Patents

Literature

250results about "Magnetostrictive material selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetostrictive actuator of a medical ultrasound transducer assembly, and a medical ultrasound handpiece and a medical ultrasound system having such actuator

ActiveUS8487487B2Efficiently sculpt teeth or remove boneLow powerUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonographyUltrasonic sensor

Owner:CILAG GMBH INT

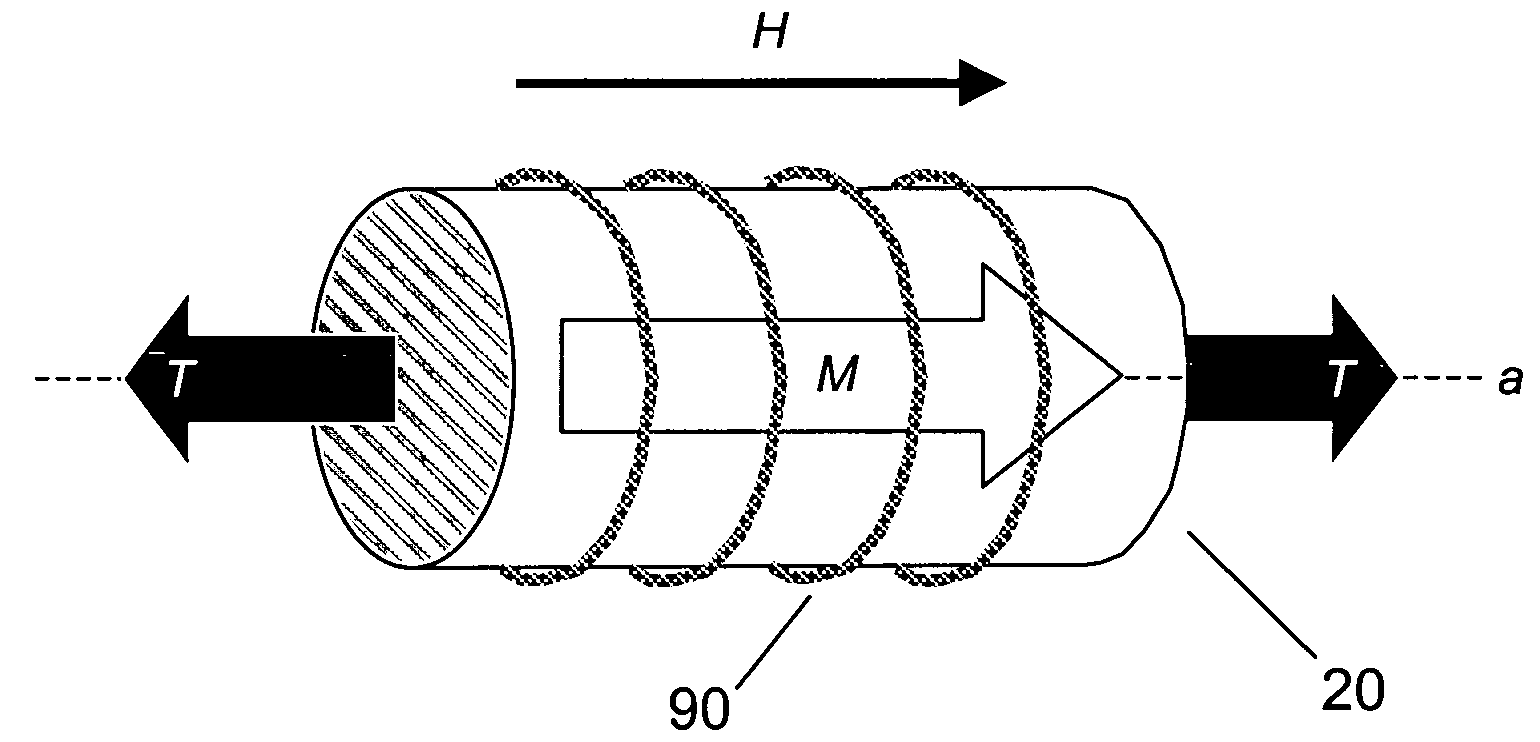

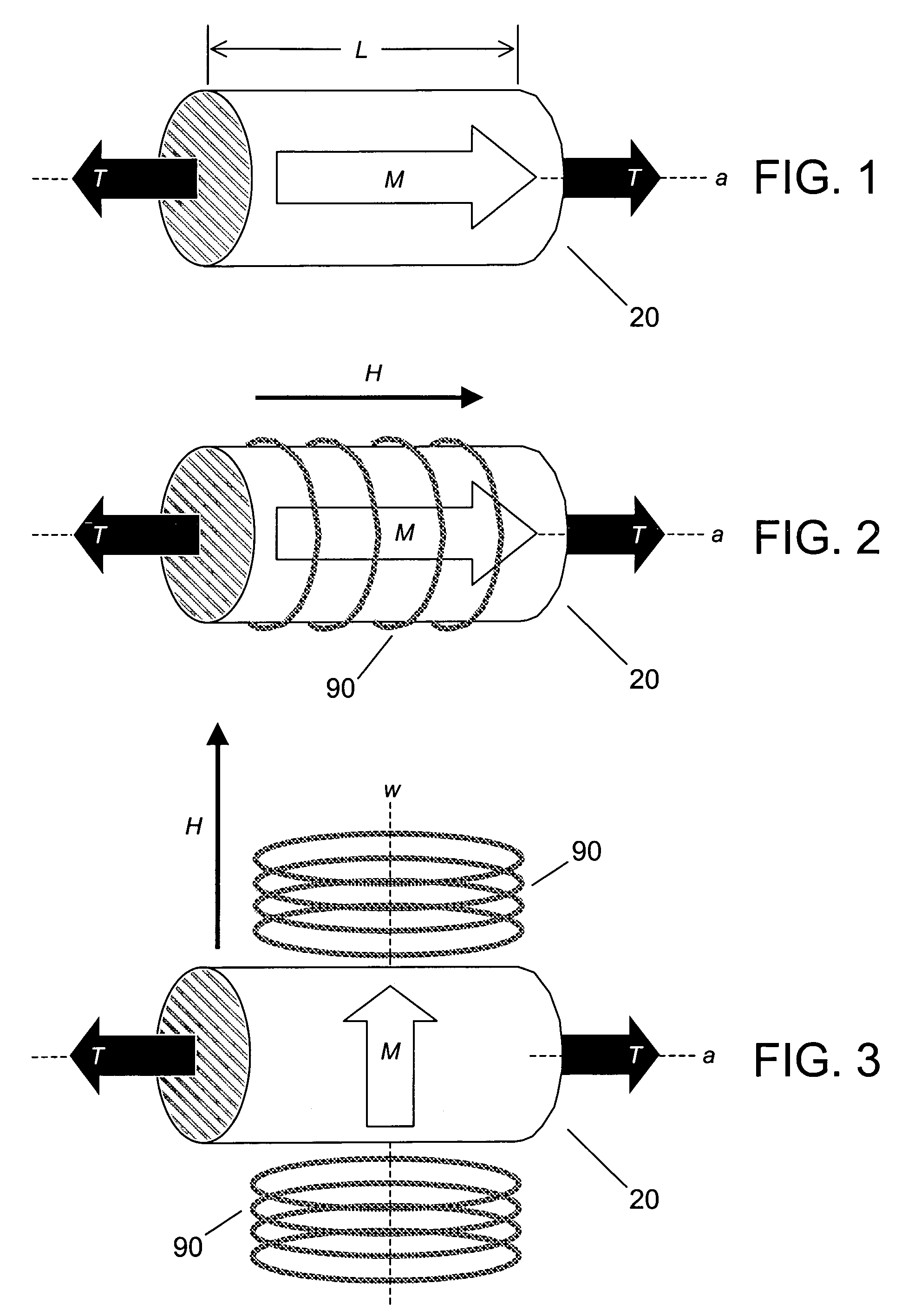

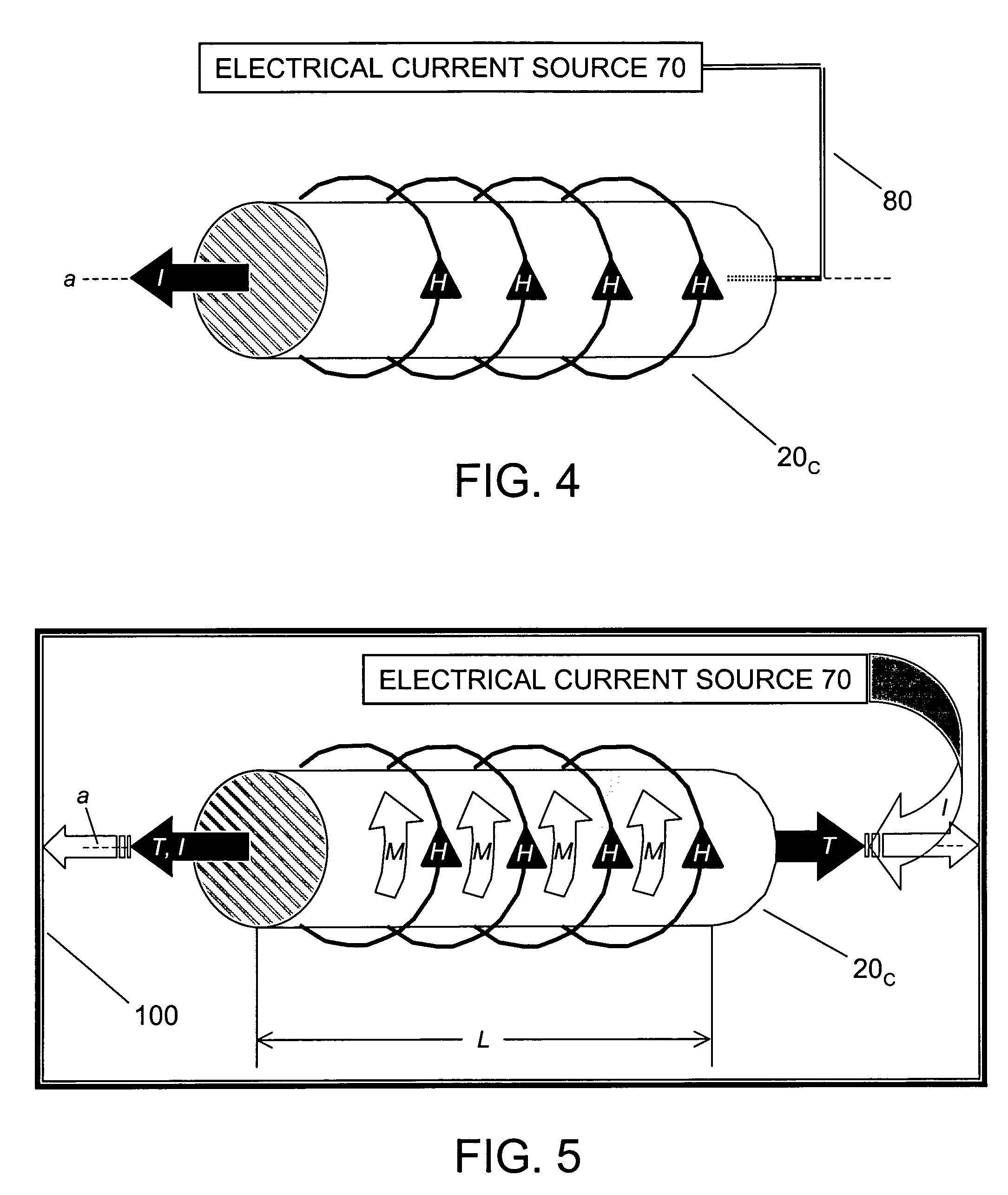

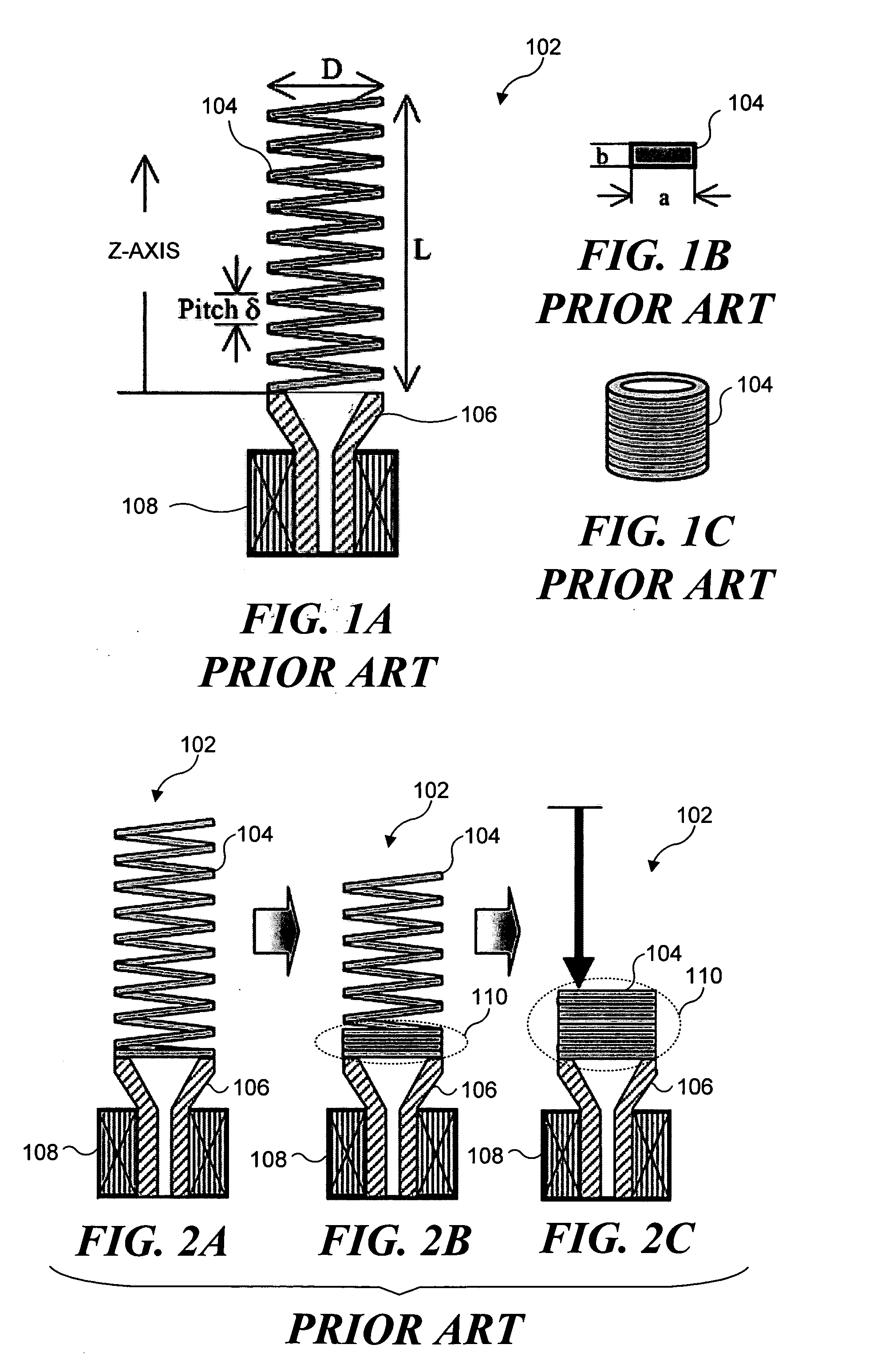

High magnetostriction of positive magnetostrictive materials under tensile load

InactiveUS7564152B1Magnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorMagnetization

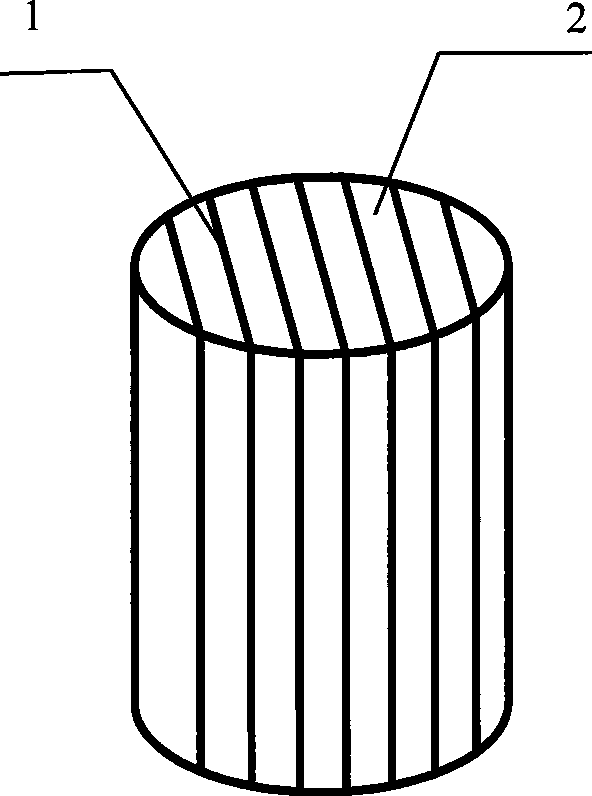

An elongate structure having a magnetostrictive material composition is subjected to tensile stress in the longitudinal-axial direction, thereby generally orienting the magnetization of the elongate structure in the longitudinal-axial direction. Electrical current is conducted through the elongate structure and / or through at least one adjacent elongate conductor, thereby generally orienting the magnetization of the elongate structure in the transverse direction, generally in parallel with the transverse direction of the magnetic field concomitant the conduction of current through the elongate structure. The elongate structure magnetostrictively contracts due to the (generally 90°) repositioning of the magnetization of the elongate structure. Examples of inventive configurational variants include: (i) an elongate structure itself conducting current; (ii) a hollow elongate structure accommodating placement therethrough of at least one elongate conductor; (iii) an elongate structure flanked by a pair of elongate conductors conducting current in opposite directions; (iv) plural elongate structures bordering a centralized elongate conductor.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

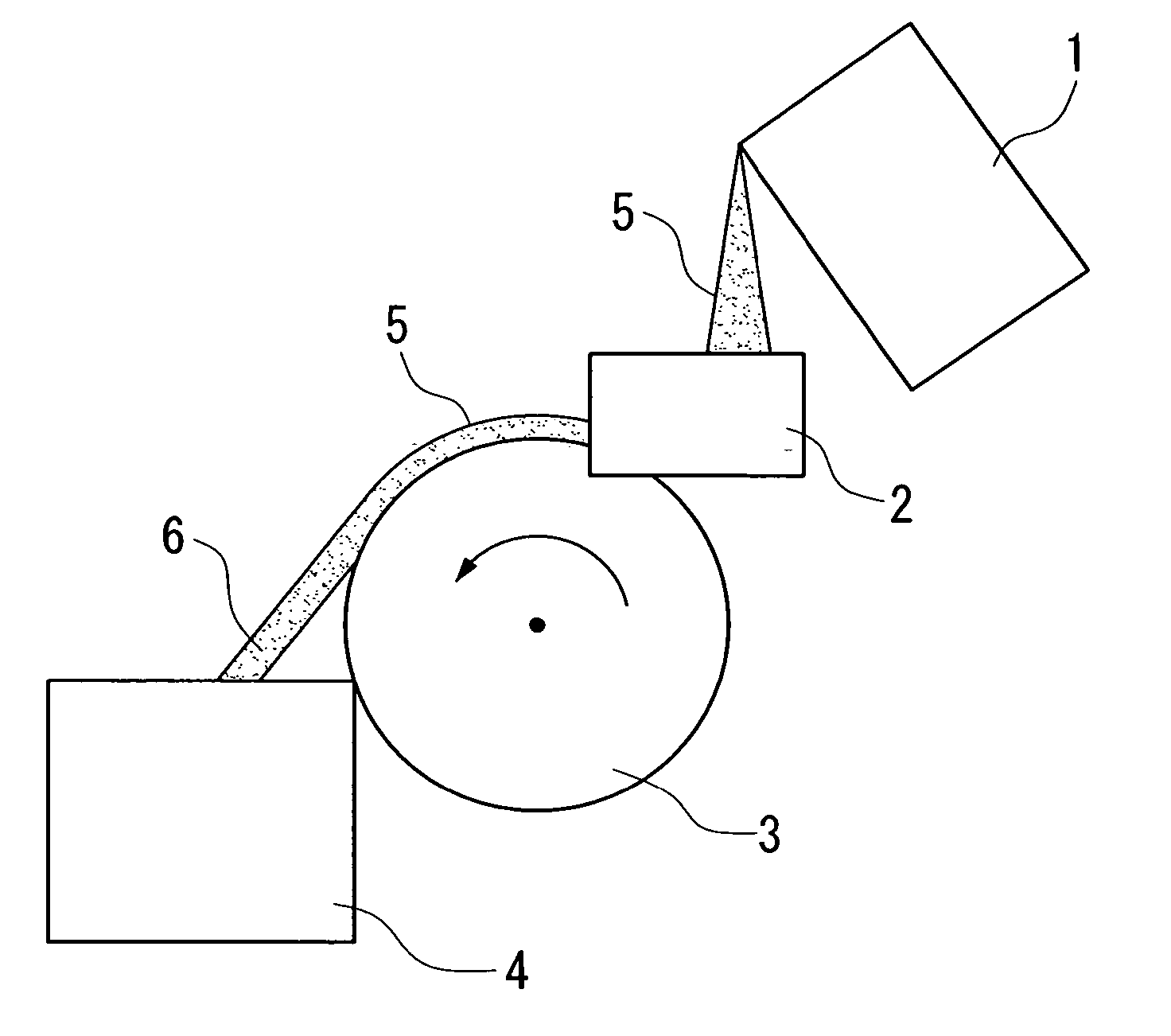

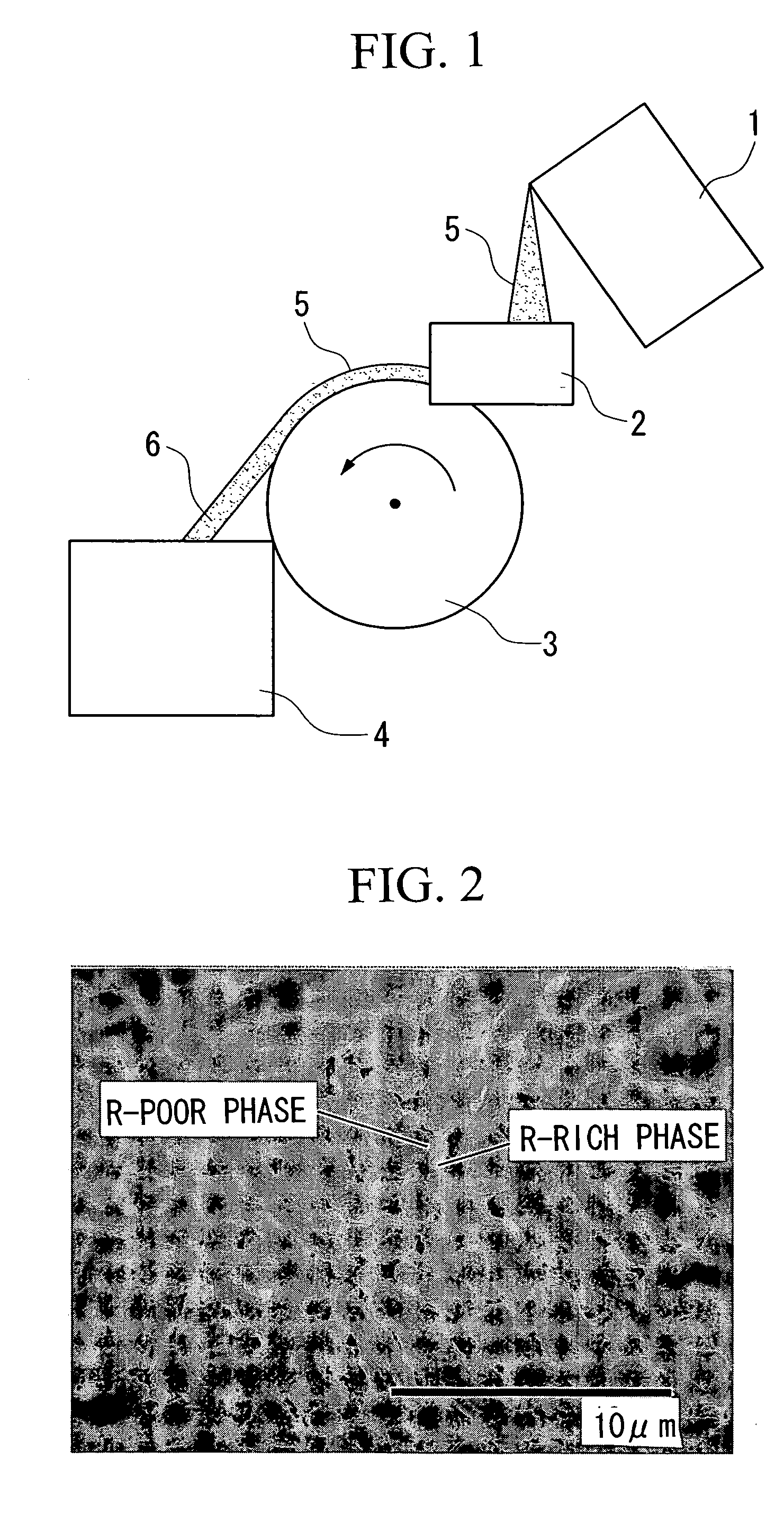

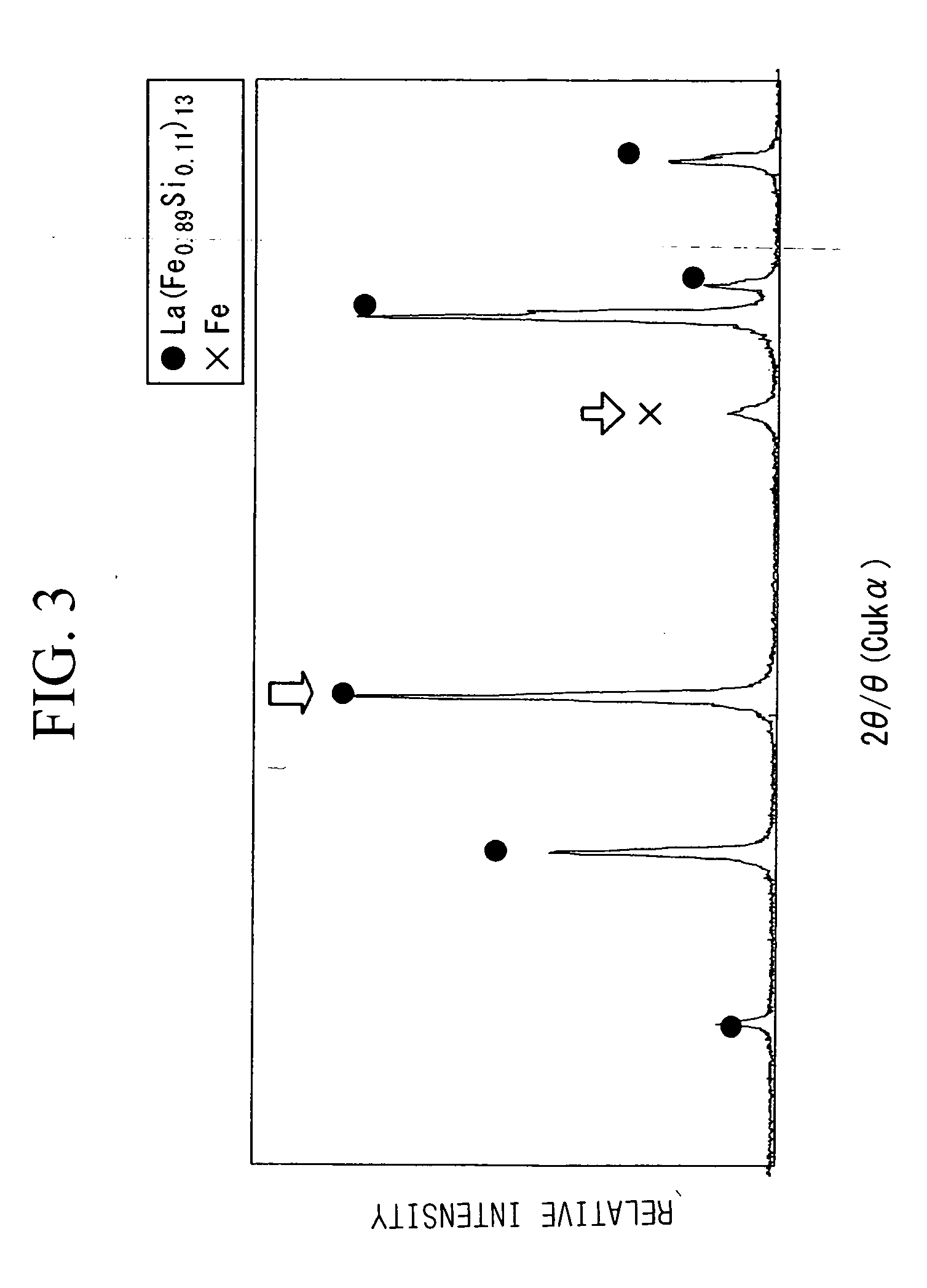

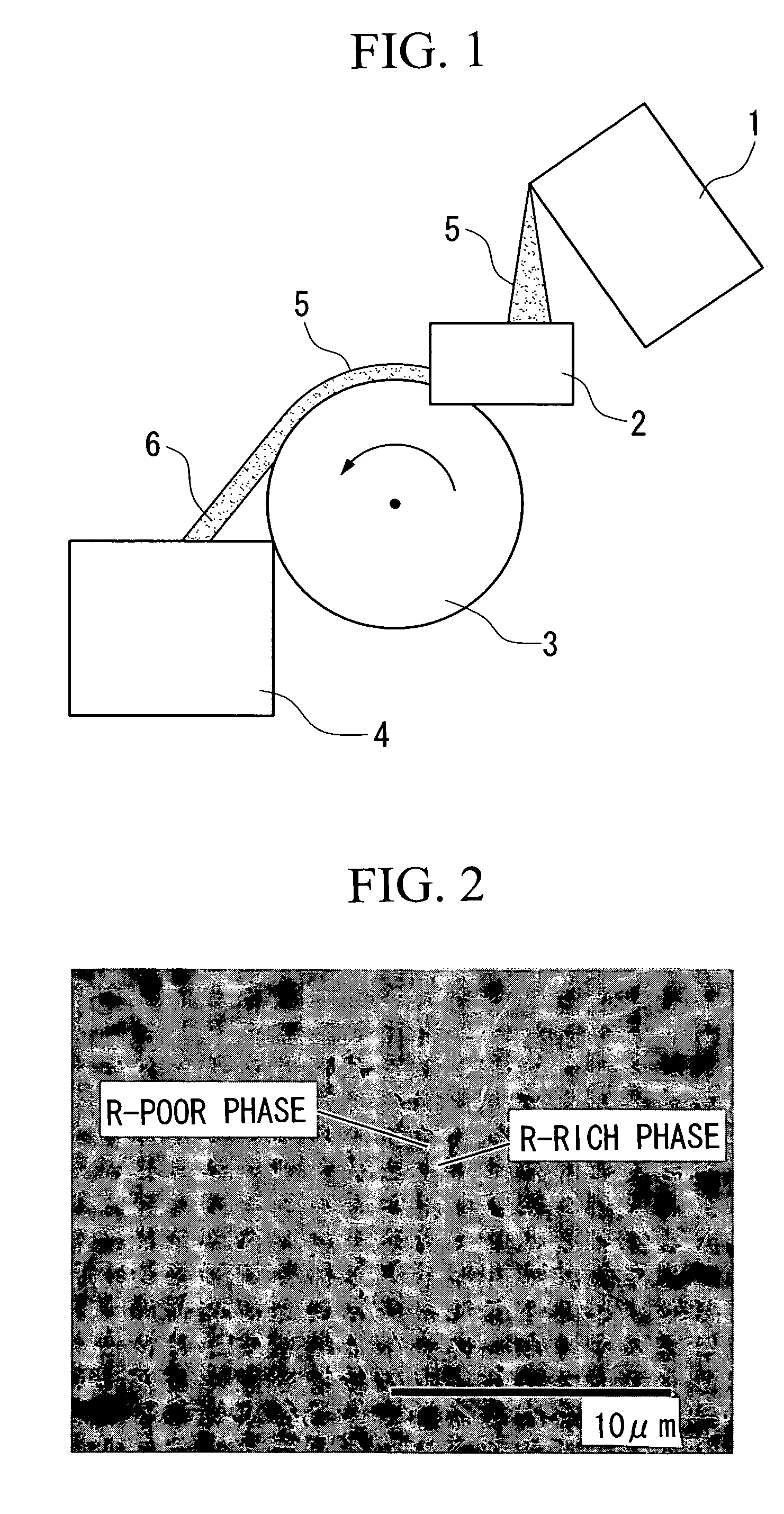

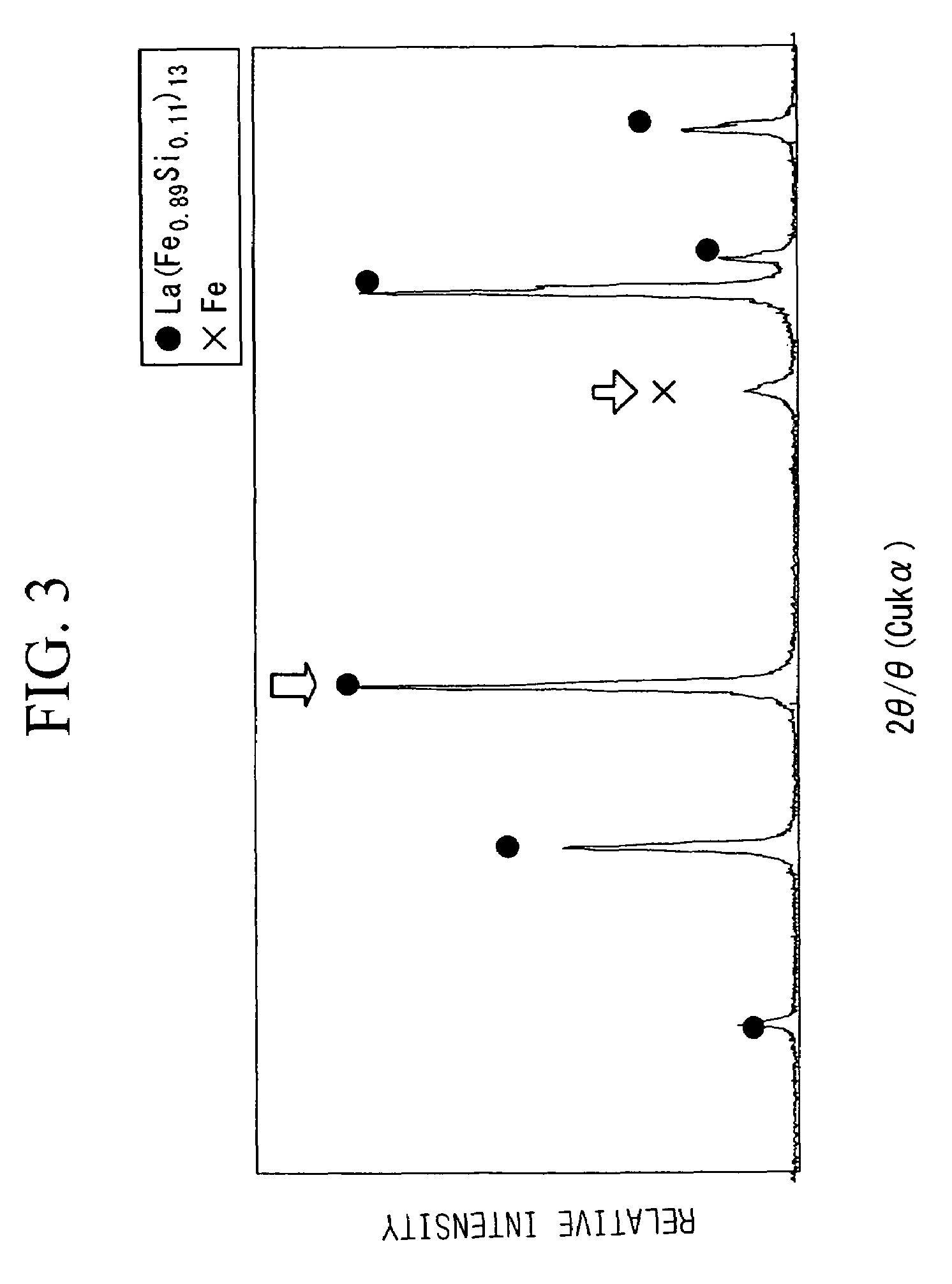

Alloy containing rare earth element, production method thereof, magnetostrictive device, and magnetic refrigerant material

InactiveUS20060076084A1Improve efficiencyReliably producedEnergy efficient heating/coolingInorganic material magnetismRare-earth elementCrystal structure

A method for producing an RE-containing alloy represented by formula R(T1−xAx)13−y (wherein R represents Ce, etc.; T represents Fe, etc.; and A represents Al, etc; 0.05≦x≦0.2; and −1≦y≦1) including a melting step of melting alloy raw materials at 1,200 to 1,800° C.; and a solidification step of rapidly quenching the molten metal produced through the above step, to thereby form the first RE-containing alloy, wherein the solidification step is performed at a cooling rate of 102 to 104° C. / second, as measured at least within a range of the temperature of the molten metal to 900° C.; and an RE-containing alloy, which is represented by a compositional formula of RrTtAa(wherein R and A represent the same meaning as above, T represents Fe, etc.; 5.0 at. %≦r≦6.8 at. %, 73.8 at. %≦t≦88.7 at. %, and 4.6 at. %≦a≦19.4 at. %) and has an alloy microstructure containing an NaZn13-type crystal structure in an amount of at least 85 mass % and α-Fe in an amount of 5-15 mass % inclusive.

