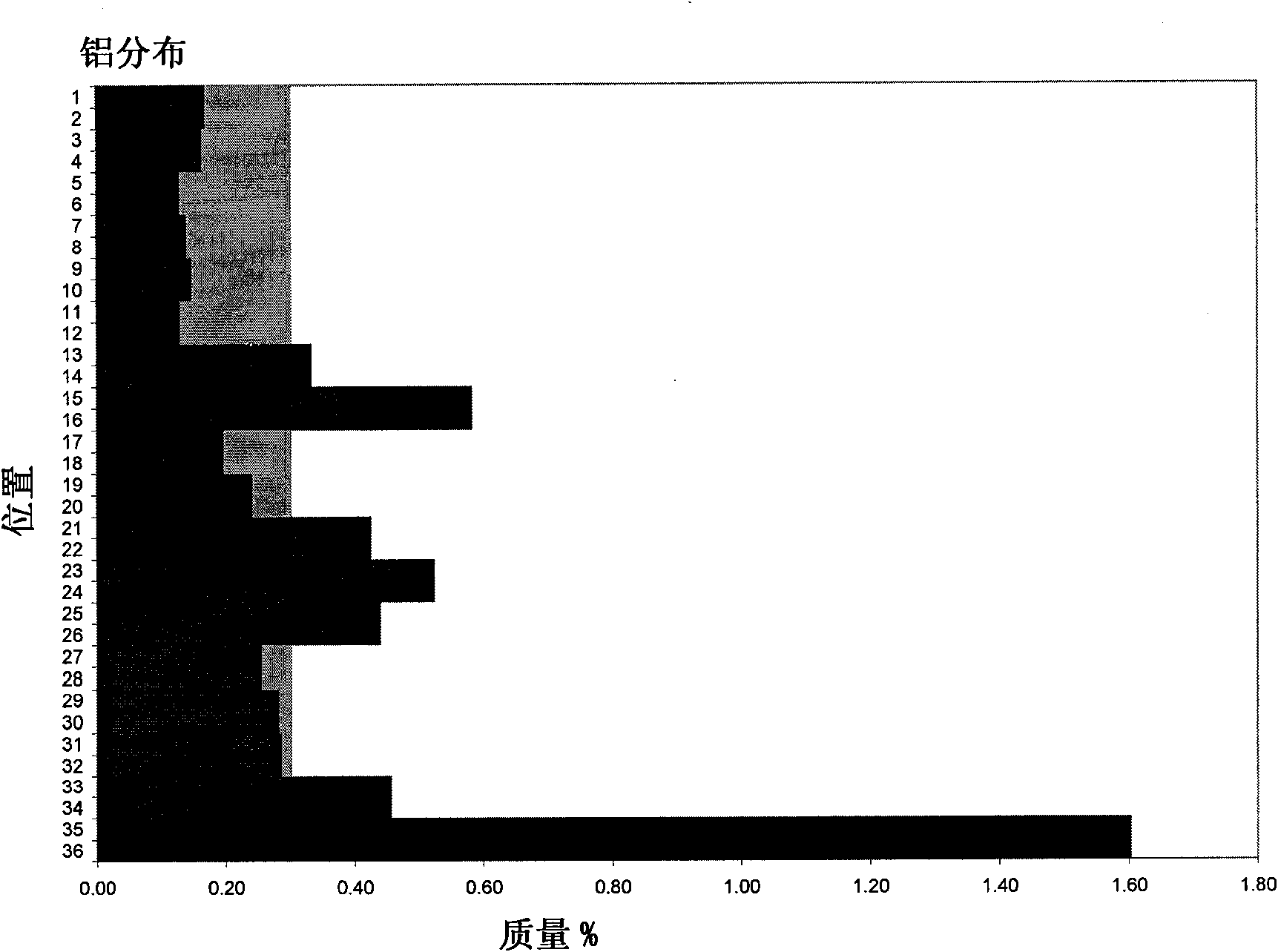

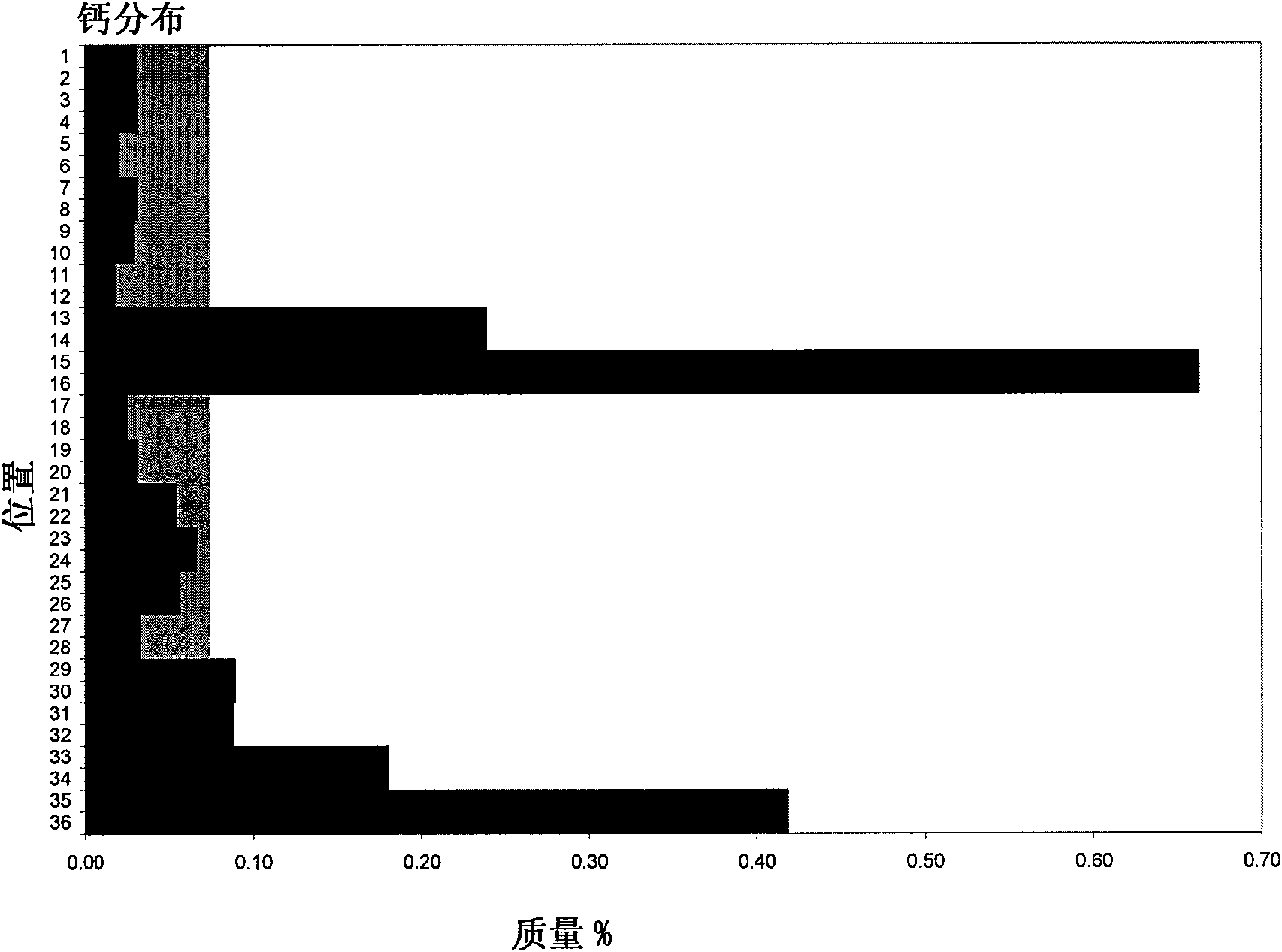

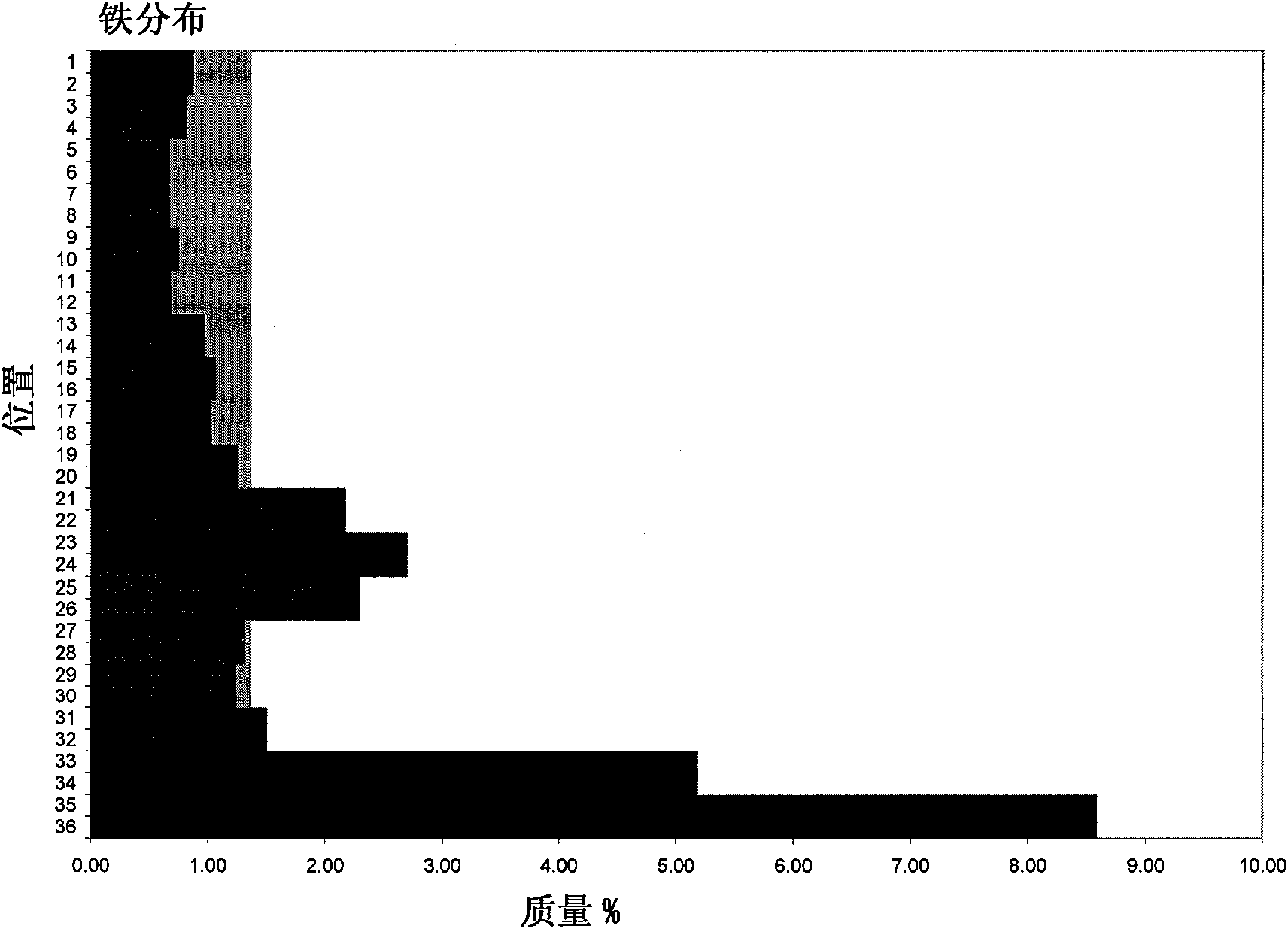

InactiveUS20080274367A1Excellent brazeabilityHigh post-braze tensile strengthWelding/cutting media/materialsThin material handlingIngot castingHigh intensity

A multi-layer metallurgical product comprising a core aluminum alloy, purposefully tailored through chemistry and processing route to resist recrystallization during the brazing cycle to intentionally exploit the higher strengths immediately after brazing of a deformed and recovered microstructure, the core aluminum alloy being positioned on one side to an aluminum alloy interliner designed to be resistant to localized erosion, which, in turn, is adjacent to a 4xxx cladding alloy. The multi-layer product can be fabricated at least in part via any multi-alloy ingot casting processes such as the Simultaneous Multi-Alloy Casting process or the Unidirectional Solidification of Castings process.

