Cementing magnetostrictive material and preparation thereof

A magnetostrictive material and magnetostrictive technology, applied in the direction of material selection for magnetostrictive devices, manufacture/assembly of magnetostrictive devices, manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve Problems such as large degree of freedom in size, to achieve the effect of large degree of freedom in size, regular shape, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

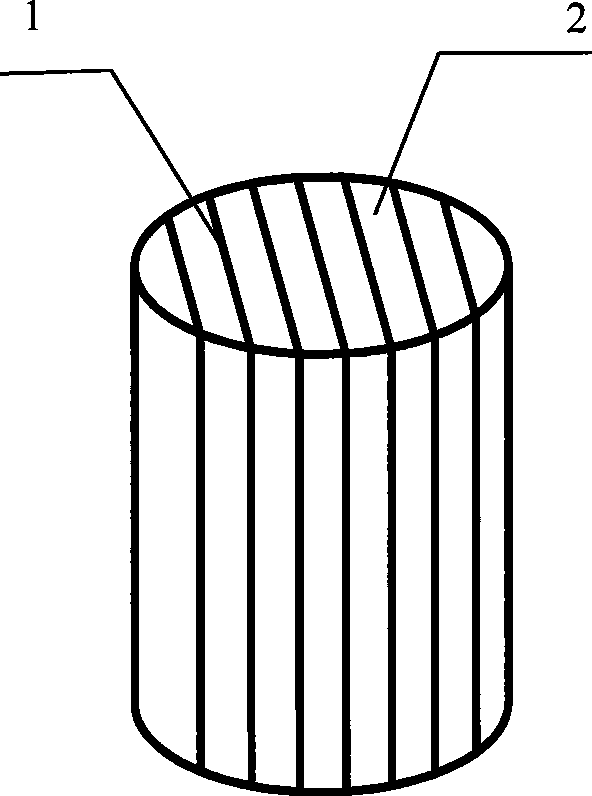

Embodiment 1

[0043] The bonded magnetostrictive material in this embodiment is a cylinder of Φ52.35×60 mm. The material used is a directionally solidified rare earth giant magnetostrictive rod of Φ52.25×59.9mm. The chemical formula of the rod is: (Tb 0.2 Dy 0.8 )Fe 1.8 . First, the directionally solidified rare earth giant magnetostrictive rod of Φ52.25×59.9mm was uniformly cut into 10 pieces along the diameter direction by wire cutting, and each piece had a thickness of 5mm (the width of the wire cutting slit was 0.15-0.30mm). After the slices were cleaned, they were fixed in a stainless steel mold with a gap of 0.25 mm between each slice, kept parallel to each other, and perpendicular to the base of the mold. The gap between the sheet and the stainless steel mold is 0.05mm. After a certain proportion of epoxy resin and its curing agent are evenly prepared, it is poured into the mold as a binder, and the binder is fully immersed in the gap between the sheets. Then, it is cured at roo...

Embodiment 2

[0047] The bonded magnetostrictive material in this embodiment is a cylinder of Φ32×40 mm. The material used is a directionally solidified rare earth giant magnetostrictive rod of Φ31.8×39.8mm. The chemical formula of the rod is: (Tb 0.3 Dy 0.7 )Fe 1.95 . The directionally solidified rare earth giant magnetostrictive rod of Φ31.8×39.8 mm was uniformly cut into thin slices with a thickness of 3 mm by the same method as in Example 1. After the slices were cleaned, they were fixed in a stainless steel mold with a gap of 0.2 mm between each slice, kept parallel to each other, and perpendicular to the base of the mold. The gap between the sheet and the stainless steel mold is 0.1mm. After a certain proportion of epoxy resin and its curing agent are evenly prepared, it is poured into the mold as a binder, and the binder is fully immersed in the gap between the sheets. Then, it is cured under a temperature field of 60° C. for 12 hours, and the bonded magnetostrictive material ha...

Embodiment 3

[0051] The bonded magnetostrictive material in this embodiment is a cylinder of Φ32.35×50 mm. The material used is Φ32.25×49.9mm directionally solidified rare earth giant magnetostrictive rod, the rod chemical formula: (Tb 0.3 Dy 0.7 )(Fe 0.82 co 0.09 mn 0.05 V 0.04 ) 2.2. The directionally solidified rare earth giant magnetostrictive rod of Φ32.25×49.9mm was uniformly cut into 10 pieces along the diameter direction by the same method as in Example 1, and each piece had a thickness of 3mm. After the slices were cleaned, they were fixed in a stainless steel mold with a gap of 0.25 mm between each slice, kept parallel to each other, and perpendicular to the base of the mold. The gap between the sheet and the stainless steel mold is 0.05mm. After a certain proportion of epoxy resin and its curing agent are evenly prepared, it is poured into the mold as a binder, and the binder is fully immersed in the gap between the sheets. Then, it is cured at room temperature for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com