Owner:ERASTEEL

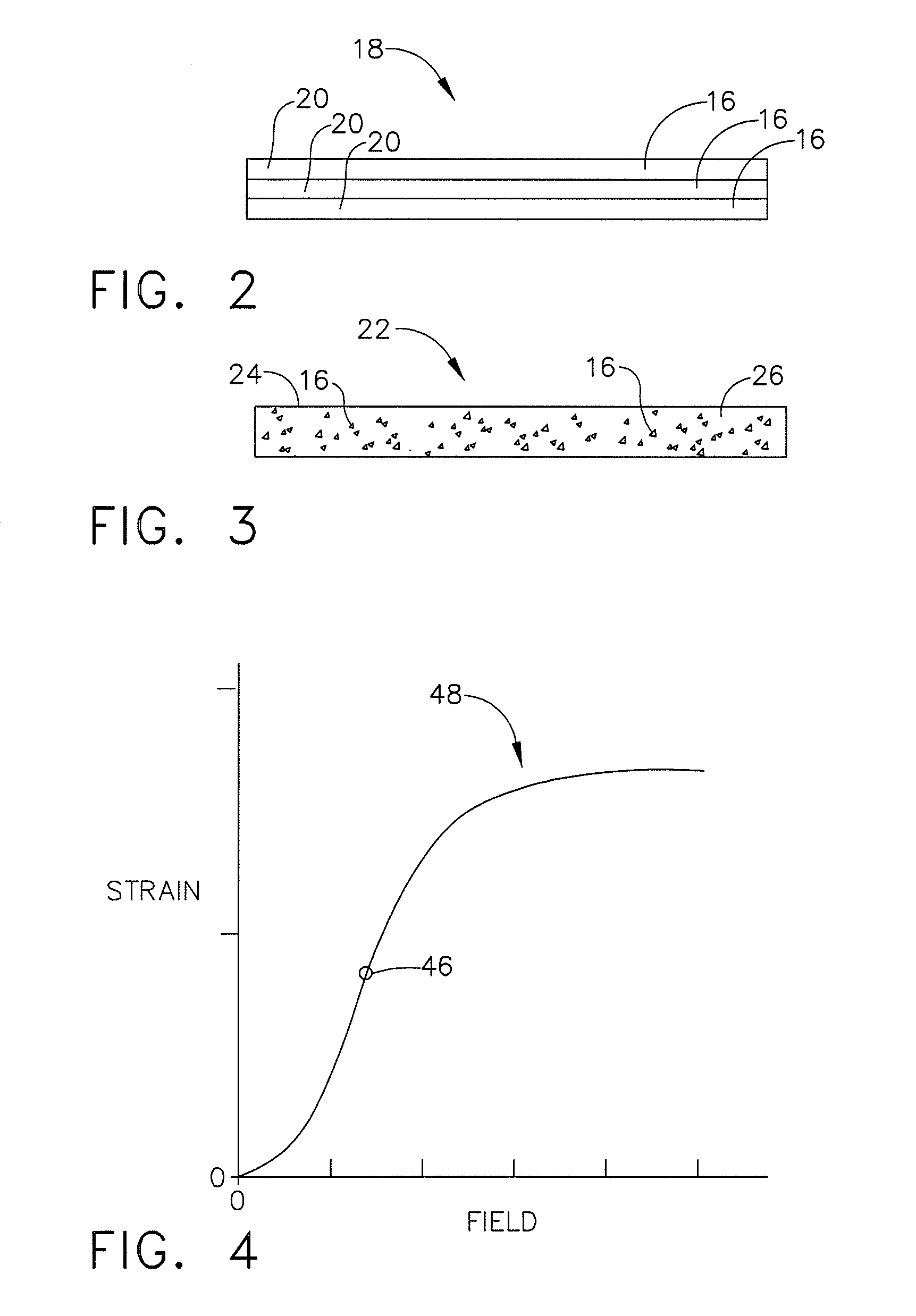

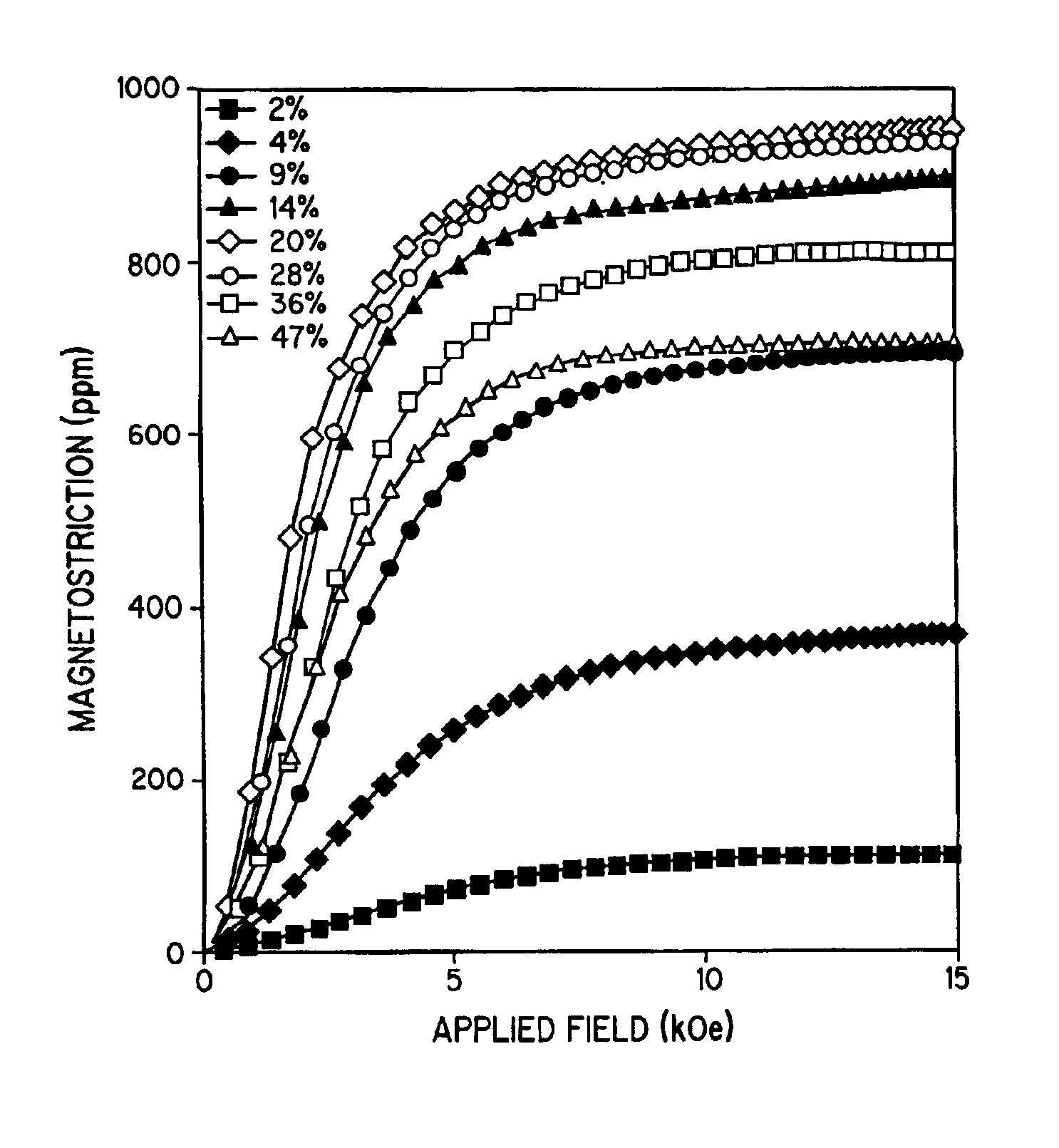

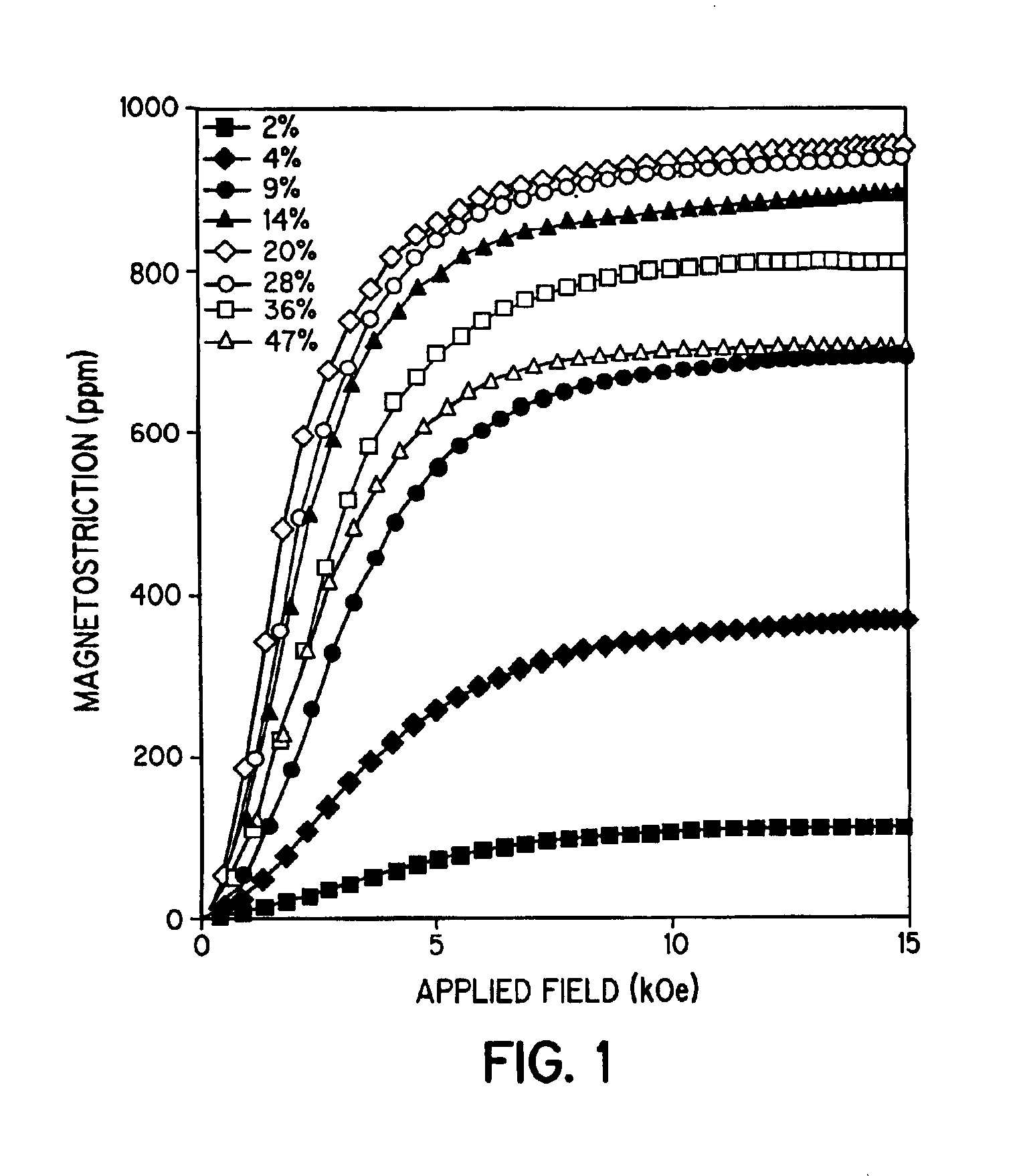

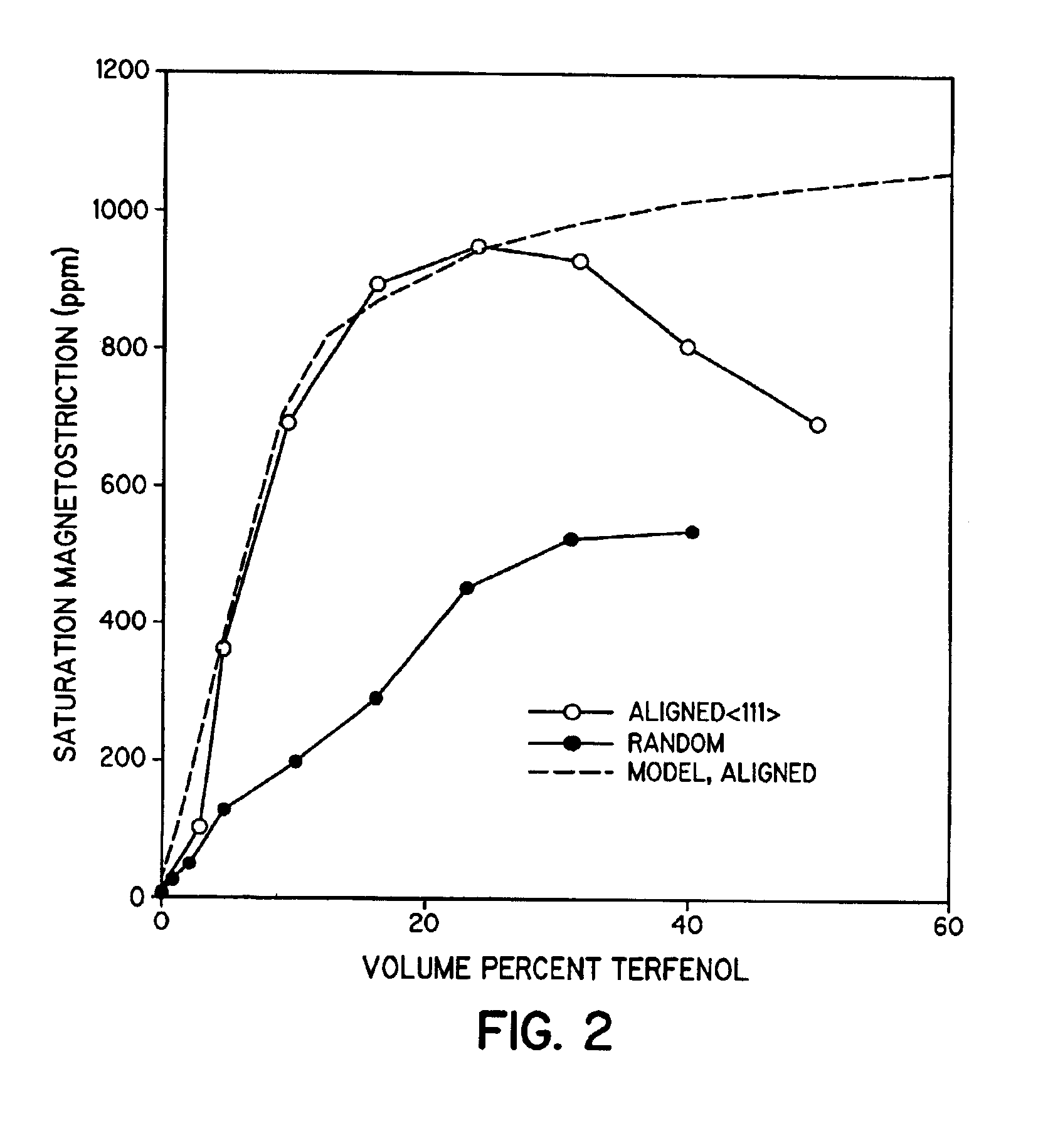

Composites with large magnetostriction

InactiveUS6849195B2Inorganic material magnetismMagnetostrictive material selectionResin matrixSilicon dioxide

A magnetostrictive composite having large magnetostriction by virtue of 2-50 vol. % magnetostrictive particles dispersed throughout a resin matrix formed from a thermosetting resin, an amine curing agent, fumed silica and a flexibilizing agent, wherein the magnetostrictive particles are aligned in the direction of their magnetic easy axes by the presence of a magnetic field prior to or during curing of the resin matrix. In an exemplary embodiment, an epoxy-Terfenol composite is formed by mixing an epoxy resin, fumed silica, a cycloaliphatic amine curing agent, and a flexibilizing agent that is a flexible diepoxide of EEW 390-470 or a mixture of a high molecular weight polyamine of MW 2000-5000 and a low molecular weight polyamine of MW 230-450 with Terfenol particles and curing the mixture in the presence of a magnetic field.

Owner:DELPHI TECH INC

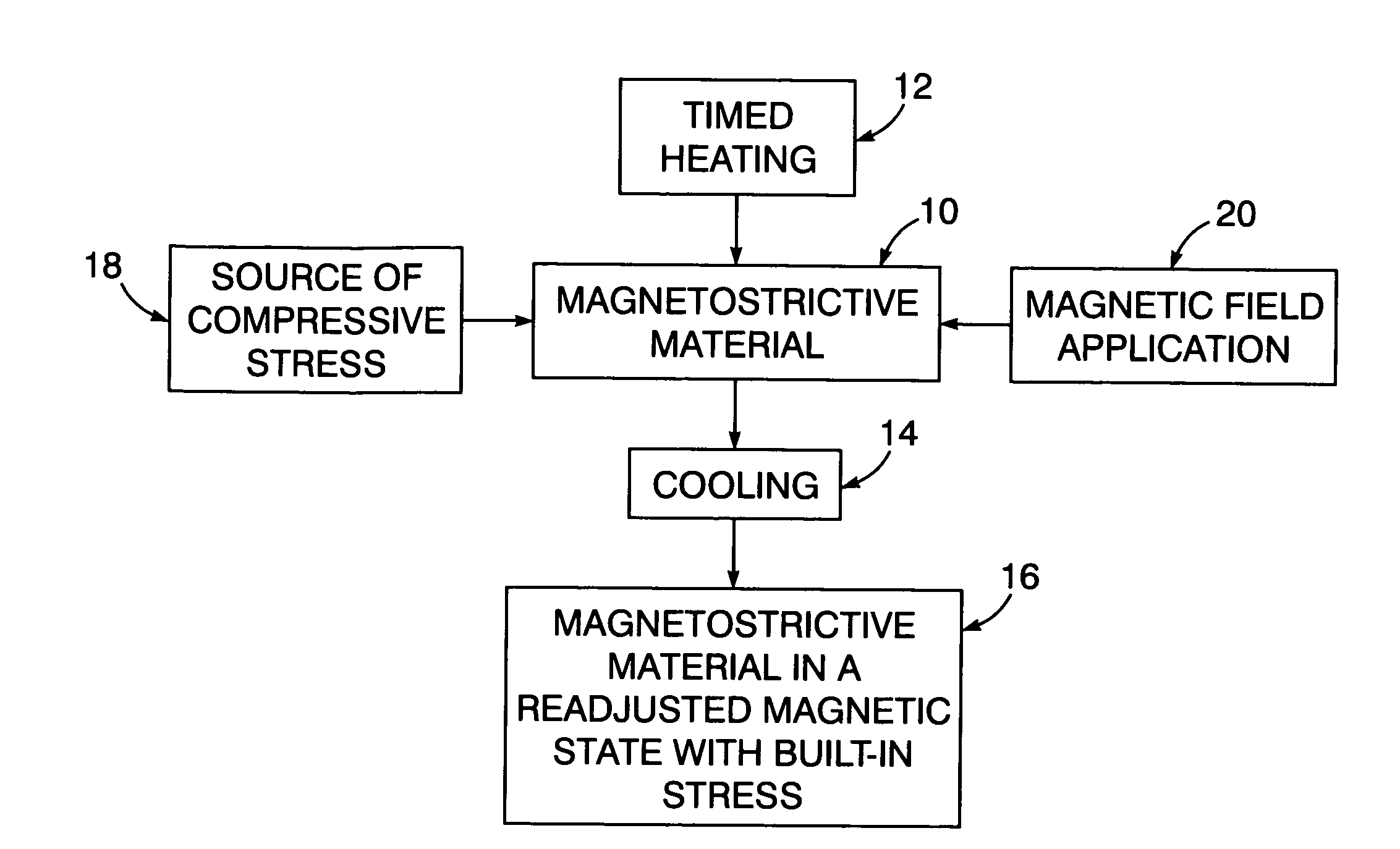

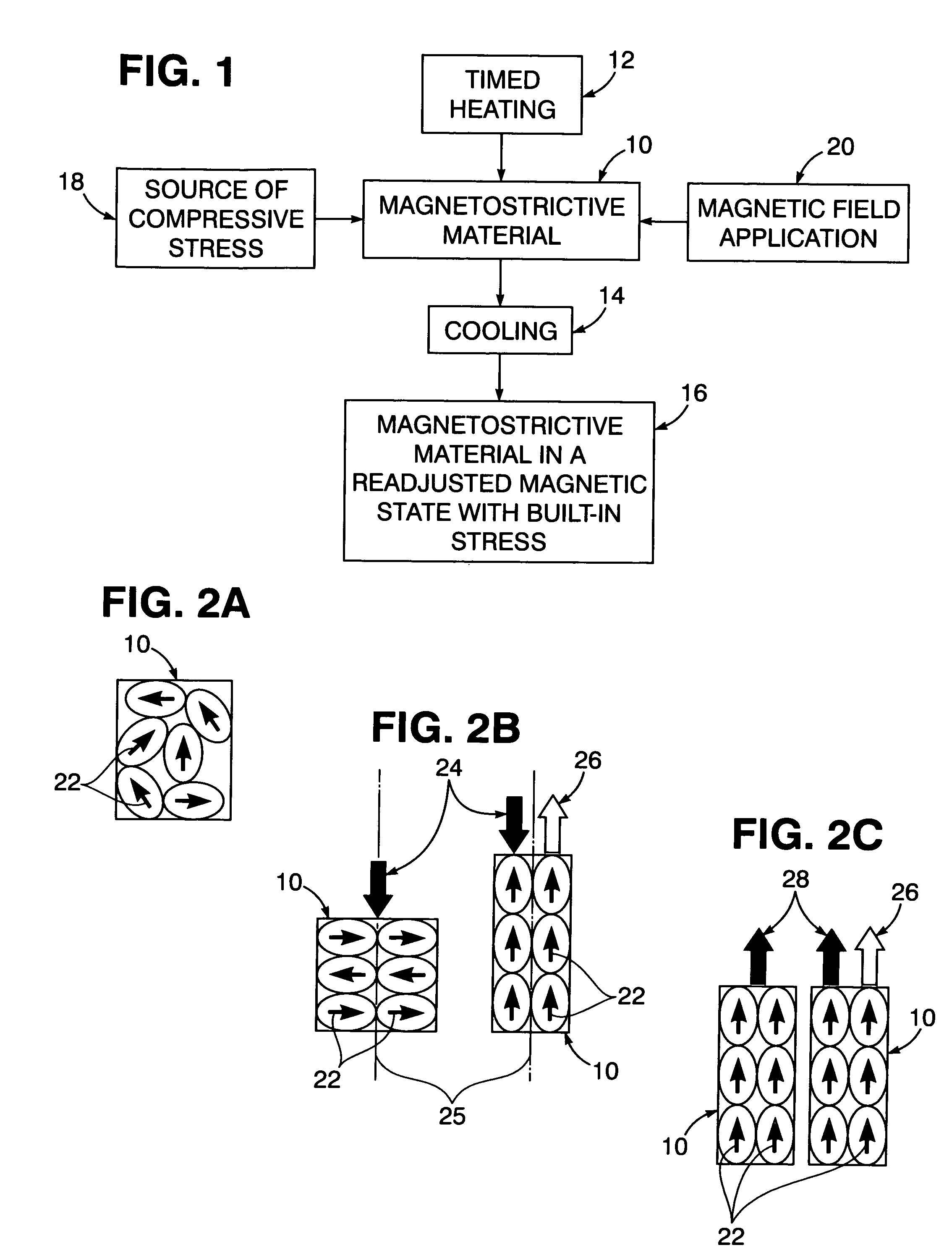

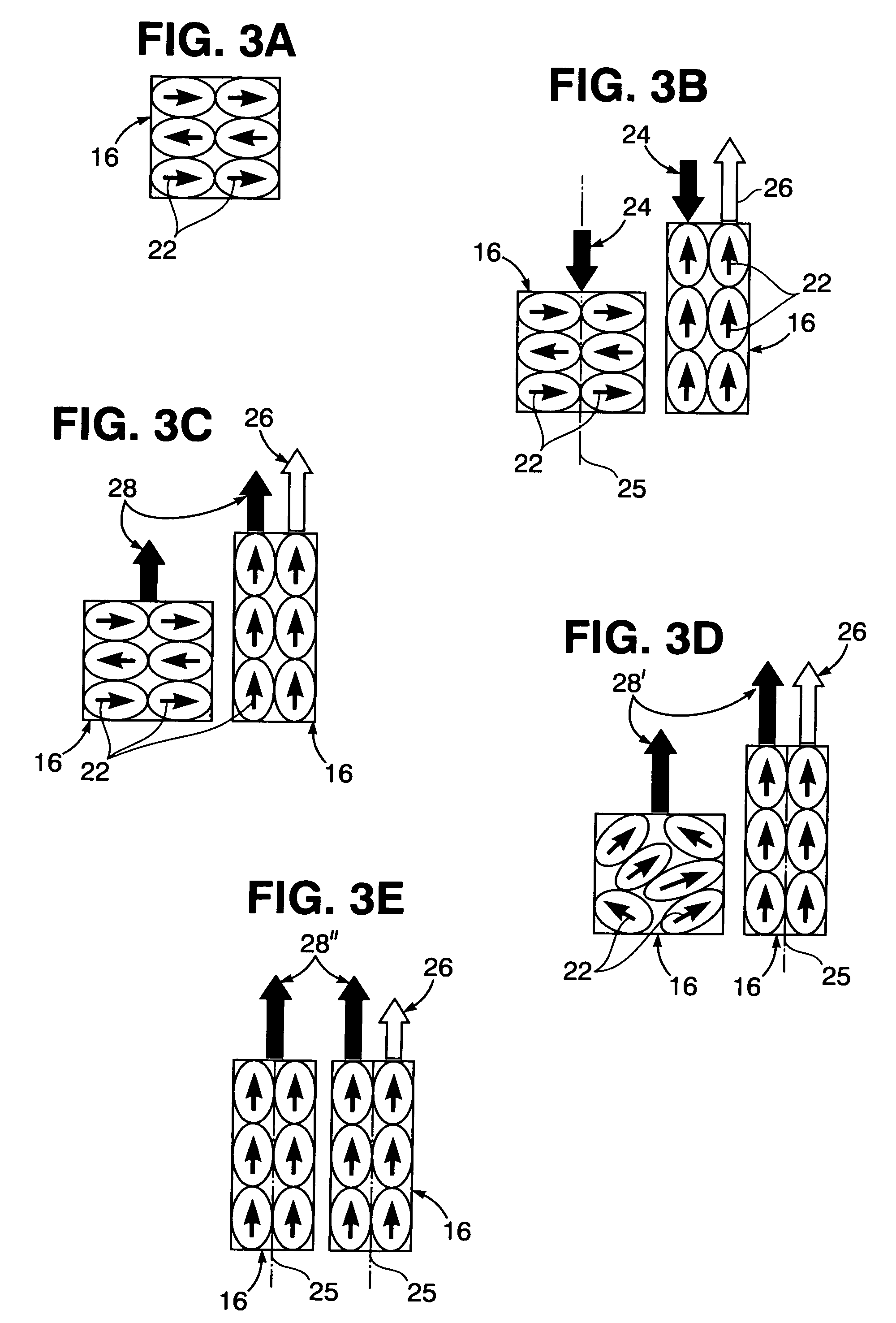

Preparation of positive magnetostrictive materials for use under tension

ActiveUS7479193B1Magnetostrictive device manufacture/assemblyInorganic material magnetismAlloyUltimate tensile strength

A positive magnetostrictive material such as a ferromagnetic alloy is subjected to a magnetic field during annealing treatment while being heated for a predetermined period of time at an elevated temperature below its softening temperature followed by cooling resulting in a treated ferromagnetic material having high tensile strength and positive magnetostriction properties for enhancing use thereof under tensile loading conditions. Such treatment of the ferromagnetic alloy may be augmented by application thereto of a compressive stress.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

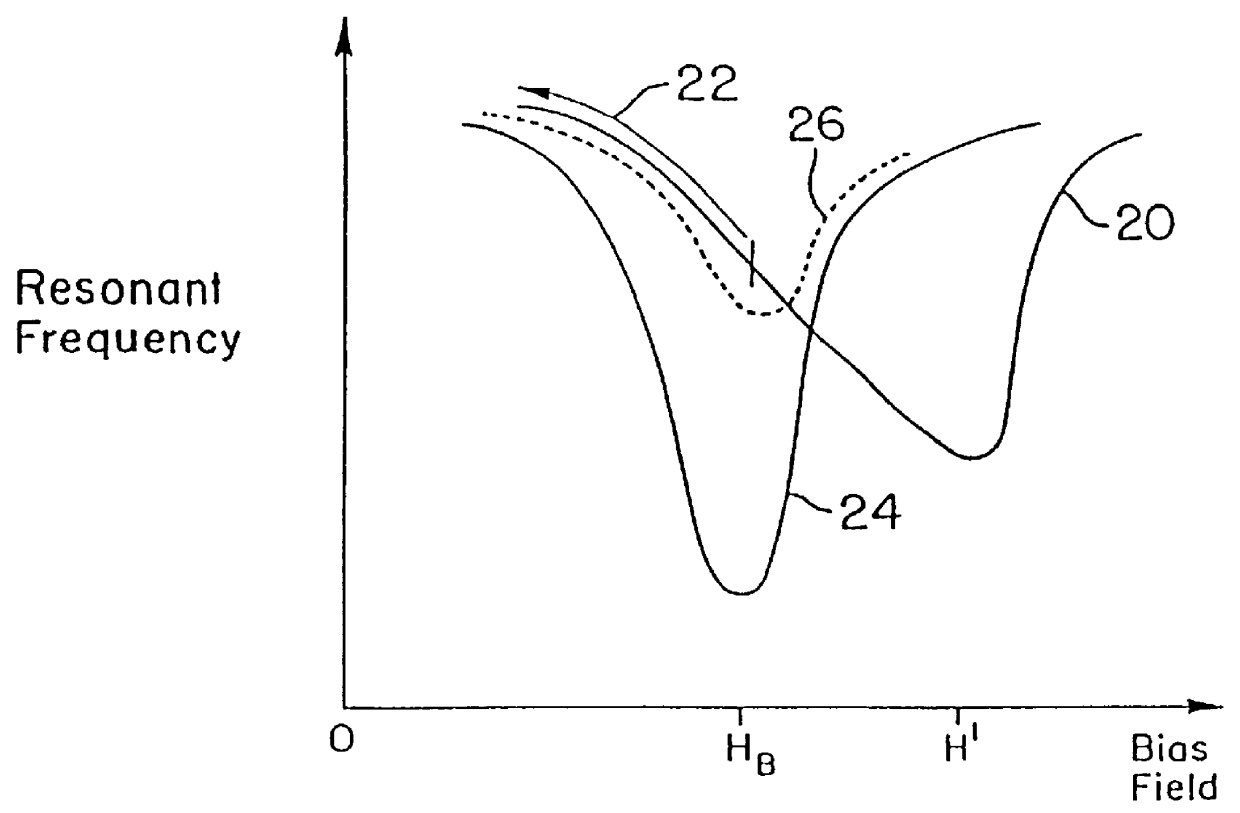

Iron-rich magnetostrictive element having optimized bias-field-dependent resonant frequency characteristic

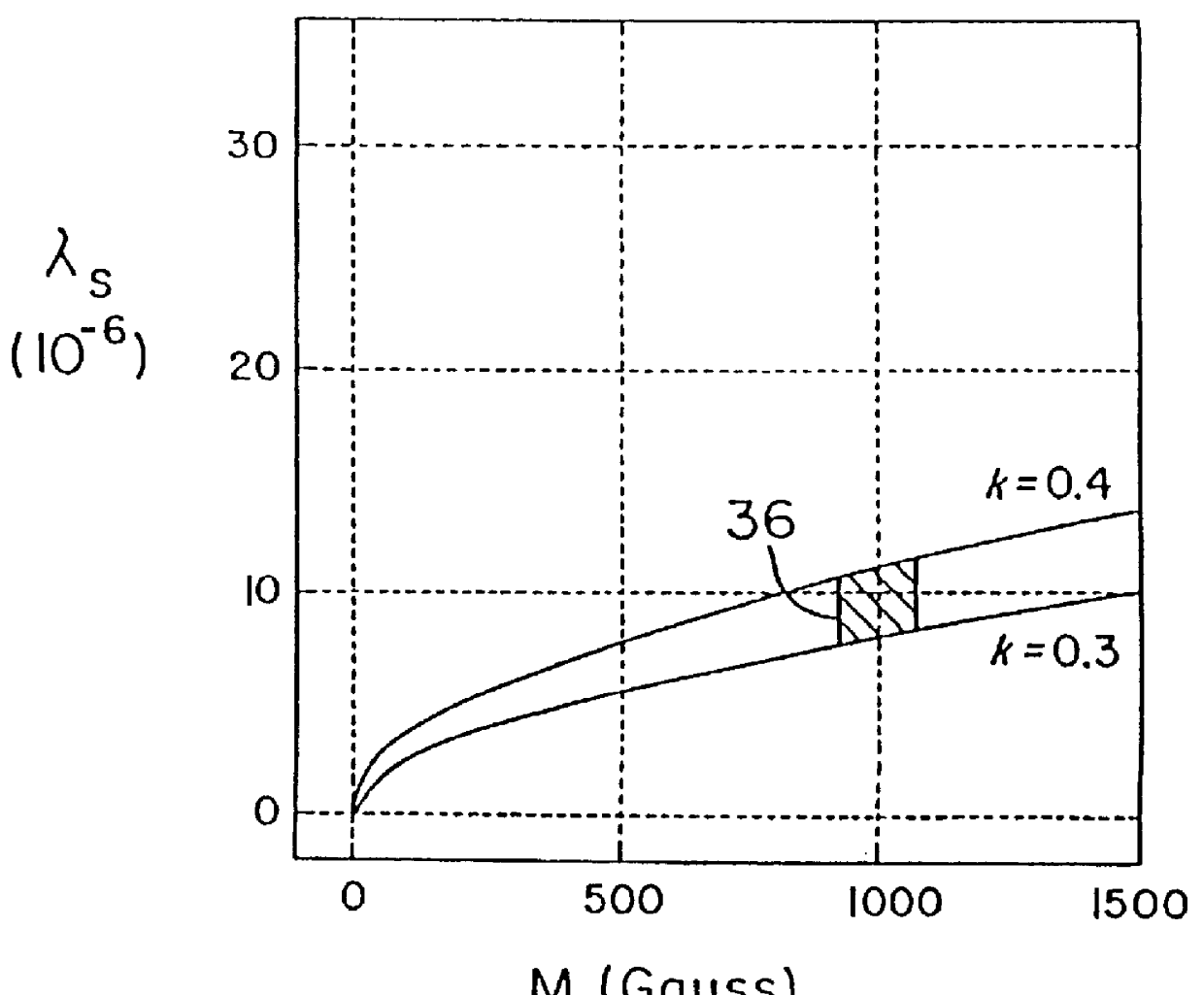

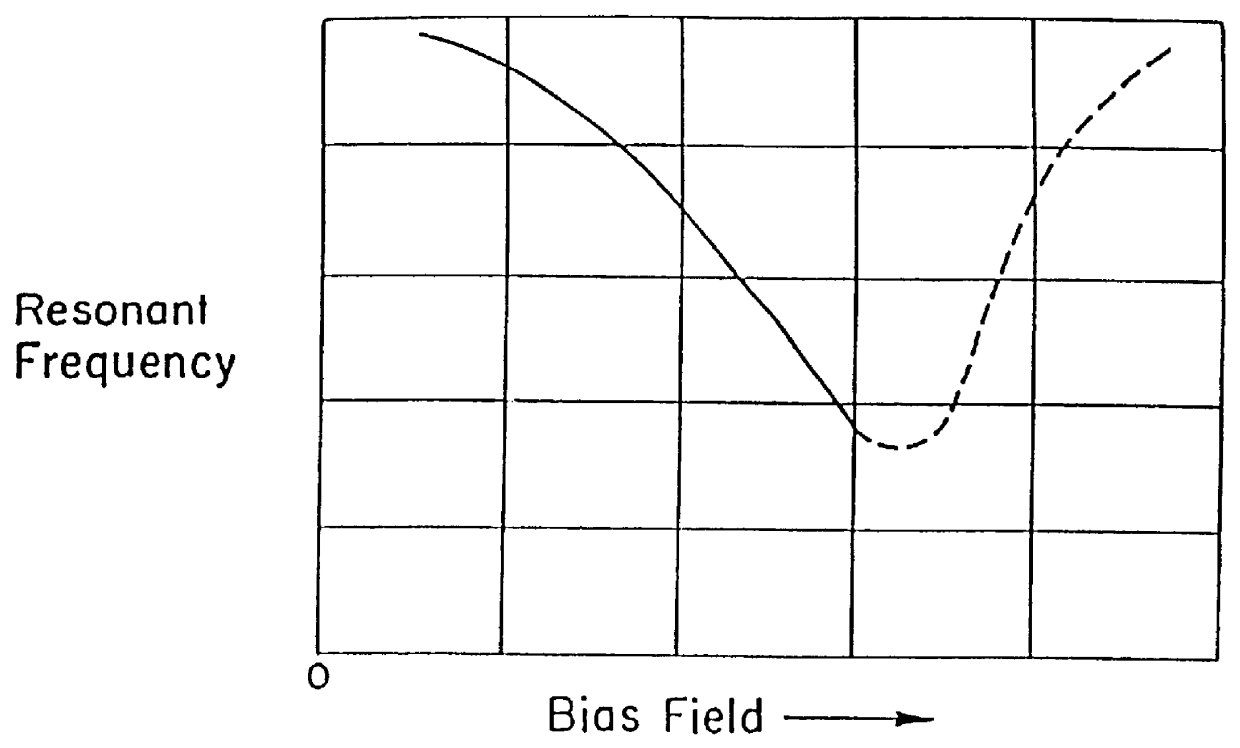

InactiveUS6057766ALow costInorganic material magnetismMagnetostrictive material selectionOperating pointCobalt

A magnetostrictive element for use in a magneto-mechanical marker has a resonant frequency characteristic that is at a minimum at a bias field level corresponding to the operating point of the magnetomechanical marker. The magnetostrictive element has a magnetomechanical coupling factor k in the range 0.28 to 0.4 at the operating point. The magnetostrictive element is formed by applying cross-field annealing to an iron-rich amorphous metal alloy ribbon (45 to 82 percent iron) which includes a total of from 2 to 17 percent of one or more of Mn, Mo, Nb, Cr, Hf, Zr, Ta, V. Cobalt, nickel, boron, silicon and / or carbon may also be included. The metal alloy may include one early transition element selected from the group consisting of Zr, Hf and Ta, and also a second early transition element selected from the group consisting of Mn, Mo, Nb, Cr, and V.