Owner:ARCONIC INC

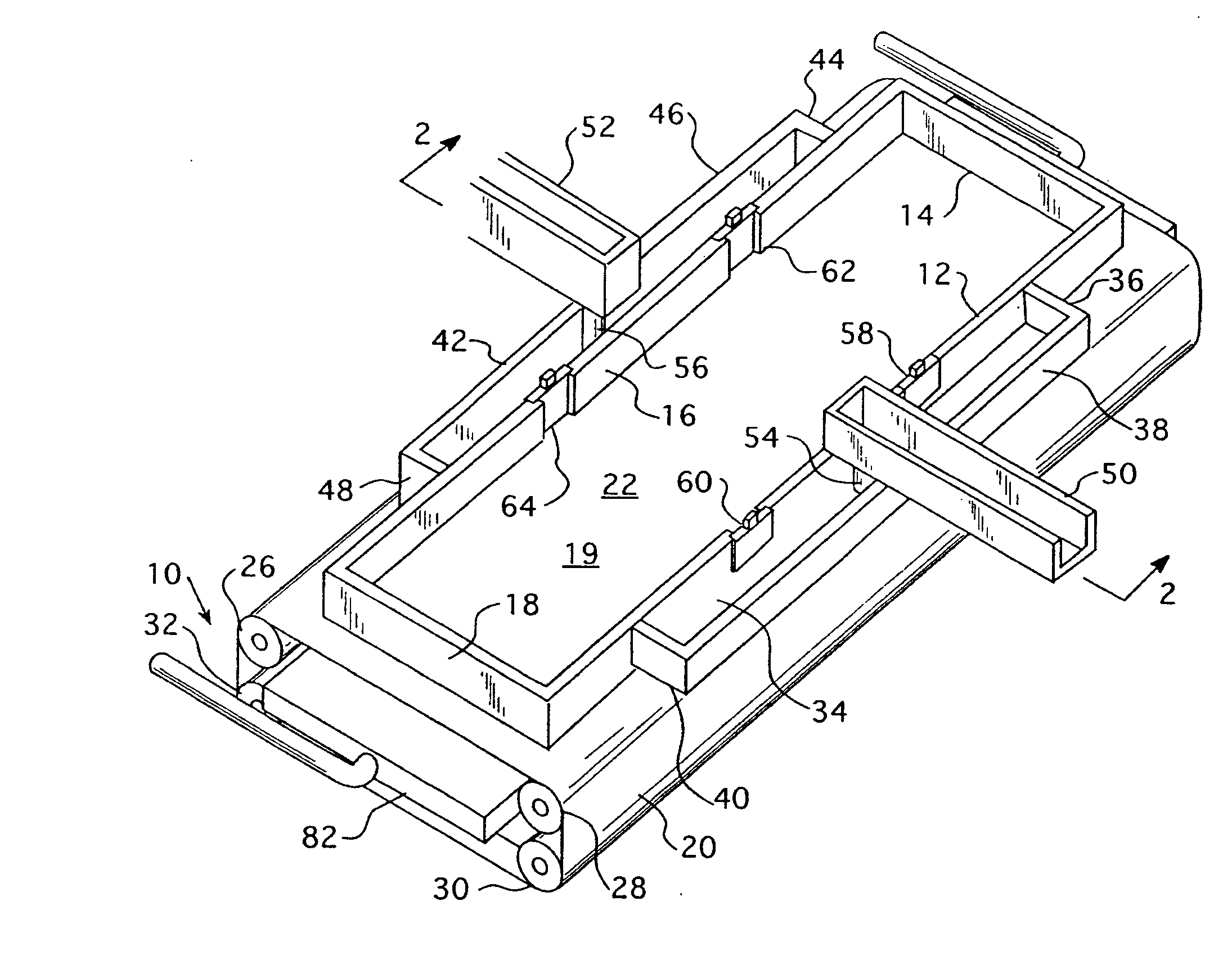

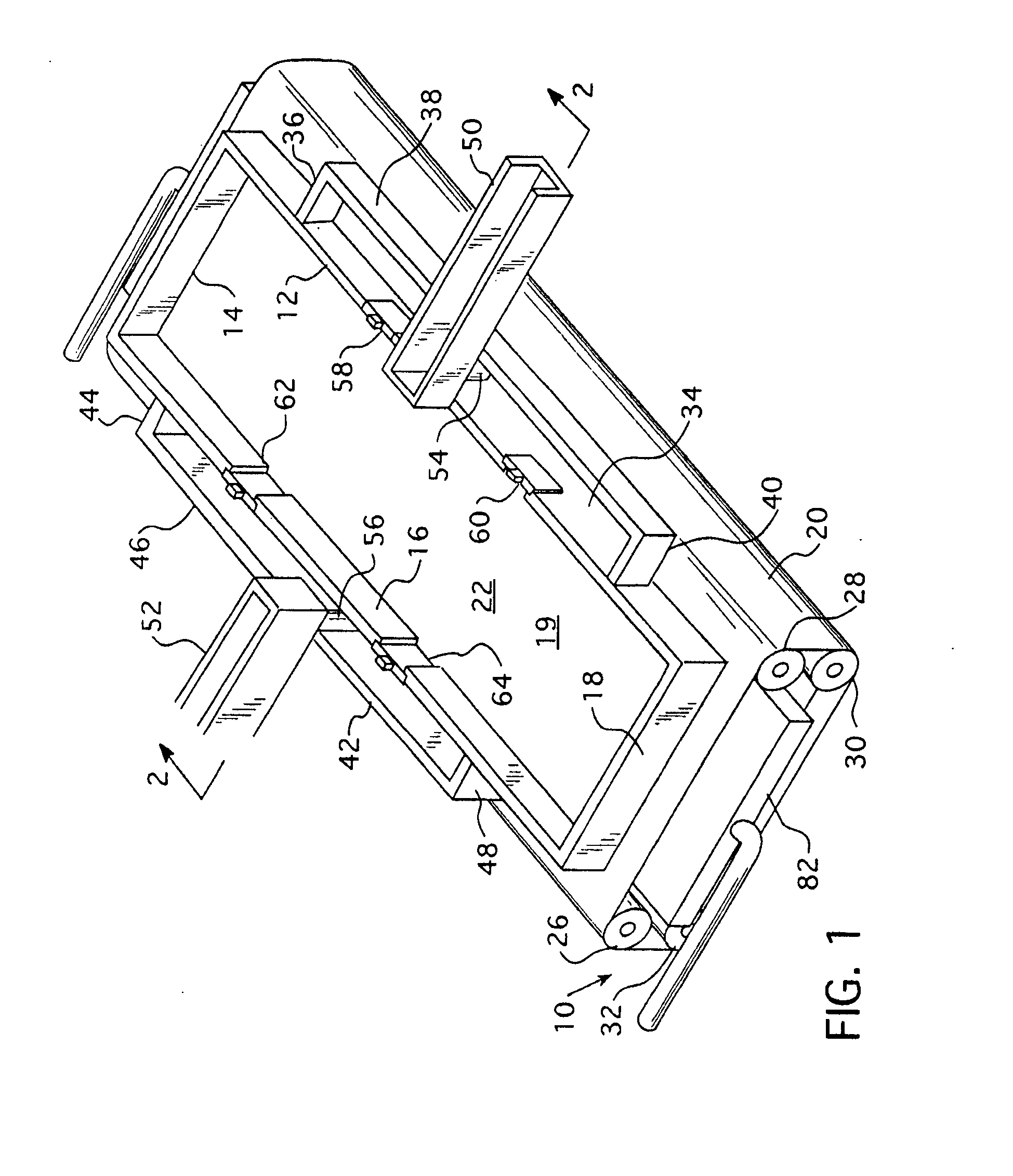

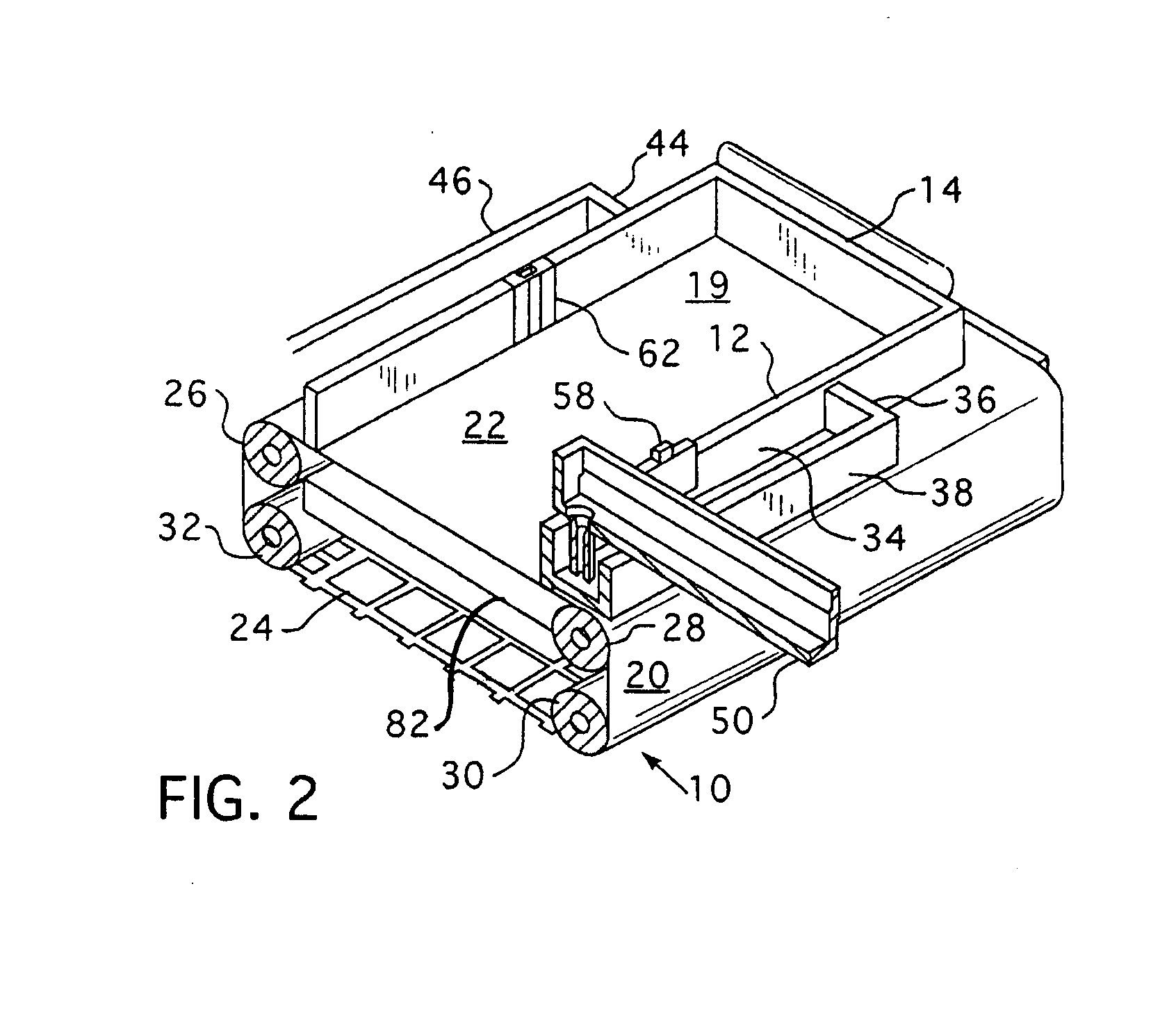

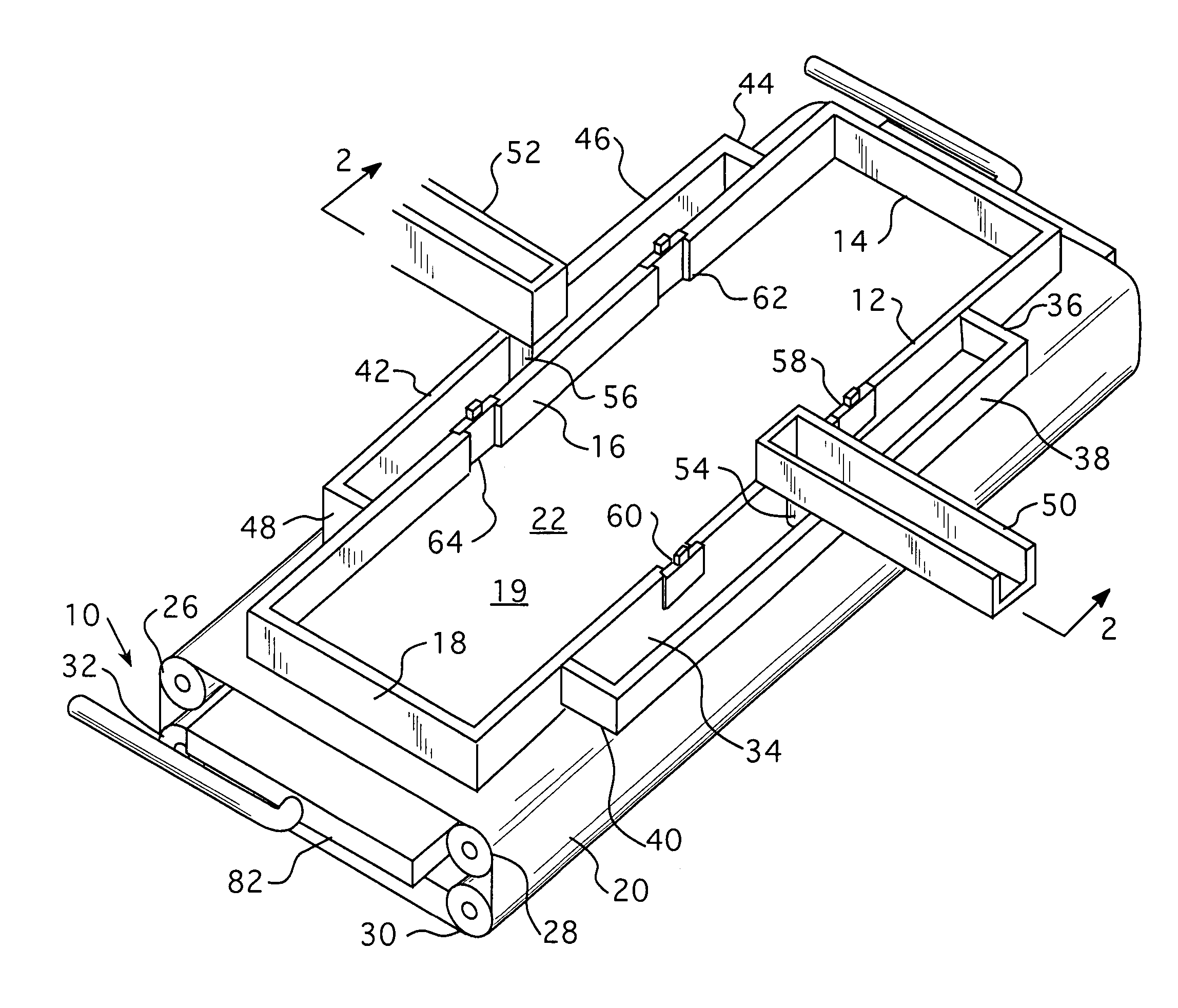

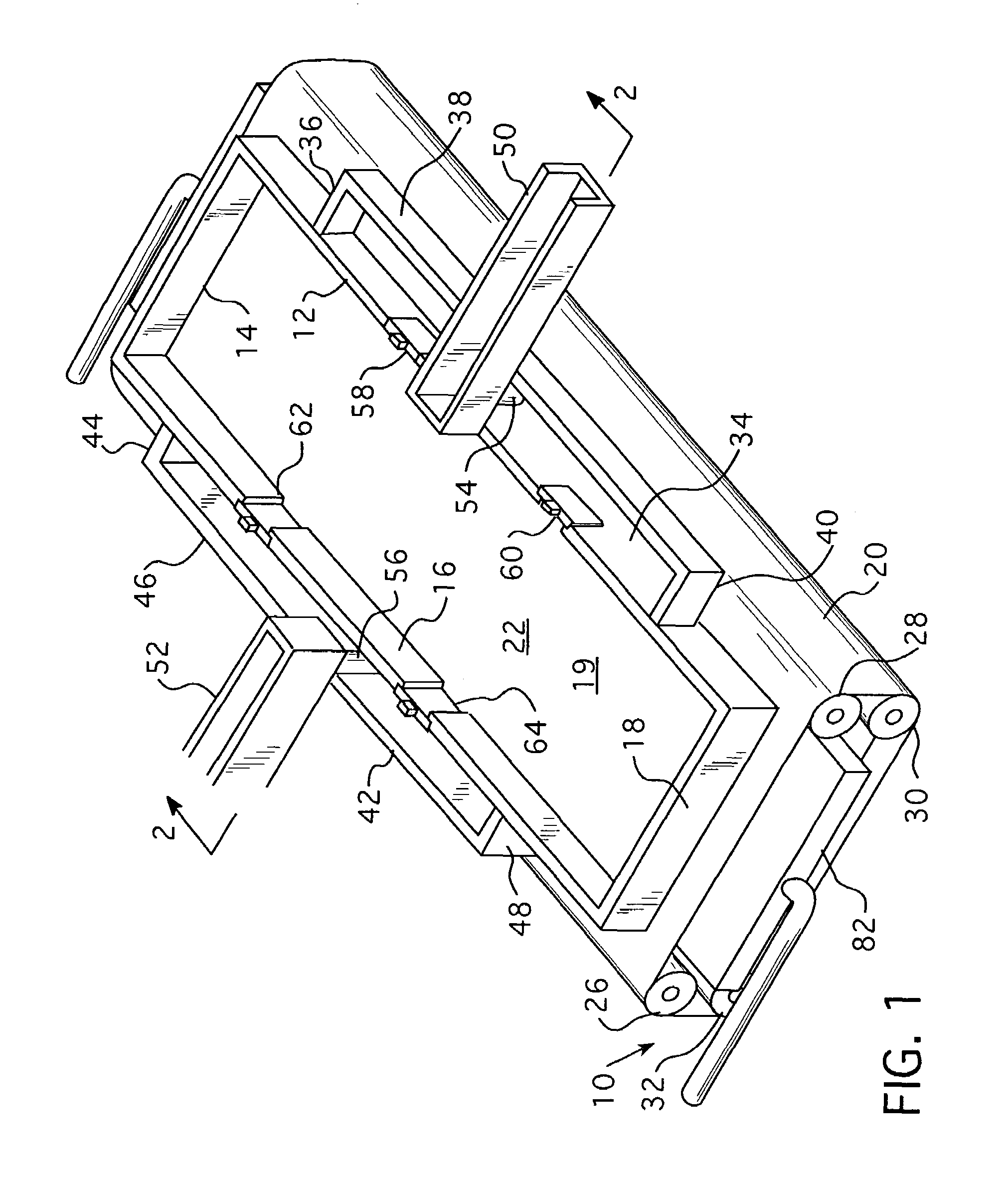

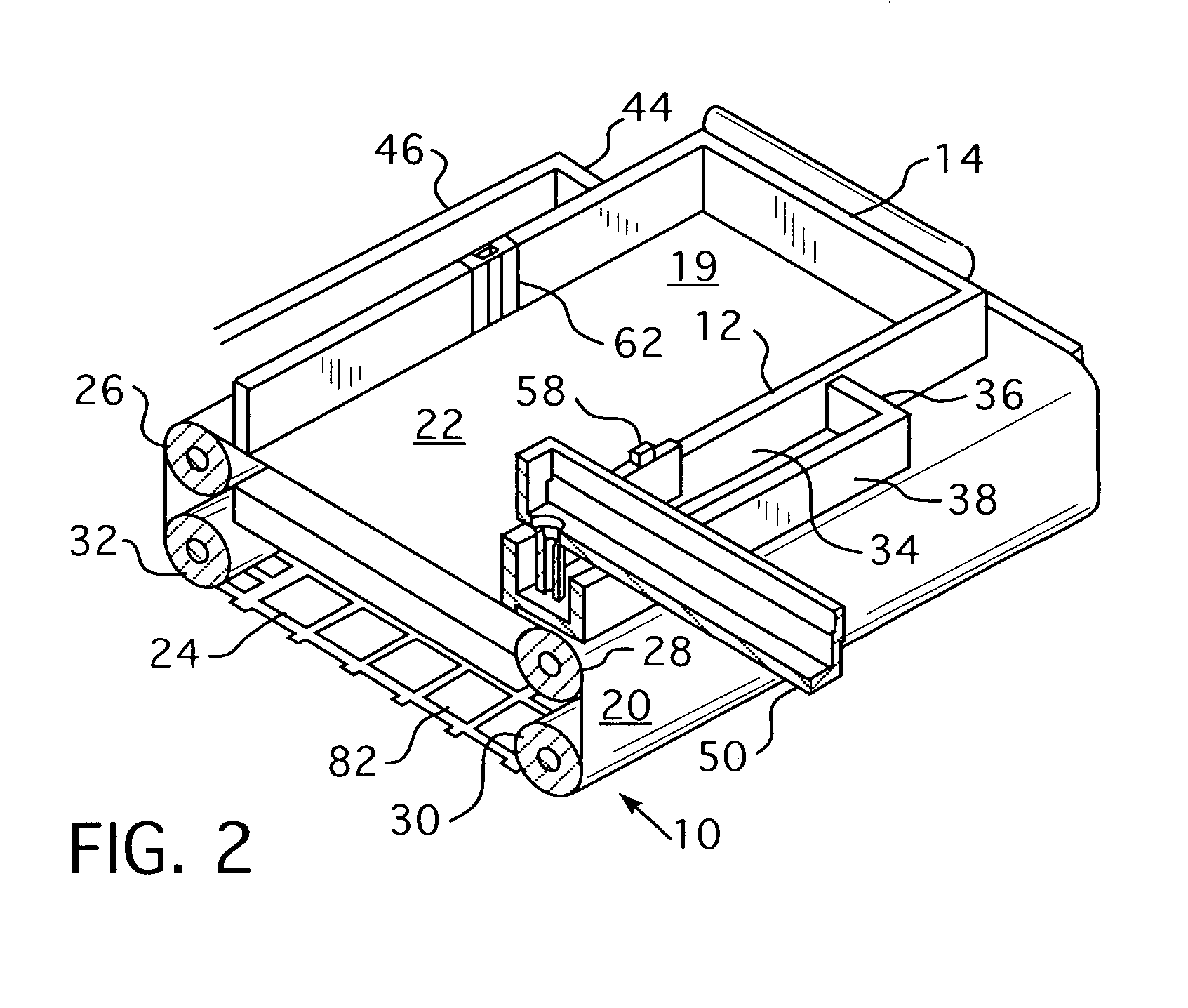

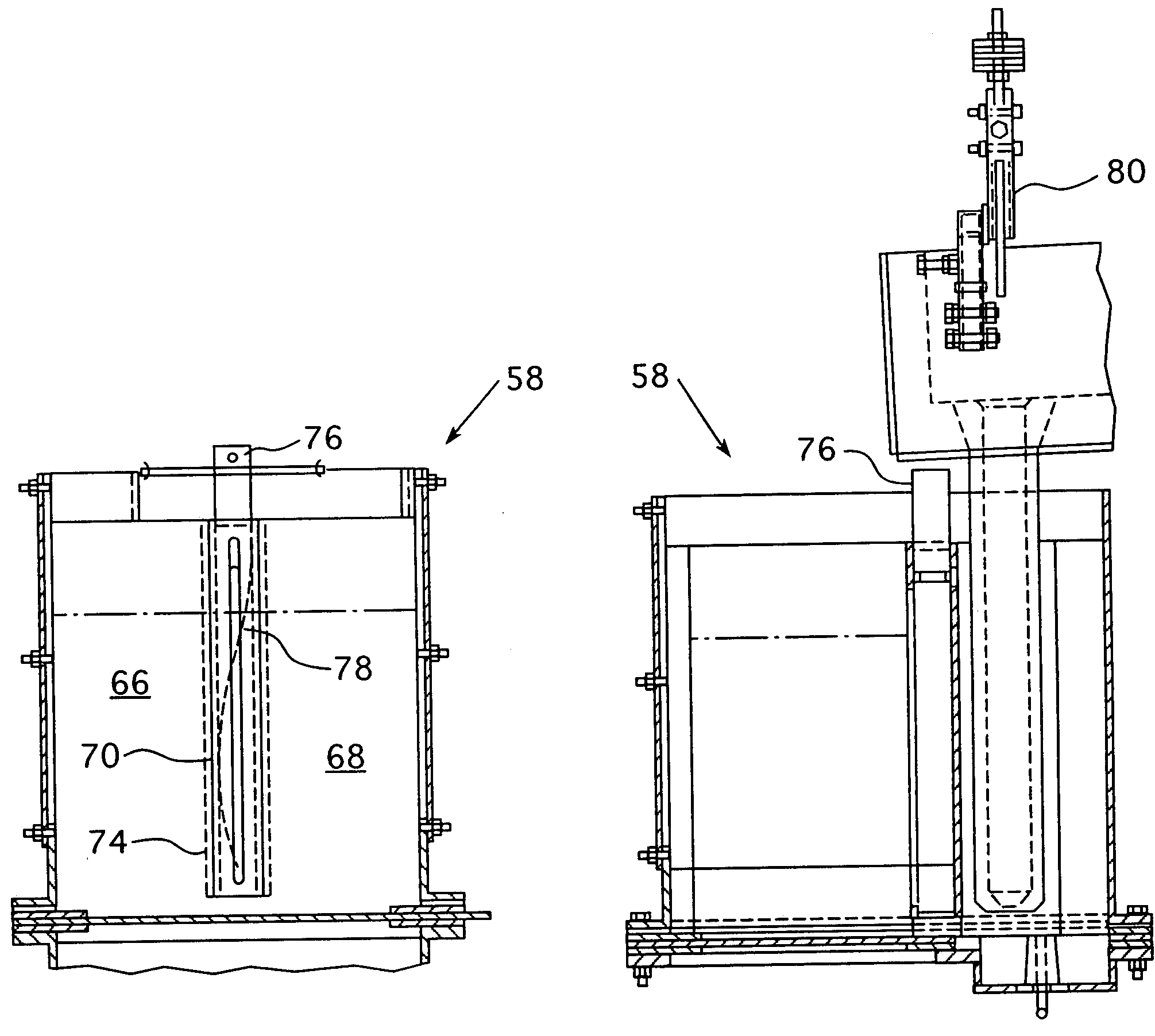

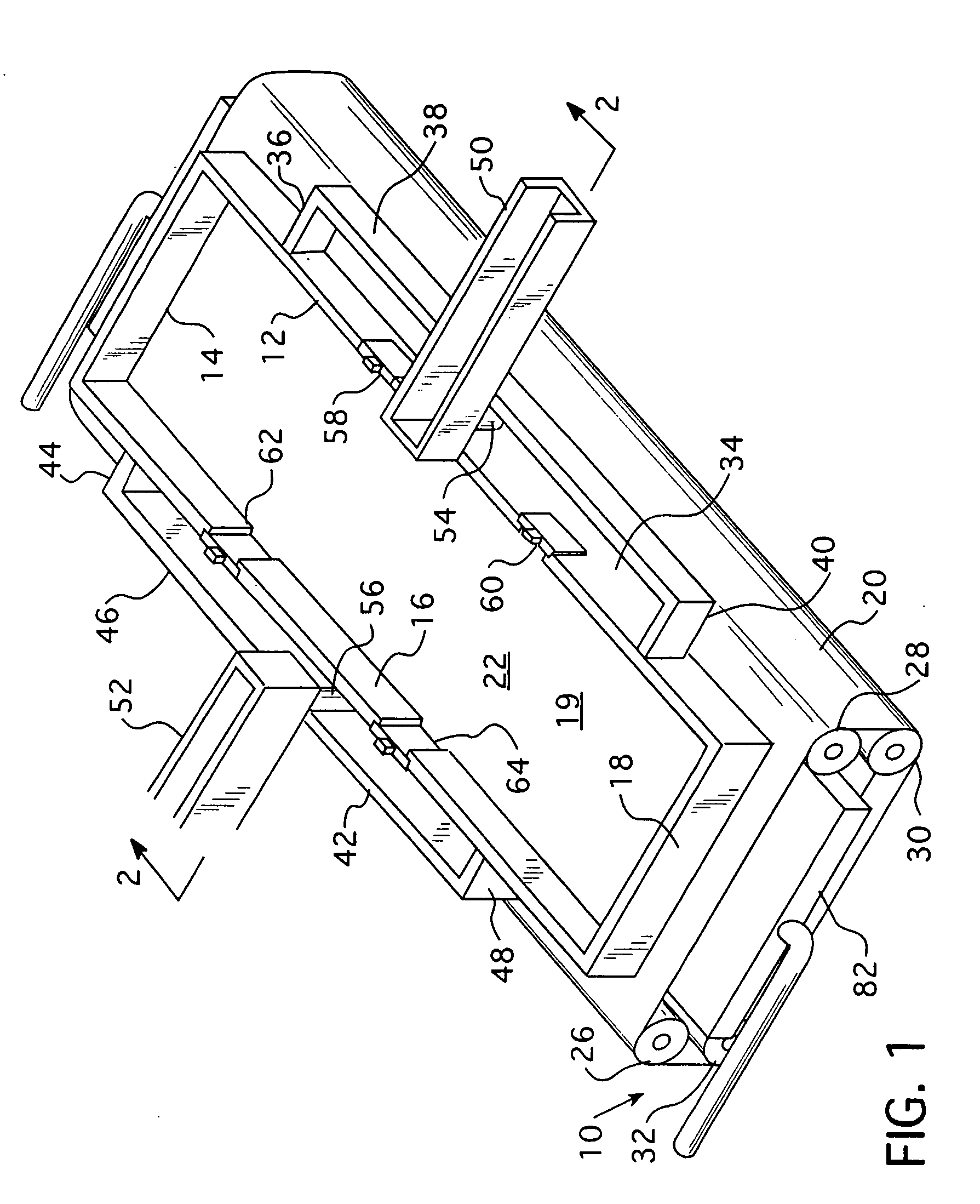

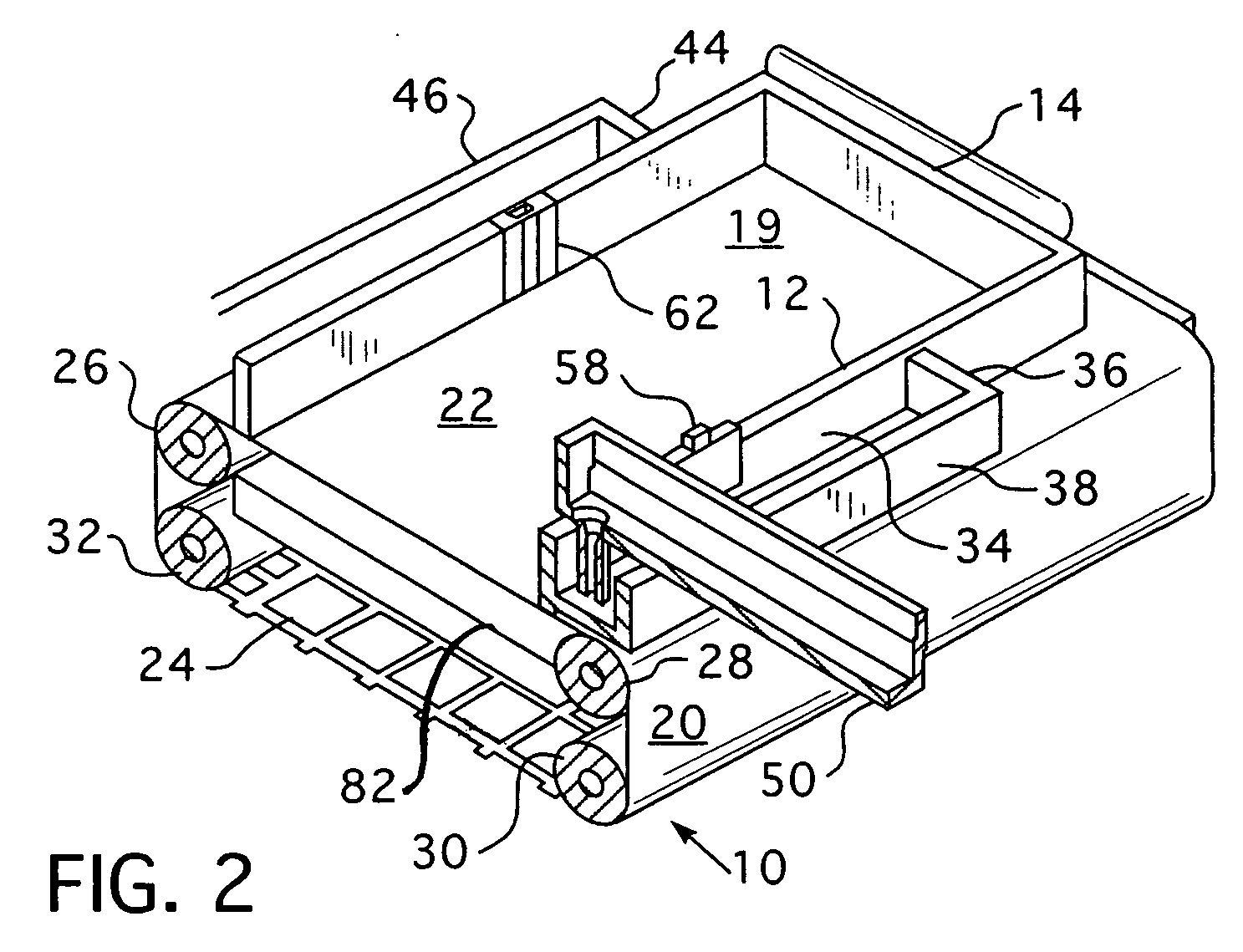

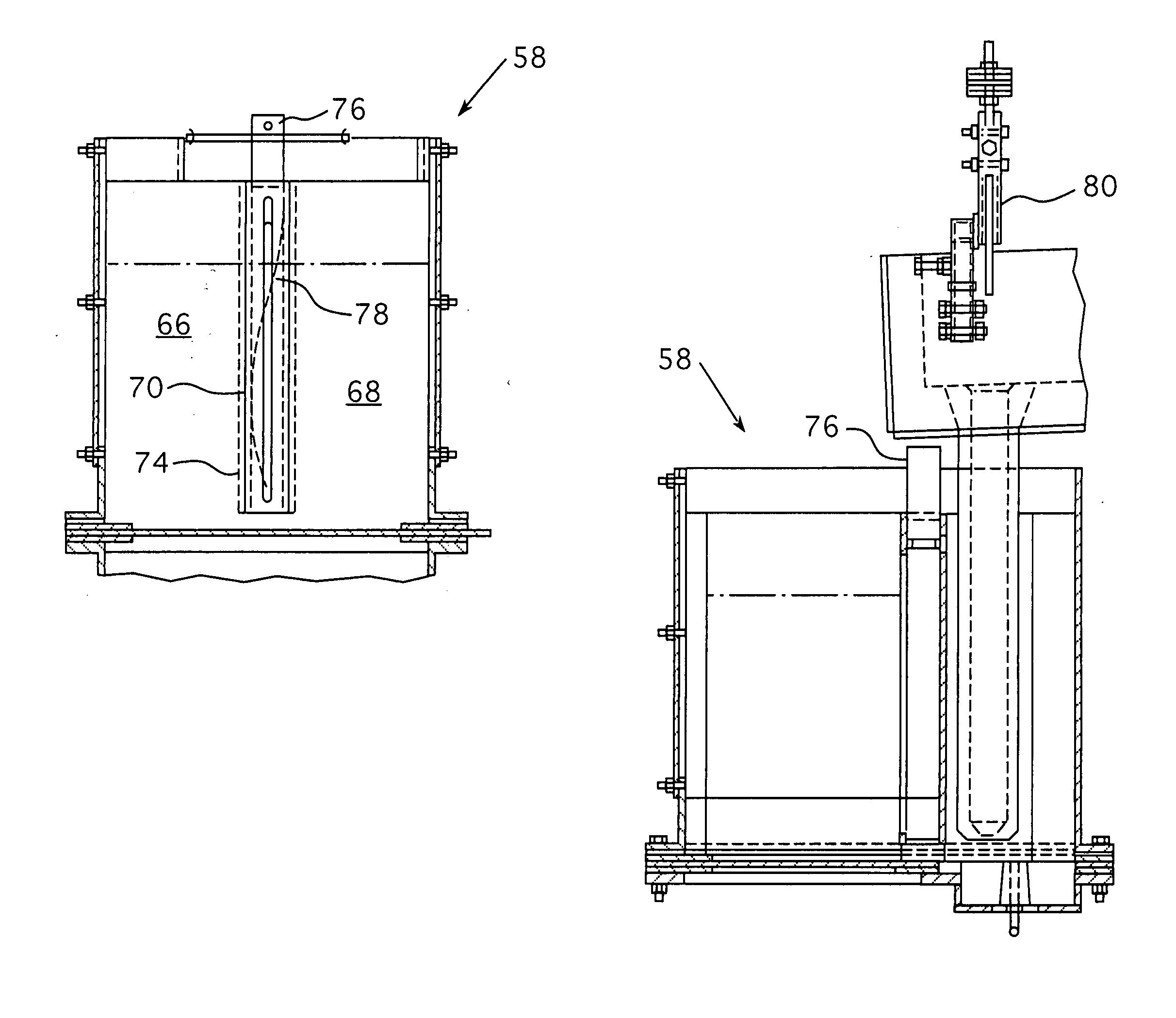

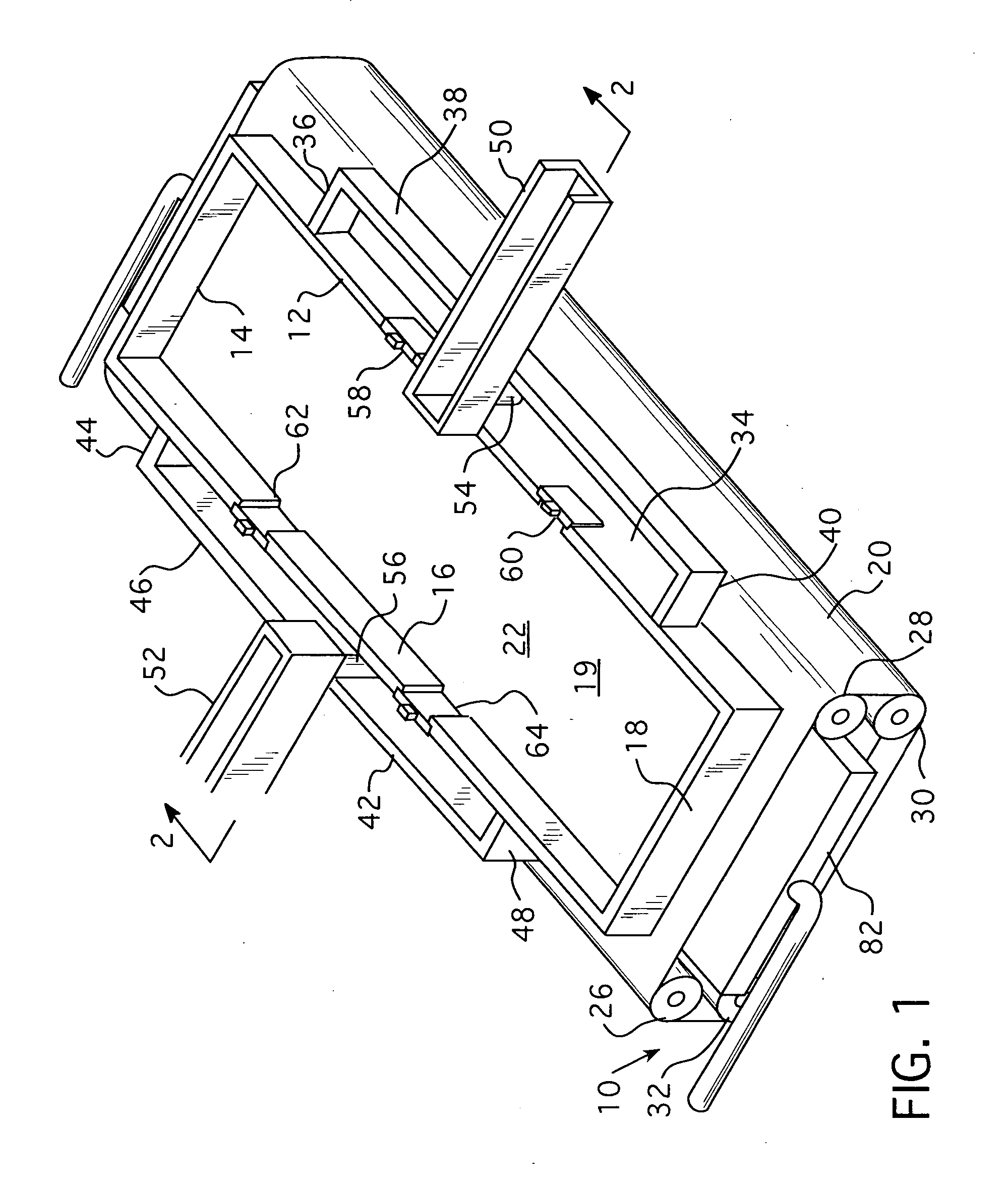

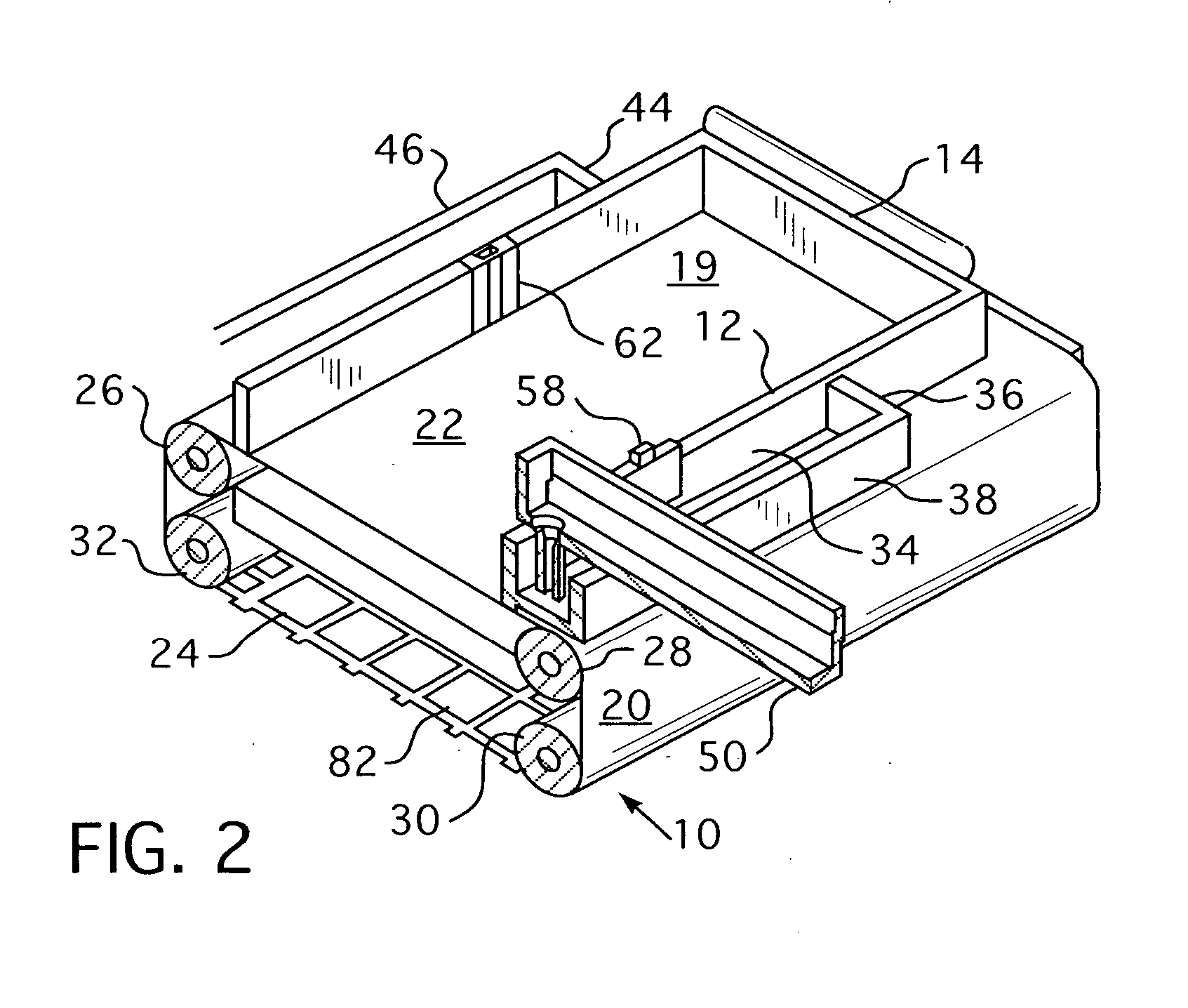

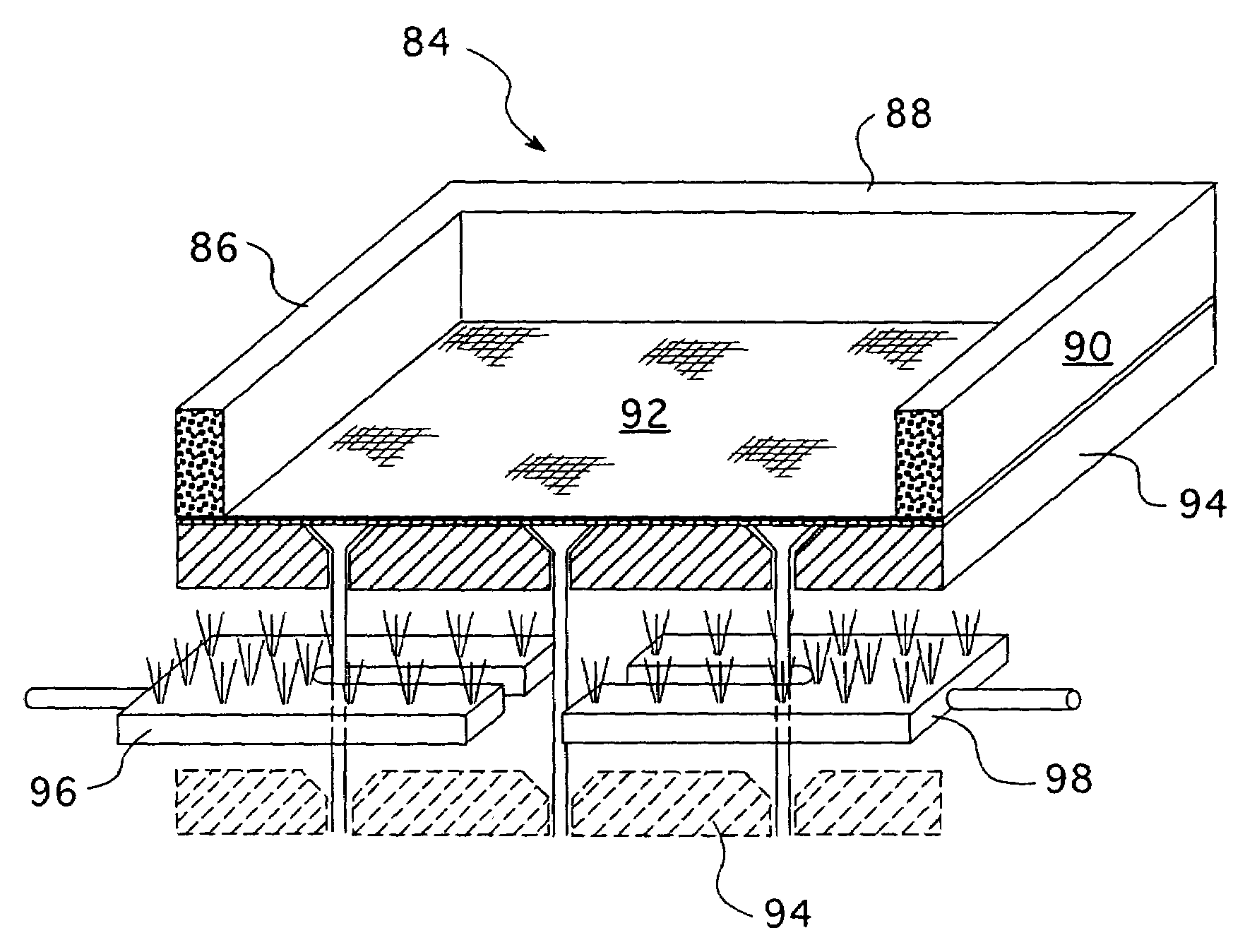

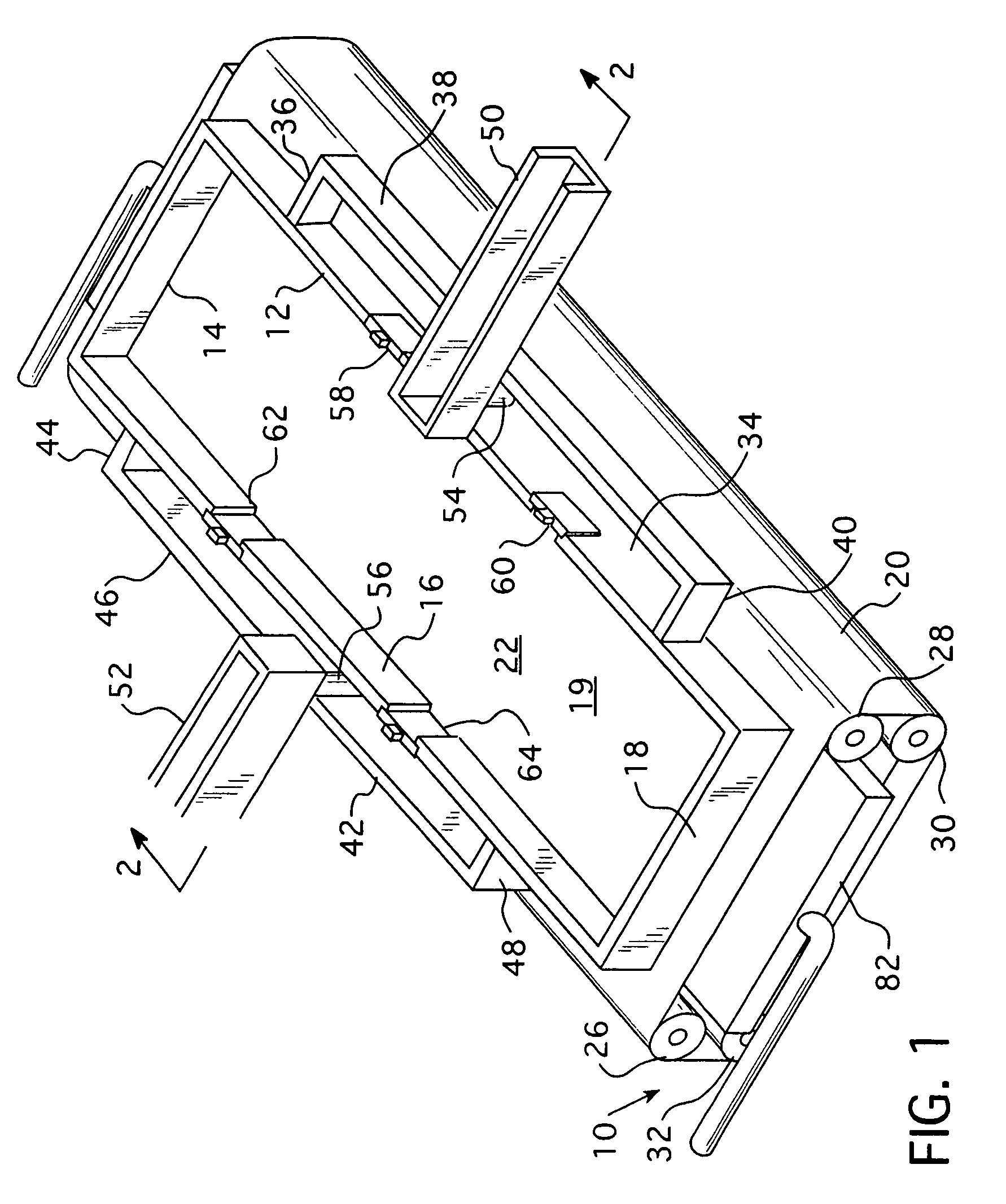

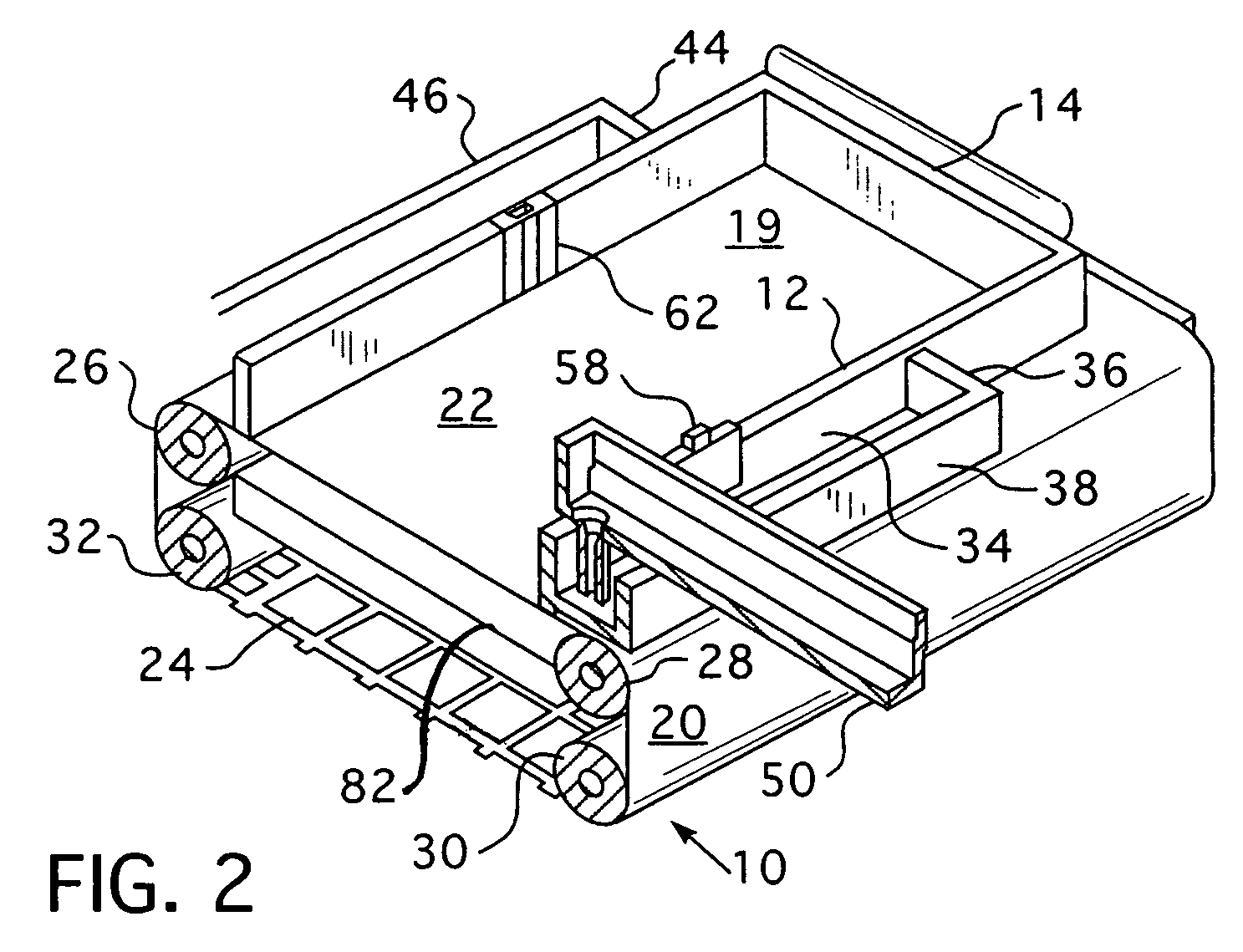

Method of unidirectional solidification of castings and associated apparatus

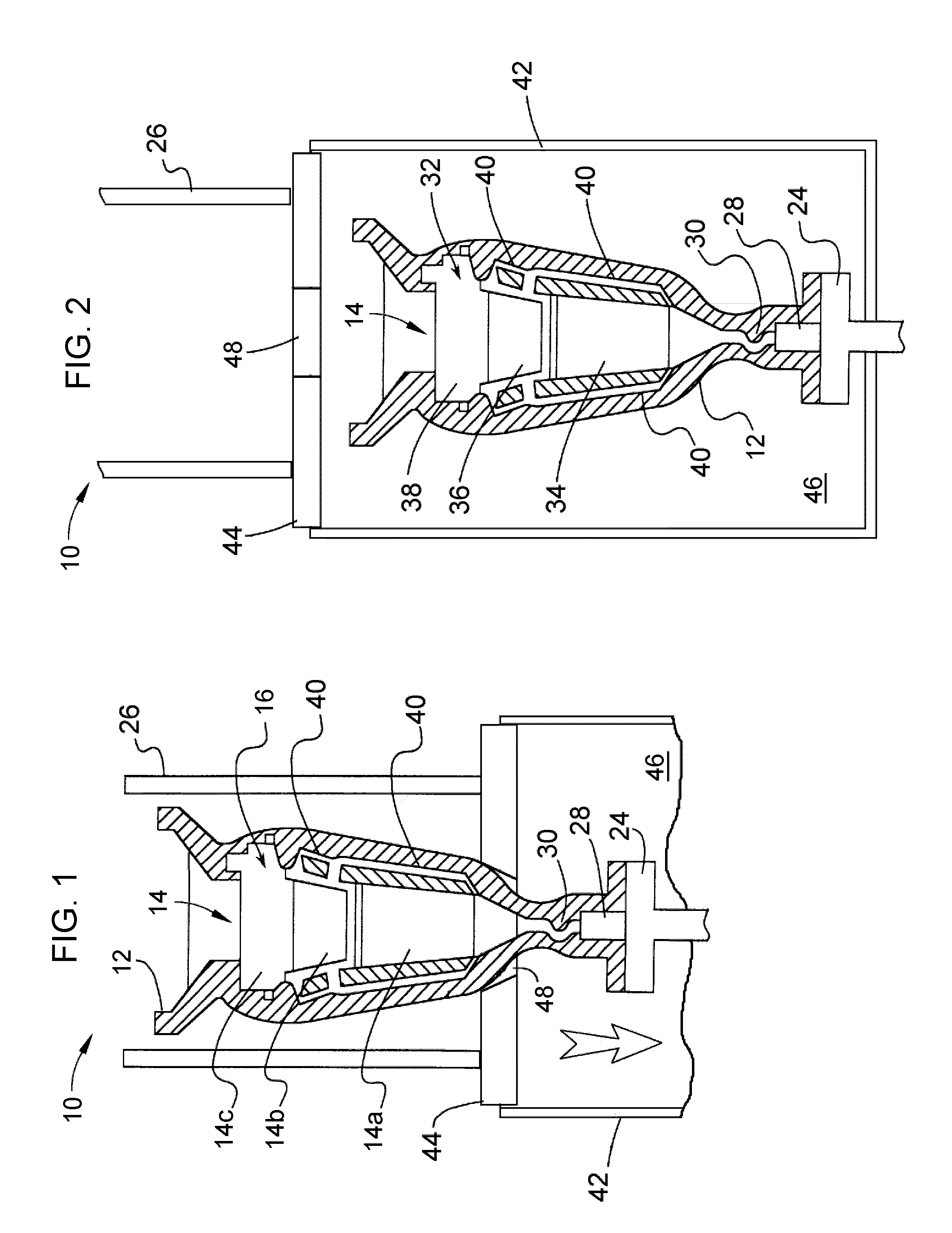

InactiveUS20080182122A1Simple methodConstant rateDomestic articlesThin material handlingMolten stateIngot

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal or vertical direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting. A multiple layer ingot product is also provided comprising a base alloy layer and at least a first additional alloy layer, the two layers having different alloy compositions, where the first additional alloy layer is bonded directly to the base alloy layer by applying the first additional alloy in the molten state to the surface of the base alloy while the surface temperature of the base alloy is lower than the liquidus temperature and greater than eutectic temperature of the base alloy −50 degrees Celsuis.

