Magnetostrictive material and preparation method thereof

A magnetostrictive material and raw material technology, applied in the field of magnetic materials, can solve the problems of poor magnetostrictive performance and inability to meet the needs of use, and achieve the effects of complete solid solution, easy single crystal growth, and inhibition of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 prepares (Fe 0.83 Ga 0.17 ) 99.95 Tb 0.05

[0053] The preparation composition is (Fe 0.83 Ga 0.17 ) 99.95 Tb 0.05 A method for a magnetostrictive material, comprising the steps of:

[0054] 1. Ingredients

[0055] The purity of the selected raw materials Fe, Ga and Tb (RE raw materials) is greater than 99.99wt%, and in order to prevent the burning of elements during the smelting process, when the Fe, Ga and Tb raw materials are prepared according to the above composition, the burning loss of about 1wt% Add Ga and Tb respectively. Specifically, 27.72g of Fe, 7.158g of Ga and 0.048g of Tb were weighed and set aside.

[0056] 2. Preparation of master alloy ingot

[0057] Put the above-mentioned raw materials Fe, Ga and RE into the crucible of the vacuum non-consumable arc melting furnace. When placing, put the metal elements that are easy to burn at the bottom of the crucible, and the metal elements that are not easy to burn at the top of the cruci...

Embodiment 2

[0069] Embodiment 2 prepares (Fe 0.83 Ga 0.17 ) 99.97 Lu 0.03

[0070] In addition to the batching step, weigh 28.05g of Fe, 7.242g of Ga and 0.031g of Lu for later use; in the step of preparing magnetostrictive materials, heat the graphite heating body to 1575 ° C, and control the temperature gradient to 5 × 10 5 K / m, except that the growth rate is 8000mm / h, other steps are the same as in Example 1, and the obtained composition is (Fe 0.83 Ga 0.17 ) 99.97 Lu 0.03 Magnetostrictive material (size Φ7mm×20mm).

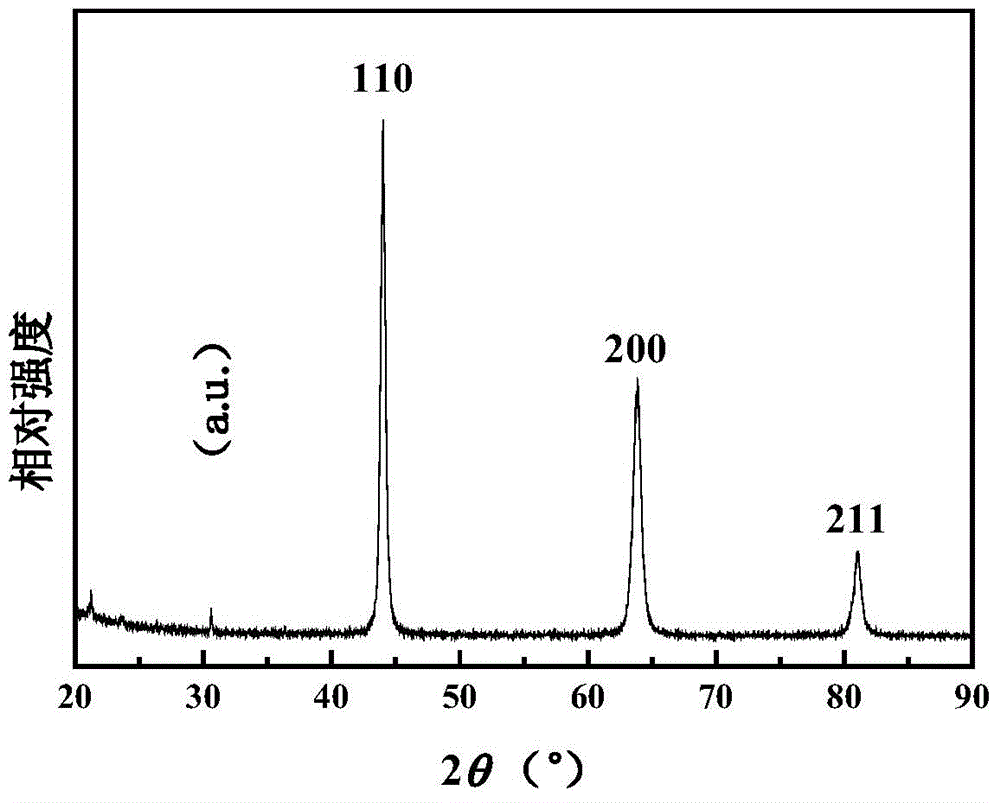

[0071] After testing, the (Fe 0.83 Ga 0.17 ) 99.97 Lu 0.03 The Lu element in the magnetostrictive material is completely dissolved in the FeGa matrix, and the material is a single crystal material with a orientation; in addition, the (Fe 0.83 Ga 0.17 ) 99.97 Lu 0.03 The saturation magnetostriction coefficient of the material is 330ppm, the saturation magnetic field is about 350Oe, and the magnetostriction performance and comprehensive usability are good. ...

Embodiment 3

[0072] Embodiment 3 prepares (Fe 0.81 Ga 0.19 ) 99.96 Dy 0.04

[0073] The preparation composition is (Fe 0.81 Ga 0.19 ) 99.96 Dy 0.04 A method for a magnetostrictive material, comprising the steps of:

[0074] 1. Ingredients

[0075] Weigh 27.88g of Fe, 8.25g of Ga and 0.04g of Dy for later use.

[0076] 2. Preparation of master alloy ingot

[0077] Put the above-mentioned raw materials Fe, Ga and Dy into the crucible of the vacuum non-consumable arc melting furnace, and evacuate the vacuum non-consumable arc melting furnace to 1.0×10 -3 After Pa, fill the furnace body with high-purity argon gas with a purity of more than 99.99%, and wait until the vacuum degree in the furnace rises to 5.0×10 -1 After Pa, stop inflating, repeat this step three times, set the melting current to 120A, melt the raw materials, control the time of each melting to about 5 minutes, repeat the melting four times, and obtain the master alloy ingot.

[0078] 3. Preparation of master alloy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com