Owner:SENSORMATIC ELECTRONICS CORP

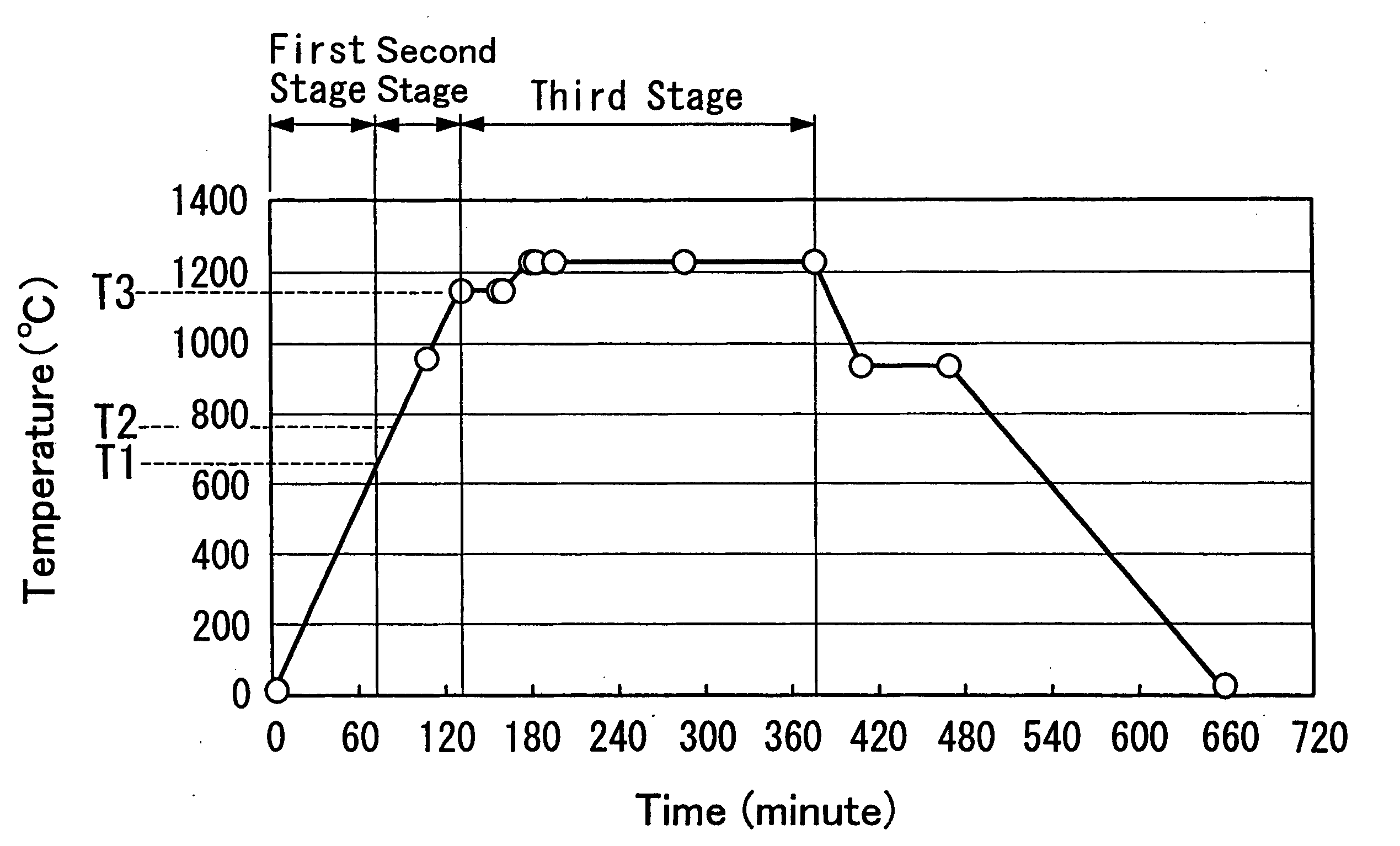

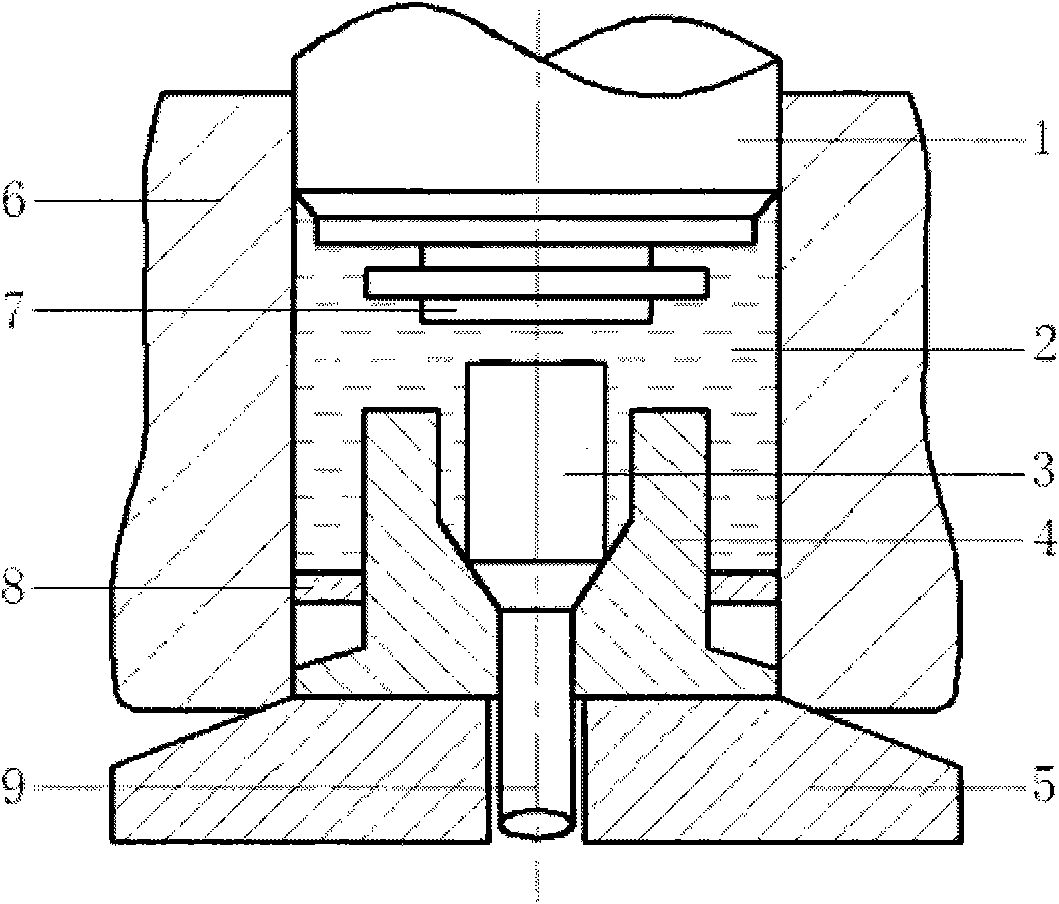

Method for producing magnetostrictive element and sintering method

InactiveUS20050061401A1Increase productionInhibition formationPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyMetallurgyVacuum pump

In the step of sintering a compact that is finally to be a magnetostrictive element, when the temperature in a furnace is elevated, the atmosphere in the furnace is evacuated by a vacuum pump to keep the pressure in the furnace at negative pressure in a temperature range that allows thermal decomposition of hydride present in the compact to release hydrogen gas to accelerate release of hydrogen from the compact.

Owner:TDK CORPARATION

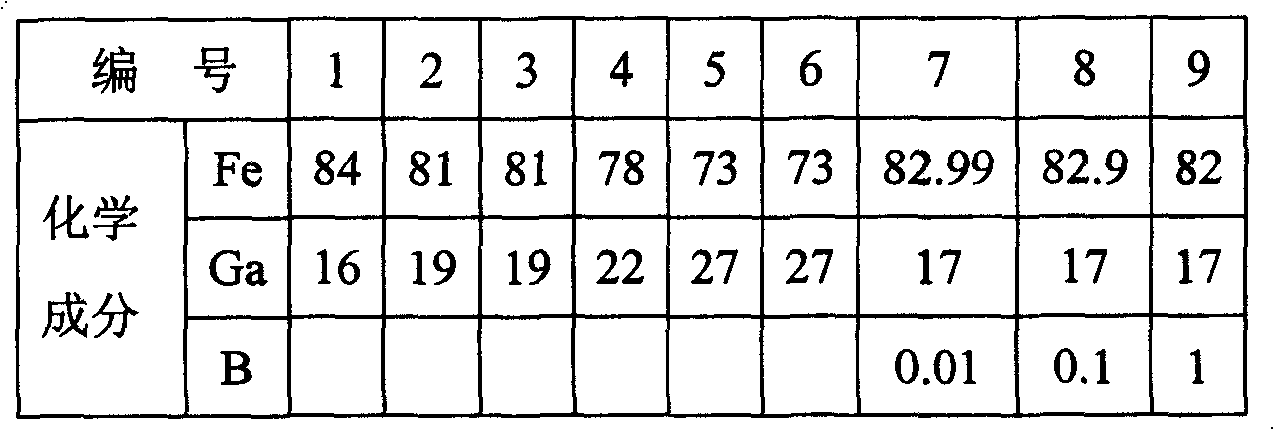

Fe-Ga series magnetostriction material and its producing process

InactiveCN1392616AEfficient use ofLow costMagnetostrictive material selectionRoom temperatureSingle crystal

This invention relates to a magnetic material. The components of material are Fe100-x-yGaxMyQ where x=10-40, M is Al, Be, Cr, In, Cd, Mo, Ge, y=0-15, Q is C, N, O additional doping. Main points of its technique are according to the requirement of the invented material components to smelt the mother alloy in a magnetic suspension over or vacuum induction furnace, to process monocrystal or polycrystal oriented materials with the high-temperature gradient quick directional solidification or czochralski or Bridgeman method under 1000-1200 deg.C for 1-48 hours then cool to 750-600 deg.C in the furnace and keep temp. for 0.2-48 hours, then quenching with water, or cool furnace to room temperature with different cooling speed for 750 to 600 deg.C or apply 500-20000 e magnetic field in the cooling process.

Owner:UNIV OF SCI & TECH BEIJING

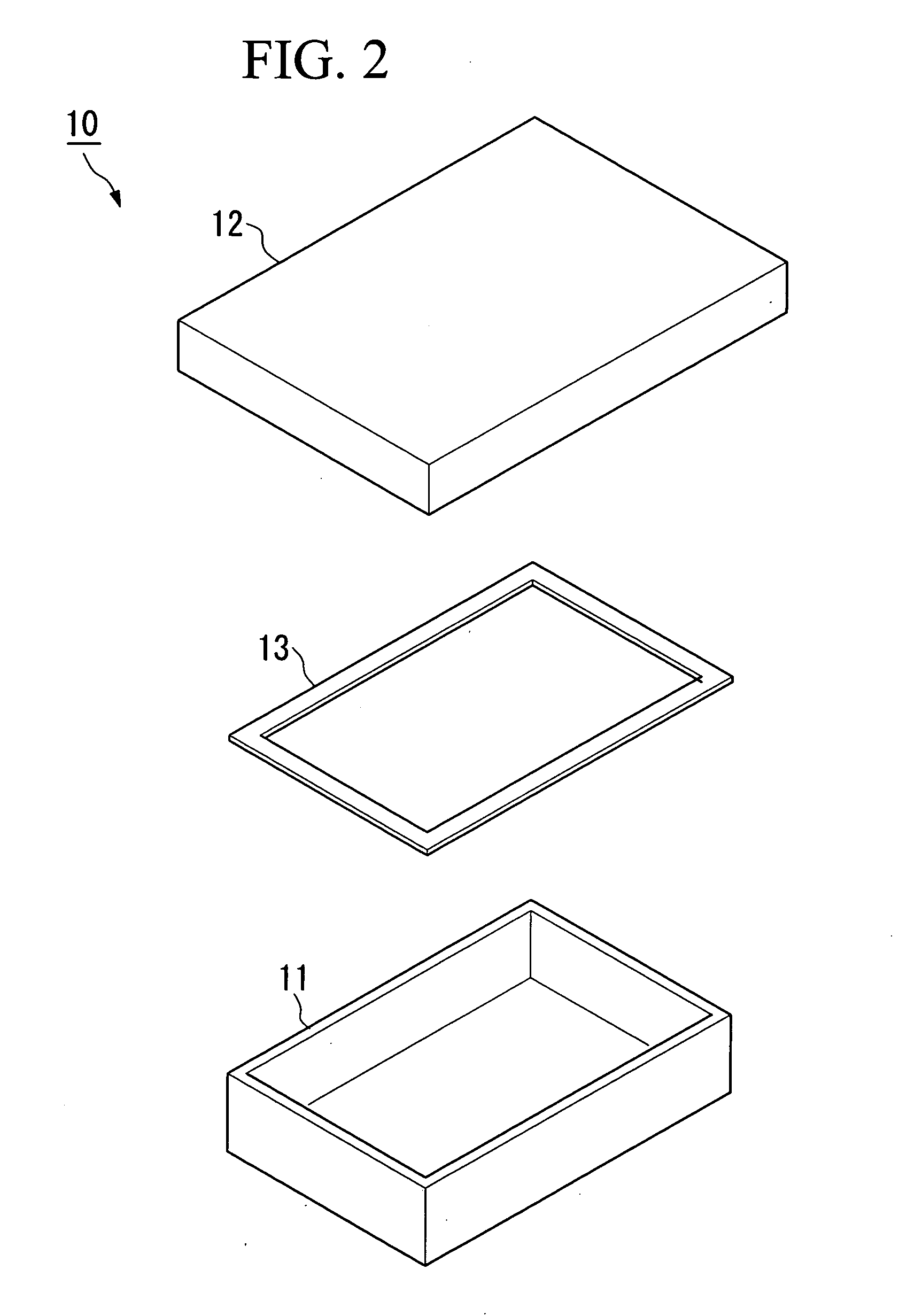

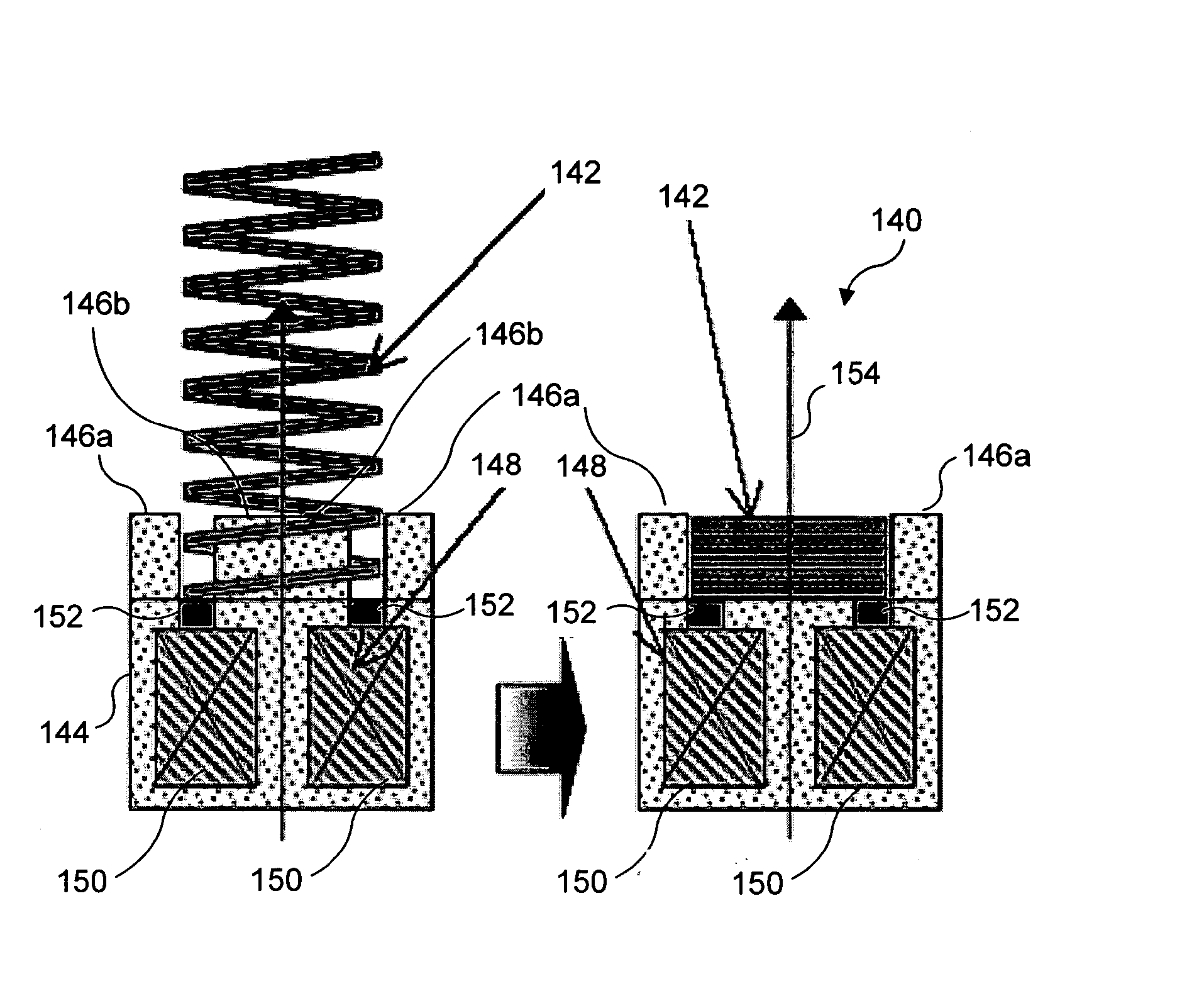

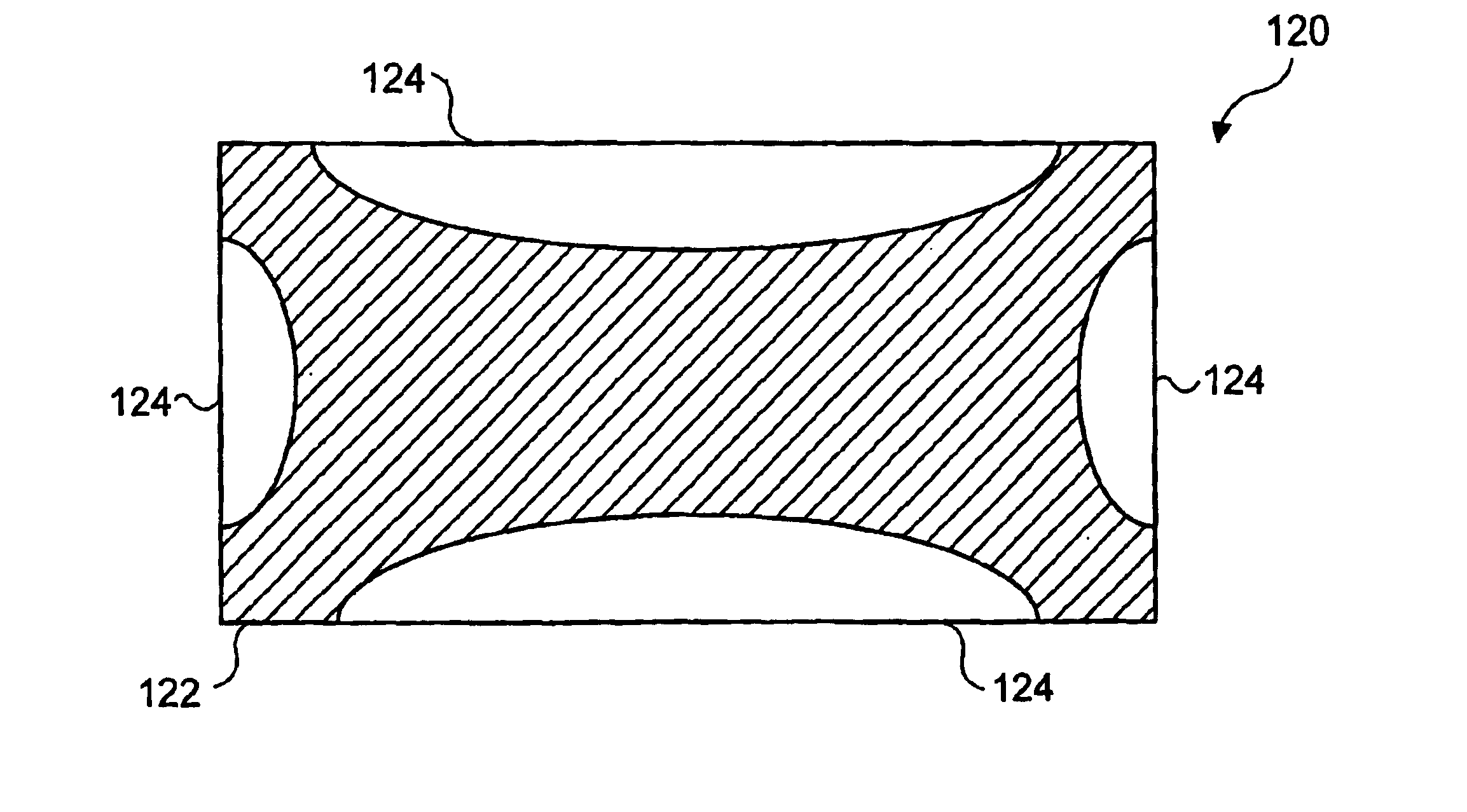

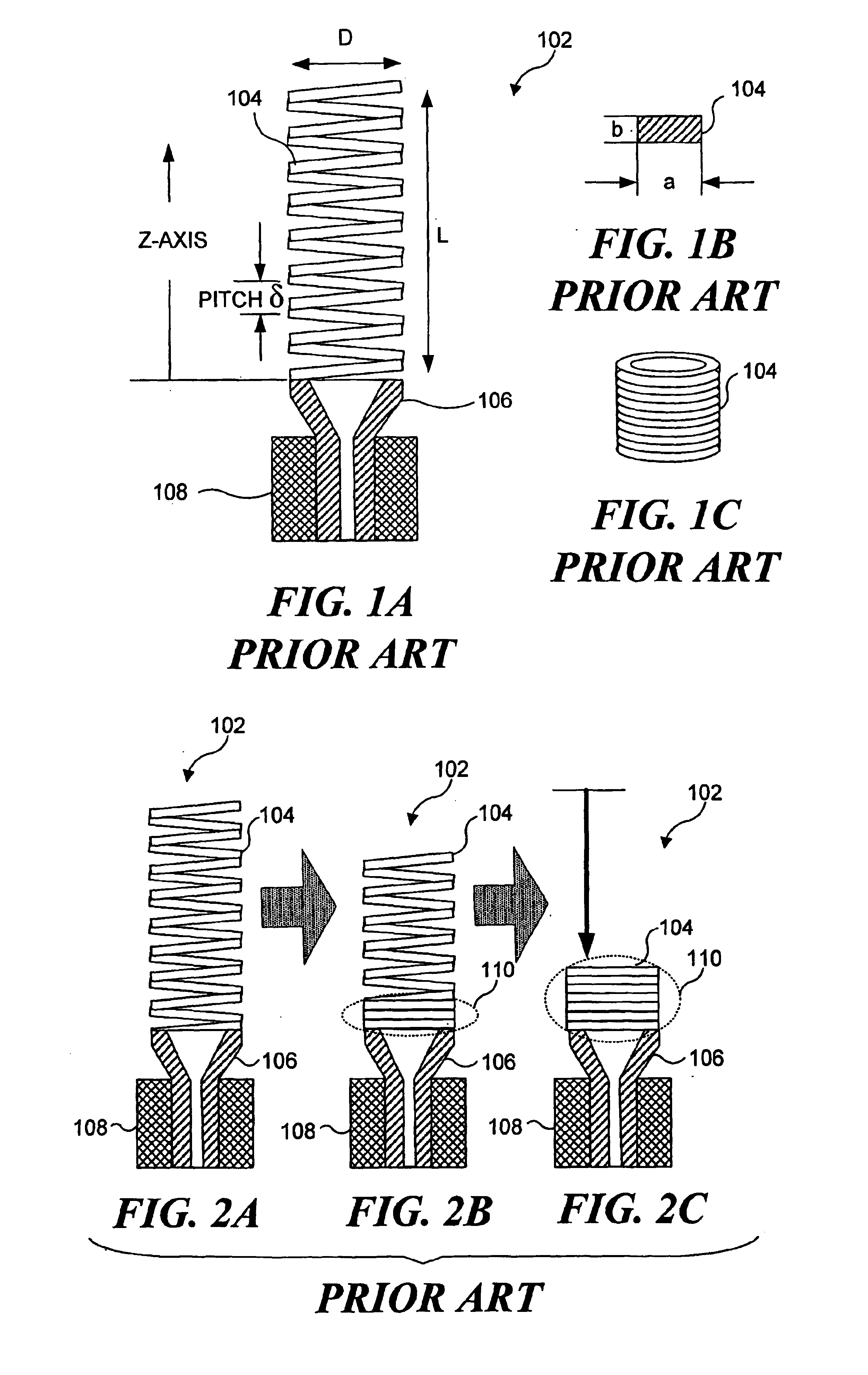

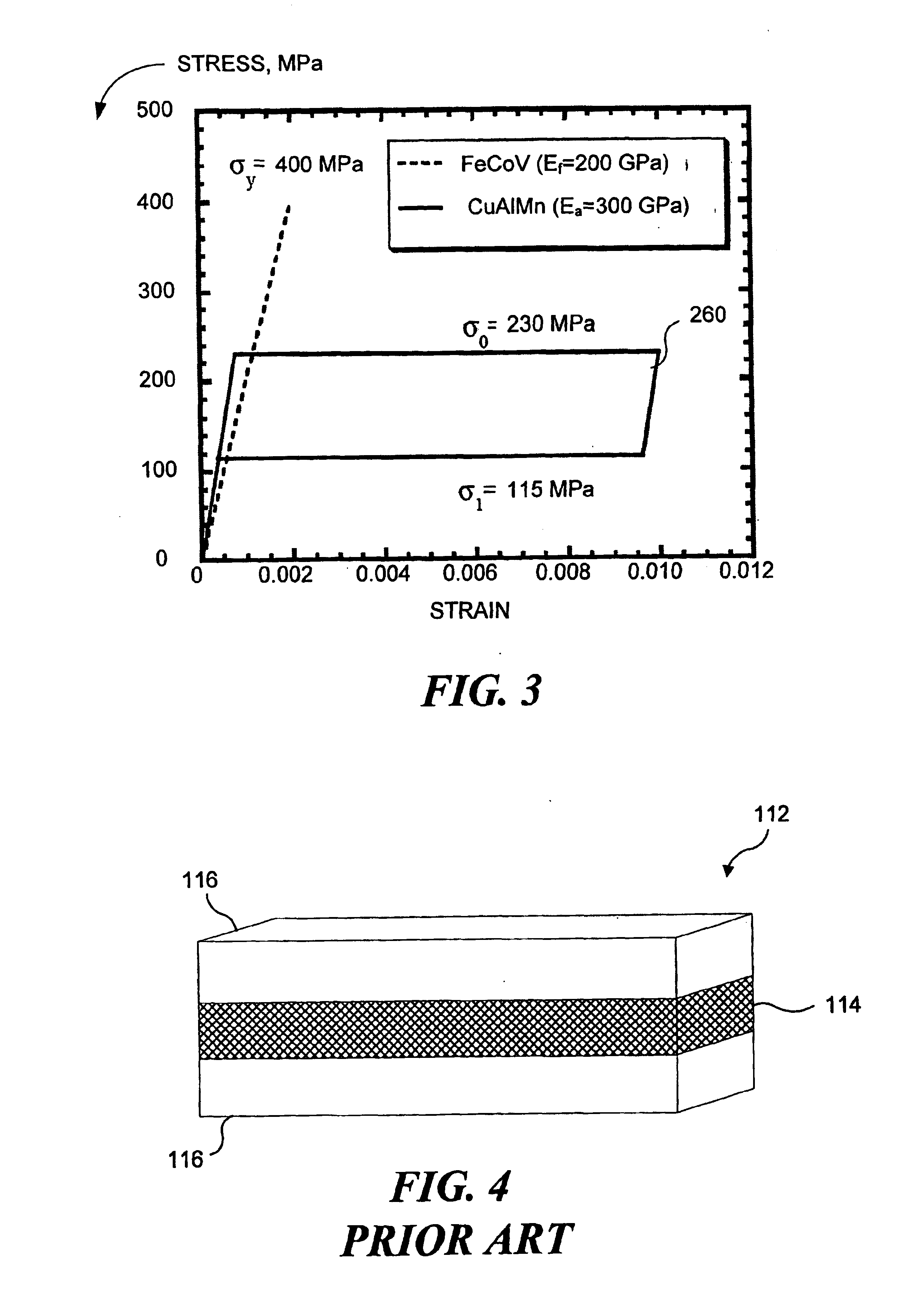

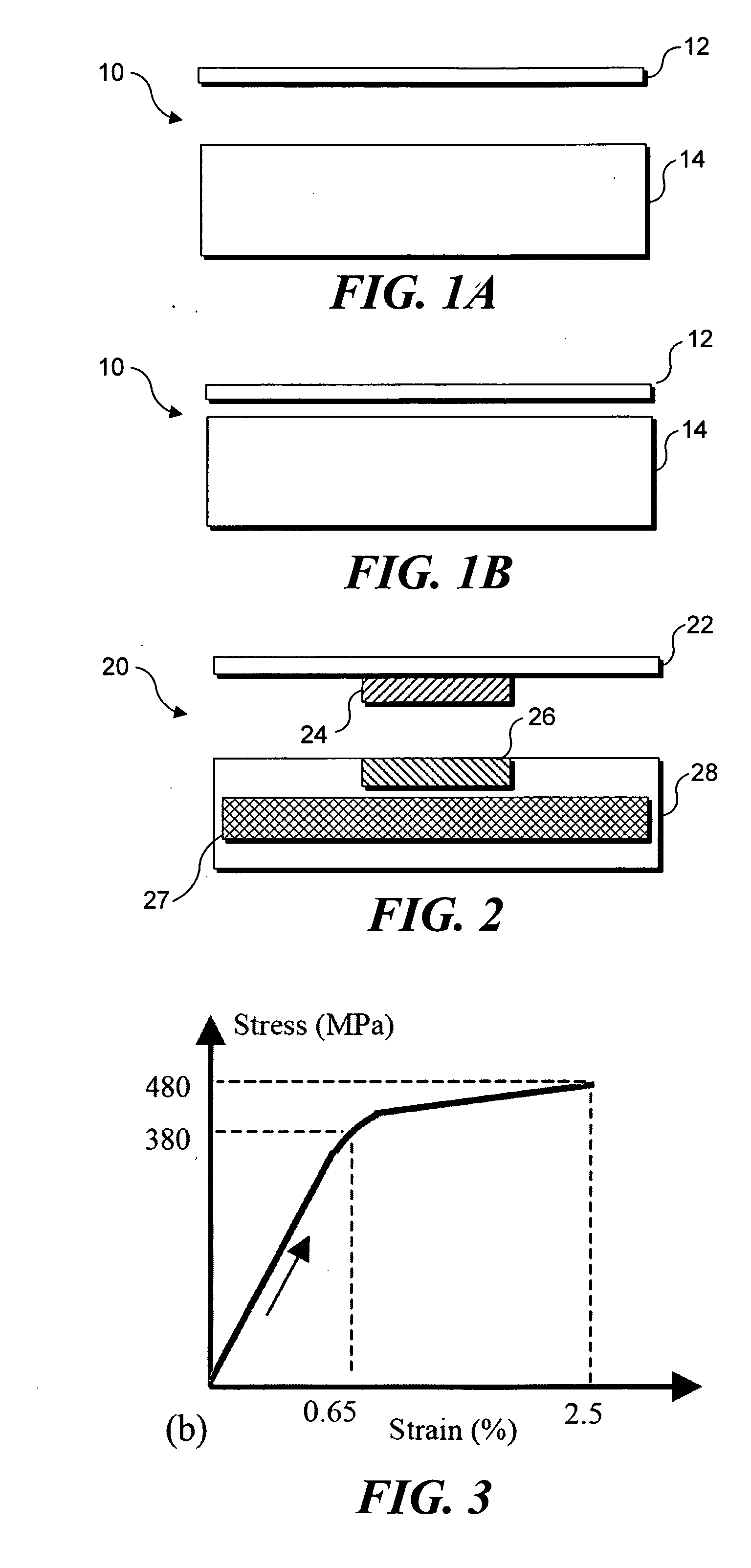

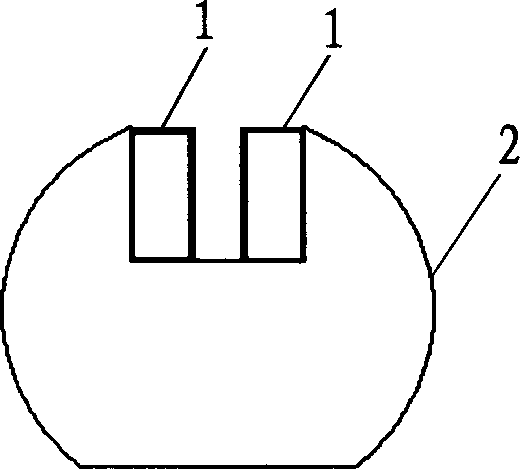

Design of ferromagnetic shape memory alloy composites and actuators incorporating such materials

InactiveUS20050001367A1Operating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesShape-memory alloyAlloy composite

The present invention employs an optimized cross-sectional shape for a ferromagnetic shape memory alloy (FSMA) composite that is used in a spring-type actuator, an improved hybrid magnetic trigger for use in FSMA based actuators, an a FSMA composite based spring type actuator, an a FSMA based spring type actuator including a stack of triggering units and FSMA springs, a FSMA composite based torque actuator. The invention also includes a model that can be employed to evaluate different materials being considered as components a FSMA for a FSMA composite used in either a FSMA based torque actuator or a FSMA spring actuator.