Owner:ARCONIC INC

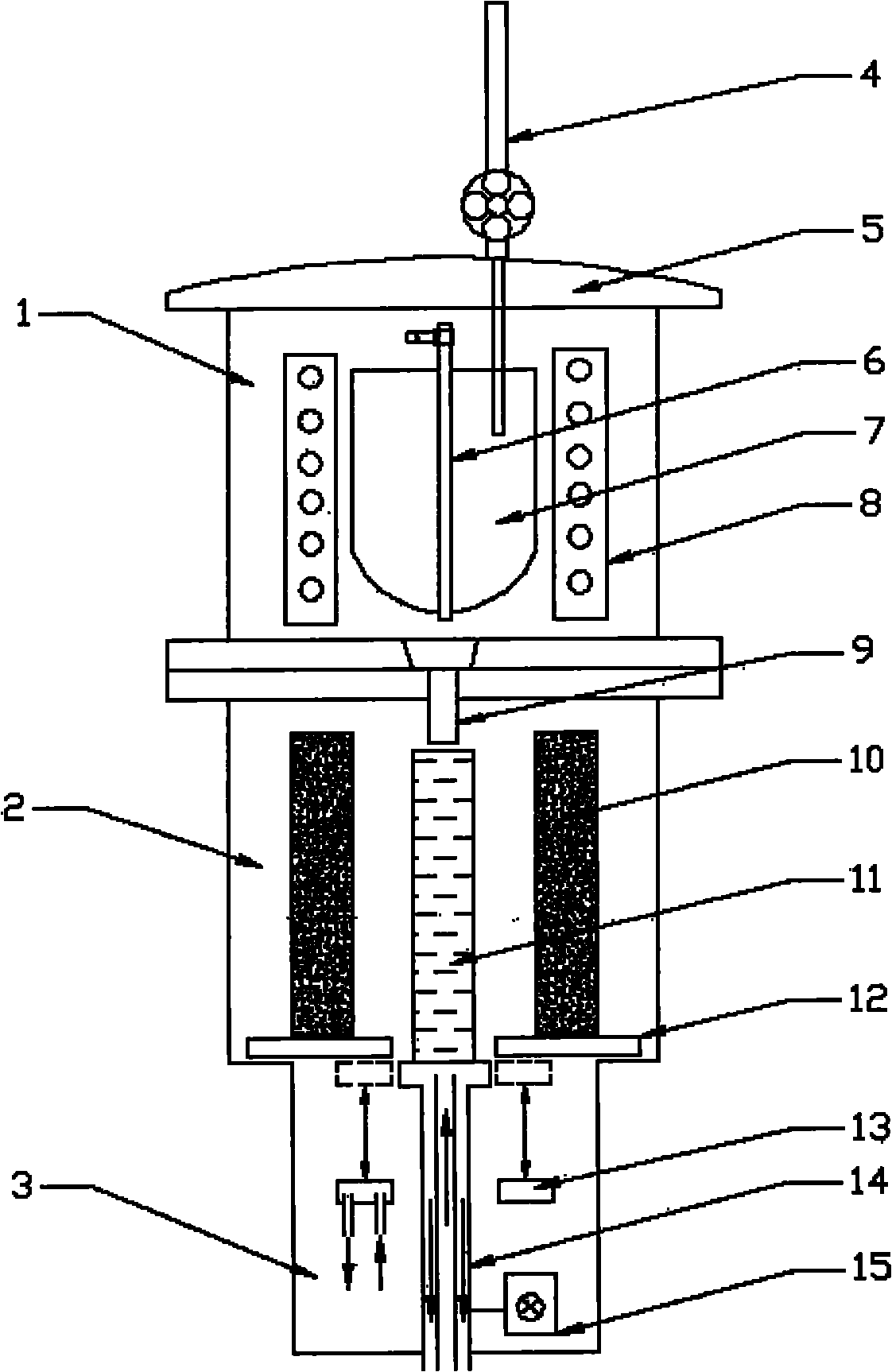

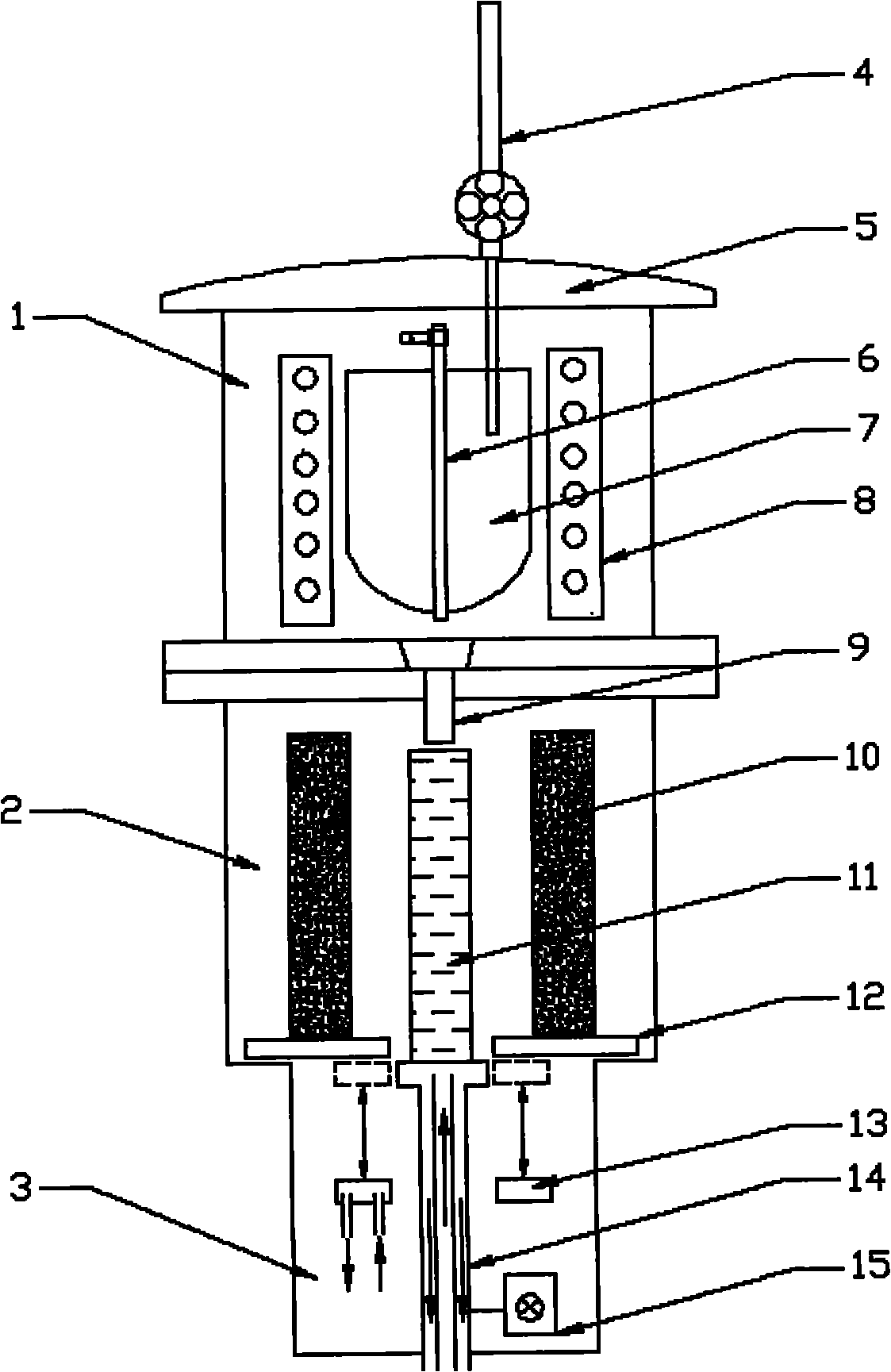

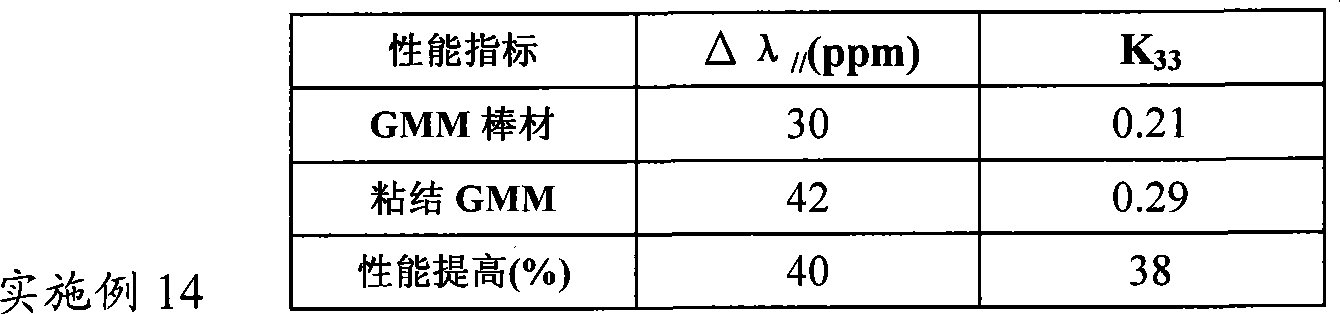

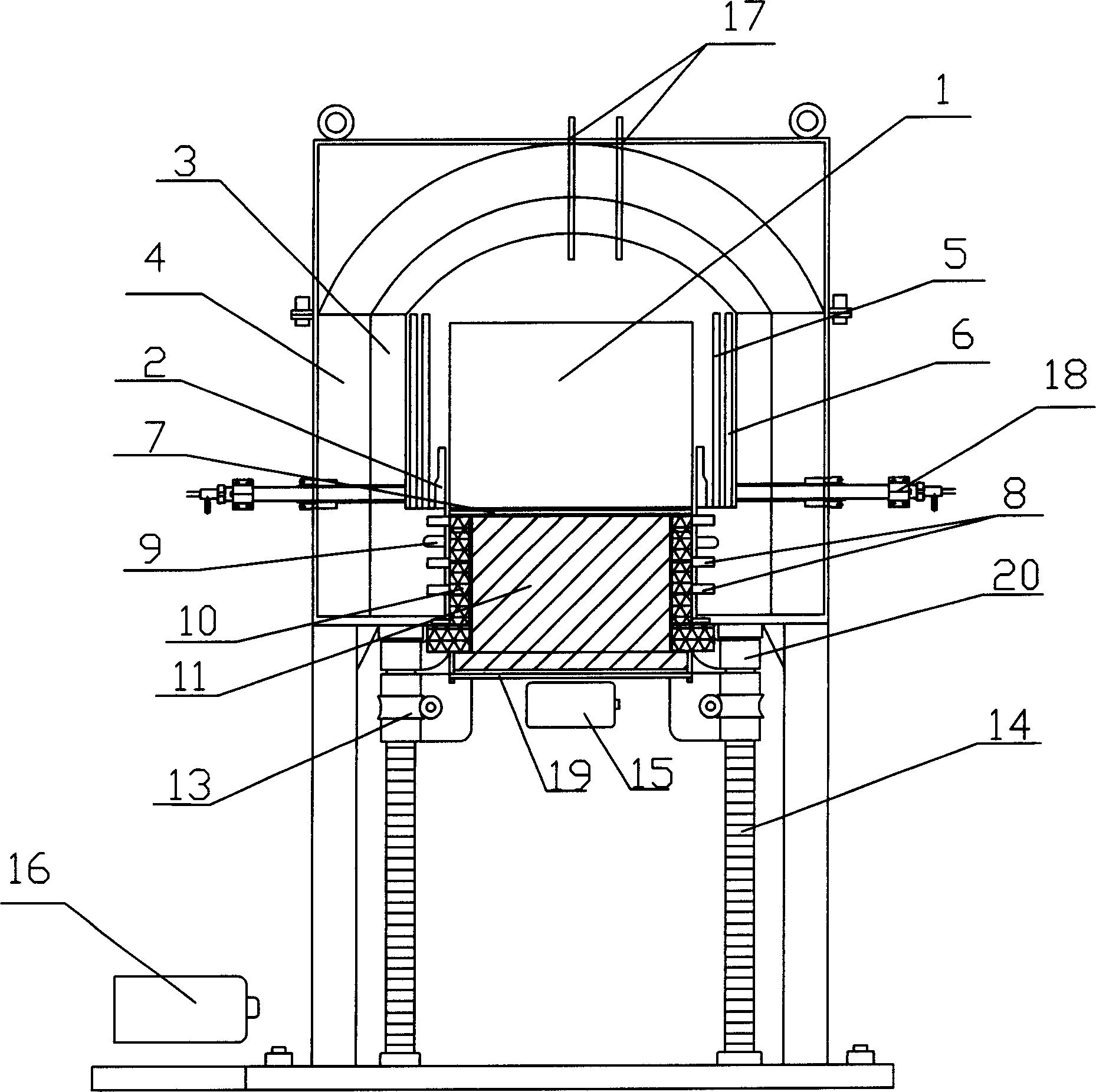

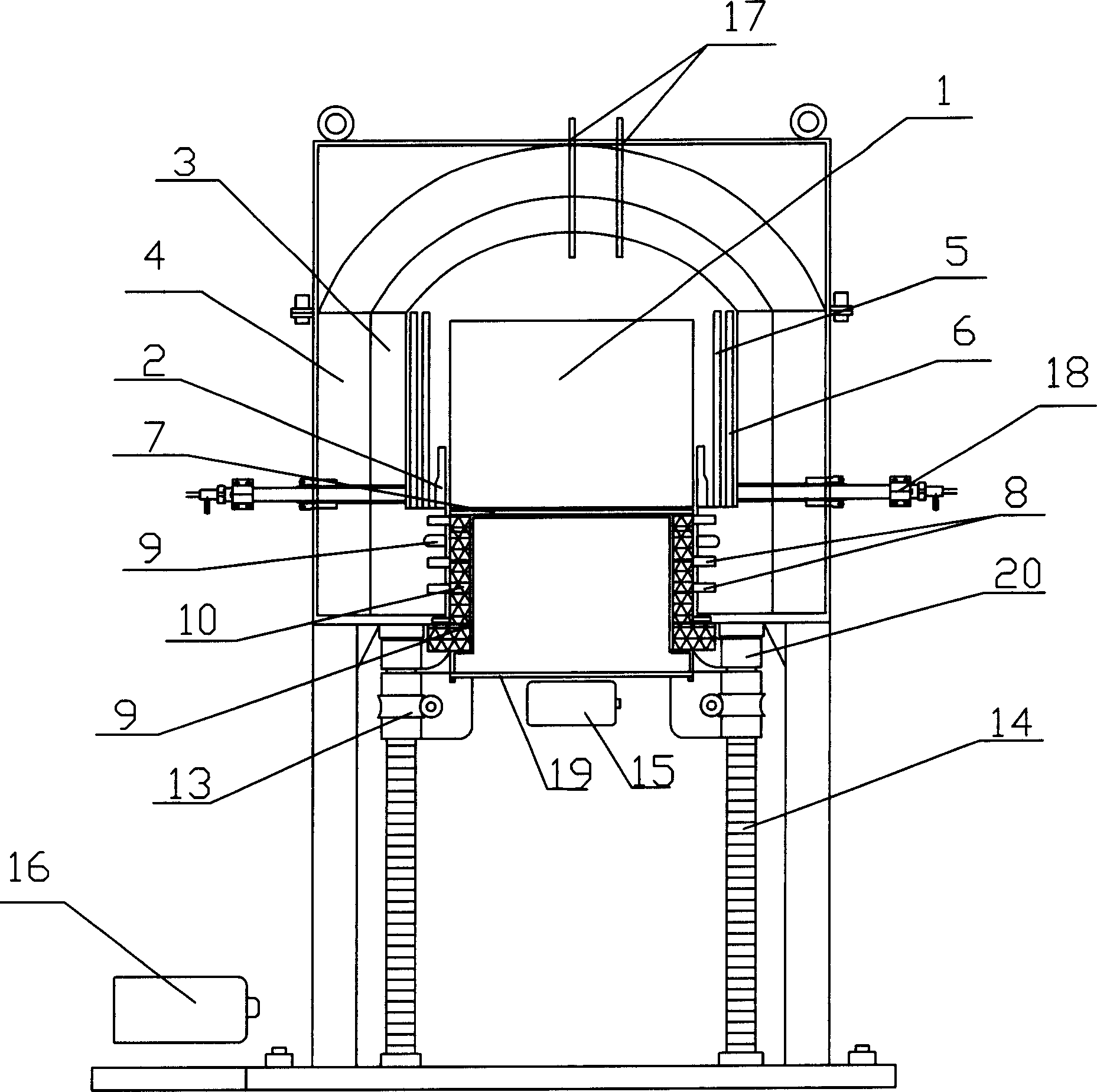

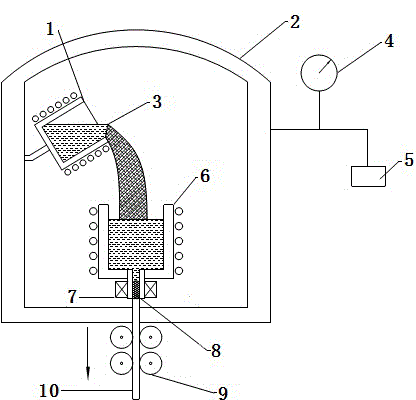

Controllable temperature gradient unidirectional solidification device and method

InactiveCN101844222AImprove consistencyImprove yieldDirectional solidificationUnidirectional solidification

The invention belongs to the material preparation field, which provides a controllable temperature gradient unidirectional solidification device and a method and is applicable to the preparation of the material with magnetic anisotropy and structural anisotropy. The unidirectional solidification device consists of fusion, heat preservation, a pull-down mechanism, a cooling system and a control system. The fusion, unidirectional solidification and thermal processing are completed on the same device. By adjusting the relative position of a movable cooling ring (13) and a solid liquid interface, the temperature gradient of the solid liquid interface in the solidification process is controlled. The cooling ring and the solid liquid interface can be regulated and controlled at 10 to 200mm. The temperature gradient of the solid liquid interface can be regulated and controlled at 5 to 500 degrees centigrade / cm. The invention is applicable to the preparation of the rare earth giant magnetostrictive material, the Nd-Fe-B permanent magnet material and the samarium-cobalt permanent magnet material with magnetocrystalline anisotropy and the high temperature ally and steel material with the structural anisotropy. The invention has the advantages of stable technology, the good consistency of the prepared unidirectional solidification material and high finished product rate.

Owner:UNIV OF SCI & TECH BEIJING

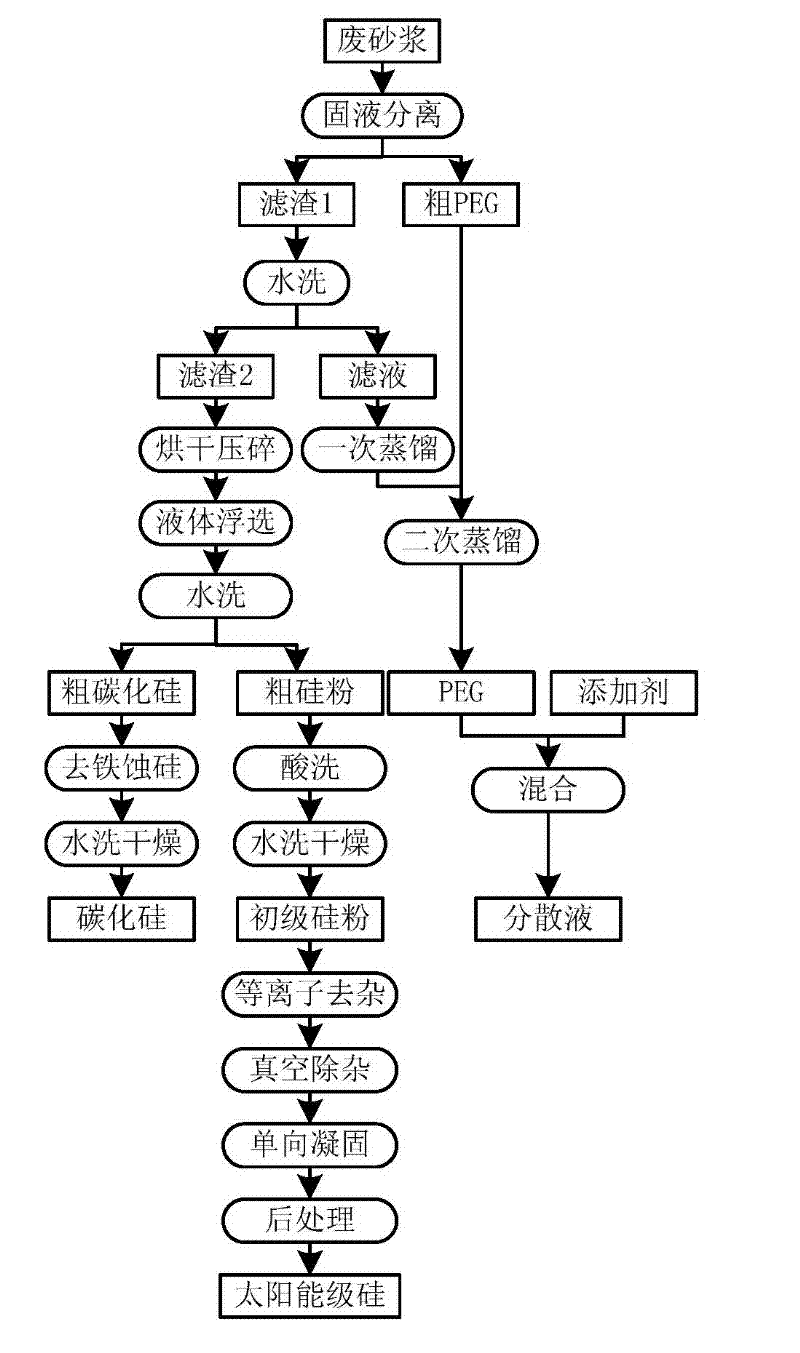

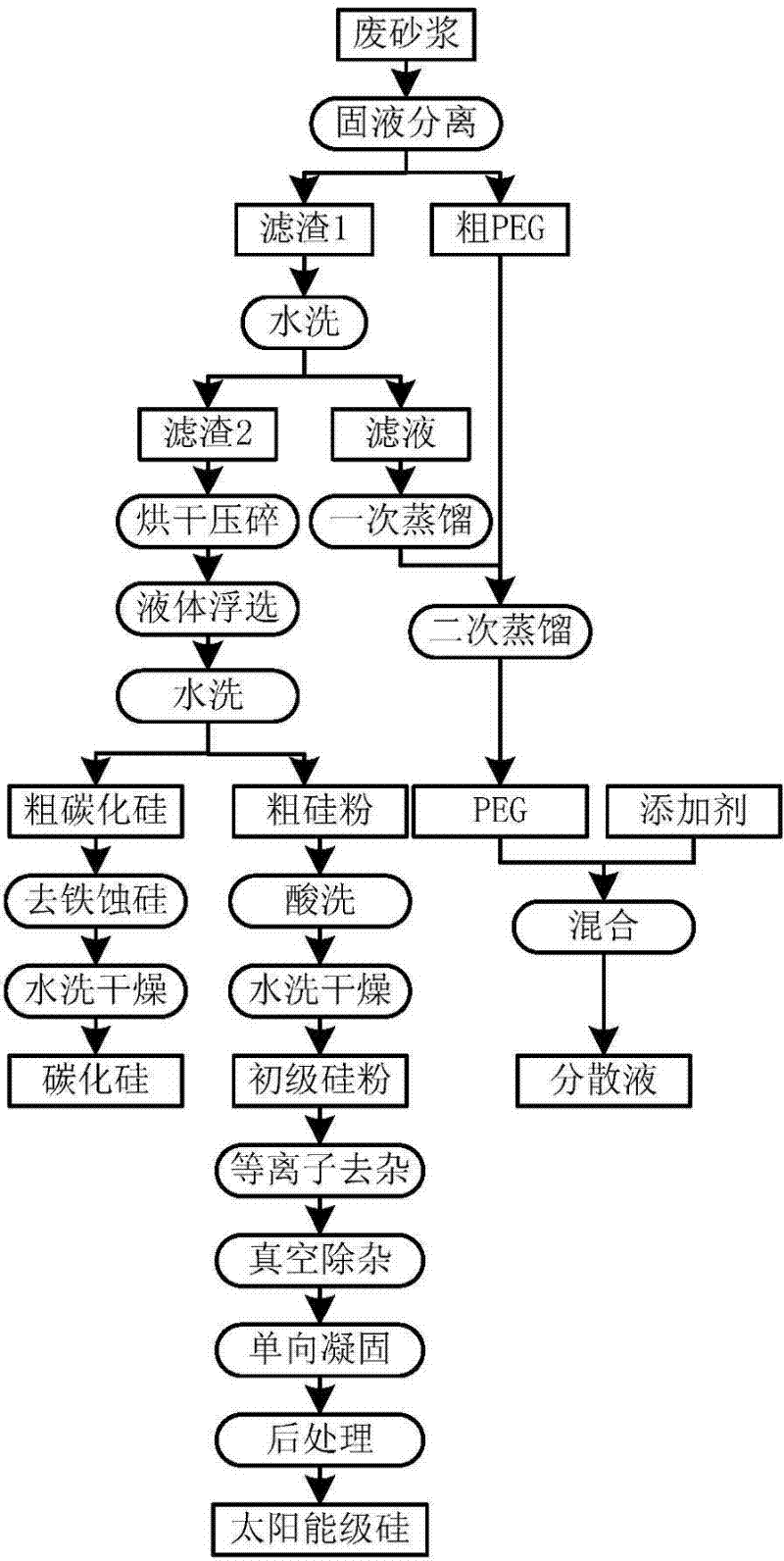

Method for recovering silicon carbide, high-purity silicon and dispersion liquid from silicon material linear cutting waste mortar

InactiveCN102351184AEfficient removalDoes not affect the cutting effectPolycrystalline material growthSingle crystal growth detailsMetal impuritiesSolar battery

The invention relates to a method for recovering silicon carbide, high-purity silicon and dispersion liquid from silicon material linear cutting waste mortar, which is characterized in that the solid and liquid separation on the waste mortar is carried out, recovered dispersing agents are obtained after the liquid is refined, solid is washed by water for further removing residual dispersing agents, then, flotation liquid is used for carrying out floatation for many times, crude silicon carbide and crude silicon powder are separated, the recovered silicon carbide is obtained after the crude silicon carbide is refined, the crude silicon powder is treated through acid cleaning, drying, melting, plasma refining, vacuum refining, unidirectional solidification and the like, and the solar grade polysilicon is obtained. The method has the advantages that the important indexes such as the viscosity, the acid-base degree and the like of the recovered dispersing agents are more similar to those of the novel dispersing liquid, more cutting capability of the silicon carbide can be recovered after the silicon carbide is subjected to the silicon corrosion treatment, metal impurities in high-purity silicon powder are removed, an important index of the phosphorus and boron content of the solar grade silicon is reduced to a value conforming to the solar grade silicon requirements that the phosphorus is lower than 0.01 ppmw and the boron is lower than 0.16ppmw, and the attenuation of the photoelectric conversion efficiency is greatly reduced after solar batteries are made.

Owner:刘荣隆

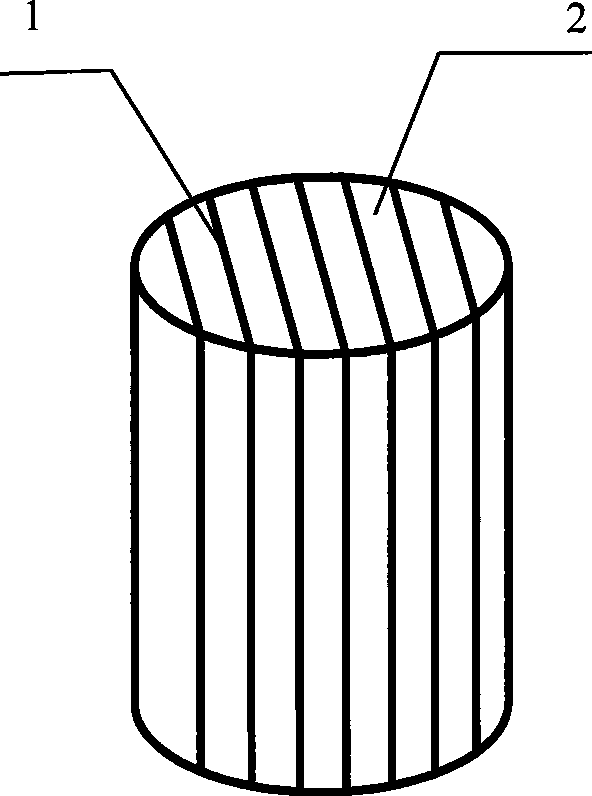

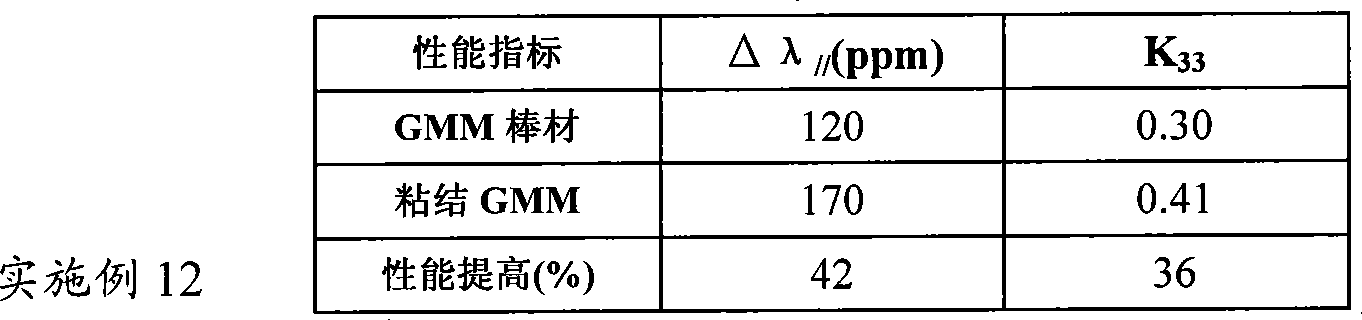

Cementing magnetostrictive material and preparation thereof

ActiveCN101388433APiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyRare earthMagnetostriction

A bonded magnetostrictive composite material and a process for preparation belong to the technical field of magnetic functional materials and preparation, which is characterized by being formed by magnetostrictive sheets with 1-15mm thickness through bonding, wherein the major components of the magnetostrictive sheet is (Tb, Dy) Fe2 rare-earth giant magnetostrictive materials, FeGa and NiMnGa magnetostrictive composite materials. The bonded magnetostrictive composite material has excellent eddy resistance performance, and increases over 30-80% magnetostrictive property under high frequency compared with common mangetostrictive composite materials. In addition, the process for preparation has simple operation and low cost, and has regular product appearance and large freedom degree in dimension, and overcomes the disadvantage that the traditional unidirectional solidification technique hardly obtains magnetostrictive composite material in large dimension.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

Process and apparatus for purifying low-grand silicon material

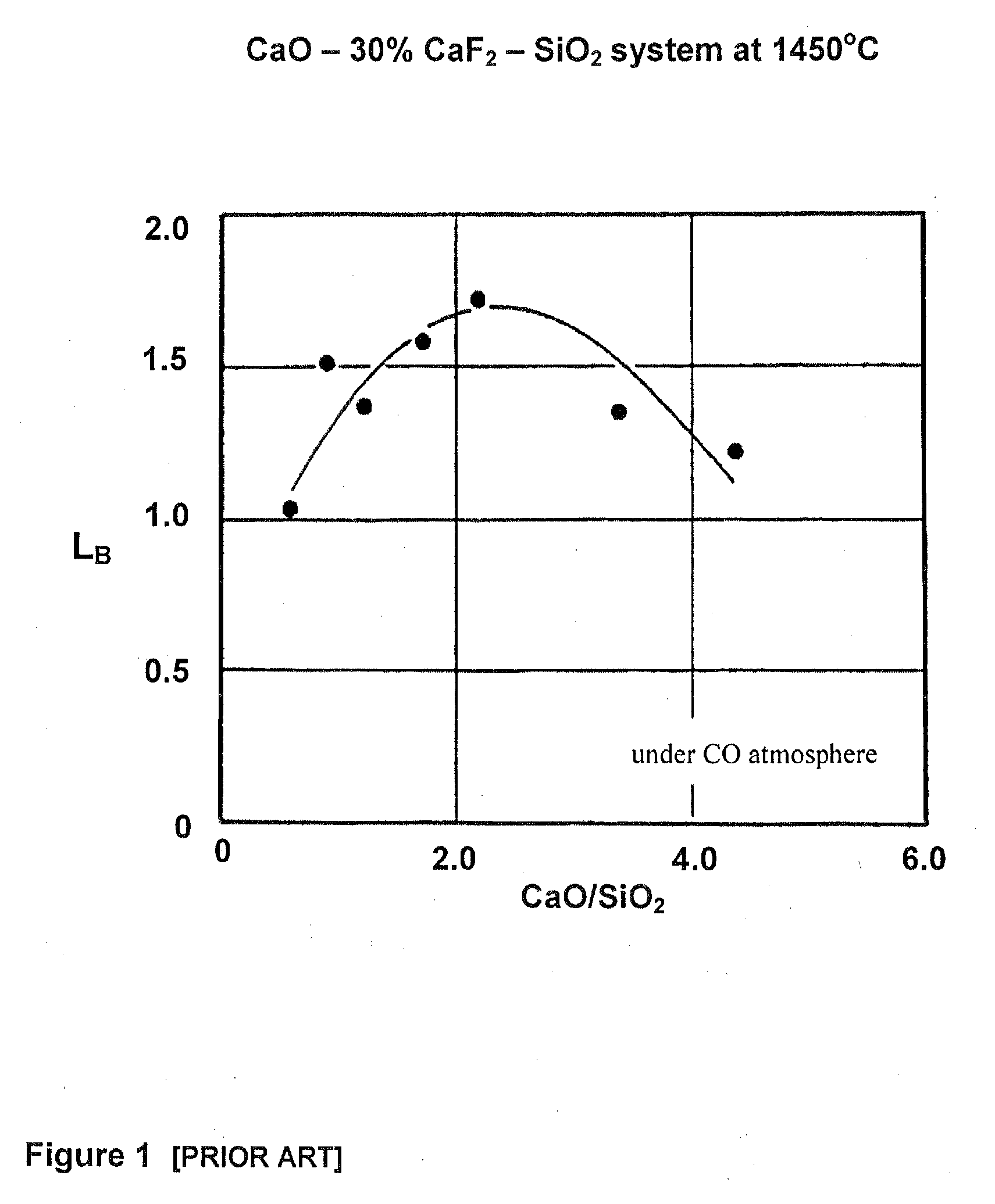

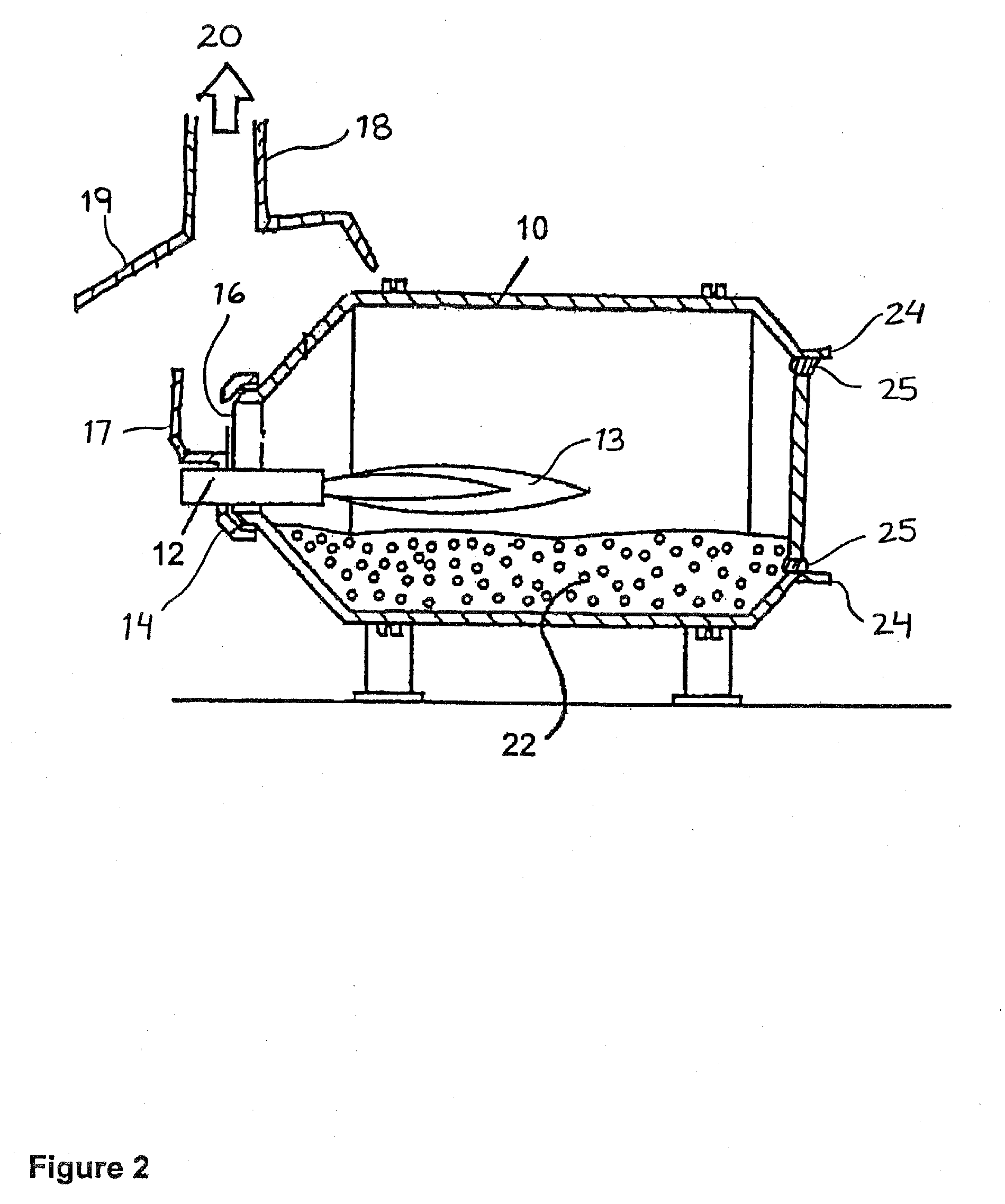

InactiveUS20080253955A1Improve purification effectSafe and controlled and mannerPolycrystalline material growthSilicaSlagReducing atmosphere

A process and apparatus for purifying low-purity silicon material and obtaining a higher-purity silicon material is provided. The process includes providing a melting apparatus equipped with an oxy-fuel burner, and melting the low-purity silicon material in the melting apparatus to obtain a melt of higher-purity silicon material. The melting apparatus may include a rotary drum furnace and the melting of the low-purity silicon material may be carried out at a temperature in the range from 1410° C. to 1700° C. under an oxidizing or reducing atmosphere. A synthetic slag may be added to the molten material during melting. The melt of higher-purity silicon material may be separated from a slag by outpouring into a mould having an open top and insulated bottom and side walls. Once in the mould, the melt of higher-purity silicon material can undergo controlled unidirectional solidification to obtain a solid polycrystalline silicon of an even higher purity.

Owner:BANK OF AMERICA N A +1

Vertical ceramic mould housing for single crystal blade forming and forming method of ceramic mould housing

InactiveCN104923734APrevent leakageDoes not affect growing conditionsFoundry mouldsFoundry coresWaxSingle crystal

The invention discloses a vertical ceramic mould housing for single crystal blade forming and a forming method of the ceramic mould housing. The ceramic mould housing is characterized in that the ceramic mould housing is erected above a chassis; a crystal selector and a plurality of supporting columns are arranged between the chassis and the ceramic mould housing; the supporting columns are arranged at the periphery of the crystal selector in a surrounding manner; and the supporting columns and the ceramic mould housing are molded integrally. The forming method of the ceramic mould housing comprises the steps that 1) a blade wax mould, a chassis wax mould and a crystal selection wax mould are manufactured; 2) the blade wax mould is assembled on the crystal selection wax mould, the crystal selection wax mould is assembled on the chassis wax mould, a plurality of supporting rods are arranged between the chassis wax mould and the blade wax mould, and arranged at the periphery of the crystal selection wax mould in a surrounding manner; and 3) and the ceramic mould housing is manufactured in a slurry dipping and sand leaching manner. According to the vertical ceramic mould housing and the forming method, reliable and stable supporting for the vertical ceramic mould housing is formed on the chassis, and the whole supporting structure is simple and compact, so that obstruction to heat transfer by radiation is avoided effectively, and the vertical ceramic mould housing does not affect crystal growth conditions of an alloy melt in unidirectional solidification.

Owner:DONGFANG TURBINE CO LTD

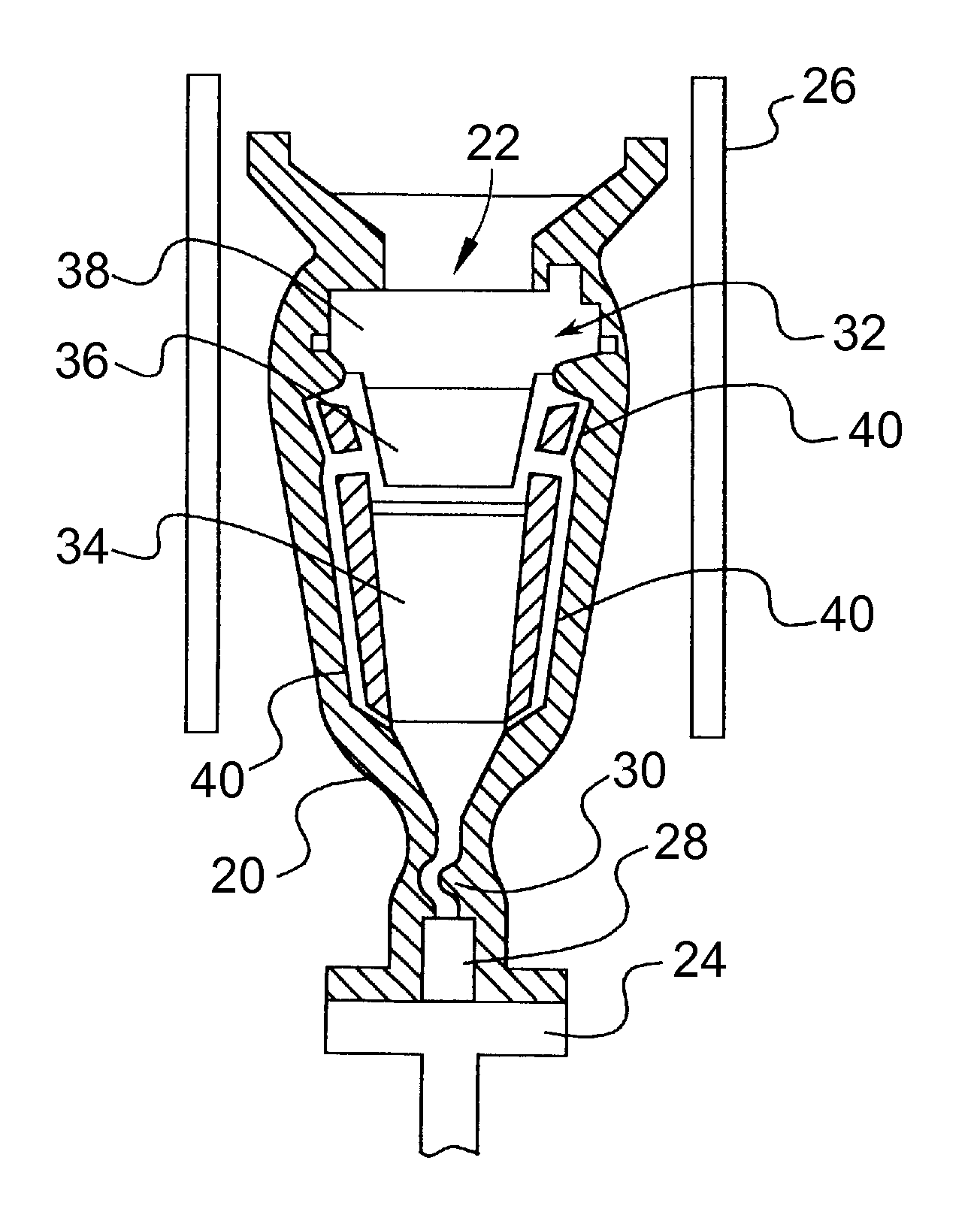

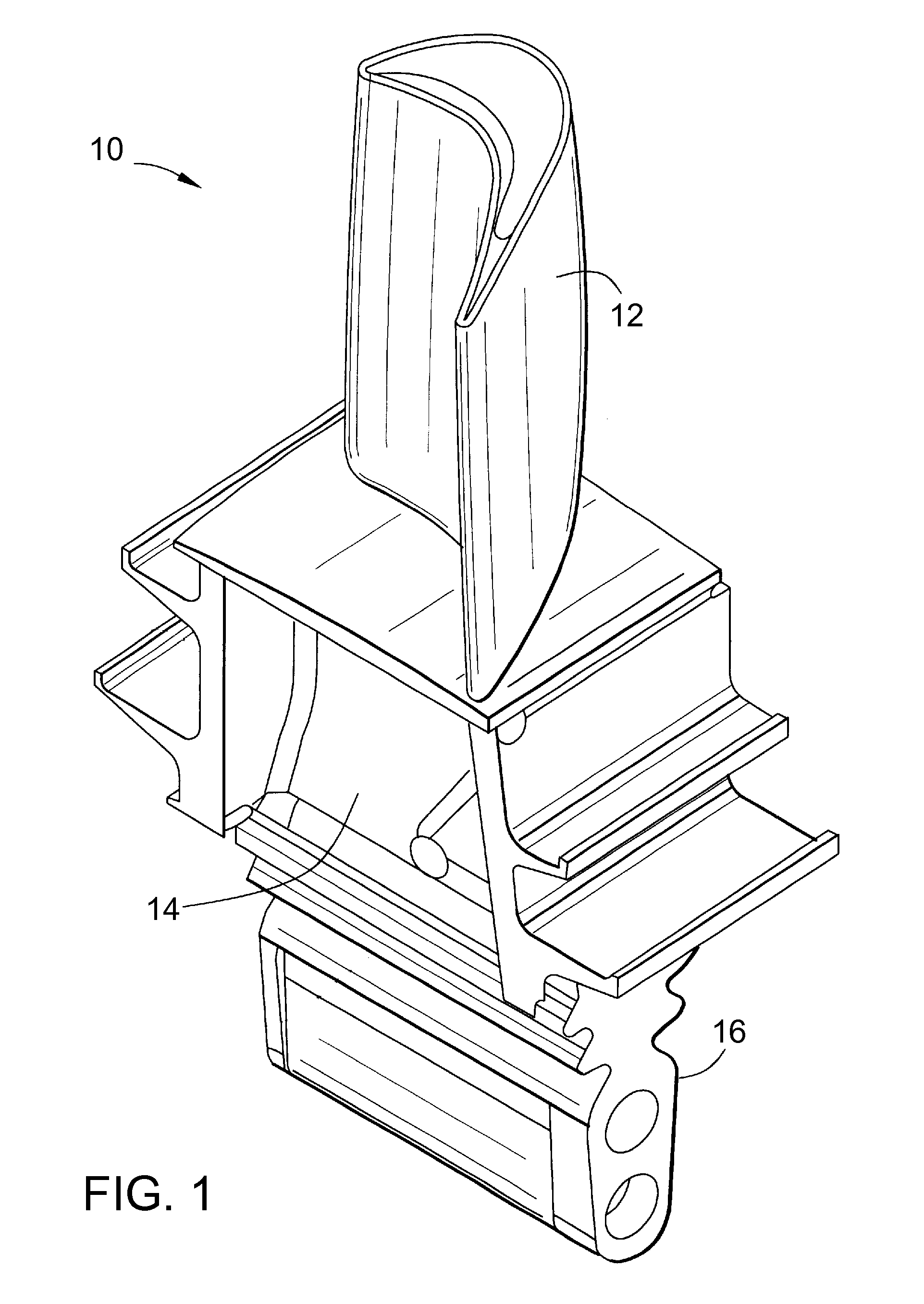

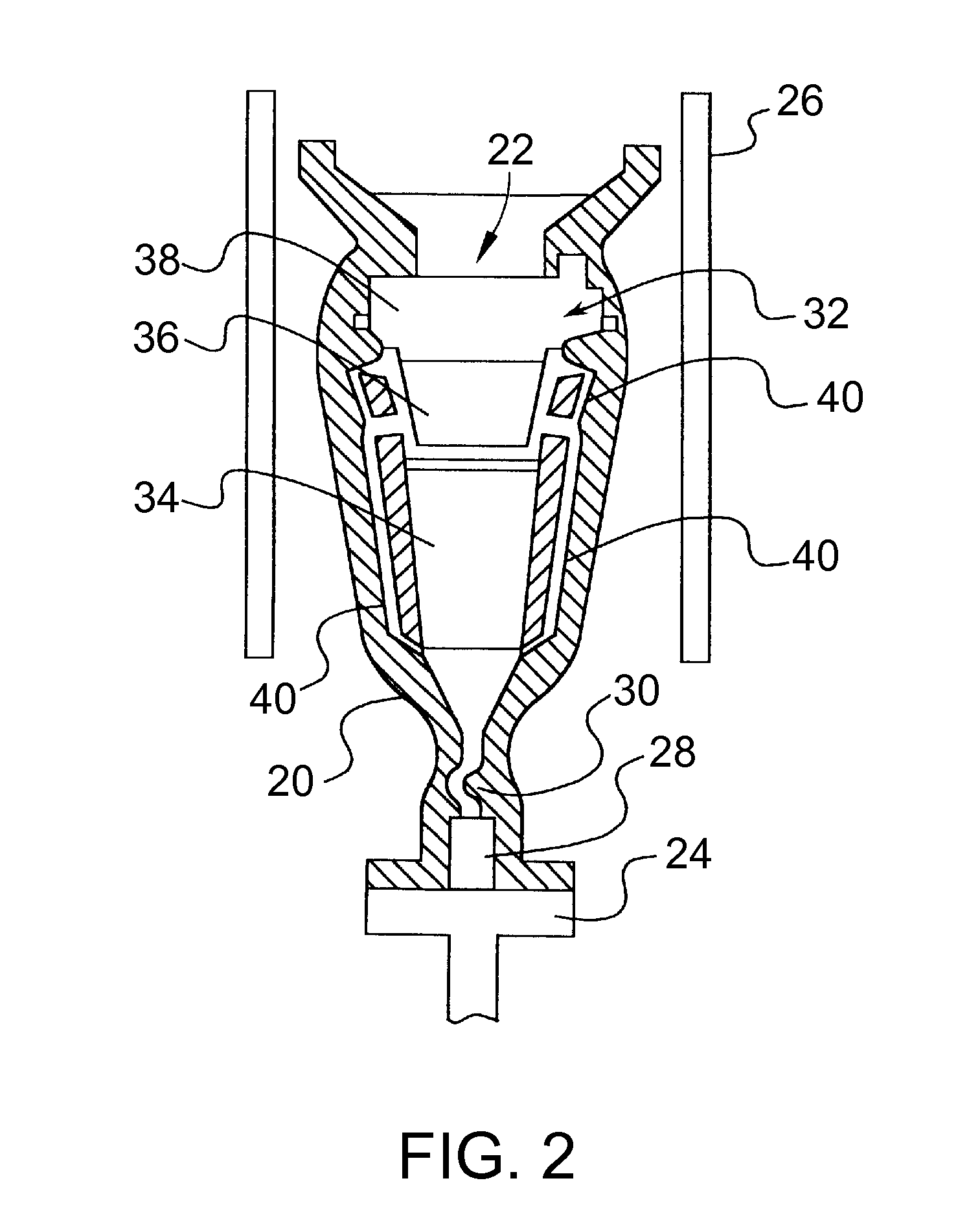

Method of unidirectional solidification of castings and associated apparatus

InactiveUS7264038B2Simple methodConstant rateMelt-holding vesselsMolten metal pouring equipmentsHomogeneous microstructureMolten metal

Owner:ARCONIC INC

Method of unidirectional solidification of castings and associated apparatus

InactiveUS20070012417A1Reduce stressReduce probabilityMelt-holding vesselsMolten metal pouring equipmentsMolten stateIngot

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal or vertical direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting. A multiple layer ingot product is also provided comprising a base alloy layer and at least a first additional alloy layer, the two layers having different alloy compositions, where the first additional alloy layer is bonded directly to the base alloy layer by applying the first additional alloy in the molten state to the surface of the base alloy while the surface temperature of the base alloy is lower than the liquidus temperature and greater than eutectic temperature of the base alloy −50 degrees Celsuis.

Owner:ARCONIC INC

Giant magnetostrictive large volume Fe81Ga19 alloy material and preparation method thereof

The invention relates to a giant magnetostrictive large volume Fe81Ga19 alloy material and a preparation method thereof, belonging to the technical field of the alloy material and the atom percent of the alloy material is Fe81at.% and Ga19 at.%; the preparation method comprises the steps of Fe element and Ga element arc melting, solidification remelting superheat cycle process and high undercooling activation unidirectional solidification. The invention adopts high undercooling activation process so that Fe-Ga alloy blocks can be obtained while the alloy has the giant magnetostrictive property. The magnetostrictive strain of the Fe-Ga alloy blocks is above 500*10 generally and the maximum magnetostrictive strain can reach 830*10.

Owner:SHANGHAI JIAO TONG UNIV

Method of unidirectional solidification of castings and associated apparatus

InactiveUS20070012416A1Reduce stressReduce probabilityMelt-holding vesselsMolten metal pouring equipmentsHomogeneous microstructureMolten metal

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting.

Owner:ARCONIC INC

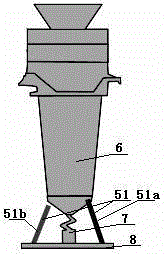

Directional solidifying smelter

InactiveCN1862201ASimple structureReduce the number of vacuum stagesCrucible furnacesCrucibleSmall footprint

The present invention discloses a kind of unidirectional solidification smelting furnace. It includes the following main several portions: crucible, refractory external heat-insulating stool with hollow structure, internal heat-insulating stool, radiation bearing plate, lifting hoop, circular recessed groove and elastic sealing ring, lifting screw rod, water cooler and lifting worm, sliding supporting plate, lifting servo motor and speed-reducing control device. Said invention also provides the connection mode of all the above-mentioned portions and concrete operation method of said smelting furnace.

Owner:高文林

Continuous unidirectional solidification preparation method of high-purity oxygen-free copper rod

The invention discloses a continuous unidirectional solidification preparation method of a high-purity oxygen-free copper rod. The preparation method comprises the following steps of: firstly roasting cathode copper with the purity of 99.99% for 2-4 hours in a heat preserving furnace with the temperature of 200 degrees centigrade to be fully degassed, secondly placing the cathode copper into a smelting pot in a vacuum unidirectional solidification furnace, smelting at 1250-1350 degrees centigrade, performing heat preservation for 20-30min, and casting by the continuous unidirectional solidification furnace. The vacuum degree of the continuous unidirectional solidification furnace is in the range from 0.01 to 1Pa, the casting speed is in the range from 10 to 150mm / min, the cooling water consumption is in the range from 200 to 1000L / h, the cooling water temperature is in the range from 20 to 25 degrees centigrade, and the high-purity oxygen-free copper rod with the diameter of 6-18mm is prepared. The high-purity oxygen-free copper rod is characterized in that the oxygen content is less than 4ppm, the single crystal structure or the continuous column crystal structure along a length direction is present, the conductivity, mechanical property and processing performance is excellent, the finished product ratio is high and the production cost is low.

Owner:JIANGXI UNIV OF SCI & TECH

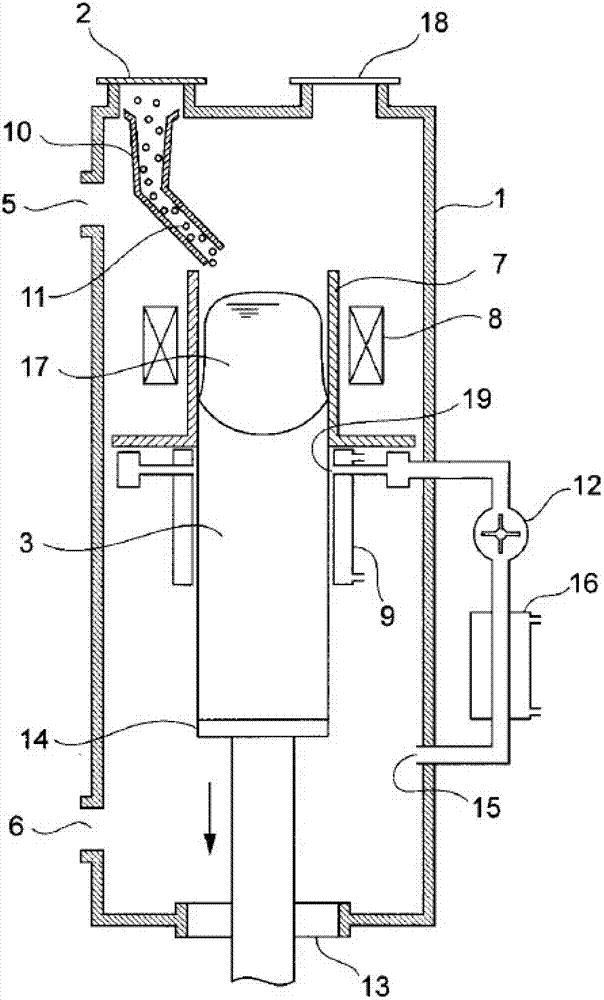

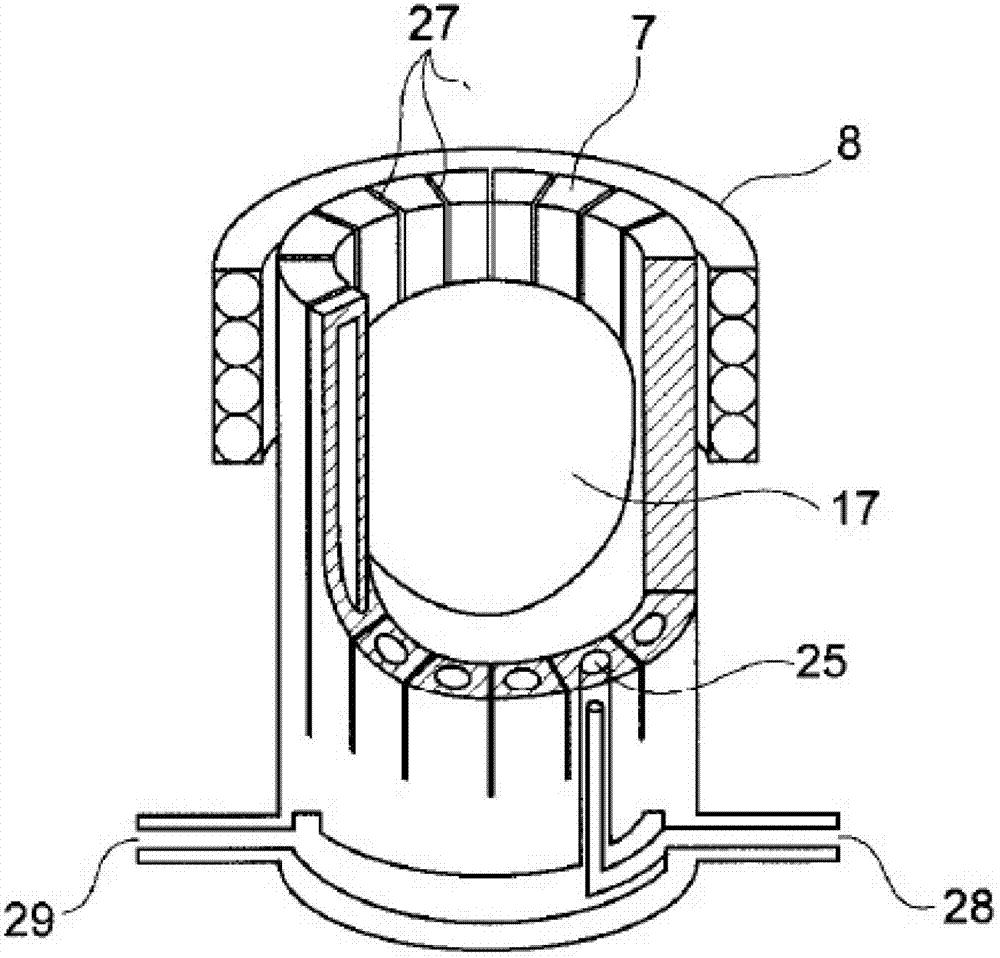

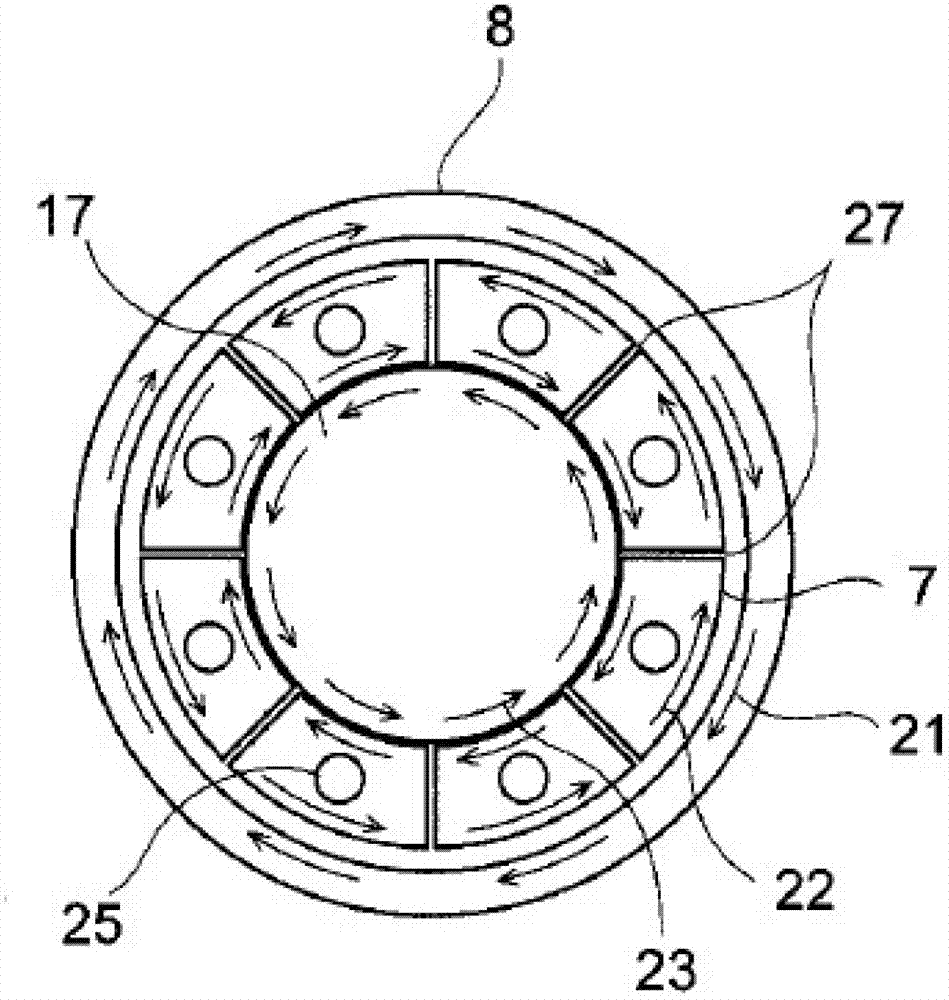

Silicon purification method

InactiveCN102774839ADirectional Solidification ConciseDirectional solidification is accuratePolycrystalline material growthFrom frozen solutionsPurification methodsElectromagnetic induction

The invention refers to a silicon purification method which utilizes eutectic reaction to separate out crystals of silicon crystal from Al-Si meltwater at a temperature lower than a silicon melting point. Solid materials composed of aluminum, silicon and other elements are thrown into a cooling crucible. The cooling crucible is a bottomless conductive cooling crucible (7) and at least part of the cooling crucible in a direction of principal axis is divided into a plurality of parts in a peripheral direction; the periphery of the cooling crucible is enclosed with inductance coils (8) and a support table (14) is arranged below the cooling crucible. Meanwhile, electromagnetic induction caused through the inductance coils at a temperature lower than a silicon melting point and higher than an eutectic temperature in the cooling crucible melts the solid materials to cool crystals and separate out silicon crystals on a solidification interface below the Al-Si meltwater and the support table is used for pulling down crystallized silicon crystals to realize continuous unidirectional solidification and manufacture silicon ingot (3). The silicon purification method can simply and accurately implement unidirectional solidification and devices are not complicated and have the characteristics of high efficiency, low energy consumption and costs; metal grade silicon can be used as raw materials to produce solar polycrystalline silicon.