Owner:UNIV OF WASHINGTON

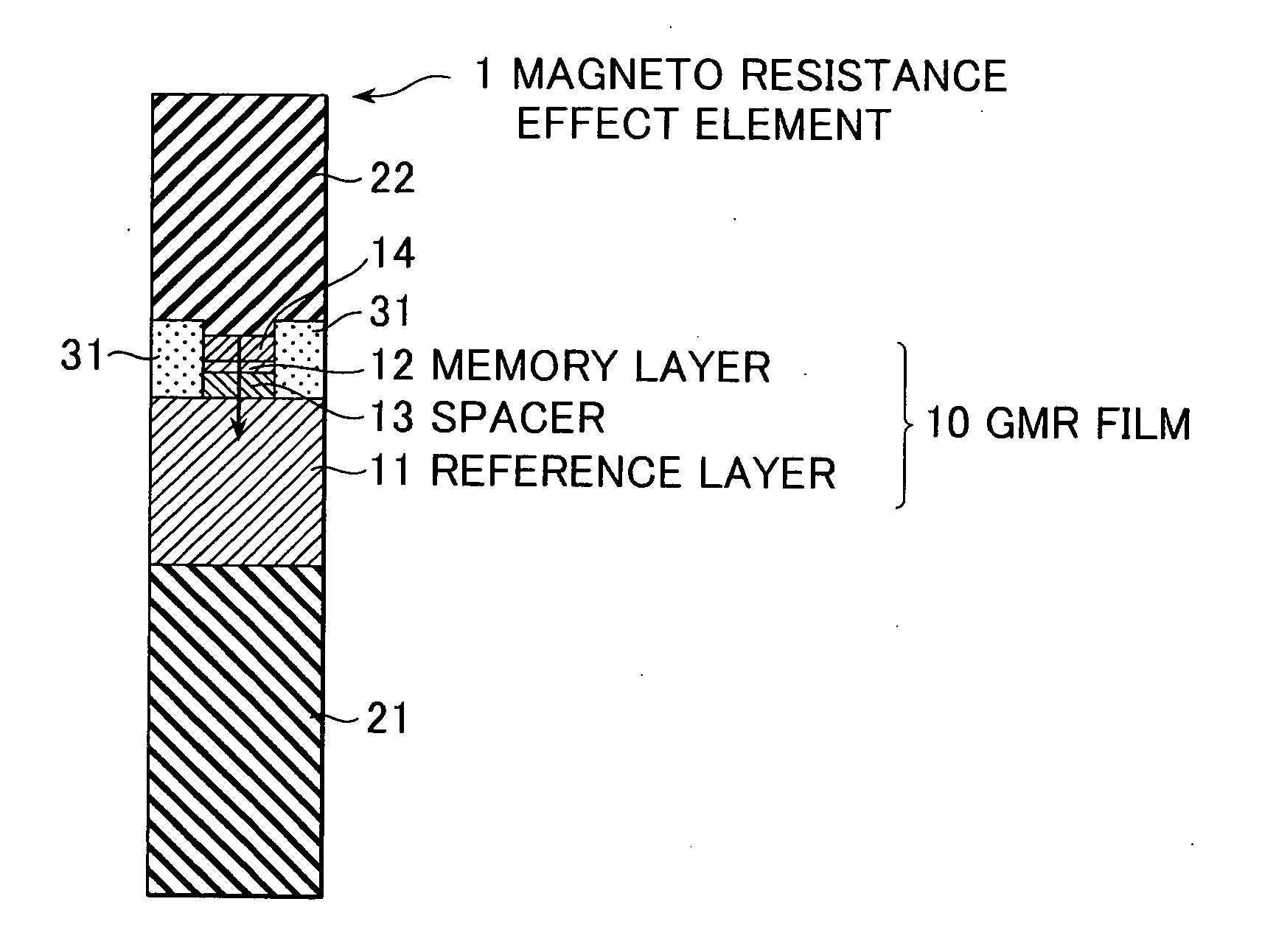

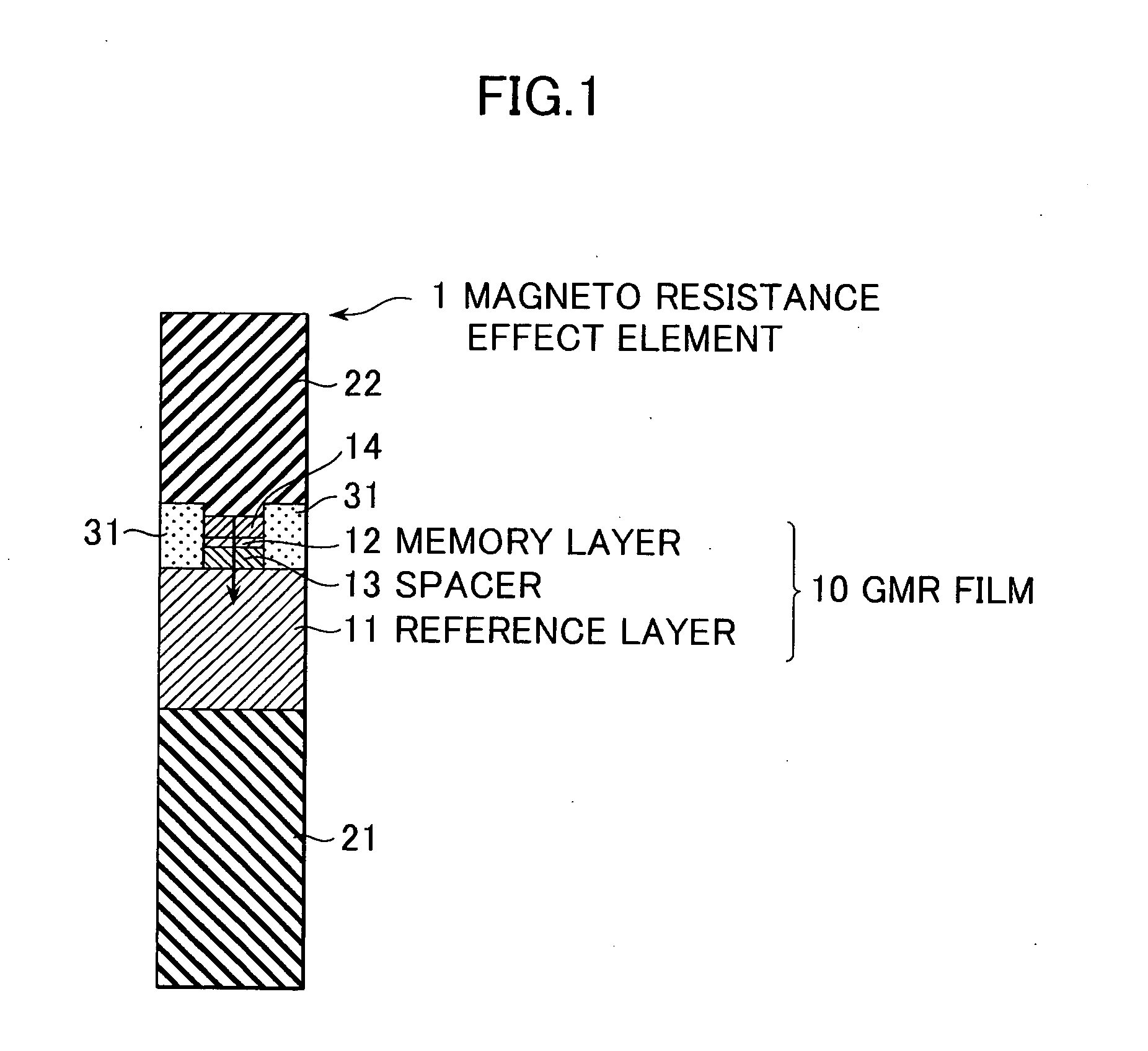

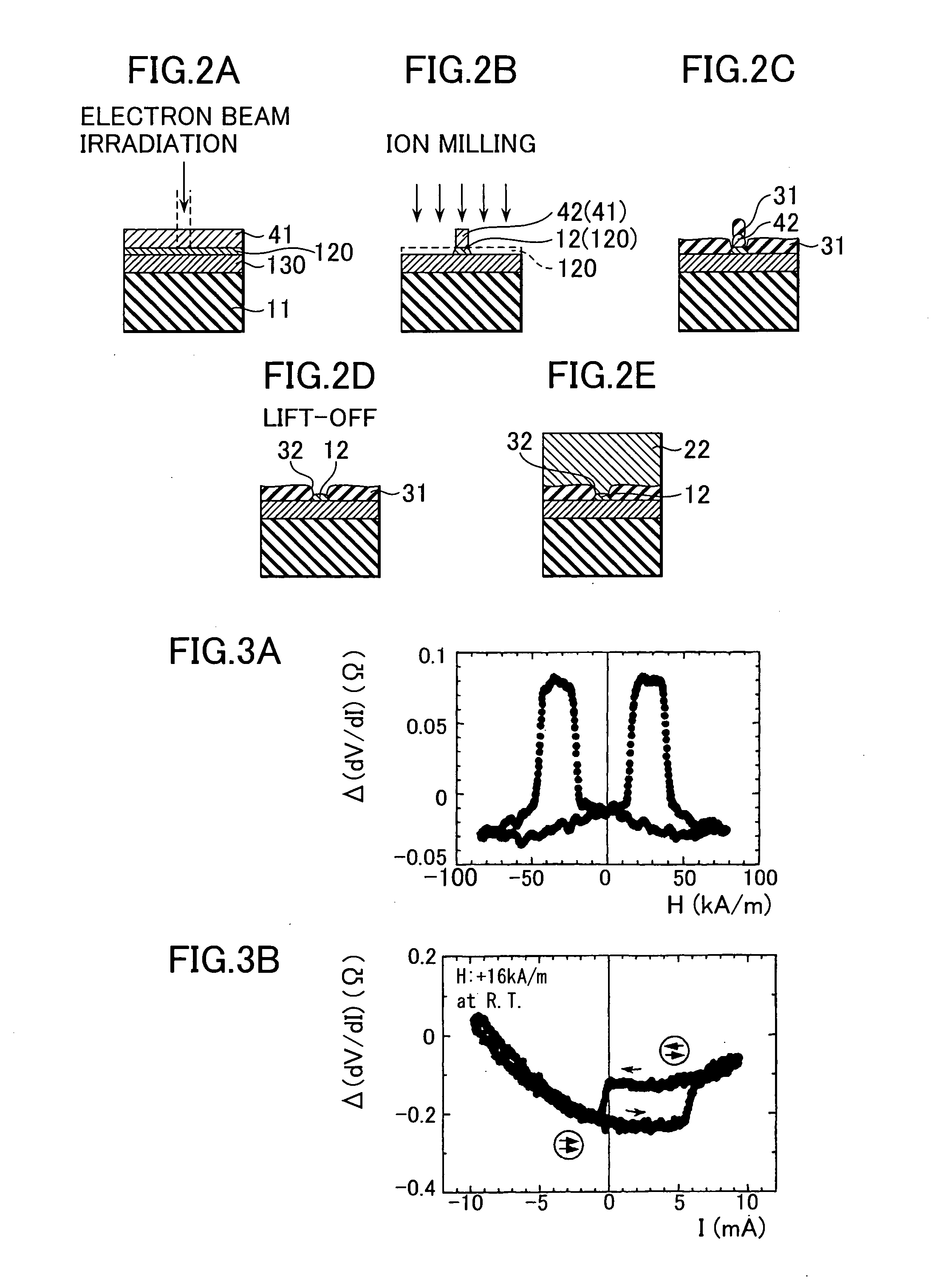

Magnetoresistance effect element, method of manufacture thereof, magnetic storage and method of manufacture thereof

ActiveUS20050057992A1Enabling a spin-transfer magnetization switchingLow densityNanomagnetismNanoinformaticsSwitched currentMagnetic storage

The present invention is aimed at enabling a spin-transfer magnetization switching in the random access magnetic memory by reducing a switching current density in the spin-transfer magnetization switching to an order smaller than 10 MA / cm2 and without causing breakdowns neither in the memory element which uses a TMR film nor in the element selection FET. The memory layer in the magnetoresistance effect element comprises a magnetic film having a value of saturation magnetization in a range from 400 kA / m to 800 kA / m. The memory layer comprises a magnetic film which contains one or more magnetic elements selected from the group of, for example, cobalt, iron and nickel, and which further contains a non-magnetic element. The non-magnetic element is contained at a ratio of, for example, 5 at % or more and less than 50 at %. A memory layer 12 in the memory cell has a dimension less than 200 nmφ.

Owner:SONY CORP

A FeGa-RE magnetic-driven flexible materials and its making technology

InactiveCN101086912AHigh magnetostrictive performanceEfficient use ofInorganic material magnetismMagnetostrictive material selectionBridgman methodAdditive ingredient

The invention relates to a FeGa-RE magnetostrictive material and manufacturing technique. The characteristics of magnetostrictive material are that: the ingredient of material consists of Fe, Ga and RE, the content of Ga is 10-40at%, the content of RE is 0.01-20at%, the content of additional intermingle is: C=200-600ppm,N=200-600ppm,O=200-700ppm,other is Fe, the optimal value of Ga is 12-28at%, FeGa-RE magnetostrictive material, the ingredient of material adds one or more kinds of La, Ce, Pr, Nd, Tb, Dy whose content is 0.01-20at%. The manufacturing technique includes the alloy with purified material is cast as the needed round bar, and the alloy bar is crystallized by high temperature gradient flash freezing method and Bridgman method.

Owner:BAOTOU RES INST OF RARE EARTHS

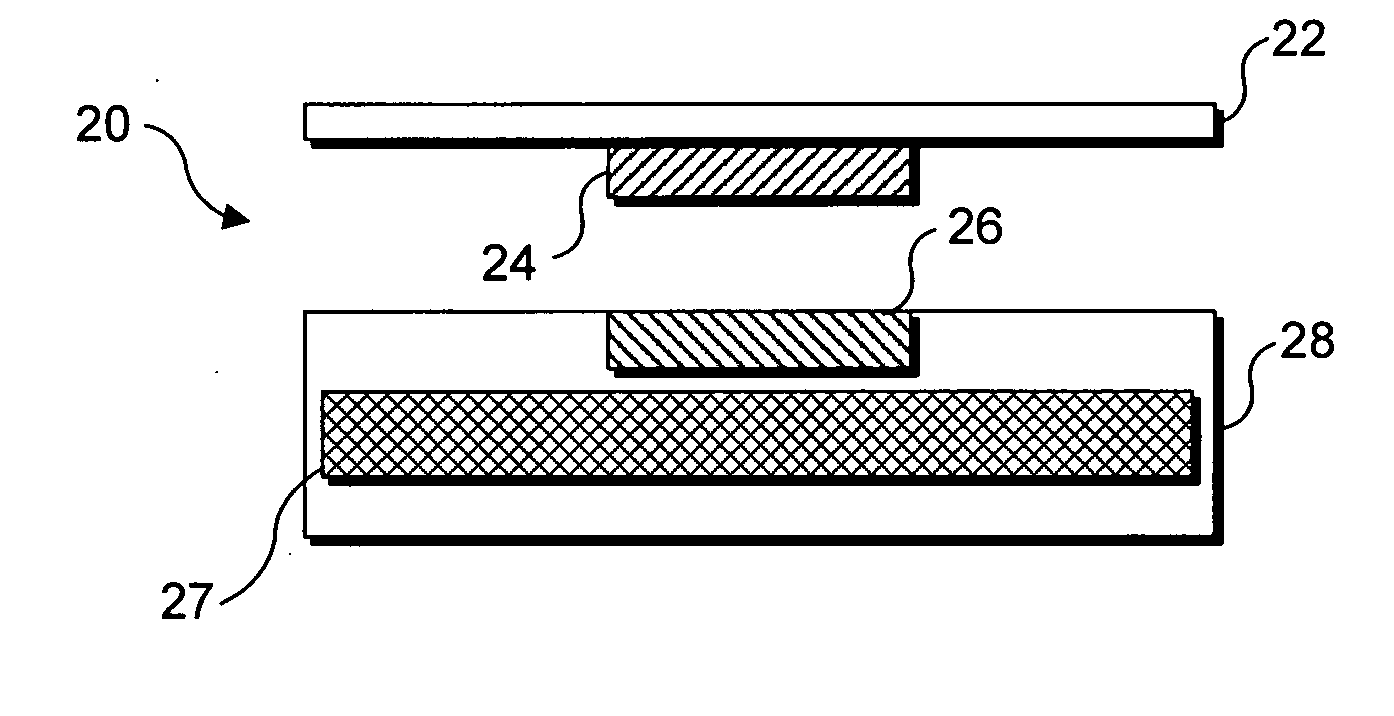

Design of ferromagnetic shape memory alloy composites and actuators incorporating such materials

InactiveUS7104056B2Piezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionShape-memory alloyAlloy composite

The present invention employs an optimized cross-sectional shape for a ferromagnetic shape memory alloy (FSMA) composite that is used in a spring-type actuator, an improved hybrid magnetic trigger for use in FSMA based actuators, an a FSMA composite based spring type actuator, an a FSMA based spring type actuator including a stack of triggering units and FSMA springs, a FSMA composite based torque actuator. The invention also includes a model that can be employed to evaluate different materials being considered as components a FSMA for a FSMA composite used in either a FSMA based torque actuator or a FSMA spring actuator.

Owner:UNIV OF WASHINGTON

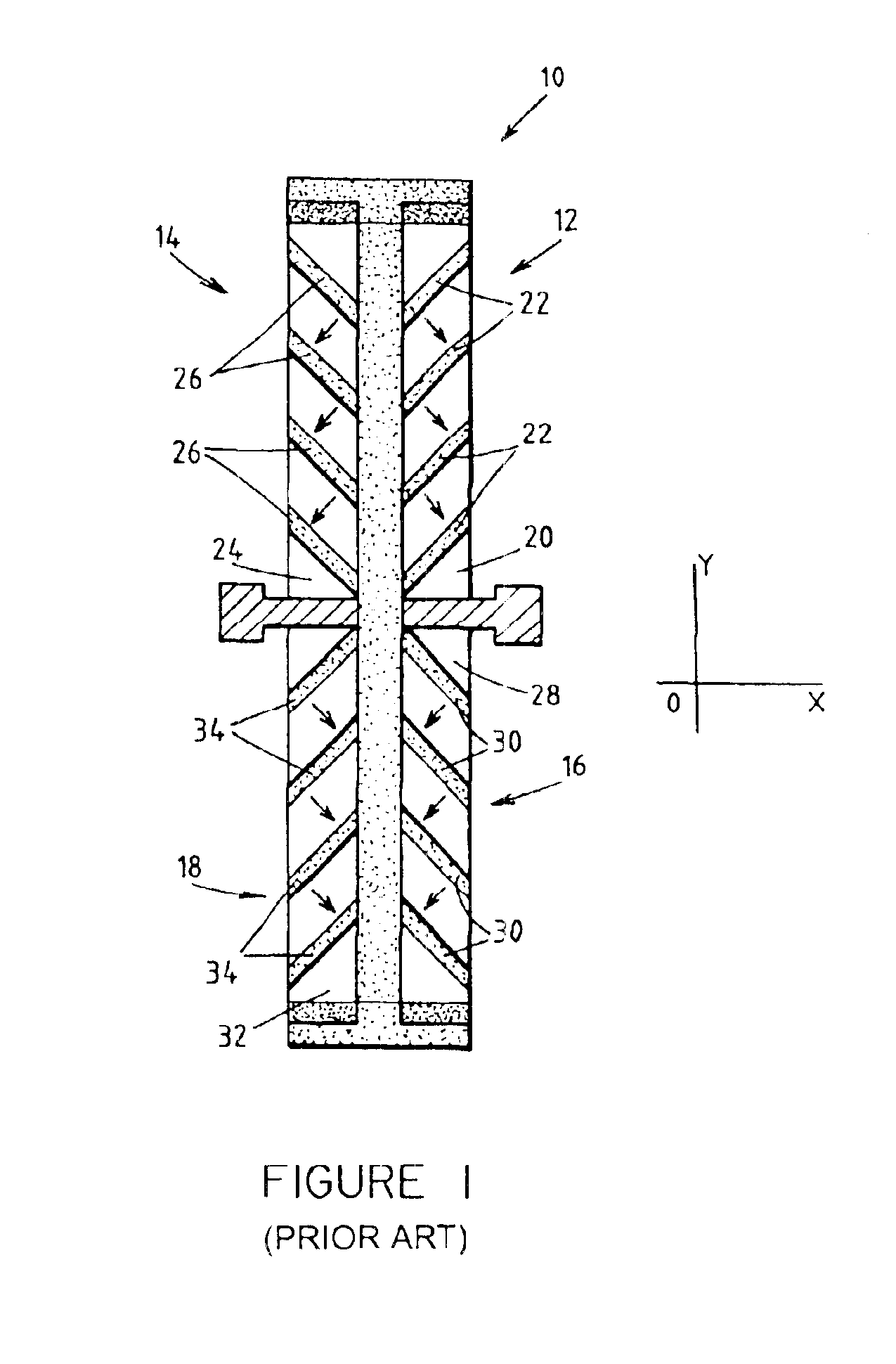

Barber pole structure for magnetoresistive sensors and method of forming same

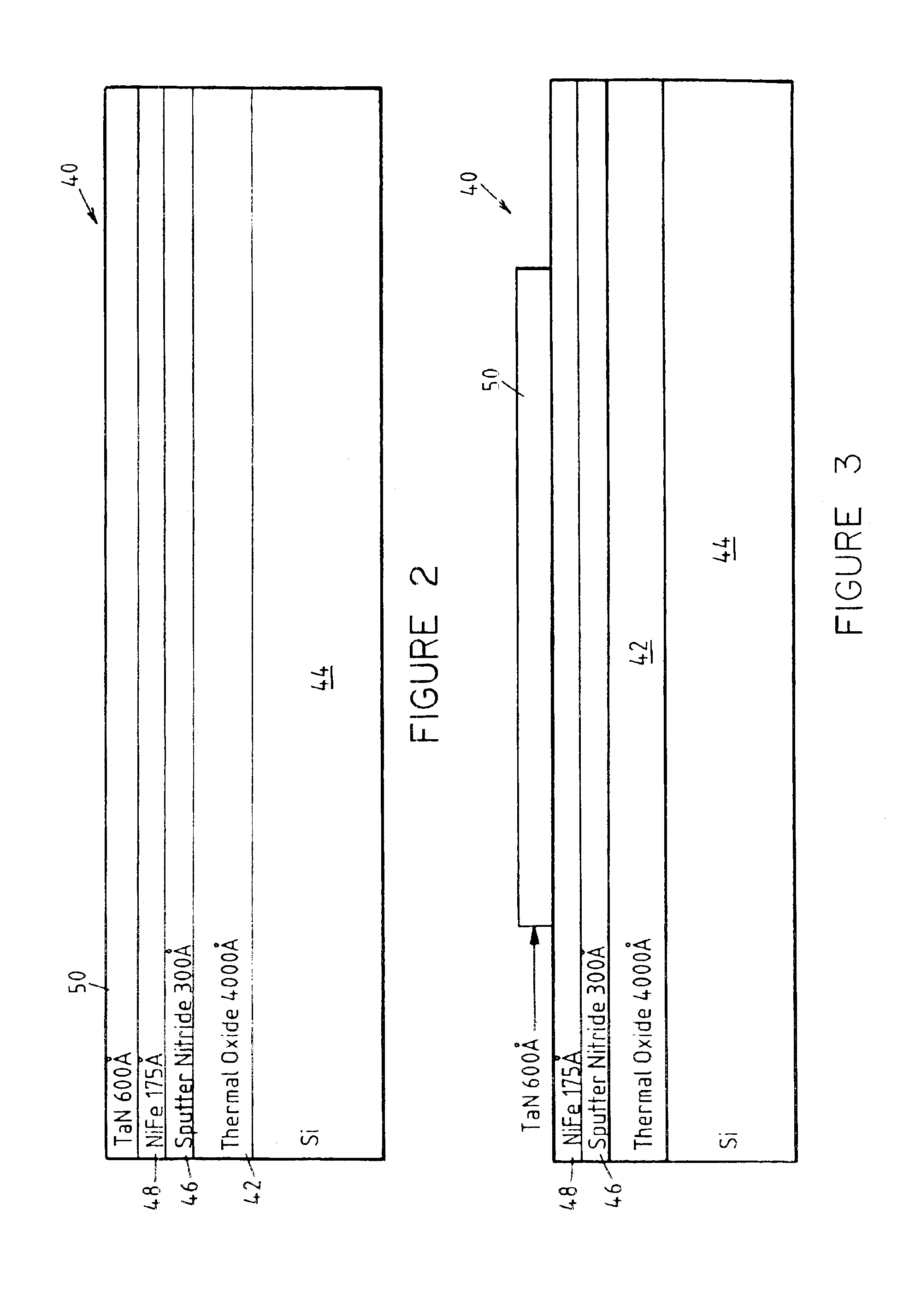

InactiveUS6850057B2Piezoelectric/electrostrictive device manufacture/assemblyMagnetic field measurement using galvano-magnetic devicesEtchingConductive materials

A method of making a magnetorestrictive sensor involves the deposition of a magnetorestrictive strip over a substrate, the deposition of an insulating layer over the magnetorestrictive strip, the etching of barber pole windows through the insulating layer, the deposition of a conductive material over the insulating layer and into the barber windows, and the etching away of the conductive material between the barber pole windows so as to form barber poles. In this manner, the formation of the barber poles is controlled by the windows formed in the insulating layer.

Owner:HONEYWELL INT INC

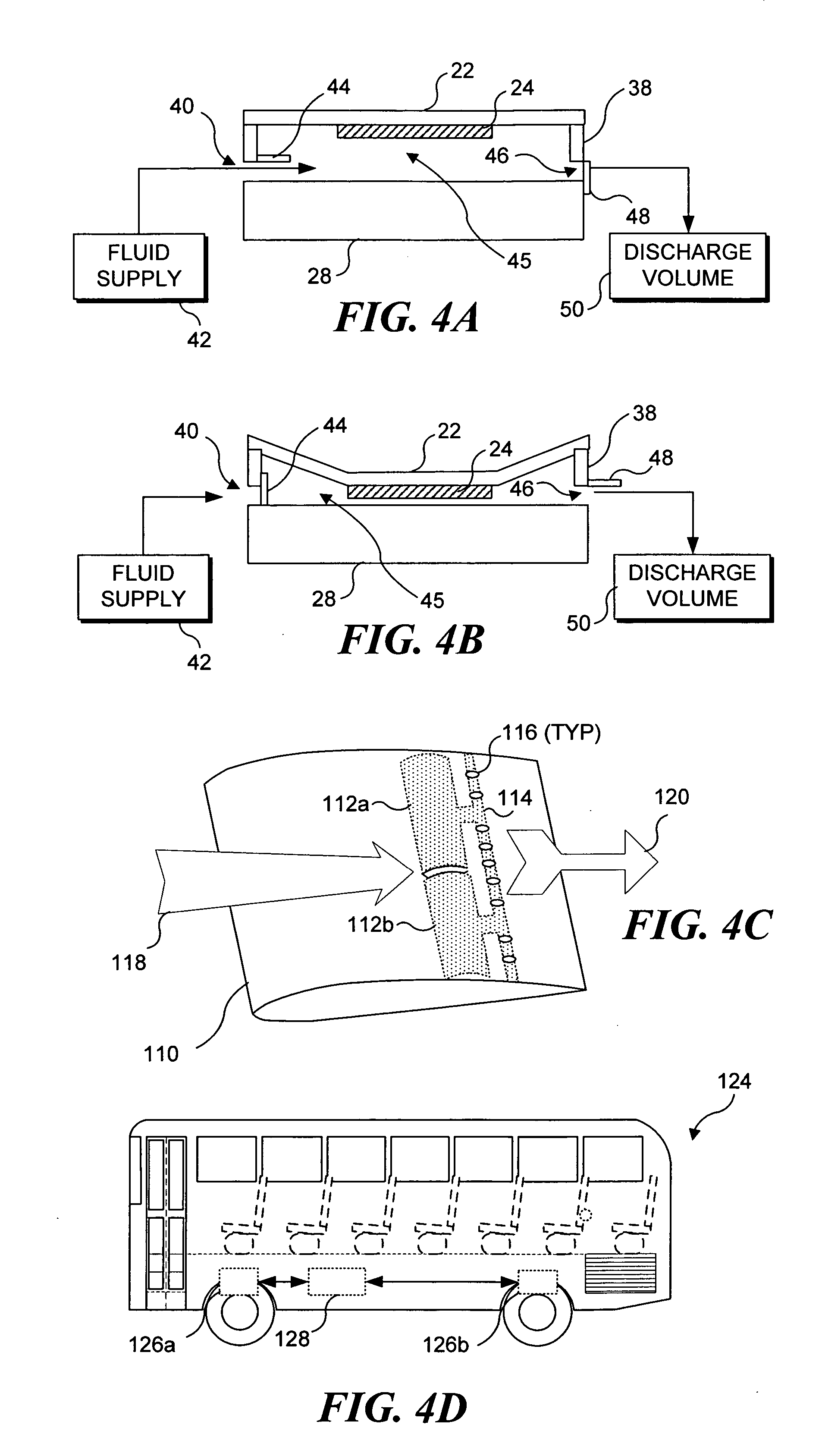

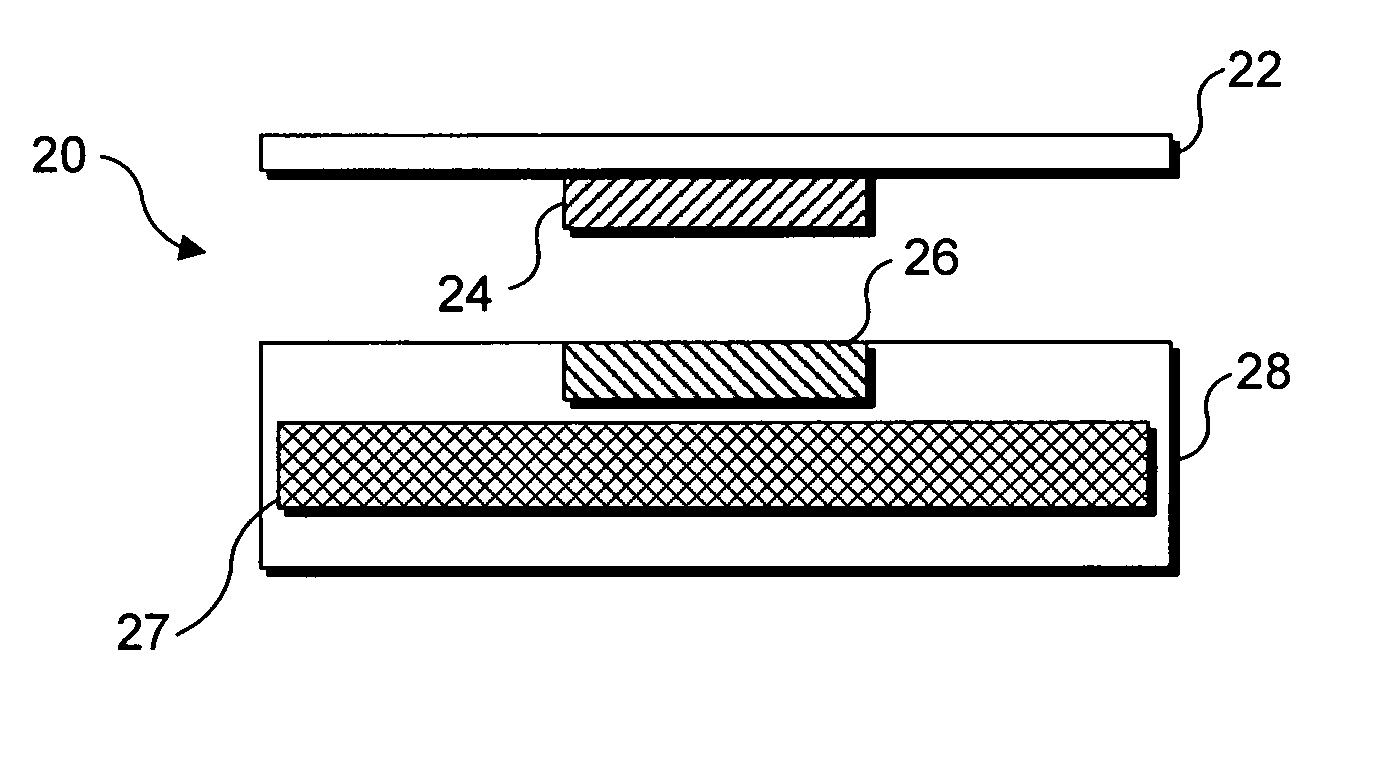

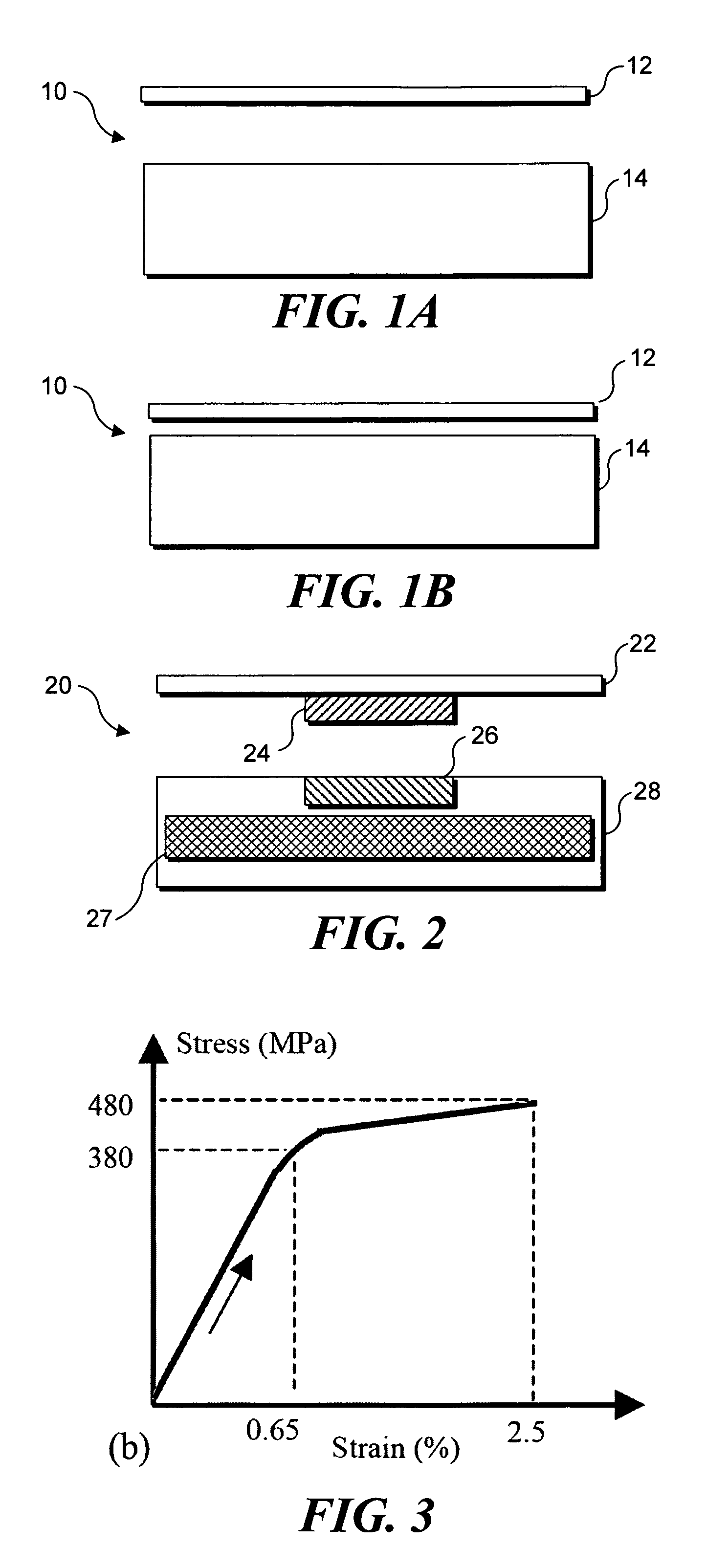

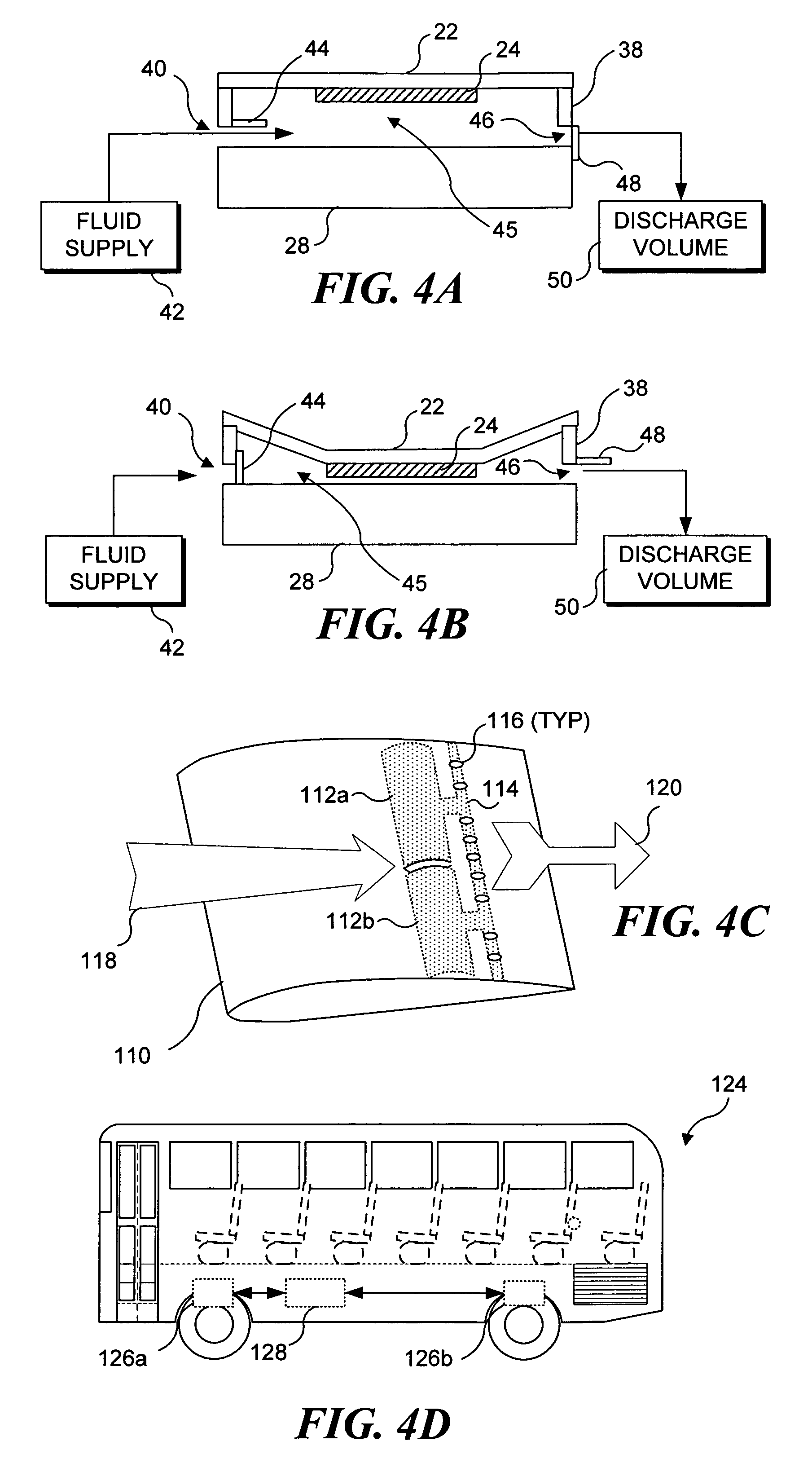

Design of membrane actuator based on ferromagnetic shape memory alloy composite for sythentic jet actuator