Owner:金子恭二郎 +2

Process for the production of medium and high purity silicon from metallurgical grade silicon

A process for purifying low-purity metallurgical grade silicon, containing at least one contaminant and obtaining a higher-purity solid polycrystalline silicon is provided. The process includes containing a melt of low-purity metallurgical grade silicon in a mould having insulated bottom and side walls, and an open top; solidifying the melt by unidirectional solidification from the open top towards the bottom wall while electromagnetically stirring the melt; controlling a rate of the unidirectional solidification; stopping the unidirectional solidification when the melt has partially solidified to produce an ingot having an exterior shell including the higher-purity solid polycrystalline silicon and a center including an impurity-enriched liquid silicon; and creating an opening in the exterior shell of the ingot to outflow the impurity-enriched liquid silicon and leave the exterior shell which has the higher-purity solid polycrystalline silicon.

Owner:费罗格洛布创新有限公司

Method for producing industrial silicon by using petroleum coke as reducing agent

ActiveCN101112986AQuality improvementLow impurity contentSilicon compoundsReaction speedPetroleum coke

The invention relates to a production method of industrial silicon, comprising the steps: preparation of raw materials, reduction reaction, deslagging and unidirectional solidification. The invention solves the technical problem that the existing industrial silicon production methods fail to solve the problems of upward of a hearth and high content of impurities, thereby having the advantages of low content of impurities, removal of upward situation of the hearth, rapid reaction speed, low energy consumption and simple structure of an oven body.

Owner:SHANGNAN ZHONGJIAN INDAL

Method of unidirectional solidification of castings and associated apparatus

InactiveUS7377304B2Simple methodConstant rateMelt-holding vesselsMolten metal pouring equipmentsMolten stateIngot

Molten metal is injected uniformly into a horizontal mold from a feed chamber in a horizontal or vertical direction at a controlled rate, directly on top of the metal already within the mold. A cooling medium is applied to the bottom surface of the mold, with the type and flow rate of the cooling medium being varied to produce a controlled cooling rate throughout the casting process. The rate of introduction of molten metal and the flow rate of the cooling medium are both controlled to produce a relatively uniform solidification rate within the mold, thereby producing a uniform microstructure throughout the casting, and low stresses throughout the casting. A multiple layer ingot product is also provided comprising a base alloy layer and at least a first additional alloy layer, the two layers having different alloy compositions, where the first additional alloy layer is bonded directly to the base alloy layer by applying the first additional alloy in the molten state to the surface of the base alloy while the surface temperature of the base alloy is lower than the liquidus temperature and greater than eutectic temperature of the base alloy −50 degrees Celsuis.

Owner:ARCONIC INC

Short process high efficiency preparation method of high aluminium coppe alloy precision pipe material

InactiveCN100999011AExcellent cold deformation abilityImprove mechanical propertiesSingle crystalIngot

The present invention relates to a short-process high-effective preparation method of high-aluminium copper alloy precision pipe material. It is characterized by adopting a continuous unidirectional solidification method to prepare the high-aluminium copper alloy precision pipe material, its preparation process includes the following steps: melting copper alloy ingot with high aluminium content or oxygen-free copper and pure aluminium (for alloy containing more than three components, it also includes other alloy element, for example nickel) at 1150-1550 deg.C, continuous unidirectional solidification billet-drawing speed is 1-200 mm / min, cooling water rate is 100-1300 L / h, cooling water temperature is 20-30 deg.C and degree of vacuum is 0.1-2Pa, preparing the high-aluminium copper alloy precision pipe material whose outer diameter is 8-40 mm and wall thickness is 1-5 mm.

Owner:UNIV OF SCI & TECH BEIJING

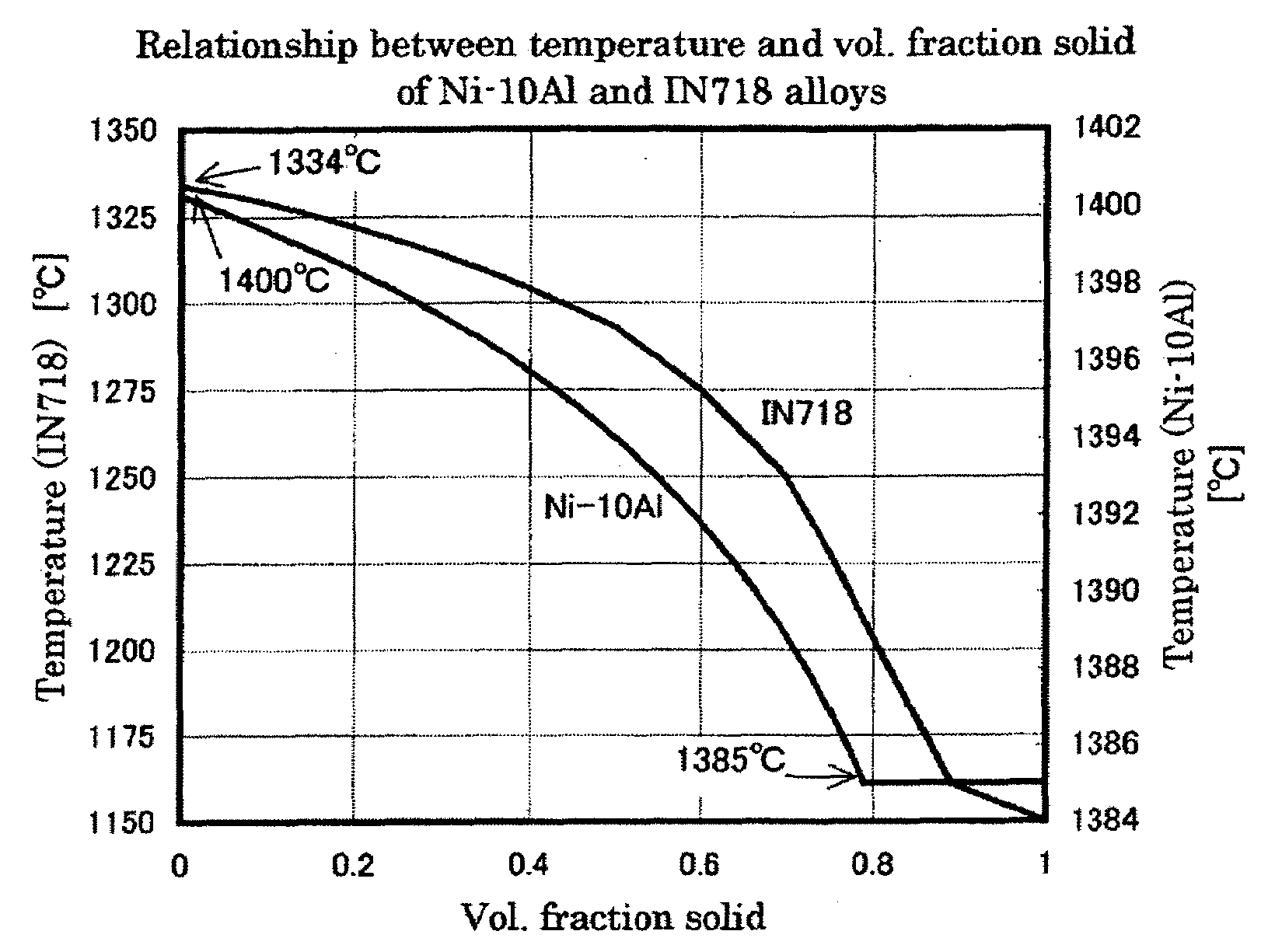

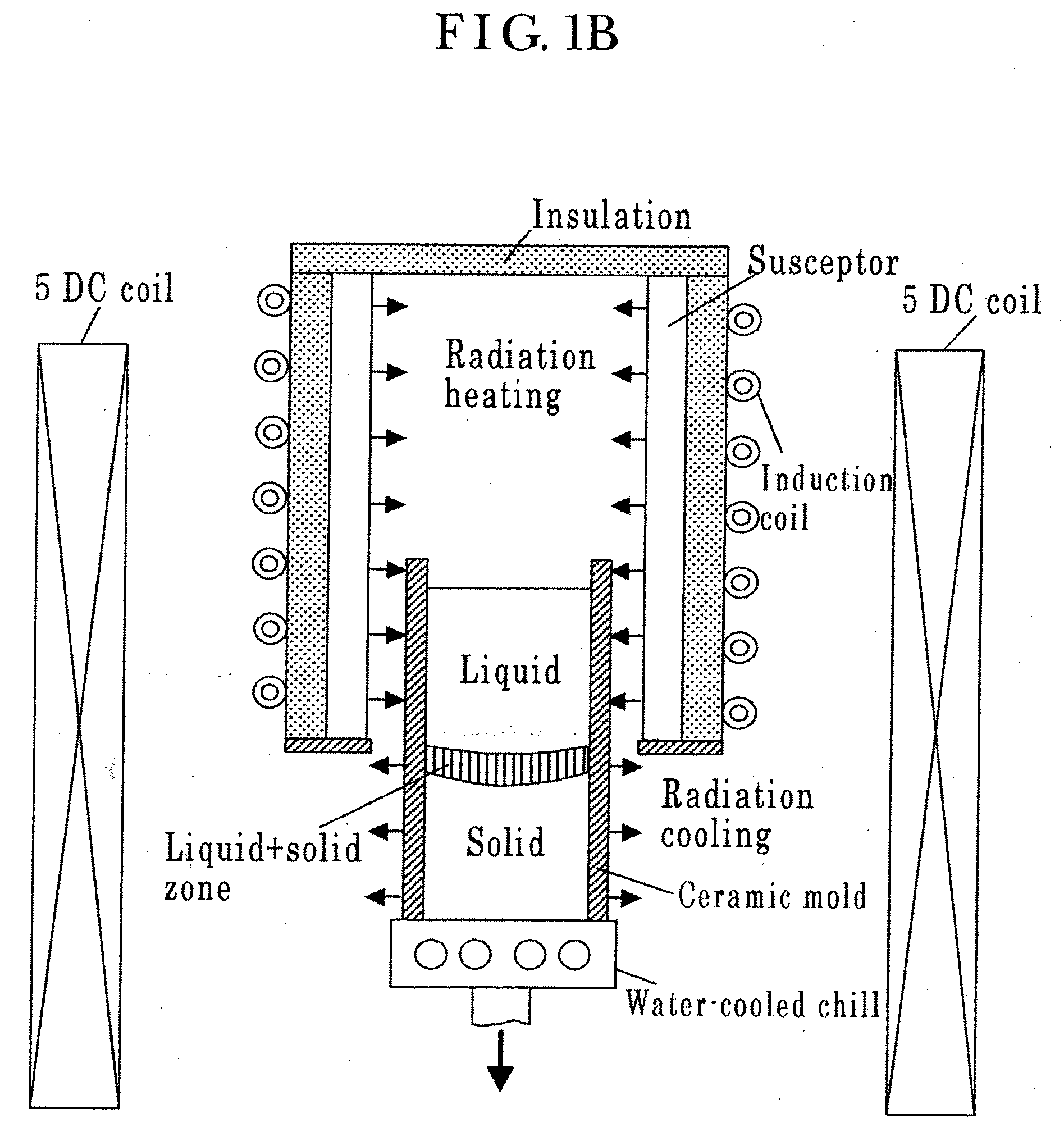

Casting method and apparatus

InactiveUS20090165989A1Quality improvementDefect formationPolycrystalline material growthPig casting plantsIngotMaterials science

This invention is concerned with the productions of unidirectionally solidified castings and remelting-processed ingots such as ESR or VAR, which has paid special attention to the liquid flow phenomena within solid-liquid coexisting phase (mushy phase) during solidification, and made it clear for the first time that by applying high static magnetic field onto the whole mushy phase, the extremely slow interdendritic liquid flow responsible for the formation of macrosegregation can be suppressed, and thereby that the macrosegregation such as freckles can completely be eliminated. Thus, this invention provides with a novel casting technology for producing high quality castings and ingots without macrosegregation.

Owner:EBISU

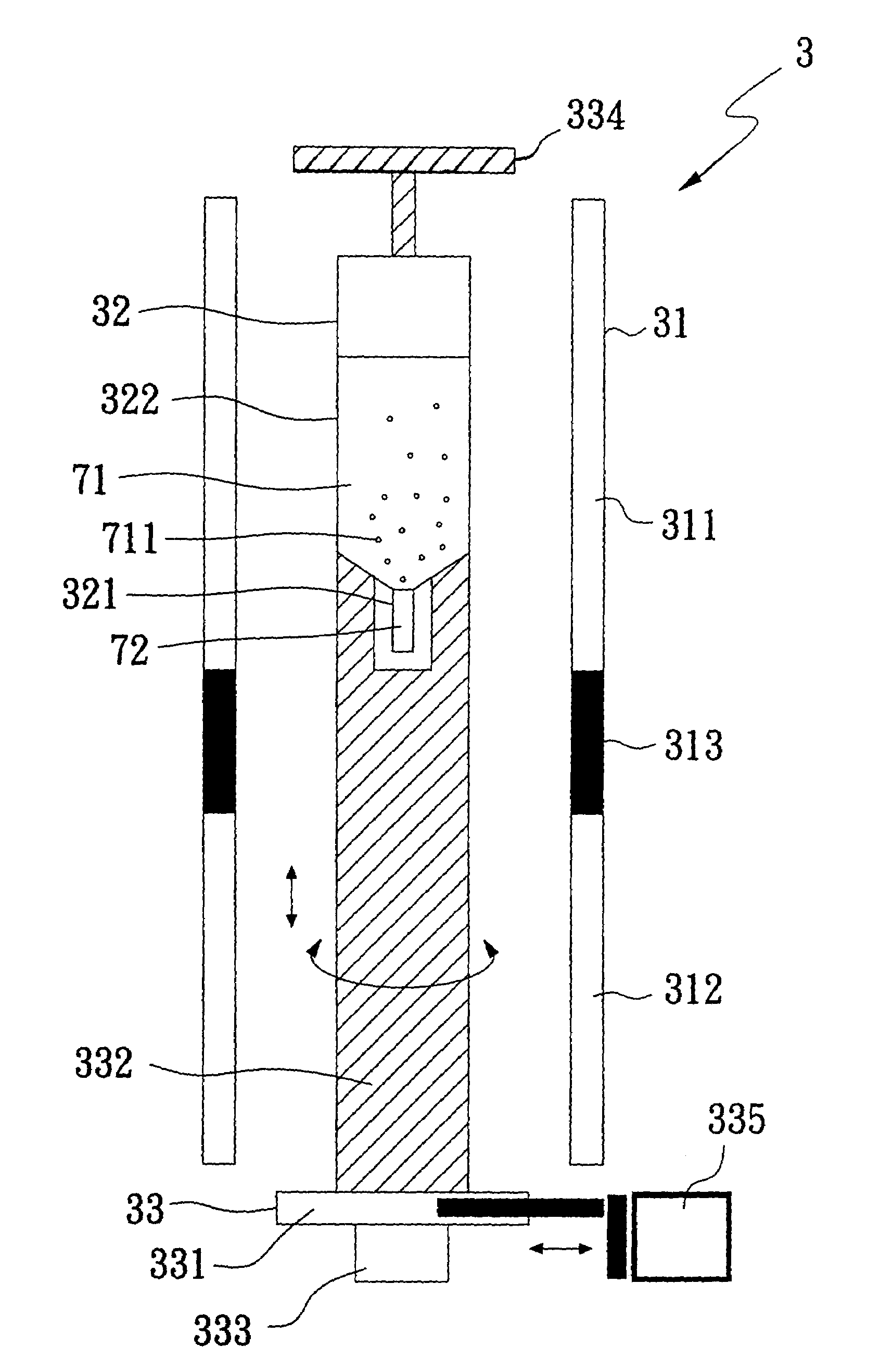

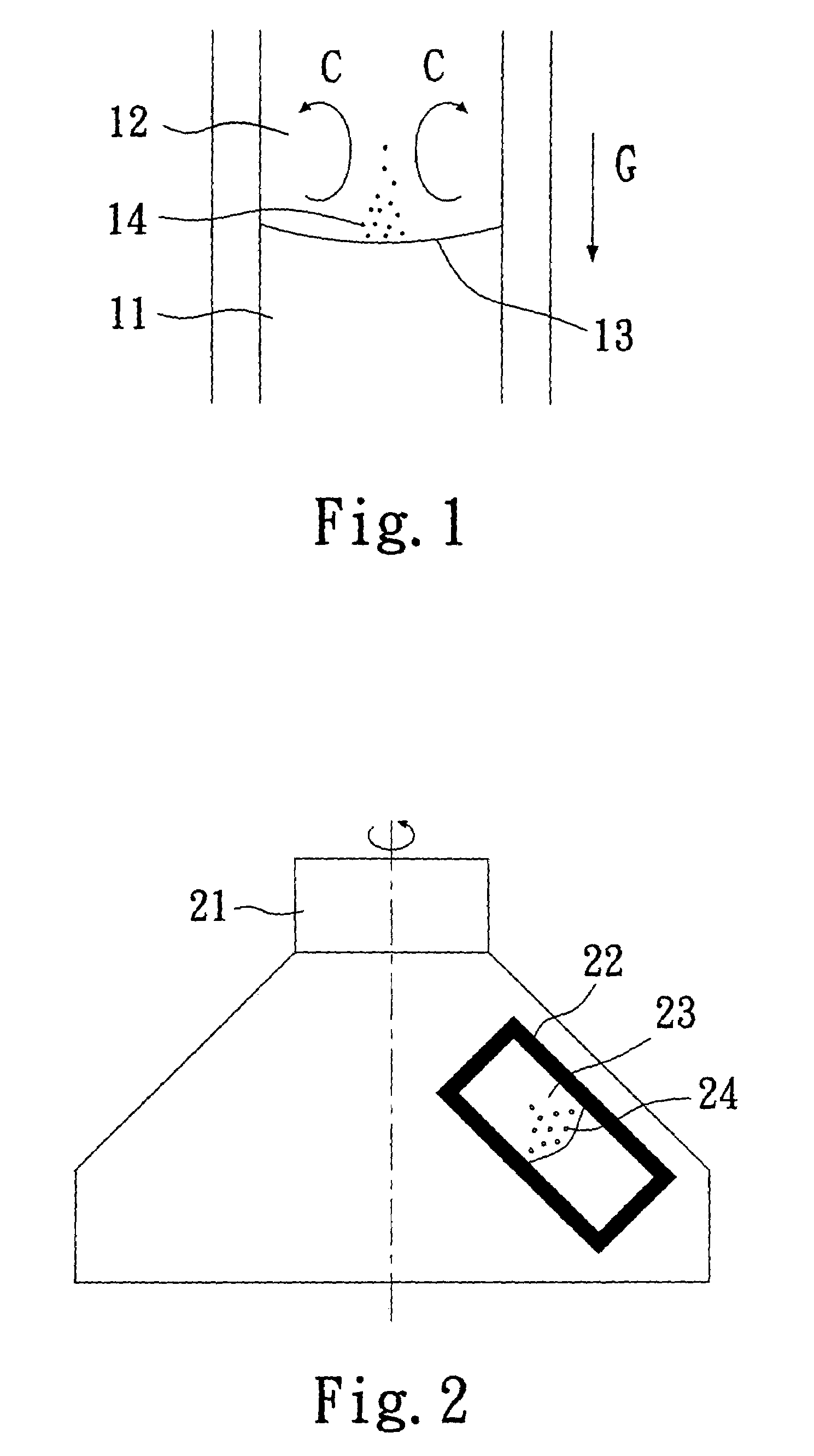

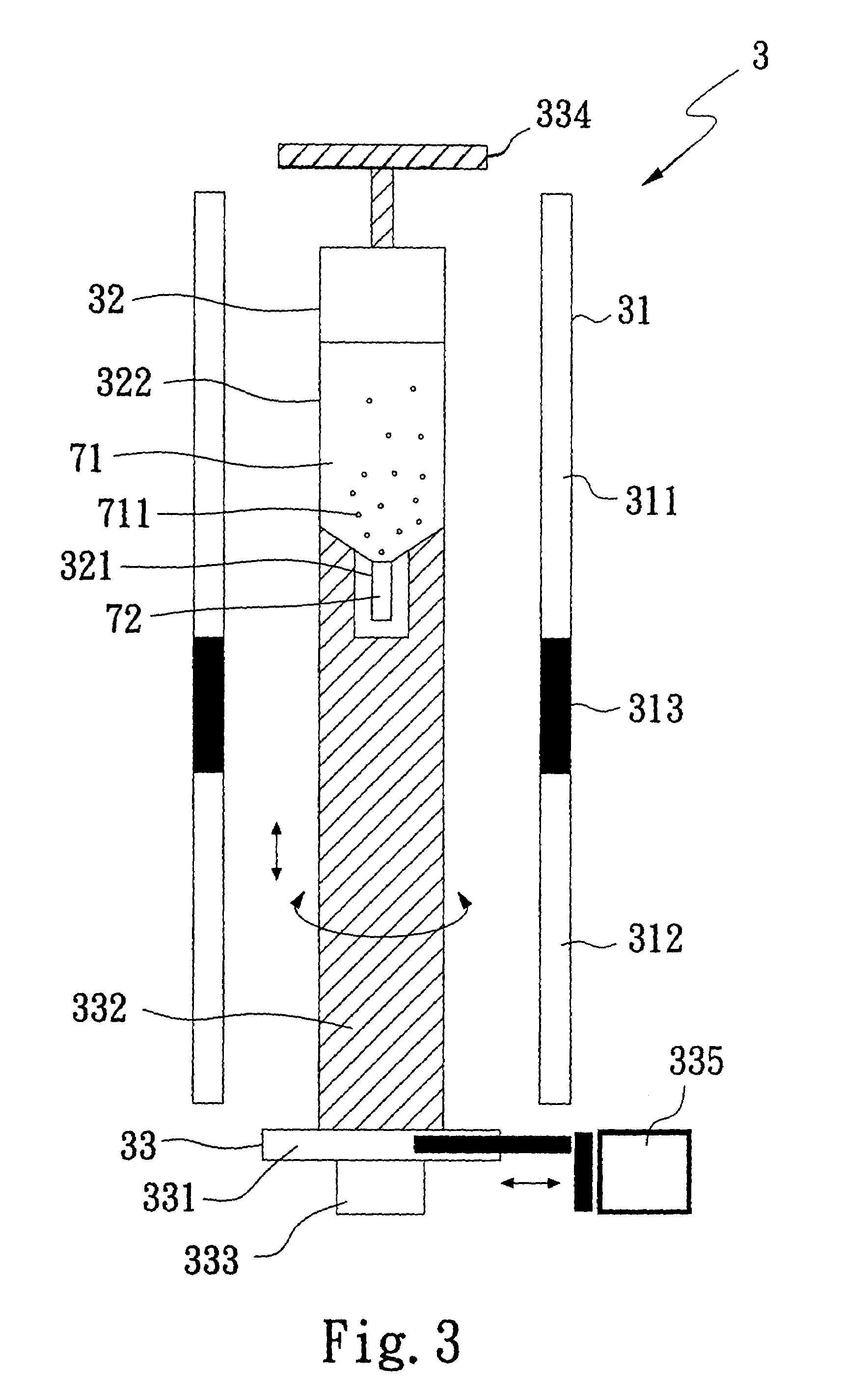

Rotationally-vibrated unidirectional solidification crystal growth system and its method

InactiveUS7344598B2Improve distributionQuality improvementAfter-treatment apparatusPolycrystalline material growthThermal isolationRotational vibration

A rotationally-vibrated unidirectional solidification crystal growth system comprises a furnace, a crucible, a rotational-vibration device including a mounting holder, a motor and a vibrating apparatus. The furnace contains a high temperature portion, a thermal isolation portion and a low temperature portion. The crucible connected to the rotational-vibration device within the furnace has a seed well down to a crystal growth arena. The crystal is grown as the ambient temperature profile moving from high to low, which can be achieved through a relative movement between the furnace and the crucible. That is either the furnace or the crucible is undergoing a top-down movement. The rotational-vibration device offers the crucible the required rotation and angular vibration, with a vibrating frequency no less than 0.2 Hz.

Owner:TRANSPACIFIC IP II

Method for modifying single crystal copper with graphene

ActiveCN106077535AHigh strengthImprove thermal conductivityPolycrystalline material growthFrom frozen solutionsCrucibleCopper wire

The invention provides a method for modifying single crystal copper with graphene. The method for modifying single crystal copper with graphene comprises the following steps: (1) under protective atmosphere, putting raw copper into a crucible to heat and melt, thereby obtaining molten copper; (2) introducing the molten copper into a casting mould, heating, adding graphene powder, and stirring; (3) cooling the molten copper at an outlet of the casting mould, enabling the molten copper to realize unidirectional solidification in the outlet direction of the casting mould, and continuously pulling and casting, thereby obtaining copper ingot; and (4) performing thermal treatment and cold drawing on the copper ingot to prepare a single crystal copper wire. Graphene-modified single crystal copper prepared by the method has good electrical conductivity, and stable and reliable signal transmission, and electrical resistivity of the graphene-modified single crystal copper is reduced by 25% or more in comparison with that of the single crystal copper.

Owner:SHENZHEN GRAPHENE LAND LEGEND TECH CO LTD

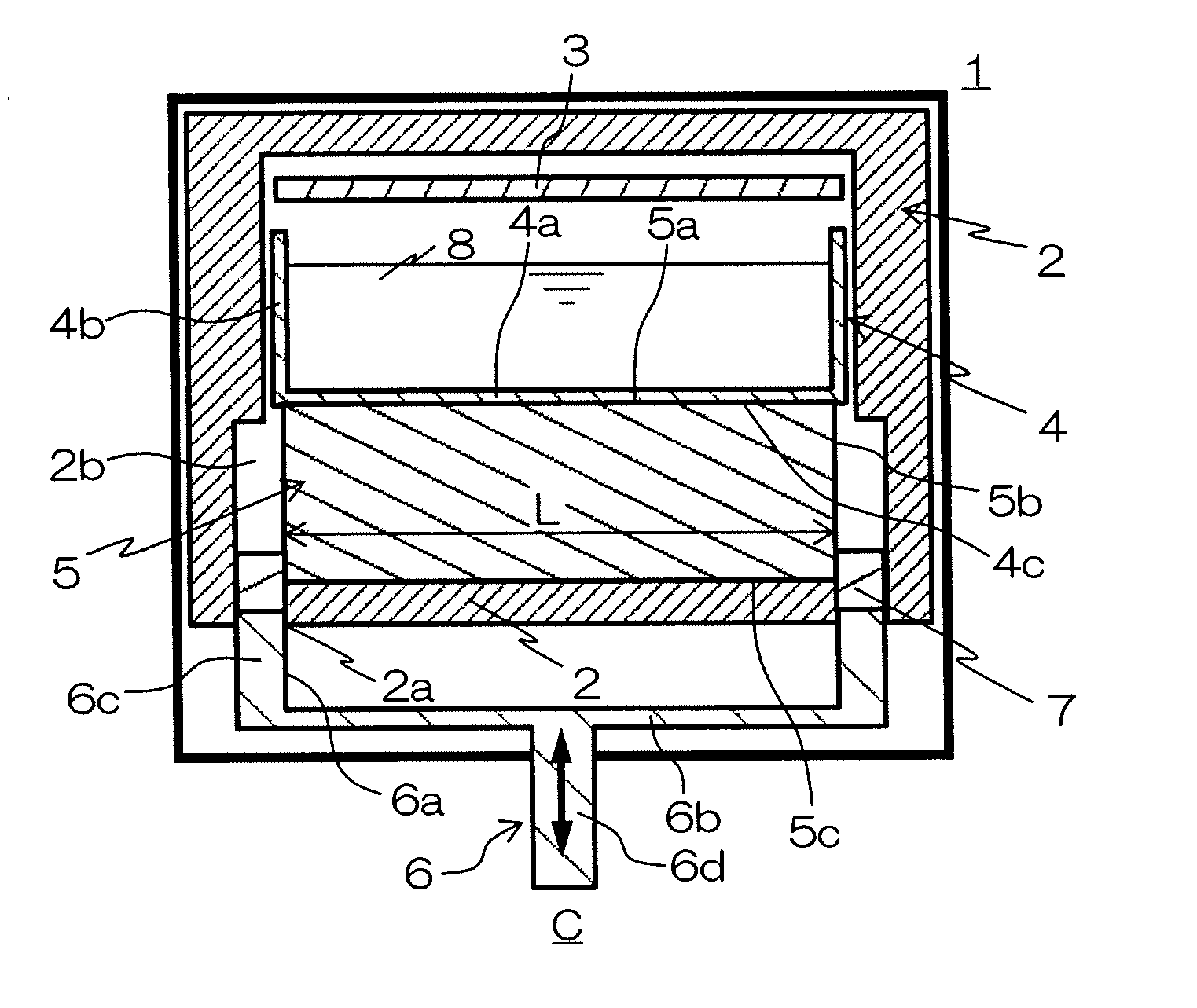

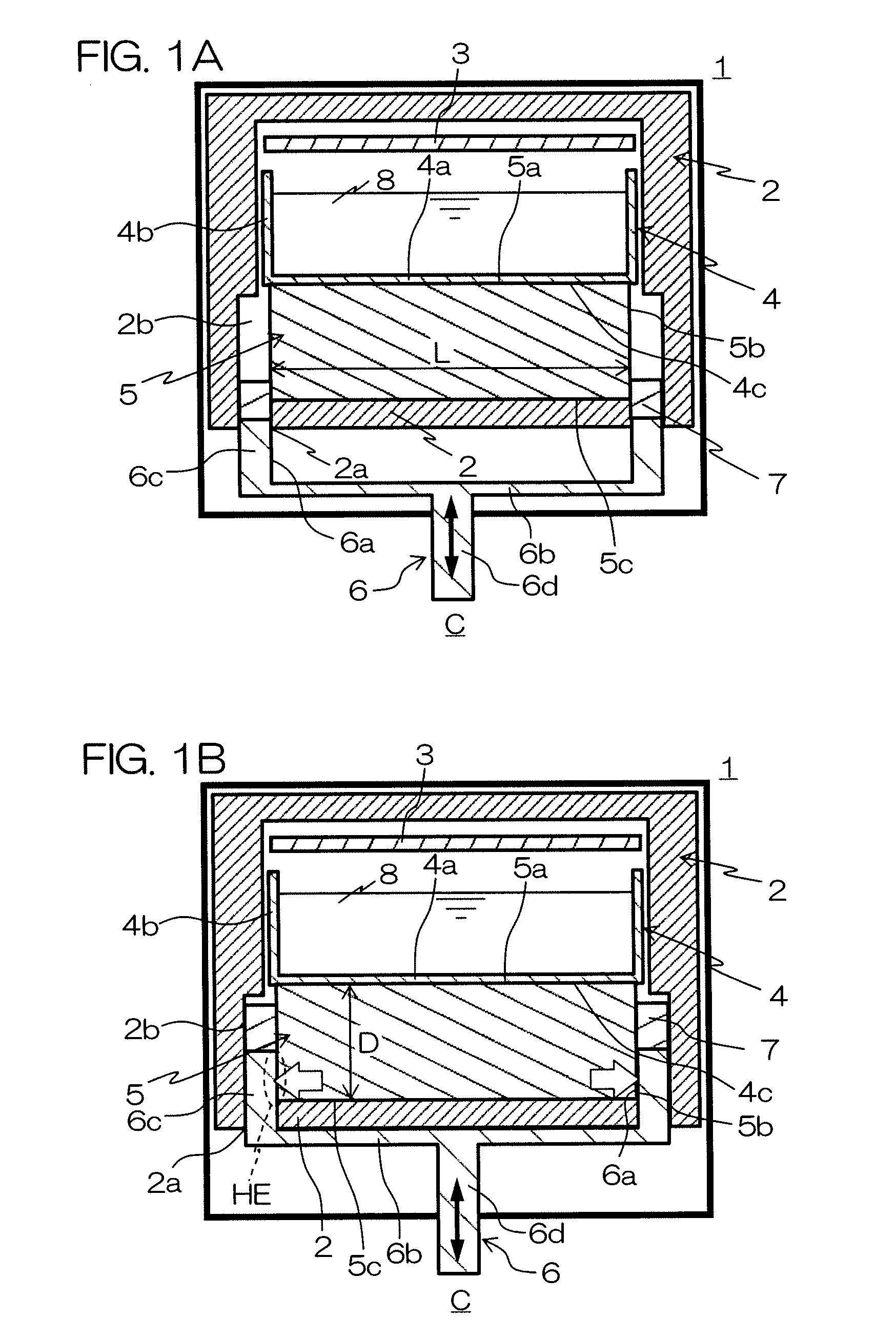

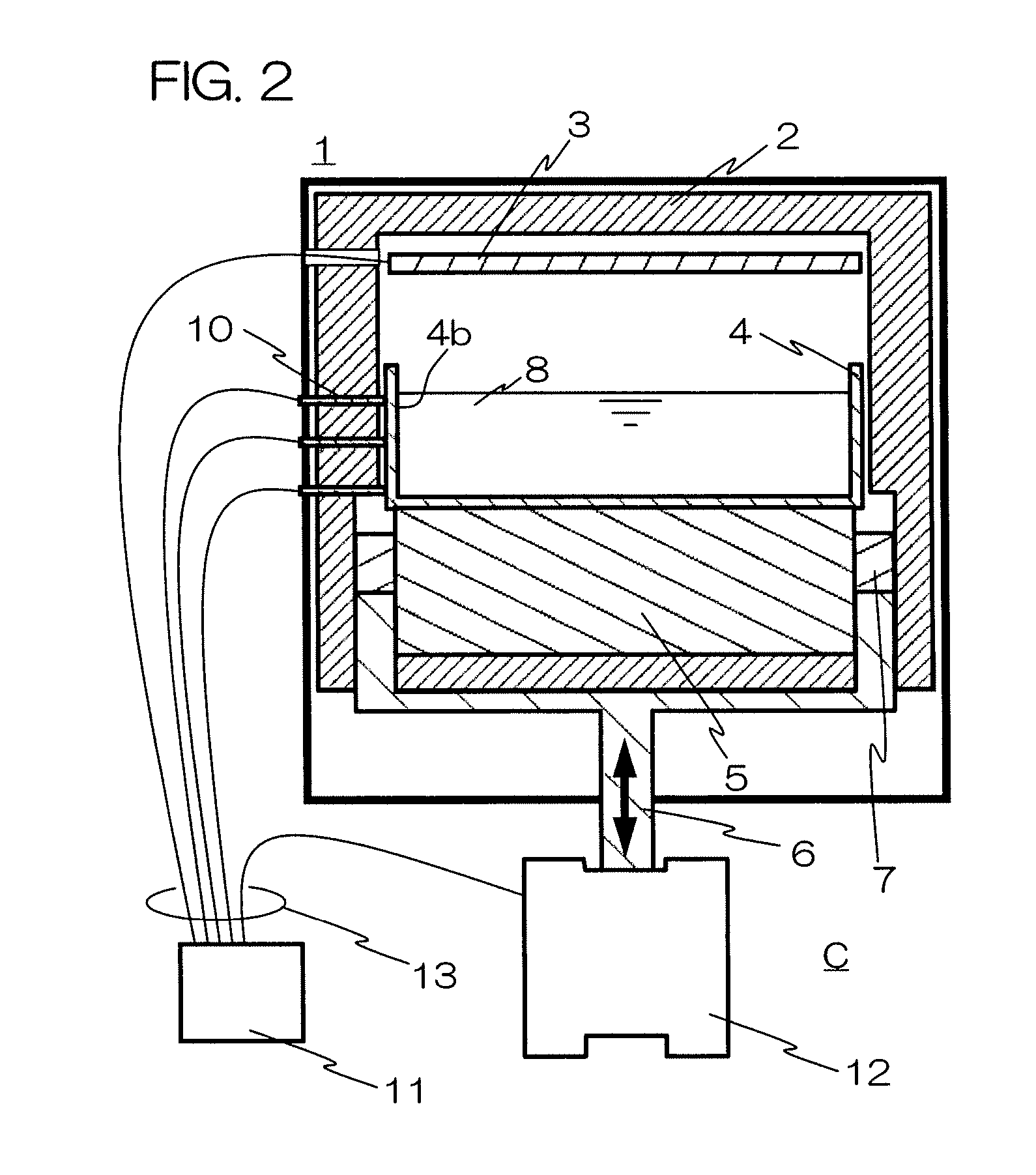

Silicon casting apparatus and method of producing silicon ingot

InactiveUS7867334B2Good reproducibilityLow costFinal product manufactureGlass drawing apparatusIngotMaterials science

A silicon casting apparatus for producing polycrystal silicon ingot by heating a silicon melt (8) held in a mold (4) from above by a heater (3) and cooling it from below while changing the heat exchange area of a heat exchange region (HE), defined between a pedestal (5) having the mold (4) placed thereon and a bottom cooling member (6), in such a manner as to keep pace with the rise of the solid-liquid interface of the silicon melt (8), thereby causing unidirectional solidification upward along the mold (4); and a method of producing polycrystal silicon ingot using such apparatus. According to this production method, the temperature gradient given to the silicon melt (8) can be maintained at constant by adjusting the heat exchange area, so that polycrystal silicon ingot having good characteristics can be produced with good reproducibility.

Owner:KYOCERA CORP

Continuous unidirectional solidification preparation method of in-situ reaction of nano-particle copper- ferroalloy

The invention belongs to the field of mental materials and relates to a continuous unidirectional solidification preparation method of in-situ reaction of nano-particle copper- ferroalloy. The process comprises putting raw materials into a graphite crucible after cleaning and purification, vacuumizing a vacuum melting furnace to 10-3Pa and beginning heating and melting; leading high-purity argon into the vacuum melting furnace after the raw materials are fully melted, maintaining melt temperature to be in a range of 1200 + / -5 DEG C to 1300+ / -5 DEG C and meantime starting a cooling system, enabling cooling water amount to be 900L / h and preparing blank in a downward-drawing type continuous unidirectional solidification device at a casting speed of 1.5-3mm / 10s. By means of the continuous unidirectional solidification preparation method of the in-situ reaction of the nano-particle copper- ferroalloy, in-situ nano-particles coherent or semi-coherent with a collective interface can be directly produced in a continuous unidirectional solidification process, and the nano-particles are evenly dispersed and distributed in a substrate.

Owner:UNIV OF SCI & TECH BEIJING

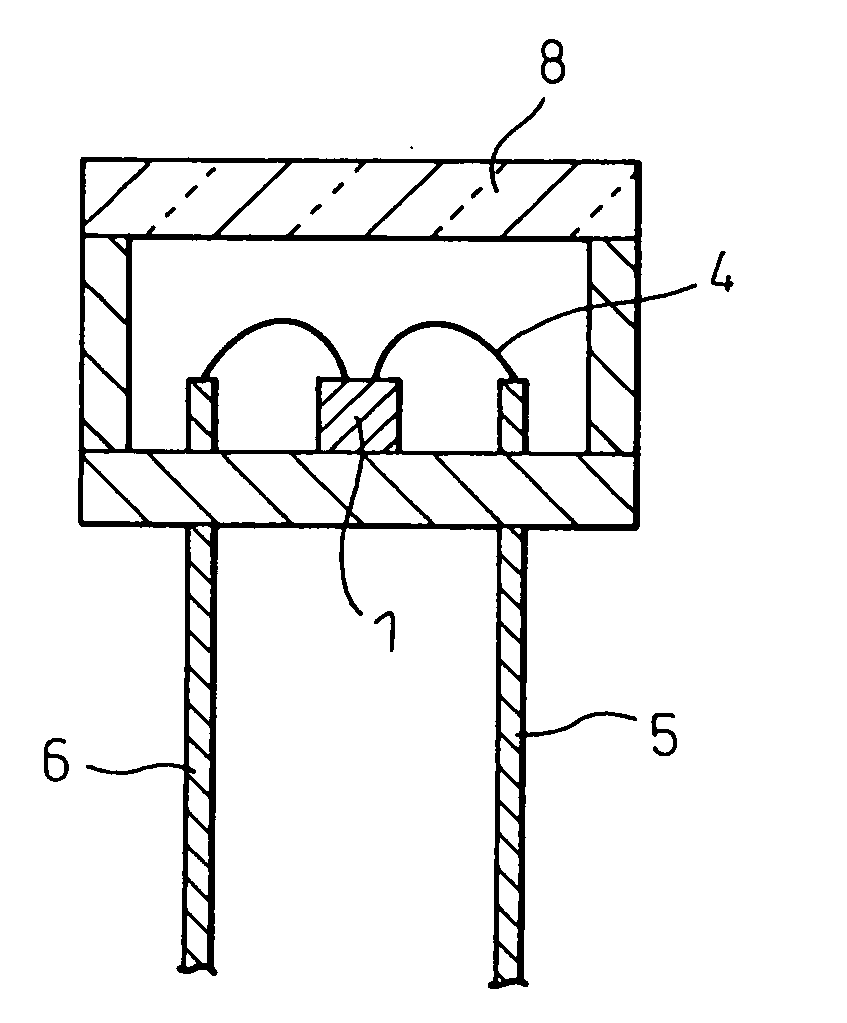

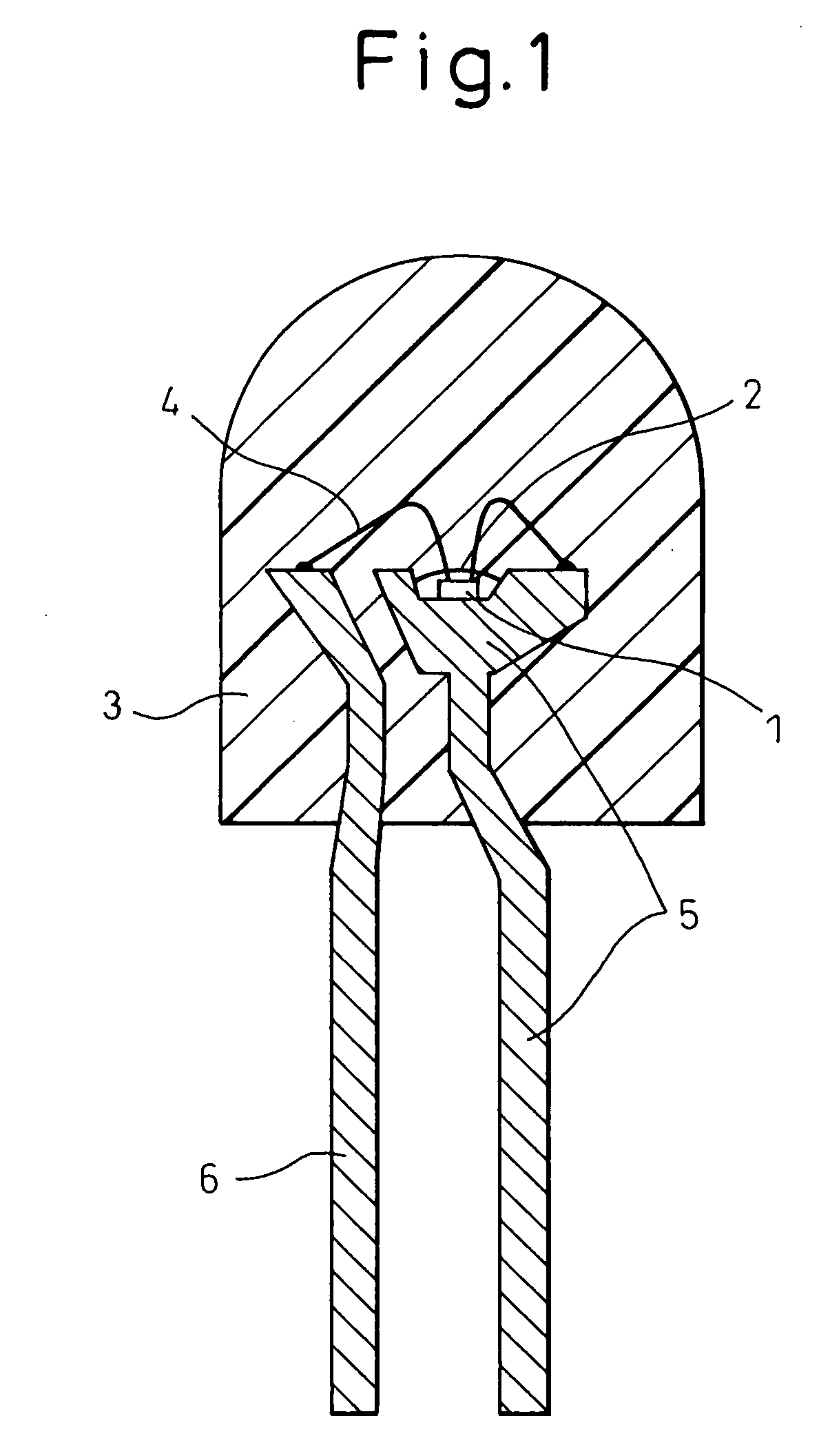

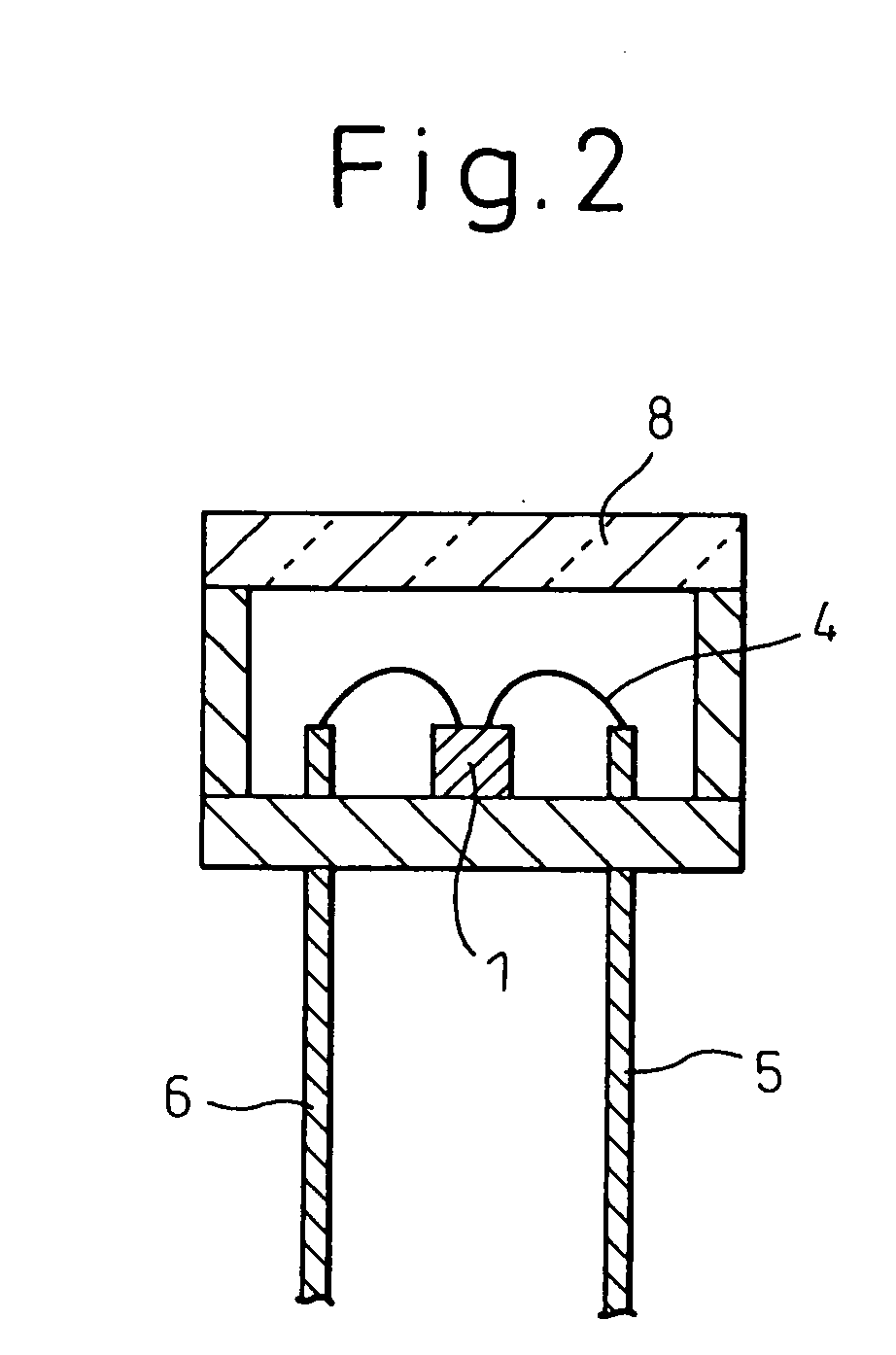

Substrate for light-emitting diode, and light-emitting diode

ActiveUS7863636B2Reduce deteriorationWell mixedElectroluminescent light sourcesSolid-state devicesCeramic compositeFluorescence

A substrate for light-emitting diodes, obtained by stacking a single crystal layer to form a light-emitting diode element onto a ceramic composite layer for light conversion, the ceramic composite layer having been formed by a unidirectional solidification method so that the ceramic composite layer comprises a solidified body having formed therein at least two or more oxide phases selected from single metal oxides and complex metal oxides to be continuously and three-dimensionally entangled with each other, with each oxide phase having a single crystal orientation, wherein at least one oxide phase out of the oxide phases in the solidified body contains a metal element oxide capable of emitting fluorescence.