InactiveUS20070205853A1Rapid responseLarge deformationPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionMagnetic gradientShape-memory alloy

A membrane actuator includes a magnetically actuatable membrane and a magnetic trigger. The membrane includes a shape memory alloy (SMA), and the magnetic trigger is configured to induce a martensitic transformation in the SMA, to produce a larger force than would be achievable with non-SMA-based materials. Such a membrane actuator can be beneficially incorporated into a wide variety of devices, including fluid pumps, shock absorbing systems, and synthetic jet producing devices for use in an aircraft. The membrane / diaphragm can be formed from a ferromagnetic SMA, or a ferromagnetic material can be coupled with an SMA such that the SMA and the ferromagnetic material move together. A hybrid magnetic trigger, including a permanent magnet and an electromagnet, is preferably used for the magnetic trigger, as hybrid magnetic triggers are easy to control, and produce larger magnetic gradients than permanent magnets or electromagnets alone.

Owner:UNIV OF WASHINGTON

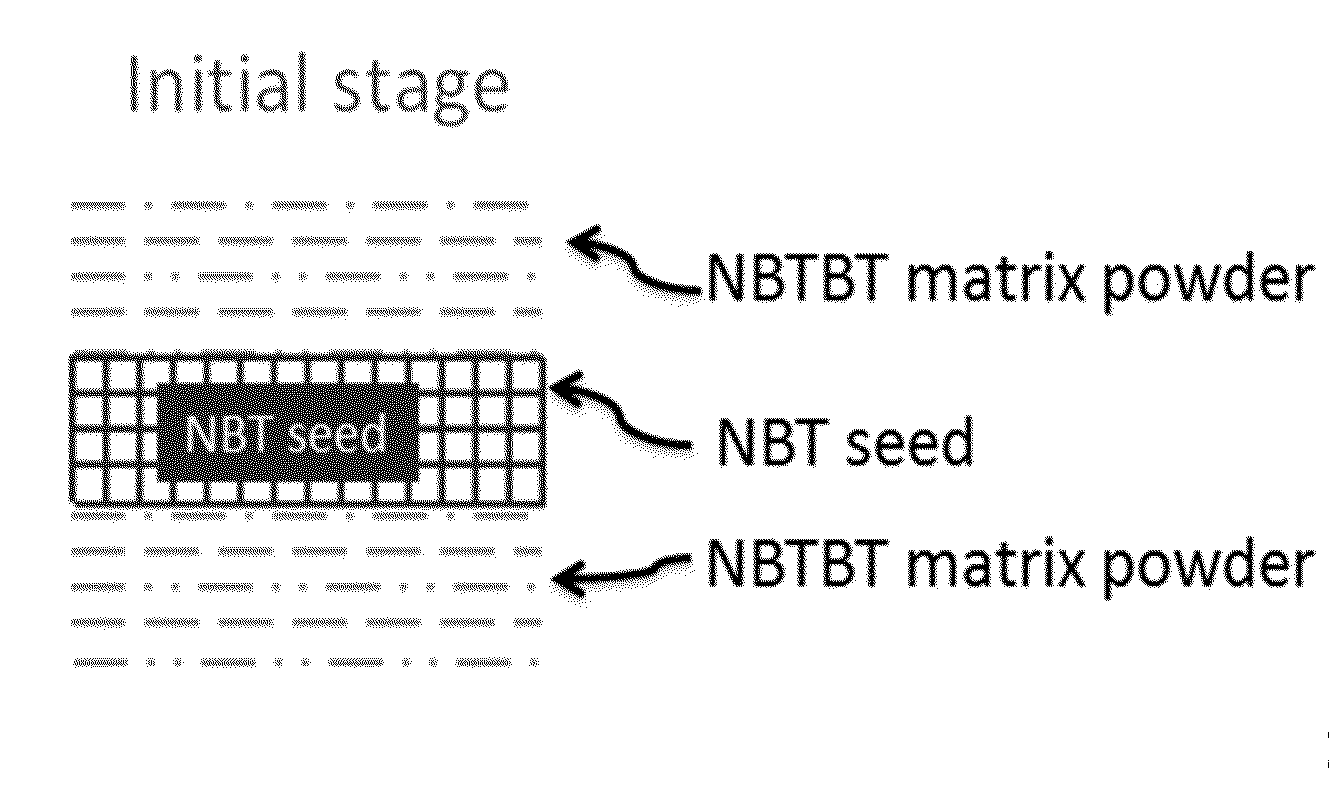

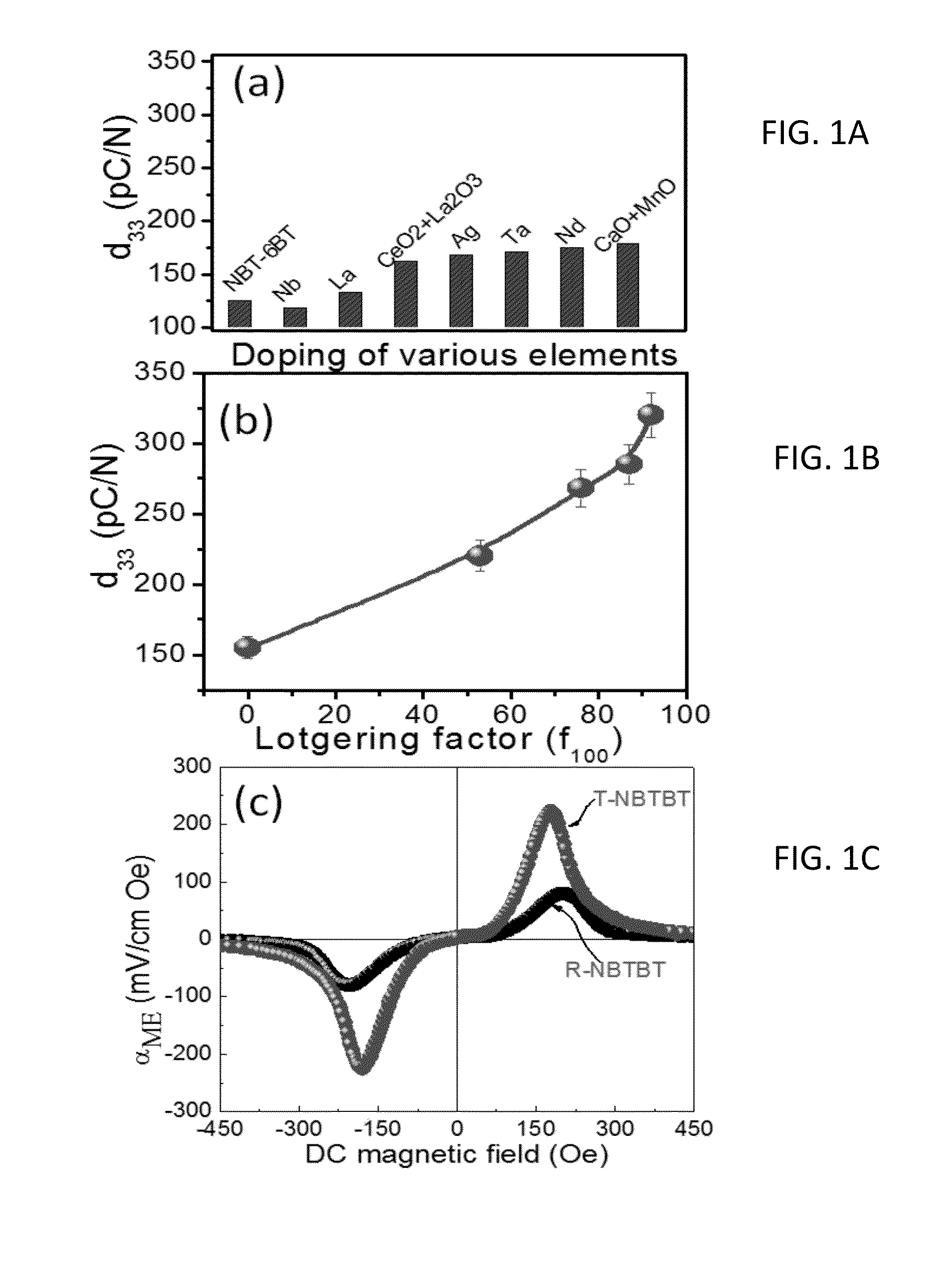

NEW PROCESSING METHOD FOR GRAIN-ORIENTED LEAD-FREE PIEZOELECTRIC Na0.5Bi0.5TiO3-BaTiO3 CERAMICS EXHIBITING GIANT PERFORMANCE

InactiveUS20140239774A1High aspect ratioImprove propertiesPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionElectricityCoupling

Textured ceramic compositions having improved piezoelectric characteristics as compared with their random counterparts are provided. Methods of making the compositions and devices using them are also included. More particularly, compositions comprising textured ceramic Na0.5Bi0.5TiO3—BaTiO3(NBT-BT) materials synthesized from high aspect ratio NBT seeds exhibit improved characteristics, including an increased longitudinal piezoelectric constant (d33) and magnetoelectric coupling coefficient over randomly oriented NBT-BT. Additionally provided are compositions comprising of nanostructured Na0.5B0.5TiO3—BaTiO3 ferroelectric whiskers having a high aspect ratio. Nanostructured whiskers can be used to improve the piezoelectric properties of the bulk ceramics. The inventive materials are useful in microelectronic devices, with some finding particular application as multilayer actuators and transducers.

Owner:VIRGINIA TECH INTPROP INC

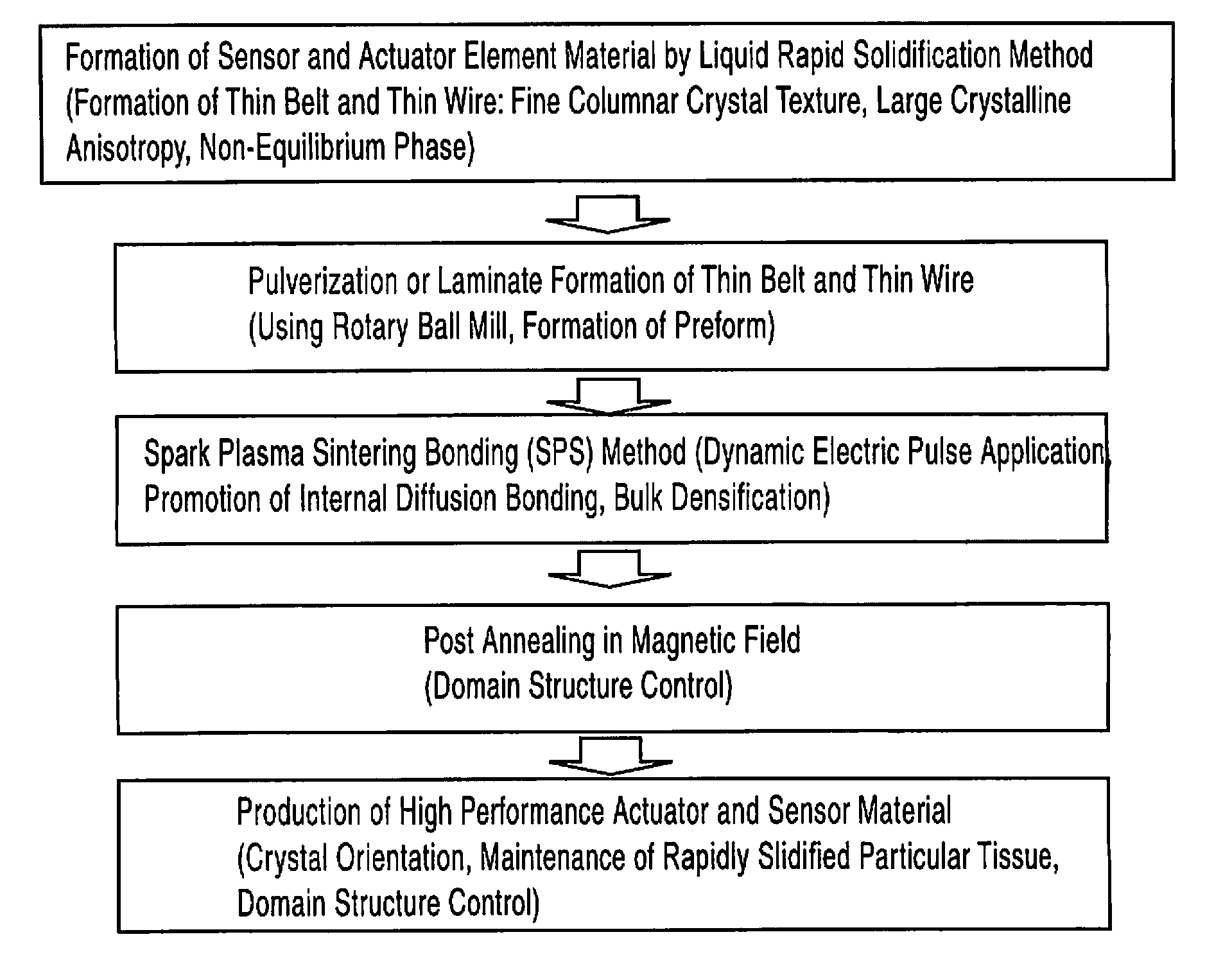

Bulk solidified quenched material and process for producing the same

InactiveUS20070183921A1Improve performanceImprove rigidityPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyHigh densityLiquid state

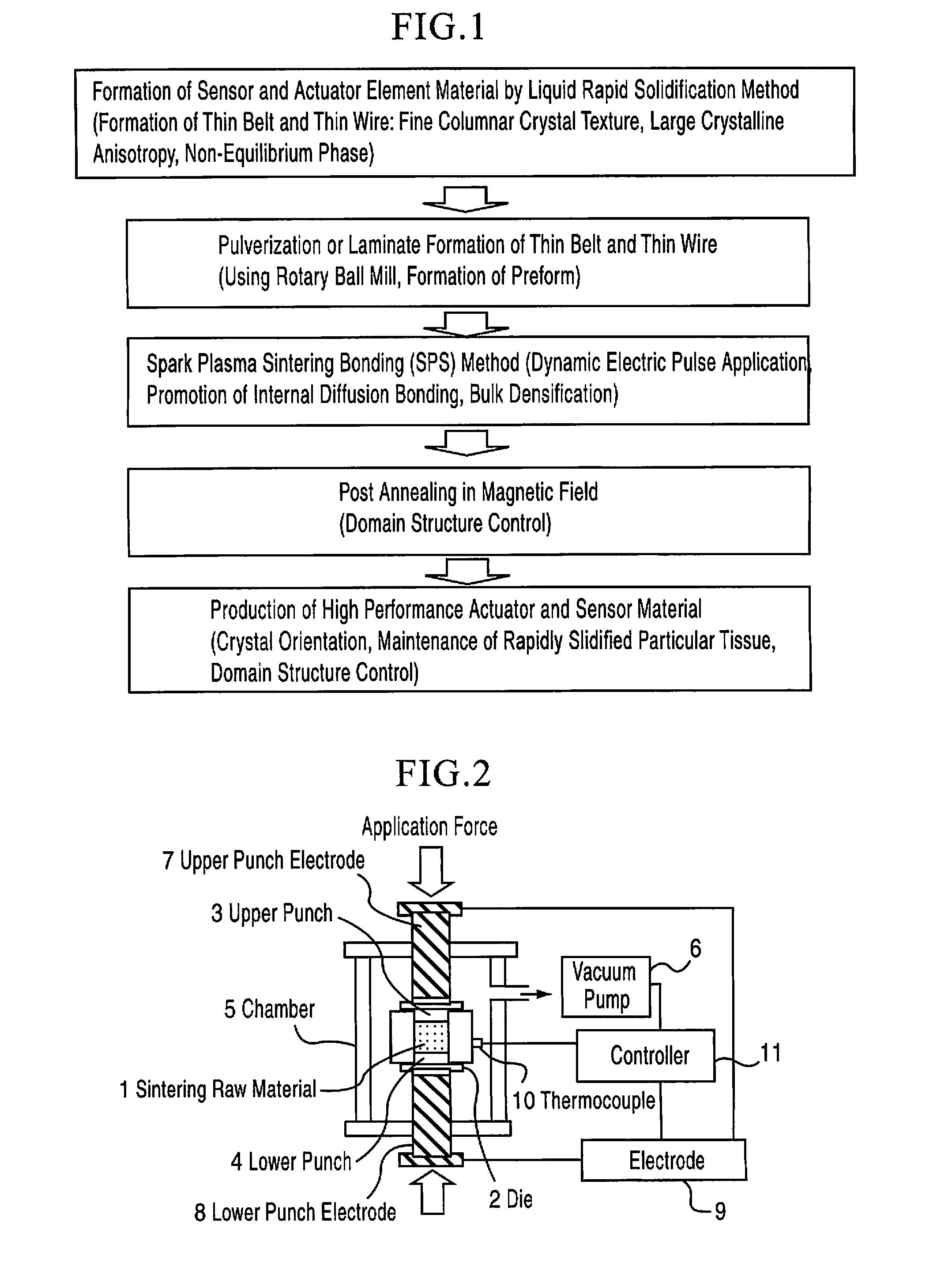

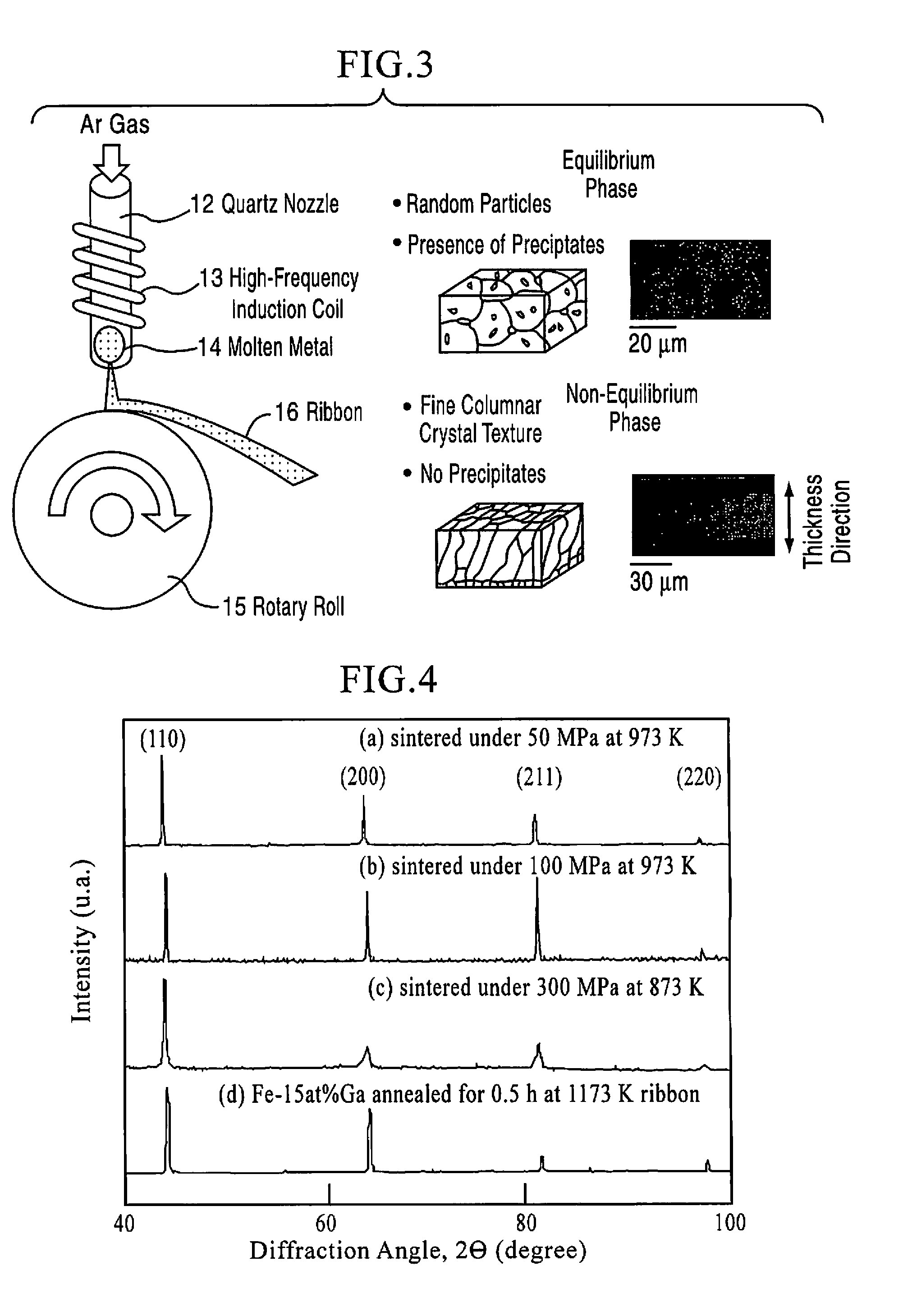

[Object] A bulk material which is suitably used as a material for actuator and sensor elements is formed from a Fe—Ga base magnetoresistive alloy and a Ti—Ni base shape memory alloy taking advantage of crystal miniaturization and anisotropy as well as reduction of precipitates (equilibrium state in state diagram) and non-equilibrium phases peculiar to liquid rapidly solidified materials, and the performance of the material is enhanced by a production method thereof which has cost advantage over a melt method. [Construction] A rapidly solidified material having a particular rapidly solidified texture of a Fe—Ga magnetostrictive alloy or a TiNi-based shape-memory alloy and properties derived therefrom is formed into slices which are laminated to each other in a die, or is formed into a powder or chops which are filled in the die. Subsequently, spark plasma sintering is performed so that bonds between the slices, grains of the powder, or the chops are formed at a high density to form a bulk alloy, followed by annealing whenever necessary, so that the properties of the alloy are improved.