Owner:UBE IND LTD

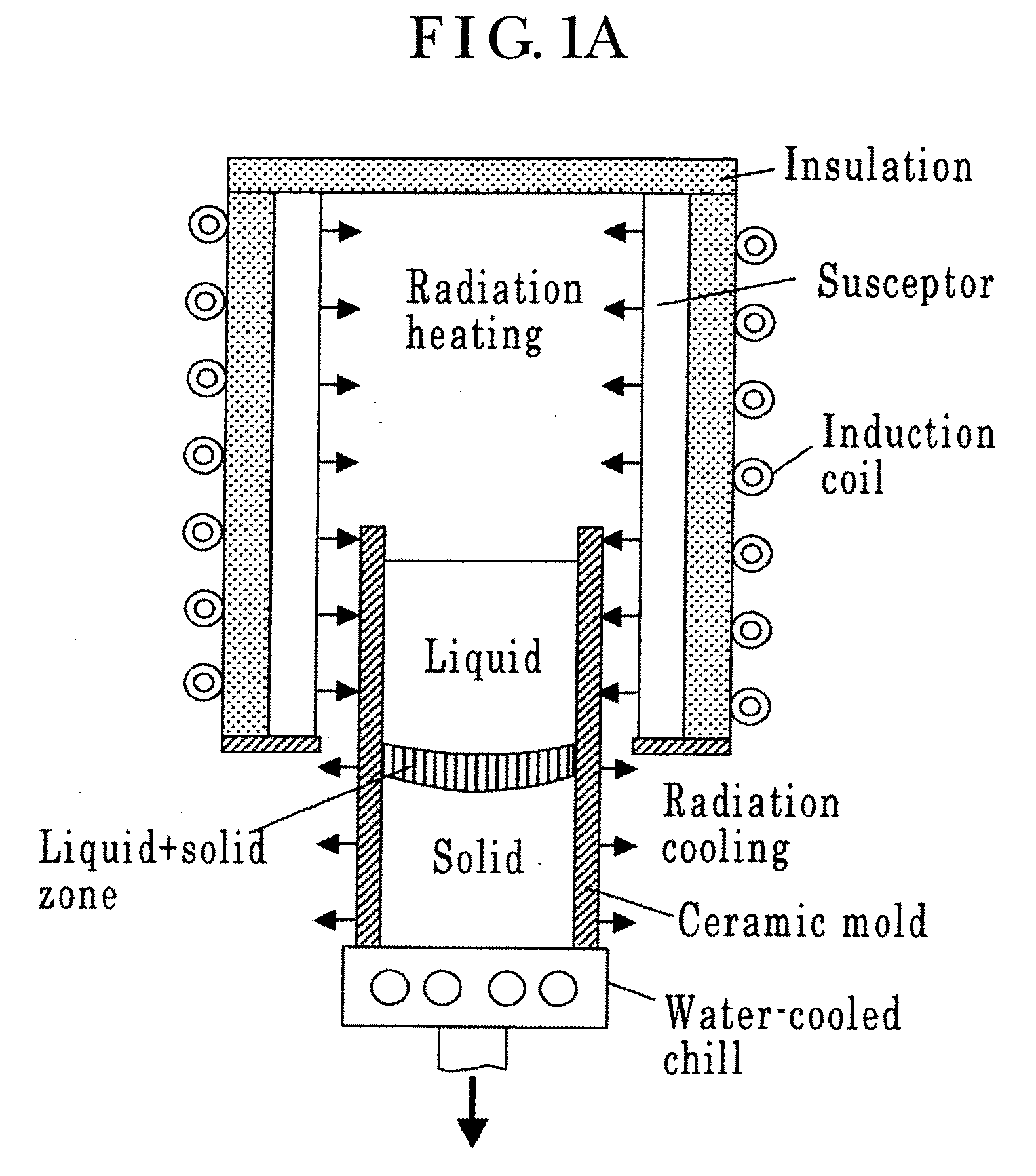

Unidirectional solidification process and apparatus therefor

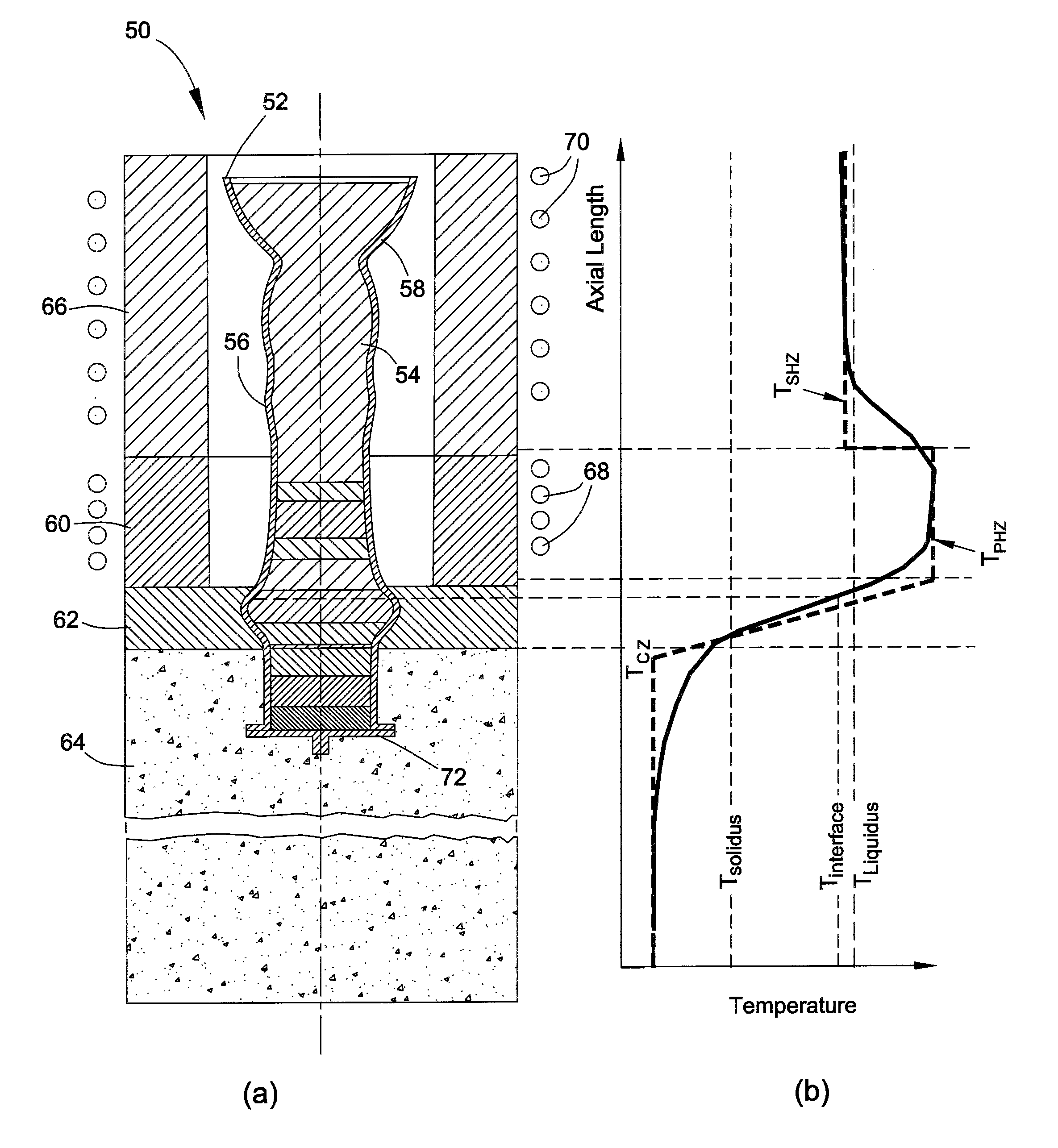

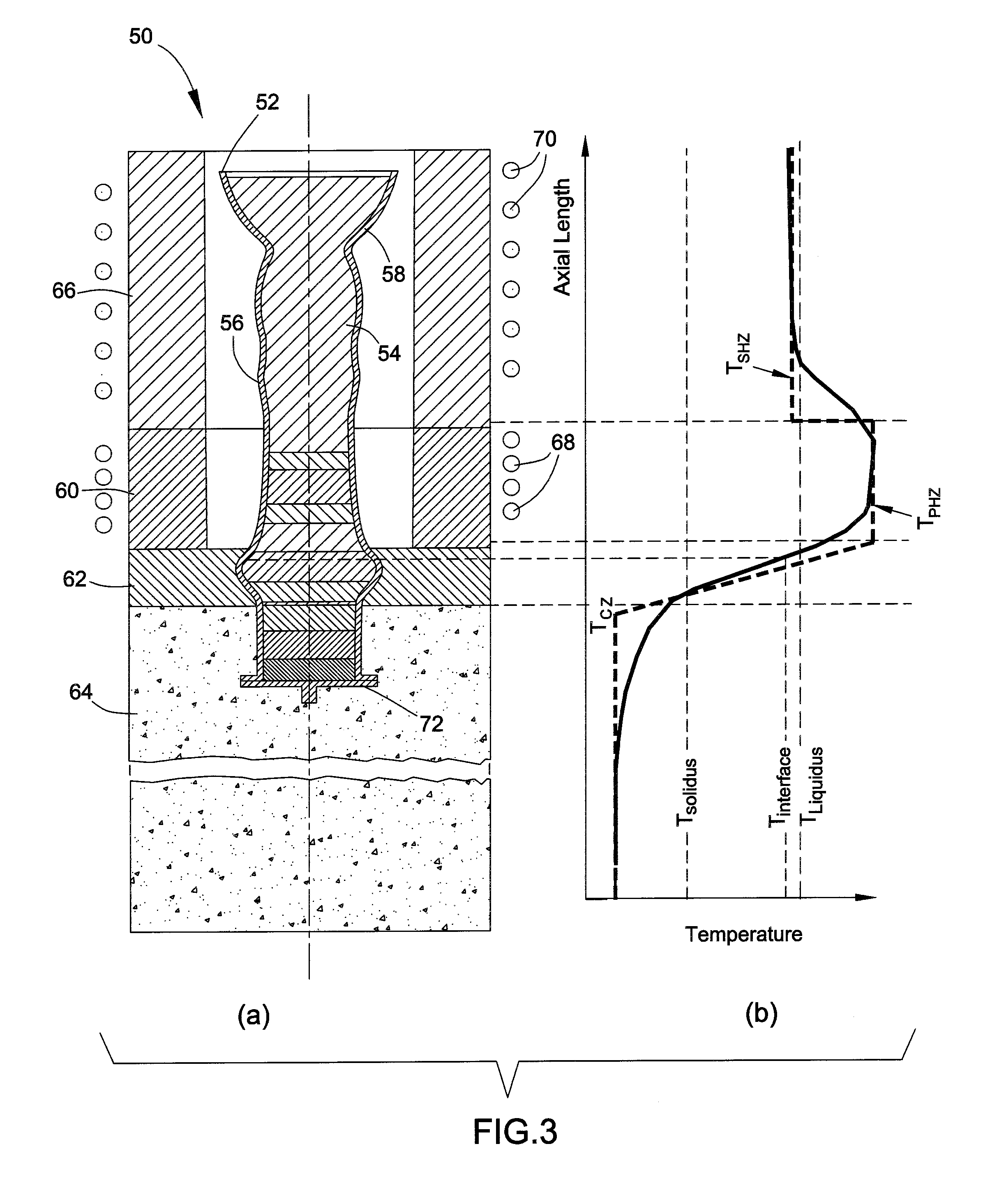

ActiveUS20120080158A1Improve mechanical propertiesQuality improvementMelt-holding vesselsLiquidusUnidirectional solidification

An apparatus and method for casting an alloy using a unidirectional casting technique. The apparatus includes a mold adapted to contain a molten quantity of an alloy, a primary heating zone adapted to heat the mold and the molten alloy therein to a temperature above the liquidus temperature of the alloy, a cooling zone adapted to cool the mold and molten alloy therein to a temperature below the solidus temperature of the alloy and thereby yield the unidirectionally-solidified casting, and an insulation zone between the primary heating zone and the cooling zone. The apparatus also has a secondary heating zone separated from the insulation zone by the primary heating zone. The secondary heating zone maintains the mold and the molten alloy therein at a temperature below the liquidus temperature of the alloy. The temperatures within the primary and secondary heating zones are individually set and controlled.

Owner:GENERAL ELECTRIC CO

Nickel-base superalloy, unidirectional-solidification process therefor, and castings formed therefrom

An alloy composition and method by which the incidence of freckling can be reduced in castings produced with properties similar to the René N5 nickel-base superalloy. The casting has a unidirectional crystal structure and a composition consisting of, by weight, 6% to 8% chromium, 6% to 9% cobalt, 0% to 2% molybdenum, 4% to 6% tungsten, 6.4% to 6.9% tantalum, 0% to 2% titanium, 5% to 7% aluminum, 2.7% to 3.0% rhenium, 0.3% to 0.7% haffiium, 0.04% to 0.08% carbon, 0.002% to 0.006% boron, 0% to 0.075% yttrium, 0.002% to 0.004% zirconium, the balance being nickel and incidental impurities.

Owner:GENERAL ELECTRIC CO

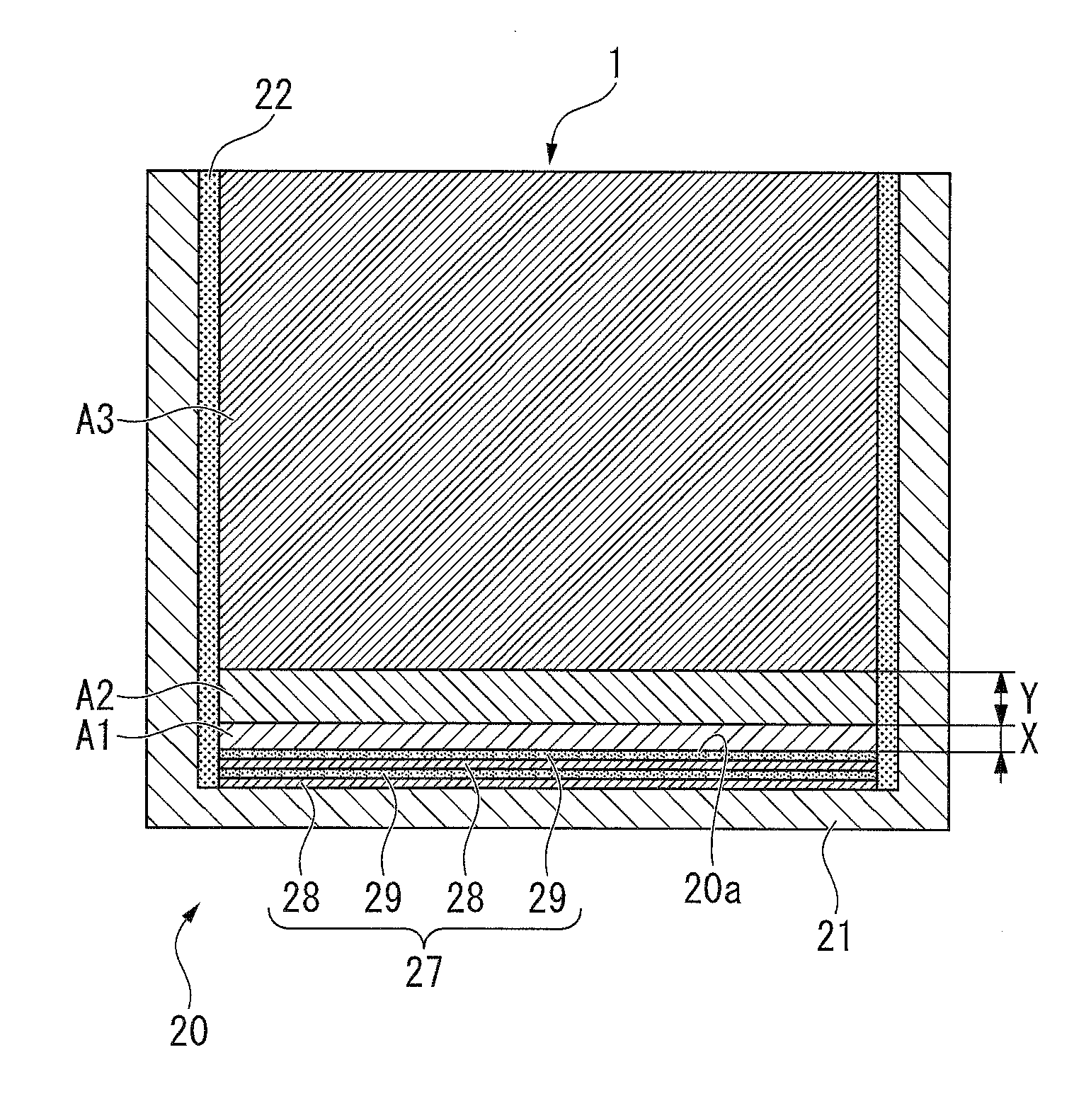

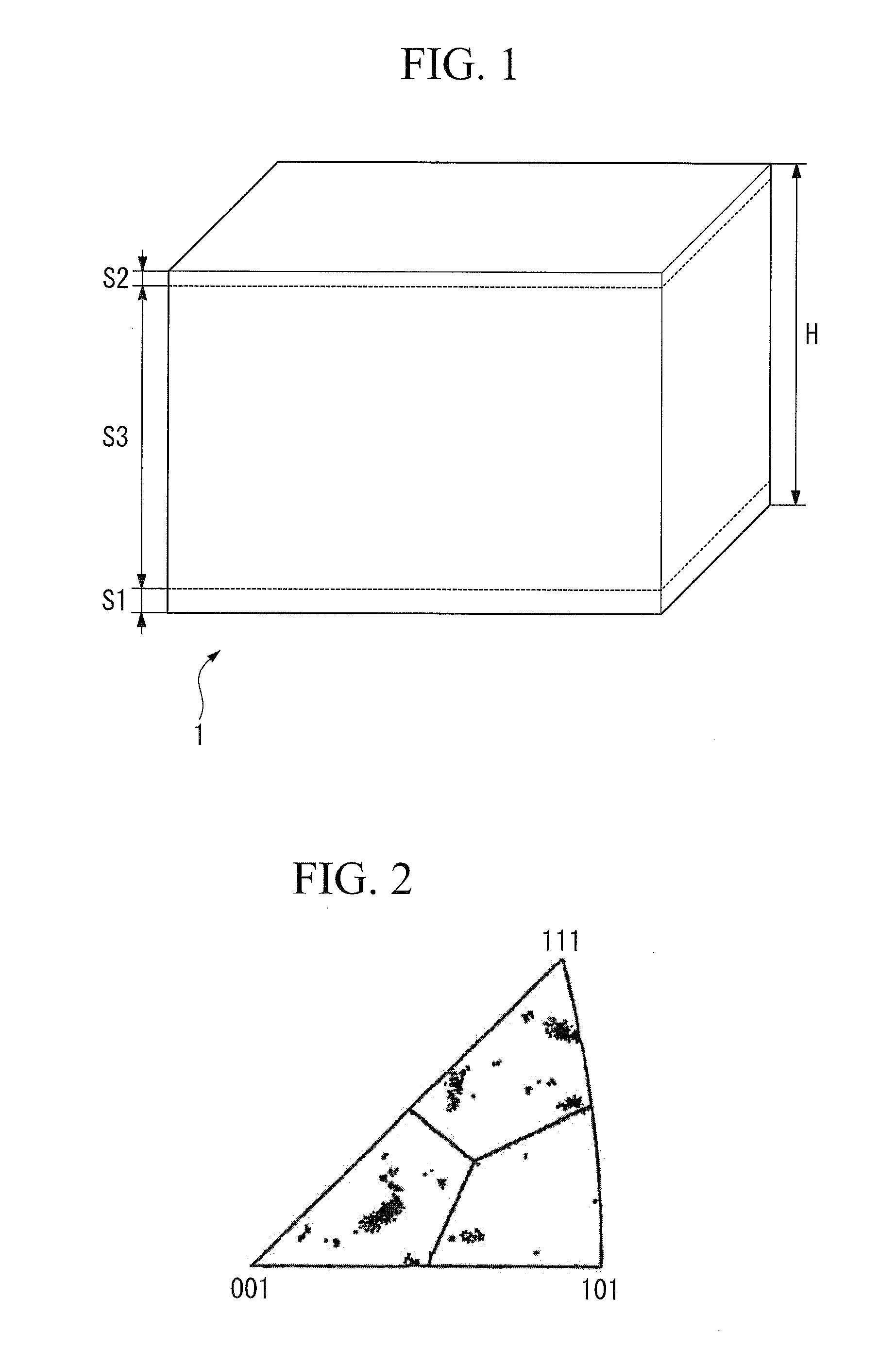

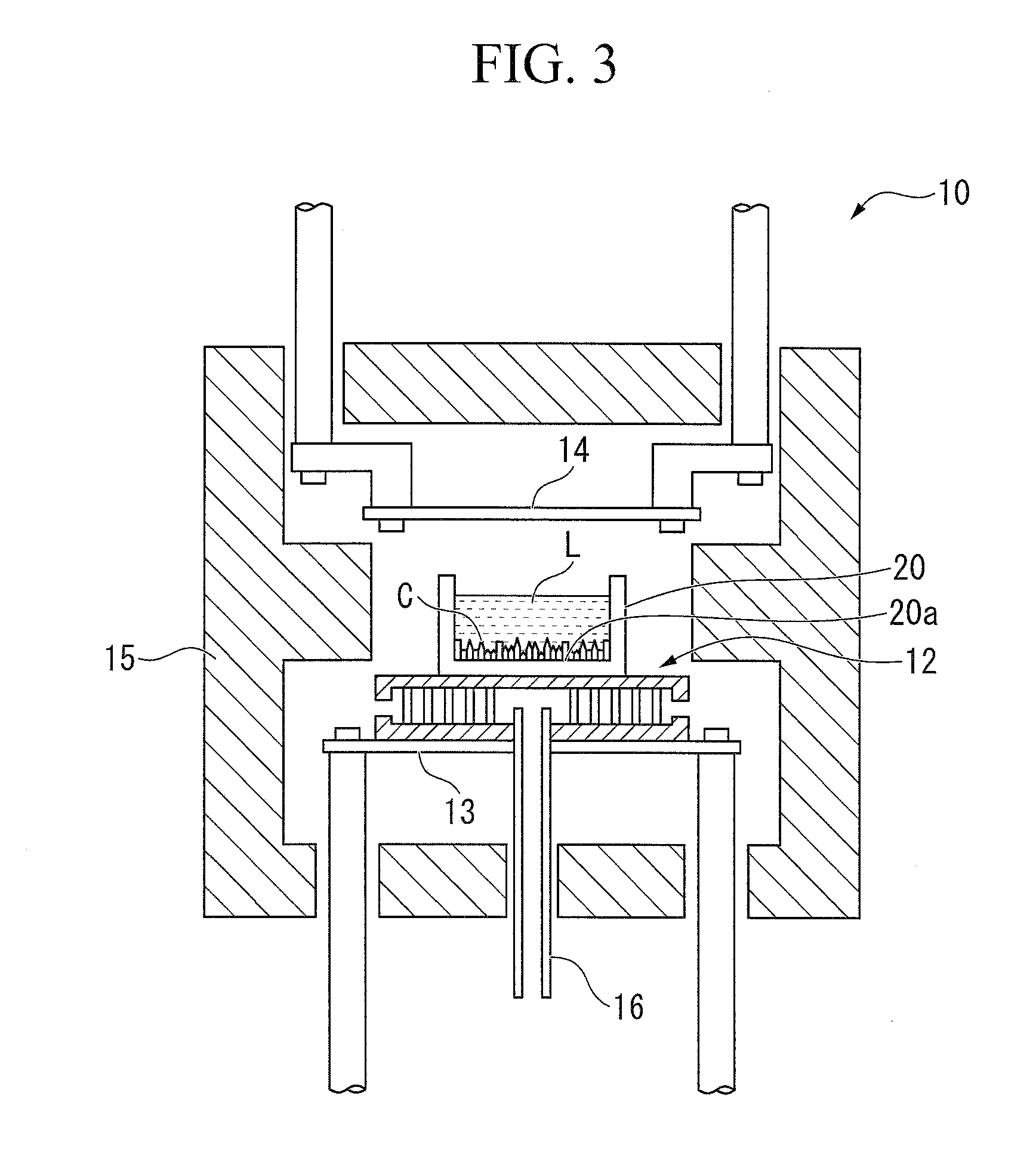

Method for manufacturing polycrystalline silicon ingot, and polycrystalline silicon ingot

ActiveUS20130008371A1Improve production yieldHigh oxygen contentPolycrystalline material growthSiliconMolten siliconPolycrystalline silicon

A method for manufacturing a polycrystalline silicon ingot includes unidirectionally solidifying a molten silicon upwardly from the bottom of a crucible, wherein the crucible is provided with silica deposited on the bottom of the crusible; and then dividing the degree of solidification in the crucible into a first zone from 0 mm to X in height (10 mm≦X<30 mm), a second zone from X to Y in height (30 min≦Y<100 mm) and a third zone of Y or more in height, based on the bottom of the crucible, wherein a solidification rate V1 in the first zone is set in the range of 10 mm / h≦V1≦20 mm / h and a solidification rate V2 in the second zone is set in the range of 1 mm / h≦V2≦5 mm / h.

Owner:MITSUBISHI MATERIALS ELECTRONICS CHEM CO LTD

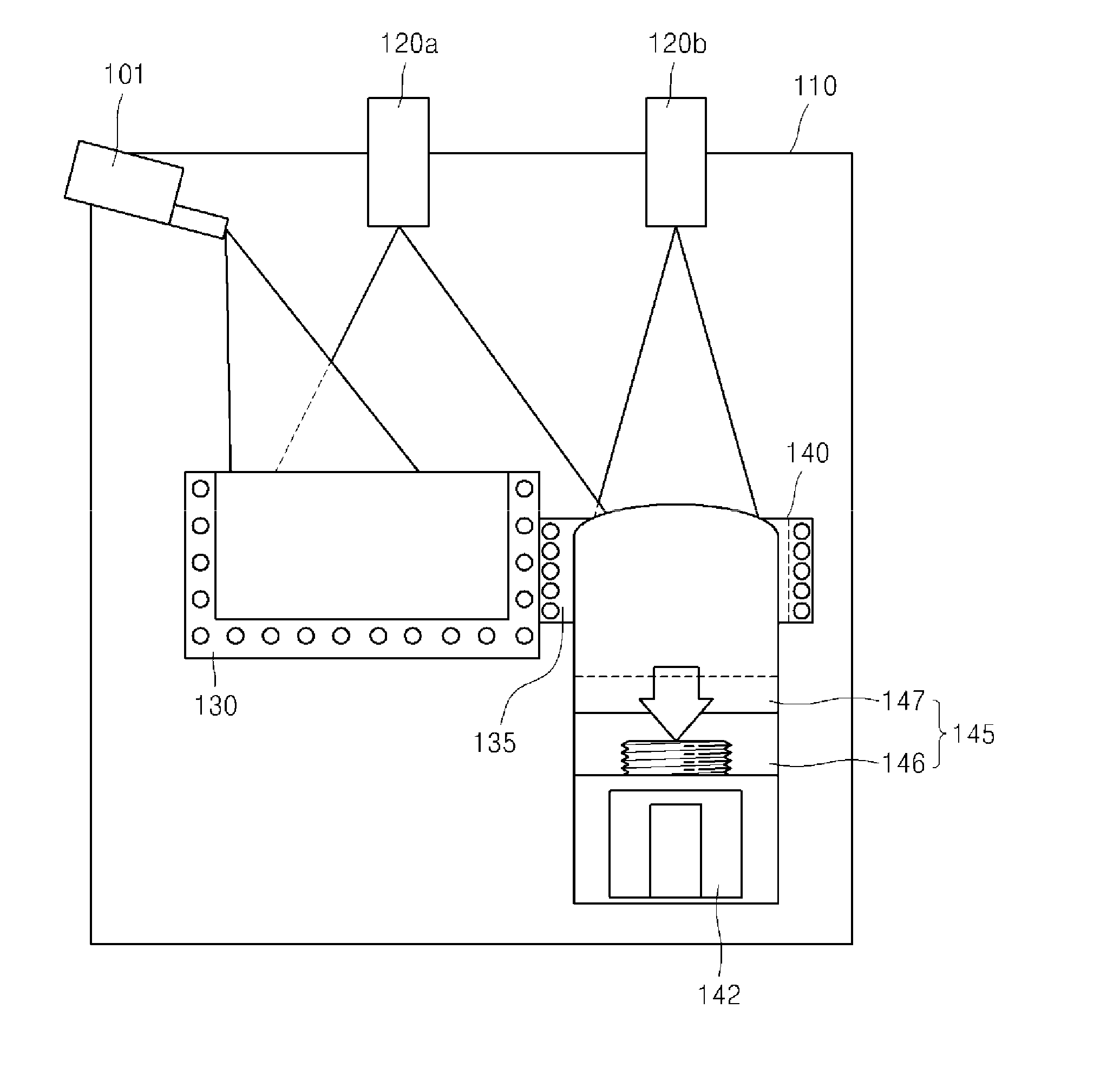

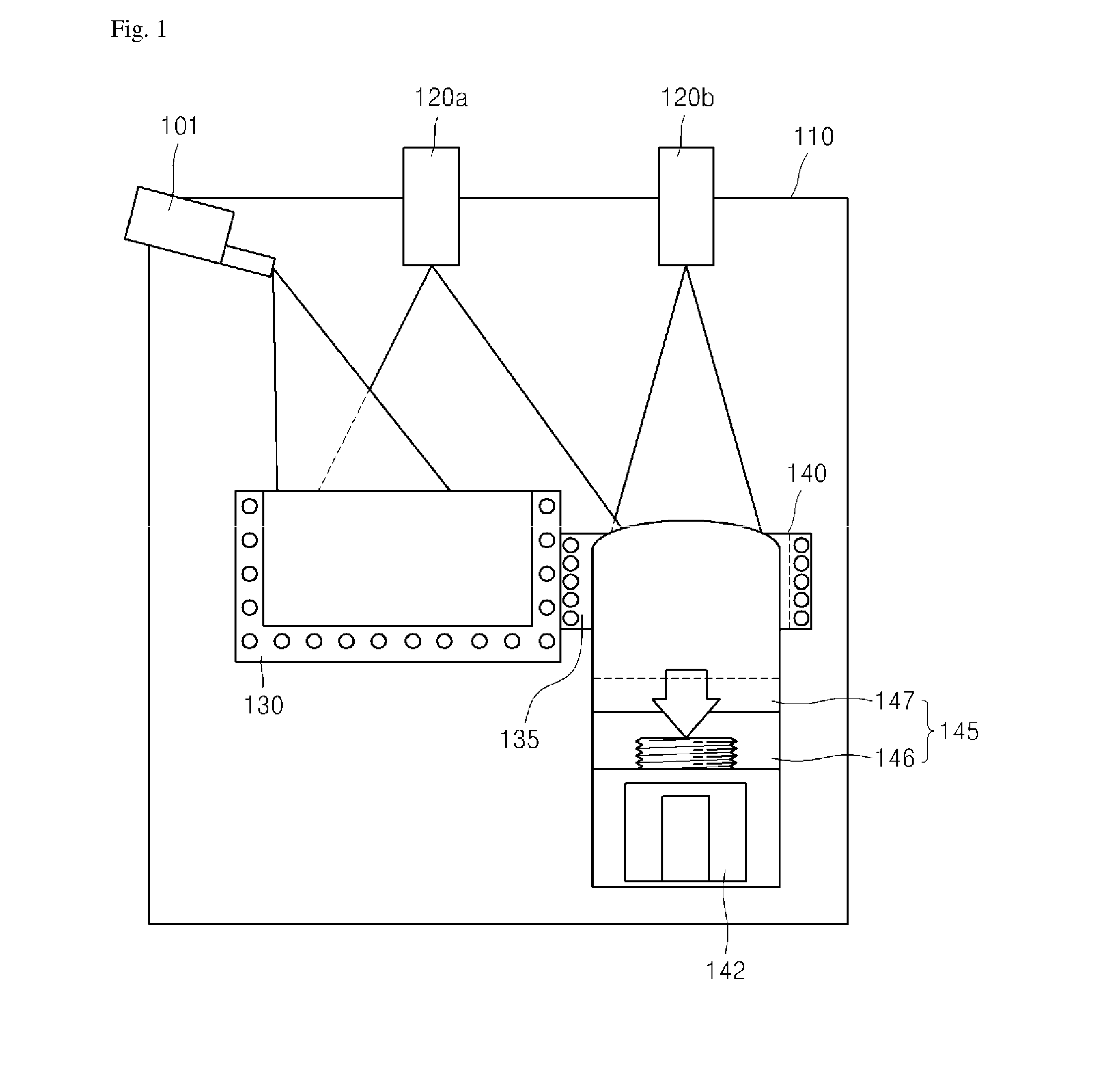

Apparatus for manufacturing polysilicon based electron-beam melting using dummy bar and method of manufacturing polysilicon using the same

ActiveUS20130291596A1Improve silicon refining efficiencyHigh puritySiliconBy zone-melting liquidsVacuum chamberElectron

Methods and apparatus for manufacturing high purity polysilicon. The apparatus includes a vacuum chamber; first and second electron guns disposed at an upper side of the vacuum chamber to irradiate electron beams into the vacuum chamber; a silicon melting unit which is placed on a first electron beam-irradiating region corresponding to the first electron gun and to which powdery raw silicon is fed and melted by the first electron beam; and a unidirectional solidification unit placed on a second electron beam-irradiating region corresponding to the second electron gun. The unidirectional solidification unit is provided therein with a start block driven in a downward direction to transfer molten silicon in the downward direction and is formed at a lower side thereof with a cooling channel. The start block includes a dummy bar having a silicon button joined to an upper portion of the dummy bar.

Owner:KOREA INST OF ENERGY RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com