Owner:JAPAN SCI & TECH CORP

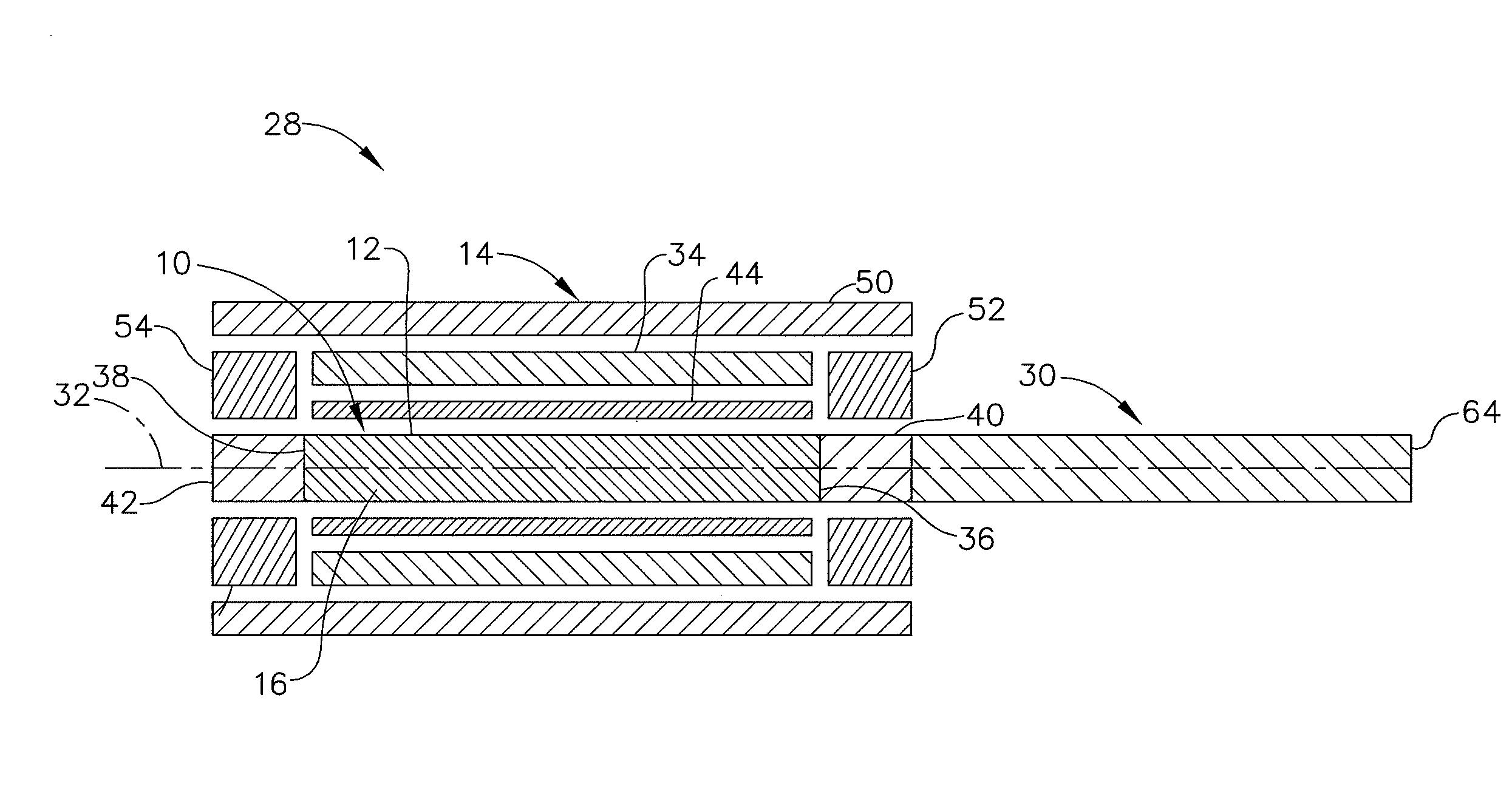

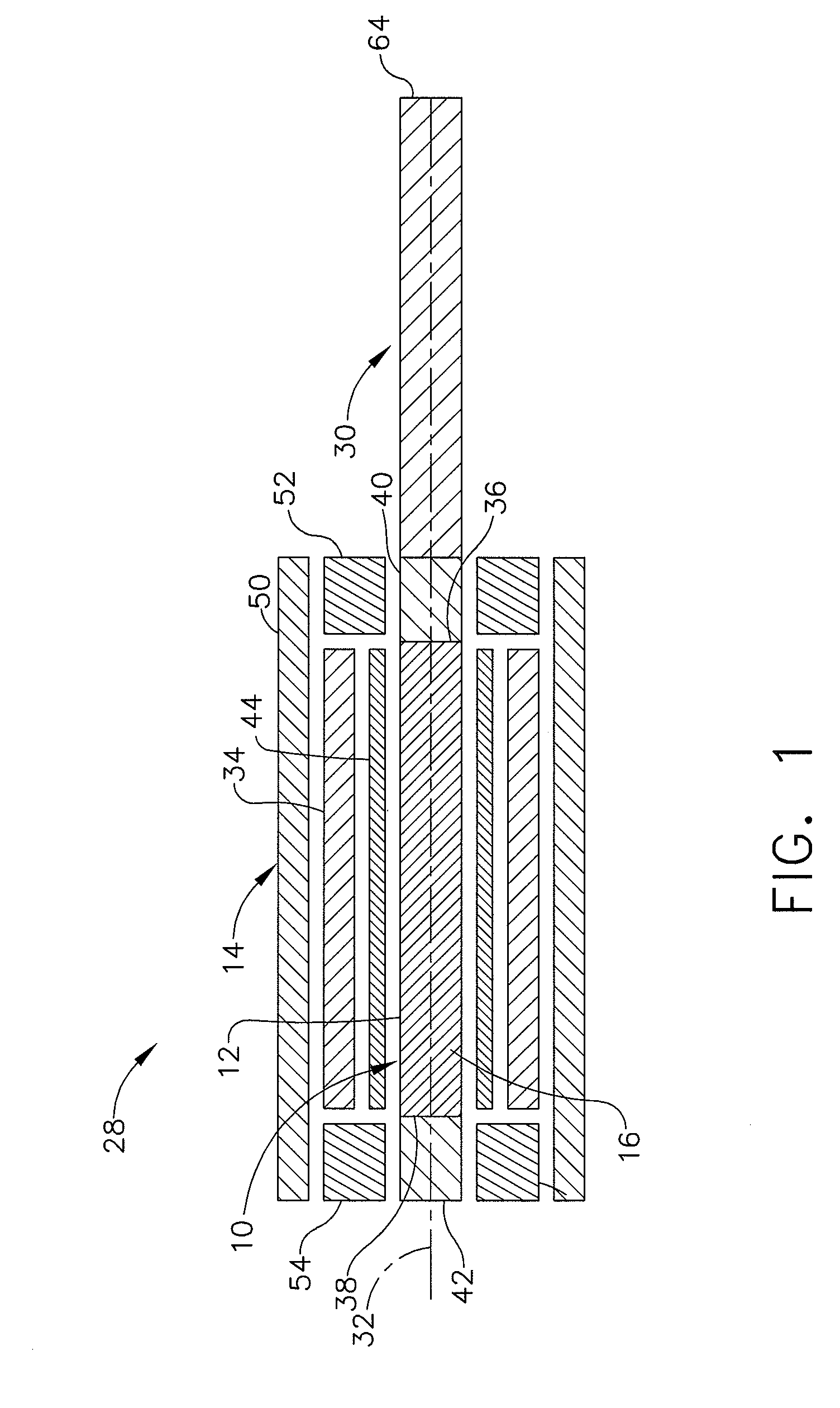

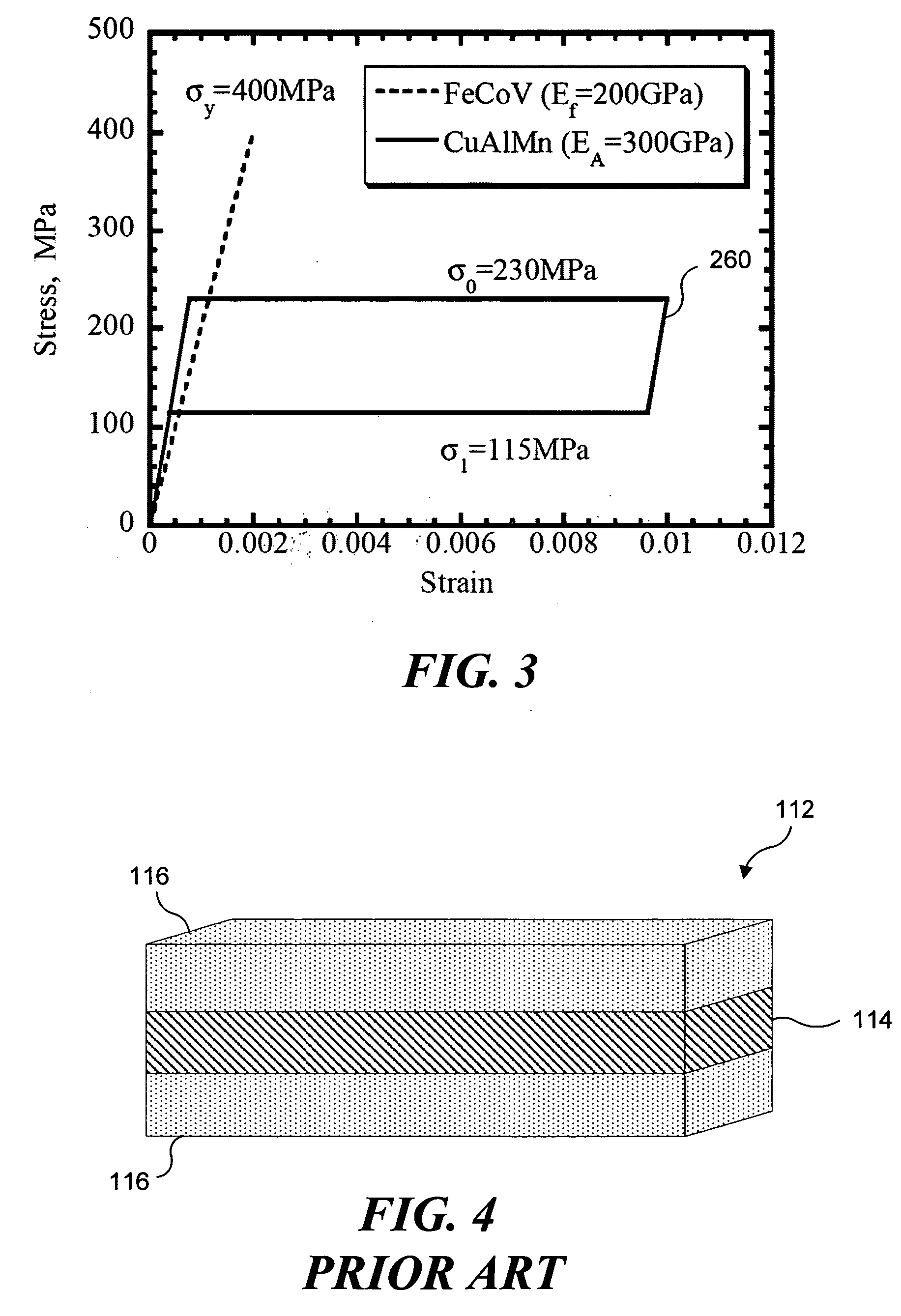

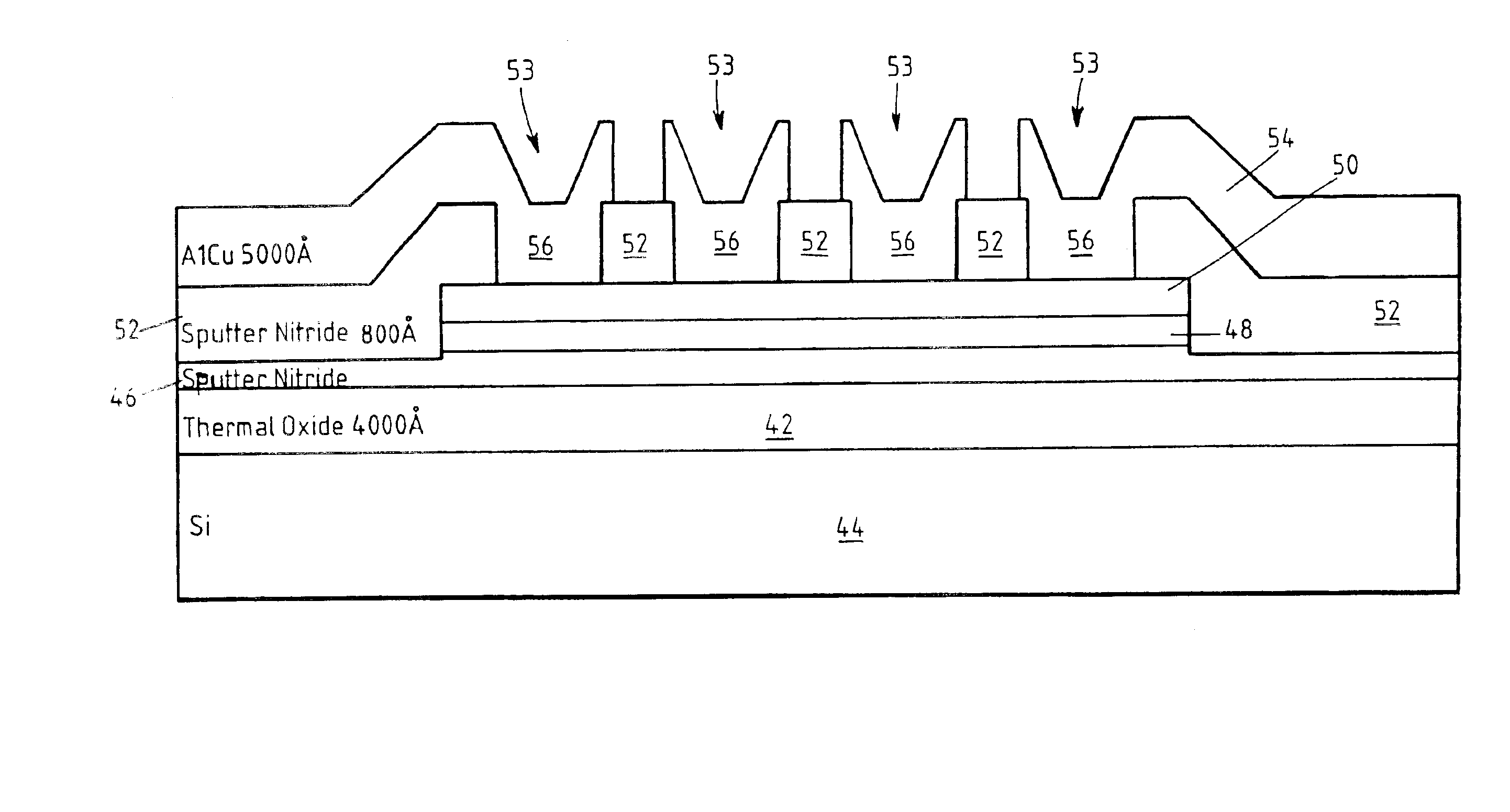

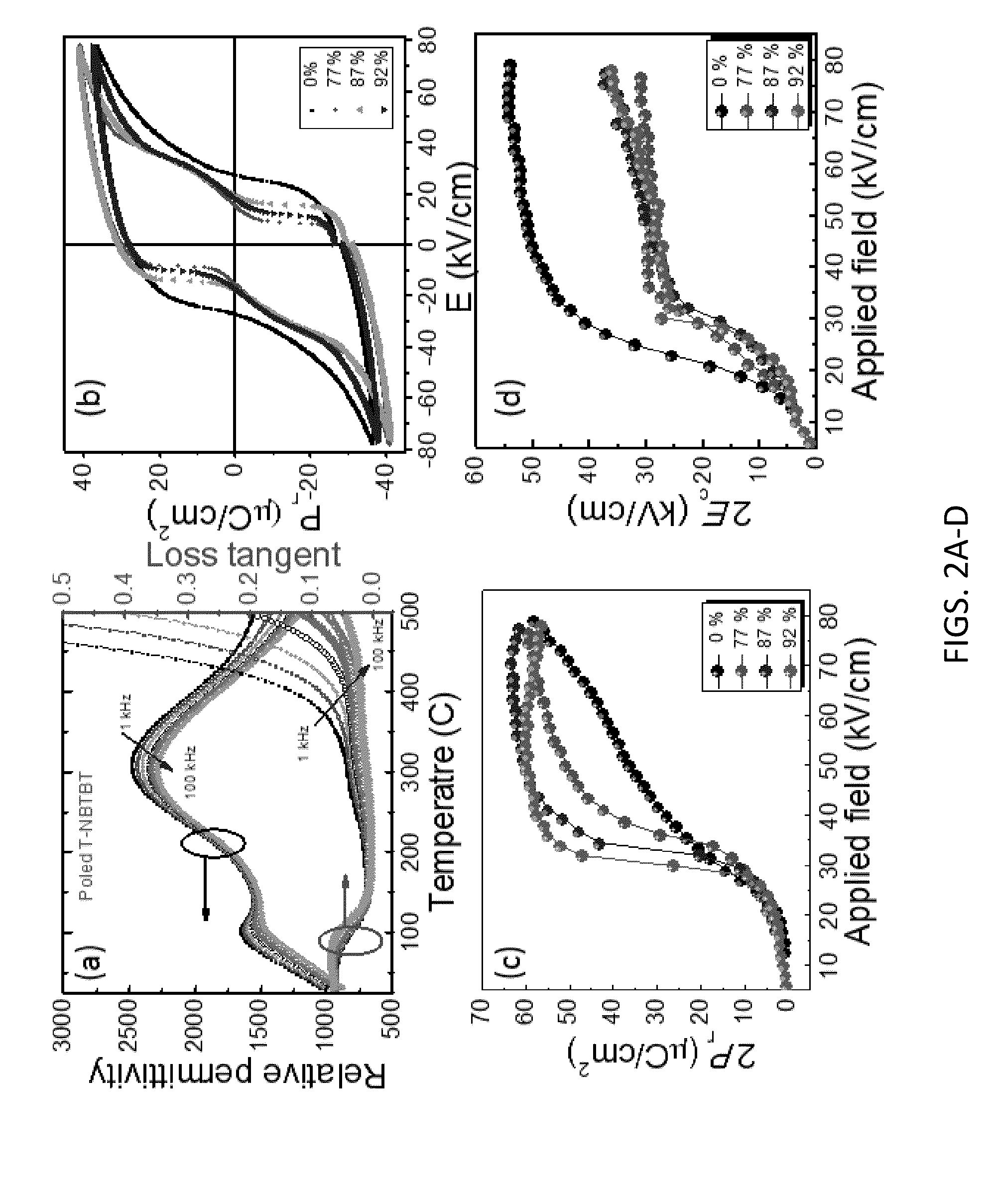

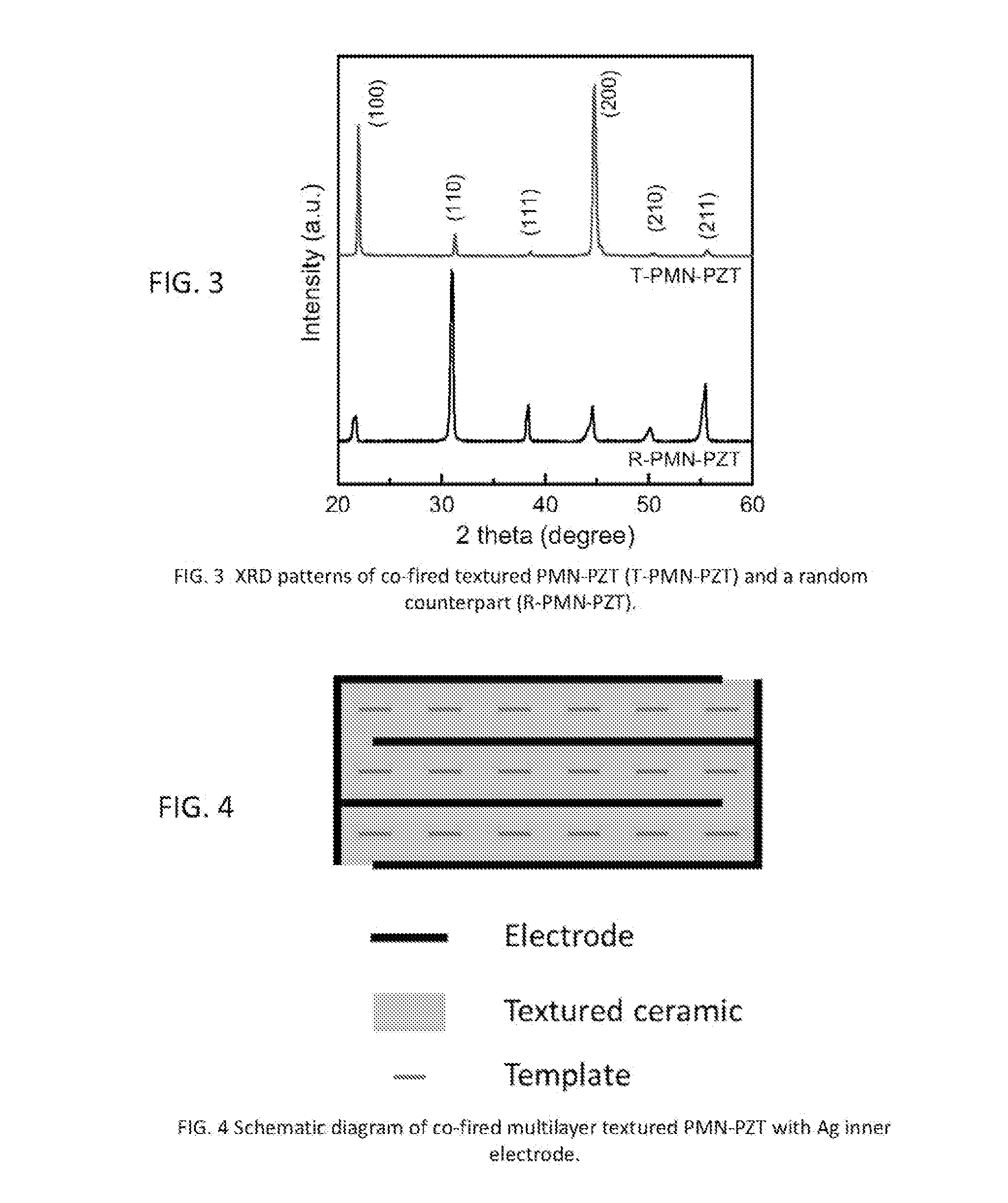

Low-temperature co-firing of multilayer textured piezoelectric ceramics with inner electrodes

ActiveUS20140375174A1Rapid responseReduce power consumptionPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionUltrasonic sensorEnergy harvester

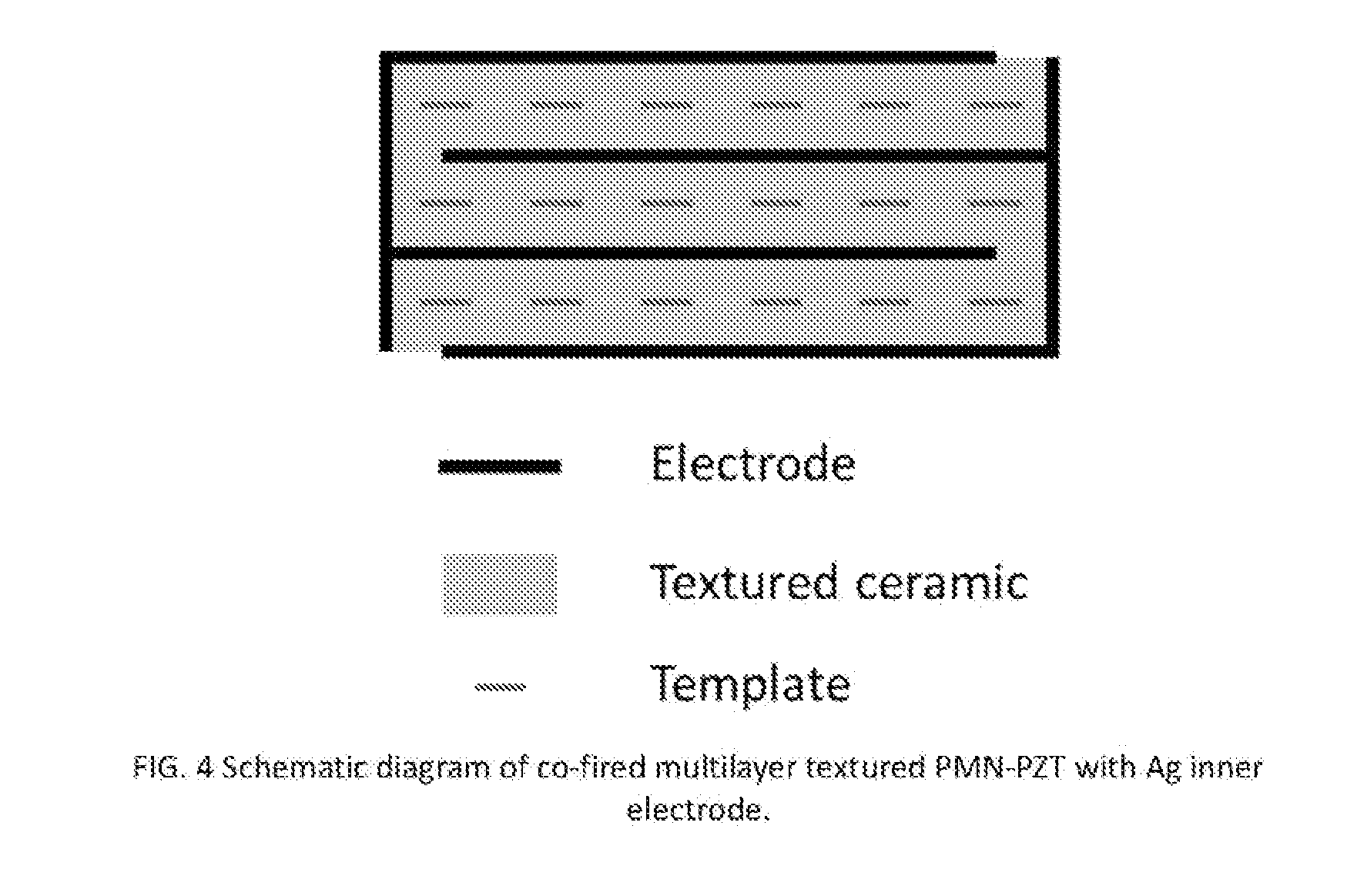

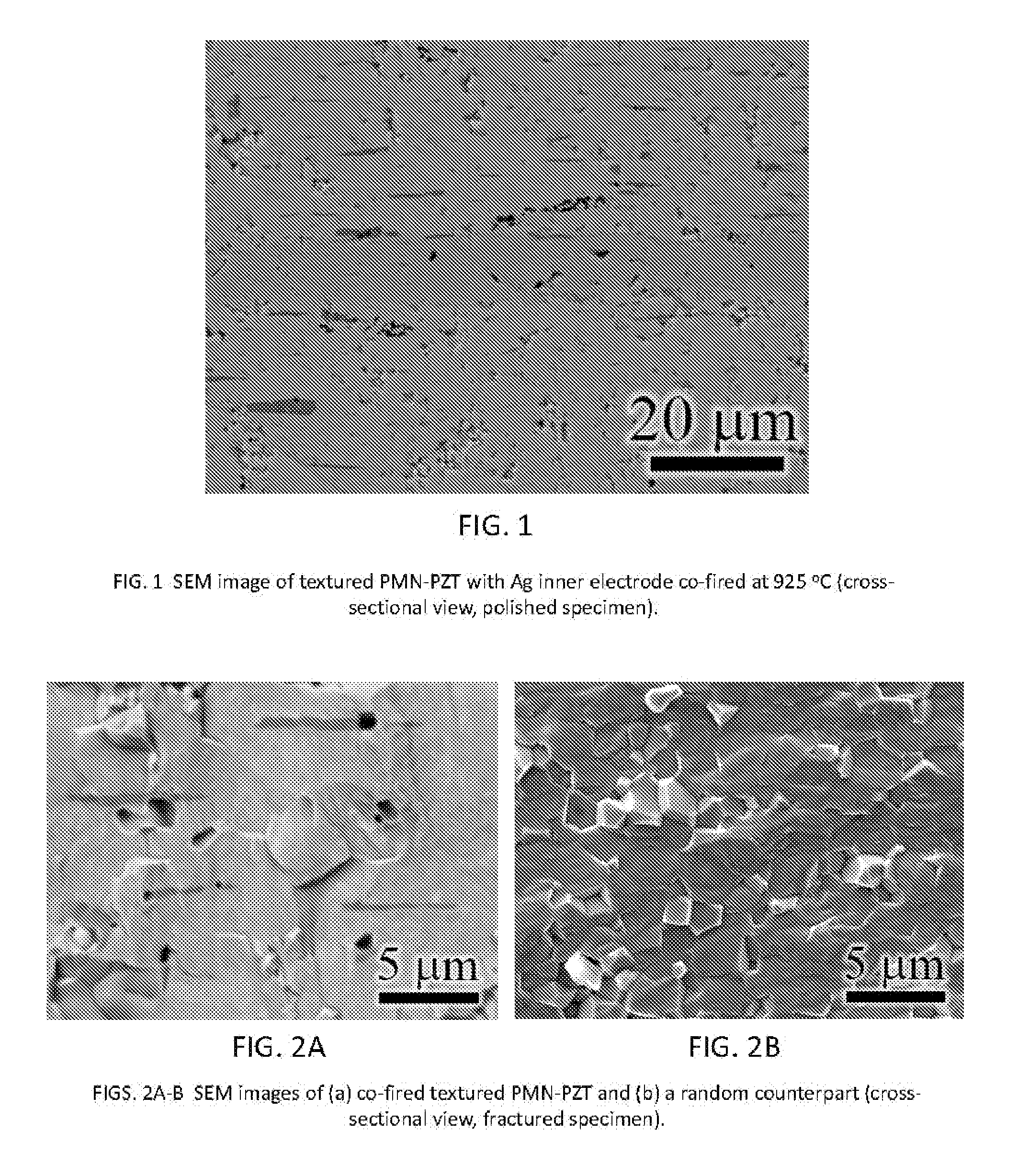

Textured PMN-PZT fabricated by templated grain growth (TGG) method has a piezoelectric coefficient (d) of 3 to 5 times that of its random counterpart. By combining this TGG method with low-temperature co-firing ceramics (LTCC) techniques, co-fired multilayer textured piezoelectric ceramic materials with inner electrodes were produced at a temperature as low as 925° C., which silver could be used. Trilayer PMN-PZT ceramics prepared by this method show a strain increase of 2.5 times, a driving voltage decrease of 3 times, and an equivalent piezoelectric coefficient (d*) improvement of 10 to 15 times that of conventional random ceramic counterparts. Further, a co-fired magnetostrictive / piezoelectric / magnetostrictive laminate structure with silver inner electrode was also synthesized. The integration of textured piezoelectric microstructure with the cost-effective low-temperature co-fired layered structure achieves strong magnetoelectric coupling. These new materials have promising applications including as actuators, ultrasonic transducers, and use in energy harvesters.

Owner:VIRGINIA TECH INTPROP INC

Fe-Ga base magnetism driven elastic silk and part using this material

ActiveCN101262039AGood magnetostrictive inverse effectHigh strengthInorganic material magnetismMagnetostrictive material selectionMetalMaterials science

The invention relates to a Fe-Ga group magnetostriction wire and material composition thereof is Fe1-x-yGaxMy, wherein, M is tantalum of transition group except for Fe and one or a plurality of Be, B, Al, In, Si, Ge, Sn, Pb, Sb, Bi, N, S and Se; x is equal to 5-30at percent and y is equal to 0-15at percent and the allowance is Fe; diameter d is 0.1-5mm. A device adopts the Fe-Ga group magnetostriction wire is also disclosed.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Directionally oriented particle composites

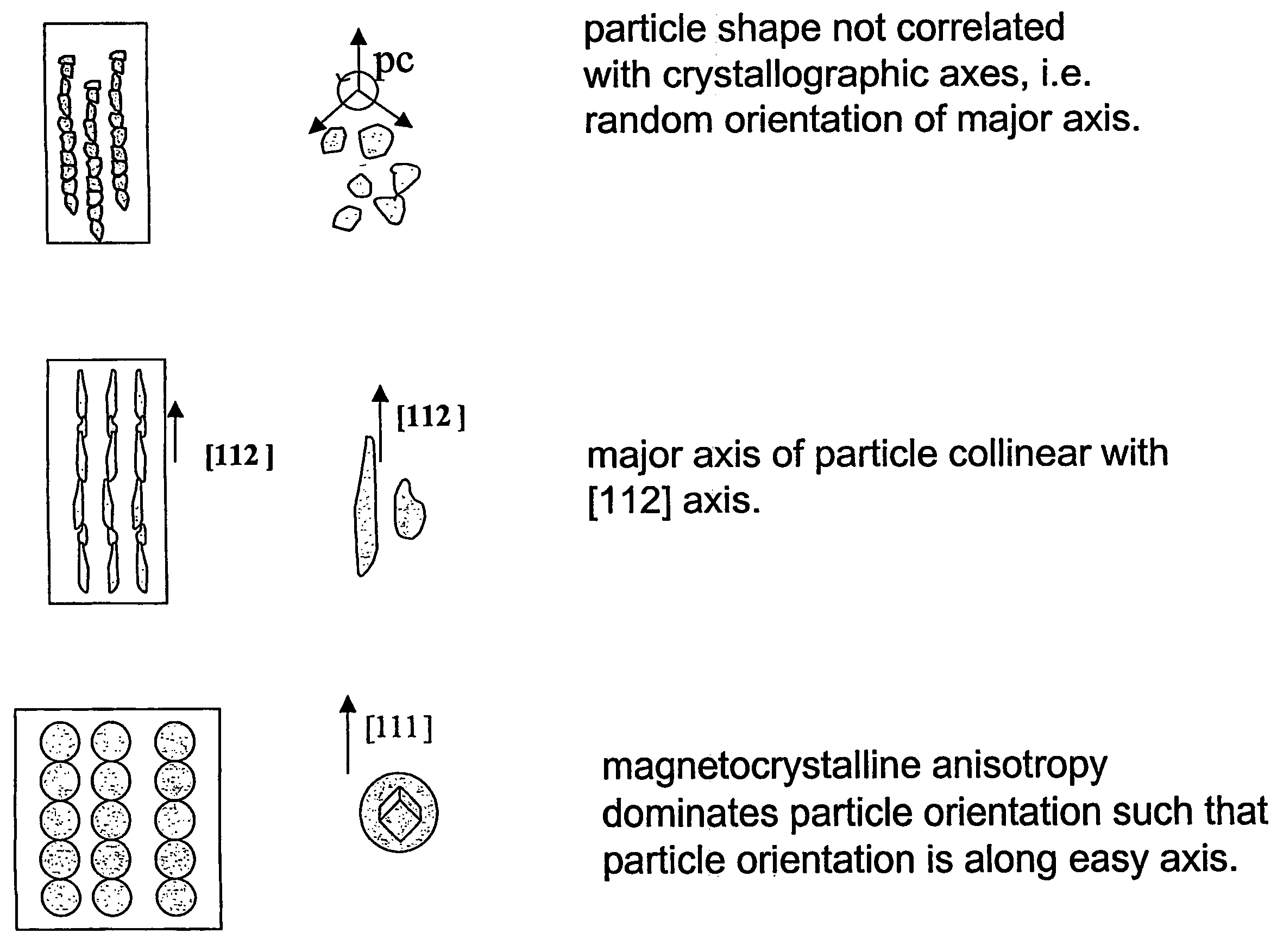

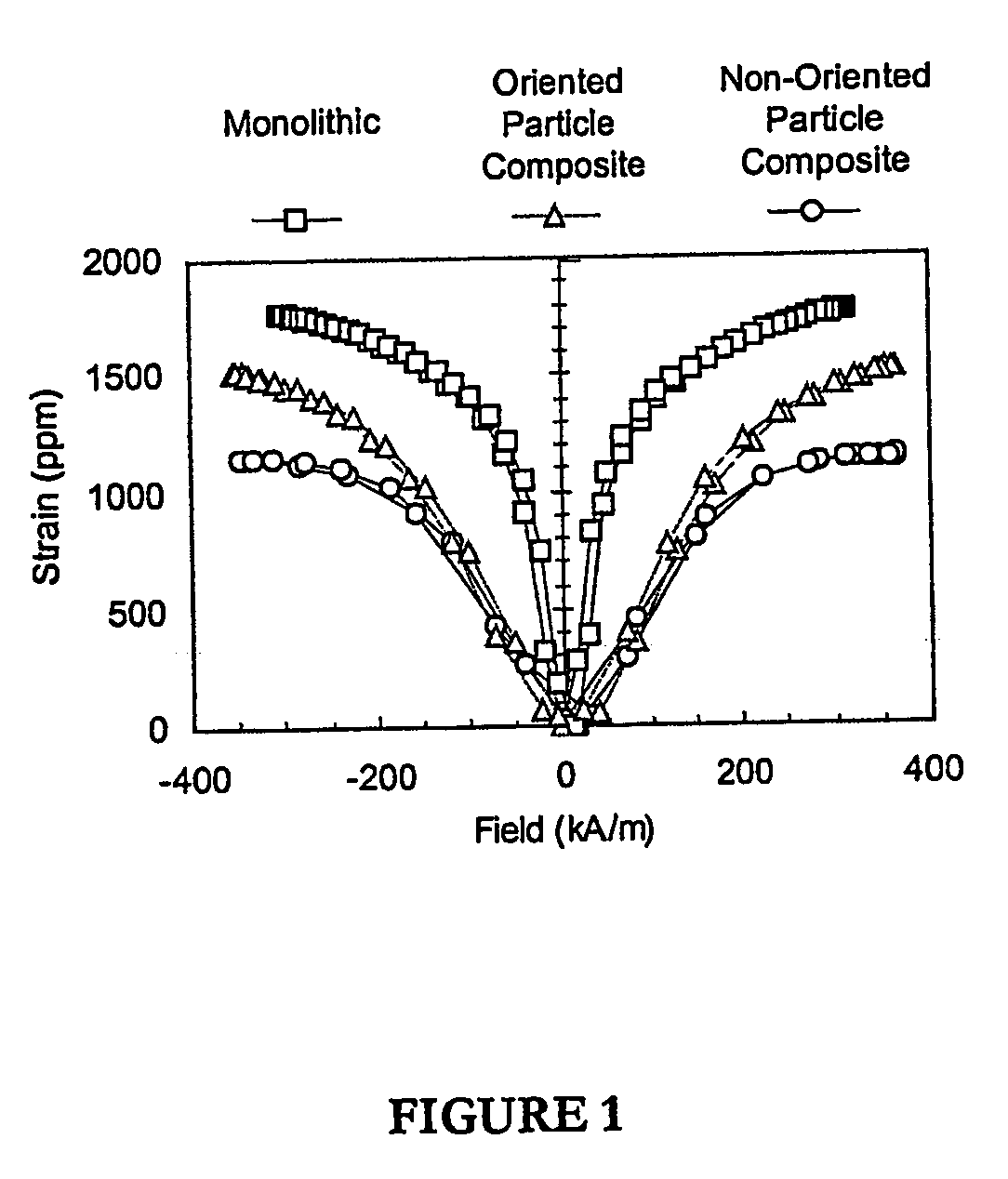

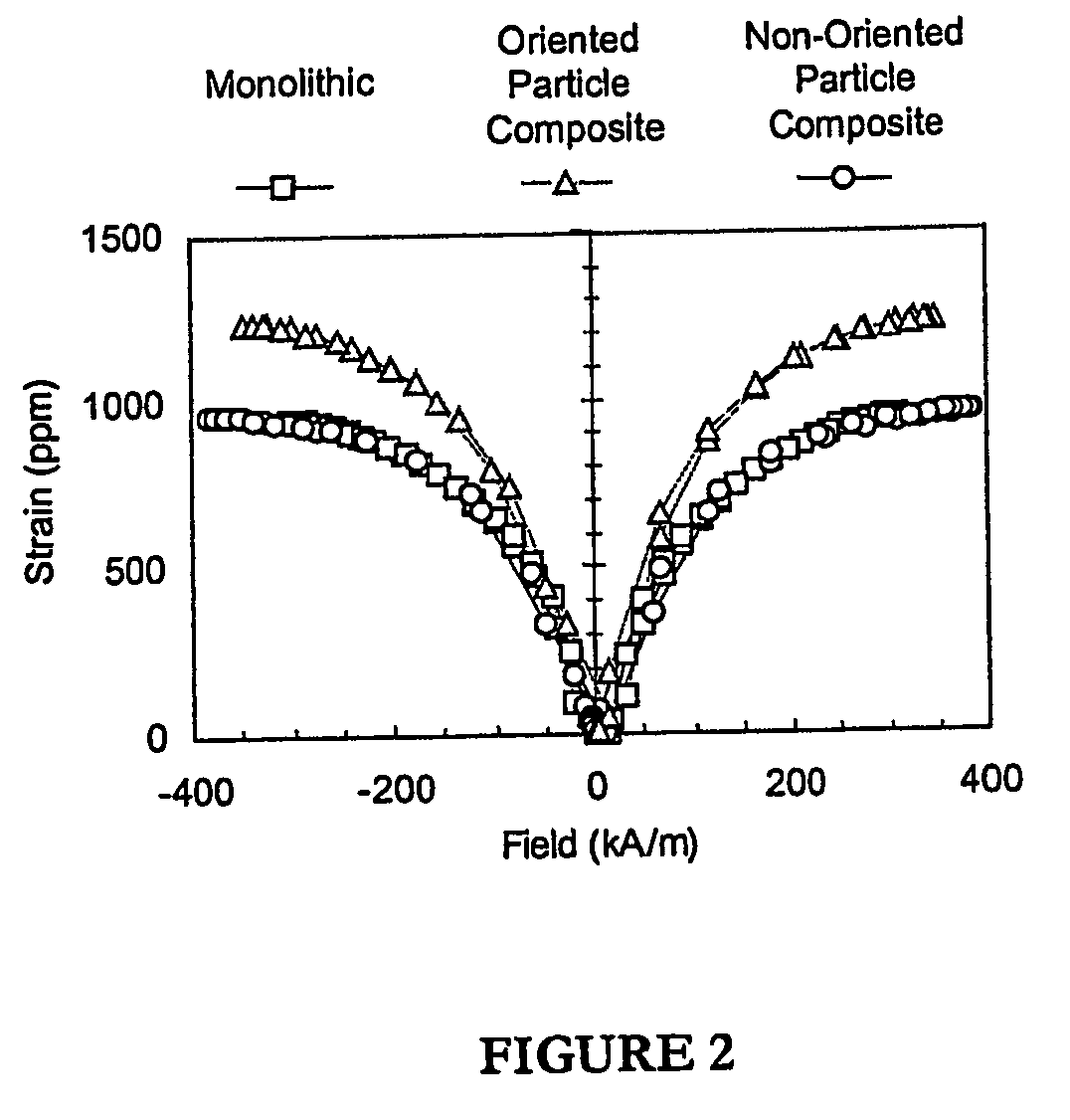

InactiveUS20050161119A1Large saturation strainImprove propertiesPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyCrystal orientationMaterials science

Magnetostrictive particulate composites with a preferred crystal orientation of the particles and methods for their manufacture are described. In a representative embodiment, a 25% volume Terfenol-D fraction polymer matrix composite was fabricated in a magnetic field using geometric anisotropy to orient needle shaped particles with long axis [112] orientation along the length of the composite. Results demonstrate that the magnetostriction of a [112] oriented particle composite saturates near 1600 ppm. This is a significant increase when compared to composites without preferential orientation (1200 ppm) and represents the largest reported magnetostriction for a particulate composite material.

Owner:RGT UNIV OF CALIFORNIA

Huge magnetostriction material and mfg. process thereof

InactiveCN1435851AGood low field performanceEase of mass productionInorganic material magnetismMagnetostrictive material selectionChemical compositionHigh volume manufacturing

A giant-magnetostrictive material is (Tb1-x-yDyxRy)(Fe1-z-pBe2Mp)g, where R is chosen from Ho, Er, Pr and Nd, M is chosen from Ti, V, Cr, Co, Ni, Mn, Si, Ga and Al, x=0.65-0.80, y=0-0.15, and g=1.75-2.55. Its preparing process includes smelting mother alloy in Ar atmosphere in vacuum furnace, growing oriented crystallizing material in vacuum or inert gas, and heat treating in vacuum furnace. Its advantages are high magnetostrictive strain ratio, good low-field performance, and low cost.

Owner:UNIV OF SCI & TECH BEIJING

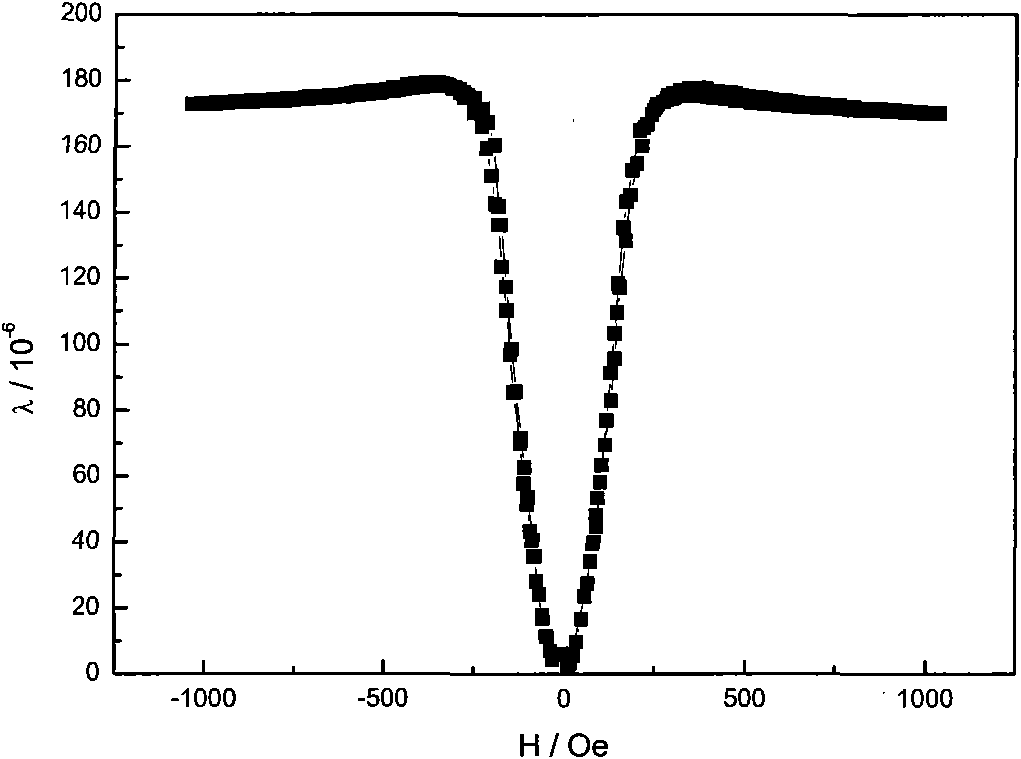

Fe-Ga based magnetostrictive wire and preparation method thereof

ActiveCN101812628AImprove surface qualityExcellent low-field magnetostrictive performanceMagnetostrictive material selectionAlloyProcessing cost

The invention relates to an Fe-Ga based magnetostrictive wire and a preparation method thereof. The raw material component used by the method is (Fel-x-yGaxMy)l-z(NC)z, wherein M is selected from one or more types of all transition elements other than Fe, B, Be, Al, In, Ge, Sn, Sb, Bi, Pb, S and Se, and N is Nb, Ti, Si, Zr, Mo and the like, x is equal to 0.10 to 0.30, y is equal to 0.00 to 0.05, z is equal to 0.00 to 0.02, and the balance Fe. The method processes an Fe-Ga alloy into a finished wire through cold- or warm-hydrostatic extrusion. The invention solves the problems of poor plasticity, larger flow friction resistance and high processing cost when in Fe-Ga alloy plastic processing. The diameter of the prepared Fe-Ga based magnetostrictive wire is between 0.01mm and 2mm, the surface finishment is high, and the magnetostrictive properties under the low-magnetic field environment can reach 180*10-6.

Owner:BEIJING MAGORIENTAL MATERIALS TECH CO LTD

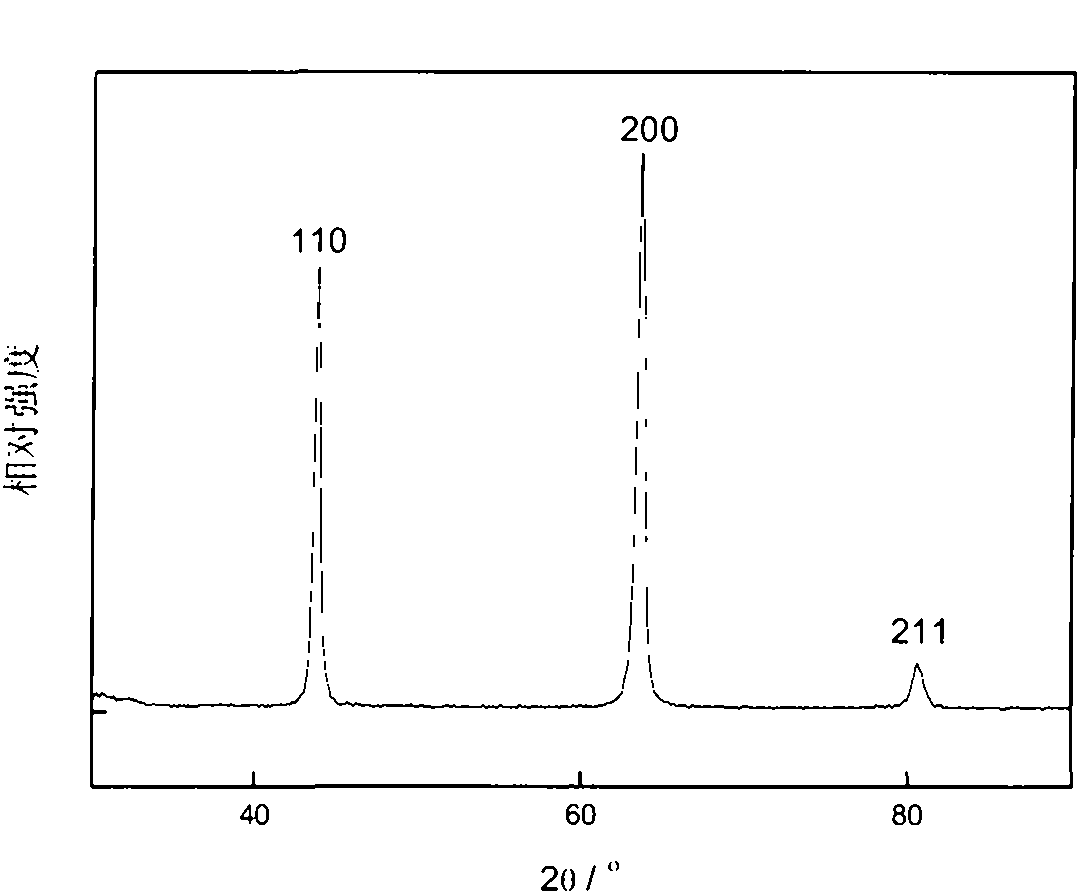

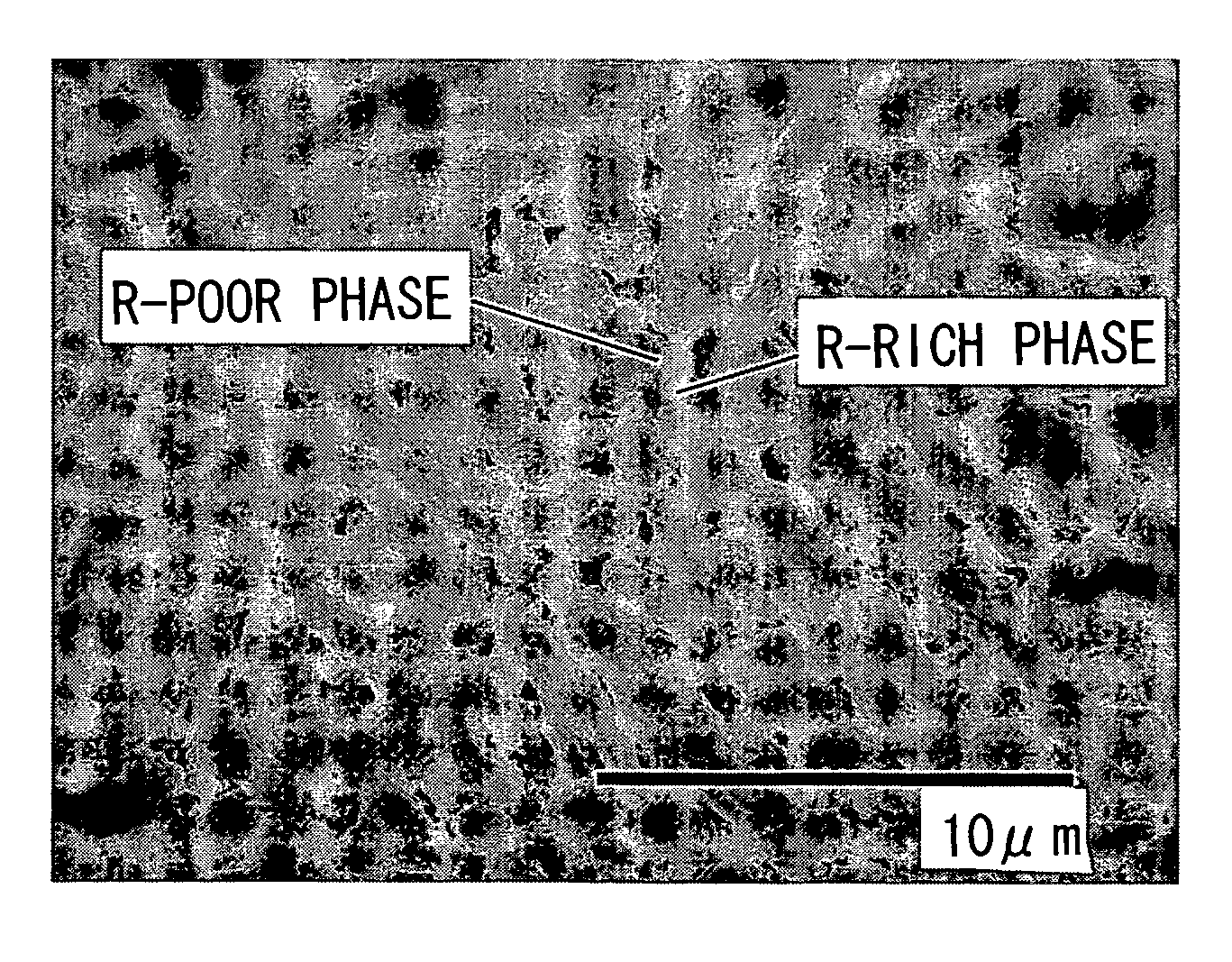

Alloy containing rare earth element, production method thereof, magnetostrictive device, and magnetic refrigerant material

InactiveUS7695574B2Easy to crushNot too brittleEnergy efficient heating/coolingInorganic material magnetismRare-earth elementCrystal structure

A method for producing an RE-containing alloy represented by formula R(T1−xAx)13−y (wherein R represents Ce, etc.; T represents Fe, etc.; and A represents Al, etc; 0.05≦x≦0.2; and −1≦y≦1) including a melting step of melting alloy raw materials at 1,200 to 1,800° C.; and a solidification step of rapidly quenching the molten metal produced through the above step, to thereby form the first RE-containing alloy, wherein the solidification step is performed at a cooling rate of 102 to 104° C. / second, as measured at least within a range of the temperature of the molten metal to 900° C.; and an RE-containing alloy, which is represented by a compositional formula of RrTtAa (wherein R and A represent the same meaning as above, T represents Fe, etc.; 5.0 at. %≦r≦6.8 at. %, 73.8 at. %≦t≦88.7 at. %, and 4.6 at. %≦a≦19.4 at. %) and has an alloy microstructure containing an NaZn13-type crystal structure in an amount of at least 85 mass % and α-Fe in an amount of 5-15 mass % inclusive.

Owner:ERASTEEL

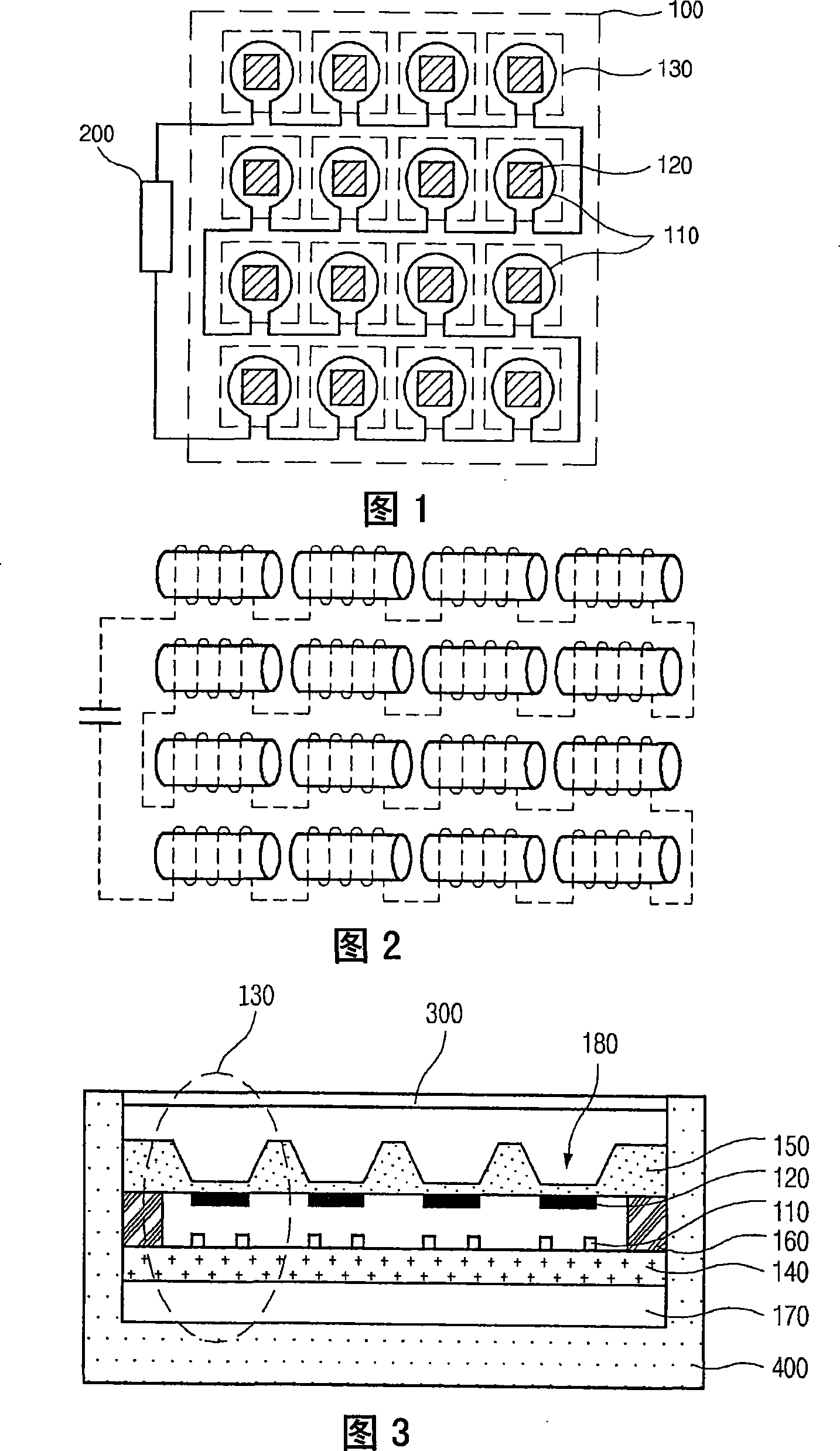

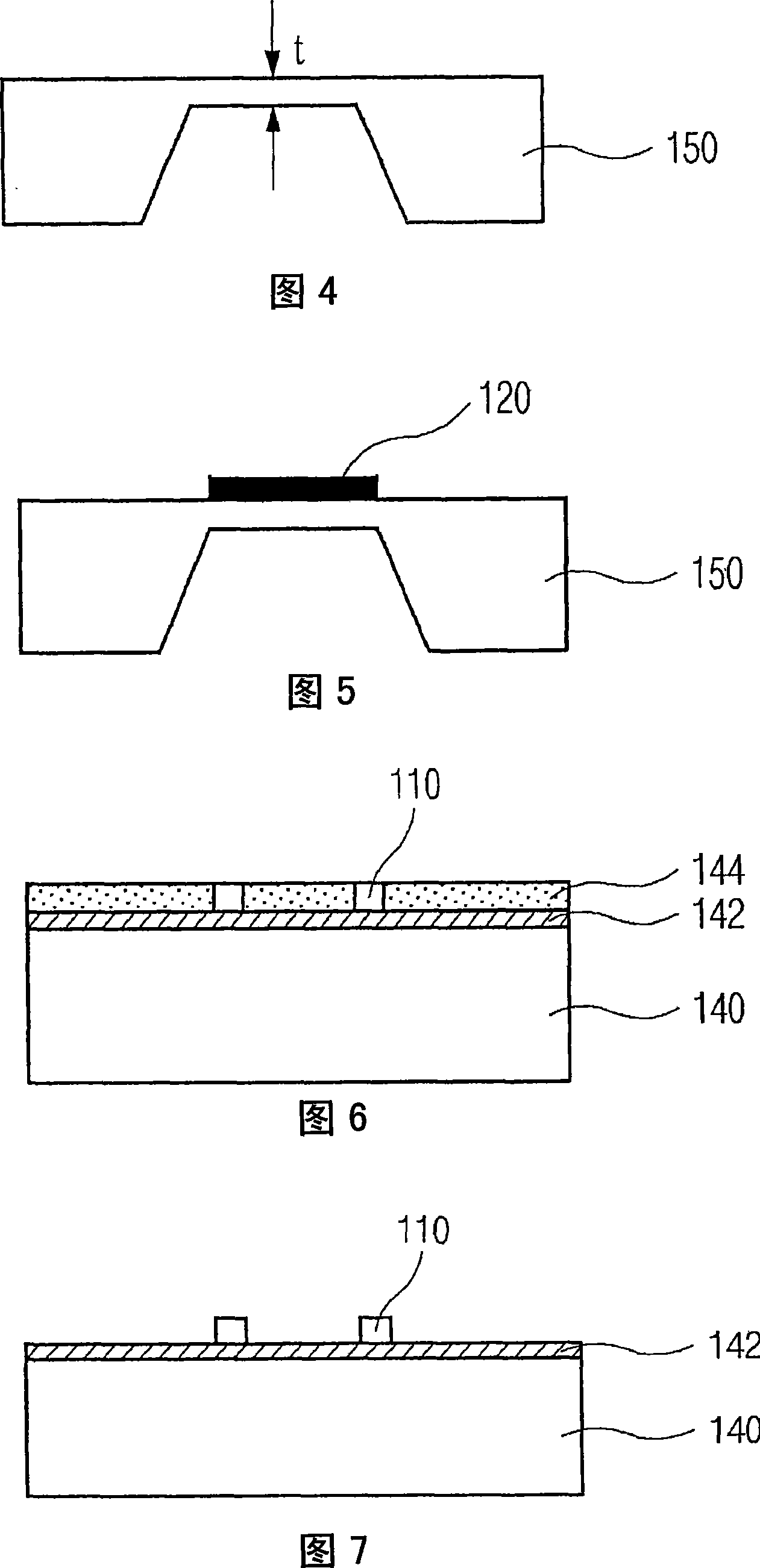

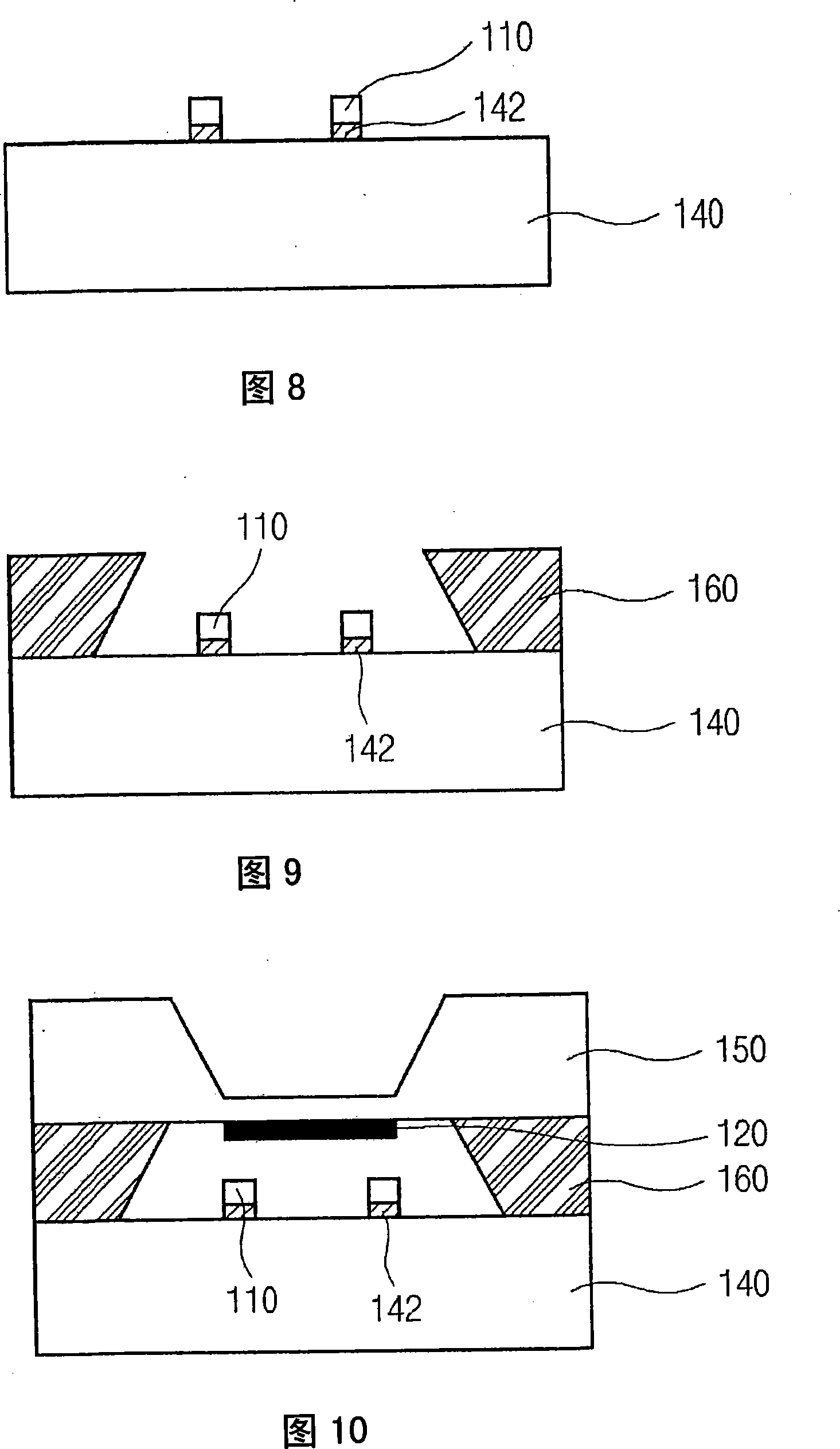

Variable inductor type mems pressure sensor using magnetostrictive effect

InactiveCN101160514AHigh sensitivitySuitable for high frequency applicationsPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLc resonant circuitEngineering

A variable inductor type MEMS pressure sensor using a magnetostrictive effect comprises an inductor array unit and a capacitor unit. The inductor array unit includes a coil unit having a plurality of serially connected circular electrodes formed on a first substrate and a magnetostrictive material thin film corresponding one by one to the circular electrode formed on a second substrate opposite to the first substrate at a predetermined distance in parallel to form an inductor which has the magnetostrictive material thin film as a core of the coil unit for inducing change of magnetic permeability of the magnetostrictive thin film depending on external pressure to vary inductance of the inductor. The capacitor unit constitutes a LC resonant circuit with the inductor array unit to convert magnetic energy discharged in the inductor array unit into a voltage. The variable inductor type MEMS pressure sensor has an excellent resolution because it is more sensitive than a conventional piezoresistive or capacitance sensor, and is manufactured using a MEMS process technology exchangeable with a semiconductor process, thereby enabling miniaturization and a mass package process to reduce the cost of production.

Owner:MDT CORP

Design of membrane actuator based on ferromagnetic shape memory alloy composite for synthetic jet actuator

InactiveUS7280016B2Large deformationIncrease size and cost and complexityPiezoelectric/electrostriction/magnetostriction machinesMagnetostrictive material selectionMagnetic gradientShape-memory alloy

Owner:UNIV OF WASHINGTON

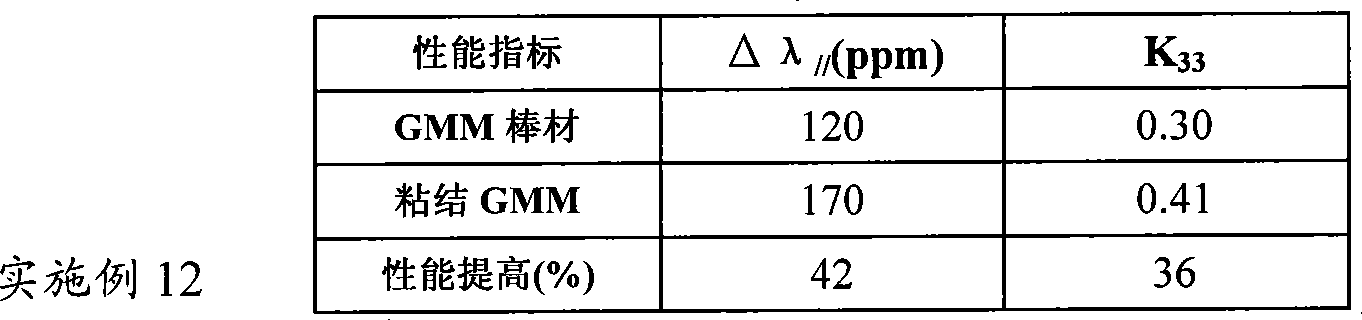

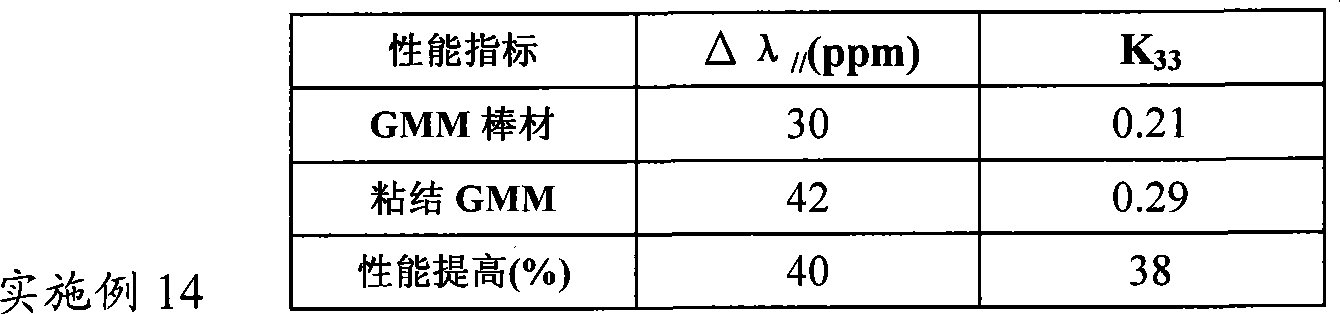

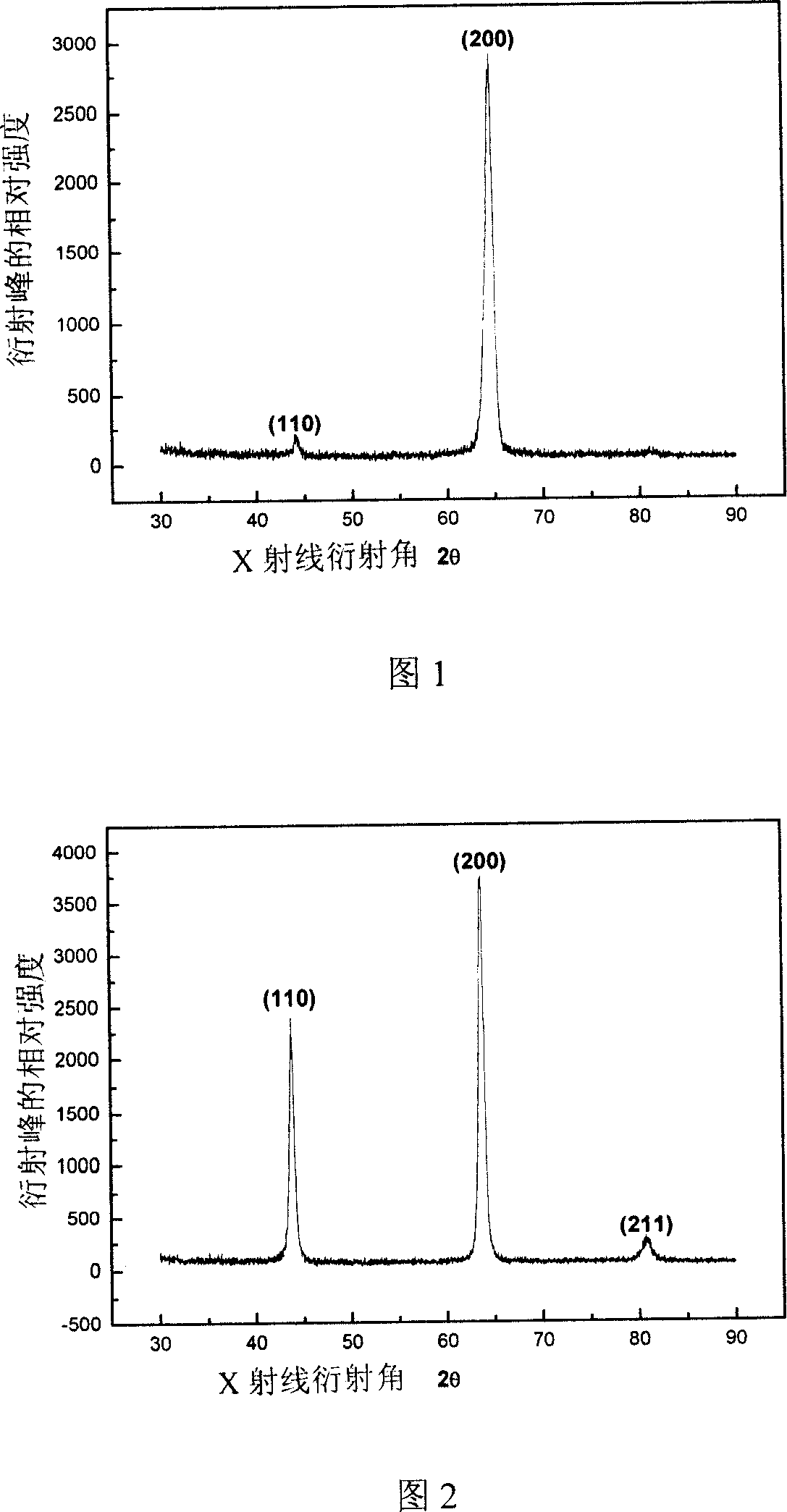

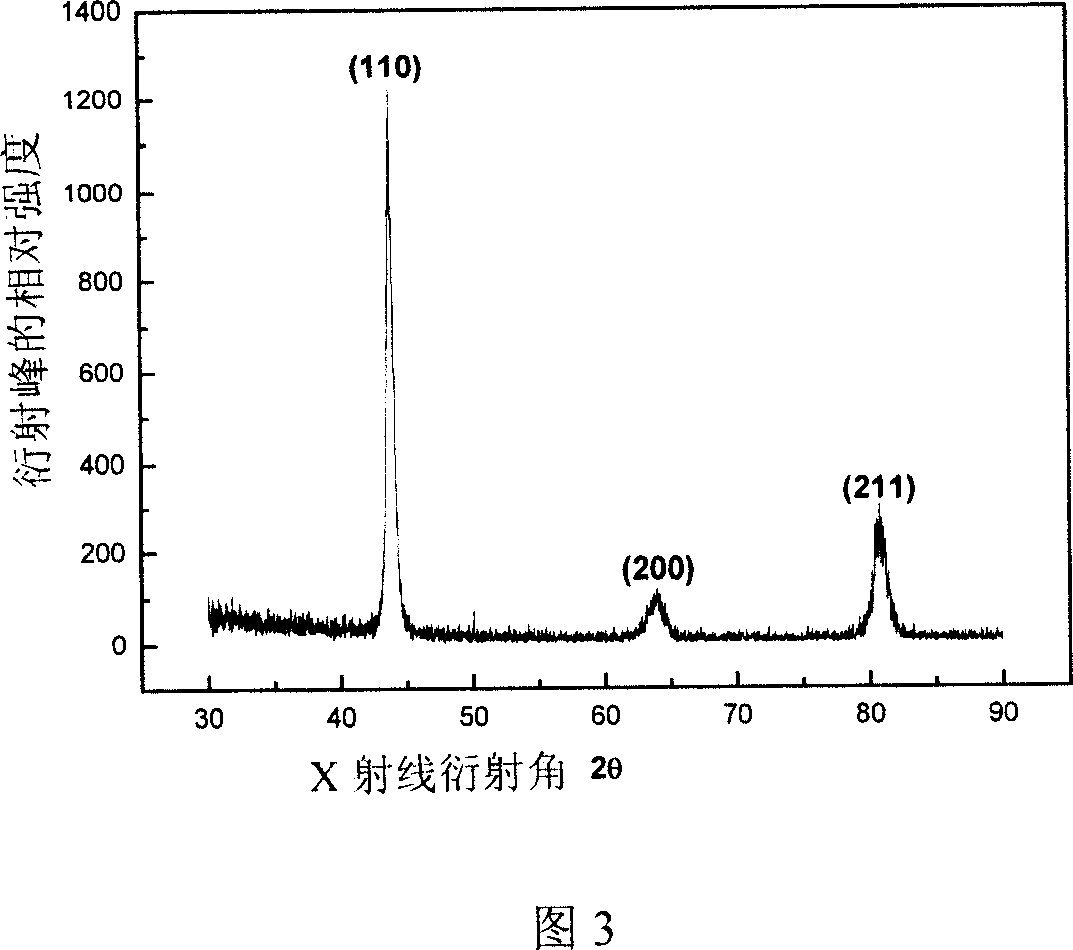

Cementing magnetostrictive material and preparation thereof

ActiveCN101388433APiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyRare earthMagnetostriction

A bonded magnetostrictive composite material and a process for preparation belong to the technical field of magnetic functional materials and preparation, which is characterized by being formed by magnetostrictive sheets with 1-15mm thickness through bonding, wherein the major components of the magnetostrictive sheet is (Tb, Dy) Fe2 rare-earth giant magnetostrictive materials, FeGa and NiMnGa magnetostrictive composite materials. The bonded magnetostrictive composite material has excellent eddy resistance performance, and increases over 30-80% magnetostrictive property under high frequency compared with common mangetostrictive composite materials. In addition, the process for preparation has simple operation and low cost, and has regular product appearance and large freedom degree in dimension, and overcomes the disadvantage that the traditional unidirectional solidification technique hardly obtains magnetostrictive composite material in large dimension.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

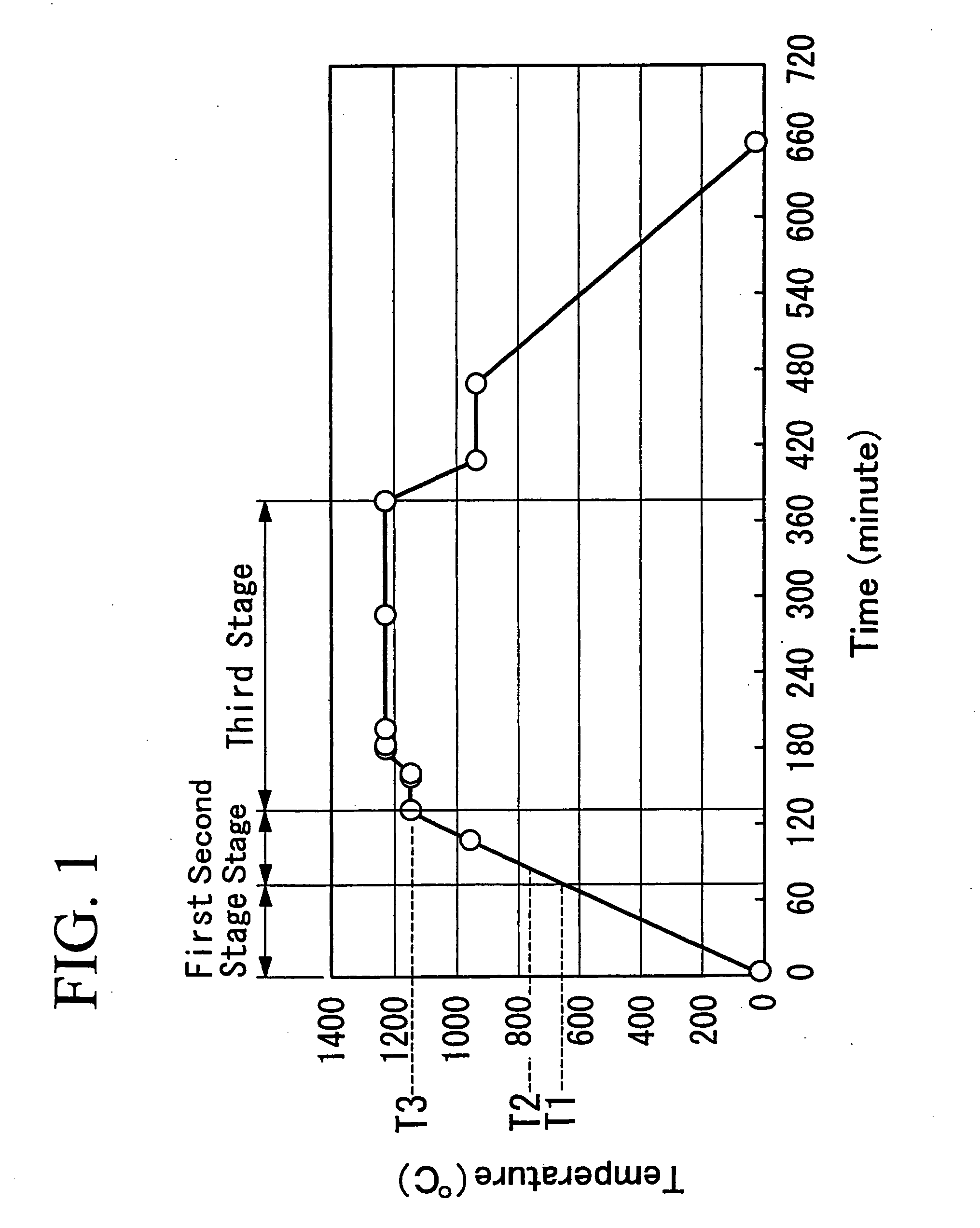

<100> Fe-Ga magnetostriction material on axial orientation and method of preparing the same

ActiveCN101109057ASimple structural designHigh magnetic field sensitivityFrom frozen solutionsMagnetostrictive material selectionBridgman methodRoom temperature

The invention discloses a <, a 100>, an axial orientation Fe-Ga magnetostriction material and the preparation method thereof. The material composites are Fe1-x-yGaxAly; wherein, x is between 16 per cent and 21 per cent or 25 per cent and 28 per cent; y is between 0 per cent and 10 per cent; the rest part is iron. The preparation method is that the raw material is melted under the protection of the inert gas, and the improved percy williams bridgman method is adopted to prepare the Fe-Ga magnetostriction material through the directional solidification; The heat treatment conditions are that the material is preserved at 1100 DEG C. to 1200 DEG C. for 0.5 hours to 24 hours, cooled with the furnace till 900 DEG C. to 750 DEG C. for 0.5 hours to 24 hours temperature preservation and then quenched or cooled by air to room temperature; or the material is preserved at 1100 DEG C. to 1200 DEG C. temperature for 0.5 hours to 24 hours and is cooled with the furnace till 500 to 700 DEG C..

Owner:GRIREM ADVANCED MATERIALS CO LTD

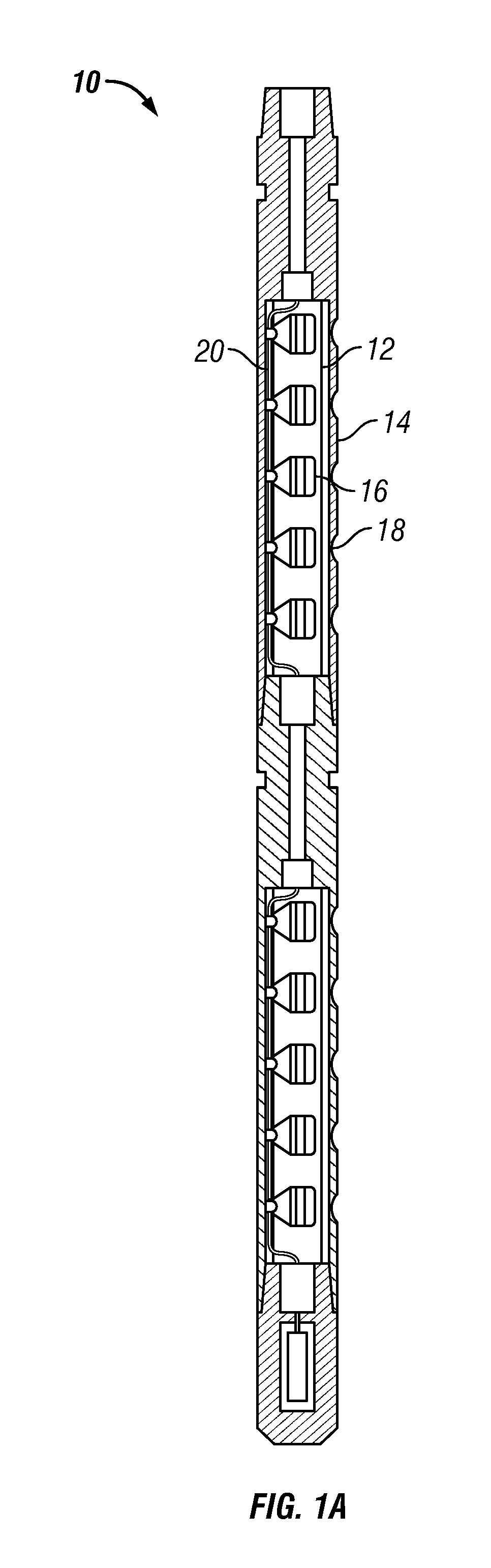

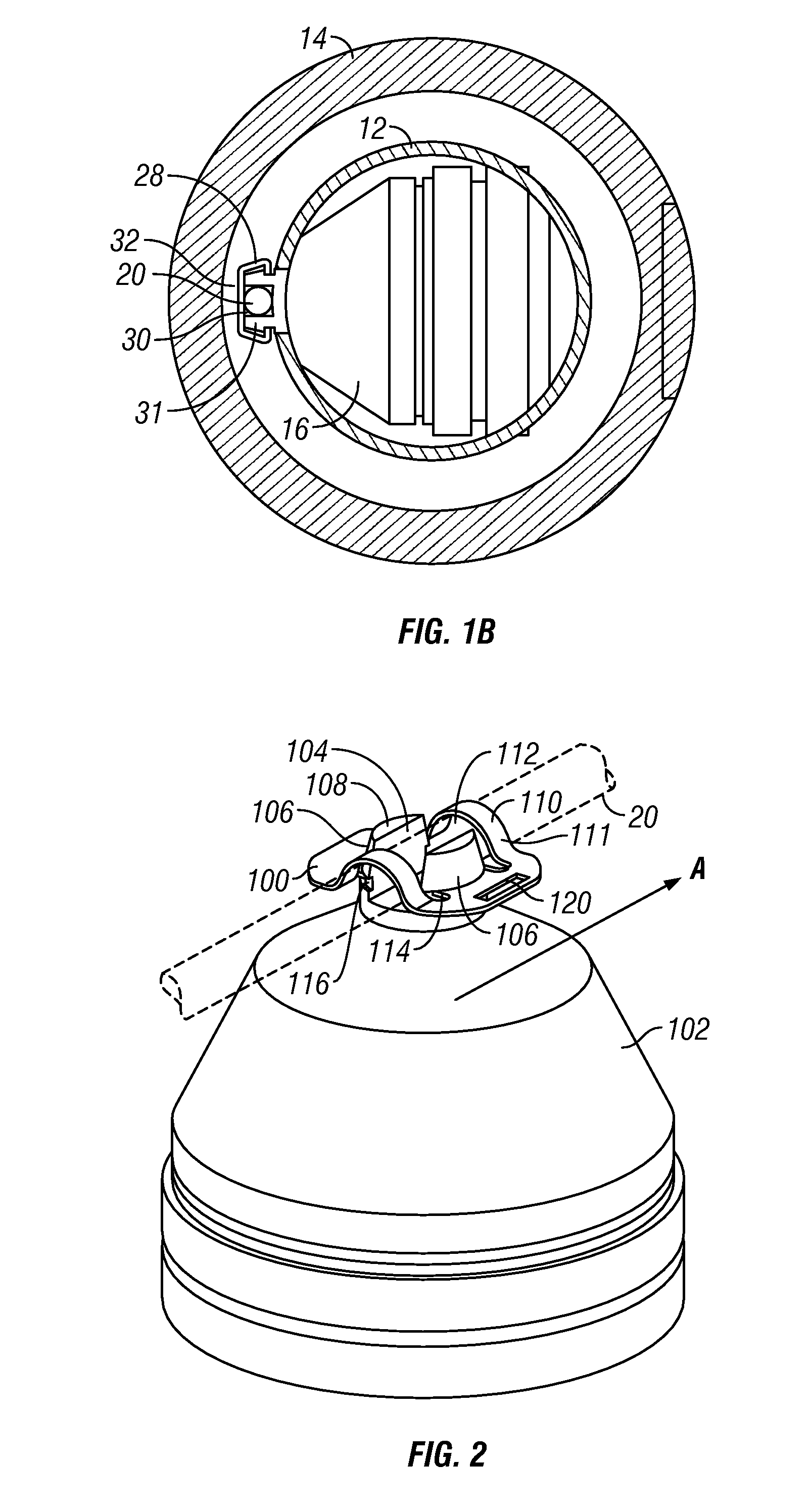

Retention member for perforating guns

ActiveUS20100263523A1Enhanced energetic couplingRemained chargedFuse ignition meansFuse connectorsDetonatorShaped charge

A perforating gun includes a charge tube having shaped charges affixed thereto. Each shaped charge includes a radially outward pointing post adapted to receive a detonator cord. A retention member installed on the post provides a compressive force that energetically couples the detonator cord to the post. The radially outermost portion of the retention member is radially flush with or radially recessed relative to the radially outermost portion of each post. In one embodiment, the retention member has a rounded medial portion, a central opening and a pair of locking tabs that point radially inward to the central opening. Each post may include a slot for receiving the detonator cord and a circumferential groove that is adapted to receive the locking tabs.

Owner:OWEN OIL TOOLS

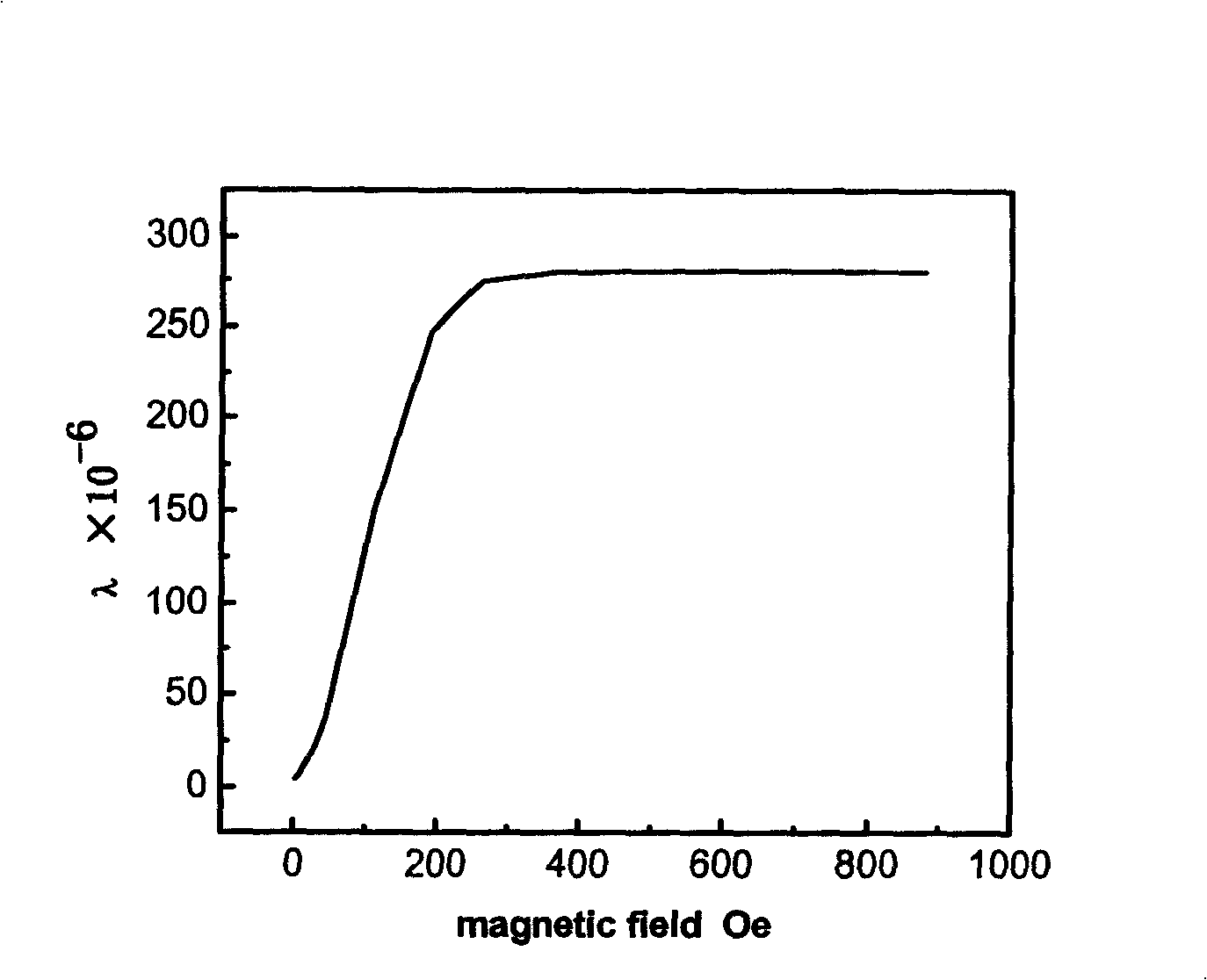

Magnetostrictive material and preparation method thereof

ActiveCN104947194AAchieve <100> single crystal orientationRaise the temperature gradientPolycrystalline material growthFrom frozen solutionsRare earthShielding gas

The invention provides a magnetostrictive material and a preparation method thereof. The composition of the magnetostrictive material is (Fe[]1-x]Gax)[100-y]REy, wherein 0.17<=x<=0.19, 0.01<=y<=0.2, and RE is selected from one or more of Tb, La, Sm, Dy, Lu, Ho, Er and Tm. The preparation method comprises the following steps: smelting the Fe Ga and RE prepared according to the composition requirements into a mother alloy cast ingot, preparing a mother alloy bar, putting the mother alloy bar and a <100>-oriented FeGa monocrystal seed in a directional solidification apparatus, vacuumizing the directional solidification apparatus, charging protective gas, heating to melt all the mother alloy bar and melt the upper part of the FeGa monocrystal seed, and drawing the molten material into a coolant along the lower part of the FeGa monocrystal seed to carry out directional solidification, wherein the temperature gradient is controlled at 1*10<5>-9*10<5> K / m, and the growth rate is 1000-20000 mm / hour. The magnetostrictive material prepared by the method is a <100>-oriented monocrystal material in which the RE elements are completely dissolved in the FeGa matrix; the saturated magnetic field is only 100-5000e, and the magnetostriction coefficient is up to 300-1500 ppm; and the magnetostrictive material has favorable comprehensive usability and wide application prospects.

Owner:BEIHANG UNIV

Magnetic and heating treatment method to improve magnetically driven reversible strain property of polycrystalline Ni2 MnGa

InactiveCN1453388AInorganic material magnetismMagnetostrictive material selectionIngotUltimate tensile strength

The magnetic field heating treatment to improve magnetically driven reversible strain property of polycrystalline Ni2MnGa includes the following steps: preparing Ni2MnGa alloy in nonstoichiometeric ratio with Ni content of 50.3-53.0 at% and Mn / Ga ratio 1.05-1.15; electric arc smelting with high purity element Ni, Mn and Ga material under Ar protection to produce polycrystalline ingot; homogenizing annealing treatment of the polycrystalline ingot at 1100-1200 K for 1-3 days; heat treatment in magnetic field of strength H 0.7T, temperature 240-350 K or 360-460 K for 20-30 min and final air cooling or water quenching. The said process of the present invention raises the magnetically driven reversible strain amount of polycrystalline Ni2MnGa by about 17 %.

Owner:EMERSON ELECTRIC (CHINA) HLDG CO LTD

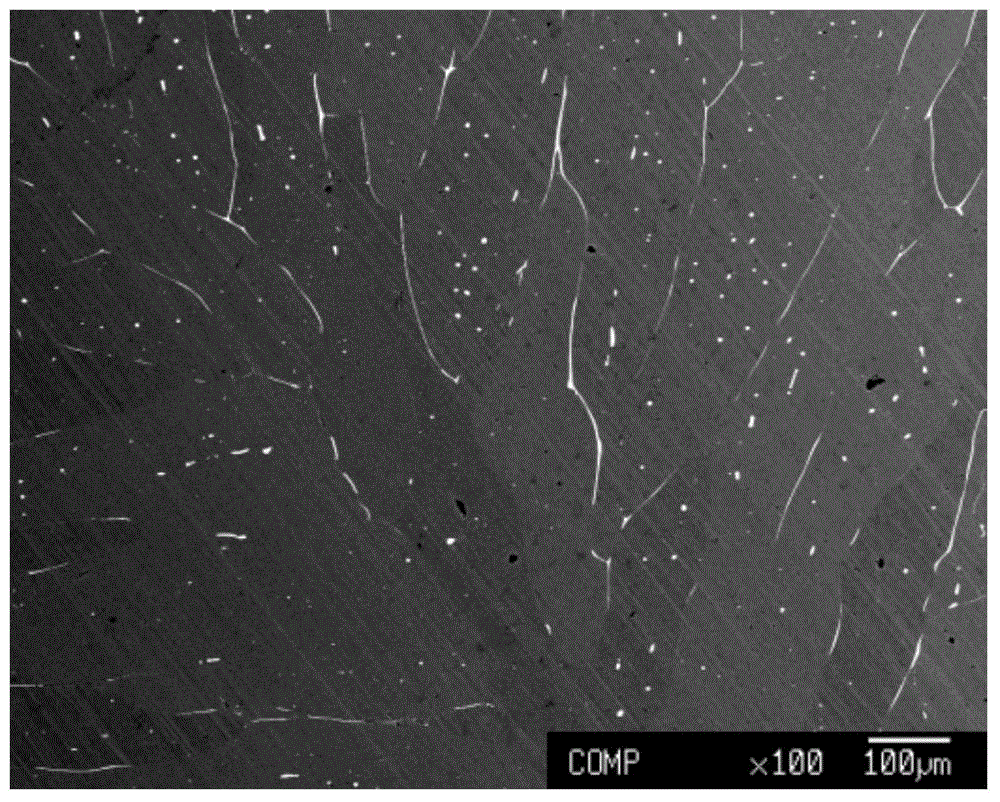

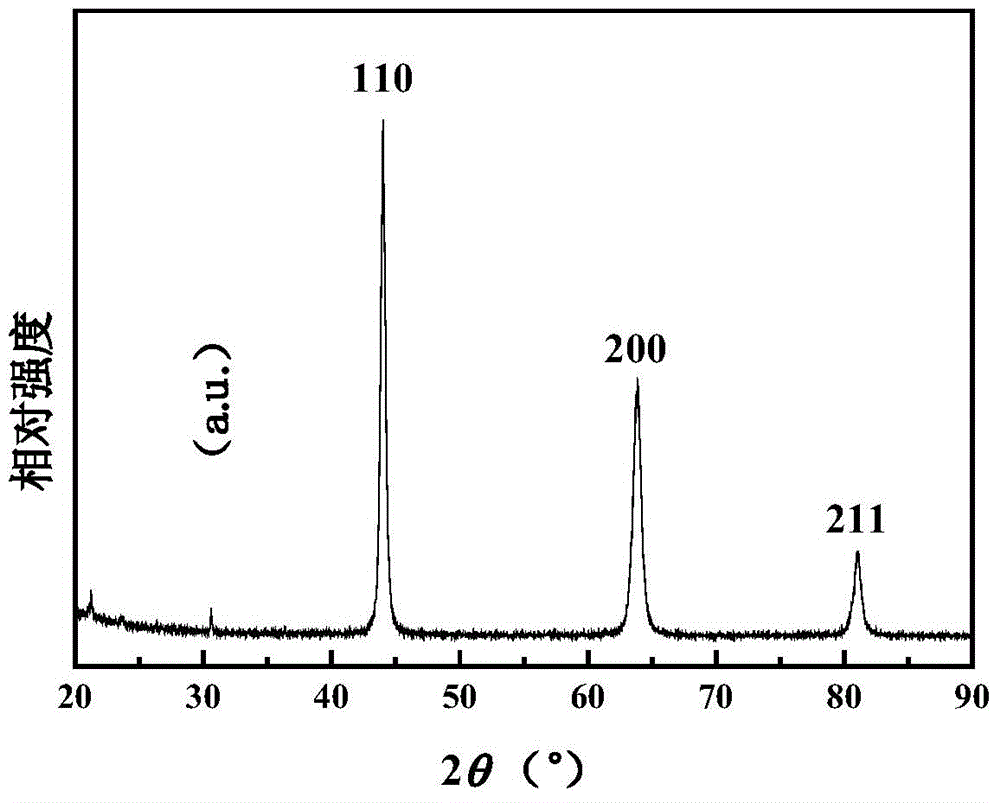

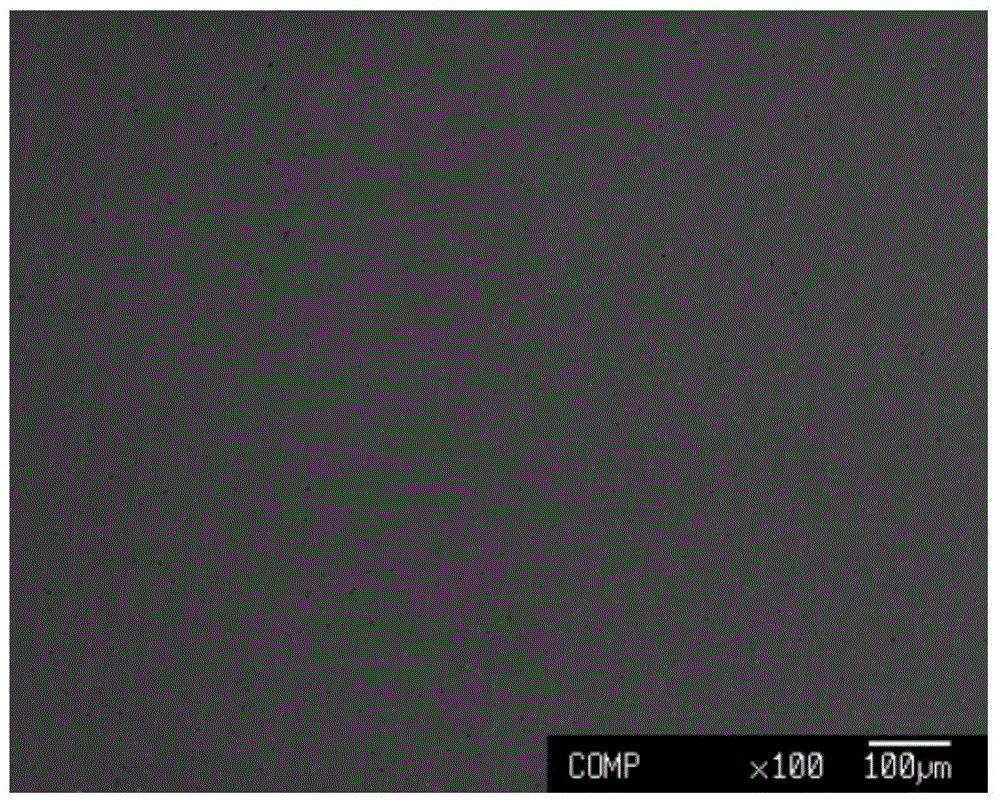

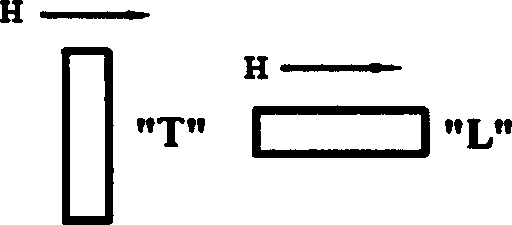

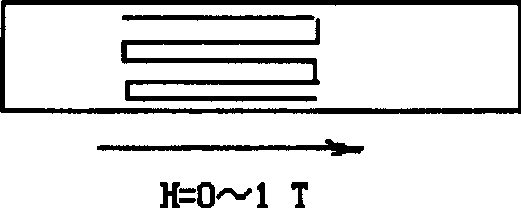

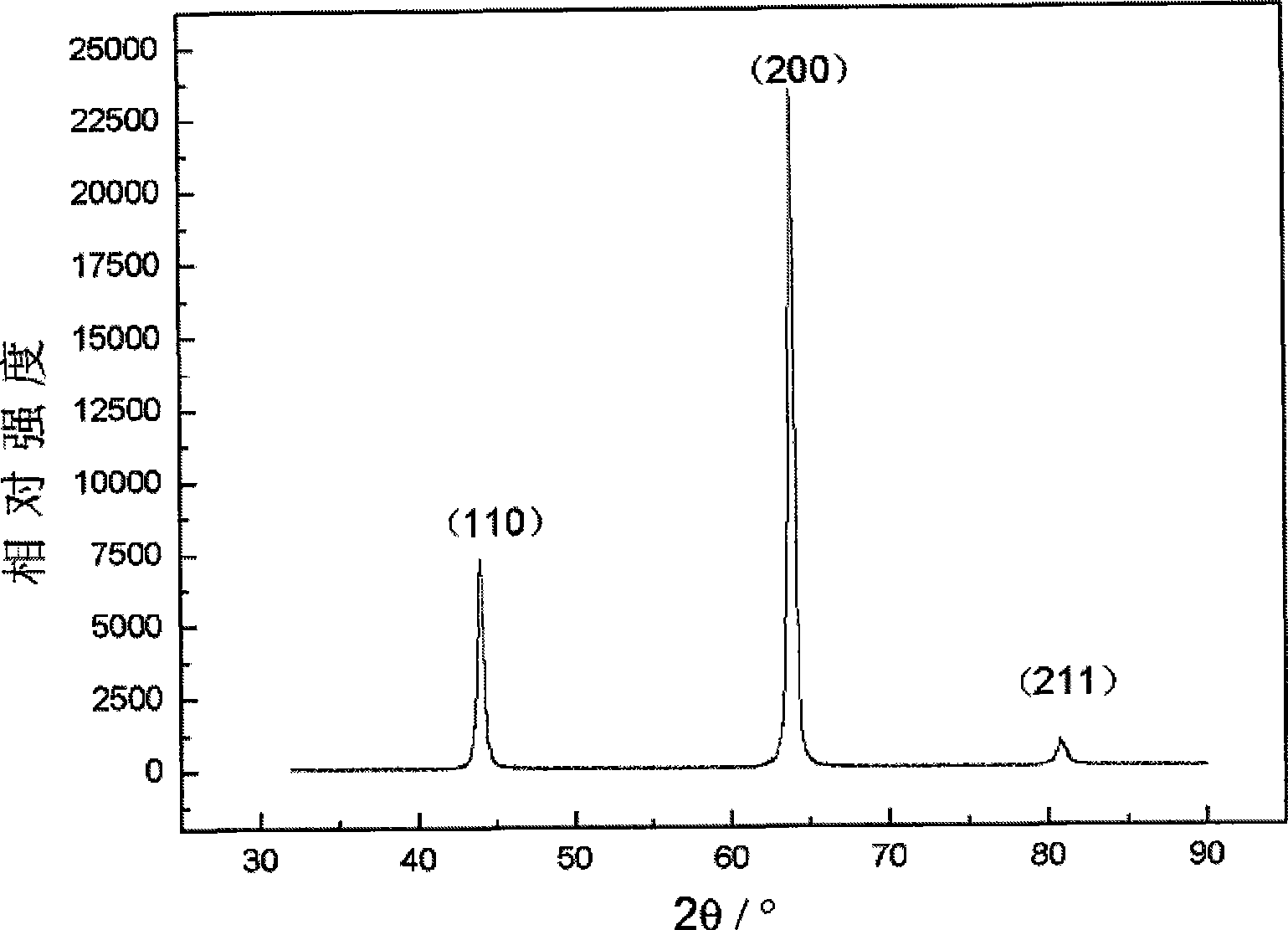

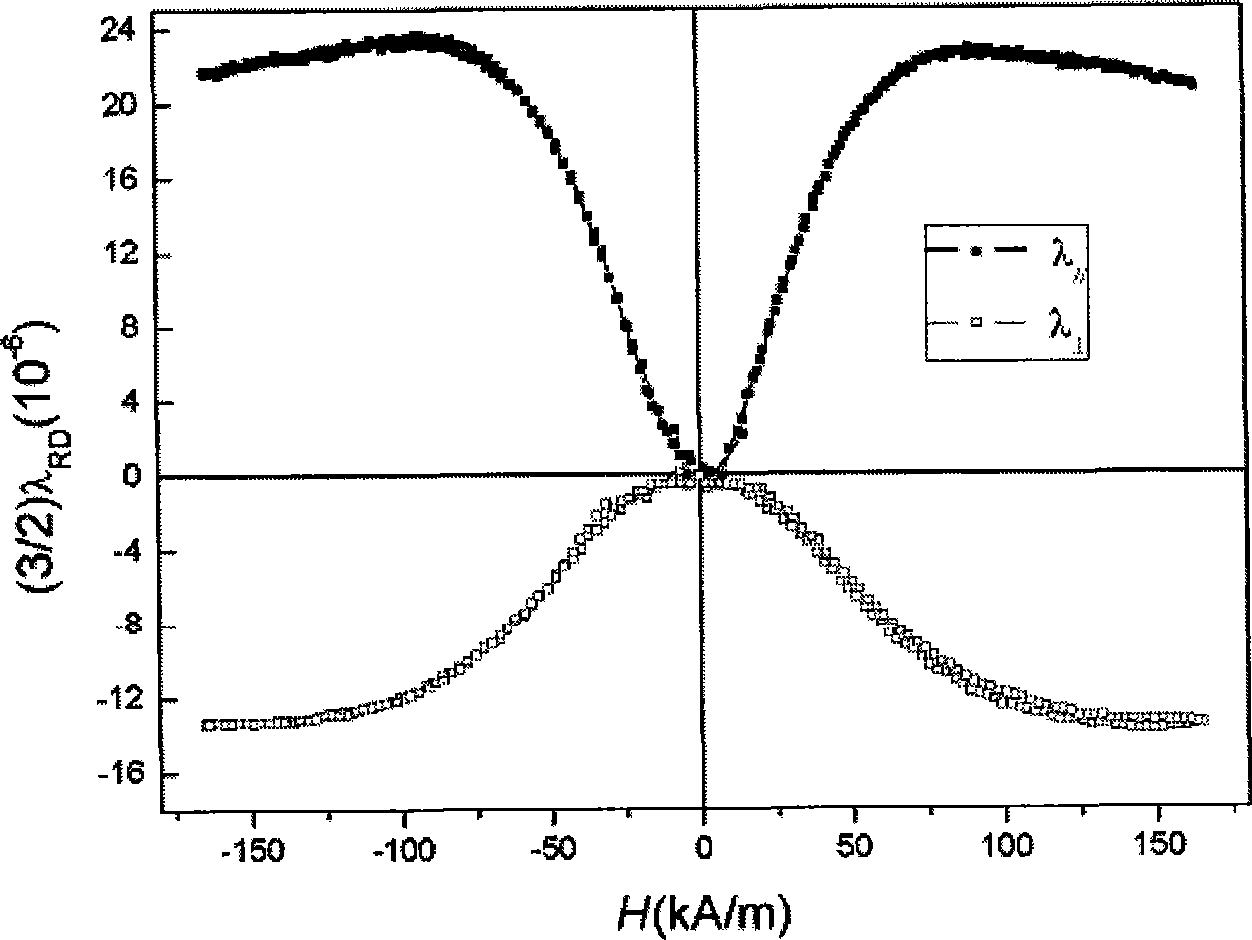

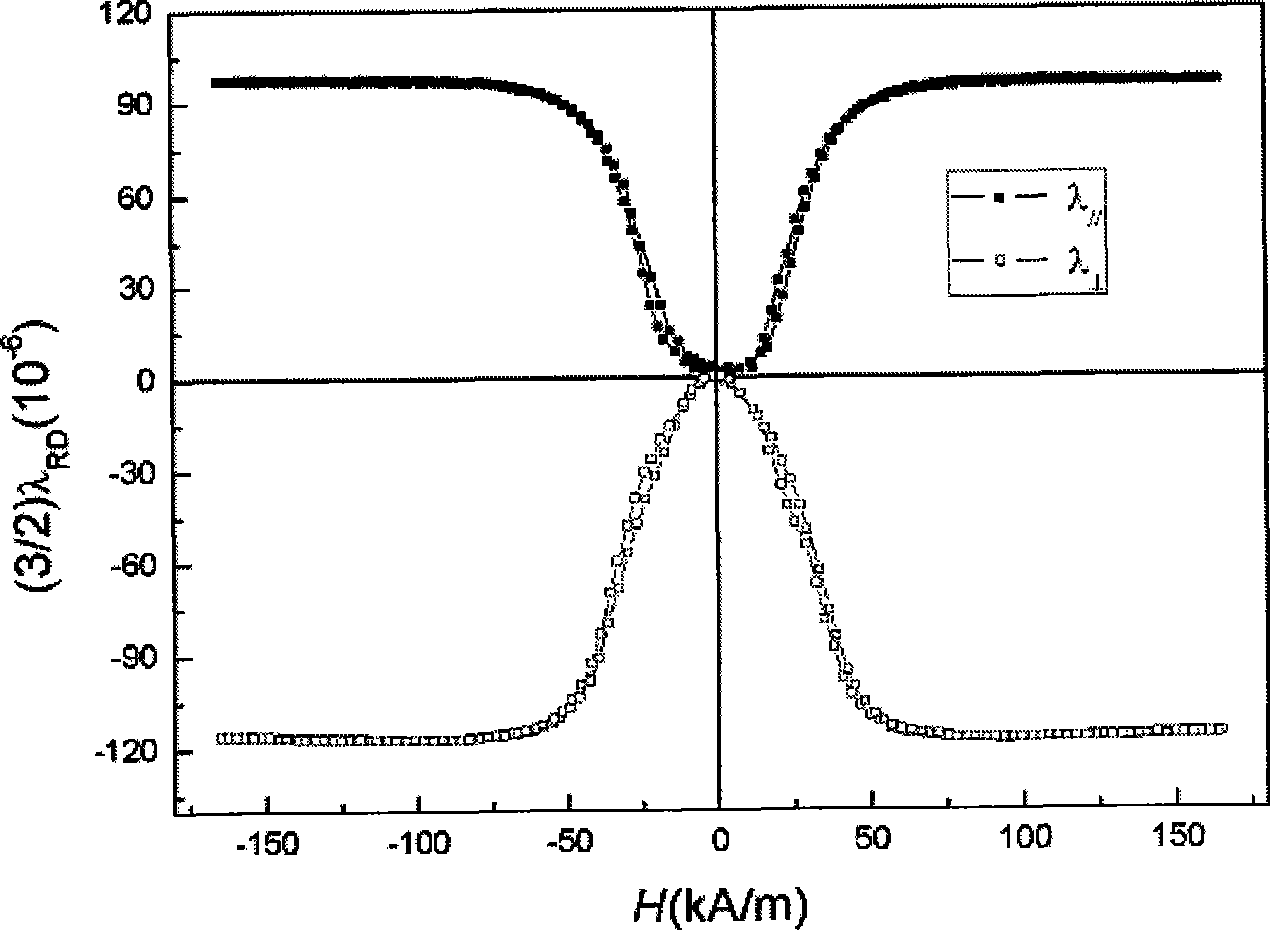

High-performance polycrystal texture Fe-Ga-based magnetic deformation slice material and preparation method thereof

InactiveCN101465406AImprove textureHigh magnetostrictive performancePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyIngotHeat treated

The invention relates to a high-performance polycrystalline texture Fe-Ga-based magnetostrictive thin material and a preparation method thereof; the component of the material is Fe100-x-y-zGaxMyNz; M stands for one or more among B, Nb, Cr, VC, TiC, MnS and AlN; N stands for one or more among S, Sb and Sn; wherein, x is equal to 15-25; y is equal to 0.5-3.0; z is equal to 0.01-0.05; and the residual is iron. The method has the following process key points: based on the requirements of the material composition, melting master alloy; casting alloy ingot; hot-forging and cogging; rolling the material into the appropriate thickness; and a variety of follow-up heat treatment. The Fe-Ga-based magnetostrictive thin material has obvious (100)<001>cubic texture or (110) <001> goss texture; and the maximum magnetostriction coefficient (3 / 2)lambdas is up to 280 multiplying 10<-6>.

Owner:UNIV OF SCI & TECH BEIJING

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com